Kyocera DP-420, PF-420, DF-420, JS-420 Service manual

DP-420/PF-420

DF-420/JS-420

FAX System (R)

SERVICE

MANUAL

Published in May 2009

3MZSM060

First Edition

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF

USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

It may be illegal to dispose of this battery into the municipal waste stream. Check with your local

solid waste officials for details in your area for proper disposal.

ATTENTION

IL Y A UN RISQUE D’EXPLOSION SI LA BATTERIE EST REMPLACEE PAR UN MODELE DE

TYPE INCORRECT. METTRE AU REBUT LES BATTERIES UTILISEES SELON LES INSTRUCTIONS DONNEES.

Il peut être illégal de jeter les batteries dans des eaux d’égout municipales. Vérifiez avec les fonctionnaires municipaux de votre région pour les détails concernant des déchets solides et une mise

au rebut appropriée.

Revision history

Revision Date Replaced pages Remarks

This page is intentionally left blank.

Safety precautions

This booklet provides safety warnings and precautions for our service personnel to ensure the safety of

their customers, their machines as well as themselves during maintenance activities. Service personnel

are advised to read this booklet carefully to familiarize themselves with the warnings and precautions

described here before engaging in maintenance activities.

Safety warnings and precautions

Various symbols are used to protect our service personnel and customers from physical danger and

to prevent damage to their property. These symbols are described below:

DANGER: High risk of serious bodily injury or death may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

WARNING: Serious bodily injury or death may result from insufficient attention to or incorrect compliance

with warning messages using this symbol.

CAUTION: Bodily injury or damage to property may result from insufficient attention to or incorrect

compliance with warning messages using this symbol.

Symbols

The triangle ( ) symbol indicates a warning including danger and caution. The specific point

of attention is shown inside the symbol.

General warning.

Warning of risk of electric shock.

Warning of high temperature.

indicates a prohibited action. The specific prohibition is shown inside the symbol.

General prohibited action.

Disassembly prohibited.

indicates that action is required. The specific action required is shown inside the symbol.

General action required.

Remove the power plug from the wall outlet.

Always ground the copier.

1.Installation Precautions

WARNING

• Do not use a power supply with a voltage other than that specified. Avoid multiple connections to

one outlet: they may cause fire or electric shock. When using an extension cable, always check

that it is adequate for the rated current. .............................................................................................

• Connect the ground wire to a suitable grounding point. Not grounding the copier may cause fire or

electric shock. Connecting the earth wire to an object not approved for the purpose may cause

explosion or electric shock. Never connect the ground cable to any of the following: gas pipes,

lightning rods, ground cables for telephone lines and water pipes or faucets not approved by the

proper authorities. ............................................................................................................................

CAUTION:

• Do not place the copier on an infirm or angled surface: the copier may tip over, causing injury. .......

• Do not install the copier in a humid or dusty place. This may cause fire or electric shock. ................

• Do not install the copier near a radiator, heater, other heat source or near flammable material.

This may cause fire. .........................................................................................................................

• Allow sufficient space around the copier to allow the ventilation grills to keep the machine as cool

as possible. Insufficient ventilation may cause heat buildup and poor copying performance. ...........

• Always handle the machine by the correct locations when moving it. ...............................................

• Always use anti-toppling and locking devices on copiers so equipped. Failure to do this may cause

the copier to move unexpectedly or topple, leading to injury. ...........................................................

• Avoid inhaling toner or developer excessively. Protect the eyes. If toner or developer is accidentally ingested, drink a lot of water to dilute it in the stomach and obtain medical attention immediately. If it gets into the eyes, rinse immediately with copious amounts of water and obtain medical

attention. ......................................................................................................................................

• Advice customers that they must always follow the safety warnings and precautions in the copier’s

instruction handbook. .....................................................................................................................

2.Precautions for Maintenance

WARNING

• Always remove the power plug from the wall outlet before starting machine disassembly. ...............

• Always follow the procedures for maintenance described in the service manual and other related

brochures. .......................................................................................................................................

• Under no circumstances attempt to bypass or disable safety features including safety mechanisms

and protective circuits. .....................................................................................................................

• Always use parts having the correct specifications. ..........................................................................

• Always use the thermostat or thermal fuse specified in the service manual or other related brochure when replacing them. Using a piece of wire, for example, could lead to fire or other serious

accident. ..........................................................................................................................................

• When the service manual or other serious brochure specifies a distance or gap for installation of a

part, always use the correct scale and measure carefully. ................................................................

• Always check that the copier is correctly connected to an outlet with a ground connection. .............

• Check that the power cable covering is free of damage. Check that the power plug is dust-free. If it

is dirty, clean it to remove the risk of fire or electric shock. ..............................................................

• Never attempt to disassemble the optical unit in machines using lasers. Leaking laser light may

damage eyesight. ...........................................................................................................................

• Handle the charger sections with care. They are charged to high potentials and may cause electric

shock if handled improperly. ............................................................................................................

CAUTION

• Wear safe clothing. If wearing loose clothing or accessories such as ties, make sure they are

safely secured so they will not be caught in rotating sections. ..........................................................

• Use utmost caution when working on a powered machine. Keep away from chains and belts. ........

• Handle the fixing section with care to avoid burns as it can be extremely hot. ..................................

• Check that the fixing unit thermistor, heat and press rollers are clean. Dirt on them can cause

abnormally high temperatures. ........................................................................................................

• Do not remove the ozone filter, if any, from the copier except for routine replacement. ....................

• Do not pull on the AC power cord or connector wires on high-voltage components when removing

them; always hold the plug itself. .....................................................................................................

• Do not route the power cable where it may be stood on or trapped. If necessary, protect it with a

cable cover or other appropriate item. .............................................................................................

• Treat the ends of the wire carefully when installing a new charger wire to avoid electric leaks. ........

• Remove toner completely from electronic components. ...................................................................

• Run wire harnesses carefully so that wires will not be trapped or damaged. ....................................

• After maintenance, always check that all the parts, screws, connectors and wires that were

removed, have been refitted correctly. Special attention should be paid to any forgotten connector,

trapped wire and missing screws. ...................................................................................................

• Check that all the caution labels that should be present on the machine according to the instruction

handbook are clean and not peeling. Replace with new ones if necessary. ......................................

• Handle greases and solvents with care by following the instructions below: .....................................

· Use only a small amount of solvent at a time, being careful not to spill. Wipe spills off completely.

· Ventilate the room well while using grease or solvents.

· Allow applied solvents to evaporate completely before refitting the covers or turning the power

switch on.

· Always wash hands afterwards.

• Never dispose of toner or toner bottles in fire. Toner may cause sparks when exposed directly to

fire in a furnace, etc. .......................................................................................................................

• Should smoke be seen coming from the copier, remove the power plug from the wall outlet imme-

diately. ............................................................................................................................................

3.Miscellaneous

WARNING

• Never attempt to heat the drum or expose it to any organic solvents such as alcohol, other than the

specified refiner; it may generate toxic gas. .....................................................................................

This page is intentionally left blank.

DP-420

First Edition

CONTENTS

1-1 Specifications

1-1-1 Specifications..........................................................................................................................................1-1-1

1-1-2 Parts names............................................................................................................................................1-1-2

1-1-3 Machine cross section ............................................................................................................................1-1-3

1-2 Installation

1-2-1 Installation environment ..........................................................................................................................1-2-1

1-2-2 Unpacking ...............................................................................................................................................1-2-2

(1) Unpacking .........................................................................................................................................1-2-2

(2) Removing the tapes and the spacer..................................................................................................1-2-3

1-3 Maintenance Mode

1-3-1 Maintenance mode (operation panel is a 7-segment type) .....................................................................1-3-1

(1) Executing a maintenance item ..........................................................................................................1-3-1

(2) Maintenance mode item list...............................................................................................................1-3-2

(3) Contents of maintenance mode items...............................................................................................1-3-3

1-3-2 Maintenance mode (operation panel is an LCD type)...........................................................................1-3-15

(1) Executing a maintenance item ........................................................................................................1-3-15

(2) Maintenance mode item list.............................................................................................................1-3-16

(3) Contents of maintenance mode items.............................................................................................1-3-17

3MX

1-4 Troubleshooting

1-4-1 Original misfeed detection ......................................................................................................................1-4-1

(1) Original misfeed indication ................................................................................................................1-4-1

(2) Original misfeed detection conditions................................................................................................1-4-1

(3) Paper misfeeds .................................................................................................................................1-4-3

1-4-2 Self-diagnosis .........................................................................................................................................1-4-4

(1) Self-diagnostic function (operation panel is a 7-segment type).........................................................1-4-4

(2) Self diagnostic codes (operation panel is a 7-segment type)............................................................1-4-4

(3) Self-diagnostic function (operation panel is an LCD type) ................................................................1-4-4

(4) Self diagnostic codes (operation panel is an LCD type)....................................................................1-4-4

1-4-3 Electric problems ....................................................................................................................................1-4-5

1-4-4 Mechanical problems ..............................................................................................................................1-4-6

1-5 Assembly and Disassembly

1-5-1 Precautions for assembly and disassembly............................................................................................1-5-1

(1) Precautions .......................................................................................................................................1-5-1

1-5-2 Original feed section ...............................................................................................................................1-5-2

(1) Detaching and refitting the DP forwarding pulley and DP feed pulley...............................................1-5-2

(2) Detaching and refitting the DP separation pad..................................................................................1-5-5

1-5-3 Image adjustment ...................................................................................................................................1-5-6

(1) Adjusting the angle of leading edge ..................................................................................................1-5-6

(2) Adjusting the angle of trailing edge ...................................................................................................1-5-8

2-1 Mechanical construction

2-1-1 Mechanical construction .........................................................................................................................2-1-1

(1) Operation of original switchback .......................................................................................................2-1-3

2-2 Electrical Parts Layout

2-2-1 Electrical parts layout..............................................................................................................................2-2-1

(1) PWBs ................................................................................................................................................2-2-1

(2) Switches and sensors .......................................................................................................................2-2-2

(3) Motors ...............................................................................................................................................2-2-3

(4) Solenoids...........................................................................................................................................2-2-4

2-3 Operation of the PWBs

2-3-1 DP main PWB .........................................................................................................................................2-3-1

3MX

2-4 Appendixes

List of maintenance parts........................................................................................................................2-4-1

Periodic maintenance procedures ..........................................................................................................2-4-2

Wiring diagram........................................................................................................................................2-4-4

1-1 Specifications

1-1-1 Specifications

Type................................................Duplex sheet-through document feeder

Original feed method ......................Automatic feed

Original weight ................................Single-sided original mode: 45 to 160 g/m

Double-sided original mode: 50 to 120 g/m

Original type....................................Sheet originals

Original size .................................... A3 to A5R/Ledger to StatementR

Original No. of sheets .....................50 sheets or less (50 to 80 g/m

Mixed original sizes: 30 sheets or less (50 to 80 g/m2)

Original scanning speed .................53.5 to 107 mm/s

Power source..................................Electrically connected to the machine

Dimensions .....................................559 (W) x 487 (D) x 131 (H) mm

22" (W) x 19

3/16" (D) x 5 3/16" (H)

Weight.............................................7 kg/15.4 lbs or less

NOTE: These specifications are subject to change without notice.

2

)

3MX

2

2

1-1-1

3MX

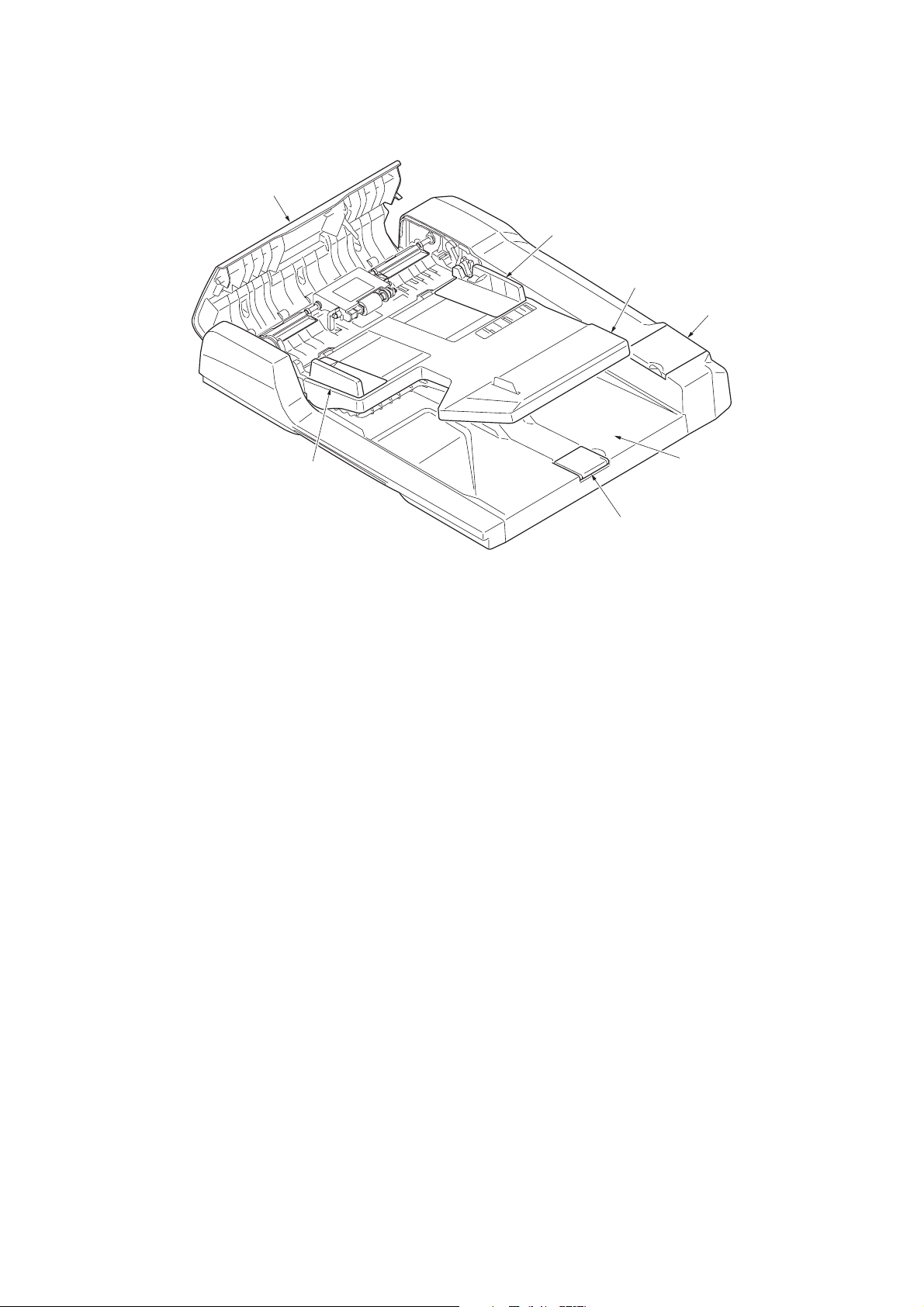

1-1-2 Parts names

4

2

1

6

2

Figure 1-1-1

1. Original table

2. Original width guides

3. Original eject table

4. Document processor top cover

5. Original stopper

6. Cleaning cloth compartment

3

5

1-1-2

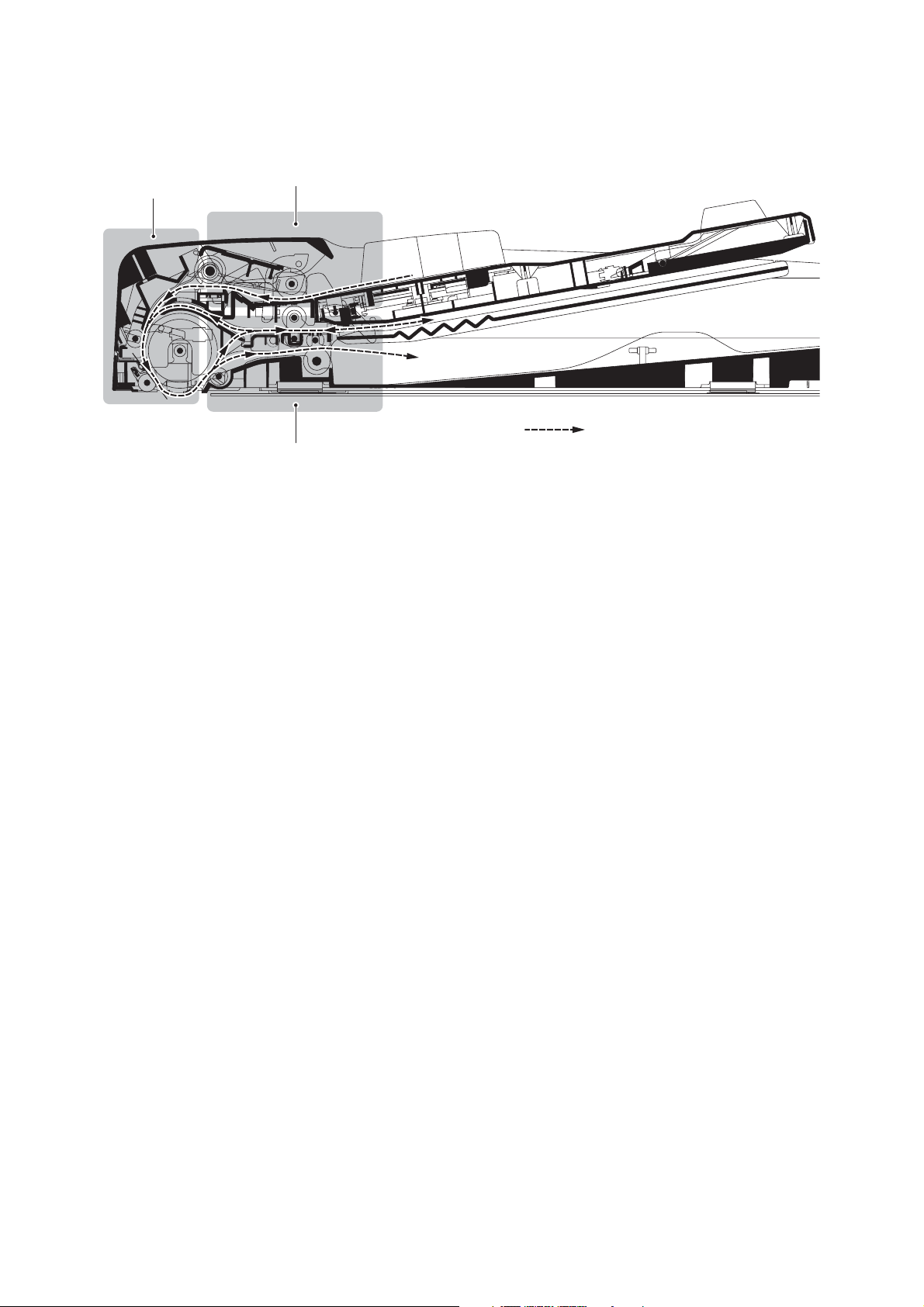

1-1-3 Machine cross section

3MX

2

1

Original path

3

Figure 1-1-2 Machine cross section

1. Original feed section

2. Original conveying section

3. Original switchback section

1-1-3

3MX

This page is intentionally left blank.

1-1-4

3MX

1-2 Installation

1-2-1 Installation environment

Installation location (Be based on the machine establishment place.)

Avoid direct sunlight or bright lighting. Ensure that the photoconductor will not be exposed to direct sunlight or other strong

light when removing paper jams.

Avoid locations subject to high temperature and high humidity or low temperature and low humidity; an abrupt change in

the environmental temperature; and cool or hot, direct air.

Avoid places subject to dust and vibrations.

Choose a surface capable of supporting the weight of the machine.

Place the machine on a level surface (maximum allowance inclination: 1

Avoid air-borne substances that may adversely affect the machine or degrade the photoconductor, such as mercury, acidic

of alkaline vapors, inorganic gasses, NOx, SOx gases and chlorine-based organic solvents.

Select a well-ventilated location.

°).

1-2-1

3MX

1-2-2 Unpacking

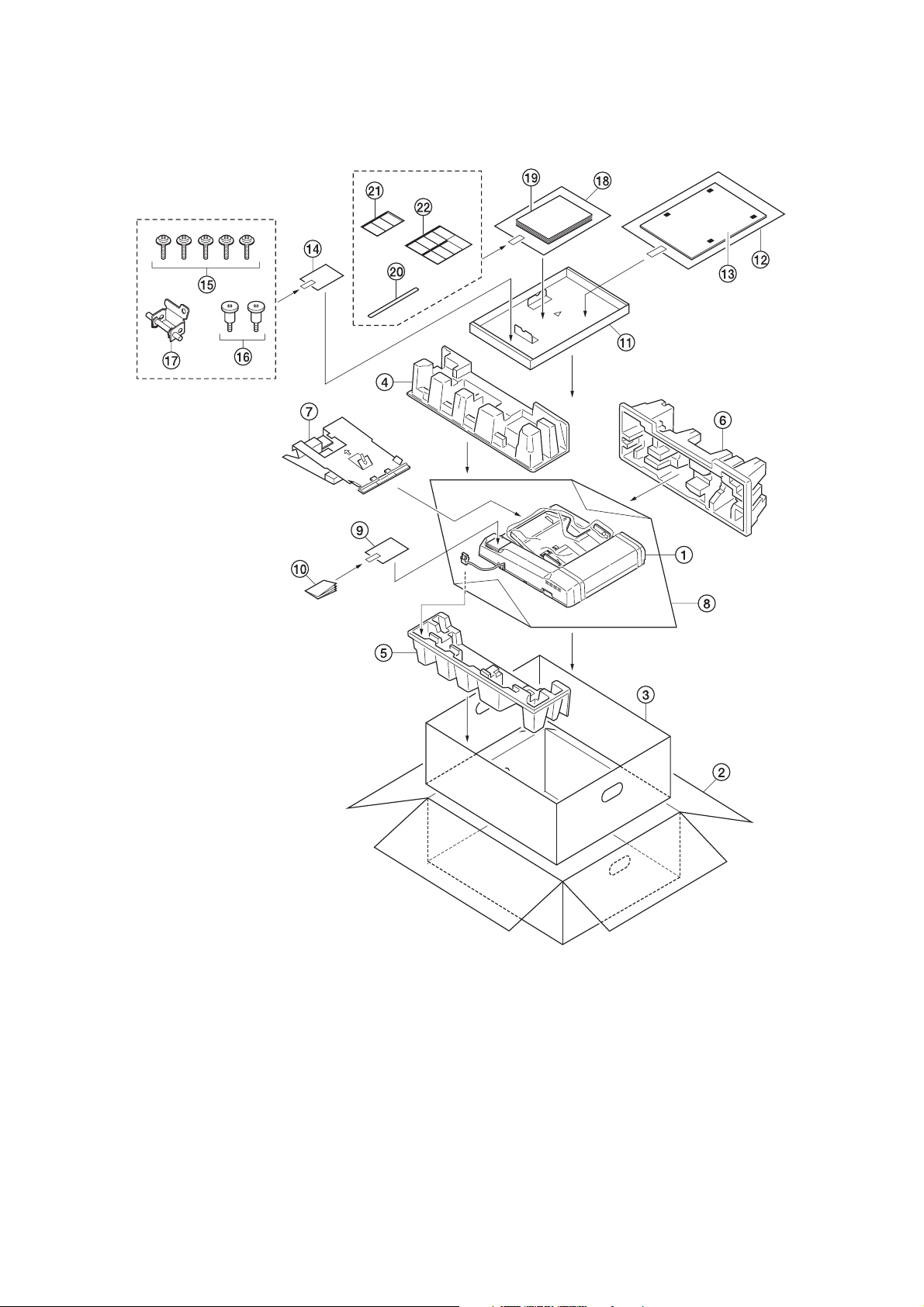

(1) Unpacking

1. Document processor

2. Outer case

3. Inner case

4. Rear upper pad

5. Rear lower pad

6. Front pad

7. Spacer

8. Plastic sheet

Caution: See the Installation Guide for installation.

1-2-2

Figure 1-2-1 Unpacking

9. Plastic bag

10. Cleaning cloth

11. Tray spacer

12. Plastic bag

13. Original mat

14. Plastic bag

15. M4 x 14 screws

16. Pins

17. Angle adjusting plate

18. Plastic bag

19. Installation guide

20. Film

21. Label A

22. Label B (220 V - 240 V

specifications only)

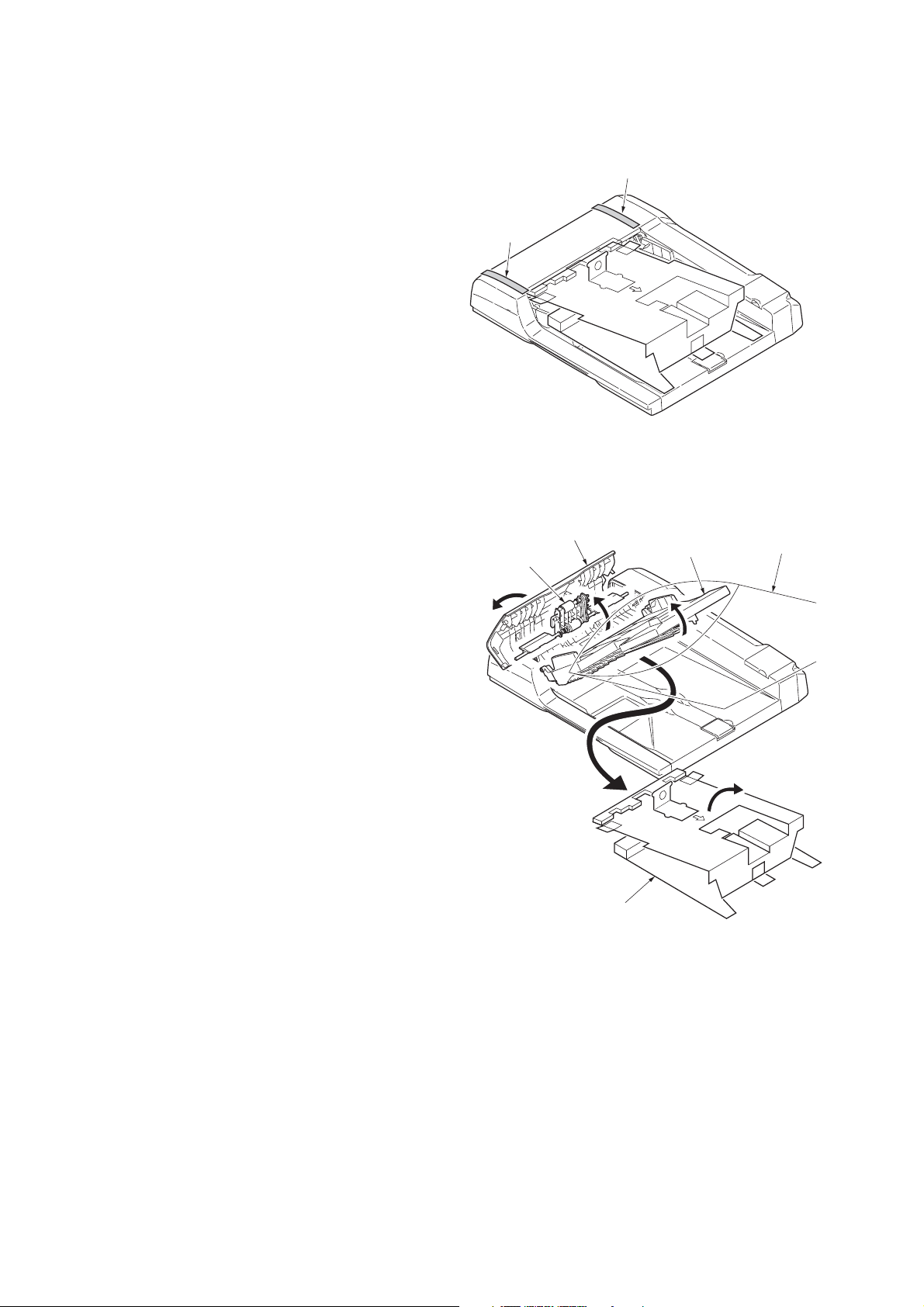

(2) Removing the tapes and the spacer

3MX

Procedure

1. Remove two tapes.

2. Open the document processor top cover.

3. Raise the DP feed pulley unit.

4. Open the spacer.

5. Raise the original table.

6. Remove the spacer.

7. Remove the plastic bag.

Ta pe

Document processor

top cover

DP feed pulley unit

Ta pe

Figure 1-2-2

Original table

Plastic bag

Spacer

Figure 1-2-3

1-2-3

3MX

This page is intentionally left blank.

1-2-4

1-3 Maintenance Mode

1-3-1 Maintenance mode (operation panel is a 7-segment type)

The machine is equipped with a maintenance function which can be used to maintain and service the machine.

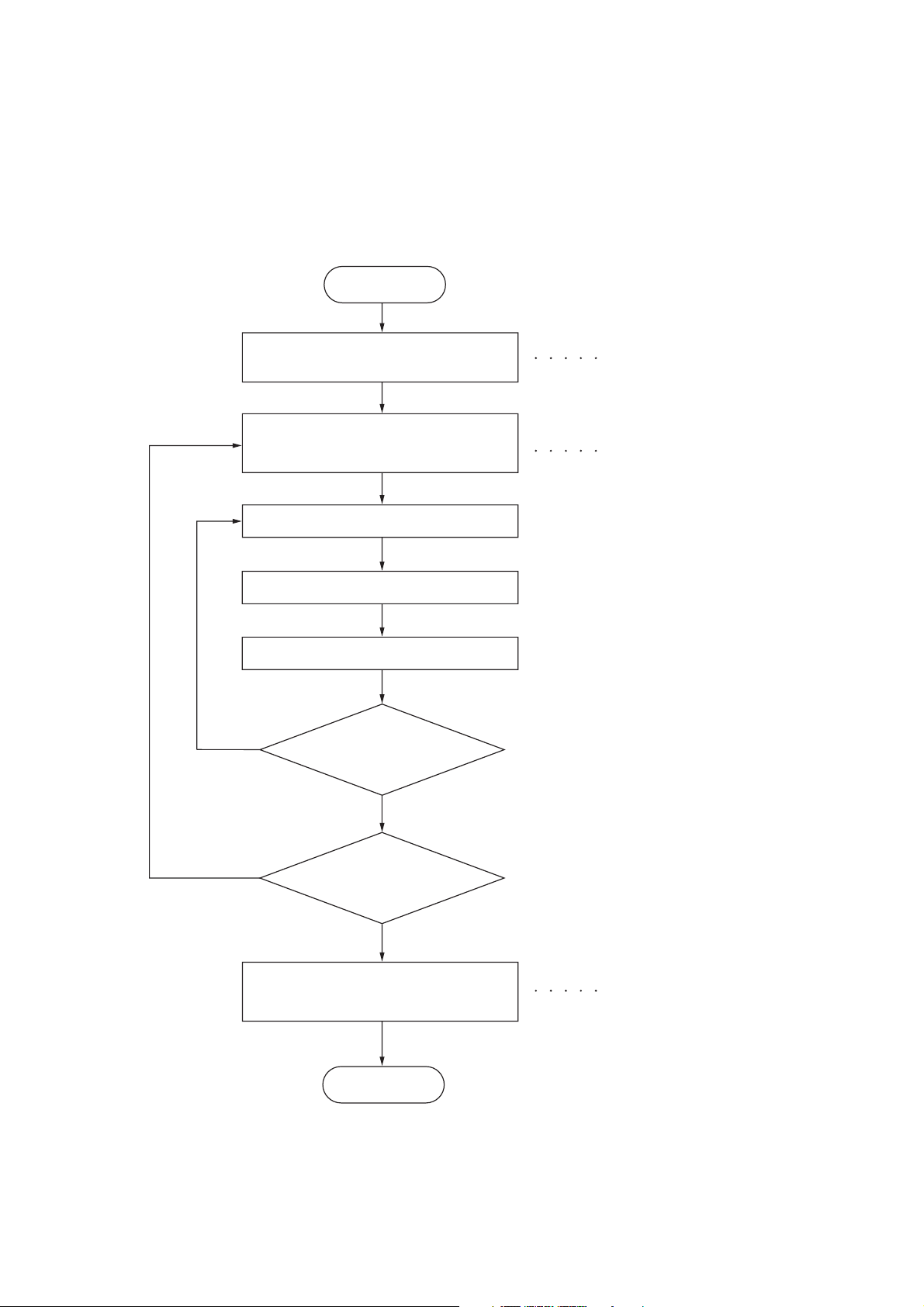

(1) Executing a maintenance item

Start

3MX

Yes

Enter “10871087” using

the numeric keys.

Enter the maintenance item

number using the zoom

+/- keys or numeric keys.

Press the start key.

The selected maintenance item is run.

Press the stop/clear key.

Repeat the same

maintenance item?

Maintenance mode is entered.

The maintenance item is

selected.

Yes

No

Run another maintenance

item?

No

Enter “001” using the

or numeric keys

+/- keys

zoom

and press the start key.

End

Maintenance mode is exited.

1-3-1

3MX

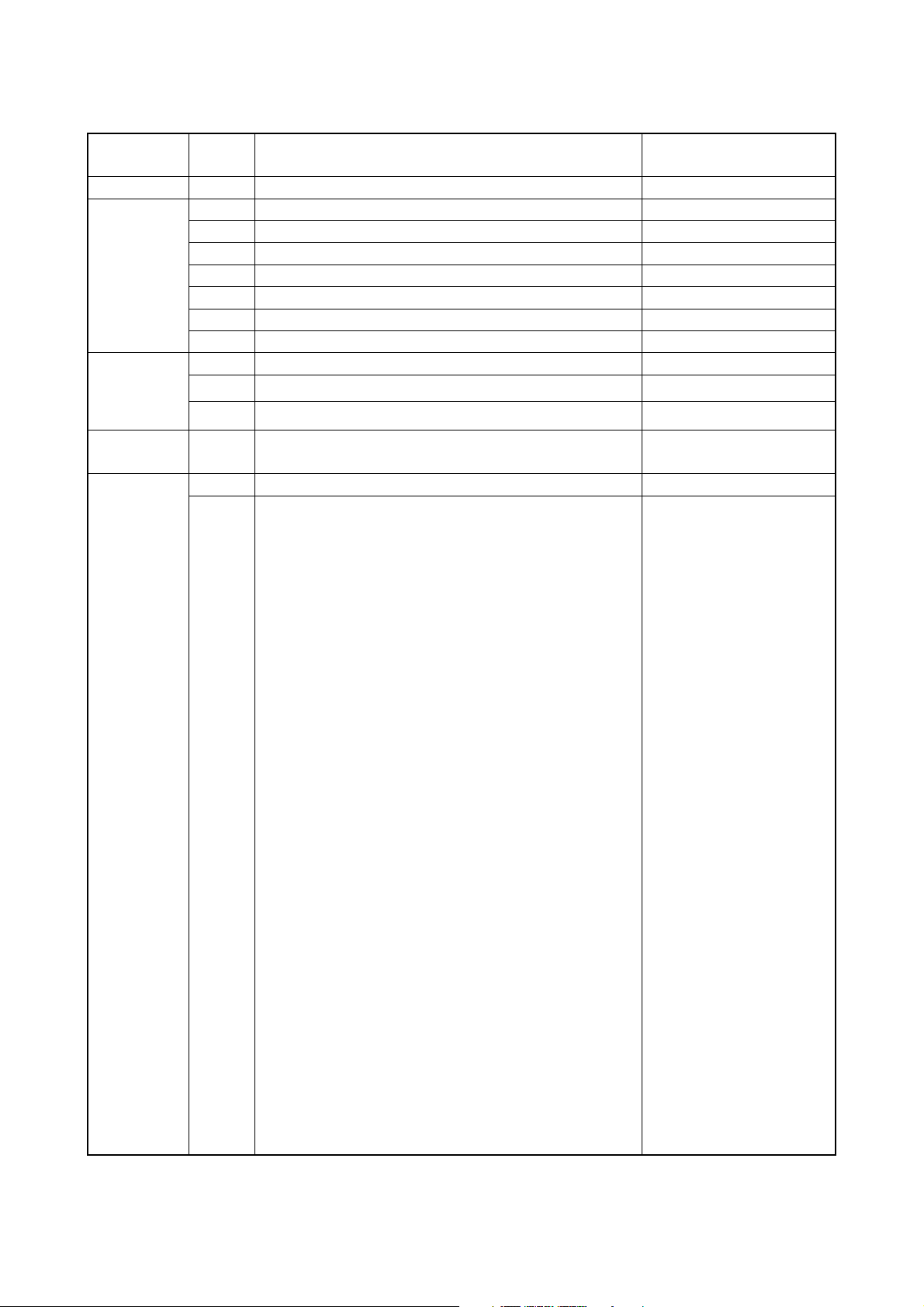

(2) Maintenance mode item list

Section

Item

No.

Content of maintenance item

Initial

setting*

General U019 Displaying the ROM version -

Optical U068 Adjusting the scanning position for originals from the DP 0

U070 Adjusting the DP magnification 0/0

U071 Adjusting the DP scanning timing 0/0/0/0

U072 Adjusting the DP center line 0/0

U074 Adjusting the DP input light luminosity 1

U076 Adjusting the DP automatically -

U087 Setting DP reading position modification operation ON/35

Operation

panel and

support

equipment

Image

U203 Checking DP operation -

U243 Checking the operation of the DP motors -

U244 Checking the DP switches -

U404 Adjusting margins for scanning an original from the DP 2.0/3.0/2.0/2.0

processing

Other U905 Checking/clearing counts by optional devices -

U942 Setting of deflection for feeding from DP 0/0

*1

*1

*1

*1

*1

*1

*1

*1

*Initial setting for executing U020, *1: The item initialized for executing U020, *2: The item initialized for executing U021

1-3-2

(3) Contents of maintenance mode items

3MX

Maintenance

item No.

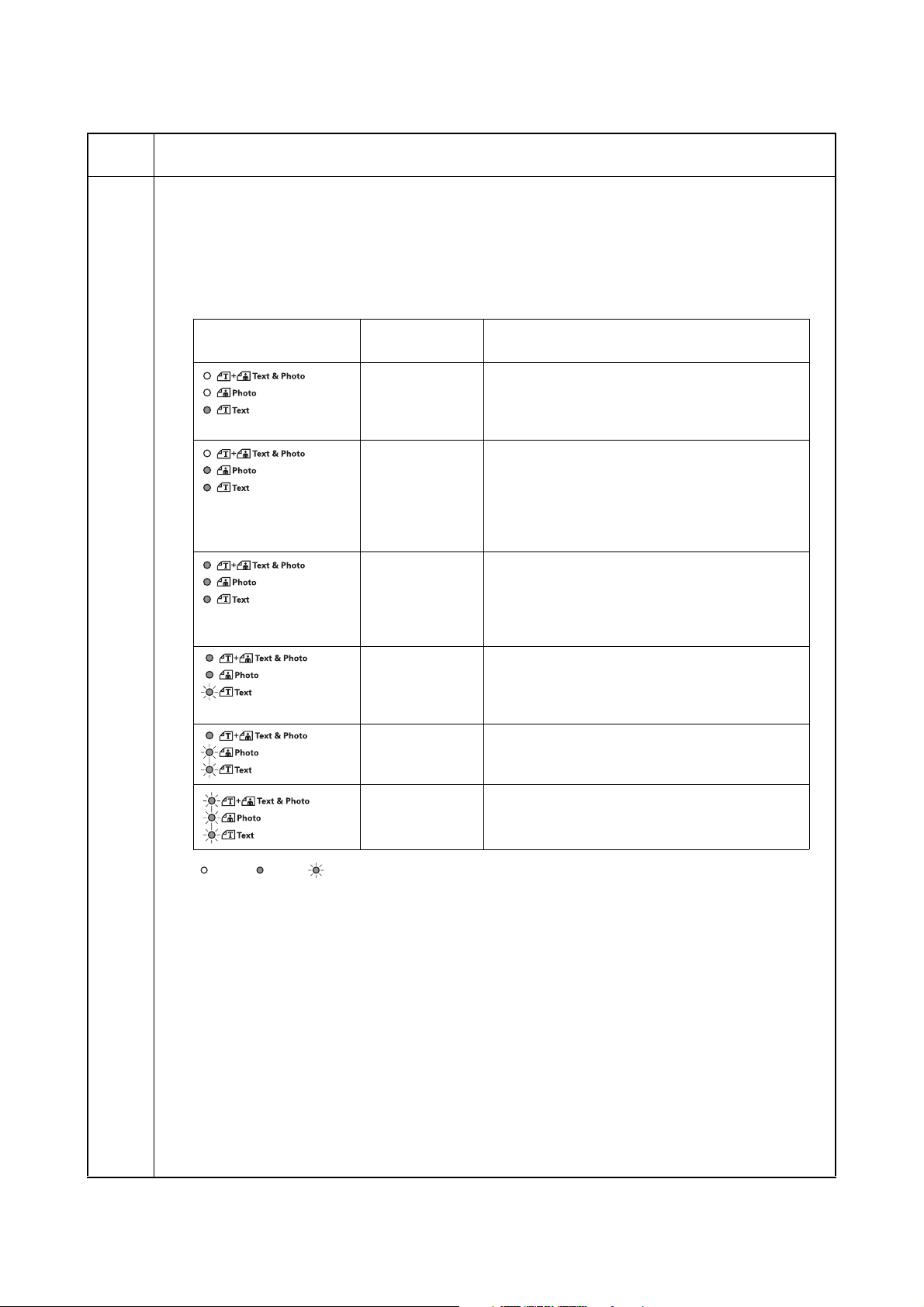

U019

Description

Displaying the ROM version

Description

Displays the part number of the ROM fitted to each board.

Purpose

To check the part number or to decide if the ROM version is new from the last digit of the number.

Method

1. Press the start key.

2. Select the item to be displayed using the image mode selection key and exposure adjustment keys.

Image mode LEDs

Exposure

indicator

Exp. 1 (lit)

Exp. 2 (lit)

Exp. 3 (lit)

Exp. 4 (lit)

Exp. 1 (lit)

Exp. 2 (lit)

Exp. 3 (lit)

Exp. 4 (lit)

Exp. 5 (lit)

Exp. 1 (flashing)

Exp. 1 (lit)

Exp. 2 (lit)

Exp. 3 (lit)

Exp. 4 (lit)

Exp. 5 (lit)

Copy quantity display

“A” Part Code: Main PWB

Change history of the main PWB

Number of the main ROM

Number of the main ROM sub

“E” Part Code: Engine PWB

Change history of the engine PWB

Number of the engine ROM

Number of the engine ROM sub

Change history of the engine PWB BOOT

Number of the engine PWB BOOT

“L” Part Code: Language

Change history of the standard language

Number of the standard language ROM

Change history of the optional language

Number of the optional language ROM

Exp. 1 (lit)

Exp. 2 (lit)

Exp. 3 (lit)

Exp. 4 (lit)

Exp. 1 (lit)

Exp. 2 (lit)

Exp. 1 (lit)

Exp. 2 (lit)

Exp. 3 (lit)

: Off, : On, : Flashing

When the optional equipment is not installed, [non] is displayed.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

“C” Part Code: Cassette

Number of the optional first paper feeder ROM

Number of the optional second paper feeder ROM

Number of the optional third paper feeder ROM

“d” Part Code: DP

Number of the DP ROM

“P” Part Code: Printer

Change history of the optional printer

Number of the optional printer ROM

1-3-3

3MX

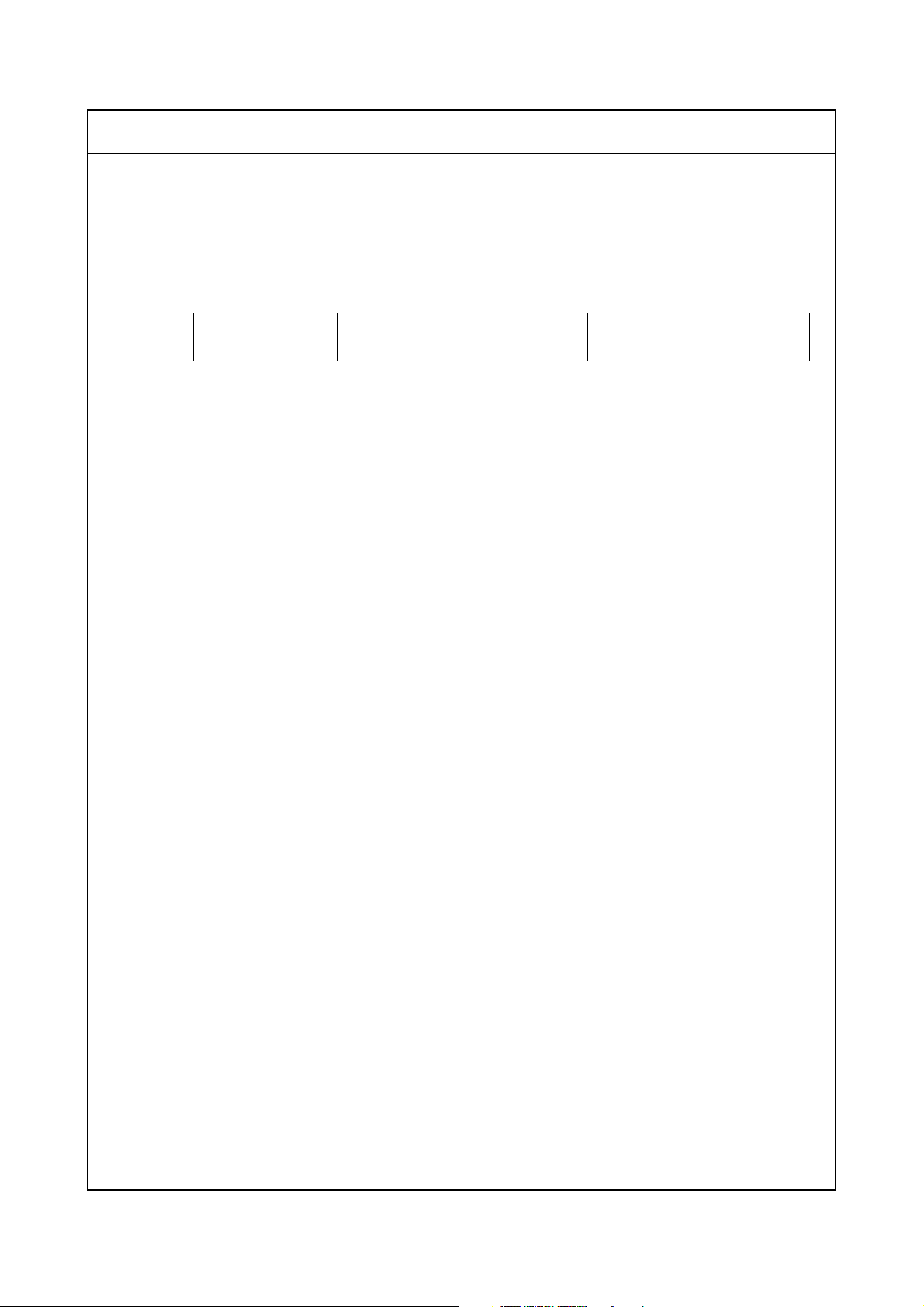

Maintenance

item No.

U068

Description

Adjusting the scanning position for originals from the DP

Description

Adjusts the position for scanning originals from the DP.

Purpose

Used when the image fogging occurs because the scanning position is not proper when the DP is used. Run

U071 to adjust the timing of DP leading edge when the scanning position is changed.

Setting

1. Press the start key.

2. Change the setting using the zoom +/- keys.

Description Setting range Initial setting Change in value per step

Scanning position -17 to 17 0 0.17 mm

Increasing the value moves the image backward, and decreasing it moves the image forward.

Supplement

While this maintenance item is being executed, copying from an original is available in interrupt copying mode

(which is activated by pressing the interrupt key).

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

1-3-4

3MX

Maintenance

item No.

U070

Description

Adjusting the DP magnification

Description

Adjusts the DP original scanning speed.

Purpose

Make the adjustment if the magnification is incorrect in the auxiliary scanning direction when the optional DP

is used.

Adjustment

1. Press the start key.

2. Select the item using the exposure adjustment keys.

Display Description Setting

range

Exp. 1 Magnification in the auxiliary scan-

-25 to 25 0 0.2 mm

Initial

setting

Change in

value per step

ning direction (first page)

Exp. 2 Magnification in the auxiliary scan-

-25 to 25 0 0.2 mm

ning direction (second page)

3. Press the interrupt key.

4. Place an original on the DP and press the start key to make a test copy.

5. Change the setting value using the zoom +/- keys.

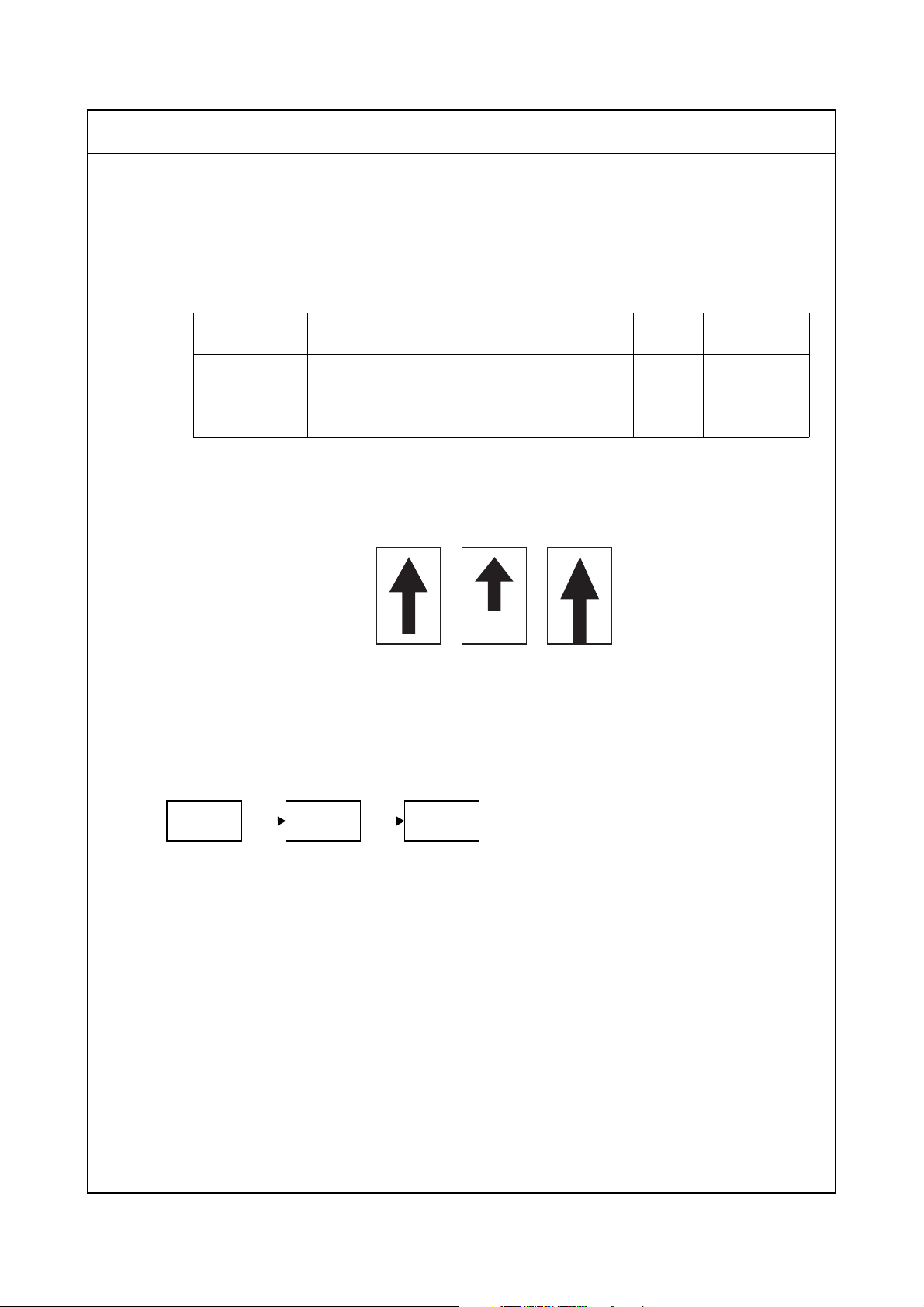

For copy example 1, increase the value.

For copy example 2, decrease the value.

Original Copy

example 1

Copy

example 2

Figure 1-3-1

6. Press the start key. The value is set.

Caution

Check the copy image after the adjustment. If the image is still incorrect, perform the following adjustments in

maintenance mode.

U070

U071

(P.1-3-6)

U404

(P.1-3-13)

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

1-3-5

3MX

Maintenance

item No.

U071

Description

Adjusting the DP scanning timing

Description

Adjusts the DP original scanning timing.

Purpose

Make the adjustment if there is a regular error between the leading or trailing edges of the original and the

copy image when the optional DP is used.

Method

1. Press the start key.

2. Select the item using the exposure adjustment keys.

Exposure

indicator

Exp. 1 DP leading edge registration

Description Setting

range

-32 to 32 0 0.2 mm

Initial

setting

Change in

value per step

(first side)

Exp. 2 DP trailing edge registration

-42 to 32 0 0.2 mm

(first side)

Exp. 3 DP leading edge registration

-32 to 32 0 0.2 mm

(second side)

Exp. 4 DP trailing edge registration

-42 to 32 0 0.2 mm

(second side)

3. Press the interrupt key.

4. Place an original on the DP and press the start key to make a test copy.

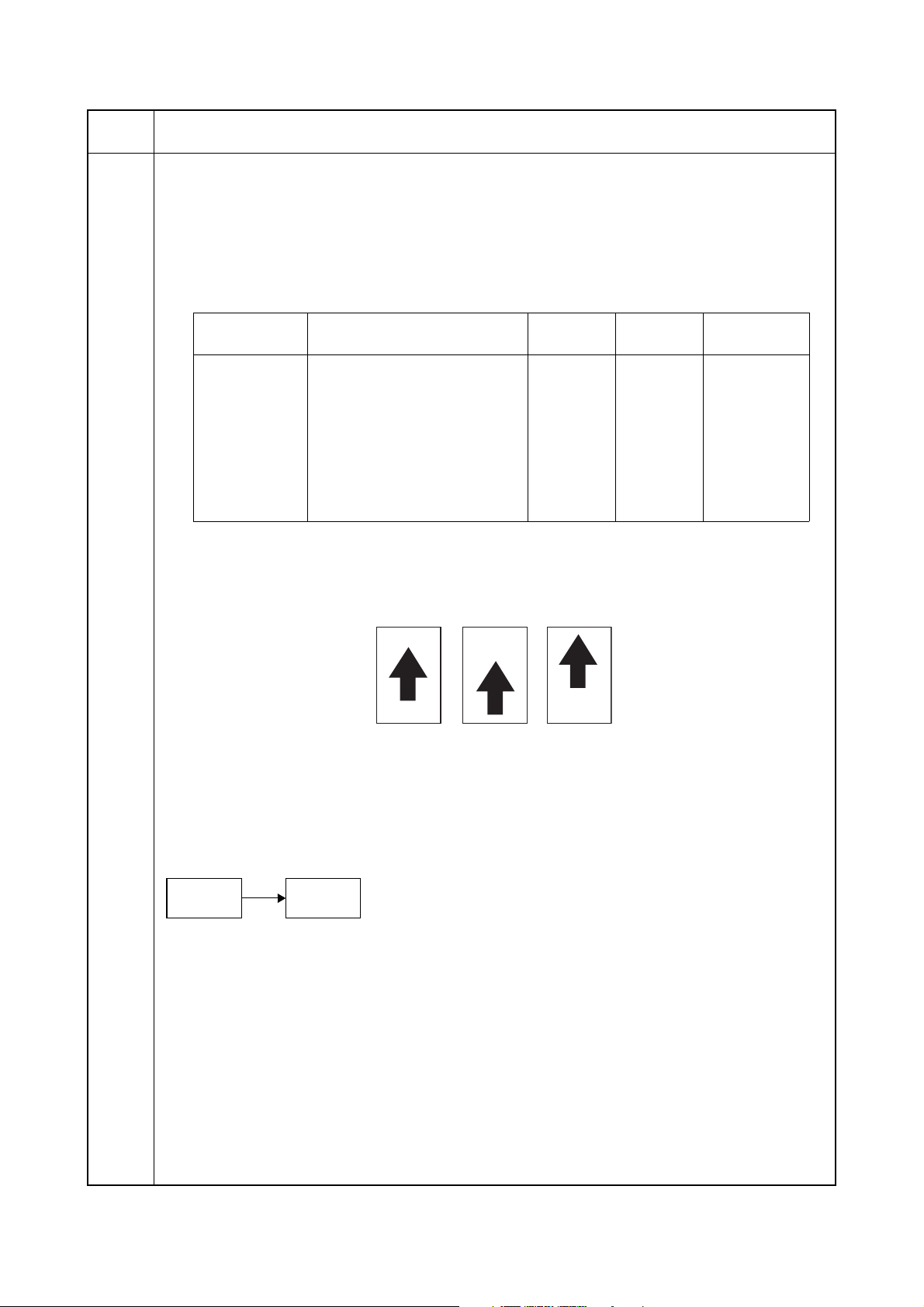

5. Change the setting value using the zoom +/- keys.

For copy example 1, decrease the value of exp.1.

For copy example 2, increase the value of exp.1.

Original Copy

example 1

Copy

example 2

Figure 1-3-2

6. Press the start key. The value is set.

Caution

Check the copy image after the adjustment. If the image is still incorrect, perform the following adjustments in

maintenance mode.

U071

U404

(P.1-3-13)

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

1-3-6

3MX

Maintenance

item No.

U072

Description

Adjusting the DP center line

Description

Adjusts the scanning start position for the DP original.

Purpose

Make the adjustment if there is a regular error between the centers of the original and the copy image when

the optional DP is used.

Adjustment

1. Press the start key.

2. Select the item using the exposure adjustment keys.

Exposure

indicator

Description

Setting

range

Initial

setting

Change in

value per step

Exp. 1 DP center line (first side) -6.6 to 6.6 0 0.15 mm

Exp. 2 DP center line (second side) -3.0 to 3.0 0 0.15 mm

3. Press the interrupt key.

4. Place an original on the DP and press the start key to make a test copy.

5. Change the setting value using the zoom +/- keys.

For copy example 1, increase the value.

For copy example 2, decrease the value.

Original Copy

example 1

Copy

example 2

Figure 1-3-3

6. Press the start key. The value is set.

Caution

Check the copy image after the adjustment. If the image is still incorrect, perform the following adjustments in

maintenance mode.

U072

U404

(P.1-3-13)

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

1-3-7

3MX

Maintenance

item No.

U074

Description

Adjusting the DP input light luminosity

Description

Adjusts the luminosity of the exposure lamp for scanning originals from the DP.

Purpose

Used if the exposure amount differs significantly between when scanning an original on the platen and when

scanning an original from the DP.

Setting

1. Press the start key.

2. Change the setting using the zoom +/- keys.

Description Setting range Initial setting

DP input light luminosity 0 to 8 1

Increasing the setting makes the luminosity higher, and decreasing it makes the luminosity lower.

3. Press the start key. The value is set.

Supplement

While this maintenance item is being executed, copying from an original is available in interrupt copying mode

(which is activated by pressing the interrupt key).

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

1-3-8

3MX

Maintenance

item No.

U076

Description

Adjusting the DP automatically

Description

Uses a specified original and automatically adjusts the following items in the DP scanning section.

Adjusting the DP magnification (U070)

Adjusting the DP scanning timing (U071)

Adjusting the DP center line (U072)

When you run this maintenance mode, the preset values of U070, U071 and U072 will also be updated.

Purpose

To perform automatic adjustment of various items in the DP scanning section.

Method

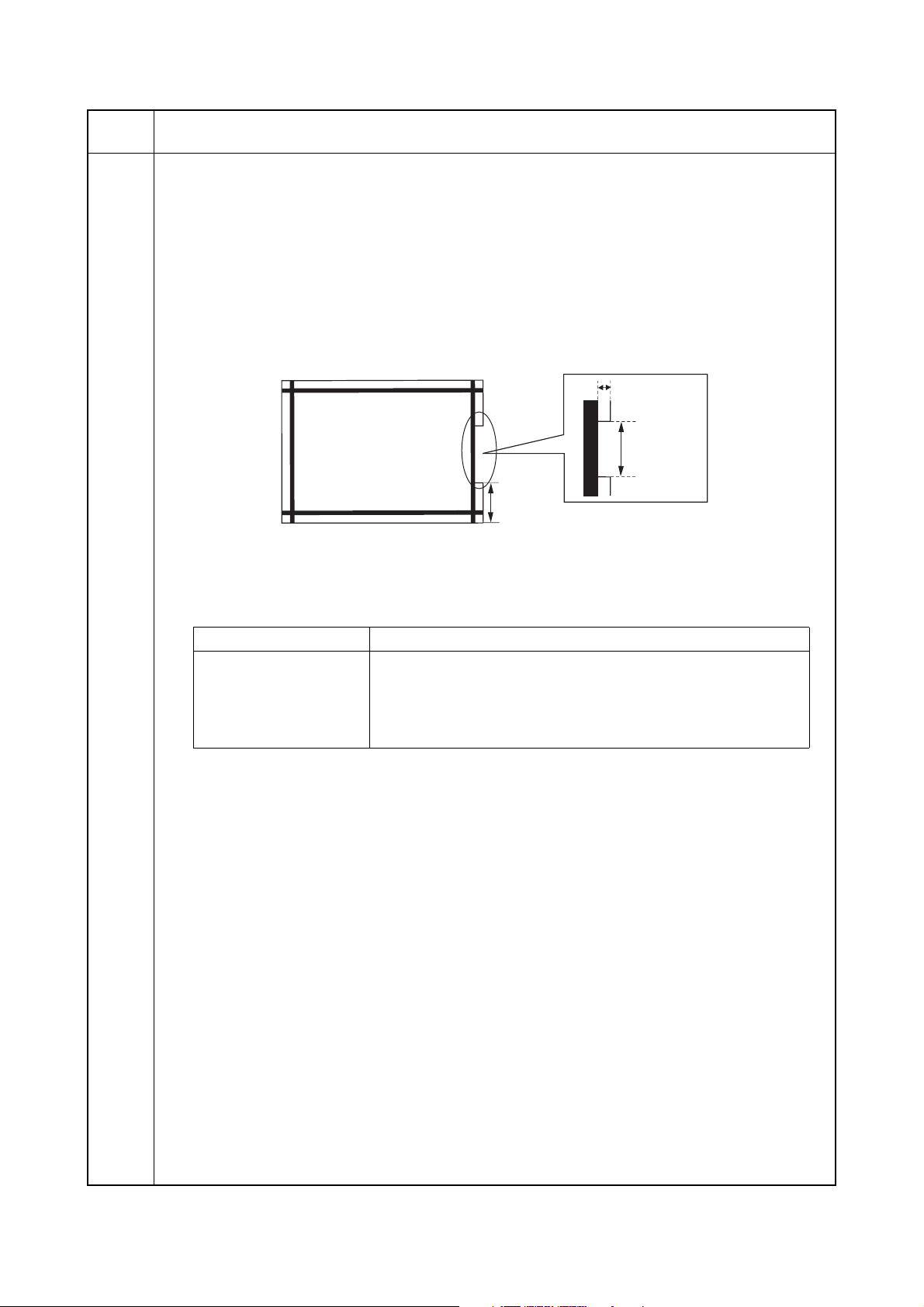

1. Set a specified original (P/N: 302AC68243) in the DP.

Cut the trailing edge of the original.

F

5 mm

149 ± 1 mm

R

74 ± 1 mm

Figure 1-3-4

2. Press the start key. "on" appears.

3. Press the start key. Auto adjustment starts. When adjustment is complete, "Gd" appears.

4. Display each setting value after adjustment using the exposure adjustment keys.

Exposure indicator Description

Exp. 1 Execution result

Exp. 2 DP scanning timing

Exp. 3 DP center line

Exp. 4 DP magnification

If a problem occurs during auto adjustment, "nG" is displayed and operation stops. Determine the details

of the problem and either repeat the procedure from the beginning, or adjust the remaining items manually by running the corresponding maintenance items.

Completion

Press the stop/clear key after auto adjustment is complete.The screen for selecting a maintenance item No. is

displayed.

If the stop/clear key is pressed during auto adjustment, adjustment stops and no settings are changed.

1-3-9

Loading...

Loading...