Page 1

Service

PM7003 /

F N/K1SG/N1SG

/N1B

Manual

STANDBY

POWER ONOFF

SECTION PAG E

1. TECHNICAL SPECIFICATIONS ........................................................................................... 1

2. ALIGNMENTS ....................................................................................................................... 2

3. SERVICE MODE ................................................................................................................... 4

4. PROTECTION MODE ........................................................................................................... 5

5. WRITING MAIN MICROPROCESSOR PROCEDURE ......................................................... 7

6. WIRING DIAGRAM .............................................................................................................25

7. BLOCK DIAGRAM ..............................................................................................................27

8. SCHEMATIC DIAGRAM ...................................................................................................... 29

9. PARTS LOCATION .............................................................................................................. 37

10. EXPLODED VIEW AND PARTS LIST ................................................................................. 47

11. MICROPROCESSOR AND IC DATA ................................................................................... 51

12. ELECTRICAL PARTS LIST ................................................................................................. 56

13.

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE ...............................71

INTEGRATED AMPLFIER PM7003

INPUT SELECTOR VOLUME

PHONES

POWER AMP DIRECT

SPEAKERS

A

B

OFF

A+B

-

AUXDVD MUTERECORDER1TUNERPHONO CD

SOURCE DIRECT

TREBLEBASS

+

+

-

TABLE OF CONTENTS

Integrated Amplifier

BALANCE

RL

MAXMN

P 7 03

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

PM7003

Part no. 90M24AJ855010

First Issue 2008.07

MZ

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specifications for which

company has created the ultimate in stereo sound.

it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specified.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

KOREA

D&M SALES AND MARKETING KOREA LTD.

CHUNG JIN B/D., #1001,

53-5, WONHYORO 3 GA, YONGSAN-GU,

SEOUL, 140-719, KOREA

PHONE : +82 - 2 - 323 - 2155

FAX : +82 - 2 - 323 - 2154

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

NOTE ON SAFETY :

Symbol Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol .

Any other component substitution (other than original type), may increase risk of fire or electrical shock hazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号のものを使用して下さい。

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product and

controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied, and

verified before it is return to the user/customer.

In case of difficulties, do not hesitate to contact the Technical

Department at above mentioned address.

080702MZ

Page 3

1. TECHNICAL SPECIFICATIONS

Power output

(20 Hz – 20 kHz sim

8 Ω load ..............................................................70 W x 2

4 Ω load ...........................................................100 W x 2)

Total harmonic distortion

(20 Hz – 20 kHz simultaneous drive of both channels, 8 Ω load)

.........................................................................0.02 %

Output band width (8 Ω load, 0.05 %)

............................................................. 5 Hz – 60 kHz

Frequency response (CD, 1 W, 8 Ω load)

.................................................5 Hz – 100 kHz ±3 dB

Dumping factor (8 Ω load, 20 Hz – 20 kHz) ......................100

Input sensitivity/Input impedance

PHONO (MM) ................................................2 mV/47 kΩ

CD, LINE, TUNER, AUX/DVD, RECORDER

.............................................................200 mV/20 kΩ

MAIN IN .........................................................1.6 V/20 kΩ

Output voltage/Output impedance

PRE OUT .......................................................1.6 V/600 Ω

Maximum allowable PHONO input level (1 kHz)

MM ....................................................................... 100 mV

RIAA deviation (20 Hz ~ 20 kHz) ......................... ±0.5 dB

S/N (IHF-A, 1 W, 8 Ω load)

PHONO (MM)) ........................................................ 85 dB

CD, LINE, TUNER, AUX/DVD, RECORDER ........... 88 dB

POWER AMP DIRECT IN ..................................... 106 dB

Tone control

Bass (50 Hz) ......................................................... ±10 dB

Treble (20 kHz) ...................................................... ±10 dB

Power requirement

[F] .....................................................AC 100 V, 50/60 Hz

[N] ..........................................................AC 230 V, 50 Hz

Power consumption

EN60065/J60065 ....................................................200 W

Standby power consumption .........................................0.3 W

ultaneous drive of both channels)

DIMENSIONS (unit : mm)

Accessories

Remote controller (RC003PM)........................................1

AAA batteries ..................................................................2

Detachable AC power cable ............................................1

Maximum outer dimensions (Amplifier)

Width ....................................................................440 mm

Height ..............................................................126.8 mm

Depth ................................................................... 368 mm

Weight (Amplifier) .................................................10.5 kg

22

368

328.5

17.5

440

16.3

110.5

126.8

1

Page 4

2. ALIGNMENTS

2. ALIGNMENTS

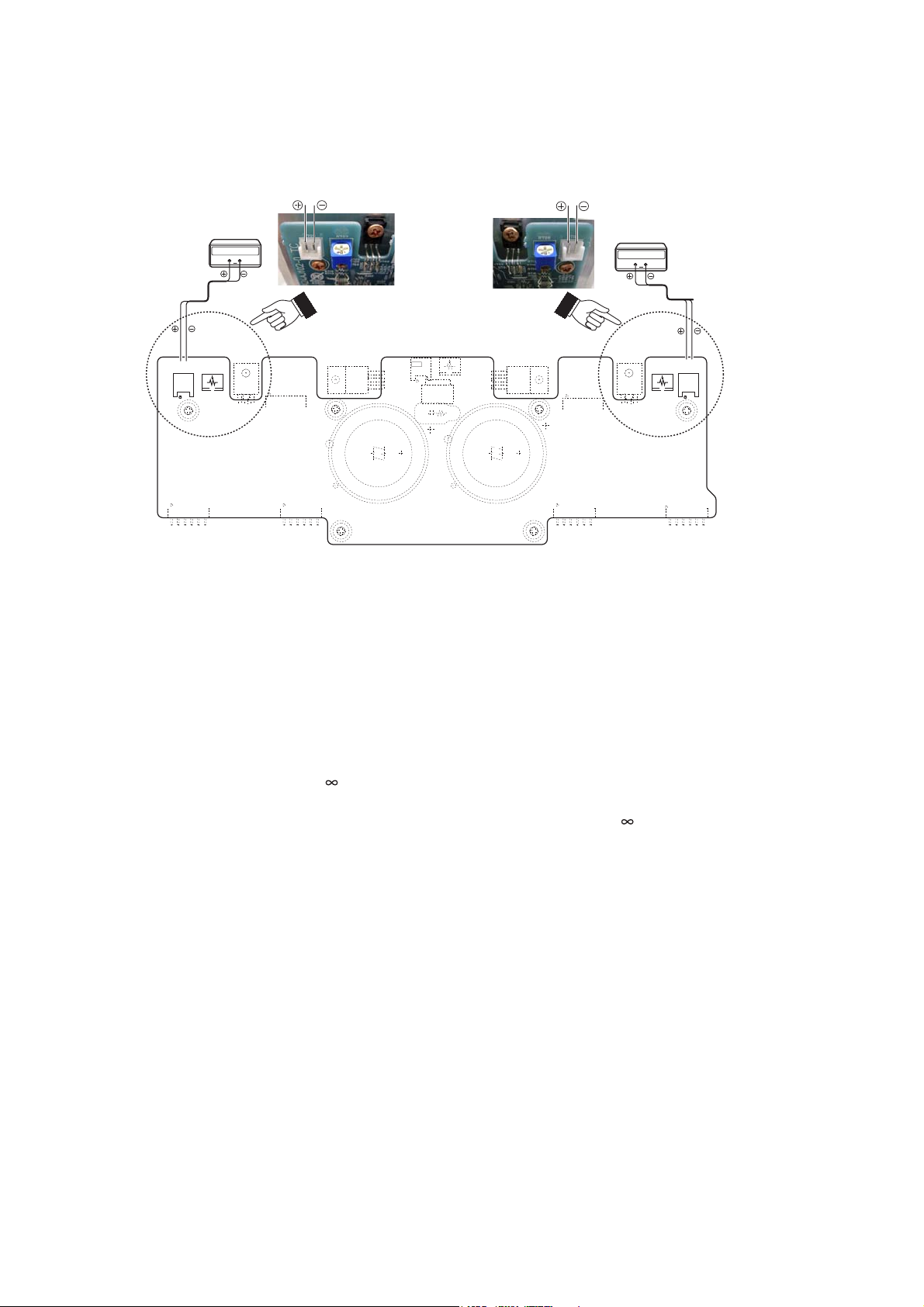

1. Idling Current Alignment

Digital Voltmeter

V

L ch

ADJ

T.P.

R707

J707

P701

Adjustment Procedure

Set the power voltage to rated voltage for this adjustment.

Adjust the Idling Current with the variable resistor R707 1.

and R708 on the PWB P701.

Turn off the power.2.

"+" of Connect Digital Voltage is connected to the No. 1 3.

pin and connected "-" to No. 2 pin of J707.

"+" of Connect Digital Voltage is connected to the No. 1 4.

pin and connected "-" to No. 2 pin of J708.

Before turning on the power, R707 and R708 have been 5.

counter clockwise turned with the adjustment driver.

Turn on the power, VOLUME is set as -6.

After 2 minutes.7.

With seeing the digital voltage meter turn the variable

resister clockwise slowly to adjust the idling current.

Idling adjustment with R707 (R708).

s 4URN 2 2 CLOCKWISE TO INCREASE THE IDLING

current.

s 4HE ADJUSTMENT VALUE OF IDLING CURRENT IS

5 mV(25 mA) ± 0.5 mV(2.5 mA) each.

After 8 minutes.8.

Repeat the same procedure as 7.

s 4HE ADJUSTMENT VALUE OF IDLING CURRENT IS

13.4 mV(67 mA) ± 0.5 mV(2.5 mA) each.

Adjustment is completed.

Remove connection cable, attach the top cover.9.

NOTE : Idling current decreases with the temperature rise

inside the unit, and it is set to 10 mV (50 mA) of

setting value in about 30 minutes after turn on the

power.

.

1. アイドリング電流調整

Digital Voltmeter

V

R ch

ADJ

T.P.

R708

J708

調整手順

調整時は必ず電源電圧を定格電圧に合わせてください。

P701基板上の半固定抵抗R707とR708でアイドリング電流1.

を調整します。

電源を

OFFします。2.

P701

基板のJ707にデジタルボルトメーターを接続します。3.

デジタルボルトメーターはJ707の1番ピン(丸印側)を"+"、

2

番ピンを"-"に接続します。

P701基板のJ708にデジタルボルトメーターを接続します。4.

デジタルボルトメーターはJ708の1番ピン(丸印側)を"+"、

2

番ピンを"-"に接続します。

電源を投入する前に半固定抵抗

イバーで反時計方向に回しきってください。

電源を投入しボリュームを

電源を投入後

P701

2分経過後。7.

基板のJ707(J708)に接続したデジタルボルトメー

ターの電圧値を監視しながら、半固定抵抗

をゆっくりと時計向に回してください。

s R707と R708を時計方向に回すとアイドリング電流が増加

します。

s アイドリング電流の調整値はそれぞれ

"5 mV(25 mA) ± 0.5 mV(2.5 mA)"にします。

さらに

8分経過後。8.

上記7.の手順でもう一度調整します。

s アイドリング電流の調整値はそれぞれ

"13.4 mV(67 mA) ± 0.5 mV(2.5 mA)"にします。

以上で調整は完了です。

デジタルボルトメーターの接続を外し、トップカバーを取

9.

付けます。

注意

: 調整終了後トップカバーを取付けるとセット内部の温度

上昇に伴いアイドリング電流が減少し、電源投入後約

分で設定値の"10 mV(50 mA)"になります。

R707とR708を、調整ドラ5.

-6. にしてください。

R707(R708)

30

2

Page 5

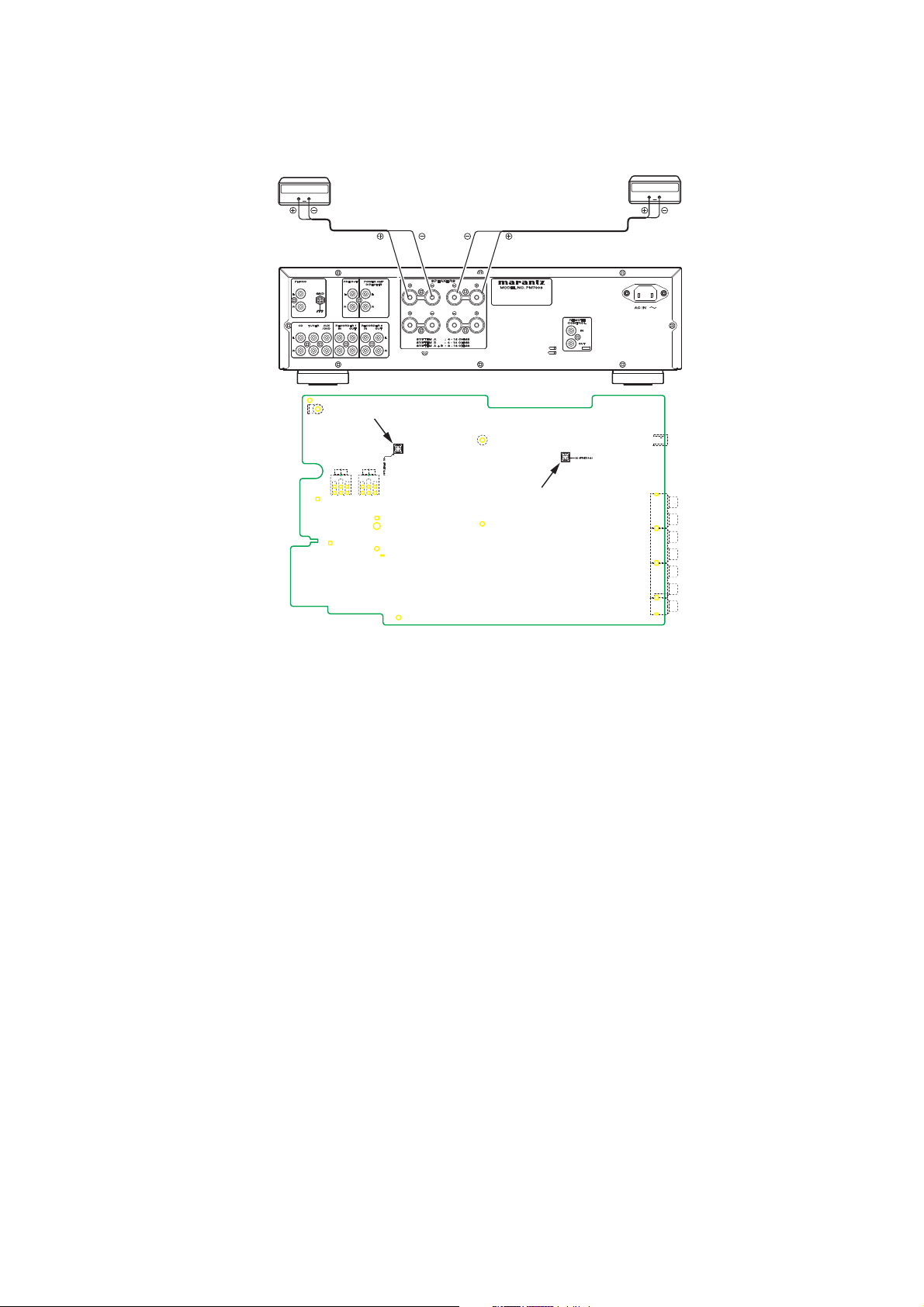

2. DC Offset Voltage Adjustment

Digital Voltmeter Digital Voltmeter

2. DC Offset Voltage Adjustment

P101

V

R ch

N

R639

SYSTEM A

RL

SYSTEM B

Y A

B

R640

L ch

N

V

Adjustment Procedure

Set the power voltage to rated voltage for this adjustment.

Before turning on the power, Insert Digital Voltage Meter 1.

between the SPEAKERS SYSTEM A (L CH) "+" and "-".

Insert Digital Voltage Meter between the SPEAKERS

SYSTEM A (R CH) "+" and "-".

Adjust the VOLUME to MIN.2.

Turn on the power. Then turn the SPAKERS knob to A. 3.

Adjustment is started immediately after a speaker relay

turns on.

First L CH is adjusted. 4.

The variable resistor R639 on P101 is turned with

adjustment driver, and the Digital Voltage Meter is

adjusted to "0 mV ± 3 mV".

Then, R CH is adjusted. 5.

The variable resistor R640 on P101 is turned with

adjustment driver, and the Digital Voltage Meter is

adjusted to "0 mV ± 3 mV".

NOTE : DC offset voltage drops when turn the semi-fixed

resistor (R639 and R640) clockwise. DC offset

voltage rises when turn the semi-fixed resistor unclockwise. Please turn it slowly, because value of

Digital Voltage Meter changes slowly.

Although after-adjustment DC offset voltage has some 6.

change, Please check that the range of DC offset voltage

between L ch (R ch) "+" and L ch (R ch) "-" terminal of

SPEAKERS SYSTEM A is "0 mV ± 20 mV". CHART OF

FACTORY MODE

調整手順

調整時は必ず電源電圧を定格電圧に合わせてください。

電源を

ONする前にリアパネルのSPEAKERS SYSTEM A1.

のL CHおよび、R CHそれぞれの"+"端子と"-"端子間にデジ

タルボルトメーターを接続します。

ボリュームを

MINにセットします。2.

電源を投入し本体前面のSPEAKERSノブを回し、Aにしま3.

す。

スピーカーリレーがONした後に調整を開始します。

最初に

L CHを調整します。 4.

P101

基板の半固定抵抗R639を調整ドライバーで回し、L

CH

スピーカー出力端子に接続したデジタルボルトメーター

の電圧が"

次に

P101

CH

の電圧が"

注意

: 半固定抵抗(R639、R640)を時計回りに回すと、DCオ

0 mv ± 3 mV"以内になるように調整します。

R CHを調整します。 5.

基板の半固定抵抗R640を調整ドライバーで回し、R

スピーカー出力端子に接続したデジタルボルトメーター

0 mv ± 3 mV"以内になるように調整します。

フセット電圧は減少し、反時計回りに回すと増加しま

す。

DCオフセット電圧の値は非常にゆっくりと増減し

ますので、半固定抵抗はゆっくりと回してください。

調整後

DCオフセット電圧は多少の変動がありますが、 6.

SPEAKERS SYSTEM A

の

"+"端子と"-"端子間のDCオフセット電圧は"0 mV ± 20

mV"

の範囲であることを確認してください。

のL CHおよび、R CHそれぞれ

3

Page 6

3. SERVICE MODE

3. SERVICE MODE

Microprocessor (QU01) version check

Connect the mains cord into the unit.1.

Press the 2. POWER button with pressing the SOURCE

DIRECT button on the Unit.

The firmware version is displayed on the front LED.3.

(Display time is only for 3 seconds.)

Version : 8 4 2 1

The firmware version is displayed in the lighting position of

LED.

Ex. :

Light up RECORDER-2 [1 ], Version : 1

Light up RECORDER-2 [1 ] and AUX/DVD [4 ], Version : 5

Light up RECORDER-2 [1 ] and TUNER [8 ], Version : 9

Each LED light up then all LED light up.4.

Turn off the power to quit Service Mode. 5.

(The unit to the default status)

Microprocessor (QU01) version 確認

1.

本機に電源ケーブルを接続します。

SOURCE DIRECT2.

押します。

ボタンを押しながら、POWERボタンを

FIRMWAREのバージョンがLEDにて表示されます。 3.

(

表示は3秒間のみです)

MUTERECORDER 21PHONO CD TUNER AUX/DVD

LED

が点灯している箇所がバージョン表示です。

表示例:

点灯RECORDER 2 [

点灯RECORDER 2 [

点灯RECORDER 2 [1 ] and TUNER [

フロントパネルのLEDが順次点灯し、その後全点灯しま4.

す。

電源を切ると

(

本機は、各種設定された内容が初期化され、工場出荷時の

状態に戻ります

SERVICEモードが解除されます。 5.

1

], Version:1

1

] and AUX/DVD [4 ], Version:

)

8

], Version:

5

9

4

Page 7

4. PROTECTION MODE

Explanation of microprocessor (QU01) [PROT-1 (pin6) and

PROT-2 (pin7)].

[A] The PROT-1 (pin6) is the port to detect the following

abnormalities of the Power AMP

Detection of an abnormality in the DC offset voltage from 1.

the Speaker Output terminal.

If the voltage from the Speaker Output terminal exceeds

approximately 1.2V (DC), Q955 or Q956 will turn on and

the signal from the PROT-1 terminal will change to L from

H.

Detection of an abnormal current from the power 2.

transistors (Q713 ~ Q716).

If an electric current of over 7A flows in Q713 or Q715,

Q951, Q953 and Q957 turn on, and the signal from the

PORT-1 terminal will change to L from H.

If an electric current of over 7A flows in Q714 or Q716,

Q952, Q954 and Q957 turn on, and the signal from the

PORT-1 terminal will change to L from H.

Detection of an abnormal temperature of the Heat Sink.3.

If the temperature of the Heat Sink exceeds

approximately +110 degrees C, the posistor (R969) will

turn on Q958 and the signal from the PROT-1 terminal

will change to L from H.

4. PROTECTION動作について

マイコン(QU01)のPROT-1 (pin6)とPROT-2 (pin7)の説明。

[A] PROT-1 (pin6)は、パワーアンプの下記の異常動作を検出

するポートです

スピーカー出力端子の

出。

スピーカー出力端子が約1.2V (DC) を超えるとQ955もしく

は

Q956がONして、PROT-1端子が "H→L" になる。

パワートランジスタ

Q713

もしくはQ715に約7Aを超える電流が流れるとQ951,

Q953, Q957

がONして、PROT-1端子が "H→L" になる。

Q714もしくはQ716に約7Aを超える電流が流れると

Q952,Q954,Q957がONして、PROT-1端子が "H→L" にな

る。

ヒートシンクの異常温度を検出。

3.

ヒートシンクの温度が約110℃を超えると、ポジスター

(R969)によってQ958がONして、PROT-1端子が "H→L" に

なる。

1.〜 3.のいずれかの異常検出でPROT-1端子が "H→L" になる

と保護回路が動作して、

て、即座にスピーカーリレー

す。

DCオフセット電圧の異常電圧を検1.

(Q713〜Q716)の異常電流を検出。2.

SPK_OUT (pin10) を "L→H" にし

L751, L752, L753をOFFにしま

If any of the above three abnormalities is detected, the

signal from the PROT-1 terminal will change to L from H,

and the protection circuit will be activated, the signal from

the SPK_OUT (pin10) changing to H from L and the speaker

relays L751, L752 and L753 immediately turned off.

What this protection operation results in after this depends

on how long the signal from the PROT-1 has to remain L.

s )F THE 02/4 PIN RECOVERS TO ( WITHIN AS SHORT A

period of time as one second or less.

The MUTE indicator starts flickering, thereby indicates

that the protection circuit has come into operation and

automatically turns down the volume. The protection

circuit is deactivated after approximately 15 seconds,

so that readjusting the volume will allow normal use

of the unit again. This protection operation is intended

for the situation wherein the user has misused the unit

temporarily and automatically resets the unit while the

amp circuit is functioning properly.

s )F THE 02/4 PIN REMAINS , FOR MORE THAN ONE SECOND

The amp will be powered off by the P_ON (pin15)

changing to H from L and Power relay L852 turned off

Then, the STANDBY indicator flickers, thereby indicating

that an error has occurred. This protection operation is

intended for a failure in the amp circuit and immediately

turns the power off to avoid the risk of any damage.

Depending on how the user is handling the unit, this

operation may be performed no matter if the amp is

functioning properly.

PROTECTION動作はPROT-1端子が "L" になっている時

この

間によって、その後の動作が異なります。

s PROT-1 (pin6)が1秒以内の短時間の間に "H" に復帰した場

合。

MUTEインジケーターが点滅しPROTECTION動作になっ

たことを知らせ、自動的にボリュームを下げます。

約15秒後に保護回路が解除しますのでボリュームを再調整

すればそのまま使用することができます。

これは、ユーザーが一時的に使用法を誤った場合を想定し

た

PROTECTION動作で、アンプ回路は故障していない場

合に自動復帰する動作です。

s PROT-1 (pin6)が1秒以上 "L" になっている場合。

P_ON (pin15) を "H→L" にして電源リレー L852 をOFF

し、アンプの電源をシャットダウンします。

このときSTANDBYインジケーターが点滅し、異常が起き

たことを表示します。

これは、アンプ回路の故障を想定したPROTECTION動作

で、危険回避のため即座に電源を切る動作です。

ユーザーの使用状況によっては、アンプが故障していなく

てもこの状態になる可能性もあります。

アンプが故障しているかどうかを確認するには、一旦電源

を切り1分ほど待ってから電源SWを再投入します。

この操作で

電源

は、約

ターが点滅します。

電源を再投入しても

は、アンプ回路が故障していると考えられます。

PROTECTION動作が解除します。

SWを再投入してもPROT-1 (pin6)が "L" の異常状態の場合

3秒後に再びシャットダウンしてSTANDBYインジケー

PROTECTION動作が解除されない場合

SW

5

Page 8

To check if the amp is in order, switch off the unit and switch

it on again one minute later. This action will deactivate

the protection operation. If the PROT-1 (pin6) remains

"L", which constitutes an abnormality, the unit shuts down

approximately 3 seconds later and the STANDBY indicator

starts flickering.

If the protection operation will not be deactivated after the

power is turned on again, the amp circuit may be broken.

[B] The PROT-2 (pin7) is the port to detect abnormalities

of the power supply circuit.

Detection of an abnormality in the power amp power 1.

supply circuit.

This port monitors the midpoint voltage of the power amp

power supply between +48V and -48V. If the voltage at

the connection point of R801 and R802 exceeds DC

±1.2V, Q903 or Q904 will turn on to change the signal

from the PROT-2 (pin7) to L from H.

Detection of an abnormality in the preamp power supply 2.

circuit.

Q901 and Q902 monitor the midpoint voltage between

+28V and -28V. If the voltage at the connection point of

R905 and R906 exceeds DC ±1.2V, Q901 or Q902 will

turn on to change the signal from the PROT-2 (pin7) to L

from H

Detection of an abnormality in the function relay power 3.

supply circuit.

If the +24VL of the relay power supply receives an

electric current of over 80 mA, Q815 and Q901 will turn

on to change the signal from the PORT-2 (pin7) to L from

H.

If any of the above three abnormalities is detected, the signal

from the P_ON (pin15) terminal will be changed to L from

H, the power relay L852 will be turned off and the unit will

be shut down. Then, the STANDBY indicator flickers and

indicates that an abnormality has occurred.

[B] PROT-2 (pin7)は、電源回路の異常を検出するポートです

パワーアンプ用電源回路の異常を検出。

1.

パワーアンプ用電源の+48V と-48Vの中点電圧を監視

し、

R801とR802の接続点の電圧が約 ±1.2V(DC) を超え

ると、

Q903もしくはQ904がONしてPROT-2 (pin7)が "H

→L"

になる。

プリアンプ用電源回路の異常を検出。

2.

Q901

とQ902 はプリアンプ用電源の +28V と -28V の

中点電圧を監視し、

±1.2V(DC) を超えると、Q901もしくはQ902がONして

R905とR906の接続点の電圧が約

PROT-2 (pin7)が "H→L" になる。

ファンクションリレー用電源回路の異常を検出。

3.

リレー用電源の+24VL に約80 mAを超える電流が流れる

と、

Q815, Q901がONしてPROT-2 (pin7)が "H→L" にな

る。

1.〜 3. のいずれかの異常を検出すると、P_ON (pin15) を

"L→H" にして、電源リレー L852 をOFFしシャットダウンし

ます。このとき

きたことを表示します。

これは、アンプ回路もしくは電源回路の故障を想定した

STANDBYインジケーターが点滅し、異常が起

PROTECTION動作で、危険回避のため即座に電源を切る動作

です。

アンプ回路もしくは電源回路が故障しているかどうかを確認す

るには、一旦電源

入します。

この操作で

電源

SWを再投入してもPROT-2 (pin7)が "L" の異常状態の場合

は、約

3秒後に再びシャットダウンしてSTANDBYインジケー

ターが点滅します。

電源を再投入しても

は、アンプ回路もしくは電源回路が故障していると考えられま

す。

SWを切り1分ほど待ってから電源SWを再投

PROTECTION動作が解除します。

PROTECTION動作が解除されない場合

This protection operation is intended for a breakdown of the

AMP circuit or the power supply circuit and immediately shut

s off the power in order to avoid the risk of damage.

To check if the amp circuit or the power supply circuit is

broken, switch off the power and then switch it on again

one minute later. This action will deactivate the protection

operation.

If the RPOT-2 (pin7) remains L after the power is switched on

again, the unit will be shut down again three seconds later

with the STANDBY indicator flickering.

If the unit is powered on again and yet cannot get the

protection operation deactivated, the amp circuit or the

power supply circuit may be broken.

6

Page 9

5. WRITING MAIN MICROPROCESSOR

PROCEDURE

Microprocessor needs writing software, when a

microprocessor (QU01) is replaced.

5. WRITING MAIN MICROPROCESSOR

PROCEDURE

QU01を交換したときはQU01へプログラムを書き込む必要が

あります。下記手順に沿って書き込みをしてください。

NECESSARY EQUIPMENT

s 7INDOWS 0# OR 80 WITH 3ERIAL 0ORT

s 23# #ABLE STRAIGHT TYPE 0IN FEMALE 0IN

female)

s #ONNECTION *)' -0-3*)'

s 7RITING 4OOL AND SOME FILES &LASH0ROGEXE ETC IN

TM86FH47pass folder)

s 7RITING DATA 0-?XXXXH

WRITING PROCEDURE

Disconnect the mains cord from the unit.1.

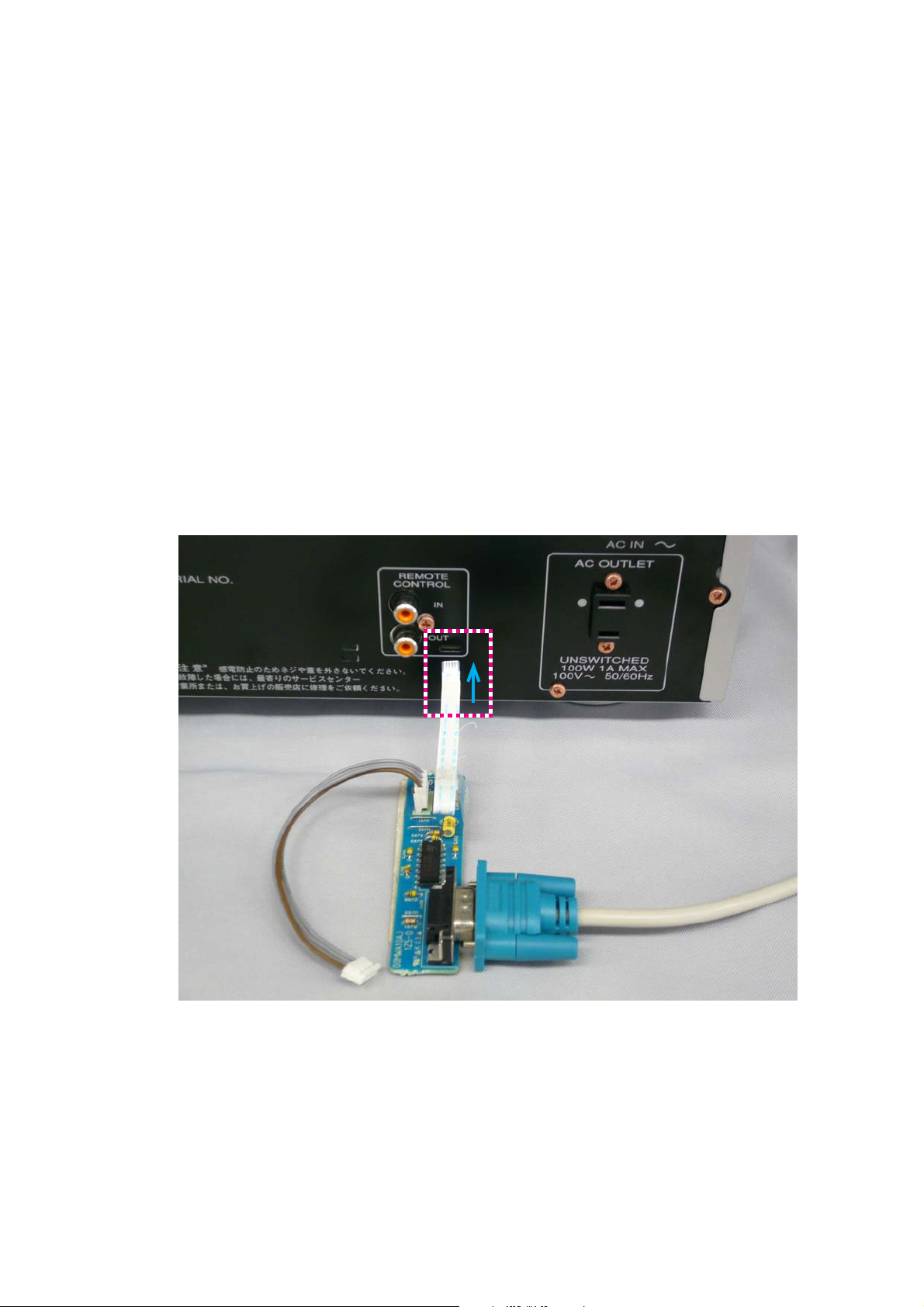

#ONNECT 23# ON THE CONNECTION *)' AND 3ERIAL 0ORT2.

of windows PC with RS-232C cable.

Connect FPC (upside contact) to the rear panel of the 3.

UNIT FROM CONNECTION *)'

必要機器

s Windows PC (2000またはXP、Serialポートつき)

s RS-232C

s

接続冶具(90M-PM11S1JI')

s

書き込み用ソフトウェア一式(FlashProg.exe、他)

s

書き込み用データ(PM7003_xxxx.h16)

ストレートケーブル(9Pinメス-9Pinメス)

書き込み手順

本機の電源ケーブルを抜きます。1.

Windows PC

で接続します。

本機のリアパネルに接続冶具の

して差し込みます。

のSerial Portと接続冶具をRS-232Cケーブル2.

FPCをコンタクト面を上に3.

Reconnect the mains cord to the unit. 4.

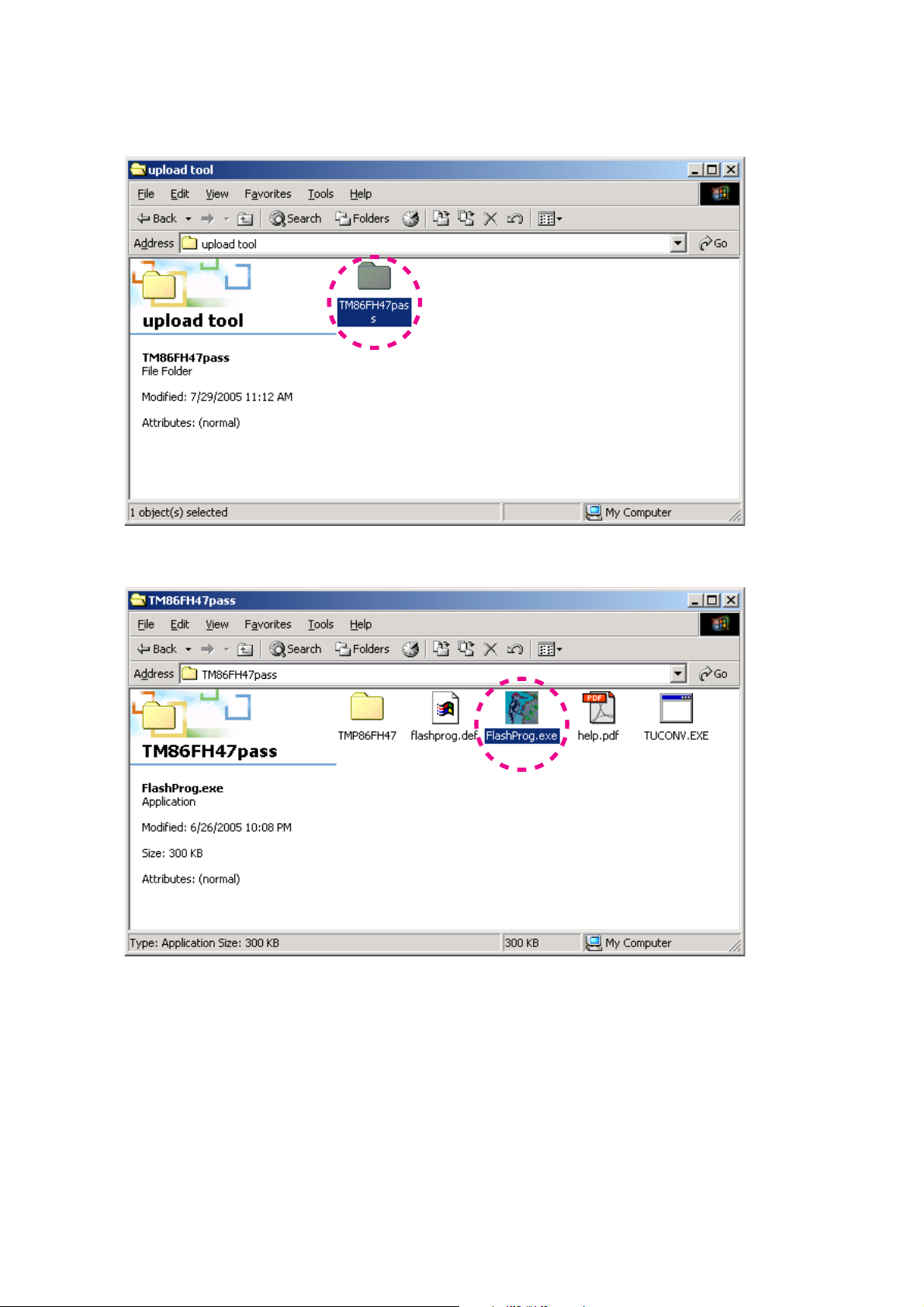

Put the "TM86FH47pass" folder into anywhere on your 5.

PC’s hard disc.

本機の電源ケーブルを差し込みます。4.

TM86FH47pass

にコピーします。

7

フォルダをWindows PCの任意のフォルダ5.

Page 10

Double click the 6. TM86FH47pass folder.

TM86FH47pass6. フォルダをダブルクリックして開きます。

Double click 7. FlashProg.exe.

FlashProg.exe7.

をダブルクリックします。

8

Page 11

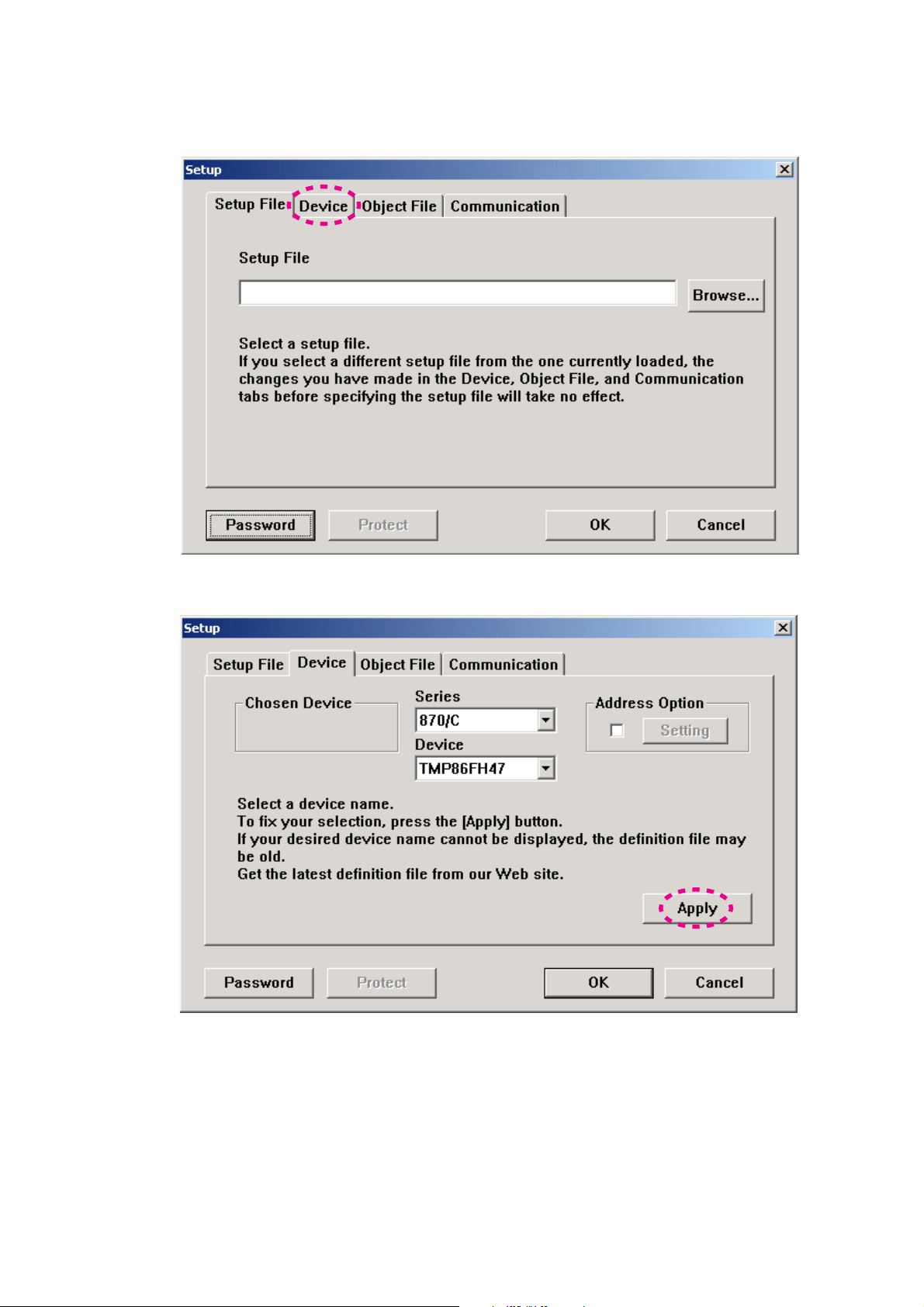

Click 8. Device.

Device8. をクリックします。

Click 9. Apply.

をクリックします。

Apply9.

9

Page 12

TMP86FH47 appear in Chosen Device.10.

Chosen DeviceにTMP86FH47が入力されます。10.

Click 11. Object File, and click Browse...

Object File11. をクリックし、Browse...をクリックします。

10

Page 13

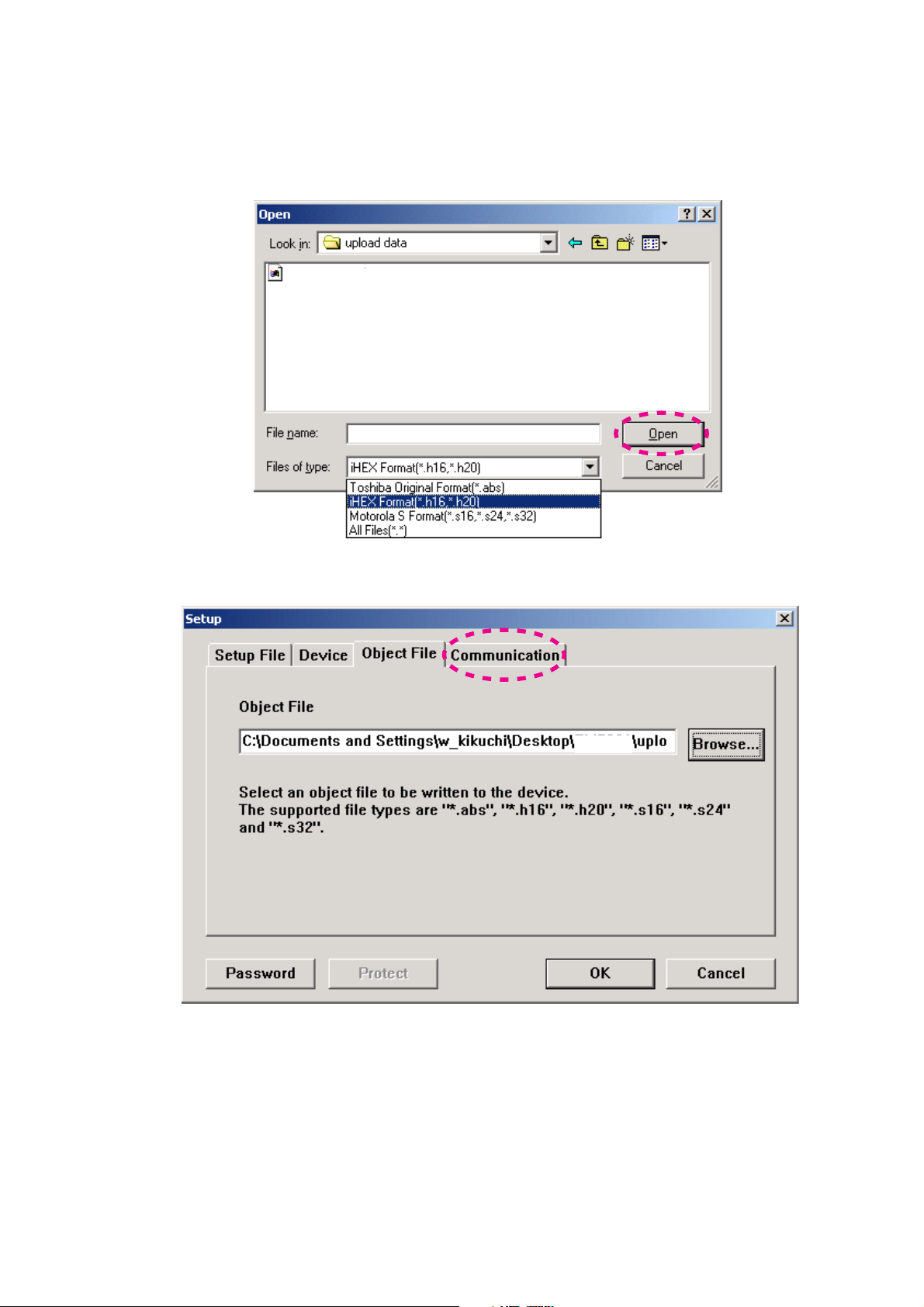

Choose 12. iHEX Fomat[*.h16,*.h20] in Files of type.

Choose writing data, and click Open.

PM7003_V09.h16

Files of typeから12. iHEX Fomat[*.h16,*.h20]を選び、書き込

み用データファイルを選択して

書き込むファイル名は変わることがあります。)

Openをクリックします。(

Click 13. Communication.

Communication13.

をクリックします。

PM7003

11

Page 14

Choose 14. COM port number in COM port.

Choose 9600 in Data Rate.

Click OK.

COM Portから接続する14. COM Port番号を選びます。

Data Rateから9600を選択します。

OKをクリックします。

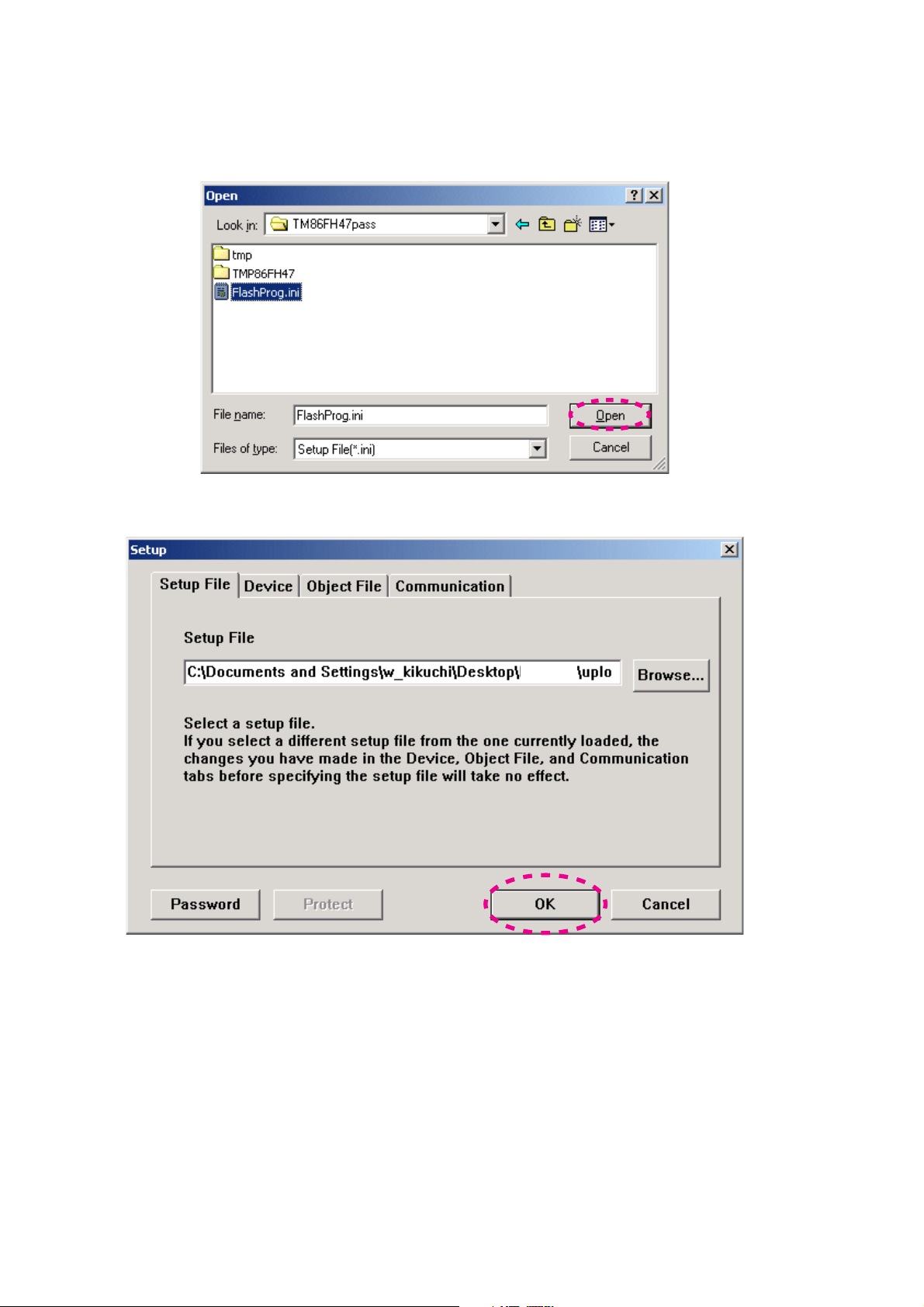

When Setup window is closed, the tmp folder and 15.

FlashProg.ini file are created simultaneously.

NOTE : These are the original set-up configuration files for

that PC. They do not operate, if these files moved

to another PC. When you make it operate with other

PC, delete the tmp folder and the FlashProg.ini file

and redo a setup.

この時TMP86FH47passフォルダにtmpフォルダと15.

FlashProg.ini

注意

: これらは今設定したWindows PC独自の設定ファイルに

なります。他の

正しく動作しません。もし他の

ファイルが作成されます。

PCにこれらのファイルをコピーしても

PCで動作させる場合は

tmpフォルダとFlashProg.iniファイルは削除して設定を

やり直してください。

12

Page 15

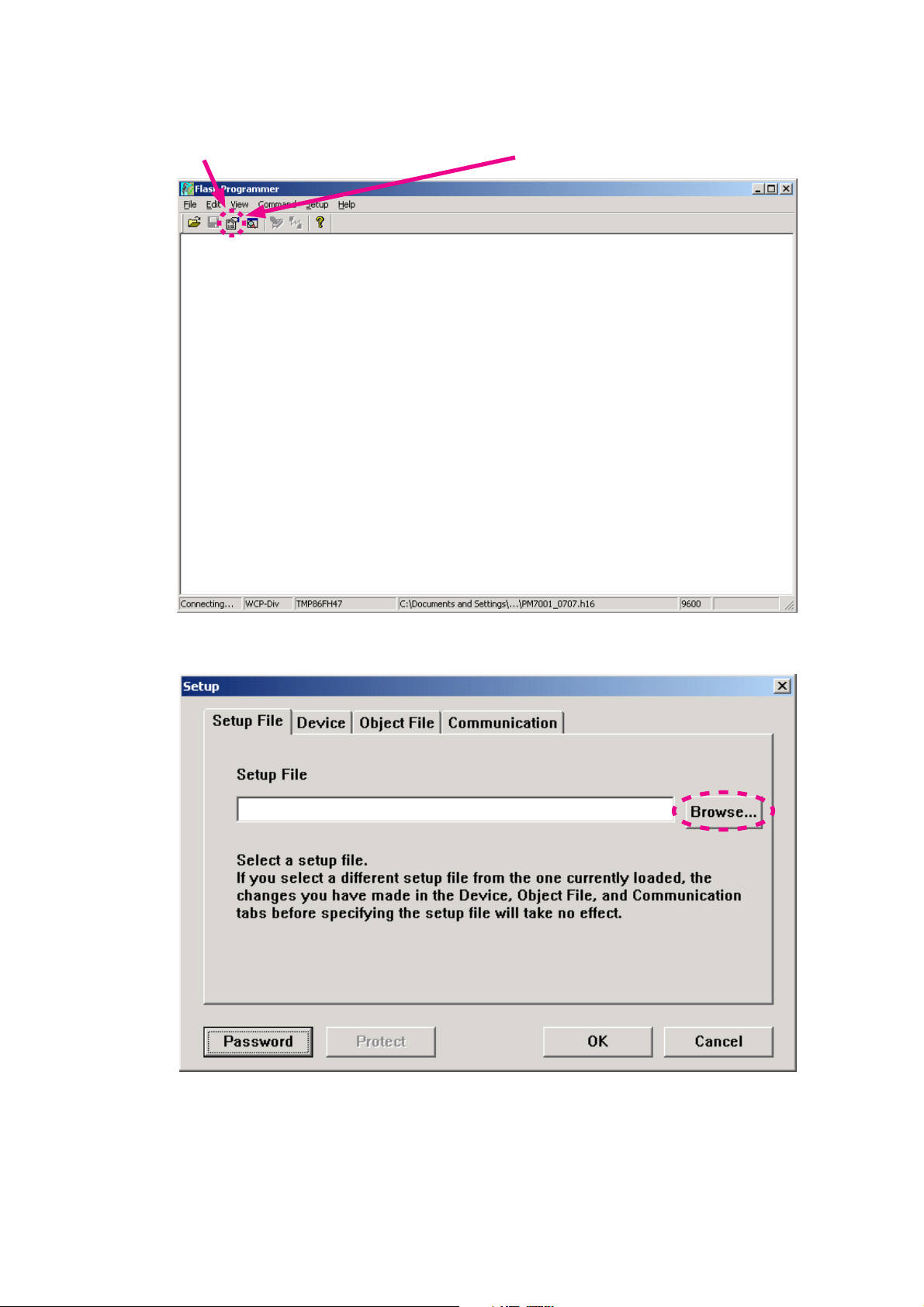

The Flash Programmer is launched.16.

Click setup icon.

setupが閉じ、Flash Programmerが立ち上がります。16.

setup

アイコンをクリックします。

Click 17. Browse....

Browse...17.

をクリックします。

13

Page 16

Choose 18. FlashProg.ini in TM86FH47pass folder, and

click Open.

Click 19. OK.

TM86FH47passフォルダから18. FlashProg.iniを選

び、

Openをクリックします。

をクリックします。

OK19.

PM7003

14

Page 17

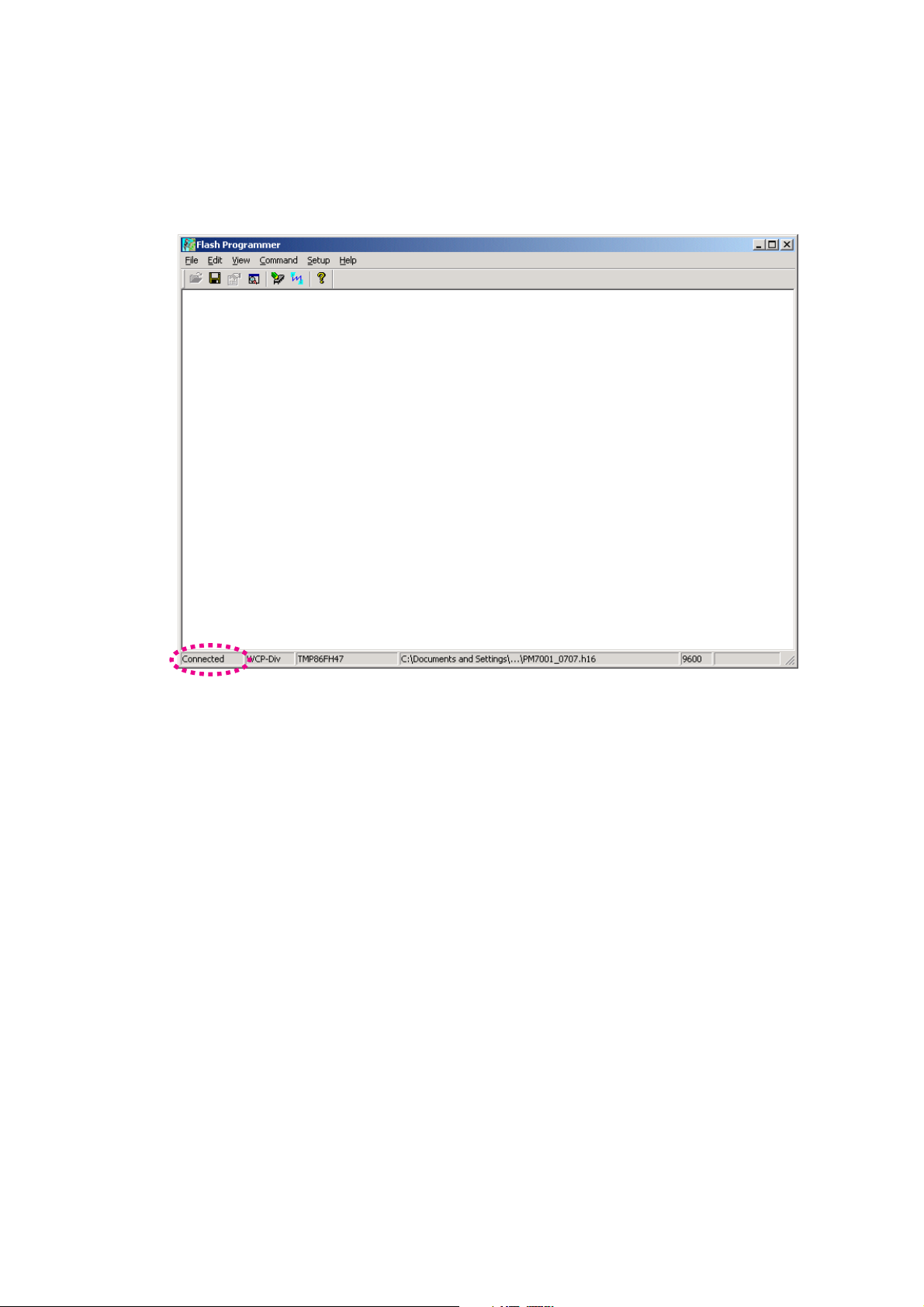

Press the 20. POWER ON/OFF button, and turn on the unit.

Status indication at lower left in Flash Programming

window is changed to "Connected" from "Connecting".

When it did not changed, check the connection of FPC or

RS-232C cable.

本機の電源スイッチをオンにします。20.

Flash Programming

ウィンドウの左下のステータスが

ConnectingからConnectedに変わります。もしConnected

に変わらないときは接続を確認してください。

15

Page 18

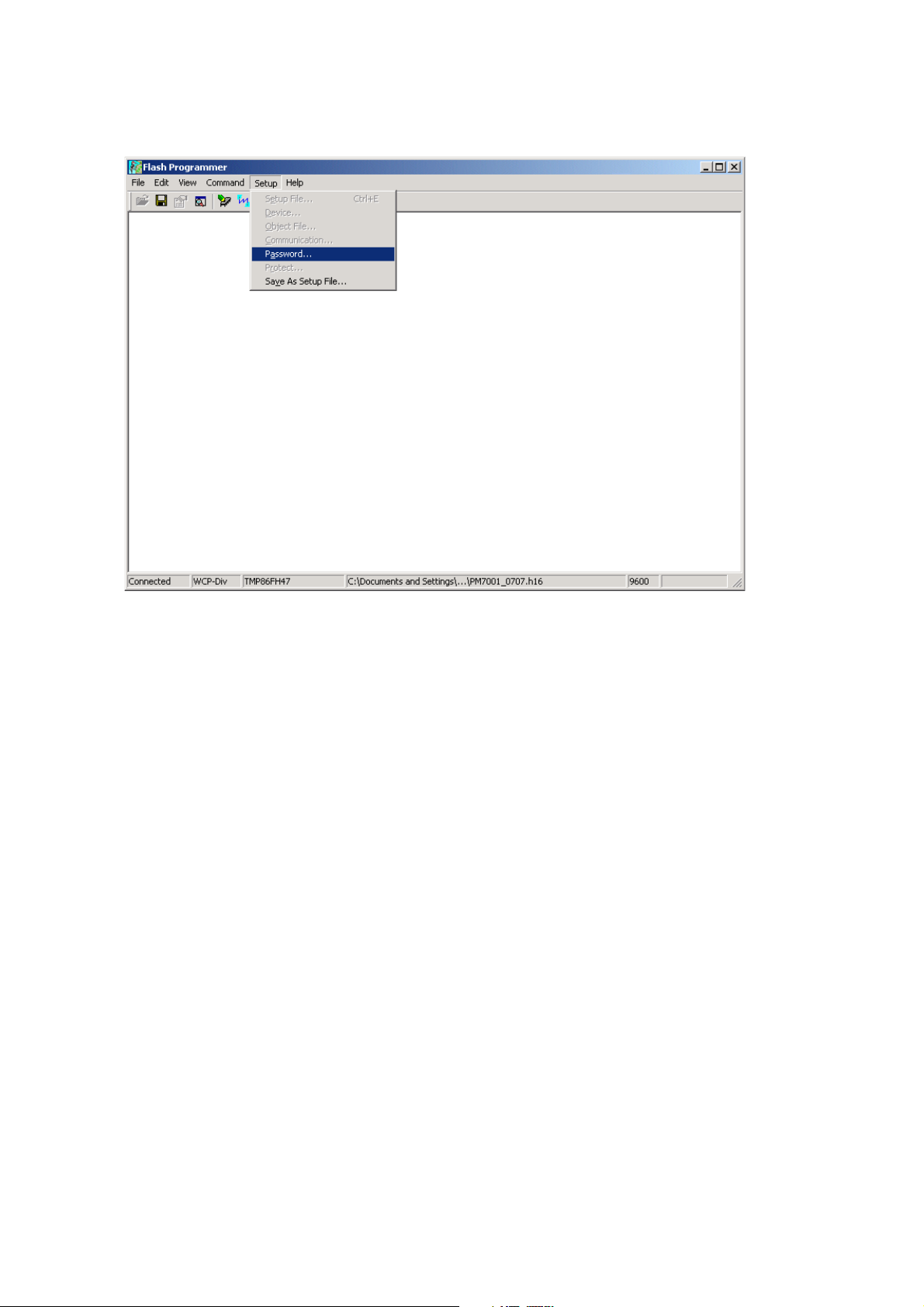

Select 21. Password in Setup.

Setup21. からPasswordを選びます。

16

Page 19

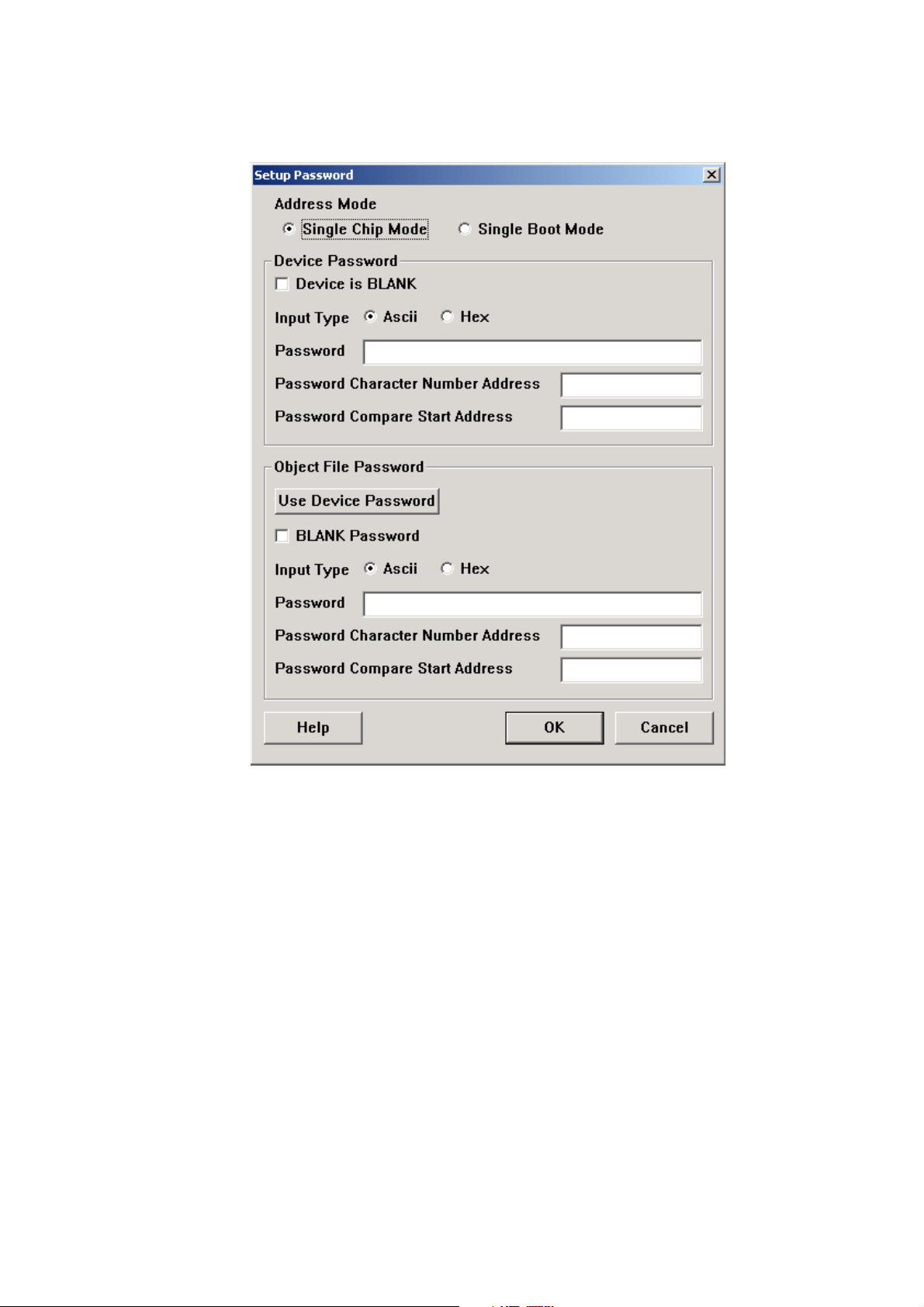

Setup Password opens.22.

Setup Password画面が開きます。22.

s When writing in a blank microprocessor

Refer to next page

s When writing (update) in the already written-in

microprocessor

Refer to 19 page

s

ブランクマイコンに書き込む場合は、次のページへ

s 既に書き込まれたマイコンに書き込む場合(アップデート)は

19ページへ

17

Page 20

When writing in a blank microprocessor

Check Single Boot Mode in Address Mode.

Setting in Device Password

Check Device is BLANK.

Check Hex in input type.

Since they are inputted automatically, please do

not change text box of "Password", "Password

Character Number Address" and “Password

Compare Start Address”.

Setting in Object File Password

Do not check BLANK password.

Check Hex in Input Type.

Type 0102030405060708 into Password.

Type 0xFF00 into Password Character Number

Address.

Type 0xFF01 into Password Compare Start

Address.

Click OK.

ブランクマイコンに書き込む場合

Address ModeからSingle Boot Modeにチェックを入れます。

Device Password内の設定

Device is BLANKのチェックボックスにチェックを

入れます。

input typeからHexにチェックを入れます。

Password、Password Character Number

Address

的に入力されますので変更しないでください。

、Password Compare Start Addressは自動

Object File Password内の設定

BLANK Passwordにはチェックを入れないでください。

Input TypeからHexにチェックを入れてください。

Passwordに0102030405060708を入力します。

Password Character Number Addressに0xFF00を

入力します。

Password Compare Start Addressに0xFF01を入力

します。

OKをクリックします。

18

Page 21

When writing in the already written-in microcomputer

(update)

. Check Single Boot Mode in Address Mode.

Setting in Device Password

Do not check Device is BLANK.

Check Hex in input type.

Type 0102030405060708 into Password.

Type 0xFF00 into Password Character Number

Address.

Type 0xFF01 into Password Compare Start

Address.

Setting in Object File Password

Do not check BLANK password.

Check Hex in Input Type.

Type 0102030405060708 into Password.

Type 0xFF00 into Password Character Number

Address.

Type 0xFF01 into Password Compare Start

Address.

Click OK.

既に書き込まれたマイコンに書き込む場合(アップデート)

Address Mode

す。

からSingle Boot Modeにチェックを入れま

Device Password内の設定

Device is BLANKにはチェックを入れないでください。

input typeからHexにチェックを入れます。

Passwordに0102030405060708を入力します。

Password Character Number Addressに0xFF00を

入力します。

Password Compare Start Addressに0xFF01を入力

します。

Object File Password内の設定

BLANK Passwordにはチェックを入れないでください。

Input TypeからHexにチェックを入れてください。

Passwordに0102030405060708を入力します。

Password Character Number Addressに0xFF00を

入力します。

Password Compare Start Addressに0xFF01を入力

します。

OKをクリックします。

19

Page 22

Auto Programming opens.23.

Auto Programmingの設定画面が開きます。23.

20

Page 23

Check 24. All Erase, Programming, Verify with SUM and

File Compare in Flash Memory Programming.

Check Manual in Recover Process by Programming

Error.

Click Start.

Flash Memory Programmingから24. All Erase,

Programming, Verify with SUM, File Compare

クを入れます。

にチェッ

Recover Process by Programming ErrorからManualにチ

ェックを入れます。

Startをクリックします。

21

Page 24

Writing data is written into the microprocessor (QU01).25.

メインマイコン(QU01)への書き込みが行われます。25.

Click 26. Yes, when writing is successful.

書き込みが成功すると下記のような画面が出ますので26. Yes を

クリックします。

22

Page 25

Click 27. Cancel.

Click 28. Cancel.

Cancel27. をクリックし終了します。

をクリックします。

Cancel28.

23

Page 26

Select the 29. Exit in File, and finish.

File29. からExitを選び終了します。

Press the 30. POWER ON/OFF button, and turn off the unit.

Disconnect each cable.

Check the software version.31.

Refer to "3. SERVICE MODE" on page 4.

本機の電源スイッチを切りケーブルを外します。30.

Software

4

のVersion確認をしてください。31.

ページの"3.SERVICE MODE"で確認します。

24

Page 27

6. WIRING DIAGRAM

PHONO AMP PWB

W202

P401

J281J282

W201

W401

W291

T0 WU01

W005

J331

J283

J901

JU02

J591

J592

J501

P591

VOLUME PWB

1234567

WU01

J593

P101

MAIN PWB

TO J591

J913

CHASSIS

W007

J755

T0 JU07

P751 (P971)

SPEAKER TERMINAL

J701W601

J709

W008

PWB

J751

J754

J702W602

P701

POWER STAGE PWB

J821

CHASSIS

J911 W951

J824J912

CHASSISCHASSIS

J811

W801

J801

WA01

WIRE ASSY

J792

P791

HEADPHONE PWB

W791

CHASSS

WA01

L001

MAIN TRANSFORMER

J855

W204

CHASSIS

P201

TONE PWB

W203

J201

JU06

PU01

U-COM PWB

JU01

J861

P851

STANDBY BWB

J864 J862J852

SOFT UPDATE PORT

W011

JU05

W181

P181

INPUT SELECTOR PWB

JU03

JU07

JU04

W191

P191

STANDBY LED PWB

TO J755

POWER SW PWB

CHASSIS

W003

J891

P891

25 26

J851

W002

J854

J853

J001

W001

AC CORD

Page 28

7. BLOCK DIAGRAM

PHONO

CD

TUNER

AUX / DVD

RECORDER 1

IN

RECORDER 2

IN

RECORDER 1

OUT

RECORDER 2

OUT

JAPAN VERSION ONLY

AC OUTLET

AC IN

CD DIRECT

BUFFER

FUSE

PRE OUT

RIAA

SOURCE DIRECT

CD

DIRECT

STANDBY

RELAY

POWER

ON/OFF

INPUT SERECTOR

FUSE

LINE BUFFER

REC OUT SELECTOR

REC BUFFER

MA N TRANS

SUB TRANS

VOLUME

NFB

±50V

±18V

24V

12V μ COM

MUTE

TREBLE

BALANCE

BASS

R CH

POWER AMP

PRE AMP

RELAY

5V

INDICATOR

5V

RELAY

POWER DETECT

PROTECTION

CONTROLLER NDICAT ON LED

EEPROM

I/R SENSOR

NFB

PROTECION

CIRCUIT

μ COM

RC5

STANDBY RELAY

FUNCTION RELAY

INPUT SELECTOR

RC5 IN/OUT

POWER AMP

DIRECT

SPEAKER A

SPEAKER B

SPEAKER B

SPEAKER B

HEADPHONE

(+)

( )

(+)

( )

2827

Page 29

8. SCHEMATIC DIAGRAM

P401 PHONO AMP PWB

PHONO GND

J002

J401

TPF301

EARTH

2

TPF 02

3

PHONO

TPF303

1

TPF304

4

J291

TPF305

2

TPF 06

3

PRE OUT

TPF307

1

TPF308

5

TPF 9

6

MAIN IN

4

TPF310

7

TPF311

WU01

R401R402

F 33

N K 100

R401

100k

R403

R404

100k

R402

220k 220k

R295

1k

220k 220k

R296

1k

TO SPK TERMNAL PWB

P591 VOLUME PWB

TPF251

3

TPF252

2

1

J591

TO MAIN PWB

164V

TPZ 01

8

5

0V

6

0V

C403

10u/50

C405

470u10

220p

R407

100k

R405

C401

82

R408

82

100k

220p

C402

R406

C406

470u/10

C404

10u/50

0V

2

0V

3

4

TPZ302

330p 330p

C296 C295

P791

HEADPHONE PWB

TPF331

W010

1

2

TPF 2 TPF3 4

J754

3

J792

C591

C592

07MQ ST L

J501

Q401

NJM2068DD

R409

Q401

NJM2068DD

164V

87

R591

10u/50

M

10u50

PF253

PF254

0V

7

82k

C407

0039u

C408

0039u

R410

82k

1

0V

R791

TPF333

10

R792

TO U COM PWB

4

L401

320uH320uH

132

EX03

JAMPER

220p

C419

01u

220p

C420

C421

EX04

JAMPER

EX03EX04

L402

F version only

3 4

220p

C291

01u

C297

R292 R291

220p220p 220p

C293C294 C292

01u

C298

R294 R293

NK version only

31

2

50k50k

R591R591

46

5

PF258

PF259

PF257

PF256

PF255

TPF260

J592

1 3

1234567

J593

R419

165V

10

C413

R413

TPZ303

10u/50

R417

100

68k

100

R411

C411

1000p

NC

47k

C415

R415

001u

C409

C410

001u

1000p

C412

68k

R412

R414

100

C417

220u25

NC

47k

C418

C416

R416

220u/25

R418

C414

100

10u/50

R420

10

TO MAN PWB

J331

W401

TPF312

1

+18V

TPF313

2

18V

TPF314

3

PH OUT L

TPF315

4

AGND

TPF316

5

PH OUT R

165V

W291

TPF317

1

PRE OUT R

TPF318

2

AGND

TPF319

3

PRE OUT L

4

5

6

MAIN IN R

AGND

MAIN IN L

TO MAIN PWB

J283

TPF320

TPF321

TPF322

EX07

220V

TPF293

TPF294

230V

EX06

12

W001

12

J001

12

21

W002

J851 J852

21 21

TPF261

L851

SUB TRANSFORMER

4

NC

2

1

P851 STANDBY BWB

P891 POWER SW PWB

S891

C891

470p

TPF601

J891

12

12

W003

21

TPF262

TPF264

TPF263

J858

250V

F852

315A

J859

TPZ205

21

J860

JAPAN VERSON ONLY

R851

TPZ208

TPF 95

D855

D851

1D3

1D3

PZ201

5

9

5 9 AC11 8V

D856

D852

1D3

1D3

D853

C853

001u

R857

1D3

TPZ207

TPZ202

1D3

D854

TPZ209

290V

TPF602

C861C862

3300UF

PZ2 1

A GND

3300UF

290V

TPZ210

C851

C863

TPZ20

4

001

001

1

F85

J857

J856

3

T63A/250V FOR JAPAN

2

T315A/250V FOR OTHER

L852

Q851

KTC3199

4

1

C852

10u50

TPZ203

A GND

102V

10k

R861

22

Q854

116V

TPZ 06

KTA1268

R860

1k

TPZ 3

R859

1k

C860

2200u25

NC

C854

1u50

TPZ 1

4

A GND

EX21

F

EX22

N

EX23

K

EX24

L

EX25

U

NK version only

J791

2

3

1

HEAD PHONE

W791

C792

C791

001u10001u

1

TPF335

EARTH

35V

35V

C855

D857

D1NJ10

D858

D1NJ10

D859

D1NJ10

D860

D1NJ10

TPZ 96

260V

C857

A GND

Q852

PQ050ES1MXPQ

N

115V

10u50

TPF292

1

J864

EARTH

PZ 12

Q853

NJM7805FA

N

220u35

POWER ON0 7V

POWER OFF0V

OUT

GND

R854

100k

A GND

J855

290V

290V

R855

12W1

G851

21

R856

12W1

068 4 7

1D3

1D3

1D3

D861

D863

D865

1D

1D3

3

D862

D866

1D3

D864

R858

260V

100k

C859

1u50

TPZ 97

L855

5V

OU

GND

C858

10u50

TPZ298

R853

R852

47k

A GND

L853

50 V

C856

10u50

L854

Q855

KRA102M

PF291

J862

TPF265

TPF266

TPF267

J854

TPF268

TPF269

TPF270

J853

TPF271

TPF272

47k

0 6V

5 0V

5 0V

5 0V

0 6V

0V

5 0V

5 0V

C864

01u

PF290

PF289

54321

CE

RXD

FOR SOFT UPDATE

W006

+28V

2

To MAN PWB

28V

1

J811

+24VL

AC210V

1

1

2

2

3

3

AC210V

L001

MAIN TRANSFORMER

3

1

4

2

2

1

1

TPF273

TPF274

47

01u

C865

R862

C866

01u

TPF277

0V

TPF278

TPF279

TPF280

TPF281

0V

TPF282

TPF283

TPF284

TPF285

TPF286

PF288

PF287

TXD

+5VL

D-GND

5

6

2

8

J863

1

IN

3

RC BUS

PF275

2

OUT

4

TPF27

6

J861

1

RC5

2

P DOWN

3

+5VD

4

P ON

5

+5VL

TO U COM PWB

6

D GND

JU01

7

W007

P OFF

8

CE4

9

RXD

1

TXD

29 30

Page 30

To PHONO AMP PWB

W401

PH OUT L

PH OUT R

CD

TUNER

AUX/DVD

IN

OUT

RECORDER1

IN

OUT

RECORDER2

+18V

18V

A-GND

J331

J301

J302

4

6

5

1

3

2

7

J303

4

6

5

1

3

2

7

J304

4

6

5

1

3

2

7

E 1

F

EX12

N

EX13

K

EX14

L

EX15

U

P101 MAIN PWB

1

+18V

2

18V

3

4

5

A-GND

1

100p100p

C303C304

3

01u

C301

2

4

N K verson only

NK vers on on y

C333C334

01u

C331

C335C336

01u

C332

C339

01u

C337

C341

01u

C342 C340

C338

01u

C346

C343

C347

01u

C348 C345

C344

TO TONE PWB

TO VOLUME PWB

J592

B 7P MQ-C

PH L

KTC3200

KTA1268

0V

0V

KTC3200KTA1268

165V

C311C312

-165V

Q313

C353

C354

R387

10

A GND

R388

10

L

L

C309

22u/25

R323

10

100k100k

R321R322

220u25220u/25

A-GND

R324

10

C310

22u/25

R361

15k

22

R357R359R358R360

06 V

KTA1268

-06V

Q315

R363

222222

KTC3200

15k

330p

R362

330p

15k

06 V

KTA1268

Q314

06V

Q316

KTC3200

R364

15k

C

10u/50

R383R384

C386 C385

C3 4

220u25 220u/25

10u/50

R386

47

R385

R 1

0V

0V

0V

0V

0V

0V

0V

0V

-165V

CE

0V 16 5V

DATA

0V

CLK

0V

PH R

+18V

-18V

Q317

KTC3200

22

R365

C355

22

22u/25

R367

165V

Q319

KTA1268

Q318

KTC3200

-165V

22

R366

0V0V

C356

22

22u/25

R368

Q320

KTA1268

165V

8

1

NJM206

0V

100k100k

7

NJM206

0V

-165V

47

Q391

LC78212

0V

1

PH L

0V

2

CD L

0V

3

TU L

4

SL L

5

DV L

6

R1 L

7

R2 L

8

SL L

9

R1 LO

10

R2 LO

11

RO L

12

VEE

13

CE

14

DATA

15 16

CLK VSS

+24VL

10

R325

1345

301

CD DRECT

R371

10

100k

R369

C357

220u/25

A-GND

100k

R370

C358

220u25

R372

10

C381

3

0V

10u/50

Q381

2

100k100k

R381R382

0V

C382

5

0V

10u/50

Q381

6

0V

4

30

0V

PH R

R392

29

0V

CD R

22k22k

28

TU R

0V

27

0V

A GNDA-GND

SL R

0V

26

DV R

0V

25

R1 R

0V

24

R2 R

0V

23

SL R

0V

22

R1 RO

0V

21

R2 RO

0V

20

RO R

165V

19

VDD

18

RES

17

SET

0V

10k10u50

R393C393

D391

A-GND

R311

15k

22222222

R307R309

Q305Q307

06 V

KTA1268

Q301

0V

22 22

C305

10u/50

220k220k

R303R304

R301R302

C306

10u/50

220k

100p100p

R331

A GND

220k

R332

220k220k

100p100p

R333R334

A GND

220k

100p

R335

A GND

R339

560

220k 220k220k

100p

R337 R336R338

A GND

100p 100p

R340

560

220k

R341

A GND

220k220k

100p

R342R344

R345

560

220k

100p

R343

A GND

100p 100p

R346

560

R317R315

R305

06V

Q303

470

KTC3200

R313

15k

22k22k

330p330p

C307C308

R312

15k

R308

R306

TA1268

Q306Q308

06V

470

Q302

0V

22 22

R318 R316

06V

Q304

KTC3200

R310

4

15k

TU L

TU R

DV L

R355

C351

470

10u/50

27k

220k

R353

R351

DV R

R1 L

R1 R

R1 LO

R1 RO

R2 L

R2 R

R2 LO

R2 RO

27k

220k

R354

R352

R356

C352

470

10u/50

+18V

18V

PH

DV L

R1 L

R2 L

R1 LO

R2 LO

1234567

J501

A-GND

A-GND A-GND

VOL N LCH

VOL N RCH

VOL OUT LCH

VOL OUT RCH

D301

Q309

KRC102M

1k

R327

D-GND

1k

R328

+18V

-18V

PH R

TU RTU

DV R

R1 R

R2 R

R1 RO

R2 RO

CLK

DATA

CE

J901

L

18V

+18V

A-GND

W201

1

2

3R4

5

J281 J282

A-GND A GND

-18V

+18V

4

L281

SOURCE DREC

CD DRECT

ON 5V

OFF 0V

CD D

NCJUMPERNCJUMPER

R505

C501

22u/50

10k

R501

C503

NC

R507

C513

A-GND

R506

R504

C502

100

22u/50

10k

C504

R502

NC

C514

R508

A-GND

R819

+18V

47

168V

165V

C815

220u/25

A-GND

C816

220u25

-165V

R820

18V

47

168V

MUTE

PA_D

CD D

SO_D

1 34 678 10 11 12

TO TONE PWB

L

A-GND

W202

1R2

3

+24VL

10

R281

345121

L282

D281

MUTE

Q501

Q503

-06V

-12V

220u25 220u/25

220u25

Q502

-06V

-12V

220u25

Q813

18V

18V

470 470

Q814

12 V

06V

1 2V

0V

Q504

2SD1415

275V

275V

KTA1268

0V

KTC3200

SPL

KTA1268

KTC3200

Q811

Q812

R513

D501

R511 R509

D503

R515

R514

D502

R510

R512

D504

R516

KT 1267

C813

C814

KTC3199

SPK

SOURCE DIRECT

15k

0 6

22 22

06V

15k

15k

06V

22

22

06V

15k

470

R815

R811D811R813

268V

220u/25

R814D812R812

220u25

-268V

470

R816

C916

D-GND

TO U COM PWB

121198

SOURCE DREC

A GND

Q281

ON 5V

KRC102M

OFF 0V

D GND

SO D

470

R521C509

157V

157

Q509Q511

KTC3200KTA1268

Q513Q515

KTA1268KTC3200

Q505

151V

KTC3200

0V

22

R517

R519

R518

R520

JU02

W005

1M

R529

100p

22

0V

151V

Q507

KTA1268

470

R523

R543R545

470

R522

157V

157V

Q510

KTC3200

Q514

KTA1268

Q506

151V

KTC3200

0V

22

1M

100p

C510

R530

22

0V

151V

KTA1268

Q508

Q516

KTC3200

Q512

KTA1268

470

R524

R544

R546

330

290V

1k15k

33k33k

R905

15k

R906

C812 C811

22u50 22u50

1k

290V

01u

J811

123

+24V

-28V

+28V

109

100p

C507 C505

R547

100

C506

100p

C508

R548

100

180V

D813

D814

-180V

R818 R817

2SB1020

PROT_2

PROT_1

A GND

PRE-OUT-R

1

2

3

J283

+24VL +24VL

10

270

R290

R289

R283

R285

270

R287

470k470k

345

D282

L283

11198

TPZ28 TPZ27

R288

R286

270

MUTE

Q283

ON 5V

KRC102M

OFF 0V

D GND

MUTE

165V

15k15k

220

R525

R535R537

0 6V

Q517

Q525

KTA1268

KTC3200KTA1268

2222

R531R533

0V

0 6V

Q521

2222

R539R541

0V

0V

Q523

06V

KTC3200 KTA1268

Q527

Q519

06V

KTC3200

-157V-15 7V

220

R527

165V

330330

165V

15k22

220

R526

R536R532

0 6V

Q518

KTA1268

Q526

KTC3200

0V

KTA1268

Q522

22

R540

V

22

R542

0V

Q524

KTC3200

Q528

KTA1268

Q520

06V

KTC3200

-157V-15 7V

15k 22

220

R538 R534

R528

165V

330

+24VL

VOLTAGE DETECT

FOR PRE AMP

R901

10k

0V

10k

C901

1u/50

R902

D-GND

VOLTAGE DETECT

FOR POWER AMP

R903

0

10k

10k

C902

R904

10u50

D-GND

PRT 2

TO STANDBY PCB

J863

w006

PRE-OUT-L4MA N- N-R

270

POWER DRECT

R553

10

C511

22u/25

R555

10

R554

10

C512

22u/25

R556

10

R822

10

Q901

KTC3199

Q903

KTC3199

J821

EARTH

A GND

TO PHONO AMP PWB

MA N- N-L

5

6

A-GND

L284

POWER DRECT

ON 5V

OFF 0V

R551R503

JAMPER100

100k

R549

JAMPER

100k

R550

OVER CURRENT DETECT

FOR +24VL

R825

33k

R823

10k

R824

10k

Q902

PROTECT0V

NORMAL5V

Q904

C903

01u

A-GND

J912

W291

R284

345

121198

D GND

PA D

+18V

-18V

+18V

R552

18V

Q815

KTA1267

D GND

KTC3199

KTC3199

PROT_2

D-GND

L912

J913

EARTH EARTH

R659

490V

488V

481V

KTC3199KTC3199KTA1267KTA1267

R653R655

0V

481V

KTC3199

KTC3199

R654

R656

KTA1267

KTA1267

Q911

NORMAL0V

10 1/4W

R635

D609

11 V

D611

12V

47k

R639

11

06 V

D613

06V

470k

R641

D615

2222 100k100k

-11V

R645R647 D605D607 R649R651

0V

06V

Q625Q627

R637

47k 47k

2222

KTA1267KTC3199

0V

-06V

-06V

06V

R643

-12V

481V

-488V

11V

100k

R650

12V

06

V

D606

06V

R642

22

0V

R646

Q626

22

KTA1267

0V

22

KTC3199

Q628

0V

22

R648

-06V

-06V

R644

D608

-12V

100k

R652

481V

-488V

47k

R912

R911

260V

100k

KTA1267

+24VL

TO POWERSTAGE PWB

C609

TO J701

W601

220u/25

+47V

LOUT+

LOUT

4

-47V

5

100k

10 1/4W

10 1/4W

R636

D610

D614

470k

-11V

220u/25

100k

10 1/4W

C911

01u

NFB

R661

490V

490V488V

R660

47k

D612

47k

R640

D616

47k

R638

TO POWERSTAGE PWB

C610

TO J702

W602

+47V

ROUT+

3

ROUT

4

47V

5

NFB

R662

490V

TO POWERSTAGE PWB

W951

J911

D GND

1

PRT-1

2

PRT-2

3

+24VL

4

260V

D-GND

R667

470

R623

12 V

06 V

TA1268

0V

KTC3200

06V

0V

KTC3200 TA1268

Q916

R663

R611

D601

R607

R609

D603

R613

R665R664R666

A-GND

R612

R608 D602

R610R614

D604

A-GND

D-GND

PROTECT0V

NORMAL0 6V

KRC102M

R619

481V 48 1V

Q613

KTA1268

469V

-469V

Q615

KTC3200

R621

R631

470

R620

481V

Q614

KTA1268

469V

-469V

Q616

KTC3200

R622

R632

C913

D GND

Q918

260V

47k

R914

0V

Q917

KTC3199

68k

475

Q633Q629Q631Q635

18 V

1M1M150 150

680p

C607

R627R629

7

22

-18V

Q623 Q621

2SC2705 2SA1145

475V

Q619 Q617

KTC3200 KTA1268

-481V

-481V

R669

68k

470

R625

2W15 K

R668

150150

R624

68k

481V

475V

Q618

KTA1268

Q634

Q622

Q630

18V

1M

680p

C608

R628

R658

22

1M

R630

-18V

Q632

Q624

2SC2705

-475V

Q636

Q620

KTC3200 2SA1145

-481V

481V

R670

68k

470

R626

2W15 K

01u

C912

01u

Q912

KRC102M

D-GND

D912

PROTECT0V

NORMAL26V

PROT 1

SPL

27k27k27k27k

D617

NC

18k

Q609Q605

KTC3200KTC3200

06V

2222

0V

2222

TPZ63

R615R617

0V

0V

KTA1268

Q607

-06V

18k

Q611

619

KTA1268

NC

R633

100

D618

NC

18k

Q610

KTC3200

06V

Q606

22

KTC3200

0V

22

TPZ64

R616

0V

22

R618

KTA1268

2218k

Q608

-06V

Q612

D620

KTA1268

NC

R634

100

260V

PROTECT0V

NORMAL26V

Q914

KRC102MKRC10M

KT 67

R915

Q915

22k

D-GND

10

C613

22u/50

TPZ29TPZ30

D283

Q601

C601

R605

22u/25

100

Q284

KRC102M

220k

22k

R603

Q603

06V

F NC

N K 100P

12V

C615

22u/50

C605 C603

220u/63 220u/63

A-GND

C604

220u/63

C614

22u/50

12 V

C602

R606

22u/25

100

22k

220k

C612 C611

R602 R601

R604

Q604 Q602

06V

F NC

N K 100P

-12V

C616

22u/50

C606

220u/63

A-GND

R821

22

C821

220u/35

111

D911

26V

Q913

KRA102M

PROTECT26V

NORMAL0V

01u

C914

PROTECT0V

D-GND

NORMAL5V

22k

R913

D GND

SPK

3231

Page 31

P701 POWER STAGE PWB

J701

1

+47V

2

W601

PF192

LOUT+

3

PF193

LOUT

4

47V

5

PF195

NFB

TO MAN PWB

J702

1

+47V

W602

2

PF197

ROUT+

3

PF198

ROUT

4

47V

5

PF200

NFB

TO MAN PB

P751 (P971) SPEAKER TERMINAL PWB

TPZ 4

NORMAL0V

TPZ 3

C801

63V

15000u

C802

P GND

63V

15000u

47k

47k

R801

R802

D802

TPZ205

FCH10A15

FROM MAIN POWER TRANSFORMER

J801

G801

TPF2 7

1

068/4 7

TPZ 6

1

354V

AC

TPF2 8

2

GND

TPF2 9

3

354V

AC

TPZ207

12 12

D801

FRH10A15

TPZ208

0V

SPK L(+)

SPK R(+)

J709

TPF220

TPF221

TPF222

TPF223

P GND

P GND

PF224

1

W801

4

SPK L+

3

SPK L

2

SPK R

1

SPK R+

EARTH

W008

TO SPK TERMINAL PWB

J751

TO POWER STAGE PWB

490V

490V

Q713

2SC283

2SC2705

C705

2SA1145

06V

2SC3423

654321

J703

Q709

TPF 02

R725

06 V

TP

10

TPF201

1

R729R731

TPF204TPF205

2

220220

J707

R723

TPF206

R727

06V

10

TPF208

PF207

Q711

654321

J705

06V

2SA1360

Q715

2SA1186

490V

R713

18V

Q705

470

18 V

82k

R703

10u/50

NC

15k

R705

C701

R701

1

2

1k

R709

R707

3

18V

R719

47

12V

Q703

2SC3419

1k

R717

NC

D701

001u

47k

12V

R721

47

R715

Q707

18V

470

490V

68k

R963

C951

KTA1268

047u/50

Q953

490V

22k

R961

490V

TP 1

R951

470

Q951

KTC3200

47k

R955

R953

470

0V

R733

D953

D951R957R958 D952

10 2W

HSS81TD

HSS81TD

22k

22k22k

C707

R959

0039u10 2W

P GND

P GND

P GND

R965

68k

490V

490V

Q714

2SC2837

R714

18V

Q706

470

2SC2705

2SC3419

R720

47

12V

Q704

1k

R718

NC

D702

47k

12V

R722

47

R716

Q708

18V

470

2SA1145

18 V

82k

R704

10u50

NC

15k

R706

R702

C702

1

2

1k

R710

R708

3

18V

06 V

2SC3423

654321

J704

Q710

TPF210

R726

06 V

T

10

TPF209

1

R730R732

01 3W0 1 3W 0 1 3W01 3W

2

J708

R724

C706

001u

TPF214

R728

10

Q712

2SA1360

PF213 TPF212

TPF 16

PF2 5

654321

J706

06V

Q716

2SA1186

490V

06V

490V

68k

C952

R964

047u/50

Q954

490V

KTA1268

22k

R962

OVER CURRENT DETECT OVER CURRENT DETECT

490V

TP 2

NORMAL0V

R952

470

KTC3200

Q952

R956

47k

R954

470

0V

R734

HSS81TD

HSS81TD

22k

R960 D954

C708

0039u

P GND

P GND

P GND

R966

68k

DC OFFSET DETECT

NORMAL26V

KTC3199

Q955

0V

Q956

47u/25

R968

TPZ209

0V

10u/50

t

R969

C954

OVER HEAT DETECT

PROTECT MODE PRT 1

OVER CURRENT 0V DETECT

DC OFFSET 0V DETECT

OVER HEAT 0V DETECT

100k

NORMAL26V

PTH487

KTC3199

KTC3199

Q958

TO MAIN PWB

J911

4

PF225

+24VL

3

PF226

PRT 2

2

TPF227

PRT 1

1

TPF228

D GND

W951

0V

NC

R967

C953

Q957

KRC102M

TPZ210

J752

TPF239

1

R753

255V

22

2

3

NK version only

C751

001u

J751

PF231

SPK L+

4

TPF 3

SPK L

3

J709

SPK R

PF232

2

TPF234

SPK R+

1

C752

001u

TO U COM PWB

C753

R754

22

R751

3302W

R755

260V

R752

22

3302W

PF238

PF237

PF236

PF235

4

3

2

1

J755

W009

JU07

L751

10u/50

61

L752

C754

10u50

6

4

5

255V

TPF 9

10 9

L753

D751

1SS133

11234 5

260V

TPF250

+

SPK A(L)

TPF 0

2

5

TPF241

3

+

SPK B(L)

TPF 2

4

TPF243

1

+

SPK A(R)

TPF244

2

5

TPF245

3

+

SPK B(R)

TPF246

4

J753

J754

TPF247

TPF248

1

HP L

2

3

HP R

W010

TO HEADPHONE PWB

J792

33 34

Page 32

5V

1ms

ms ms

ms 7ms

0V

JU04 3 pin WAVE FORM at STAND BY mode

PU01 U-COM PWB

R

MUTE

MUTE0V

POWER SW ON5V

5VL

RU42

100k

0V

KRA102M

5V

QU41

KTC3199

47k

CU42

RU43

RU41

5VL

D GND

RU46

100k

RU44

QU46 QU42

33k

KRA102M

5V

QU45

KTC3199

47k

01u 01u

CU46

RU47

D GND

5VL

5VD

01u

CU31

CU32

10u25

TPF 6

D GND DGND

0V

REC2

RECORDER20V

5V

0V

L852 RELAY ON5V

6V

0

33k

CU41

56k

RU45

LU31

LU32

CU33

10u25

JU01

0V

AUX

REC1

AUX0V

RECORDER10V

QU01 2PIN3PI N

01u

06V

CU45

1

2

RC-5

CD

TUNER

CD0V

TUNER0V

80MHz

01u

TPF407

TPF408

3

P_DWN

QU72

KRA102M

QU73

KRA102M

0V

PHONO

PHONO0V

POWER ON5V

L852 ON

TPF409

4

+5VD

TO STANDBY PWB

P191

STANDBY LED PWB

D191

SLI 325URT31W

TPZ 6

R191

1 8V

15k

TPF452 PF453

1 2 3

W191

JU04

1 2 3

TPF401

5VL

5VL

100

RU75

QU74

P_ON5+5VL

5V

KR 102M

TPF410

RU74

5V

QU75

KTC3199

RU72

DU71

0V

47k

RU73

18k

TPZ 02

PM7003

47k

47k

PM8003

RU26

RU27

5VL

01u

CU01

D GND

TPZ412

CLOCK:8 0MHz

CD0V

TPF411

TPF412

TPF413

TPF414

TPF415

6

7

8

9

W007

GND

CE4

RXD10TXD

P_OFF

J861

P181

INPUT SELECTOR PWB

STANDBY

12

TPF402

47k

5V

CU73

220u/10V

D GND

5VL

RU25

47k

47k

RU23

5V

47k

RU24

D GND

NC

ENC-1

ENC-2

KLL_ R

M_MUTE

34

VAREF

35

MODEL_SELE

AVDD

36

AVSS

3

LED STD

38

LED PHONO

QU01

39

LED CD

40

TMP86FH47UG

LED TUNER

41

ED AUX DVD

42

LED REC1

43

LED REC2

44

LED MUT E

VSSXNXOUT

TEST

VDD

PROT-1

123456789

XU01

CST80MHZ

1

3

D GND

TPZ413

5VD

QU10

KRA102M

CD5V

5VL

47k

01u

RU28

CU13

D GND

D GND

TPZ438

TPZ437

RU21

TACT

M_B_DOWN

PROT-2

RESET

QU12

KRA102M

TPF4 4

5VL

47k

RU22

TACT

TPZ414

2324252627282930313233

RC-5_N

BOOT-2/TXD

BOOT-1/RXD

I2C DATA

VOL DWN

P OFF

SPK_OUT

RC-5_OUT

10

11

CU04

QU11

JU02

2C CLK

VOL UP

KRA102M

8

2

6

4

S181

7

1

5

3

C182

C181

001u

001u

TPF 56

TPF4 5

1 2 3 4

W181

1 2 3 4

JU03

D GND

TPF 03

TPF 04

47k

5VL

QU04

KRA102M

5VL

QU05

KRA102M

22

PA DI

21

SO DI

20

NC

19

18

1

CE

16

CLK

15

P ON

14

DI

13

12

5VL

RU01

47k

RU02

47k

01u

01u

01u

CU02

CU03

D GND

5VL

POWER ON0V

TPF418

TPF419

TPF420

TPF421

TPF416

TPF417

1CE2

3

4

5

6

SPK

CLK

DATA

MUTE

CD D

TO MAN PWB J901

TPF422

7

SO_D8PA_D

TPF405

PA_D

SO_D

TPF423

9

POWER AMP DIRECT5V

SOURCE DIRECT5V

47k

RU11

RU05

TPZ417

VOL DOWN 0V

VOL UP 0V

34 V

5VD

10k

RU29

RU30

10k

10k

RU31

TPF424

TPF425

TPF426

11

12

SPL

PROT 210PROT 1

PA DI

SO DI

PHONO

CD

TUNER

AUX

REC1

REC2

MUTE

IR

TACT

10k

47k47k

RU04

5678

QU02

RU06

D GND

QU03

PST600D

47k

RU07

OUT

5V

01u

CU07

D GND

RU81

10k

RU82

34V

10k

1234

LB1630

CU82

10u/25

D GND

PN

1

4

5

8

PROTECT 2 0V ACT VE

NORMAL5V

PROTECT 1 0V ACT VE

NORMAL5V

SPEAKER RELAY ON 5V

PROTECT 0V

D GND

TPF427

W005

D-GND

AT24C08AN

GND

QU81

MOTOR

OFF

34 V

34 V

TPF4

V N

1 2 3 4

13

5 6 7

43 V

5VL

RU03

TPZ416

TPF443

D GND

5VL

VOLUPVOL

34V

0V0V42V

42V

TPF428

1

TPF429

2

TPF430

3

TPF431

4

TPF432

5

TPF433

6

TPF434

7

TPF435

8

TPF436

9

TPF437

10

TPF438

11

5VL

TPF439

12

D GND

JU06

SPK A

1

SPK B

2

TPF4 0

HP

3

TPF 1

4

TPF442

5

6

TPF445

47k

01u

CU05

D GND

5V

01u

CU06

5VD

1D3

001u

CU81

DU81

RU83

22

DOWN

0V

34V0V

J201JU05

PA DI

TPF461

1

TPF462

2

TPF463

3

4

TPF464

TPF465

5

W011

TPF466

6

TPF467

7

TPF468

8

9

TPF469

10

11

TPF470

12

D GND

W203

1

SPK A

2

SPK B

3

HP

W203

4

5

TACT

6

D GND

JU07

TPF446

4

HP

TPF447

TPF448

TPF449

TO SPK TERMNAL PWB

3

SPK B

J755

2

SPK A

1

W009

WU01

T 450

MOT+

3

TO VOLUME PWB

J591

2

MOT

1

TPF451

5VD

SO DI

PHONO

PZ403

CD

TUNER

10k

01u

AUX

REC1

R231

C231

REC2

MUTE

PF471

IR

TPF472

5VL

C241

10u/25

TPF473

TPF474

TPF475

PF476

TPF477

TP 478

5VD5VD

C240

10u25

W205

D GND

1

EARTH

W201

CD

PHONO

330

330

R240

R241

PZ404

10k

01u

R232

C232

SELT2E10C-S

SELT2E10C-S

D232

D231

CD0V

PHONO0V

PHONO

CD

D271

D272

1D3

1D3

1D3

1D3

D274

D273

P201 TONE PWB

R223

17V

TREBLE

R207

TPZ418

R205

C201

22u/16

27k

33k

R203

33k 33k

33k

R202 R201

R204

C202

R206

22u/16

27k

TPZ419

R207

TREBLE BASS

R224

17V

PF479

PF480

PF481

PF482

PF483

1

2

3R4

5

L

18V

+18V

A-GND

TO MAIN PWB

J281

01u

C233

OFF

A

B

A+B

SPEAKER SW

10

6

(B )

10k

4

C203

C204

(B )

3 1

10k

10

AUX/DVD

TUNER

330

330

R242

R243

TPZ406

TPZ405

10k

R233

SELT2E10C-S

D233

TUNER0V

TUNER

TPZ407

10k

10k

01u

01u

R234

C234

C235

R235

SELT2E10C-S

D234

AUX0V

AUX

RECORDER-2

RECORDER 1

330

330

R244

R245

PZ408

TPZ409

10k

01u

R236

C236

SELT2E10C-S

SELT2E10C-S

D236

D235

REC10V

REC20V

REC2

REC1

5VL

10K

R261

TPZ4 9 TPZ 0

R262

R263

39 K

22K

C261

001u

2

3

1

D GND

PIN26 A/D VOLTAGE

4

1OFF (PULL UP)

5

S271

3RESERVED

4POWER AMP DIRECT

5SOURSE D RECT

6RESERVED

TPZ 4

TPZ420

BASS

64

5

5

(B )

8

2

R208

10k

0V

3

Q201

0V

NJM2068DD

TPZ4 1

100p

100p

TPZ422

Q201

NJM2068DD

0V

5

0V

(B)

6

2

4

R208

3 1

10k

TPZ4 3

TPZ 35

S261

S262

POWER DIRECTSOURCE DIRECT

50 V

39 V2RESERVED

29 V

19 V

09 V

0V

165V

C205 C211

100p 001u

TPZ424TPZ425

R209

0V

27k

7

R210

27k

C206

100p

C209

100u/25V

R213

C207

1

100

22u/16

4

(MN)

5

100k

R211

R215

20k

6

1

(MN)

2

100k

R215

R212

20k

3

C208

R214

0V

22u/16

100

C210

100u25V

165V

PF484

PF485

PF486

2

3

1

W202

R

L

A GND

TO MAIN PWB

J282

PA_D

MUTE

330

R246

PZ410

10k

NC

01u

LT3D8B

R237

R238

D237

MUTE0V

NC

R249

MUTE

R

PA_D

5V

TPZ 26

C215

100p

TPZ427

R219

TPZ428

C217

C213

22u/50

0068

56k

12k

R221

R273

56k

12k 1 2k

R222

R274 R217

C218

C214

22u/50

0068

TPZ431

R220

TPZ432

C212

C216

100p

001u

12k

R218

TPZ 33

SO_D

220

220

R247

R248

PZ411

01u

10k

C238

C239

R239

SELT2E10C-S

SELT2E10C-S

D238

D239

5VD5VD

NC

R250

Q232

Q231

KRC102M

Q251

R SENSOR

1 2 3

6

5

3

2

6

5

3

2

D GND

SO D

NJM2068DD

NJM2068DD

NJM2068DD

NJM2068DD

KRC102M

D GND

5VL

R251

001u

C251

C252

220u10V 100

8

7

Q203

Q203

1

4

8

7

Q204

Q204

1

4

W204

1

D GND

TPZ401

0V

0V

56k

0V

0V

TPZ429

TP 30

0V

0V

56k

0V

0V

EARTH

3635

Page 33

9. PARTS LOCATION

P401 PWB

C291 D4

C292 D4

C293 D5

C294 D5

C295 D5

C296 D5

C297 E5

C298 E5

C401 D2

C402 D1

C403 D2

C404 D2

C405 C3

C406 C1

C407 C3

C408 C1

C409 B3

C410 B1

C411 B3

C412 B1

C413 B2

C414 B2

C415 B2

C416 B2

C417 A2

C418 A2

C419 D2

C420 D1

C421 E1

EX03 D2

EX04 D1

J291 E5

J401 E2

L401 D2

L402 D1

Q401 C2

R291 D4

R292 D4

R293 D5

R294 D5

R295 D5

R296 D5

R401 D2

R402 D1

R403 D2

R404 D1

R405 C2

R406 C1

R407 C2

R408 C1

R409 B3

R410 B1

R411 B3

R412 B1

R413 C2

R414 C2

R415 B2

R416 B2

R417 B2

R418 B2

R419 B3

R420 B1

U451 D2

U452 C2

U453 C2

U454 C3

U455 C1

U456 A2

W291 D4

W401 A2

P851 B PWB

C851 E4

C852 E3

C853 D2

C854 D1

C855 C2

C856 C1

C857 C3

C858 B2

C859 C3

C860 C1

C861 D6

C862 C6

C863 F5

C864 B6

C865 B5

C866 C6

D851 D2

D852 D2

D853 D2

D854 D2

D855 D3

D856 D1

D857 D5

D858 D5

D859 B5

D860 B5

D861 B5

D862 C5

D863 B4

D864 B4

D865 B5

D866 B5

EX06 F3

EX07 F2

EX21 D7

EX22 D7

EX23 D7

EX24 D7

EX25 D7

G851 D5

J851 F5

J852 G2

J853 F4

J854 C4

J855 B2

J856 F5

J857 F3

J858 F6

J859 E6

J860 E7

J861 B1

J862 C7

J863 B7

J864 D3

L851 E2

L852 E3

L853 B1

L854 C2

L855 B2

Q851 D3

Q852 C1

Q853 C3

Q854 C2

Q855 B6

R851 D3

R852 D4

R853 D4

R854 C1

R855 D5

R856 C5

R857 D1

R858 B4

R859 C2

R860 C2

R861 D3

R862 B5

U461 G4

U462 G5

U463 G5

U464 E5

U465 E5

U466 E5

U467 D3

U468 C2

U469 C6

37 38

U470 C5

U471 C5

U472 C6

U473 C6

U474 B4

U475 B3

U476 B2

U477 B6

U478 B5

U479 F6

U480 F6

鉛フリー 田

半田付けには、鉛フリー半田

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

(Sn-Ag-Cu)

を使用してください。

Page 34

P591 B PWB

P791 B PWB P891 B PWB

C791 A2

C792 B2

J791 A1

J792 B1

R791 B2

R792 B2

W791 B1

鉛フ

半田付けには、鉛フリー半田