Page 1

Accessories

INTERBUS

Servo Drives 9400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

E94AYCIB

Communication Manual EN

Ä.N+øä

13451099

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2.1 General safety and application notes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

2.2 Device and application-specific safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2.3 Residual hazards _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

3 Product description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3.1 Application as directed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3.2 Identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3.3 Product features _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3.4 Terminals and interfaces _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

4 Technical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4.1 General data and operating conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4.2 Protocol data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.3 Communication time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.4 Protective insulation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.5 Dimensions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

5Installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

5.1 Mechanical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

5.1.1 Assembly _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

5.1.2 Disassembly _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

5.2 Electrical installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

5.2.1 Wiring according to EMC guidelines _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

5.2.2 Wiring of the INTERBUS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

5.2.3 INTERBUS connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

5.2.4 Dimensions of 9-pole sub-D connectors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

5.2.5 Bus cable specification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

5.2.6 Bus cable length _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

5.2.7 External voltage supply _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

6 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

6.1 Before initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

6.2 Possible settings via DIP switch _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

6.2.1 Setting the number of process data words _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

6.2.2 Setting the number of parameter data words _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

6.2.3 Setting the baud rate _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

6.3 Settings in »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

6.4 Initial switch-on _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

2 Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

8 Process data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

9 Parameter data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

9.1 Addressing of the parameter data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

9.2 Initialising PCP communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

9.3 Supported PMS services _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

9.3.1 Initiate _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

9.3.2 Abort _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

9.3.3 Reject _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

9.3.4 Read/Write _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

9.3.5 Get-OD _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

9.3.6 Identify _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

9.3.7 Status _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

10 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

10.1 Interruption of the INTERBUS communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

10.2 Interruption of internal communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

11 Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

11.1 LED status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

11.2 Diagnosing with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

12 Error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

12.1 Short overview of the INTERBUS error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

12.2 Possible causes and remedies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

13 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

13.1 Parameters of the standard device that are relevant to communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

13.2 Parameters of the communication module for slot MXI1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

13.3 Parameters of the communication module for slot MXI2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

13.4 Table of attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

14 Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 74

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 77

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 3

Page 4

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This documentation exclusively describes the E94AYCIB communication module (INTERBUS).

Note!

This documentation supplements the mounting instructions supplied with the

communication module and the Servo Drives 9400 hardware manual.

The mounting instructions contain safety instructions which must be observed!

The features and functions of the communication module are described in detail.

Examples illustrate typical applications.

The theoretical context is only explained as far as it is required for understanding the function of

the communication module.

This documentation does not describe any software provided by other manufacturers. No warranty

can be given for corresponding data provided in this documentation. For information on how to use

the software, please refer to the host (PLC, master) documents.

All brand names mentioned in this documentation are trademarks of their corresponding owners.

Tip!

More information on the INTERBUS can be found on this internet page:

www.interbus.com

Maintenance activities for the INTERBUS technologies are carried out by the user

organisation PROFIBUS & PROFINET International (PI).

www.profibus.com

4 Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 5

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Target group

This documentation is intended for all persons who plan, install, commission and maintain the

networking and remote servicing of a machine.

Tip!

Current documentation and software updates with regard to Lenze products can be found

in the download area at:

www.lenze.com

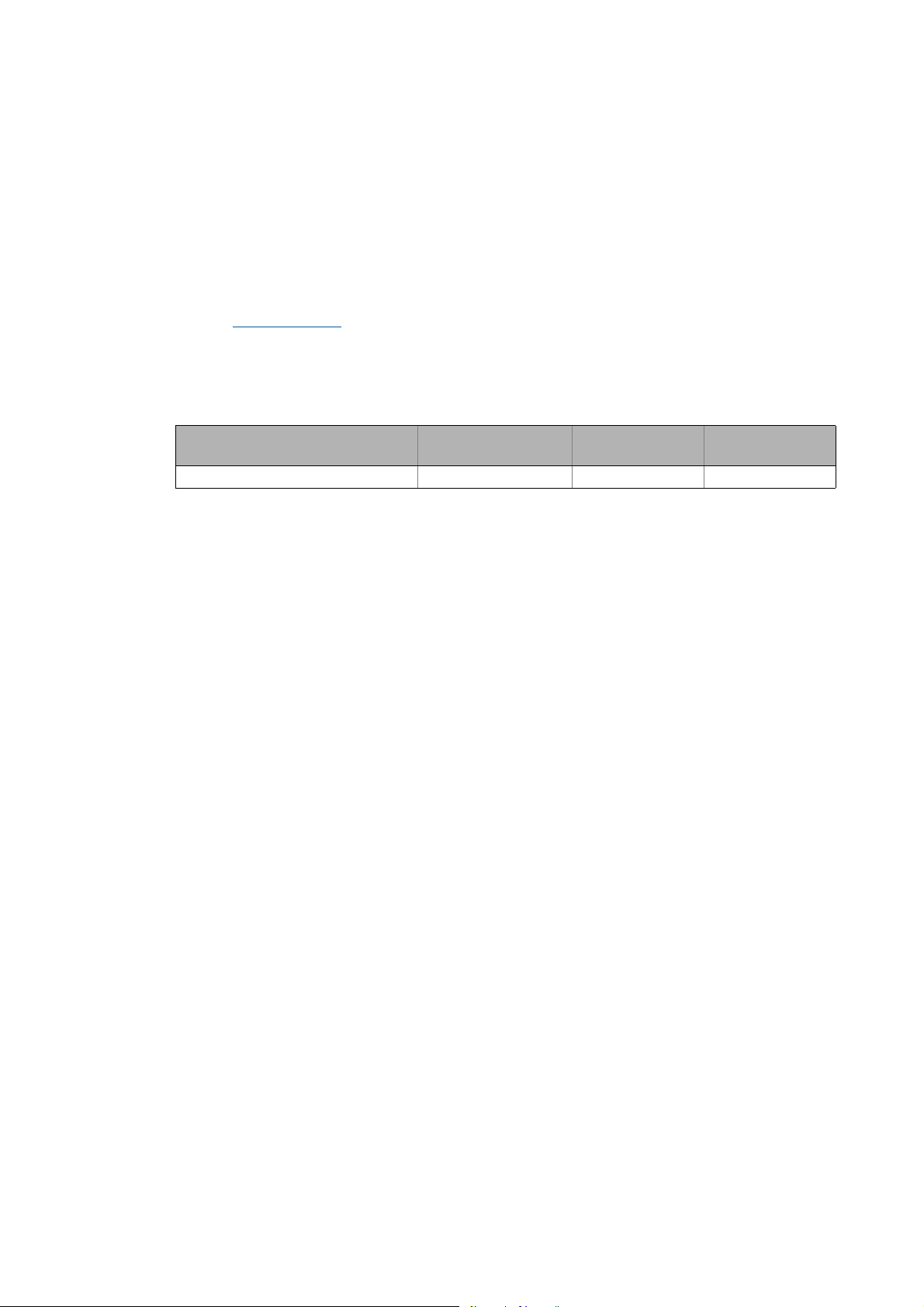

Information regarding the validity

The information given in this documentation is valid for the following devices:

Extension module Type designation From hardware

version

Communication module INTERBUS E94AYCIB PA 01.00

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the communication module and the software version of the engineering tools installed

(e.g. »Engineer«), the screenshots in this documentation may differ from the actual screen

representation.

From software

version

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 5

Page 6

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

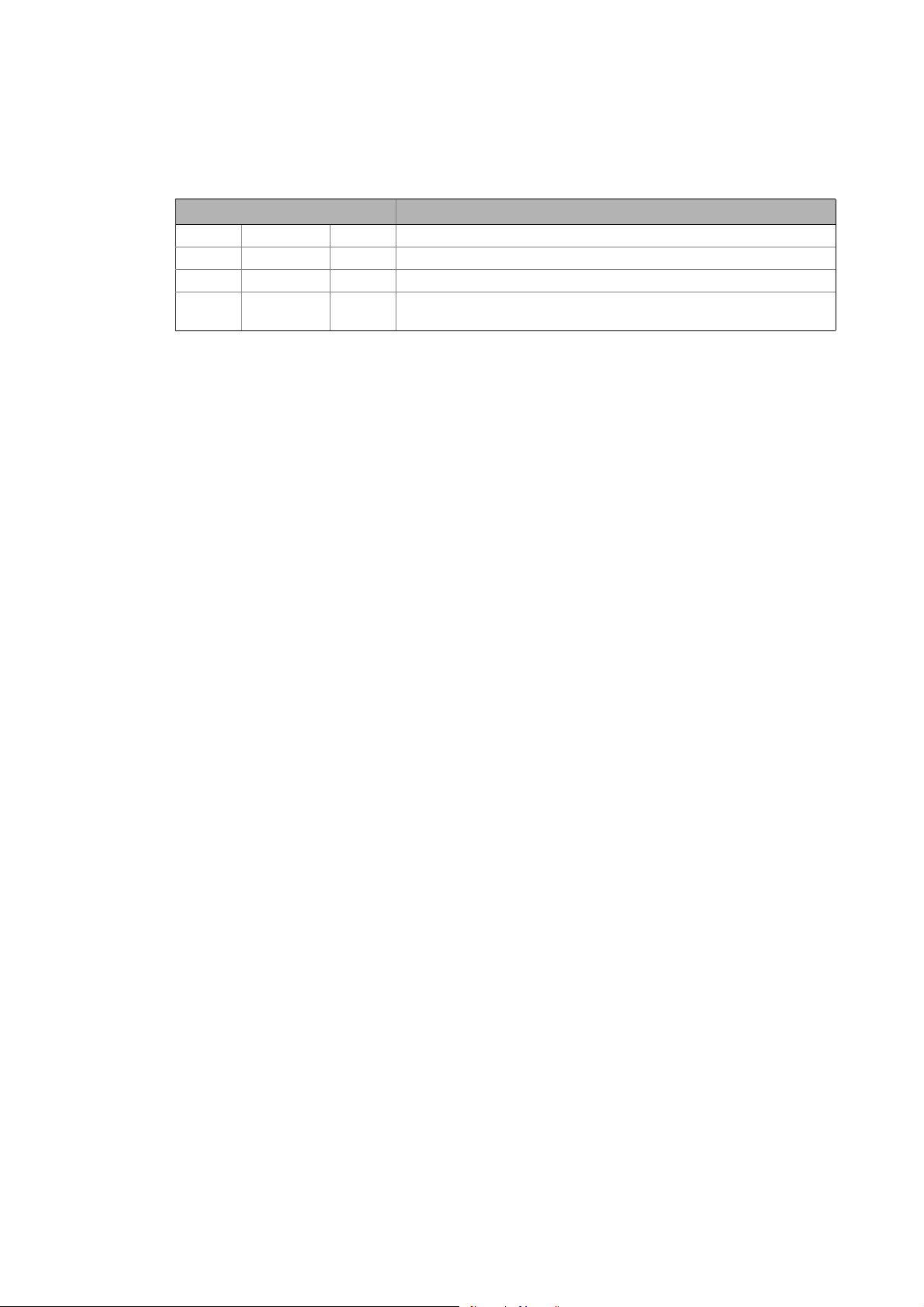

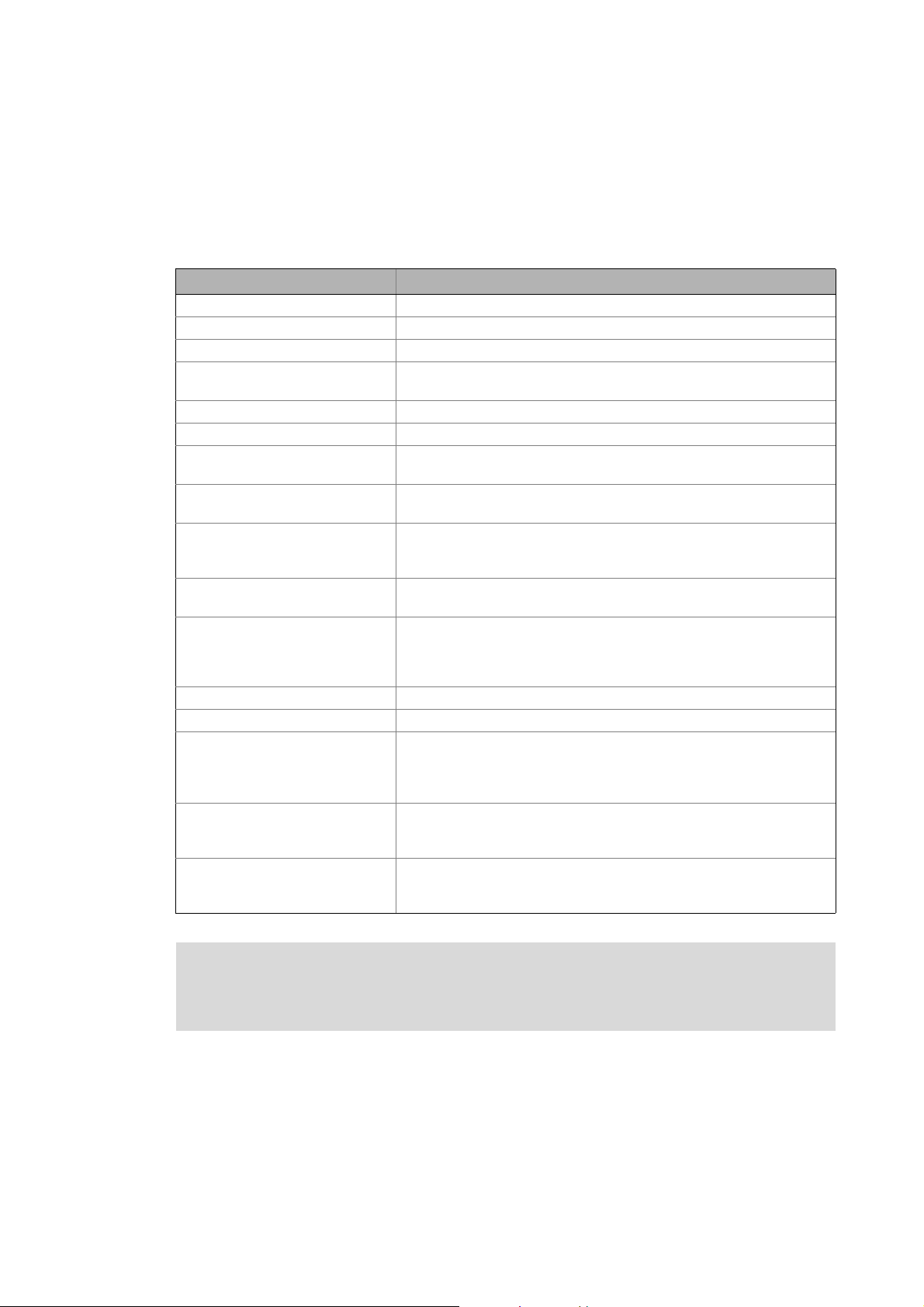

1.1 Document history

Version Description

1.0 03/2009 TD17 Field test version

2.0 06/2009 TD17 General revision

3.0 11/2009 TD17 General revision

4.0 02/2014 TD17 • New layout

• General updates

6

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 7

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal Normal spelling Example: 1234

Decimal separator Point The decimal point is always used.

For example: 1234.56

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Text

Version information Blue text colour All information that applies to from a certain software

Program name » « The Lenze PC software »Engineer«...

Control element bold The OK button ... / The Copy command ... / The Properties tab

Sequence of menu

commands

Hyperlink Underlined

Icons

Page reference ( 8) Optically highlighted reference to another page. In this

Step-by-step instructions

In inverted commas

Point

Example: ’100’

Example: ’0110.0100’

version of the device onwards are marked accordingly in this

documentation.

Example: This function extension is available from software

version V3.0 onwards!

... / The Name input field ...

If several commands are required to execute one function,

the single commands are separated by an arrow: Select the

Open command to...

File

Optically highlighted reference to another topic. It is

activated with a mouse-click in this online documentation.

online documentation activated via mouse-click.

Step-by-step instructions are indicated by a pictograph.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 7

Page 8

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

Drive Lenze inverter of the "Servo Drives 9400" product series, with which the

Inverter

Standard device

Code Parameter which serves to parameterise and monitor the drive. In normal usage,

Subcode If a code contains several parameters, they are stored in "subcodes".

»Engineer« Lenze PC software which supports you during the "Engineering" process

communication module can be used.

Application as directed

the term is usually referred to as "Index".

In the documentation, the slash "/" is used as a separator between the code and

the subcode (e.g. "C00118/3").

In everyday language, the term is also referred to as "subindex".

(parameterisation, diagnostics, and configuration) throughout the whole life

cycle, i. e. from planning to maintenance of the machine commissioned.

INTERBUS was developed as sensor/actuator bus system for transmitting

process data.

Maintenance activities for the INTERBUS technologies are carried out by the user

organisation PROFIBUS & PROFINET International (PI).

( 12)

Host PLC, INTERBUS master

PCP Peripherials Communication Protocol for transmitting parameter data

PDO Process data object

PDU Process Data Unit

PMS Peripheral Message Specification

HW Hardware

SW Software

8

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 9

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Definition of the notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious personal

injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Reference to another document

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 9

Page 10

2 Safety instructions

2.1 General safety and application notes

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Note!

It is absolutely vital that the stated safety measures are implemented in order to prevent

serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during operation.

2.1 General safety and application notes

Danger!

If the following basic safety measures are disregarded, severe injuries to persons and

damage to material assets may result.

Lenze drive and automation components ...

• must only be used as directed.

Application as directed

• must never be commissioned if they display signs of damage.

• must never be technically modified.

( 12)

• must never be commissioned if they are not fully mounted.

• must never be operated without required covers.

• during and after operation can have live, moving and rotating parts, depending on their degree

of protection. Surfaces can be hot.

The following applies to Lenze drive components ...

• only use the accessories approved.

• Only use original manufacturer spare parts.

Observe all specifications contained in the enclosed documentation and related documentation.

• This is the precondition for safe and trouble-free operation and for obtaining the product

features specified.

Product features

• The specifications, processes, and circuitry described in this document are for guidance only and

must be adapted to your own specific application. Lenze does not take responsibility for the

suitability of the process and circuit proposals.

( 13)

10

All works on and with Lenze drive and automation components must only be carried out by qualified

personnel. According to IEC 60364 or CENELEC HD 384 these are persons who ...

• are familiar with installing, mounting, commissioning, and operating the product.

• who have the corresponding qualifications for their work.

• who know and can apply all regulations for the prevention of accidents, directives, and laws

applicable at the place of use.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 11

2 Safety instructions

2.2 Device and application-specific safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Device and application-specific safety instructions

• During operation, the communication module must be securely connected to the standard

device.

• With external voltage supply, always use a separate power supply unit, safely separated to

EN 61800-5-1 in every control cabinet (SELV/PELV).

• Only use cables corresponding to the given specifications.

Bus cable specification

( 27)

Documentation for the standard device, host (PLC, master), system/machine

All the other measures prescribed in this documentation must also be implemented.

Observe the safety instructions and application notes contained in this manual.

2.3 Residual hazards

Protection of persons

If Servo Drives 9400 are used on a phase earthed mains with a rated mains voltage 400 V,

protection against accidental contact is not guaranteed without external measures.

Protective insulation

Device protection

The communication module contains electronic components which may be damaged or destroyed

by electrostatic discharge.

Installation

( 21)

( 17)

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 11

Page 12

3 Product description

3.1 Application as directed

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Product description

3.1 Application as directed

The communication module ...

• is an accessory module that can be used in conjunction with the following standard devices:

Product series Type designation From hardware

Servo Drives 9400 HighLine E94AxHExxx 1A 03.00

Servo Drives 9400 PLC E94AxPExxxx VA 02.00

Regenerative power supply module E94ARNxxxx VA 01.00

• is a device intended for use in industrial power systems.

• should only be used under the operating conditions prescribed in this documentation.

• can only be used in INTERBUS networks.

Any other use shall be deemed inappropriate!

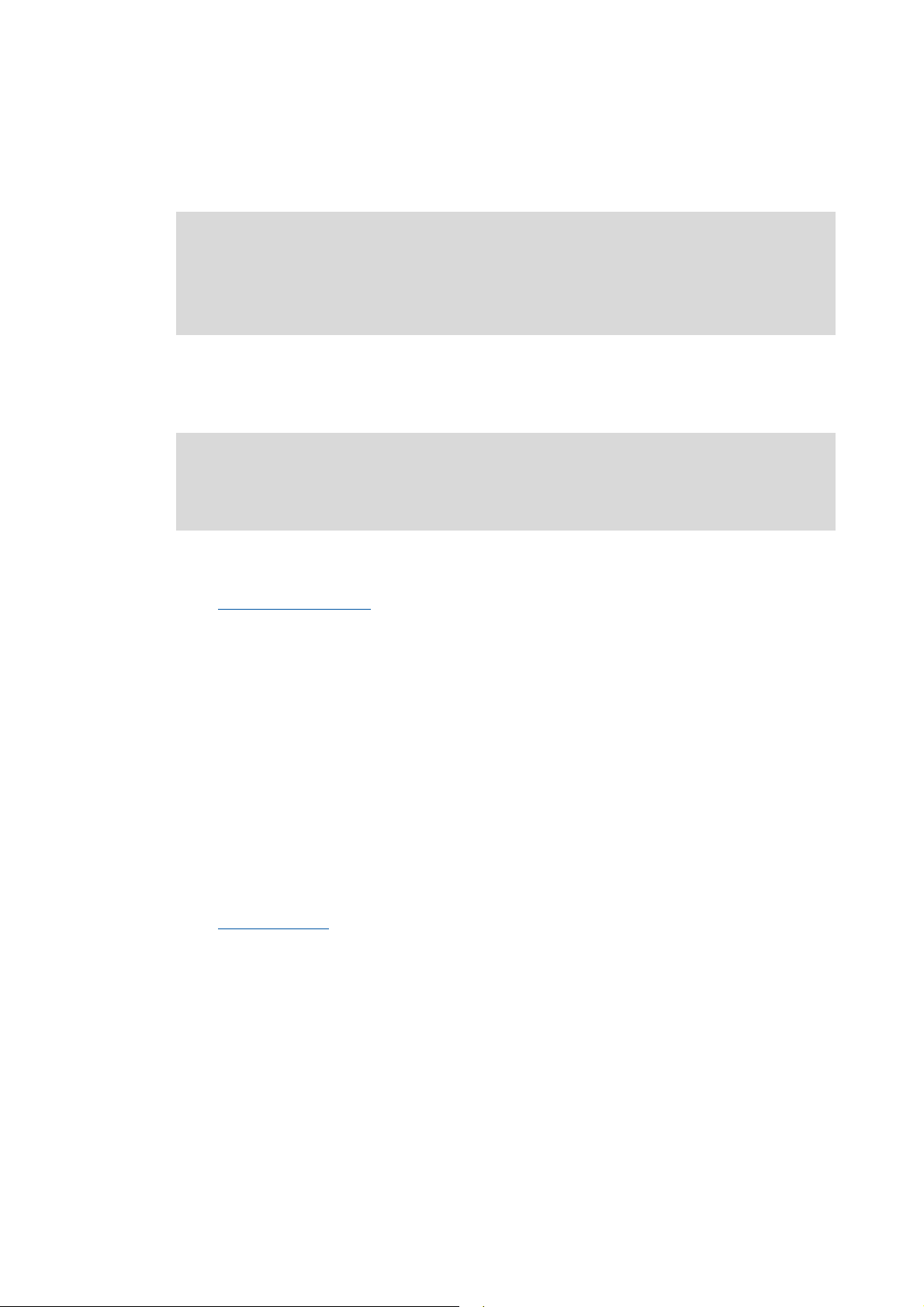

3.2 Identification

The type designation and hardware and software version of the communication module are

specified on the nameplate:

[3-1] Identification data

E94YCIB005

version

1 Type designation (type)

E94 Product series

AVersion

Y Module identification: Extension module

C Module type: Communication module

IB INTERBUS

2 Hardware version (HW)

3 Software version (SW)

From software

version

12

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 13

3 Product description

3.3 Product features

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.3 Product features

• Interface module for the INTERBUS communication system to be connected to the expansion

slots of the Servo Drives 9400

• The communication module can either be supplied internally by the standard device or

externally by a separate voltage source.

• Slave functionality

• DIP switch settings:

• Number of process data words and parameter data words

• Baud rate (500 kbps or 2 Mbps)

• Bus coupling via remote bus according to the RS485 standard

• Up to 10 process data words (20 bytes) can be used.

• 0, 1, 2 order 4 parameter data words can be used.

• The parameter data is transmitted in accordance with the Peripherials Communication Protocol

(PCP).

• Access to all Lenze parameters

• Support of the PMS services:

•Initiate

•Abort

• Reject

•Read

•Write

•Get-OD

•Identify

• Status

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 13

Page 14

3 Product description

3.4 Terminals and interfaces

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

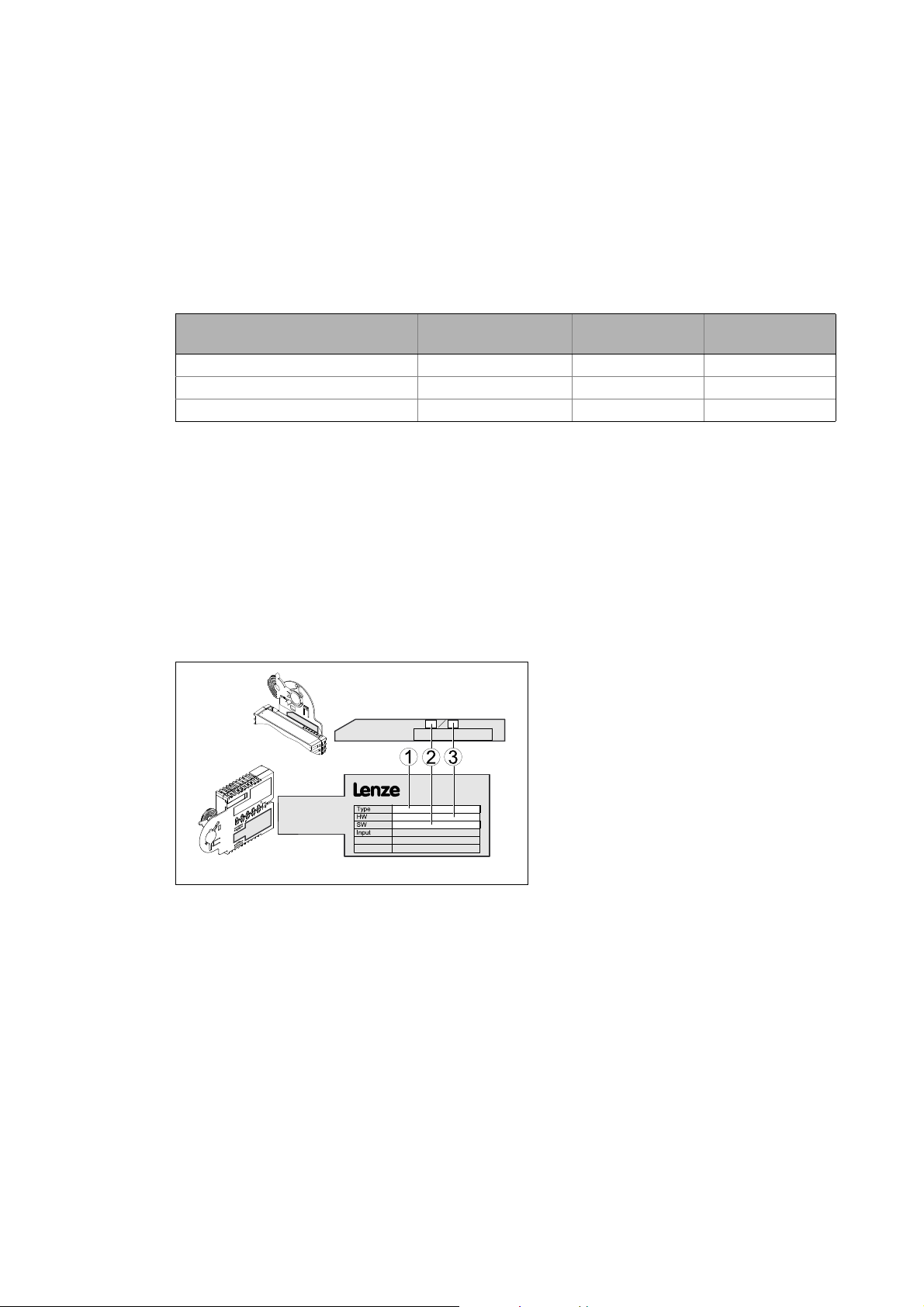

3.4 Terminals and interfaces

S205 DIP switches for setting the ...

• Number of process data words and

parameter data words

•Baud rate

Possible settings via DIP switch

X205 External voltage supply of the communication

module

• 2-pin plug connector with spring connection

External voltage supply

X206 INTERBUS connection, input (IN)

• 9-pole Sub-D plug

Wiring of the INTERBUS

( 30)

( 28)

( 24)

X207 INTERBUS connection, output (OUT)

• 9-pin Sub-D socket

Wiring of the INTERBUS

MS

E94YCIB001B

[3-2] E94AYCIB communication module (INTERBUS)

LED status displays for diagnostic purposes

ME

LED status displays

BS

BE

DE

( 24)

( 47)

14

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 15

4Technical data

4.1 General data and operating conditions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 Technical data

4.1 General data and operating conditions

Range Values

Order designation E94AYCIB

Communication profile INTERBUS

Communication medium RS485

Interface for communication • Input (IN): 9-pole Sub-D plug

• Output (OUT): 9-pole Sub-D socket

Network topology Ring

Type of node Slave

Number of nodes • 1 master

• 512 slaves

Baud rate 500 kbps or 2 Mbps

(can be set via DIP switch or code)

Max. cable length • 400 m at 500 kbps

• 150 m at 2 Mbps

(between the single INTERBUS nodes)

Process data words 0 ... 10 words (16 bits/word)

(can be set via DIP switch or code)

Parameter data words 0, 1, 2, 4 words (16 bits/word)

(can be set via DIP switch or code)

The parameter data is transmitted in accordance with the Peripherials

Communication Protocol (PCP).

Max. number of data words 10 words (process data word + parameter data words), 16 bits/word

Max. PDU length 64 bytes

Device identification (module ID) • 3 = 0x03 (0 parameter data words)

• 227 = 0xE3 (1 parameter data words)

• 224 = 0xE0 (2 parameter data words)

• 225 = 0xE1 (4 parameter data words)

Voltage supply External supply via separate power supply unit

+: U = 24 V DC (+/- 10 %), I

- : Reference potential for external voltage supply

Conformities, approvals • CE

•UL

(see also hardware manual)

= 180 mA

max

Servo Drives 9400 hardware manual

Here you can find the ambient conditions and information on the electromagnetic

compatibility (EMC) which also apply to the communication module.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 15

Page 16

4Technical data

4.2 Protocol data

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 Protocol data

Range Values

Process data words 0 ... 10 words (16 bits/word)

Parameter data words 0, 1, 2, 4 words (16 bits/word)

The parameter data is transmitted in accordance with the Peripherials

Communication Protocol (PCP).

Supported PMS services • Initiate

•Abort

• Reject

•Read

•Write

•Get-OD

•Identify

• Status

Note!

The data word sum (process data words + parameter data words) has to consist of 1 ... 10

words (16 bits/word).

4.3 Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The communication times in an INTERBUS network depend on the ...

• processing time in the inverter;

• telegram runtime (baud rate / telegram length);

• nesting depth of the network.

processing time within the inverter

Data Processing time

Process data Approx. 4 ms

Parameter data Approx. 30 ms + a tolerance of 20 ms (typically)

Update cycle

+ 0 ... 1 ms

+ 1 ... x ms

Some codes may require a longer processing time (see reference manual/

»Engineer« online help for the Servo Drive 9400).

Processing time in the module

Runtime of the application task of the technology

application used (tolerance)

16

There are no interdependencies between parameter data and process data.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 17

4Technical data

4.4 Protective insulation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.4 Protective insulation

Danger!

Dangerous voltage

If the Servo Drives 9400 are operated on a phase earthed mains with a rated mains

voltage 400 V, external measures need to be implemented in order to ensure

protection against accidental contact.

Possible consequences:

Death or severe injuries

Protective measures:

If protection against accidental contact is required for the control terminals of the

inverter and the connections of the plugged device modules, ...

• a double isolating distance must exist.

• the components to be connected must be provided with the second isolating

distance.

Note!

The protective insulation provided in Servo Drives 9400 is implemented in accordance

with EN 61800-5-1.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 17

Page 18

4Technical data

Ext. DC

I/O

X4

X6X6

X5

X7X7

X8X8

X3

X2

X1

X105X105

X106

X100

X107

MXI1

MXI2

Bus

Ext. DC

MSI

MMI

X207

X206

X205

4.4 Protective insulation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

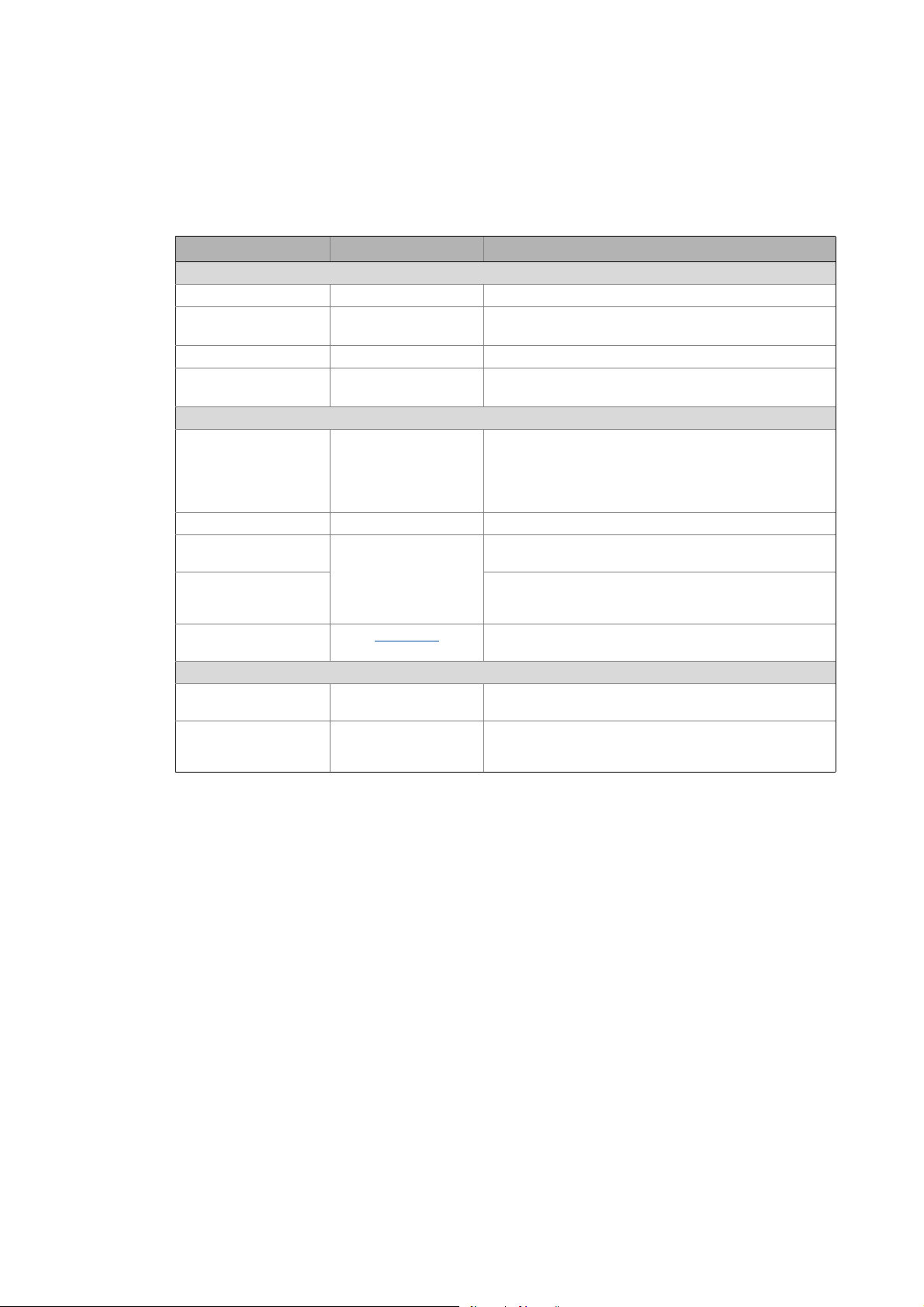

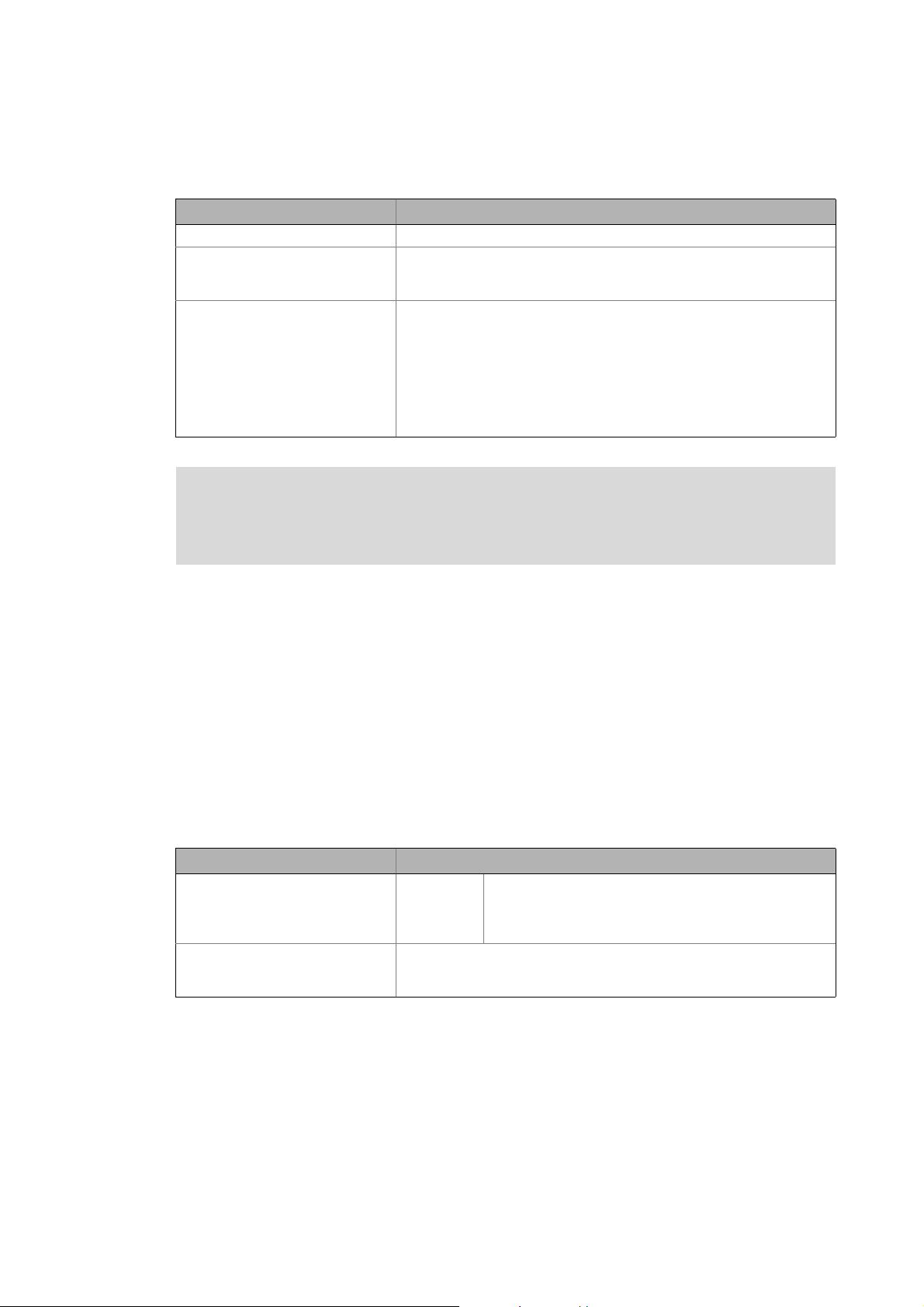

The following illustration ...

• shows the arrangement of the terminal strips and the separate potential areas of the Servo

Drive 9400.

• serves to determine the decisive protective insulation between two terminals located in

differently insulated separate potential areas.

Note!

The INTERBUS input (X206) is isolated from the voltage supply (X205) and the INTERBUS

output (X207).

Reinforced insulation

Basic insulation

Functional insulation

E94YCIB007

[4-1] Protective insulation in accordance with EN61800-5-1

18

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 19

4Technical data

4.4 Protective insulation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Terminal strip Connection Terminal strip Connection

X100 L1, L2, L3 (Single Drive only) X1 CAN on board 9400

+UG, -UG X2 State bus

X105 U, V, W 24 V (ext.)

Rb1, Rb2 (Single Drive only) X3 Analog inputs/outputs

X106 Motor PTC X4 Digital outputs

X107 Control of the motor holding

brake

MXI1, MXI2 Extension module

X5 Digital inputs

X6 Diagnostics

X7 Resolver

X8 Encoder

MMI Memory module

MSI Safety module

X205 External voltage supply (24 V DC)

X206 INTERBUS connection, input (IN)

X207 INTERBUS connection, output

(OUT)

Example

Which type of protective insulation is used between the bus terminal of the device module in slot

MXI1 or MXI2 and the mains terminal X100?

The separate potential area with the better protective insulation is decisive.

• The separate potential area of the bus terminal of the device module has a "functional

insulation".

• The separate potential area of the mains terminal has a "reinforced insulation".

Result: The insulation between mains terminal X100 and the bus terminal is of the "reinforced

insulation" type.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 19

Page 20

4Technical data

4.5 Dimensions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

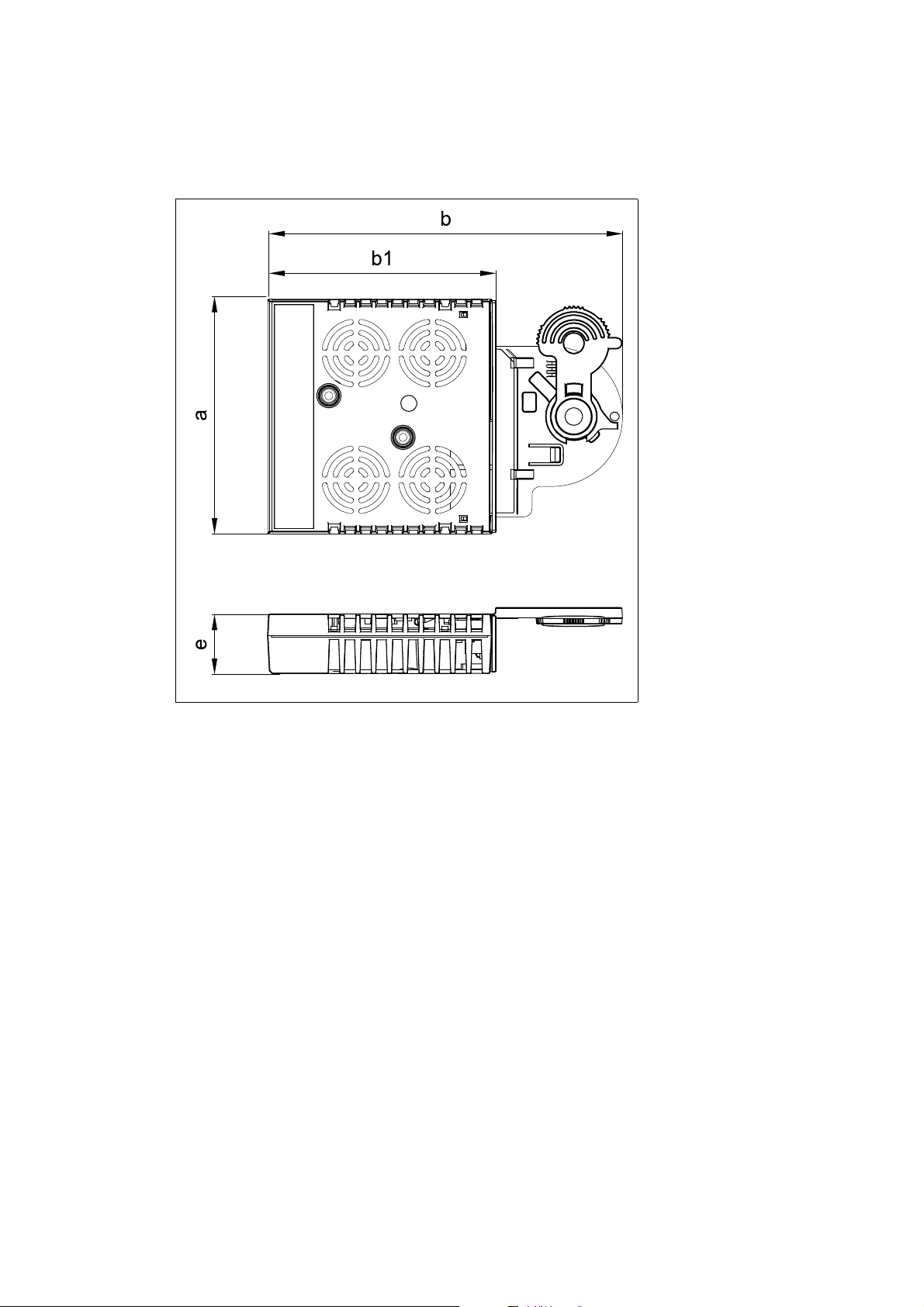

4.5 Dimensions

a 89 mm

b 134 mm

b1 87 mm

e 23 mm

E94YCXX005

[4-2] Dimensions

20

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 21

5 Installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Installation

Stop!

Electrostatic discharge

Electronic components within the communication module can be damaged or destroyed

by electrostatic discharge.

Possible consequences

• The communication module is defective.

• Fieldbus communication is not possible or faulty.

Protective measures

• Before touching the module, be sure that you are free of electrostatic charge.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 21

Page 22

5 Installation

5.1 Mechanical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

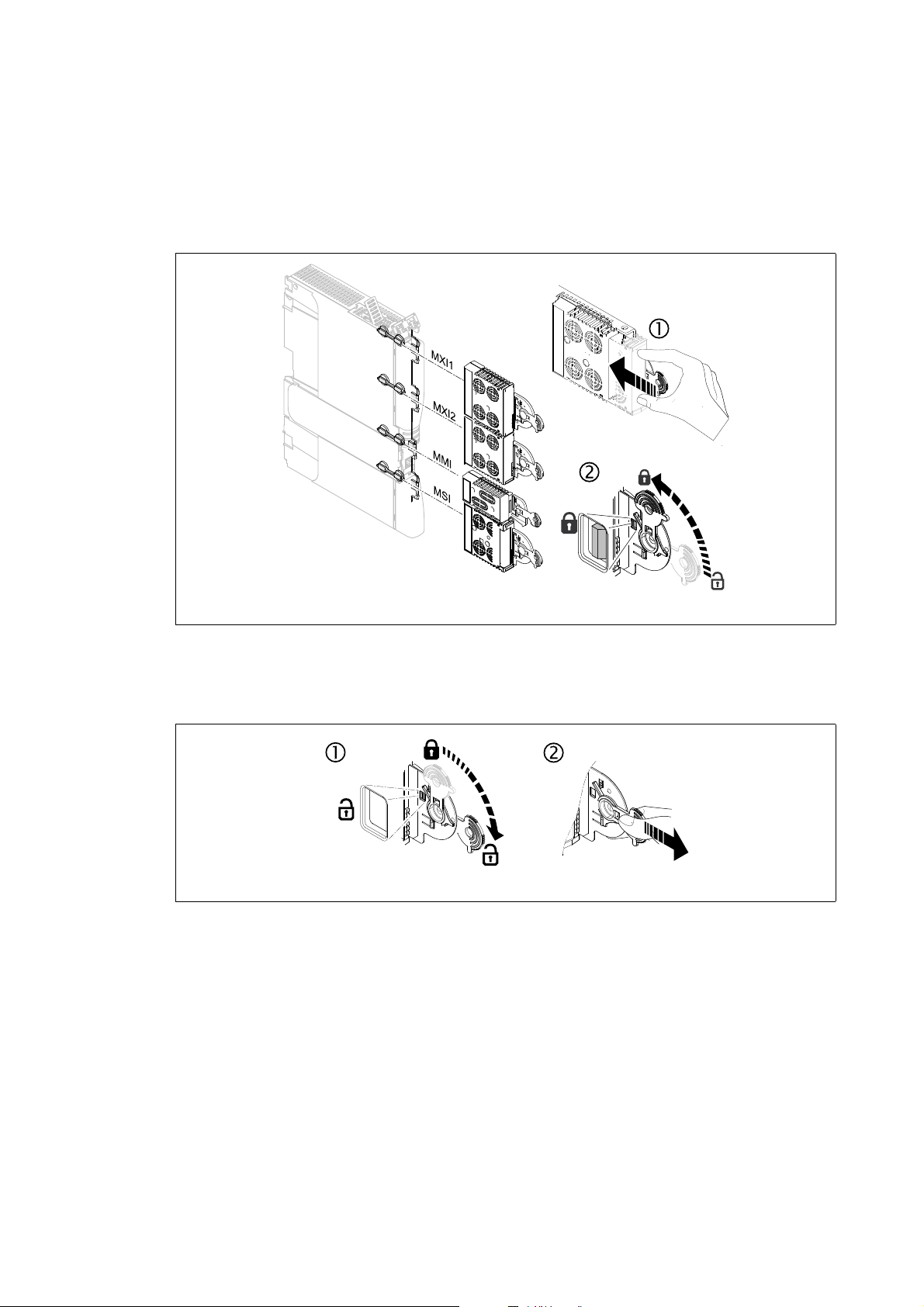

5.1 Mechanical installation

5.1.1 Assembly

[5-1] Assembly

5.1.2 Disassembly

[5-2] Disassembly

E94YCXX001G

E94AYCXX001H

22

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 23

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2 Electrical installation

Documentation for the standard device, host (PLC, master), system/machine

Observe the notes and wiring instructions contained in this documentation.

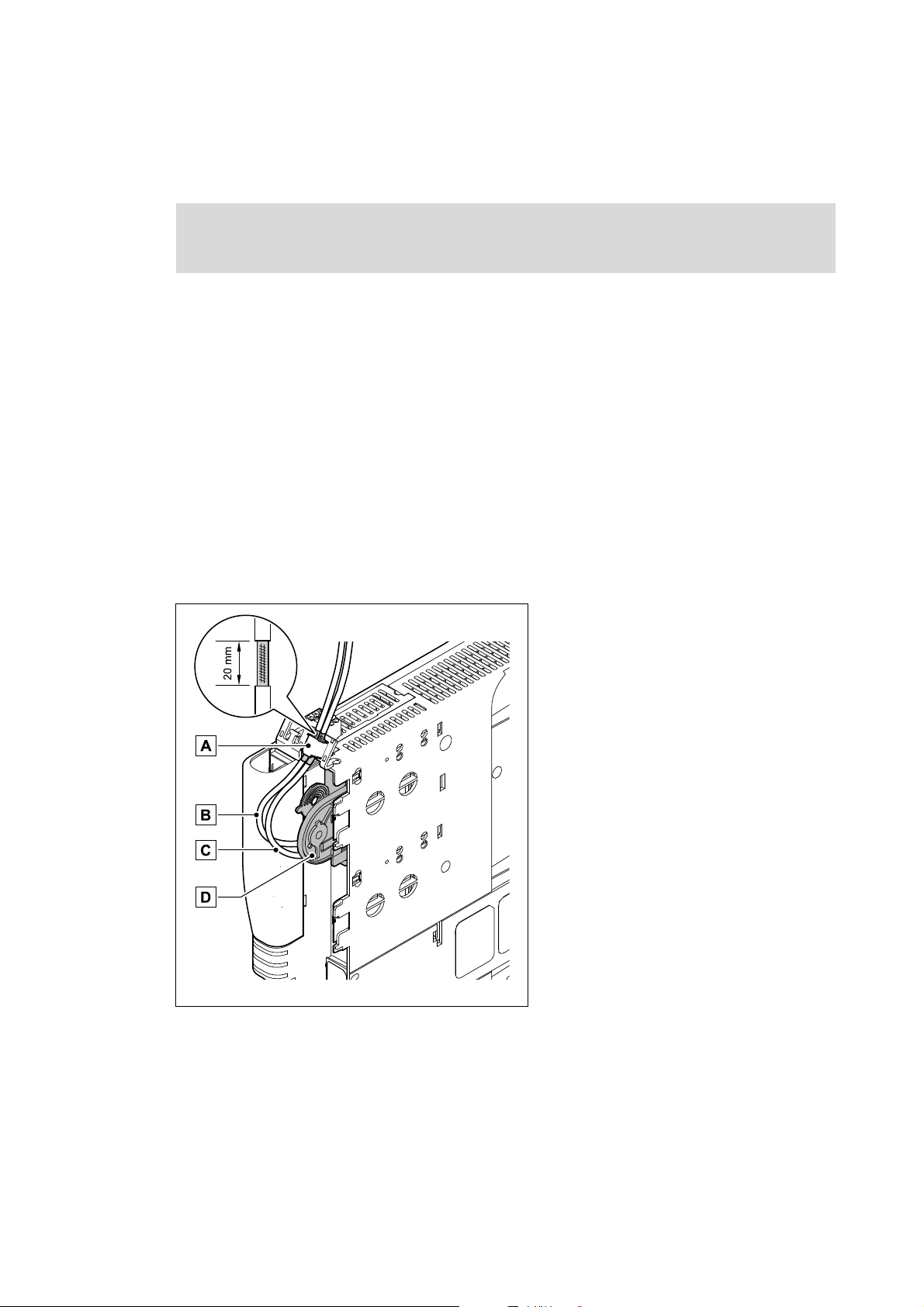

5.2.1 Wiring according to EMC guidelines

In typical systems, standard shielding is sufficient for the INTERBUS cable.

In environments with very strong interferences, the EMC compatibility can be improved by an

additional earthing of the cable shield.

For this observe the following notes:

1. The distance of the additional earthing of the INTERBUS plug (Sub-D, 9-pole) depends on the

module slot and is as follows ...

• approx 10 cm for the upper slot (MXI1);

• approx. 20 cm for the lower slot (MXI2).

2. Measure the appropriate distance along the cables and, starting from this point, remove 2 cm

of the cable's plastic sheath.

3. Connect the cable shield to the shield sheet of the Servo Drive 9400.

[5-3] Wiring according to EMC guidelines

A Connection to the shield sheet of the Servo

Drive 9400

B IncomingINTERBUS line at X206 (IN)

C Outgoing INTERBUS line at X207 (OUT)

D Communication module in slot MXI1 of the

Servo Drive 9400

E94YCXX008

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 23

Page 24

5 Installation

500 kBit/s: 400 m

2 MBit/s:£150 m£

Servo Drive

9400

E94AYCIB

X206

X207

Servo Drive

9400

E94AYCIB

X206

X207

Servo Drive

9400

E94AYCIB

X206

X207

OUT

IN

OUT

IN IN

M

S2

S1

Sn

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

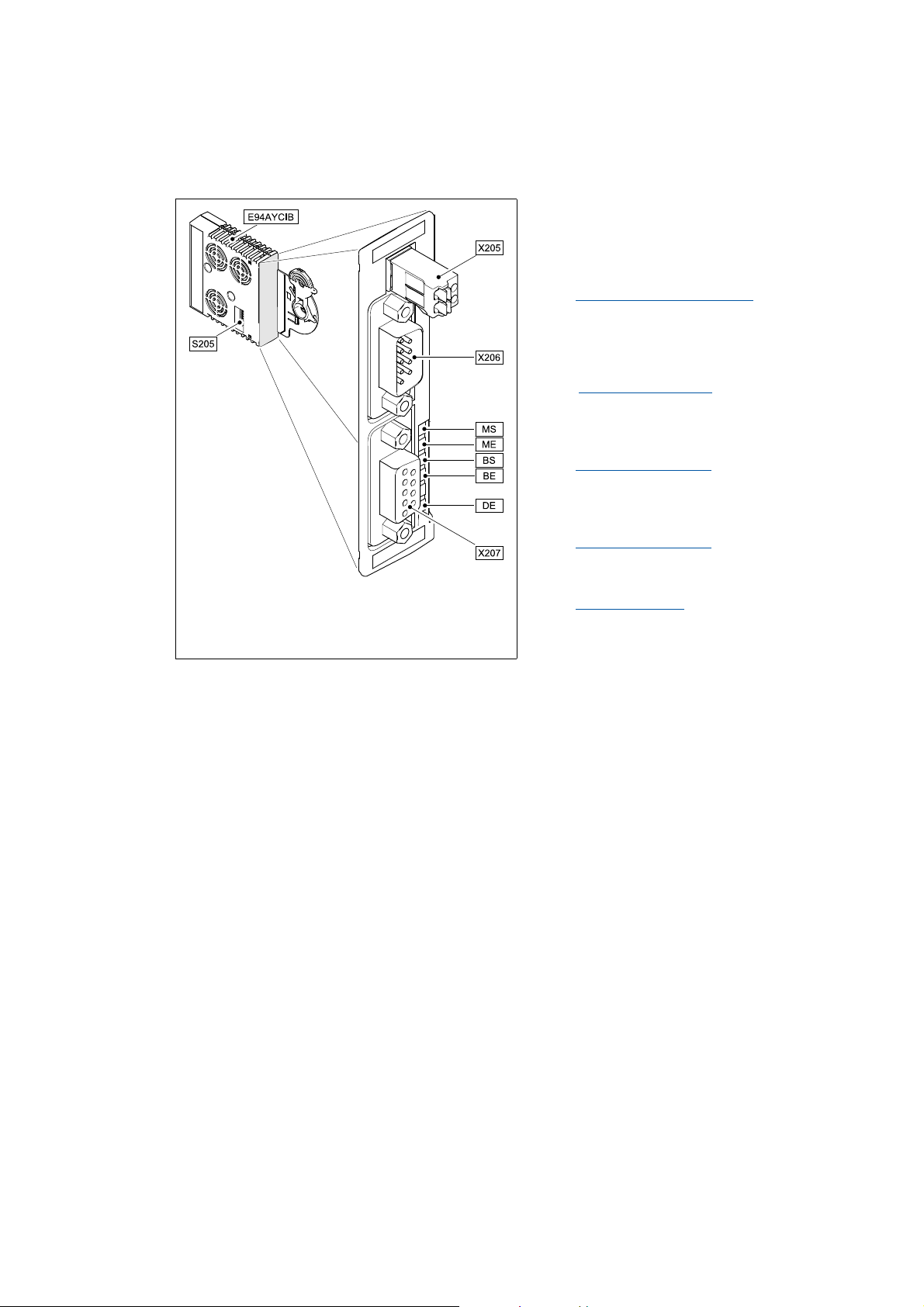

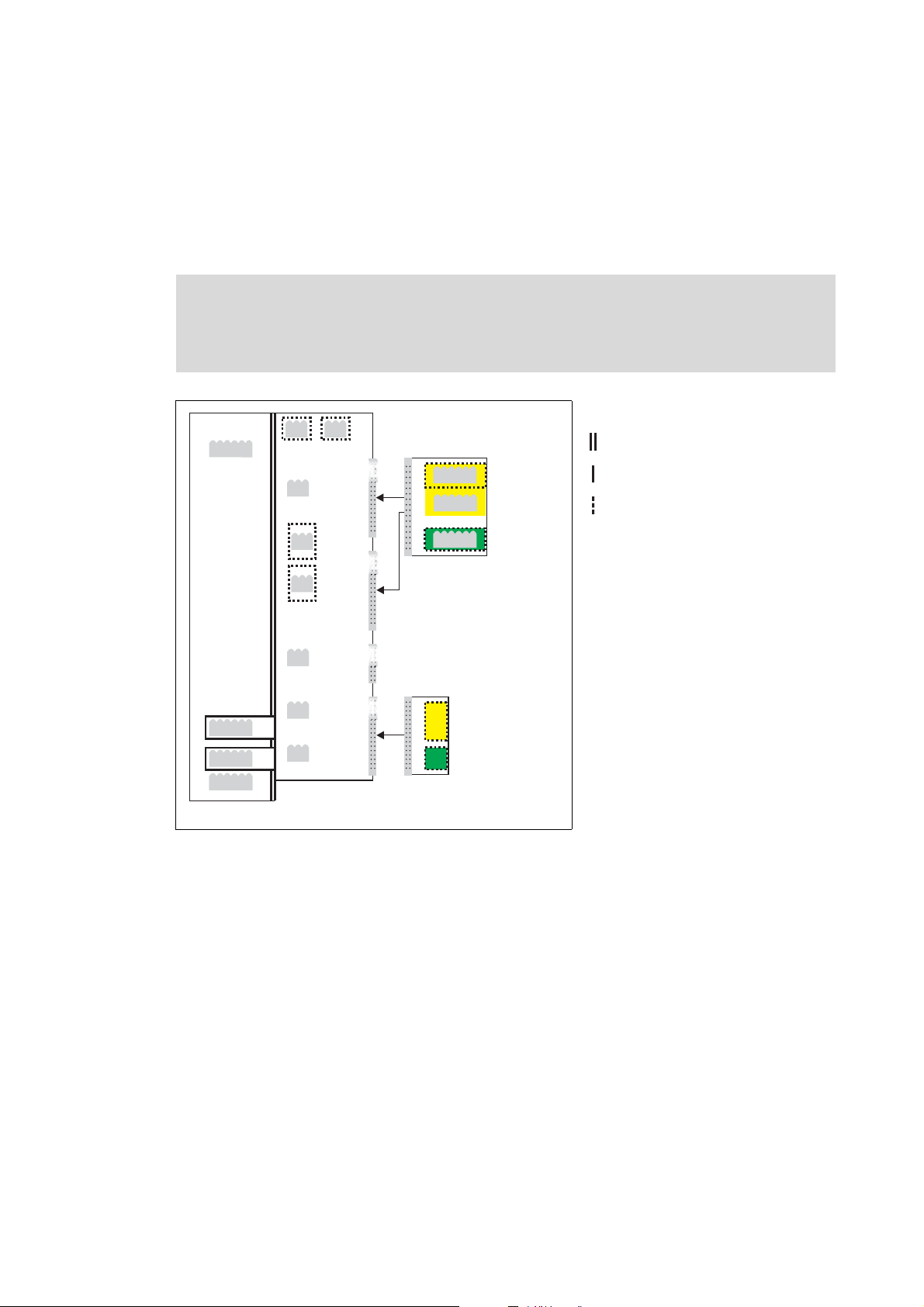

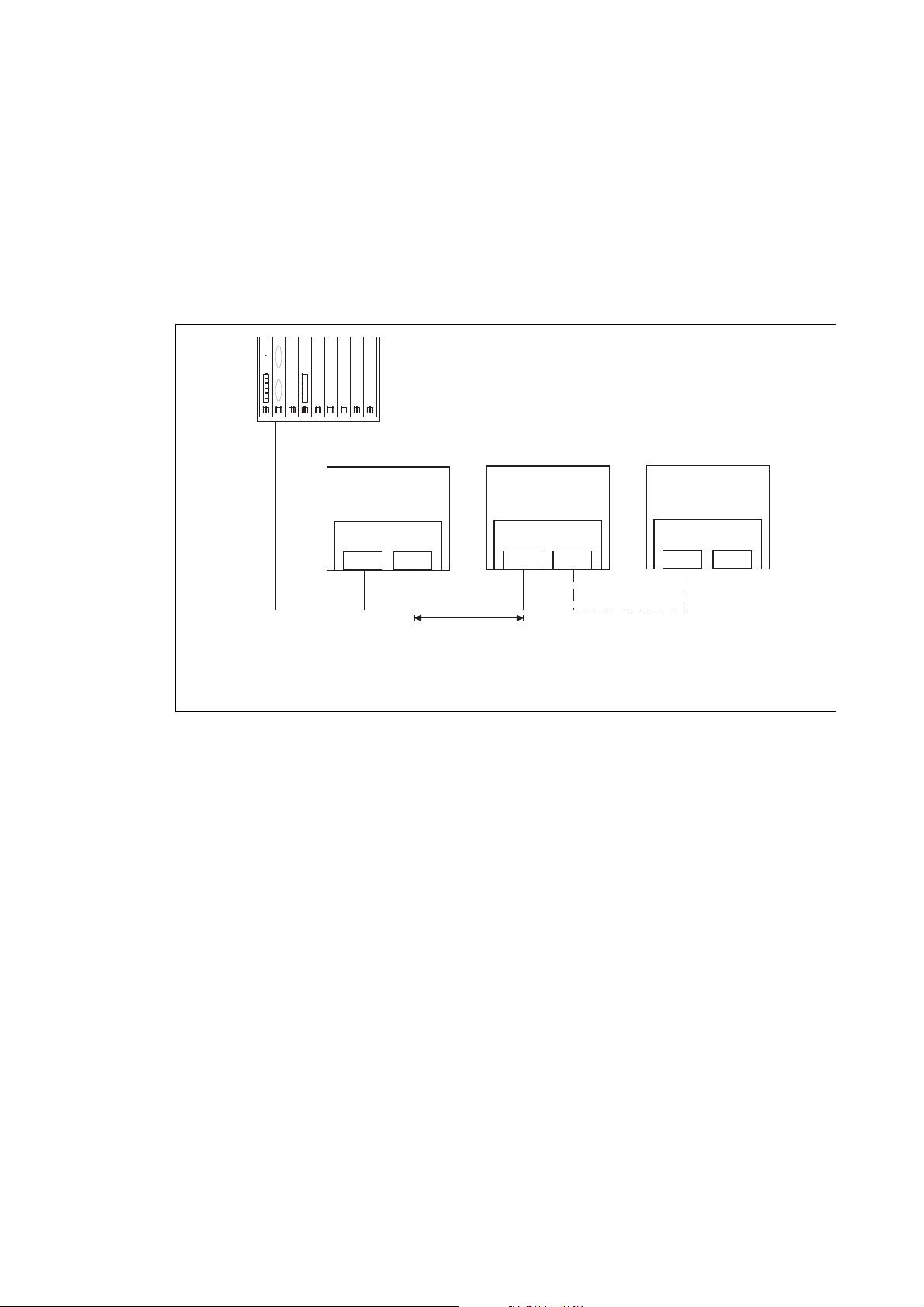

5.2.2 Wiring of the INTERBUS

For communication with the master and all further components, Servo Drives 9400 have to be

assembled with communication modules.

The INTERBUS system has to be designed as a ring. Here, go and return lines are integrated in the

same bus cable. The ring comes from the INTERBUS master via all other nodes back again to the

master.

An INTERBUS ring can consist of maximally 513 nodes (1 master + further slaves (slaves)).

[5-4] INTERBUS ring

M: Master (e.g. PLC, Industrial PC)

S1 ... Sn: Slaves

E94YCIB008

24

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 25

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.3 INTERBUS connection

The INTERBUS of the communication module is connected via the 9-pole Sub-D plug X206 (input)

and the 9-pole Sub-D socket X207 (output).

[5-5] INTERBUS terminals X206 (input) and X207 (output)

Assignment of the 9-pole Sub-D plug X206 (IN)

Pin Name Input/output Description

1DO1 Input RS485: DO1 not inverted

2 DI1 Output RS485: DI1 not inverted

3GND Reference potential

4 Free not assigned

5Vcc5 Output 5 V DC

6 /DO1 Input RS485: DO1 inverted

7/DI1 Output RS485: DI1 inverted

8Vcc5 Output 5 V DC

9 Free not assigned

E94YCIB001C

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 25

Page 26

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Assignment of the 9-pole Sub-D socket X207 (OUT)

Pin Name Input/output Description

1 DO2 Output RS485: DO2 not inverted

2 DI2 Input RS485: DI2 not inverted

3GND Reference potential

4GND

5Vcc5 Output 5 V DC

6/DO2 Output RS485: DO2 inverted

7 /DI2 Input RS485: DI2 inverted

8Vcc5 Output 5 V DC

9 RBST Signalling input Connection to the outgoing INTERBUS is plugged.

5.2.4 Dimensions of 9-pole sub-D connectors

Note!

Comply with the dimensions for width and depth of the 9-pole Sub-D connectors for the

INTERBUS terminals X206/X207.

[5-6] Dimensions of 9-pole sub-D connectors

26

E94YCIB001G

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 27

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.5 Bus cable specification

The nodes at the bus system must be wired with one of the fieldbus cables that complies with the

INTERBUS specification.

A manufacturer of INTERBUS cables is e.g. PHOENIX CONTACT (Germany).

Note!

A cable which does not fulfil the requirements of the INTERBUS specification must not

be used!

Properties of the bus cable according to the INTERBUS specification

General properties

Cable type Sold by the meter

(e.g. PHOENIX CONTACT: IBS RBC meter-T, order no. 28 06 28 6)

No. of conductors 3 x 2, twisted in pairs, with joint shielding

Conductor cross-section > 0.2 mm

DC-cable resistance < 96 /km

Impedance (characteristic) • 120 ± 20 % (f = 64 kHz)

Capacitance per unit length < 60 nF/km (f = 800 Hz)

2

• 100 ± 15 (f > 1 MHz)

5.2.6 Bus cable length

Set the baud rate according to the length of the bus cable between the single INTERBUS nodes:

Baud rate Cable length between the single INTERBUS nodes

500 kbps max.400 m

2 Mbps max. 150 m

Note!

Select the baud rate which depends on the data volume, cycle time, and number of

nodes just high enough to suit your application.

Possible settings via DIP switch

Settings in »Engineer«

( 30)

( 34)

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 27

Page 28

5 Installation

5.2 Electrical installation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.2.7 External voltage supply

The communication module can be externally supplied with voltage via separate supply cables at

the 2-pin plug connector X205.

Note!

With external voltage supply, always use a separate power supply unit, safely separated

to EN 61800-5-1 in every control cabinet (SELV/PELV).

External voltage supply of the communication module is required if the communication via the bus

should be maintained when the supply of the standard device fails.

The parameters of a standard device separated from the mains cannot be accessed.

Assignment of the plug connector X205

Name Explanation

+ U = 24 V DC (+/- 10 %)

I = 180 mA

- Reference potential for external voltage supply

Terminal data

Range Values

Electrical connection 2-pin plug connector with spring connection

Possible connections Rigid:

2

1.5 mm

Flexible:

Without wire end ferrule

1.5 mm

With wire end ferrule, without plastic sleeve

1.5 mm

With wire end ferrule, with plastic sleeve

1.5 mm

Stripping length 9 mm

(AWG 16)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

28

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 29

6 Commissioning

6.1 Before initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6 Commissioning

During commissioning, system-related data such as motor parameters, operating parameters,

responses, and parameters for fieldbus communication are defined in the inverter. For Lenze

devices, this is done by means of codes.

The codes of the inverter and for communication are saved to the memory module in a non-volatile

data set.

In addition, there are codes for diagnosing and monitoring the stations.

Parameter reference

( 53)

Note!

When parameterising the communication module, please note that the code number

depends on the slot of the standard device into which the communication module is

plugged.

The first two digits of the code number indicate the slot:

•C13nnn for slot MXI1

Parameters of the communication module for slot MXI1

•C14nnn for slot MXI2

Parameters of the communication module for slot MXI2

You also have to set the Parameters of the standard device that are relevant to

communication ( 53).

6.1 Before initial switch-on

Stop!

( 55)

( 63)

Before switching on the Servo Drive 9400 and the communication module for the first

time, check the entire wiring for completeness, short circuit and earth fault.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 29

Page 30

6 Commissioning

6.2 Possible settings via DIP switch

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2 Possible settings via DIP switch

The following can be set via the S205 DIP switch:

• Number of the process data words

switches: 1 ... 4

• Number of the parameter data words

switches: 5 and 6

•Baud rate

switch: 8

Lenze setting: All switches "OFF"

Switch 7 has no function.

E94YCIB001D

[6-1] DIP switch

( 31)

( 32)

( 33)

Note!

• All DIP switches = "OFF" (Lenze setting):

At switch-on, the configuration from the codes gets active (Settings in »Engineer«

( 34)

).

• At least one DIP switch = "ON":

At switch-on, the values are accepted from the switch positions.

• The data word sum (process data words + parameter data words) has to consist of

1 ... 10 words (16 bits/word).

• Switch off the voltage supply of the communication module and afterwards on again

to activate changed settings.

30

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 31

6 Commissioning

12345678

ON

OFF

6.2 Possible settings via DIP switch

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

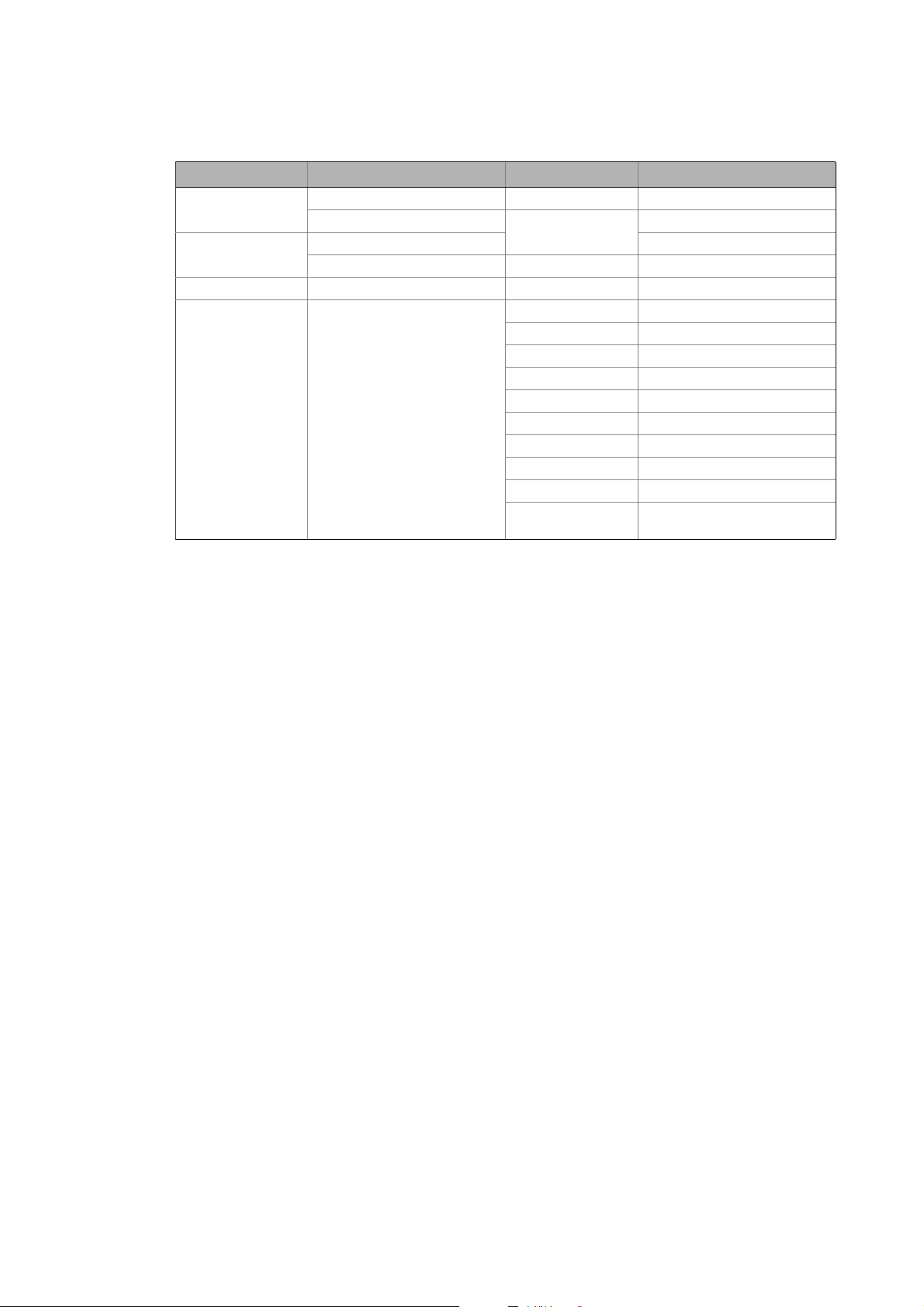

6.2.1 Setting the number of process data words

• The number of process data words can be set via the switches 1 ... 4.

• 0 ... 10 process data words can be used.

• The current setting is displayed in the »Engineer« in C13860/2

/ C14860/2.

Note!

The data word sum (process data word + parameter data words) has to consist of 1 ... 10

words (16 bits/word).

Impermissible settings are reported by the BE LED (red blinking).

LED status displays

The communication module then operates internally with the following values:

• 2 process data words (PD)

• 1 parameter data word (PCP)

( 47)

DIP switch Number of

PD

0 OFF OFF OFF OFF 4

1 OFF OFF OFF ON

2OFFOFFON OFF

3OFFOFFON ON

4OFFON OFF OFF

5OFFON OFF ON

6OFFON ON OFF

7OFFON ON ON 2

8 ON OFF OFF OFF

9 ON OFF OFF ON 1

10 ON OFF ON OFF 0

Switch Max. number

1 2 3 4

of PCP

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 31

Page 32

6 Commissioning

12345678

ON

OFF

6.2 Possible settings via DIP switch

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.2 Setting the number of parameter data words

• The number of parameter data words can be set via the switches 5 and 6.

• 0, 1, 2 order 4 parameter data words can be used.

• The current setting is displayed in the »Engineer« in C13860/1

/ C14860/1.

Note!

The data word sum (process data word + parameter data words) has to consist of 1 ... 10

words (16 bits/word).

Impermissible settings are reported by the BE LED (red blinking).

LED status displays

The communication module then operates internally with the following values:

• 2 process data words (PD)

• 1 parameter data word (PCP)

( 47)

DIP switch Number of PCP Switch Max. number of

5 6

0OFFOFF100x03

1OFFON 90xE3

PD

ID code

[hex]

2 ON OFF 8 0xE0

4 ON ON 60xE1

32

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 33

6 Commissioning

12345678

ON

OFF

6.2 Possible settings via DIP switch

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2.3 Setting the baud rate

Note!

Select the baud rate which depends on the data volume, cycle time, and number of

nodes just high enough to suit your application.

• The baud rate can be set via the switch 8.

• Set the baud rate according to the length of the bus cable between the single INTERBUS nodes.

• The current setting is displayed in the »Engineer« in C13863

DIP switch Switch 8 Baud rate Cable length between adjacent nodes

OFF 500 kbps max. 400 m

/ C14863.

ON 2 Mbps max. 150 m

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 33

Page 34

6 Commissioning

6.3 Settings in »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3 Settings in »Engineer«

Note!

The data word sum (process data words + parameter data words) has to consist of 1 ... 10

words (16 bits/word).

Impermissible settings are reported by the BE LED (red blinking).

LED status displays

The communication module then operates internally with the following values:

• 2 process data words

• 1 parameter data word

Setting Description

Select the baud rate which depends on the data volume, cycle time, and number of

nodes just high enough to suit your application.

PCP data length 0, 1, 2 or 4 parameter data words can be used (C13892

Process data length 1 ... 10 process data words can be used (C13893

Clear process data Setting (C13885

Baud rate Set the baud rate (C13894

( 47)

/ C14892).

/ C14893).

/ C14885) the selection of the process data the Servo Drive

9400 is to process for maintaining the internal communication when the

INTERBUS has exited the "IBS-ACTIVE" state.

• 0: Use of the last master process data

• 1: PDOs are set to the value "0". (Standard setting)

/ C14894) according to the length of the bus cable

between the single INTERBUS nodes:

• 500 kbps: Max. 400 m between the single nodes

• 2 Mbps: Max. 150 m between the single nodes

34

How to activate changed settings in the »Engineer«:

1. Execute the device command C00002 = "11: Save start parameters".

2. Carry out a "Reset node" of the node, or

module off and then on again.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

switch the voltage supply of the communication

Page 35

6 Commissioning

6.4 Initial switch-on

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.4 Initial switch-on

Documentation for the standard device

Observe the safety instructions and information on residual hazards.

Note!

Establishing communication

In order to establish communication via an externally supplied communication module,

the standard device must be switched on as well.

For further communication of the externally supplied module it is not relevant whether

the standard device is switched on or not.

Protection against uncontrolled restart

After a fault (e.g. short-term mains failure), it is sometimes undesirable or even

impermissible for the drive to restart.

In the Lenze setting of Servo Drives 9400, the restart protection is activated.

The restart behaviour of the inverter can be set via C00142 ("auto restart after mains

connection"):

C00142 = "0: Inhibited" (Lenze setting)

• The inverter remains inhibited (even if the fault is no longer active).

• An explicit controller enable causes the drive to start up in a controlled manner: LOWHIGH edge at digital input X5/RFR.

C00142 = "1: Enabled"

• An uncontrolled restart of the drive is possible.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 35

Page 36

7 Data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Data transfer

The INTERBUS transmits parameter data, configuration data, diagnostic data, alarm messages and

process data between the host (master) and the inverters (slaves) participating in the fieldbus.

Depending on their time-critical nature, the data are transmitted via different communication

channels.

Communication channels

The process data channel transmits process data.

• The process data serve to control the inverter.

• The transmission of process data is time-critical.

• Process data are cyclically transferred between the host (master) and the inveters connected to

the fieldbus (slaves) (continuous exchange of current input and output data).

• The host (master) can directly access the process data. In the PLC, for instance, the data are

directly saved to the IO area.

• 0 ... 10 process data words can be used.

• Process data are not saved in the inverter.

• Process data are e.g. setpoints, actual values, control words, and status words.

The parameter data channel serves to transfer parameter data.

• The parameter data channel provides access to all Lenze codes.

• The transmission of parameter data is usually not time-critical.

• Parameter data are, for instance, operating parameters, diagnostic information, and motor

data.

• 0, 1, 2 order 4 parameter data words can be used.

• The parameter data is transmitted in accordance with the Peripherials Communication Protocol

(PCP).

• The parameter data channel is identical for both transmission directions.

Note!

The data word sum (process data words + parameter data words) has to consist of 1 ... 10

words (16 bits/word).

Please observe the direction of the flow of information:

• Input data (Rx data): Process data from the inverter (slave) to the master

• Output data (Tx data): Process data from the master to the inverter (slave)

36 Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 37

8 Process data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8 Process data transfer

Configuring process data (PDO mapping)

The Servo Drives 9400 enable the individual mapping of process data. For this purpose, the

»Engineer« is provided with a port configurator.

Note!

• The port mapping for the Servo Drive 9400 is no configuration that can be carried out

online. For this purpose, an update of the »Engineer« project and a subsequent

download of the application is always required.

• The data word sum (process data words + parameter data words) has to consist of

1 ... 10 words (16 bits/word).

How to set the PDO mapping with the »Engineer«:

1. The process data mapping to the port variables is executed in the »Engineer« under the

Process data objects tab of the corresponding fieldbus communication module:

2. Select the receive object PDO_RX0:

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 37

Page 38

8 Process data transfer

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3. Click the Edit PDO button.

The selection window for editing the process data object is opened:

Here you can transfer the individual ports from the Port Selection list to the receive PDO

"PDO_RX0" by clicking the >> button.

The Up and Down buttons serve to shift the sequence of the ports within the PDOs.

4. Confirm the selection with OK.

5. Repeat the steps 2. to 4. for the transmit object PDO_TX0.

6. Then link the ports to application signals in the technology application selected.

The »FB Editor« can be activated in the multiplexer codes (> C03000), if necessary.

If the »FB Editor« is activated, the multiplexer codes (> C03000) are no longer available. In

this case, you must carry out the interconnection directly in the »FB Editor«.

38 Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 39

9 Parameter data transfer

9.1 Addressing of the parameter data

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 Parameter data transfer

The parameter data of Lenze devices are contained in codes which are listed in this documentation

and the documentation of the Servo Drive 9400.

Parameter reference

9.1 Addressing of the parameter data

The parameters of a Lenze device are not directly addressed via codes but via an index and subindex.

The conversion is made via an offset: 24575 or 0x5FFF

• INTERBUS index (decimal) = 24575 - Lenze code number (decimal)

• INTERBUS index (hexadecimal) = 0x5FFF - Lenze code number (hexadecimal)

Example of C00105 (deceleration time quick stop (QSP)):

• INTERBUS index (decimal) = 24575 - 105 = 24470

( 53)

• INTERBUS index (hexadecimal) = 0x5FFF - 0x69 = 0x5F96

Parameter changes must be saved via code C00002 of the Servo Drive 9400.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 39

Page 40

9 Parameter data transfer

9.2 Initialising PCP communication

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.2 Initialising PCP communication

Make entries into the CRL (communication relation list) in order that communication between the

INTERBUS master and the communication module can take place.

Make the following entries in the CRL of the INTERBUS master:

Field name Entry

Communication reference 2

Connection type Master slave acyclic

Connection attribute Defined

Max-PDU Sending-High-Prio 0

Max-PDU Sending-Low-Prio 64

Max-PDU Receiving-High-Prio 0

Max-PDU Receiving-Low-Prio 64

Supported Services Request 0x803000

Supported Services Response 0x000000

Maximum SCC 1

Maximum RCC 1

Maximum SAC 1

Maximum RAC 1

40

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 41

9 Parameter data transfer

9.3 Supported PMS services

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.3 Supported PMS services

The parameter data is transferred via PMS services.

In the following, only parameters and their contents are given that are returned by the Lenze

inverters. All other transfer parameters of the given PMS services can be obtained from the

corresponding descriptions of the INTERBUS master.

The following PMS services are supported by Lenze inverters:

• Initiate: Establish a connection of the INTERBUS master to the inverter

• Abort: Abort connection

• Reject: Reject impermissible PMS service

• Read: Read parameters

• Write: Write parameters

• Get-OD: Read out the object directory

•Identify: Identification of the inverter

• Status: Read the status of the inverter

9.3.1 Initiate

The "Initiate" PMS service establishes a logic connection between the INTERBUS master and the

communication module.

The inverter provides the following parameters:

Name Value Description

Profile number 0 No profile is supported.

Password 0 The password function of INTERBUS is not supported.

Access groups 0 No access groups exist.

Access-Protection Supported TRUE Access protection is supported.

Version OD 0 Version of the object directory

9.3.2 Abort

The "Abort" PMS service aborts a logic connection between the INTERBUS master and the

communication module.

9.3.3 Reject

The "Reject" PMS service rejects a non-supported PMS service.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 41

Page 42

9 Parameter data transfer

9.3 Supported PMS services

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.3.4 Read/Write

The "Read" PMS service reads parameters from the inverter. The inverter outputs the requested

parameter or an error message.

The "Write" PMS service writes on parameters of the inverter. The inverter outputs a positive

feedback or an error message.

The following error messages can occur:

Error Class Error code Additional

6 3 0x00 No access authorisation

6 5 0x10 Impermissible job parameter

650x11Invalid subindex

6 5 0x12 Data length too large

6 5 0x13 Data length too small

6 6 0x00 Object is no parameter

6 7 0x00 Object does not exist

6 8 0x00 Data types do not comply with each other

8 0 0x00 Request cannot be executed

8 0 0x20 Request cannot be executed at the moment

8 0 0x21 Cannot be executed because of local control

8 0 0x22 Cannot be executed because of device state

8 0 0x30 Quit value range / parameter can only be changed when the

8 0 0x31 Parameter value too high

8 0 0x32 Parameter value too low

8 0 0x33 Sub parameter outside the value range

8 0 0x34 Value of the subparameter is too high

8 0 0x35 Value of the subparameter is too low

8 0 0x36 Maximum value is lower than minimum value

8 0 0x41 Communication object cannot be displayed on process data

8 0 0x42 Length of the process data exceeded

8 0 0x43 General collision with other values

Code

[hex]

Description

controller is inhibited.

9.3.5 Get-OD

The "Get-OD" PMS service reads out the object description for every parameter and data type.

42

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 43

9 Parameter data transfer

9.3 Supported PMS services

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.3.6 Identify

The P "Identify" MS service provides information on how to identify the inverter.

The inverter with the plugged-on communication module provides the following parameters for

this:

Parameter Type Description

Device manufacturer Visible string Company name "Lenze"

Device type Visible-string (15 characters) Device name for inverter and communication

Device version Visible-string (15 characters) Firmware version of the inverter and the

Example: Visible string "device type" (15 characters)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

E 9 4 A F H B A F C I B

module

communication module

Character Description

1 ... 3 Product range of the inverter and the communication module ("E94" = 9400 series)

4Blank

5 ... 8 Firmware of the inverter (from C00200/0)

• Character 5: Version ("A" = 1st generation)

• Character 6 ... 8: Firmware version

• "FHB" = Servo Drive 9400 HighLine

• "FRB" = Servo Drive 9400 regenerative power supply module

• "VPB" = Servo Drive 9400 PLC

9Blank

10 ... 14 Firmware of the communication module (from C13900

• Character 10: Version ("A" = 1st generation)

• Characters 11 ... 14: Firmware version

• "FCIB" = INTERBUS module

15 Blank

/ C14900)

Example: Visible string "device version" (15 characters)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0 5 . 0 0 0 1 . 0 0

Character Description

1 ... 5 Firmware version of the inverter (from C00099/0 = "05.00.xx.yy", without internal revision status

6Blank

7 ... 11 Firmware version of the communication module (from C13902

12...15 Blank

["xx"] and build status ["yy"])

/ C14902 = "01.00.xx", without

internal revision status ["xx"])

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 43

Page 44

9 Parameter data transfer

9.3 Supported PMS services

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.3.7 Status

The "Status" PMS service provides status information about the inverter.

The inverter provides the following values:

Status Value Description

Logical status 0 = ready for communication Information about the current operating

Physical status • 0 = ready for operation (device state

"OPERATION ENABLED")

• 1 = ready for operation to a limited extent

(all other device states)

Local Detail 0 Is not supported.

mode of the inverter with regard to

communication

Information about the current operating

status of the

inverter.

44

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 45

10 Monitoring

10.1 Interruption of the INTERBUS communication

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10 Monitoring

10.1 Interruption of the INTERBUS communication

An interruption of the INTERBUS communication, e.g. by cable break or failure of the host (PLC,

master), is recognised by the communication module.

Responses to communication faults can be set in the Monitoring tab:

Settings Description

Response to interrupted

INTERBUS communication

Response time if the INTERBUS

communication is interrupted

When the INTERBUS communication is interrupted, the response set here

(C13880/1

A change in the monitoring response becomes immediately effective.

If the "IBS-ACTIVE" status (INTERBUS active, cyclic data exchange) is left, the

response set under takes place after the response time set here

(C13881

• A value of "65535" in this code deactivates the monitoring function.

• A change in the monitoring is immediately effective.

• The monitoring time elapses when the "IBS-ACTIVE" status is left.

• After this response delay has elapsed, the response set is executed with

/ C14880/1) takes place in the inverter.

/ C14881) has elapsed.

the error message "INTERBUS: Data exchange stopped [0x00c88131]

( 52).

"

If the Servo Drive 9400 does not receive any valid process data in the "IBS-ACTIVE" state, the setting

in C13885

/ C14885 is taken as a basis for the process data. (Like this the data sent last by the master

can be used or reset to zero.)

Settings in »Engineer«

( 34)

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 45

Page 46

10 Monitoring

10.2 Interruption of internal communication

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10.2 Interruption of internal communication

The response to a communication error between the communication module and the Servo Drive

9400 can be set via these codes:

• C01501

• C01502

(module in slot MXI1)

(module in slot MXI2)

46

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 47

11 Diagnostics

11.1 LED status displays

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11 Diagnostics

For purposes of fault diagnostics, the communication module is provided with the LEDs on the front.

Furthermore you can carry out the Diagnosing with the »Engineer«

11.1 LED status displays

( 48).

Note!

During normal operation, the LED BS blinks and the LED MS is permanently lit.

LEDs Pos. Colour Status Description

MS Green On The communication module is supplied with voltage

Blinking The communication module is supplied with voltage,

ME Red On An error has occurred in the communication module.

BS Green Blinking The INTERBUS communication has been established

Off The communication module is not active at the

BE Red On The INTERBUS communication has been interrupted.

Blinking Impermissible setting:

E94YCIB001E

DE Red On The communication module is not accepted by the

and is connected to the standard device.

but has no connection to the standard device. (The

standard device is either switched off, in the

initialisation phase, or not available).

via the communication module. The INTERBUS is

active. Data cycles are executed.

fieldbus. Data cycles are not executed.

Data cycles are not executed.

• Process data words + parameter data words

>10

• Process data words + parameter data words

=0

The communication module has been initialised and

operates internally with the following values:

•2 process data words

• 1 parameter data word

basic device or the basic device is not active (see

notes in the documentation relating to the basic

device.)

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 47

Page 48

11 Diagnostics

11.2 Diagnosing with the »Engineer«

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.2 Diagnosing with the »Engineer«

In the »Engineer« under the Diagnostics tab, you will find INTERBUS diagnostics information.

Querying the current bus status

C13861

Value

C13861/14861

[hex]

0xyyy0 IBS-INIT Initialisation

0xyyy1 IBS-ACTIVE The bus is active. Data cycles are executed.

0xyyy2 IBS-READY The bus is ready for operation. No data cycles are executed.

yyy = device-internal use

/ C14861 displays the bus status of the INTERBUS node:

Bus status Description

48

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 49

12 Error messages

12.1 Short overview of the INTERBUS error messages

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

12 Error messages

This chapter supplements the error list for the Servo Drive 9400 contained in the reference manual

and in the »Engineer« online help with the error messages of the communication module.

Reference manual/»Engineer« online help for the Servo Drive 9400

Here you will find general information on diagnostics & fault analysis and on error

messages.

12.1 Short overview of the INTERBUS error messages

The following table lists all INTERBUS error messages in the numerical order of the error numbers.

Furthermore, the preset error response and - if available - the parameter for setting the error

response are specified.

Tip!

If you click on the cross-reference in the first column, you will get a detailed description

(causes and remedies) of the corresponding error message.

Error number Name Response (Lenze setting) Adjustable in

hex dec

0x00c85531

0x00c85532

0x00c85533

0x00c86010

0x00c86011

0x00c86100

0x00c86101

0x00c86110

0x00c8641f

0x00c86420

0x00c88125

0x00c88126

0x00c88127

0x00c88131

0x00c88211 13140497 INTERBUS: Received process data length is contradictory 5: Warning -

0x00c88212

13129009 INTERBUS: No access to the memory 6: Information -

13129010 INTERBUS: Error while reading the memory 6: Information -

13129011 INTERBUS: Error while writing into the memory 6: Information -

13131792 INTERBUS: Internal error 1: No Response -

13131793 INTERBUS: Internal error 1: No Response -

13132032 INTERBUS: Internal error 1: No Response -

13132033 INTERBUS: Internal error 1: No Response -

13132048 INTERBUS: Internal mapping error 4: Warning locked -

13132831 INTERBUS: Parameter set invalid 1: No Response -

13132832 INTERBUS: Lenze setting loaded 1: No Response -

13140261 INTERBUS: Invalid configuration 5: Warning -

13140262 INTERBUS: Reset of communication 1: No Response -

13140263 INTERBUS: Invalid initialisation 5: Warning -

13140273 INTERBUS: Data exchange stopped None C13880/1 /

13140498 INTERBUS: Process data length to be sent is contradictory 5: Warning -

C14880/1

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 49

Page 50

12 Error messages

12.2 Possible causes and remedies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

12.2 Possible causes and remedies

This chapter lists all INTERBUS error messages in the numerical order of the error numbers. Possible

causes and remedies as well as responses to the error messages are described in detail.

INTERBUS: No access to memory [0x00c85531]

Response (Lenze setting printed in bold) Setting: not possible

None System error Error Fault Quick stop by trou ble Warning locked Warning Information

Cause Remedy

Memory could not be accessed. Send module with error description to Lenze.

INTERBUS: Error while reading the memory [0x00c85532]

Response (Lenze setting printed in bold) Setting: not possible

None System error Error Fault Quick stop by trou ble Warning locked Warning Information

Cause Remedy

Parameter could not be read. Send module with error description to Lenze.

INTERBUS: Error while writing into the memory [0x00c85533]

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

INTERBUS: Internal error [0x00c86010]

INTERBUS: Internal error [0x00c86011]

Cause Remedy

Parameter could not be written. Send module with error description to Lenze.

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Module is defective. Send module with error description to Lenze.

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Module is defective. Send module with error description to Lenze.

INTERBUS: Internal error [0x00c86100]

Response (Lenze setting printed in bold)

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Module is defective. Send module with error description to Lenze.

50

Setting: not possible

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17

Page 51

12 Error messages

12.2 Possible causes and remedies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

INTERBUS: Internal error [0x00c86101]

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Internal error Send module with error description to Lenze.

INTERBUS: Internal mapping error [0x00c86110]

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

The selected PDO mapping is invalid:

• An object not supporting the required properties has

been specified.

• The data word sum (process data words + parameter

data words) has to consist of 1 ... 10 words (16 bits/

word).

Repeat Configuring process data (PDO mapping)

( 37).

INTERBUS: Invalid parameter set [0x00c8641f]

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

No active parameter set could be loaded. Download application again (including module).

INTERBUS: Lenze setting loaded [0x00c86420]

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked Warning Information

Cause Remedy

Access via standard device to the parameter set in the

memory module failed.

INTERBUS: Invalid configuration [0x00c88125]

Response (Lenze setting printed in bold) Setting: not possible

None System error Error Fault Quick stop by trou ble Warning locked Warning Information

Cause Remedy

The active configuration is invalid:

• Process data words + parameter data words > 10

• Process data words + parameter data words = 0

The data word sum (process data words + parameter

data words) has to consist of 1 ... 10 words (16 bits/

word).

Download application again (including module).

Adapt the number of process data words and parameter

data words:

• Process data words + parameter data words = 1 ... 10

INTERBUS: Reset of the communication stack [0x00c88126]

Response (Lenze setting printed in bold) Setting: not possible

None System fault Fault Trouble Quick stop by trouble Warning locked warning Information

Cause Remedy

Error when processing the INTERBUS services Execute renewed initialisation by the master.

Lenze · E94AYCIB communication module (INTERBUS) · Communication Manual · DMS 4.0 EN · 02/2014 · TD17 51

Page 52

12 Error messages

12.2 Possible causes and remedies