Page 1

INSTALLATION & OPERATION

MANUAL

IT400

Remote Totalizer & Rate Indicator

Page 2

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page:

DOC#: MN-IT400-R2d.doc

ii

Notice

Proprietary Notice

The information contained in this publication is derived in part from proprietary data and trade secrets.

This information has been prepared for the expressed purpose of assisting operating and

maintenance personnel in the efficient use of the instrument described herein. Publication of this

information does not convey any rights to use or reproduce it or to use for any purpose other than in

connection with the installation, operation and maintenance of the equipment described herein.

Copyright 2008

Printed in the USA. All Rights Reserved.

SAFETY INSTRUCTIONS

The following instructions must be observed.

• Every effort has been made to design and manufacture this instrument to be safe for its intended

use. A hazardous situation may occur if this instrument is not used for its intended purpose or is

used incorrectly. Please note operating instructions provided in this manual.

• The instrument must be installed, operated and maintained by personnel who have been properly

trained. Personnel must read and understand this manual prior to installation and operation of the

instrument.

• An auto-resettabl e fuse internally protects this instrument. To reset the fuse, remove all power

from the unit for one minute.

• The manufacturer assumes no liability for damage caused by incorrect use of the instrument or for

modifications or changes made to the instrument.

Technical Improvements

Liquid Controls Sponsler, Inc. may modify the technical data herein without notice.

Warning: Do not open the enclosure when an explosive gas atmosphere is present.

Page 3

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page:

DOC#: MN-IT400-R2d.doc

iii

Table of Contents

Description ............................................................................................................................................ 1

CE Declaration of Conformity ............................................................................................................ 2

Specifications .................................................................................................................................... 3

Wiring and Hookup Diagrams ............................................................................................................... 4

IT400 Operational Ov erv i ew ................................................................................................................. 8

Calibration ......................................................................................................................................... 8

Temperature Compensation .............................................................................................................. 8

Linearization ...................................................................................................................................... 8

LCD Display ...................................................................................................................................... 9

User Controls .................................................................................................................................. 10

Non-User interfaces ........................................................................................................................ 10

Inputs............................................................................................................................................... 12

Backlight .......................................................................................................................................... 13

Power .............................................................................................................................................. 13

Enclosure ........................................................................................................................................ 14

Menu System ...................................................................................................................................... 15

Button functions ............................................................................................................................... 15

Editing numbers .............................................................................................................................. 15

Menu descriptions ........................................................................................................................... 16

Appendix ............................................................................................................................................. 24

Appendix 1: Menu Quick Reference ................................................................................................ 25

Appendix 2: Coefficient of Thermal Expansion for Common Fluids ................................................. 26

Appendix 3: Menu Flow Chart ......................................................................................................... 27

Appendix 4: Manual Revision History .............................................................................................. 34

Page 4

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 1 DOC#: MN-IT400-R2d.doc

Description

General Unit Operation

The IT400 Remote Totalizer and Rate Indicator is a microcontroller based flow instrument capable of

translating flow in format ion and conditions to the built-in display and various outputs.

Features

• Pulse input supports turbine as well as many other pulse-type flowm et ers

• All features/configuration settings are available via field programmability

• Independent rate/t otal dis pl ay

• Magnetically operated internal switches maintain enclosure integrity

• Built-in digital multimeter and simulation functions for testing

• 2-20 point Linearization available

• Non-resettable “Grand” totalizer

• All outputs are fully opto-isolated (not RS-232)

• RS-232 port available

• Temperature compensation (RTD probe) available

• Backlight and backlight timer for low light display viewing

• Autoranging Rate display (decimal point will shift based on the size of the rate)

• Selectable power modes for customized battery life

• Available Datalogger can capture up to seven process/system values

Page 5

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

CE Declaration of Conformity

Page: 2 DOC#: MN-IT400-R2d.doc

Page 6

Liquid Controls

Sponsler, Inc.

Specifications

IT400 Remote Totalizer & Rate Indicator

Page: 3 DOC#: MN-IT400-R2d.doc

Display

• Total

• 8 digit 5.40mm high LCD (continuous display)

• Batch total (magnetic reset)

• Grand total (no reset)

• Rate

• 5 digit 8.66mm high LCD (continuous display)

• Range over/under limit indication

• Refresh rate: Multiple depending on power

mode (1/16s, 1/8s, 1/4s, 1s, 0.5s)

• Backlighted green w/ LED (magnetically activated

and timed)

• Dual segment low-battery warning

• Maintenance due warning

• Temperature range warning

Power:

• Internal: D Lithium battery

• Battery life: Various: typical per power mode:

1: 1yr, 2: 1yr; 3: 3.6yr; 4: 3yr; 5: 8yr

• External DC: 5 to 48VDC +/- 2 VDC reverse

polarity protected (Max: 12mA w/ backlight)

• Loop: requires 7VDC of loop supply

• Loop powered from the 4-2 0m A loop input

(non-isolated)

K-Factor range

• Pulses per gallon: 0.0000001 to 999999

Signal Input (flow)

• Frequency: 0-3000Hz

• Impedance: 10k ohms

• Magnetic

• Sensitivity: 50mV-36V (field adjustable) sine

or square wave

• Modulated carrier

• Carrier frequency 50kHz (requires external

power or loop power)

Compensation Input

• Temperature - RTD

• Two wire 10k ohm

• Coefficient of Thermal Expansion method

• Frequency

• Linearization table 2 to 20 poin ts

Engineering Unit Conversions

• Pre-programmed units: Gallons, Liters, Ft3, M3,

Pounds, BBL, KG (custom weight available)

• Custom units available with given units/gallon

• Rate and Total may have separate unit displays

Decimal Locations

• Total: Two places (and x10, x100)

• Rate: Three places (and x10, x100), autorange

Time Base

• Rates can be displayed in units per second,

minute, hour, day, and custom (in seconds)

Outputs

• Factored Pulse (Max: 150mA, 30VDC, 150mW)

• Opto-isolated open collector output

• Frequency or fixed pulse width (1, 2, 5, 10,

50, 100, & custom ms) output setting

• Output pulse Divider: 1, 2, 5, 10, 50, 100,

1000, & custom

• Alarm (Max: 150mA, 30VDC, 150mW)

• Programmable opto-isolated open collector

output

• Can be used to control totalization

(Max values at 25°C. Max combined Pulse/Alarm

output power: 190mW @ 25°C, 32mW @) 65°C)

• Rate (4-20mA)

• Factored rate to current loop output

• Programmable low and high

• Fully isolated (unless loop powered)

• Loop Voltage limit: 7-36VDC

Accuracy

• Display: ±0.01% reading (rate) or ± 1 count (total)

• Analog output: ±0.025% of fs @20°C

• Digital output: ±1 count

Environmental

• Operating: -30 to 65°C (-22 to 150°F)

• Storage: -40 to 85°C (-40 to 185°F)

Enclosure

• Explosion Proof Aluminum

• FM Approved, CSA Certified

• Class I, Division1, Groups B, C, & D

• Class II, Division 1, Groups E, F, & G

• NEMA 4X, IP66

• All openings ¾” FNPT

• Weight: 2.5lbs.

• Mount: Directly on flowmeter or Wall mount

Compliance

• CE 0575

• ATEX Ex II 2 G Ex d IIC T6 Gb (X and WX

enclosure types only)

• DNV-2008-OSL-ATEX-19241X

Communications

• RS-232

Datalogger

• Up to four triggers (including timer)

• Up to seven system values

• Real-time clock

• RS-232 or Internal SD/MMC Flash media card

Other features

• EEPROM setup storage (>100 year retention)

• All features/settings are field programmable.

Convenient number input via 0 -9 rotary switch and

two pushbuttons

Page 7

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 4 DOC#: MN-IT400-R2d.doc

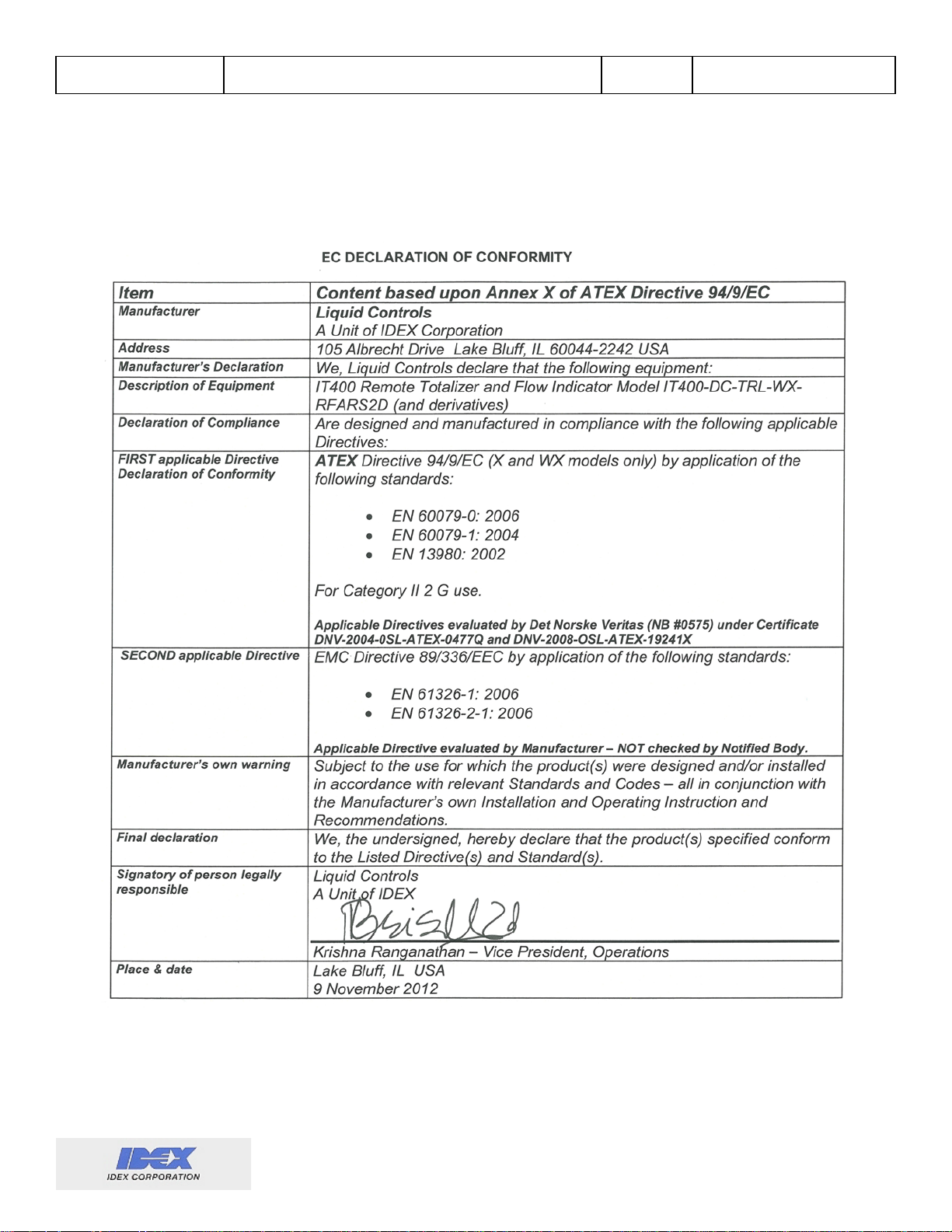

Wiring and Hookup Diagrams

The IT400 has many connections all made through the bottom/mounting board. It is

recommended to remove the battery when connecting wires to the connectors and when plugging

the connectors into their sockets.

Wiring

In order to maintain the rated CE marking, the following practices must be followed:

• All wires connected to the IT400 must be shielded (exception: SI supplied signal cable).

o All shields must be connected to one of the internal mounting screws to achieve their

ground connection.

o It is recommended that the non-IT400 end of these shields is left unconnected. This

will help avoid ground loops and unexpected behavior.

o It is recommended that only one spade type terminal be used on each of the screws.

Care should be taken to avoid shorting any spade with other circuitry on the mounting

board. If a longer screw is needed to attach the shielding spade, then the screw

must be chosen to ensure at least one extra thread of space behind the screw. The

hole depth is approximately 0.250 inches.

o Shields should not cover more than one pair of signal wires at a time.

• The IT400’s chassis must be connected to an earth ground via the screw attached to the

outside of the unit. At least a 12 AWG preferably green wire is recommended.

• All connections are to be made to the unit via rigid conduit.

• All connected wires must not exceed 98’ length.

• DC powered devices requiring the CE marking must be 4-20mA loop powered.

If no wires are required for a particular installation; the only requirement is the chassis ground

connection.

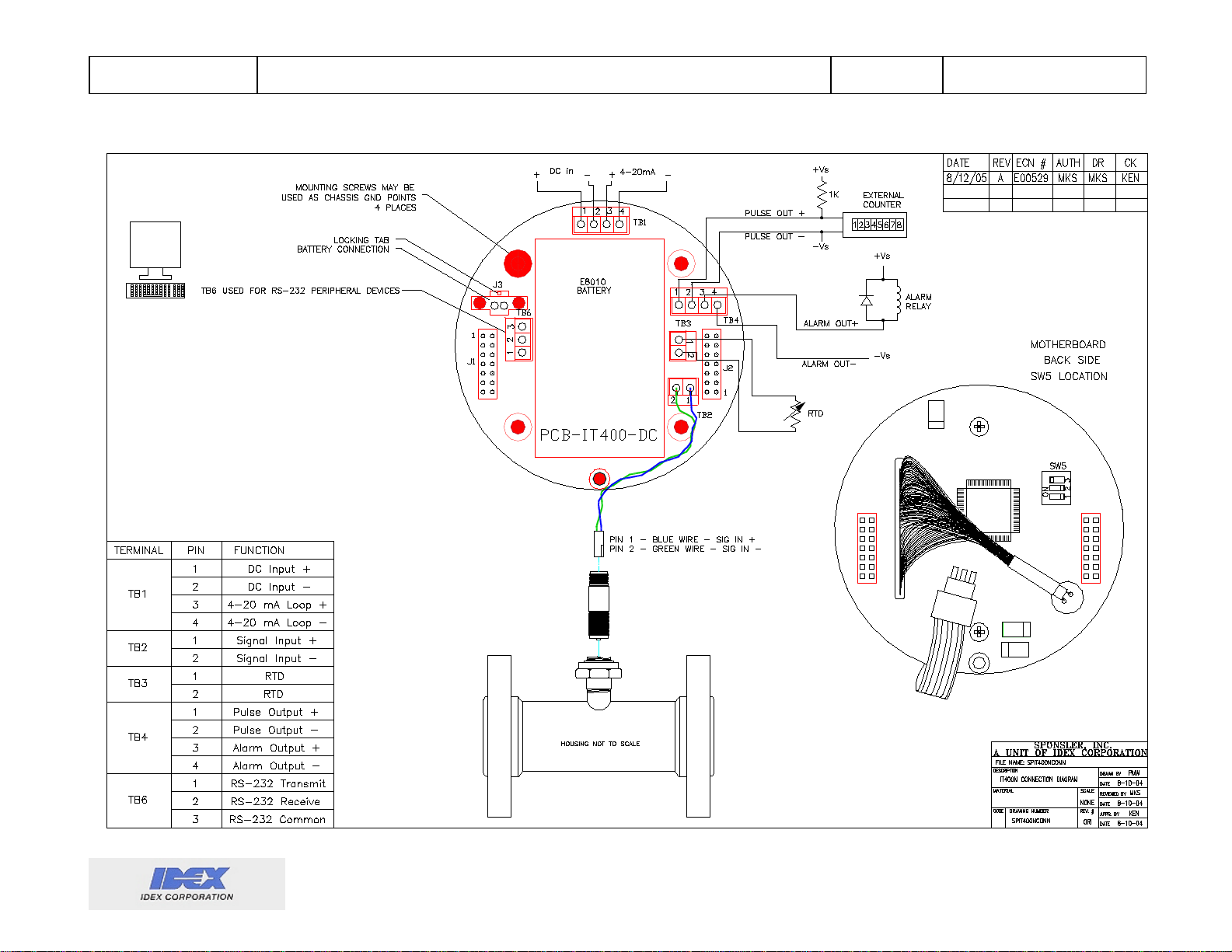

Battery Removal and Installation

Battery Replacement:

- E8010 from Liquid Control s Sponsler, Inc.

- TL-5930/F from Tadiran Batteries, Ltd.

Battery Removal:

reset the totalizer appears, the totalizer/grand totalizer/service timer will be saved to memory.

Using two fingers inserted in the slots on the top and bottom of the main board overlay, gently rock

the board top to bottom while pulling straight out. If this is done too quickly or unevenly, the main

board will be damaged. After the main board is removed, the battery is accessible by opening the

hook-loop strap. Once the battery is loose, the battery clip is removed by compressing the locking

tab on the connector (locking tab is on the top of the connector {J3}) and pulling it out.

Battery installation: Reverse the pr ocess for installation. Ensure the battery connector key is in the

proper orientation pri or to inser ti on.

The internal battery may only be replaced with one of two batteries:

Unscrew the IT400 cover, press and hold the menu button until the option to

Page 8

Liquid Controls

Sponsler, Inc.

Diagrams:

IT400 Remote Totalizer & Rate Indicator

Page: 5 DOC#: MN-IT400-R2d.doc

Figure 1 IT400 Connections

Page 9

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 6 DOC#: MN-IT400-R2d.doc

Grand

TB1

J3

1

2

TB6

1

J1

TB5

4

3

2

1

TB4

4

3

2

1

TB3

3

2

1

TB5

1

2

1

2

1

TB2

JP3

Grand

LIQUID CONTROLS GROUP

SPONSLER

Precision Turbine Flowmeters

A UNIT OF

IDEX

CORPORATION

2363 SANDIFER BLVD. WESTMINSTER, SC 29693

1.864.647.2065 WWW.SPONSLER.COM

I

T

4

0

0

b

e

r

m

u

N

LIQUID CONTROLS GROUP

SPONSLER

2363 SANDIFER BLVD. WESTMINSTER, SC 29693

I

T

4

0

0

Precision Turbine Flowmeters

A UNIT OF

IDEX

CORPORATION

1.864.647.2065 WWW.SPONSLER.COM

b

e

r

m

u

N

Figure 2 IT400 Board Stack Assembly and Battery Removal

Page 10

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Grand

I

T

4

0

0

r

e

b

m

u

N

2363 SANDIFER BLVD. WESTMINSTER, SC 29693

1.864.647.2065 WWW.SPONSLER.COM

LIQUID CONTROLS GROUP

SPONSLER

Precision Turbine Flowmeters

A UNIT OF

IDEX

CORPORATION

Page: 7 DOC#: MN-IT400-R2d.doc

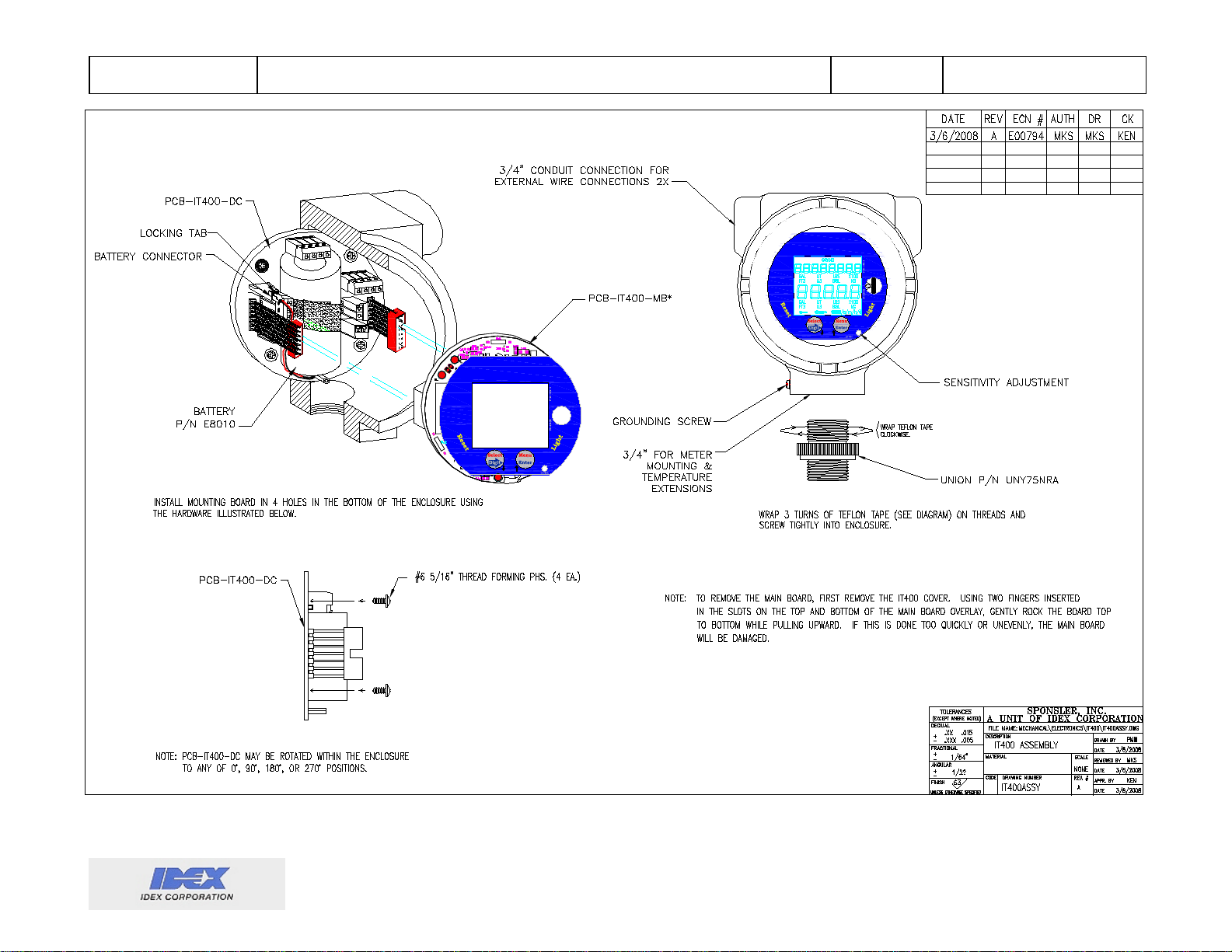

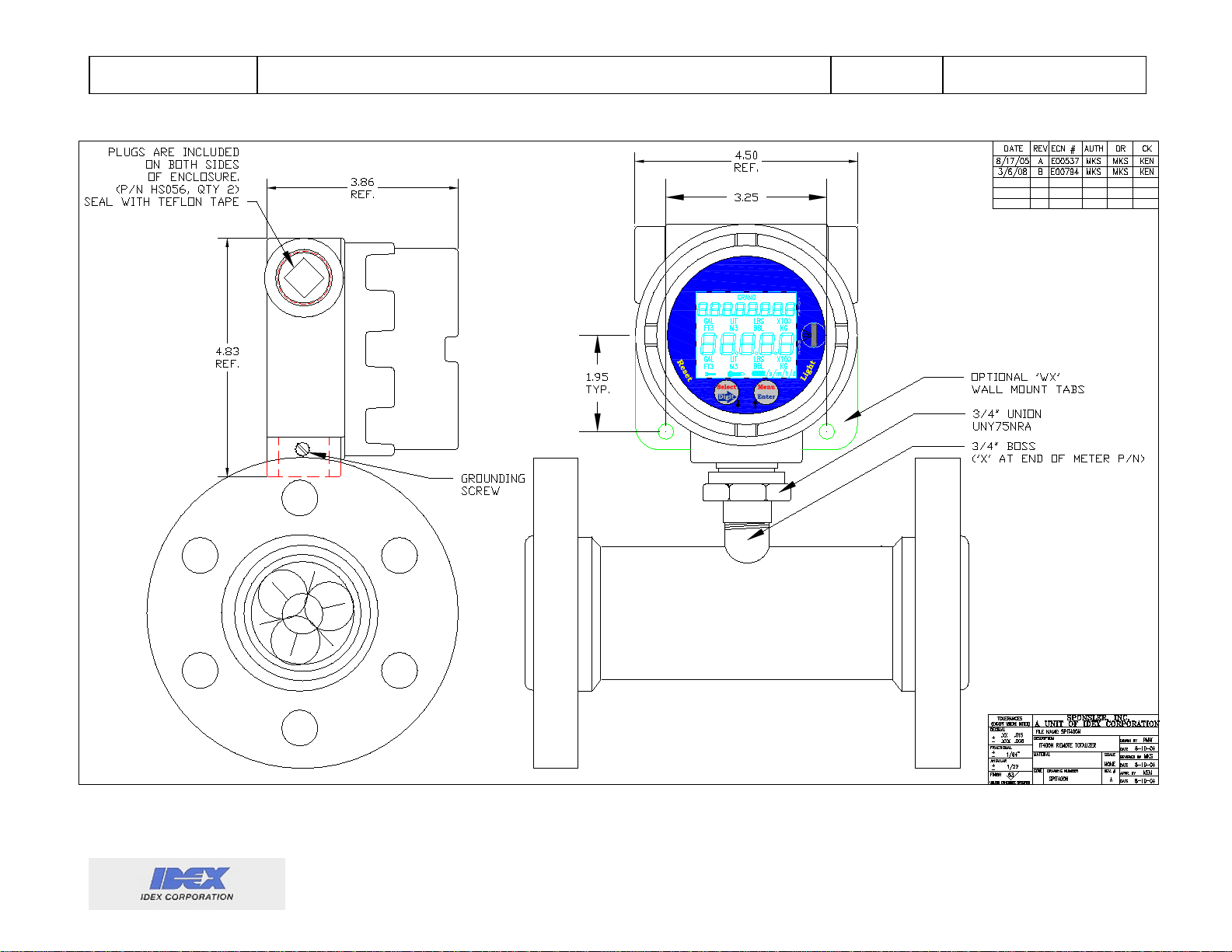

Figure 3 Meter Mounting and Dimensional

Page 11

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 8 DOC#: MN-IT400-R2d.doc

IT400 Operational Overview

The IT400 flowmeter system will perform the necessary calculations to provide the user with an

optional temperature compensated and optional linearized output of the following values:

• Rate

• Total

• Grand total

• Errors/warnings

• Various outputs

Calibration

Calibration of the IT400 is accomplished using either a linear K-Factor (pulses per gallon) or a

linearized K-Factor linearization table (when the linearizer is enabled). Independent unit conversion

factors and decimal points are available for the rate and total displays. Calibration and configuration

data are stored in an onboard EEPROM for permanent storage. Calibration of the IT400’s reference

circuitry is factory set and is not user accessible. Calibration of the IT400’s reference circuitry should

be performed by factory trained service personnel.

Temperature Compensation

The temperature compensator utilizes a platinum RTD to detect the process temperature. Process

temperature is used in conjunction with the reference temperature and Coefficient of Thermal

Expansion of the measured liquid (menu items) to adjust the rate and total values. When the

temperature compensation is enabled, the temperature warning annunciator (thermometer on the

LCD) will indicate when the process temperature is out of a programmable range. Optionally, an

alarm output as well as a totalizer inhibit function can also be tied to this temperature warning.

Various Coefficient of Thermal Expansions and their reference temperatures can be found in the

appendix. The temperature circuit and associated algorithm, when enabled, increase the IT400

current consumption fr om the power source and diminish battery life if running solely from the battery.

A programmable delay function has been provided in order to minimize the impact of the temperature

sampling on the battery life. The delay feature specifies the number of seconds between temperature

value samples. The higher the delay, the longer the battery will last.

Linearization

The linearizer utilizes a linear interpolation algorithm to calculate the rate and total based on a set of

calibration data points pr ogrammed by the user. The linearizer has21 points, the first point (lowest) is

automatically set at zero hertz, the remaining 2 to 20 are user programmable. The linearizer table

must have at least two data points in addition to the first (fixed) point and must be ascending in

frequency from the first point to the last. To have fewer than 20 points in the linearizer table, after the

last desired linearization point add one additional point and set the frequency at zero. Zero is an

invalid frequency; this will indicate the end of the table. The IT400 will not allow frequencies to be

entered out numerical order. Frequencies between zero and the first programmed point will use the

K-Factor of the first programmed point.

Page 12

Liquid Controls

Sponsler, Inc.

8 digit

IT400 Remote Totalizer & Rate Indicator

Page: 9 DOC#: MN-IT400-R2d.doc

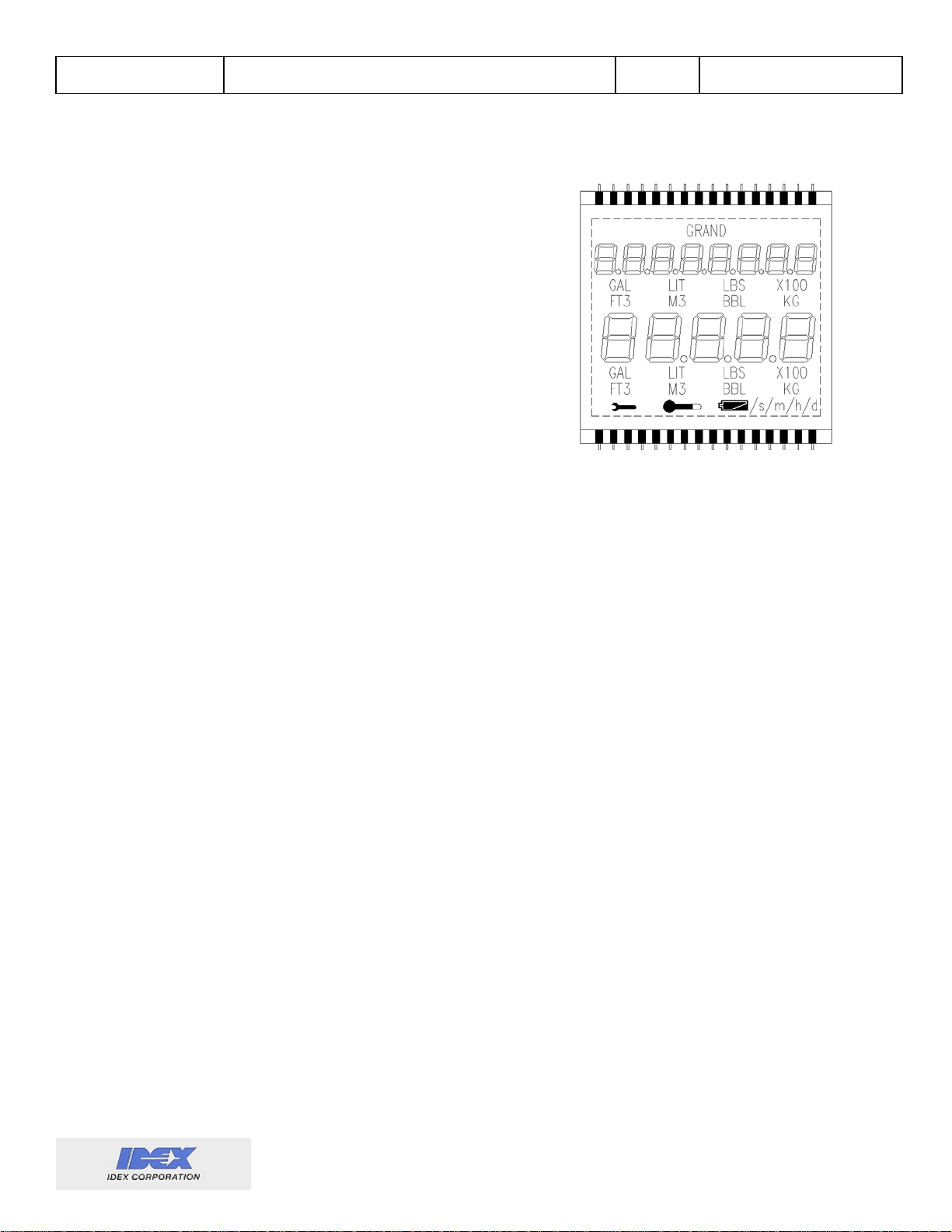

LCD Display

The LCD display has three main areas: The 8 digit totalizer,

5 digit rate indicator, and the annunciators.

• The 8-digit totalizer shows the total number of units

of volume through put of the flowmeter since the last

time the totalizer was reset. The totalizer is

resettable by 2 methods, via a magnetic reed sw it ch

in the lower left side of the unit and by menu. Th e

grand total is displayed as long as a magnet is

placed near the top of the face of the unit. The word

"GRAND" indicates the displayed value is the grand

total. Grand should be activated prior to battery

replacement to save total/grand total values to nonvolatile memory. Engineering unit annunciators

display the units and decimal place selected to compute total and grand total values. The

grand totalizer uses the same engineering unit as programmed for the totalizer.

• The 5-digit rate display shows the rate of the flowmeter throughput. If the rate exceeds the

high flow warning setpoint, "-oL-" is displayed. “-UL-“ is displayed when the rate is less than

the low flow warning setpoint. The warning is displayed until flowrate within these setpoints

resumes. The totalizer is not affected by this warning unless programmed to inhibit totalizer

when out of range. The range limits are established by the flow warning setpoints (Warning

menu) in the menu system. Indicators on the display also show the engineering units of

volume, time and decimal place used to compute the rate value.

Note: When the Grand Total magnetic reed switch is activated (and GRAND is displayed on the

screen), the rate display will display the current rate regardless of the range limits. This is

helpful when troubleshooting flow condition problems when the low rate setpoint is set above

zero.

• Refresh rate of the display of the unit happens at pre-determined intervals depending on the

selected power mode (see “Power”). Once the power mode is programmed (in the menu), the

refresh rate is fixed. This prevents a low refresh rate from being automatically selected which

could cause measurement delay.

• Other display annunciators. These are warning indicators and do not inhibit the operation of

the unit (unless explicitly enabled to do so by the alarm opti o n). These indicators may

however indicate the condition causing an inaccurate reporting of rate or total information.

o Wrench – The service annunciator is user programmable to a specific amount of

“turbine hours” (activ e flowmeter hours).

o Thermometer – The thermometer annunciator is displayed continuously any time the

temperature compensator is enabled and the process temperature is out of range.

o Battery – The battery annunciator is composed of two segments. The segments

indicate the level of the battery charge, like an automotive gas gauge.

Two segments – The battery is within normal operating voltage range.

One segment – A replacement battery should be acquired and installed. This will

also cause high temperature range on the temperature circuit to be reduced.

Total

5 digit

Rate

Page 13

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 10 DOC#: MN-IT400-R2d.doc

No segments – The batter y must be replaced to guarantee accur a te r epor ti ng .

User Controls

There are two main groups of user controls, internal and external. The internal controls are only

accessible when the enclosure cover is removed. The external controls are magnetically accessed

by strategic placement of a magnet along the outside of the unit.

• Internal

o Menu / Enter Button – This button is used primarily within the menu system. Press this

button at any time during RUN mode to enter the menu system. Note: the higher the

power mode, the longer the button will need to be held down for it to trigger the menu

system.

o Select / Digit Button – This button is also used primarily within the menu system.

However, when the temperature compensation option is purchased and enabled,

pressing this button while in RUN mode causes the 5-digit display to indicate the

current process temperature in degrees Fahrenheit.

o Number Dial – The number dial is only used while selecting values or editing numbers

while in the menu system. The number dial is disabled in RUN mode.

• External

o Magnetic Switches – There are three magnetically activated reed switches located

around the edge of the IT400 (indicated on the front panel with yellow text). These

switches allow external activation of the following functions:

Grand – The following actions are taken when the grand reed switch is activated:

The total display will indicate the value of the grand totalizer.

The rate display will indicate the current rate regardless of any out of range

warning conditions.

The GRAND annunciator will indicate.

The IT400 will store the values of the grand totalizer, the totalizer, and the

elapsed service time to non-volatile memory. This is useful if the IT400 is to

be removed from service (replace bat ter y, recalibrate, etc).

Light – When activated, the backlight timer will be engaged according to the chart in

the Backlight section.

Reset – When activated, the main totalizer will be reset.

Note: The internal user controls are described in more detail in the Menu section.

Non-User interfaces

Non-user interfaces are those that are wired to external devices. 4-20mA rate output and open

collector pulse output are standard, open collector alarm output, RS-232, datalogger, and real time

clock interfaces are optional.

• 4-20mA rate output

high setpoints.

is a linear representation of flow rate between the progra mmed low and

Example: A flowmeter has a calibrated range of 10 to 100gpm, the desired low and

high setpoints of the 4-20mA output are 10 and 100 respectively. Using these values,

the IT400 will calculate and output the proper current reading for a given flowrate.

Page 14

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

R – Rate

Z – Reset Totalizer

K – K Factor

T – Total

Q – Total CF

L – Linearizer Table

G – Grand total

W – Rate CF

F – Process Temperatur e (Deg F)

C – Capture Data (Trigger a datalogger event)

Page: 11 DOC#: MN-IT400-R2d.doc

Given a flow rate of 25gpm, the current loop reading will be 6.667mA. The output

engineering units are the same as for the rate display.

Note: For loop powered operation, refer to the Power section.

Note: The IT400 requires 7VDC of the loop supply.

• Pulse output

is an open collector design. A pull up resistor is required for interface with most

systems. An output pulse occurs with each increment of the totalizer if a pulse output divider of

1 has been programmed. For programmed pulse divider values other than 1 the output pulse

will occur at the divided value. Functions for a frequency output, pulse width, and pulse output

divider are programmable. When the frequency output is not selected, pulses are output in

bursts at each refresh.

Example: The totali z er incr em ents 15 puls es ( over the last refresh time) and the pulse

output divider is 5. The number of output pulses that will be generated will be 3.

Note: If the output pulse width programmed exceeds the time required to output the proper

number of output pulses an E will be displayed in the left-most character of the total display.

The IT400 will output as many pulses as time permits at the programmed pulse width.

Example: At a maximum flow of 900gpm the proper number of output pulses is 15 per

second, but the pulse width is programmed to 100ms and the pulse divider to 1. The 15

pulses would take 1.5 seconds (15x100ms); only 10 pulses would be outputted. Either

the pulse width must be reduced or if acceptable the divider increased.

Guideline: calculate the maximum output pulse width:

Maximum pulse width = 1/(output pulses per second/output pulse divider)

Using the example above: 1/(15/1) = 66.6ms is maximum pulse width.

• Alarm output• is an open collector output that can be used to externally indicate the presence

of several out of range conditions. These conditions include: temperature, flow rate, and

battery level. The ranges of temperature and flow rate are edited in their respective sections of

the Menu system. The Battery low level is factory set. Any Alarm condition of the enabled

alarms will activate the alarm output. Identical to the output pulse, a pull up resistor is required

to interface with most systems.

RS-232 interface

allows calculated values of the unit to be viewed upon request. To use this

interface, a serial device (computer or datalogger) is used to poll the IT400 by sending one of

the listed letters (the letter by itself) to the serial port. No carriage return is necessary. The

IT400 will reply with the requested data and a CR+LF. The BAUD rate is fix ed at 9600 ba ud

8N1. Currently, the datalogger data can only be captured via the RS-232 port. The func tions

available on this interface are:

Note: Using the RS-232 interface when loop powered will cause errors in the loop reading.

Page 15

Liquid Controls

Sponsler, Inc.

2147498935, 1073, 919.532, 37211, 32.2, 58.71818, 0

2147498945, 1227, 919.385, 37365, 32.0, 58.72917, 0

Date/Time: Mon Jan 18 2038 13:14:54 GMT-5:00:00

Warnings: 0:

• Datalogger

use this interface, a serial input device (computer or printer) is used to capture the data from

the IT400. Refer to the menu section of the manual to see the data that can be captured and

what triggers are available. Each line of data is terminated by a CR+LF combination (0x0D

and 0x0A). There are two data format outputs available, DB and non-DB:

DB Format: The DB format lists the enabled data in the following order: Time, Total, Rate,

Grand Total, Temperatur e, K-Factor, and Warnings. Units are the same as displayed on the

LCD. The time listed is the “UNIX” time or the number of seconds from the UNIX Epoch time

(Jan 1, 1970, 0:00:00 GMT). No Daylight Savings Time (DST) or time zone adjustment is

made. Example:

Non-DB Format: The non-DB format lists the enabled data in the same order as in the DB

format, but will be listed one item per line. In addi ti o n, this format shows the engineering units

of each value. The date/time is adjusted for local time zone as set in the menu. DST is not

included as this would allow duplicate time stamps. Example:

IT400 Remote Totalizer & Rate Indicator

Page: 12 DOC#: MN-IT400-R2d.doc

allows various working data to be captured based on several different triggers. To

2147498937, 1104, 919.687, 37242, 32.2, 58.71818, 0

2147498939, 1135, 919.506, 37273, 32.2, 58.71818, 0

2147498941, 1165, 919.557, 37303, 32.2, 58.71818, 0

2147498943, 1196, 919.609, 37334, 32.2, 58.71818, 0

Total: 98 G

Grand Total: 36235 G

Temperature: 32.0F

K-Factor: 58.72917 P/G

• Real-time clock

maintains the current date and time for use with the datalogger. Each

datalog event is preceded with the current date and time. Time is calculated by maintaining

the number of seconds since the UNIX Epoch time (Jan 1, 1970, 0:00:00 GMT). The real-time

clock does not increment unless the IT400 is power ed (either by DC-in, battery, or 4-20mA).

When the battery is replaced, the internal clock will be slow by the amount of time between the

time the menu is entered (just prior to removing the battery) and the time the IT400 is again

powered (after the battery replacement). The real-time clock can be set in the menu system

and is only available when the datalogger option is purchased.

Inputs

The IT400 has four inputs: RS-232 interface, user interface, temperature, and input signal.

•

RS-232• interface is described above.

User• interface is described above.

Temperature input is a standard 2-wire platinum RTD te mper a tur e pr obe ( 0.38 5 TCR ) . The

temperature probe is typically mounted within a few inches downstream of the attached

flowmeter. The temperature input will increase the drain rate on the battery when the IT400 is

battery powered. The temperature input is ignored if the temperature compensator is disabled.

Page 16

Liquid Controls

Sponsler, Inc.

Page: 13 DOC#: MN-IT400-R2d.doc

DC

4-20mA

Battery

value

Backlight

in - RUN-

Backlight

Yes

Don’t Care

Don’t Care

Non-Zero

ON

ON

No

No

Good

Non-Zero

Timer

ON

No

No

Low

Don’t Care

Manual

OFF

No

Yes**

Good

Non-Zero

Timer

ON

No

Yes

Don’t Care

Don’t Care

Manual

OFF

Don’t Care

Don’t Care

Don’t Care

DI SABLED

Manual

OFF

Don’t Care

No

Good

ALWAYSoN

ON

ON

• Signal

IT400 Remote Totalizer & Rate Indicator

input from practically any frequency generating device producing a sinusoidal signal, a

square wave pulse or can be connected to a modulated carrier pickup coil.

Sinusoidal signal: low amplitude crossing signal that doesn’t exceed the IT400’s input

specification. This signal can come directly from the pickup coil sensing rotation of the

attached Sponsler, Inc. turbine flowmeter or other flowmeter device.

Square signal: any zero referenced pulse that doesn’t exceed the IT400’s input

specification.

Modulated carrier: derived by modulating a carrier signal of the pickup coil caused by

the change in impedance resulting from the rotor blades passing in proximity to the coil.

This is an inductive coil therefore there is no drag on the rotor. MC coil operation is

factory enabled only. MC coil operation requires DC or loop power.

Note: SW5-3 must be “On” for MC coil operation when externally DC powered.

Backlight

The backlight is controlled by a combination of system parameters. The following table lists the

operation of the backlight and how it is controlled by these vari ous s y s tem para met er s:

BLI TE

Powered

Powered*

Condition

in Menu

* SW5-1, SW5-2, & SW5-3 “On”.

** SW5-3 “Off” (4-20mA loop to power modulated input and battery to power main circuit).

*** If the timer is set to ALWAYSoN, the battery will last about two months when not DC powered.

The front panel magnetic reed switch activates the backlight regardless of anything (as long as power

is applied). Backl ight activation may increment one additional input pulse and will cause 4-20mA

errors.

Power

The IT400 may be powered externally by any 5-48VDC source, 4-20mA loop, internally by battery, or

by a combination of these. Power consumption is affected by programmed options, inp ut si g nal

frequency, and the programmed power mode.

•

External Power

o DC: 5-48VDC

o 4-20mA Loop: used to power the IT400 or just the modulated carrier circuit (which

requires more voltage than is available from the battery). The IT400 requires 7VDC of

the loop supply.

Page 17

Liquid Controls

Sponsler, Inc.

Main

Power

Modulated

Power

Yes

Yes*

No

Off

Off

On

External

External

No

No**

No

On

On

On

Loop

Loop

No

No**

Yes

On

On

Off

Battery

Loop

Approximate

Battery (years)

0

500

0 500

0

6.5

500

3.2

0 500

0 500

• Internal Battery

external power sources. Battery life estimates are in the Power Mode chart below and are

affected by the options enabled. The battery may be replaced at any time with the only side

effect being a loss of normal operati on (all calibration and configuration information is

maintained). Total, Grand Total, and service hours may be saved at any time by activating the

Grand Total display or by entering the menu system. Upon system startup, the saved values

will be retrieved.

IT400 Remote Totalizer & Rate Indicator

Page: 14 DOC#: MN-IT400-R2d.doc

functions either as a primary power source or as a backup to either of the

External

DC

Loop

Isolation

Battery

Powered

SW5-1 SW5-2 SW5-3

IT400

Carrier

*For External power, the loop isolation switches SW5-1, 2 must be “Off” (isolated).

** Loop powered operation; the loop isolation switches SW5-1, 2 must be “On” (non-isolated).

• Power Mode

: controls the refresh rate of both the display and outputs of the IT400 and is a

user selectable menu item. Refresh times and approximate battery life are in the following

table:

Mode

Refresh Input frequency

1 16 refreshes/s

2 8 refreshes/s

3 4 refreshes/s

4 1 refreshes/s

*Battery life calculations are worst case based on continuous flow , enabled linearizer,

temperature compensator, 4-20mA output, and pulse output.

Enclosure

The IT400 is contained in an explosion proof enclosure. This enclosure is typically meter mounted

via a union or a temperature extension (consult factory for lengths and applications). There is

typically a short cable (4 feet) that connects the IT400 to an external temperature probe (a few inches

downstream). Rigid conduit is recommended for this connection to maintain the explosi on pr oo f

rating of the enclosure and to maintain CE marking.

5 2s/refresh

Page 18

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 15 DOC#: MN-IT400-R2d.doc

Menu System

The IT400’s menu system is designed to allow a simple means of entering all of the data required for

the system to perform its calculations. This section steps through the menu system and provides a

description of each item. To enter the menu system, simply press Menu.

Button functions

Menu / Enter – The menu button advances through the menu system. When editing values, this

button provides the “enter” function. Note: The menu may be exited while viewing any main menu

item by pressing and holding Menu, then pressing and holding Select, then releasing Menu, next

releasing Select.

Select / Digit – The select button is used to change values and edit numbers. To edit a displayed

number, Select is pressed to allow editing. When editing num bers, each press of Digit shifts right

the digit to be edited. When selecting between two values, Select is used (this includes yes/no,

ENABLED/DI SABLED, and pos/neg)

Number – The number dial is used to set the current displayed item to a specific value. When editing

numbers, the flashing number will change according to the number dial. When editing decimal

placement of a number, the decimal point will change according to the number dial.

Editing numbers

Some menu items require the editing of a number. All three controls are used to edit the number.

Here is a short example of editing the low temperature warning set point :

1. Number to be edited is displayed:

2. Press Select to edit the number.

3. If the number can be positive or negative, press Select to toggle between

positive (PoS) and negative (NEG).

4. Press Enter to accept the desired sign.

5. Next, the actual number can be edi te d. Num ber s are edit e d

from left to right. The digit that is currently being edited will

flash. Use the Number dial to change the flashing number to

the desired value. If no change is needed, do not move the Number dial.

6. Press Digit to move the edit focus to the next digit. Repeat these steps as

necessary to edit all the digits in the number.

7. Press Enter to accept the changes to t he nu mber.

8. If the number can have a decimal, the current decimal location will flash. Use

the Number dial to change the flashing decimal to the desired location. If no change is needed,

do not move the Number dial.

9. Press Enter to accept the decimal loca ti on.

10. In most cases, an opportunity to re-edit the number is presented.

POS

T MPL o

- 350.0000

t mpLo

NEG

t mpLo

350.00000

T MPL o

Page 19

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

o

r ef t

Page: 16 DOC#: MN-IT400-R2d.doc

Menu descriptions

The menu is composed of a list of editable items which control the operation of the IT400. This is a

listing of all of the menu items. The IT400 reverts to the Run Mode if no user input is detected within

30 seconds while viewing any of the following top level menu items.

1. Reset Totalizer

Resets the totalizer without using an external magnet. If the totalizer reset is set to

no, the subsequent submenu is not displayed.

1.1 Reset Totalizer Done

This is an informational message that indicates that the main totalizer has been

reset.

2. Temperature Compensation E na ble

Displayed only if purchased as an option. Temperature compensation can be

enabled or disabled. If compensation is dIsabLed, the next two sub-menus are

skipped.

2.1 Reference Temperature

Temperature at which the Coefficient of Thermal Expansion is referenced. The

temperature units are degrees Fahrenheit and must match the Coefficient of

Thermal Expansion used in the next item (and is listed in the Appendix).

2.2 Coefficient of Thermal Expansion

The Coefficient of Thermal Expansion for select fluids can be found in the

Appendix.

RST No

ToTAL

r st done

t ot aL

ENABLED

t c o mp

f 60.000

0.0001015

t coef

Displayed only if purchased as an option. Linear interpolation can be enabled or

disabled. If linearization is dI SABLEd, the next three sub-menus are skipped.

Permits the editing of the linearizer table and is only set if the linearizer has been

enabled. If set to no, the linearizer table will not be edited and the menu system

jumps to menu 4 (K-Factor) below. If the table is to be edited, the menu will step through the list of

points in the order of frequency then K factor. The frequency values must be ascending starting with

the first point being the lowest.

Note: To enter a table of fewer than 20 points in the linearizer table, after the last desired linearization

point add one additional point and set the frequency to zero. Example: For 15 point linearization, set

the frequency for point 16 to zero.

Note: The table must have at least two points.

3. Linear Interpolation Enable

3.1 Linear Interpolation Table Edit

ENABLED

LI NER

edI t no

TABLE

Page 20

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 17 DOC#: MN-IT400-R2d.doc

3.2 Frequency Input

Permits setting of the frequency of a given run in the linearizer. The number listed

on the display indicates which point in the table is being edited. Frequencies must

be in ascending order (point 1 is the lowest frequency). When the frequency is set,

press Enter to accept.

Note: If a frequency point is entered that is not ascending, the device will restore the original value

and return to the frequency for that point.

10.000000

FY 01

5.0000000

3.3 K-Factor Input

Allows the setting of the K-Factor of a given point in the linearizer. The number

listed on the display indicates which point in the table is being edited. When the KFactor is set, press Enter to accept.

Note: If the table was edited, upon accepting the last K-Factor, the menu will return to menu 3.1

Linear Interpolation Table Edit.

Note: The table edit may be exited while viewing any K-Factor by pressing and holding Menu, then

pressing and holding Select, then rele as ing Menu, then releasing Select.

FAC01

60.000000

4. K-Factor

Only available if the linearizer is dI sabLed. The K-Factor is the non-linearized

base meter factor and is always in pulses per gallon. Both total and rate displays

use this K-factor in their base conversion.

FCToR

1.0000000

5. Totalizer Units

Set by turning the Number dial to the desired position. The dial positions allow

several standard conversions as well as three customizable settings. The

conversion (from gallons) of each position is listed in the upper display. The customizable settings

are LBS, KG, and {blank}. For each of these engineering units, the system allows a customized “per

gallon” conversion to be entered. The {blank} item is for engineering units that are not included in the

standard list. Example: To display pounds of liquid nitrogen, LBS (#2) is selected with the dial and

the value is edited to read 6.745 (6.745 pounds of LN2 per gallon).

UNI TT

Set by turning the Number dial to the desired position. If no decimal is shown, the

decimal is assumed one place to the right of the least significant digit.

Set by turning the Number dial to the desired position. The dial positions allow

several standard conversions as well as three customizable settings. The

conversion (from gallons) of each position is listed in the upper display. The customizable settings

are LBS, KG, and {blank}. For each of these engineering units, the system allows a customized “per

gallon” conversion to be entered. The {blank} item is for engineering units that are not included in the

standard list. Example: To display pounds of liquid nitrogen, LBS (#2) is selected with the number

dial and the number is edited to read 6.745 (6.745 pounds of LN2 per gallon).

6. Totalizer Decimal Place

7. Ratemeter Units

DEC T

1.0000000

UNI TR

Page 21

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 18 DOC#: MN-IT400-R2d.doc

8. Ratemeter Decimal Place

Set by turning the Number dial to the desired position. If no decimal is shown, the

decimal is assumed one place to the right of the least significant digit. There is one

special setting named aut orange. The autorange setting allows the ratemeter

display to self adjust the decimal point based on the size of the number to be displayed. Example:

Ratemeter decimal set to aut orange. If the rate is 12.873 GPM, then 12.873 will be displayed. If the

rate increases to 128.73 GPM, then 128.73 will be displayed.

DEC R

60.000000

9. Rate Time Base

The time the ratemeter is based on in seconds. The Number dial positions allow

several standard time bases as well as one customizable setting. The conversion

(in seconds) of each position is listed in the upper display. The customizable setting is indicated by

the absence of any time annunciator at the bottom of the display. The {blank} item is for units that are

not included in the standard list. Example: To display the rate in units per week, the customized

number would be edited to read 604800.00 and no annunciator is di spl ayed.

10. 4-20mA Output

The 4-20mA analog output is enabled or disabled in this menu. If the 4-20mA

output is dI SABLEd, the next two sub-menu items are skipped.

RT I ME

ENABLED

4- 20

10.1 4-2 0mA Output Low Setting

Used by the 4-20mA output as the low setpoint. Edit the number to read the

desired low flowrate setting. The setpoint engi neeri ng units are the same as the

ratemeter engineer ing units.

0.0000000

out Lo

99999.000

10.2 4-2 0mA Output High Setting

Used by the 4-20mA output as the high setpoint. Edit the number to read the

desired high flowrate setting. The setpoint engineering units are the same as the

ratemeter engineer ing units.

out hI

ENABLED

11. Pulse Output Enable

The pulse output is enabled or disabled in this menu. If the pulse output is

disabled, the next two sub-menu items are skipped.

11.1 P uls e Output - Pulse Width

The pulse width of the pulse output is set by turning the Number dial to the desired

position. The dial positions allow several standard pulse widths as well as one

customizable setting. The selected pulse width in milliseconds is listed in the upper display. There is

one special setting named f requenCy. The frequency setting allows the pulse output to auto adjust

the pulse width based on the number of pulses to be outputted per second. Example: Pulse width

set to f r equenCy. If the totalizer is counting to 14 every second, then the output pulse width will be

71.428ms. If the totalizer is now counting to 55 every second, then the output pulse width will auto

p oUT

2

p WI D

Page 22

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

pmoDE

adjust to 18.2ms. The f r equenCy setting is especially useful when using the pulse output as a

ratemeter, howev er , if a ratemeter output is desired, the 4-20mA loop will provide better results. Dial

position #7 provides a customized pulse output setting initially set to 75, which can be edited for any

pulse width (max 999ms).

Note: If the pulse width exceeds the inverse of the number of requested output pulses per sec on d,

the total display will indicate this error with an e in the left most totalizer character during Run Mode.

When the e is displayed, output pulses are being lost. Example: If the pulse width is set to 500(ms),

then the maximum number of pulses that may be outputted is two per second.

Page: 19 DOC#: MN-IT400-R2d.doc

11.2 P uls e Output - Pulse Divider

1

Divides the pulse output by the displayed value. The divider is set by turning the

Number dial to the desired position. The dial positions allow several standard

pulse dividers as well as one customizable setting. The selected pulse divider is listed in the upper

display. The customized pulse divider setting is switch position #8 (initially set to 75), and can be

edited for any value (max 9999).

12. Backlight Timer

Determines the length of time the backlight remains “On” when activated. Set by

turning the Number dial to the desired position. The dial positions allow several

standard timer values in seconds as well as one customizable setting. The selected timer value is

listed in seconds in the upper display. If the timer is set to ALWAYSoN, the battery will last about two

months. This setting is not needed for DC powered units as the backlight is always on when DC

powered anyway. The customized backlight timer setting is switch position #9 (initially set to 75), and

can be edited for any number of seconds (max 9999s).

Note: The backlight timer is only a timer. Even when disabled, the backlight may be used when a

magnet is located by the Light magnetic reed switch.

Note: The backlight is the highest current drawing component of the IT400. Use it sparingly;

excessive use will quickly reduce the battery life (when running on the internal battery).

p DI V

10

bLI TE

Sets the IT400’s internal power savings functions and the refresh rate. The power

mode is set by turning the Number dial to the desired position. Power modes

range from mode 1 (fastest refresh, shortest battery life) to mode 5 (slowest refresh, longest battery

life). The power mode is described in greater detail in the Power section of this manual.

Note: When power mode is set to 5, the datalogger activation timer period (AT I MR) will be rounded

down to the nearest even number.

13. Power Mode

3

Page 23

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

aLARM

123456

Page: 20 DOC#: MN-IT400-R2d.doc

14. Alarm

Displayed only if purchased as an option. The alarm menu allows the setting of various system

warnings to trigger an alarm. The number at the top of the display indicates which alarms are

enabled: A 1 indicates the associated alarm is enabled, and a 0 indicates disabled. Starting from the

left side of the screen, the alar ms ar e in order in the following list:

1. Lbat t – Low battery. Enables the low battery warning (absence of any battery annunciator

when running off battery) to trigger the alarm.

2. t empu – Temperature under. Enables a low process temperature warning to trigger the alarm.

3. t empo – Temperature over . Enables a high process temperature warning to trigger the alarm.

4. RATEU – Rate under. Enables a low flow rate warning to trigger the alarm.

5. rat eo – Rate over. Enables a high flow rate warning to trigger the alarm.

6. not ot – No totalize during alarm. Inhibits the totalizer whenever there is an alarm condition.

Using this setting prevents special “out of range” flow conditions from affecting the totalizer.

Example: The temperature set points are set for the liquid state range of LN2, and the not ot

is set to ENABLED. The totalizer will not count any “gassing” of the meter (it will

not totalize when the detected temperature is outside the liquid temperature

range).

To set an alarm, press Select. A prompt to enable the Low battery alarm is

presented. Press Select again to toggle between enabLed, and dI sabLed. When

the selection is set, press Enter to accept and move to the next alarm. Continue

through all alarm settings. When the last alarm is set, the original list of all alarms is presented.

000000

15. Service Hours

Displays the number of hours remaining until the service hours have elapsed. If the

service hours setpoint is to be programmed or to reset the service hours counter,

press Select. Press Menu to skip the next two sub-menu items.

999

SERVE

1000

15.1 Serv ice Hours Set Point

Displays the number of hours the flowmeter sees a rate other than zero before the

wrench annunciator i s di s played. When this number is edited (press Select), the

Service Hours count er is automa ti cal l y reset to zero elapsed hours (proceed to the next sub-menu

item). To exit without resetting the Service Hours counter, press Menu (skip the next sub-menu

item).

CURNT

01000

15.2 S erv ice Hours Set Point Edit/Reset

When the Service Hours setpoint Edit/Reset menu is entered, the Service Hours

counter is automatically reset to zero. The Service Hours setpoint may be set to

any number of hours less than 99999 hours.

s set

Page 24

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

123456

Page: 21 DOC#: MN-IT400-R2d.doc

16. Datalogger

Displayed only if purchased as an option. The datalogger menu allows the setting

of various data outputs and when to capture. Every datalog event is preceded by

the date and time of the capture (See the Real Time Clock section). The number

at the top of the display indicates which data are enabled: A 1 indicates the

associated data is enabled, and a 0 indicates disabled. Starting from the left side of the screen, the

data are in order in the following list:

1. WARNG – Warning. Enables any warnings to be included in the log.

2. FCToR – K-Factor. Enables the K-Factor value to be included in the log. This will track the K-

Factor (and will change only during linearizer and temperature compensation use).

3. TEMP – Temperature. Enables the temperature value to be included in the log.

4. GToTL – Grand Total. Enables the grand totalizer value to be included in the log.

5. RATE – Rate. Enables the rate value to be included in the log.

6. ToTAL – Total. Enables the totalizer value to be included in the log.

000000

DTALG

16.1 Setting Data to be Captured to the Datalogger

To set the data to be included in the log, press Select. A prompt to enable the warnings output is

presented. Press Select again to toggle between enabLed, and dI sabLed. When the selection i s set,

press Enter to accept and move to the next data setting. Continue through all data settings as listed

above. When the last data setting is set, the menu automatically proceeds to the Datalogger

Activation and Output Settings.

16.2 Datalogger Activation and Output Settings

Setting the datalogger activation and output settings flows seamlessly from the previous menu listing.

The same procedure as in the data settings above is used to enable and disable these settings. The

list below describes the menu items in this section:

1. A RST – Activate by Reset. Will activate a datalog event when the reset input is activated. The

logged event will actually occur just prior to the reset action. Therefore, the data that is

captured will be for the last total displayed. To get a datalog event that shows a total of zero,

activate the reset function a second time.

2. AWARN – Activate by Warning. Will activate a datalog event whenever there is a change in a

warning. An event will be triggered when the warning is indicated, as well as another event

when the warning changes (shows no warning or a secondary warning).

3. AGRND – Activate by Grand. Will activate a datalog event when the grand total is activated.

4. ATI ME – Act ivate by timer. Will activate a datalog event based on an internal timer. The period

of the timer is set by AT I MR (below). If this option is disabled, the Activation timer period is not

asked.

5. SERDB – Serial output in DB format. This is a toggle between the two output format types:

DB format Enabled – Database format. This format will list the output data in a raw

“listing” form. Each data value is listed as a comma separated list. The time/date that will

be logged when this setting is enabled is based on GMT and will reflect the number of

seconds that have passed since Jan 1, 1970 at 0:00:00 (including leap years, but not leap

seconds, time zone, or DST). This is commonly referred to as “UNIX” time. This format is

Page 25

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

tIme

HR:MN:SEC

DY.MO.YEAR

useful when the data is captured to a computer and later imported into a data analysis

program or database.

DB format Disabled – Pretty-Print format. This format will list data on separate lines,

preceded by the name of the data and followed by the given units of measure. This format

is more useful for ticket printing and human readability. The time/date that will be logged

when this setting is enabled will be in the format: Fri Aug 12 2005 12:36:56 GMT-0400

6. ATI MR – Activation timer period. Only available if ATI ME i s enabled. Sets the number of

seconds between timer triggered datalog activations.

Note: If the power mode is set to 5, the activation timer period will be rounded down to the

nearest even number.

Page: 22 DOC#: MN-IT400-R2d.doc

17. Real-Time Clock

The real time clock menu allows the viewing and setting of the internal real time

clock. Pressing Select toggles between the current date and time (the next two

submenu items). Holding Select for more t ha n 3 seconds allows editing.

12=36=56

17.1 Current Time

Allows the setting of the time portion of the real time clock. The current time is set by holding Select

for more than 3 seconds. Prompts for time zone (TZoNE), hour (Ho UR), minute

(MI N), and second (SEC) are displayed. The internal time will resume the instant

Enter is pressed after entering seconds.

17.2 Current Date

Allows the setting of the date portion of the real time clock. The current date is set

by holding Select for more than 3 seconds. Prompts for year (YEAR), month (MoNTH), and day (DAY)

are displayed. Setting the date will not affect the time portion of the real time clock.

15.08.2005

DATE

edI t no

18. Warnings

The editing of the system warnings used for the on-screen warnings and the alarm

set points (if purchased) is allowed when yes is selected here. Temperature limits

and temperature delay are only available if temperature compensation is enabled or temperature is

enabled in the alarm output, or the datalog ger.

WA R N

0.0000000

18.1 Edit Low Flow Limit

The minimum valid flow rate before triggering a low flow warning.

Note: In order to have the rate display show a low flow warning (- UL- ) at zero flow,

FLoLo

set this output low setting to 0.0001.

The maximum valid flow rate before triggering a high flow warning.

The minimum valid temperature before triggering a low temperature warning.

18.2 E dit High Flow Limit

18.3 E dit Low Temperature Limit

9999999.2

FLohI

- 350.0000

t mpLo

Page 26

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

18.4 E dit High Temperature Limit

Page: 23 DOC#: MN-IT400-R2d.doc

200.00000

The maximum valid temperature before triggering a high temperature warning.

Note: After setting a high limit, a display of I NVALI D indicates the low was not less

than the high.

t mphI

10

18.5 Temperat ure delay

The number of seconds to wait between temperature measurements. The shorter

the delay, the more accurately the temperature profile will represent the flow.

Shorter delay periods reduce battery life (when powered exclusively by battery). To edit the delay,

turn the Number dial to select from one of the pre-programmed values, or select 75 (dial position 9)

and edit the number for a custom delay. In Run Mode, the temperature annunciator will flash each

time the temperature is sampled.

19. Test

The test menu allows the viewing, testing, and simulating of various system inputs

and outputs. Here is a listing of the test items:

1. raw freQ – The displayed value is the raw input frequency (autoranged) being received by the

flowmeter input. The value is in Hz. Pressing Select displays the max frequency received by

the flowmeter input.

2. r t d ohm – The displayed value is the raw resistance value of the RTD in ohms. The value is

indeterminate if no RTD is installed.

3. bat t er y / - DC I N- / - Loop- – The displayed v al ue is the battery voltage (if BATTERY is

displayed) or internal voltage regulator if -DC I n- or -Loop- is dis pl a yed.

4. LCD t est – Pressing Select causes the IT400’s LCD to indicate all segments.

5. 4- 20t est – Pressing Select causes the IT400 to simulate five values on the 4-20mA output.

The Number dial is used to step through the following values: 0%, 25%, 50%, 75%, & 100 %.

The backlight will be disabled during the 4-20mA output test so as to not affect the 4-20mA

output. The dial must be turned until one of the values is displayed.

6. ver sI on – The displayed value is the internal software version.

DELAY

t est

Enables or disables the menu lockout. If the menu lockout is disabled, the menu is

exited and RUN mode is resumed.

Displays and allows the edit of the code that must be entered to gain access to the

menu. A code of 0000 disables the lockout. Edit the number to read the desired

lockout code setting. Only four digits are available for the lockout code. The default lockout code is

1000.

20. Menu Lockout Enable

20.1 Menu Lock out Code

ENABLED

LoC

1000

CoDE

Page 27

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 24 DOC#: MN-IT400-R2d.doc

Appendix

Page 28

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Appendix 1: Menu Quick Reference

Page: 25 DOC#: MN-IT400-R2d.doc

1. Reset Totalizer

Done

2. Enable Temperature

Compensation

Reference Temperature*

{60.0}

Coefficient of Thermal

Expansion* {0.0001015}

3. Enable Linearizer

Edit Linearizer Table

Table Points*

4. K Factor (if Linearizer is

disabled)* {60.0}

5. Totalizer Units

0) Gallons

1) Liters

2) Pounds*

3) Cubic Feet

4) Cubic Meters

5) Barrels

6) Kilograms*

7) Custom*

6. Totalizer Decimal Place

0) 0.01

1) 0.1

2) none

3) x10

4) x100

7. Ratemeter Units

0) Gallons

1) Liters

2) Pounds*

3) Cubic Feet

4) Cubic Meters

5) Barrels

6) Kilograms*

7) Custom*

8. Ratemeter Decimal Place

0) 0.001

1) 0.01

2) 0.1

3) none

4) x10

5) x100

6) Auto-range

* User Editable value

Default values in bold. Your default values may be different depending on the configuration requested at order time.

9. Ratemeter Time-base

0) Seconds

1) Minutes

2) Hours

3) Days

4) Custom*

10. Enable 4-20mA Output

4-20mA Output Low* {0.0}

4-20mA Output High *

{99999.0}

11. Enable Pulse Output

Pulse Width

0) Frequency

1) 1 ms

2) 2 ms

3) 5 ms

4) 10 ms

5) 50 ms

6) 100ms

7) Custom*

Pulse Outp ut Divider

0) 1

1) 2

2) 5

3) 10

4) 50

5) 100

6) 1000

7) Custom*

12. Backlight Timer

0) Disabled

1) 2s

2) 5s

3) 10s

4) 30s

5) 1m

6) 3m

7) 5m

8) Always On

9) Custom*

13. Power Mode Selection

0) Mode 1 refresh 16/s

1) Mode 2 refresh 8/s

2) Mode 3 refresh 4/s

3) Mode 4 refresh 1/s

4) Mode 5 refresh 2s

14. Alarm Bits

Low Battery

Temperature Under

Temperature Over

Rate Under

Rate Over

No Totalize During Alarm

15. Service Hours

Service Hours Set Point

Service Hours Set Point

Edit/Reset* {1000}

16. Datalogger

17. Real-Time Clock

18. Warnings

Flow Rate

Low* {0.0}

High* {9999999.2}

Temperature

Low* {-350.0}

High* {200.0}

Temperature Sample Delay

0) 1s

1) 2s

2) 5s

3) 10s

4) 30s

5) 1m

6) 3m

7) 5m

8) 10m

9) Custom*

19. Unit Test

Raw Frequency

RTD ohms

DC Input / Battery Voltage

(DC in if > 2.7Vdc)

LCD Test

4-20mA Output Test %

0) 0

1) 25

2) 50

3) 75

4) 100%

Software Version

20. Enable Menu Lockout

Menu Lockout Code*

{1000}

Page 29

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Fluid

Reference Density

(Lb/Gal)

Reference Temperature

(ºF)

Air

7.294

-317.8

0.0016262

Ammonia

5.699

-28.2

0.0005704

Argon

11.616

-302.6

0.0014861

CO2

8.733

-10.0

0.0012609

Methane

3.540

-258.7

0.0010523

Natural Gas

3.540

-258.7

0.0010523

Nitrogen

6.743

-320.4

0.0014917

Oxygen

9.519

-297.4

0.0013458

Propane

4.234

60.0

0.0007178

Gasoline

6.256

60.0

0.0003703

Kerosene

6.923

60.0

0.0002681

#2 Fuel Oil

7.883

60.0

0.0000885

Water

8.338

60.0

0.0001015

Page: 26 DOC#: MN-IT400-R2d.doc

Appendix 2: Coefficie nt of Ther ma l Exp ansi on for Common Fluids

Fluid Properties Table

LIQUID

Coefficient of Thermal Expansion

Page 30

Liquid Controls

Sponsler, Inc.

Run Mode

Setup Start

Lockout

1. Reset

Totalizer

2.

Temperature

Compensator

ToTAL

RATE

SETUP

PRESS SEL

LoC

RST No

ToTAL

Lockout

Enabled?

Yes

No

0000

CoDE

Number

Entry

Lockout

Correct?

RST YES

ToTAL

Feature 'C'

Purchased?

oF 60.000

REF T

Number

Entry

0.0001015

TCo EF

Number

Entry

No

Yes

ENABLED

T Co MP

Temperature

Compensator

Enabled?

Yes

No Yes

Select

Digit

Select

Digit

Select

Digit

Select

Digit

Select

Digit

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

DI SABLED

T Co MP

I NCoRRECT

LoC

- RUN-

Menu

Enter

P2-1

RST DoNE

ToTAL

Menu

Enter

No

REF T or TCo EF

Changed?

No

Yes

IT400 Remote Totalizer & Rate Indicator

Appendix 3: Menu Flow Chart

Page: 27 DOC#: MN-IT400-R2d.doc

Page 31

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

3. Linear

Interpolation

4. K-F actor

5. Totali zer

Units

6. Totali zer

Decimal Pl ace

DI SABLED

LI NER

ENABLED

LI NER

Feature 'L'

Purchased?

Yes

EDI T No

TABLE

EDI T YES

TABLE

*10.000000

FY 01

Number

Entry

*5.0000000

FAC01

Number

Entry

No

Repeat at

most 20

times

--EXIT--

FAC01

Last Point

-OR-

FY = 0?

No

Note: Set FY to z ero

after las t valid entry

Yes

1.0000000

UNI TT

60.000000

FCt or

Se t with

Dial*

Number

Entry

DEC T

Se t with

Dial*

Linearizer

Enabled?

No Yes

8.3359000 LBS

3.7810000 KG

1.2000000 (Custom)

Select

Digit

*GAL, LIT, LBS, FT3, M3, BBL, KG, Custom

*0.01, 0.1, 0, x10, x100

Menu

Enter

Menu

Enter

Select

Digit

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

Select

Digit

Select

Digit

Select

Digit

Select

Digit

Select

Digit

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

Select

Digit

Number

Entry

P2-1

P3-1

* Actual readings will vary

**To Exit: Hold Menu fi r st, then

pre ss Select, then release Menu

**

**

Page: 28 DOC#: MN-IT400-R2d.doc

Page 32

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

604800.00

8.3359000

3.7810000

1.2000000

AUTo RANGE

Page: 29 DOC#: MN-IT400-R2d.doc

P3-1

7. Rate Uni ts

8. Rate

Decim al Plac e

9. Rate Time

Base

1.0000000

UNI TR

Menu

Enter

DEC R

Menu

Enter

60.000000

RT I ME

Menu

Enter

Set w ith

Dial*

Set w ith

Dial*

Set w ith

Dial*

LBS

(Custom)

KG

(Custom)

Select

Digit

Select

Digit

Number

Entry

*GAL, LIT, LBS, FT3, M3, BBL, KG, Custom

*0.001, 0.01, 0.1, 0, x10, x100,

Number

Entry

* /S, /M, /H, /D, Custom

10. 4-20mA

Setup

No Yes

DI SABLED

4- 20

Menu

Enter

4-20mA

Enabled?

Select

Digit

P4-1

ENABLED

4- 20

Menu

Enter

0.0000000

oUTLo

Menu

Enter

99999.000

oUThI

Menu

Enter

Select

Digit

Select

Digit

Number

Entry

Number

Entry

Page 33

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Pulse Output

Backlight

Power Mode

Alarm

DI SABLED

P out

Menu

ENABLED

P o UT

Menu

Pulse Out

Enabled?

No

Yes

2

P WI D

1

P DI V

Set w ith

Dial*

Set w ith

Dial**

10

BLI TE

Set w ith

Dial*

Menu

Enter

Select

Digit

75

(Custom)

75

(Custom)

75

(Custom)

Select

Digit

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

*FREQUENCY,2,5,10,50,100,75(Custom)

**1,2,5,10,30,100,1000,75(Custom)

*DI SABLED,2,5,10,30,60,180,300,600,75(Custom)

Menu

Enter

Select

Digit

PMo DE

Set w ith

Dial*

Menu

Enter

*1,2,3,4,5

Number

Entry

Number

Entry

Number

Entry

P4-1

Menu

Enter

000000

ALARM

Select

Digit

DI SABLED

LBATT

Option 'AL'

Purchased?

Yes

Enable /

Disable*

DI SABLED

TEMPU

DI SABLED

TEMPo

DI SABLED

RATEU

DI SABLED

RATEo

DI SABLED

NoTot

Enable /

Disable*

Enable /

Disable*

Enable /

Disable*

Enable /

Disable*

* Exampl e a t e nd of flowchart

P5-1

No

Page: 30 DOC#: MN-IT400-R2d.doc

Page 34

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Page: 31 DOC#: MN-IT400-R2d.doc

Service Timer

Datalogger

P5-1

Option 'D'

Purchased?

No

Yes

DI SABLED

A RST

999

SERVE

Menu

Enter

000000

DTALG

Menu

Enter

Select

Digit

Select

Digit

Enable /

Disable*

1000

CURNT

Menu

Enter

DI SABLED

WARNG

DI SABLED

T e mp

DI SABLED

RATE

DI SABLED

AWARN

Select

Digit*

Enable /

Disable*

Enable /

Disable*

Enable /

Disable*

Enable /

Disable*

01000

S SET

DI SABLED

FCToR

DI SABLED

GToTAL

DI SABLED

ToTAL

DI SABLED

AGRND

Number

Entry

* Resets the service timer

Enable /

Disable*

Enable /

Disable*

Enable /

Disable*

Enable /

Disable*

Real Time

Clock

*12=36=56

T I ME

Menu

Enter

P6-1

DI SABLED

ATI ME

Select

Digit

Select

Digit

Enable /

Disable*

*16.01.2006

DATE

Menu

Enter

DI SABLED

SERDB

Select

Digit

*08

Mo N

*NEG

TZoNE

*36

MI N

Enable /

Disable*

* Actual readings w ill vary. Date format is DD.MM.YEAR

*2005

YEAR

Number

Entry

Number

Entry

Number

Entry

ENABLED

ATI ME

No

Number

Entry

Yes

?

*12

DAY

*12

hoUR

*56

SEC

2

ATI MR

* Exampl e at end of flowcha rt

Hold for more than

Select

Digit

3 seconds to edit

Number

Entry

Number

Entry

Number

Entry

Number

Entry

Page 35

Liquid Controls

Sponsler, Inc.

IT400 Remote Totalizer & Rate Indicator

Warnings:

Flow Rate and

Temperature

Setpoints

Test

(Multimeter

Functions)

TEST

RAW F REQ

*- ERR-

Select

Digit

Menu

Enter

Menu

Enter

* Actual readings will vary

RTD o hM

*429.0

Menu

Enter

- DC I N-

*3.614

Menu

Enter

Powered by?

BATTERY

*3.614

DC in

Battery

Menu

Enter

- LooP-

*3.614

Menu

Enter

Loop

L CD TEST

88888888

#88888

Select

Digit

Menu

Enter

# All se gments w ill be on

4- 20test Select

Digit

Menu

Enter

Menu

Enter

Se t with

Dial**

**0%, 10%,50%, 75%,100%

Menu

Enter

VERSI ON

*1.10

P6-1

0.0000000

FLoLo

Number

Entry

9999999.2

FLohI

Number

Entry

Select

Digit

Select

Digit

10

DELAY

Se t with

Dial*

75 (Custom)

Select

Digit

Menu

Enter

Number

Entry

EDI T No

WA RN

EDI T YES

WA RN

Select

Digit

Menu

Enter

Menu

Enter

- 350.0000

T MPL o

Number

Entry

200.00000

T MPh I

Number

Entry

Select

Digit

Select

Digit

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

Menu

Enter

P7-1

**Any of: T Co MP, ALARM:TEMPU/TEMPo, or

DTAL G:TE MP set to ENABLED

Is tem perature

measurement

enabled? **

No

Yes

*1,2,5,10,30,60,180,300,600,75(Custom)

Select

Digit

FREQ MAX

*- ERR-

Hold

Select

Digit

Page: 32 DOC#: MN-IT400-R2d.doc