Page 1

Technical Datasheet

Technical Datasheet

TIDALFLUX 2300 F

TIDALFLUX 2300 F

TIDALFLUX 2300 FTIDALFLUX 2300 F

Technical DatasheetTechnical Datasheet

Electromagnetic flow sensor for partially filled pipes

•

Measurement in partially filled pipes up to DN1600 / 64"

•

Patented, non-contact level measurement

•

Measurement possible down to 10% filling of pipe

The documentation is only complete when used in combination with the relevant

documentation for the signal converter.

© KROHNE 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 2

CONTENTS

TIDALFLUX 2300 F

1 Product features 3

1.1 Solution for partially filled pipes...................................................................................... 3

1.2 Options.............................................................................................................................. 5

1.3 Measuring principle.......................................................................................................... 6

2 Technical data 7

2.1 Technical data................................................................................................................... 7

2.2 Measuring accuracy ....................................................................................................... 11

2.3 Dimensions and weights ................................................................................................ 12

3 Installation 14

3.1 Intended use ................................................................................................................... 14

3.2 General notes on installation ......................................................................................... 14

3.2.1 Vibration ................................................................................................................................ 14

3.2.2 Magnetic field........................................................................................................................ 14

3.3 Installation conditions ....................................................................................................15

3.3.1 Inlet and outlet...................................................................................................................... 15

3.3.2 Control valve ......................................................................................................................... 15

3.3.3 Slope...................................................................................................................................... 15

3.3.4 Mounting advice for difficult situations ................................................................................ 16

3.3.5 Open discharge ..................................................................................................................... 16

3.3.6 Cleaning of flow sensor ........................................................................................................ 17

3.3.7 Flange deviation.................................................................................................................... 17

3.3.8 Mounting position.................................................................................................................. 18

3.3.9 Torques and pressures......................................................................................................... 18

4 Electrical connections 20

4.1 Safety instructions.......................................................................................................... 20

4.2 Important notes on electrical connection...................................................................... 20

4.3 Cable lengths.................................................................................................................. 21

4.4 Grounding ....................................................................................................................... 22

4.4.1 Mounting grounding rings .................................................................................................... 22

5 Notes 23

2

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 3

TIDALFLUX 2300 F

1.1 Solution for partially filled pipes

The TIDALFLUX 2000

TIDALFLUX 2000 flow sensor with integrated and non-contact capacitive level measuring

TIDALFLUX 2000TIDALFLUX 2000

system provides accurate flow measurement in partially filled pipes. TIDALFLUX is designed to

measure reliably between 10% and 100% of the pipe cross-section. The integrated level sensors

in the liner are in no contact with the liquid and are therefore insensitive to fat and oil floating on

the surface.

PRODUCT FEATURES

1

1 Various flange standards

2 Patented, capacitive and non-contact flow level measuring system integrated in the liner

3 Remote converter IFC 300 ( PF)

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

3

Page 4

1

PRODUCT FEATURES

Highlights

• For partially filled pipes in the water and wastewater industry

• Broad diameter range up to DN1600 / 64"

• High abrasion- and chemical resistance

• Measurement possible between 10% and 100% filling

• Electrodes for flow measurement are below 10% filling level, therefore no blind folding by fat

and oil floating on the water surface

• Complete factory calibration, no on-site calibration required

Industries

• Water

• Wastewater

Applications

• For partially filled pipes instead of expensive siphon tube constructions

• Water and wastewater

• Surface water

• Biological and chemical wastewater

TIDALFLUX 2300 F

4

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 5

TIDALFLUX 2300 F

1.2 Options

The solution for the water and wastewater industry

The solution for the water and wastewater industry

The solution for the water and wastewater industryThe solution for the water and wastewater industry

PRODUCT FEATURES

Flanged flowsensor

Flanged flowsensor

Flanged flowsensorFlanged flowsensor

• Robust construction, completely welded

• Various flange standards like DIN, ANSI and JIS

• IP 68

• ATEX / IEC(x Zone 1 / Class1 Div 2

• 220/110 V or 24 VDC power supply

• Polyurethane liner

1

Remote converter

Remote converter

Remote converterRemote converter

• IFC 300 F (PF)

• Stainless steel

• ATEX / IEC(x Zone 1 / Class1 Div 2

• Extra connector space (for use with NPT)

• Mounting to wall or 2" pipe with clamps

• mA, HART or Modbus

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

5

Page 6

1

PRODUCT FEATURES

1.3 Measuring principle

The TIDALFLUX 2000 is an electromagnetic flow sensor with an integrated capacitive level

measurement system, designed for electrically conductive process liquids. The flow rate Q(t)

through the tube is: Q(t) = v(t) x A(t)

in which

v(t) = flow velocity of liquid product

A(t) = wetted area of tube section.

The flow velocity is determined on basis of the known electromagnetic measurement principle.

The two measuring electrodes are located in the lower part of the measuring tube, on a level of

approx. 10% of the inner diameter of the pipe in order to get a reliable measurement up from a

level of 10%.

Q(t) = v(t) x A(t),

Q(t) = v(t) x A(t)Q(t) = v(t) x A(t)

TIDALFLUX 2300 F

An electrically conductive fluid flows inside an electrically insulat

HG pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils. Inside of

the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = distance between electrodes

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate q. The signal voltage is quite small (typically 1 mV at v = 3 m/s / 10 ft/s and

field coil power of 1 W). Finally, a signal converter is used to amplify the signal voltage, filter it

(separate from noise) and convert it into signals for totalising, recording and output processing.

Figure 1-1: Measuring principle TIDALFLUX

1 Electrodes

2 Induced voltage (proportional to flow velocity)

3 Capacitive plates in liner for height measurement

4 Magnetic field

5 Field coils

The wetted area A is computed from the known inside diameter of the pipe by the patented

capacitive level measurement system that is built into the measuring tube liner. The required

electronics unit is accommodated in a compact housing that is mounted on top of the measuring

sensor. This electronics is connected to the remote IFC 300 F converter by means of a digital

communication line.

6

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 7

TIDALFLUX 2300 F

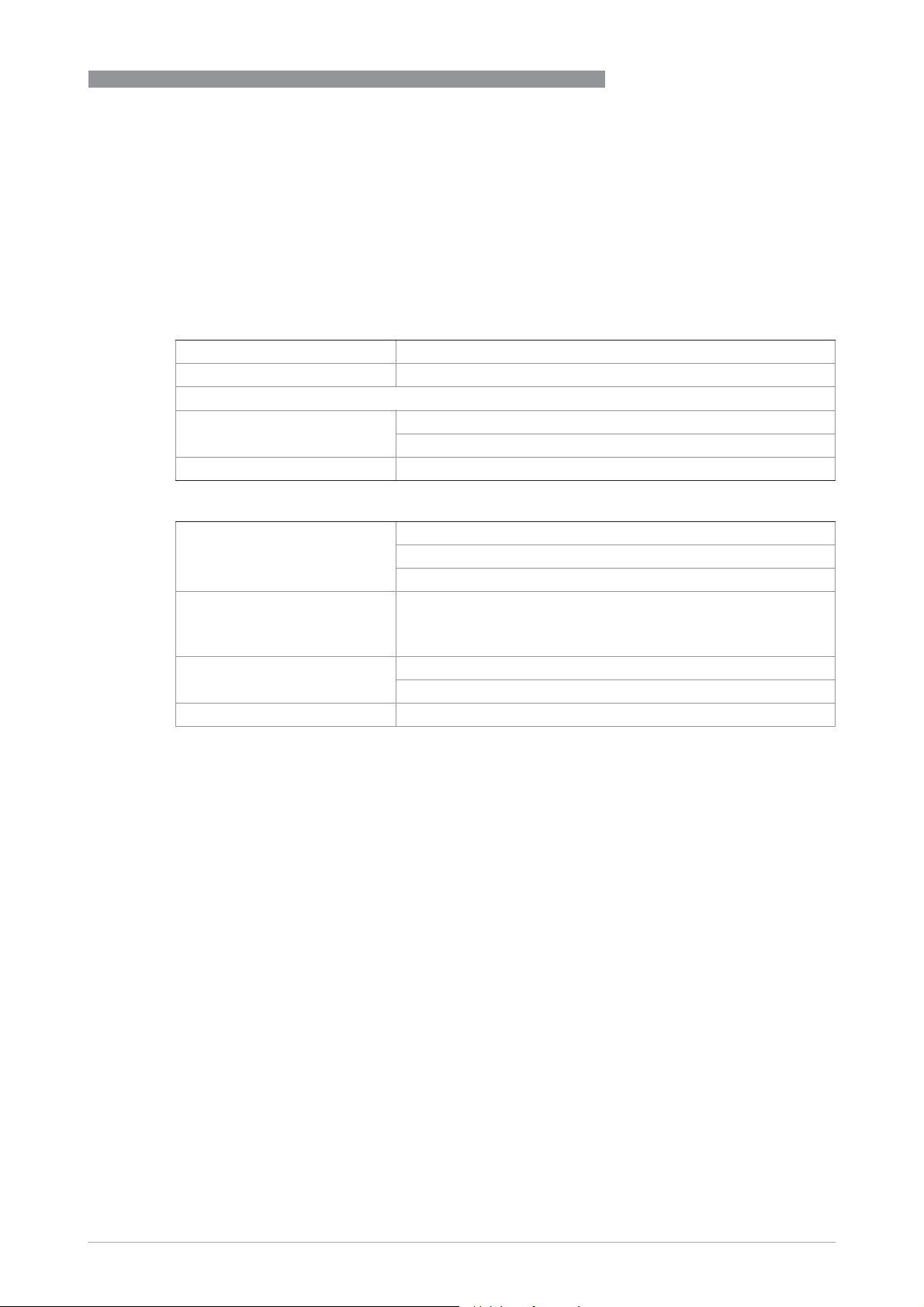

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

Measuring system

Measuring principle Faraday's law

Application range Electrically conductive fluids

Measured value

Measured value

Measured valueMeasured value

Primary measured value Flow velocity

Secondary measured value Volume flow

Design

Features Flange version with full bore flow tube

Modular construction The measurement system consists of a flow sensor and a signal

Remote version In field (F) version with IFC 300 signal converter: TIDALFLUX 2300 F.

Nominal diameter DN200...1600 / 8...64"

TECHNICAL DATA

Level

Standard as well as higher pressure ratings

Broad range of nominal sizes

converter. It is available as remote version. More information about

the signal converter can be found in the documentation of the signal

converter.

Note: Compact versions are not available.

2

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

7

Page 8

2

TECHNICAL DATA

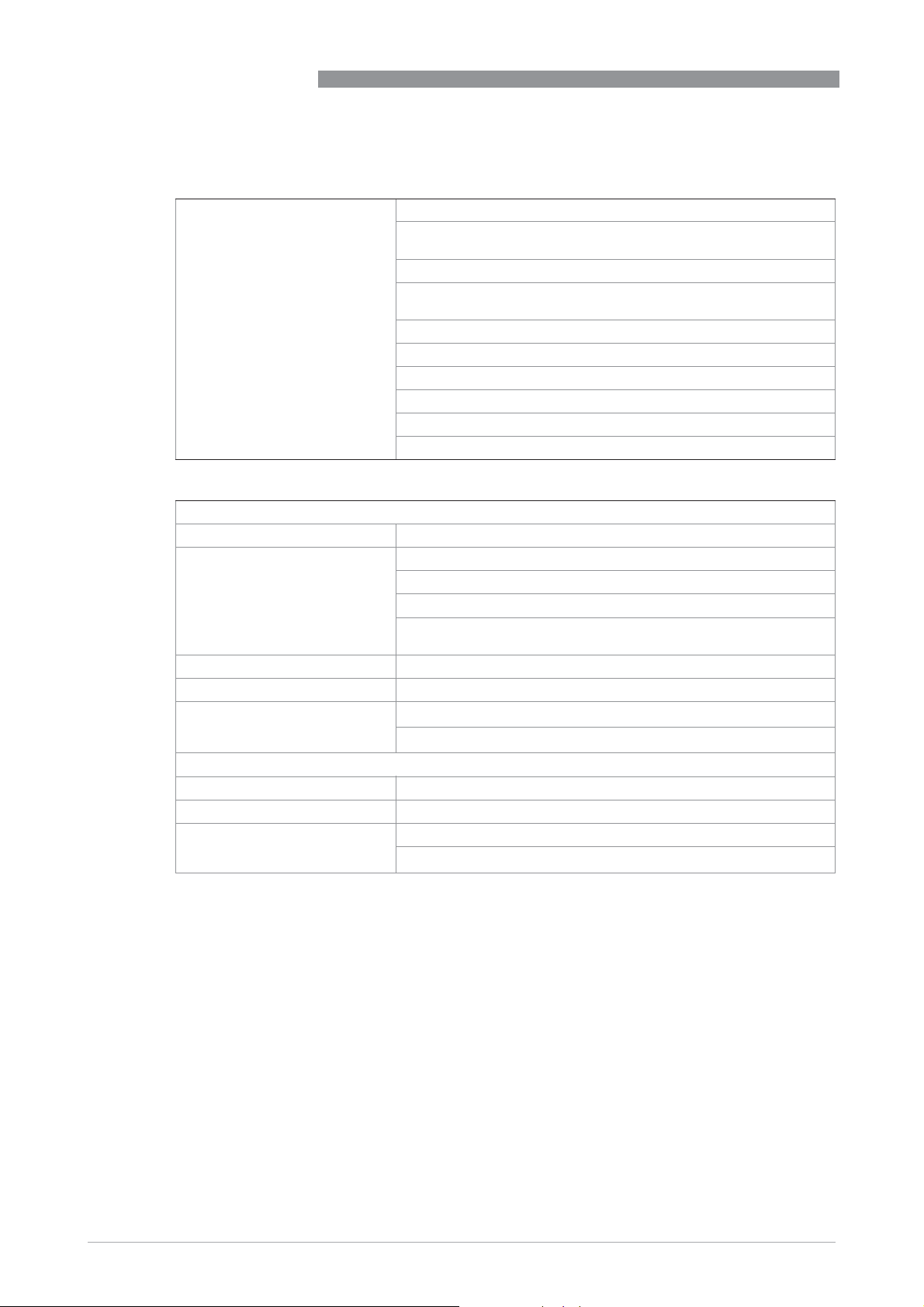

Measuring accuracy

Maximum measuring error Related to volume flow (MV = Measured Value, FS = Full Scale)

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature 0...+60°C / +32...+140°F

Ambient temperature Non ATEX: -40…+65°C / -40…+149°F

Storage temperature -50…+70°C / -58…+158°F

Measurement range -12...+12 m/s / -40...+40 ft/s

Vacuum load

(DN200...DN1600 / 8...64")

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Physical condition Conductive liquids

Electrical conductivity t 50 PS/cm

Permissible solid content

(volume)

TIDALFLUX 2300 F

For detailed information on the measuring accuracy, refer to

Measuring accuracy

These values are related to the pulse / frequency output

The additional typical measuring deviation for the current output is

±10 PA

Partly filled:

Partly filled:

Partly filled:Partly filled:

v @ Full Scale t 1 m/s / 3.3 ft/s: d 1% of FS

Fully filled:

Fully filled:

Fully filled:Fully filled:

v t 1 m/s / 3.3 ft/s: d 1% of MV

v < 1 m/s / 3.3 ft/s: d 0.5% of MV + 5 mm/s (0.2 inch/s)

Minimum level: 10% of inner diameter

ATEX zone 1: -20…+65°C / -4…+149°F

QPS, Class 1 Div 2: -20…+60°C / -4…+140°F

Protect electronics against self-heating with ambient temperatures

above 55°C/ 131°F.

500 mbar abs. at T

7.3 psia at T

d 20%

If process liquid is slurry: density < 1.15 kg/dm3.

process

on page 11.

= 40°C / 600 mbar abs. at T

process

= 104 °F / 8.7 psia at T

process

process

= 140 °F

= 60°C

8

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 9

TIDALFLUX 2300 F

Installation conditions

Installation For detailed information, refer to

Flow direction Forward and reverse.

Inlet run t 5 DN (without disturbing flow, after a single 90° bend)

Outlet run t 3 DN

Dimensions and weights For detailed information, refer to

Materials

Sensor housing Standard: sheet steel

Measuring tube Austenitic stainless steel

Flange Standard: carbon steel, polyurethane coated

Liner Polyurethane

Connection box IP 67: die-cast aluminium

Coating Standard coating: Polysiloxane

Measuring electrodes

Grounding rings Stainless steel

TECHNICAL DATA

Installation

Arrow on flow sensor indicates positive flow direction.

t 10 DN (after a double bend 2x 90°)

t 10 DN (behind a control valve)

Dimensions and weights

12.

Other materials on request

Other materials on request.

IP 68: Stainless steel

Option: protective coating (off-shore, burial coating)

Hastelloy® C

Tailor made to inner diameter of connecting pipeline.

Necessary if inner side of connecting pipeline isn't electrically

conductive.

on page 14.

on page

2

Process connections

Flange

Flange

FlangeFlange

EN 1092-1 DN200...1600 in PN 6...40 (others on request)

ASME 8...64" in 150...300 lb RF (others on request)

JIS DN200...1600 in JIS 10...20 K (others on request)

Design of gasket surface RF (others on request)

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

9

Page 10

2

TECHNICAL DATA

Electrical connections

General Electrical connection is carried out in conformity with the VDE 0100

Power supply Standard: 100...230 VAC (-15% / +10%), 50/60 Hz

Power consumption AC: 22 VA

Field current cable Shielded cable must be used, no part of delivery.

Signal cable DS 300 (type A)

Data interface cable For transmission of measured level to IFC 300 F.

Cable entries Standard: 2x M20 x 1.5 + 2x M16 x 1.5 EMC type

TIDALFLUX 2300 F

directive "Regulations for electrical power installations with line

voltages up to 1000 V" or equivalent national specifications.

Option: 12...24 VDC (-55% / +10%)

12 VDC -10% is included in the tolerance range

DS 300 (type A)

DS 300 (type A)DS 300 (type A)

Max. length: 600 m / 1968 ft (dependent on electrical conductivity)

BTS 300 (type B)

BTS 300 (type B)

BTS 300 (type B)BTS 300 (type B)

Max. length: 600 m / 1968 ft

Shielded LIYCY cable, 3 x 0.75 mm

Option: ½" NPT

2

Approvals and certificates

CE

CE

CECE

This device fulfils the statutory requirements of the EU directives. The manufacturer certifies successful

testing of the product by applying the CE mark.

For full information of the EU directives and standards and the

approved certifications, please refer to the EU Declaration of

Conformity or the website of the manufacturer.

Hazardous areas

Hazardous areas

Hazardous areasHazardous areas

ATEX / IECEx Option: Ex zone 1, IEC(x

DEKRA 12ATEX0235 X

IECEx DEKRA 12.0079X

QPS Class 1, Division 2

LR1338

Other approvals and standards

Other approvals and standards

Other approvals and standardsOther approvals and standards

Protection category acc. to

IEC/EN 60529

Vibration resistance IEC 60068-2-6

Random vibration test IEC 60068-2-34

Shock test IEC 60068-2-27

Standard: IP 66/67 (NEMA 4/4X/6)

Option: IP 68 (NEMA 6P)

10

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 11

TIDALFLUX 2300 F

2.2 Measuring accuracy

Every electromagnetic flowmeter is calibrated by direct volume comparison. The wet calibration

validates the performance of the flowmeter under reference conditions against accuracy limits.

The accuracy limits of electromagnetic flowmeters are typically the result of the combined effect

of linearity, zero point stability and calibration uncertainty.

Reference conditions

• Medium: water

• Temperature: +5...35°C / +41...95°F

• Operating pressure: 0.1...5 barg / 1.5...72.5 psig

• Inlet section: t 10 DN

• Outlet section: t 5 DN

The measuring accuracy for partly filled pipes and completely filled pipes are different. In these

graphs it is assumed that the velocity at full scale value is at least 1 m/s (is also the standard

value for calibration, since it will result in the most accurate measurements). Additional

conditions; slope of pipe line 0%, electrical conductivity medium 50...5000 PS/cm.

TECHNICAL DATA

2

Partly filled:

• v @ Full Scale t 1 m/s / 3.3 ft/s: d 1% of Full Scale

Fully filled:

• v t 1 m/s / 3.3 ft/s: d 1% of MV

• v < 1 m/s / 3.3 ft/s: d 0.5% of MV + 5 mm/s / 0.2 inch/s (see following graph)

Fully filled pipes

Figure 2-1: Maximum measuring error of measured value (=Y)

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

11

Page 12

2

TECHNICAL DATA

2.3 Dimensions and weights

The inner pipe diameter should match the inner diameter of the flowmeter. Since the inner

diameter is not a standard DN size, choose the inner pipe diameter to be just a little bit bigger

than the flowmeter diameter. If a lot of sediment or fat is expected the optimal solution is to use

a customized diameter compensation ring on both sides to have smooth transits.

TIDALFLUX 2300 F

k = 230 mm / 89.1"

m = 265 mm / 10.4"

n = 251 mm / 9.9"

Detailed 2D and 3D drawings are available on the website of the manufacturer.

EN 1092-1

Nominal size Dimensions [mm] Approx.

DN PN a b Øc d ØD ØD

200 10 350 582 291 146 340 189 40

250 10 400 630 331 166 395 231 54

300 10 500 680 381 191 445 281 66

350 10 500 733 428 214 505 316 95

400 10 600 791 483 242 565 365 115

500 10 600 894 585 293 670 467 145

600 10 600 1003 694 347 780 567 180

700 10 700 1120 812 406 895 666 265

800 10 800 1235 922 461 1015 768 350

900 10 900 1356 1064 532 1115 863 425

1000 10 1000 1447 1132 566 1230 965 520

1200 6 1200 1639 1340 670 1405 1169 659

1400 6 1400 1842 1521 761 1630 1367 835

1600 6 1600 2042 1721 861 1830 1549 1659

i

weight

[kg]

12

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 13

TIDALFLUX 2300 F

150 lb flanges

Nominal size Dimensions [inches] Approx.

ASME 1PN

1 Nominal size d 24": ASME; > 24": AWWA

TECHNICAL DATA

a b Øc d ØD ØD

[psi]

8 284 13.78 22.93 11.46 5.75 13.5 7.44 90

10 284 15.75 24.80 13.03 6.54 16.0 9.09 120

12 284 19.69 26.76 15 7.52 19.0 11.06 145

14 284 27.56 30.22 16.85 9.8 21.0 12.44 210

16 284 31.5 31.13 19.02 9.53 23.5 14.37 255

20 284 31.5 35.21 23.03 11.54 27.5 18.39 320

24 284 31.5 39.50 27.32 13.66 32.0 22.32 400

28 Class D 35.43 44.71 31.97 15.98 36.5 26.22 692

32 Class D 39.37 49.51 36.3 18.15 41.8 30.24 1031

36 Class D 43.31 54.42 41.89 20.94 46.0 33.98 1267

40 Class D 47.24 58.14 44.57 22.28 50.8 37.99 1554

48 Class D 55.12 66.61 52.76 26.38 59.5 46.02 2242

weight

i

[lb]

2

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

13

Page 14

3

INSTALLATION

3.1 Intended use

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

3.2 General notes on installation

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

Do a check of the packing list to make sure that you have all the elements given in the order.

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

TIDALFLUX 2300 F

3.2.1 Vibration

Figure 3-1: Avoid vibrations

3.2.2 Magnetic field

14

Figure 3-2: Avoid magnetic fields

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 15

TIDALFLUX 2300 F

3.3 Installation conditions

3.3.1 Inlet and outlet

Figure 3-3: Recommended inlet and outlet sections, top view

1 t 5 DN

2 t 3 DN

3.3.2 Control valve

INSTALLATION

3

3.3.3 Slope

Figure 3-4: Installation before control valve

The accuracy is influenced by the slope. Stay within s% to get the most accurate

measurements!

Figure 3-5: Recommended slope

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

15

Page 16

3

INSTALLATION

3.3.4 Mounting advice for difficult situations

If you can not meet the installation conditions install the flowmeter between two containers. The

inlet to the flowmeter must be higher than the outlet of the fluid. In this way you will have a calm

flow into the flowmeter, resulting in a highly accurate measurement. The sizes of the containers

must be proportional to the size of the flowmeter.

Figure 3-6: Installing in difficult situations

1 Use a container 2 if the Inlet pipe has a slope > 1%. Make sure that the outlet level of this pipe is below the inlet to the

flowmeter.

2 Inlet container

3 Inlet section of 10 DN

4 Outlet section of 5 DN

5 Outlet container advisable if outlet pipe has a slope > 1%.

TIDALFLUX 2300 F

Always use a free exit pipe to prevent backflow in the flow sensor and to keep the velocity at the

maximum flow at least at 1 m/s.

3.3.5 Open discharge

Figure 3-7: Open discharge

1 t 5 DN

2 Make sure that the water level stays below the pipe outlet.

16

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 17

TIDALFLUX 2300 F

3.3.6 Cleaning of flow sensor

The flow sensor is highly resistant against dirt and the measurement will rarely be influenced by

anything. However, it is advisable to create a possiblity for cleaning just in front or behind the

sensor.

Figure 3-8: Option for cleaning of flow sensor

1 Opening for cleaning

3.3.7 Flange deviation

INSTALLATION

3

Max. permissible deviation of pipe flange faces:

- L

L

max

Figure 3-9: Flange deviation

1 L

max

2 L

min

d 0.5 mm / 0.02"

min

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

17

Page 18

3

INSTALLATION

3.3.8 Mounting position

Only install the flow sensor in the shown position to keep the electrodes under water. Limit the

rotation to

Figure 3-10: Mounting position

±2°

TIDALFLUX 2300 F

to maintain the accuracy.

3.3.9 Torques and pressures

Figure 3-11: Tightening of bolts

Tightening of bolts

• Always tighten the bolts uniformly and in diagonally opposite sequence.

• Do not exceed the maximum torque value.

• Step 1: Apply approx. 50% of max. torque given in table.

• Step 2: Apply approx. 80% of max. torque given in table.

• Step 3: Apply 100% of max. torque given in table.

18

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 19

TIDALFLUX 2300 F

Tighten the bolts uniformely in diagonally opposite sequence.

INSTALLATION

3

Nominal size

DN [mm]

Nominal size

[inch]

Pressure

Bolts Max. torque [Nm]

r a t i n g

200 PN 10 8 x M 20 68

250 PN 10 12 x M 20 65

300 PN 10 12 x M 20 76

350 PN 10 16 x M 20 75

400 PN 10 16 x M 24 104

500 PN 10 20 x M 24 107

600 PN 10 20 x M 27 138

700 PN 10 24 x M 27 163

800 PN 10 24 x M 30 219

900 PN 10 28 x M 30 205

1000 PN 10 28 x M 33 261

1200 PN 6 32 x M30 252

Flange class

Bolts Max. torque [Nm]

[lb]

8 150 8 x 3/4" 69

10 150 12 x 7/8" 79

12 150 12 x 7/8" 104

14 150 12 x 1" 93

16 150 16 x 1" 91

18 150 16 x 1 1/8" 143

20 150 20 x 1 1/8" 127

24 150 20 x 1 1/4" 180

28 150 28 x 1 1/4" 161

32 150 28 x 1 1/2" 259

36 150 32 x 1 1/2" 269

40 150 36 x 1 1/2" 269

Information for bigger sizes is available on request.

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

19

Page 20

4

ELECTRICAL CONNECTIONS

4.1 Safety instructions

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

Observe the national regulations for electrical installations!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

4.2 Important notes on electrical connection

TIDALFLUX 2300 F

Electrical connection is carried out in conformity with the VDE 0100 directive "Regulations for

electrical power installations with line voltages up to 1000 V" or equivalent national regulations.

•

Use suitable cable entries for the various electrical cables.

•

The sensor and converter are configured together in the factory. For this reason, please

connect the devices in pairs. Ensure that the sensor constant GK (see nameplates) are

identically set.

•

The TIDALFLUX 2300 sensor and converter need both a separate power supply.

For more information about the grounding of the flowmeter, refer to Grounding on page 22

.

20

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 21

TIDALFLUX 2300 F

4.3 Cable lengths

The maximum allowed distance between the flow sensor and the converter is determined by the

shortest cable length.

Interface cable

Interface cable: maximum length is 600 m / 1968 ft.

Interface cableInterface cable

Type B (BTS) signal cable

Type B (BTS) signal cable: maximum length is 600 m / 1968 ft.

Type B (BTS) signal cableType B (BTS) signal cable

Type A (DS) signal cable

Type A (DS) signal cable: maximum length depends on the conductivity of the fluid:

Type A (DS) signal cableType A (DS) signal cable

Electrical conductivity Maximum length

[μS/cm] [m] [ft]

50 120 394

100 200 656

200 400 1312

t400 600 1968

ELECTRICAL CONNECTIONS

4

Field current cable

Field current cable: The cross section of the cable determines the maximum length:

Field current cableField current cable

Cross section Maximum length

[mm2]

2 x 0.75 2 x 18 150 492

2 x 1.5 2 x 16 300 984

2 x 2.5 2 x 14 600 1968

[AWG] [m] [ft]

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

21

Page 22

4

ELECTRICAL CONNECTIONS

4.4 Grounding

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

4.4.1 Mounting grounding rings

TIDALFLUX 2300 F

In order to get a reliable height measurement it is absolutely necessary

absolutely necessary that the inner side of the

absolutely necessaryabsolutely necessary

connecting pipeline is electrically conductive and connected to ground. If not, tailor-made

grounding rings with a cylindrical part can be delivered. Please contact your local agency in case

of doubt.

Figure 4-1: Grounding with grounding rings

1 Existing pipeline

2 Grounding rings, custom made to inner diameter of pipeline

3 TIDALFLUX

4 Insert the cylindrical part of the grounding ring into the pipeline. Use an appropiate gasket between the grounding ring

and the flange.

Sizes of the grounding rings are diameter dependent and available on request.

For the connection diagrams and more information on connection of the sensor, please refer to

the manual of the TIDALFLUX 2300 and the applicable signal converter.

22

www.krohne.com 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

Page 23

TIDALFLUX 2300 F

NOTES

5

www.krohne.com11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en

23

Page 24

K

K

K

KROHNE – Process instrumentation and measurement solutions

•

Flow

•

Level

•

Temperature

•

Pressure

•

Process Analysis

•

Services

© KROHNE 11/2018 - 4002489804 - TD TIDALFLUX 2300 F R04 en - Subject to change without notice.

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.: +49 203 301 0

Fax: +49 203 301 10389

info@krohne.com

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...