Page 1

Kubota Diesel Engine

English

Français

Deutsch

Italiano

Español

5.963-388.0 05/09

Page 2

Page 3

Page 4

Page 5

CONTENTS

SAFE OPERATION .................................................................................................. 1

SERVICING OF THE ENGINE .................................................................................... 1

NAMES OF PARTS .....................................................................................................2

PRE-OPERATION CHECK .......................................................................................... 3

BREAK-IN.................................................................................................................3

DAILY CHECK..........................................................................................................3

OPERATING THE ENGINE ......................................................................................... 4

STARTING THE ENGINE(NORMAL) .......................................................................4

COLD WEATHER STARTING ................................................................................. 5

STOPPING THE ENGINE ........................................................................................ 6

CHECKS DURING OPERATION .............................................................................6

Radiator Cooling water(Coolant) ...................................................................................... 6

Oil pressure lamp ............................................................................................................. 6

Fuel .................................................................................................................................. 7

Color of exhaust ............................................................................................................... 7

Immediately stop the engine if;......................................................................................... 7

REVERSED ENGINE REVOLUTION AND REMEDIES ..........................................7

How to tell when the engine starts running backwards .................................................... 7

Remedies ......................................................................................................................... 7

MAINTENANCE ...........................................................................................................8

SERVICE INTERVALS .............................................................................................9

PERIODIC SERVICE ................................................................................................. 12

FUEL ...................................................................................................................... 12

Fuel level check and refueling ........................................................................................ 12

Air bleeding the fuel system ........................................................................................... 13

Checking the fuel pipes .................................................................................................. 14

Cleaning the fuel filter pot............................................................................................... 14

Fuel filter cartridge replacement ..................................................................................... 15

ENGINE OIL ...........................................................................................................15

Checking oil level and adding engine oil ........................................................................ 15

Changing engine oil........................................................................................................ 16

Replacing the oil filter cartridge ...................................................................................... 17

RADIATOR .............................................................................................................17

Checking coolant level, adding coolant .......................................................................... 18

Changing coolant ........................................................................................................... 19

Remedies for quick decrease of coolant ........................................................................ 19

Checking radiator hoses and clamp bands .................................................................... 19

Precaution at overheating .............................................................................................. 19

Cleaning radiator core(outside) ...................................................................................... 19

Anti-freeze ...................................................................................................................... 20

Radiator cement ............................................................................................................. 20

AIR CLEANER........................................................................................................21

Evacuator valve.............................................................................................................. 21

For the air cleaner with a dust cup (optional) ................................................................. 21

Dust indicator (optional) ................................................................................................. 22

BATTERY ...............................................................................................................22

Battery charging ............................................................................................................. 22

ENGLISH

Page 6

ENGLISH

CONTENTS

Direction for long term storage ....................................................................................... 23

ELECTRIC WIRING ............................................................................................... 23

FAN BELT ..............................................................................................................24

Adjusting Fan Belt Tension ............................................................................................ 24

CARRIAGE AND STORAGE .....................................................................................25

CARRIAGE ............................................................................................................. 25

STORAGE ..............................................................................................................25

TROUBLESHOOTING ............................................................................................... 26

SPECIFICATIONS ..................................................................................................... 28

WIRING DIAGRAMS.................................................................................................. 31

Page 7

FOREWORD

You are now the proud owner of a KUBOTA Engine. This engine is a

product of KUBOTA quality engineering and manufacturing. It is made

of fine materials and under a rigid quality control system. It will give

you long, satisfactory service. To obtain the best use of your engine,

please read this manual carefully. It will help you become familiar with

the operation of the engine and contains many helpful hints about

engine maintenance. It is KUBOTA's policy to utilize as quickly as

possible every advance in our research. The immediate use of new

techniques in the manufacture of products may cause some small

parts of this manual to be outdated. KUBOTA distributors and dealers

will have the most up-to-date information. Please do not hesitate to

consult with them.

ENGLISH

3

This symbol, the industry's "Safety Alert Symbol", is used throughout

this manual and on labels on the machine itself to warn of the

possibility of personal injury. Read these instructions carefully. It is

essential that you read the instructions and safety regulations before

you attempt to assemble or use this unit.

DANGER : Indicates an imminently hazardous situation which,

3

WARNING : Indicates a potentially hazardous situation which,

3

CAUTION : Indicates a potentially hazardous situation which,

3

IMPORTANT : Indicates that equipment or property damage

NOTE : Gives helpful information.

SAFETY FIRST

if not avoided, will result in death or serious

injury.

if not avoided, could result in death or serious

injury.

if not avoided, may result in minor or moderate

injury.

could result if instructions are not followed.

Page 8

ENGLISH

Page 9

SAFE OPERATION

1SAFE OPERATION

Careful operation is your best assurance against an accident. Read and understand this

section carefully before operating the engine. All operators, no matter how much

experience they may have, should read this and other related manuals before operating

the engine or any equipment attached to it. It is the owner's obligation to provide all

operators with this information and instruct them on safe operation.

Be sure to observe the following for safe operation.

OBSERVE SAFETY INSTRUCTIONS

1.

A Read and understand carefully this "OPERATOR'S

MANUAL" and "LABELS ON THE ENGINE" before

attempting to start and operate the engine.

A Learn how to operate and work safely. Know your

equipment and its limitations. Always keep the engine in

good condition.

A Before allowing other people to use your engine, explain

how to operate and have them read this manual before

operation.

A DO NOT modify the engine. UNAUTHORIZED

MODIFICATIONS to the engine may impair the function

and/or safety and affect engine life. If the engine does not

perform properly, consult your local Kubota Engine

Distributor first.

2. WEAR SAFE CLOTHING AND PERSONAL PROTECTIVE EQUIPMENT (PPE)

A DO NOT wear loose, torn or bulky clothing around the

machine that may catch on working controls and

projections or into fans, pulleys and other moving parts

causing personal injury.

A Use additional safety items-PPE, e.g. hard hat, safety

protection, safety goggles, gloves, etc., as appropriate or

required.

A DO NOT operate the machine or any equipment attached

to it while under the influence of alcohol, medication, or

other drugs, or while fatigued.

A DO NOT wear radio or music headphones while

operating the engine.

ENGLISH

Page 10

SAFE OPERATION2

3. CHECK BEFORE STARTING & OPERATING THE ENGINE

ENGLISH

A Be sure to inspect the engine before operation. Do not

operate the engine if there is something wrong with it.

Repair it immediately.

A Ensure all guards and shields are in place before

operating the engine. Replace any that are damaged or

missing.

A Check to see that you and others are a safe distance

from the engine before starting.

A Always keep the engine at least 3 feet (1 meter) away

from buildings and other facilities.

A DO NOT allow children or livestock to approach the

machine while the engine is running.

A DO NOT start the engine by shorting across starter

terminals. The machine may start in gear and move. Do

not bypass or defeat any safety devices.

4. KEEP THE ENGINE AND SURROUNDINGS CLEAN

A Be sure to stop the engine before cleaning.

A Keep the engine clean and free of accumulated dirt,

grease and trash to avoid a fire. Store flammable fluids in

proper containers and cabinets away from sparks and

heat.

A Check for and repair leaks immediately.

A DO NOT stop the engine without idling; Allow the engine

to cool down, first. Keep the engine idling for about 5

minutes before stopping unless there is a safety problem

that requires immediate shut down.

5. SAFE HANDLING OF FUEL AND LUBRICANTS -KEEP AWAY FROM FIRE

A Always stop the engine before refueling and/or

lubricating.

A DO NOT smoke or allow flames or sparks in your work

area. Fuel is extremely flammable and explosive under

certain conditions.

A Refuel at a well ventilated and open place. When fuel

and/or lubricants are spilled, refuel after letting the

engine cool down.

A DO NOT mix gasoline or alcohol with diesel fuel. The

mixture can cause a fire or severe engine damage.

A Do not use unapproved containers e.g. buckets, bottles,

jars. Use approved fuel storage containers and

dispensers.

Page 11

3SAFE OPERATION

6. EXHAUST GASES & FIRE PREVENTION

A Engine exhaust fumes can be very harmful if allowed to

accumulate. Be sure to run the engine in a well ventilated

location and where there are no people or livestock near

the engine.

A The exhaust gas from the muffler is very hot. To prevent

a fire, do not expose dry grass, mowed grass, oil or any

other combustible materials to exhaust gas. Keep the

engine and muffler clean at all times.

A To avoid a fire, be alert for leaks of flammable

substances from hoses and lines. Be sure to check for

leaks from hoses or pipes, such as fuel and hydraulic

fluid by following the maintenance check list.

A To avoid a fire, do not short across power cables and

wires. Check to see that all power cables and wirings are

in good condition. Keep all electrical connections clean.

Bare wire or frayed insulation can cause a dangerous

electrical shock and personal injury.

7. ESCAPING FLUID

A Relieve all pressure in the air, the oil and the cooling

systems before disconnecting any lines, fittings or

related items.

A Be cautious of possible pressure relief when

disconnecting any device from a pressurized system that

utilizes pressure. DO NOT check for pressure leaks with

your hand. High pressure oil or fuel can cause personal

injury.

A Escaping fluid under pressure has sufficient force to

penetrate skin causing serious personal injury.

A Fluid escaping from pinholes may be invisible. Use a

piece of cardboard or wood to search for suspected

leaks: do not use hands and body. Use safety goggles or

other eye protection when checking for leaks.

A If injured by escaping fluid, see a medical doctor

immediately. This fluid can produce gangrene or severe

allergic reaction.

ENGLISH

Page 12

SAFE OPERATION4

8. CAUTIONS AGAINST BURNS & BATTERY EXPLOSION

ENGLISH

A To avoid burns, be cautious of hot components, e.g.

muffler, muffler cover, radiator, hoses, engine body,

coolants, engine oil, etc. during operation and after the

engine has been shut off.

A DO NOT remove the radiator cap while the engine is

running or immediately after stopping. Otherwise hot

water will spout out from the radiator. Wait until the

radiator is completely cool to the touch before removing

the cap. Wear safety goggles.

A Be sure to close the coolant drain valve, secure the

pressure cap, and fasten the pipe band before operating.

If these parts are taken off, or loosened, it will result in

serious personal injury.

A The battery presents an explosive hazard. When the

battery is being charged, hydrogen and oxygen gases

are extremely explosive.

A DO NOT use or charge the battery if its fluid level is below

the LOWER mark.

Otherwise, the component parts may deteriorate earlier

than expected, which may shorten the service life or

cause an explosion. Immediately, add distilled water until

the fluid level is between the UPPER and LOWER marks.

A Keep sparks and open flames away from the battery,

especially during charging. DO NOT strike a match near

the battery.

A DO NOT check the battery charge by placing a metal

object across the terminals. Use a voltmeter or

hydrometer.

A DO NOT charge a frozen battery. There is a risk of

explosion. When frozen, warm the battery up to at least

16 C (61 F).

9. KEEP HANDS AND BODY AWAY FROM ROTATING PARTS

A Be sure to stop the engine before checking or adjusting

the belt tension and cooling fan.

A Keep your hands and body away from rotating parts,

such as the cooling fan, V-belt, fan drive V-belt, pulley or

flywheel. Contact with rotating parts can cause severe

personal injury.

A DO NOT run the engine without safety guards. Install

safety guards securely before operation.

Page 13

5SAFE OPERATION

10. ANTI-FREEZE & DISPOSAL OF FLUIDS

A Anti-freeze contains poison. Wear rubber gloves to avoid

personal injury. In case of contact with skin, wash it off

immediately.

A DO NOT mix different types of Anti-freeze. The mixture

can produce a chemical reaction causing harmful

substances. Use approved or genuine KUBOTA Antifreeze.

A Be mindful of the environment and the ecology. Before

draining any fluids, determine the correct way to dispose

of them. Observe the relevant environmental protection

regulations when disposing of oil, fuel, coolant, brake

fluid, filters and batteries.

A When draining fluids from the engine, place a suitable

container underneath the engine body.

A DO NOT pour waste onto the ground, down a drain, or

into any water source. Dispose of waste fluids according

to environmental regulations.

ENGLISH

Page 14

SAFE OPERATION6

11. CONDUCTING SAFETY CHECKS & MAINTENANCE

ENGLISH

A When inspecting the engine or servicing, place the

engine on a large flat surface. DO NOT work on anything

that is supported ONLY by lift jacks or a hoist. Always use

blocks or the correct stands to support the engine before

servicing.

A Disconnect the battery from the engine before

conducting service. Put a "DO NOT OPERATE!" tag on

the key switch to avoid accidental starting.

A To avoid sparks from an accidental short circuit always

disconnect the battery's ground cable (-) first and

reconnect it last.

A Be sure to stop the engine and remove the key when

conducting daily and periodic maintenance, service and

cleaning.

A Check or conduct maintenance after the engine, coolant,

muffler, or muffler cover have cooled off completely.

A Always use the appropriate tools and fixtures. Verify that

they are in good condition before performing any service

work. Make sure you understand how to use them before

service.

A Use ONLY correct engine barring techniques for

manually rotating the engine. DO NOT attempt to rotate

the engine by pulling or prying on the cooling fan and Vbelt. This practice can cause serious personal injury or

premature damage to the cooling fan and belt.

A Replace fuel pipes and lubricant pipes with their hose

clamps every 2 years or earlier whether they are

damaged or not. They are made of rubber and age

gradually.

A When servicing is performed together by two or more

persons, take care to perform all work safely.

A Keep a first aid kit and fire extinguisher handy at all times.

Page 15

7SAFE OPERATION

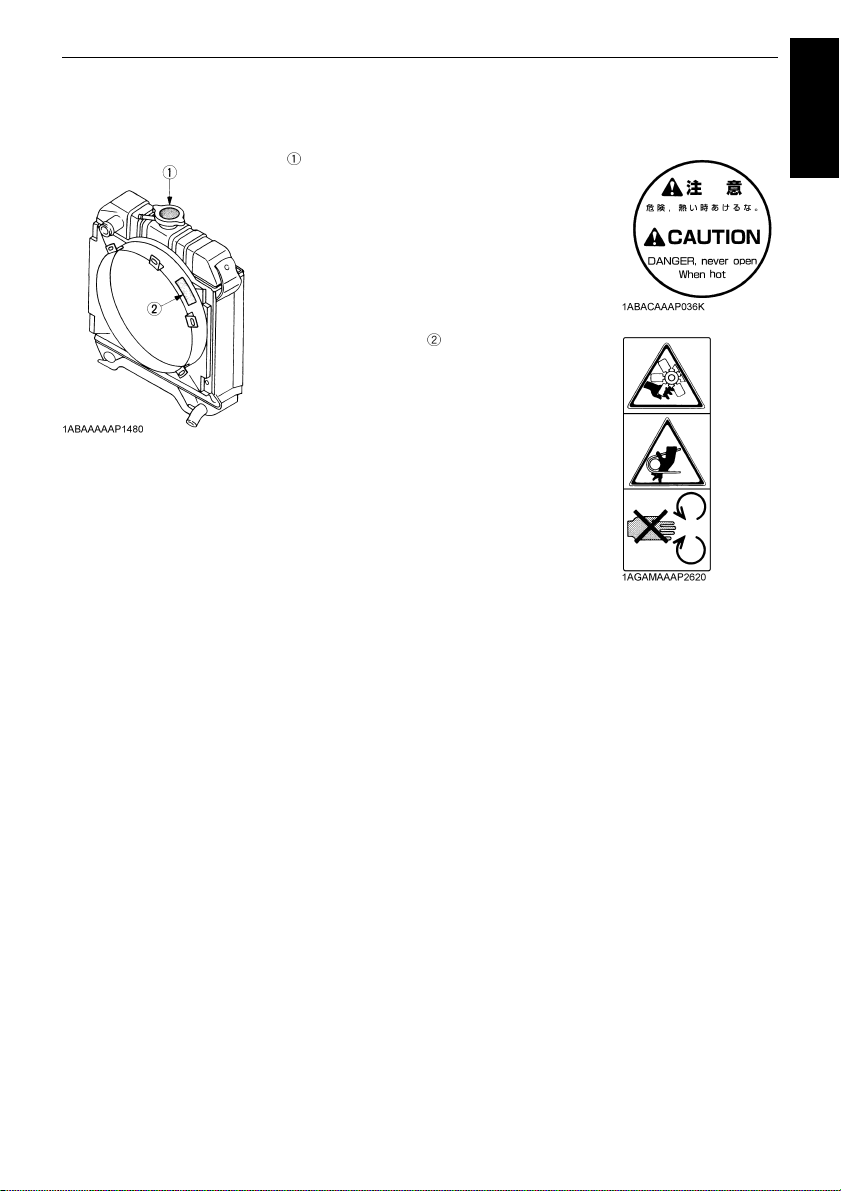

12. WARNING AND CAUTION LABELS

Part No.19077-8724-1 or 16667-8724-1

(55mm in diameter) (37mm in diameter)

Part No.TA040-4957-1

Do not get your hands close

to engine fan and fan belt.

13. CARE OF WARNING AND CAUTION LABELS

1. Keep warning and caution labels clean and free from obstructing material.

2. Clean warning and caution labels with soap and water, dry with a soft cloth.

3. Replace damaged or missing warning and caution labels with new labels from your local

KUBOTA dealer.

4. If a component with warning and caution label(s) affixed is replaced with a new part, make

sure the new label(s) is (are) attached in the same location(s) as the replaced component.

5. Mount new warning and caution labels by applying to a clean dry surface and pressing any

bubbles to the outside edge.

ENGLISH

Page 16

8 SAFE OPERATION

ENGLISH

Page 17

SERVICING OF THE ENGINE

1SERVICING OF THE ENGINE

Your dealer is interested in your new engine and has the

desire to help you get the most value from it. After reading

this manual thoroughly, you will find that you can do some

of the regular maintenance yourself.

However, when in need of parts or major service, be sure

to see your KUBOTA dealer.

For service, contact the KUBOTA Dealership from which

you purchased your engine or your local KUBOTA dealer.

When in need of parts, be prepared to give your dealer

the engine serial number.

Locate the serial number now and record them in the

space provided.

Type Serial No.

Engine

Date of Purchase

Name of Dealer

(To be filled in by purchaser)

ENGLISH

(1) Engine serial number

Page 18

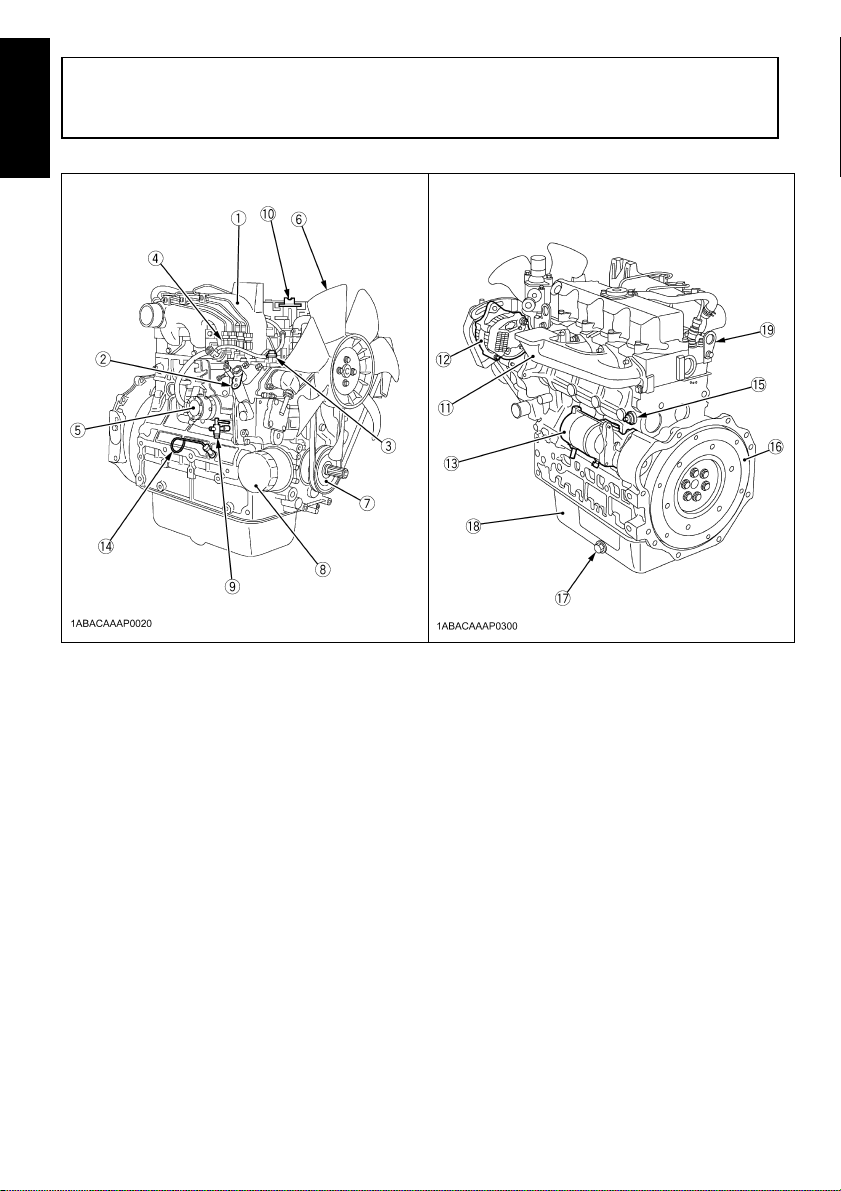

2 NAMES OF PARTS

NAMES OF PARTS

ENGLISH

(1) Intake manifold

(2) Speed control lever

(3) Engine stop lever

(4) Injection pump

(5) Fuel feed pump

(6) Cooling fan

(7) Fan drive pulley

(8) Oil filter cartridge

(9) Water drain cock

(10) Oil filler plug

(11) Exhaust manifold

(12) Alternator

(13) Starter

(14) Oil level gauge

(15) Oil pressure switch

(16) Flywheel

(17) Oil drain plug

(18) Oil pan

(19) Engine hook

Page 19

PRE-OPERATION CHECK

BREAK-IN

During the engine break-in period, observe the following by all means:

1. Change engine oil and oil filter cartridge after the first 50 hours of operation. (See "ENGINE OIL" in "PERIODIC

SERVICE" section.)

2. When ambient temperature is low, operate the machine after the engine has been completely warmed up.

DAILY CHECK

To prevent trouble from occurring, it is important to know the conditions of the engine well. Check it before starting.

To avoid personal injury:

A Be sure to install shields and safeguards attached to the engine when operating.

A Stop the engine at a flat and wide space when checking.

A Keep dust or fuel away from the battery, wiring, muffler and engine to prevent a fire.

Check and clear them before operating everyday. Pay attention to the heat of the

exhaust pipe or exhaust gas so that it can not ignite trash.

Item Ref. page

1. Parts which had trouble in previous operation -

2. By walking around the machine (1) Oil or water leaks 15 to 20

(2) Engine oil level and contamination 15,16

(3) Amount of fuel 12

(4) Amount of coolant 18 to 20

(5) Dust in air cleaner dust cup 21

(6) Damaged parts and loosened bolts and nuts -

3. By inserting the key into the starter

switch

4. By starting the engine (1) Color of exhaust fumes 7

(1) Proper functions of meters and pilot lamps; no stains on

these parts

(2) Proper function of glow lamp timer -

(2) Unusual engine noise 7

(3) Engine start-up condition 5

(4) Slow-down and acceleration behavior 7

-

3PRE-OPERATION CHECK

ENGLISH

Page 20

4 OPERATING THE ENGINE

OPERATING THE ENGINE

ENGLISH

STARTING THE ENGINE(NORMAL)

To avoid personal injury:

A Do not allow children to approach the

machine while the engine is running.

A Be sure to install the machine on

which the engine is installed, on a flat

place.

A Do not run the engine on gradients.

A Do not run the engine in an enclosed

area. Exhaust gas can cause air

pollution and exhaust gas poisoning.

A Keep your hands away from rotating

parts (such as fan, pulley, belt,

flywheel etc.) during operation.

A Do not operate the machine while

under the influence of alcohol or

drugs.

A Do not wear loose, torn or bulky

clothing around the machine. It may

catch on moving parts or controls,

leading to the risk of accident. Use

additional safety items, e.g. hard hat,

safety boots or shoes, eye and

hearing protection, gloves, etc., as

appropriate or required.

A Do not wear radio or music

headphones while operating engine.

A Check to see if it is safe around the

engine before starting.

A Reinstall safeguards and shields

securely and clear all maintenance

tools when starting the engine after

maintenance.

A Do not use ether or any starting fluid for starting the

engine, or a severe damage will occur.

A When starting the engine after a long storage (of more

than 3 months), first set the stop lever to the "STOP"

position and then activate the starter for about 10

seconds to allow oil to reach every engine part.

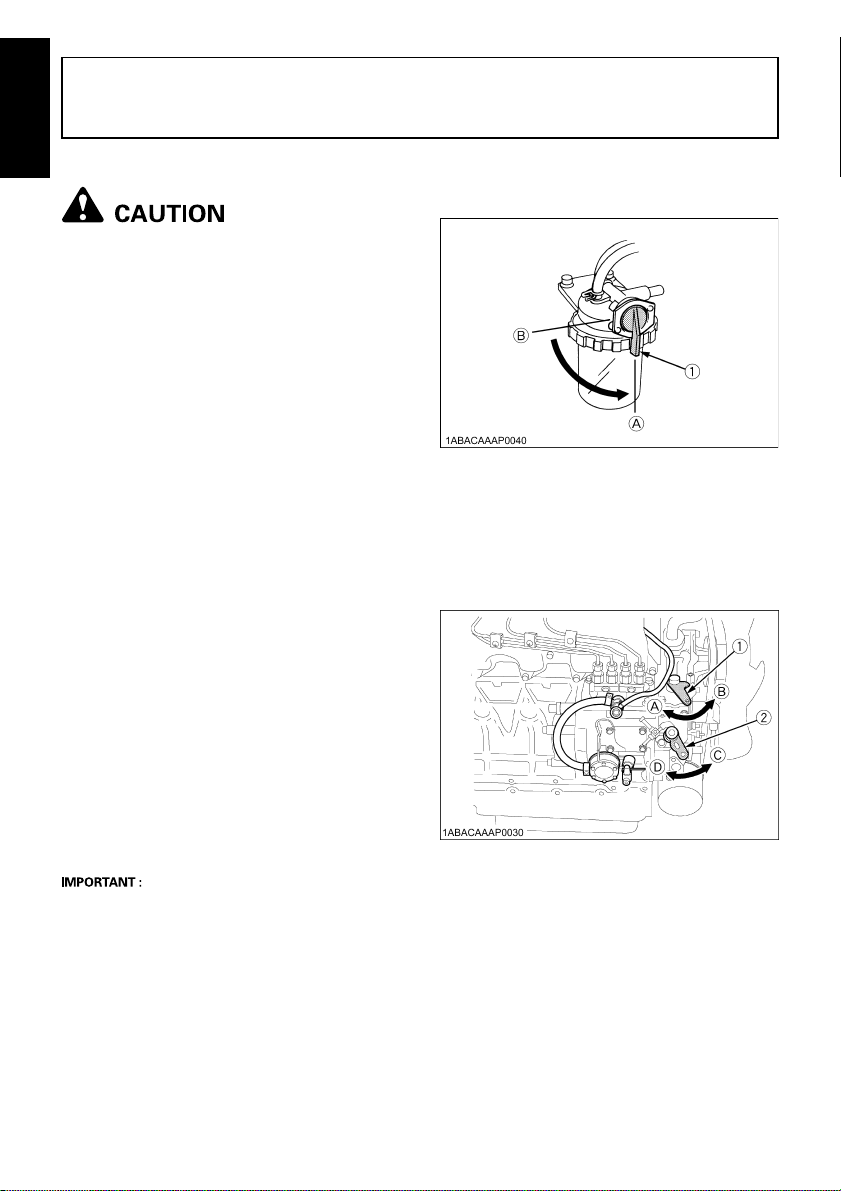

1. Set the fuel lever to the "ON" position.

(1) Fuel lever (A) "ON"

2. Place the engine stop lever to the

"START" position.

3. Place the speed control lever at more

than half "OPERATION".

(1) Engine stop lever

(2) Speed Control lever

(B) "OFF"

(A) "STOP"

(B) "START"

(C) "IDLING"

(D) "OPERATION"

Page 21

5OPERATING THE ENGINE

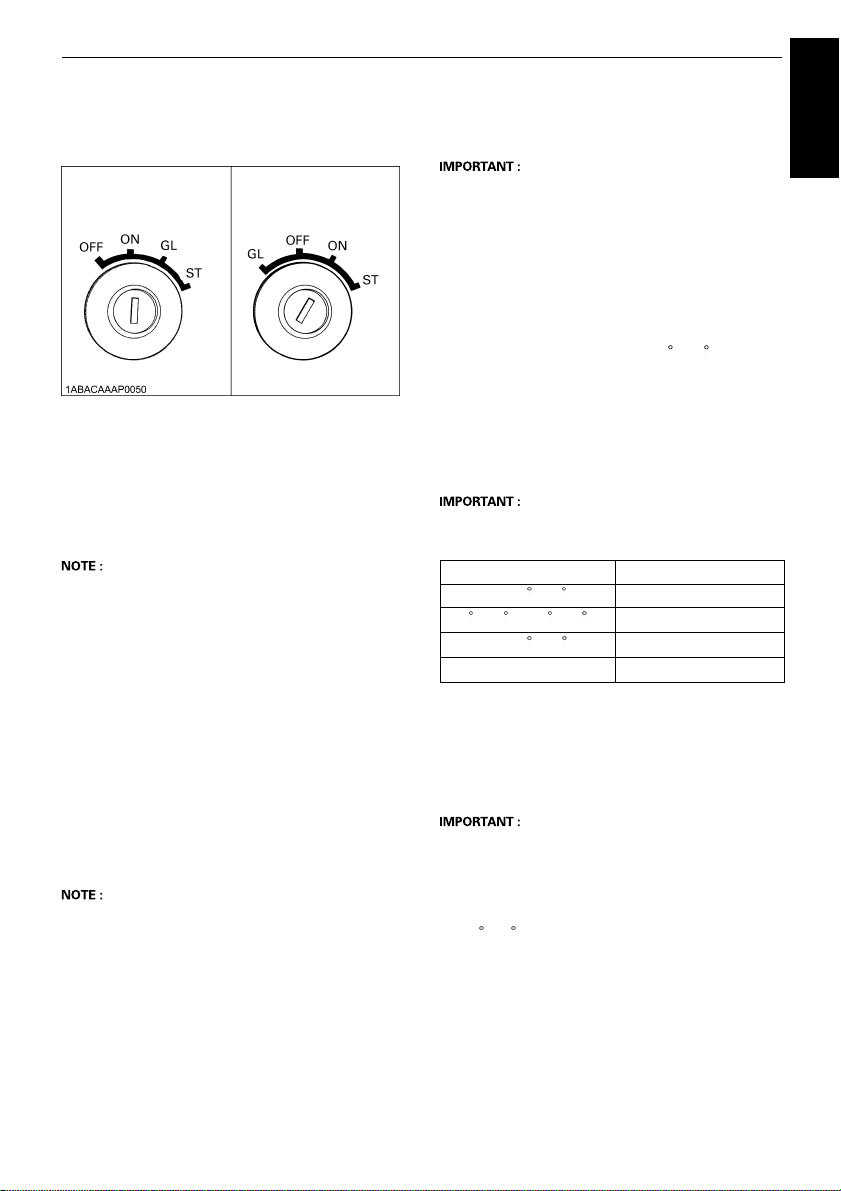

4. Insert the key into the key switch and

turn it to the "OPERATION" position.

(A) "OFF" SWITCHED OFF

(B) "ON" OPERATION

(C) "GL" PREHEATING

(D) "ST" STARTING

(A) "GL" PREHEATING

(B) "OFF" SWITCHED OFF

(C) "ON" OPERATION

(D) "ST" STARTING

5. Turn the starter switch to the

"PREHEATING" position to allow the

glow lamp to redden.

(with lamp timer in use)

A The glow lamp goes out in about 5 seconds when the

lamp timer is up. Refer to this for pre-heating.

Even with the glow lamp off, the glow plug can be preheated by turning the starter switch to the

"PREHEATING" position.

6. Turn the key to the "STARTING"

position and the engine should start.

Release the key immediately when the

engine starts.

7. Check to see that the oil pressure lamp

and charge lamp are off. If the lamps

are still on, immediately stop the

engine, and determine the cause.

(See "CHECKS DURING OPERATION" in

"OPERATING THE ENGINE" section.)

A If the oil pressure lamp should be still on, immediately

stop the engine and check;

- if there is enough engine oil.

- if the engine oil has dirt in it.

- if the wiring is faulty.

8. Warm up the engine at medium speed

without load.

A If the glow lamp should redden too quickly or too

slowly, immediately ask your KUBOTA dealer to

check and repair it.

A If the engine does not catch or start at 10 seconds

after the starter switch is set at "STARTING" position,

wait for another 30 seconds and then begin the engine

starting sequence again. Do not allow the starter

motor to run continuously for more than 20 seconds.

COLD WEATHER STARTING

If the ambient temperature is below -5 C(23 F)* and the

engine is very cold, start it in the following manner:

Take steps (1) through (4) above.

5. Turn the key to the "PREHEATING"

position and keep it there for a certain

period mentioned below.

A Shown below are the standard preheating times for

various temperatures. This operation, however, is not

required, when the engine is warmed up.

Ambient temperature Preheating time

Above 10 C (50 F) NO NEED

10 C (50 F) to -5 C (23 F)

*Below -5 C (23 F)

Limit of continuous use

6. Turn the key to the "STARTING"

position and the engine should start.

(If the engine fails to start after 10 seconds, turn off

the key for 5 to 30 seconds. Then repeat steps (5)

and (6).)

A Do not allow the starter motor to run continuously for

more than 20 seconds.

A Be sure to warm up the engine, not only in winter, but

also in warmer seasons. An insufficiently warmed-up

engine can shorten its service life.

A When there is fear of temperature dropping below

-15 C (5 F) detach the battery from the machine, and

keep it indoors in a safe area, to be reinstalled just

before the next operation.

Approx. 5 seconds

Approx. 10 seconds

20 seconds

ENGLISH

Page 22

OPERATING THE ENGINE6

STOPPING THE ENGINE

1. Return the speed control lever to low

ENGLISH

idle, and run the engine under idling

conditions.

2. Set the engine stop lever to the "STOP"

position.

3. With the starter switch placed to the

"SWITCHED OFF" position, remove the

key. (Be sure to return the engine stop

lever to the "START" position to be

ready for the next start.)

(1) Engine stop lever

(2) Speed control lever

A If equipped with a turbo-charger, allow the engine to

idle for 5 minutes before shutting it off after a full load

operation.

Failure to do so may lead to turbo-charger trouble.

(A) "STOP"

(B) "START"

(C) "IDLING"

(D) "OPERATION"

CHECKS DURING OPERATION

While running, make the following checks to see that all

parts are working correctly.

BRadiator Cooling water(Coolant)

To avoid personal injury:

A Do not remove radiator cap until

coolant temperature is well below its

boiling point. Then loosen cap

slightly to the stop position, to

relieve any pressure, before

removing cap completely.

When the engine overheats and hot coolant overflows

through the radiator and hoses, stop the engine

immediately and make the following checks to determine

the cause of trouble:

Check item

1. Check to see if there is any coolant leak;

2. Check to see if there is any obstacle around the

cooling air inlet or outlet;

3. Check to see if there is any dirt or dust between

radiator fins and tube;

4. Check to see if the fan belt is too loose;

5. Check to see if radiator water pipe is clogged; and

6. Check to see if anti-freeze is mixed to a 50/50% mix of

water and anti-freeze.

BOil pressure lamp

The lamp lights up to warn the operator that the engine oil

pressure has dropped below the prescribed level. If this

should happen during operation or should not go off even

after the engine is accelerated more than 1000rpm,

immediately stop the engine and check the following:

1. Engine oil level (See "ENGINE OIL" in "PERIODIC

SERVICE" section.)

2. Lubricant system (See "ENGINE OIL" in "PERIODIC

SERVICE" section.)

Page 23

7OPERATING THE ENGINE

BFuel

To avoid personal injury:

A Fluid escaping from pinholes may be

invisible. Do not use hands to search

for suspected leaks; Use a piece of

cardboard or wood, instead. If

injured by escaping fluid, see a

medical doctor at once. This fluid can

produce gangrene or a severe

allergic reaction.

A Check any leaks from fuel pipes or

fuel injection pipes. Use eye

protection when checking for leaks.

Be careful not to empty the fuel tank. Otherwise air may

enter the fuel system, requiring fuel system bleeding.

(See "FUEL" in "PERIODIC SERVICE" section.)

BColor of exhaust

While the engine is run within the rated output range:

A The color of exhaust remains colorless.

A If the output slightly exceeds the rated level, exhaust

may become a little colored with the output level kept

constant.

A If the engine is run continuously with dark exhaust

emission, it may lead to trouble with the engine.

BImmediately stop the engine if;

A The engine suddenly slows down or accelerates.

A Unusual noises are suddenly heard.

A Exhaust fumes suddenly become very dark.

A The oil pressure lamp or the water temperature alarm

lamp lights up.

REVERSED ENGINE REVOLUTION AND REMEDIES

ENGLISH

To avoid personal injury:

A Reversed engine operation can make

the machine reverse and run it

backwards. It may lead to serious

trouble.

A Reversed engine operation may

make exhaust gas gush out into the

intake side and ignite the air cleaner;

It could catch fire.

Reversed engine revolution must be stopped immediately

since engine oil circulation is cut quickly, leading to

serious trouble.

BHow to tell when the engine starts running

backwards

1. Lubricating oil pressure drops sharply. Oil pressure

warning light, if used, will light.

2. Since the intake and exhaust sides are reversed, the

sound of the engine changes, and exhaust gas will

come out of the air cleaner.

3. A louder knocking sound will be heard when the

engine starts running backwards.

BRemedies

1. Immediately set the engine stop lever to the "STOP"

position to stop the engine.

2. After stopping the engine, check the air cleaner, intake

rubber tube and other parts, and then replace parts as

needed.

Page 24

8 MAINTENANCE

MAINTENANCE

ENGLISH

To avoid personal injury:

A Be sure to conduct daily checks,

periodic maintenance, refueling or

cleaning on a level surface with the

engine shut off and remove the key.

A Before allowing other people to use

your engine, explain how to operate,

and have them read this manual

before operation.

A When cleaning any parts, do not use

gasoline but use regular cleanser.

A Always use proper tools, that are in

good condition. Make sure you

understand how to use them, before

performing any service work.

A When installing, be sure to tighten all

bolts lest they should be loose.

Tighten the bolts by the specified

torque.

A Do not put any tools on the battery,

or battery terminals may short out.

Severe burns or fire could result.

Detach the battery from the engine

before maintenance.

A Do not touch muffler or exhaust

pipes while they are hot; Severe

burns could result.

Page 25

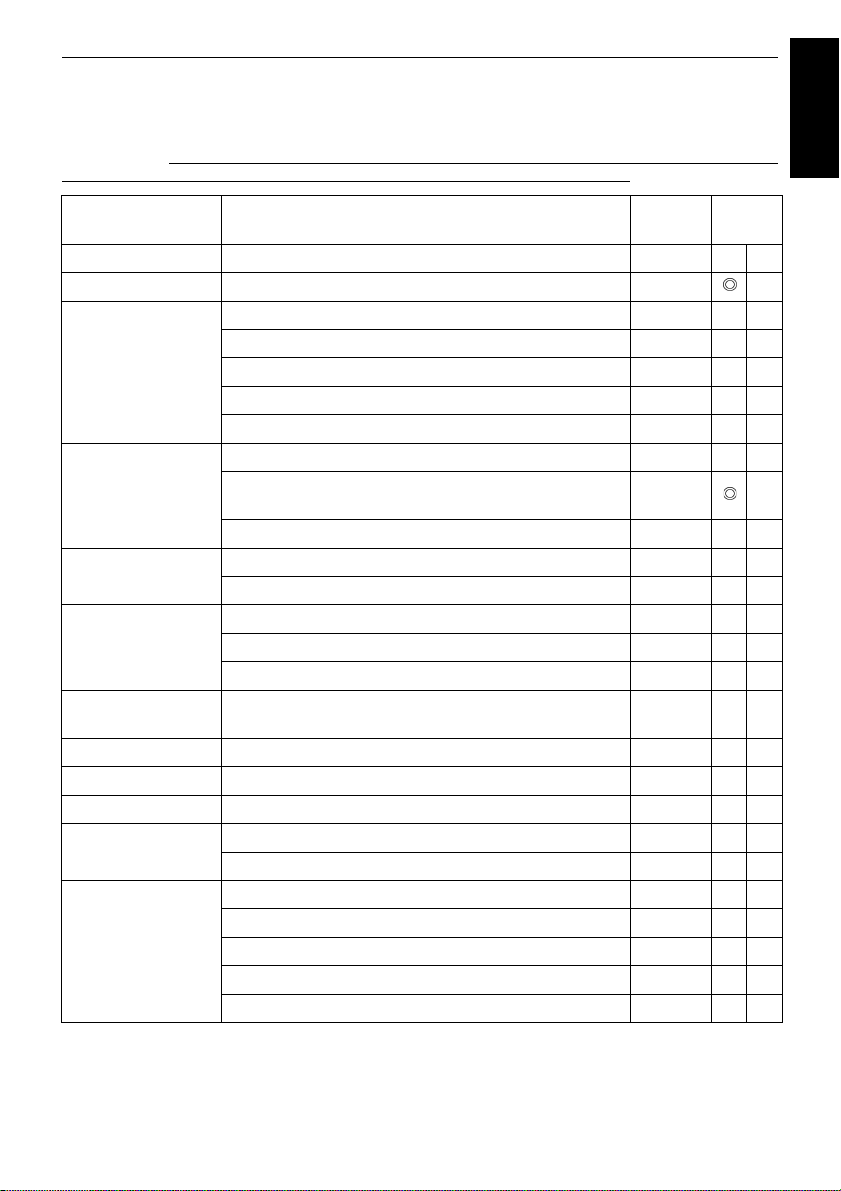

SERVICE INTERVALS

Observe the following for service and maintenance.

The lubricating oil change intervals listed in the table below are for Class CF lubricating oil of API classification with a lowsulfur fuel in use. If the CF-4, CG-4, CH-4 or CI-4 lubricating oil is used with a high-sulfur fuel, change the lubricating oil

at shorter intervals than recommended in the table below depending on the operating condition. (approximately half)

Interval Item

Every 50 hours Check of fuel pipes and clamp bands 14 @

See NOTE Change of engine oil (depending on the oil pan) 15 to 17

Cleaning of air cleaner element 21 *1 @

Cleaning of fuel filter 14

Every 100 hours

Check of battery electrolyte level 22,23

Check of fan belt tightness 24

Draining water separator -

Check of radiator hoses and clamp bands 19

Every 200 hours

Replacement of oil filter cartridge (depending on the

oil pan)

Check of intake air line - @

Every 400 hours

Replacement of fuel filter cartridge 15 @

Cleaning of water separator -

Removal of sediment in fuel tank -

Every 500 hours

Cleaning of water jacket (radiator interior) 18 to 20

Replacement of fan belt 24

Every one or two

months

Recharging of battery 22,23

Every year Replacement of air cleaner element 21 *2 @

Every 800 hours Check of valve clearance 26

Every 1500 hours Check of fuel injection nozzle injection pressure - *3 @

Every 3000 hours

Check of turbo charger - *3 @

Check of injection pump - *3 @

Change of radiator coolant (L.L.C.) 18 to 20

Replacement of battery 22,23

Every two years

Replacement of radiator hoses and clamp bands 19

Replacement of fuel pipes and clamp bands 14 *3 @

Replacement of intake air line - *4 @

Ref.

page

17

9MAINTENANCE

ENGLISH

Page 26

10 MAINTENANCE

A The jobs indicated by must be done after the first 50 hours of operation.

*1 Air cleaner should be cleaned more often in dusty conditions than in normal conditions.

*2 After 6 times of cleaning.

ENGLISH

*3 Consult your local KUBOTA Dealer for this service.

*4 Replace only if necessary.

A When the battery is used for less than 100 hours in a year, check its electrolyte yearly. (for refillable battery's only)

A The items listed above (@ marked) are registered as emission related critical parts by KUBOTA in the U.S. EPA

nonroad emission regulation. As the engine owner, you are responsible for the performance of the required

maintenance on the engine according to the above instruction.

Please see the Warranty Statement in detail.

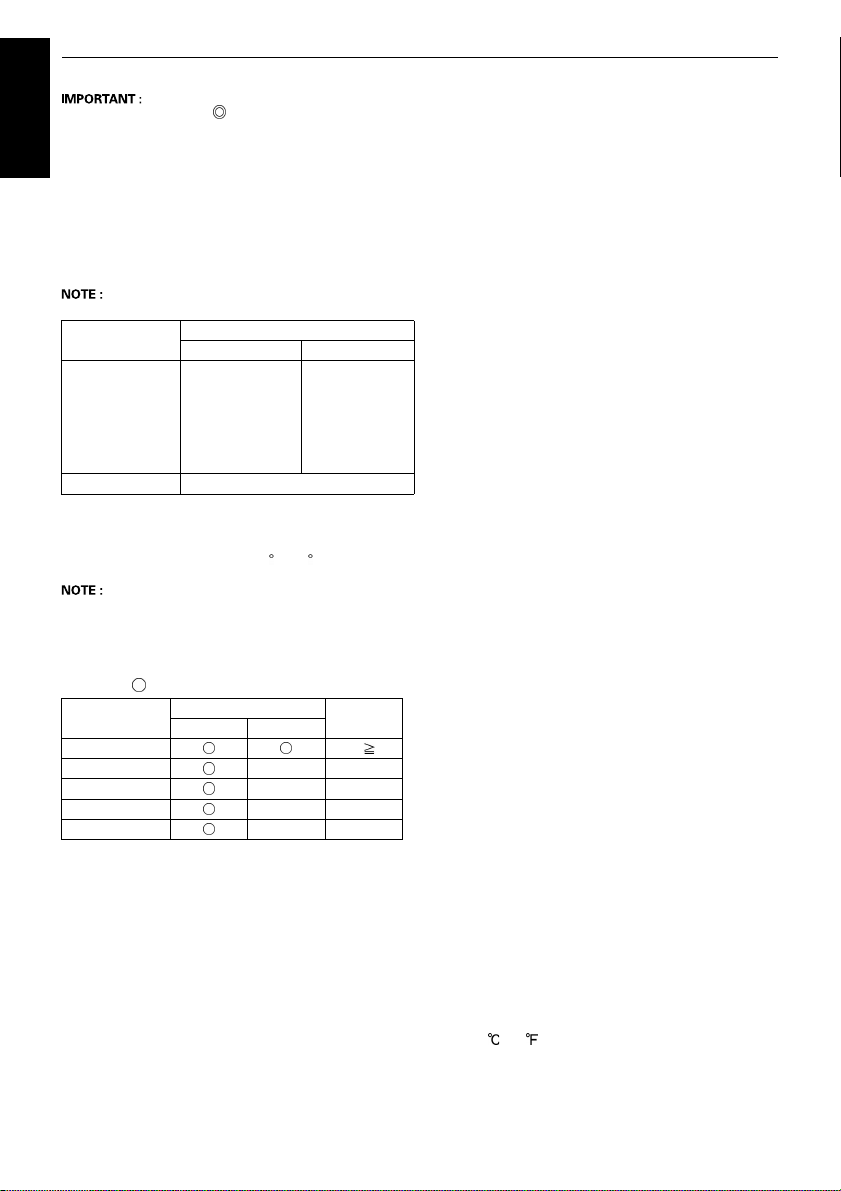

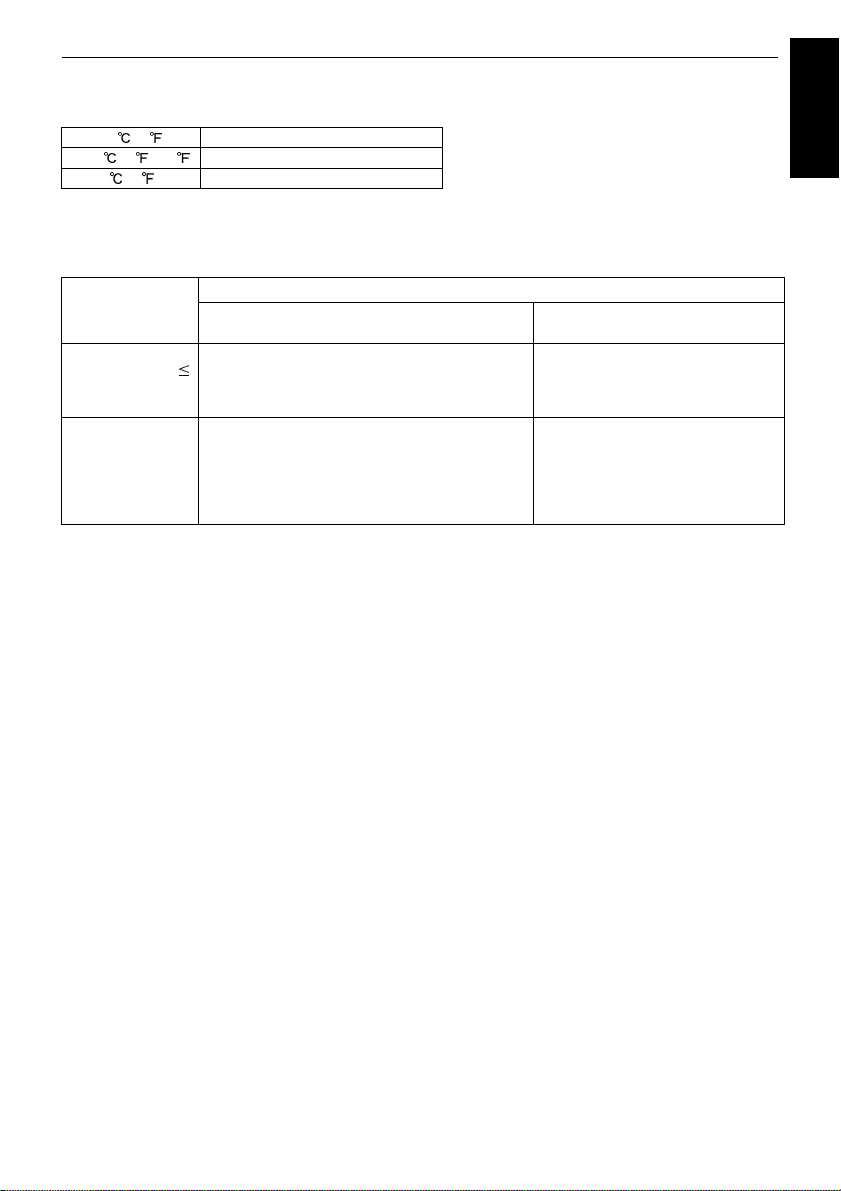

A Changing interval of engine oil

Models

D1503-M-E3

D1703-M-E3

D1803-M-E3

V2003-M-E3

V2203-M-E3

V2403-M-E3

V2403-M-T-E3

124 mm (4.88 in.) *90 mm (3.54 in.)

Initial

* 90 mm (3.54 in.) oil pan depth is optional.

**Standard replacement interval

A American Petroleum Institute (API) classification: above CF

A Ambient temperature: below 35 C (95 F)

Lubricating oil

With strict emission control regulations now in effect, the CF-4 and CG-4 engine oils have been developed for use with

low sulfur fuels, for On-Highway vehicle engines. When a Non-Road engine runs on high sulfur fuel, it is advisable to

use a "CF or better" classification engine oil with a high Total Base Number (a minimum TBN of 10 is recommended).

A Lubricating oil recommended when a low-sulfur or high-sulfur fuel is employed.

: Recommendable X : Not recommendable

Lubricating

oil classification

CF *TBN 10

CF-4 X

CG-4 X

CH-4 X

CI-4 X

Low-sulfur High-sulfur

* TBN: Total Base Number

**Fuel

A Diesel Fuel Specification Type and Sulfur Content % (ppm) used, must be compliant with all applicable emission

regulations for the area in which the engine is operated.

A Use of diesel fuel with sulfur content less than 0.10 % (1000 ppm) is strongly recommended.

A If high-sulfur fuel (sulfur content 0.50 % (5000 ppm) to 1.0 % (10000 ppm)) is used as a diesel fuel, change the engine

oil and oil filter at shorter intervals. (approximately half).

A DO NOT USE Fuels that have sulfur content greater than 1.0 % (10000 ppm).

A Since KUBOTA diesel engines of less than 56 kW (75 hp) utilize EPA Tier 4 and Interim Tier 4 standards, the use of

low sulfur fuel or ultra low sulfur fuel is mandatory for these engines, when operated in US EPA regulated areas.

Therefore, please use No.2-D S500 or S15 diesel fuel as an alternative to No.2-D, and use No.1-D S500 or S15 diesel

fuel as an alternative to No.1-D for ambient temperatures below -10 (14 ).

1) No.1-D or No.2-D, S500 : Low Sulfur Diesel (LSD) less than 500 ppm or 0.05 wt.%

No.1-D or No.2-D, S15 : Ultra Low Sulfur Diesel (ULSD) 15 ppm or 0.0015 wt.%

A CJ-4 classification oil is intended for use in engines equipped with DPF (Diesel Particulate Filter) and is Not

Recommended for use in Kubota E3 specification engines.

*Oil pan depth

200 Hrs 150 Hrs

50 Hrs

**Fuel

Remarks

Page 27

11MAINTENANCE

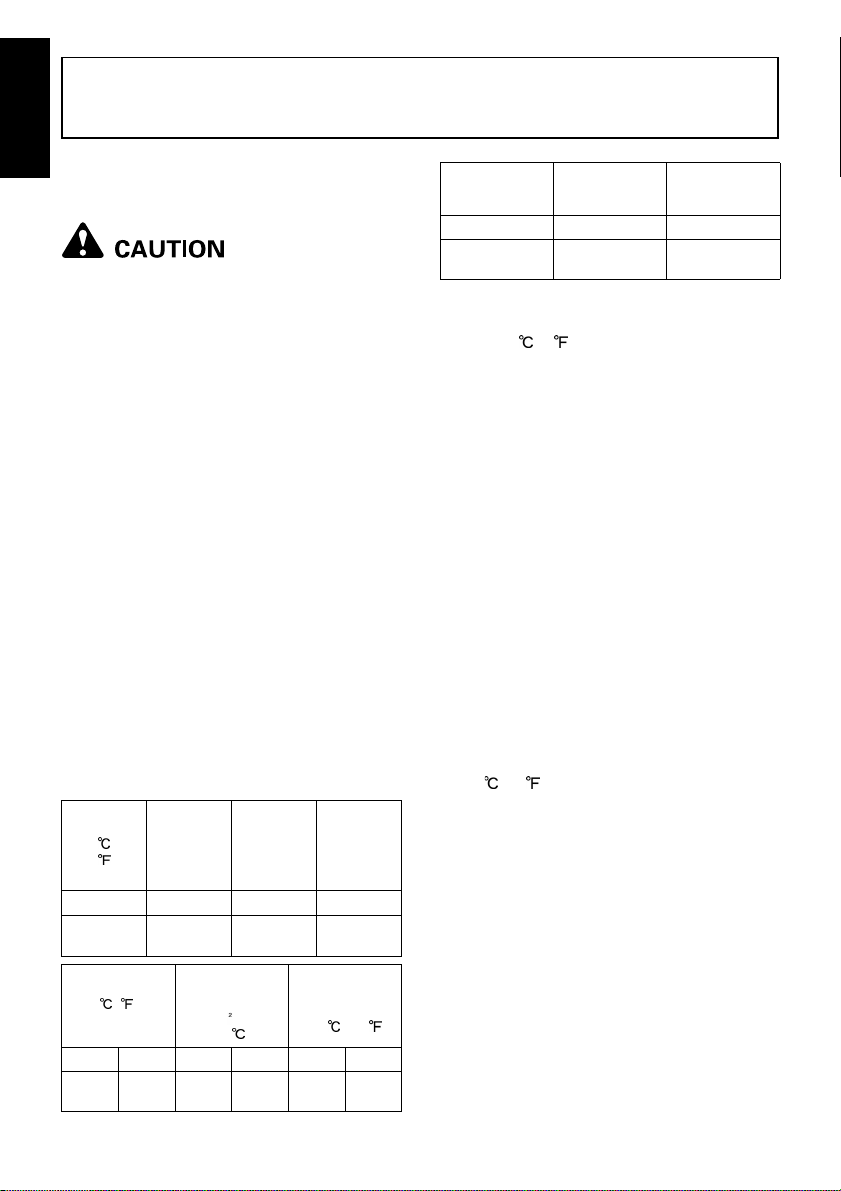

A Oil used in the engine should have API classification and Proper SAE Engine Oil according to the ambient

temperatures as shown below:

Above 25 (77 ) SAE30, SAE10W-30 or 15W-40

0 to 25 (32 to 77 ) SAE20, SAE10W-30 or 15W-40

Below 0 (32 ) SAE10W, SAE10W-30 or 15W-40

A Recommended API classification

Refer to the following table for the suitable American Petroleum Institute (API) classification of engine oil according to

the engine type (with internal EGR, external EGR or non-EGR) and the Fuel Type Used : (Low Sulfur, Ultra Low Sulfur

or High Sulfur Fuels).

Engine oil classification (API classification)

Fuel type

High Sulfur Fuel

[0.05 % (500 ppm)

Sulfur Content <

0.50 % (5000 ppm)]

Low Sulfur Fuel

[Sulfur Content <

0.05 % (500 ppm)] or

Ultra Low Sulfur Fuel

[Sulfur Content <

0.0015 % (15 ppm)]

EGR: Exhaust Gas Re-circulation

CF

(If the "CF-4, CG-4, CH-4 or CI-4" engine oil is used

with a high-sulfur fuel, change the engine oil at shorter

intervals. (approximately half))

CF, CF-4, CG-4, CH-4 or CI-4

Engines with non-EGR

Engines with internal EGR

Engines with external EGR

---

CF or CI-4

(Class CF-4, CG-4 and CH-4 engine, oils

cannot be used on EGR type engines.)

ENGLISH

Page 28

12 PERIODIC SERVICE

PERIODIC SERVICE

ENGLISH

FUEL

Fuel is flammable and can be dangerous. You should

handle fuel with care.

To avoid personal injury:

A Do not mix gasoline or alcohol with

diesel fuel. This mixture can cause

an explosion.

A Be careful not to spill fuel during

refueling. If fuel should spill, wipe it

off at once, or it may cause a fire.

A Do not fail to stop the engine before

refueling. Keep the engine away from

the fire.

A Be sure to stop the engine while

refueling or bleeding and when

cleaning or changing fuel filter or fuel

pipes. Do not smoke when working

around the battery or when refueling.

A Check the fuel systems at a well

ventilated and wide place.

A When fuel and lubricant are spilled,

refuel after letting the engine cool off.

A Always keep spilled fuel and

lubricant away from engine.

BFuel level check and refueling

1. Check to see that the fuel level is above the lower limit

of the fuel level gauge.

2. If the fuel is too low, add fuel to the upper limit. Do not

overfill.

Carbon

Residue on,

10 percent

Residuum,

%

Viscosity

Kinematic

cSt or

mm /s at

40

1.9 4.1 32.6 40.1

Ash,

weight

%

Viscosity

Saybolt,

SUS at

37.8(100)

()

90%

Point

Water and

Sediment,

volume

%

0.05 0.35 0.01

338

(640)

Flash Point,

()

Min Max Max Max

52

(125)

Distillation

Temperatures,

Min Max Min Max Min Max

282

(540)

Sulfur,

weight

%

Max Max Min

0.50 No. 3 40

A Cetane Rating : The minimum recommended Fuel

Cetane Rating is 45. A cetane rating greater than 50

is preferred, especially for ambient temperatures

below -20 (-4 ) or elevations above 1500 m (5000

ft).

A Diesel Fuel Specification Type and Sulfur Content %

(ppm) used, must be compliant with all applicable

emission regulations for the area in which the engine

is operated.

A Use of diesel fuel with sulfur content less than 0.10 %

(1000 ppm) is strongly recommended.

A If high-sulfur fuel (sulfur content 0.50 % (5000 ppm) to

1.0 % (10000 ppm)) is used as a diesel fuel, change

the engine oil and oil filter at shorter intervals.

(approximately half).

A DO NOT USE Fuels that have sulfur content greater

than 1.0 % (10000 ppm).

A Diesel fuels specified to EN 590 or ASTM D975 are

recommended.

A No.2-D is a distillate fuel of lower volatility for engines

in industrial and heavy mobile service.

(SAE J313 JUN87)

A Since KUBOTA diesel engines of less than 56 kW (75

hp) utilize EPA Tier 4 and Interim Tier 4 standards, the

use of low sulfur fuel or ultra low sulfur fuel is

mandatory for these engines, when operated in US

EPA regulated areas. Therefore, please use No.2-D

S500 or S15 diesel fuel as an alternative to No.2-D,

and use No.1-D S500 or S15 diesel fuel as an

alternative to No.1-D for ambient temperatures below

-10 (14 ).

1) SAE : Society of Automotive Engineers

2) EN : European Norm

3) ASTM : American Society of Testing and Materials

4) US EPA : United States Environmental Protection

Agency

5) No.1-D or No.2-D, S500 : Low Sulfur Diesel (LSD)

less than 500 ppm or 0.05 wt.%

No.1-D or No.2-D, S15 : Ultra Low Sulfur Diesel

(ULSD) 15 ppm or 0.0015 wt.%

Copper

Strip

Corrosion

Cetane

Number

Page 29

13PERIODIC SERVICE

A Be sure to use a strainer when filling the fuel tank, or

dirt or sand in the fuel may cause trouble in the fuel

injection pump.

A For fuel, always use diesel fuel. You are required not

to use alternative fuel, because its quality is unknown

or it may be inferior in quality. Kerosene, which is very

low in cetane rating, adversely affects the engine.

Diesel fuel differs in grades depending on the

temperature.

A Be careful not to let the fuel tank become empty, or air

can enter the fuel system, necessitating bleeding

before next engine start.

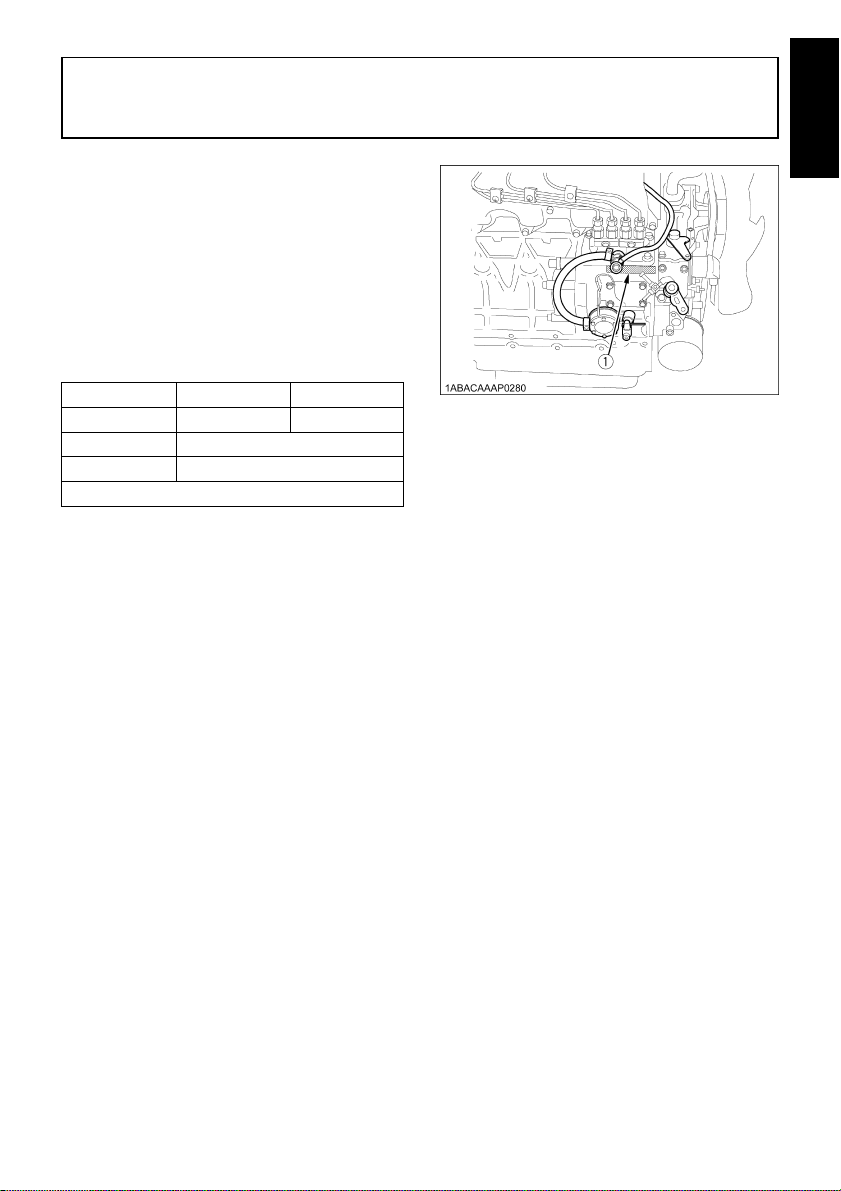

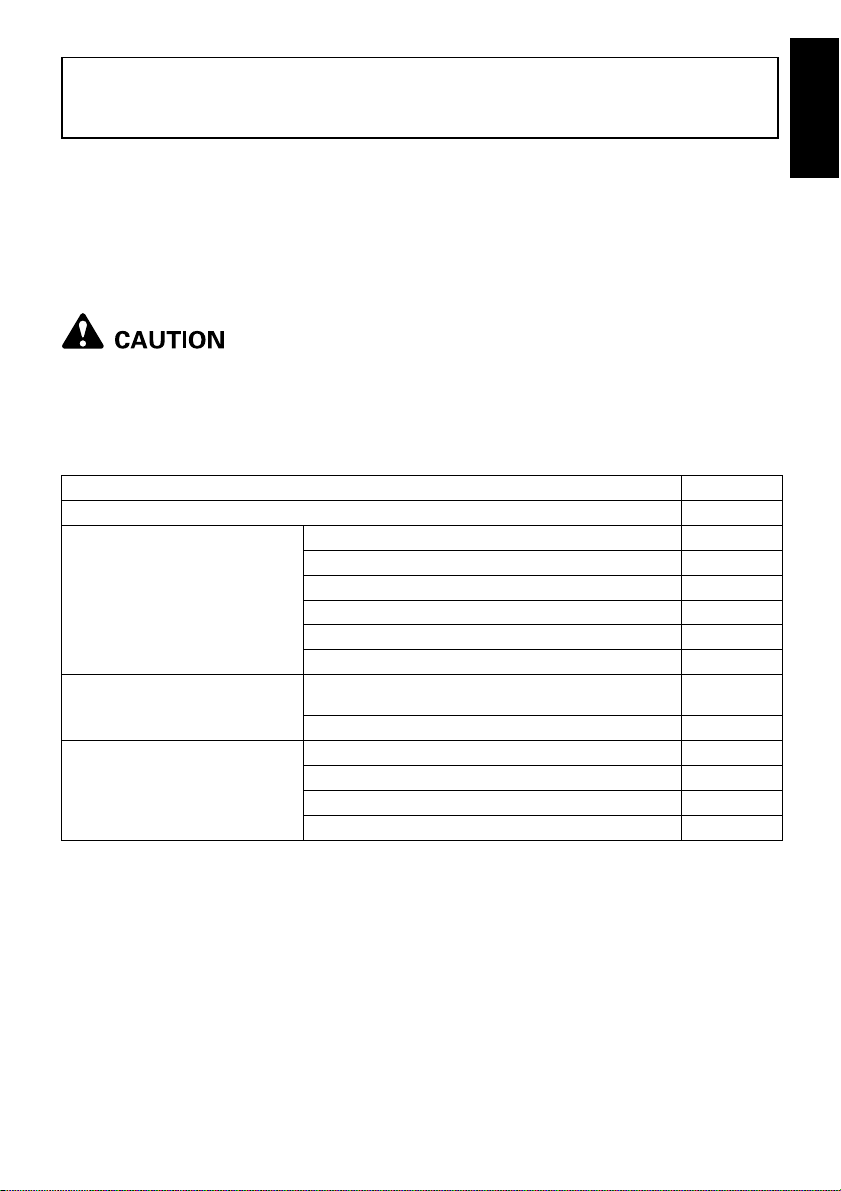

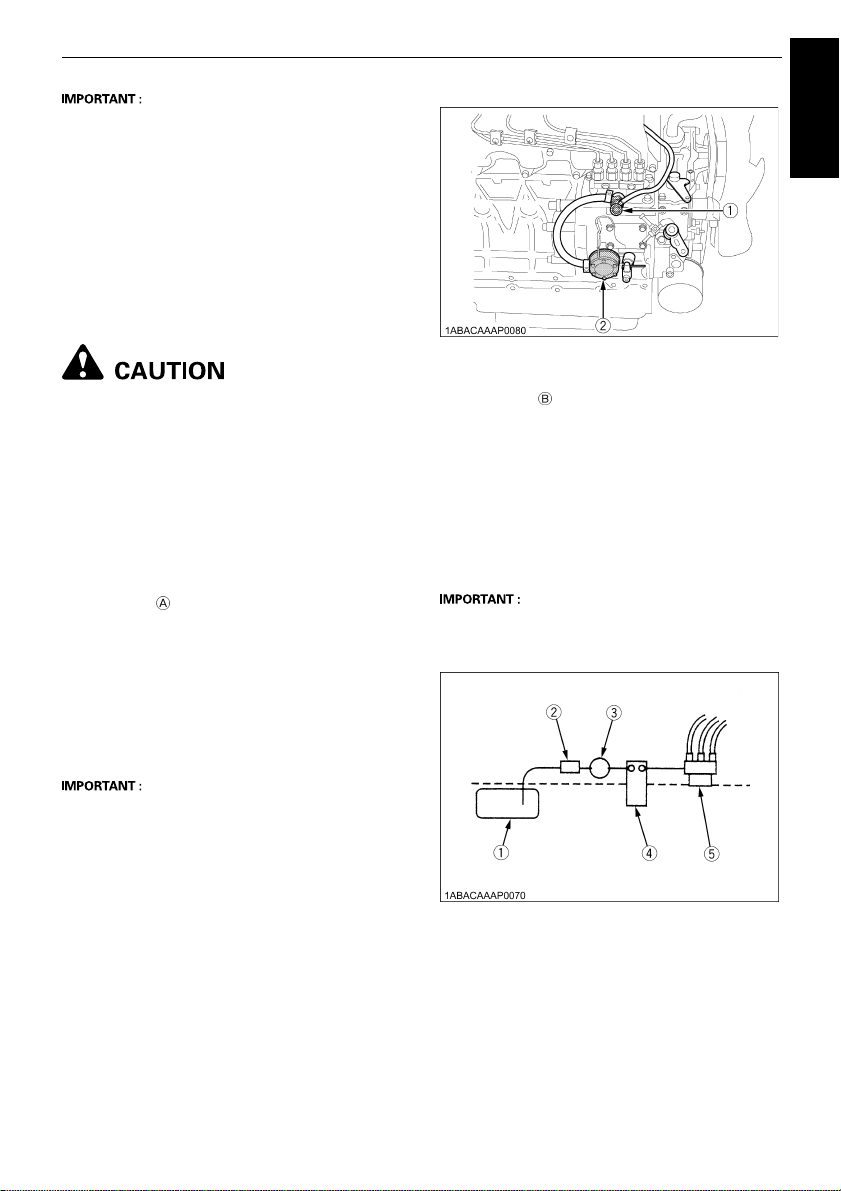

BAir bleeding the fuel system

To avoid personal injury;

A Do not bleed a hot engine as this

could cause fuel to spill onto a hot

exhaust manifold creating a danger

of fire.

Air bleeding of the fuel system is required if;

A after the fuel filter and pipes have been detached and

refitted;

A after the fuel tank has become empty; or

A before the engine is to be used after a long storage.

[PROCEDURE ] (gravity feed fuel tanks only)

1. Fill the fuel tank to the fullest extent. Open the fuel

filter lever.

2. Open the air vent cock on top of the fuel injection

pump.

3. Turn the engine, continue it for about 10 seconds,

then stop it, or move the fuel feed pump lever by hand

(optional).

4. Close the air vent cock on top of the fuel injection

pump.

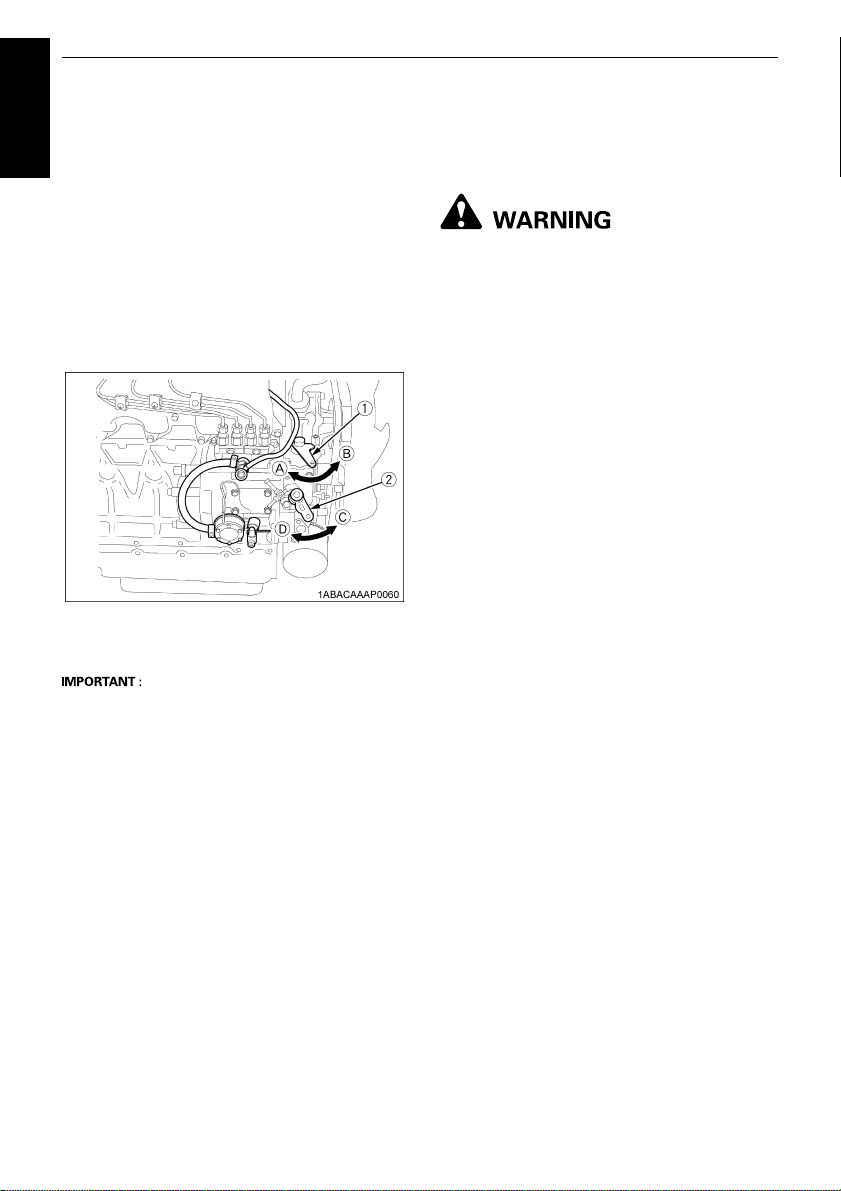

[GRAVITY FEED SYSTEM]

(1) Air vent cock

(2) Fuel feed pump

[PROCEDURE ] (fuel tanks lower than injection

pump)

1. For fuel tanks that are lower than the injection pump.

The fuel system must be pressurized by the fuel

system electric fuel pump.

2. If an electric fuel pump is not used, you must manually

actuate the pump by lever to bleed.

3. The primary fuel filter must be on the pressure side of

the pump if the fuel tank is lower than the injection

pump.

4. To bleed, follow (2) through (4) above.

A Tighten air vent plug of the fuel injection pump except

when bleeding, or it may stop the engine suddenly.

[TANK BELOW INJECTION PUMP SYSTEM]

ENGLISH

A Always keep the air vent cock on the fuel injection

pump closed except when air is vented, or it may

cause the engine to stop.

(1) Fuel tank below injection pump

(2) Pre-filter

(3) Electric or Mechanical pump

(4) Main Filter

(5) Injection pump

Page 30

PERIODIC SERVICE14

BChecking the fuel pipes

ENGLISH

To avoid personal injury;

A Check or replace the fuel pipes after

stopping the engine. Broken fuel

pipes can cause fires.

Check the fuel pipes every 50 hours of operation. When if;

1. If the clamp band is loose, apply oil to the screw of the

band, and tighten the band securely.

2. If the fuel pipes, made of rubber, become worn out,

replace them and clamp bands every 2 years.

3. If the fuel pipes and clamp bands are found worn or

damaged before 2 years' pass, replace or repair them

at once.

4. After replacement of the pipes and bands, air-bleed

the fuel system.

A When the fuel pipes are not installed, plug them at

both ends with clean cloth or paper to prevent dirt from

entering. Dirt in the pipes can cause fuel injection

pump malfunction.

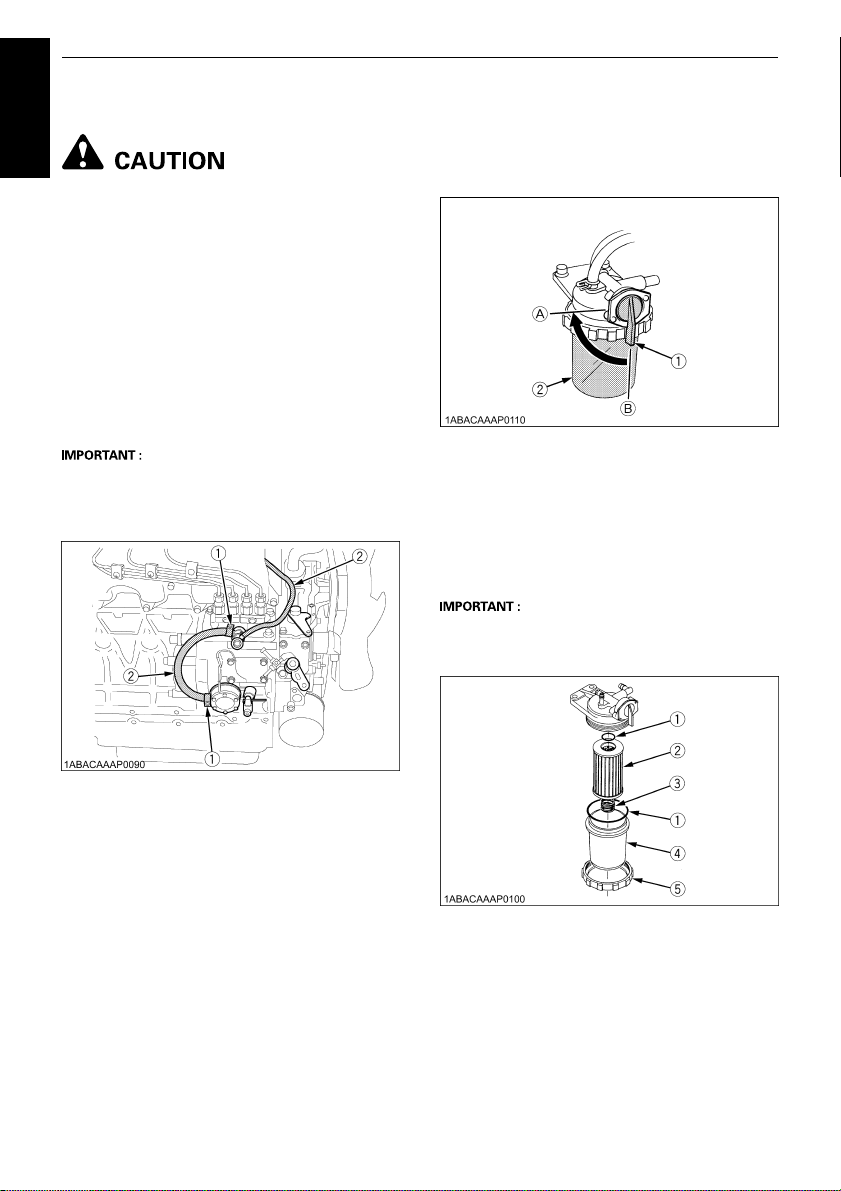

BCleaning the fuel filter pot

Every 100 hours of operation, clean the fuel filter in a

clean place to prevent dust intrusion.

1. Close the fuel filter lever.

(1) Fuel filter lever

(2) Fuel filter pot

2. Remove the top cap, and rinse the inside with diesel

fuel.

3. Take out the element, and rinse it with diesel fuel.

4. After cleaning, reinstall the fuel filter, keeping out of

dust and dirt.

5. Air-bleed the injection pump.

A Entrance of dust and dirt can cause a malfunction of

the fuel injection pump and the injection nozzle. Wash

the fuel filter cup periodically.

(A) "OFF"

(B) "ON"

(1) Clamp band

(2) Fuel pipe

(1) O ring

(2) Filter element

(3) Spring

(4) Filter bowl

(5) Screw ring

Page 31

15PERIODIC SERVICE

BFuel filter cartridge replacement

1. Replace the fuel filter cartridge with a new one every

400 operating hours.

2. Apply fuel oil thinly over the gasket and tighten the

cartridge into position by hand-tightening only.

3. Finally, vent the air.

A Replace the fuel filter cartridge periodically to prevent

wear of the fuel injection pump plunger or the injection

nozzle, due to dirt in the fuel.

(1) Fuel filter cartridge

(2) Air vent plug

(3) O ring

(4) Pipe joint

(5) Cover

ENGINE OIL

To avoid personal injury:

A Be sure to stop the engine before

checking and changing the engine

oil and the oil filter cartridge.

A Do not touch muffler or exhaust

pipes while they are hot; Severe

burns could result. Always stop the

engine and allow it to cool before

conducting inspections,

maintenance, or for a cleaning

procedure.

A Contact with engine oil can damage

your skin. Put on gloves when using

engine oil. If you come in contact

with engine oil, wash it off

immediately.

A Be sure to inspect the engine, locating it on a level

place. If placed on gradients accurately, oil quantity

may not be measured.

BChecking oil level and adding engine oil

1. Check the engine oil level before starting or more than

5 minutes after stopping the engine.

2. Remove the oil level gauge, wipe it clean and reinstall

it.

3. Take the oil level gauge out again, and check the oil

level.

ENGLISH

(1) Oil filler plug

(2) Oil level gauge

[Lower end of oil level gauge]

(A) Engine oil level within this

range is proper.

Page 32

PERIODIC SERVICE16

4. If the oil level is too low, remove the oil filler plug, and

add new oil to the prescribed level.

5. After adding oil, wait more than 5 minutes and check

the oil level again. It takes some time for the oil to drain

ENGLISH

down to the oil pan.

Engine oil quantity

Model

D1503-M-E3

D1703-M-E3

D1803-M-E3

V2003-M-E3

V2203-M-E3

V2403-M-E3

V2403-M-T-E3

* 90 mm (3.54 in.) oil pan depth is optional.

Oil quantities shown are for standard oil pans.

A Engine oil should be MIL-L-2104C or have properties

of API classification CF or higher.

Change the type of engine oil according to the

ambient temperature.

Above 25 C (77 F)

0 C to 25 C (32 F to 77 F)

Below 0 C (32 F)

A When using oil of different brands from the previous

one, be sure to drain all the previous oil before adding

the new engine oil.

124 mm (4.88 in.) *90 mm (3.54 in.)

(1.85 U.S.gals.)

(2.51 U.S.gals.)

Oil pan depth

7.0 L

(1.48 U.S.gals.)

9.5 L

(2.01 U.S.gals.)

SAE30 o r SAE10W-30

SAE2 0 o r S AE10 W-30

SAE10W or SAE10W-30

5.6 L

7.6 L

SAE15W-40

SAE15W-40

SAE15W-40

BChanging engine oil

A Changing interval thereafter

Models

D1503-M-E3

D1703-M-E3

D1803-M-E3

V2003-M-E3

V2203-M-E3

V2403-M-E3

V2403-M-T-E3

Initial 50 Hrs

* 90 mm (3.54 in) oil pan depth is optional.

**Standard replacement interval

A API classification : above CF

A Ambient temperature : below 35 C (95 F )

2. Remove the drain plug at the bottom of the engine,

and drain all the old oil. Drain oil will drain easier when

the oil is warm.

(1) Oil drain plug

3. Add new engine oil up to the upper limit of the oil level

gauge.

124 mm (4.88 in.) *90 mm (3.54 in.)

Oil pan depth

200 Hrs 150 Hrs

To avoid personal injury:

A Be sure to stop the engine before

draining engine oil.

A When draining engine oil, place

some container underneath the

engine and dispose it according to

local regulations.

A Do not drain oil after running the

engine. Allow engine to cool down

sufficiently.

1. Change oil after the initial 50 hours of operation and

every 200 hours thereafter. (See table below.)

Page 33

17PERIODIC SERVICE

BReplacing the oil filter cartridge

To avoid personal injury:

A Be sure to stop the engine before

changing the oil filter cartridge.

A Allow engine to cool down

sufficiently, oil can be hot and cause

burns.

1. Replace the oil filter cartridge. Oil filter cartridge

should be replaced, as following operation hours.

Models

D1503-M-E3

D1703-M-E3

D1803-M-E3

V2003-M-E3

V2203-M-E3

V2403-M-E3

V2403-M-T-E3

Initial 50 Hrs

* 90 mm (3.54 in.) oil pan depth is optional.

2. Remove the old oil filter cartridge with a filter wrench.

3. Apply a film of oil to the gasket for the new cartridge.

4. Screw in the cartridge by hand. When the gasket

contacts the seal surface, tighten the cartridge enough

by hand. Because, if you tighten the cartridge with a

wrench, it will be tightened too much.

124 mm (4.88 in.) *90 mm (3.54 in.)

Oil pan depth

200 Hrs 150 Hrs

RADIATOR

Coolant will last for one day's work if filled all the way up

before operation start. Make it a rule to check the coolant

level before every operation.

To avoid personal injury:

A Do not stop the engine suddenly,

stop it after about 5 minutes of

unloaded idling.

A Work only after letting the engine and

radiator cool off completely (more

than 30 minutes after it has been

stopped).

A Do not remove the radiator cap while

coolant is hot. When cool to the

touch, rotate cap to the first stop to

allow excess pressure to escape.

Then remove cap completely.

If overheats should occur, steam

may gush out from the radiator or

recovery tank; Severe burns could

result.

ENGLISH

(1) Oil filter cartridge

(2) Remove with a filter wrench

(Tighten with your hand)

5. After the new cartridge has been replaced, the engine

oil level normally decreases a little. Thus, run the

engine for a while and check for oil leaks through the

seal before checking the engine oil level. Add oil if

necessary.

A Wipe off any oil sticking to the machine completely.

Page 34

PERIODIC SERVICE18

BChecking coolant level, adding coolant

1. Remove the radiator cap, after the engine has

ENGLISH

completely cooled, and check to see that coolant

reaches the supply port.

(1) Radiator pressure cap

2. If the radiator is provided with a recovery tank, check

the coolant level of the recovery tank. When it is

between the "FULL" and "LOW" marks, the coolant

will last for one day's work.

3. When the coolant level drops due to evaporation, add

water only up to the full level.

4. Check to see that two drain cocks; one is at the

crankcase side and the other is at the lower part of the

radiator as figures below.

(1) Recovery tank (A) "FULL"

(B) "LOW"

(1) Coolant drain cock

A If the radiator cap has to be removed, follow the

caution and securely retighten the cap.

A If coolant should be leak, consult your local KUBOTA

dealer.

A Make sure that muddy or sea water does not enter the

radiator.

A Use clean, fresh water and 50% anti-freeze to fill the

recovery tank.

A Do not refill recovery tank with coolant over the

"FULL" level mark.

A Be sure to close the radiator cap securely. If the cap is

loose or improperly closed, coolant may leak out and

decrease quickly.

Page 35

19PERIODIC SERVICE

BChanging coolant

1. To drain coolant, always open both drain cocks and

simultaneously open the radiator cap as well. With the

radiator cap kept closed, a complete drain of water is

impossible.

2. Remove the overflow pipe of the radiator pressure cap

to drain the recovery tank.

3. Prescribed coolant volume (U.S.gallons)

Models Quantity

D1503-M-E3,D1703-M-E3 5.5 L (1.45 U.S.gals.)

D1803-M-E3 5.8 L (1.53 U.S.gals.)

V2003-M-E3,V2203-M-E3 8.1 L (2.14 U.S.gals.)

V2403-M-E3,V2403-M-T-E3 8.4 L (2.22 U.S.gals.)

A Coolant quantities shown are for standard radiators.

4. An improperly tightened radiator cap or a gap between

the cap and the seat quickens loss of coolant.

5. Coolant (Radiator cleaner and anti-freeze)

Season Coolant

Summer

Winter (when temperature

drops below 0 C (32 F))

or all season

Pure water and radiator

cleaner

Pure water and anti-freeze

(See "Anti-freeze" in

“RADIATOR” section.)

BRemedies for quick decrease of coolant

1. Check any dust and dirt between the radiator fins and

tube. If any, remove them from the fins and the tube.

2. Check the tightness of the fan belt. If loose, tighten it

securely.

3. Check the internal blockage in the radiator hose. If

scale forms in the hose, clean with the scale inhibitor

or its equivalent.

BChecking radiator hoses and clamp

bands

To avoid personal injury:

A Be sure to check radiator hoses and

clamp bands periodically. If radiator

hose is damaged or coolant leaks,

overheats or severe burns could

occur.

Check to see if radiator hoses are properly fixed every

200 hours of operation or 6 months, whichever comes

first.

1. If hose clamps are loose or water leaks, tighten hose

clamp securely.

2. Replace hoses and tighten hose clamps securely, if

radiator hoses are swollen, hardened or cracked.

Replace hoses and hose clamps every 2 years or earlier,

if checked and found that hoses are swollen, hardened or

cracked.

BPrecaution at overheating

Take the following actions in the event the coolant

temperature is nearly or more than the boiling point, what

is called "Overheating". Take these actions if the engine's

alarm buzzer sounds or the alarm lamp lights up.

1. Stop the engine operation in a safe place and keep

the engine unloaded idling.

2. Do not stop the engine suddenly. Stop it after about 5

minutes of unloaded idling.

3. If the engine stalls within about 5 minutes of running

under no load, immediately leave and keep yourself

away from the machine. Do not open the hood and

any other part.

4. Keep yourself and others well away from the engine

for further 10 minutes or while the steam blown out.

5. Checking that there gets no danger such as burn, get

rid of the causes of overheating according to the

manual, see "TROUBLESHOOTING" section. And

then, start the engine again.

ENGLISH

BCleaning radiator core(outside)

If dust is between the fin and tube, wash it away with

running water.

A Do not clean radiator with firm tools such as spatulas

or screwdrivers. They may damage specified fin or

tube. It can cause coolant leaks or decrease cooling

performance.

Page 36

PERIODIC SERVICE20

BAnti-freeze

ENGLISH

To avoid personal injury:

A When using anti-freeze, put on some

protection such as rubber gloves

(Anti-freeze contains poison.).

A If should drink anti-freeze, throw up

at once and take medical attention.

A When anti-freeze comes in contact

with the skin or clothing, wash it off

immediately.

A Do not mix different types of anti-

freeze. The mixture can produce

chemical reaction causing harmful

substances.

A Anti-freeze is extremely flammable

and explosive under certain

conditions. Keep fire and children

away from anti-freeze.

A When draining fluids from the

engine, place some container

underneath the engine body.

A Do not pour waste onto the grounds,

down a drain, or into any water

source.

A Also, observe the relevant

environmental protection

regulations when disposing of antifreeze.

Always use a 50/50 mix of long-life coolant and clean soft

water in KUBOTA engines.

Contact KUBOTA concerning coolant for extreme

conditions.

1. Long-life coolant (hereafter LLC) comes in several

types. Use ethylene glycol (EG) type for this engine.

2. Before employing LLC-mixed cooling water, flush the

radiator with fresh water. Repeat this procedure 2 or 3

times to clean up the radiator and engine block from

inside.

3. Mixing the LLC

Premix 50% LLC with 50% clean soft water. When

mixing, stir it up well, and then fill into the radiator.

4. The procedure for the mixing of water and anti-freeze

differs according to the make of the anti-freeze. Refer

to SAE J1034 standard, more specifically also to SAE

J814c.

Vol %

Anti-freeze

50 -37 -34 108 226

*At 1.013 x 10 Pa (760 mmHg) pressure

(atmospheric). A higher boiling point is obtained by

using a radiator pressure cap which permits the

development of pressure within the cooling system.

5. Adding the LLC

(1) Add only water if the coolant level reduces in the

cooling system by evaporation.

(2) If there is a coolant leak, add the LLC of the same

manufacturer and type in the same coolant

percentage.

*Never add any long-life coolant of different

manufacturer. (Different brands may have different

additive components, and the engine may fail to

perform as specified.)

6. When the LLC is mixed, do not employ any radiator

cleaning agent. The LLC contains anti-corrosive

agent. If mixed with the cleaning agent, sludge may

build up, adversely affecting the engine parts.

7. Kubota's genuine long-life coolant has a service life of

2 years. Be sure to change the coolant every 2 years.

A The above data represent industry standards that

necessitate minimum glycol content in the

concentrated anti-freeze.

Freezing Point Boiling Point *

BRadiator cement

As the radiator is solidly constructed, there is little

possibility of water leakage. Should this happen,

however, radiator cement can easily fix it. If leakage is

serious, contact your local KUBOTA dealer.

Page 37

21PERIODIC SERVICE

AIR CLEANER

Since the air cleaner employed on this engine is a dry

type, never apply oil to it.

1. Open the evacuator valve once a week under ordinary

conditions - or daily when used in a dusty place. This

will get rid of large particles of dust and dirt.

2. Wipe the inside air cleaner clean with cloth if it is dirty

or wet.

3. Avoid touching the element except when cleaning.

4. When dry dust adheres to the element, blow

compressed air from the inside turning the element.

Pressure of compressed air must be under 205 kPa

(2.1 kgf/cm , 30 psi).

5. Replace the element every year or every 6 cleanings.

(1) Air cleaner body

(2) Element

(3) Wing bolt

(4) Evacuator valve

BEvacuator valve

Open the evacuator valve once a week under ordinary

conditions - or daily when used in a dusty place - to get rid

of large particles of dust and dirt.

BFor the air cleaner with a dust cup

(optional)

Remove and clean out the dust cup before it becomes

half full with dust; usually once a week, or even every day

if the working surroundings are dusty.

Install the air cleaner dust cup with "TOP" indicated on the

rear of the cup in the up position. (However, it may be

installed in either direction when the cover is placed at the

lower part.)

A If the dust cup is mounted incorrectly, dust or dirt does

not collect in the cup, and direct attachments of the

dust to the element will cause its lifetime to shorten to

a great extent.

ENGLISH

A Make sure the wing bolt for the element is tight

enough. If it is loose, dust and dirt may be sucked in,

wearing down the cylinder liner and piston ring earlier

and thereby resulting in poor power output.

A Do not overservice the air cleaner element.

Overservicing may cause dirt to enter the engine

causing premature wear. Use the dust indicator as a

guide on when to service.

(1) Air cleaner body

(2) Element

(3) Wing bolt

(4) Dust cup

(5) "TOP" mark

Page 38

PERIODIC SERVICE22

BDust indicator (optional)

If the red signal on the dust indicator attached to the air

ENGLISH

cleaner is visible, the air cleaner has reached the service

level.

Clean the element immediately, and reset the signal with

the "RESET" button.

(1) "RESET" button

(2) Dust indicator

(3) Service level

(4) Signal

BATTERY

To avoid personal injury:

A Be careful not to let the battery

electrolyte contact your body or

clothing.

A Wear eye protection and rubber

gloves, since the diluted sulfuric acid

solution burns skin and eats holes in

clothing. Should this occur,

immediately wash it off with running

water and get medical attention.

Mishandling of the battery shortens the service life and

adds to maintenance costs. Obtain the maximum

performance and the longest life of the battery by

handling properly and with care.

Engine starting will be more difficult, if the battery charge

is low. Be careful to recharge it at an early occasion

before it is too late.

BBattery charging

The battery comes in two types:

refillable and non-refillable.

A For using the refillable type battery,

follow the instructions below.

Do not use or charge the battery if its

fluid level stands below the LOWER

(lower limit level) mark.

Otherwise, the battery component

parts may deteriorate earlier than

expected, which may shorten the

battery's service life or cause an

explosion.

Immediately, add distilled water until

the battery's fluid level is between

the UPPER and LOWER levels.

To avoid personal injury:

A When the battery is being activated,

hydrogen and oxygen gases in the

battery are extremely explosive.

Keep open sparks and flames away

from the battery at all times,

especially when charging the

battery.

A When charging the battery, remove

the battery vent plugs.

A When disconnecting the cable from

the battery, start with the negative

terminal, and when connecting them,

start with the positive terminal first.

A DO NOT check the battery charge by

placing a metal object across the

terminals. Use a voltmeter or

hydrometer.

Page 39

1. Make sure each electrolyte level is to the bottom of

vent wells, if necessary, add only distilled water in a

well-ventilated place.

23PERIODIC SERVICE

ENGLISH

(1) Battery electrolyte level (A) "TOO LOW"

2. To slow charge the battery, connect the charger

positive terminal to the battery positive terminal, and

the negative to the negative, then recharge in the

standard fashion.

3. Quick recharging charges the battery at a high rate in

a short time. This is only for emergencies.

4. Recharge the battery as early as possible, or battery

life will be extremely shortened.

5. When exchanging an old battery for a new one, use

battery of equal specification shown in Page 28 .

(1) Thick cable red(+)

(2) Battery case

(3) Earth cable black(-)

(B) "PROPER"

(C) "TOO HIGH"

(1) Plug (A) "HIGHEST LEVEL"

A Connect the charger positive terminal to the battery

positive terminal, and negative to the negative.

A When disconnecting the cable from the battery, start

with the negative terminal first.

When connecting the cable to the battery, start with

the positive terminal first.

If reversed, the contact of tools on the battery may

cause a short.

(B) "LOWEST LEVEL"

BDirection for long term storage

1. When storing the engine for long periods of time,

remove the battery, adjust the electrolyte to the proper

level, and store in a dry and dark place.

2. The battery naturally discharges while it is stored.

Recharge it once a month in summer, and every 2

months in winter.

ELECTRIC WIRING

To avoid personal injury:

C Shorting of electric cable or wiring

may cause a fire.

A Check to see if electric cables and

wiring are swollen, hardened or

cracked.

A Keep dust and water away from all

power connections.

Loose wiring terminal parts, make

bad connections. Be sure to repair

them before starting the engine.

Damaged wiring reduces the capacity of electrical parts.

Change or repair damaged wiring immediately.

Page 40

PERIODIC SERVICE24

FAN BELT

BAdjusting Fan Belt Tension

ENGLISH

To avoid personal injury:

A Be sure to stop the engine and

remove the key before checking the

belt tension.

A Be sure to reinstall the detached

safety shield after maintenance or

checking.

Proper fan belt

tension

1. Stop the engine and remove the key.

2. Apply moderate thumb pressure to belt between the

pulleys.

3. If tension is incorrect, loosen the alternator mounting

bolts and, using a lever placed between the alternator

and the engine block, pull the alternator out until the

deflection of the belt falls within acceptable limits.

4. Replace fan belt if it is damaged.

A If belt is loosen or damaged and the fan is damaged,

it could result in overheats or insufficient charging.

Correct or replace belt.

A deflection of between 7 to 9 mm

(0.28 to 0.35 in.) when the belt is

pressed in the middle of the span.

(1) Fan belt

(2) Bolt and nut

(A) 7 to 9 mm (0.28 to 0.35 in.)

(under load of 10 kgf (22.1 lbs))

Page 41

CARRIAGE AND STORAGE

CARRIAGE

STORAGE

25CARRIAGE AND STORAGE

ENGLISH

To avoid personal injury:

A Fix the engine securely not to fall

during operation.

A Do not stand near or under the

engine while carrying it.

A The engine is heavy. In handling it,

be very alert not to get your hands

and body caught in.

1. Use carrier such as crane when carrying the engine,

or hurt your waist and yourself. Support the engine

securely with rope not to fall while carrying it.

2. When lifting the engine, put the hook securely to metal

fittings attached to the engine. Use strong hook and

fittings enough to hang the engine.

To avoid personal injury:

A Do not clean the machine with engine

running.

A To avoid the danger of exhaust fume

poisoning, do not operate the engine

in a closed building without proper

ventilation.

A When storing the engine just after

running, let the engine cool off.

Before storing the engine for more than a few months,

remove any dirt on the machine, and:

1. Drain the coolant in the radiator. Open the cock at the

bottom of the radiator, and remove the pressure cap

to drain water completely. Leave the cock open. Hang

a note written "No water" on the pressure cap. Since

water may freeze when the temperature drops below

0 C (32 F), it is very important that no water is left in

the machine.

A When using anti-freeze, it is not necessary to take

step (1) above.

2. Remove dirty engine oil, fill with new oil and run the

engine for about 5 minutes to let the oil penetrate to all

the parts.

3. Check all the bolts and nuts, and tighten if necessary.

4. Remove the battery from the engine, adjust the

electrolyte level, and recharge it. Store the battery in a

dry and dark place.

5. When the engine is not used for a long period of time,

run it for about 5 minutes under no load every 2 to 3

months to keep it free from rust. If the engine is stored

without any running, moisture in the air may condense

into dew over the sliding parts of the engine, resulting

in rust there.

6. If you forget to run the engine for longer than 5 to 6

months, apply enough engine oil to the valve guide

and valve stem seal and make sure the valve works

smoothly before starting the engine.

7. Store the engine in a flat place and remove the key

from engine.

8. Do not store the engine in a place where has

flammable materials such as dry grass or straw.

9. When covering the engine for storage, let engine and

muffler cool off completely.

10.Operate the engine after checking and repairing

damaged wirings or pipes, and clearing flammable

materials carried by mouse.

Page 42

26 TROUBLESHOOTING

TROUBLESHOOTING

ENGLISH

If the engine does not function properly, use the following chart to identify and correct the cause.

B When it is difficult to start the engine B When output is insufficient

Cause Countermeasures

*

Check the fuel tank and fuel filter.

*

Remove water, dirt and other

Fuel is thick and

doesn't flow.

Air or water mixed

in fuel system

Valve clearance is

not as specified.

Leaking valves * Grind valve.

Fuel injection timing

is not as specified.

Engine oil becomes

thick in cold

weather and engine

cranks slow.

Low compression*

Battery is

discharged and the

engine will not

crank.

impurities.

*

As all fuel will be filtered by the filter, if

there should be water or other foreign

matters on the filter, clean the filter

with kerosene.

*

If air is in the fuel filter or injection lines,

the fuel pump will not work properly.

*

To attain proper fuel injection

pressure, check carefully for loosened

fuel line coupling, loose cap nut, etc.

*

Loosen joint bolt stop fuel filter and air

vent screws of fuel injection pump to

eliminate all the air in the fuel system.

*

Adjust valve clearance to 0.18 to 0.22

mm (0.007 to 0.0087 in.) when the

engine is cold.

* Check injection timing

* Change grade of oil according to the

weather (temperature.)

Bad valve or excessive wear of rings,

pistons and liners cause insufficient

compression. Replace with new parts.

*

Charge battery.

*

In winter, always remove battery from

machine, charge fully and keep

indoors. Install in machine at time of

use.

Cause Countermeasures

Compression is

insufficient.

Leaking valves

Fuel is insufficient. * Check fuel system.

Overheating of

moving parts

Valve clearance is

not as specified.

Air cleaner is dirty

Fuel injection

pressure is wrong.*

Injection pump

wear

*

*

*

*

*

*

*

*

*

* Clean the element every 100 hours of

*

*

Bad valve and excessive wear of rings,

pistons and liners cause insufficient

compression. Replace with new parts.