Page 1

BD 530 Bp Classic

Register and win!

www

.kaercher

.com!

FOR U. S. USE ONLY

English 3

Español 19

Français 37

5.963-660.0 03/10

Page 2

2

Page 3

IMPORTANT SAFETY IN-

STRUCTIONS

READ ALL INSTRUCTIONS

BEFORE USING.

WARNING

To reduce the risk of fire, electric shock,

or injury:

– Do not leave the unit when plugged

in. Unplug from outlet when not in

use and before servicing.

and anything that may reduce air

flow.

– Keep hair, loose clothing, fingers,

and all parts of body away from

openings and moving parts.

– Turn off all controls before unplug-

ging.

– Do not use to pick up flammable or

combustible liquids, such as gasoline, or use in areas where they may

be present.

SAVE THESE INSTRUCTIONS

WARNING

– TO REDUCE THE RISK OF ELEC-

TRIC SHOCK-USE INDOORS

ONLY

– Do not allow to be used as a toy.

Close attention is necessary when

used near children.

– Use only as discribed in this manual.

Use only manufacturer’s recommended attachments.

– Do not use with damaged cord or

plug. If the unit is not working as it

should, has been dropped, damaged, left outdoors, or dropped into

water, return it to a service center.

– Do not pull or carry by cord, use cord

as a handle, close a door on cord, or

pull cord around sharp edges or corners. Do not run the unit over cord.

Keep cord away from heated surfaces.

– Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

– Do not handle plug or appliance with

wet hands.

– Do not put any object into openings.

Do not use with any opening

blocked; keep free of dust, lint, hair,

OPERATING SAFETY RULES

AND PRACTICES

Operator Responsibility

Save operation is in the responsibility of

the operator.

The operator shall be familiar with the

operation and function of all controls

and instruments before undertaking to

operate the unit.

Before operating the unit, operators

shall have read and be familiar with the

operator’s manual for the particular unit

being operated and they shall also

abide by the safety rules and practices

in the following paragraphs.

Before operating any unit, the operator

shall be familiar with unusual operating

conditions which may require additional

safety precautions or special operating

instructions.

General

Before starting to operate the unit be in

operating position.

Do not start or operate the unit, any of

its functions or attachments, from any

place other than from the designated

operators position.

Before leaving the operator’s position:

English 3

Page 4

A bring the unit to a complete stop;

B if the unit must be on an incline,

block the wheels.

Do not add to, or modify the unit.

Do not block access to fire aisles, stairways or fire equipment.

Travelling

Yield the right of way to pedestrians and

emergency vehicles such as ambulances and fire trucks.

Cross railroad tracks at an angle wherever possible. Do not park closer than 6

ft (1800 mm) to the nearest rail of a railroad track.

Keep a clear view of the path of travel

and observe for other traffic, personnel,

and safe clearances.

Under all travel conditions, operate the

unit at a speed that will permit it to be

brought to a stop in a safe manner.

Do not indulge in stunt driving or horseplay.

Slow down for wet and slippery floors.

Before driving over a dockboard or

bridge plate, be sure that it is properly

secured. Drive carefully and slowly

across the dockboard or bridge plate,

and never exceed its rated capacity.

When negotiating turns, reduce speed

to a safe level consistent with the operating environment. Make the turns

smoothly.

Operator care of the unit

If the unit is found to be in need of repair

or in any way unsafe, or contributes to

an unsafe condition, the matter shall be

reported immediately to the user’s designated authority, and the unit shall not

be operated until it has been restored to

safe operating condition.

If during operation the unit becomes unsafe in any way, the matter shall be re-

ported immediately to the user’s

designated authority, and the unit shall

not be operated until it has been restored to safe operating condition.

Do not make repairs or adjustments unless specifically authorized to do so.

Do not use open flames when checking

electrolyte level in storage batteries.

MAINTENANCE AND RE-

BUILD PRACTICES

Operation of the unit may be hazardous

if maintenance is neglected or repairs,

rebuilds, or adjustments are not performed in accordance with the manufacturer’s design criteria. Therefore,

maintenance facilities (on or off premises), trained personnel, and detailed

procedures shall be provided.

Maintenance and inspection of the unit

shall be performed in conformance with

the following practices:

A a schedules planned maintenance,

lubrication, and inspection system

shall be followed; consult the manufacturer’s recommendations.

B only tranined and authorized person-

nel shall be permitted to maintain,

repair, adjust, and inspect the unit,

and in accordance with manufactur-

er’s specifications.

Avoid fire hazards and have fire protection equipment present in the work area.

Do not use an open flame to check the

level of any fluid, especially battery

electrolyte. Do not use open pans of fuel

or flammable cleaning fluids for cleaning parts.

FIRE SAFETY STANDARD

Any unit not in safe operating condition

shall be removed from service.

Repairs shall not be made in Class I,

Class II, and Class III locations.

4 English

Page 5

Fire Prevention.The unit shall be kept

in a clean condition and reasonably free

of lint, excess oil, and grease. Noncombustible agents are preferred for cleaning the unit. Flammable liquids [those

having flash points at or above 100°F

(37,8°C)] are not allowed. Precautions

regarding toxicity, ventilation, and fire

hazard shall be appropriate for the

agent or solvent used.

Nameplate Visibility. The unit type

designations as shown on the nameplate and the type markers shall not be

covered over with paint so that their

identification information is obscured.

The unit shall not be used in classified

areas.

Please read and comply with

these original instructions prior to the initial operation of your appliance and store them for later use or

subsequent owners.

Contents

Safety instructions 5

Function 6

Proper use 6

Environmental protection 6

Control elements 7

Before Startup 8

Operation 11

Maintenance and care 14

Faults 15

Technical specifications 18

Warranty 18

Spare parts 18

Safety instructions

Before using the appliance for the first

time, read and observe these operating

instructions and the accompanying brochure: Safety information for brush

cleaning units and spray-extraction

units, 5.956-251.

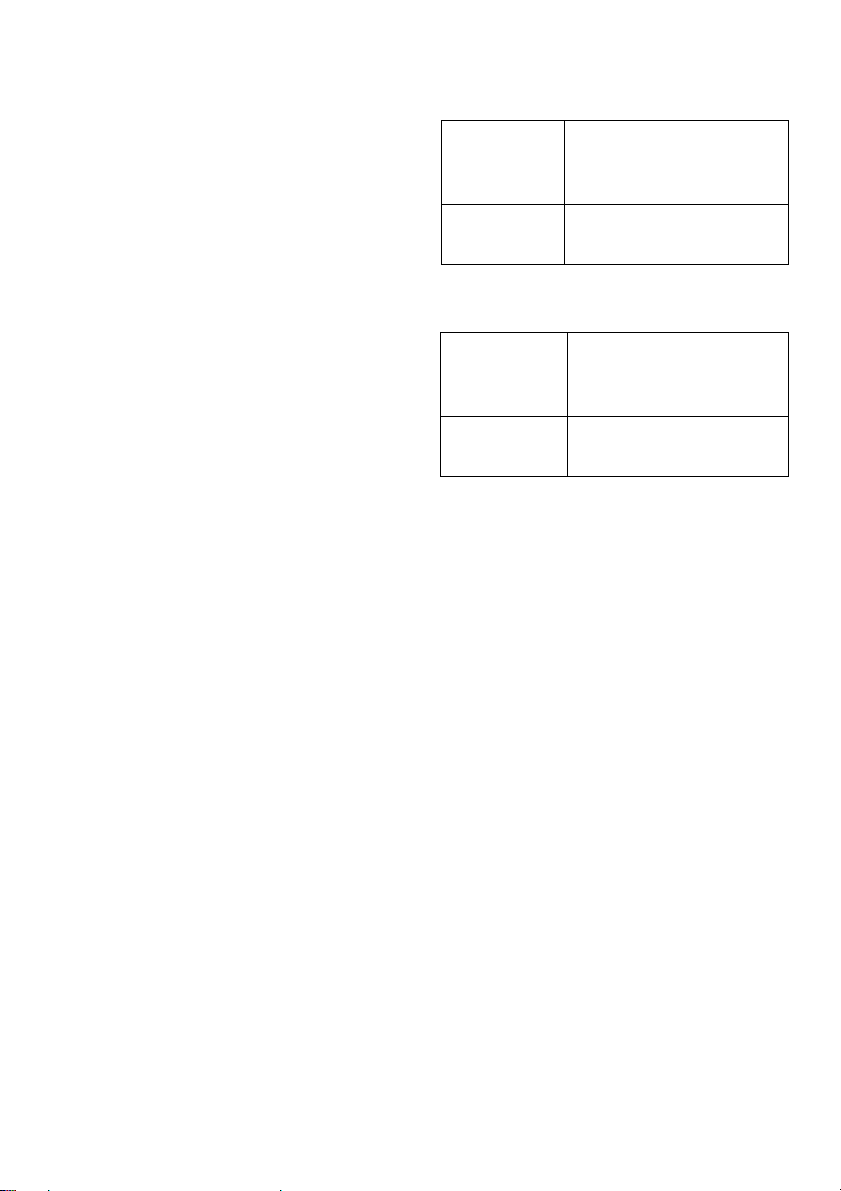

The machine has been approved for

use on surfaces with gradients of up to

2%.

The appliance may only be operated

when the container and all lids are

closed.

Symbols

The following symbols are used in this

operating manual:

Danger

Indicates an immediate threat of danger. Failure to observe the instruction

may result in death or serious injuries.

English 5

Page 6

몇 Warning

Indicates a possibly dangerous situation. Failure to observe the instruction

may result in light injuries or damage to

property.

Note

Indicates useful tips and important information about the product.

Function

The appliance is used for the wet cleaning of level floors. It can be easily adjusted to the cleaning task by setting the

water quantity and the dirt water suction.

A working width of 460 mm and a capacity of 40 l each of the fresh and dirt

water reservoirs enable an effective

cleaning even when the machine is

used for long duration.

Proper use

Use this appliance only as directed in

these operating instructions.

– The appliance should only be used

for cleaning level floors that are not

affected by moisture.

– The appliance is not suited for the

cleaning of frozen grounds (e.g. in

cold stores).

– The appliance may only be equipped

with original accessories and spare

parts.

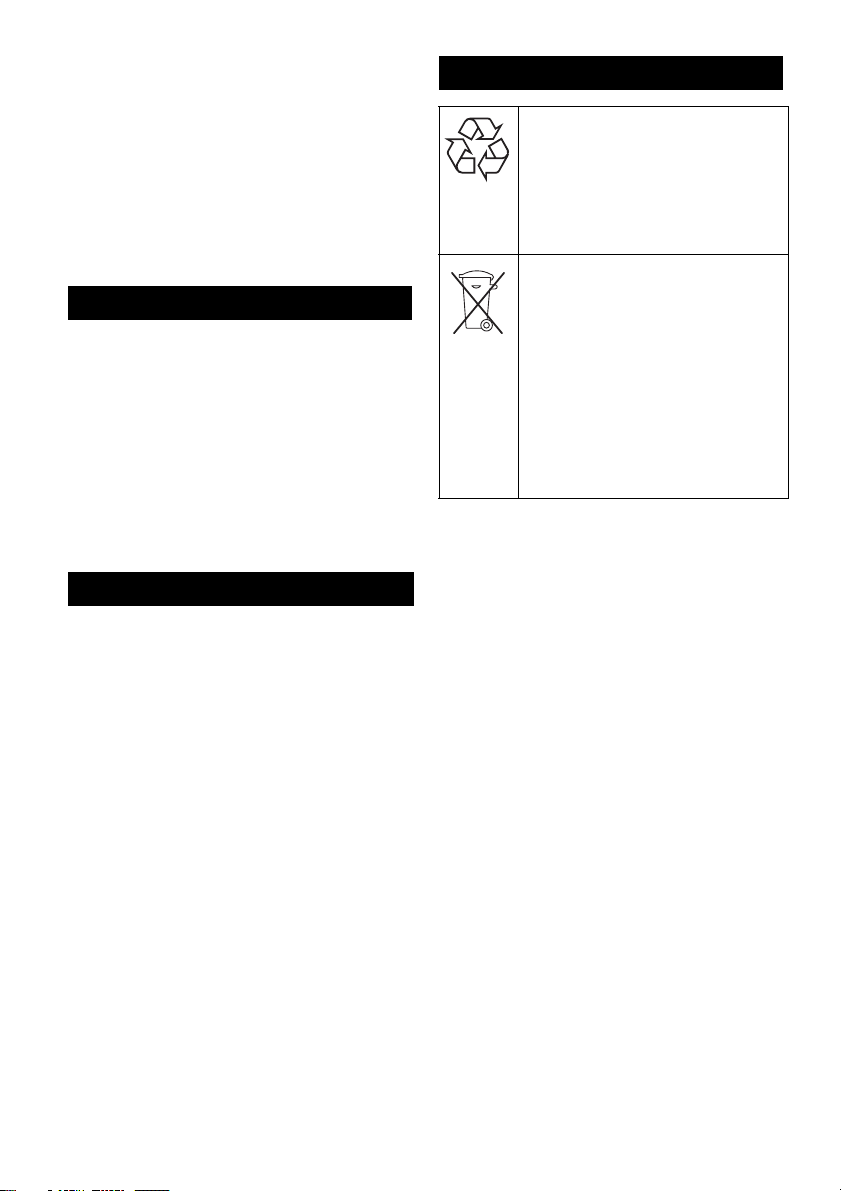

Environmental protection

The packaging material can

be recycled. Please do not

place the packaging into the

ordinary refuse for disposal,

but arrange for the proper recycling.

Old appliances contain valuable materials that can be recycled. Please arrange for

the proper recycling of old

appliances. Batteries, oil,

and similar substances must

not enter the environment.

Please dispose of your old

appliances using appropriate

collection systems.

Notes about the ingredients

(REACH)

You will find current information about

the ingredients at:

http://www.karcher.de/de/unternehmen/

umweltschutz/REACH.htm

6 English

Page 7

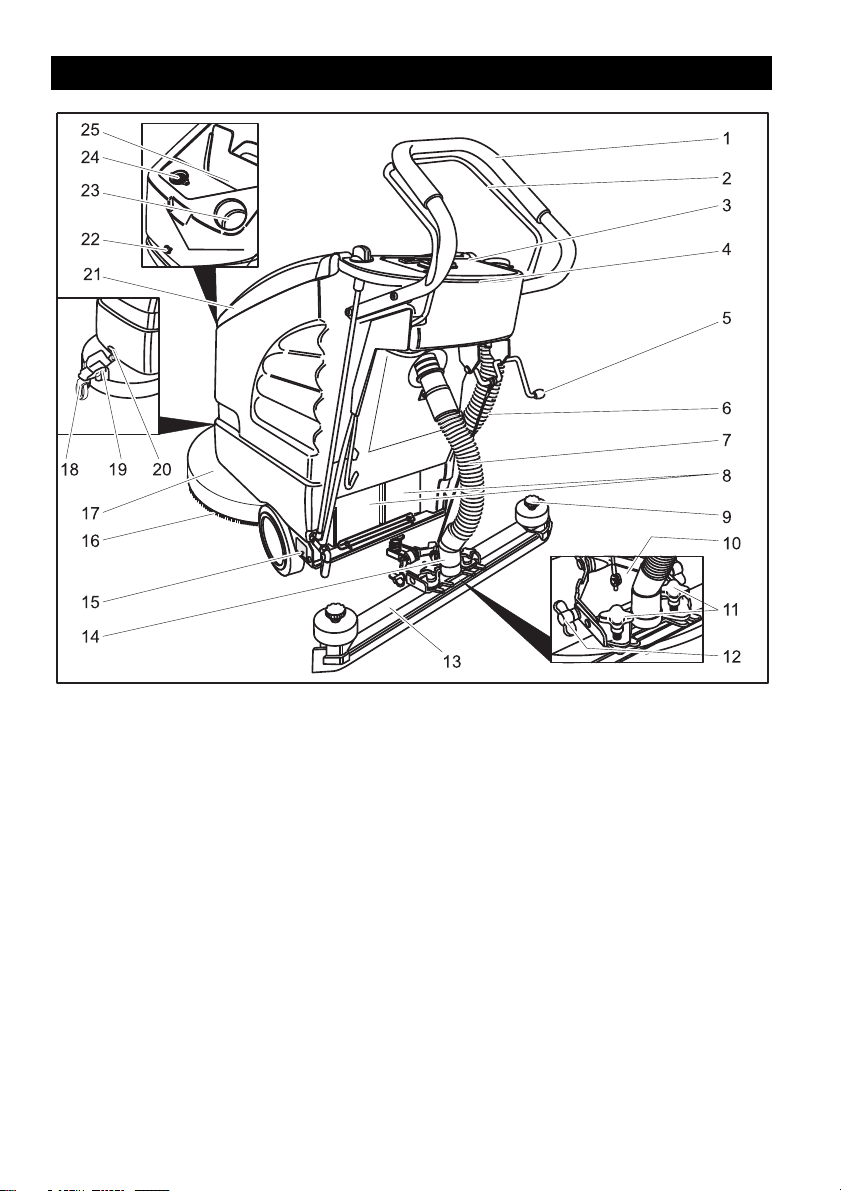

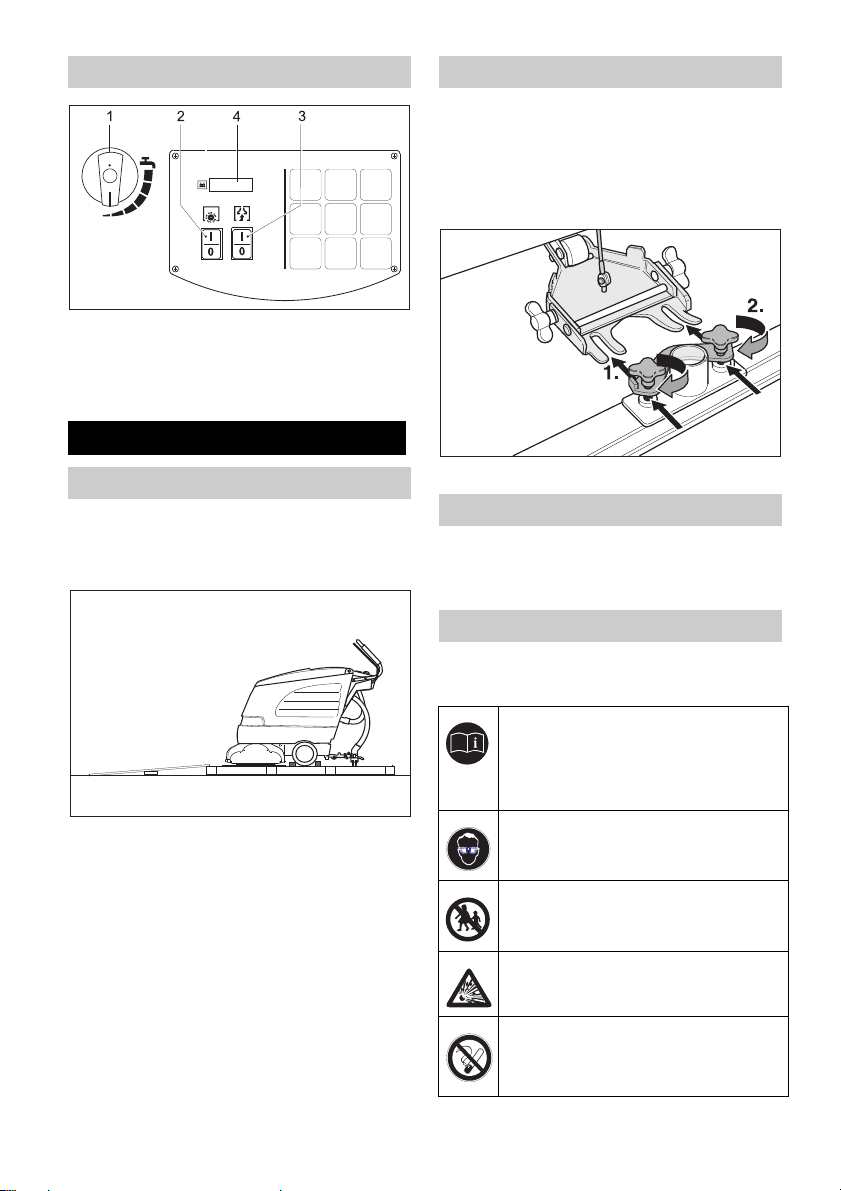

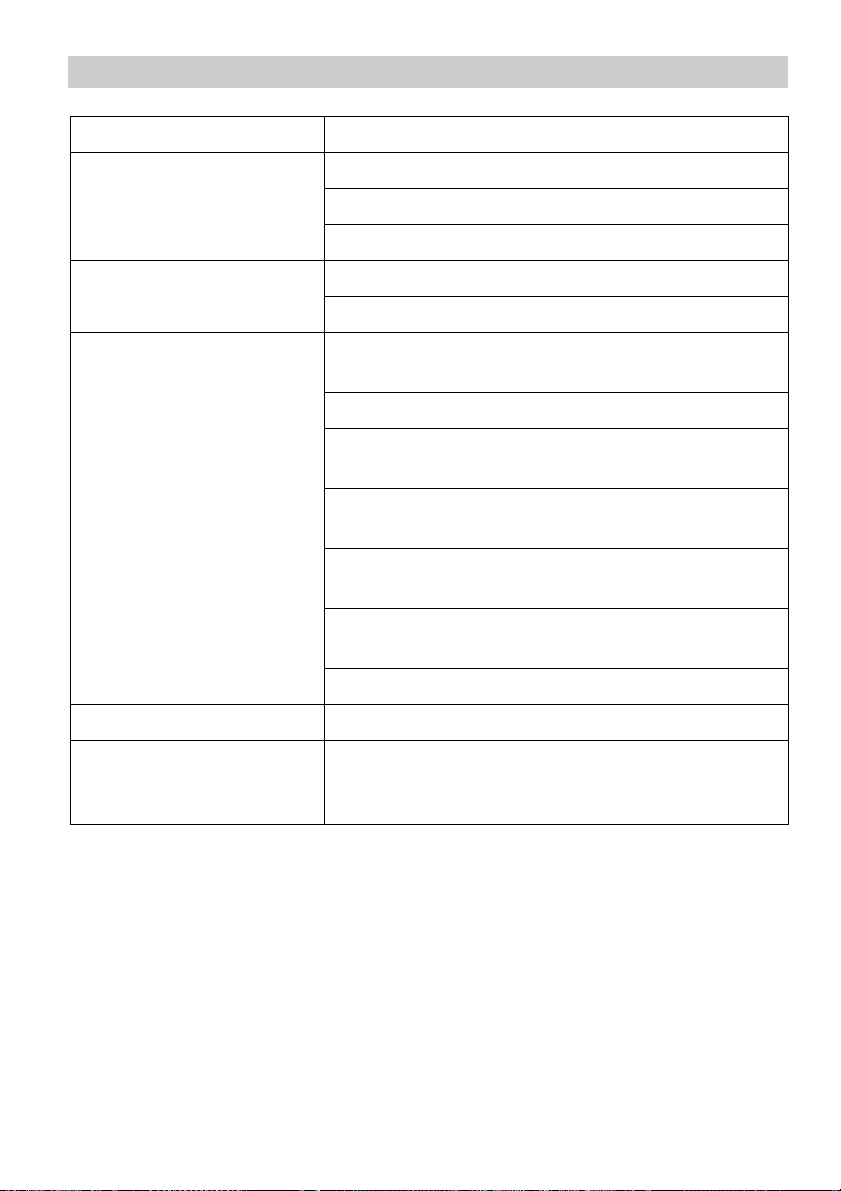

Control elements

1 Push handle

2 Control handle

3 Operator console

4 Electronics and fuses

(under the operations panel)

5 Vacuum bar lowering lever

6 Dirt water discharge hose

7 Suction hose

8 Battery (BD 530 Bp only)

9 Star grips to exchange the vacuum

lips

10 Vacuum bar suspension

11 Cross handles for fastening and

slanting the vacuum bar

12 Wing nuts for tilting the vacuum bar

13 Vacuum bar (not included in the de-

livery)

14 Connecting the suction hose to the

suction turbine

15 Nameplate

16 Disc brush

17 Cleaning head

18 Chassis

19 Locking

20 Handle

21 Cover dirt water reservoir

22 Screw for locking the container; in

the container. Batteries *

Under the lid of the dirt water tank:

23 Fresh water reservoir filler neck

24 Lint sieve (suction)

25 Dirt water reservoir

English 7

Page 8

Operator console

1 Water quantity regulator

2 Switch for brush operations

3 Switch of suction turbine

4 Display

Before Startup

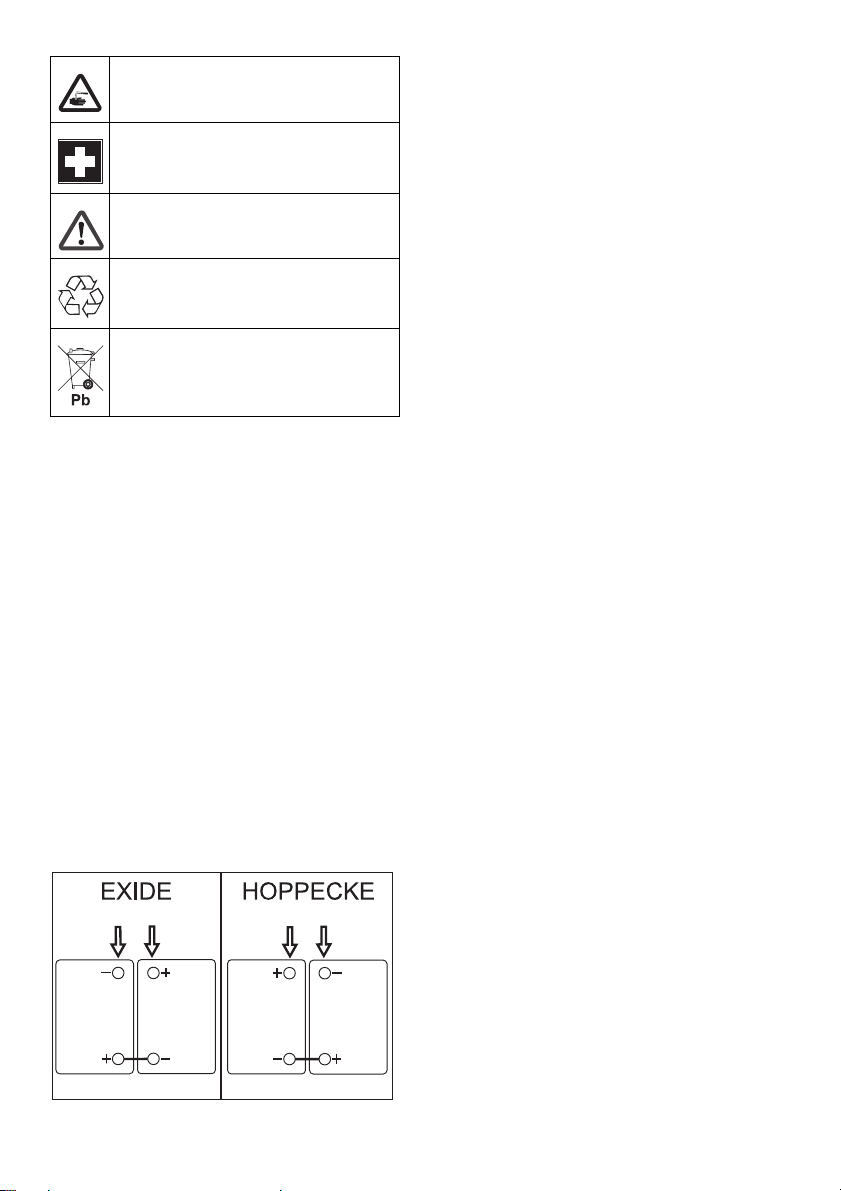

Installing the Vacuum Bar

Î Insert the vacuum bar into the vacu-

um bar suspension in such a manner

that the profiled sheet is positioned

above the suspension.

Î Tighten the cross-handles.

Unloading

Î Fasten the pushing handle using the

four screws that have been delivered

and fit the protective caps.

Î

Place long lateral boards of the packaging as a ramp next to the pallet.

Î Fix the ramp on the pallet with nails.

Î Place short boards as a support un-

derneath the ramp.

Î Remove the wooden bars in front of

the wheels.

Î Raise the cleaning head and remove

the cartonage.

Î Push down the appliance through

the ramp from the pallet.

Î Insert the suction hose.

Install the brush

The disc brush must be installed before

the initial operation (see "Maintenance

work").

Batteries

Please observe the following warning

notes when handling batteries:

Observe the directions on the

battery, in the instructions for

use and in the vehicle operating instructions

Wear eye protection

Keep children away from acid

and batteries

Danger of explosion

Fire, sparks, naked flames and

smoking must be strictly avoided

8 English

Page 9

Danger of chemical burns

First aid

Warning note

Disposal

Do not throw the battery into

the regular waste

Danger

Danger of explosion. Do not put tools or

similar on the battery, i.e. on the terminal poles and cell connectors.

Risk of injury. Ensure that wounds never come into contact with lead. Always

clean your hands after having worked

with batteries.

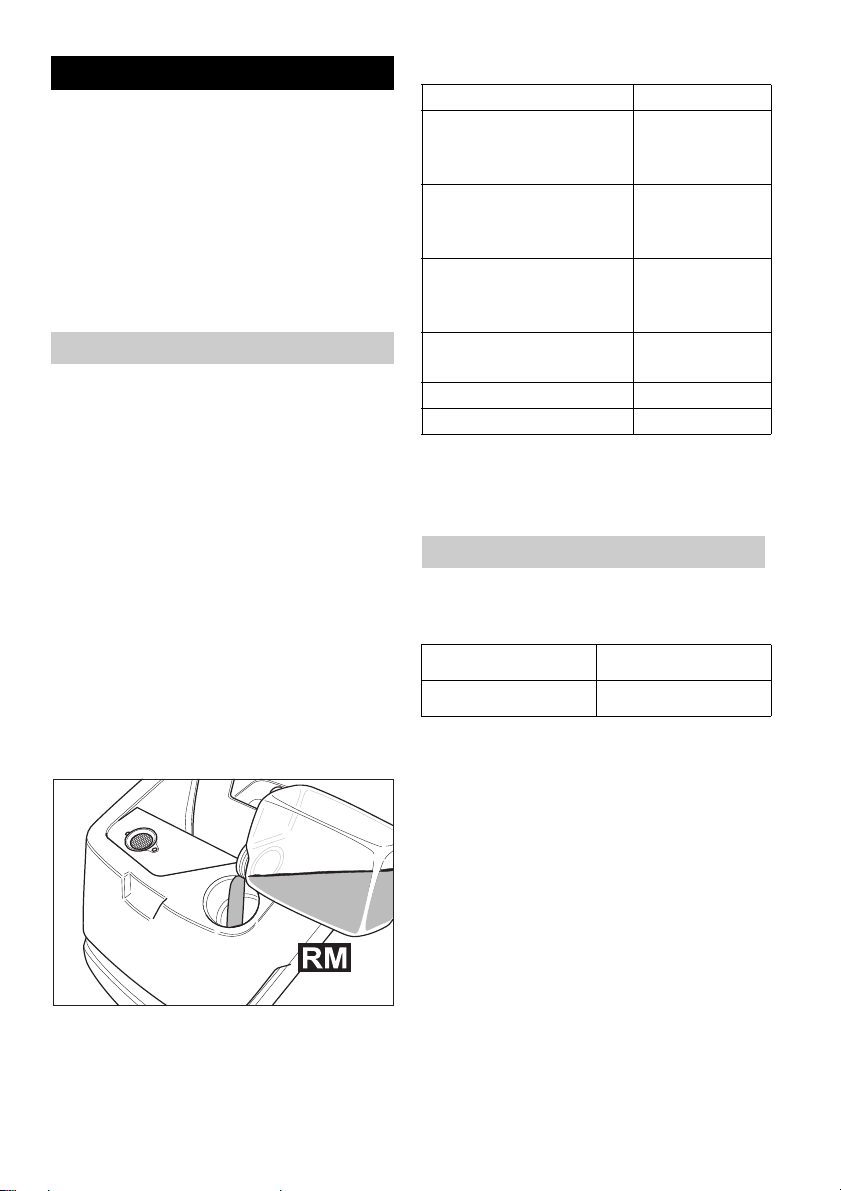

Insert batteries and connect

Î Release the lock screw for the con-

tainer and open the container.

Î Place the batteries facing the clean-

ing head closely in the trough.

Î Lubricate the battery pole with pole

grease.

Î Connect pole using the enclosed

connecting cable.

Caution

Risk of damage during repoling the connecting cable. Connect the red cable to

the plus pole and the black cable to the

minus pole of the battery. The battery

model can easily be recognised by the

casing color of the batteries: EXIDE:

grey, HOPPECKE: green.

Î Connect the connection cable to the

free battery poles (+) and (-).

Î Close the container and tighten the

screw.

Î Screw in the the lock screw for the

container and tighten it.

몇 Warning

Charge the battery before commissioning the machine.

Charging battery

Danger

Danger of explosion. Wet batteries can

only be charged with opened battery

cover.

Note

The device is equipped with a safety

mechanism to prevent total discharge,

i.e. when the permissible minimum capacity is reached, then the brush motor

and the turbine are switched off. The

message "LOW BAT“ is displayed on

the operations panel.

Note

Average charging time is approx. 10 -15

hours.

The recommended chargers (matching

the batteries used) are regulated electronically and will automatically switch

off the charging process.

All functions of the machine are automatically interrupted during the charging process.

English 9

Page 10

Î

Move the machine directly to the

charging station.

Recommended batteries

Charging process

Î Pull out the suction hose from the

vacuum bar.

Î Release the lock screw for the con-

tainer and open the container.

Î Remove battery plug and join it to

the charging cable.

Î Connect the charger to the mains

and turn it on.

Low maintenance batteries (wet

batteries)

Î Add distilled water one hour before

the charging process comes to an

end; follow the correct acid level.

There are corresponding indicators

on the battery.

Danger

Danger of causticization!

– Adding water to the battery in its dis-

charged state can cause the acid to

leak.

– Use safety glasses while handling

battery acid and follow the safety instructions to avoid personal injury or

damage to clothes.

– Should the acid spray on to the skin

or clothes, rinse immediately with

lots of water.

몇 Warning

Risk of damage!

– Use only distilled or desalinated wa-

ter (EN 50272-T3) for filling the battery.

– Do not add any substances (so-

called performance improving

agents), else warranty claims will not

be entertained.

Manufactur-

Description

er, Kärcher

order no.

EXIDE

6.654-097.0

12 V, 80 Ah, low main-

tenance

Recommended chargers

Manufactur-

Description

er, Kärcher

order no.

KÄRCHER

6.654-179.0

Separate charger for

battery 6.654-097.0

Batteries and chargers are available in

specialised stores.

Battery control display

The charging status of the battery is

shown in the display on the operations

panel:

– After switching on the button for

brush operations or suction turbine,

the operating hours are displayed for

5 seconds.

– A bar diagram is then displayed to

show the charging status of the battery.

10 English

Page 11

Operation

몇

Warning!

Risk of damage. Raise the vacuum bar

before reversing.

Note

The appliance is designed and built in

such a way that the brush head is projecting towards the right. This enables

working in a comfortable way close to

the edges.

Filling in detergents

몇 Warning

Risk of damage. Only use the recommended detergents. With respect to different detergents the operator bears the

increased risk regarding the operational

safety and danger of accident. Only use

detergents that are free from solvents,

hydrochloric acid and hydrofluoric acid.

Note

Do not use highly foaming detergents.

Observe the dosing notes.

Î Open the cover of the fresh water

reservoir.

Î Fill in fresh water (maximum 60 °C).

Î Add detergent. Follow dosing in-

structions for detergent.

Recommended detergents:

Application Detergent

Regular cleaning

(even for floors sensi-

RM 745

RM 746

tive to alkalies)

Cleaning dirt from

grease

RM 69 ES

ASF

RM 69 ASF

Basic cleaning (strip-

RM 752

ping) of alkali-resistant hard coatings

Basic cleaning (strip-

RM 754

ping) linoleum

Sanitary cleaning RM 25 ASF

Disinfection cleaning RM 732

Detergents are available in specialised

stores.

Î Close the cover of the dirt water res-

ervoir.

Cleaning

Chassis

Down Transport

Up Cleaning

Î Raise the device slightly at the han-

dle.

Î Pull out the lock.

Î Tilt the chassis to the desired posi-

tion.

Î Put the lock.

Driving to the Place of Use

Î

Tilt the chassis downward and lock it.

Î Push the machine to the place

where it is to be used.

Cleaning

Î Tilt the chassis upward and lock it.

Î Switch on the button for brush oper-

ations and suction turbine

English 11

Page 12

Î

Press control switch.

Note

If the brush motor does not run when

switched on, then brush motor is to be

released by pulling the machine backward.

Î Perform the cleaning operation.

Setting the advance speed

Î Reducing the speed: Turn the button

in "–" direction.

Î Increasing the speed: Turn the but-

ton in "+" direction.

Setting the water quantity

Î Set the water quantity at the regula-

tion knob according to the dirt level

and the type of flooring.

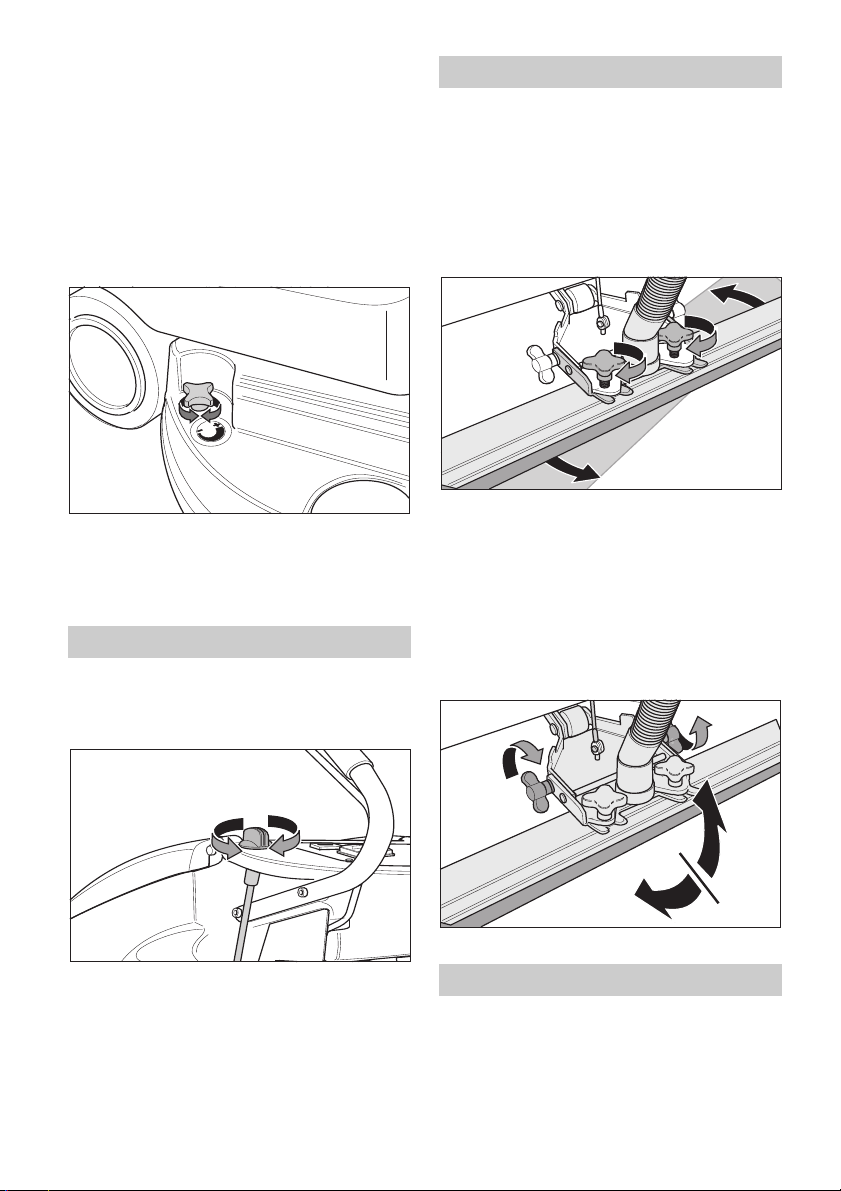

Setting the Vacuum Bar

Oblique position

To improve the vacuuming result on

tiled floors the vacuum bar can be

turned to an oblique position of up to 5°.

Î Loosen cross-handles.

Î Turn the vacuum bar.

Î Tighten the cross-handles.

Inclination

If the vacuum result is unsatisfactory the

inclination of the straight vacuum bar

can be modified.

Î Release the wing nuts.

Î Tilt the vacuum bar.

Note

Carry out initial cleaning attempts with

low quantity of water. Slowly increase

the water quantity till the desired cleaning result is achieved.

12 English

Î Tighten the wing nuts.

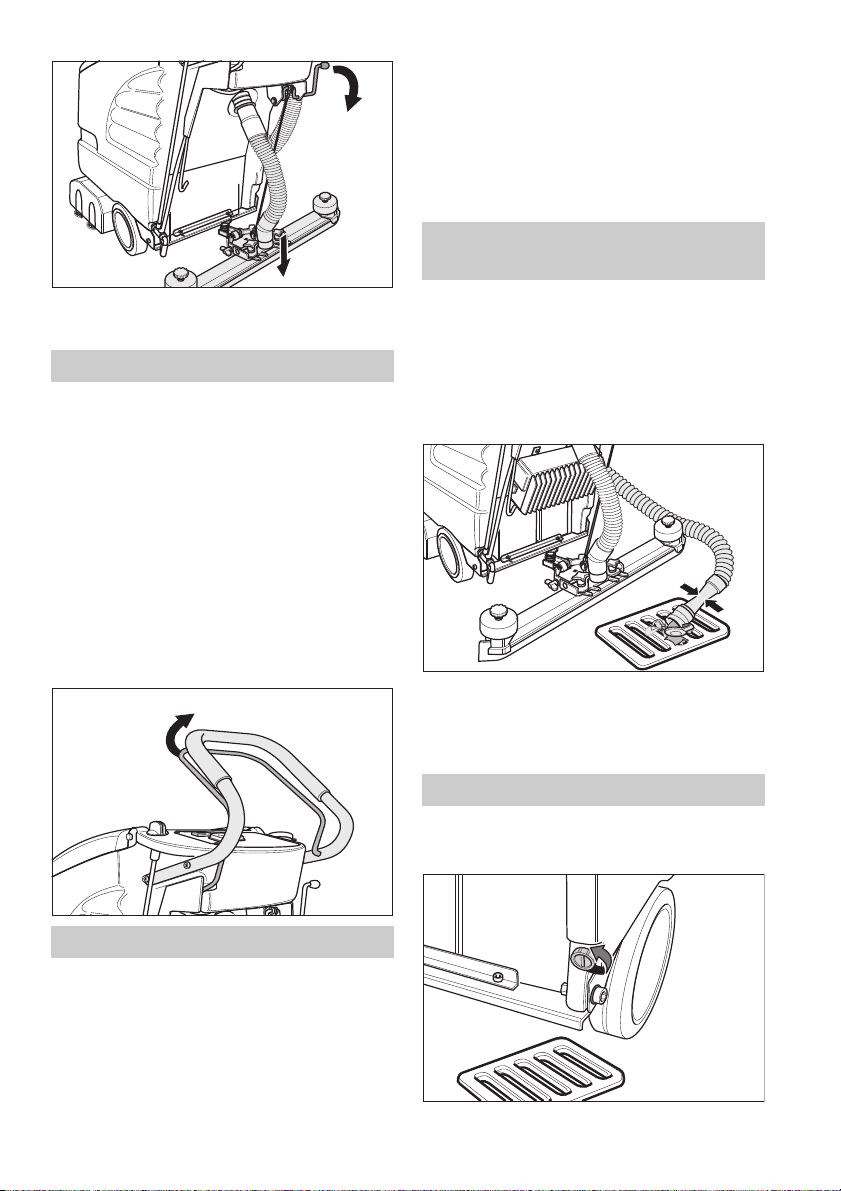

Lower the vacuum bar

Î Turn the lever downwards; the vacu-

um bar is lowered.

Page 13

Î Raise the vacuum bar.

Î

Tilt the chassis downward and lock it.

몇 Warning!

Danger of deformation of the brush(es).

When shutting down the appliance relieve the brush(es) by lowering the running gear.

Emptying the Dirt Water Reser-

voir

Î Switch on the suction turbine using

the switch.

Switching on the cleaning head

몇 Warning!

Risk of damage to the floor covering. Do

not operate the appliance on the spot.

Î Switch on the button for brush oper-

ations.

Î Activate the control handle; the

brush motor starts up.

Note

First turn on the switch for brush operation, then use the control handle. If you

do this in reverse order, there will an error message on the display.

몇 Warning

Please observe the local provisions regarding the wastewater treatment.

Î Take the dirt water discharge hose

from the support and lower above a

suited collection device.

Î Let off water by opening the dosage

device at the discharge hose.

Î The rinse the dirt water reservoir

with clear water.

Emptying the Fresh Water Tank

Î Open the lock of the fresh water tank

using a suitable tool (such as a coin).

Shutting Down the Appliance

Î Close the water quantity regulator.

Î

Drive the appliance forward for another 1-2 m to draw off residual water.

Î Release the control handle.

Î Switch off the button for brush oper-

ations and suction turbine

English 13

Page 14

Maintenance and care

Danger

Risk of injury!

Before carrying out any tasks on the device, switch off the button for brush operations and suction turbine and pull out

the charger plug.

몇 Warning

Risk of damage to the appliance on account of water leakage. Drain out dirt

water and the remaining free water before wokring at the machine.

Maintenance schedule

After the work

몇 Warning

Risk of damage. Do not wash down the

appliance with water and do not use aggressive detergents.

Î Drain off dirt water.

Î Rinse the dirt water reservoir with

clear water.

Î Clean the outside of the appliance

with a damp cloth which has been

soaked in mild detergent.

Î Check the fluff filter, clean if required

Î Clean the vacuum lips and the wip-

ing lips, check for wear and replace

if required.

Î Check the brushes for wear, replace

if required.

Î Charge battery if required.

Monthly

Î Check the condition of the seals be-

tween dirt water reservoir and cover,

replace if required.

Î Check battery pole for oxidation;

brush it if required and lubricate it using pole grease. Ensure that the connection cable sits firmly.

Î Check the acid density of the cells if

the batteries are not maintenancefree batteries.

Yearly

Î Have the prescribed inspection car-

ried out by the customer service.

Maintenance Works

Turn or replace vacuum lips

Î Remove the vacuum bar.

Î Unscrew the star grips.

Î Remove the plastic parts.

Î Remove the vacuum lips.

Î Turn the vacuum lips or insert new

ones.

Î Insert the plastic parts.

Î Screw in and tighten the star grips.

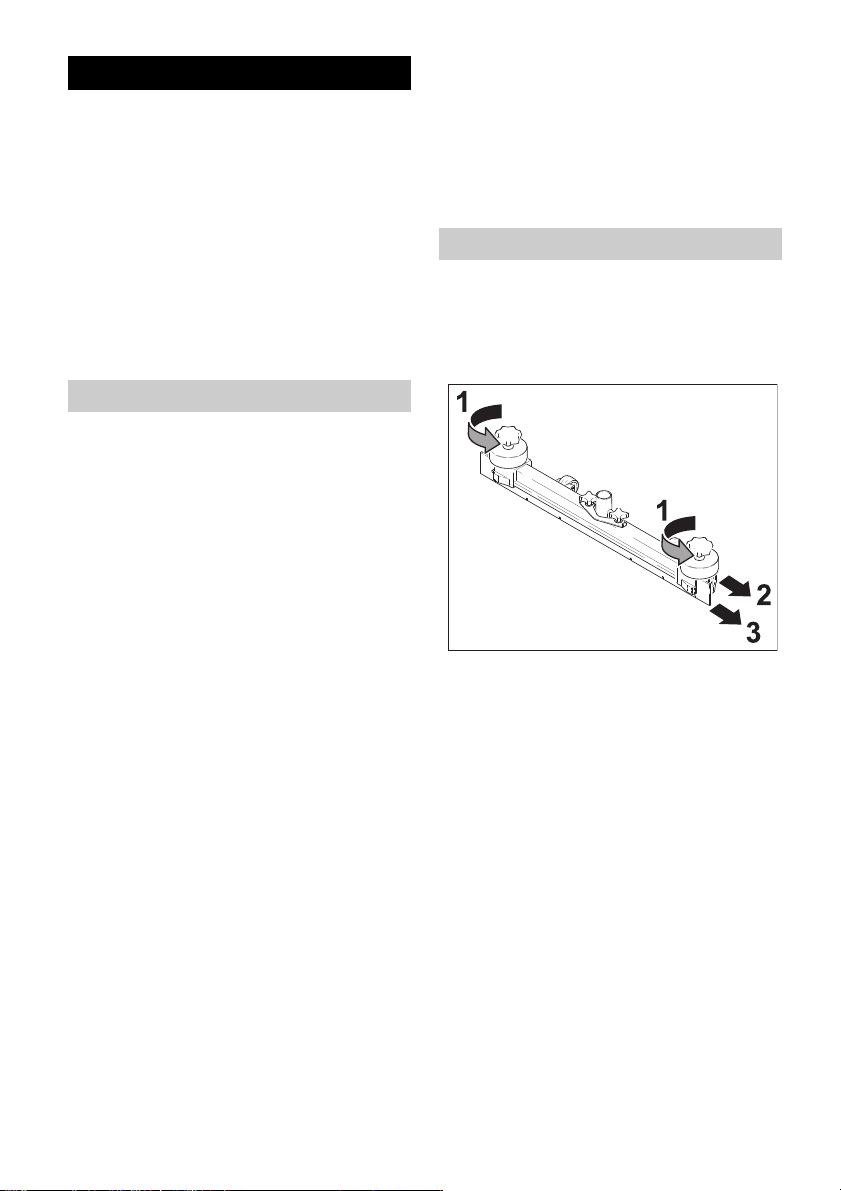

Replacing the disk brushes

Î Turn the button for the setting of the

advance speed in "– " direction.

Î Raise the disk brush.

Î Turn the disk brush by approx. 45° in

anti-clock-wise direction.

Î Remove the disk brush at the bot-

tom.

Î Insert new disk brush in reverse se-

quence.

Î Set the advance speed.

14 English

Page 15

Maintenance contract

To ensure a reliable operation of the appliance maintenance contracts can be

concluded with the competent Kärcher

sales office.

Frost protection

In case of danger of frost:

Î Empty the fresh and dirt water reser-

voirs.

Î Store the appliance in a frost-pro-

tected room.

Transport

Î Remove brushes to avoid damage to

the brushes.

Î If you want to transport the machine

on a vehicle secure it from slipping

using belts/ ropes.

Faults

Danger

Risk of injury!

Before carrying out any tasks on the device, switch off the button for brush operations and suction turbine and pull out

the charger plug.

몇 Warning

Risk of damage to the appliance on account of water leakage. Drain out dirt

water and the remaining free water before wokring at the machine.

Faults with display

Display Remedy

ERR B Check if foreign matters block the brushes; remove for-

eign matter if required.

ERR T Call customer service.

LOW BAT Charging battery

ERR TEMP Allow device to cool down.

Reduce brush contact pressure, if necessary.

HandsOff Release the control handle and wait until the operating

hours or the battery status is shown in the display. After

that, activate the control handle again.

ERR REL Turn off the switch for brush operation, turn off the switch

for the vacuum turbine, release the control handle, wait 3

seconds and turn back on.

If the event recurs, call Customer Service.

English 15

Page 16

Faults without display on the console

Fault Remedy

Appliance cannot be start-edPress control switch.

Check battery; replace, if needed.

Check if the mains plug is connected.

Insufficient water quantity Check fresh water level, refill tank if necessary.

Check hoses for blockages; clean if required.

Insufficient vacuum performance

Insufficient cleaning result Check the brushes for wear, replace if required.

Brushes do not turn Press control switch.

Clean the seals between dirt water reservoir and

cover and check for tightness, replace if required.

Clean the fluff filter.

Clean the vacuum lips on the vacuum bar, turn or

replace if required

Check if the suction hose and vacuum bar are

chocked, clean if required

Check the suction hose for tightness; replace if required.

Check if the cover on the dirt water discharge hose

is closed

Check the setting of the vacuum bar.

Check if foreign matters block the brushes; remove

foreign matter if required.

16 English

Page 17

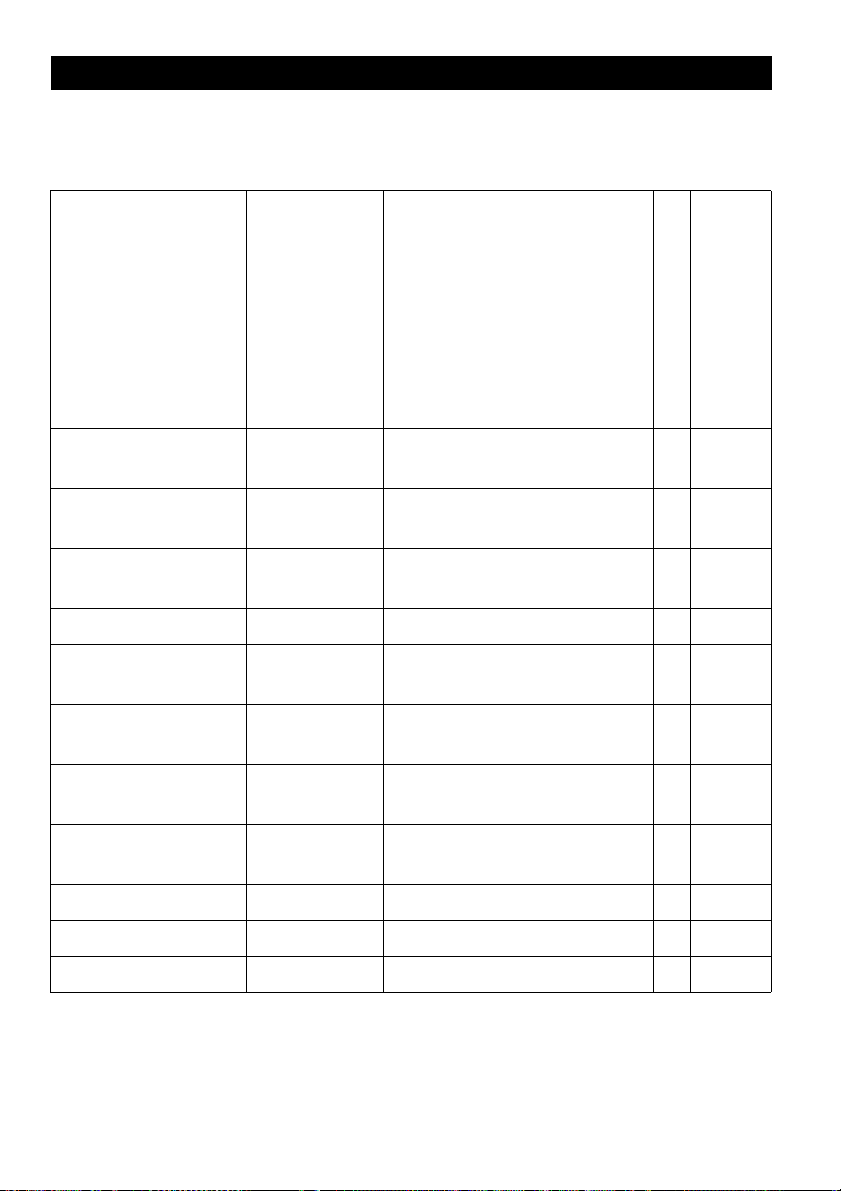

Accessories

The appliance can be equipped with

various accessories depending on the

cleaning task. Please request our cata-

Description

Disk brush, natural

(white)

Disk brush, red (medium, standard)

Disk brush, black

(hard)

Driver plate 6.906-332.0 For intake of pads. 1 1

Disc pad, red (medium)

Part no.:

BD 530

6.906-056.0 For polishing floors. 1 1

6.906-054.0 For cleaning slightly dirtied

6.906-055.0 For cleaning heavily dirtied

6.369-024.0 For cleaning slightly dirtied

logue or visit us on the Internet at

www.kaercher.com.

Description

or sensitive floors.

floors.

floors.

Each/packaging

11

11

51

Machine requires piece

Disc pad, green

(hard)

Disc pad, black

(very hard)

Vacuum bar,

straight

Vacuum bar, bent 4.777-054.0 Standard 1 1

Rubber lip, blue 6.273-204.0 Standard 1 1

Rubber lip, brown 6.273-207.0 oil-resistant 1 1

6.369-023.0 For cleaning normal dirtied

floors.

6.369-022.0 For cleaning heavily dirtied

floors.

4.777-047.0 Standard 1 1

51

51

English 17

Page 18

Technical specifications

BD 530 Bp

Power

Nominal voltage V 24

Battery capacity Ah (5h) 75

Average power consumption W 1200

Suction engine output W 500

Brush engine output W 600

Vacuuming

Cleaning power, air quantity l/s (gpm) 30 (475)

Cleaning power, negative pressure kPa (psi) 14 (2)

Cleaning brushes

Working width mm (in) 460 (18,1)

Brush diameter mm (in) 460 (18,1)

Brush speed 1/min 140

Dimensions and weights

Theoretical surface cleaning performance m

Fresh/dirt water reservoir volume l (gal) 40/40 (10,5/

Total weight kg (lbs) 115 (253,5)

Noise emission

Sound pressure level (EN 60704-1) dB(A) 70

Machine vibrations

Vibration total value (ISO 5349) m/s² 0,4

2

/h (ft2/h) 1840 (19800)

10,5)

Warranty Spare parts

The warranty terms published by our

competent sales company are applicable in each country. We will repair potential failures of your accessory within

the warranty period free of charge, provided that such failure is caused by

faulty material or defects in fabrication.

In the event of a warranty claim please

contact your dealer or the nearest authorized Customer Service center.

Please submit the proof of purchase.

18 English

– Only use accessories and spare

parts which have been approved by

the manufacturer. The exclusive use

of original accessories and original

spare parts ensures that the appliance can be operated safely and

troublefree.

– At the end of the operating instruc-

tions you will find a selected list of

spare parts that are often required.

– For additional information about

spare parts, please go to the Service

section at www.kaercher.com.

Page 19

CONSIGNES DE SÉCURITÉ

IMPORTANTES

LIRE L'INTÉGRALITÉ DES

INSTRUCTIONS AVANT

L'UTILISATION.

AVERTISSEMENT

Afin de réduire les risques d'incendie,

d'électrocution et de blessures, prendre

les précautions suivantes :

– Ne pas laisser l'appareil sans sur-

veillance lorsqu'il est branché. Débrancher l'appareil lorsqu'il n'est pas

utilisé et avant de procéder à l'entretien.

AVERTISSEMENT

– UTILISER L'APPAREIL EXCLUSI-

VEMENT À L'INTÉRIEUR POUR

RÉDUIRE LES RISQUES D'ÉLECTROCUTION

– Cet appareil n'est pas un jouet. Ne

jamais le laisser sans surveillance

lorsqu'il est utilisé à proximité d'enfants.

– Respecter impérativement les consi-

gnes d'utilisation de ce manuel. Utiliser uniquement les accessoires

recommandés par le fabricant.

– Ne pas mettre l'appareil en service

en cas d'endommagement du cordon ou de la prise. Si l'appareil ne

fonctionne pas correctement, s'il est

tombé, s’il a été endommagé, s’il est

resté à l’extérieur ou est tombé dans

l’eau, le retourner à un centre de service.

– Ne pas tirer ou transporter l’appareil

par le cordon électrique ou se servir

de ce dernier comme d’une poignée.

Veiller à ne pas coincer le cordon

dans une porte et éviter de le tirer

sur des bords ou des coins tranchants. Ne pas rouler sur le cordon

électrique. Tenir le cordon à l'écart

des surfaces chaudes.

– Ne pas tirer sur le cordon électrique

pour débrancher l'appareil. Tirer au

niveau de la fiche pour déconnecter

l'appareil du secteur.

– Ne pas manipuler l’appareil ou la fi-

che électrique avec les mains

mouillées.

– Ne rien introduire dans les orifices.

Ne pas utiliser l’appareil si l’un des

orifices est obstrué. Protéger les orifices de la poussière, des peluches,

des cheveux et autres matières susceptibles de réduire le débit d'air.

– Veiller à ne pas approcher les che-

veux, vêtements larges, doigts ou

toute autre partie du corps des orifices et composants mobiles de l’appareil.

– Désactiver toutes les commandes

avant de débrancher l'appareil.

– Ne pas aspirer de liquides inflamma-

bles ou combustibles, tels que de

l’essence avec l'appareil. Ne pas utiliser ce dernier dans des zones susceptibles de contenir de tels

produits.

CONSERVER CES CONSI-

GNES

REGLES DE SECURITE ET

PRATIQUES RELATIVES A

L'UTILISATION

Responsabilité de l'utilisateur

L'utilisateur est responsable de l'utilisation en toute sécurité de l'appareil.

Français 19

Page 20

Avant d'utiliser l'appareil, l'utilisateur devra avoir acquis une connaissance approfondie des fonctions et du

fonctionnement de toutes les commandes et de tous les instruments.

Avant d'utiliser l'appareil, l'utilisateur devra avoir lu et s'être familiarisé avec le

manuel d'utilisation de l'appareil en

question. Il devra par ailleurs se conformer aux règles de sécurité et pratiques

décrites dans les paragraphes suivants.

Avant d'utiliser quelque appareil que ce

soit, l'utilisateur doit être conscient des

éventuelles conditions d'utilisation inhabituelles pouvant nécessiter des précautions de sécurité supplémentaires

ou la mise en œuvre d'instructions d'utilisation particulières.

Généralités

Avant de commencer à faire fonctionner

l'unité, soyez dans une position d'opération.

Ne pas démarrer ou utiliser l'appareil, ni

aucune de ses fonctions ou accessoires, à partir d'un autre endroit que celui

réservé à l'utilisateur.

Avant de quitter le poste de l'utilisateur :

A arrêter l'appareil ;

B si l'appareil doit stationner sur une

pente, caler les roues.

Ne pas ajouter d''accessoires à l'appareil ni le modifier de quelque manière

que ce soit.

Ne pas stationner à un endroit où l'appareil risque d'entraver les issues de

secours, les cages d'escaliers ou les

équipements de lutte contre l’incendie.

Conduite

Céder la priorité aux piétons ainsi

qu'aux véhicules d'urgence comme les

ambulances et les camions de pompiers.

Traverser les voies ferrées à angle droit

lorsque c'est possible. Ne pas garer

l'appareil à moins de 1,8 m de la voie

ferrée ou du rail le plus proche.

Veiller à conserver une vue bien dégagée du trajet à emprunter et être attentif

à la circulation des autres véhicules,

aux déplacements des membres du

personnel, ainsi qu'aux espaces de dégagement.

Quelles que soient les conditions de circulation, conserver une vitesse permettant d'arrêter l'appareil en toute

sécurité.

Ne jamais adopter de conduite dangereuse (cascades, acrobaties etc.)

Ralentir sur les sols mouillés et glissants.

Avant de déplacer l'appareil sur un pont

de chargement ou un pont de laison,

s'assurer que celui-ci est correctement

sécurisé. Avancer prudemment et lentement sur le pont de chargement ou

pont de liaison. Ne jamais dépasser la

charge maximale autorisée.

Dans les virages, ralentir et adopter une

vitesse de sécurité adaptée à l'environnement d'utilisation. Les virages doivent

être abordés sans à-coups.

Entretien de l'appareil par l'utili-

sateur

Si le véhicule a besoin d'être réparé ou

présente un risque quelconque, l'utilisateur doit le signaler immédiatement à

son responsable et ne pas utiliser l'appareil avant résolution du problème.

Si, en cours d'utilisation, le véhicule

s'avère dangereux de quelque façon

que ce soit, signaler immédiatement le

problème au responsable concerné et

cesser l'utilisation de l'appareil avant résolution du problème.

20 Français

Page 21

Ne pas effectuer de réparations ou réglages à moins d'y être expressément

autorisé.

Ne pas éclairer les batteries à l'aide

d'un flamme vive pour vérifier le niveau

d'électrolyte.

PROCEDURES D'ENTRETIEN

ET DE REMISE EN ETAT

L'utilisation de l'appareil peut devenir

dangereuse si l'entretien est négligé ou

si la remise en état ou les réglages nécessaires ne sont pas effectués en conformité avec les recommandations du

fabricant. Par conséquent, il est nécessaire de prévoir des ateliers de maintenance, à l'intérieur ou l'extérieur des

bâtiments, avec du personnel dûment

formé, ainsi que d'établir des procédures détaillées.

La maintenance et l'inspection de l'appareil doivent être effectuées conformément aux procédures suivantes :

A Les intervalles prescrits pour la

maintenance, la lubrification et le

contrôle du système doivent être

respectés; se reporter aux instructions du fabricant.

B La maintenance, les réparations, les

réglages et l'inspection de l'appareil

doivent être confiés exclusivement à

des personnes formées et habilitées

et effectués conformément aux recommandations du fabricant.

Eviter les risques d'incendie et s'assurer

que les locaux sont dotés des équipements nécessaires pour la lutte contre

l'incendie. Ne jamais éclairer les batteries à l'aide d'une flamme vive pour vérifier le niveau des liquides, en

particulier celui de l'électrolyte. Ne jamais utiliser de bacs ouverts contenant

du carburant ou des produits de nettoyage inflammables pour nettoyer les

composants de l'autolaveuse motorisée.

NORMES DE SECURITE IN-

CENDIE

Tout appareil dont le fonctionnement représente un risque doit être mis hors

service.

Les réparations ne doivent pas être effectuées dans les zones de classe I, II

et III.

Prévention des

incendies :L'autolaveuse motorisée

doit être tenue propre et dans la mesure

du possible, protégée des peluches,

des déversements d'huile et de la graisse. L'utilisation de produits non inflammables est recommandée pour le

nettoyage de l'autolaveuse motorisée.

Les liquides inflammables dont le point

d'ignition est égal ou supérieur à

37,8 °C (100 °F) ne sont pas autorisés.

Prendre les mesures appropriées concernant la toxicité, l'aération, et les risques d'incendie selon le produit ou

solvant utilisé.

Visibilité de la plaque signalétique :

Les données techniques figurant sur la

plaque signalétique de l'appareil ne doivent pas être recouvertes de peinture et

les informations d'identification doivent

rester visibles.

L'autolaveuse motorisée ne doit pas

être utilisée dans les zones classées.

Français 21

Page 22

Lire ces notice originale avant

la première utilisation de votre

appareil, se comporter selon ce qu'elles

requièrent et les conserver pour une utilisation ultérieure ou pour le propriétaire

futur.

Table des matières

Consignes de sécurité 22

Fonction 22

Utilisation conforme 22

Protection de l’environnement 23

Eléments de commande 24

Avant la mise en service 25

Fonctionnement 28

Entretien et maintenance 31

Pannes 33

Caractéristiques techniques 36

Garantie 36

Pièces de rechange 36

Consignes de sécurité

Lire la présente notice d'instructions

ainsi que la brochure ci-jointe Consignes de sécurité pour les nettoyeurs à

brosses n° 5.956-251 avant d'utiliser

l'appareil et respecter les instructions.

à la mort ou entraîner de graves blessures.

몇 Avertissement

Signalise une situation éventuellement

dangereuse. Un non respect de cette

consigne peut entraîner de légères

blessures ou encore des dégâts matériels.

Remarque

Donne des conseils pour l'utilisation et

d'importantes informations relatives au

produit.

Fonction

L’appareil est mis en oeuvre pour nettoyer des sols plans par voie humide. Il

peut être aisément adapté à l'application respective en ajustant la quantité

d'eau et l'aspiration pour évacuer l'eau

sale.

Une largeur de travail de 460 mm et une

capacité de 40 l pour le réservoir d'eau

fraiche et le réservoir d'eau sale assurent un nettoyage efficace, même si la

machine est utilisée pendant une période prolongée.

Utilisation conforme

Cette balayeuse doit être utilisée uniquement sur des surfaces qui présentent une pente maximale de 2%.

L'appareil peut être seulement exploité, lorsque le réservoir et tous les

couvercles sont fermés.

Symboles

Les symboles suivants sont utilisés

dans ces instructions de service :

Danger

Signalise un danger imminent. Un non

respect de cette consigne peut conduire

22 Français

L'utilisation de l'appareil doit être faite

en conformité avec les consignes figurant dans les instructions de service.

– L'apareil peut être urilizé que pour le

polissage des sols plats qui ne sont

pas sensibles à l'humidité.

– L'appareil n'est pas approprié pour

nettoyer des sols gelés (par exemple

dans des entrepôts frigorifiques)

– L'appareil doit uniquement être équi-

pé d'accessoires et de pièces de rechange d'origine.

Page 23

Protection de l’environne-

ment

Les matériaux constitutifs de

l’emballage sont recyclables.

Ne pas jeter les emballages

dans les ordures ménagères,

mais les remettre à un système de recyclage.

Les appareils usés contiennent des matériaux précieux

recyclables lesquels doivent

être apportés à un système

de recyclage. Il est interdit de

jeter les batteries, l'huile et

les substances similaires

dans l'environnement. Pour

cette raison, utiliser des systèmes de collecte adéquats

afin d'éliminer les appareils

usés.

Instructions relatives aux ingrédients (REACH)

Les informations actuelles relatives aux

ingrédients se trouvent sous :

http://www.karcher.de/de/unternehmen/

umweltschutz/REACH.htm

Français 23

Page 24

Eléments de commande

1 Guidon de poussée

2 Etrier de commande

3 Pupitre de commande

4 Électronique et fusibles

(sous le pupitre de commande)

5 Levier pour abaisser la barre d'aspi-

ration

6 Flexible de vidange pour eau sale

7 Flexible d’aspiration

8 Batterie (BD 530 Bp seulement)

9 Bouton cannelé pour le remplace-

ment des lèvres d'aspiration

10 Suspension de la barre d'aspiration

11

Écrous à croisillon pour fixer et points

diagonaux de la barre d'aspiration.

12 Ecrous-papillon pour incliner la barre

d'aspiration

13 Barre d'aspiration (non fournie)

24 Français

14 Raccordement flexible d'aspiration -

turbine

15 Plaque signalétique

16 Disque-brosse

17 Tête de nettoyage

18 Train de roulement

19 Verrouillage

20 Poignée

21 Couvercle du réservoir d'eau sale

22 Vis pour le verrouillage du réservoir,

dans le réservoir : Batteries *

Sous le couvercle du réservoir d'eau

sale :

23 Orifice de remplissage pour réser-

voir d'eau propre

24 Filtre pour des bouloches de dé-

chets (aspiration)

25 Réservoir d'eau sale

Page 25

Pupitre de commande

1 Bouton de régulation pour la quanti-

té d'eau

2 Sélecteur mode brosse

3 Sélecteur turbine

4Ecran

Avant la mise en service

Î Descendre l'appareil de la palette en

le poussant sur la rampe.

Montage de la barre d'aspiration

Î Poser les barres d'aspiration dans la

suspension de la barre d'aspiration

que la tôle profilée se trouve au-dessous de la suspension.

Î Visser les écrous à croisillon.

Déchargement de la machine

Î Fixer le guidon de poussée avec les

quatre vis fournies et enficher les

bouchons de protection.

Î Poser les longues planches latérales

d'emballage sur la palette pour qu'el-

les servent de rampe de descente.

Î Clouer la rampe sur la palette.

Î Poser les planches courtes sous la

rampe pour qu'elles servent d'appui.

Î Retirer les listeaux en bois figurant

devant les roues.

Î Soulever la tête de nettoyage et reti-

rer les cartons.

Î Emmancher le flexible d'aspiration.

Mettre la brosse en place

La brosse rotative doit être mise en place avant la première opération (voir

« Maintenance »).

Batteries

Respecter impérativement ces consignes en cas de manipulation des

batteries :

Respecter les consignes situées sur la batterie, dans les

instructions de service et dans

le mode d'emploi du véhicule

Porter des lunettes de protection

Tenir les enfants à l'écart des

acides et des batteries

Risque d'explosion

Français 25

Page 26

Toute flamme, matière incandescente, étincelle ou cigarette

est interdite à proximité de la

batterie.

Risque de brûlure

Premiers soins

Attention

Mise au rebut

Ne pas mettre la batterie au rebut dans le vide-ordures

Danger

Risque d'explosion. Ne jamais déposer

d'outils ou d'objets similaires sur les

bornes et les barrettes de connexion de

la batterie.

Risque de blessure. Ne jamais mettre

en contact des plaies avec le plomb.

Prendre soin de toujours se laver les

mains après avoir manipulé la batterie.

Montage et branchement de la batterie

Î Desserrer la vis pour le verrouillage

du récipient et relever le récipient.

Î Mettre en place les batteries dans la

cuve en les alignant par rapport à la

tête de nettoyage.

Î Graisser les bornes de batterie avec

graisse de borne.

Î Connecter les bornes avec le câble

de raccordement ci-joint.

Attention

Risque d'endommagement en cas d'inversion des pôles du câble de raccordement. Connecter le câble rouge au pôle

plus et le câble noir au pôle moins. La

version de la batterie peut être facilement identifiée au moyen de la couleur

du corps de la batterie : EXIDE : gris,

HOPPECKE : vert.

Î Brancher le câble de raccordement

ci-joint aux bornes de batterie encore libres (+) et (-).

Î Fermer le réservoir et serrer la vis.

Î Visser la vis pour le verrouillage du

récipient et la serrer.

몇 Avertissement

Charger la batterie avant de mettre l'appareil en service.

Chargement de la batterie

Danger

Risque d'explosion. Le chargement des

batteries humides est seulement permis

avec réservoir ouvert.

Remarque

L'appareil dispose d'un dispositif de protection anti-décharge, c'est-à-dire se le

minimum admissible de capacité est attendu, le moteur des brosses et la turbine sont arrêtés. L'affichage "LOW VAT"

apparaît dans l'écran sur le pupitre de

commande.

26 Français

Page 27

Remarque

Le temps de charge s'élève en moyenne à environ 10-15 heures.

Les chargeurs recommandés (adaptables à toutes les batteries) disposent

d'une réglage électronique et mettent

fin automatiquement à la procédure de

charge.

Lors de la procédure de charge, toutes

les fonctions de l'appareil sont automatiquement interrompues.

Î Pousser directement l'appareil jus-

qu'à la station de charge.

Processus de charge

Î Retirer le tuyau d'aspiration de la

bare d'aspiration.

Î Desserrer la vis pour le verrouillage

du récipient et relever le récipient.

Î Débrancher le connecteur de batte-

rie et le raccorder au câble du char-

geur.

Î Brancher le chargeur au réseau et le

mettre en marche.

Batteries pour service à maintenance réduite (batteries humides)

sures et l'endommagement des vêtements.

– En cas de projection d'acide sur la

peau ou les vêtements, rincer immédiatement et abondamment à l'eau.

몇 Avertissement

Risque d'endommagement!

– Pour remplir la batterie, utiliser uni-

quement de l'eau distillée ou dessalée (EN 50272-T3).

– N'employer aucun additif (produit dit

d'amélioration) sous peine d'annulation de toute garantie.

Batteries recommandées

Fabricant,

N° de commande de

Kärcher

EXIDE

6.654-097.0

Chargeurs recommandés

Description

12 V, 80 Ah, quasiment

exempte de maintenance

Î Ajouter de l'eau distillée une heure

avant la fin de la procédure de char-

ge. Respecter le niveau d'acidité ap-

proprié. Les mentions

correspondantes figurent sur la bat-

terie.

Danger

Risque de brûlure!

– Des fuites d'acide peuvent survenir

lors du remplissage de la batterie

déchargée.

– Porter impérativement des lunettes

de protection lors de toute manipula-

tion d'acide de batterie et respecter

les consignes afin d'éviter les bles-

Fabricant,

Description

N° de commande de

Kärcher

KÄRCHER

6.654-179.0

Chargeur séparé pour

la batterie 6.654-097.0

Les batteries et chargeurs sont disponibles dans le commerce.

Témoin de contrôle de la batterie

L'état de charge de la batterie est affiché dans l'écran sur le pupitre de commande :

– Après la mise en service du sélec-

teur mode brosse ou turbine, les

Français 27

Page 28

heures de service sont affichées

pendant 5 secondes.

– Ensuite, un affichage à barre appa-

raît pour le niveau de charge de la

batterie.

Fonctionnement

몇 Avertissement !

Risque d'endommagement. Toujours

soulever la barre d'aspiration avant de

rouler en marche arrière.

Remarque

Lorsque la tête de brosse dépasse à la

côté droite, l'appareil est bien installé.

Ce-ci permet un travail clair et prêt de la

bord.

Remplissage de carburant

몇 Avertissement

Risque d'endommagement. Utiliser uniquement les détergents recommandés.

Pour tout autre détergent, l'exploitant

prend des risques plus élevés quant à la

sécurité du travail et au risque d'accident. Utiliser uniquement des détergents exempts de solvants, d'acide

chlorhydrique et fluorhydrique.

Remarque

Ne jamais utiliser de détergents extrêmement moussants. Tenir compte des

consignes de dosage.

Î Ouvrir le couvercle du réservoir

d'eau sale.

Î Remplir d'eau fraîche (maximum 60°

C)

Î Ajouter de détergent. Observer les

consignes pour le dosage.

Détergents recommandés :

Application Produit dé-

tergent

Nettoyge d'entretien

(y compris pour les

sols sensibles aux alcalins)

Nettoyages des salissures graisseuses

Nettoyage minutieux

(stripage) des revêtements durs résistants

aux alcalins

Nettoyage de base

(stripage) du linoléum

Détergent sanitaire RM 25 ASF

Détergent désinfectant

Les détergents sont disponibles dans le

commerce spécialisé.

Î Fermer le couvercle du réservoir

d'eau sale.

RM 745

RM 746

RM 69 ES

ASF

RM 69 ASF

RM 752

RM 754

RM 732

28 Français

Page 29

Nettoyage

Train de roulement

en bas Transport

en haut Nettoyage

Î Soulever légèrement l'appareil au ni-

veau de la poignée.

Î Retirer le verrouillage.

Î Pivoter le train de roulement dans la

position désirée.

Î Enclencher le verrouillage.

Déplacement vers le lieu d'utilisation

Î Le faire ensuite pivoter vers le bas et

le retirer.

Î Pousser l'appareil jusqu'au site de

mise en oeuvre.

Nettoyage

Î Faire pivoter le train de roulement

vers le haut et le verrouiller.

Î Mettre en service les sélecteurs

mode brosse et turbine.

Î Actionner le guidon à poussée.

Remarque

Lorsque le moteur de brosses ne démarre pas à la mise en service, soulager la contrainte du moteur de brosses

en tirant l'appareil en arrière.

Î Procéder au nettoyage.

Réglage de la vitesse d'avance

Î Pour réduire la vitesse : tourner le

bouton dans le sens "–".

Î Pour augmenter la vitesse : tourner

le bouton dans le sens "+".

Réglage de la quantité d'eau

Î Régler la quantité d'eau correspon-

dant à la salissure et l'espèce du sol

au bouton de réglage.

Remarque

Effectuer des premières essaies de nettoyage avec une faible quantité d'eau.

Augmenter peu à peu la quantité d'eau

jusqu'à atteindre le résultat souhaité du

nettoyage.

Réglage de la barre d'aspiration

Position inclinée

Pour améliorer le résultat de l'aspiration

sur des revêtements carrelés, il est possible de tourner la barre d'aspiration jusqu'à une position inclinée de 5°.

Î Deserrer les écrous à croisillon.

Î Tourner la barre d'aspiration.

Î Visser les écrous à croisillon.

Français 29

Page 30

Inclinaison

Si le résultat de l'aspiration n'est pas

suffisant, il est possible de modifier le

degré d'inclinaison de la barre d'aspiration.

Î Desserrer les écrous-papillons.

Î Incliner la barre d'aspiration.

Î Actionner l'étrier de commande, le

moteur de brosse démarre.

Remarque

Enclencher en premier le commutateur

de fonctionnement des brosses puis actionner l'étrier de commande. Un message de défaut est affiché dans l'écran

dans l'ordre inverse.

Î Serrer à fond les écrous-papillons.

Abaisser la barre d'aspiration

Î Pousser le levier vers le bas, la barre

d'aspiration est abaissée.

Î Mettre la turbine en service avec le

sélecteur.

Mettre en marche la tête de net-

toyage

몇 Avertissement !

Risque d'endommagement pour le revêtement de sol. Ne pas exploiter l'appareil sur place.

Î Activer l'interrupteur mode brosse.

Arrêt et mise hors marche de

l'appareil

Î Fermer le bouton de régulation pour

la quantité d'eau.

Î Encore avancer l'appareil de 1 à 2 m

pour aspirer toute l'eau restante.

Î Relâcjer la poignée de commande.

Î Désactiver les sélecteurs mode

brosse et turbine.

Î Soulever la barre d'aspiration.

Î Le faire ensuite pivoter vers le bas et

le retirer.

몇 Avertissement !

Risque de déformer la/les brosse/s.

Lors de la mise hors marche/stationnement de l'appareil, soulager la/les brosse/s en abaissant le train de roulement

vers l'avant

Vidange du réservoir d'eau sale

몇 Avertissement

Tenir compte des prescriptions locales

pour le traitement des eaux usées.

30 Français

Page 31

Î Sortir le flexible de vidange pour

l'eau sale du dispositif de maintien et

l'abaisser au-dessus d'un collecteur

approprié.

Î Vider l'eau en ouvrant le dispositif de

dosage sur le flexible de vidange.

Î Puis rincer le réservoir d'eau sale à

l'eau propre.

Vidange du réservoir d'eau propre

Î Ouvrir le bouchon du réservoir d'eau

fraîche avec un outil approprié (par

ex. une pièce).

propre résiduaire avant comencer les

travaux à l'appareil.

Plan de maintenance

Après le travail

몇 Avertissement

Risque d'endommagement. Ne pas laver l'appareil au jet d'eau et ne jamais

utiliser de détergents agressifs.

Î Vider l'eau sale.

Î Rincer le réservoir d'eau sale à l'eau

propre.

Î Nettoyer l'extérieur de l'appareil

avec un chiffon humide et imbibé de

détergent doux.

Î Contrôler le tamis à peluches et le

cas échéant, le nettoyer.

Î Nettoyer les lèvres d'aspiration et les

lèvres d'enlèvement, puis contrôler

leur degré d'usure et le cas échéant,

les nettoyer.

Î Vérifier si les brosses sont usées,

les remplacer si nécessaire.

Î Charger la batterie, en cas de be-

soin.

Mensuellement

Entretien et maintenance

Danger

Risque de blessure !

Avant d'effectuer des opérations sur

l'appareil, mettre le bouton d'enclenchement de la brosse et de l'aspiration hors

circuit et débrancher la fiche.

몇 Avertissement

Risque de dommage pour l'appareil par

eau que fuit. Vider l'eau sale et l'eau

Î Contrôler les joints entre le réservoir

d'eau sale et le couvercle ; le cas

échéant, les remplacer.

Î Contrôler les bornes de la batterie,

en cas de besoin brosser et graisser

avec graisse de borne. Faire attention que les câbles de raccordement

sont bien branché.

Î Contrôler en cas de batteries avec

maintenance la concentration de

l'acide des celulles.

Tous les ans

Î L'inspection prescrite doit être effec-

tuée par le service après-vente.

Français 31

Page 32

Travaux de maintenance

Contrat de maintenance

Changer ou tourner les lèvres d'aspiration.

Retirer la brosse d'aspiration.

Î

Î Dévisser le bouton cannelé.

Î Retirer les pièces plastiques.

Î Retirer les lèvres d'aspiration.

Î Tourner les lèvres d'aspiration ou

mettre des nouvelles lèvres d'aspiration.

Î Mettre en place des pièces plasti-

ques.

Î Visser et serrer les boutons can-

nelés.

Afin de pouvoir garantir un fonctionnement fiable de l'appareil, il est possible

de conclure des contrats de maintenance avec le bureau de ventes Kärcher

responsable.

Protection antigel

En cas de risque de gel :

Î Vider le réservoir d'eau propre et le

réservoir d'eau sale.

Î Déposer l'appareil dans une pièce à

l'abri du gel.

Transport

Î Retirer les brosses pour éviter qu'el-

les ne soient endommagées.

Î Pour le transport sur un véhicule,

bloquer l'appareil avec des sangles

pour tendre/cordes pour l'empêcher

de glisser.

Échanger les disques-brosses

Î Tourner le bouton de régulation de la

vitesse de traction avant dans le

sens "–".

Î Soulever le disque-brosse.

Î Tourner le disque-brosse d'environ

45° dans le sens anti-horaire.

Î Retirer le disque-brosse par le bas.

Î Mettre en place le nouveau disque-

brosse dans l'ordre inverse.

Î Régler la vitesse de traction avant.

32 Français

Page 33

Pannes

Danger

Risque de blessure !

Avant d'effectuer des opérations sur

l'appareil, mettre le bouton d'enclenchement de la brosse et de l'aspiration hors

circuit et débrancher la fiche.

몇 Avertissement

Risque de dommage pour l'appareil par

eau que fuit. Vider l'eau sale et l'eau

propre résiduaire avant comencer les

travaux à l'appareil.

En cas de pannes ne pouvant pas être

résolues grâce aux instructions de ce

tableau, appeler le service après-vente.

Défauts qui s'affichent à l'écran

Affichage de l'écran Remède

ERR B Vérifier si des corps étrangers bloquent les brosses et le

cas échéant, éliminer les corps étrangers.

ERR T Contacter le service après-vente

LOW BAT Chargement de la batterie

ERR TEMP Laisser refroidir l'appareil.

Réduire éventuellement la pression d'appui des brosses.

HandsOff Relâcher l'étrier de commande et attendre jusqu'à ce que

les heures de service ou l'état de la batterie soient affichés dans l'écran. Actionner ensuite de nouveau l'étrier

de commande.

ERR REL Mettre l'interrupteur de fonctionnement de brosse hors

service, mettre l'interrupteur de turbine d'aspiration, relâcher l'étrier de commande, attendre 3 secondes, remettre

en service.

Si cela se renouvelle, appeler le service après-vente.

Français 33

Page 34

Défauts qui ne s'affichent pas à l'écran

Panne Remède

Il est impossible de mettre

l'appareil en marche

Quantité d'eau insuffisante Contrôler le niveau d'eau propre et en cas de be-

Puissance d'aspiration insuffisante

Actionner le guidon à poussée.

Vérifier la batterie, la remplacer si nécessaire.

Vérifier si la fiche secteur est branchée.

soin, remplir le réservoir

Contrôler si les flexibles sont bouchés, en cas de

besoin nettoyer.

Nettoyer les joints entre le réservoir d'eau sale et le

couvercle et vérifier s'ils sont étanches, en cas de

besoin remplacer.

Nettoyer le tamis à peluches.

Nettoyer les lèvres d'aspiration sur la barre d'aspiration et en cas de besoin tourner ou remplacer.

Vérifiier si le flexible d'aspiration et la barre d'aspiration sont colmatés et le cas échéant, éliminer le

colmatage

Contrôler si les flexibles d'aspiration sont étanches

et en cas de besoin remplacer.

Vérifier si le couvercle sur le flexible de vidange

d'eau sale est fermé.

Résultat de nettoyage insuffisant

Les brosses ne se tournent

pas

34 Français

Vérifier le réglage de la barre d'aspiration.

Vérifier si les brosses sont usées, les remplacer si

nécessaire.

Actionner le guidon à poussée.

Vérifier si des corps étrangers bloquent les brosses

et le cas échéant, éliminer les corps étrangers.

Page 35

Accessoires

L'appareil peut être équipé de différents

accessoires en fonction de l'application

respective. De plus amples détails figu-

Désignation

Disque-brosse, nature (douce)

Disque-brosse, rouge (moyenne, standard)

Disque-brosse, noire (dure)

Plateau de propulsion

Disc-Pad, rouge

(moyen)

Disc-Pad, vert (dur) 6.369-023.0 Pour le nettoyage des sols

Disc-Pad, noir (très

dur)

Barre d'aspiration,

droit

Barre d'aspiration,

courbée

Lèvre en caoutchouc, bleu

Lèvre en caoutchouch, marron

Référence

BD 530

6.906-056.0 Pour le polissage des sols. 1 1

6.906-054.0 Pour le nettoyage des sols

6.906-055.0 Pour le nettoyage des sols

6.906-332.0 Pour la réception de pads. 1 1

6.369-024.0 Pour le nettoyage des sols

6.369-022.0 Pour le nettoyage des sols

4.777-047.0 Standard 1 1

4.777-054.0 Standard 1 1

6.273-204.0 Standard 1 1

6.273-207.0 résistante à l'huile 1 1

rent dans notre catalogue ou sur notre

site Internet www.kaercher.com.

Description

pas trop sales ou sensibles.

très sales.

pas trop sales.

normalement sales.

très sales.

Pièce/emballage

L'appareil besoin la pièce

11

11

51

51

51

Français 35

Page 36

Caractéristiques techniques

BD 530 Bp

Performances

Tension nominale V 24

Capacité de la batterie Ah (5h) 75

Puissance absorbée moyenne W 1200

Puissance du moteur d'aspiration W 500

Puissance de moteur de brosses W 600

Aspiration

Puissance d'aspiration, débit d'air l/s (gpm) 30 (475)

Puissance d'aspiration, dépression kPa (psi) 14 (2)

Brosses de nettoyage

Largeur de travail mm (pouce) 460 (18,1)

Diamètre des brosses mm (pouce) 460 (18,1)

Vitesse des brosses t/min 140

Dimensions et poids

Surface théoriquement nettoyable m

Volume du réservoir d'eau propre/réservoir

d'eau sale

Poids total kg (lbs) 115 (253,5)

Emissions sonores

Niveau de pression acoustique (EN 60704-1) dB(A) 70

Vibrations de l'appareil

Valeur globale de vibrations (ISO 5349) m/s² 0,4

2

/h (ft2/h) 1840 (19800)

l (gal) 40/40 (10,5/

10,5)

Garantie Pièces de rechange

Dans chaque pays, les conditions de

garantie en vigueur sont celles publiées

par notre société de distribution responsable. Les éventuelles pannes sur les

accessoires sont réparées gratuitement

dans le délai de validité de la garantie,

dans la mesure où celles-ci relèvent

d'un défaut matériel ou d'un vice de fabrication. En cas de recours en garantie, adressez-vous à votre revendeur ou

au service après-vente agréé le plus

proche munis de votre preuve d'achat.

36 Français

– Utiliser uniquement des accessoires

et des pièces de rechange autorisés

par le fabricant. Des accessoires et

des pièces de rechange d’origine

garantissent un fonctionnement sûr

et parfait de l’appareil.

– Une sélection des pièces de rechan-

ge utilisées le plus se trouve à la fin

du mode d'emploi.

– Plus information sur les pièces de

rechange vous les trouverez sous

www.kaercher.com sous le menu

Service.

Page 37

INSTRUCCIONES IMPOR-

TANTES DE SEGURIDAD

LEER TODAS LAS INSTRUC-

CIONES ANTES DE USAR.

ADVERTENCIA

Para reducir el riesgo de fuegos, descarga eléctrico o lesiones:

– no abandonar la unidad mientras

esté enchufada. Desenchufar cuando no esté en uso y antes de revisar.

ADVERTENCIA

– PARA REDUCIR EL RIESGO DE

DESCARGA ELÉCTRICA, USAR

SOLO EN INTERIORES

– No permita que se use como jugue-

te. Prestar mucha atención cuando

se use cerca de niños.

– Usar exclusivamente como se des-

cribe en este manual. Usar solamente con los complementos

recomendados por el fabricante.

– No usar con el cable o la clavija da-

ñados. Si el aparato no funciona

como debería, se ha caído al suelo,

dañado, dejado al aire libre, o caído

al agua, devuélvalo a servicio de

atención al cliente.

– No tirar del cable ni transportar el

aparato cogido por el cable, no cerrar una puerta sobre el cable, ni pasar el cable por bordes o esquinas

afiladas. No pasar el aparato por encima del cable. Mantener el cable

alejado de superficies calientes.

– No tirar del cable para desenchufar

el aparato. Para desechufar, tire de

la clavija no del cable.

– No manipular la clavija ni el aparato

con las manos mojadas.

– No introducir objetos en los orificios.

No usar con cualquiera de los orificios bloqueados; mantener sin polvo, pelusa, pelo y cualquier otra

cosa que pueda reducir el flujo de aire.

– Mantener el cabello, la ropa floja, los

dedos y todas las partes del cuerpo

alejadas de los orificios y partes móviles.

– Apagar los mandos de control antes

de desenchufar.

– No usar para recoger líquidos infla-

mables o combustible, como gasolina, ni utilizar el aparato en áreas

donde puedan estar presentes.

CONSERVE ESTAS INS-

TRUCCIONES

NORMAS Y PRÁCTICAS DE

SEGURIDAD PARA EL FUN-

CIONAMIENTO

Responsabilidad del operario

El operario es responsable de un funcionamiento seguro.

El operario estará familiarizado con el

trabajo y funcionamiento de todos los

controles e instrumentos antes de poner en funcionamiento el equipo.

Antes de poner el funcionamiento el

aparato, los operarios tendrán que leer

y estar familiarizados con el manual del

operario de la unidad en concreto y

también cumplirán con las normas y

prácticas de seguridad indicadas en los

siguientes párrafos.

Antes de poner en funcionamiento cualqueir unidad, el operario se familiarizarán con las condiciones inusuales de

funcionamiento que puedan requerir

precauciones de seguridad adicionales

Español 37

Page 38

o instrucciones de funcionamiento especiales.

Generalidades

Antes de poner en funcionamiento la

unidad, ésta deberá encontrarse en la

posición de servicio.

No arrancar ni poner en funcionamiento

la unidad, cualquiera de sus funciones o

complementos, en otro sitio que no sea

la posición designada de operario.

Antes de dejar la posición del operario:

A parar completamente el equipo;

B si el equipo tiene que estar en una

inclinación, bloquear las ruedas.

No realice modificaciones ni añadidos

al equipo.

No bloquear el acceso a las salidas de

emergencias de incendios, escaleras o

equipo antiincendios.

Conducción

Ceder el paso a peatones y vehículos

de emergencias como ambulancias o

camiones de bomberos.

Cruce vías de tren en ángulo siempre

que sea posible. No aparcar a menos

de 1800 mm de la vía del tren.

Mantener una buena vista del camino

por el que conduce y preste atención al

tráfico, personal y seguridad.

Operar el equipo siempre a una velocidad que permita parar de manera segura.

No permita realizar escenas peligrosas

ni juguetear con el equipo.

Reducir la velocidad en suelos húmedos y resbaladizos.

Antes de conducir sobre un muelle o

puente, asegúrese de que esté bien seguro. Conducta con cuidado y lentamente por el muelle o puente, y no

exceda nunca la capacidad indicada.

Al sortear curvas, reduzca la velocidad

a un nivel seguro de acuerdo con el ambiente de funcionamiento. Sortear las

curvas con cuidado.

Cuidados del equipo realizados

por el operario

Si el equipo necesita ser reparado o es

inseguro, o favorece una situación insegura, se deberá informar del problema

inmediatamente al encargado designado por el usuario, y no se pondrá en funcionamiento el equipo hasta que se

recupere el estado de funcionamiento

seguro.

Si el equipo se vuelve inseguro de cualquier modo durante su funcionamiento,

se deberá informar del problema inmediatamente al encargado designado por

el usuario, y no se pondrá en funcionamiento el equipo hasta que se recupere

el estado de funcionamiento seguro.

No realizar reparaciones o ajustes a no

ser que se autorizado específicamente.

No usar llamas directas cuando se comprueba el nivel de electrolitos en las baterías de almacén.

MANTENIMIENTO Y PRÁCTI-

CAS DE RECONSTRUCCIÓN

El funcionamiento del equipo puede resultar peligros si no realiza el mantenimiento o se llevan a cabo reparaciones,

reconstrucciones o ajustes que no correspondan con los criterios de diseño

del fabricante. Por lo tanto, se deben

poner a disposición lugares de mantenimiento (en el mismo local o en otro lugar), personal cualificado, y

procedimientos detallados.

El mantenimiento e inspección de la

unidad se realizará de acuerdo con las

siguientes prácticas:

38 Español

Page 39

A a un mantenimiento planificado, le

seguirán lubricación e inspección

del sistema: consulte las recomendaciones del fabricante.

B sólo se permitirá realizar manteni-

miento, reparaciones, ajustes e inspecciones del equipo a personal

formado y autorizado y de acuerdo

con las especificaciones del fabricante.

Evitar los riesgos de incendios y tener

equipo de protección de incendios en el

área de trabajo. No usar llama directa

para comprobar el nivel que cualquier

fluido, especialmente electrolitos de la

batería. No usar recipientes abiertos de

fuel o líquidos inflamables de limpieza

para las limpiar las piezas.

NORMA DE SEGURIDAD

CONTRA INCENDIOS

Cualquier unidad que no esté en un estado de funcionamiento seguro será retirada de servicio.

No se realizarán reparaaciones en ubicaciones de clase I, clase II y clase III.

Prevención de incendios.Se mantendrá el equipo limpio y sin pelusas, exceso de aceite y grasa en la medida de lo

posible. Es preferible utilizar productos

no combustibles para limpiar el equipo.

No está permitido utilizar líquidos inflamables [aquellos que tengan puntos de

inflamación de o superior a 37,8ºC

(100ºF)]. Se deberá tomar precauciones ante la toxicidad, ventilación e incendios con el producto o disolvente

usado.

Visibilidad de la placa identificadora.

Las denominaciones de tipo de equipo

se indican en la placa identificadora y

no se deben cubrir las marcas de tipo

con pintura para que no se vea la información de identificación.

No se usará la unidad en áreas clasificadas.

Antes del primer uso de su

aparato, lea este manual original, actúe de acuerdo a sus indicaciones y guárdelo para un uso posterior o

para otro propietario posterior.

Índice de contenidos

Indicaciones de seguridad 39

Función 40

Uso previsto 40

Protección del medio ambiente 40

Elementos de mando 41

Antes de la puesta en marcha 42

Funcionamiento 44

Cuidados y mantenimiento 48

Averías 49

Datos técnicos 53

Garantía 53

Piezas de repuesto 53

Indicaciones de seguridad

Antes de utilizar por primera vez el aparato, lea y tenga en cuenta el presente

manual de instrucciones y el folleto adjunto relativo a las indicaciones de seguridad para aparatos de limpieza con

cepillos y aparatos pulverizadores,

5.956-251.

El equipo está diseñado para funcionar

en superficies con una pendiente de

hasta 2%.

El aparato sólo se puede poner en

funcionamiento cuando el depósito y

todas las tapas estén cerradas.

Símbolos

En este manual de instrucciones se emplean los siguientes símbolos:

Peligro

Indica la existencia de un peligro inminente. El incumplimiento de la indica-

Español 39

Page 40

ción puede acarrear la muerte o

lesiones de suma gravedad.

몇 Advertencia

Hace alusión a una situación potencialmente peligrosa. El incumplimiento de

la indicación puede provocar lesiones

leves o daños materiales.

Nota

Identifica consejos de manejo e información importante sobre el producto.

Función

El aparato sirve para efectuar la limpieza en húmedo de pisos llanos. Se puede adaptar fácilmente a la tarea de

limpieza que corresponda ajustando el

caudal de agua y la aspiración de agua

sucia.

Un ancho de trabajo de 460 mm y una

capacidad de 40 l de agua fresca y

agua sucia permiten realizar una limpieza eficaz incluso cuando la máquina se

usa durante un período largo.

Uso previsto

Utilice el aparato únicamente de conformidad con las indicaciones del presente

manual de instrucciones.

– El aparato sólo se puede utilizar

para limpiar suelos lisos resistentes

a la humedad.

– El aparato no es apto para la limpie-

za de pisos congelados (p. ej., en almacenes frigoríficos).

– Sólo está permitido dotar al aparato

de accesorios y piezas de repuesto

originales.

Protección del medio ambiente

Los materiales de embalaje

son reciclables. Po favor, no

tire el embalaje a la basura

doméstica; en vez de ello,

entréguelo en los puntos oficiales de recogida para su

reciclaje o recuperación.

Los aparatos viejos contienen materiales valiosos reciclables que deberían ser

entregados para su aprovechamiento posterior. Evite el

contacto de baterías, aceites

y materias semejantes con el

medioambiente. Por este

motivo, entregue los aparatos usados en los puntos de

recogida previstos para su

reciclaje.

Indicaciones sobre ingredientes (REACH)

Encontrará información actual sobre los

ingredientes en:

http://www.karcher.de/de/unternehmen/

umweltschutz/REACH.htm

40 Español

Page 41

Elementos de mando

1 estribo de empuje

2 Estribo de conexión

3 Pupitre de mando

4 Sistema electrónico y fusibles

(bajo el pupitre de mando)

5 Palanca de bajada de la barra de as-

piración

6 Manguera de salida de agua sucia

7 manguera de aspiración

8 Batería (sólo la BD 530 Bp)

9 Mangos en estrella para cambiar los

labios de aspiración

10 Soporte para barra de aspiración

11 Mango en cruz para fijar e inclinar la

barra de aspiración.

12 Tuercas de mariposa para inclinar la

barra de aspiración

13 Barra de aspiración (no incluida en

el suministro)

14 Conexión de la turbina de aspiración

con la manguera de aspiración

15 placa de características

16 cepillo en forma de disco

17 Cabezal limpiador

18 Tren de desplazamiento

19 dispositivo de bloqueo

20 Mango

21 Tapa del depósito de agua sucia

22 Tornillo para bloquear el depósito;

en el depósito: Baterías *

Debajo de la tapa del depósito de

agua sucia:

23 Orificio de llenado del depósito de

agua limpia

24 Filtro de pelusas (aspiración)

25 depósito de agua sucia

Español 41

Page 42

Pupitre de mando

1 Botón regulador del caudal de agua

2 Interruptor modo de cepillo

3 Interruptor turbina de aspiración

4 anuncio

Montaje de la barra de aspiración

Î Coloque la barra de aspiración en su

soporte de modo que la chapa perfilada quede por encima del soporte.

Î Ajustar bien los mangos en cruz.

Antes de la puesta en marcha

Descarga

Î Fijar el estribo con los cuatro torni-

llos suministrados e insertar la tapa

protectora.

Î

Coloque las tablas largas laterales del

embalaje como rampa en el palet.

Î Fije la rampa al palet con clavos.

Î Coloque las tablas cortas debajo de

la rampa a modo de soporte.

Î Retire los listones de madera de de-

lante de las ruedas.

Î Levantar el cabezal de limpieza y re-

tirar el cartón.

Î Baje el aparato del palet por la ram-

pa.

Î Coloque la manguera de aspiración.

Montar los cepillos

Antes de la puesta en servicio, se tienen que montar la escobilla de disco

(véase "Trabajos de mantenimiento").

Baterías

Al manipular baterías, tenga siempre en

cuenta las siguientes advertencias: