Page 1

Instructions for Use

Leica CM1850, V2.6, English – 10/2012

Order No. 14 0471 85101 RevC

Always keep this manual near the instrument!

Read carefully prior to operating the instrument!

Leica CM1850

Cryostat

Page 2

Page 3

INFORMATION

The information, numerical data, notes and value

judgments contained in this manual represent the

current state of scientific knowledge and stateof-the-art technology as we understand it following thorough investigation in this field. We are

under no obligation to update the present manual

periodically and on an ongoing basis according

to the latest technical developments, nor to provide our customers with additional copies, updates etc. of this manual.

For erroneous statements, drawings, technical illustrations etc. contained in this manual we exclude liability as far as permissible according to

the national legal system applicable in each individual case. In particular, no liability whatsoever

is accepted for any financial loss or consequential damage caused by or related to compliance

with statements or other information in this

manual.

Statements, drawings, illustrations and other information as regards contents or technical details of the present manual are not to be considered as warranted characteristics of our

products.

These are determined only by the contract provisions agreed between ourselves and our

customers. Leica reserves the right to change

technical specifications as well as manufacturing processes without prior notice. Only in this

way is it possible to continuously improve the

technology and manufacturing techniques used

in our products.

This document is protected under copyright laws.

Any copyrights of this document are retained by

Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods – including any electronic systems and media – requires

express prior permission in writing by Leica

Biosystems Nussloch GmbH.

For the instrument serial number and year of

manufacture, please refer to the name plate at

the back of the instrument.

© Leica Biosystems Nussloch GmbH

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Phone: +49 (62 24) 143-0

Fax: +49 (62 24) 143-268

Internet: http://www.LeicaBiosystems.com

Leica CM 1850 – Cryostat

3

Page 4

Table of contents

1. Important Information ............................................................................................................................ 6

1.1 Symbols used in this manual and their meaning ........................................................................................ 6

1.2 Qualification of personnel ...............................................................................................................................6

1.3 Designated use ................................................................................................................................................. 6

1.4 Instrument type: ............................................................................................................................................. 6

2. Safety ........................................................................................................................................................ 7

2.1 Safety features .............................................................................................................................................. 7

2.1.1 Locking the handwheel ................................................................................................................................ 7

2.1.2 Knife guard ..................................................................................................................................................... 8

2.2 General information on instrument design and safe handling .................................................................8

2.3 Operating conditions .................................................................................................................................... 9

2.4 Operating the instrument ............................................................................................................................. 9

2.5 Cleaning and disinfection .......................................................................................................................... 10

2.6 Removal of the microtome .........................................................................................................................10

2.7 Maintenance ................................................................................................................................................ 11

3. Technical data ...................................................................................................................................... 12

4. Unpacking and installation................................................................................................................. 14

4.1 Site requirements ........................................................................................................................................ 14

4.2 Transport to the desired location .............................................................................................................14

4.3 Standard delivery ........................................................................................................................................ 15

4.4 Handwheel assembly ................................................................................................................................. 16

5. Setup ....................................................................................................................................................... 17

5.1 Connection to mains power ...................................................................................................................... 17

5.2 Prior to operation ........................................................................................................................................ 17

5.3 Leica CM1850 - Overview .......................................................................................................................... 18

5.4 Mains switch and automatic mains fuse ................................................................................................ 20

5.5 Turning the instrument on ......................................................................................................................... 20

6. Control panel operation ....................................................................................................................... 21

6.1 Control panel 1 ............................................................................................................................................. 21

6.2 Programming the desired values ............................................................................................................. 21

6.2.1 Setting the time ............................................................................................................................................ 21

6.2.2 Setting the automatic defrost time (cryochamber) ..............................................................................22

6.2.3 Selecting the cryochamber temperature ............................................................................................... 22

6.2.4 Activation of the Peltier element .............................................................................................................. 23

6.2.5 Manual defrosting of the quick freeze shelf .......................................................................................... 23

6.2.6 Manual defrosting of the cryochamber .................................................................................................. 24

6.3 Display lock .................................................................................................................................................. 24

6.4 Control panel 2 - Electric coarse feed .....................................................................................................25

4

Instructions for use V 2.6 – 10/2012

Page 5

Table of contents

7. Daily use of the instrument ................................................................................................................. 26

7.1 Specimen freezing ...................................................................................................................................... 26

7.1.1 Quick freeze shelf ........................................................................................................................................ 26

7.1.2 Stationary heat extractor ........................................................................................................................... 26

7.2 Specimen discs ........................................................................................................................................... 27

7.2.1 Inserting the specimen discs in the specimen head ............................................................................ 27

7.2.2 Specimen orientation ................................................................................................................................. 27

7.3 Sectioning ..................................................................................................................................................... 28

7.3.1 Trimming the specimen ..............................................................................................................................28

7.3.2 Section thickness setting ........................................................................................................................... 28

7.4 Temperaturew selection chart (in minus °C) ........................................................................................ 29

7.5 Defrosting ..................................................................................................................................................... 30

7.5.1 Automatic defrosting of the cryochamber ............................................................................................. 30

7.5.2 Manual defrosting of the cryochamber .................................................................................................. 30

7.5.3 Manual defrosting of the quick freeze shelf .......................................................................................... 31

7.6 Terminating work ........................................................................................................................................ 31

7.6.1 Terminating daily work ...............................................................................................................................31

7.6.2 Shutdown for a longer period ................................................................................................................... 32

8. Troubleshooting .................................................................................................................................... 33

8.1 Error messages in the display ................................................................................................................... 33

8.2 Temperature control button ...................................................................................................................... 33

8.3 Possible causes and remedies .................................................................................................................34

9. Cleaning, disinfection, maintenance ................................................................................................ 39

9.1 Cleaning ........................................................................................................................................................ 39

9.2 Spray disinfection with Leica Cryofect ................................................................................................... 40

9.3 Maintenance ................................................................................................................................................ 41

9.3.1 General maintenance ................................................................................................................................. 41

9.3.2 Removal of the microtome .........................................................................................................................42

9.3.3 Removal of the microtome cover ............................................................................................................. 44

9.3.4 Reinstallation of the microtome ................................................................................................................44

9.3.5 Replacement of the fuses .......................................................................................................................... 46

9.3.6 Replacement of the lamp ........................................................................................................................... 46

10. Ordering information, optional accessories .................................................................................... 48

10.1 Ordering information ................................................................................................................................... 48

10.2 Optional accessories .................................................................................................................................. 50

10.2.1 Mobile heat extractor .................................................................................................................................50

10.2.2 Thermal block .............................................................................................................................................. 50

11. Warranty and service .......................................................................................................................... 51

12. Decontamination Certificate (master)........................................................................................................... 52

Leica CM1850 – Cryostat

5

Page 6

1. Important Information

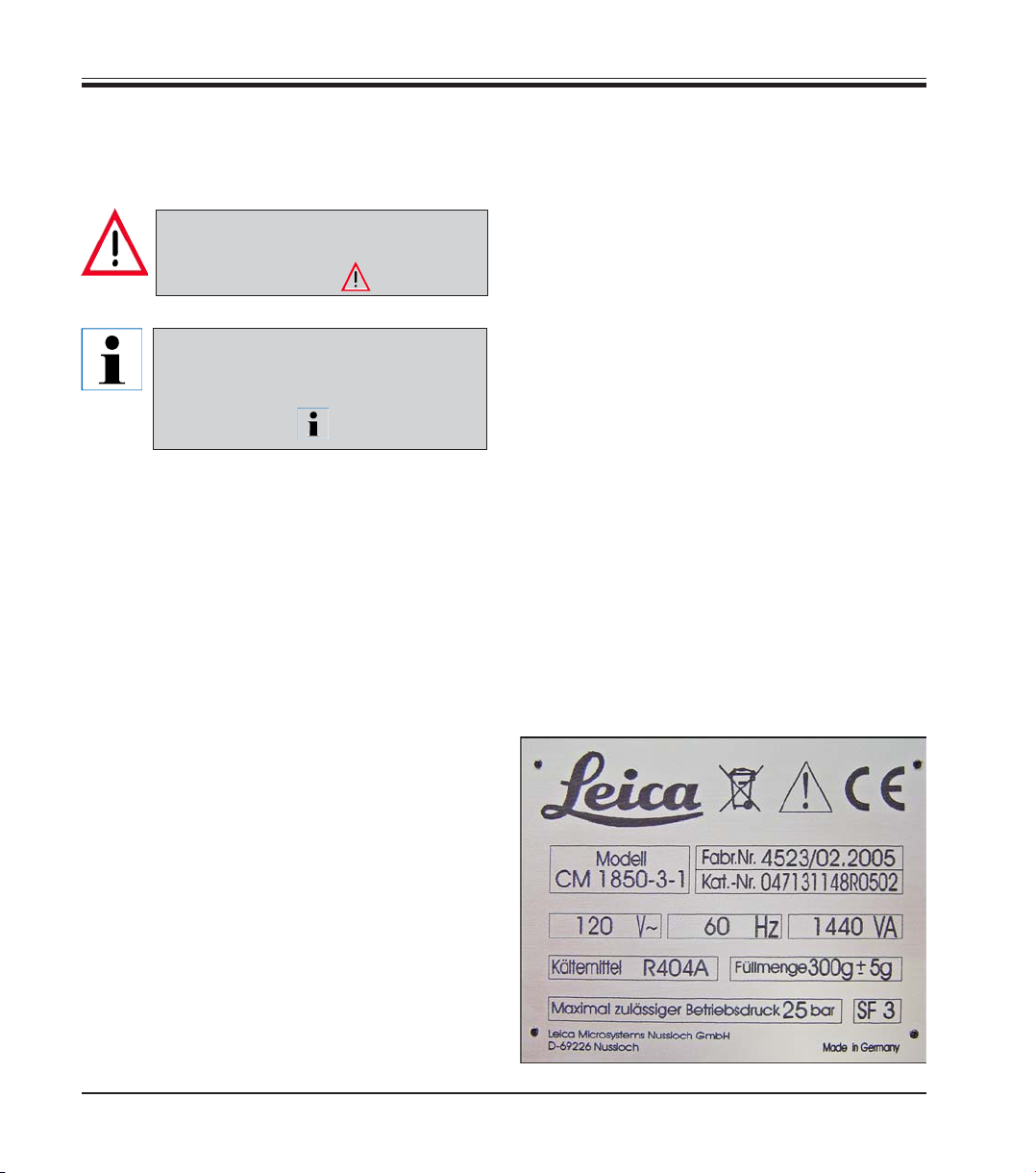

1.1 Symbols used in this manual and their meaning

Warnings

appear in a grey box and are marked

by a warning triangle .

Notes

i.e. important user information appears in a grey box and is marked by

an information symbol.

Figures in brackets refer to item num-

(5)

(Fig.5)

bers in drawings or to the drawings

themselves.

1.2 Qualification of personnel

The Leica CM1850 may only be operated by

trained laboratory personnel.

All laboratory personnel designated to operate the

instrument must carefully read the present instruction manual prior to starting work with the

instrument.

1.3 Designated use

The Leica CM1850 is a powerful cryostat for routine as well as research applications in biology,

medicine and industry.

The instrument has been designed for rapid

freezing and sectioning of tissue samples.

The instrument has not been designed for unattended storage of tissue material.

The instrument may only be operated within the

scope of its designated use as described above

and as per the instructions given in this manual.

Any other use of the instrument is considered

improper.

The Leica CM1850 is also suitable for IVD (in vitro

diagnostics).

1.4 Instrument type:

All information given in this instruction manual

applies only to the instrument type indicated on

the title page.

A name plate, indicating the instrument serial

number, is attached to the back of the instrument.

Fig. 1

6

Instructions for use V 2.6 – 10/2012

Page 7

2.1 Safety features

2. Safety

This instruction manual includes important instructions and information related to the operating safety and maintenance of the instrument.

The instruction manual is an important part of the product. It must be read

carefully before using the instrument for the first time and must always be

kept with the instrument.

If additional requirements, which exceed the scope of this manual, are imposed by regulations and/or laws on accident prevention and environmental protection in the country of operation, appropriate instructions for compliance with such requirements must be added to this manual.

Read this instruction manual carefully before attempting to use or operate

the instrument.

The instrument and its accessory equipment incorporate the following safety

features: safety handwheel and knife guards on the knife holders.

The consistent use of these safety features and strict observation of the

warnings and cautions in this manual, will safeguard the operator from accidents and/or personal injury to a great extent.

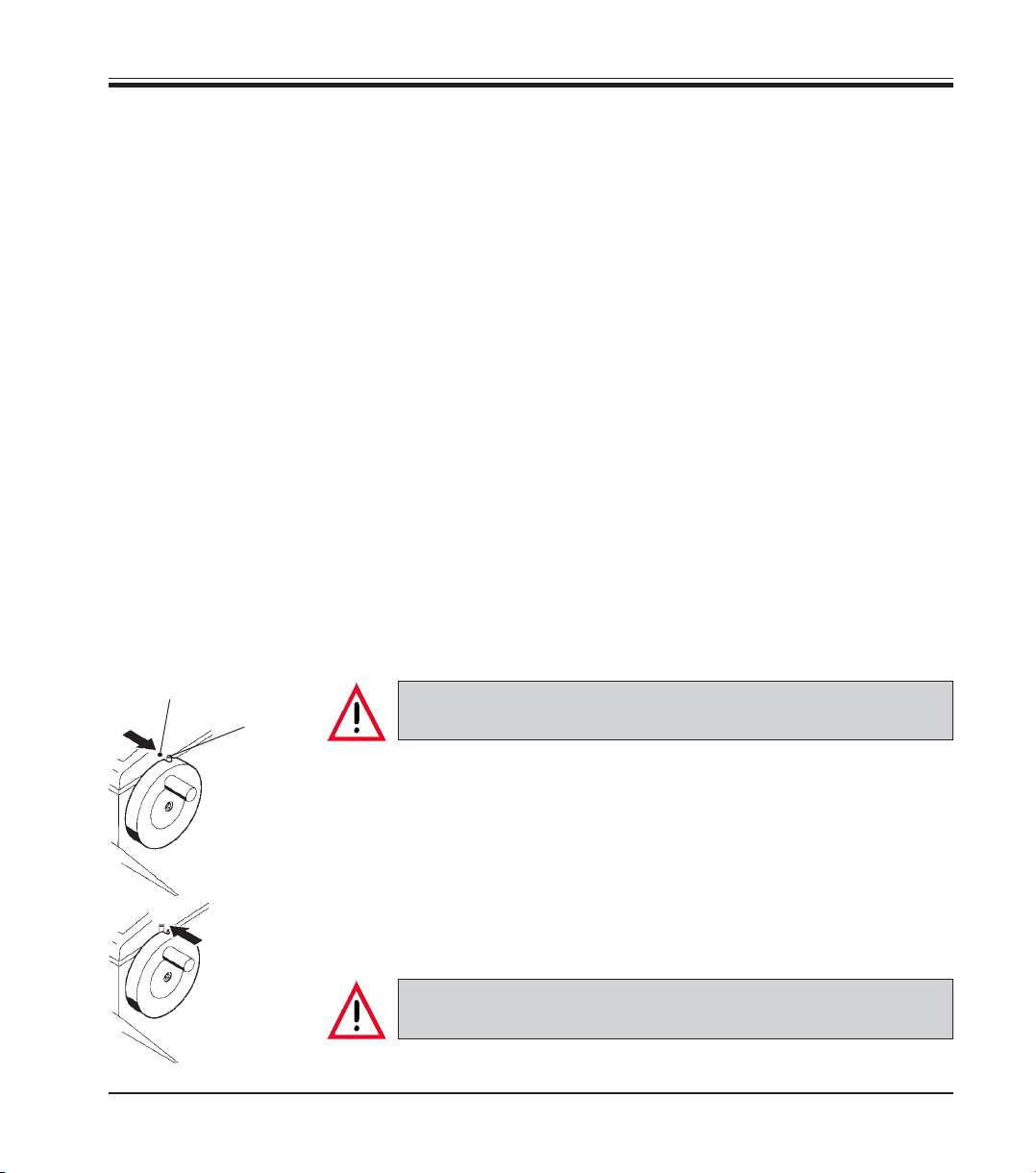

2.1.1 Locking the handwheel

2

1

For locking the handwheel rotate the handle until it is in the upper position.

Push the locking pin (1) into the recess at the handwheel. The locking position is marked by a black dot (2). If necessary, move the handwheel slightly

Fig. 2

Fig. 3

Leica CM1850 – Cryostat

forth and back until the locking mechanism engages.

To unlock, push the locking pin (1) to the left from the recess at the handwheel.

Prior to manipulating the knife and specimen, or changing the

specimen or knife, and during breaks, always lock the handwheel!

Only rotate the handwheel when the refrigeration system is on

and the cryochamber is cold.

7

Page 8

2. Safety

2.1.2 Knife guard

For every manipulation in the cryochamber, or upon changing a

specimen when the knife or disposable blade is clamped, or during breaks, cover the cutting edge with the knife guard.

The knife holders CN is equipped with knife guards; on the knife holder CE

and CE-TC the glass plate of the anti-roll guide constitutes the knife guard

(please refer to the separate instruction manual for your knife holder). Prior

to manipulating the knife and specimen, or changing the specimen or knife,

and during breaks, always lock the handwheel!

2.2 General information on instrument design and safe handling

This instrument has been built and tested in accordance with the safety

regulations for electrical measuring, control, regulating and laboratory devices.

In order to maintain this condition and to ensure safe operation, the operator must observe the instructions and warnings contained in this instruction

manual.

For current information about applicable standards, please refer to the CE

declaration of conformity on our Internet site:

www.LeicaBiosystems.com

8

Instructions for use V 2.6 – 10/2012

Page 9

2.3 Operating conditions

Transport and installation

• After transporting do not turn the instrument on for a minimum of 4 hours!

• Do not operate in rooms with explosion hazard!

• To ensure an adequate cooling capacity, the instrument must be set up

Connection to mains

• Before connecting to the mains power, please check if the local voltage

• During the compressor start-up the nominal voltage must not drop be-

• After transporting, wait at least 4 hours before turning the instrument on.

Defrosting

2. Safety

with at least 10 cm distance from walls and furniture!

complies with the power rating specified on the name plate of the instrument!

low the values specified in the ‘Technical data‘!

The compressor requires a start-up current between 45 and 50 A.

Therefore, the electric circuit at the place of installation must be inspected

by an electrical engineer to ensure that it meets the requirements for a

smooth operation of the instrument.

A constant adequate power supply to the instrument must be ensured at

all times.

Failure to comply with the above will cause severe damage to the instrument.

This waiting period is necessary to allow the compressor oil, which may

have been displaced during transport, to return to its original position.

Failure to comply with this can cause severe damage to the instrument.

• The quick freeze shelf may become hot during defrosting!

Therefore, do not touch it!

2.4 Operating the instrument

• Take care when handling microtome knives and disposable blades. The

cutting edge is extremely sharp and can cause severe injury!

Leica CM1850 – Cryostat

9

Page 10

2. Safety

• Never leave knives and knife holders with a knife/blade mounted lying

around!

• Do not place a knife on a table with the cutting edge facing upward!

• Never try to catch a falling knife!

• Always clamp the specimen before the knife!

• Prior to manipulating the knife and specimen, or changing the specimen

or knife, and during breaks, always lock the handwheel and cover the

cutting edge with the knife guard!

• Avoid contact with cold parts of the instrument as this can cause frostbite!

• To make sure that the condensation water stemming from the defrost

cycles drains into the waste container and to avoid the risk of possible

contaminations, ensure that the tap of the waste container (2, Fig. 31.1) is

open when operating the instrument. Only shut the tap when draining

the waste container!

2.5 Cleaning and disinfection

• It is not necessary to remove the microtome for routinely disinfecting the

cryochamber.

The instrument is appropriate for spray disinfection with Leica Cryofect!

• Do not use organic solvents or any other aggressive substances for cleaning and disinfection!

Only use the cleaning agents and disinfectants specified in this instruction manual such as Leica Cryofect (alcohol or common disinfectants

based on alcohol)!

2.6 Removal of the microtome

• Prior to removing the microtome, turn the instrument off with the mains

switch and pull the mains plug.

• Prior to removing the microtome, bring the specimen head to the lower

position with the handwheel.

Otherwise the specimen head would rapidly fall down and might injure

the operator‘s hands, when taking out the microtome.

• Wear appropriate protective gloves to take the cold microtome out of

the cryochamber.

10

Instructions for use V 2.6 – 10/2012

Page 11

2.7 Maintenance

Replacement of the fuses

2. Safety

Extended skin contact with cold parts of the instrument may cause frost

bite!

• The microtome must be entirely dry before reinstallation. Humidity inside

will condense and freeze in the cold cryostat and thus cause malfunctions or damage.

• Do not use external heaters for drying the cryochamber. This can cause

damage to the cooling system!

• All components removed from the cryostat must be carefully dried be-

fore they are replaced in the cryochamber

• Turn the instrument off with the automatic mains fuse and pull the mains

plug, before replacing the fuses.

• Only use fuses of the same specification! For the required values, please

refer to Chapter 3 ‘Technical data‘.

The use of fuses other than specified by the manufacturer may cause

severe damage to the instrument!

Replacement of the lamp

Leica CM1850 – Cryostat

• Turn the instrument off with the automatic mains fuse and pull the mains

plug, before replacing the lamp.

• If the lamp is broken, it must be replaced by the technical service, as the

replacement involves a high risk of injury.

11

Page 12

3. Technical data

Operating temperature range (ambient temperature): 18 °C to 35 °C.

All specifications related to temperature are valid only up to an ambient temperature of 22 °C

and an air humidity lower than 60 %!

Type CM1850 CM1850 CM1850-08 CM1850-01

Mark of conformity CUL - - VDE

Nominal voltage (±10%) 120 V AC 220 V AC 230 V AC 240 V AC

Nominal frequency 60 Hz 60 Hz 50 Hz 50 Hz

Power draw 1600 VA 1600 VA 1600 VA 1600 VA

Max. start-up current for 5 sec 45A eff. 45A eff. 45A eff. 45A eff.

Protective class IIII

Automatic mains fuse T12A T1 T12A T1 T10A T1 T10A T1

Pollution degree

Overvoltage installation category

Heat emission (max.) 1600 J/s 1600 J/s 1600 J/s 1600 J/s

① according to IEC-1010, UL 3101

Refrigeration system 50 Hz 60 Hz

Cryochamber

Temperature setting range 0 °C to -35 °C (+ 2 K / - 0 K) 0 °C to -35 °C (+ 2 K / - 0 K)

Defrosting automatic hot gas defrosting, automatic hot gas defrosting,

Refrigeration capacity ② 690 W 690 W

Safety factor 3 3

Refrigerant 300 g ±5g refrigerant R 404A * 300 g ±5g refrigerant R 404A *

Compressor oil 0.6 l EMKARATE RL-22S, ICI * 0.6 l EMKARATE RL-22S, ICI *

①

2222

II II II II

temperature controlled temperature controlled

1 automatic defrost cycle/24 hours, 1 automatic defrost cycle/24 hours,

temperature controlled temperature controlled

manual defrost cycle manual defrost cycle

Quick freeze shelf

Max. temperature - 43 °C (+ 3 K/- 2 K) - 43 °C (+ 3 K/- 2 K)

Number of quick freeze stations 10 10

Defrosting manual hot gas defrosting manual hot gas defrosting

time controlled time controlled

Peltier element

Max. temperature -60 °C (+5 K) -60 °C (+5 K)

Number of freezing stations 2 2*

Defrosting together with quick freeze shelf together with quick freeze shelf

②

according to CECOMAF Liquid temperature 45°C, evaporation temperature -25°C

12

Instructions for use V 2.6 – 10/2012

Page 13

3. Technical data

* Refrigerant and compressor oil must only be replaced by qualified, authorized service personnel!

Microtome

Rotary microtome

Section thickness setting 1 - 60 μm

Specimen feed 25 mm

Vertical stroke 59 mm

Maximum specimen size 55 x 55 mm

Specimen orientation 8° (x-, y-, z-Achse)

Electric coarse feed

slow 200 μm/s

rapid 700 μm/s

Cryocabinet

Dimensions

Width (w/o handwheel) 600 mm

Width (with handwheel) 730 mm

Depth 730 mm

Height 1140 mm

Weight (incl. microtome,

without specimen cooling) approx.135 kg

Fluorescent lamp

50 Hz version: Osram Dulux S 11 W/21

Color: LUMILUX light white

60 Hz version: Osram Dulux S 13 W/21

Color: LUMILUX light white

➀ according to IEC-1010, UL 3101

➁ according to CECOMAF

Liquid temperature 45°C

Evaporation temperature -25°C

Please refer to section 5.2 ‘Site requirements‘!

Storage conditions

Temperature: 5 - 55 °C

Relative humidity: <85 %, non-condensing

All CM 1850 types require the following fuses:

F1: T0,25 A Fa. Schurter, Typ FST; 6,3x32 mm or T0,25 A Fa. Littlefuse, Typ 313; 6,3x32 mm

F2: T0,6 A Fa. Schurter, Typ FST; 6,3x 32 mm or T0,6 A Fa. Littlefuse, Typ 313; 6,3x 32 mm

F3: T1,6 A Fa. Schurter, Typ FST; 6,3x 32 mm or T1,6 A Fa. Littlefuse, Typ 313; 6,3x 32 mm

F4: T6,25 A Fa. Schurter, Typ FST; 6,3x32 mm or T6,25 A Fa. Littlefuse, Typ 313; 6,3x32 mm

F5: T4 A Fa. Schurter, Typ FST; 6,3x 32 mm or T4 Fa. Littlefuse, Typ 313; 6,3x32 mm

Leica CM 1850 – Cryostat

13

Page 14

4. Unpacking and installation

4.1 Site requirements

Do not operate in rooms with explosion hazard!To ensure an adequate cooling capacity, the instrument must be set up with at

least 10 cm distance from walls and furniture.

• The place of installation must meet the following requirements:

– no direct sunlight,

– mains power socket at a distance no greater than approximately 1.5 m,

– no drafts (air condition outlets, etc.) directly over the instrument,

– even floor,

– mainly vibration-free floor,

– obstruction-free access to the handwheel,

– room temperature max. 35 °C,

– Air humidity must not exceed 60% High room temperatures and exces-

sive air humidity affect the cooling capacity of the cryostat.

– The instrument is designed for indoor use only.

High room temperatures and excessive air humidity affect the

cooling capacity of the cryostat.

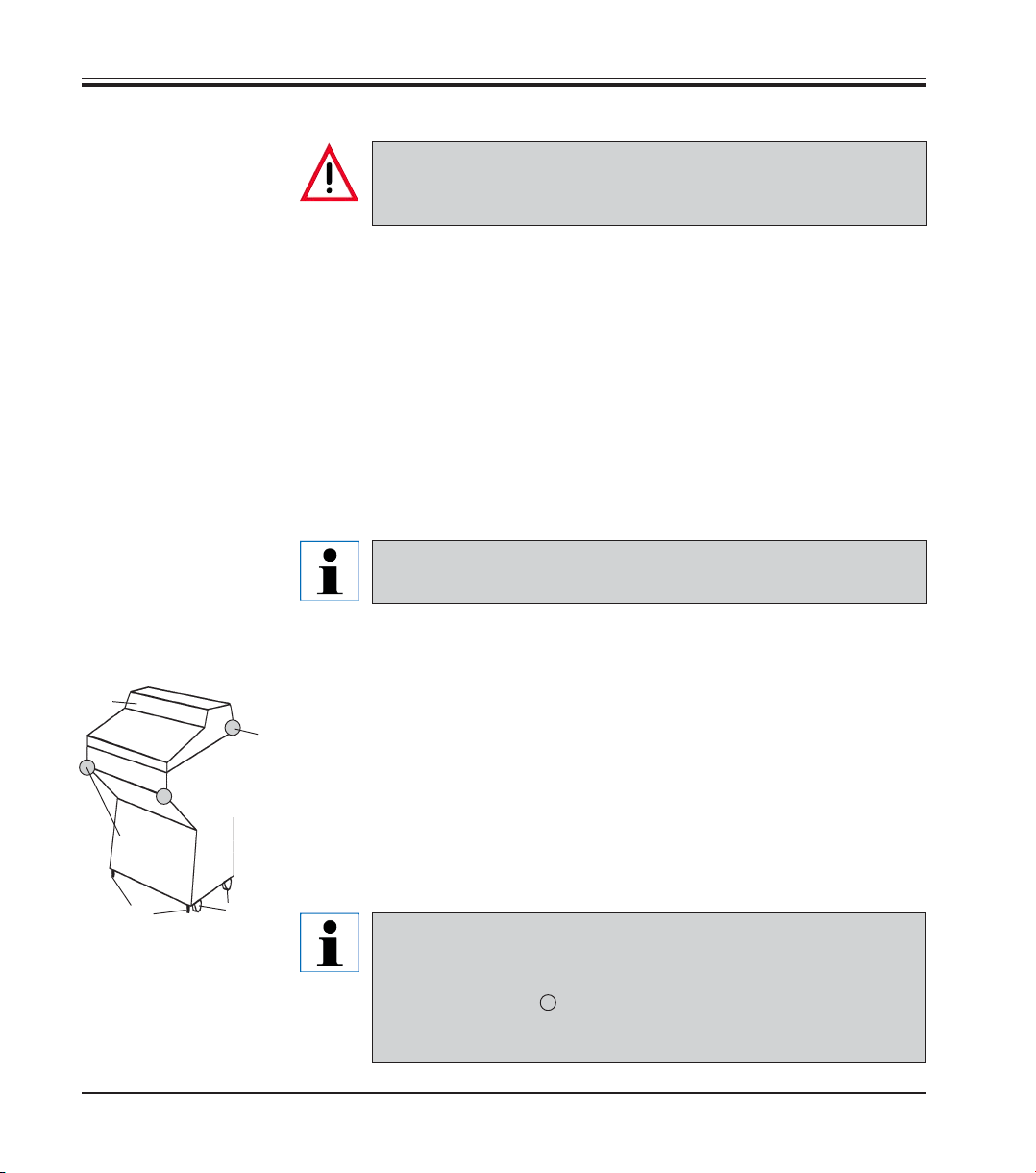

4.2 Transport to the desired location

16

Fig. 4

Lengthwise

movement

15

Sideways

movement

14

• Move the instrument to the installation site on its wheels (14). Please

note the areas which are reinforced for tarnsporting and grip the cabinet

Tilt

only at these locations (Fig. 4).

• The adjustable feet (15) can support the weight of the instrument when

tipping at a slight angle (max. 30 °).

• At the installation site unscrew the screws in the adjustable feet (15)

using a fork wrench.

This is necessary to ensure stability.

• Align the adjustable feet to level the instrument.

The instrument must be transported in an upright position only.

When the instrument is tilted, the compressor oil is displaced.

Do not grip the cabinet at the lid. Grip the cabinet only at the

marked locations ( ).

The alignment of the adjustable feet is necessary to ensure an unobstructed drain of the quick freeze shelf defrosting water.

14

Instructions for use V 2.6 – 10/2012

Page 15

4. Unpacking and installation

4.3 Standard delivery

It gives following variations: - CM1850 with Retraction, different voltages

- CM1850 without Retraction (only US) ................ 14 0471 31148

1 Handwheel with marking, antibacterial....................................... 14 0471 42558

1 Heat extractor, stationary.............................................................. 14 0471 30792

1 Low temperature stabilizer for heat extractor,

(Parking station) ............................................................................. 14 0471 30793

1 Set of specimen discs ................................................................... 14 0470 43550

- 4 specimen discs, 25 mm ............................................................ 14 0416 19275

- 4 specimen discs, 30 mm ............................................................ 14 0370 08587

1 Section waste tray ......................................................................... 14 0471 30787

1 Storage shelf, right......................................................................... 14 0471 30789

1 Storage shelf, left ........................................................................... 14 0471 30790

1 Brush shelf ...................................................................................... 14 0398 13088

1 toolkit: ............................................................................................... 14 0436 43463

- 1 brush, fine .................................................................................. 14 0183 28642

- 1 “Leica” brush w/magnet ........................................................ 14 0183 40426

- 1 Allen key, no. 1.5........................................................................ 14 0222 10050

- 1 Allen key, no. 2.5........................................................................ 14 0222 04137

- 1 Allen key, no. 3.0........................................................................ 14 0222 04138

- 1 Allen key, no. 4.0........................................................................ 14 0222 04139

- 1 Allen key with spherical head, no. 4.0 .................................. 14 0222 32131

- 1 Allen key, no. 5........................................................................... 14 0222 04140

- 1 Allen key with handle, no. 5..................................................... 14 0194 04760

- 1 Allen key, no. 6........................................................................... 14 0022 04141

- 1 Single-head wrench, no. 13 .................................................... 14 0330 33149

- 1 Single-head wrench, no. 16 .................................................... 14 0330 18595

1 Bottle of cryostat oil, type 407, 50 ml ........................................... 14 0336 06098

1 Bottle of OCT-Compound, mounting medium

for cryosectioning, 125 ml ............................................................. 14 0201 08926

1 Instructions for use Leica CM1850 - G/E/F/S.............................. 14 0471 80001

Compare the delivered components with the parts list and your order.

Should you find any discrepancies, please contact your Leica sales office

without delay.

Leica CM 1850 – Cryostat

A choice of different knife holders is available for the CM 1850. The

knife holder is accompanied by its own separate instruction manual.

Please contact your Leica sales office if the instr. manual is missing.

15

Page 16

4. Unpacking and installation

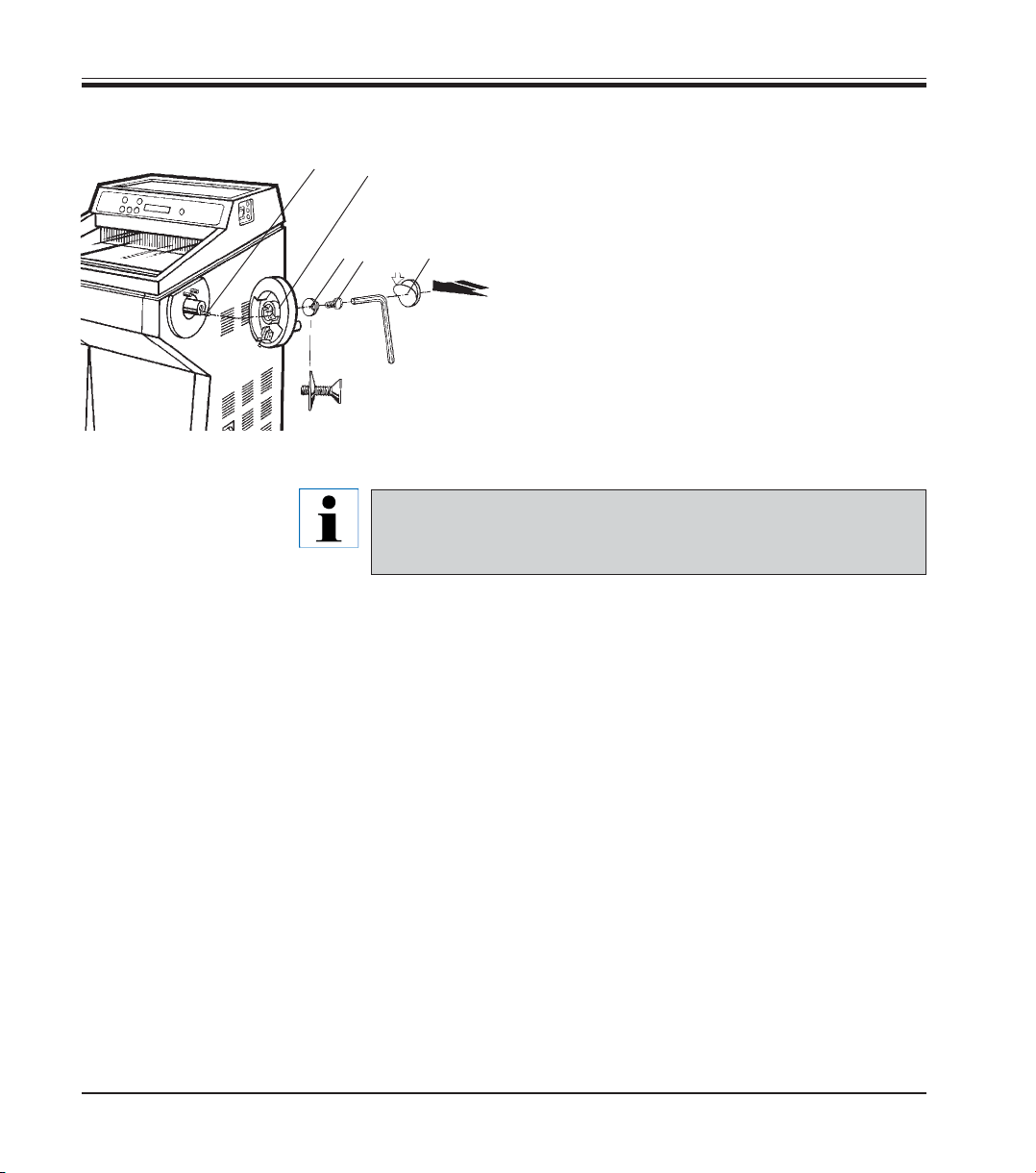

4.4 Handwheel assembly

1

2

• Insert the pin (1) of the handwheel shaft in to

the hole (2) of the handwheel.

Fig. 5

3

4

5

• Mount the spring washer (3) on the screw (4)

as shown in Fig. 16.

• Tighten the screw (4) with an Allen key (5 mm).

• Attach the cover disc (5) (self-adhesive).

To dismount, proceed in reverse order.

The handwheel including the fixing components are packed in the

cardboard box for the accessories.The handwheel can be dismounted for transporting (e.g. narrow doors).

16

Instructions for use V 2.6 – 10/2012

Page 17

5.1 Connection to mains power

• The electric circuit at the place of installation must be protected separately.

• Do not connect any other consumers to this electric circuit.

5.2 Prior to operation

• Before connecting the instrument to the mains power, please check if

the local mains voltage complies with the power rating indicated on the

name plate of the instrument.

5. Setup

During the start-up of the compressor the nominal voltage must not

drop below the values specified in the ‘Technical data‘.

Please note that the compressor requires a start-up current between 45 and 50 A.

Therefore, the electric circuit at the installation site must be inspected by an electrical engineer to ensure that it meets the requirements for a smooth operation of the instrument.

A constant adequate power supply to the instrument must be ensured at all times.

Failure to comply with the above will cause severe damage to the

instrument.

Leica CM1850 – Cryostat

• Place the storage shelves in the cryochamber.

• Place the section waste tray and brush shelf in the cryochamber.

• Place the knife holder base on the microtome base plate.

• Insert the knife holder and clamp it on the base plate For details, please

refer to the separate instruction manual for your knife holder).

• Open the knife box with the knife and place it in the cryochamber for

precooling.

• Place all tools needed for specimen preparation in the cryochamber.

• Close the sliding window.

• Connect the mains plug to the mains power outlet at the wall.

17

Page 18

5. Setup

5.3 Leica CM1850 - Overview

17

13

15

4

16

21

Fig. 6

18

20

8

13

12

19

18

10

14

9

13

11

Instructions for use V 2.6 – 10/2012

Page 19

5. Setup

3

5

2

6

1 Cryostat CM1850

2 Waste container

3 Control panel 1

4 Control panel 2

5 Storage shelf, left

6 Storage shelf, right

7 Automatic mains fuse

8 Support for stationary heat

7

1

extractor

9 Quick freeze shelf

10 Peltier element

11 Parking station

12 Stationary heat extractor

13 Specimen disc

14 Thermal bloc (accessory)

15 Section waste tray

16 Brush shelf

17 Orientable specimen head

18 Knife holder base (accessory)

19 Knife holder CE (accessory)

20 Knife holder CN (accessory)

21 Knife holder CE-TC (accessory)

Leica CM1850 – Cryostat

19

Page 20

5. Setup

5.4 Mains switch and automatic mains fuse

The automatic mains fuse is used as mains switch.

To turn the automatic mains fuse on, the switch must be set in the upper

position (pos. 1).

To turn the automatic mains fuse off, the switch must be set in the lower

position (pos. 0).

Fig. 7

Automatic mains fuse

5.5 Turning the instrument on

After transporting, wait at least 4 hours before turning the instrument on.

This waiting period is necessary to allow the compressor oil,

which may have been displaced during transport, to return to its

original position.

Failure to comply with this can cause severe damage to the instrument.

20

• Turn the instrument on with the automatic mains fuse.

• The instrument has been configured ex works as follows:

Time: 00:00

Defrost time: 10:00

Cryochamber cooling: On

(Indication of the temperature)

Peltier element: Off

Indication ‘PE‘

• Set the desired values as described in the sections 6.2.1 to 6.2.3.

During normal operation pressure compensation prior to the compressor start-up might lead to a hissing sound.

Instructions for use V 2.6 – 10/2012

Page 21

6.1 Control panel 1

Fig. 8

6. Control panel operation

Function keys

Lamp button

ON/OFF switch for cryochamber illumination.

Manual defrost button

To activate and deactivate manual defrosting.

Key button

To lock and unlock the control panel to protect the entered parameters from

unintended modifications. To lock or unlock, hold down for approximately 5

seconds.

6.2 Programming the desired values

6.2.1 Setting the time

The actual time is set on the panel marked with the clock symbol using the

and keys.

When pushing the or button for more than 1 second, the time value

increases or decreases continuously (autorepeat function).

Fig. 9

Leica CM1850 – Cryostat

21

Page 22

6. Control panel operation

6.2.2 Setting the automatic defrost time (cryochamber)

The automatic defrost cycle takes place once within 24 hours.

Touch the or button for indication of the beginning of the defrost cycle

which has actually been set. At the same time, the LEDs between the indication of hours and minutes are flashing.

To change the beginning of the defrost cycle in steps of 15 minutes, push

Fig. 10

6.2.3 Selecting the cryochamber temperature

Fig. 11

the or button.

The temperature of the cryochamber is set and indicated on the panel marked

with the cryostat symbol.

The actual temperature is the standard indication.

For indication of the desired value, touch the or button.

Set the desired value with the and buttons. When pushing the or

button for more than 1 second, the chamber temperature value increases

or decreases continuously.

The actual value will be indicated 5 seconds after finishing the programming.

22

Instructions for use V 2.6 – 10/2012

Page 23

6.2.4 Activation of the Peltier element

The Peltier element is used for cooling the quick-freeze stations. Upon activation of the Peltier element, the compressor of the cooling system is started

after 40 seconds to reinforce the thermal conductivity effect.

Fig. 12

Display reading of instruments: ‘PE‘ (=peltier-element)

The Peltier element is activated by pressing .

Once activated, the display indication changes to ‘10‘ (i.e. the Peltier element will operate for 10 minutes). The countdown of the remaining cooling

time is permanently displayed.

The Peltier element turns off automatically after 10 minutes.

Once the remaining cooling time displayed is 4 minutes, the figure 4 is followed by a point (‘ 4. ‘). At this stage the Peltier element may be deactivated

by pressing again.

Once deactivated, the display indication returns to ‘PE‘.

6.2.5 Manual defrosting of the quick freeze shelf

The quick freeze shelf may become hot during defrosting!

Therefore, do not touch it!

6. Control panel operation

Fig. 13

Leica CM1850 – Cryostat

The manual defrosting of the quick freeze shelf is activated by subsequently

pressing the button (audible signal turns on) and the key (audible

signal turns off). During the defrost cycle, the indication is flashing.

To turn off the manual defrosting cycle of the quick freeze shelf prior to the

automatic deactivation, press again and .

Quick freeze shelf and cryochamber defrosting can be run independently. However, it is not possible to defrost both systems simultaneously.

23

Page 24

6. Control panel operation

6.2.6 Manual defrosting of the cryochamber

The manual defrosting of the cryochamber is activated by subsequently

button (audible signal turns on) and the or button on

Fig. 14

6.3 Display lock

pressing the

the panel for the cryochamber temperature (audible signal turns off).

During the defrost cycle, the indication is flashing.

If you want to turn off the manual defrosting of the quick freeze shelf prior to

the automatic deactivation, press again

the cryochamber temperature.

The programmed values cannot be modified after having pushed the key

button.

Push the key button once more for 5 seconds to unlock the display.

and or on the panel for

Fig. 15

24

When the display is locked, the LEDs between the hour and minute indication on the time panel are turned off.

Instructions for use V 2.6 – 10/2012

Page 25

6.4 Control panel 2 - Electric coarse feed

Move the specimen away from the knife

• Press to start a rapid return travel of the specimen to the rear limit.

LED (1) flashes, while the specimen head is in motion.

rapid

1

On reaching the rear limit, the LED (1) starts illuminating.

• The return movement can be stopped by pressing one of the coarse feed

buttons.

• Press to start a slow return movement of the specimen to the rear limit.

6. Control panel operation

2

slow

slow

rapid

The specimen will slowly move to the rear limit, as long as the button is

held down.

Move the specimen towards the knife

• Press to start a rapid or slow advance of the specimen towards the knife.

The advance movement operates as long as the button is pressed. This

is a safety feature to protect both the specimen and knife from damage!

On reaching the front limit, the LED (2) of the button starts illuminating.

Leica CM1850 – Cryostat

25

Page 26

7. Daily use of the instrument

7.1 Specimen freezing

• Select the appropriate sectioning temperature (cryochamber temperature) for the sample material (please refer to 7.4 Temperature selection

chart‘).

7.1.1 Quick freeze shelf

The cryochamber has a quick freeze shelf (5, Fig. 17) for up to 10 specimen discs.

The temperature of the quick freeze shelf is always lower than the cryochamber

1

temperature.

2

5

• Cut the specimen to size.

• Activate the Peltier element (4), if available - it

may take up to 40 seconds until the maximum

refrigeration output is available.

• Apply enough cryocompound to a specimen

disc at room temperature.

• Place the specimen on the disc and orient.

• Place the specimen disc in one of the holes of

the quick freeze shelf and freeze the specimen

at a low temperature.

• Once the specimen is frozen, insert the

specimen disc in the specimen head

(Fig. 18) and start sectioning.

Fig. 17

7.1.2 Stationary heat extractor

• Fix the support (1) of the heat extractor (2) by tightening the 2 screws to

the threaded holes on the left sidewall of the cryochamber and insert the

heat extractor.

• Lower the heat extractor cylinder on the specimen surface. After approximately 30 seconds contact, the specimen will be entirely frozen.

• Once the specimen is frozen, place the heat extractor on the parking

station (3).

26

4

3

Instructions for use V 2.6 – 10/2012

Page 27

7. Daily use of the instrument

7.2 Specimen discs 7.2.1 Inserting the specimen discs in the

specimen head

• Lock the handle of the handwheel in the upper

position.

• If the knife holder and a knife are in place,

cover the knife edge with the knife guard.

• Loosen the screw (1) on the specimen head.

• Insert the shaft of the specimen disc (3) in the

location hole (2) of the specimen head.

Make sure that the shaft of the specimen disc is

fully inserted. The entire rear surface of the prism

must have a good contact with the specimen

head.

Fig. 18

• Retighten screw (1).

7.2.2 Specimen orientation

• To release, loosen screw (4).

• Orient the specimen surface with lever (5).

• Retighten screw (4).

Leica CM 1850 – Cryostat

27

Page 28

7. Daily use of the instrument

7.3 Sectioning

All necessary adjustments on the knife holder and anti-roll guide

are described in the separate instruction manual for your knife

holder in detail.

7.3.1 Trimming the specimen

Take care when handling microtome knives and disposable

blades. The cutting edge is extremely sharp and can cause severe

injury!

• Insert the precooled knife/blade in the knife holder and clamp.

• Adjust the appropriate clearance angle on the knife holder. Adjustments between 4 ° and 6 ° (knife

holder CN and CE-TC) or between 1 ° and 2 ° (knife holder CE) are suitable for most applications.

• Align the knife holder/knife with the specimen.

• Remove the knife guard (knife holder CN) or fold the glass anti-roll guide (knife holder CE and CETC) over to the left.

• Unlock the handwheel.

• Trim the specimen to shape approach the specimen towards the knife by means of the coarse feed

buttons. Trim the specimen down to the required sectioning plane by turning the handwheel.

• Position the anti-roll guide on the knife and align with the cutting edge.

Readjust the anti-roll plate if necessary.

7.3.2 Section thickness setting

The section thickness is adjusted in a range of 1 to 60 μm by turning the knob (1) :

from 0 - 10 μm in 1 μm increments,

from 10 - 20 μm in 2 μm increments,

from 20 - 60 μm in 5 μm increments.

The selected section thickness is indicated on the index mark on the microtome.

• Select the required section thickness with the control knob on the microtome.

Start sectioning at approximately 20 μm.

• Decrease the section thickness continually down to the appropriate value.

After changing from one section thickness to another, the first two or three sections should be

rejected.

• When sectioning, turn the handwheel at a constant speed.

28

Instructions for use V 2.6 – 10/2012

Page 29

7. Daily use of the instrument

7.4 Temperaturew selection chart (in minus °C)

Tissue -10°C – -15°C -15°C – -25°C -25°C – -35°C

Adrenal ❄❄

Bone marrow ❄

Brain ❄

Bladder ❄

Breast - fatty ❄

Breast - little fat ❄

Cartilage ❄❄

Cervical ❄

Fatty ❄

Heart and vascular ❄

Intestinal ❄

Kidney ❄

Laryngeal ❄

Lip ❄

Liver ❄

Lung ❄

Lymphoid ❄

Muscular ❄

Nose ❄

Pancreatic ❄

Prostate ❄

Ovarian ❄

Rectal ❄

Skin with fat ❄

Skin without fat ❄

Spleenal or bloody tissue ❄

Testicular ❄❄

Thyroid ❄

Tongue ❄

Uterus curettage ❄

The temperature values given above are based on long-term experience, however, these are only approximate values,

as any tissue may require particular adjustments.

Leica CM1850 – Cryostat

29

Page 30

7. Daily use of the instrument

7.5 Defrosting

Defrosting the cryochamber actually means defrosting the evaporator to

prevent excessive frost buildup. The evaporator is flushed with hot gas during defrosting. The cryochamber virtually is frostfree and does not need to

be defrosted.

The condensation water that is produced during defrosting is collected in a

container, which is located at the front of the cryostat cabinet.

To make sure that the condensation water stemming from the defrost cycles drains into the waste container and to avoid the risk of

possible contaminations, ensure that the tap of the waste container (2, Fig. 22) is open when operating the instrument. Only shut

the tap when draining the waste container!

The quick freeze shelf is cooled during the automatic cryochamber

defrosting. However, the Peltier element is turned off. The maximum duration of a defrost cycle is 12 minutes. Defrosting is terminated automatically once the cryochamber has reached a temperature of -5 °C.

Cooling turns back on automatically.

7.5.1 Automatic defrosting of the cryochamber

An automatic defrost cycle takes place once in 24 hours.

The time of the automatic defrost cycle is programmed via the control panel

1 (see 6.2.1 and 6.2.2).

7.5.2 Manual defrosting of the cryochamber

In addition to the programmable automatic defrost cycle a manual defrost

cycle can be activated (see also 6.2.6).

To avoid an unintended defrosting, the activation of a manual defrost cycle is confirmed by an audible signal.

Cooling turns back on automatically.

30

Instructions for use V 2.6 – 10/2012

Page 31

7.5.3 Manual defrosting of the quick freeze shelf

The quick freeze shelf may become hot during defrosting!

Therefore, do not touch it!

If increased frost formation occurs on the quick freeze shelf, especially after spray disinfection, a manual defrost cycle should be started (see 6.2.5),

which can be terminated when required.

7.6 Terminating work

7.6.1 Terminating daily work

• Lock the handwheel.

• Take the knife out of the knife holder and put it back into the knife box in

the cryochamber.

• Remove frozen section waste with a cold brush.

• Empty the section waste tray.

• Clean the storage shelves and brush shelf.

7. Daily use of the instrument

Leica CM1850 – Cryostat

Only common detergents and disinfectants that contain 95 - 98%

alcohol should be used for cleaning.

All components removed from the cold environment will collect

condensation. Therefore, dry them thoroughly before placing them

back into the cryochamber.

• Remove all specimens from the cryostat.

• Close the sliding window.

• Turn out the cryochamber illumination.

• Lock control panel 1 (Fig. 8) with the KEY button.

• Do not turn the instrument off with the automatic mains fuse as there

would be no cooling.

31

Page 32

8. Troubleshooting

7.6.2 Shutdown for a longer period

If you do not intend to use the instrument for several weeks you

may turn it off.

Please note, however, that it may take up to several hours to cool

the cryochamber down to very low temperatures after turning the

instrument on again.

After turning off, the instrument should be cleaned and disinfected

thoroughly (see chapter 9 ‘Cleaning, disinfection and maintenance').

• Turn the instrument off with the automatic mains fuse.

• Open the sliding window to allow the cryochamber to dry.

• Remove all the specimens from the cryostat.

• Lock the handwheel.

• Take the knife/blade out of the knife holder. Put the knife back into the

knife box or push the blade into the receptacle for used blades provided

at the bottom of the dispenser.

• Remove all section waste with a cold brush.

• Empty the section waste tray and remove it for cleaning and disinfection.

• Remove the storage shelves and the brush shelf for cleaning and disinfection.

Turning off the instrument with the automatic mains fuse will not affect the

programmed parameters.

Before turning the instrument on again, the cryochamber microtome and all

accessory components must be absolutely dry.

32

Instructions for use V 2.6 – 10/2012

Page 33

8. Troubleshooting

8.1 Error messages in the display

Error messages are displayed on the clock panel as follows: EO: XX. The

following error messages might occur during operation:

Fig. 20

Error Description Remedy

20 Calibrating error; possibly defective controller board. Turn the instrument on again.

If the error is displayed again:

Call service.

21 Clock battery on the controller board empty. Call service.

22 Microtome wet. Dry microtome.

23 Cryochamber temperature out of range of indication. Remove cause.

(from -35 °C to +55 °C)

24 Short circuit at the temperature sensor Call service.

of the chamber cooling system.

25 Breaking of the temperature sensor Call service.

of the chamber cooling system.

26 Short circuit at the temperature sensor of the evaporator. Call service.

27 Breaking of the temperature sensor of the evaporator. Call service.

8.2 Temperature control button

On the back of the cryostat cabinet there is a temperature control button (1). If the temperature of the

cryochamber exceeds 60 °C the switch is automatically activated and turns the instrument off.

Possible causes and remedies:

• Temperature of the direct surroundings is

constantly higher than 40 °C.

-->Drop the temperature of the direct surroundings.

• When setting up the instrument the minimum

distance of 10 cm to walls and furniture was

not kept.

--> Keep the minimum distance.

• The ventilation slits of the liquefier are dirty.

Fig. 21

After eliminating the possible source of error, push the temperature control button (1) to turn the instrument back on. If the instrument fails to turn on, make a service call.

Leica CM 1850 – Cryostat

--> Clean the ventilation slits (see 9.3.1).

33

Page 34

8. Troubleshooting

8.3 Possible causes and remedies

Problem Cause Remedy

Frost on chamber walls and microtome

Ice formation on the bottom of

the cryochamber

Sections smear

Sections splinter

Sections not properly flattened

- Cryostat is exposed to air currents (open windows and

doors, air conditioning).

- Sliding window was open and

exposed to air currents too

long.

- Frost built up by breathing into

the cryochamber.

- Condensation water drain obstructed.

- Drain of the quick freeze shelf

defrosting water obstructed.

- Specimen not cold enough.

- Knife/blade and/or anti-roll

plate not yet cold enough and

thus warm the sections.

- Specimen too cold

- Static electricity/air currents.

- Specimen not cold enough.

- Large area specimen.

- Anti-roll plate poorly positioned.

- Anti-roll plate poorly aligned

with knife edge.

- Incorrect clearance angle.

- Knife/blade blunt or damaged.

- Change place of installation for

the cryostat.

- Open the tap of the drain tube

(2, Fig. 31), switch off the instrument and let it thaw and dry.

- Align the instrument with a

spirit level.

- Select lower temperature.

- Wait until knife/blade and/or

anti-roll plate have reached

chamber temperature.

- Select higher temperature.

- Remove cause.

- Select lower temperature.

- Trim the specimen parallel,

increase section thickness.

- Reposition anti-roll plate.

- Align correctly.

- Set correct angle.

- Use different part of the cutting

edge or replace.

34

Instructions for use V 2.6 – 10/2012

Page 35

8. Troubleshooting

Problem Cause Remedy

Sections not properly flattened

despite correct temperature and

correctly aligned anti-roll plate

Sections curl on the anti-roll

plate

Scraping noise during sectioning

and specimen return movement

Ridged sections

Chatter during sectioning

- Knife/blade and/or anti-roll

plate dirty.

- Edge of anti-roll pate damaged.

- Blunt knife/blade.

- Anti-roll plate does not protrude far enough beyond the

cutting edge.

- Anti-roll plate protrudes too far

beyond the cutting edge and is

scraping against the specimen.

- Knife/blade damaged.

- Edge of anti-roll plate damaged.

- Specimen insufficiently frozen

onto the specimen disc.

- Specimen disc not clamped

tightly.

- Specimen holder ball joint not

clamped.

- Knife/blade not clamped tightly

enough.

- Specimen has been sectioned

too thickly and has detached

from the disc.

- Very hard, inhomogeneous

specimen.

- Blunt knife/blade.

- Clean with dry cloth or brush.

- Replace plate.

- Use different part of the cutting

edge or replace.

- Readjust correctly.

- Readjust correctly.

- Use different part of the cutting

edge or replace.

- Replace the plate.

- Refreeze specimen onto the

disc.

- Check disc clamping.

- Check ball joint clamping.

- Check knife/blade clamping.

- Refreeze specimen onto the

disc.

- Increase section thickness;

reduce specimen surface area

if necessary.

- Use different part of the cutting

edge or replace the knife/

blade.

Leica CM1850 – Cryostat

35

Page 36

8. Troubleshooting

Problem Cause Remedy

Condensation on anti-roll plate

and knife during cleaning

Anti-roll plate damage after adjustment

Thick-thin sections

- Knife profile inappropriate for

the specimen to be cut.

- Incorrect clearance angle.

- Brush, forceps and/or cloth are

too warm.

- Plate too high above the cutting edge. The adjustment was

carried out in the direction of

the cutting edge.

- Temperature incorrect for the

tissue cut.

- Knife profile inappropriate for

the specimen cut.

- Ice buildup in the knife back.

- Handwheel speed not uniform.

- Knife/blade not clamped tightly

enough.

- Specimen holder not clamped

tightly.

- Cryocompound applied to cold

specimen disc; specimen detached from the disc after

freezing.

- Blunt cutting edge.

- Incorrect clearance angle.

- Microtome not properly dried

before reinstallation.

- Dried specimen.

- Use knife with different profile.

- Set correct angle.

- Store all tools on shelf in the

chamber.

- Raise plate when aligning.

- Be more careful next time.

- Select correct temperature.

- Wait until the correct temperature is reached.

- Use knife with different profile

(c or d).

- Remove ice.

- Adapt speed.

- Check knife/blade clamping.

- Check clamping.

- Apply cryocompound on warm

disc; mount specimen and

freeze.

- Use different part of the cutting

edge or replace the knife/

blade.

- Set correct angle.

- Dry microtome thoroughly.

- Prepare new specimen.

Tissue sticks or crumbles on the

anti-roll plate

36

- Anti-roll plate is too warm or

incorrectly positioned.

- Static electricity.

- Cool down anti-roll plate or

reposition plate.

- Remove static electricity.

Instructions for use V 2.6 – 10/2012

Page 37

8. Troubleshooting

Problem Cause Remedy

Flattened sections curl up when

anti-roll plate is picked up

Sections tear

Inconsistent or insufficient specimen feed

Specimen disc cannot be removed

Fat on the corner or edge of the

anti-roll plate.

- Rusty knife/blade.

- Static electricity or air currents.

- Anti-roll plate too warm.

- Temperature too low for the

tissue cut.

- Blunt part, dirt, dust, frost or

rust on the knife/blade.

- Leading edge of anti-roll plate

damaged.

- Hard particles in the tissue.

- Knife back dirty.

- Microtome was not entirely dry

when switching on refrigeration; consequently ice built up

in the micrometer feed system.

- Defective microtome.

- Moisture on the underside

caused the disc to freeze to the

freezing shelf or specimen

head.

- Remove fat with alcohol.

- Remove rust.

- Remove static electricity.

- Cool down the anti-roll plate.

- Increase temperature and

wait.

- Remove cause.

- Replace the plate.

- - -

- Clean.

- Remove the microtome and

dry it thoroughly before reinstallation.

- Call technical service.

- Apply concentrated alcohol to

the contact point or heat the

specimen head.

Cryostat inoperational

Leica CM1850 – Cryostat

- Mains plug not properly connected.

- Defective fuses.

- Temperature control switch

activated.

- Check the mains plug is properly connected.

- Replace the fuses.

- Check site conditions as described in section 5.2, and

reset the temperature control

switch.

37

Page 38

8. Troubleshooting

Problem Cause Remedy

No or insufficient refrigeration

Scraping noise at the microtome

- Compressor defective.

- Leak in the cooling system.

- Inappropriate site conditions.

- Ventilation slits of the liquefier

dirty.

- Friction between the slot cover

and the microtome housing.

- Call technical service.

- Call technical service.

- Check site conditions as described in section 5.2.

- Clean the ventilation slits as

described in section 10.3.1.

- Apply cryostat oil to the slot

cover and distribute by turning

the handwheel or with a cloth.

38

Instructions for use V 2.6 – 10/2012

Page 39

9.1 Cleaning

2

3

9. Cleaning, disinfection, maintenance

• Remove frozen section waste from the cryostat with a cold brush every

day.

• Remove the section waste tray for emptying.

• Remove the storage shelves and the brush shelf for cleaning.

• Remove the sliding window by slightly lifting and pulling it to the front

when closed (see 9.3.6 'Replacement of the lamp').

Do not use organic solvents or any other aggressive substances for

cleaning and disinfecting! Only use the cleaning agents specified

in this instruction manual such as Leica Cryofect (alcohol or common disinfectants based on alcohol)!

• Drain the cleaning liquid through the hose after the prescribed reagent

time is over and collect it in the waste container (1).

• Dispose of the waste liquid according to the

waste disposal regulations.

• To remove the waste container (1), shut off the

tap (2) and unscrew the lid (3).

1

Leica CM 1850 – Cryostat

Fig. 22

Condensation water produced during defrosting collects in the

waste container. Therefore, check the liquid level regularly and

empty the container if necessary.

39

Page 40

9. Cleaning, disinfection, maintenance

9.2 Spray disinfection with Leica Cryofect

For easy-to-use spray disinfection we recommend Leica Cryofect.

The cryostat has to be disinfected after each daily use.

Comply with the instructions for use!

The glass anti-roll plate can remain in place during disinfection.

1. Select a cryochamber temperature value down to -20 °C.

2. Remove the knife or blade from the knife holder.

3. Remove all samples, microscope slides and tools from the cryochamber.

4. Remove debris from the cryochamber.

Allow the cryochamber to reach the previously selected temperature.

Once the selected temperature is reached, either

5a. spray the disinfectant evenly on the contaminated surfaces- the sur-

faces should be covered with an even layer - or

40

5b. soak a cloth with disinfectant and apply it on the contaminated surfaces.

6. Allow a reaction time of no less than 15 minutes.

7. Wipe it off with a tissue.

8. Dispose of tissue in compliance with the ruling waste disposal regulations of your institution.

9. Set the cryochamber temperature to the originally selected value.

If increased frost buildup occurs, start a manual defrost cycle.

Instructions for use V 2.6 – 10/2012

Page 41

9. Cleaning, disinfection, maintenance

9.3 Maintenance 9.3.1 General maintenance

1

The microtome is virtually maintenance-free. To

ensure a smooth operation of the instrument over

several years we recommend the following:

4

2

3

• Have the instrument inspected by a qualified

service engineer authorized by us once a year.

• Enter into a service contract at the end of the

warranty period.

For further information, please contact your

local Leica service center.

• Clean the instrument every day.

Fig. 23

Once a week:

• Apply a drop of oil to the plastic coupling (5,

Fig. 26).

• Lubricate the specimen cylinder (1):

Push the appropriate coarse feed button to

move the specimen cylinder out to the front

stop position, apply a drop of cryostat oil and

move the specimen cylinder back to the home

position by pressing the appropriate coarse

feed button.

Fig. 24

Leica CM 1850 – Cryostat

Occasionally, or when required:

5

• Lubricate the clamping piece (T-piece) (2) on

the microtome base plate and the clamping

lever (3).

• Lubricate the slot cover (4).

To do so, turn the handwheel to place the

specimen head to the uppermost position and

apply some drops of cryostat oil on to the slot

cover; after that place the specimen head to

41

Page 42

9. Cleaning, disinfection, maintenance

the lowest position and apply some drops of cryostat oil on to the slot

cover; distribute the applied oil by turning the handwheel or with a soft

tissue.

• Clean the ventilation slits (5) of the liquefier on the right side of the instrument with a brush, broom or vacuum cleaner from dust and dirt in the

direction of the fins.

• Do not carry out any repairs on your own as this will invalidate the warranty.

Repairs may only be carried out by qualified service engineers authorized by Leica.

The microtome can be removed for thorough cleaning and disinfecting, or for extensive drying after a long power failure!

9.3.2 Removal of the microtome

Turn the instrument off and disconnect the mains plug before removing the microtome.

Prior to removing the microtome, place the specimen head to the

lowest position by placing the handle of the handwheel in the lowest position.

When removing the microtome, the specimen head will rapidly fall

down and might injure the operator‘s hands.

Wear appropriate protective gloves to take the cold microtome out

of the cryochamber!

Extended skin contact with cold parts of the instrument may cause

frost bite!

42

• Slightly lift the sliding window when closed holding it at the grip provided

and pull it out to the front (Fig. 30) - see ‘9.3.6 Replacement of the lamp‘.

• Remove the accessories in the following order: brush shelf, knife holder,

section waste tray, specimen discs, stationary heat extractor, left storage shelf, right storage shelf.

Instructions for use V 2.6 – 10/2012

Page 43

9. Cleaning, disinfection, maintenance

1

Fig. 25

2

4

• Loosen the screws (3) with an Allen key (4 mm).

Do not loosen the screws (7) for removing the

microtome.

• Disconnect the coarse feed motor plug (1) by

pulling the metal head.

• Disconnect the temperature sensor (2) from

3

8

8

7

the microtome.

Leica CM 1850 – Cryostat

5

• Slightly lift the microtome and pull it to the left

to disengage the plastic coupling (5)

connecting the axes.

• Take the microtome out of the cryochamber.

Fig. 26

43

Page 44

9. Cleaning, disinfection, maintenance

9.3.3 Removal of the microtome cover

8

8

8

Fig. 27

The microtome cover may be removed

to expeditethorough drying of the microtome in an oven. Note:

Place the microtome in an oven at 40

°C to 50 °C for several hours.

After repeatedly drying the microtome

in this manner, it may become necessary to relubricate the cross roller

bearings!

For further information, please contact

your sales company!

• Loosen the two screws (8) on both sides of the

8

cover.

• To remove, pull the cover upwards. The front

plate of the microtome with the specimen head

remains in place.

Do not use external heaters for drying

the cryochamber!

This can cause damage to the cooling

system!

9.3.4 Reinstallation of the microtome

• Place the microtome slightly left from the original position into the

cryochamber. Make sure that the specimen head is in the lowest position.

• Lubricate the surface of the plastic coupling (5) with a drop of cryostat

oil.

• Mount the plastic coupling (5) on the shaft (4).

• Use your right hand to bring the handwheel handle in the lowest position

and keep the handle in place. The specimen head remains in the lower

position.

44

Instructions for use V 2.6 – 10/2012

Page 45

9. Cleaning, disinfection, maintenance

Ensure that the microtome is completely dry before reinstallation.

Humidity inside will condense and freeze and thus cause malfunctions or damage to the feed

system of the microtome.

• Use your right hand to bring the handwheel handle in the lowest position

and keep the handle in place. The specimen head remains in the lower

position.

• Push the microtome to the right with your left hand, and, if necessary,

turn the handwheel back and forth to ensure proper alignment of the

parts until the plastic coupling (5) engages to the shaft (6).

• Tighten the screws (3).

• Reconnect the coarse feed motor plug (1) and the temperature sensor

(2).

• Replace the storage shelves, heat extractor, brush shelf and knife holder

in the cryochamber.

2

1

Fig. 28

Leica CM 1850 – Cryostat

• Replace the sliding window.

4

3

Fig. 29

5

6

Ensure that all components removed

from the cold environment are completely dry before placing them back

into the cryochamber.

45

Page 46

9. Cleaning, disinfection, maintenance

9.3.5 Replacement of the fuses

Turn the instrument off with the automatic mains fuse and pull the

mains plug, before replacing the fuses!

Only use fuses of the same specification! For the required values,

please refer Chapter 3 ‘Technical Data‘. The use of fuses other than

specified by the manufacturer may cause severe damage to the instrument!

Fig. 29

Fuse Protection Type

F1 Display T 0.25 A

F2 Coarse feed T 0.6 A

F3 Processor board supply T 1.6 A

F4 Peltier element T 6.25 A

F5 Heaters T 4 A

On the back of the instrument there is a fuse box

with 5 fuses:

• Unscrew the fuse cap with a screwdriver.

• Remove both fuse cap and fuse.

• Put the new fuse in the cap and screw the fuse

cap back on.

9.3.6 Replacement of the lamp

46

Turn the instrument off with the automatic mains fuse and pull the

mains plug, before replacing the lamp!

If the lamp is broken, it must be replaced by the technical service,

as the replacement involves a high risk of injury.

Instructions for use V 2.6 – 10/2012

Page 47

1

Fig. 30

9. Cleaning, disinfection, maintenance

• Turn the instrument off with the automatic

mains fuse.

• Pull the mains plug.

• Slightly lift the sliding window (1) holding it by

the grip (2) and pull it out to the front.

• For the technical specification of the lamp,

please refer to Chapter 4. ‘Technical data‘.

2

Fig. 31

Fig. 32

45

3

6

Removal of the lamp

The lamp (3) is mounted behind a glare shield (4)

and therefore not visible.

• Touch the lamp for better orientation.

• Lightly tilt the fluorescent tube down to the left

and pull it out of the clip (5).

• Hold the lamp with both hands and pull it to

the left out of the holder (6).

Installation of the new lamp

• Hold the lamp in the correct mounting position

as shown (Fig. 32) and push it to the right until

it engages in the holder.

• Lightly push the fluorescent tube upward to

engage in the clip.

• Replace the sliding window.

• Reconnect the instrument to the mains power

and turn it on.

Leica CM 1850 – Cryostat

47

Page 48

10. Ordering information, optional accessories

Knife holder base ............................................................................................................... 14 0419 26140

Knife holder CN ..................................................................................................................

Knife support.......................................................................................................................

Knife support for long knives............................................................................................

Antiroll plate, assy. 50mm - 100μm ..................................................................................

Antiroll plate, glass - 50mm ..............................................................................................

Knife holder CE, low profile ..............................................................................................

Knife holder CE, high profile .............................................................................................

Knife holder CE ...................................................................................................................

Pressure plate B (high profile), 22° .................................................................................

Pressure plate S (low profile), 22° ...................................................................................

Antiroll plate, assy., 70mm - 100 μm spacer (standard) ...............................................

Antiroll plate, 70mm - 50 μm spacer ................................................................................

Antiroll plate, 70mm - 150 μm spacer ..............................................................................

Antiroll plate, glass - 70mm ..............................................................................................

Antiroll guide, assy. (swiveling arm + antiroll guide, 70mm - 100μm) .......................

Knife holder CE-TC .............................................................................................................

Specimen disc, ø 20mm ....................................................................................................

Specimen disc, ø 25mm ....................................................................................................

Specimen disc, ø 30 mm....................................................................................................

Specimen disc, ø 40mm ....................................................................................................

Specimen disc, ø 55mm ....................................................................................................