Page 1

L

Manual

Global Drive

PLC Developer Studio

Global Drive

Function library

Lenze9300Servo.lib

Page 2

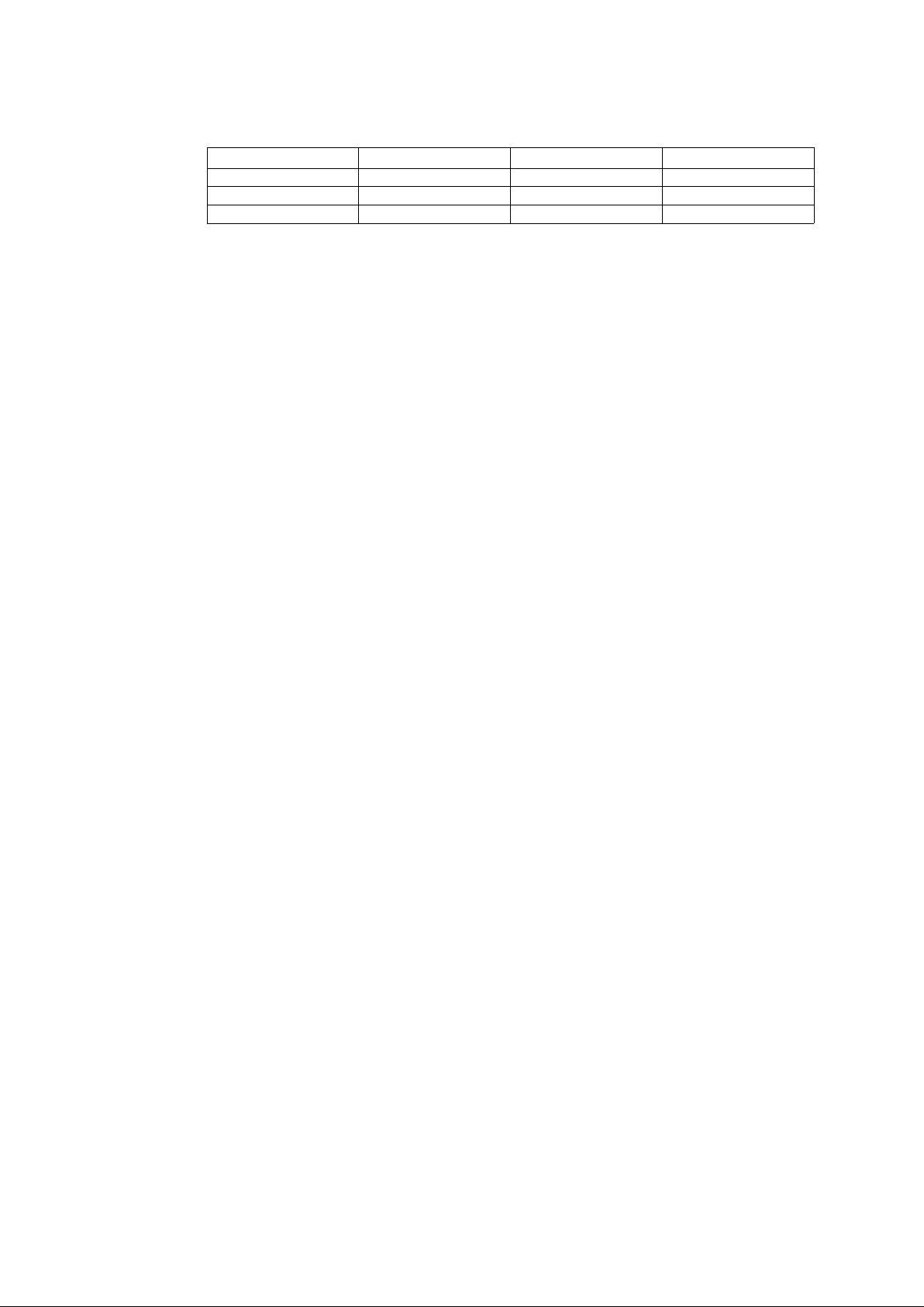

The function library Lenze9300Servo.lib can be used for the following Lenze PLCs:

Type from hardware version from software version

9300 Servo PLC EVS93XX−xI 2K 10

9300 Servo PLC EVS93XX−xT 2K 10

ECSxA ECSxAxxx 1C 7.0

Important Note:

The software is made available to the user in the currently existing form. All risks with regard to the quality and the results arising from its

use remain the responsibility of the user. The user must implement the appropriate security precautions against possible erroneous

application.

We do not accept any responsibilty for direct or consequential damages, such as loss of profits, loss of orders, or effects on the course of

business of any kind.

2000 Lenze GmbH & Co KG

No part of this documentation may be copied or made available to third parties without the express written permission of

Lenze GmbH & Co KG.

We have take great care in assembling the information in this documentation, and checked that it corresponds to the hardware and software

that is described. Nevertheless, we cannot guarantee that there are no discrepancies. We do not accept any legal responsibility or liability

for damage that may thereby ensue. Any necessary corrections will be implemented in subsequent versions.

Windows, Windows NT and MS−DOS are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

IBM and VGA are registered trademarks of International Business Machines, Inc.

All other designations are trade names of their owners.

Version 1.1 08/2000 − TD22

Page 3

Function block library Lenze9300Servo.lib

Contents

1 Preface and general information 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Conventions in this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Pictograms in this Manual 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Terminology used 1−2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Lenze software guidelines for variable names 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Hungarian Notation 1−3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.1 Recommendation for designating variable types 1−4 . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.2 Designation of the signal type in the variable name 1−5 . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1.3 Special handling of system variables 1−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Version identifiers of the function library 1−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Function blocks 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Special functions 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Holding brake (L_BRK) 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 Supply−failure control (L_MFAIL) 2−6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Appendix 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Code table 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 L_BRK 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 L_MFAIL 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Index 4−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l

Lenze9300Servo.lib EN 1.1

i

Page 4

Function block library Lenze9300Servo.lib

Contents

ii

Lenze9300Servo.lib EN 1.1

l

Page 5

Function block library Lenze9300Servo.lib

Preface and general information

1 Preface and general information

1.1 About this Manual

This Manual contains information on the function blocks that are included in the function block library

Lenze9300Servo.lib for the Drive PLC Developer Studio .

· These function blocks can be used, for instance, in the 9300 Servo PLC automation system.

· The function blocks are based on the functions that are available in the 9300 servo controller(

V2.0).

In Drive PLC Developer Studio (DDS) you make the basic settings for your drive application offline,

by using variables (in accordance with the IEC1131−3 standard) as aids for parameterizing the

appropriate function blocks.

Using Global Drive Control (GDC) or keypad you can then Online set the parameters for the required

functionality of your drive application, by accessing the code positions for the various instances of

the function blocks.

1.1.1 Conventions in this Manual

This Manual uses the following conventions to distinguish between different types of information:

Variable names

are shown in the explanatory texts in italics:

· The signal at nIn_a ..."

can be recognized by the names. They always begin with L_":

· The FB L_ARIT can ..."

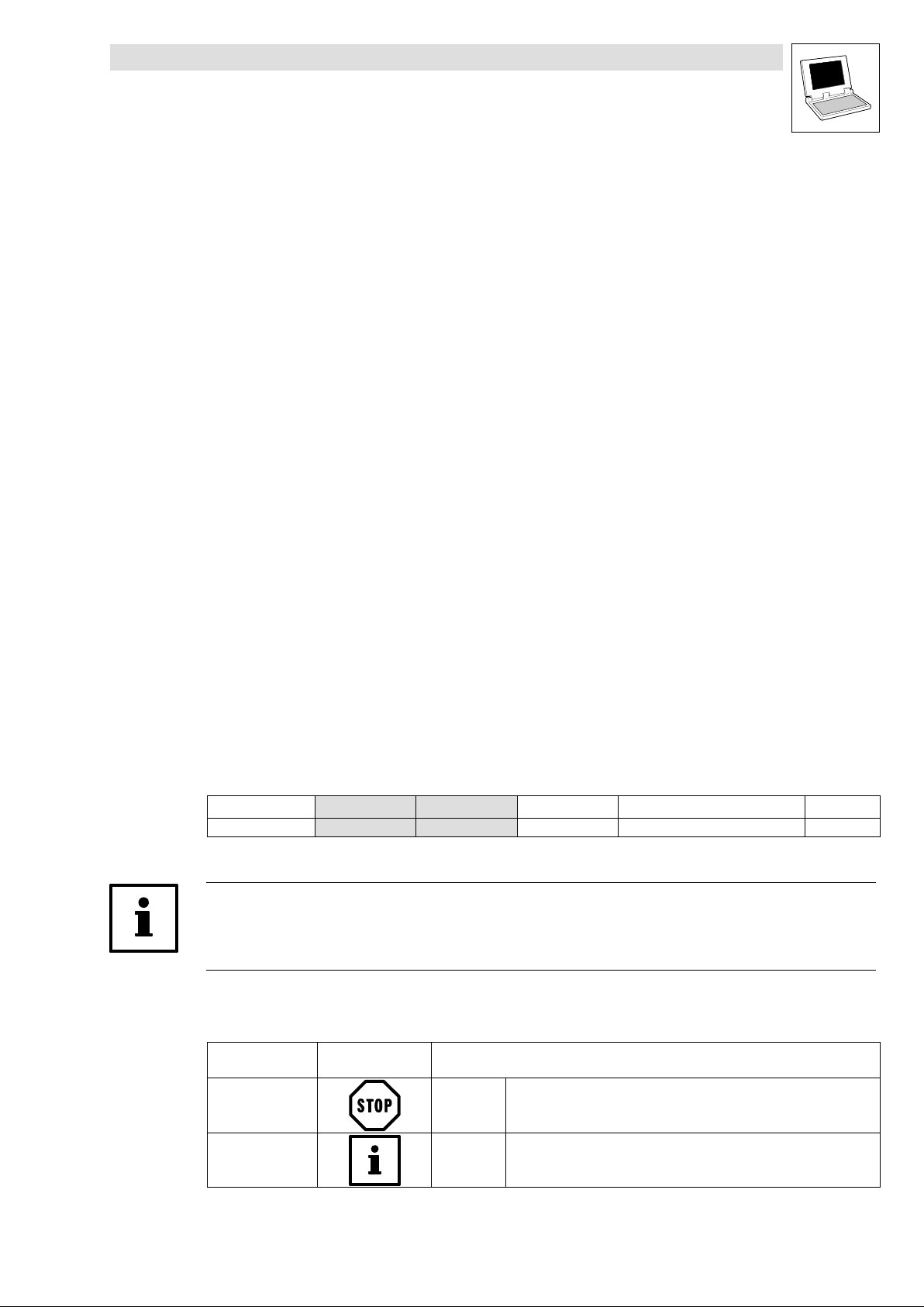

Instances

For function blocks that have one or more first instances, there are tables that describe the

corresponding codes:

Variable name L_ARIT1 L_ARIT2 Setting range Lenze

byFunction C0338 C0600 0 ... 5 1

You can access these codes Online is linked to Global Drive Control (GDC) or keypad .

Tip!

You can use the Parameter Manager to assign the same codes to these instances that are assigned

in the 9300 servo controller( V2.0).

1.1.2 Pictograms in this Manual

Use of

Pictographs

Warning of

material damage

Other notes Tip! This note designates general, useful notes.

l

Lenze9300Servo.lib EN 1.1

Signal words

Stop! Warns of potential damage to material.

Possible consequences if disregarded:

Damage of the controller/drive system or its environment

If you observe it, handling of the controller/drive system is made easier.

.

1−1

Page 6

Function block library Lenze9300Servo.lib

Preface and general information

1.1.3 Terminology used

Term In the following text used for

FB Function block

SB System block

Parameter codes Codes for setting the functionality of a function block

GDC Global Drive Control (parameterization program from Lenze)

1−2

Lenze9300Servo.lib EN 1.1

l

Page 7

Function block library Lenze9300Servo.lib

Preface and general information

1.2 Lenze software guidelines for variable names

The previous concepts for Lenze controllers were based on codes that represented the input and

output signals, and the parameters of function blocks.

· For the sake of clarity, names were defined for the codes in the documentation.

· In addition, the signal types were defined by graphical symbols.

The user could see at a glance which kind of signal (analog, phase−angle etc.) had to be present at

the particular interface.

The concept for the new automation system does not use direct codes in the

programming. The IEC 61131−3 standard is used instead.

· This standard is based on a structure of variable names.

· If the user applies variables in his project, then he can name the variables as he chooses.

In order to avoid the growth of a multitude of different conventions for naming variables in existing

and future projects and function libraries that are programmed by Lenze personnel, we have set up

software guidelines that must be followed by all Lenze staff.

In this convention for creating variable names, Lenze keeps to the Hungarian Notation that has been

specifically expanded by Lenze.

If you make use of Lenze−specific functions or function blocks, you will immediately be able to see,

for instance, which data type you must transfer to a function block, and which type of data you will

receive as an output value.

1.2.1 Hungarian Notation

These conventions are used so that the most significant characteristics of a program variable can

instantly be recognized from its name.

Variable names

consist of

· a prefix (optional)

· a data−type entry

· and an identifier

The prefix and data−type entry are usually formed by one or two characters. The identifier (the

"proper" name) should indicate the application, and is therefore usually somewhat longer.

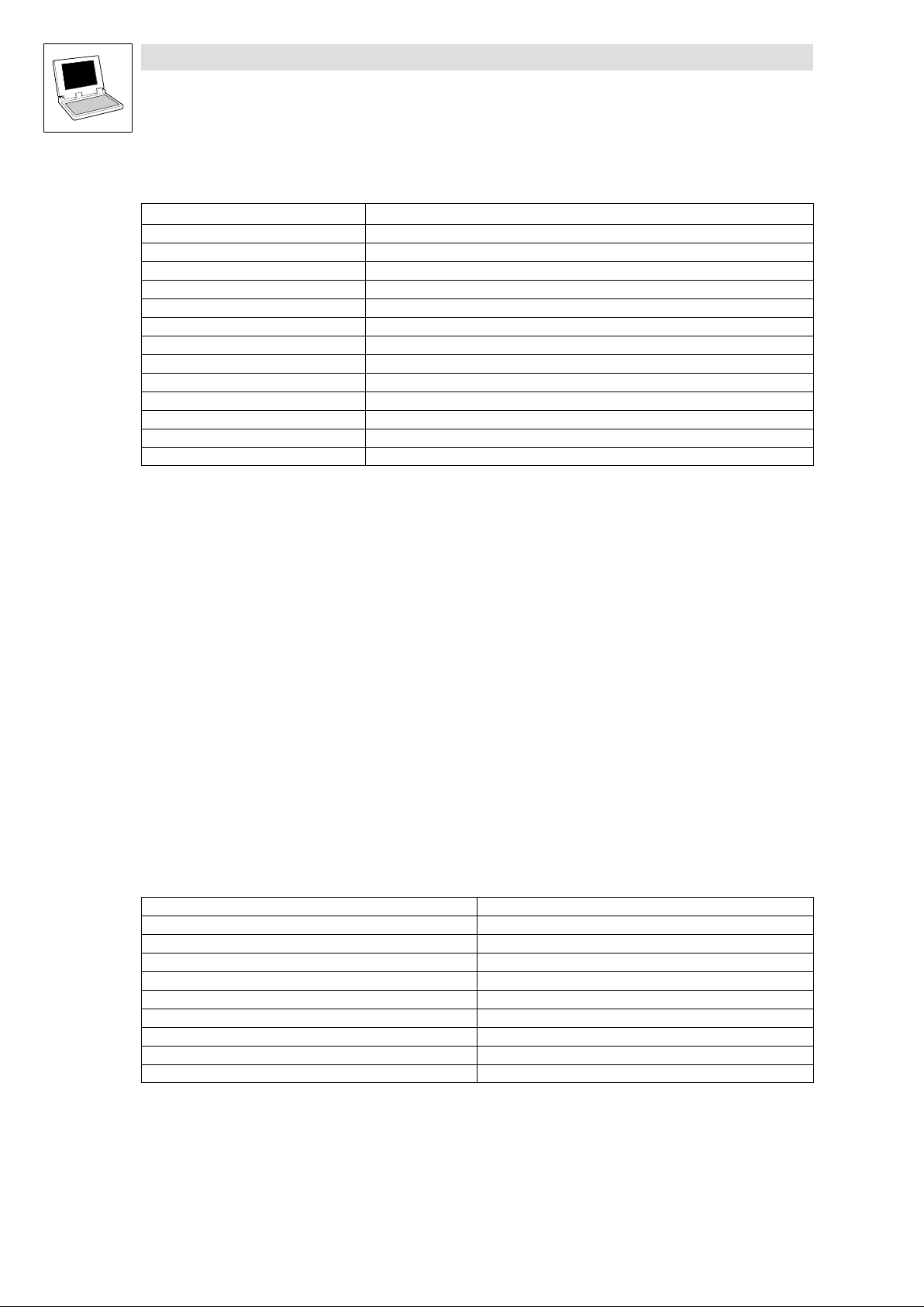

Prefix examples

prefix Meaning

a Array (combined type), field

p Pointer

l

Lenze9300Servo.lib EN 1.1

1−3

Page 8

Function block library Lenze9300Servo.lib

Preface and general information

Examples of the data−type entry

Examples of a data−type Meaning

b Bool

by Byte

n Integer

w Word

dn Double integer

dw Double word

s String

f Real (float)

sn Short integer

t Time

un Unsigned integer

udn Unsigned double integer

usn Unsigned short integer

Identifier (the proper variable name)

· An identifier begins with a capital letter.

· If an identifier is assembled from several "words", then each "word" must start with a capital

letter.

· All other letters are written in lower case.

Examples:

Array of integers anJogValue[10] ;

Bool bIsEmpty ;

Word wNumberOfValues ;

Integer nLoop ;

Byte byCurrentSelectedJogValue ;

1.2.1.1 Recommendation for designating variable types

In order to be able to recognize the type of variable in a program according to the name, it makes

sense to use the following designations, which are placed in front of the proper variable name and

separated from it by an underline stroke:

I_<Variablename> VAR_INPUT

Q_<Variablename> VAR_OUTPUT

IQ_<Variablename> VAR_IN_OUT

R_<Variablename> VAR RETAIN

C_<Variablename> VAR CONSTANT

CR_<Variablename> VAR CONSTANT RETAIN

g_<Variablename> VAR_GLOBAL

gR_<Variablename> VAR_GLOBAL RETAIN

gC_<Variablename> VAR_GLOBAL CONSTANT

gCR_<Variablename> VAR_GLOBAL CONSTANT RETAIN

1−4

Example

for a global array of type integer that includes fixed setpoints (analog) for a speed setting:

g_anFixSetSpeedValue_a

Lenze9300Servo.lib EN 1.1

l

Page 9

Function block library Lenze9300Servo.lib

Preface and general information

1.2.1.2 Designation of the signal type in the variable name

The inputs and outputs of the Lenze function blocks each have a specific signal type assigned. These

may be: digital, analog, position, or speed signals.

For this reason, each variable name has an ending attached that provides information on the type of

signal.

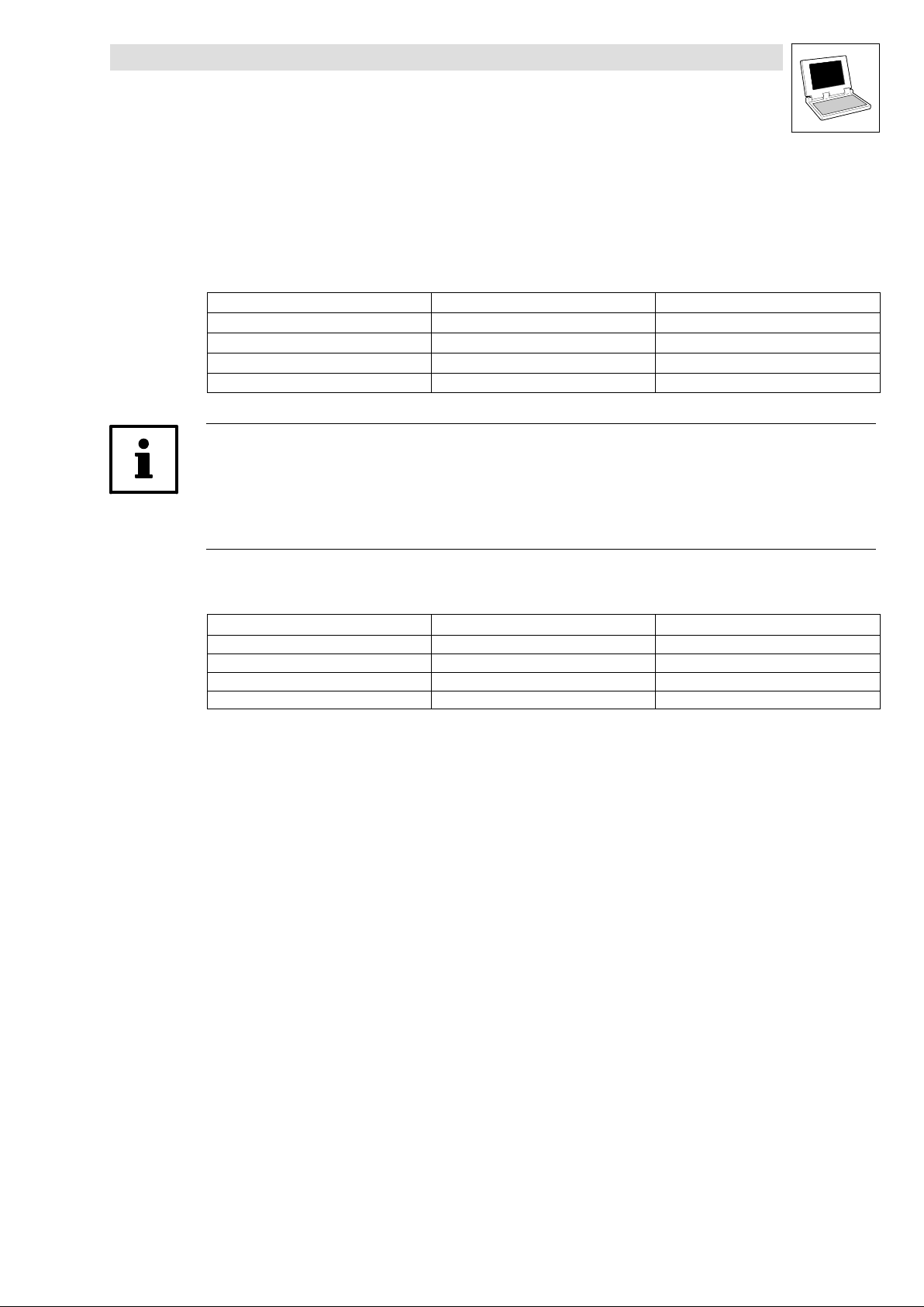

Signal type Ending Previous designation

analog _a (analog)

digital _b (binary)

Phase−angle difference or speed _v (velocity)

Phase−angle or position _p (position)

Tip!

Normalizing to signal type phase−angle difference/speed: 16384 (INT) ¢ 15000 rpm

Normalizing to signal type analog: 16384 ¢ 100 % ¢ value under [C0011] = n

Normalizing to signal type angle or position: 65536 ¢ 1 motor revolution

H

G

F

E

max

Examples:

Variable name Signal type Type of variable

nIn_a Analog input value Integer

dnPhiSet_p Phase signals Double integer

bLoad_b Binary value (TRUE/FALSE) Bool

nDigitalFrequencyIn_v Speed input value Integer

1.2.1.3 Special handling of system variables

System variables require special handling, since the system functions are only available for the user

as I/O connections in the control configuration.

In order to be able to access a system variable quickly during programming, the variable name must

include a label for the system function.

For this reason, the name of the corresponding system block is placed before the name of the

variable.

Examples:

AIN1_nIn_a

CAN1_bCtrlTripSet_b

DIGIN_bIn3_b

l

Lenze9300Servo.lib EN 1.1

1−5

Page 10

Function block library Lenze9300Servo.lib

Preface and general information

1.3 Version identifiers of the function library

The version of the function library can be found under the global constant

C_w[Function library name]Version .

Version identifiers as of PLC software version 7.x:

Constant Meaning

C_w[FunctionLibraryName]VersionER External Release 01

C_w[FunctionLibraryName]VersionEL External Level 05

C_w[FunctionLibraryName]VersionIR Internal Release 00

C_w[FunctionLibraryName]VersionBN Build No. 00

The value of this constant is a hexadecimal code.

· In the example, "01050000" stands for version "1.05".

Example

value

Version: 01 05 00 00

1−6

Lenze9300Servo.lib EN 1.1

l

Page 11

Function block library Lenze9300Servo.lib

Special functions

2.1.1 Holding brake (L_BRK)

2 Function blocks

2.1 Special functions

2.1.1 Holding brake (L_BRK)

This FB controls a holding brake. You can use it, for instance, for hoists and traversing drives, as well

as for active loads.

Abb. 2−1 Holding brake (L_BRK)

VariableName

bSet_b Bool binary VAR_INPUT

nNx_a Integer analog VAR_INPUT Speed threshold from which the drive can output the

nSign_a Integer analog VAR_INPUT Direction of the torque which the drive has to build up

bQSP_b Bool binary VAR_OUTPUT QSP can be triggered in conjunction with MCTRL.

bOut_b Bool binary VAR_OUTPUT Set the brake

bMStore_b Bool binary VAR_OUTPUT provide a defined holding torque

bCInh_b Bool binary VAR_OUTPUT A controller inhibit can be set in conjunction with

nMSetOut_a Integer analog VAR_OUTPUT Holding torque of the DC injection brake

wReleaseTime Word − VAR CONSTANT RETAIN Brake disengaging time

wActivationTime Word − VAR CONSTANT RETAIN Brake engaging time

nMSet Integer − VAR CONSTANT RETAIN Holding torque

DCTRL_bCInh_b Bool − −

MCTRL_nNAct_a Integer − −

MCTRL_nNSet2_a Integer − −

MCTRL_nMAct_a Integer − −

wReleaseTime

nNx_a

t 0

DCTRL_bCInh_b

MCTRL_nNAct_a

MCTRL_nNSet2_a

MCTRL_nMAct_a

bSet_b

nSign_a

CTRL

wActivationTime

t 0

nMSet

SIGN

nMSetOut_a

DataType SignalType VariableType Note

signal "close brake". The signal source for this input

can be a control code, a fixed value or any other

analog output of a FB.

against the brake. The signal source for this input can

be a control code, a fixed value or any other analog

output of a FB.

DCTRL.

16384 = value of C0057 (max. possible torque for the

drive configuration)

These signals are processed as quantities within the

FB.

L_BRK

bQSP_b

bOut_b

bMStore_b

bCInh_b

L

Parameter codes of the instances

VariableName L_BRK1 SettingRange Lenze

wReleaseTime C0196 0.0 ... 60.0 s 0.0

wActivationTime C0195 0.0 ... 99.9 s 99.9

nMSet C0244 −199.99 ... 199.99 % 0.00

Lenze9300Servo.lib EN 1.1

2−1

Page 12

Function block library Lenze9300Servo.lib

Special functions

2.1.1 Holding brake (L_BRK)

Range of functions

· Close brake

· Open the brake (release)

· Set controller inhibit

2.1.1.1 Close brake

bSet_b

bQSP_b

MCTRL_nNSet2_a

bOut_b

bCInh_b

Abb. 2−2 Signal sequence when the brake is closed

Functional sequence

1. Select the constant FIXED0% (selection number 1000) using bSet_b = TRUE, the function

close brake" is activated.

– At the same time, bQSP_b swtiches immediately = TRUE. You can use this signal to steer

the drive down to zero speed along a deceleration ramp.

2. If the speed setpoint goes below the value at nNx_a , then bOut_b switches = TRUE (operation

of the brake by a digital output).

– Invert the signal at the digital output, if you require a version that is safe against cable

breakage (e.g. through C0118).

3. Select the constant FIXED0% (selection number 1000) using bOut_b = TRUE, a timer is

started. After the time defined by wActivationTime has elapsed, then bCInh_b swtiches

immediately = TRUE.

– With this signal you can, for instance, switch the controller inhibit (device−internal). In

general, the brake−closing time is set here. This is necessary, because the brake does not

engage immediately with bOut_b = TRUE, and so the drive must provide a holding moment

during this preset period.

wActivationTime

t

t

|nNx_a|

t

t

t

2−2

Lenze9300Servo.lib EN 1.1

L

Page 13

Function block library Lenze9300Servo.lib

Special functions

2.1.1 Holding brake (L_BRK)

2.1.1.2 Open the brake (release)

bSet_b

bCInh_b

bQSP_b

bMStore_b

MCTRL_MAct_a

bOut_b

wRelease

MCTRL_nNSet2_a

Abb. 2−3 Signal sequence when the brake is opened (released)

Time

Functional sequence

1. Select the constant FIXED0% (selection number 1000) using bSet_b = FALSE, then bCInh_b

switches = FALSE immediately. At the same time, bMStore_b switches immediately = TRUE.

– You can use this signal to make the drive build up a defined torque against the brake. The

drive thus takes up the torque while the brake opens. The signal is reset only after the time

set by wReleaseTime has elapsed.

2. As soon as the torque set by nMSet has been reached (holding torque), then bOut_b = FALSE,

immediately.

3. When the input is reset, a time element is triggered. After the time defined by wReleaseTime

has elapsed, then bQSP_b = FALSE, immediately.

– With this signal you can, for instance, enable the setpoint integrator after the brake−opening

period.

t

t

t

t

MCTRL_MAct_a = nMSet

t

t

t

L

Note!

If, before the end of the brake−opening period, ( wReleaseTime) an actual speed is detected, that is

greater than the value at bNx_a, then bQSP_b switches = FALSE and bMStore_b = FALSE,

immediately. The drive can immediately operate speed− or phase controlled. If bQSP_b has an

influence on the control word QSP, then the drive synchronises itself to the momentary speed and

follows its setpoint.

Lenze9300Servo.lib EN 1.1

2−3

Page 14

Function block library Lenze9300Servo.lib

Special functions

2.1.1 Holding brake (L_BRK)

2.1.1.3 Set controller inhibit

The controller inhhibit can, for instance, be set in the event of a fault (LU, OU).

DCTRL_bCInh_b

MCTRL_nNAct_a

bOut_b

bQSP_b

BMStore_b

MCTRL_MAct_a

Abb. 2−4 Operate brake by controller inhibit

Functional sequence

1. By setting the controller inhibit (DCTRL_bCInh_b = TRUE) bOut_b switches immediately =

TRUE.

– The drive is then braked by its mechanical brake.

2. If the controller inhibit (DCTRL_bCInh_b = FALSE) before the actual speed falls below the

threshold at nNx_a, then bOut_b = FALSE, immediately.

– The drive synchronizes itself to the momentary speed and follows its setpoint.

– If the value falls below the threshold, the drive starts.

wRelease

Time

t

|nNx_a|

t

t

t

t

MCTRL_MAct_a = nMSet

t

(^ 2−3)

2−4

Lenze9300Servo.lib EN 1.1

L

Page 15

Function block library Lenze9300Servo.lib

Special functions

2.1.1 Holding brake (L_BRK)

bSet_b

bQSP_b

bM−Store_b

MCTRL_MAct_a

bOut_b

bCInh_b

MCTRL_nNSet2_a

Abb. 2−5 Switching cycle when braking

wActivation

Time

wReleaseTime

t

t

t

MCTRL_MAct_a = nMSet

t

t

t

|nNx_a|

t

L

Lenze9300Servo.lib EN 1.1

2−5

Page 16

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

2.1.2 Supply−failure control (L_MFAIL)

If the supply voltage via L1, L2, L3 or +UG, −UG fails, then the drive (drive network) can be decelerated

(braked) in a controlled manner.

Without this function, the drive (drive network) would coast down.

Abb. 2−6 Supply−failure control (L_MFAIL)

VariableName

DataType SignalType VariableType Note

nAdapt_a Integer analog VAR_INPUT Dynamic adjustment of the proportional gain of the

nConst_a Integer analog VAR_INPUT Proportional gain of the U

nDcSet_a Integer analog VAR_INPUT Voltage setpoint at which the DC bus voltage is to be

nNSet_a Integer analog VAR_INPUT Speed setpoint in [%] of C0011

bFault_b Bool binary VAR_INPUT TRUE = activates the supply−failure control

bReset_b Bool binary VAR_INPUT TRUE = reset

nThreshold_a Integer analog VAR_INPUT Restart threshold in [%] of C0011

nNAct_a Integer analog VAR_INPUT Comparison value for the restart threshold in [%] of

nSet_a Integer analog VAR_INPUT Speed starting point for run−down/deceleration in [%]

nNOut_a Integer analog VAR_OUTPUT Speed setpoint in [%] of C0011

bStatus_b Bool binary VAR_OUTPUT TRUE = supply−failure control is active

bIReset_b Bool binary VAR_OUTPUT TRUE = supply−failure control active, the drive is

nVp Integer − VAR CONSTANT RETAIN Gain

nTn Integer − VAR CONSTANT RETAIN Integral−action time T

nTi Integer − VAR CONSTANT RETAIN Acceleration time

wRetriggerTime Unsigned

Integer

nAdapt_a

nConst_a

nDCSet_a

nNSet_a

bFault_b

bReset_b

nThreshold_a

nNAct_a

nSet_a

nTi

MCTRL_nDCVolt_a

wRetriggerTime

CTRL

nVp

nTn

L_MFAIL

1

0

U

Gsetp

from nVp . (16384 º 100 %)

maintained. (1000 V º 100 %)

(C0011 º 100 % º 16384)

(C0011 º 100 % º 16384)

C0011

of C0011

(C0011 º 100 % º 16384)

(C0011 º 100 % º 16384)

braking

− VAR CONSTANT RETAIN Retrigger time

nNOut_a

bStatus_b

bIReset_b

−control in [%] of nVp . (16384 º 100 %)

controller in [%]

Gsetp

2−6

Parameter codes of the instances

VariableName L_MFAIL1 SettingRange Lenze

nVp C0980 0.001 ... 31.000 0.500

nTn C0981 20 ... 2000 ms 100

nTi C0982 0.001 ... 16.000 s 2.000

wRetriggerTime C0983 0.001 ... 60.000 s 1.000

Lenze9300Servo.lib EN 1.1

L

Page 17

Function block library Lenze9300Servo.lib

1

Special functions

2.1.2 Supply−failure control (L_MFAIL)

Range of functions

· Supply−failure detection

· Supply−failure control

· Restart protection

· Reset of the supply failure control

· Dynamic adaptation of the control parameters

· Fast supply recovery (KU)

· Application example

2.1.2.1 Supply failure detection

The type of the supply−failure detection to be used depends on the drive system used.

A failure of the voltage supply of the power stage is detected:

· by the level of the DC−bus voltage

· by an external system (e.g. supply module 934X or voltage−detection relay).

· Different systems can be combined.

Supply−failure detected by the level of the DC bus voltage

Use with single drives or multi−axis drives, which do not use external monitoring systems. For this,

you can use a comparator (e.g. L_CMP).

L_CMP2

L_CMP

FCODE_nC472_20_a

MCTRL_nDCVolt_a

Abb. 2−7 Example of a supply−failure detection with internal function blocks (section)

nIn1_a

nIn2_a

bOut_b

Programming the example in Abb. 2−7:

1. Set the signal links according to Abb. 2−7

2. In FB L_CMP, set byFunction = 3 (nIn1 < nIn2)

nAdapt_a

nConst_a

nDcSet_a

nNSet_a

bFault_b

bReset_b

nThreshold_a

nAct_a

nSet_a

L_MFAIL

L_MFAIL

nNout_a

bStatus_b

bIReset_b

L

Lenze9300Servo.lib EN 1.1

2−7

Page 18

Function block library Lenze9300Servo.lib

1

1

Special functions

2.1.2 Supply−failure control (L_MFAIL)

Supply−failure detection of the supply module

· A digital output of the supply module 934x is switched to the function block L_MFAIL via the

digital inputs DIGIN of the 93XX controller. In the example, input X5/E4 is used.

nAdapt_a

nConst_a

nDcSet_a

nNSet_a

DIGIN_bIn5_b

Abb. 2−8 Example of a supply−failure detection by an external monitoring system

Programming the example in Abb. 2−8:

1. Set the signal links according to Abb. 2−8

2. Select the input level (TRUE− or FALSE−active) for X5/E4 with C0114/4

bFault_b

bReset_b

nThreshold_a

nAct_a

nSet_a

L_MFAIL

L_MFAIL

nNout_a

bStatus_b

bIReset_b

Combination of these methods

These methods are combined via an OR link.

DIGIN_bIn5_b

FALSE

L_CMP2

L_CMP

FCODE_nC472_20_a

MCTRL_nDCVolt_a

nIn1_a

nIn2_a

bOut_b

Abb. 2−9 Example of a supply−failure detected by different sources

Programming the example in Abb. 2−9:

1. Set the signal links according to Abb. 2−9

2. In FB L_CMP, set byFunction = 3 (nIn1 < nIn2)

bIn1_b

bIn2_b

bIn3_b

L_OR5

L_OR

bOut_b

nAdapt_a

nConst_a

nDcSet_a

nNSet_a

bFault_b

bReset_b

nThreshold_a

nAct_a

nSet_a

L_MFAIL

L_MFAIL

nNout_a

bStatus_b

bIReset_b

2−8

Lenze9300Servo.lib EN 1.1

L

Page 19

Function block library Lenze9300Servo.lib

1

Special functions

2.1.2 Supply−failure control (L_MFAIL)

2.1.2.2 Supply failure control

Integration of the FB into the signal flow of the controller

L_MFAIL

L_MFAIL

L_NSET1

nCInhVal_a

bRfgStop_b

bRfg0_b

bNInv_b

nN_a

bJog1_b

bJog2_b

bJog4_b

bJog8_b

bTI1_b

bTI2_b

bTI4_b

bTI8_b

nSet_a

bLoad_b

bNAddInv_b

nNAdd_a

L_NSET

bRfgIEqO_b

nOut_a

16384

FCODE_nC472_19_a

L_CMP2

L_CMP

nIn1_a

nIn2_a

DIGIN_bIn5_b

FCODE_nC472_18_a

MCTRL_nDCVolt_a

FCODE_nC472_20_a

bOut_b

MCTRL_nNAct_a

nAdapt_a

0

nConst_a

nDcSet_a

nNSet_a

bFault_b

bReset_b

nThreshold_a

nAct_a

nSet_a

nNout_a

bStatus_b

bIReset_b

MCTRL_nNSet_a

MCTRL_bILoad_b

Abb. 2−10 Links for the configuration CFG1000.lpc

Programming the example (SpeedModeInternal24VSupply.lpc) in Abb. 2−10:

1. Set the signal links according to Abb. 2−10 (see the following table for explanation).

Function Inputs/outputs of L_MFAIL Note

Speed setpoint path nNSet_a, nNOut_a

Start value for deceleration nSet_a Here, the actual speed value

Source for the setpoint of the DC bus voltage nDCSet_a Here, from the freely linkable code

Source for the activation of the supply−failure

control:

Proportional gain and adaptation of the

DC−bus voltage controller:

Restart protection nThreshold_a, nNAct_a In FCODE_nC472_18_a first, enter approx.

Reset input bReset_b Here, with terminal DIGIN_bIn5_b

Note!

Use C0003 to save all settings in the parameter set, if they are to be retained on power−off.

FCODE_nC472_19_a

b_Fault_b ^ 2−7: Supply−failure detection

n_Adapt_a, nConst_a

2% (reference: n

max

, C0011)

L

Lenze9300Servo.lib EN 1.1

2−9

Page 20

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

Activation of the supply−failure control

· bFault_b TRUE = activates the supply−failure control

· bFault_b = FALSE triggers a timing element. After elapse of the preset time in wRetriggerTime

the supply−failure control is ended/cancelled.

– The drive is accelerated to the speed setpoint if the restart protection is not active.

– The drive is still braked to zero speed, if the restart protection is active. (^ 2−14: Restart

protection)

– When restart protection is active, the drive can only be reset by bReset_b = TRUE.

Function of the supply−failure control

The drive controller gains the required energy from the rotational energy of the driven machine. The

drive is braked through the power loss of the controller and the motor. The speed deceleration ramp

is thus shorter than for an uncontrolled system (coasting drive).

After activation of the supply−failure control:

1. The DC bus voltage is controlled to the value at nDCSet_a

2. At nNOut_a an internally generated speed setpoint is output. The drive can thus be braked to

zero speed (via the speed setpoint).

– The start value for the controlled deceleration is the value at nSet_a . This input is usually

connected to MCTRL_nNAct_a (actual speed), MCTRL_nNIn_a or L_MFAIL_nNOut_a (set

speed).

– The speed deceleration ramp (and thus the brake torque) results from the moment of inertia

of the driven machine(s), the power loss of the drive (group), and the parameter settings.

(^ 2−15: fast return of supply power)

Stop!

· If a connected brake unit is activated, the drive is braked with the maximum possible torque

). In this case, it may be necessary to adapt the parameterization (see folowing page).

(I

max

· If the power stage is not supplied, the drive cannot generate a standstill torque (important for

active loads such as hoists).

2−10

Lenze9300Servo.lib EN 1.1

L

Page 21

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

Parameterization of the supply−failure control

The parameters to be set are strongly dependent on the motor used, the inertia of the driven machine

and the drive configuration (single drive, drive network, master−slave operation, etc.). This function

must therefore be adapted to the individual application in every case.

The following specifications refer to Chapter 2.1.2.1

Important settings prior to the initial commissioning:

Stop!

With internal voltage supply to the terminals, terminal X6/63 is used as a voltage source for external

potentiometers. In this case, measure across terminals +UG, −UG.

Note!

To perform the measurements, a new download that includes the changes must be made.

1. Measure the DC−bus voltage with an oscilloscope (channel 1)

– with a suitable voltage divider across the terminals +U

, −UG or

G

– by providing the DC bus voltage at terminal X6/62, for instance. To do this, connect the

system variable MCTRL_nDCVolt_a with the system variable AOUT2_nOut_a .

2. Measure the speed with an oscilloscope (channel 2)

– by supplying the speed on terminal X6/62, for instance, (standard setting). To do this,

connect the system variable MCTRL_nNAct_a with the system variable AOUT1_nOut_a .

3. Enter, in C0472/20 ( FCODE_nC0472_20_a ) the threshold for the supply−failure detection.

The entry depends on the setting in C0173 (adjsutment of the U

−threshold).

G

– Set the threshold approx. 50 V above the switch−off threshold LU

(example for C0173 = 0.1; C0472/20 = 48 % = 480 V).

Supply voltage range C0173 = Switch−off

< 400 V 0 285 V 430 V 770 V 755 V

400 V 1 285 V 430 V 770 V 755 V

400 V ... 460 V 2 328 V 473 V 770 V 755 V

480 V without brake chopper 3 342 V 487 V 770 V 755 V

Operation with brake chopper (up to

480 V)

4 342 V 487 V 800 V 785 V

threshold LU

Switch−on

threshold LU

Switch−off

threshold OU

Switch−on

threshold OU

4. Set the setpoint to which the DC bus voltage is to be controlled:

– Set the setpoint to approx. 700 V (C0472/18 = 70%).

L

Stop!

This setpoint must be below the threshold of any brake unit which may be connected.If a connected

brake unit is activated, the drive is braked with the maximum possible torque (I

operating behaviour is lost.

Lenze9300Servo.lib EN 1.1

). The desired

max

2−11

Page 22

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

Commissioning of the supply−failure control

The commissioning should be carried out with motors without any load.

1. Start the drive with a FALSE−TRUE trasnsition at X5/E5 (when DIGIN_bIn5_b is connected to

bReset_b ).

2. Setting the acceleration time nTi :

– Set speed setpoint to 100%, operate controller with maximum speed.

– Inhibit controller via terminal X5/28 (you can also use any other source for the controller

inhibit, CINH) and measure the deceleration time to standstill.

– Set approx. 1/10 of the deceleration time in nTi .

3. Setting the retrigger time

– For supply−failure detection by detecting the DC−bus voltage level:

In wRetriggerTime set the run−down/deceleration time measured under point 2. .

– For supply−failure detection via an external system (e.g. supply module 934X):

In wRetriggerTime set the time for which the drive continues to be braked in a controlled

way in the event of short−term supply recovery.

4. Switch off the supply voltage (supply or DC−bus).

The oscilloscope should display the following sequence

n

0

U G

Q

R

n D c S e t _ a

L _ C M P _ b O u t _ b

Abb. 2−11 Schematic representation with activated supply−failure control (ideal characteristic)

Switch−off threshold OU

Switch−on threshold for brake unit

Threshold

Threshold LU

n Speed of the drive

t1 Supply−failure

t2 Zero speed reached

S

T

0

t 1 t 2

t

t

2−12

Lenze9300Servo.lib EN 1.1

L

Page 23

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

Fine setting of the supply−failure control

For the fine setting, you will have to repeat the following points several times.

1. Obtain a very low final speed without the controller reaching the undervoltage threshold LU:

– Increase the proportional gain nVp .

– Reduce the integral−action time nTn .

2. Avoid activation of the brake unit or the overvoltage threshold:

– Increase the integral−action time nTn until the characteristic in Abb. 2−11 is almost reached.

– If necessary, also reduce the setpoint of the DC−bus voltage at nDCSet_a (in the example

C0472/19 ( FCODE_nC472_19_a )).

3. An increase of the run−down/deceleration time or reduction of the brake torque (see

Abb. 2−12) is only possible with restrictions:

– Increasing the acceleration time nTi reduces the initial brake torque and simultaneously

increases the deceleration time.

– Increasing the intergral−action time nTn reduces the initial brake torque and simultaneously

increases the deceleration time. If the integral−action times are too long, the controller

reaches the LU threshold before zero speed is reached. The drive is thus no longer under

control.

4. Re−establish any signal connections which may be required to the outputs of the drive

controller (terminals X6).

Note!

Use C0003 to save all settings im a parameter set, if they are to be retained on power−off.

n

0

U G

Q

R

n D c S e t _ a

L _ C M P _ b O u t _ b

Abb. 2−12 Schematic representation with different brake torques

Switch−off threshold OU

Switch−on threshold for brake unit

Threshold

Threshold LU

n Speed of the drive

t = t1 Supply−failure

t = t2 Zero speed with higher brake torque (short adjustment time)

t = t3 Drive reaches the LU switch−off threshold with lower brake torque (high adjustment time),

without reaching zero speed

t > t3 Drive is no longer under control (is braked by friction)

S

T

0

t 1 t 2

t

t 3

t

L

Lenze9300Servo.lib EN 1.1

2−13

Page 24

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

Reset of the supply failure control

· The supply−failure control is reset with bReset_b = TRUE (in the example, through X5/E5

(when DIGIN_bIn5_b is connected to bReset_b ).

· The reset pulse is always required if:

– The restart protection is active.

– The restart protection is used and the supply (supply or DC supply) was switched on.

2.1.2.3 Restart protection

The integrated restart protection is to avoid a restart in the lower speed range, after the supply voltage

was interrupted for a short time only (supply recovery before the drive has come to standstill).

· Establish the restart protection (^ 2−9: Parameterization of the example in Abb. 2−10)

· In C0472/18 ( FCODE_nC472_18_a ), enter the threshold in [%] of n

no automatic start is wanted after supply recovery.

– If the speed at supply recovery < threshold in C0472/18 ( FCODE_nC472_18_a ): the drive

will still be braked under control. This function can only be ended by bReset_b = TRUE.

– If the speed at supply recovery > threshold in C0472/18 ( FCODE_nC472_18_a ): the drive

accelerates to its setpoint along the set ramps.

– The function is deactivated by: nThreshold_a = 0%.

· A reset is made by bReset_b = TRUE

– This is required after every supply (re)connection, and is shown by bStatus_b = HIGH, when

bFault_b = FALSE.

(C0011) below which

max

Note!

To be able to make the settings through the system block (SB) FCODE, you must also have used the

free codes of the SB FCODE.

2.1.2.4 Dynamic adaptation of the control parameters

In special cases, a dynamic modification of the proportional gain may be useful. Two inputs are

available for this purpose at FB L_MFAIL ( nConst_a and nAdapt_a ). The resulting proportional gain

results from:

+ nVp @

V

p

(100 % º 16384)

nConst_a * |nAdapt_a|

100%

2−14

Lenze9300Servo.lib EN 1.1

L

Page 25

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

2.1.2.5 Fast supply power recovery (KU)

The fast supply recovery causes a restart of the controller, unless the restart protection is active. The

drive accelerates to its setpoint. If this is not wanted, you can delay the restart by wRetriggerTime

or prevent it in combination with the restart protection.

A fast supply recovery occurs:

· Due to the system, the supply recovery is indicated by the supply−failure detection via the level

of the DC−bus voltage.

· because of a "short interruption" (KU) of the utility company (e.g. in a thunderstorm).

· Because of faulty components in the supply cables (e.g. slip−rings)

So set wRetriggerTime > the measured deceleration time that can be achieved in braking operation.

2.1.2.6 Application example

Drive network with digital frequency coupling

(^ 2−7)

Stop!

Für drive networks which are connected via digital frequency (a master and one or more slaves):

· the supply−failure detection and control must only be activated for the master.

– You must link the supply−failure control into the signal flow to meet this requirement.

· You must operate all the controllers through the terminals +U

Observe the specifications in the System Manual Servo controller 9300", Part F.

, −UG in a DC−bus configuration.

G

L

Lenze9300Servo.lib EN 1.1

2−15

Page 26

Function block library Lenze9300Servo.lib

Special functions

2.1.2 Supply−failure control (L_MFAIL)

2−16

Lenze9300Servo.lib EN 1.1

L

Page 27

Function block library Lenze9300Servo.lib

3 Appendix

3.1 Code table

How to read the code table:

Column Abbreviation Meaning

Code C0039

1

2

…

14

15

[C0156] Parameter value of the code can only be modified when the controller is inhibited

LCD Keypad LCD

Lenze Factory setting of the code

* The column "Important" contains further information

Choice 1 {1 %} 99 Minimum value {smallest step/unit} maximum value

IMPORTANT− Additional, important explanation of the code

Code C0039

Subcode 1 of code C0039

Subcode 2 of code C0039

…

Subcode 14 of code C0039

Subcode 15 of code C0039

· DIS: ... display only

· all others are parameter values

Appendix

3.1.1 L_BRK

FB description: (^ 2−1)

Code

LCD

C0195 wActivationTime 99.9 0.0 {0.1 s} 99.9

C0196 wReleaseTime 0.0 0.0 {0.1 s} 60.0 Brake opening time of L_BRK1

C0244 nMSet 0.00 −100.00 {0.01 %} 100.00

Possible settings

Lenze Choice

99.9 s infinite

100 % = value of C0057

IMPORTANT

Brake closing time of L_BRK1

· Engaging time of the mechanical holding

brake (see technical data of the brake).

· After the time under C0195 has elapsed,

the status "mechanical brake closed" is

reached

· Disengaging time of the mechanical

holding brake (see technical data of the

brake).

· After the time under C0196 has elapsed,

the status "mechanical brake opened" is

reached

Holding moment of the DC−brake of L_BRK1

3.1.2 L_MFAIL

FB description: (^ 2−6)

Code

LCD

C0980 nVp 0.500 0.001 {0.001} 31.000 Gain Vp of L_MFAIL1

C0981 nTn 100 20 {1 msec} 2000 Time constant of L_MFAIL1

C0982 nTir 2.000 0.001 {0.001 sec} 16.000 Acceleration time Tir of L_MFAIL1

C0983 wRetriggerTime 1.000 0.001 {0.001 sec} 60.000 Retrigger time of L_MFAIL1

Possible settings

Lenze Choice

IMPORTANT

L

Lenze9300Servo.lib EN 1.1

3−1

Page 28

Function block library Lenze9300Servo.lib

Appendix

3−2

Lenze9300Servo.lib EN 1.1

L

Page 29

4 Index

Function block library Lenze9300Servo.lib

Index

A

Appendix, 3−1

C

Code table, 3−1

Codes

Holding brake (L_BRK), 3−1

Supply−failure control (L_MFAIL), 3−1

D

data−type entry, Explanation of, 1−4

Definitions, 1−2

F

Fast supply recovery (KU), 2−15

Function blocks

Holding brake (L_BRK), 2−1

Close brake, 2−2

Open the brake, 2−3

Setting controller inhibit, 2−4

Supply−failure control (L_MFAIL), 2−6

L

L_BRK, 2−1

L_MFAIL, 2−6

Lenze software guidelines, Hungarian Notation, 1−3

P

prefix, Explanation of, 1−3

R

Restart protection, 2−14

S

Safety information, Layout

Other notes, 1−1

Warning of damage to material, 1−1

Signal type, Explanation of, 1−5

Supply−failure control, 2−9

Supply−failure control (L_MFAIL), 2−6

Fast supply recovery (KU), 2−15

Restart protection, 2−14

Supply−failure control, 2−9

Supply−failure detection, 2−7

Supply−failure detection, 2−7

System variables, Explanation of, 1−5

H

Holding brake (L_BRK), 2−1

I

identifier, Explanation of, 1−4

T

Type of variable, Identification, 1−4

V

Variable names

Conventions, Hungarian Notation, 1−3

Lenze software guidelines, Explanation of, 1−3

Version identifiers of the function library, 1−6

l

Lenze9300Servo.lib EN 1.1

4−1

Loading...

Loading...