Page 1

Supplementary instructions

Supplementary instructions

OPTITEMP TRA/TCA

OPTITEMP TRA/TCA

OPTITEMP TRA/TCAOPTITEMP TRA/TCA

Supplementary instructions Supplementary instructions

Industrial thermometers with replaceable measuring

inserts.

Category

II 1/2 G

II 1 G

II 1 D

© KROHNE 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 2

CONTENTS

OPTITEMP TRA/TCA

1 Safety instructions 3

1.1 General notes ................................................................................................................... 3

1.2 EC conformity ................................................................................................................... 3

1.3 Safety instructions............................................................................................................ 3

2 Device description 4

2.1 Device description ............................................................................................................ 4

2.2 Description code............................................................................................................... 5

2.3 Marking............................................................................................................................. 7

2.4 Flammable products ........................................................................................................ 7

2.5 Equipment category .........................................................................................................8

2.6 Protection types................................................................................................................ 9

2.6.1 Protection type with zone separator for gas hazard areas.................................................... 9

2.6.2 Type of protection for gas hazard areas................................................................................. 9

2.6.3 Type of protection for dust hazard areas ............................................................................. 10

2.7 Temperature classes..................................................................................................... 11

2.7.1 Maximum permitted product temperature .......................................................................... 12

2.7.2 Temperature at process connection (without temperature transmitter)............................ 13

2.7.3 Temperature at process connection (with temperature transmitter) ................................15

2.7.4 Temperature at process connection (with temperature transmitter, classes T5 and T6).. 17

2.7.5 Temperature at process connection for thermometers with connecting cable................. 18

2.8 Electrical data................................................................................................................. 20

3 Installation 21

3.1 Selecting the right thermometer and calculating limit values ..................................... 21

3.2 Assembly ........................................................................................................................ 25

4 Electrical connections 26

4.1 General notes ................................................................................................................. 26

4.2 Power supply .................................................................................................................. 26

4.3 Inputs / Outputs.............................................................................................................. 27

4.3.1 Pt100 measuring inserts....................................................................................................... 27

4.3.2 Thermocouple measuring inserts ........................................................................................ 27

4.4 Grounding and equipotential bonding............................................................................ 28

5 Operation 29

5.1 Starting up for the first time .......................................................................................... 29

5.2 Operation ........................................................................................................................ 29

6 Service 30

6.1 Maintenance ................................................................................................................... 30

6.2 Dismantling .................................................................................................................... 30

2

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 3

OPTITEMP TRA/TCA

1.1 General notes

These additional "Ex" instructions apply to explosion-protected models of industrial

thermometers with the marking II 1/2 G, II 1 G and II 1 D. They complement the standard

documentation for non-explosion-protected models.

The information given in these Instructions contains only the data relevant to Category 1

explosion protection. The technical details given in the standard documentation for the nonexplosion protected versions apply unchanged unless excluded or superseded by these

Instructions.

1.2 EC conformity

The manufacturer declares with the EC Declaration of Conformity on his own responsibility

conformity with the protection goals of Directive 94/9/EC for use in hazardous areas with gas.

The EC Type Test Certificate of the Physikalisch Technische Bundesanstalt (PTB) forms the basis

of the EC Declaration of Conformity:

SAFETY INSTRUCTIONS 1

The "X" after the certificate number refers to special conditions for safe use of the device as

described in these Instructions.

You can download the EC Type Test Certificate from the manufacturer's website as needed.

1.3 Safety instructions

Assembly, installation, start-up and maintenance may only be performed by personnel trained in

explosion protection!

CAUTION!

Should operating conditions and locations require the observance of further standards,

guidelines and laws, this is the responsibility of the operator and/or those commissioned by him.

PTB 10 ATEX 2017 X

PTB 10 ATEX 2017 X

PTB 10 ATEX 2017 XPTB 10 ATEX 2017 X

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

3

Page 4

2 DEVICE DESCRIPTION

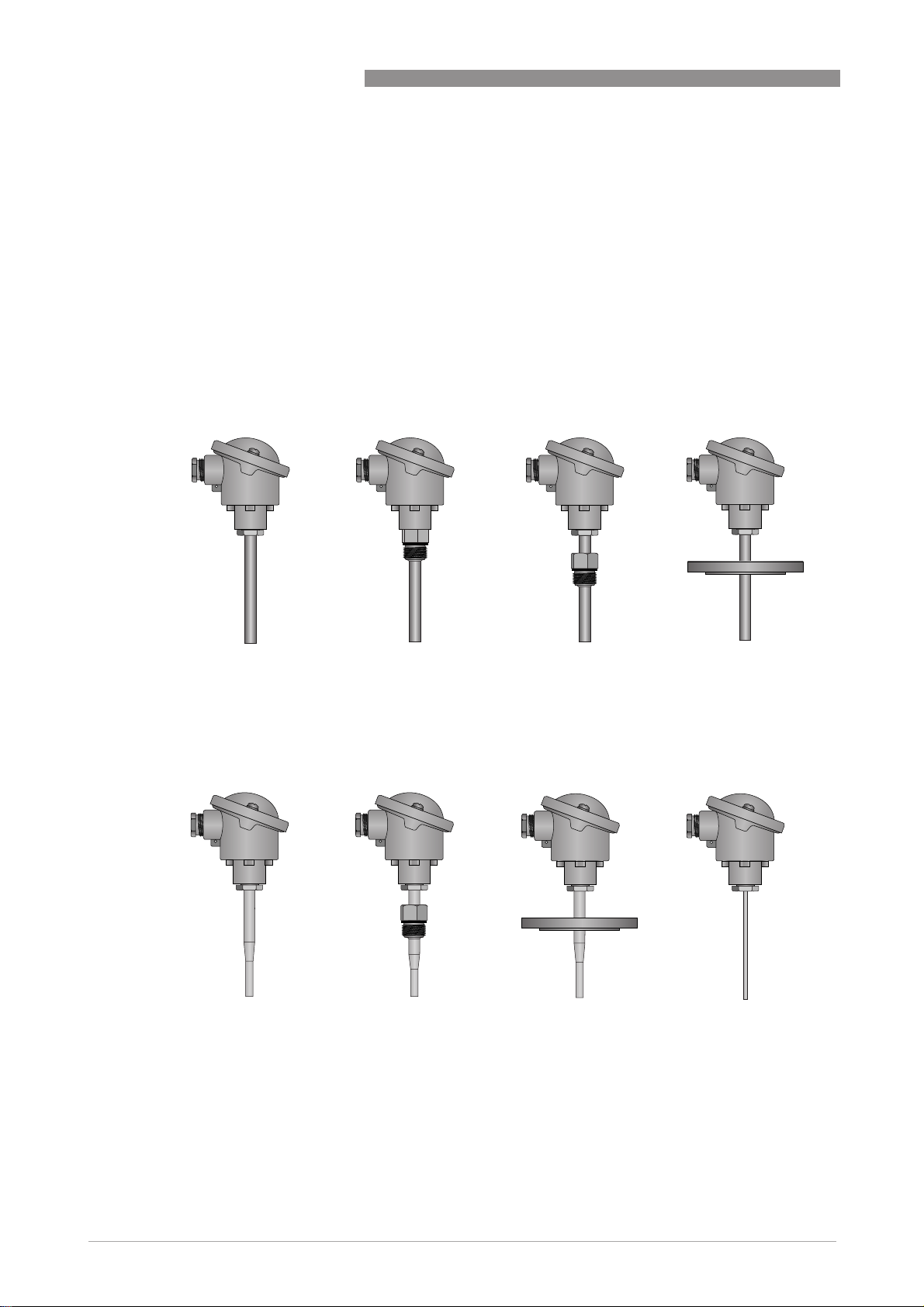

2.1 Device description

Industrial thermometers measure the temperature of flammable and non-flammable gases and

liquids. They consist of a thermometer assembly comprising a connection head and usually a

thermowell (only version TRA/TCA-P14 does not have a thermowell).

The thermometer assembly contains a measuring insert, which can have either a thermocouple

or a Pt100 measuring resistor as sensor. The manufacturer offers measuring inserts with a

terminal block, free connection wires or a directly fitted head-mounted transmitter.

Standard version (straight thermowells)

Standard version (straight thermowells)

Standard version (straight thermowells)Standard version (straight thermowells)

TRA-P10 / TCA-P10

TRA-P10 / TCA-P10 TRA-S11 / TCA-S11

TRA-P10 / TCA-P10TRA-P10 / TCA-P10

TRA-S11 / TCA-S11 TRA-S12 / TCA-S12

TRA-S11 / TCA-S11TRA-S11 / TCA-S11

OPTITEMP TRA/TCA

TRA-S12 / TCA-S12 TRA-F13 / TCA-F13

TRA-S12 / TCA-S12TRA-S12 / TCA-S12

TRA-F13 / TCA-F13

TRA-F13 / TCA-F13TRA-F13 / TCA-F13

With tapered tip

With tapered tip Without thermowell

With tapered tipWith tapered tip

TRA-P40 / TCA-P40

TRA-P40 / TCA-P40 TRA-S41 / TCA-S41

TRA-P40 / TCA-P40TRA-P40 / TCA-P40

TRA-S41 / TCA-S41 TRA-F42 / TCA-F42

TRA-S41 / TCA-S41TRA-S41 / TCA-S41

TRA-F42 / TCA-F42 TRA-P14 / TCA-P14

TRA-F42 / TCA-F42TRA-F42 / TCA-F42

Without thermowell

Without thermowellWithout thermowell

TRA-P14 / TCA-P14

TRA-P14 / TCA-P14TRA-P14 / TCA-P14

4

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 5

OPTITEMP TRA/TCA

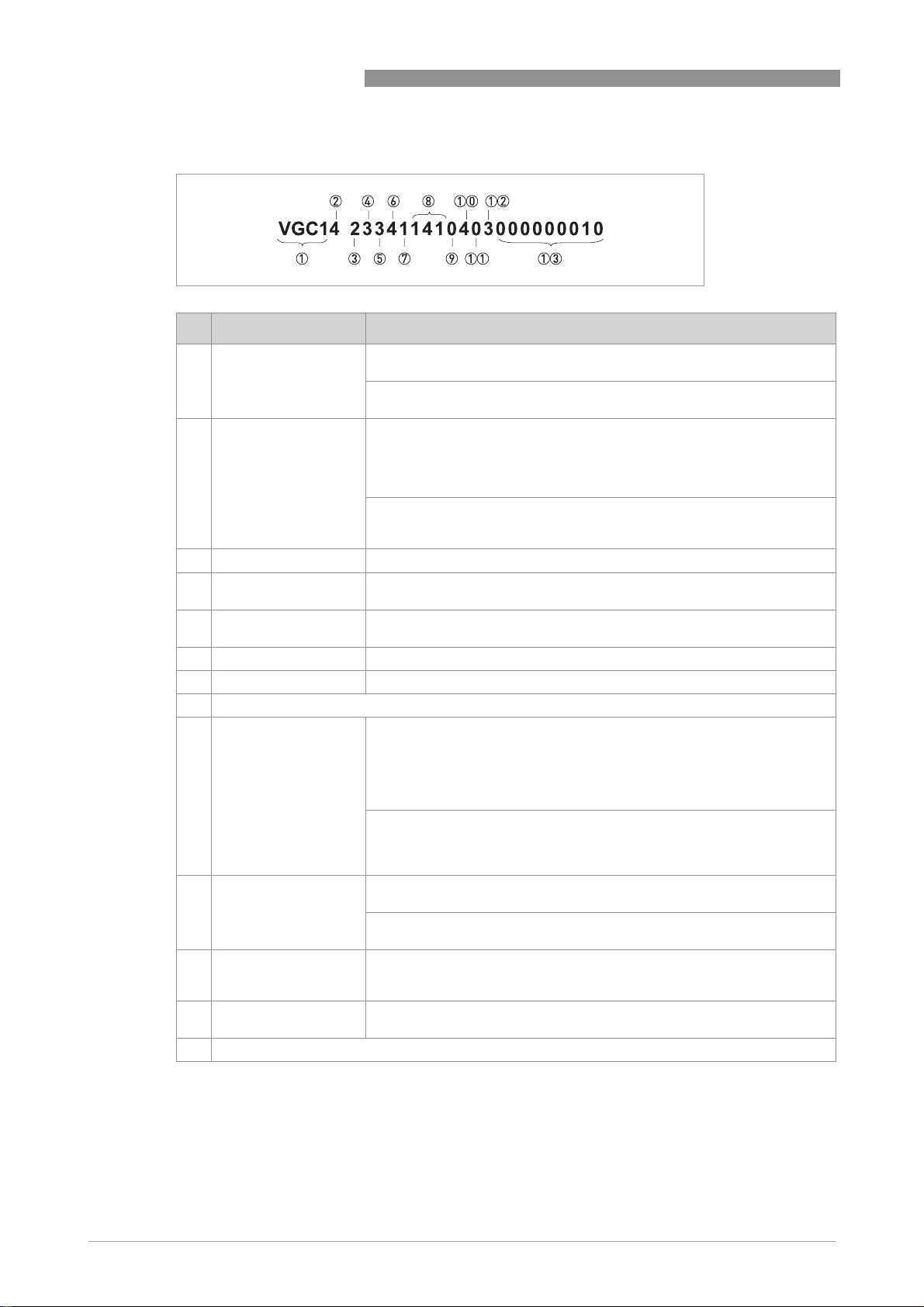

2.2 Description code

The safety description code of the measuring inserts is made up of the model name and the VGC

key. The following are examples to help explain the composition of the model name and the VGC

key:

Model name

1 Sensor type: TCA = thermocouple, TRA = resistance thermometer

2 Type of process connection: P = insert version, S = threaded version, F = flange version

3 Internal manufacturer's designation of thermowell version

INFORMATION!

In the following chapters of this manual the model names of the thermometers start with "TxA"

to avoid using the full title "TRA/TCA". Blanks in the VGC key can be omitted.

DEVICE DESCRIPTION 2

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

5

Page 6

2 DEVICE DESCRIPTION

VGC key

Designation Variants

OPTITEMP TRA/TCA

1 Type of thermowell tip

2 Abbreviation for full

description of

thermometer

3 Ex-Approval 0 = without; 2 = ATEX- Ex-i

4 Type of connection

head

5 Sensor circuit type 0 = without; 1 = 1xPt100 2-wire; 2 = 1xPt100 3-wire; 3 = 1xPt100 4-wire;

6 Sensor class 4 = class A, Mi, WW;, A = Class 1, thermocouple

7 Thermowell material 0 = without; 1 = 1,4571, 316Ti; 2 = 1,4841, 314

8 Not Ex-relevant

9 Insertion length For VGC1: 0 = without; 1 = 75 mm / 2.95"; 2 = 100 mm / 3.94"; 3 = 115 mm /

10 Length of neck pipe For VGC1: 0 = without; 1 = 80 mm / 3.15"; 3 = 145 mm / 5.71; Z = special

11 Connection type

(head-mounted

transmitter)

12 Connection type (rail-

mount transmitter)

13 Not Ex-relevant (14th to 20th position), not used (21st to 25th position)

VGC 1 = straight tip

VGC 4 = tapered tip

For VGC1: 1 = TRA-P10 (insert version); 2 = TRA-S11 (threaded version);

3 = TRA-S12 (threaded version); 4 = TRA-F13 (flange version); A = TCA-P10

(insert version); B = TCA-S11 (threaded version);

C = TCA-S12 (threaded version); D = TCA-F13 (flange version); L = TRAP14 (without thermowell); T = TCA-P14 (without thermowell)

For VGC4: 1 = TRA-P40 (insert version); 2 = TRA-S41 (threaded version);

3 = TRA-F42 (flange version); A = TCA-P40 (insert version); B = TCA-S41

(threaded version);C = TCA-F42 (flange version)

3=BUZ-T; 5=BUZ-H

A = 1xthermocouple type J; B = 1xthermocouple type K

4.53"; 4 = 160 mm / 6.30"; 6 = 225 mm / 8.86"; 7 = 250 mm / 9.84";

8 = 270 mm / 10.63"; A = 305 mm / 12.01"; B = 315 mm / 12.40";

C = 390 mm / 15.35"; D = 395 mm / 15.55";

E = 400 mm / 15.75"; F = 465 mm / 18.31"; G = 480 mm / 18.90";

H = 545 mm / 21.46"; K = 725 mm / 28.54"; Z = special length

For VGC4: 0 = without; 1 = 160 mm / 6.30"; 2 = 220 mm / 8.66";

3 = 225 mm / 8.86"; 4 = 280 mm / 11.02"; 5 = 285 mm / 11.22"; 6 = 307mm;

7 = 345 mm / 13.58"; 8 = 367 mm / 14.45"; A = 427 mm / 16.81"; Z = special

length

length

For VGC4: 0 = without; 1 = 80 mm / 3.15"; 2 = 82 mm / 3.23"; 3 = 145 mm /

5.71; 4 = 147 mm / 5.79

0 = without; 2 = head-mounted transmitter TT10C; 7 = head-mounted

transmitter TT30C; D = head-mounted transmitter TT50C; E = headmounted transmitter TT51C; F = head-mounted transmitter TT60C

0 = without; 6 = rail-mount transmitter TT30R; 7 = rail-mount transmitter

TT31R (1channel); 8 = rail-mount transmitter TT31R (2channel)

6

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 7

OPTITEMP TRA/TCA

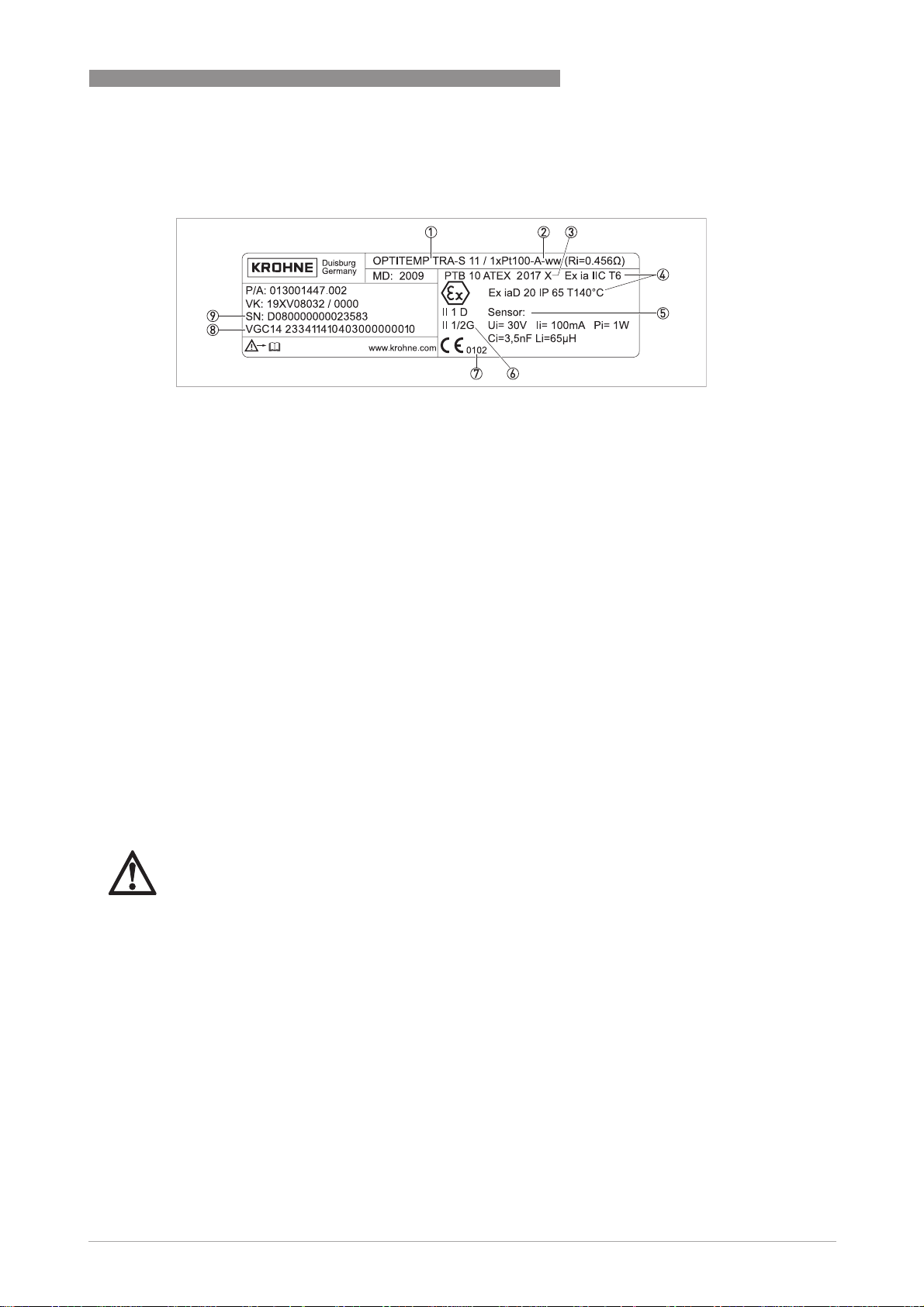

2.3 Marking

1 Type designation

2 Sensor designation

3 Number of the EC Type Test Certificate

4 Ex-marking for gas and dust

5 Electrical sensor values (this information is different if a transmitter is used as the transmitter values then apply)

6 Equipment group and category for gas and dust

7 Identification number of the notified body as per Directive 94/95, Appendix IV

8 VGC key

9 Unique serial number

DEVICE DESCRIPTION 2

2.4 Flammable products

Atmospheric conditions

An explosive atmosphere is a mixture of air and flammable gases, vapours, mists or dusts under

atmospheric conditions. It is defined by the following values:

= -20...+60°C / -4...+140°Fand P

T

atm

Outside of this range, no key data are available as to ignition behaviour for most mixtures.

Operating conditions

Outside of atmospheric conditions you cannot apply explosion protection according to Directive

94/9/EC (ATEX) – regardless of the zone assignment - due to the lack of key safety data.

DANGER!

The operator is responsible for ensuring that the industrial thermometers are operated safely

as regards the temperature and pressure of the products used. Include the thermometer

assembly in the periodic pressure tests of the system when operating with flammable products.

= 0.8...1.1 bar / 11.6...15.9 psi

atm

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

7

Page 8

2 DEVICE DESCRIPTION

2.5 Equipment category

Industrial thermometers are designed for use in zone 0 in category II 1 G, for use in zone 20 in

category II 1 D. In category II 1/2 G all thermometers have a separator (thermowell) which

separates zone 0 and zone 1.

INFORMATION!

Definition of Zone 0 according to EN 1127-1:

An area with a constant or long-term or frequent explosive atmosphere made up of a mixture of

flammable substances in the form of gas, vapours or mist.

For more information see the chapter entitled "Flammable products".

INFORMATION!

Definition of Zone 20 according to EN 61241-0:

An area with a constant or long-term or frequent explosive atmosphere in the form of a cloud of

flammable dust in air.

INFORMATION!

Definition of a device with separator as per EN 60079-26:

Devices which are installed in the wall to an area requiring EPL Ga or which are part of this wall

and contain electrical circuits which do not meet the requirements of the Ga protection level,

must, at minimum, comply with one of the protection types that an EPL Gb offers. In addition,

they must feature an integrated mechanical separator to separate the device's electrical circuits

from the area requiring EPL Ga.

OPTITEMP TRA/TCA

For further information refer to

Flammable products

on page 7.

8

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 9

OPTITEMP TRA/TCA

DEVICE DESCRIPTION 2

2.6 Protection types

2.6.1 Protection type with zone separator for gas hazard areas

In protection type "intrinsic safety" the industrial thermometer meets the requirements of

EN 60079-11. The explosion protection is guaranteed because the current and voltage are

limited so that ignitable energy cannot occur.

If zone 0 and zone 1 are separated as per EN 60079-26, this will ensure that a thermowell is

fitted properly. In such cases the thermometer marking is:

II 1/2G Ex ia IIC T6

II 1/2G Ex ia IIC T6

II 1/2G Ex ia IIC T6II 1/2G Ex ia IIC T6

Components of the Ex marking and what they mean

II

II Group II explosion protection

IIII

1/2

1/2 Equipment category 1/2

1/21/2

GGGG Gas explosion protection

Ex ia

Ex ia Intrinsically safe equipment

Ex iaEx ia

IIC

IIC Gas groups IIA, IIB, IIC

IICIIC

T6

T6 Temperature classes T6...T1

T6T6

2.6.2 Type of protection for gas hazard areas

In protection type "intrinsic safety" the industrial thermometer meets the requirements of

EN 60079-11. The explosion protection is guaranteed because the current and voltage are

limited so that ignitable energy cannot occur. In such cases the thermometer marking is:

II 1G Ex ia IIC T6

II 1G Ex ia IIC T6

II 1G Ex ia IIC T6II 1G Ex ia IIC T6

Components of the Ex marking and what they mean

II

II Group II explosion protection

IIII

1111 Equipment category 1

GGGG Gas explosion protection

Ex ia

Ex ia Intrinsically safe equipment

Ex iaEx ia

IIC

IIC Gas groups IIA, IIB, IIC

IICIIC

T6

T6 Temperature classes T6...T1

T6T6

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

9

Page 10

2 DEVICE DESCRIPTION

2.6.3 Type of protection for dust hazard areas

In protection type "Protection through instrinsic safety" the industrial thermometer meets the

requirements of EN 61241-11. The dust protection is guaranteed by housing which provides

appropriate protection against penetration by dust. Current and voltage are also limited so that

ignitable energy cannot occur. All thermometers with these features have the following

marking:

II 1D Ex iaD 20 IP65 T140

II 1D Ex iaD 20 IP65 T140°C

II 1D Ex iaD 20 IP65 T140II 1D Ex iaD 20 IP65 T140

Components of the Ex marking and what they mean

II

II Group II explosion protection

IIII

1111 Equipment category 1

DDDD Dust explosion protection

Ex ia D

Ex ia D Dust protection type intrinsic safety "iaD"

Ex ia DEx ia D

20

20 Use in zone 20

2020

IP65

IP65 Foreign bodies and water pollution control

IP65IP65

T140

T140°C

C Maximum surface temperature of industrial thermometer without dust coating at ambient

T140T140

CC

temperature 100°C / 212°F and product temperature 100°C / 212°F

C

CC

OPTITEMP TRA/TCA

DANGER!

As the TxA-P14 model does not have a thermowell, you must allow for a higher maximum

surface temperature! The marking is therefore:

II 1D Ex iaD 20 IP65 T175

II 1D Ex iaD 20 IP65 T175°C

II 1D Ex iaD 20 IP65 T175II 1D Ex iaD 20 IP65 T175

C

CC

Components of the Ex marking and what they mean (TxA-P14)

II

II Group II explosion protection

IIII

1111 Equipment category 1

DDDD Dust explosion protection

Ex ia D

Ex ia D Dust protection type intrinsic safety "iaD"

Ex ia DEx ia D

20

20 Use in zone 20

2020

IP65

IP65 Foreign bodies and water pollution control

IP65IP65

T175

T175°C

C Maximum surface temperature of industrial thermometer without dust coating at ambient

T175T175

CC

temperature 100°C / 212°F and product temperature 100°C / 212°F

10

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 11

OPTITEMP TRA/TCA

2.7 Temperature classes

The permitted ambient temperature range of the industrial thermometer without temperature

transmitter on the measuring insert ("head-mounted transmitter") is:

= -40...+100°C / -40...+212°F

T

amb

DANGER!

If you are using an industrial thermometer with head-mounted transmitter, refer to the Exdocumentation of the temperature transmitter for the permitted maximum values for the

ambient temperature.

Due to the influence of the product temperature, no fixed temperature class is assigned to

industrial thermometers. The temperature class of the devices is instead a function of the

following parameters:

DEVICE DESCRIPTION 2

• Present product temperature (T

• Maximum value of sensor output of connected temperature transmitter (P

• Maximum permitted temperature at the process connection of the measuring point (T

• Surface temperature of the sensor (T

The classification for the respective model is outlined in the following subchapters.

)

M

)

O

)

P

)

O

WARNING!

The maximum permitted product temperatures and process connection temperatures in the

tables of the following subchapters are only valid if you observe the following points:

•

The industrial thermometer has been installed in accordance with the assembly instructions

in these supplementary Ex instructions and the manual.

•

There is no additional thermal radiation at the measuring point (solar radiation, adjacent

equipment) which could heat up the industrial thermometer causing the maximum permitted

ambient temperature to be exceeded.

•

There is no additional convection from the container wall or adjacent pipes which could heat

up the industrial thermometer and cause the maximum permitted ambient temperature to be

exceeded.

•

The connection head is adequately ventilated.

•

All insulation measures only include the pipes, never the components of the industrial

thermometer.

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

11

Page 12

2 DEVICE DESCRIPTION

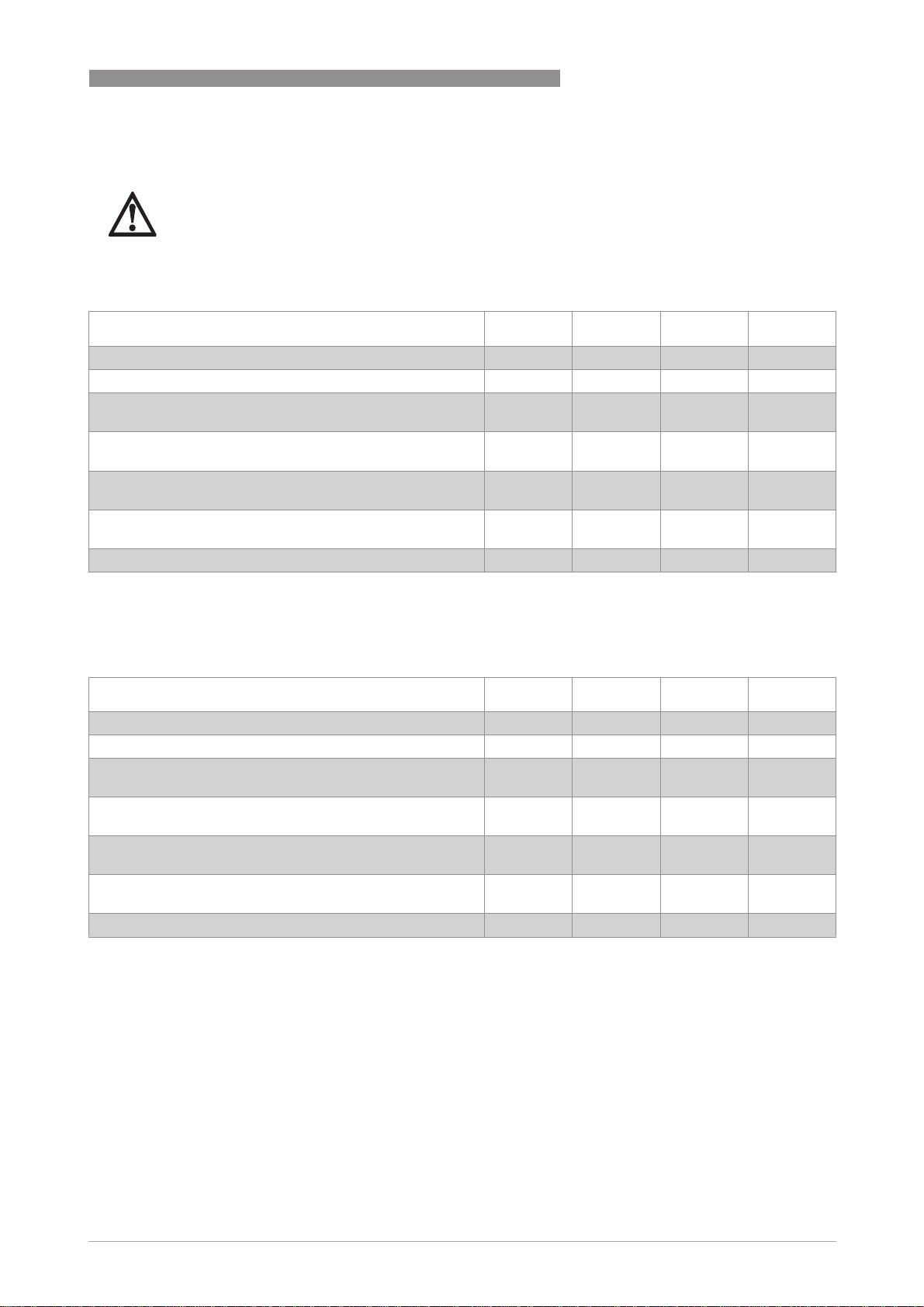

2.7.1 Maximum permitted product temperature

DANGER!

Regardless of the temperature class the various measuring inserts have the following lower

limit values for the product temperature (T

•

TC 100: -40°C/ -40°F

•

TR 100: -200°C / -328°F

Maximum permitted product temperature [°C]

M

OPTITEMP TRA/TCA

):

Temperature

class

T1 450 436 432 425 402 391 383 380 365

T2 300 286 282 275 252 241 233 230 215

T3 200 191 187 180 157 146 138 135 120

T4 135 126 122 115 92 81 73 70 55

T5 100 91 87 80 57 46 - - -

T6 85 76 72 65 42 - - - -

T

in [°C] P

o

≤

0

50 mW

P0 ≤

100 mW

P0 ≤

200 mW

P0 ≤

500 mW

P0 ≤

650 mW

P0 ≤

750 mW

P0 ≤

800 mW

P0 ≤

1000 mW

Maximum permitted product temperature [°F]

Temperature

class

T1 842 816 809 797 755 735 721 716 689

T2 572 546 539 527 485 465 451 446 419

T3 392 375 368 356 314 294 280 275 248

T4 275 258 251 238 197 177 163 158 131

T5 212 195 188 176 134 114 - - -

T6 185 168 161 149 107 - - - -

T

in [°F] P

o

≤

0

50 mW

P0 ≤

100 mW

P0 ≤

200 mW

P0 ≤

500 mW

P0 ≤

650 mW

P0 ≤

750 mW

P0 ≤

800 mW

P0 ≤

1000 mW

12

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 13

OPTITEMP TRA/TCA

DEVICE DESCRIPTION 2

2.7.2 Temperature at process connection (without temperature transmitter)

DANGER!

The maximum permitted temperature at the process connection for all industrial thermometers

°

C/ 752ºF.

is 400

Maximum permitted temperature at process connection for thermometers without temperature

transmitter in [°C]

Thermometer models T

TxA-S11, threaded thermometer, neck pipe length ≤ 80mm 182 155 127 100

TxA-S12/41, threaded thermometer, neck pipe length ≥ 80mm 400 400 312 100

TxA-P10/40, insert thermometer with thermowell TxA-P10,

neck pipe length ≤ 80mm

TxA-P10/40, insert thermometer with thermowell, neck pipe

length ≥ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≤ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≥ 80mm

TxA-F13/42, flange thermometer, neck pipe length ≥ 80mm 400 400 339 100

= 40ºC

a

323 248 174 100

400 400 290 100

323 248 174 100

400 400 290 100

a

T

= 60ºC

T

= 80ºC Ta = 100ºC

a

Maximum permitted temperature at process connection for thermometers without temperature

transmitter in [°F]

Thermometer models T

TxA-S11, threaded thermometer, neck pipe length ≤ 80mm 361 311 261 212

TxA-S12/41, threaded thermometer, neck pipe length ≥ 80mm 752 752 594 212

TxA-P10/40, insert thermometer with thermowell TxA-P10,

neck pipe length ≤ 80mm

TxA-P10/40, insert thermometer with thermowell, neck pipe

length ≥ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≤ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≥ 80mm

TxA-F13/42, flange thermometer, neck pipe length ≥ 80mm 752 752 643 212

= 104ºF Ta = 140ºF Ta = 176ºF Ta = 212ºF

a

613 479 345 212

752 752 554 212

613 479 345 212

752 752 554 212

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

13

Page 14

2 DEVICE DESCRIPTION

Temperature at process connection without temperature transmitter

1 Maximum permitted temperature at the process connection ( Tp)

2 Ambient temperature at the measuring point (T

3 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; TxA-S12/41,

threaded thermometer; TxA-F13/42, flange thermometer; neck pipe length in each case ≥ 80 mm

4 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; neck pipe length in

each case ≤ 80 mm / 3.1

5 TxA-S11, threaded thermometer, neck pipe length ≤ 80 mm / 3.15"

OPTITEMP TRA/TCA

)

a

14

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 15

OPTITEMP TRA/TCA

DEVICE DESCRIPTION 2

2.7.3 Temperature at process connection (with temperature transmitter)

DANGER!

The maximum permitted temperature at the process connection for all industrial thermometers

= 400°C / 752ºF. The maximum permitted ambient temperature is Ta=85°C / 185°F.

is T

P

Maximum permitted temperature at process connection for thermometers with temperature

transmitter in [°C]

Thermometer models T

TxA-S11, threaded thermometer, neck pipe length ≤ 80mm 135 107 86 80

TxA-S12/41, threaded thermometer, neck pipe length ≥ 80mm 400 292 133 80

TxA-P10/40, insert thermometer with thermowell TxA-P10,

neck pipe length ≤ 80mm

TxA-P10/40, insert thermometer with thermowell, neck pipe

length ≥ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≤ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≥ 80mm

TxA-F13/42, flange thermometer, neck pipe length ≥ 80mm 400 319 139 80

= 40ºC Ta = 60ºC Ta = 75ºC Ta = 80ºC

a

228 154 98 80

400 270 127 80

228 154 98 80

400 270 127 80

Maximum permitted temperature at process connection for thermometers with temperature

transmitter in [°F]

Thermometer models T

TxA-S11, threaded thermometer, neck pipe length ≤ 80mm 275 225 188 176

TxA-S12/41, threaded thermometer, neck pipe length ≥ 80mm 752 558 271 176

TxA-P10/40, insert thermometer with thermowell TxA-P10,

neck pipe length ≤ 80mm

TxA-P10/40, insert thermometer with thermowell, neck pipe

length ≥ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≤ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≥ 80mm

TxA-F13/42, flange thermometer, neck pipe length ≥ 80mm 752 607 283 176

= 104ºF Ta = 140ºF Ta = 167ºF Ta = 176ºF

a

443 309 209 176

752 518 261 176

443 309 209 176

752 518 261 176

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

15

Page 16

2 DEVICE DESCRIPTION

Temperature at process connection with temperature transmitter

1 Maximum permitted temperature at the process connection ( Tp)

2 Ambient temperature at the measuring point (T

3 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; TxA-S12/41,

threaded thermometer; TxA-F13/42, flange thermometer; neck pipe length in each case ≥ 80 mm

4 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; neck pipe length in

each case ≤ 80 mm / 3.15"

5 TxA-S11, threaded thermometer, neck pipe length ≤ 80 mm / 3.15"

OPTITEMP TRA/TCA

)

a

16

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 17

OPTITEMP TRA/TCA

DEVICE DESCRIPTION 2

2.7.4 Temperature at process connection (with temperature transmitter, classes T5 and

T6)

As special restrictions apply to temperature classes T5 and T6, you must heed the information

about the maximum ambient temperature in the temperature transmitter documentation.

Calculate the maximum permitted temperature at the process connection for all thermometers

with a temperature transmitter in temperature classes T5 and T6 as follows:

DANGER!

Always refer to your temperature transmitter documentation for the maximum permitted

ambient temperature of the temperature transmitter (T

1 TP = process connection temperature

2 k = coupling factor of thermometer versions (see table later in this subchapter)

= ambient temperature around the temperature transmitter (see transmitter documentation)

3 T

aTT

4 T

= ambient temperature at the measuring point

a

aTT

).

DANGER!

In order to prevent injury and material damage, always observe the limit values of the assigned

temperature class. For further information refer to Maximum permitted product temperature on

page 12

Coupling factors of the thermometer models

Thermometer model Coupling factor [k]

TxA-S11, threaded thermometer, neck pipe length ≤ 80mm 0.42

TxA-S12/41, threaded thermometer, neck pipe length ≥ 80mm 0.086

TxA-P10/40, insert thermometer with thermowell TxA-P10, neck pipe

length ≤ 80mm

TxA-P10/40, insert thermometer with thermowell, neck pipe length

≥ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe length

≤ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe length

≥ 80mm

TxA-F13/42, flange thermometer, neck pipe length ≥ 80mm 0.077

0.212

0.095

0.212

0.095

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

17

Page 18

2 DEVICE DESCRIPTION

OPTITEMP TRA/TCA

2.7.5 Temperature at process connection for thermometers with connecting cable

DANGER!

The maximum permitted temperature at the process connection for all industrial thermometers

= 400°C / 752ºF. The maximum permitted ambient temperature is Ta=70°C / 158°F. Always

is T

P

refer to the table below!

DANGER!

Always refer to the tables below. Always use heat-resistant connecting cables if the temperature

at the process connection exceeds the values in the tables below.

Maximum permitted temperature at process connection for thermometers with connecting cable

in [°C]

Thermometer models T

TxA-S11, threaded thermometer, neck pipe length ≤ 80mm 99 78 71 65

TxA-S12/41, threaded thermometer, neck pipe length ≥ 80mm 330 171 118 65

TxA-P10/40, insert thermometer with thermowell TxA-P10,

neck pipe length ≤ 80mm

TxA-P10/40, insert thermometer with thermowell, neck pipe

length ≥ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≤ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≥ 80mm

TxA-F13/42, flange thermometer, neck pipe length ≥ 80mm 364 184 124 65

= 40ºC Ta = 55ºC Ta = 60ºC Ta = 65ºC

a

157 102 83 65

303 160 112 65

157 102 83 65

303 160 112 65

Maximum permitted temperature at process connection for thermometers with connecting cable

in [°F]

Thermometer models T

TxA-S11, threaded thermometer, neck pipe length ≤ 80mm 211 173 161 149

TxA-S12/41, threaded thermometer, neck pipe length ≥ 80mm 627 340 244 149

TxA-P10/40, insert thermometer with thermowell TxA-P10,

neck pipe length ≤ 80mm

TxA-P10/40, insert thermometer with thermowell, neck pipe

length ≥ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≤ 80mm

TxA-P14, insert thermometer without thermowell, neck pipe

length ≥ 80mm

TxA-F13/42, flange thermometer, neck pipe length ≥ 80mm 688 364 256 149

= 104ºF Ta = 131ºF Ta = 140ºF Ta = 149ºF

a

316 215 182 149

577 320 234 149

316 215 182 149

577 320 234 149

18

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 19

OPTITEMP TRA/TCA

Temperature at process connection for thermometers with connecting cable

1 Maximum permitted temperature at process connection ( Tp)

2 Ambient temperature at measuring point (T

3 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; TxA-S12/41,

threaded thermometer; TxA-F13/42, flange thermometer; neck pipe length in each case ≥ 80 mm / 3.15"

4 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; neck pipe length in

each case ≤ 80 mm / 3.15"

5 TxA-S11, threaded thermometer, neck pipe length ≤ 80 mm / 3.15"

DEVICE DESCRIPTION 2

)

a

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

19

Page 20

2 DEVICE DESCRIPTION

2.8 Electrical data

DANGER!

Connect the sensor circuit of an industrial thermometer only to intrinsically safe circuits as well

as separate transmitters certified as intrinsically safe or zener barriers. Observe the following

maximum values when connecting a measuring insert without temperature transmitter:

•

Ui =30V

•

Ii = 140 mA

•

Pi =1.0W

DANGER!

When connecting a thermometer to an electricity supply please observe the maximum values for

the effective capacities and inductances in the following table:

OPTITEMP TRA/TCA

Sensor length

up to 5 m / 16.4 ft up to 30 m / 98.4 ft

Ci= [nF] L

TR100 with Pt100 wire wound 3.5 65 21 390

TC100 type K 2.5 25 14 150

TC100 type J 2 48.5 11.5 289.5

= [µH] C

i

= [nF] L

i

= [µH]

i

DANGER!

Always observe the maximum values of the transmitter used with industrial thermometers

featuring a measuring insert with head-mounted transmitter. These maximum values can be

found on the transmitter nameplate. The sensor output P

is one of the the deciding factors

o

when assigning to a temperature class . For further information refer to Temperature classes

on page 11

.

20

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 21

OPTITEMP TRA/TCA

INSTALLATION 3

3.1 Selecting the right thermometer and calculating limit values

DANGER!

In order to prevent injury and material damage, always ensure that the process conditions do not

exceed the permitted limit values of the thermometer. Ask yourself the following questions

when planning a measuring point:

•

What are the temperatures (ambient temperature, product temperature, process connection

temperature) at the measuring point?

•

Do the process conditions necessitate heat-resistant feed lines?

•

Which industrial thermometer model would you like to use with which process connection?

•

Which type of sensor would you like to use?

Answering the above questions will help you deduce the following parameters and necessary

device properties:

• Whether or not you need a temperature transmitter

• Sensor output P

• Product temperature T

• Ambient temperature T

• Process connection temperature at the measuring point T

0

M

a

P

INFORMATION!

The temperature at the process connection of an industrial thermometer depends on how the

device is installed. The diagram below shows possible installations (T

is the point at which the

P

temperature at the process connection is measured):

Possible installations

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

21

Page 22

3 INSTALLATION

Once you have calculated the specified parameters and device properties, you must determine

the maximum permitted temperatures for your specific measuring point in three steps. Use the

tables in the previous subchapters to do this:

OPTITEMP TRA/TCA

• Determine the maximum permitted product temperature ( refer to

product temperature

on page 12).

Maximum permitted

• Determine the maximum permitted temperature at the process connection ( refer to

Temperature at process connection (without temperature transmitter)

Temperature at process connection (with temperature transmitter)

Temperature at process connection (with temperature transmitter, classes T5 and T6)

on page 13, refer to

on page 15 or refer to

on

page 17).

• Find out whether the thermometer requires a heat-resistant connecting cable; if so ensure

that the connecting cable can withstand the process conditions ( refer to

process connection for thermometers with connecting cable

on page 18).

Temperature at

Example: Determining the maximum permitted temperatures

This example is based on a TxA-F13 thermometer with head-mounted transmitter. It has the

following features and is subjected to the following process conditions:

• Length of neck pipe: min. 80 mm / 3.15"

• Maximum ambient temperature of transmitter: 85°C / 185°F

• Sensor output: P

• Ambient temperature at measuring point: T

• Product temperature: T

• Temperature at process connection: T

= 500 mW

o

M

= 70°C / 158°F

=40°C / 104°F

a

= 50°C / 122°F

P

Step 1: Calculate the maximum product temperature

• Refer to the table with the maximum permitted product temperatures ( refer to

permitted product temperature

on page 12).

• Look along the header of the table until you come to the column with your sensor output P

this case: 500 mW).

• Look down this column and find the product temperature at your measuring point (in this case:

70°C / 158°F).

• If you can't find this figure, always look at the next figure up.

Maximum

o

(in

i The maximum permitted product temperature is 92°C / 198°F and the temperature class is

T4.

22

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 23

OPTITEMP TRA/TCA

Step 2: Calculate the maximum permitted temperature at the process connection

• You must always calculate the highest permitted temperature at the process connection for

temperature classes T5 and T6 ( refer to

temperature transmitter, classes T5 and T6)

subchapter and omit the following steps.

• For all temperature classes except T5 and T6 refer to the tables with the maximum permitted

temperatures at the process connection; these also differentiate between thermometers with

and without a temperature transmitter ( refer to

temperature transmitter)

temperature transmitter)

• Find the model of thermometer used with the right neck pipe length in the first column of the

table (in this case: TxA-F13, neck pipe ≥ 80 mm / 3.15").

• Keep going to the right until you reach the column with the right ambient temperature T

this case: 40°C / 104°F).

i The maximum permitted temperature at the process connection is T

Step 3: Calculate the maximum permitted temperature at the process connection with

a thermometer connecting cable

• Refer to the table with the maximum permitted temperatures at the process connection with a

thermometer connecting cable refer to

thermometers with connecting cable

• Calculate the maximum permitted temperature as explained above ("step 2").

i The maximum permitted temperature at the process connection for a thermometer with

connecting cable is T

Temperature at process connection (with

on page 13, refer to

on page 15).

Temperature at process connection for

on page 18).

= 364°C / 687°F.

P

INSTALLATION 3

on page 17); therefore go directly to the specified

Temperature at process connection (without

Temperature at process connection (with

(in

a

= 400°C/ 752°F.

P

In this example the selected industrial thermometer is suitable for the specified process

conditions having checked all the maximum permitted temperatures. It falls into temperature

class T4.

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

23

Page 24

3 INSTALLATION

If the process conditions at your measuring point are outside of the values in the tables used in

the example above, you will have to use charts. These can be found in the subchapters below

following the tables. The charts also include less common temperatures.

The following sample chart shows you how to calculate the temperature at the process

connection at an ambient temperature T

• Find the ambient temperature at your measuring point along the X-axis (in this case: 60°C/

140°F).

• From this point trace straight up until you reach the temperature curve of your thermometer.

• From this intersection, move horizontally to the left until you reach the Y-axis.

• At the intersection with the Y-axis read off the temperature at the process connection (in this

case: 108°C / 226°F).

=60°C / 140°F:

a

OPTITEMP TRA/TCA

Example: Calculating the temperature at the process connection (T

1 Maximum permitted temperature at process connection ( Tp)

2 Ambient temperature at the measuring point (T

3 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; TxA-S12/41,

threaded thermometer; TxA-F13/42, flange thermometer; neck pipe length in each case ≥ 80 mm / 3.15"

4 TxA-P14, insert thermometer without thermowell; TxA-P10, insert thermometer with thermowell; neck pipe length in

each case ≤ 80 mm / 3.15"

5 TxA-S11, threaded thermometer, neck pipe length ≤ 80 mm / 3.15"

)

a

=85°C/ 185°F)

a

24

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 25

OPTITEMP TRA/TCA

3.2 Assembly

DANGER!

The manufacturer is not liable for any damage or injuries resulting from improper use or use

other than the intended purpose. This applies in particular to hazards due to insufficient

corrosion resistance and suitability of the materials in contact with products.

DANGER!

Installation and setup must be carried out according to the applicable installation standards (e.g.

EN 60079-14) by qualified personnel trained in explosion protection. Observe the information

contained in the manuals and the supplementary instructions. Assembly must always comply

with the following requirements:

•

There are no external forces on the thermometer assembly.

•

The device is accessible for any necessary visual inspections and can be viewed from all

sides.

•

The nameplate is clearly visible.

•

All seals are fit for purpose.

INSTALLATION 3

Installing an industrial thermometer with flange or thread connection

• Ensure that you use a seal suitable for the dimensions of the process connection (flange or

thread) and the requirements of the measuring point.

• Align the seal precisely (for thermometers with flange connection this applies to the flange

surface of the connection nozzle).

• Carefully lower the thermometer into the tank or the pipe.

• Observe all the relevant regulations and in particular the right torques and tighten the flange

screws or the thread connection.

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

25

Page 26

4 ELECTRICAL CONNECTIONS

4.1 General notes

DANGER!

In order to prevent injury and material damage, always take heed of the information about

temperatures at the process connection before connecting an industrial thermometer to an

electricity supply ( on page 18

Ensure that all connecting cables conform to the valid installation standards (e.g. EN 60079-

•

14) and withstand the maximum operating temperature.

•

Adjust the outer diameter of the connecting cables to the sealing range of the cable entries.

•

Securely lay the connecting cables and sufficiently protect them against damage.

•

Securely connect all the cores not in use with the ground potential of the explosive area or

carefully insulate them from each other and from ground (test voltage ≥ 500V

Industrial thermometers are connected to an electricity supply by connecting the sensor circuit

in the connection head to the interchangeable measuring insert.

DANGER!

Also refer to the transmitter's Ex manual for all industrial thermometers with an explosionproof transmitter.

). In addition, always observe the following points:

OPTITEMP TRA/TCA

).

eff

4.2 Power supply

The supply voltage of an industrial thermometer specifically refers to the supply voltage of the

measuring insert (for further information refer to

DANGER!

If you are operating the measuring insert together with a transmitter, pay attention to the details

of the power supply in the Ex documentation of the transmitter used. Also observe the maximum

values of the sensor circuit.

Electrical data

on page 20).

26

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 27

OPTITEMP TRA/TCA

4.3 Inputs / Outputs

The electrical connection of an industrial thermometer depends on the type of measuring insert

used. The manufacturer offers measuring inserts with two different sensor types, either with

Pt100 resistor (TR 100) or with thermocouple (TC 100).

4.3.1 Pt100 measuring inserts

A measuring insert with a Pt RTD is connected according to DIN EN 60751 in three different

wiring variants (from left to right: 2, 3 and 4 wire switch):

TR 100: Wiring (simple design)

ELECTRICAL CONNECTIONS 4

1 white

2 red

4.3.2 Thermocouple measuring inserts

Wiring of a thermocouple measuring insert is done in accordance with DIN EN 60584.

TC 100: Wiring (simple design)

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

27

Page 28

4 ELECTRICAL CONNECTIONS

4.4 Grounding and equipotential bonding

DANGER!

In order to prevent injury and material damage, always observe the following points regarding

grounding and equipotential bonding:

•

Always include the thermometer and its measuring insert as per EN 60079-14 in the

equipotential bonding of the installation site (when installed correctly, the fixing screws

guarantee this).

•

If the thermometer is not connected to a grounded metal pipe system or a container through

the process connection, you must include it in the equipotential bonding of the explosive area.

•

The connection for equipotential bonding is via the PA terminals or the process connection.

•

If there is a cable shield you must ground it according to EN 60079-14. A terminal in the

connection head means that the cable shield can be grounded by the shortest route.

The manufacturer's measuring insert connections withstand a test voltage of 500 VAC to earth.

OPTITEMP TRA/TCA

28

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 29

OPTITEMP TRA/TCA

5.1 Starting up for the first time

DANGER!

To prevent injury and material damage, only operate industrial thermometers under the

following conditions:

•

The equipment was installed and connected in accordance with the manufacturer's

instructions.

•

At the operator's request, a test was conducted prior to start-up to ensure the correct

installation and connection.

•

The check prior to start-up was in compliance with the national regulations for checks before

start-up.

5.2 Operation

DANGER!

To avoid injury and material damage, only operate the measuring inserts under the following

conditions:

OPERATION 5

•

Temperatures, pressures and electrical limit values are in the manufacturer's specified

range.

•

The equipment parts necessary for safety are effective in the long run, never disable them

during operation!

•

When using flammable products, the thermowell must be included in the periodic pressure

tests of the system.

You can open the connection head when live (thanks to the "intrinsic safety" protection type) even

in explosive areas to work on the electrical connections for measuring and setting purposes (e.g.

to configure a temperature transmitter):

CAUTION!

When using the thermometer, and in particular after work to the connection head, ensure that it

is closed properly. Otherwise the degree of IP protection is not guaranteed.

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

29

Page 30

6 SERVICE

6.1 Maintenance

DANGER!

Maintenance measures of a safety-relevant nature within the meaning of explosion protection

may only be carried out by the manufacturer, his authorised representative or under the

supervision of authorised inspectors.

For systems in explosive areas, regular tests are required in order to maintain the proper

condition. The manufacturer recommends the following maintenance measures:

• Check the housing, the cable entries and the feed lines for corrosion and/or damage.

• Check the process connection and the piping connections for leakage.

• Check the entire thermometer for dust deposits.

6.2 Dismantling

You can replace a separately certified intrinsically safe temperature transmitter or measuring

insert with an identical device from the manufacturer:

OPTITEMP TRA/TCA

DANGER!

In order to prevent injury and material damage when replacing components of the industrial

thermometer, always observe the following points:

•

To avoid electric shock, dismantle the measuring insert when it is de-energized where

possible. If this is not possible, the basic conditions for intrinsic safety (e.g. no grounding or

connection of different intrinsically safe circuits to one another) must be observed during

dismantling.

•

So as not to damage the cover of the connection head, only open it using a suitable tool (e.g. a

screwdriver).

•

When replacing both a separately certified intrinsically safe temperature transmitter and a

separately certified intrinsically safe measuring insert with an identical device from the

manufacturer, always refer to the Ex documentation for the devices. Ensure that the

construction is the same by checking the nameplates.

30

www.krohne.com 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

Page 31

OPTITEMP TRA/TCA

As well as replacing individual components, it is also possible to replace the entire

thermometer, however you as operator have sole responsibility for this:

DANGER!

In order to prevent injury or material damage when replacing components of the industrial

thermometer, always observe the following points:

•

Before dismantling the electrical connecting lines of the device, ensure that all the cables

leading to the measuring insert are de-energised themselves and to the reference potential

of the explosive area. This also applies to equipotential bonding conductors (PA).

•

All the relevant process controls or containers must be depressurized before dismantling the

thermowell.

•

If the process cables or the container contain products that are harmful to the environment

or to health, implement the appropriate safety measures before dismantling the thermowell.

•

Replace all the seals when reinstalling the device in the process cable or container.

SERVICE 6

www.krohne.com10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en

31

Page 32

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Measuring systems for the oil and gas industry

• Measuring systems for sea-going tankers

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

D-47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

© KROHNE 10/2010 - 4001087001 - Ex AD OPTITEMP TRA/TCA R02 en - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...