Page 1

BA_ELx8xx

.NnG

Ä.NnGä

L−force Controls

Operating Instructions

Industrial PC

+

-

F4

F3F1 F2

EWQ

R

@

€

D

SA

FF5G H J

XY

VC

EL 1800 ... EL 9800

S1

S2

Power

Fail

Status

F1

F2

+

F3

-

/

(

87 9

$

54 6

"

!

1 2 3

=

>

,

<

0

Bs

Einfg

Entf

Pos 1

Ende

Alt Gr

F9F8F6 F7 F10

T

NB

*

OI P ÜUZ

+

Ä

Ö

LK

_

;

:

M

,

-

.

μ

Alt Strg

F12

Esc

F11

~

Enter

\?ß

Space

S3

S4

S5

S6

S7

+

F1

Esc

Q+R

F1 F2 F5

S T

-

F3 F4

-

F3F2

F4

WVU

F7F6

F11F10YXF9F8 F12

F11 F12F6F5 F7 F8 F9 F10

@\Z

Power

Fail

Status

)

-

&

+

§

*

|

/

Power

Fail

Status

Bild

Bild

S8

S9

S10

S11

S12

S13

S14

Enter

A

B C D

-

7

9

8

E

F G H

4

+6

5

I

J K L

1

3

2

*

M

N O P

,

.

0

/

Power

Pg Up

Fail

Status

Home

End

Pg Dn

EscDelIns

Bs

MenuAltCtrl

Shift

Space

Alpha

Enter

Embedded Line Panel PC (EL)

Page 2

Please read these instructions before you start working!

Follow the enclosed safety instructions.

Page 3

Contents i

1 About this documentation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Notes used 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Product−specific safety instructions 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Safety instructions for the installation according to UL 13. . . . . . . . . . . . . . . . . . . . .

3 Product description 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Scope of supply 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Application as directed 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Device features 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Identification 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Controls and displays 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Options 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.1 ACU UPS control unit 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.12 Baseboard 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data and operating conditions 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Electrical data 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Mechanical data 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Mechanical installation 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Important notes 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Mounting cutout 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Mounting steps 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Panel PC EL 1800(s) / EL 1850(s) 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Panel PC EL 2800 / EL 2850 / EL 5800 / EL 5820 / EL 5850 / EL 5870 / EL 9800 . . .

35

BA_ELx8xx EN 3.0

3

Page 4

Contentsi

6 Electrical installation 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Important notes 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Wiring according to EMC 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Connecting the supply and peripheral devices 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Terminal diagram supply 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 24 V connection (X101) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.3 UPS−PACK connection (X102) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.4 PS/2 interface (X108) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.5 Serial interface (X103) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.6 Ethernet interface (X107) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.7 USB interface (X104, X105, X106) 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.8 Communication interface (MC card) 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.9 USB interface on the front face (option) 40. . . . . . . . . . . . . . . . . . . . . . . . . .

7 Operation 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Important notes 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Controls and displays 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Panel PC EL 1800 / EL 1800s / EL 2800 / EL 5800 / EL 9800 42. . . . . . . . . . .

7.2.2 Panel PC EL 5820 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Panel PC EL 1850 / EL 1850s / EL 2850 / EL 5850 44. . . . . . . . . . . . . . . . . . . .

7.2.4 Panel PC EL 5870 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Maintenance 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Regular checks 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Cleaning 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Repair 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Remove the PC housing 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Mount the PC housing 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Battery change 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.4 Fuse change 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Index 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

BA_ELx8xx EN 3.0

Page 5

0Fig. 0Tab. 0

1 About this documentation

Contents

This documentation provides you with information about the intended use of the

Industrial PC.

The present manual is part of the "PC−based automation" manual collection which you can

find on the DVDs of the same name.

Target group

This documentation is directed at qualified skilled personnel according to IEC 60364.

Qualified skilled personnel are persons who have the required qualifications to carry out

all activities involved in installing, mounting, commissioning, and operating the product.

Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

About this documentation 1

Validity

These instructions are valid for

ƒ EL 1800, EL 1800s, 1800 TC, 1800s TC

ƒ EL 1850, EL 1850s, EL 1850 TC, EL 1850s TC

ƒ EL 2800, EL 2800 TC

ƒ EL 2850, EL 2850 TC

ƒ EL 5800, EL 5800 TC

ƒ EL 5820, EL 5820 TC

ƒ EL 5850, EL 5850 TC

ƒ EL 5870, EL 5870 TC

ƒ EL 9800, EL 9800 TC

BA_ELx8xx EN 3.0

5

Page 6

1

About this documentation

Document history

1.1 Document history

Material number Version Description

.NnG 3.0 02/2014 TD06 New:

13433080 2.0 03/2013 TD29 General revision

13391236 1.3 10/2011 TD29 Supplement of the note concerning the protection

13370129 1.2 07/2011 TD29 Pin assignment SUB−D plug corrected

13370129 1.1 02/2011 TD29 First edition

l UL notes (French language)

l Notes RJ45 cable laying

against direct solar radiation, as well as revision of

the sections ˆReplacing the battery˜ and ˆReplacing

the fuse˜.

6

BA_ELx8xx EN 3.0

Page 7

About this documentation

Conventions used

1

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator Point In general, the decimal point is used.

Warnings

UL warnings

UR warnings

Text

Program name » « PC software

Icons

Page reference Reference to another page with additional

Documentation reference Reference to another documentation with

For instance: 1234.56

Given in English and French

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: 16 = see page 16

additional information

For example: EDKxxx = see

documentation EDKxxx

BA_ELx8xx EN 3.0

7

Page 8

1

About this documentation

Notes used

1.3 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Special safety instructions and application notes

Pictograph and signal word Meaning

Warnings!

Warnings!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

Safety note or application note for the operation according to

UL or CSA requirements.

The measures are required to meet the requirements according

to UL or CSA.

8

BA_ELx8xx EN 3.0

Page 9

2 Safety instructions

2.1 General safety information

Scope

The following general safety instructions apply to all Lenze drive and automation

components.

The product−specific safety and application notes given in this documentation must be

observed!

For your own safety

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

Safety instructions

General safety information

2

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ For Lenze drive and automation components ...

... only use approved accessories.

... only use original manufacturer spare parts.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

BA_ELx8xx EN 3.0

9

Page 10

2

Safety instructions

General safety information

Transport, storage

ƒ Transport and storage in a dry, low−vibration environment without aggressive

atmosphere; preferably in the packaging provided by the manufacturer.

– Protect against dust and shocks.

– Comply with climatic conditions according to the technical data.

Mechanical installation

ƒ Install the product according to the regulations of the corresponding

documentation. In particular observe the section "Operating conditions" in the

chapter "Technical data".

ƒ Provide for a careful handling and avoid mechanical overload. During handling

neither bend components, nor change the insulation distances.

ƒ The product contains electrostatic sensitive devices which can easily be damaged by

short circuit or static discharge (ESD). Thus, electronic components and contacts

must not be touched unless ESD measures are taken beforehand.

Electrical installation

ƒ Carry out the electrical installation according to the relevant regulations (e. g. cable

cross−sections, fusing, connection to the PE conductor). Additional notes are

included in the documentation.

ƒ When working on live products, observe the applicable national regulations for the

prevention of accidents (e.g. BGV 3).

ƒ The documentation contains notes for the EMC−compliant installation (shielding,

earthing, arrangement of filters and installation of the cables). The manufacturer of

the system or machine is responsible for the compliance with the limit values

required in connection with EMC legislation.

ƒ For compliance with the limit values for radio interference emission at the site of

installation, the components − if specified in the technical data − have to be mounted

in housings (e. g. control cabinets). The housings have to enable an EMC−compliant

installation. In particular observe that for example control cabinet doors preferably

have a circumferential metallic connection to the housing. Reduce openings or

cutouts through the housing to a minimum.

ƒ Only plug in or remove pluggable terminals in the deenergised state!

Commissioning

ƒ If required, you have to equip the system with additional monitoring and protective

devices in accordance with the respective valid safety regulations (e. g. law on

technical equipment, regulations for the prevention of accidents).

10

BA_ELx8xx EN 3.0

Page 11

Safety instructions

General safety information

Maintenance and servicing

ƒ The components are maintenance−free if the required operating conditions are

observed.

ƒ If the cooling air is polluted, the cooling surfaces may be contaminated or the air

vents may be blocked. Under these operating conditions, the cooling surfaces and air

vents must be cleaned at regular intervals. Never use sharp objects for this purpose!

ƒ After the system has been disconnected from the supply voltage, live components

and power connections must not be touched immediately because capacitors may

be charged. Please observe the corresponding notes on the device.

Disposal

ƒ Recycle or dispose of the product according to the applicable regulations.

ƒ This device contains a battery. According to European legislation you are obliged to

dispose of batteries separately via the take−back systems specified.

2

BA_ELx8xx EN 3.0

11

Page 12

2

Safety instructions

Product−specific safety instructions

2.2 Product−specific safety instructions

ƒ Protect the device against direct solar radiation, since the housing may heat up

strongly.

ƒ The device is classified as a class A device and can cause radio interference in

residential areas. In this case, the operator may have to take special measures. Any

costs arising from these measures have to be paid by the operator.

ƒ A touchscreen does not comply with the Ergonomics Directive ZH 1/618. This is why

it is only designed for short−time inputs and monitoring functions. For longer inputs,

connect an external keyboard.

ƒ In the event of a fault, unplug the power connector immediately and send back the

device to the manufacturer. The address can be found on the self−addressed

envelope included in this documentation. Please use the original packaging to

return the device!

ƒ Printed circuit boards which might be damaged by short circuit or electrostatic

discharge (ESD) must be handled appropriately.

ƒ The BIOS of the mainboard is configured by the factory. After the BIOS has been

updated, malfunctions are possible. Please address to our service.

ƒ If the optionally ACU UPS power supply is used:

– Before commissioning the basic device, establish the connection between the

power supply unit and the capacitor/battery pack.

– Observe that the basic device is only deenergised if the mains cable and the supply

cable of the capacitor/battery pack have been disconnected.

– If the basic device is disconnected from the mains for a longer time, the supply

cable of a battery pack has to be disconnected, so that the rechargeable batteries

are not damaged by a possible exhaustive discharge.

– If stored, the rechargeable batteries lose energy in the course of time. Thus the

rechargeable batteries have to be charged completely by the basic device at the

latest after half a year of storage.

– The rechargeable batteries of the battery pack may not be charged with external

battery chargers, but only with the ACU UPS power supply of the basic device!

12

BA_ELx8xx EN 3.0

Page 13

Safety instructions

Safety instructions for the installation according to UL

2

2.3 Safety instructions for the installation according to UL

Original − English

Approval

Underwriter Laboratories (UL), UL508 and CSA C22.2 No. 142−M1987, (UL File Number

E236341)

Ratings

ƒ Input 24 V DC, 65 W

ƒ Max. Ambient Temperature 40 °C

– EL6xx, EL1xxx, EL5xxx, EL9xxx only

ƒ Max. Surrounding Temperature 50 °C

– EL8xx, EL2xxx, EL7xxx only

ƒ Optional communication ratings:

– RS232−Connection: max. 3 A

– USB−Connection: max. 1 A

– PS/2−Connection: max. 1 A

– LAN−Connection: Standard ISDN or RJ45

ƒ Environmental ratings: If these devices are mounted into a door or front cover of an

enclosure: Type 1 enclosure.

Warnings!

Field Wiring Markings

Wiring Terminal MSTB 2,5/3−STF−5,08:

ƒ Use Copper Wire only.

ƒ AWG 18 ... AWG 12 (0.82 mm

ƒ Torque 5...7 lb−in (0.5 ... 0.6 Nm)

Power supply

ƒ Must be used as isolating source.

ƒ Rated data: 24 VDC, 4 A max.

Battery

ƒ Replace Battery with any from the list below, Part No. CR 2450 only. Use of

another battery may present a risk of fire or explosion.

Recommended CR2450 (R/C, BBVC2) types:

Renata Part.no. CR2450N, Sony Corp. part no. CR2450B, Toshiba part no.

CR2450, Varta part no. CR2450, Matsushita part no. CR2450

ƒ Battery may explode if mistreated. Do not recharge, disassemble, dispose of

in fire or heat above 100 °C (212 °F).

ƒ Dispose of used battery according to the regulation of recycling or waste.

2

... 3.3 mm2)

BA_ELx8xx EN 3.0

13

Page 14

2

Safety instructions

Safety instructions for the installation according to UL

Original − French

Homologation

Underwriter Laboratories (UL), UL508 et CSA C22.2 n° 142−M1987, (n° de dossier UL

E236341)

Caractéristiques assignées

ƒ Entrée 24 V CC, 65 W

ƒ Température ambiante maximale : 40 °C

– Uniquement EL6xx, EL1xxx, EL5xxx, EL9xxx

ƒ Température ambiante maximale : 50 °C

– Uniquement EL8xx, EL2xxx, EL7xxx

ƒ Caractéristiques de communication assignées (option) :

– Port RS232 : maximum 3 A

– Port USB : maximum 1 A

– Port PS/2 : maximum 1 A

– Port LAN : RNIS standard ou RJ45

ƒ Evaluations environnementales : en cas de montage des équipements dans la porte

ou le capot avant d’un coffret de protection : coffret de type 1.

Warnings!

Marquage du câblage à pied d’oeuvre

Bornier de câblage MSTB 2,5/3−STF−5,08 :

ƒ Utiliser exclusivement des conducteurs en cuivre.

ƒ AWG 18 ... AWG 12 (0.82 mm

ƒ Couple de 5 à 7 lb−in (0,5 ... 0,6 Nm)

Alimentation

ƒ Doit servir de source isolante.

ƒ Caractéristiques assignées : 24 VCC, 4 A max.

Batterie

ƒ Remplacer la batterie par l’un des types répertoriés dans la liste ci−dessous,

n° de référence CR 2450 uniquement. L’utilisation d’une autre batterie

présente un risque d’incendie ou d’explosion.

Types CR2450 recommandés (R/C, BBVC2) :

Renata référence CR2450N, Sony Corp. référence CR2450B, Toshiba

référence CR2450, Varta référence CR2450, Matsushita référence CR2450

ƒ Toute utilisation non conforme de la batterie entraîne un risque d’explosion.

Ne pas recharger, démonter, jeter au feu ni exposer la batterie à une chaleur

supérieure à 100 °C (212 °F).

ƒ Eliminer la batterie conformément à la réglementation en vigueur en

matière de recyclage ou de traitement des déchets.

2

... 3.3 mm2)

14

BA_ELx8xx EN 3.0

Page 15

3 Product description

3.1 Scope of supply

QuantityName

1 Embedded Line Panel PC

Screw clamp fixings

8

EL 1800, EL 1800s, EL 1850, EL 1850s

4

EL 2800

6

EL 2850, EL 5800, EL 5820, EL 5850

5

EL 5870

6

EL 9800

1 Connection plug for voltage supply

1 DVD "PC based Automation"

1 Test report

1 Device pass card

Product description

Scope of supply

3

Note!

After receipt of the delivery, check immediately whether the items match the

accompanying papers. We do not accept any liability for deficiencies claimed

subsequently.

Claim

ƒ visible transport damage immediately to the forwarder

ƒ visible deficiencies/incompleteness immediately to your Lenze

representative.

BA_ELx8xx EN 3.0

15

Page 16

3

3.2 Application as directed

Product description

Application as directed

The industrial PC is used as directed if it is solely used for implementing control and

operating concepts or for presenting information in usual industrial and commercial

fields. A different use, or one beyond these purposes, is not permissible.

A use that is not intended also includes a use harbouring fatal risks or dangers which,

without the provision of exceptionally high safety measures, may result in death, injury or

damage to material assets.

The industrial PC in particular must not be used ...

ƒ in private areas.

ƒ in potentially explosive atmospheres.

ƒ in areas with harmful gases, oils, acids, radiation, etc.

ƒ in applications where vibration and impact loads occur, exceeding the requirements

of EN 50178.

ƒ for performing safety functions, for instance

– in air traffic control / in flight−control systems

– for the monitoring/control of nuclear reactions

– for the monitoring/control of means of mass transport

– for the monitoring/control of medical systems

– for the monitoring/control of weapon systems

Higher−level safety systems must be used to guarantee the protection of persons and

material assets!

16

BA_ELx8xx EN 3.0

Page 17

3.3 Device features

Design l PC housing made of sheet steel, in the case of passive cooling partly of

Mounting l For installation in control cabinets, control boards or machine enclosures

Electrical supply l 24 V DC voltage supply

Computer unit l ETX module with

Ports l 1 x PS/2

Product description

Device features

EL x8xx

aluminium

l Front frame made of anodised and etched aluminium

l Front with polyester foil

l Lithium battery for buffering the real time clock (RTC)

â

– Intel

Atom N270, 1.6 GHz, 512 kB L2 Cache

â

– Chipset: Intel

– Ethernet controller: Intel

– Integrated with Intel

(GMA950, DirectX

or

– Intelâ Core Duo, 1.66 GHz, 512 kB L2 Cache

– Chipset: Intel

– Ethernet controller: Intel

– Integrated with Intel

(GMA950, DirectX

l 1 x LAN (Ethernet)

l 3 x USB type A (V 2.0)

l 1 x serial (RS232)

l 2 x MC card slot

l 1 x Compact Flash slot (type I)

945GSE, Intelâ ICH7M

â

945GM, Intelâ ICH7M

â

82562V, 10/100 MBit Ethernet

â

Graphics Media Accelerator

â

9, PS 2.0)

â

82562VZ, 10/100 MBit Ethernet

â

Graphics Media Accelerator

â

9, PS 2.0)

3

Accessories

ƒ MC card

ƒ Battery pack (ACCU PACK)

ƒ Capacitor pack (CAPS PACK)

BA_ELx8xx EN 3.0

17

Page 18

3

Product description

Device features

Overview

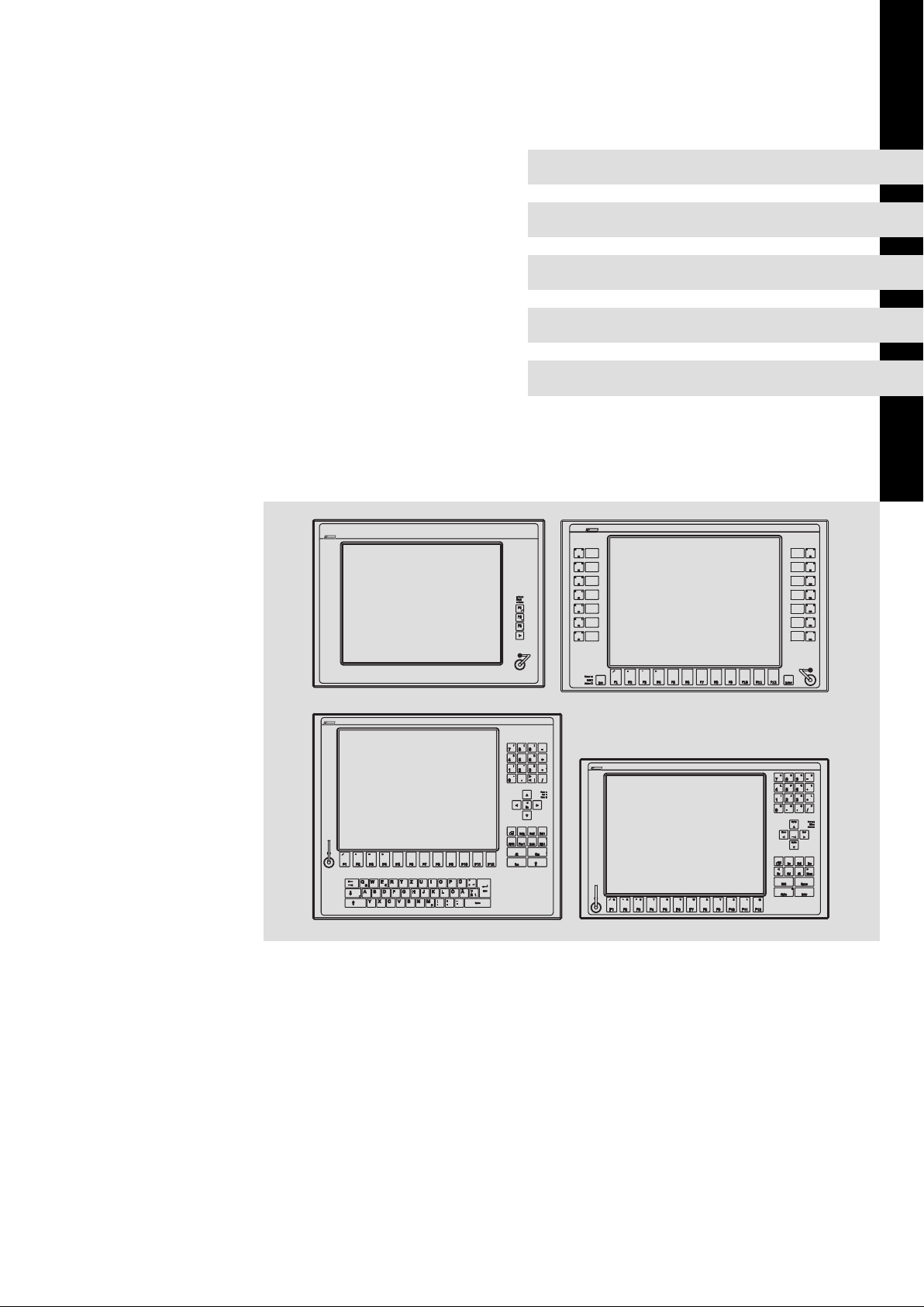

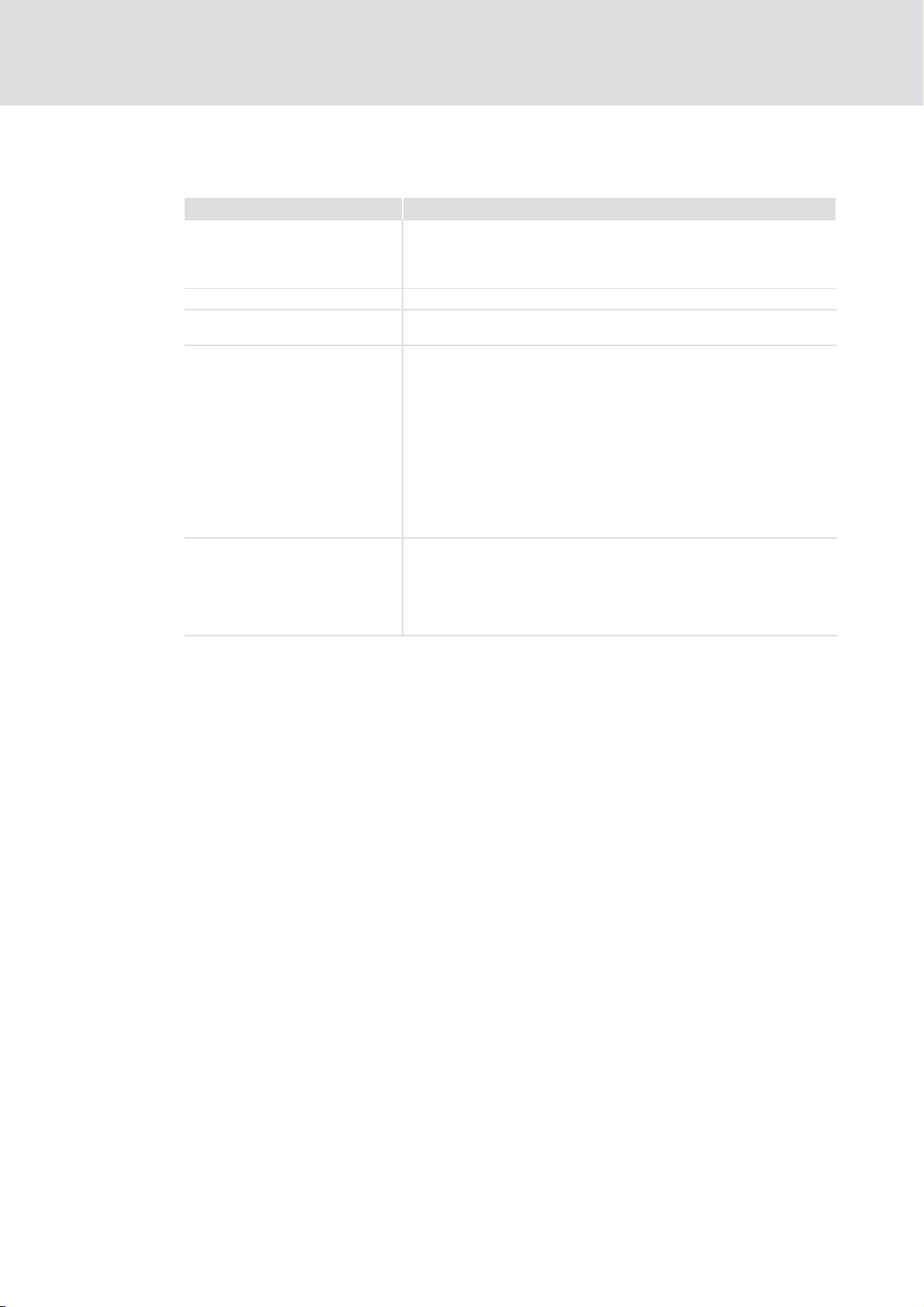

Panel PC EL 1800 / EL 1800s / EL 2800 / EL 5800 / EL 9800

Thin Client EL 1800 TC / EL 1800s TC / EL 2800 TC / EL 5800 TC / EL 9800 TC

l EL 1800 (TC): VGA touchscreen 26.4 cm (10.4")

EL 1800s (TC): SVGA touchscreen 26.4 cm (10.4")

EL 2800 (TC): SVGA touchscreen 30.7 cm (12.1")

EL 5800 (TC): XGA touchscreen 38.1 cm (15")

EL 9800 (TC): SXGA touchscreen 48.3 cm (19")

l 3 freely assignable function keys

l XGA touchscreen 38.1 cm (15")

l 12 freely assignable function keys

l 14 freely assignable special keys

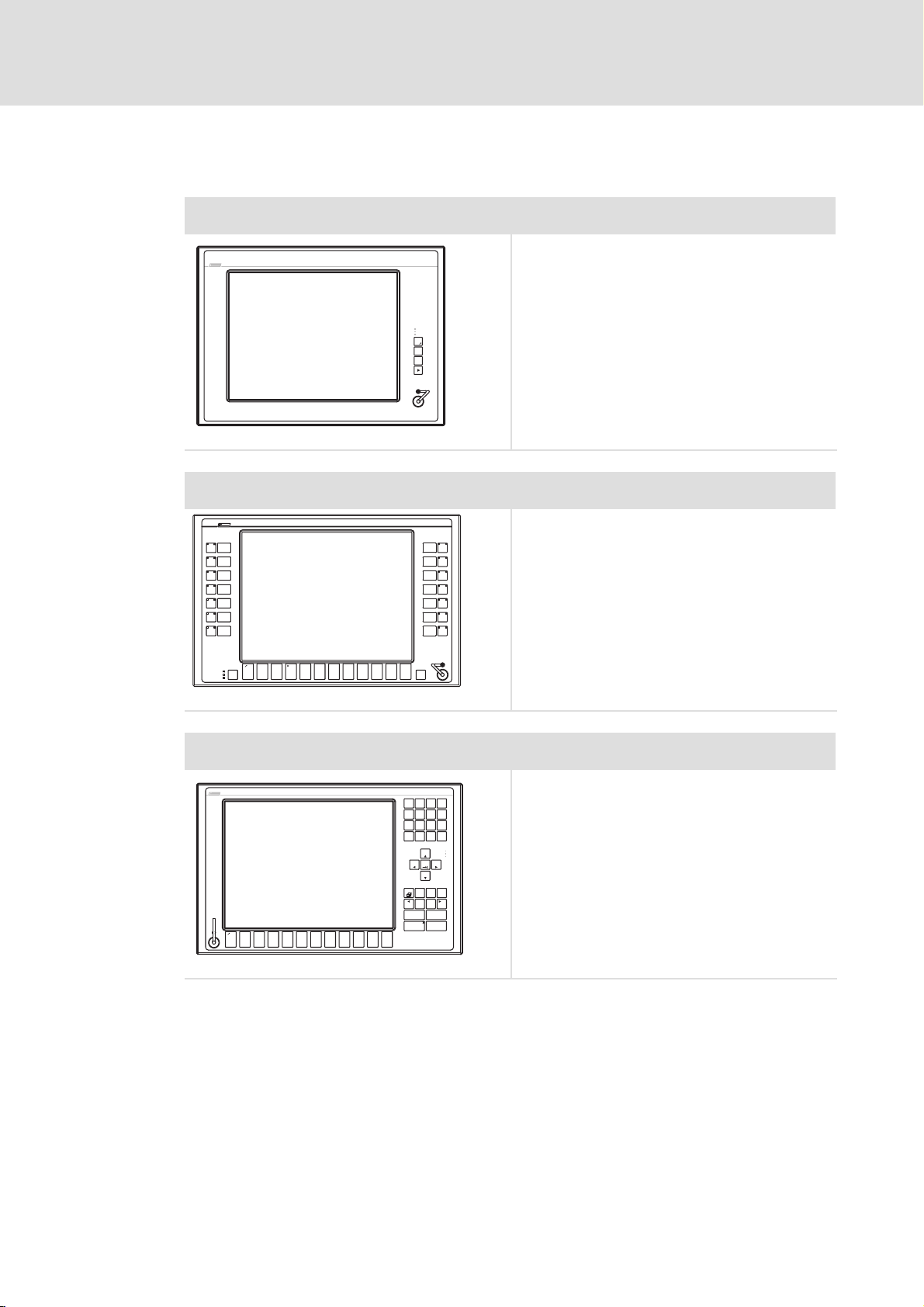

Panel PC EL 5820

Thin Client EL 5820 TC

S1

S2

S3

S4

S5

S6

S7

Power

Fail

Status

F1

F2

+

F3

-

CS57x0−026

S8

S9

S10

S11

S12

S13

S14

+

Power

Fail

Status

-

F4

F3F2

F1

Esc

F11 F12F6F5 F7 F8 F9 F10

Enter

ELx7xx−002

Panel PC EL 1850 / EL 1850s / EL 2850 / EL 5850

Thin Client EL 1850 TC / EL 1850s TC / EL 2850 TC / EL 5850 TC

l EL 1850 (TC): VGA touchscreen 26.4 cm (10.4")

A

BCD

-

9

7

8

E

FGH

4

5

+6

I

JKL

3

1

2

*

M

NOP

.

,

0

Q+R

ST

-

F1 F2 F5

F3 F4

/

Power

PgUp

Fail

Status

Home

End

PgDn

EscDelIns

Bs

Menu

AltCtrl

Shift

Space

Alpha

Enter

WVU

F7F6

F11F10YXF9F8 F12

@\Z

CS57x0−028

l 12 freely assignable function keys

l Numeric keypad, control keys, level switch−over

EL 1850s (TC): SVGA touchscreen 26.4 cm (10.4")

EL 2850 (TC): SVGA touchscreen 30.7 cm (12.1")

EL 5850 (TC): XGA touchscreen 38.1 cm (15")

Alpha

18

BA_ELx8xx EN 3.0

Page 19

Panel PC EL 5870

Thin Client EL 5870 TC

+

-

F4

F3F1 F2

F5

T

R

EWQ

@

€

F

D

SA

GHJ

VC

XY

Product description

3

Device features

l XGA touchscreen 38.1 cm (15")

l 12 freely assignable function keys

/

(

)

-

879

$

&

+

546

§

!

"

123

*

=

>

,

|

<

/

0

Power

Fail

Status

Bs

Einfg

Entf

Bild

Pos1

Ende

Bild

AltGr

F9F8F6 F7 F10

*

OIPÜUZ

+

Ö

Ä

LK

_

;

:

M

NB

,

-

.

μ

Alt Strg

F12

Esc

F11

~

Enter

\?ß

Space

CS57x0−029

l MF2 keyboard

BA_ELx8xx EN 3.0

19

Page 20

3

107AT12345

Product description

Identification

3.4 Identification

31855 Aerzen; Germany

Made in Germany

Typ e

107AT12345

Type code EL x8xx EP8GAP x x x 00 x x x x x 00− x x xx x x x x xxx

Screen diagonal (resolution)

3 = 26.4 cm (10.4") / 640 x 480 pixels

4 = 26.4 cm (10.4") / 800 x 600 pixels

5 = 30.7 cm (12.1") / 800 x 600 pixels

6 = 38.1 cm (15") / 1024 x 768 pixels

7 = 48.3 cm (19") / 1280 x 1024 pixels

Keyboard

1 = standard (4 F−keys)

4 = F− / special keys

5 = Num− / Alpha− / F−keys

6 = Num− / F− / special / control keys, DE

7 = Num− / F− / special / control keys, EN

Type designation

Type code (catalogue/order no.)

Technical data

Customised material number

Bar code with serial number

Manufacturer address

Certification

CE mark

DVIUSB−012

Front design

Standard layout, analog, resistive touchscreen

3 = without front face USB socket

4 = with front face USB socket

Processor

â

C = Intel

9 = Intel

Main memory

4 = ³1024 MB

5 = ³2048 MB

Internal mass storage

0 = no mass storage

1 = hard disk, 6.4 cm (2.5"), ³80 GB, for continuous

operation

2 = hard disk, 6.4 cm (2.5"), ³80 GB, extended temp.

range

3 = hard disk, 6.4 cm (2.5"), ³160 GB

Atomä 1.6 GHz

â

Core Duoä1.66 GHz (smart cool)

20

BA_ELx8xx EN 3.0

Page 21

MC card slot 1

0 = without

9 = MC−CAN2

B = MC−CAN2 (with Light API licence)

1 = MC−ETH

D = MC−ISI

C = MC−MPI

5 = MC−PBM

6 = MC−PBS

8 = MC−PND

MC card slot 2

0 = without

9 = MC−CAN2

B = MC−CAN2 (with Light API licence)

1 = MC−ETH

D = MC−ISI

C = MC−MPI

5 = MC−PBM

6 = MC−PBS

8 = MC−PND

Product description

Identification

3

xxxxxxxxxxx00−xxxxx00xxxEP8GAPType code EL x8xx

DVD drive

0 = without

1 = DVD writer drive

UPS

0 = without

1 = ACU UPS control unit

External memory card

00 = without

C3 = Compact Flash ³512 MB

C6 = Compact Flash ³4 GB

C7 = Compact Flash ³8 GB

Operating system

0 = without

4 = Windowsâ CE 6 Prof.

5 = Windows

6 = Windows

7 = Windows

B = Thin Client

Control technology runtime software

0 = without

1 = LPC1000 (V2.x)

2 = MPC1200 (V2.x)

Visualisation runtime licence type

0 = without

1 = VisiWinNETâ Compact

2 = VisiWinNET

â

Embedded Std. 2009 on Compact Flash

â

Embedded Std. 2009 on hard disk

â

XP on hard disk

â

Standard

BA_ELx8xx EN 3.0

21

Page 22

3

Product description

Identification

xxxxxxxxxxx00−xxxxx00xxxEP8GAPType code EL x8xx

Number of power tags for visualisation

0 = without

1 = 50 power tags

2 = 100 power tags

3 = 250 power tags

4 = 500 power tags

5 = 1000 power tags

6 = 2000 power tags

7 = 4000 power tags

8 = 64000 power tags

Customer version variant

22

BA_ELx8xx EN 3.0

Page 23

Product description

Controls and displays

3

3.5 Controls and displays

4

0 1

10

PS/2

LAN

8

2

USB

3

5

Power

Fail

Status

6

F1

F2

+

7

F3

-

RS232

CF Card

MC Card

Reset

ACU UPS

24 V DC

ELx7xx−001

Pos. Description

Panel PC / Thin Client (here Panel PC EL 5800)

Front face USB port (option)

Screw clamp fixings

DVD drive (optional)

PC

Nameplate

Front face status LEDs (Power, Fail, Status)

Front face control elements

Status LEDs (Error, HD, Power)

Note!

Further information on the control and display elements can be gathered from

the chapter "Operation" ( 41).

BA_ELx8xx EN 3.0

23

Page 24

3

Product description

Options

ACU UPS control unit

3.6 Options

3.6.1 ACU UPS control unit

Description

The optional ACU UPS control unit in connection with a battery or capacitor pack adds a

UPS functionality to the Industrial PC of the EL 1800−9800, CS 5800−9800, CPC 2800, and

3241 C series.

The ACU UPS control unit is either pre−equipped by the factory or can be refitted by the

Lenze Service staff.

Features of the ACU UPS control unit

with battery pack (ACCU PACK) with capacitor pack (CAPS PACK)

l Bridges a short−term mains failure or mains

fluctuations and shuts down the PC.

l Software−based configuration

l Documentation for the battery pack

ACCU-Pack

l Data backup in the event of mains failure.

l Not suitable for Windows XP and Windows

Embedded Standard 2009.

l Software−based configuration

l Documentation for the capacitor pack

EPC50

ACU

0

S

3

Before

instruction

opening,

manual.

read

the

1

U

S

V

2

FAN3

FAN2

BLIGHT

USB-μCON

CR2450

20

19

T4A

F1

POWER

1

2

ACCU

RESET

4

CS57x0−042

2700 battery pack or 2701 capacitor pack (accessories)

Connection cable (included in delivery of battery pack/capacitor pack)

Port on industrial PC

ACU UPS control unit

Baseboard

24

BA_ELx8xx EN 3.0

Page 25

3.7 Baseboard

Product description

Baseboard

3

HARDDISK / CD-ROM

POWER

FLAT-PANEL-LVDS

0

VGA

X3

X4

FAN0

1

5

FAN3

FAN2

2

CR2450

20

BLIGHT

USB-μCON

T4A

4

F1

POWER

Hard disk

CPU module

Battery ( 52)

ACU UPS control unit ( 24)

Fuse ( 53)

Socket connector for MC card

19

X1 X2

3

1

2

ACCU

RESET

CF-CARD

COM1

RT

USB_B

USB_C

GE

GN

USB_A

FAN1

MOUSE

x8xx_001

BA_ELx8xx EN 3.0

25

Page 26

4

Technical data

General data and operating conditions

4 Technical data

4.1 General data and operating conditions

General data

Conformity and approval

Conformity

CE

Approbation

UL UL 508

Other

RoHS − Products lead−free in accordance with CE Directive

EN 61000−6−4

EN 61000−6−2

CSA C22.2

EMC Directive Class A, industrial premises

Programmable Controllers (File−No. E236341)

2011/65/EU

Protection of persons and equipment

Safety VDE0805 (EN60950),

Enclosure EN 60529 IP65 (front) / IP20 (back)

Class of protection 3

EMC

Noise emission EN 61000−6−4

Noise immunity Zone B EN 61000−6−2

* Due to the high−energy single current pulses, a surge requires a suitable external connection with lightning

protection elements like for instance lightning conductors and overvoltage arresters.

VDE0870, UL

UL 508 (NEMA 250) Type 1 enclosure

Class A (industrial premises)

Industrial premises

EN 61000−4−2 ESD; severity: 3, i.e.

8 kV in the case of air discharge,

4 kV in the case of contact discharge

EN 61000−4−3 RF interference (housing)

80 MHz 1000 MHz, 10 V/m 80 % AM (1 kHz)

EN 61000−4−4 Burst, severity: 3

EN 61000−4−5 Surge, severity 3 *

EN 61000−4−6 RF conducted

150 kHz 80 MHz, 10 V/m 80 % AM (1 kHz)

26

BA_ELx8xx EN 3.0

Page 27

Technical data

General data and operating conditions

Operating conditions

Mounting conditions

Place of installation

Mounting position Connections at the bottom

Ambient conditions

Climatic

Storage

Transport −10 ... +60 °C

Operation Depending on the equipment ( 28)

Relative humidity 10 ... 90 %, non−condensing

Site altitude

StoragetTransport < 12000 m amsl

Operation < 3000 m amsl

Chemical resistance

Decor film

Touch/display

Mechanical load capacity

Decor film

Touch/display

Switching element

DIN 42115

DIN 42115 max. 100 N

In the control cabinet, screen protected against direct solar

radiation

−10 ... +60 °C

4

BA_ELx8xx EN 3.0

27

Page 28

4

Technical data

General data and operating conditions

Note!

The failure probability of an electronic component increases with the ambient

temperature to which the component is subjected. Regarding the

serviceability and reliability, particular attention should be paid to the cooling

of the device. For every application, you should take care to keep the heating

of the device as low as possible.

ƒ We recommend to use forced−ventilated systems with "Smart Cool" fan

control to ensure sufficient heat dissipation.

The fan control monitors the internal temperature of the device and the

functioning of the fan. When a preset maximum temperature is exceeded,

the control system switches on the fan. When the fan speed falls below a

minimum speed, the control system signals a fault.

ƒ Systems with passive cooling via heatsinks should only be used if it is

guaranteed that there is always sufficient convection (e.g. by means of

external fan modules in the control cabinets or the installation of the device

in air−conditioned areas).

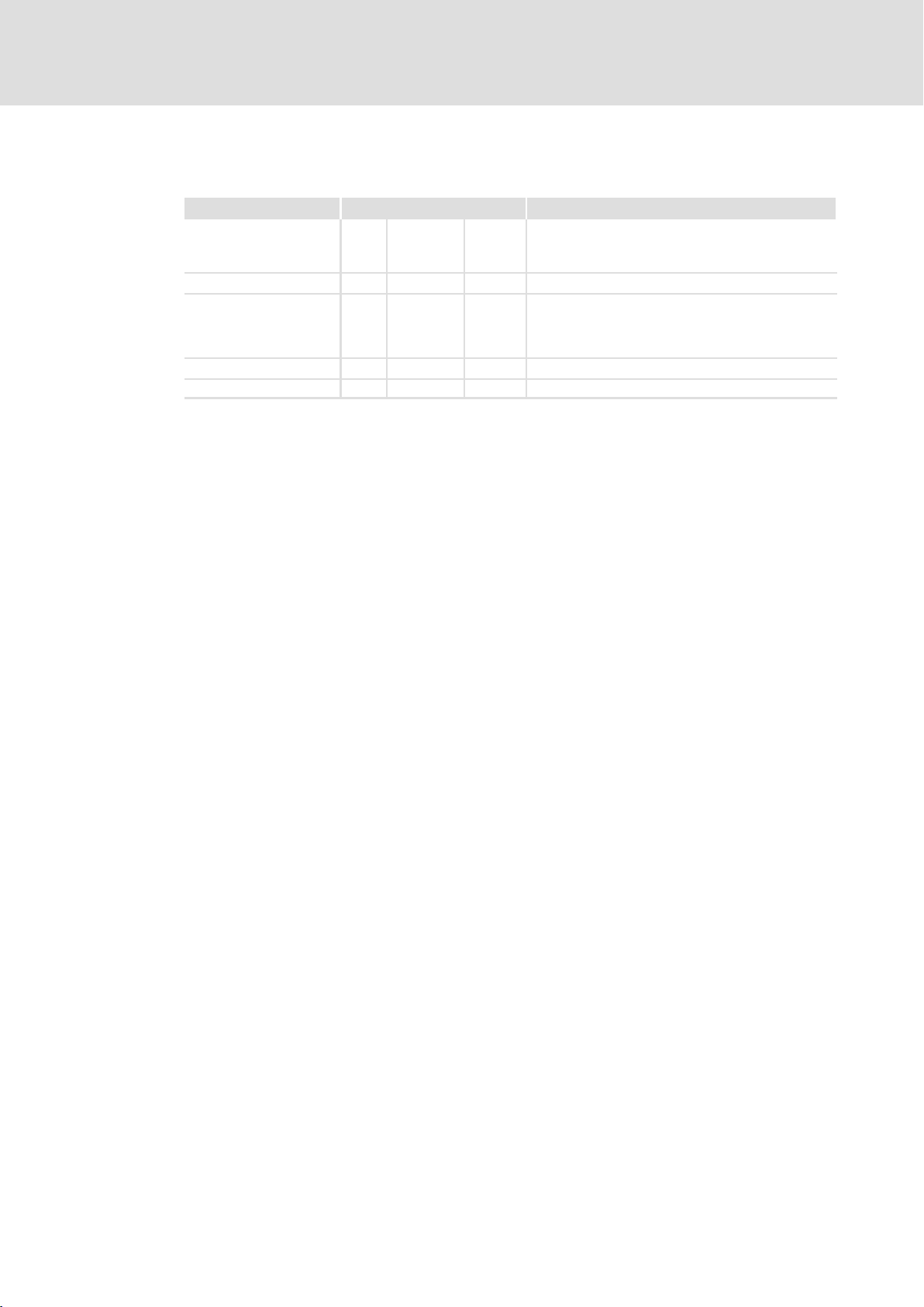

Permissible ambient temperatures for fanless systems

Standard device l With standard

Processor [°C]

Intelâ Atomä N270,

1.6 GHz

Permissible ambient temperatures for systems with "Smart Cool" cooling

Standard device l With standard

Processor [°C]

Intelâ Coreä Duo

1.66 GHz at max.

50 % CPU

utilisation

Intelâ Coreä Duo

1.66 GHz at max.

100 % CPU

utilisation

1) We recommend replacing the hard disk after 30,000 operating hours or after 5 years.

2) The CPU utilisation can be determined via the Windows task manager (register "System performance")

2)

2)

hard disk

5 ... 40 5 ... 45 0 ... 45 5 ... 40

hard disk

5 ... 45 5 ... 45 0 ... 45 5 ... 40

5 ... 40 5 ... 40 0 ... 40 5 ... 40

l With hard disk for

continuous

operation (24/7)

1)

l With hard disk for

continuous

operation (24/7)

1)

l With hard disk for

extended

temperature

range

l Up to 1 GB RAM

l With CF card

l With hard disk for

extended

temperature

range

l Up to 1 GB RAM

l With CF card

l With DVD writer

drive

l With DVD writer

drive

28

BA_ELx8xx EN 3.0

Page 29

Technical data

Electrical data

4

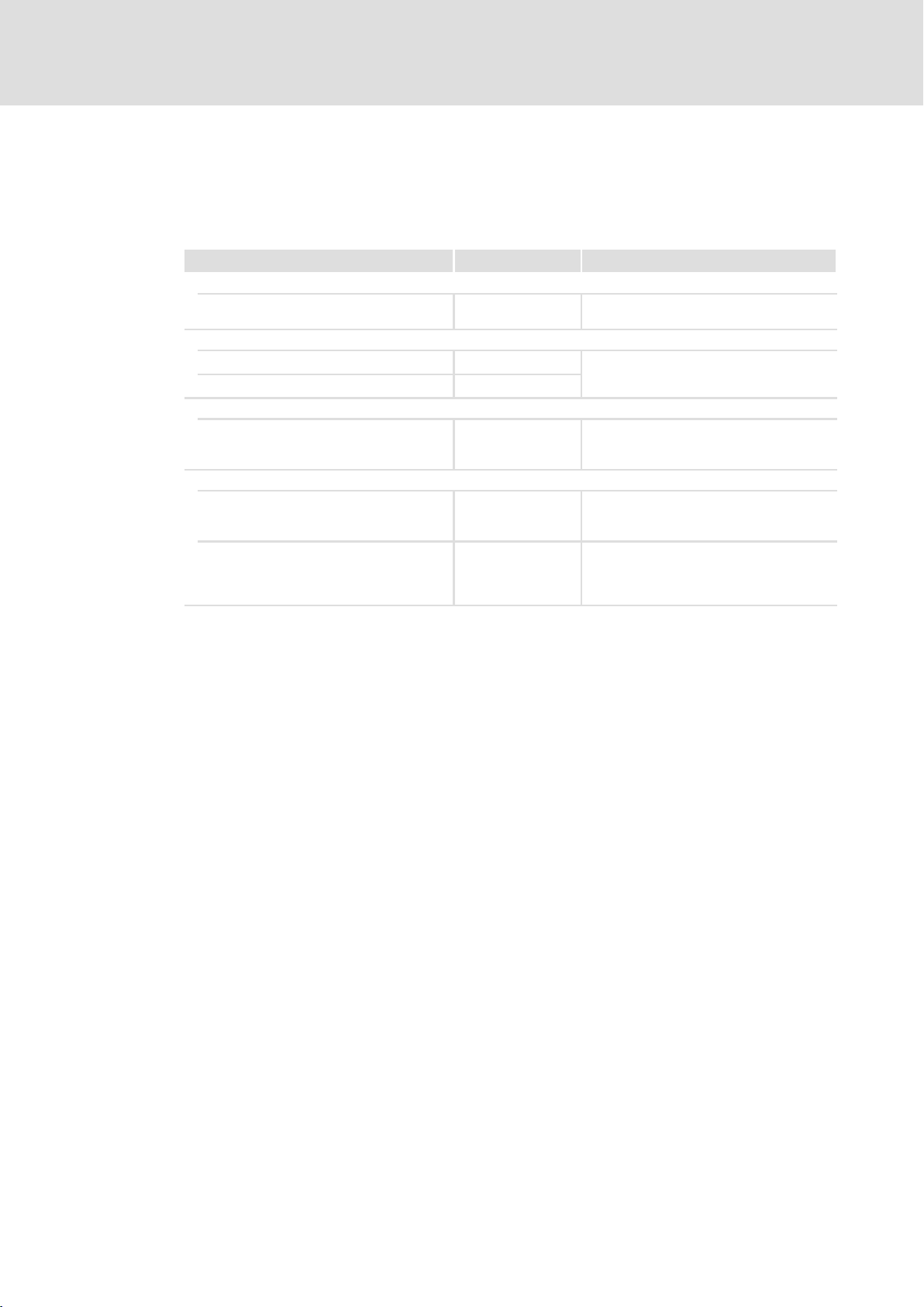

4.2 Electrical data

Standard device

Supply

EL 1800

EL 1800s

EL 1850

EL 1850s

EL 2800

EL 2850

EL 5800

EL 5820

EL 5850

EL 5870

EL 9800 2.4 1.5

1) Without ACU UPS control unit, DVD−Drive, MC card, and USB consumer

2) With ACU UPS Control Unit DC +20 ... 30 V

24 (+18 ... 30)

Voltage Current at 24 V

Intelâ Core Duoä Intelâ Atomä Type Type Service life

[DC V] [A] [A] [years]

1.5 1.0

2)

1.6 1.1

1)

Fuse Buffer battery

53 52 > 6 (25 °C)

Screen

Visible size Aspect ratio Resolution Brightness Contrast MTBF

[cm] [pixels] [cd/m2] [h]

EL 1800

EL 1850

EL 1800s

EL 1850s

EL 2800

EL 2850

EL 5800

EL 5820

EL 5850

EL 5870

EL 9800 48.3 (19") 1280 x 1024 300 1 : 2000 50,000

26.4 (10.4")

30.5 (12.1") 300 1 : 200

38.1 (15") 1024 x 768 250 1 : 550 40,000

4:3

640 x 480 400 1 : 300 40,000

400 1 : 500

800 x 600

50,000

ACU UPS control unit (option)

Type

ACU UPS 12 / 5 10 10 ... 600

1)

Subject to charging

Operating voltage Max. current Charging current in operating

[V DC] [mA] [mA]

At 5 V At 12 V

1)

range

Approx. 250

BA_ELx8xx EN 3.0

29

Page 30

4

Technical data

Mechanical data

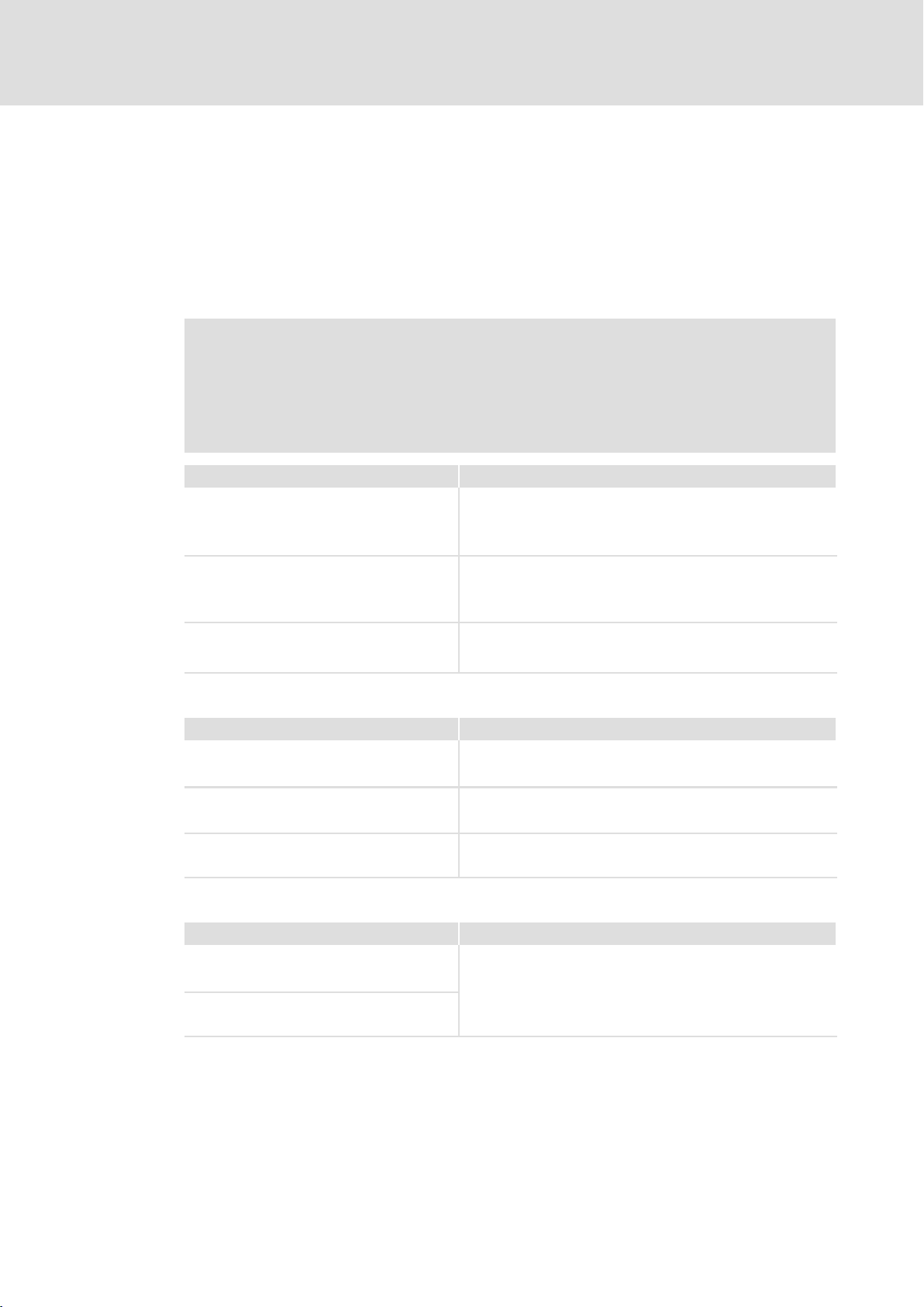

4.3 Mechanical data

Versions and weights

Front frame / housing Touchscreen Mass

EL 1800

EL 1800s

EL 1850

EL 1850s

EL 2800

EL 2850

EL 5800

EL 5820

EL 5850

EL 5870

EL 9800

*)

Without optional accessories (hard disk, DVD drive, etc.)

Aluminium/sheet steel

Polyester foil

*)

[kg]

4.6

4.6

5.0

5.0

5.8

6.0

6.6

6.8

6.8

7.6

10.6

30

BA_ELx8xx EN 3.0

Page 31

Technical data

4

Mechanical data

a

b

CD/DVD

disc

CD/DVD

6e27.5

65

All dimensions in millimetres.

Dimensions

a b e

[mm]

EL 1800

EL 1800s

EL 1850

EL 1850s

EL 2800

EL 2850

EL 5800

EL 5820

EL 5850

EL 5870

EL 9800 490 400 109

325

240

365

390 300

425 310

450 325

483

310 (7 U)

399 (9 U)

ELx7xx−003

99

BA_ELx8xx EN 3.0

31

Page 32

5

Mechanical installation

Important notes

5 Mechanical installation

5.1 Important notes

The installation must be carried out by qualified, skilled personnel familiar with the

applicable national standards.

Stop!

Sensitive front frame gasket

During mounting, the gasket of the front frame is exposed and can be

damaged.

Possible consequences:

ƒ The degree of protection provided by the enclosure mentioned in the

technical data is not attained.

Protective measures:

ƒ Handle the gasket with care during mounting.

ƒ Protect the gasket against ultraviolet rays.

ƒ Each time before you mount the device, check whether the gasket is intact.

Stop!

Sensitive touchscreen surface

The touchscreen foil is very sensitive to external forces and can be damaged by

improper handling.

Possible consequences:

ƒ The touchscreen foil becomes damaged, scratched or dull.

Protective measures:

ƒ Avoid contact of the touchscreen foil with pointed or hard objects.

ƒ Always use a touch pen or your fingers to operate the touchscreen. Never

use objects such as ballpoint pens, pencils, etc.

ƒ When removing dirt and fingerprints, observe the notes given in the chapter

"Cleaning" ( 48).

Note!

When selecting the place where the PC is to be installed, pay attention to an

ergonomic positioning of the screen and to the incidence of light which might

cause reflections on the screen.

32

BA_ELx8xx EN 3.0

Page 33

5.2 Mounting cutout

b3

b4

b1

b5

b2

a2

a1

Mechanical installation

Mounting cutout

1

0

5

D

Mounting cutout

Outline of front panel

Control board

2

£ 5

ELx7xx−004

All dimensions in millimetres.

Dimensions

a1 a2 b1 b2 b3 b4 b5 D

[mm]

EL 1800

EL 1800s

EL 1850

EL 1850s

EL 2800

EL 2850

EL 5800

EL 5820

EL 5850

EL 5870

EL 9800 438.0 451.0 386.0 172.0 172.0 60.0 60.0 8 x Æ4.5

305.0

343.0 − 228.0 − − − − −

340.0 351.0 288.0 122.0 122.0 0.0 −

375.0 386.0 288.0 122.0 122.0 0.0 −

400.0 411.0 313.0 134.5 134.5 0.0 −

452.0 462.4 299.0 104.9 104.6 15.7 −

452.0 462.4 388.2 149.3 149.3 15.9 −

− 228.0 − − − − −

6 x Æ5.5

BA_ELx8xx EN 3.0

33

Page 34

5

5.3 Mounting steps

5.3.1 Panel PC EL 1800(s) / EL 1850(s)

Mechanical installation

Mounting steps

Panel PC EL 1800(s) / EL 1850(s)

How to perform the installation:

1. Cut the mounting cutout into the control board ( 33).

2. Check that the gasket under the front panel is located correctly.

3. Place the device in the mounting cutout and secure it against falling−down with one

hand.

4. Fit all screw clamp fixings as explained below:

– Insert the screw clamp fixing into the slot in the housing of the device (see above

figure).

– Press the screw clamp fixing downwards, tilt it towards the housing and check

that it has firmly snapped into place.

– Tighten the screw clamp fixing hand−tight with a screwdriver.

5. Check that the device is securely located in the mounting cutout and that the front

panel gasket is located correctly.

– If necessary, realign the device/gasket.

– If the gasket is not located correctly, protection class IP65 is not achieved on the

front of the device!

ELx7xx−011

34

BA_ELx8xx EN 3.0

Page 35

Mechanical installation

Mounting steps

Panel PC EL 2800 / EL 2850 / EL 5800 / EL 5820 / EL 5850 / EL 5870 / EL 9800

5

5.3.2 Panel PC EL 2800 / EL 2850 / EL 5800 / EL 5820 / EL 5850 / EL 5870 / EL 9800

Note!

Types EL 5820, EL 5850, and EL 5870 can be installed in any control panel and

in 19" mounting racks in accordance with DIN 41494.

Control board mounting

How to perform the installation:

1. Prepare the control board by cutting the mounting cutout and drilling the mounting

holes into it ( 33).

2. Check that the gasket under the front panel is located correctly.

3. Place the device in the mounting cutout, secure it by hand against falling down and

screw the nuts and washers onto the threaded bolts.

4. Fit all screw clamp fixings as explained below:

ELx7xx−012

– Insert the screw clamp fixing into the slot in the housing of the device (see above

figure).

– Press the screw clamp fixing downwards, tilt it towards the housing and check

that it has firmly snapped into place.

– Tighten the screw clamp fixing hand−tight with a screwdriver.

5. Check that the device is securely located in the mounting cutout and that the front

panel gasket is located correctly.

– If necessary, realign the device/gasket.

– If the gasket is not located correctly, protection class IP65 is not achieved on the

front of the device!

Installation in 19" mounting racks (only EL 5820, EL 5850, and EL 5870)

How to perform the installation:ounting rack installation"#

BA_ELx8xx EN 3.0

1. Remove the set screws from the back of the front frame.

2. Drill through the blind holes at the back of the front frame using a 6.5 mm drill.

3. Place the device in the 19" mounting rack and screw it.

35

Page 36

6

Electrical installation

Important notes

6 Electrical installation

6.1 Important notes

The installation must be carried out by qualified, skilled personnel familiar with the

applicable national standards.

Stop!

Short circuit and static discharge

The device contains components which are endangered in the case of short

circuit or static discharge.

Possible consequences:

ƒ The device or parts of it will be destroyed.

Protective measures:

ƒ Always switch off the voltage supply when working on the device. This

particularly applies:

– Before connecting / disconnecting connectors.

– Before plugging in / plugging out modules.

ƒ All persons handling printed circuit boards have to take account of ESD

measures.

ƒ Contacts of plug connectors must not be touched.

ƒ Printed circuit boards may be touched only at places free from electrical

contacts and may be placed only on appropriate materials (e.g. on ESD

packaging or conductive foam material).

ƒ Printed circuit boards may only be transported and stored in ESD packaging.

36

BA_ELx8xx EN 3.0

Page 37

6.2 Wiring according to EMC

Electrical installation

Wiring according to EMC

6

General notes l The electromagnetic compatibility of the system depends on the type and accuracy of the

installation. Please especially note the following:

– Structure

– Shielding

– Earthing

l In the case of a differing installation it is required for evaluating the conformity to the EMC

Directive to check the system with regard to compliance with the EMC limit values. This for

instance applies to:

– The use of unshielded cables

l The end user is responsible for compliance with the EMC Directive.

– If you observe the following measures, you can be sure that no EMC problems will occur

during operation and that the EMC Directive or the EMC law is met.

– If devices which do not meet the CE requirement with regard to noise immunity

EN 61000−4−2 are actuated near the system, these devices can be affected

electromagnetically by the system.

Structure l Connect device to the earthed mounting plate:

– Mounting plates with an electroconductive surface (zinc−coated or stainless steel) allow for

continuous contacting.

– Coated plates are not suitable for an EMC−compliant installation.

l If you use several mounting plates:

– Connect mounting plates to each other on a large surface and in a conductive manner (e.g.

by means of copper strips).

l When installing the cables, observe a spatial separation of signal and mains cables.

l Route the cables as near to the reference potential as possible. Freely suspended cables act

like aerials.

Shielding l Preferably only use cables with a braid.

l The coverage of the shield should be more than 80%.

l In the case of data lines for a serial coupling, always use metallic or metallised plugs. Connect

the shield of the data line on the connector shell.

Earthing l Earth all metallically conductive components by the use of corresponding cables from a

central earthing point (PE rail).

l Comply with the minimum cross−sections defined in the safety instructions:

– With regard to EMC, however, not the cable cross−section, but the surface of the cable and

of the extensive contacting is decisive.

BA_ELx8xx EN 3.0

37

Page 38

6

Electrical installation

Connecting the supply and peripheral devices

Terminal diagram supply

6.3 Connecting the supply and peripheral devices

6.3.1 Terminal diagram supply

L1

N

PE

0

0 VUSV

PE+24 V

+

23

S

F

N

L1

~ =

1

0V

+

+

+24

IPC

Power supply unit

Battery pack (Option)

Capacitor pack (Option)

Note!

6.3.2 24 V connection (X101)

ƒ Observe the max. permissible input voltage.

Professionally fuse the device on the input side against voltage fluctuations

and voltage peaks.

ƒ The IPC boots up as soon as the supply voltage is applied.

After the operating system has been shut down, the IPC switches off

automatically. For restarting, the supply voltage has to be disconnected for a

short time.

0V U

IPC001

Description Connection type Cable type

Cable (conductor

cross−section max. 2.5 mm

with Phoenix Combicon plug,

MSTB 2.5 / 3−STF−5.08

DC 24 V connection

3−pole Phoenix Combicon

socket

Elx7xx−006

2

)

38

PE connection M4 threaded bolt

IPC001

Separate earthing conductor

(min. 2.5 mm

2

) with ring

cable lug

BA_ELx8xx EN 3.0

Page 39

6.3.3 UPS−PACK connection (X102)

Description Connection type Cable type

Terminal for Battery pack /

Capacitor pack

IPC001

6.3.4 PS/2 interface (X108)

Description Connection type Cable type

PS/2 connection 6−pin, mini DIN

IPC001

Electrical installation

Connecting the supply and peripheral devices

UPS−PACK connection (X102)

In the scope of supply of the

2−pin socket

pack; length 2.5 m; extension

available

PS/2 mouse

(a keyboard and a mouse can

be connected via a PS/2 Y

6

cable)

6.3.5 Serial interface (X103)

Description Connection type Cable type

1

6

RS232 connection

Pin 1: DCD

Pin 2: RxD

Pin 3: TxD

Pin 4: DTR

Pin 5: GND

Pin 6: DSR

Pin 7: RTS

Pin 8: CTS

Pin 9: RI

IPC001

6.3.6 Ethernet interface (X107)

Description Connection type Cable type

Ethernet connection

10/100 Mbps

Green LED (SPEED):

on = 100 MBPS

off = 10 Mbps

Yellow LED (LINK/ACTIVITY):

on or blinking = LINK

/ACTIVITY

off = no LINK

IPC001

9−pin Sub−D plug

RJ45 socket

Control cable, shielded, with

9−pin Sub−D socket

Network cable CAT5 S/UTP or

CAT5e S/FTP (recommended),

cable length: max. 100 m

BA_ELx8xx EN 3.0

Note!

If the RJ45 plug connection is exposed to oscillating or vibrating stress:

ƒ Use a strain relief in the immediate vicinity of the RJ45 socket.

ƒ Select the contact surface on which the device is mounted as fixing point of

the strain relief.

ƒ Comply with the related minimum bending radius of the cable used.

39

Page 40

6

Electrical installation

Connecting the supply and peripheral devices

USB interface (X104, X105, X106)

6.3.7 USB interface (X104, X105, X106)

Description Connection type Cable type

USB 2.0 host connection

Max. load: 5 V/500 mA

IPC001

6.3.8 Communication interface (MC card)

Description Connection type Cable type

Interface for MC card Socket connector −

EL100−013

6.3.9 USB interface on the front face (option)

USB−A socket USB cable with USB−A plug

EL100−013

Note!

If you use USB interfaces routed to the outside, the data integrity cannot be

guaranteed. On the "PC based Automation" DVD you’ll find the "FM Tool"

software which can be used to deactivate the front USB interface if it is not

needed.

Description Connection type Cable type

USB 2.0 host connection with

IP 65 cover

Max. load: 5 V/500 mA

USB−A socket USB cable with USB−A plug

40

BA_ELx8xx EN 3.0

Page 41

7 Operation

7.1 Important notes

Stop!

Sensitive touchscreen surface

The touchscreen foil is very sensitive to external forces and can be damaged by

improper handling.

Possible consequences:

ƒ The touchscreen foil becomes damaged, scratched or dull.

Protective measures:

ƒ Avoid contact of the touchscreen foil with pointed or hard objects.

ƒ Always use a touch pen or your fingers to operate the touchscreen. Never

use objects such as ballpoint pens, pencils, etc.

ƒ When removing dirt and fingerprints, observe the notes given in the chapter

"Cleaning" ( 48).

Operation

Important notes

7

BA_ELx8xx EN 3.0

41

Page 42

7

Operation

Controls and displays

Panel PC EL 1800 / EL 1800s / EL 2800 / EL 5800 / EL 9800

7.2 Controls and displays

7.2.1 Panel PC EL 1800 / EL 1800s / EL 2800 / EL 5800 / EL 9800

0

Power

Fail

Status

1

F1

F2

+

F3

2

-

4

Pos. Designation

3

Function

Standard mode Service mode

Switch on mode: Press "" for 4 s

Switch off mode: Press "" or wait for 35 s

Display Application−dependent

Status LEDs Power (green):

l Is ON when the supply voltage is present.

Fail (red):

l Is On when a power supply failure has occurred.

l Is blinking when the screen signal is missing.

Status (yellow):

l Application−dependent

Function keys F1 ... F3: Send key code for Shift−F1 ...

Shift−F3

Tool: Application−dependent

+: Increase screen brightness

−: Reduce screen brightness

Reset button Reset PC (restart)

Status LEDs Error (red):

l Is lit if a power supply failure has occurred.

l Is blinking when the screen signal is missing.

HD (yellow):

l Indicates access to a storage medium.

Power (green):

l Is lit when the supply voltage is present.

l Flashes (

l Is blinking (

l Is blinking (

supplied by the ACU UPS.

l Is blinking (

rechargeable battery is empty or missing).

l Blinks 4 x per second if the ACCU−PACK causes a short circuit or if the CAPS−PACK

−

) in the case of a hardware error.

−−−−−−−

−−−−−

) when the ACU UPS (optional) is being charged.

−

−−−−−−

) when there is a supply voltage failure and the device is being

−−

−−−

) when the supply voltage of the ACU UPS is too low (e.g.

−

is completely discharged.

ELx7xx007

42

BA_ELx8xx EN 3.0

Page 43

Operation

Controls and displays

Panel PC EL 5820

7

7.2.2 Panel PC EL 5820

S1

S2

S3

S4

S5

S6

S7

+

Power

Fail

F1

Esc

Status

1

Pos. Designation

Switch on mode: Press "" for 4 s

Switch off mode: Press "" or wait for 35 s

Display Application−dependent

Status LEDs Power (green):

Function keys F1 ... F12: Send key code for F1 ... F12 Tool: Application−dependent

Reset button Reset PC (restart)

Status LEDs Error (red):

Special keys S1 ... S7: Send key code for shift−F1 ... shift−F7

0

S8

S9

S10

S11

5

S12

S13

S14

-

F3F2

F4

F11 F12F6F5 F7 F8 F9 F10

Enter

2

4

3

ELx7xx010

Function

Standard mode Service mode

l Is ON when the supply voltage is present.

Fail (red):

l Is On when a power supply failure has occurred.

l Is blinking when the screen signal is missing.

Status (yellow):

l Application−dependent

+: Increase screen brightness

−: Reduce screen brightness

l Is lit if a power supply failure has occurred.

l Is blinking when the screen signal is missing.

HD (yellow):

l Indicates access to a storage medium.

Power (green):

l Is lit when the supply voltage is present.

l Flashes (

l Is blinking (

l Is blinking (

supplied by the ACU UPS.

l Is blinking (

rechargeable battery is empty or missing).

l Blinks 4 x per second if the ACCU−PACK causes a short circuit or if the CAPS−PACK

is completely discharged.

S8 ... S14: Send key code for ctrl−F1 ...ctrl−F7

−

) in the case of a hardware error.

−−−−−−−

−−−−−

) when the ACU UPS (optional) is being charged.

−

−−−−−−

) when there is a supply voltage failure and the device is being

−−

−−−

) when the supply voltage of the ACU UPS is too low (e.g.

−

BA_ELx8xx EN 3.0

43

Page 44

7

Operation

Controls and displays

Panel PC EL 1850 / EL 1850s / EL 2850 / EL 5850

7.2.3 Panel PC EL 1850 / EL 1850s / EL 2850 / EL 5850

0

-

+6

6

*

/

Power

Fail

Status

1

7

EscDelIns

Menu

9

2

Q+R

ST

-

F1 F2 F5

F3 F4

A

BCD

8

9

7

E

FGH

4

5

I

JKL

3

1

2

M

NOP

,

.

0

PgUp

Home

End

PgDn

AltCtrl

Bs

Shift

Space

Alpha

WVU

F7F6

4

@\Z

F11F10YXF9F8 F12

3

Enter

ELx7xx008

44

BA_ELx8xx EN 3.0

Page 45

Operation

Controls and displays

Panel PC EL 1850 / EL 1850s / EL 2850 / EL 5850

7

Pos. Designation

Switch on mode: Press "alpha key" (LED is on) Press "menu key"

Switch off mode: Press "alpha key" (LED is off) Press "menu key" or wait for

Display Application−dependent

Status LEDs Power (green):

Function keys F1 ... F12: Send key code for

Reset button Reset PC (restart)

Status LEDs Error (red):

Numeric

keypad

Cursor keys Without "Shift" key: Move cursor/marker in steps and set

Control keys Standard functions of a MF2 keyboard

Function

Standard mode Alpha mode Service mode

35 s

l Is ON when the supply voltage is present.

Fail (red):

l Is ON when a power supply failure has occurred

l Is blinking when the screen signal is missing.

Status (yellow):

l Indicates access to a storage medium.

Shift−F1 ... Shift−F12

l Is lit if a power supply failure has occurred;

l Is blinking when the screen signal is missing.

HD (yellow):

l Indicates access to a storage medium.

Power (green):

l Is lit when the supply voltage is present.

l Flashes (

l Is blinking (

l Is blinking (

by the ACU UPS.

l Is blinking (

battery is empty or missing).

l Blinks 4 x per second if the ACCU−PACK causes a short circuit or if the CAPS−PACK is

completely discharged.

Send key codes for "0" ... "9"

and calculation operators

tab

With "Shift" key: Move cursor/marker to the beginning/end

or page by page

(For "alpha" and "menu" see "Switch on/off mode")

−

) in the case of a hardware error.

−−−−−−−

−−−−−

) when the ACU UPS (optional) is being charged.

−

−−−−−−

) when there is a supply voltage failure and the device is being supplied

−−

−−−

) when the supply voltage of the ACU UPS is too low (e.g. rechargeable

−

F1 ... F12: Send key codes for

"Q" ... "@"

Send key codes for "A" ... "P" Functionality same as in

Tool: Application−dependent

+: Increase screen brightness

−: Reduce screen brightness

standard/alpha mode

Functionality same as in

standard/alpha mode

Functionality same as in

standard/alpha mode

BA_ELx8xx EN 3.0

45

Page 46

7

Operation

Controls and displays

Panel PC EL 5870

7.2.4 Panel PC EL 5870

+

Pos. Designation

Switch on mode: Press " (F4)" for 4 s

Switch off mode: Press " (F4)" or wait for 35 s

Display Application−dependent

Status LEDs Power (green):

Function keys F1 ... F12: Send key code for Shift−F1 ...

Reset button Reset PC (restart)

Status LEDs Error (red):

MF2 keys Standard function of a MF2 keyboard

/

(

)

879

&

$

546

§

"

!

123

=

>

,

|

<

0

Bs

Einfg

Entf

Pos 1

Ende

-

F4

F3F1 F2

F5

EWQ

T

R

@

€

D

SA

GHJ

F

XY

VC

4

F9F8F6 F7 F10

OIPÜUZ

Ä

LK

Ö

_

;

:

M

NB

,

-

.

μ

3

Alt Gr

Alt Strg

F12

Esc

F11

*

~

+

Enter

\?ß

Space

0

-

+

5

*

/

Power

Fail

Status

1

5

Bild

Bild

5

2

5

ELx7xx009

Function

Standard mode Service mode

l Is ON when the supply voltage is present.

Fail (red):

l Is ON when a power supply failure has occurred.

l Is blinking when the screen signal is missing.

Status (yellow):

l Indicates access to a storage medium.

Tool: Application−dependent

Shift−F12

+: Increase screen brightness

−: Reduce screen brightness

l Is lit if a power supply failure has occurred;

l Is blinking when the screen signal is missing.

HD (yellow):

l Indicates access to a storage medium.

Power (green):

l Is lit when the supply voltage is present.

l Flashes (

l Is blinking (

l Is blinking (

supplied by the ACU UPS.

l Is blinking (

rechargeable battery is empty or missing).

l Blinks 4 x per second if the ACCU−PACK causes a short circuit or if the CAPS−PACK

−

) in the case of a hardware error.

−−−−−−−

−−−−−

) when the ACU UPS (optional) is being charged.

−

−−−−−−

) when there is a supply voltage failure and the device is being

−−

−−−

) when the supply voltage of the ACU UPS is too low (e.g.

−

is completely discharged.

46

BA_ELx8xx EN 3.0

Page 47

8 Maintenance

Stop!

Short circuit and static discharge

The device contains components which are endangered in the case of short

circuit or static discharge.

Possible consequences:

ƒ The device or parts of it will be destroyed.

Protective measures:

ƒ Always switch off the voltage supply when working on the device. This

particularly applies:

– Before connecting / disconnecting connectors.

– Before plugging in / plugging out modules.

ƒ All persons handling printed circuit boards have to take account of ESD

measures.

ƒ Contacts of plug connectors must not be touched.

ƒ Printed circuit boards may be touched only at places free from electrical

contacts and may be placed only on appropriate materials (e.g. on ESD

packaging or conductive foam material).

ƒ Printed circuit boards may only be transported and stored in ESD packaging.

Maintenance

Regular checks

8

8.1 Regular checks

The device is free of maintenance. Nevertheless, visual inspections should be carried out

at regular intervals which must not be too long, depending on the ambient conditions.

Please check the following:

ƒ Does the environment of the device meet the operating conditions specified in the

Technical data?

ƒ Is the heat dissipation of the device not impeded by dust or dirt?

ƒ Are the mechanical and electrical connections o.k.?

BA_ELx8xx EN 3.0

47

Page 48

8

8.2 Cleaning

Maintenance

Cleaning

Stop!

ƒ Before cleaning, disconnect the device from the power supply as otherwise

unintentional commands may be activated via the touchscreen, for example a

response of the control.

Sensitive surfaces and components

The device can be damaged if it is not appropriately cleaned.

Possible consequences:

ƒ The housing or the screen gets scratched or dull if you use alcoholic,

solvent−containing or scouring cleaning agents.

ƒ Electrical components can be damaged ...

– by a short circuit caused by humidity.

– by static discharge.

Protective measures:

ƒ Observe the following notes.

ƒ Clean the device front (screen and frame) as follows:

– Use a clean, lint−free and soft cloth.

– Moisten the cloth with the detergent. Do not spray the detergent directly on the

device.

– Only use water with a fluid addition as detergent or a detergent declared

especially for flat screens.

ƒ Clean the rear side of the device with a clean, lint−free and soft cloth. Do not use

liquid or foaming detergent since it may enter the housing or terminals.

48

BA_ELx8xx EN 3.0

Page 49

8.3 Repair

disc

disc

8.3.1 Remove the PC housing

With DVD drive

Maintenance

Repair

Remove the PC housing

8

a

1

disc

0

disc

2

5

4

6

3

b

c

3

ELx7xx−013

Proceed as follows when a DVD drive is mounted:

1. Remove the 24 V cable ( 38)

2. Remove the DVD drive :

– Loosen the fixing screw .

– Push the DVD drive to the right.

– Carefully take off the DVD drive.

– Remove the ribbon cable .

3. Only for fanless devices: Loosen the three screws .

4. Remove the housing :

– Loosen the three screws .

– Carefully pull the housing off towards the front while passing the ribbon cable

through the housing aperture.

BA_ELx8xx EN 3.0

49

Page 50

8

Maintenance

Repair

Remove the PC housing

Without DVD drive

1

3

0

Proceed as follows when no DVD drive is mounted:

1. Remove the 24 V cable ( 38).

2. Only for fanless devices: Loosen the three screws .

3. Remove the housing :

– Loosen the four screws .

– Carefully pull the housing off towards the front.

2

3

ELx7xx−015

50

BA_ELx8xx EN 3.0

Page 51

8.3.2 Mount the PC housing

disc

disc

With DVD drive

Maintenance

Repair

Mount the PC housing

8

2

0

4

5

3

1

b

a

1

c

disc

disc

6

Proceed as follows when a DVD drive is mounted:

1. Mount the housing :

– Pass the ribbon cable through the housing aperture and carefully place the

housing on the housing base.

– Screw in the three screws .

2. Only for fanless devices: Screw in the three screws and tighten them.

The internal heatsink must be firmly connected with the housing. Otherwise, the heat

dissipation will not suffice, and the device might be damaged.

3. Mount the DVD drive :

– Plug on the ribbon cable .

– Carefully place the DVD drive on the slots in the housing.

– Push the DVD drive to the left until it snaps into place.

– Screw in the fixing screw .

ELx7xx−014

BA_ELx8xx EN 3.0

51

Page 52

8

Maintenance

Repair

Battery change

Without DVD drive

0

1

1

Proceed as follows when no DVD drive is mounted:

1. Mount the housing :

– Carefully place the housing on the housing base.

– Screw in the four screws .

2. Only for fanless devices: Screw in the three screws and tighten them.

The internal heatsink must be firmly connected with the housing. Otherwise, the heat

dissipation will not suffice, and the device might be damaged.

8.3.3 Battery change

2

3

ELx7xx−016

Danger!

Danger of fire and explosion

On the baseboard there is a battery for buffering the clock (RTC) when the

device has been switched off.

Possible consequences:

ƒ The use of other batteries than the approved ones or improper handling can

result in a fire, explosion, or environmental damage.

Protective measures:

ƒ The battery may only be replaced by an approved battery type according to

the following list.

ƒ The battery may not be recharged or opened. Furthermore it may not be

thrown into a fire or be heated above 100 °C (212 °F).

Approved types:

ƒ Matsushita CR2450, Renata CR2450N, Sony Corp. CR2450B, Toshiba CR2450, Varta

CR2450

52

BA_ELx8xx EN 3.0

Page 53

Maintenance

Repair

Fuse change

FAN3

M

C-

CAN

2

CA

N2

CAN1

How to proceed:

1. Remove the MC Card, if inserted.

2. Remove the old battery from the support.

3. Insert a new approved battery into the support so that the positive pole is at the

top.

FAN2

BLIGHT

USB-μCON

T4A

F1

POWER

+

CR2450

0

20

19

1

2

ACCU

RESET

CF-CARD

ELx7xx−017

8

According to European legislation you are obliged to dispose of batteries separately, using

the take−back systems specified.

8.3.4 Fuse change

Stop!

Damage of the device by non−permissible fuse possible

The baseboard in the device is protected by a fuse which will be damaged if

the supply voltage applied is too high.

Possible consequences:

ƒ The device can be damaged if a non−approved fuse is installed.

Protective measures:

ƒ The fuse may only be replaced by an approved type.

Approved types:

ƒ Littelfuse 0454 004

BA_ELx8xx EN 3.0

53

Page 54

8

Maintenance

Repair

Fuse change

FAN3

M

C-

CAN

2

CAN

2

CAN1

FAN2

CR2450

20

BLIGHT

0

USB-μCON

T4A

F1

POWER

19

1

2

ACCU

RESET

CF-CARD

ELx7xx−018

How to proceed:

1. Remove the MC Card, if inserted.

2. Remove the old fuse from the support.

3. Insert a new approved fuse into the support.

54

BA_ELx8xx EN 3.0

Page 55

9 Index

Index 9

A

ACU UPS control unit, 24

Ambient conditions

− climatic, 27

− Site altitude, 27