Page 1

Automation Systems

Controller-based

Automation

Visualisation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

System Manual EN

Ä.O<Aä>

13462732

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

3 Controller-based Automation: Central motion control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

4System description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4.1 Visualisation system structure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4.1.1 Stand-alone application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.1.2 Integrated control system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.1.3 Client/server system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

4.2 System components _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

4.2.1 Controller: "Controller-based Automation" (control technology version 3.x) _ _ _ _ _ _ _ 19

4.2.2 Industrial PCs (IPC): "PC-based Automation" (control technology version 2.x) _ _ _ _ _ _ _ 19

4.2.3 Runtime software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

4.2.3.1 "Logic" and "Motion" runtime software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

4.2.3.2 "Visu" runtime software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

4.2.3.3 "Visu" runtime software - licence information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

4.2.4 Field devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

4.2.4.1 Direct access to the field devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

4.2.4.2 Access to the control system and the field devices connected _ _ _ _ _ _ _ _ _ 28

4.2.5 Engineering tool»VisiWinNET®« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

4.2.5.1 »VisiWinNET®« Smart _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

4.2.6 Backup of visualisation data (UPS functionality) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

4.3 Network topologies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

4.3.1 Channels _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

4.3.2 Browsing variables _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

4.3.3 EtherCAT® _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

4.3.4 CANopen® _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

4.3.5 PROFIBUS® _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

4.3.6 PROFINET® _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

4.3.7 Ethernet _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

4.3.8 Further bus systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

4.2.5.2 »VisiWinNET®« Professional _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

4.2.5.3 Visualisation kit _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

4.2.6.1 Capacitor pack (CAPS-PACK) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

4.2.6.2 Battery pack (ACCU-PACK) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

2 Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

6 Remote maintenance and diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

6.1 Remote maintenance with an external router _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

6.2 Remote maintenance with a separate remote PC _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

6.3 Log-in on an IPC of the x800 device series (PC-based automation) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

6.4 Computer access via Telnet _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

6.5 File transfer via FTP _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

6.6 Web server/»WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

6.7 »Virtual Network Computing (VNC)«: Redirecting screen contents/entries _ _ _ _ _ _ _ _ _ _ _ _ _ 56

7Appendix _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

7.1 Information regarding the FDA conformance _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

8Glossary _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 3

Page 4

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This system manual contains some information relating to the system structure ...

• of the controller-based visualisation technology (control technology release 3.x), and

• of the PC-based visualisation technology (control technology release 2.x).

As a higher-level system manual, the document provides an overview of the visualisation

technology's system components and their interaction.

Detailed information on the components, target systems and the Engineering software to be used

can be found in the manuals for the related components and devices as well as in the

communication manuals of the supported bus systems.

This manual is part of the "Controller-based Automation" manual collection. It consists of the

following sets of documentation:

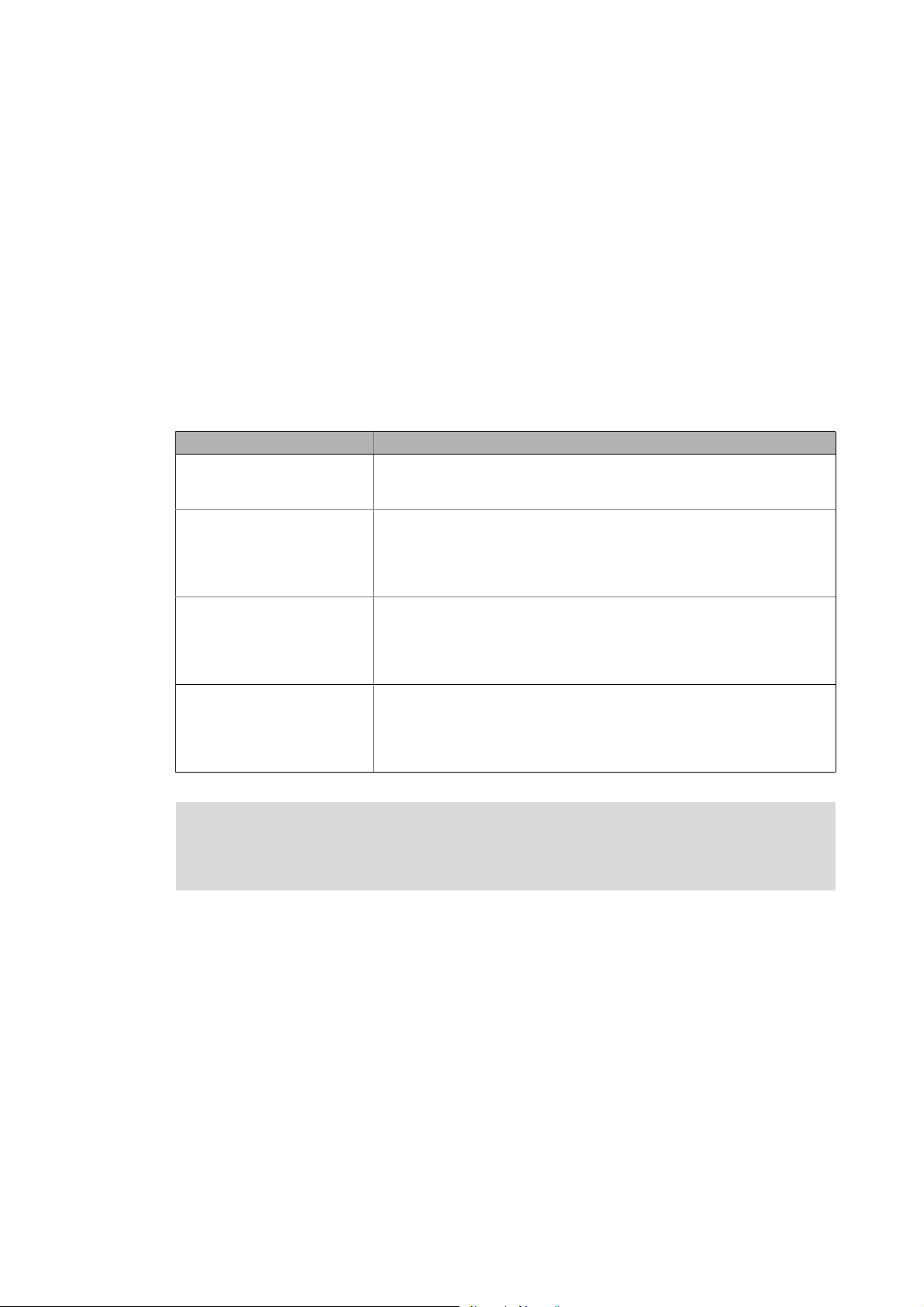

Documentation type Subject

System manuals System overview/sample topologies

• Controller-based Automation

• Visualisation

Communication manuals

Online helps

Reference manuals

Online helps

Software manuals

Online helps

Bus systems

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

Lenze Controller:

• Controller 3200 C

• Controller c300

• Controller p300

• Controller p500

Lenze Engineering Tools:

• »PLC Designer«: Programming

• »Engineer«: Inverter configuration

• »VisiWinNET® Smart«: Visualisation

• »Backup & Restore«: Back up/restore data

"PC-based Automation" system manual

Here you'll find more information relating to the designs and configuration options of

the Lenze Industrial PCs.

4 Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 5

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

More technical documentation for Lenze components

Further information on Lenze products which can be used in conjunction with Controller-based

Automation can be found in the following sets of documentation:

Mounting & wiring Symbols:

Mounting instructions

• Controller

• Communication cards (MC-xxx)

• I/O system 1000 (EPM-Sxxx)

• Inverter, Servo Drives

•Communication modules

Operating instructions

• Controller

• Servo system ECS (ECSxE, ECSxM)

Sample applications/Using application templates

Online help/software manuals

• Application Sample i700

• Application Samples

• ApplicationTemplate

Parameterisation, configuration, commissioning

Online help/reference manuals

• Controller

• Inverter, Servo Drives

• I/O system 1000 (EPM-Sxxx)

Online help/communication manuals

• Bus systems

•Communication modules

Operating instructions

• Servo system ECS (ECSxE, ECSxM)

Printed documentation

Online help in the Lenze Engineering

Tool (also available as PDF file at

www.lenze.com

.)

Tip!

Current documentation and software updates with regard to Lenze products can be found

in the download area at:

www.lenze.com

Target group

This documentation addresses to all persons who want to be pr ovided with an overvi ew of PC -based

visualisation with a Lenze Industrial PC (IPC)/controller.

Information on validity

The information in this documentation applies to the Lenze automation system.

"Controller-based Automation" (from software version 3.x):

• Panel Controller p300/p500

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

"PC-based Automation" (from software release 2.x):

•HMI series EL 100

• Industrial PCs: EL 1800-9800, CS 5800-9800 and CPC 2800

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 5

Page 6

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Document history

Version Description

1.0 10/2009 TD11 First edition

1.1 08/2010 TD11 Update for the "Controller-based Automation" 3.x Lenze automation system

• Lenze Controller 3200 C supplemented.

1.2 02/2011 TD11 Update for the "PC-based Automation" 2.5 Lenze automation system

• Industrial PC x800 supplemented.

1.3 07/2011 TD11 Update for the Lenze automation system "Controller-based Automation" 3.1

• Updated for new software version.

1.4 06/2012 TD11 Update for the Lenze automation system "Controller-based Automation" 3.3

• Supplemented by Controllers p500 (panel controllers).

1.5 04/2014 TD17 Update for the Lenze automation system "Controller-based Automation" 3.8

• Controller p300 (panel controller) supplemented.

6

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 7

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This documentation uses the following conventions to highlight different types of information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal Normal spelling Example: 1234

Decimal separator Point The decimal point is always used.

For example: 1234.56

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Text

Version information Text colour blue All information that only applies to or from a certain

Program name » « »PLC Designer«...

Window area Italics The Message window... / The Options dialog box...

Variable identifier By setting bEnable to TRUE...

Control element Bold The OK button... / The Copy command... / The Properties

Sequence of menu

commands

Shortcut <Bold> Use <F1> to open the online help.

Hyperlink underlined

Icons

Page reference ( 11) Optically highlighted reference to another page. In this

Step-by-step instructions

0b[0, 1] Example: ’0b0110’

Example: ’0b0110.0100’

software version of the inverter is marked correspondingly in

this documentation.

Example: This function extension is available from software

version V3.0!

tab... / The Name input field...

If several commands must be used in sequence to carry out a

function, the individual commands are separated by an

arrow. Select File

If a key combination is required for a command, a "+" is

placed between the key identifiers: With <Shift>+<ESC>...

Optically highlighted reference to another topic. It is

activated with a mouse-click in this online documentation.

online documentation activated via mouse-click.

Step-by-step instructions are marked by a pictograph.

Open to...

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 7

Page 8

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

Controller The Industrial PC (IPC) or controller is the central component of the automation

IPC

Engineering PC The Engineering PC and the Engineering tools installed serve to configure and

Fieldbus node Devices integrated in the bus system as, for instance, Controller and inverter

Field device

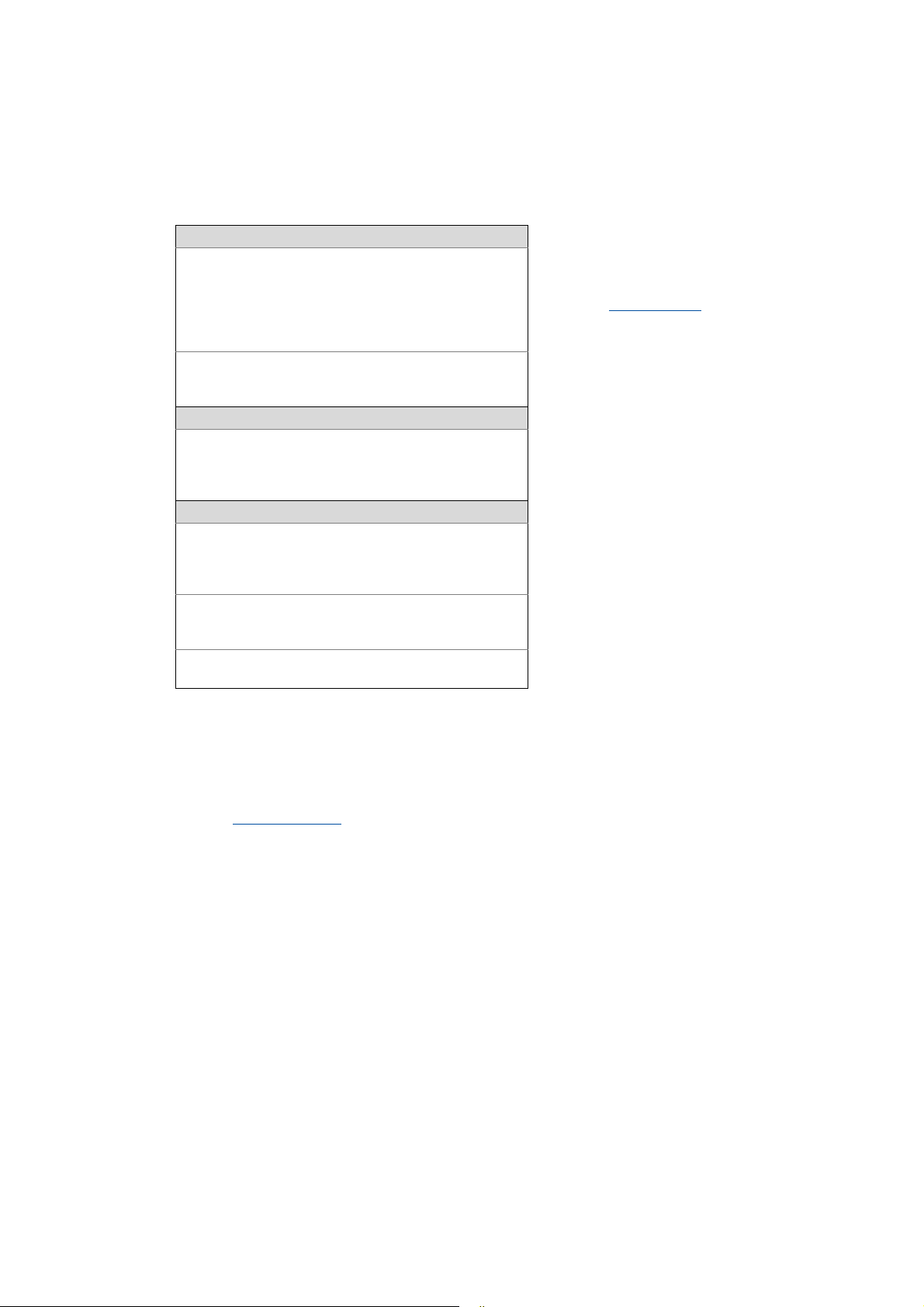

HMI Human Machine Interface (HMI) is a synonym for MMI (Man - Machine -

system which controls the Logic and Motion functionalities by means of the

runtime software.

The controller communicates with the field devices via the fieldbus.

parameterise the system "Controller-based Automation".

The Engineering PC communicates with the controller via Ethernet.

Interface). The term stands for the user interface of a machine.

Via the HMI, the operator can operate the machine, monitor system states, and,

if necessary, intervene in the process. Information is either provided by means of

hardware via operator panels with signal lamps, display fields, and buttons, or,

by means of software, via a visualisation system running on a terminal.

The HMI communicates with the machine PLC via different communication

paths.

Simplified description of the exchange of information:

operator <-> HMI <-> machine

In this context, the term Supervisory Control And Data Acquisition (SCADA

often used.

Inverter Generic term for Lenze frequency inverter, servo inverter

MPI The multi-point interface is used for connecting programming units, operator

OPC tunnel OPC tunnel

PLC Programmable Logic Controller

SCADA Supervisory Control And Data Acquisition (SCADA)

PLC Programmable Logic Controller (PLC)

Bus systems

CAN CAN (Controller Area Network) is an asynchronous, serial fieldbus system.

panels, and other SIMATIC-S7 devices. The MPI is based on the EIA-485 standard

(formerly RS-485) and operates at a baud rate of 187.5 kbps - 12 Mbps.

The voltage supply gets the interface from the control system via the MPI line.

The interface is hardware-compatible with the Profibus interface on Siemens

control systems.

Different manufacturers offer PCI plug-in cards, PCMCIA plug-in cards, USB

adapters, or Ethernet adapters for communication via MPI. All S7 stations can be

interconnected via the MPI bus.

The MPI bus is not standardised, but a Siemens-specific bus. The multi-point

interface is a communication interface integrated in every SIMATIC®-S7

automation device (SIMATIC® S7/M7, and C7). It can be easily used for simple

networks.

( 60)

• A SCADA system is a process visualisation or host system on which several

machines or lines are interconnected.

• Central alarm management, archiving of data, the creation of time control

software programs, and a messaging service (SMS, e-mail, text-to-speech)

are typical of a SCADA system.

HMI

( 8)

) is

8

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 9

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Term Meaning

CANopen® is a communication protocol based on CAN. The Lenze system bus

(CAN on board) operates with a subset of this communication protocol.

CANopen® is a registered community trademark of the CAN user organisation

CiA® (CAN in Automation e. V.).

EtherCAT® (Ethernet for Controller and Automation Technology) is an Ethernetbased fieldbus system which fulfils the application profile for industrial realtime systems.

EtherCAT® is a registered trademark and patented technology, licensed by

Beckhoff Automation GmbH, Germany.

Ethernet specifies the software (protocols) and hardware (cables, connectors,

etc.) for wired data networks. In the form of "Industrial Ethernet", the Ethernet

standard is applied in industrial production plants.

Standard Ethernet is specified in accordance with IEEE 802.3 by the Institute of

Electrical and Electronics Engineers (IEEE), USA.

PROFIBUS® (Process Field Bus) is a widely used fieldbus system for the

automation of machines and production lines.

PROFIBUS® is a registered trademark and patented technology licensed by the

PROFIBUS & PROFINET International (PI) user organisation.

PROFINET® (Process Field Network) is a real-time capable fieldbus system based

on Ethernet.

PROFINET® is a registered trademark and patented technology licensed by the

PROFIBUS & PROFINET International user organisation (PI).

IEC 61131 programming languages

With the Lenze »PLC Designer«, programming of the PLC according to IEC 61131-3 can be carried out. The IEC 61131

standard describes the following programming languages:

SFC Sequential function chart (SFC) is one of the five programming languages

standardised in DIN EN 61131-3.

• SFC is used for programming a PLC control system in the form of a Petri net.

• Under Siemens STEP® 7, sequential function chart is known as S7 GRAPH.

IL Instruction lists (IL) are mainly used for logic operations of control inputs and

outputs. Typically, a (digital) input is loaded into the working register

(accumulator) (load digital input 0, "LD %IX0.0"), linked with other inputs,

co nstants , or memory v alu es (e xcl usive-OR memor y bi t 3, " XOR %MX 0.3" ), a nd is

written to an output (store digital output 1, "ST %QX0.1").

CFC CFC (Continuous Function Chart) is a language similar to FBD.

• FBD editors are network-oriented and arrange the function blocks

automatically. CFC enables the free arrangement of all function blocks, which

makes it possible to program feedback loops without interim variables.

• CFC is convenient for representing application overviews.

FBD Function block diagram (FBD) is a graphical programming language within

STEP® 7 and there corresponds to the function block language as PLC

programming language in accordance with EN 61131-3 [1] to a large extent.

The function block diagram (FBD) has been defined as a project planning tool for

sequence control systems in the former DIN 40719. [1]

Grafcet in accordance with EN 60848 has replaced FBD. Both languages are

similar to the sequential function chart (SFC) as PLC programming language in

accordance with EN 61131-3. With Siemens STEP® 7 this language is called S7GRAPH.

LD Ladder diagram is a graphical programming language standardised in the IEC

standard DIN EN 61131-3, that represents a graphical diagram based on circuit

diagrams.

• LD is primarily used for programmable logic controllers.

• If the elements are connected in series this is an AND operation. If the

elements are connected in parallel this is an OR operation. A line across the

element indicates a negation of the element.

• Inputs are represented as two vertical parallel lines, outputs are represented

as two opposite curved lines.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 9

Page 10

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Term Meaning

ST ST allows a more structured programming than IL and therefore replaces IL more

Windows® operating systems

Windows® CE The Windows® CE operating system (abbreviation: WinCE) is a resource-saving

Windows® XP Windows® XP is an operating system for Microsoft® PCs. A "Home" and a

Windows® XP Embedded Windows® XP Embedded is based on Windows® XP Professional, but has a

and more. Many software developers continue programming with IL because of

the increased memory requirements of the ST programs (after compilation).

When using smaller PLCs, the memory limits will be reached sooner in the event

of increased memory requirements.

variant of Microsoft® Windows® for PDA and embedded systems.

Windows® CE uses a different Microsoft® Windows® kernel. Therefore

conventional Windows® programs do not run under Windows® CE.

Windows® CE supports the processor architectures Intel x86, MIPS, ARM, and

Hitachi SuperH.

"Professional" version are available. Windows® XP is the technical successor of

Windows® 2000 with Windows® NT® operating system kernel. Furthermore,

Windows® XP has replaced Windows® Me of the MS-DOS line in the "Home

Edition" version as product for home and private users.

The "Professional" version is used in industrial applications. This version contains

functions such as remote control, file encryption (EFS), central maintenance by

means of guidelines or the use of several processors.

modular (component-based) structure.

Like this, IPC manufacturers can only install the Windows® XP elements really

required on their IPC to save resources.

• Certainly, a Windows® XP Embedded installation is always bigger than a

Windows® CE installation, but it is much smaller than a Windows® XP full

version. Thus, Windows® XP Embedded combines the advantages of a small

system which can be used on Industrial PCs without a hard disk, with the

advantages that a Windows® XP system offers compared to Windows® CE.

• Windows® XP Embedded is equipped with a so-called "write" filter. In this

way, individual files (FBWF: File-Based Write Filter) or a whole partition (EWF:

Enhanced Write Filter) can be protected against write access. The data to be

written is redirected into the main memory instead of the storage medium

(e.g. CF card).

• After a restart, the system will be in the original state again. This protects the

system against unintended changes. Furthermore, the "write" filter positively

affects the service life of the memory card since the number of real accesses

can be clearly reduced.

10

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 11

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Definition of the notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Refere nce to an i mmin ent d ange r tha t may resu lt in deat h or serio us pe rsonal in jury

if the corresponding measures are not taken.

Refere nce to an i mmin ent d ange r tha t may resu lt in deat h or serio us pe rsonal in jury

if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Reference to another document

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 11

Page 12

2 Safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Please observe the following safety instructions when you want to commission an inverter or

system using the Industrial PC.

Read the documentation supplied with the system components thoroughly before

starting to commission the devices and the Industrial PC!

The system manual contains safety instructions which must be observed!

Danger!

According to today's scientific knowledge it is not possible to ensure absolute freedom

from defects of a software.

If necessary, systems with built-in inverters must be provided with additional

monitoring and protective equipment complying with the relevant safety regulations

(e.g. law on technical equipment, regulations for the prevention of accidents) in each

case, so that an impermissible operating status does not endanger persons or facilities.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there would be a risk of injury by the

moving machine parts.

Stop!

If you change parameters in the engineering software while a device is connected online,

the changes will be directly accepted by the device.

A wrong parameter setting can cause unpredictable motor movements.

By an unintended direction of rotation, too high speed, or jerky operation, the driven

machine parts may be damaged.

12 Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 13

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

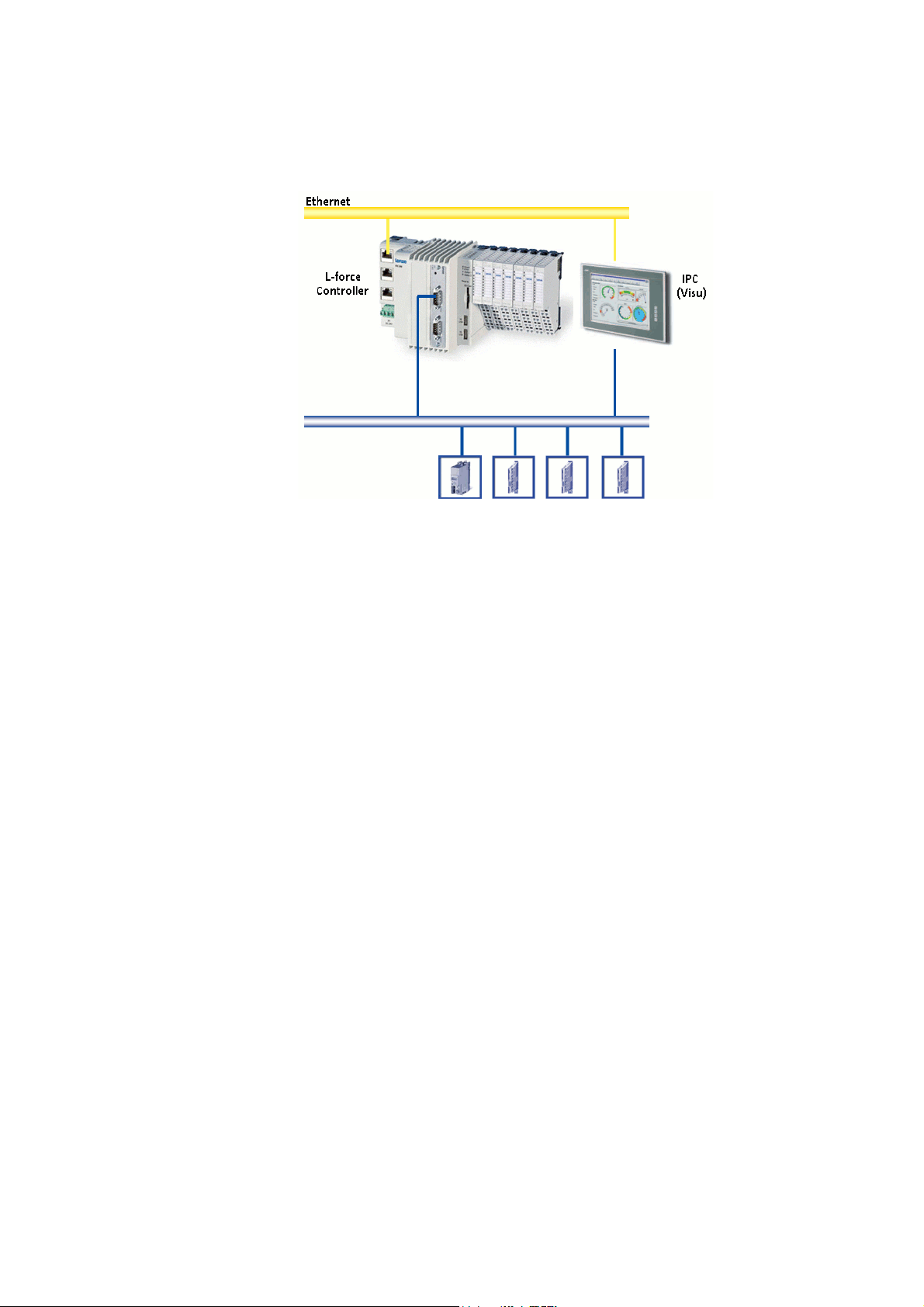

3 Controller-based Automation: Central motion control

The Lenze automation system "Controller-based Automation" serves to create complex automation

solutions with central motion control. Here, the controller is the control centre of the system.

System structure of the Controller-based Automation: "All from one single source"

[3-1] Example configuration (EtherCAT bus system): 3200 C controller with I/O system 1000 and i700 servo inverter

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 13

Page 14

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Lenze provides especially coordinated system components:

• Engineering software

The Lenze Engineering tools on your Engineering PC (Windows® operating system) serve to

parameterise, configure, and diagnose the system. The Engineering PC communicates with the

controller via Ethernet.

•Controller

The Lenze controller is available as Panel Controller with integrated touch display and as

Cabinet Controller in control cabinet design.

Cabinet Controllers provide a direct coupling of the I/O system 100 via the integrated backplane

bus.

The Runtime software

These software versions are available:

• "Logic": Sequence control in the controller, motion control in the inverter

• "Motion": Sequence control and motion control in the controller, inverter as actuating drive

• "Visu": Optional visualisation of the automation system, can be used separately or in addition

to "Logic" or "Motion"

An external monitor panel/display can be connected to the Cabinet Controller 3231 C/

3241 C.

• Without software: Controller as single component with operating system only

•Bus systems

EtherCAT is a standard "on board" bus system of the Controller-based Automation. EtherCAT

enables the control of all nodes (Motion/Logic) on one common fieldbus.

Optionally, CANopen, PROFIBUS and PROFINET can be used as extended topologies.

The Controllers c300/p300 have a CANopen interface "on board" as well (in addition to

EtherCAT).

• Inverter (e.g. Servo Inverter i700)

( 20) provides the control and/or visualisation of motion sequences.

"Logic & Motion" runtime software

The "Controller-based Automation" system allows for the central control of devices for Logic and

Motion applications. The runtime software runs on the controller.

In case of Logic applications, the sequence control is carried out in the controller and the motion

control is carried out in the inverter.

In case of Motion applications , the sequence control and motion control are carried out in the

controller. The inverter is used as actuating drive.

• Motion applications make special demands on the cycle time and real-time capability of the bus

system between the controller and the subordinate fieldbus nodes.

• this is for instance the case if the field devices, for example, are to move in a synchronised way

or if position setpoints are to be transmitted.

14 Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 15

4 System description

4.1 Visualisation system structure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 System description

This chapter describes the use of an Industrial PC as a visualisation device and the required

components.

4.1 Visualisation system structure

The field of visualisation technology distinguishes between three system architectures. The system

structure describes where to find the control system, the visualisation application, and the operator

device in the system.

Depending on the application ...

• control, visualisation, and operation can be carried out from one common controller.

Integrated control system

• the system structure can be composed of different devices (optionally from different

manufacturers in each case).

Stand-alone application

Since the system architectures are independent of the communication between the »VisiWinNET®«

visualisation system and the field devices, they can be freely combined.

( 17)

( 16)

More information regarding the communication with field devices can be found here:

Field devices

( 26)

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 15

Page 16

4 System description

4.1 Visualisation system structure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

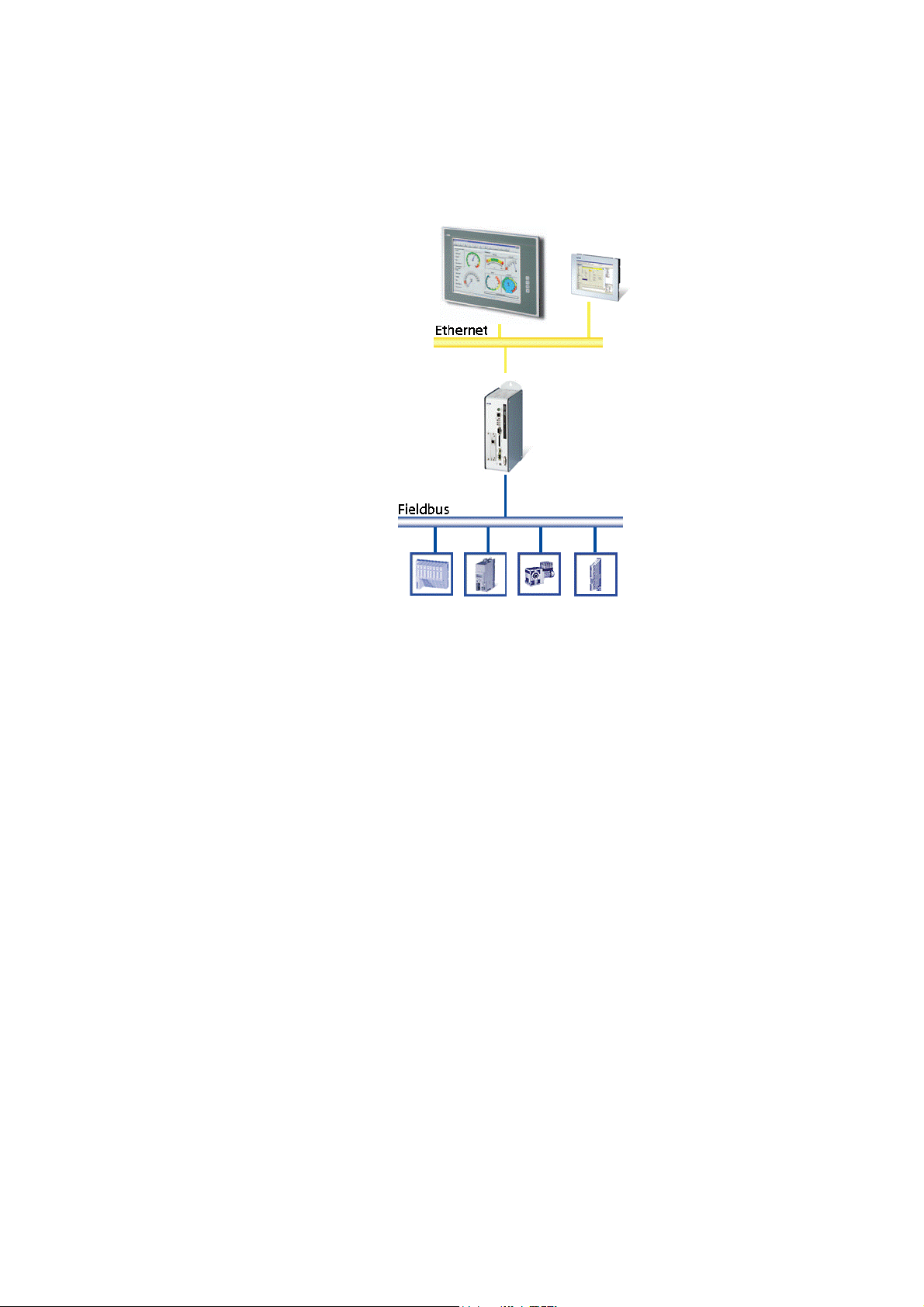

4.1.1 Stand-alone application

The control system (controller) and visualisation (Visu) run on separate controllers, respectively.

• The visualisation IPC (Visu IPC) directly communicates with an external control system and the

lower-level field devices. A fieldbus or a higher-level Ethernet network are used for

communication.

• The visualisation can access variables of the control system and (depending on the bus system)

in addition can directly access parameters of the field devices.

• For the visualisation, a Panel PC/Industrial PC Embedded Line or a control cabinet PC with an

external monitor panel can be used.

16

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 17

4 System description

4.1 Visualisation system structure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

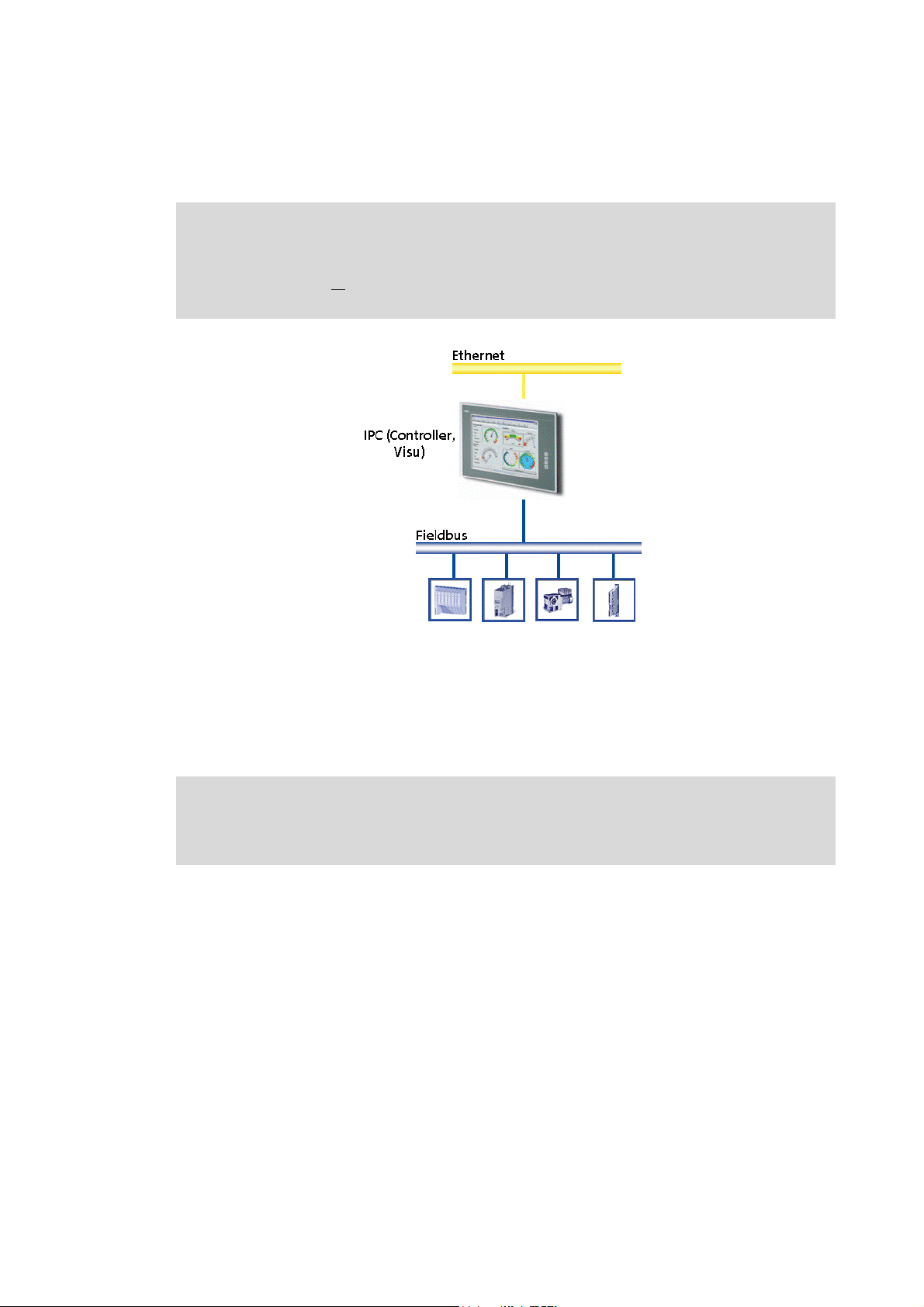

4.1.2 Integrated control system

Note!

The integrated control system is only provided for IPCs/controllers with an integrated

monitor panel or

display.

for IPCs/controllers with a DVI interface for an external monitor panel/

The control system (Logic/Motion) and the visualisation run on the same IPC (controller, Visu).

The visualisation (Visu) ...

• is directly coupled to the control system (Logic/Motion);

• can access variables of the control system and (depending on the bus system) in addition can

directly access the parameters of the field devices.

"Controller-based Automation" system manual

Here you'll find more information relating to the visualisation as part of a control

system.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 17

Page 18

4 System description

4.1 Visualisation system structure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.3 Client/server system

The client/server system is a classical SCADA application (Supervisory Control and Data Acquisition).

• A central server, IPC (controller) for data management (alarm, recipe, trend management) is

typical of this application.

• Operation and monitoring of the machine/system can be carried out via an optional number of

client devices.

18

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 19

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 System components

4.2.1 Controller: "Controller-based Automation" (control technology version 3.x)

Lenze offers a range of different controllers in cabinet and panel design. Depending on the

application, the controllers are provided with different processors, panel sizes, and runtime modes.

More information about Lenze controllers in the "Controller-based Automation" system

can be found in the following sets of documentation:

• "Controller-based Automation" system manual

• Controller reference manual

4.2.2 Industrial PCs (IPC): "PC-based Automation" (control technology version 2.x)

The platform strategy of the Lenze Industrial PCs provides for individual system concepts with

regard to the power, display size, and function, producing various designs from which you can select

the platform for your automation solution customised for each case.

This universal and scalable IPC platform is complemented by HMIs which are provided in fixed

configurations and can also fulfil automation functions in a restricted way.

More information about Lenze Industrial PCs in the "PC-based Automation" system can

be found in the following sets of documentation:

• "PC-based Automation" system manual

• Industrial PC (IPC) software manual

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 19

Page 20

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.3 Runtime software

The Industrial PC is the core of the visualisation system. To perform the tasks required, the Industrial

PC requires the so-called "runtime software".

The runtime software for instance comprises the operating system (Windows® CE). Moreover,

further software components are required which, for example, execute the control tasks of the IPC

or the visualisation application of the different applications.

These software versions are available:

• "Logic": Sequence control in the controller, motion control in the inverter

• "Motion": Sequence control and motion control in the controller, inverter as actuating drive

• "Visu": visualisation of the automation system, can be used separately or in addition to "Logic"

or "Motion"

An external monitor panel/display can be connected to the Cabinet Controller 3231 C/3241 C.

• Without software: controller as single component with operating system only

The runtime software and the licence required for using the software are usually ordered together

with the Industrial PC.

4.2.3.1 "Logic" and "Motion" runtime software

Logic Motion

The controller controls...

• simple motion sequences;

• by logically

Logic applications are suitable for the control of inverters

without

• execute simple motion sequences;

• can only be controlled via PLC functionality.

combined control signals.

a Motion functionality which ...

"Controller-based Automation" system manual

Here you'll find more information relating to the "Logic" and "Motion" runtime software.

The controller controls extensive motion sequences.

The runtime software "Motion" ...

• contains the PLCopen library;

• contains the "Logic" mode;

• supports "SoftMotion".

Motion applications are suitable...

• for the control of inverters executing complex motion

sequences of multi-axes in several dimensions;

• ...for the control of devices that are to traverse

synchronously;

• for the transfer of setpoints.

20

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 21

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.3.2 "Visu" runtime software

All visualisation applications are executed within a runtime

environment (runtime). The licence required for this purpose

depends on the hardware operating system.

The "Visu" runtime software is not pre-installed on the Lenze Industrial PCs, but is loaded to the IPC

together with the visualisation application. By means of »VisiWinNET®«, the program parts

required are automatically compiled.

If you use the »VisiWinNET®« compact runtime software, the download is carried out directly from

»VisiWinNET®«. In the case of the other runtime variants, »VisiWinNET®« creates a setup file which,

apart from the actual runtime software, also contains the complete visualisation application, which

must be installed on the respective target system.

Depending on the target system/operating system which is to be used for the visualisation process,

various versions of the runtime software with different functional ranges are provided.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 21

Page 22

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

»VisiWinNET®« Compact CE

This runtime system for Windows® CE systems only requires a small amount of memory space and

is specially designed for systems with a lower processor power. Typical scopes of application are the

machine-oriented operation and monitoring with low demands with regard to the visualisation.

They are used in stand-alone applications and integrated control systems.

The following Lenze devices can be used:

•Controller:

• Panel Controller p300/p500

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

• Industrial PCs:

• Embedded Line EL 1800 - 9800

• Command Station CS 5800 - 9800

• Control cabinet PC CPC 2800

•HMIs:

•EL 100

• EL 100 PLC

»VisiWinNET®« Compact XP

This runtime system for Windows® XP Embedded systems only requires a small amount of memory

space and is specially designed for systems with a lower processor power. Typical scopes of

application are the machine-oriented operation and monitoring on Industrial PCs, where

customised applications run alongside with the visualisation software. They are used in stand-alone

applications.

The following Lenze devices can be used:

• Cabinet Controller 3241 C (with an external monitor panel/display)

• Industrial PCs:

• Embedded Line EL 1800 - 9800

• Command Station CS 5800 - 9800

• Control cabinet PC CPC 2800

»VisiWinNET®« Standard XP

This runtime system for Windows® XP or Windows® XP Embedded is designed for a medium to high

performance class. It is used in stand-alone applications.

The following Lenze devices can be used:

• Cabinet Controller 3241 C (with an external monitor panel/display)

• Industrial PCs:

• Embedded Line EL 1800 - 9800

• Command Station CS 5800 - 9800

• Control cabinet PC CPC 2800

22

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 23

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

»VisiWinNET®« Standard Client/Server (C/S)

This runtime system for Windows® XP as client/server system offers the whole functional range of

the »VisiWinNET®« standard. However, all information used commonly is managed centrally on one

server.

So-called "Terminal Clients" serve as clients. They are simple Industrial PCs and HMIs under

Windows® CE or Windows® XP without a special runtime software, to which only the visualisation

application must be imported.

As an alternative, "Thin Clients" can also be used, which do not require any further installation, since

the application completely runs in the server in this case.

The following Lenze devices are suitable for the use as server:

• Industrial PCs:

• Embedded Line EL 1800 - 9800

• Command Station CS 5800 - 9800

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

The following Lenze devices are suitable for the use as client:

•Controller:

• Panel Controller p300/p500

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

• Industrial PCs:

• Embedded Line EL 1800 - 9800

• Command Station CS 5800 - 9800

• Control cabinet PC CPC 2800

•HMIs:

•EL 100

• EL 100 PLC

• Thin clients:

• Embedded Line EL 1800 - 9800 TC

• Command Station CS 5800 - 9800 TC

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 23

Page 24

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

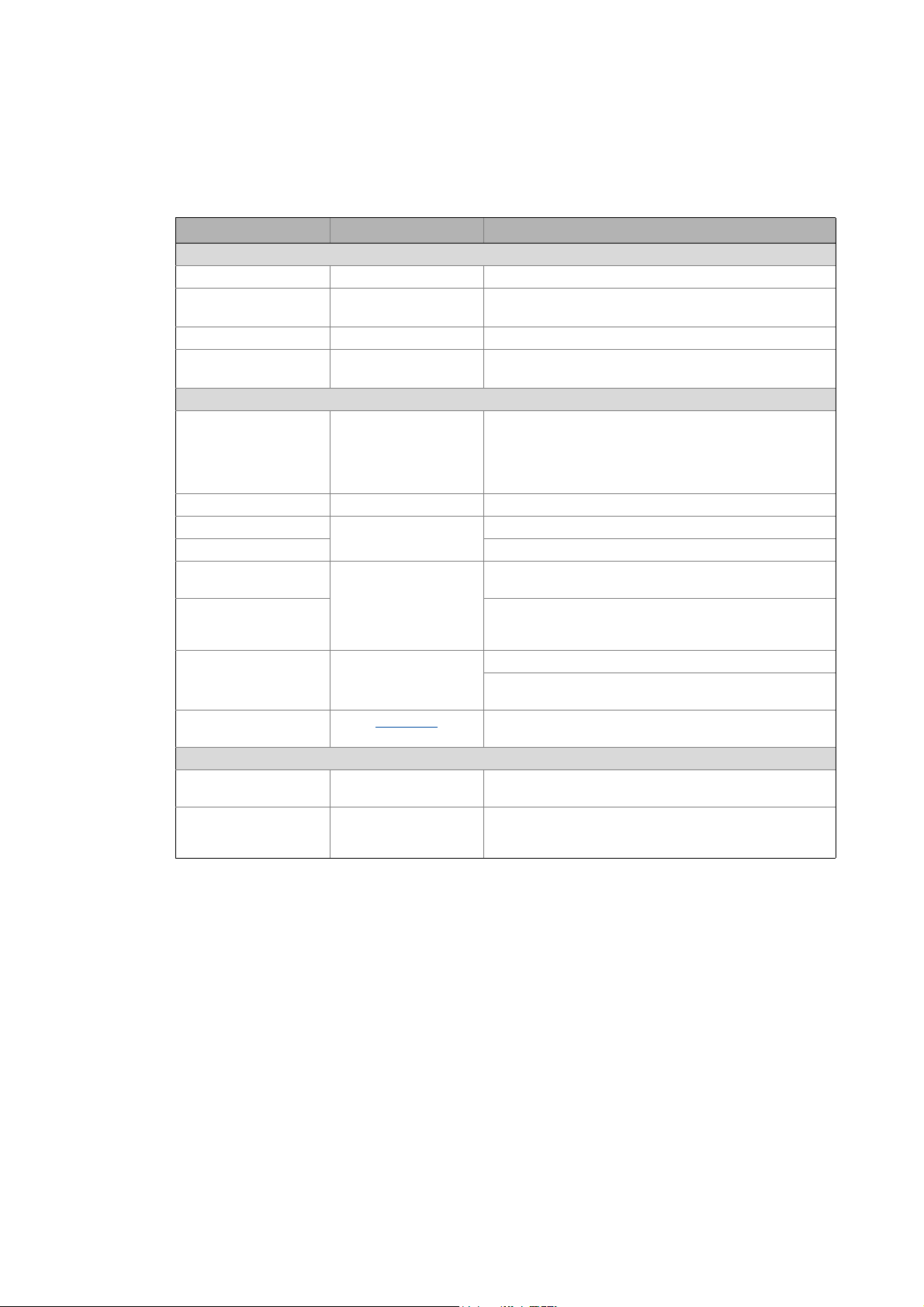

Functional range of the runtime software variants

Application Easy operation &

Target system Windows® CE Windows® XP

Runtime version Compact CE Compact XP Standard XP Standard XP / CS

Client / server Only client - -

Development system(s) »VisiWinNET®« Smart / Professional »VisiWinNET®«

Microsoft® Visual Studio .NET

Required

Use of Word, Excel, and Outlook -

Printing Only PCL printers

History / archive / trend Online history

Alarm history

Logging Restricted Restricted

Number of pages Depending on

Object per image Depending on

System is OPC server - -

Connection via OPC

Connection via driver Yes (only

Number of process variables Max. 2000 Max. 2000 Unlimited Unlimited

Logic Under »VisiWinNET®« Smart restricted

Recipes XML XML XML / MDB XML / MDB

Colour gradients - Option Option Option

Transparent objects - Option Option Option

FDA Restricted Restricted

Database handling Only if application has been developed with

: Function available

-: Function not available

monitoring

under Windows®

CE

(depending on

the memory

capacity)

the memory

capacity

the memory

capacity

»VisiWinNET®«

drivers)

With »VisiWinNET®« Professional, individual system

Operation &

monitoring

under Windows®

XP

Embedded

Only for »VisiWinNET®« Professional

Online history

(depending on

the memory

capacity)

Depending on

the memory

capacity

Depending on

the memory

capacity

Yes (only

»VisiWinNET®«

drivers)

extensions can be integrated.

»VisiWinNET®« Professional.

Visualisation

under

Windows® XP for

complex machine

operation

Windows® XP Windows® XP or

Online history Online history

Client/server

applications for

control room

solutions

Windows® Server

2003

Professional

Unlimited Unlimited

Unlimited Unlimited

24

"Controller-based Automation" system manual

Here you'll find more information relating to the visualisation as part of a control

system.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 25

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.3.3 "Visu" runtime software - licence information

A licence is required for executing the "Visu" runtime software.

The licence information indicates which runtime software version

(Compact, Standard, etc.) may be used, how many clients are

allowed to log on to a client/server system, and how many

variables (power tags) can be displayed via the visualisation.

Depending on the device type, the licence information is stored in different ways.

•Controller:

• Panel Controller p300/p500

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

• Industrial PCs:

• Embedded Line EL 1800 - 9800

• Command Station CS 5800 - 9800

• Control cabinet PC CPC 2800

Under Windows® XP, the licence information can optionally be provided via a "Dongle" for the USB

interface or via a licence file that is connected to the MAC address of the network interface card. The

licence file is used by default.

Under Windows® CE, solely the use of the licence file is possible. The licence desired is specified with

the order, so that the device can be delivered in a fully configured state.

The EL 100 and EL 100 PLC HMIs are provided with a Visu licence by default (»VisiWinNET®« compact

CE with a fixed number of power tags). This makes a separate dongle/separate licence file

dispensable.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 25

Page 26

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.4 Field devices

The following field devices are supported:

•Inverter:

• i700 servo inverter

• Inverter Drives 8400 / 8400 motec / 8400 protec

• Servo Drives 9400 Highline

• ECS servo system

• 8200 vector frequency inverter

• 9300 servo inverters

• Further field devices:

• I/O system 1000

• I/O system IP20 compact/modular

• Other devices for which an applicable device description file is available.

• Control systems:

• Logic & Motion

• Siemens Simatic® S7 300/400

•VIPA

•SAIA

• Other control systems for which an OPC server or a »VisiWinNET®« direct driver is available.

Basically, two different scenarios with external control systems must be distinguished for the data

to be visualised. This may lead to restricted access possibilities.

More information relating to the system structure and the control system (Logic &

Motion) can be found in the following sets of documentation:

• "PC-based Automation" system manual (control technology V2.x)

• "Controller-based Automation" system manual (control technology V3.x)

26

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 27

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.4.1 Direct access to the field devices

• The controller and the IPC (Visu) access the fieldbus independently of each other.

• The visualisation (Visu) can access the parameters of the field devices and the parameters of the

controller.

Note!

• Direct access to the field devices connected to the fieldbus ensures a maximum

independence of the two systems, but is rarely reasonable in practical operation.

• The configuration with independent control and visualisation systems is only

recommended for systems without

• Depending on the bus system used, several bus masters that are independent of each other can

be used.

• The visualisation may impact the real-time capability of the bus. Therefore this configuration is

only suitable for Motion systems to a limited extent. (It also depends on the bus system used)

Direct access to field devices is possible for the following bus systems:

•CANopen

Details regarding the suitability of the respective field devices can be found here:

Network topologies

( 32)

a Lenze control system!

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 27

Page 28

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.4.2 Access to the control system and the field devices connected

• When using the Lenze control technology, the visualisation can directly access the field devices

without any further impact, using the Industrial PC as gateway. When different control systems

are used, this is usually not possible. Therefore it is recommended to only use data of the

controller.

• To display field device data in the visualisation, the controller must import these data cyclically

and transfer them to a transfer section (e.g. a data block) which is only accessed by the

visualisation. This ensures field device data access without any further effects.

28

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 29

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.5 Engineering tool»VisiWinNET®«

With »VisiWinNET®«, Lenze provides a scalable Engineering tool to create visualisation applications

according to individual requirements and load them on the Industrial PCs.

»VisiWinNET®« is provided in the versions »VisiWinNET®« Smart and »VisiWinNET®« Professional.

4.2.5.1 »VisiWinNET®« Smart

For easy interface creation, »VisiWinNET®« Smart provides a user-friendly visualisation system. It

can be used as a flexible tool for the creation of simple applications or for service purposes.

»VisiWinNET®« Smart is provided with an individual full-graphics integrated development

environment and supports the user by ready-made templates. One of the system's strong points is

the possibility of combining it with »VisiWinNET®« Professional.

Functions

Suitable for machine-oriented applications.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 29

Page 30

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.5.2 »VisiWinNET®« Professional

»VisiWinNET®« Professional is completely integrated into the Microsoft® Visual Studio .NET

integrated development environment and provides the basis for the creation of visualisation and

SCADA applications with a high functionality.

The ready-made templates and modules can be used to smoothly create applications via "drag and

drop". If required, the system permits individual program-related changes on the basis of Visual

Basic .NET and C#. This serves to solve company-specific and complex tasks when the standard

visualisation functions are not sufficient.

Functions

• For complex applications

• For client/server systems with SCADA applications

• For individual and company-related programming

• For the connection to databases or other Microsoft® Office programs

• For the use of complex report functions

• For establishing an individual visualisation kit

4.2.5.3 Visualisation kit

The .NET functions and object-oriented programming enable the creation of individual control

elements and machine modules. Using ready-made modules, individual visualisation kits can be

implemented according to your personal requirements. In both systems, applications, except for

scripts, can be edited reciprocally.

The easy handling of »VisiWinNET®« Smart and the openness of the more complex »VisiWinNET®«

Professional provide substantial advantages when projects are edited reciprocally.

Note!

30

»VisiWinNET®« Professional is an expert system that requires special program

knowledge and goes far beyond the creation of a drag-and-drop system.

»VisiWinNET®«This is why Professional is not available as a pure catalog product.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 31

4 System description

4.2 System components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.6 Backup of visualisation data (UPS functionality)

The Controllers 3221 C/3231 C back up the visualisation data cyclically every 60 seconds. The

visualisation data backed up are therefore not exactly up-to-date after a voltage failure. Depending

on the time at which the voltage failure occurs, the data status backed up may be out-of-date for up

to 59 seconds (the interval between two backup processes is 60 seconds).

When a voltage failure occurs, the Controllers 3241 C back up the visualisation data on the SD card

in an exactly isochronous fashion if a capacitor pack (CAPS-PACK) is connected.

The Controllers p300/p500 are equipped with implemented UPS for the buffering of visualisation

data.

The EL 100 and EL 100 PLC HMIs are provided with an internal capacitor for buffering the current

supply. Like this, remanent PLC variables can be saved with mains failure protection.

Operating instructions for controllers / Industrial PCs / HMI

Here, further information can be found.

4.2.6.1 Capacitor pack (CAPS-PACK)

The capacitor pack serves to buffer the current supply of the controller/IPC for some seconds. Like

this, current fluctuations can be compensated.

In the case of a power failure, the capacitors ensure the current supply. Within this protected time,

specially marked variable contents (remanent PLC variables) can be saved.

The following controllers and Industrial PCs can be equipped with a capacitor pack (CAPS-PACK) for

backup:

• Controller 3241 C

• EL 1800 - 9800

• CS 5800 - 9800

• CPC 2800

4.2.6.2 Battery pack (ACCU-PACK)

The battery pack serves to bridge longer power failures. Within this protected time, further data

from the visualisation can be saved (in addition to the remanent PLC variables).

Alarms, batch protocols, trends, or recipe data can be saved. If this data has been defined as

remanent memory data it will be written to the memory card via a cache of a variable size.

If a power failure occurs, the battery pack activates an alarm and all data in the cache will be saved.

When the system is restarted, the data saved with mains failure protection will still be available.

The following controllers and Industrial PCs can be equipped with a battery pack (ACCU-PACK) for

backup:

• Controller 3241 C

• EL 1800 - 9800

• CS 5800 - 9800

• CPC 2800

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 31

Page 32

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3 Network topologies

The Lenze visualisation system supports different control and bus systems connected via

»VisiWinNET®« channels. Depending on the control or bus system used, the communication and

network options are different.

Communication has an impact on the usability of the operating systems and device lines.

4.3.1 Channels

The following »VisiWinNET®« communication channel types are distinguished:

• »VisiWinNET®« driver (direct driver)

•OPC server

Note!

There is no OPC server available for PROFIBUS and PROFINET.

Controller p300:

• The OPC communication for »VisiWinNET« is exclusively available for Controller p300

without

• Otherwise, only the Lenze "Logic&Motion" direct driver can be used for the data

exchange between »VisiWinNET« and PLC.

PLC.

32

Depending on the bus system, there will be either a »VisiWinNET®« driver (direct driver) or an OPC

server available.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 33

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Direct drivers... OPC servers...

• are contained in the scope of supply of the

»VisiWinNET®« development packages.

• are transferred from the Engineering PC to the

Industrial PC when the visualisation application is

downloaded.

• are specially tailored to »VisiWinNET®« and can only

be used for this software program.

• can be universally used and offer an open interface.

Like this, it is basically possible to integrate other

control or bus systems into »VisiWinNET®« if a

suitable OPC server is available.

• usually must be installed separately.

Stand-alone application

( 16)

Integrated control system ( 17)

Remote access

Remote access allows you to separate the control system and visualisation on physically separated

IPCs. The system structure is basically similar to a Client/server system

( 18).

• Remote access may be reasonable if a control system runs on a control cabinet PC, but no

monitor is available. In contrast to the client/server system, it is not possible to implement

several operator terminals.

• Depending on the fieldbus, direct drivers (optimised for remote access) or remote-capable OPC

servers can be used.

Channels

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 33

( 32)

Page 34

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.2 Browsing variables

For defining the variables to be displayed, »VisiWinNET®« allows you to "browse" variables.

Depending on the bus system and the control system type, there are different file formats available

from which »VisiWinNET®« can take the variable information and offer it for selection.

• In the case of CANopen, this is for instance an EDS file containing the parameters of the

corresponding device.

• This can also be the project file of a control program (e.g. Logic & Motion, CoDeSys, STEP 7®

program), containing the variables of the control.

Tip!

The »VisiWinNET®« project wizard helps you to select the right browser.

Browsing online/offline

With an automation system that is already completely available, some browsers allow you to

browse the system from »VisiWinNET®« (online "browsing").

In practical operation, online "browsing" is rarely used because the system is often not yet complete

and still has to be commissioned.

As an alternative, offline browsing is possible, which requires special device description files that

contain the parameter information of a specific device type. Depending on the control and bus

system, these files differ from each other.

The following chapters describe the way of browsing and the file types that can be used.

34

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 35

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

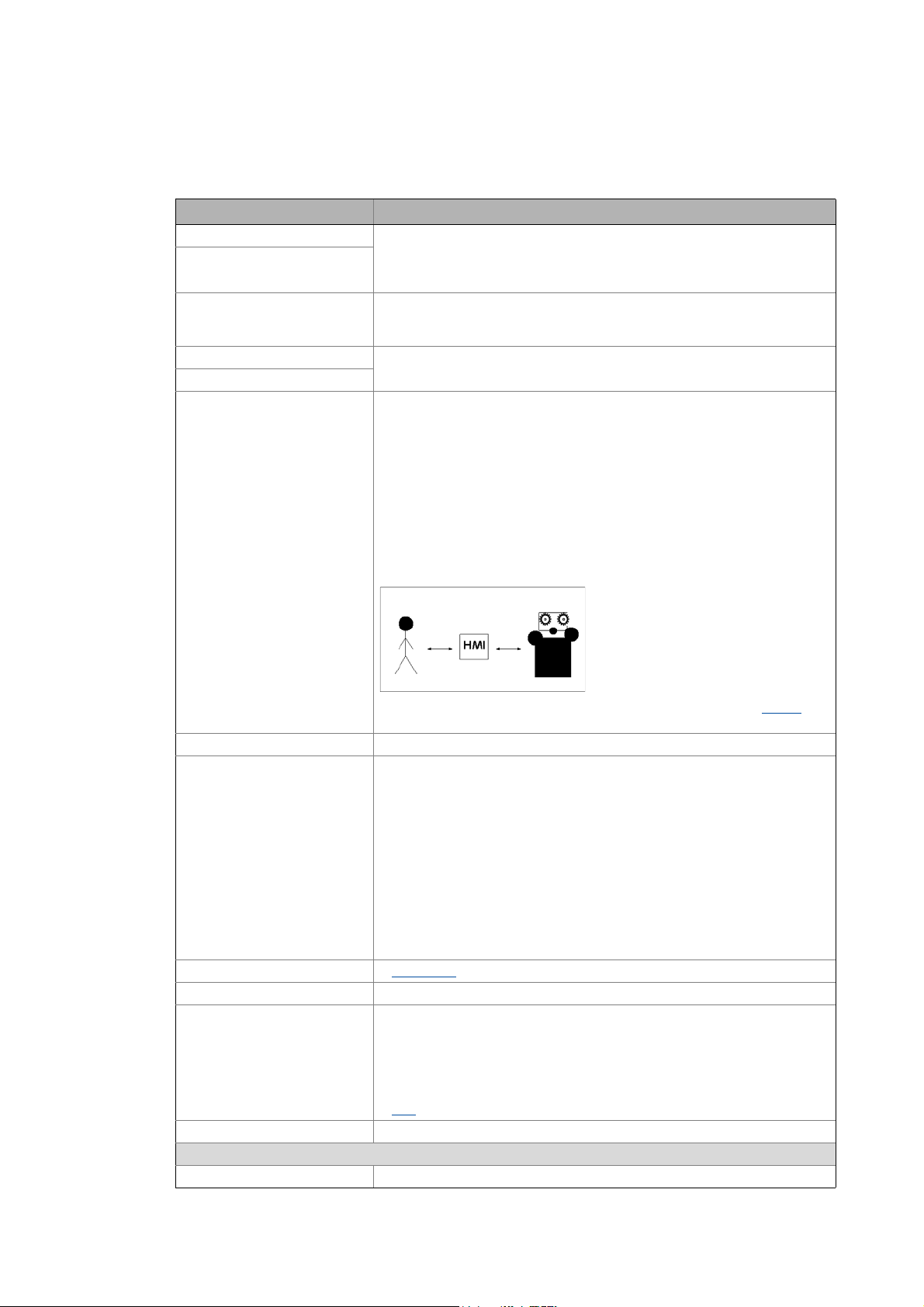

4.3.3 EtherCAT®

Note!

For Industrial PCs of the EL 1xx, EL x8xx, CS x8xx, and CPC x8xx series in control

technology release 2.5, the EtherCAT bus system is not

The EtherCAT bus system only allows one single master. Since the master functionality is typically

assigned to the control system, it is not possible that another controller accesses field devices

independently of the control system.

The Lenze controllers 3231 C/3241 C and p300/p500 are equipped with an "on board" EtherCAT

interface.

provided.

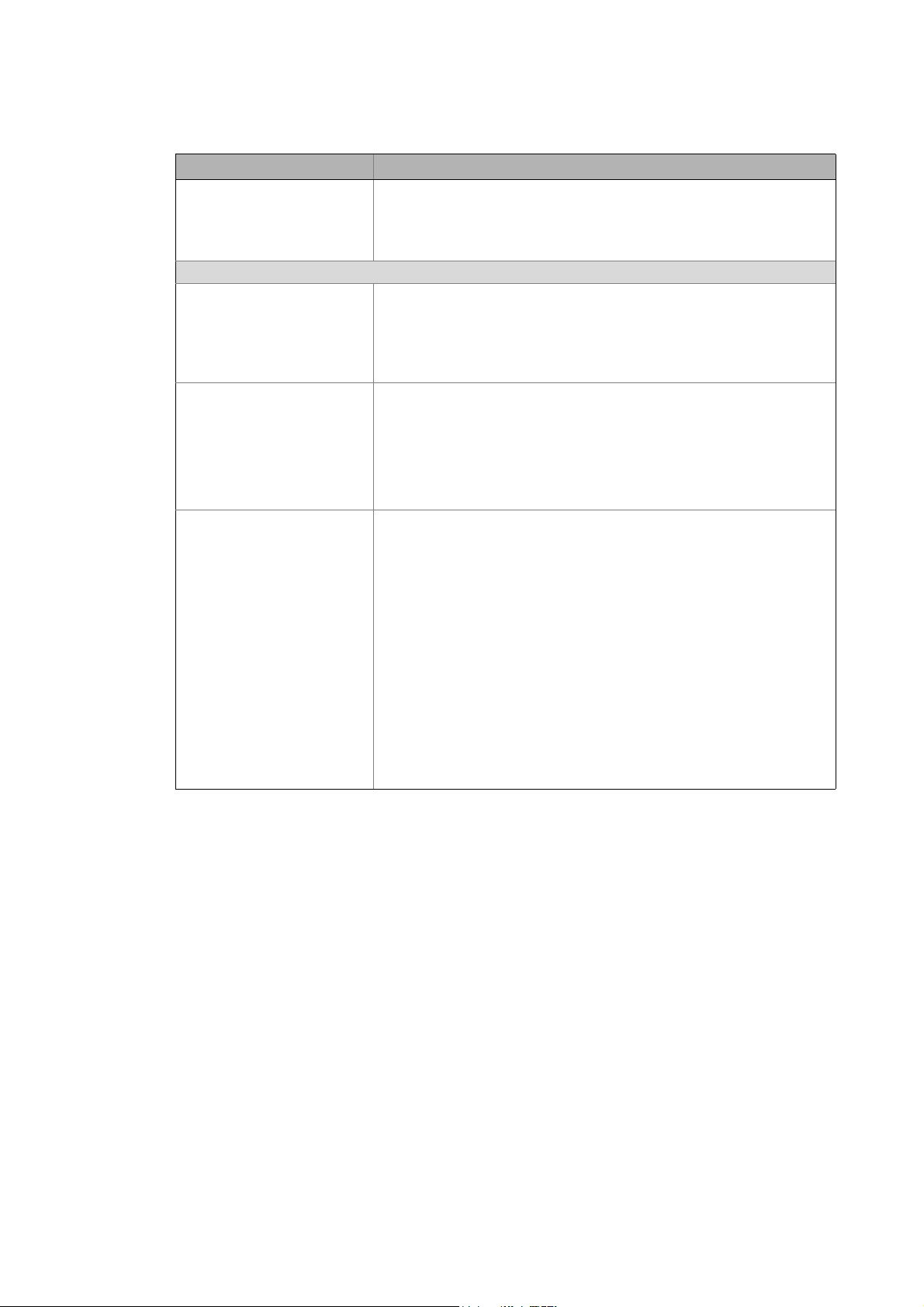

[4-1] Sample configuration: Controller 3200 C with EtherCAT

For more information on the use of EtherCAT®, please see the following sets of

documentation:

• "Controller-based Automation" system manual

• "Controller-based Automation - EtherCAT®" communication manual

Tip!

Lenze offers complete solutions for EtherCAT as part of the "Logic & Motion" control

technology.

Furthermore, »VisiWinNET®« can be used together with other EtherCAT control systems via

Ethernet if appropriate OPC servers or »VisiWinNET®« direct drivers are available.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 35

Page 36

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Available runtime software for Lenze controllers

Controller Runtime

Software

3231 C

3241 C

p300

p500

1) Available from »VisiWinNET®« version 6.4.

Windows®

Compact CE

Logic

Motion

Visu

Access Driver type Driver name Communication

Field devices OPC

PLC variables

(Logic & Motion)

IPC parameters OPC

OPC

Lenze.Digitec.OPCTunnel.DA )

Lenze.OPC_EtherCAT_CE

Lenze.Digitec.OPCTunnel.DA )

CoDeSys.OPC.DA )

Lenze.Digitec.OPCTunnel.DA )

type

EtherCAT OPC

Tunnel

EtherCAT OPC

Server

SoftPLC OPC

Tunnel

SoftPLC OPC

Server

Datamanager

OPC tunnel

Browser

Offline

(EDS/DCF/GDC 1))

Offline

(EDS/DCF/GDC 1))

Offline

(SYM)

Online/offline

(SYM)

Offline

(EDS/DCF)

36

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 37

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.4 CANopen®

Note!

• Due to the access mechanisms of the CAN bus, the real-time capability of the bus may

be influenced by the visualisation if visualisation and control system communicate

independently of each other with the field devices via CAN. Therefore, this

constellation is only with restrictions suitable for the use in Motion systems.

This restriction does not apply to the Lenze Logic & Motion control system!

• As an alternative, it is recommended to access the variables of the field devices via

Ethernet and control system IPC.

Access to the control system and the field devices connected

Controller p300 ...

• are equipped with an integrated CAN communication interface (on board);

• only support the CAN master functionality

The optional MC-CAN2 communication card is not supported by controllers p300.

.

( 28)

Visualisation applications with CANopen are available for the following Lenze devices:

•HMI series EL 100

• Industrial PCs: EL 1800-9800, CS 5800-9800 and CPC 2800

The Industrial PCs use an OPC server for communication.

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

• Panel Controller p300/p500

Under Windows® CE, a direct driver is provided for communication.

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 37

Page 38

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Functions

• Direct access to field devices via CANopen.

Access to the control system and the field devices connected

( 28)

• Control system access via CAN if the control systems have an SDO object directory.

• Control system access via Ethernet if an OPC server is available.

• SDO and PDO access (only with direct drivers).

• Visualisation variables can be imported from EDS/DCF/GDC files.

For more information regarding the use of CANopen®, please see the following sets of

documentation:

• "Controller-based Automation" system manual

• "Controller-based Automation - CANopen®" communication manual

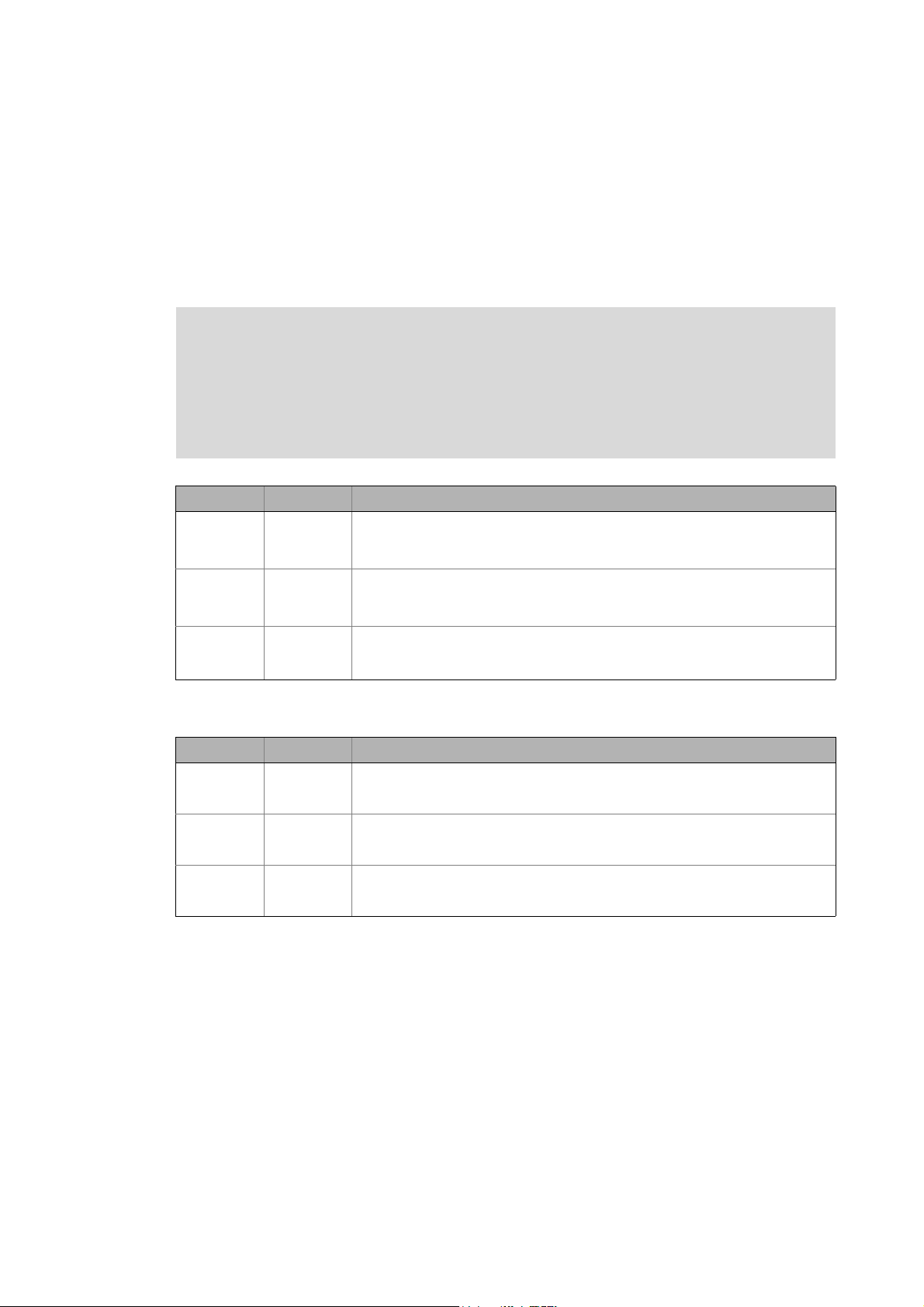

Runtime software available for the corresponding device series

Hardware HMI Industrial PCs Controller

Device series EL 100

Example illustration

EL 100 PLC

Embedded

Line

EL 1800 -

9800

Command

Station

CS 5800 -

9800

Control

cabinet PC

CPC 2800 3231 C 3241 C p300 p500

Cabinet Controller Panel Controller

"Visu" runtime software

»VisiWinNET®«

Compact CE

»VisiWinNET®«

Compact XP

»VisiWinNET®«

Standard XP

»VisiWinNET®«

Standard

Client/server XP

Communication

CAN interface

(on board)

MC-CAN2

(optional)

: Function available

-: Function not available

1) For 3231 C/3241 C, only with external monitor panel/display at DVI interface.

2) Controllers p300 only support the CAN master functionality

- -

- -

- -

----- 2) -

- -

.

1) 1)

1) --

1) --

1) --

38

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 39

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Overview of the communication drivers and browsers available

Device series Runtime

Access Driver type Driver name Communication

Software

Controller

3231 C

3241 C

p300

p500

Windows® CE

Logic

Motion

Visu

Field devices OPC

PLC variables

OPC

(Logic & Motion)

Parameter of the

OPC

controller/IPC

EL 1800-9800

CS 5800-9800

CPC 2800

Windows® XP

Visu

Windows® CE

Field devices OPC

Field devices OPC

Logic

Motion

Visu

PLC variables

OPC

(Logic & Motion)

Parameter of the

OPC

controller/IPC

EL 100 Field devices Direct driver

EL 100 PLC Field devices Direct driver

PLC variables

Direct driver

(Logic & Motion)

1) Function is available from »VisiWinNET®« version 6.4!

Lenze.Digitec.OPCTunnel.DA

Lenze.OPC_CANbus_CE

Lenze.Digitec.OPCTunnel.DA

CoDeSys.OPC.DA

Lenze.Digitec.OPCTunnel.DA )

Lenze OPC system bus server

Lenze.Digitec.OPCTunnel.DA

Lenze.OPC_CANbus_CE

Lenze.Digitec.OPCTunnel.DA

CoDeSys.OPC.DA

Lenze.Digitec.OPCTunnel.DA )

Lenze CAN CE driver

Lenze CAN CE driver

Driver for CoDeSys runtimes

1)

1)

1)

1)

type

1)

CAN OPC tunnel Offline

CAN OPC server Offline

1)

SoftPLC OPC

Tunnel

SoftPLC OPC

Server

Datamanager

OPC tunnel

Lenze system bus

OPC server

1)

CAN OPC tunnel Offline

CAN OPC server Offline

1)

SoftPLC OPC

Tunnel

SoftPLC OPC

Server

Datamanager

OPC tunnel

»VisiWinNET®«

LenzeCAN Driver

»VisiWinNET®«

Lenze CAN Driver

»VisiWinNET®«

CoDeSys driver

Browser

(EDS/DCF/GDC 1))

(EDS/DCF/GDC 1))

Offline

(SYM)

Online/offline

(SYM)

Offline

(EDS/DCF)

Offline

(EDS/DCF/GDC1))

(EDS/DCF/GDC 1))

(EDS/DCF/GDC 1))

Offline

(SYM)

Online/offline

(SYM)

Offline

(EDS/DCF)

Offline

(EDS/DCF1)/GDC)

Offline

(EDS/DCF1)/GDC)

Offline

(SYM)

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 39

Page 40

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.5 PROFIBUS®

Visualisation applications with PROFIBUS are available for the following Lenze devices:

•HMI series EL 100

• Industrial PCs: EL 1800-9800, CS 5800-9800 and CPC 2800

The Industrial PCs use an OPC server for communication.

• Cabinet Controller 3231 C/3241 C (with an external monitor panel/display)

• Panel Controller p300/p500

Under Windows® CE, a direct driver is provided for communication.

The connection of the visualisation to PROFIBUS makes use of the properties that the MPI protocol

is "tunnelled" on PROFIBUS and the connection of an MPI node to PROFIBUS is identical as regards

the hardware. Thus a direct connection to a Siemens S7 control is possible without logging on a

separate PROFIBUS node in the control configuration.

For this purpose, the Industrial PCs are equipped with a communication card (MC-MPI), whereas the

interface is already available on-board for the EL 100 with the MPI variant.

To facilitate the creation of an application in »VisiWinNET®«, the variables can be imported from an

S7-PLC program. Communication drivers are available for all runtime systems.

Functions

• Access to Siemens S7-300/400 control systems via PROFIBUS (MPI)

• Access to other controls via Ethernet if an OPC server or »VisiWinNET®« direct driver is available.

• Visualisation variables can be imported from STEP 7®.

40

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 41

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Note!

The data of the connected PROFIBUS slaves cannot be directly accessed!

As an alternative, the control system can access variables of the field devices. The control

system automatically reads in the variables and provides them to the visualisation in a

transfer area.

Access to the control system and the field devices connected

( 28)

For more information regarding the use of PROFIBUS®, please see the following sets of

documentation:

• "Controller-based Automation" system manual

• "Controller-based Automation - PROFIBUS®" communication manual

Runtime software available for the corresponding device series

Hardware HMI Industrial PCs Controller

Embedded

Line

Device series EL 100

Example illustration

"Visu" runtime software

»VisiWinNET®«

Compact CE

»VisiWinNET®«

Compact XP

»VisiWinNET®«

Standard XP

»VisiWinNET®«

Standard

Client/server XP

Communication

MPI

(on board)

MC-MPI

(optional)

MC-PBM, master

(optional)

MC-PBS, slave

(optional)

: Function available

-: Function not available

1) For 3231 C/3241 C, only with external monitor panel/display at DVI interface.

EL 100 PLC

- -

- -

- -

----- -

- -

- -

- -

EL 1800 -

9800

Command

Station

CS 5800 -

9800

Control

cabinet PC

CPC 2800 3231 C 3241 C p300 p500

Cabinet Controller Panel Controller

1) 1)

1) --

1) --

1) --

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17 41

Page 42

4 System description

4.3 Network topologies

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Overview of the communication drivers and browsers available

Device series Runtime

Software

Controller

3231 C

Windows® CE

Visu

3241 C

p300

p500

EL 100

EL 100 PLC

EL 1800-9800

CS 5800-9800

Windows® XP

Visu

CPC 2800

Windows® CE

Visu

Windows® CE

Logic

Motion

1) Function is available from »VisiWinNET®« version 6.4!

Access Driver type Driver name Communication

type

PLC variables

(external control)

Direct driver

Lenze MPI CE driver

»VisiWinNET®«

LenzeMPI Driver

(Basic datatypes

syntax /

Instruction list

AWL syntax)

PLC variables

(external control)

Direct driver

»VisiWinNET®« driver S7 for

Lenze MC MPI

»VisiWinNET®«

LenzeMPI Driver

(Basic datatypes

syntax /

Instruction list

AWL syntax)

PLC variables

(external control)

Direct driver

»VisiWinNET®« driver S7 for

Lenze MC MPI

»VisiWinNET®«

LenzeMPI Driver

(Basic datatypes

syntax /

Instruction list

AWL syntax))

PLC variables

(Logic & Motion)

OPC

Lenze.Digitec.OPCTunnel.DA

CoDeSys.OPC.DA

1)

1)

SoftPLC OPC

Tunnel

SoftPLC OPC

Server

IPC parameters OPC

Lenze.Digitec.OPCTunnel.DA )

Datamanager

OPC tunnel

Browser

Offline

(SDF, IL)

Offline

(SDF, IL)

Offline

(SDF, IL)

Offline

(SYM)

Online/offline

(SYM)

Offline

(EDS/DCF)

42

Lenze · Controller-based Automation - Visualisation · System Manual · DMS 1.5 EN · 04/2014 · TD17

Page 43

4 System description