Page 1

Automation Systems

Controller

Parameter setting and programming

_ _ _ _ _ _ _ _ _

Reference Manual EN

Ä.O+Kä

13461042

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

3 Controller-based Automation: Central motion control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4System structure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

4.1 Engineering tools _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

4.2 Controller: The control centre of the Controller-based Automation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

4.3 Runtime software of the Lenze Controllers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

4.3.1 "Logic" runtime software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

4.3.2 "Motion" runtime software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

4.3.3 "Visu" runtime software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

4.3.3.1 Sample topology 1: External monitor panel/display for

cabinet controllers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

4.3.3.2 Sample topology 2: Separate control and visualisation _ _ _ _ _ _ _ _ _ _ _ _ _ 28

4.3.3.3 Sample topology 3: Independent control and visualisation

(CANopen) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

5 Commissioning the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

5.1 Identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

5.2 Control elements of the controllers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 31

5.3 Starting the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

5.4 Configuring the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

5.4.1 Establishing an automatic dial-up connection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

5.4.2 Entering the IP address of the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

5.4.2.1 Cabinet controllers with external monitor panels (3231 C/3241 C) _ _ _ _ _ _ 34

5.4.2.2 Cabinet Controller without external monitor panel (c300/3221 C) _ _ _ _ _ _ 35

5.4.3 Specifying the IP address of the controller via file (optional) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

5.4.4 Establishing Windows® CE access rights _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

5.4.4.1 Setting up Windows® CE users in »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

5.4.5 Using your own wallpaper on the controller (Windows® CE) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

5.5 I/O system 1000 at the backplane bus of a cabinet controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

5.5.1 Configuring I/O modules at the backplane bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

5.5.2 Determining the topology of the I/O modules automatically _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

5.6 Tabs of the I/O modules at the backplane bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

5.7 Error messages (backplane bus) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

2 Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6 Parameter setting using »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

6.1 System structure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

6.2 Parameterising the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

6.3 Online connection from the Engineering PC to the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

6.3.1 Setting IP addresses on the Engineering PC (example: Windows® XP) _ _ _ _ _ _ _ _ _ _ _ 46

6.4 Start »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

6.5 User interface of »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

6.5.1 Device parameters of the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 50

6.5.2 Diagnostic/device commands _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

6.5.3 Logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

6.5.3.1 Structure of a logbook entry: example _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

6.5.3.2 Filter options _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

6.5.3.3 Time filter for the display of logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

6.5.3.4 Saving log files with mains failure protection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

6.5.3.5 Export logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

6.5.4 Device commands _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

6.5.5 User management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

6.5.6 General parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

6.5.7 Parameters of the communication cards _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

6.5.7.1 CAN communication card (MC-CAN2) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 56

6.5.7.2 Optional PROFIBUS/PROFINET communication cards _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

6.5.8 Automatic update _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

6.5.9 Language selection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

6.5.10 Parameter list buttons _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

7 Programming with the »PLC Designer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

7.1 System structure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 59

7.2 Function blocks _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

7.3 Configuring and parameterising the controller using the control application _ _ _ _ _ _ _ _ _ _ _ _ 61

7.4 Controller c300/p300: Access to odd Controller addresses _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 62

7.5 Creating remanent variables (retain/persistent) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 64

7.5.1 Storage of retain data on the SD card (only Controllers 3221 C/3231 C) _ _ _ _ _ _ _ _ _ _ 65

8»Backup & Restore« (data backup/restore) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

9 Data integrity in the event of a voltage failure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

9.1 UPS functionality of the controllers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

9.1.1 Internal UPS (for Controllers without UPS connection) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

9.1.2 External UPS (for Controllers 3241 C with UPS connection) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 69

9.2 Storage of »VisiWinNET® Smart« visualisation data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

9.3 Storage of retain/persistent variables of the PLC _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

10 Device replacement - replacing the controller (in the event of service) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 72

10.1 Removing the connected (defective) controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 72

10.2 Connecting the new controller/replacement device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 73

10.3 After the device replacement: Automatic data update _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

10.4 Subsequent use of retain data on the new controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 77

10.5 Error messages after a device replacement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 78

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11 Remote maintenance and diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 79

11.1 Status LEDs of the Controllers _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

11.2 Diagnostics via Telnet _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 82

11.2.1 »WebConfig« settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

11.3 Data transfer via FTP _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

11.3.1 FTP settings with the »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

11.3.2 FTP and web settings in the Internet Explorer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

11.4 Diagnostics with the logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 89

11.4.1 Logbook query via »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 90

11.4.2 Logbook parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 91

11.5 Activate Windows® CE interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 92

11.5.1 Remote Display: Remote control of Controller via Internet or LAN _ _ _ _ _ _ _ _ _ _ _ _ _ 94

11.5.2 Virtual Network Computing (VNC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 95

12 Visualisation with »VisiWinNET®« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

12.1 Visualisation on the controller: local and remote _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

12.2 System structure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 98

12.3 Using the visualisation to access data of the control/parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 99

12.4 Use the Direct driver "LogicAndMotionV3" (local visualisation) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

12.4.1 Selecting the target device using the Windows® CE operating system

(example 3200 C/p500) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 102

12.4.2 Project Explorer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 104

12.4.3 Using the variables browser to access variables (browse variables) _ _ _ _ _ _ _ _ _ _ _ _ 105

12.4.4 Accept variable definitions to project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

12.4.5 Creating control elements/linking them to variables _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 108

12.4.6 Transferring an application to the target device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 109

12.4.7 Start the »VisiWinNET®« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 110

12.5 Using the LogicAndMotionV3 direct driver (remote access) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 111

12.6 OPC tunnel for local visualisation (integrated control system) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 112

12.6.1 Integrating the OPC tunnel in »VisiWinNET®« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 113

12.6.2 Browsing variable definitions / configuring the device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 114

12.6.3 Manual integration of variables (experts only - background knowledge required!) _ _ _ _ 116

12.6.4 Configure OPC tunnel _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

12.7 OPC tunnel for external visualisation (remote access) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 120

12.7.1 Windows® CE operating system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 120

12.7.1.1 Configure OPC tunnel for remote access (Windows® CE) _ _ _ _ _ _ _ _ _ _ _ _ 121

12.7.2 Windows® XP/XP Embedded operating system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 122

12.7.2.1 Configure OPC tunnel for remote access (Windows® XP/XP Embedded) _ _ _ 123

12.7.3 Browsing variables _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 124

12.8 Lenze specifications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

12.8.1 Install additional fonts _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

12.8.2 Timeout (waiting position) of the CAN OPC server influences the time response of the

visualisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 126

4 Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

13 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 127

13.1 Structure of the parameter description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 128

13.1.1 Data types _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 128

13.1.2 Parameters with read access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

13.1.3 Parameters with write access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

13.1.3.1 Parameters with a setting range _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

13.1.3.2 Parameters with a selection list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

13.1.3.3 Parameters with a bit-coded setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 130

13.1.4 Parameter attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 130

13.2 Basic parameters of the Controllers 3200 C/c300 and p300/p500 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 131

13.3 Voltage buffering by external UPS (optional, for Controller 3241 C) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

13.4 Ethernet (on board) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 161

13.5 EtherCAT _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

13.6 Monitor panel (integrated/external) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 168

13.7 PLC (Logic/Motion) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 172

13.8 Backup&Restore _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 174

13.9 Communication cards: optional interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 178

13.9.1 CAN (MC-CAN2) communication card / CAN interface for Controller c300/p300 _ _ _ _ _ 179

13.9.2 PROFIBUS and PROFINET communication cards _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 185

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 187

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 194

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 5

Page 6

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This documentation contains general information on how to parameterise, configure and diagnose

the Lenze Controllers.

This manual is part of the "Controller-based Automation" manual collection. It consists of the

following sets of documentation:

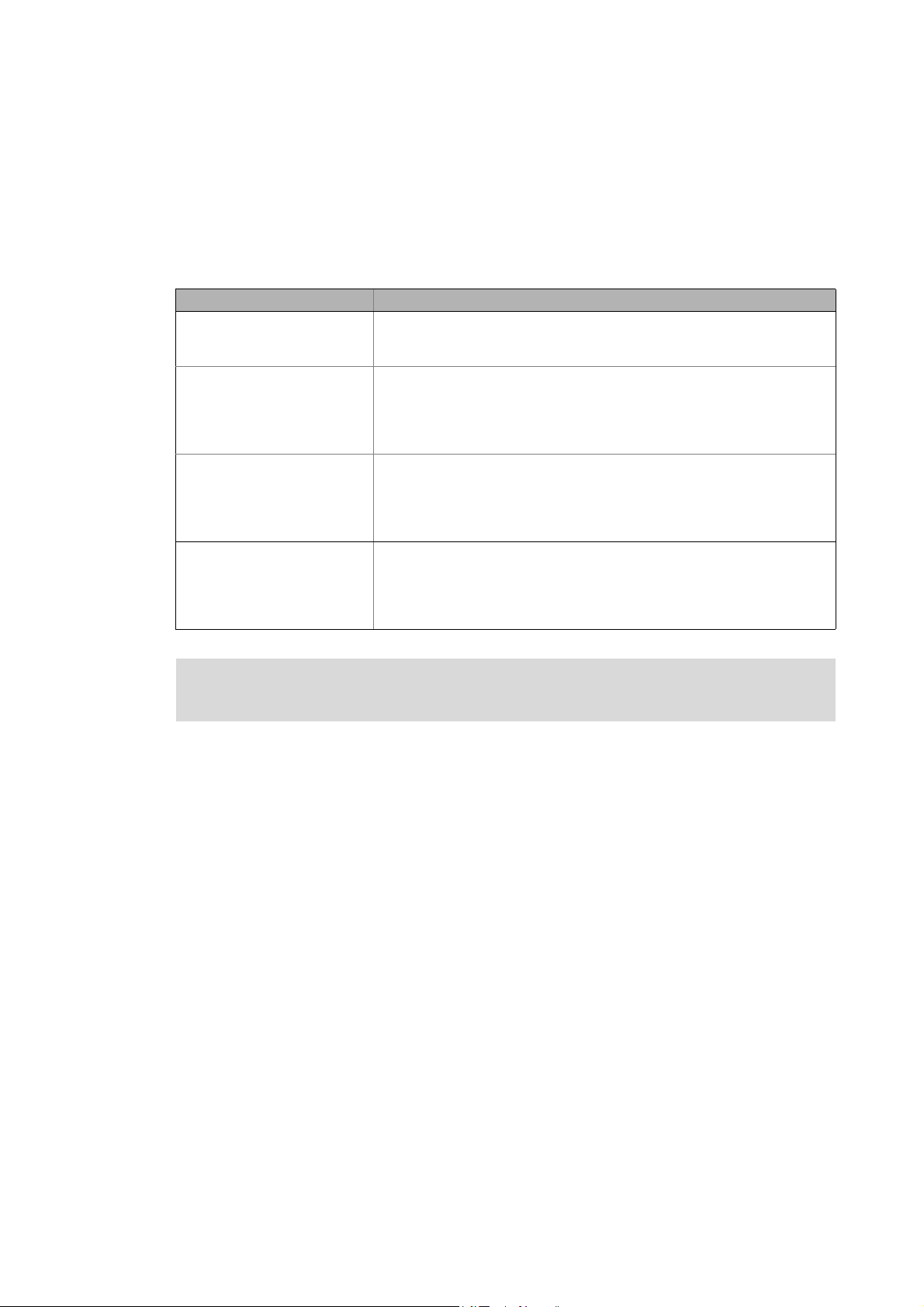

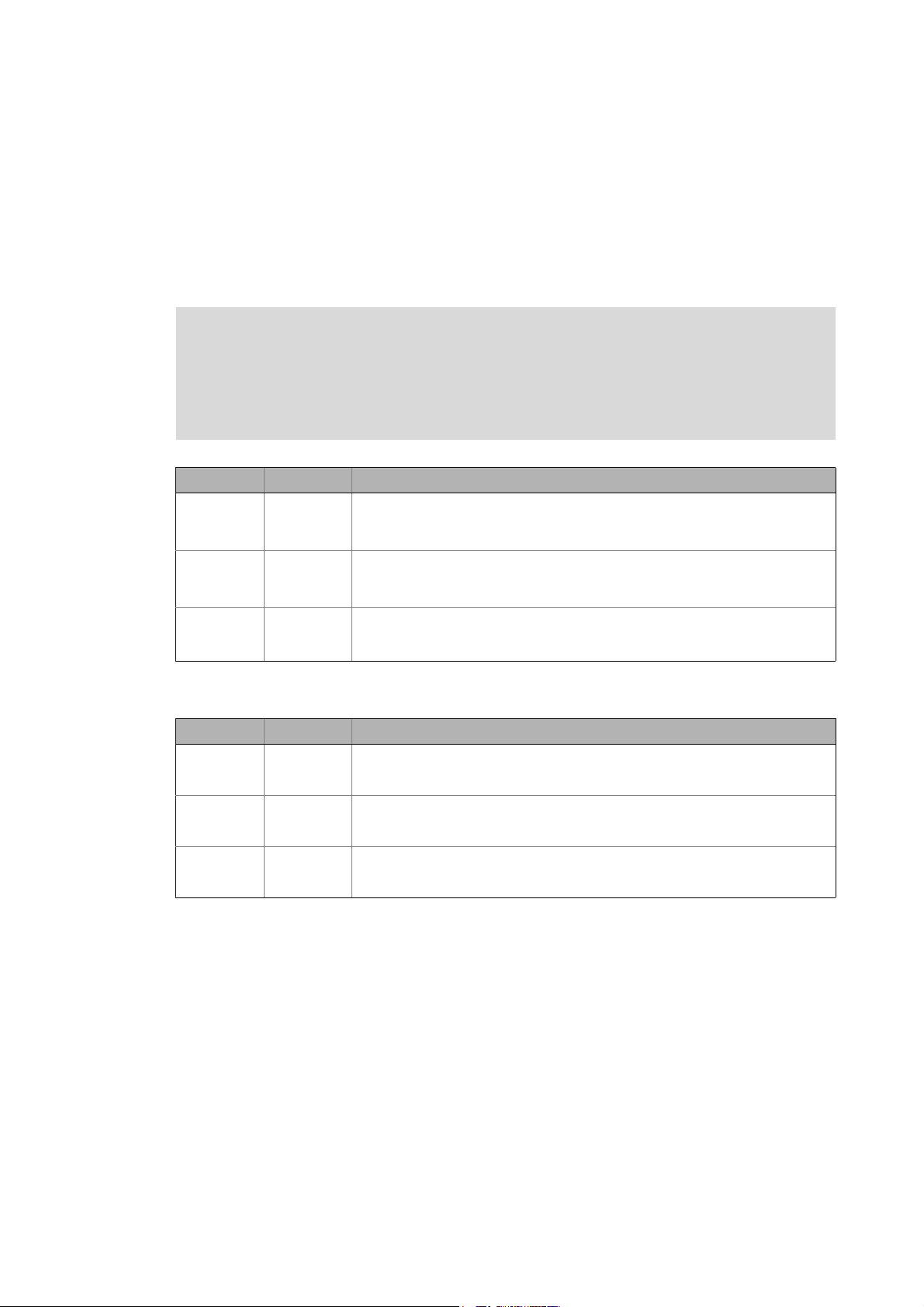

Documentation type Subject

System manuals System overview/sample topologies

• Controller-based Automation

• Visualization

Communication manuals

Online helps

Reference manuals

Online helps

Software manuals

Online helps

Bus systems

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

Lenze Controller:

• Controller 3200 C

• Controller c300

• Controller p300

• Controller p500

Lenze Engineering Tools:

• »PLC Designer«: Programming

• »Engineer«: Inverter configuration

• »VisiWinNET® Smart«: Visualisation

• »Backup & Restore«: Back up/restore data

Information on how to use the controllers outside the control technology can be found

in the system manuals created for the prevailing application case.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 6

Page 7

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

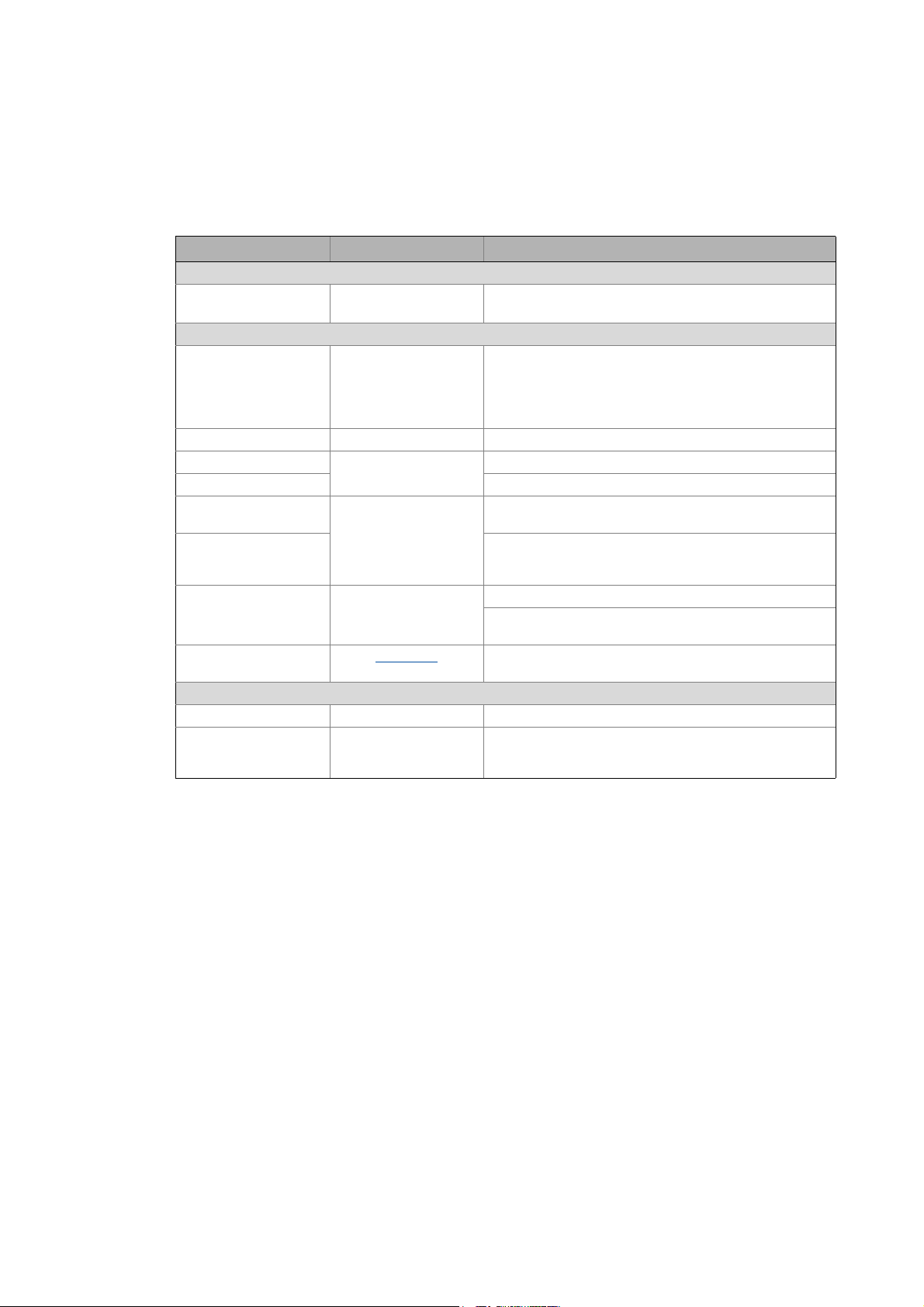

More technical documentation for Lenze components

Further information on Lenze products which can be used in conjunction with Controller-based

Automation can be found in the following sets of documentation:

Mounting & wiring Symbols:

Mounting instructions

• Controller

• Communication cards (MC-xxx)

• I/O system 1000 (EPM-Sxxx)

• Inverter, Servo Drives

•Communication modules

Operating instructions

• Controller

• Servo system ECS (ECSxE, ECSxM)

Sample applications/Using application templates

Online help/software manuals

• Application Sample i700

• Application Samples

• ApplicationTemplate

Parameterisation, configuration, commissioning

Online help/reference manuals

• Controller

• Inverter, Servo Drives

• I/O system 1000 (EPM-Sxxx)

Online help/communication manuals

• Bus systems

•Communication modules

Operating instructions

• Servo system ECS (ECSxE, ECSxM)

Printed documentation

Online help in the Lenze Engineering

Tool (also available as PDF file at

www.lenze.com

.)

Tip!

Current documentation and software updates with regard to Lenze products can be found

in the download area at:

www.lenze.com

Target group

This documentation is intended for persons who commission and maintain a Controller-based

automation system by means of a Lenze Controller and the »PLC Designer« engineering tool.

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the field devices and the software version of the Engineering tools installed (e.g. »PLC

Designer« ), screenshots in this documentation may differ from the representation on the screen.

7 Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 8

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Information regarding the validity

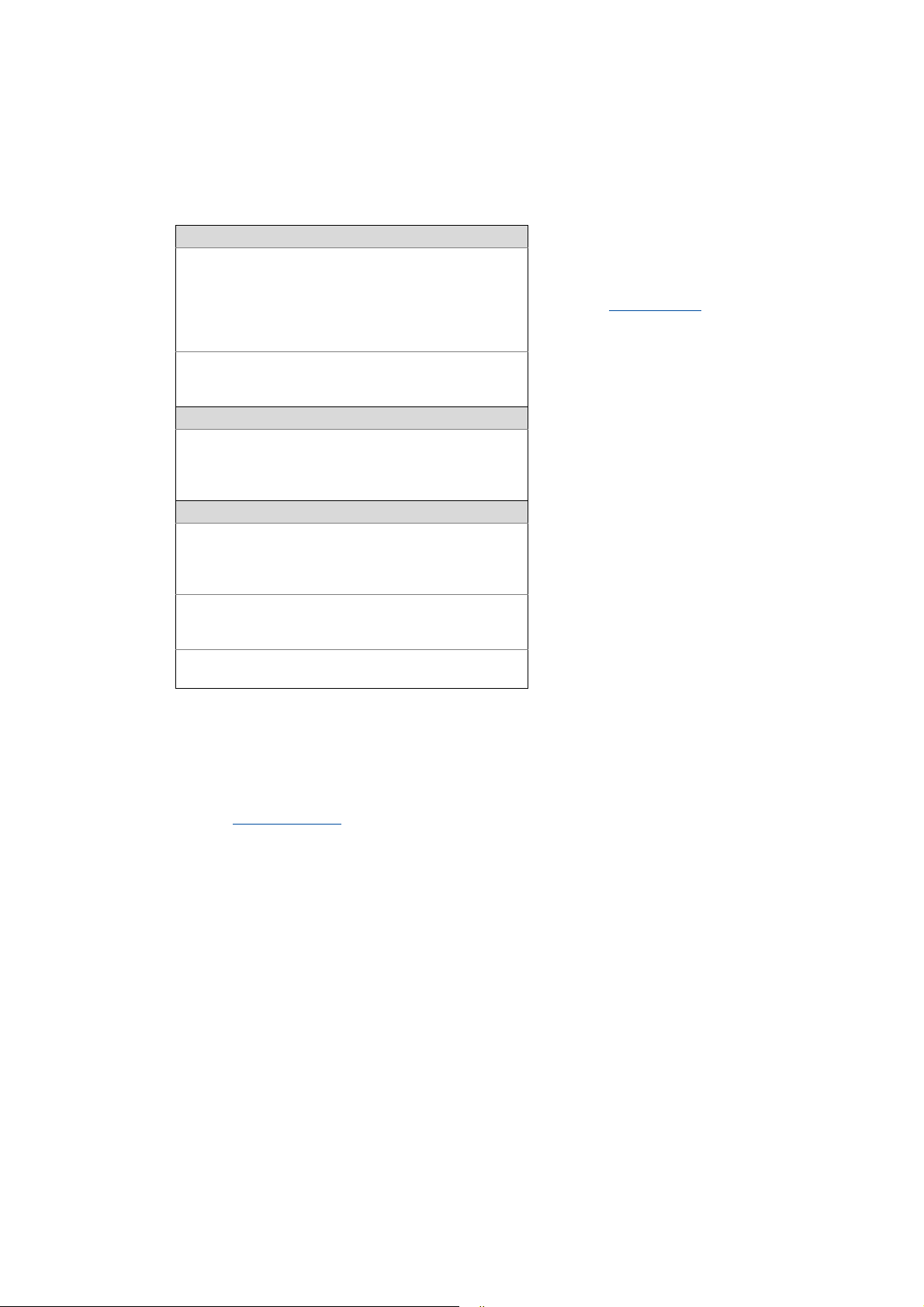

The information provided in this documentation is valid for the following Lenze Controllers:

Controller Versions

Cabinet Controller

• Controller 3221 C

• Controller 3231 C

• Controller 3241 C

Example: Controller 3241 C with connected I/O system 1000

• Controller c300

Example: Controller c300 with connected I/O system 1000

Panel Controller

• Controller p300

• Controller p500

Example: Controller p500

Operating instructions/mounting instructions of the Controllers

Here you will find technical data and information on how to install the devices.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 8

Page 9

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

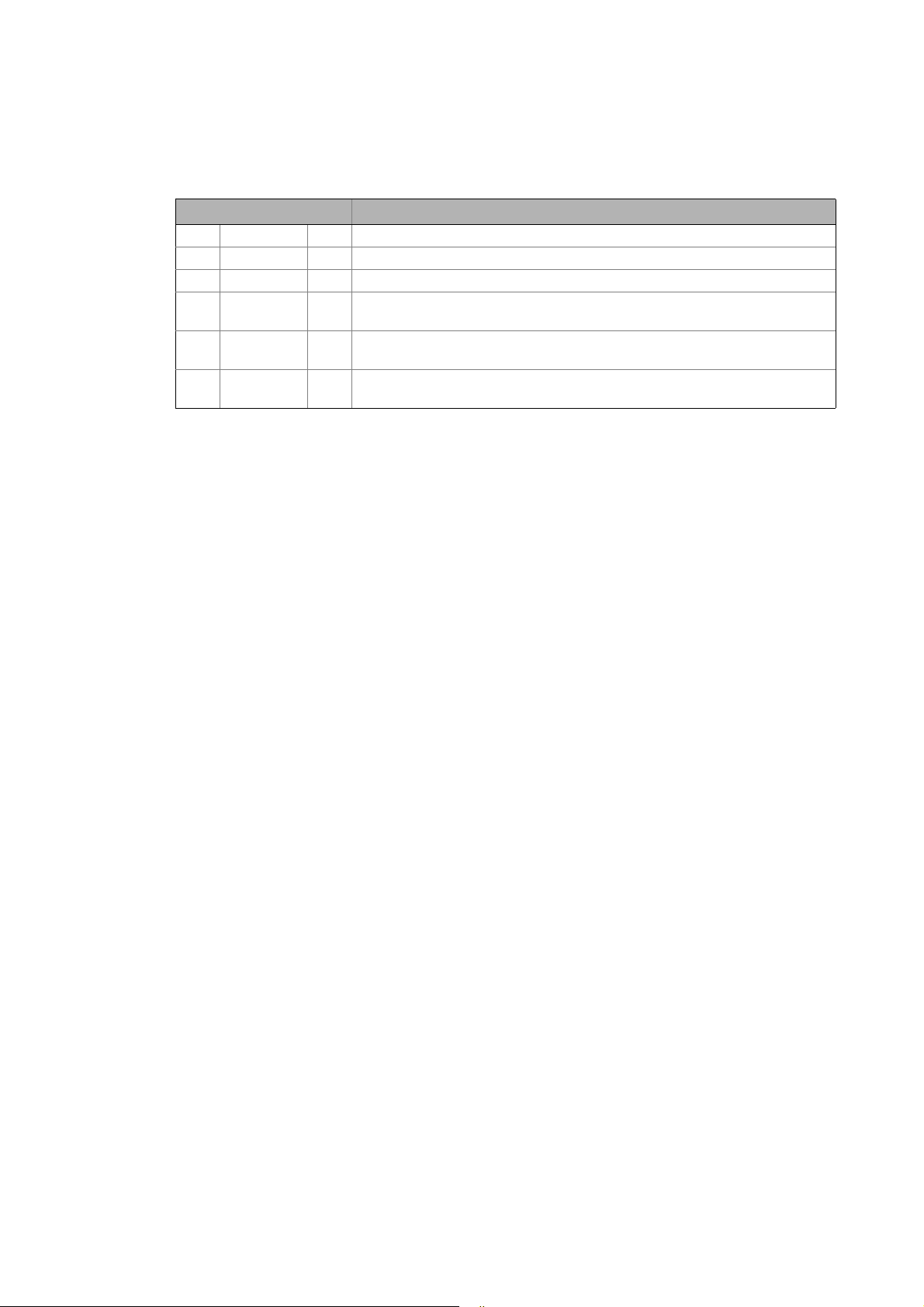

1.1 Document history

Version Description

1.0 10/2010 TD11 First edition for the Lenze automation system "Controller-based Automation" 3.x

1.1 04/2011 TD11 Update for the Lenze automation system "Controller-based Automation" 3.1

1.2 12/2011 TD11 Update for the Lenze automation system "Controller-based Automation" 3.2

1.3 05/2012 TD11 Update for the Lenze automation system "Controller-based Automation" 3.3

• Amended by Controllers p500 (panel controllers)

1.4 11/2012 TD11 Update for the Lenze automation system "Controller-based Automation" 3.6

• Controller c300/p300 added (in preparation)

1.5 04/2014 TD17 Update for the Lenze automation system "Controller-based Automation" 3.8

• Controller c300/p300

9

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 10

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Highlighting Examples/notes

Spelling of numbers

Decimal separators Point The decimal point is generally used.

For example: 1234.56

Text

Version information Text colour blue All pieces of information that only apply to or from a specific

Program name » « »PLC Designer«...

Window italics The message window... / The Options dialog box ...

Variable names Setting bEnable to TRUE...

Control element bold The OK button ... / The Copy command ... / The Properties tab

Sequence of menu

commands

Shortcut <bold> Use <F1> to open the online help.

Hyperlink underlined

Symbols

Page reference ( 10) Reference to further information: Page number in PDF file.

Step-by-step instructions

software version of the inverter are highlighted

correspondingly in this documentation.

Example: This function extension is available from software

version V3.0!

... / The Name input field ...

If several commands must be used in sequence to carry out a

function, the individual commands are separated by an

arrow: Select File

If a key combination is required for a command, a "+" is

placed between the key identifiers: With <Shift>+<ESC>...

Reference to further information: Hyperlink to further

information.

Step-by-step instructions are marked by a pictograph.

Open to...

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 10

Page 11

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

Controller The controller is the central component of the automation system which controls the

Engineering PC The Engineering PC and the Engineering tools installed serve to configure and

Fieldbus stations Devices integrated in the bus system as, for instance, Controller and inverter

Field device

Inverter Generic term for Lenze frequency inverter, servo inverter

PLC Programmable Logic Controller

PLC Programmable Logic Controller (PLC)

UPS Uninterruptible power system (UPS)

Engineering tools

Software solutions for easy engineering in all phases which serve to commission, configure, parameterise and

diagnose the Lenze automation system.

Engineering tools

Logic and Motion functionalities by means of the runtime software.

The controller communicates with the field devices via the fieldbus.

parameterise the system "Controller-based Automation".

The Engineering PC communicates with the controller via Ethernet.

( 20)

»EASY Navigator« – provides for orientation

• All convenient Lenze Engineering tools at a glance

• Tools can be selected quickly

• Simplifies the access to the engineering process by its clarity.

»EASY Starter« – easy-to-use tool for service technicians

• For the maintenance of Lenze devices

• For the commissioning of Lenze devices

• Online diagnostics, parameterisation and commissioning

• Loading of ready-to-use applications to the device

»Engineer« – multi-device engineering

• Suitable for all products of the Lenze portfolio

• Easy handling by means of graphical user interfaces

•

Can be used in all engineering phases (project planning, commissioning,

production)

• Parameterisation and configuration of Lenze devices

»PLC Designer« – programming processes

• Creating individual programs

• Programming Logic & Motion according to IEC 61131-3 (AWL, KOP, FUP,

ST, AS and CFC-Editor), based on CoDeSys V3

• Certified function blocks according to PLCopen part 1 + 2

• Graphic DIN 66025 Editor (G code) with DXF import

• Integrated visualisation for the simple representation of processes

»VisiWinNET« – visualisation tool

• Visualise the applications of the automation system

• Create the visualisation/user interface

11

»Backup & Restore« – back up/restore/update data

•Create data backups

• Restore data after device replacement

• Carry out software update of the Controller

Bus systems

CAN CAN (Controller Area Network) is an asynchronous, serial fieldbus system.

CANopen® is a communication protocol based on CAN. The Lenze system bus (CAN on

board) operates with a subset of this communication protocol.

CANopen® is a registered community trademark of the CAN user organisation CiA® (CAN

in Automation e. V.).

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 12

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Term Meaning

EtherCAT® (Ethernet for Controller and Automation Technology) is an Ethernet-based

fieldbus system which fulfils the application profile for industrial real-time systems.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

PROFIBUS® (Process Field Bus) is a widely used fieldbus system for the automation of

machines and production lines.

PROFIBUS® is a registered trademark and patented technology licensed by the PROFIBUS

& PROFINET International (PI) user organisation.

PROFINET® (Process Field Network) is a real-time capable fieldbus system based on

Ethernet.

PROFINET® is a registered trademark and patented technology licensed by the PROFIBUS

& PROFINET International (PI) user organisation.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 12

Page 13

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Definition of the notes used

This documentation uses the following signal words and symbols to indicate dangers and

important information:

Safety instructions

Structure of the safety instructions:

Pictograph and signal word!

(characterises the type and severity of danger)

Note

(describes the danger and informs how to prevent dangerous situations)

Pictograph Signal word Meaning

Danger! Danger of personal injuries through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of material damage

Reference to an imminent danger that may result in death or serious personal

injury unless the corresponding measures are taken.

Reference to an imminent danger that may result in death or serious personal

injury unless the corresponding measures are taken.

Indicates a potential danger that may lead to material damage unless the

corresponding measures are taken.

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure troublefree operation

Tip! Useful tip for easy handling

Reference to another document

13

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 14

2 Safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Please observe the following safety instructions when you want to commission an automation

system or a plant using a controller.

Read the documentation supplied with the corresponding field device thoroughly before

starting to commission the devices with the controller!

The device documentation contains safety instructions which must be observed!

Danger!

According to today's scientific knowledge it is not possible to ensure absolute freedom

from defects of a software.

If necessary, systems with built-in inverters must be provided with additional

monitoring and protective equipment complying with the relevant safety regulations

(e.g. law on technical equipment, regulations for the prevention of accidents) in each

case, so that an impermissible operating status does not endanger persons or facilities.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there would be a risk of injury by the

moving machine parts.

Stop!

If you change parameters in the engineering software while a device is connected online,

the changes will be directly accepted by the device.

A wrong parameter setting can cause unpredictable motor movements.

By an unintended direction of rotation, too high speed, or jerky operation, the driven

machine parts may be damaged.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 14

Page 15

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Controller-based Automation: Central motion control

The Lenze automation system "Controller-based Automation" serves to create complex automation

solutions with central motion control. Here, the Controller is the control centre of the system.

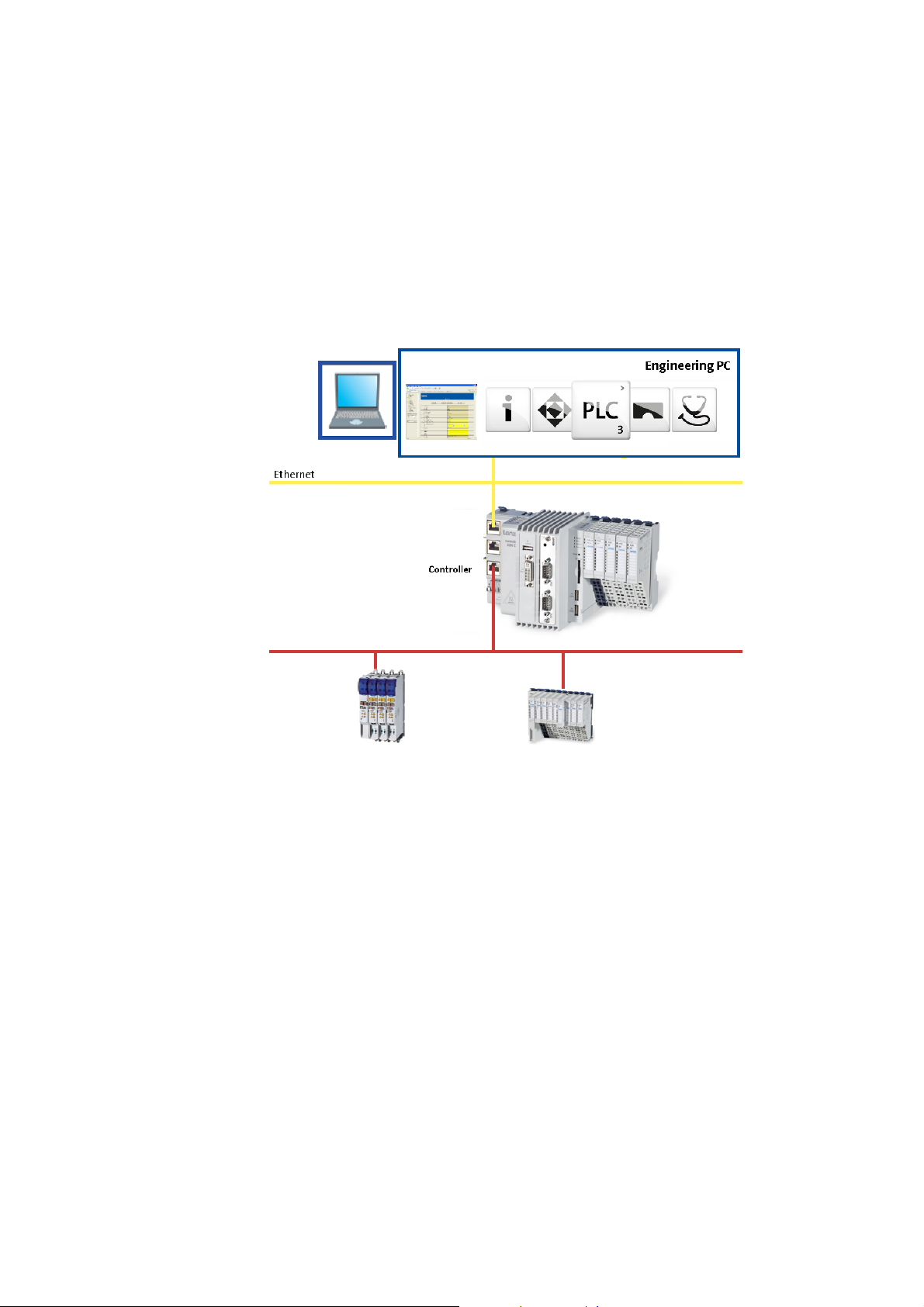

System structure of the Controller-based Automation: "All from one single source"

[3-1] Example configuration (EtherCAT bus system): Controller 3200 C with I/O system 1000 and Servo Inverter i700.

15 Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 16

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

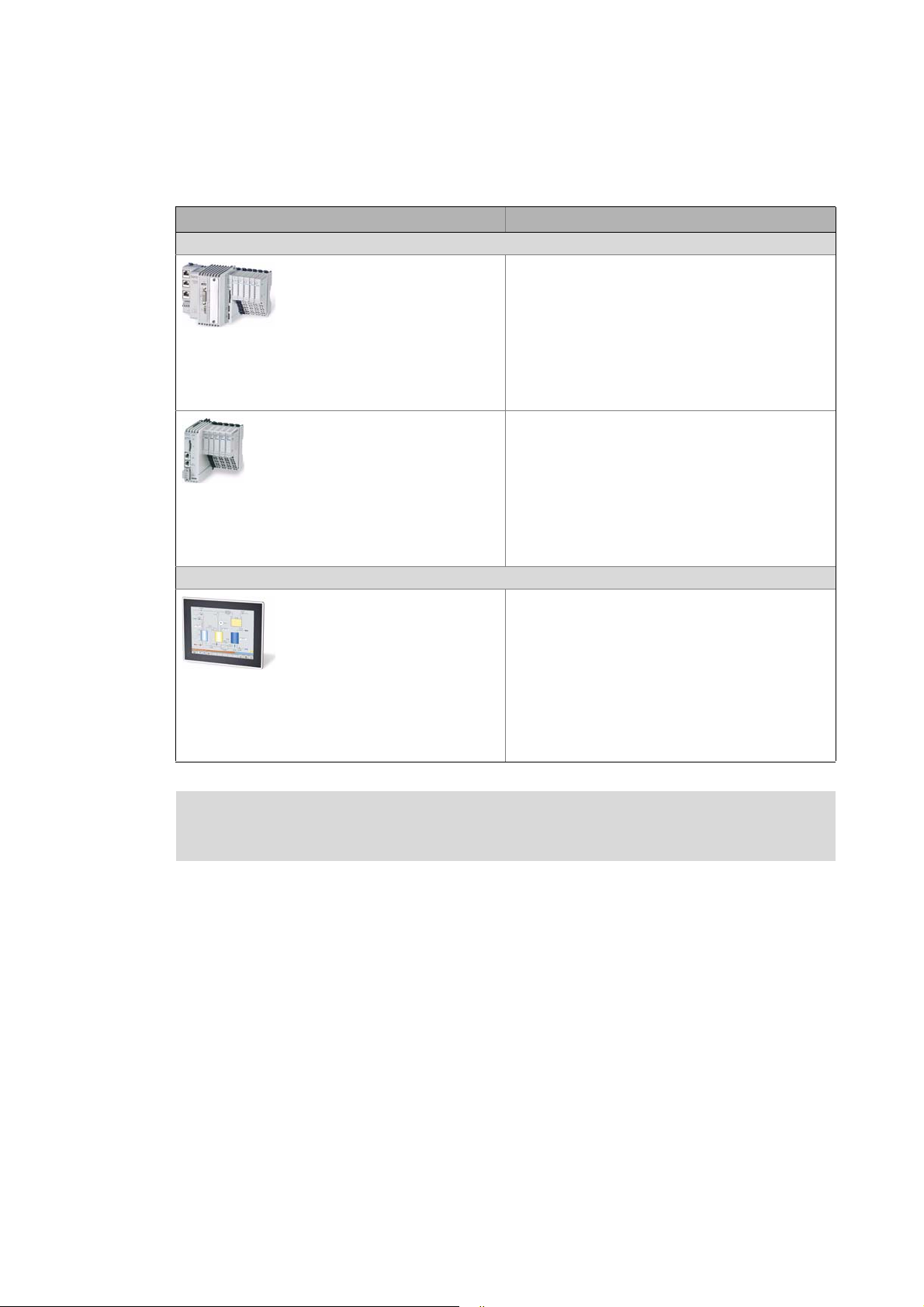

Lenze supply specially matched system components:

• Engineering software

The Lenze Engineering tools

to parameterise, configure and diagnose the system. The Engineering PC communicates with

the Controller via Ethernet.

•Controller

The Lenze Controller is available as Panel Controller with integrated touch display and as

Cabinet Controller in control cabinet design.

Cabinet Controllers provide a direct coupling of the I/O system 100 via the integrated backplane

bus.

The Runtime software of the Lenze Controllers

of motion sequences. These software versions are available:

• "Logic": Sequence control in the Controller, motion control in the inverter

• "Motion": Sequence control and motion control in the Controller, inverter as actuating drive

• "Visu": Optional visualisation of the automation system, can be used separately or in addition

to "Logic" or "Motion"

An external monitor panel/display can be connected to the Cabinet Controller 3231 C/

3241 C.

• Without software: Controller as single component with operating system only

•Bus systems

EtherCAT is a standard "on board" bus system of the Controller-based Automation. EtherCAT

enables the control of all nodes (Motion/Logic) on one common fieldbus.

Optionally, CANopen, PROFIBUS and PROFINET can be used as extended topologies.

The Controllers c300/p300 have a CANopen interface "on board" as well (in addition to

EtherCAT).

• Inverter (e.g. Servo Inverter i700)

( 20) on your Engineering PC (Windows® operating system) serve

( 24) provides the control and/or visualisation

"Logic & Motion" runtime software

The "Controller-based Automation" system allows for the central control of devices for Logic and

Motion applications. The runtime software runs on the Controller.

In case of Logic applications, the sequence control is carried out in the Controller and the motion

control is carried out in the inverter.

In case of Motion applications , the sequence control and motion control are carried out in the

Controller. The inverter is used as actuating drive.

• Motion applications make special demands on the cycle time and real-time capability of the bus

system between the Controller and the subordinate fieldbus nodes.

• This is e.g. the case if the nodes must traverse synchronously or if position setpoints must be

transmitted.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 16

Page 17

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

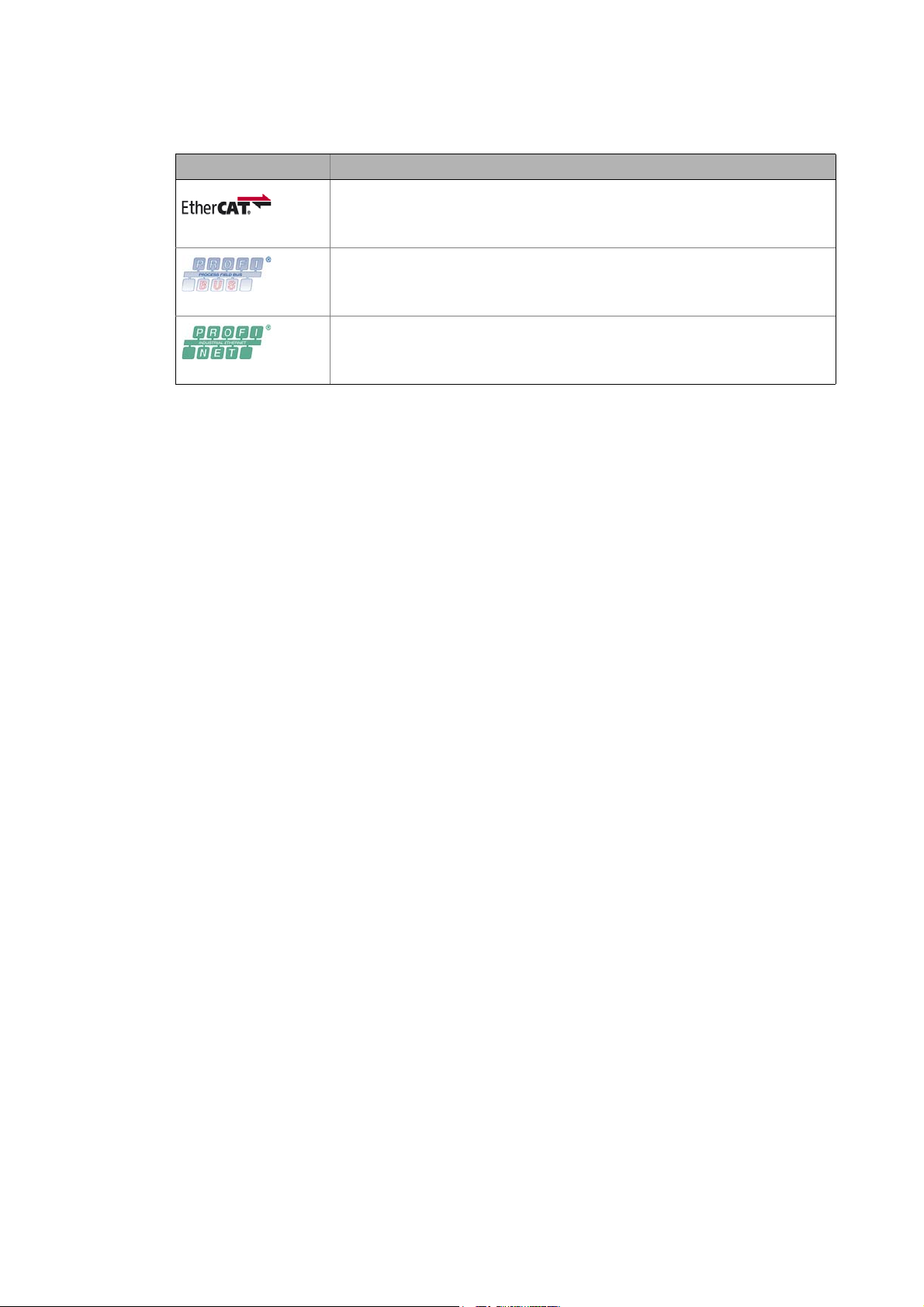

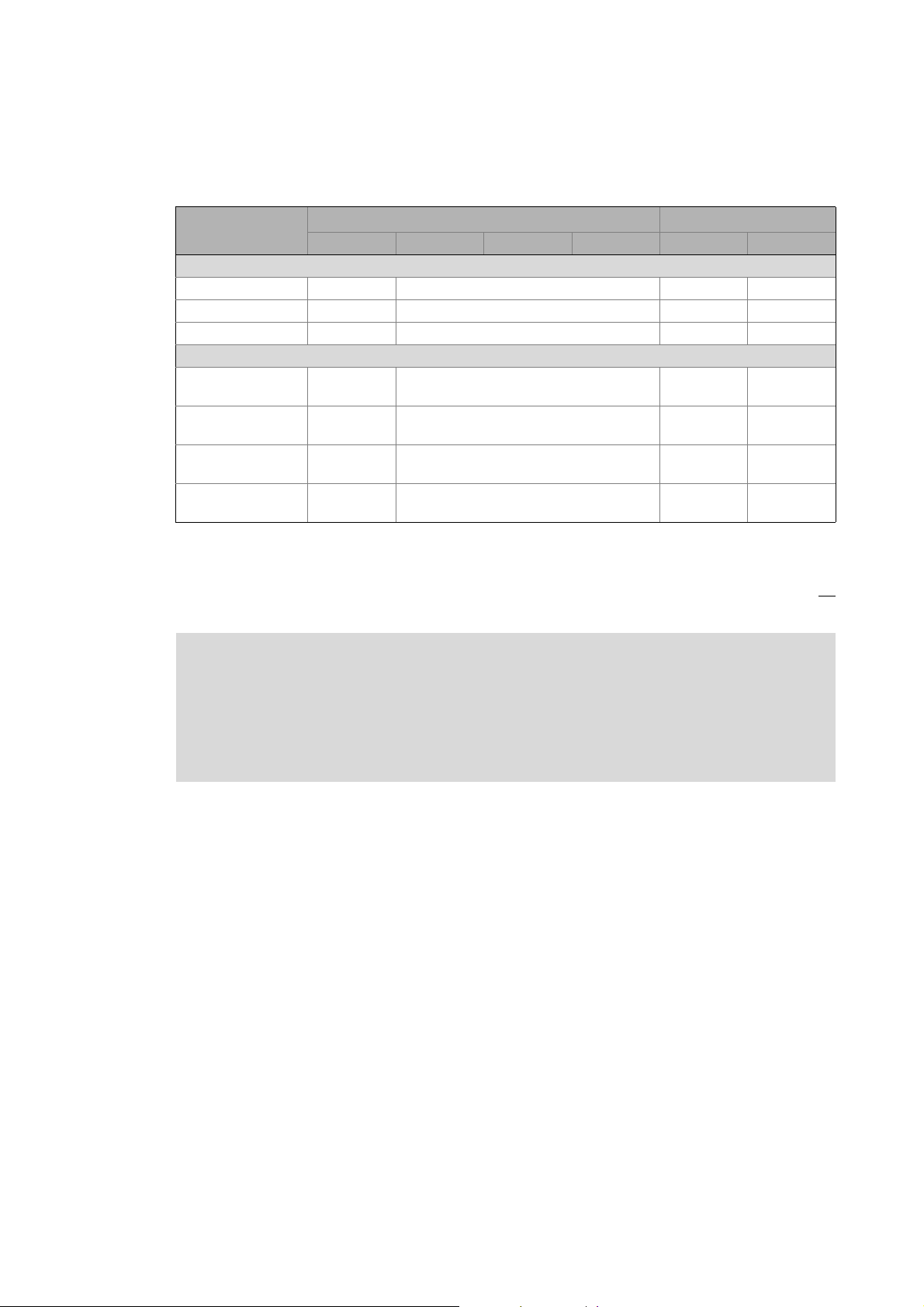

Fieldbus communication

The Lenze Controllers have different interfaces for fieldbus communication:

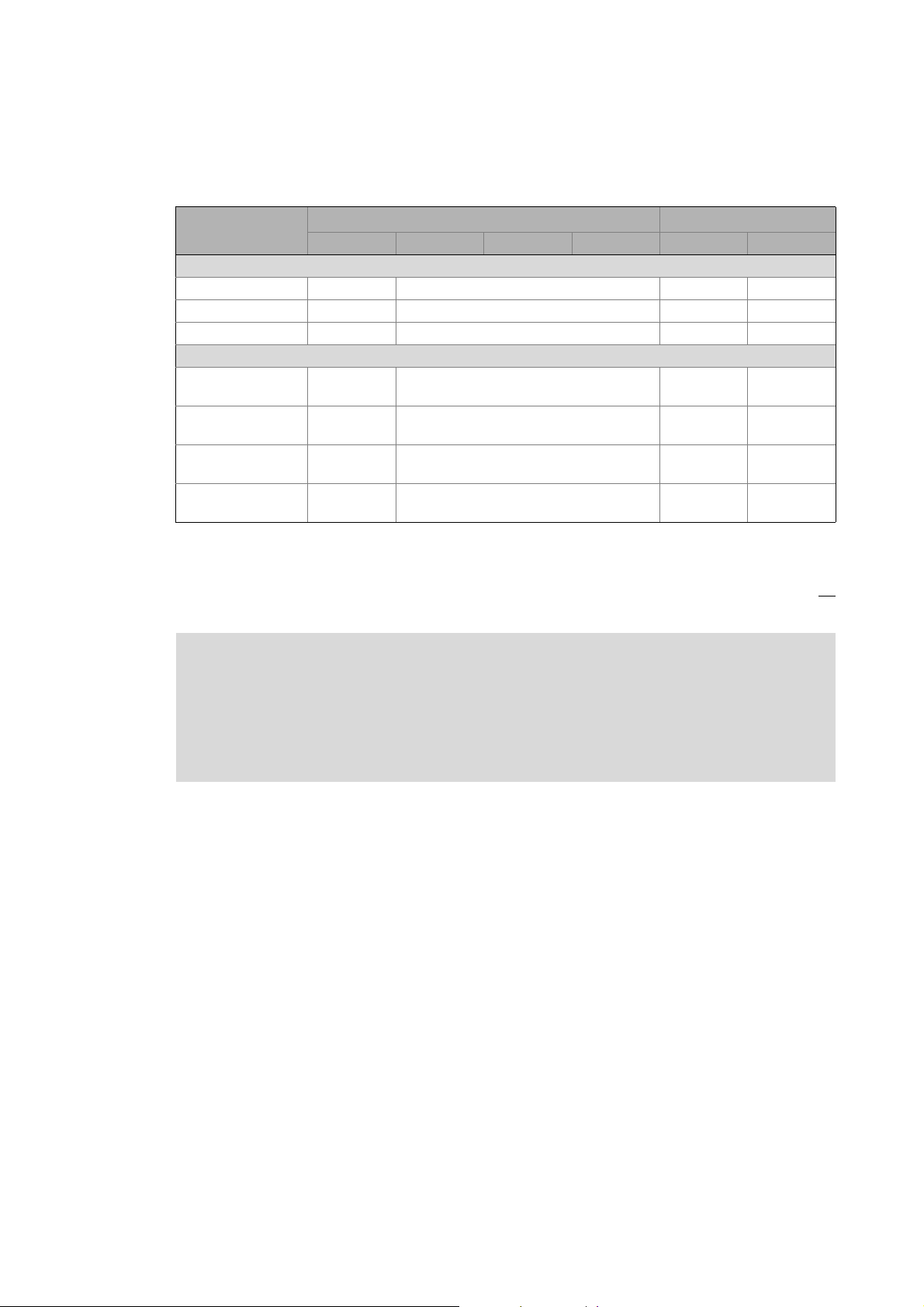

Area Cabinet Controller Panel Controller

c300 3221 C 3231 C 3241 C p300 p500

Interfaces (on board)

Ethernet1212

EtherCAT 1

CANopen 1

Optional interfaces (communication cards)

CANopen

MC-CAN2

PROFIBUS master

MC-PBM

PROFIBUS slave

MC-PBS

PROFINET device

MC-PND

1)

2)

- -

- -

- -

- -

11

-1

1)

2)

1

-

1) In preparation

2) Only the CAN master functionality is supported.

The Ethernet interface serves to connect the Engineering PC or to create line topologies (no

integrated switch for Controller c300/p300).

More information on the bus systems and configuration can be found in the

communication manuals:

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

17 Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 18

4 System structure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

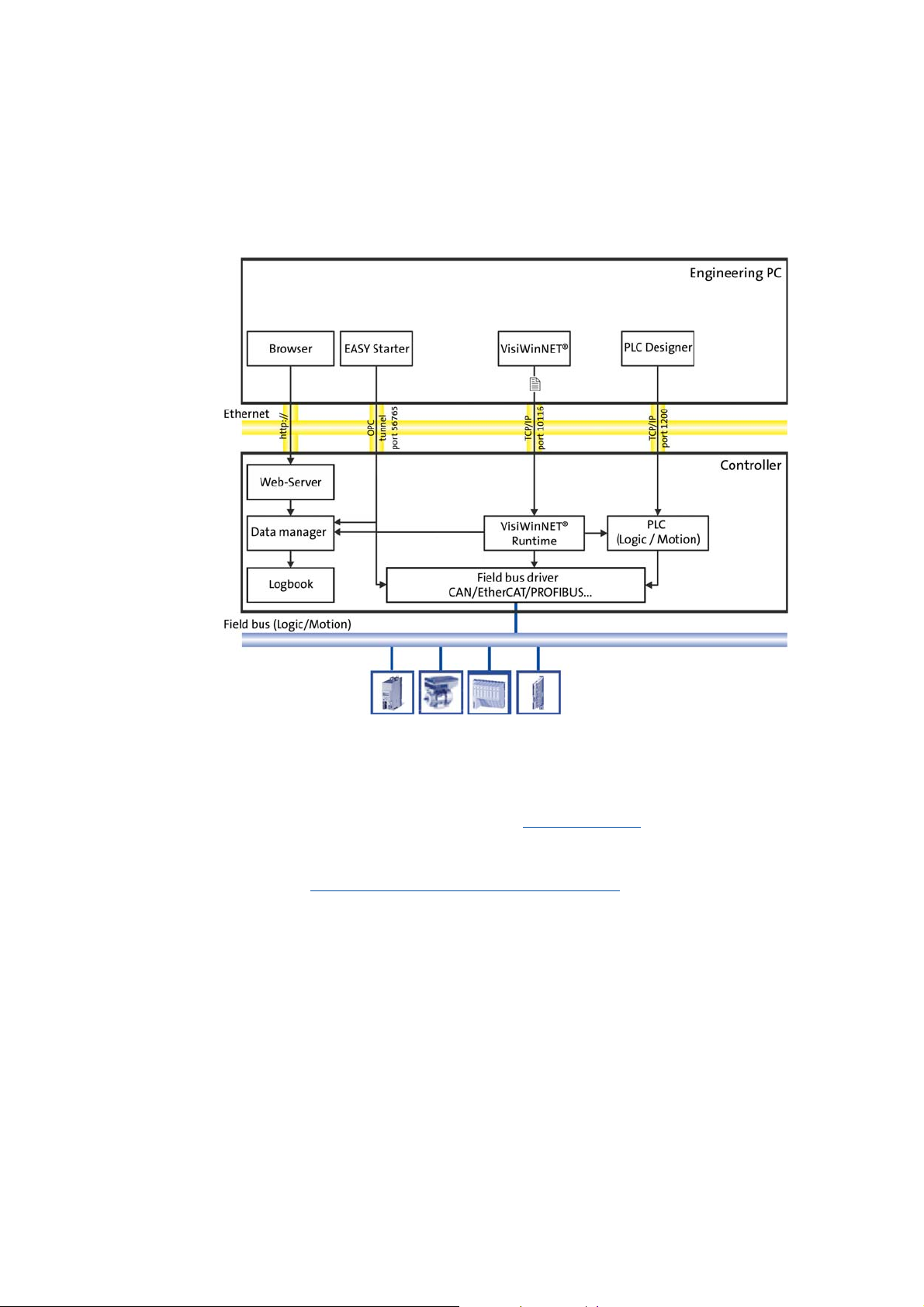

4 System structure

This chapter provides you with an overview of the basic system structure of the Lenze "Controllerbased Automation" system. The system consists of an Engineering PC, a Controller and the devices

communicating with the Controller via the fieldbus.

[4-1] * The PROFIBUS fieldbus driver can only be accessed via PLC (Logic/Motion). Access via EASY Starter and VisiWinNET®

Runtime is not provided.

Controllers and field devices form the automation system to be commissioned via the Engineering

PC. The Engineering PC is a PC/Laptop with Windows® operating system and network connection.

The Engineering PC comes installed with the Lenze Engineering tools

configuration, programming and diagnostics.

The Controller with the PLC (Logic/Motion) is the central control section, consisting of the PLC

runtime program (Runtime software of the Lenze Controllers

application.

Device-internally, the Controller comes with a data manager for configuring and managing the data

of the automation system. The data manager and the fieldbus driver enable the PLC (Logic/Motion)

to access the system components and the field devices.

The fieldbus (Logic/Motion) enables the Controller to read and write the parameters of the

connected field devices.

( 20) for parameter setting,

( 24)) with the running PLC

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 18

Page 19

4 System structure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Note!

There is no OPC server available for PROFIBUS and PROFINET.

Controller c300/p300:

• The »EASY Starter« cannot

• The OPC communication for »VisiWinNET« is exclusively available for Controller p300

without

• Otherwise, only the Lenze "Logic&Motion" direct driver can be used for the data

exchange between »VisiWinNET« and PLC.

PLC.

be used for these devices (in preparation).

19 Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 20

4 System structure

4.1 Engineering tools

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1 Engineering tools

The Engineering PC is a PC/Laptop with Windows® operating system and network connection.

The Engineering PC comes installed with the Lenze Engineering tools which enable the desired

automation solution to be ...

• parameterised/configured;

•programmed;

•diagnosed.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 20

Page 21

4 System structure

4.1 Engineering tools

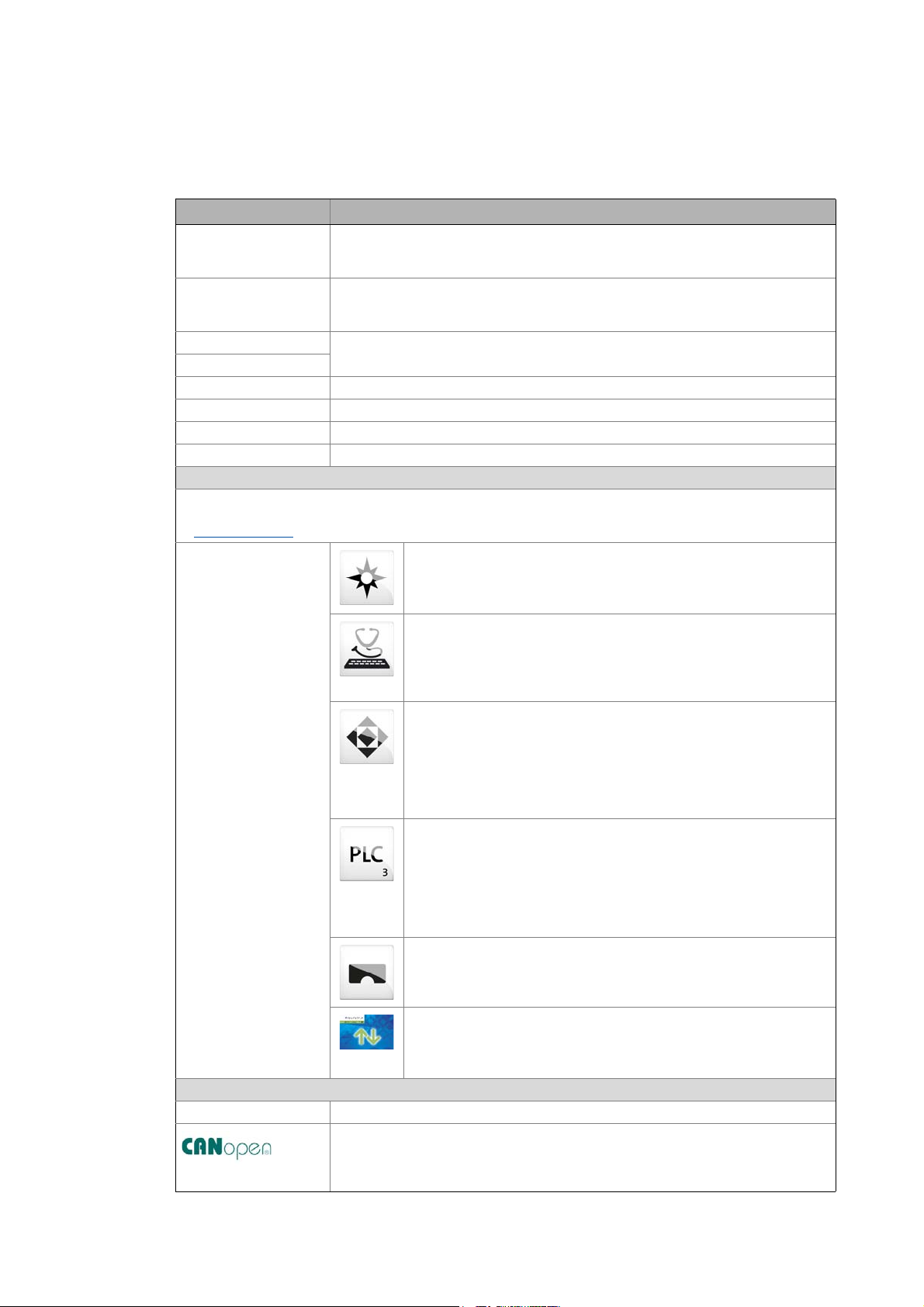

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

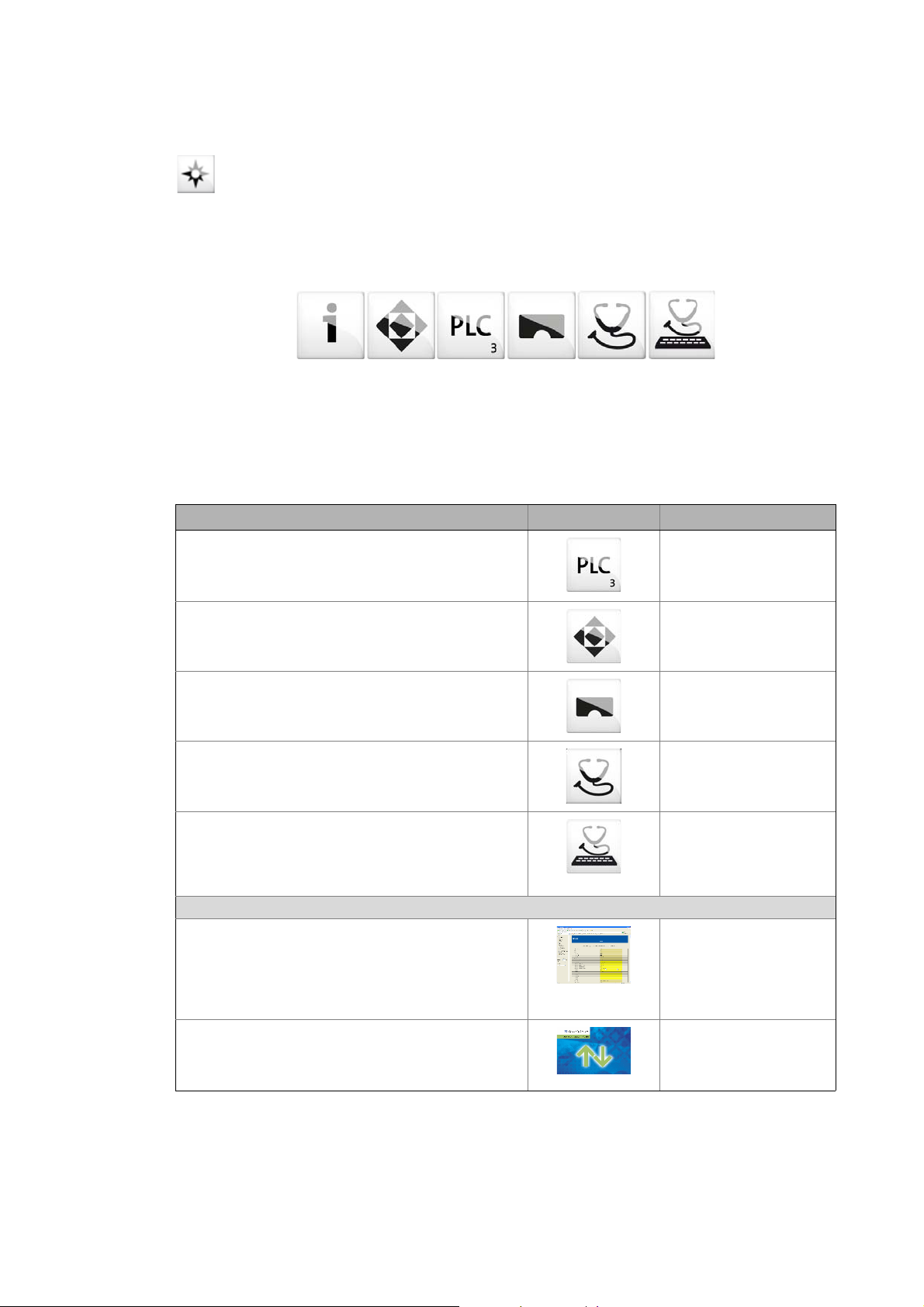

»EASY Navigator«: Starting the suitable Engineering tool

The Lenze Engineering software consists of the Engineering tools optimised for the respective

Engineering phase.

The »EASY Navigator« shows the Lenze Engineering tools installed on the Engineering PC. Start the

desired Engineering tool via the corresponding button:

The »EASY Navigator« ...

• simplifies the selection of the Engineering tool, depending on the Engineering phase.

• simplifies starting the desired Engineering tool (depending on the application case).

• makes it possible to select the Engineering tool suitable for the Engineering phase.

The overview displays the respective function of the Engineering tools:

What would you like to do? Button Engineering tool

Programming

• Program the controller

• Parameterise/commission the Servo-Inverter i700

• Parameterise the I/O system 1000

Parameterising/configuring the inverter

• Parameterise and configure the automation/drive

system

• Parameterise Inverter Drives 8400/Servo Drives 9400

Visualization

• Visualise the applications of the automation system

• Create the visualisation/user interface

Online diagnostics

• Easy online diagnostics of the Controllers (from»EASY

Starter« V1.2) and other Lenze devices

Online parameterisation

• Online parameterisation/commissioning of Lenze

devices

• Direct online parameterisation with an active online

connection to the Lenze devices

Engineering tools that are not included in the »EASY Navigator«:

Controller parameterisation/diagnostics

• »WebConfig« can be used on the controller without

commissioning (integrated web server).

• By the use of »WebConfig«, the parameters of the

controller can be accessed via web browser.

• »WebConfig« can also be started in the »PLC Designer«.

Backup of controller data

•Create data backups

• Restore data after device replacement

• Carry out software update of the Controller

»PLC Designer«

»EASY Starter«

»VisiWinNET«

»EASY Starter«

(Reading parameters)

»EASY Starter«

(Reading/writing

parameters)

»WebConfig«

»Backup & Restore«

1)

1)

21

1) For Controllers c300/p300 in preparation

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 22

4 System structure

4.2 Controller: The control centre of the Controller-based Automation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 Controller: The control centre of the Controller-based Automation

Cabinet controllers: Compact control cabinet design

Cabinet controllers are designed for the demanding continuous use in industrial applications.

Compared to panel controllers, they are not equipped with an integrated display. The Controllers

3231 C and 3241 C are provided with a DVI interface for the connection of an external monitor

panel.

Mounting is carried out in a control cabinet or a corresponding built-in housing on a standard DIN

rail (35 mm). The device-internal backplane bus provides for a direct connection of the I/O system

1000.

Panel controllers: controlling and visualising

Panel controllers are designed for the installation into control cabinets, machine panels, or other

mounting cutouts. They are equipped with rear bolts and clamping screws which provide for easy

mounting and reliable sealing (front panel enclosure IP65/rear panel IP20) in rough industrial

environments. They can be operated easily by directly touching the screen.

General features

• Controller programming, configuration and diagnostics using the »PLC Designer« (on the basis

of CoDeSys 3.x)

• USB 2.0 interfaces and SD card slot, e.g. for data backup/restore

»Backup & Restore« (data backup/restore)

• 4 LEDs for diagnostic purposes:

• Current supply

• Status of the PLC

• Status of the backplane bus

• Freely programmable LED

( 67)

Operating instructions for the Controller

Here, further information on the device-specific properties can be found.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 22

Page 23

4 System structure

4.2 Controller: The control centre of the Controller-based Automation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Fieldbus communication

The Lenze Controllers have different interfaces for fieldbus communication:

Area Cabinet Controller Panel Controller

c300 3221 C 3231 C 3241 C p300 p500

Interfaces (on board)

Ethernet1212

EtherCAT 1

CANopen 1

Optional interfaces (communication cards)

CANopen

MC-CAN2

PROFIBUS master

MC-PBM

PROFIBUS slave

MC-PBS

PROFINET device

MC-PND

1)

2)

- -

- -

- -

- -

11

-1

1)

2)

1

-

1) In preparation

2) Only the CAN master functionality is supported.

The Ethernet interface serves to connect the Engineering PC or to create line topologies (no

integrated switch for Controller c300/p300).

More information on the bus systems and configuration can be found in the

communication manuals:

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

23

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 24

4 System structure

4.3 Runtime software of the Lenze Controllers

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3 Runtime software of the Lenze Controllers

By default, the runtime software is installed in the Lenze Controller as "Logic" mode for the central

control of PLC applications.

Optionally, the "Motion" mode is available, additionally enabling extensive motion control of

Motion functions. The inverter then only acts as an actuating drive.

In addition, the "Visu" mode is available, enabling a central visualisation with the Controller.

The runtime software consists of:

• Operating system (Windows® CE)

• Software components (Logic/Motion), which for instance execute the control program.

• Optional visualisation software (»VisiWinNET« Compact CE).

Differences between "Logic" and "Motion"

Logic Motion

The controller controls...

• simple motion sequences;

• by logically

Logic applications are suitable for the control of inverters

without

• execute simple motion sequences;

• can only be controlled via PLC functionality.

combined control signals.

a Motion functionality which ...

Note!

Depending on the runtime software (Logic/Motion) used, a bus system for a Lenze

device series can only be used in a limited way.

Details can be found in the communication manuals:

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

The controller controls extensive motion sequences.

The runtime software "Motion" ...

• contains the PLCopen library;

• contains the "Logic" mode;

• supports "SoftMotion".

Motion applications are suitable...

• for the control of inverters executing complex motion

sequences of multi-axes in several dimensions;

• ...for the control of devices that are to traverse

synchronously;

• for the transfer of setpoints.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 24

Page 25

4 System structure

4.3 Runtime software of the Lenze Controllers

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.1 "Logic" runtime software

"Logic" refers to the use of logically combined control signals without Motion functions. When the

"Logic" mode is used, the controller solely controls the motion sequences via logically combined

control signals.

Functionality

• Programming PLC functionality according to IEC 61131-3.

• SoftPLC functionality for executing PLC programs.

• The multi-tasking Windows® CE operating system processes the PLC

programs cyclically.

Performance

The "Logic" mode defines the program function. The performance of the entire

automation system results from the interaction of the runtime software and

the target system in each case. The system performance thus depends on the

processor of the respective controller, and on other factors.

Engineering tool required: »PLC Designer«

4.3.2 "Motion" runtime software

The "Motion" mode makes it possible to execute more complex motion sequences than with the

Logic mode.

In the case of a Motion system, the whole motion control (Motion) of the axes to be controlled takes

place in the controller. The higher-level controller generates the motion profiles for all Motion axes

and transfers the data to the axes via EtherCAT.

A Motion-application...

• ...makes special demands on the cycle time and real-time capability of the bus system between

the controller and the connected field devices.

• for instance is to be used if the axes to be controlled are to be traversed in a synchronised

manner or position setpoints are to be transmitted.

Functionality

• Motion functions according to PLCopen "Function blocks for Motion

• Contains the "Logic" runtime software for the use of logically combined

Additional functions

• Motion function blocks/libraries

• Supports programs for the control of complex motion sequences with

Engineering tool required: »PLC Designer«

Control" version 2.0

control signals.

several axes.

25

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 26

4 System structure

4.3 Runtime software of the Lenze Controllers

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.3 "Visu" runtime software

The "Controller-based Automation" system enables the central visualisation of the automation

system.

The visualisation can either run on a separate Controller or monitor panel or on the Controller on

which the "Logic" or "Motion" runtime software is running.

Various options described in the following sections are available for the communication link.

Functionality

The "Visu" mode ...

• extends the Controller to a visualisation device;

• can be used separately or in addition to "Logic" or "Motion".

Engineering tool required: »VisiWinNET«

Note!

There is no OPC server available for PROFIBUS and PROFINET.

Controller c300/p300:

• The OPC communication for »VisiWinNET« is exclusively available for Controller p300

without

• Otherwise, only the Lenze "Logic&Motion" direct driver can be used for the data

exchange between »VisiWinNET« and PLC.

PLC.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 26

Page 27

4 System structure

4.3 Runtime software of the Lenze Controllers

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

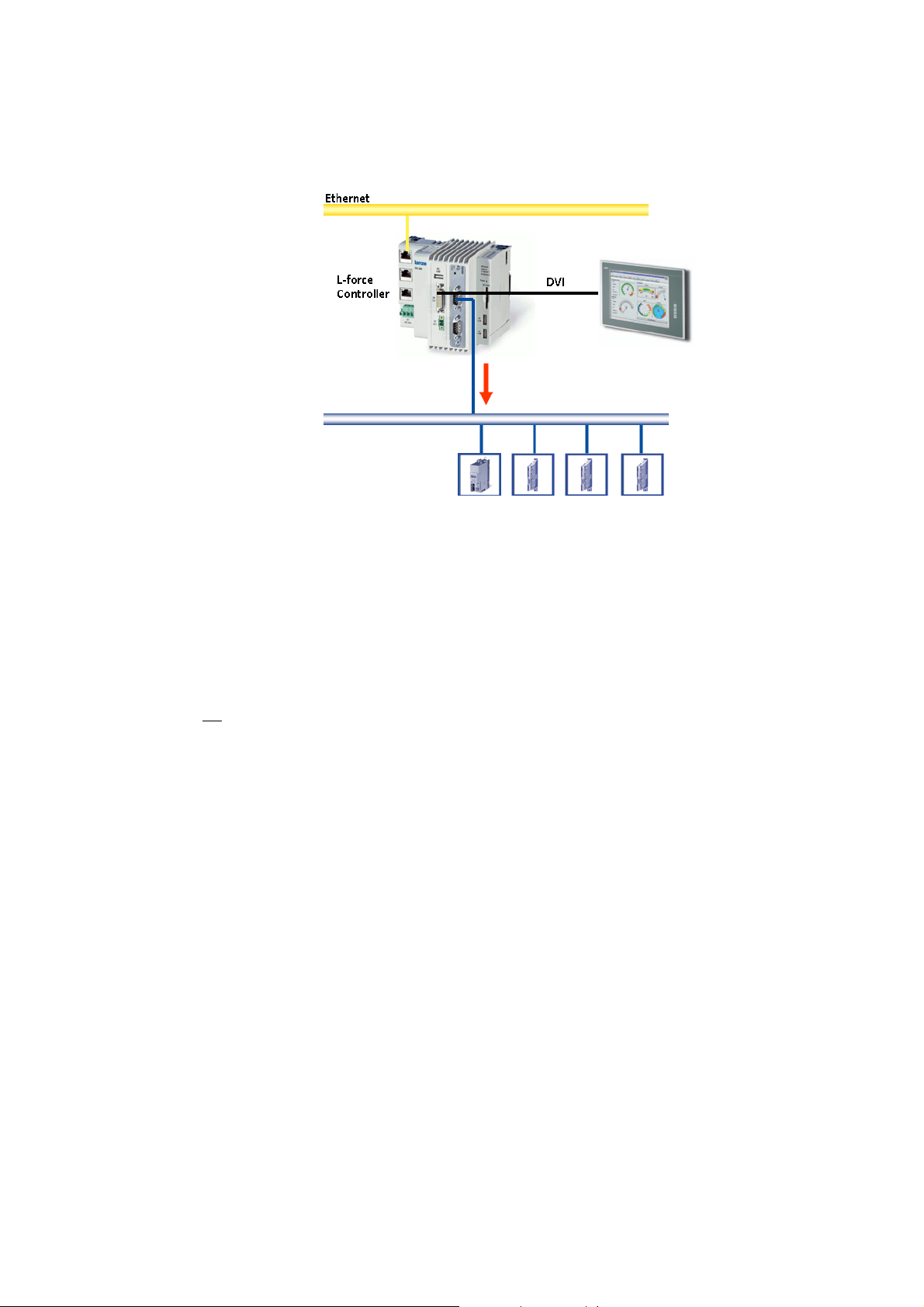

4.3.3.1 Sample topology 1: External monitor panel/display for cabinet controllers

[4-2] Sample topology: Controller 3231 C with an external monitor panel (connected to the DVI interface)

This topology with regard to its performance corresponds to the implemented solution (control/

visualisation on the same controller). The external monitor panel/display shows the visualisation.

Advantages

• Small amount of cabling

• Protected operating conditions

• Extensible topology

•No

impact on the real-time capability of the fieldbus by the visualisation

27

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 28

4 System structure

4.3 Runtime software of the Lenze Controllers

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

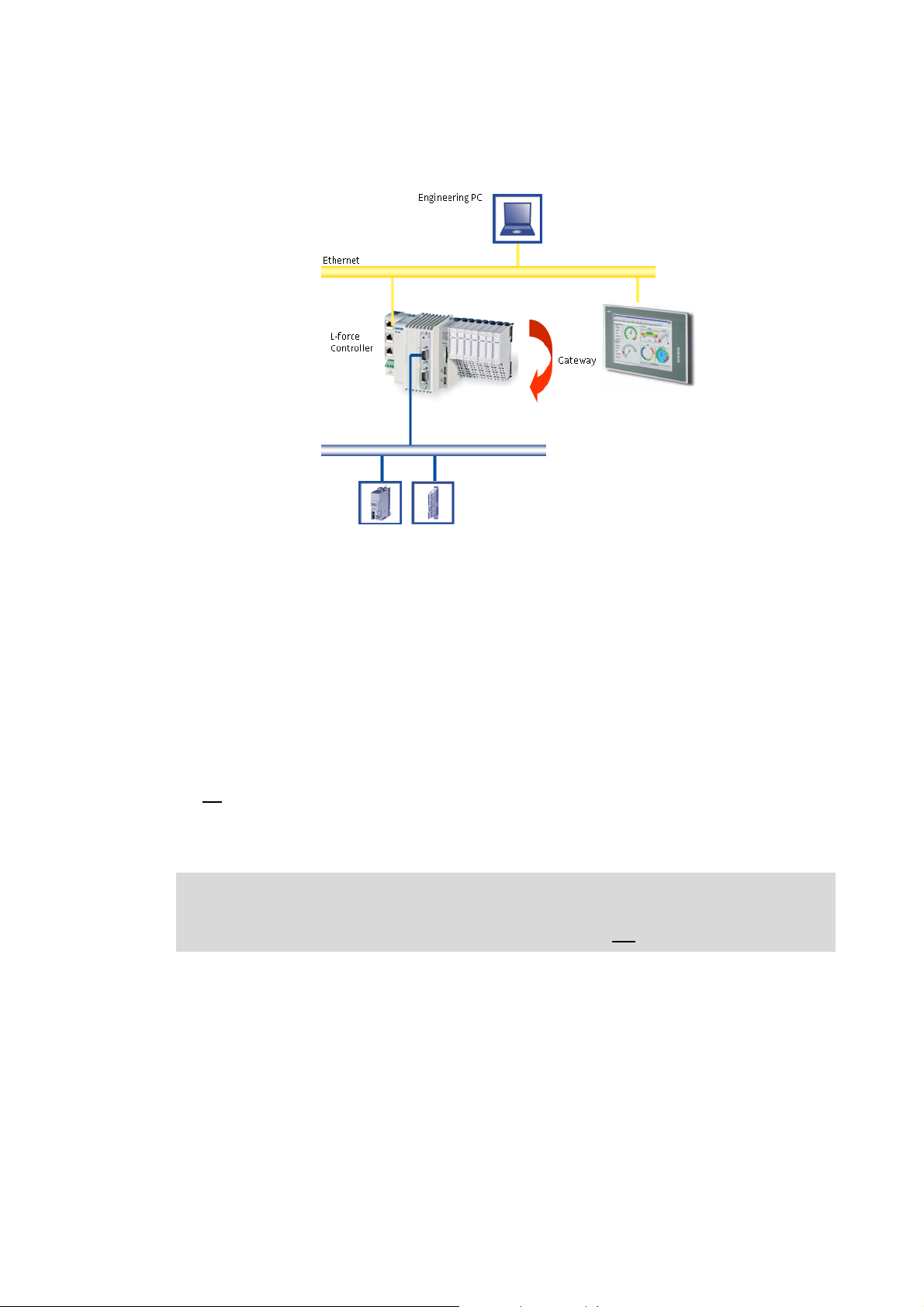

4.3.3.2 Sample topology 2: Separate control and visualisation

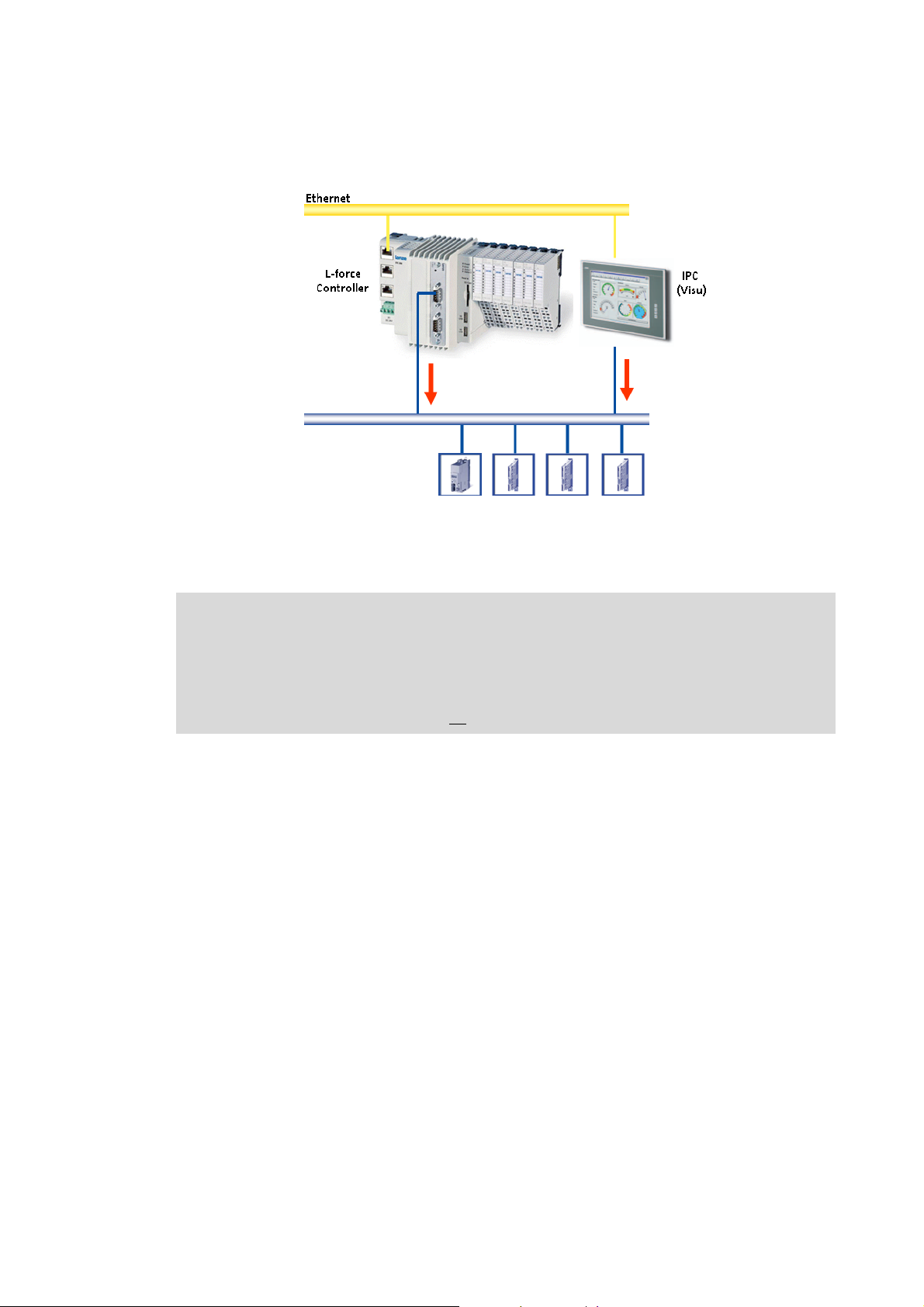

[4-3] Sample topology: Controller 3200 C as gateway for the Visualisation Controller (IPC)

The Visualisation Controller (IPC) accesses the field devices via the Controller 3200 C as gateway.

In order to separate the control and visualisation, the integrated gateway function of the controller

can be used.

The use of this topology is advisable...

• to achieve a higher performance;

• for the use of different operating systems within one automation system.

Engineering tools required: »EASY Starter«, »Engineer«

Advantages

•No

impact on the real-time capability of the fieldbus by the visualisation.

• Several visualisations can access the controller.

• Most suitable for extensive visualisation processes.

Note!

In case of Controller c300/p300, the gateway function is not supported (in preparation).

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 28

Page 29

4 System structure

4.3 Runtime software of the Lenze Controllers

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.3.3 Sample topology 3: Independent control and visualisation (CANopen)

[4-4] Sample configuration: Parallel access of Controller 3200 C and Visualisation Controller (IPC)

If this topology is used, the Controller 3200 C and the Visualisation Controller (IPC) access the

fieldbus independently of each other.

Note!

Advantages

Disadvantage

The configuration with a control and configuration independent of each other is only

available for the CANopen bus system!

• CANopen enables (several) fieldbus master independent of each other.

• In connection with EtherCAT, no

• Spatially separate control and visualisation.

• The visualisation has access to the parameters of the field devices.

• The visualisation may disrupt the real-time capability of the fieldbus. This topology therefore is

only suitable for Motion systems to a limited extent (depending on the bus system used).

configuration with two fieldbus masters is possible.

29

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 30

5 Commissioning the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Commissioning the controller

This chapter provides some general information on the commissioning of a controller. Depending

on the actual hardware installed, different settings are required for integrating the controller into a

network.

Note!

Please observe the predefined IP address of the controller for the initial commissioning:

192.168.5.99 (Lenze setting).

Further information on how to set the IP address of the Controller can be found here:

Entering the IP address of the controller

( 33)

Read the mounting instructions supplied before you start working!

The mounting instructions contains safety instructions which must be observed!

Operating instructions for the Controller

Here, further information on the device-specific properties can be found.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 30

Page 31

5 Commissioning the controller

5.1 Identification

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.1 Identification

Note!

Here the documentation provides some general information about the commissioning

of a controller. Depending on the design and version of the controller, the

commissioning process can be different.

Every controller is provided with a nameplate containing the device data. The device data are

helpful for identifying the technical equipment of the controller. Detailed information relating to

the nameplate data can be found in the operating instructions for the Controller.

Web-based diagnostics/parameter setting

Via »WebConfig« the configuration of the controller can be identified. The parameter values of the

controller can be represented using the web browser.

Online connection from the Engineering PC to the controller

( 46)

Assigning a unique name to the controller

In order to be able to clearly identify a Controller, the desired name has to be assigned for parameter

13 System identification: Name C0013

Engineering tool (e.g. »PLC Designer«), in order to be able to identify the controller.

5.2 Control elements of the controllers

Depending on the equipment and type, the different device series are provided with various control

elements (e.g. function keys for external monitor panels) and status LEDs for diagnostic purposes.

Status LEDs of the Controllers

The controllers can be operated via external input devices (keyboard/mouse). This makes it possible

to carry out comprehensive diagnostics and configuration tasks directly on the controller.

Operating instructions for the Controller

Here, further information on the device-specific properties of the Controller can be

found.

. The name assigned can then be used in the corresponding

( 80)

31

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 32

5 Commissioning the controller

5.3 Starting the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.3 Starting the controller

Note!

During the starting process of the controller

If a non

stopped!

When the controller is running

Removal of the SD card will lead to a system failure!

-bootable USB flash drive is connected during the starting sequence, it will be

• Remove the USB stick and restart the Controller.

• Alternatively, the USB stick can be prepared using the »Backup & Restore« software.

Further information can be found in the online help of the »Backup & Restore«

software.

• The SD card must not be removed while the controller is running (no "Hot Plugging"

of the SD card possible).

• The SD card is required for the system start since it contains the system files for the

starting process.

The SD card and the internal flash memory are the storage media of the controller. Depending on

the device, the SD card can be used optionally. Detailed information can be found in the devicespecific operating instructions.

The controller saves the user data (like projects and individual data) on the SD card. The operating

system and the Lenze software are saved in the internal flash memory.

Note!

The standard-IP address of the controller is 192.168.5.99 (Lenze setting)

The preset IP configuration can be changed in the »WebConfig«.

Setting IP addresses on the Engineering PC (example: Windows® XP)

Entering the IP address of the controller ( 33)

After 15 seconds, the network configuration dialog box will close automatically; the

controller continues with the starting process.

Error case: Controller c300/p300 does not start

In case the Controller c300 or p300 does not start, the Lenze standard settings can be activated

using the reset pushbutton.

How to activate the Lenze standard settings:

1. Switch off voltage supply.

( 46)

2. Press reset pushbutton.

3. While pressing the reset pushbutton, switch on the voltage supply and keep the reset

pushbutton pressed for at least 10 s.

• If the error LED is blinking (green/red) after this action, a manual mains switching is

required.

• The Controller has to be disconnected from the mains until all LEDs go off.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 32

Page 33

5 Commissioning the controller

5.4 Configuring the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.4 Configuring the controller

This chapter provides information on how to configure the Controller during initial commissioning.

The IP address setting is preserved after a restart of the system.

5.4.1 Establishing an automatic dial-up connection

Further information on how to establish an automatic dial-up connection, remote maintenance and

diagnostics options can be found under:

Remote maintenance and diagnostics

In order to carry out a remote maintenance on the controller different mechanisms are provided:

( 79)

Diagnostics via Telnet

Data transfer via FTP ( 85)

Activate Windows® CE interface ( 92)

Diagnostics with the logbook ( 89)

( 82)

Note!

Controller c300/p300:

• These devices come with a deactivated Telnet and FTP in the Lenze standard setting.

• The functions can be activated via the »WebConfig«. The activation of the functions

5.4.2 Entering the IP address of the controller

The controller has the following network settings by default:

Address Lenze setting

IP address 192.168.5.99

Subnetwork 255.255.255.0

Default gateway 192.168.5.1

can influence the real-time behaviour.

• After a restart of the Controller, the functions are deactivated again.

33

During initial commissioning of the Controller, the desired IP address has to be entered.

Optionally, the network settings can be selected via a file:

Specifying the IP address of the controller via file (optional)

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

( 36)

Page 34

5 Commissioning the controller

5.4 Configuring the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.4.2.1 Cabinet controllers with external monitor panels (3231 C/3241 C)

Note!

If an external display (monitor panel) is used, the switch-on sequence of display/

controller must be observed so that it can be correctly controlled by the controller:

• Connect the external display to the DVI output of the controller and switch it on

before

switching on the controller.

After connection of a monitor panel/an external display to a running controller, the

display resolution is VGA .

• Calibrate the monitor panel/ display connected, so that the screen content can be

displayed correctly.

Tip!

Connect a keyboard to the Controller to be able to enter the IP address.

Then you can make the entries:

[5-1] IP settings of the controller by default

• Start the control panel with <Shift+F4>.

• Start the network connections by double-click and enter the IP address, subnet mask, and the

default gateway.

• After clicking the button the IP address is saved and need not be entered again when the

system is restarted.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 34

Page 35

5 Commissioning the controller

5.4 Configuring the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.4.2.2 Cabinet Controller without external monitor panel (c300/3221 C)

To configure a Cabinet Controller without a connected monitor panel (e.g. Controller 3221 C), a PC/

laptop with the suitable addresses (IP address, subnet mask, default gateway) is required.

• Connect the PC/laptop to the controller by means of a "crossed" network cable.

• Change the settings on an HTML compliant browser:

Setting IP addresses on the Engineering PC (example: Windows® XP)

• Connection establishment: enter the IP address of the controller in the browser: 192.168.5.99

(Lenze default setting).

• In »WebConfig«, click the Ethernet button.

• Enter the desired IP address, subnet mask and default gangway of the Controller.

•Click Accept & Save all.

•Set Use IP configuration to the value "Activate device".

• Click again Accept & Save all in order to save the network settings permanently.

( 46)

35

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 36

5 Commissioning the controller

5.4 Configuring the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.4.3 Specifying the IP address of the controller via file (optional)

How to proceed:

1. Create file "ip.txt" on the Engineering PC.

2. Save file "ip.txt" to the SD card of the controller by connecting the SD card to the

Engineering PC using a memory card reader.

File "ip.txt"

172.31.207.88 {IP address}

255.255.255.0 {subnet mask}

172.31.201.1 {gateway}

[5-2] Example of an "ip.txt" file for selecting the IP address

In ASCII file "ip.txt" an IP address is defined which can be selected for the controller.

• Copy file "ip.txt" to the root directory of the SD card.

• Insert the SD card into the controller. Then start the controller.

Starting the controller

• When the system is started ...

• the controller reads in the IP address file "ip.txt" from the SD card;

• the controller writes the result (Result) to the ip.txt file:

( 32)

172.31.207.88

255.255.255.0

172.31.201.1

Result: 2010-9-24 14:42:23 :Success: IP Settings taken from file.

[5-3] Example of an "ip.txt" file for IP address selection with result entry

• Then, the Controller renames the file: "ip_old.txt".

• To select the IP address once again using the file, the file must be renamed to "ip.txt".

Tip!

The "ip.txt" file can be used to select the use of the DHCP. For this, write "DHCP" into the

first line of the file. Then, the following lines will no longer be considered.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 36

Page 37

5 Commissioning the controller

5.4 Configuring the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.4.4 Establishing Windows® CE access rights

In order to be able to establish a connection to the controller, each user has to be assigned access

rights. For this the respective user has to be set up as a Windows® CE user with a user name and a

password. Windows® CE users can be set up via »WebConfig« and the »EASY Starter«:

Setting up Windows® CE users in »WebConfig«

The representation for user 1 is displayed. The users 2 to 10 are displayed analogously.

5.4.4.1 Setting up Windows® CE users in »WebConfig«

( 37)

Note!

You have to be set up as Windows® CE user to have authorisations for further services

like FTP, telnet, or web server access.

• Up to ten Windows® CE users can be set up in »WebConfig« the User management 10 area.

• Use parameters 101 to 169 to set up the user name, password, and various authorisations for a

maximum of ten users.

The representation for user 1 is displayed. The users 2 to 10 are displayed analogously.

Detailed information on the parameters can be found here:

Basic parameters of the Controllers 3200 C/c300 and p300/p500

( 131)

37

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 38

5 Commissioning the controller

5.4 Configuring the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.4.5 Using your own wallpaper on the controller (Windows® CE)

The standard wallpaper of the controller can be replaced by your own wallpaper.

The wallpaper must meet the following conditions:

• File format: bitmap (*.bmp)

• The resolution of the image must correspond to the resolution of the monitor panel to achieve

a correct representation:

Screen sizes Panel Controller

p300 p500

Diagonal

measurement

Resolution [pixel] 480 x 272

10.9 cm

(4.3")

(PSP)

17.8 cm

(7.0")

800 x 480

(WVGA)

26.4 cm

(10.4")

800 x 600

(SVGA)

17.8 cm

(7.0")

800 x 480

(WVGA)

26.4 cm

(10.4")

800 x 600

(SVGA)

38.1 cm

(15.0")

1024 x 768

(XGA)

How to proceed:

Copy the desired bitmap file to the SD card of the controller, directory: \CustomBitmap.

Directory name on the controller if the SD card has been inserted into the controller:

\USBStorage\CustomBitmap)

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 38

Page 39

5 Commissioning the controller

5.5 I/O system 1000 at the backplane bus of a cabinet controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.5 I/O system 1000 at the backplane bus of a cabinet controller

The Cabinet Controllers 3200 C and c300 allow for a direct connection of the I/O system 1000 to the

integrated backplane bus.

The modules of the I/O system 100 connected to the backplane bus of the Controller can be

parameterised in the »PLC Designer«.

System manual for I/O system 1000 (EPM-Sxxx)

Here, further information on the parameter setting/configuration can be found.

5.5.1 Configuring I/O modules at the backplane bus

The following illustration is a schematic representation of the controller hardware structure

including I/O modules.

The I/O system 1000 includes the following components:

• I/O module coupler for voltage supply of the I/O compound modules

• I/O compound modules:

Up to 64 modules are possible which are connected to the Controller 3200 C via the Lenze

backplane bus.

In order to be able to access the modules by means of a PLC program (read input signals/write

output signals), the modules have to be configured in the »PLC Designer«. For this, map the physical

arrangement of the I/O modules in the »PLC Designer«.

[5-4] Example: mapping the physical arrangement of modules 1...7 in the »PLC Designer«

39

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 40

5 Commissioning the controller

5.5 I/O system 1000 at the backplane bus of a cabinet controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

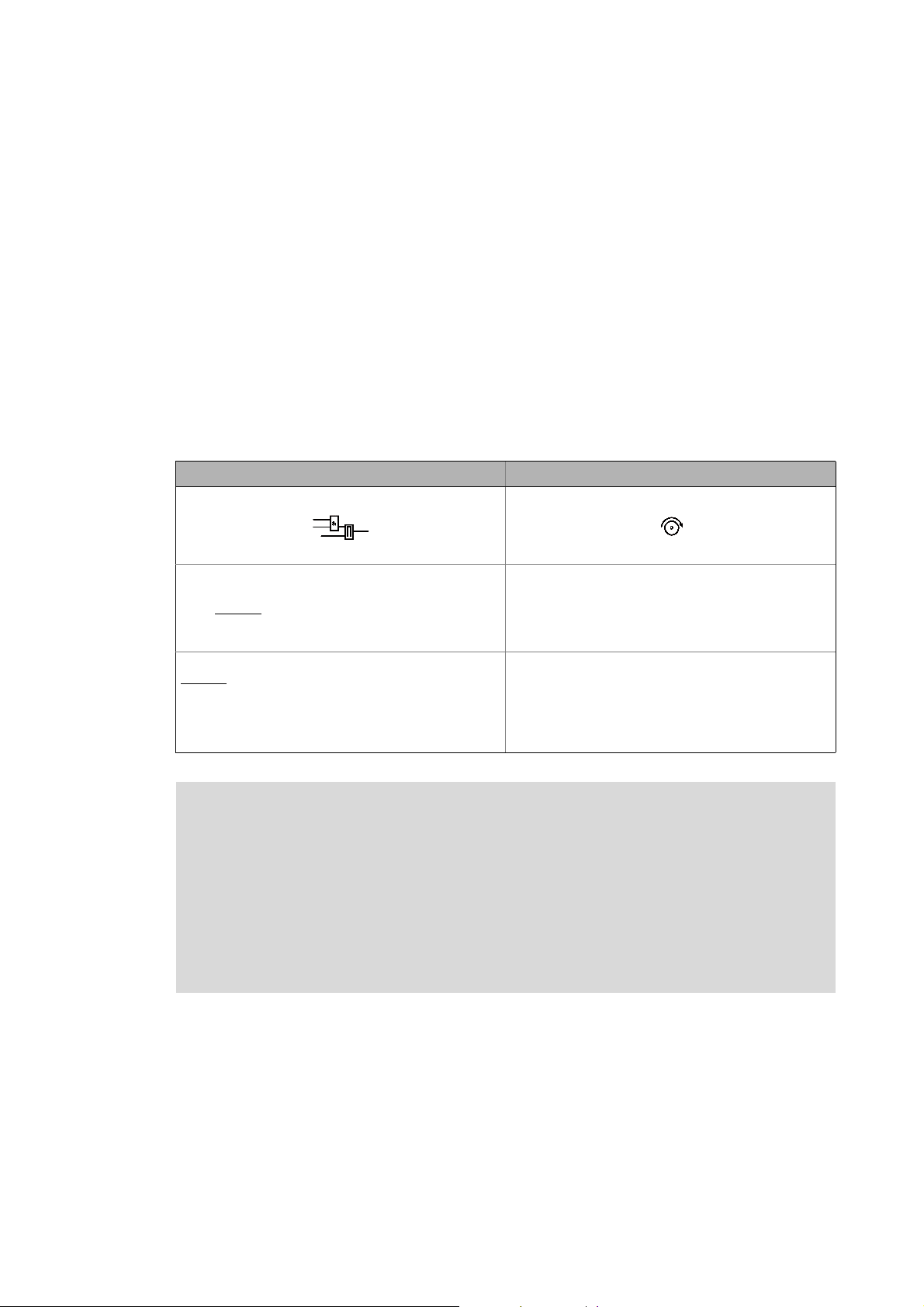

How to configure the I/O modules in the »PLC Designer«:

1. Append the I/O modules used as Devices to the I/O module coupler:

Note: The sequence of the I/O modules in the device tree must comply with the physical

arrangement.

2. View in the device tree/Device view:

• If everything is configured correctly, all modules are marked with the symbol in the

device tree after going online and starting the PLC.

• In the event of an error, i.e. if the configuration deviates from the physical arrangement,

the modules are marked with the symbol.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 40

Page 41

5 Commissioning the controller

5.5 I/O system 1000 at the backplane bus of a cabinet controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Use the I/O module coupler tab for diagnostics purposes using the PLC application.

Example: Insert the b_myError variable in this tab. The variable is globally declared and the PLC

application is able to evaluate it.

5.5.2 Determining the topology of the I/O modules automatically

In addition to appending devices manually, the »PLC Designer« allows for the automatic recognition

of I/O modules connected (fieldbus scan).

For this purpose, execute the Start Search command in the context menu of the I/O module coupler:

41

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 42

5 Commissioning the controller

5.6 Tabs of the I/O modules at the backplane bus

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.6 Tabs of the I/O modules at the backplane bus

The Workspace ...

• uses various tabs to display the properties and settings of the module selected from the Device

view.

• serves to edit the parameters of the individual I/O compound modules.

Depending on the module selected from the Device view, different tabs are available in the

Workspace.

I/O module coupler (backplane bus)

Tab Contents

Diagnostics Error status of the modules.

Error messages (backplane bus)

I/O module coupler List of all available objects for the parameter setting of the I/O compound

modules - digital I/O.

Status Status information of the module coupler.

Information Project information and catalogue information of the module coupler.

( 43)

Every I/O module at the backplane bus is represented by means of the following tab:

I/O compound modules

Tab Contents

Parameter • Offline configuration of the I/O module

• All parameters of the I/O compound module

• Parameterising digital modules:

Polarity of the control signals, status in the event of an error for digital

output modules.

• Parameterising analog modules:

Signal functions, status in the event of an error.

Depending on the type of I/O module, specific settings are possible.

Further information is provided in the online help of the I/O system 1000.

I/O module image Process image of the I/O module

Status Status information of the I/O compound module.

Information Designation and connection diagram of the I/O compound module.

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17 42

Page 43

5 Commissioning the controller

5.7 Error messages (backplane bus)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.7 Error messages (backplane bus)

Error messages are represented on the Diagnostics tab of the I/O module coupler.

[5-5] Example: Topology error, the EPM-S501 module cannot be reached at the backplane bus.

Error messages

The following error messages can be displayed:

Error number Error text/remedy

11 Too many I/O modules for the task cycle time selected.

• Increase cycle time.

12 FIFO response full.

• Contact Lenze

32 Timeout reset

• Contact Lenze

33 Timeout reset error

96 Too many I/O modules for the task cycle time selected.

97 Too many I/O modules for the task cycle time selected.

98 Too many I/O modules for the task cycle time selected.

99 Too many I/O modules for the task cycle time selected.

100 Too many I/O modules for the task cycle time selected.

101 Timeout for master queue operation

102 Bus initialisation error with one I/O module

103 Master queue operation error

104 Read semaphore timeout for group 1

105 Read semaphore timeout for group 2

106 Read semaphore timeout for group 3

107 Write semaphore timeout for group 1

108 Write semaphore timeout for group 2

109 Write semaphore timeout for group 3

110 Internal error of the backplane bus hardware

116 Read semaphore timeout for group 1

• Contact Lenze

• Increase cycle time.

• Increase cycle time.

• Increase cycle time.

• Increase cycle time.

• Increase cycle time.

• Contact Lenze

• Contact Lenze

• Not all I/O modules can be reached.

• Contact Lenze

43

Lenze · Controller | Parameter setting & programming · Reference Manual · DMS 1.5 EN · 04/2014 · TD17

Page 44