Page 1

EDS94AYCCA

13411721

Ä.J26ä

L-force Communication

Communication Manual

9400

E94AYCCA

CANopen® communication module

L

Page 2

2 L EDS94AYCCA EN 5.0 - 06/2012

Page 3

E94AYCCA communication manual (CANopen®)

Contents

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Document history

1.2 Conventions used

1.3 Terminology used

1.4 Notes used

2 Safety instructions

2.1 General safety and application notes

2.2 Device and application-specific safety instructions

2.3 Residual hazards

3 Product description

3.1 Application

3.2 Identification

3.3 Features

3.4 Terminals and interfaces

4 Technical data

4.1 General data and operating conditions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

as directed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Supported protocols

4.3 Communication time

4.4 Protective insulation

4.5 Dimensions

5 Installation

5.1 Mechanical installation

5.2 Electrical installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1.1 Mounting

5.1.2 Dismounting

5.2.1 System bus (CANopen) connection

5.2.2 Specification of the bus cable

5.2.3 Bus cable length

5.2.4 Voltage supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

EDS94AYCCA EN 5.0 - 06/2012 L 3

Page 4

E94AYCCA communication manual (CANopen®)

Contents

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Before initial switch-on

6.2 Possible settings via DIP switches

6.2.1 Setting the node address

6.2.2 Setting the baud rate

6.3 Settings in the »Engineer«

6.4 Initial switch-on

7 Data transfer

7.1 Structure of the CAN data telegram

7.1.1 Identifier

7.1.2 User data

7.2 Communication phases / network management

7.2.1 State transitions

7.2.2 Network management telegram (NMT)

7.2.3 Parameterising the controller as a CAN master

8 Process data transfer

8.1 Identifiers of the process data objects

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.2 Transmission type

8.3 Masking of the TPDOs for event control

8.4 Synchronisation of PDOs via sync telegram

8.4.1 Parameter setting

8.4.2 Effect of C01130 on the sync phase position

8.5 PDO mapping

9 Parameter data transfer

9.1 Identifiers of the parameter data objects

9.2 User data

9.2.1 Command

9.2.2 Addressing through index and subindex

9.2.3 Data 1 ... data 4

9.2.4 Error messages

9.3 Examples for a parameter data telegram

9.3.1 Reading parameters

9.3.2 Writing parameters

9.3.3 Reading block parameters

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4 L EDS94AYCCA EN 5.0 - 06/2012

Page 5

E94AYCCA communication manual (CANopen®)

Contents

10 Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.1 Node guarding protocol

10.1.1 Telegram structure

10.1.2 Parameter setting

10.1.3 Commissioning example

10.2 Heartbeat protocol

10.2.1 Telegram structure

10.2.2 Parameter setting

10.2.3 Commissioning example

10.3 Emergency telegram

10.4 Settings in the »Engineer«

11 Diagnostics

11.1 LED status displays

11.2 Diagnostics with the »Engineer«

12 Error messages

12.1 Short overview of the CANopen error messages

12.2 Possible causes and remedies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

13 Parameter reference

13.1 Communication-relevant parameters of the standard device

13.2 Parameters of the communication module for slot MXI1

13.3 Parameters of the communication module for slot MXI2

13.4 Table of attributes

14 Implemented CANopen objects

15 DIP switch positions for setting the CAN node address

16 Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

. . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

EDS94AYCCA EN 5.0 - 06/2012 L 5

Page 6

E94AYCCA communication manual (CANopen®)

About this documentation

1 About this documentation

Contents

This documentation solely contains descriptions for the E94AYCCA communication

module (CANopen®).

Note!

This documentation supplements the Mounting Instructions supplied with the

communication module and the "Servo Drives 9400" hardware manual.

The Mounting Instructions contain safety instructions which must be observed!

The product features and functions of the communication module are described in detail.

Examples illustrate typical applications.

This documentation also contains ...

safety instructions that must be observed;

key technical data relating to the communication module;

information about the versions of the Lenze standard devices to be used;

notes on troubleshooting and fault elimination.

The theoretical concepts are only explained to the level of detail required to understand

the function of the communication module.

This documentation does not describe any software provided by other manufacturers. No

warranty can be given for corresponding data provided in this documentation. For

information about how to use the software, please refer to the host (PLC, master)

documents.

All product names mentioned in this documentation are trademarks of their

corresponding owners.

Tip!

Detailed information about the CAN/CANopen bus system can be found on the

website of the CAN user organisation CiA® (CAN in Automation):

www.can-cia.org

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the

firmware version of the field devices and the software version of the Engineering tools

installed (e.g. »Engineer«), the screenshots in this documentation may deviate from the

actual screens shown.

6 L EDS94AYCCA EN 5.0 - 06/2012

Page 7

E94AYCCA communication manual (CANopen®)

About this documentation

Target group

This documentation is intended for people involved in configuring, installing,

commissioning, and maintaining the networking and remote maintenance of a machine.

Tip!

Current documentation and software updates for Lenze products can be found in

the ”Download” area at:

www.Lenze.com

Validity information

The information in this documentation applies to the following devices:

Extension module Type designation From hardware

CANopen communication manual E94AYCCA VA 01.00

version

From software

version

EDS94AYCCA EN 5.0 - 06/2012 L 7

Page 8

E94AYCCA communication manual (CANopen®)

About this documentation

Document history

1.1 Document history

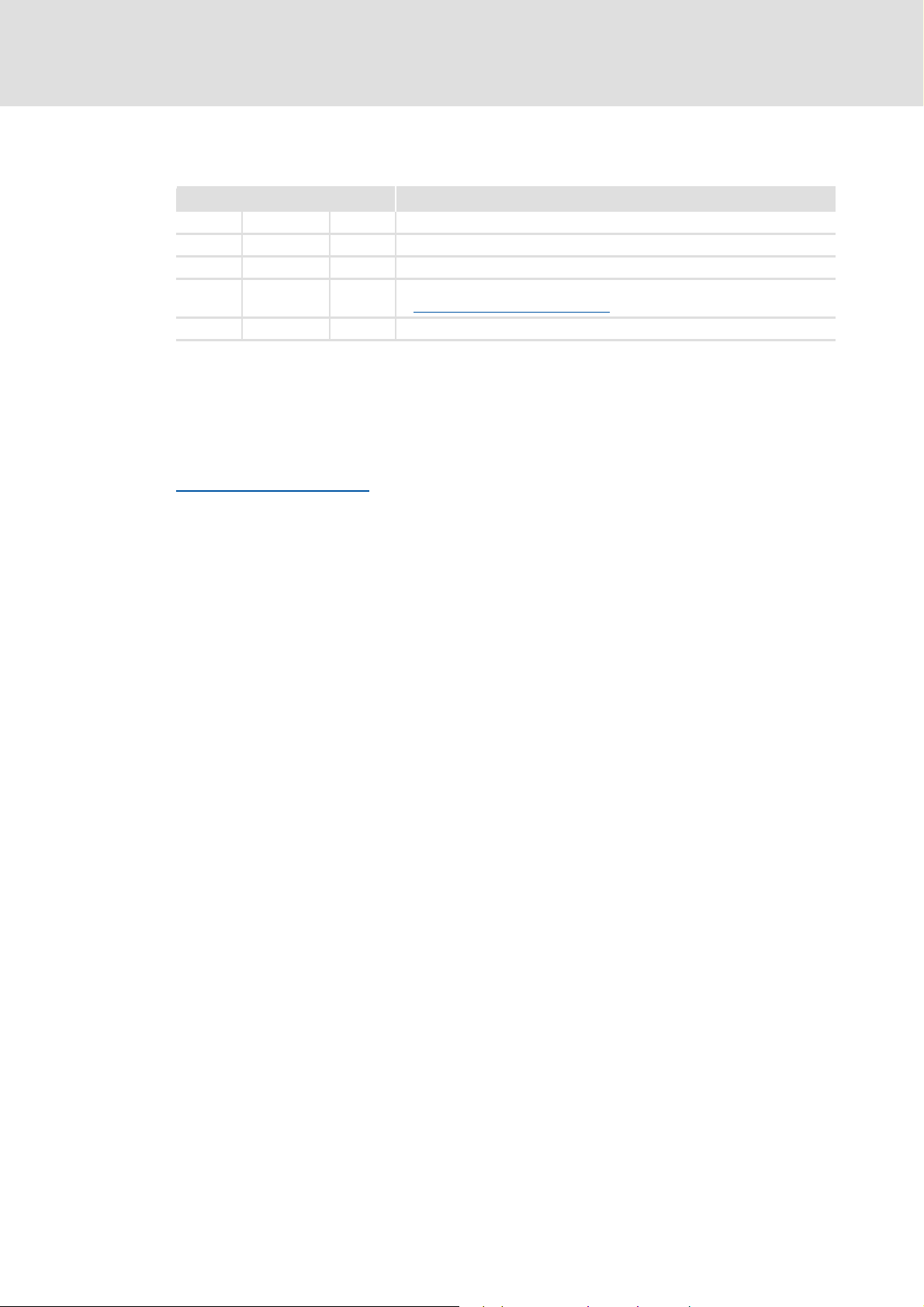

Version Description

1.0 08/2006 TD17 First edition

2.0 04/2008 TD17 General revision

3.0 02/2011 TD17 General revision

4.0 11/2011 TD17 Assignment of the 9-pin Sub-D plug connector corrected.

System bus (CANopen) connection

5.0 06/2012 TD17 General revision

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e-mail us to:

feedback-docu@Lenze.de

( 26)

Thank you for your support.

Your Lenze documentation team

8 L EDS94AYCCA EN 5.0 - 06/2012

Page 9

1.2 Conventions used

This documentation uses the following conventions to distinguish different types of

information:

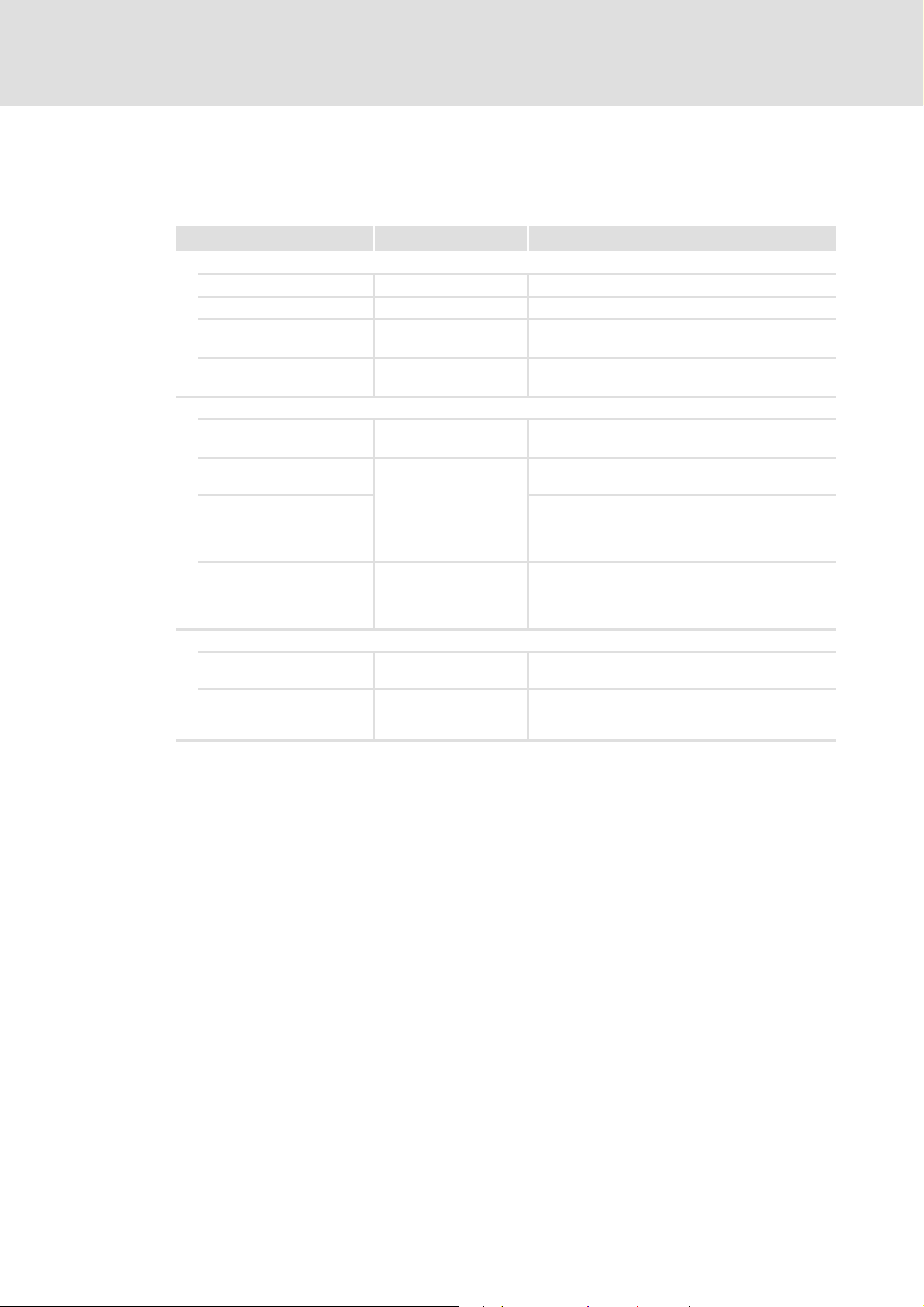

Information type Display Examples/notes

Spelling of numbers

Decimal Standard spelling Example: 1234

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Decimal separator Point The decimal point is generally used.

Text

Program name » « PC software

Control element Bold The OK button... / the copy command... / the

Sequence of menu

commands

Hyperlink Underlined

E94AYCCA communication manual (CANopen®)

About this documentation

Conventions used

In inverted commas

Point

Example: ’100’

Example: ’0110.0100’

For example: 1234.56

Example: Lenze »Engineer«

Properties tab... / the Name input field...

If the execution of a command requires several

commands in succession, the individual commands

are separated by an arrow: Select the File

command to...

Optically highlighted reference to another subject

which is activated with a mouse-click.

Open

Symbols

Page reference ( 9) Optically highlighted reference to another page

Step-by-step instructions

which is activated with a mouse-click.

Step-by-step instructions are indicated by a

pictograph.

EDS94AYCCA EN 5.0 - 06/2012 L 9

Page 10

E94AYCCA communication manual (CANopen®)

About this documentation

Terminology used

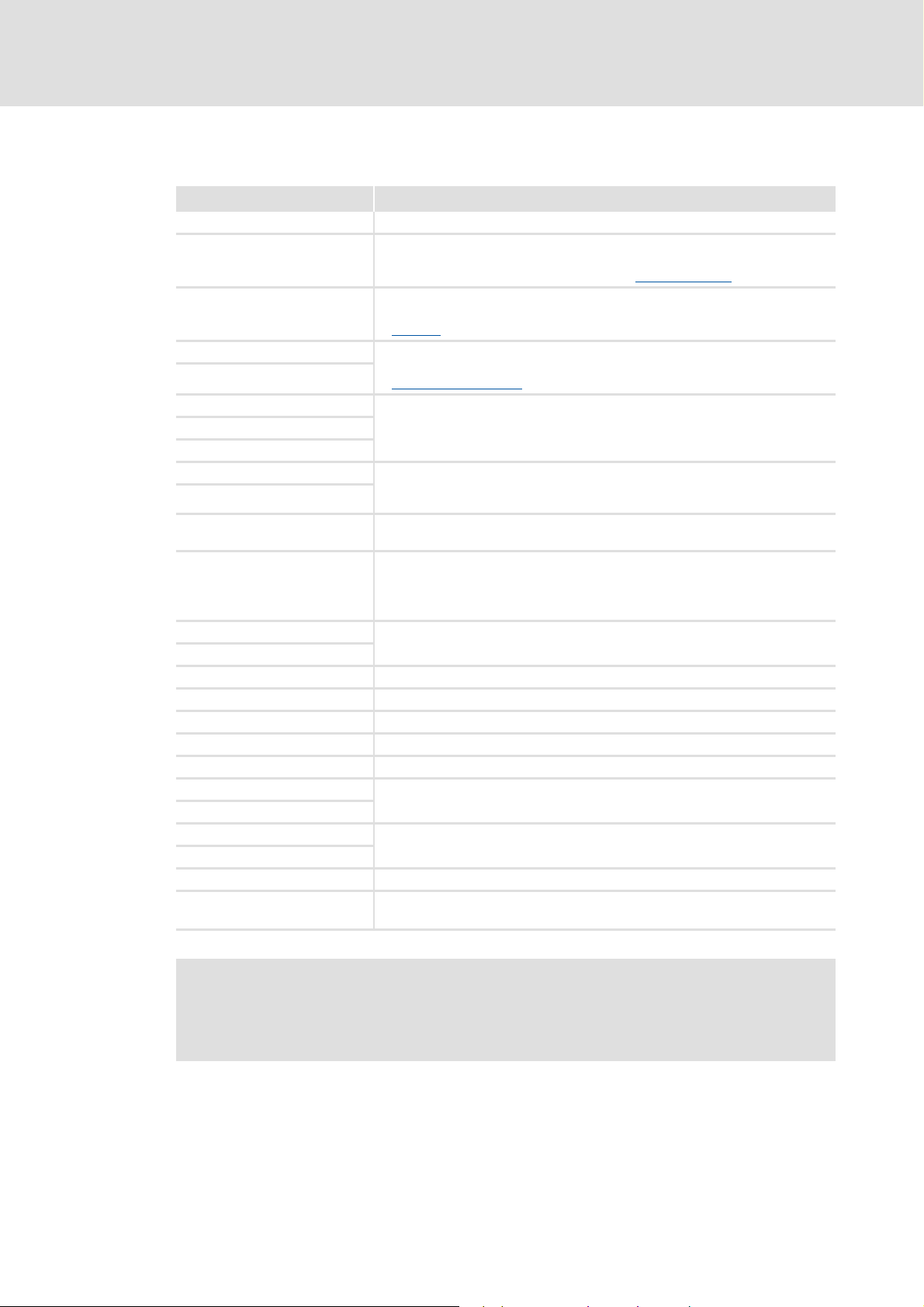

1.3 Terminology used

Term Meaning

CAN CAN (Controller Area Network) is an asynchronous, serial fieldbus system.

CANopen® CANopen® is a communication protocol based on CAN.

CANopen® is a trademark and patented technology, licensed by the CAN user

organisation CiA® (CAN in Automation e. V.), www.can-cia.org

System bus (CAN/CANopen) The Servo Drives 9400 system bus (CANopen) is an advancement of the 9300

Standard device Lenze controller of the "Servo Drives 9400" product series, with which the

Controller

Module Accessories and extension modules such as communication modules,

Interface module

Communication module

»Engineer« Lenze PC software which supports you during the "Engineering" process

»PLC Designer«

Code Parameter by means of which you can parameterise or monitor the controller. In

Subcode If a code contains several parameters, they are stored in "subcodes".

Lenze setting Default settings for the device.

Basic setting

PDO Process data object (process data communication)

SDO Service data object (parameter data communication)

HW Hardware

SW Software

PLC Programmable Logic Controller

Host CAN master

Control

Node Components of a CAN network (PLC, controller, etc.)

Bus node

Node address Unique ID for addressing the individual components of a CAN network

I-1600.20 CANopen index (hexadecimal representation)

controller series' system bus (CAN).

Features

communication module can be used.

Application as directed

distributed terminals, operator and input devices (HMIs) as well as external

controls and control systems

(parameterisation, diagnostics, and configuration) throughout the whole life

cycle, i. e. from planning to maintenance of the machine commissioned.

everyday language, the term is also referred to as "index".

In the documentation, the slash "/" is used as a separator between the code and

the subcode (e.g. "C00118/3").

In everyday language, the term is also referred to as "subindex".

• In the example: index 0x1600, subindex 0x20

( 15)

.

( 14)

Note!

Some of the terms used derive from the CANopen protocol. These terms are not

listed here.

10 L EDS94AYCCA EN 5.0 - 06/2012

Page 11

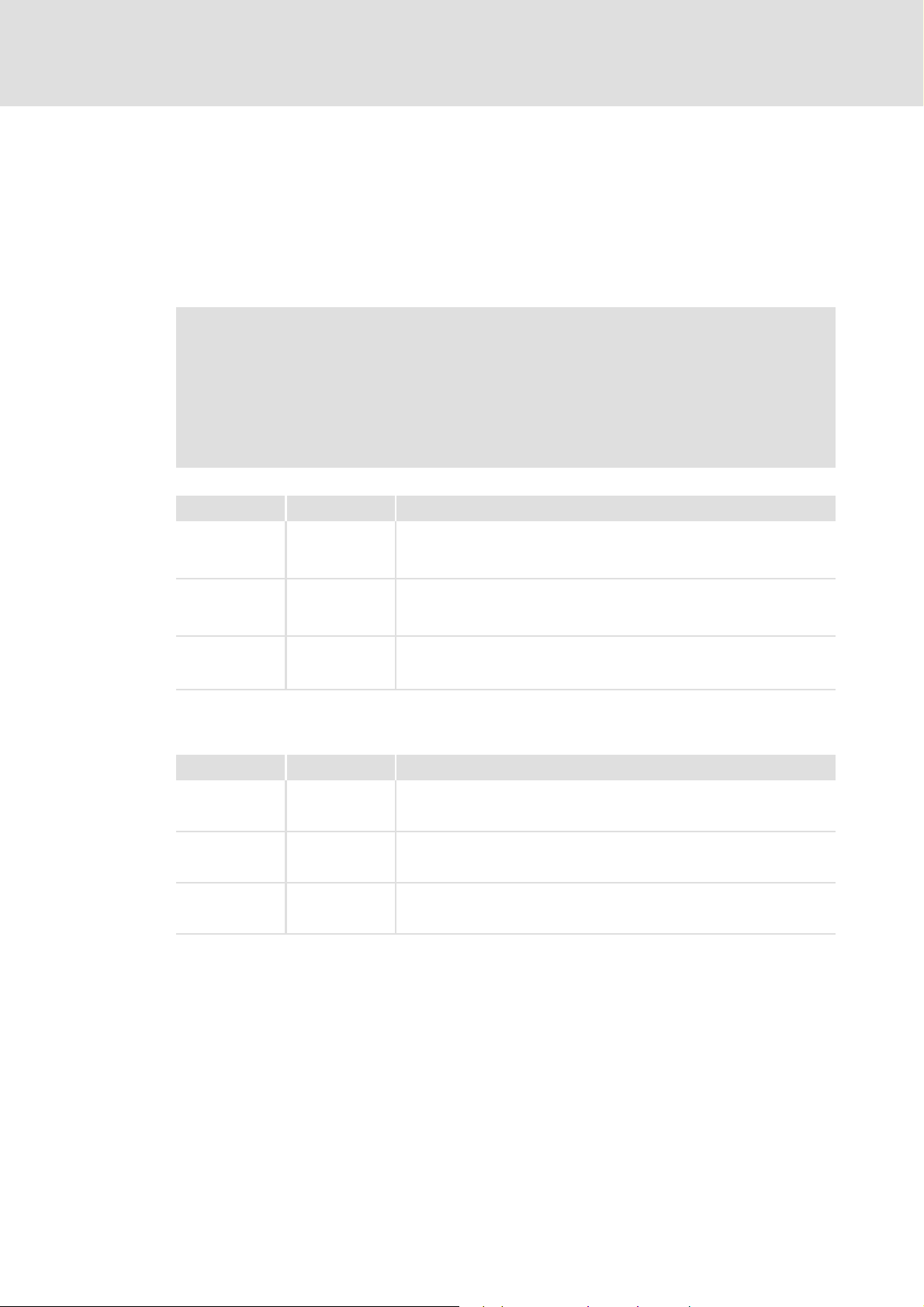

1.4 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of the safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and provides information about how to prevent

dangerous situations)

E94AYCCA communication manual (CANopen®)

About this documentation

Notes used

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure troublefree operation

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for simple handling

Reference to another documentation

EDS94AYCCA EN 5.0 - 06/2012 L 11

Page 12

E94AYCCA communication manual (CANopen®)

Safety instructions

General safety and application notes

2 Safety instructions

Note!

It is absolutely vital that the stated safety measures are implemented in order to

prevent serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during

operation.

2.1 General safety and application notes

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets.

Lenze drive and automation components ...

– may only be used as directed.

Application as directed

– must never be commissioned if they display any signs of damage.

– must never be modified technically.

– must never be commissioned if they are not fully mounted.

– must never be operated without the required covers.

– can have live, moving and rotating parts during and after operation, depending on

their degree of protection. Surfaces can be hot.

For Lenze drive components ...

– only use approved accessories.

– only use genuine spare parts supplied by the manufacturer of the product.

Observe all the specifications contained in the enclosed and corresponding

documentation.

– This is a precondition for ensuring safe, trouble-free operation and for making use of

the stated product features.

Features

– The specifications, processes, and circuitry described in this document are for

guidance only and must be adapted to your own specific application. Lenze does not

take responsibility for the suitability of the process and circuit proposals.

( 15)

( 14)

12 L EDS94AYCCA EN 5.0 - 06/2012

Page 13

E94AYCCA communication manual (CANopen®)

Device and application-specific safety instructions

All works on and with Lenze drive and automation components may only be carried out

by qualified personnel. According to IEC 60364 and CENELEC HD 384 these are persons

who ...

– are familiar with installing, mounting, commissioning, and operating the product.

– have the qualifications necessary for their occupation.

– know and are able to apply all regulations for the prevention of accidents, directives

and laws that apply to the location of use.

2.2 Device and application-specific safety instructions

During operation, the communication module must be securely connected to the

standard device.

With external voltage supply, always use a separate power supply unit, safely

separated in accordance with EN 61800-5-1 in every control cabinet ("SELV"/"PELV").

Only use cables that meet the given specifications.

Specification of the bus cable

( 27)

Safety instructions

Documentation of the standard device, control system, and plant/machine

All the other measures prescribed in this documentation must also be

implemented. Observe the safety instructions and application notes stated in

this manual.

2.3 Residual hazards

Protection of persons

If Servo Drives 9400 are used on a corner grounded system with a rated mains voltage

≥ 400V, external measures need to be implemented to provide reliable protection

against accidental contact.

Protective insulation

Device protection

The communication module contains electronic components that can be damaged or

destroyed by electrostatic discharge.

Installation

( 20)

( 24)

EDS94AYCCA EN 5.0 - 06/2012 L 13

Page 14

E94AYCCA communication manual (CANopen®)

Product description

Application as directed

3 Product description

3.1 Application as directed

The communication module ...

is an accessory module which can be used with the following standard devices:

Product series Type designation From hardware

Servo Drives 9400 HighLine E94AxHExxx VA 01.30

Servo Drives 9400 PLC E94AxPExxxx VA 01.00

Servo Drives 9400 regenerative power

supply module

is an item of equipment intended for use in industrial power systems.

may only be operated under the operating conditions specified in this documentation.

may only be used in CAN networks.

Any other use shall be deemed inappropriate!

3.2 Identification

The type designation and the hardware and software version of the communication

module are specified on the nameplate:

[3-1] Identification data

version

E94ARNxxxx VA 01.00

1 Type designation (type)

E94 Product series

AVersion

Y Module identification: extension module

C Module type: communication module

CA CANopen

2 Hardware version (HW)

3 Software version (SW)

E94YCET005

From software

version

14 L EDS94AYCCA EN 5.0 - 06/2012

Page 15

3.3 Features

For many years the system bus (CAN) based on the CANopen communication profile has

been integrated in Lenze controllers. Due to the lower number of data objects available,

the functionality and compatibility of the old system bus are lower as compared with

CANopen. For parameter setting, two parameter data channels are always available to the

user while CANopen provides only one active parameter data channel (along with the

possibility to establish further channels).

The system bus (CANopen) of the Servo Drives 9400 is an advancement of the 9300

controller series' system bus (CAN).

The communication module E94AYCCA (CANopen) provides the following features:

Interface module for the system bus (CANopen), connectable to the expansion slots of

Servo Drives 9400

Internal voltage supply of the communication module via the Servo Drive 9400.

Full compatibility according to CANopen DS301, V4.02

E94AYCCA communication manual (CANopen®)

Product description

Features

Support of the NMT master/slave function "node guarding" (DS301,V4.02)

Support of the NMT slave function "heartbeat" (DS301,V4.02)

No restrictions regarding the selection of node addresses

Number of parameterisable server and client SDO channels:

– max. 10 channels with 1 ... 8 bytes

Number of parameterisable PDO channels:

– max. 4 Transmit-PDOs (TPDOs) with 1 ... 8 bytes

– max. 4 Receive-PDOs (RPDOs) with 1 ... 8 bytes

All PDO channels are functionally equivalent.

Monitoring of the RPDOs for data reception

Telegram counters for SDOs and PDOs

Bus status diagnostics

Boot-up telegram generation

Emergency telegram generation

Reset node telegram generation (with master configuration)

Sync telegram generation and response to sync telegrams:

– Transmit/receive data

– Synchronisation of the device-internal time base

Abort codes

All CAN functions parameterisable via codes

Object directory (all mandatory functions, optional functions, indexes)

EDS94AYCCA EN 5.0 - 06/2012 L 15

Page 16

E94AYCCA communication manual (CANopen®)

Product description

Terminals and interfaces

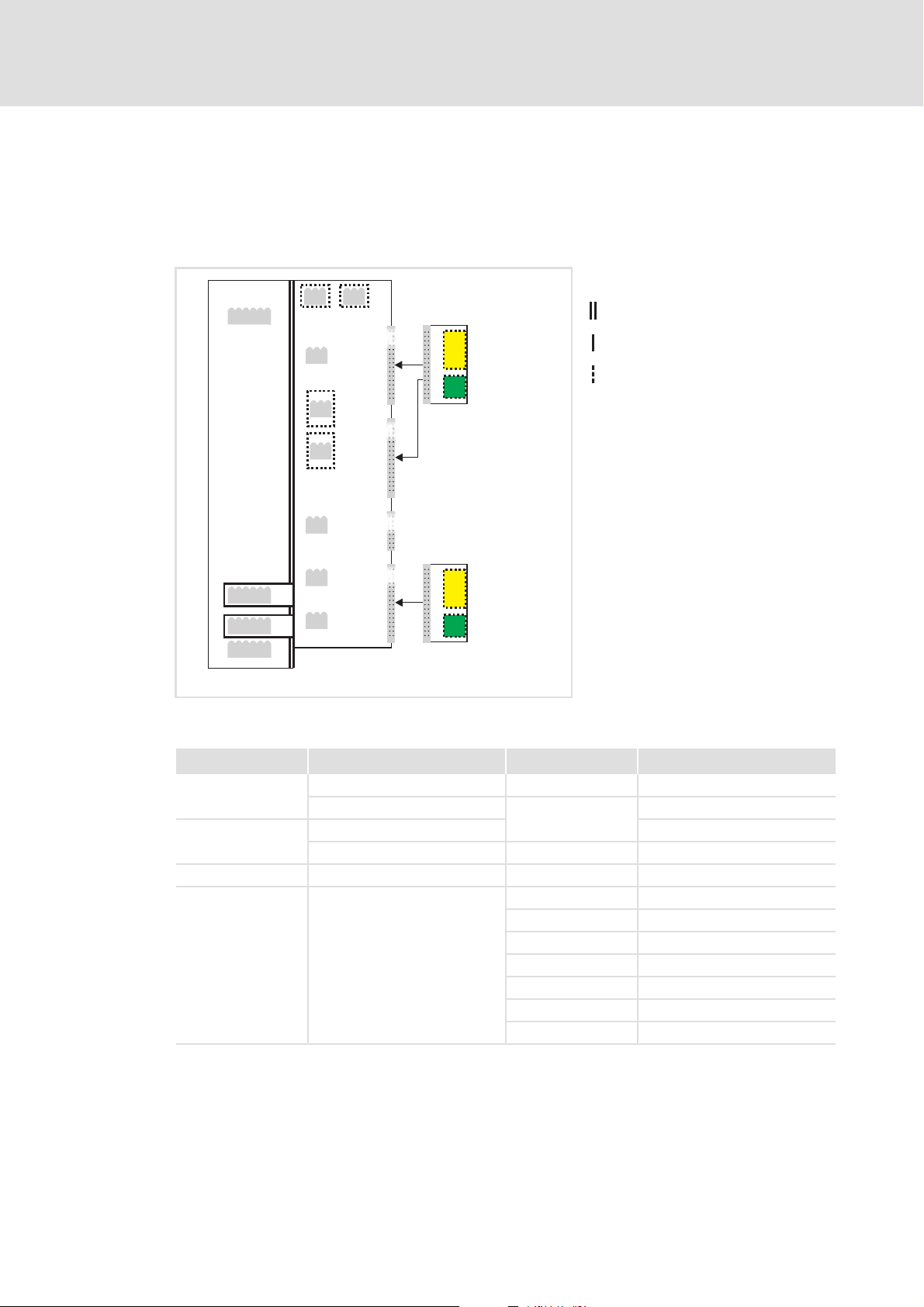

3.4 Terminals and interfaces

9-pin Sub-D plug connector for system bus connection (CANopen)

DIP switches for ...

– setting the CAN node address

– setting the baud rate

Front LEDs for diagnosing the ...

– voltage supply of the communication module;

– connection to the standard device;

– CANopen state machine and error states;

– physical CAN connection.

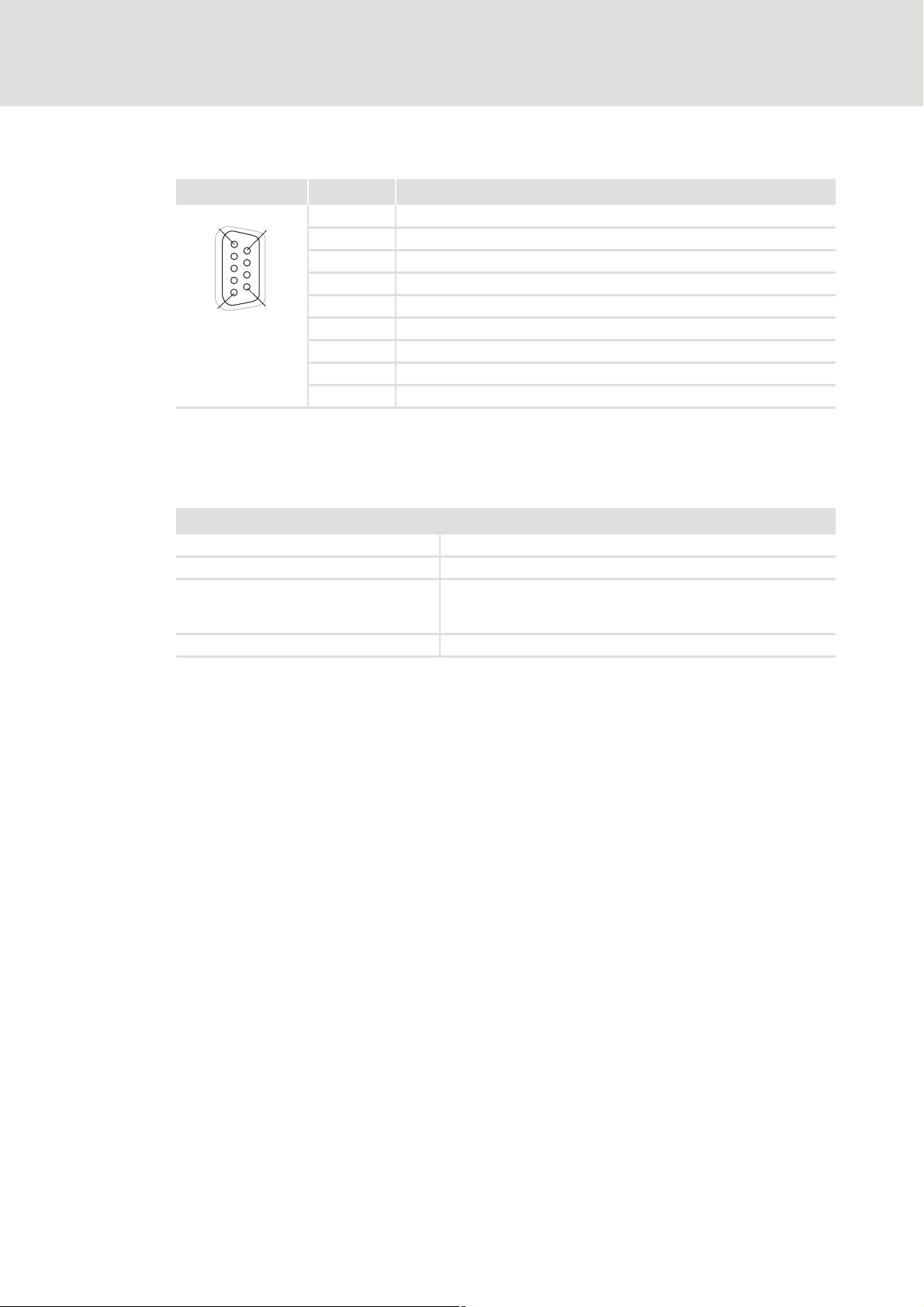

X220 9-pin Sub-D plug connector for the ...

System bus (CANopen) connection

( 26)

[3-2] E94AYCCA communication module (CANopen)

E94YCCA001B

S220 DIP switches for ...

• setting the CAN node address

• setting the baud rate

Possible settings via DIP switches

LED status displays for diagnostics

MS

LED status displays

BS

BE

DE

( 33)

( 86)

16 L EDS94AYCCA EN 5.0 - 06/2012

Page 17

E94AYCCA communication manual (CANopen®)

4 Technical data

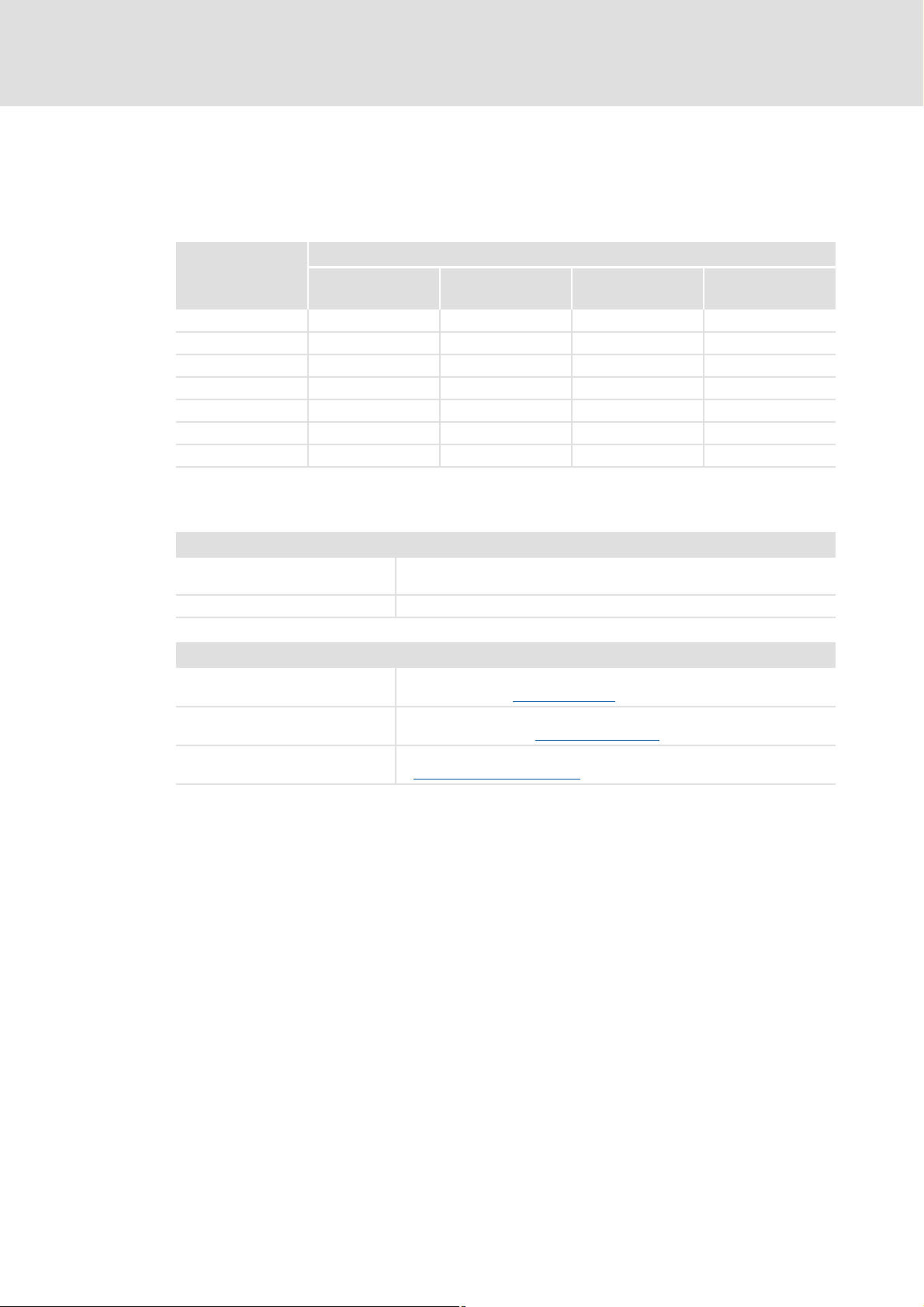

4.1 General data and operating conditions

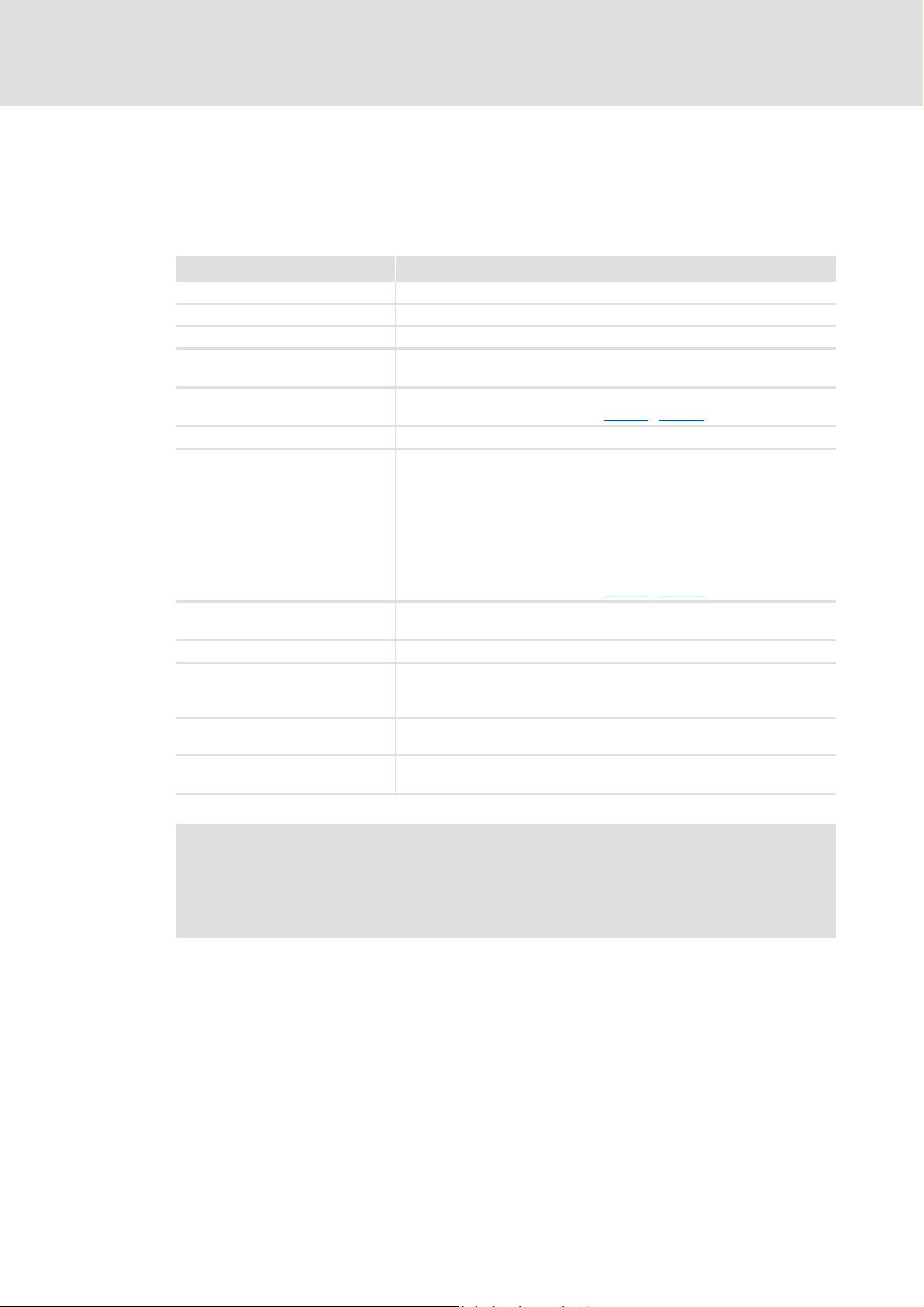

Field Values

Order designation E94AYCCA

Communication profile CANopen (DS301, V4.02)

Communication medium CAN cable according to ISO 11898-2

Network topology Line terminated on both sides

(e.g. termination with Lenze system connector EWZ0046)

Adjustable node addresses 1 ... 127

Adjustable via DIP switches or code C13350

Max. number of nodes 127

Baud rates [kbps] • 10

•20

•50

• 125

• 250

• 500

• 800

• 1000

Adjustable via DIP switches or code C13351

Process data • max. 4 TPDOs with 1 ... 8 bytes

• max. 4 RPDOs with 1 ... 8 bytes

Parameter data Max. 10 client and server SDO channels with 1 ... 8 bytes

Transfer mode for TPDOs • With change of data

• Time-controlled, 1 to x ms

• After the reception of 1 to 240 sync telegrams

Voltage supply Internal voltage supply of the communication module via the Servo Drive

9400.

Conformities, approvals • CE

•UL

Technical data

General data and operating conditions

/ C14350.

/ C14351.

"Servo Drives 9400" hardware manual

Here you can find the ambient conditions and data regarding the

electromagnetic compatibility (EMC) which also apply to the communication

module.

EDS94AYCCA EN 5.0 - 06/2012 L 17

Page 18

E94AYCCA communication manual (CANopen®)

Technical data

Supported protocols

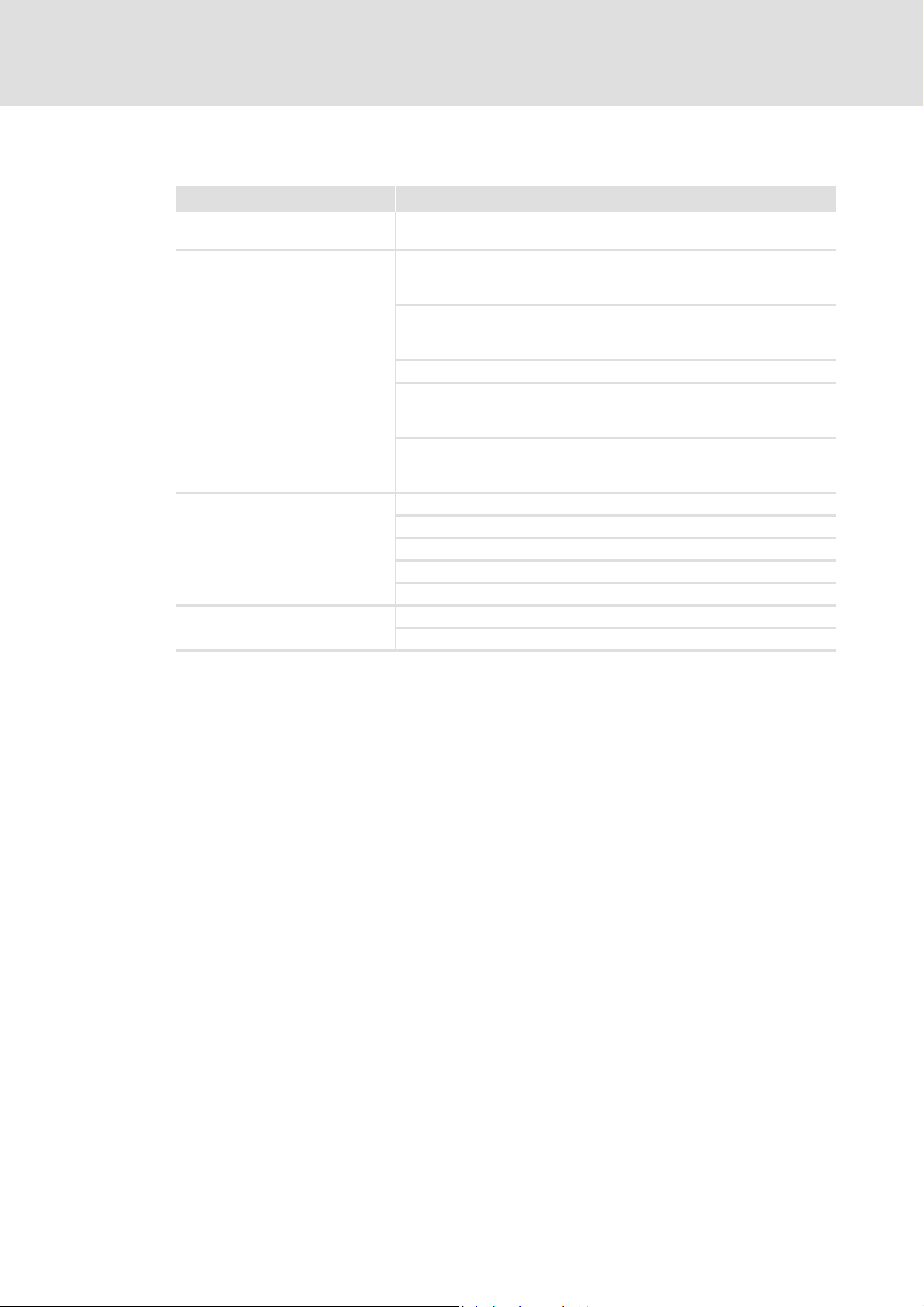

4.2 Supported protocols

Category Protocol

Standard PDO protocols PDO write

PDO read

SDO protocols SDO download

SDO download initiate

SDO download segment

SDO upload

SDO upload initiate

SDO upload segment

SDO abort transfer

SDO block download

SDO block download initiate

SDO block download end

SDO block upload

SDO block upload initiate

SDO block upload end

NMT protocols Start remote node (master and slave)

Stop remote node (slave)

Enter pre-operational (slave)

Reset node (slave and local device)

Reset communication (slave)

Monitoring protocols Node guarding (master and slave)

Heartbeat (heartbeat producer and heartbeat consumer)

18 L EDS94AYCCA EN 5.0 - 06/2012

Page 19

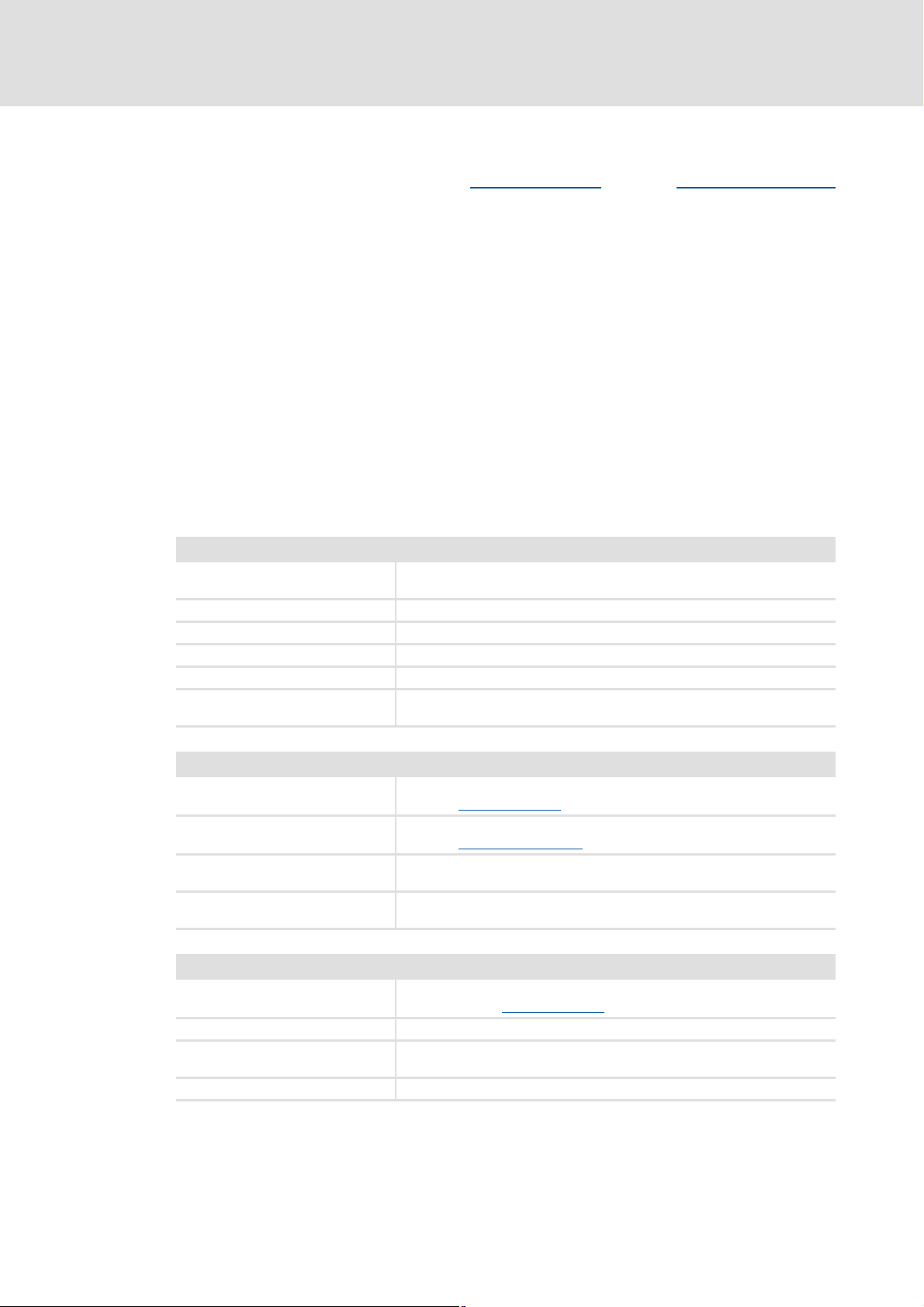

4.3 Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The communication times in the CAN network depend on the ...

processing time in the device;

telegram runtime (baud rate/telegram length);

bus load (especially if the bus is loaded with PDOs and SDOs at a low baud rate).

Servo Drives 9400 processing time

There are no interdependencies between parameter data and process data.

Parameter data:

– For controller-internal parameters: approx. 30 ms ± 20 ms tolerance (typically)

– For some codes the processing time can be longer.

E94AYCCA communication manual (CANopen®)

Technical data

Communication time

Process data are transported in real time.

EDS94AYCCA EN 5.0 - 06/2012 L 19

Page 20

E94AYCCA communication manual (CANopen®)

Technical data

Protective insulation

4.4 Protective insulation

Danger!

Dangerous electrical voltage

If Servo Drives 9400 are used on a corner grounded system with a rated mains

voltage ≥ 400 V, external measures need to be implemented to provide reliable

protection against accidental contact.

Possible consequences:

• Death or serious injury

Protective measures:

• If protection against accidental contact is required for the control terminals

of the controller and the connections of the plugged device modules, ...

– there must be a double isolating distance.

– the components to be connected must be provided with a second isolating

distance.

Note!

The available protective insulation in Servo Drives 9400 is implemented in

accordance with EN 61800-5-1.

20 L EDS94AYCCA EN 5.0 - 06/2012

Page 21

E94AYCCA communication manual (CANopen®)

Technical data

Protective insulation

The illustration below ...

shows the arrangement of the terminal strips and the separate potential areas of the

controller.

serves to determine the decisive protective insulation between two terminals located

in differently insulated separate potential areas.

X2

X100

X1

X3

X4

X5

MXI1

Bus

Ext. DC

MXI2

Reinforced insulation

Basic insulation

Functional insulation

X6X6

X7X7

X107

X106

X105X105

[4-1] Protective insulation according to EN61800-5-1

Terminal strip Connection Terminal strip Connection

X8X8

X100 L1, L2, L3 (only Single Drive) X1 CAN on board 9400

+UG, -UG X2 State bus

X105 U, V, W 24 V (ext.)

Rb1, Rb2 (Single Drive only) X3 Analog inputs/outputs

X106 Motor PTC X4 Digital outputs

X107 Control of the motor holding

brake

MMI

MSI

I/O

Ext. DC

E94YCXX007

X5 Digital inputs

X6 Diagnostics

X7 Resolver

X8 Encoder

MXI1, MXI2 Extension module

MMI Memory module

MSI Safety module

EDS94AYCCA EN 5.0 - 06/2012 L 21

Page 22

E94AYCCA communication manual (CANopen®)

Technical data

Protective insulation

Example

Which type of protective insulation is used between the bus terminal of the device module

in slot MXI1 or MXI2 and the mains terminal X100?

The separate potential area with the better protective insulation is decisive.

– The separate potential area of the bus terminal of the device module has a "basic

insulation".

– The separate potential area of the mains terminal has a "reinforced insulation".

Result: The insulation between the X100 mains terminal and the bus terminal is of the

"reinforced insulation" type.

22 L EDS94AYCCA EN 5.0 - 06/2012

Page 23

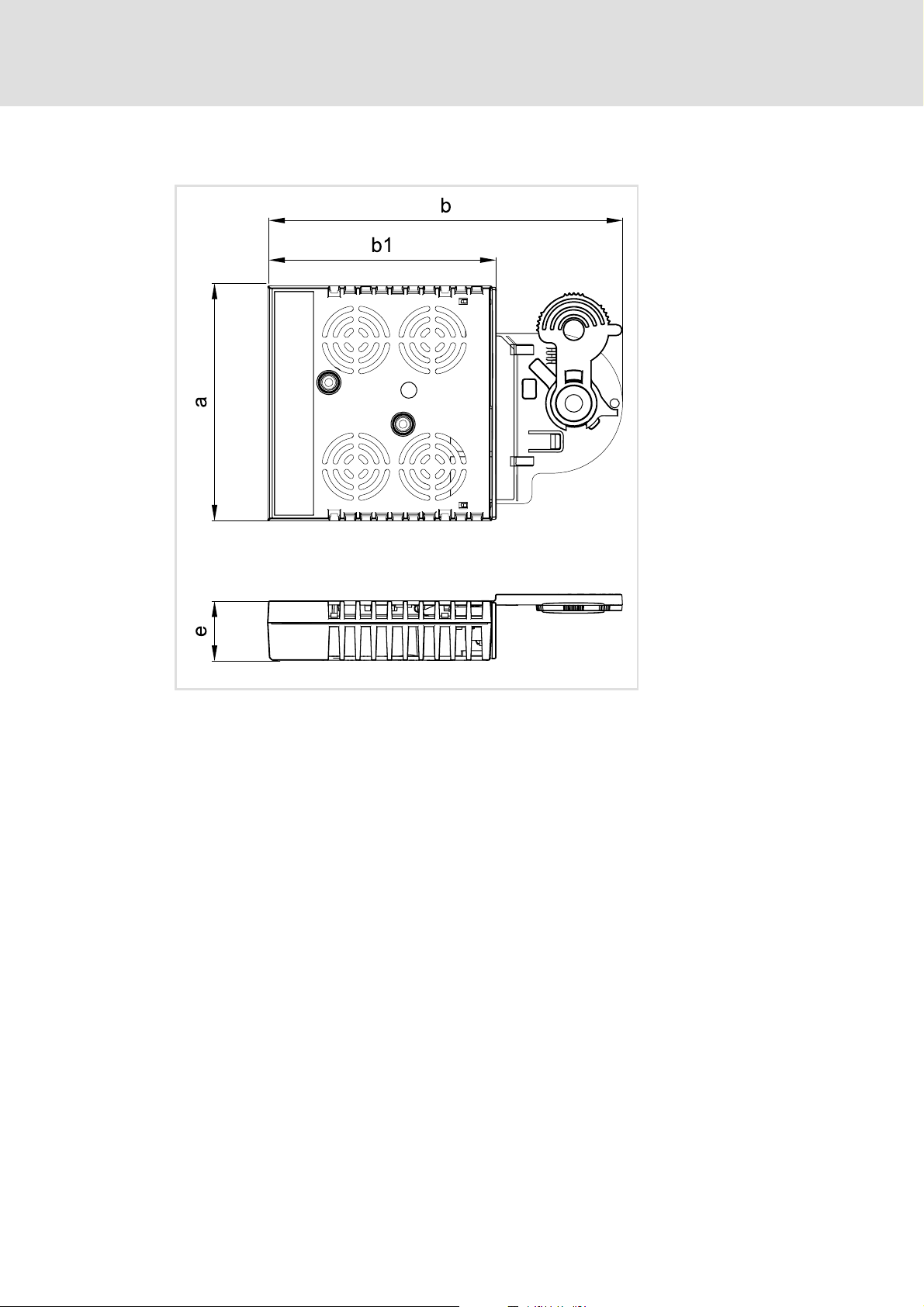

4.5 Dimensions

E94AYCCA communication manual (CANopen®)

Technical data

Dimensions

a 89 mm

b 134 mm

b1 87 mm

e 23 mm

[4-2] Dimensions

E94YCXX005

EDS94AYCCA EN 5.0 - 06/2012 L 23

Page 24

E94AYCCA communication manual (CANopen®)

Installation

5 Installation

Stop!

Electrostatic discharge

Electronic components in the communication module can be damaged or

destroyed by electrostatic discharge.

Possible consequences:

• The communication module is defective.

• Fieldbus communication is faulty or not possible.

Protective measures

• Before touching the module, make sure that you are free of electrostatic

charge.

24 L EDS94AYCCA EN 5.0 - 06/2012

Page 25

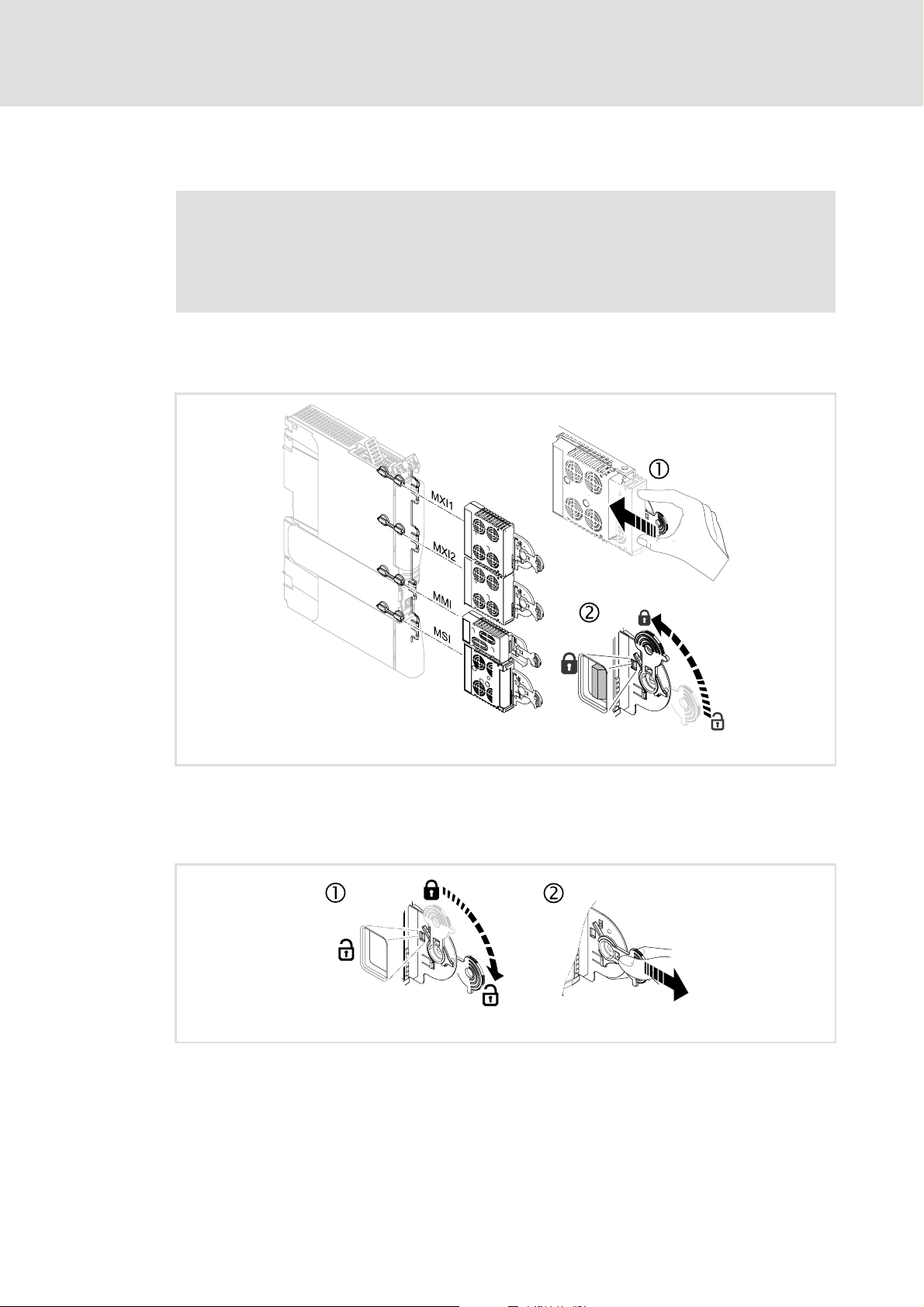

5.1 Mechanical installation

Note!

• Only one communication module E94AYCCA (CANopen) may be inserted per

Servo Drive 9400.

• The slot used (MX1 or MX2) can be selected freely.

5.1.1 Mounting

E94AYCCA communication manual (CANopen®)

Installation

Mechanical installation

[5-1] Mounting

5.1.2 Dismounting

[5-2] Dismounting

E94YCXX001G

E94AYCXX001H

EDS94AYCCA EN 5.0 - 06/2012 L 25

Page 26

E94AYCCA communication manual (CANopen®)

OFF

ON

Installation

Electrical installation

5.2 Electrical installation

Documentation of the standard device, control system, and plant/machine

Observe the notes and wiring instructions stated.

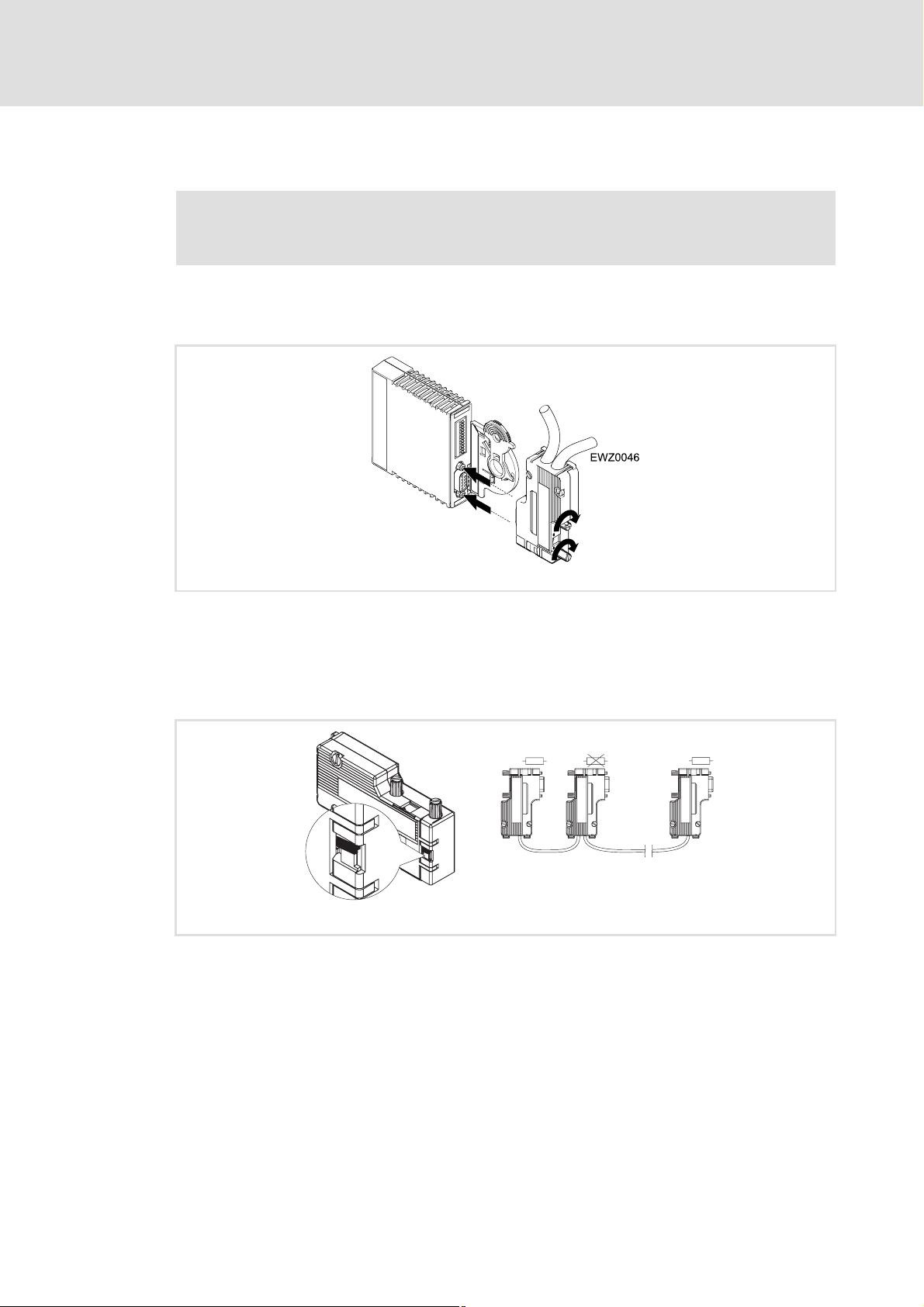

5.2.1 System bus (CANopen) connection

E94YCCA002A

The system bus (CANopen) must be terminated with resistors (120 Ω) between CAN-

low and CAN-high.

The Lenze system connector EWZ0046 with integrated terminating resistor complies

with the DS102-1 recommendation of the CAN user organisation CiA. The system

connector is not contained in the scope of supply of the communication module.

On

120

EWZ0046

L

ð

2181FEW004

L

EWZ0046

120 120

On

OFF

ON

F

F

O

N

O

Off

EWZ0046

L

EWZ0046

L

ð

ð

ð

OUTIN IN IN

26 L EDS94AYCCA EN 5.0 - 06/2012

Page 27

Assignment of the 9-pin Sub-D plug connector

View Pin Assignment

1

5

6

9

1 -

2 CAN-LOW

3 CAN-GND

4 -

5 -

6 -

7 CAN-HIGH

8 -

9 -

5.2.2 Specification of the bus cable

We recommend the use of CAN cables according to ISO 11898-2:

E94AYCCA communication manual (CANopen®)

Installation

Electrical installation

CAN cable according to ISO 11898-2

Cable type Twisted in pairs with shield

Impedance 120 Ω (95 ... 140 Ω)

Cable resistance/cross-section

Cable length ≤ 300 m:

Cable length 301 ... 1000 m:

Signal propagation delay ≤ 5 ns/m

≤ 70 mΩ/m / 0.25 ... 0.34 mm

≤ 40 mΩ/m / 0.5 mm

2

(AWG20)

2

(AWG22)

EDS94AYCCA EN 5.0 - 06/2012 L 27

Page 28

E94AYCCA communication manual (CANopen®)

Installation

Electrical installation

5.2.3 Bus cable length

Note!

• It is absolutely necessary to comply with the permissible cable lengths.

• If the total cable lengths of the CAN nodes differ for the same baud rate, the

smaller value must be used to determine the max. cable length.

• Observe the reduction of the total cable length due to the signal delay of the

repeater.Checking the use of repeaters

5.2.3.1 Total cable length

The baud rate also determines the total cable length.

Baud rate [kbps] Max. bus length [m]

10 8075

20 4012

50 1575

125 600

250 275

500 112

800 38

1000 12

( 30)

28 L EDS94AYCCA EN 5.0 - 06/2012

Page 29

5.2.3.2 Segment cable length

The segment cable length is determined by the cable cross-section used and by the number

of nodes. Repeaters divide the total cable length into segments. If no repeaters are used,

the segment cable length is identical to the total cable length.

E94AYCCA communication manual (CANopen®)

Installation

Electrical installation

Max. number of

nodes per segment

2 240 m 430 m 650 m 940 m

5 230 m 420 m 640 m 920 m

10 230 m 410 m 620 m 900 m

20 210 m 390 m 580 m 850 m

32 200 m 360 m 550 m 800 m

63 170 m 310 m 470 m 690 m

100 150 m 270 m 410 m 600 m

Cable cross-section (can be interpolated)

0.25 mm

(AWG 24)

2

0.50 mm

(AWG 21)

2

0.75 mm

(AWG 19)

2

1.00 mm

(AWG 18)

Example: selection help

Given

Total cable length to be

implemented

Number of nodes 63

Results

Max. possible baud rate 250 kbps

Cable cross-section required

(interpolated)

Cable cross-section of standard CAN

cable

200 m

(derived from table Total cable length

0.30 mm

(derived from the table Segment cable length

0.34 mm

Specification of the bus cable

2

(AWG23)

2

(AWG22)

( 28))

( 27)

( 29))

2

EDS94AYCCA EN 5.0 - 06/2012 L 29

Page 30

E94AYCCA communication manual (CANopen®)

Installation

Electrical installation

5.2.3.3 Checking the use of repeaters

Compare the values derived from tables Total cable length

( 29).

( 28) and Segment cable length

If the sum of the segment cable lengths is smaller than the total cable length to be

implemented, either repeaters must be used or the cable cross-section must be

increased.

If the use of repeaters reduces the max. possible total cable length so much that it is

smaller than the total cable length to be implemented, then the cable cross-section

must be increased or less repeaters must be used or the baud rate must be decreased.

The use of a further repeater is recommended as ...

– service interface

Advantage: trouble-free connection during bus operation is possible.

– calibration interface

Advantage: the calibration/programming unit remains electrically isolated.

Example

Given

Total cable length to be

implemented

Number of nodes 32

Cable cross-section 0.50 mm

Baud rate 125 kbps

Repeater used Lenze repeater EMF2176IB

Reduction of the max. total cable

length per repeater (EMF2176IB)

450 m

30 m

2

(AWG 20)

Results

Max. possible total cable length 600 m

(see table Total cable length

Max. segment cable length 360 m

(see table Segment cable length

Comparison The max. segment cable length is smaller than the total cable length to be

implemented.

Conclusion A repeater must be installed at the determined max. segment cable length

of 360 m.

Results with 1 repeater

Max. possible total cable length 570 m

(Reduction of the Total cable length

Sum of the segment cable lengths 720 m

Comparison Both the possible total cable length and the segment cable lengths are larger

than the total cable length to be implemented.

Conclusion 1 repeater is sufficient to implement the total cable length of 450 m.

( 28))

( 29))

( 28) by 30 m)

30 L EDS94AYCCA EN 5.0 - 06/2012

Page 31

5.2.4 Voltage supply

The communication module is only internally supplied with voltage via the standard

device.

If the standard device fails, data transfer between the communication module and

other CAN nodes is interrupted.

E94AYCCA communication manual (CANopen®)

Installation

Electrical installation

EDS94AYCCA EN 5.0 - 06/2012 L 31

Page 32

E94AYCCA communication manual (CANopen®)

Commissioning

Before initial switch-on

6 Commissioning

During commissioning, the controller receives system-specific data, e.g. motor

parameters, operating parameters, responses, and parameters for the fieldbus

communication. In case of Lenze devices, this is done via codes.

The codes for the controller and for the communication are saved as a non-volatile data set

in the memory module.

In addition to codes for the configuration, there are codes for diagnosing and monitoring

the nodes.

Note!

When parameterising the communication module, please note that the code

number depends on the slot of the Servo Drive 9400 which the communication

module is plugged into.

The first two digits of the code number indicate the slot:

•C13nnn for slot MXI1

Parameters of the communication module for slot MXI1

•C14nnn for slot MXI2

Parameters of the communication module for slot MXI2

Furthermore, the Communication-relevant parameters of the standard device

( 101)

must be set.

6.1 Before initial switch-on

Stop!

Before switching on the controller for the first time, check ...

• the entire wiring with regard to completeness, earth fault and short circuit.

• whether the bus system is terminated by a bus terminating resistor at the

physically first and last node.

System bus (CANopen) connection

( 107)

( 128)

( 26)

32 L EDS94AYCCA EN 5.0 - 06/2012

Page 33

E94AYCCA communication manual (CANopen®)

6.2 Possible settings via DIP switches

Commissioning

Possible settings via DIP switches

O

O

O

N

N

N

[6-1] DIP switch

643216 8

643216 8

643216 8

cdba

cdba

cdba

Baud

Baud

Baud

CAN Address

CAN Address

CAN Address

6.2.1 Setting the node address

If several CAN nodes are interconnected, their node addresses must differ from each

other.

The node address can be set with the DIP switches 1 ... 64 or via the »Engineer« (code

C13350

/ C14350).

Valid address range: 1 … 127

Prerequisite At least one switch 1…64=ON Switches 1...64=OFF

The labelling on the package corresponds to the values of the individual DIP switches for

determining the node address.

DIP switch 64 32 16 8 4 2 1

Switch position OFF OFF ON OFF ON ON ON

Value 00

Node address = Sum of the values = 16 + 4 + 2 + 1 = 23

421

421

421

The front DIP switches can be used to set:

address (switches 1 ... 64)

baud rate (switches a ... d)

9400CAN003

Node address determined by ...

DIP switch C13350 / 14350

DIP switch positions for setting the CAN node address

Lenze setting: all switches OFF

16 0 4 2 1

( 178)

Note!

Switch the voltage supply of the communication module off and then on again

to activate altered settings.

Tip!

The node address resulting from the DIP switch setting applied at last mains

power-up is indicated under C13349/1

EDS94AYCCA EN 5.0 - 06/2012 L 33

/ C14349/1.

Page 34

E94AYCCA communication manual (CANopen®)

Commissioning

Possible settings via DIP switches

6.2.2 Setting the baud rate

The baud rate can be set with the DIP switches a...d or via the »Engineer« (code

C13351

If several CAN nodes are interconnected, their baud rates must be identical.

d c b a

OFF ON ON OFF 10 kbps

OFF ON OFF ON 20 kbps

OFF OFF ON ON 50 kbps

OFF OFF ON OFF 125 kbps

OFF OFF OFF ON 250 kbps

OFF OFF OFF OFF 500 kbps

ON ON ON OFF 800 kbps

OFF ON OFF OFF 1000 kbps

OFF ON ON ON Automatic detection

/ C14351).

Switch positions Baud rate

Note!

Switch the voltage supply of the standard device off and then on again to

activate altered settings.

Tip!

The baud rate resulting from the DIP switch setting applied at last mains power-up

is indicated under C13349/2

/ C14349/2.

34 L EDS94AYCCA EN 5.0 - 06/2012

Page 35

6.3 Settings in the »Engineer«

E94AYCCA communication manual (CANopen®)

Commissioning

Settings in the »Engineer«

Go to the Settings tab to ...

set the node address (C13350

Setting the node address

select the procedure for automatic allocation of the COB-IDs in the »Engineer«.

configure the CAN node as a master or slave (C13352

display the time that must elapse after mains power-up before the CAN NMT

master transmits the "Start remote node" telegram via the system bus (CANopen)

(C13378 / C14378).

( 33)

/ C14350).

/ C14352).

EDS94AYCCA EN 5.0 - 06/2012 L 35

Page 36

E94AYCCA communication manual (CANopen®)

Commissioning

Initial switch-on

6.4 Initial switch-on

Documentation of Servo Drive 9400

Observe the safety instructions and residual hazards stated.

Note!

Establishing communication

When the communication module is externally supplied, the standard device

must also be switched on for establishing communication.

After communication has been established, communication of the externally

supplied module is independent of the on/off state of the standard device.

Activating changed settings

In order to activate changed settings ...

• execute device command "11: Save start parameters" via standard device

code C00002 and ...

• then execute a "CAN reset node" on the node using C00002 = 92 or switch off

and on again the voltage supply of the communication module.

Protection against uncontrolled restart

After a fault (e.g. short-term mains failure), it is sometimes not wanted or even

impermissible that the drive restarts.

In the Lenze setting of the Servo Drives 9400, the restart protection is activated.

Via the standard device code C00142 ("Auto restart after mains connection") you

can set the restart behaviour of the controller:

• C00142 = "0: Inhibited" (Lenze setting)

– The controller remains inhibited (even if the fault is no longer active).

– The drive starts up in a controlled manner by explicit controller enable:

LOW-HIGH edge at digital input X5/RFR.

• C00142 = "1: Enabled"

– An uncontrolled restart of the drive is possible.

36 L EDS94AYCCA EN 5.0 - 06/2012

Page 37

E94AYCCA communication manual (CANopen®)

7 Data transfer

Via the CANopen interface, process data and parameter values can be exchanged between

the CAN nodes. In addition, the interface enables the connection of further modules such

as distributed terminals, operator and input devices (HMIs), or external controls and

control systems.

The interface transfers CAN objects following the CANopen communication profile

(DS301, V4.02) ) developed by the umbrella organisation of CiA (CAN in Automation) in

conformity with the CAL (CAN Application Layer).

7.1 Structure of the CAN data telegram

Data transfer

Structure of the CAN data telegram

6WDUW 575ELW

,GHQWLILHU 8VHUGDWD

%LW %LW %LW %LW %LW %LW %LW %LW %LW

[7-1] Basic structure of the CAN telegram

&RQWUROILHOG

&5&VHTXHQFH

%\WH

1HWZRUNPDQDJHPHQW

3URFHVVGDWD

3DUDPHWHUGDWD

&5&GHOLPLWHU $&.GHOLPLWHU

$&.VORW (QG

The identifier and the user data are described in detail in the following subchapters. The

other signals refer to the transfer characteristics of the CAN telegram that are not

described in this documentation.

Tip!

For further information please refer to the website of the CiA (CAN in Automation)

user organisation:

www.can-cia.org

EDS94AYCCA EN 5.0 - 06/2012 L 37

Page 38

E94AYCCA communication manual (CANopen®)

Data transfer

Structure of the CAN data telegram

7.1.1 Identifier

The principle of the CAN communication is based on a message-oriented data exchange

between a transmitter and many receivers. All nodes can transmit and receive quasisimultaneously.

The identifier, also called "COB-ID" (Communication Object Identifier), is used to control

which node is to receive a transmitted message. In addition to the addressing, the

identifier contains information on the priority of the message and the type of the user

data.

The identifier consists of a basic identifier and the node address of the node to be

addressed:

Identifier (COB-ID) = basic identifier + node address (node ID)

Exception:

management and sync telegrams, the identifier can be assigned freely by the user (either

manually or automatically by a network configurator) or is firmly allocated.

Node address (node ID)

For the purpose of unique identification, a node address, also referred to as node ID, in the

valid address range (1 ... 127) is to be assigned to each node within the CAN network.

A node address may not be assigned more than once within a network.

The node address can be configured with the DIP switches of the communication

module or with code C13350

Setting the node address

For process data, heartbeat and emergency objects as well as network

/ C14350.

( 33)

38 L EDS94AYCCA EN 5.0 - 06/2012

Page 39

E94AYCCA communication manual (CANopen®)

Data transfer

Structure of the CAN data telegram

Identifier assignment

The system bus (CANopen) is message-oriented and not node-oriented. Each message has

a unique identification, the identifier. In the case of CANopen, a node-orientation is

achieved by the fact that for each message there is only one sender.

The basic identifiers for network management (NMT) and sync as well as the basic SDO

channel (SDO1) are specified in the CANopen protocol and cannot be changed.

In the Lenze setting, the basic identifiers of the PDOs are preset according to the

"Predefined Connection Set" of DS301, V4.02. They can be changed via parameters/

indexes if required.

Identifiers of the process data objects

Object Direction Basic identifier

from the device to the device dec hex

Network management (NMT) 0 0

Sync 128 80

Emergency z 128 80

PDO1

(Process data channel 1)

PDO2

(Process data channel 2)

PDO3

(Process data channel 3)

PDO4

(Process data channel 4)

SDO1

(Basic SDO channel)

SDO2 ... SDO10

(Parameter data channel 2 ... 10)

Node guarding, heartbeat z 1792 700

TPDO1

RPDO1

TPDO2

RPDO2

TPDO3

RPDO3

TPDO4

RPDO4

z 384 180

z 640 280

z 896 380

z 1152 480

z 1408 580

z 1472 5C0

( 46)

z 512 200

z 768 300

z 1024 400

z 1280 500

z 1536 600

z 1600 640

EDS94AYCCA EN 5.0 - 06/2012 L 39

Page 40

E94AYCCA communication manual (CANopen®)

Data transfer

Structure of the CAN data telegram

7.1.2 User data

All nodes communicate with each other by exchanging data telegrams via the system bus

(CANopen). The user data area of the CAN telegram contains network management data,

parameter data or process data:

Network management data

(NMT data)

Control information on start, stop, reset, etc. of communication to certain or all nodes

of the CAN network.

Process data

(PDOs – Process Data Objects)

Process data are transferred via the process data channel.

The controller can be controlled using process data.

Process data are not

Process data are transferred between the host and the nodes to ensure a continuous

exchange of current input and output data.

Process data usually are unscaled/scalable raw data

Process data are, for instance, setpoints and actual values.

Parameter data

(SDOs – Service Data Objects)

Parameter data are the CANopen indexes or, in the case of Lenze devices, the codes.

The parameters are, for instance, set for the initial system set-up during

commissioning or when material is changed on the production machine.

Parameter data are transmitted as SDOs via the parameter data channel. They are

acknowledged by the receiver, i.e. the sender receives a feedback about the

transmission being successful or not.

The parameter data channel enables access to all Lenze parameters (codes) and

CANopen indexes.

Parameter changes are automatically saved in the controller until the mains is

switched.

saved in the controller.

In general, the parameter transfer is not time-critical.

Parameter data are, for instance, operating parameters, diagnostic information and

motor data.

40 L EDS94AYCCA EN 5.0 - 06/2012

Page 41

E94AYCCA communication manual (CANopen®)

Communication phases / network management

7.2 Communication phases / network management

Regarding communication via the system bus (CANopen), the drive distinguishes between

the following states:

Status Explanation

"Initialisation"

(Initialisation)

"Pre-operational"

(before being ready for operation)

"Operational"

(ready for operation)

"Stopped"

(Stopped)

After power-up, initialisation is executed.

• During this phase, the controller does not take part in the data transfer on

the system bus (CANopen).

• All CAN-relevant parameters are written with their standard values

again.

• After initialisation has been completed, the controller is automatically set

to the "pre-operational" status.

Parameter data can be received, process data is ignored.

Parameter data and process data can be received!

Only network management telegrams can be received.

Data transfer

Communication object Initialisation Pre-operational Operational Stopped

PDO z

SDO zz

Sync zz

Emergency zz

Boot-up z

Network management (NMT) zzz

Tip!

In every state, the initialisation can be re-executed partly or completely by

transmitting appropriate network management telegrams.

EDS94AYCCA EN 5.0 - 06/2012 L 41

Page 42

E94AYCCA communication manual (CANopen®)

Data transfer

Communication phases / network management

7.2.1 State transitions

,QLWLDOLVDWLRQ

[7-2] NMT state transitions in the CAN network

3UH2SHUDWLRQDO

2SHUDWLRQDO

6WRSSHG

Transition NMT command State after

Effect on process and parameter data after state change

change

(1) - Initialisation Initialisation starts automatically when the mains is

switched on.

• During initialisation, the controller does not take part in

the data transfer.

• After initialisation has been completed, the node sends a

boot-up message with an individual identifier and

automatically changes to the "pre-operational" status.

(2) - Pre-operational In this phase, the master determines the way in which the

node(s) takes/take part in the communication.

From here, the states are changed over by the master for the entire network.

• A target address contained in the NMT command specifies the receiver(s).

• If the 9400 controller has been configured as a CAN master, the state automatically changes to

"operational" after a waiting time (C13378

/ C14378) has expired, and the NMT command

0x0100 ("Start remote node") is sent to all nodes.

• Data can only be exchanged via process data objects if the state is "Operational".

(3), (6) 0x01 xx

Start Remote Node

Operational Network management, sync and emergency telegrams as

well as process data (PDO) and parameter data (SDO) are

active.

Optional: When the state is changed, event and timecontrolled process data (PDOs) will be sent once.

(4), (7) 0x80 xx

Enter Pre-Operational

(5), (8) 0x02 xx

Stop Remote Node

(9), (10), (11) 0x81 xx

Reset node

(12), (13), (14) 0x82 xx

Reset communication

Pre-operational Network management, sync and emergency telegrams as

well as parameter data (SDO) are active.

Stopped Only network management telegrams can be received.

Initialisation Initialisation of all CAN-relevant parameters (DS301, V4.02)

with the stored values.

Initialisation of all CAN-relevant parameters (DS301, V4.02)

with the stored values.

Meaning of the node address in the NMT command:

• xx = 0x00: With this assignment, all nodes are addressed by the telegram (broadcast telegram).

The state can be changed for all nodes at the same time.

• xx = Node-ID: If a node address is indicated, the state will only be changed for the node

addressed.

42 L EDS94AYCCA EN 5.0 - 06/2012

Page 43

E94AYCCA communication manual (CANopen®)

7.2.2 Network management telegram (NMT)

The telegram for the network management contains the identifier "0" and the command

included in the user data, which consists of the command byte and the node address.

,GHQWLILHU 8VHUGDWD%\WH

&2%,'

%LW %LW %LW %LW %LW %LW %LW %LW %LW

[7-3] Network management telegram for changing the communication phases

Command specifier (cs) NMT command

dec hex

1 0x01 Start Remote Node

20x02Stop Remote Node

128 0x80 Enter Pre-Operational

129 0x81 Reset node

130 0x82 Reset communication

FRPPDQG

VSHFLILHU

FV

Data transfer

Communication phases / network management

QRGH

DGGUHVV

QRGH,'

The changeover of the communication phases is carried out by one node, the CAN master,

for the entire network. The role of the CAN master can also assumed by the drive controller.

Parameterising the controller as a CAN master

( 44)

Example:

Data can only be exchanged via the process data objects in the "Operational" state. To

change all nodes on the bus from "Pre-Operational" to "Operational" via the CAN master,

the following identifiers and user data must be set as follows in the transmit telegram:

Identifier: 0x00 (network management)

User data: 0x0100 (NMT command "Start Remote Node" to all nodes)

EDS94AYCCA EN 5.0 - 06/2012 L 43

Page 44

E94AYCCA communication manual (CANopen®)

Data transfer

Communication phases / network management

7.2.3 Parameterising the controller as a CAN master

If the initialisation of the system bus (CANopen) and the state change from "preoperational" to" operational" is not carried out by a higher-level control system, the

controller can be defined to be a "quasi" master to take over this task.

The controller can be configured to be a CAN master in C13352

As a CAN master, the controller sets all

telegram) to the "operational" communication state using the "Start remote node"

NMT telegram. Only this communication state enables a data exchange via the process

data objects.

In C13378

switching before the controller transmits the "Start remote node" NMT telegram on the

system bus (CANopen).

Parameter Information Lenze setting

C13352 / C14352 CAN slave/master Slave

C13378

/ C14378 CAN delay boot-up - Operational 3000 ms

/ C14378, a delay time can be set. This delay time must elapse after mains

nodes connected to the bus (broadcast

/ C14352.

Value Unit

Note!

Changing the master/slave operation in C13352 / C14352 will only be effective

• after switching the mains power of the controller off and then on again

or

• by sending the NMT telegram "Reset Node" or "Reset Communication" to the

controller.

As an alternative to the "Reset node" NMT telegram, the device command

C00002 = "92: CAN module: reset node" can be used to reinitialise the CANspecific device parameters.

Tip!

The master functionality is only required for the initialisation phase of the drive

system.

44 L EDS94AYCCA EN 5.0 - 06/2012

Page 45

8 Process data transfer

E94AYCCA communication manual (CANopen®)

Process data transfer

[8-1] PDO data transfer from / to the higher-level host system

For the transfer of process data, four separated process data channels (PDO1 ... PDO4) are

available.

Definitions

Process data telegrams between the host and the devices are distinguished as follows:

– Process data telegrams to

– Process data telegrams from

The CANopen process data objects are designated as seen from the node's view:

– Receive PDO (RPDOx): process data object received by a node

– Transmit PDO (TPDOx): process data object transmitted by a node

the device (RPDO)

the device (TPDO)

Note!

Data can only be exchanged via the process data objects if the state is

"Operational".

Communication phases / network management

( 41)

EDS94AYCCA EN 5.0 - 06/2012 L 45

Page 46

E94AYCCA communication manual (CANopen®)

Process data transfer

Identifiers of the process data objects

8.1 Identifiers of the process data objects

In the Lenze setting, the identifier for the process data objects PDO1 ... PDO4 results from

a basic identifier and the node address set in C13350

Identifier (COB-ID) = basic identifier + node address (node ID)

In the Lenze setting, the basic identifiers of the PDOs are preset according to the

"Predefined Connection Set" of DS301, V4.02.

The identifiers for the PDOs can be set individually via the Lenze codes and CANopen

indexes listed in the following table. Thus, you can also set an identifier independently

of the node address for certain PDOs.

Process data object Basic identifier Individual setting

dec hex Lenze code CANopen index

PDO1 RPDO1 512 0x200 C13321/1

TPDO1 384 0x180 C13320/1

PDO2 RPDO2 768 0x300 C13321/2

TPDO2 640 0x280 C13320/2

PDO3 RPDO3 1024 0x400 C13321/3

TPDO3 896 0x380 C13320/3

PDO4 RPDO4 1280 0x500 C13321/4

TPDO4 1152 0x480 C13320/4

/ C14350:

I-1400/1

C14321/1

I-1800/1

C14320/1

I-1401/1

C14321/2

I-1801/1

C14320/2

I-1402/1

C14321/3

I-1802/1

C14320/3

I-1403/1

C14321/4

I-1803/1

C14320/4

Note!

When the node address has been changed (C13350 / C14350) and then "Reset

node" (C00002 = 92) has been executed, the subcodes of C13320

C13321

respective basic identifier and the node address set.

Tip!

The "Predefined Connection Set" can be re-established anytime using the following

device commands of C00002:

• "93: CAN on board: Pred.Connect.Set" for CAN on board

• "94: CAN module: Pred.Connect.Set" for communication module E94AYCCA

/ C14320 and

/ C14321 are automatically reset to the identifiers resulting from the

46 L EDS94AYCCA EN 5.0 - 06/2012

Page 47

8.2 Transmission type

The process data objects are transmitted in an event-controlled or time-controlled way.

Event-controlled: The PDO is sent if a special device-internal event has occurred, for

instance, when the data contents of the TPDO have changed or when a transmission

cycle time has elapsed.

Synchronous: A TPDO (or RPDO) is transmitted (or received) after the device has

received a sync telegram (with identifier 0x80).

Cyclically: The PDOs are transmitted in fixed time intervals after the transmission cycle

time has elapsed.

The table shows that combinations of logic operations (AND, OR) are also possible between

the different transmission modes:

Transmission type PDO transmission Logic operation

0 zzAND

1 ... 240 z -

254, 255 zzOR

E94AYCCA communication manual (CANopen®)

Process data transfer

Transmission type

cyclic synchronous event-controlled

Transmission type Description

0 The PDO is transmitted at every sync in an event-controlled manner (e. g. by means of a bit

1 ... 240 SYNC (with response)

254, 255 Event-controlled (with mask) with cyclic overlay

change within the PDO).

• Selection n = 1: The PDO is transmitted with every

• Selection 1 < n ≤ 240: The PDO is transmitted with every n-th

If this value is entered, the PDO transmission is event-controlled or

(Note: The values "254" and "255" have the same meaning).

For cyclic overlay, a cycle time must be set for the respective PDO. In this case, cyclic

transmission takes place in addition to event-controlled transmission (e.g. through a bit

change in the PDO).

sync.

sync.

cyclic.

EDS94AYCCA EN 5.0 - 06/2012 L 47

Page 48

E94AYCCA communication manual (CANopen®)

Process data transfer

Transmission type

The communication parameters (as e.g. transmission mode and cycle time) can be freely

adjusted for any PDO and independent of the settings of other PDOs:

Parameter Information Lenze setting

C13322/1...4

C14322/1...4

C13323/1...4

C14323/1...4

C13324/1...4

C14324/1...4

C13356/1...4

C14356/1...4

CAN TPDOx Tx mode 254

CAN RPDOx Rx mode 254

CAN TPDOx delay time 0 1/10 ms

CAN TPDOx cycle time 0 ms

Tip!

The setting can also be made via the following CANopen objects:

• I-1400

• I-1800

... I-1403: Communication parameters for RPDO1 ... RPDO4

... I-1803: Communication parameters for TPDO1 ... TPDO4

Value Unit

48 L EDS94AYCCA EN 5.0 - 06/2012

Page 49

E94AYCCA communication manual (CANopen®)

8.3 Masking of the TPDOs for event control

For TPDO1 ... TPDO4, a mask can be parameterised for every byte. In case of eventcontrolled transmission of a PDO, only the masked bits are used for the event control.

Mask "0x0" means that no bit of the corresponding byte triggers the transmission.

Mask "0xff" means that each bit of the corresponding byte can trigger the

transmission.

Short overview: Parameters for masking the TPDOs

Parameter Information Lenze setting

C13311/1...8

C14311/1...8

C13312/1...8

C14312/1...8

C13313/1...8

C14313/1...8

C13314/1...8

C14314/1...8

CAN TPDO1 mask byte x 0x00

CAN TPDO2 mask byte x 0x00

CAN TPDO3 mask byte x 0x00

CAN TPDO4 mask byte x 0x00

Process data transfer

Masking of the TPDOs for event control

EDS94AYCCA EN 5.0 - 06/2012 L 49

Page 50

E94AYCCA communication manual (CANopen®)

Process data transfer

Synchronisation of PDOs via sync telegram

8.4 Synchronisation of PDOs via sync telegram

In case of cyclic transmission, one or several PDOs are transmitted or received at fixed time

intervals. For synchronising the cyclic process data, an additional special telegram, the sync

telegram, is used.

The sync telegram is the trigger point for the transmission of process data from the

frequency inverters to the master and for the acceptance of process data from the

master by the slaves.

For sync-controlled process data processing, the sync telegram must be generated

accordingly.

The response to a sync telegram is determined by the transmission type selected.

Transmission type

General procedure

( 47)

1 Sync cycle time (C01121)

[8-2] Sync telegram

A. After the sync telegram has been received, the slaves send the synchronous process

data to the master (TPDOs). The master reads them as process input data.

B. When the sending process has been completed, the slaves (RPDOs) receive the process

output data (from the master).

– All other telegrams (e.g. parameters or the event-controlled process data) are

accepted acyclically by the slaves after the transmission has been completed

successfully.

– The acyclic data are not shown in figure [8-2]

cycle time is dimensioned.

C. The data in the slave is accepted with the next sync telegram if the Rx mode is set to

1 ... 240. When the Rx mode is set to 254 or 255 the data is accepted in the next device

cycle independent of the sync telegram.

SYNC SYNC

01 2

They must be considered when the

50 L EDS94AYCCA EN 5.0 - 06/2012

Page 51

8.4.1 Parameter setting

Short overview: Parameters for synchronisation via sync telegram

Parameter Information Lenze setting Assignment

C13367

C14367

C13368

C14368

C00369/1

C01120

C01121

C01122

C01123

C01124

C01130

E94AYCCA communication manual (CANopen®)

Process data transfer

Synchronisation of PDOs via sync telegram

Value Unit Sync

CAN SYNC Rx identifier 128 z

CAN SYNC Tx identifier 128 z

CAN SYNC transmit cycle time 0 ms z

Sync source Off z

Sync cycle time 1000 μs z

Sync phase position 400 μs z

Sync tolerance 0 μs z

Sync-PLL increment 109 ns z

Sync application cycle 1000 μs z

Master

Sync

Slave

Sync source

C01120

is used to select the source of the synchronisation signals. Basically, only one

source can synchronise the node.

Sync cycle time

Time with which the internal phase-locking loop (PLL) expects the synchronisation signals.

The time must be set in C01121

selected in C01120

.

in accordance with the cycle of the synchronisation source

Note!

For synchronisation via the system bus (CANopen), only integer multiples of

1000 μs should be set in C01121

Example: For the system bus (CANopen), the interval between two synchronisation signals

has been set to 2 ms. If the system bus (CANopen) is to be used as synchronisation source,

a sync cycle time of 2000 μs must be set in C01121

.

.

EDS94AYCCA EN 5.0 - 06/2012 L 51

Page 52

E94AYCCA communication manual (CANopen®)

Process data transfer

Synchronisation of PDOs via sync telegram

Sync phase position

The phase position defines the zero point of time for the application relating to the

synchronisation signal (bus cycle). Since PDO processing is integrated in the system part of

the application, the instant of the PDO acceptance also changes if the phase position is

changed.

If 0 is set, the application is started together with the synchronisation signal.

If a value > 0 is set, the application starts by the set time interval before the

synchronisation signal arrives (the phase position acts negatively).

Example: If the phase position is set to 400 μs, the system part of the application starts

400 μs before the synchronisation signal arrives.

Note!

From Servo Drive 9400 software version V3.0:

The effect of the sync phase position can be influenced by the application cycle

set in C01130

. For the Lenze setting of C01130, the behaviour remains as before.

Sync tolerance

Time slot for monitoring the synchronisation signal via the LS_SyncInput system block.

If the last synchronisation signal has been within this time slot around the expected

value, the SYNC_bSyncInsideWindow output of the LS_SyncInput system block is set to

TRUE.

This setting does not affect the synchronisation process.

Sync-PLL increment

If the cycle times of the synchronisation signal and the phase-locking loop (PLL) differ from

each other, the setting in C01124

can be readjusted.

If the system bus (CANopen) is used as synchronisation source, the recommended time

increment for deviations is 109 ns (Lenze setting).

defines the increment with which the phase-locking loop

52 L EDS94AYCCA EN 5.0 - 06/2012

Page 53

Sync application cycle

E94AYCCA communication manual (CANopen®)

Process data transfer

Synchronisation of PDOs via sync telegram

This parameter influences the effect of the sync phase position (C01122

instant of acceptance of the synchronous PDOs by the application or the instant of

transmission of the synchronous PDOs to the system bus (CANopen).

For Servo Drive 9400 software versions lower than V3.0 the following applies:

The sync application cycle is permanently set to 1000 μs.

The resulting PDO delay can be calculated with the following formula taking into

consideration an internal processing time of 150 s: