Page 1

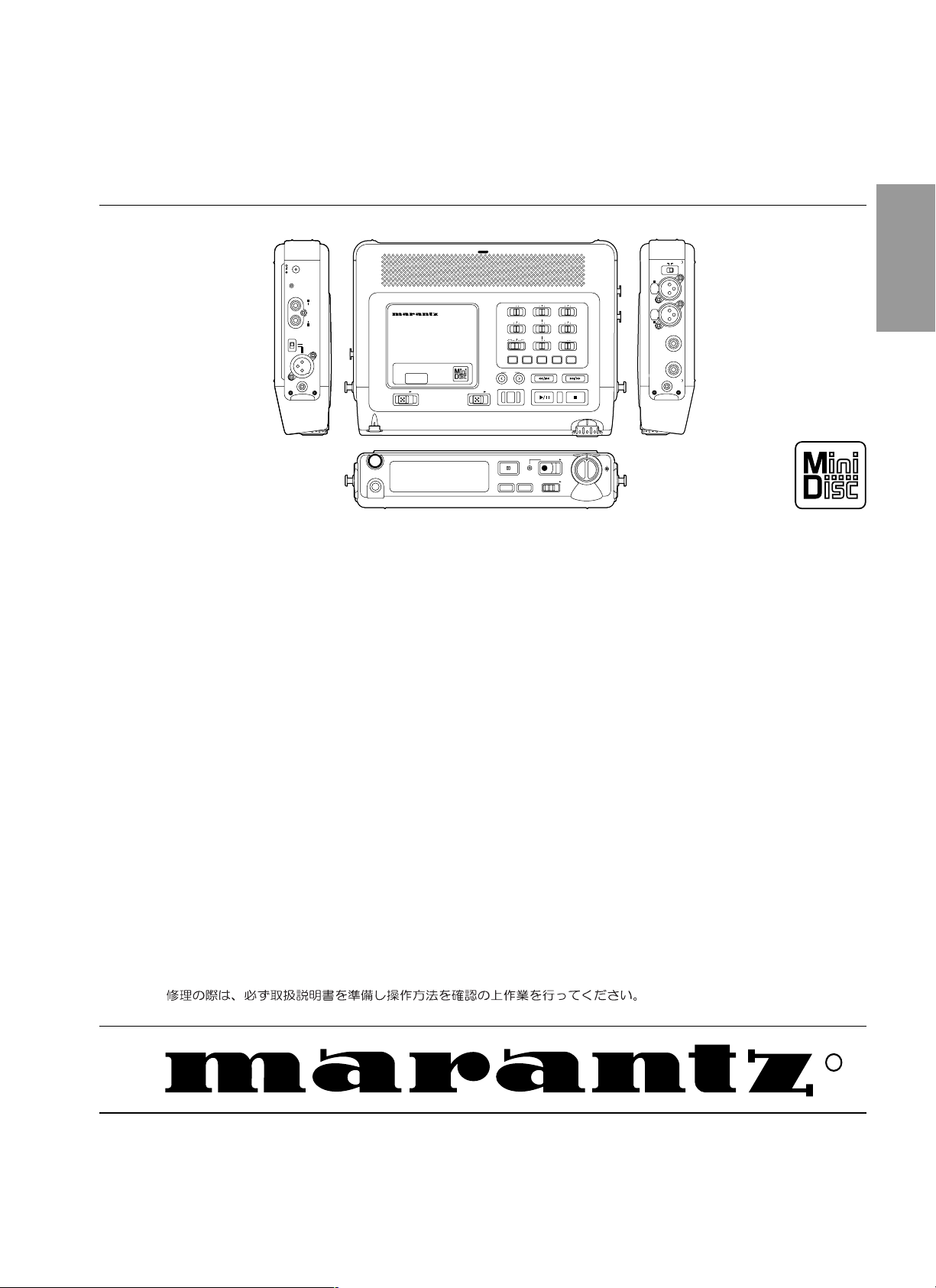

Service

DIGITAL IN REMOTE

(RC-5)

➀

GND

➁

HOT

➂

COLD

MIC/LINE IN

PHANTOM

+48V

L R

OFF

ON

PMD650 /N1B, /U1B, /F1B

Manual

SECTION PAGE

1. TECHNICAL SPECIFICATIONS ................................................................................................................. 1

2. SERVICE MODE ....................................................................................................................................... 2

3. MD MODULE(KML-252 with PCB) ELECTRICAL ADJUSTMENTS.................................................. 4

4. LCD CONTRAST ADJUSTMENT ......................................................................................................... 11

5. HOW TO DISASSEMBLE ...................................................................................................................... 11

6. WAVEFORMS ......................................................................................................................................... 17

7. BUGS AND PROBLEMS ........................................................................................................................ 18

8. WIRING DIAGRAM ................................................................................................................................. 19

9. BLOCK DIAGRAM .................................................................................................................................. 21

10. LEVEL DIAGRAM ................................................................................................................................... 23

11. SCHEMATIC DIAGRAM......................................................................................................................... 25

12. PARTS LOCATIONS .............................................................................................................................. 45

13. MICROPROCESSOR AND IC DATA ................................................................................................... 53

14. EXPLODED VIEW AND MECHANISM PARTS LIST......................................................................... 57

15. ELECTRICAL PARTS LIST ................................................................................................................... 59

CHARGE

Portable Mini Disc Recorder

DC IN 12V

L R

LINE OUT

DIGITAL OUT

OFF

ON

➂

➁

➀

PORTABLE MINIDISC RECORDER PMD650

DIGITAL RECORDING

POWER EJECT

HP/SPK VOLUME

PHONES

TABLE OF CONTENTS

MIC

0dB

REPEAT A-B/DEL TITLE CHAR ENTER

EDIT

BACKSPACE

REC PAUSE

DISPLAY

REC MODE

MIC ATTEN

SP LP

-15dB

FLAT

ANC

-30dB MIC LINE

LIGHT

MONO (L ch)

STEREO INT MIC L R

SOURCE

HP/SPK MODE

ALC

INPUT LEVEL

ANALOG DIGITAL

INPUT SELECT

REC/MARK

KEY LOCK

STEREO

REC LEVEL

OFF

PMD650

LIMITER

MANUAL

ON

LSR

L

R

REC

LEVEL

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

R

Printed in Japan

PMD650

409S855010 MIT

3120 785 22260

First Issue 2000.03

Page 2

MARANTZ DESIGN AND SERVICE

MARANTZ AMERICA, INC.

WILDASH AUDIO SYSTEMS NZ

Using superior design and selected high grade components, MARANTZ company has created the ultimate in stereo sound.

Only original MARANTZ parts can insure that your MARANTZ product will continue to perform to the specifications for which

it is famous.

Parts for your

MARANTZ equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

440 MEDINAH ROAD

ROSELLE, ILLINOIS 60172

USA

PHONE : 630 - 307 - 3100

FAX : 630 - 307 - 2687

AMERICAS

SUPERSCOPE TECHNOLOGIES, INC.

MARANTZ PROFESSIONAL PRODUCTS

2640 WHITE OAK CIRCLE, SUITE A

AURORA, ILLINOIS 60504 USA

PHONE : 630 - 820 - 4800

FAX : 630 - 820 - 8103

AUSTRALIA

JAMO AUSTRALIA PTY LTD

1 EXPO COURT, P.O. BOX 350

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - 3 - 9543 - 1522

FAX : +61 - 3 - 9543 - 3677

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE : +64 - 9 - 8451958

FAX : +64 - 9 - 8463554

EUROPE / TRADING

MARANTZ EUROPE B.V.

P.O.BOX 80002, BUILDING SFF2

5600 JB EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2732241

FAX : +31 - 40 - 2735578

AUSTRALIA

TECHNICAL AUDIO GROUP PTY, LTD

558 DARLING STREET,

BALMAIN, NSW 2041,

AUSTRALIA

PHONE : 61 - 2 - 9810 - 5300

FAX : 61 - 2 - 9810 - 5355

THAILAND

MRZ STANDARD CO.,LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE : +66 - 2 - 222 9181

FAX : +66 - 2 - 224 6795

TAIWAN

PAI- YUING CO., LTD.

6 TH FL NO, 148 SUNG KIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE : +886 - 2 - 25221304

FAX : +886 - 2 - 25630415

BRAZIL

PHILIP DA AMAZONIA IND. ELET. ITDA

CENTRO DE INFORMACOES AO

CEP 04698-970

SAO PAULO, SP, BRAZIL

PHONE : 0800 - 123123

FAX : +55 11 534. 8988

(Discagem Direta Gratuita)

CANADA

LENBROOK INDUSTRIES LIMITED

633 GRANITE COURT,

PICKERING, ONTARIO L1W 3K1

CANADA

PHONE : 905 - 831 - 6333

FAX : 905 - 831 - 6936

SINGAPORE

WO KEE HONG (S) PTE LTD

WO KEE HONG CENTRE

NO.23, LORONG 8, TOA PAYOH

SINGAPORE 319257

PHONE : +65 2544555

FAX : +65 2502213

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

SUITE 8.1, LEVEL 8, MENARA GENESIS,

NO. 33, JALAN SULTAN ISMAIL,

50250 KUALA LUMPUR, MALAYSIA

PHONE : +60 3 - 2457677

FAX : +60 3 - 2458180

JAPAN

Technical

MARANTZ JAPAN, INC.

35- 1, 7- CHOME, SAGAMIONO

SAGAMIHARA - SHI, KANAGAWA

JAPAN 228-8505

PHONE : +81 42 748 1013

FAX : +81 42 741 9190

KOREA

MK ENTERPRISES LTD.

ROOM 604/605, ELECTRO-OFFICETEL, 16-58,

3GA, HANGANG-RO, YONGSAN-KU, SEOUL

KOREA

PHONE : +822 - 3232 - 155

FAX : +822 - 3232 - 154

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

Ref. UL Standard No. 813.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

991207MIT

Page 3

1. TECHNICAL SPECIFICATIONS

DIGITAL AUDIO SYSTEM

System

MiniDisc digital audio system

Disc

MiniDisc

Recording method

Magnetic field modulation, overwrite system

Reading method

Non-contact optical pickup (using semiconductor

laser)

Laser

Semiconductor laser

Laser Diode Properties

Material: GaAIAs

Wavelength: 780 nm

Record/playback time

SP mode (stereo): 80 minutes max.

LP mode (mono): 160 minutes max.

Revolutions

Approx. 400~900 rpm (CLV)

Error Correction

ACIRC (Advanced Cross Interleave Reed-solomon

Code)

Sampling frequency

44.1 kHz (32 kHz and 48 kHz signals converted to

44.1 kHz for recording)

Coding

ATRAC (Adaptive Transform Acoustic Coding)

Modulation System

EFM (Eight-to-Fourteen Modulation)

Number of channels

2 (stereo) or 1 (mono)

AUDIO SPECIFICATIONS

Frequency Response

20 Hz ~ 20 kHz

Signal-to-Noise Ratio (IEC-A weighted)

85 dB

Total Harmonic Distortion (at 0 VU)

0.02%

Dynamic Range

85 dB

Headphone Output Power

15 mW /32 ohms

Speaker Output Power

200 mW

Phantom Power

+48V, 5 mA

Inputs:

Reference level: -12 dB (Full scale 0 dB)

0 dBu = 0.775 Vrms

(MIC/LINE IN L/R)

Type: XLR (1: GND, 2: HOT, 3: COLD)

Input sensitivity (MIC): -60 dBu/9 kilohms

Input sensitivity (LINE): -20 dBu/47 kilohms

(DIGITAL IN)

Type: coaxial (RCA) jack

Input impedance: 75 ohms

Input level: 0.5 Vp-p

Outputs:

(LINE OUT L/R)

Type: RCA jack

Output level: 2 Vrms max./2 kilohms

(DIGITAL OUT)

Type: XLR

Output impedance: 110 ohms

Output level: 3.3 Vp-p

GENERAL

Power Supply

DC 13 V

Power Consumption

Recording: 5.5 W

Standby: 3.5 W

Dimensions (W x H x D)

264 x 54.8 x 185 mm

Weight (without battery)

1.3 kg (2 lbs. 14 oz.)

Accessories

AC adaptor :

DA600PMDF [F version]

DA600PMDU [U version]

Battery holder: 1

Carrying Strap: 1

User Guide: 1

Optional Accessories

AC adaptor :

74 DA600/02B, 74 DA600/05B : [N version]

NiCd Battery Pack (RB1100)

Carrying Case (74CLC650/09B)

Manufactured under license from Dolby Laboratories

Licensing Corporation.

Specifications subject to change without notice.

1

Page 4

2. SERVICE MODE

2-1. PRECAUTIONS FOR USE OF SERVICE MODE

1. As loading related operations will be performed regardless

of the SERVICE MODE operations being performed, be sure

to check that the disc is stopped before setting and removing it. Even if the EJECT switch is slid while the disc is

rotating during continuous playback, etc., the disc will not

stop rotating. Therefore, it will be ejected while rotating. Be

sure to slide the EJECT switch after pressing the STOP

button and the rotation of disc is stopped.

2.The erasing-protection tab is not detected in the SERVICE

MODE. Therefore, when operating in the recording laser

emission mode and pressing the REC button, the recorded

contents will be erased regardless of the position of the

tab. When using a disc that is not to be erased in the SERVICE MODE, be careful not to ENTER the continuous recording mode and traverse adjustment mode.

2-1-1. Recording Laser Emission Mode and Operating

Button

1. Continuous recording mode (CREC MODE)

2. Traverse adjustment mode (EFBAL ADJ)

3. Laser power adjustment mode (LDPWR ADJ)

4. Laser power check mode (LDPWR CHK)

5. When pressing the REC button.

2.2.

サービスモードサービスモード

2.

サービスモード

2.2.

サービスモードサービスモード

2‑1.2‑1.

サービスモード使用時の注意サービスモード使用時の注意

2‑1.

サービスモード使用時の注意

2‑1.2‑1.

サービスモード使用時の注意サービスモード使用時の注意

1. ローディング関係の動作が、サービスモードの動作とは全く

無関係に働くので、必ずディスクが停止したことを確認して

からディスクの出し入れを行ってください。連続再生中等

ディスクが回転中に

クの回転は停止しません。従って、ディスクが回転された状

態でイジェクトされますので、必ず

スクの回転が止まってから

ださい。

2.サービスモード時は、誤消去防止つめの検出を行いません。そ

のため次の項目に示す" 記録用レーザーが発光するモード "

での作業および、

なくそれまでの記録内容が消去されます。従って、消去して

はいけないディスクをやむをえずサービスモード時に使用す

る場合、連続録音モードおよびトラバース調整モードに入ら

ないように注意してください。

2‑1‑1.2‑1‑1.

記録用レーザーが発光するモードおよびボタン操作記録用レーザーが発光するモードおよびボタン操作

2‑1‑1.

記録用レーザーが発光するモードおよびボタン操作

2‑1‑1.2‑1‑1.

記録用レーザーが発光するモードおよびボタン操作記録用レーザーが発光するモードおよびボタン操作

1.連続録音モード(CRECMODE)

2.トラバース調整モード(EFBALADJ)

3.レーザーパワー調整モード(LDPWRADJ)

4.レーザーパワー確認モード(LDPWRCHK)

RECREC

5.

RECボタンを押した時

RECREC

EJECTEJECT

EJECTスイッチをスライドしてもディス

EJECTEJECT

STOPSTOP

STOPボタンを押してディ

STOPSTOP

EJECTEJECT

EJECTスイッチをスライドしてく

EJECTEJECT

RECREC

RECボタンを押した時は、つめの位置の関係

RECREC

2-2. HOW TO CONFIRM THE VERSION OF MICROPRO-

CESSOR

1. Confirm the product with Power Off.

2. While holding the FF/NEXT button, at the same time slide

the POWER switch.

3. And, the display shows "Ver=M@@S@@" (the version of

microprocessor. M:QL04 S:QU01).

4. When the display shows the version of microprocessor, slide

the POWER switch. Then the product will be in normal mode.

2-3. HOW TO SET THE SERVICE MODE

1. Confirm the product with Power Off.

2. While holding the PLAY/PAUSE button, at the same time

slide the POWER switch (At this moment the display shows

"Test Mode?" with blinking.).

3. Press the ENTER button.

4. It will be the service mode. Then the display shows “TEMP

ADJ” (the first content of table 2-2).

2-3. HOW TO STOP THE SERVICE MODE

Slide the POWER switch.

2‑2.2‑2.

マイコンバージョンの確認方法マイコンバージョンの確認方法

2‑2.

マイコンバージョンの確認方法

2‑2.2‑2.

マイコンバージョンの確認方法マイコンバージョンの確認方法

1.PowerOFF の状態にします。

2. まず、

3.マイコンバージョン表示のときは、一度PowerOFF するまで

2‑3.2‑3.

2‑3.

2‑3.2‑3.

1.PowerOFF の状態にします。

2.まず、

3.

4. この時、ディスプレイ表示は表2‑2 の1行目「TEMPADJ」が

2‑3.2‑3.

2‑3.

2‑3.2‑3.

PowerPower

PowerOFFします。以後通常動作になります。

PowerPower

FF/NEXTFF/NEXT

FF/NEXTボタンを押しながら、さらに、PowerONする

FF/NEXTFF/NEXT

と、ディスプレイに「Ver=M@@S@@」とマイコンのバージョン

が表示されます。(M:QL04S:QU01)

通常動作になりません。

サービスモードの設定方法サービスモードの設定方法

サービスモードの設定方法

サービスモードの設定方法サービスモードの設定方法

PLAYPLAY

PLAYボタンを押しながら、次にPowerONすると、ディ

PLAYPLAY

スプレイに「TestMode?」と点滅します。

ENTERENTER

ENTERボタンを押すとサービスモードになります。

ENTERENTER

表示されます。

サービスモードの解除方法サービスモードの解除方法

サービスモードの解除方法

サービスモードの解除方法サービスモードの解除方法

2

Page 5

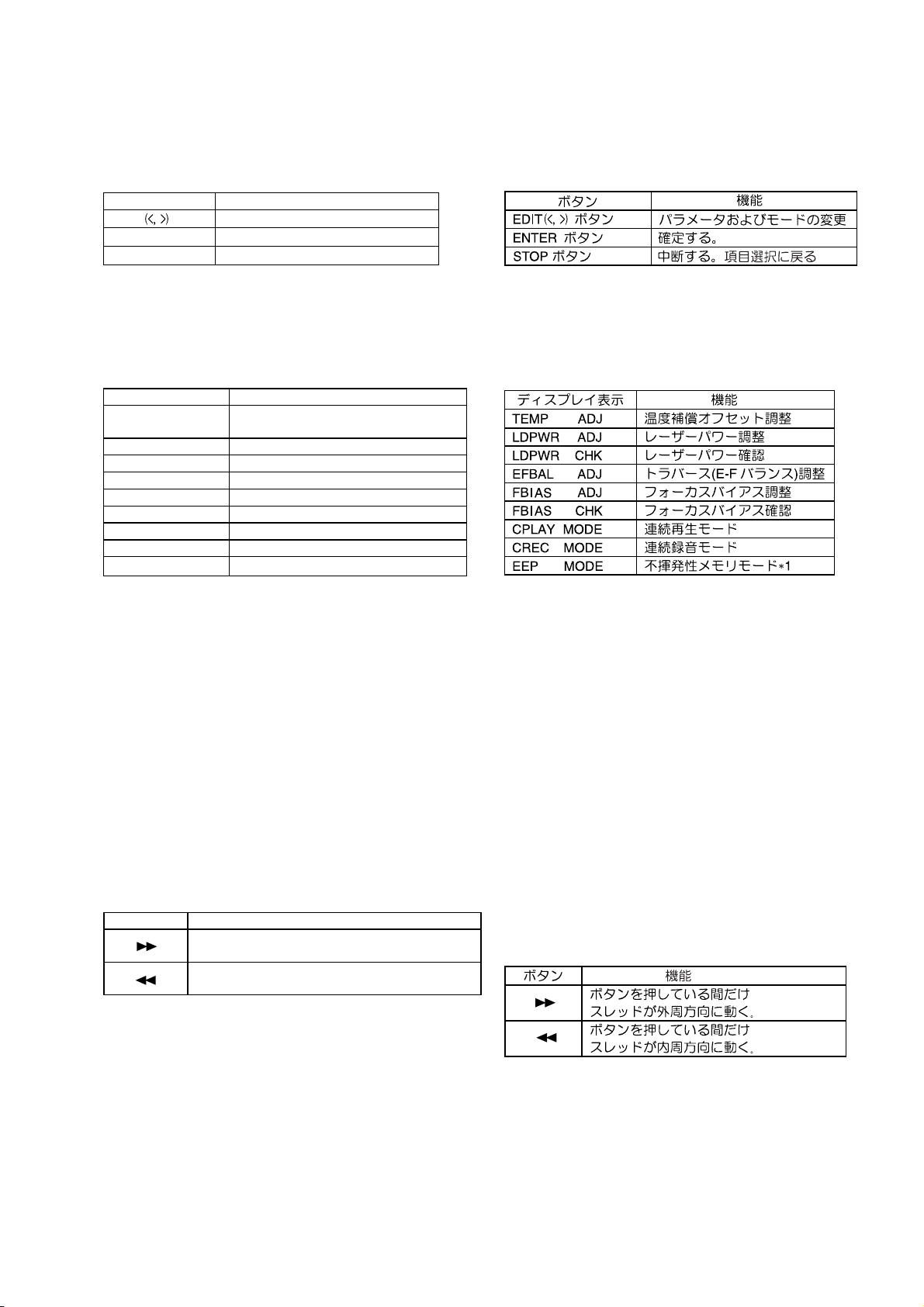

2-4. BASIC OPERATIONS OF THE SERVICE MODE

All operations are performed using the STOP button, ENTER

button, and EDIT(<, >) buttons. The functions of these buttons are as follows.

Table 2-1.

Button Function

EDIT button

ENTER button

STOP button

Changes parameters and modes.

Finalizes input.

Stops operations.

2-5. SELECTING THE SERVICE MODE

Nine SERVICE MODEs are selected by using the EDIT(<, >)

buttons.

Table 2-2.

Display Contents

TEMP ADJ

Temperature compensation offset

adjustment

LDPWR ADJ Laser power adjustment

LDPWR CHK Laser power check

EFBAL ADJ Traverse (E-F balance) adjustment

FBIAS ADJ Focus bias adjustment

FBIAS CHK Focus bias check

CPLAY MODE Continuous playback mode

CREC MODE Continuous recording mode

EEP MODE

Non-volatile memory mode (✱1)

• For detailed description of each adjustment mode, refer to

the " MD UNIT ELECTRICAL ADJUSTMENTS".

• If a different adjustment mode has been selected by mistake, press the STOP button to exit from it.

✱1: The EEP MODE is not used in servicing. If set acciden-

tally, press the STOP button immediately to exit it.

2-6. EEP MODE

This mode reads and writes the contents of the non-volatile

memory.

It is not used in servicing. If set accidentally, press the STOP

button immediately to exit it.

2-7. FUNCTIONS OF OTHER BUTTONS

Table 2-3.

2‑4.2‑4.

サービスモードの基本操作サービスモードの基本操作

2‑4.

サービスモードの基本操作

2‑4.2‑4.

サービスモードの基本操作サービスモードの基本操作

全ての操作は

ンので行います。

表2‑1にそれぞれの機能を記します。

2‑5.2‑5.

サービスモードの選択サービスモードの選択

2‑5.

サービスモードの選択

2‑5.2‑5.

サービスモードの選択サービスモードの選択

サービスモードは表2‑2に示す9項目があり、各テストモードの

選択は

•各調整モードの詳しい説明は、" MDユニット電気調整" の各項

目を参照してください。

•誤って別の調整モードに入ってしまった場合は、

を押しそのモードから抜けてください。

*1:EEPMODEは、 各調整時自動処理されるので、このモード

を直接選択しないでください。誤ってこのモードに入って

しまった場合はすぐに、

ら抜けてください。

2‑6.EEP2‑6.EEP

2‑6.EEP

2‑6.EEP2‑6.EEP

EEPモードは不揮発性メモリの内容の読み書きを行うモードです

が、このモードは各調整時自動処理されるので、このモードを直

接選択しないでください。

従って、誤ってこのモードに入ってしまった場合はすぐに、

ボタンを押してこのモードから抜けてください。

STOPSTOP

STOPボタン、

STOPSTOP

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンで選択します。

EDIT(<,>)EDIT(<,>)

モードモード

モード

モードモード

ENTERENTER

ENTERボタンおよび

ENTERENTER

表2‑1

表2‑2

STOPSTOP

STOPボタンを押してこのモードか

STOPSTOP

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタ

EDIT(<,>)EDIT(<,>)

STOPSTOP

STOPボタン

STOPSTOP

STOPSTOP

STOP

STOPSTOP

Button Contents

The sled moves to the outer circumference

only when this is pressed.

The sled moves to the inner circumference

only when this is pressed.

Note : The erasing-protection tab in not detected during the

SERVICE MODE. Recording will start regardless of the

position of the erasing-protection tab when the REC

button is pressed.

2‑7.2‑7.

その他のボタンの機能その他のボタンの機能

2‑7.

その他のボタンの機能

2‑7.2‑7.

その他のボタンの機能その他のボタンの機能

表2‑3

注意注意

::

注意

:サービスモード時は、誤消去防止つめの検出を行いませ

注意注意

::

ん。RECボタンを押すと誤消去防止つめの位置に関係な

く録音されますので注意してください。

3

Page 6

3. MD MODULE(KML-252 with PCB)

ELECTRICAL ADJUSTMENTS

3-1. PRECAUTIONS FOR CHECKING LASER DIODE

EMISSION

To check the emission of the laser diode during adjustments,

never view directly from the top as this may cause loss of

eyesight.

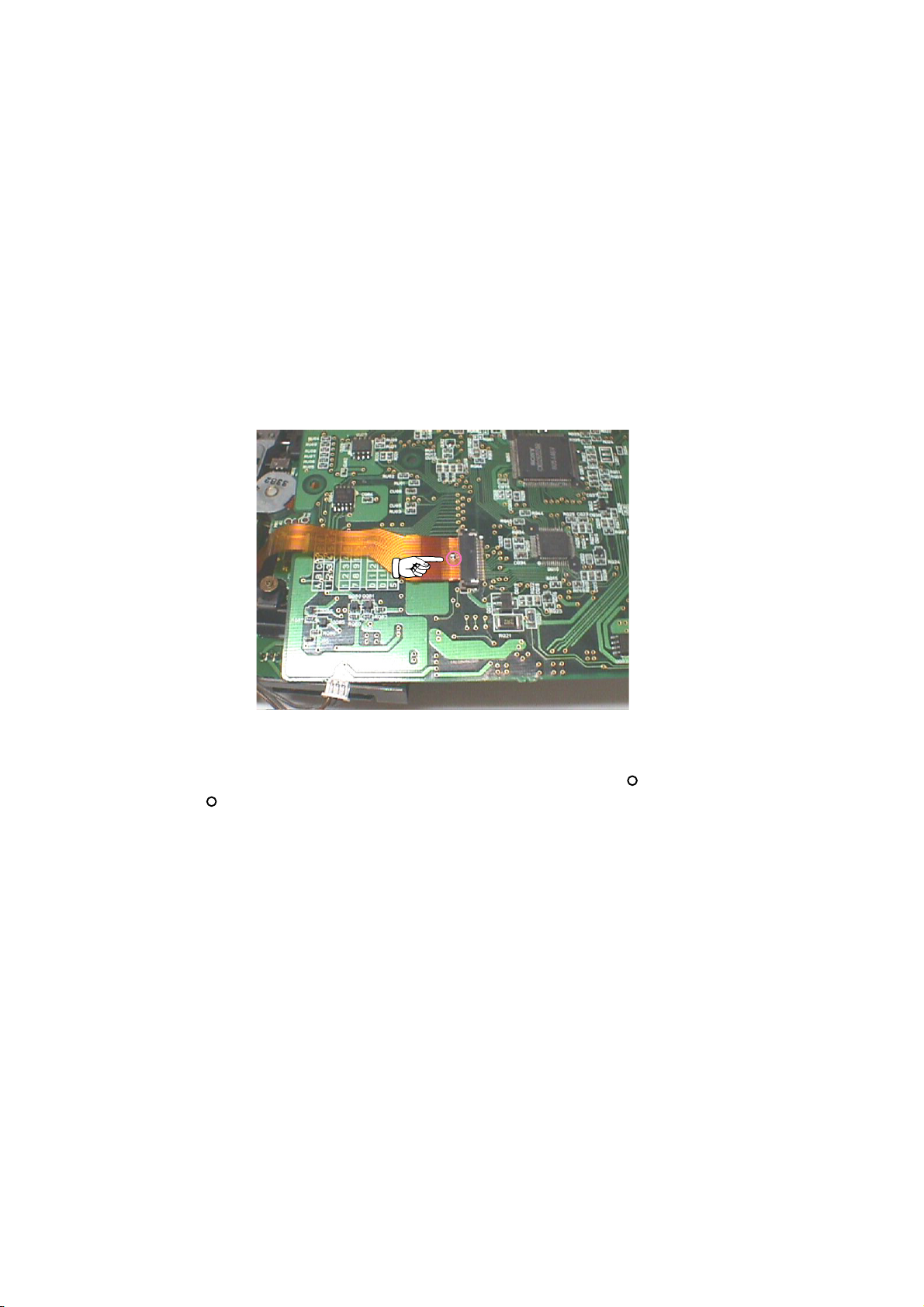

3-2. PRECAUTIONS FOR USE OF OPTICAL PICK-UP

As the laser diode in the optical pick-up is easily damaged by

static electricity, solder the laser tap of the flexible board when

using it.

Before disconnecting the connector, de-solder first. Before

connecting the connector, be careful not to remove the sol-

der. Also take adequate measures to prevent-damage by static

electricity. Handle the flexible board with care as it breaks

easily.

3.3.

MDMD

3.

3.3.

3‑1.3‑1.

3‑1.

3‑1.3‑1.

調整時にレーザーダイオードの発光を確認する場合は失明のおそ

れがありますので絶対に真上から覗かないでください。

3‑2.3‑2.

3‑2.

3‑2.3‑2.

光ピックアップ内のレーザーダイオードは非常に静電破壊し易い

ため、取扱時はフレキシブル基板のレーザータップを半田ブリッ

ジしてください。

コネクタから外す時は、事前に半田ブリッジをしてから外してく

ださい。またコネクタを差す前に半田ブリッジをとらないように

注意してください。また静電破壊を防止する対策を充分に行い作

業してください。フレキシブル基板は切れ易いので取扱に注意し

てください。

モジュールモジュール

MD

モジュール

MDMD

モジュールモジュール

レーザーダイオード発光確認時の注意レーザーダイオード発光確認時の注意

レーザーダイオード発光確認時の注意

レーザーダイオード発光確認時の注意レーザーダイオード発光確認時の注意

光ピックアップ取扱時の注意光ピックアップ取扱時の注意

光ピックアップ取扱時の注意

光ピックアップ取扱時の注意光ピックアップ取扱時の注意

(KML‑252withPCB)(KML‑252withPCB)

(KML‑252withPCB)

(KML‑252withPCB)(KML‑252withPCB)

電気調整電気調整

電気調整

電気調整電気調整

Optical pick-up flexible board

3-3. PRECAUTIONS FOR ADJUSTMENTS

1. When replacing the following parts, perform the adjust-

ments and checks with in the order shown in the follow

ing table.

Notes:

The following tools and measuring devices are necessary for

the adjustments.

• Laser power meter ( TQ8210 )

• Optical sensor ( TQ82017 )

• Oscilloscope (Measure after pre-forming CAL of prove.)

• Jitter meter

• Thermometer

If you cannot prepare them, please replace the adjusted MD

module <Part Number : ZZ409S3010> (refer to "5. HOW TO

DISASSEMBLE Fig.15").

3‑3.3‑3.

調整時の注意調整時の注意

3‑3.

調整時の注意

3‑3.3‑3.

調整時の注意調整時の注意

1.下記の部品を交換した時は、

で行ってください。

注意:

以降の調整を行うには、下記の治具、測定器が必要です。

• レーザーパワーメータ(アドバンテストTQ8210)

• オプティカルセンサー(アドバンテストTQ82017)

• オシロスコープ

(プローブのCALを行ってから測定してください。)

•ジッターメータ

•寒暖計

上記の治具、測定器がない場合には、調整済のMD モジュール

<Parts Number :ZZ409S3010> (5. 分解方法のFig.15 を参照) の

交換を行ってください。

印の調整、確認を下記表の順番

4

Page 7

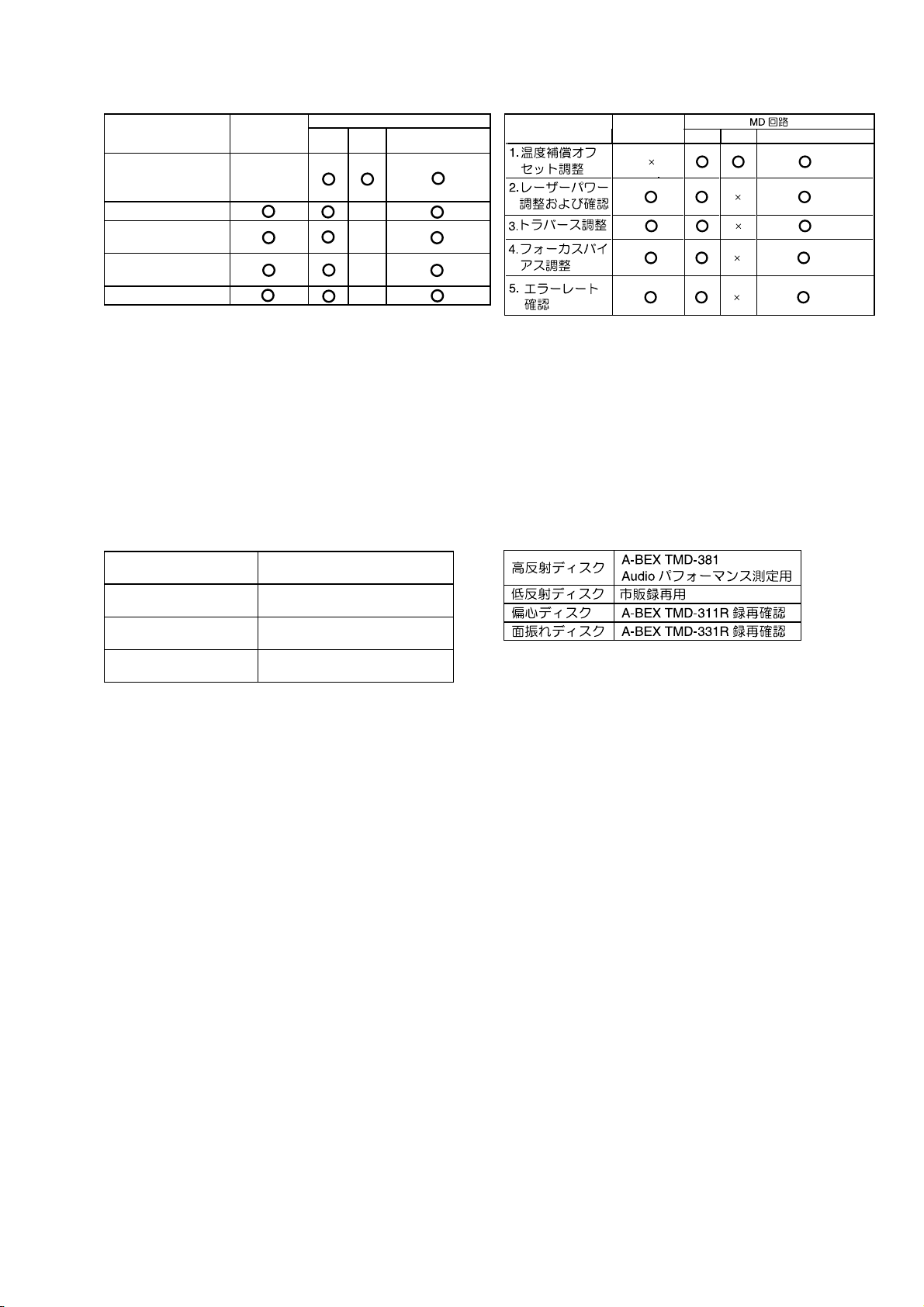

Table 3-1.

j

j

j

表3‑1

MD

board

MD Mechanism

KML-252

(001M)

QU20

DQ10

MD circuit

QU01, QQ01,

QQ10, QQ50

1.Temperature

compensation

offset ad

ustment

2.Laser power

3.Traverse

ad

ustment

4.Focus bias

ad

ustment

5.Error rate check

X

X

X

X

X

2. Set the SERVICE MODE when performing adjustments.

After completing the adjustments, exit the SERVICE MODE.

3. Perform the adjustments in the order shown.

4. When observing several signals on the oscilloscope, etc.,

make sure that VC and ground do not connect inside the

oscilloscope.

(VC and ground will become short-circuited)

5. Test disc

Table 3-2

High reflection disc

Low reflection disc

Eccentricity disc

Surface distortion disc

A-BEX, TMD-381, for audio

performance measurement

Blank disc on market for

Rec/Play

A-BEX, TMD-311R, Confirm

Rec/Play operation

A-BEX, TMD-331R, Confirm

Rec/Play operation

3-4. CREATING CONTINUOUSLY RECORDED DISC

This disc is used in focus bias adjustment and error rate check.

The following describes how to create a continuous record-

ing disc.

1. Set the SERVICE MODE.

2. Insert a low reflection disc (blank disc) commercially avail-

able.

3. Use the EDIT(<, >) buttons and display "CREC MODE".

4. Press the ENTER button and display "CREC MID".

"CREC (0300)" is displayed and recording starts.

5. Complete recording within 5 minutes.

6. Press the STOP button and stop recording.

7. Slide the EJECT switch and remove the low reflection disc.

The above has been how to create a continuous recording

data for the focus bias adjustment and error rate check.

Note : Be careful not to apply vibration during continuous

recording.

3-5. TEMPERATURE COMPENSATION OFFSET

ADJUSTMENT

Save the temperature data at that time in the non-volatile

memory as 25 °C reference data.

Notes :

1. Usually, do not perform this adjustment.

MD Mechanism

KML-252

(001M)

2.調整はサービスモードにして行ってください。

調整終了後はサービスモードを解除してください。

3.調整は掲載順に行ってください。

4.オシロスコープ等で複数の信号を見る場合、VC とGND がオシ

ロスコープ内部で接続されないようにしてください。

(VCとGND がショートしてしまいます。)

5.テストディスク

3‑4.3‑4.

連続録音ディスクの作り方連続録音ディスクの作り方

3‑4.

連続録音ディスクの作り方

3‑4.3‑4.

連続録音ディスクの作り方連続録音ディスクの作り方

このディスクはフォーカスバイアス調整および確認、エラーレー

ト確認において使用するディスクです。以下その連続録音ディス

クの作り方を記します。レーザーは通常、間欠発光ですが、連続

録音中は連続発光しています。

1.市販の低反射ディスク(ブランクディスク)を挿入する。

EDIT(<,>)EDIT(<,>)

2.

EDIT(<,>)ボタンを押して表示を" CRECMODE" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

3.

ENTERボタンを押すと" CRECMID" になる。

ENTERENTER

"CREC0300" と表示し録音を始める(数字が変化する)。

4.5 分間以内に録音を終えてください。

STOPSTOP

5.

STOP ボタンを押して録音を止める。

STOPSTOP

EJECTEJECT

6.

EJECTスイッチをスライドして低反射ディスクを取り出す。

EJECTEJECT

以上でフォーカスバイアス調整および確認、エラーレート確認用

の連続録音ディスクを作ることができます。

注意注意

::

注意

:連続録音中は振動などが加わらないように注意してくだ

注意注意

::

さい。

3‑5.3‑5.

温度補償オフセット調整温度補償オフセット調整

3‑5.

温度補償オフセット調整

3‑5.3‑5.

温度補償オフセット調整温度補償オフセット調整

その時点の温度データを25 ℃基準データとして不揮発性メモリ

にセーブします。

注意注意

::

注意

:

注意注意

::

1.通常、この調整は行わないでください。

2.この調整を行う際の周囲温度は22℃〜28℃の範囲で行うよ

うにしてください。また、セットの内部温度が周囲温度と同

じ22℃〜28 ℃の状態である電源投入直後に行ってください。

3.DQ01交換後は、部品の温度が十分周囲温度になってからこの調

整を行ってください。

QU20

表3‑2

QU01,QQ01,QQ10,QQ50

DQ10

5

Page 8

2. Perform this adjustment in an ambient temperature of 22

°C to 28 °C. Perform it immediately after the power is turned

on when the internal temperature of the unit is the same as

the ambient temperature of 22 °C to 28 °C.

3. When DQ10 has been replaced, perform this adjustment

after the temperature of this part has become the ambient

temperature.

Adjusting Method:

1. Selected by Use the EDIT(<, >) buttons and display "TEMP

ADJ".

2. Press the ENTER button. The display shows "TEMP +25C".

By using the EDIT(<, >) buttons, set the current temperature.

3. To save the data, press the ENTER button.

4. When the ENTER button is pressed, "DATA SAVE" will be

displayed for 1 second, followed by "TEMP ADJ".

3-6. LASER POWER ADJUSTMENT

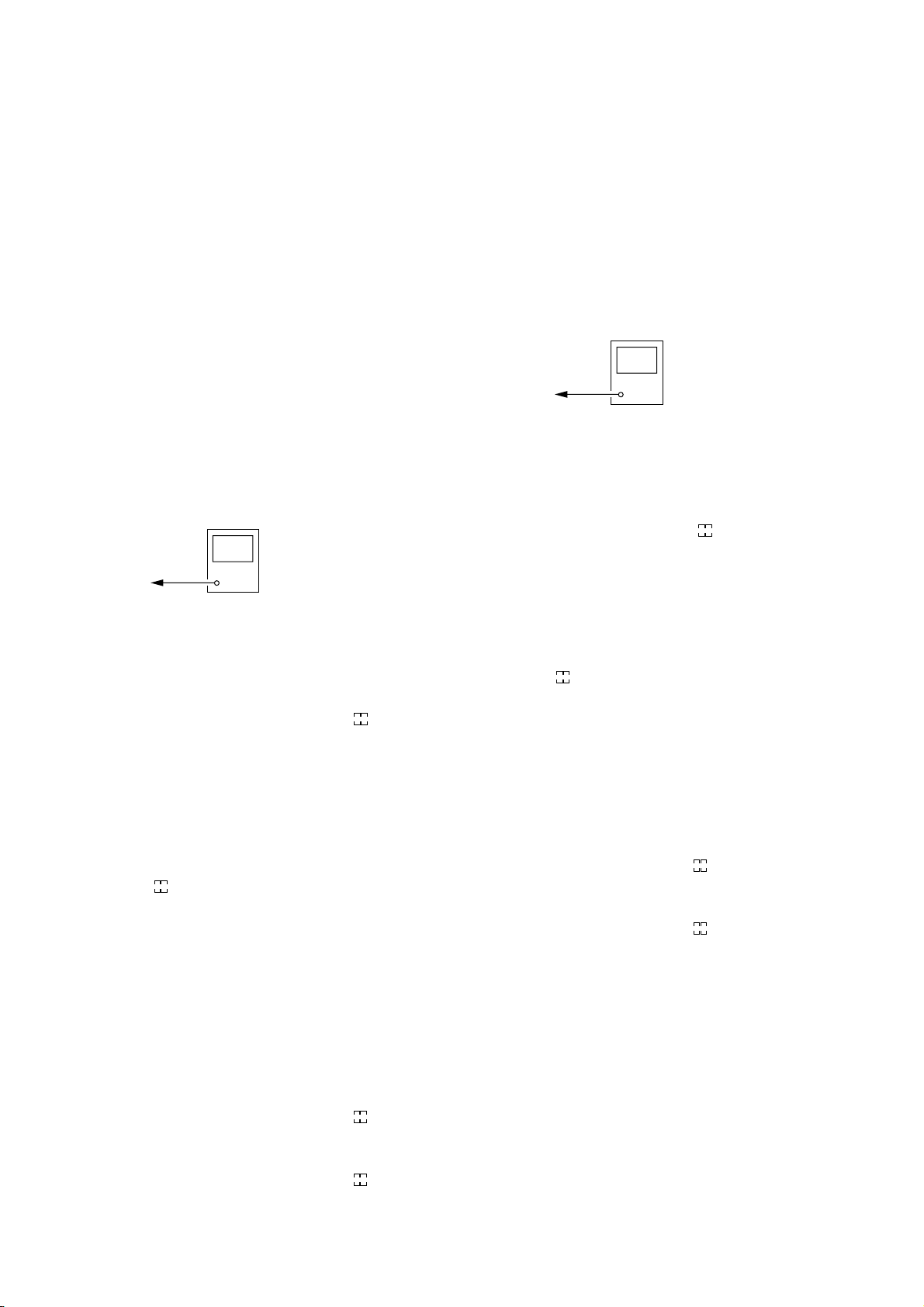

Connection:

Laser

power mater

Optical pick-up

objective lens

Adjusting Method:

1. Set the sensor disc of power meter into the MD mechanism.

2. Selected by Use the EDIT(<, >) buttons and display "LDPWR

ADJ". (Laser power : for adjustment)

3. Press the ENTER button and display "LD 0.9 $

". (Then

the pickup will move to inside automatically.)

4. Selected by Use the EDIT(<, >) buttons so that the reading

of the laser power meter becomes 0.88 to 0.92 mW.

Set the range control on the laser power meter to 10 mW,

then press the ENTER button to save the adjustment result

in the non-volatile memory. ("DATA SAVE" will be displayed

for a moment.)

5. Then "LD 7.0 $ " will be displayed.

6. Press the PLAY button, selected by Use the EDIT(<, >)

buttons so that the reading of the laser power meter becomes 6.95 to 7.05 mW, press the ENTER button and save

the adjustment result in the non-volatile memory. ("DATA

SAVE" will be displayed for a moment.)

Note : The emission stops after 10 seconds automatically.

When the adjustment resume, press the PLAY button.

7. Selected by Use the EDIT(<, >) buttons and display

"LDPWR CHK".

8. Press the ENTER button and display "LD 0.9 $

".

Check that the reading of the laser power meter becomes

0.80 to 0.96 mW.

9. Press the ENTER button and display "LD 7.0 $

".

Check that the reading of the laser power meter satisfy 6.95

to 7.05 mW.

調整方法調整方法

調整方法

調整方法調整方法

1.

2.

3. 温度表示を室温に合わせた後、

3‑6.3‑6.

3‑6.

3‑6.3‑6.

接続接続

接続

接続接続

::

:

::

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を"TEMPADJ" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

ENTERボタンを押すと"TEMP+25"と表示される。その時

ENTERENTER

(<,>)(<,>)

(<,>)ボタンを使って現在の室温に合わせる。

(<,>)(<,>)

ENTERENTER

ENTERボタンを押すと入力した

ENTERENTER

データをEEPROM に書き込み、"DATASAVE"を1秒間表示して

から項目選択に戻ります。

レーザーパワー調整および確認レーザーパワー調整および確認

レーザーパワー調整および確認

レーザーパワー調整および確認レーザーパワー調整および確認

::

:

::

EDITEDIT

EDIT

EDITEDIT

Laser

power mater

Optical pick-up

objective lens

調整方法調整方法

調整方法

調整方法調整方法

1.レーザーパワーメータのセンサーMDディスクをMDメカにセッ

2.

3.

4. レーザーパワーメータの読みが0.9mW±0.02mWになるよう

5.表示が"LD7.0$

6.

7.

8.

9.

10.

STOPSTOP

STOPボタンはいつでも受け付け、レーザ発光を止めます。

STOPSTOP

3‑7.3‑7.

3‑7.

3‑7.3‑7.

トラバース調整には、2種類のディスクで4つのデータをセーブ

します。

注意注意

注意

注意注意

::

:

::

トする。

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を "LDPWRADJ" にする。(レー

EDIT(<,>)EDIT(<,>)

ザーパワー:調整用)

ENTERENTER

ENTERボタンを押して表示を"LD 0.9 $

ENTERENTER

ピックアップは自動的に最内周に移動する。)

EDIT(<,>)EDIT(<,>)

に

EDIT(<,>)ボタンを押して調整する。次にレーザーパワー

EDIT(<,>)EDIT(<,>)

メータのレンジつまみを10mWにセットしてから

ンを押して不揮発性メモリに調整結果をセーブする。(この時、

一瞬"DATASAVE" と表示される。)

" になる。

PLAYPLAY

PLAYボタンを押して(レーザーが発光する)、レーザーパワー

PLAYPLAY

メータの読みが7.0mW± 0.05mW になるように

ボタンを押して調整し、

に調整結果をセーブする。(この時、一瞬"DATASAVE " と表示さ

れる。)

注意注意

::

注意

:発光は、10 秒で自動的に停止しますが、その場合は

注意注意

::

PLAYPLAY

PLAYボタンを押して、調整を行ってください。

PLAYPLAY

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を"LDPWRCHK" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

ENTERボタンを押して表示を"LD0.9$

ENTERENTER

レーザーパワーメータの読みが0.9mW±0.02mWであること

を確認する。

ENTERENTER

ENTERボタンを押して表示を"LD7.0$

ENTERENTER

レーザーパワーメータの読みが7.0mW±0.05mWであること

確認する。

STOPSTOP

STOPボタンを押してレーザー発光を止める。表示は"LDPWR

STOPSTOP

CHK" に戻る。

トラバーストラバース

トラバース

トラバーストラバース

::

:記録済ディスクをこの調整に使用すると書き込み時デー

::

タが消去されます。

(E‑F(E‑F

(E‑F

(E‑F(E‑F

ENTERENTER

ENTERボタンを押して不揮発性メモリ

ENTERENTER

バランスバランス

バランス

バランスバランス

))

調整調整

)

調整

))

調整調整

" にする。(この時、

ENTERENTER

ENTERボタ

ENTERENTER

EDIT(<,>)EDIT(<,>)

EDIT(<,>)

EDIT(<,>)EDIT(<,>)

" にする。この時の

" にする。この時の

6

Page 9

10. Press the STOP button and display "LDPWR CHK". and

stop the laser emission.

The STOP button is effective at all times to stop the laser

emission.

接続接続

接続

接続接続

::

:

::

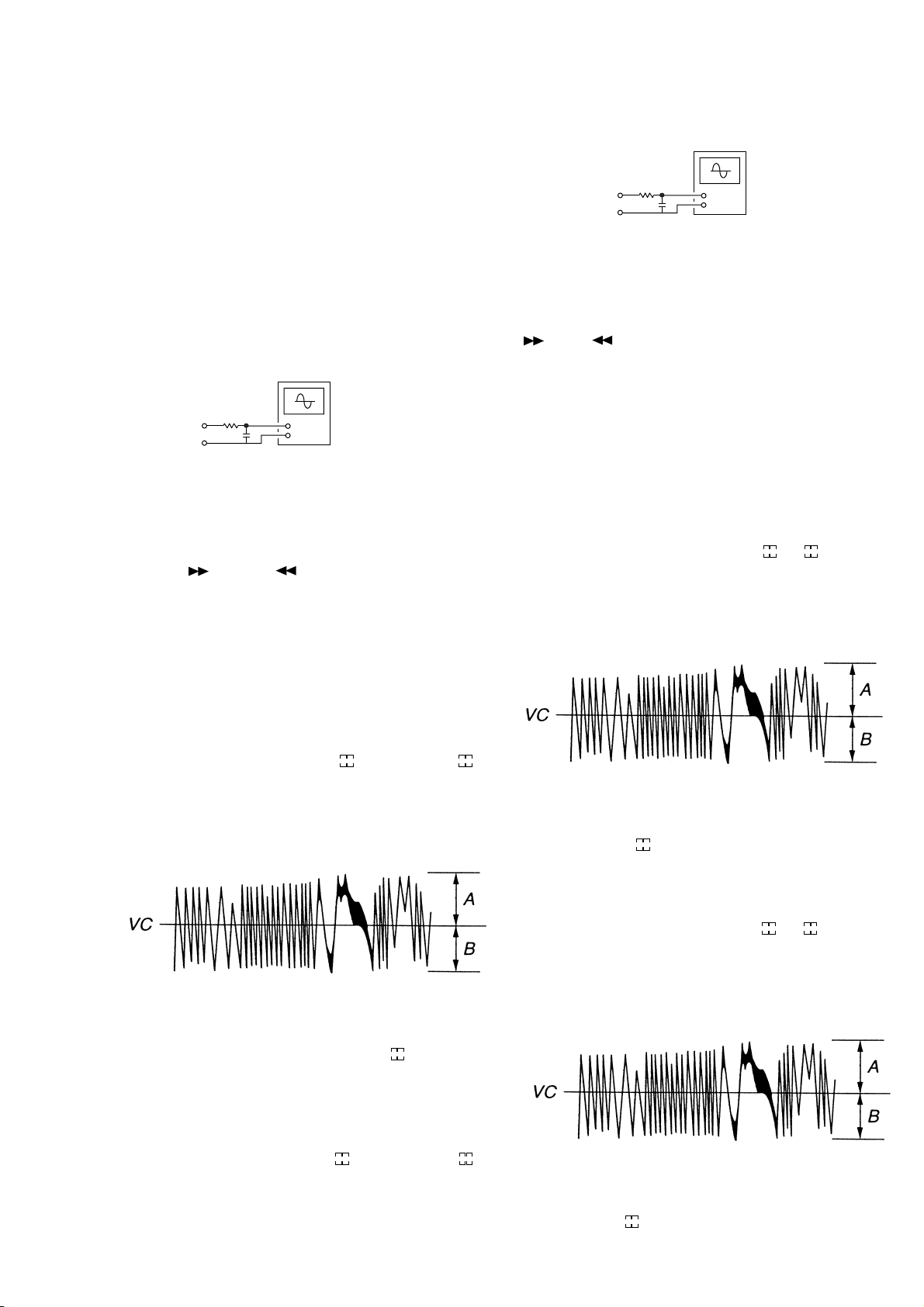

Osilloscope

(DC range)

3-7. TRAVERSE (E-F BALANCE) ADJUSTMENT

Note 1 : Data will be erased during MO reading if a recorded

disc is used in this adjustment.

Note 2 : If the traverse waveform is not clear. connect the

oscilloscope as shown in the following figure so that

it can be seen more clearly.

Connection:

Osilloscope

(DC range)

JQ20 pin 3 (TEO)

JQ20 pin 2 (VC)

330k

10p

+

-

V : 0.1 V/div

( )

H : 10 ms/div

Adjusting Method:

1. Connect an oscilloscope to JQ20 pin 3 (TEO) and JQ20

pin 2 (VC) of the MD board (PQ01).

2. Load a low reflection disc (any available on the market).

(Refer to Note 1.)

3. Press the

button or button and move the optical

pick-up outside the pit.

4. Use the EDIT(<, >) buttons and display "EFBAL ADJ".

5. Press the ENTER button and display "EFBAL MO".

(Laser power READ power/Focus servo ON/tracking servo

OFF/spindle (S) servo ON)

6. Press the ENTER button.

7. Use the EDIT(<, >) buttons so that the waveforms of the

oscilloscope becomes the specified value. (When the the

EDIT(<, >) buttons is Used, the "

" of "MOr EFB= "

changes and the waveform changes.) In this adjustment,

waveform varies at intervals of approx. 2%. Adjust the waveform so that the specified value is satisfied as much as

possible. (MO read power traverse adjustment)

(Traverse Waveform)

specification : A = B

8. Press the ENTER button, and save the result of adjustment to the non-volatile memory. ("DATA SAVE" will be

displayed for a moment. Then "MOw EFB=

" will be displayed.) The optical pick-up moves to the pit area automatically and servo is imposed.

9. Use the EDIT(<, >) buttons so that the waveforms of the

oscilloscope becomes the specified value. (When the the

EDIT(<, >) buttons is Used, the "

" of "MOw EFB= "

changes and the waveform changes.) In this adjustment,

waveform varies at intervals of approx. 2%. Adjust the

waveform so that the specified value is satisfied as much

as possible.

JQ20 pin 3 (TEO)

JQ20 pin 2 (VC)

調整方法調整方法

調整方法

調整方法調整方法

1.オシロスコープをMD基板(PQ01)のJQ203 ピン(TEO)とJQ20

2.市販の低反射ディスク(ブランクディスク)を挿入する。(注意

3.

4.

5.

6. 再度、

7. オシロスコープの波形が規格値になるように

::

:

::

2ピン(VC)に接続する。

.参照)

ボタン、 ボタンを押して光ピックアップをピット部よ

り外周に移動する。

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を"EFBALADJ" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

ENTERボタンを押して表示を"EFBALMO" にする。

ENTERENTER

(これはレーザーパワー: READ パワー,フォーカスサーボ

:ON, トラッキングサーボ:OFF,スピンドル(S)サーボ:

ONの状態)

ENTERENTER

ENTERボタンを押します。

ENTERENTER

タンを押して調整する。

EDIT(<,>)EDIT(<,>)

(

EDIT(<,>)ボタンを押すと、"MOrEFB=

EDIT(<,>)EDIT(<,>)

化し、波形も変化します。)

この調整は約2%刻みで変化し、最も規格値に近づくように

調整する。

(MOリードパワートラバース調整)

330k

10p

+

-

V : 0.1 V/div

( )

H : 10 ms/div

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボ

EDIT(<,>)EDIT(<,>)

" の" " 数字が変

(トラバース波形規格:A=B)

ENTERENTER

8.

ENTERボタンを押して不揮発性メモリに調整結果をセーブす

ENTERENTER

る。(この時、一瞬 "DATASAVE" と表示される。 )

その後に"MOwEFB=

周まで光ピックアップが移動してサーボがかかる。

9.この時のオシロスコープの波形が規格値に近づくように

(<,>)(<,>)

(<,>)ボタンを押して調整する。

(<,>)(<,>)

EDIT(<,>)EDIT(<,>)

(

EDIT(<,>)ボタンを押すと、"MOwEFB=

EDIT(<,>)EDIT(<,>)

化し、波形も変化します。)

この調整は約2%刻みで変化し、最も規格値に近づくように調

整する。

(MOライトパワートラバース調整)

"と表示される。自動的にピット部の内

" の" " 数字が変

(トラバース波形規格:A=B)

ENTERENTER

10.

ENTERボタンを押して不揮発性メモリに調整結果をセーブす

ENTERENTER

る。(この時、一瞬 "DATASAVE" と表示される。)

その後"MOpEFB=

" と表示される。

7

EDITEDIT

EDIT

EDITEDIT

Page 10

(Traverse Waveform)

specification : A = B

10. Press the ENTER button, and save the result of adjust-

ment to the non-volatile memory. ("DATA SAVE" will be

displayed for a moment. Then "MOp EFB=

" will be dis-

played.)

11. Use the EDIT(<, >) buttons so that the waveforms of the

oscilloscope becomes the specified value. (When the the

EDIT(<, >) buttons is Used, the " " of "MOp EFB= "

changes and the waveform changes.) In this adjustment,

waveform varies at intervals of approx. 2%. Adjust the

waveform so that the specified value is satisfied as much

as possible.

(MO write power traverse adjustment)

(Traverse Waveform)

specification : A = B

12. Press the ENTER button, and save the result of adjust-

ment to the non volatile memory. ("DATA SAVE" will be

displayed for a moment.) Then "MOp EFB=

" will be dis-

played.

13. Slide the EJECT switch and remove the low reflection

disc.

14. Load the test disc. ( High reflection disc TMD-381 )

15. Press the ENTER button and display "CD EFB=

".

16. Press the ENTER button. Servo is imposed automatically.

17. Use the EDIT(<, >) buttons so that the waveforms of the

oscilloscope becomes the specified value. (When the the

EDIT(<, >) buttons is Used, the " " of "CD EFB= "

changes and the waveform changes.) In this adjustment,

waveform varies at intervals of approx. 2%. Adjust the

waveform so that the specified value is satisfied as much

as possible.

(Traverse Waveform)

11. オシロスコープの波形が規格値になるように

タンを押して調整する。

EDIT(<,>)EDIT(<,>)

(

EDIT(<,>)ボタンを押すと、"MOpEFB=

EDIT(<,>)EDIT(<,>)

化し、波形も変化します。)

この調整は約2%刻みで変化し、最も規格値に近づくように

調整する。

(ピットトラバース調整)

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボ

EDIT(<,>)EDIT(<,>)

" の" " 数字が変

(トラバース波形規格:A=B)

ENTERENTER

12.

ENTERボタンを押して不揮発性メモリに調整結果をセーブす

ENTERENTER

る。(この時、一瞬"DATASAVE" と表示される。)

EJECTEJECT

13.

EJECTスイッチをスライドして低反射ディスクを取り出す。

EJECTEJECT

14.テストディスク高反射ディスクA‑BEXTMD‑381を挿入する。

ENTERENTER

15.

ENTERボタンを押して表示を"CDEFB=

ENTERENTER

16.再度、

17. オシロスコープの波形が規格値に近づくように

ENTERENTER

ENTERボタンを押します。自動的にサーボがかかりま

ENTERENTER

す。

ボタンを押して調整する。

EDIT(<,>)EDIT(<,>)

(

EDIT(<,>)ボタンを押すと、"CDEFB=

EDIT(<,>)EDIT(<,>)

化し、波形も変化します。)

この調整は約2%刻みで変化し、最も規格値に近づくように調

整する。

" にする。

EDIT(<,>)EDIT(<,>)

EDIT(<,>)

EDIT(<,>)EDIT(<,>)

" の" " 数字が変

(トラバース波形規格:A=B)

ENTERENTER

18.

ENTERボタンを押して不揮発性メモリに調整結果をセーブす

ENTERENTER

る。(この時、一瞬"DATASAVE" と表示される。)

その後に"EFBALADJ" と表示される。

EJECTEJECT

19.

EJECTスイッチをスライドしてテストディスク高反射ディス

EJECTEJECT

クA‑BEXTMD‑381を取り出す。

3‑8.3‑8.

フォーカスバイアス調整フォーカスバイアス調整

3‑8.

フォーカスバイアス調整

3‑8.3‑8.

フォーカスバイアス調整フォーカスバイアス調整

接続接続

::

接続

:

接続接続

::

Jitter Meter

JQ20 1pin(RF)

JQ20 2pin(VC)

+

-

specification : A = B

調整方法調整方法

調整方法

調整方法調整方法

1.連続録音済ディスク("3-4. 連続録音ディスクの作り方"を参

2.

3.

::

:

::

照してください。)を挿入する。

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を"FBIASADJ" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

ENTERボタンを押して表示を"a=

ENTERENTER

" にする。

8

Page 11

18. Press the ENTER button, and save the result of adjustment to the non-volatile memory. ("DATA SAVE" will be displayed for a moment. Then "EFBAL ADJ" will be displayed.)

19. Press the EJECT switch and remove the test disc. ( High

reflection disc TMD-381 )

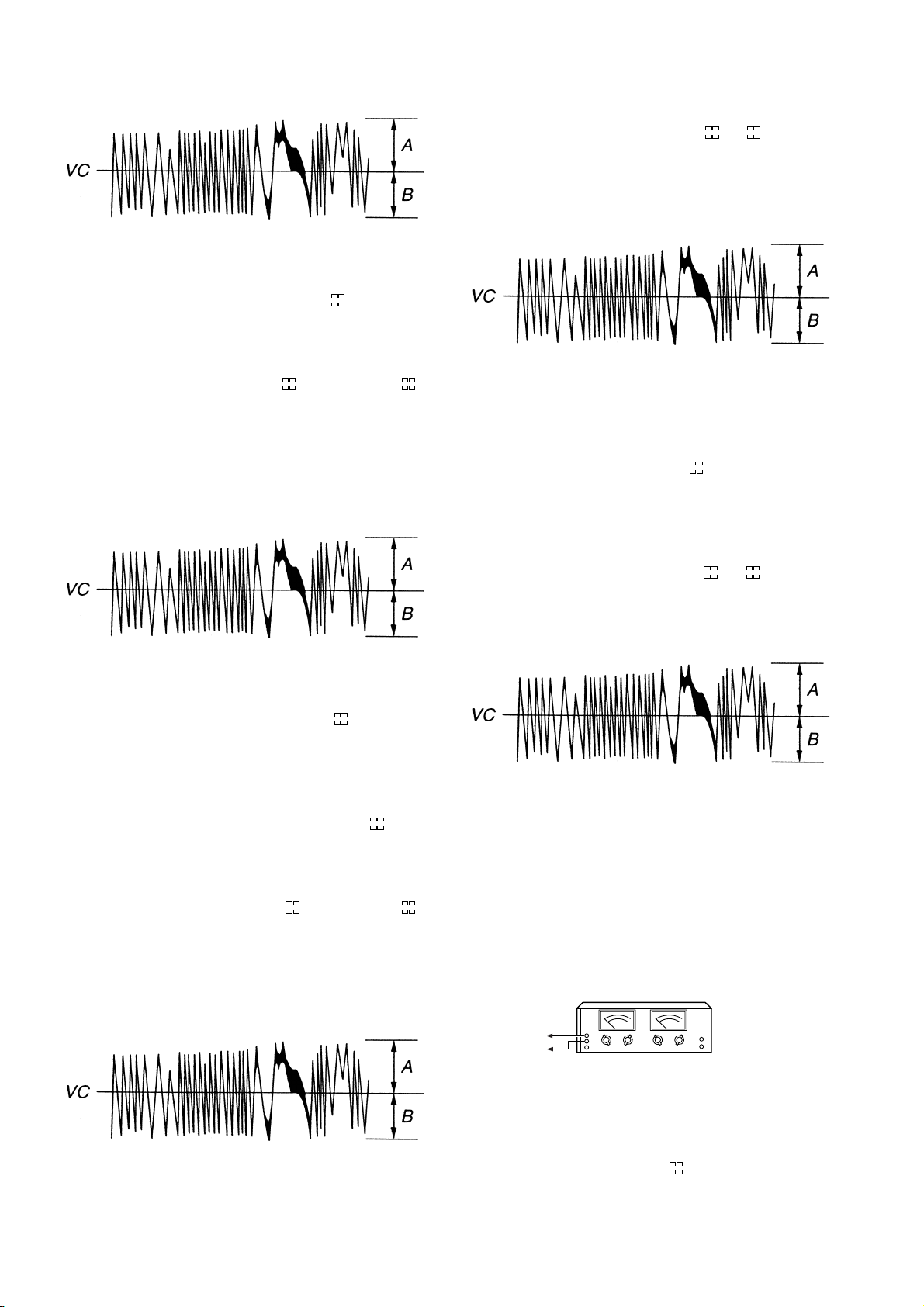

3-8. FOCUS BIAS ADJUSTMENT

Connection:

Jitter Meter

JQ20 1pin(RF)

JQ20 2pin(VC)

+

-

Adjusting Method:

1. Load a continuously recorded disc (Refer to "3-4. Creating

MO Continuously Recorded. Disc".).

2. Use the EDIT(<, >) buttons and display "FBIAS ADJ".

3. Press the ENTER button and display "a = ".

4. Press the ">" of the EDIT(<, >) button and find the focus

bias value at which the reading of the jitter meter becomes

27 ns to 30 ns. (Refer to note 2.) If the reading of the jitter

meter is over 30 ns, press the "<" of the EDIT(<, >) button.

It will be down.

5. Press the ENTER button and display "b = ".

6. Press the "<" of the EDIT(<, >) button and find the focus

bias value at which the reading of the jitter meter becomes

27 ns to 30 ns. (Refer to note 2.) If the reading of the jitter

meter is over 30 ns, press the ">" of the EDIT(<, >) button.

It will be down.

Note : If the sarvo is out and It stops to adjust, press the STOP

button. The display will show "ADJ CANCEL", and the

display return to "FBIAS ADJ".

7. Press the ENTER button, and save the result of adjustment

to the non-volatile memory. ("DATA SAVE" will be displayed

for a moment. ) Then "c =

8. Press the DISPLAY button and display "C1

" will be displayed.

AD " and

check that the C1 error rate is below 50 and ADER is 00.

Then press the STOP button. The first four digits indicate

the C1 error rate, the two digits after indicate ADER.

9. If the reading of the jitter meter is over 28 ns, press the

STOP button ("FBIAS ADJ" will be displayed.) and adjust it

again.

10. Press the STOP button and slide the EJECT switch to

remove the continuously recorded disc.

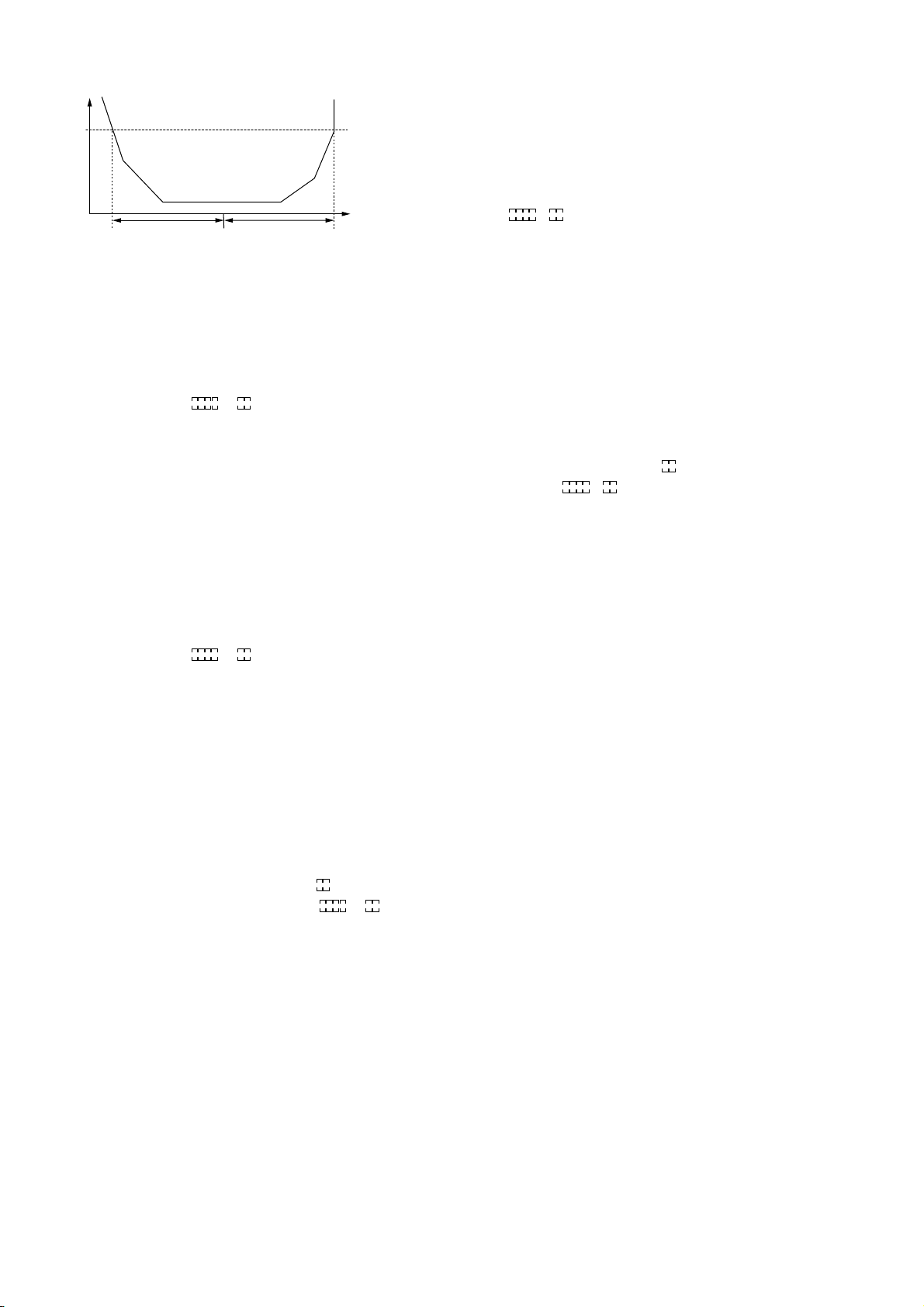

Note 1 : The relation between the C1 error and jiter meter is as

shown in the following figure. Find points a and b in

the following figure using the above adjustment. The

focal point position c is automatically calculated from

points

a

and b.

Note 2 : As the jiter meter changes, perform the adjustment

using the average vale.

EDIT(>)EDIT(>)

4.

EDIT(>)ボタン(必ず、>)を押してジッターメータ値が27nS

EDIT(>)EDIT(>)

〜30nSになるフォーカスバイアス量を見つける。(注意2.参

照)30nSを超えたときのみ

ジッターの最大値を設定)

ENTERENTER

5.

ENTERボタンを押して表示を"b=

ENTERENTER

EDIT(<)EDIT(<)

6.

EDIT(<)ボタン(必ず、<)を押してジッターメータ値が27nS

EDIT(<)EDIT(<)

〜30nSになるフォーカスバイアス量を見つける。(注意2.参

照)30nSを超えたときのみ

ジッターの最大値を設定)

注意注意

::

注意

:サーボが外れたとき及び調整を中止するときは、

注意注意

::

ボタンを押すと"ADJCANCEL"を表示して(調整データは

セーブされない。)、その後表示は"FBIASADJ" に戻る。

(項目選択)

STOPSTOP

STOPボタンはいつでも受け付け、調整を止めます。

STOPSTOP

ENTERENTER

7.

ENTER ボタンを押して不揮発性メモリに調整結果をセーブす

ENTERENTER

る。(この時、一瞬 "DATASAVE" と表示される。)

その後"c=

8.この時、

C1エラーレート表示が50以下でADERが00であることを確認

STOPSTOP

して

STOPボタンを押す。最初の4 桁の数字がC1 エラーレー

STOPSTOP

ト、後の2桁の数字が ADERを示す。

9.ジッターメータ値が28nS以上の時は

度、調整をする。"FBIASADJ" に戻る。(項目選択)

STOPSTOP

10.

STOPボタンを押し、次に

STOPSTOP

録音済ディスクを取り出す。

注意注意

::

注意

:

注意注意

::

1.C1エラーとジッターメータ値の関係を示すと下図のようにな

ります。上記調整で下図の

cc

aa

c

点は

a

cc

aa

2.ジッターメータ値は変動しますので、平均値を読み調整を行

うようにしてください。

Error

30ns

b

3‑9.3‑9.

エラーレート確認エラーレート確認

3‑9.

エラーレート確認

3‑9.3‑9.

エラーレート確認エラーレート確認

3‑9‑1.3‑9‑1.

3‑9‑1.

3‑9‑1.3‑9‑1.

確認方法確認方法

確認方法

確認方法確認方法

1.高反射ディスクA‑BEXTMD‑381 を挿入する。

2.

3.

4.C1エラーレートが20 以下であることを確認する。

5.

高反射ディスクエラーレート確認高反射ディスクエラーレート確認

高反射ディスクエラーレート確認

高反射ディスクエラーレート確認高反射ディスクエラーレート確認

::

:

::

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を"CPLAYMODE" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

ENTER ボタンを押すと表示が1 秒間"CPLAYMID" となった後、

ENTERENTER

表示が"C1

STOPSTOP

STOP ボタンを押して再生を止め、

STOPSTOP

して高反射ディスクを取り出す。

" と表示される。(c点は自動調整)

DISPLAYDISPLAY

DISPLAYボタンを押して、"C1

DISPLAYDISPLAY

bb

,

b

点から自動的に計算し求めます。

bb

AD " に変わる。

(<)(<)

(<)ボタンで少し下げる。(a点側の

(<)(<)

" にする。

(>)(>)

(>)ボタンで少し下げる。(b点側の

(>)(>)

AD " と表示する。

STOPSTOP

STOPボタンを押して再

STOPSTOP

EJECTEJECT

EJECTスイッチをスライドして連続

EJECTEJECT

aa

bb

a

,

b

点を見つけます。合焦点位置

aa

bb

Focus bias value

c

EJECTEJECT

EJECTスイッチをスライド

EJECTEJECT

(F.BIAS)

a

STOPSTOP

STOP

STOPSTOP

9

Page 12

Error

30ns

Focus bias value

b

c

(F.BIAS)

a

3-9. ERROR RATE CHECK

3-9-1. High Reflection Disc Error Rate Check

Checking Method:

1. Load a test disc.( High reflection disc TMD-381 )

2. Use the EDIT(<, >) buttons and display "CPLAY MODE" .

3. Press the ENTER button and the display shows "CPLAY MID"

for 1 second. Then "C1 AD " is displayed.

4. Check that the C1 error is below 20.

5. Press the STOP button, stop playback, slide the EJECT

switch, and remove the test disc. ( High reflection disc TMD381 )

3-9-2. Low Reflection Disc Error Rate Check

Checking Method:

1. Load a continuously recorded disc (Refer to "3-4. Creating

MO Continuously Recorded Disc".).

2. Use the EDIT(<, >) buttons and display "CPLAY MODE".

3. Press the ENTER button and the display shows "CPLAY MID"

for 1 second. Then "C1 AD " is displayed.

4. If the C1 error is below 50, check that ADER is 00.

5. Press the STOP button, stop playback, slide the EJECT switch

and remove the continuously recorded disc.

3‑9‑2.3‑9‑2.

3‑9‑2.

3‑9‑2.3‑9‑2.

確認方法確認方法

確認方法

確認方法確認方法

1.連続録音済ディスク("3-4. 連続録音ディスクの作り方"を参照

2.

3.

4.C1エラーレートが50以下でADERが00であることを確認する。

5.

3‑10.3‑10.

3‑10.

3‑10.3‑10.

フォーカスバイアス量を変化させフォーカストレランス量の確認

をします。

確認方法確認方法

確認方法

確認方法確認方法

1.連続録音済ディスク("3-4. 連続録音ディスクの作り方"を参照

2.

3.

4.

低反射ディスクエラーレート確認低反射ディスクエラーレート確認

低反射ディスクエラーレート確認

低反射ディスクエラーレート確認低反射ディスクエラーレート確認

::

:

::

してください。)を挿入する。

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を"CPLAYMODE" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

ENTERボタンを押すと表示が1秒間"CPLAYMID"となった後、表

ENTERENTER

示が"C1

STOPSTOP

STOPボタンを押して再生を止め、

STOPSTOP

て低反射ディスクを取り出す。

フォーカスバイアス確認フォーカスバイアス確認

フォーカスバイアス確認

フォーカスバイアス確認フォーカスバイアス確認

してください。)を挿入する。

EDIT(<,>)EDIT(<,>)

EDIT(<,>)ボタンを押して表示を"FBIASCHK" にする。

EDIT(<,>)EDIT(<,>)

ENTERENTER

ENTERボタンを押して表示を"c=

ENTERENTER

タンを押すと"C1

C1エラーレート、後の2桁の数字がADER を示す。この時のC1

エラーレートが50以下で ADERが 00 であることを確認する。

STOPSTOP

STOPボタンを押して再生を止め、

STOPSTOP

連続録音済ディスクを取り出す。

AD " に変わる。

::

:

::

EJECTEJECT

EJECTスイッチをスライドし

EJECTEJECT

" にする。次に

AD " を表示する。最初の 4桁の数字が

EJECTEJECT

EJECTボタンをスライドして

EJECTEJECT

DISPLAYDISPLAY

DISPLAYボ

DISPLAYDISPLAY

3-10. FOCUS BIAS CHECK

Change the focus bias and check the focus tolerance amount.

Checking Method:

1. Load a continuously recorded disc (Refer to " 3-4. Creating

Continuously Recorded Disc".).

2. Use the EDIT(<, >) buttons and display "FBIAS CHECK".

3. Press the ENTER button and display "c =

4. Press the DISPLAY button and display "C1

".

AD " .

The first four digits indicate the C1 error rate, the two digits

after indicate ADER. Check that the C1 error is below 50 and

ADER is 00.

5. Press the STOP button, next slide the EJECT switch, and

remove the continuously recorded disc.

10

Page 13

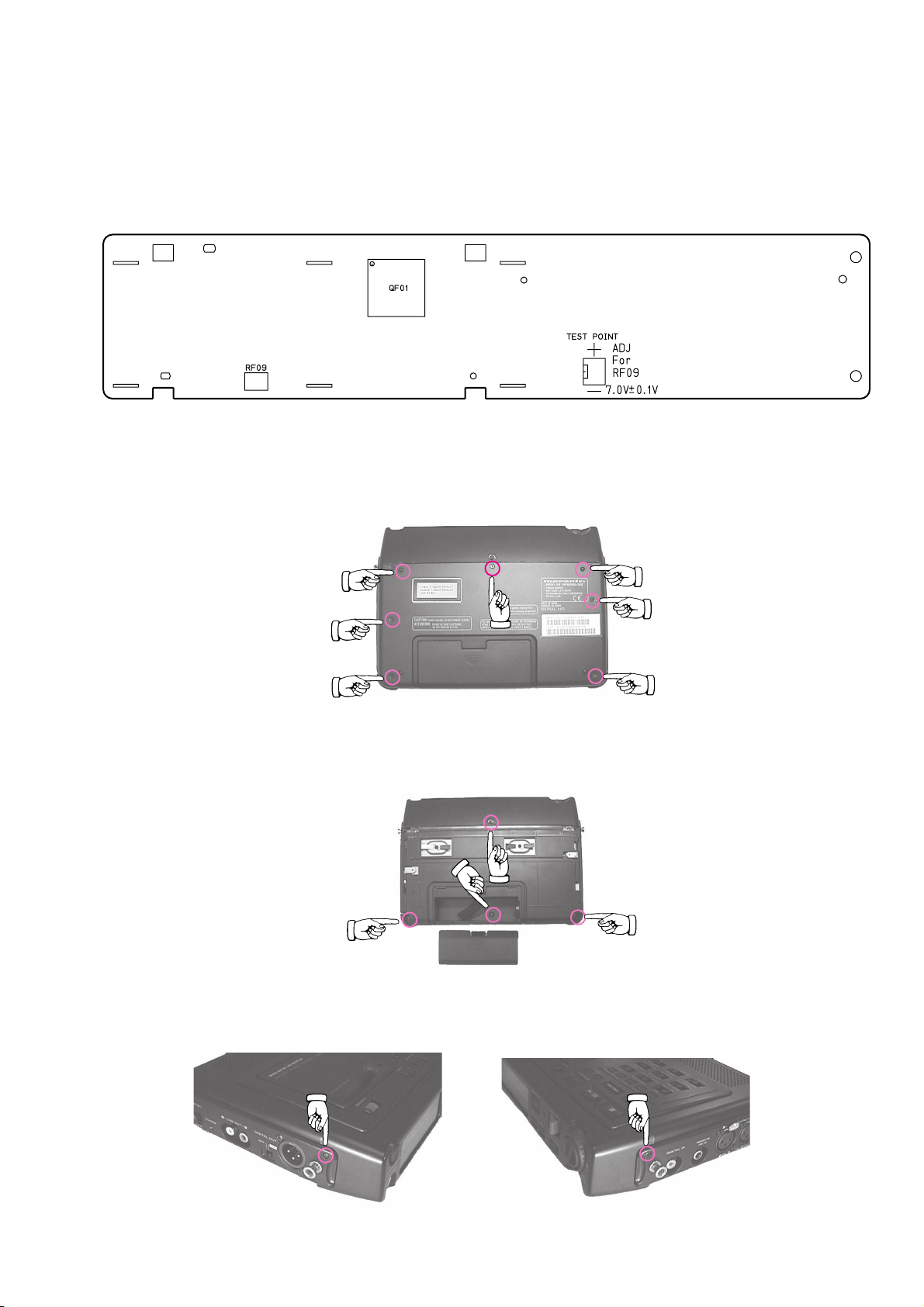

4. LCD CONTRAST ADJUSTMENT

1. Connect the TEST POINT (See below) with the tester.

2. Turn the variable resistor RF09 so that the reading of the

testor becomes 7.0 V ± 0.1 V and conform the contrast of

the LCD becames maximum.

5. HOW TO DISASSEMBLE

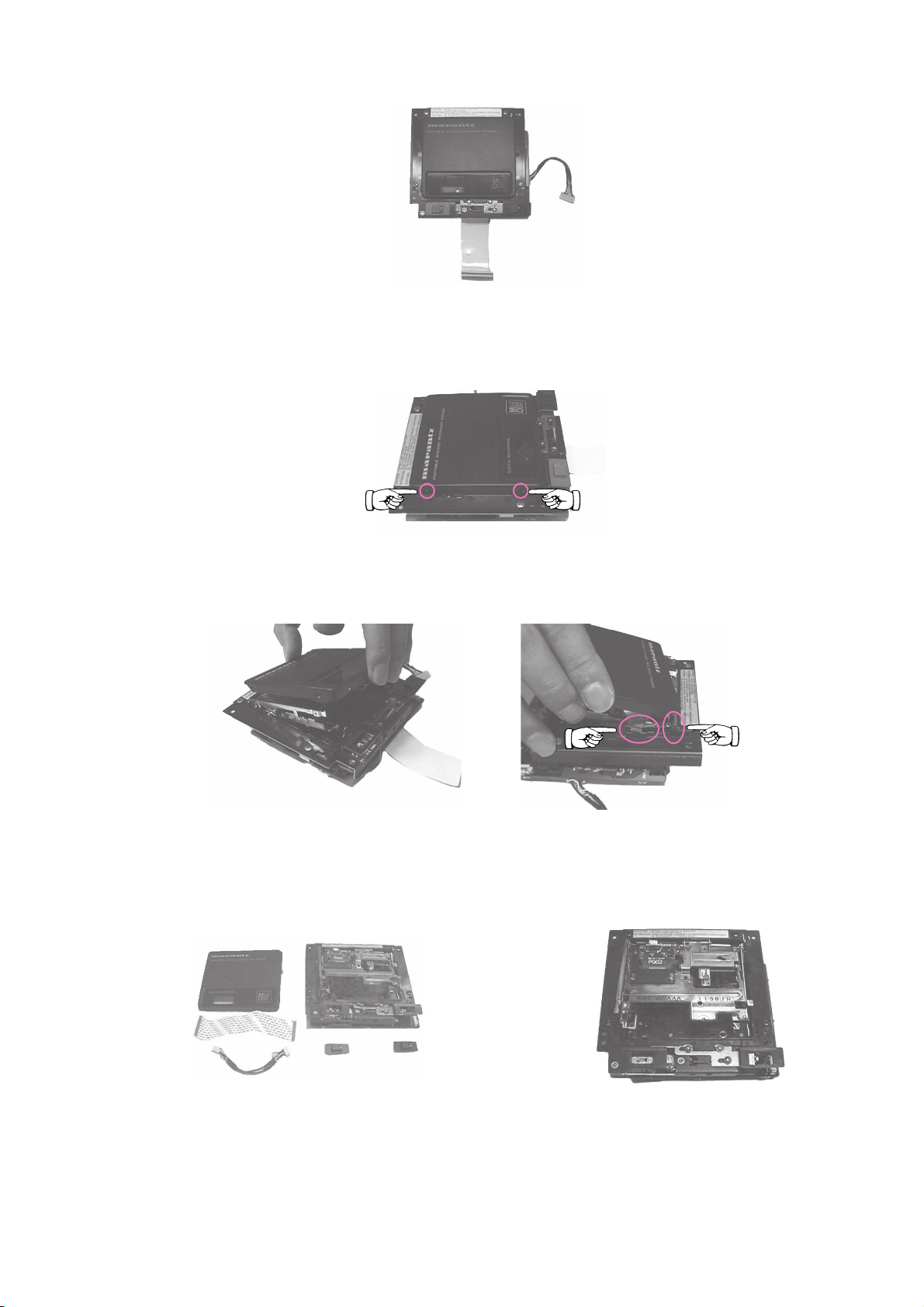

1. Taking the MD module apart

1) Remove 7 screws as shown in Fig.1.

4.LCD4.LCD

4.LCD

4.LCD4.LCD

1.LCDモジュールとメイン基板をペアーとして以下の調整をお

2. TEST POINT にテスターを接続し、輝度電圧測りながらボ

3.LDCを正面から見て、コントラストが最大になることを確認

5.5.

5.

5.5.

1.MD1.MD

1.MD

1.MD1.MD

1) 下図1に示すビス7本を外します。

輝度電圧調整輝度電圧調整

輝度電圧調整

輝度電圧調整輝度電圧調整

こなってください。

リュームRF09の抵抗値を調整する。

しながら輝度電圧を7.0V± 0.1Vに調整する。

分解方法分解方法

分解方法

分解方法分解方法

モジュールの外し方モジュールの外し方

モジュールの外し方

モジュールの外し方モジュールの外し方

<Fig.1 Position of 7 screws>

2) Remove the battery cover.

3) Remove 4 screws as shown in Fig.2.

<Fig.2 Position of 4 screws>

4) Remove 2 screws from both sides as shown in Fig.3 and

Fig.4.

2) バッテリーカバーを外します。

3) 下図2に示すビス4本を外します。

4) 下図3〜4に示す両サイドのビス計2本を外します。

<Fig.3 Position of screw> <Fig.4 Position of screw>

11

Page 14

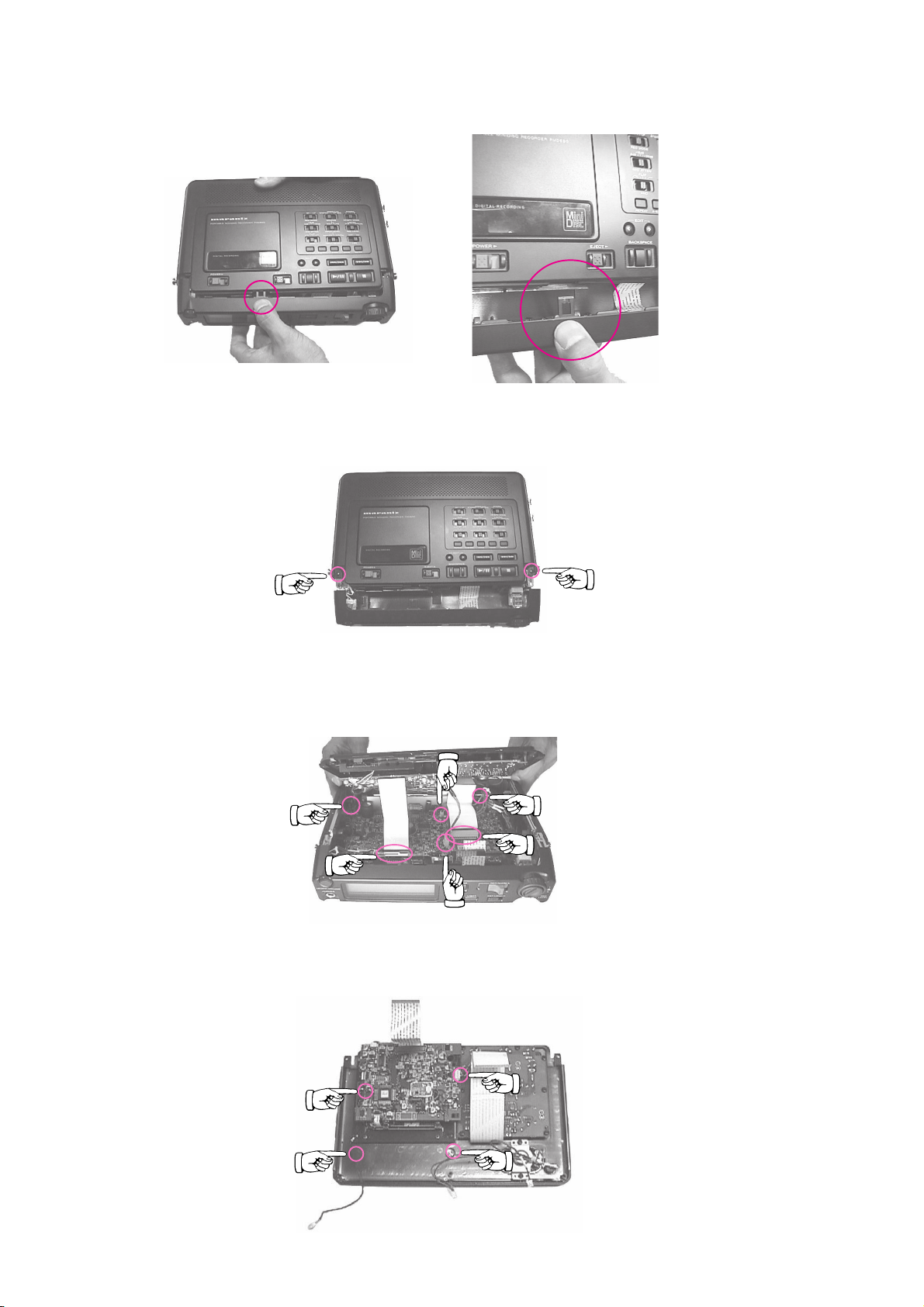

5) Remove the front panel, holding it and pushing down with

thumb as shown in Fig.5 and Fig.6.

<Fig.5 Holding position> <Fig.6 Removing the front panel>

5) フロントパネルを下図5 〜6 の位置を指で押さえながら外し

ます。

6) Remove 4 screws as shown in Fig.7.

<Fig.7 Position of 4 screws>

7) Remove 5 connectors and screw as shown in Fig.8. And

remove the top case.

6) 下図7に示すビス2本を外します。

7) トップケースを持ち上げます。下図8 に示す5つのコネクタ

とビスを外し、トップケースを外します。

8) Remove 4 screws as shown in Fig.9.

<Fig.8 Position of connectors>

8) 下図9に示すMDメカユニット部分のビス4本を外します。

<Fig.9 Position of 4 screws>

12

Page 15

9) Remove the MD unit part.

9) MDメカユニット部分を取り外します(図10)。

<Fig.10 The part of the MD unit>

10) Remove 2 screws as shown in Fig.11.

11) Lift up the MD lid. Remove the hinge.

10)下図11のビス2本外します。

<Fig.11 Position of 2 screws>

11)MDの蓋を持ち上げます(図12)。HINGEを外します(図13)。

<Fig.12 lifting up the MD lid> <Fig.13 Removing the hinge>

12) Remove the MD lid. Remove the lever of EJECT and

POWER and the cables.

<Fig.14 Removed the MD module> <Fig.15 The MD module (Part Number : ZZ409S3010)>

Notes:

When the MD module is replaced, please confirm the version

of µ-Processors, QU01 and QL04 (refer to "7. BUGS AND

PROBLEMS").

12)MDの蓋を取り外します。EJECT、POWER スイッチレバーと

ケーブル2本を外します(図14)。

注意:

MDモジュールを交換する際は、2つのマイコン(QU01、QL04)の

バージョンを確認してください。詳しくは、7.不具合対応を参

照してください。

13

Page 16

2. Taking The MD PCB apart

13) Remove 3 cables and screw as shown in Fig.16.

<Fig.16 Position of 3 cables and screws>

2.MD2.MD

基板の外し方基板の外し方

2.MD

基板の外し方

2.MD2.MD

基板の外し方基板の外し方

13)下図16に示すコネクタ3つ、ビス1本を外します。

14) Turn over the MD PCB.

<Fig.17 Turning over the MD PCB>

15) Solder in the position as shown in Fig.18. Then remove

the connector.

14)基板を裏返します(図17)。

15)下図18に示す部分に半田を付けます。それから、コネクタ

を外します。

3. Taking the MD mechanism a part

16) Remove 4 screws as shown in Fig.19.

<Fig.18 Soldering position>

3.MD3.MD

メカの外し方メカの外し方

3.MD

メカの外し方

3.MD3.MD

メカの外し方メカの外し方

16)下図19のビス4本を外します。

<Fig.19 Position of 4 screws>

14

Page 17

17) Remove the MD mechanism.

<Fig.20 The MD mechanism>

4. The spare parts of MD mechanism (KML-252)

SW1

MO1

17)MDメカを外します。

4.MD4.MD

メカメカ

4.MD

4.MD4.MD

メカ

メカメカ

(KML‑252)(KML‑252)

(KML‑252)

(KML‑252)(KML‑252)

のスペアパーツのスペアパーツ

のスペアパーツ

のスペアパーツのスペアパーツ

<Fig.21>

No. PART No. DESCRIPTION

MO1

SW1

SW2

SW3

MM001030R MOTOR FOR EJECT LOCK

*

SP000970R SWITCH FOR PICK-UP

*

SP000950R SWITCH (SHORT)

*

SP000960R SWITCH (LONG)

*

<Fig.22>

SW2

<Fig.23>

SW3

15

Page 18

5. Caution on reassemble

18) When reattaching the lid, position the hook as shown in

Fig.19.

<Fig.24 Position of the hook>

5.5.

組立時の注意組立時の注意

5.

組立時の注意

5.5.

組立時の注意組立時の注意

18) MDの蓋を取り付ける時、金具を図19に示すように合せます。

19) Reconnect cables as shown in Fig.20.

19)図20に示す様に配線します。

<Fig.25 Reconnecting cables>

16

Page 19

6. WAVEFORMS

QQ90 ( PLAY MODE )

C2M (1pin)

X=2V Y=2µs

QQ90 ( PLAY MODE )

C2P (2pin)

X=2V Y=2µs

6.6.

波形図波形図

6.

波形図

6.6.

波形図波形図

QQ10

QQ10

QQ10

QQ50

QQ50

22.5782 MHz

QQ50

QQ10

QQ50

QQ50

2.8223 MHz

11.2891 MHz

QU01

QU01

(X1)

2.2 Vp-p

(X2)

2.8 Vp-p

17

Page 20

QL04 ( STOP MODE )

g

)

E (36pin)

X=2V Y=50µs

QD20 ( STOP MODE )

LRCK (10pin)

X=2V Y=5µs/d

QD20 ( REC MODE )

X=2V Y=50µs

RW (35pin)

RS (346pin)

QL04 ( PLAY START MODE )

CTS (11pin)

RTS (7pin)

TXD

(6pin)

RXD (5pin)

X=2V Y=50µs

ADDT (12pin)

7. BUGS AND PROBLEMS

When the symptoms appear as shown in the Table 7-1, solve

by referring to Table 7-1, Table 7-2 and Table 7-3. Other

symptoms caused by µ-processors (QU01, QL04) will be

published via "Service Bulletin".

7.7.

不具合対応不具合対応

7.

不具合対応

7.7.

不具合対応不具合対応

下記のTable7‑1のような不具合があった場合には、Table7‑1、

Table7‑2、Table7‑3を参考に対応してください。Table7‑3に

記載されていないServicecode及びLOTの不具合については、今

後発行されるサービスブリテンを参照して下さい。

DADT (15pin)

Table 7-1 Symptom and Solution

Symptom Symptom description Solution description

Phantom *1

REC DATE *2

MONO/ST sel. *3

80 min MD *4

P-ON No read *5

Phantom Power line (+48V) will

be shut down when press the

PLAY button while RECORDING.

Recorded DATE/TIME data by

PMD650 has no compatibility

with other MD recorders.

MONO/ST (at the STOP mode )

switch will not work correctly

while LP recordin

Time indication can be shown

only 160min while LP mode

recording with 80min MD disc.

Disc detect will not work. Short soldering pins (pin33 and

.

Remove the transistor QP33 (PCB

PK01).

Replace microprocessors QU01

(PCB PQ01) and QL04 (PCB

to latest version ones.

PK01

Replace microprocessor QL04

(PCB PK01) to latest version one.

Replace microprocessors QU01

(PCB PQ01) and QL04 (PCB

PK01) to latest version ones.

pin34) of micrprocessor QU01.

Table 7-2 µ-processor

MD (QU01)

µ-processor

HU409ST00F

996500001345

Main (QL04)

µ-processor

HU409ST10F

996500003625

S20 First version

For solution of 80min MD disc time

indication : pairing with Main

S22

microprocessor V57 or later is

y.

necessar

For solution of REC date/time

compatibility with other MD recorder

S23

: pairing with Main microprocessor

V58 or later is necessary.

V54 First version

For solution of MONO/STEREO

V55

selector problem

For solution of 80min MD disk time

indication : pairing with MD

V57

microprocessor S22 or later is

y

necessar

.

For solution of REC date/time

compatibility with other MD recorder

V58

: pairing with Main microprocessor

S23 or later is necessary.

Table 7-3 Service cord and Lot

µ-Processor

SERVICE

CODE

02 02 U 200 S20 V55 OK NG OK NG OK

00 03 N 200 S20 V54 NG NG NG NG NG

00 04 N 200 S20 V54 NG NG NG NG NG

00 N 100 S20 V54 OK NG NG NG OK

02 N 115 S20 V55 NG NG OK NG NG

02 N 35 S20 V55 OK NG OK NG OK

02 N 200 S20 V55 OK NG OK NG OK

02 U 100 S20 V55 OK NG OK NG OK

03 N 300 S22 V57 OK NG OK OK OK

03 U 100 S22 V57 OK NG OK OK OK

04 F 100 S23 V58 OK OK OK OK OK

04 08 F 100 S23 V58 OK OK OK OK OK

05 09 N 160 S24 V59 OK OK OK OK OK

03 10 U 200 S22 V57 OK NG OK OK OK

04 N 250 S23 V58 OK OK OK OK OK

04 U 100 S24 V59 OK OK OK OK OK

04 F 100 S23 V58 OK OK OK OK OK

05

LOT Version Quantity

05

06

07

11

12 S24 V59

MD

(QU01)

version

Main

Phantom*1REC DATE*2MONO/ST sel.*380min MD*4P-ON No read

(QL04)

Symptom

*5

18

Page 21

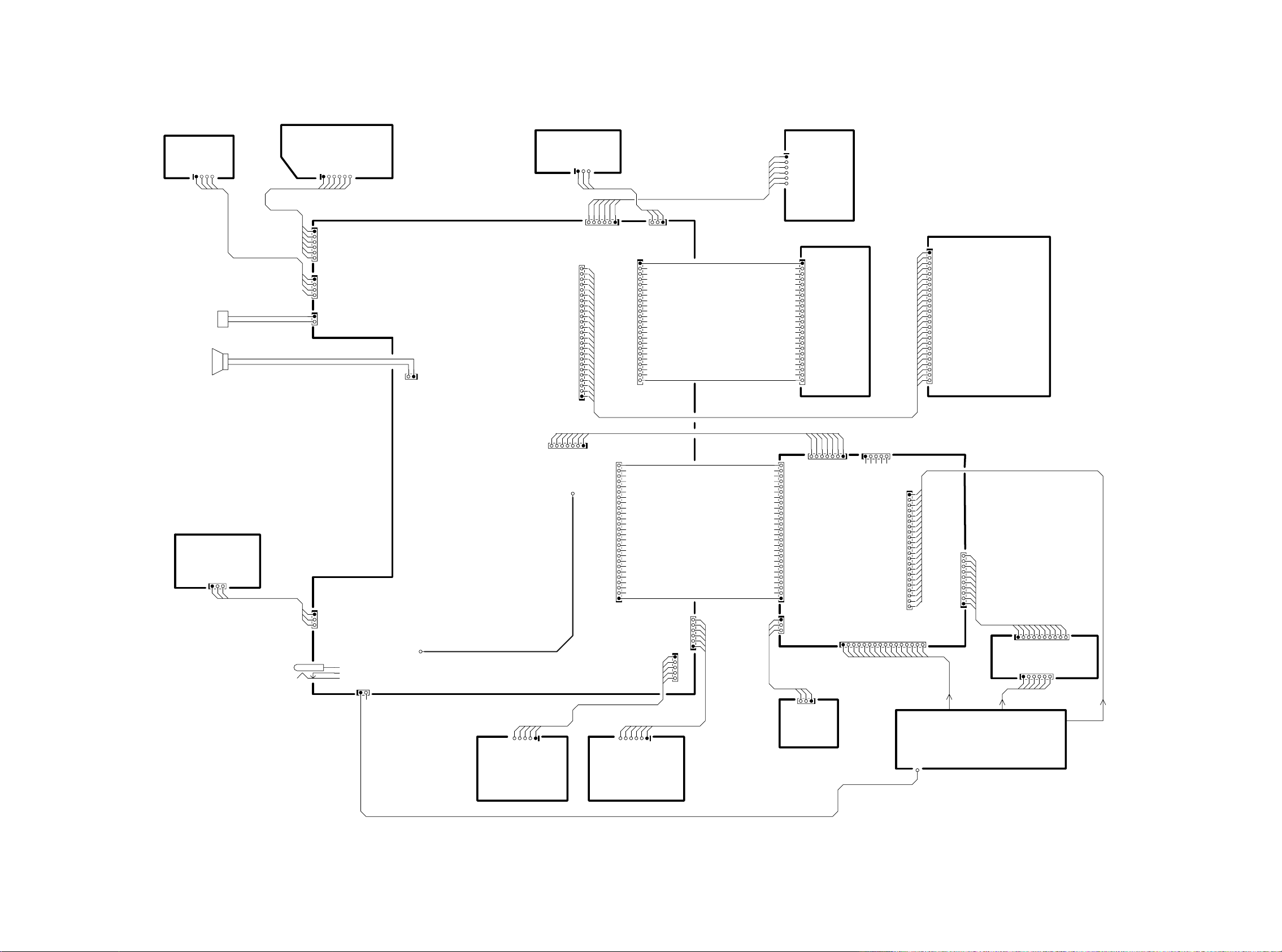

8. WIRING DIAGRAM

123

4

1

2

3

4

12345

6

1

2

3

4

5

6

1

2

1

2

1

2

3

123

123

123

1

2

3

4

5

6

12345

6

1234567

1234567

1

2

3

4

5

12345

12345

6

1

2

3

4

5

6 1

2

3

123

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

123456789

10111213141516

12345

6

JQ10

123456789

10

JQ11

1

2

3

4

5

6

7

8

9

10

JQ03

PK01

PK02

PW02

PW01

PW07

PS01

PF01

PQ01

PQ02

PW05

PW06PW03

P801

MECHANISM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

JQ01

INT Mic

SPEAKER

(WT03)

(WT01)

(WG01)

(WK01)

(WT07)

(WT04)

(WL01)

(WL02)

(WD01)

(WL03)

(WP01)

(WT05)

(WT06)

(WT02)

(WQ02)

(WQ03)

1

2

3

1

2

(WK02)

12345

Test Point

(WP03)

GND

Pantom

+48V

Pantom On/Off

POWER SW

CTS

RTS

TXD

RXD

AMUTE

P_DOWN

SYS_RST

STB

POWER_V

SYS+3.3V

+12VA

M+3.3V

M+3.3V

MGND

MGND

M+5V

M+5V

GND

GND

DIN

H+5V

DOUT

+5V

+5V

HGND

POWER SW

CTS

RTS

TXD

RXD

AMUTE

P_DOWN

SYS_RST

STB

POWER_V

SYS+3.3V

+12VA

M+3.3V

M+3.3V

MGND

MGND

M+5V

M+5V

GND

GND

DIN

H+5V

DOUT

+5V

+5V

HGND

GND

Pantom

+48V

Pantom On/Off

LCH INVERT

GND

LCH NORMAL

RCH INVERT

GND

RCH NORMAL

GND

INT MIC

LCH INVERT

GND

LCH NORMAL

RCH INVERT

GND

RCH NORMAL

GND

SENS5

SENS4

SENS3

SENS2

SENS1

SCAN3

SCAN2

SCAN1

HPF

FLAT

BPF

MIC_ATT_SEL1

MIC_ATT_SEL0

MIC/LINE_SEL

VOLSW

REC_MODE_SEL

ST/MONO

MIC_SEL0

MIC_SEL1

PHANTOM_SW

RCH_LINE_SEL

LCH_LINE_SEL

+48V

REF12B

GND

SENS5

SENS4

SENS3

SENS2

SENS1

SCAN3

SCAN2

SCAN1

HPF

FLAT

BPF

MIC_ATT_SEL1

MIC_ATT_SEL0

MIC/LINE_SEL

VOLSW

REC_MODE_SEL

ST/MONO

MIC_SEL0

MIC_SEL1

PHANTOM_SW

RCH_LINE_SEL

LCH_LINE_SEL

+48V

REF12B

LCH IN

REF12B

RCH IN

LCH OUT

REF12B

RCH OUT

LCH IN

REF12B

RCH IN

LCH OUT

REF12B

RCH OUT

GND

DIGITAL IN

RC-5

GND

DIGITAL IN

RC-5

BLIGHT

RECLED

SENS5

SENS4

SENS3

SENS2

SENS1

SCAN4

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

RS

RW

E

LRESET

GND

+3VD

+5VD

BLIGHT

RECLED

SENS5

SENS4

SENS3

SENS2

SENS1

SCAN4

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

RS

RW

E

LRESET

GND

+3VD

+5VD

FCS+

TRKTRK+

FCS-

NC

PD-K

PD

VR

MOD

LD-GND

ILCC

VEE

E

D

C

F

I

VC

A

B

J

VCC

DA R

GND

DA L

GND

AD R

GND

AD L

DA R

GND

DA L

GND

AD R

GND

AD L

VS

DIR

FGIN

RHMD+

RHMD-NCHDOWN

SD+

SD-

(RESERVED)

RROTECT

RFLECT

HUP

INLS

GND

VCC

EFMO

EFMO

EFMO

EFMO

EFMO

HGND

HGND

HGND

HGND

HGND

HGND

HGND

HGND

HGND

HGND

S+3.3V

PON

DGND

S+3.3V

PON

DGND

HGND

HGND

HGND

OUT

GND

B SENS

GND

SUPPLY

B SENS

GND

SUPPLY

RCH

GND

LCH

GND

SP MUTE

LCH IN

GND

LCH OUT

RCH IN

GND

RCH OUT

RCH

GND

LCH

GND

SP MUTE

LCH IN

GND

LCH OUT

RCH IN

GND

RCH OUT

EFMO

EFMO

EFMO

EFMO

EFMO

EFMO

EFMO

EFMO

SHASIS

RFVCTE

IOP

I+3V

JG02

JG03

JG01

JK01

JL01

JZ01

JE01

JL02

JQ20

JF01

JY01

JD01

JQ04

JQ05

JK05

JL03

JK03

JK04

JB01

JP01

JP02

JQ02

19 20

Page 22

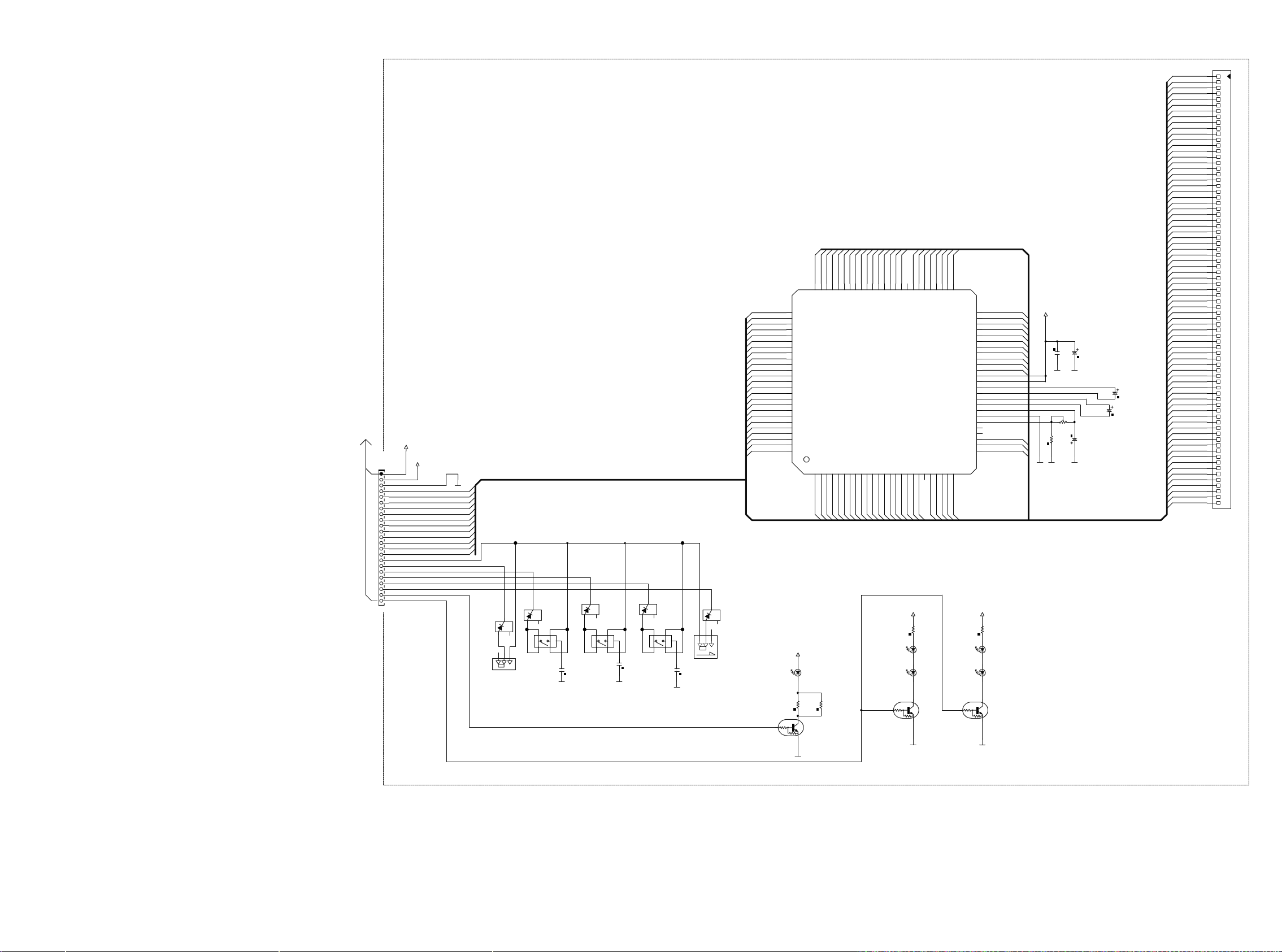

9. BLOCK DIAGRAM

1

2

3

1

2

3

1

2

3

4

1

2

3

1

2

1

2

1

2

3

NC3FBH1

NC3FBH1

MIC/Line

Lch.

Rch.

MIC/Line

GND

GND

Ref.

Ref

MIC

Line

On

Off

Phantom SW

Balanced Amp

1

32

1

32

SOURCE

MIC ATTEN.

ANC

Input

Ref

Ref

NC3MH1

RCA2

1

23

VR

1

23

VR

Internal Speaker

HP /SPK Mode

Phone Amp.

Power Amp.

Phone Output

Line Output

Digital Audio Output

GND

GND

GND

GND

SN75176B TI

RS-422 Driver

GND

MD Servo Block

DOUT

GND

+5

MUTE

SP_MUTE

MUTE

A to D D to A

AK4512

Display Block

µ

-COM Block

KEY Inputs

GND

GND

Power Supply

AGND DGND GND

+3VM +3VD +3VR +5VD +48V

DIN

Digital Audio Input

COAX(RCA)

RC-5 Input

Internal MIC

DC Connector

Battery

DC Input(12V)

Balanced Amp

Digital Output ON/OFF Switch

Mute

MuteMute

GND

+48v

ALC/Limiter

ALC/Limiter

GND

GND

Line

L.P.Filter

Manual / ALC,Limiter

ALC / Limiter

Input

Input

(REC LEVEL)

PK01

PW01

PW02

PK02

PW07

PW06

PQ01

PW03

PS01

PF01

P801

HPS_MUTE

PWM

Converter Converter

QG10(1/2)

QG10(2/2)

QG08(1/2)

QG03(1/2)

QG08(2/2)

QG03(2/2)

QG11(1/2)

QG11(2/2)

QG01(1/2)

QG01(2/2)

QG02(1/2)

QG02(2/2)

QG04(2/2)

QG04(1/2)

QE01(1/2)

QE01

QE11(1/2)

QE11(2/2)

QE04(1/2)

QE04(2/2)

QE10(1/2)

QE10(1/2)

QE02

QE02(2/2)

QG06(1/2)

QG06(2/2)

QE91,QE93

QE92,QE94

QG12

QD20

QD30(1/2)

QD30(1/2)

QD30(1/2)

QD30(2/2)

QK01

QK01

QK06(1/2)

QK06(2/2)

QK03(2/2)

QK03(1/2)

QK02

QK05(1/2)

QK05(2/2)

QK09(1/2)

QK09(2/2)

QK10

GND

QZ01

ENDEC

&

ATRAC

MD

CONTROL

µ

-COM

SERVO

DRIVER

HF AMP

PICK UP

FOCUS

TRACK

SPINDLE

MOTER

SLED

MOTOR

HEAD

DRIVE

QQ50

QU01

QQ90

QQ10

QQ70

QZ02

+3VS

Battery Charger

SEL

Level

(1/2)

(2/2)

(1/2)

(2/2)

XPWDA

XPWDA

+12VA

+5

GND

21 22

Page 23

10. LEVEL DIAGRAM

NC3FBH1

MIC/Line

Lch.

GND

Ref.

MIC

Line

1

32

SOURCE

MIC ATTEN.

ANC

Input

Ref

RCA2

1

23

VR

Internal Speaker

HP/SPK Mode

Power Amp.

Phone Output

Line Output

GND

GND

GND

A to D D to A

AK4512

Balanced Amp

ALC/Limiter

GND

L.P.Filter

ALC / Limiter

Input

REC LEVEL

Converter Converter

QG10(1/2)

QG10(2/2)

QG08

QG03

QG01

QG02

QG04

QE01

QE11

QE04

QE10

QE02

QG06

QE91,QE93

QD20

QD30

QK04

QK01

QK06

QK03

QK05(1/2)

QK05(2/2)

QK09

QK10

SEL

Level

Output Level

+20dBu

+10dBu

0dBu

-10dBu

-20dBu

-30dBu

-40dBu

-50dBu

-60dBu

GND

GND

GNDGND

GNDGND

VR Level = 2

Line Out

1-1'

2

34

5

6

7

+48v

GND

1

1'

2

3

4

7

6

8

9

10

11 12

13

14 15

16

5

Phone Amp.

(4 ohm Load)

(60 ohm Load)

0dBu=0.775v

VR Max

HP/SPK VR

Speaker Out

Phone Out

8

9

10

11

12

13

14

15

16

(Test Disk 0dB Playback)

= Level 2

Play Mode

Rec Mode

PQ01

16mV

52mV

46mV

720mV

630mV

2000mV

17mV

36mV

165mV

3mV

85mV 60mV

43mV 1.75mV

200mV

1

2

3 1

2

3

23 24

Page 24

11. SCHEMATIC DIAGRAM

RG01

6.8k(1/2W)

RG02

6.8k(1/2W)

RG05

4.7k

RG06

4.7k

RG09

4.7k

RG10

4.7k

RG03

6.8k(1/2W)

RG04

6.8k(1/2W)

RG07

4.7k

RG08

4.7k

RG11

4.7k

RG12

4.7k

CG01

10/63

CG02

10/63

CG03

10/63

CG04

10/63

CG05

0.1

AGND

AGND

AGND

Lch Normal

GND

Lch Invert

Rch Normal

GND

Rch Invert

CG16

10/16

CG17

10/16

QG01

74HC4052A

JG01

RG16

2.2k

RG17

10k

RG23

470

CG18

10/16

CG19

10/16

AGND

CG06

0.1

AGND

RG28

82k

RG30

22k

RG25

100k

RG29

82k

RG31

22k

CG07

0.1

AGND

MIC SOURCE SEL

MIC ATT.

RG32

15k

RG35

33k

RG36

33k

RG33

15k

CG08

0.1

CG24

0.15

CG25

0.15

CG26

1000p

CG27

1000p

CG29

1u

AGND

AGND

AGND

QG03A

NJM2068V

QG03B

NJM2068V

QG04

74HC4066A

QG05

74HC4066A

CG09

0.1

AGND

CG10

0.1

+12VA

AGND

CG53

0.1

AGND

AUDIO_L

AUDIO_R

MICLINE

ATTSEL0

ATTSEL1MICSEL0

MICSEL1

MICSEL0

ATTSEL1

ATTSEL0

MICLINE

ST_MONO

AGND

RECMODESEL

VOLSW

RL06

10k

RL07

100k

RL08

6.8k

RL09

100k

RL10

100k

RL11

100k

RL12

100k

MICSEL0 MICSEL1

6.5v

11.3v

Don't

MONO

6.5v

11.3v

INT

STEREO

ATTSEL0 ATTSEL1

Don't

-15dB

0dB

-30dB

FLAT

BPF

FLAT

HPF

+48V

MIC SOURCE SELECTOR

MIC ATTENUATION

ANC

ANC Lch

ANC Rch

CG30

10/16

CG31

10/16

REF12B

RL13

100k

MICSEL1

RL14

10k

+12VA +12VA +12VA +12VA +12VA +12VA +12VA +12VA +12VA

+12VA

+12VA

+12VA

+12VA+12VA

REF12B

REF12B

+12VA

+12VA

RG26

68k

RG66

22k

REF12B

RG27

68k

RG67

22k

REF12B

QG02

74HC4052A

JG02

B6B-PH

Phantom

CG32

33/10

CG33

33/10

CG34

33/10

CG35

33/10

REF12B

REF12B

REF12B

REF12B

REF12B

RG56

100k

CG36

47p

CG37

47p

RG57

3.3k

RG58

3.3k

REF12B

REF12B

CG38

220p

CG39

220p

DG01

1SS302

CG40

56p

CG41

56p

RG37

4.7k

RG38

4.7k

RG39

560

RG40

560

CG20

22/16

RG41

2.7k

RG42

2.7k

RG43

560

RG44

560

CG21

22/16

REF12B

REF12B

RG59

100k

RG60

100k

MIC_SEL1

MIC_SEL0

MIC_ATT_SEL1

MIC_ATT_SEL0

FLAT

HPF

BPF

MIC/Line SEL

ST/MONO

REC MODE SEL

VOLSW

Lch Line SEL

Rch Line SEL

SENS1

SENS2

SENS3

SENS4

SCAN1

SCAN2

SCAN3

REF12B

Phantom SW.

SENS5

GND

JL01

YJ07011550

LLINESEL

RLINESEL

SCAN1

SCAN2

SCAN3

SENS1

SENS2

SENS3

SENS4

SENS5

DGND

Int.MIC

QG08A

NJM2068V

QG08B

NJM2068V

QG10A

NJM2068V

QG10B

NJM2068V

QG11A

NJM2068V

QG11B

NJM2068V

RG61

100k

REF12B

RG18

560

+12VA

AGND

CG13

0.1

AGND

+12VA

CG14

0.1

AGND

RG62

100k

REF12B

RG19

560

RG63

100k

REF12B

RG20

560

RG64

100k

REF12B

RG68

560

AGND

QG12A

NJM2068V

QG12B

NJM2068V

RG65

100k

REF12B

RG34

3.3k

CG22

10/16

AGND

AGND

+12VA

CG15

0.1

AGND

RG45

47k

CG44

33p

CG23

10/16

RG46

47k

RG47

47k

RG48

47k

RG49

47k

RG50

2.7k

RG51

2.7k

RG52 2.7k

RG53

2.7k

+48V

JG03

B3B-PH

RG54

100k

RG55

100k

+12VA

RG21

18k

RG22

10k

AGND

CG51

100/10

REF12B

AGND

CG52

10/10

DG09

1SS302

RG13

47k

AGND

QG13

2SA1586CIP

QG14

2SC4116CIP

+12VA+12VA

AGND

RG14

47k

AGND

MIC_SEL0

MIC_SEL1

RG69

10

CG54

0.1

FG

FG01

FRAME-GND

FGND

MICSEL1

MICSEL0

AGND

AGND

AGND

AGND

RG15

100k

RG70

100k

QG16

DTC114TE

AGND

+12VA

MIC_INT

RG71

100

RG72

100

CG47

47p

CG48

47p

CG49

47p

CG50

47p

CG42

10/16

CG43

10/16

CG45

10/16

CG46

10/16

AGND

AGND

QG09

DTC144TE

QG17

DTC144TE

QG18

DTC144TE

QG19

DTC144TE

AGND

AGND

AGND

AGND

DG10

MA704WA

DG11

MA704WA

AGND

AGND

AGND

AGND

QG24

DTA114EE

+12VA

MICLINE

AGND

ATTSEL1

ATTSEL1

QG20

RN1113

REF12B

QG06

74HC4052A

REF12B

REF12B

CG11

10/16

CG12

10/16

RG73

100k

RG74

100k

RG75

15k

RG76

15k

REF12B REF12B

REF12B

REF12B

QG07

DTC114TE

QG21

DTC114TE

QG22

DTC114TE

RG77

100k

RG78

100k

+12VA

+12VA

+12VA

AGND

AGND

AGND

RG79

18k

AGND

AGND

AGND

AGND

+12VA

REF12B

+12VA

REF12B REF12B

REF12B

REF12B

REF12B

REF12B

CG28

1u

REF12B

RG88

220k

RG90

220k

RG92

10k

RG91

10k

QG23

2SA1586CIP

RG81

100k

RG82

100k

RG84

100k

RG83

100k

RG85

220k

RG86

220k

REF12B

RG89

220k

RG87

220k

+48V

DG05

O2CZ12Z

DG08

O2CZ12Z

DG07

O2CZ12Z

DG06

O2CZ12Z

QG15

DTC114TS

6.57v

6.6v

6.6v

6.65v

6.6v

6.64v

6.64v

0v

6.6v

6.6v

6.6v

6.6v

6.6v

12.5v

6.64v

6.65v 11.4v

10.8v

5.98v

6.53v

1.35v

1.35v

6.5v

6.5v

12.0v

0v

6.64v

6.64v

6.62v

6.64v

6.62v

6.64v

6.64v

6.64v

6.65v

6.65v

6.65v

6.65v

0v

12.5v

0v

48.5v

6.5v

12.4v

12.4v

0v

12.0v

12.0v

0v

11.4v

11.4v

12.5v

12.4v

6.65v

1.62v

0v

1.62v

+12VA=12.5v

RG97

0

RG93

100k

QG25

DTC144TE

Phan_Mute_in

AGND

+12VA

RG96

100k

REF12B

QG26

DTC144EE

RG95

100k

AGND

REF12B

+12VA

+12VA

Phan_Mute_out

RG94

100k

QG27

DTC114TE

QG28

DTC144EE

RG98

100k

+12VA

RG80

1M

CG61

0.047

AGND

AGND

RG99

100k

+12VA

DG21

DAN235U

CP32

1/50

AGND

REF12B

A

B

C

PK01(1/6)

TO WT01(PW02)

TO WT03(PK02)

GND

Pantom On/Off

TO JY01

D

E

F

G

WM01

KUC21

H

(PS01)

Shasis GND

(5/10)

(7/10)

(4/10)

(7/10)

(3/10)

(2/10)

(5/10)

(5/10)

(5/10)

(5/10)

(2/10)

Mic 0dB 12.3v

Mic -15dB,-30dB

Line

-0.2v

6.6v

6.6v

6.6v

6.6v

Int Mic ON / OFF

9.7v / 0v

Phantom ON / OFF

Phantom ON / OFF

4.1v / 0v

0v / 2.7v

6.5v

6.5v

11.3v

11.3v

6.5v

11.6v

6.5v

11.6v

6.5v

6.5v

12.2v

12.2v

FLAT

HPF

BPF

1.67v

1.67v

0v

0v

0v

1.67v

1.67v

1.67v

0v

(WG01)

(WT01)

(WT03)

(WL01)

DG12

1SS322

Y3

4

Y2

2

Y1

5

Y0

1

X1

14

X0

12

VEE

7

INH

6

Vcc

16

GND

8

A

10

B

9

X2

15

X3

11

Y

3

X

13

1

2

(BP)

2

3

1

84

5

6

7

1CON

13

4O/I

10

1O/I

2

3O/I

9

1I/O

1

2O/I

3

Vcc

14

GND

7

4CON

12

2CON

5

3CON

6

4I/O

11

3I/O

8

2I/O

4

1CON

13

4O/I

10

1O/I

2

3O/I

9

1I/O

1

2O/I

3

Vcc

14

GND

7

4CON

12

2CON

5

3CON

6

4I/O

11

3I/O

8

2I/O

4

Y3

4

Y2

2

Y1

5

Y0

1

X1

14

X0

12

VEE

7

INH

6

Vcc

16

GND

8

A

10

B

9

X2

15

X3

11

Y

3

X

13

1

2

3

4

5

6

1

3

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

2

3

1

84

5

6

7

2

3

1

84

5

6

7

2

3

1

84

5

6

7

2

3

1

84

5

6

7

1

2

3