Page 1

EDSLCMX3024-SPS

.4%j

Ä.4%jä

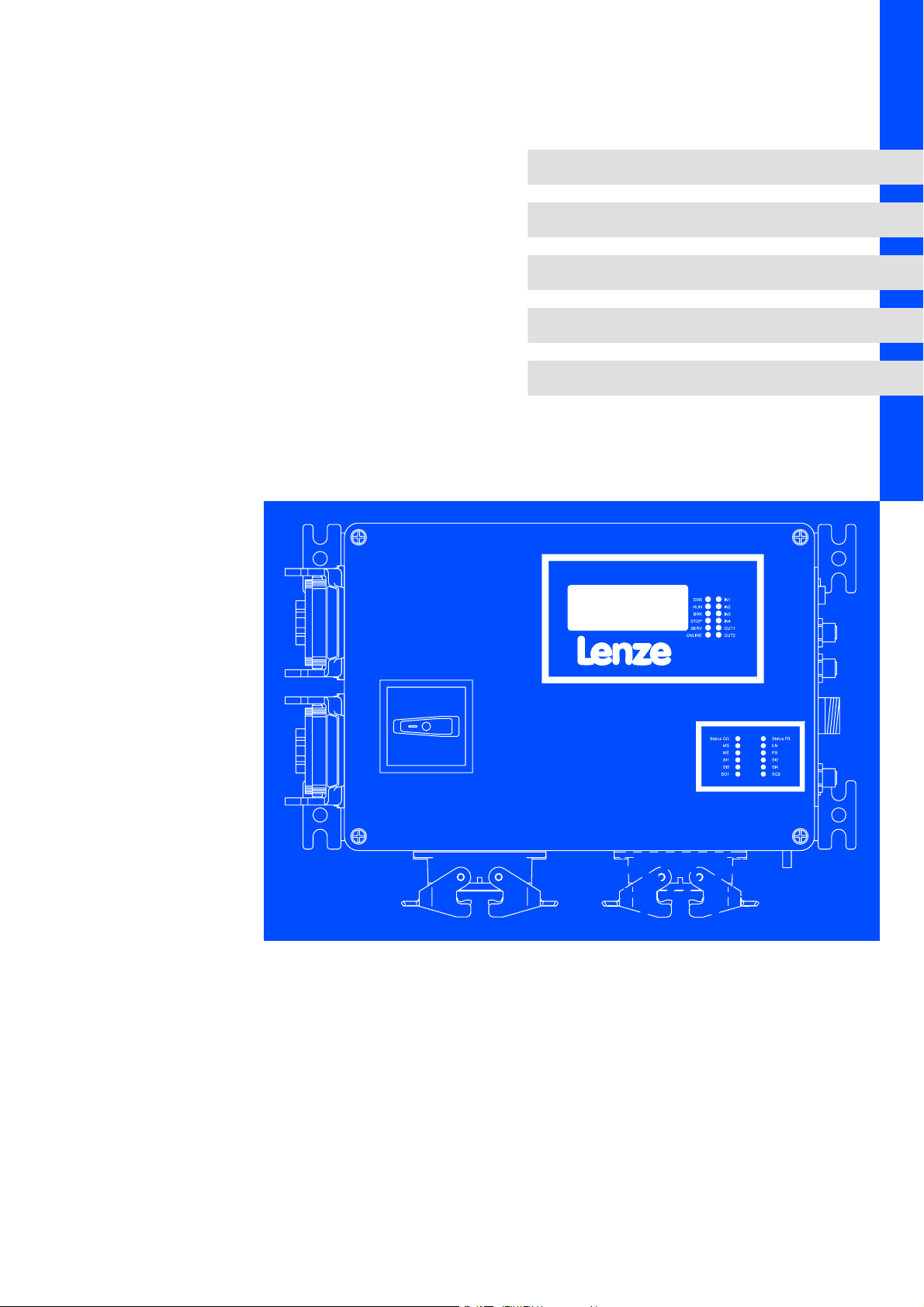

L-force Drives

Hardware Manual

LCU 0.75 ... 3 kW

ELCAMWIxxx4SNNPSNN (LCU121), ELCAMZIxxx4SNNPSNN (LCU122)

Decentralised motor starters

Page 2

This documentation is valid for ...

... ELCAM... motor starters as of nameplate designation:

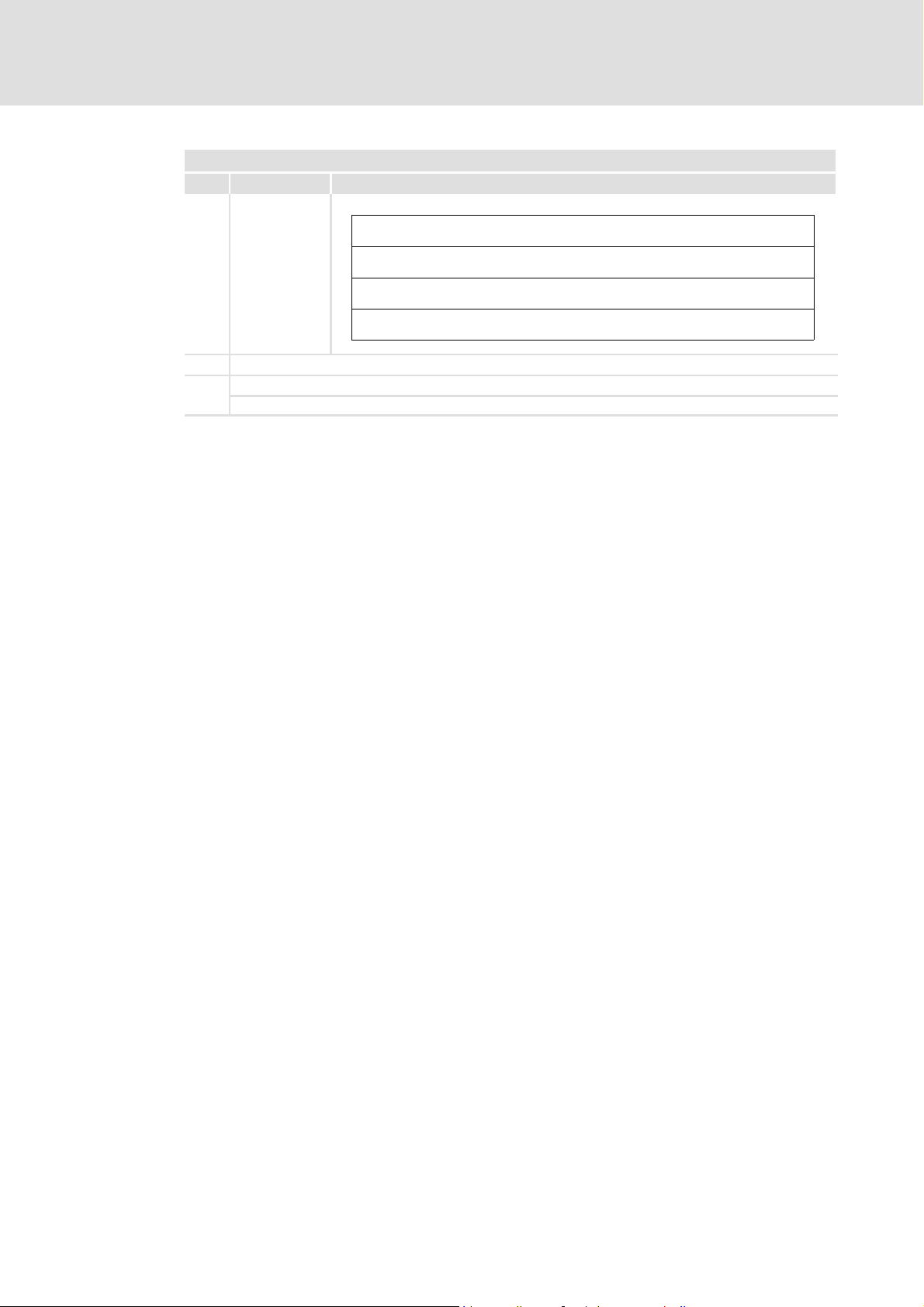

c d e Nameplate

ELC A M x I xxx x S NN PS NN 1B 20

Product series

LCU

Version

A= 1st generation

Type

M= motor starter

Variant

E= one motor, one direction of

rotation

Z = two motors, one direction of

rotation

W = one motor, two directions of

rotation

Mechanical version

I= housing in high enclosure IP54

Rated power [W]

e.g.

75 x 10

15 x 10

1

W = 750 W

2

W=1.5kW

751 =

152 =

Voltage class

2= 230 V AC

4 = 400 V AC

Safety function

A= without safety functions

S= withdrive-basedsafety

Communication

PM = PROFIBUS-DP-V0

PS = PROFIBUS-DP-V0, PROFIBUS-DP-V1, PROFIsafe

Hardware version

Px = prototype, version x

1C = series, version C

lcu12x_002

Software version

12 = software 1.2

22 = software 2.2

Page 3

Document history

Material number Version Description

-1.005/2005 TD00 Preliminary version

13131793 3.0 04/2006 TD00 Complete revision for series-production version

Revision of chapter ”Safety engineering”

13140447 4.0 05/2006 TD00 Revision of chapter ”Technical data”

.4%j 5.0 01/2007 TD19 New functions of SW 3.4 added:

Chapter ”Electrical installation”

Chapter ”Commissioning”

0Fig.0Tab. 0

Tip!

Current documentation and software updates concerning Lenze products can be found

on the Internet in the ”Services & Downloads” area under

http://www.Lenze.com

© 2007 Lenze Drive Systems GmbH, Hans-Lenze-Straße 1, D-31855 Aerzen

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze Drive

Systems GmbH.

All information given in this documentation has been selected carefully and complies with the hardware and software

described. Nevertheless, discrepancies cannot be ruled out. We do not take any responsibility or liability for any damage that

may occur. Necessary corrections will be included in subsequent editions.

Page 4

Contentsi

1 Safety instructions 7.........................................................

1.1 General safety and application notes for Lenze motor starters 7...............

1.2 Residual hazards 9.....................................................

1.3 Definition of notes used 10...............................................

2 Device description 11........................................................

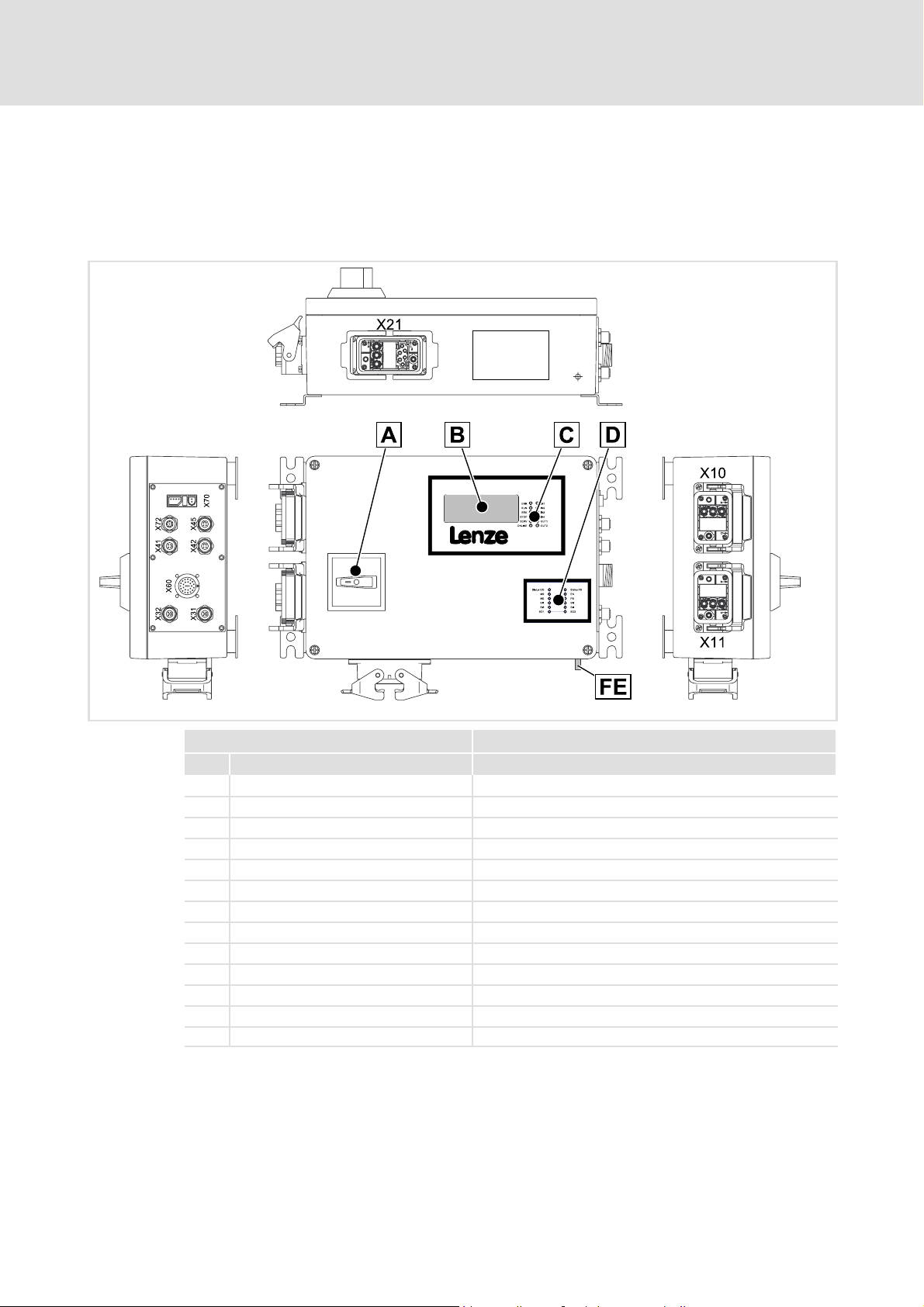

2.1 ELCAMWIxxx4SNNPSNN motor starter 11..................................

2.2 ELCAMZIxxx4SNNPSNN motor starter 13...................................

3 Technical data 15............................................................

3.1 General data and operating conditions 15..................................

3.2 Rated data 17..........................................................

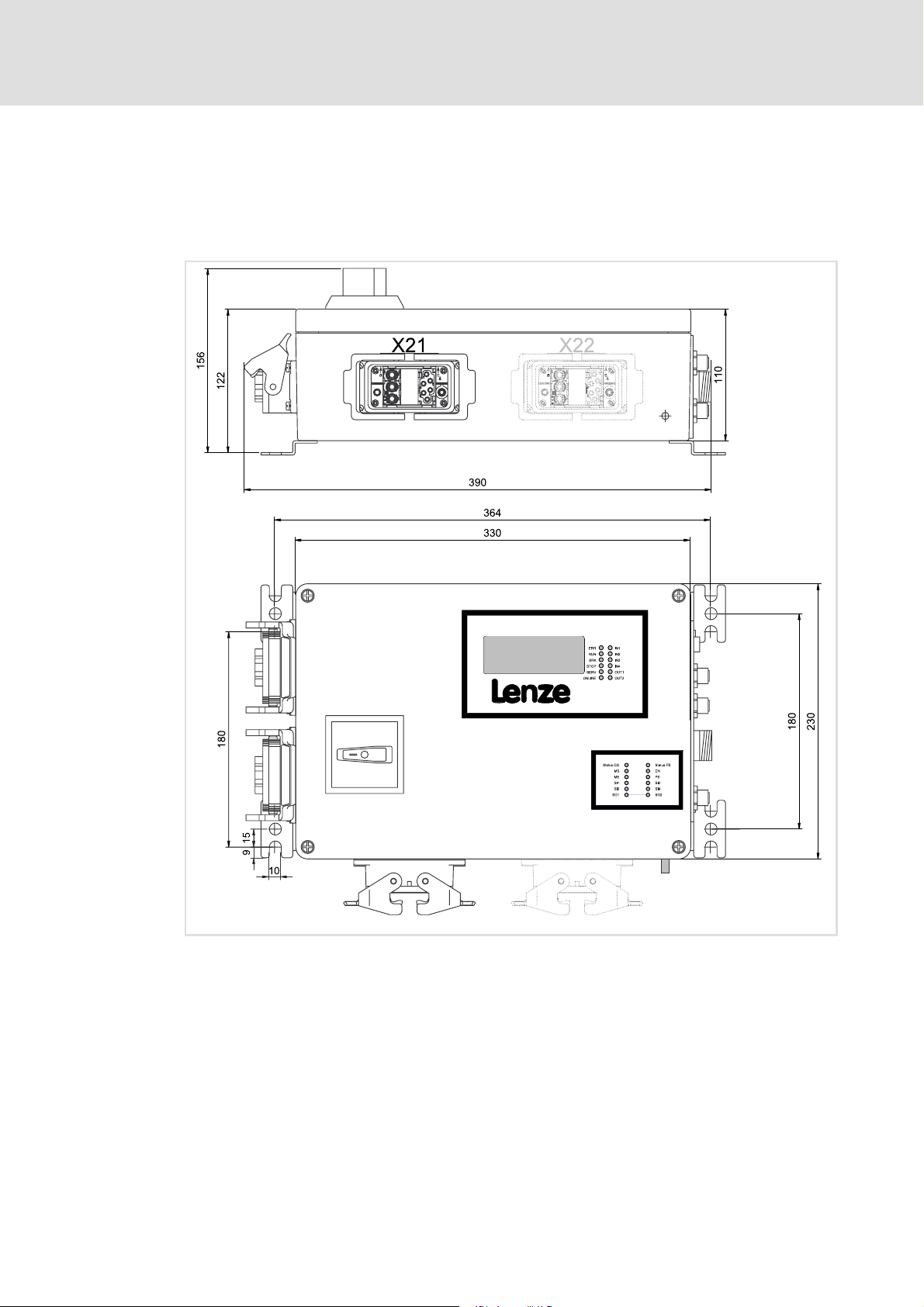

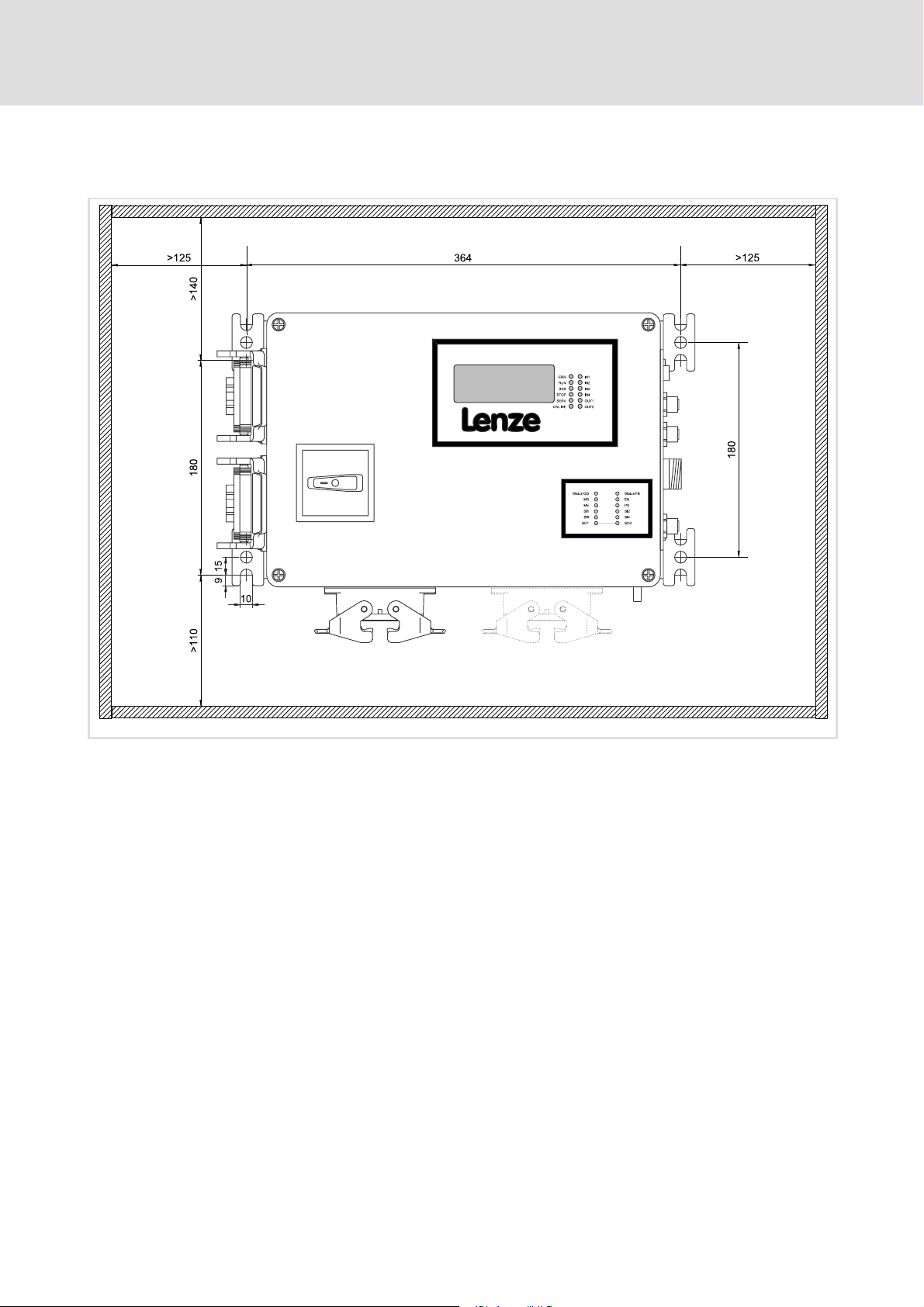

4 Mechanical installation 20.....................................................

4.1 Dimensions 20..........................................................

4.2 Mounting clearance 21...................................................

5 Electrical installation 22.......................................................

5.1 Important notes 22......................................................

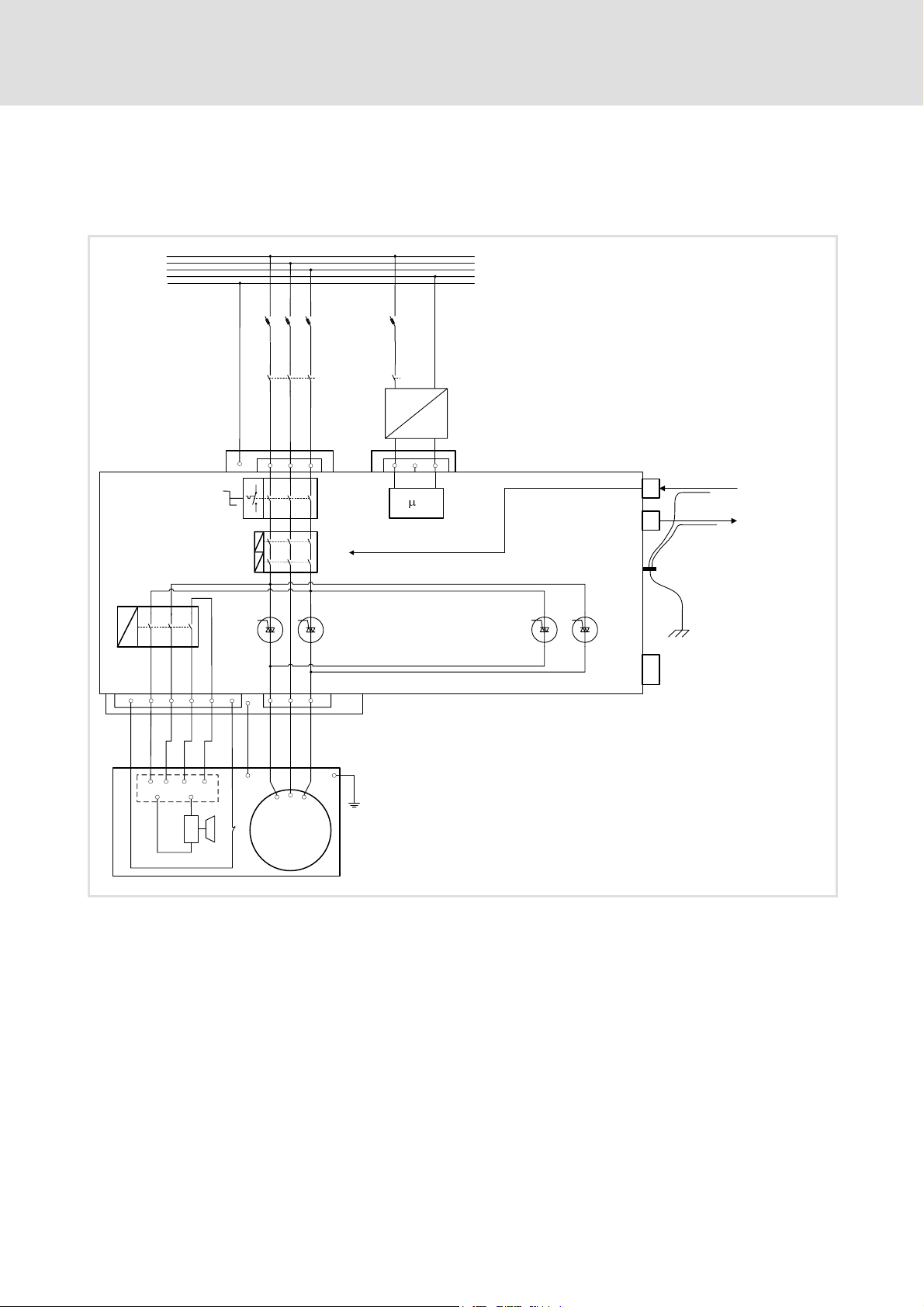

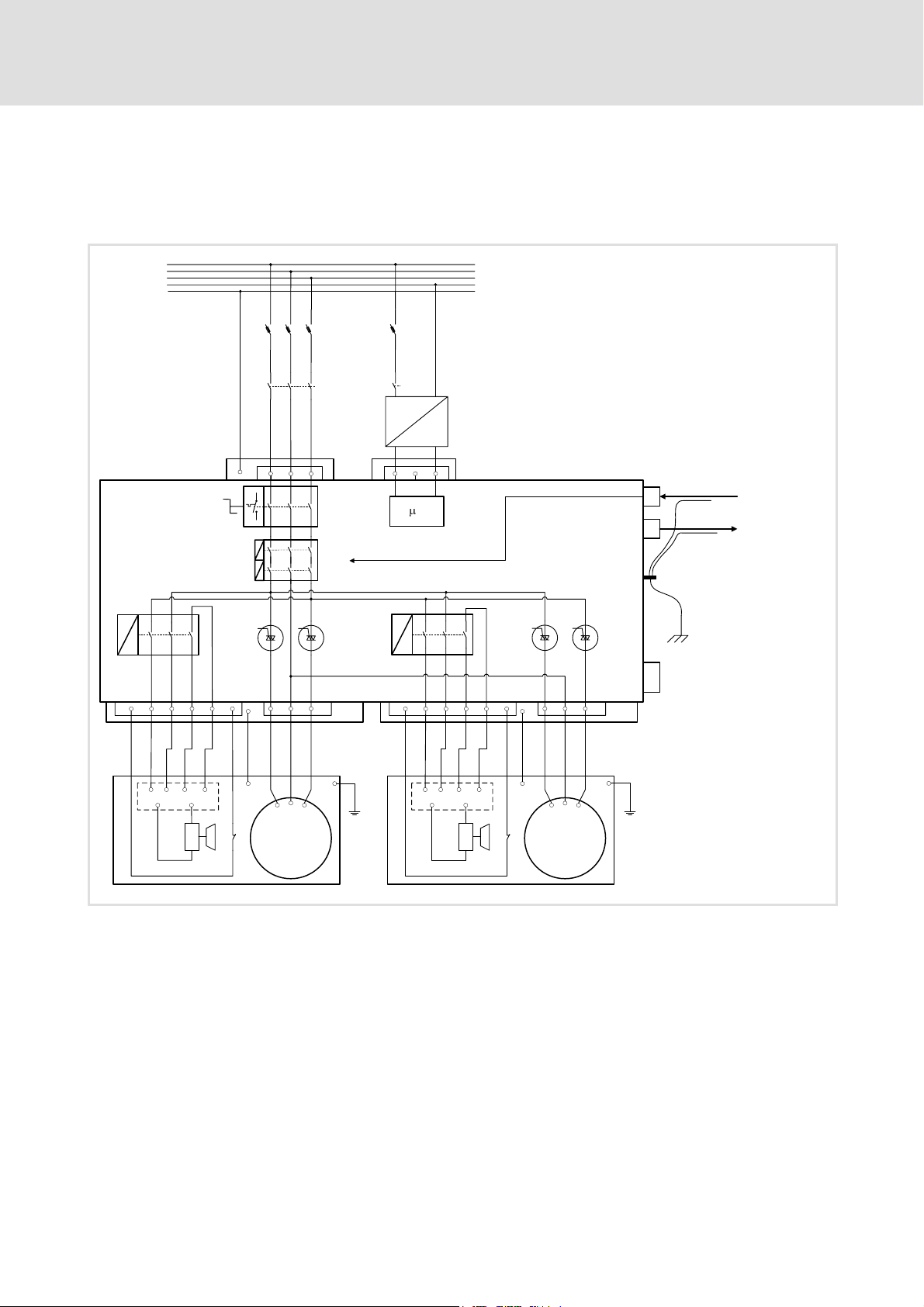

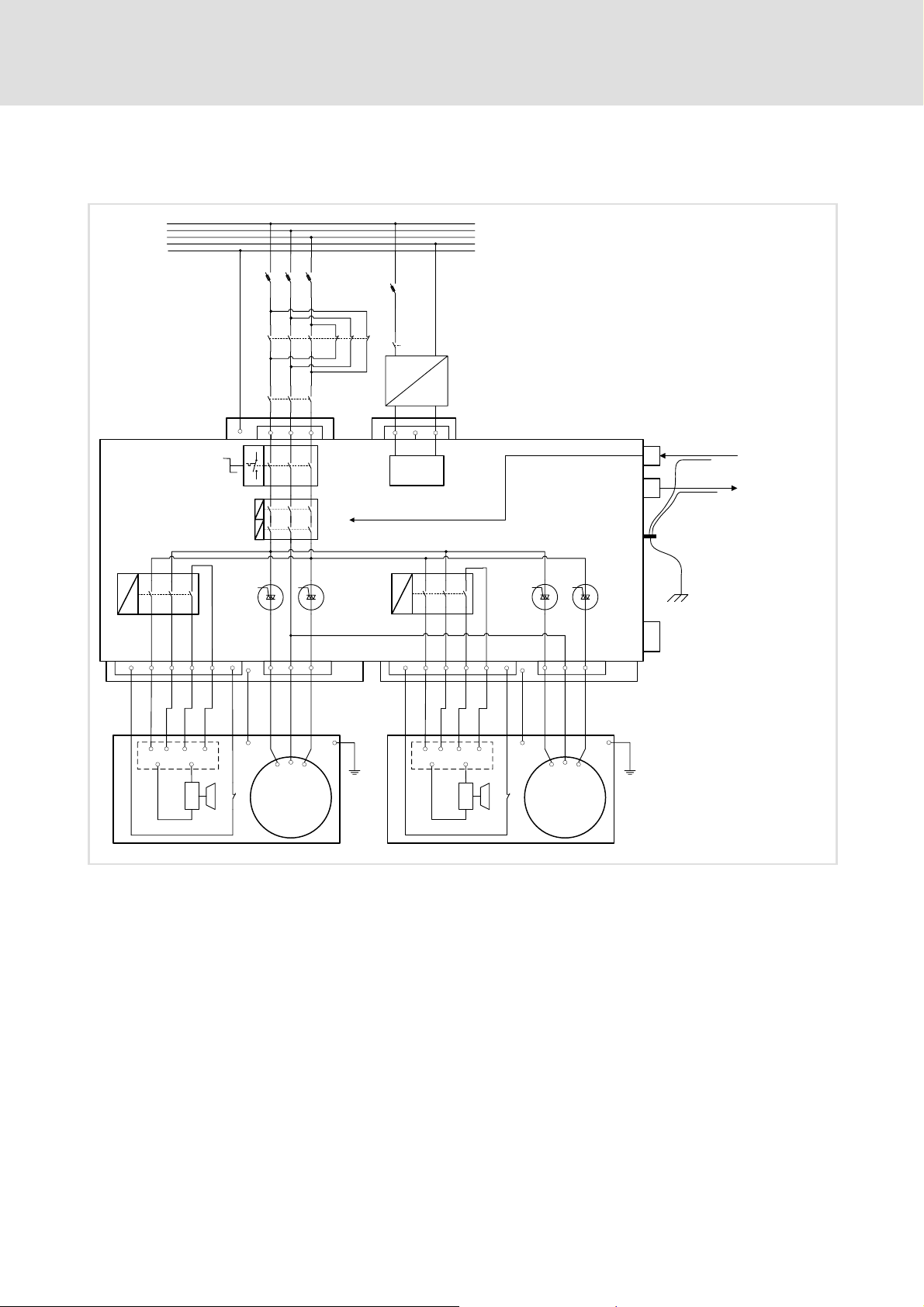

5.2 Basic circuit d iagram 24..................................................

5.2.1 ELCAMWIxxx4SNNPSNN motor starter 24..........................

5.2.2 ELCAMZIxxx4SNNPSNN motor starter 25...........................

5.3 Mains connection 27....................................................

5.4 Motor connection 28...................................................

5.4.1 ELCAMWIxxx4SNNPSNN motor starter 28..........................

5.4.2 ELCAMZIxxx4SNNPSNN motor starter 29...........................

5.5 Safety engineering 30...................................................

5.6 Control terminals 34.....................................................

5.7 Communication 36......................................................

5.8 Final works 41..........................................................

4

EDSLCMX3024-SPS EN 5.0

Page 5

Contents i

6PROFIsafeonboard 42........................................................

6.1 Technical data 42.......................................................

6.1.1 General data and operating conditions 42..........................

6.1.2 Protective insulation 42..........................................

6.1.3 Communication times 43.........................................

6.2 Establishing of PROFIBUS communication 44................................

6.2.1 Configuration of the host 44......................................

6.2.2 Safe addressing 46..............................................

6.2.3 Addressing 46..................................................

6.3 Process data transfer 47.................................................

6.3.1 Device control 48...............................................

6.4 Parameter data transfer 53...............................................

6.4.1 DRIVECOM parameter data channel (DP-V0, cyclic) 54.................

6.4.2 PROFIdrive parameter data channel (DP-V1, acyclic) 62................

6.4.3 PROFIdrive parameter data channel (PCW) 77........................

6.4.4 Parameter set transfer 82.........................................

6.5 Commissioning 83......................................................

6.6 Code table 84..........................................................

6.6.1 Communication-relevant Lenze codes 86............................

6.6.2 Monitoring 91..................................................

6.6.3 Diagnostics 93..................................................

6.7 Appendix 102...........................................................

6.7.1 Special characteristics for the use of Lenze standard devices 102.........

6.7.2 Consistent parameter data 102.....................................

7 Safety engineering 104........................................................

7.1 Basics 104..............................................................

7.1.1 Introduction 104.................................................

7.1.2 Drive-based safety with L-force | LCU 104............................

7.1.3 Terms and abbreviations of the safety engineering 105.................

7.1.4 Safety instructions 106............................................

7.1.5 Hazard and risk analysis 108.......................................

7.1.6 Standards 108...................................................

7.1.7 Overview of sensors 109...........................................

7.2 Test certificate 110.......................................................

7.3 Display elements 111.....................................................

7.4 Safe inputs and safe outputs 112...........................................

7.4.1 Overview 112....................................................

7.4.2 Technical data 113...............................................

7.4.3 Safe inputs 114..................................................

7.4.4 Safe outputs 118.................................................

7.4.5 Connection plans 119.............................................

EDSLCMX3024-SPS EN 5.0

5

Page 6

Contentsi

7.5 Safety functions 120......................................................

7.5.1 Function mode 120...............................................

7.5.2 Description 121..................................................

7.5.3 Error states 122..................................................

7.5.4 Safe torque off 123...............................................

7.5.5 Safe PROFIsafe connection 125.....................................

7.6 Commissioning 135......................................................

7.7 Acceptance 136..........................................................

7.7.1 Description 136..................................................

7.7.2 Periodic inspections 137...........................................

8 Commissioning 138...........................................................

8.1 Preconditions 138........................................................

8.1.1 The E82ZBB diagnosis terminal 138.................................

8.1.2 Configuration of the host 140......................................

8.2 Before switching on 141..................................................

8.3 Switch-on sequence 142..................................................

8.4 Switching over between normal operation and reversing operation 143..........

8.5 Code table 144..........................................................

9 Troubleshooting and fault elimination 158.......................................

9.1 Status display 158.......................................................

9.2 Malfunction of the drive 162...............................................

9.3 Fault messages 163......................................................

6

EDSLCMX3024-SPS EN 5.0

Page 7

Safety instructions

General safety and application notes for Lenze motor starters

1 Safety instructions

1.1 General safety and application notes for Lenze motor starters

(according to Low-Voltage Directive 73/23/EEC)

General

Lenze motor starters - according to their enclosure - can have live, and also moving or

rotating parts during operation. Surfaces can be hot.

Non-authorised removal of the required cover, inappropriate use, incorrect installation or

operation create the risk of severe injury to persons or damage to material assets.

More information can be obtained from the documentation.

All operations concerning transport, installation, and commissioning as well as

maintenance must be carriedout byqualified, skilled personnel(IEC 364/CENELEC HD 384

or DIN VDE 0100 and IEC report 664 or DIN VDE 0110 and national regulations for the

prevention of accidents must be observed).

1

According to this basic safety information qualified, skilled personnel are persons who are

familiar with the assembly, installation, commissioning, and operation of the product and

who have the qualifications necessary for their occupation.

Application as directed

Motor starters are components intended for the installation in electrical systems or

machines. They are nothousehold appliances,but are designed as componentsexclusively

for application for commercial or professional use in accordance with EN 61000-3-2. The

documentation contains notes concerning the compliance with the limit values in

accordance with EN 61000-3-2.

When installing the motor starters into machines, commissioning (i.e. starting of

operation as directed) is prohibited until it is proven that the machine corresponds to the

regulations of the EC Directive 98/37/EC (Machinery Directive); EN 60204 must be

observed.

Commissioning (i.e. starting of operation as directed) is only allowed when there is

compliance with the EMC Directive (89/336/EEC).

The motor starters comply with the requirements of Low-Voltage Directive 73/23/EEC.

The harmonised standards of the E N 60947-4-2/DIN VDE 0660 series are applied to the

motor starters.

The technical data as well as the connection conditions can be obtained from the

nameplate and the documentation. They must be strictly observed.

Warning: The motor starters are products with a limited availability in accordance with

EN 60947-4-2/DIN VDE 0660. These products c an cause radio interferences in residential

areas. In this case, the operator may be required to implement corresponding measures.

EDSLCMX3024-SPS EN 5.0

7

Page 8

1

Safety instructions

General safety and application notes for Lenze motor starters

Transport, storage

Please observe the notes on transport, storage and appropriate handling.

Observe the climatic conditions in accordance with EN 60947-4-2/DIN VDE 0660.

Installation

The motor starters must be installed and cooled according to the instructions given in the

corresponding documentation.

Ensure proper handling and avoid mechanical stress. Do not bend any components and do

not change any insulation distances during transport or handling. Do not touch any

electronic components and contacts.

Motor starters contain electrostatically sensitive components, which can easily be

damaged by inappropriate handling. Do not damage or destroy any electrical components

since this might endanger your health!

Electrical connection

When working on live m otor starters, the valid national regulations for the prevention of

accidents (e.g. VBG 4) must be observed.

The electrical installation must be carried out according to the appropriate regulations

(e.g. cable cross-sections, fuses, PE connection). Additional information can be obtained

from the documentation.

Notes about installation according to EMC regulations (shielding, earthing, filters and

cable routing) are included in the documentation. These notes also apply to CE-marked

motor starters. The compliance with limit values required by the EMC legislation is the

responsibility of the manufacturer of the machine or system.

Operation

If necessary, systems including motor starters must be equipped with additional

monitoring and protection devices according to the valid safety regulations (e.g. law on

technical equipment, regulations for the prevention of accidents). The motor starters can

be adaptedto your application. Please observe the corresponding information givenin the

documentation.

All protection covers and doors must be shut during operation.

Note for UL-approved systems with integrated motor starters: UL warnings are notes that

only apply to UL systems. The documentation contains special UL notes.

Maintenance and servicing

The motor starters do not require any maintenance if the prescribed conditions of

operation are observed.

Disposal

Recycle metal and plastic materials. Ensure professional disposal of assembled PCBs.

Observe the product-specific safety and application notes given in these instructions!

8

EDSLCMX3024-SPS EN 5.0

Page 9

1.2 Residual hazards

Protection of persons

ƒ The X2x power connector contacts can conduct hazardous voltages if the motor

starter is connected to the mains. Therefore, disconnect the motor starter before

carryingoutanyworkonit.

ƒ The X2x power connector contacts also conduct hazardous voltages when the motor

starter is disabled. Depending on the risk analysis of the machine/system, you may

have to take additional protective measures.

ƒ Operation at ambient temperatures > 40°C:

– The operating temperature of the motor starter housing is > 60°C.

– Depending upon the risk analysis of the machine/system, you may have to use

additional protective covers.

Motor protection

ƒ The connected motor can overheat if

– motors are operated on the motor starter that do not feature temperature

monitoring with PTC thermistor (PTC) or thermal contact (NC contact)

– temperature monitoring with PTC thermistor (PTC) or thermal contact (NC

contact) is not connected to the motor starter

– temperature monitoring is not activated (C0119)

– the set rated motor current for I

2

t monitoring is switched off (C0121)

–I

Safety instructions

Residual hazards

2

t monitoring is not adjusted to the motor (C0120)

1

EDSLCMX3024-SPS EN 5.0

9

Page 10

1

1.3 Definition of notes used

Safety instructions

Definition of notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Danger of property damage.

Reference to a possible danger t hat may result in property damage if the

corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

10

EDSLCMX3024-SPS EN 5.0

Page 11

ELCAMWIxxx4SNNPSNN motor starter

2 Device description

2.1 ELCAMWIxxx4SNNPSNN motor starter

Device description

2

Operational controls and connections

Pos. Function Description

Service switch Triple locking

FE Functional earth M6 threaded bolts

X10 Mains connection Connector: Pins, Harting HAN-Modular

X11 Connection for 24 V supply Connector: Pins, Harting HAN-Modular

X21 Motor 1 connection Connector: Socket, Harting HAN-Modular

X31 PROFIBUS input Connector: Pins, 5-pin, M12, B-coded

X32 PROFIBUS output or bus termination Connector: Socket, 5-pin, M12, B-coded

X41 Digital inputs I1, I2 Connector: Socket, 4-pin, M12

X42 Digital inputs I3, I4 Connector: Socket, 4-pin, M12

X45 Digital outputs Q1, Q2 Connector: Socket, 4-pin, M12

X60 Safe inputs, safe outputs Connector: Socket, 26-pin, M27, N-coded

X70 Diagnostic interface Connector: Plug connector, 4-pin

X721)Manual operation Connector: Socket, 8-pin, M12

1)

Designationinproductionlotwith hardware version PB: X20

lcu121_000A

EDSLCMX3024-SPS EN 5.0

11

Page 12

2

Device description

ELCAMWIxxx4SNNPSNN motor starter

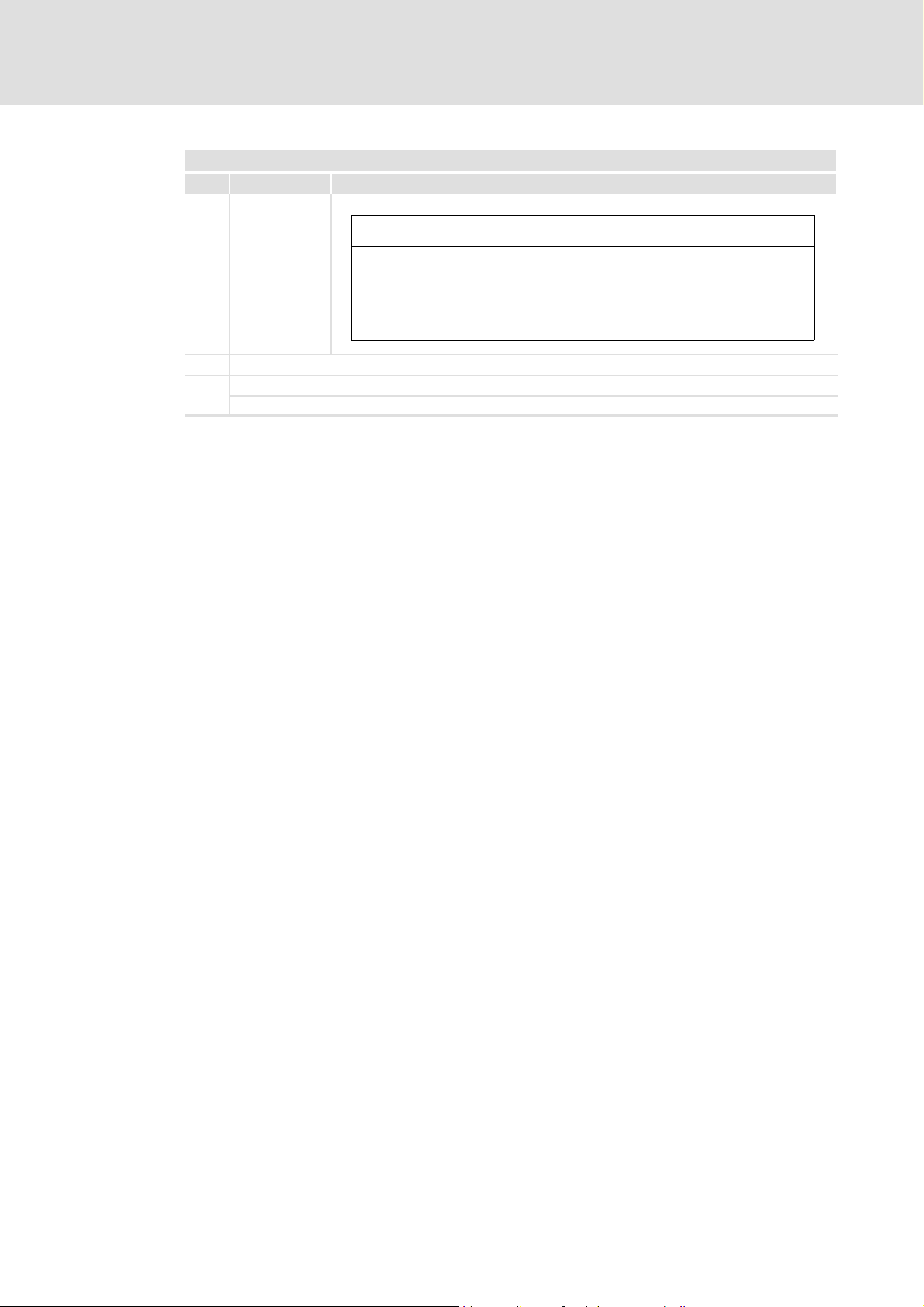

Display elements

Pos. Function

Plain text

display, 4 lines,

20 characters

per line

Status display: device (LED) 159

Status display: fieldbus interface (LED) 160

Status display: drive-based safety (LED) 111

Status ”Operating mode” Status ”Inhibit”

Status ”Motor 1”

”Motor 1 apparent current”

”Error abbreviation” ”Error in plain text”

12

EDSLCMX3024-SPS EN 5.0

Page 13

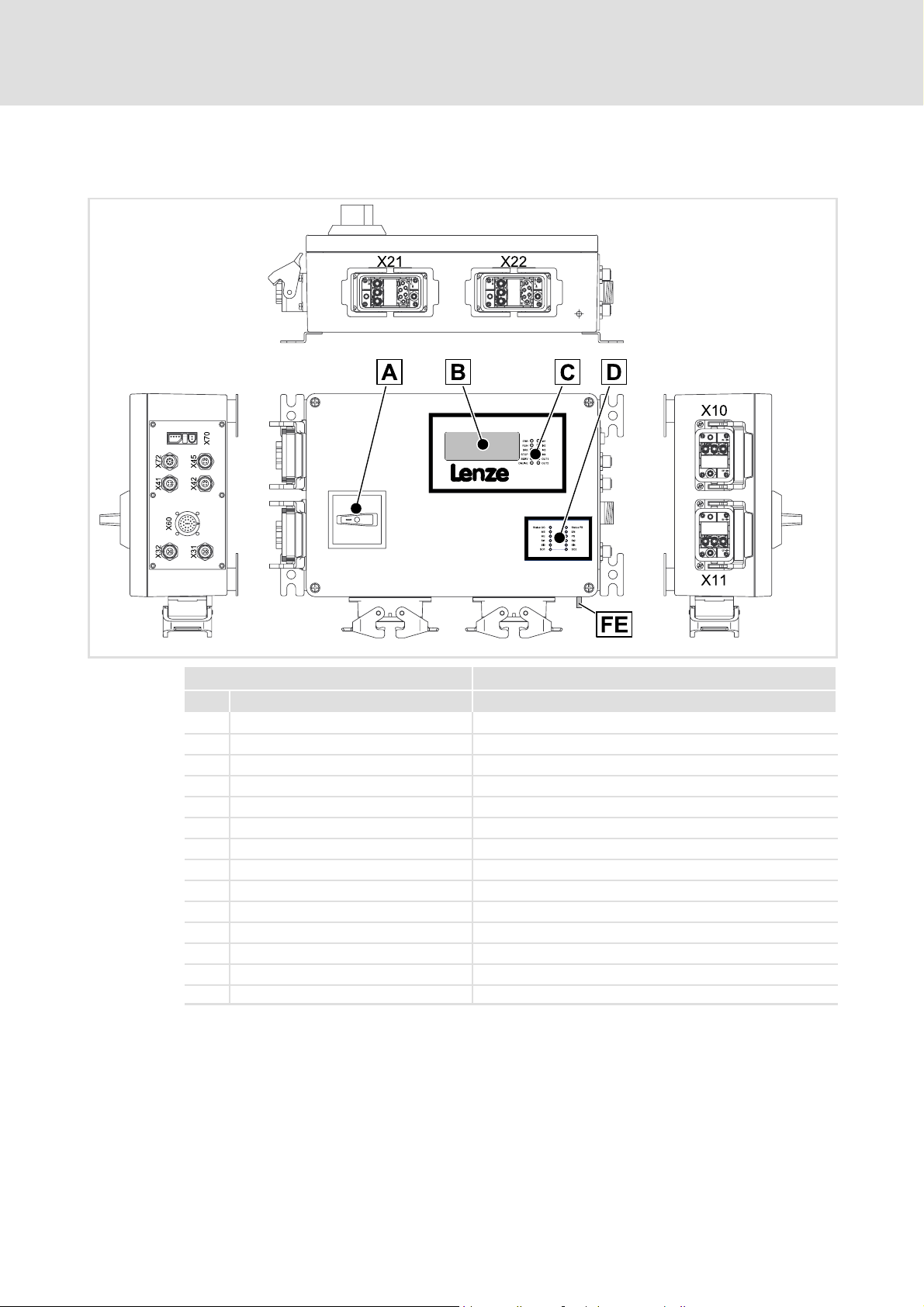

2.2 ELCAMZIxxx4SNNPSNN motor starter

Device description

ELCAMZIxxx4SNNPSNN motor starter

2

Operational controls and connections

Pos. Function Description

Service switch Triple locking

FE Functional earth M6 threaded bolts

X10 Mains connection Connector: Pins, Harting HAN-Modular

X11 Connection for 24 V supply Connector: Pins, Harting HAN-Modular

X21 Motor 1 connection Connector: Socket, Harting HAN-Modular

X22 Motor 2 connection Connector: Socket, Harting HAN-Modular

X31 PROFIBUS input Connector: Pins, 5-pin, M12, B-coded

X32 PROFIBUS output or bus termination Connector: Socket, 5-pin, M12, B-coded

X41 Digital inputs I1, I2 Connector: Socket, 4-pin, M12

X42 Digital inputs I3, I4 Connector: Socket, 4-pin, M12

X45 Digital outputs Q1, Q2 Connector: Socket, 4-pin, M12

X60 Safe inputs, safe outputs Connector: Socket, 26-pin, M27, N-coded

X70 Diagnostic interface Connector: Plug connector, 4-pin

X72 Manual operation Connector: Socket, 8-pin, M12

lcu122_000A

EDSLCMX3024-SPS EN 5.0

13

Page 14

2

Device description

ELCAMZIxxx4SNNPSNN motor starter

Plain text display

Pos. Function

Plain text

display, 4 lines,

20 characters

per line

Status display: device (LED) 159

Status display: fieldbus interface (LED) 160

Status display: drive-based safety (LED) 111

Status ”Operating mode” Status ”Inhibit”

Status ”Motor 1” Status ”Motor 2”

”Motor 1 apparent current” ”Motor 2 apparent current”

”Error abbreviation” ”Error in plain text”

14

EDSLCMX3024-SPS EN 5.0

Page 15

General data and operating conditions

3 Technical data

3.1 General data and operating conditions

General data Values

Conformity CE Low-Voltage Directive (73/23/EEC)

Standards

General technical data Values

EMC Compliance with the requirements in accordance with EN 60947-4-2

Noise emission Compliance with limit class B in accordance with EN 60947-4-2

Leakage current to PE

(according to EN 50178)

Enclosure

Protective measures against Motor overtemperature

Protective insulation of c ontrol

circuits

Insulation resistance Overvoltage category III to VDE 0110

Service switch Rotary switch, triple locking

DIN EN 60947-4-2 Semiconductor motor control units and motor starters for

EN954 KAT3 Safe torque off (STO) according to category 3

<3.5mA

IP 54

NEMA 250 type 4

(input for PTC or thermal contact, I

Safe disconnection from mains:

double/reinforced insulation to EN 50178

reset feedback contact for status message and fault message (TRIP reset)

Technical data

EMC Directive (93/68/EEC)

AC voltage

All connectors that are not used have to be closed by

means of protection covers or blanking plugs.

2

t monitoring)

3

EDSLCMX3024-SPS EN 5.0

15

Page 16

3

Technical data

General data and operating conditions

Operating conditions Values Deviating values

Mechanical tests

Accelerational stability Up to 1 g in accordance with

Vibration resistance In accordance with EN 50178 or

Shock resistance 2m2 in accordance with

Ambient conditions

Climatic conditions

Storage 1k3 in accordance with

Transport 2k3 in accordance with

Operation 3k3 in accordance with

Site altitude 0 ... 4000 m amsl Reduce the rated output current by 5%/1000

Degree of pollution 2 in accordance with VDE 0110 part 2

Mounting location

Mounting positions

vertical Motor plug downwards

horizontal Front cover upwards

Mounting clearances

to the sides

Germanischer Lloyd, general

conditions

EN 60068-2-6

IEC/EN 60721-3-2

IEC/EN 60721-3-1

IEC/EN 60721-3-2

IEC/EN 60721-3-3

21 Theactualfreespaceisdeterminedbythe

above

below

-25 °C ... +70 °C

-10 °C ... +45 °C

m above 1000 m amsl.

connectors used and the cable bending radii.

16

EDSLCMX3024-SPS EN 5.0

Page 17

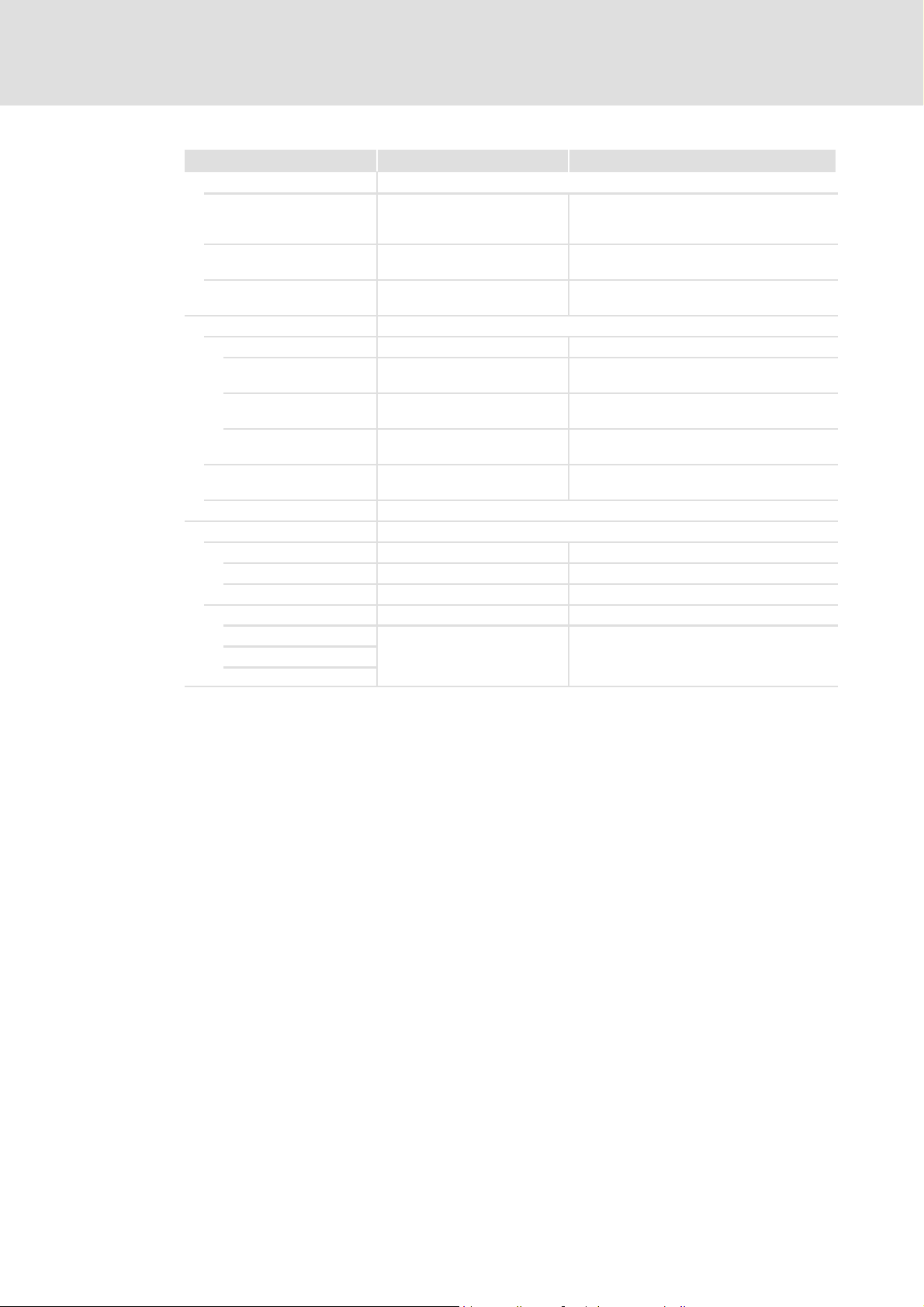

3.2 Rated data

Motor starter type ELCAMxI 7514SNNPSNN 1524SNNPSNN 2224SNNPSNN 3024SNNPSNN

Supply voltage (safely separated power supply unit SELV/PELV)

Voltage range U

Current consumption at

+24VDC

Motor switch

Mains voltage

(switched voltage)

Cyclic switching Max. 600 switchings / h

Cable protection 16 A, integrated into the housing

Max. motor power

(total power of connected

Lenze motors)

Max. continuous output

current

(sum of the output currents)

Brake switch (AC3 contact)

Output voltage U

Max. output current IB[A] 0.4

Cyclic switching Max. 600 switchings / h

Control connections

Digital inputs 4 (X41, X42)

Digital outputs 2 (X45)

Safe inputs 4 (X60)

Safe outputs 2 (X60)

Manual operation 1 (X72)

Sum of all input currents and

output currents on X41, X42,

X45, X60, X72

Monitoring functions

Motor protection switch I2t monitoring, tripping classes adjustable

Motor temperature PTC thermistor (PTC) or thermal contact (NC contact)

Device protection I2t monitoring class 10A,

Mains failure control Yes

Load failure control Yes, programmable switch-off limit

Mass Approx.

Technical data

Rated data

DC

U

N

PN[kW] 0.75 1.5 2.2 3.0

IN[A] 2.0 3.5 5.0 7.0

B

[A] Max. 1.3

max. Irclass 10A [A] 2.0 3.5 5.0 7.0

max. Irclass 10 [A] 1.7 3.3 4.8 6.5

max. Irclass 20 [A] 1.5 3.0 4.4 6.0

max. Irclass 30 [A] 1.3 2.5 3.8 5.0

[kg]

+ 24 V DC (+20 V DC - 0% ... +26.5 V DC + 0%)

Min. 1 A (no digital inputs and outputs connected)

Max. 5 A (all digital inputs and outputs connected)

3/PE AC 320 V - 0% ... 530 V + 0%; 45 Hz - 0% ... 65 Hz + 0%

= mains voltage

2

t tripping characteristic: 19)

(I

relating to max. continuous output current

5.5 5.5 5.5 5.5

3

EDSLCMX3024-SPS EN 5.0

17

Page 18

3

Technical data

Rated data

Note!

The motor starters are designed for rated currents between 1 A and 7 A.

If motors with rated currents < 1 A are operated on the motor starters, please

observe the following:

ƒ The internal I

– Switch off the internal I

– Use a PTC or thermal contact (NC contact) to monitor the motor

temperature

– Appropriate external motor protection switches can be used in addition.

ƒ The mains phase failure control can respond during operation, although no

main failure has occurred.

– Deactivate the mains phase failure control (C0122 = 3) to ensure that the

drive will not switch off with an error message.

2

xt monitoring cannot be used because of the low current.

2

xt monitoring (C0121 = 0).

18

EDSLCMX3024-SPS EN 5.0

Page 19

Technical data

Rated data

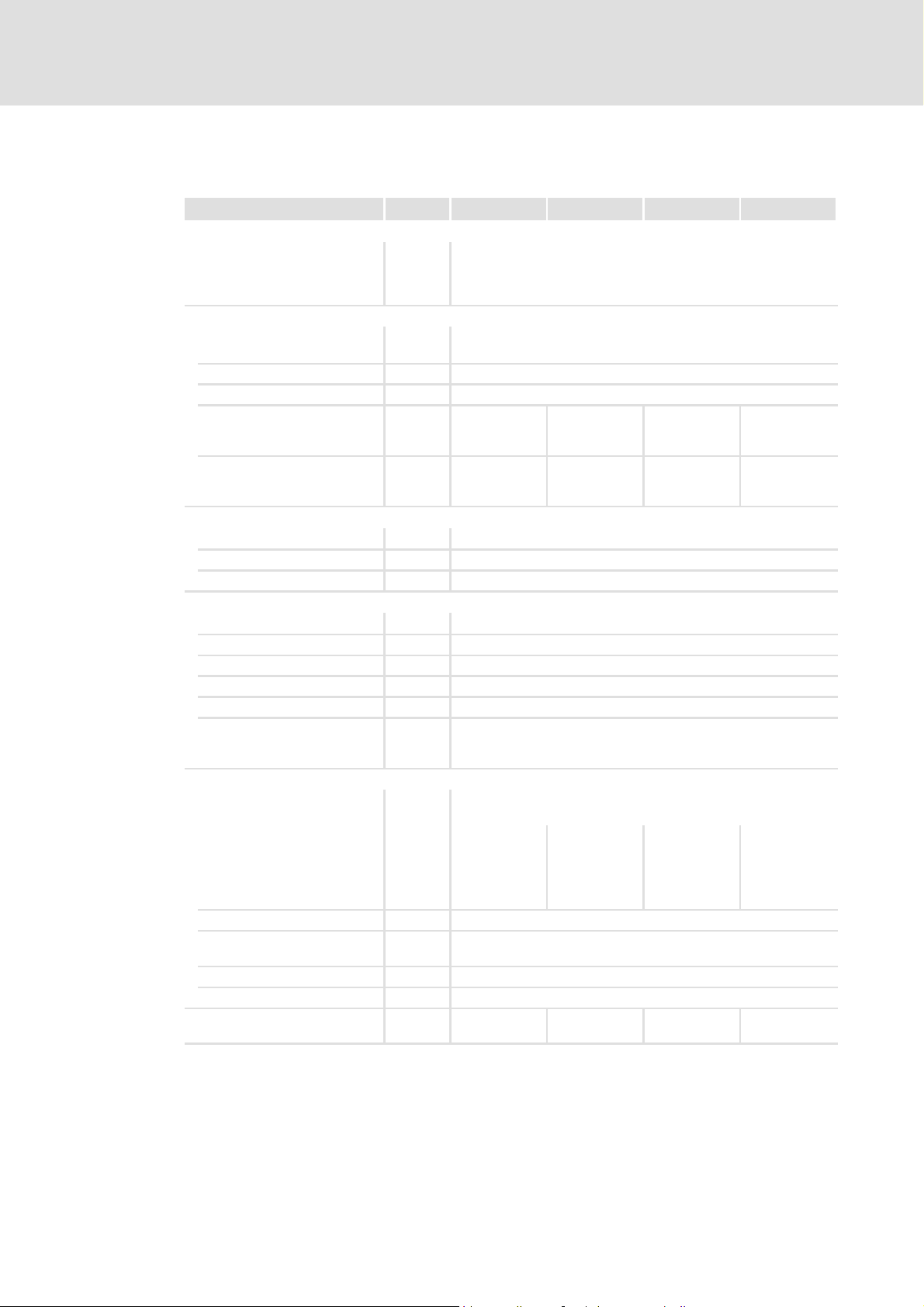

I2t tripping characteristic:

According to DIN EN 60947-4-2 (AC semiconductor motor controllers and starters)

8

7.2

6

5

r

I/I

1.05

4

3

2

0.01 0.1 1 10 100 1000 100000.02

Class 10A

Class 10

t [s]

Class 20

Class 30

3

start031

Tripping classes

Class 10A

Class 10

= Lenze setting

Class 20

Class 30

I = Output current

I

r

Example for

Class 10:

= Rated motor current, can be set in C0120

The motor starter shuts down with an error message, if the output current I measures 4 times

the set rated motor current I

Note!

Regardless of the tripping class set, the motor starter always shuts down if the

output current I measures 8 times the set rated motor current I

Tripping classes, can be set in C0121

for approx. 13 s.

r

for 20 ms.

r

EDSLCMX3024-SPS EN 5.0

19

Page 20

4

Mechanical installation

Dimensions

4 Mechanical installation

4.1 Dimensions

20

lcu12x_000b

EDSLCMX3024-SPS EN 5.0

Page 21

4.2 Mounting clearance

Mechanical installation

Mounting clearance

4

lcu12x_000f

EDSLCMX3024-SPS EN 5.0

21

Page 22

5

Electrical installation

Important notes

5 Electrical installation

5.1 Important notes

Note!

ƒ Please keep the plastic covers on the connectors for the control connections

and interfaces!

ƒ Cover unused connections during transport, storage and operation with the

plastic covers to preserve the certified safety engineering features.

Danger!

ƒ The X2x power connector contacts can conduct hazardous voltages if the

motor starter is connected to the mains. Therefore, disconnect the motor

starter before carrying out any work on it.

ƒ All control terminals feature only basic insulation (single isolating distance)

following the connection of a PTC thermistor (PTC) or a thermal switch (NC

contact):

– Protection against accidental contact with defective isolating distance can

only be ensured through external measures, e.g. double insulation.

ƒ To avoid injury to persons and breakdowns, it is essential that the motor

starter is properly earthed via X10!

Stop!

Ensure trouble-free operation of the motor starter:

ƒ Avoid compensating currents via the PROFIBUS cable shield:

– For this, connect all devices with a 16 mm

– Lay cable in parallel to bus cable.

– Use a copper braid cable to connect the FE bolts with the mounting

surface.

ƒ Properly lock the connector plugs.

2

cableviatheFEbolts.

22

EDSLCMX3024-SPS EN 5.0

Page 23

EMC-compliant wiring

Note!

ƒ Use a copper braid cable to connect the PE bolt with the mounting surface.

ƒ Separate control and data cables from motor cables.

ƒ Connect control and data cable shields at both ends.

Integrated safety engineering

Note!

Please observe during transport, storage and operation:

ƒ Cover unused connectors for control connections and interfaces with the

plastic covers provided to preserve the certified safety technology features.

Electrical installation

Important notes

5

EDSLCMX3024-SPS EN 5.0

23

Page 24

5

Electrical installation

Basic circuit diagram

ELCAMWIxxx4SNNPSNN motor starter

5.2 Basic circuit diagram

5.2.1 ELCAMWIxxx4SNNPSNN motor starter

BS1

X10

3/PE AC 400 V

PE

a

F1

16 A

K1

4 * 2.5 mm

1

2 3

S0

STO

K2

~

2

X11

24 V DC

-

+

b

1

2 3

C

X31

X32

FE

PROFIsafe

FE

PROFIsafe

FE

X60

L1

L2

L3

N

PE

1 2 3 4 5 6

ca

X21

~ ~ S1 S2

- +

BRK1

1 2 3

PE

PE

V1

U1

Th

M

3~

PE

W1

F1 Cable protection (observe cable protection standards for fuse dimensioning!)

K1 Main contactor

K2 Contactor for 24 V supply

FE Functional earth for compliance with EMC conditions, prevents compensating currents

via the PROFIBUS cable shield

S0 Service switch

BS1 Brake control, motor 1

BRK1 Spring-operated brake, motor 1

Th PTC thermistor (PTC) or thermal contact (NC contact)

STO SafetorqueoffviaPROFIsafe

lcu121_001

24

EDSLCMX3024-SPS EN 5.0

Page 25

5.2.2 ELCAMZIxxx4SNNPSNN motor starter

Basic circuit diagram for normal operation

Electrical installation

Basic circuit diagram

ELCAMZIxxx4SNNPSNN motor starter

5

BS1

X10

3/PE AC 400 V

PE

a

F1

16 A

K1

4* 2.5 mm

1

2 3

S0

STO

K2

~

2

X11

24 V DC

-

+

b

1

2 3

C

BS2

X31

X32

FE

PROFIsafe

FE

PROFIsafe

FE

X60

L1

L2

L3

N

PE

1 2 3 4 5 6

ca

X21

~ ~ S1 S2

- +

BRK1

1 2 3

PE

PE

V1

U1

Th

M

3~

PE

W1

1 2 3 4 5 6

c

X22

~ ~ S1 S2

- +

BRK2

F1 Cable protection (observe cable protection standards for fuse dimensioning!)

K1 Main contactor

K2 Contactor for 24 V supply

FE Functional earth for compliance with EMC conditions, prevents compensating currents

via the PROFIBUS cable shield

S0 Service switch

BS1 Brake control, motor 1

BRK1 Spring-operated brake, motor 1

BS2 Brake control, motor 2

BRK2 Spring-operated brake, motor 2

Th PTC thermistor (PTC) or thermal contact (NC contact)

STO SafetorqueoffviaPROFIsafe

1 2 3

PE

PE

U1

Th

a

V1

M

3~

PE

W1

lcu122_001

EDSLCMX3024-SPS EN 5.0

25

Page 26

5

Electrical installation

Basic circuit diagram

ELCAMZIxxx4SNNPSNN motor starter

Basic circuit diagram for reversing operation

BS1

2

3/PE AC 400 V

K10

F1

16 A

K2

L1

L2

L3

N

PE

4 * 2.5 mm

~

X10

K1

PE

a

1

2 3

S0

STO

X11

24 V DC

-

+

b

1

2 3

μC

BS2

X31

X32

FE

PROFIsafe

FE

PROFIsafe

FE

X60

1 2 3 4 5 6

ca

X21

~ ~ S1 S2

- +

BRK1

1 2 3

PE

PE

V1

U1

Th

M

3~

PE

W1

1 2 3 4 5 6

c

X22

~ ~ S1 S2

- +

BRK2

F1 Cable protection

Observe cable protection standards for fuse dimensioning!

K1 Main contactor

K10 Contactor relay: Changeover between normal operation and reversing operation

K2 Contactor for 24 V supply

FE Functional earth for compliance with EMC conditions, prevents compensating currents

via the PROFIBUS cable shield

S0 Service switch

BS1 Brake control, motor 1

BRK1 Spring-operated brake, motor 1

BS2 Brake control, motor 2

BRK2 Spring-operated brake, motor 2

Th PTC thermistor (PTC) or thermal contact (NC contact)

STO SafetorqueoffviaPROFIsafe

1 2 3

PE

PE

U1

Th

a

V1

M

3~

PE

W1

lcu122_010

26

EDSLCMX3024-SPS EN 5.0

Page 27

5.3 Mains connection

X10 - Mains connection

Pin Connection Description Data

a1 L1 Phase L1

a2 L2 Phase L3

a3 L3 Phase L3

PE PE conductor

Electrical installation

Mains connection

Connector: Pins, Harting HAN-Modular

3/PE AC 320 V - 0% ... 530 V + 0%

5

lcu12x_000c

X11 - 24 V DC connection

Pin Connection Description Data

Connector: Pins, Harting HAN-Modular

b1 24 V DC Voltage supply for control electronics

b2 n. c. Not assigned

b3 GND Reference potential

Safely separated power supply unit

(SELV/PELV)

+24 V DC

(+20 V DC - 0% ... +26.5 V DC + 0%)

Max. 5 A

EDSLCMX3024-SPS EN 5.0

27

Page 28

5

Electrical installation

Motor connection

ELCAMWIxxx4SNNPSNN motor starter

5.4 Motor connection

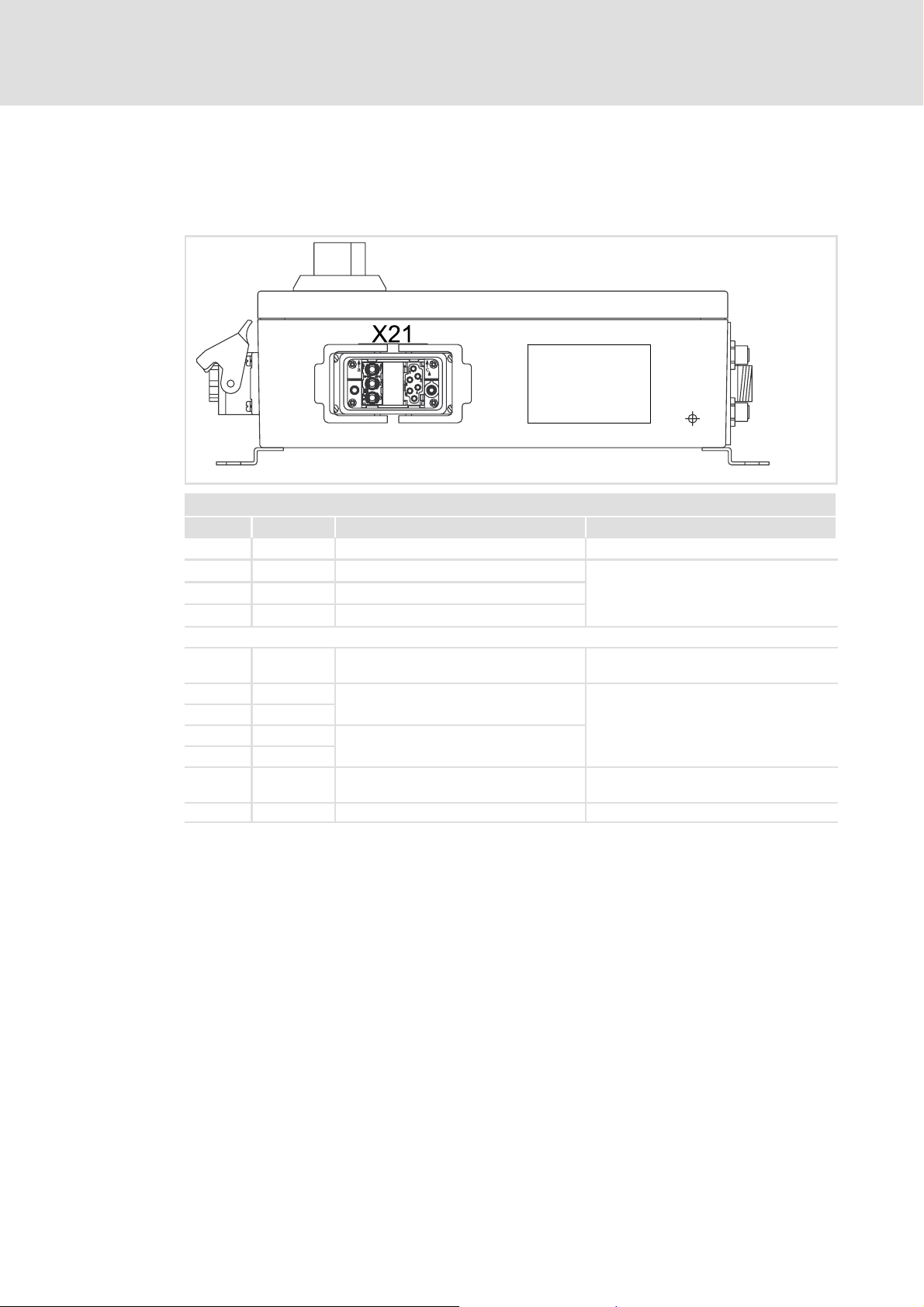

5.4.1 ELCAMWIxxx4SNNPSNN motor starter

X21 - Motor 1 connection

Pin Connection Description Data

a1 U1 Phase U1

a2 V1 Phase V1

a3 W1 Phase W1

lcu121_000d

Connector: Socket, Harting HAN-Modular

Output voltage = mains voltage

Max. continuous output current

dependent on type

(sum of all output currents)

c1 +PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact

c2 ~

c3 ~

c4 S1

c5 S2

c6 -PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact

PE PE conductor

Brake rectifier supply voltage The brake rectifier is installed in the motor

Switch for disconnection on the DC side

(NC contact)

terminal box

(NC contact)

28

EDSLCMX3024-SPS EN 5.0

Page 29

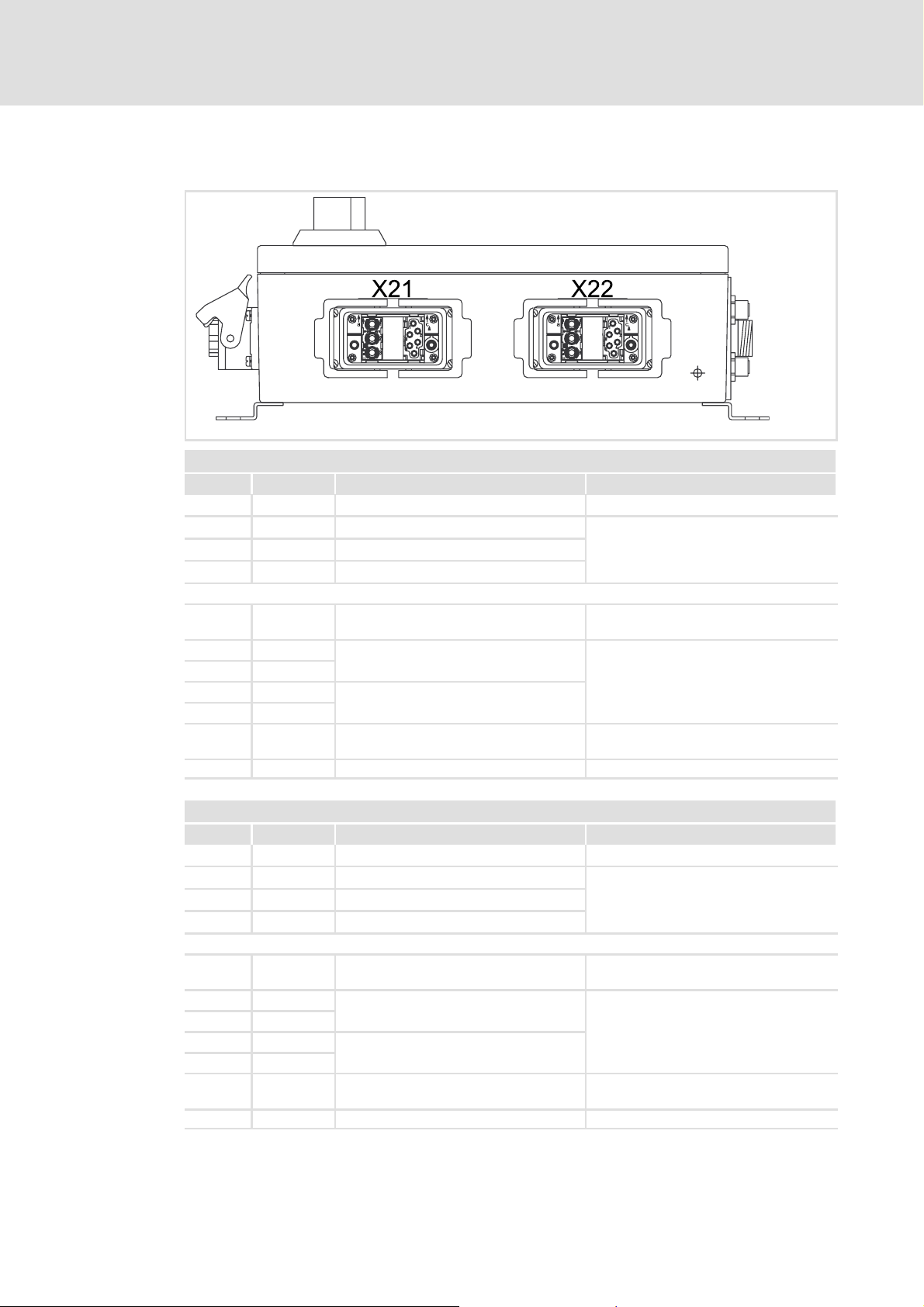

5.4.2 ELCAMZIxxx4SNNPSNN motor starter

X21 - Motor 1 connection

Pin Connection Description Data

a1 U1 Phase U1

a2 V1 Phase V1

a3 W1 Phase W1

Electrical installation

Motor connection

ELCAMZIxxx4SNNPSNN motor starter

Connector: Socket, Harting HAN-Modular

Output voltage = mains voltage

Max. continuous output current

dependent on type

(sum of all output currents)

5

lcu122_000d

c1 +PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact

c2 ~

c3 ~

c4 S1

c5 S2

c6 -PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact

PE PE conductor

X22 - Motor 2 connection

Pin Connection Description Data

a1 U1 Phase U1

a2 V1 Phase V1

a3 W1 Phase W1

c1 +PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact

c2 ~

c3 ~

c4 S1

c5 S2

c6 -PTC Motor temperature monitoring PTC thermistor (PTC) or thermal contact

PE PE conductor

Brake rectifier supply voltage The brake rectifier is installed in the motor

Switch for disconnection on the DC side

Brake rectifier supply voltage The brake rectifier is installed in the motor

Switch for disconnection on the DC side

(NC contact)

terminal box

(NC contact)

Connector: Socket, Harting HAN-Modular

Output voltage = mains voltage

Max. continuous output current

dependent on type

(sum of all output currents)

(NC contact)

terminal box

(NC contact)

EDSLCMX3024-SPS EN 5.0

29

Page 30

5

5.5 Safety engineering

Electrical installation

Safety engineering

Please observe the following safety instructions and application notes to preserve the

certified safety engineering features and to ensure trouble-free and safe operation.

Danger!

Danger to life through improper installation

Improper installation of the safety engineering systems can cause an

uncontrolled restart of the drives.

Possible consequences:

ƒ Death or severe injuries

Protective measures:

ƒ Safety engineering systems may only be installed and commissioned by

qualified and skilled personnel.

ƒ All control components (switches, relays, PLC, ...) and the control cabinet

must comply with the requirements of EN 954-1 and ISO 13849-2. This

includes i.a.:

– Switches, relays in IP54 enclosure.

– Control cabinet in IP54 enclosure.

– Please refer to EN 954-1 and ISO 13849-2 for all further requirements.

ƒ It is essential to use insulated wire end ferrules for wiring.

ƒ If safety-relevant cables are installed outside the control cabinet, they have

to be protected, e.g. by means of a cable duct:

– Ensure that there are no short circuits.

– For further measures see ISO 13849-2.

ƒ If an external force acts upon the drive axes, additional brakes are required.

Please observe that hanging loads are subject to the force of gravity!

30

Danger!

Danger to life through improper installation

Improper installation of the safety engineering systems can cause an

uncontrolled restart of the drives.

Possible consequences:

ƒ Death or severe injuries

Protective measures:

Total cable length between X60 and the connected components (e.g. sensors,

devices, etc.) > 3 m:

ƒ It is essential to shield the cable installed between X60 and the connected

components:

– Connect the shield at least to X60 in the connector shell.

– If possible, connect the shield to the connected component as well.

Total cable length between X60 and the connected components (e.g. sensors,

devices, etc.) < 3 m:

ƒ Unshielded wiring is permitted.

EDSLCMX3024-SPS EN 5.0

Page 31

Note!

Please observe during transport, storage and operation:

ƒ Cover unused connectors for control connections and interfaces with the

plastic covers provided to preserve the certified safety technology features.

Note!

The sums of all inputs currents and output currents on X41, X42, X45, X60 and

X72maybemax.1.3A.

If the total current is higher, the device switches off!

Electrical installation

Safety engineering

5

EDSLCMX3024-SPS EN 5.0

31

Page 32

5

Electrical installation

Safety engineering

lcu12x_000e

X60 - Safe inputs, safe outputs

Pin Signal Description Data

Connector: Socket, 26-pin, M27, N-coded

1 O1A Output 1 channel A

2 O1B Output 1 channel B

3 GO Reference potential for O1A and O1B

4 O2A Output 2 channel A

5 O2B Output 2 channel B

6 GO Reference potential for O2A and O2B

7 CLB Clock output, channel B

8 CLA Clock output, channel A

9 GCL Reference potential for CLA and CLB

10 I1A Sensor input 1, channel A

11 I1B Sensor input 1, channel B

12 GI1 Reference potential for I1A and I1B

13 I2A Sensor input 2, channel A

14 I2B Sensor input 2, channel B

15 GI2 Reference potential for I2A and I2B

16 I3A Sensor input 3, channel A

17 I3B Sensor input 3, channel B

18 GI3 Reference potential for I3A and I3B

19 I4A Sensor input 4, channel A

20 I4B Sensor input 4, channel B

21 GI4 Reference potential for I4A and I4B

22 n. c. Not assigned

23 n. c. Not assigned

24 n. c. Not assigned

25 n. c. Not assigned

26 n. c. Not assigned

Only for passive sensors

Only for equivalently switching passive

sensors

Only for equivalently switching passive

sensors

Only for active sensors

Only for active sensors

32

EDSLCMX3024-SPS EN 5.0

Page 33

Electrical installation

Safety engineering

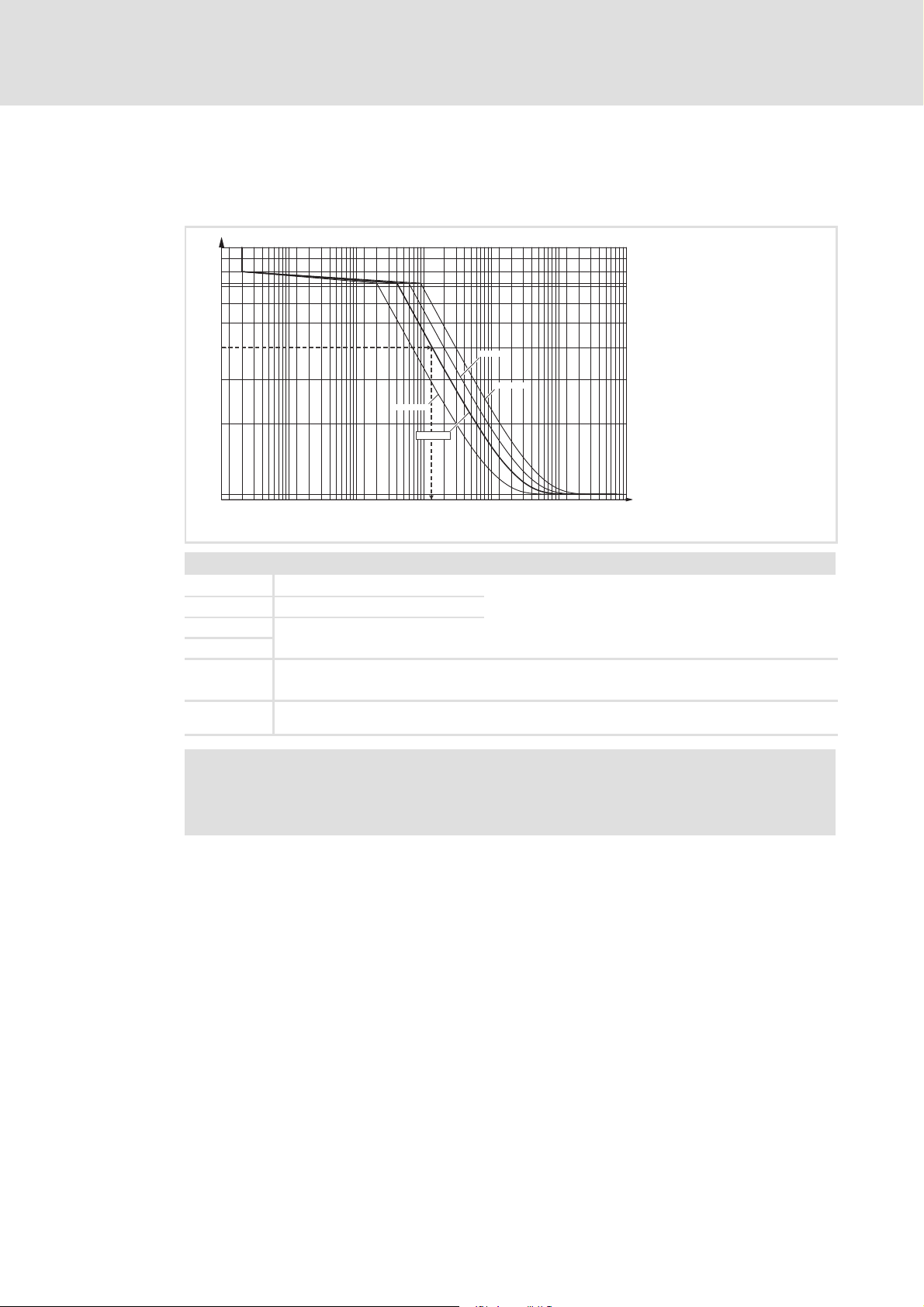

Detail characteristics of the safe inputs and safe outputs

Signal Specification Min. Typ. Max.

I1A, I1B

I2A, I2B

I3A, I3B

I4A, I4B

CLA, CLB

O1A, O1B

O2A, O2B

PLC input, IEC-61131-2, 24 V, type 1

LOW signal [V] -3 0 5

Input current [mA] 15

HIGH signal [V] 15 24 30

Input current [mA] 2 15

Input capacitance [nF] 3.3

Switch-off time (depending on the standard device) [ms] 2 4

Switch-on time [ms] 2 4

Input delay (tolerated test pulse) [ms] 1

PLC output, IEC-61131-2, 24 V DC, 50 mA

Supply voltage of the outputs [V] 18 24 30

LOW signal [V] 0 0.8

HGH signal [V] 17 24 29

Output current [mA] 50

Width of test pulse [μs] 750

Frequency of test pulse [s] 1 1.8 3

Specific resistance of a passive sensor [kΩ] 2

PLC output, IEC-61131-2, 24 V DC, short-circuit-proof

Supply voltage of the outputs [V] 18 24 30

Output voltage for LOW signal [V] 0 0.8

Output voltage for HIGH signal [V] 17 24 29

Output current [mA] 500

Width of test pulse [μs] 750 900

Frequency of test pulse [s] 1 1.8 3

5

EDSLCMX3024-SPS EN 5.0

33

Page 34

5

Electrical installation

Control terminals

5.6 Control terminals

Note!

The sums of all inputs currents and output currents on X41, X42, X45, X60 and

X72maybemax.1.3A.

If the total current is higher, the device switches off!

Digital inputs

X41 - Digital inputs I1, I2

Pin Signal Description Data

Connector: Socket, 4-pin, M12

1 +24 V Supply

2 Sign al 2 I2 HIGH +13 .... 26.5 V DC

3

4

X42 - Digital inputs I3, I4

Pin Signal Description Data

1 +24 V Supply

2 Sign al 2 I4 HIGH +13 .... 26.5 V DC

3

4

GND Reference potential LOW 0...+4V

Signal 1 I1 8mAat24VDC

Connector: Socket, 4-pin, M12

GND Reference potential LOW 0...+4V

Signal 1 I3 8mAat24VDC

lcu12x_000e

34

EDSLCMX3024-SPS EN 5.0

Page 35

Electrical installation

Control terminals

Digital outputs

Note!

If inductive loads are being connected, it is essential to use a spark suppressor

at the digital output.

X45 - Digital outputs O1, O2

Pin Signal Description Data

Connector: Socket, 4-pin, M12

1 +24 V Supply

2 Sign al 1 O1 HIGH UDCat X11

3

4

Diagnostic interface

X70 - Diagnostic interface

Pin Signal Description Data

1 ... 4 Connection for handheld keypad or PC

GND Reference potential LOW 0...+4V

Signal 2 O2 Max. 500 mA

interface

Connector: Plug connector, 4-pin

Connection only possible using a Lenze

system cable E82ZWLxxx

Only use PC interfaces featuring electrical

isolation:

LECOM-A (RS232) EMF2102IBCV004 or

LECOM A/B (RS232/RS485)

EMF2102IBCV001

5

Automatic / manual operation

Note!

Manual operation is only possible if the motor starter is enabled by the safety

PLC!

X721)- Manual operation

Pin Signal Description Data

Connector: Socket, 8-pin, M12

1 +24 V Supply (switch in manual operation)

2 Sign al 1 Input automatic/manual operation

3

4 HI1 Input 1 HIGH CW rotation

5 HI2 Input 2 HIGH CCW rotation

6 ... 8 Reserved

1)

GND Reference potential

Designationinproductionlotwith hardware version PB: X20

HIGH Manual operation

LOW Automatic operation

EDSLCMX3024-SPS EN 5.0

35

Page 36

5

Electrical installation

Communication

5.7 Communication

Stop!

High compensation currents

High compensating currents can flow via the PROFIBUS cable shield.

Possible consequences:

Property damage or operational malfunction

Protective measures:

Avoid compensation currents via the PROFIBUS cable shield:

ƒ Connect all PROFIBUS stations with a 16 mm

ƒ Lay this cable in parallel to the bus cable.

ƒ Use copper braid cable to establish a conductive connection between the FE

bolts and the mounting surface.

2

cableviatheFEbolts.

lcu12x_001j

FE Functional earth for compliance with EMC conditions, prevents compensating currents

16 mm

via the PROFIBUS cable shield

2

equalizing conductor

36

EDSLCMX3024-SPS EN 5.0

Page 37

Electrical installation

X31 - PROFIBUS input

Pin Signal Description Data

Connector: male, 5-pin, M12, B-coded

1 n. c. Not assigned

2 A Data line A

3 n. c. Not assigned

4 B Data line B

5 Shld Shield

PROFIBUS-DP-V1

Max. 12 Mbps

5

Communication

lcu121_000i

X32 - PROFIBUS output

Pin Signal Description Data

Connector: female, 5-pin, M12, B-coded

1 VP +5 V for bus termination

2 A Data line A

3 GND Reference potential for bus termination

4 B Data line B

5 Shld Shield

PROFIBUS-DP-V1

Max. 12 Mbps

Bus termination via separate bus

terminating connector

Note!

Plug the bus terminating connector on the last bus station to ensure

trouble-free operation of the PROFIBUS.

EDSLCMX3024-SPS EN 5.0

37

Page 38

5

Electrical installation

Communication

Basic structure of a PROFIBUS network with RS485 cabling without repeater

1

M

333

SSS

222

< 1200 m

0m

lcu12x_005

No. Element Comment

1Host E.g. PC or PLC with PROFIBUS master interface module

2 Bus cable Adapt baud rate to bus cable length

3 PROFIBUS slave Device with PROFIsafe on board

Note!

If a repeater is used, max. 125 stations can communicate via the PROFIBUS.

Please observe the following when wiring

ƒ Do not change the bus topology, i.e. do not use stubs.

ƒ Observe the notes and wiring regulations in the documentation for the control

system.

ƒ Do not use cables other than s pecified in the specifications. ( 40).

ƒ Plug bus terminating connector on X32 at the last bus station. Ensure that the

PROFIBUS is also terminated at the first bus station (master).

38

EDSLCMX3024-SPS EN 5.0

Page 39

Electrical installation

Communication

Number of bus stations

M

RR

SS S S S

123

Segment Master (M) Slave (S) Repeater (R)

1 1

2

2 - 30 1

3 - 30 1

31

30

-

-

5

2133PFB004

Tip!

Repeaters do not have a station address but in the calculation of the

maximum number of stations they reduce the number of stations by 1 on

each side of the segment.

Repeaters can be used to build up line and tree topologies. In this case, the

maximum total bus system expansion depends on

ƒ the baud rate used

ƒ the number of repeaters used

EDSLCMX3024-SPS EN 5.0

39

Page 40

5

Electrical installation

Communication

Baud rate / bus cable length

Baud rate [kbps] Length [m]

9.6 - 93.75 1200

187.5 1000

500 400

1500 200

3000 - 12000 100

Note!

Ensure that the baud rate depending on the amount of data, cycle time and

number of stations is only selected as high as required for the application.

Specification of the transmission cable

Please follow the specifications of the PROFIBUS user organisation (PUO) for signal cables:

Bus cable specification

Specific resistance 135 - 165 Ω/km,(f=3-20MHz)

Capacitance per unit length ≤ 30 nF/km

Loop resistance < 110 Ω/km

Core diameter >0.64mm

Core cross-section >0.34mm

Cores Double twisted, insulated and shielded

2

40

EDSLCMX3024-SPS EN 5.0

Page 41

5.8 Final works

Note!

Please observe during transport, storage and operation:

ƒ Cover unused connectors for control connections and interfaces with the

Electrical installation

Final works

plastic covers provided to preserve the certified safety technology features.

5

EDSLCMX3024-SPS EN 5.0

41

Page 42

6

PROFIsafe on board

Technical data

General data and operating conditions

6PROFIsafeonboard

6.1 Technical data

6.1.1 General data and operating conditions

Area Values

PNO ID number 0951

Communication profile

(DIN 19245 part 1 and part 3)

Communication medium RS485

Network topology Without repeater: line / with repeaters: line or tree

PROFIBUS station Slave

Baud rate [kbps] 9.6 ... 12000 (automatic recognition)

Process data words (PCD)

(16 bits)

PROFIBUS user data length Parameter data channel (4 words) +

PROFIsafe user data 4words

Max. number of stations Standard:32(=1bussegment)/withrepeaters:125

Max. cable length per bus

segment

hex

z PROFIBUS-DP-V0

z PROFIBUS-DP-V1

z PROFIsafe

1word...10words

process data words (1 ... 10 words)

1200 m (depending on the baud rate and cable type used)

6.1.2 Protective insulation

Protective insulation between bus

and ..........

Power connections Basic insulation

PE Basic insulation

24 V supply Functional insulation

Type of insulation according to EN 61800-5-1

42

EDSLCMX3024-SPS EN 5.0

Page 43

6.1.3 Communication times

Tip!

The communication time is the time between the start of a request and the

arrival of the corresponding response.

The PROFIBUS communication times depend on:

ƒ Processing time in the controller

ƒ Transmission delay time

– Transmission rate (baud rate)

– Telegram length

Processing time in the motor starter

The parameter data and process data are independent of each other.

ƒ Parameter data: approx. 30 ms + 20 ms tolerance

PROFIsafe on board

Technical data

Communication times

6

ƒ Process data: approx. 3 ms + 2 ms tolerance

ƒ PROFIsafe

The PROFIsafe communication time depends on the PROFIsafe cycle time. This time is

defined by the F-CPU. It depends on the F-WD time that is set and on the set cycle time

of the monitoring OB in the control.

ƒ PROFIsafe process data in the motor starter:

– F-input data: max. 14 ms

– F-output data: max. 24 ms

EDSLCMX3024-SPS EN 5.0

43

Page 44

6

PROFIsafe on board

Establishing of PROFIBUS communication

Configuration of the host

6.2 Establishing of PROFIBUS communication

6.2.1 Configuration of the host

Device data base file

By means of the device data base file (GSE file), the PROFIBUS is configured.

Note!

IntheGSEfileyoucanselectthetypeoftheparameterdatachannelused

(DRIVECOM or PROFIdrive) and the number of the process data words.

Settings on the master

In the GSE file ”LENZ0951.GSE” you’ll find the configurations:

Module

Safety (4W) - 4 words with consistency 2words

Drivecom-PAR (cons.) +PCD(nW)

Drivecom-PAR (cons.) +PCD(nWcons) n words with consistency 4+nwords

PCW (cons.) +PCD(nW)

PCW (cons.) +PCD(nWcons) n words with consistency 4+nwords

PCD (nW) Without parameter data channel n words without consistency nwords

PCD (nW cons) Without parameter data channel n words with consistency nwords

nW = 1 word ... 10 words

Parameter data

with consistency

DRIVECOM

PCW

Process data

with/without consistency

n words without consistency 4+nwords

n words without consistency 4+nwords

Occupied

I/O memory

Procedure:

1. Import the GSE file ”LENZ0951.GSE” for the motor starter in the master.

2. Select the ”Safety (4W)” module received in the GSE file and copy (drag & drop) it to

slot 1.

3. Select one of the other modules and copy it to slot 2.

Adaptation of the device controls

Tip!

Use total consistency

ƒ Please note that the processing of consistent data varies between hosts.

This must be considered in the PROFIBUS application program.

ƒ Detailed description of consistency: see appendix

44

EDSLCMX3024-SPS EN 5.0

Page 45

PROFIsafe on board

Establishing of PROFIBUS communication

Configuration of the host

Defining user data length

Theuser datalength is defined during thePROFIBUS initialisationphase. Youcan configure

up to 10 process data words.

Optionally you can activate a parameter data channel. If the parameter data channel is

active, it additionally occupies 4 words of the process input and process output data.

ƒ PIW: process data input word

(process data from the motor starter to the master)

ƒ POW: process data output word

(process data from the master to the motor starter)

The user data lengths for process input data and process output data are identical. The

selection takes place via identification bytes in the configuration software for the

PROFIBUS system.

Parameter data channel Process data channel

Without /

with

Without -

With

Identification / user data length Identification / user data length

z Identification

z Identification: F3

z User data length: 4 words

(word 1 ... word 4)

hex

(243)

– without consistency: 70

– with consistency: F0

z User data length: 1 ... 10 words

(POW/PIW 1 ... POW/PIW 10)

z Identification

– without consistency: 70

– with consistency: F0

z User data length: 1 ... 10 words

(POW/PIW 1 ... POW/PIW 10)

hex

hex

hex

... F9

hex

... F9

... 79

hex

(240 ... 249)

hex

... 79

hex

(240 ... 249)

hex

(112 ... 121)

(112 ... 121)

6

General structure of the identification byte

MSB LSB

7 6 5 4 3 2 1 0

User data length

00 1(byte/word)

...

15 16 (bytes / words)

Input/Output

00 Specific identification format

01 Input

10 Output

11 Input and output

Length/Format

0 Byte

1Word

Consistency

0 Byte or word

1Totallength

EDSLCMX3024-SPS EN 5.0

45

Page 46

6

6.2.2 Safe addressing

6.2.3 Addressing

PROFIsafe on board

Establishing of PROFIBUS communication

Safe addressing

Every slave must be provided with an unambiguous PROFIsafe target address.

The PROFIsafe target address can be set in C1570 via the diagnosis terminal or the PC.

( 90)

Valid address range: 1 ... 65534

To address the motor starters, each station must be allocated an unambiguous address.

The station address in set via code C1509, see ( 86), using the diagnosis terminal or the

PC.

Valid address range: 3 ... 126

46

EDSLCMX3024-SPS EN 5.0

Page 47

6.3 Process data transfer

PROFIBUS transmits different telegram contents between the master computer and the

motor starters:

ƒ Parameter data

ƒ Process data

ƒ PROFIsafe

As indicated in the table, this data is distributed into different communication channels

according to their time-critical response.

Process data

z Process data is transferred via the process data channel.

z Use process data to control the motor starter.

z The master computer has direct access to the process data. In the PLC, for instance, the data is directly

assigned to the I/O area. An exchange between the master drive and the motor starter is required in the

shortest possible time with small amounts of data being transferred cyclically.

z Process data is

– not stored in the motor starter.

– transferred between the host and the motor starters in order to exchange current input and output data

continuously.

z Process data for instance refers to setpoints and actual values.

An exchange between the master drive and the motor starter is required in the shortest possible time with small

amounts of data being transferred cyclically.

PROFIsafe on board

Process data transfer

6

Parameter data

z Parameter data is transferred via the parameter data channel.

z If the parameter data channel is active, it additionally occupies 4 words of input and output process data.

z Observe the notes on code C0003 when saving parameter changes.

z In general, the transfer of parameters is not time-critical.

z Parameter data for instance refers to operating parameters, diagnostics information and motor data.

Tab. 6-1 Distribution of parameter data and process data into different communication channels

EDSLCMX3024-SPS EN 5.0

47

Page 48

6

6.3.1 Device control

6.3.1.1 Configuration of process data

PROFIsafe on board

Process data transfer

Device control

Use the free process data configuration to assign the max. 10 PROFIBUS process data

words to the motor starter process data words. Define the assignments in codes C1511

(process output data) and C1510 (process input data).

Tip!

The ”view” is always from the master.

ƒ The master sends process output data in max. 10 process data output words

(POW) to the bus device.

ƒ The master receives process input data in max. 10 process data input words

(PIW) from the bus device.

48

EDSLCMX3024-SPS EN 5.0

Page 49

6.3.1.2 Process data signals f or motor starters

Configuration of process output data

The assignment of the max. 10 process data output words (POW) of the master to bit

control commands or setpoints of the motor starter can be freely configured via C1511.

ƒ You can set up a freely selectable Lenze device control using the FIF control words

( 50).

Note!

When C1511 is modified, the process output data is automatically inhibited in

order to ensure data consistency.

Use C1512 to reenable individual or all POWs.

Configuration of process output data

Code Subcode Index LENZE setting Data type

C1511 23064d=

1(POW1)

2(POW2)

3(POW3)

4(POW4)

5(POW5)

6(POW6)

7(POW7)

8(POW8)

9(POW9)

10 (POW 10)

5A18

PROFIsafe on board

Process data transfer

1 Control word (FIF-CTRL1)

h

6

Device control

FIX32

Tip!

For the description of the complete code see ( 88)

EDSLCMX3024-SPS EN 5.0

49

Page 50

6

PROFIsafe on board

Process data transfer

Device control

The bit assignments forthe applicable controlword 1 (FIF-CTRL1)can be gatheredfrom the

following table:

FIF control word 1 (FIF-CTRL1)

Bit Assignment

0S1(motor 1 start/stop)

0

1

1 S2 (motor 2 start/stop or selection of direction of rotation)

0

1

2 Brake 1 (control of brake 1)

3 Brake 2 (control of brake 2)

4 Reserved

5 Reserved

6 Reserved

7 Reserved

8 Reserved

9 Controller inhibit (FIF-CTRL1-CINH)

0

1

10 External fault

0

1

11 Fault reset

0=>1 (FIF-CRTL1-TRIP-RESET)

12 Reserved

13 Reserved

14 Reserved

15 Reserved

Stop motor 1

Start motor 1

Stop motor 2 or CCW rotation

Start motor 2 or CW rotation

Enable motor starter

Inhibit motor starter

(FIF-CTRL1-TRIP-SET)

External error active

No fault

Bit change causes trip reset

50

EDSLCMX3024-SPS EN 5.0

Page 51

PROFIsafe on board

Process data transfer

Device control

Configuring the process input data

The assignment of the bit status information or actual values of the motor starter to the

max. 10 process data input words (PIW) of the master can be configured freely.

Configuration of process input data

Code Subcode Index LENZE setting Data type

C1510 23065d=

5A19

1(PIW1)

2(PIW2)

3(PIW3)

4(PIW4)

5(PIW5)

6(PIW6)

7(PIW7)

8(PIW8)

9(PIW9)

10 (PIW 10)

h

1 Status word (FIF-STAT1)

FIX32

6

Tip!

For the description of the complete code see ( 87)

EDSLCMX3024-SPS EN 5.0

51

Page 52

6

PROFIsafe on board

Process data transfer

Device control

The bit assignments for the applicable status words can be gathered from the following

table:

Status word 1 (FIF-STAT1) Status word 2 (FIF-STAT2)

Bit

0 Image of C0417/1 Image of C0418/1

1 Image of C0417/2 Image of C0418/2

2 Image of C0417/3 Image of C0418/3

3 Image of C0417/4 Image of C0418/4

4 Image of C0417/5 Image of C0418/5

5 Image of C0417/6 Image of C0418/6

6 Image of C0417/7 Image of C0418/7

7 Controller inhibit Image of C0418/8

8

9 Image of C0418/10

10 Image of C0418/11

11 Image of C0418/12

Assignment Assignment

01Motor starter enabled

Motor starter inhibted

Bits 11 ... 8

Device status

11 10 9 8

0 0 1 1 Operation inhibited

0 1 1 0 Operation enabled

1 0 0 0 Fault active

1 1 1 1 Communication with standard

device not possible

Image of C0418/9

12 Overtemperature warning Image of C0418/13

01No warning

Housing temperature > +75 °C

13 Image of C0417/14 Image of C0418/14

14 Image of C0417/15 Image of C0418/15

15 Image of C0417/16 Image of C0418/16

Note!

The status words FIF-STAT1 and FIF-STAT2 are freely configurable via the codes

C0417 or C0418.

52

EDSLCMX3024-SPS EN 5.0

Page 53

6.4 Parameter data transfer

The PROFIdrive parameter data channel (DP-V0, cyclic)

ƒ enables parameter setting and diagnostics of the motor starter.

ƒ allows access to Lenze parameters (codes).

ƒ additionally occupies the first 4 words of the input and output words in the master.

ƒ has an identical structure for both directions of transmission.

Parameter data is addressed via codes listed in the code table of the corresponding

Operating Instructions for your controller.

Lenze parameter sets

The motor starter features 4 parameter sets, the parameters of which cannot be directly

addressed via the PROFIdrive parameter data channel (DP-V0, cyclic).

PROFIsafe on board

Parameter data transfer

6

Note!

Parameter changes:

Cyclic writing to codes via the PROFIBUS only is permissible if the automatic

parameter set storage of the motor starter (C0003) is deactivated (value 0).

Process data changes:

No automatic storage

EDSLCMX3024-SPS EN 5.0

53

Page 54

6

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

6.4.1 DRIVECOM parameter data channel (DP-V0, cyclic)

Addressing of the Lenze parameters

For the DRIVECOM parameter data channel, the parameters of a device are not addressed

directly via Lenze code numbers, but via indexes (byte 3 / byte 4) and subindexes (byte 2).

The Lenze code numbers are converted into indexes via an offset (24575

Addressing of the Lenze codes Example for C0001 (operating mode)

–PROFIBUSindex=

24575 - Lenze code number

–PROFIBUSindex

- Lenze code number

5FFF

hex

hex

=

hex

–PROFIBUSindex=

24575 - 1 = 24574

–PROFIBUSindex

5FFF

hex-1hex

hex

= 5FFE

=

hex

dec

or 5FFF

hex

):

Lenze parameters are mainly represented in the fixed point format, data type integer32

withfour decimal digits.For thisreason, the valueof theparameter orthe value of the code

must be multiplied by 10000 in order to obtain integer values.

This parameter value is entered into the user data (byte 5 - byte 8) of the telegram.

Telegram structure

(overview)

The telegram of the DRIVECOM parameter data channel consists of a total of 8 bytes. The

individual bytes are described in detail on the following pages.

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

High byte

Index

Low byte

Data 4 /

Error 4

Data 3 /

Error 3

Data 2 /

Error 2

Data 1 /

Error 1

54

EDSLCMX3024-SPS EN 5.0

Page 55

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

Byte 1: service

Job and response control for the parameter data channel

MTSRQPON

Representation of bits 7 ... 0 in byte 1

Job

MON

Job for the motor starter. The bits are only set by the master.

z 000=nojob

z 001 = read job (reading data from the motor starter)

z 010 = write job (writing data to the motor starter)

6

P

RQ

S

T

Fig.6-1 Byte 1: job and response control

Bit 7 0

(Reserved)

Data length

Data length in bytes 5...8 (data 1...4 / error 1...4)

z 00 = 1 byte

z 01 = 2 bytes

z 10 = 3 bytes

z 11 = 4 bytes

Handshake

Indicates a new job. The master changes this bit for every new job. The motor

starter copies the bit to its response telegram.

Status

Status information from the motor starter to the master when sending the job

confirmation. This bit informs the master whether the job has been carried out

without errors.

z 0 = job completed without fault.

z 1 = job not completed. A fault has occurred. The data in the Data/Error field

is interpreted as an error message.

MuNNMMMN

“1” (read)

(reserved)

“3”(= data length 4 bytes)

Handshake

Status, relevant for response telegram only

Bit 7 0

Fig.6-2 Example of byte 1

EDSLCMX3024-SPS EN 5.0

MuNNMMNM

“2” (write)

(reserved)

“3”(= data length 4 bytes)

Handshake

Status, relevant for response telegram only

55

Page 56

6

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

Byte 2: subindex

Additional addressing via thesubindex isrequired for thosecodes that have a subcode(see

code table).

Example:

Code C0012 / subcode 2 addresses motor 2 acceleration time

Byte 3 / 4: index

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

High byte

Index

Low byte

Data 4 /

Error 4

Data 3 /

Error 3

Data 2 /

Error 2

Data 1 /

Error 1

The parameters or the Lenze codes are selected with these two bytes according to the

formula:

Index = 24575 - Lenze code number

Example:

The parameter C0012 (acceleration time) is to be addressed:

24575 - 12 = 24563 = 5 FF3

hex

The entries for this example would be:

ƒ Byte 3: Index high byte = 5F

ƒ Byte 4: Index low byte = F3

hex

hex

Byte 5 - 8:

Parameter value (data) or error information (error)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

High byte

Index

Low byte

Data 4 /

Error 4

Data 3 /

Error 3

Data 2 /

Error 2

Data 1 /

Error 1

The status of the (”status”) bit 7 in byte 1 (”service”) determines the meaning of this data

field:

Meaning of bytes 5 - 8 if

bit7=0 bit7=1

Parameter value (data 1 - 4 ) Error information (error 1 - 4) for an invalid access.

56

EDSLCMX3024-SPS EN 5.0

Page 57

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

Parameter value (data)

Depending on the data format, the length of the parameter value is between 1 to 4 bytes.

Data issaved in the Motorola format, i.e. first the high byte orhigh word, thenthe low byte

or low word.

Byte 5 Byte 6 Byte 7 Byte 8

High byte Low byte High byte Low byte

High word Low word

Double word

Assignment of bytes 5 .. 8 with parameter values of different lengths

Byte 5 Byte 6 Byte 7 Byte 8

Parameter value

(length 1)

Parameter value (length 2) 00 00

Note: Strings or data blocks cannot be transmitted.

00 00 00

Parameter value (length 4)

6

Error messages

The following error messages may appear:

Data 1 Data 2 Data 3 Data 4 Meaning

63

6 5 10 Impermissible job parameter

6 5 11 Invalid subindex

6 5 12 Data length too large

6 5 13 Data length too small

6 6 00 Object is no parameter

6 7 00 Object does not exist

6 8 00 Data types do not correspond

8 0 00 Job cannot be executed

8 0 20 Job cannot be executed at the moment

8 0 21 Not executable because of local control

8 0 22 Not executable because of device status

8 0 30 Out of value range/parameter can only be changed with inhibited

8 0 31 Parameter value too large

8 0 32 Parameter value too small

8 0 33 Subparameter out of value range

8 0 34 Subparameter value too large

8 0 35 Subparameter value too small

8 0 36 Maximum value smaller than minimum value

8 0 41 Communication object cannot be mapped on process data

8 0 42 Process data length exceeded

8 0 43 General collision with other values

Data contents in hexadecimal format

00

00 No right to access

controller

EDSLCMX3024-SPS EN 5.0

57

Page 58

6

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

6.4.1.1 Programming of read jobs

Step Read job

1. Define user data range of the motor starter, i.e. define the location of the user data in the host system

2. Enter the address of the desired parameter in the field ”Index and subindex“ (PROFIBUS output data).

3. Job = read job. The ”Job/handshake“ bit must be changed (PROFIBUS output data).

4. Check whether the ”Job/handshake“ bit is the same for the PROFIBUS input and output data. If the bit

5. Check whether the bit ”Job / status“ is set.

(observe manufacturer-specific information).

”Job / handshake“ is the same, the response has been received. You should implement a time

monitoring.

z The ”Job/status“ bit is not set:

The field ”Data/error“ contains the desired parameter value.

z The ”Job/status“ bit is set:

The read job has not been carried out correctly.

The error information is located in the field ”Data/error“.

58

EDSLCMX3024-SPS EN 5.0

Page 59

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

Example: read parameter

Thehousing temperature(assumption: ϑ =43° C) of the motor starter is to beread (C0061).

ƒ Byte 1: job

Bit 7 0

MuNNMMMN

“1” (read)

(reserved)

“3”(= data length 4 bytes)

Handshake

Status, only relevant for response telegram

ƒ Byte 2: subindex

Subindex = 0, as there is no subindex under code C0061.

ƒ Byte 3/4: index (calculation)

Index (of the read request) = 24575 - code no.

6

Index = 24575 - 61 = 24514 = 5F C2

hex

(5F

=bighbyte,C2

hex

=lowbyte)

hex

ƒ Byte 5 ...8: data (contained in the response telegram)

Data1todata4=43° C x 10000 = 430000 = 00 06 8F B0

hex

Result:

ƒ Request telegram from master to the motor starter

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

(high byte)

01

hex

00000001

bin

00

hex

00000000

bin

5F

hex

01011111

Wait for change of handshake bit (bit 6 here: 0 Æ 1) in the response

ƒ Response telegram from the motor starter to the master (for faultless execution)

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7 Byte 8

Service Subindex Index

(high byte)

30

hex

0011 0000

00

hex

0000 0000

bin

5F

hex

0101 1111

bin

Tab. 6-2 Telegram exchange in the parameter data channel

bin

bin

Index

(low byte)

C2

hex

11000010

Index

(low byte)

C2

hex

1100 0010

Data 4 Data 3 Data 2 Data 1

bin

00

hex

00000000

bin

00

hex

00000000

bin

00

hex

00000000

Data 4 Data 3 Data 2 Data 1

bin

00

hex

0000 0000

06

hex

0000 0110

bin

8F

hex

1000 1111

bin

bin

bin

00

hex

00000000

B0

hex

1011 0000

bin

bin

EDSLCMX3024-SPS EN 5.0

59

Page 60

6

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

6.4.1.2 Programming of write jobs

Step Write job

1. Define user data range of the motor starter, i.e. define the location of the PROFIBUS user data in the

2. Enter the address of the desired parameter in the field ”Index and subindex“ (PROFIBUS output data).

3. Enter parameter value in field ”Data/Error“.

4. Job/service = write job and the ”Job/handshake“ bit must be changed (PROFIBUS output data).

5. Check whether the ”Job/handshake“ bit is the same for the PROFIBUS input and output data. If the bit

6.

host system (observe manufacturer-specific information).

”Job / handshake“ is the same, the response has been received. You should implement a time

monitoring.

Check whether the ”Job/status“ bit is set:

z If the ”Job/status“ bit is not set: The job was executed faultlessly

z The ”Job/status“ bit is set:

The job has not been carried out correctly if the ”Job/status“ bit is set.

The error information is located in the field ”Data/error“.

60

EDSLCMX3024-SPS EN 5.0

Page 61

Example: write parameter

PROFIsafe on board

Parameter data transfer

DRIVECOM parameter data channel (DP-V0, cyclic)

6

The acceleration time (C0012) for the motor 1 is to be set to T

=2.5s.

ir

ƒ Byte 1: job

Bit 7 0

MuNNMMNM

“2” (write)

(reserved)

“3”(= data length 4 bytes)

Handshake

Status, only relevant for response telegram

Fig.6-3 Example

ƒ Byte 2: subindex

Subindex = 1

ƒ Byte 3/4: index (calculation)

Index = 24575 - code number

Index = 24575 - 12 = 24563 = 5F F3

ƒ Byte 5 - 8: data

hex

(5F

= high byte, F3

hex

=lowbyte)

hex