LG F4V5VGP2T User guide

website :http://biz.lgservice.com

e-mail : http://LGEservice.com/techsup.html

WASHING MACHINE

SERVICE MANUAL

CAUTION

READ THIS MANUAL CAREFULLY TO DIAGNOSE PROBLEMS CORRECTLY BEFORE OFFERING SERVICE.

BEFORE SERVICING THE WASHING MACHINE, UNPLUG THE POWER CORD TO AVOID THE RISK OF AN ELECTRIC SHOCK.

WHEN SERVICING INTERNAL PARTS ,

USE ONLY SERVICE PARTS SUPPLIED FROM LG.

AFTER SERVICING THE ELECTRIC WIRE, INSURE THAT INSULATION TAPE IS APPLIED TO PREVENT AN ELECTRICAL SHORT.

MODEL :

F*V7*CP(0~9)

|

CONTENTS |

|

1. |

SPECIFICATIONS ............................................................................................................................. |

3 |

2. |

FEATURES & TECHNICAL EXPLANATION ..................................................................................... |

4 |

3. |

PARTS IDENTIFICATION ................................................................................................................. |

6 |

4. |

INSTALLATION .................................................................................................................................. |

7 |

5. |

OPERATION ................................................................................................................................... |

12 |

6. |

WIRING DIAGRAM / PCB LAYOUT ................................................................................................ |

17 |

7. |

TROUBLESHOOTING...................................................................................................................... |

19 |

|

7-1.BEFORE PERFORMING SERVICE ......................................................................................... |

19 |

|

7-2.LOAD TEST MODE .................................................................................................................. |

19 |

|

7-3.HOW TO CHECK THE WATER LEVEL FREQUENCY ............................................................ |

20 |

|

7-4.ERROR DISPLAY ..................................................................................................................... |

21 |

|

7-5.TROUBLESHOOTING WITH ERROR ..................................................................................... |

23 |

|

• IE (Water Inlet Error) .............................................................................................................. |

24 |

|

• UE (Unbalanced Error) ........................................................................................................... |

25 |

|

• OE (Water Outlet Error) .......................................................................................................... |

26 |

|

• FE (Over Flow Error) .............................................................................................................. |

28 |

|

• PE (Pressure Sensor S/W Error) ............................................................................................ |

29 |

|

• dE2 (Door open Error).............................................................................................................. |

31 |

|

• dE1 (Door switch Error).............................................................................................................. |

31 |

|

• tE (Thermistor (Heating) Error) ............................................................................................... |

33 |

|

• LE (Motor Lock Error) ............................................................................................................. |

36 |

8. |

TROUBLESHOOTING WITHOUT ERROR CODES ...................................................................... |

38 |

|

• Power Failure or no power .................................................................................................... |

38 |

|

• Vibration & Noise during spin ................................................................................................. |

39 |

|

• Detergent & Softener does not flow in .................................................................................... |

40 |

|

• Water Leak ............................................................................................................................. |

41 |

|

• Before using the Tag On function .......................................................................................... |

43 |

9. PART INSPECTION ........................................................................................................................ |

45 |

|

|

9-1.FILTER ASSEMBLY (LINE FILTER) ......................................................................................... |

45 |

|

9-2.DOOR LOCK SWITCH ASSEMBLY ......................................................................................... |

46 |

|

9-3.STATOR ASSEMBLY ............................................................................................................... |

48 |

10. DISASSEMBLY INSTRUCTIONS .................................................................................................. |

49 |

|

11. EXPLODED VIEW AND PART LIST .............................................................................................. |

57 |

|

1. SPECIFICATION

|

|

ITEM |

|

Refer to 1 page |

|

|

|

|

|

||

POWER SUPPLY |

|

220 V - 240 V ~,50Hz/60Hz |

|||

|

|

|

|

||

PRODUCT WEIGHT |

|

73kg |

|||

|

|

|

|

|

|

|

|

|

WASHING |

|

155 W |

ELECTRICITY |

|

SPIN |

|

490 W |

|

|

DRAIN MOTOR |

|

20 W |

||

CONSUMPTION |

|

||||

WASH HEATER |

|

2200 W |

|||

|

|

|

|

||

|

|

|

DRY HEATER |

|

1350 W |

REVOLUTION |

|

WASH |

|

46 rpm |

|

|

SPIN |

F4V******* |

: No Spin / 400 / 800 / 1000 / 1200 / 1400 |

||

SPEED |

|

|

|||

|

|

|

|

||

|

|

F2V******* |

: No Spin / 400 / 800 / 1000 / 1100 / 1200 |

||

|

|

|

|

||

|

|

|

|||

OPERATION WATER PRESSURE |

0.1 ~ 1.0 MPa (1.0 kgf / cm2 ~ 10.0 kgf / cm2) |

||||

CONTROL TYPE |

|

Electronic |

|||

|

|

|

|

||

WASH & DRY CAPACITY |

|

Refer to the Rating Label |

|||

|

|

|

|

|

|

|

DIMENSION |

|

600mm x 560mm x 850mm |

||

|

|

|

|

|

|

WASH PROGRAM |

Cotton , Cotton+, Turbo Wash 39, Mixed Fabric, Easy Care, |

||||

Steam Refresh, Allergy Care, Delicate, Hand/Wool, Dry Only, |

|||||

|

|

|

|

Speed 14, Wash+Dry, Tub Clean, Download Cycle |

|

|

|

|

|

|

|

|

|

RINSE |

|

Rinse+ |

|

DOOR SWITCH TYPE |

|

PTC+Solenoid |

|||

WATER LEVEL |

|

by Pressure Sensor S/W |

|||

RESERVATION |

|

From 3 hours to 19 hours |

|||

SENSING LAUNDRY AMOUNT |

|

Adapted |

|||

FUZZY LOGIC |

|

Adapted |

|||

DISPLAY REMAINING TIME |

|

Adapted |

|||

ERROR DIAGNOSIS |

|

13 items |

|||

POWER AUTO OFF |

|

Adapted |

|||

CHILD LOCK |

|

Adapted |

|||

AUTO RESTART |

|

Adapted |

|||

TIME SAVE |

|

Adapted |

|||

|

SMART |

|

Wi-fi (Smart ThinQ 3.0) |

||

|

|

|

|||

|

|

|

|

|

|

WARNING

WARNING

To reduce the risk of personal injury, adhere to all industry recommended safety procedures including

To reduce the risk of personal injury, adhere to all industry recommended safety procedures including

the use of long sleeved gloves and safety glasses.

Failure to follow all of the safety warnings in this manual could result in property damage, personal injury or death.

2. FEATURES & TECHNICAL EXPLANATION

2-1. Product Features

Inverter Direct Drive system

The advanced Brushless DC motor directly drives the drum without belt and pulley.

6 Motion

Washer is able to perform various drum actions or a combination of different actions depending on the wash program selected. Combined with a controlled spin speed and the ability of the drum to

rotate both left and right, the wash performance of the machine is greatly improved, giving you perfect results every time.

Turbo Wash

Wash the laundries in 1 hour with energy and water saving.

Smart ThinQ (Wi-Fi feature)

This feature lets you use various functions of the product, e.g., remote control, smart alert, mode download, and smart self-diagnosis via the smartphone app.

More economical with Intelligent Wash system

Intelligent Wash System detects the size of load and water temperature, and then determines the optimum water level and washing time to minimize energy and water consumption.

Child Lock

The Child Lock prevents children from pressing any button to change the settings during operation.

Low noise speed control system

By sensing the amount of load and balance, it evenly distributes load to minimize the spinning noise level.

Auto Restart

Auto Restart allows the program to restart all by itself in case of power failure. It does from the stage where it stopped.

SmartDiagnosis™

Should you experience any technical difficulty with your washing machine, it has the capability of transmitting data by phone to the Customer Information Center. The call center agent records the data transmitted from your machine and uses it to analyze the issue, providing a fast and effective diagnosis.

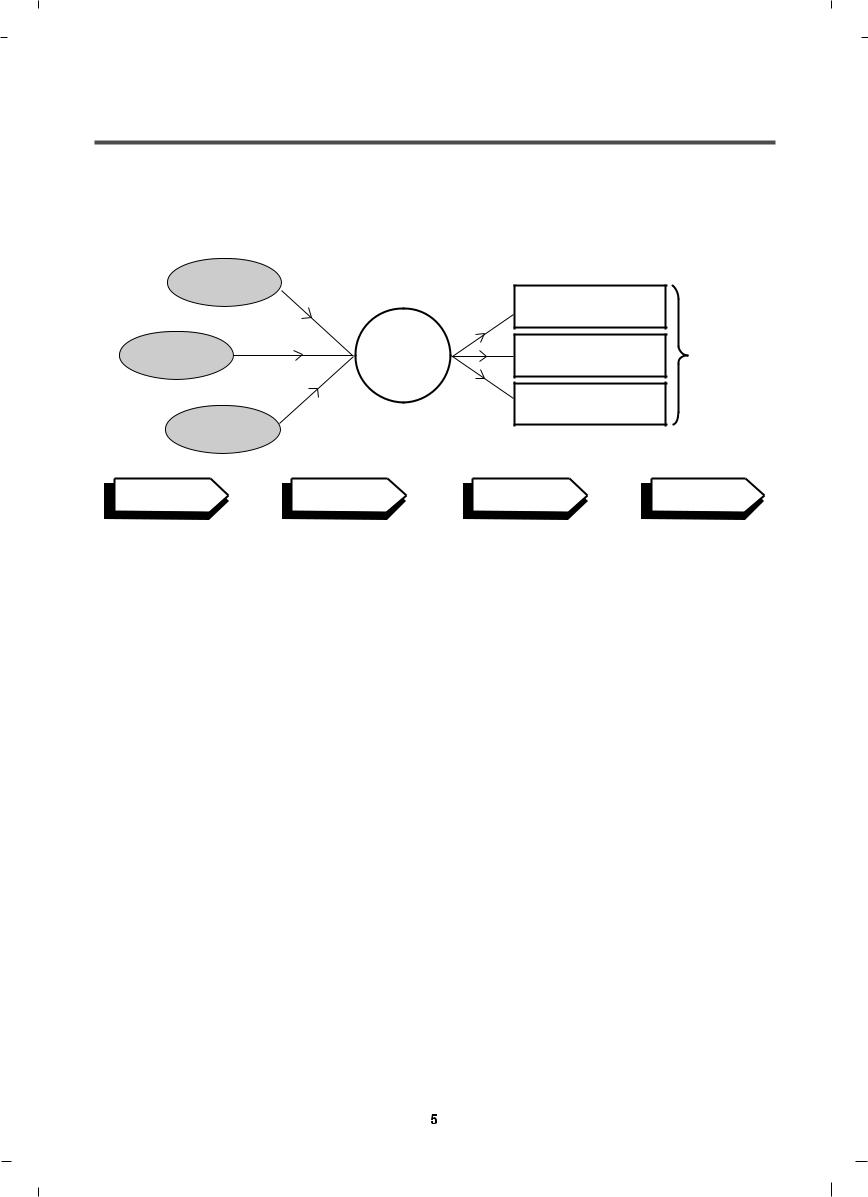

2-2. DETERMINE WASHING TIME BY FUZZY LOGIC

To get the best washing performance optimal time is determined by sensing the water temperature, selected washing temperature and laundry amount.

water temperature

washing time

selected |

|

FUZZY |

|

the best |

washing |

|

rinse time |

washing |

|

|

LOGIC |

|||

temperature |

|

|

performance |

|

|

|

|

|

|

|

|

|

spin rhythm, time |

|

laundry |

|

|

|

|

amount |

|

|

|

|

SENSING |

PROCESSING |

|

DETERMINATION |

EFFECT |

2-3. WATER LEVEL CONTROL

This model adopts a pressure sensor which can sense the water level in the tub.

This model adopts a pressure sensor which can sense the water level in the tub.

Watersupplyisstoppedwhenthewaterlevelreachthepresetlevel,thenwashingprogramproceeds.

Watersupplyisstoppedwhenthewaterlevelreachthepresetlevel,thenwashingprogramproceeds.

Spinning does not proceed until the water in the tub reduces to a certain level.

Spinning does not proceed until the water in the tub reduces to a certain level.

2-4. THE DOOR CAN NOT BE OPENED

While program is operating.

While program is operating.

WhileDoor Lock light is on.

WhileDoor Lock light is on.

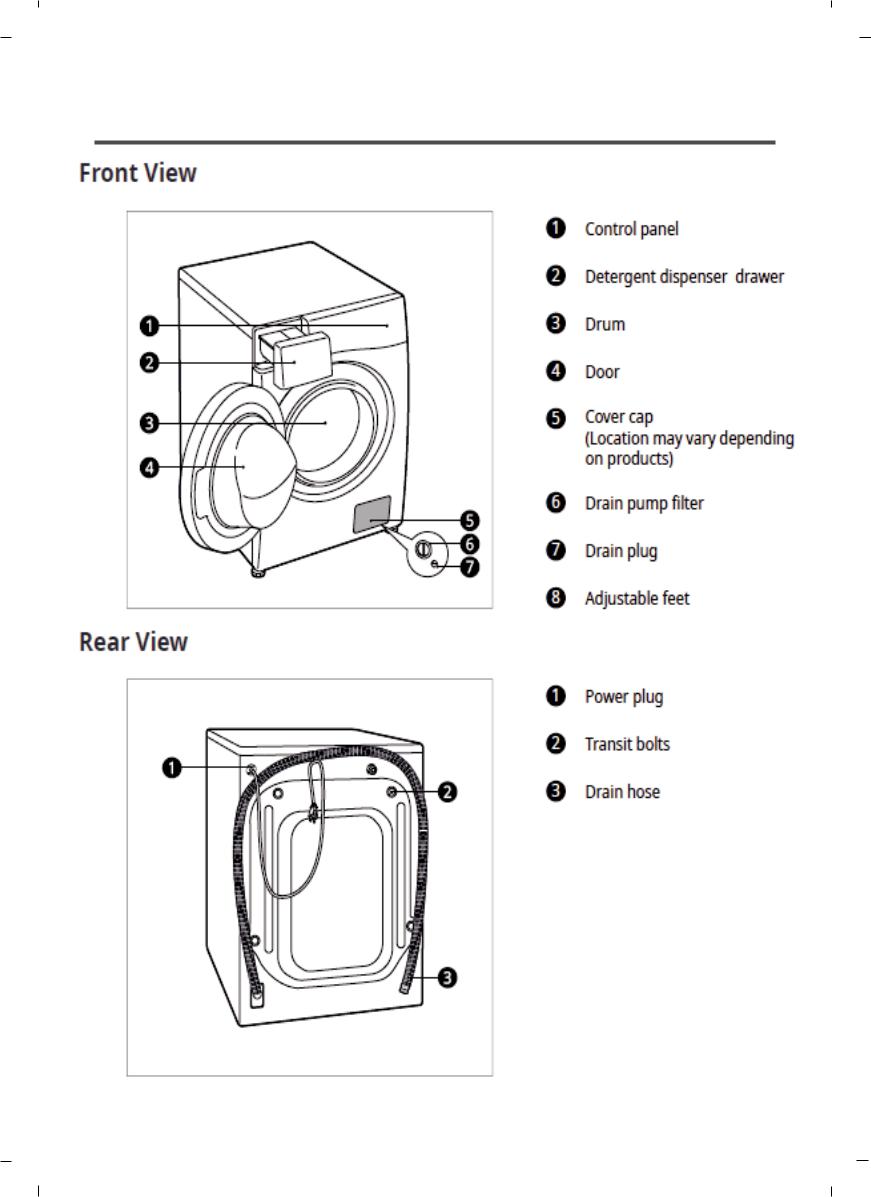

3.PARTS IDENTIFCATION

6

3.PARTS IDENTIFCATION

7

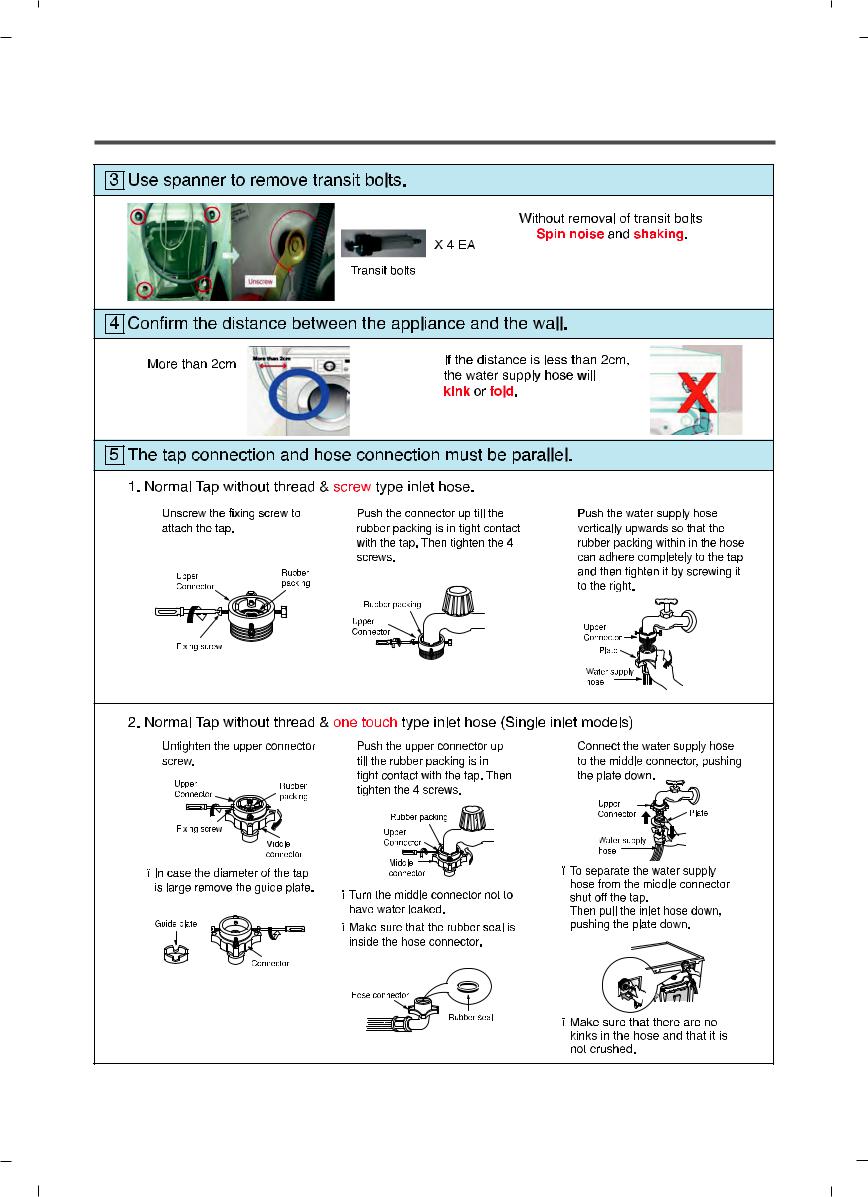

4. INSTALLATION

INSTALLATION

INSTALLATION

The appliance should be installed as follows.

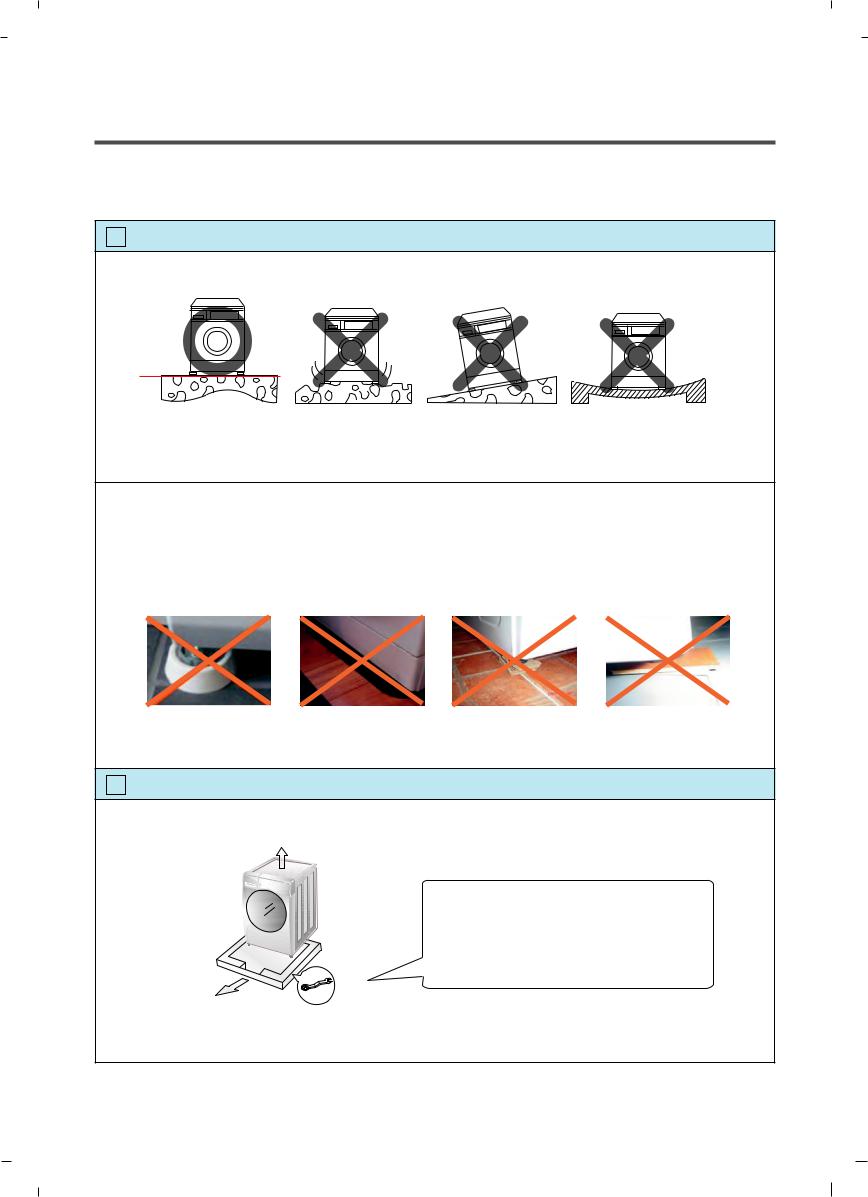

1Check the conditions of installation area.

1. Check level ground.

horizontal

On raised foundations or upper level homes, the vibrations can be caused by the type of flooring. It may be necessary to move the machine to a different area in the home or have the floor reinforced to properly support the operation of the unit.

2. Check for humidity or any foreign objects under the feet.

Clean the floor, there should be no foreign objects under the feet.

If the unit has foreign objects underneath the feet, this will prevent the unit from being leveled properly and will cause vibrations and slipping.

Remove any foreign objects, if any from underneath the machine and level unit properly. See below for examples of foreign objects.

|

|

|

|

|

|

|

Purchased |

|

Carpet |

|

Paper |

|

Laminated |

stopper |

|

|

|

|

|

paper |

|

|

|

||||

|

|

|

|

|

|

|

2 Open the box and check appliance condition.

Washer

Base Packing

This leveling (or spanner) wrench must be used to remove the shipping bolts and level the unit. This should be kept for future use.

Spanner

8

1. |

2. |

3. |

1. |

2. |

3. |

|

|

9 |

6 Connect Drain Hose.

If the drain hose is not installed properly, the unit will not drain properly. This allows water to back flow into the unit which can cause odors. Refer to Owner Manual for proper drain hose installation.

The odor could also be coming from the home’s drain to which the drain hose is attached.

about 100 cm

about 145 cm

about 105 cm

|

<![if ! IE]> <![endif]>max. 100 cm |

|

| <![if ! IE]> <![endif]>min. 60 cm |

|

|

|

|

|

Laundry tub

Hose |

|

Retainer |

|

Tie |

Max. 100cm |

strap |

min. 60cm |

Max. 100cm

min. 60cm

In this type of drain hose installation, the odor could be coming from the standpipe. This odor can come up the drain hose and into the unit.

Pour a cup or two of bleach or vinegar down the home drain and let it sit for 24 hours before running another cycle.

This will help eliminate odor from the home drain.

If a cycle is started too soon after doing this, it will not help the issue.

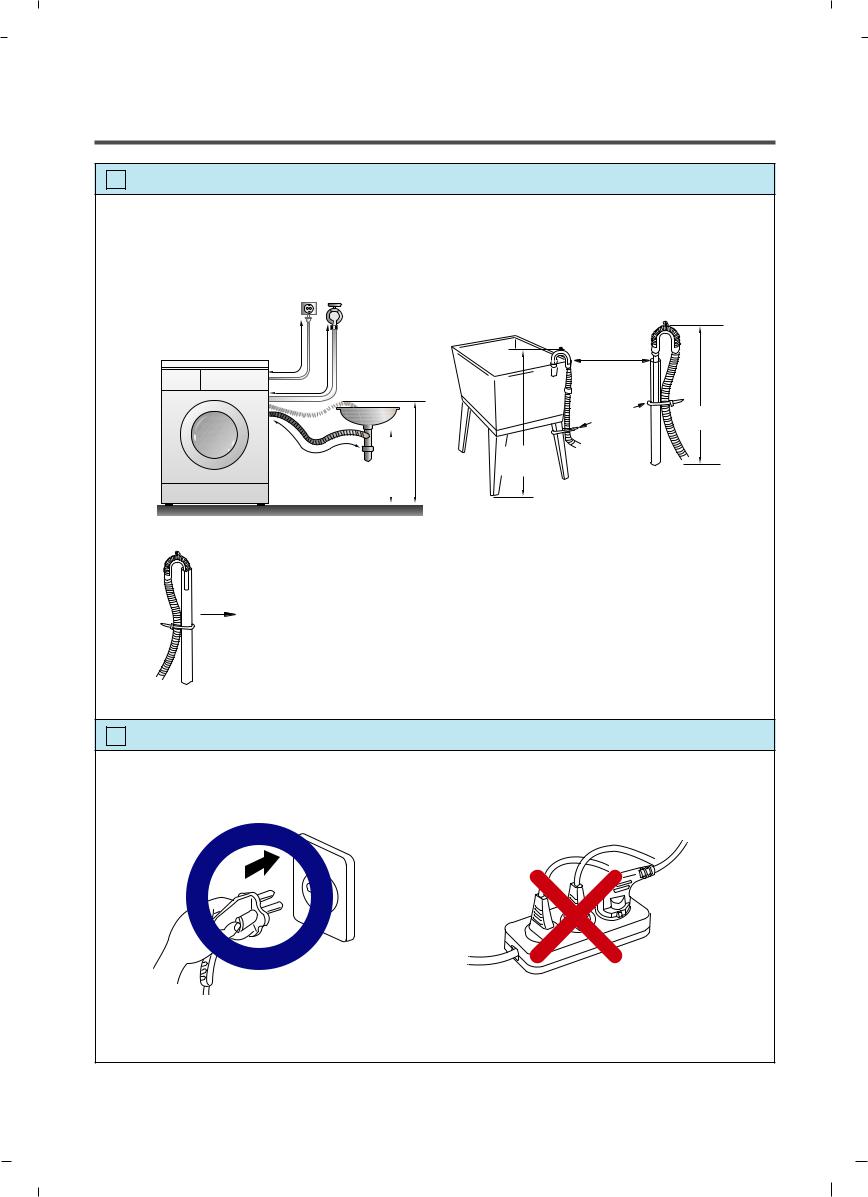

7 Connect power plug.

Connect the power plug to the wall outlet.

Avoid connecting several electric devices, it may be the cause of a fire.

10

8 Check the horizontality with a level (Gage).

Step 1

If washing machine legs are loose or not Screwed in, then tighten with the spanner wrench. Using the level, level the washing machine from front to back and side to side.

A level

Higher

Tighten

Adjustable feet

Step 2

Use the spanner wrench to adjust Legs until level and try the Diagonal test.

Diagonal test |

How to perform a diagonal test: |

Place your right hand on the back, right corner and your left hand on the front, left corner of the unit, then attempt to rock the unit from corner to corner. Then, move your right hand to the front, right side and your left hand to the back, left corner and attempt to rock the unit from corner to corner.

If the unit is level, it will not rock. However, if the unit is not level, it will rock. If the unit rocks, it will be necessary to adjust the leveling feet of the unit. Adjust the foot under the hand that is on the front of the machine.

|

Higher |

Lower |

Lock nut |

|

|

||

Tighten |

Tighten |

|

|

|

|

|

Adjustable bolt |

|

Adjustable feet |

Adjustable feet |

|

Gap

Floor |

No Gap |

10mm |

Floor |

Lower the foot until there is no gap between floor and foot.

And only use adjustment rubber when difference at the leg adjustment is more than 10mm.

Rubber Cup |

4620ER4002A |

4620ER4002B |

|

(Black) |

(Gray) |

|

for Tile floors |

for Wooden floors |

Step 3

Perform a Rinse and Spin with some clothing in the machine.

To do this, put 2~3kg of clothing in the unit, turn on the unit, Select the Rinse+Spin and then start. When the unit reaches the spin cycle, watch for vibrations.

If the unit is vibrating, make small adjustments to the leg until they subside. (Repeat step 2)

Step 4

Tighten the lock nut against the base of the machine to lock the position leg.

Tighen the lock nut

No Gap

Floor |

11

9 Test operation |

|

|

|

|

|

1 |

Preparation |

2 |

Press the power button. |

3 |

Press the START/PAUSE |

|

for |

|

|

|

button. |

|

washing. |

|

|

|

|

·Connect the power plug to the outlet.

·Connect the inlet hose.

· In case of Coloreds program.

6 Check the water heating. |

5 Check automatic reverse turn. |

4 Check the water supply. |

·Touch the Temp and Medic Rinse button simultaneously and the present temperature will be displayed.  Page 20

Page 20

7 Check the drain and spin functions.

· Check if the drum rotates |

· Check if water is supplied through |

clockwise and counterclockwise. |

the detergent dispenser. |

8 Turn power off and open |

9 Water removal. |

the door. |

|

·Turn power off and then power on.

·Select the spin rpm

·Press the START PAUSE button.

·Check the spin and drain functions.

·Turn power off and then power on.

·Listen for a click to determine if the door is unlocking.

·If SVC is needed during check, remove the remaining water by pulling out the hose cap.

12

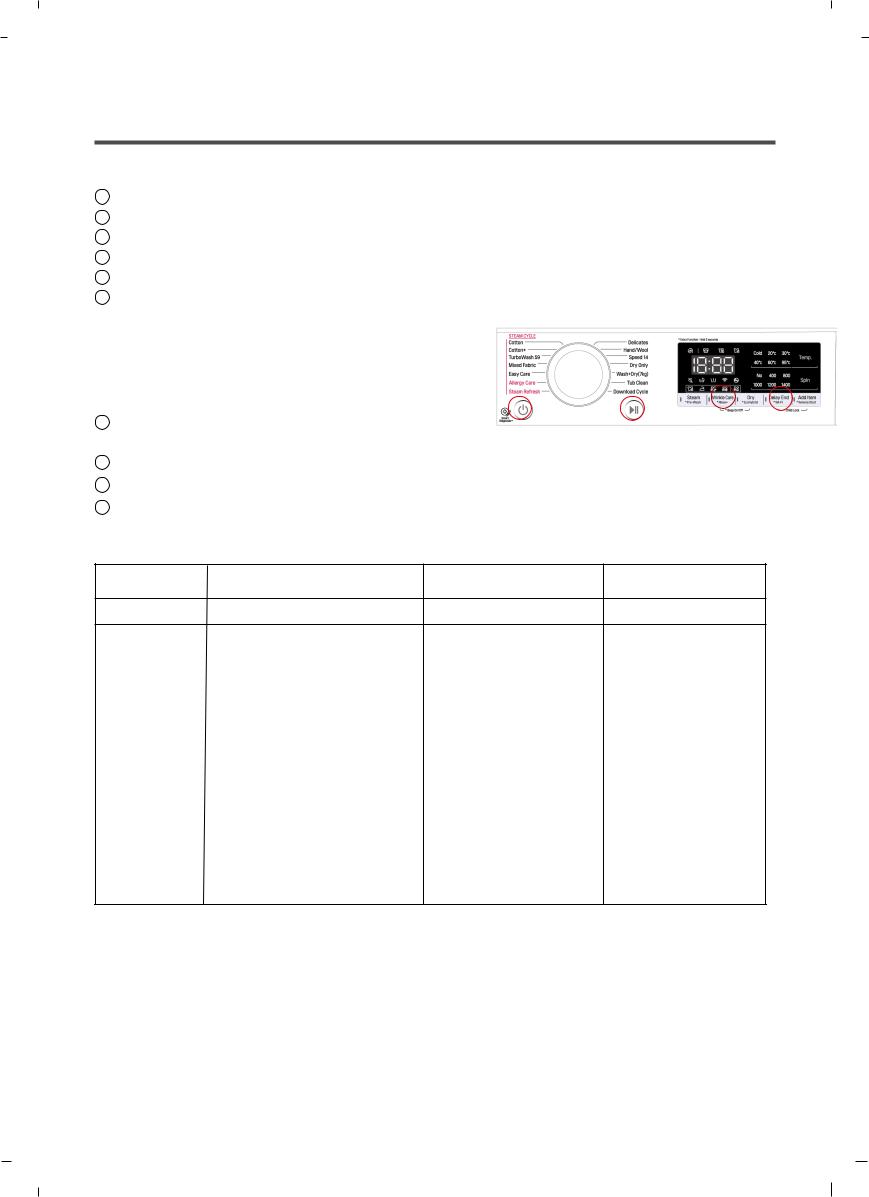

5. OPERATION

How to use washer

Control panel

Control panel

SmartDiagnosis™ function is |

|

|

|

|

available only for the products with |

|

LED display |

||

a SmartDiagnosis™ mark. |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Power Button |

Start/Pause |

Options |

Program dial |

Button |

|

|

|

|

Power |

Program Dial |

|

Press the Power button to turn power on |

Programs are available according to the |

|

and off. |

laundry type. |

|

To cancel the Time Delay function, the |

Lamp will light up to indicate selected |

|

power button should pressed. |

program. |

|

Start/Pause

This Start/Pause button is used to start wash cycle or pause the wash cycle.

If temporary stop of wash cycle is needed, touch theStart/Pause button.

When in Pause, the power is turned off automatically after 4 minutes.

LED display

The display shows the settings, estimated time remaining, options, and status messages for your washer.

The display will remain on through the cycle.

Options

This allows you to select an additional cycle and will light when selected.

Use thise buttons to select the desired cycle options for the selected cycle.

13

How to use washer

Options

Options

Steam: Thisoptionisfeaturedwiththe enhancedwashingperformance.This

Steam: Thisoptionisfeaturedwiththe enhancedwashingperformance.This

optionconsumeslowenergy.

Rinse + ( ) : Addrinseonce.

Rinse + ( ) : Addrinseonce.

Dealy End :

Dealy End :

Youcansetatimedelaysothatthewashing machinewillstartautomaticallyand finish afteraspecifedtimeinterval.

NOTE

NOTE

The delay time is the time to the end of the programme, not the start. The actual running time may vary due to water temperature, wash load and other factors.

The delay time is the time to the end of the programme, not the start. The actual running time may vary due to water temperature, wash load and other factors.

To cancel the function, the power button should be pressed.

To cancel the function, the power button should be pressed.

Avoid using liquid detergent for this option.

Avoid using liquid detergent for this option.

1.TouchthePowerbutton.

2.Selectawashingprogramme.

3.TouchtheTimeDelaybuttonandsettime required.

4.TouchtheStart/Pausebutton.

14

How to use washer

Temp.

BytouchingtheTemp.buttonthewater

temperaturecanbeselected.

-Cold

-20°C,30°C,40°C,60°C,95°C

Watertemperaturecanbeselected

accordingtotheprogram.

Spin

SpinSpeedlevelcanbeselectedby touching'Spin'buttonrepeatedly.

SpinOnly

1.TouchthePowerbutton.

2.TouchtheSpinbuttontoselectRPM.

3.TouchtheStart/Pause.

NOTE

NOTE

Whenyouselect ,itwillstillrotatefora shorttimetodrainquickly.

Pre Wash

Ifthelaundryisheavilysoiled,“PreWash” courseiseffective.

1.TouchthePowerbutton.

2.Selectacycle.

3.TouchthePreWashbutton.

4.TouchtheStart/Pausebutton.

Wrinkle Care

This washing programme reduces wrinkles by steaming after spin.

1.PressthePowerbutton.

2.Selectawashingprogramme.

3.PresstheWrinkleCarebuttonfor3seconds.

4.PresstheStart/Pausebutton.

15

How to use washer

Child Lock

Child Lock

Select this function to lock the buttons on the control assembly to prevent tampering. "Child Lock" can be set only during the washing cycle.

Locking the control panel

1.TouchandholdtheChildLockbuttonfor

3seconds.

2.Abeeperwillsound,and'

'willappearon

'willappearon

theLEDdisplay.

Whenthechildlockisset,allbuttonsare

lockedexceptthePowerbutton.

NOTE

NOTE

Turningoffthepowerwillnotresetthe childlockfunction.Youmustdeactivate childlockbeforeyoucanaccessany otherfunctions.

Unlocking the control panel

1.TouchandholdtheChildLock buttonfor 3seconds.

2.Abeeperwillsoundandtheremainingtime forthecurrentprogrammewillreappearon theLEDdisplay.

Beep On / Off

Beep On / Off

TheBeepon/offfunctioncanbesetonlyduringthewashingcycle.

1.TouchthePowerbutton.

2.TouchtheStart/Pausebutton.

3.Touchandholdthe Spin button

threesecondstosetBeepon/offfunction.

OncetheBeepon/offfunctionisset,thesetting

ismemorizedevenafterthepoweristurnedoff.

NOTE

NOTE

IfyouwanttoturntheBeeperoff, simplyrepeatthisprocess.

16

How to use washer

Tub Clean

Tub Clean

TubCleanisaspecialcycletocleantheinsideofthewashing machine.

Ahigherwaterlevelisusedinthiscycleathigherspinspeed .Performthiscycleregularly.

1. Remove any clothing or items from the washer and close the door.

2. Open the dispenser drawer and add Anti limescale(e.g. Calgon) to the main wash compartment.

3. Close the dispenser drawer slowly.

4. PowerOnandselecttheTubClean.Then willbe displayedonthedisplay.

willbe displayedonthedisplay.

5. Touch the Start/Pause button to start.

6. After the cycle is complete, leave the door open to allow the washer door opening,

flexible gasket and door glass to dry.

NOTE

NOTE

Do not add any detergent to the detergent compartments.

Excessive suds may generate and leak from the washer.

CAUTION

CAUTION

If there is a child, be careful not to leave the door open for too long.

Door Lock & Detecting

Door Lock & Detecting

“Door Lock”- For safety reasons, the door will lock while machine is in use and the “Door Lock” icon will light up. You can safely open the door after the “Door Lock” icon turns off.

“Door Lock”- For safety reasons, the door will lock while machine is in use and the “Door Lock” icon will light up. You can safely open the door after the “Door Lock” icon turns off.

While"Detecting" is shown on the display the washing machine rotates slowly and detects how much laundry is loaded in the drum.

While"Detecting" is shown on the display the washing machine rotates slowly and detects how much laundry is loaded in the drum.

It will take a short time.

17

Motor |

Fan Motor |

|

|

|

Vibration Sensor |

|

|

1 |

2 |

|

3 |

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

|

3 |

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RD |

BL |

YL |

|

|

|

|

WH BK |

YL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RD |

BL |

|

BK |

YL |

|

|

RD |

BL |

YL |

|

|

|

WH BK |

YL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

1 |

|

2 |

3 |

4 |

|

|

|

1 |

2 |

|

3 |

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>11 11 |

|

1 |

|

2 |

3 |

4 |

|

|

|

1 |

2 |

|

3 |

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>PCBADisplay |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| <![if ! IE]> <![endif]>8765432 9 10 8765432 9 10 CN11 |

|

|

NA5 |

|

|

|

|

|

GY3 |

|

|

|

|

YL3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

GY6 |

|

|

|

|

|

Main PCBA |

|

|

BK |

YL |

NA |

|

|

|

NA4 |

|

|

|

|

|

NA8 |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

BL6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||

|

|

1 |

|

2 |

|

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

5 |

6 |

|

|

|

1 |

2 |

1 |

2 |

1 |

2 |

|

|

1 |

2 |

3 |

4 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

||

|

<![if ! IE]> <![endif]>1 1 |

|

|

|

|

4 |

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

1 |

|

2 |

|

3 |

4 |

5 |

6 |

|

1 |

2 |

3 |

|

4 |

5 |

6 |

|

|

|

1 |

2 |

1 |

2 |

1 |

2 |

|

|

1 |

2 |

3 |

4 |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

|

YL |

|

BK |

OR |

|

|

|

RD |

SB |

BL |

OR |

|

PL |

WH |

|

BL |

YL |

BR RD |

BK |

GR |

YL/RD |

BL |

BK |

|

|

GY |

|

WH |

PL |

|

BL |

YL BK |

|

|||||||||

| <![if ! IE]> <![endif]>18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

OR |

WH PL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

YL |

|

BK |

OR |

|

|

|

|

|

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

YL/RD |

BL |

RD |

BK |

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

1 |

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

YL |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

2 |

3 |

4 |

|

|

|

|

|

|

|

|

|

|||||

|

|

1 |

|

2 |

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 2 3 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

1 |

|

2 |

3 |

4 |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise Filter |

|

|

|

1 |

1 |

|

|

|

|

|

|

|

|

|

|

1 2 3 |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flow meter |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

2 |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Drain |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Door S/W |

|

|

BL |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BR Earth |

BL |

|

|

|

|

|

|

|

BK |

BK |

|

|

|

|

|

|

|

|||||||||

|

|

Pump |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

WH |

WH SB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

|

|

|

|

|

Earth |

|

|

|

|

|

|

|

|

|

Pre |

BK |

BK GY |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

|

|

|

BK |

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

YL |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

BK WH |

BL |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

Main |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

2 |

1 |

2 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet V/V |

|

|

1 |

2 |

1 |

2 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Heater |

|

RD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steam |

Filter Clean |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TH |

1 |

1 |

|

|

BK |

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earth |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

1 |

RD

1 |

1 |

<![endif]>LAYOUT DIAGRAM/PCB WIRING .6

PCB Layout (Main)

PCB Layout (Main)

Dry Heater

PCB POWER

Door Switch

yellow&red:door switch black:door switch orange:door switch

Drain motor

BLDC pump white:U black:V yellow:W

Display

Dry Fan motor

Heater

Heater

Moter Stator Control

Moter Stator Control

V-U/U-W

/W-V →R:8~11Ω

Water sensor

blue&white:thermister

blue:common violet:pressure switch orange:pressure switch

Vibration Sensor

Vibration Sensor

DC Valve

Thermistor

19

7.TROUBLESHOOTING

7-1. CHECK BEFORE SERVICE

1 |

Before servicing ask the customer what the trouble is. |

2 |

Check the adjustments. (Power supply :220-240V~, Removal of transit bolts etc..) |

3 |

Check the troubles referring to the troubleshooting. |

4 |

Decide service steps referring to disassembly instructions. |

5 |

Then, service and repair. |

6 |

Afterservicing,operatetheappliancetoseewhetheritworksOKorNOT. |

7-2. LOAD TEST MODE

1Turn on, and touch ‘Wrinkle Care’ and ‘Delay End’ at the same time in 1 second.

2 The washer must be empty and the controls must be in the off state.

3 Press Power with above two buttons pressed and then buzzer will sound.

4 Press the Start/Pause button repeatedly to cyclethrough the test modes

Numbers |

Check Point |

Display Status |

Remark |

|

|

|

|

0Turnsonalllightandlocksthedoor. PGM Version Information

1 |

Tumbleclockwise |

rpm(42~50) |

|

|

|

|

|

2 |

Lowspeedspin |

rpm (60) |

|

|

|

|

|

3 |

Highspeedspin |

rpm (130~140) |

|

|

|

|

|

4 |

Inletvalveforprewashturnson. |

Water level frequency |

|

|

|

|

|

5 |

Inletvalveformainwashturnson. |

Water level frequency |

|

|

|

|

|

6 |

Inletvalveforhotwaterturnson. |

Water level frequency |

For Hot&Cold Model |

|

|

|

|

7 |

Inletvalveforatomizingturnon. |

Water level frequency |

|

|

|

|

|

8 |

Tumblecounterclockwise |

rpm |

|

|

|

|

|

9 |

Heaterturnsonfor3sec. |

Water temperature |

|

|

|

|

|

10 |

Drainpumpturnson. |

Water level frequency |

|

|

|

|

|

11 |

Off |

- |

|

20

7-3. HOW TO CHECK THE WATER LEVEL FREQUENCY

Touch the Spin and Wrinkle Care button simultaneously. Keeping touch, the digits indicate the water level frequency.

21

Loading...

Loading...