Page 1

KHB 13.0002−EN

.Ckò

Ä.Ckòä

Communication Manual

Servo Drives 930

931E/K

CANopen

l

Page 2

0Fig. 0Tab. 0

2

l

KHB 13.0002−EN 4.1

Page 3

Contents i

1 About this documentation 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Document history 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Conventions used 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Notes used 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Product description 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Product features 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Technical data 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Communication data 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Electrical installation 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Wiring according to EMC 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Electrical connections of CANopen 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Connection of CAN bus slave 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Connection of CAN bus master 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 CANopen communication 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 About CANopen 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Structure of the CAN data telegram 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Identifier 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Node address (node ID) 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.4 User data 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Parameter data transfer (SDO transfer) 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Telegram structure 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Reading parameters (example) 23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Writing parameters (example) 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Process data transfer (PDO transfer) 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 Telegram structure 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.2 Available process data objects 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.3 Objects for PDO parameterisation 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.4 Description of the objects 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.5 Example of a process data telegram 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.6 Activation of the PDOs 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Sync telegram 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Telegram structure 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Synchronisation of the process data 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Description of the objects 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Network management (NMT) 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Communication phases of the CAN network (NMT) 41 . . . . . . . . . . . . . . . .

5.5.2 Telegram structure 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KHB 13.0002−EN 4.1

l 3

Page 4

Contentsi

5.6 Emergency telegram 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Telegram structure 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Description of the objects 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Heartbeat telegram 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Telegram structure 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Description of the objects 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 Boot−up telegram 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8.1 Telegram structure 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 Node guarding telegram 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.1 Overview 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.2 Telegram structure 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.3 Description of the objects 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Commissioning 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Activation of CANopen 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Speed control 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Parameterising of a process data object (TPDO and RPDO) 57 . . . . . . . . . . .

6.2.2 Parameterising of the motor and the current controller 60 . . . . . . . . . . . . .

6.2.3 Parameterising of the speed control 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 Running through the state machine 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Position control 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Parameter setting 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Parameterising of the homing run 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Running through the state machine 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Loading and saving of parameter sets 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 Overview 69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Description of the objects 71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Conversion factors (factor group) 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Overview 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Description of the objects 74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Power stage parameters 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Overview 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Description of the objects 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Current controller and motor adaptation 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.1 Overview 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4.2 Description of the objects 79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Speed controller 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Overview 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Description of the objects 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 4

KHB 13.0002−EN 4.1

Page 5

Contents i

7.6 Position controller (position control function) 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.1 Overview 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.2 Description of the objects 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 Analog inputs 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7.1 Overview 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 Digital inputs and outputs 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.1 Overview 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.2 Description of the objects 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9 Limit switches 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.1 Overview 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.9.2 Description of the objects 88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10 Device information 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.10.1 Description of the objects 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Device control 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 State diagram 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Overview 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 State diagram of the drive controller 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.3 States of the drive controller 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.4 State transitions of the drive controller 94 . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.5 Control word 95 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.6 Controller state 98 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.7 Status word 99 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Operating modes 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Setting of the operating mode 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 Overview 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2 Description of the objects 101 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Speed control 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Overview 103 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Description of the objects 105 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Homing 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.1 Overview 106 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.2 Description of the objects 107 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3.3 Control of the homing run 108 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Positioning 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.1 Overview 109 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 Description of the objects 110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 Functional description 111 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KHB 13.0002−EN 4.1

l 5

Page 6

Contentsi

9.5 Synchronous position selection 113 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.1 Overview 113 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Description of the objects 114 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.3 Functional description 115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 Torque control 119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.1 Overview 119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 Description of the objects 120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Appendix 121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Index table 121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 Index 145 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 6

KHB 13.0002−EN 4.1

Page 7

1 About this documentation

Contents

This documentation only contains descriptions for the CAN bus system and

CANopen−specific functions for servo inverters of the 931 series.

) Note!

This documentation completes the mounting instructions coming with the

931 servo inverter and the corresponding hardware manual.

The mounting instructions and the hardware manual contain safety

instructions which must be observed!

ƒ The features of the CAN bus system and CANopen−specific functions for servo

inverters of the 931 series are described in detail.

ƒ Typical applications are illustrated by use of examples.

About this documentation 1

ƒ Furthermore, this documentation contains:

– the most important technical data for CAN communication;

– information on the installation and commissioning of the CAN network;

– information on the CAN data transfer, CAN monitoring functions,

communication−relevant parameters, and different operating modes.

The theoretical connections are only explained as far as required for understanding the

CAN communication for servo inverters of the 931 series.

All trade names listed in this manual are trademarks of their respective owners.

Validity information

The information given in this documentation is valid for servo inverters of the 931 series.

Target group

This documentation addresses to all persons designing, installing, commissioning, and

setting the servo inverters of the 931 series.

I Tip!

Documentation and software updates for further Lenze products can be found

on the Internet in the "Services & Downloads" area under

http://www.Lenze.com

KHB 13.0002−EN 4.1

l

7

Page 8

1

About this documentation

Document history

1.1 Document history

Material number Version Description

– 1.0 LKA First edition

– 1.1 LKA Revision

13190599 2.0 11/2006 TD34 Complete revision

13344512 3.0 04/2010 TD34 Extended by the 931K servo inverter, chapter "Node

13347463 4.0 08/2010 TD09 Complete revision

.Ckò 4.1 03/2012 TD09 Extended table − index 1018

Your opinion is important to us!

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e−mail us to:

feedback−docu@Lenze.de

guarding telegram" has been added, general revision

h

Thank you for your support.

Your Lenze documentation team

1.2 Conventions used

This documentation uses the following conventions to distinguish between different

types of information:

Type of information Identification Examples/notes

Spelling of numbers

Decimal separator

Text

Program name » « PC software

Icons

Page reference ^ Reference to another page with additional

Point In general, the decimal point is used.

For instance: 1234.56

For example: »Engineer«, »Global Drive

Control« (GDC)

information

For instance: ^ 16 = see page 16

8

l

KHB 13.0002−EN 4.1

Page 9

About this documentation

Notes used

1

1.3 Notes used

The following pictographs and signal words are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

} Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph and signal word Meaning

{ Danger!

} Danger!

( Stop!

Danger of personal injury through dangerous electrical voltage.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of personal injury through a general source of danger.

Reference to an imminent danger that may result in death or

serious personal injury if the corresponding measures are not

taken.

Danger of property damage.

Reference to a possible danger that may result in property

damage if the corresponding measures are not taken.

Application notes

Pictograph and signal word Meaning

) Note!

I Tip!

,

Important note to ensure troublefree operation

Useful tip for simple handling

Reference to another documentation

KHB 13.0002−EN 4.1

l

9

Page 10

2

Product description

Product features

2 Product description

2.1 Product features

CAN bus features:

ƒ Full compatibility according to CANopen DS301, V4.02.

ƒ Support of NMT slave "Heartbeat" function (DS301 V4.02).

ƒ Number of parameterisable server SDO channels:

– max. 2 channels with 1 ... 8 bytes

ƒ Number of parameterisable PDO channels:

– max. 2 transmit PDOs (TPDOs) with 1 ... 8 bytes (can be set)

– max. 2 receive PDOs (RPDOs) with 1 ... 8 bytes (can be set)

ƒ All PDO channels have the same functions.

ƒ Data reception monitoring of RPDOs

ƒ Adjustable error response to ...

– physical CAN errors (frame, bit, ACK errors)

– bus stop, bus working

– absent PDOs

ƒ Bus status diagnostics

ƒ Emergency telegram generation

ƒ Sync telegram generation and response to sync telegrams:

– Send/receive data

– Synchronisation of internal time base

ƒ Abort codes

10

l

KHB 13.0002−EN 4.1

Page 11

3 Technical data

3.1 Communication data

Communication

Field Values

Communication profile DS 301, DSP 402

Communication medium RS232

Network topology Without repeater: line / with repeaters: line or tree

CAN node Slave

Baud rate (in kbps) 125, 250, 500

Max. cable length per bus segment 1000 m (depending on baud rate and cable type)

Bus connection RJ45 (931E), M12 (931K)

Technical data

Communication data

3

KHB 13.0002−EN 4.1

l

11

Page 12

4

Electrical installation

Wiring according to EMC

4 Electrical installation

4.1 Wiring according to EMC

General notes l The electromagnetic compatibility of the drive depends on the type of installation and the care taken.

Assembly l Electrical contacting of the mounting plate:

Shielding l If possible, only use braided cables.

Earthing l Electrical contacting of the mounting plate:

Especially observe:

– Assembly

– Shielding

– Earthing

l In the case of differing installations, the evaluation of the conformity to the EMC Directive requires the

system to be checked for compliance with the EMC limit values. This applies, for instance, to:

– Use of unshielded cables

l The user is responsible for compliance with the EMC Directive.

– If the following measures are observed, you can assume that no EMC problems will occur during operation

and that the EMC Directive / EMC law is met.

– If devices are operated close to the system which do not meet the CE requirements regarding the noise

immunity according to EN 61000−4−2, these devices may be electromagnetically impaired by the drive.

– Mounting plates with conductive surface (galvanised or stainless steel) enable a permanent contact.

– Painted plates are not suitable for an EMC−compliant installation.

l If you use several mounting plates:

– Contact the mounting plates to each other over a large area (e.g. with copper strips).

l Route signal cables separately from mains cables.

l Route the cables as close as possible to the reference potential. Freely suspended cables act like aerials.

l The overlap rate of the shield should be higher than 80%.

l Always use metal or metallised connectors for the serial data cable coupling. Connect the shield of the data

cable to the connector shell.

l Use metal cable clamps to attach the shield braid.

l Connect the shield to the shield bus in the control cabinet.

l Connect the shields of analog control cables at one end.

– Mounting plates with conductive surface (galvanised or stainless steel) enable a permanent contact.

– Painted plates are not suitable for an EMC−compliant installation.

l If you use several mounting plates:

– Contact the mounting plates to each other over a large area (e.g. with copper strips).

l Route signal cables separately from mains cables.

l Route the cables as close as possible to the reference potential. Freely suspended cables act like aerials.

12

l

KHB 13.0002−EN 4.1

Page 13

Electrical installation

Electrical connections of CANopen

4

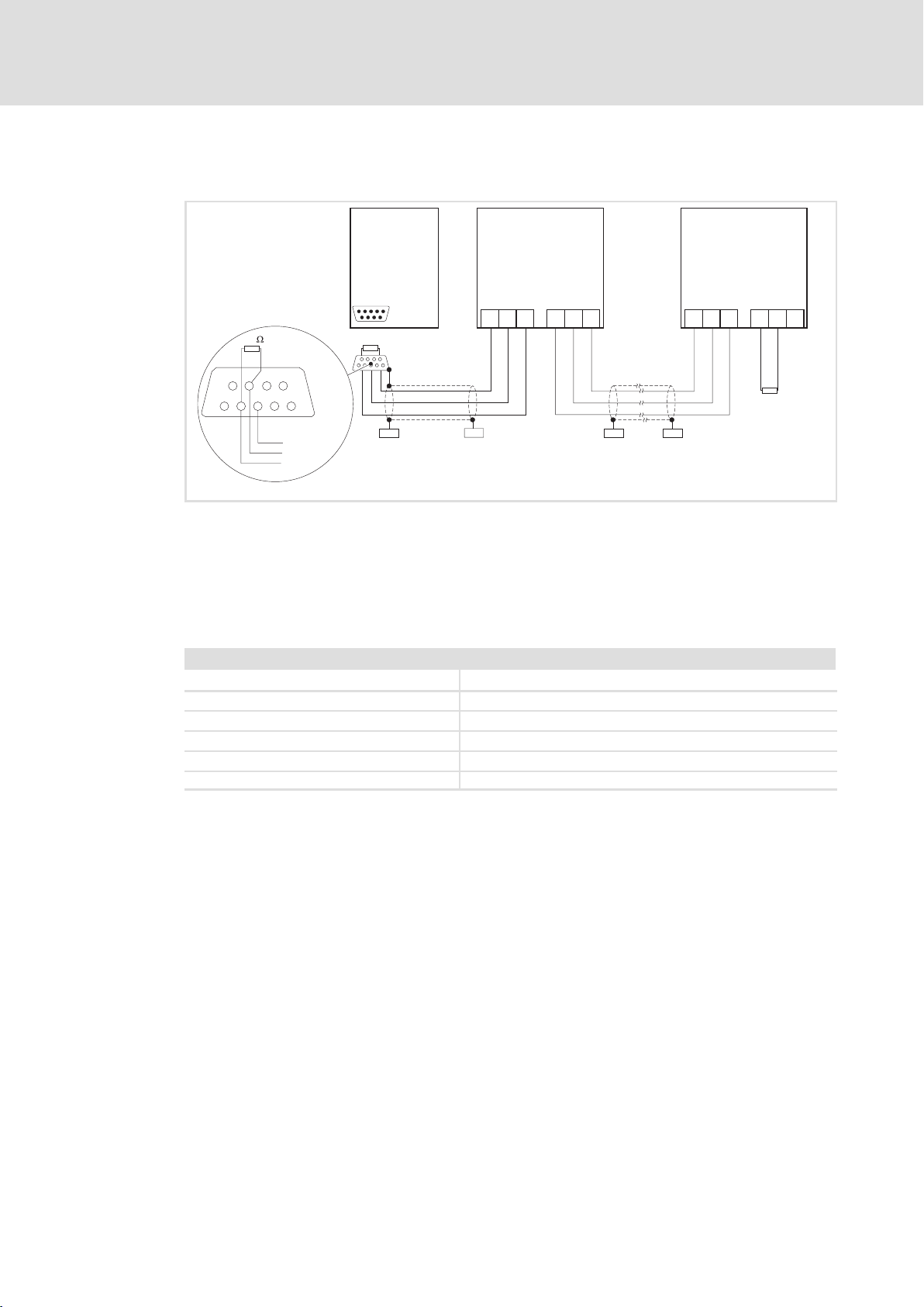

4.2 Electrical connections of CANopen

A

1

120

6

1

2

9

7

8

5

3

4

CAN-GND

CAN-HIGH

CAN-LOW

Fig. 1 Basic wiring of CANopen with Sub−D connector to the master

Node 1 − master (e.g. PLC)

A

1

Node 2 − slave (e.g. drive controller 931E)

A

2

A

Node n − slave, n = max. 127

n

120

W

PES

A

2

X4.1 X4.1X4.2 X4.2

CG CGCG CGHI HIHI HI

LO LOLO LO

PES

PES

PES

A

n

W

120

931e_420

Specification of the transmission cable

Please observe our recommendations for signal cables.

Bus cable specification

Cable resistance 135 − 165 W/km, (f = 3 − 20 MHz)

Capacitance per unit length £ 30 nF/km

Loop resistance < 110 W/km

Wire diameter > 0.64 mm

Wire cross−section > 0.34 mm

2

Wires double twisted, insulated and shielded

ƒ Connection of the bus terminating resistors:

– One resistor of 120 W each at the first and last bus node

ƒ Communication protocol

– CANopen (CAL−based communication profile DS 301/DSP 402)

ƒ Bus extension:

– 40 m for max. data transfer rate of 1 Mbps

– Up to 1 km for reduced data transfer speed

ƒ Signal level according to ISO 11898

ƒ Up to 128 bus nodes possible

KHB 13.0002−EN 4.1

l

13

Page 14

4

Electrical installation

Connection of CAN bus slave

4.3 Connection of CAN bus slave

Features

ƒ Parameter selection

ƒ Data exchange between drive controllers

ƒ Connection of operator and input devices

ƒ Connection of higher−level controls

ƒ Baud rates of 125, 250, 500 kBaud

( Stop!

An external 120 W terminating resistor is required to terminate the bus system.

Connection plan for RJ45 socket (931E)

X4.1 / X4.2

931E−001.iso

Fig. 2 Connection of CAN bus (X4.1, X4.2)

Pin no. Meaning Comment

1 CAN−HIGH CAN−HIGH (high is dominant)

2 CAN−LOW CAN−LOW (low is dominant)

3 CAN−GND CAN ground

4 Reserved

5 Reserved

6 CAN−SHLD CAN shield (hardware version 1.1 and higher)

7 CAN−GND CAN ground

8 Reserved

14

l

KHB 13.0002−EN 4.1

Page 15

Connection plan for M12 socket (931K)

X4.1 / X4.2

Input contact

pattern

Output contact

pattern

Pin Signal Explanation

1 CAN_SHLD CAN_Shield

2 Reserved

3 CAN_GND CAN_Ground

4 CAN_H CAN_HIGH (high is dominant)

5 CAN_L CAN_LOW (low is dominant)

4.4 Connection of CAN bus master

The below table shows the assignment of a 9−pin Sub−D socket such as provided by most

CAN masters for the connection of field devices.

Electrical installation

Connection of CAN bus master

4

Connection of the CAN bus to a 9−pin Sub−D socket

View Pin Signal Explanation

1

2

3

4

5

Tab. 1 CAN Sub−D socket

1 Reserved

6

2 CAN−LOW CAN−LOW (low is dominant)

7

3 CAN−GND CAN ground

8

4 Reserved

9

5 (CAN−SHLD) Optional CAN shield

6 (GND) Optional ground

7 CAN−HIGH CAN−HIGH (high is dominant)

8 Reserved

9 (CAN−V+) Optional external CAN voltage supply

KHB 13.0002−EN 4.1

l

15

Page 16

5

CANopen communication

About CANopen

Structure of the CAN data telegram

5 CANopen communication

5.1 About CANopen

The CANopen protocol is a standardised layer 7 protocol for the CAN bus. This layer is based

on the CAN application layer (CAL), which has been developed as a universal protocol.

In practice, however, it became clear that applications with CAL were too complex for the

user. CANopen is a uniform, easy−to−use structure which has been developed to provide a

connection for CAN devices from different manufacturers.

5.1.1 Structure of the CAN data telegram

Control field CRC delimit. ACK delimit.

Start RTR bit

CRC sequence ACK slot End

Fig. 3 Basic structure of the CAN telegram

5.1.2 Identifier

The principle of the CAN communication is based on a message−oriented data exchange

between one sender and many receivers. All nodes can send and receive

quasi−simultaneously.

The identifier in the CAN telegram − also called COB ID (communication object identifier) −

is used to control which node is to receive a sent message. In addition to the addressing,

the identifier contains information on the priority of the message and on the type of the

user data.

With the exception of the network management and the sync telegram, the identifier

contains the node address of the drive:

Identifier Data

1 bit 11 bits 1 bit 2 bits 4 bits

) Note!

To the user, only the identifier, the data length and the user data are relevant.

All other data of the CAN telegram is automatically processed by the system.

length

User data (0 ... 8 bytes)

l Network management

l Process data

l Parameter data

15 bits 1 bit 1 bit 1 bit 7 bits

16

Identifier (COB ID) = basic identifier + adjustable node address (node ID)

The identifier assignment is specified in the CANopen protocol.

The ex works default setting of the basic identifier is:

l

KHB 13.0002−EN 4.1

Page 17

CANopen communication

About CANopen

Identifier

5

Object

NMT 0

Sync 80

Emergency X 80

PDO1

(process data channel 1)

PDO2

(process data channel 2)

SDO1

(parameter data channel 1)

Heartbeat/boot−up X 700

5.1.3 Node address (node ID)

Each node of the CAN network must be assigned with a node address (also called node ID)

within the valid address range for unambiguous identification.

ƒ A node address may not be assigned more than once within a network.

TPDO1

RPDO1

TPDO2

RPDO2

Direction Basic identifier

From the drive To the drive Hex

X 180

X 200

X 280

X 300

X 580

X 600

KHB 13.0002−EN 4.1

l

17

Page 18

5

5.1.4 User data

CANopen communication

About CANopen

User data

The master and the drive controller communicate with each other by exchanging data

telegrams via the CAN bus.

The user data range of the CAN telegram contains network management data, parameter

data or process data:

ƒ Network management data (NMT data)

Network service: E.g. all CAN nodes can be addressed at the same time.

ƒ Process data (PDO, process data objects)

– Process data is transferred via the process data channel.

– Process data can be used to control the drive controller.

– The master can directly access the process data. The data is, for instance, directly

assigned to the I/O area of the master. It is necessary that the control and the drive

controller can exchange data within a very short time interval. For this purpose,

small amounts of data can be transferred cyclically.

– Process data is not stored in the drive controller.

– Process data is transferred between the master and the drive controllers to ensure

a continuous exchange of current input and output data.

– Examples for process data are, for instance, setpoints and actual values.

ƒ Parameter data (SDO, service data objects)

– Parameters are set, for instance, for the initial system set−up during

commissioning or when the material is changed on a production machine.

– Parameter data is transferred by means of so−called SDOs via the parameter data

channel. The transfer is acknowledged by the receiver, i.e. the sender gets a

feedback about the transfer being successful or not.

– The parameter data channel enables the access to all CANopen indexes.

– Parameter changes are automatically stored in the drive controller.

– In general, the transfer of parameters is not time−critical.

– Examples for parameter data are, for instance, operating parameters, diagnostic

information and motor data.

18

l

KHB 13.0002−EN 4.1

Page 19

CANopen communication

Parameter data transfer (SDO transfer)

Telegram structure

5

5.2 Parameter data transfer (SDO transfer)

5.2.1 Telegram structure

The telegram for parameter data has the following structure:

11 bits 4 bits User data (up to 8 bytes)

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Identifier

ƒ The following subchapters explain in detail the different parts of the telegram.

Data

length

Command

code

Index

low byte

high byte

Identifier

11 bits 4 bits User data (up to 8 bytes)

Identifier

Data

length

Command

code

Index

low byte

high byte

With the exception of the network management and the sync telegram, the identifier

contains the node address of the drive:

Identifier (COB ID) = basic identifier + adjustable node address (node ID)

The identifier assignment is specified in the CANopen protocol.

Index

Index

Subindex

Subindex

Data 1 Data 2 Data 3 Data 4

Error code

Data 1 Data 2 Data 3 Data 4

The ex works default setting of the basic identifier is:

Object

SDO (parameter data channel)

From the drive To the drive Hex

Direction Basic identifier

X 580

X 600

KHB 13.0002−EN 4.1

l

19

Page 20

5

CANopen communication

Parameter data transfer (SDO transfer)

Telegram structure

Command code

11 bits 4 bits User data (up to 8 bytes)

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Identifier

Data

length

Command

code

Index

low byte

Index

high byte

Subindex

Data 1 Data 2 Data 3 Data 4

Error code

The command code contains the services for writing and reading parameters and the

information on the length of the user data.

Structure of the command code:

Bit 7

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

MSB

Write command code

Write command / write request 0 0 1 0 x x 1 1

Response to write command / write

response

Read command code CS 0 Length e s

Read command / read request 0 1 0 0 x x 0 0

Response to read command / read

response

Error command code CS 0 Length e s

Error response 1 0 0 0 0 0 0 0

CS 0 Length e s

0 1 1 0 x x 0 0

0 1 0 0 x x 1 1

LSB

Comment

CS: command

specifier

User data length

is coded in bits 2

and 3:

l 00 = 4 bytes

l 01 = 3 bytes

l 10 = 2 bytes

l 11 = 1 byte

The command code specifies whether a value is to be read or written. The command code

also determines the data length (1 byte, 2 bytes, 4 bytes).

Write command code

Write command / write request

(Send parameters to the drive)

Response to write command / write response

(Response of the drive controller to the write request

(acknowledgement))

Read command code

Read command / read request

(Request to read a parameter from the drive controller)

Response to read command / read response

(Response to the read request with the actual value)

Error command code

Error response

(The drive controller signals a communication error)

4−byte data

(5th ... 8th

byte)

hex hex hex

23 2B 2F

60 60 60

40 40 40

43 4B 4F

80 80 80

2−byte data

(5th and 6th

byte)

1−byte data

(5th byte)

20

l

KHB 13.0002−EN 4.1

Page 21

CANopen communication

Parameter data transfer (SDO transfer)

Telegram structure

Index low byte / index high byte

11 bits 4 bits User data (up to 8 bytes)

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Identifier

Data

length

The object to be addressed is contained in bytes 2 and 3 of the telegram.

ƒ The value for the index is split up into low byte and high byte and entered in the

left−justified Intel format.

Subindex

11 bits 4 bits User data (up to 8 bytes)

Identifier

ƒ If an object (e.g. controller parameter) consists of several sub−objects, the

Data

length

sub−objects are addressed via subindexes. The number of the corresponding

subindex is entered in byte 4 of the telegram. (See following tables for sub−objects).

Command

code

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Command

code

Index

low byte

Index

low byte

Index

high byte

Index

high byte

Subindex

Subindex

Data 1 Data 2 Data 3 Data 4

Data 1 Data 2 Data 3 Data 4

5

ƒ If an object has no sub−objects, the value "0" is entered in byte 4 of the telegram.

(See following sub−object tables).

Data (data1...data4)

11 bits 4 bits User data (up to 8 bytes)

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Identifier

Data

length

Command

code

Index

low byte

Index

high byte

Subindex

Data 1 Data 2 Data 3 Data 4

For the data of the parameter up to 4 bytes (data 1 ... data 4) are available.

The data is represented in the left−justified Intel format with data 1 as the LSB and data 4

as the MSB.

KHB 13.0002−EN 4.1

l

21

Page 22

5

CANopen communication

Parameter data transfer (SDO transfer)

Telegram structure

Error code (F0 ... F3)

11 bits 4 bits User data (up to 8 bytes)

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Identifier

ƒ Byte 1:

Code 80

ƒ Bytes 2, 3 and 4:

Data

length

in the command code byte indicates that an error has occurred.

h

Command

code

Index

low byte

Index

high byte

Subindex

F0 F1 F2 F3

Error code

These bytes contain the index (bytes 2 and 3) and the subindex (byte 4) at which an

error occurred.

ƒ Bytes 5 to 8:

The data bytes 5 to 8 contain the error code. The error code is represented opposite

to the direction of reading.

Example:

The representation of the error code 06 04 00 41

in bytes 5 to 8

h

Reading direction of the error code

41 00 04 06

5th byte 6th byte 7th byte 8th byte

Low word High word

Low byte High byte Low byte High byte

The below table lists the meanings of the error codes:

Error code Explanation

F3 F2 F1 F0

06 01 00 00 Access to object is not supported

06 01 00 01 Attempt to read a write−only object

06 01 00 02 Attempt to write to a read−only object

06 02 00 00 Object does not exist in the object directory

06 04 00 41 Object cannot be mapped to the PDO

06 04 00 42 The number and length of objects to be mapped would exceed PDO length.

06 07 00 10 Data type does not match, length of service parameter does not match

06 07 00 12 Data type does not match, length of service parameter is too large

06 07 00 13 Data type does not match, length of service parameter is too small

06 09 00 11 Subindex does not exist

06 09 00 30 Value range of parameter exceeded

06 09 00 31 Parameter values too large

06 09 00 32 Parameter values too small

08 00 00 20 Data cannot be transferred/saved to the application.

08 00 00 21 Data cannot be transferred/saved to the application due to local control.

08 00 00 22 Data cannot be transferred/saved to the application due to current device state.

22

l

KHB 13.0002−EN 4.1

Page 23

CANopen communication

Parameter data transfer (SDO transfer)

Reading parameters (example)

5

5.2.2 Reading parameters (example)

Problem

The numerator setting (object 6093_01) of the drive controller with node address 1 is to

be read via the parameter channel.

Telegram to the drive controller

Value Info

Identifier = Basic identifier + node address

= 600 + 1 = 601

h

Data length = 08

Command code = 40

Index = 6093

h

h

Subindex = 1 l Subindex = 1 (numerator)

Data 1

Data 2

Data 3

Data 4

Data 1 ... 4

= 00

h

= 00

h

= 00

h

= 00

h

= 00 00 00 00

h

11 bits 4 bits User data

Identifier

601

h

Data

length

08

h

Command

code

40

h

Index

low byte

Telegram from the drive controller

93

h

l Basic identifier for parameter channel = 600

l Node address = 1

l Read request" command (request to read a

parameter)

l Index of the position_factor

l Read request only

Index

high byte

60

h

Subindex

01

Data 1 Data 2 Data 3 Data 4

h

00

h

00

h

h

00

h

00

h

Value Info

Identifier = Basic identifier + node address

= 580 + 1 = 581

h

l Basic identifier for parameter channel = 580

l Node address = 1

Data length = 08

Command code = 43

h

Index = 6093

h

l Read response" command (response to the read

request with the actual value)

l Index of the position_factor

Subindex = 1 l Subindex = 1 (numerator)

Data 1

Data 2

Data 3

Data 4

Data 1 ... 4

= C0

h

= 4B

h

= 03

h

= 00

h

= C0 4B 03 00

l Assumption: The set numerator value is 00 03 4B C0

(216000d).

h

11 bits 4 bits User data

Identifier

581

h

Data

length

08

h

Command

code

43

h

Index

low byte

93

h

Index

high byte

60

h

Subindex

01

h

Data 1 Data 2 Data 3 Data 4

C0

h

4B

h

h

h

03

h

00

h

KHB 13.0002−EN 4.1

l

23

Page 24

5

CANopen communication

Parameter data transfer (SDO transfer)

Writing parameters (example)

5.2.3 Writing parameters (example)

Problem

The numerator (object 6093_01) of the drive controller with node address 1 is to be set to

216000 via the SDO (parameter data channel).

Telegram to the drive controller

Value Info

Identifier = Basic identifier + node address

= 600 + 1 = 601

Data length = 08

Command code = 23

Index = 6093

h

h

Subindex = 1 l Subindex = 1 (numerator)

Data 1

Data 2

Data 3

Data 4

Data 1 ... 4

= C0

h

= 4B

h

= 03

h

= 00

h

= C0 4B 03 00

11 bits 4 bits User data

Identifier

601

h

Data

length

08

Command

h

code

23

h

h

low byte

h

Index

93

h

l Basic identifier for parameter channel = 600

l Node address = 1

l Write request" command (send parameter to the

drive)

l Index of the position_factor

l Assumption: The numerator value to be set is to be

Index

high byte

60

h

00 03 4B C0

Subindex

01

(216000d).

h

Data 1 Data 2 Data 3 Data 4

h

C0

h

4B

h

03

h

h

00

h

Telegram from the drive controller (acknowledgement for faultless execution)

Value Info

Identifier = Basic identifier + node address

= 580 + 1 = 581

h

Data length = 08

Command code = 60

Index = 6093

h

h

Subindex = 1 l Subindex = 1 (numerator)

Data 1 ... 4 = 00 00 00 00

h

11 bits 4 bits User data

Identifier

581

h

Data

length

08

h

Command

code

60

h

Index

low byte

93

h

l Basic identifier for parameter channel = 580

l Node address = 1

l Write response" command (acknowledgement from

the drive controller)

l Index of the position_factor

l Acknowledgement only

Index

high byte

60

h

Subindex

01

Data 1 Data 2 Data 3 Data 4

h

00

h

00

h

00

h

h

00

h

24

l

KHB 13.0002−EN 4.1

Page 25

CANopen communication

Process data transfer (PDO transfer)

Telegram structure

5

5.3 Process data transfer (PDO transfer)

Process data objects (PDOs) can be used, for instance, for the fast event−controlled transfer

of data. The PDO transfers one or several parameters specified in advance. Unlike with an

SDO, the transfer of a PDO is not acknowledged. After the PDO activation, all receivers

must therefore always be able to process any arriving PDOs. This usually means a

considerable software load on the master. However, this disadvantage is compensated by

the advantage that the master does not need to cyclically poll the parameters transferred

by a PDO, which results in a significant reduction of the CAN bus load.

Example:

The master wants to know when the drive controller has completed the positioning from

A to B.

When SDOs are used for this purpose, the master continuously (e.g. every millisecond) has

to poll the status word object, i.e. the load on the bus is high.

When a PDO is used, right from the start of the application the drive controller is

parameterised in such a way that it transmits a PDO containing the status word object as

soon as the status word object changes.

Instead of polling continuously, the master automatically receives a corresponding

message as soon as the event has occurred.

The following types of process data telegram are distinguished

ƒ Process data telegrams to the drive controller: Receive PDO (RPDOx)

ƒ Process data telegrams from the drive controller: Transmit PDO (TPDOx)

5.3.1 Telegram structure

The telegram for process data has the following structure:

11 bits 4 bits User data (up to 8 bytes)

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Identifier

Data

length

Data 0 Data 1 Data 2 Data 3 Data 4 Data 5 Data 6 Data 7

5.3.2 Available process data objects

The drive controller is provided with two transmit and two receive PDOs.

Almost all objects of the object directory can be entered in (mapped to) the PDOs, i.e. the

PDO contains for instance the actual speed value or actual position value as data. The drive

controller must know in advance which data is to be transferred because the PDO only

contains user data and no information about the type of the parameter.

In this way almost all kinds of data telegrams can be defined. The settings required are

described in the following chapters.

KHB 13.0002−EN 4.1

l

25

Page 26

5

CANopen communication

Process data transfer (PDO transfer)

Objects for PDO parameterisation

5.3.3 Objects for PDO parameterisation

Two transmit PDOs (TPDO) and two receive PDOs (RPDO) are available in the drive

controller. The different objects of the PDOs are identical.

1. Transmit PDO

Index Name Possible settings

Lenze Selection Description

1800

Transmit PDO1

h

Communication

Parameter

0 number_of_entries

1 COB−ID_used_by_

PDO

00000181

h

2 transmission_type 255

3 inhibit_time 0

Characteristics

00

h

03

h

00000181

Bit no. Value

0 − 10 x 11−bit identifier

11 − 28 0

29 0

30 1 RTR of this PDO is not

31

0 {1} 240, 254, 255

0 Function is switched off

n = 1 ... 240 By entering a value n, this

n = 254, 255 Event−controlled

0 {0.1 ms} 65535

h

0 PDO is active

1 PDO is inactive

{1h} 04

{1h} 000001FF

REC UINT8 RO

h

Maximum number of

supported subindexes.

3 subindexes are supported.

UINT32 RW

h

Identifier of transmit PDO1,

+ node address).

(180

h

For processing, bits 30 and

31 must be set

(parameterisation of

mapping).

The extended identifier

(bit 29) is not supported.

Each bit of this range must

be "0".

permitted (unadjustable).

UINT8 RW

Setting of the transmission

mode

PDO is accepted with every

n−th sync.

transmission mode

UINT16 RW

Setting of the minimum

delay time between two

PDOs. The time can only be

changed if the PDO is not

active (subindex 1, bit 31 = 1)

26

l

KHB 13.0002−EN 4.1

Page 27

Index Name Possible settings

Lenze Selection Description

1A00

Transmit PDO1

h

Mapping Parameter

0 number_of_

mapped_objects

1 first_mapped_

object

2 second_mapped_

object

...

4 fourth_mapped_

object

60410010

h

00

01

CANopen communication

5

Process data transfer (PDO transfer)

Objects for PDO parameterisation

Characteristics

h

h

{1h} 04

{1h}

REC UINT32 RW

h

Maximum number of

supported subindexes

1 subindex is supported

UINT32 RW

Entry of the COB ID of the

first mapped object

UINT32 RW

Entry of the COB ID of the

second mapped object

UINT32 RW

Entry of the COB ID of the

fourth mapped object

KHB 13.0002−EN 4.1

l

27

Page 28

5

CANopen communication

Process data transfer (PDO transfer)

Objects for PDO parameterisation

2. Transmit PDO

Index Name Possible settings

Lenze Selection Description

1801

Transmit PDO2

h

Communication

Parameter

0 number_of_entries

1 COB−ID_used_by_

PDO

00000281

2 transmission_type 255

3 inhibit_time 0

Characteristics

00

h

03

h

00000281

h

Bit no. Value

0 − 10 x 11−bit identifier

11 − 28 0

29 0

30

31

0 {1} 240, 254, 255

0 Function is switched off

n = 1 ... 240 By entering a value n, this

n = 254, 255 Event−controlled

0 {0.1 ms} 65535

h

0 RTR of this PDO is permitted

1 RTR of this PDO is not

0 PDO is active

1 PDO is inactive

{1h} 04

{1h} 000002FF

REC UINT8 RO

h

Maximum number of

supported subindexes

3 subindexes are supported.

UINT32 RW

h

Identifier of transmit PDO2,

(280

+ node address).

h

For processing, bits 30 and

31 must be set

(parameterisation of

mapping).

The extended identifier

(bit 29) is not supported.

Each bit of this range must

be "0".

(Lenze)

permitted (unadjustable)

UINT8 RW

Setting of the transmission

mode

PDO is accepted with every

n−th sync.

transmission mode

UINT16 RW

Setting of the minimum

delay time between two

PDOs. The time can only be

changed if the PDO is not

active (subindex 1, bit 31 = 1)

28

l

KHB 13.0002−EN 4.1

Page 29

Index Name Possible settings

Lenze Selection Description

1A01

Transmit PDO2

h

Mapping Parameter

0 number_of_

mapped_objects

1 first_mapped_

object

2 second_mapped_

object

3 third_mapped_

object

4 fourth_mapped_

object

60410010

60610008

h

h

00

02

CANopen communication

5

Process data transfer (PDO transfer)

Objects for PDO parameterisation

Characteristics

h

h

{1h} 04

{1h}

{1h}

REC UINT32 RW

h

Maximum number of

supported subindexes.

2 subindexes are supported.

UINT32 RW

Entry of the COB ID of the

first mapped object.

UINT32 RW

Entry of the COB ID of the

second mapped object.

UINT32 RW

Not supported.

UINT32 RW

Not supported.

KHB 13.0002−EN 4.1

l

29

Page 30

5

CANopen communication

Process data transfer (PDO transfer)

Objects for PDO parameterisation

1. Receive PDO

Index Name Possible settings

Lenze Selection Description

1400

Receive PDO1

h

Communication

Parameter

0 number_of_entries

1 COB−ID_used_by_

PDO

00000201

2 transmission_type 255

Characteristics

00

h

02

h

00000201

h

Bit no. Value

0 − 10 x 11−bit identifier

11 − 28 0

29 0

30

31

0 {1} 240, 254, 255

0 Function is switched off

n = 1 ... 240 By entering a value n, this

n = 254, 255 Event−controlled

h

0 RTR of this PDO is permitted

1 RTR of this PDO is not

0 PDO is active

1 PDO is inactive

{1h} 04

{1h} 000002FF

REC UINT8 RO

h

Maximum number of

supported subindexes

2 subindexes are supported.

UINT32 RW

h

Identifier of receive PDO1

(200

+ node address)

h

For processing, bits 30 and

31 must be set

(parameterisation of

mapping).

The extended identifier

(bit 29) is not supported.

Each bit of this range must

be "0".

(Lenze)

RTR = remote transmission

request

permitted (unadjustable)

UINT8 RW

Setting of the transmission

mode

PDO is accepted with every

n−th sync.

transmission mode, PDO is

accepted immediately

30

l

KHB 13.0002−EN 4.1

Page 31

Index Name Possible settings

Lenze Selection Description

1600

Receive PDO1

h

Mapping Parameter

0 number_of_

mapped_objects

1 first_mapped_

object

2 second_mapped_

object

...

4 fourth_mapped_

object

60400010

h

00

01

CANopen communication

5

Process data transfer (PDO transfer)

Objects for PDO parameterisation

Characteristics

h

h

{1h} 04

{1h}

REC UINT32 RW

h

Maximum number of

supported subindexes.

1 subindex is supported.

UINT32 RW

Entry of the COB ID of the

first mapped object.

UINT32 RW

Not supported.

UINT32 RW

Not supported.

KHB 13.0002−EN 4.1

l

31

Page 32

5

CANopen communication

Process data transfer (PDO transfer)

Objects for PDO parameterisation

2. Receive PDO

Index Name Possible settings

Lenze Selection Description

1401

Receive PDO2

h

Communication

Parameter

0 number_of_entries

1 COB−ID_used_by_

PDO

00000301

2 transmission_type 255

Characteristics

00

h

02

h

00000301

h

Bit no. Value

0 − 10 x 11−bit identifier

11 − 28 0

29 0

30

31

0 {1} 240, 254, 255

0 Function is switched off

n = 1 ... 240 By entering a value n, this

n = 254, 255 Event−controlled

h

0 RTR of this PDO is permitted

1 RTR of this PDO is not

0 PDO is active

1 PDO is inactive

{1h} 04

{1h} 000003FF

REC UINT8 RO

h

Maximum number of

supported subindexes

2 subindexes are supported.

UINT32 RW

h

Identifier of receive PDO2

(300

+ node address)

h

For processing, bits 30 and

31 must be set

(parameterisation of

mapping).

The extended identifier

(bit 29) is not supported.

Each bit of this range must

be "0".

(Lenze)

RTR = remote transmission

request

permitted (unadjustable)

UINT8 RW

Setting of the transmission

mode

PDO is accepted with every

n−th sync.

transmission mode, PDO is

accepted immediately

32

l

KHB 13.0002−EN 4.1

Page 33

Index Name Possible settings

Lenze Selection Description

1601

Receive PDO2

h

Mapping Parameter

0 number_of_

mapped_objects

1 first_mapped_

object

2 second_mapped_

object

3 third_mapped_

object

4 fourth_mapped_

object

60400010

60600008

h

h

00

02

CANopen communication

5

Process data transfer (PDO transfer)

Objects for PDO parameterisation

Characteristics

h

h

{1h} 04

{1h}

{1h}

REC UINT32 RW

h

Maximum number of

supported subindexes.

2 subindexes are supported.

UINT32 RW

Entry of the COB ID of the

first mapped object.

UINT32 RW

Entry of the COB ID of the

second mapped object.

UINT32 RW

Not supported.

UINT32 RW

Not supported.

KHB 13.0002−EN 4.1

l

33

Page 34

5

CANopen communication

Process data transfer (PDO transfer)

Objects for PDO parameterisation

1. Transmit masking

Index Name Possible settings

Lenze Selection Description

2014

Transmit PDO1

h

Mask

0 number_of_entries

1 tpdo1_transmit_

mask_low

2 tpdo1_transmit_

mask_high

FFFFFFFF

FFFFFFFF

2. Transmit masking

Index Name Possible settings

Lenze Selection Description

2015

Transmit PDO2

h

Mask

0 number_of_entries

1 tpdo2_transmit_

mask_low

FFFFFFFF

2 tpdo2_transmit_

mask_high

FFFFFFFF

h

h

h

h

00000000

00000000

00000000

00000000

Characteristics

ARR UINT8 RO

Maximum number of

supported subindexes

h

h

h

h

{1h} FFFFFFFF

{1h} FFFFFFFF

{1h} FFFFFFFF

{1h} FFFFFFFF

UINT32 RW

h

Mask for masking out

individual bits of the PDOs.

UINT32 RW

h

Mask for masking out

individual bits of the PDOs.

Characteristics

ARR UINT8 RO

Maximum number of

supported subindexes

UINT32 RW

h

Mask for masking out

individual bits of the PDOs.

UINT32 RW

h

Mask for masking out

individual bits of the PDOs.

34

l

KHB 13.0002−EN 4.1

Page 35

CANopen communication

Process data transfer (PDO transfer)

Description of the objects

5

5.3.4 Description of the objects

Identifier of the PDO (COB_ID_used_by_PDO)

The identifier on which the respective PDO is to be sent or received must be entered in the

COB_ID−used_by_PDO object. If bit 31 is set, the respective PDO is deactivated. This is the

default setting for all PDOs. In addition, bit 30 (no RTR allowed) must be set for every access.

The COB ID can only be changed if the PDO is deactivated, i.e. if bit 31 is set. For changing

the COB ID, you therefore have to keep to the following sequence:

ƒ Read out the COB ID

ƒ Write the read−out COB ID + C0000000

ƒ Write the new COB ID + C0000000

ƒ Write the new COB ID, the PDO is active again.

Transmission mode (transmission_type and inhibit_time)

For each PDO, the event leading to a message being sent (transmit PDO) or evaluated

(receive PDO) can be defined:

Value Meaning Permitted for

00h − F0

FE

h

FF

h

Sync telegram

h

The numerical value specifies how many sync telegrams are ignored between two

transmissions before the PDO is

− sent (TPDO) or

− evaluated (RPDO).

Cyclic

The TPDO is cyclically updated and sent by the drive controller. The time interval is

specified with the inhibit_time object.

RPDOs, however, are evaluated immediately after the receipt.

Change

The TPDO is sent if at least one bit of the PDO data has changed.

The inhibit_time can be used to additionally specify the minimum time interval (in

100 ms steps) between the transmission of two PDOs.

h

h

TPDO

RPDO

TPDO

(RPDO)

TPDO

KHB 13.0002−EN 4.1

The use of all other values is not permitted.

Number of objects to be transferred (number_of_mapped_objects)

This object specifies how many objects are to be mapped into the corresponding PDO. The

following restrictions have to be taken into account:

ƒ It is not possible to map more than 4 objects per PDO

ƒ A PDO can have a maximum of 64 bits (8 bytes).

l

35

Page 36

5

CANopen communication

Process data transfer (PDO transfer)

Description of the objects

Objects to be transferred (first_mapped_object ... fourth_mapped_object)

For every object to be contained in the PDO, the drive controller must know the

corresponding index, subindex and length. The specified length must be identical to the

length specified in the object dictionary. It is not possible to map parts of an object.

The mapping information has the following format:

Index Subindex Length

16 bits 8 bits 8 bits

ƒ Index: Main index of the object to be mapped (hex)

ƒ Subindex: Subindex of the object to be mapped (hex)

ƒ Length: Length of the object (hex)

The following mandatory procedure serves to simplify the mapping:

1. The number of the mapped objects is set to 0.

2. The first_mapped_object ... fourth_mapped_object parameters can be written (the

total length of all objects is not relevant at this time).

3. The number of the mapped objects is set to a value between 1 ... 4. The total length

of these objects must not exceed 64 bits.

Masking (transmit_mask_high

If "change" is selected for the transmission_type, the TPDO is always sent if at least 1 bit

of the TPDO has changed.

However, very often it is necessary to send the TPDO only if a certain bit has changed. For

this purpose, the TPDO can be provided with a mask. Only those bits of the TPDO are

evaluated which are set to "1" in the mask.

In the default setting all bits of the masks are set.

and transmit_mask_low)

36

l

KHB 13.0002−EN 4.1

Page 37

CANopen communication

Process data transfer (PDO transfer)

Example of a process data telegram

5

5.3.5 Example of a process data telegram

The following objects are to be transferred together in a PDO:

ƒ Status word, index 6041_00

ƒ Modes_of_operation_display, index 6061_00

ƒ Digital_inputs, index 60FD_00

(controller control),

h

h

The first transmit PDO (TPDO 1) is to be used, and it is always to be sent if one of the digital

inputs changes, but not more often than every 10 ms. The identifier used for this PDO is to

be 187

.

h

1. Delete the number of objects.

Description Name Value

To enable the change of the object mapping, the number of

objects has to be set to zero.

2. Parameterise the objects which are to be mapped.

Description Name Value

The objects listed above have to be composed to form a 32−bit

value:

Index = 6041h, subindex = 00h, length = 10h (UINT16) first_mapped_object 60410010

Index = 6061h, subindex = 00h, length = 08h (INT8) second_mapped_object 60610008

Index = 60FDh, subindex = 00h, length = 20h (UINT32) third_mapped_object 60FD0020

3. Parameterise the number of objects.

(digital inputs)

(operating mode)

h

number_of_mapped_objects 0

h

h

h

Description Name Value

The PDO has to contain 3 objects number_of_mapped_objects 3

h

4. Parameterise the transmission mode.

Description Name Value

The PDO has to be sent if one or several of the above digital

inputs change.

In order to ensure that only changes of the digital inputs cause

the transmission of the PDO, it is masked in such a way that

only the above 16 bits of the object 60FD

The PDO is to be sent not more often than every 10 ms

(100 × 100 ms).

"come through".

h

transmission_type FF

transmit_mask_high 00FFFF00

transmit_mask_low 00000000

inhibit_time 64

h

h

5. Parameterise the identifier.

Description Name Value

The PDO is to be sent with the identifier 187h. If the PDO is

active, it first has to be deactivated.

Read out the identifier: cob_id_used_by_pdo 00000181

Set bit 31 (deactivate PDO): cob_id_used_by_pdo C0000181

Write new identifier: cob_id_used_by_pdo C0000187

Activate PDO by deleting bit 31: cob_id_used_by_pdo 40000187

) Note!

The parameterisation of the PDO can only be changed if the network state

(NMT) is not operational.

h

h

h

h

h

h

KHB 13.0002−EN 4.1

l

37

Page 38

5

5.3.6 Activation of the PDOs

CANopen communication

Process data transfer (PDO transfer)

Activation of the PDOs

The following criteria must be met to enable the drive controller to send or receive PDOs:

ƒ The number_of_mapped_objects object must be non−zero.

ƒ Bit 31 of the cob_id_used_for_pdos object must be deleted.

ƒ The communication state of the controller must be operational (see chapter 5.5,

network management).

The following criterion must be met to enable the parameterisation of PDOs:

ƒ The communication state of the drive controller must not be operational.

38

l

KHB 13.0002−EN 4.1

Page 39

CANopen communication

Sync telegram

Telegram structure

5

5.4 Sync telegram

The sync telegram is an additional and special telegram which enables the drive controller

to cyclically read / accept process data.

5.4.1 Telegram structure

11 bits 4 bits

Identifier

Data

length

The identifier on which the drive controller receives the sync telegram is permanently set

to 080

. The data length is 0.

h

5.4.2 Synchronisation of the process data

The sync telegram is the trigger point for data acceptance in the drive controller and it

starts the sending process of the drive controller. Cyclic process data processing requires

an appropriate generation of the sync telegram.

PDO1-TX PDO1-RX

1.

Fig. 4 Synchronisation of cyclic process data by means of a sync telegram (without consideration of

asynchronous data)

Sync telegram

2. 3. 4.

epm−t111

Transmission sequence

1. After the sync telegram has been received, the cyclic process data are send from the

drive controllers to the master. The data is read by the master as process input data.

2. When the sending process is completed, the process output data (of the master) is

received by the drive controllers.

3. The data is accepted by the drive controllers with the next sync telegram.

4. All other telegrams (e.g. for parameters or event−controlled process data) are

accepted asynchronously by the drive controllers after the transmission has been

completed.

KHB 13.0002−EN 4.1

l

39

Page 40

5

CANopen communication

Sync telegram

Description of the objects

5.4.3 Description of the objects

Index Name Possible settings

Lenze Selection Description

1005h0 COB−ID_sync_

message

00000080

h

Characteristics

00000080

Bit no. Value

0 − 10 x 11−bit identifier.

11 − 28 0

29 0

30

31 x Any

h

0 Device does not generate

1 Device generates sync

{1h} 00000080

VAR UINT32 RW

h

Synchronisation object

identifier 80

The extended identifier

(bit 29) is not supported.

Each bit of this range must

be "0".

sync telegrams.

telegrams.

h.

40

l

KHB 13.0002−EN 4.1

Page 41

CANopen communication

Network management (NMT)

Communication phases of the CAN network (NMT)

5

5.5 Network management (NMT)

Via the network management, the master can carry out state changes for the entire CAN

network. For this purpose, the identifier with the highest priority (000

5.5.1 Communication phases of the CAN network (NMT)

With regard to communication the controller knows the following states:

Status Explanation

"Initialisation"

(Initialisation)

"Pre−operational"

(before ready for operation)

"Operational"

(Ready for operation)

"Stopped" Only network management telegrams can be received.

After the controller is switched on, the initialisation process starts. During this

phase the controller is not involved in the data exchange on the bus.

Furthermore, a part of the initialisation or the entire initialisation process can

be executed in each NMT status by transmitting different telegrams (see "state

transitions"). All parameters will be written with their set values.

After the initialisation is completed, the controller is in the "Pre−Operational"

status.

The controller can receive parameter data.

The process data is ignored.

The controller can receive parameter data and process data.

) is reserved.

h

KHB 13.0002−EN 4.1

l

41

Page 42

5

CANopen communication

Network management (NMT)

Telegram structure

5.5.2 Telegram structure

11 bits 4 bits User data (2 bytes)

Identifier

Via the NMT, commands can be sent to one or all drive controllers. Each command consists

of two bytes. The first byte contains the command code (command specifier, CS) and the

second byte contains the node address (node ID, NI) of the addressed drive controller. Via

the node address zero, all nodes of the network can be addressed simultaneously. It is thus,

for instance, possible to reset all drive controllers simultaneously. The drive controllers do

not acknowledge the NMT commands. The successful execution can only be inferred

indirectly e.g. from the switch−on message after a reset.

The NMT states of the CANopen nodes are defined in a state diagram. Via the CS byte in the

NMT message state changes can be initiated. These changes are mainly orientated

towards the target state.

In the NI parameter, the node address of the drive controller has to be specified. If all nodes

of the network are to be addressed (broadcast), the parameter must be set to zero.

) Note!

Communication via process data only is possible with a state change to

operational"!

Example:

For changing the state of all nodes on the bus from "pre−operational" to

operational" via the CAN master, the following identifier and user data must

be set in the telegram:

ƒ Identifier: 00 (broadcast telegram)

ƒ User data: 0100 (hex)

Data

length

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

CS NI

42

l

KHB 13.0002−EN 4.1

Page 43

State transitions

(1)

Initialisation

(2)

(14)

Pre-Operational

(7)

(4)

(13)

(3)

(12)

Operational

Fig. 5 Network management state transitions

(5)

(6)

Stopped

(8)

CANopen communication

Network management (NMT)

Telegram structure

(11)

(10)

(9)

5

E82ZAFU004

State

transition

(1) − Initialisation

(2) − Pre−operational

From this moment on, the master changes the states for the entire network. A target address, which is part of the command, specifies the

receiver/s.

(3), (6) 01 xx Operational

(4), (7) 80 xx Pre−operational

(5), (8) 02 xx Stopped Only network management telegrams can be received.

(9)

(10)

(11)

(12)

(13)

(14)

Command

xx = 00

(hex)

82 xx

81 xx

hex

Network state after

change

Initialisation

Effect on process and parameter data after state change

At power−on the initialisation is started automatically.

During the initialisation, the drive controller does not take part in the data

transfer.

After the initialisation is completed, a boot−up message with an own

identifier is sent from the drive controller to the master and the drive

controller automatically changes to the pre−operational state.

In this phase, the master decides how the drive controller/s is/are to

participate in the communication.

Network management telegrams, sync, emergency, process data (PDO)

and parameter data (SDO) are active (corresponds to start remote node")

Optional:

Event−controlled and time−controlled process data (PDO) are sent once in

the case of a change.

Network management telegrams, sync, emergency and parameter data

(SDO) are active (corresponds to enter pre−operational state)

Initialisation of all parameters in the communication module with the

stored values (corresponds to reset node")

Initialisation of communication−relevant parameters (CIA DS 301) in the

communication module with the stored values (corresponds to reset

communication")

With this assignment, all devices connected are addressed by the telegram. The

state can be changed for all devices at the same time.

xx = node ID If a node address is specified, only the state of the addressed device will be

changed.

KHB 13.0002−EN 4.1

l

43

Page 44

5

CANopen communication

Emergency telegram

Telegram structure

5.6 Emergency telegram

The drive controller monitors the functioning of its main components (including voltage

supply, power stage, angle encoder evaluation, technology slots). In addition, the motor

(temperature, angle encoder) and the limit switches are checked continuously. Incorrect

parameter settings can also cause error messages (division by zero, etc.).

If an error occurs, the error number is indicated on the display of the drive controller. If

several errors occur at the same time, the message with the highest priority (the lowest

number) is displayed.

5.6.1 Telegram structure

11 bits 4 bits Error code 1001

1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte 7th byte 8th byte

Identifier

Data

length

The drive controller sends an emergency telegram if an error occurs. The identifier of this

message is composed of the identifier 80

concerned.

The emergency telegram consists of eight bytes. The first and second byte contain the

error_code. In the third byte there is an additional error code (object 1001

eighth byte are always set to zero.

h

E0 E1 R0 00 00 00 00 00

and the node address of the drive controller

h

). The fourth to

h

44

l

KHB 13.0002−EN 4.1

Page 45

The following error codes may appear:

CANopen communication

Emergency telegram

Telegram structure

5

Error cause Display 2nd byte 1st byte 3rd byte 4th ... 8th

E1 E0 R0

Motor overtemperature 03 43 10 00 ... 00

Insufficient temperature/overtemperature of power

electronics

SINCOS supply error 05 73 92 00 ... 00

SINCOS−RS485 communication error 06 73 91 00 ... 00

SINCOS track signal error 07 73 90 00 ... 00

Resolver track signal error / carrier failure 08 73 80 00 ... 00

5V−electronic supply error 09 51 13 05 00 ... 00

12V−electronic supply error 10 51 14 00 ... 00