Page 1

EDS82ZAFPC010

.IFJ

Ä.IFJä

L−force Communication

Communication Manual

PROFIBUS−DP

E82ZAFPC001 / E82ZAFPC010

Function module

Page 2

Contentsi

1 About this documentation 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Terminology used 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Notes used 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Safety instructions 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General safety information 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Device− and application−specific safety instructions 8 . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Residual hazards 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Product description 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Application as directed 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Identification 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Product features 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Connections and interfaces 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Technical data 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 General data 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Operating conditions 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Protective insulation 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Connection terminals 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Communication time 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Dimensions 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Installation 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Mechanical installation 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Electrical installation 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Wiring according to EMC (CE−typical drive system) 19 . . . . . . . . . . . . . . . . .

5.2.2 Wiring with a host (master) 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Voltage supply 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Terminal assignment 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Cable cross−sections and screw−tightening torques 28 . . . . . . . . . . . . . . . . .

5.2.6 Use of plug connectors 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Bus cable length 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

EDS82ZAFPC010 EN 4.0

Page 3

Contents i

6 Commissioning 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Before switching on 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Commissioning steps 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Configuring the host system (master) 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Adapting device controls 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Defining the user data length 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Activating the bus terminating resistor 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Setting the node address 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 Connecting the mains voltage 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Process data transfer 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Lenze device control 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Process output data configuration 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Process input data configuration 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 DRIVECOM control 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 DRIVECOM state machine 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 DRIVECOM control word 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 DRIVECOM status word 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 Bit control commands 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.5 Status bits 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Parameter data transfer 54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 DRIVECOM parameter data channel 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Addressing of the parameter data 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Addressing of the Lenze parameters 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 Telegram structure 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.4 Error codes (DRIVECOM) 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.5 Reading parameters 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.6 Writing parameters 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Parameter set transfer 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Diagnostics 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 LED status displays 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Troubleshooting and fault elimination 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Codes 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Overview 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Communication−relevant Lenze codes 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 Monitoring codes 73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.4 Diagnostics codes 75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.5 Important controller codes 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDS82ZAFPC010 EN 4.0

3

Page 4

Contentsi

11 Appendix 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Particularities for use in conjunction with Lenze standard devices 84 . . . . . . . . . . . .

11.2 Consistent parameter data 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 Parallel operation of AIF and FIF interfaces 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 Index 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

EDS82ZAFPC010 EN 4.0

Page 5

0Fig. 0Tab. 0

1 About this documentation

Contents

This documentation exclusively contains descriptions of the function modules

E82ZAFPC001 (PROFIBUS−DP) and E82ZAFPC010 (PROFIBUS−DP PT).

Note!

This documentation supplements the mounting instructions supplied with the

function module and the documentation for the standard devices used.

The mounting instructions contain safety instructions which must be

observed!

ƒ The features and functions of the function module are described in detail.

ƒ Typical applications are explained by means of examples.

ƒ Moreover, this documentation contains the following:

– Safety instructions which must be observed.

– The essential technical data of the function module

– Information on versions of the Lenze standard devices to be used

– Notes on troubleshooting and fault elimination

About this documentation 1

The theoretical concepts are only explained to the level of detail required to understand

the function of the function module.

Depending on the software version of the controller and the version of the »Engineer«

software installed, the screenshots in this documentation may deviate from the

»Engineer« representation.

This documentation does not describe any software provided by other manufacturers. No

liability can be accepted for corresponding data provided in this documentation. For

information on how to use the software, please refer to the host system (master)

documents.

All brand names mentioned in this documentation are trademarks of their respective

owners.

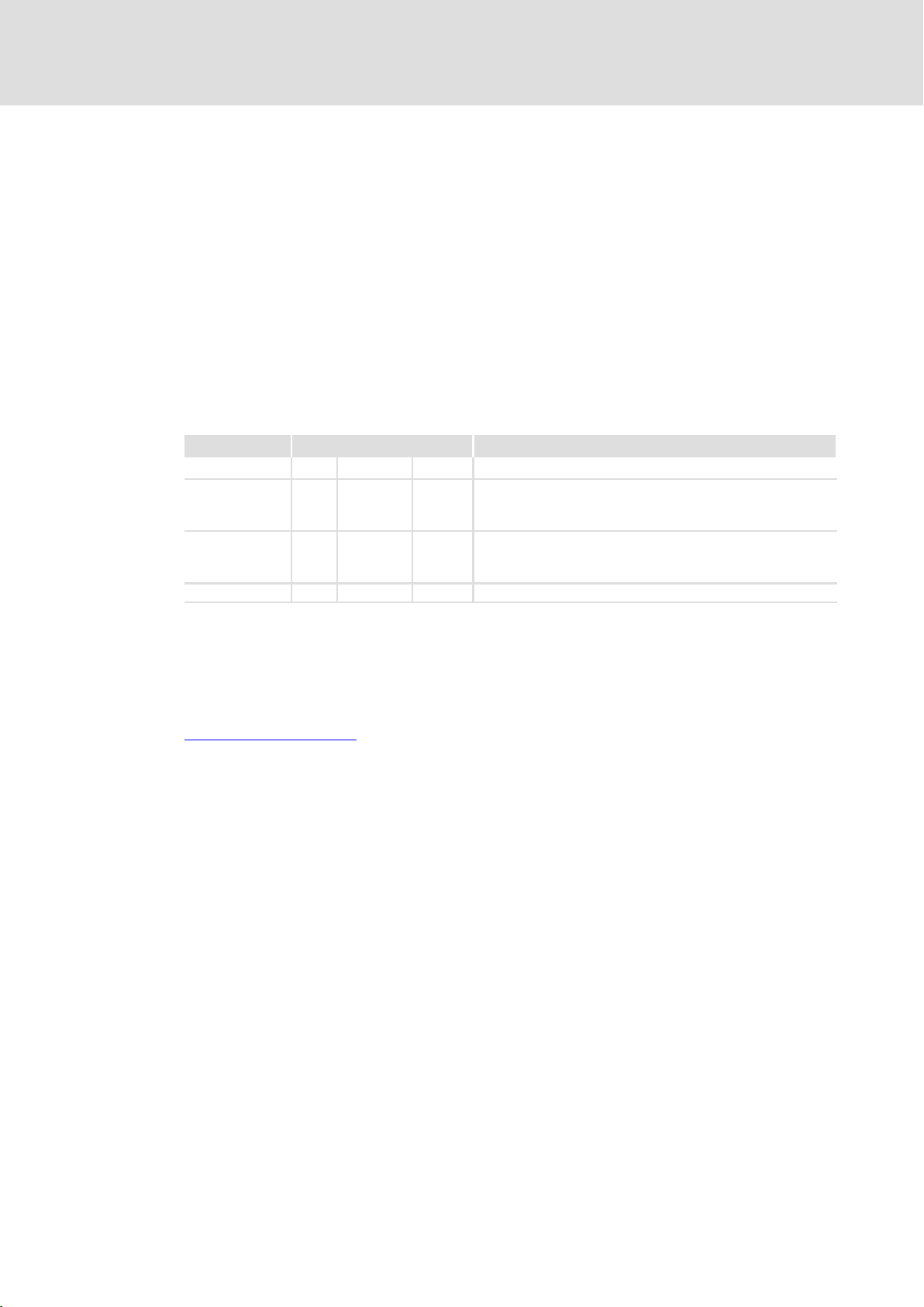

Validity information

The information given in this documentation is valid for the following devices:

Function module Type designation From hardware version From software version

PROFIBUS−DP E82ZAFPC001 3A 10

PROFIBUS−DP PT E82ZAFPC010 3A 10

EDS82ZAFPC010 EN 4.0

5

Page 6

1

About this documentation

Document history

Target group

This documentation is intended for all persons who plan, install, commission and maintain

the networking and remote service of a machine.

Tip!

Information and auxiliary devices related to the Lenze products can be found

in the download area at

http://www.Lenze.com

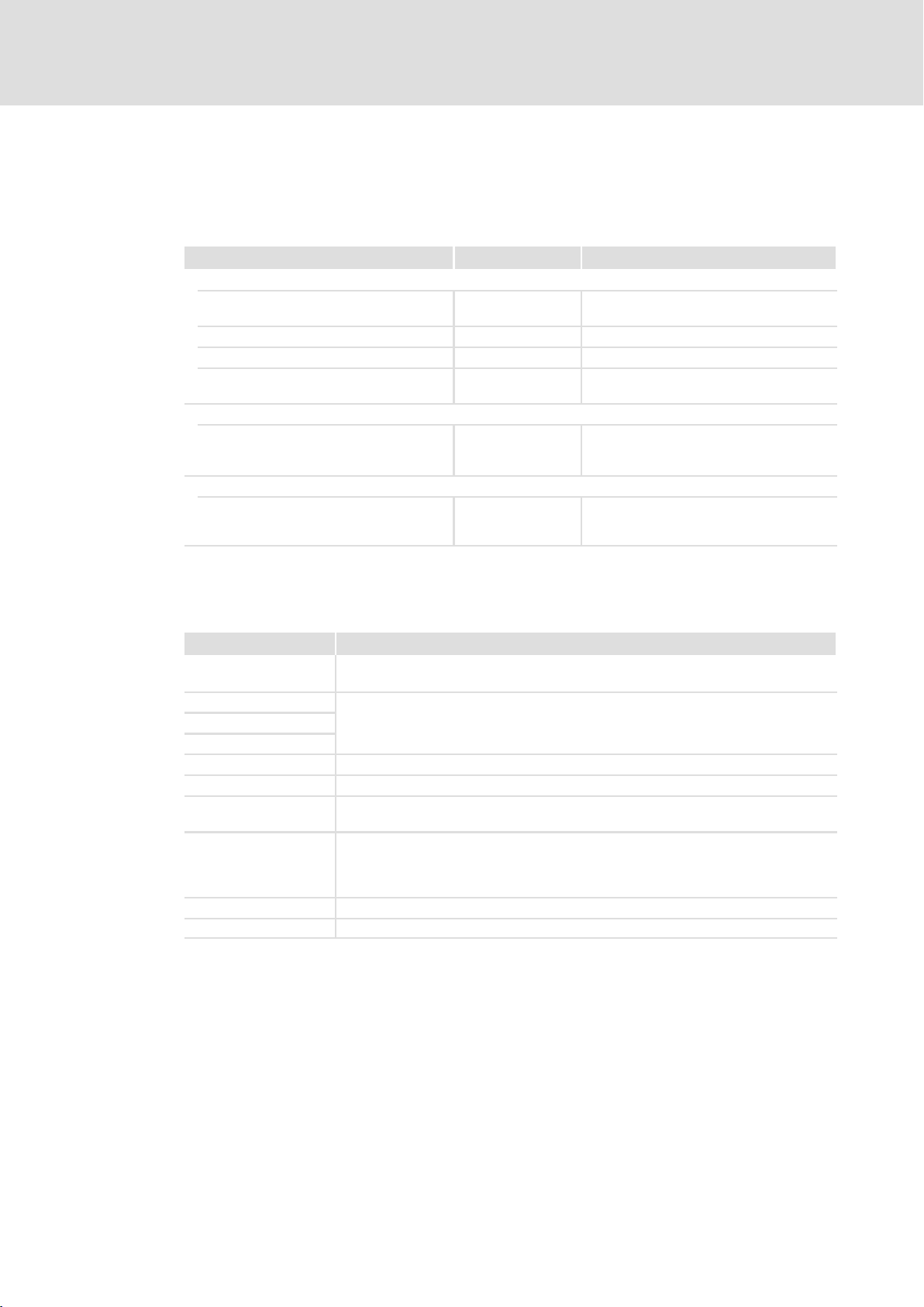

1.1 Document history

Material no. Version Description

− 1.0 11/2001 TD06 First edition

− 2.0 06/2004 TD06 Complete revision due to

− 3.0 03/2005 TD06 General revision

.IFJ 4.0 03/2012 TD29 General revision

l Layout change

l New German orthography

l Load capacity of terminal 20

l Structural and editorial adjustments

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e−mail us to:

feedback−docu@Lenze.de

Thank you for your support.

Your Lenze documentation team

6

EDS82ZAFPC010 EN 4.0

Page 7

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Decimal Standard notation For example: 1234

Hexadecimal 0x[0 ... 9, A ... F] For example: 0x60F4

Binary

l Nibble

Text

Program name » « PC software

Icons

Page reference Reference to another page with additional

About this documentation

Conventions used

Point In general, the decimal point is used.

For instance: 1234.56

In quotation marks

Point

For example: ´100´

For example: ´0110.0100´

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: 16 = see page 16

1

1.3 Terminology used

Term Meaning

PROFIBUS The term stands for the PROFIBUS−DP variant according to IEC 61158/IEC 61784. A

Standard device

Controller

Frequency inverter

Master PROFIBUS station which takes over the master function in the fieldbus system.

Slave PROFIBUS station which acts as a slave in the fieldbus system.

Code "Container" for one or more parameters which can be used to parameterise or

Subcode If a code contains more than one parameter, these parameters are stored in

POW Process output data word

PIW Process input data word

different PROFIBUS variant is not described in this manual.

Lenze controllers/frequency inverters for which the function module can be used.

11

monitor the controller.

"subcodes".

In this documentation, a slash "/" is used as a separator when specifying a code and

its subcode (e.g. "C00118/3").

EDS82ZAFPC010 EN 4.0

7

Page 8

1

1.4 Notes used

About this documentation

Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Application notes

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Pictograph and signal word Meaning

Note!

Tip!

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

8

EDS82ZAFPC010 EN 4.0

Page 9

2 Safety instructions

Note!

It is absolutely vital that the stated safety measures are implemented in order

to prevent serious injury to persons and damage to material assets.

Always keep this documentation to hand in the vicinity of the product during

operation.

2.1 General safety information

Danger!

Disregarding the following basic safety measures may lead to severe personal

injury and damage to material assets!

Safety instructions

General safety information

2

ƒ Lenze drive and automation components ...

... must only be used for the intended purpose.

... must never be operated if damaged.

... must never be subjected to technical modifications.

... must never be operated unless completely assembled.

... must never be operated without the covers/guards.

... can − depending on their degree of protection − have live, movable or rotating parts

during or after operation. Surfaces can be hot.

ƒ All specifications of the corresponding enclosed documentation must be observed.

This is vital for a safe and trouble−free operation and for achieving the specified product

features.

The procedural notes and circuit details provided in this document are proposals which

the user must check for suitability for his application. The manufacturer does not

accept any liability for the suitability of the specified procedures and circuit proposals.

ƒ Only qualified skilled personnel are permitted to work with or on Lenze drive and

automation components.

According to IEC 60364 or CENELEC HD 384, these are persons ...

... who are familiar with the installation, assembly, commissioning and operation of

the product,

... possess the appropriate qualifications for their work,

... and are acquainted with and can apply all the accident prevent regulations, directives

and laws applicable at the place of use.

EDS82ZAFPC010 EN 4.0

9

Page 10

2

2.2 Device− and application−specific safety instructions

Safety instructions

Device− and application−specific safety instructions

ƒ During operation, the function module must be firmly connected to the standard

device.

ƒ With external voltage supply, always use a separate power supply unit, safely

separated to EN 61800−5−1 ("SELV"/"PELV"), in every control cabinet.

ƒ Only use cables corresponding to the given specifications ( 24).

Documentation for the standard device, control system, system/machine

All other measures prescribed in this documentation must also be

implemented. Observe the safety instructions and application notes stated in

the documentation.

2.3 Residual hazards

Protection of persons

ƒ If the controllers are used on a phase earthed mains with a rated mains voltage

³ 400 V, protection against accidental contact is not ensured without implementing

external measures. (See chapter "4.3", 16)

Device protection

ƒ The module contains electronic components that can be damaged or destroyed by

electrostatic discharge.

10

EDS82ZAFPC010 EN 4.0

Page 11

3 Product description

3.1 Application as directed

The E82ZAFPC001 function module ...

ƒ is an accessory module for use in conjunction with the following Lenze standard

devices:

Product range Device designation From hardware version

Frequency inverter

Motor starter starttec Vx1x

ƒ is a device intended for use in industrial power systems.

Any other use shall be deemed inappropriate!

Product description

Application as directed

8200 vector

8200 motec Vx14

Vx14

3

The E82ZAFPC010 function module ...

ƒ is an accessory module for use in conjunction with the following Lenze standard

devices:

Product range Device designation From hardware version

Frequency inverter 8200 vector Vx14

ƒ is a device intended for use in industrial power systems.

Any other use shall be deemed inappropriate!

EDS82ZAFPC010 EN 4.0

11

Page 12

3

APPLICATION

010 / 3A22

Product description

Identification

3.2 Identification

APPLICATION

010/ 3A22

Type code E82ZAF P C 0xx 3A 10

Device type

PROFIBUS−DP

Version

Variant

001: Coated design

010: PT design

Hardware version

Software version

L

Type

Id.-No.

Prod.-No.

Ser.-No.

E82AF000P0B201XX

E82ZAFX005

12

EDS82ZAFPC010 EN 4.0

Page 13

3.3 Product features

ƒ Interface module for the PROFIBUS communication system which can be connected

to the AIF slots of the Lenze 8200 vector, 8200 motec and starttec device series.

ƒ Support of the PROFIBUS−DP−V0 communication profile

ƒ Drive profile:

– DRIVECOM profile "Drive technology 20" (can be switched off)

ƒ Support of I&M0 functionality for standard device identification

ƒ Automatic detection of the baud rate (9.6 kbps ... 12 Mbps)

ƒ External 24V supply for maintaining the PROFIBUS network when the standard

device fails

ƒ DIP switch for activating the bus terminating resistor

ƒ LED status displays:

– Voltage supply for function module

– Connection between the function module and the PROFIBUS network

– Connection between the function module and the standard device

Product description

Product features

3

EDS82ZAFPC010 EN 4.0

13

Page 14

3

Product description

Connections and interfaces

3.4 Connections and interfaces

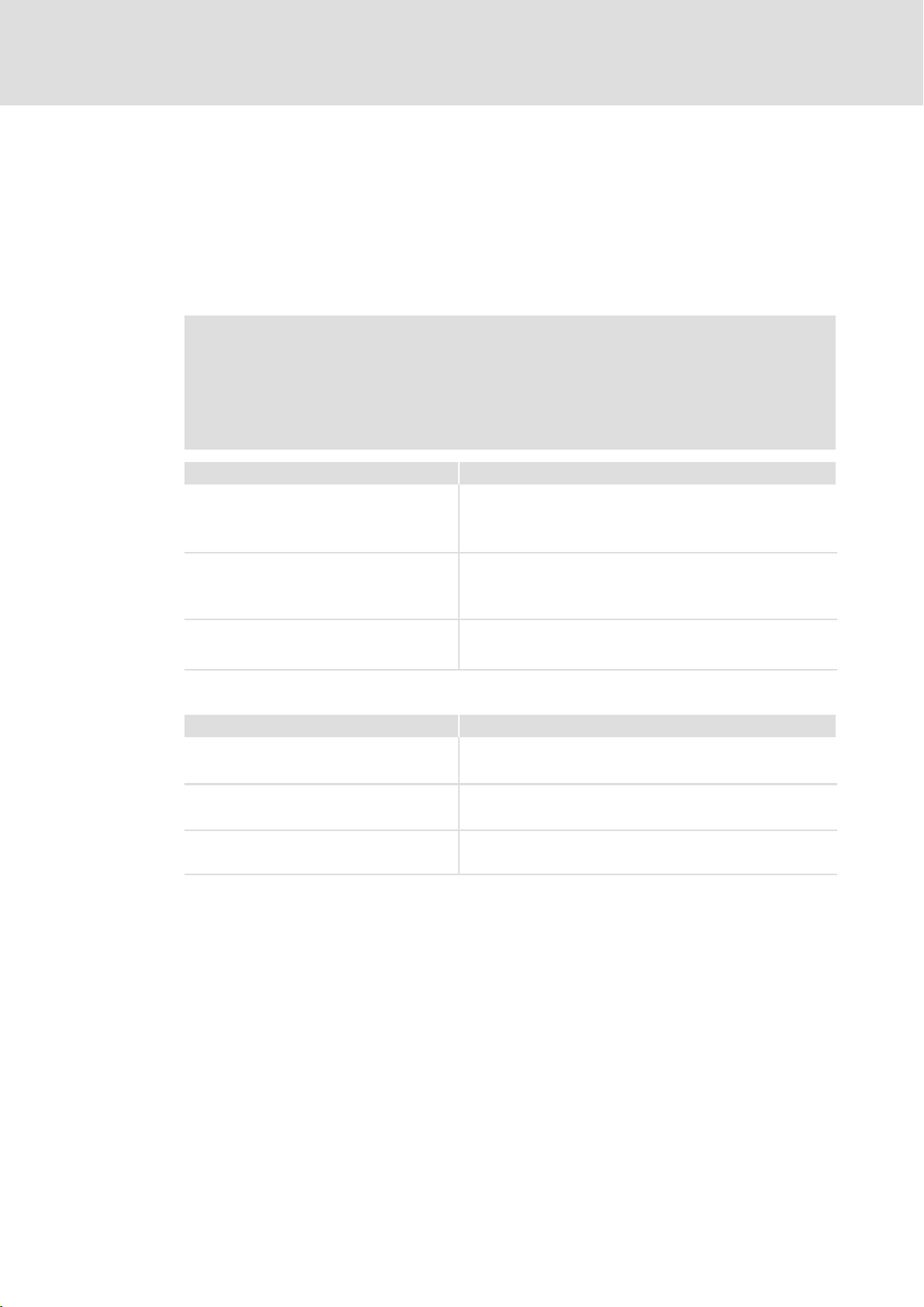

E82ZAFPC001function module

E82ZAFPC001

0

ON

2

1

AABB

CN

+

VP

7

40 39 28 20 59

3

4

7

E82ZAFP004/AFX009

Pos. Description Detailed

DIP switch for activating the bus terminating resistor 40

Status of PROFIBUS communication (yellow LED)

Connection status to the standard device (green LED)

Terminal strip X3, connection for

l PROFIBUS

l Controller inhibit (CINH)

l External voltage supply

Nameplate 12

information

67

28

E82ZAFPC010 function module

E82ZAFPC010

3

1

2

0

4

6

5

E82ZAFP012/E82ZAFX015

14

Pos. Description Detailed

DIP switch for activating the bus terminating resistor 40

Status of PROFIBUS communication (yellow LED)

Connection status to the standard device (green LED)

Plug connector X3.1, connection for PROFIBUS

Plug connector X3.2, connection for external voltage supply

Plug connector X3.3, connection for controller inhibit (CINH)

Nameplate 12

information

67

29

EDS82ZAFPC010 EN 4.0

Page 15

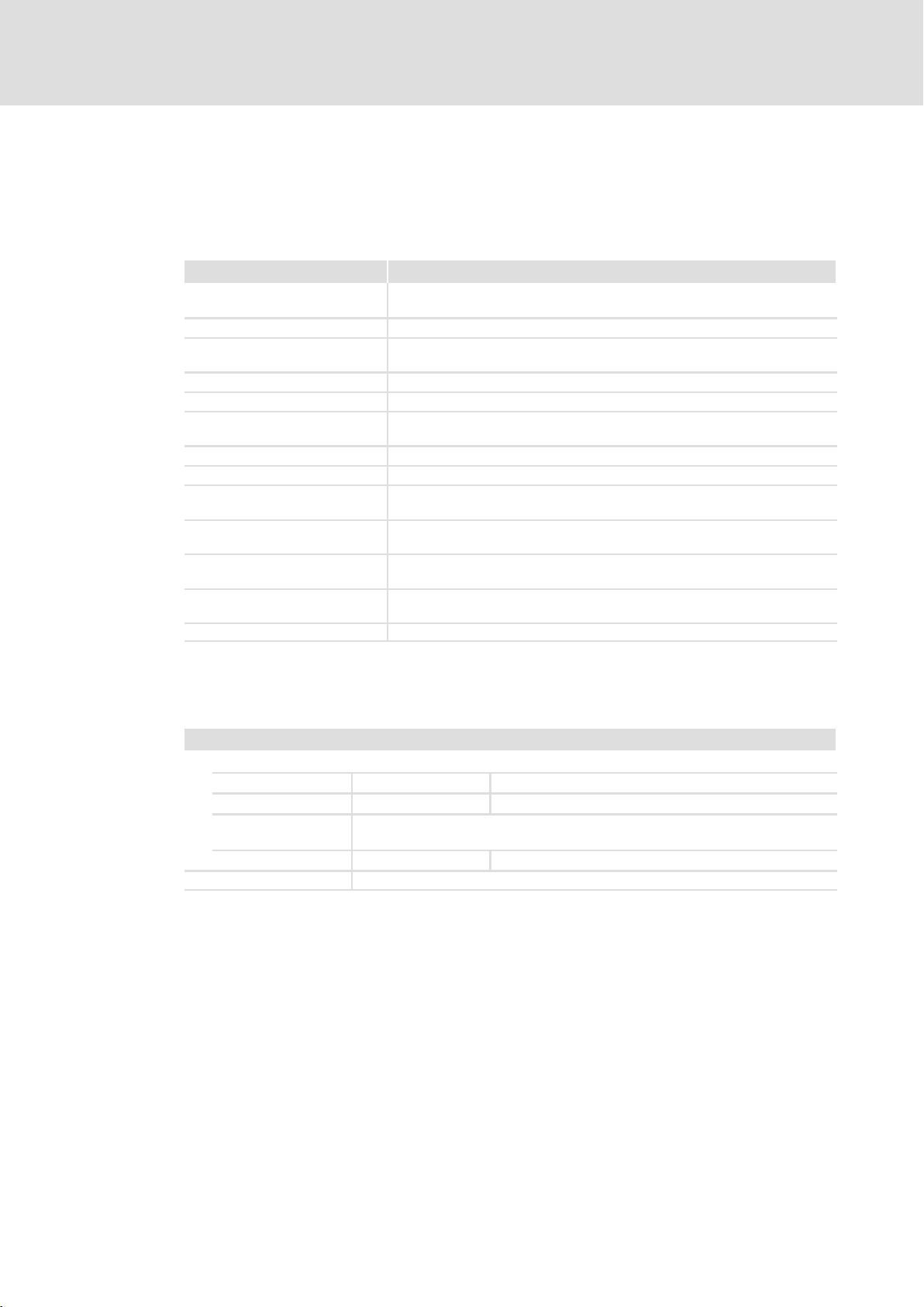

4 Technical data

4.1 General data

Field Values

Order designation E82ZAFPC001 (coated)

PUO ID number 0x00DA

Communication profile

(DIN 19245 Part 1 and Part3)

Communication medium RS485

Drive profile l DRIVECOM profile "Drive technology 20" (can be switched off)

Network topology l Without repeaters: line

PROFIBUS stations Slave

Baud rate [kbps] 9.6 ... 12000 (automatic detection)

Process data words 1 ... 10 words

DP user data length 1 ... 10 process data words +

Max. number of bus devices l Standard: 32 (= 1 bus segment)

Max. cable length per bus

segment

External DC−voltage supply +24 V DC ±10 %, max. 80 mA

Technical data

General data

E82ZAFPC010 (PT design)

l PROFIBUS−DP−V0

l With repeaters: line or tree

(16 bits/word)

4 parameter data words

l With repeaters: 125

1200 m (depending on the baud rate and cable type used)

4

4.2 Operating conditions

Ambient conditions

Climate

Storage

Transport IEC/EN 60721−3−2 2K3 (−25 to +70 °C)

Operation Corresponding to the data of the Lenze standard device used (see documentation

Pollution EN 61800−5−1 Degree of pollution 2

Degree of protection IP20 (protection against accidental contact according to NEMA 250 type 1)

IEC/EN 60721−3−1 1K3 (−25 to +60 °C)

of the standard device).

EDS82ZAFPC010 EN 4.0

15

Page 16

4

Technical data

Protective insulation

4.3 Protective insulation

Danger!

Dangerous electrical voltage

If Lenze controllers are used on a phase earthed mains with a rated mains

voltage ³ 400 V, protection against accidental contact is not ensured without

implementing external measures.

Possible consequences:

ƒ Death or serious injury

Protective measures:

ƒ If protection against accidental contact is required for the control terminals

of the controller and the connections of the plugged device modules, ...

– a double isolating distance must exist.

– the components to be connected must be provided with the second

E82ZAFPC001function module

Protective insulation between bus and ... Type of insulation (according to EN 61800−5−1)

l Power section

– 8200 vector Reinforced insulation

– 8200 motec Reinforced insulation

– starttec Reinforced insulation

l Reference earth / PE (X3/7) Functional insulation

l External supply (X3/59) Functional insulation

l Terminal X3/20 Functional insulation

l Terminal X3/28 Functional insulation

isolating distance.

E82ZAFPC010 function module

Insulation between bus and ... Type of insulation (in accordance with EN 61800−5−1)

l 8200 vector power stage Reinforced insulation

l Reference earth / PE (X3.2/7, X3.3/7) Functional insulation

l External supply (X3.2/59) Functional insulation

l Supply for CINH (X3.3/20) Functional insulation

l Controller inhibit, CINH (X3.3/28) Functional insulation

16

EDS82ZAFPC010 EN 4.0

Page 17

Technical data

Connection terminals

4

4.4 Connection terminals

E82ZAFPC001function module

Terminal strip X3/

VP Level: 5 V (reference: GND3)

28 External supply of terminal with

20 DC voltage source for internal supply of controller inhibit (CINH)

59 External supply of function module with

E82ZAFPC010 function module

Terminal strip X3.2/

59

Terminal strip X3.3/

28 External supply of terminal with

20

Load capacity: I

U(ext.) = +12 V DC − 0% ... +30 V DC + 0%

U = + 20 V (reference: GND1),

= 20 mA

I

max

U(ext.) = +24 V DC ± 10%

External supply of function module with

U(ext.) = +24 V DC ± 10%

U(ext.) = +12 V DC − 0% ... +30 V DC + 0%

DC voltage source for internal supply of controller inhibit (CINH)

U = + 20 V (reference: GND1)

Load capacity: I

max

max

= 10 mA

= 20 mA

EDS82ZAFPC010 EN 4.0

17

Page 18

4

Technical data

Communication time

4.5 Communication time

The communication time is the time between the start of a request and the arrival of the

corresponding response.

The communication times depend on ...

ƒ the processing time in the controller

ƒ the transmission delay time

– the baud rate

– the telegram length

Processing time 8200vector / 8200motec / starttec

There are no interdependencies between parameter data and process data.

ƒ Parameter data: approx. 30 ms + 20 ms tolerance

ƒ Process data: approx. 3 ms + 2 ms tolerance

18

EDS82ZAFPC010 EN 4.0

Page 19

Technical data

Dimensions

4

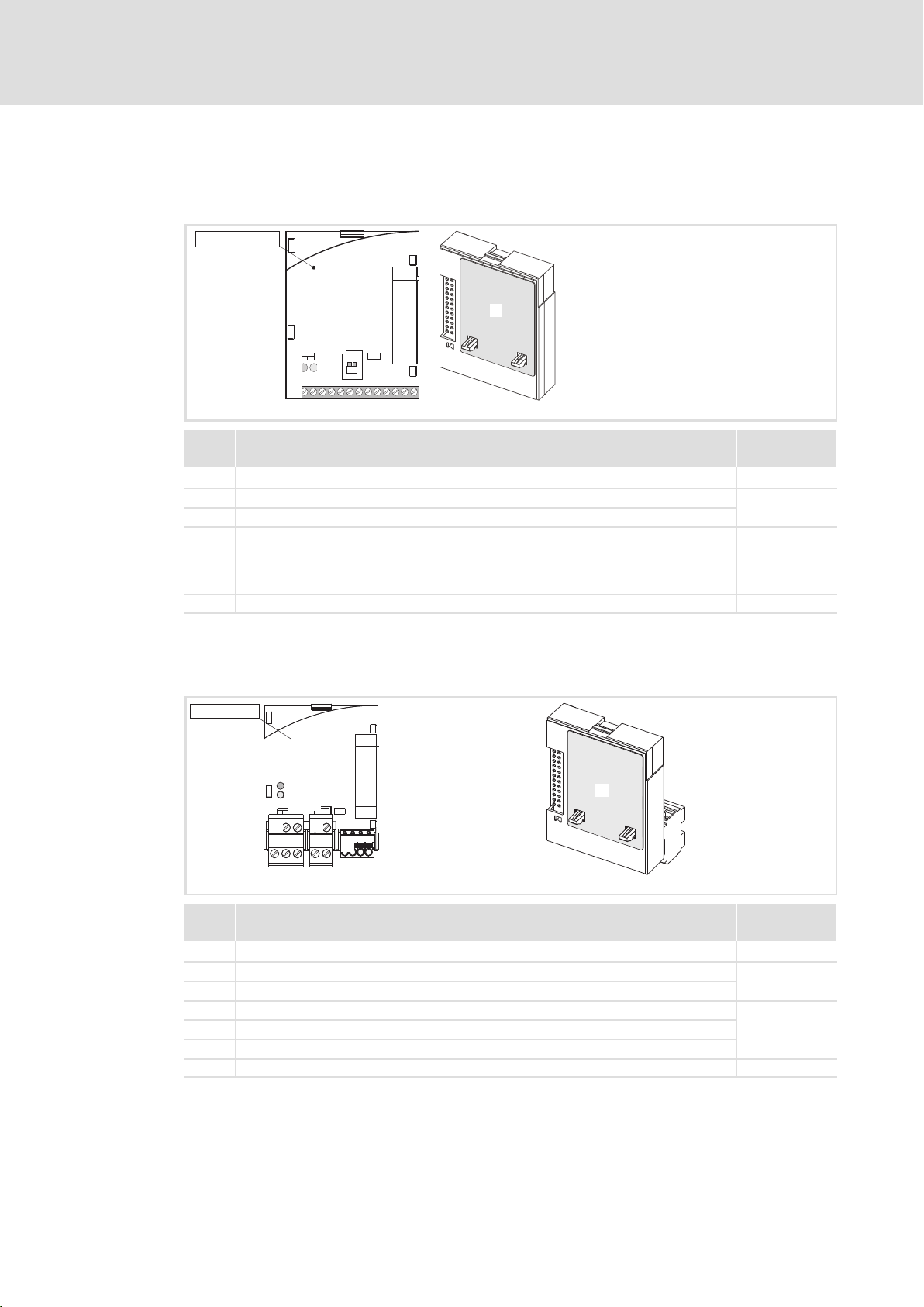

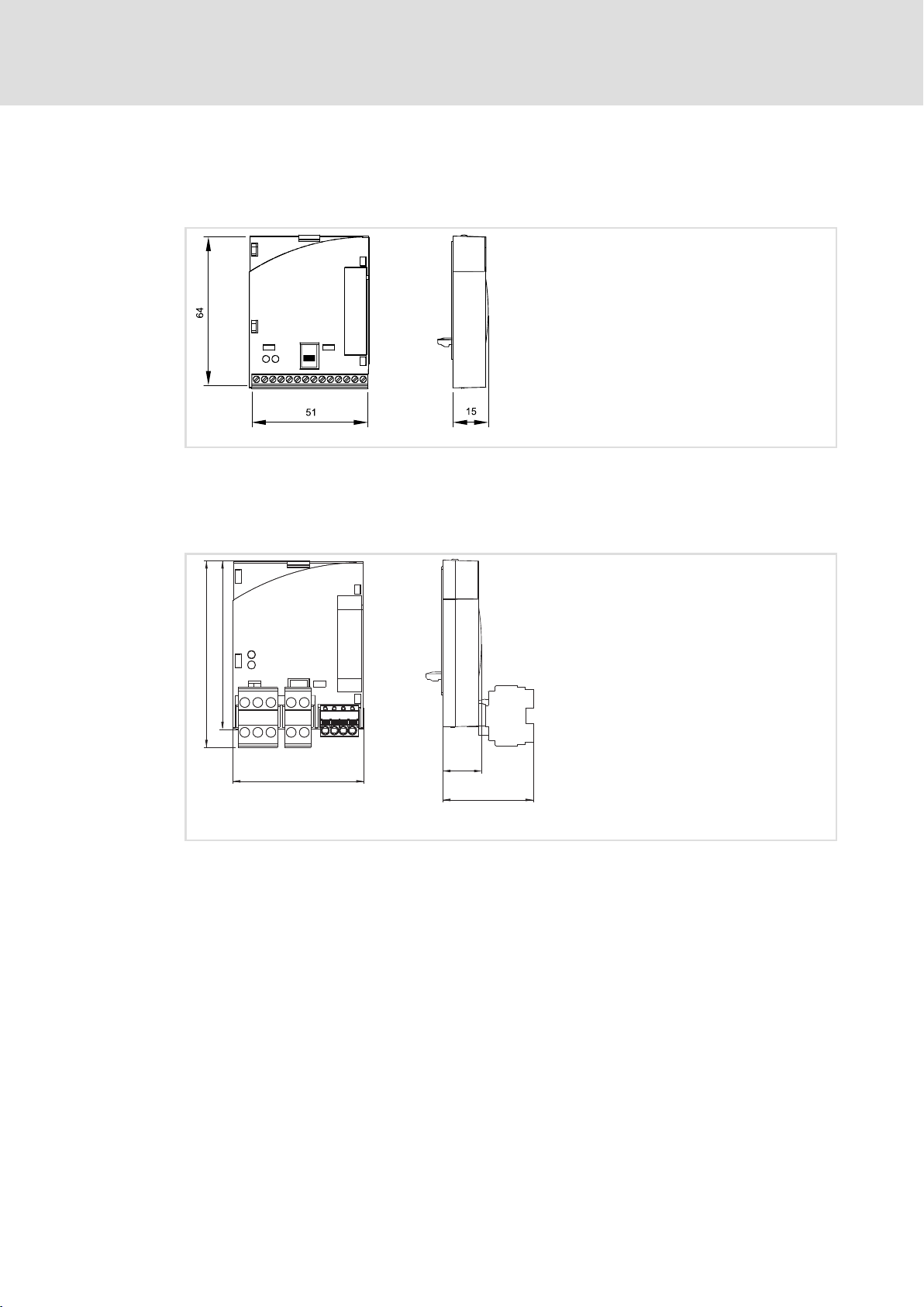

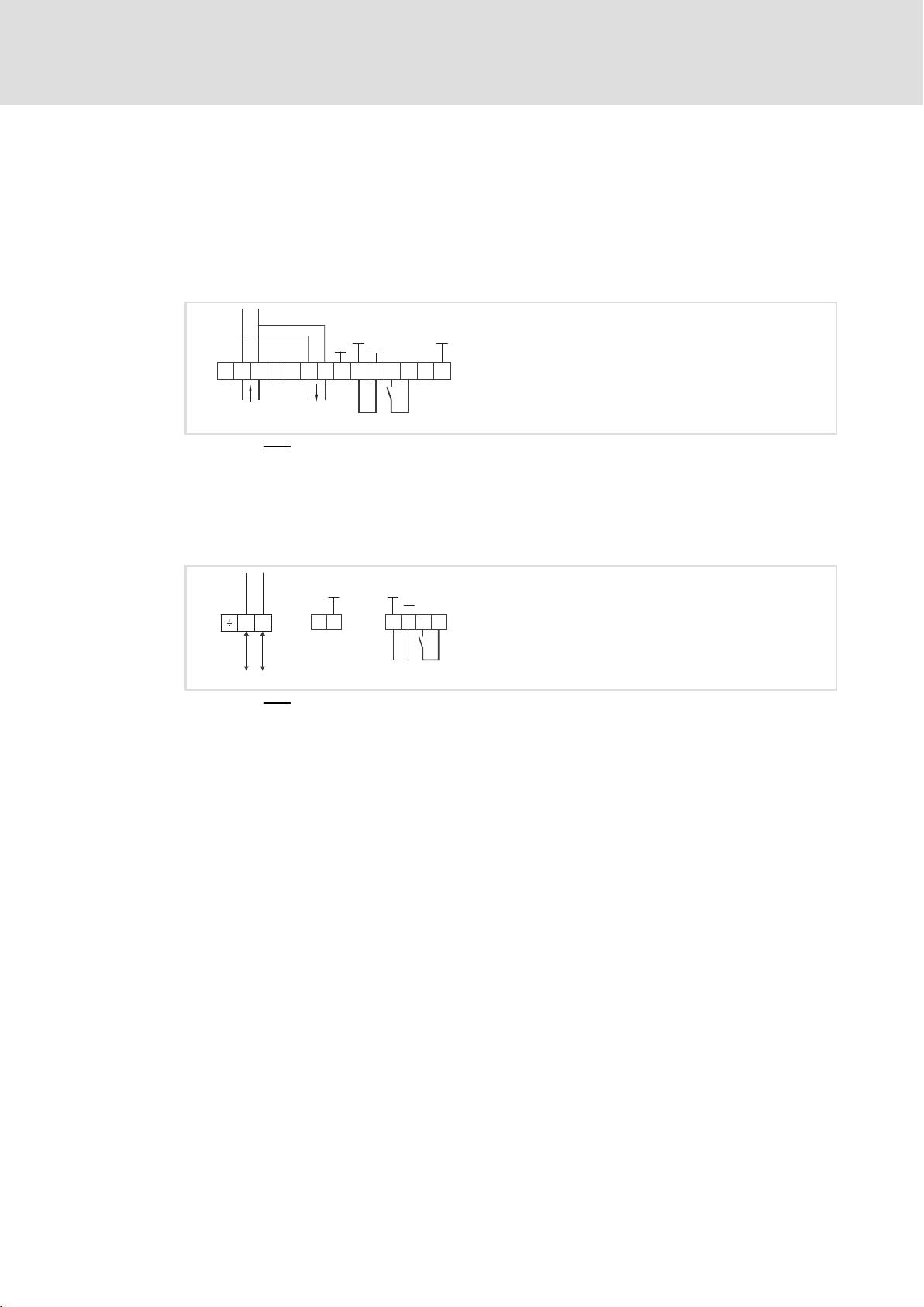

4.6 Dimensions

E82ZAFPC001function module

E82ZAFPC010 function module

E82ZAFL011B

All dimensions in mm

72

64

51

All dimensions in mm

15

30

E82ZAFP007

EDS82ZAFPC010 EN 4.0

19

Page 20

5

Installation

Mechanical installation

5 Installation

Danger!

Inappropriate handling of the function module and the standard device can

cause serious injuries to persons and damage to material assets.

Observe the safety instructions and residual hazards included in the

documentation of the standard device.

Stop!

The device contains components that can be destroyed by electrostatic

discharge!

Before working on the device, the personnel must ensure that they are free of

electrostatic charge by using appropriate measures.

5.1 Mechanical installation

Follow the notes given in the Mounting Instructions for the standard device for the

mechanical installation of the function module.

The Mounting Instructions for the standard device ...

ƒ are part of the scope of supply and are enclosed with each device.

ƒ provide tips to avoid damage provide tips to avoid damage through improper

handling.

ƒ describe the obligatory order of installation steps.

20

EDS82ZAFPC010 EN 4.0

Page 21

Wiring according to EMC (CE−typical drive system)

5.2 Electrical installation

5.2.1 Wiring according to EMC (CE−typical drive system)

For wiring according to EMC requirements observe the following points:

Note!

ƒ Separate control cables/data lines from motor cables.

ƒ Connect the shields of control cables/data lines at both ends in the case of

digital signals.

ƒ Use an equalizing conductor with a cross−section of at least 16mm

(reference:PE) to avoid potential differences between the bus nodes.

ƒ Observe the other notes concerning EMC−compliant wiring given in the

documentation for the standard device.

Wiring procedure

Installation

Electrical installation

5

2

1. Observe the bus topology, do not use any stubs.

2. Observe the notes and wiring instructions given in the documents for the control

system.

3. Only use cables corresponding to the listed specifications ( 24).

4. Observe the notes for the voltage supply of the module ( 25).

5. Activate the bus terminating resistors on the first and last physical bus device

( 40).

EDS82ZAFPC010 EN 4.0

21

Page 22

5

Installation

Electrical installation

Wiring with a host (master)

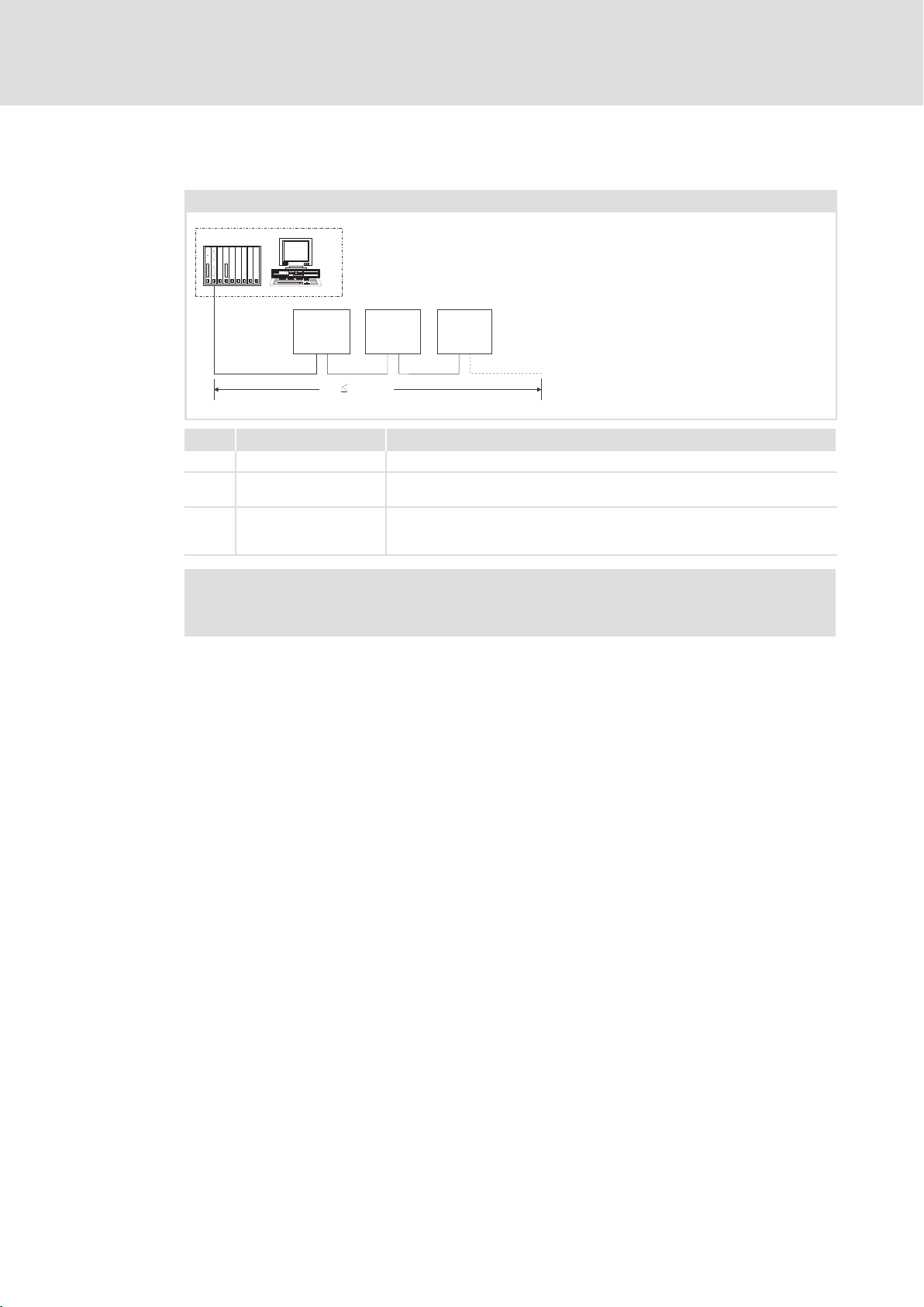

5.2.2 Wiring with a host (master)

Basic design of a PROFIBUS network with RS485 cabling without repeater

1

333

starttec

8200 vector

8200 motec

+

E82ZAFPC0xx

222

No. Element Note

1 Host E.g. PC or PLC with PROFIBUS master interface module

2 Bus cable Connects the PROFIBUS master interface module to the function modules.

3 PROFIBUS slave Applicable standard device ( 11)with function module

1200 m

0m

8200 vector

8200 motec

E82ZAFPC0xx

starttec

+

l The baud rate depends on the length of the bus cable ( 24).

l Activate bus terminating resistors at the first and last physical node

starttec

8200 vector

8200 motec

+

E82ZAFPC0xx

( 40).

E82ZAFP005

Note!

When using a repeater, max. 125 nodes can communicate via the PROFIBUS.

22

EDS82ZAFPC010 EN 4.0

Page 23

Installation

Electrical installation

Wiring with a host (master)

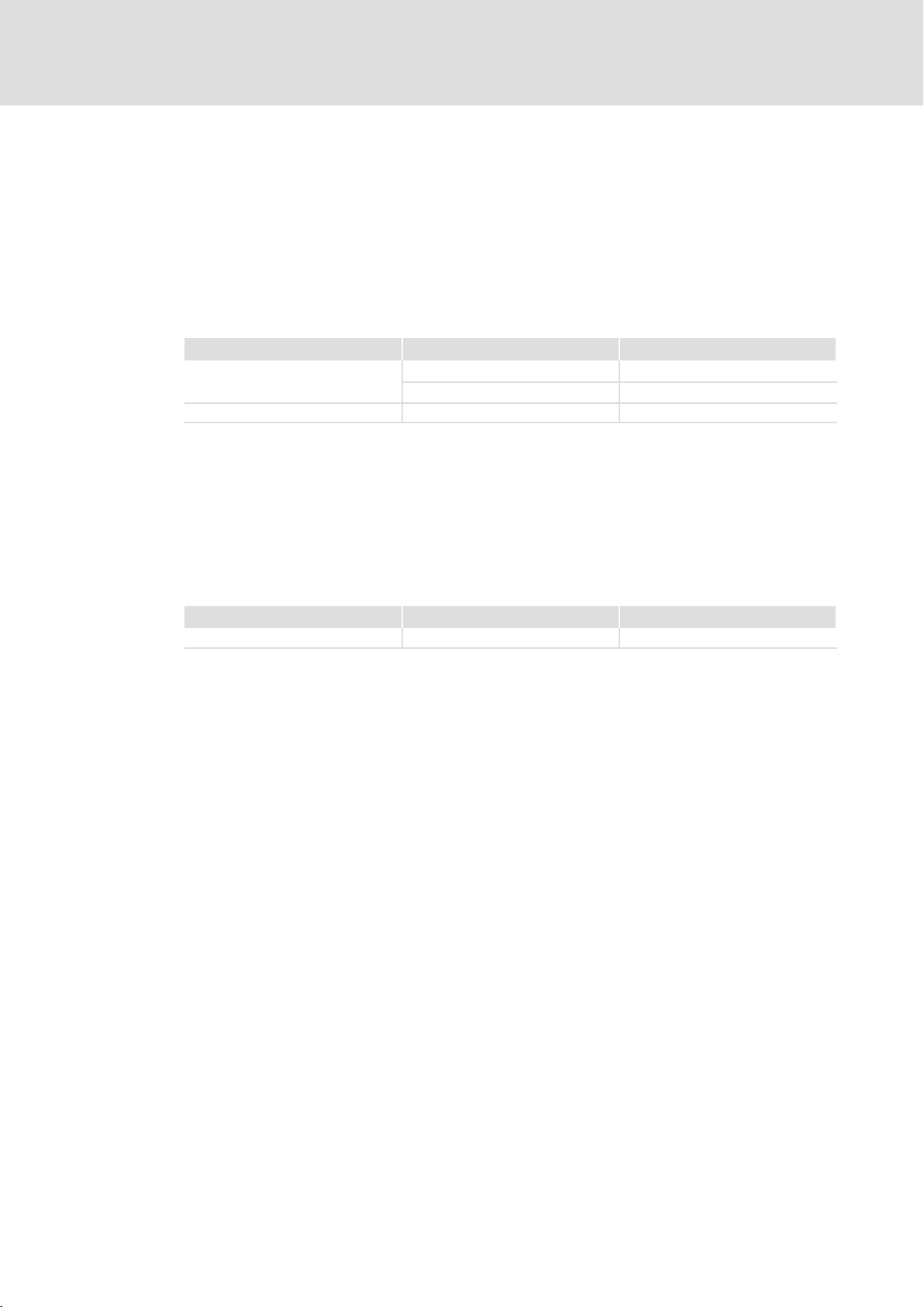

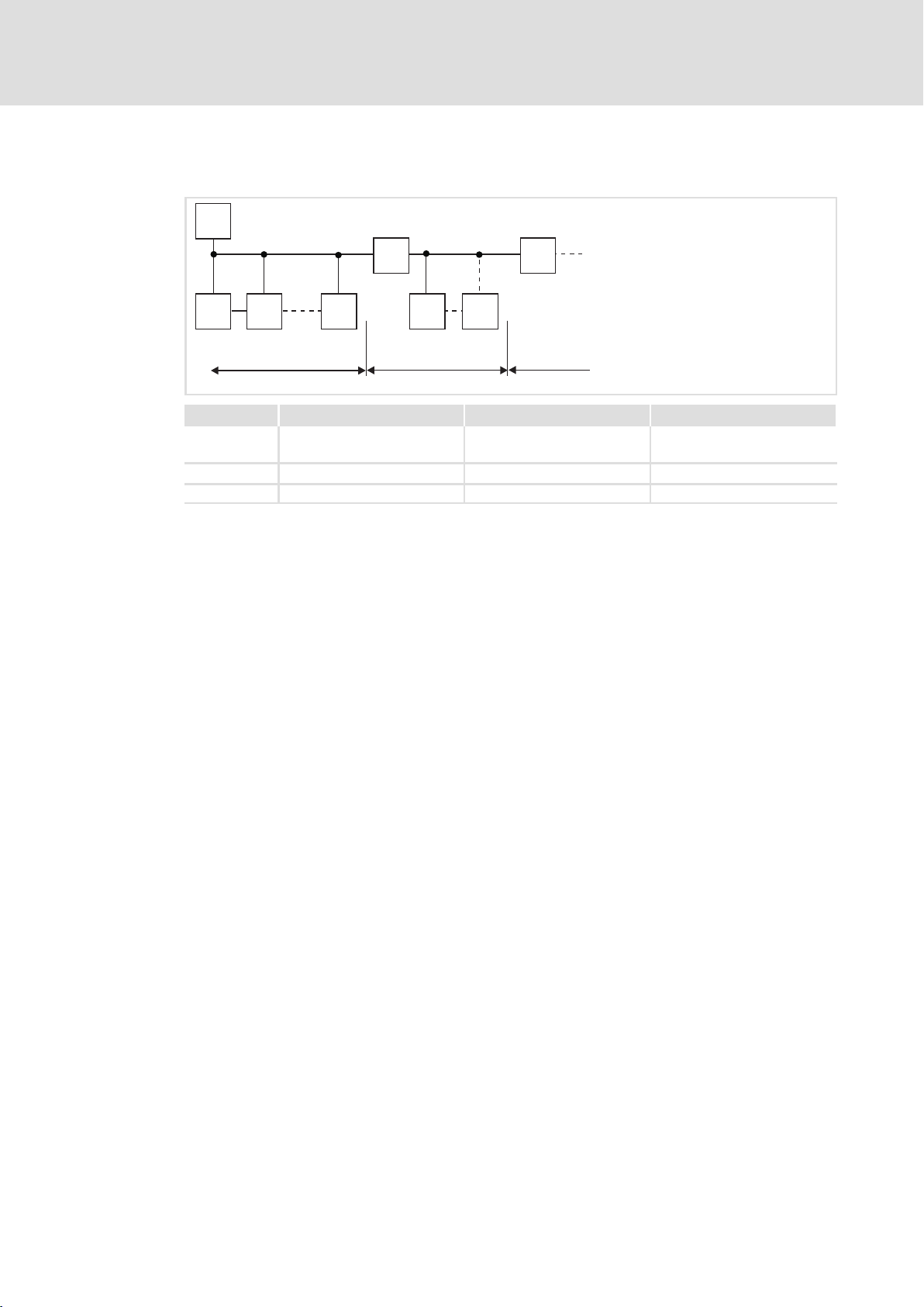

Number of bus devices

M

RR

SS S S S

123

Segment Master (M) Slave (S) Repeater (R)

11231

30

2 − 30 1

3 − 30 1

−

−

5

2133PFB004

Tip!

Repeaters do not have a device address. When calculating the maximum

number of bus devices, they reduce the number of devices by 1 on each side of

the segment.

Repeaters can be used to build up line and tree topologies. The maximum total

bus system expansion depends on ...

ƒ the baud rate used;

ƒ the number of repeaters used.

EDS82ZAFPC010 EN 4.0

23

Page 24

5

Installation

Electrical installation

Wiring with a host (master)

Specification of the transmission cable

Note!

Only use cables complying with the listed specifications of the PROFIBUS user

organisation.

Field Values

Specific resistance 135 ... 165 W/km, (f = 3 ... 20 MHz)

Capacitance per unit length £ 30 nF/km

Loop resistance < 110 W/km

Core diameter > 0.64 mm

Core cross−section > 0.34 mm

Cores Twisted double, insulated and shielded

2

Bus cable length

The length of the bus cable depends on the baud rate used:

Baud rate [kbps] Length [m]

9.6 ... 93.75 1200

187.5 1000

500 400

1500 200

3000 ... 12000 100

Note!

The baud rate depending on the data volume, cycle time, and number of nodes

should only be selected as high as required for the application.

Tip!

For high baud rates we recommend to consider the use of optical fibres.

Advantages of optical fibres:

ƒ On the transmission path external electromagnetic interference remains

ineffective.

ƒ Bus lengths of several kilometres are also possible with higher baud rates.

The bus length

– is irrespective of the baud rate.

– depends on the optical fibre used.

24

EDS82ZAFPC010 EN 4.0

Page 25

Installation

Electrical installation

Voltage supply

5

5.2.3 Voltage supply

Internal DC voltage supply

E82ZAFPC001function module

The internal voltage is provided at terminal X3/20. It serves to supply the controller inhibit

(CINH).

+5V

B

AVP

+

X3

T/R(A) T/R(B) T/R(A) T/R(B)

CN

E82ZAFPC010 function module

The internal voltage is provided at terminal X3.3/20. It serves to supply the controller

inhibit (CINH).

T/R(A) T/R(B)

A

X3.1 X3.2

B

GND1

+20V

7

20 59

2839

BA

GND3

40

GND1

7

GND2

The min. wiring requirements for operation

GND1

720

59

X3.3

GND1

GND2

+20V

28397

E82ZAFP001

T/R(A) T/R(B)

E82ZAFP011

The min. wiring requirements for operation

EDS82ZAFPC010 EN 4.0

25

Page 26

5

Installation

Electrical installation

Voltage supply

External voltage supply

Note!

Always use a separate power supply unit in every control cabinet and safely

separate it according to EN 61800−5−1 ("SELV"/"PELV") in the case of external

voltage supply and larger distances between the control cabinets.

External voltage supply of the function module is required if communication via the

fieldbus is to be maintained even when the power supply of the standard device fails.

Note!

With external voltage supply of the function module, the active bus

terminating resistor is fed independently of the operation of the standard

device. In this way, the bus system remains active even when the standard

device is switched off or fails.

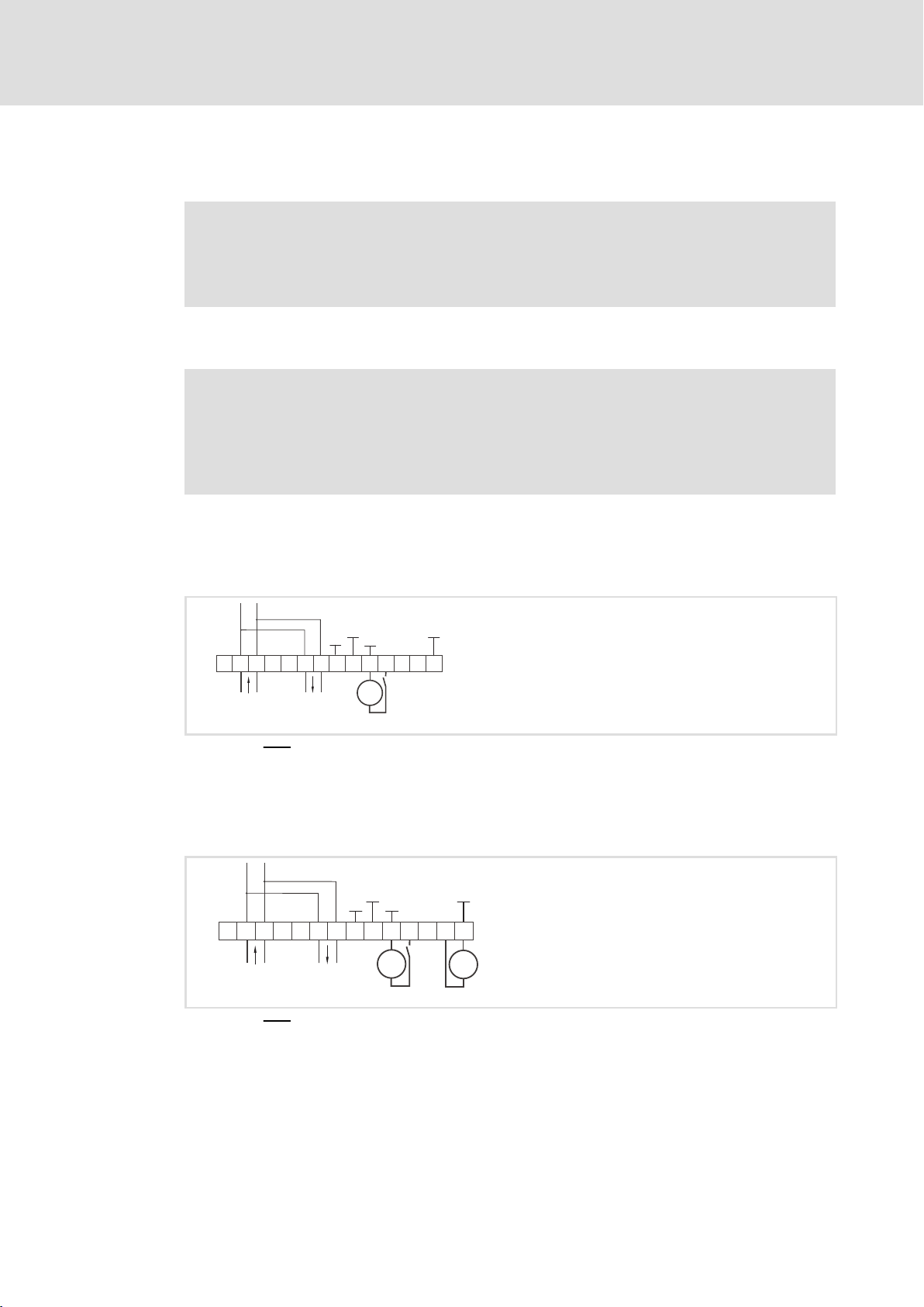

E82ZAFPC001function module

External voltage supply with one voltage source for

ƒ X3/28 (controller inhibit (CINH))

GND1

+20V

7

20 59

2839

B

AVP

X3

+

CN

T/R(A) T/R(B) T/R(A) T/R(B)

GND1

GND3

+5V

GND2

7

BA

40

_

+

The min. wiring requirements for operation

External voltage supply with two voltage sources for

1. X3/28 (controller inhibit (CINH))

2. X3/59 (function module)

+20V

GND1

720

59

_

X3

GND1

GND2

+5V

A

+

VP

B

CN

GND3

40

BA

28397

_

E82ZAFP002

26

T/R(A) T/R(B) T/R(A) T/R(B)

The min. wiring requirements for operation

+

+

E82ZAFP003

EDS82ZAFPC010 EN 4.0

Page 27

E82ZAFPC010 function module

External voltage supply with one voltage source for

ƒ X3.3/28 (controller inhibit (CINH))

T/R(A) T/R(B)

A

X3.1 X3.2

B

GND1

720

59

X3.3

GND1

GND2

_

+20V

28397

Installation

Electrical installation

Voltage supply

5

T/R(A) T/R(B)

+

The min. wiring requirements for operation

External voltage supply with two voltage sources for

1. X3.3/28 (controller inhibit (CINH))

2. X3.2/59 (function module)

T/R(A) T/R(B)

A

X3.1 X3.2

T/R(A) T/R(B)

B

GND1

720

59

The min. wiring requirements for operation

GND1

GND2

+20V

X3.3

_

+

28397

_

+

E82ZAFP012

E82ZAFP013

EDS82ZAFPC010 EN 4.0

27

Page 28

5

Installation

Electrical installation

Terminal assignment

5.2.4 Terminal assignment

E82ZAFPC001function module

B

AVP

CN

Designation Function / level

PES Additional HF−shield termination

+

X3

Terminal

X3/

A T/R(A) RS485 data line A

B T/R(B) RS485 data line B

CN CNTR For function see PROFIBUS standard *)

VP For function see PROFIBUS standard *)

40 GND3 Reference potential for PROFIBUS network *)

7 GND1 Reference potential for X3/20

39 GND2 Reference potential for controller inhibit (CINH) at X3/28

28 CINH Controller inhibit

20 DC voltage source for internal supply of controller inhibit (CINH)

59 External DC voltage supply for the function module

*) E.g. for repeater connection

+5V

+20V

20 59

GND1

7

E82ZAFP001

GND1

GND3

GND2

7

BA

40

2839

l Level during data transmission: CNTR = HIGH

(+5 V DC, reference:GND3)

l U = +5 V DC (reference:GND3)

l I

= 10 mA

max

l Start = HIGH (+12 ... +30 V DC)

l Stop = LOW (0 ... +3 V DC)

(reference: GND2)

l +20 V DC (reference: GND1)

l I

= 20 mA

max

l +24VDC±10% (reference: GND1)

l Current consumption on 24 V DC: 80 mA

The current for looping through the supply voltage to other nodes via

terminal 59 must be max. 3A.

28

EDS82ZAFPC010 EN 4.0

Page 29

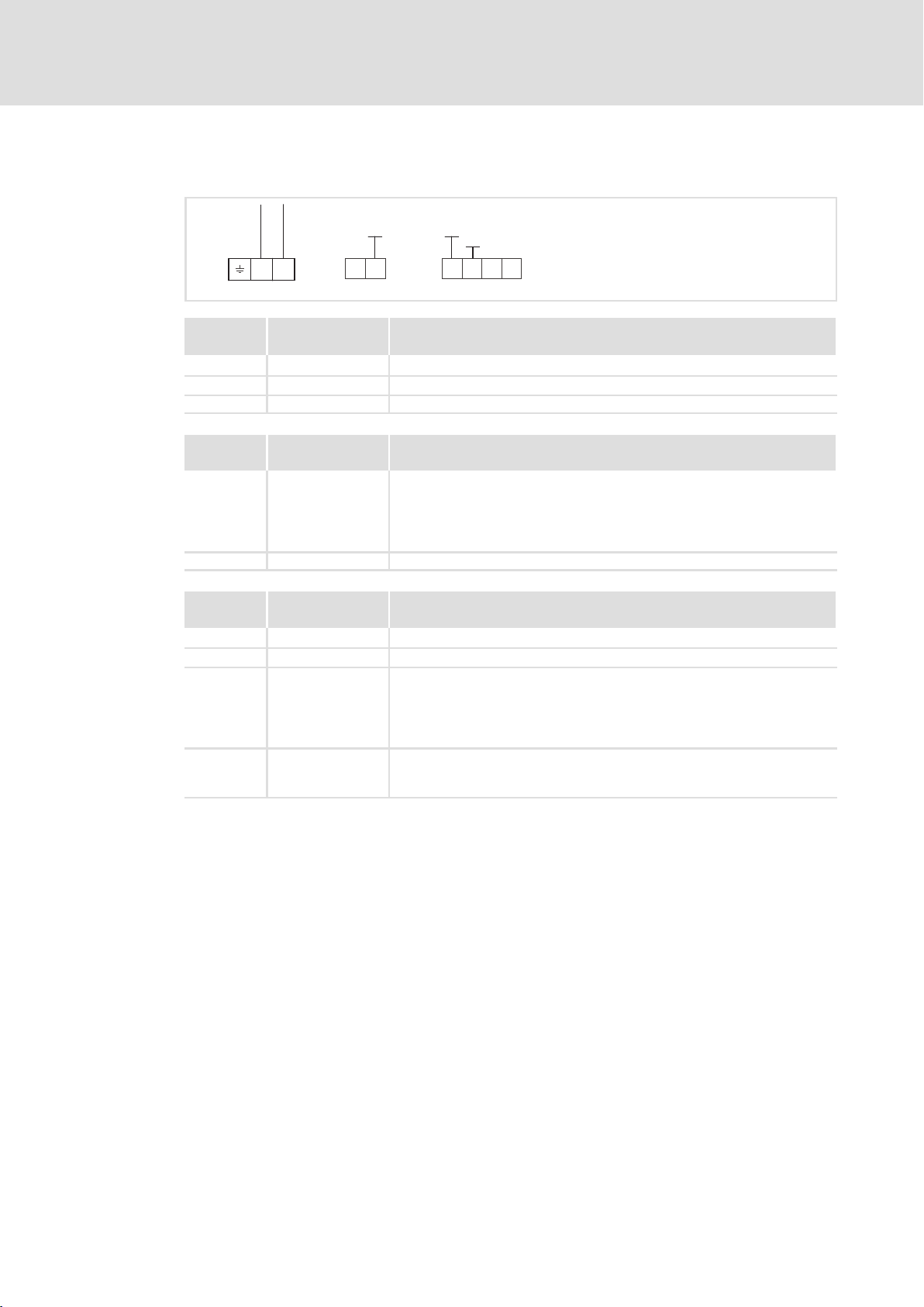

E82ZAFPC010 function module

T/R(A) T/R(B)

GND1

720

A

X3.1 X3.2

B

59

X3.3

GND1

GND2

Installation

5

Electrical installation

Terminal assignment

+20V

28397

E82ZAFP011

Terminal

X3.1/

A T/R(A) RS485 data line A

B T/R(B) RS485 data line B

Terminal

X3.2/

59 External DC voltage supply for the function module

7 GND1 Reference potential for X3.3/20

Terminal

X3.3/

7 GND1 Reference potential for X3.3/20

39 GND2 Reference potential for controller inhibit (CINH) at X3.3/28

28 CINH Controller inhibit

20 DC voltage source for external supply of controller inhibit (CINH)

Designation Function / level

PES Additional HF shield termination

Designation Function / level

l +24VDC±10% (reference: GND1)

l Current consumption on 24 V DC: 80 mA

The current for looping through the supply voltage to other nodes via

terminal 59 must be max. 3A.

Designation Function / level

l Input resistance: 3.3 kW

l Start = HIGH (+12 ... +30 V)

l Stop = LOW (0 ... +3 V)

(reference: GND2)

l +20 V (reference: GND1)

l I

= 10 mA

max

EDS82ZAFPC010 EN 4.0

29

Page 30

5

Installation

Electrical installation

Cable cross−sections and screw−tightening torques

5.2.5 Cable cross−sections and screw−tightening torques

Range Values

Electrical connection Terminal strip with screw connection

Possible connections

rigid:

flexible:

Tightening torque 0.22 ... 0.25 Nm (1.9 ... 2.2 lb−in)

Bare end 5 mm

Field Values

Electrical connection Plug connector with double screw connection

Possible connections

rigid:

flexible:

Tightening torque 0.5 ... 0.6 Nm (4.4 ... 5.3 lb−in)

Stripping length 10 mm

2

1.5 mm

without wire end ferrule

1.0 mm

with wire end ferrule, without plastic sleeve

0.5 mm

with wire end ferrule, with plastic sleeve

0.5 mm

1.5 mm

without wire end ferrule

1.5 mm

with wire end ferrule, without plastic sleeve

1.5 mm

with wire end ferrule, with plastic sleeve

1.5 mm

(AWG 16)

2

(AWG 18)

2

(AWG 20)

2

(AWG 20)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

2

(AWG 16)

Field Values

Electrical connection 2−pin plug connector with spring connection

Possible connections

rigid:

1.5 mm

2

(AWG 16)

flexible:

without wire end ferrule

2

1.5 mm

with wire end ferrule, without plastic sleeve

1.5 mm

with wire end ferrule, with plastic sleeve

1.5 mm

(AWG 16)

2

(AWG 16)

2

(AWG 16)

Stripping length 9 mm

30

EDS82ZAFPC010 EN 4.0

Page 31

5.2.6 Use of plug connectors

Stop!

Observe the following to prevent any damage to plug connectors and

contacts:

ƒ Only pug in / unplug the plug connectors when the controller is

disconnected from the mains.

ƒ Wire the plug connectors before plugging them in.

ƒ Unused plug connectors must also be plugged in.

Use of plug connectors with spring connection

Installation

Electrical installation

Use of plug connectors

5

E82ZAFX013

EDS82ZAFPC010 EN 4.0

31

Page 32

5

Installation

Bus cable length

Use of plug connectors

5.3 Bus cable length

Max. possible bus cable length

The following bus cable lengths are possible in dependence on the baud rate and the cable

used:

Baud rate [kbit/s] Thin Cable Thick Cable

125

250 250 m

500 100 m

When using both, Thick" and Thin" cables, the maximum cable lengths are to be selected

according to the baud rate:

Baud rate [kbit/s] Bus cable length

125 L

250 L

500 L

100 m

= 500 m = L

max

= 250 m = L

max

= 100 m = L

max

thick

thick

thick

+ 5 L

+ 2.5 L

+ L

thin

500 m

thin

thin

32

EDS82ZAFPC010 EN 4.0

Page 33

6 Commissioning

During commissioning, system−dependent data as e.g. motor parameters, operating

parameters, responses and parameters for fieldbus communication are selected for the

controller.

In Lenze devices, this is done via codes. The codes are stored in numerically ascending order

in the Lenze controllers and in the plugged−in communication/function modules.

In addition to these configuration codes, there are codes for diagnosing and monitoring

the bus devices.

6.1 Before switching on

Stop!

Before switching on the standard device with the function module for the first

time, check...

ƒ the entire wiring for completeness, short circuit, and earth fault.

ƒ whether the integrated bus terminating resistor is activated at the first and

last physical node ( 40).

Commissioning

Before switching on

6

EDS82ZAFPC010 EN 4.0

33

Page 34

6

Commissioning

Commissioning steps

6.2 Commissioning steps

Note!

Do not change the setting sequence.

Step−by−step commissioning of the function module with the DRIVECOM device control is

described below.

Step Description Detailed

1. Configure master system (master) for communication with the function

2. Inhibit standard device via terminal 28 (CINH).

3.

4. Activate bus terminating resistor via DIP switch = ONfor the first and last

5. A Set node address via ...

6.

7. Select function module as source for control commands and setpoints.

8.

module.

l Set terminal 28 to LOW level.

l Later the standard device can be inhibited and enabled via the bus.

Connect mains voltage and, if available, separate voltage supply of the

function module.

l The standard device will be ready for operation after approx. 1 second.

l Controller inhibit (CINH) is active.

Response

l The green LED "Connection status to the standard device" at the front of

the function module is lit (only visible in the case of 8200 vector).

l Keypad: (if plugged in)

node.

l Lenze setting: OFF

– C1509

After a parameter set transfer the address has to be reassigned.

B Switch off the voltage supply of the function module and the standard

device and then switch it on again in order to accept changed settings.

The address that is modified via keypad becomes effective immediately.

Now you can communicate with the standard device, i. e. you can read all

codes and adapt all writable codes to your application.

Response

The yellow LED on the function module is blinking when the PROFIBUS is

active.

l Set C0005 = 200.

– A preconfiguration for operation with the function module is carried

out.

– Control words and status words are already linked.

Assign process data output words (POW) of the master to process data input

words of the standard device via C1511.

Lenze setting:

POW1: DRIVECOM control word (DRIVECOM CTRL)

POW2:

POW3:

POW4:

POW5:

POW6:

POW7:

POW8:

Setpoint1 (NSET1−N1)

Setpoint2 (NSET1−N2)

Additional setpoint (PCTRL1−NADD)

Actual process controller value (PCTRL1−ACT)

Process controller setpoint (PCTRL1−SET1)

Reserved (FIF−RESERVED)

Torque setpoint or torque limit (MCTRL1−MSET)

information

36

Documentation of

the standard device

42

67

40

Documentation of

the standard device

Documentation of

the standard device

67

PROFIBUS

communication

manual

34

EDS82ZAFPC010 EN 4.0

Page 35

Commissioning

Commissioning steps

6

DescriptionStep

POW9: PWM voltage (MCTRL1−VOLT−ADD)

POW10: PWM angle (MCTRL1−PHI−ADD)

9.

10.

11. Enable standard device via terminal 28 (CINH).

12. Enter the setpoint.

13. Change to the READY TO START status:

14. The standard device is in the READY TO START status.

15. Change to the OPERATION ENABLED status.

16. Now the drive starts up.

Assign process data output words of the standard device to the process data

input words (PIW) of the master via C1510.

Lenze setting:

PIW1: DRIVECOM status word (DRIVECOM STAT)

Output frequency with slip (MCTRL1−NOUT+SLIP)

PIW2:

PIW3:

Output frequency without slip (MCTRL1−NOUT)

PIW4:

Apparent motor current (MCTRL1−IMOT)

PIW5:

Actual process controller value (PCTRL1−ACT)

PIW6:

Process controller setpoint (PCTRL1−SET1)

PIW7:

Process controller output (PCTRL1−OUT)

PIW8:

Controller load (MCTRL1−MOUT)

PIW9:

DC−bus voltage (MCTRL1−DCVOLT)

PIW10:

Enable process output data via C1512 = 65535.

l Only required if C1511 has been changed.

l Deactivate process data words that are not used by setting the respective

subcode of code C1511 to 0.

l The value in C1512 is volatile, and all process data are enabled after every

switch−on.

l Set terminal 28 to HIGH level.

l The master transmits the setpoint via the process data output word

selected.

l The master transmits the DRIVECOM control word:

0000 0000 0111 1110

l The master receives the DRIVECOM status word:

xxxx xxxx x01x 0001

l The master transmits DRIVECOM control word:

0000 0000 0111 1111

Ramp function generator input (NSET1−RFG1−IN)

bin

bin

bin

(007E

(007F

hex

hex

).

).

Detailed

information

PROFIBUS

communication

manual

PROFIBUS

communication

manual

EDS82ZAFPC010 EN 4.0

35

Page 36

6

6.3 Configuring the host system (master)

Commissioning

Configuring the host system (master)

The host must be configured before communication with the communication module is

possible.

Master settings

For configuring the PROFIBUS, the device data base file (GSE file) of the communication

module has to be imported into the configuring software of the master.

Tip!

The GSE file can be downloaded from www.Lenze.com.

36

EDS82ZAFPC010 EN 4.0

Page 37

Commissioning

Configuring the host system (master)

Device data base file

The following configurations are saved in the device data base file LENZ00DA.GSE:

6

Parameter data

Modules in LENZ00DA.GSE

PAR (Cons.) + PZD (n Words)

PAR (Cons.) + PZD (n Words Cons.)

PAR + PZD (n Words)

PZD (n Words) Without parameter data channel n words n words

PZD (n Words Cons.) Without parameter data channel n words n words

n = 1 ... 10

without/with consistency

Without With Without With

·

·

·

Process data

without/with consistency

n words 4 + n words

n words 4 + n words

n words 4 + n words

Assigned

I/O memory

Note!

Device control via FIF status/control word

Device control is only possible if the DRIVECOM status machine (Lenze setting)

is switched off.

ƒ Set C1510 /1 (PIW1) to the value 1":

FIF status word 1 (FIF−STAT1).

ƒ Set C1511 /1 (POW1) to the value 1":

FIF control word 1 (FIF−CTRL1).

ƒ Set C1512 to 65535" to reenable process output words.

For Lenze codes see ( 69)

Tip!

Use overall consistency

ƒ We recommend to use exclusively configurations with consistency for the

parameter data channel to avoid data conflicts between PROFIBUS−DP

master and host CPU.

ƒ Please note that the processing of consistent data varies between hosts.

This must be considered in the PROFIBUS−DP application program.

ƒ Detailed description of consistency: ( 87)

EDS82ZAFPC010 EN 4.0

37

Page 38

6

6.3.1 Adapting device controls

Commissioning

Configuring the host system (master)

Adapting device controls

ƒ Lenze device control

– Set C1511/1 (POW1) = 1 ð FIF control word 1 (FIF−CTRL1)

– Set C1510/1 (PIW1) = 1 ð FIF status word 1 (FIF−STAT1)

ƒ Device control via DRIVECOM

– Set C1511/1 (POW1) = 17 ð DRIVECOM control word (DRIVECOM−CTRL)

– Set C1510/1 (PIW1) = 18 ð DRIVECOM status word (DRIVECOM−STAT)

For detailed information about the configuration of process data, see chapter "Process

data transfer", 43)

Tip!

Use overall consistency

ƒ Please observe that the processing of consistent data varies between hosts.

This must be taken into account in the PROFIBUS application program.

ƒ A detailed description of consistency can be found in the appendix ( 86)

38

EDS82ZAFPC010 EN 4.0

Page 39

Commissioning

Configuring the host system (master)

Defining the user data length

6

6.3.2 Defining the user data length

The user data length is defined during the initialisation phase of the PROFIBUS. It is

possible to configure up to 10 process data words (see chapter "Process data transfer",

43).

Optionally you can activate a parameter data channel. If the parameter data channel is

active, it additionally occupies 4 words of the process input and process output data.

ƒ PIW: process data input word (process data from standard device to master)

ƒ POW: process data output word (process data from master to standard device)

The user data lengths for process input data and process output data are identical. The

selection takes place via identification bytes in the configuration software for the

PROFIBUS system.

Parameter data channel Process data channel

Without /

with

Without −

With

Identification / user data length Identification / user data length

l Identification: F3

l User data length: 4 words

(word 1 ... word 4)

hex

(243)

l Identification

hex

hex

hex

... F9

hex

... F9

... 79

... 79

– without consistency: 70

– with consistency: F0

l User data length: 1 ... 10 words

(POW1/PIW1 ... POW10/PIW10)

l Identification

– without consistency: 70

– with consistency: F0

l User data length: 1 ... 10 words

(POW1/PIW1 ... POW10/PIW10)

(112 ... 121)

hex

(240 ... 249)

hex

(112 ... 121)

hex

(240 ... 249)

hex

General structure of the identification byte

MSB LSB

7 6 5 4 3 2 1 0

Data length

00 1 byte or 1 word

...

15 16 bytes or 16 words

Input/output

00 Special identification format

01 Input

10 Output

11 Input and output

Length/format

0 Byte

1 Word

Consistency

0 Byte or word

1 Total length

EDS82ZAFPC010 EN 4.0

39

Page 40

6

Commissioning

Activating the bus terminating resistor

6.4 Activating the bus terminating resistor

0

ON

1

7

AABB

VP

CN

+

DIP switch

40 39 28 20 59

7

E82ZAFPC004 E82ZAFPC004

DIP switch = ON Integrated active bus terminating resistor is switched on

DIP switch = OFF Integrated active bus terminating resistor is switched off

0

40

EDS82ZAFPC010 EN 4.0

Page 41

Commissioning

Setting the node address

6

6.5 Setting the node address

To address the basic devices, each device (station) is allocated a different node address in

the PROFIBUS−DP network.

Valid address range: 3 126

(Lenze setting: 3)

The node address can be selected freely via code C1509.

It can be set with

ƒ the keypad,

ƒ the PC / communication module, type 2102 LECOM, or

ƒ the class 2 master.

EDS82ZAFPC010 EN 4.0

41

Page 42

6

Commissioning

Connecting the mains voltage

6.6 Connecting the mains voltage

Note!

If the external voltage supply of the function module is used, the supply must

be switched on as well.

ƒ The standard device will be ready for operation approx. 1 s after switching on the

supply voltage.

ƒ Controller inhibit is active.

ƒ The green LED at the front of the function module is lit (only visible in the case of the

8200 vector frequency inverter).

Protection against uncontrolled start−up

Note!

Establishing communication

For establishing communication via an externally supplied function module,

the standard device must be switched on as well.

ƒ After communication has been established, the externally supplied module

is independent of the power on/off state of the standard device.

Protection against uncontrolled start−up

After a fault (e.g. short−term mains failure), a restart of the drive is not always

wanted and − in some cases − even not allowed.

The restart behaviour of the controller can be set in C0142:

ƒ C0142 = 0 (Lenze setting)

– The controller remains inhibited (even if the fault is no longer active).

– The drive starts in a controlled mode by explicitly enabling the controller:

LOW−HIGH edge at terminal 28 (CINH)

ƒ C0142 = 1

– An uncontrolled restart of the drive is possible.

42

EDS82ZAFPC010 EN 4.0

Page 43

7 Process data transfer

PROFIBUS transmits parameter data and process data between the host (master) and the

controllers connected to the bus (slaves). Depending on their time−critical nature, the data

are transmitted via different communication channels.

ƒ Process data are transmitted via the process data channel.

ƒ Process data serve to control the drive controller.

ƒ The transmission of process data is time−critical.

ƒ Process data are cyclically transferred between the host and the controllers

(continuous exchange of current input and output data).

ƒ The host can directly access the process data. In the PLC, for instance, the data are

directly assigned to the I/O area.

ƒ With the function module a maximum of 10 process data words (16 bits/word) can

be exchanged in each direction.

Process data transfer 7

ƒ Process data are not stored in the controller.

ƒ Process data are, for instance, setpoints, actual values, control words and status

words.

Note!

Observe the direction of the information flow!

ƒ Process input data (Rx data):

– Process data from controller (slave) to host (master)

ƒ Process output data (Tx data):

– Process data from host (master) to controller (slave)

EDS82ZAFPC010 EN 4.0

43

Page 44

7

7.1 Lenze device control

Process data transfer

Lenze device control

Process output data configuration

Codes C1510 (process input data) and C1511 (process output data) can be used to freely

assign up to 10 process data words of the PROFIBUS to the process data words of the

controller.

Note!

ƒ The PROFIBUS master sends process output data in up to 10 process data

output words (POW) to the slave.

ƒ The PROFIBUS master receives process input data in up to 10 process data

input words (PIW) from the slave.

7.1.1 Process output data configuration

The assignment of up to 10 process data output words (POW) of the master to bit control

commands, actual values or setpoints of the controller can be freely configured via code

C1511.

Note!

ƒ The assignment of control words of different device controls is not

permitted.

ƒ If C1511 is changed, the process output data are automatically inhibited to

ensure data consistency.

ƒ Via C1512 you can re−enable individual or all POWs.

ƒ To activate the DRIVECOM device control, assign the DRIVECOM control word to a

POW (C1511/x = 17).

– The DRIVECOM control word is mapped to the FIF control word 1.

– The controller operates in compliance with the DRIVECOM state machine. ( 51).

ƒ You can set up an extended Lenze device control using the FIF control words ( 47).

44

EDS82ZAFPC010 EN 4.0

Page 45

Process data transfer

Lenze device control

Process output data configuration

C1511:

Configuration of process output data

Possible settings

Code Subcode Index

C1511 23064d =

1 (POW1) 17

2 (POW2) 3

3 (POW3) 4

4 (POW 4) 5

5 (POW 5) 6

6 (POW 6) 7

7 (POW 7) 8

8 (POW 8) 9

9 (POW 9) 10

10 (POW 10) 11

5A18

The process data output words (POW) of the master can be freely assigned to bit control

commands or setpoints of the controller via C1511.

Lenze Selection

h

Data type

FIX32

see table below

7

Selection Scaling

1 FIF control word 1 (FIF−CTRL1) 16 bits

2 FIF control word 2 (FIF−CTRL2) 16 bits

3 Setpoint 1 (NSET1−N1) ±24000 º ±480 Hz

4 Setpoint 2 (NSET1−N2) ±24000 º ±480 Hz

5 Additional setpoint (PCTRL1−NADD) ±24000 º ±480 Hz

6 Actual process controller value (PCTRL1−ACT) ±24000 º ±480 Hz

7 Process controller setpoint (PCTRL1−SET1) ±24000 º ±480 Hz

8 Reserved

9 Torque setpoint/torque limit value (MCTRL1−MSET) 214 º100 % rated motor torque

10 PWM voltage (MCTRL1−VOLT−ADD)

11 PWM angle (MCTRL1−PHI−ADD)

12 Reserved

13 FIF−IN.W1 16 bits or 0 ... 65535

14 FIF−IN.W2 16 bits or 0 ... 65535

15 FIF−IN.W3 0 ... 65535

16 FIF−IN.W4 0 ... 65535

17 DRIVECOM control word (DRIVECOM−CTRL) 16 bits

For special applications only.

System manual for 8200 vector

EDS82ZAFPC010 EN 4.0

45

Page 46

7

Process data transfer

Lenze device control

Process output data configuration

POW1 POW1

POW2 POW2

POW3 POW3

POW4 POW4

POW5 POW5

POW6 POW6

PROFIBUS

POW7 POW7

POW8 POW8

POW9 POW9

POW10 POW10

A

B

CN

C1511/1 = 17

C1511/2 = 3

C1511/3 = 4

C1511/4 = 5

C1511/5 = 6

C1511/6 = 7

C1511/7 = 8

C1511/8 = 9

C1511/9 = 10

C1511/10 = 11

Byte 35

Byte 36

Byte 33

Byte 34

DRIVECOM-CTRL PROFIdrive-CTRL

Byte 1

FIF-CTRL1

Byte 2

Byte 3

FIF-CTRL2

Byte 4

Byte 5,6

Byte 7, 9

Byte 9, 10

Byte 11, 12

Byte 13, 14

Byte 15,16

Byte 17, 18

Byte 19, 20

Byte 21, 22

Byte 23, 24

FIF-IN.W1

Byte 25,26

FIF-IN.W2

Byte 27, 28

FIF-IN.W3

Byte 29,30

FIF-IN.W4

Byte 31,32

CTRL.B0

CTRL.B1

CTRL.B2

…

CTRL.B13

CTRL.B14

CTRL.B15

CTRL.B0

CTRL.B1

CTRL.B2

…

CTRL.B13

CTRL.B14

CTRL.B15

FIF-CTRL.B0

FIF-CTRL.B1

FIF-CTRL.B2

FIF-CTRL.B3

…

FIF-CTRL.B4

FIF-CTRL.B5

FIF-CTRL.B6

FIF-CTRL.B7

FIF-CTRL.B8

FIF-CTRL.B9

FIF-CTRL.B10

FIF-CTRL.B11

…

FIF-CTRL.B12

FIF-CTRL.B13

FIF-CTRL.B14

FIF-CTRL.B15

FIF-CTRL.B16

FIF-CTRL.B17

FIF-CTRL.B18

FIF-CTRL.B19

FIF-CTRL.B20

FIF-CTRL.B21

FIF-CTRL.B22

FIF-CTRL.B23

FIF-CTRL.B24

FIF-CTRL.B25

FIF-CTRL.B26

FIF-CTRL.B27

FIF-CTRL.B28

FIF-CTRL.B29

FIF-CTRL.B30

FIF-CTRL.B31

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

QSP

CINH

TRIP-SET

TRIP-RESET

…

FIF-IN.W1.B0 … FIF-IN.W1.B15

FIF-IN.W2.B0 … FIF-IN.W2.B15

FIF-IN

DCTRL

DCTRL

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-RESERVED

FIF-IN.W1

FIF-IN.W2

FIF-IN.W3

FIF-IN.W4

FIF-OUT

C0410/1 = 200

C0410/2 = 200

C0410/3 = 200

C0410/4 = 200

C0410/5 = 200

C0410/6 = 200

C0410/7 = 200

C0410/8 = 200

C0410/9 = 200

C0410/10 = 200

C0410/11 = 200

C0410/12 = 200

C0410/13 = 200

C0410/14 = 200

C0410/15 = 200

C0410/17 = 200

C0410/18 = 200

C0410/19 = 200

C0410/20 = 200

C0410/21 = 200

C0410/22 = 200

C0410/23 = 200

C0410/24 = 200

C0412/1 = 200

C0412/2 = 200

C0412/3 = 200

C0412/4 = 200

C0412/5 = 200

C0412/6 = 200

C0412/7 = 200

C0412/8 = 200

C0412/9 = 200

NSET1-JOG1/3

NSET1-JOG2/3

DCTRL1-CW/CCW

DCTRL1-QSP

NSET1-RFG1-STOP

NSET1-RFG1-0

MPOT1-UP

MPOT1-DOWN

RESERVED

DCTRL1-CINH

DCTRL1-TRIP-SET

DCTRL1-TRIP-RESET

DCTRL1-PAR2/4

DCTRL1-PAR3/4

MCTRL1-DCB

DCTRL1-H/RE

PCTRL1-I-OFF

PCTRL1-OFF

RESERVED

PCTRL1-STOP

DCTRL1-CW/QSP

DCTRL1-CCW/QSP

DFIN1-ON

NSET1-N1

NSET1-N2

PCTRL1-NADD

PCTRL1-SET1

PCTRL1-ACT

MCTRL1-MSET

RESERVED

MCTRL1-VOLT-ADD

MCTRL1-PHI-ADD

C0410/x = 30 … 45

C0415/x = 60 … 75

C0417/x = 60 … 75

C0418/x = 60 … 75

C0412/x = 20

C0419/x = 50

C0421/x = 50

C0410/x = 50 … 65

C0415/x = 80 … 95

C0417/x = 80 … 95

C0418/x = 80 … 95

C0412/x = 21

C0419/x = 51

C0421/x = 51

C0412/x = 22

C0419/x = 52

C0421/x = 52

C0412/x = 23

C0419/x = 53

C0421/x = 53

46

Fig. 7−1 Free configuration of the 10 PROFIBUS process output words

8200vec512

EDS82ZAFPC010 EN 4.0

Page 47

Process data transfer

Lenze device control

Process output data configuration

FIF control word 1 (FIF−CTRL1) FIF control word 2 (FIF−CTRL2)

Bit Assignment Bit Assignment

0 / 1 JOG values (NSET1−JOG2/3 | NSET1−JOG1/3) 0 Manual/remote changeover (DCTRL1−H/Re)

Bit 1 0

0001C0046 active

1101JOG2 (C0038) active

JOG1 (C0037) active

JOG3 (C0039) active

2 Current direction of rotation (DCTRL1−CW/CCW) 2 Switch off process controller (PCTRL1−OFF)

01Not inverted

Inverted

3 Quick stop (QSP) (FIF−CTRL1−QSP)

01Not active

Active (deceleration via QSP ramp C0105)

4 Stop ramp function generator (NSET1−RFG1−STOP) 4 Stop process controller (PCTRL1−STOP)

01Not active

Active

5 Ramp function generator input = 0 (NSET1−RFG1−0) 5 CW rotation/quick stop (QSP) (DCTRL1−CW/QSP)

01Not active

Active (deceleration via C0013)

6 UP function of motor potentiometer (MPOT1−UP) 6 CCW rotation/quick stop (QSP) (DCTRL1−CCW/QSP)

01Not active

Active

7 DOWN function of motor potentiometer (MPOT1−DOWN) 7 X3/E1 is digital frequency input (DFIN1−ON)

01Not active

Active

8

Reserved

9 Controller inhibit (FIF−CTRL1−CINH) 9

01Controller enabled

Controller inhibited

10 External fault (FIF−CTRL1−TRIP−SET) 10

11 Reset fault (FIF−CTRL1−TRIP−RESET)

0 Þ 1 Bit change resets TRIP

12 / 13 Parameter set changeover

(DCTRL1−PAR3/4 | DCTRL1−PAR2/4)

Bit 13 12

0001PAR1

1101PAR3

PAR2

PAR4

14 DC injection brake (MTCRL1−DCB)

01Not active

Active

15

Reserved

Tab. 7−1 Parameter structure of FIF control word (FIF−CTRLx)

01Not active

Active

1 Switch off I−component of process controller

(PCTRL1−I−OFF)

01Not active

Active

01Not active

Active

3

Reserved

Do not write to this bit!

01Not active

Active

01Not active

Active

01Not active

Active

01Not active

Active

8

11

12

13

14

15

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

7

Note!

EDS82ZAFPC010 EN 4.0

Use of bit 5 and bit 6 in FIF control word 2

Set codes C0410/22 (DCTRL1−CW/QSP) and C0410/23 (DCTRL1−CCW/QSP) to

"200".

47

Page 48

7

Process data transfer

Lenze device control

Process input data configuration

7.1.2 Process input data configuration

The assignment of the bit status information or the actual controller values to the up to 10

process data input words (PIW) of the master can be freely configured:

ƒ To call DRIVECOM−conform status information, assign the DRIVECOM status word to

a PIW (C1511/x = 18).

The FIF status word1 is mapped to the DRIVECOM status word.

C1510:

Configuration of process input data

Code Subcode Index

C1510 23065d =

1 (PIW1) 18

2 (PIW2) 3

3 (PIW3) 4

4 (PIW 4) 5

5 (PIW 5) 6

6 (PIW 6) 7

7 (PIW 7) 8

8 (PIW 8) 9

9 (PIW 9) 10

10 (PIW 10) 11

5A19

Possible settings

Lenze Selection

h

Data type

FIX32

See table below

The bit status information or the actual values of the controller can be freely assigned to

the max. 10 process data input words (PIW) of the master.

Selection Scaling

1

FIF status word 1 (FIF−STAT1)

2

FIF status word 2 (FIF−STAT2)

3

Output frequency with slip (MCTRL1−NOUT+SLIP)

4

Output frequency without slip (MCTRL1−NOUT)

5

Apparent motor current (MCTRL1−IMOT)

6

Actual process controller value (PCTRL1−ACT)

7

Process controller setpoint (PCTRL1−SET)

8

Process controller output (PCTRL1−OUT)

9

Controller load (MCTRL1−MOUT)

10

11

12

13

14

15

16

17

18

DC−bus voltage (MCTRL1−DCVOLT)

Ramp function generator input (NSET1−RFG1−IN)

Ramp function generator output (NSET1−NOUT)

FIF−OUT.W1

FIF−OUT.W2

FIF−OUT.W3

FIF−OUT.W4

DRIVECOM control word (DRIVECOM−CTRL)

DRIVECOM status word (DRIVECOM−STAT)

16 bits

16 bits

±24000 º ±480 Hz

±24000 º ±480 Hz

214 º 100 % rated device current

±24000 º ±480 Hz

±24000 º ±480 Hz

±24000 º ±480 Hz

±214 º±100 % rated motor torque

16383 º 565 V DC for 400 V mains

16383 º 325 V DC for 230 V mains

±24000 º ±480 Hz

±24000 º ±480 Hz

16 bits or 0 ... 65535

16 bits or 0 ... 65535

0...65535

0...65535

16 bits

16 bits

48

EDS82ZAFPC010 EN 4.0

Page 49

FIF-IN

NSET1

PCTRL1

MCTRL1

DCTRL1

CTRL.B0

CTRL.B1

CTRL.B2

…

CTRL.B13

CTRL.B14

CTRL.B15

STAT.B0

STAT.B1

STAT.B2

…

STAT.B13

STAT.B14

STAT.B15

CTRL.B0

CTRL.B1

CTRL.B2

…

CTRL.B13

CTRL.B14

CTRL.B15

STAT.B0

STAT.B1

STAT.B2

…

STAT.B13

STAT.B14

STAT.B15

FIF-OUT

Byte37

Byte 38

Byte39

Byte 40

Byte33

Byte 34

Byte35

Byte 36

Process data transfer

Lenze device control

Process input data configuration

PROFIDrive-CTRL

PROFIDrive-STAT

DRIVECOM-CTRL

DRIVECOM-STAT

7

FIF-STAT.B0

FIF-STAT.B1

…

FIF-STAT.B14

FIF-STAT.B15

FIF-STAT.B16

FIF-STAT.B17

…

FIF-STAT.B30

MCTRL1-NOUT+SLIP

MCTRL1-NOUT

MCTRL1-IMOT

PCTRL1-ACT

PCTRL1-SET1

PCTRL1-OUT

MCTRL1-MOUT

MCTRL1-DCVOLT

NSET1-RFG1-IN

NSET1-NOUT

STAT1

2

C0417/1

2

2

C0417/16

2

C0421/3

2

C0418/1

2

2

C0418/16

2

C0421/4

…...

…...

STAT1.B0

…...

STAT1.B15

STAT2

STAT2.B0

…...

STAT2.B15

FIF-OUT.W1.B0

…...

FIF-OUT.W1.B15

FIF-OUT.W2.B0

…...

FIF-OUT.W2.B15

FIF-STAT.B31

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

Byte1

Byte 2

Byte 3

Byte 4

Byte 5,6

Byte 7, 8

Byte 9, 10

Byte 11, 12

Byte 13, 14

Byte 15,16

Byte 17, 18

Byte 19, 20

Byte 21, 22

Byte 23, 24

Byte 25,26

Byte 27, 28

FIF-STAT1

FIF-STAT2

FIF-OUT.W1

FIF-OUT.W2

C1510/ = 181

C1510/ = 32

C1510/ = 43

C1510/ = 54

C1510/ = 65

C1510/ = 76

C1510/ = 87

C1510/ = 98

C1510/ = 109

C1510/ = 1110

PIW1

PIW2

PIW3

PIW4

PIW5

PIW6

PIW7

PIW8

PIW9

PIW10

CN

PIW1

PIW2

PIW3

PIW4

A

PIW5

B

PIW6

PROFIBUS

PIW7

PIW8

PIW9

PIW10

2

C0421/5

2

C0421/6

Fig. 7−2 Free configuration of the 10 PROFIBUS process input words

EDS82ZAFPC010 EN 4.0

16 bits

16 bits

Byte 29, 30

FIF-OUT.W3

Byte 31, 32

FIF-OUT.W4

8200vec513

49

Page 50

7

Process data transfer

Lenze device control

Process input data configuration

FIF status word 1 (FIF−STAT1) FIF status word 2 (FIF−STAT2)

Bit Assignment Bit Assignment

0 Current parameter set bit 0 (DCTRL1−PAR−B0) 0 Current parameter set bit 1 (DCTRL1−PAR−B1)

01Parameter set 1 or 3 active

Parameter set 2 or 4 active

1 Pulse inhibit (DCTRL1−IMP) 1 TRIP, Q

01Power outputs enabled

Power outputs inhibited

2 I

limit (MCTRL1−IMAX)

max

(If C0014 = 5: Torque setpoint)

01Not reached

Reached

3 Output frequency = frequency setpoint

(DCTRL1−RFG1=NOUT)

01False

True

4 Ramp function generator input 1 = ramp function

01False

5 Q

01Not reached

generator output 1

True

threshold (PCTRL1−QMIN) 5 C0054 < C0156 and NSET1−RFG1−I=O

min

Reached

(NSET1−RFG1−I=O)

6 Output frequency = 0 (DCTRL1−NOUT=0) 6 LP1 warning (fault in motor phase) active

01False

True

7 Controller inhibit (DCTRL1−CINH) 7 f < f

01Controller enabled

Controller inhibited

11...8 Device status (DCTRL1−STAT*1 ... STAT*8) 8 TRIP active (DCTRL1−TRIP)

Bit 11 10 9 8

00000100Controller initialisation

00011010Operation inhibited

0 1 0 1 DC−injection brake active

00111101Operation enabled

1 0 0 0 Fault active

1 1 1 1 Communication with basic device not

Switch−on inhibit

Flying−restart circuit active

Message active

possible

12 Overtemperature warning (DCTRL1−OH−WARN) 12

01No warning

− 10 C reached

J

max

13 DC−bus overvoltage (DCTRL1−OV) 13

01No overvoltage

Overvoltage

14 Direction of rotation (DCTRL1−CCW) 14 C0054 > C0156 and NSET1−RFG1−I=0

01CW rotation

CCW rotation

15 Ready for operation (DCTRL1−RDY) 15

01Not ready for operation (fault)

Ready for operation (no fault)

Tab. 7−2 Parameter structure FIF status word (FIF−STATx)

01Parameter set 1 or 2 active

Parameter set 3 or 4 active

or pulse inhibit active (DCTRL1−TRIP−QMIN−IMP)

min

01False

True

2 PTC warning active (DCTRL1−PTC−WARN)

01False

True

3

Reserved

Do not write to this bit!

4 C0054 < C0156 and Q

(DCTRL1−(IMOT<ILIM)−QMIN)

01False

True

(DCTRL1−(IMOT<ILIM)−RFG−I=O)

01False

True

(DCTRL1−LP1−WARN)

01False

True

(NSET1−C0010 ... C0011)

min

01False

True

01False

True

threshold reached

min

9 Motor is running (DCTRL1−RUN)

01False

True

10 Motor is running clockwise (DCTRL1−RUN−CW)

01False

True

11 Motor is running counter−clockwise (DCTRL1−RUN−CCW)

01False

True

Reserved

Reserved

(DCTRL1−(IMOT>ILIM)−RFG−I=O)

01False

True

Reserved

50

EDS82ZAFPC010 EN 4.0

Page 51

7.2 DRIVECOM control

7.2.1 DRIVECOM state machine

The control information is provided by the function module via the control word.

ƒ The controllers have standardised device states according to DRIVECOM Profile 20.

ƒ Information on the current device status is stored in the DRIVECOM parameter

"status word".

ƒ Commands in the DRIVECOM parameter "control word" can change the device

status. These commands are represented by arrows in the following diagram.

Switch on device

NOT READY TO SWITCH ON

Status word xxxx xxxx x0xx 0000

Automatically when

initialisation is

completed

SWITCH−ON INHIBIT

Status word xxxx xxxx x0xx 0000

9

Inhibit voltage

xxxx xxxx xxxx xx0x

READY TO SWITCH ON

Status word xxxx xxxx x01x 0001

8

Standstill

xxxx xxxx xxxx

x110

SWITCHED ON

Status word xxxx xxxx x01x 0011

2

Standstill

xxxx xxxx xxxx x110

3

Switch on

xxxx xxxx xxxx x111

FAULT REACTION ACTIVE

Status word xxxx xxxx x0xx 1111

FAULT

Status word xxxx xxxx x0xx 1000

Inhibit voltage

10

xxxx xxxx xxxx xx0x

7

Quick stop

xxxx xxxx xxxx x01x

6

Standstill

xxxx xxxx xxxx x110

Process data transfer

DRIVECOM control

DRIVECOM state machine

13

Fault recognised

Automatically when

fault reaction is completed

14

Reset fault

xxxx xxxx 0xxx xxxx

xxxx xxxx 1xxx xxxx

12

Inhibit voltage

xxxx xxxx xxxx xx01

or

quick stop completed

7

Fig. 7−3 Status diagram of DRIVECOM device control

EDS82ZAFPC010 EN 4.0

45

Enable operation

xxxx xxxx xxxx 1111 and

act. speed value <> 0*

OPERATION ENABLED

Status word xxxx xxxx x01x 0111