Lenze E70ACxS User Manual

PLC Designer

Application Sample i700 - sample project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Software manual

EN

Ä.JjVä

13417353

L

Contents

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 3

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.3 Notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

3 Preconditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

3.1 System requirements _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

3.2 Setting up communication to the Controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

4 What is the Application Sample? _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

4.1 Target of the Application Sample _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

4.2 Overview of the features of the Application Sample _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

4.3 Elements of the Application Sample _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

4.3.1 The L_SMC_AxisBasicControl block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

5 Overview - The structure of the Application Sample _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

5.1 A11_ProgramCalls _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

5.2 A20_Visualisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

5.3 A70_POUs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

5.4 A90_Resources _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

5.4.1 Use of the oscilloscope function: example of AxisX _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

5.4.2 EPM_S202: Digital inputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

5.4.3 EPM_S303: Digital outputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

5.4.4 EPM_S400: Analog inputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

6 Opening the Application Sample _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

6.1 Creating a new project - opening the Application Sample _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

6.2 Updating the Controller in the project (optional) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

6.3 Going online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

6.3.1 Transferring the project to the control system - "logging in" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

6.4 Loading and starting the PLC program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

6.5 Simulation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

7 Getting started - operating the Application Sample _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

7.1 The buttons of the visualisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

7.2 Commissioning an axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

7.3 Motor data parameterisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

7.4 SoftMotion data parameterisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

7.5 Axis control during manual operation: manual control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

7.6 Axis control in the automatic mode: "CyclicMove" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

7.7 Coupling/decoupling of an axis: "GearingAxisY" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

7.8 Holding brake: Application "BrakeAxisZ" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

7.9 EtherCAT diagnostics: "Diagnostic" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

2 Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 DE - 09/2012 - TD11

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This documentation describes the sample project for the i700 servo inverter for commissioning a

Lenze automation system. The used automation system consists of a PLC for "Controller-based

Automation" and drive components connected (via a bus system).

The explanation of the procedure includes the installation of the integrated development

environment, the »PLC Designer«, and the diagnostics of the application.

Read the Mounting Instructions accompanying the controller first before you

start working!

The mounting instructions contain safety instructions that must be observed!

Note!

This documentation supplements the software manuals of the »PLC Designer« and »PLC

Designer«.

Tip!

Information and tools regarding the Lenze products can be found in the download area at:

http://www.Lenze.com

This manual is part of the Controller-based Automation manual collection. The manual collection

consists of the following parts:

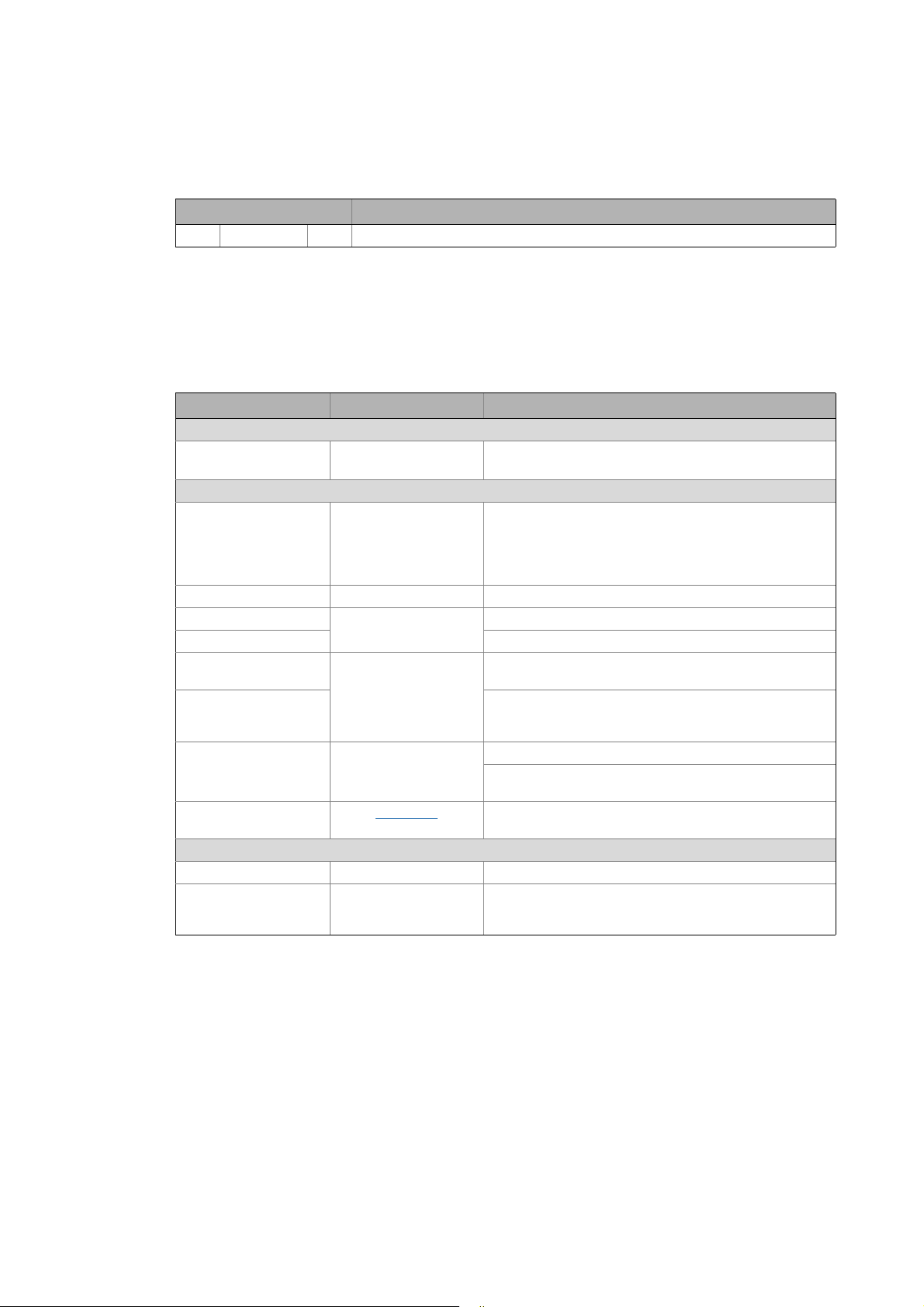

Documentation Subject

System manuals • Controller-based Automation - System structure & configuration

(Software) manual • Controller - Parameter setting & configuration

Communication manuals • Controller-based Automation EtherCAT - Commissioning & configuration

Further software manuals • »PLC Designer«

• Visualisation - System structure & configuration

• Controller-based Automation CANopen - Commissioning & configuration

• Controller-based Automation PROFIBUS - Commissioning & configuration

• »Engineer«

• »Global Drive Control« (»GDC«)

• L-force Controller as gateway - Parameter setting & configuration

• »VisiWinNET® Smart«

•»Backup & Restore«

Information on the use of the controller beyond the field of "Controller-based

Automation" can be found in the system manuals tailored to the application

case.

Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11 3

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

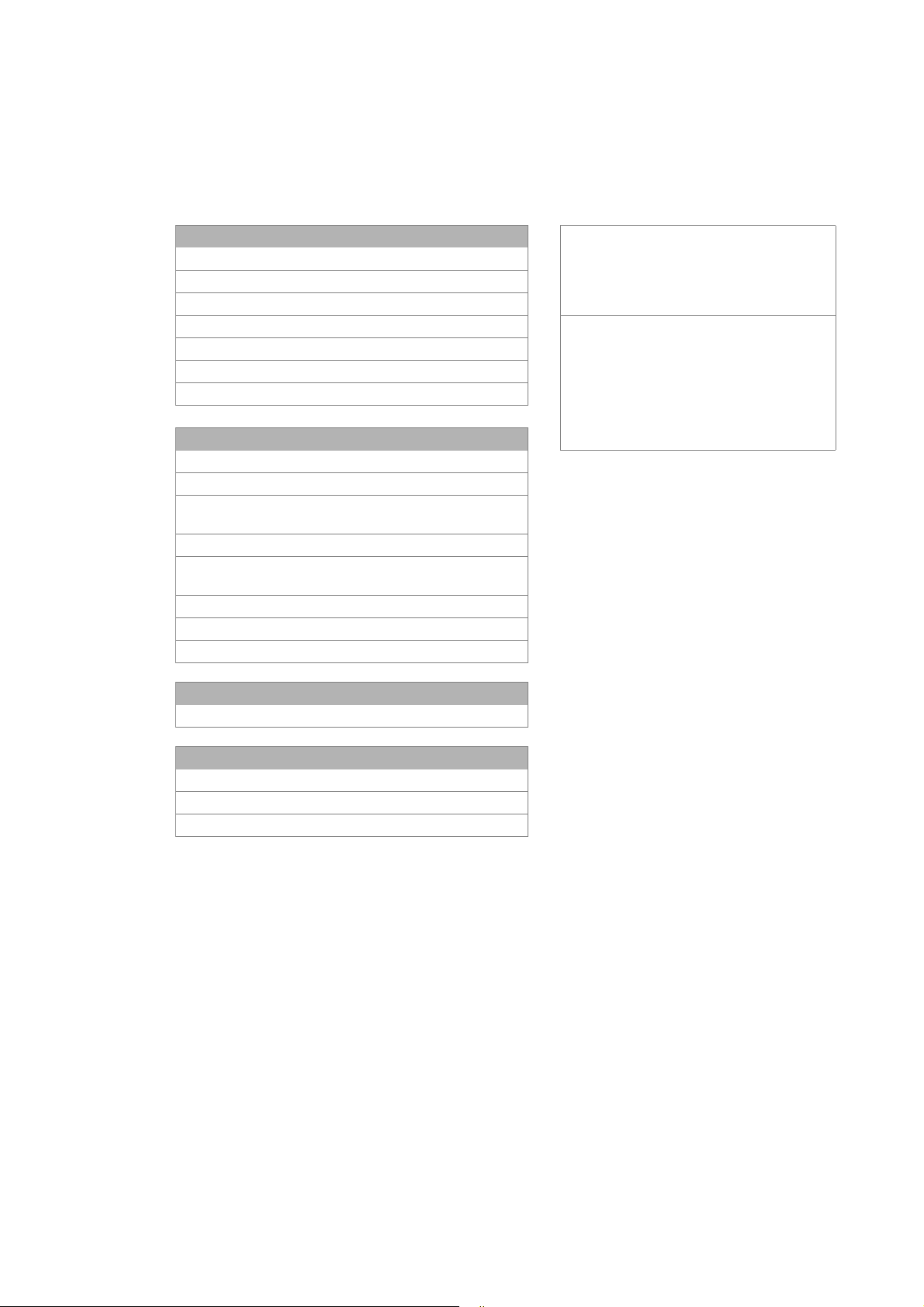

More technical documentation for Lenze components

More information on Lenze components that can be used in connection with Controller-based

automation can be found in the following documentation:

Mounting & wiring Symbols:

MAs Controller Printed documentation

MA i700 servo inverter Online help / PDF file

MAs Servo Drives 9400

MAs Inverter Drives 8400 Abbreviation:

MA I/O system 1000 (EPM-Sxxx) BA Operating instructions

MAs for communication cards (MC-xxx) KHB Communication manual

MAs for communication modules MA Mounting instructions

SW Software manual

Parameterisation, configuration, commissioning SHB System manual

SW L-force Controller

SW Servo-Inverter i700

SW Servo Drive 9400 HighLine/PLC /

Regenerative power supply module

9400 HighLine commissioning guidelines

SW Inverter Drives 8400

StateLine/HighLine/TopLine

SHB I/O system 1000 (EPM-Sxxx)

BAs for servo system ECS (ECSxE, ECSxM)

KHBs for communication modules

Programming

SW 9400 function library

Reuse

SW Application Sample i700

SW Application Samples

SW ApplicationTemplate

Target group

This documentation is directed at all persons who commission and program the Lenze Teachware

case i700 on the basis of the "Application Sample i700" sample project in the context of "Controllerbased Automation".

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the Lenze devices and software version of the engineering tools installed (»PLC

Designer«), the screenshots in this documentation may deviate from the screen representation.

4 Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

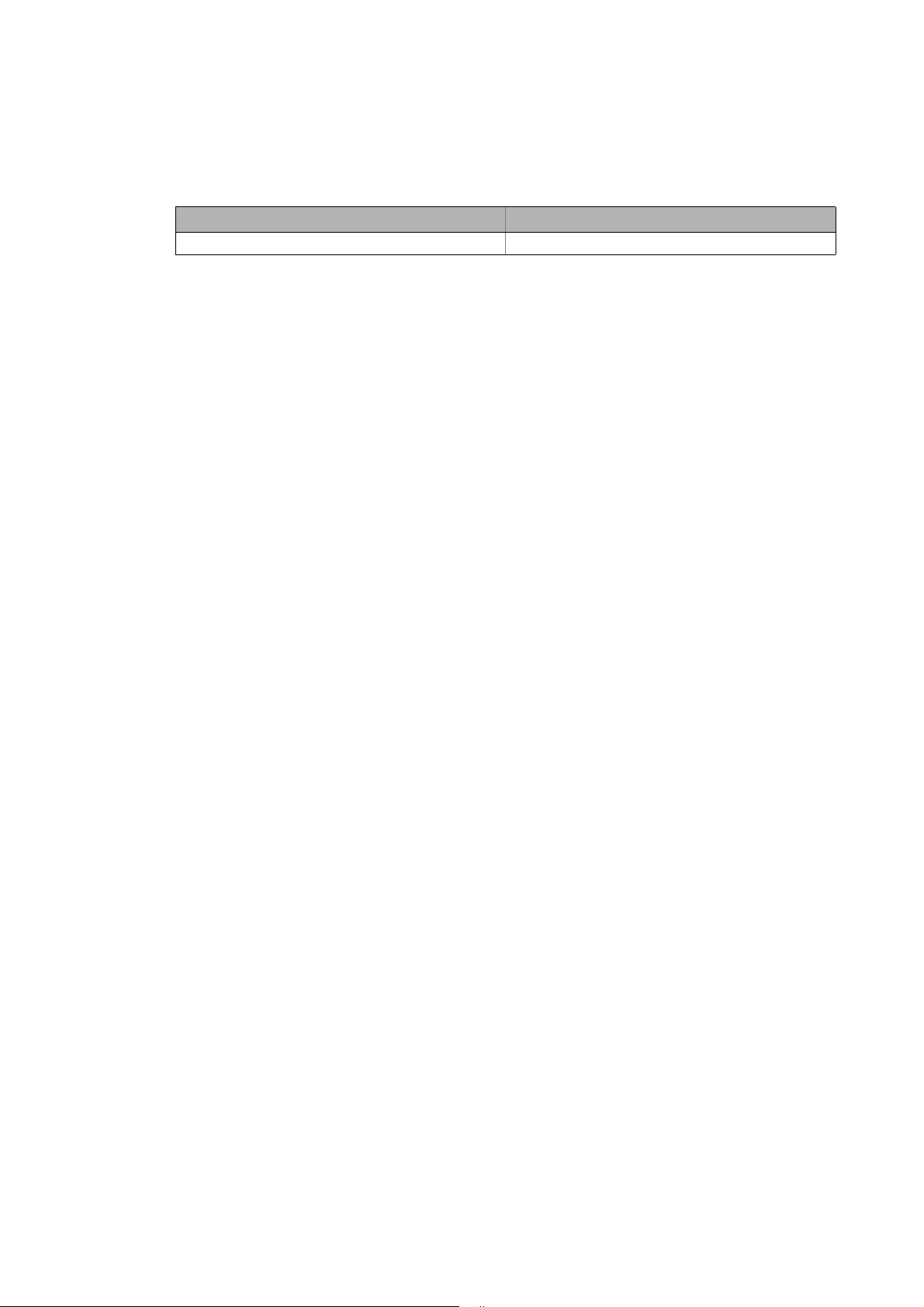

Validity information

The information in this documentation is valid for the following Lenze software:

Software From software version

»PLC Designer« 3.3.x

Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11 5

About this documentation

Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Document history

Version Description

1.0 09/2012 TD11 First edition

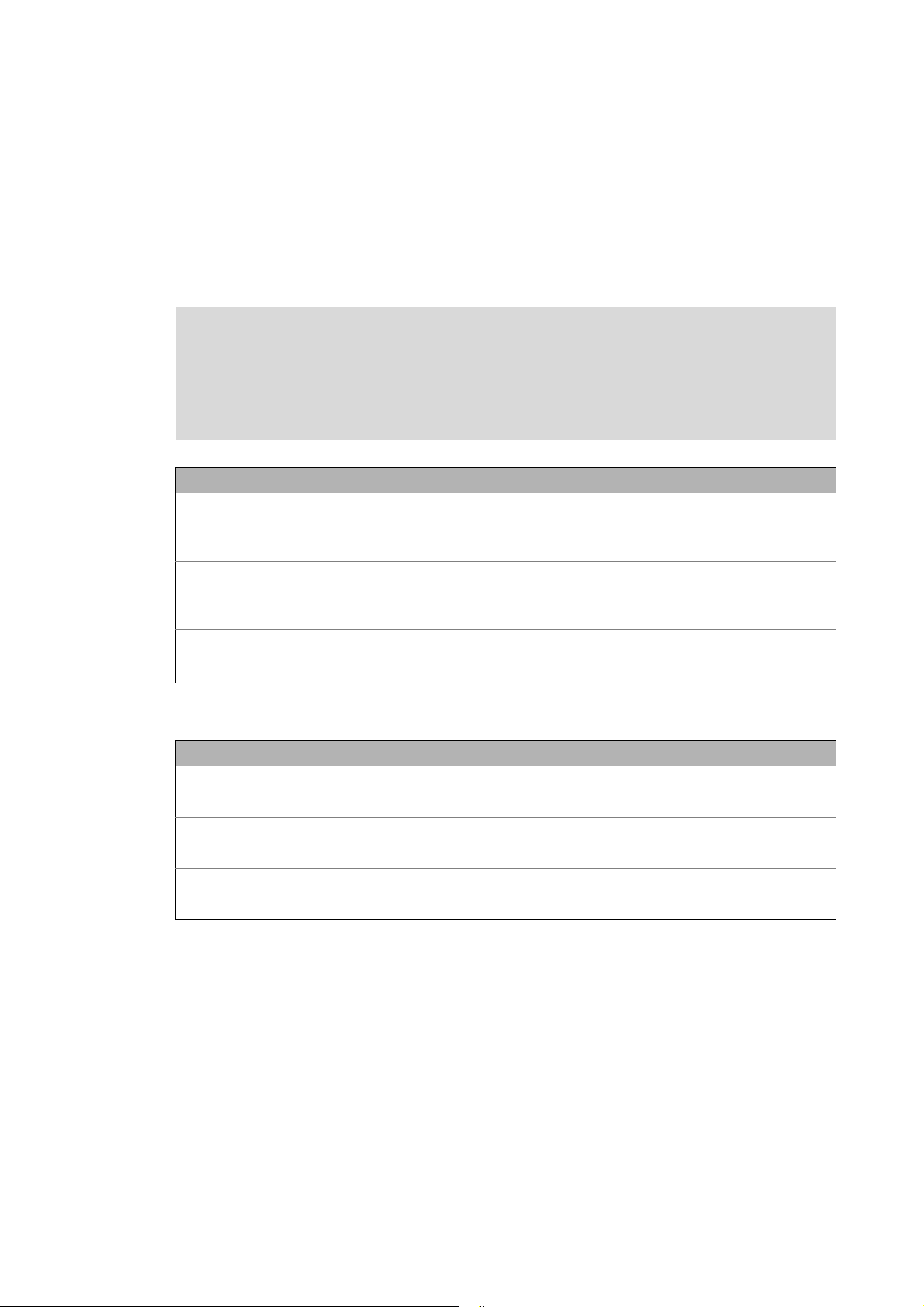

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Display Examples/notes

Numbers

Decimal separator Point The decimal point is generally used.

Example: 1234.56

Text

Version information Text colour blue All pieces of information that only apply to or from a certain

Program name » « »PLC Designer«...

Window Italics The Message window... / The Options ... dialog box

Variable name By setting bEnable to TRUE...

Control element Bold The OK... button / The Copy... command / The Properties...

Sequence of menu

commands

Shortcut <Bold> Use <F1> to open the online help.

Hyperlink underlined

Symbols

Page reference ( 6) Reference to further information: Page number in PDF file.

Step-by-step instructions

controller software version are identified accordingly in this

documentation.

Example: This function extension is available as from

software version V3.0!

tab / The Name ... input field

If the execution of a function requires several commands in

a row, the individual commands are separated by an arrow:

Select File

If a key combination is required for a command, a "+" is

placed between the key identifiers: With <Shift>+<ESC>...

Reference to further information: Hyperlink to further

information.

Step-by-step instructions are marked by a pictograph.

Open to...

6

Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11

About this documentation

Notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Structure of safety instructions:

Pictograph and signal word!

(characterises the type and severity of danger)

Note

(describes the danger and informs how to prevent dangerous situations)

Pictograph Signal word Meaning

Danger! Danger of personal injuries through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of material damage

Reference to an imminent danger that may result in death or serious

personal

injury unless the corresponding measures are taken.

Reference to an imminent danger that may result in death or serious

personal

injury unless the corresponding measures are taken.

Indicates a potential danger that may lead to material damage unless the

corresponding measures are taken.

Application notes

Pictograph Signal word Meaning

Note! Important note for trouble-free operation

Tip! Useful tip for easy handling

Reference to another document

Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11 7

Safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Please observe the following safety instructions when you want to commission a controller or

system using the »Engineer«.

Read the documentation supplied with the controller or the individual

components of the system carefully before you start to commission the devices

with the »Engineer«!

The device documentation contains safety instructions which must be observed!

Danger!

According to today's scientific knowledge it is not possible to ensure absolute freedom

from defects of a software.

If required, systems with integrated controllers have to be equipped with additional

monitoring and protective equipment in accordance with the safety regulations valid in

each case (e.g. law on technical equipment, regulations for the prevention of accidents),

so that an impermissible operating status does not endanger persons or equipment.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there would be a risk of injury by the

moving machine parts.

Stop!

If you change parameters in the »PLC Designer« during an online connection to the

device is established, the changes are directly accepted in the device!

An incorrect parameterisation can result in unpredictable motor movements. By an

unintentional direction of rotation, too high speeds or jerky operation, powered

machine parts can be damaged!

8 Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11

Preconditions

System requirements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Preconditions

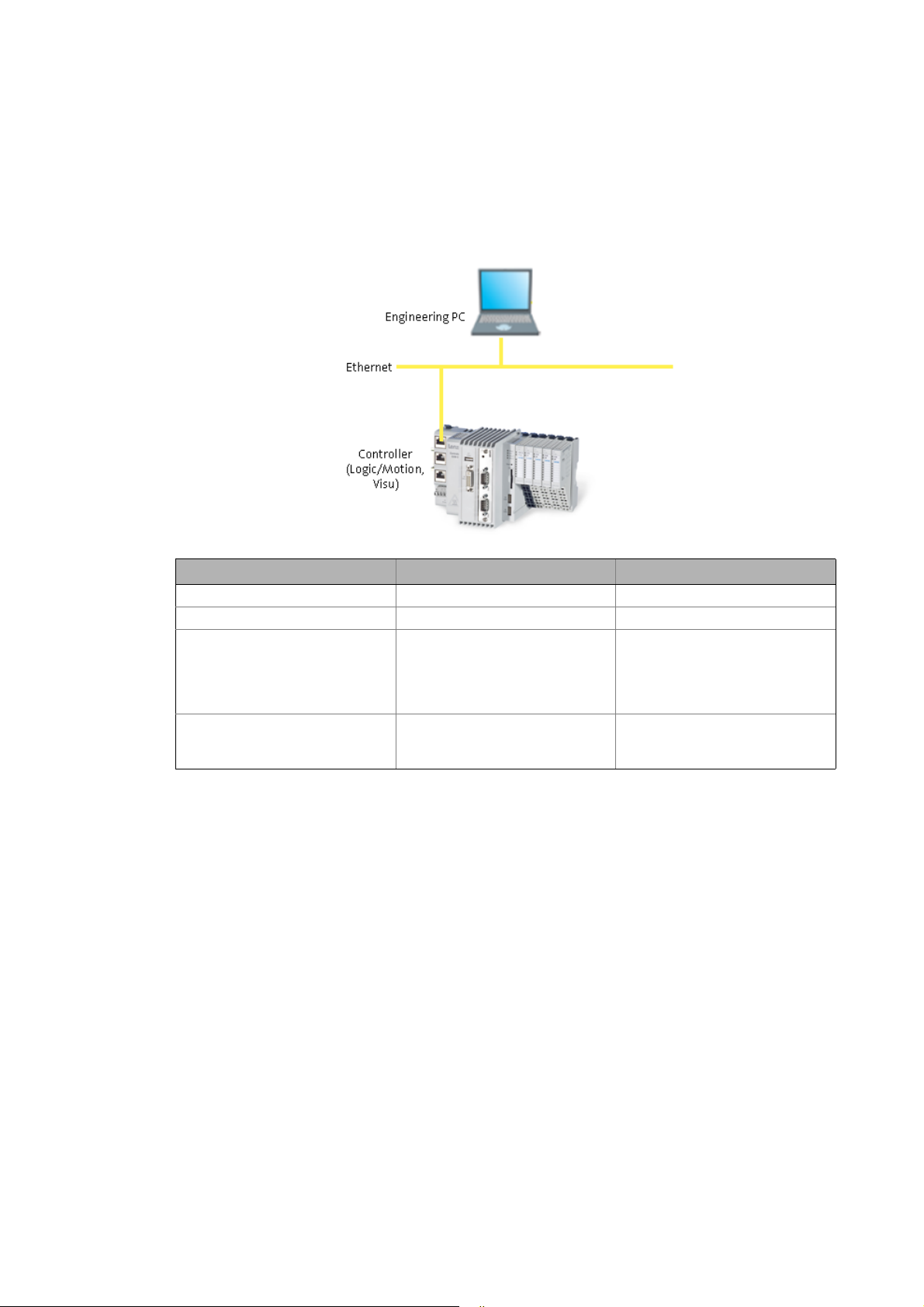

3.1 System requirements

Engineering PC Controller

Hardware PC/notebook PLC (Logic) from firmware V3.3

Operating system Windows XP Windows CE

Required Lenze software »PLC Designer« from V3.3 Runtime Software

Further requirements -Bus system

3.2 Setting up communication to the Controller

• Connect the Engineering PC to the Controller via a network cable. The »PLC Designer« accesses

the Controller via Ethernet.

• Make the IP settings with the »PLC Designer« afterwards.

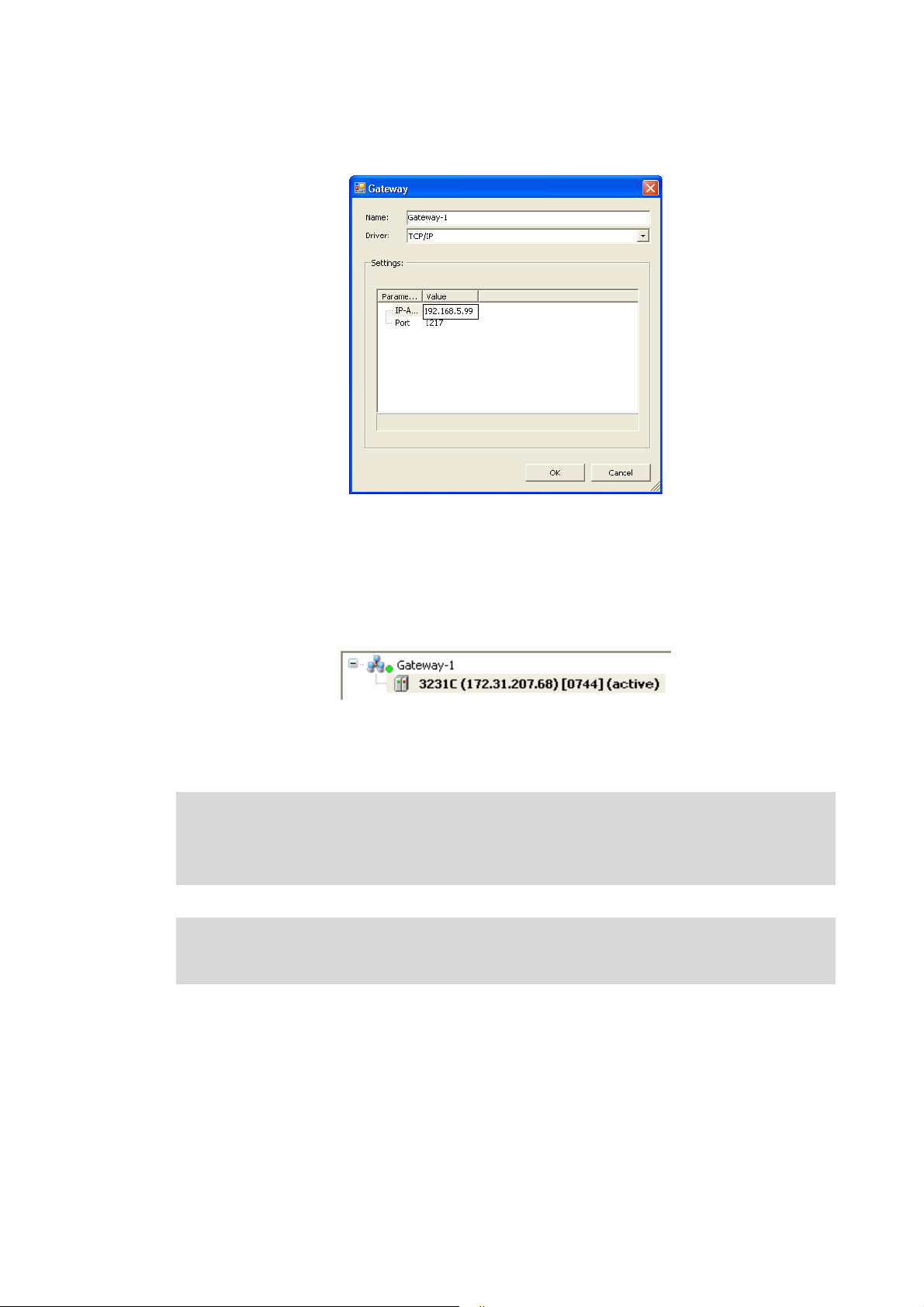

How to check the communication settings:

1. Go to the Device view and double-click the desired Controller.

2. Make the desired settings on the Communication settings tab.

•Click the Add gateway button to insert a gateway.

•Logic

• Motion (for this purpose, the

project data must be updated:

"Update Device")

• EtherCAT bus system

•EtherCAT node

Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11 9

Preconditions

Setting up communication to the Controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• Enter the desired IP address of the Controller.

[3-1] Example: Enter the IP address of the Controller

3. Click OK to add the Controller as gateway.

4. By double-clicking the desired channel (or clicking the Set active path button) set the

channel selected in the Device View below the gateway as active path for control.

• Thus, all communication actions directly refer to this channel.

• The currently active path is represented in bold in the list and "(active)" is attached:

5. A device represented in italics is set as active path but has not been identified during the

last network scan.

Note!

• During initial commissioning, observe the following predefined IP addresses of the

Controllers: 192.168.5.99

Further information can be found in the following documentation:

• Controller - Parameter setting & Configuration

10

Lenze · Servo Inverter i700 | Application Sample · DMS 1.0 EN - 09/2012 - TD11

Loading...

Loading...