Page 1

HDS-E 3.3/25-4M Ec

HDS-E 3.3/25-4M Ef

English 5

Français 18

Español 34

www.kaercher.com/register-and-win

59646740 06/14

Page 2

1

12726252423

22

21

20

19

18

17

16

2

3

4

5

6

151413

9

12

11

2

10

89

7

Page 3

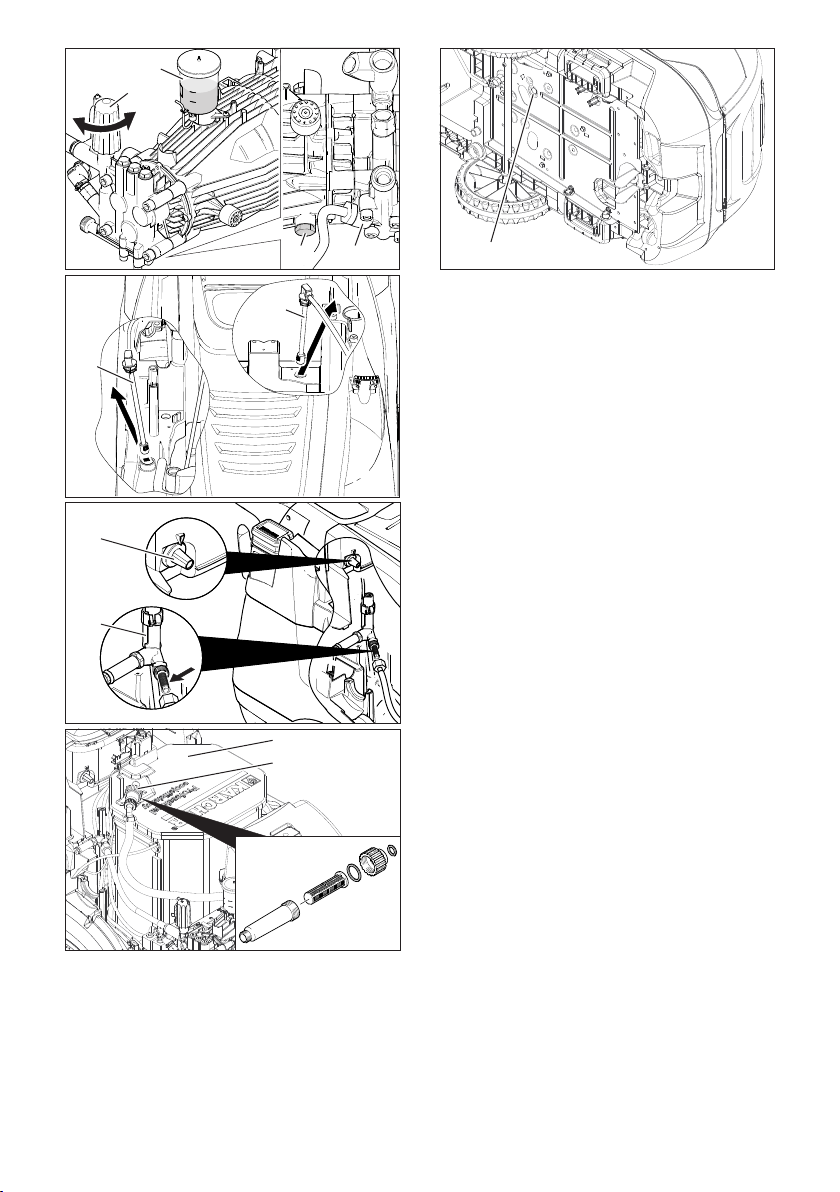

28

MAX MIN

29

MAX

MIN

33

34

35

30 31

32

36

37

38

3

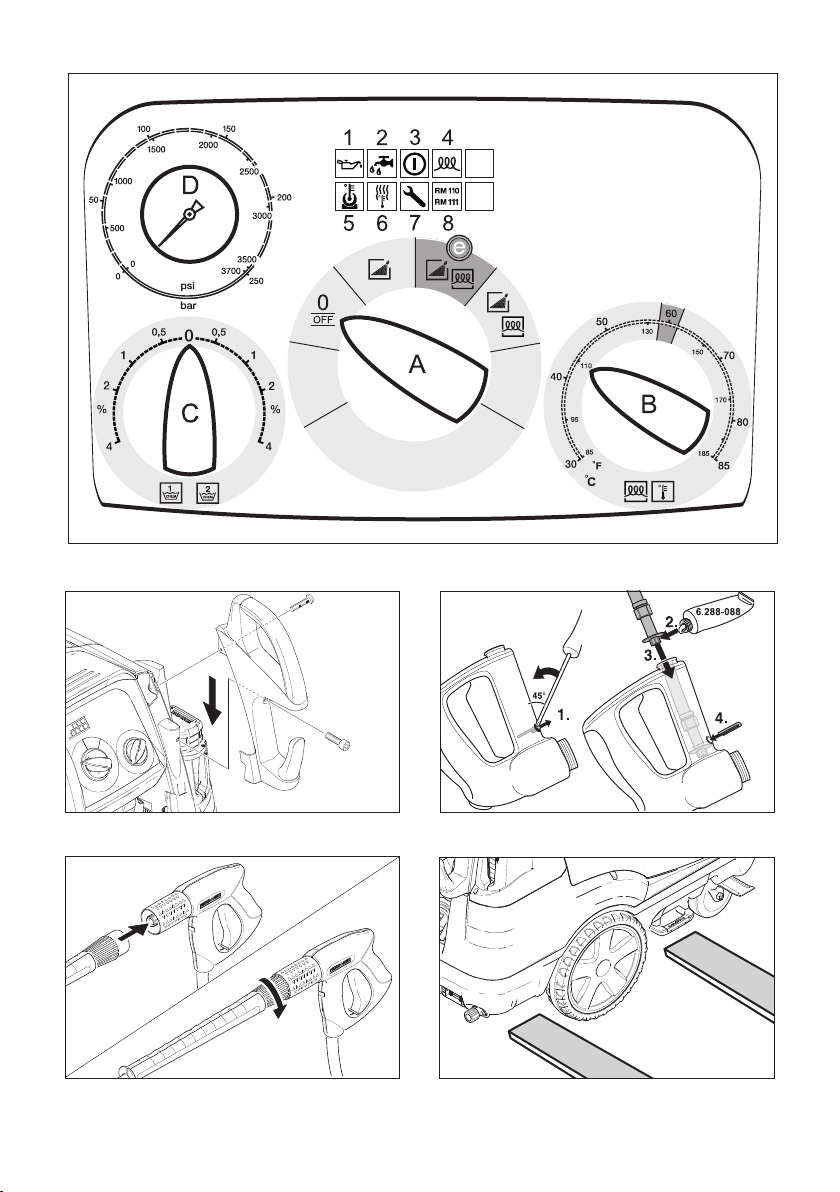

Page 4

2

3

4

5

6

1.

2.

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

몇 WARNING

When using this product basic precautions

should always be followed, including the

following:

1 Read all the instructions before using

the product.

2 High pressure jets can be dangerous if

misused. The jet must not be directed at

persons, animals, electrical devices, or

the unit itself.

3 To reduce the risk of injury, close super-

vision is necessary when a product is

used near children.

4 Know how to stop the product and

bleed pressures quickly. Be thoroughly

familiar with the controls.

5 Stay alert – watch what you are doing.

6 Wear safety goggles.

7 Do not use acids, alkaline, solvents, or

any flammable material in this product.

These products can cause physical in-

juries to the operator and irreversible

damage to the machine.

8 Do not operate the product when fa-

tigued or under the influence of alcohol

or drugs.

9 Do not overreach or stand on unstable

support. Keep good footing and bal-

ance at all times.

10 To reduce the risk of electrocution,

keep all connections dry and off the

ground. Do not touch plug with wet

hands.

11 The Trigger Gun Safety Lock prevents

the trigger from accidentally being en-

gaged. This safety feature DOES NOT

lock trigger in the ON position.

12 Keep operating area clear of all per-

sons.

13 Close cover before operating the ma-

chine.

14 This appliance is intended for commer-

cial use.

15 Follow the maintenance instructions

specified in the manual.

16 This machine has been designed for

use with cleaning chemicals supplied or

recommended by the manufacturer.

The use of other cleaning chemicals

may affect the operation of the machine

and void the warranty.

– Injection hazard: equipment can cause

serious injury if the spray penetrates the

skin. Do not point the gun at anyone or

any part of the body. In case of penetration seek medical aid immediately.

– This system is capable of producing

2520 psi/17.3 MPa.

To avoid rupture and injury, do not op-

erate this pump with components rated

less than 2520 psi/17.3 MPa working

pressure (including but not limited to

spray guns, hose and hose connections).

– Before servicing, cleaning, or removal

of any part, shut off power and relieve

pressure.

– Do not spray electrical apparatus and

wiring.

– High Pressure. Keep clear of nozzle.

– If connection is made to a potable water

system, the system shall be protected

against backflow.

Owner/User Responsibility

– The owner and/or user must have an

understanding of the manufacturer’s

operating instructions and warnings before using this pressure washer.

– Warning information should be empha-

sized and understood.

– If the operator is not fluent in English,

the manufacturer’s instructions and

warnings shall be read to and discussed with the operator in the operator’s native language by the purchaser/

owner, making sure that the operator

comprehends its contents.

– Owner and/or user must study and

maintain for future reference the manufacturers’ instructions.

5EN

Page 6

GROUNDING INSTRUCTIONS

This product must be grounded. If it should

malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock.

This product is equipped with a cord having

an equipment-grounding conductor for a

grounding plug. The plug must be plugged

into an appropriate outlet that is properly installed and grounded in accordance with all

local codes and ordinances.

DANGER

Improper connection of the equipmentgrounding conductor can result in a risk of

electrocution. Check with a qualified electrician or service personnel if you are in doubt

as to whether the outlet is properly grounded. Do not modify the plug provided with

the product - if it will not fit the outlet, have

a proper outlet installed by a qualified electrician. Do not use any type of adapter with

this product.

USA

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To comply with the National Electrical Code

(NFPA 70) and to provide additional protection from the risk of electric shock, this

pressure washer should only be connected

to a receptacle that is protected by a

ground fault circuit interrupter (GFCI).

CANADA

NOTE - In Canada, the use of a temporary

adaptor is not permitted by the Canadian

Electrical Code.

WATER SUPPLY

몇 CAUTION

When connecting the water inlet to the water supply mains, local regulations of your

water company must be observed. In some

areas the unit must not be connected directly to the public drinking water supply.

This is to ensure that there is no feedback

of chemicals into the water supply. Direct

6 EN

connection via a receiver tank or backflow

preventer, for example, is permitted.

Dirt in the feed water will damage the unit.

To avoid this risk, we recommend fitting a

water filter.

– Garden hose must be at least 3/4 inch

in diameter.

– Flow rate of water supply must not fall

below 4.4 GPM (gallons per minute).

– Flow rate can be determined by running

the water for one minute into an empty

5-gallon container.

– The water supply temperature must not

exceed 86°F/30°C.

– Never use the pressure washer to draw

in water contaminated with solvents,

e.g. paint thinners, gasoline, oil, etc.

– Always prevent debris from being

drawn into the unit by using a clean water source. Use additional water filter.

EXTENSION CORDS

Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole

cord connectors that accept the plug from

the product. Use only extension cords that

are intended for outdoor use. These extension cords are identified by a marking "Acceptable for use with out-door appliances:

store indoors while not in use." Use only extension cords having an electrical rating not

less than the rating of the product. Do not

use damaged extension cords. Examine

extension cord before using and replace if

damaged. Do not abuse extension cord

and do not yank on any cord to disconnect.

Keep cord away from heat and sharp edges. Always disconnect the extension cord

from the receptacle before disconnecting

the product from the extension cord.

SAVE THESE INSTRUCTIONS!

Page 7

Please read and comply with

these original instructions prior

to the initial operation of your appliance and

store them for later use or subsequent owners.

– Before first start-up it is definitely nec-

essary to read the operating instructions and safety indications Nr. 5.951-

949.0!

– In case of transport damage inform ven-

dor immediately

– Check the contents of the pack before

unpacking. For scope of delivery see illustration 1.

Contents

Environmental protection . . . . EN 1

Danger or hazard levels . . . . . EN 1

Overview . . . . . . . . . . . . . . . . . EN 2

Symbols on the machine. . . . . EN 2

Proper use . . . . . . . . . . . . . . . EN 2

Safety instructions. . . . . . . . . . EN 3

Safety Devices . . . . . . . . . . . . EN 3

Start up . . . . . . . . . . . . . . . . . . EN 3

Operation . . . . . . . . . . . . . . . . EN 5

Storage . . . . . . . . . . . . . . . . . . EN 7

Transport. . . . . . . . . . . . . . . . . EN 7

Maintenance and care . . . . . . EN 7

Troubleshooting . . . . . . . . . . . EN 8

Warranty . . . . . . . . . . . . . . . . . EN 10

Accessories and Spare Parts . EN 10

Technical specifications . . . . . EN 11

Environmental protection

The packaging material can be

recycled. Please do not throw

the packaging material into

household waste; please send it

for recycling.

Old appliances contain valuable

materials that can be recycled;

these should be sent for recycling. Batteries, oil, and similar

substances must not enter the

environment. Please dispose of

your old appliances using appropriate collection systems.

Please do not release engine oil, fuel oil,

diesel and petrol into the environment Protect the ground and dispose of used oil in

an environmentally-clean manner.

Notes about the ingredients (REACH)

You will find current information about the

ingredients at:

www.kaercher.com/REACH

Danger or hazard levels

DANGER

Immediate danger that can cause severe

injury or even death.

몇 WARNING

Possible hazardous situation that could

lead to severe injury or even death.

몇 CAUTION

Pointer to a possibly dangerous situation,

which can lead to minor injuries.

ATTENTION

Pointer to a possibly dangerous situation,

which can lead to property damage.

– 1

7EN

Page 8

Overview

Device elements

Figure 1

1 Cover

2 Support for spray lance

(both sides)

3 System care Advance RM 110/RM 111

4 Steering roller with fixed position brake

5 Mounting location for transport

(both sides)

6 Wheel

7 Water supply set

8 High pressure hose

9 O-ring set (for replacement)

10 Hand spray gun

11 Spray lance

12 High-pressure nozzle (stainless steel)

13 Pressure/ quantity regulation at the

hand spray gun

(Option)

14 Safety latch of the hand spray gun

15 Power supply

16 Connection for water supply with filter

17 High pressure connection

18 Step depression

19 Pouring vent for detergent 2

20 Pouring vent for detergent 1

21 Folding compartment

22 Handle

23 Operating field

24 Closing flap for storage compartment

25 Storage compartment for accessories

26 Nameplate

27 Cover lock

28 Oil tank

29 Pressure/quantity regulation of the

pump unit

30 Oil drain screw

31 Backflow valve of the detergent infeed

32 Detergent suction hose 1 with filter

33 Detergent suction hose 2 with filter

34 System care service switch

35 Safety block with sieve

36 Boiler

37 Fine filter (water)

38 Boiler drain screw

Operating field

Figure 2

A Power switch

B Temperature controller

C Dosage valve for detergent

D Manometer

1 Indicator lamp pump

2 ”Low water” indicator lamp

3 “Ready for use” indicator lamp

4 Indicator lamp - heating

5 Engine indicator lamp

6 Indicator lamp boiler fault

7 Indicator lamp service

8 Indicator lamp system care

Colour coding

– The operating elements for the cleaning

process are yellow.

– The controls for the maintenance and

service are light gray.

Symbols on the machine

High-pressure jets can be dan-

gerous if improperly used. The

jet may not be directed at persons, animals,

live electrical equipment or at the appliance

itself.

Risk of electric shock!

Only electricians or authorised

technicians are permitted to

work on parts of the plant.

Risk of burns on account of hot

surfaces!

Proper use

Cleaning of: Machines, Vehicles, Structures, Tools, Facades, Terraces, Gardening tools, etc.

DANGER

Risk of injury! Follow the respective safety

regulations when operating at gas stations

or other dangerous areas.

8 EN

– 2

Page 9

Please do not let mineral oil contaminated

waste water reach soil, water or the sewage system. Perform engine cleaning and

bottom cleaning therefore only on specified places with an oil trap.

Safety instructions

– Please follow the national rules and

regulations for fluid spray jets of the respective country.

– Please follow the national rules and

regulations for accident prevention of

the respective country. Fluid spray jets

must be tested regularly and the results

of these tests must be documented in

writing.

Safety Devices

Safety devices serve for the protection of

the user and must not be put out of operation or bypassed with respect to their function.

Overflow valve with two pressure

switches

– While reducing the water supply at the

pump head or with the Servopress regulation the overflow valve opens and

part of the water flows back to the pump

suck side.

– If the hand-spray gun is closed, so that

the whole water flows back to the pump

suck side, the pressure switch at the

overflow valve shuts down the pump.

– If the hand spray gun is opened, the

pressure switch on the cylinder head

turns the pump back on.

The overflow valve is set by the manufacturer and sealed. Setting only by customer

service.

Safety valve

– The safety valve opens, when the over-

flow valve resp. the pressure switch is

broken.

The safety valve is set by the manufacturer

and sealed. Setting only by customer service.

Water shortage safeguard

– The lack of water fuse prevents the

heater from being switched on when

there is a water shortage.

– The lack of water fuse switches the

pump off after 2 minutes in case of a

water shortage to prevent dry runs.

Temperature controller

– The temperature limiter switches off the

heater when the temperature becomes

too high.

Start up

몇 WARNING

Risk of injury! Device, tubes, high pressure

hose and connections must be in faultless

condition. Otherwise, the appliance must

not be used.

Lock parking brake.

Installing the handle

Figure 3

Replace the system care bottle

Note: Push the bottle in securely to pene-

trate the closure. Do not remove bottle until

it is empty.

Note: To protect the appliance, the heater

is switched off 5 hours after the system

care bottle is empty.

– The system care effectively prevents

the calcification of the pump while operating with calcified tap water. It is dosed

into the supply in the boiler drop by

drop.

– The metering is set to medium water ri-

gidity by the manufacturer

Note: A system care bottle is included in

the delivery.

Replace the system care bottle.

Adjusting the dosage of the system

care Advance RM 110/RM 111

Determining the hardness of tap water:

– through the public water supply works,

– using a hardness tester (order no.

6.768-004)

– 3

9EN

Page 10

Water hardness (°dH)

<3 OFF (no dosing)

3...7 1

7...14 2

14...21 3

>21 4

Set the service switch according to the

water hardness in the table.

Note: Observe the following when using

system care Advance 2 RM 111:

– Calcification protection: See table

– Pump care: Set the service switch to at

least setting 3.

Scale on the system care

service switch

Refill detergent

DANGER

Risk of injury!

– Use Kärcher products only.

– Under no circumstances fill solvents

(petrol, aceton, diluting agent etc.)

– Avoid eye and skin contact.

– Observe safety and handling instruc-

tions by the detergent manufacturer.

Kärcher offers an individual cleaning

and care appliances program.

Your dealer will consult you gladly.

Refill detergent.

Install the hand-spray gun, the jet

pipe, the nozzle and the high

pressure hose

Figure 4

Connect ray tube with hand spray gun

Tighten the screw connection of the

spray lance finger tight.

Insert high pressure nozzle into cover-

ing nut

Install covering nut and tighten firmly

Connect the high pressure hose to the

high pressure connection point of the

machine.

Installing spare high pressure hose

Figure 5

Water connection

For connection values refer to technical

specifications

Attach supply hose (minimum length

24.6 ft/7.5 m, minimum diameter 3/4“)

to the water supply set by means of a

hose clamp.

Connect the supply hose to the water

connection point of the machine and at

the water supply point (for e.g. a tap).

Note: The supply hose and the hose clamp

are not included in the scope of delivery.

Power connection

– For connection values, see technical

data and type plate.

– The electrical connections must be

done by an electrician according to IEC

60364-1.

– The voltage indicated on the type plate

must correspond to the voltage of the

electrical source.

– The installation of the electrical plug

may only be performed by the authorised customer service/electrician. The

electrical plug is not included.

DANGER

Danger of injury by electric shock.

– Unsuitable electrical extension cables

can be hazardous. Only use electrical

extension cables outdoors which have

been approved and labelled for this purpose and have an adequate cable

cross-section.

– Always unwind extension lines com-

pletely.

– The plug and coupling of the extension

cable used must be watertight.

10 EN

– 4

Page 11

Operation

DANGER

Risk of explosion!

Do not spray flammable liquids.

DANGER

Risk of injury! Never use the appliance

without the spray lance attached. Check

and ensure proper fitting of the spray lance

prior to each use. The screw connection of

the spray lance must be fingertight.

Safety instructions

몇 WARNING

Long hours of using the appliance can

cause circulation problems in the hands on

account of vibrations.

It is not possible to specify a generally valid

operation time, since this depends on several factors:

– Proneness to blood circulation deficien-

cies (cold, numb fingers).

– Low ambient temperature. Wear warm

gloves to protect hands.

– A firm grip impedes blood circulation.

– Continuous operation is worse than an

operation interrupted by pauses.

In case of regular, long-term operation of

the device and in case of repeated occurrence of the symptoms (e.g. cold, numb fingers) please consult a physician.

Boiler

Note: With especially hard water, calcium

can be flocculated at a higher rate inside

the boiler. This is a natural phenomenon

and it does not impact the function of the

appliance, so long as the maintenance intervals are adhered to (see "Care and

Maintenance").

Replace the nozzle

DANGER

Switch the appliance off prior to replacing

nozzle and activate hand spray gun until

device is pressureless.

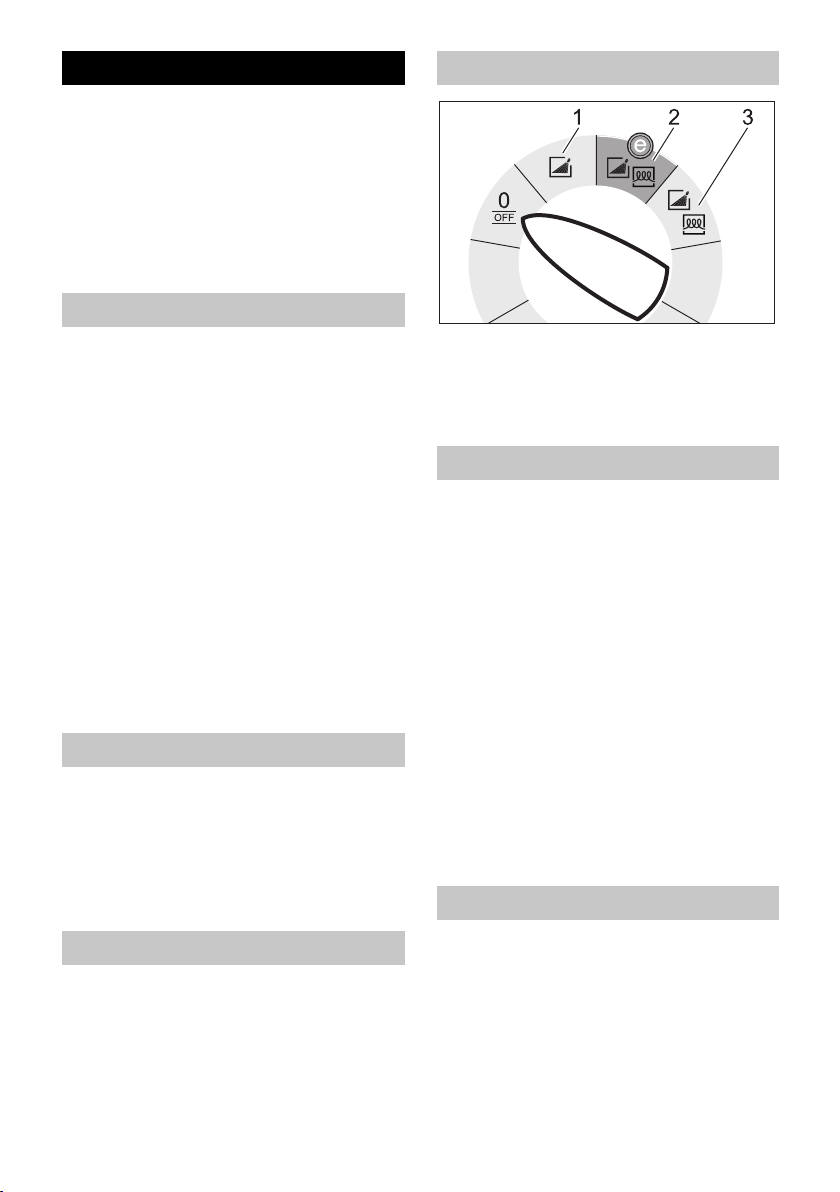

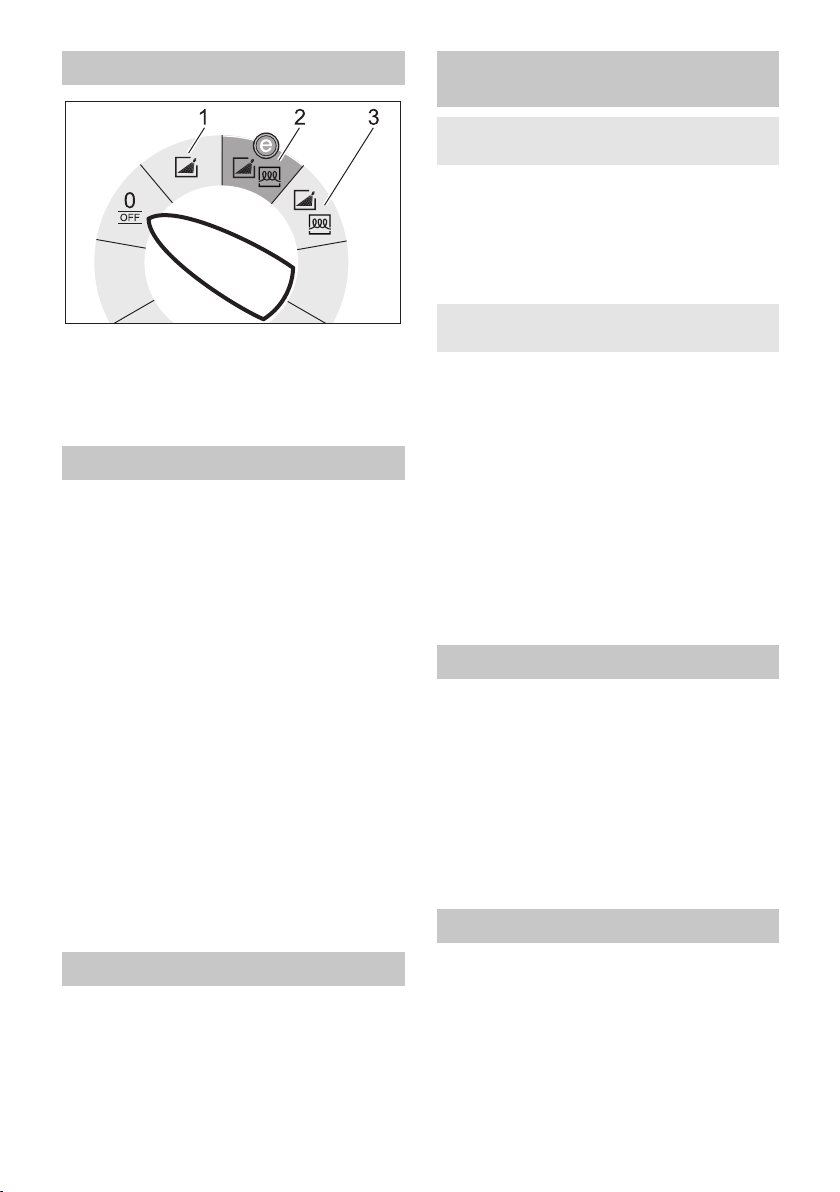

Operating modes

0/OFF = Off

1 Operating with cold water

2 Eco! efficiency setting (hot water max.

140 °F/60 °C)

3 Operating with hot water

Turning on the Appliance

Set appliance switch to desired operat-

ing mode.

Indicator lamp for operational readiness

lights up.

The device starts briefly and turns off, as

soon as the working pressure is reached.

Note: If the indicator lamps for pump, lack

of water, boiler malfunction or motor, turn

off the appliance immediately and repair

malfunction, refer to "Help with malfunctions".

Release the trigger gun.

When activating the hand spray gun the device switches back on.

Note: If no water comes out of the high

pressure nozzle, vent pump. Refer to "Help

with malfunctions - appliance is not building

up pressure".

Adjust cleaning temperature

Set temperature regulator to desired

temperature.

86 °F/30 °C to 185 °F/85 °C:

– Clean with hot water.

– 5

11EN

Page 12

Set working pressure and flow rate

Pressure/quantity regulation of the pump unit

Turn the regulation spindle in a clock-

wise direction: Increase working pressure (MAX).

Turn the regulation spindle in an anti-

clockwise direction: Reduce working

pressure (MIN).

Pressure/ quantity regulation at the hand spray gun

Set the operating pressure on the pump

unit to the maximum value.

Set the working pressure and feed

quantity by turning (steplessly) the

pressure/quantity regulation mechanism at the hand spray gun (+/-).

DANGER

When adjusting the pressure/quantity regulation, make sure that the screw connection

of the spray lance does not become loose.

Note: For long term work with low pressure, set pressure at the pump unit.

Operation with detergent

– For considerate treatment of the envi-

ronment use detergent economically.

– The detergent must be suitable for the

surface to be cleaned.

With support of the detergent dose

valve set detergent concentration as

determined by the manufacturer.

Note: Recommended values at the control

panel at maximum working pressure.

Cleaning

Set pressure/temperature and deter-

gent concentration according to the surface to be cleaned.

Note: To prevent damage due to too much

pressure, always position high pressure ray

first from a greater distance towards object

to be cleaned.

Recommended cleaning method

– Loosen the dirt:

Spray detergent economically and let it

work for 1...5 minutes but do not let it

dry up.

– Remove the dirt:

Spray off loosened dirt with the high

pressure jet.

Operating with cold water

Removal of light contaminations and clear

rinse, i.e.: Gardening tools, terrace, tools,

etc.

Set operating pressure according to

need.

Eco! efficiency setting

The appliance works in the most economical temperature range.

Note: The temperature can be regulated

up to 140 °F/60 °C.

Operating with hot water

We recommend the following cleaning temperatures:

– Light contaminations

86 °F/30 °C-122 °F/50 °C

– Contaminations containing protein, i.e.

in the food processing industry

max. 140 °F/60 °C

– Vehicle cleaning, machine cleaning

140 °F/60 °C-185 °F/85 °C

DANGER

Scalding danger!

Set temperature regulator to desired

temperature.

Note: Changing the working pressure and

the feed volume will also change the water

temperature.

After operation with detergent

Set dosing value for detergent to "0".

Set the appliance switch to "1" (opera-

tion with cold water).

Open the hand spray gun and rinse the

appliance for at least 1 minute.

12 EN

– 6

Page 13

Turn off the appliance

DANGER

Danger of scalding by hot water. After operation with hot water, the appliance must be

operated with an open gun with cold water

for at least five minutes to cool it off.

Set the appliance switch to "0/OFF“.

Shut off water supply.

Open the hand spray gun.

Turn on pump shortly (appr. 5 seconds)

with device switch.

Pull main plug out of socket with dry

hands only.

Remove water connection.

Activate hand spray gun until device is

pressure less.

Lock the trigger gun.

Storing the Appliance

Lock in the steel pipe into the holder of

the appliance hood.

Roll up high pressure hose and electri-

cal conduit and hang them into the respective holders.

Note: Do not twist high pressure hose and

electrical conduit.

Frost protection

ATTENTION

Frost will destroy the not completely water

drained device.

Store in a frost free area.

If it is not possible to store frost free, shut

down device.

Shutdown

For longer work breaks or if a frost free storage is not possible:

Drain water.

Flush device with anti-freeze agent.

Empty detergent tank.

Dump water

Screw off water supply hose and high

pressure hose.

Unscrew the drain screw of the boiler

on the bottom of the boiler and empty

the boiler.

Operate device for max. 1 minute until

the pump and conduits are empty.

Flush device with anti-freeze agent

Note: Observe handling instructions of the

anti-freeze agent manufacturer.

Fill commercial grade anti-freeze into

the boiler.

Switch on appliance (without heater)

until the appliance has been completely

rinsed.

A certain corrosion protection is achieved

with this as well.

Storage

몇 CAUTION

Risk of injury and damage! Note the weight

of the appliance in case of storage.

Transport

Figure 6

ATTENTION

Risk of damage! When loading the appliance with a forklift, observe the illustration.

몇 CAUTION

Risk of injury and damage! Observe the

weight of the appliance when you transport

it.

When transporting in vehicles, secure

the appliance according to the guide-

lines from slipping and tipping over.

Maintenance and care

DANGER

Risk of injury by inadvertent startup of appliance and electrical shock.

First pull out the plug from the mains before

carrying out any tasks on the machine.

Set the appliance switch to "0/OFF“.

Shut off water supply.

Open the hand spray gun.

Turn on pump shortly (appr. 5 seconds)

with device switch.

Pull main plug out of socket with dry

hands only.

Remove water connection.

Activate hand spray gun until device is

pressure less.

Lock the trigger gun.

– 7

13EN

Page 14

Allow device to cool down.

Your Kärcher vender will inform you

about the performance of a periodic

safety inspection resp. signing of a

maintenance contract.

Maintenance intervals

Weekly

Clean the sieve in the water connection.

Clean the fine filter.

Check oil level.

ATTENTION

In case of lacteous oil inform Kärcher customer service immediately

Monthly

Clean the sieve in the safety block.

Clean filter at the detergent suck hose.

After 400 operating hours, at least annually

Check the calcification degree of the

boiler and consider having it cleaned by

customer service.

After 500 operating hours, at least annually

Oil change.

Maintenance Works

Clean the sieve in the water connection

Take out sieve.

Clean sieve in water and reinstall.

Cleaning the fine filter

Unpressurize the appliance.

Unscrew the fine filter from the boiler.

Remove the fine filter and the filter in-

sert.

Clean the filter with clean water or com-

pressed air.

Reinstall in reverse sequence.

Clean the sieve in the safety block

Loosen covering nut and take off hose.

Take out sieve.

Note: If necessary turn in screw M8 appr.

0.2 in/5 mm inwards and therewith pull out

sieve.

Clean sieve in water.

Push sieve inwards.

Put on hose.

Tighten covering nut firmly.

Clean filter at the detergent suck hose

Take out detergent suck supports.

Clean filter in water and reinstall.

Oil change

Ready a catch bin for appr. 0.26 gal/

1 Liter oil.

Loosen release screw.

Dispose of old oil ecologically or turn in at

a gathering point.

Tighten release screw.

Fill oil slowly up to the MAX marking.

Note: Air pockets must be able to leak out.

For oil type refer to technical specifications.

Troubleshooting

DANGER

Risk of injury by inadvertent startup of appliance and electrical shock.

First pull out the plug from the mains before

carrying out any tasks on the machine.

Indicator lamp pump

1x blinking

– Lack of oil

Replenish oil.

2x blinking

– Leak in the high pressure system

Check high pressure system and con-

nections for tightness.

3x blinking

– Lack of water after 2 minutes - the pump

is switched off to prevent dry runs.

Check water supply, check connec-

tions.

4x blinking

– Heater contactor fault

Set the appliance switch to "0/OFF“.

Turn on the appliance.

– Error occurs repeatedly.

Inform Customer Service

14 EN

– 8

Page 15

”Low water” indicator lamp

– Lack of water - heater is switched off

Check water supply, check connec-

tions.

Indicator lamp "Ready for use"

turns off

– No line voltage, see "Appliance is not

running".

Indicator lamp for heater lights up

– Heater operation

Engine indicator lamp

2x blinking

– Engine overload/overheat

Set the appliance switch to "0/OFF“.

Allow device to cool down.

Turn on the appliance.

– Error occurs repeatedly.

Inform Customer Service

3x blinking

– Fault in the voltage supply.

Check main connections and mains

fuse.

4x blinking

– Excessive power consumption.

Check main connections and mains

fuse.

Inform Customer Service

Indicator lamp boiler fault

1x blinking

– Temperature limiter has got triggered.

Set the appliance switch to "0/OFF“.

Allow device to cool down.

Turn on the appliance.

– Error occurs repeatedly.

Inform Customer Service

3x blinking

– System care detection defective

Inform Customer Service

4x blinking

– Temperature sensor defective

Inform Customer Service

Indicator lamp service

– Service interval

Perform service work.

Indicator lamp system care is

illuminated

Note: Heater can only operate 5 more

hours.

– System care bottle empty.

Replace the system care bottle.

Indicator lamp system care is

blinking

Note: Heater operation no longer possible.

– System care bottle empty.

Replace the system care bottle.

Appliance is not running

– No power

Check power connection/conduit.

Device is not building up pressure

– Air within the system

Vent pump:

Set dosing value for detergent to "0".

With open hand spray gun turn device

on and off multiple times with the device

switch.

Open and close the pressure/quantity

regulation at the pump unit with the

hand spray gun open.

Note: By dismantling the high pressure

hose from the high pressure connection the

venting process is accelerated.

If detergent tank is empty, refill.

Check connections and conduits.

– Pressure is set to MIN

Set pressure to MAX.

– Sieve in the water connection is dirty

Clean sieve.

Clean the fine filter; replace it, if neces-

sary.

– Amount of water supply is too low.

Check water supply level (refer to tech-

nical data).

– 9

15EN

Page 16

Device leaks, water drips from the

bottom of the device

– Pump leaky

Note: 3 drops/minute are allowed.

With stronger leak, have device

checked by customer service.

Note: Condensate can cause increased

drop generation on the appliance.

Device turns on and off while hand

spray gun is closed

– Leak in the high pressure system

Check high pressure system and con-

nections for tightness.

Device is not sucking in detergent

Leave the appliance running with open

detergent dosing valve and closed water supply, until the boiler is sucked

empty and the pressure falls to "0".

Open the water supply again.

If the pump still is not sucking in any detergent, it could be because of the following

reasons:

– Filter in the detergent suck hose dirty

Clean filter.

– Backflow valve stuck

Remove the detergent hose and loosen

the backflow valve using a blunt object.

Boiler does not heat up

– System care bottle empty.

Replace the system care bottle.

– Water shortage

Check water supply, check connec-

tions.

– Heater defective.

Inform Customer Service

Set temperature is not achieved

while using hot water

– Working pressure/flow rate to high

Reduce working pressure/flow quantity

at the pressure/volume regulator in the

pump unit.

Customer Service

If malfunction can not be fixed, the device must be checked by customer service.

Warranty

The warranty terms published by our competent sales company are applicable in

each country. We will repair potential failures of the appliance within the warranty

period free of charge, provided that such

failure is caused by faulty material or defects in fabrication.

Accessories and Spare Parts

– Only use accessories and spare parts

which have been approved by the manufacturer. The exclusive use of original

accessories and original spare parts

ensures that the appliance can be operated safely and trouble free.

– At the end of the operating instructions

you will find a selected list of spare parts

that are often required.

– For additional information about spare

parts, please go to the Service section

at www.kaercher.com.

16 EN

– 10

Page 17

Technical specifications

HDS-E 3.3/25-4M EcHDS-E 3.3/25-4M

Ef

Main Supply

Voltage V 460 575

Current type Hz 3~ 60 3~ 60

Connected load kW 30 30

Protection (slow) A 50 50

Type of protection -- IPX5 IPX5

Protective class -- I I

Water connection

Max. feed temperature °F (°C) 86 (30) 86 (30)

Min. feed volume gpm (l/min) 4.4 (16.7) 4.4 (16.7)

Max. feed pressure psi (MPa) 87 (0.6) 87 (0.6)

Performance data

Water flow rate gpm (l/min) 1.6-3.3 (6.1-12.3) 1.6-3.3 (6.1-12.3)

Operating pressure of water (using standard

nozzle)

Max. excess operating pressure (safety

valve)

Max. operating temperature of hot water °F (°C) 185 (85) 185 (85)

Switch-off temperature hot water °F (°C) 208 (98) 208 (98)

Operating temperature during continuous

operation with 59 °F/15 °C input temperature

Detergent suck in gpm (l/min) 0-0.13 (0-0.5) 0-0.13 (0-0.5)

Heating output kW 24 24

Max. recoil force of trigger gun N 37.2 37.2

Nozzle size -- 045 045

Values determined as per EN 60355-2-79

Noise emission

Sound pressure level L

Uncertainty K

pA

pA

Sound power level LWA + Uncertainty K

Hand-arm vibration value

Hand spray gun m/s

Spray lance m/s

Uncertainty K m/s

Fuel

Amount of oil gal (l) 0.2 (0.75) 0.2 (0.75)

Oil grade -- SAE 90 SAE 90

Dimensions and weights

Length x width x height in (mm) 52.5 x 29.5 x 41.5

Typical operating weight lbs (kg) 423 (192) 423 (192)

Detergent Tank gal (l) 2.6+5.3 (10+20) 2.6+5.3 (10+20)

Total boiler capacity gal (l) 13.2 (50) 13.2 (50)

psi (MPa) 465-2520 (3.2-17.3) 465-2520 (3.2-17.3)

psi (MPa) 2972 (20.5) 2972 (20.5)

°F (°C) 113 (45) 113 (45)

dB(A) 67 67

dB(A) 3 3

dB(A) 85 85

WA

2

2

2

4.5 4.5

1.9 1.9

0.3 0.3

52.5 x 29.5 x 41.5

(1330 x 750 x 1060)

(1330 x 750 x 1060)

– 11

17EN

Page 18

CONSIGNES DE SÉCURITÉ IMPORTANTES

몇 AVERTISSEMENT

En utilisant ce produit, toujours observer

une certaine prudence élémentaire, incluant notamment :

1 Lire toutes les instructions de service

avant d'utiliser l'appareil.

2 En cas d'utilisation incorrecte, les jets

haute pression peuvent être dange-

reux. Ne jamais diriger les jets de va-

peur en direction d'individus,

d'animaux, de dispositifs électriques ou

de l'appareil lui-même.

3 Afin de minimiser les risques de bles-

sure, ne jamais laisser l'appareil sans

surveillance lorsque celui-ci est utilisé à

proximité d'enfants.

4 Il est impératif de savoir arrêter et

mettre l'appareil hors pression rapide-

ment. Une connaissance approfondie

des commandes est nécessaire.

5 Rester attentif – se concentrer sur la

tâche en cours.

6 Le port de lunettes de protection est

obligatoire.

7 N'utiliser en aucun cas d'acides, de so-

lutions alcalines, de solvants ou de pro-

duits inflammables dans cet appareil.

Ces produits peuvent être à l'origine de

blessures graves ou d'endommage-

ment irréversible de l'appareil.

8 L'utilisateur ne doit jamais faire usage

de l'appareil lorsqu'il est fatigué ou sous

l'emprise d'alcool ou de drogues.

9 Ne jamais passer ou monter sur des

supports instables. Toujours rester

stable et équilibré.

10 Afin de réduire le risque d'électrocution,

garder toutes les connexions au sec et

ne pas les laisser à terre. Ne pas tou-

cher la fiche avec les mains mouillées.

11 Le dispositif de sécurité de la poignée-

pistolet permet d'éviter tout actionne-

ment accidentel de la gâchette. Ce dis-

positif de sécurité NE verrouille PAS la

gâchette en position marche (ON).

12 Veiller à ce qu'aucun individu ne se

trouve dans la zone de travail.

13 Fermer le couvercle avant d'utiliser la

machine.

14 Cet appareil est prévu pour un usage

commercial.

15 Respecter les consignes d'entretien fi-

gurant dans le manuel.

16 Cette machine a été conçue pour une

utilisation avec des produits chimiques

utilisés pour le nettoyage, fournis ou recommandés par le fabricant. L'utilisation d'autres produits chimiques pour le

nettoyage peut influer sur le fonctionnement de la machine et annuler la garantie.

– Risque d'injection : le produit peut pro-

vo-quer de graves blessures en cas de

péné-tration dans la peau. Ne pas diriger le ca-non vers quelqu'un ou vers

une partie du corps. En cas de pénétration, consulter im-médiatement un médecin.

– Ce système peut produire 2520 psi/

17.3 MPa.

Afin d'éviter une rupture et des bles-

sures, ne pas utiliser cette pompe avec

des composants ayant une puissance

nominale inférieure à une pression de

service de 2520 psi/17.3 MPa (comprend des pistolets pulvérisateurs, des

tuyaux et des raccords de tuyaux).

– Avant d'effectuer l'entretien, le net-

toyage ou le retrait de toute pièce, couper le cou-rant et réduire la pression.

– Ne pas pulvériser sur des appareils ou

des fils électriques.

– Haute pression. Maintenir sans tuyères.

– Si le branchement à un système d'eau

potable est effectué, le système doit

être protégé contre un retour de courant.

18 FR

Page 19

Responsabilité du propriétaire/de

l'utilisateur

– Avant d'utiliser ce nettoyeur pression, le

propriétaire et/ou l'utilisateur doit impé-

rativement avoir pris connaissance des

consignes d'utilisation et mises en

garde du fabricant.

– Il est nécessaire d'insister sur les aver-

tissements et de les comprendre.

– Si l'utilisateur ne parle pas couramment

l'anglais, l'acheteur/le propriétaire doit

lire les consignes et mises en garde du

fabricant avec l'utilisateur dans la

langue maternelle de ce dernier et s'as-

surer qu'il en comprend bien le contenu.

– Le propriétaire et/ou l'utilisateur doit se

familiariser avec les consignes du fabri-

cant et les conserver afin de pouvoir s'y

référer ultérieurement.

INSTRUCTIONS DE MISE À

LA TERRE

Ce produit doit-être mis à la terre. En cas

de mauvais fonctionnement ou de panne,

la mise à la terre établit un chemin de

moindre résistance pour le courant électrique afin de réduire le risque de décharge

électrique. Ce produit est équipé d'un cordon doté d'un conducteur de mise à la terre

de l'équipement pour une prise de mise à la

terre. La prise doit être branchée dans une

prise appropriée qui est correctement installée et mise à la terre en conformité avec

les codes et ordonnances locaux.

DANGER

Un conducteur de mise à la terre d'équipement incorrectement branché peut entraîner un risque d'électrocution. Vérifier avec

un électricien ou un technicien d'entretien

qualifié en cas de doute sur la mise à terre

correcte de la prise. Ne pas modifier la

fiche fournie avec le produit - si elle ne peut

pas être branchée, faire installer une prise

appropriée par un électricien qualifié. Ne

pas utiliser n'importe quel type d'adaptateur avec ce produit.

USA

PROTECTION PAR INTERRUPTEUR DE

COURT-CIRCUIT À LA MASSE

Afin de satisfaire à la norme électrique nationale (NFPA 70) et d'offrir une protection

supplémentaire contre le risque de décharge électrique, ce jet sous pression ne

devrait être raccordé qu'à une prise protégée par un interrupteur de court-circuit à la

masse (GFCI).

CANADA

NOTE - Au Canada, l'utilisation d'un adaptateur temporaire n'est pas autorisée par le

Code canadien de l'électricité.

19FR

Page 20

ALIMENTATION EN EAU RALLONGES

몇 ATTENTION

Lors de la connexion de l'entrée d'eau à la

canalisation d'alimentation en eau, les régulations locales de votre compagnie d'eau

doivent être observées. Dans certaines

zones, l'appareil ne doit pas être connecté

directement à l'alimentation en eau potable

publique. Il s'agit de s'assurer qu'il n'y a pas

de retour de produits chimiques dans l'alimentation en eau. Une connexion directe

par l'intermédiaire d'un réservoir de réception ou d'un disconnecteur hydraulique par

exemple est autorisée.

D'éventuelles impuretés dans l'eau d'alimentation endommagent l'appareil. Pour

prévenir ce risque, nous recommandons

d'installer un filtre à eau.

– Le tuyau d'arrosage doit avoir un dia-

mètre minimum de 3/4 pouces.

– Le débit de l'alimentation en eau ne doit

pas être inférieur à 4.4 GPM (gallons

par minute).

– Pour calculer le débit, faire couler l'eau

pendant une minute dans un récipient

vide d'une contenance de 5 gallons.

– La température de l'eau d'alimentation

ne doit pas excéder 86 °F/30 °C.

– Ne jamais aspirer d'eau contaminée par

des solvants, par exemple des diluants

pour peinture, de l'essence, de l'huile,

etc..

– Toujours utiliser une source d'eau

propre afin d'éviter toute infiltration de

débris dans l'appareil. Utiliser un filtre à

eau supplémentaire.

Utiliser uniquement des rallonges à 3 fils,

dotées de fiches de terre à 3 fourches et de

connecteurs tripolaires adaptés à la fiche

du produit. Utiliser uniquement des rallonges prévues pour une utilisation extérieure. Ces rallonges sont repérables au

marquage "Peut être utilisé avec des appareils électriques à l'extérieur : ranger à l'intérieur lorsque l'appareil n'est pas utilisé."

Utiliser uniquement des rallonges ayant

une puissance nominale qui n'est pas inférieure à celle du produit. Ne pas utiliser de

rallonges endommagées. Examiner la rallonge avant de l'utiliser et la remplacer si

elle est endommagée. Ne pas abîmer la

rallonge et ne pas tirer brusquement sur un

cordon pour le débrancher. Tenir le cordon

éloigné des sources de chaleur et des

bords pointus. Toujours débrancher la rallonge de la prise de courant avant de débrancher le produit de la rallonge.

CONSERVER CES INSTRUCTIONS !

20 FR

Page 21

Lire ce manuel d'utilisation origi-

nal avant la première utilisation

de votre appareil, le respecter et le conserver pour une utilisation ultérieure ou pour le

futur propriétaire.

– Avant la première mise en service, vous

devez impérativement avoir lu les

consignes de sécurité N° 5.951-949.0 !

– Contactez immédiatement le revendeur

en cas d'avarie de transport.

– Vérifier le contenu de l'emballage à l'ou-

verture. Étendue de livraison cf. figure

1.

Table des matières

Protection de l’environnement FR 1

Niveaux de danger . . . . . . . . . FR 1

Aperçu général . . . . . . . . . . . . FR 2

Symboles sur l'appareil. . . . . . FR 2

Utilisation conforme . . . . . . . . FR 3

Consignes de sécurité . . . . . . FR 3

Dispositifs de sécurité . . . . . . . FR 3

Mise en service . . . . . . . . . . . . FR 3

Utilisation . . . . . . . . . . . . . . . . FR 5

Entreposage . . . . . . . . . . . . . . FR 8

Transport. . . . . . . . . . . . . . . . . FR 8

Entretien et maintenance . . . . FR 8

Assistance en cas de panne . . FR 9

Garantie . . . . . . . . . . . . . . . . . FR 11

Accessoires et pièces de re-

change . . . . . . . . . . . . . . . . . . FR 12

Caractéristiques techniques . . FR 13

Protection de

l’environnement

Les matériaux constitutifs de

l’emballage sont recyclables. Ne

pas jeter les emballages dans

les ordures ménagères, mais les

remettre à un système de recyclage.

Les appareils usés contiennent

des matériaux précieux recyclables lesquels doivent être apportés à un système de recyclage. Il est interdit de jeter les

batteries, l'huile et les substances similaires dans l'environnement. Pour cette raison, utiliser des systèmes de collecte

adéquats afin d'éliminer les appareils hors d'usage.

Ne jetez pas l'huile moteur, le fuel, le diesel

ou l'essence dans la nature. Protéger le sol

et évacuer l'huile usée de façon favorable

à l'environnement.

Instructions relatives aux ingrédients

(REACH)

Les informations actuelles relatives aux ingrédients se trouvent sous :

www.kaercher.com/REACH

Niveaux de danger

DANGER

Pour un danger immédiat qui peut avoir

pour conséquence la mort ou des blessures corporelles graves.

몇 AVERTISSEMENT

Pour une situation potentiellement dangereuse qui peut avoir pour conséquence des

blessures corporelles graves ou la mort.

몇 PRÉCAUTION

Remarque relative à une situation potentiellement dangereuse pouvant entraîner

des blessures légères.

ATTENTION

Remarque relative à une situation éventuellement dangereuse pouvant entraîner

des dommages matériels.

– 1

21FR

Page 22

Aperçu général

Éléments de l'appareil

Figure 1

1 Capot

2 Dispositif de fixation de la lance

(bilatéral)

3 Entretien système Advance RM 110/

RM 111

4 Roulettes pivotantes et frein de station-

nement

5 Point de fixation pour le transport

(bilatéral)

6 Roue

7 Kit de raccord d'alimentation en eau

8 Flexible haute pression

9 Kit joint torique (pour le remplacement)

10 Poignée-pistolet

11 Lance

12 Buse haute pression (acier inoxydable)

13 Réglage de la pression/ du débit à la

poignée-pistolet.

(option)

14 Cran de sécurité de la poignée-pistolet

15 Alimentation électrique

16 Arrivée d'eau avec tamis

17 Raccord haute pression

18 Cavité de marche

19 Orifice de remplissage pour détergent 2

20 Orifice de remplissage pour détergent 1

21 Compartiment pliant

22 Poignée

23 Pupitre de commande

24 Capot du compartiment de rangement

25 Compartiment de rangement pour ac-

cessoires

26 Plaque signalétique

27 Fermeture du capot

28 Réservoir d'huile

29 Réglage de la pression/ du débit de

l'unité de pompe

30 Bouchon de vidange d'huile

31 Soupape anti-retour de l'aspiration de

détergent

32 Flexible d'aspiration du détergent 1

avec filtre

33 Flexible d'aspiration du détergent 2

avec filtre

34 Interrupteur de service Entretien du

système

35 Bloc de sécurité avec filtre

36 Chauffe-eau

37 Filtre fin (eau)

38 Vis de purge du chauffe-eau

Zone de commande

Figure 2

A Interrupteur principal

B Thermostat

C Vanne de dosage du détergent

D Manomètre

1 Lampe témoin pompe

2 Voyant témoin de manque d’eau

3 Témoin de contrôle d’état de service

4 Lampe témoin chauffage

5 Témoin de contrôle Moteur

6 Voyant de contrôle de défaut du

chauffe-eau

7 Lampe témoin service

8 Lampe témoin soin système

Repérage de couleur

– Les éléments de commande pour le

processus de nettoyage sont jaunes.

– Les éléments de commande pour la

maintenance et l'entretien sont en gris

clair.

Symboles sur l'appareil

Une utilisation incorrecte des

jets haute pression peut présenter des dangers. Le jet ne doit pas être dirigé sur des personnes, animaux, installations électriques actives ni sur l'appareil luimême.

Danger lié à la tension

électrique !

Seul les électriciens spécialisés

ou le personnel autorisé sont habilités à réaliser des travaux sur

des composants de l'appareil.

Risque de brûlure provoqué par

les pièces chaudes de l'installation!

22 FR

– 2

Page 23

Utilisation conforme

Nettoyage de : machines, véhicules, bâtiments, outils, façades, terrasses, appareils

de jardinage, etc.

DANGER

Risque de blessure ! En cas d'utilisation

dans l'enceinte d'une station service ou

dans d'autres zones à risque, respecter les

consignes de sécurité correspondantes.

Ne pas évacuer les eaux usées contenant

de l'huile minérale dans la terre, les dispositifs pour eaux usées ou les canalisations.

Dès lors, effectuer le nettoyage du moteur

ou du bas de caisse uniquement aux

postes de lavage appropriés et équipés

d'un séparateur d'huile.

Consignes de sécurité

– Respecter les dispositions légales na-

tionales respectives pour les jets de liquide.

– Respecter les dispositions légales na-

tionales respectives pour la prévention

des accidents. Les jets de liquides

doivent être contrôlés régulièrement et

le résultat du contrôle consigné par

écrit.

Dispositifs de sécurité

Les dispositifs de sécurité ont pour but de

protéger l'utilisateur. Par conséquent, ils ne

doivent en aucun cas être désactivés ou

transformés.

Clapet de décharge doté de deux

pressostats

– En cas de réduction du débit d'eau au

niveau de la tête de la pompe ou avec

le réglage de la servopresse, la clapet

de décharge s'ouvre et une partie de

l'eau est évacuée vers le côté aspiration

de la pompe.

– Si la poignée-pistolet est fermés, de

sorte que toute l'eau retourne vers le

côté aspiration de la pompe, le pressostat du clapet de décharge désactive la

pompe.

– Si la poignée-pistolet est de nouveau

ouverte, le pressostat de la culasse

réactive la pompe.

Le clapet de décharge est réglé et plombé

d'usine. Seul le service après-vente est autorisé à effectuer le réglage.

Soupape de sûreté

– La soupape de sûreté s'ouvre lorsque le

clapet de décharge ou le pressostat est

défectueux.

La soupape de sûreté est réglée et plombée d'usine. Seul le service après-vente est

autorisé à effectuer le réglage.

Dispositif de sécurité en cas de

manque d'eau

– Le dispositif de sécurité en cas de

manque d'eau permet d'éviter que le

chauffage se mette en marche lorsque

la quantité d'eau est insuffisante.

– La protection contre le manque d'eau

désactive la pompe au bout de 2 mi-

nutes après le manque d'eau, pour évi-

ter une marche à sec.

Limiteur de température

– Le limiteur de la température déclenche

l'installation lors de l'atteinte d'une tem-

pérature trop élevée.

Mise en service

몇 AVERTISSEMENT

Risque de blessure ! L'appareil, les

conduites d'alimentation, les flexibles haute

pression et les raccords ne doivent présenter aucun défaut. Ne pas utiliser l'appareil si

son état n'est pas irréprochable.

Serrer le frein de stationnement.

Monter la poignée

Figure 3

Remplacer la bouteille d'entretien

système

Remarque : Presser fortement la bouteille

lors de la mise en place afin de traverser la

fermeture. Ne pas retirer la bouteille avant

qu'elle ne soit vide.

– 3

23FR

Page 24

Remarque : Pour la protection de l'appareil, le chauffage est mis hors service avec

une temporisation de 5 heures quand la

bouteille d'entretien système est vide.

– L'entretien système enraye l'entartrage

de la pompe avec une forte efficacité en

cas d'utilisation d'eau du robinet calcaire. Il est ajouté goutte-à-goutte à l'alimentation dans le chauffe-eau.

– Le dosage est effectué d'usine pour ob-

tenir une dureté d'eau moyenne.

Remarque :Le contenu de la livraison comporte une bouteille d'entretien système.

Remplacer la bouteille d'entretien sys-

tème.

Régler le dosage de l'entretien

système Advance RM 110/RM 111

Déterminer la dureté de l'eau locale :

– En contactant le distributeur local,

– avec un appareil pour essai de dureté

(N° de commande 6.768-004).

Dureté d'eau

(°dH)

<3 OFF (pas de dosage)

3...7 1

7...14 2

14...21 3

>21 4

Régler le commutateur de service selon

le tableau en fonction de la dureté de

l'eau.

Remarque : Respecter ce qui suit lors de

l'utilisation du soin système Advance 2

RM 111 :

– Protection contre l'entartrage : voir le ta-

bleau

– Entretien des pompes : régler l'interrup-

teur de service au moins sur la position

3.

Echelle sur l'interrupteur de

service de l'entretien du système

Faire le plein de détergent

DANGER

Risque de blessure !

– Utiliser uniquement les produits Kärcher.

– N'utiliser en aucun cas de solvant (es-

sence, acétone, diluant, etc.).

24 FR

– Eviter tout contact avec les yeux ou la

peau.

– Respecter les consignes de sécurité et

d'utilisation fournies par le fabricant du

détergent.

Kärcher propose un assortiment individualisé de produits d'entretien et de nettoyage.

Votre revendeur se fera un plaisir de vous

conseiller.

Faire le plein de détergent.

Monter pistolet pulvérisateur à

main, lance, buse et flexible haute

pression

Figure 4

Relier la lance à la poignée-pistolet.

Serrer le raccord vissé de la lance à la

main.

Fixer la buse haute pression dans

l'écrou-raccord.

Installer l'écrou-raccord et le fixer soli-

dement.

Fixer le flexible haute pression au rac-

cord haute pression de l'appareil.

Montage du flexible haute pression

de rechange

Figure 5

Arrivée d'eau

Pour les valeurs de raccordement, se reporter à la section Caractéristiques techniques.

Fixer le flexible d'alimentation (longueur

minimale 24.6 ft/7.5 m, diamètre mini-

mal 3/4“) avec collier de flexible au ni-

veau du kit de raccord d'alimentation en

eau.

Raccorder la conduite d'alimentation au

raccord pour l'arrivée d'eau de l'appareil

et à l'alimentation en eau (ex. un robi-

net).

Remarque : Le flexible d'alimentation et le

collier de flexible ne sont pas contenus

dans l'étendue de livraison.

– 4

Page 25

Raccordement électrique

– Pour les données de raccordement, se

référer à la section Caractéristiques

techniques et à la plaque signalétique.

– Le raccordement électrique doit être ef-

fectué par un électricien et doit correspondre à la CEI 60364-1.

– La tension indiquée sur la plaque signa-

létique de l'appareil doit correspondre à

celle de la prise.

– Seul le service client/un électricien spé-

cialisé est autorisé à procéder au montage du connecteur électrique. Le

connecteur électrique n'est pas compris

dans la livraison.

DANGER

Risque d'électrocution.

– Des rallonges électriques non adaptées

peuvent présenter des risques. Utiliser

à l’air libre uniquement des câbles de

rallonge électriques autorisés et marqués de façon adéquate avec une section suffisante du conducteur .

– Toujours dérouler complètement les

conduites de rallonge.

– Les fiches mâles et les raccords des

câbles de rallonge utilisés doivent être

étanches à l’eau.

Utilisation

DANGER

Risque d'explosion !

Ne pas pulvériser de liquides inflammables.

DANGER

Risque de blessure ! Ne jamais utiliser l'appareil si la lance n'est pas montée. Contrôler avant chaque utilisation la bonne fixation de la lance. Le raccord vissé de la

lance doit être serré à la main.

Consignes de sécurité

몇 AVERTISSEMENT

Á cause des vibrations, une durée d'utilisation plus long de l'appareil peut amenée

aux troubles de l'irrigation sanguine dans

les mains.

Il est impossible de définir une durée d'utilisation universelle. Celle-ci dépend en effet

de plusieurs facteurs d'influence :

– Mauvaise circulation sanguine de l'utili-

sateur (doigts souvent froids, sensation

de picotement dans les doigts).

– Température ambiante faible. Porter

des gants chauds pour protéger les

mains.

– Une préhension ferme peut entraver la

circulation sanguine.

– Il est conseiller de ponctuer le travail de

pauses plutôt que d'assurer un service

ininterrompu.

En cas d'utilisation régulière et de longue

durée de l'appareil et en cas d'apparition

répétée des symptômes caractéristiques

(par exemple, une sensation de picotement

dans les doigts, les doigts froids), nous recommandons de consulter un médecin.

Chauffe-eau

Remarque : Si le degré de dureté de l'eau

utilisée est particulièrement élevé, cela

peut entraîner une floculation de calcaire

dans le chauffe-eau. Ceci est un processus

naturel et n'entrave pas le fonctionnement

de l'appareil, si les intervalles de maintenance sont respectés (cf. Entretien et

maintenance").

Remplacer la buse

DANGER

Mettre l'appareil hors service et actionner la

poignée-pistolet jusqu'à ce que l'appareil

soit hors pression avant de procéder au

remplacement de la buse.

– 5

25FR

Page 26

Modes de fonctionnement

0/OFF = Arrêt

1 Utilisation avec de l'eau froide

2 Niveau Eco!Efficiency (eau chaude

maxi 140 °F/60° C)

3 Utilisation avec de l'eau chaude

Mettre l'appareil en marche

Mettre l'interrupteur principal sur le

mode de fonctionnement souhaité.

Le témoin de contrôle d'état de service

s'allume.

L'appareil se met en marche pendant une

courte durée puis s'arrête dès que la pression de service est atteinte.

Remarque :Si, au cours du service, les témoins de contrôle pompe, manque d'eau,

défaut du chauffage ou moteur s'allument,

mettre immédiatement l'appareil hors tension et réparer la panne. Cf. "Aide en cas

de Pannes".

Armer la poignée-pistolet.

Dès que la poignée-pistolet est actionnée,

l'appareil se remet en marche.

Remarque :S'il ne sort pas d'eau de la

buse haute pression, purger l'air de la

pompe. Se reporter à la section "Aide en

cas de pannes - L'appareil n'établit aucune

pression".

Régler la température de nettoyage

Régler le thermostat sur la température

souhaitée.

86 °F/30 °C à 185 °F/85 °C :

– Nettoyer à l'eau chaude.

Régler la pression de service et le

débit

Réglage de la pression/ du débit de l'unité de pompe

Tourner la tige de réglage dans le sens

des aiguilles d'une montre : augmentation de la pression de service (MAX).

Tourner la tige de réglage dans le sens

inverse des aiguilles d'une montre : réduction de la pression de service (MIN).

Réglage de la pression/ du débit à la poignée-pistolet.

Régler la pression de travail sur l’unité

de pompe à la valeur maximale.

Régler la pression d'utilisation et le dé-

bit à la poignée-pistolet en tournant (en

continu) le régulateur de pression/de

débit (+/-).

DANGER

Lors du réglage de la régulation de quantité/de pression, veiller que le raccord vissé

de la lance ne se desserre pas.

Remarque :Si des travaux de longue durées doivent être effectués à pression réduite, régler la pression au niveau de l'unité

de pompe.

Fonctionnement avec détergent

– Respecter l'environnement en utilisant

le détergent avec parcimonie.

– Le détergent doit être adapté à la sur-

face à nettoyer.

A l'aide de la vanne de dosage du dé-

tergent, régler la concentration du détergent conformément aux prescriptions du fabricant.

Remarque :Valeurs indicatives sur le pupitre de commande pour la pression de service maximale.

26 FR

– 6

Page 27

Nettoyage

Adapter la pression/la température et la

concentration de détergent en fonction

de la surface à nettoyer.

Remarque :Toujours diriger le jet haute

pression sur l'objet tout d'abord à bonne

distance afin d'éviter tout dommage provoqué par une pression trop élevée.

Méthode de nettoyage conseillée

– Dissoudre la saleté :

Pulvériser le détergent avec parcimonie

puis le laisser agir entre 1 et 5 minutes

sans toutefois le laisser sécher.

– Eliminer la saleté :

Retirer les saletés dissoutes au moyen

du jet haute pression.

Utilisation avec de l'eau froide

Elimination de salissures légères et rinçage

à l'eau claire, ex. : appareils de jardinage,

terrasse, outils, etc.

Régler la pression de service en fonc-

tion des besoins.

Niveau Eco!Efficiency

L'appareil fonctionne dans la plage de température économique.

Remarque : La température peut être régulée jusqu'à 140 °F/60 °C.

Utilisation avec de l'eau chaude

Nous recommandons les températures de

nettoyage suivantes :

– Salissures légères

86 °F/30 °C-122 °F/50 °C

– Salissures albuminées, par ex. dans

l'industrie alimentaire

max. 140 °F/60 °C

– Nettoyage de véhicules, de machines

140 °F/60 °C-185 °F/85 °C

DANGER

Risque de brûlure !

Régler le thermostat sur la température

souhaitée.

Remarque :En cas de changement du réglage de la pression de travail et du débit,

la température de l'eau change aussi.

Après utilisation avec un détergent

Positionner la vanne de dosage du dé-

tergent sur "0".

Mettre l'interrupteur principal sur le ni-

veau (fonctionnement avec de l'eau

froide).

Rincer l'appareil à l'eau claire pendant 1

minute au minimum en gardant la poignée-pistolet ouverte.

Mise hors service de l'appareil

DANGER

Risque de brûlure provoquée par l'eau

chaude ! Après l'utilisation de l'appareil

avec de l'eau chaude, ce dernier doit être

actionné, pistolet ouvert, au minimum cinq

minutes avec de l'eau froide afin de le faire

refroidir.

Positionner l'interrupteur sur '0/OFF'.

Couper l'alimentation en eau.

Ouvrir le pistolet manuel.

Actionner la pompe un court moment

(environ 5 secondes) au moyen de l'interrupteur principal.

En veillant à avoir les mains bien

sèches, débrancher la fiche secteur.

Déconnecter l'arrivée d'eau.

Actionner la poignée-pistolet jusqu'à ce

que l'appareil soit hors pression.

Sécuriser la poignée-pistolet.

Ranger l’appareil

Enclencher la lance dans le dispositif de

fixation situé sur le capot de l'appareil.

Enrouler le flexible haute pression et le

câble électrique et les placer dans les

dispositifs de fixation prévus à cet effet.

Remarque :Ne pas plier le flexible haute

pression ni le câble électrique.

Protection antigel

ATTENTION

Le gel peut endommager l'appareil si l'eau

n'a pas été intégralement vidée.

Stocker l'appareil dans un lieu à l'abris

du gel.

S'il n'est pas possible de le conserver dans

un endroit protégé du gel, remiser l'appareil.

– 7

27FR

Page 28

Remisage

En cas d'interruption de longue durée ou s'il

n'est pas possible de conserver l'appareil

dans un lieu protégé du gel :

Purger l'eau.

Rincer l'appareil au moyen de produit

antigel.

Vider le réservoir de détergent.

Purger l'eau

Dévisser le tuyau d'alimentation en eau

et le flexible haute pression.

Dévisser la vis de purge du chauffe-eau

et laisser couler le chauffe-eau.

Faire tourner l'appareil au max. 1 mi-

nute jusqu'à ce que la pompe et les

conduites soient entièrement vides.

Rincer l'appareil au moyen de produit antigel

Remarque : Respecter les consignes d'uti-

lisation du fabricant du produit antigel.

Verser un produit antigel du commerce

dans le chauffe-eau.

Mettre l'appareil sous tension (sans

chauffage) jusqu'à ce que celui-ci soit

intégralement rincé.

Cette opération permet en outre de bénéficier d'une certaine protection anticorrosion.

Entreposage

몇 PRÉCAUTION

Risque de blessure et d'endommagement !

Prendre en compte le poids de l'appareil à

l'entreposage.

Transport

Figure 6

ATTENTION

Risque d'endommagement ! Lors du chargement de l'appareil avec un chariot élévateur, respecter l'illustration.

몇 PRÉCAUTION

Risque de blessure et d'endommagement !

Respecter le poids de l'appareil lors du

transport.

Sécuriser l'appareil contre les glisse-

ments ou les basculements selon les directives en vigueur lors du transport

dans des véhicules.

Entretien et maintenance

DANGER

Risque de blessure et de choc électrique

par un démarrage inopiné de l'appareil.

Avant d'effectuer tout type de travaux sur

l'appareil, le mettre hors service et débrancher la fiche électrique.

Positionner l'interrupteur sur '0/OFF'.

Couper l'alimentation en eau.

Ouvrir le pistolet manuel.

Actionner la pompe un court moment

(environ 5 secondes) au moyen de l'interrupteur principal.

En veillant à avoir les mains bien

sèches, débrancher la fiche secteur.

Déconnecter l'arrivée d'eau.

Actionner la poignée-pistolet jusqu'à ce

que l'appareil soit hors pression.

Sécuriser la poignée-pistolet.

Laisser refroidir l'appareil.

Votre commerçant spécialisé Kärcher

vous informe de l'exécution d'une inspection de sécurité régulière ou de la

conclusion d'un contrat de maintenance.

Fréquence de maintenance

Hebdomadairement

Nettoyer le tamis de l'arrivée d'eau.

Nettoyer le filtre fin.

Vérifier le niveau d'huile.

ATTENTION

Si l'huile prend une apparence laiteuse,

contacter immédiatement le service aprèsvente Kärcher.

Mensuellement

Nettoyer le filtre dans le bloc de sécuri-

té.

Nettoyer le filtre situé sur le tuyau d'as-

piration de détergent.

28 FR

– 8

Page 29

Après 400 heures de service, au moins annuellement.

Contrôler le degré d'entartrage du

chauffe-eau et faire nettoyer si néces-

saire le chauffe-eau par le service

après-vente.

Après 500 heures de service, au moins annuellement

Remplacer l'huile.

Travaux de maintenance

Nettoyer le tamis de l'arrivée d'eau

Déposer le tamis.

Nettoyer le tamis dans l'eau puis le re-

mettre en place.

Nettoyage du filtre fin

Mettre l'appareil hors pression.

Dévisser le filtre de précision sur le

chauffe-eau.

Démonter le filtre de précision et retirer

la cartouche filtrante.

Nettoyer la cartouche filtrante à l'eau

propre ou à l'air comprimé.

Remonter en suivant les étapes dans

l'ordre inverse.

Nettoyer le filtre dans le bloc de sécurité

Desserrer l'écrou-raccord et retirer le

tuyau.

Extraire le tamis.

Remarque : Le cas échéant, tourner la vis

M8 d'environ 0.2 in/5 mm vers l'intérieur de

manière à pouvoir retirer le tamis.

Nettoyer le tamis dans l'eau.

Replacer le tamis.

Positionner le tuyau.

Serrer l'écrou-raccord.

Nettoyer le filtre situé sur le tuyau d'aspiration de détergent

Retirer les tubulures d'aspiration de dé-

tergent.

Nettoyer le filtre dans l'eau puis le re-

mettre en place.

Remplacer l'huile

Préparer un récipient de récupération

pouvant contenir environ 0.26 gal/1 litre

d'huile.

Desserrer la visse de vidange.

Eliminer l'huile usagée en respectant l'environnement ou l'apporter à un centre de

collecte.

Revisser la vis de vidange.

Remplir doucement le réservoir d'huile

jusqu'au repère MAX.

Remarque :Les bulles d'air doivent pouvoir

s'échapper.

Pour les types d'huile et les quantités de

remplissage, se reporter à la section Caractéristiques techniques.

Assistance en cas de panne

DANGER

Risque de blessure et de choc électrique

par un démarrage inopiné de l'appareil.

Avant d'effectuer tout type de travaux sur

l'appareil, le mettre hors service et débrancher la fiche électrique.

Lampe témoin pompe

1x clignotement

– Manque d'huile

Verser l'huile.

2x clignotement

– Présence d'une fuite dans le système

haute pression

Vérifier l'absence de fuite au niveau du

système haute pression et des raccords.

3x clignotement

– Manque d'eau après 2 minutes - La

pompe est désactivée pour éviter une

marche à sec

Contrôler le raccord d'eau, contrôler les

conduites d'alimentation

4x clignotement

– Défaut de contacteur du chauffage

Positionner l'interrupteur sur '0/OFF'.

Allumer l’appareil.

– Le défaut se reproduit.

Informer le service après-vente.

– 9

29FR

Page 30

Voyant témoin de manque d’eau

– Manque d'eau - Le chauffage est mis

hors service

Contrôler le raccord d'eau, contrôler les

conduites d'alimentation

Le témoin de contrôle d’état de

service s'éteint

– Absence de tension secteur, voir "L'ap-

pareil ne fonctionne pas".

La lampe témoin chauffage est

allumée

– Fonctionnement du chauffage

Témoin de contrôle Moteur

2x clignotement

– Le moteur est excessivement sollicité/

en surchauffe

Positionner l'interrupteur sur '0/OFF'.

Laisser refroidir l'appareil.

Allumer l’appareil.

– Le défaut se reproduit.

Informer le service après-vente.

3x clignotement

– Défaut dans l'alimentation électrique.

Vérifier l'alimentation électrique et les

fusibles.

4x clignotement

– Le courant absorbé est trop grand.

Vérifier l'alimentation électrique et les

fusibles.

Informer le service après-vente.

Voyant de contrôle de défaut du

chauffe-eau

1x clignotement

– Le limiteur de température s'est déclen-

ché

Positionner l'interrupteur sur '0/OFF'.

Laisser refroidir l'appareil.

Allumer l’appareil.

– Le défaut se reproduit.

Informer le service après-vente.

3x clignotement

– Identification du soin système défec-

tueux

Informer le service après-vente.

4x clignotement

– Capteur de température défectueux

Informer le service après-vente.

Lampe témoin service

– Intervalle de service

Exécuter des travaux de service.

La lampe témoin soin système est

allumée

Remarque : Le fonctionnement du chauf-

fage est encore possible pendant 5 heures.

– La bouteille de soin système est vide.

Remplacer la bouteille d'entretien sys-

tème.

La lampe témoin soin système

clignote

Remarque :Le fonctionnement du chauf-

fage n'est plus possible.

– La bouteille de soin système est vide.

Remplacer la bouteille d'entretien sys-

tème.

L'appareil ne fonctionne pas

– Pas de tension secteur

Contrôler le raccordement au réseau/le

câble électrique.

L'appareil n'établit aucune pression

– Présence d'air dans le système

Purger la pompe :

Positionner la vanne de dosage du dé-

tergent sur "0".

En gardant la poignée-pistolet ouverte,

mettre plusieurs fois l'appareil hors et

sous tension.

Ouvrir et fermer la régulation de quanti-

té / de pression de l'unité de pompe

avec une poignée-pistolet ouverte.

Remarque :En démontant le flexible haute

pression du raccord haute pression, le processus de purge est accéléré.

30 FR

– 10

Page 31

Si le réservoir de détergent est vide, le

remplir.

Contrôler les raccords et les conduites.

– La pression est réglée sur MIN

Régler la pression sur MAX.

– Le tamis de l'arrivée d'eau est encrassé

Nettoyer le tamis.

Nettoyer le filtre fin, le remplacer si né-

cessaire.

– Le débit de l'alimentation en eau est

trop faible

Contrôler le débit de l'alimentation en

eau (voir la section Caractéristiques

techniques).

L'appareil présente un fuit, de l'eau

s'écoule de l'appareil par le bas

– La pompe fuit.

Remarque :Une fuite de 3 gouttes/minute

est autorisée.

En cas de fuite plus importante, faire

vérifier l'appareil par le service après-

vente.

Remarque : En raison des condensats, il

est possible que davantage de gouttes se

déposent sur l'appareil.

Lorsque la poignée-pistolet est

fermée, l'appareil ne cesse de se

mettre sous et hors tension

– Présence d'une fuite dans le système

haute pression

Vérifier l'absence de fuite au niveau du

système haute pression et des rac-

cords.

L'appareil n'aspire pas de détergent

Lasser fonctionner l'appareil avec la

vanne de dosage de détergent ouverte

et l'alimentation en eau coupée jusqu'à

ce que le chauffage soit vide et que la

pression retombe à "0".

Ouvrir de nouveau l'arrivée d'eau.

Si la pompe n'aspire toujours pas de détergent, les causes peuvent en être les

suivantes :

– Le filtre du tuyau d'aspiration du dé-

tergent est encrassé

Nettoyer le filtre.

– Le clapet anti-retour est collé

Démonter le tuyau de détergent et dé-

visser le clapet anti-retour à l'aide d'un

objet non contondant.

Le chauffe-eau ne chauffe pas

– La bouteille de soin système est vide.

Remplacer la bouteille d'entretien sys-

tème.

– Manque d'eau

Contrôler le raccord d'eau, contrôler les

conduites d'alimentation

– Chauffage défectueux.

Informer le service après-vente.

Lorsque l'appareil est utilisé avec

de l'eau chaude, il n'atteint pas la

température réglée

– La pression de service/le débit est trop

élevé(e)

Réduire la pression de travail/le débit à

la régulation de la pression / de la quan-

tité de l'unité de pompe.

Service après-vente

Si la panne ne peut être réparée, l'appareil doit être contrôlé par le service

après-vente.

Garantie