Page 1

Engineering Tools

Drive Solution

Designer

Manual EN

Ä.NS?ä

13455030

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 Notes on usage _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

1.1 Licencing and contractual conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

1.2 Terms and conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

1.3 Important information on the program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

2.1 Structure of the documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

2.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

2.3 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

3 User interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

3.1 Control and function elements _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

3.1.1 Menu bar _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

3.1.2 Toolbar _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

3.1.3 Drawing _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

3.1.4 Navigation tree and result tree _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

3.1.5 Input area _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

3.1.6 Notes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

3.2 Shortcuts _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

3.3 Closing the program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

4 Setting up the DSD workplace _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

4.1 Settings during installation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

4.2 Registering and activating DSD licence _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

4.3 Communication with the Lenze DSD server _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

4.3.1 Messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

4.3.2 Software updates _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

4.3.3 Assistance in dealing with problems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

4.4 Language _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

4.5 Settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

4.5.1 "General" register _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

4.5.2 Register "Local area network" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

4.5.3 "Help" tab _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

4.5.4 "Motion" register _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

4.5.5 "Units" tab _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

4.5.6 "Protocol" tab _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

4.5.7 "Customer data" tab _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

4.5.8 "User data" tab _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

4.6 User-specific settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

4.6.1 User-defined defaults _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

5 Managing projects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

5.1 Create new project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

5.1.1 Login template _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

5.2 Open project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

5.2.1 Displaying the project in the project viewer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

5.3 Saving the project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

6 Drive dimensioning tools _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

6.1 Data collection via checklists _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

6.2 Optimising drive solutions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

6.2.1 Creating an alternative _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

6.2.2 Application Tuner _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 59

6.2.3 Project comparison _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

2 Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.3 Dimensioning "easily and quickly" or "complex and precisely" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 62

6.3.1 Roughly estimated calculation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

6.3.2 Product features _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

6.4 Cost optimisation factors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 64

7 Applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

7.1 Overview _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 66

7.2 Basic calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

7.2.1 Torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

7.2.2 Power of the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 69

7.2.3 Motion of the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

7.2.4 Symbols used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

7.3 Belt drive, rotating _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 72

7.3.1 Applications with a horizontal direction of movement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 73

7.3.2 Applications with a vertical direction of movement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 74

7.3.3 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

7.3.4 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

7.4 Omega belt drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

7.4.1 Applications with a horizontal direction of movement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 84

7.4.2 Applications with a vertical direction of movement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

7.4.3 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

7.4.4 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 91

7.5 Rack drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

7.5.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

7.5.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

7.6 Spindle drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

7.6.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

7.6.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

7.7 Wheel drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

7.7.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

7.7.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 109

7.8 Hoist drive without counterweight _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 113

7.8.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 114

7.8.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

7.9 Hoist drive with counterweight _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

7.9.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 123

7.9.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 127

7.10 Chain conveyor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 132

7.10.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 132

7.10.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 135

7.11 Roller conveyor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

7.11.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

7.11.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 140

7.12 Belt conveyors for unit loads _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

7.12.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

7.12.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 146

7.13 Belt conveyor for bulk material _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

7.13.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

7.13.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 152

7.14 Synchronous drive - single roll _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

7.14.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

7.14.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

7.15 Synchronous drive of squeegees _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 162

7.15.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

7.15.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 165

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.16 General rotary drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 168

7.16.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 168

7.16.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 169

7.17 Rotary table drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 170

7.17.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 170

7.17.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 171

7.18 Pump _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

7.18.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

7.18.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 175

7.19 Fan _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 177

7.19.1 Calculations _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 177

7.19.2 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 179

7.20 Importing M-n-operating points _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

7.20.1 Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 182

7.21 Dimension the multi-axis system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 183

7.21.1 Using braking energy _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 183

7.21.2 Combining drive axes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 185

7.21.3 Combining Lenze products _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 191

7.21.4 Dimensioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 192

7.21.5 Parameterising projects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 193

7.21.6 Defining options _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 195

7.22 Winding drive for rewinder/unwinder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 198

7.22.1 Rewinder (single) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 198

7.22.2 Unwinder (single) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 203

7.22.3 Dimensioning strategies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 208

7.22.4 Traction-controlled winding drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 210

7.22.5 Checking emergency-off scenarios _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 211

7.22.6 Application data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 212

7.22.7 Data for the motion _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 219

8Motion design _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 224

8.1 Selection of motion profile _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 224

8.2 MotionDesigner _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 225

8.2.1 Control and function elements _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 226

8.2.2 Toolbar _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 227

8.2.3 Screen divider _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 228

8.2.4 Object area _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 229

8.2.5 Managing motion profiles _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 234

8.2.6 Graphic area _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 239

8.2.7 Parameter area: Description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 247

8.2.8 Positioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 255

8.2.9 Parameter area: Data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 257

8.2.10 Application notes for motion profiles _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 263

8.3 Predefined motion profile according to operating mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 270

8.3.1 S1, continuous operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 270

8.3.2 S2, short-term operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 271

8.3.3 Intermittent operation S3, S4, S5 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 272

8.3.4 Intermittent load S6, S7 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 273

8.3.5 Description of the data for the entry _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 274

9 Mains and environment _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 277

9.1 Electrical supply system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 277

9.1.1 Power system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 277

4 Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9.2 Ambient conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 278

9.2.1 Max. ambient temperature, motor/gearbox _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 278

9.2.2 Max. ambient temperature, inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 279

9.2.3 Site altitude _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 280

9.3 Calculation of the mains current _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 281

10 Structure of the drive axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 282

10.1 Mechanical drive axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 283

10.1.1 Lenze gearbox _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 283

10.1.2 Additional drive element _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 284

10.1.3 Feedback _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 284

10.1.4 Electromechanical brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 284

10.2 Electrical drive axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 285

10.2.1 Inverter with mains supply (single-axis application) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 285

10.2.2 Inverter with DC supply (multi-axis application) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 285

10.3 Drive concept _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 286

10.3.1 Gearbox features _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 287

10.3.2 Motor properties _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 289

10.3.3 Motor/gearbox: Direct mounting or standard mounting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 293

10.3.4 Inverter properties _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 294

10.3.5 Overview of motor/inverter control types _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 300

10.3.6 Selection help: Products for applications (without winders) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 304

10.3.7 Selection help: Products for winding drive systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 305

10.3.8 Selection help: Control types for winding drive systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 307

11 Drive Dimensioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 308

11.1 Preselection of the geared motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 308

11.1.1 Additional moment of inertia _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 308

11.1.2 Mounting position _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 309

11.1.3 Average daily operating time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

11.1.4 Additional drive element (K) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

11.1.5 Minimum ratio (K) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 312

11.1.6 Maximum ratio (K) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 312

11.2 Motor selection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 313

11.2.1 Motors for 87-Hz operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 313

11.2.2 Motors for 120-Hz operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 313

11.2.3 Dimensioning guidelines and dimensioning information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 314

11.2.4 Field weakening for winding drives _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 314

11.2.5 M-n characteristic _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 316

11.2.6 Thermal utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 318

11.2.7 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 319

11.2.8 Load-matching factor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 321

11.2.9 Radial forces/axial forces _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 325

11.3 Mechanical brake selection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 326

11.3.1 Spring-applied brake (BFK) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 327

11.3.2 Permanent magnet holding brake (PMB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 327

11.3.3 Dimensioning criteria _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 328

11.3.4 Holding torque diagram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 329

11.3.5 Design _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 330

11.3.6 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 331

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 5

Page 6

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.4 Lenze gearbox selection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 332

11.4.1 Check of the torque load _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 332

11.4.2 Check of the speed load _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 337

11.4.3 Radial and axial forces _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 337

11.4.4 M-n characteristic _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 338

11.4.5 Thermal utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 339

11.4.6 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 341

11.5 Selection of an additional drive element _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 344

11.5.1 Type identifier _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 344

11.5.2 Ratio _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 344

11.5.3 Efficiency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 344

11.5.4 Moment of inertia _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 344

11.5.5 Permissible torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 345

11.5.6 Constant torque loss _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 345

11.6 Inverters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 346

11.6.1 Dimensioning criteria _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 346

11.6.2 Preselection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 353

11.6.3 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 355

11.7 Motor components _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 357

11.7.1 Feedback selection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 357

11.7.2 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 360

12 Components in the DC bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 361

12.1 Supply concept _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 361

12.2 9400 power supply module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 362

12.2.1 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 362

12.2.2 Utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 363

12.3 9400 regenerative power supply module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 364

12.3.1 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 364

12.3.2 Utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 365

12.4 i700 power supply module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 366

12.4.1 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 366

12.4.2 Utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 367

12.5 Selection of components _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 367

12.6 Brake resistor selection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 368

12.6.1 Number of integrated brake transistors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 368

12.6.2 Interconnection of brake resistors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 369

12.6.3 Selection table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 370

12.6.4 IP enclosure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 371

12.6.5 Integrated brake transistor utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 372

12.6.6 Brake resistor utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 374

13 Details on Lenze products _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 377

14 Energy efficiency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 378

14.1 Lenze BlueGreen Solutions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 379

14.1.1 Basic data for the calculation of energy costs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 379

14.1.2 Project data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 380

14.1.3 Diagrams and project comparison _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 381

14.1.4 Cost comparison TOP 3 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 381

14.2 Tips for optimising the drive systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 382

14.2.1 Cost-cutting potentials in applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 383

14.2.2 Optimising the single-axis application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 384

14.2.3 Optimising the multi-axis application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 384

6 Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 7

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

15 Results: comparing, optimising, logging _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 385

15.1 Drawing _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 386

15.1.1 Diagrams for the components _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 387

15.2 Results _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 390

15.3 Protocols _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 391

15.3.1 Summarised protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 391

15.3.2 Detailed protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 391

15.3.3 Commissioning data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 392

15.3.4 SAP list of the configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 392

15.3.5 Output settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 393

15.4 Comparison and additional results _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 394

15.4.1 Application Tuner _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 394

15.4.2 Comparison of the open projects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 394

15.4.3 BlueGreen

Solutions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 394

15.5 Construction data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 395

15.5.1 CAD data

geared motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 395

15.5.2 CAD data

inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 395

15.6 Reserves with regard to the drive dimensioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 396

15.6.1 Dynamic reserves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 396

15.6.2 Stationary reserves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 396

15.6.3 Speed reserves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 397

15.6.4 Torque reserves of the motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 397

15.6.5 Reserves for inverters, power supply modules, regenerative power supply modules _ _ _ 397

15.6.6 Reserves for brake resistors and brake choppers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 398

15.6.7 Reserves for gearboxes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 399

15.6.8 Reserves for drive systems with an active load _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 400

15.6.9 Reserves for drive systems with a passive load _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 400

16 Auxiliary means _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 401

16.1 Auxiliary means integrated in the DSD _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 402

16.1.1 Auxiliary calculator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 402

16.1.2 Tables of values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 423

16.1.3 MotionDesigner _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 424

16.1.4 Lenze intranet _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 424

16.1.5 Lenze Internet _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 425

16.1.6 Lenze «Drive Solution Catalogue» (DSC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 425

17 Restrictions of the drive dimensioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 426

17.1 Field weakening _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 426

17.2 Worldwide mains voltages and supply forms _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 427

17.3 Undervoltages: Impact on operational performance _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 427

17.4 Highly dynamic applications with acceleration times < 50 ms _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 427

17.5 Feedback systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 427

17.6 Mechanical brakes for winding drives _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 428

17.7 Saturation effects in the motor at > 200 % Mrated _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 429

17.8 Radial and axial loads of the motor or gearbox shaft _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 430

17.9 Service brake, holding brake with safety function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 431

17.10 Displacement of the M-n characteristic _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 432

17.11 Maximum permissible motor cable length _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 433

17.12 Effects of low switching frequencies on the motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 433

17.13 Motor temperature monitoring acc. to UL 508C _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 434

17.14 Operation of inverters on the earth-leakage circuit breaker _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 435

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 7

Page 8

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

17.15 Qualitative requirements with regard to the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 435

17.16 System disturbances _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 435

17.17 Parallel operation of several motors on one inverter (group drives) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 436

17.18 Parallel operation of several motors on several inverters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 437

17.19 ATEX for gearbox _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 437

17.20 Applications with low field frequencies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 438

17.21 Emergency-off scenarios _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 438

17.22 Switching in the motor cable _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 438

17.23 Filter in the motor cable _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 438

17.24 Application of bearing current chokes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 439

17.25 Improved motor control with temperature detection (KTY) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 439

17.26 Cooling servo motors without gearbox via mounting flange _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 440

17.27 Permanent load at low motor speeds for applications acc. to UL _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 440

18 Drive dimensioning messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 441

18.1 Applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 441

18.1.1 Ratio of the tensile forces F

18.1.2 Ratio of the tensile forces F

18.1.3 Difference of the tensile forces F

18.1.4 Speed of the application = 0 (standstill) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 442

18.1.5 Safety check of controller inhibit failed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 442

18.1.6 No values available for the torque of the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 442

18.1.7 Parameter of the motion profile is not evaluated _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 443

18.1.8 Utilisation of the DC busbar system is xxx % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 443

18.1.9 Torque setting range > 50 for winding control mode xxx _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 443

18.1.10 Low-friction dancer required for tensile force setting range xxx _ _ _ _ _ _ _ _ _ _ _ _ _ _ 444

18.1.11 Value range for the reel diameter not plausible _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 444

18.1.12 Value range for the tensile force of the winder not plausible _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 444

18.2 Drive system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 445

18.2.1 Utilisation >100 %, regarding the max. torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 445

18.2.2 In the DC-bus connection, the braking circuit of the inverter is not checked _ _ _ _ _ _ _ _ 445

18.2.3 In the DC-bus connection, the EMC protection of the device is ineffective _ _ _ _ _ _ _ _ _ 445

18.2.4 Product has been discontinued _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 446

18.2.5 No effective starting current limitation available _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 446

18.2.6 Dissipation of the regenerative power is not guaranteed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 446

18.2.7 Checking the drive system and the tensile force sensor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 446

18.2.8 Torque setting range yyy requires measures _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 447

18.2.9 Torque setting range yyy and tensile force setting range zzz require measures _ _ _ _ _ _ 447

18.2.10 Max. torque for emergency stop exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 448

18.3 Additional drive element _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 449

18.3.1 Rated torque loss is exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 449

18.3.2 Min. ratio (K) is higher than max. ratio (K) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 449

18.4 Lenze gearbox _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 450

18.4.1 Utilisation >100 % regarding the equivalent torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 450

18.4.2 Utilisation >200 %, regarding the max. torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 450

18.4.3 Utilisation >100 % regarding the max. speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 451

18.4.4 Utilisation >100 % regarding the thermal speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 451

18.4.5 Utilisation of the clutch >100 % regarding the torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 451

18.4.6 Utilisation of the clutch >100 % regarding the speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 452

18.4.7 Thermal overload when mineral gearbox oil is used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 452

18.4.8 Utilisation is xxx %, regarding the max. torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 452

18.4.9 Load of the shaft sealing ring is xxx %, regarding the speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 453

18.4.10 Wear of the gearbox >100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 453

18.4.11 Using synthetic oil for gearboxes of the winding application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 453

/ F

in

out

> limit value _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 441

out

/ Fin > limit value _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 441

- F

in

> limit value _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 441

out

8 Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 9

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

18.4.12 No product options available _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 454

18.5 Lenze motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 455

18.5.1 Utilisation >100 %, regarding the effective torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 455

18.5.2 Max. motor speed is higher than the permissible motor speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 455

18.5.3 Max. motor torque is higher than the permissible motor torque _ _ _ _ _ _ _ _ _ _ _ _ _ _ 455

18.5.4 Motor is operated in the field weakening range _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 456

18.5.5 Max. mismatch is higher than permissible mismatch _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 456

18.5.6 Motor speed too low _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 456

18.5.7 Max. permissible motor current of yyy is exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 457

18.5.8 Overload of the motor >xxx % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 457

18.5.9 Max. permissible ambient temperature of the blower is exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ 457

18.5.10 A continuous operation characteristic for inverter operation is not available _ _ _ _ _ _ _ 458

18.5.11 Motor temperature too high at switching frequency < 8 kHz _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 458

18.5.12 The limit value of xxx % of the rated torque is exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 458

18.5.13 Compliance of the ErP Directive 2009/125/EC _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 459

18.5.14 Overdimensioned motor in the case of traction-controlled winding drive _ _ _ _ _ _ _ _ _ 459

18.5.15 Speed-controlled winding drive may show unstable behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ 459

18.5.16 Field weakening factor k

18.6 Brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 461

18.6.1 Rated torque/dimensioning torque < safety factor of the brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ 461

18.6.2 Service brake is not checked _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 461

18.6.3 No brake available _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 461

18.6.4 Permanent magnet holding brake is not suitable for hoist drives _ _ _ _ _ _ _ _ _ _ _ _ _ 462

18.7 Feedback _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 463

18.7.1 Inverter/feedback combination not possible _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 463

18.7.2 No feedback selected _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 463

18.7.3 Feedback system is not checked _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 463

18.7.4 Feedback system for safety-oriented applications is not checked _ _ _ _ _ _ _ _ _ _ _ _ _ 464

18.8 Inverters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 465

18.8.1 Ambient temperature too high _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 465

18.8.2 Max. permissible site altitude exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 465

18.8.3 Max. output current exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 465

18.8.4 Max. thermal utilisation >100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 466

18.8.5 Control mode not suitable for hoist drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 466

18.8.6 Inverter designed as double axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 466

18.8.7 Current resolution is not adapted to the motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 467

18.8.8 Utilisation of the inverter >100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 467

18.8.9 Utilisation of the inverter too high after mains connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 467

18.8.10 Control mode VFCplus without feedback is not permissible _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 468

18.8.11 The SLVC control mode is not permissible for inverters >55 kW _ _ _ _ _ _ _ _ _ _ _ _ _ _ 468

18.8.12 Too low braking torques at low speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 468

18.8.13 Motor limit rating is exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 468

18.8.14 The inverter cannot provide the rated output current _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 469

18.8.15 VFCplus eco control mode for quasi-stationary drives _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 469

18.8.16 Activate VVC control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 469

18.8.17 SLVC and VFCplus control modes not possible for synchronous motors _ _ _ _ _ _ _ _ _ _ 470

18.8.18 No product options available _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 470

18.8.19 Mains choke required _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 470

18.8.20 Special measures for operation with increased rated power _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 470

18.8.21 Motor control xxx not suitable for winding control mode yyy _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 471

18.8.22 Motor control xxx suitable to a limited extent for winding control mode yyy _ _ _ _ _ _ _ 471

18.8.23 No electrical brake components available _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 471

18.8.24 I×t utilisation of the brake transistor is >100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 471

18.8.25 Thermal utilisation of the inverter is > 80 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 472

> as winding ratio q _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 460

f

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 9

Page 10

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

18.9 Regenerative power supply module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 473

18.9.1 Ambient temperature too low _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 473

18.9.2 Ambient temperature too high _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 473

18.9.3 Max. site altitude exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 473

18.9.4 Utilisation (supply) relative to the max. DC-bus current > 100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ 473

18.9.5 Utilisation (supply) relative to the continuous DC-bus current > 100 % _ _ _ _ _ _ _ _ _ _ 474

18.9.6 Utilisation relative to the permissible continuous power exceeded _ _ _ _ _ _ _ _ _ _ _ _ 474

18.9.7 Max. DC-bus current (power recovery) too high _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 474

18.9.8 Continuous DC-bus current (power recovery) too high _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 474

18.9.9 I×t utilisation of the brake transistor is >100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 475

18.9.10 Permissible pulse power is exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 475

18.9.11 Permissible power of the regenerative power supply module is exceeded _ _ _ _ _ _ _ _ _ 475

18.10 Supply module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 476

18.10.1 Ambient temperature too low _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 476

18.10.2 Ambient temperature too high _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 476

18.10.3 Max. site altitude exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 476

18.10.4 Utilisation exceeded, regarding the max power (supply) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 476

18.10.5 Utilisation exceeded, regarding the max. power (power recovery) _ _ _ _ _ _ _ _ _ _ _ _ _ 477

18.10.6 Utilisation exceeded, relative to the max. power of the brake transistor _ _ _ _ _ _ _ _ _ _ 477

18.10.7 Utilisation >100 %, regarding the DC-bus power (supply) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 477

18.10.8 Utilisation of the power supply module in supply mode is > 100 % _ _ _ _ _ _ _ _ _ _ _ _ _ 477

18.10.9 Utilisation of the power supply module is >100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 478

18.11 Brake chopper _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 479

18.11.1 Ambient temperature of the brake chopper too high _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 479

18.11.2 Permissible site altitude of the brake chopper exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 479

18.11.3 Permanent utilisation of the brake chopper > 100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 479

18.11.4 Utilisation >100 %, regarding the peak braking power _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 480

18.11.5 Regenerative power is not dissipated safely _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 480

18.12 Brake resistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 481

18.12.1 Resulting brake resistance too low _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 481

18.12.2 Permanent utilisation of the equivalent resistance > 100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 481

18.12.3 Max. utilisation of the equivalent resistance is >100 % _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 481

18.12.4 Max. permissible resistance value is exceeded _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 482

18.12.5 Thermal time constant of the brake resistor is too small _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 482

18.12.6 Temperature monitoring of the cartridge responds _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 482

18.13 User motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 483

18.13.1 Limited check of the user motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 483

18.13.2 No options available for the user motor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 483

19 Feedback, help & support _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 484

19.1 Acquisition of application data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 484

20 Glossary _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 486

Your opinion is important to us! _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 494

10 Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 11

1 Notes on usage

1.1 Licencing and contractual conditions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 Notes on usage

1.1 Licencing and contractual conditions

The use of the »Drive Solution Designer« is only permitted if the user accepts the licencing and contractual conditions in the currently valid version.

• The valid version of the licencing and contractual conditions can be found under

http://www.Lenze.com

1.2 Terms and conditions

For deliveries and counselling services the respective valid terms and conditions of the Lenze group

apply.

• The valid terms and conditions can be found under

http://www.Lenze.com

1.3 Important information on the program

The »Drive Solution Designer« supports you on the basis of Lenze products, in order to find a correct

and feasible solution for a drive task.

• For this purpose, a knowledge base with inverters, motors, gearboxes, electrical brake units, me-

chanical brakes, and feedback systems is stored in the »Drive Solution Designer«, which is used

for the calculation of the drive solution.

• The »Drive Solution Designer« not only calculates the physical connections by means of formu-

las, but filters suggested solutions from the knowledge base according to different criteria.

Note!

The product-specific data of drive components contained in this documentation are not

subject to a regular revision service!

In case of doubt, the information in the current product documentation (catalogues, Operating Instructions, System Manuals, etc.) available in printed form and via the internet

is valid!

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 11

Page 12

1 Notes on usage

1.3 Important information on the program

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Why have we developed the DSD?

Drive systems become more and more powerful and have to be optimally adapted to mechatronic

requirements. The cost pressure in the field of engineering increases permanently. At the same

time, however, less time is available for planning, dimensioning, and selecting the drive system.

These high market requirements have motivated us to develop an efficient software which can carry out complex calculations of drive physics. The program is based on complex product knowledge

and can be easily used by every engineer. With the DSD you can solve your drive task professionally

in a few minutes and document it consistently. Like this, others are able to follow your calculations

anytime, too. Moreover, the DSD serves to optimise the application and the drive system regarding

energy efficiency.

Who has developed the DSD?

The program was developed by drive specialists and computer scientists in cooperation with experienced Lenze sales staff. The cooperation of this interdisciplinary development team makes it possible to carry out practically relevant dimensioning processes with the DSD.

Who has worked with the DSD so far?

Today, Lenze sales staff is working with DSD worldwide. Already since 2002 we have been gaining

experience with this kind of drive dimensioning program. On the basis of this experience the DSD

was advanced and optimised. Now we want to provide the program to a broad range of customers.

What is dimensioned with the DSD and what isn't?

A dimensioning includes the drive components: gearbox, motor, inverter, encoder on the motor

side, electrical brake units, regenerative power supply modules, and electromechanical brakes.

Further accessories as e. g. mains filters, automation modules, drive software etc. are not yet configured by the DSD at present and can for example be determined via the electronic catalogue Drive

Solution Catalogue (DSC).

• The Drive Solution Catalogue (DSC) can be found in the internet:

http://www.Lenze.com

"E-catalogue" area

12

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 13

1 Notes on usage

1.3 Important information on the program

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Who is responsible for the dimensioning result?

In the past years the DSD has stood the test of time during countless drive dimensioning processes.

In the context of our quality management the program is maintained continuously.

• In the "Downloads" area at http://www.Lenze.com

are provided.

• The Application Knowledge Base (AKB) is an important means of support for your work with the

DSD.

In the AKB you'll find:

• Release notes (notes for restrictions)

• Frequently Asked Questions (FAQ)

• Tips and tricks

• The AKB can be found in the internet:

http://AKB.Lenze.de

All drive dimensionings with the DSD primarily are based on your default settings and the data that

you have entered. When the program-based calculations are carried out, we therefore depend on

correct and complete information by the customer. If our counselling services or program calculations are incorrect, unfeasible, or incomplete, and if this is due to incorrect and incomplete information by the respective user, liability by Lenze is excluded.

If error messages of the program cannot be eliminated by other entries, or if there are other doubts

during the use of the program, please consult your responsible Lenze sales representative at any

rate.

, free-of-charge service packs and updates

The dimensioning calculated by the DSD is based on general physical laws. If products of other manufacturers are used, of course Lenze does not give a warranty for their function. After all: The DSD

carries out physical drive dimensioning. Characteristics of the operational performance of a drive

solution therefore cannot be taken into consideration necessarily.

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 13

Page 14

2 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 About this documentation

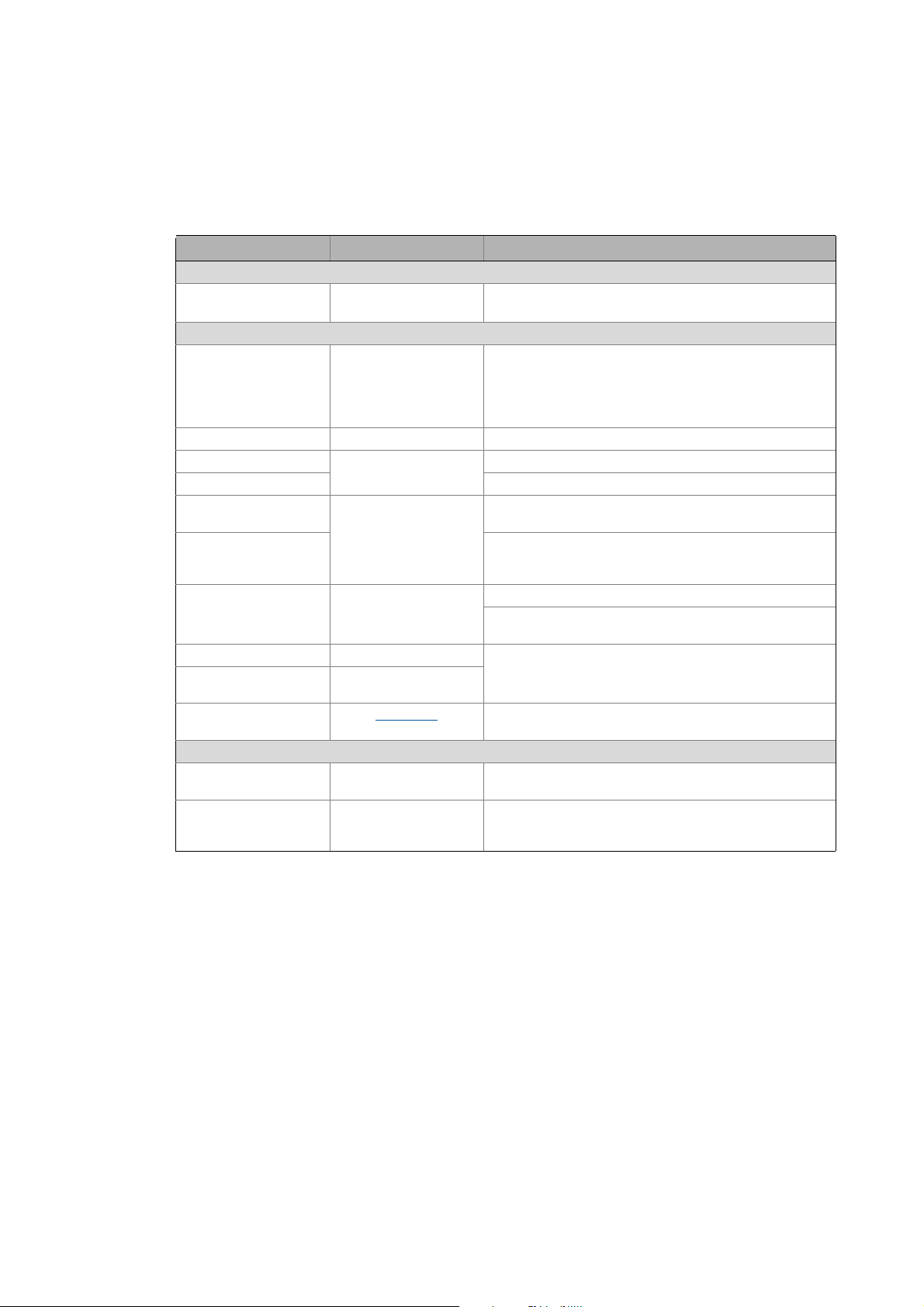

Target group

This documentation is directed at all persons who want to dimension drive systems with the »Drive

Solution Designer«Engineering software.

Information regarding the validity

This documentation applies to the Lenze »Drive Solution Designer« from version 4.1 onwards.

Document history

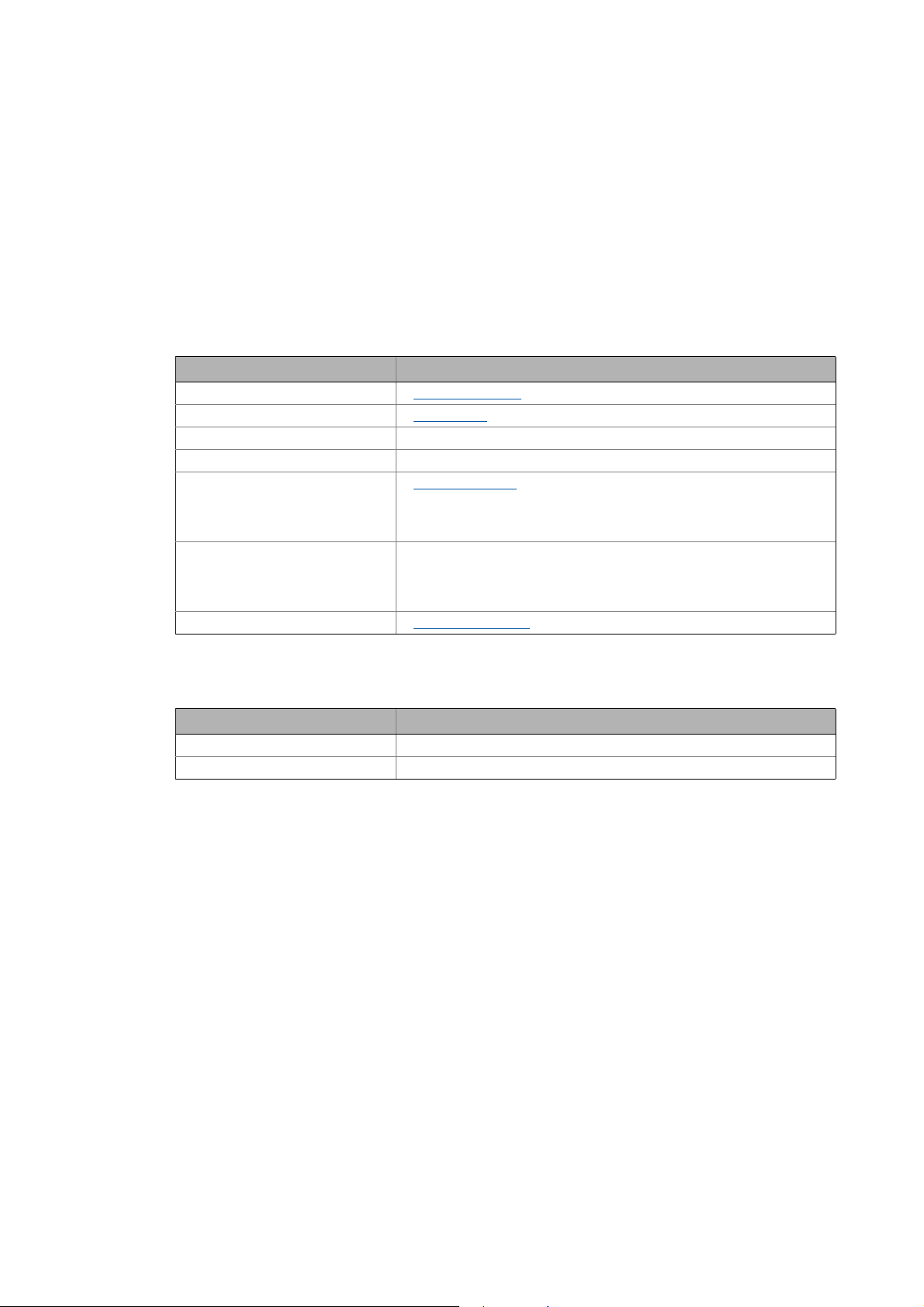

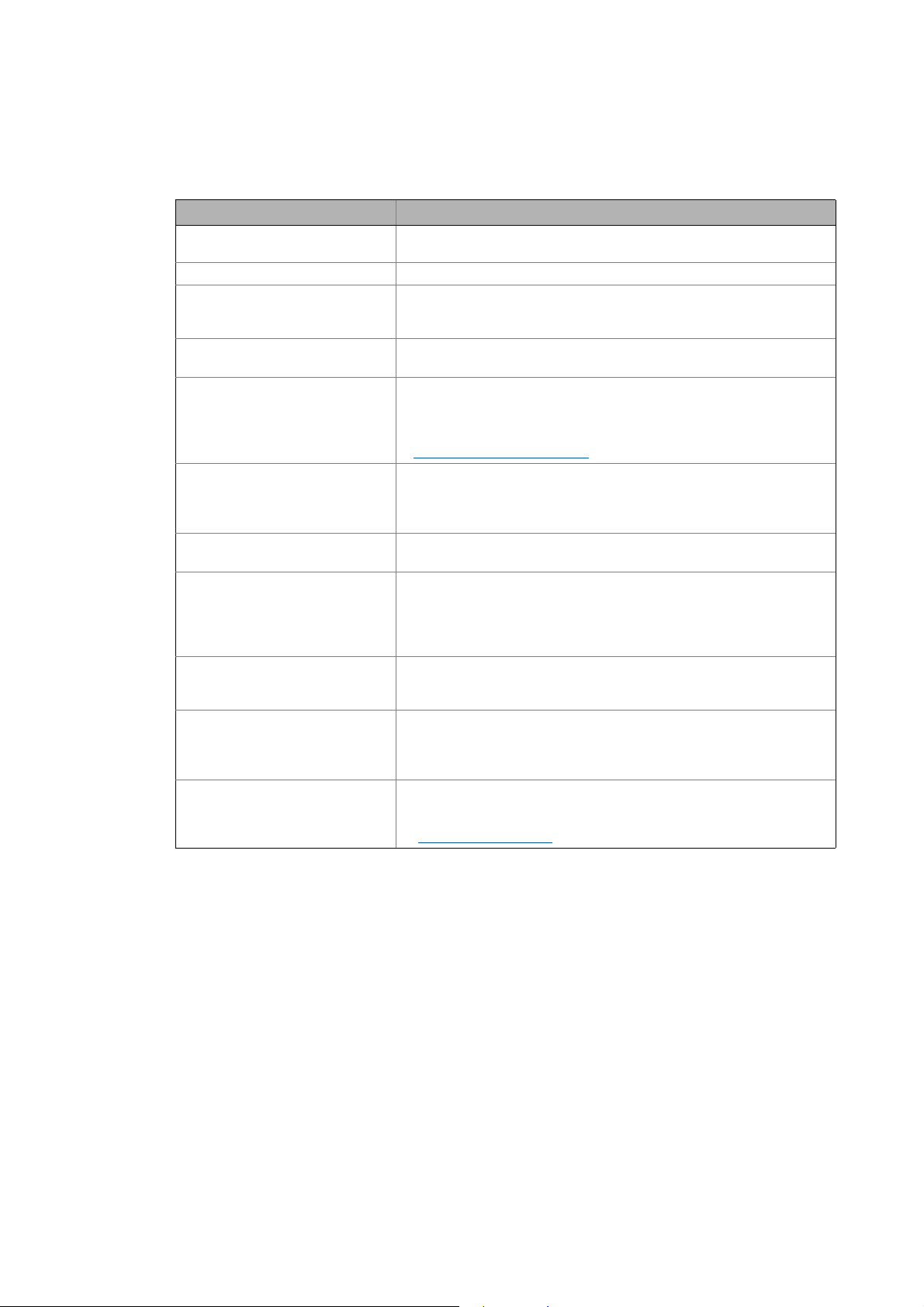

Version Description

4.2 12/2013 TD23 Revision for DSD version 4.1

4.1 07/2013 TD23 Revision for DSD version 4.0

4.0 02/2013 TD23 Partly revised for DSD version 4.0

3.1 01/2012 TD23 Descriptions for multi-axis application, structure of the drive axis, DC bus, energy ef-

3.0 02/2011 TD23 Revision for DSD version 3.0

ficiency, warning signals extended; errors corrected.

14 Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 15

2 About this documentation

2.1 Structure of the documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.1 Structure of the documentation

•In the chapter "User interface" you get to know the user interface of the »Drive Solution Design-

er«.

( 18)

•In the chapter "Setting up the DSD workplace

of the DSD.

( 41)

" it is described how you change the basic settings

•In the chapter "Drive dimensioning tools

are described.

( 55)

• In the chapter "Managing projects

• In the chapter "Applications

calculations.

( 65)

• In the chapter "Motion design

" the applications provided in the DSD are described with detailed

" the different motion profiles are described. ( 224)

• In the chapter "Mains and environment

scribed.

( 277)

• In the chapter "Structure of the drive axis

define the mechanical and electrical drive axis and the drive concept.

• In the chapter "Drive Dimensioning

nents are described.

( 308)

• In the chapter "Components in the DC bus

the auxiliary multi-axis calculator are described.

•The "Drive dimensioning messages

during the configuration of the application.

• In the chapter "Auxiliary means

" you are provided with information on the auxiliary calculators

and value tables integrated in the DSD.

• In the chapter "Details on Lenze products

• In the chapter "Restrictions of the drive dimensioning

" the required preparations for the project to be created

" the actual work on a DSD project is described. ( 52)

" the electrical supply systems for the drive are de-

" you are provided with comprehensive information to

( 282)

" the parameters for dimensioning the individual compo-

" the components in the DC bus and the function of

( 361)

" chapter describes messages, notes and tips which can occur

( 441)

( 401)

" options for Lenze products are described. ( 377)

" the operating modes & scenarios that

are not checked or only checked to a limited extent by the DSD are described.

• In the chapter "Results: comparing, optimising, logging

the DSD are described.

•In the chapter "Feedback, help & support

( 385)

", among other things, you are provided with informa-

tion on the acquisition of application data integrated in the DSD.

" the different result presentations of

( 484)

( 426)

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 15

Page 16

2 About this documentation

2.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Conventions used

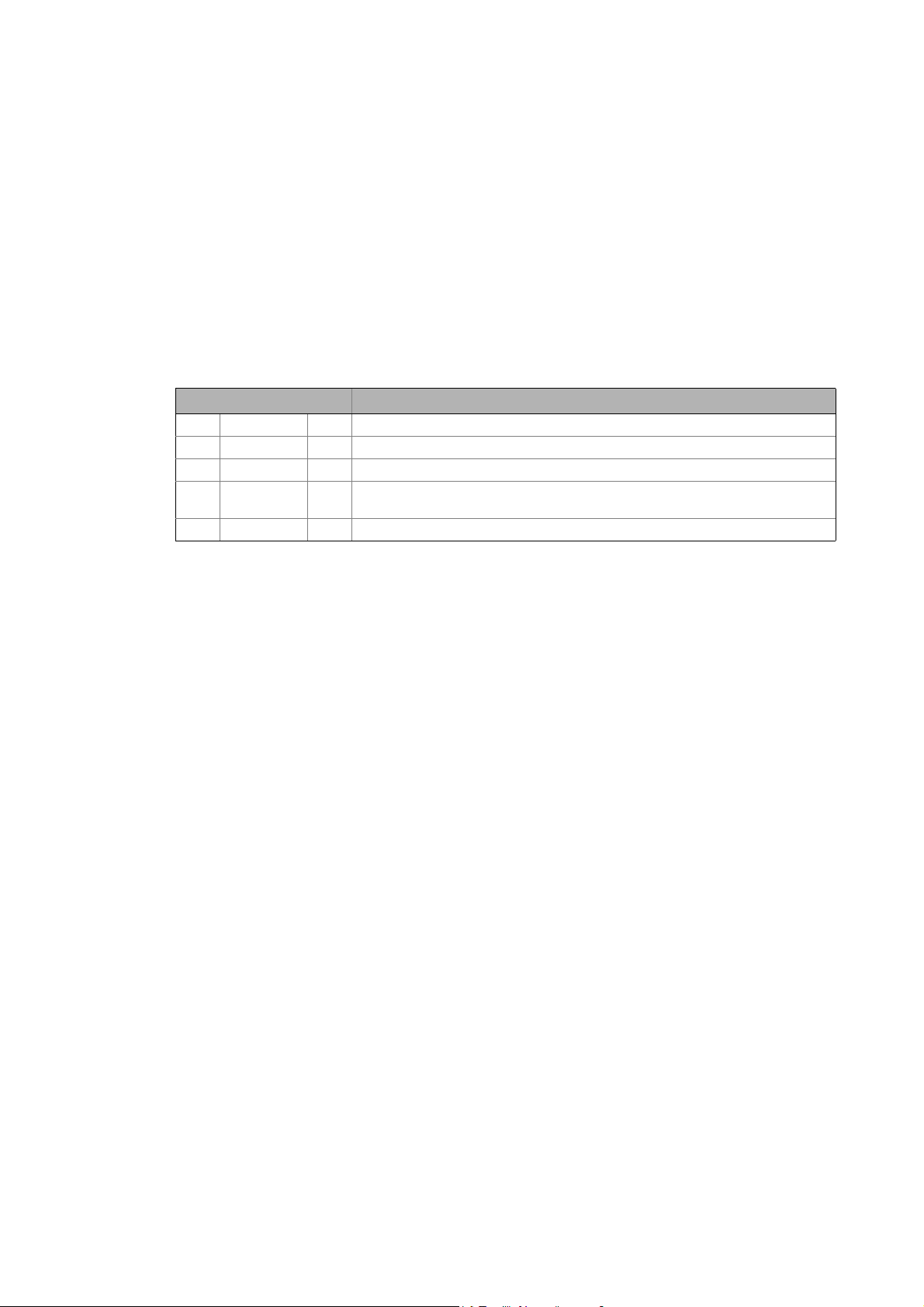

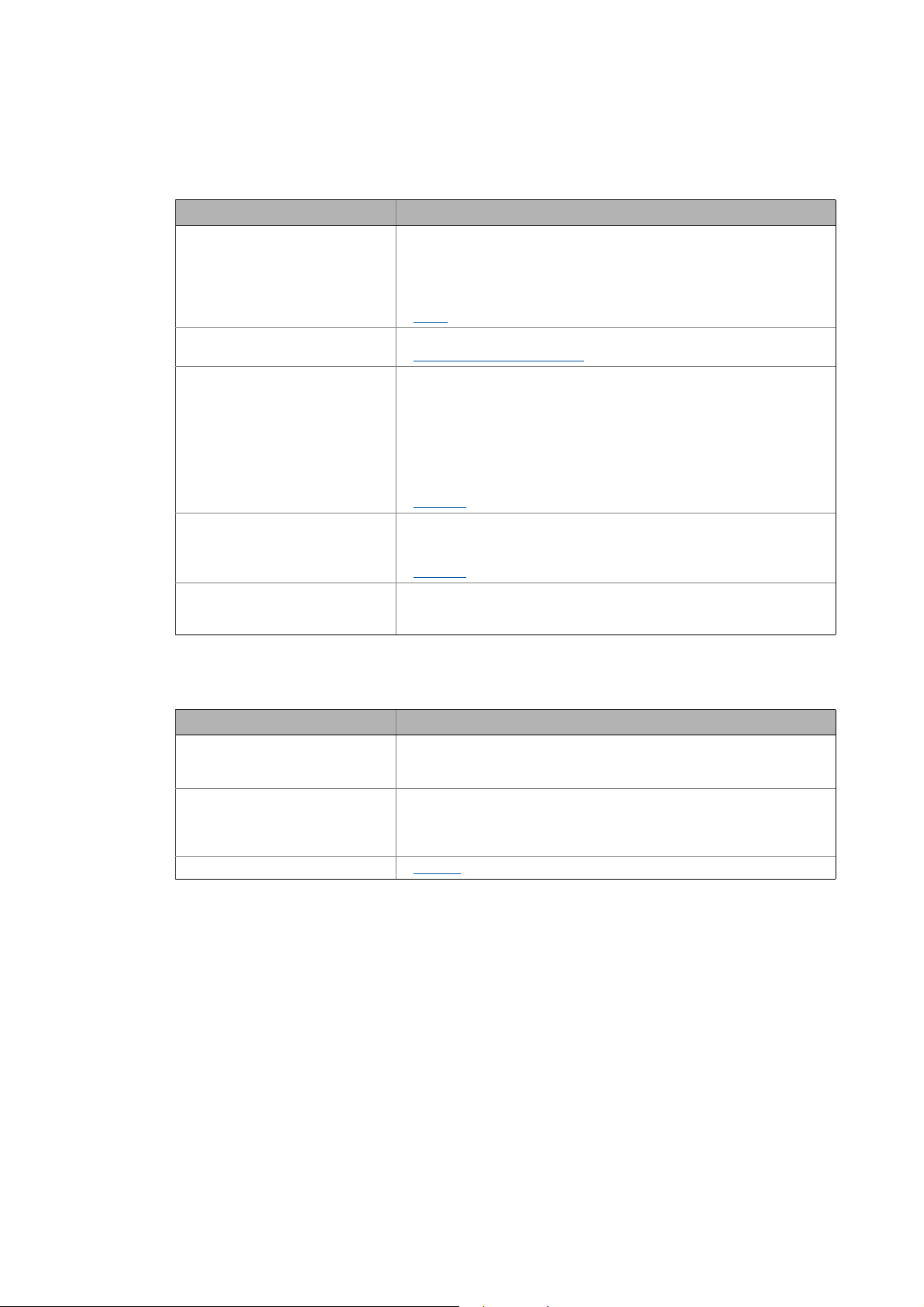

This documentation uses the following conventions to distinguish the following types of information:

Type of information Marking Examples/notes

Spelling of numbers

Decimal separator Point The decimal point is generally used.

For example: 1234.56

Text

Version info Blue text colour Information that is only valid for or as from a certain soft-

Program name » « The Lenze PC software »PLC Designer«...

Window area Italics The Message window... / The Options dialog box...

Variable identifiers By setting bEnable to TRUE...

Control element Bold The OKbutton... / The Copy command ... / The Properties

Sequence of menu commands

Keyboard command <Bold> By <F1>, you call up the online help.

Program code Courier

Keyword Courier bold

ware version of the controller is marked accordingly in this

documentation.

Example: The function extension is available from software

version V3.0 or higher!

tab... / The Name input field ...

If several commands in succession are required to carry out a

function, the individual commands are separated by an arrow: select the command File

If a keyboard combination is required for a command, a "+" is

placed between the keyboard identifiers: by <Shift>+<ESC>...

IF var1 < var2 THEN

a = a + 1

END IF

Open to...

Hyperlink underlined

Icons

Page reference ( 16) Optically highlighted reference to another page which is ac-

Step-by-step instruction

Optically highlighted reference to another topic which is activated via mouse-click in this online documentation.

tivated via mouse-click in this online documentation.

Step-by-step instructions are indicated by a pictograph.

16

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 17

2 About this documentation

2.3 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3 Definition of the notes used

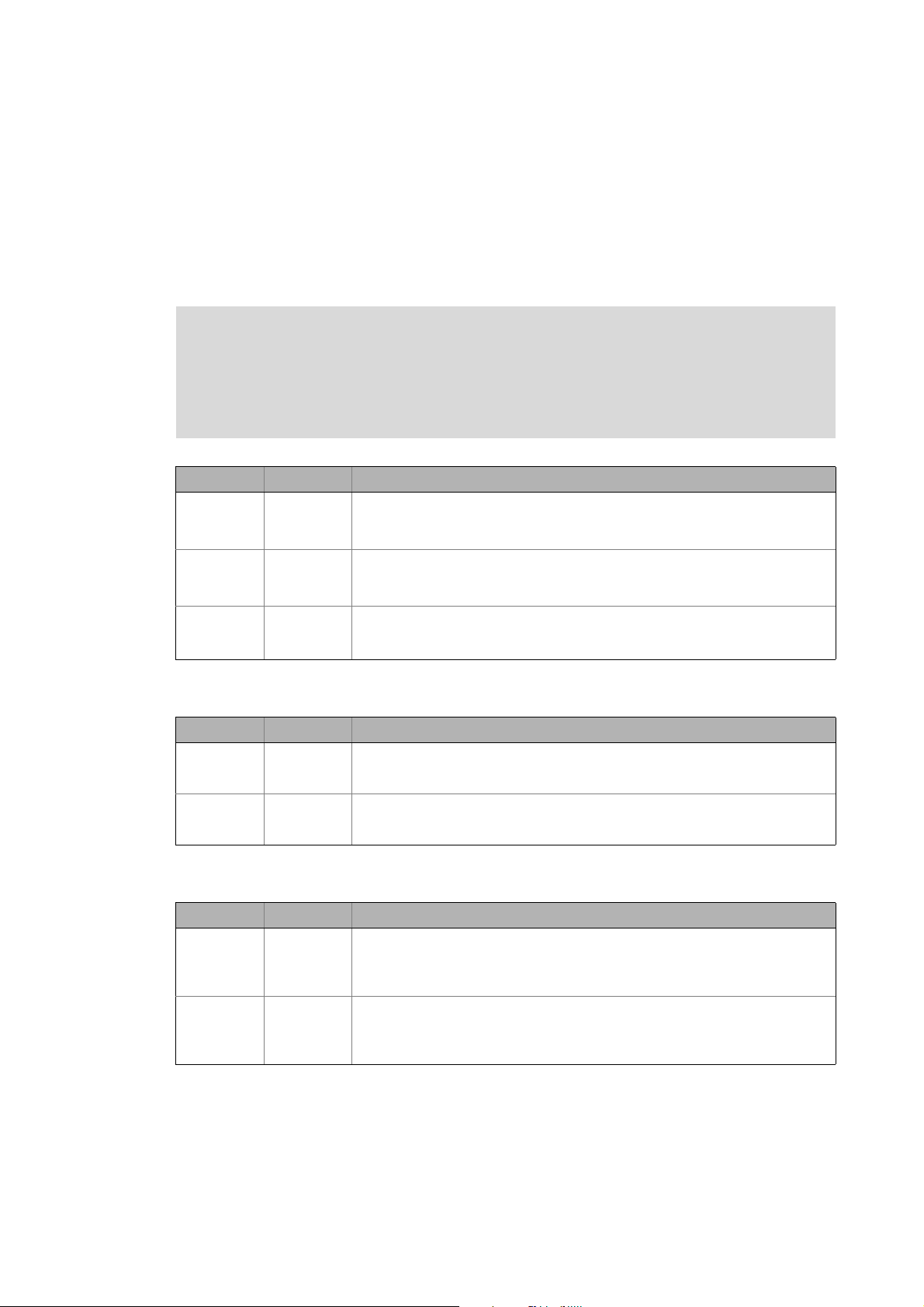

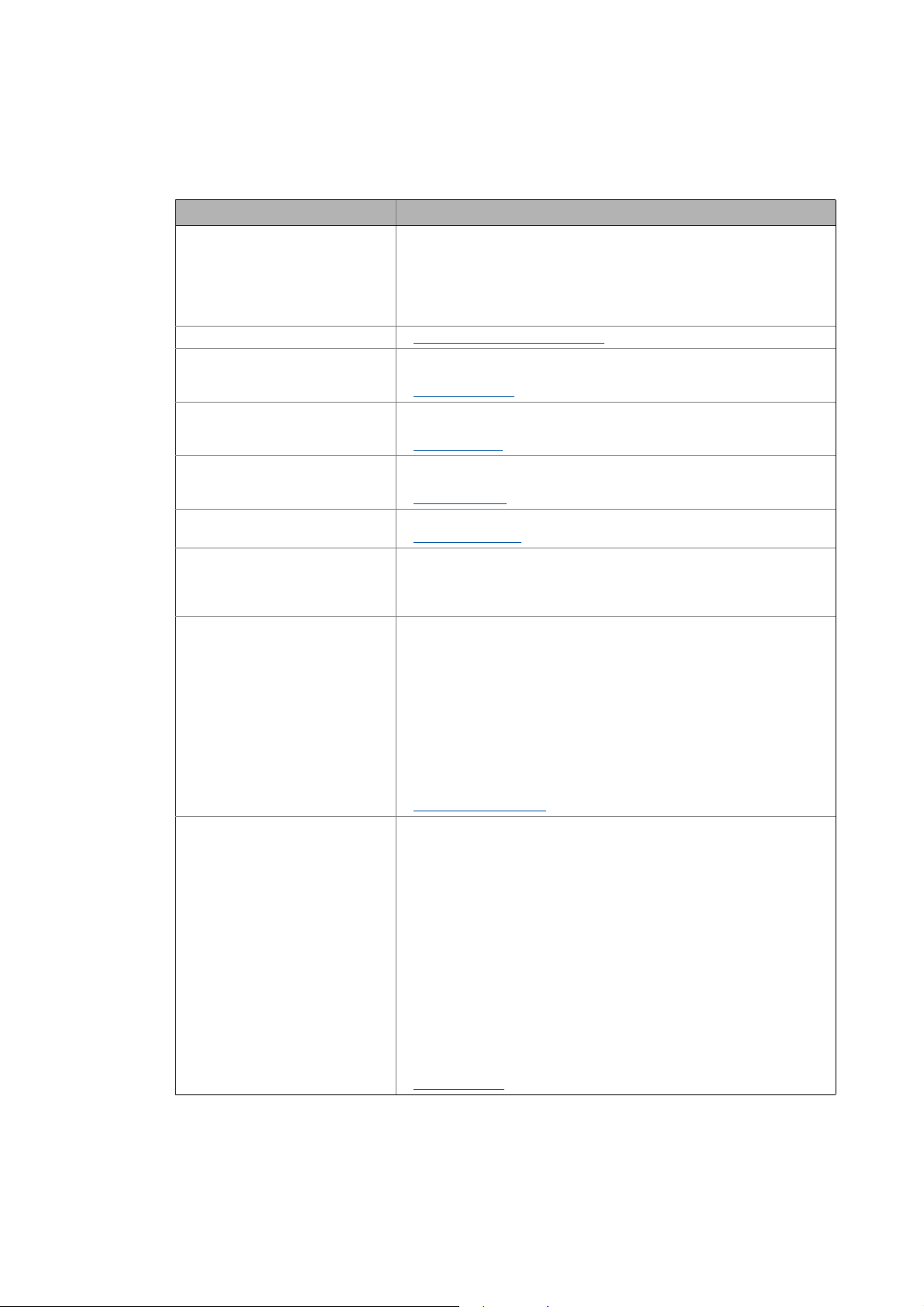

In order to indicate dangers and important information, the following signal words and symbols are

used:

Safety information

Layout of the safety instructions:

Pictograph and signal word!

(indicate the type and the degree of the danger)

Note

(describes the danger and provides information on its prevention)

Pictograph Signal word Meaning

Danger! Danger of injuries to persons by hazardous electrical voltage

Danger! Danger of personal injury by a general source of danger

Stop! Danger of damage to material assets

Application notes

Note with regard to an imminent danger, which may result in death or severe injuries if the appropriate measures are not taken.

Note with regard to an imminent danger, which may result in death or severe injuries if the appropriate measures are not taken.

Note with regard to a possible danger which ma y result in damage to material assets

if the appropriate measures are not taken.

Pictograph Signal word Meaning

Note! Important note for the trouble-free function

Tip! Useful tip for simple handling

Specific safety instructions and application notes for UL and UR

Pictograph Signal word Meaning

Warnings! Safety instruction or application note for the operation of a UL approved drive in UL

Warnings! Safety instruction or application note for the operation of a UR approved drive in UL

approved systems

Possibly the drive system is not operated in a UL approved manner, if the appropriate

measures are not taken.

approved systems

Possibly the drive system is not operated in a UL approved manner, if the appropriate

measures are not taken.

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 17

Page 18

3User interface

3.1 Control and function elements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

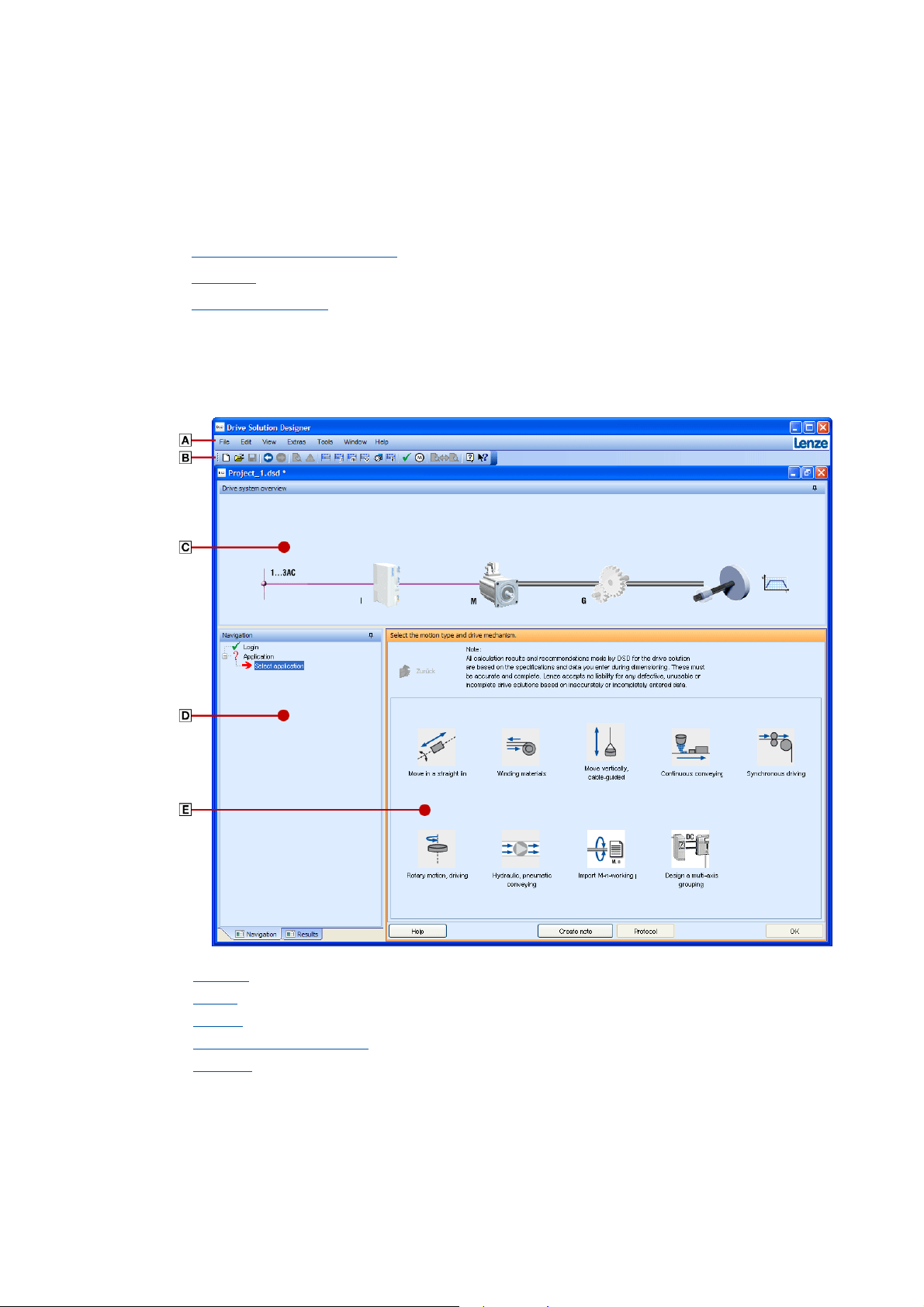

3 User interface

This chapter introduces different control and function elements of the user interface to you and explains how you can close the program again.

Control and function elements

Shortcuts

( 39)

Closing the program

( 40)

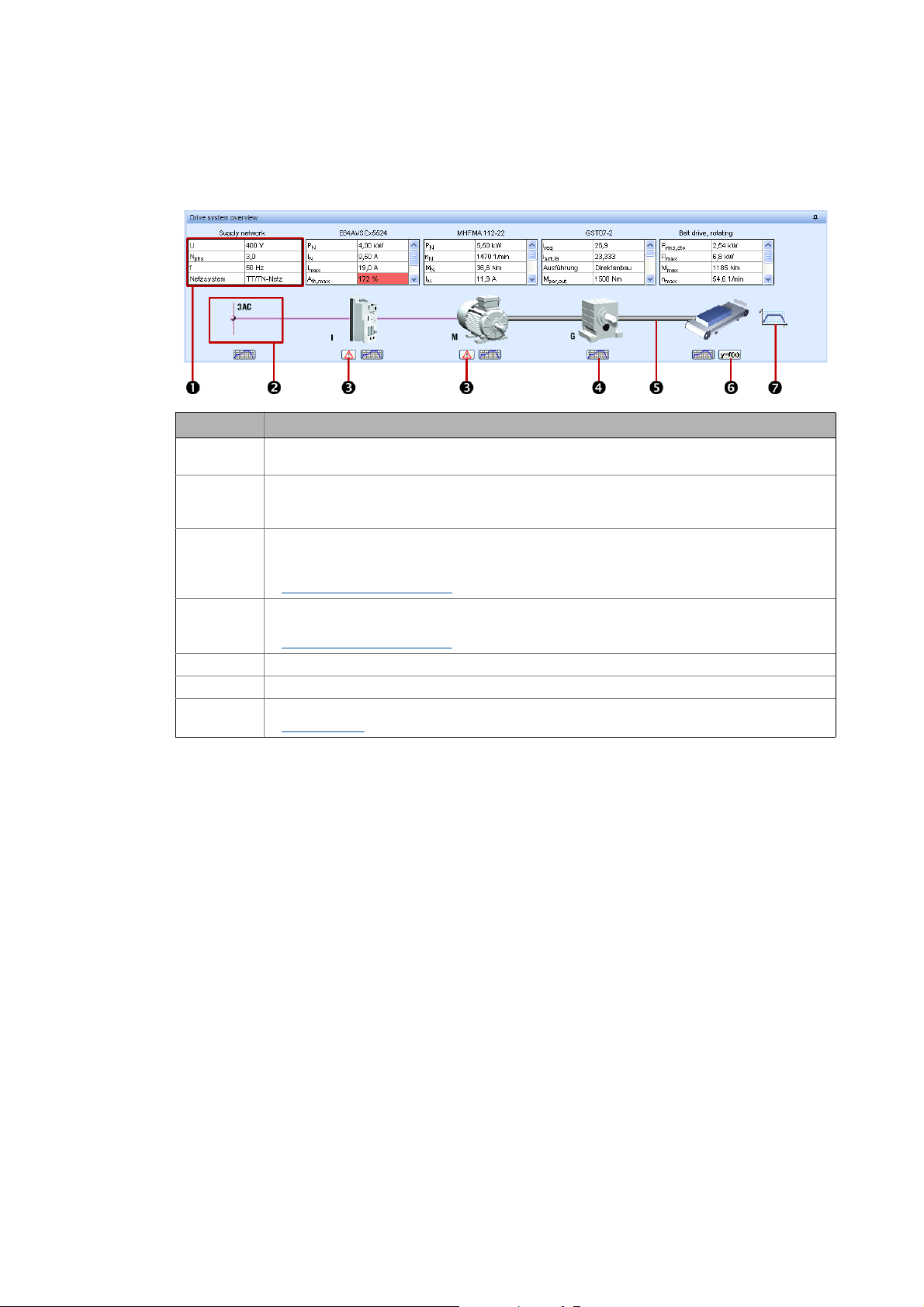

3.1 Control and function elements

The user interface has the following control and function elements:

18

Menu bar ( 19)

Toolbar

Drawing

Navigation tree and result tree

Input area

( 24)

( 27)

( 33)

( 32)

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 19

3User interface

3.1 Control and function elements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

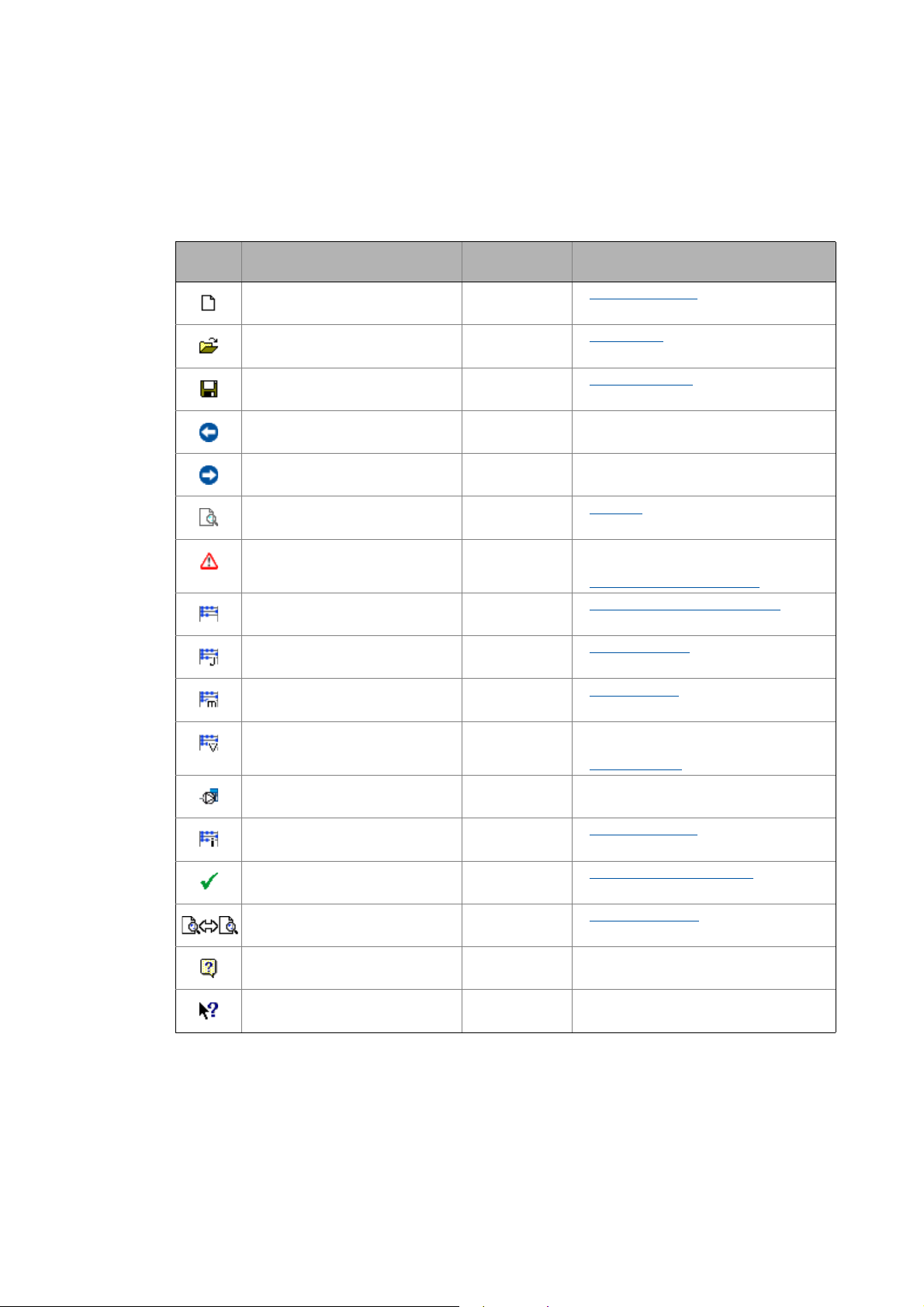

3.1.1 Menu bar

Via the Menu bar you have access to all menu commands.

• Click a menu to show the contained menu commands.

• Click a menu command to execute the connected function.

• Grey menu commands are inactive during the current program state.

3.1.1.1 File

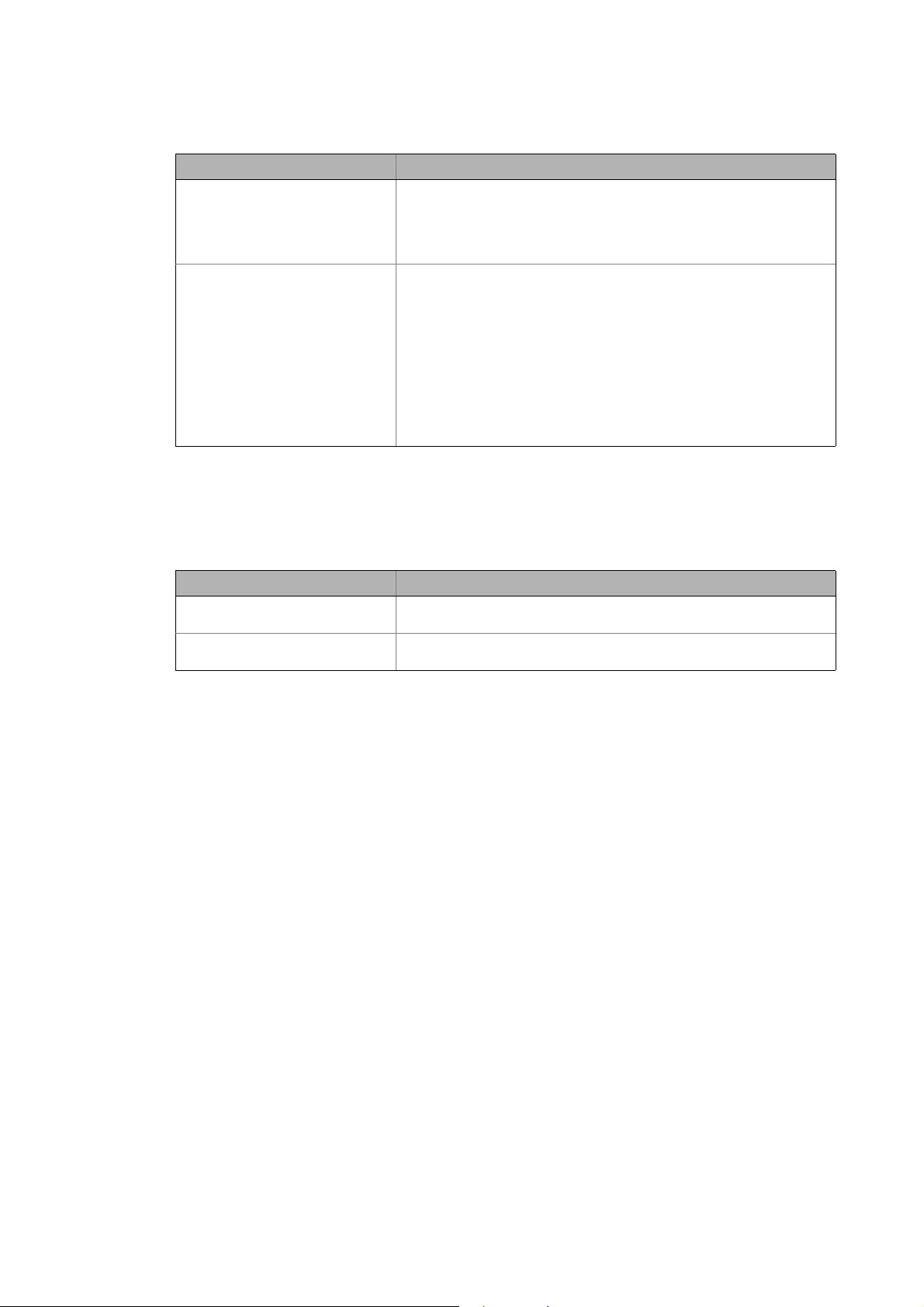

Menu command Function

New Create new project

Open Open project

Open last project A list of the last five projects edited is provided

Close project Close the open project.

Saving Saving the project

• The current dimensioning state is saved in a project file.

• If the project file is already existing, it is overwritten by the current dimensioning status.

Save as... Save the current dimensioning status as a project with the specified name.

• If the project name is different from the project that may currently be edited, it is renamed.

• The project name is displayed in the window headline.

Exit Closing the program

( 52)

( 54)

( 54)

( 40)

3.1.1.2 Edit

Menu command Function

Move one step back Move one entry back in the navigation tree.

Move one step forward Move one entry forward in the navigation tree.

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 19

Page 20

3User interface

3.1 Control and function elements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

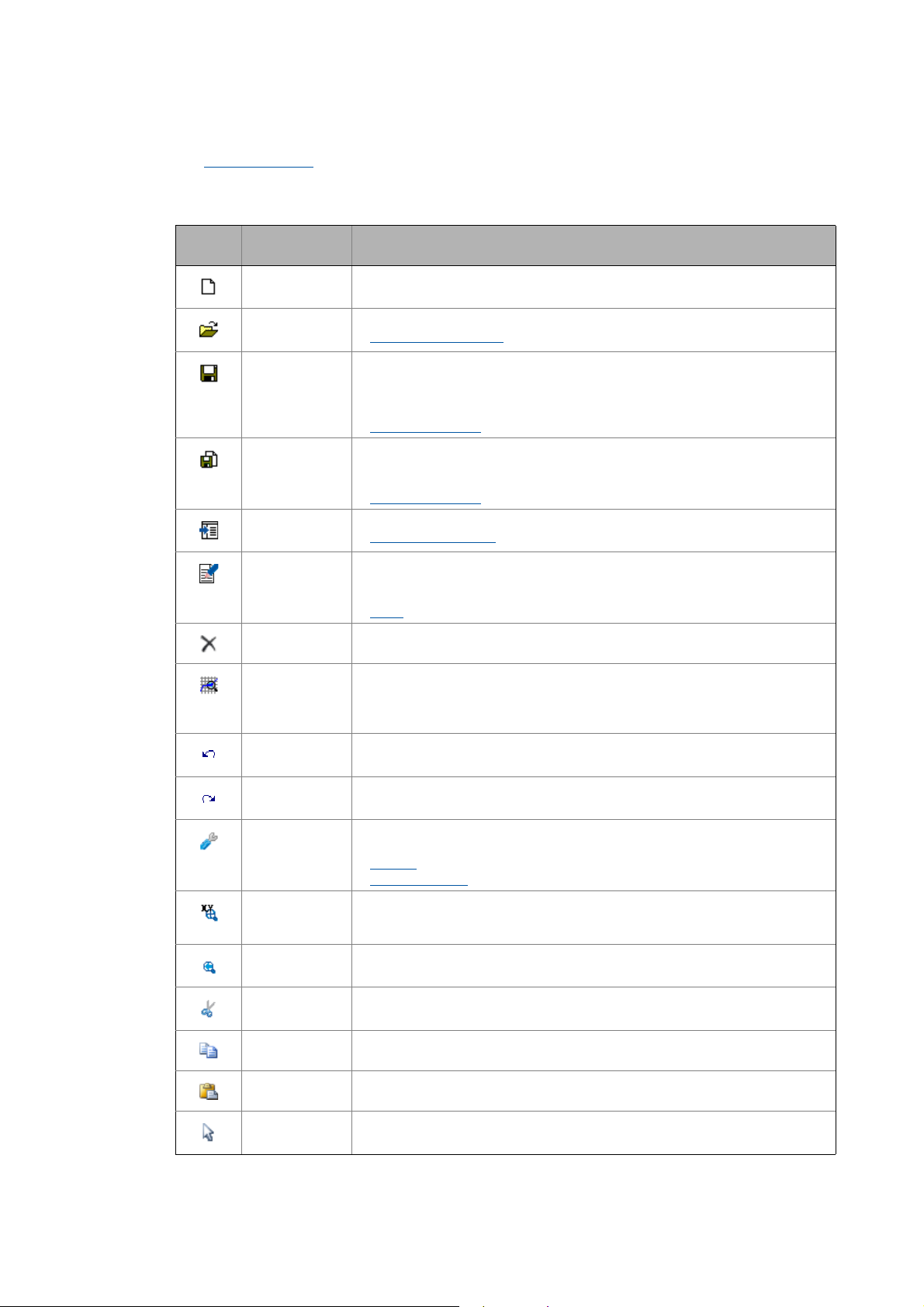

3.1.1.3 View

Menu command Function

Notes • Note recording current dimensioning step

• Display or write a comment on the current dimensioning step.

• All notes

• Display, print or deletion of all comments that were created for the

project.

Notes

( 37)

Messages Shows all warnings, notes and tips for the current drive dimensioning.

Drive dimensioning messages

Dimensioning report Create and display Protocol.

• The dimensioning protocol that is generated can be printed or opened in

Microsoft Word.

• The completeness of the report depends on the progress of the dimensioning. If the dimensioning report is opened early, some components

possibly are not displayed.

• At the end of the drive dimensioning the DSD offers different possibilities

of presenting the results.

Protocols

Project comparison Compare projects among each other.

• If several projects are open at the same time, they can be compared with

respect to the application and the utilisation of the components.

Protocols

Product features for DSC / SAP Shows product features of the components which are required for the pur-

chase order with »Drive Solution Catalogue« (DSC). DSC is the electronic catalogue on the Lenze web page.

( 391)

( 391)

( 441)

3.1.1.4 Extras

Menu command Function

User-defined defaults Display/definition of user-defined specifications.

• User-defined specifications can be established for specific parameters requiring manual entries or featuring an option.

Select language Change the language of the user interface.

• German, English (British), Czech, Danish, English (American), Spanish,

French, Italian, Dutch, Russian, Swedish, Chinese (simplified) and Chinese

(traditional) are provided.

Settings Settings

( 46)

20

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 21

3User interface

3.1 Control and function elements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

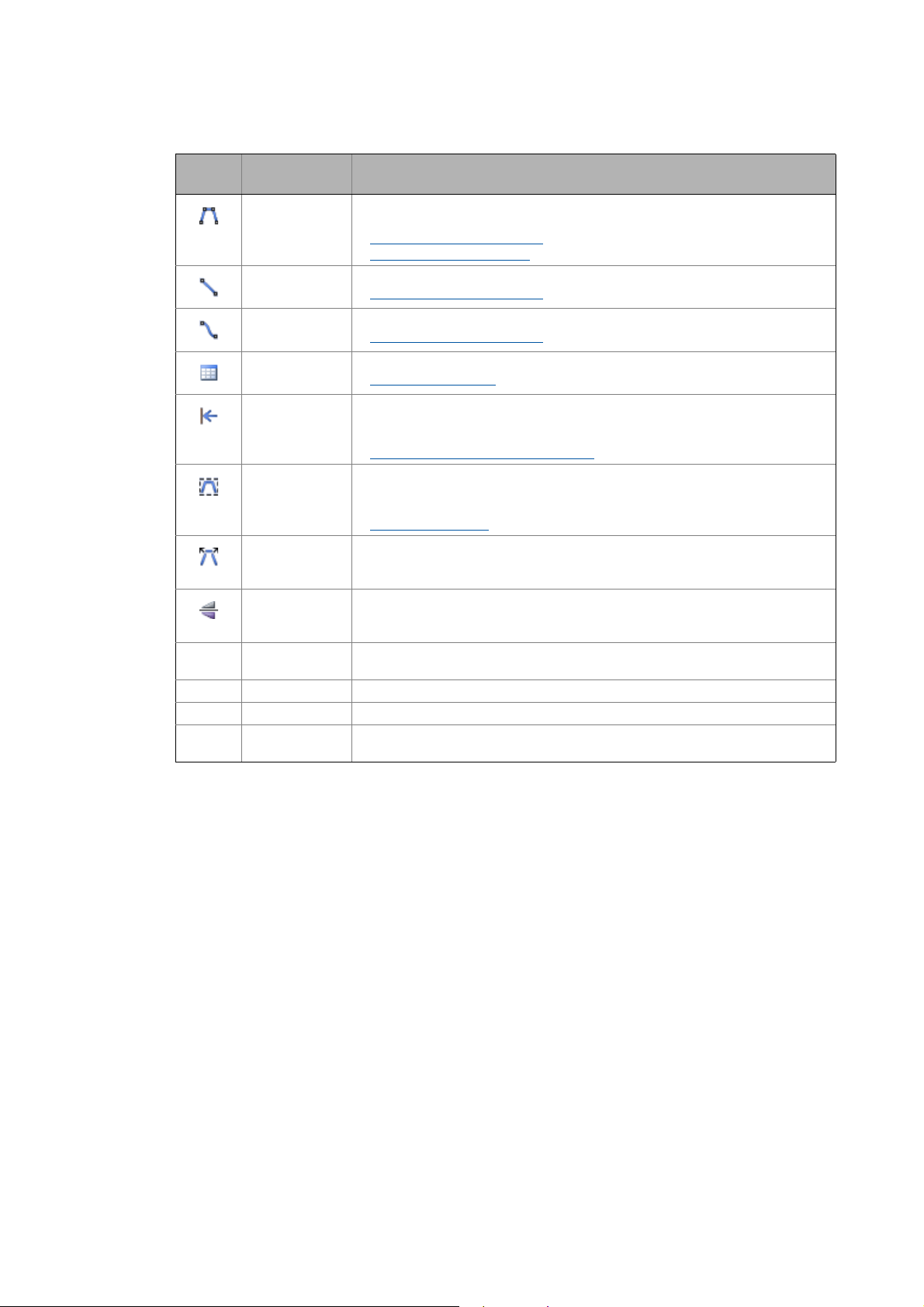

3.1.1.5 Tools

Menu command Function

Checklist Display check list.

• Every application provides a check list including requests for the respective application.

• Parameters indicated with * have to be known for the dimensioning.

• The calculability at least requires the *parameters of the process and of

the motion; all further requests concerning components are optional.

Calculator Calculator (Microsoft® calculator)

Inertial calculator Calculation of moments of inertia on the basis of geometric quantities and

Mass calculator Calculation of masses on the basis of geometric quantities and the material-

MotionDesigner Irrespective of the dimensioning of a project, motion profiles can be created,

Gearbox calculator Conversion of gearbox sizes.

Energy efficiency, fan/pump Host computer to detect energy savings for applications with pumps or fans.

Special host computers Determination of specific parameters of an application. The following auxil-

Physical coefficients Value tables with physical coefficients. The tables can also be called in aux-

the material-specific density.

Inertial calculator

specific density.

Mass calculator

loaded, edited, and saved graphically or manually.

MotionDesigner

Gearbox calculator

• Comparison of an electronic control (frequency inverter) with a lossy mechanical control. The system parameters and the frequency distribution

of the load are defined.

iary calculators are included in the DSD:

• Travelling resistance

• Pinion diameter

• Spindle efficiency

• Mass of belt

• Mass of delivery volume (materials handling technology)

• Uniform load mass (materials handling technology)

•Backing force

• Mass of counterweight (hoist drive)

• Mass of rope/cable (hoist drive)

Special host computers

iliary calculators and input templates. Like this the coefficients can be accepted directly in the input field. The following value tables are included in

the DSD:

• Density of solids

• Density of winding material

• Density of liquids

• Static friction coefficient

• Sliding friction coefficient

• Coefficient of friction for rolls

• Bearing and leadscrew friction

• Wheel flange and lateral friction

• Lever arm of rolling friction

• Shunt-force factor for belt conveyors

• Filling factor for belt conveyors

• Efficiency of drive elements

Tables of values

( 407)

( 405)

( 225)

( 410)

( 403)

( 423)

( 404)

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23 21

Page 22

3User interface

3.1 Control and function elements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Menu command Function

Collection of formulae "Drive solutions – formulae, tables and dimensioning" Manual in the PDF

Other tools (web links) Useful references to the Lenze web page. For using it, an internet connection

3.1.1.6 Window

format.

• The reference book, formulary and tables provide the physical-mathematical basics in drive technology.

• The Manual can be read e.g. with the free-of-charge Adobe Reader.

is required.

• Drive Solution Catalogue (DSC)

• Electronic catalogue to configure and/or order drive components and

accessories.

• Sales documents, technical documentation, software

• Generation of CAD data

• CAD data of Lenze motors

• EPLAN macros for Lenze products

• Generation of torque characteristics

• Check Overload capacity of motor/inverter combinations

In the Window menu, all open DSD projects are listed. By selecting the corresponding menu item

the project window is shown in the front. Project windows can be arranged using the following

menu commands:

Menu command Function

Cascading window If several windows are open, they are arranged one behind the other in a

Split window horizontally The display window is split horizontally into several areas. The projects are

slightly staggered manner; by this other windows can be quickly selected.

arranged one below the other.

22

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

Page 23

3User interface

3.1 Control and function elements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.1.1.7 Help

Menu command Function

About DSD Open the information dialog showing the version number, registration in-

Help Open online help.

Dimensioning examples Examples of different drive dimensionings.

Check for updates Search for available updates for the DSD.

Acquisition of application data Send log file with application information to the Lenze DSD server.

Support on the Web (AKB) Weblink to the Lenze Application Knowledge Base.

Search AKB Search the Lenze Application Knowledge Base for information and solutions.

Version information (AKB) Search the Lenze Application Knowledge Base for up-to-date information

Subscribe to the AKB newsletter Automatic e-mail notification when new issues in the Lenze Application

Software downloads The download area of the Lenze Application Knowledge Base contains the

Lenze on the Internet The Lenze webpage contains current information on the company and its

formation, and important information about DSD.

• The DSD files can be used as a template for individual drive dimensionings.

• For using it, an internet connection is required.

• The log file contains important information on the Lenze development

for optimising the Drive Solution Designer.

• For using it, an internet connection is required.

Acquisition of application data

• The Application Knowledge Base contains various information on the

Drive Solution Designer.

• For using it, an internet connection is required.

• For using it, an internet connection is required.

and solutions about DSD.

•Under SoftwareDrive Solution Designer, e.g. Release Notes or notes re-

garding functional restrictions can be found.

• For using it, an internet connection is required.

Knowledge Base are released.

• For using it, an internet connection is required.

current DSD version and the published service packages.

• Always use the most current service package!

• For using it, an internet connection is required.

products.

• For using it, an internet connection is required.

http://www.Lenze.com