Page 1

Software Manual

Cam Designer Basic

L

Page 2

This Manual is valid for the Cam Designer Basic from version 2.3

Copyright

© 2005 Lenze Drive Systems GmbH. All rights reserved.

Imprint

Lenze Drive Systems GmbH

POB 10 13 52, 31763 Hameln, Germany

Phone: ++49 (0)5154 / 82-0

Fax: ++49 (0)5154 / 82-2111

E-mail: Lenze@Lenze.de

Copyright information

All texts, photos and graphics contained in this documentation are subject to

copyright protection. No part of this documentation may be copied or made

available to third parties without the explicit written approval of Lenze Drive

Systems GmbH.

Liability

All information given in this documentation has been selected carefully and

tested for compliance with the described hardware and software. Nevertheless, discrepancies cannot be ruled out. We do not accept any responsibility or

liability for any damage that may occur. Required corrections will be included

in updates of this documentation.

Trademarks

Microsoft, Windows and Windows NT are either registered trademarks or

trademarks of Microsoft Corporation in the U.S.A. and/or other countries.

Adobe and Reader are either registered trademarks or trademarks of Adobe

Systems Incorporated in the U.S.A.and/or other countries.

All other product names contained in this documentation are trademarks of

the corresponding owners.

2 Version 2.1 EN - 09/2005 - TD16 L

Page 3

Contents

Cam Designer Basic

Contents

1 About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Layout of the safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 System requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Connection with the target system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Software installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Motion tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Scaled motion rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 User interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 Using the direct help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Language selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Title bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.4 Menu bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Project structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7 Screen divider . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8 Workspace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.9 Output area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.10 Status bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.11 Document window (worksheet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Create a new project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1.1 Step 1: Defining the features of the master axes . . . . . . . . . . . . . . . 22

6.1.2 Step 2: Defining the properties of the slave axis . . . . . . . . . . . . . . . 24

6.1.3 Step 3: Set profile options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.4 Step 4: Defining the file name and directory for a project. . . . . . . 29

6.1.5 Step 5: Adding a slave axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1.6 Creating further products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Open an existing project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.1 Selecting the properties of a slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2.2 Deleting a slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3 Connection with the OPC server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.4 Downloading the drive data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

L 2.1 EN - 09/2005 3

Page 4

Cam Designer Basic

Contents

6.5 Saving the project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.6 Saving a project under another name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.7 Exiting Cam Designer Basic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7 Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 Working with the worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Settings for the worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 Object Input Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.4 Interpolation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.5 Worksteps required for a new cam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.6 Settings of the worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.7 Creation of profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.8 Closed profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.9 The cam group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.9.1 Defining the cam type and cam reference . . . . . . . . . . . . . . . . . . . . . 46

7.9.2 Cam types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.10 Export of profile data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.11 Cam Designer Basic Online Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1 Error numbers, causes & remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.2 Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4 2.1 EN - 09/2005 L

Page 5

1 About this Manual

This Manual contains information about Lenze Cam Designer Basic.

The »Cam Designer Basic« is a software which is used to transfer recipes consisting of motion profiles, cam tracks and position markers from a PC to Lenze target systems.

Special features of the »Cam Designer Basic« are:

Import of CAD data via standardised interfaces (VDI 2143).

Program operation via an easy-to-use PC user interface for the first commissioning and

the preparation of additional functions to be provided to the final user by the mechanical engineer.

Smoothing of imported CAD data (motion profiles) for a smoother running of the

drives.

1.1 Conventions used

Cam Designer Basic

About this Manual

Conventions used

This Manual uses the following conventions to distinguish between different types of information:

Type of information Marking Examples/notes

Variable identifier italic Set bEnable to TRUE to...

Window The message window... / The Options dialog box...

Control element bold The OK button... / The Copy command... / The Properties tab... / The

Sequence of menu

commands

Keyboard command <bold> Use <F1> to call the Online Help.

Program listings Courier

Keyword Courier

bold

Link underlined

Safety information

Name input field...

If the execution of a function requires several commands, the individual

commands are separated by an arrow: Select File

If a command requires a combination of keys, a "+" is placed between

the key symbols:

Use <Shift>+<ESC> to...

IF var1 < var2 THEN

a = a + 1

END IF

Links are highlighted references which are activated by means of a

mouse click.

Layout of the safety information ( 6)

Open to...

Step-by-step instructions

Tip

Like safety information, step-by-step instructions and tips can be recognised by an icon.

L 2.1 EN - 09/2005 5

Page 6

Cam Designer Basic

About this Manual

Layout of the safety information

1.2 Layout of the safety information

All safety information have a uniform structure:

The icon characterises the type of danger.

The signal word characterises the severity of danger.

The note describes the danger and suggests how to avoid the danger.

Signal word

Note

Icon Signal word Meaning Consequences if disregarded

hazardous

electrical

voltage

Danger! Impending danger to persons Death or severe injuries

general dan-

ger

Stop! Potential damage to material Damage to the controller or its environment

Note! Note

6 2.1 EN - 09/2005 L

Page 7

2 System requirements

The following minimum requirements on hardware and software must be met to use the

»Cam Designer Basic«.

Microsoft® Windows® 98, Windows NT® 4.0 (as of Service Pack 5),

Windows® 2000 (as of Service Pack 2) or Windows® XP.

64 MByte RAM

128 MByte RAM (Windows® XP/2000)

IBM compatible PC (CPU: Pentium 90 MHz processor or faster)

Super VGA screen

Hard disk with at least 120 MB of free disk space

CD-ROM drive

Mouse (Microsoft-compatible)

Cam Designer Basic

System requirements

Connection with the target system

2.1 Connection with the target system

The communication with the target system (controller, Servo PLC or 9300EK servo cam) requires a fieldbus-specific interface module for the PC and the corresponding fieldbus modules for the target systems to be connected.

For system bus (CAN) communication, Lenze offers the following components as interface

module for the PC:

Bus system Max. number of target systems

PC port Required hardware components

System bus (CANopen) 63

Parallel

port

(LPT port)

USB

(Universal Serial Bus)

PC system bus adapter 2173

incl. connection cable and voltage-supply adapter

• for DIN keyboard connection

• for PS/2 keyboard connection

• for PS/2 keyboard connection with electrical isolation

PC system bus adapter 2177

incl. connection cable

(EMF2177IB)

(EMF2173IB)

(EMF2173IBV002)

(EMF2173IBV003)

L 2.1 EN - 09/2005 7

Page 8

Cam Designer Basic

Software installation

3 Software installation

How to install the »Cam Designer Basic«:

1. Start Windows.

2. Insert the CD-ROM »Cam Designer Basic« into the CD-ROM drive.

• If the auto-start function of the CD-ROM drive is active, the installation program

is started automatically and you can proceed with step 5.

3. Select Run ... from the start menu.

4. Enter the letter for your CD-ROM drive followed by ":\setup.exe" (e.g. "e:\set-

up.exe") in the command line and confirm with OK.

5. Follow the instructions of the installation program.

Note!

Installation under Windows NT/2000/XP requires administrator rights!

8 2.1 EN - 09/2005 L

Page 9

4 Introduction

»Cam Designer Basic« is a graphic tool for the easy creation of electronic cams.

»Cam Designer Basic« provides the features of the »Cam Designer Professional« in reduced

form.

Main features of the »Cam Designer Basic«

Easy creation of cams by means of graphic objects (e.g. lines, polynomials).

Data is directly input using the physical unit.

Display of speed, acceleration torque and jerk.

Printing of the cam graphics with project information and date.

Main features of the Software Package - Cam

48 profiles can be stored in the PLC

Cam Designer Basic

Introduction

289 base points per profile in the relative data model

116 base points per profile the absolute data model

Increased number of the available base points with reduced number of profiles re-

served

48 cam groups can be stored

Three tracks per cam group

Four cams per tracks

Main features of the 9300EK servo cam

8 profiles can be stored in the PLC

256 base points per profile in the relative data model

64 base points per profile the absolute data model

Note!

No names are used for profiles and projects in the documentation. The examples

use the names assigned by the system. You can assign names on your own in

your system.

The »Cam Designer Basic« is a product of the Software Package - Cam. It manages the relevant data of the machine and also creates projects. However, it lacks the »Cam Manager«

and hence the ability of managing several products at the same time.

L 2.1 EN - 09/2005 9

Page 10

Cam Designer Basic

Introduction

Entries via the »Cam Designer Basic«

The project

Only one product at a time is available, i.e. only one product at a time can be processed.

– Machine structure

– Names of the axes

The feed constant and gearbox factor of each axis

Scaling of the axes for profile creation

The master axis

– Number of cycles of the machine

The value is a rated value and can maximally amount to 199% during operation.

The slave axes

– Number of profiles to be stored

– Number of base points to be assigned

– Selection of the data model

The product (profiles)

–Product name

– Product number

Note!

No names are used for projects and products. The names given by the »Cam Designer Basic« are continued to be used. You are able to select the names on your

own in your project.

10 2.1 EN - 09/2005 L

Page 11

Cam Designer Basic

Introduction

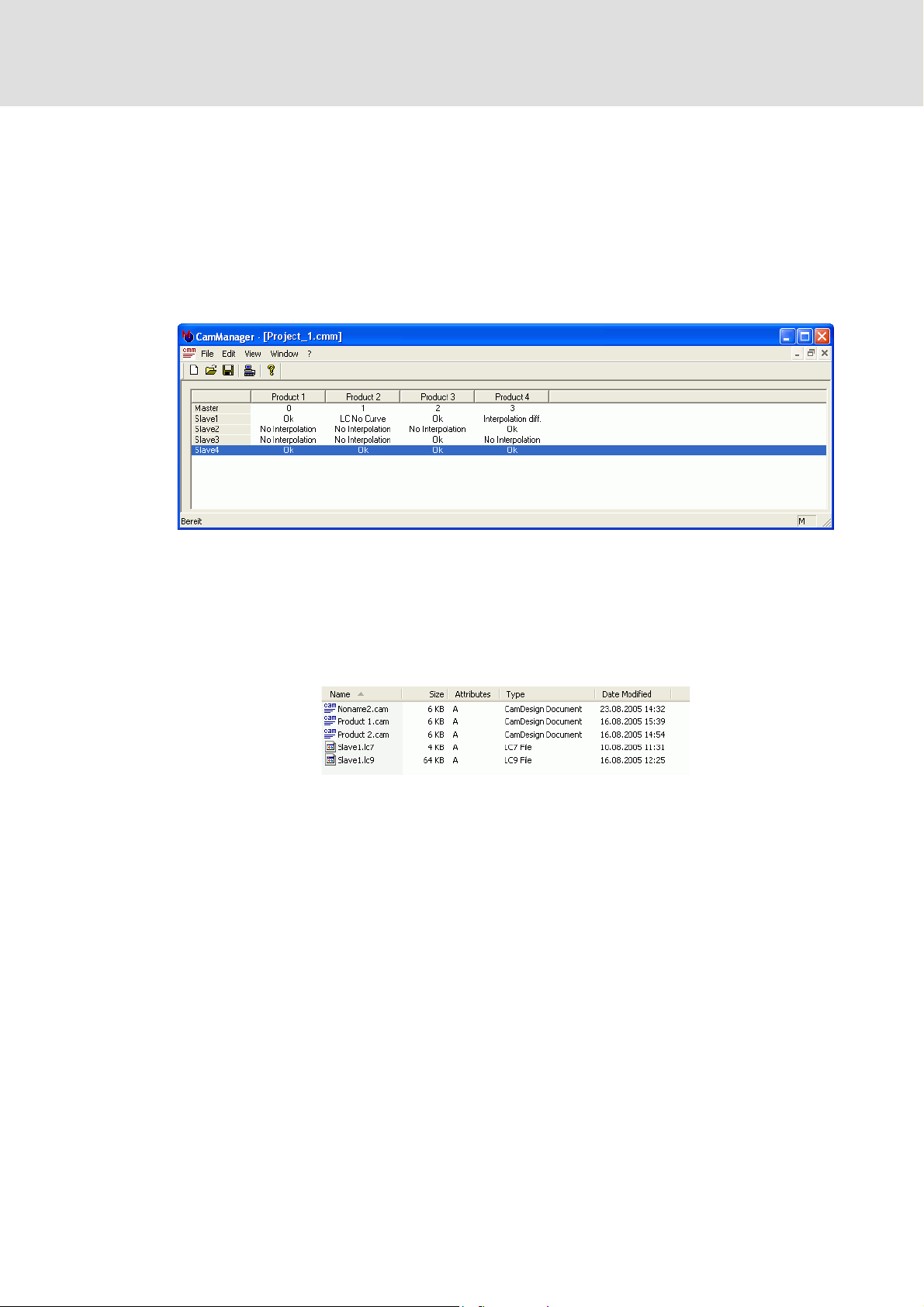

Advantages of »Cam Manager«

the »Cam Manager« is not included in the »Cam Designer Basic«.

The management of projects with several products and the corresponding axes using the

»Cam Designer Basic« is only possible with a directory structure.

The »Cam Designer Professional« manages the projects using the integrated »Cam Manager«.

The assignment between products and axes is displayed in the »Cam Manager«.

The products and axes are stored and managed automatically in the »Cam Designer

Professional«.

The storage and management of the products and axes in the »Cam Designer Basic«

are provided by means of the *.LCx-files and *.cam-files

– LC9 for Servo PLC and ECS EA

– LC7 for 9300 EK servo cam

L 2.1 EN - 09/2005 11

Page 12

Cam Designer Basic

Introduction

Motion tasks

4.1 Motion tasks

According to the VDI 2143 with the title "Motion rules for cam mechanisms" the motion

tasks can be classified as follows:

Motion task Abbreviation Speed in the

Break R v = 0 a = 0 Line

Constant speed G v

Reversal U v = 0 a

Motion B v

boundary point

≠ 0a = 0 Line

≠ 0a ≠ 0Point

Acceleration in the

boundary point

≠ 0Point

Graphical

representation

These four motion tasks serve to formulate the technological specifications for all problems relevant to practice.

For calculating the profile segments between the defined sections, the boundary values of

the specifications are required.

Since the acceleration for R and G is = 0, these two motion tasks can be described line-

arly. The boundary values on the left and right connection are identical in this case.

The acceleration for U and B is ≠ 0. These elements can be represented as a point on the

worksheet.

After entering these basic elements for the motion tasks and determining the required

boundary values, the connections can be entered according to the motion rules. Depending

on the connection type used, a jerk-free motion can be achieved.

12 2.1 EN - 09/2005 L

Page 13

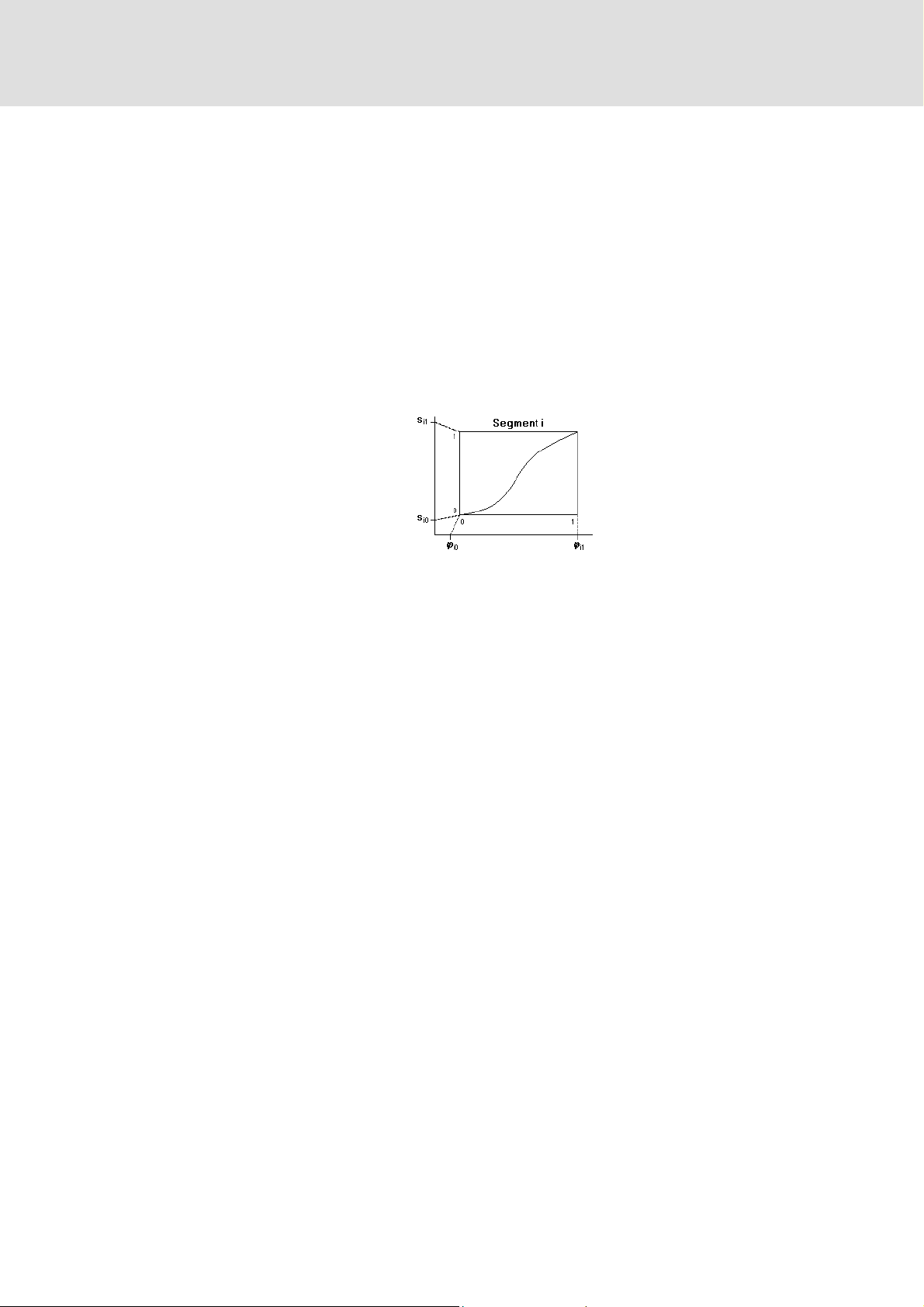

4.2 Scaled motion rules

Each segment i of the whole cam describes a part which is defined by the value range si0 =

f(ji0) and si1 = f(ji1).

The corresponding functions are imaged internally to the scaled value range of 0...1.

The coefficients of the profiles, included in the property pages, also refer to this scaled

value range.

The speeds and accelerations in the property page represent the real boundary value

with regard to the geometrical dimensions. Thus, the calculation is based on the rule

v = ds / dj and a = d2s / dj2.

These geometrical values for speed and and acceleration are also used in the graphical

representation.

Cam Designer Basic

Introduction

Scaled motion rules

L 2.1 EN - 09/2005 13

Page 14

Cam Designer Basic

User interface

Using the direct help

5 User interface

Go to the Start menu and select

ProgramsLenzeGlobal Drive Cam Designer Basic to start the

»Cam Designer Basic« with user interface.

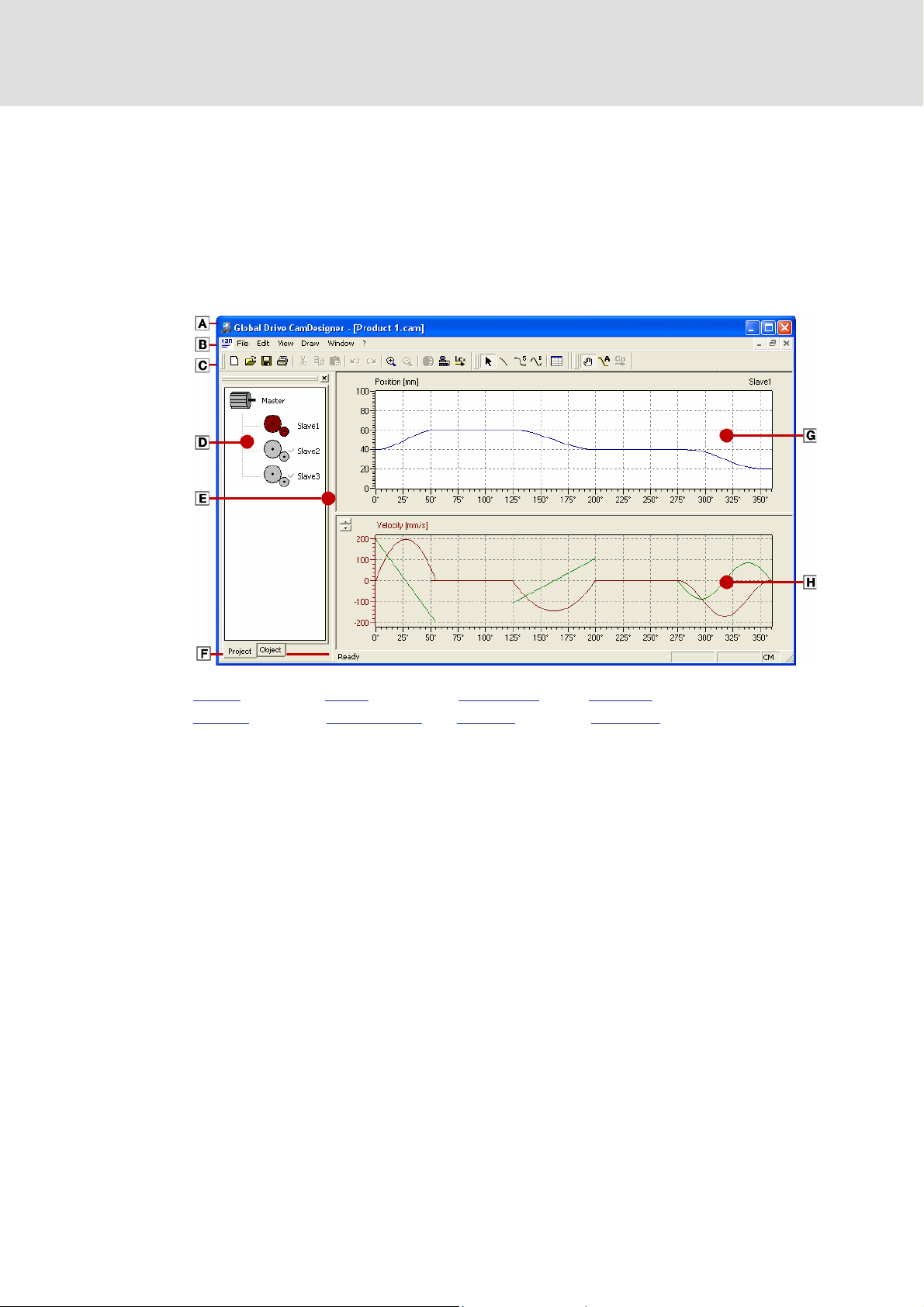

The user interface contains the following control and function elements:

Title bar Toolbar Screen divider Workspace

Menu bar Project structure Status bar Output area

5.1 Using the direct help

The »Cam Designer Basic« has a direct help which can be used to display information about

specific areas of the user interface.

Select the command HelpDirect help and click the area about which you want to

obtain more detailed information.

If you have opened e.g. the dialog box Project settings and click the input field Rated quan-

tity cycle/min, information about this dialog object is displayed when pressing <F1>.

14 2.1 EN - 09/2005 L

Page 15

5.2 Language selection

You can always select another language for the menu, dialog and help texts of the »Cam

Designer Basic«.

The available languages depend on the language files that have been installed togeth-

er with the »Cam Designer Basic«.

How to select another language...

1. Select command ViewSet language.

2. Go to the Language configuration dialog box and select the desired language.

3. Click OK to confirm your selection and close the dialog box.

5.3 Title bar

Cam Designer Basic

User interface

Language selection

The title bar at the top of the application window shows the program icon and the program

name on the left and the window icons on the right.

With a click on the Window icons you can change the representation of the

application window as follows:

–Icon in the task bar ()

– Full screen ()

–Window size ()

A click on the program icon opens the system menu which also includes commands for

positioning and changing the size of the application window.

A click on the window icon or a double-click on the program icon exits the »Cam De-

signer Basic«

5.4 Menu bar

Via this menu bar you have access to all menu commands of the »Cam Designer Basic«. In

contrast to the »Cam Designer Professional« the profile functions are reduced

A click on an item of the main menu opens the corresponding menu and lists the menu

items contained in it.

Click a menu item to execute the corresponding function.

– Menu items which are displayed in light grey are currently deactivated because the

execution of the corresponding function would not make any sense in the current

program state.

.

Tip!

Many frequently used functions can be executed faster by means of the Toolbar

icons. ( 16)

L 2.1 EN - 09/2005 15

Page 16

Cam Designer Basic

User interface

Toolbar

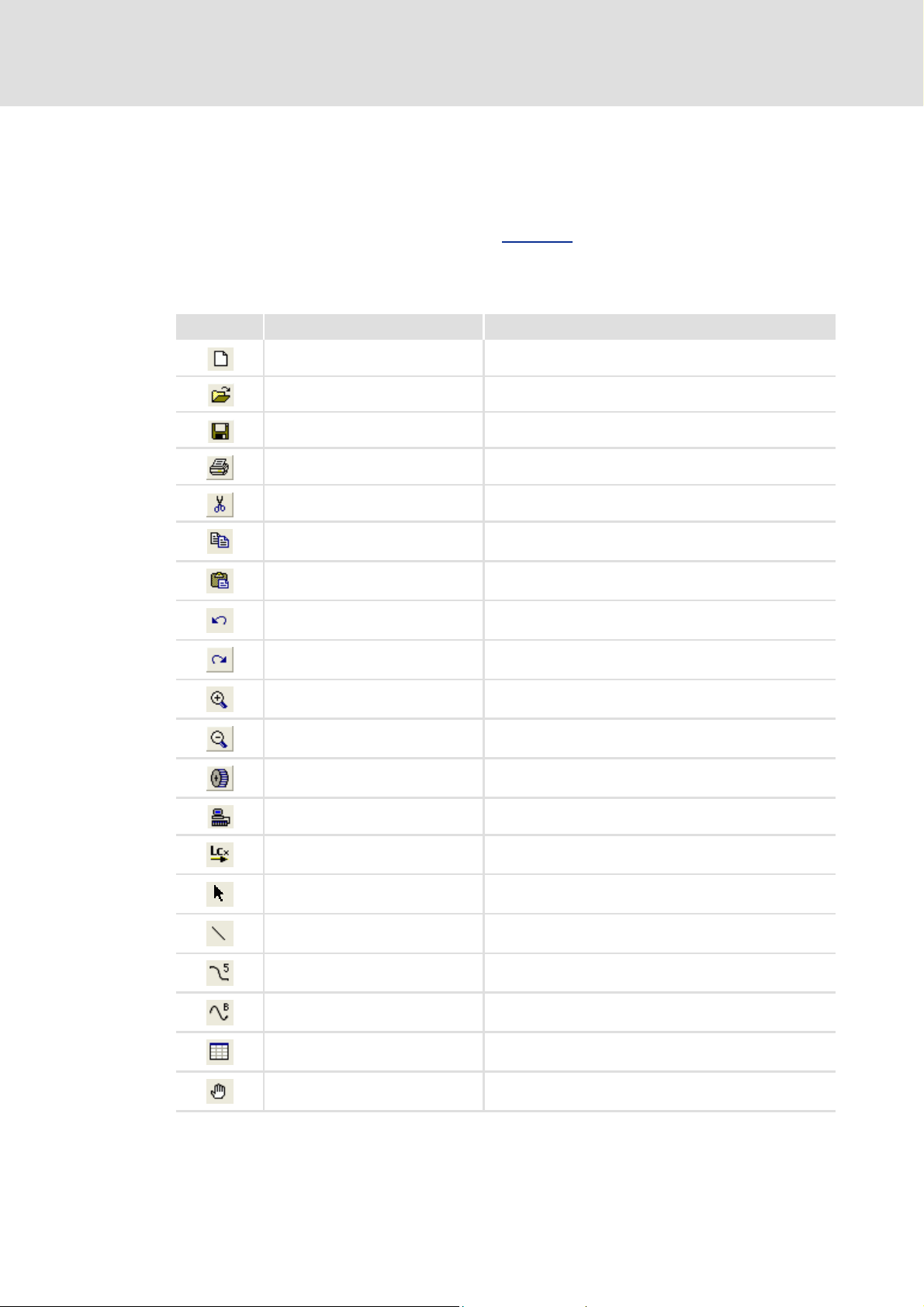

5.5 Toolbar

The display is optional.

Via the icons of the toolbar you can easily execute some of the most frequently used menu

commands without making a detour via the Menu bar

tions depends on the active mode/window.

Simply click an icon to activate the corresponding command.

Icon Menu command Function

. The selection of the available func-

FileNew Creates a new Cam Designer Basic project.

FileOpen Opens a Cam Designer Basic project.

FileSave Saves the project under the current name.

FilePrint Prints the project.

EditCut Deletes a selected object and moves it to the clipboard.

EditCopy Copies a selected object and moves it to the clipboard.

EditPaste Pastes a copied or cut object into the current position.

EditUndo Undoes the last action.

EditRedo Redoes the last undone action.

ViewZoom In Enlarges the worksheet view.

ViewComplete View Resets the worksheet view to standard size.

Edit

Acceleration Dimensioning

File

Connect to OPC Server

File

Create LCx-file and Download

DrawSelect Selects the drawing objects.

DrawLine Draws a line.

Opens the acceleration dimensioning dialog.

Establishes a connection to the OPC server.

Opens a dialog for selecting a drive.

DrawPolynomial (5.) Draws a 5th grade polynomial.

DrawSloped Sine Draws a sloped sine function (Bestehorn).

DrawTable Draws a table.

ViewObject Input Mode Input of motion objects.

16 2.1 EN - 09/2005 L

Page 17

Icon Menu command Function

ViewInterpolation mode Changes to the interpolation mode.

Cam Designer Basic

User interface

Project structure

Edit

Start Calculation

Tip!

If you move the mouse pointer over an icon, a tool tip pops up providing a short information on the corresponding function. Moreover, an additional information is

displayed in the Status bar

5.6 Project structure

The display is optional.

The project structure consists of the tabs Project and Object.

Project

In this tab the master axis and the created slave axes are displayed.

A double-click on the icon activates the corresponding slave axis. The associated pro-

files are displayed accordingly.

A mouse-click highlights the name of the master or slave axis in blue. When clicking the

blue field, the name can be changed.

Connects the profile segments.

.

L 2.1 EN - 09/2005 17

Page 18

Cam Designer Basic

User interface

Screen divider

Object

This tab shows the list of all objects in the active mode. Optionally, the objects of the lower

levels, highlighted in grey, can also be shown.

Each line in the list contains the object type and coordinates of the object. The lines are

sorted according to the X values (master) as standard. A different sort sequence can be

achieved by a mouse-click on the fields in the headline.

It is possible to select one or several objects in the list by means of the mouse. The se-

lection is also transferred to the graph of the worksheet.

A click with the right mouse button on the corresponding object opens a submenu

which contains various functions. The property dialogs of the objects can be opened,

the object can be copied or deleted.

In the Objects tab, the lines, profiles etc. can be edited.

5.7 Screen divider

The screen divider is the border between two non-overlapping windows. In the »Cam Designer Basic« there is a screen divider between the worksheet, time derivations and the object list.

5.8 Workspace

The document windows (worksheets) are displayed in the workspace.

When the»Cam Designer Basic« is started, the workspace is blank because there are no

open projects.

The worksheet is the area for entering and editing graphic objects.

5.9 Output area

The display is optional.

This diagram displays the time derivations of the objects from the worksheet.

In this diagram, the cams of the individual tracks for the target systems Servo PLC and

ECS EA can be created and edited.

18 2.1 EN - 09/2005 L

Page 19

5.10 Status bar

The display is optional.

The program status is indicated in the status bar.

The status bar describes the action which is executed by the menu item selected or a

pressed button of the toolbar and displays the coordinates of the mouse pointer.

Tip!

Cam Designer Basic

User interface

Status bar

If you position the mouse pointer over an icon in the Toolbar

more information about the corresponding function will be indicated in the status

bar.

or a menu command,

L 2.1 EN - 09/2005 19

Page 20

Cam Designer Basic

User interface

Document window (worksheet)

5.11 Document window (worksheet)

If you open a project, the corresponding worksheet will be indicated in a document window

in the Workspace

By default, the document window is displayed on a full screen, i.e. the document window

fills the whole workspace of the»Cam Designer Basic«.

With a click on the window icons at the top right of the document window

you can change the representation of the document window as follows:

– Icon within the workspace ()

– Full screen ()

–Window size ()

A click on the program icon opens the system menu which also includes commands for

the positioning and size of the document window.

A click on the window icon or a double-click on the program icon closes the docu-

ment window.

of the Cam Designer Basic.

Use the key combination <Ctrl>+<F6> to jump from one document window to the next

document window.

"Window" menu

The Window menu contains the following commands for the arrangement of the document window:

Command Function

New window Opens a new window with the same contents as the active window.

In this way, it is possible to display different parts or views of a worksheet simultaneously.

• The new window will be automatically the active window and will be indicated above all

other open windows.

• If the contents of an open window is changed the contents of all other open windows of

the project change as well.

Cascade Cascades all windows in the workspace.

Horizontal Arranges all windows in the workspace horizontally.

Arrange icons Arranges all windows reduced to an icon at the bottom of the workspace.

• If a window opens in this section, it may happen that one or all icons are hidden because

they are under the window.

1, 2, 3... All open windows are listed at the end of the Window menu.

A click on an entry activates the corresponding window (and places it on top of the desktop).

• The active window is indicated by a hook in front of the entry.

20 2.1 EN - 09/2005 L

Page 21

6Operation

After the first start of »Cam Designer Basic« the user interface is displayed with an empty

workspace.

Now you can create a new project (worksheet) or open an existing project.

Tip!

In the installation directory of the »Cam Designer Basic« you can find example

projects which can be used to make yourself familiar with the operation of the

»Cam Designer Basic«.

What do you want to do?

Cam Designer Basic

Operation

Create a new project

Open an existing project

( 22)

( 34)

L 2.1 EN - 09/2005 21

Page 22

Cam Designer Basic

Operation

Create a new project

6.1 Create a new project

After starting the »Cam Designer Basic« the user interface is displayed with the master axis

and a slave axis. You can either continue to process the project or call a new project.

How to create a new project...

Go to the symbol bar of the »Cam Designer Basic« and click the symbol

FileNew to start a new project:

Detailed information about the individual steps can be found in the following subsections.

6.1.1 Step 1: Defining the features of the master axes

The entries in the axes reflect the machine constants. Therefore, only work with real values.

or select

The master axis can be a real or virtual axis.

Note!

If you only use a virtual master, then enter in the group field Machine under

Gearbox factor in the input field z2 100 and in z1 1. This serves to achieve a high-

er resolution of the master angle.

The master axis has the features of an electrical shaft.

22 2.1 EN - 09/2005 L

Page 23

Cam Designer Basic

Operation

Create a new project

The following overview shows the relevant global data for the electrical shaft function. Signal flow between the template functions for the Electrical shaft.

Enter the indicated values into the dialog box Master ein.

Dialog object Description

Input field Name Name of the master axis

Input field Minimum In the dialog box Master the 0.0000 must always be entered here.

Combination field Unit * The unit used

Input field Maximum *Cycle

• An electrical shaft can be divided e.g. from 0° to 360° or from 0 to 100mm.

• In this case, one master cycle amounts to 360° or 100mm

Input field Cycles/min Production cycles in 1/min

Input field

Rated cycles/min

Input field

Gear factors z2/z1 *

Input field Feed constant * Path per revolution at the output end of the gearbox

Fields must be filled with * !

The value can maximally amount to 199%.

• The machine speed which you want to reach with this profile can be set in the in-

put field Cycles/min.

• Serves the display

–to dimension the acceleration

–of the time cams of the cam group.

Production cycles in 1/min

The nominal value can maximally amount to 199%.

• The maximum possible machine speed can be entered in the input field Rated

quantity cycle/min.

This entry is important for the acceleration precontrol.

(Servo PLC / servo cam 9300EK)

Ratio of an upstream gearbox.

(e.g. 100/1 as real value)

(if an angle is stated, one revolution = 360°)

The physical unit entered is converted to the encoders.

•Enter, for instance, the leadscrew pitch.

• When entering increments, enter the number of increments per revolution.

L 2.1 EN - 09/2005 23

Page 24

Cam Designer Basic

Operation

Create a new project

Note!

If you use a virtual master, enter in the group field "Machine" under "Gearbox

factor" 100 in the input field z2 and 1 in the input field z1. This serves to achieve

a higher resolution of the master angle.

How to define the properties of the master...

1. Go to the Master dialog box and select the properties of the master.

•The Name of the master is indicated on your worksheet.

•The Cycles are the maximum number of operating cycles per minute.

2. Click Next to proceed with the next step.

6.1.2 Step 2: Defining the properties of the slave axis

The entries in the axes reflect the machine constants. Therefore, only work with real values.

Enter the indicated values into the dialog box Slave.

24 2.1 EN - 09/2005 L

Page 25

Cam Designer Basic

Dialog object Description

Input field Name • The slave axis must have a definite name (e.g. Slave1)

Input field Minimum * Set range of motion

Input field Maximum *

Combination field Unit * Selection of the unit

Control field

Absolute data model

Relative data model

Input field Curves * Maximum number of the curve profile to be stored.

Input field Points * Number of base points

Group field

Background layout

Input field Gearbox factors

z2/z1 *

Input field Feed constant * Path per revolution at the output end of the gearbox.

Group field

Data of drive controller

Fields must be filled with * !

and must not be used for other slaves at the same time.

• The name of the slave axis is used by the CamDesigner. CamDesigner creates a

Slave1.LC9 or Slave1.LC7.

In this *.LC9-file or *.LC7-file all profile data, cams and position marker are stored.

When using the absolute data model, you have internal or external (PC) access to

each single base point. However, a fewer number of base points is available then.

• If the control field Absolute data model is not marked, the relative data model is

used. When using the relative data model, more base points are available. The

base points are distributed automatically.

• If the relative data model is used, the entire profile can only be accessed with the

Cam Designer Basic/Professional or Cam Loader to change profile data. The profile data cannot be changed via access from a PLC.

Reserves should be considered in the maximum number of curve profiles.

Maximally 1 base point/ms or less

Curves are distinguished by colour.

Improved representation of the curves in multi-axis applications.

Ratio between motor and tool

Example: multi-stage gearbox

Gearbox numerator = z2

Gearbox denominator = z1

(If an angle is stated, one revolution = 360°)

The physical unit entered is converted to the encoders.

•Enter, for instance, the leadscrew pitch.

• When entering increments, enter the number of increments per revolution.

The selection field Type serves to select a target system.

• Servo PLC/ECS servo system

• 9300 EK (9300 servo cam)

The input field GDC file serves to import a GDC file.

• Only if 9300 EK (9300 servo cam) has been selected.

Assignment of a drive via the bus address.

Shows the path of the selected drive.

The button ... serves to select a drive.

• The assignment is only necessary if profiles, cams etc. are to be changed.

• To change profiles, cams etc. online, all drives must be online.

× z4 = 28 × 32 = 896 (value of z2)

× z3 = 23 × 15 = 359 (value of z1)

Operation

Create a new project

L 2.1 EN - 09/2005 25

Page 26

Cam Designer Basic

Operation

Create a new project

The name of the slave axis is shown in the worksheet and also used for the LCx-file.

Moreover, a subdirectory with this name is created in the project directory.

When selecting the Type "9300 EK (9300 servo cam profiler)" you can optionally indi-

cate the corresponding GDC file. The Gear factors and the Feed constant will then be

automatically read from this file.

If you have an online connection you can use the button after the Drive input field

to assign a drive to the slave axis.

The selections under Absolute data model and Curve have a direct influence on the

maximum number of points. If you need more points for the table of points deactivate

the selection Absolute data model and use the relative data model or reduce the value

under Curve.

The maximum Curve depends on the selected type.

How to define the properties of the slave...

1. Go to the Slave dialog box to select the properties of the slave axis.

2. Click Next to proceed with the next step.

26 2.1 EN - 09/2005 L

Page 27

6.1.3 Step 3: Set profile options

The General dialog box can be accepted as shown.

When using the menu command EditProject Settings... the Settings dialog box is displayed. In the dialog box the project settings can be changed afterwards.

Cam Designer Basic

Operation

Create a new project

Enter the indicated values into the dialog box General ein.

L 2.1 EN - 09/2005 27

Page 28

Cam Designer Basic

Operation

Create a new project

Dialog object Description

Option field

Automatic rounding

Option field

Defined steps

Option field None The position values are not rounded.

Input field X steps Value for Defined steps

Input field Y steps Value for Defined steps

Control field

Activate Expert Mode

Control field

Normalized Velocity and Acceleration for curves

Control field

Show Derivatives of Polygons as Interpolated Points

Control field

Use same Scale for

Backgound Axis like Active

Axis

Input field Product number Number of the product. The index of the profile data is integrated in the structure of

Input field Path LCx-file Display of the index for storing the LCx-files.

All position values of the master(X) and slave(Y) are automatically rounded to suitable values.

The position values of master and slave are rounded to a multiple of the defined increments X steps/Y steps.

The position values of the master are rounded to a multiple of the value entered.

The position values of the slave are rounded to a multiple of the value entered.

Values of the profile objects Sloped Sine (Bestehorn) and Polynomials can be modi-

fied.

Scaled display of the derivations.

In the linear interpolation, the speed is mathematically indicated as staircase and

the acceleration as pulse.

The axes in the background are indicated with the same scaling as the axis in the

foreground. This enables the profiles to be compared directly.

the controller.

In the input field Product number a numerical value can be entered for the profile to be

processed.

– Servo PLC, 0 to 47

– 9300EK servo cam, 0 to 7

Press the button to open the path in which the files (LCx-files) are stored.

For the download via DDS or Global Drive Loader the files can be loaded from the directory.

Note!

Information on the single menu items can be found in the Online Help.

Make sure that the product numbers are not assigned twice and the correct path

has been selected for the LCx-file.

If the project is stored with Save as..., it should be stored in the same directory as

the LCx-files.

After the basic settings have been selected by means of the wizard, you can add more

slaves to your project if required for your drive application.

28 2.1 EN - 09/2005 L

Page 29

6.1.4 Step 4: Defining the file name and directory for a project

Tip!

We recommend to store the project now so that the settings in the dialog boxes do

not get lost. In case of simple storing the project is called Noname.

An own project directory should be prepared for each project to be created. For this

purpose, the project should be stored with Save as into a particular project directory.

• All path names within a project are relative and refer to the project directory.

• If you want to transfer a project to another PC, simply copy the project directory

to the corresponding PC.

How to define the file name and directory for a new project...

1. Go to the Save as dialog box and select the directory in which you want to store the

new project.

Cam Designer Basic

Operation

Create a new project

2. Enter a name for the new project in the File name input field.

3. Click OK to confirm the settings for the new project and close the Save as dialog

box.

4. Go to the New project dialog box and click Next to proceed with the next step.

6.1.5 Step 5: Adding a slave axis

New slaves are added at the end of the list. You can enter a symbolic name for the new

slave which will be indicated on your worksheet.

Tip!

The menu commands mentioned are partly also included in the context menu of

the right mouse button.

L 2.1 EN - 09/2005 29

Page 30

Cam Designer Basic

Operation

Create a new project

How to add another slave to your worksheet...

1. Mark the master axis in the object list.

2. Select the command EditSlave axesAdd new axes.

• The dialog box Project settings of slave 2 is displayed (optional). You can accept

the settings.

3. Define the name and properties of the slave axis in the dialog box Project settings.

• The name of the slave is also used as name for the LCx file.

• The maximum product number determines the minimum number of curves.

The maximally possible entry depends on the target system.

How to define the properties of the slave...

4. Select OK to accept the setting and close the dialog box.

( 26)

30 2.1 EN - 09/2005 L

Page 31

Create for the example a project with three slave axes.

The finished product must look as follows:

Cam Designer Basic

Operation

Create a new project

L 2.1 EN - 09/2005 31

Page 32

Cam Designer Basic

Operation

Create a new project

6.1.6 Creating further products

Note!

The path of the LCx-file must not be changed.

How to create further projects in »Cam Designer Basic«:

1. Select the command FileOpen to open a project already created from the directory which already contains project data (*.cam).

2. Select an available product to be loaded and press the Open button.

• The selected product, in this example product2, is loaded by the »Cam Designer

Basic«.

3. Select the command EditProject settings to open the dialog box Settings.

32 2.1 EN - 09/2005 L

Page 33

Cam Designer Basic

Operation

Create a new project

4. Enter a product number which has not been assigned yet, e.g. 3, into the register

General, input field Product number.

5. Store the profile e.g. as product3 and process it, if required.

Next steps

Now you can assign the import files for the slave to the product and add more slaves and

products to your worksheet, if required.

L 2.1 EN - 09/2005 33

Page 34

Cam Designer Basic

Operation

Open an existing project

6.2 Open an existing project

Tip!

• It is possible to open several projects (worksheets) simultaneously in the »Cam

Designer Basic«. The commands for arranging the worksheets can be found in

the "Window" menu.

• With a click on the entries 1...4 in the File menu you can open one of the four

projects edited last.

How to open an existing project...

1. Click the symbol

2. Select the corresponding project file (*.cam) in the dialog box Open.

3. Press the button Open .

• After this, the project worksheet will be displayed in the workspace.

6.2.1 Selecting the properties of a slave

The properties of a slave can always be changed.

in the symbol bar or select FileOpen.

How to change the properties of a slave...

1. Select the corresponding slave axes and select Properties of the slave axis from the

menu of the right mouse button.

2. Go to the Project settings dialog box and enter the new settings.

How to define the properties of the slave...

3. Select OK to accept the settings and close the dialog box.

( 26)

34 2.1 EN - 09/2005 L

Page 35

Cam Designer Basic

Open an existing project

Tip!

If you want to change the settings of several axes/products you can also use the

command EditProject settings....

In the Project settings dialog box that appears you can quickly change between the

different axes/products by clicking the corresponding tabs:

Operation

6.2.2 Deleting a slave

Note!

This function only deletes a slave from the project/worksheet. The corresponding LCx file is not deleted!

Deleting a slave cannot be undone!

How to delete a slave...

1. Select a certain slave axis in the project structure.

2. Select EditSlave axes...Delete a slave axis or select Delete slave axis from the

menu of the right mouse button.

3. Confirm the query with Yes or No accordingly.

L 2.1 EN - 09/2005 35

Page 36

Cam Designer Basic

Operation

Connection with the OPC server

6.3 Connection with the OPC server

The internal Lenze DriveServer is used for communication between »Cam Designer Basic«

and target system and LCx-file transfer.

The DriveServer provides easy integration of drives into open automation structures

based on OPC (OLE for Process Control).

A specially adapted variant of the DriveServer and the bus server for the system bus

(CAN) is part of the »Cam Designer Basic« installation package.

Select FileConnect to OPC server to connect the Cam Loader to the OPC server or

cancel the connection.

A hook in front of the menu command indicates the connection with the

OPC server.

6.4 Downloading the drive data

If connection with the OPC server has been established it is possible to transfer the drive

data for several slaves in one step. Connection with the OPC server

The configuration files (LCx files) for the selected axes are created first.

If you have an online connection with the corresponding target system the LCx file will

be directly transferred to the target system.

Note!

With the 9300 servo PLC, the LC9 file can only be downloaded if the target system includes a DDS project based on Template Cam.

How to download the drive data...

1. Select FileDownload of several axes... .

• This command can only be executed if the Cam Loader is connected to the OPC

server.

2. Go to the Download to controllers and select the slaves to be downloaded:

• If the option If necessary, download all data without queries is activated the

data will be downloaded without further queries.

• If the option Do not show this dialog again until next program start is activated

this dialog will not be indicated again until the next program start. This can be

useful for the commissioning of standard systems or in case of frequent downloads.

36 2.1 EN - 09/2005 L

Page 37

3. Click the Start Download button to start the data transfer.

Note: If you have not yet assigned a drive to one of the slaves the Drive selection

dialog box opens automatically.

• Double-click the drive to be assigned to the slave in the DriveServer tree:

•Click OK to confirm your selection and repeat the assignment for other slaves, if

necessary.

6.5 Saving the project

Note!

If you open several project simultaneously in the »Cam Designer Basic«, this

function refers to the project in the active window.

Cam Designer Basic

Operation

Saving the project

Click the icon or select FileSave to save the project.

Tip!

Save your project at regular intervals to protect your data against power failures or

system problems.

If you want to create a backup project on another data carrier or in another directory use the command FileSave as... instead.

Saving a project under another name

6.6 Saving a project under another name

Note!

If you open several project simultaneously in the »Cam Designer Basic«, this

function refers to the project in the active window.

How to save an open project under another name...

1. Select FileSave as... to open the Save as dialog box.

2. Go to the Save as list field and select the directory in which you want to store the

project.

3. Enter a name for the new project in the File name input field.

L 2.1 EN - 09/2005 37

Page 38

Cam Designer Basic

Operation

Exiting Cam Designer Basic

4. Click OK to save the project under the specified name in the selected directory and

close the dialog box.

• If you select the command FileSave the project will be saved with the new set-

tings.

Note!

Information on the single menu items can be found in the Online Help.

Make sure that the product numbers are not assigned twice and the correct path

has been selected for the LCx-file.

If the project is stored with Save as..., it should be stored in the same directory as

the LCx-files.

Tip!

This way you can create a new project or a backup project on another data carrier

or in a directory other than the project directory on the basis of the current project.

6.7 Exiting Cam Designer Basic

Note!

If you have not saved the changes made in one or several projects you will be

asked if you want to save them before exiting the Cam Loader.

Select FileExit or click the Window icon in the Title bar to exit the »Cam De-

signer Basic«.

38 2.1 EN - 09/2005 L

Page 39

7 Functions

7.1 Working with the worksheet

To create a cam profile in the »Cam Designer Basic«, specify the required data (boundary

conditions) on the worksheet using graphical elements. This worksheet has two levels arranged on top of each other. The lowest level is the Object Input Mode and the second level

is the Interpolation Mode.

In each of the levels the graphical elements of the underlying levels are visible and are used

for the following calculations. Only the elements of the active level can be edited, not the

elements of the underlying level(s). This principle is analogous to working with tracing paper. Here, too, information from the lower sheets is available without being able to change

them.

7.2 Settings for the worksheet

Cam Designer Basic

Functions

Working with the worksheet

Select EditProject settings... to open the Settings dialog box. Here you can change the settings of the corresponding project.

Note!

• Ensure that the maximum value of the range is higher than the minimum val-

ue.

• If you change the area boundaries afterwards and the project already con-

tains graphical objects, the objects outside the new area boundaries will be

deleted!

7.3 Object Input Mode

The Object Input Mode uses graphical elements (objects) to describe the problem to be

solved.

L 2.1 EN - 09/2005 39

Page 40

Cam Designer Basic

Functions

Interpolation mode

7.4 Interpolation mode

In Interpolation Mode, a table of base points is generated from the ideal cam. These value

pairs can then be transferred to the selected target system (Servo PLC,

ECS EA... or 9300EK servo cam).

Uniform distribution of the base points

All points are distributed with the same spacing along the domain.

Note!

Before executing the interpolation, ensure that the curve trace is closed.

7.5 Worksteps required for a new cam

The following steps are required to create a new cam:

Settings of the worksheet

Creation of profiles

( 41)

( 41)

40 2.1 EN - 09/2005 L

Page 41

7.6 Settings of the worksheet

How to configure the worksheet:

1. Select the menu command EditProject settings in the »Cam Designer Basic«.

•The Settings opens.

2. Go to the Settings dialog box, change to the Master or Slave tab for the master and

slave axis and define the units for the axes.

3. Close the Settings dialog box with OK.

7.7 Creation of profiles

A simple profile is created and transferred to the controller.

For a better representation and obtaining a zero axis, go to the Settings dialog box of the

slave axis and select a negative value (e.g. -20,000) in the Minimum input field and a positive value (20,000) in the Maximum field.

Cam Designer Basic

Functions

Settings of the worksheet

Tip!

The following figure shows the options of creating a profile in the »Cam Designer

Basic«.

How to create a profile:

1. Select the command ViewObject Input Mode to take the worksheet to the input

mode.

2. Create the graphical elements required by using the command in the Draw menu.

3. Create a profile using all tools available. Ensure that the profile objects do not overlap each other and the profile is closed.

4. Go to the interpolation mode selecting View Interpolation mode.

5. Compile the profile selecting FileCreate and download LCx-file.

6. The profiles, cams etc. are transmitted to the LCx-files.

L 2.1 EN - 09/2005 41

Page 42

Cam Designer Basic

Functions

Creation of profiles

The worksheet and time derivation might look as follows:

Profile object Function

A Table Creates a polyline. The base points are connected by lines. If

B Line: Section with a straight line.

C 5th-grade polynomial (x5) This section contains a mathematical

D Sloped sine function This section contains a sloped sine function

the object is selected, it can be edited using the command

EditObject Properties...

f(x)=ax5+bx4+cx3+dx2+ex+f

42 2.1 EN - 09/2005 L

Page 43

7.8 Closed profile

Tip!

To clearly represent the creation of closed profiles, only the corresponding sections

of the »Cam Designer Basic« are shown.

How to create a closed profile:

First, the important sections (gradients, lines etc.) of the profile must be defined.

Then, the sections must be connected without jerk, if possible. For this purpose, the

»Cam Designer Basic« has

– the sloped sine function

– the 5th-grade polynomial (x5)

Cam Designer Basic

Functions

Closed profile

A jerk-free connection in a profile means:

The coordinates of the end point of an object must be identical with the initial point of

the following connected object.

The gradient of the end point of an object must be identical with the following connect-

ed object.

Optimise the connection between the 5th-grade polynomial (x5) and a sloping line.

Here, the right end point of the polynominal must be connected with the left end point of

the line.

L 2.1 EN - 09/2005 43

Page 44

Cam Designer Basic

Functions

Closed profile

Select the line with a mouse-click.

Select the menu command EditProject settings.

Go to the Line properties dialog box to open the Conditions register.

Select and copy the value for velocity. The tab cannot be edited.

Select the 5th-grade polynomial (x5) with a mouse-click.

Select the menu command EditProject settings.

Go to the 5th-grade polynomial properties to open the Conditions register.

Paste the copied value into the input field Right Velocity.

44 2.1 EN - 09/2005 L

Page 45

Cam Designer Basic

Functions

Closed profile

The characteristic of both objects is smooth at the connecting point.

Proceed the same way for all connections. A closed profile with several objects can look

as follows :

L 2.1 EN - 09/2005 45

Page 46

Cam Designer Basic

Functions

The cam group

7.9 The cam group

Note!

Only available for Software Package - Cam

The settings only apply to the product selected. For the other products, the settings have to be repeated.

Select ViewEdit Cam in the »Cam Designer Basic« to take the bottom window (output area) to the corresponding mode.

7.9.1 Defining the cam type and cam reference

Tip!

The cam group can either refer to the X axis or to the Y axis. The cam group functions are available in the context menu of the right mouse button.

How to define the cam type and cam reference:

1. First, define the cam reference for the current data set under Cam for Slave Axis.

• Subsequent changes are not possible. The selected cam data will be deleted and

must be entered again.

2. The cam types for the individual tracks can be defined using the context menu of

the right mouse button.

Position cam in positive effective direction

Position cam in negative effective direction

Position cam Both

Time-based cam in positive effective direction

Time-based cam in negative effective direction

• If you right-click in the track, you can directly change the came type.

3. Select Add New Cam to add a new cam to the corresponding track.

• You can add up to four cams to every track.

46 2.1 EN - 09/2005 L

Page 47

7.9.2 Cam types

Illustration Meaning

Cam Designer Basic

Functions

The cam group

Position cam in positive effective direction

Switch on and switch off point are defined by positions.

The cam switches if the direction of the axis is positive (positive speed).

Position cam in negative effective direction

Switch on and switch off point are defined by positions.

The cam switches if the direction of the axis is negative (negative speed).

Position cam Positive and negative

Switch on and switch off point are defined by positions.

The cam switches in positive and negative direction of the axis.

Time-based cam in positive effective direction

The cam switches on at the switch on point if the direction of the axis is positive (positive

speed).

After the selected time, the cam switches off.

Time-based cam in negative effective direction

The cam switches on at the switch on point if the direction of the axis is negative (negative

speed).

After the selected time, the cam switches off.

Select Properties of Cam to edit the cam subsequently. In this dialog, time and length data

can be accurately entered. The dialog box is always the same for all cam types. Only the corresponding fields on the dialog box are active.

Dialog object Meaning

Input field Left Initial value of the cam

Input field Right Final value of the cam

Selection field Effective Di-

rection

Input field Length [ms] Cam is active (only with time cam)

Positive or negative effect

L 2.1 EN - 09/2005 47

Page 48

Cam Designer Basic

Functions

Export of profile data

7.10 Export of profile data

Exporting the profile data to the controller via

– Drive PLC Developer Studio (Servo PLC and ECSEA).

– Global Drive Loader.

– Cam Loader.

Target system - Servo PLC, ECSEA and 9300EK servo cam

Note!

The 9300EK servo cam exclusively works with the Online download.

How to export the profile data:

1. The data must be compiled before being exported.

• For this purpose select ViewInterpolation Mode or click and then select Ed-

itStart of Calculation or press .

2. Select the corresponding slave axis in the »Cam Designer Basic« by means of double-click.

3. Go to the interpolation mode and press the LCx file.

• If this function is executed for the first time, a dialog appears which is confirmed

with OK. The system now creates a file with the name of the slave axis and the

ending *.lc9 or *.lc7.

• Compiling must be repeated for new profiles, cam groups or position markers

and changes made.

• After every compiling, the data are transferred to the *.lc9-file or *.lc7-file.

The following two steps are only required for the Software Package - Cam Offline download.

4. Double-click ResourcesCamSupport in the DDS.

5. Click Add Profile Data to Project .

• A dialog appears in which you can select the *.lc9-file.

Tip!

Do not forget to save your CamDesigner Basic project on hard disk or diskette, in

case you want to make subsequent changes. Select FileSave as... to save the

CamDesigner Basic project under a new name.

48 2.1 EN - 09/2005 L

Page 49

Repeat the above-described steps to create all cams required by means of the »Cam De-

signer Basic«.

After creating all profiles required by means of »Cam Designer Basic«, you can exit the

»Cam Designer Basic« with FileExit.

7.11 Cam Designer Basic Online Download

Note!

The download time increases if

• a high bus load (cross communication) exists.

• many data was changed.

How to make an Online Download:

Cam Designer Basic

Functions

Cam Designer Basic Online Download

1. Switch the »Cam Designer Basic« online by clicking FileConnection to OPC server

or .

• The button online/offline is only active if the LDS-DriveServer has been started.

The icon for the LDS-DriveServer is situated in the status bar.

• If the red point in the icon becomes green, the system is online.

2. Select EditProject settings to open the Settings dialog box.

3. Select in Controller data the drive to which the data is to be downloaded.

4. Select FileCreate and download LCx-file or to activate the profile or cam

download.

• The data for the current slave axis are written into the *.lcx-file.

• After the download has been started with the button, a progress dialog appears.

Tip!

For the commissioning of production machines, the *.lc9-file can be attached to the

PLC program.

L 2.1 EN - 09/2005 49

Page 50

Cam Designer Basic

Appendix

Error numbers, causes & remedies

8 Appendix

8.1 Error numbers, causes & remedies

Error number Cause Remedy

Errors within the DriveServer

E7C18000 Error during download preparation. Repeat download.

E7C18001 PLC has not stopped. Stop the PLC program in the target system.

E7C18002 Controller inhibit is not set. Set controller inhibit in the target system

E7C18003 Incorrect data type (no LC9 file). Create new LC9 file.

E7C18004 Check sum check is negative

(faulty check sum).

E7C18005 Item can momentarily not be accessed due to

download.

E7C18006 Target system is momentarily busy copying

RAM blocks.

E7C18007 Error occurred after the download. Repeat download.

E7C18008 Error after version comparison during down-

load of an LC7 file.

• Different versions in LC7 file and target

system.

E7C18009 No template "Cam" in the target system. Create DDS project based on Template Cam

(e.g. via terminal 28 or code C0040).

Restart the download. Increase time-out

time in the system bus configuration tool

(e.g. to 3 seconds).

Repeat download after a few minutes or restart your PC.

Start the PLC program in the target system.

Update the operating system of the 9300 EK.

and transfer it into the target system.

50 2.1 EN - 09/2005 L

Page 51

8.2 Glossary

A

Absolute data model Contains both the X and the Y coordinate. Therefore requires more space than

Application window Window in which programs are displayed under Windows.

C

Code Lenze device parameter used to select the device functionality.

COM Abbreviation for "Component Object Model": Architecture developed by Mi-

Cam Designer Basic

Appendix

Glossary

the relative data model. The points are 1:1 transferred from the Cam Loader to

the target system:

• Advantage: The distance between the points can be variable. This allows to

optimise the distribution of the points according to the cam profile characteristics.

• Disadvantage: Compared to the relative data model, less points can be

saved.

Relative data model

crosoft® for the interaction of separately executable software components

(objects) that communicate with each other in the same way and are only connected to each other when the program is being executed.

D

DCOM Abbreviation for "Distributed Component Object Model": COM in which the

DDS Abbreviation for "Drive PLC Developer Studio": Development environment for

Document window Window with graphical user interface displayed by a user program in which a

Drive PLC Developer Studio See DDS.

DriveServer Lenze software which enables easy integration of drives into open automa-

executable objects can be distributed to different computers within a local

network.

COM

the creation of IEC 61131 programs for Lenze PLCs.

document is created, displayed and edited. Document windows are usually

sub-windows of the program windows.

tion structures based on OPC ("OLE for Process Control").

OPC

G

Global Drive Loader Lenze software used to transfer PLC programs, parameter sets and application

data to Lenze target systems.

H

Hyperlink Highlighted reference which is activated by a mouse click.

L 2.1 EN - 09/2005 51

Page 52

Cam Designer Basic

Appendix

Glossary

I

IPC Abbreviation for Industrial PC. Industrial PCs are used in case of special envi-

O

OLE Abbreviation for "Object Linking and Embedding": Integration of operational

OPC Abbreviation for "OLE for Process Control": Defines an interface based on the

P

PDF Abbreviation for "Portable Document Format". Universal file format devel-

PLC Abbreviation for "Programmable Logic Controller".

PLC Abbreviation for "Programmable Logic Controller".

Relative data model Only contains the difference between ad jacent Y coordinates and therefore re-

ronmental conditions, e.g. dirt or vibrations. They are slot CPUs with powerful

processors and TFT displays (often with touch screens).

objects into other applications, e.g. Microsoft® Excel spreadsheets into Microsoft® Word documents.

Microsoft® Windows® technologies OLE, COM and DCOM which enables data

exchange between different automation devices and PC programs regardless

of driver and interface problems.

COM

DCOM

oped by Adobe for the exchange of electronic documents. The Adobe® Reader® is provided free of charge and can be used to display and print PDF files

independently of the application and platform used to create them.

PLC

PLC

quires less space than the absolute data model. The distance between the X

coordinates is transferred as a fixed-comma value to the target system. This

leads to a certain difference between the imported data and the coordinates

calculated by the target system. To compensate for this inaccuracy, the Y values are re-calculated by means of interpolation .

• Advantage: Compared to the absolute data model, more points can be

saved.

• Disadvantage: The distance between the X coordinates of the points must

always be the same.

Absolute data model

T

Title bar Bar at the top of the application window including the program icon and the

program name on the left and the window icons on the right.

V

VDI 2143 VDI guideline "Motion rules for cam mechanisms"

W

Window icon Button at the right end of the title bar which can be used to change the size of

Worksheet Table including all axes and products of a system or machine project.

52 2.1 EN - 09/2005 L

the window or to close the window.

Page 53

9Index

Cam Designer Basic

Index

A

Absolute data model 26

Acc a slave axis 29

Adding a slave 34

Appendix 50

C

Cam controller 46

Cam Designer Professional 11

Cam Manager 11

Cam type, cam reference 46

Cam types 47

Closed profile 43

Conventions used 5

Copyright 2

Copyright information 2

Creating products 32

Creation of profiles 41

Curve 26

Cycles 24

D

Data model 26

Deleting a slave axis 35

Direct help 14

Document window 20

Download 36

E

Electrical shaft 22

Error numbers 50

Example project 21

Exiting the program 38

Export of profile data 48

F

Feed constant 26

Functions 39

G

GDC file 26

Gear factors 26

I

Imprint 2

Input mode 39

Interpolation mode 40

Liability 2

M

master 22

Menu bar 15

Motion rules 13

Motion tasks 12

N

New project 22

O

Object 18

Online Download 49

OPC server 36

Open project 34

Operation 21

Output area 18

P

Profile options 27

Project 17

Project directory 29

Project structure 17

S

Saving the project 37

Screen divider 18

Servo cam 9

Slave axis 24

Software Package - Cam 9

Status bar 19

T

Title bar 15

Toolbar 16

Trademarks 2

U

Uniform distribution 40

User interface 7, 14

W

Working with the worksheet 39

Worksheet setting 39, 41

L

Language selection 15

Layout of the safety information 6

LCx file 32

L 2.1 EN - 09/2005 53

Loading...

Loading...