Page 1

K-HB 13.0001-EN

.1kj

Ä.1kjä

L-force Drives

Communication Manual

Servo Drives 930 fluxxtorque

931M/W

PROFIBUS-DP

Page 2

This documentation is valid for 931M/W servo inverters.

Document history

Material No. Version Description

.1kj 2.1 10/2006 TD14 First edition

0Fig.0Tab. 0

Tip!

Current documentation and software updates concerning Lenze products can be found on

the Internet in the ”Services & Downloads” area under

http://www.Lenze.com

Important note:

Software is provided to the user ”as is”. All risks regarding the quality of the software and any results obtained from its use

remain with the u ser. The user should take appropriate security precautions against possible maloperation.

We do not accept any responsibility for direct or indirect damage caused, e.g. loss of profit, loss of orders or adverse

commercial effects of any kind.

All trade names listed in this documentation are trademarks of their respective owners.

© 2006 Lenze GmbH & Co KG Kleinantriebe, Hans-Lenze-Straße 1, D-32699 Extertal

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze GmbH &

Co KG Kleinantriebe.

All information given in this documen tation has been selected carefully and complies with the hardware and software described.

Nevertheless, discrepancies cannot be ruled out. We do not take any responsibility or liability for any damage that may occur.

Necessary corrections will be included in subsequent editions.

2

K-HB 13.0001-EN 2.1

Page 3

Contents i

1Preface 6..................................................................

1.1 Introduction 6.........................................................

1.2 Comparison of industrial fieldbus systems 7...............................

1.3 About this Communication Manual 8.....................................

1.4 Legal regulations 9.....................................................

2 Safety instructions 10.........................................................

2.1 Persons responsible for safety 10..........................................

2.2 General safety instructions 11.............................................

2.3 Definition of notes used 12...............................................

3 Technical data 13............................................................

3.1 General data and operating conditions 13..................................

4 Electrical installation 14.......................................................

4.1 Electrical connection of the servo inverter with the PROFIBUS master 17.........

5 Commissioning 18...........................................................

5.1 Before switching on 18..................................................

5.2 Activation of PROFIBUS at the servo inverter 18..............................

5.3 PROFIBUS settings in the operating program 22..............................

5.4 PROFIBUS communication 25.............................................

5.4.1 GSE file for PROFIBUS connection 25................................

5.4.2 Hardware configuration 25.......................................

5.4.3 Structure of communication channel 26.............................

6 Control word and status word (Profidrive state machine) 27........................

6.1 General information 27..................................................

6.2 Control word 28........................................................

6.3 The status word (ZSW) 31................................................

6.4 The Profidrive state machine 33...........................................

6.4.1 State machine and general state diagram 33........................

6.4.2 Example: State machine for speed operation 36......................

6.4.3 State diagram for positioning 38...................................

6.4.4 State diagram for speed control 40.................................

K-HB 13.0001-EN 2.1

3

Page 4

Contentsi

7 Parameter channel (PCV mechanism) 41.........................................

7.1 Access authorisation 41..................................................

7.2 Structure of the parameter characteristic value 42............................

7.2.1 Structure of parameter identification (PKE) 42.......................

7.2.2 Subindex 42....................................................

7.2.3 Parameter value 42..............................................

7.3 Job and response processing 43...........................................

7.3.1 Job identification (master -> slave) 43..............................

7.3.2 Response identification (slave -> master) 44.........................

7.3.3 Error numbers at response 45.....................................

7.3.4 Examples of PCV mechanism 46...................................

7.3.5 Transfer of PPO with PROFIBUS-DP 50..............................

8 Parameter numbers 51........................................................

8.1 Explanation of the parameter numbers 51..................................

8.1.1 Node address (PNU 918) 51.......................................

8.1.2 Parameter change rights (PNU 927) 52..............................

8.1.3 Control authority (PNU 928) 52....................................

8.1.4 Selector switch for operating mode (PNU 930) 52.....................

8.1.5 Selector switch - control word bit 8 (PNU 931) 53.....................

8.1.6 Selector switch - control word bit 9 (PNU 932) 54.....................

8.1.7 Selector switch - control word bit 11 (PNU 933) 54....................

8.1.8 Selector switch - control word bit 12 ... 15 (PNU 934 ... 937) 54..........

8.1.9 Selector switch - status word bit 8 (PNU 938) 55......................

8.1.10 Selector switch - status word bit 11 (PNU 939) 56.....................

8.1.11 Selector switch - status word bit 12 (PNU 940) 56.....................

8.1.12 Selector switch - status word bit 13 (PNU 941) 57.....................

8.1.13 Selector switch - status word bit 14 (PNU 942) 57.....................

8.1.14 Selector switch - status word bit 15 (PNU 943) 57.....................

8.2 Device-specific parameter numbers 58.....................................

8.2.1 Data type - jogging setpoint 1 and 2 (PNU 107 und 108) 58............

8.2.2 Fault number (PNU 947) 58.......................................

8.2.3 Load parameter set (PNU 970) 59..................................

8.2.4 Transfer to the non-volatile memory (PNU 971) 59....................

8.3 Overview of the device-specific active parameters 60.........................

8.4 Overview of the device-specific passive parameters 60........................

8.5 Data type - travel data record (PNU 1 to 100) 61..............................

8.6 Data type - reference parameter (PNU 101) 62...............................

8.7 Data type - IO settings (PNU 102) 63.......................................

8.8 Data type - control parameters (PNU 103) 65................................

8.9 Data type - system parameters (PNU 104) 65................................

4

K-HB 13.0001-EN 2.1

Page 5

Contents i

8.10 Data type - service parameters (PNU 105) 66................................

8.11 Data type - PROFIBUS parameters (PNU 106) 67..............................

8.12 Data type status (PNU 1000) 68...........................................

8.13 Data type info (PNU 1001) 71.............................................

8.14 Data type options (PNU 1002) 71..........................................

8.15 Overview of all PNUs 72..................................................

9 Troubleshooting and fault elimination 76.......................................

10 Appendix 77................................................................

10.1 Data formats 77........................................................

10.2 GSE file 77.............................................................

11 Index 80....................................................................

K-HB 13.0001-EN 2.1

5

Page 6

1

Preface

Introduction

1Preface

1.1 Introduction

The competitive situation in the mechanical and system engineering sector requires new

means to optimise the production costs. This is why modular machine and system

engineering is becoming increasingly more important, since individual solutions can now

be set up easily and cost-effectively from a single modular system.

Lenze fieldbus systems in industrial applications

For an optimal communication between the single modules of a system, fieldbus systems

are increasingly used for process automation. Lenze offers the following communication

modules for the standard fieldbus systems:

ƒ Profibus DP

ƒ CANOpen

Decision support

The decision for a fieldbus system depends on many different factors. The following

overviews will help you to find the solution for your application.

Profibus DP

For bigger machines with bus lengths of more than 100 metres, INTERBUS or PROFIBUS-DP

(PROFIBUS-Decentralised Periphery) are frequently used. The PROFIBUS-DP is always used

together with a master control (PLC) – here the PROFIBUS master transmits e.g. the

setpoints to the single PROFIBUS stations (e. g. Lenze controllers).

When using the data transfer rate of 1.5 Mbits/s typical for the PROFIBUS-DP, thesensors

and actuators receive the process data. Due to the data transmission mode and the

telegram overhead, a bus cycle time results at 1.5 Mbits/s, which is sufficient to control

e. g. conveyors. If, for technical reasons, the process data must be transmitted faster to the

sensors and actuators, the PROFIBUS can also be operated with a data transmission rate

of maximally 12 Mbit/s.

CANOpen

CANopen is a communication protocol specified to the CiA (CAN in Automation) user

group. Lenze can provide communication modules for communicating with CANopen

masters. These modules are compatible with the specification DS 301 V4.01.

6

K-HB 13.0001-EN 2.1

Page 7

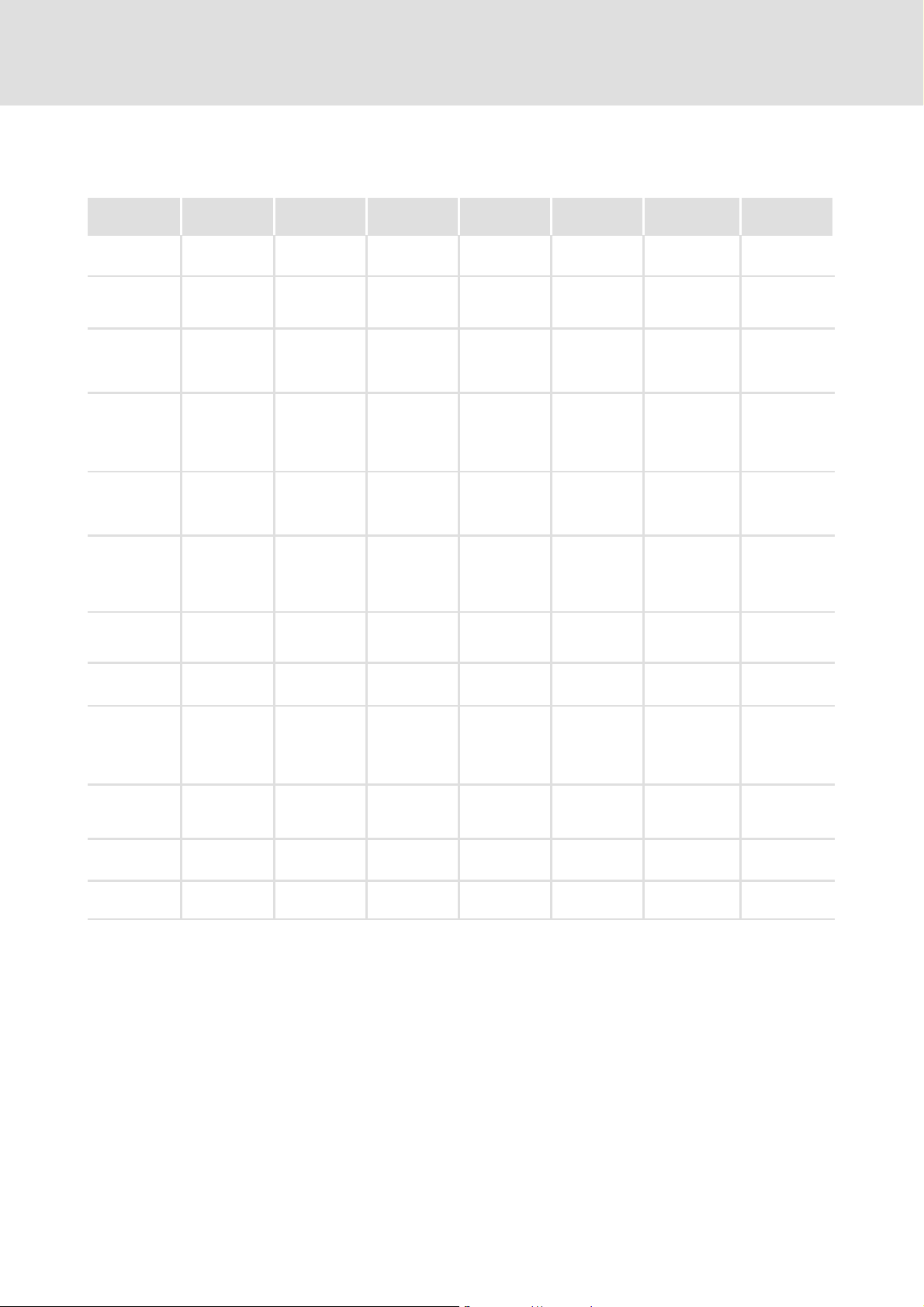

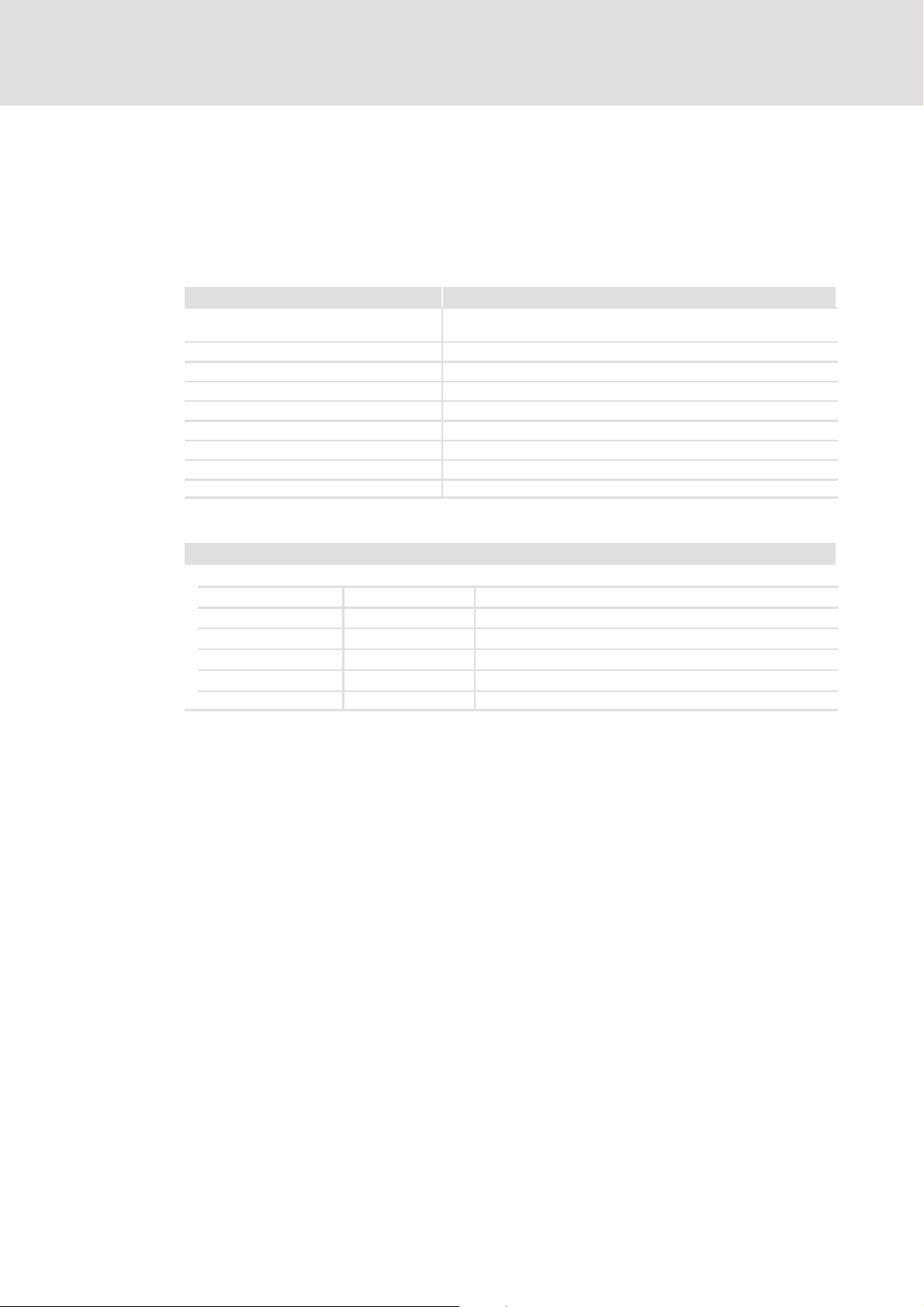

Comparison of industrial fieldbus systems

1.2 Comparison of industrial fieldbus systems

Preface

1

Topology

Bus

management

Max. number

of nodes

(master and

slaves)

Max. distance

between

stations

without

repeater

Max. distance

between

stations with

repeater

Transmission

medium

Auxiliary

energy supply

via bus cable

Baud rate

Typical update

time (e.g. 8

stations, 4

Bytes user

data)

Telegram

length (user

data)

Telegram

length (total)

Bus access

methods

CAN /

DeviceNet Profibus DP AS-i INTERBUS INTERBUS-Loop LON

CANopen

Line with

terminating

resistors

Multi master Single master Single master Single master Single master Only together with

64 64 124 (4 segments,3

Dependent on the

baud rate used

1km(50kbit/s)

25 m (1 Mbit/s)

General length

reduction,

dependenton the

repeater used

Shielded, twisted

pair cable

Possible via

additional wires in

the bus cable

10 kbit/s - 1 Mbit/s 125 kbit/s,

Approx. 1.32 ms at

1Mbit/s(high

priority)

0to8bytes 0to8bytes 0to 246 bytes 4bits 1to64bytesdata,

106 bits at 8 bytes

user data

CSMA/CA

message-oriented

Line with

terminating

resistors

100 m (500 kbit/s)

250 m (250 kbit/s)

500 m (125 kbit/s)

Not specified 10 km (93.75

Shielded, twisted

pair cable

Possible via

additional wires in

the bus cable

250 kbit/s,

500 kbit/s

Approx. 2.64 ms at

500 kbit/s (high

priority)

106 bits at 8 bytes

user data

CSMA/CA

message-oriented

Line with

terminating

resistors

repeaters),

max. 32 per

segment

1.2 km (93.75

kbit/s)

100 m (12 Mbit/s)

kbit/s)

Shielded, twisted

pair cable

Possible via

additional wires in

the bus cable

9.6 kbit/s - 12

Mbit/s

Approx. 2.5 ms at

500 kbit/s

User data +

6to11bytes

Cyclic polling Cyclic polling Time base /

Line, tree, ring

(possible)

124

sensors/actuators

1master

100 m 1.5 m (local bus)

300 m (2

repeaters)

Unshielded,

untwisted flat pair

cable

Current supply via

data cable

(2 to 8 A)

167 kbit/s 500 kbit/s or

Typically 5 ms

(4 bits each)

21 bits, of which:

14 bits master, 7

bits slave

Ring Ring Line (2 wire) or any

512 slaves,

1master

400 m (remote

bus)

2.5 km (optical

fibre)

13 km (remote

bus),

100 km (optical

fibre)

Shielded, twisted

5-wire cable

Optical fibre,

infrared

Separate, Group

via bus terminal

(remote bus)

2Mbit/s

At least 2 ms

(process data)

up to 246 bytes

parameters

User data +

6bytes

distributed shift

register

INTERBUS-S; single

master (bus

terminal)

32 slaves 32385 stations

10 m (max. 100 m

cable length

without repeater)

No repeater

required

Unshielded, twisted

pair cable

Current supply via

data cable

(ca. 1.5 A)

500 kbit/s 78 kbit/s - 1.25

At least 2 ms

(process data)

1to64bytesdata,

up to 246 bytes

parameters

User data +

6bytes

Time base /

distributed shift

register

Tab. 1 Comparison of industrial fieldbus systems

other

Multi master

distributed to 255

subnetworks with

127 stations each

2kmat78kbit/s

(twisted pair),

6.1 km at 5.48

kbit/s (optical fibre

plastics)

Almost any,

expandable by

subnetworks (no

repeater)

Unshielded,

untwisted pair

cable

Radio, optical fibre,

power supply

system (Powerline)

possible via

additional wires in

the bus cable

Mbit/s

Approx. 70 ms

1to228bytes

data,

Typically approx.

11 bytes

max. 255 bytes,

User data + 27

bytes

Modified

CSMA/CD

K-HB 13.0001-EN 2.1

7

Page 8

1

Preface

About this Communication Manual

1.3 About this Communication Manual

Target group

This Manual is intended for all persons who plan, install, commission, and set servo

inverters of the 931M/W series.

Together with the catalogue, it forms the basis for project planning for the mechanical

engineer and system engineer.

Contents

The PROFIBUS Manual complements the Mounting Instructions and Software Manual

included in the scope of supply:

ƒ The features and functions are described in detail.

ƒ It provides detailed information on possible applications.

ƒ Parameter setting is clarified by means of examples.

ƒ In case of doubt, the supplied Mounting Instructions are always valid.

How to find information

ƒ The table of contents and the index help you to find information on a certain topic.

ƒ Descriptions and data with regard to further Lenze products can be gathered from

the respective catalogues, Operating Instructions, and Manuals.

ƒ You can request Lenze documentation from your responsible Lenze sales partner or

download it as a PDF file from the Internet.

8

K-HB 13.0001-EN 2.1

Page 9

1.4 Legal regulations

Preface

Legal regulations

1

Labelling

Application as

directed

Liability z The information, data, and notes in these instructions met the state of the art at the time of printing. Claims

Warranty z Terms of warranty: see Sales and Delivery Conditions of Lenze GmbH & Co KG Kleinantriebe.

Disposal

Nameplate CE identification Manufacturer

Lenze drive controllers are definitely

identified by the contents of the

nameplate.

931M/W servo inverters

z must only be operated under the operating conditions prescribed in these instructions.

z are components

– for the open and closed loop control of variable speed drives,

– for installation in a machine,

– for assembly with other components to form a machine.

z comply with the requirements of the Low-Voltage Directive.

z are not machines for the purpose of the Machinery Directive.

z are not to be used as domestic appliances, but only for industrial purposes.

Drive systems with 931M/W servo inverters

z comply with the EMC Directive if they are installed according to the guidelines of CE-typical drive systems.

z can be used

– for operation on public and non-public mains

– for operation in industrial premises.

z The user is responsible for the compliance of his application with the EC directives.

Any other use shall be deemed inappropriate!

on modifications referring to controllers which have already been supplied cannot be derived from the

information, illustrations, and descriptions.

z The specifications, p rocesses, and circuitry described in these Instructions are for guidance only and must be

adapted to your own specific application. Lenze does not take responsibility for the suitability of the process

and circuit proposals.

z Lenze does not accept any liability for damage and operating interference caused by:

– disregarding the Operating Instructions

– unauthorised modifications to the controllers

– operating errors

– improper working on and with the drive controllers

z Warranty claims must be made to Lenze immediately after detecting the deficiency or fault.

z The warranty is void in all cases where liability claims cannot be made.

Material Recycle Dispose

Metal D -

Plastic D -

Assembled PCBs - D

In compliance with the EC

Low-Voltage Directive

Lenze GmbH & Co KG

small drives

Postfach 10 13 52

D-31763 Hameln

K-HB 13.0001-EN 2.1

9

Page 10

2

Safety instructions

Persons responsible for safety

2 Safety instructions

2.1 Persons responsible for safety

Operator

An operator is any natural or legal person who uses the drive system or on behalf of whom

the drive system is used.

The operator or his safety personnel is obliged

ƒ to ensure the compliance with all relevant regulations, instructions and legislation.

ƒ to ensure that only qualified personnel works on and with the drive system.

ƒ to ensure that the personnel has the Operating Instructions available for all work.

ƒ to ensure that all unqualified personnel are prohibited from working on and with

the drive system.

Qualified personnel

Qualified personnel are persons who -due totheir education,experience, instructions, and

knowledge about relevant standards and regulations, rules for the prevention of

accidents, and operating conditions - are authorised by the person responsible for the

safety of the plant to perform the required actions andwho are able torecognise potential

hazards.

(Definition for skilled personnel to VDE 105 or IEC 364)

10

K-HB 13.0001-EN 2.1

Page 11

2.2 General safety instructions

ƒ These safety information are not claimed to be complete. In case of questions and

problems, please contact your Lenze representative.

ƒ At the time of delivery the servo inverter meets the state of the art and is generally

safe to operate.

ƒ The information given in these Operating Instructions refer to the specified

hardware and software versions of the modules.

ƒ The servo inverter is a source of danger if:

– unqualified personnel work on and with the servo inverter.

– the servo inverter is used improperly.

ƒ The specifications, processes, and circuitry described in these Instructions are for

guidance only and must be adapted to your own specific application.

ƒ Make sure by appropriate measures that in the event of failure of the servo inverter

no personal injury or material damage is caused.

Safety instructions

General safety instructions

2

ƒ Operate the drive system only when it is in proper state.

ƒ Modifications or redesigns of the servo inverter are basically prohibited. In all cases

the manufacturer must be contacted.

K-HB 13.0001-EN 2.1

11

Page 12

2

2.3 Definition of notes used

Safety instructions

Definition of notes used

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

Danger!

Danger!

Stop!

Danger of personal injury through dangerous electrical

voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

Note!

Tip!

Important note to ensure trouble-free operation

Useful tip for simple handling

Reference to another documentation

12

K-HB 13.0001-EN 2.1

Page 13

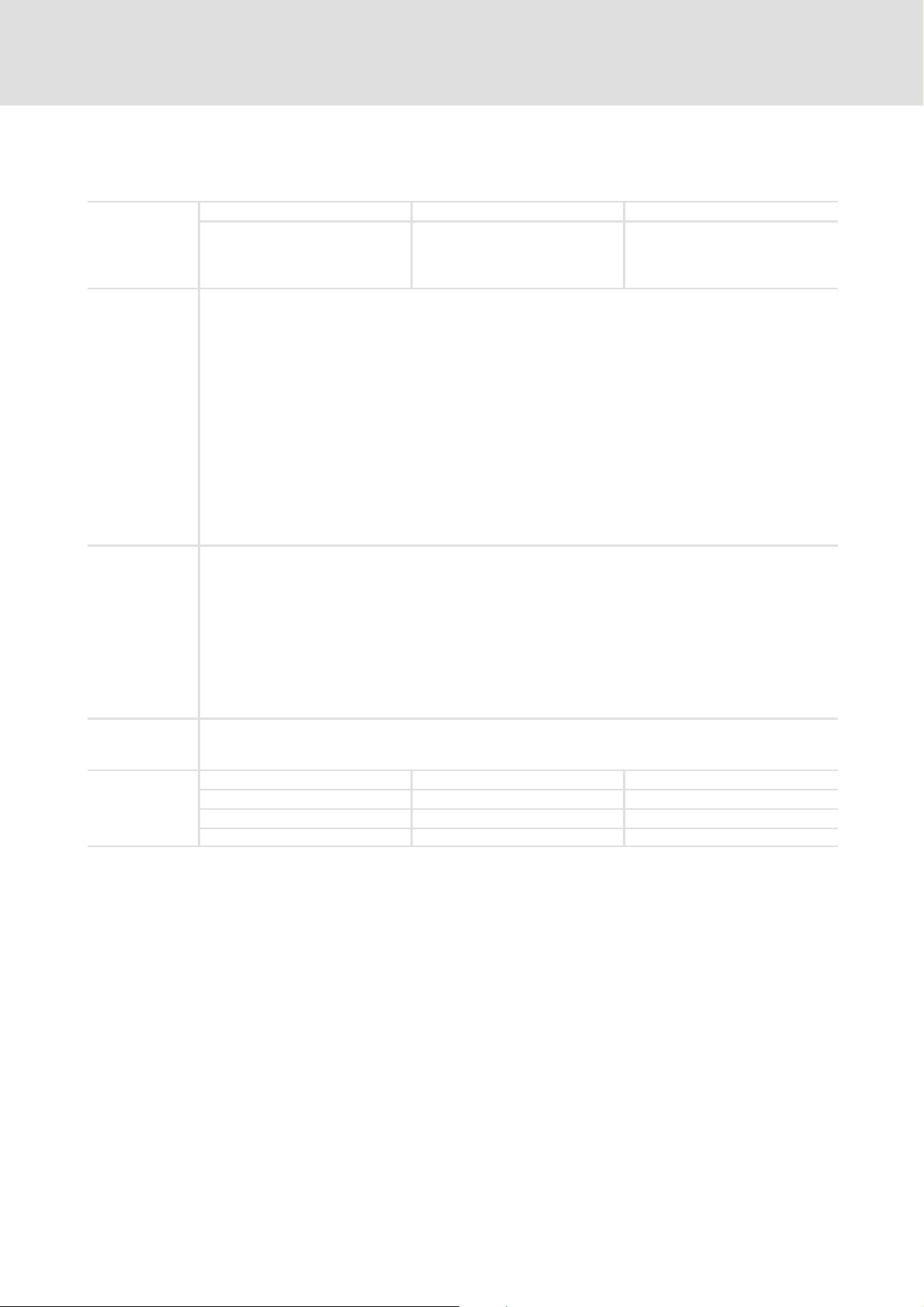

General data and operating conditions

3 Technical data

3.1 General data and operating conditions

General data

Area Values

Communication profile

(DIN 19245 part 1 and part 3)

Communication medium RS485

Drive profile Profidrive

Network topology Without repeater: Line / with repeaters: line or tree

PROFIBUS-DP station Slave

Baud rate (in kbits/s) 9.6, 19.2, 93.75, 187.5, 500, 1500

Max. cable length per bus segment 1200 m (depending on the baud rate and cable type used)

External DC voltage supply +24 V DC ±10 %

Enclosure IP54

PROFIBUS-DP-V0

Technical data

3

Operating conditions

Ambient conditions

Climatic

Storage IEC/EN 60721-3-1 1K3 (deviation: -25 ... +70 °C)

Transport IEC/EN 60721-3-2 2K3 (deviation: -25 ... +70 °C)

Operation IEC/EN 60721-3-3 3K3 (deviation: 0 ... +40 °C)

Cooling Passively via housing surface and heatsink

Pollution EN 61800-5-1 Degree of pollution 2

Site altitude < 1000 m amsl

K-HB 13.0001-EN 2.1

13

Page 14

Electrical installation4

4 Electrical installation

Structure of a PROFIBUS-DP network with RS485 cabling without repeater

1

333

931M

931W

222

1200 m

0m

No. Element Note

1 Master computer e.g. PC or PLC with PROFIBUS-DP master interface module

2 Bus cable Adapt baud rate to the length of the bus cable.

3 PROFIBUS-DP slave Applicable basic device

931M

931W

931M

931W

931m_021

Note!

When using a repeater, max. 125 stations can communicate via the PROFIBUS.

EMC-compliant wiring

For wiring according to EMC please observe the following points:

Note!

ƒ Separate control cables from motor cables.

ƒ Connect the shields of the control or data cables as follows:

– On both sides for cables with digital signals.

ƒ Further notes on wiring according to EMC can be obtained from the

instructions of the basic unit.

Wiring procedure

1. Do not change the bus topology, i.e. do not use stubs.

2. Observe the wiring notes given in the documentation for the control system.

3. Only use cables which correspond to the listed specifications.

4. Activate the bus terminating resistors at the first and last physical station.

14

K-HB 13.0001-EN 2.1

Page 15

Electrical installation 4

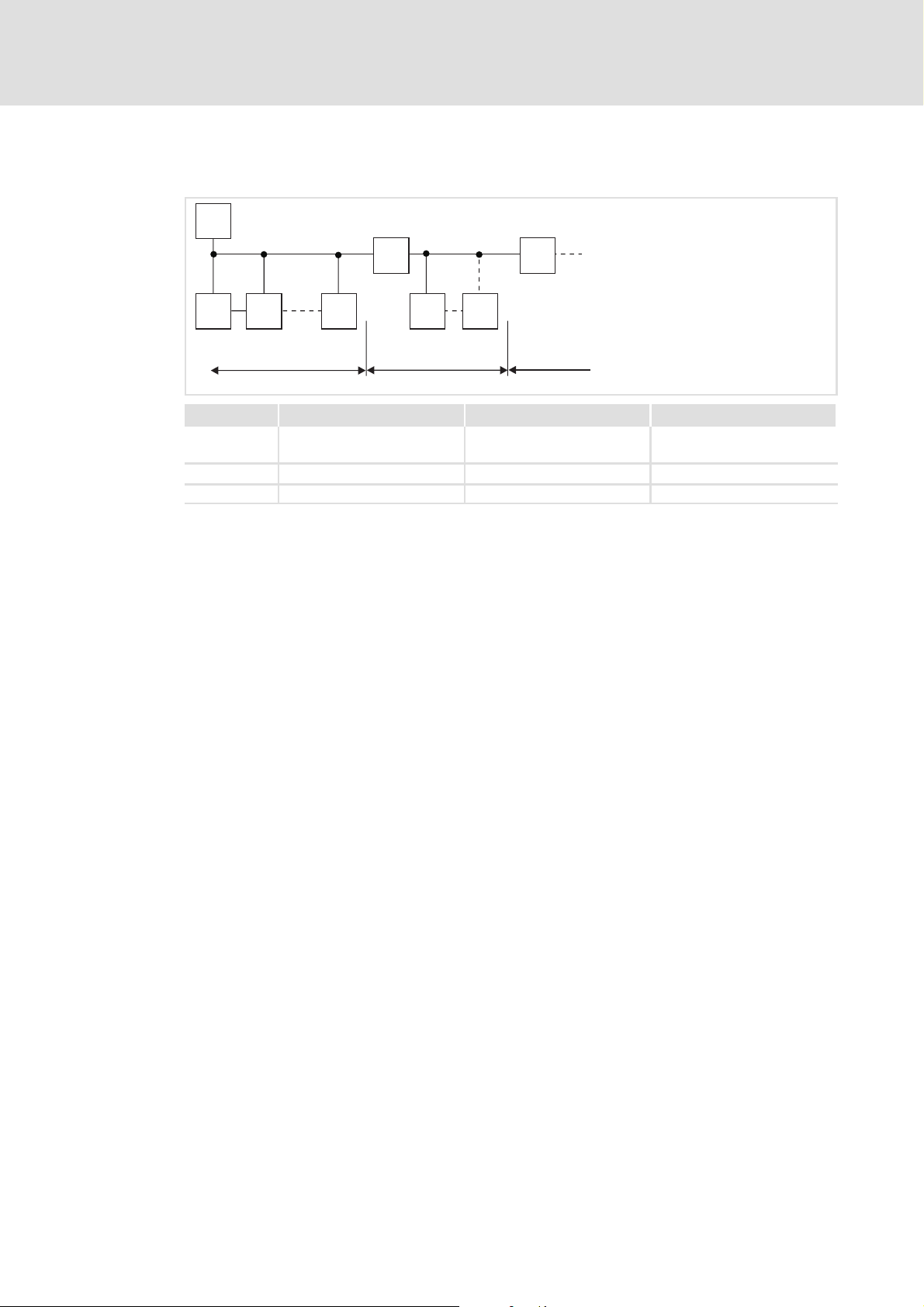

Number of bus stations

M

RR

SS S S S

123

Segment Master (M) Slave (S) Repeater (R)

1 1

2

2 - 30 1

3 - 30 1

31

30

-

-

2133PFB004

Tip!

Repeaters do not have a station address but in the calculation of the number

of stations they reduce the number of stations by 1 on each side of the

segment.

Repeaters can be used to build up line and tree topologies. In this case, the

maximum total bus system expansion depends on

ƒ the baud rate used

ƒ the number of repeaters used

K-HB 13.0001-EN 2.1

15

Page 16

Electrical installation4

Baud rate / length of the bus cable

Baud rate [kbit/s] Length [m]

9.6 - 93.75 1200

187.5 1000

500 400

1500 200

Note!

The baud rate, depending on data volume, cycle time, and number of stations,

should be only as high as required for the application.

Tip!

For high baud rates we recommend to check the use of optical fibres.

Advantages of the optical fibre:

ƒ External electromagnetic interferences have no effects on the transmission

path.

ƒ Bus lengths of several kilometres are also possible with higher baud rates.

The bus length

– does not depend on the baud rate.

– depend on the optical fibre used.

Specification of the transmission cable

Please observe our recommendations for signal cables.

Bus cable specification

Cable resistance 135 - 165 Ω/km,(f=3-20MHz)

Capacitance per unit length ≤ 30 nF/km

Loop resistance < 110 Ω/km

Wire diameter >0.64mm

Wire cross-section >0.34mm

Wires double twisted, insulated and shielded

2

16

K-HB 13.0001-EN 2.1

Page 17

Electrical installation

Electrical connection of the servo inverter with the PROFIBUS master

4.1 Electrical connection of the servo inverter with the PROFIBUS master

To meet the requirements of the enclosure IP 54, the servo inverter is equipped with screw

connectors with M12 threads.

The connection plan and assignment of the power connector of the devices can be

obtained from the Operating Instructions 931 M / W.

The following shows the assignment of a 9-pole Sub-D socket the most PROFIBUS masters

are equipped with for connecting field devices.

Connection of the PROFIBUS to 9-pole SubD socket

View Pin Designation Explanation

1

2

3

4

5

Tab. 2 Sub-D connection PROFIBUS

1 free —

6

2 free —

7

3 RxD/TxD-P Data line B (Receive / transmit data plus)

8

4 RTS Request To Send (receive / transmit data, no differential signal)

9

5 M5V2 Data ground (5 V)

6 P5V2 DC5V/30mA(bustermination)

7 free —

8 RxD/TxD-N Data line-A (receive / transmit data minus)

9 free —

4

K-HB 13.0001-EN 2.1

17

Page 18

5

Commissioning

Before switching on

5 Commissioning

5.1 Before switching on

Stop!

Before you switch on the basic unit for the first time in the PROFIBUS-DP

network, check

ƒ the entire wiring for completeness, short circuit, and earth fault.

ƒ whether the bus system is terminated at the first and last station with the

integrated active bus terminating resistor.

5.2 Activation of PROFIBUS at the servo inverter

Before operating on the PROFIBUS the configurationis carried out via the user interface of

the system. If you are not familiar with the user interface, you will find a detailed

description in the corresponding documentation (see Software Manual 931 M/W).

pÉíìé

Start the operating program and check the settings of the serial communicationinterface

in the Setup menu. The servo inverters are set by default to a baud rate of 1.5 MBaud.

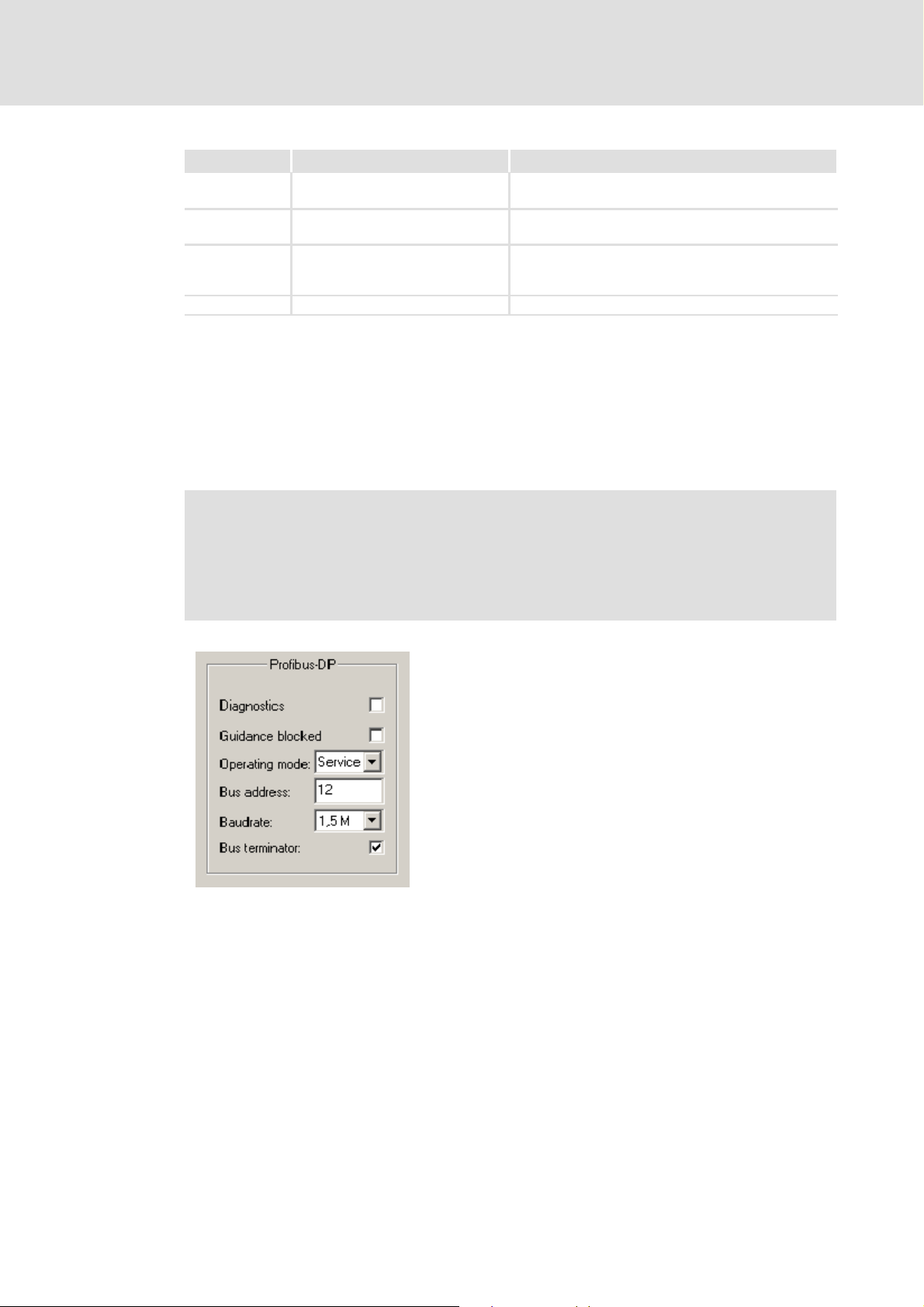

931mPro_001

18

K-HB 13.0001-EN 2.1

Page 19

Commissioning

Activation of PROFIBUS at the servo inverter

The Lenze standard RS232connecting cable is plugged in between theinverter (M8 circular

connector, 3-pole) and the COM interface of the PC (Sub-D connector 9-pole). The settings

oftheCOMinterfacemustbecheckedinthehardwaresettingsofthePC.

Note!

Select from the Setup menu Online Level 4 or Service.

5

931mPro_002

When the Diagnostics function is activated, the diagnostic alarm is switched on. As soon

as a diagnostic alarmis triggered, thedrive automatically sends 4 bytes of diagnostic data

and its start address to thecontrol. Thisserves to obtain information about ifand when an

error occurred in the servo inverter and the data in the control can be evaluated.

TheGuidance blocked servesto exclude thePROFIBUS masterfrom the access to the drive.

As soon as the PROFIBUS master requests the control authority via the drive, the drive can

onlybe startedvia thebus system(intheStatus tab the message”Fieldbus active” appears

in the status field)

K-HB 13.0001-EN 2.1

19

Page 20

5

Commissioning

Activation of PROFIBUS at the servo inverter

931mPro_003

This prevents a simultaneous access to the bus system and the operating program.

The access authorisations of the control to the inverter can be set via the operating mode

on the Setup tab. Restrictions of the access depth like before the access on the inverterby

the operating program are carried out. See Software Manual ”Access authorisations via

access levels.

Note!

ƒ In order that the PROFIBUS master has full access to the inverter (slave),

select the Service operating mode. In this mode, the process and parameter

data can be changed.

ƒ For the parameter setting of the inverter, select from the Setup tab Online

Level 4 or Service.

20

K-HB 13.0001-EN 2.1

Page 21

Commissioning

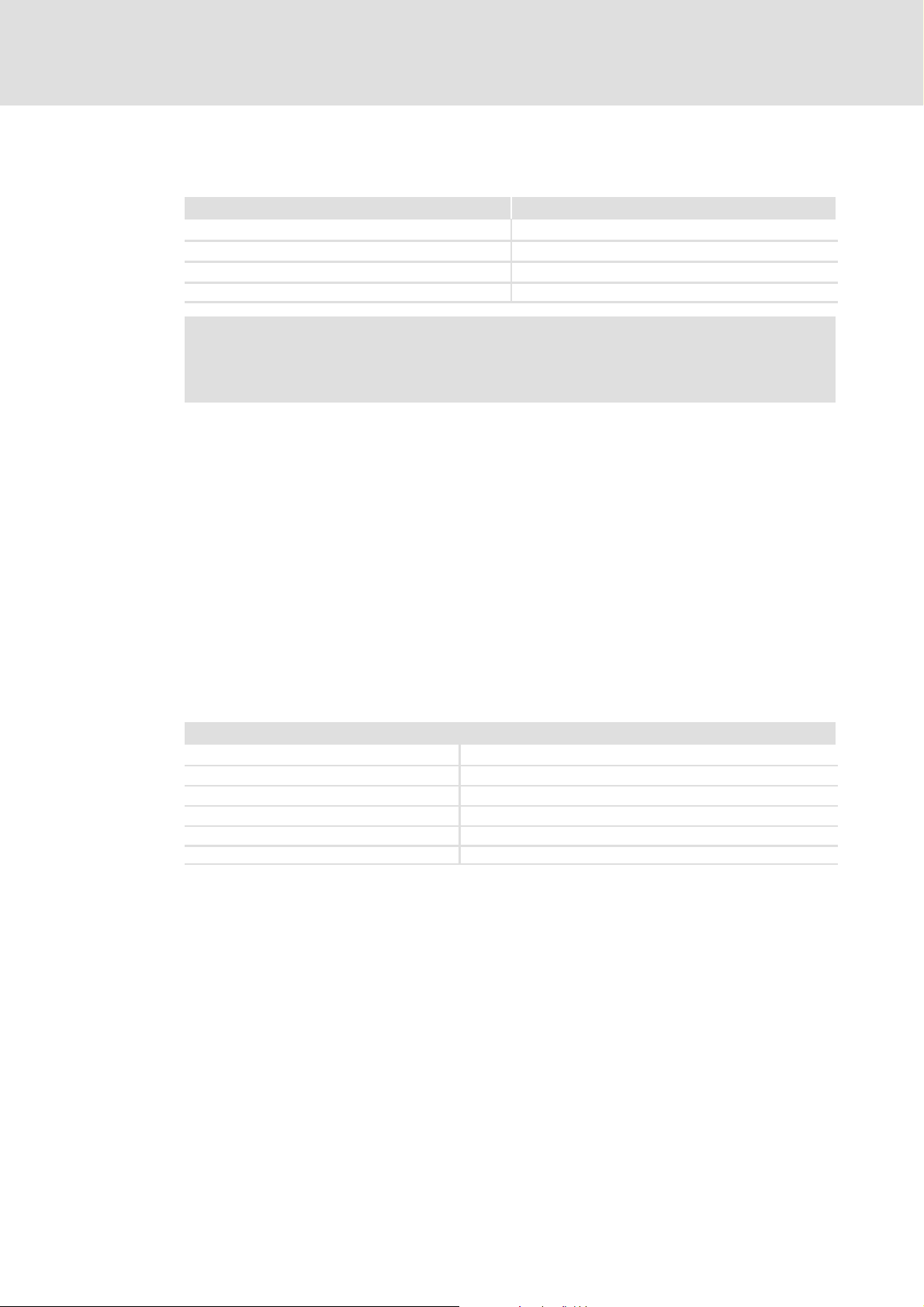

Activation of PROFIBUS at the servo inverter

Operating mode Access Restrictions

Online level 1 Observing the drive No write access, no change of parameters or process

Online level 3 Access to process data. (Setpoint

selection)

Online level 4 Access to process data and

parameter data (controller settings,

bus settings)

Service Full access No restriction

Tab. 3 Operating modes

Inthe lowerpart of theServicetab, inthe PROFIBUS-DP field,thePROFIBUSaddressandthe

baud rate can be set. Possible are baud rates of 9.6k (k = Kilobyte / 124 bytes) , 19.2k,

93.75k, 187.5k, 500k, 1.5M (M = Megabyte).

In case of the servoinverters, thebus system can belooped through.The devices have a bus

input (X4.1) and a bus output (X4.2). Ifa device shall be connected to theend of the bus line,

a terminating resistor can be activated.

data possible.

No access to parameter data (controller settings, bus

settings, basic drive configuration)

No access to basic drive settings (maximum speed,

maximum torque, …)

5

Note!

To prevent reflections of the signals, the last node must be equipped with a

terminating resistor.

In the Service tab, the checkmark must be set after ”Bus terminator” and

activated via ”Save” in the menu bar.

931mPro_005

K-HB 13.0001-EN 2.1

21

Page 22

5

5.3 PROFIBUS settings in the operating program

Commissioning

PROFIBUS settings in the operating program

mкзСбДмл am

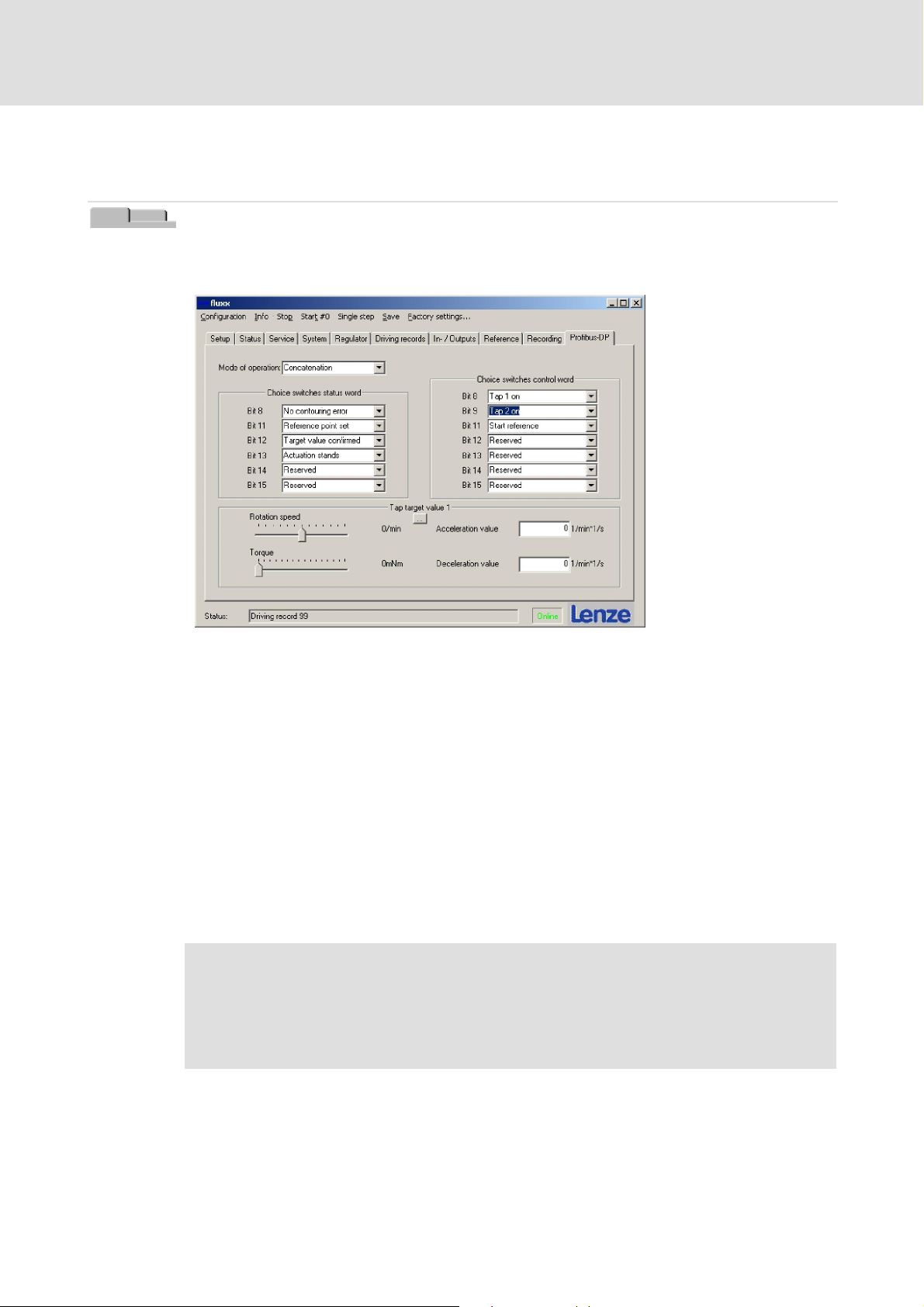

In the operating program, yet further settings can be made for the PROFIBUS operation in

the PROFIBUS-DP tab.

931mPro_004

In caseof an access authorisation higher thanlevel 3,settings can be made here which can

also be executed directly via PROFIBUS. To make access easier for the users, this tab is

inserted. After saving via PROFIBUS and re-reading the travel data records,the settings can

be displayed.

In the upper left of the operating program in the Operating mode field the following

control modes can be selected. You can change-over between the following modes:

ƒ Speed + position

ƒ Speed

ƒ Position

ƒ Concatenation (following error operation / speed control)

This change-over has the same effect as using the parameter number 930 (PNU930).

Note!

If a series of travel data records is to be started via the PROFIBUS which is

written into the drive via the operating program, the concatenation mode

must be selected. In the other operating modes, no series of travel data records

is executed. The drive only carries out single-step operation!

22

K-HB 13.0001-EN 2.1

Page 23

Commissioning

PROFIBUS settings in the operating program

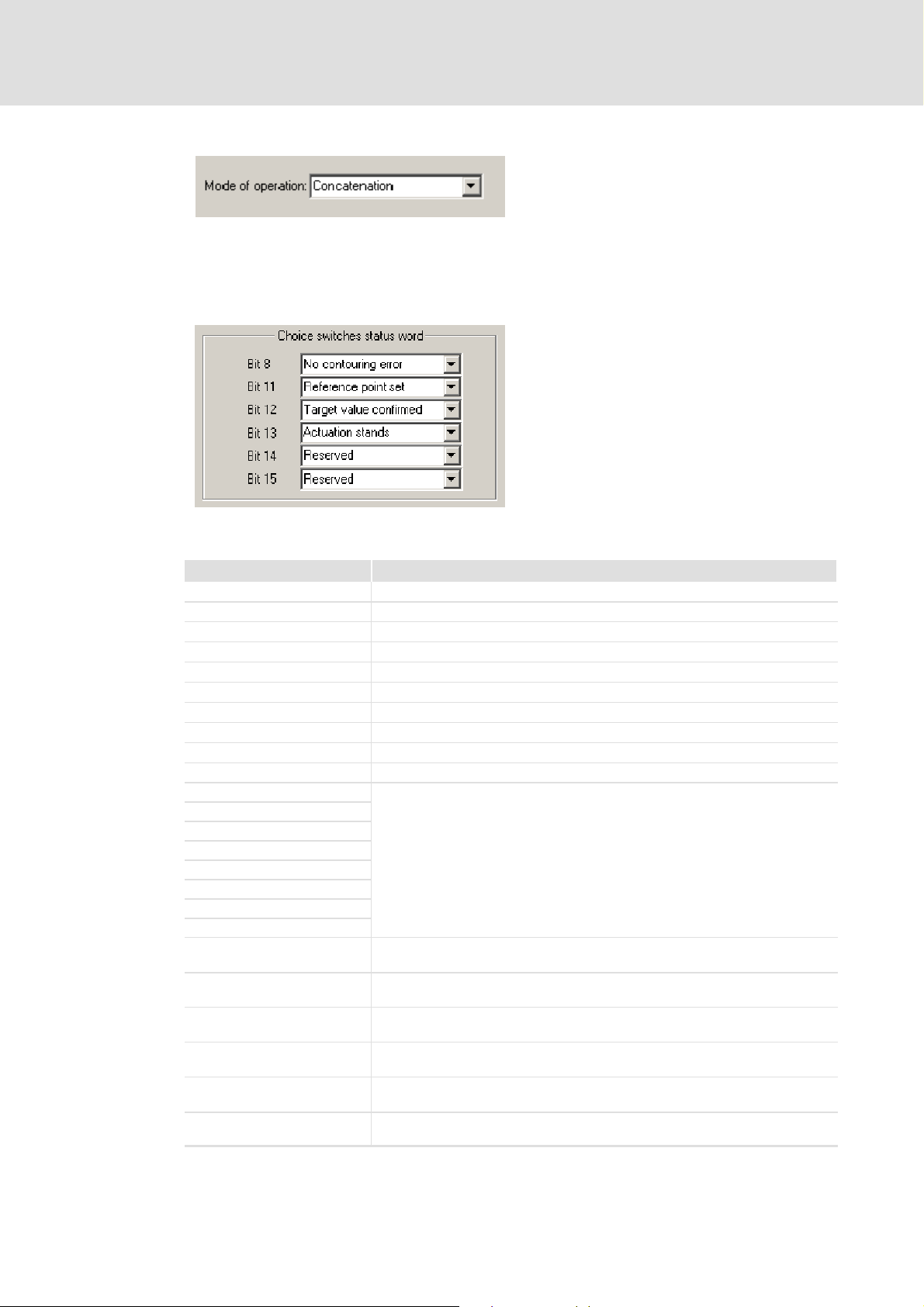

931mPro_006

The operating program also offers the option to display further binary drive data in the

status word.. The bits 8, 11, 12, 13 and 14 can be assigned with other functions than set by

default.

5

931mPro_007

The following display functions listed in the table are available:

Function Description

Brake engaged Brake is applied

Limit switch, left Left limit switch is activated

Limit switch, right Right limit switch is activated

Quick stop Quick stop has been initiated

Reference switch The reference switch is activated

Reference window

Edit data record Data record is being edited / control is active

Digital output Display output of a device with I/O option

Application box output Display application box output of a device with Local CAN option

Digital input Display input of a device with I/O option

Application box 1-BCD

Application box 2-BCD

Application box 4-BCD

Application box 8-BCD

Application box 10-BCD

Application box 20-BCD

Application box 40-BCD

Application box 80-BCD

Application box start Display application box start of a device with Local CAN option (see description

Application box stop Display application box stop of a device with Local CAN option (see description

Application box - left limit

switch

Application box - right limit

switch

Application box - quick stop Display application box quick stop of a device with Local CAN option

Application box input Display application box of a device with Local CAN option (see description of

Tab. 4 Additional functions - status word

Display application box of a device with Local CAN option (see description of

application box)

of application box)

of application box)

Address left application box limit switch of a device with Local CAN option

(see description of application box)

Display right application box limit switch of a device with Local CAN option

(see description of application box)

(see description of application box)

application box)

K-HB 13.0001-EN 2.1

23

Page 24

5

Commissioning

PROFIBUS settings in the operating program

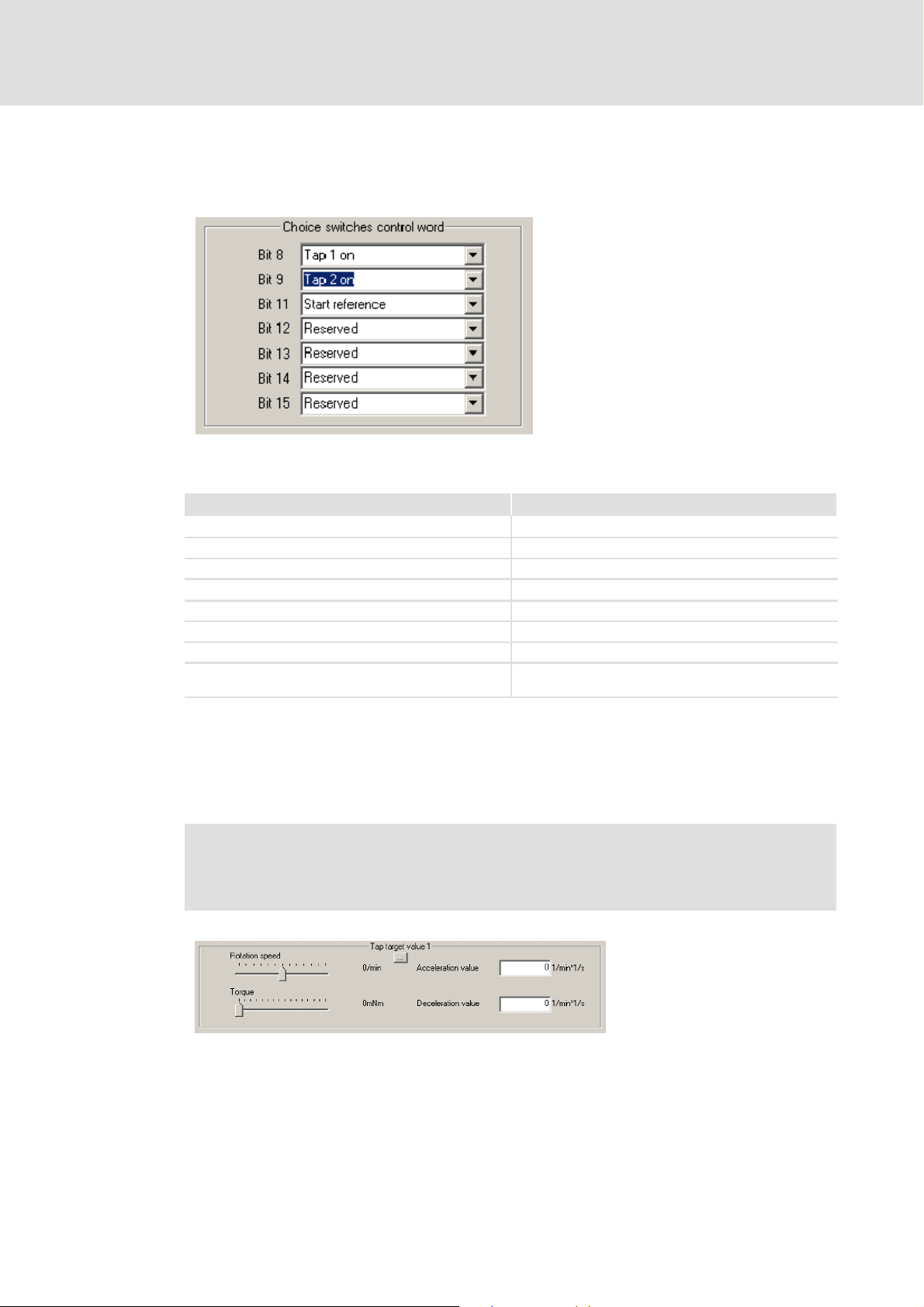

In addition to the display functions, it is possible to set other actions in the control word

which can be addressed.

931mPro_008

The functions are as follows:

Function Description

Engage brake Trigger brake

Activate left limit switch Activate left limit switch

Activate right limit switch Activate right limit switch

Quick stop Activate quick stop

Activate reference switch Activate reference switch

Activate reference window Activate reference window

Activate digital output Activate output of a device with I/O option

Activate application box output Activate application box output of a device with Local

Tab. 5 Additional functions - control word

CAN option.

In the lower part of the PROFIBUS DP field values for the jogging mode can be entered.

Speed, torque, acceleration valueand deceleration value for both joggingsetpoints can be

entered for thejogging mode, which is designed as a mechanical setting-up operation. The

change-over between jogging setpoint 1 and jogging setpoint 2 is done via the field ” ...”.

Danger!

In the jogging mode it is possible to traverse beyond the mechanical limit

switches! The software limit switches are active.

931mPro_009

24

K-HB 13.0001-EN 2.1

Page 25

5.4 PROFIBUS communication

5.4.1 GSE file for PROFIBUS connection

The device data base file (GSE) for DP slaves (e.g. servo inverter of type 931) contains

characteristic device features of the DP components. Here, it is stored, for instance, which

baud rates and special DP modes are supported by the slave.

Each master needs the corresponding device data base file for a non-ambiguous

identification of slaves on the bus. The GSE file for the servo inverters of the Fluxxtorque

series is attached in the appendix and can also be downloaded from www.Lenze.com.

5.4.2 Hardware configuration

Steps for installing the hardware in the PROFIBUS project:

ƒ Install the GSE file ”93MW058F.GSE” (version 1.0) according to the settings of the

project planning software for the DP master. After the installation is completed, the

”931_M_W” device appears among the slave nodes.

Commissioning

PROFIBUS communication

GSE file for PROFIBUS connection

5

ƒ Insert the fieldbus interface module into the PROFIBUS structure using the name

”931_M_W” and assign the PROFIBUS address.

ƒ Select the process data configuration required for your application ( 26).

ƒ Indicate the I/O address for the projected data widths.

ƒ Save the configuration.

ƒ Expand your user program by the data exchange with the servo inverter.

ƒ After the project is saved and loaded into the DP master (e.g. an S7 control of the Fa.

Siemens) and the DP master is started, the LED ”Bus-F” of the MFP/MQP should go

off. If not, check the wiring and terminating resistors of the PROFIBUS as well as the

project planning, especially the PROFIBUS address.

K-HB 13.0001-EN 2.1

25

Page 26

5

Commissioning

PROFIBUS communication

Structure of communication channel

5.4.3 Structure of communication channel

Generally, only communication functions can beset under theHW configurationwhich are

also supported by the servo inverter. The bandwidth of this communication is defined via

the process data configuration. The parameter process data objects (PPOs) serve to select

a pre-defined write and read access to the control and status word by certain ”modules”.

Depending on the selected PPO a certain number of input and output areas, or combined

input and output areas are available. Furthermore, the area selection also determines the

consistency check, data length, and the unit of the data to be transmitted.

PPOs which are sent to the slave by themaster are interpreted as output data (Write-PPO).

Master -> data -> slave: Output data.

PPOs which are received by the master from the slave are interpreted as input data

(Read-PPO). Slave -> data -> master: Input data.

Four different module combinations (PPOs) are available for the process data

configuration:

PPO type 3 PPO Write type

Process data input (input data)

PZD1: Status word X X X X

PZD2: Active travel data record X X X X

PZD3: S p eed — X — X

PZD4: Torque — X — X

PZD5 ... 6: Position — X — X

Process data output (output data)

PZD1: Control word X X X X

PZD2: Actual value = active travel

data record

Parameter data input (input data/PPO

Read)

Number — 2 2 6

Parameter data output (output data/PPO

Write)

Number — — 2 2

Tab. 6 Configuration of the PPO types

X X X X

3 PPO Read type

4

PPO type 1 PPO Write type

1 PPO Read type

2

The configurations ”PPO Write type 3, PPO Read type 4“ and ”PPO type 3” cannot be used

for parameterising the drive. These configurations, however, only provide a lower

utilisation of the bus system, which means a lower data volume. They transmit 16 bytes

less data (8 bytes transmitted data and 8 bytes received data) per telegram than the PPOs

3and4.

Note!

In case of some PROFIBUS master systems HIGH and LOW byte of the process

data and parameter data channel are exchanged!

26

K-HB 13.0001-EN 2.1

Page 27

Control word / status word

General information

6 Control word and status word (Profidrive state machine)

6.1 General information

The servo inverter is controlled via two different access types:

1. The parameters of the inverter are accessed via the acyclic parameter channel

DP-V1. This serves to adapt, change, or set e.g., the controller settings or the driving

records. ( 41).

2. The state of the drive is changed via the state machine. The control word (STW) and

the status word (ZSW) are especially important here. The control word, which is sent

as process data cyclically from the PROFIBUS master (e.g. of a control) to the servo

inverter, changes the state of the drive. This change is detected and confirmed by

the status word which is transmitted from the servo inverter to the master. A

master control can use this information on the drive status to manage the servo

drive.

6

According to the Profidrive profile 2 control words (STW1 and STW2) and 2 status words

(ZSW1 and ZSW2), the single bits of which are defined in this standard with regard to their

meaning, to control the drive. Regarding the control, only the control word 1 (STW1) and

status word 1 (ZSW1) are important for the 931M/W servo inverter. For this reason, only

control and status word 1 will be explained in the following, leaving out the figure ”1” in

the description.

The next three subchapters describe in detail the structure of the control and status word

as well as the state machine and status changes. The change of parameters via the

parameter channel will be explained in the chapter ”Parameter channel” ( 41).

K-HB 13.0001-EN 2.1

27

Page 28

6

6.2 Control word

Control word / status word

Control word

The meaning of the single bits of the control word partly depends on the control selected.

Two control types, speed and positioning control, are available (concerning this see the

parameter PNU 930). In theTab. 7 those bits of the control word are explainedthe meaning

of which are firmly defined irrespective of the controller type. The Tab. 8 and Tab. 9

describe the bits with a controller type-specific meaning. The Tab. 8 contains a detailed

description of the bits for a speed-controlled system and the Tab. 9 describes a

position-controlled system.

To address the inverter via the PROFIBUS master, first the control authority must be

requested bysetting the bit 10 in the control word. Without the control authority thedrive

cannot be accessed. The control authority enables the user to e.g. to start and stop a drive

via the control word or the state machine. ( 33). The user cannot change parameters

with the control authority(e.g. driving records or controlparameters). For this purpose, the

parameter change rights must be requested, see PNU 927 ( 52). The following chapters

describe indetail the connection between thecontrol authority andthe parameter change

rights.

28

K-HB 13.0001-EN 2.1

Page 29

Control word / status word

Bit Value Significance Meaning

0

1

ON Condition for the S3 status ”Ready for operation”: In this status the output

0 OFF 1 Switched-off status: The drive returns to S2 status ”Ready to switch on”.

1

1 No OFF 2 No coasting of the drive is requested.

0 OFF 2

(coasting of the

drive)

2

1 No OFF 3 No quick stop of the drive is requested.

0 OFF 3

(quick stop)

3

1 Enable operation The pulses for the output stage are switched on and the drive changes to

0 Disable operation The drive is braked along the set deceleration ramp to 0 min-1.Afterthat,

7

1 Acknowledging error

(0 → 1)

0

10

1 Control via PLC

(requesting control

authority)

0 No control via PLC No control authority via the drive. Drive status cannot be influenced by

12-15 Device-specific These device-specific bits are not used.

Tab. 7 Overview of the non-controller-type specific bits of the control word

stage is supplied with voltage but not yet connected through (no voltage

at the motor).

When the drive is switched on it is braked along a ramp to zero speed.

When the drive is at standstill, the output stage will be switched off.

Coasting of the drive: The output stage is switched off and the motor

coasts without control to zero speed. After that, the drive changes to the

S1 status ”Switch-on inhibit”.

Quick stop: The drive is braked with maximum power to 0 min-1.Aquick

stop command cannot be cancelled once it has been issued. After quick

stop is terminated, the drive changes to the S1 status ”Switch-on inhibit”.

S4 status ”Operation enabled”. A voltage is applied to the motor

terminals. If a setpoint has been accepted before (see bit 6 STW), this

setpoint is approached.

the drive changes to S3 status ”Ready for operation”.

An error is acknowledged by a positive edge (0→1) on bit 7. The response

of the drive depends on the severity of the error. In case of fatal errors the

drive changes to S1 status ”Switch-on inhibit”.

Requesting control authority: When a control authority is requested, the

status can be changed by a PLC via the PROFIBUS.

the PLC.

6

Control word

K-HB 13.0001-EN 2.1

29

Page 30

6

Control word / status word

Control word

Bit Value Significance Meaning

4

1

Switched-on ramp

generator

0 Reset of the ramp

generator

5

1 Standard ramp

generator

0 Freezing of the ramp

generator

6

1 Accept the setpoint The setpoint which is defined via the current driving record is accepted

0 Do not accept the

setpoint

8

1 JOG1 on Jogging: If JOG1 is switched on from the S4 status ”Operation enabled”,

0 JOG1 off No jogging: If a jogging mode is running it will be terminated. The drive is

9

1 JOG2 on Jogging: If JOG1 is switched on from the S4 status ”Operation enabled”,

0 JOG2 off No jogging: If a jogging mode is running it will be terminated. The drive is

11 Device-specific This device-specific bit is not used.

Tab. 8 Overview of the controller-type specific bit of the control word for a speed-controlled drive

The ramp generator which prevents an abrupt rise of the speed setpoint is

active.

The output of the ramp generator is set to 0 min-1. The drive brakes

considering the current limitation.

No impact (standard function of the ramp generator)

The current setpoint of the ramp generator is ”frozen”.

and transmitted to the ramp function generator.

The setpoint for the ramp function generator is set to 0.

the drive (JOG setpoint selection: see XXX) runs until JOG1 is switched off.

braked to standstill along the deceleration ramp. Afterwards the drive

changes to the S4 status ”Operation enabled”.

the drive (JOG setpoint selection: see XXX) runs until JOG1 is switched off.

braked to standstill along the deceleration ramp. Afterwards the drive

changes to the S4 status ”Operation enabled”.

Bit Value Significance Meaning

4

1

Do not reject the

setpoint

0 Reject the setpoint The drive is braked with maximum acceleration ? to zero speed and

5

1 No intermediate

stop

0 Intermediate stop The drive is braked to zero speed from the active positioning along the

6 Accept the setpoint

(Edge, 0 → 1or

1 → 0)

8

1 JOG1 on Jogging: If JOG1 is switched on from the S4 status ”Operation enabled”,

0 JOG1 off No jogging: If a jogging mode is running it will be terminated. The drive is

9

1 JOG2 on Jogging: If JOG1 is switched on from the S4 status ”Operation enabled”,

0 JOG2 off No jogging: If a jogging mode is running it will be terminated. The drive is

11 Device-specific This device-specific bit is not used.

Tab. 9 Overview of the controller-type specific bit of the control word f or a position-controlled drive

The selected setpoint which is accepted with an edge of bit 6 is

approached.

remains on this position.

No intermediate stop is made. The selected setpoint which is accepted

with the edge of bit 6 is approached.

deceleration ramp. The standstill position is held with a holding torque. By

resetting bit 5 the running positioning is continued.

An edge serves to accept or start a new positioning job or setpoint. A new

setpoint shall only be accepted if a homing process (bit 1 of the status

word) and the previous driving request (bit 12 of the status word) have

been terminated before.

the drive (JOG setpoint selection: see XXX) runs in a speed-controlled

mode until JOG1 is switched off.

braked to standstill along the deceleration ramp. Afterwards the drive

changes to the S4 status ”Operation enabled”.

the drive (JOG setpoint selection: see XXX) runs in a speed-controlled

mode until JOG1 is switched off.

braked to standstill along the deceleration ramp. Afterwards the drive

changes to the S4 status ”Operation enabled”.

30

K-HB 13.0001-EN 2.1

Page 31

6.3 The status word (ZSW)

The current status of the drive is output in the status word and made available to the

master control or PLC. By analogy with the explanation of the control word, first the

meanings of the controller type independent bits of the status word are explained in

Tab. 10. Then the bits with the controller type-specific meaning are explained in Tab. 11

(speed control) and Tab. 12 (position control).

Bit Value Significance Meaning

0

1

Ready to switch on Device is power-supplied, electronics is initialised. Pulses for power section

0 Not ready to switchonDrive is in the S1 status ”Switch-on inhibit”.

1

1 Ready for operation The drive is ready for operation (status S2). In this status, the output stage

0 Not ready for

operation

2

1 Operation enabled The drive is in S4 status ”Operation enabled”. The current setpoint is

0 Operation not

enabled

3

1 Error is pending A non-acknowledged error (see bit 7 of the control word) or an error that

0 No error No error is currently pending.

4

1 Coasting function is

deactivated (no

OFF 2)

0 Coasting function is

active (OFF 2)

5

1 Quick stop function

is deactivated (no

OFF 3)

0 Quick stop function

is active (OFF 3)

6

1 Switch-on inhibit The drive can only change from the S1 state ”Switch-on inhibit” to the S2

0 No switch-on inhibit The drive is in a higher status than S1 ”Switch-on inhibit”.

7

1 Warning is active A warning is pending. The warning does not need to be acknowledged.

0 No warning No warning is pending.

9

1 Control authority is

required

0 Control authority is

not required

14-15 Device-specific These device-specific bits are not used.

Tab. 10 Overview of the non-controller-type specific bits of the status word (ZSW)

Control word / status word

The status word (ZSW)

are suppressed.

is supplied with voltage but not yet enabled (see bit 0 of the control word).

The device is not ready for operation.

processed (see bit 3 of the control word).

Either the pulses are switched off (no voltage at the motor) or the drive

does not follow the setpoint.

cannot be acknowledged is pending at the drive. The response of the drive

is error and device-specific. In case of a fatal error it is changed to status S1

”Switch-on inhibit”. The error can - if the cause has been removed - be

cancelled by an acknowledgement.

The coasting function (see bit 1 ”OFF 2” of the control word) is not active

(bit1STW=1).

The coasting function (see bit 1 ”OFF 2” of the control word) is active (bit 1

STW = 0).

The quick stop function (see bit 2 ”OFF 3” of the control word) is not active

(bit2STW=1).

The quick stop function (see bit 2 ”OFF 3” of the control word) is active (bit

2STW=0).

state ”Ready to switch on” by changing the control word (no OFF2 (bit 1

STW) and no OFF3 (bit 2 STW) followed by ON (bit 0 STW)). After that the

bit 6 of the ZSW returns to 0 (no switch-on inhibit).

The control authority is required for the control (PLC) communicating via

PROFIBUS (see bit 10 of the control word). The drive can be commissioned

via the PROFIBUS.

The drive cannot be controlled via the control (PROFIBUS). Either the

control authority must be requested (see bit 10 of the control word) or the

drivemustbecommissionedviaanotherinterface(seeparameterisation

software Fluxx).

6

K-HB 13.0001-EN 2.1

31

Page 32

6

Control word / status word

The status word (ZSW)

Bit Value Significance Meaning

8

1

Setpoint inside a

tolerance margin

0 Setpoint outside the

tolerance margin

10

1 Setpoint reached The setpoint speed (n) or setpoint frequency (f) has been reached.

0 Setpoint not reached The setpoint speed (n) or setpoint frequency (f) has not been reached.

11-13 Device-specific These device-specific bits are not used.

Tab. 11 Overview of the controller-type specific bit of the status word for a speed-controlled drive

Bit Value Significance Meaning

8

1

Following errors

inside the following

error window

0 Following errors

outside the

following error

window

10

1 Target position

reached

0 Target position not

reached

11

1 Reference set Homing has been executed and a home position has been set.

0 Reference has not

been set

12 Edge for setpoint

13

Tab. 12 Overview of the controller type-specific bits of the status word for a position-controlled drive.

acceptance (0 → 1,

1 → 0)

1 Drive in standstill Thedrivestandsduetoastop/intermediatestoporbecausethetarget

0 Drive is moving Positioning is carried out (n ≠ 0min-1).

The setpoint is inside a required tolerance margin.

The setpoint is outside the required tolerance margin.

The following error is inside the required following error window.

The following error is outside the required following error window.

The current position corresponds to the position setpoint, considering the

position window.

Position setpoint and actual value do not correspond, considering the

position window.

No valid home position exists.

An edge of this bit indicates that a new setpoint / driving record has been

accepted (see bit 6 of the control word)

position has been reached.

32

K-HB 13.0001-EN 2.1

Page 33

State machine and general state diagram

6.4 The Profidrive state machine

6.4.1 State machine and general state diagram

The status of the drive can be changed via the state machine. The single state transitions

are carried out depending on the control word or error management. Basically, the

following states exist according to the Profidrive profile:

ƒ S1: Switch-on inhibit

ƒ S2: Ready to switch on

ƒ S3: Ready for operation

ƒ S4: Operation enabled

ƒ S5: Switching-off/braking

In addition to these states the following substates can be defined which permit a further

concretion of the states mentioned above.

Control word / status word

TheProfidrivestatemachine

6

ƒ Not ready to switch on (initialisation phase of the inverter)

ƒ Fault (drive stands due to an error, acknowledgement is required)

ƒ Fault reaction is active (braking process is active due to an error)

ƒ Quick stop is active

The controland positioning processestake place inthe S4 status (”Operation enabled”).To

reach this status, the other single states must be passed before by changing the

corresponding bits of the control word.

Note!

To change states, the control authority is required (see bit 10 of the control

word)!

Fig. 1 shows the state machine in theform ofa statediagram. To provide a better overview,

only the main states from S1 to S5 are represented. For the sake of simplicity, the state

transitions marked by arrows are provided with the required changes of the bits of the

control word.

K-HB 13.0001-EN 2.1

33

Page 34

6

Control word / status word

TheProfidrivestatemachine

State machine and general state diagram

Bit 1 = 0: No Off2 = 0

Bit 2 = 0: No Off3 = 0

Bit 1 = 0: No Off2 = 0

Bit 2 = 0: No Off3 = 0

Bit 0 = 0: No Off2=0

Switch-on

of power

supply

S1:

Switch-on

inhibit

Bit 0 = 0: ON = 0

Ready to

switch on

Bit 0 = 1: ON = 1 Bit 0 = 0: ON = 0

Ready for

operation

Bit 3 = 1:

Enable Operation = 1

Operation

enabled

Bit 0 = 0: On = 0

Bit 1 = 0: No Off2 = 0

Bit 2 = 0: No Off3 = 0

S2:

S3:

Bit 3 = 0:

Enable Op eration = 0

S4:

At standstill or

Bit 3 = 0, Enable Operation = 0

Bit 0 = 0: ON = 0

At standstill or

Bit 3 = 0, Enable Operation = 0

Braking along

Bit 0 = 1: ON = 1

Fig. 1 General representation of the state diagram

Bit 1 = 0: No Off2 = 0

Bit 1 = 0:

No Off2 = 0

S5: Switching-off

Quick stop:

ramp

Bit 2 = 0: No Off3 = 0 (Quick s top)

Braking along

Bit 2 = 0:

ramp

931m_022

The current status of the drive can be obtained from the status word (ZSW) of the drive. In

the Tab. 13 the single bits of the status word and the states are listed.

34

K-HB 13.0001-EN 2.1

Page 35

Control word / status word

TheProfidrivestatemachine

State machine and general state diagram

6

Status

S1 switch-on inhibit 1 X 0 0 0 0

S2 ready to switch on 0 1 0 0 0 1

S3 ready for operation 0 1 0 0 1 1

S4 operation enabled 0 1 0 1 1 1

S5 switch-off 0 X X 1 1 1

Not ready to switch on 0 X 0 0 0 0

Fault 0 X 1 0 0 0

Fault response is active 0 X 1 1 1 1

Quick stop is active 0 0 0 1 1 1

Tab. 13 Confrontation of the states of the device and the status word (ZSW) in bit format

Bit 6 Bit 5 Bit 3 Bit 2 Bit 1 Bit 0

Switch-on

inhibit

Quick stop Fault Enable

operation

Ready for

operation

Ready to

switch on

In all states - despite the ”Not ready to switch on” status, which is only pending a short

while after switching on the voltage supply (self-initialisation) - the parameters of the

servo inverters may be reparameterised by the parameter channel ifthe parameterchange

rights (see PNU 927) was requested before. The changes of the control word required for

the status changes are shown in Fig. 1.

Note!

For safety reasons the servo inverter can only be operated from an interface.

This means that the parameter change rights may either be occupied by the

Fluxx operating program or the control (PROFIBUS).

If an operating program with level 2 or higher has been selected at the

inverter, no parameter change rights can be requested via the PROFIBUS. In

this case it is required to change the operating mode of the Fluxx program on

level 1 (monitoring) or offline.

As aforementioned, the real control process takes place in the status S4 ”operation

enabled”. To, e.g. accept a setpoint or start homing, further changes o f the controlword are

required. Since these changes depend on the set control, the state diagrams for a

speed-controlled and a position-controlled system will be described separately.

K-HB 13.0001-EN 2.1

35

Page 36

6

Control word / status word

TheProfidrivestatemachine

Example: State machine for speed operation

6.4.2 Example: State machine for speed operation

In this example, the drive is to be commissioned with the predefined driving record no. 1

(n = 2400 1/min; M = 1320 mNm) with speed control.

The selected PPO type 3 permits the writing and reading of the control word / status word

and the selection of the pre-programmed driving records. The selected PPO type

determines the input and output addresses of the registersto bedescribed (”buffer”)in the

frequency inverter. It is mandatory for the state transitions to write the control words

stepwise; the following table displays the bit patterns for a better understanding:

Status High byte STEW (1. address) Low byte STEW (2. address)

s1 0000 0100 0011 0110

S2 0000 0100 0011 0111

S3 0000 0100 0111 1111

S4 0000 0100 1011 1111

S5 0000 0100 1011 1110

Tab. 14 Control word state transitions - speed example

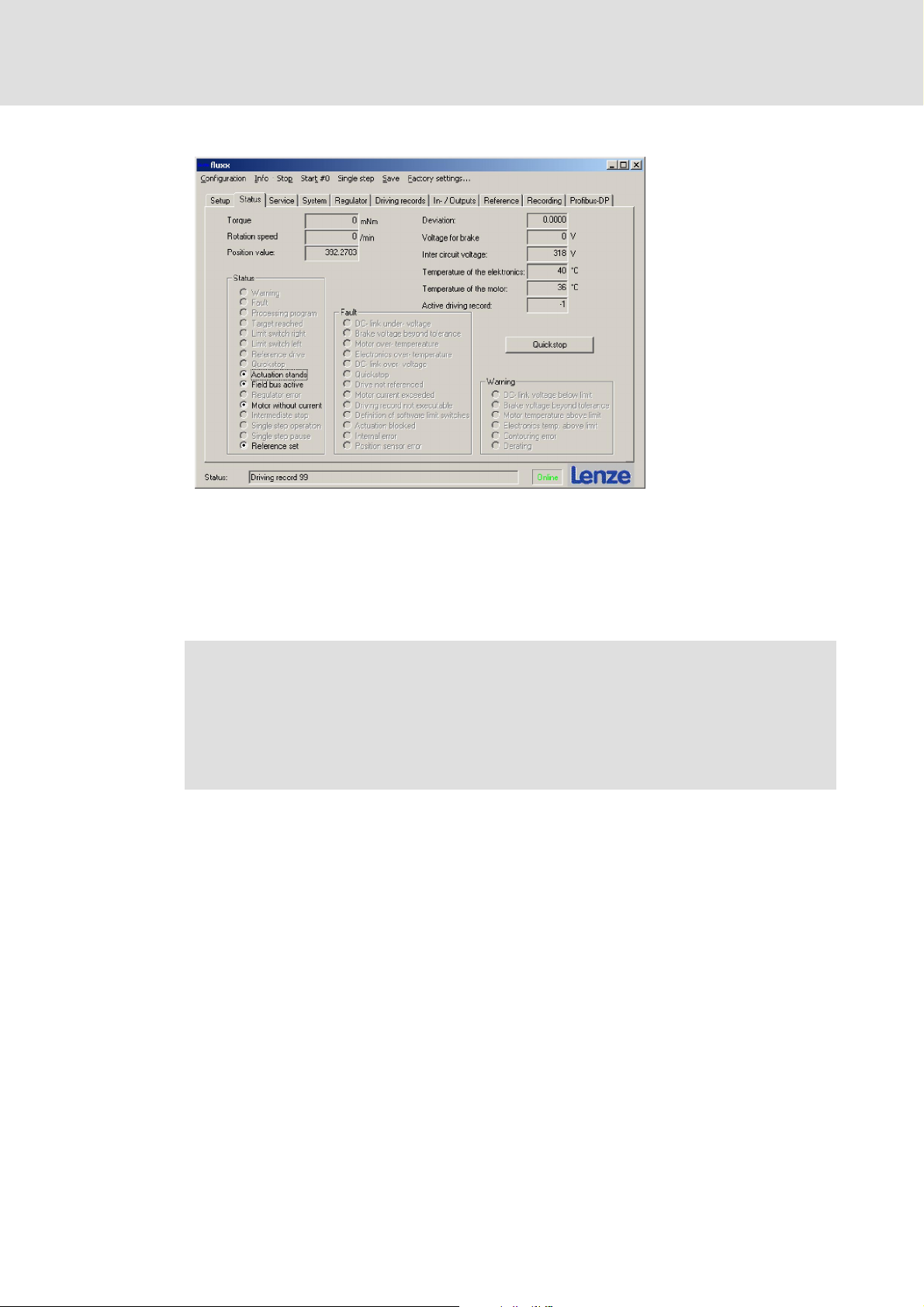

As aforementioned, it is possible to open a PROFIBUS monitor via the ”Display fieldbus”

field in the ”Service”tab ofthe operatingprogram. The following screenshots illustrate the

single steps of the state machine by means of the PROFIBUS monitor:

Status S1: Switch-on inhibit Status S2: Ready to switch on

931mPro_010 931mPro_011

36

K-HB 13.0001-EN 2.1

Page 37

Control word / status word

TheProfidrivestatemachine

Example: State machine for speed operation

Status S3: Ready for operation Status S4: Operation enabled

931mPro_013 931mPro_012

S5: Switching off / Braking -> identical with S4 except for bit no. 0.

6

K-HB 13.0001-EN 2.1

37

Page 38

6

6.4.3 State diagram for positioning

Control word / status word

TheProfidrivestatemachine

State diagram for positioning

Fig. 2 shows the state machine for aposition-controlled drive in the basic state ”Operation

enabled”.

931m_023

Fig. 2 State machine ins the ”positioning” mode

In this operating status, the following actions can be executed via the control word:

1. Via bit 11 of the STW homing can be started. Bit 11 in the ZSW ”Home position is

set” indicates if a home position is set (valid). If homing is started, the display

”Homing set” (bit 11) is cancelled. The type of homing (direction, speed, etc.) is

application and device-specific and is hence not described in the profile. For this

purpose the parameters required for homing (PNU 101) must be checked before.

2. To accept a new setpoint or change a driving record, the edge of bit 12 of STW

”Setpoint acknowledgement” must be changed. This starts and executes the

positioning mode.

3. Via the function JOG1 and JOG2 (bit 8 and bit 9 of STW) a jogging mode can be

carried out.

38

K-HB 13.0001-EN 2.1

Page 39

Control word / status word

TheProfidrivestatemachine

State diagram for positioning

Stop!

In case of a jogging mode (JOG1 and JOG2) the software and hardware limit

switches are not evaluated!

The drive is not limited with regard to its permitted travel range!

During the positioning process, several options exist to intervene in the process:

1. A travel request can be interrupted using the command ”Intermediate stop” (bit 5 of

STW). The drive brakes along the set deceleration ramp to standstill. The current job

request is stopped and can be continued by cancelling the command ”Intermediate

stop”.

2. In the ”Intermediate stop” state, homing can be started.

3. A travel request can be cancelled using the command OFF1 (bit 0 of STW: Drive off),

OFF2 (bit 1 of STW: Coasting) or OFF3 (bit 2 of STW: Quick stop). The drives brakes

depending on the mode selected to standstill and then changes to S1 status

”Switch-on inhibit” (OFF2, OFF3) or S2 ”Ready to switch on”.

6

A travel request is terminated when the drive has reached its setpoint. This is displayed

with the status bit 10 ”Setpoint reached”.

The ”Concatenation” mode enablesspeed-controlled and positioning driving recordsto be

started without taking special measures. Here, the following driving records and waiting

times between the concatenated driving records are considered. Further information can

be obtained from the explanation of the object PNU 100.

K-HB 13.0001-EN 2.1

39

Page 40

6

6.4.4 State diagram for speed control

Control word / status word

TheProfidrivestatemachine

State diagram for speed control

Fig. 3 shows the state machinefor aspeed-controlled drive in the basic state S4”Operation

enabled”. Many functions of the illustrations shown are similar to the ones of section

( 38) so that only deviant functions shall be explained here.

40

931m_024

Fig. 3 State machine in the ”speed control” mode

As explained in section ”State diagram for positioning” ( 38),the jogging mode can also

run in speed-controlled operation.

Through an edge of bit 6 of STW a new speed setpoint or driving record is accepted and

executed. The drive can be braked via the functions OFF1, OFF2 and OFF3. ( 38).

K-HB 13.0001-EN 2.1

Page 41

Parameter channel (PCV mechanism)

7 Parameter channel (PCV mechanism)

Certain drive functions are further accessed via the parameter characteristic value (PCV)

mechanism.The PCVmechanism servesto process parameters in cyclicdata exchange.The

PCV mechanism is used to:

ƒ operate and observe parameters (master -> slave).

ƒ transfer spontaneous messages (slave -> master -> slave).

Moreover, it serves to, e.g.:

ƒ set control authority and parameter change rights

ƒ define setpoints

ƒ read out status information

ƒ configure limit switches.

Inthe PCVmechanism, themaster definesa job,the slaveprocesses thejob andformulates

the response. Jobs and responses cannot be blocked. Each PPO-Write contains exactly one

job and each PPO-Read contains exactly one response. Hence, maximally 4 user data bytes

can be transmitted with one job or one response. In the parameter ID, job/response and

the corresponding parameters are coded.

7

Access authorisation

7.1 Access authorisation

Since the parameter characteristic value mechanism (PCV) serves to access setpoints and

parameters, the user should pay attention to the access authorisation. For setpoint

selection, the PROFIBUS master requires the parameter change rights over the servo

inverter. A simultaneous access of the operating program and a PROFIBUS master is

neither possible nor sensible.

In the ”Level 0” operating mode, the operating program can be used to observe the drive.

When commissioning, the current status of the drive can be observed at the same time. If

the operatingprogram is logged onthe servo inverter with an operating mode higher than

”Level 1”, an access conflict occurs and the PROFIBUS master cannot access the drive.

The operating program enables the user to configure the access authorisation of the

PROFIBUS master to the servo inverter, as described in chapter ”Activation of PROFIBUS at

the servo inverter”. ( 18) .

K-HB 13.0001-EN 2.1

41

Page 42

7

Parameter channel (PCV mechanism)

Structure of the parameter characteristic value

Structure of parameter identification (PKE)

7.2 Structure of the parameter characteristic value

When processing the PCV, a job identification, the corresponding PNU (parameter

number) and a value are transmitted. The job identification indicates if data of different

sizes are to be written or requested. The single job identifications are listed in Tab. 19. The

PNUs which arespecified subsequently serve to define the object, the value to be changed

and the access. The PNU number (represented decimally) must be first converted into a

hexadecimal numerical format and can thus be processed directly or entered binary. Then

the basicstructure of the PCV mechanism is shown.The procedure is to be explained using

an example.

Area Description

Parameter

characteristic

value (PCV)

PKE Parameter number (PNU) and job or response identification

IND Subindex and reserved area

PWE Since the higher-order bits (bits 16 ... 31) are not used, they must be set to ”0”. Lower-order

bits (bits 0 ... 15): Parameter values.

Tab. 15 Abbreviations - PCV mechanism

7.2.1 Structure of parameter identification (PKE)

The following table shows the binary structure of the PCV message:

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

SPM

Job identification

Tab. 16 Structure of parameter identification

Job identification Job or response identification (value range 0 ... 15)

SPM Toggle bit for spontaneous message processing

PNU Parameter number (value range 1 ... 1999)

7.2.2 Subindex

The subindex serves to ensure, e.g., an assignment to the correct parameter value in an

array

Bit 7 6 5 4 3 2 1 0

Value

Tab. 17 Subindex

Parameter number (PNU)

7.2.3 Parameter value

The values of the individual objects are transmitted with the parameter value.

Byte 7 6 5 4 3 2 1 0

Value

Tab. 18 Parameter value

42

K-HB 13.0001-EN 2.1

Page 43

Parameter channel (PCV mechanism)

7.3 Job and response processing

The job andresponse processing is defined sothat the identification shows which fields of

the PCV interface (IND,PWE) must be evaluated. Moreover, a distinction is made between

parameter value and parameter description.

7.3.1 Job identification (master -> slave)

To change a parameter value the slave must receive a job identification from the master

(see Tab. 19). This job identification depends on the data type or format to be changed

(word, double word, array).

After the slave has received and executed the job successfully, a corresponding response

is generated (see Tab. 20), which also shows transmission errors. The response data is

available at the slave as long as a new job is transmitted.

7

Job and response processing

Job identification (master -> slave)

Job identification Function

0Nojob 0

1 Request parameter value 1, 2 7

2 Change parameter value (word) 1 7, 8

3 Change parameter value (double word) 2 7, 8

4 Request describing element (double word) 3 7

5 Change describing element 3 7, 8

6 Request parameter value (array) 4, 5 7

7 Change parameter value (array word) 4 7, 8

8 Change parameter value (array double word) 5 7, 8

9 Request number of array elements 6 7

Tab. 19 Overview of job identifications

Response identification

Positive Negative

K-HB 13.0001-EN 2.1

43

Page 44

7

Parameter channel (PCV mechanism)

Job and response processing

Response identification (slave -> master)

7.3.2 Response identification (slave -> master)

The response shows if the transmission was successful or if a transmission error occurred.

The response helps to exactly locate the error. The following table contains all responses

to the implemented job identifications.

Note!

If a parameter of the slave in double word format is to be changed, but the job

identification refers to a change of a parameter in word format, the slave

responds with a corresponding error message / number (see Tab. 21).

Response identification Function

0Nojob

1 Transmit parameter value (word)

2 Transmit parameter value (double word)

3 Transmit describing element

4 Transmit describing element (array word)

5 Transmit describing element (array double word)

6 Transmit number of array elements

7 Job cannot be executed (with error number)

8 No parameter change rights for PCV interface

9 Spontaneous message - word

10 Spontaneous message - double word

Tab. 20 Overview of response identifications

If jobs cannot be executed, the slave responds with an error number.

44

K-HB 13.0001-EN 2.1

Page 45

7.3.3 Error numbers at response

Error number Information Detailed description

0 Impermissible PNU The parameter number is not assigned.

1 Parameter value cannot be

changed

2 Loweroruppervaluelimit

exceeded

3 Faulty subindex The indicated subindex of the object does not exist or a

4 No array The addressed object is no array type.

5 Wrong data type The object has been addressed as a wrong data type. See

6 No setting permitted (only

resettable)

7 Describing element cannot be

changed

8 PPO - Write requested in the IR is

not available

9 Description data not available

10 Wrong access group Access error! The PROFIBUS interface has no parameter

11 No parameter change rights Parameter change rights not requested or access not

12 Wrong password A password has been assigned which must be entered for

13 Text in cyclic traffic cannot be

read

14 Name in cyclic traffic cannot be

read

15 No text array available

16 PPO - Write is missing When installing the hardware a wrong data type was

17 Job cannot be executed due to

operating status

18 Other errors

19 ... 100 Date in the cyclic traffic cannot

be read

Tab. 21 Overview of error messages - job identifications

Parameter channel (PCV mechanism)

Job and response processing

Error numbers at response

This is a non-writable object, e.g. an actual value.

Thepermissiblewritablelimitrangeoftheobjecthasbeen

exceeded. Please observe object limits.

format error exists. Check entries.

job identification table.

No setting permitted (only resettable)

Elements such as the serial numbers cannot be changed.

When installing the hardware a wrong data type was

selected. Please check the HW settings.

change rights. See PNU 927.

Possible error: Parameter change rights have not been

requested. The operating program and PROFIBUS master try

to access the drive simultaneously. Wrong software

settings in the operating program. (See activation of

PROFIBUS)

possible.

processing. See password.

selected. Please check the HW settings.

Check operating status. Is an error pending at the drive?

Errorscanbeobservedviathesoftwareintheonlinelevel1

under Status.

7

The error numbers 0 ... 100 are defined or reserved profile-oriented.

K-HB 13.0001-EN 2.1

45

Page 46

7

Parameter channel (PCV mechanism)

Job and response processing

Examples of PCV mechanism

7.3.4 Examples of PCV mechanism

Example 1: Request parameter change rights:

To requestthe parameter change rights a parameter valuemust be transmitted, sothe job

identificationis 2.The PNUnumber is927. Thiscorresponds to39F inthe hexadecimaldata

format. The value 1 is transmitted as parameter value. The parameter value serves to

transmit the control authority to the PROFIBUS master. After this action, the operating

program cannot access the servo inverter anymore.

Parameter identification:

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Binary value 0 0 1 0 0 0 1 1 1 0 0 1 1 1 1 1

Hexadecimal value 2 3 9 F

Request parameter

value

Subindex

PNU