Page 1

EDB8600UE

00387996

Operating Instructions

Frequency inverters

8600 series

Page 2

These Operating Instructions are valid for controllers with the nameplate data:

8601 E.6x.6x

8602 E.6x.6x

8603 E.6x.6x

8604 E.6x.6x

8605 E.6x.6x

8606 E.6x.6x

8607 E.6x.6x

8608 E.6x.6x

8609 E.6x.6x

8610 E.6x.6x

8611 E.6x.6x

Controller type

Built-in unit

(Enclosure IP20)

Hardware version +

index

Software version +

index

8612 E.6x.6x

8613 E.6x.6x

8614 E.6x.6x

8615 E.6x.6x

corresponds to the German edition of 22/11/1995

revised:

Edition of: 12/02/1996 06/11/1996

Page 3

How to use these Operating

Instructions...

To locate information on specific topics, simply refer to the table of

contents at the beginning and to the index at the end of the Operating

Instructions.

These Operating Instructions use a series of different symbols to

provide quick reference and to highlight important items.

This symbol refers to items of information intended to facilitate

operation.

Notes which should be observed to avoid possible damage to or

destruction of equipment.

Notes which should be observed to avoid health risks to the operating

personnel.

1

Page 4

General safety and operating instructions for drive converters

in conformity with the Low-Voltage Directive 79/23/EEC

1. General

In operation, drive converters, depending on their

degree of protection, may have live, uninsulated, and

possibly also moving or rotating parts, as well as hot

surfaces.

In case of inadmissible removal of the required covers,

or improper use, wrong installation or maloperation,

there is the danger of serious personal injury and

damage to property. For further information, see

documentation.

All operations serving transport, installation and

commissioning as well as maintenance are to be

carried out by skilled technical personnel. (Observe

IEC 364 or CELEC HD 384 or DIN VDE 0100 and IEC

664 or DIN/VDE 0110 and national accident

prevention rules!)

For the purposes of these basic safety instructions,

"skilled technical personnel" means persons who are

familiar with the installation, mounting, commissioning

and operation of the product and have the

qualifications needed for the performance of their

functions.

2. Intended use

Drive converters are components designed for

inclusion in electrical installations or machinery.

In case of installation in machinery, commissioning of

the drive converter (i.e. the starting of normal

operation) is prohibited until the machinery has been

proved to conform to the provisions of the directive

89/392/EEC (Machinery Safety Directive - MSD).

Account is to be taken of EN 60204.

Commissioning (i.e. the starting of normal operation) is

admissible only where conformity with the EMC

directive (89/336/EEC) has been established.The drive

converters meet the requirements of the low-voltage

directive 73/23/EEC. They are subject to the

harmonized standards of the series prEN 50178/DIN

VDE 0160 in conjunction with EN 50439-1/VDE 0660,

part 500, and EN 60146/VDE 0558.

The technical data as well as information concerning

the supply conditions shall be taken from the rating

plate and from the documentation and shall be strictly

observed.

3. Transport, storage

The instructions for transport, storage and proper use

shall be complied with.

The climatic conditions shall be in conformity with

prEN 50178.

4. Installation

The installation and cooling of the appliances shall be

in accordance with the specifications in the pertinent

documentation.

The drive converters shall be protected against

excessive strains. In particular, no components must

be bent or isolating distances altered in the course of

transportation or handling. No cantact shall be made

with electronic components and contacts. Drive

converters contain electrostatic sensitive components

which are liable to damage through improper use.

Electric components must not be mechanically

damaged or destroyed (potential health risks).

5. Electrical connection

When working on live drive converters, the applicable

national accident prevention rules (e.g. VB 4) must be

complied with.

The electrical installation shall be carried out in

accordance with the relevant requirements (e.g. cross

sectional areas of conductors, fusing, PE connection).

For further information, see documentation.

Instructions for the installation in accordance with the

EMC requirements, like screening, earthing, location of

filters and wiring, are contained in the drive converter

documentation. They must always be complied with,

also for drive converters bearing a CE marking.

Observance of the limit values required by EMC law is

the responsibility of the manufacturer of the installation

or machine.

6. Operation

Installations, which include drive converters shall be

equipped with additional control and protective devices

in accordance with the relevant applicable safety

requirements, e.g. Act respecting technical equipment,

accident prevention rules, etc. Changes to the drive

converters by means of the operating software are

admissible.

After disconnection of the drive converter from the

voltage supply, live applicance parts and power

terminals must not be touched immediately because of

possibly energized capacitors. In this respect, the

corresponding signs and markings on the drive

converter must be respected.

During operation, all covers and doors shall be kept

closed.

7. Maintenance and servicing

The manufacturer’s documentation shall be followed.

KEEP SAFETY INSTRUCTIONS IN A SAFE PLACE!

Please observe the product-specific safety and operating instructions stated in these Operating

Instructions.

2

Page 5

Contents

3ODQQLQJ

)HDWXUHVRIWKHLQYHUWHUVHULHV

7HFKQLFDOGDWD

2.1 General data 8

2.2 Dimensions 9

2.3 Scope of supply 9

2.4 Application as directed 10

2.5 CE conformity 11

2.5.1 EC Declaration of Conformity ´95 for the purpose of the EC Low-Voltage

Directive (73/23/EEC) 12

2.5.2 EC Declaration of Conformity ´95 for the purpose of the EC directive relating

to Electromagnetic Compatibility (89/336/EEC) 13

2.5.3 Manufacturer's Declaration for the purpose of the EC directive relating to

machinery (89/392/EEC) 15

$SSOLFDWLRQVSHFLILFFRQWUROOHUVHOHFWLRQ

3.1 Applications with extreme overload, peak torque up to 230% of the rated motor

torque 16

3.2 Applications with high overload, peak torque up to 170% of the rated motor

torque 17

3.3 Application with medium overload, peak torque up to 135% of the rated motor

torque 18

,QVWDOODWLRQ

4.1 Mechanical installation 19

4.2 Electrical installation 20

4.2.1 Motor protection 21

4.2.2 Installation in compliance with EMC 21

4.2.3 CE-typical drive systems 22

4.2.4 Switching on the motor side 24

:LULQJ

5.1 Power connections 26

5.1.1 Tightening torques of the power terminals 27

5.2 Control connections 27

5.2.1 Analog inputs and outputs 28

5.2.2 Further inputs and outputs 28

5.2.3 Description of the analog inputs and outputs 29

5.2.4 Description of other inputs and outputs 29

5.2.5 Digital inputs and outputs 30

5.2.6 Description of the digital inputs and outputs 32

5.2.7 Frequency output 6⋅ fd 33

5.3 Operation with DC bus supply 34

5.3.1 Connection of several drives for energy-sharing 34

5.3.2 DC voltage supply 34

5.4 Screenings 35

5.5 Grounding of control electronics 35

3

Page 6

$FFHVVRULHV

6.1 Brake resistors 36

6.1.1 Selection of the brake resistor 37

6.1.3 Technical data of brake resistors 39

6.2 Mains chokes 40

6.2.1 Selection of the mains choke 41

6.2.2 Technical data of mains chokes 42

6.3 Motor filter 43

6.3.1 Technical data of motor filter 44

6.4 Motor voltage filter 45

6.4.1 Technical data of motor supply filters 46

6.5 Cable protection 47

6.6 RFI filters 48

6.6.1 Ratings of RFI filters 48

6.6.2 Technical data of RFI filters 49

6.7 Accessories for digital frequency networking 49

$FFHVVRULHVIRUQHWZRUNLQJ

7.1 Connecting module 2110IB− InterBus-S 50

7.2 Connecting module 2130IB− PROFIBUS 50

7.3 Connecting elements for optical fibre cables−LECOM-LI 51

7.4 Level converter 2101IP− LECOM-A/B 51

7.5 Adapter RS485 (LECOM interface X6) 51

,QLWLDOVZLWFKRQ

3DUDPHWHUVHWWLQJ

.H\SDG

1.1 Key functions 53

1.2 Plain text display 53

%DVLFFRQWURORSHUDWLRQV

2.1 Changing parameters 54

2.1.1 Parameter setting by two codes 56

2.2 Save parameters 56

2.3 Load parameters 56

%DVLFVHWWLQJV

3.1 Operating mode 57

3.1.1 Controller enable 58

3.1.2 Quick stop / Select direction of rotation 58

3.2 Configuration 60

3.2.1 Example of how to select a configuration 61

3.3 Signal flow chart 62

3.4 Features of set-value 1 64

3.4.1 Set-value input with master current 64

3.4.2 Digital frequency input 65

3.5 Features of set-value 2 66

3.6 Offset and gain adjustment 66

4

Page 7

3.7 Control mode 67

3.7.1 V/f characteristic control 68

3.7.2 I0 control 70

3.8 Minimum field frequency fdmin 71

3.9 Maximum field frequency fdmax 71

3.10 Acceleration and deceleration times Tir, Tif 72

&ORVHGORRSVSHHGFRQWURO

4.1 Analog feedback 73

4.2 Digital feedback 73

4.3 Frequency pilot control 74

4.4 Adjustment of the feedback gain 75

4.4.1 Automatic adjustment 75

4.4.2 Manual adjustment 76

4.5 Setting of the controller parameters 76

4.6 Additional functions 77

3URJUDPPLQJRIWKHIUHHO\DVVLJQDEOHLQSXWVDQGRXWSXWV

5.1 Freely assignable digital inputs 78

5.2 Functions of the freely assignable digital inputs 79

5.2.1 Set TRIP 79

5.2.2 Reset TRIP 79

5.2.3 DC injection braking 79

5.2.4 JOG frequencies 80

5.2.5 Additional acceleration and deceleration times 82

5.2.6 Ramp generator stop 84

5.2.7 Ramp generator input = 0 84

5.2.8 Integral action component = 0 84

5.2.9 Process control 84

5.2.10. Select parameter set, Load parameter set 85

5.3 Freely assignable digital outputs, relay output 86

5.4 Functions of the freely assignable digital outputs 87

5.4.1 Frequency below a certain level , Qmin 87

5.4.2 Maximum current reached, Imax 87

5.4.3 Set-value reached 87

5.4.4 Fault indication TRIP 88

5.4.5 Ready, RDY 88

5.4.6 Pulse inhibit, IMP 88

5.4.7 Feedback = Set-value 88

5.4.8 Feedback = 0 88

5.4.9 Flying restart circuit active 89

5.4.10 Process control active, process step active 89

5.5 Monitor outputs 89

5.6 Digital frequency output X9 (Option) 90

$GGLWLRQDORSHQORRSDQGFORVHGORRSFRQWUROIXQFWLRQV

6.1 Chopping frequency 91

6.1.1 Automatic chopping frequency reduction 92

6.2 Automatic DC injection braking 92

6.3 Slip compensation 92

6.4 S-shaped ramp generator characteristic 93

6.5 Limitation of the frequency setting range 93

6.6 Process control 94

6.7 Flying restart circuit 95

5

Page 8

6.8 Oscillation damping 96

6.9 Load change damping 96

2YHUORDGSURWHFWLRQV

7.1 Overload protection of the frequency inverter (I⋅t monitoring) 97

7.2 Overload protection of the motor 97

7.2.1 PTC input 97

7.2.2 I²⋅t monitoring 98

'LVSOD\IXQFWLRQV

8.1 Code set 99

8.2 Language 99

8.3 Display of the actual values 100

8.4 Switch-on display 100

8.5 Identification 100

&RGHWDEOH

6HULDOLQWHUIDFHV

10.1 LECOM1 interface X6 109

10.2 LECOM2 interface (option) 110

10.3 LECOM codes 110

10.3.1 Controller address 110

10.3.2 Operating state 110

10.3.3 Controller state 110

10.3.4 Pole pair number 110

10.3.5 Baud rate (LECOM1) 111

10.3.6 History of reset faults 111

10.3.7 Code bank (LECOM1) 111

10.3.8 Enable automation interface (LECOM2) 111

10.3.9 High resolution data 112

10.4 Attribute table 113

6HUYLFH

)DXOWLQGLFDWLRQ

:DUQLQJ

0RQLWRULQJ

&KHFNLQJWKHSRZHUVWDJH

4.1 Checking the mains rectifier 120

4.2 Checking the power stage 120

4.3 Checking the voltage supply on the control board 8602MP 120

,QGH[

6

Page 9

Planning

1 Features of the 8600 inverter series

Liability

• The information given in these Operating Instructions describe

the features of the products but do not guarantee them.

Power stage

• Large mains voltage range: 3 x 330 to 528V AC or

470 to 740V DC

• Inverter with IGBTs, protected against short circuits

• 4kHz chopper frequency, adjustable up to 16kHz

• Output frequency up to 480Hz,

V/f rated frequency up to 960Hz

• Overload capacity up to 200% rated current for a short time

• Overload monitoring can be set

• Integrated brake transistor, external brake resistors in IP20

enclosure as option

• Connections for DC bus supply

Control stage

• Digital control unit with 16-bit microprocessor

• Simple parameter setting and diagnosis using keypad and two-

line display in German, English, and French language

• Parameter setting during operation

• V/f-characteristic control with linear or square characteristic

• High breakaway torque by magnetizing current control

• Constant speed due to slip compensation

• Speed control using DC tacho or incremental encoder

• Current limitation with V/f lowering for stall-protected operation

• Motor overload monitoring via PTC input or

²

I

⋅t-monitoring

• Process control with a maximum of eight steps

• Synchronisation coasting motor due to flying restart circuit

• Serial interface (RS232C/RS485) for external parameter setting

and operation

• Field bus connecting modules as option to be integrated into the

device

Approvals (unit types 8602 to 8611)

• VDE 0160, VDE reg.-no. 86694

• UL 508, file no. 132659

7

Page 10

2 Technical data

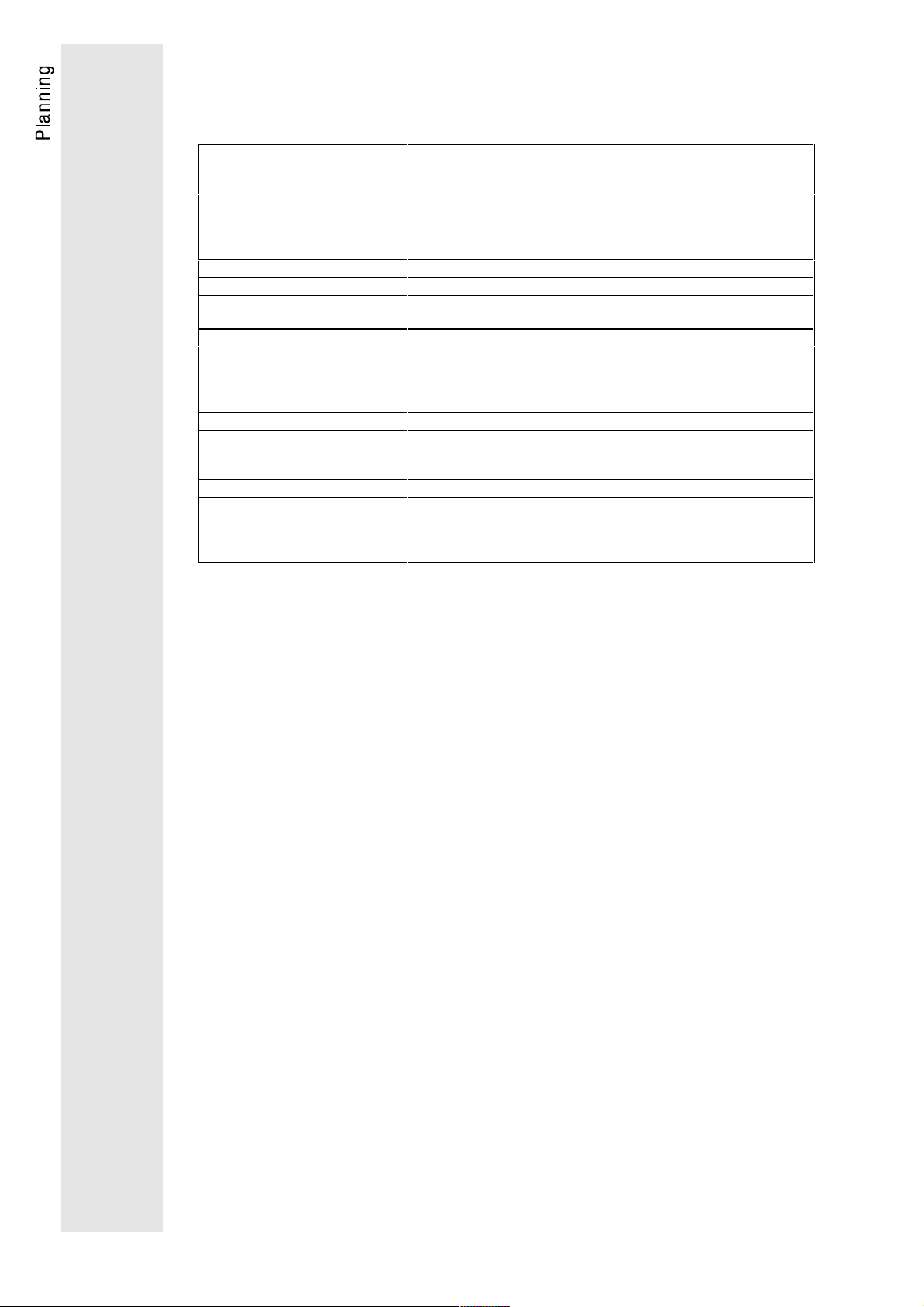

2.1 General data

Mains voltage: 3 x 480 V AC, 45 to 65 Hz

Permissible voltage range: 330 ... 528 V

(alternatively 470 to 740 V DC supply)

Output voltage: 3 x 0 to V

(V ~ fd with 400 V at 50 Hz, adjustabl e, mains-independent)

When using a mains choke, the maximum possible output voltage is

reduced to approx. 96 % of the mai ns voltage.

Output frequency: 0 ... 50 Hz, adjustable up to 480 Hz

Chopper frequency: 4 kHz factory setting, adjustable from 2 ... 16 kHz

Threshold of the integrated brake

chopper:

Enclosure: Steel-sheet housing, IP20 to DIN 40050

Ambient temperature: 0 to 50 °C during operation

Noise immunity: Severity class 4 to IEC 801-4

Permissible pollution: Pollution level

Permissible humidit y: rel at i ve humidity 80 %, no condens ation

Influence of install at i on al titude on

the rated current:

765 V DC in the DC bus

(for rating see page 11)

-25 to 55 °C during storage

-25 to 70 °C during transport

˝ 2 to VDE 0110, part 2. The inv ert er should not be exposed to

corrosive or explosiv e gases.

1000 m: 100 % rated current

2000 m: 95 % rated current

3000 m: 90 % rated current

4000 m: 85 % rated current

mains

8

Page 11

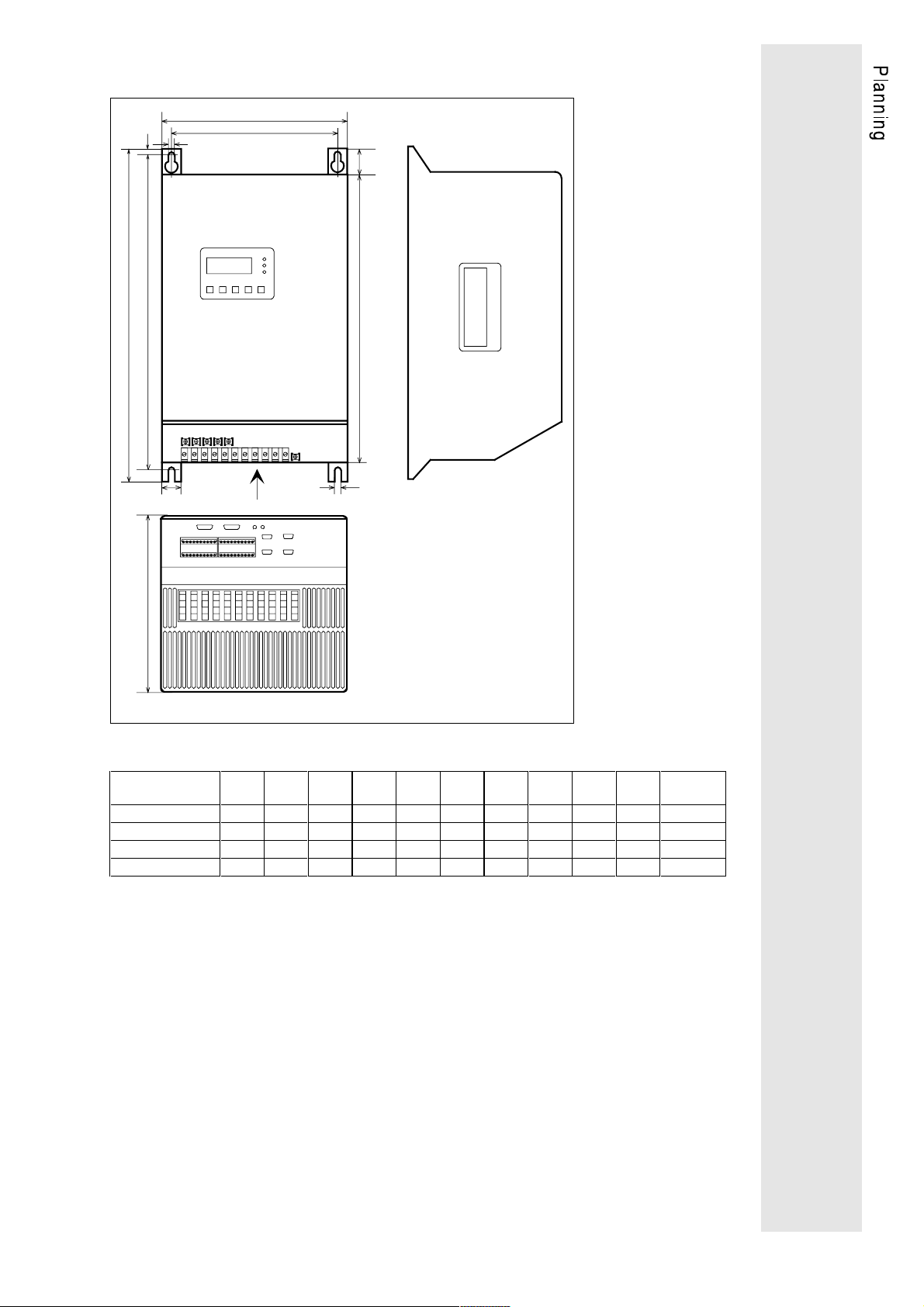

2.2 Dimensions

a

h

g

c

i

d

b

k

e

Bottom view

f

g

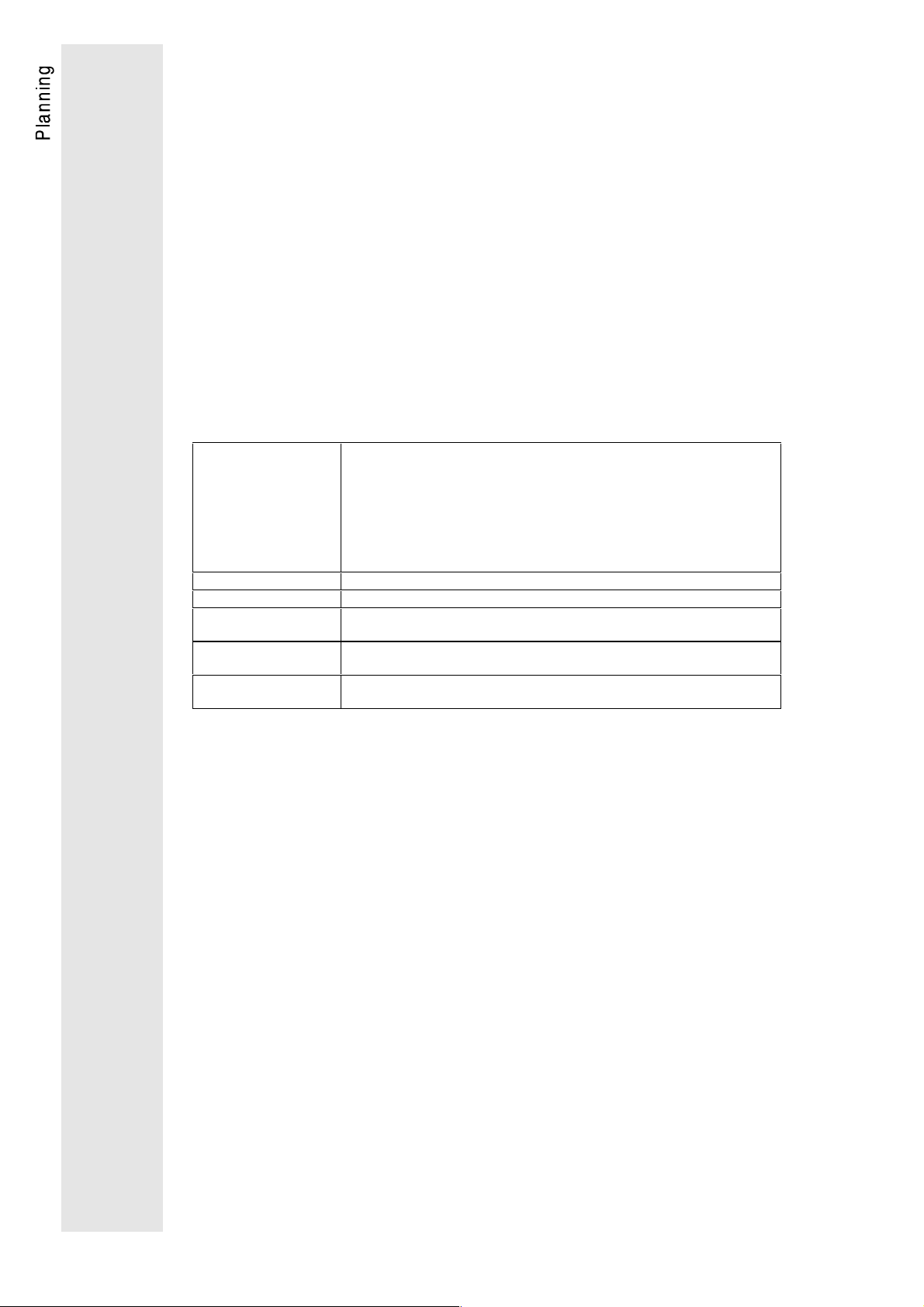

Type a

mmbmmcmmdmmemmfmmgmmhmmimmkmm

8601-05 204 330 185 315 180 295 6.5 8 21 20 7.0

8606-07 269 415 242 395 222 360 6.5 8 30 26 12.5

8608-11 360 500 300 480 249 440 6.5 8 30 50 28.5

8612-15 400 690 350 655 345 600 10.5 13 50 50 60.5

2.3 Scope of supply

The scope of supply includes:

• frequency inverter type 86XX_E

• set-value potentiometer

• accessory kit incl. plug-in terminals and

protective covers for interface plugs

• operating instructions

Weight

kg

9

Page 12

2.4 Application as directed

The controllers of the 8600 series are electrical equipment intended

for installation in control cabinets of high power plants.

The controllers are directed as components

• for the control of variable speed drives with three-phase AC

motors.

• for the installation in control cabinets or control boxes.

• for the assembly together with other components to form a

drive system.

• The controllers correspond to the Low-Voltage EMC directive.

• Drive systems with the 8600 controllers which are installed

according to the requirements of the CE-typical drive systems

correspond to the EC directive relating to EMC (see chapter

4.2.2).

The CE-typical drive with the 8600 controllers are suitable for

• the operation on public and non-public mains systems.

• the use in industrial areas as well and in residential and

commercial premises.

• Because of the earth-potential reference of the RFI filter, the

described CE-typical drive systems are not suitable for the

connection to IT mains (mains without earth-reference

potential).

• The controllers are not domestic appliances. They are intended

as drive-system components for commercial use.

• The controllers themselves are not machines for the purpose of

the EC directive relating to machinery.

10

Page 13

2.5 CE conformity

What is the purpose of the EC directives?

EC directives are issued by the European Council and are intended

for the determination of common technical requirements

(harmonization) and certification procedures within the European

Community. At the moment, there are 21 EC directives of product

ranges. The directives are or will be converted to national

standards of the member states. A certification issued by one

member state is valid automatically without any further approval in

all other member states.

The texts of the directive are restricted to the essential

requirements. Technical details are or will be determined by the

European harmonized standards.

What does the CE mark imply?

After a verification, the conformity to the EC directives is certified by

affixing a CE mark. Within the EC, there are no commercial barriers

for a product with the CE mark. The enclosure of a conformity

certification is not necessary according to most directives.

Therefore, the customer cannot clearly see which of the 21 EC

directives applies to a product and which harmonized standards are

considered in the conformity verification.

Drive controllers with the CE mark themselves correspond

exclusively to the Low-voltage Directive. For the compliance with

the EMC directive only general recommendations have been issued

so far. The CE conformity of the installed machine remains the

responsibility of the user. For the installation of CE-typical drive

systems, Lenze has already proved the CE conformity to the EMC

directive.

What is the purpose of the EMC directive?

The EC directive relating to electromagnetic compatibility is

effective for "equipment" which may either cause electromagnetic

disturbances or be affected by such disturbances.

The aim is the limitation of the generation of electromagnetic

disturbances so that the operation of radio and telecommunication

systems and other equipment is possible. Furthermore, the units

must be immune against electromagnetic disturbances to ensure an

application as directed.

What is the objective of the Low-Voltage Directive?

The Low-Volgate Directive is effective for all electrical equipment

for the use with a rated voltage between 50 V and 1000 V AC and

between 57 V and 1500 V DC under normal ambient conditions.

The use of electrical equipment in e.g. explosive atmospheres and

electrical parts in passenger and goods lifts are excepted.

The objective of the Low-voltage Directive is to ensure that only

such electrical equipment which does not endanger the safety of

man or animals is placed on the market. It should also be designed

to conserve material assets.

11

Page 14

2.5.1 EC Declaration of Conformity ´95 for the purpose of the EC

Low-Voltage Directive (73/23/EEC)

amended by: CE mark directive (93/68/EEC)

The controllers of the series 8600 were developed, designed, and

manufactured in compliance with the above-mentioned EC directive

under the sole responsibility of

Lenze GmbH & Co KG, Postfach 101352, D-31763

Hameln

The compliance with the DIN VDE 0160 / 5.88 with the

amendments A1 /4.89 and A2 / 10.88 as well as pr DIN EN 50178

classification VDE 0160 / 11.94 was confirmed by awarding the

VDE label of the test laboratory VDE Prüf- und

Zertifizierungsinstitut, Offenbach.

Standards considered:

DIN VDE 0160

5.88

+ A1 / 4.89

+ A2 / 10.88

prDIN EN 50178

Classification

VDE 0160 / 11.94

DIN VDE 0100 Standards for the erection of power i nstallations

EN 60529 IP enclosures

IEC 249 / 1 10/86

IEC 249 / 2-15 / 12/89

IEC 326 / 1 10/90

EN 60097 / 9.93

DIN VDE 0110

/1-2 /1/89 /20/ 8/90

Electronic equipment f or use in electrical power instal l ations

Material for printed circ ui ts

Printed circuits, printed boards

Creepage distances and clearances

Hameln, November 27,1995

12

........................................... ...........................................

(i.V. Langner) (i.V. Tinebor)

Product manager Engineer in charge of

CE

Page 15

2.5.2 EC Declaration of Conformity ´95 for the purpose of the EC

directive relating to Electromagnetic Compatibility

(89/336/EEC)

amended by: 1st amended directive (92/31/EEC)

CE mark directive (93/68/EEC)

Controller of the 8600 series cannot be driven in stand-alone

operation for the purpose of the regulation about electromagnetic

compatibility. (EMC regulation of 9/11/92 and 1st amended directive

of 30/8/95).The EMC can only be checked when integrating the

controller into a drive system.

Lenze GmbH & Co KG, Postfach 10 13 52, D-31763 Hameln

declares that the described "CE-typical drive sytem" with the

controllers of the 8600 series comply with the above described EC

directive.

The compliance with the protected requirements of the EC-EMC

directive was confirmed by an accredited test laboratory.

The conformity evaluation is based on the working paper of the

product standard for drive systems:

IEC 22G-WG4 5/94 EMC product standard includi ng specific test m ethods for power drive systems

Considered generic standards:

EN 50081-1

/92

EN 50081-2 /93 Generic standard for noise emission

prEN 50082-2 3/94 Generic standard for noi se immunity

Generic standard for noise emission

Part 1: Residential areas, commercial premises and small businesses

Part 2: Industrial premises

The noise emission in indust ri al prem i ses is not limited in I EC 22G. This generic

standard is applied in addition t o the requirements of IEC 22G.

Part 2: Industrial premises

The requirements of noise immuni ty for residential areas were not considered since

these are less strict.

Considered basic standards for the test of noise emission:

Basic standard Test Limit value

EN 55022 7/92 Radio i nterference

Housing and mains

Frequency range: 0.15...1000 MHz

EN 55011 7/92 Radio i nterference

Housing and mains

Frequency range: 0.15...1000 MHz

The noise emission in indust ri al prem i ses

is not limited in IEC 22G. This basic

standard is applied in addition t o the

requirements of IEC 22G.

Class B

for use in residential and com m ercial

premises

Class A

for use in industrial premises

13

Page 16

Considered basic standards for the test of noise immunity:

Basic standard Test Limit value

IEC 801-2 /91 Electrostatic di scharge

on housing and heat sink

IEC 1000-4-3 Electromagnetic fi el ds

Frequency range: 26...1000 MHz

ENV 50140 /93 High frequency field

Frequency range: 80...1000 MHz,

80 % amplitude modulated

Fixed frequency 900 MHz with 200 Hz

100% modulated

IEC 801-4 /88 Fast transients,

burst on power terminals

Burst on bus and control cabl es Severity 4

IEC 801-5 Surge strength test on

mains cables

This basic standard is appl i ed i n addi tion

to the requirements of the prEN 50082-2.

Severity 3

6 kV for contact

8 kV clearance

Severity 3

10 V/m

Severity 3

10 V/m

10 V/m

Severity 3

2 kV / 5 kHz

2 kV / 5 kHz

Installation class 3

Hameln, November 27, 1995

........................................... ...........................................

(i.V. Langner) (i.V. Tinebor)

Product manager Enginee in charge of

CE

14

Page 17

2.5.3 Manufacturer’s Declaration for the purpose of the EC directive

relating to machinery (89/392/EEC)

amended by: 1st amended directive (91/368/EEC)

2nd amended directive (93/44/EEC) /

CE mark directive (93/68/EEC)

The controllers of the 8600 series were developed, designed, and

manufactured under the sole responsibility of

Lenze GmbH & Co KG, Postfach 101352, D-31763 Hameln

The controllers are directed as components to be installed in a

machine or to be assembled together with other components to

form a machine or a system. The controllers themselves are not

machines for the purpose of the EC directive relating to machinery.

The commissioning of the controllers in machines is prohibited until

the conformity with the protection and safety regulations of the EC

directive relating to machinery is proved.

Hameln, November 27,1995

........................................... ...........................................

(i.V. Langner) (i.V. Tinebor)

Product manager Engineer in charge of

CE

15

Page 18

3 Application-specific controller selection

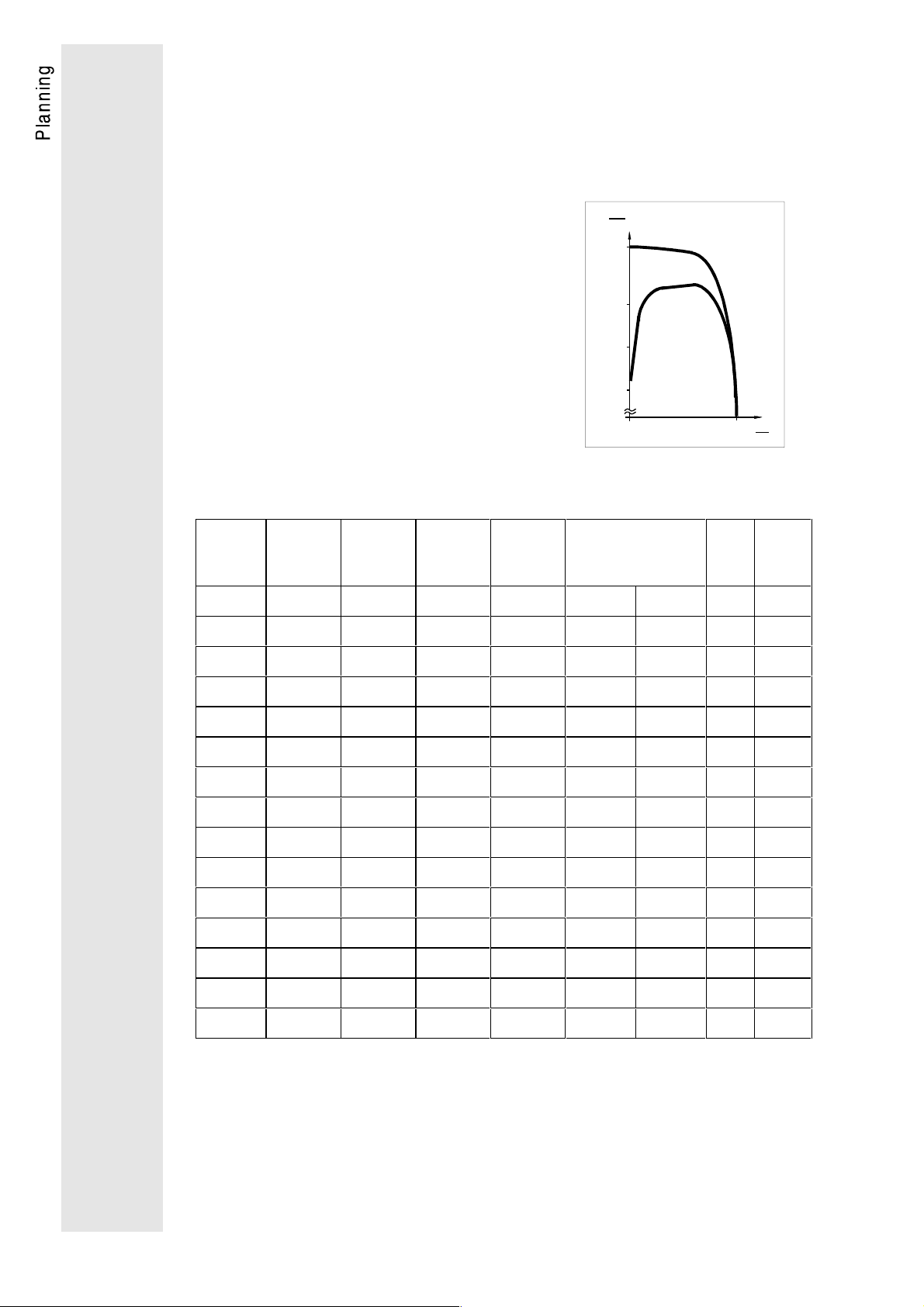

3.1 Applications with extreme overload,

peak torque up to 230% of the rated motor torque

− For applications where very extreme starting and

overload torques are necessary (e.g. presses, drilling

machines).

− The inverter provides 200% of the rated torque for a

maximum of 30s.

In the event of cyclic overload, the ratio of overload

time and cycle time must not exceed 0.2.

− For these applications, the monitoring of the output

current is set to operation with rated power

(factory setting) using the codes C119 and C120

(see page 97)

- Please note that a maximum ambient temperature of

50°C is permissible.

M

2.3

1.8

1.5

1.2

M

N

V/f-control

I -control

0

n

1

n

N

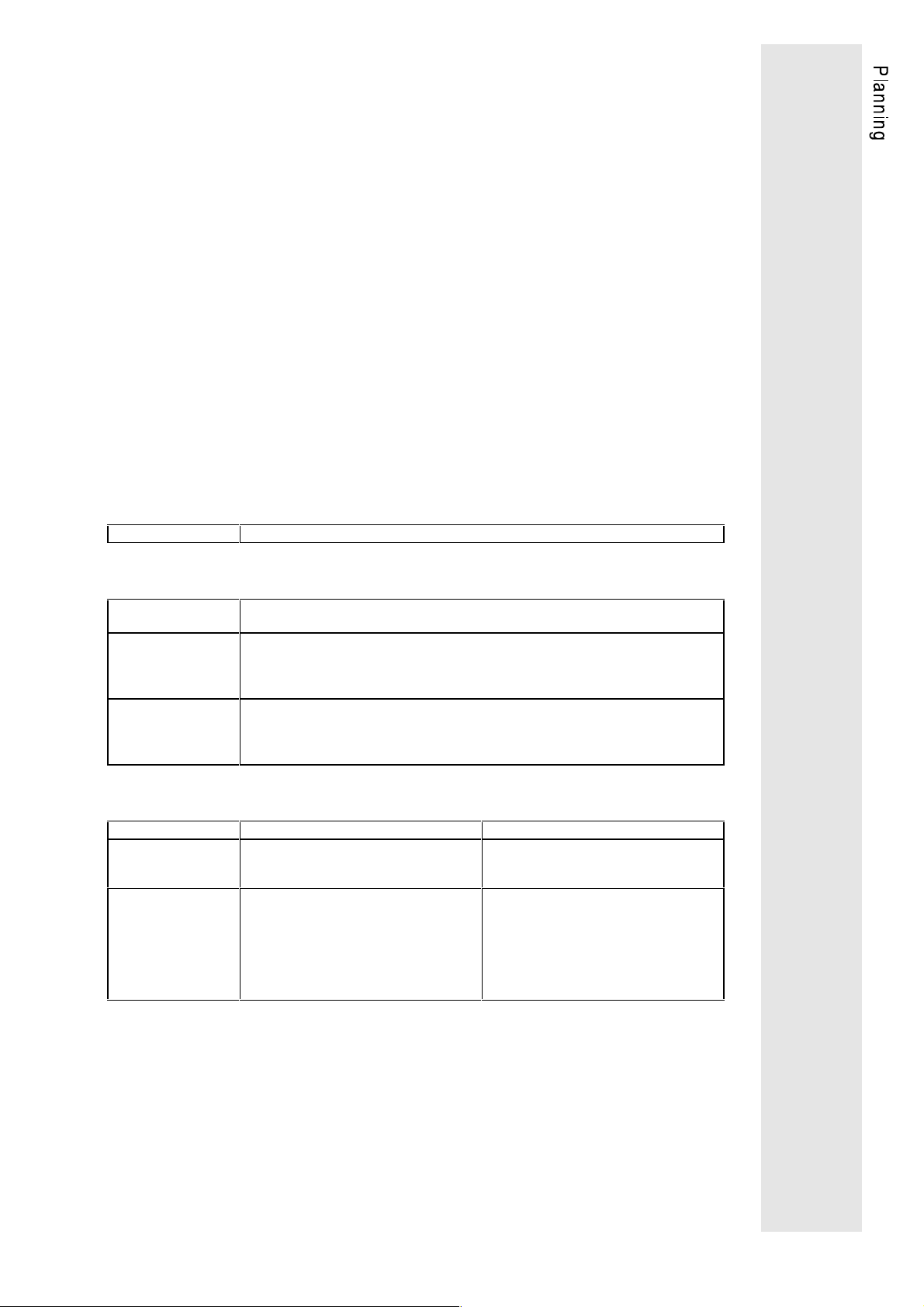

Type Order no. Rated

motor

power

kW

8601 33.8601_E 1.1 3.0 6.0 2.07 2.5 3.0 130

8602 33.8602_E 1.5 3.9 7.8 2.7 3.24 3.9 140

8603 33.8603_E 2.2 5.5 11.0 3.81 4.57 5.5 160

8604 33.8604_E 3.0 7.5 15.0 5.2 6.24 7.0 180

8605 33.8605_E 4.0 9.4 19.0 6.51 7.82 8.8 200

8606 33.8606_E 5.5 13.0 26.0 9.01 10.8 12.0 240

8607 33.8607_E 7.5 16.5 33.0 11.4 13.7 15.0 275

8608 33.8608_E 11.0 23.5 47.0 16.3 19.5 20.5 350

8609 33.8609_E 15.0 32.0 64.0 22.2 26.6 28.5 420

8610 33.8610_E 18.5 39.5 79.0 27.4 32.8 34.5 600

8611 33.8611_E 22.0 47.0 94.0 32.6 39.1 41.0 740

8612 33.8612_E 30.0 60.0 120.0 41.6 49.9 53.0 900

8613 33.8613_E 37.0 75.0 150.0 52.0 62.3 66.0 1050

Rated

output

current

A

max.

output

current

A for 30s

Output power

kVA

400V 50Hz 480V 60Hz

Mains

current

A

Power

loss

W

16

8614 33.8614_E 45.0 89.0 178.0 61.7 74.0 78.0 1050

8615 33.8615_E 55.0 110.0 220.0 76.2 91.4 96.0 1270

Page 19

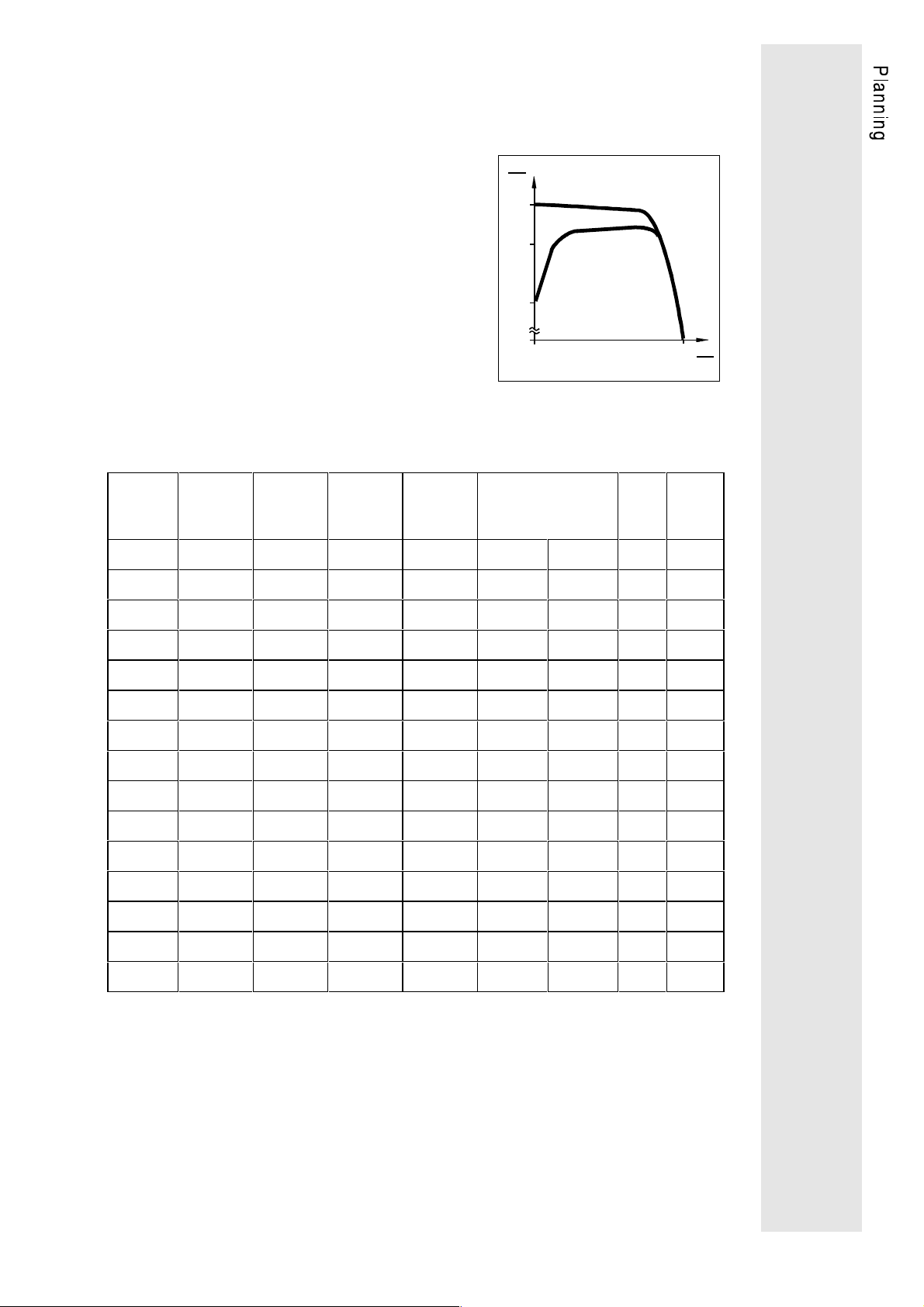

3.2 Applications with high overload,

peak torque up to 170% of the rated motor torque

− For applications which require a standard

overload behaviour of an inverter (e.g. general

mechanical engineering, hoists, travelling drives,

calenders).

− The inverter provides 150% of the rated torque for

a maximum of 30s.

In the event of cyclic overload, the ratio of overload

time and cycle time must not exceed 0.1.

− For this application, the monitoring of the output

current is set to operation with increased power

using the codes C119 and C120 (see page 97).

− Please note that a maximum ambient temperature

of 45°C is permissible.

Type Order no. Rated

motor

power

kW

8601 33.8601_E 1.5 4.0 6.0 2.77 3.33 4.0 140

8602 33.8602_E 2.2 5.3 7.8 3.67 4.41 5.3 155

8603 33.8603_E 3.0 7.4 11.0 5.13 6.15 7.4 180

8604 33.8604_E 4.0 10.1 15.0 7.0 8.4 9.4 210

8605 33.8605_E 5.5 12.7 19.0 8.8 10.6 11.8 235

8606 33.8606_E 7.5 17.6 26.0 12.2 14.6 16.3 290

8607 33.8607_E 11.0 22.7 33.0 15.7 18.9 20.7 340

8608 33.8608_E 15.0 31.7 47.0 22.0 26.3 28.0 440

8609 33.8609_E 18.5 43.2 64.0 29.9 35.9 38.0 560

8610 33.8610_E 22.0 53.3 79.0 36.9 44.3 47.0 670

8611 33.8611_E 30.0 63.5 94.0 44.0 52.8 55.0 775

8612 33.8612_E 37.0 81.0 120.0 56.1 67.3 71.0 960

8613 33.8613_E 45.0 101.0 150.0 70.0 84.0 84.0 1175

Rated

output

current

A

max.

output

current

A for 30s

Output power

kVA

400V 50Hz 480V 60Hz

Mains

current

A

Power

loss

W

8614 33.8614_E 55.0 120.0 178.0 83.1 99.8 105.0 1375

8615 33.8615_E 75.0 148.0 220.0 103.0 123.0 129.0 1675

17

Page 20

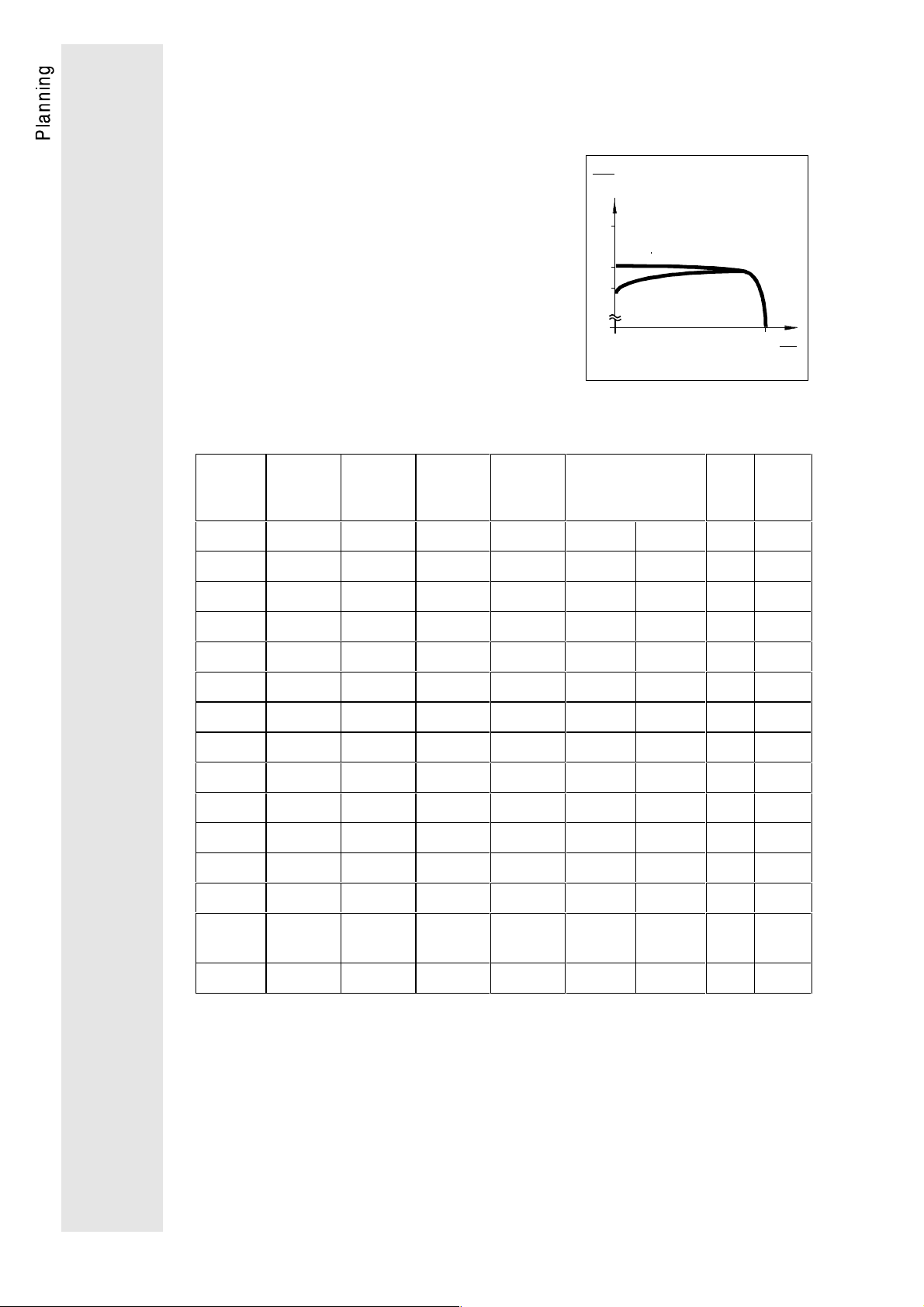

3.3 Application with medium overload,

peak torque up to 135% of the rated motor torque

− For applications where only small starting and

overload torques are necessary (e.g. ventilators,

pumps).

− The inverter provides 110% of the rated torque for

a maximum of 30s.

In the event of cyclic overload, the ratio of overload

time and cycle time must not exceed 0.1.

− For this application, the monitoring of the output

current is set to operation with maximum power

using the codes C119 and C120 (see page 97)

− Please note that a maximum ambient temperature

of 40°C is permissible.

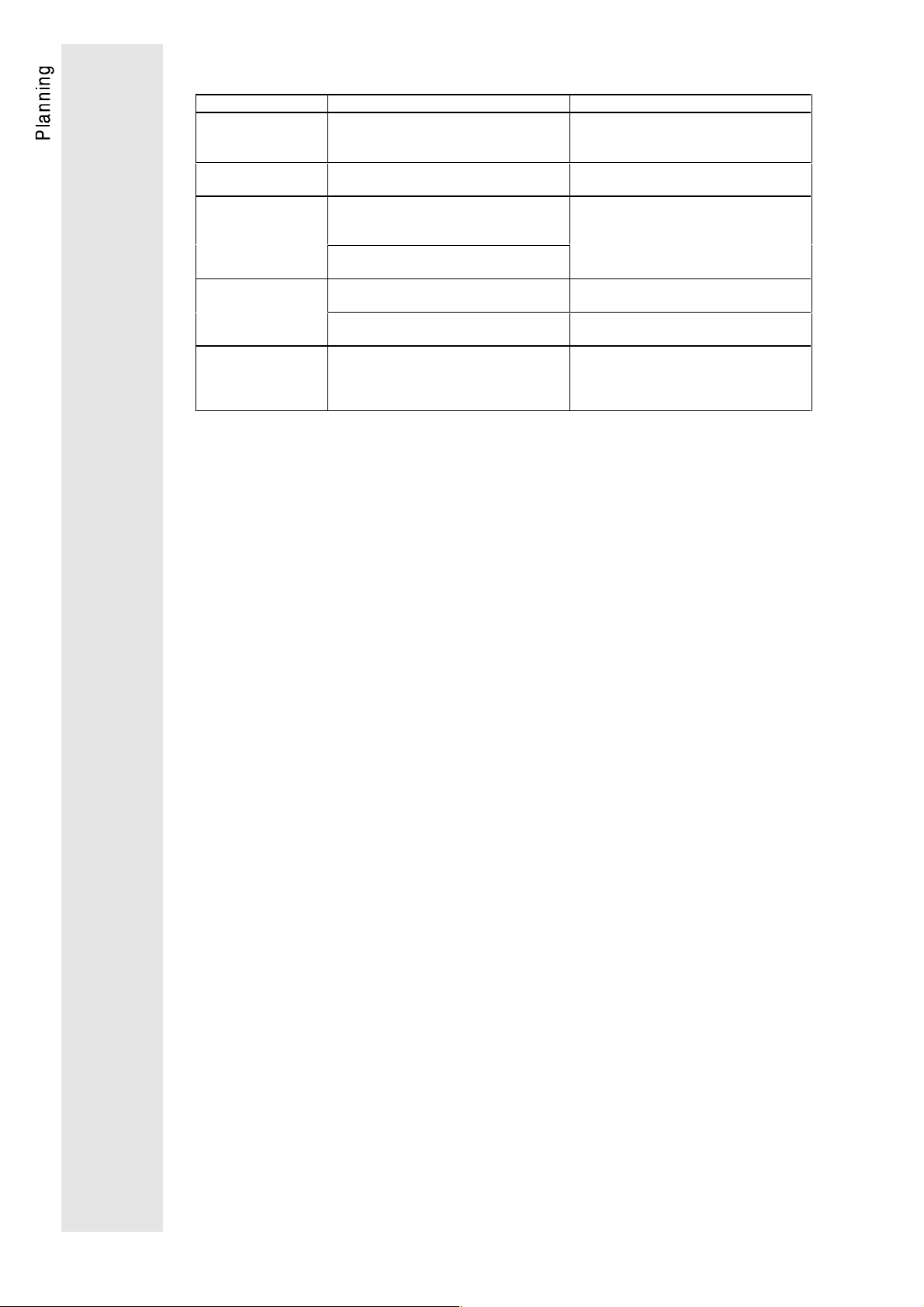

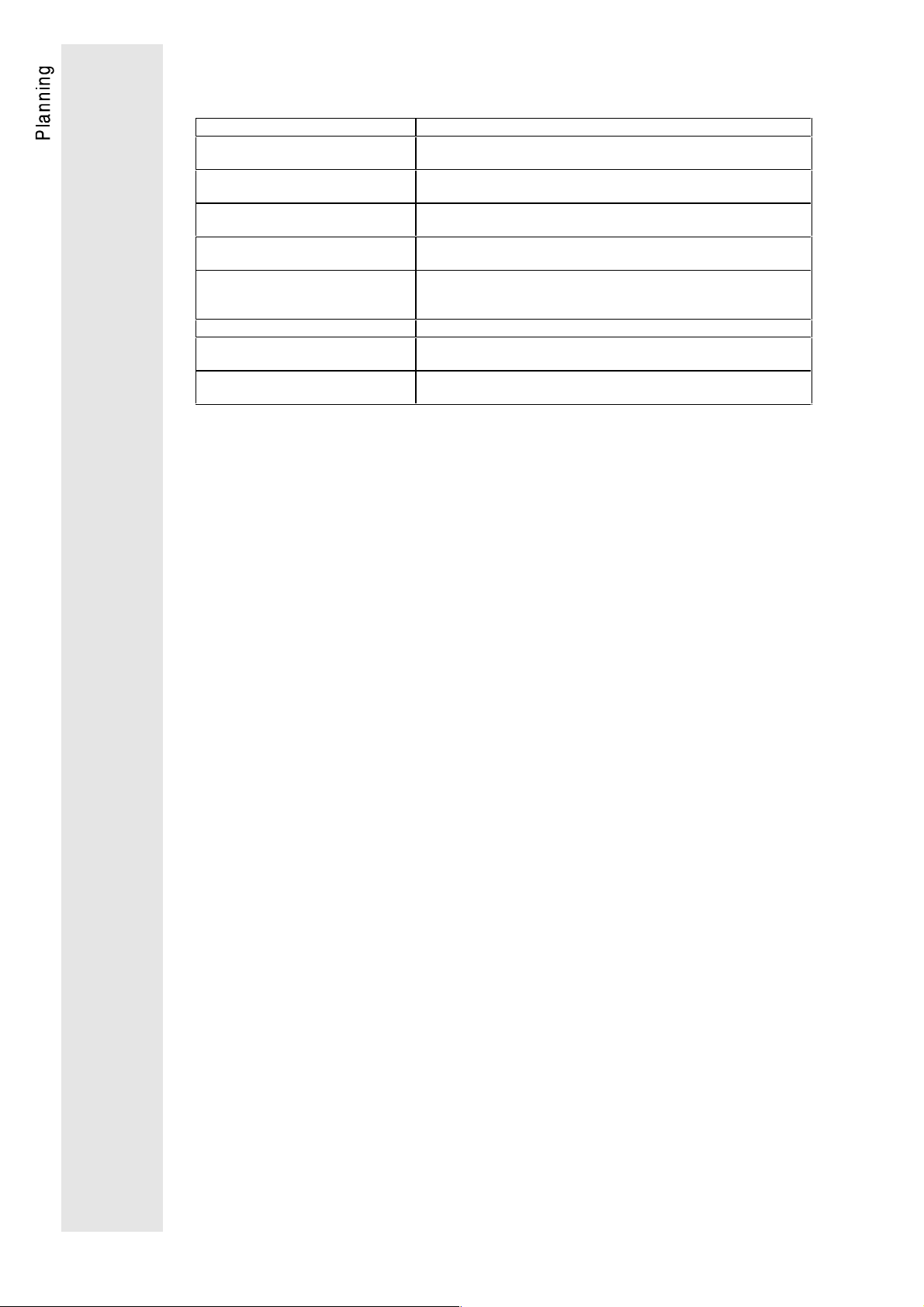

Type Order no. Rated

motor

power

kW

8601 33.8601_E 2.2 5.3 6.0 3.67 4.41 5.3 155

8602 33.8602_E 3.0 7.0 7.8 4.85 5.82 7.0 175

8603 33.8603_E 4.0 9.9 11.0 6.86 8.23 9.2 205

8604 33.8604_E 5.5 12.5 15.0 8.66 10.4 11.6 235

8605 33.8605_E −−−−−−−

8606 33.8606_E 11.0 22.5 26.0 15.6 18.7 20.5 340

8607 33.8607_E −−−−−−−

8608 33.8608_E 18.5 42.3 47.0 29.3 35.2 37.2 550

8609 33.8609_E 22.0 57.6 64.0 39.9 47.9 50.0 710

8610 33.8610_E 30.0 62.0 79.0 43.0 51.5 54.0 760

8611 33.8611_E −−−−−−−

8612 33.8612_E 45.0 95.0 120.0 65.8 79.0 83.0 1110

8613 33.8613_E 55.0 115.0 150.0 79.7 59.6 100.0 1320

Rated

output

current

A

max.

output

current

A for 30s

Output power

kVA

400V 50Hz 480V 60Hz

Mains

current

A

Power

loss

W

18

8614 33.8614_E 75.0 145.0 178.0 100.5 120.5 125.0 1640

90.0* 160.0* 178.0* 110.9* 133.0 138.0* 1640*

8615 33.8615_E −−−−−−−

* These data are valid for a maximum ambient temperature of 30°C.

Page 21

4 Installation

4.1 Mechanical installation

• These frequency inverters must only be used as built-in units.

• Install the inverter vertically with the terminal strips at the

bottom.

• Allow a free space of 100 mm at the top and bottom. For the

units 8612 ... 8615 this free space is also required at both

sides.

Ensure unimpeded ventilation of cooling air.

• If the cooling air contains pollutants (dust, flakes, grease,

aggressive gases), which may impair the inverter functions,

suitable preventive measures must be taken, e.g. separate air

duct, installation of a fiter, regular cleaning, etc.

• If the inverters are permanently subjected to vibration or

shaking, shock absorbers may be necessary.

19

Page 22

4.2 Electrical installation

• The drive controllers are equipped with electrostatically

endangered components. The service and maintenance

personnel must be electrostatically discharged before working at

the units.

They can discharge by touching the PE fastening screw or

another earthed metallic surface in the control cabinet.

• All control inputs and outputs of the inverter are mains-isolated.

The mains isolation has a basic insulation. The control inputs

and outputs must be integrated into another level of protection

against direct contact.

Use insulated operating elements, connect the mechanical

screwed joint of the set-value potentiometer to PE (assembly

kit).

• Not used control inputs and outputs should be covered with

plugs or protective covers which are supplied together with the

unit.

• When using current-operated protective units:

− The controllers are equipped with an internal mains rectifier.

As result, a DC fault current may prevent the tripping of the

current-operated protective device after a short-circuit to

frame.

Therefore, additional measures as protective multiple

earthing or universal-current sensitive current-operated

e.l.c.b. are required.

− When dimensioning the tripping current of current-operated

e.l.c.b. it must be observed that there are capacitive leakage

currents between cable screens and RFI filters during

operation. These currents may result in false tripping of the

current-operated e.l.c.b.

• The regulation about the min. cross-section of PE cables must

be observed. The cross-section of the PE cable must be at least

as large as the cross-section of the power connections.

• In the event of condensation, only connect the inverter to the

mains when visible moisture has evaporated.

• Before switching on the inverter for the first time check whether

there is an earth fault at the output side, if this is the case, clear

the earth fault. Earth faults which occur during operation are

detected, the inverter is then switched off and the message

"OC1" is set.

• Frequent mains switching may overload the internal switch-on

current limitation. For repeated mains connection, the inverter

must not switched more often than every 3 minutes.

• Replace defective fuses only with the specified type and when

the device is disconnected from the mains. The inverter remains

live for up to 3 minutes after mains disconnection.

20

Page 23

4.2.1 Motor protection

The units do not have a full motor protection.

For monitoring the motor temperature PTCs or thermal contacts

can be used.

The connection possibilities are shown on page 28.

When using group drives, a motor protection relay is required for

each motor.

When using motors which do not have a suitable insulation for

inverter operation:

- Connect motor filters for protection (see page 43). Please

contact your motor manufacturer.

Please note:

These frequency inverters generate an output frequency of up to

480 Hz when set correspondingly. The connection of a motor which

is not suitable for this frequency may result in a hazardous

overspeed.

4.2.2 Installation in compliance with EMC

• Lenze has built up typical drives with these controllers and has

verified the conformity. In the following this system is called "CEtypical drive system".

If you observe the partially easy measures for the installation of

CE-typical drive system, the inverter will not cause any EMC

problems and you can be sure to comply with the EMC directive.

• The following configurations can now be selected by the user:

− The user himself can determine the system components and

their integration into the drive system and is then held

responsible for the conformity of the drive.

− The user can select the CE-typical drive system for which the

manufacturer has already proved the conformity.

For deviating installations, e.g.

− use of unscreened cables,

− use of group filters instead of the assigned RFI filters,

− without mains choke

the conformity to the CE-EMC directives requires a check of the

machine or system regarding the EMC limit values.

The user of the machine is responsible for the compliance

with the EMC directive.

21

Page 24

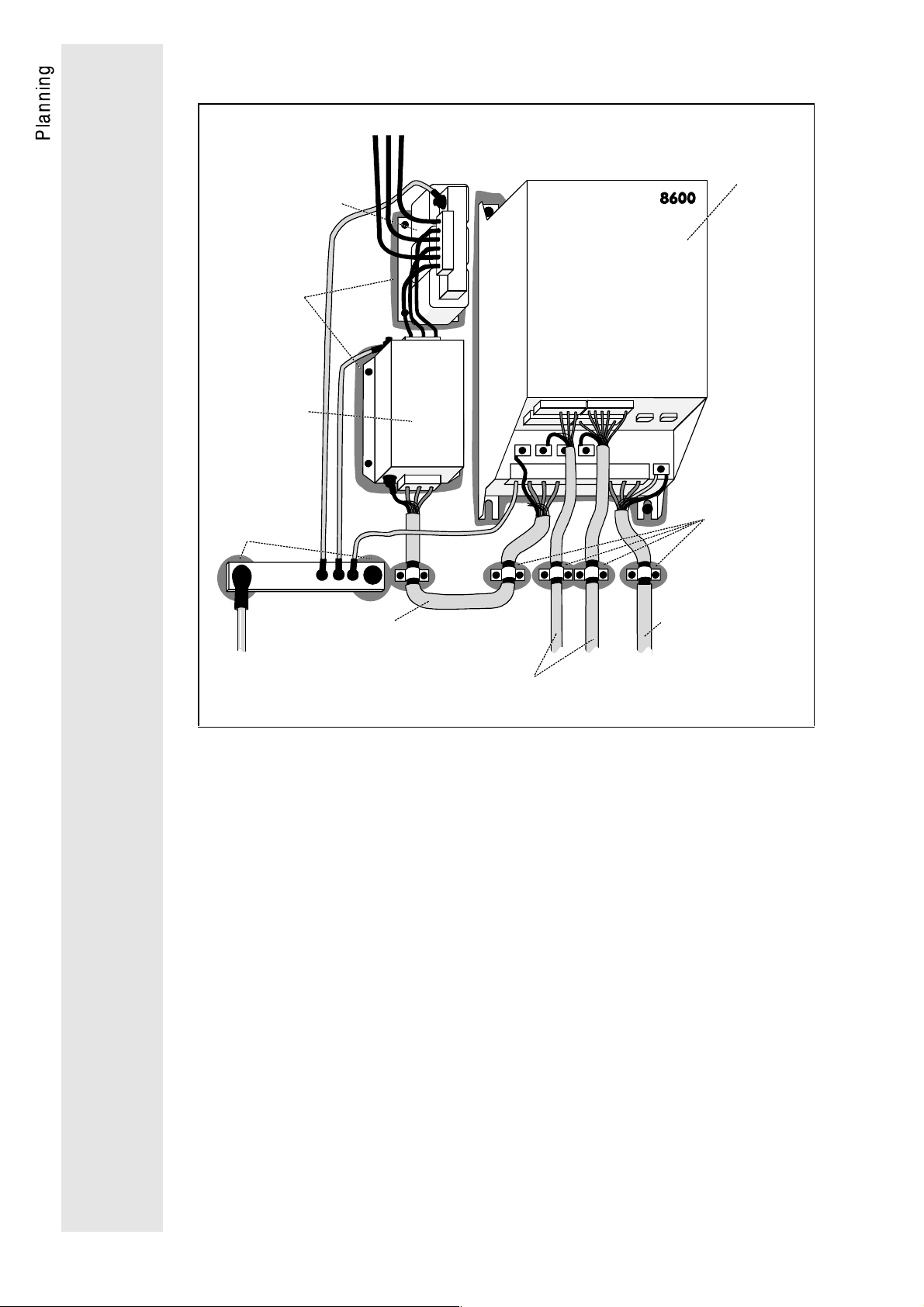

4.2.3 CE-typical drive system

Components of the CE-typical drive sytem

System components Specification

Controller Unit types 8600

For type designation see inner cover page

RFI filter For data and data assignment see c hapt er 6.6, section: Planning of

the Operating Instructions.

Mains choke For data and data assignment see chapter 6.2, section: Planning of

the Operating Instructions.

Motor cable Screened power cable with tin-plat ed E -CU brai d (85 % optically

covered)

Mains cable between RFI filter and

controller

Control cables Screened signal cable type LIYCY

Encoder cable for incremental encoder

or master frequency

Motor Standard three-phase AC asynchronous motor

Controller, RFI filter and mains choke are mounted on one

assembly board.

The system components are functionally wired according to the

chapter 5, section: Planning of the Operating Instructions.

Installation of CE-typical drive systems

The electromagnetic compatibility of a machine depends on the

method and accuracy of the installation. Special care must be taken

of:

• filters,

• screens and

• grounding.

Longer than 0.3 m:

Screened power cable with tin-plat ed E -CU brai d (85 % optically

covered).

Screened signal cable, paarweise verdrillt, t wisted in pairs, tin-plated

E-CU braid (at least 75 % optically covered).

Lenze type DXRA or similar

Filters

Only use suitable mains filters and mains chokes.

Mains filters reduce impermissible high-frequency disturbances to a

permissible value.

Mains chokes reduce low-frequency disturbances, especially those

caused by long motor cables.

Motor cables which are longer than 50 m must be protected

additionally (motor filter or motor supply filter).

Screens

All cables from and to the inverter must be screened.

Lenze system cables meet these requirements.

Ensure that the motor cable is laid separately from the other cables

(signal cables and mains cables). Mains input and motor output

must not be connected to one terminal strip.

Lay cables as close as possible to the reference potential. Dangling

cables are like antennas.

Grounding

Ground all metall-conductive components (controllers, mains filters,

mains chokes) using suitable cables from a central point (PE bar).

Maintain the min. cross sections prescribed in the safety

regulations. For EMC, the surface of the contact is important, not

the cross section.

22

Page 25

Installation

• Connect the inverter, mains filter, and mains choke to the

grounded mounting plate. Zinc-coated mounting plates allow a

permanent contact. If the mounting plates are painted, the paint

must be removed in every case.

• When using several mounting plates they must be connected

with as large surface as possible (e.g. using copper bands).

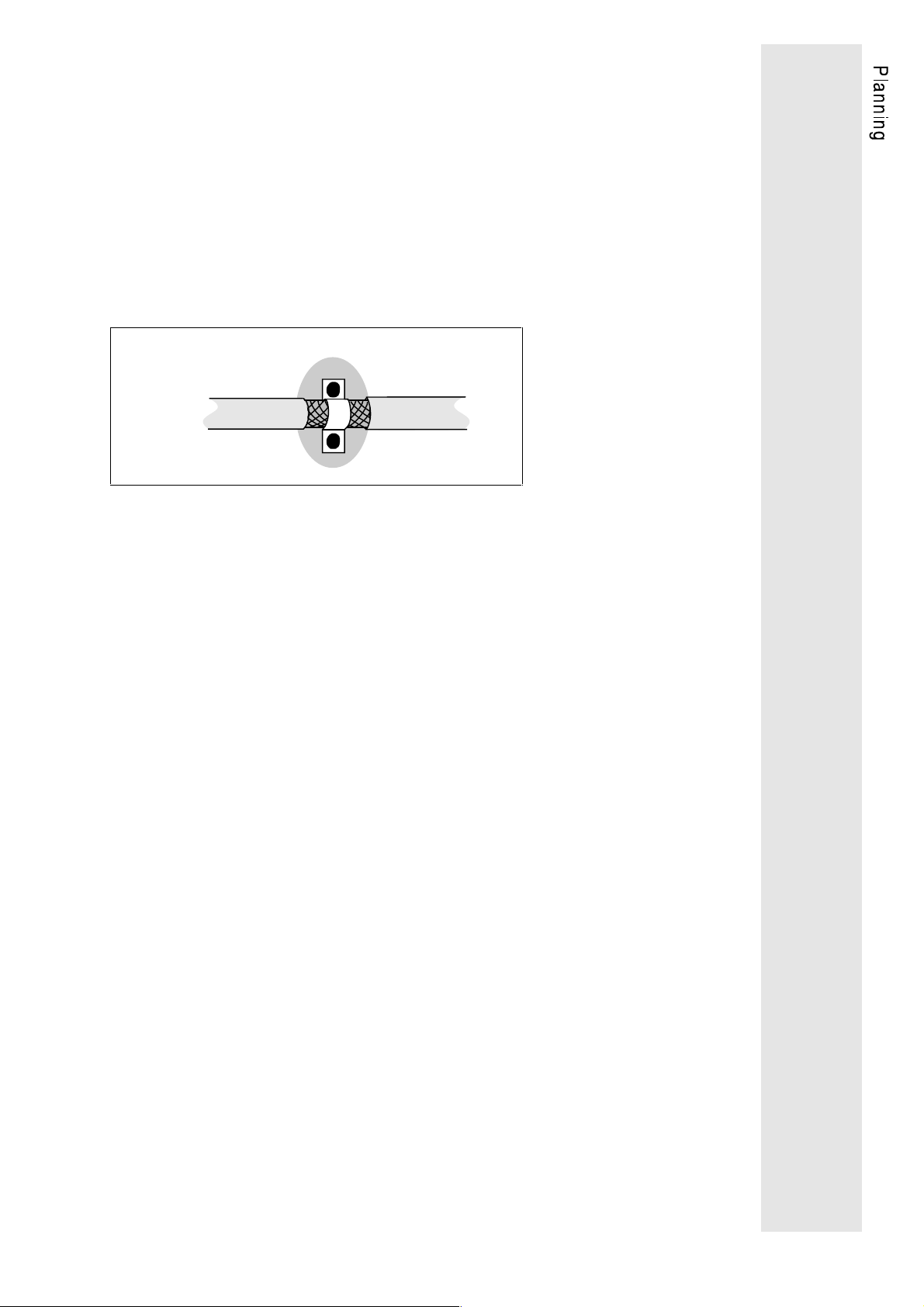

• Connect the screen of the motor cable to the screen connection

of the inverter and to the mounting plate of a surface as large as

possible. We recommend to use ground clamps on bare metal

mounting surfaces to connect the screen to the mounting plate

with as large surface as possible.

bare metal

screened cable

mounting surfac

braid

• If contactors, motor protection switches or terminals are located

in the motor cable, the screens of the connected cables must

also be connected to the mounting plate with as large surface as

possible.

• PE and the screen should be connected in the motor terminal

box. Metal cable glands at the motor terminal box ensure a

connection of the screen and the motor housing with as large a

surface as possible.

• If the mains cable between mains filter and inverter is longer

than 0.3 m, the cable must be screened. Connect the screen of

the mains cable directly to the inverter module and to the mains

filter and connect it to the mounting plate with as large as

possible surface.

• When using a brake resistor, the screen of the brake resistor

cable must be directly connected to the inverter and the brake

resistor and it must be connected to the mounting plate with a

surface as large as possible.

• The control cables must be screened. Digital control cables

must be screened at both ends. Connect the screens of the

control cables to the screen connections of the controllers

leaving as little unscreened cable as possible.

• When using the inverters in residential areas an additional

screening with a damping of

noise emission. This is usually achieved by installation into

enclosed, grounded conrol cabinets or boxes made of metal.

≥ 10 dB is required to limit the

ground clamp

Please note:

• If units, which do not comply with the noise immunity EN 50082-

2 required by the CE, are operated next to the inverters, an

electromagnetic interference of these units is possible.

23

Page 26

Part of the CE-typical drive system on mounting plate

L1 L2 L3 Connection mains fuse

Paint-free bare metal

contact surfaces

Mains choke

Paint-free

bare metal

contact

surfaces

LINE

Mains filt er

Controller

Conductive

connection between

mounting plate and

PE required

PE

PE bar

PE connection

LOAD

Cables betweem mains filter

and controller longer than 0.3 m

must be screened

PE L1 L2

Screened

control cables

L3

UVW

4.2.4 Switching on the motor side

Switching on the motor side is permissible for an emergency stop

as well as during normal operation.

Please note that when switched with the controller enabled, this

may cause the fault message OC1 (short circuit/earth fault). For

long motor cables, the fault current on the interfering cable

capacitances can become so large that the short circuit monitoring

of the device is triggered. In these cases, a motor filter is necessary

to reduce the fault currents (see page 43).

Paint-free

connection of a

large surface

to the mounting

plate

Screened motor cable,

connect screen to PE

also at the motor side,

large cross-section

contact to the motor

housing required

24

Page 27

This page is empty !

25

Page 28

5 Wiring

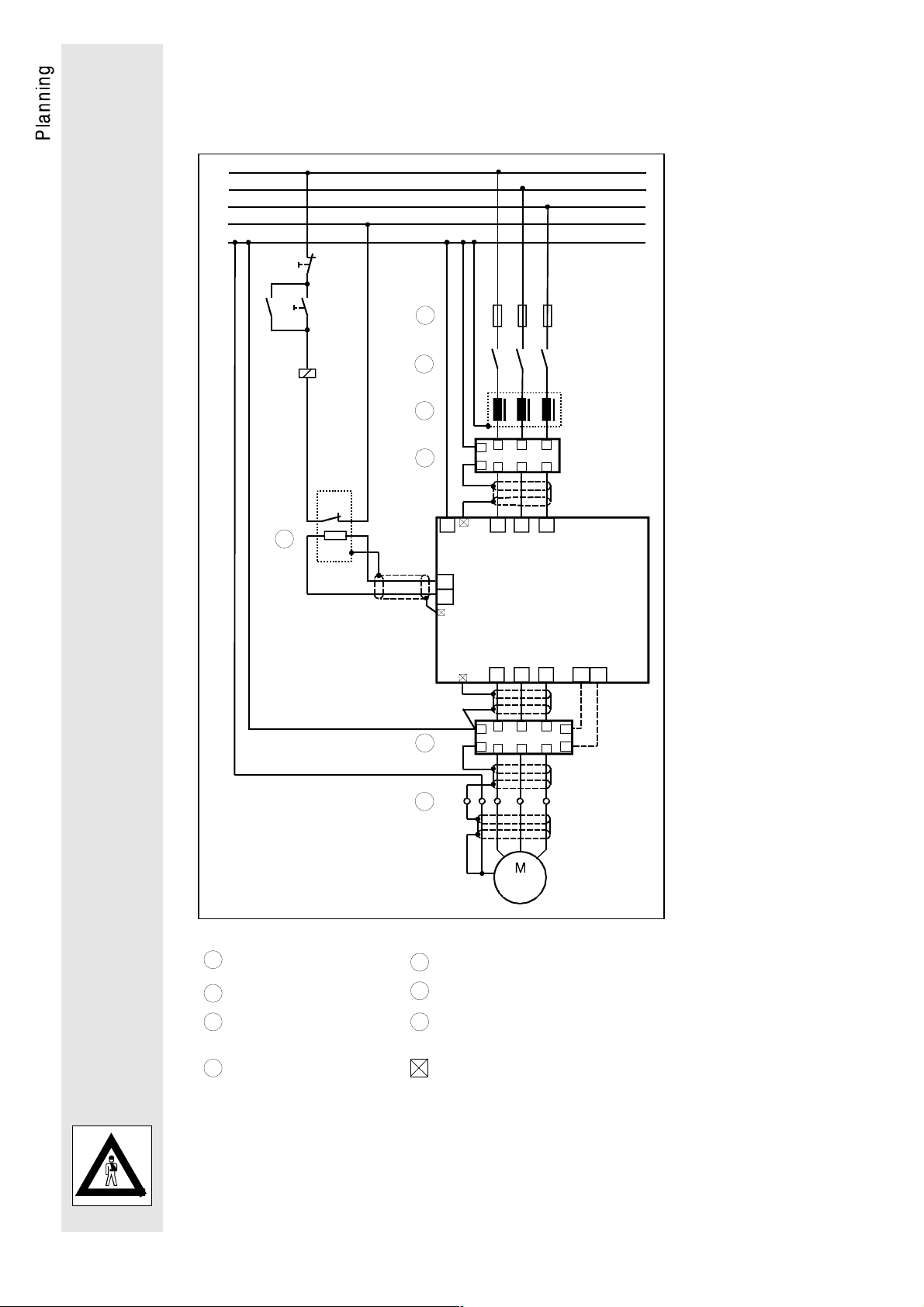

5.1 Power connections

L1

L2

L3

N

PE

OFF

ON

K1

K1

1

K1

2

K1

K1

3

L1 L2 L3

4

ϑ

RB

5

R

B

6

PE

PE

L1 L2 L3

PE

BR1

BR2

L1 L2 L3

U

U V W

PE

PE

U1 V1 W1

;;

V W

+U

G

-U

G

+U

G

G

-U

7

PE

3~

1

Cable protection

Mains contactor

2

3

Mains choke

Brake resistor

5

6

Motor filter/Motor supply filter

7

Terminal strip in the control

cabinet

4

Mains filter Screen connections at the

controller

All power terminals remain live up to 3 minutes after mains

disconnection!

26

Page 29

5.1.1 Tightening torques of the power terminals

Type 8601...8605 8606, 8607 8608...8611 8612, 8613 8614, 8615

Tightening

torque

0.6...0.8 Nm

(5.3...7.1 lbfin)

1.2...1.5 Nm

(10.6...13.3 lbfin)

1.5...1.8 Nm

(13.3...16 lbfin)

6...8 Nm

(53...70 lbfin)

15...20 Nm

(133...177 lbfin)

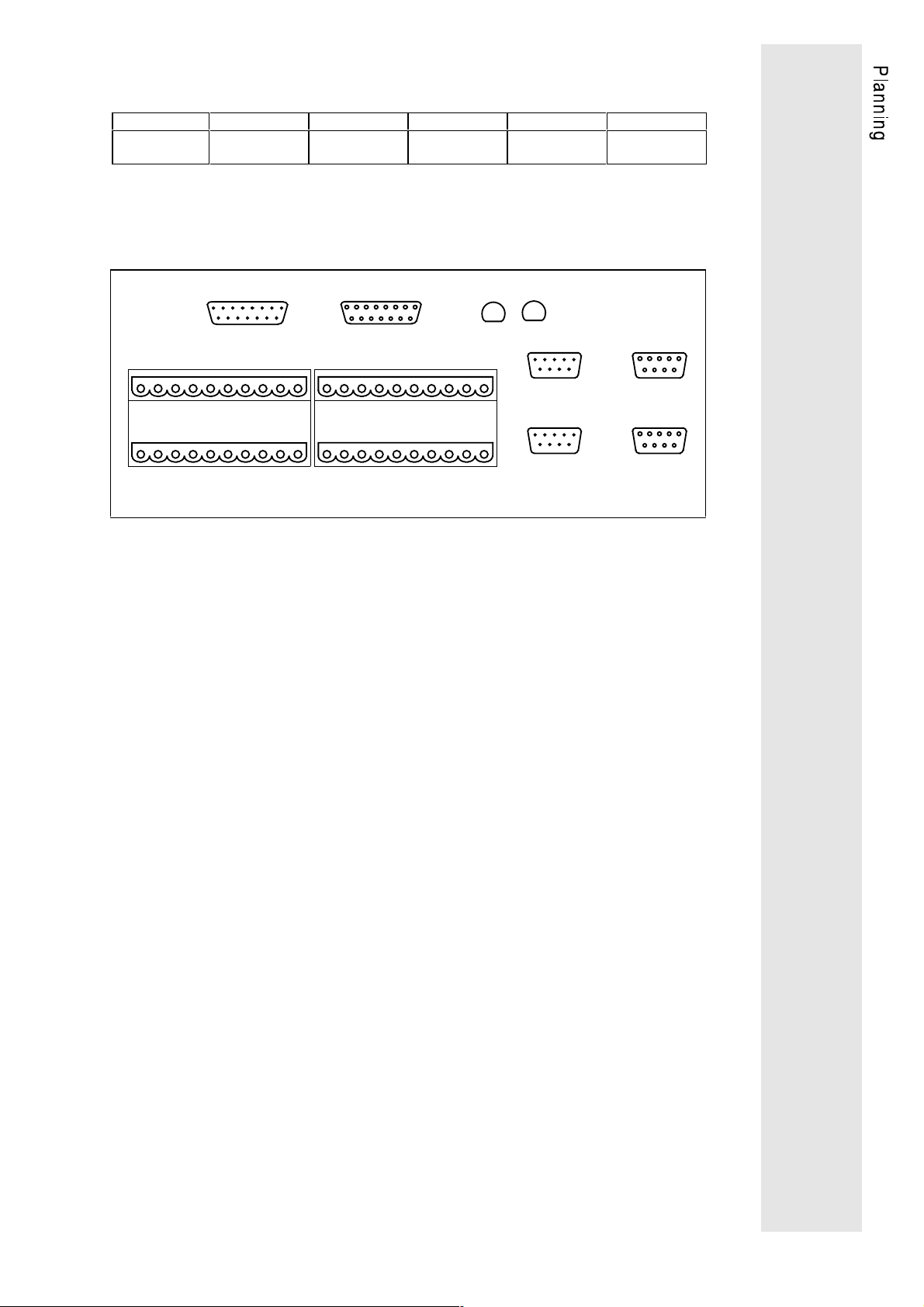

5.2 Control connections

Layout:

X2

X4

1

9

V1

81

9

123478

15

X10

9 101112 20212228E1E2E3E4E5E6

X1

E7 E8 39 40 41 4445K11K14 A1

X3

8

15

X11

A2

A3 A4 59 60 62 63 VE9 GND FE

X1 to X4: Control terminals

X5: Input of digital frequency/incremental encoder

X6: LECOM interface (RS232/485)

X8: 2nd input of digital frequency/incremental encoder

(option)

X9: Output of digital frequency (option)

X10, X11: Field bus connections

(Option, e.g. 2110IB for InterBus-S)

V1, V2; Displays for field bus options

V2

15

69

51

X8 X9

15

69

51

X5 X6

96

96

Note

Always connect the plug-in terminals (accessory kit) to the plug

connectors X1 to X4.

When not using the interface plugs (plug-in connectors) X5 and X6

protect them with the supplied covers.

It is possible to change the functions of certain control terminals

using switches (see chapters 5.2.1 to 5.2.7, page 28ff ). To adjust

the switches, remove the cover of the device.

In addition to this, there are numerous possibilities to change the

inputs and outputs of the device using codes (see page 78ff).

27

Page 30

5.2.1 Analog inputs and outputs

168k

S1/4

100k

100k

+10V

250R

7mA

GND

47k

168k

168k

X1

12

3

4

78910

-10V

7mA

X4

GND

60

62

63

+

+

+

Master voltage/

Master current

(unipolar

Set-value 2

R > 2.2k

Feedback

R > 4.7k

Set-value 1 Monitor outputs

set-value)

5.2.2 Further inputs and outputs

X5, X8 Pin 4

(bipolar

set-value)

GND

28

11

12

PTC

temperaturesensor

thermal

contact

temperature

monitoring

X3X1

K11 K14

relay

output

X4

VE9 GND

FE

+

incremental encoder

supply

Page 31

5.2.3 Description of the analog inputs and outputs

F

Analog inputs

Terminal Switch setting Use

(factory setting)

1, 2 Set-value 2 -10V...+10V

3, 4

7 internal ground (GND) −

8 Set-value 1, Master

9 Voltage supply for

10 Voltage supply for

S1

123

ON

Actual value -10V...+10V

OF

Actual value -30V...+30V

Actual value -60V...+60V

Actual value -90V...+90V

Actual value -120V...+120V

voltage

Set-value 1,

master current

potentiometer

potentiometer

Level/Resolution Parameter

12bit + sign

12bit + sign

12bit + sign

12bit + sign

12bit + sign

12bit + sign

-10V...+10V

12bit + sign

-20mA...+20mA or

±4...20mA

+10V/7mA −

-10V/7mA −

setting see

page

66

73 and 66

73 and 66

73 and 66

73 and 66

73 and 66

64

64 and 66

Analog outputs (monitor outputs)

Terminal Switch setting Use

(factory setting)

60 internal ground (GND) −

62 Monitor 1 (Output

frequency)

Monitor 1 (output

frequency)

63 Monitor 2 (output current) -10V...+10V 89

Monitor 2

(output current)

Level Parameter

-10V...+10V 89

-20mA...+20mA 89

-20mA...+20mA 89

5.2.4 Description of other inputs and outputs

Terminal Use

(factory setting)

11, 12 Input for temperature monitoring of the connected motor

(PTC thermistor/thermal contact)

If a thermistor/therm al contact is not used:

- Link terminals 11 and 12 or deact ivate function

K11, K14 Relay output, Contact capacity: 50V/0. 5A

(Trip fault indication)

VE9 Supply input for connected incremental encoder (X5/X8) −

GND internal ground (GND) −

FE Functional earth −

setting see

page

Parameter

setting see

page

97

86

29

Page 32

5.2.5 Digital inputs and outputs

2

The functions for the digital inputs and outputs shown below are

factory-set. To switch the signal cables, only use relays with low-

current contacts. Relays with gold-plated contacts have proven for

this.

All digital inputs and outputs are PLC compatible and are - when

operated with an external voltage supply (24 V) - isolated from the

rest of the control stage. To connect the voltage supply, use

terminals 39 and 59. If there is no external voltage supply, the

internal 15 V-supply can be used.

External voltage supply (24 V)

Inputs:

Input voltage: 0 to 30 V

LOW signal: 0 to 5 V

HIGH signal: 13 to 30 V

Input current: for 24 V 8 mA per input

Outputs:

Maximum voltage supply: 30 V

Maximum output current: 50 mA per output (external

resistor at least 480

e.g. relay, part no. 326 005)

Ω for 24 V,

GND ext.

22k 10R

+15V 100mA

X2 X4

20 21 28 E1 E2 E3 E4 E5 E6 E7 E8

R

QSP

L

Ctrl.

enable

3k

3k

TRIP set/reset

3k

3k

DC brake

3k3k3k

JOG Ti

3k

X3

3k

3k

39

GND

_

+

TRIP

50mA

50mA

50mA

41

44 A1 A2 A4 59

IMP

RDY

50mA

Qmin

Imax

50mA

50mA

A3454022

6 x f

RFG/O=I

10k

2.7k

50mA

S

d

30

Page 33

Internal voltage supply (15V)

2

Inputs:

Input voltage: 0 to 30 V

LOW signal: 0 to 5 V

HIGH signal: 13 to 30 V

Input current: for 15 V 5 mA per input

Outputs:

Maximum voltage supply: 30 V

Maximum output current: 50 mA per output external

resistor at least 300

Ω for

5 V, e.g. relay

part no. 326 850)

GND ext.

22k 10R

10k

2.7k

+15V 100mA

X2 X4

20 21 28 E1 E2 E3 E4 E5 E6 E7 E8

R

QSP

3k

L

Ctrl.

enable

3k

3k

DC brake

TRIP set/reset

3k

3k3k3k

JOG Ti

3k

X3

3k

3k

39

GND

TRIP

50mA

50mA

50mA

41

44 A1 A2 A4 59

IMP

RDY

Qmin

Caution: The internal 15 V supply may be loaded with a

maximum of 100 mA.

The terminals 39 and 40 must be linked in case

of internal 15 V supply.

50mA

50mA

Imax

RFG/O=I

50mA

50mA

S

A3454022

6 x f

d

31

Page 34

5.2.6 Description of the digital inputs and outputs

Digital inputs

Terminal Use

(factory setting)

20 Supply voltage 15V, 100mA 21 Remove quick stop, CW rot ation HIGH 58

22 Remove quick stop, CCW rotation HIGH 58

28 Controller enable HIGH 58

E1 Freely assignable input

(TRIP-set)

E2 Freely assignable input

(TRIP reset)

E3 Freely assignable input

(Activate DC injection braking)

E4, E5,

E6

E7, E8 Freely ass i gnabl e i nput

Freely assignable input

(Enable JOG set-values, seven JOG values)

(Enable additional acceleration and deceleration

times, three ramp times)

Signal for

activation

HIGH 78ff.

HIGH 78ff.

HIGH 78ff.

HIGH 78ff.

HIGH 78ff.

Digital outputs

Terminal Use

(factory setting)

"ready" "Function

41 Fault indication − TRIP HIGH LOW 88

44 Ready − RDY HIGH HIGH 88

45 Pulse inhibit − IMP HIGH LOW 88

A1 Freely assignable output

(Output frequency < Q

A2 Freely assignable output

(Maximum current reached - I

A3 Freely assignable output

(Set-value reached - RFG/O=I)

threshold)

min

max

LOW LOW 86ff.

LOW HIGH 86ff.

)

HIGH HIGH 86ff.

Message

in the state

active"

Programming see

page

Programming see

page

Terminal Switch

setting

A4 Frequency output

39 Ground of the digital inputs and outputs

40 Internal ground (GND) −−

59 Supply input of the digital outputs (24V

Use

(factory setting)

(6 times field frequency 6 ⋅ f

Freely assignable output

(no function)

(external GND)

ext. or 15V int.)

Message Programming see

page

Pulse train −

d

− 86ff.

−−

−−

32

Page 35

5.2.7 Frequency output 6⋅ f

If you want to display, for example, the output frequency or the

speed of the drive via a digital display device, you can use the

frequency output "6 times field frequency". As factory setting, this

function is assigned to terminal A4. This output is, like the other

digital outputs, isolated and can be supplied via terminals 39 and

59.

digital output

10k

2k7

S2

d

X3 39 A4 59

digital tacho

( Lenze type 322 )

X4

n

+

supply

-

15...30 V

33

Page 36

5.3 Operation with DC bus supply

5.3.1 Connection of several drives for energy-sharing

Drives which are supplied by a three-phase voltage can also be

linked via the terminals +UG and -UG for energy-sharing. This type

of connection requires all controllers to be supplied simultaneously

with the same mains voltage, with each controller being connected

to the recommended mains choke.

8600

L1/2/3+UG-UG

*

8600

L1/2/3 +UG-UG

8600

L1/2/3+UG-UG

*

*

further

contr.

* The fuses must be dimensioned for the rated output current of the device and a

voltage strength of 1000 V DC.

5.3.2 DC voltage supply

With direct supply into the DC bus, energy feedback is also

possible. If the drive is in the generator mode (braking), the

absorbed energy will be passed to the DC source. A brake chopper

is then often not necessary.

PE

L1

L2 L3

+U

-U

G

G

BR1

BR2

U

VW

*

Motor

(DC contactor)

+

further

drives

-

PE

* The fuses must be dimensi oned for the rated output current of the device

and a voltage strength of 1000 V DC.

470...740V DC ±0 %

34

Page 37

5.4 Screenings

Cable screenings increase the noise immunity of the drive system

and reduce the interfering radiation.

The power and control terminals of the inverters are noise immune

without screened cables up to severity class 4 to IEC 801-4. Burst

of 4kV on the power terminals and 2kV on the control terminals are

permissible.

Screenings are only required when you want to operate the inverter

in environments, where severity class 4 is not sufficient.

If your drive corresponds to the CE-typical drive system and you do

not want to carry out the radio-interference measurements

necessary for the conformity, screened cables are required.

5.5 Grounding of control electronics

The grounding of the control electronics is to ensure that the

potential of the control electronics does not exceed 50V to PE

(housing).

Single drives

Bridge the control terminals GND and PE.

Network of several drives

Avoid GND loops. Lead all GND cables to external, insulated

central points, centralize again from there and connect to PE in the

central supply.

Make sure that the grounding of the control electronics does not

damage any external devices.

35

Page 38

6 Accessories

Accessories are not included in the scope of supply.

6.1 Brake resistors

In the generator mode, e.g. when decelerating the drive, the

machine returns energy to the DC bus of the controller. If large

inertias are braked and/or short deceleration times are set, the DC

bus voltage may exceed its maximum permissible value. In the

case of overvoltage in the DC bus, the controller sets pulse inhibit

and indicates "overvoltage ". The controller cancels the pulse inhibit

once the votlage has returned to the permissible range.

To avoid overvoltage during braking, a brake chopper is used,

which switches an external brake resistor when the voltage in the

DC bus exceeds 765 V.

The absorbed energy is dissipated as heat so that the voltage in the

DC bus does not rise further.

• The brake chopper is already included in the standard controller.

• The suitable brake chopper is available as an option. It is

connected to the terminals BR1 and BR2

(see connecting diagram, page 26).

36

Page 39

6.1.1 Selection of the brake resistor

• The following combinations ensure

- a maximum braking time of 15 seconds

- a maximum relative duty time of 10%.

• The set continuous power of the inverter is the reference for the

combination.

Operation at rated power (factory setting)

Inverter type 8601 8602 8603 8604 8605

Resistor/Ω 370 370 240 180 180

Power/kW 0.15 0.15 0.2 0.3 0.3

Order number ERBM370R150W ERBM370R150W ERBM240R200W ERBD180R300W ERBD180R300W

Inverter type 8606 8607 8608 8609 8610

Resistor/Ω 100 100 68 47 33

Power/kW 0.6 0.6 0.8 1.2 2.0

Order number ERBD100R600W ERBD100R600W ERBD068R800W ERBD047R01K2 ERBD033R02K0

Inverter type 8611 8612 8613 8614 8615

Resistor/Ω 33 22 15 15 15

Power/kW 2.0 3.0 4.0 4.0 4.0

Order number ERBD033R02K0 ERBD022R03K 0 ERBD015R04K0 ERBD015R04K0 ERBD015R04K0

Operation at increased power

Inverter type 8601 8602 8603 8604 8605

Resistor/Ω 370 240 180 180 180

Power/kW 0.15 0.2 0.3 0.3 0.3

Order number ERBM370R150W ERBM240R200W ERBD180R300W ERB D180R300W ERBD180R300W

Inverter type 8606 8607 8608 8609 8610

Resistor/Ω 100 100 47 33 33

Power/kW 0.6 0.6 1.2 2.0 2.0

Order number ERBD100R600W ERBD100R600W ERBD047R01K2 ERBD033R02K0 ERBD033R02K0

Inverter type 8611 8612 8613 8614 8615

Resistor/Ω 33 15 15 15 15

Power/kW 2.0 4.0 4.0 4.0 4.0

Order number ERBD033R02K0 ERBD015R04K 0 ERBD015R04K0 ERBD015R04K0 ERBD015R04K0

Operation at maximum power

Inverter type 8601 8602 8603 8604 8605

Resistor/Ω 240 180 180 180 Power/kW 0.2 0.3 0.3 0.3 Order number ERBM240R200W ERBD180R300W ERBD180R300W E RB D180R300W -

Inverter type 8606 8607 8608 8609 8610

Resistor/Ω 100- 333333

Power/kW 0.6 - 2.0 2.0 2.0

Order number ERBD100R600W - ERBD033R02K0 ERBD033R02K0 ERBD033R03K0

Inverter type 8611 8612 8613 8614 8615

Resistor/Ω - 151515Power/kW - 4.0 4.0 4.0 Order number - ERBD015R04K0 ERBD015R04K0 ERBD015R04K0 -

A higher brake power can be obtained by using other resistors or

by connecting several resistors in parallel or in series. However, the

minimum resistance given on page 38 must be maintained!

37

Page 40

• If the above conditions do not apply, you can determine the

[

]

suitable brake resistor as follows:

1. Determine the resistance:

22

Resistance

[]

≤Ω

Depending on the unit the resistances must not fall below the

following values:

Inverter type 8601 8602 8603 8604 8605 8606 8607

minimum resistance 180Ω 180Ω 180Ω 180Ω 180Ω 100Ω 100Ω

Inverter type 8608 8609 8610 8611 8612 8613 8614 8615

minimum resistance 33Ω 33Ω 33Ω 33Ω 15Ω 15Ω 15Ω 15Ω

2. Determine the rated power of the brake resistor:

Rated power W

The permissible continuous power of the internal brake chopper

does not restrict the unit. It corresponds to the max. permissible

brake power.

duty time

≥⋅

cycle time

V 765

22

[V ]

765

resistance

Ω

[]

Wpower brakepeak required

3. Determine the thermal capacitance of the resistor:

22

Thermal capacitance

kWs ≥

765 V

Resistance

max. brake time s

Ω

38

Page 41

6.1.3 Technical data of brake resistors

All listed brake resistors are equipped with an integrated

temperature monitoring. The brake contact which is switched in the

event of overtemperature is designed for:

• max. 250 V AC

• max. 0.5 A

Grid-protected brake resistors

Brake resistor Dimensions

Resistance

Ω

180 ERBD180R300W 440 89 354 64 115 326 6.5

100 ERBD100R600W 640 89 554 64 115 526 6.5

68 ERBD068R800W 540 177 454 150 115 426 6.5

47 ERBD047R01K2 640 177 554 150 115 526 6.5

33 ERBD033R02K0 640 265 554 240 115 526 6.5

22 ERBD022R03K0 740 177 654 150 229 626 6.5

15 ERBD015R04K0 640 265 554 240 229 526 15

Brake resistor Resistor values

Resistance

Ω

180 ERBD180R300W 0.3 3.0 45

100 ERBD100R600W 0.6 5.5 82.5

68 ERBD068R800W 0.8 8.0 120

47 ERBD047R01K2 1.2 11.5 180

33 ERBD033R02K0 2.0 16.5 300

22 ERBD022R03K0 3.0 24.8 450

15 ERBD015R04K0 4.0 36.5 600

Order number a

mm

Order number Power

kW

b

mm

c

mm

Peak brake power

d

mm

kW

e

mm

f

mm

Heat capacitance

g

mm

kWs

39

Page 42

Moulded module resistors on heat sink

e

c

a

Resistor Dimensions

Resistance

Ω

370 ERBM370R150W 80 240 70 225 95 5 7.5

240 ERBM240R200W 80 340 70 325 70 5 7.5

Brake resistor Resistor values

Resistance

Ω

370 ERBM370R150W 0.15 1.4 30

240 ERBM240R200W 0.2 2.2 30

Order number a

Order number Power

k

b

mm

mm

kW

d

bg

c

mm

Peak brake power

d

mm

kW

e

mm

6.2 Mains chokes

Advantages of using a mains choke:

• Less mains disturbance

The wave shape of the mains current approaches sinusoidal; at

the same time the r.m.s. current is reduced by up to 40%

(reduction of the mains load, the cable load and the fuse load).

• Increased life of the inverter

A mains choke reduces the AC load of the DC bus capacitors

and thus doubles its service life.

• The transient high-energy overvoltages which are sometimes

generated at the mains side by circuit breakers or fuses are

stopped by the mains choke and thus the units are usually not

damaged.

• Low-frequent radio interference can be reduced.

g

mm

Heat capacitance

k

mm

kWs

40

Please note:

• When a mains choke is used, the maximum possible output

voltage does not reach the value of the mains voltage.

- typical voltage drop at the rated point: 4 to 5%.

• Mains chokes are always required when the inverter is operated

with increased or maximum power.

Page 43

6.2.1 Selection of the mains choke

• The set permanent power of the inverter is the reference for the

combination.

Operation at rated power (factory setting)

Inverter type 8601 8602 8603 8604 8605

Rat. mains curr./A 3.0 3.9 5.5 7.0 8.8

Inductivity/mH 3 x 2.5 3 x 2.5 3 x 2.5 3 x 1.6 3 x 1.6

Current/A 7.0 7.0 7.0 12.0 12.0

Order number ELN3-0250H007 ELN3-0250H007 ELN3-0250H007 ELN3-0160H012 ELN3-0160H012

Inverter type 8606 8607 8608 8609 8610

Rat. mains curr./A 12.0 15.0 20.5 28.0 34.5

Inductivity/mH 3 x 1.2 3 x 1.2 3 x 1.2 3 x 0.88 3 x 0.75

Current/A 17.0 17.0 25 35 45

Order number ELN3-0120H017 ELN3-0120H017 ELN3-0120H025 ELN3-0088H035 ELN3-0075H045

Inverter type 8611 8612 8613 8614 8615

Rat. mains curr./A 41.0 53.0 66.0 78.0 96.0

Inductivity/mH 3 x 0.88 3 x 0.38 3 x 0.38 3 x 0.27 3 x 0.22

Current/A 55 85 85 105 130

Order number ELN3-0088H055 ELN3-0038H085 ELN3-0038H085 ELN3-0027H105 ELN3-0022H130

Operation at increased power

Inverter type 8601 8602 8603 8604 8605

Rat. mains curr./A 4.0 5.3 7.4 9.4 11.8

Inductivity/mH 3 x 2.5 3 x 2.5 3 x 2.5 3 x 1.6 3 x 1.6

Current/A 7.0 7.0 7.0 12.0 12.0

Article

Order number

Inverter type 8606 8607 8608 8609 8610

Rat. mains curr./A 16.3 20.7 28 38 47

Inductivity/mH 3 x 1.2 3 x 1.2 3 x 0.88 3 x 0.75 3 x 0.75

Current/A 17 25 35 45 45

Order number ELN3-0120H017 ELN3-0120H025 ELN3-0088H035 ELN3-0075H045 ELN3-0075H045

Inverter type 8611 8612 8613 8614 8615

Rat. mains curr./A 55 71 84 105 129

Inductivity/mH 3 x 0.88 3 x 0.38 3 x 0.38 3 x 0.27 3 x 0.22

Current/A 55 85 85 105 130

Order number ELN3-0088H055 ELN3-0038H085 ELN3-0038H085 ELN3-0027H105 ELN3-0022H130

325293

ELN3-0250H007

325293

ELN3-0250H007

325293

ELN3-0250H007

325294

ELN3-0160H012

325294

ELN3-0160H012

Operation at max. power

Inverter type 8601 8602 8603 8604 8605

Rat. mains curr./A 5.3 A 7.0 A 9.2 A 11.6 A −

Inductivity/mH 3 x 2.5 3 x 2.5 3 x 1.6 3 x 1.6 −

Current/A 7.0 7.0 12.0 12.0 −

Order number ELN3-0250H007 ELN3-0250H007 ELN3-0160H012 ELN3-0160H012 −

Inverter type 8606 8607 8608 8609 8610

Rat. mains curr./A 20.5 A − 37.2 50 54

Inductivity/mH 3 x 1.2 − 3 x 0.88 3 x 0.55 3 x 0.55

Current/A 25.0 − 35 55 55

Order number ELN3-0120H025 − ELN3-0088H035 ELN3-0055H055 ELN3-0055H055

Inverter type 8611 8612 8613 8614 8615

Rat. mains curr./A − 83 100 125 −

Inductivity/mH − 3 x 0.38 3 x 0.27 3 x 0.22 −

Current/A − 85 105 130 −

Order number − ELN3-0038H085 ELN3-0027H105 ELN3-0022H130 −

41

Page 44

6.2.2 Technical data of mains chokes

k

f

e

m

c

a

Mains

choke

7A / 2.5mH ELN3-0250H007 120 61 84 45 130 105 73 6.0 11 1.8

12A / 1.6mH ELN3-0160H012 150 70 90 54 155 130 81 6. 0 11 3.8

17A / 1.2mH ELN3-0120H017 120 65 109 51 162 110 80 5.0 10 2.7

25A / 1.2mH ELN3-0120H025 150 76 140 61 180 140 95 5.0 10 6.0

35A / 0.88mH ELN3-0088H035 180 91 161 74 225 165 120 6.3 11 9. 8

45A / 0.75mH ELN3-0075H045 180 91 161 74 225 165 120 6.3 11 9. 8

55A / 0.88mH ELN3-0088H055 228 114 176 94 270 205 131 8.8 13 17.0

85A / 0.38mH ELN3-0038H085 228 111 206 94 263 205 140 6.3 11 19.5

105A / 0.27mH ELN3-0027H105 228 111 206 94 273 205 150 6.3 11 20.0

130A / 0.22mH ELN3-0022H130 264 102 240 81 265 237 135 6.3 11 20.0

Order number ammb

mmcmmdmmemmfmmkmmmmmnmm

n

d

b

Weight

kg

42

Page 45

6.3 Motor filter

Advantages of using a motor filter:

• The motor filter reduces capacitive currents caused by parasitic

cable capacitances.

• The slope of the motor voltage (dv/dt) is limited to 500 V/µs.

Motor filters are always required for:

• unscreened cables longer than 100m.

• screened cables longer than 50m.

• when using motors which do not have suitable insulation for

inverter operation. (Observe data of the motor manufacturer.)

Please note:

• Install the motor filter as close as possible to the inverter

- Maximum cable length 5 m

• Connect +U

terminals of the same designation.

• Select the control mode "V/f characteristic control"

(C006 = -0-). The control "magnetizing current control" is not

permissible.

• The chopping frequency must be at least 4 kHz.

• The max. permissible output frequency is 300 Hz.

• The inverter is loaded in addition to the motor current with

approx. 12% of the rated filter current.

• The voltage drop across the motor filter at rated current and

rated frequency (f

voltage.

• For motor cable lengths > 100 m (screened) and > 200 m (un-

screened) a motor supply filter should be used.

• With unscreened motor cables it should be tested whether the

system complies with the interference levels required for the CEEMC conformity.

and -UG of the motor filter only to the inverter

G

= 50 Hz) is 2 to 3% of the inverter output

d

43

Page 46

6.3.1 Technical data of motor filter

c

Design A

d

a

e

b

c

f

d

e

b

a

44

Design B

Filter type Order number a b c d e f Weight

Design Rated current mm mm mm mm mm mm kg

A 4.0 A ELM3-030H004 210 75 160 197 50 − 3.5

A 10.0 A E LM 3-014H010 280 92 175 267 65 − 6.5

A 25.0 A E LM 3-007H025 280 130 256 267 100 − 15

B 55.0 A E LM 3-004H055 500 235 185 400 220 40 40

With motor currents > 55 A please use motor filters which are

connected in parallel.

Motor current Motor fil ter

bis 100A 2 x ELM3-004H060

bis 150A 3 x ELM3-004H060

bis 200A 4 x ELM3-004H060

Page 47

6.4 Motor voltage filter

Advantages of using a motor supply filter:

• Sinusoidal output voltages to supply electronic devices.

Please note:

• Install the motor supply filter as close as possible to the inverter.

• Select the control mode "V/f characteristic control"

(C006=-0-). The "magnetizing current control" form of control is

not permissible.

• The chopping frequency must be set to 8 kHz (C018 = -4-).

• The inverter is loaded additionally with approximately 10% of the

rated current of the motor supply filter.

• The voltage drop across the motor supply filter at rated current

and rated frequency (f

voltage.

• The maximum permissible output frequency is 120 Hz.

• With unscreened motor cables it should be tested whether the

system complies with the interference levels required for the CEEMC conformity.

= 50 Hz) is 7% of the inverter output

d

45

Page 48

6.4.1 Technical data of motor supply filters

c

Design A

d

a

c

e

b

g

d

a

e

b

46

Design B

Filter type Order number a b c d e g Weight

Design Rated current mm mm mm mm mm mm kg

A 4.0 A EZS 3-004A 001 210 75 160 200 50 − 4.0

A 5.5 A EZS 3-006A 001 280 92 175 270 65 − 8.0

A 7.0 A EZS 3-007A 002 280 92 175 270 65 − 8.0

A 9.5 A EZS 3-010A 002 280 130 256 267 100 − 16.0

A 13.0 A EZS3-013A001 280 130 256 267 100 − 16.0

A 16.5 A EZS3-017A001 280 130 256 267 100 − 19.0

B 24.0 A EZS3-024A001 325 200 170 260 185 40.0 20.0

If you need a motor supply filter for higher currents, please contact

the factory.

Page 49

6.5 Cable protection

Cable protecting fuses for recommended cross-sections:

Inverter type 8601 - 03 8604, 05 8606, 07 8608, 09

Rated fuse current 16 A 20 A 35 A 50 A

Cable cross-section 2.5 mm

AWG 13 (12)

Inverter type 8610, 11 8612 8613 8614 8615

Rated fuse current 63 A 100 A 125 A 160 A 200 A

Cable cross-section 25 mm

Replace defective fuses only with the specified type and when the

device is disconnected from the mains. All power terminals remain

live up to 3 minutes after mains disconnection!

Instead of cable protection fuses you can also use miniature circuit

breakers (e.g. Siemens type 5SX2, 3.. - 6)

or

or

AWG 3

2

2

2

4 mm

or

AWG 11 (10)

2

50 mm

or

AWG 0

2

10 mm

or

AWG 7 (6)

2

50 mm

or

AWG 0

16 mm

or

AWG 5 (4)

95 mm

or

AWG 3/0

2

2

95 mm

AWG 3/0

2

or

47

Page 50

6.6 RFI filters

Advantage of using a RFI filter:

• Reduction of high-frequent radio interference.

Please note:

• Because of the generation of leakage currents, the RFI filters

must be connected to earth. The RFI filter must always be

connected to earth at first even if you only want to test the

system.

Otherwise, the system is not protected against shock.

• The filters listed in the following can be connected to the 400 V

mains.

If you need filters for mains voltages of 460 V or 480 V, please

contact the factory.

6.6.1 Ratings of RFI filters

The ratings of the RFI filters depend on the mains current which is

permanently applied.

Operation at rated power (factory setting)

Inverter type Rated filter current Order number

8601...8603 8 A EZF3-008A001

8604...8606 16 A EZF3-016A001

8607...8608 25 A EZF3-025A001

8609...8610 36 A EZF3-036A001

8611 50 A EZF3-050A004

8612...8613 80 A EZF3-080A001

8614 110 A EZF3-110A 001

8615 180 A EZF3-180A 001

Operation at increased power

Inverter type Rated filter current Order number

8601...8603 8 A EZF3-008A00

8604...8606 16 A EZF3-016A001

8607 25 A EZF3-025A001

8608 36 A EZF3-036A001

8609...8610 50 A EZF3-050A004

8611...8612 80 A EZF3-080A001

8613...8614 110 A EZF3-110A001

8615 180 A EZF3-180A 001

Operation at maximum power

Inverter type Rated filter current Order number

8601...8602 8 A EZF3-008A001

8603...8604 16 A EZF3-016A001

8606 25 A EZF3-025A001

8608...8609 50 A EZF3-050A004

8610 80 A EZF3-080A001

8612 110 A EZF3-110A 001

8613...8614 180 A EZF3-180A001

48

Page 51

6.6.2 Technical data of RFI filters

e

b

c

b

g

g

c

f

f

d

d

a

a

Design A Design B

Filter type Order number a b c d e f g m Weight

Design Rt. current mm mm mm mm mm mm mm mm kg

A 8.0A EZF3-008A001 220 115 100 180 60 17 115 6.5 1.8

A 16.0A EZF3-016A001 240 150 135 200 65 17 115 6.5 1.8

A 25.0A EZF3-025A001 250 150 135 200 65 17 115 6.5 3.0

A 36.0A EZF3-036A001 250 150 135 200 65 17 115 6.5 3.0

A 50.0A EZF3-050A004 250 150 135 200 65 17 115 6.5 3.1

B 80.0A EZF3-080A001 427 170 130 350 90 70 375 15.0 9.5

B 110.0A EZF3-110A001 436 170 130 350 90 70 375 15.0 9.5

B 180.0A EZF3-180A001 537 180 156 350 152 88 470 16.0 13.0

e

6.7 Accessories for digital frequency networking

• System cable for master-slave connection between the

individual controllers

• Second digital frequency input (SubD-plug X8),

including assembly kit

• Digital frequency output (SubD-socket X9),

including assembly kit

• Adapter for incremental encoder

The adapter is required when the incremental encoder is to be

connected to the inverter via terminals - X5 or X8.

Name Order no.

System cable (2.5 m l ong) EWLD002GGBB92

X8 9-pole SubD-plug (2nd digital frequency i nput ) E WZ0008

X9 9-pole SubD-socket (digital f requency output) E WZ0009

Adapter for incremental encoder (t erm i nal /SubD-plug) EWZ00011

49

Page 52