Page 1

Instructions for use

Leica CM3600 XP, 6v3, English - 01/2013

Order-No.: 14 0417 80101 RevB

Always keep this manual with the instrument.

Read carefully before working with the instrument.

Leica CM3600 XP

Cryomacrotome

Page 2

Page 3

NOTE

The information, numerical data, notes and value

judgments contained in this manual represent the

current state of scientific knowledge and stateof-the-art technology as we understand it following thorough investigation in this field. We are

under no obligation to update the present manual

periodically and on an ongoing basis according

to the latest technical developments, nor to provide our customers with additional copies, updates etc. of this manual.

To the extent permitted in accordance with the

national legal system as applicable in each individual case, we shall not be held liable for erroneous statements, drawings, technical illustrations etc. contained in this manual. In particular,

no liability whatsoever is accepted for any financial loss or consequential damage caused by or

related to compliance with statements or other

information in this manual.

Statements, drawings, illustrations and other

information as regards contents or technical

details of the present manual are not to be

considered as warranted characteristics of our

products. These are determined only by the contract provisions agreed between ourselves and

our customers.

Leica reserves the right to change technical

specifications as well as manufacturing processes without prior notice. Only in this way is it

possible to continuously improve the technology

and manufacturing techniques used in our products.

This document is protected under copyright laws.

All copyrights to this documentation are held by

Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods – including any electronic systems and media – requires

express prior permission in writing by Leica

Biosystems Nussloch GmbH.

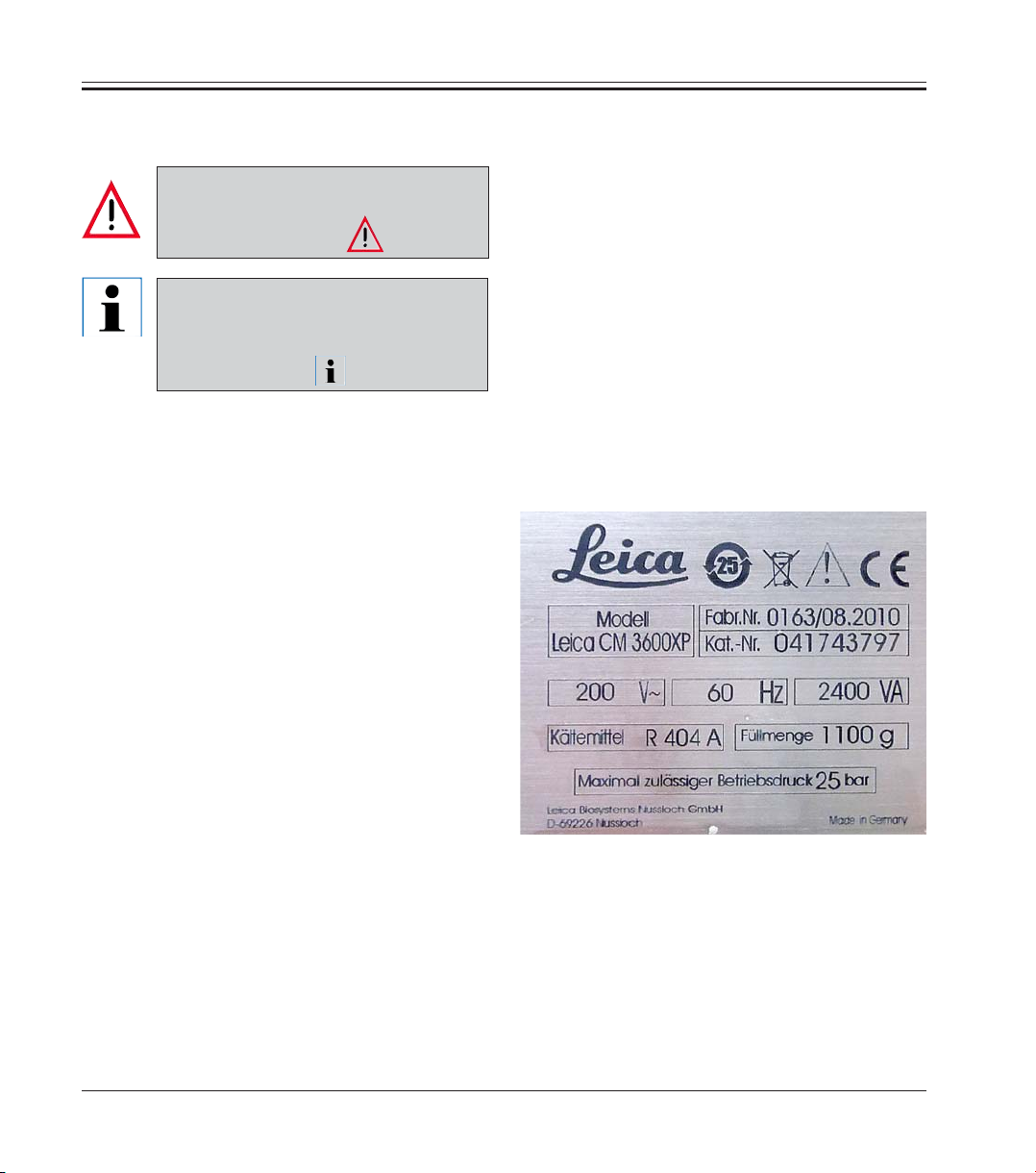

For the instrument serial number and year of

manufacture, please refer to the name plate at

the back of the instrument.

© Leica Biosystems Nussloch GmbH

Published by:

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Phone: +49 62 24 143-0

Fax: +49 62 24 143-2 68

Internet: http://www.LeicaBiosystems.com

Leica CM3600 XP – Cryomacrotome

3

Page 4

Table of contents

1. Important Information ........................................................................................................ 8

1.1 Symbols in the text and their meanings .......................................................................................................................... 8

1.2 Qualification of personnel .................................................................................................................................................. 8

1.3 Instrument type..................................................................................................................................................................... 8

1.4 Designated use ..................................................................................................................................................................... 9

1.5 Warranty .............................................................................................................................................................................. 10

1.6 Service information ........................................................................................................................................................... 10

1.7 Decommissioning and disposal ...................................................................................................................................... 10

2. Characteristics of the Leica CM3600 XP ...................................................................... 12

2.1 Layout of the CM3600 XP .................................................................................................................................................. 12

2.2 Technical Data ................................................................................................................................................................... 14

2.2.1 Microtome type ...................................................................................................................................................... 14

2.2.2 Control unit ......................................................................................................................................................... 14

2.2.3 Dimensions and weight ........................................................................................................................................ 15

2.2.4 Electrical connections.......................................................................................................................................... 15

2.2.5 Refrigeration system - cooling chamber .......................................................................................................... 16

2.2.6 General parameters .............................................................................................................................................. 17

2.3 Instrument parts ................................................................................................................................................................. 17

2.4 Function................................................................................................................................................................................ 18

3. Safety................................................................................................................................... 20

3.1 Safety notes ........................................................................................................................................................................ 20

3.2 Warnings.............................................................................................................................................................................. 20

3.3 Safety devices .................................................................................................................................................................... 24

3.3.1 Emergency stop switch ........................................................................................................................................ 24

3.3.2 Knee lever ......................................................................................................................................................... 25

3.3.3 Window ......................................................................................................................................................... 25

3.3.4 Cryochamber ......................................................................................................................................................... 25

4. Site requirements .............................................................................................................26

4.1 Site requirements at place of installation ..................................................................................................................... 26

4.2 Electrical connections ...................................................................................................................................................... 27

4.3 Other connections ............................................................................................................................................................. 27

5. Installation ......................................................................................................................... 28

5.1 Unpacking and installation .............................................................................................................................................. 28

5.2 Standard delivery ............................................................................................................................................................... 28

5.3 Port and switch panel ....................................................................................................................................................... 29

5.3.1 Port and switch functions .................................................................................................................................... 30

5.3.2 Fuses ......................................................................................................................................................... 32

5.4 PC .......................................................................................................................................................................................... 33

4

Instructions for use, 6v3, RevB – 01/2013

Page 5

Table of contents

6. Software ............................................................................................................................. 34

6.1 Start and log-in procedure............................................................................................................................................... 34

6.2 Description of the window elements ............................................................................................................................. 35

6.2.1 Title bar ......................................................................................................................................................... 35

6.2.2 Tool bar ......................................................................................................................................................... 35

6.2.3 Work space ......................................................................................................................................................... 37

6.2.4 Information bar ....................................................................................................................................................... 37

6.3 Initialization ......................................................................................................................................................................... 38

6.4 Main window ...................................................................................................................................................................... 40

6.4.1 Chamber temperature .......................................................................................................................................... 41

6.4.2 Time ......................................................................................................................................................... 41

6.4.3 Automatic defrost cycle ....................................................................................................................................... 41

6.4.4 Automatic dehydration ......................................................................................................................................... 42

6.4.5 Knife movement ..................................................................................................................................................... 42

6.4.6 Extraction system .................................................................................................................................................. 45

6.4.7 Sectioning program .............................................................................................................................................. 45

6.4.8 Sledge speed ......................................................................................................................................................... 46

6.4.9 Mode of operation ................................................................................................................................................. 47

6.4.10 Cutting window ...................................................................................................................................................... 48

6.5 Parameter settings ............................................................................................................................................................ 49

6.5.1 Parameter setting .................................................................................................................................................. 50

6.5.2 Password list ......................................................................................................................................................... 54

6.5.3 Configuration ......................................................................................................................................................... 57

6.5.4 Reference voltages ............................................................................................................................................... 64

6.5.5 Language selection ............................................................................................................................................... 64

6.5.6 Initialization ......................................................................................................................................................... 64

6.6 Temperature curves .......................................................................................................................................................... 65

6.6.1 Work space ......................................................................................................................................................... 66

6.6.2 Diagram ......................................................................................................................................................... 68

6.7 Chronological event list .................................................................................................................................................... 69

6.7.1 Work space ......................................................................................................................................................... 70

6.7.2 Event table ......................................................................................................................................................... 72

6.8 Alarm list .............................................................................................................................................................................. 73

6.8.1 Work space ......................................................................................................................................................... 74

6.8.2 Event table ......................................................................................................................................................... 75

6.8.3 Error codes: meaning and troubleshooting ..................................................................................................... 76

6.9 Chamber illumination ........................................................................................................................................................ 77

6.10 Section documentation ..................................................................................................................................................... 77

6.10.1 Tree diagram ......................................................................................................................................................... 78

6.10.2 Studies protocol ..................................................................................................................................................... 79

6.10.3 Event table ......................................................................................................................................................... 82

6.11 Photo mode ......................................................................................................................................................................... 83

6.12 Screen printout ................................................................................................................................................................... 83

6.13 Remote inquiry .................................................................................................................................................................... 84

6.14 Help ....................................................................................................................................................................................... 86

Leica CM3600 XP – Cryomacrotome

5

Page 6

Table of contents

6.15 Saving ................................................................................................................................................................................... 86

6.16 Printing labels ..................................................................................................................................................................... 86

6.17 Foot switch .......................................................................................................................................................................... 86

6.18 User log-in / log-out ........................................................................................................................................................... 87

6.19 Quitting the application ..................................................................................................................................................... 87

7. Operating the Leica CM3600 XP ..................................................................................... 88

7.1 Check list.............................................................................................................................................................................. 88

7.2 Switching the instrument on ............................................................................................................................................ 89

7.3 Starting the software......................................................................................................................................................... 89

7.4 Setting the chamber temperature .................................................................................................................................. 89

7.5 Specimen stages ................................................................................................................................................................ 90

7.5.1 Inserting the specimen stage, orientable, with ball-joint ............................................................................. 92

7.5.2 Inserting the specimen stage, non-orientable ................................................................................................ 94

7.6 Knife ...................................................................................................................................................................................... 96

7.6.1 Inserting standard knives .................................................................................................................................... 98

7.6.2 Inserting the disposable blade holder with disposable blade ................................................................... 100

7.6.3 Adjusting the knife angle ................................................................................................................................... 102

7.7 Setting the trimming parameters .................................................................................................................................. 103

7.8 Setting the sectioning parameters ............................................................................................................................... 104

7.8.1 Sectioning the specimen ................................................................................................................................... 104

7.8.2 Collecting the sections ....................................................................................................................................... 104

7.9 Dehydrating the sections ............................................................................................................................................... 106

8. Cleaning and Maintenance .......................................................................................... 108

8.1 Cleaning ............................................................................................................................................................................. 108

8.1.1 Removing the microtome from the cryochamber ......................................................................................... 108

8.2 Maintenance ..................................................................................................................................................................... 110

8.2.1 Oiling 110

8.2.2 Defrosting 111

9. Optional accessories ..................................................................................................... 112

9.1 Ordering information ....................................................................................................................................................... 112

6

Instructions for use, 6v3, RevB – 01/2013

Page 7

Leica CM3600 XP – Cryomacrotome

7

Page 8

1. Important Information

1.1 Symbols in the text and their meanings

Warnings

appear in a gray box and are marked

by a warning triangle.

Useful tips,

i.e. important information for the user,

appear in gray boxes and are marked

by an information symbol.

ENTER

(5)

Buttons and function keys which need

to be pushed on the data entry screen,

are printed in bold capitals.

Numbers in parentheses refer to item

numbers in illustrations.

1.2 Qualification of personnel

1.3 Instrument type

All information contained in this Instructions for

use applies exclusively to the instrument type

indicated on the title page.

Caution!

This Instructions for use is valid ONLY

for the instrument with Prod. No.

0163/08.2010

Refer to the nameplate attached to

the rear side of the instrument.

Only trained laboratory personnel may operate the

Leica CM3600 XP.

All laboratory personnel designated to operate the

Leica instrument must read this Instructions for

use carefully and must be familiar with all technical features of the instrument before attempting

to operate it.

8

Instructions for use, 6v3, RevB – 01/2013

Page 9

1.4 Designated use

1. Important Information

The Leica CM3600 XP is a PLC-controlled and motorized precision

cryomacrotome for large-surface sections, equipped with a convectioncooled cryochamber for deep-freezing, sectioning, storing and freezedrying large biological and industrial specimens.

The instrument is designed for the above described applications only and

must be operated according to the instructions in the present Instructions

for use.

Any use of the instrument not described in this Instructions for

use is considered improper.

If you wish to use the instrument for special applications or modes of

operation not listed in this manual, it is absolutely necessary that you

contact your local Leica representation prior to doing so.

Otherwise, you will loose the Leica warranty on your instrument.

Only trained personnel, skilled in the use of the above-mentioned applications, may operate the Leica CM3600 XP.

Prior to operating the instrument, the operator must thoroughly read and

understand this Instructions for use.

Leica CM3600 XP – Cryomacrotome

9

Page 10

1. Important Information

1.5 Warranty

Leica Biosystems Nussloch GmbH guarantees that the contractual product

delivered has been subjected to a comprehensive quality control procedure based on the Leica in-house testing standards, and that the product is

faultless and complies with all technical specifications and/or agreed characteristics warranted.

The scope of the warranty is based on the content of the concluded agreement. The warranty terms of your Leica sales organization or the organization from which you have purchased the contractual product shall apply

exclusively.

1.6 Service information

If you require technical service or replacement parts, please contact your

Leica sales representative or Leica dealer who sold the product.

Please provide the following information:

• Model name and serial number of the instrument

• Location of the instrument and name of the person to contact

• Reason for the service call

• Date of delivery

1.7 Decommissioning and disposal

The instrument or parts of the instrument must be disposed of according to

existing applicable, local regulations.

10

Instructions for use, 6v3, RevB – 01/2013

Page 11

1. Important Information

Leica CM3600 XP – Cryomacrotome

11

Page 12

2. Characteristics of the Leica CM3600 XP

2.1 Layout of the CM3600 XP

PC

Port and

switch panel

Refrigeration

and control unit

Microtome

(in chamber)

Window Chamber lidEmergency stop switch

Drain valve for

condensation

water

Cryochamber

Knee lever

12

Instructions for use, 6v3, RevB – 01/2013

Page 13

2. Characteristics of the Leica CM3600 XP

Drain valve

Condensation water is drained through the drain valve. The tray at the

drain valve must remain at the instrument at all times and must be emptied regularly.

Refrigeration and control unit

The refrigeration and control unit cools the cryochamber and controls the

microtome and the entire electronics.

Knee lever

The knee lever is used for manual operation of the specimen sledge.

PC

Commercial PC, monitor, keyboard, mouse and internal modem.

Emergency stop switch

Press the emergency stop switch to stop the microtome immediately.

Cryochamber cabinet

The cryochamber cabinet contains the cryochamber which houses the

microtome.

Chamber lid

The chamber lid can be opened completely for maintenance and cleaning

work on microtome and/or cryochamber.

Window

The window is heated and can be opened completely.

Microtome

The microtome is used to section the specimens.

Port and switch panel

The port and switch panel contains the mains switch and several sockets

and ports.

Leica CM3600 XP – Cryomacrotome

13

Page 14

2. Characteristics of the Leica CM3600 XP

2.2 Technical Data

2.2.1 Microtome type

450 C Sliding microtome

Section thickness selection: 1 - 200 μm

Sectioning range: 0 - 450 mm

Max. sectioning speed: 80mm/s

Knife retraction after sectioning stroke: 50 - 250μm

Total vertical stroke of knife: 70mm (standard)

Total vertical stroke of knife: 100mm (version with

Total horizontal stroke: 450mm

Specimen orientation via ball-joint: ca. 5° (x/y/z axis)

Specimen orientation w/large spec. stage

Maximum specimen size (L x W x H): 450 x 150 x 70mm

Maximum specimen size (L x W x H): 450 x 150 x 200mm

Knife holder for steel and

tungsten carbide knives: 160mm

Knife holder for disposable blade holder: 160 mm

Knife (160 mm) with facet angle of: 20°, 35°

extended vertical stroke)

(450 x 150mm)

Rotation around

longitudinal axis (x-axis)

(standard)

(version with extended

stroke)

2.2.2 Control unit

14

The Leica CM3600 XP is equipped with a commercial PC, monitor,

keyboard, mouse and an internal modem. For further information,

please refer to the manual of the PC.

Operating system: XP.

Software: CM3600 XP Version 3.2.2.

Instructions for use, 6v3, RevB – 01/2013

Page 15

2.2.3 Dimensions and weight

Inner (cryochamber L x H x W): 1650 x 720 x 600mm

Outer (L x H x W): 2800 x 1090 x 920mm

Total dimensions with connecting lines:

Outer length (total): 2800 mm

Outer length (chamber only): 1940 mm

Outer length (control unit only): 860 mm

Outer height (total): 1090 mm

Outer height (work surface height): 1050 mm

Outer width: 920 mm

Weight (total, incl. microtome): 660 kg

Weight (microtome only): 190 kg

2.2.4 Electrical connections

380 V / 50 Hz, three-phase

Nominal voltage: 380V AC ± 10 %

Nominal frequency: 50 Hz

Line voltage tolerance: ± 10 %

Power draw: 2400VA

Circuit breaker/ 3 x 8A / 1 x 10A

Power safety switch to DIN IEC 127-2

2. Characteristics of the Leica CM3600 XP

208 V / 60 Hz, two-phase

Nominal voltage: 208 V AC

Nominal frequency: 60 Hz

Line voltage tolerance: ± 10 %

Power draw: 2400VA

Automatic cutout/ 2 x 8A / 1 x 16A

Power safety switch UL-listed

200 V / 50 Hz, two-phase

Nominal voltage: 200 V AC

Nominal frequency: 50 Hz

Line voltage tolerance: ± 10 %

Power draw: 2400VA

Automatic cutout/ 2 x 8A / 1 x 16A

Power safety switch UL-listed

Leica CM3600 XP – Cryomacrotome

15

Page 16

2. Characteristics of the Leica CM3600 XP

200 V / 60 Hz, two-phase

Nominal voltage: 200 V AC

Nominal frequency: 60 Hz

Line voltage tolerance: ± 10 %

Power draw: 2400 VA

Automatic cutout/ 2 x 8A / 1 x 16A

Power safety switch UL-listed

220 V / 60 Hz, two-phase

Nominal voltage: 220 V AC

Nominal frequency: 60 Hz

Line voltage tolerance: ± 10 %

Power draw: 2400 VA

Automatic cutout/ 2 x 8A / 1 x 16A

Power safety switch UL-listed

2.2.5 Refrigeration system - cooling chamber

16

Selectable temperature range: 0° C to -30 °C

at an ambient temperature

of 22°C, closed window

and humidity ≤ 60%: -30°C ±10 % (adjustable

in 1 K increments)

Control accuracy: +1 to -3 K

Electrical power draw: 1160 W

Refrigerating output at -25°C: 1370 W

Nominal pressure: 20bar (maximum value)

Cutoff pressure: 25bar (via Pressostat)

Safety factor: 2, as per UL 1262

Refrigerant: 1100g, refrigerant R404A

Compressor oil: 1220 ccm alpha 22, Kyodo

Defrost: Automatic hot gas defrost, programmable,

2 x automatic hot gas defrost / 24 hours.

Duration: 1 - 15 minutes, manual defrosting as needed.

Instructions for use, 6v3, RevB – 01/2013

Page 17

2.2.6 General parameters

Noise information

2.3 Instrument parts

2. Characteristics of the Leica CM3600 XP

Protective class: I

Pollution degree: 2

Overvoltage installation category: II

A-weighted noise level: 78.5 dB (A)

Distance between sound meter and instrument: 1 meter

Measuring uncertainty: ±1.5 dB (A)

Instrument settings at measurement: Normal instrument

operation with

extraction

The user must wear hearing protection when using the

extraction.

The Leica CM3600 XP consists of a sliding microtome in a large-volume

cryochamber. The instrument is designed for cryosectioning large specimens or for processing specimens with the so-called cryo-planing

technique.

The large-scale heavy-duty microtome is made for sectioning large

biomedical and industrial specimens such as whole animals or large

tissue specimens by applying the sectioning techniques for large-surface

sections. The sturdy construction of the instrument also permits sectioning very hard specimens such as undecalcified bones.

The microtome is housed in a convection-cooled large-volume

cryochamber. The large chamber in connection with the special cooling

system enables dehydration of sections within a very short time.

The low temperatures are achieved and maintained by cold air circulating inside the cryochamber. A fan controls the air circulation speed.

The large specimens are frozen onto metal specimen stages which are

subsequently clamped in the specimen sledge.

Optionally the instrument can be operated with an extraction system

which largely prevents the cryochamber being soiled with section waste.

Leica CM3600 XP – Cryomacrotome

17

Page 18

2. Characteristics of the Leica CM3600 XP

2.4 Function

The motor-driven specimen sledge moves horizontally underneath the

knife, either producing a section (cryosectioning) with each stroke or a

high-quality specimen surface (cryo-planing technique).

Prior to each sectioning stroke, a stepper motor feeds the microtome

knife downwards towards the specimen by a selected amount of microns

(section thickness).

During each return stroke of the specimen sledge, the stepper motor

automatically carries out a knife retraction movement, programmable

between 50 and 250 μm. This protects both the knife edge and the specimen surface from being damaged.

Before starting the next sectioning stroke, the motor lowers the knife

towards the specimen surface by the selected sectioning feed plus the

set value for knife retraction.

Trimming is programmable; the desired section thickness can be

preselected.

The number of sections to be performed during trimming can be programmed via the section counter. When the programmed number of

sections has been carried out, the microtome will stop automatically.

Once the desired specimen block height has been reached, those sections that will actually be used for further examination are collected

manually via the knee lever.

The Leica CM3600 XP is operated via PC and/or manually via the knee

lever. All data entries are made via the PC.

The Leica CM3600 XP features two automatic defrost cycles.

Defrost cycle duration is software-controlled. If the evaporator surface is

already completely deiced before the programmed defrost time is up, the

defrost cycle will be aborted. In addition, manual defrost cycles can be

set as needed.

18

Instructions for use, 6v3, RevB – 01/2013

Page 19

2. Characteristics of the Leica CM3600 XP

Leica CM3600 XP – Cryomacrotome

19

Page 20

3. Safety

The safety and caution notes in this chapter must be observed at all times.

Be sure to read these notes even if you are already familiar with the operation and use of

other Leica products.

3.1 Safety notes

This Instructions for use contains important instructions and information regarding the operational safety and maintenance of the instrument.

The Instructions for use is an important part of

the product, and must be read carefully prior to

startup and use and must always be kept near

the instrument.

If additional requirements on accident prevention and environmental

protection exceeding the scope of

this Instructions for use are imposed

by laws/regulations of the country

of operation, this Instructions for

use must be supplemented by appropriate instructions to ensure

compliance with such

requirements.

The protective devices located on the instrument and the accessories must not be

removed or modified. Only qualified service personnel authorized by Leica may repair

the instrument and access its internal components.

This instrument has been built and tested in

accordance with the safety requirements for

electrical equipment for measurement, control,

and laboratory use.

In order to maintain this condition and ensure safe

operation, the operator must observe all the

instructions and warnings contained in this

Instructions for use.

For current information about applicable standards, please refer to the

CE declaration for the instrument on

our Internet site:

http://www.LeicaBiosystems.com

3.2 Warnings

The safety devices installed in this instrument by the manufacturer only constitute the basis for

accident prevention. Operating the instrument safely is, above all, the responsibility of the owner,

as well as the designated personnel who operate, service or repair the instrument.

To ensure trouble-free operation of the instrument, make sure to comply with the following

instructions and warnings.

20

Instructions for use, 6v3, RevB – 01/2013

Page 21

3. Safety

The protective devices on the instrument must neither be

removed nor modified.

Only connect the instrument to a grounded power socket.

Do not interfere with the grounding function by using an

extension cord without a ground wire.

Use extreme caution when handling microtome knives and

disposable blades.

Handle knives and blades as per manufacturer's directions.

Never operate the instrument in rooms with explosion hazard.

Leica CM3600 XP – Cryomacrotome

During instrument setup / installation do not switch the

instrument on before being instructed to do so by this manual.

While working through the Instructions for use, do not use

either the knife or the specimen block.

The lid of the instrument must always be opened by two

persons. No one must work on the instrument until it has

been ensured that the lid has latched into place.

21

Page 22

3. Safety

Below you find a summary of all warnings contained in this Instructions

for use.

Any use of the instrument not described in this Instructions for

use is considered improper.

Always swing the knee lever upwards before leaving the

instrument.

The chamber lid must be lifted by 2 persons when opened.

When opening the chamber lid, the lid retainer must engage.

Only when the lid is lifted can the user work in the instrument.

Prior to any work involving the knife, microtome or inside

the cryochamber, activate the emergency stop switch.

For further information, refer to chapter 3.3.1.

22

The chamber lid must be closed at all times when the instrument is operated, as otherwise the emergency stop switch is

not accessible.

The user must be able to reach the specimen easily while

working on the microtome. During all work, wear closefitting clothing and use safety glasses.

Caution when using the foldaway extraction!

Before you manipulate the specimen or the knife, the extraction must always be folded all the way to the side. Otherwise,

it could fold back and press your hand against the knife.

Instructions for use, 6v3, RevB – 01/2013

Page 23

3. Safety

Prior to any work involving the knife, microtome or inside the

cryochamber, swing the knee lever upwards.

For any work involving the knife, microtome or inside the

cabinet always wear special protective gloves.

For reasons of safety and accuracy, the maximum trimming

thickness should not exceed 100 μm per section.

When trimming biological material (particularly bone),

section thickness should not exceed 50μm.

Never try to catch or grab the knife.

Never introduce your hands into the space between

specimen and knife.

Leica CM3600 XP – Cryomacrotome

Caution when adjusting the knife holder from

100 to 200mm – a crushing hazard exists.

Radioactive specimen waste must be disposed of according

to the local radiation safety regulations.

For removing the microtome (approx. 190kg) from the

cryochamber, a ceiling crane capable of carrying that weight

should be available.

For safety reasons, we strongly advise you against lifting the

microtome (approx. 190kg) from the cryochamber without

appropriate lifting gear. Do not attempt to lift the microtome

from the chamber manually, even if several persons are there

to help.

23

Page 24

3. Safety

3.3 Safety devices

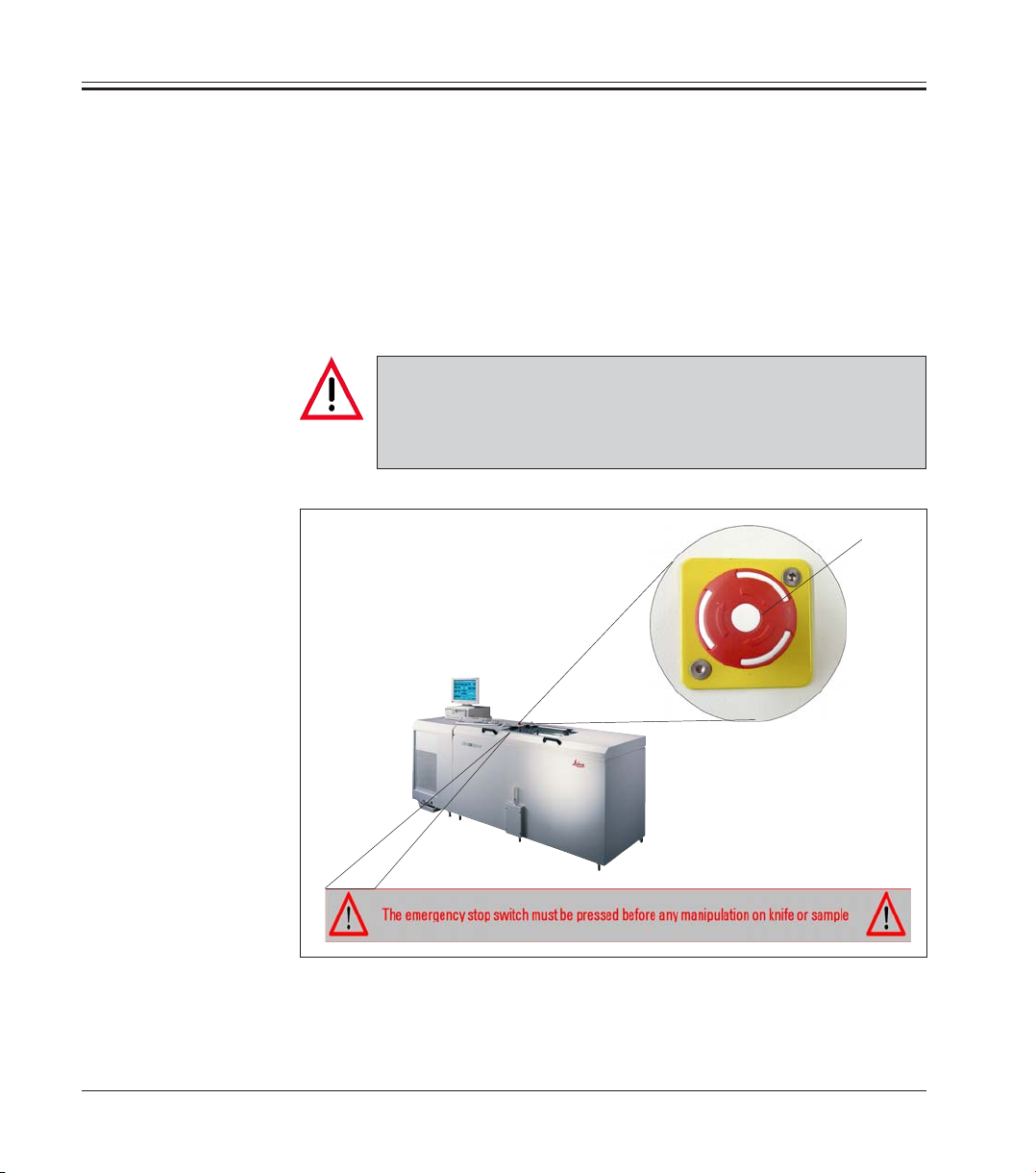

3.3.1 Emergency stop switch

The Leica CM3600 XP is equipped with an emergency stop switch (1)

located on the chamber surface to the left of the window.

Activating the emergency stop switch

Press the Emergency stop switch (1) to stop the microtome immediately.

Always press the emergency stop switch before making modifications to the microtome, knife or specimen (see warning

message below the disc) to prevent accidental activation of

the microtome using the knee lever.

1

24

Resetting the emergency stop switch.

To reset the emergency stop switch (1) turn it in the direction of the

arrow until it is released upwards back to its original position.

Instructions for use, 6v3, RevB – 01/2013

Page 25

3.3.2 Knee lever

3. Safety

3.3.3 Window

3.3.4 Cryochamber

1

Never leave the instrument unattended when

the knee lever is folded out (1) to prevent the

microtome from being set in motion accidentally.

Always swing the knee lever upwards before leaving the instrument.

The window is heatable and equipped with a

lock button (2). To open the window, lift lock

button (2) slightly upwards and turn it by 180°.

2

Before opening the large chamber lid, first

close the window and lock with the lock

button (2).

When opening the chamber lid, make sure the

lid retainer (3) engages to prevent the chamber

3

lid from falling.

Leica CM3600 XP – Cryomacrotome

When opening the chamber lid,

the lid retainer must engage.

25

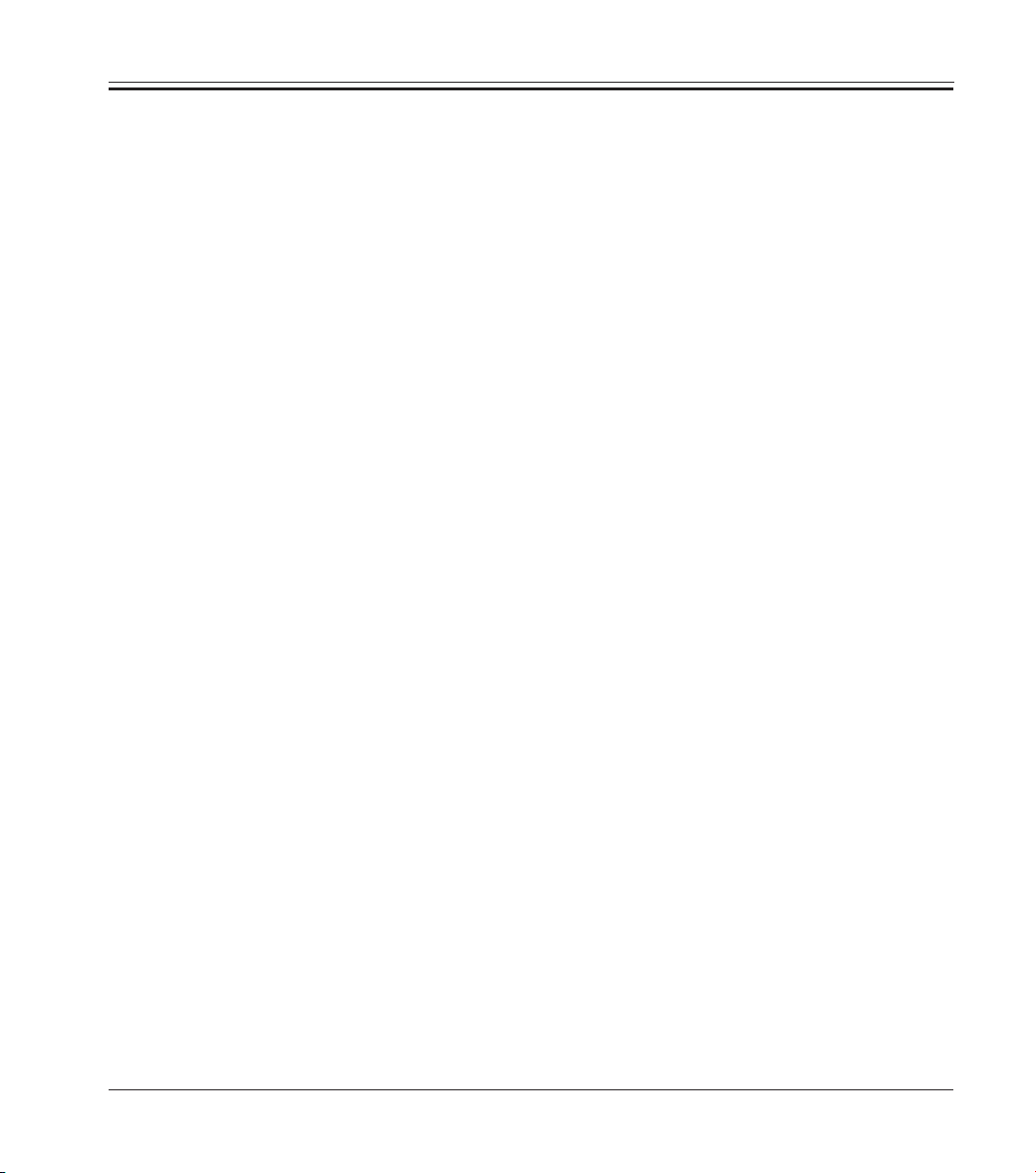

Page 26

4. Site requirements

4.1 Site requirements at place of installation

• Relative humidity not over 60 % and non-condensing.

• Room temperature consistently between +5 °C and +22°C.

• Room volume must be at least 30 m3.

• The substrate must have sufficient load capacity and rigidity for the weight

of the instrument, 660kg.

• Do not operate the instrument in rooms with explosion hazard.

• The instrument is designed for indoor use only.

• The instrument must be connected to a

grounded socket. Only use the cable provided;

never use an extension cable.

• The power plug and emergency stop switch

must be without obstruction.

• Avoid vibrations, direct sunlight and heavy

variation in temperature.

• Installation elevation up to 2000 m above sea

level.

If possible at all, the room should be air-conditioned. If ambient conditions are not maintained

as specified, instrument performance may be

negatively affected (lowest specified temperature

may not be reached, frost may accumulate).

Approx. 3.5 m

All transport paths for the Leica CM3600 XP must

be at least 1.50 m wide; especially doorways must

have that width. This specification already takes

into account the swivel range of the instrument

when passing through doors (if it is possible to

keep the instrument straight while passing though

doors, a door width of 95cm is sufficient). The

Leica CM3600 XP has a total length (refrigeration

and control unit and cryochamber) of 2.70m or,

with the connecting lines on the left side of the

refrigeration and control unit, of approx. 2.80m,

i.e. a minimum width of the installation wall of

2.90m is required. Ideally the wall should measure 3.50 m more to provide easy access to the

left side of the unit for technical service work. The

required minimum distance between the back

panel of the instrument and the wall is 30cm, the

recommended distance is 50cm.

Installation wall, ideal dimensions (view from above)

0.5 m

26

Approx. 0.8 m

Leica CM3600 XP

Approx. 2.7 m

High room temperatures and excessive

air humidity affect

the cooling capacity

of the instrument.

Instructions for use, 6v3, RevB – 01/2013

Page 27

4.2 Electrical connections

4. Site requirements

4.3 Other connections

Country: Europe USA Japan

Installation cord cross section: 2.5mm

2

2.5mm

2

2.5mm

2

Fuse/connection: 16 A/380 V 25 A/208 V 25 A/200 V

Power cable length is 3m

Leakage current > 3.5 mA

A second protective conductor terminal is located on the instrument.

Both terminals must be used.

There must not be any differences in potential between the two

protective conductor terminals.

Telephone connection

For remote failure diagnosis, a telephone connection must be available to

hook up the modem. The phone connection must be direct, i.e. must not

be controlled by an additional computer (server).

Compressed air supply

If you want to use the optional extraction system:

Compressed air supply for the extraction system (p = 5 - 8 bar) must be

available.

Leica CM3600 XP – Cryomacrotome

27

Page 28

5. Installation

5.1 Unpacking and installation

Only duly trained personnel may unpack and install the Leica CM3600 XP.

Please contact your local Leica sales organization for appropriate advice.

5.2 Standard delivery

The standard delivery includes:

• 1 Leica CM3600 XP, consisting of:

• Cabinet

• Refrigeration and control unit

• PC (computer, monitor, keyboard, mouse)

• Microtome 450 C with integrated knife holder

• 1 Disposable blade holder 157 AR

• 1 Dispenser with 10 disposable blades, type H 45 L

• 1 Roll of section collecting tape, type 810

• 1 Roll of section collecting tape, type 4248

• 1 Bottle of low temperature oil PDP 40, 500 ml

• 1 Positioning tool for disposable blade holder

28

• 1 Tool set, consisting of:

• Allen keys, set of 7, in different sizes: 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0

• Fork wrenches, set of 2, sizes 15 and 17

• 1 Syringe, 10 ml with injection needle,

• 1 Instructions for use

• 1 Set of manuals for PC

• 1 Pressure plate

• 1 Plug for alarm contact

• 1 Pair of protective gloves

Check the delivery carefully against the packing list, delivery

note and your order.

If you notice any discrepancies, please contact your local

Leica sales office or dealer immediately.

Instructions for use, 6v3, RevB – 01/2013

Page 29

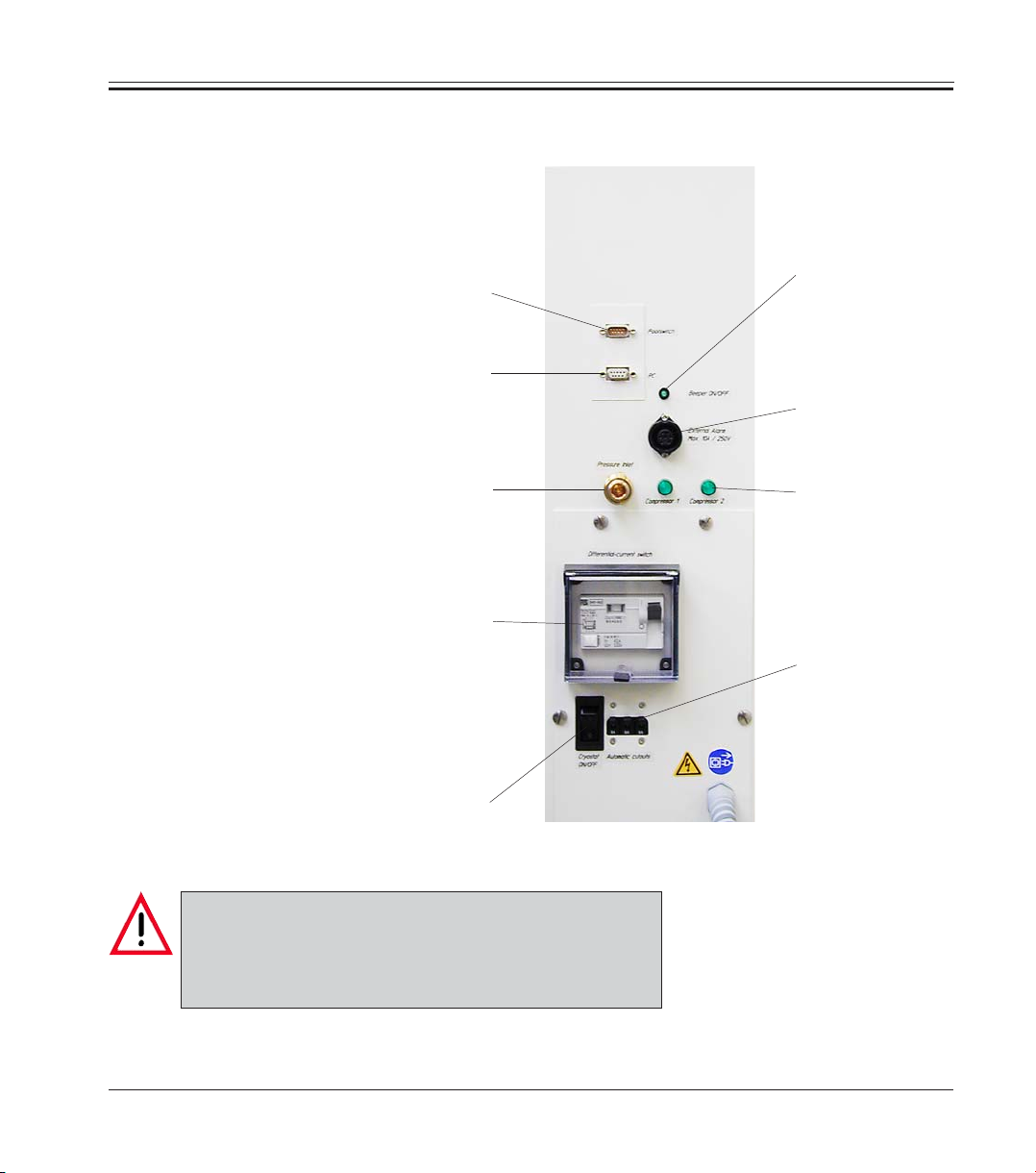

5.3 Port and switch panel

5. Installation

Port and switch panel

Interface

RJ 45

Connection for

foot switch

Connection for

compressed air

GFCI

switch

Main switch

Switch for

local

alarm signal

Connection for

external alarm

Control

lamps

Circuit

breaker

Caution!

Only the POWER SWITCH disconnects the instrument

from the power supply!

To do so, move the switch into the "0" position.

Leica CM3600 XP – Cryomacrotome

29

Page 30

5. Installation

5.3.1 Port and switch functions

Main switch

In the "0" position, this switch disconnects the instrument from the power

supply.

Connection for footswitch

Optionally, a foot switch can be connected for the purpose of section

thickness documentation (GLP).

RS 232 interface

The RS 232 interface links the PC to the PLC.

Switch for local alarm signal

To activate the local alarm function, press the alarm signal switch.

The green LED in the switch button lights up.

To deactivate the local alarm function, press the alarm signal switch

once again. The green LED in the switch button is extinguished.

30

Compressed air supply

Connection of compressed air hose to extraction unit.

Control lamps

Indicate function of the refrigerating sets.

Instructions for use, 6v3, RevB – 01/2013

Page 31

5. Installation

Connection for external alarm

Forwarding an external alarm.

The external alarm is triggered, when the chamber temperature exceeds

the selected value.

When the temperature dips back down below the defined threshold, the

external alarm is immediately switched off.

Loss of mains power supply (instrument switched off or power failure) will

also trigger the external alarm.

On return of mains supply the alarm is automatically switched off.

The instrument has a socket via which an external alarm can

be output (see Fig. on p. 29 and wiring diagram). The maximum permitted voltage that can be switched is 250V.

Because a compatible plug is provided with the instrument,

the user must make a corresponding connection onsite.

Important!

The connection of an alarm to the plug provided must be

carried out by trained personnel if the voltages are greater

than 33V AC or 70 V DC.

Wiring the connection for external alarm in the instrument

21

24

Leica CM3600 XP – Cryomacrotome

Rel

-g1

22

1

Socket

CA 6

5

The wiring diagram shown here illustrates how the socket for the external

alarm is wired in the instrument.

The specified digits correspond to those

on the plug provided.

3

31

Page 32

5. Installation

5.3.2 Fuses

GFCI switch

Protects the entire instrument.

Automatic cutout

Protects the refrigerating sets and all electronic components.

The Leica CM3600 XP is equipped with the following fuses:

• GFCI switch

• Automatic cutout

• Fuse protecting the main power switch

GFCI switch

After the GFCI switch has been activated, it will be in the lower position.

To switch it back on, flip the GFCI switch upwards.

To check the

function, trigger

the GFCI switch

once a month.

GFCI switch

32

Automatic cutout

After the automatic cutout has been activated, it will be in the lower

position. To activate, push the switch upwards.

Automatic cutout

Instructions for use, 6v3, RevB – 01/2013

Page 33

5.4 PC

Fuse for

power

switch

5. Installation

Fuse protecting the mains switch

If the mains switch fuse has blown, please call Technical

Service.

The Leica CM3600 XP is equipped with a commercial PC, monitor,

keyboard, mouse and an internal modem. For further information,

please refer to the manual of the PC.

If the PC is provided by the user, it must fulfill the following requirements:

Processor: Intel Celeron or Pentium 5

Clock frequency: >= 800 MHz

Hard disk drive: >= 500MB

Operating system: Microsoft Windows 2000 or XP

Screen resolution: 1024 x 768 pixels

Keyboard and mouse

Leica CM3600 XP – Cryomacrotome

33

Page 34

6. Software

6.1 Start and log-in procedure

Requirements:

PC must be on and the Microsoft Windows XP® operating system must

have booted and be ready for service.

Registration mask

Doubleclicking on Icon "CM3600 XP" starts the application.

34

1. Type the user name in the identification field.

2. Type the correct password in the password field.

3. Click the OK button to complete registration.

After successful registration, the "Main window" will open. For further

information, refer to chapter 6.4.

After 5 faulty registration attempts, access to the unit will

be denied. Only an Administrator can remove the lock.

For further information, refer to chapter 6.5.2.

Instructions for use, 6v3, RevB – 01/2013

Page 35

6.2 Description of the window elements

The window surface is divided into several areas:

• Title bar

• Tool bar

• Work space

• Status bar

6. Software

Title bar

Tool bar

Work space

Status bar

6.2.1 Title bar

The "Title bar" displays information on instrument name and software

version number.

6.2.2 Tool bar

The "Tool bar" provides quick access (via mouse-click) to individual

software functions.

When clicking on an icon, the corresponding window will open up.

Active icons will light up in green.

Leica CM3600 XP – Cryomacrotome

35

Page 36

6. Software

Icons

Clicking on the icon opens the "Main window", which also

opens up after completion of the start and log-in procedure.

Clicking on the icon opens the "Parameter settings" window.

Clicking on the icon opens the "Temperature curve" window.

Clicking on the icon opens the "Chronological event list"

window.

Clicking on the icon opens the "Alarm list" window.

Clicking on the icon switches the chamber illumination on or

off. Active icons will light up in yellow.

Clicking on the icon opens the "Section documentation"

window.

36

Clicking on the icon activates the "Photo mode".

Clicking on the icon creates a printout of the current screen.

Clicking on the icon opens the "Remote inquiry" window.

Clicking on the icon opens the "Help" window.

Clicking on the icon opens the "Saves" window.

When activated, the icon will light up in green.

Instructions for use, 6v3, RevB – 01/2013

Page 37

6. Software

Clicking on the icon opens the "Label printing" window.

When activated, the icon will light up in green.

Clicking on the icon activates the "Foot switch". When activated, the icon will light up in green and the current sectioning

data will be saved.

The "Stop" icon appears immediately when the emergency

stop switch is pressed - it will be blinking in red color. The

instrument will be inoperational until the operator acknowledges the corresponding error message in the "Alarm list"

window.

For further information, refer to chapter 6.8.

Clicking on the "Log off" icon logs off the user currently logged

on. Clicking again reopens the registration mask for Log-in.

Clicking on "Quit" closes the application.

Clicking on the icon opens a window providing information on

software version number, date, copyright and serial number of

the application.

6.2.3 Work space

In the work space area all control entries and settings are made.

Display format may vary depending on the icon selected in the tool bar.

6.2.4 Information bar

The information bar displays the following information:

• the currently registered user,

• instrument name and software version number,

• number of sections carried out so far,

• name of laboratory.

Leica CM3600 XP – Cryomacrotome

37

Page 38

6. Software

6.3 Initialization

To be able to work with the instrument, after completion

of the start and log-in procedure the microtome must be

initialized.

For initialization, proceed as follows:

1. In the "Main window", click on the INIT button blinking in yellow color

(in "Mode" field).

The "Safety check - initialization" window will open up.

38

2. Check whether you can confirm each safety query - if not, carry out

the required actions. Subsequently, confirm each safety query by

mouse click on the corresponding check box.

3. Having confirmed all safety queries, click on OK.

The microtome will then be initialized:

• The knife holder moves to the uppermost position.

• The microtome sledge moves to the end positions on the right and left.

Instructions for use, 6v3, RevB – 01/2013

Page 39

6. Software

Once initialization has been started, it can only be interrupted

by pressing the emergency stop switch. For further information, refer to chapter 3.4.1.

After the initialization procedure has been completed, the color of the

INIT button will first change from yellow to green and after a few seconds, the caption on the button will change from INIT to AUTOMATIC.

The microtome is now ready for service. For further information, refer to

chapter 6.4.9.

Leica CM3600 XP – Cryomacrotome

39

Page 40

6. Software

6.4 Main window

The main window either opens up automatically after completion of the start and log-in procedure or by clicking on the

"Main window" icon.

40

The work space of the main window is divided as follows:

• Chamber temperature

• Time

• Automatic defrost

• Automatic dehydration

• Knife movement

• Extraction

• Section program

• Sledge speed

• Mode (of operation)

• Cutting window

Instructions for use, 6v3, RevB – 01/2013

Page 41

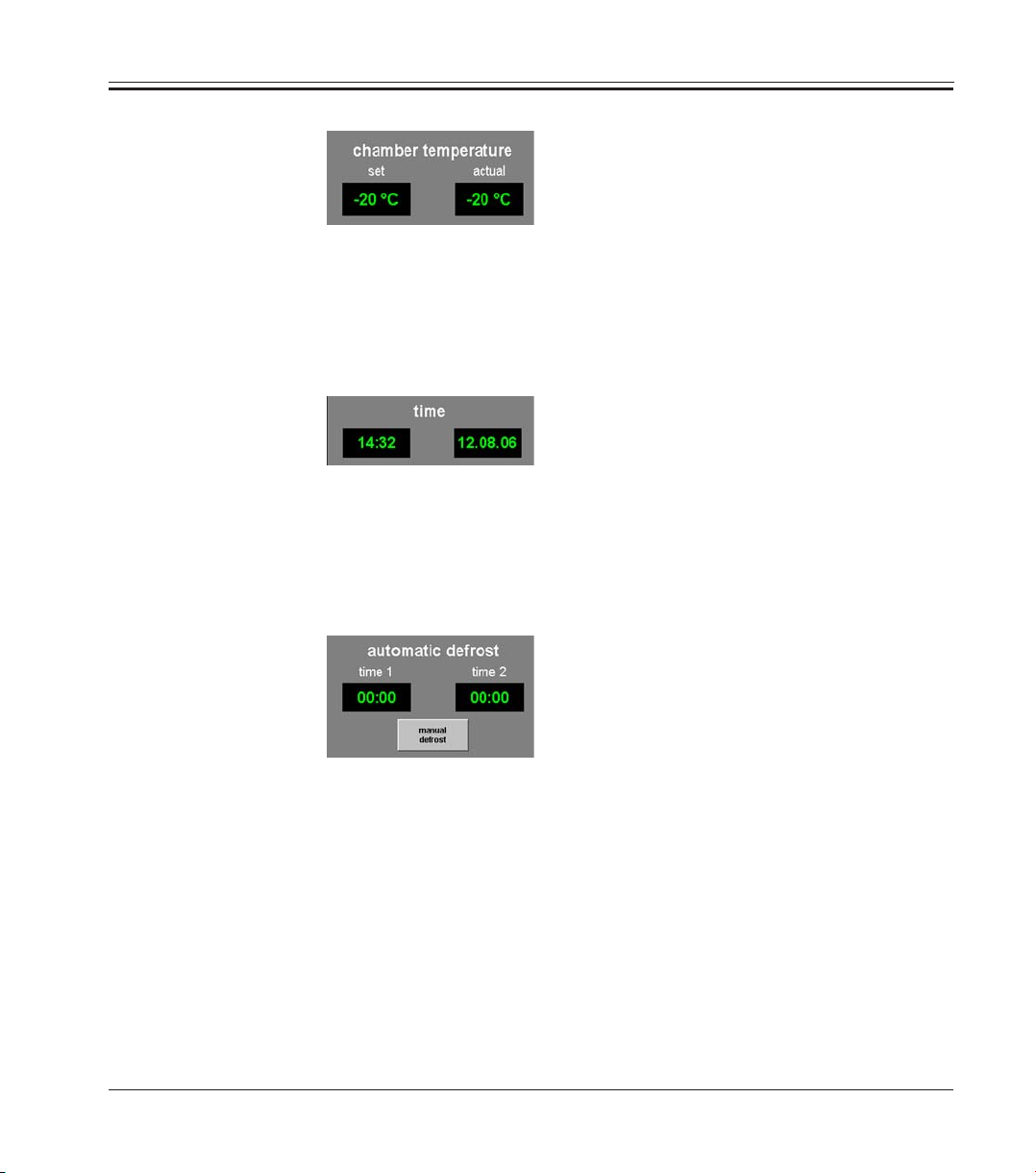

6.4.1 Chamber temperature

Indication of set or actual chamber temperature.

See chapter 6.5.1 "Parameter settings" on how to configure these

settings.

6.4.2 Time

Indication of real time and date.

See chapter 6.5.1 "Parameter settings" on how to set the chamber

temperature.

6.4.3 Automatic defrost cycle

6. Software

Indication of start time of 1st or 2nd automatic defrost cycle.

See chapter 6.5.1 "Parameter settings" on how to configure these

settings.

Manual defrost button

Clicking on this button immediately starts a defrost cycle. During the

defrost cycle, the button blinks in yellow color. Clicking on the button

once more aborts the defrost cycle.

Leica CM3600 XP – Cryomacrotome

41

Page 42

6. Software

6.4.4 Automatic dehydration

Indication of start time, start date and duration of the automatic

dehydration.

See chapter 6.5.1 "Parameter settings" on how to configure these

settings.

MANUAL DEHYDRATION button

Clicking on this button immediately starts a dehydration cycle. Clicking on

this button once more, stops dehydration. When activated, the button

blinks in yellow color.

If the temperature is to be decreased during automatic dehydration,

this must be specified in the "Parameter settings" window. For further

information, refer to chapter 6.5.1.

6.4.5 Knife movement

42

Indication of section and retraction thickness. Actual indicates the

current position of the knife holder. Set indicates the desired position

of the knife holder.

Instructions for use, 6v3, RevB – 01/2013

Page 43

6. Software

The red "Retraction" caption is displayed only during the return stroke of

the sledge.

The "Knife movement" icons can be activated only in

MANUAL Mode. For further information, refer to chapter 6.4.9.

The entry limit for actual and set position may vary between

70 - 200μm depending on the instrument version. The standard

version is shipped with a limit of 70 μm.

To modify any of the settings, mouse-click on the corresponding icon.

Entries are completed by pressing the ENTER key.

KNIFE UP button on the left

Clicking on this icon moves the knife holder upwards for a short while.

If you click on and hold this icon, the knife holder will continue to move

upward until the left mouse button is released. While active, the icon

blinks in yellow color.

KNIFE DOWN button on the left

Clicking on this icon moves the knife holder downwards for a short while.

If you click on and hold this icon, the knife holder will continue to move

downward until the left mouse button is released. While active, the button

lights up in yellow.

KNIFE UP button on the right

Clicking on the KNIFE UP button on the right activates the corresponding

function. The knife holder will move upwards until reaching the upper

limit position. To stop the knife movement, click on the button once more.

When activated, the button will light up in green.

Leica CM3600 XP – Cryomacrotome

43

Page 44

6. Software

KNIFE DOWN button on the right

Clicking on this button moves the knife holder fast downwards for a short

while. If you click on and hold this button, the knife holder will continue to

move downward until the left mouse button is released. While active, the

button lights up in yellow.

PRESELECTION button

Clicking on this button activates the "Set position" display. Click on the

displayed value to change the setting. While active, the icon lights up in

green color.

START/STOP button

The START/STOP button can be activated only when the PRESELECTION

button is active. Clicking on START/STOP moves the knife holder so the

selected set position. When activated, this button will light up in green.

Clicking on this button once more stops the knife holder.

Once the knife holder has reached the upper limit position,

both KNIFE UP buttons blink in green color.

Once the knife holder has reached the lower limit position,

both KNIFE DOWN buttons blink in yellow color.

44

Once the set position has been reached, it can only be left

by activating the knee lever. For further information, refer to

chapter 3.4.2. A corresponding message will appear on the

screen.

Instructions for use, 6v3, RevB – 01/2013

Page 45

6.4.6 Extraction system

6.4.7 Sectioning program

6. Software

The extraction is active only if an extraction device

is connected to the instrument. For further information, refer

to chapter 9.1.

Button EXTRACTION ON/OFF in continuous mode

Clicking on this button activates or deactivates continuous extraction.

When activated, the button will light up in green.

Button EXTRACTION ON/OFF in intermittent mode

Clicking on this button activates or deactivates intermittent extraction.

When activated, the button will light up in green.

Indication of set or actual number of sections.

To modify any of the settings, mouse-click on the corresponding button.

Entries are completed by pressing the ENTER key.

PROGRAM button

Clicking on this button activates the set value display.

Leica CM3600 XP – Cryomacrotome

The buttons can be activated only in AUTOMATIC Mode.

Clicking on the START/STOP button located in the "Mode"

field starts or stops the sectioning program. For further

information, refer to chapter 6.4.9.

45

Page 46

6. Software

6.4.8 Sledge speed

Click on the activated set value field to modify the setting.

PAUSE button

Clicking on this button stops the sectioning program. Clicking on the

button once more restarts the sectioning program, resuming the current

section where if was left off.

Indication of current sectioning or return stroke speed in mm/s

(millimeters per second). To modify any of the settings, click on the

corresponding value.

The graphic display is active only while sectioning is in progress.

The currently selected sectioning and return stroke speed are displayed

via a green bar on a scale from 0 - 80mm/s.

46

Instructions for use, 6v3, RevB – 01/2013

Page 47

6.4.9 Mode of operation

6. Software

To be able to work with the instrument, after completion of the start and

log-in procedure the microtome must be initialized. For further information, refer to chapter 6.3.

Buttons prior to initialization

Buttons after initialization

INIT button

Clicking on INIT opens the "Initialization" window. For further information,

refer to chapter 6.3. Prior to initialization, the button blinks in yellow color.

After the initialization procedure has been completed, the color of the

INIT button will change from yellow to green. After a few seconds, the

caption on the button will change from INIT to AUTOMATIC.

AUTOMATIC button

Clicking on this button switches the instrument to automatic mode. When

activated, the button will light up in green.

MANUAL button

Clicking on this button switches the instrument to manual mode. When

activated, the button will light up in green.

START/STOP button

This button can only be activated in automatic mode, where it starts or

stops the sectioning program. When activated the START/STOP and

AUTOMATIC buttons will light up in green.

Leica CM3600 XP – Cryomacrotome

47

Page 48

6. Software

6.4.10 Cutting window

Indication of the left and right block edge, graphically displayed by blue

lines. They indicate the maximum horizontal stroke of the microtome

sledge on a scale from 0 - 500mm.

Indication of the actual position of the microtome sledge. The sledge

position is graphically displayed by the green line.

To modify any of the settings, mouse-click on the "Actual position"

indication.

Clicking on the icons on the left and right of the scale lets you

adjust the left and/or right half of the block to the actual

microtome sledge position indicated.

LEFT BLOCK EDGE button

Clicking on the inscription LEFT BLOCK EDGE opens up an entry window.

Select the left limit position to where the microtome sledge can move on

a scale from 0 - 500 mm.

48

RIGHT BLOCK EDGE button

Clicking on the inscription RIGHT BLOCK EDGE opens up an entry

window. Select the right limit position to where the microtome sledge can

move on a scale from 0 - 450mm.

Instructions for use, 6v3, RevB – 01/2013

Page 49

6.5 Parameter settings

6. Software

Click on "Parameter settings" to open the corresponding

window.

The work space of the parameter settings window is divided as follows:

• Parameter setting

• Password list

• Configuration

• Reference voltages

• Language selection

• Initialization

Leica CM3600 XP – Cryomacrotome

49

Page 50

6. Software

6.5.1 Parameter setting

Set chamber temperature

Click on this indication to change the currently selected value.

Temperature values from -30 to +1°C can be selected.

Alarm temperature

Click on this indication to change the currently selected value.

Temperature values from -25 to -5°C can be selected.

50

The alarm temperature should not be too close to the set

chamber temperature. If the alarm temperature is too close to

the set chamber temperature, an alarm can be triggered

simply when working with the instrument during a prolonged

period of time or during the daily defrost cycle. A temperature

difference of approx. 5 K (Kelvin) is recommended.

Instructions for use, 6v3, RevB – 01/2013

Page 51

6. Software

Time and date

Indication of time and date. Clicking on this indication opens the dialog

box "System time".

Clicking on individual parameters (day, month, year,

hour or minutes) the corresponding setting can be changed.

Click OK to confirm.

Start time 1 defrost

Indication of start time of the 1st automatic defrost cycle.

Clicking on this indication opens the dialog box "defrost time 1".

Click on individual parameters (hours or minutes) to change the corresponding settings. Click OK to confirm.

Start time 2 defrost

Indication of start time of the 2nd automatic defrost cycle. Clicking on this

indication opens the dialog box "defrost time 2".

Click on individual parameters (hours or minutes) to change the corresponding settings. Click OK to confirm.

Button active/inactive

Clicking on this button activates or deactivates the 2nd automatic defrost

cycle.

Leica CM3600 XP – Cryomacrotome

51

Page 52

6. Software

Dehydration date

Dehydration start time

Dehydration duration

Indication of start date and time, and duration of the automatic dehydration cycle. Clicking on one of the parameters opens the dialog box

"Dehydration time".

Click on individual parameters (day, month, year, hour or minutes) to

change the corresponding settings.

The desired duration of the dehydration procedure can be selected in the

duration field. Values from 1 - 48h (hours) can be selected. Click OK to

confirm.

To speed up the dehydration procedure, the dehydration

cryochamber temperature can be lowered. This can be done

via the "Dehydration T-reduction" indication.

52

Dehydration T-reduction

Indication of temperature reduction for dehydration. Click on this

indication to change the currently selected value. Values from 0 - 20K

can be selected.

Section thickness

Indication of section thickness. Click on this indication to change the

currently selected value. Values from 0 - 200μm can be selected.

Retraction value

Indication of the currently selected retraction value. Click on this

indication to change the currently selected value. Values from

50 - 250μm can be selected.

Instructions for use, 6v3, RevB – 01/2013

Page 53

6. Software

Cutting speed

Return speed

Indication of cutting and return speed. Click on one of the indications to

change the currently selected value. Values from 0 - 80 mm/s can be

selected.

Left block edge

Right block edge

Indication of left and right block edge. Click on the individual indication to

change the currently selected value. Values from 0 - 500mm/s can be

selected. For further information, refer to chapter 6.4.10.

Photo position dwelling time

Photo position triggering time

Indication of photo position dwell and triggering time. Click on the individual indication to change the currently selected value. Values from

0 - 255s (seconds) can be selected. For further information, refer to

chapter 6.11.

EDIT button in the password list

Clicking on this button opens the "User configuration" window. For further

information, refer to chapter 6.5.2.

EDIT button in the configuration field

Clicking on this button opens the "Configuration" window. For further

information, refer to chapter 6.5.3.

Leica CM3600 XP – Cryomacrotome

53

Page 54

6. Software

6.5.2 Password list

To access the "User configuration", the registered user must

be an administrator.

The "user configuration" indication consists of the following columns:

54

• No.

Indication of the program-controlled running number.

• Active

Indication of status of the user selected. Active users are displayed

with an "X".

• User name

Indication of the user name, which is introduced in the identification

field during the start and log-in procedure.

• Full name

Indication of full user name.

• User rights

Indication of the corresponding access right. The administrator has

full access to all application functions. Users have only limited access.

Instructions for use, 6v3, RevB – 01/2013

Page 55

6. Software

CLOSE button

Clicking on this button closes the "User configuration" window.

Doubleclicking on a line in the configuration indication

opens the dialog box "User configuration".

In the "user configuration" dialog box the following settings can be

selected:

• No.

Indication of the running number. No changes can be made in this

field.

• Active

Clicking on the check box sets the user status to "active". Only after

this step can a user successfully register via the start and log-in

procedure.

• User name

Enter the desired user name. This must not be more than

10 characters (numeric or alphanumeric) long.

• Full name

Enter full first and last name of user.

Leica CM3600 XP – Cryomacrotome

55

Page 56

6. Software

• User rights

Click on the USER RIGHTS line to open a drop down menu. User

property "Administrator" or "User" can be selected.

Administrators have full access to all application functions.

Users do not have access to the password list and to the

configuration parameters in the "Parameter settings"

window.

• Identification

Type in the identification which is needed for the start and log-in

procedure.

• Confirm identification

Repeat the identification.

DELETE button

Clicking on this button deletes the selected user without any prior safety

query.

OK button

Clicking on this button saves the entries and closes the "User configuration" dialog box.

56

CANCEL button

Clicking on this button closes the "User configuration" dialog box. Any

changes made are not saved.

Instructions for use, 6v3, RevB – 01/2013

Page 57

6.5.3 Configuration

6. Software

To access "Configuration", the registered user must be an

administrator.

The "Configuration" window contains the following tabs:

• Text main study

• Text substudy

• Measured values

• General

• Labels

• Comments

OK button

Clicking on this button saves the entries and closes the "Configuration"

dialog box.

CANCEL button

Clicking on this button closes the "Configuration" window without saving

any of the changes made.

Leica CM3600 XP – Cryomacrotome

57

Page 58

6. Software

Tabs "Text main study" and "Text substudy"

The structure of the two tabs is identical. A header and 7 freely selectable comments for each main and/or substudy can be defined.

The text entered into the 8 entry fields is copied into the dialog box for

creating main studies and substudies. Each individual text can consist of

up to 30 characters. For the configuration of a main study or substudy see

chapter 6.10.

58

Tab "Measured values"

Select the measurements to be shown in the "Data function" window after

selecting a main study or substudy.

Instructions for use, 6v3, RevB – 01/2013

Page 59

6. Software

For the configuration of a main study or substudy see chapter 6.10.

The following measured values can be selected:

• Set chamber temperature

• Actual chamber temperature

• Alarm temperature

• Set section thickness

• Actual section thickness

• Knife holder position

• Dehydration

• Comment

Tab "General"

The "General" tab contains the following entry fields:

• Company/lab

• Printer for label printing

• Font size

• Printer for protocoling

• Printer for hardcopies

• Path for export

• Millitron

• Activate millitron

Leica CM3600 XP – Cryomacrotome

59

Page 60

6. Software

Company/lab

Enter the name of the company or the laboratory. The name will be

displayed in the "information bar", on the right side, see chapter 6.2.4.

Printer for label printing

Clicking on this line opens a drop down menu. If a printer for label printing

is connected, it can be selected in this menu.

Font size

Clicking on this line opens a drop down menu. Here you can select the

desired font size for the labels.

Printer for protocoling

Clicking on this line opens a drop down menu. If a printer for protocoling

is connected, it can be selected in this menu.

Printer for hardcopies

Clicking on this line opens a drop down menu. If a printer for hardcopies

is connected, it can be selected in this menu.

If no printer can be selected, a printer must be retroinstalled

in the PC's Microsoft Windows XP® operating system.

60

Path for export

Clicking on the "Export path" symbol opens the dialog box "Path

for export".

Here you can select a directory where you want to save the

data.

Instructions for use, 6v3, RevB – 01/2013

Page 61

6. Software

The export file is filed as a text file and according to the export path

selected.

Millitron

Provided an external Millitron measuring device is connected to the PC,

the corresponding serial connecting port can be selected via the drop

down menu.

Activating the millitron

Clicking on the check box activates the external millitron measuring

device.

"Labels" tab