Page 1

Engineering tools

PLC Designer

Application Template PackML _ _ _ _ _ _ _ _ _

Software manual EN

Ä.OJ_ä

13464162

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 4

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 7

1.3 Notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.4 Terminology used (presented according to the order in the device view) _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

3 Preconditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

3.1 System requirements _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

3.2 Setting up communication to the Controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 11

4 What is the ApplicationTemplate PackML? _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

4.1 Targets of the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

4.2 Features of the Application Sample PackML at a glance _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

4.3 Elements of the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4.3.1 Machine Module Tree - MMT _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

4.3.2 Machine modules (MM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 16

4.3.3 Addressing the machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.3.4 Module application (MAP) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.3.5 Modes: Machine operating modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

4.3.6 Communication between the machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

4.3.6.1 Predefined operating modes in ModApp1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

4.3.6.2 Creating own modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

4.3.7 State machine _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

4.3.7.1 State transitions - overview _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

4.3.8 Alarmhandling (error handling) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

4.3.7.2 Methods for changing over the states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

5 Structuring the automation system: Standard procedure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

5.1 Assign the relative address to the machine modules. _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 27

5.2 Structuring within a machine module: Assigning MAP subfunction to the tasks _ _ _ _ _ _ _ _ _ _ 28

6 Overview - the folder structure in the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

7 Opening the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

7.1 Create a new project - open the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

7.2 Updating the controller in the project (optional) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

7.3 Going online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

7.3.1 Compiling the project data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

7.3.2 Transferring the project to the control - "Log in" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

7.4 Downloading and starting the PLC program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

7.5 Getting started - operating the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

7.6 Visualisation of the machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

8 Working with the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

8.1 Mapping the actual machine structure: Add devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

8.2 Creating machine modules: Copy/insert machine module templates _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 41

8.3 Integrating machine modules in the MMT _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

8.4 Assigning the module application (ModApp) to the task _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

8.5 Create MM Instance: Creating instances of a machine module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

8.6 Delete Machine Module: Remove instances of a machine module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 46

8.7 Removing machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

8.8 Module ID _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

8.9 Inserting an axis _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

2 Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.10 Integrating I/O modules of the I/O system 1000 with a machine module _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

8.11 Creating module applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

8.11.1 Programming with the module application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

8.11.2 Integrating a module application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 55

9 Architecture: The ApplicationTemplate PackML in detail _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

9.1 Accessing structure variables of machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

9.1.1 Accessing module's intrinsic structure variables _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

9.1.2 User Tags: Defining own data elements _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 59

9.1.3 Accessing structures of other machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

9.2 The AppChannelData structure(ACD) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 60

9.2.1 Declaring/recording the ACD structure in the MFB _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

9.2.2 Accessing the ACD structure of the master module - by means of the MFB module application 61

9.2.3 Accessing the ACD structure of the slave modules - by means of the modes of the master module

62

9.2.4 The structure MachineModuleData (MMD) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 64

9.3 State machine in detail _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

9.3.1 State transitions and conditions - overview _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

9.3.2 Methods for changing over the state transitions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 66

9.3.3 The state transitions in detail: Command_CtrlCmds() method _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

9.3.4 Possible states in detail _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 69

9.4 Standard coupling of the machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

9.4.1 Predefined standard mechanism of the state machine _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

9.4.1.1 The Command_DisableModule method: Decoupling modules _ _ _ _ _ _ _ _ _ 72

9.4.1.2 Renewed coupling of machine modules _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 72

9.5 Influencing state transitions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 72

9.6 Stater machine: Query examples _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 73

9.7 Where can the response of a machine module be programmed? _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

9.7.1 State transition (state entry/state exit) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

9.8 Alarm handling (error handling) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

9.8.1 Defining alarms _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

9.8.2 Acknowledging alarms _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 77

9.8.3 Acknowledging alarms: Response in the machine module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 77

9.9 Triggering alarms _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 78

9.10 Central management of alarms _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 79

9.11 The alarm information block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

9.12 Export overview of the alarms of all machine modules: CSV file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

9.13 Logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 81

9.14 Module diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 82

9.15 Multitasking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 82

9.16 Consistent data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

10 Visualising in the ApplicationTemplate PackML _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

10.1 Extending the visualization _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

10.2 Defining the properties of buttons _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 88

10.3 Adding a visualization: Standard procedure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 89

11 An overview of the methods _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 91

11.1 An overview of the admin methods : Admin_xxx _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 91

11.2 An overview of the command methods: Command_xxx _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 92

11.3 An overview of the status methods: Status_xxx _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 94

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 98

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 3

Page 4

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This documentation describes the operating mode of the Lenze "ApplicationTemplate PackML"

which serves as a basis for programming a Lenze automation system. The used "Controller-based

automation" system consists of a Lenze Controller and drive components which are connected via

the bus system.

Note!

This documentation is a supplement to the »PLC Designer« online help.

Tip!

Information and tools regarding the Lenze products can be found in the download area at:

http://www.Lenze.com

This manual is part of the "Controller-based Automation" manual collection. The manual collection

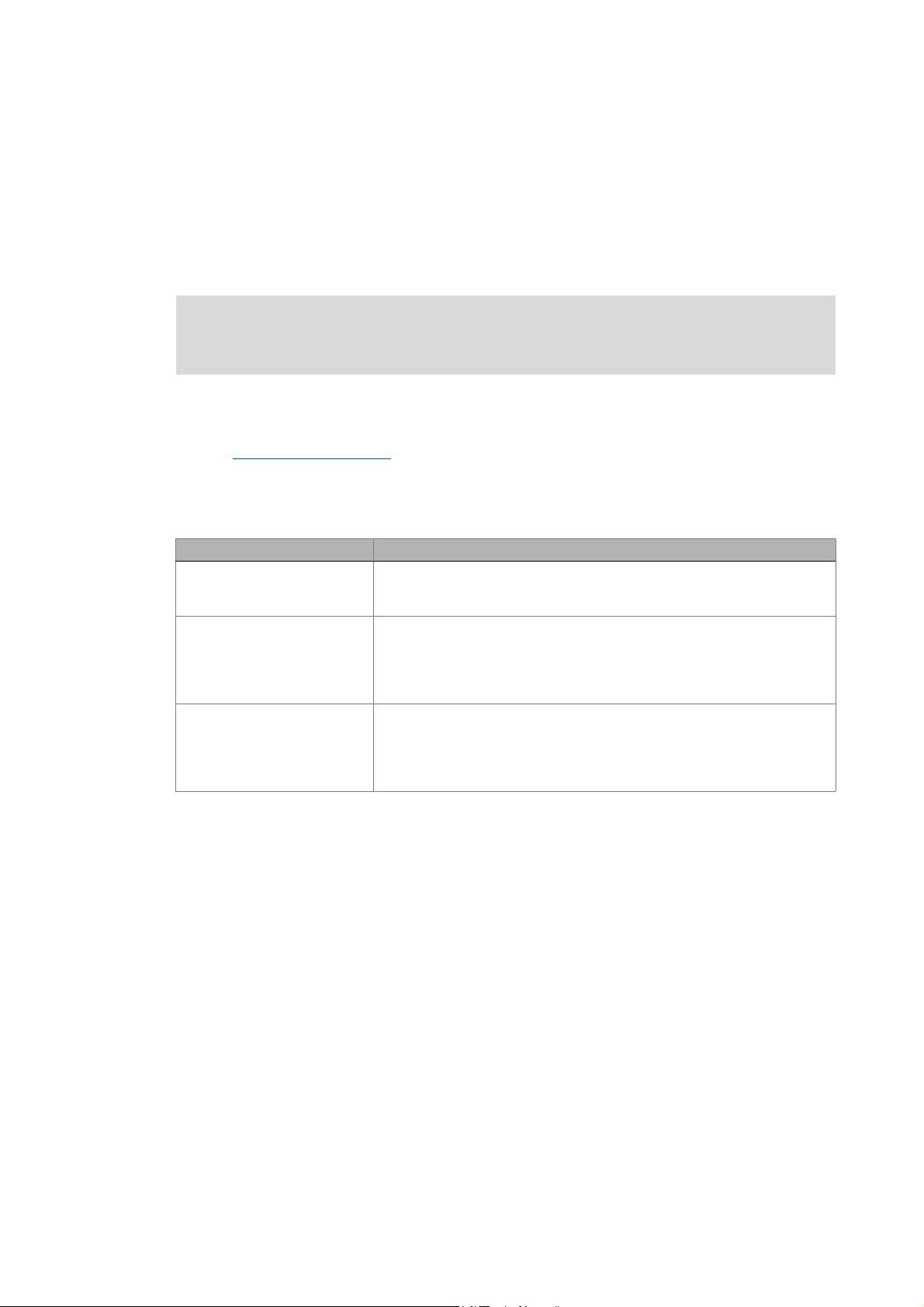

consists of the documents:

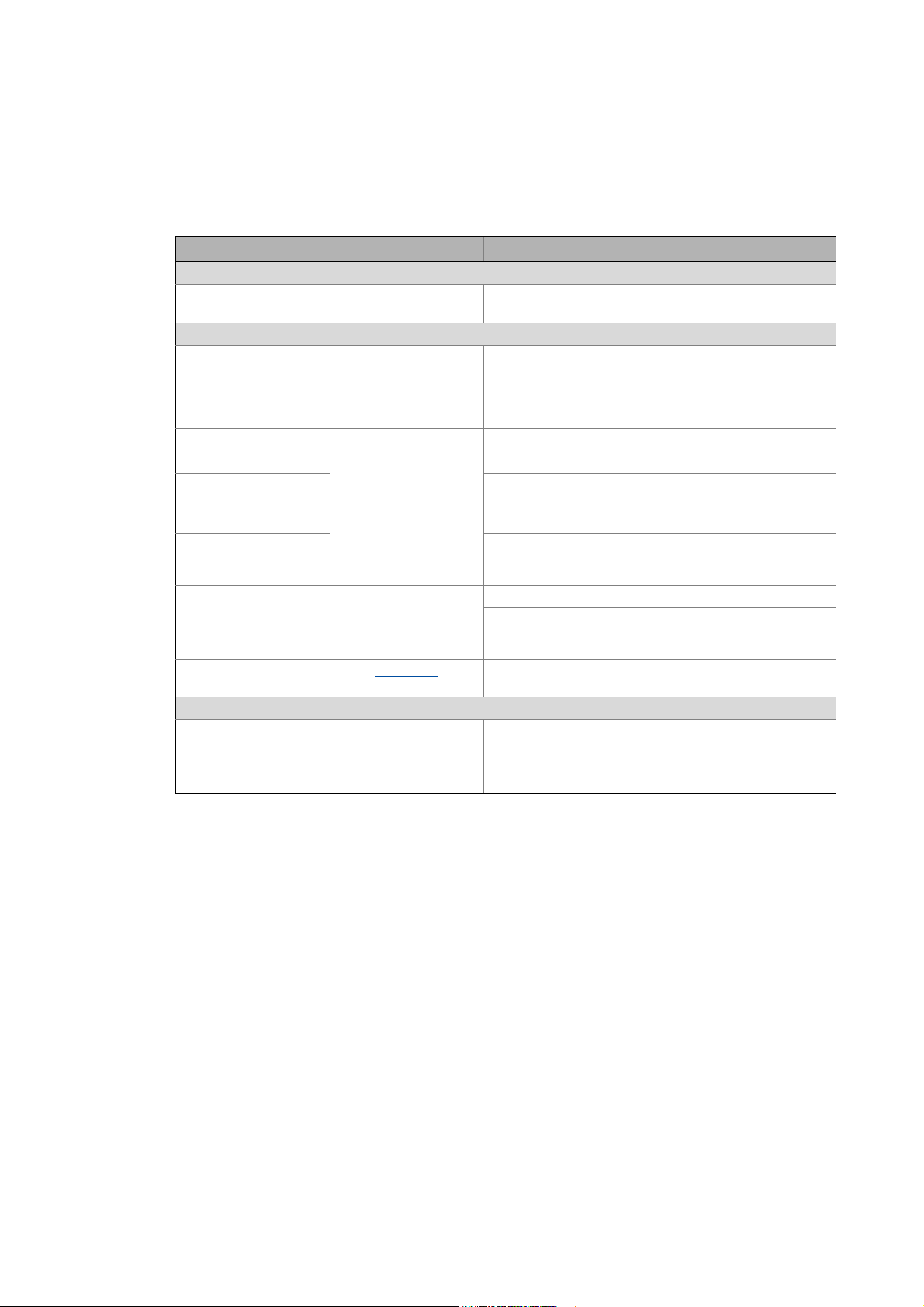

Type of documentation Subject

System manuals System overview/example topologies

• Controller-based Automation

• Visualisation

Communication manuals Bus systems

• Controller-based Automation EtherCAT®

Online helps/

software manuals

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

Lenze Engineering tools

• »PLC Designer«: Programming

• »Engineer«: Configuration of controllers

• »VisiWinNET® Smart«: Visualisation

• »Backup & Restore«: Backing up/restoring data

4 Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 5

About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

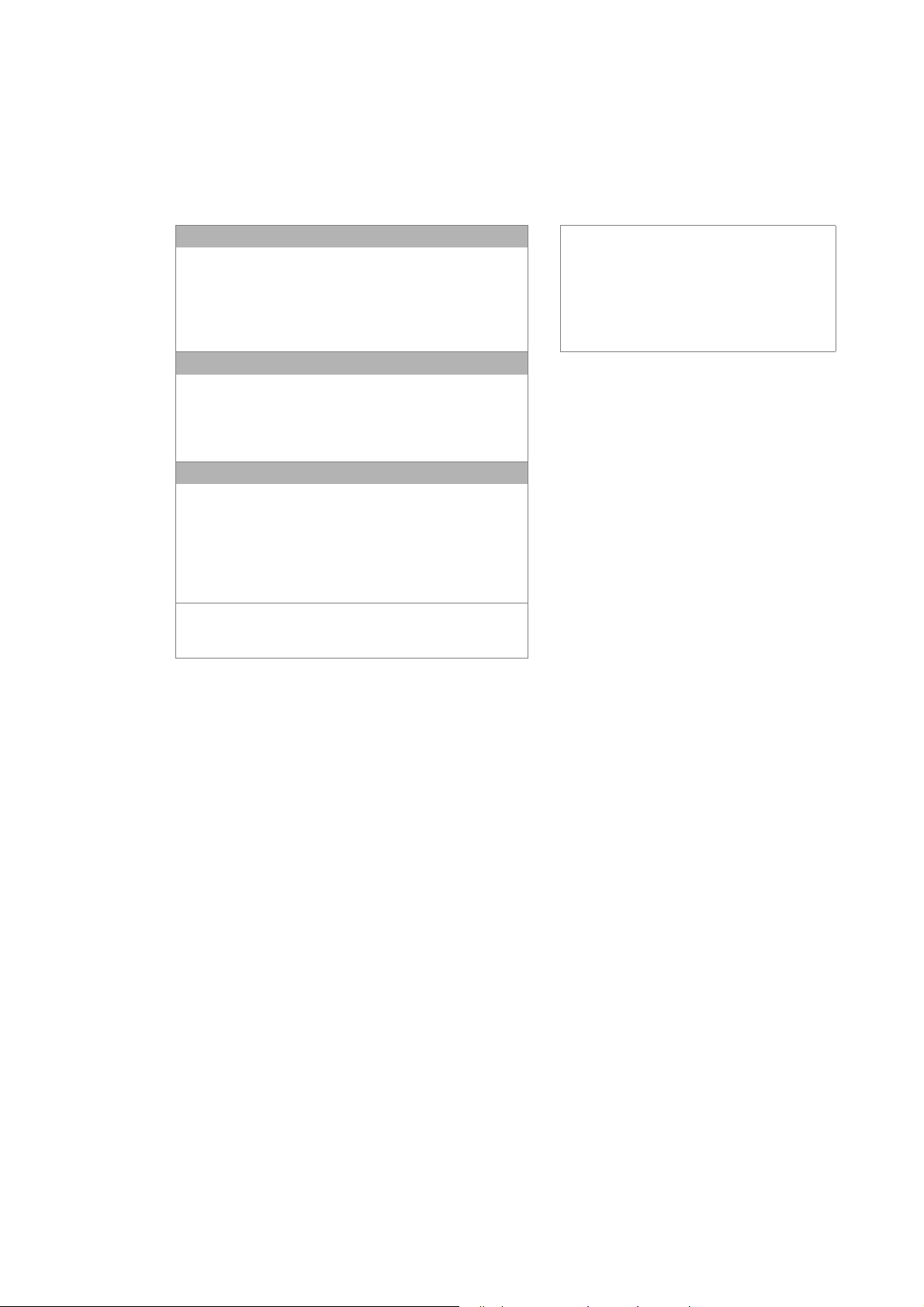

Further technical documentation on Lenze products

Further information on Lenze products which can be used in connection with Controller-based

Automation can be found in the following documentation:

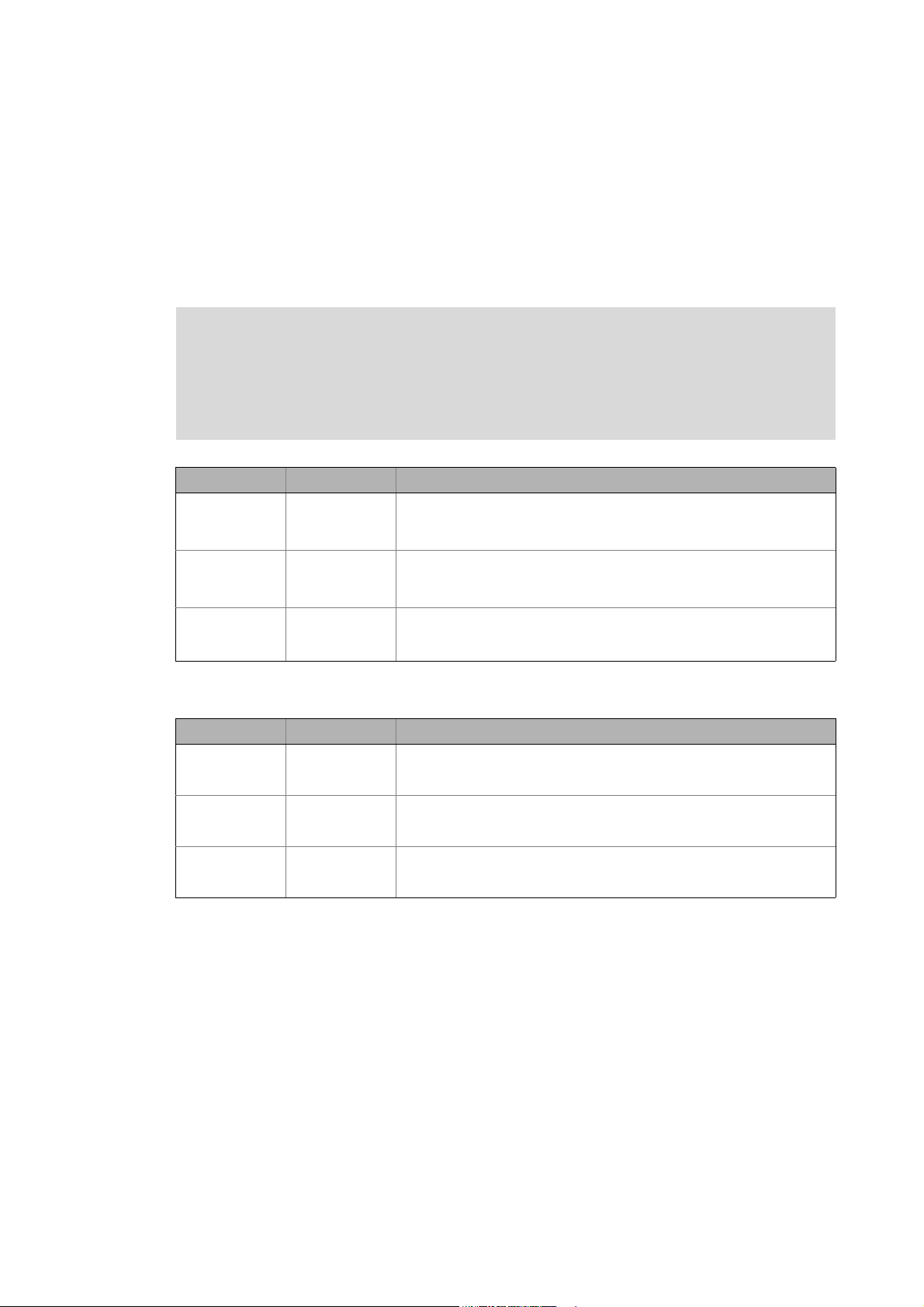

Mounting & wiring Icons

Mounting instructions

• Controller

• Communication cards (MC-xxx)

• I/O system 1000 (EPM-Sxxx)

•Inverter

•Communication modules

Using sample applications/an application template

Online help/software manuals

• i700 Application Sample

• Application Samples

• ApplicationTemplate

• ApplicationTemplate PackML

Parameterisation, configuration, commissioning

Online help/software manuals

• Controller

• i700 servo inverter

• Servo Drive 9400 HighLine/PLC/

regenerative power supply module

• Inverter Drive 8400 StateLine/HighLine/TopLine

• 1000 I/O system (EPM-Sxxx)

Online help/communication manuals

• Bus systems

•Communication modules

Target group

This documentation addresses to all persons who plan, commission, and program a Lenze

automation system on the basis of the Lenze "ApplicationTemplate PackML" as part of the

"Controller-based Automation".

Printed documentation

Online help in the Lenze Engineering

tool/

software manuals and communication

manuals are provided as PDF files on

the Internet.

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the Lenze devices and the software version of the engineering tools installed (»PLC

Designer«), the screenshots in this documentation may deviate from the screen representation.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 5

Page 6

About this documentation

Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

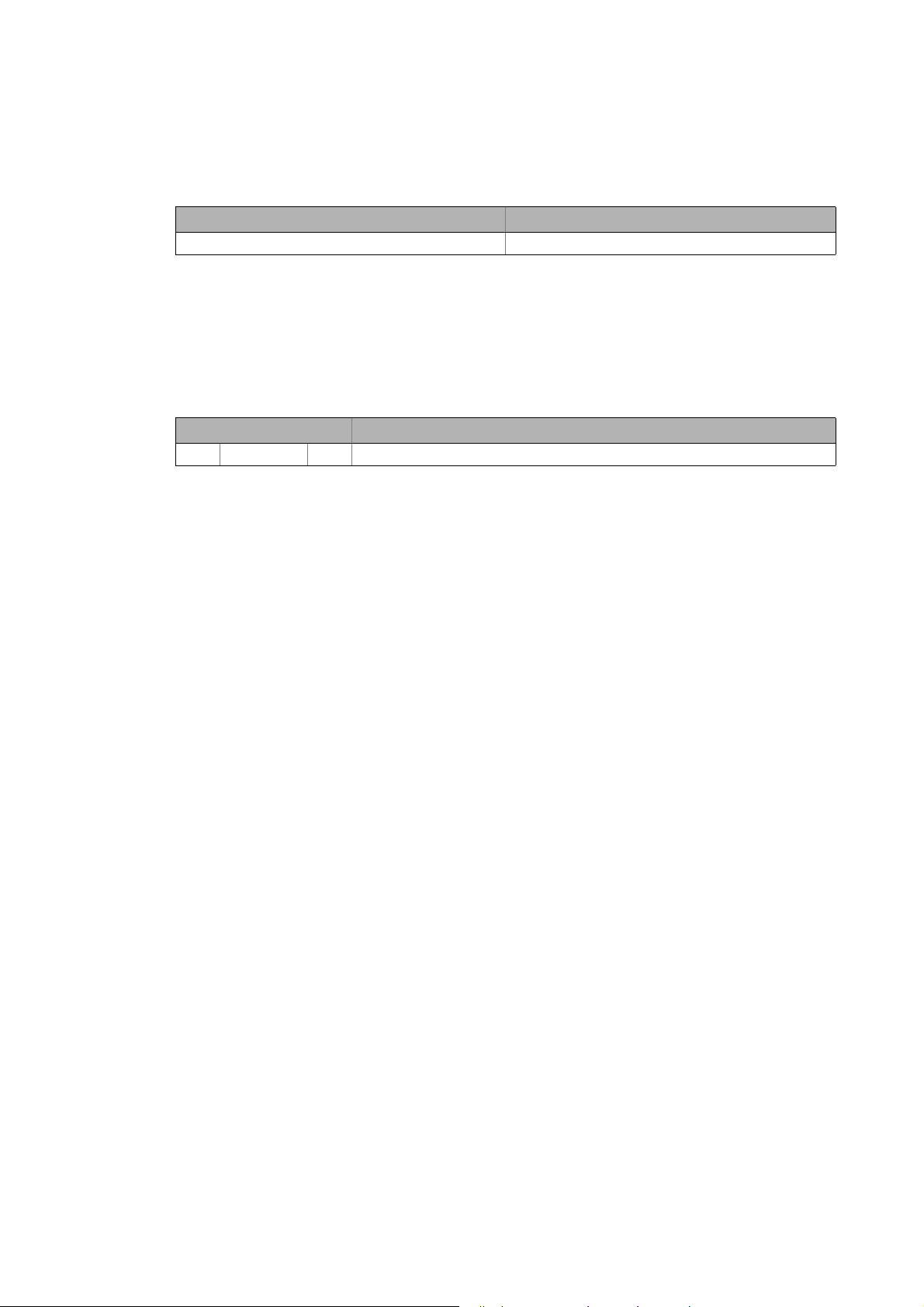

Information regarding the validity

The information in this documentation is valid for the following Lenze software:

Software from software version

»PLC Designer« 3.8

Valid for the following Lenze application templates:

• "Application Template PackML" according to PackML standard: L_ApplicationTemplate PackML

1.1 Document history

Version Description

1.0 05/2014 TD11 First edition

6

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 7

About this documentation

Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types of

information:

Type of information Writing Examples/notes

Spelling of numbers

Decimal separator Point The decimal point is always used.

For example: 1234.56

Text

Version information Blue text colour All information that applies to from a certain software

Program name » « »PLC Designer«...

Window italics The message window... / The Options dialog box ...

Variable names Setting bEnable to TRUE...

Control element bold The OK button ... / The Copy command ... / The Properties tab

Sequence of menu

commands

Shortcut <bold> Use <F1> to open the online help.

Hyperlink underlined

Icons

Page reference ( 7) Reference to further information: Page number in PDF file.

Step-by-step instructions

version of the drive onwards are marked accordingly in this

documentation.

Example: This function extension is available from software

version V3.0!

... / The Name input field ...

If several commands must be used in sequence to carry out a

function, the individual commands are separated by an

arrow: Select File

If a shortcut is required for a command to be executed, a "+"

has been put between the key identifiers: With

<Shift>+<ESC> ...

Reference to further information: Hyperlink to further

information.

Step-by-step instructions are indicated by a pictograph.

Open to...

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 7

Page 8

About this documentation

Notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and explains how to avoid it.)

Pictograph Signal word Meaning

Danger! Danger of personal injuries through electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of property damage

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Tip! Useful tip for easy handling

Reference to another document

8

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 9

About this documentation

Terminology used (presented according to the order in the device view)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Terminology used (presented according to the order in the device view)

Term/abbreviation Position in the device view Function

Machine module tree

MMT

ModuleApplicationCalls

MAC

Machine module

MM

Machine module

application

ModApp/MAP

Machine function block

MFB

A10_MachineModuleTree

A11_ModuleAppCalls

A70_MachineModuleSources

The "MachineModuleTree" (MMT) maps the

structure of the automation system in the form of

machine modules.

• In the "MachineModuleTree", all machine

modules required for the machine are

interconnected hierarchically according to the

mechatronic interaction.

The module applications are to be assigned to the

corresponding task within the

"ModuleApplicationCalls".

• Thus it is defined which module application is to

be processed within the individual tasks.

A machine module maps a unit of the real machine

structure in the »PLC Designer«.

• The machine module is part of the

MachineModuleTree(MMT) within which the

individual machine modules are

interconnected.

The machine module application provides the

functionality of a machine module.

• A machine module can contain one or several

machine module applications.

The machine function block represents the

machine module in the machine module tree

(MMT).

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 9

Page 10

Safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Please observe the following safety instructions when you want to commission a controller or

system.

Read the documentation supplied with the controller or the individual components of

the system carefully before you start commissioning the devices!

The device documentation contains safety instructions which must be observed!

Danger!

According to today's scientific knowledge it is not possible to ensure absolute freedom

from defects of a software product.

If necessary, systems with built-in controllers must be provided with additional

monitoring and protective equipment complying with the relevant safety regulations

(e.g. law on technical equipment, regulations for the prevention of accidents) in each

case, so that an impermissible operating status does not endanger persons or facilities.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there is a risk of injury by the moving

machine parts.

Stop!

If you cha nge par ameter s in the »PLC De signer« whil e an onl ine con nectio n to the devic e

is established, the changes are directly accepted in the device!

A wrong parameter setting can cause unpredictable motor movements. By an

unintended direction of rotation, a too high speed, or jerky operation, the driven

machine parts may be damaged!

10 Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 11

Preconditions

System requirements

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Preconditions

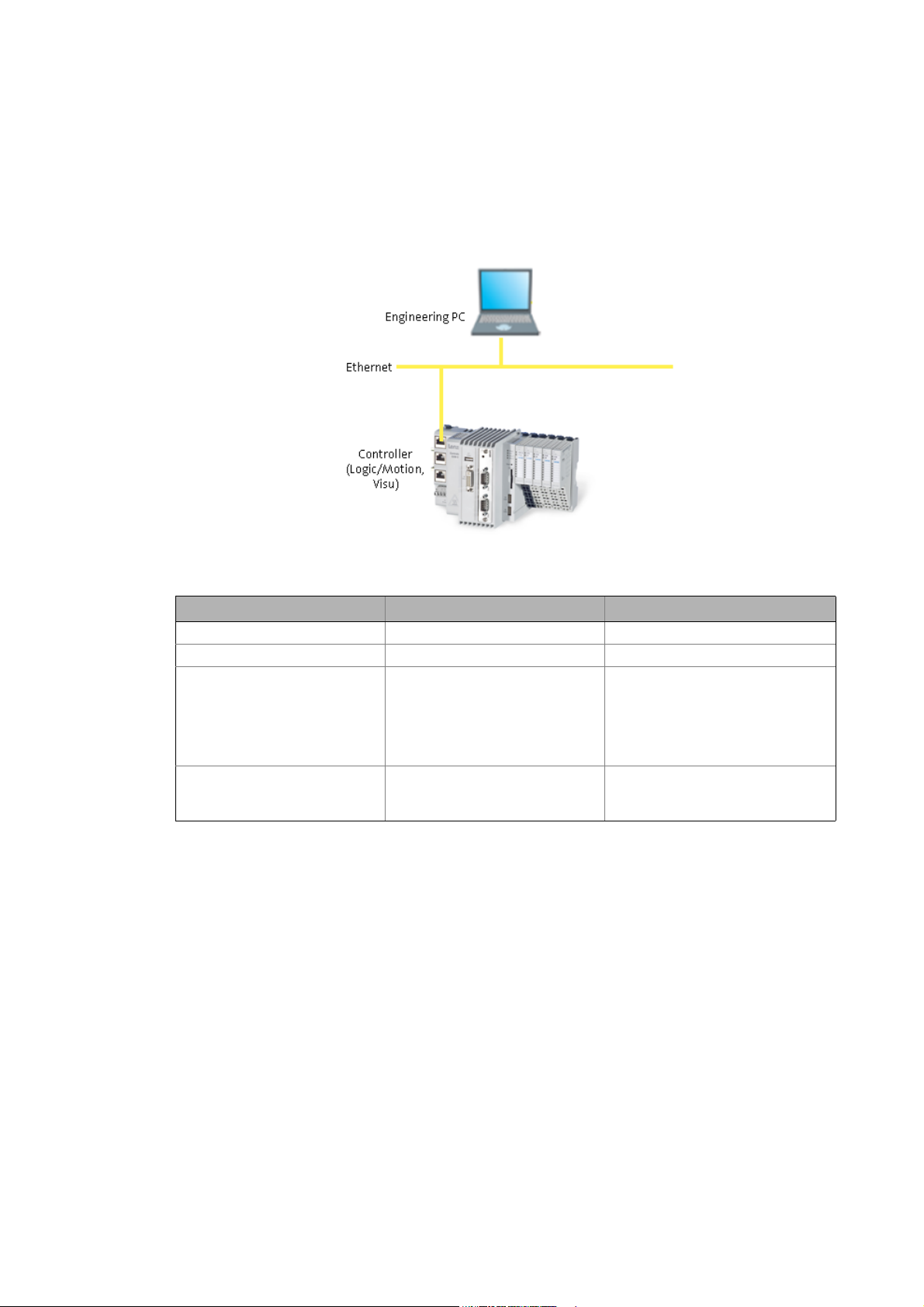

3.1 System requirements

[3-1] Sample configuration with a Controller 3200 C

Engineering PC Controller

Hardware PC/notebook PLC (Logic) from firmware V3.8

Operating system Windows XP Windows CE

Required Lenze software »PLC Designer« from V3.8

•Contains the

ApplicationTemplate PackML

• Contains the Lenze library

"L_EATP_ApplicationTemplate.co

mpiled-library"

Further requirements - Depending on the application case:

3.2 Setting up communication to the Controller

• Connect the Engineering PC with the controller via a network cable. The »PLC Designer«

accesses the controller via Ethernet.

• Make the IP settings with the »PLC Designer«.

How to check the communication settings:

1. Double-click the desired controller in the Devices view.

Runtime software

•Logic

• Motion (for this purpose, the project

data must be updated: "Update

Device")

• CAN-/EtherCAT bus system

• CAN-/EtherCAT node

2. Make the desired settings on the Communication settings tab.

•Click the Add gateway button to insert a gateway.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 11

Page 12

Preconditions

Setting up communication to the Controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

•Enter the desired IP address of the controller.

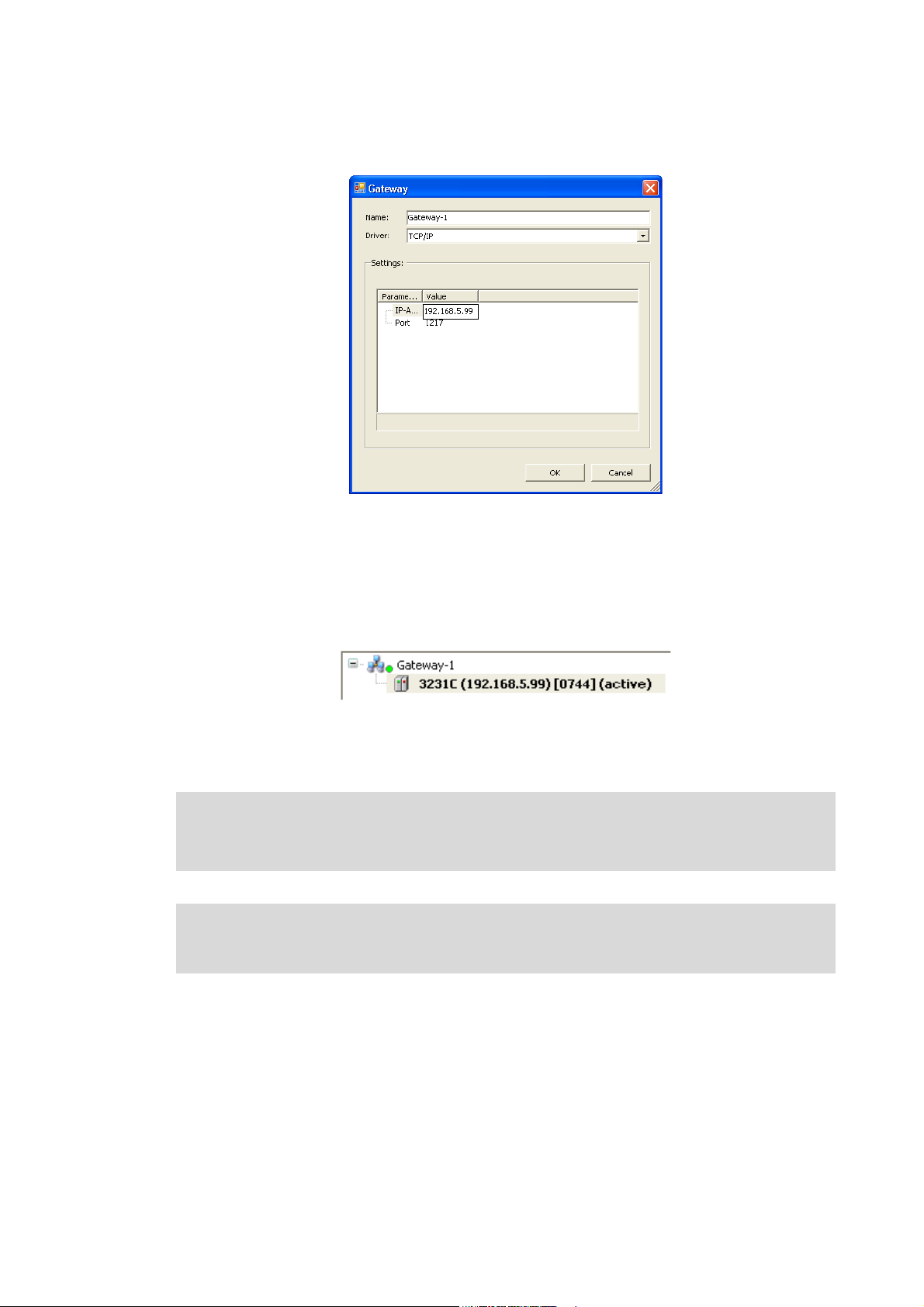

[3-2] Example: Enter the IP address of the Controller, standard setting: 192.168.5.99

3. Click OK to add the controller as gateway.

4. By double-clicking the desired channel (or clicking the Set active path button), set the

channel selected in the device view below the gateway as active path to the controller.

• Thus, all communication actions directly refer to this channel.

• The currently active path is represented in bold in the list and "(active)" is attached:

5. A device represented in italics is set as active path but has not been found during the last

network scan.

Note!

During initial commissioning, observe the predefined IP address: 192.168.5.99

Further information can be found in the following documentation:

Controller - Parameter setting & configuration

12

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 13

What is the ApplicationTemplate PackML?

Targets of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 What is the ApplicationTemplate PackML?

The Lenze ApplicationTemplate PackML is an application template for standardised and convenient

programming in the »PLC Designer« according to PackML standard in compliance with the OMAC

("The Organization for Machine Automation and Control").

• From »PLC Designer« version 3.8 onwards, the ApplicationTemplate PackML is included as

project template. Create a new project - open the ApplicationTemplate PackML

•The L_EATP_ApplicationTemplate.compiled-library library includes the structure and

functionality of the standardised Lenze application template and the extension for the

ApplicationTemplate PackML. Die Bibliothek L_EATP_ApplicationTemplate

4.1 Targets of the ApplicationTemplate PackML

The ApplicationTemplate PackML...

• ...helps to implement the mechatronic structure of an automation system (which has been

previously implemented as tree topology) in a modular manner according to the PackML

standard.

( 33)

( 89)

• ...enables the integration of predefined machine modules with prepared applications/

technology modules (for instance the functionality for cross-cutting).

• ...simplifies and speeds up the creation of PLC programs in the long term by re-use of a

standardised project structure in the form of a modularised folder structure.

What are the advantages of the ApplicationTemplate PackML?

The ApplicationTemplate PackML facilitates programming with the »PLC Designer« ...

• ...by the defined folder structure which "cleans up" and which can be extended individually.

• ...renders the navigation for extending or creating machine programming easier.

• The ApplicationTemplate PackML contains ready-made, re-usable machine modules and

module applications which minimise the risk of compilation errors in order to thus reduce time

and costs.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 13

Page 14

What is the ApplicationTemplate PackML?

Features of the Application Sample PackML at a glance

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 Features of the Application Sample PackML at a glance

The following predefined functions facilitate implementing a machine application in a PLC:

State machine

Alarm handling (error handling) ( 76)

Multitasking ( 82)

Further advantages if the ApplicationTemplate PackML is used:

( 23)

• Consistent data transfer

• Diagnostic function for every machine module ("generic module diagnosis").

• A defined standard response ("DefaultCoupling") of the state machine. Standard coupling of

the machine modules ( 71)

For more information on the respective functions, please see the corresponding subchapter.

between the tasks.

14

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 15

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3 Elements of the ApplicationTemplate PackML

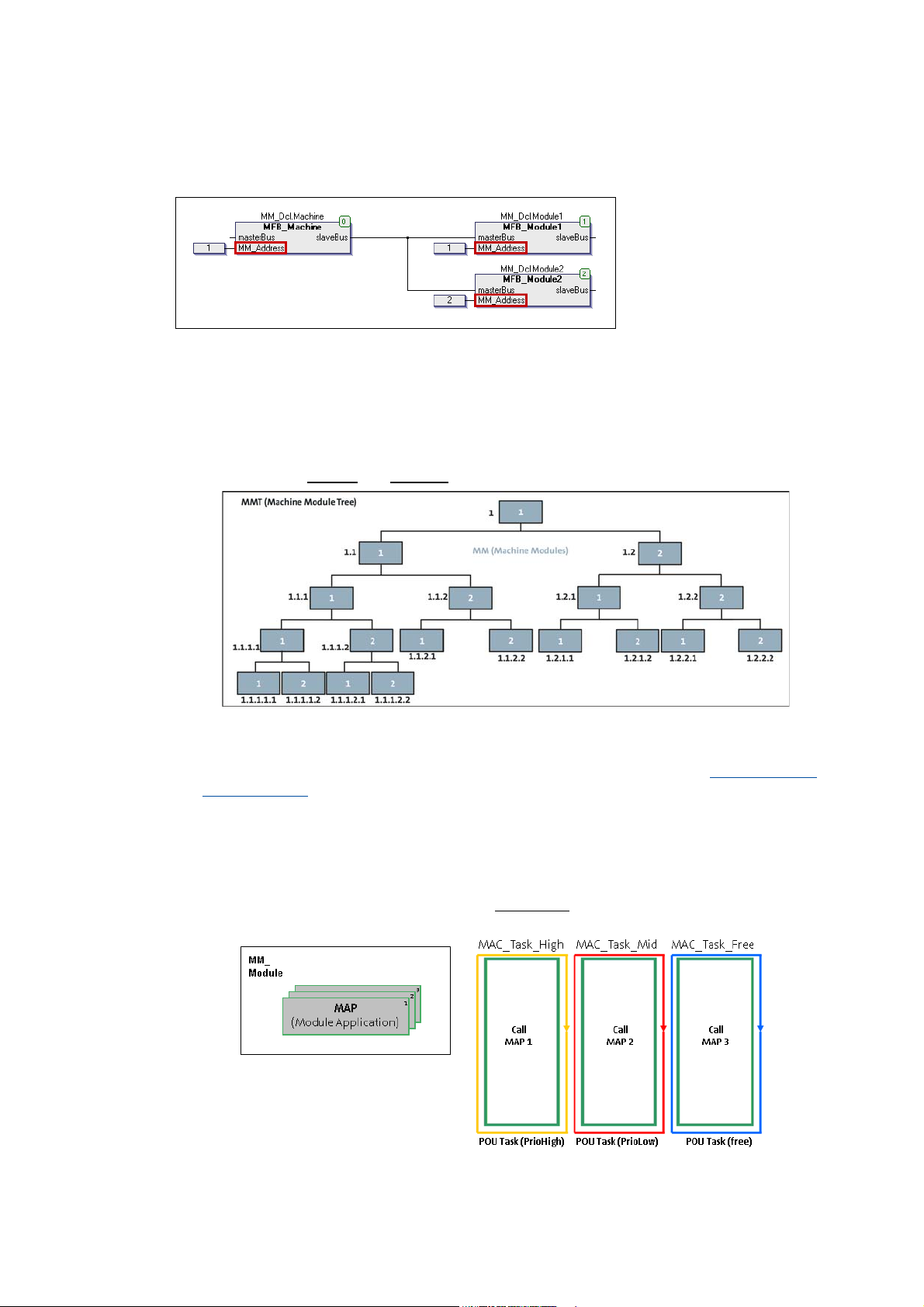

4.3.1 Machine Module Tree - MMT

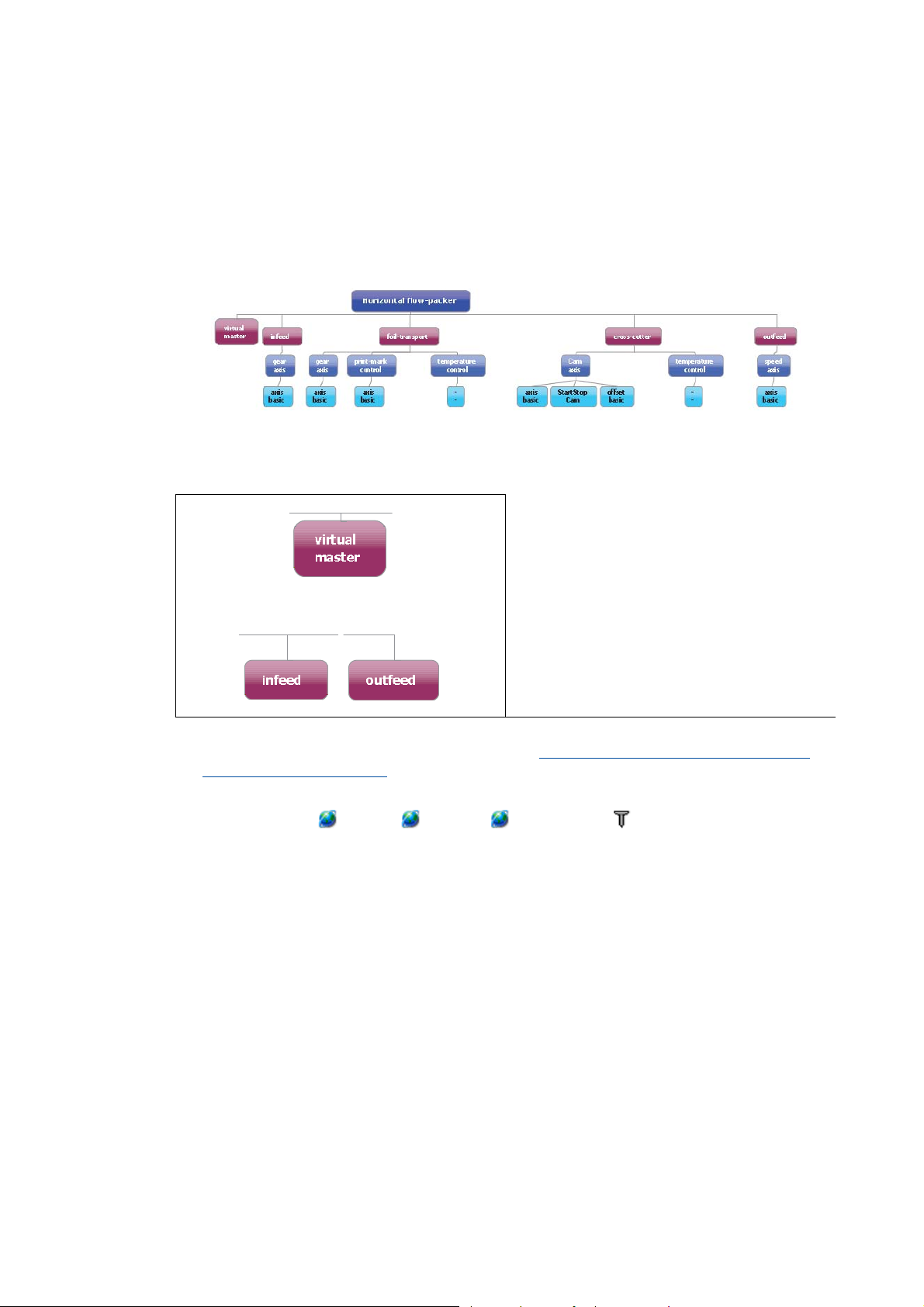

In order to map the desired automation system in the »PLC Designer« using the

ApplicationTemplate PackML, the structure of the whole machine application must be created in

the »PLC Designer«.

• In a first step, the electronic machine structure (total functionality of the machine) has to be

divided into machine modules (subfunctions of the machine).

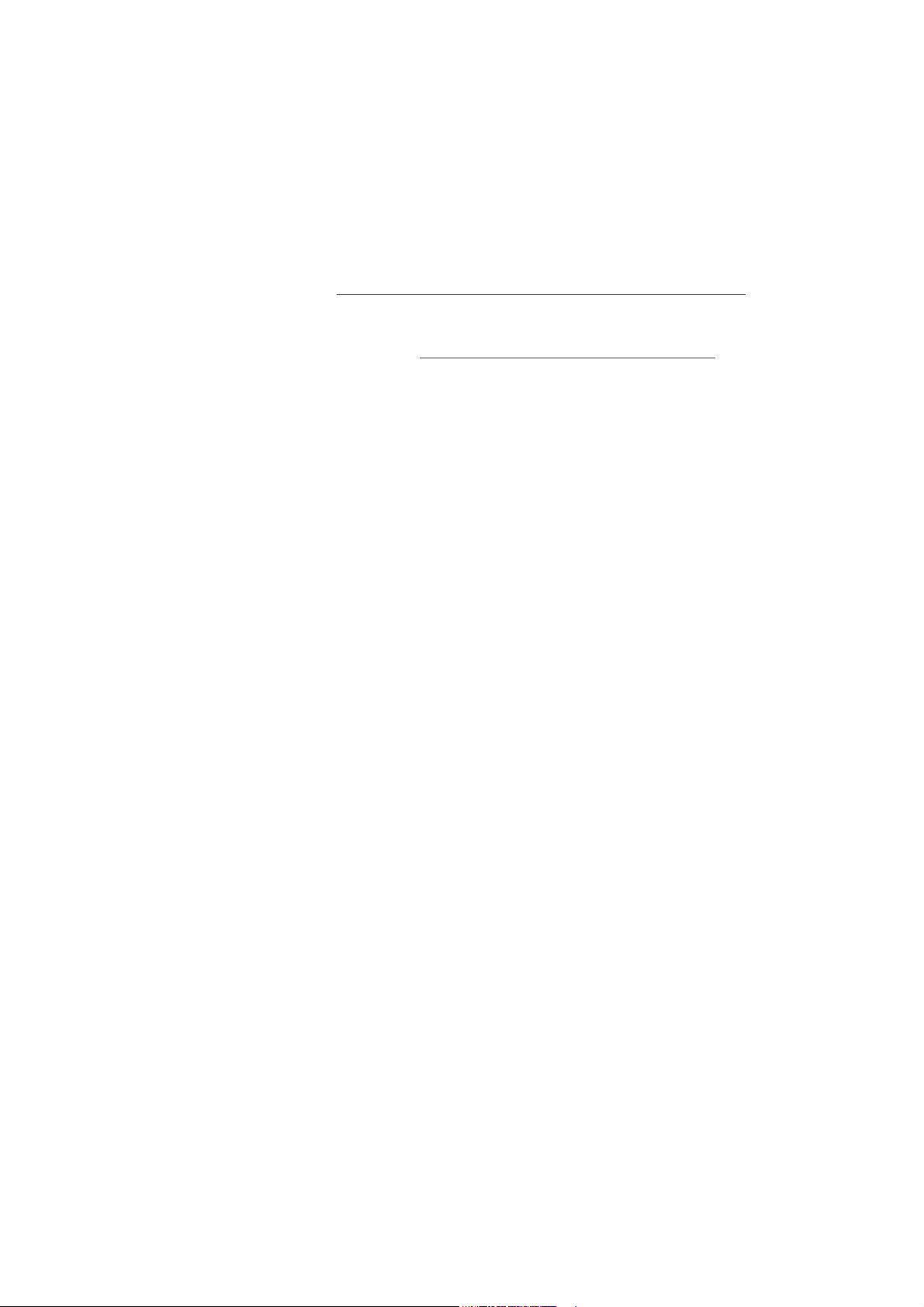

•The A10_MachineModuleTree machine module tree (MMT) shows the machine modules in

the form of a tree structure from left to right.

• The top module is the machine control module. The other functions of the machine are

subordinated to the machine control module.

[4-1] Illustration example: Machine structure tree (MMT) in the ApplicationTemplate, folder A10_MachineModuleTree

The ApplicationTemplate PackML...

• ...supports two to five hierarchy levels of machine modules.

• ...supports up to 30 machine modules.

[4-2] MMT (Machine Module Tree) with up to five possible hierarchy levels of machine modules

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 15

Page 16

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.2 Machine modules (MM)

The overall functionality of the automation system is structured in a modular manner in the

ApplicationTemplate PackML. This means that every subfunction of the machine is included in one

of the machine modules. Due to the modular structure, individual (or multiple) subfunctions of a

machine can be reused

further machine parts.

• A machine module represents the function of a machine part; for instance a conveying belt, or

a cross cutter.

• The overall functionality of, for example, a bag form, fill, and seal machine, contains the "Cross

cutter" and "Transport unit" subfunctions. The two subfunctions are to be converted to a

separate machine module each.

Machine module in the ApplicationTemplate PackML

. Advantage: The respective function does not have to be recreated for

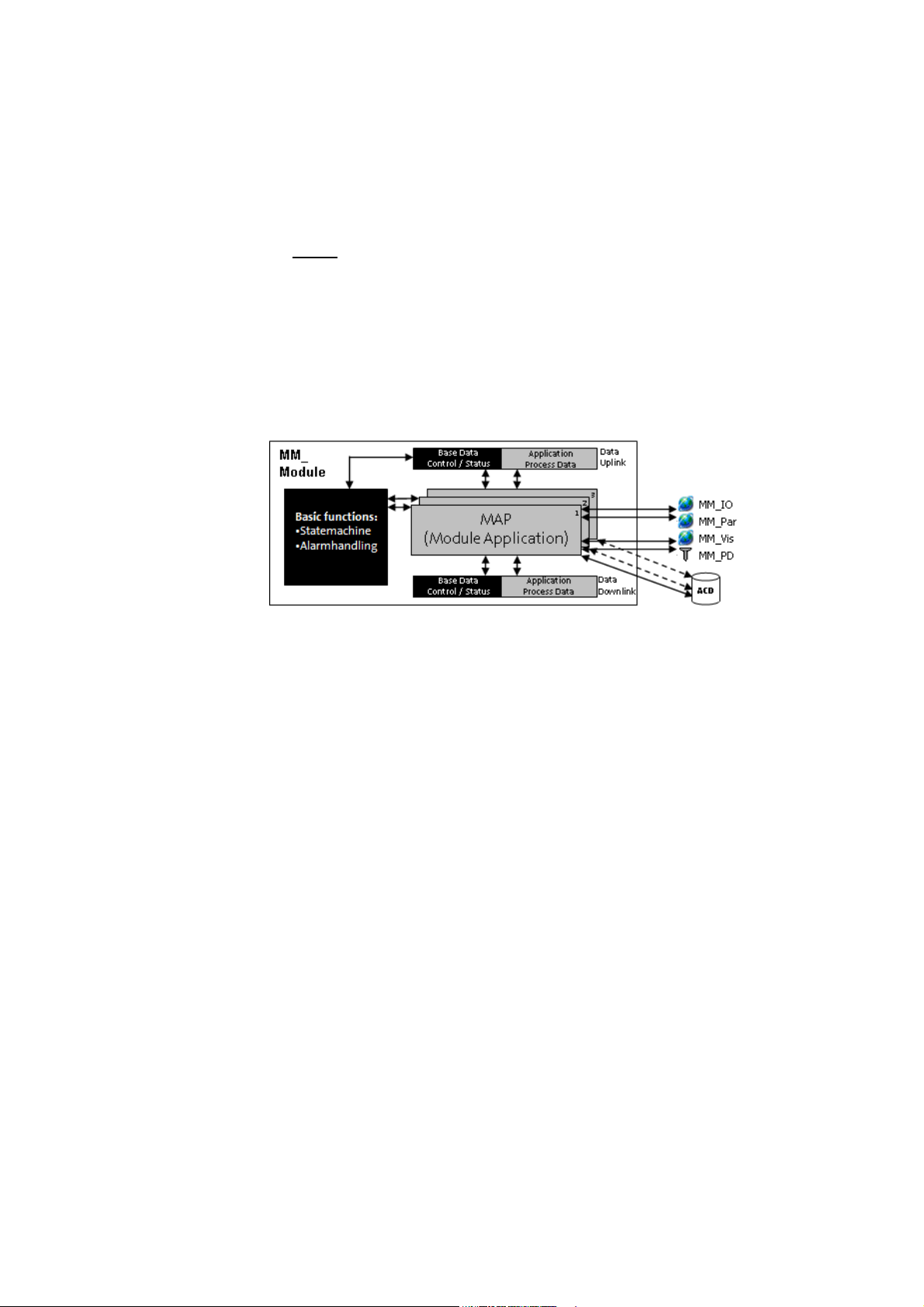

[4-3] Structure of a machine module

• Every machine module contains the BaseChannel ("Base Data") which serves as a data

channel for the basic functions of the ApplicationTemplate PackML.

• The basic functions of the ApplicationTemplate PackML are the State machine and the Error

handling.

Every machine module has an AppChannelData structure (ACD structure). An ACD structure can be

defined in a machine module if necessary.

• Via the ACD structure, data are provided to/received from the higher-level machine module.

• Via the ACD structure, process data can be exchanged between the user's own module

applications.

A machine module (MFB) always contains at least one module application (MAP). Up to three MAPs

per MFB are possible.

•Via the MM_IO, MM_Par; MM_Vis, MM_PD structures, the module application (MAP) is to be

connected to the "outside world" (the respective sub-function of the automation system).

•By means of the MM_IO structure, the inputs/outputs of the terminals/the fieldbus are to be

connected.

•The MM_Par structure contains all variables that are to be managed by the recipe manager.

•The MM_Vis structure contains all variables that can be controlled or are to be displayed via an

external visualization.

•The MM_PD structure contains all persistent variables.

16

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 17

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.3 Addressing the machine modules

Every machine module has an

MM_Address input which

serves to assign the relative

address to the machine

module.

[4-4] Illustration example: Sample illustration MMT in the L_ApplicationTemplate sample project

The following must be observed when relative addresses are assigned to the machine modules:

•The relative address is to be assigned to every machine module (value range: 1...29).

• During the initialisation phase, the »PLC Designer« generates an absolute address for every

machine module.

• Example of the relative

The diagram shows the absolute module address (black) and the relative module address (white).

• In the event of an error, the absolute address enables an error analysis. This for instance makes

it possible to retrace the module which has caused the error in each case. Alarm handling

(error handling) ( 76)

4.3.4 Module application (MAP)

The module application (MAP) contains the function of the corresponding machine module.

• The ApplicationTemplate Pack ML supports up to three

used per machine module.

and absolute module addressing:

tasks. Hence, up to three MAPs can be

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 17

Page 18

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

•In the A11_ModuleAppCalls folder, the MAPs are to be assigned to the tasks:

ModuleAppCalls (MAC).Assigning the module application (ModApp) to the task

4.3.5 Modes: Machine operating modes

In the ApplicationTemplate PackML, the following machine operating modes are firmly defined:

Producing, Maintenance and Manual. Further modes can be added individually.

( 43)

Operating mode "Producing"

Operating mode "Maintenance"

Operating mode "Manual"

[4-5] The ApplicationTemplate PackML includes three firmly defined operating modes, more can be freely defined.

Each operating mode includes a separate state machine.

• If required, more operating modes can be defined. Creating own modes

• The modes and the respective state machine are integrated in the ModApp 1 module

application.

• The behaviour of the states is defined in the A12_PackML_Configuration folder in

PackMLConfig. There, it is defined, for instance, which state is when active and in which

states a changeover of the modes is permissible. Predefined operating modes in ModApp1

( 20)

• When another operating mode is created, the desired features of the states have to be defined

in the PackMLConfig area.

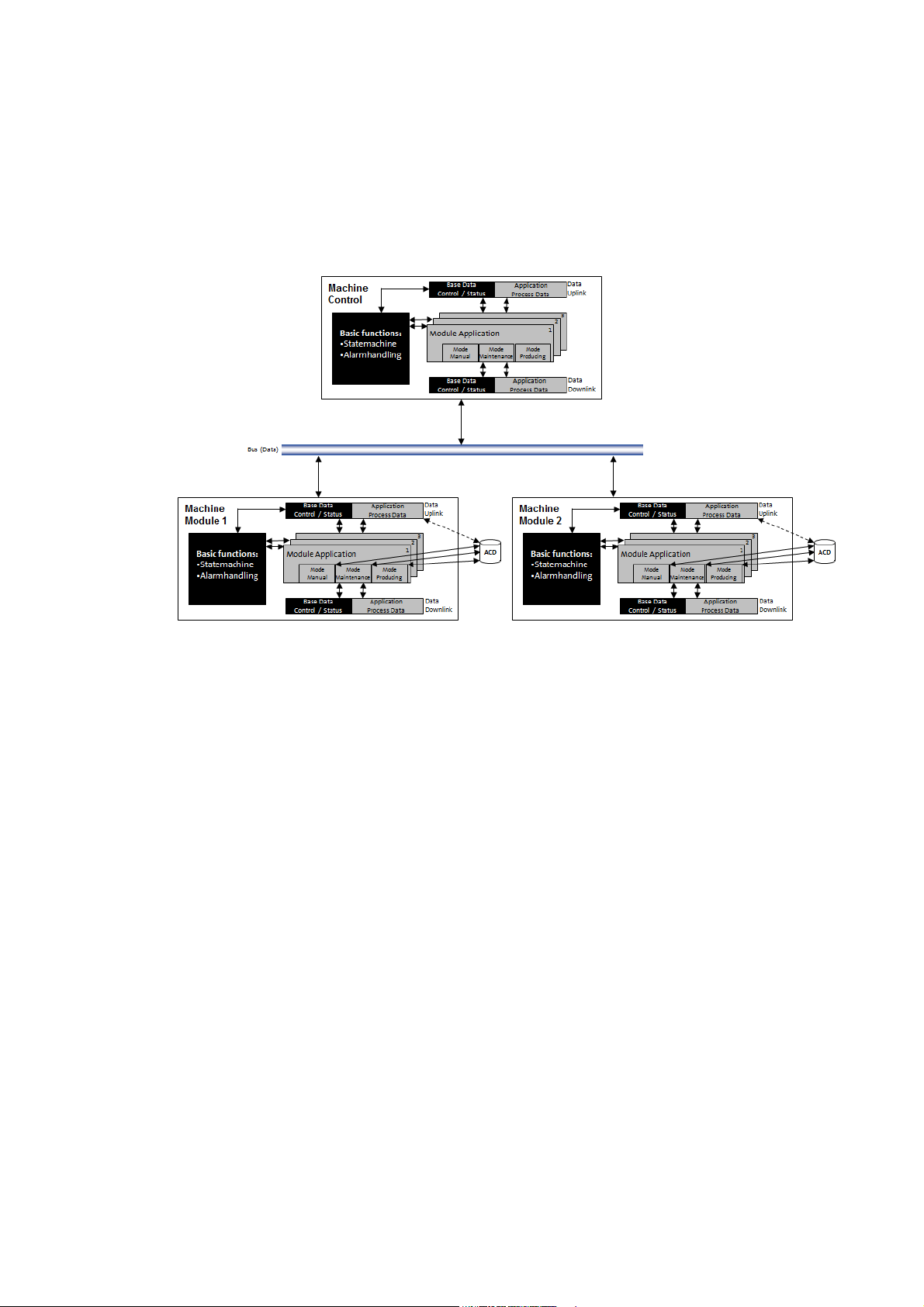

4.3.6 Communication between the machine modules

The machine modules (MM_xxx) communicate with each other via the higher-level MM_Machine

machine control module by means of the BaseChannel communication channel and the

AppChannelData structure.

( 21)

18

• The communication channels provide for a bidirectional data exchange.

• The BaseChannel is defined as a structure in the ApplicationTemplate PackML.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 19

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

One or several slave modules are always exactly connected to one higher-level master module.

However, the master only always communicates with one slave module. Slave modules cannot

communicate directly with each other, but only via the higher-level master module.

The higher-level machine module (master) communicates with the lower-level machine modules

(slaves) via data channels (channels). During the initialisation, the ApplicationTemplate PackML

generates a BaseChannel and an AppChannelData(ACD) structure.

[4-6] Exchange of information between the machine modules (L_ApplicationTemplate)

Bus (data): Exchange of control and state data (basic data Control/Status)

Basic functions in the ApplicationTemplate PackML are...

• ...the control / status information of the state machine.

• ...the alarm handling (error handling/error responses).

The ACD structure...

• ...serves to exchange application process data between machine modules.

• ...is a data structure for the definition of own process data.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 19

Page 20

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

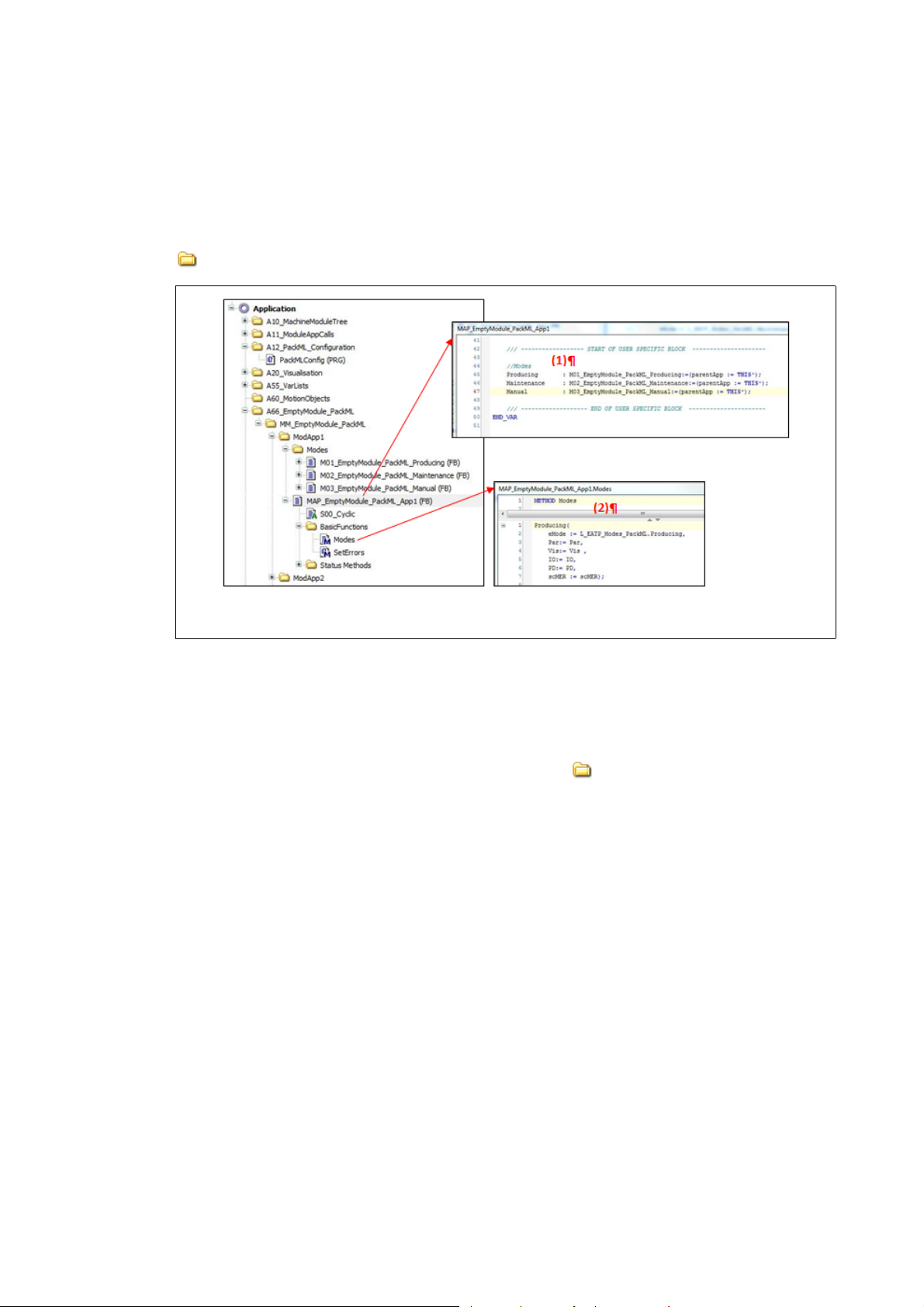

4.3.6.1 Predefined operating modes in ModApp1

Each machine module contains the predefined operating modes Producing, Maintenance and

Manual.

The operating modes are located in the machine module template in the folder

A66_EmptyModule_PackML ModApp1\Modes.

The mode FBs are declared in the MAP-FB in the \ModApp1 folder.

Call of the mode FBs in the respective modes method

• The module application App1 contains the instances of the mode blocks Producing,

Maintenance and Manual.

• The mode block instances are called in the modes method.

Where can the operating modes be defined?

The configuration of the operating modes is defined in the A12_PackMLConfiguration folder.

There, it is defined, for instance, which state is active and in which states a changeover of the mode

is permissible.

20

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 21

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[4-7] Defined PackML operating modes in the folder A12

• In this area, the states to be used within the single modes can be defined so that individual state

machines can be created by parameterisation (example: xDisableState…) which can be defined

in the PackML configuration.

• The transition of the single modes can also be defined in this block. The corresponding inputs

(example: xEnableModeTrans…) enable the changeover from the respective state into another

mode of the same state. The block base defines the initial mode and state. This configuration is

identical in all machine modules of the application.

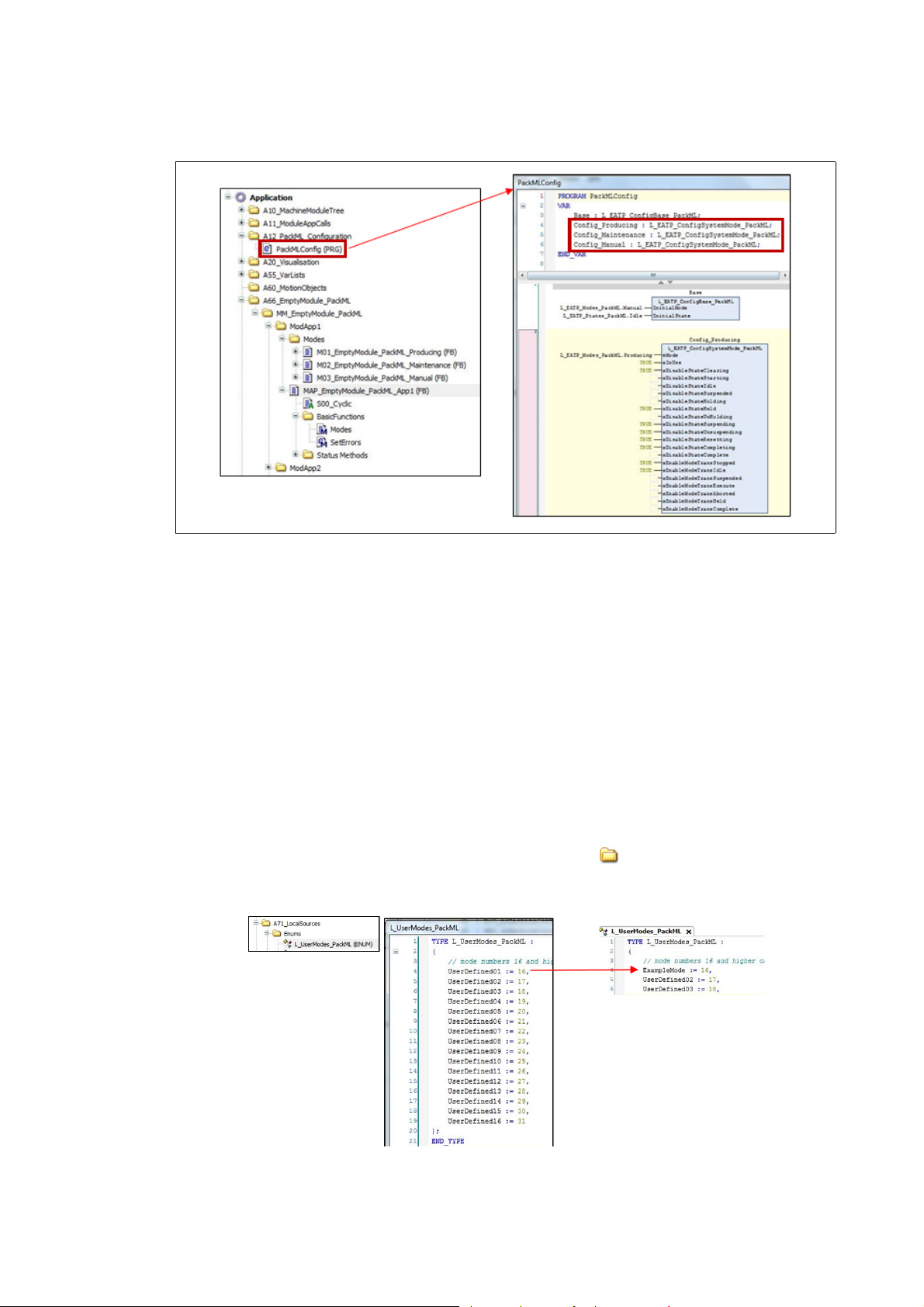

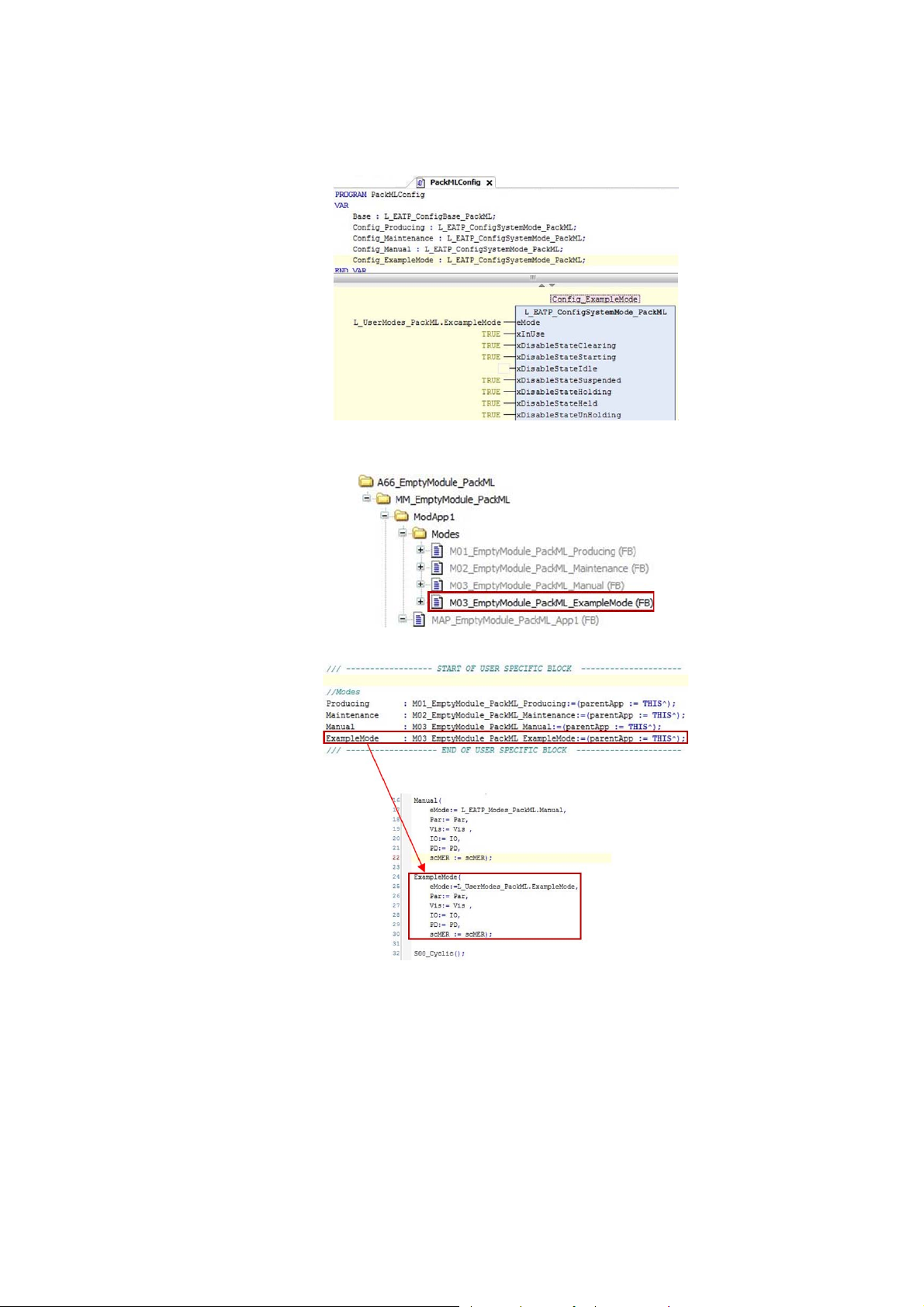

4.3.6.2 Creating own modes

If required, further operating modes can be defined.

How to create a mode:

1. Enter the desired name for the additional mode in the A71_LocalSources. folder

in the ENUM L_UserModes_PackML by replacing "UserDefined", example: Replacing

UserDefined01.

2. Create an instance and set the configuration for the new mode.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 21

Page 22

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3. Add the ENUM value for this mode to the configuration block.

4. Add the new mode to ModApp1 by copy/paste of an already available mode and rename it,

example: ExampleMode.

5. Instance the newly created mode (FB) in the declaration part of the MAP:

6. Add the additional mode to the modes method and assign the ENUM value of the new

mode.

Changeover of the operating modes/Modes

After the additional mode has been implemented, the state machine and the changeover of the

modes can be operated with the PackML tags.

22

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 23

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Method Description

Command_UnitMode (eUnitMode:=

L_UserModes_PackML.ExampleMode,

xUnitModeRequest:=TRUE)

Status_ModeChangeAllowed

(L_UserModes_PackML.ExampleMode)

Changes over a mode if this is permissible.

Checks if a changeover of the mode is permissible in the

current state.

An overview of the methods

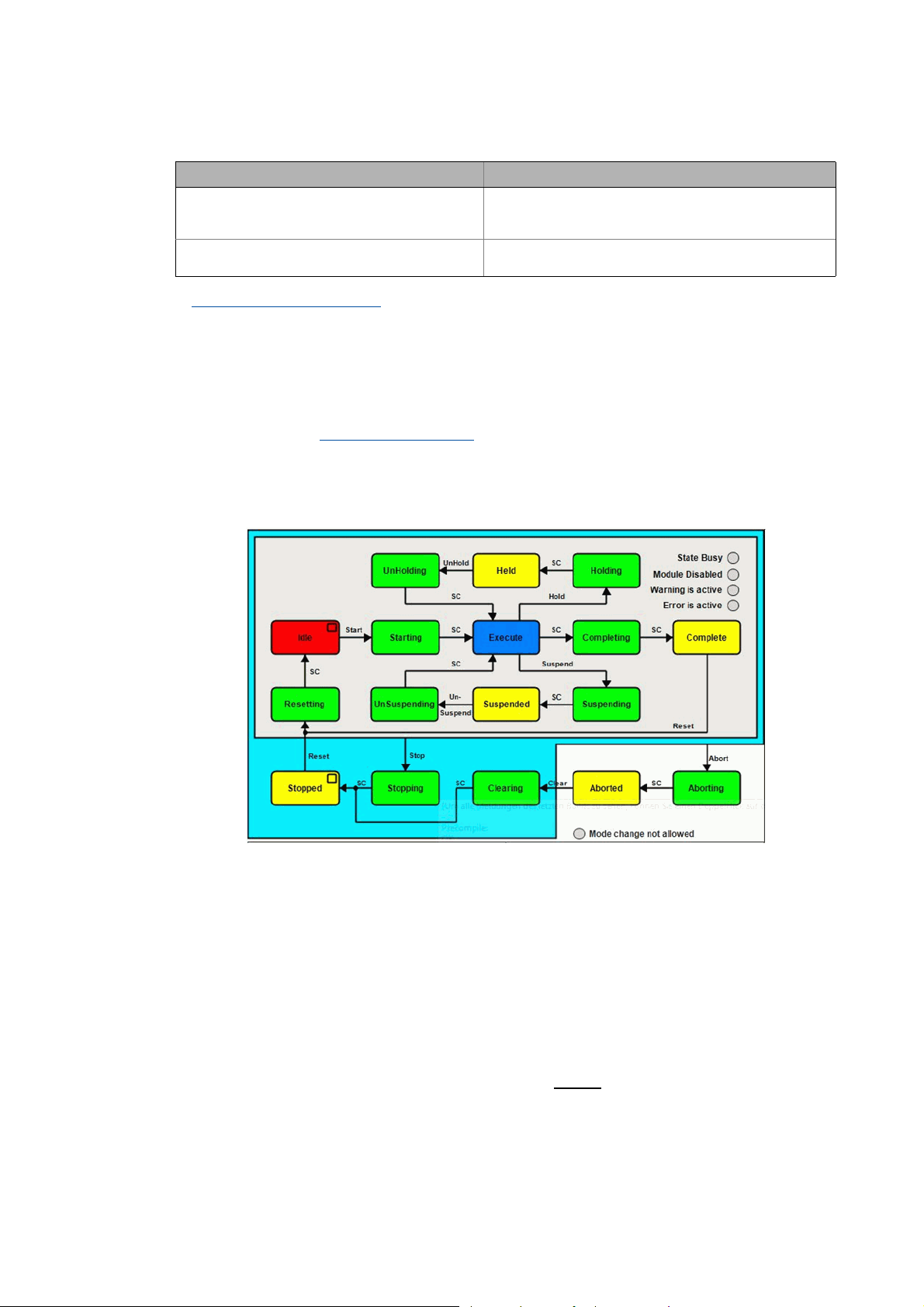

4.3.7 State machine

Each machine module has an own state machine. The state machine of a mode can be created

individually: By deactivating single states in the entire state machine.

More information: State machine in detail

4.3.7.1 State transitions - overview

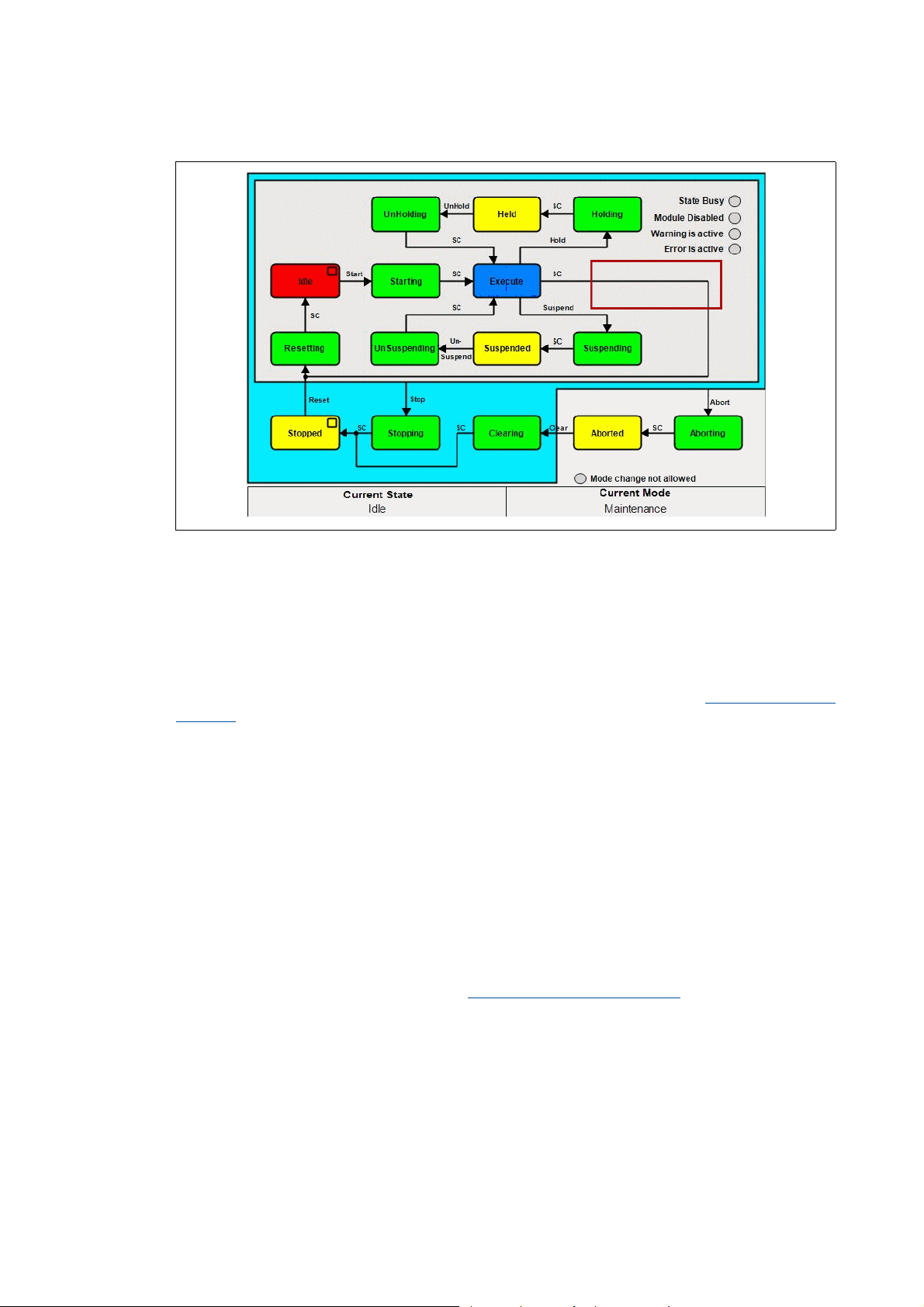

The following status diagram illustrates the possible state transitions of the state machine:

( 91)

( 65)

[4-8] State machine in the ApplicationTemplate PackML

The current state of the state machine is highlighted in red.

• Active state in the illustration: "Idle"

• "Idle" corresponds to the "Waiting" state and is thus highlighted in yellow.

The colouring in the state machine distinguishes the following states:

• Yellow: Waiting state

• Green: Acting state

• Blue: Dual state (can be "waiting" or "acting")

The "waiting" states "Stopped", "Aborted" and "Execute" cannot

Deactivating a state simultaneously switches off the respective (outbound) transitions. If it is the

"Wait" state, it also switches off its "Active" state.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 23

be deactivated.

Page 24

What is the ApplicationTemplate PackML?

Elements of the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[4-9] Example: State machine with deactivated "Complete" state.

Example: Deactivating the "Complete" state deletes the respective "Reset" edge, the "Completing"

state and its post edge.

4.3.7.2 Methods for changing over the states

The ApplicationTemplate PackML contains predefined methods to change over the states of the

state machine. The following section provides an overview of all methods: An overview of the

methods ( 91)

4.3.8 Alarmhandling (error handling)

The ApplicationTemplate PackML contains a predefined alarm handling. This error handling

provides mechanisms which serve to define and trigger reactions (errors, warnings, messages) in

the module applications (ModApps) of the machine modules (MM).

Further mechanisms of the alarm handling are:

• The forwarding of error states in the MachineModuleTree (MMT).

• An application-global error list with the current error status of all machine modules contained

in the MMT.

• Transmission of errors and events to the central logbook of the controller.

Further information can be found under: Alarm handling (error handling)

( 76)

24

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 25

Structuring the automation system: Standard procedure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

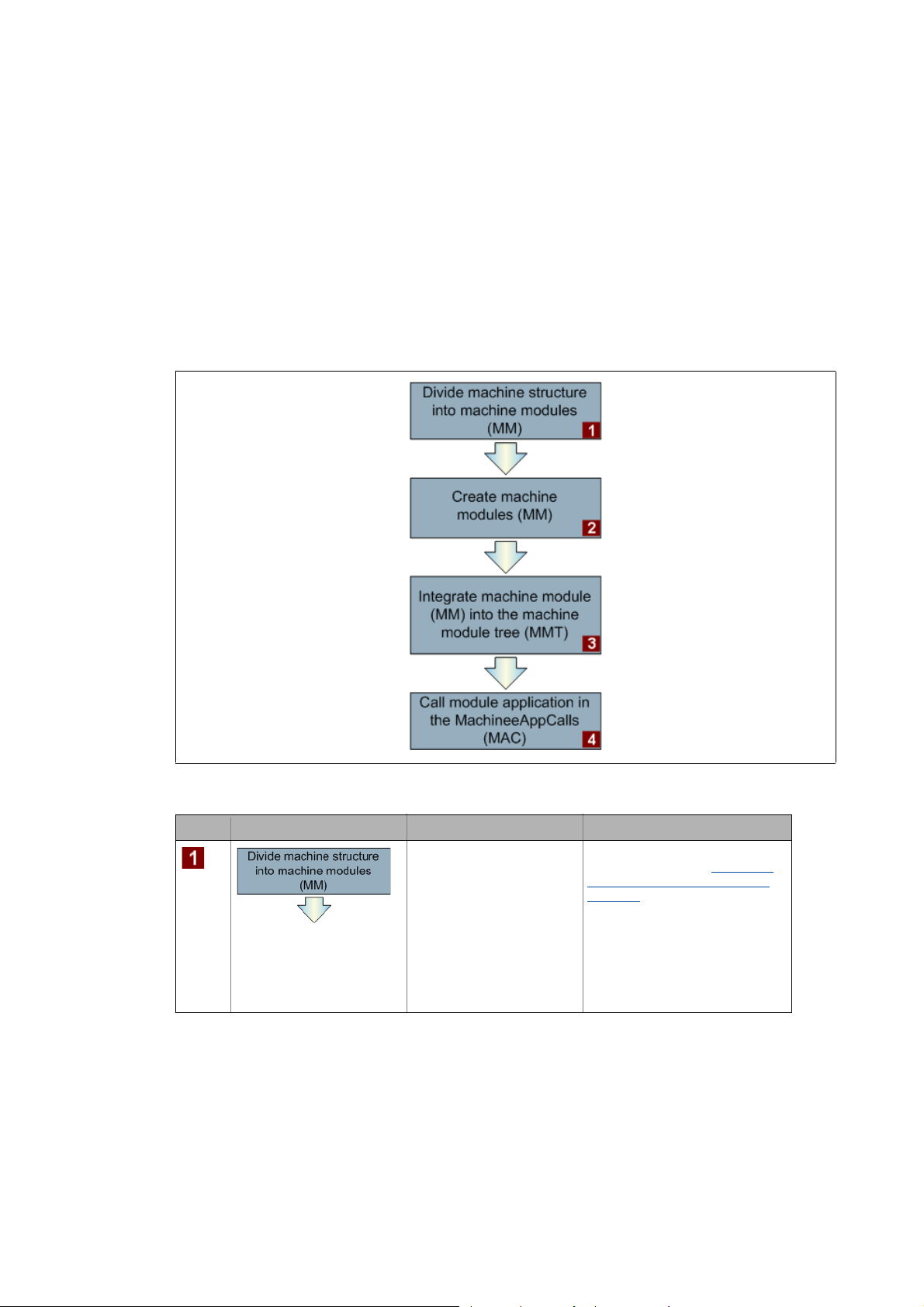

5 Structuring the automation system: Standard procedure

This section describes the standard procedure to create an application with the »PLC Designer«

based on the ApplicationTemplate PackML.

• Use the following recommendations as a guide in order to be able to then create a PLC project

in the »PLC Designer« in a structured manner using the ApplicationTemplate PackML and to

program it effectively.

• Due to the structured layout of the ApplicationTemplate PackML (the consistency in these

structures and the compliance with these structures), applications can be created more quickly

and hence integrated in an existing PLC program more quickly.

[5-1] Recommended procedure for creating a project efficiently.

Step Activity What has to be done? Description

Gain an overview of the

overall functionality of the

machine structure.

• Divide the overall

functionality of the

machine structure into

subfunctions.

• Transfer the identified

subfunctions of the

machine structure to

machine modules.

In this project phase, programming

is not yet required! Assign the

relative address to the machine

modules. ( 27)

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 25

Page 26

Structuring the automation system: Standard procedure

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

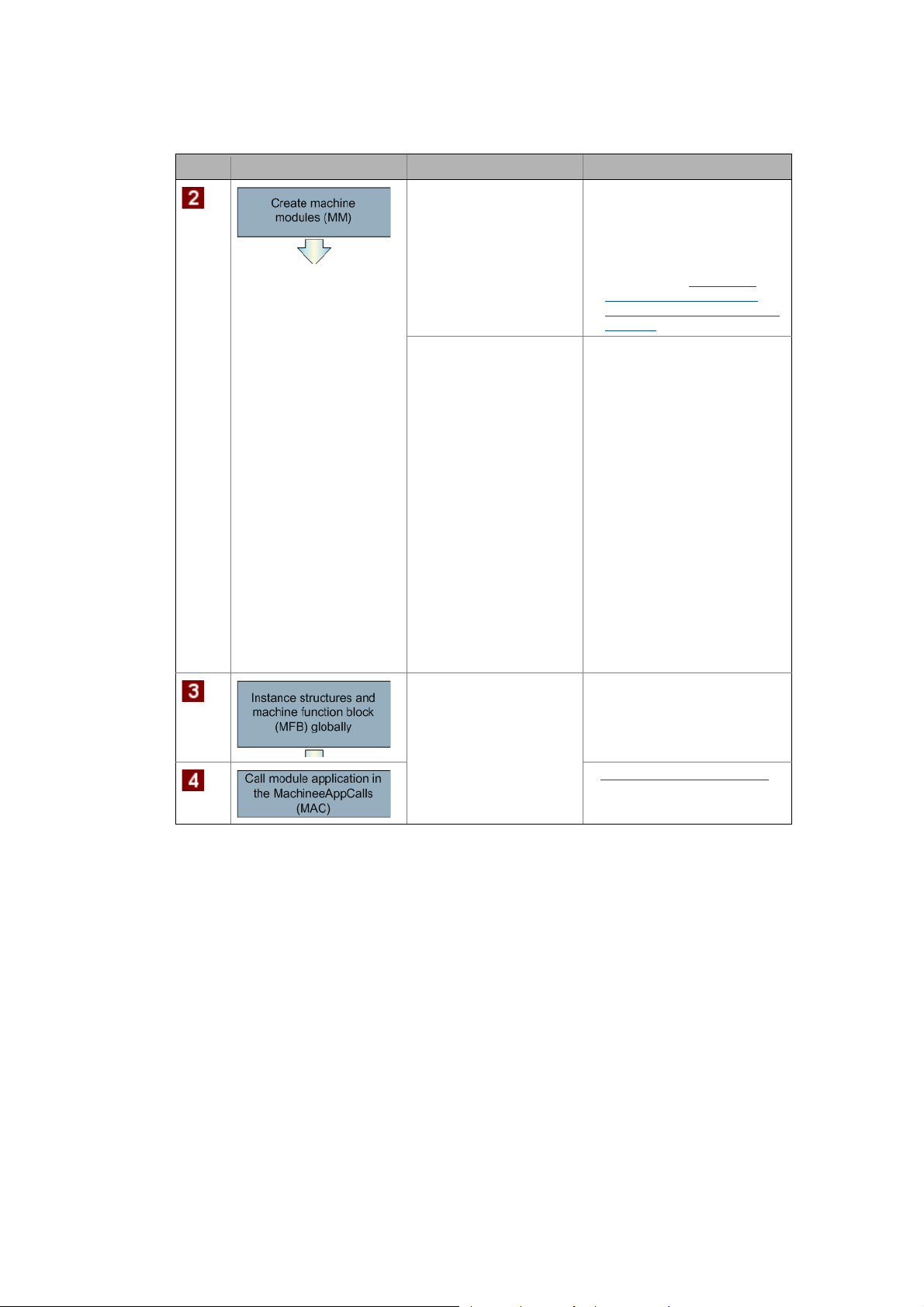

Step Activity What has to be done? Description

Create machine modules

containing the subfunctions

of the machine structure in

each case: one subfunction =

one machine module.

• Define the interfaces for

the module applications

(MAPs).

• Optionally create the

visualization for the

respective machine

module.

• Each machine module is

provided with a state

machine. Irrespective of

the active status, the

module application (MAP)

calls a corresponding

action. The action is

subordinated to the

module application.

• Within these actions,

create the logic which is to

be executed if the

machine module (MM) is

in the corresponding

status.

• In order to be able to call

machine functions in different

tasks, corresponding module

applications have to be created.

• More information about

structuring within a module

application: Structuring

within a machine module:

Assigning MAP subfunction to

the tasks ( 28)

• Define variables.

• Declare variables in the

(MM_IO, MM_Par, MM_Vis,

MM_PD) variable lists.

• Integrate newly created

machine modules into the MMT

(machine module tree).

• Assign the relative address to

the machine modules.

Creating module applications

( 53)

26 Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 27

Structuring the automation system: Standard procedure

Assign the relative address to the machine modules.

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.1 Assign the relative address to the machine modules.

In order to modularise programming of a machine system, the individual subfunctions of the overall

functionality of the automation system have to be mapped in the form of machine modules.

Example: Bag form, fill, and seal machine ("Flow Packer")

• It is helpful to outline the machine structure with t he indi vidual subfun ctions in a tree st ructur e.

• For this, the individual sub functions of the machine have to be transferred to corresponding

machine modules.

Examples of machine modules

•"Virtual master"

•"Infeed" (feeder)

•"Outfeed" (extractor)

• If the individual subfunctions are structured in the form of machine modules, the interfaces are

to be assigned to the module application (MAP).Creating machine modules: Copy/insert

machine module templates ( 41)

• Assign the input and output variables...

...in variable lists MM_IO, MM_Par, MM_Visu and MM_PD and

...to the variables of the AppChannelData (ACD) structure.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 27

Page 28

Structuring the automation system: Standard procedure

Structuring within a machine module: Assigning MAP subfunction to the tasks

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

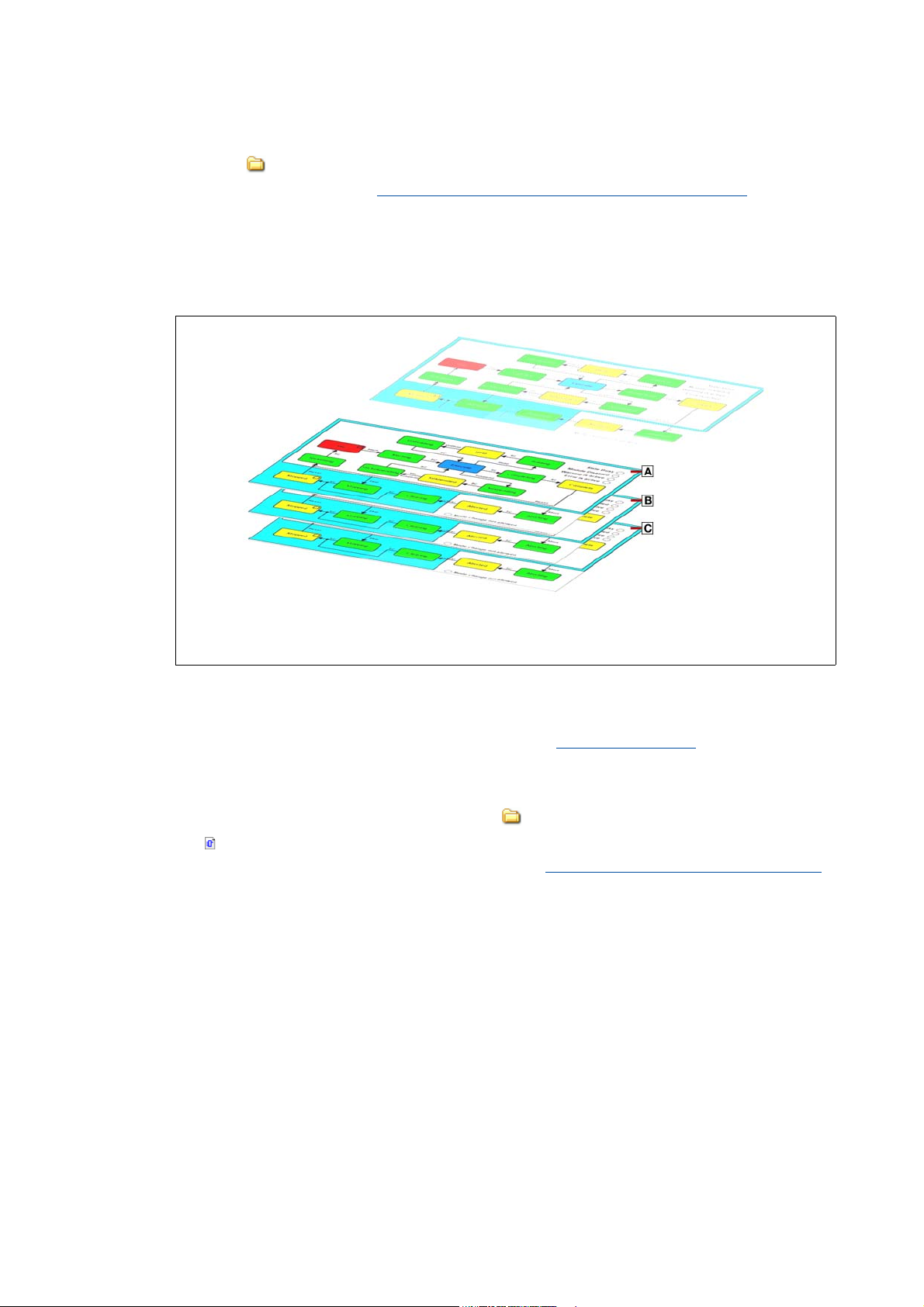

5.2 Structuring within a machine module: Assigning MAP subfunction to the tasks

In order to create a clearly arranged module application, it is advisable to divide the module

applications (MAPs) into subfunctions and to structure them correspondingly.

• Each machine module contains three module applications MAP 1-3 which can be assigned to

tasks differently prioritised.

• Task and module application are assigned in the A11_ModuleAppCalls folder. The

assignment can be made by right-clicking the folder: With command Create Task Call .

Assigning the module application (ModApp) to the task

In a first step, the functions are to be assigned to the individual tasks. The ApplicationTemplate

PackML supports multitasking with three tasks. More information can be found under:

Multitasking

Predefined tasks

Task/priority Standard value To be used for... (example)

"High"

"Mid"

"Free"

One module application can be used per task.

• Task and module application are assigned in the A11_ModuleAppCalls folder.

( 82)

2 ms Execution of Motion functions

HighPriority

6 ms Conversion for an external visualization

MidPriority

Unsolicited Communicating via NRT Ethernet

Unsolicited

( 43)

28

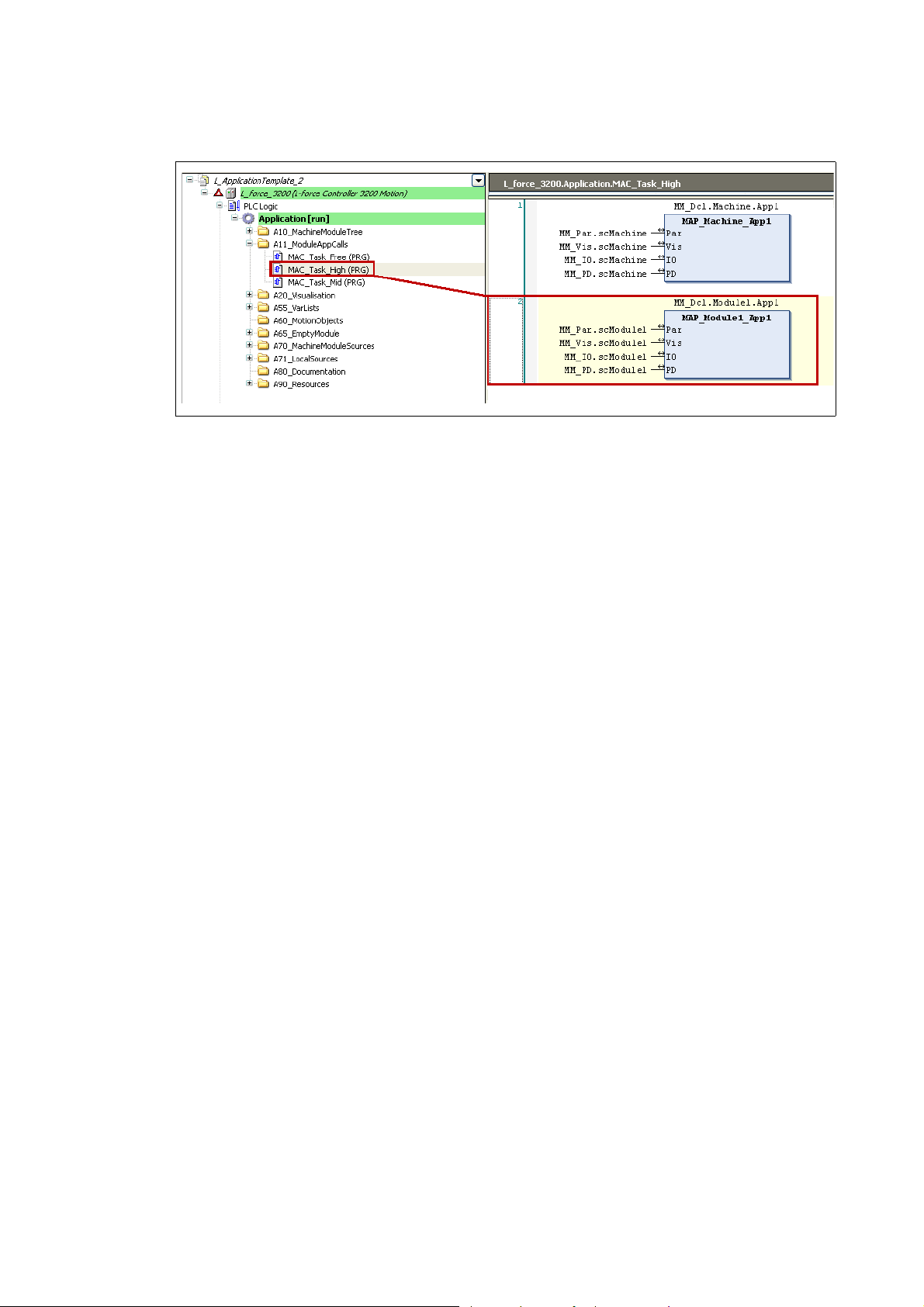

•The MAC_Task_High program part for instance calls all module applications which are to

pass through a high priority task Task_High.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 29

Structuring the automation system: Standard procedure

Structuring within a machine module: Assigning MAP subfunction to the tasks

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[5-2] Sample project ApplicationTemplate Counter: MAC_Task_High calls the Module1_App1 module application.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 29

Page 30

Overview - the folder structure in the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

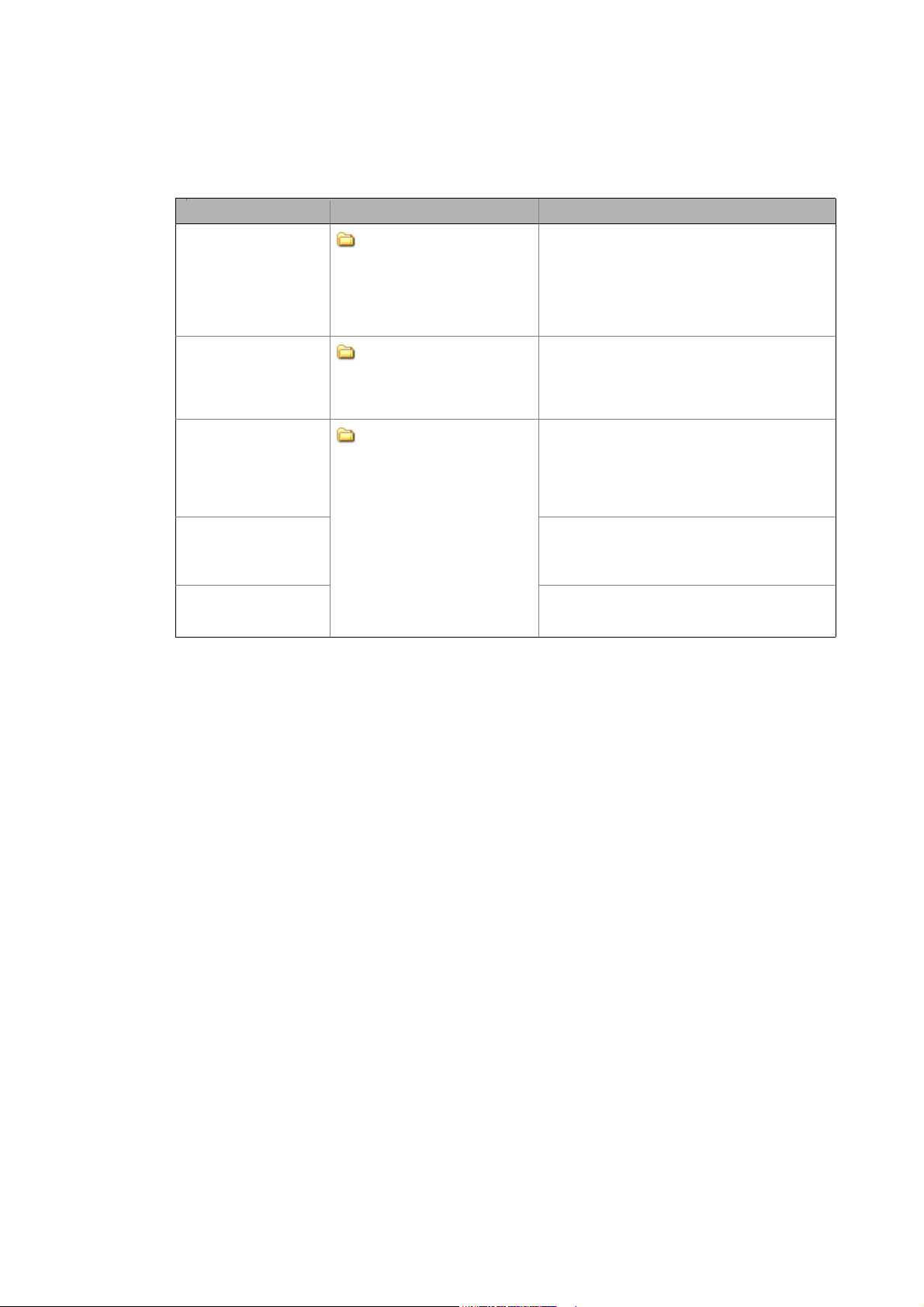

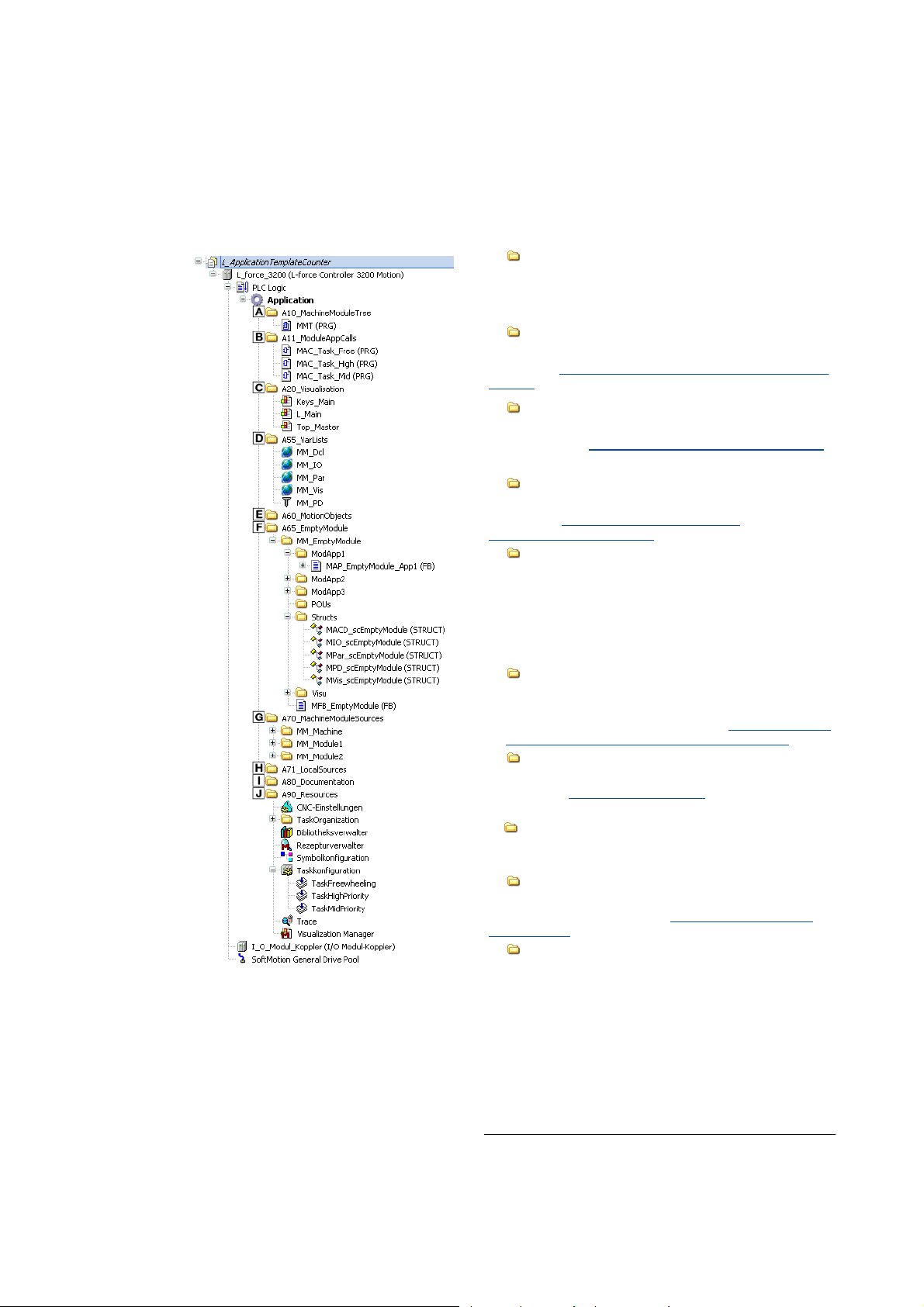

6 Overview - the folder structure in the ApplicationTemplate PackML

The Lenze ApplicationTemplate PackML facilitates programming with the »PLC Designer«. The

ApplicationTemplate PackML has the following structure:

A10_MachineModuleTree (MMT)

The Machine module tree maps the mechatronic

functionality of the machine structure in the form of

machine modules (MM).

A11_ModuleAppCalls (MAC)

...contains the assignments of module applications (MAP) to

the tasks. Assigning the module application (ModApp) to

the task ( 43)

A12_PackML_Configuration

...contains the configuration of the operating modes and the

state machine. Predefined operating modes in ModApp1

( 20)

A20_Visualisation

...contains the visualizations for the device-independent

functions. Getting started - operating the

ApplicationTemplate PackML ( 35)

A55_VarLists

...contains the declarations of the global variables:

• Machine modules used: MM_Dcl

•IO variables: MM_IO

• Parameters: MM_Par

• Variables for an external visualization: MM_Vis

• Persistent data: MM_PD

A66_EmptyModule_PackML

• ...contains the source data of the machine modules

•...contains the EmptyModule_PackML template for

creating your own machine modules. Creating machine

modules: Copy/insert machine module templates ( 41)

A70_MachineModuleSources

• ...contains the individually created machine

modulesMachine modules (MM)

• ...contains the visualization of the machine modules.

( 16)

A71_LocalSources

...contains machine-independent enumerations, function

blocks, structures, visualisations.

A75_UserTags

...contains data elements to be defined individually that can

be programmed additionally. User Tags: Defining own

data elements ( 59)

A90_Resources

...contains the system information such as:

•task settings,

• used libraries,

• Recipe manager,

•Visualization manager.

30 Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 31

Overview - the folder structure in the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Tip!

Combine the "local sources" from the A71_LocalSources folder in one library.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 31

Page 32

Opening the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Opening the ApplicationTemplate PackML

General procedure

The main steps are summarised in the following table:

Step Activity

1st Create a new project - open the ApplicationTemplate PackML

2nd Updating the controller in the project (optional)

3rd Going online

• Compiling the project data

• Transferring the project to the control - "Log in"

4th Downloading and starting the PLC program

5th Getting started - operating the ApplicationTemplate PackML

( 34)

( 34)

( 34)

( 34)

( 34)

( 33)

( 35)

Further information on the parameter setting and configuration of the respective bus

system can be found in the communication manuals for the corresponding bus system:

The commissioning steps in detail

The following section provides a detailed description of every commissioning step.

Please follow the instructions below carefully to commission your automation system.

32 Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 33

Opening the ApplicationTemplate PackML

Create a new project - open the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.1 Create a new project - open the ApplicationTemplate PackML

The ApplicationTemplate PackML is included as a project template (*.project, ) im »PLC Designer«

from .3.8 onwards. In order to call the ApplicationTemplate PackML, a new project has to be created,

taking the ApplicationTemplate PackML as template.

How to proceed:

1. Creating a new project:

• File New project

•Select category Lenze Application Template PackML

• Open template L_ApplicationTemplate_PackML

Which template do you want to use? Function

ApplicationTemplate PackML The Lenze application template L_ApplicationTemplatePackML includes a

structure predefined by Lenze which serves to...

• ... standardise applications by means of a defined folder structure

according to PackML standard.

• ... structure applications by means of machine modules.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 33

Page 34

Opening the ApplicationTemplate PackML

Updating the controller in the project (optional)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.2 Updating the controller in the project (optional)

Cases in which the project must be updated

The controller in the »PLC Designer« must be updated if ...

• ...the project contains firmware information that is older than the hardware to be used or

• ...a controller other than the integrated 3200 C controller is desired (example: p500).

If the controller is marked with the icon after the project is opened, the device information of

the »PLC Designer« project have to be updated.

Determining the firmware of the controller

How to proceed:

• Use the »WebConfig« to check which firmware is used by the controller to select the

appropriate device information in the »PLC Designer«.

7.3 Going online

In order to be able to establish an online connection to the controller, the communication settings

(Set active path) must be commissioned before. Setting up communication to the Controller

( 11)

7.3.1 Compiling the project data

To compile the project data, select the BuildBuild menu command or press the <F11> function

key.

• If errors occur during the compilation, they are to be localised on the basis of the »PLC Designer«

error messages and corrected correspondingly. Recompile the project data afterwards.

• If no errors occur during the compilation, the »PLC Designer« project must be saved:

File Save project

7.3.2 Transferring the project to the control - "Log in"

Note!

To "log in" the PLC program must be error-free. For this it must be possible to execute the

BuildBuild (F11) menu command without an error message.

The desired project must be transferred to the PLC device by "Logging in" to the controller: Call menu

command Online Log in.

7.4 Downloading and starting the PLC program

• Load the PLC program to the controller: Call OnlineLoad menu command.

34

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 35

Opening the ApplicationTemplate PackML

Getting started - operating the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• Start the PLC program: Call OnlineStart menu command.

• As an alternative, you can execute the DebugStart menu command or press <F5>.

Tip!

In order to load a project automatically after a device is restarted, it can be defined as

"boot project".

Setting up the project as boot application

How to install the project as boot project:

1. Select the OnlineGenerate boot project for L-force Controller menu command.

7.5 Getting started - operating the ApplicationTemplate PackML

In the Device view, select the A20_Visualisation folder: Double-click the L_Main visualization.

Welcome page - L_Main visualisation

The user interface of the visualisation is divided into the following areas:

[7-1] Example: ApplicationTemplate Counter with two machine modules (modules 1, modules 2)

Select machine module Select state machine/admin tags/alarm handling

Detailed view of the machine modules Activate states

Select global alarm overview Acknowledging alarms

State machine Activate modes

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 35

Page 36

Opening the ApplicationTemplate PackML

Visualisation of the machine modules

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.6 Visualisation of the machine modules

• If, for instance, Machine Control has been

selected, the fields Al[01...04] of

L_EATP_Alarm_PackML serve to trigger

alarms.

• Possible reactions (Reac.) are: Abort, Stop,

Error, SystemFault, Warning, Information.

• The machine module transmits the

reaction type to the higher-level machine

module. The desired response to the alarm

can be programmed individually, except

for the commands Abort/Stop.

• If no error response has been programmed,

the state machine remains in the current

state.

•The Modules button calls the detailed view

for the machine modules.

• Click the desired machine module to show

the respective status and further details.

• All alarm messages are visible in the global

alarm list which can be called via the Alarm

List button. The global alarm list provides

an overview of all alarms occurred.

•The Alarm Quit button has to be pressed to

reset the error. The reason for the tripping

has to be removed. Then, the

corresponding alarm can be reset.

36

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 37

Working with the ApplicationTemplate PackML

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8 Working with the ApplicationTemplate PackML

This chapter provides information on how to create machine modules in the ApplicationTemplate

PackML using the machine module template EmptyModule_PackML. EmptyModule_PackML is a

template for making the creation of your own machine modules easier.

Programming with the ApplicationTemplate PackML: What has to be done?

Step Activity Detailed information

1st Structuring the automation system

• The overall functionality (machine

application) of the automation system is to

be mapped modularly:

One subfunction = one machine module

• In this project phase, programming is not

yet required!

2nd Starting the ApplicationTemplate PackML Opening the ApplicationTemplate PackML

3rd Updating the project (optional)

• Adjust the device information version in the

»PLC Designer« project to the firmware

version of the controller.

• Integrate another controller in the project if

required. The controller included is the

3200 C.

4th Mapping the actual machine structure in the

»PLC Designer«

6. Creating/integrating individual machine

modules

7. Integrating devices Inserting an axis

8. Going online Going online

9. Starting the PLC program Downloading and starting the PLC program

Assign the relative address to the machine modules.

( 27)

Updating the controller in the project (optional)

( 34)

Mapping the actual machine structure: Add devices

( 38)

Creating machine modules: Copy/insert

module templates ( 41)

( 49)

Integrating I/O modules of the I/O system 1000 with a

machine module ( 51)

Integrating a module application

( 34)

machine

( 55)

( 32)

( 34)

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 37

Page 38

Working with the ApplicationTemplate PackML

Mapping the actual machine structure: Add devices

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.1 Mapping the actual machine structure: Add devices

The ApplicationTemplate PackML contains a predefined structure that can be extended by the

individual requirements. Carry out the following steps to map the actual machine structure.

Note!

Before creating an EtherCAT configuration in »PLC Designer«, ensure that the following

conditions have been met:

• The sequence of the EtherCAT slaves in the device view must correspond to the

physical arrangement of the EtherCAT topology.

• Select the cycle times according to the technical data, from 1 ... 10 ms.

How to create the control configuration in the »PLC Designer«:

1. Open the context menu of the target system and execute the command Append device

in order to extend the control configuration with "EtherCAT Master".

38

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 39

Working with the ApplicationTemplate PackML

Mapping the actual machine structure: Add devices

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2. Add an EtherCAT slave below the EtherCAT Master: Right-click the EtherCAT Master

Add device:

Select the desired device from the selection list .

The »PLC Designer« provides a "fieldbus scan" during which the devices connected to the

fieldbus are automatically detected.

Further information is provided in the "Controller-based Automation EtherCAT" section of

the online help for the »PLC Designer« and in the Controller-based Automation EtherCAT

communication manual (KHB).

Repeat the Add device until all slaves connected to the fieldbus are implemented in the

device view.

Allocate unique designations to the slaves inserted

(example: "L_94_HL_ActuatorSpeed").

The names can be selected freely and must …

•only

contain the characters "A ... Z", "a ... z", "0 ... 9", or "_";

•not

start with a digit.

You can enter a name by clicking the element.

Example:

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 39

Page 40

Working with the ApplicationTemplate PackML

Mapping the actual machine structure: Add devices

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3. Setting the cycle time

• The value for the EtherCAT master cycle time has to be defined according to the cycle

time of the quickest task.

• The icon in front of the respective device indicates the successful

EtherCAT communication.

Note: The EtherCAT cycle time is to be set to the quickest task cycle time set. In this

ApplicationTemplate PackML, the quickest task cycle time is set to 2 ms, therefore 2000 μs

have to be set here.

• If the "Distributed Clocks" option is activated for all controllers and communication is

successful, the EtherCAT Master provides the "DC In-Sync" message:

40

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 41

Working with the ApplicationTemplate PackML

Creating machine modules: Copy/insert machine module templates

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.2 Creating machine modules: Copy/insert machine module templates

Tip!

If individual machine modules are created, the ApplicationTemplate PackML automatically

assigns the corresponding machine module-internal names.

Creating machine modules: What has to be done?

The machine module template EmptyModule_PackML...

• ...has to be copied in the A66 EmptyModule_PackML

folder using the Copy Empty Module command and

• ...then using the Insert Empty Module command to

insert it into the A70_MachineModuleSources

folder.

How to proceed:

1. Copy the EmptyModule_PackML machine module template:

•Right-click the A66 EmptyModule_PackML\MM_EmptyModule_PackML folder

Copy Empty Module.

2. Insert the previously copied machine module (MM_Empty Module_PackML) below the

A70_MachineModuleSources folder:

•Right-click the A70_MachineModuleSources

3. Enter the desired module name.

The module name can be selected freely and …

• must not

•may only

• must not

4. Click Insert to insert the machine module.

• The machine module has been inserted with the applicable names of the MAPs/MFB,

structures, and visualization.

• The machine module is instanced with the previously assigned name.

5. The machine module inserted (MFB_*) is to be inserted in the MMT in the

A10_MachineModuleTree folder. Integrating machine modules in the MMT

contain "MM_"

contain the characters "A ... Z", "a ... z", "0 ... 9"

contain any special characters.

Insert Empty Module

6. The module application (MAP_*) in the A11_ModuleAppCalls folder is to be inserted in

the desired module application call (MAC_Task_*). Assigning the module application

(ModApp) to the task

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 41

Page 42

Working with the ApplicationTemplate PackML

Integrating machine modules in the MMT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.3 Integrating machine modules in the MMT

A machine module (created on the basis of the EmptyModule_PackML machine module template)

has to be integrated into the MachineModuleTree (MMT) in order to integrate it functionally into

the ApplicationTemplate PackML.

[8-1] Example: MachineModuleTree in the ApplicationTemplate PackML

How to proceed:

1. Double-click the A10_MachineModuleTree folder in the device view.

• Double-click MMT (PRG).

Note: The programming language of MMT (PRG) is CFC (Continuous Function Chart).

•In the Tools dialog window, click the Block button.

• Create the new FB via drag-and-drop.

• Double-click the area of the FB, click the button.

Use the Input assistance from the Application element...

• ...to assign the MFB_CrossCutter FB.

• ...to assign the CrossCutter instance.

Note: Go to the Input assistant and select the Insert with namespace prefix when

assigning the instance name.

2. Specify the relative address for the machine module.

•In the Tools dialog window, click the Input button.

• Add the new input at MM_Address

• Assign the relative address (example: "3").

42

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 43

Working with the ApplicationTemplate PackML

Assigning the module application (ModApp) to the task

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3. Connect FBs MFB_MachineControl and MFB_CrossCutter to each other.

•Example:

Note: After inserting a machine module, the processing order

which results after inserting the further machine module is to be checked.

For changing the Processing order

the corresponding machine module.

• For this, call the Processing order menu item in the context menu of the element

number (right mouse button).

Note: If the "Structured view" option is deactivated, an FB (example: MFB_CrossCutter) can

be reached via the input assistance (category: Instances).

8.4 Assigning the module application (ModApp) to the task

For machine modules that have been created using the EmptyModule_PackML machine module

template, the MAP and task can be easily assigned via a dialog window.

, adapt the element number in the top right corner of

Tip!

For creating machine modules, use the EmptyModule_PackML machine module template

in the A66_EmptyModule_PackML folder to easier assign module application and tasks.

How to proceed:

of the machine modules

1. Right-click the A11_ModuleAppCalls folder:

•Call Create Task Call.

2. The module applications have to be assigned to the different tasks. Go to the following

dialog window and mark the module application in the area (example:

MM_NewModule) and in area mark the task to be assigned to the MAP.

• Assign/unassign the task to the respective MAP using <</>>.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 43

Page 44

Working with the ApplicationTemplate PackML

Assigning the module application (ModApp) to the task

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

[8-2] Example: ModuleApp1 is assigned to the task with the highest priority Task_High.

•Confirm assignment by clicking OK.

The functions of the machine module can be programmed in the "State" methods of the single

operating modes.

States: States with predefined functions

[8-3] The states of the state machine contain a predefined programming

Each state of the state machine already contains a predefined programming.

• By double-clicking the prevailing state, the program code that contains the commented user

functions becomes visible.

• The comments point out where further functions can be added.

44

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 45

Working with the ApplicationTemplate PackML

Create MM Instance: Creating instances of a machine module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

• The MAP block contains the S00_Cyclic action which is processed cyclically.

8.5 Create MM Instance: Creating instances of a machine module

In order to create further instances of a machine module, the ApplicationTemplate contains the

Create MM Instance function.

How to proceed:

1. Right-click the folder A70_MachineModuleSourcesCreate MM Instance:

2. Select the machine module from you want to create an instance.

• Enter an instance name, example: Modul_1_NewInstance.

•Click Insert to create and implement the instance.

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 45

Page 46

Working with the ApplicationTemplate PackML

Delete Machine Module: Remove instances of a machine module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.6 Delete Machine Module: Remove instances of a machine module

In order to delete the instance of a machine module, the ApplicationTemplate contains the Delete

Machine Module References function.

• Executing the command causes all entries in the data containers and calls to be deleted.

Manual removal of the instances

The instances of a machine module have to be removed from the global variable lists in the

A55_VarLists folder.

How to proceed:

1. Double-click the A55_VarLists folder.

2. Double-click the global MM_Dcl variable list.

3. Right-click the instance to be deleted (example: NewModule):

46

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 47

Working with the ApplicationTemplate PackML

Removing machine modules

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.7 Removing machine modules

In order to remove a machine module including all instances from the »PLC Designer« project,

execute the Delete command.

How to proceed:

Right-click the module name in the A70_MachineModuleSources folder and execute

the Delete command.

8.8 Module ID

• Each machine module can be identified by a unique CompID module ID which is stored in every

MFB of the machine module in each case.

• The module ID is defined in the BaseChannel and can be set by the setCompIDAndVersion()

method.

• The respective module ID (CompID) can be viewed in the visualisation under Machine Module

Details: Folder A20_Visualisation L_Main, Module List button .

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 47

Page 48

Working with the ApplicationTemplate PackML

Module ID

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Tip!

Allocate a suitable module ID CompID for every newly created machine module.

When revising a module, update the Version accordingly.

48

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 49

Working with the ApplicationTemplate PackML

Inserting an axis

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.9 Inserting an axis

In order to connect an axis to a machine module, the following has to be observed when creating a

machine module.

• The following example shows how an axis is to be connected to the MM_Module2 machine

module.

• The axis is to be connected to the task with the highest priority MAC_Task_High.

How to proceed:

1. Call the module application within which an axis is to be connected:

• Extend the module application by the declaration: AXIS: AXIS_REF_SM3

2. In the A11_ModuleAppCalls folder, update the task into which the module application

is integrated: MAC_Task_High

• Delete the present module name (here: MAP2_Modul2_App1) in the FB of the module

application:

3. Assign the name of the module application (example: MAP_Module2_App1) to the FB:

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014 49

Page 50

Working with the ApplicationTemplate PackML

Inserting an axis

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4. Assign the name of the instance (example: MM_Dcl.Module2.App1) to the module

application:

5. Assign the axis to the module application. The precondition for this is that the actual

machine structure is mapped in the »PLC Designer« project. Mapping the actual machine

structure: Add devices ( 38)

(The dwTestCounter input does not receive a transfer variable.)

• Select the desired axis (example: SM_Drive_ETC_9400HL)

•Click OK to insert the axis.

• The axis is connected to the machine module:

50

Lenze · ApplicationTemplate PackML · 1.0 EN - 05/2014

Page 51

Working with the ApplicationTemplate PackML

Integrating I/O modules of the I/O system 1000 with a machine module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8.10 Integrating I/O modules of the I/O system 1000 with a machine module

This chapter describes in which way the modules of an I/O system connected via CAN can be

accessed from a machine module.

Example: Access three digital inputs/outputs and one analog input /O system 1000 from the

MM_Module1 machine module.

How to proceed:

1. Right-click I_O_module_coupler