Page 1

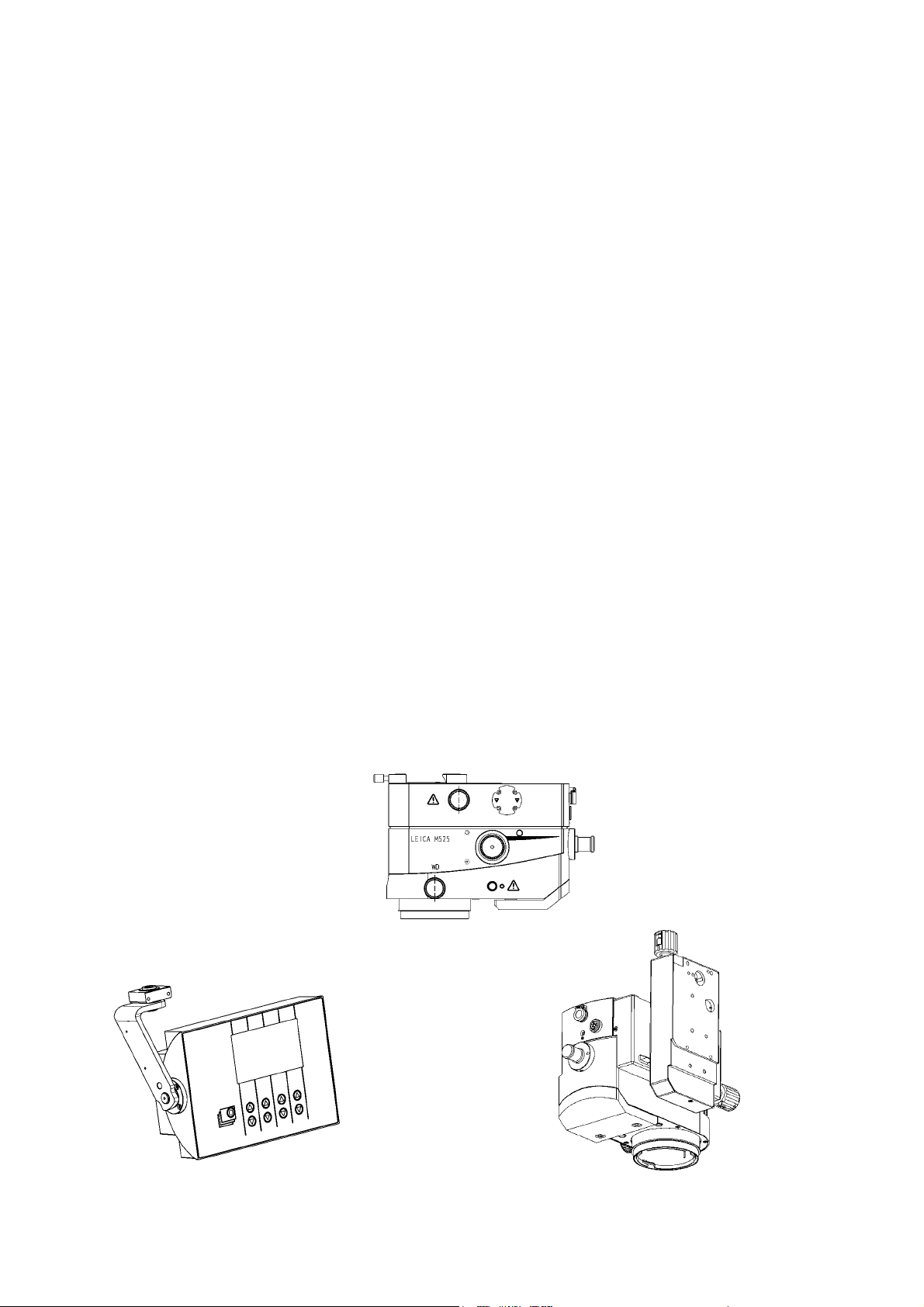

Service manual Leica M500 N, M520,

M525

10 665 751 – Release 09/2007

Table of contents

1. Technical Description

2. Wiring Diagram and Locations

3. Service Programs

4. Fault Finding

5. Replacing Modules

6. Maintenance Service

7. Inspection

8. Spare Parts

Page 2

Release 09/2007

• First edition

Page 3

Service manual Leica M500 N, M520, M525 Description

Doc Code 10 665 751

1-I

08/2007 Gahe

1. Description - Leica M500 N, M520, M525

Table of content

Chapter Page

System description 1-1

General 1-1

Overview control unit 1-1

Overview optics carrier 1-2

Electrical accessories 1-3

Optical/mechanical accessories 1-3

Configuration M525 systems 1-4

Product history M500 N…M525 1-5

Electrical description 1-7

General 1-7

CAN bus 1-8

Optics carrier 1-9

Control unit 1-11

Technical data M525 1-13

Page 4

Description Service manual M500 N, M520, M525

08/2007 Gahe

1-II

Doc Code 10 665 751

Page 5

Service manual M500 N, M520, M525 Description

Doc Code 10 665 751

1-1 08/2007 Gahe

Description of the Leica M500 N, M520, M525

System description

General

The Leica M500 N / M520 /M525 surgical microscope is an optical instrument which uses magnification and

illumination to improve visibility. It is dedicated mainly for Neurosurgery discipline.

The microscope is always used together with a Leica stand system – refer to product history on page 1-5.

Electrically the optics carrier and the control unit are connected together to the stand system by the CAN bus.

Newer generations of stand systems (like OH4) have their own MDC (microscope device controller) and take over the

task of the M500 N control unit.

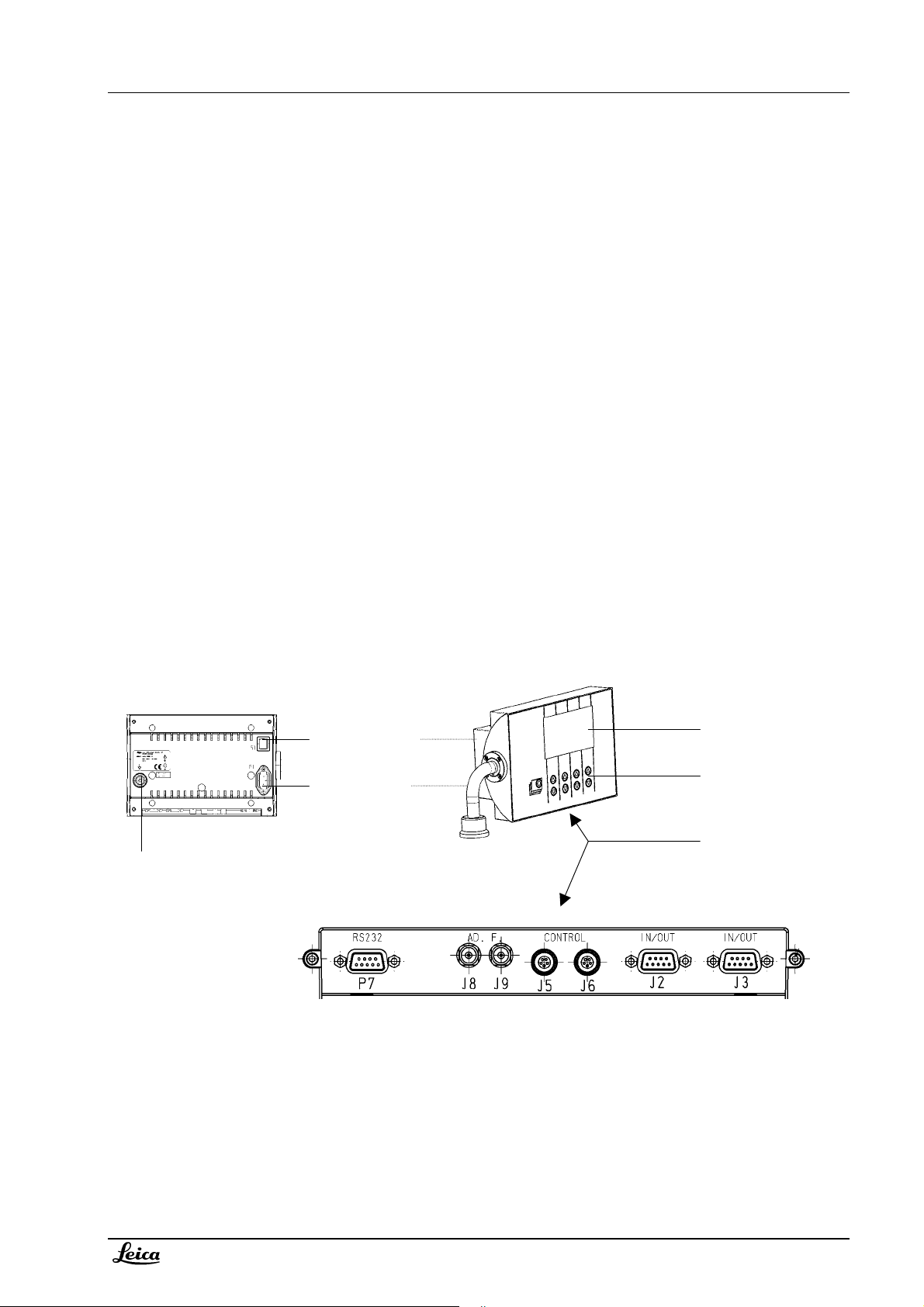

Overview control unit M500 N / M520

Grounding socket*

* Only for control

unit with internal

power supply

Power switch*

Power inlet*

Display

Switch panel

with 9 keys

Electrical

interfaces

Page 6

Description Service manual M500 N, M520, M525

p

1-2

08/2007 Gahe

Doc Code 10 665 751

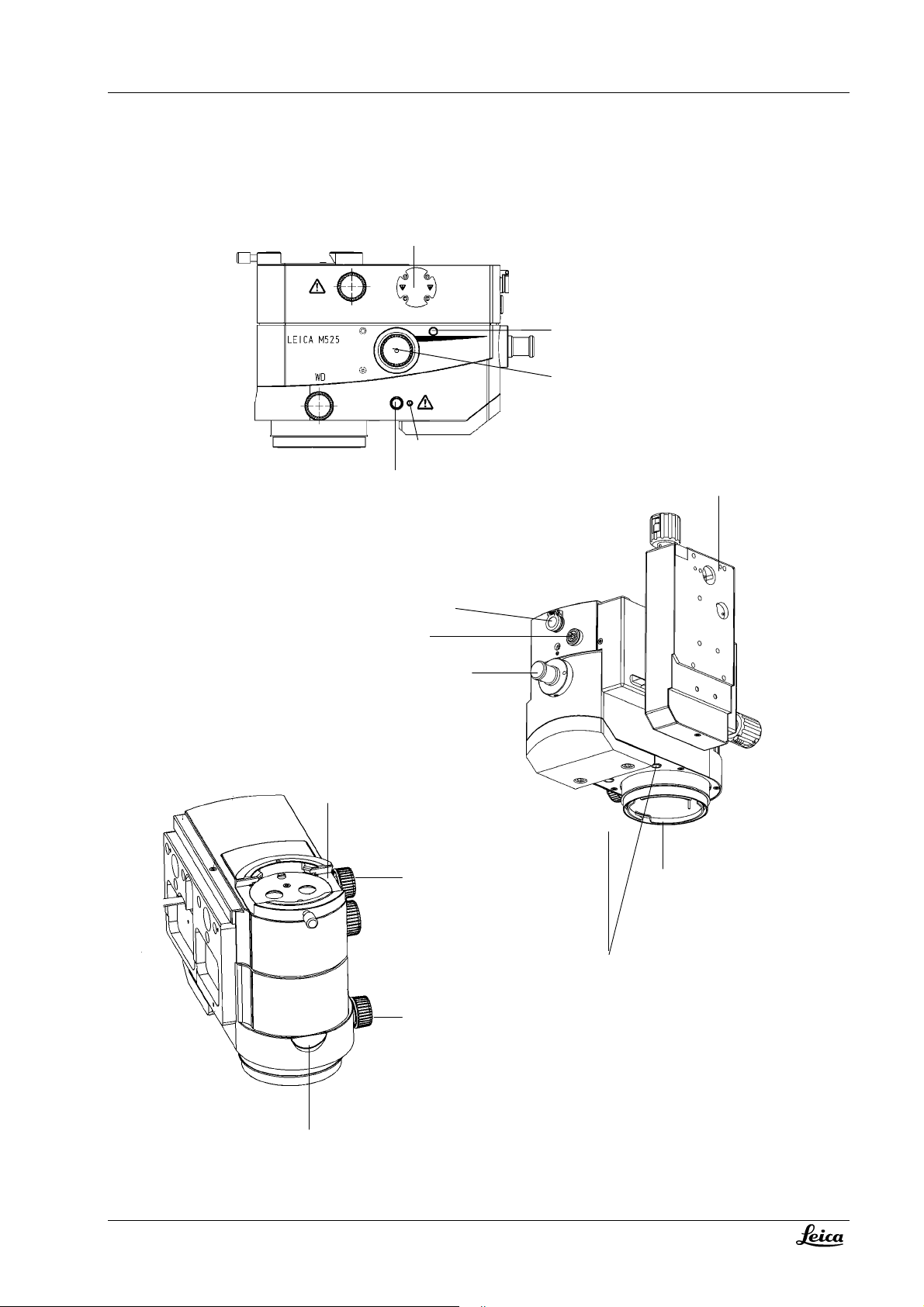

Overview optics carrier M525

Handgrip interface

M525 only: Iris reset

Drive illumination diaphragm

(M525: Iris override)

LED WD lock indication

WD lock button

A/B slide

Service & CAN res

CAN interface

Fiber optics interface

Dovetail interface

Manual drive zoom

Interface for

rotective glass

Laser interface

Manual drive WD

Display WD (M520/M525)

Page 7

Service manual M500 N, M520, M525 Description

Doc Code 10 665 751

1-3 08/2007 Gahe

Electrical accessories

- All Leica hand- and footswitches fit to the control unit M500 N / M520 (restriction for 16 function switch – it is

handled as a 12 function switch only)

- CAN handle

- DI C500

- Autofocus device

- Fluorescence devices (available for some stand systems only)

Optical/mechanical accessories

- All optical equipment with dovetail interface fit to the optics carrier. Refer to appropriate stand user manual

for allowed loads and configurations

- Interface for protective glass 10 446 058

- Interface for universal Laser adapter 10 448 079 (M520 & M525)

- Interface for universal Laser adapter 10 446 615 (M500 N)

- Sterilisable knobs

- Interface for right handgrip

- Interface for fiber optic

Page 8

Description Service manual M500 N, M520, M525

(

)

y

1-4

08/2007 Gahe

Doc Code 10 665 751

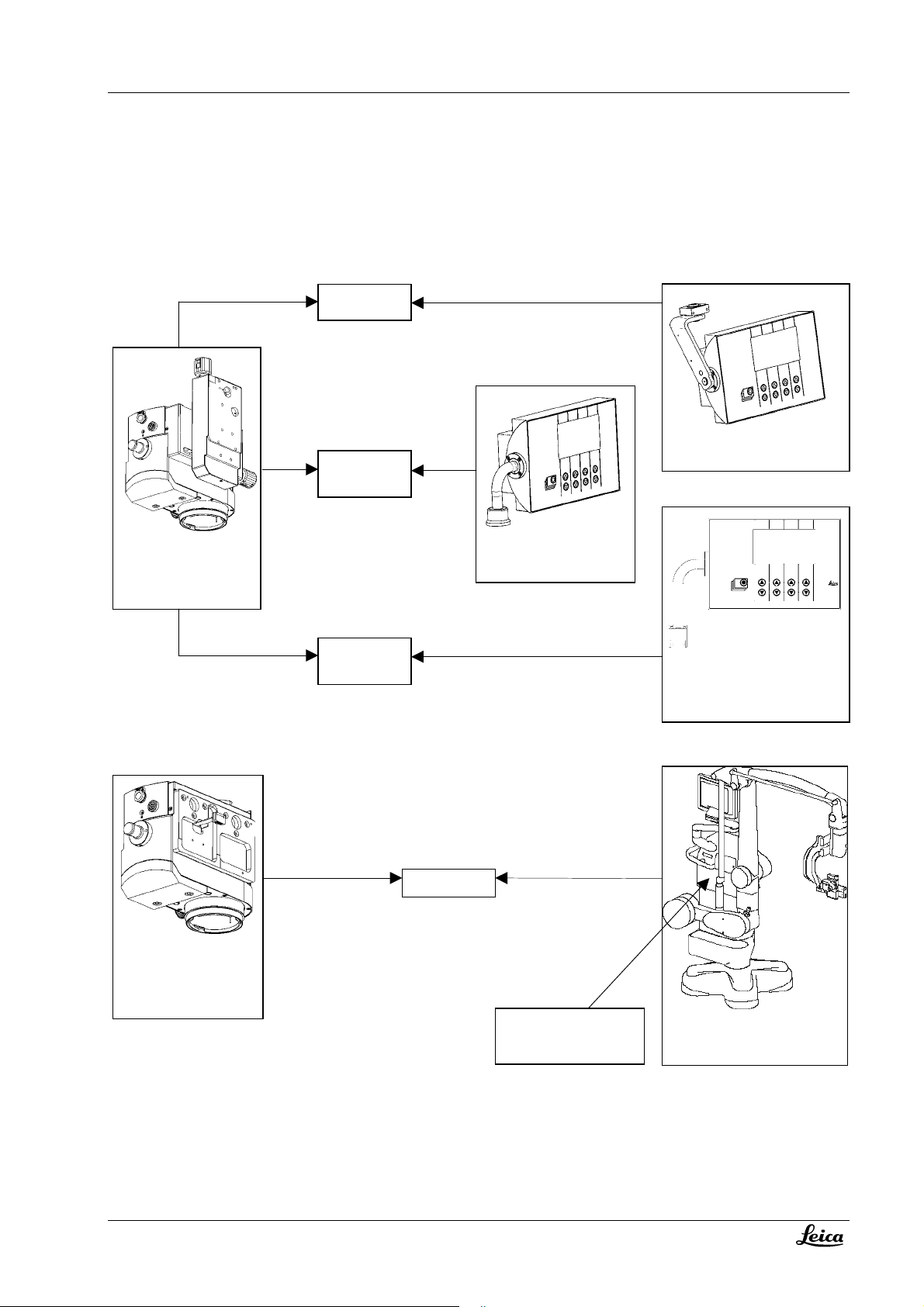

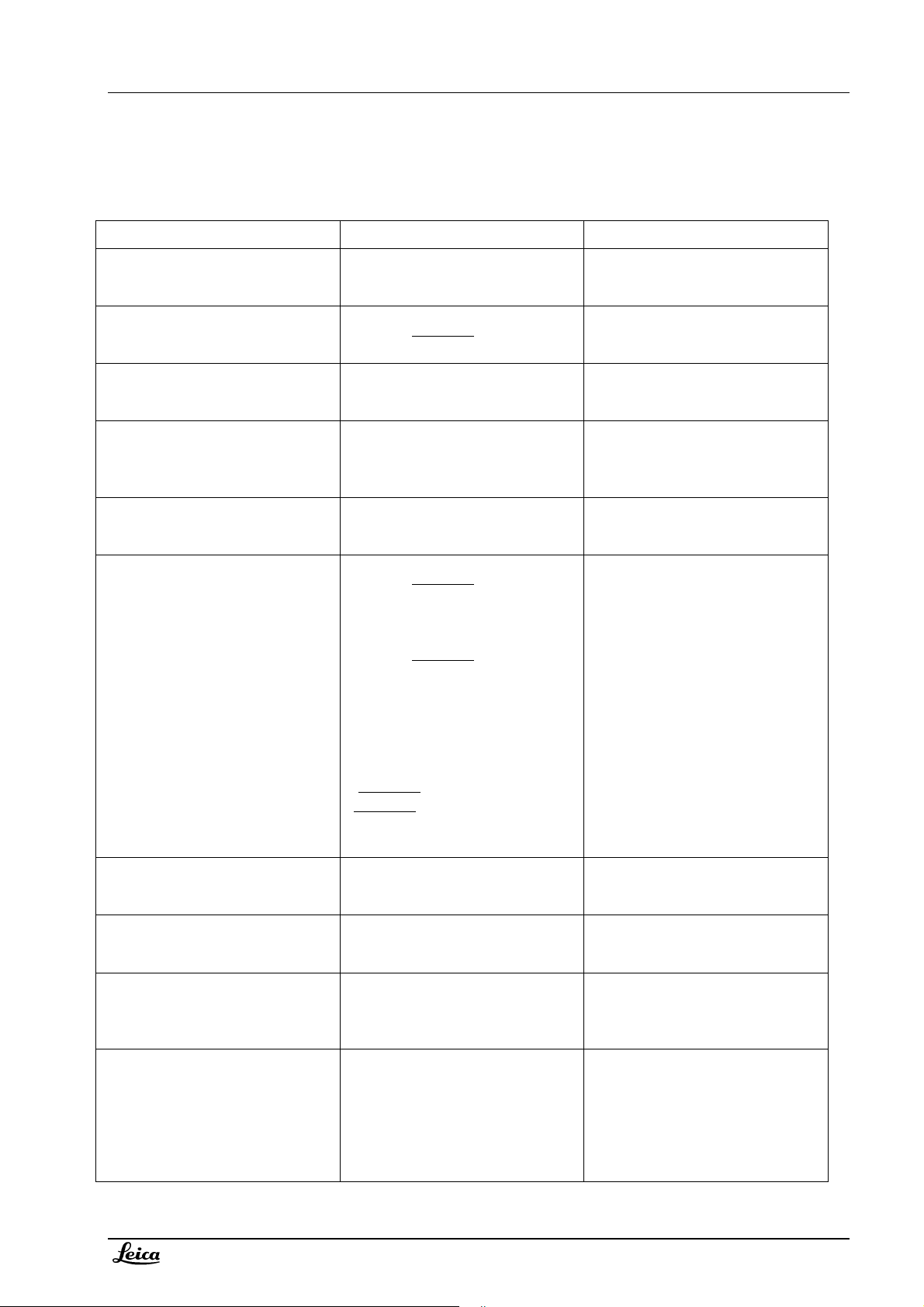

Current configurations Leica M525 (state 08/2007)

10448237 M525

optics carrier

(with A/B-slide)

10448238 M525

optics carrier

no A/B slide

M525 F40

M525

M525 MC1

M525 OH4

10448169 control

unit

Control unit M520 not used

anymore - a new controller

is integrated

in OH4 system

10448068 control unit

10448144 control

unit

10448236 OH4

stand s

stem

Page 9

Service manual M500 N, M520, M525 Description

Doc Code 10 665 751

1-5 08/2007 Gahe

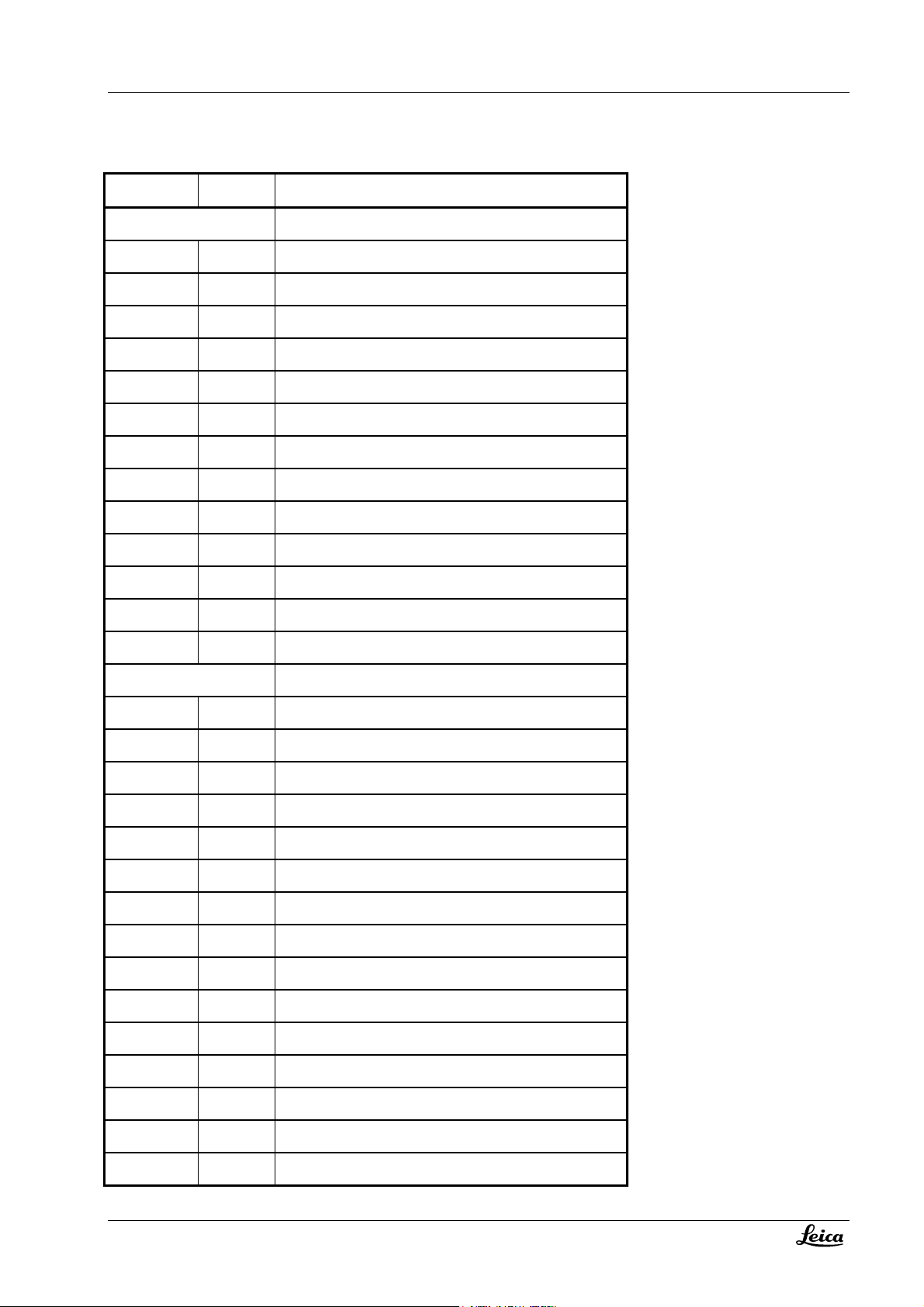

Product history Leica M500N - M520 - M525

Date / event Description: Remark

1997 / Launch M500 N

02/2001 / product change in optics

carrier

07/2001 / Launch with MS2

11/2002 / Launch with OH3

04/2003 / Launch with MS3 10 446 757 M500 N optics carrier

10/2003 / Product change in optics

carrier: New M520 optics carrier

07/2004 / Launch M520 F40 10 448 029 M520 optics carrier for

03/2005 Product change of control

unit: removed power supply

09/2005 Product launch M520 C40

and CT40

07/2006 Product change in M520

optics carrier

10 446 481 M500 N optics carrier

10 446 489 control unit

10 446 757 M500 N optics carrier

replaces 10 446 481

10 446 757 M500 N optics carrier

10 446 489 control unit

10 711851 control unit for OH3

10 448 019 M500 N optics carrier

(without A/B slide)

10 446 489 control unit

10 448 029 M520 optics carrier

replaces 10 446 757

OHS1;

10 448 035 M520 optics carrier

(without A/B slide) for OH3

replaces 10 448 019

Upgrade kit was available:

10 712 316, upgrade kit M500 N to

M520 optics carrier; description 10

665 687;

(10 446 757

10 448 019

F40, 10 448 068 control unit for F40

10 448 144 control unit replaces

10 446 489

10 448 029 M520 optics carrier and

new control unit 10 448 169 for C40

and CT40

10 448 029 M520 optics carrier and

10 448 035 M520 optics carrier

with new zoom unit

to 10 448 070;

to 10448 071)

for MS2, MS3,

;

For stand systems OHS1, MS1,

MC1

New emergency drive for zoom

Additional for MS2 stand system

Additional for OH3 stand system

Additional for MS3 stand system

New illumination unit and new

multifoc objective : More light

30%, increased working distance

from 407 to 470mm, display for

working distance, improved

illumination optics – lead free

glass.

Zoom unit : new diaphragm (10 712

255) for better depth of field reduced diameter to 12mm.

New Lemo plug instead fixed CAN

cable – external cable required.

For stand systems OH3, OHS1,

MS3, MS2, MS1, MC1

Control unit without power supply

and with new holder

All stand systems from 03/2005 on

can provide 24V;

Control unit compatible, but with

new holder

Paint on zoom lenses as a

diaphragm

Page 10

Description Service manual M500 N, M520, M525

1-6

08/2007 Gahe

Doc Code 10 665 751

09/2006 Product change to M525

optics carrier

10 448 237 M525 optics carrier

replaces 10 448 029

for MC1, F40,

MS3, C40, CT40

10 448 238 M525 optics carrier

(without A/B slide) replaces

10448 035

for OH4

Upgrade kit available for limited

time:

10 714 461 Upgrade kit M520 to

M525; description 10 665 743

(10 448 029

10 448 035

to 10 448 246;

to 10 448 247)

New illumination unit, additional

AutoIris function, new motor

controller, removed illumination

zoom.

For stand systems OH4, MS3, MC1,

F40, C40, CT40

Page 11

Service manual M500 N, M520, M525 Description

A

A

Doc Code 10 665 751

1-7 08/2007 Gahe

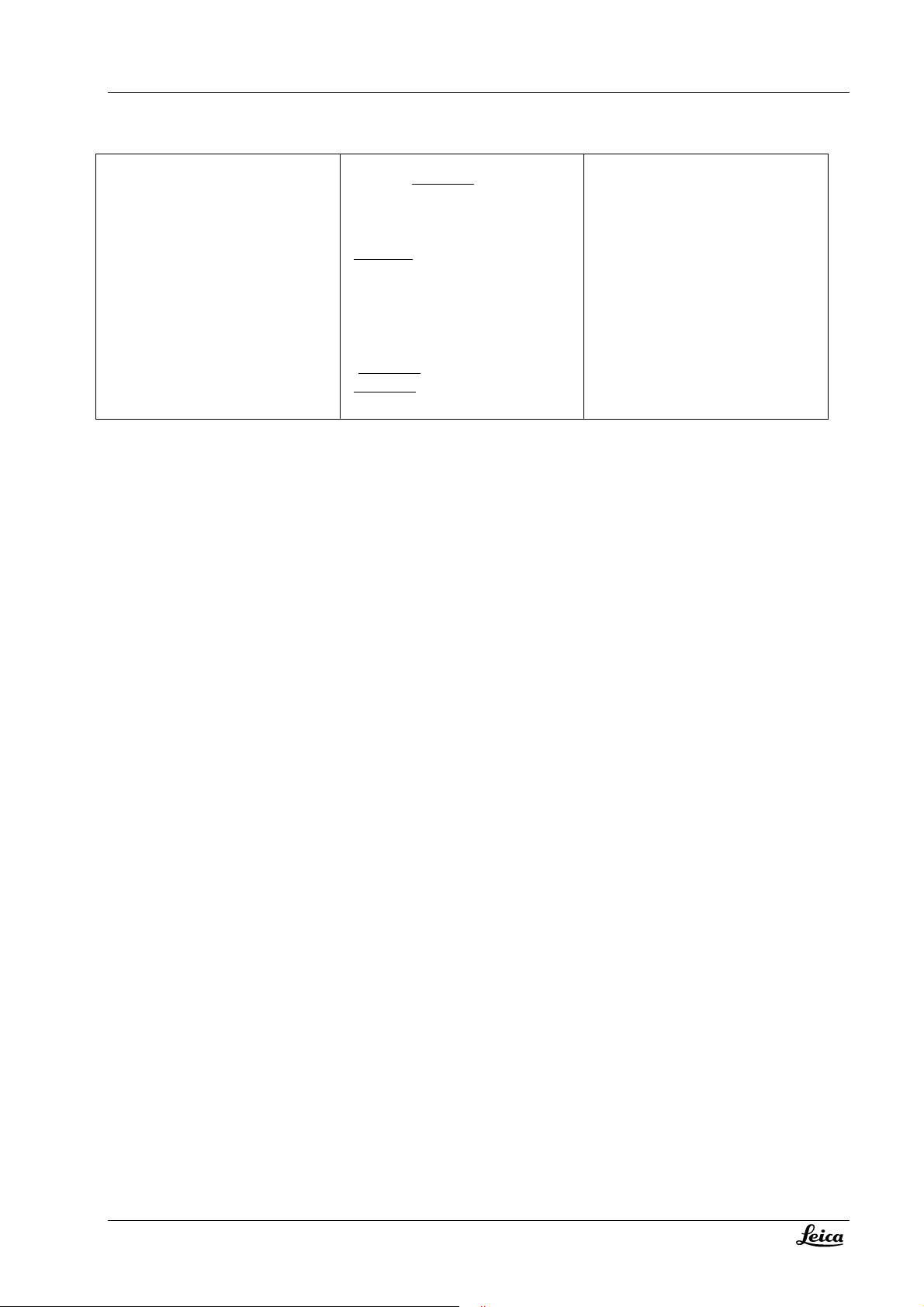

Electrical description

General

The optics carrier is a high performance operating microscope with adjustable working height and integrated zoom,

with M525 also an integrated autoIris. The zoom- and the focus functions, for M525 also the Iris functions, are

microprocessor controlled in order to give the user the maximum comfort. The electronics in the optics-carrier

consists of only one board, with the microprocessor, memory, motorcontrollers and interfaces on it.

A control unit is needed to store the settings, to read hand/footswitches and to control the optics- carrier, manage

CAN bus activities and to display the status/settings. It consists of one controller board, called control module, a LCD

module and a switch panel. Former control units contain a power supply as well.

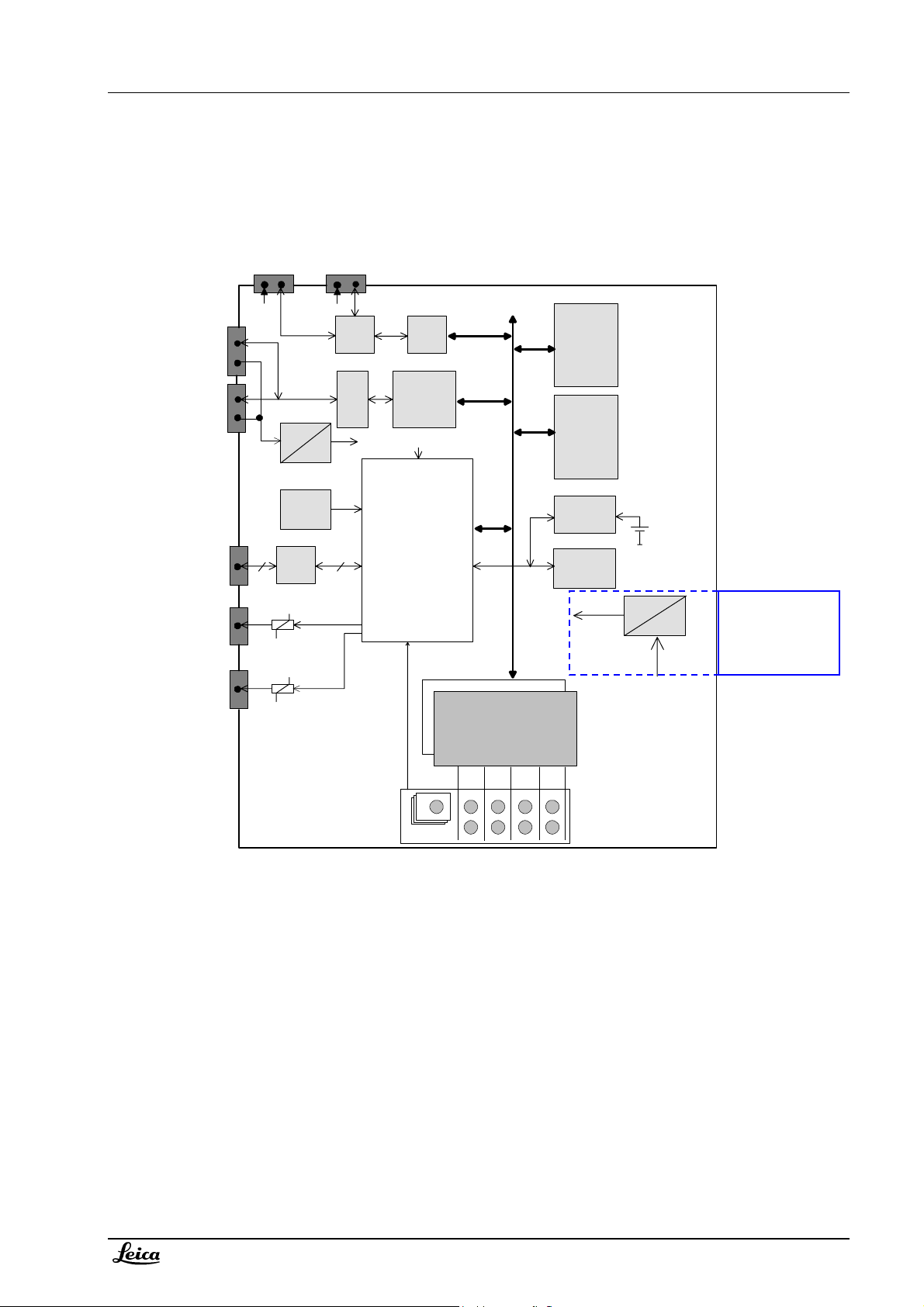

Overview of system:

*Possible options on

CAN bus:

-

CAN handle

-

DI C500

-

Autofocus

-

Swing carrier

-

Fluorescence

Optics-carrier

Zoom

Iris

Multifoc

P7

RS-232

Service

dd.

Funktion

Hand/Footswitch

MF off

Control unit

J5

J9 J8

CAN-Bus

P2

P8

P4

P5

P6

P9

Iris c ont rol

P10

Option*

CAN-Res.

Service

CAN-Bus

P7

P1

P3

Iris function (P8, P9, P10): only in M525

J6

CAN

CAN-Bus

+24V

CAN

DC

C

max 240VAC

External. CAN

modul

CAN

CAN

Leica Stand

Page 12

Description Service manual M500 N, M520, M525

08/2007 Gahe

CAN bus

CAN-bus principle

The CAN-bus (Controller Area Network) is a bi-directional, two-wire bus. It is used to handle the communication

between the control unit, the optics-carrier, the stand and other CAN devices. The CAN-bus uses a protocol which

largely suppresses transmission errors.

The CAN bus in the M500 N/M520/M525 system is operated in the configuration “standard – CAN”.

Data transfer

The bus is looped through each of the controllers. Data is transferred serially, bit by bit, with differential signals. The

data transfer is rated at with 50kBit/s.

The data can be exchanged between each of the controllers. A data transfer consists of:

• Start bit,

• Identification, enabling the priority to be determined,

• The data itself, and

• CRC (Cyclic Redundancy Check).

Each controller recognizes the data related to its task. If a controller wants to send data, it has to wait until the bus is

free. The feature of setting the priority of commands is not applied in the M500 N/M520/M525 system; all commands

have the same priority.

Command interpretation by control unit

The control unit reads CAN commands from CAN handles and from other CAN members. It interprets the received

commands and releases appropriate commands to the CAN bus. The concerning CAN device will then release a

required action.

Safety concept - brake watch dog

The control unit must periodically (100ms) send a brake state message. If no periodic brake state message is received

by the connected stand/brake controller, all brakes will lock.

Terminating impedance

In control unit: the end of the CAN-bus is terminated with an impedance of 120Ω. The controller detects if it is at the

end of the bus or if another device is connected (CAN cable is coded: Pin 4 is bridged to pin 8 in the connector

housing).

In optics carrier: the controller of the optics carrier is always terminated by 120Ω; other devices, connected to the bus

at the optics carrier are not terminated.

1-8

Doc Code 10 665 751

Page 13

Service manual M500 N, M520, M525 Description

Doc Code 10 665 751

1-9 08/2007 Gahe

Optics carrier

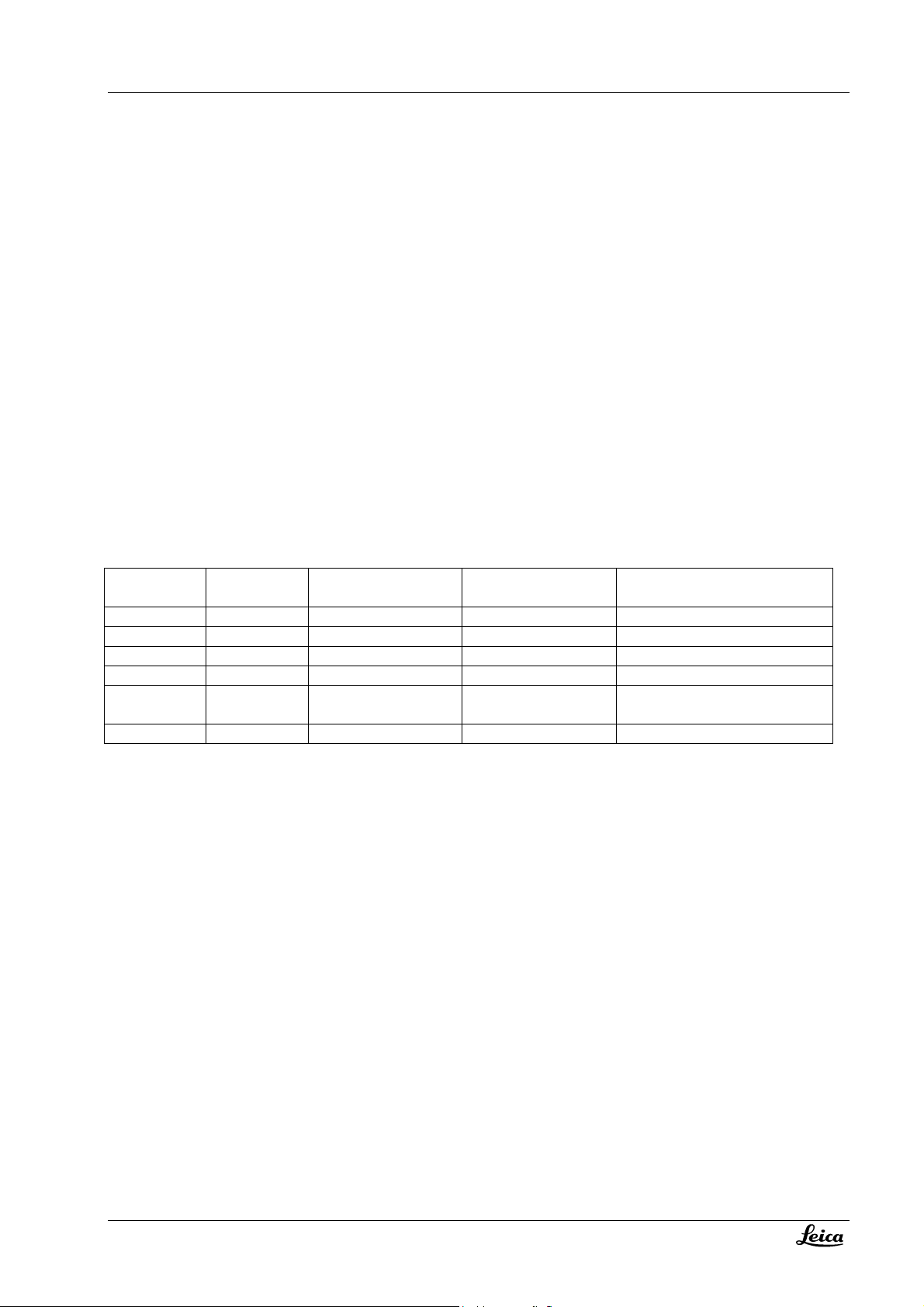

Blockdiagram motorcontroller M500 N, M520

P2

CAN

CAN-Res.

P3

Reset

EEPROM

P6

MF off

P7

Option

24V

120E

5V

CANTrans.

5V

CANController

82527

On-chip

RAM

1kx8

Prozessor

H8/532

On-chipPeripherals,

Watchdog

SCI

PWM

PWM

EPROM

128Kx8

MEM3200

Universal

Counter

ZoomMotor Driver

MultifocMotor Driver

P4

Zoom

P5

Multifoc

+24V

+24V

P1

Service

motcontr.ds4

Addition for motorcontroller M525:

P10

CAN

PWM

Iris

Motor Driver

+24V

P8

Iris

Iris control

P9

Powering

The optics-carrier is powered via the CAN-bus cable with +24VDC.

Power consumption is appr.

50mA in wait state,

150mA when one motor is running;

500mA when both motors, focus and zoom are blocked.

A DC/DC converter on the motorcontroller delivers +5V for logic supply. The +24VDC is measured on the controller

board with the microprocessor analog input. It can be asked in the diagnostic menu of the control unit.

Page 14

Description Service manual M500 N, M520, M525

1-10

08/2007 Gahe

Doc Code 10 665 751

Processor

A watch-dog is integrated in the H8-processor. It observes the running of the main program. Diagnosis LED’s might

help with trouble shooting, refer to chapter 4 – fault finding / diagnosis LED’s.

The PWM outputs are driven with the optimum frequency of 20kHz (above the noise-limit, below magnetization

problems).

Motor driver

The zoom- , focus and Iris motors are powered with a +24V PWM-signal. A one-chip controller receives enable-,

direction- and the puls-rate-information from the processor and drives the motors accordingly. All motors have an

encoder mounted directly on the motor axis. The encoder pulses are received by a counter, where the A/B-signals

(direction) are decoded and the actual position transferred further to the processor. A current limitation for the motors

becomes active for current > 0,3A.

Range

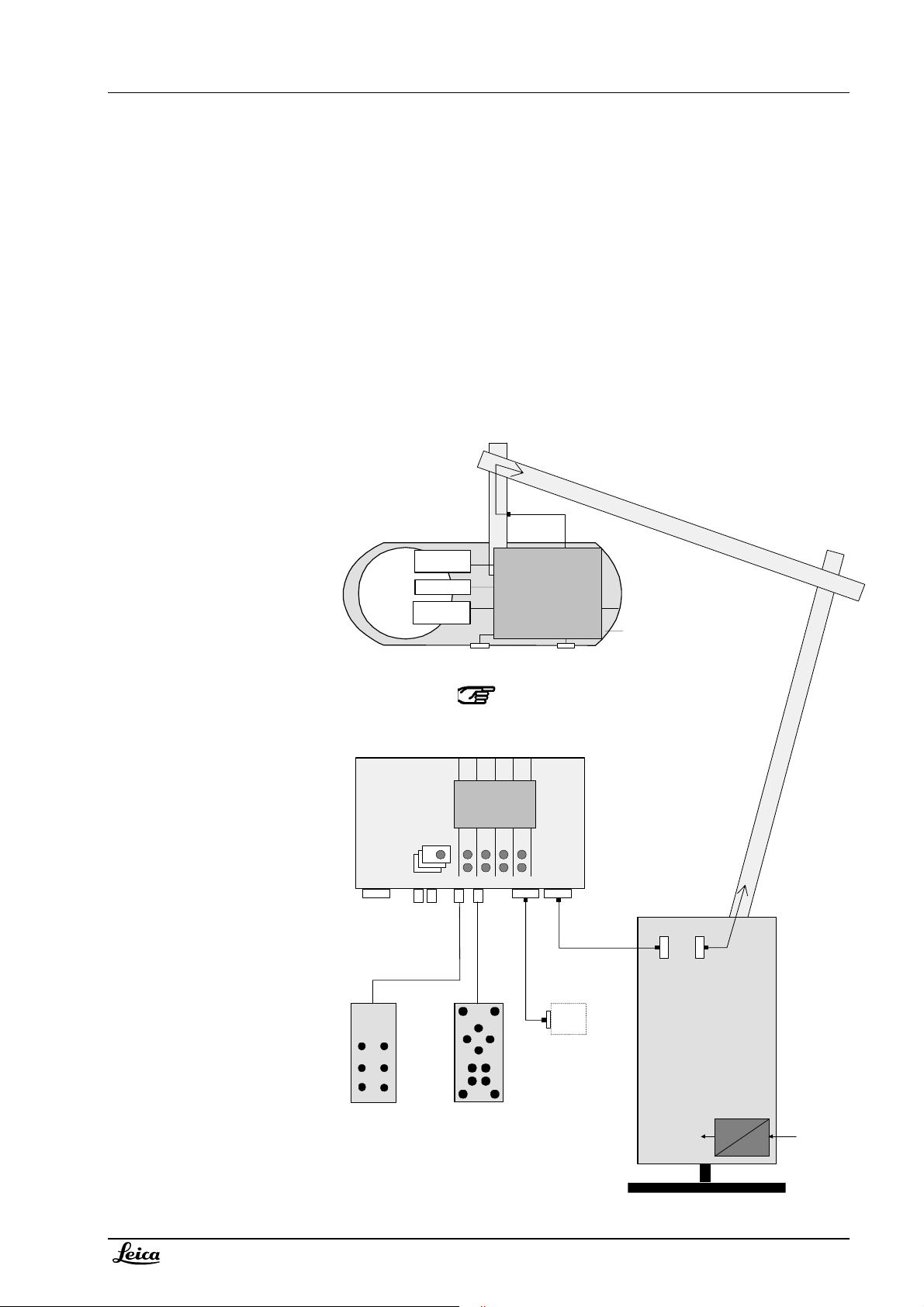

The initializing of the microscope sets the lower limit to 1000 encoder-pulses. The actual upper limit is determine with

counting the encoder-pulses (constants are stored for these values; deviations of the displayed values are possible

due to mechanical tolerances).

Focus 207mm

Zoom OU T Zoom IN

UP

DOWN UP

Focus 407mmDOWN

or 470mm (M520, M525)

800

1000

working range

upper limit

range.ds4

Zoom: 28500

Focus: 23800

RS232

A serial interface for service purposes is available. It is directly wired to the Optics-carrier processor - and has

therefore other signal level for TxD than RS232 standard.

Recognition of optics carrier type

Since the increase of the working distance from 407 to 470mm (M500 N to M520) a recognition of the optics carrier

type is required. A bridge on P6 (pin1-pin4) is installed in optics carrier M520 and M525. A status command, requested

from control unit at system start , delivers the information if the bridge is installed or not.

Additional functionality on motorcontroller for M525

The AutoIrsis function in the M525 required an additional motor and a redesign of the motorcontroller. All existing

functions were taken over (backwards compatible) and additional circuits for Iris motor drive and Iris control were

integrated. The movement of the Iris motor is completely handled by the motorcontroller, no direct access via the CAN

bus is possible.

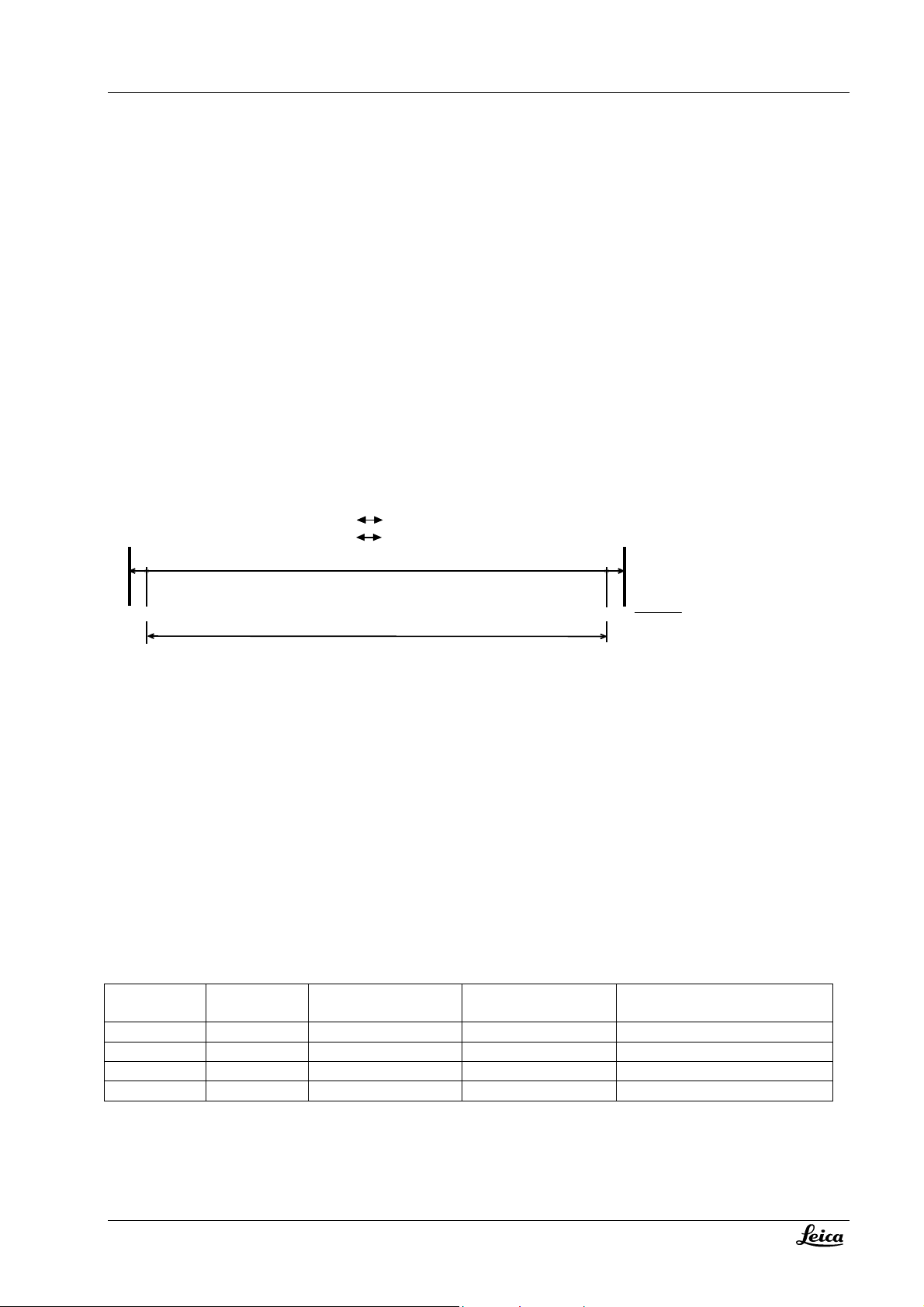

Software history

Software

Release date HW motorcontroller Compatibility Remark

version

1.4 02/98 10 661 250 M500 N

2.3 04/99 -“- M500 N

2.4 05/01 -“- M500 N, M520

4.4 xx/06 10 714 356 M500 N, M520, M525

Software compatibility in respect of control unit see chapter inspection / step 2.13.

Page 15

Service manual M500 N, M520, M525 Description

A

r

Doc Code 10 665 751

1-11 08/2007 Gahe

Control unit

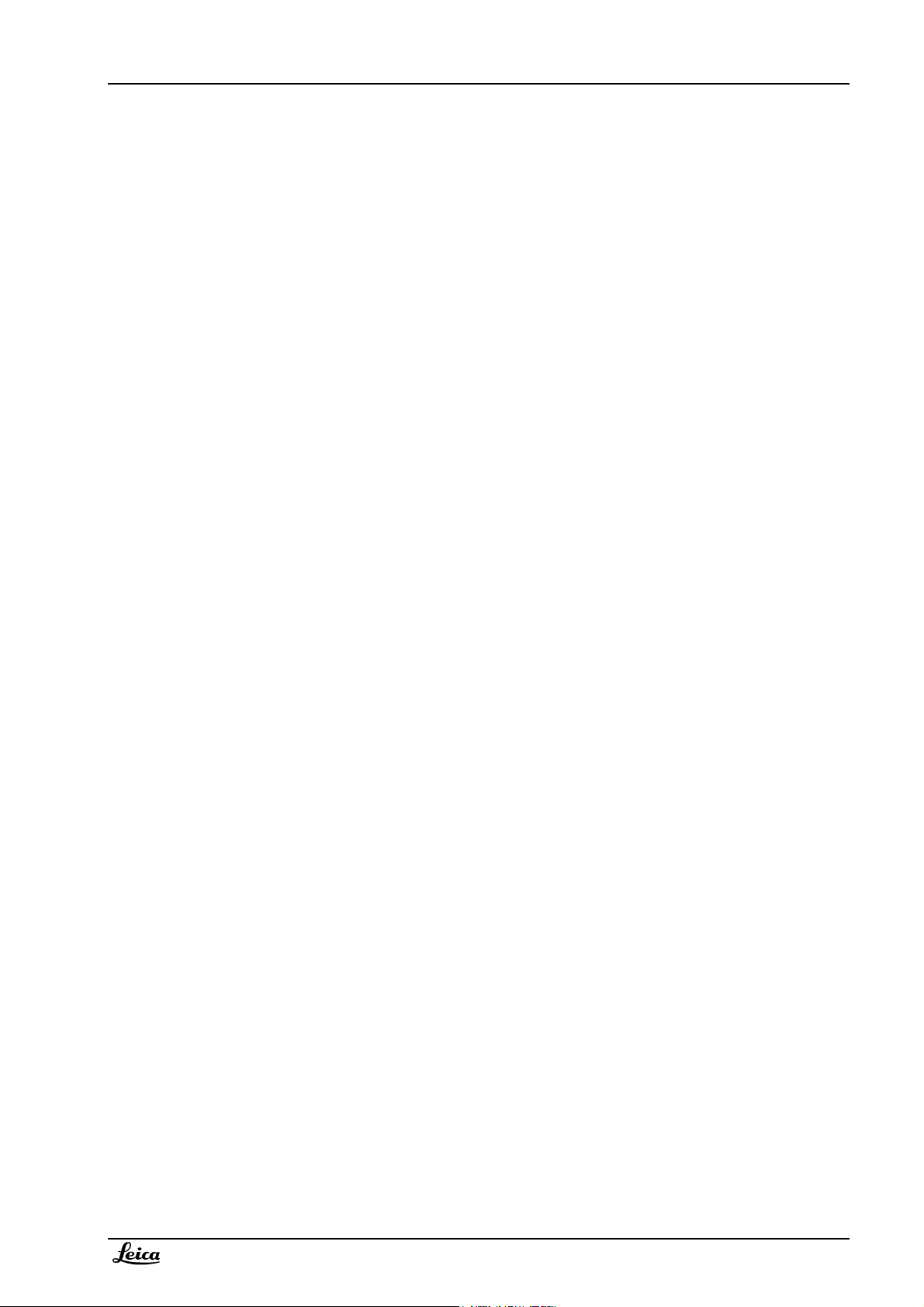

Blockdiagram

Hand-/Footswitch 1 and 2

J5

J6

CANBus

J2

5V

CANBus

J3

Service,

Download

P7

2

RS232

Relay

contact

Relay

contact

J8

J9

5V

24V

5V

Watchdog

Timer

RS232

CANTrans.

5V

386EX CPU,

2

PLD Glue Logic,

Bus Transceivers

DUART

CANController

82527

40MHz

CLK2

Processor

J10

LCD - Graphic Controlle

J11

LCD - Display

240 x 128 Dots

with VF-backlight

RAM

256kByte

FlashEPROM

256KByte

Power-off

Timer

EEPROM

4 kByte

+24V

max 230V AC

DC

"Gold"-

capacitor

C

Power supply

removed since

03/2005

Function

keys

steuerge.ds4

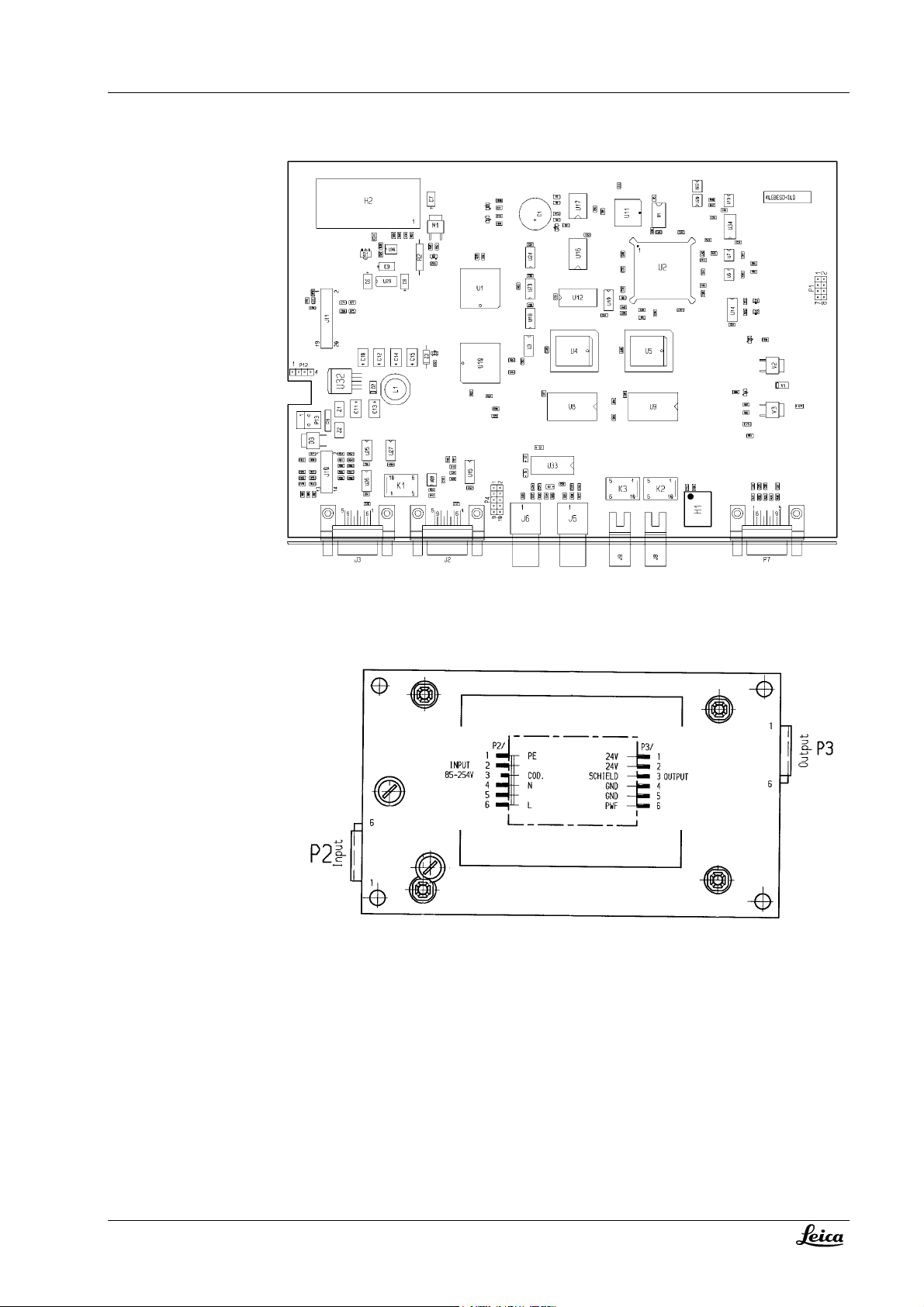

Powering

Control units before 03/2005 had a power inlet for 230VAC ad the built-in power supply could feed the system with

+24VDC. This was required in stand systems having no own power supply like the MC1.

Since 03/2005 all stand systems have their own power supply. So the power supply was removed from control unit,

now it is supplied via the CAN bus cable with 24VDC.

Processor

An Intel 386EX Processor is used. It is clocked with 20MHz. The memory consists of 256kByte RAM, 256kByte FlashEPROM and 4kByte EEPROM. The software can be updated/downloaded through the RS232 service-interface.

A watch-dog is integrated, it observes the running of the main program. Diagnosis LED’s might help with trouble

shooting, refer to chapter 4 – fault finding / diagnosis LED’s.

Page 16

Description Service manual M500 N, M520, M525

08/2007 Gahe

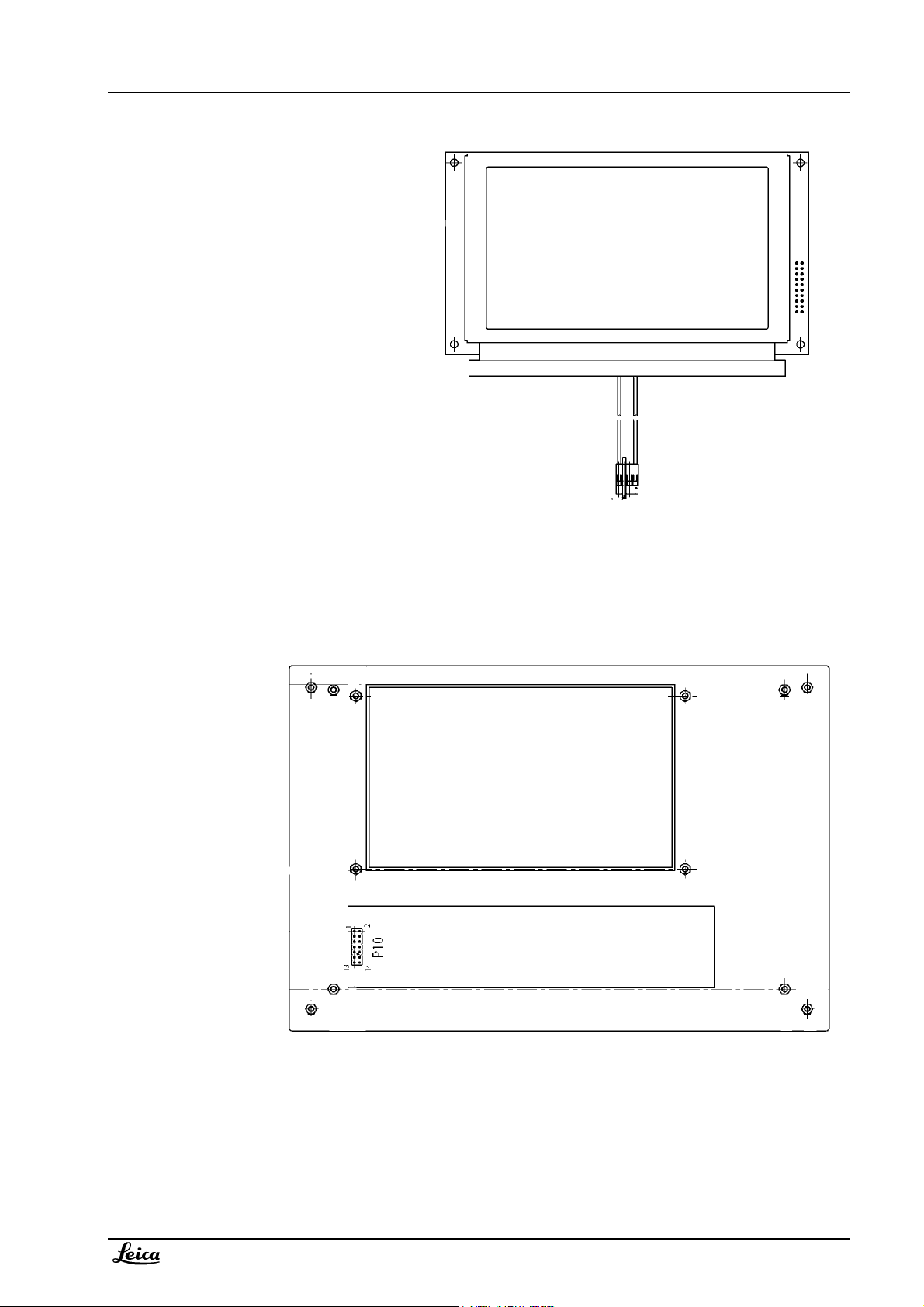

Display / Keyboard

The communication with the user is done with help of an high-contrast display and a keyboard with nine keys. The

display is a LCD Matrix (240x128 dots) with integrated Graphic controller and backlight.

Can-bus

The CAN-bus has two go-through-input/outputs with two identical parallel connectors.

Hand/Footswitch

There are two RS232 interface-connectors available for all available hand / footswitches. They are wired to the

DUART-interface and are clocked with 4800 Baud. The control unit periodically (60ms) sends a request to the

connected footswitch. It sends back a status code (2 Byte), indicating which key is pressed/not pressed.

Service interface

A double RS232 interface is provided for service purposes. They are both wired directly to the Processor (RXD0/TXD0,

RXD1/TXD1) The connector P7 is used for both of them. COM1 (RXD0/TXD0) is programmed for a service-terminal, for

example for downloading new software version into the Flash-EPROM.

Additional function

There are two relay-contacts on the control unit connector panel for additional functions. The maximum permissible

loading for one contact is 1 A/24 V DC. The relay-contacts can be programmed to switch- or toggle mode.

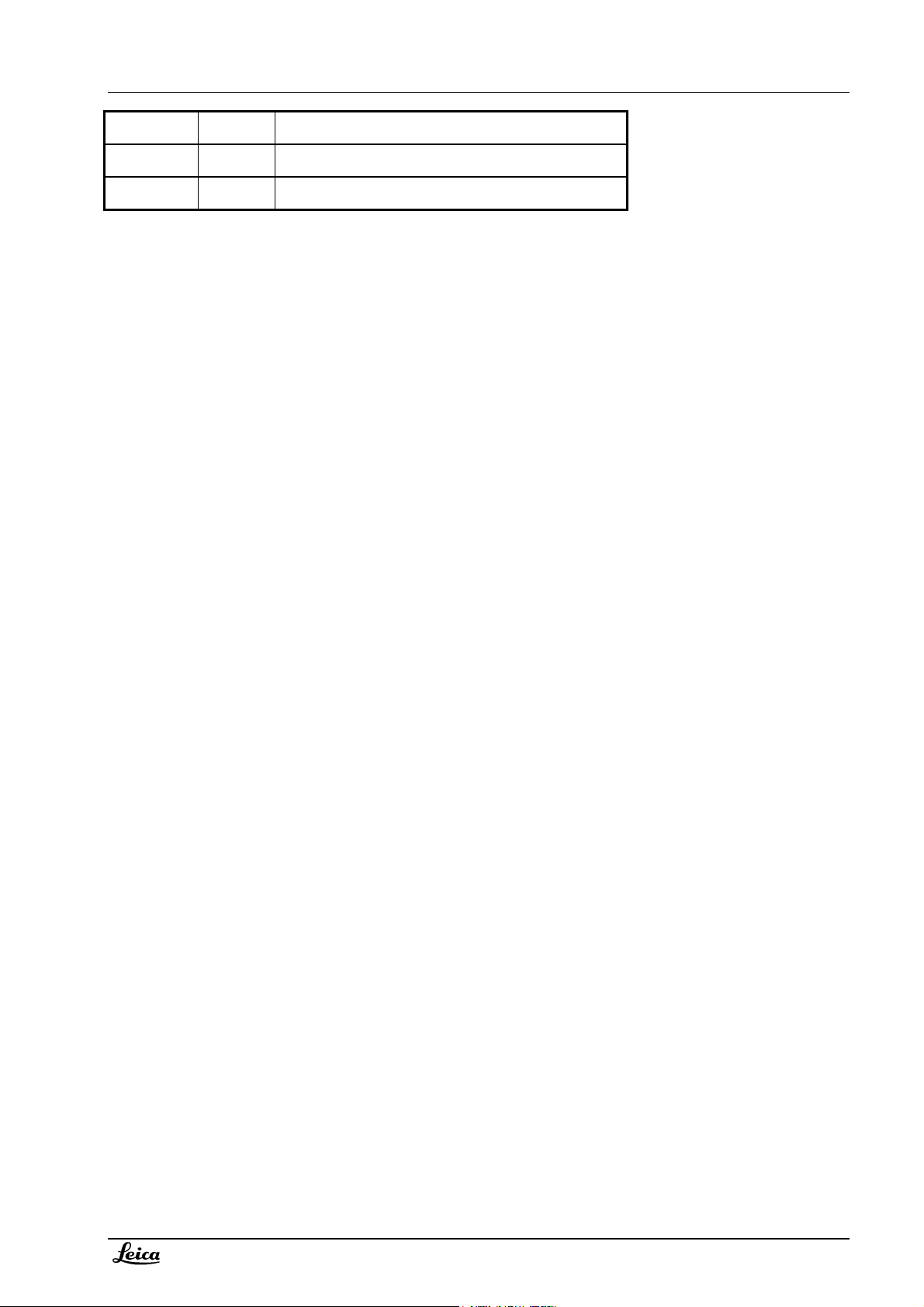

Software history

Software

version

1.4 02/98 10 661 330 M500 N

1.54 01/00 -“- M500 N

1.76 04/02 -“- M500 N Supports Can handles, DI C500

1.81 -“- M500 N Supports OH3

1.84 -“- M500 N Supports MS3, CAN handle can

1.87 -“- M500 N, M520, M525 Supports M520, M525

Software compatibility in respect of optics carrier see chapter inspection / step 2.13.

Release date HW control module Compatibility Remark

1-12

Doc Code 10 665 751

be configured separate

Page 17

Service manual M500 N, M520, M525 Description

Doc Code 10 665 751

1-13 08/2007 Gahe

Technical data

Optics carrier M525

Stock n° 10448237 M525 optics carrier

10448238 M525 optics carrier OH4

Zoom 6:1 zoom, motorized

Magnification Total magnification with 10x eyepiece 1,2 x to 12,8

Working distance 207-470 mm, variable through motorized multi-focal lens, continuously adjustable;

manually adjustable by emergency knob

Display Analog display of working distance

Field of view (diameter) 16,5mm to 180 mm with 10x eyepiece

Objective Multi-focal lens 207-470 mm variable working distance

Illumination Continually adjustable illumination field diameter with gauss-shaped light distribution

AutoIrisTM Built-in automatic zoom-synchronized illumination filed diameter with manual override and

reset feature

Outlet interface Dovetail ring

Control unit M500 N/M520

Stock n° 10448169 (M525 C40/CT40)

10448068 (M525 F40)

10448144 (MC1, MS3)

Display LCD display

Adjustment of Speed for zoom and focus, brightness and backlight intensity of display, WD and zoom

Interfaces RS232 for service

2x RS232 for foot/handswitch

2x additional function (programmable relay contact)

CAN port Two CAN-ports, 24V max 50W

Page 18

Description Service manual M500 N, M520, M525

08/2007 Gahe

1-14

Doc Code 10 665 751

Page 19

Service manual Leica M500 N, M520, M525 Wiring

Doc Code 10 665 751

-I

2

07/2007 Gahe

2. Wiring and locations Leica M500 N, M520, M525

Table of content

Chapter Page

Optics carrier 2-1

Control unit 2-4

Overview of connectors 2-6

Wiring diagrams 2-8

Wiring diagram M525 719072 2-9

Wiring diagram M500 N / M520 707276 2-11

Page 20

Wiring Service manual M500 N, M520, M525

07/2007 Gahe

2-II

Doc Code 10 665 751

Page 21

Service manual M500 N, M520, M525 Wiring

Doc Code 10 665 751

2-1 07/2007 Gahe

Wiring and locations Leica M500 N, M520, M525

Optics carrier

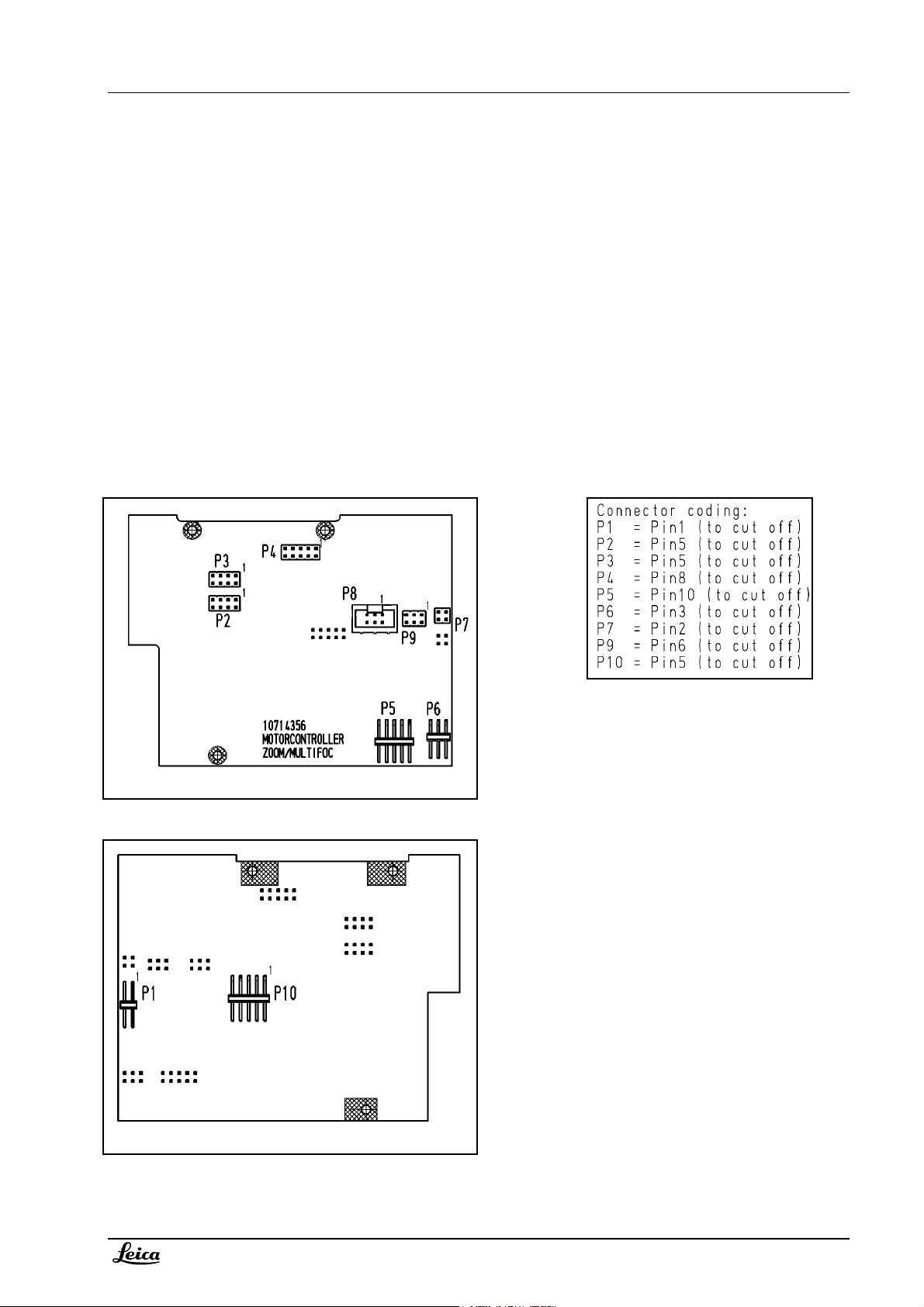

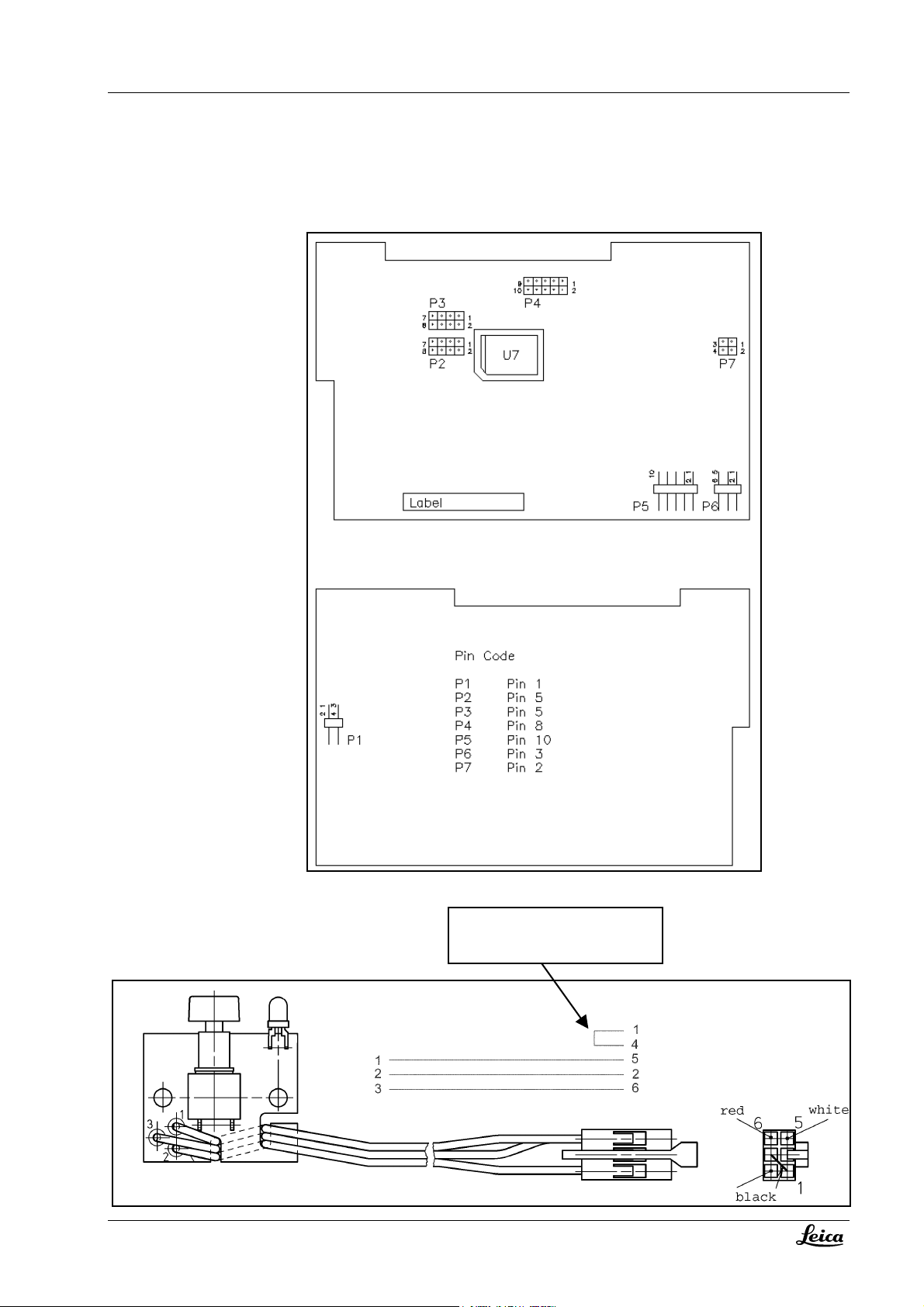

Zoom/multifoc motor controller 10714356

Page 22

Wiring Service manual M500 N, M520, M525

2-2

07/2007 Gahe

Doc Code 10 665 751

Zoom/multifoc motor controller 10661250 (M500 N/M520 only)

Bridge for M520/M525 only;

Removed when used in M500 N

Switch board

J6

View from

wiring side:

Page 23

Service manual M500 N, M520, M525 Wiring

Doc Code 10 665 751

2-3 07/2007 Gahe

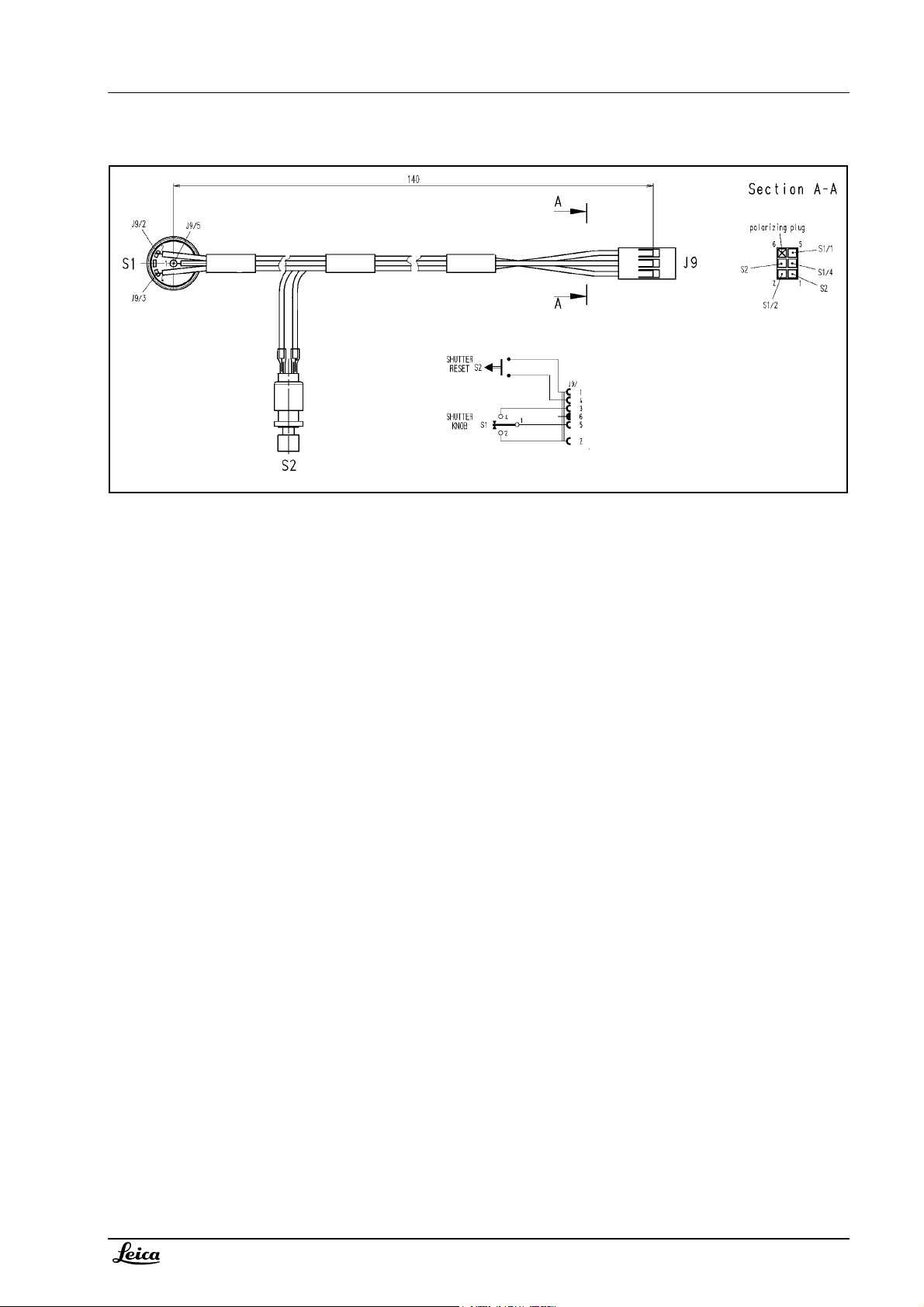

Iris switch assembly

Page 24

Wiring Service manual M500 N, M520, M525

07/2007 Gahe

2-4

Doc Code 10 665 751

Control unit

Control module

Power supply (only in control units till March 2005)

Page 25

Service manual M500 N, M520, M525 Wiring

Doc Code 10 665 751

2-5 07/2007 Gahe

LCD module

P11

J12

Switch panel

Page 26

Wiring Service manual M500 N, M520, M525

07/2007 Gahe

2-6

Doc Code 10 665 751

Overview of connectors

Connector Page Module / connecting to

Optics Carrier

P1 2-1, 2-2 Motor controller / service port

P2 2-1, 2-2 Motor controller / CAN

P3 2-1, 2-2 Motor controller / CAN res.

P4 2-1, 2-2 Motor controller / zoom motor

P5 2-1, 2-2 Motor controller / focus motor

P6 2-1, 2-2 Motor controller / switch board

J6 2-2 Switch board

P7 2-1, 2-2 Motor controller / Res.

J7 - Optics carrier / Service/CAN res. (Lemo with cap)

P8 2-1 Motor controller / Iris motor

P9 2-1 Motor controller / Iris switch assembly

J9 2-3 Iris switch assembly

P10 2-1 Motor controller / CAN (to stand system)

Control unit

P1 2-4 Control module / test port (not used)

P2 2-4 Power supply / input power

J2 2-4 Control module / CAN1

P3 2-4 Power supply / output power

J3 2-4 Control module / CAN2

P4 2-4 Control module / not used

J5 2-4 Control module / remote 1

J6 2-4 Control module / remote 2

P7 2-4 Control module / service RS232

J8 2-4 Control module / add. function 1

J9 2-4 Control module / add. function 2

J10 2-4 Control module / switch panel

P10 2-5 Switch panel / control module

P11 2-5 LCD module / control module

J11 2-4 Control module / LCD module

Page 27

Service manual M500 N, M520, M525 Wiring

Doc Code 10 665 751

2-7 07/2007 Gahe

P12 2-4 Control module / LCD module backlight

J12 2-5 LCD module /control module

P13 2-4 Control module / input from power module

Page 28

Wiring Service manual M500 N, M520, M525

07/2007 Gahe

2-8

Doc Code 10 665 751

Wiring diagrams in A3 format

Wiring diagram M525 10719072 on page 2-9

Wiring diagram M500 N/M520: 707276 A on page 2-11

Page 29

Service manual M500 N, M520, M525 Wiring

Doc Code 10 665 751

2-9 07/2007 Gahe

Page 30

Wiring Service manual M500 N, M520, M525

2-10

07/2007 Gahe

Doc Code 10 665 751

Empty page: reversed side of wiring diagram

Page 31

Service manual M500 N, M520, M525 Wiring

Doc Code 10 665 751

2-11 07/2007 Gahe

Power supply removed since 03/2005

Page 32

Wiring Service manual M500 N, M520, M525

2-12

07/2007 Gahe

Doc Code 10 665 751

Empty page: reversed side of wiring diagram

Page 33

Service manual Leica M500 N, M520, M525 Service programs

Doc Code 10 665 751

3-I

08/2007 GAHE

3. Service programs - Leica M500 N, M520, M525

Table of content

Chapter Page

Service programs control unit 3-1

Software upgrade program for control unit and optics carrier 3-3

Page 34

Service programs Service manual Leica M500 N, M520, M525

08/2007 GAHE

Stock n° Description / Specification Remark Drawing

3-II

Doc Code 10 665 751

Page 35

Service manual Leica M500 N, M520, M525 Service programs

Doc Code 10 665 751 3-1 08/2007 GAHE

Stock n°. Description / Specification Remark Drawing

Service programs – Leica M500N, M520, M525

Service programs in control unit

How to enter the service functions:

• Enter the service menu of the M500 N/M520 control unit in menue II

• Enter security code: 6642

• Select the service functions

Validity

Below description refers to SW 1.87 in the control unit and 2.4 or 4.4 in optics carrier.

Service function

Standard and user configuration Settings of user- and standard

Ad. Function 1 output configuration The output of additional function 1 can

Ad. Function 2 output configuration The output of additional function 2 can

Screen saver setting Screen saver for control unit display:

User parameter save time setting When user settings are saved, the

Power off timer setting A power off / power on within the

Description Remark

Refer to stand user manual.

configuration can be changed and

stored.

Switch mode: relais contact closes

be set and stored either to toggle or to

switch mode.

be set and stored either to toggle or to

switch mode.

after the selected time the brightness

will be reduced.

display shows “User setting saved at…”

for a certain time; this time can be

altered.

selected time will effect:

The last selected user (before switching

off) is automatically taken as the actual

user.

as long as the release button is

pressed.

Toggle mode: relais contact

opens/closes with each activation of

the release button.

-“-

Adjustable between 0..60 minutes.

Default = 5 minutes.

0 minutes will disable screen saver.

Adjustable between 2..6 seconds.

Default = 4 seconds.

Adjustable between 0..60 minutes.

Default = 5 minutes.

Page 36

Service programs Service manual Leica M500 N, M520, M525

08/2007 GAHE

3-2

Doc Code 10 665 751

Stock n° Description / Specification Remark Drawing

Service function

Description Remark

User selection timer setting During the power up routine the control

unit allows to select a user; if no user is

Adjustable between 2..20 seconds.

Default = 11 seconds.

selected within a certain time it will take

the standard settings.

Tube focal length setting The setting influences the displayed

magnification value in the main menu.

Adjustable between 100..200.

Set to focal length of main tube.

Default = 170.

Exception reboot timer setting If an error causes an exception reboot of

the control unit, the error can be

Adjustable between 0..20 seconds.

Default = 10 seconds.

displayed for a certain time before the

reboot starts.

Set device list Connected CAN devices have to be set

to “present”.

Not connected CAN devices have to be

set to “Not present”.

If the device list is not set correctly, it

may result in malfunction and/or

error messages. Available CAN

devices:

Stand (M500-N)

Microscope (M500-N)

Microscope (M500-O)

X/Y-Unit (M500-O)

Autofocus (M500-N)

Handle R (M500-N)

Handle L (M500-N)

DI control (M500-N)

Swing carrier (MS3)

Restore factory defaults All standard and user settings will be

reset to the factory default values.

All user settings will be lost.

Autofocus setup Autofocus video parameters and

autofocus range parameters are set in

Details in service manual

BIV/Autofocus 10 665 645.

this menu.

Stand setup Opens a monitor for entering setup /

service program of the connected stand

Details in the appropriate stand

service manual.

system.

DI Default Settings Shutter functions and shutter mode are

set in this menu.

Details in service manual Neuro

modules 10665683.

DI Color LCD Module Settings Video parameter for the LCD display of

the DI-module are set in this menu.

Details in service manual Neuro

modules 10665683.

Page 37

Service manual Leica M500 N, M520, M525 Service programs

(J7)

Doc Code 10 665 751 3-3 08/2007 GAHE

Stock n°. Description / Specification Remark Drawing

Software upgrade program

Software update for control unit

The M500 N/M520 control unit allows a SW update by Laptop/PC. The control unit can be set into a service mode.

In this mode the control unit accepts data via the RS232 service interface (P7). An update program, running on a

PC/laptop sends the SW via serial port (RS232).

Technical details:

RS232-parameter 19200/8/1/no; transmit and receive signals RS232 compatible;

RS232

Download cable control unit 10 710 562

Software update for optics carrier

The M500 N/M520/M525 optics carrier allows a SW update by Laptop/PC. The motorcontroller accepts data via the

RS232 service interface (either at the capped Lemo plug J7 or the internal plug J1). An update program, running on

a PC/laptop sends the SW via serial port (RS232).

Technical details:

RS232-parameter 19200/8/1/no; receive signal RS232 compatible; transmit signal 0...5V (HCMOS)

CAN/Service

port J7

Download cable optics carrier 10 710 563

Software update procedure

Refer to update description (doc code10 665 668).

The content of the Update CD is available on the intranet as well.

PC/Laptop

Win 95/98/2000/NT/ME/XP

Program Update Center

(on Update CD 10 712 463)

COM port

PC/Laptop

Win 95/98/2000/NT/ME/XP

Program Update Center

(on Update CD 10 712 463)

COM port

Page 38

Service programs Service manual Leica M500 N, M520, M525

08/2007 GAHE

3-4

Doc Code 10 665 751

Stock n° Description / Specification Remark Drawing

Page 39

Service manual Leica M500 N, M520, M525 Fault finding

Doc Code 10 665 751

4-I

08/2007 Gahe

4. Fault finding - Leica M500 N, M520, M525

Table of content

Chapter Page

Diagnosis LED 4-3

Start-up sequence 4-6

Error messages 4-7

Diagnostic functions in control unit 4-12

Page 40

Fault finding Service manual M500 N, M520, M525

08/2007 Gahe

4-II

Doc Code 10 665 751

Page 41

Service manual M500 N, M520, M525 Fault finding

Doc Code 10 665 751

4-3 08/2007 Gahe

Fault finding - M500 N, M520, M525

Diagnosis LED’s

Zoom/multifoc motor controller 10714356

LED 1 green Watchdog - blinking with 2Hz,

LED 2 red

LED 3 yellow

LED 4 green

indicates that the main program is

running.

Enable zoom - “On” when the zoom

motor is driven or short-circuited

(damaged). “Off” when the motor is

set free.

Enable multifoc - “On” when the

multifoc motor is driven or shortcircuited (damaged). “Off” when

the motor is set free.

+5V-Powering - “On” when the

switching regulator is working.

LED 4

LED 3LED 2LED 1

Page 42

Fault finding Service manual M500 N, M520, M525

08/2007 Gahe

Zoom/multifoc motor controller 10661250 (M500 N/M520 only)

LED 1 green Watchdog - blinking with 2Hz,

LED 2 red

LED 3 yellow

LED 4 green

indicates that the main program is

running.

Enable zoom - “On” when the zoom

motor is driven or short-circuited

(damaged). “Off” when the motor is

set free.

Enable multifoc - “On” when the

multifoc motor is driven or shortcircuited (damaged). “Off” when

the motor is set free.

+5V-Powering - “On” when the

switching regulator is working.

4-4

Doc Code 10 665 751

LED 4

LED 3 LED 1LED 2

Page 43

Service manual M500 N, M520, M525 Fault finding

Doc Code 10 665 751

4-5 08/2007 Gahe

Control module

LED1 green Watchdog LED - blinking when

LED2 red Not used.

LED3 green Indicates the presence of +5V.

the main program is running.

LED 3 LED 2LED 1

Page 44

Fault finding Service manual M500 N, M520, M525

t

t

q

)

4-6

08/2007 Gahe

Doc Code 10 665 751

Start-up sequence

Validity

Below description refers to SW 1.87 in the control unit and 2.4 or 4.4 in optics carrier.

Optics-carrier: Control-unit:

Initializing motor controller

Initializing microscope motors (zoom and focus drive

into their lower limit; M525 also Iris motor – drives to

most open limit)

YES

Parameters

received from

control unit?

NO

Motors move to their start positions

(defined in user settings)

NO

Start

position

reached?

YES

Display last user “User name Activating user parameters”

Parameters are sent to optics

carrier

Ready

Ready - Display of the main menu

Initializing processor

Display „RTKernel-32 Debug version“

Display “M500 N/M520 N software version 1.87”

Display “Initializing”

uesting version of optics carrier (M500 N or M520 or none

Re

YES

Display “Presetting Optic Carrier defaults”

Resetting of values for total magnification, working

distance and auto focus to the standard values of the

recognized optics carrier (user settings are lost!!)

Requesting of: IGS company ID & IGS calibration code from optics carrier

Requesting of other CAN devices

Power off/on

YES NO

ime < setting in

service menu ?

After x seconds

(User selection

imer)

Display “Standard setting Activating user parameters”

Parameters are sent to optics

carrier

Display selected “User name Activating user parameters”

Parameters are sent to optics

carrier

Request for confirming of IPD,

diopter, eyepiece mag

Optics carrier

version different

configuration

Display “Select User”

NO

to last

Any “user”

selected by

operator (key

pressed) ?

?

NO

YES

Page 45

Service manual M500 N, M520, M525 Fault finding

Doc Code 10 665 751

4-7 08/2007 Gahe

Error messages

Error messages are displayed on the control unit. For systems without using the control unit - like

M525 OH4 – refer to the appropriate service manuals (chapter fault finding and service programs).

Different levels of error messages

Level-1 error messages:

If a Level-1 error-message occurs, it will be shown in the second line of Menu I or Menu II.

The error message persists unless an appropriate action has been performed. If more than one error messages are

present, then each message is visible for a few seconds in an endless loop.

Example Menu II:

Standard setting

Microscope needs initialization

User settings

Initialize microscope

Service Menue

up/down

Level-2 error messages:

If a Level-2 error-message occurs, it will be shown in the second line in the Service Menu. Level-1 messages are

displayed here as well.

The error message persists unless an appropriate action has been performed – or the message has been cleared in

the service menu. If more than one error messages are present, then each message is visible for a few seconds in an

endless loop.

Example Service Menu:

System config./Standard setting

CAN warning 1: 96 communication errors

Select language

Service functions

Diagnostic functions

Clear error messages

up/down

Menue II

Select function

ok cancel

ok cancel

Page 46

Fault finding Service manual M500 N, M520, M525

4-8

08/2007 Gahe

Doc Code 10 665 751

Error list in diagnostic menu

All error-messages are stored in an error-list. How to display the error list - refer to chapter “Diagnostic function

control unit”.

Error interpretation

Restrictions and remarks:

Below description refers to SW 1.87 in the control unit and 2.4 or 4.4 in optics carrier.

Error messages caused by the Iris diaphragm in M525 optics carrier are NOT displayed in M500 N / M520 control unit.

Level-1 messages are underlined

, all others are Level-2 messages.

MF means multifoc controller / motor controller .

Error messages caused by the optics carrier:

Error message

Description Remedy

Microscope error/warning out of

range

Control unit received an unknown error

code from optics carrier.

Check compatibility of software in

control unit with software in optics

carrier.

Microscope needs initialization

Power-up-reset happened to optics

carrier; therefore motor positions are not

defined.

Release “initialize microscope” in

menu II.

Microscope initialization failed Initializing command, sent to optics

carrier, is not executed within 45

seconds.

If no problem with CAN

communication it is a problem of

motor controller in optics carrier.

Activating user parameter failed Motor positioning commands, sent to

optics carrier, are not executed within 45

seconds.

If no problem with CAN

communication it is a problem of

motor controller in optics carrier.

No status response from

microscope

Microscope detected (config. error) Optics carrier was found on CAN bus,

No status response from optics carrier

within 5 seconds.

although it is set to NOT PRESENT.

If no problem with CAN

communication it is a problem of

motor controller in optics carrier.

Set optics carrier in device list

PRESENT.

Microscope not detected (config.

error)

IGS Calibration Code setting error Problem writing IGS calibration code to

Optics carrier was not found on CAN

bus, although it is set to PRESENT.

optics carrier.

Set optics carrier in device list

NOT PRESENT.

• SW in optics carrier must be

2.4 or higher

• No reply from IGS

workstation on CAN bus

• Code does not match with

calibration code of IGS

workstation

• Check CAN cables

• Electronic problem on CAN

controller like inaccurate bit

MF: CAN 96 communication errors

More than 96 transmission errors did

occur on CAN bus; bus communication

is launched again.

rate or faulty bus

transceiver chip.

MF: Watchdog expired, rebooted Watchdog expired – program crashed;

resulting in power-up boot.

As long as position counters did not

loose their values, normal operation

possible. Else release “initialize

microscope” in menu II.

Page 47

Service manual M500 N, M520, M525 Fault finding

Doc Code 10 665 751

4-9 08/2007 Gahe

Error message

MF: Zoom unexpected stop

MF: Focus unexpected stop

MF: CAN bus restarted

Description Remedy

End position of zoom motor was reached

untimely.

Reason can be increased friction of

mechanic or motor problem.

End position of focus motor was reached

untimely.

Reason can be increased friction of

mechanic or motor problem.

More than 256 transmission errors did

occur on CAN bus; CAN controller chip

is initialized again and bus

communication is launched again.

• Check CAN cables

• Electronic problem on CAN

controller like inaccurate bit

rate or faulty bus

transceiver chip.

MF: Error while installing CAN

objects

Required amount of CAN objects could

not be installed.

Electronic problem on motor

controller: defect of CAN controller

chip

MF: Zoom end position not reached Could not reach end position of zoom,

therefore position counter is not properly

set.

Reason can be increased friction of

mechanic or motor problem.

MF: Focus end position not reached Could not reach end position of focus,

therefore position counter is not properly

set.

Could not reach required zoom position. Reason can be increased friction of

MF: Zoom position error

Reason can be increased friction of

mechanic or motor problem.

mechanic (or manipulation on

emergency drive knob) or motor

problem.

MF: Focus position error

Could not reach required focus position. Reason can be increased friction of

mechanic (or manipulation on

emergency drive knob) or motor

problem.

Iris init pos not reached (No 107) Iris motor could not reach end position. Mechanical problem in Iris assembly.

Unexpected Iris stop (No 125) End position of Iris motor was reached

untimely.

Reason can be increased friction of

mechanic or motor problem.

Relevant error messages caused by the control unit (basic SW errors are not listed):

Error message

Description Remedy

CAN warning 1: 96 communication

errors

More than 96 transmission errors did

occur on CAN bus; bus communication

is launched again.

• Check CAN cables

• Electronic problem on CAN

controller like inaccurate bit

rate or faulty bus

transceiver chip.

Page 48

Fault finding Service manual M500 N, M520, M525

4-10

08/2007 Gahe

Doc Code 10 665 751

Error message

Description Remedy

CAN warning 2: 256 communication

errors

More than 256 transmission errors did

occur on CAN bus; CAN controller chip

is initialized again and bus

communication is launched again.

• Check CAN cables

• Electronic problem on CAN

controller like inaccurate bit

rate or faulty bus

transceiver chip.

CAN error while installing objects Required amount of CAN objects could

not be installed.

Electronic problem on control

module: defect of CAN controller

chip

CAN invalid identifier or handle

Received unknown identifier. Check compatibility of software in

control unit with other connected

devices.

Info: CAN transmit buffer not empty Various internal reasons possible. No serious problem as long as it

does not occur together with „CAN

transmit mailbox overflow“ and as

long as it does not occur often.

EEROM invalid BCC, writing defaults EEPROM checksum not valid. EEPROM faulty.

Keyboard task watchdog error

Footswitch task watchdog error

Appropriate task crashed. SW problem or external impacts

(EMC)

Setup and display task watchdog

error

Status task watchdog error

Display parameter task watchdog

error

CAN transmit task watchdog error

Exception error reboot

No status response from stand

Stand detected (configuration error) Stand was found on CAN bus, although it

No status response from stand CAN

controller within 5 seconds.

If no problem with CAN

communication it is a problem of

CAN controller in stand.

Set stand in device list PRESENT.

is set to NOT PRESENT.

Stand not detected (configuration

error)

Stand was not found on CAN bus,

although it is set to PRESENT.

Set stand in device list

NOT PRESENT.

Autofocus detected (config.error) Autofocus device was found on CAN

bus, although it is set to NOT PRESENT.

Set autofocus in device list

PRESENT.

Autofocus not detected

(config.error)

Autofocus device was not found on CAN

bus, although it is set to PRESENT.

Set autofocus device in device list

NOT PRESENT.

Focus position (autofocus) not

found

Autofocus device terminated cycle

without detecting the optimal range.

Problem in autofocus devices

No remote response from autofocus No status response from autofocus

Problem in autofocus devices

device within 3 seconds.

Page 49

Service manual M500 N, M520, M525 Fault finding

Doc Code 10 665 751

4-11 08/2007 Gahe

Error message

Description Remedy

Timeout of autofocus function

Autofocus function was started, but no

response about the cycle termination

within 36 second.

Set CAN Handle R in device list

CAN Handle R was found on CAN bus,

although it is set to NOT PRESENT.

Set CAN Handle L in device list

CAN handle L was found on CAN bus,

although it is set to NOT PRESENT.

CAN Handle R not detected

CAN Handle L not detected

Set DI-Controller in device list

CAN handle R was not found on CAN

bus, although it is set to PRESENT.

CAN handle L was not found on CAN

bus, although it is set to PRESENT.

DI-Controller was found on CAN bus,

although it is set to NOT PRESENT.

DI-Controller not detected

DI-Controller was not found on CAN bus,

although it is set to PRESENT.

DI-Controller shutter position error Detected position of shutter does not

correlate with commanded position for

more than 5 seconds.

DIC500: Video signal not valid

DIC500: detected (config. error)

Video signal not valid or PLL not

engaged.

DI-Color LCD module was found on CAN

bus, although DI controller is set to NOT

PRESENT.

DIC500: not detected (config. error) DI-Color LCD module was not found on

CAN bus, although DI controller is set

PRESENT.

Imaging position sensor error

Stand not available

Stand is busy

Image position sensor indicates that

prism is not in left or right end position.

Setup- or diagnostic menu of stand was

called up, but stand does not respond.

Setup- or diagnostic menu of stand was

called up while stand is busy (for

example during auto balance

procedure).

Stand error pending, enter diagnose Setup menu of stand was called up,

although an error of the stand is

pending.

Problem in autofocus devices

Set CAN handle R in device list

PRESENT.

Set CAN handle L in device list

PRESENT.

Set CAN handle R in device list

NOT PRESENT.

Set CAN handle L in device list

NOT PRESENT.

Set DI-Controller in device list

PRESENT.

Set DI-Controller in device list

NOT PRESENT.

Problem in DI-Controller / DI C

module.

• Check video signal

• Check VESA settings

Set DI controller in device list

PRESENT.

Set DI controller in device list NOT

PRESENT.

• Engage rotary knob for

image left/ right to left or

right end position.

• Else defective sensor in DIC module.

• Stand not present

• Failure in CAN cabling

• Failure in stand CAN

controller

Wait until stand is ready and repeat

call up.

Confirm stand error in diagnostic

menu and repeat call up.

Page 50

Fault finding Service manual M500 N, M520, M525

08/2007 Gahe

4-12

Doc Code 10 665 751

Diagnostic functions control unit

The M500 N / M520 / M525 control unit is equipped with diagnostic functions (below description refers to SW 1.87 in

the control unit; earlier versions do contain less functions). For systems without using the control unit - like

M525 OH4 – refer to the appropriate service manuals (chapter fault finding and service programs).

How to enter the diagnostic functions:

Select [Menue II]

Select [Service Menue]

Enter the security code: 6642

Select [Diagnostic functions]

Available diagnostic function Description

Keyboard test All push-buttons on the keyboard can be tested.

Check CAN-Handle switches Keys pressed on the right CAN-handle are displayed.

Show/clear error list Appearing errors are stored in this list, up to 29 lines; clear list after

repair/service. Refer to chapter “error messages”.

Show parameters Different parameter of the control unit can be asked for:

Software version: 1.87

Boot code version: 1.05

Internal temperature: 35

Configuration size: 1831

Microscope: Max encoder positions The zoom motor and the focus motor drive to their max. range and return

Microscope: show parameters connected optics carrier: M500N M520 M525

Optics carrier: M500N M520N M520N

Software version: 2.4 2.4 4.4

supply voltage: 23.8

Zoom encoder (min/max): 1000/28321

Focus encoder (min/max): 1000/24109

IGS Company ID : xxx

IGS Calibration Code: xxxxx

Autofocus : show parameters Status of an optional autofocus is displayed.

Stand diagnose: Opens a monitor for entering diagnosis programs of optional connected

stand systems.

Swing carrier: show parameters Status and version of a connected swing carrier are displayed.

Page 51

Service manual M500 N, M520, M525 Fault finding

Doc Code 10 665 751

4-13 08/2007 Gahe

CAN-handles: show parameters HW and SW version of left and right CAN handle are displayed.

DI-controller: show parameters Status and version of a connected DI C500 module are displayed.

DI-controller: test shutters Shutters of a connected DI C500 module can be activated and monitored.

DI-LCD-module: show parameters Status and version of the LCD module of a connected DI C500 module are

displayed.

IGS-Workstation: show parameters Status and version of a connected IGS system are displayed.

Test and diagnosis in the user menu:

Select [Menue II]

Select [User settings]

Available test function Description

CAN-Handle left/right All keys of the appropriate handle can be checked; the standard

setting of the handles can be displayed.

Foot/handswitch connector 1 / 2 All keys of the appropriate foot/handswitch can be checked; the standard

setting of the foot/handswitch can be displayed.

Microscope Speed and position of focus or zoom can be displayed.

Control unit Setting of screen brightness and contrast ca be displayed.

Stand All keys of the stand handgrips (Not CAN-handles!) can be checked; the

standard configuration of the handgrip can be displayed.

Restore standard settings* Overwrite the actual user with default settings.

*not visible when standard settings

are activated

Page 52

Fault finding Service manual M500 N, M520, M525

4-14

08/2007 Gahe

Doc Code 10 665 751

Page 53

Service manual Leica M525 Replacing modules

Doc. Code 10 665 751 5-I update 07/2007 04/2004 3241 - EBTH

5 Replacing modules - Leica M500 N, M520, M525

Table of content

Chapter Page

5.1 Dismantling/assembling the optics carrier 5-1

5.1.1 Removing the optics carrier 5-1

5.1.2 Removing the zoom carrier 5-2

5.1.3 Removing the zoom motor 5-3

5.1.4 Exchange the set manual drive 5-4

5.1.5 Removing the multifocal motor 5-5

5.1.6 Removing switchboard 5-5

5.1.7 Removing the multifocal objective 5-5

5.1.8 Removing Iris switch 5-6

5.1.9 Assembly of Iris switch 5-6

5.1.10 Removing Iris motor 5-7

5.1.11 Assembly of Iris motor 5-7

5.2 Removing the A/B-slide 5-8

Page 54

Replacing modules Service manual Leica M525

04/2004 3241- EBTH update 07/2007 5-II Doc. Code 10 665 751

Page 55

Service manual Leica M525 Replacing modules

5x5

2

4

Doc Code 10 665 751 5-1 04/2004 - EBTH Update 07/2007

5 Replacing modules

5.1 Dismantling / assembling the optics

carrier

5.1.1 Removing motor controller board

P 6

Fig 3

Fig. 1

Fig 2

M6x12

DIN912

2

3

P 5

1

M2.

1

M3x10

DIN912

3

4

M3x10

DIN553

1. Remove two screws [Fig.1-1] from counter weight [Fig.1-2] and

take it off

2. Remove seven screws [Fig.1-3] from lower cover [Fig.1-4] and

take it off.

3. Pull out connectors P5 and P6 [Fig.2] from motor controller

board.

4. Separate upper part of zoom [Fig.3-1] from the illuminators

lower part [Fig.3-2], remove screws [Fig.3-3] and [Fig.3-4] until

they no longer engage.

Note: the upper screw [Fig 3-3] is a safety screw.

Page 56

Replacing modules Service manual Leica M525

04/2004 – EBTH Update 07/2007 5-2 Doc Code 10 665 751

P8

P9

4A. For M525 only: Carefully swing away illuminator [Fig.3-2]

Downwards, over dovetail segment until P8 and P9 become

accessible. Pull out connectors P9 and P8 from motor

controller board (Fig 3A).

5. Carefully swing away illuminator [Fig.3-2] downwards, over

dovetail segment.

Fig. 3A

P 4 P 3

6. Pull out connectors P1, P2, P3 and P4 from motor controller

board.

P 2

7. Remove screw [Fig.4-5] from zoom motor adapter and remove

motor controller board from zoom part [Fig.3-1].

8. Remove screw [Fig.4-6] from motor controller board positioned

and take it off.

Fig 4

7

M2.5x5

DIN7985

6

M2.5x5

DIN789

5

M3x6

DIN912

P 1

9. Remove two screws [Fig.4-7] from motor controller board

carrier and take it off.

Page 57

Service manual Leica M525 Replacing modules

Doc Code 10 665 751 5-3 04/2004 - EBTH Update 07/2007

M3x12

DIN912

2

5.1.2 Removing the zoom carrier

1. Separate zoom (upper part) and illuminator (lower part) from

one another as described in paragraph 5.1.1.

2. Remove four screws [Fig.5-1 and 5-2] from the zoom (see Fig. 6-

2) and take out the complete zoom mechanism [Fig.6-2]

slantwise upwards from zoom housing.

Fig 5

1

M3x12

DIN912

Grease the 3 guide rods with

D2M (10 289 964)

Caution: No grease at

the side of the bearing

Grease DF2M5

(10 534049)

Page 58

Replacing modules Service manual Leica M525

04/2004 – EBTH Update 07/2007 5-4 Doc Code 10 665 751

Fig 7

Fig 8

M3x6

DIN912

1

5.1.3 Removing the zoom motor

1. Separate zoom (upper part) and illuminator (lower part) from

one another as described in paragraph 5.1.1.

Zoom does not need to be removed from the zoom

housing (upper part).

2. Remove two screws [Fig.7-1] from zoom carrier.

3. Remove zoom motor completely with motor adapter and gears

1

2

M3x6

DIN912

[Fig.8-1], from zoom carrier.

4. Remove two screws [Fig.8-2] from motor adapter and take out

the zoom motor sideways through the slit.

Grease the spindle wheel with

KSB6 (10 534 035)

1

2

Fig 9

1mm

5.1.4 Exchange the set manual zoom drive

1. Separate zoom (upper part) and illuminator (lower part) from

one another as described in paragraph 5.1.2

2. Remove the knob [Fig.9-1] from the manual zoom drive.

3. Remove the manual zoom drive 10711530 with the nut [Fig.9-2]

using a 16mm fork wrench.

4. Fix the manual zoom drive 10711530 with a 16mm fork wrench.

5. Adjust a 1mm space [see Fig.10] between the two bevel gear

wheels with the nut [Fig.9-2] using a 16mm fork wrench.

Grease gear wheel with

FM4 (10 289 970)

Fig 10

Page 59

Service manual Leica M525 Replacing modules

Doc Code 10 665 751 5-5 04/2004 - EBTH Update 07/2007

3

Fig 11

Fig 12

1

5.1.5 Removing the multifocal motor

1. Remove counter weight and lower cover as described in

paragraph 5.1.2.

2. Pull out motor connector P5 [Fig.11-1] from motor controller

board through the notch in the illuminator (lower part).

3. Loose two screws [Fig.11-2] of motor-holding clip.

2

M3x5

DIN912

4. Take out the motor sideways from motor-holding clip.

5.1.6 Removing the switchboard

1. Remove counter weight and lower cover as described in

paragraph 5.1.2.

2. Pull out the switchboard plug P6 (Fig 11-3) from motor controller

board through the notch in the illuminator (lower part).

1

M2.5x5

DIN 7985

3. Remove two screws [Fig.12-1] of the switchboard and remove

switchboard in direction of the motor.

Fig 13

M3x5

DIN912

1

5.1.7 Removing the multifocal objective (10 712 073) from the

illumination device (10 712 092)

1. Remove counter weight and lower cover as described in

paragraph 5.1.2.

2. Pull off connectors from motor controller board as describes in

paragraph 5.1.1.

3. Separate zoom (upper part) and illuminator (lower part) from

one another as described in paragraph 5.1.1.

4. Loose the two screws (Fig 13-1) of the motor holding clip.

5. Take out the motor sideways from motor holding clip until no

more affect the gear rim from multifocal.

Page 60

Replacing modules Service manual Leica M525

04/2004 – EBTH Update 07/2007 5-6 Doc Code 10 665 751

3

1

6. Turn (Fig 14-1) the multifocal that the groove (Fig 14-2) is

underneath the axis of the manual drive (Fig 17-3)

2

Fig 14

7. Loose the 3 screws of the multifocal (Fig 15-1) and take out the

multifocal sideways.

Fig 15

1

M2.5x6

DIN912

Fig 15A

M3x10

DIN912

1

M2.5x8

DIN912

5.1.8 Removing Iris switch

1. Remove upper from lower part ( step 1 to 5 in 5.1.1)

4

3

2. Release switch S2: loosen 2 screws (Fig 15A-1) and hex nut

(Fig 15A-2).

M5 P0.5

2

3. Mark axial position of Iris assembly in housing (Fig 15A-3).

4. Loosen 2 screws (Fig 15A-4) and remove Iris assembly with

motor.

5. Release switch S1: remove cap of plastic cover and loosen

hex nut (M5 DIN 439), remove cover. Loosen hex nut of S1

(1/4-28).

5.1.9 Assembly of Iris switch

Reversed order of 5.1.8: put Iris assembly to former position.

Secure screws Fig 15A-4, 2, 1 with shellac.

Page 61

Service manual Leica M525 Replacing modules

Doc Code 10 665 751 5-7 04/2004 - EBTH Update 07/2007

5.1.10 Removing Iris motor

1. Perform procedure 5.1.8 step 1 to 4.

2. Dissolve shellac of pin screw (Fig 15B-1) with solvent (alcohol,

spirit) and pull out motor.

3. Dissolve shellac of pin screw (Fig15B-2) with solvent and

remove gear.

Fig 15B

2

M2x2

DIN 551

1

M3x4

DIN 553

5.1.11 Assembling Iris motor

1. Perform procedure 5.1.10 in reversed order.

2. Secure screws (Fig 15B-1, Fig 15B-2) with shellac. Grease gear

with FM5 (10 289 967).

Page 62

Replacing modules Service manual Leica M525

04/2004 – EBTH Update 07/2007 5-8 Doc Code 10 665 751

5.2. Removing the A/B-slide

M2.5x5

Fig 16

DIN965

2

1

M4x12

DIN912

1

M3x10

DIN912

2

1. Removing the optics carrier.

2. Move B-slide [Fig.16-1] to rear position (turn A-spindle).

3. Remove front cover and rear cover from A-slide by taking out

the four screws [Fig.16-2].

4. Remove only first and last screw [Fig.17-1] from A-slide.

5. Remove two screws [Fig.17-2] to release A-carrier from zoom

(upper part)

Note: Prevent the slide [Fig.18 –1 and 2] (front and rear)

from accidentally coming out of its guidance.

Fig 17

Fig 18

3

M4x12

DIN912

2

1

6. Remove last four screws [Fig.17-3] to release A/B-slide from

zoom upper part.

Page 63

Service manual Leica M525 Replacing modules

Doc Code 10 665 751 5-9 04/2004 - EBTH Update 07/2007

1

M4x12

DIN965

7. Remove four screws [Fig.19-1] and four washers [Fig.20-1] to

release A-slide from B-slide.

8. Remove three screws [Fig.19-2] to release cover from B-slide.

2

M2.5x5

DIN965

Fig 19

M4x8

DIN965

2

9. Remove four screws [Fig.20-2] and one screw [Fig.20-3] to

release B-carrier from B-slide.

10. Assembly in reverse order.

1

Fig 20

3

M4x10

DIN912

Page 64

Replacing modules Service manual Leica M525

04/2004 – EBTH Update 07/2007 5-10 Doc Code 10 665 751

Page 65

Service manual Leica M500 N, M520, M525 Maintenance

Doc Code 10 665 751

6-I

07/2007 Gahe

6. Maintenance - Leica M500 N, M520, M525

General guidelines maintenance

Instruments and their accessories are generally exposed to dust and dirt.

Each time, before you use them, carry out an external inspection of accessible mechanical and optical parts such as

eyepieces, optics carrier, objectives, binocular tubes and accessories; clean them if necessary.

Dust and dirt have a negative effect on the results of your work.

When the instruments are not in use, use the dust covers and dust plugs provided.

Specific guideline for the Leica M500 N / M520 /M525

We recommend to do a preventive maintenance every 3 years.

Maintenance work:

Dismantling the modules of the optics carrier in accordance with procedures described in section 5 of the service

manual.

Cleaning and re-greasing of the individual dismantled optical and mechanical modules.

Performing a complete inspection according to chapter 7 of this manual.

Perform maintenance work for tubes and accessories in accordance with the appropriate service manuals.

Page 66

Maintenance Service manual M500 N, M520, M525

07/2007 Gahe

6-2

Doc Code 10 665 751

Page 67

Service manual Leica M500 N, M520, M525 Inspection

Doc Code 10 665 751

7-1

07/2007 Gahe

7. Inspection Leica M500 N, M520, M525

Table of content

Chapter Page

Inspection list / entries 7-3

Test certificate 7-8

Page 68

Inspection Service manual M500 N, M520, M525

07/2007 Gahe

7-II

Doc Code 10 665 751

Page 69

Service manual M500 N, M520, M525 Inspection

Doc Code 10 665 751

7-3 07/2007 Gahe

Inspection Leica M500 N, M520, M525

Remarks

The following inspection list is an addition to the inspection list of the connected stand system.

Exceptions for the inspection of the control unit: OH4 and future stand systems do/might not use the M500 N control

unit, for such systems skip below steps 2.x and refer to particular stand inspection.

Entries

Step Description Required results O.K. Fails

1 General

WARNING!

1.1 Switch stand system on. Optics carrier and control unit perform the

2 Control unit

2.1 Display the list of errors in the service

menu/ diagnostic functions(6642). Note

and erase error messages.

2.2 Check the arrow and display key in the

submenu [Keyboard test]

Never do look directly in to the light source!

start-up sequence. No error messages on

the control unit.

No error messages are stored.

Keys are in proper condition.

2.3 Connect a foot- or hand switch to control

1 connector and select diagnostic

function for foot/hand switch connector 1

Pressed keys of connected switch are

recognized in the menue.

Page 70

Inspection Service manual M500 N, M520, M525

7-4

07/2007 Gahe

Doc Code 10 665 751

Step Description Required results O.K. Fails

2.4 Connect a foot- or hand switch to control

2 connector and select diagnostic

function for foot/hand switch connector 2

2.5 Activate additional function 1 (use

foot/hand switch with appropriate

configuration)

2.6 Activate additional function 2 (use

foot/hand switch with appropriate

configuration)

2.7 Check screen brightness and contrast:

Use arrow keys in menu “Usersettings/control unit/screen brightness

and contrast”

Pressed keys of connected switch are

recognized in the menue.

Relay contact on additional function 1

connector is activated (resistance < 1 Ohm

when activated).

Relay contact on additional function 2

connector is activated(resistance < 1 Ohm

when activated).

Brightness and contrast can be increased

and decreased from minimum to maximum;

the ideal values are intermediate.

2.8 Check CAN cable CAN cable seems undamaged and does not

limit the movement of the control unit.

2.9 Check eyepiece magnification setting in

user settings

Setting corresponds to magnification of

normally used eyepieces; default 10x

2.10 Check tube focal length setting in service

menue

Setting corresponds to focal length of

normally used tube; default f=170mm

2.11 Check device list in service menue

Setting corresponds to normally connected

devices

2.12

Read out controller parameter in

diagnostic functions/show parameter

SW version:

Boot code version: V1.05

Internal temperature:

Nominal app. 50°C (after warm-up)

Page 71

Service manual M500 N, M520, M525 Inspection

Doc Code 10 665 751

7-5 07/2007 Gahe

Step Description Required results O.K. Fails

2.13 Check software compatibility Allowed combinations:

Control unit 1.87 – optics carrier 2.4 and 4.4

Control unit 1.81 – optics carrier 2.4

Control unit 1.84 – optics carrier 2.4

Control unit 1.76 – optics carrier 2.4

Control unit 1.54 – optics carrier 2.3

Control unit 1.40 – optics carrier 1.4

2.14 Select main menue and use cursor keys

to change focus speed, zoom speed,

zoom magnification and working distance

(WD).

Values can be changed as required:

Focus and zoom speed: 1…100%

Magnification* and working distance:

M500 N optics carrier

1.4 (at WD max 407) to 13.7 (at WD min 207)

M520, M525 optics carrier

1.2 (at WD max 470) to 12.8 (at WD min 207)

*for eyepiece magnification 10x and tube focal length

170mm

3 M500 N / M520 / M525 optics carrier

Various

3.1 Inspect optics. Optics clean.

3.2 Check interface for protective glass.

Protective glass fits properly.

3.3 Check dovetail interface. Tube fits properly.

A/B slide

3.4 Inspect A- and B slide. Smooth movement through entire range:

A= min 63mm, B= min 42mm

3.5 Load available equipment onto optics

Microscope is balanced in A/B axis.

carrier and perform manual balancing of

A/B axis.

Focus functions

3.6

Press focus up button at left and right

handle.

M500 N:

Working distance (WD) increases to 407

M520 & M525:

Working distance (WD) increases to 470,

the WD indication on optics carrier is

equivalent to WD display on control unit.

Page 72

Inspection Service manual M500 N, M520, M525

7-6

07/2007 Gahe

Doc Code 10 665 751

Step Description Required results O.K. Fails

3.7

Press focus down button at left and right

handle.

Working distance decreases to 207.

M520 & M525:

WD indication on optics carrier is

equivalent to WD display on control unit.

3.8 Observe movement of focus Uniform focus movement at both, min and

max speed (32sec....8sec).

3.9 Turn emergency drive knob of focus. Display of WD on control unit and on optics

carrier indicate changes from turning knob.

3.10 Press switch for laser application. Yellow LED beside of the switch shines.

Handle switches and arrow keys of control

unit cannot alter working distance

anymore.

Zoom functions

3.11

Press zoom up button at left and right

handle.

Magnification increases.

3.12 Press zoom down button at left and right

Magnification decreases.

handle.

3.13 Observe movement of zoom. Uniform zoom movement at both min and

max speed (12sec...5sec).

3.14 Turn emergency drive knob of zoom.

Display of magnification on control unit

indicates changes from turning knob.

3.15 Determine the max. focus/zoom encoder

Controller

positions (diagnostic

Both motors, zoom and focus, travel to the

maximum position and return.

functions/Microscope: max. encoder

positions)

3.16 Read out controller parameter (diagnostic

functions/microscope/show parameters

in control unit);

Optics carrier: (M500N or M520N*)

SW version:

Voltage supply:

(24V +/- 0.6V)

Zoom encoder min/max:

(min=1000 / max=28400 nominal)**

Focus encoder min/max:

(min = 1000 / max=24200 nominal)**

* if M525 optics carrier is connected, it shows M520N

** no tolerances defined

Page 73

Service manual M500 N, M520, M525 Inspection

Doc Code 10 665 751

7-7 07/2007 Gahe

Step Description Required results O.K. Fails

Illumination

3.17 Inspect fibre optics cable and its

connectors for damages.

3.18 Plug and unplug fibre optics.

3.19 Switch on light source, dim moderate

intensity.

3.20 Observe field of illumination at

WD=207mm and max. magnification; set

diaphragm to maximum.

3.21 Observe field of illumination at

WD=207mm and min. magnification; set

diaphragm to maximum.

Seem to be intact, no dots in fibre.

Fibre optics does snap in noticeable.

Field of view is illuminated.

No reflexes, no disturbing stray light in field

of view, homogeneous illumination in the

field of view.

No reflexes, no disturbing stray light in field

of view, Gaussian distribution of illumination

in the field of view; the light spot is in centre

of field of view.

3.22 Check autoIris function (M525 only):

Press autoIris reset button and

increase/decrease zoom.

Light field diameter is automatically

following the size of the visual field, but

always slightly bigger.

(Diameter is around 29mm at WD250 and

3.23 Check Iris diaphragm diameter at WD

250, position optics carrier to a sharp

image; set diaphragm to minimum by

maximum zoom)

Diameter of illumination circle measured in

object plane:

11mm +/- 1.5mm

rotary button.

Image

3.24 Adjust parfocality, select a WD 320 Image is sharp throughout entire zoom

range.

3.25 Measure diameter of visible field of view

Diameter field of view:

in the object plane

WD at max and zoom at min: >170mm*

WD at min and zoom at max: <18mm*

*with 10x eyepieces and tube focal length 170mm

Page 74

Inspection Service manual M500 N, M520, M525

07/2007 Gahe

7-8

Doc Code 10 665 751

Test certificate

Leica M500 N/M520/M525

Select type:

0 M500 N

0 M520

0 M525

Leica Microsystems (Schweiz) AG

Surgical Division

CH-9435 Heerbrugg

Switzerland

Date

Purpose of test

System Configuration

performed inspection / steps:

Serial no. of optics carrier Stand OHS1/MS-1/MC-1/MS2/

MS3/OH3/F40/C40/CT40/OH4)

Software version optics carrier Serial no. of stand

Serial no. of control unit Software version stand

Software version control unit Serial no. of xenon unit

Mains voltage set on xenon unit

Peculiarities of test

Inspected by Date

Signature

Page 75

Service manual Leica M500 N, M520, M525 Spare parts

Doc Code 10 665 751

8-I

04/2007 GAHE

8. Spare parts - Leica M500 N, M520, M525

Table of content

Chapter Page

Optics carrier 8-1

Exchange modules 8-1

Zoom unit 8-2

Focus/illumination unit 8-4

A/B slide 8-6

Various parts 8-7

CAN cables 8-8

Control unit 8-11

Exchange modules 8-11

Components 8-12

Upgrades, upgrade tools 8-14

Page 76

Spare parts Service manual Leica M500 N, M520, M525

04/2007 GAHE

Stock n° Description / Specification Remark Drawing

8-II

Doc Code 10 665 751

Page 77

Service manual Leica M500 N, M520, M525 Spare parts

Doc Code 10 665 751 8-1 04/2007 GAHE

Stock n°. Description / Specification Remark Drawing

Spare parts – Leica M500 N, M520, M525

Optics carrier

Optics carrier exchange modules

10 448 237R Optics carrier M525 with A/B slide

10 448 029R Optics carrier M520 with A/B slide

10 446 757R Optics carrier M500 N with A/B slide

10 446 481R Optics carrier M500 N with A/B slide

10 448 238R Optics carrier M525 for OH4

10 448 035R Optics carrier M520 for OH3

10 448 019R Optics carrier M500 N for OH3

Page 78

Spare parts Service manual Leica M500 N, M520, M525

04/2007 GAHE

8-2

Doc Code 10 665 751

Stock n° Description / Specification Remark Drawing

Zoom unit

10 714 391 Zoom complete with motor For M500N/M520/M525

10 710 420 Zoom motor complete (motor, gearing, encoder)

10 712 255 Lens aperture

10 711 530 Set manual zoom drive without knob Availabe on request only

10 565 683 Rotary knob, complete Set with different clamp chucks and nuts

10 638 876 Threaded bolt

Page 79

Service manual Leica M500 N, M520, M525 Spare parts

Doc Code 10 665 751 8-3 04/2007 GAHE

Stock n°. Description / Specification Remark Drawing

10 714 356 Motor controller with software 4.4 or higher

(replaces former controller 10661250 of M520 and M500 N – but it requires the latest SW 1.87 in the

control unit; upgrade parts have to be ordered on demand)

10 704 396 Motor controller board carrier

10 706 298 Motor controller board positioner

Page 80

Spare parts Service manual Leica M500 N, M520, M525

04/2007 GAHE

8-4

Doc Code 10 665 751

Stock n° Description / Specification Remark Drawing

Focus/illumination unit

10 714 355R M525 multifocus/illumination module replacement part

10 712 092R M520 multifocus/illumination module replacement part

10 713 263R M500 N multifocus/illumination module replacement part

10 663 466 Focus motor with encoder

10 711 527 Set manual drive multi - focal objective axis and bevel wheel

10 565 683 Rotary knob, complete Set with different clamp chucks and nuts

10 712 260 Switch board M520/M525 Configure for M500 N: remove bridge in connector

10 714 365 Iris switch assembly M525 Rotary knob, pushbutton and wiring

Page 81

Service manual Leica M500 N, M520, M525 Spare parts

Doc Code 10 665 751 8-5 04/2007 GAHE

Stock n°. Description / Specification Remark Drawing

10 714 366 Iris motor with encoder M525 only

10 712 158 Counterweight

Page 82

Spare parts Service manual Leica M500 N, M520, M525

04/2007 GAHE

8-6

Doc Code 10 665 751

Stock n° Description / Specification Remark Drawing

A/B slide

Remark: A/B slide parts for optics carrier 10448238: refer to service manual OH4, doc code 10 665 744

10 446 491 A/B slide

10 663 886 A slide

10 663 887 B slide

10 638 971 X-Spindle

10 663 892 A – cover