LG EAY64548901, 32LK610BPUA Schematic

LG

LG

2018 UHD 720p LCD TV Training Materials

32LK610BPUA WebOS 4.0 FHD TV POWER SUPPLY TESTING

Using a Simple 3V Jig or

Smart TV Test Jig and Multi-Gender Board

Published October 09th, 2018

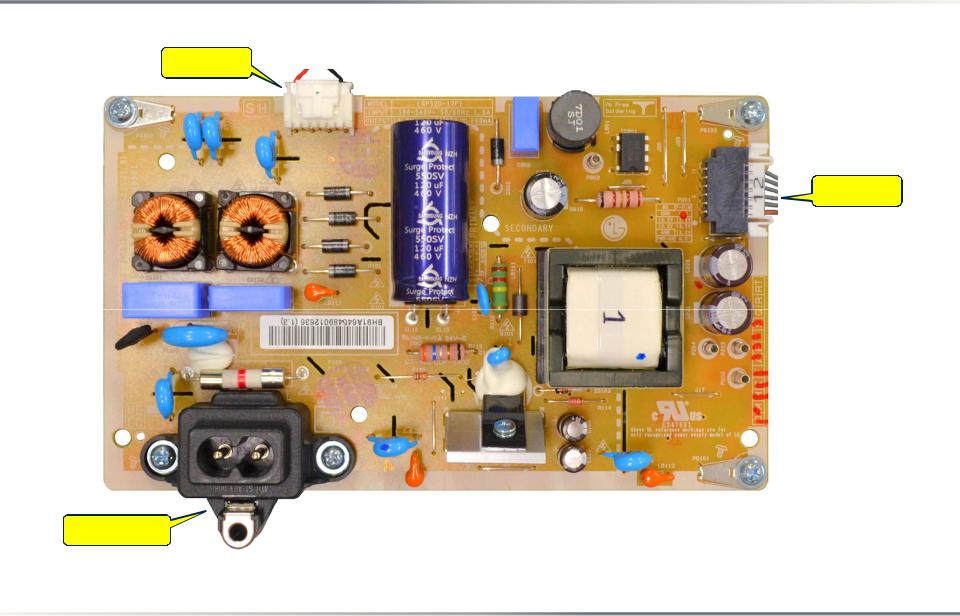

Power Supply (SMPS) Board Layout (EAY64548901)

32LK610BPUA (2018) Power Supply Testing

To Backlights

P801

To Main

Board P2300

P201

SK100

AC In

October 2018 |

Page 01 |

|

LG

LG

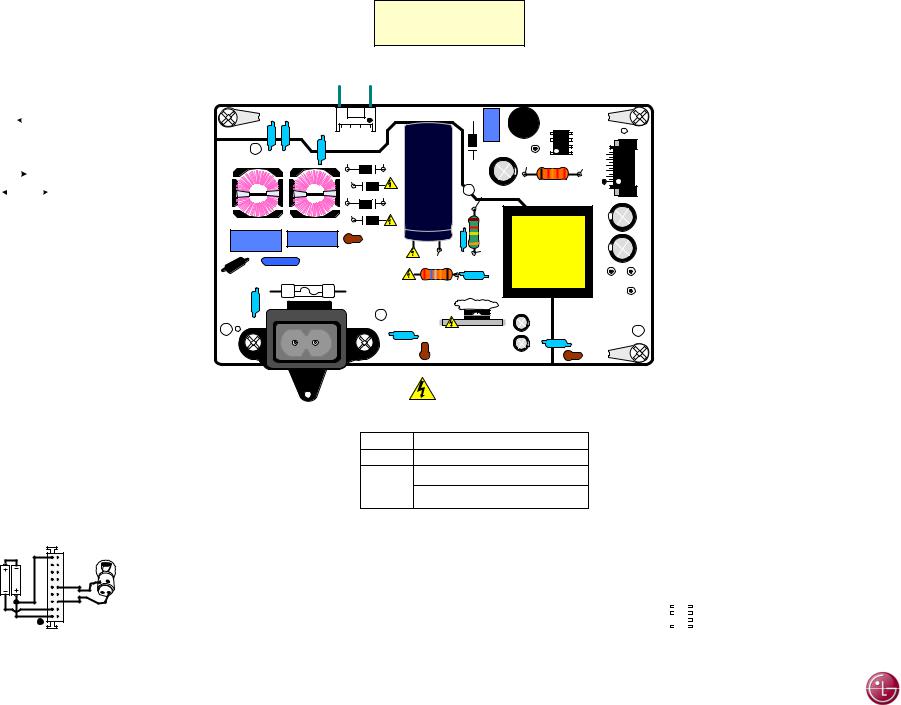

32LK610BPUA SMPS (Power Supply) Drawing

P801 To Panel Backlight Power pin 7.

P801 Pin 1 goes to Backlight Driver

Q801 (Back of SMPS)

LED- (95.8V) 50%

LED+ (118.5V) 50%

P801 "SMPS Board" To "LED Backlights"

PIN |

|

LABEL |

RUN |

Diode |

|||||||

1 |

|

|

|

|

|

|

|

LED- |

110.4V~89V |

OL |

|

|

|

|

|

|

|

||||||

3 |

|

|

|

|

|

|

|

N/C |

n/c |

n/c |

|

5 |

|

|

|

|

|

|

|

N/C |

n/c |

n/c |

|

7 |

|

|

|

|

|

|

|

LED+ |

134.8V~113.2V |

OL |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

In |

|

|

Out |

|

|

Dim to Bright |

|

||||

|

|

|

|

||||||||

AC 1st applied 168V (30sec) then fall to 76V During Stand-By LED+ will fluctuate 76V Main Board Disconnected: 69V

Backlight Setting Dim 0% to Bright 100% Pins 2-6 are not connection.

Direct Lit Backlights (8 LEDs on 1 Array Strip)

SMPS TEST: Forcing SMPS On.

This test requires simple 3V jig.

See below or Multi-Gender Board, use Port P16 (12pin), See Article 9627.

SMPS

P/N: EAY64548901

|

|

|

|

|

|

To Backlight LEDs |

|

|

|

|

|

|

|

P204 |

7.83V (13.20V) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

P203 |

7.83V (13.20V) |

|||

|

|

|

|

|

78V (116V) |

(91V) |

|

|

|

|

|

|

|

P202 |

7.83V (13.20V) |

||

|

|

|

|

|

|

|

|

|

|

|

|

P802 |

60.42V (90V) |

||||

|

|

|

|

|

|

LED+ |

LED- |

|

|

|

|

|

|

|

|||

|

|

CY101 |

|

CY103 |

|

|

|

C806 |

|

|

|

|

P201 |

||||

|

|

|

|

|

|

D802 |

L801 |

IC801 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

CY104 |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

P801 |

|

|

|

|

P802 |

|

|

0V |

|

||

|

|

|

|

|

|

69V |

168V (159V) |

|

|

|

|

|

Gnd |

|

|

||

|

|

|

|

|

|

C601 |

78V |

|

(0.15V) |

|

|||||||

|

|

|

|

|

|

|

D104 |

C205 |

|

||||||||

|

|

|

|

|

|

|

|

(116V) |

|

|

|

|

|

||||

|

|

|

|

|

|

69V |

D103 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

460V |

|

|

|

|

|

R816 |

|

|

|||

|

|

|

|

|

|

69V |

168V (159V) |

|

171V (288V) |

|

|

|

|||||

|

|

|

|

|

|

120uF |

|

SECONDARY |

|

||||||||

|

|

|

|

|

|

69V |

D102 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- + |

|

|

|

|

|

|

|

|

C203 |

|

|

|

|

LF101 |

|

LF102 |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

D101 |

|

|

R112 |

|

|

|

|

|

|||||

|

|

|

CX101 |

CX102 |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

168V |

|

T101 |

|

C201 |

||||||

|

|

|

|

|

|

LB112 |

|

|

|

|

|

||||||

|

|

|

|

|

|

F100 |

|

168V (159V) |

C107 |

(159V) |

|

|

|

||||

|

1 |

|

VA100 |

|

|

C108 |

|

|

|

|

|

P204 |

P203 |

||||

|

1 |

|

5A / 250V |

|

|

|

|

|

|

|

|

|

|||||

H |

0 |

|

|

|

|

R113 |

(0V) |

|

|

|

|

|

|

|

P202 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

CY102 |

|

|

|

PRIMARY |

Can’t Read |

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

CY111 |

|

|

|

|

C106 |

Chassis Gnd |

||||

|

|

|

|

|

|

|

Q101 |

|

C105 |

CY111 |

|

||||||

Using 3V Simple Jig: Remove AC Power. Disconnect P2300 on Main Board.

Test 1: Using a 3V jig, Jump 3V to pin 1 (PWR_ON). Apply AC Power. (No Backlights in Test 1)

(Pins 4-8) rises to 13.13V. Backlight Power LED+ 114.8V. LED95.6V. PDIM will be 3.42V. Remove AC Power.

Test 2: Using a 3V jig, Jump 3V to pin 11 (DRV_ON). Place a 12V Light Bulb on 13.2V to Gnd.

Apply AC Power. All Voltages should be produced. (13.2V) 12.95V to Main and

“LED+” 119.2V to the Backlights), “LED-“ 94.3V.

This will also force the Backlights to come on. PDIM will be 3.77V

SK100

AC

LB110 |

LB113 |

|

Hot Gnd

(Shock Hazard)

VOLTAGE LABEL

MODEL LGP32D-17F1

INPUT AC100V~240Vac 50/60Hz. 1.5A

13.2V = 1.8A

OUTPUT

31V – 660mA

Test 2 |

P201 |

|

|

11 |

12 |

|

|

AA 2 |

|

10 |

Solder 1157 |

(3V) |

|

|

|

3 |

6 |

Solder |

|

|

|

|

|

Test 1 |

1 |

2 |

|

Test Set Up |

|

||

Note:

P201 still inserted. P2300 removed. Use P2300 side to insert needles from the Jig.

Note: STBY 7.83V (Pins 4-8) Must be present when AC is applied before beginning test which indicates Standby voltage is OK.

Special Note:

The 13.2V Line “Must” be loaded using a 12V light Bulb when using the 3V Simple Jig).

3V SIMPLE JIG: Made from 2 (AA) batteries. Jump + to – on one side.

On the other side, solder two red wires (needle tipped) to the + and one black wire (needle tipped) to the – side.

See Article 8979

Note: For Ground you can use Panel Back.

32LK610BPUA (2018) Power Supply Testing

Note: The Smart Test Jig and Multi-Gender Board “Can” be used in this model for testing. Use Port P16. 13.2V Line does not have to be loaded in this case,

Jig Switch set to 24V / LCD Power (See Article 9627).

P201 "SMPS Board" To P2300 "MAIN Board" |

|

|

|||||

|

|

|

|

|

|

|

MAIN |

PIN |

LABEL |

STBY |

|

RUN |

|

Diode |

|

|

|

|

|

|

|

|

12 |

(3) 12 |

P-DIM |

0V |

|

*0.16V-3.18V |

|

OL |

|

(2) 11 |

MS (Drv_On) |

0V |

|

1.97V |

|

OL |

11 |

9-10 |

Gnd |

Gnd |

|

Gnd |

|

Gnd |

9-10 |

4-8 |

13.2V |

7.83V |

|

13.10V |

|

OL |

8-4 |

3 |

Gnd |

Gnd |

|

Gnd |

|

Gnd |

3 |

2 |

N/C |

n/c |

|

n/c |

|

n/c |

2 |

(1) 1 |

PWR_ON |

0V |

|

3.35V |

|

1.20V |

1 |

|

|

|

*Dim to Bright |

|

|

||

Voltages below for Backlight Power (LED+) are with Main disconnected and using Simple 3V Jig to supply turn-on commands on-at-a-time.

(Special Note: 13.2V Line “Must” be loaded using a 12V light Bulb when using the 3V Simple Jig).

(1)PWR-On Pin 1: Turns on 13.2V to the Main. No backlights at this time. Backlight Power is 114.6V.

(2)MS (DRV_On) Pin 11: Turns on the Backlights. Backlight power goes to 119.3V.

Voltages given below for PDIM are with Main connected and receiving normal Digital Antenna Signal.

(3) PDIM Pin 12: Will vary according to incoming video IRE level and OSD Backlight setting Output from the Video Processor. And the Backlight settings in the Customer’s Menu 0% TO 100%. It is then routed out P1001 to P201 and sent to the LED Driver IC on the Back of the SMPS. The Range is: Dim 0.17V ~ Bright 3.28V. (1.76V at 50%) PDIM is actually a 3.44V p/p pulse (PWM Control).

|

|

|

Pin |

Run |

Pin |

Run |

IC801 |

4) |

0.86V |

5) |

3.19V |

||

|

|

|

3) |

13.1V |

6) |

Gnd |

|

|

|

||||

|

|

|

2) |

n/c |

7) |

1.95V |

|

|

|

1) |

89V |

8) |

Gnd |

October 2018 |

Page 02 |

LG |

|

Loading...

Loading...