Page 1

MC-1

Digital Controller

Service

Manual

Page 2

MC-1 Service Manual

Precautions

Save these instructions for later use.

Follow all instructions and warnings marked on the unit.

Always use with the correct line voltage. Refer to the manufacturers operating instructions for power requirements. Be advised that

different operating voltages may require the use of a different line cord and/or attachment plug.

Do not install the unit in an unventilated rack, or directly above heat producing equipment such as power amplifiers. Observe the

maximum ambient operating temperature listed in the product specification.

Slots and openings on the case are provided for ventilation; to ensure reliable operation and prevent it from overheating, these

openings must not be blocked or covered. Never push objects of any kind through any of the ventilation slots. Never spill a liquid of

any kind on the unit.

This product is equipped with a 3-wire grounding type plug. This is a safety feature and should not be defeated.

Never attach audio power amplifier outputs directly to any of the unit’s connectors.

To prevent shock or fire hazard, do not expose the unit to rain or moisture, or operate it where it will be exposed to water.

Do not attempt to operate the unit if it has been dropped, damaged, exposed to liquids, or if it exhibits a distinct change in performance

indicating the need for service.

This unit should only be opened by qualified service personnel. Removing covers will expose you to hazardous voltages.

This triangle, which appears on your component, alerts you to the presence of uninsulated, dangerous voltage inside the

enclosure… voltage that may be sufficient to constitute a risk of shock.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

This triangle, which appears on your component, alerts you to important operating and maintenance Instructions in this

accompanying literature.

Notice

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the

manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply with

the limits for a Class B computing device in accordance with the specifications of Part 15 of FCC Rules, which are designated to

provide reasonable protection against such interference in a residential installation. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause interference to radio or television reception, which can be

determined by turning the equipment OFF and ON, the user is encouraged to try to correct the interference by one or more of the

following measures:

If necessary, the user should consult the dealer or an experienced radio/television technician for additional suggestions. The user may

find the following booklet prepared by the Federal Communications Commission helpful:

This booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de Ia

class B prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

Reorient the receiving antenna

Relocate the computer with respect to the receiver

Move the computer away from the receiver

Plug the computer into a different outlet so that the computer and receiver are on different branch circuits.

“How to identify and Resolve Radio/TV Interference Problems.

Copyright © 1999-2002 Lexicon, Inc.

All Rights Reserved

Lexicon Inc. ● 3 Oak Park ● Bedford, MA 01730-1441 ● Tel (781) 280-0300 ● Customer Service Fax (781) 280-0499

Lexicon Part # 070-14397 Rev 0

Printed in the United States of America

Page 3

Safety Suggestions

Lexicon

Read Instructions Read all safety and operating

instructions before operating the unit.

Retain Instructions Keep the safety and

operating instructions for future reference.

Heed Warnings Adhere to all warnings on the

unit and in the operating instructions.

Follow Instructions Follow operating and use

instructions.

Heat Keep the unit away from heat sources such

as radiators, heat registers, stoves, etc., including

amplifiers which produce heat.

Ventilation Make sure that the location or

position of the unit does not interfere with its

proper ventilation. For example, the unit should

not be situated on a bed, sofa, rug, or similar

surface that may block the ventilation openings;

or, placed in a cabinet which impedes the flow of

air through the ventilation openings.

Wall or Ceiling Mounting Do not mount the unit

to a wall or ceiling except as recommended by

the manufacturer.

Power Sources Connect the unit only to a power

supply of the type described in the operating

instructions, or as marked on the unit.

Grounding or Polarization* Take precautions

not to defeat the grounding or polarization of the

unit’s power cord.

*Not applicable in Canada.

Power Cord Protection Route power supply

cords so that they are not likely to be walked on

or pinched by items placed on or against them,

paying particular attention to cords at plugs,

convenience receptacles, and the point at which

they exit from the unit.

Nonuse Periods Unplug the power cord of the

unit from the outlet when the unit is to be left

unused for a long period of time.

Water and Moisture Do not use the unit near

water — for example, near a sink, in a wet

basement, near a swimming pool, near an open

window, etc.

Object and liquid entry Do not allow objects to

fall or liquids to be spilled into the enclosure

through openings.

Cleaning The unit should be cleaned only as

recommended by the manufacturer.

Servicing Do not attempt any service beyond

that described in the operating instructions. Refer

all other service needs to qualified service

personnel.

Damage requiring service The unit should be

serviced by qualified service personnel when:

the power supply cord or the plug has been

damaged, objects have fallen, or liquid has been

spilled into the unit, the unit has been exposed to

rain, the unit does not appear to operate normally

or exhibits a marked change in performance, the

unit has been dropped, or the enclosure

damaged.

Page 4

MC-1 Service Manual

Page 5

Lexicon

Table of Contents

Chapter 1 Reference Documents, Required Equipment............................. 1-1

Reference Documents............................................................................................................................. 1-1

Required Equipment................................................................................................................................ 1-1

Tools .................................................................................................................................................... 1-1

Test Equipment.................................................................................................................................... 1-1

Chapter 2 General Information ................................................................... 2-3

Periodic Maintenance .............................................................................................................................. 2-3

Ordering Parts ......................................................................................................................................... 2-3

Returning Units to Lexicon for Service .................................................................................................... 2-3

Chapter 3 Specifications............................................................................. 3-1

Chapter 4 Performance Verification............................................................ 4-1

Initial Inspection:...................................................................................................................................... 4-1

Functional Tests: ..................................................................................................................................... 4-1

Analog Input Test................................................................................................................................. 4-1

Audio Performance Verification: .............................................................................................................. 4-2

Input to Record Outputs Test............................................................................................................... 4-2

Input to Zone 2 Output Test ................................................................................................................. 4-3

Main Audio Output Test ....................................................................................................................... 4-4

Digital Input to Analog Output Tests .................................................................................................... 4-4

Video Input / Output Tests....................................................................................................................... 4-5

Composite Input to Composite Monitor / Records (1 and 2) Outputs Tests......................................... 4-5

S-Video Input to S-Video Monitor / Records (1 and 2) Outputs Tests.................................................. 4-6

Expansion Port Digital Input to Analog Output Test ................................................................................ 4-6

Setup.................................................................................................................................................... 4-7

Test...................................................................................................................................................... 4-7

Digital Output Test................................................................................................................................... 4-7

Setup.................................................................................................................................................... 4-7

Test...................................................................................................................................................... 4-8

Lexicon Audio Precision ATE Summary .............................................................................................. 4-9

Chapter 5 Troubleshooting ......................................................................... 5-1

V4 Release Notes.................................................................................................................................... 5-1

V1.00 bug descriptions: ....................................................................................................................... 5-1

Diagnostics .............................................................................................................................................. 5-1

Diagnostic Reporting............................................................................................................................ 5-1

VFD Display: ........................................................................................................................................ 5-2

Front Panel LEDs:................................................................................................................................ 5-2

Serial Debug Pot:................................................................................................................................. 5-2

Error Log: ............................................................................................................................................. 5-2

Diagnostic Control/Interface:................................................................................................................ 5-3

Power On Diagnostics: ........................................................................................................................ 5-3

Extended Diagnostics .......................................................................................................................... 5-6

Pre-Burn in Tests ................................................................................................................................. 5-7

Functional Suite ................................................................................................................................... 5-7

Burn-In Loop ........................................................................................................................................ 5-9

Troubleshooting Problems..................................................................................................................... 5-10

Initial Inspection ................................................................................................................................. 5-11

User Interface Problems: ................................................................................................................... 5-12

Audio Problems.................................................................................................................................. 5-12

Video Problems.................................................................................................................................. 5-13

Power Supply..................................................................................................................................... 5-14

Video Subcarrier Calibration .............................................................................................................. 5-15

Restoring Defaults ............................................................................................................................. 5-16

Page 6

MC-1 Service Manual

Chapter 6 Parts List .................................................................................... 6-1

MC1 MAIN BOARD ASSEMBLY..............................................................................................................6-1

MC1 DIGITAL INPUT BOARD ASSEMBLY .............................................................................................6-4

MC1 RCA EXPANSION BOARD ASSEMBLY .........................................................................................6-4

MC1 VIDEO BOARD ASSEMBLY............................................................................................................6-4

MC1 RCA BOARD ASSEMBLY ...............................................................................................................6-6

MC1 ENCODER BOARD ASSEMBLY.....................................................................................................6-6

MC1 IR BOARD ASSEMBLY ...................................................................................................................6-6

MC1 POWER SWITCH BOARD ASSEMBLY ..........................................................................................6-6

DTS BOARD ASSEMBLY ........................................................................................................................6-6

MC1 CHASSIS/MECHANICAL ................................................................................................................6-7

MC1 PACKAGING/MISCELLANEOUS ....................................................................................................6-8

MC1 POWER CORDS .............................................................................................................................6-8

MC1 RACK MOUNT OPTION..................................................................................................................6-8

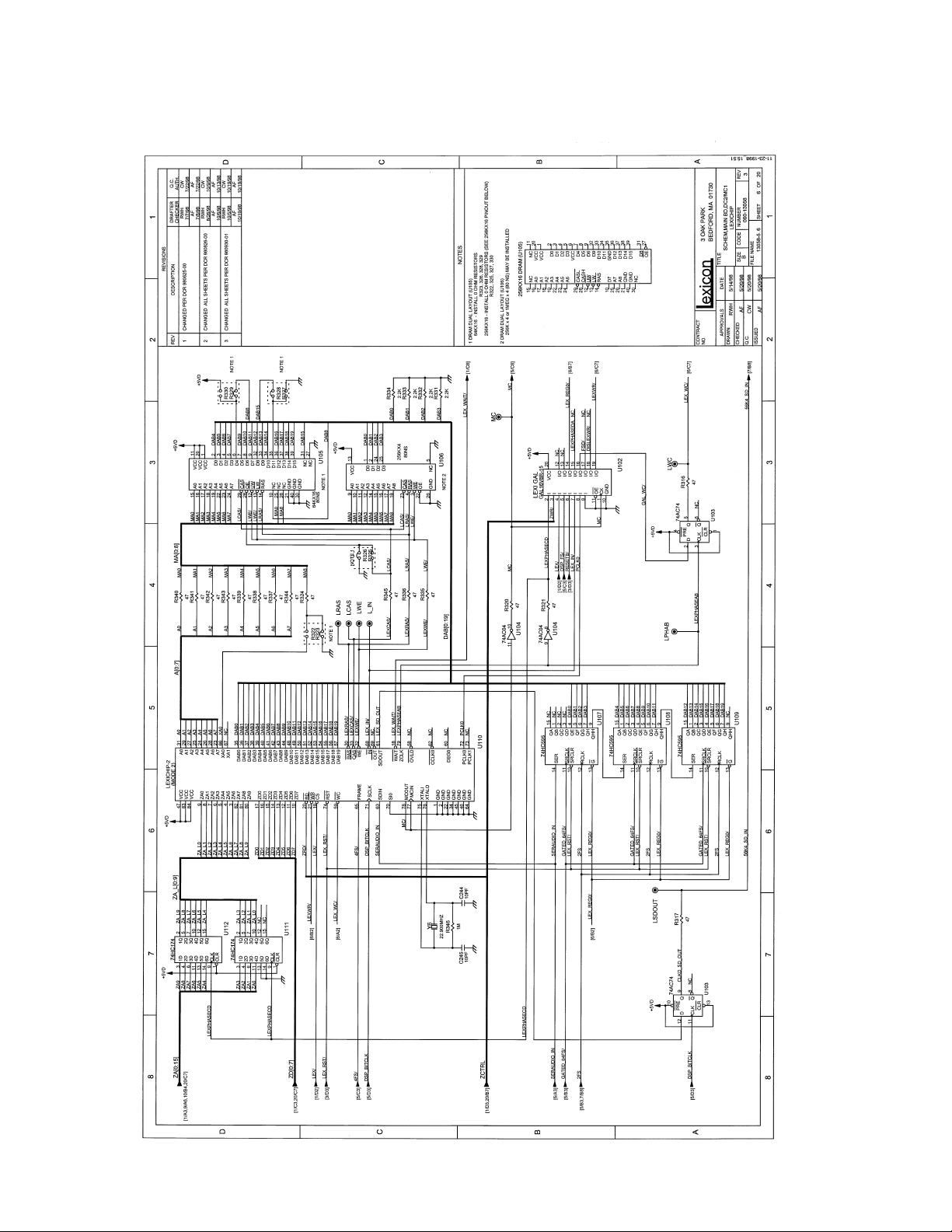

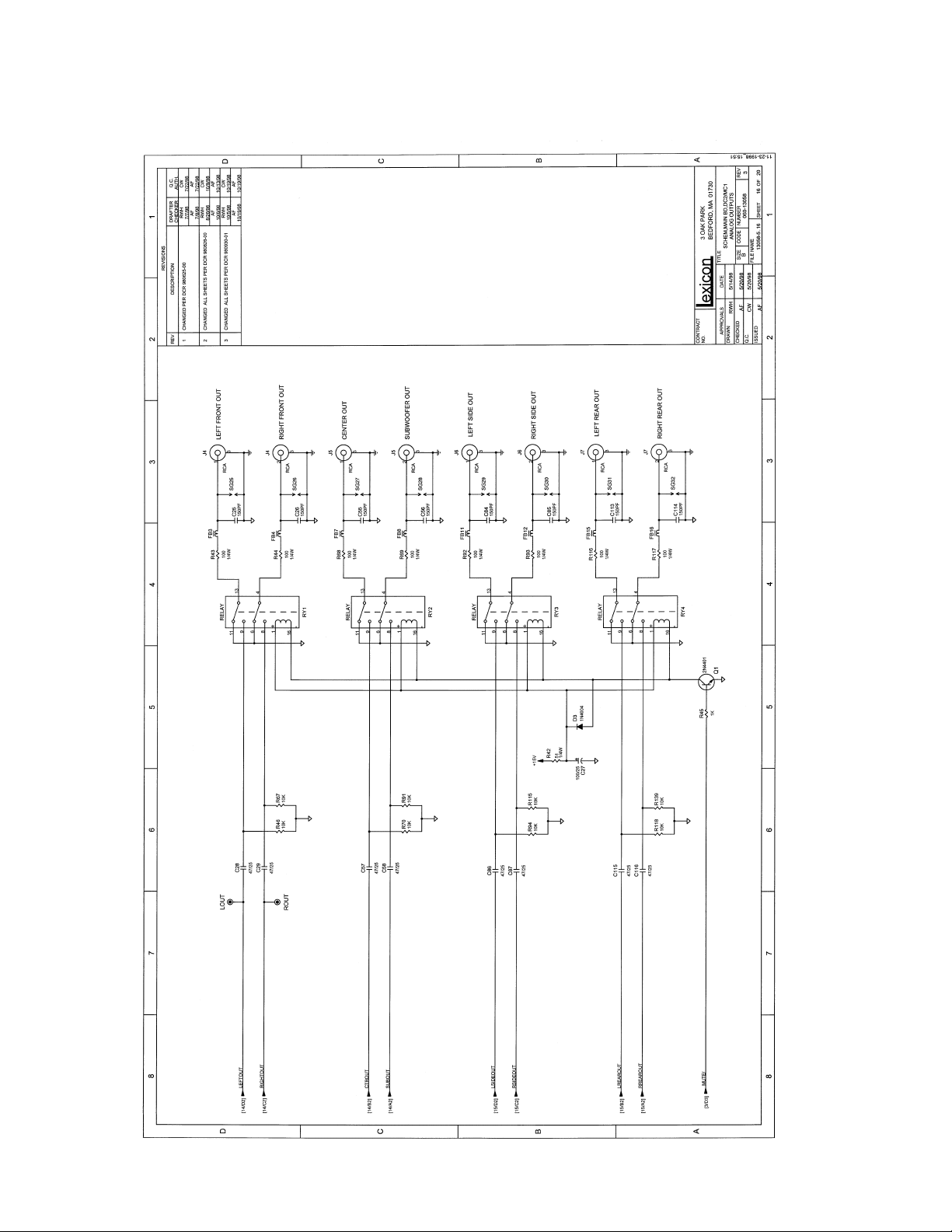

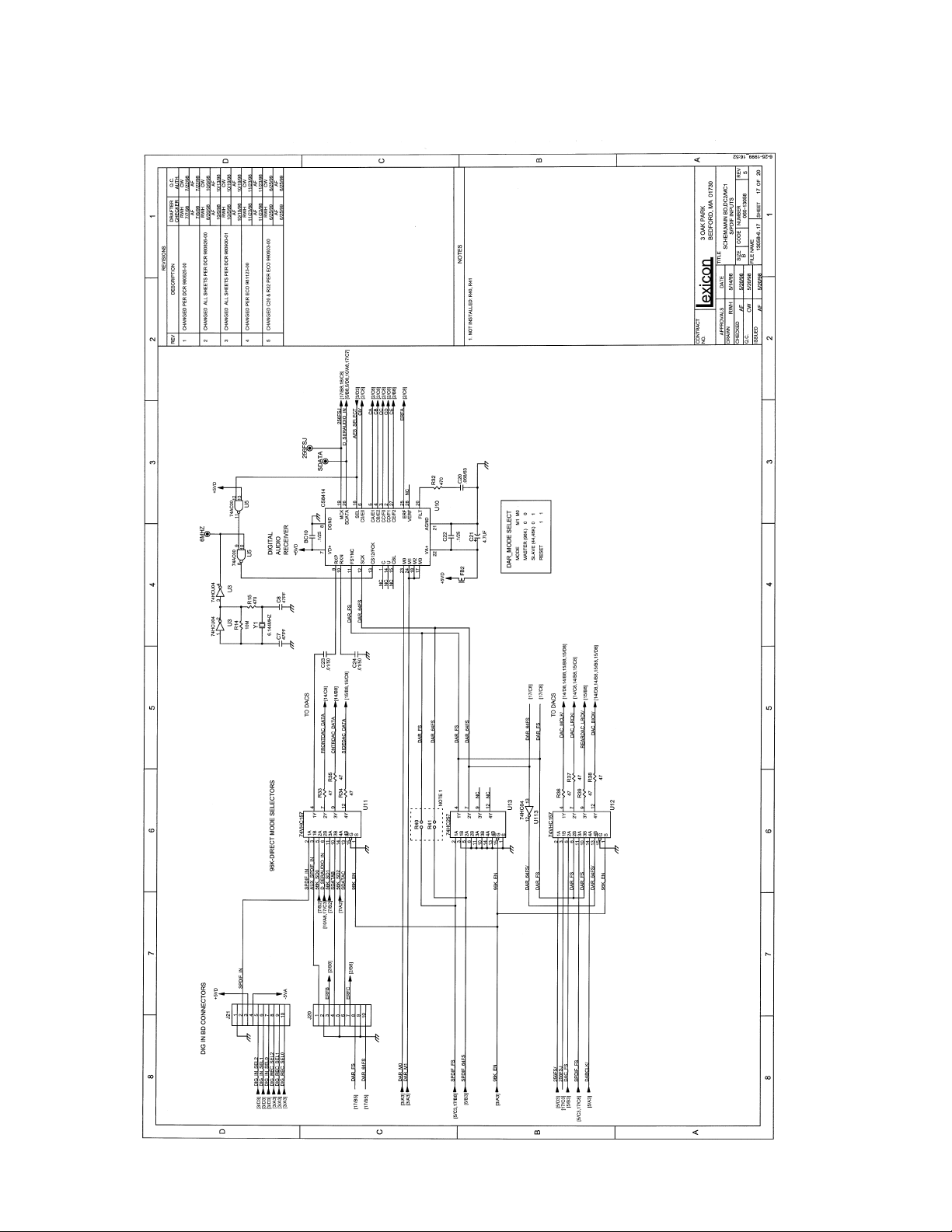

Chapter 7 Drawings .................................................................................... 7-1

Schematics...............................................................................................................................................7-1

Drawings ..................................................................................................................................................7-1

Page 7

Lexicon

Chapter 1 Refe rence Documents, Required Equipment

Reference Documents

MC-1 Owner's Manual - Lexicon P/N 070-13278

MC-1 Quick Reference Guide - Lexicon P/N 070-13279, latest revision

Required Equipment

Tools

The following is a minimum suggested technician's tool kit required for performing disassembly, assembly

and repairs:

• Clean, antistatic, well lit work area.

• (1) #1 Phillips tips screwdriver

• (1) Nut driver starter size #2

• (1) 7/16" Nut drive

• Solder: 63/37 - Tin/Lead Alloy composition, low residue, no-clean solder.

• Magnification glasses and lamps

• SMT Soldering / Desoldering bench-top repair station

Test Equipment

The following is a minimum suggested equipment list required to perform the proof of performance tests.

• A high quality A/V source playback system

• Compact Disc player or other source with 44.1kHz sample rate, digital coax and optical

outputs.

• DVD Player or other source with 48kHz kHz sample rate, digital coax and optical outputs.

• 2 full range speakers

• DVD player with both Composite and S-Video outputs

• Color TV Monitor with both Composite and S-Video inputs

• Cables: (dependent on your signal source)

• 1 single-ended, shielded 75-ohm digital audio cable with RCA plugs on both ends for

connecting the outputs of the Disc player to the digital Coax 1 input of the MC-1.

• 2 single-ended, shielded audio cables with RCA plugs on both ends for connecting the

outputs of the Disc player to the inputs of the MC-1.

• 2 single-ended shielded audio cables with RCA plugs on one end and appropriate

connectors on the other end to the input of the stereo amplifier.

• Audio input Y cable with 2 RCA plugs on the Y end and an appropriate connector to the

Low Distortion Oscillator

• 1 single-ended, shielded audio cable with a RCA connector on one end and an appropriate

connector on the other for connection to the low distortion oscillator.

• 1 single-ended shielded audio cable with RCA connector on one end and appropriate

connector on the other end to connect to the input connector of the THD+N distortion

analyzer.

• 2 single-ended, shielded 75 ohm video RCA style cables

• 2 single-ended, shielded 75 ohm video S-Video style cables

• Low distortion analog oscillator with audio bandpass or 20k - 30khz Low Pass Filter;

Single-ended 600 ohm or less output < .005% THD

• Analog distortion analyzer and level meter

• 100 MHz oscilloscope or better

• Digital distortion analyzer & digital function generator (e.g. Stanford Research Systems

Model DS360 or Audio Precision System 1 with DSP Option /System 2 - optional).

• MC-1 Remote Control, Lexicon P/N - 750-13221

1-1

Page 8

MC-1 Service Manual

• DMM (Digital Multi-Meter) - 3 1/2 digit with +/- 0.5% accuracy.

• (1) variable AC supply, 2 amp minimum.

• (1) digital multimeter (DMM) 3.5 digital, 0.5%, or better accuracy.

• (1) frequency counter with a 7 digit accuracy

Page 9

Lexicon

Chapter 2 Gene ral Information

Periodic Maintenance

Under normal conditions the MC-1 system requires minimal maintenance. Use a soft, lint-free cloth slightly

dampened with warm water and mild detergent to clean the exterior surfaces of the connector box.

Do not use alcohol, benzene or acetone-based cleaners or any strong commercial cleaners. Avoid

using abrasive materials such as steel wool or metal polish. It the unit is exposed to a dusty environment, a

vacuum or low-pressure blower may be used to remove dust from the unit's exterior.

Ordering Parts

When ordering parts, identify each part by type, price and Lexicon Part Number. Replacement parts can be

ordered from:

LEXICON, INC.

3 Oak Park

Bedford, MA 01730-1441

Telephone: 781-280-0300; Fax: 781-280-0499; email: csupport@lexicon.com

ATTN: Customer Service

Returning Units to Lexicon for Service

Before returning a unit for warranty or non-warranty service, consult with Lexicon Customer

Service to determine the extent of the problem and to obtain Return Authorization. No equipment

will be accepted without Return Authorization from Lexicon.

If Lexicon recommends that a MC-1 be returned for repair and you choose to return the unit to Lexicon for

service, Lexicon assumes no responsibility for the unit in shipment from the customer to the factory,

whether the unit is in or out of warranty. All shipments must be well packed (using the original packing

materials if possible), properly insured and consigned, prepaid, to a reliable shipping agent.

When returning a unit for service, please include the following information:

• Name

• Company Name

• Street Address

• City, State, Zip Code, Country

• Telephone number (including area code and country code where applicable)

• Serial Number of the unit

• Description of the problem

• Preferred method of return shipment

• Return Authorization #, on both the inside and outside of the package

Please enclose a brief note describing any conversations with Lexicon personnel (indicate the name of the

person at Lexicon) and give the name and telephone daytime number of the person directly responsible for

maintaining the unit.

Do no include accessories such as manuals, audio cables, footswitches, etc. with the unit, unless

specifically requested to do so by Lexicon Customer Service personnel.

2-3

Page 10

Page 11

Chapter 3 Spec ifications

Inputs

Audio: 8 stereo (RCA) pairs

Video: 8 composite (RCA), 8 S-video

Digital: 8: 5 coaxial (RCA), 3 optical (TosLink), conforms to IEC-958, S/PDIF standards;

3 Expansion Ports for 960kHz, 24-bit PCM digital audio

Outputs

Audio: 8 main (RCA): Left, Center, Right, L&R Sides, Subwoofer

3 stereo pairs: 2 Record, 1 Zone 2

Video: 3 composite (RCA), 3 S-video: 1 Monitor, 2 Record

Audio

A/D Conversion: 24-bit Delta-Sigma

D/A Conversion: 24-bit Delta-Sigma

Frequency Response: 10 Hz - 20kHz, +0.2dB, -0,2dB, referenced to 1 kHz

THD+Noise: Less than 0.005% @ 1 kHz, maximum output level

Dynamic Range: 105dB minimum, 22kHz bandwidth, referenced to 1 kHz @ 60dB below

maximum output level

Signal-to-Noise Ratio: 105dB minimum, 22kHz bandwidth, referenced to 1 kHz @ maximum

output level

Input Level: 2 Vrms for maximum output (with Input Gain=0dB); 200mVrms for Dolby

Level

Input Impedance: 100 kΩ in parallel with 150pF

Output Level: 6 Vrms (System Volume = +12dB)

Output Imepdance: 100Ω in parallel with 150pF

Lexicon

Video

NTSC M, PAL and SECAM-compatible

Output Level: 1.0 V peak-to-peak

Impedance: 75Ω

Input Return Loss: 40dB

Differential Gain: <0.5%

Differential Phase: <0.5°

Frequency Response: 10 Hz to 10 MHz ±0.1dB

Bandwidth: >25 MHz

K Factor: <0.3%

Gain: ±0.15dB

Signal/Noise Ratio: >70dB

Power Requirements

90-250 VAC, 50-60 Hx, 35 Watts (universal input); IEC detachable power cord

Dimensions

17.3"W x 11.5"D x 3.6"H (440 x 292 x 92mm)

Rack Mounted: 19.0"W x 11.5"D x 3.5"H (483 x 292 x 89mm)

Weight: 10.8 lbs. (4.9kg)

Environment

Operating Temperature: 32° to 95°F (0° to 35°C)

Storage Temperature: -22° to 167°F (-30° to 75°C)

Relative Humidity: 95% max without condensation

Remote Control

Hand-held, battery-powered infrared remote control unit, uses 2 AA batteries

Specifications subject to change without notice.

3-1

Page 12

Page 13

Lexicon

Chapter 4 Perfo rmance Verification

This section describes a quick verification of the operation of the MC-1 and the integrity of its analog and

digital audio signal paths.

Initial Inspection:

1. Check each front panel switch for smooth mechanical operation and verify that the display

acknowledges its functions.

2. Verify that all of the front panel LEDs light at power up.

3. Check all the buttons on the remote and verify that the display is responding to all the remote

commands.

Functional Tests:

Analog Input Test

Setup

1. Connect the oscillator outputs to the Left and Right inputs of the VCR input on the rear panel of the MC1

2. Connect the MC-1 Left and Right Front audio outputs to the amplifier Left and Right inputs and the

outputs of the amplifier to a pair of speakers.

3. Put the MC-1 into its Extended Diagnostics mode by applying power to the MC-1 while pressing and

holding down both the front panel REC/ZONE2 and EFFECT ▼ buttons until Extended Diagnostics

appears on the display.

4. Press the TAPE button on the remote to select Audio Test.

5. Press the VCR button on the remote. AUDIO Test 13 will appear in the display which confirms the VCR

input is connected to all 8 audio outputs of the MC-1.

6. Slowly increase the volume on the amplifier to a comfortable listening level for the speaker .

7. Sweep the oscillator from 20Hz to 20kHZ you should hear clean audio coming from both speakers.

8. Power off the amplifier and move the cables from the Front Left / Right outputs to the Center left and

Subwoofer right outputs. Repeat the oscillator sweep again checking for clean audio from the speakers.

Repeat this step for the remaining outputs on the MC-1.

9. In order to test the remaining MC-1 inputs, power off the amplifier and the MC-1. Reconnect the MC-1

Front Left / Right outputs to the amplifier.

10. Move the cables from the MC-1 VCR Left / Right inputs to the DVD Left / Right inputs.

11. Press the DVD button on the remote. The display will read AUDIO Test 12, which will confirm the DVD

input is connected to all 8 audio outputs of the MC-1.

12. Repeat steps 6 to 8 above for the DVD input. When done repeat the test for the remaining inputs.

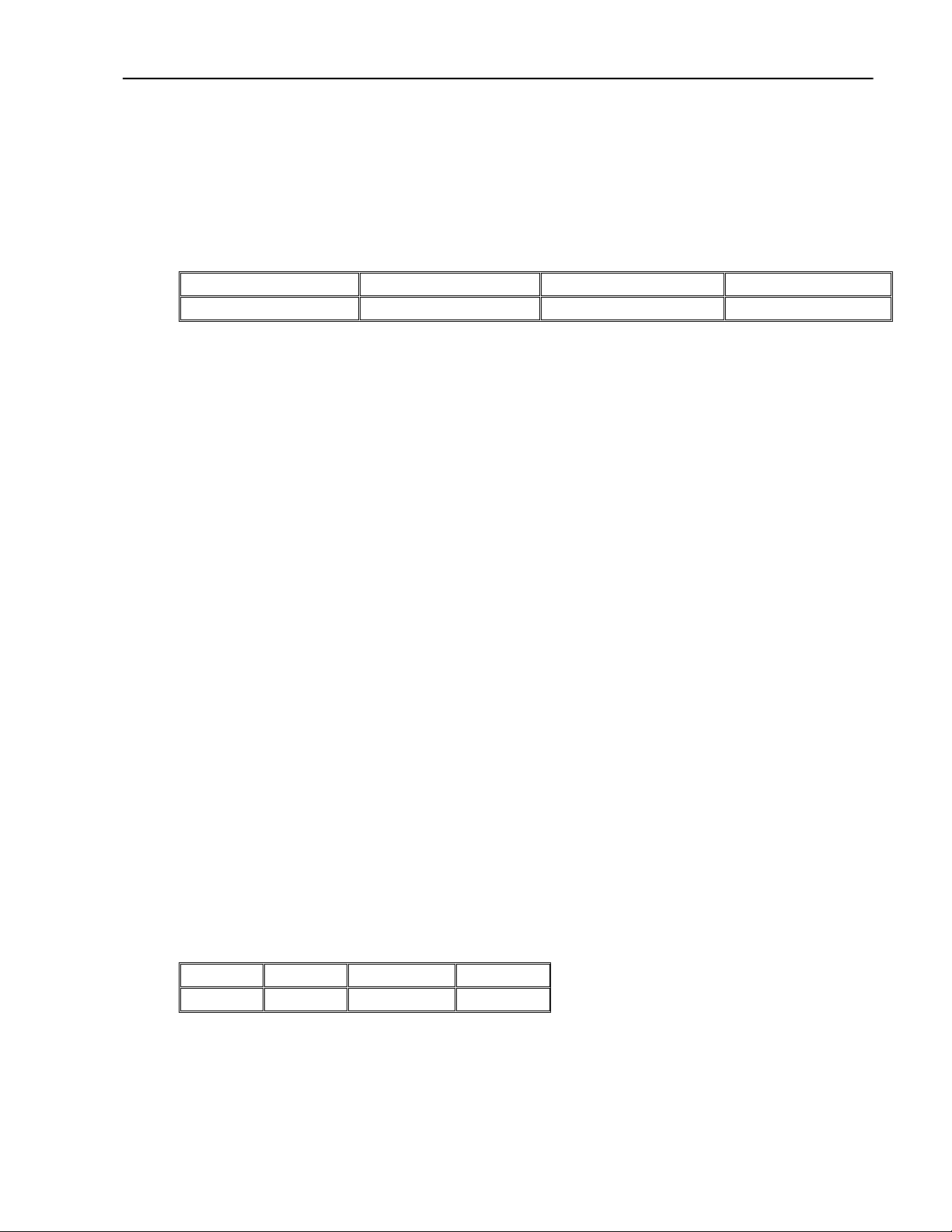

13. The following ID#s will confirm which inputs you have selected for test.

VCR: 13 DVD: 12 V-DISC: 11 TV: 10

AUX: 0F CD: 0E TUNER: 0D TAPE: 0C

14. Press and hold the Shift button on the remote then press the Done button once. This will place the MC1 at the top of the Extended Diagnostics Menu. Releasing the Shift button and then pressing the DONE

button one more time will then cause the MC-1 to exit the Extended Diagnostics and drop into normal

operation.

Listening Test

1. Power up the MC-1 in normal operating mode.

2. Connect a music source to the Left / Right VCR audio inputs of the MC-1.

3. Press "PARTY" on the remote control.

4-1

Page 14

MC-1 Service Manual

4. Connect the MC-1 Left /Right Front audio outputs to the amplifier Left / Right inputs and the outputs of

the amplifier to a pair of speakers.

5. Slowly increase the volume level on the amplifier to a comfortable listening level and verify that the

audio is free from noise, distortion, or any other audio irregularities.

6. Repeat for all other Main outputs.

Mute Test

For proper Mute testing, the MC-1 must be set to the Full Mute Setting.

1. Set the MC-1 up as described in the listening test above.

2. On the MC-1 remote, press SELECT to access the Main Menu.

3. Press Menu ▼ until the display reads: Main Menu/Setup.

4. Press SELECT to enter the top of the Setup Menu.

5. Press Menu ▼ until the Outputs Level Menu is displayed, then press SELECT.

6. Press Menu ▼ until the MUTE LEVEL -30dB is displayed.

7. Press SELECT to display: System Mute Assign/ -30dB.

8. Press Menu ▼ until the Full Mute is displayed.

9. Press SELECT.

10. Press DONE four times to place the MC-1 back into normal operation.

11. With Audio running through the MC-1 press the MUTE button on the remote and verify that the audio

signal disappears.

12. Press the MUTE button again and verify that the audio signal returns.

13. Repeat steps 1 to 7 above and reset the MUTE LEVEL to –30dB.

Audio Performance Verification:

Performing these tests assures that the audio signal paths in the MC-1 are functional and that the MC-1

meets published specifications. These tests verify the functionality of all main audio paths. The performance

of the A/D and D/A conversion circuitry are checked through gain, frequency response, THD+N, and S/N

Ratio tests.

Input to Record Outputs Test

Setup

1. Attach the audio input cable between the Low Distortion Oscillator and the MC-1 Left VCR input.

2. Attach the audio output cable between the MC-1 Left Record output and the input of the Distortion

Analyzer.

3. Put the MC-1 into Extended Diagnostics mode by powering up the MC-1 while pressing and holding

down both the front panel REC/ZONE2 and EFFECT buttons until Extended Diagnostics appears on

the display.

4. Press the TAPE button on the remote. The display will read AUDIO Test.

5. Press and hold the Shift button on the remote, then press the Off button. The # 99 will then be

displayed next to AUDIO Test.

6. Press and hold the RECORD button on the remote, then press the VCR button. The # 53 will then be

displayed confirming the VCR input is now set to the RECORD outputs.

Tests

1. Apply a 1kHz signal @ +12dB (+4 Vrms) to the input channel.

2. Set the scale on the Distortion Analyzer to measure +12dBV (+ 4Vrms ) signal level.

3. Turn all filters off on the Analyzer.

4. Verify that the output level from the MC-1 is +12dBV (+4Vrms) +0.2/-0.3dBV.

5. Adjust the scale on the Distortion Analyzer to measure 0.005% THD+N and turn on the 30kHz low pass

or audio bandpass filter.

6. Verify that the THD+N measured is less than 0.005%.

7. Set the scale on the Distortion Analyzer to measure +12dBV (+ 4Vrms) signal level.

4-2

Page 15

Lexicon

8. Use the output level from Step 4 above for a 0dB reference to check frequency response.

9. Turn the filter off. Next sweep the oscillator frequency from 10Hz to 20kHz.

10. Verify that the signal level is within +0.2/-0.3dB of reference level over the frequency band.

11. Set the scale on the Distortion Analyzer to measure –90dBr signal level with the filter on. Turn off the

oscillator to the MC-1 and verify a noise level measurement less than -100dBr.

12. Swap the cables from the Left VCR input to the Right and the Left RECORD output to the Right.

13. Repeat steps 1 to 11 above for the Right RECORD output.

14. To test the remaining inputs of the MC-1 to the RECORD outputs each path must be set with the

remote control. Press and hold the RECORD button, then press one of the analog input buttons to set

up the next input to RECORD output path. Below are the verification #’s next to their button titles that

indicate the path has been enabled. After a new input is selected the procedure above needs to be

repeated to test the path.

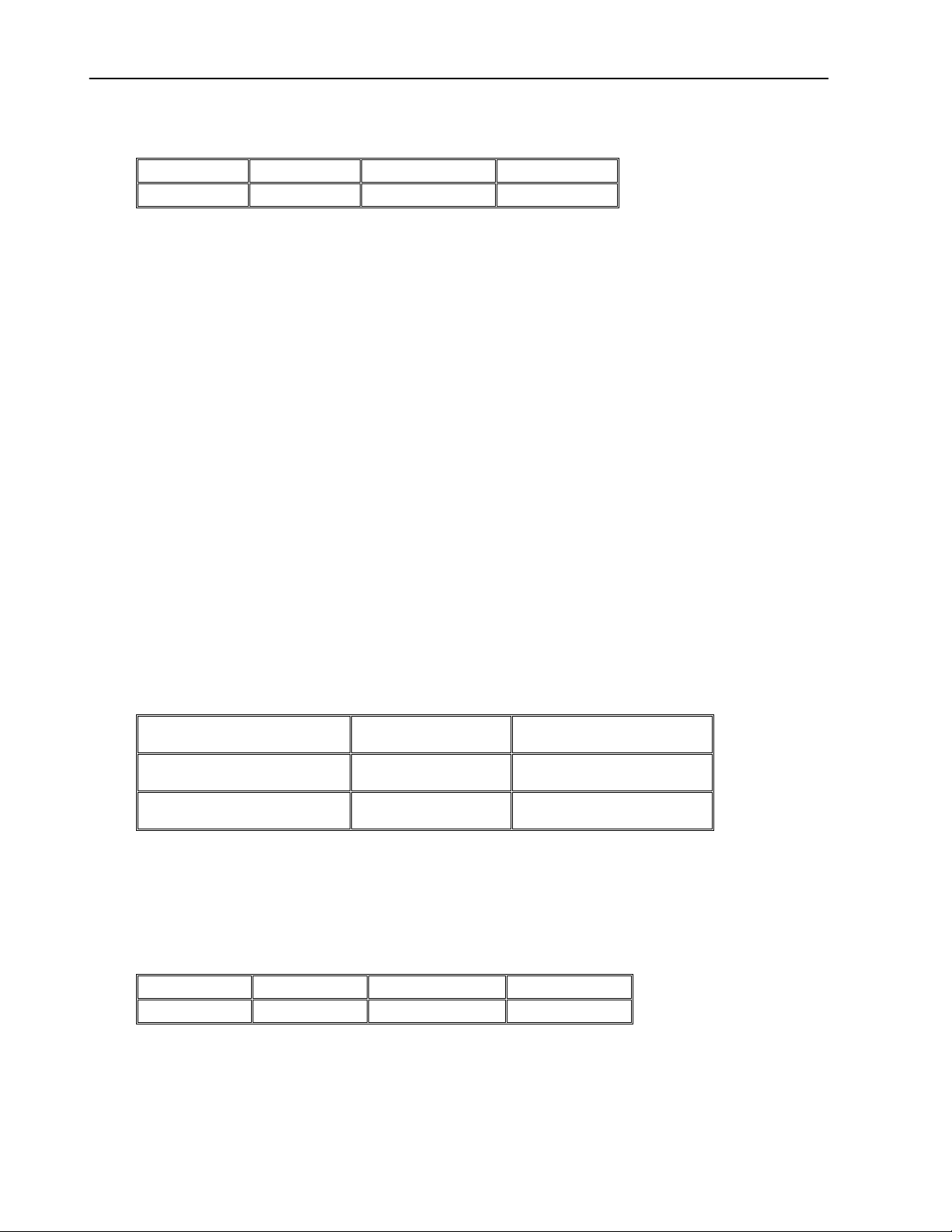

RECORD, VCR: 53 RECORED, DVD: 52 RECORD, V-DISC: 51 RECORD, TV: 50

RECORD, AUX: 4F RECORD, CD: 4E RECORD, TUNER: 4D RECORD, TAPE: 4C

Input to Zone 2 Output Test

Setup

1. Attach the audio input cable between the Low Distortion Oscillator and the MC-1 Left VCR input.

2. Attach the audio output cable between the MC-1 Zone 2 output and the input of the Distortion

Analyzer.

3. Put the MC-1 into Extended Diagnostics mode by powering up the MC-1 while pressing and holding

down both the front panel REC/ZONE2 and EFFECT buttons until Extended Diagnostics appears on

the display.

4. Press the TAPE button on the remote. The display will read AUDIO Test.

5. Press and hold the Shift button on the remote, then press the Off button. The #99 will then be displayed

next to AUDIO Test.

6. Press and hold the RECORD button on the remote then the VCR button. The # 53 will then be

displayed. This confirms the VCR input is now set to the ZONE 2 outputs.

Tests

1. Apply a 1kHz signal @ +12dB (+4 Vrms) to the input channel.

2. Set the scale on the Distortion Analyzer to measure +12dBV (+ 4Vrms ) signal level.

3. Turn all filters off on the Analyzer.

4. Verify that the output level from the MC-1 is +12dBV ( +4Vrms ) +0.2/-0.3dBV.

5. Adjust the scale on the Distortion Analyzer to measure 0.005% THD+N and turn on the 30kHz low

pass or audio bandpass filter.

6. Verify that the THD+N measured is less than 0.005%

7. Use the output level from Step 4 above for a 0dB reference to check frequency response.

8. Set the scale on the Distortion Analyzer to measure +12dBV (+ 4Vrms) signal level.

9. Turn the filter off and sweep the oscillator frequency from 10Hz to 20kHz.

10. Verify that the signal level is within +0.2/-0.3dB of reference level over the frequency band.

11. Set the scale on the Distortion Analyzer to measure –100dBr signal level with the filter on. Turn off the

oscillator to the MC-1 and verify a noise level measurement less than -105dBr.

12. Swap the cables from the Left VCR input to the Right and the Left ZONE 2 output to the Right.

13. Repeat steps 1 to 11 above for the Right ZONE 2 output.

14. To test the remaining inputs of the MC-1 to the ZONE 2 outputs, each path must be set with the

remote control. Press and hold the ZONE 2 button, then press one of the analog input buttons to set

up the next input to ZONE 2 output path. Below are the verification #’s next to their button titles that

indicate the path has been enabled. After a new input is selected the procedure above needs to be

repeated to test the path.

4-3

Page 16

MC-1 Service Manual

RECORD, VCR: 53 RECORED, DVD: 52 RECORD, V-DISC: 51 RECORD, TV: 50

RECORD, AUX: 4F RECORD, CD: 4E RECORD, TUNER: 4D RECORD, TAPE: 4C

Main Audio Output Test

Setup

1. Attach the audio input cable between the Low Distortion Oscillator and the MC-1 Left VCR input.

2. Attach the audio output cable between the MC-1 Left Front output and the input of the Distortion

Analyzer.

3. Put the MC-1 into Extended Diagnostics mode by powering up the MC-1 while pressing and holding

down both the front panel REC/ZONE2 and EFFECT buttons until Extended Diagnostics appears on

the display.

4. Press the TAPE button on the remote. The display will read AUDIO Test.

5. Press and hold the Shift button on the remote, then press the On button. The #98 will then be displayed

next to AUDIO Test. This indicates that the VCR input to Plain Analog outputs path has been enabled.

Tests

1. Apply a 1kHz signal @ +12dB (+4 Vrms) to the input channel.

2. Set the scale on the Distortion Analyzer to measure +12dBV (+ 4Vrms ) signal level.

3. Turn all filters off on the Analyzer.

4. Verify that the output level from the MC-1 is +12dBV (+4Vrms) +0.2/-0.3dBV.

5. Adjust the scale on the Distortion Analyzer to measure 0.005% THD+N and turn on the 30kHz low pass

or audio bandpass filter.

6. Verify that the THD+N measured is less than 0.005%

7. Set the scale on the Distortion Analyzer to measure +12dBV (+ 4Vrms) signal level.

8. Use the output level from Step 4 above for a 0dB reference to check frequency response.

9. Turn the filter off. Next sweep the oscillator frequency from 10Hz to 20kHz.

10. Verify that the signal level is within +0.2/-0.3dB of reference level over the frequency band.

11. Set the scale on the Distortion Analyzer to measure –100dBr signal level with the filter on. Turn off the

oscillator to the MC-1 and verify a noise level measurement less than -105dBr.

12. Swap the Left Front output cable to the Right Front output.

13. Repeat steps 1 to 11 above.

14. Test the remaining Main outputs of the MC-1 being sure to repeat steps 1 to 11 for each.

Digital Input to Analog Output Tests

This test verifies that all 8 digital inputs to an analog output of the MC-1 are functioning properly. It is

important that all previous tests from this section be preformed prior to this test.

Setup

1. Connect the coaxial digital source to the MC-1 Coax 1 input.

2. Connect the MC-1’s Left and Right Front audio outputs to the amplifier Left and Right inputs, and turn

down the volume level control on the amplifier.

3. Place the MC-1 into Extended Diagnostics mode by applying power to the MC-1 while pressing and

holding down both the REC/ZONE2 and EFFECT buttons on the front panel until Extended Diagnostics

appears on the display.

4. Press the TAPE button on the remote to select the AUDIO Test.

5. Press and hold down the SHIFT button, then press the CD button to select a digital input source. The

display should read: AUDIO Test 8E.

6. Press the Dolby Digital button on the remote to select Coax 1 digital input for testing. The #20 will be

displayed to indicate the Digital Coax 1 to output test path has been set.

4-4

Page 17

Lexicon

Tests

1. With the audio source playing, slowly increase the volume level on the amplifier to a comfortable

listening level and verify that the outputs are free from noise, distortion or any other audio anomalies.

2. To test the remaining 7 digital inputs, the following button pushes must be done to make a complete

digital input to analog output test path. Each selection below shows the digital input the button that

activates and the number that will appear in the display to confirm the path is set.

THX = Coax 2, # 21 Logic 7 = Coax 3, # 22 DTS = Coax 4, # 23 2 CH = Coax 5, # 24

Party = Optical 1,# 25 TV M = Optical 2, # 26 Music = Optical 3, # 27

3. Once all of the digital inputs are tested, press and hold the SHIFT button, then press DONE. This will exit

the Extended Diagnostics tests.

Video Input / Output Tests

These tests will verify that all 16 video inputs (8 composite / 8 S-Video inputs) pass video to the 6 video

outputs (3 composite / 3 S-Video).

Composite Input to Composite Monitor / Records (1 and 2) Outputs Tests

Setup

1. Connect the Composite video output from the DVD player to the MC-1 VCR Composite video input.

2. Connect the Composite video Monitor output of the MC-1 to the video display's Monitor Composite

video input.

3. Place the MC-1 into Extended Diagnostics mode by applying power to the MC-1 while pressing and

holding down both the REC/ZONE2 and EFFECT buttons on the front panel until Extended Diagnostics

appears n the display.

4. Press the TV button on the remote to select the VIDEO Test. Press and hold Shift, then press the ON

button. This will set the MC-1 to except an external video source for testing.

5. Turn on the video source and monitor.

Tests

1. To test the VCR Composite input to Video Monitor Composite output path, press the VCR button on the

remote. The # 13 will appear next to the Video Test message on the display, this indicates the path has

been set.

2. Press Play on the video source.

3. Verify a clear, undistorted picture appears on the monitor.

4. Pause the video source.

5. Move the Composite video input from the VCR to the DVD video input. Press the DVD button on the

remote. The # 12 will appear confirming this video path is set. Repeat steps 2-4 above.

6. To test the remaining Composite inputs move the video cable to the next Composite input and press

the corresponding button to set up the video path. Below are the buttons and code #’s for each video

input.

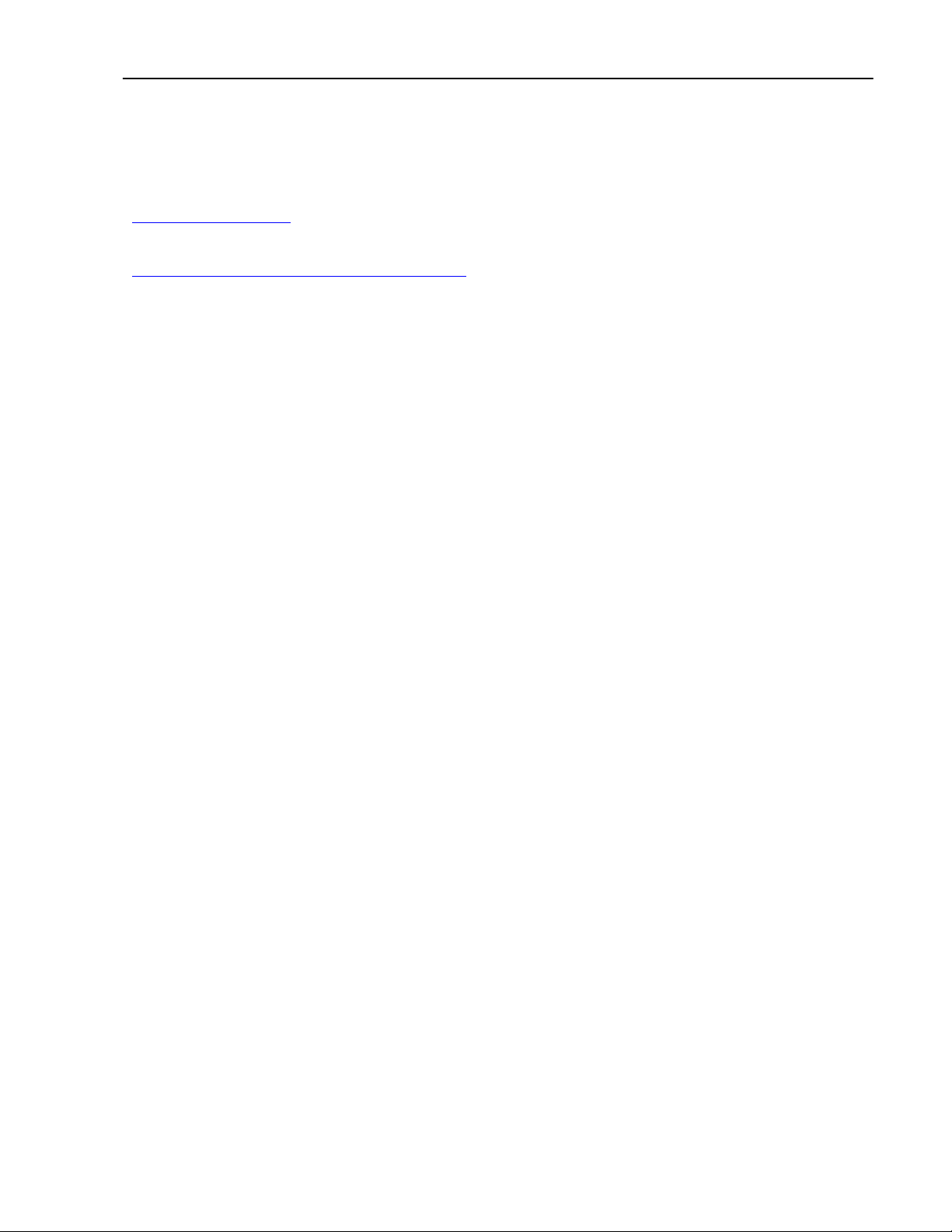

VCR: 13 DVD: 12 V-DISC: 11 TV: 10

AUX: 0F CD: 0E TUNER: 0D TAPE: 0C

7. To test the Record Composite output port of the MC-1, switch the composite cable from the Composite

Monitor output jack to the Composite Record output jack.

8. Select the MC-1's 8 composite inputs for the Composite Record output from the remote according to

the table below. Example: Pressing and holding the Record button on the remote, then pressing the

VCR button selects the VCR composite input for the Record composite output. The # 53 will appear in

the display to confirm this. Below are the button combinations and code #’s for each video input.

4-5

Page 18

MC-1 Service Manual

RecVCR: 53 RecDVD: 52 RecV-DISC: 51 RecTV: 50

RecAUX: 4F RecCD: 4E RecTUNER: 4D RecTAPE: 4C

S-Video Input to S-Video Monitor / Records (1 and 2) Outputs Tests

Setup

1. Connect the S-Video output from the DVD player to the MC-1 VCR S-Video input.

2. Connect the S-Video Monitor output of the MC-1 to the video display's Monitor S-Video input.

3. Place the MC-1 into Extended Diagnostics mode by applying power to the MC-1 while pressing and

holding down both the REC/ZONE2 and EFFECT buttons on the front panel until Extended Diagnostics

appears on the display

4. Press the TV button on the remote to select the VIDEO Test. Press and hold Shift, then press the ON

button. This will set the MC-1 to except an external video source for testing.

5. Turn on the video source and monitor.

Test

1. To test the VCR S-Video input to Video Record S-Video output path, press the Dolby button on the

remote. The # 20 will appear next to the Video Test message on the display. This indicates the path

has been set.

2. Press Play on the video source.

3. Verify a clear, undistorted picture appears on the monitor.

4. Pause the video source.

5. Move the S-Video input cable from the VCR input to the DVD input. Press the DVD button. The # 21 will

appear confirming this video path is set.

6. Repeat steps 2-4.

7. To test the remaining S-Video inputs, move the video cable to the next S-Video input and press the

corresponding buttons to set up the video paths. Below are the buttons and code #’s for each video

input.

Dolby Digital: 20 (VCR

input)

DTS: 23 (TV input) 2 CH: 24 (AUX

TV M: 26 (TUNER input) MUSIC: 27 (TAPE

8. To test the Record S-Video output port of the MC-1, switch the S-Video cable from the S-Video Monitor

output jack to the S-Video Record output jack.

9. Select the MC-1's 8 S-Video inputs for the S-Video Record output from the remote according to the

table below. Example: Pressing and holding the Shift button on the remote then pressing the VCR

button selects the VCR S-Video input for the Record S-Video output. The # 93 will appear in the display

to confirm this. Below are the button combinations and code #’s for each video input.

ShiftVCR: 93 ShiftDVD: 92 ShiftV-DISC: 91 ShiftTV: 90

ShiftAUX: 8F ShiftCD: 8E ShiftTUNER: 8D ShiftTAPE: 8C

THX: 21 (DVD input) Logic 7: 22 (V-DISC

input)

PARTY: 25 (CD input)

input)

input)

Expansion Port Digital Input to Analog Output Test

This test will confirm that the MC-1’s 3 expansion ports (A, B, and C) will pass audio.

The test does not require the MC-1 to be in Extended Diagnostics. It is preformed in normal running mode.

4-6

Page 19

Lexicon

If the MC-1 is currently in Extended Diagnostics, turn the unit off and on to bring it back to normal running

mode.

This test will confirm the MC-1 can pass a 44.1, 48, and 96kHz digital signal to the Analog outputs.

Setup

1. Connect the output of the DVD player with the Single end of the Y-ed RCA cable.

2. Connect one RCA connector of the Y-ed cable to the (A) Expansion Port on the back of the MC-1.

3. Connect the MC-1’s Left and Right Front audio outputs to the amplifier Left and Right inputs, and turn

down the volume level control on the amplifier.

4. Connect the Left and Right outputs of the amplifier to full range speakers.

5. After the MC-1 has powered up, press and hold down the Shift button then press the 2 Channel button.

Test

1. With the audio source playing, slowly increase the volume level on the amplifier to a comfortable

listening level and verify that the outputs are free from noise, distortion, or any other anomalies.

2. The display will read the following and will indicate the frequency it is passing as well as the volume

level:

EXP PORT ## K VOL

DIRECT BYPASS -30dB

3. Pause the audio, then connect the other RCA connector on the Y-ed end to the MC-1 to the (B)

Expansion Port. Keep the (A) RCA connected to MC-1 connected to the unit.

4. Move the Front Left / Right output cables to the Center / Sub RCA connectors.

5. Press play on the audio source and again, as in step one, listen for any anomalies.

6. Pause the audio once more. Disconnect the RCA connection to the (B) Expansion Port and connect it

to the (C) Expansion Port.

7. Move the Center / Sub connectors to the Side Left / Right outputs.

8. Press play on the audio source and again, as in step one, listen for any anomalies.

9. Pause the audio once more.

10. Move the Side Left / Right output cables to the Rear Left / Right outputs.

11. Press play on the audio source and again, as in step one, listen for any anomalies.

12. The above procedure must be repeated for the remaining sample frequencies not tested.

Digital Output Test

This will confirm that the MC-1 will pass a 44.1 or 48 kHz digital signal for the S/PDIF output connector on

the back of the MC-1.

Setup

1. Connect the digital output of the CD player to the digital input Coax 1 on the back of the MC-1.

2. Connect the S/PDIF output of the MC-1 to the digital input of the DAT machine.

3. Connect the Analog Left / Right outputs of the DAT to the Analog inputs of the stereo amplifier.

4. Connect the Left / Right analog output of the amplifier to a pair of speakers.

5. Put the MC-1 into Extended Diagnostics mode by powering up the MC-1 while pressing and holding

down both the front panel REC/ZONE2 and EFFECT buttons until Extended Diagnostics appears on

the display.

6. Press the TAPE button on the remote. The display will read AUDIO Test.

7. Press and hold the Shift button on the remote, then press the Off button. The # 99 will then be

displayed next to AUDIO Test,

4-7

Page 20

MC-1 Service Manual

Test

1. With the audio source playing, slowly increase the volume level on the amplifier to a comfortable

listening level and verify that the outputs are free from noise, distortion, or any other anomalies.

4-8

Page 21

Lexicon

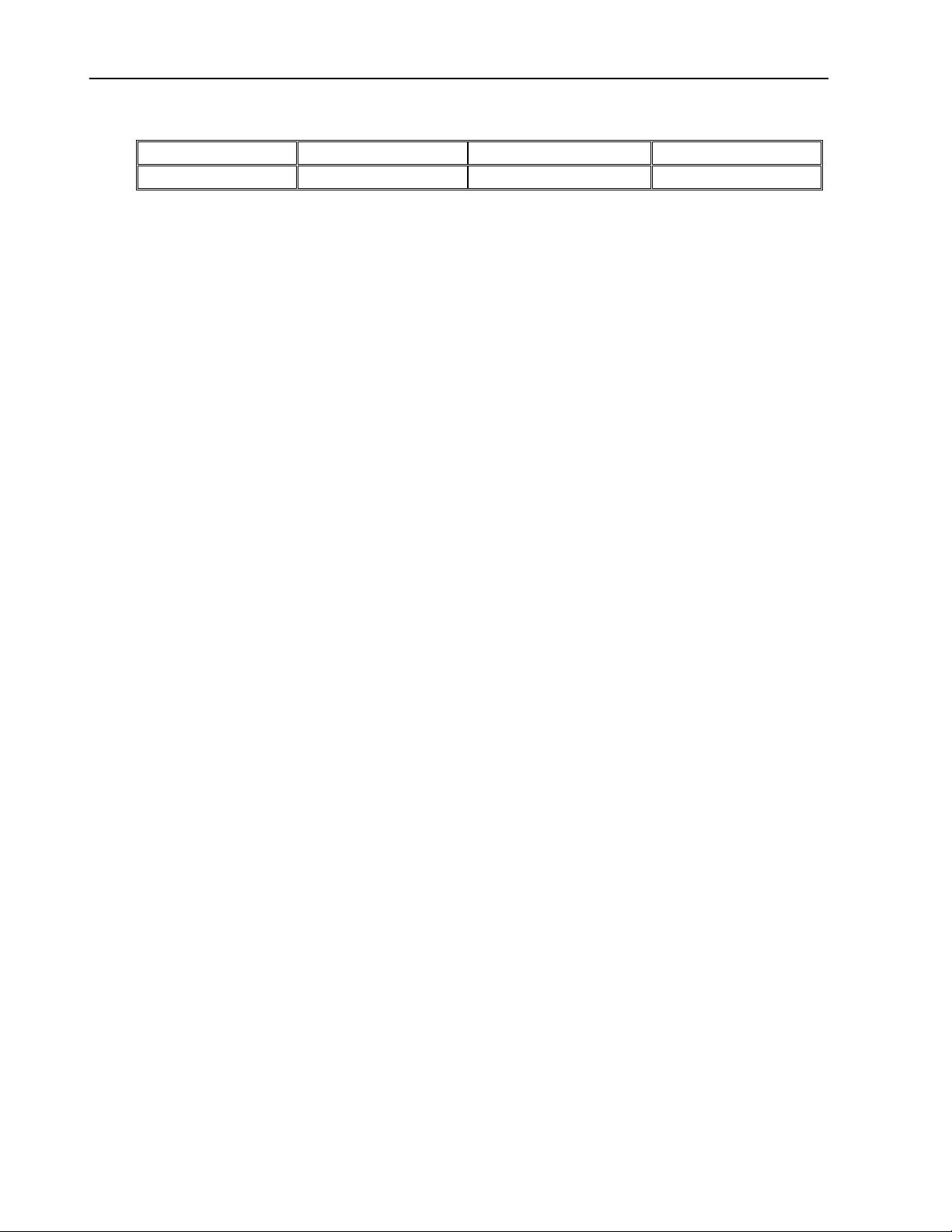

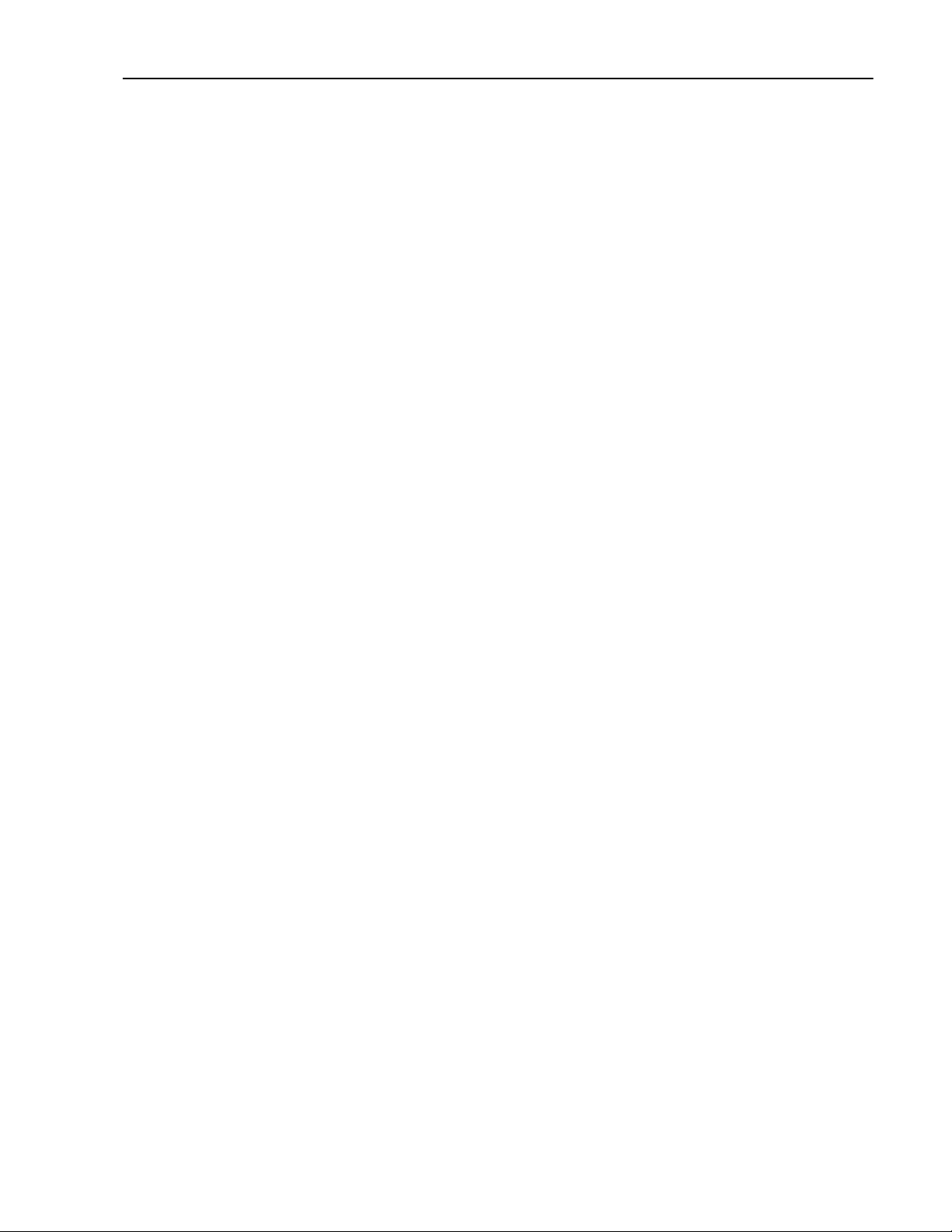

Lexicon Audio Precision ATE Summary

This chart represents a summary of test Audio Precision test equipment settings and parameters used by

Lexicon Manufacturing in production testing of all MC-1 product. This is provided as a reference and

supplement to bench test settings found in the proof of performance in this manual.

All Tests = 25 Ohm, Unbal, Float

All Tests = Filter OFF, Imp. 100K, 44.1kHz Sample Rate (Except 48K Tests)

Test Name Left Right Freq (Hz) Level Measure Reading Upper Lower Band Commands

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX1#1 ShiftCD DOLBY

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K COAX1#1 ShiftCD DOLBY

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K COAX1#1 ShiftCD DOLBY

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX1#1 ShiftCD DOLBY

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K COAX1#1 ShiftCD DOLBY

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.36 <10-22K COAX1#1 ShiftCD DOLBY

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX2#1 ShiftCD THX

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K COAX2#1 ShiftCD THX

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K COAX2#1 ShiftCD THX

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX2#1 ShiftCD THX

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K COAX2#1 ShiftCD THX

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.36 <10-22K COAX2#1 ShiftCD THX

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX3#1 ShiftCD L7

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K COAX3#1 ShiftCD L7

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K COAX3#1 ShiftCD L7

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX3#1 ShiftCD L7

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K COAX3#1 ShiftCD L7

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.36 <10-22K COAX3#1 ShiftCD L7

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX4#1 ShiftCD DTS

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K COAX4#1 ShiftCD DTS

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K COAX4#1 ShiftCD DTS

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX4#1 ShiftCD DTS

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K COAX4#1 ShiftCD DTS

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.36 <10-22K COAX4#1 ShiftCD DTS

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX5#1 ShiftCD 2 CH

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K COAX5#1 ShiftCD 2 CH

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K COAX5#1 ShiftCD 2 CH

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX5#1 ShiftCD 2 CH

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K COAX5#1 ShiftCD 2 CH

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.36 <10-22K COAX5#1 ShiftCD 2 CH

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K OPTIC1#1 ShiftCD PARTY

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K OPTIC1#1 ShiftCD PARTY

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K OPTIC1#1 ShiftCD PARTY

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K OPTIC1#1 ShiftCD PARTY

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K OPTIC1#1 ShiftCD PARTY

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.36 <10-22K OPTIC1#1 ShiftCD PARTY

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K OPTIC2#1 ShiftCD TVM

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K OPTIC2#1 ShiftCD TVM

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K OPTIC2#1 ShiftCD TVM

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K OPTIC2#1 ShiftCD TVM

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K OPTIC2#1 ShiftCD TVM

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.44 <10-22K OPTIC2#1 ShiftCD TVM

DIGGAN44 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K OPTIC3#1 ShiftCD MUSIC

DIG997 -1dBFS -1dBFS 997 % THD+N 0.003 0.005 0.0002 <10-22K OPTIC3#1 ShiftCD MUSIC

DIG100 -1dBFS -1dBFS 100 % THD+N 0.003 0.005 0.0002 <10>500K OPTIC2#1 ShiftCD MUSIC

JITTER44 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K OPTIC3#1 ShiftCD MUSIC

DIGD_R -60dBFS -60dBFS 997 dBr AMPLITUDE -103 -99.94 -120 <10-22K OPTIC3#1 ShiftCD MUSIC

DIGFREQ -1dBFS -1dBFS 10-20K dBr AMPLITUDE 0 0.26 -0.44 <10-22K OPTIC3#1 ShiftCD MUSIC

DIGREC -1dBFS -1dBFS 997 Vrms AMPLITUDE 2Vrms 2.3 1.69 <10-22K COAX1#1 ShiftCD DOLBY

CLKRNG44 -1dBFS -1dBFS 997 % THD+N 0.003 0.008 0.002 <10-22K COAX1#1 ShiftCD DOLBY

NOTE: GAIN 48, JITTER 48, AND CLKRNG48 use a 48kHz Sample

Rate

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX1#1 ShiftAUX DOLBY

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX1#1 ShiftAUX DOLBY

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX2#1 ShiftAUX THX

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX2#1 ShiftAUX THX

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX3#1 ShiftAUX L7

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX3#1 ShiftAUX L7

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX4#1 ShiftAUX DTS

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX4#1 ShiftAUX DTS

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K COAX5#1 ShiftAUX 2 CH

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K COAX5#1 ShiftAUX 2 CH

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K OPTIC1#1 ShiftAUX PARTY

Typical Remote

4-9

Page 22

MC-1 Service Manual

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K OPTIC1#1 ShiftAUX PARTY

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K OPTIC2#1 ShiftAUX TVM

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K OPTIC2#1 ShiftAUX TVM

DIGGAN48 -1dBFS -1dBFS 997 Vrms AMPLITUDE 7.1 7.66 6.54 <10>500K OPTIC3#1 ShiftAUX MUSIC

JITTER48 -1dBFS -1dBFS 10,000 % THD+N 0.003 0.008 0.0002 <10-22K OPTIC3#1 ShiftAUX MUSIC

4-10

Page 23

Lexicon

Chapter 5 Trou bleshooting

Check the Lexicon web site for the latest software and information:

http://www.lexicon.com

The Lexicon Home Theater Products downloads page:

http://www.lexicon.com/downloads/ht_index.html

The Lexicon Support Knowledgebase:

http://www.lexicon.com/kbase/index.asp

V4 Release Notes

The MC1 software has been updated to V4 which includes Surround EX. This is a list of the bugs that were

fixed in V1.1 which have carried forward to V4.

V1.00 bug descriptions:

1. Decorrelation does not work in AC3 THX 5.

2. Right rear output sometimes mutes in DTS THX 5.1.

3. Video signal bleedthrough when in Standby with SECAM Format selected.

4. Bass levels are too loud in Music Surround, Music Logic and TV Matrix effects.

5. The Bass Enhance parameter clicks when turning it on or off and may overload in the right front channel.

6. The Side Rolloff and Rear Rolloff parameters do not work in the Music Surround effect. They have been

replaced by one Surround Rolloff parameter.

7. The Center Bass Split crossover frequency points are too high, causing low frequency information to leak

into the Front Left and Right speakers in AC3 effects.

8. The Auto Azimuth parameter is not working in Logic7 and TV Matrix effects.

9. The level meters are not working correctly in AC3 and DTS effects.

Diagnostics

There are two sets of MC-1 Diagnostics: Power On Diagnostics, and Extended Diagnostics. The Power On

Diagnostics are automatically executed each time power is applied to the MC-1 via the rear panel power

switch. Extended Diagnostics are not automatically executed, but can be invoked by the user for specific

purposes. Extended Diagnostics include additional tests to verify front panel controls, inferred

communications, and audio and video performances, as well as those used to troubleshoot the MC-1.

In normal use, the MC-1 is left connected to AC power and its operation is controlled by the front panel

ON/STANDBY button or by the remote control. When controlled this way, Power On Diagnostics are not

executed.

Diagnostic Reporting

All diagnostics functionality is reported to the front panel Vacuum Fluorescent Display, and to the front

panels LEDs. These identify the test being executed, and pass and failure information. The LEDs are

utilized to report diagnostic status in the event that the VFD is not functioning. More information is available

on the diagnostic reporting operation of the VFD and the front panel LEDs in the VFD display, and front

panel LEDs section.

In the event of diagnostic failure, additional information, such as data sent, data received, address location

etc, is listed in an error log can be found in the Error Log.

Diagnostic status and data is also available to a external PC or terminal, via the Serial Port Debug Port

(RS232) on the rear panel of the MC-1.

5-1

Page 24

MC-1 Service Manual

VFD Display:

The front panel VFD display is the primary source of information during diagnostics. The exact display

information will depend on the test or tests being executed. When an individual diagnostic test is executed,

the VFD will display the name of that test. Groups of tests, such as during power on diagnostics or burn in

loops, will have a generic message on the top line of the VFD, e.g. DIAGNOSTIC TESTS, when the tests

are being executed. Any failure message will display an E followed by a number that indicates which test

failed.

Front Panel LEDs:

The test number associated with any particular test will also be displayed on the front panel LEDs. The

LEDs will be used in binary format with the MUTE LED as the LSB and the red TAPE LED as the MSB.

Running test number 1 would illuminate the MUTE LED only with all the others off. Running test number 2

would illuminate the BYPASS LED only with all others off. Running test number 3 would illuminate the

MUTE and BYPASS LEDs together with all others off, etc.

If a failure occurs, the red VCR LED is illuminated to indicate the test failure, and the LEDs indicating which

test was running when the failure occurred would also be illuminated. The diagnostics will attempt to

continuously execute the failed test, a test loop, to keep the signal lines active as an aid in debugging the

failure. Due to the MC-1 design of scanning the front panel LEDs, the diagnostics running the test loop, and

reporting the failure once during the loop, the LEDs on time is reduced. This results in the LEDs flickering,

and is normal operation.

Serial Debug Pot:

The Serial Debug Port is available to provide diagnostic status to be viewed on an external PC through one

of the serial ports on the PC. On the rear of the MC-1 is a 5-pin din connector. Pin 4 of the connector is

wired to the serial debug port. Using a terminal or a PC running a terminal program at 19.2kbs, the progress

of the diagnostics can be monitored and test failure information is reported. Also, the error log can be

dumped to the serial debug port, while in EXTENDED DIAGNOSTICS, via the remote SHIFT/ON key

combination.

Error Log:

An error log, or ring buffer, containing a log of the last 20, 13h, failures is available. If the error quantity

exceeds 20, additional error messages will be stored at the first location in the buffer (FIFO). The error log

is stored in the non- volatile section of SRAM.

Every failure stored in the error log has 6 parts:

#NN E## tXX aYYYYYY

wZZZZZZ rQQQQQQ

1. #NN: Error Log Number: the error log location number, in hexadecimal. It goes from 00 to 13. Turning

the VOLUME knob clockwise allows one to scroll through all 20 error log locations.

2. E##: Failure Number: the E stands for error and the 2-digit number after the E indicates which test

failed.

3. tXX: Failure Type

01 = Address Failure. During an address test the data sent compared to the data retrieved does not

match.

02 = Data Failure. During a data test the data sent does not match the data retrieved.

03 = Timeout Failure. The device being sent data does not return any ready or data transfers

acknowledge.

5-2

Page 25

Lexicon

04 = Counter Failure.

05 = Non-Volatile Data Failure. The data stored in non-volatile memory during the Pre-Burn In test does

not match the value tested during the Burn-in Loop.

4. aYYYYYY: Failing address location. The address, in hexadecimal, where the failure occurred.

5. wZZZZZZ: Value Written. The target value, in hexadecimal, which was written to the address where the

failure occurred.

6. rQQQQQQ: Value Read. The actual value, in hexadecimal, which was read from the address where the

failure occurred.

In addition, the error log can be viewed on an external PC or terminal via the serial debug port. The error

log is sent to the serial debug port when the MUTE F.P. button is used to select the error log or using the

SHIFT/ON infrared command if you are in the EXTENDED DIAGNOSTICS. The IR command can be sent

to the MC-1 via the handheld remote or sent to the MC-1 using IRTX.

Diagnostic Control/Interface:

Various combinations of button pushes are used to control diagnostics activity. During Power On

Diagnostics, three options are available: skipping the Power On Diagnostics, entering Extended

Diagnostics, or proceeding to the next test. Each of these options is described below.

Skip Power On Diagnostics:

Simultaneously pressing the VCR and TAPE buttons will skip the Power On Diagnostics routine and put the

unit into operating mode. The MC-1 periodically checks for this button combination during Power On

Diagnostics and will attempt to skip any remaining tests when this command is detected.

Enter Extended Diagnostics:

When power is applied to the MC-1, the VFD and the front panel LEDs are lit for 3 seconds. To enter

extended Diagnostics, press and hold down on the front panel the REC/ZONE2 and EFFECT buttons until

the end of the 3-second interval. The VFD will indicate Extended Diagnostics. Alternatively, during the

interval, press and hold SELECT on the remote until Extended Diagnostics is displayed.

Pressing and holding EFFECT and MUTE following the failure of any test other than the Z80 CPU test will

activate Extended Diagnostics. After a failure occurs the unit will attempt to display the failed test number,

and will execute a loop of the failing test.

Proceed to the Next Diagnostics Test:

Pressing and holding both the BYPASS and REC/ZONE 2 buttons after a failure occurs will cause the MC1 to attempt to execute the next power on diagnostic test. Normally if a failure occurs the MC-1 attempts to

enter a test loop to keep the signal lines active as an aid in debugging the failure. At the end of each

successive loop, the diagnostics will check to see if the BYPASS and REC/ZONE 2 buttons are being held.

Depending on the length of the test, the amount of time required to hold down the buttons in will vary.

Power On Diagnostics:

Power On Diagnostics verify the functionality of the basic MC-1 hardware. They do not completely test all

hardware, nor can they fully diagnose a failure. Power On Diagnostics take approximately 20 seconds to

complete. When the unit is powered on, an attempt is made to illuminate the VFD and front panel LEDs for

approximately three seconds. As soon as the Z80, EPROM, SRAM, and VFD are determined to be

functional, the VFD will show.

DIAGNOSTIC TESTS

………………………………………

5-3

Page 26

MC-1 Service Manual

The dots decrement in number from both sides simultaneously, as the rest of the power on diagnostic tests

are completed. This keeps a user informed as to the functioning of the MC-1.

The power on diagnostic tests are intended to verify basic hardware functionality of the MC-1. Due to the

limited time allowed to run the power on diagnostic tests, they cannot completely test all the hardware nor

can they fully diagnose a failure. Additional diagnostic tests are available for manufacturing and customer

service to completely test the hardware, and for debugging failures.

A listing of the power on tests is given first, followed by an explanation of the test. The number preceding

the test will be the test number used to display any pass or failed message. Initially, an attempt is made to

illuminate the VFD and front panel LEDs for approximately three seconds, and then the following

diagnostics will be executed:

E1 Z80 CPU Test.

E2 EPROM Checksum Test.

E3 Z80 SRAM Test, (Non-Volatile Section Saved).

E4 VFD Test.

E5 Z80 System Interrupt Timer Test.

E6 Lexichip II WCS and Word Clock Test.

E7 Lexichip II DRAM Test.

E8 56004 SPI (Serial Peripheral Interface) Test.

E9 AC3 MEM / DTS AC3MEM.

E10 DTS 56K Test.

E11 RS232 I/O Test

If a failure occurs, the test will attempt to write an entry into the error log and enter a loop cycle to exercise

signal lines to help in debugging the circuit. The error log is stored in the nonvolatile section of the SRAM so

that it is not destroyed during Power On Diagnostics. A signal error log entry is made each time the MC-1 is

powered up, a diagnostic test is executed, and a failure encountered.

E1 Z80 CPU Test

This test verifies operation of the internal Z80 registers. The test requires that the address, data and control

busses from the Z80 and the EPROM be operational. After disserting interrupts and sending the test

number to the front panel LEDs, the Z80 attempts to pass the values FFh, 55h, AAh, and 00h through the

Z80's internal registers. If a failure occurs the test will attempt to enter a loop to exercise the address, data

and control lines. If the MC-1 is successful in getting into a test loop, there will be a short periodic pulse on

the Serial Debug Port. The pulse can be viewed at the test port, J24 pin 1, or at U74 pin 4.

If any of the busses have serious problems or if the Z80 and/or EPROM is defective the unit will not boot

and will not be able to get into any test loop.

E2 EPROM Checksum Test

This test verifies the EPROM has the correct program by adding up all the values in the EPROM. The test

also verifies the 4 separate banks and the bank switching of the MC-1. First, the data in each of the 4 banks

of the EPROM is added up. The checksum of each bank is reported to the Serial Debug Port. This performs

an addition of the entire EPROM. The test verifies that the calculated checksum matches the checksum

value stored in the EPROM.

E3 Z80 SRAM Test

This test performs a non-destructive and destructive test on the SRAM. In the non-destructive test, it first

saves the data in the location being tested. Then writing and reading a FFh and then 00h tests that location.

The original data is then returned to the SRAM and the next location tested.

5-4

Page 27

Lexicon

The destructive test is actually 3 tests in one. They include a counter, data write and read test. These tests

do not save the data before writing. Also, more data patterns are written into this section of the SRAM. The

counter test writes a 0 into the first location of memory, a 1 into the next, then a 2, etc. This repeats this

until the volatile section of the SRAM is tested.

The data test of the SRAM writes and reads the volatile section with 55h, AAh, FFh, 00h, 01h, 02h, 04h,

08h, 10h, 20h, 40h, 80h, FEh, FDh, FBh, F7h, EFh, DFh, BFh, and 7Fh. Except for the first the last 16

patterns shift 1's and 0's through the memory locations.

E4 VFD Test

The VFD performs a busy test and a memory test. The busy test is performed by sending information to the

VFD and verifying that the VFD asserts then desserts its busy status. The VFD memory test consists of

writing 55h, and AAh, to the character generator memory and display memory space of the VFD and

reading them back. After the MC-1 has passed the VFD Test, for the rest of the power on diagnostics, the

VFD displays.

E5 Z80 System Interrupt Timer Test

This test checks the system interrupt timer. The PIC 16C54 microprocessor is initialized to start the interrupt

timer and the interval is measured by the Z80. A single interrupt takes approximately 2.048ms.

E6 Lexichip II WCS Test

The WCS test is the similar to the SRAM test with the exception that the entire memory testing is

destructive. A counter test and a data write and read test is performed.

The counter test writes a 0 into the first location, a 1 into the next, then a 2, etc. This repeats this until the

entire section of the WCS memory is tested.

The data write and read test, writes and reads the memory with 55h, AAh, FFh, 00h, 01h, 02h, 04h, 08h,

10h, 20h, 40h, 80h, FEh, FDh, FBh, F7h, EFh, DFh, BFh, and 7Fh. The last 16 patterns shift 1's and 0's

through the memory locations.

E7 Lexichip II DRAM Test

This test uses a counter test and a single data write and read test. A single data write and read test is used

during the power on diagnostics to conserve time. The Extended Diagnostics use additional data patterns

due to more time being allotted to perform these tests.

The counter test writes a 0 into the first location, a 1 into the next, then a 2, etc. This repeats this until the

entire section of the WCS memory is tested. The data test writes and reads the memory with 55555h.

E8 56004 SPI Test

This test verifies the 56004 is verified to be able to boot and to pass data. The test does not fully verify the

audio processing function of the 56004. However, if the 56004 can pass this test, which also exercises the

CPU of the 56004, most of the internal workings of the chip are operational. First the 56004 is reset and test

program is loaded. If the 56004’s internal ROM comes out of reset, it has booted and completed its internal

boot program. This indicates that a fair amount of its internal circuitry is working. Then test data patterns are

sent via the serial host interface and read back via the SC_RETURN_DATA line. If the data returned

matches what was sent, the test passes.

If the test fails the 56004 can be isolated from the path in the Extended Diagnostic. See section LOOP SPI

Test for information on how to remove the 56004 from the data path, thus isolating the failure to the 56004

or to the communication circuitry.

5-5

Page 28

MC-1 Service Manual

E9 AC3 MEM / DTS AC3MEM Tests

This test verifies the AC3 MEM and/or the DTS AC3MEM test is performed on their respective boards. The

tests send patterns to the 3 memory IC's on the AC3 or DTS option board. The test patterns are similar to

the test patterns that other memory sections of the unit are tested with. Data is written to and read from

memory with 55555h, AAAAAh, FFFFFh, and 00000h.

E10 DTS 56K Test

The DTS 56K Test is a SPI, (serial peripheral test), which sends a serial stream of data to the 56004 on the

DTS board. In this test the 56004 is verified to be able to boot and to pass data. The test does not fully

verify the audio processing function of the 56004. However, if the 56004 can pass this test, which also

exercises the CPU of the 56004, most of the internal workings of the chip are operational. First the 56004 is

reset and after it comes out of reset the test program is loaded. The 56004 has internal ROM so if it comes

out of reset, it has booted and completed its internal boot program. This indicates that a fair amount of its

internal circuitry is working. Then test data patterns are sent via SER_CTRL_DATA, pin 15 of the

connector, and read back via SER_RETURN_DATA on pin 21. If the data returned matches what was sent,

the test passes.

E11 RS232 Wraparound Test

This test verifies the RS232 port is working by comparing the transmitted signal (at pin 2 of J2) to the

received signal (at pin 3 of J2). If the signals are the same, the test passed. In order to test this circuit, an

RS232 Wraparound plug is needed and must be installed at the female D9 connector (J2) on the rear panel

of the MC-1 labeled “RS232”. Once this is installed, power cycle the MC-1 and verify the following message

is displayed on the top half of the VFD about 20 seconds after power up:

SERIAL PORT A PASSED

This message is displayed for about 2 seconds before entering normal operating mode. If the message isn’t

displayed, the test failed. To troubleshoot this type of failure, use the front panel buttons (except for On/Off)

or the encoder. Each time a button is pressed or the encoder is turned, a message is sent out the RS232

port at pin2 of J2. Therefore, this will activate the TXDA signal coming from U90 (Z85230) pin 16. In the

situation where the test passes, the TXDA signal is present at U90 pin 14 (RXDA) as long as the

wraparound plug is connected. Another way to test this circuit is to verify the IR Receiver (green) LED lights

briefly when a button is pressed or the encoder is turned. This approach can be helpful when

troubleshooting intermittent failures. Please note this test resides only in the power on diagnostics.

Extended Diagnostics

Extended Diagnostics contain a set of tests which check the MC-1's functionality more extensively than the

Power On Diagnostics tests, as well as troubleshooting tests which can be used to help isolate the source

of circuit failures.

The Extended Diagnostic tests are accessible via two methods. The first method is by pressing and holding

the REC/ZONE 2 and EFFECT ▼ front panel buttons when powering on a MC-1.

The second method is to press and hold the SELECT remote key, after all the VFD segments are

illuminated, while powering on a MC-1.

Any of the above methods will display the following message in the VFD display.

EXTENDED DIAGNOSTICS

Select a Test

Once this message is displayed the front panel buttons or IR remote key can then be released.

5-6

Page 29

Lexicon

Diagnostic tests are selected by rotating the VOLUME knob, (front panel encoder), to display the desired

test, or group of tests, on the VFD. The MUTE button is then pressed to execute the test. The group tests

are those diagnostics where if a test passes, the diagnostic automatically executes the next test. The power

on diagnostics is a group test. The other group tests are the Pre Burn-In test, Functional Suite and the

Burn-In Loop. If one of the group tests is selected the next test is automatically run if the current test

passes. Upon successful completion of the group tests the VFD will either display DONE, come out of the

test group to the main menu or continuously loop as in the case of the Burn-In Loop test.

If a test fails, the VFD, and red VCR F.P. LED, will attempt to indicate the failed test. The test will attempt to

loop on itself to keep the signal lines active for debugging purposes. If an individual test is selected, it will

continuously run and report if it passes every time it successfully completes the test. If the test fails it will

attempt to loop on itself to keep the signal lines active for debugging purposes.

In addition, test progress and failure information is available via the serial debug port. Specific failure

information will depend on the test executed and is covered further in section 3.4 Error Log.

Pressing and holding the BYPASS F.P. button and then pressing the MUTE F.P. button returns the user to

the diagnostic menu. Pressing the SHIFT/DONE remote key combination returns the user to the top of the

EXTENDED DIAGNOSTICS menu.

Pre-Burn in Tests

The Pre-burn in tests are a group of tests that are almost identical to the Power On Diagnostic tests, but

with more allotted to fully evaluate functionality the Lexichip DRAM memory test. The following is the list of

tests performed:

1. Z80 CPU Test.

2. EPROM Checksum Test.

3. Z80 SRAM Test (Destructive).

4. VFD Test.

5. Z80 System Interrupt Timer Test.

6. Lexichip II/WCS Test.

7. Lexichip II DRAM Test

8. 56004 SPI (Serial Peripheral Interface) Test.

9. AC3 SPI, AC3 MEM or DTS AC3SPI, DTS AC3MEM Test.

10. DTS 56K Test.

Any of these tests can be run individually by turning the VOLUME knob to the desired test and pressing the

MUTE F.P. button to execute the test. If the test is selected to be individually run, the test runs

continuously. If the test passes, the VFD will attempt to report the test passes upon each successful

completion. If the test fails the VFD will attempt to report the failure and the test will continue looping on

itself to keep the signal lines active for debugging purposes.

Functional Suite

The Functional Suite is a group of tests that are used to verify the functionality of the switches, LED's,

VOLUME knob, VFD display, logo illumination, etc. The entire user interface is verified. They are not

executed during power on. The following is a list of the tests performed:

1. Character Test.

2. Block Test.

3. Switch Test.

4. LED Test.

5. AC3 SPI Test.

6. AC3 MEM Test

7. DTS AC3SPI Test

8. DTS AC3MEM Test

5-7