Page 1

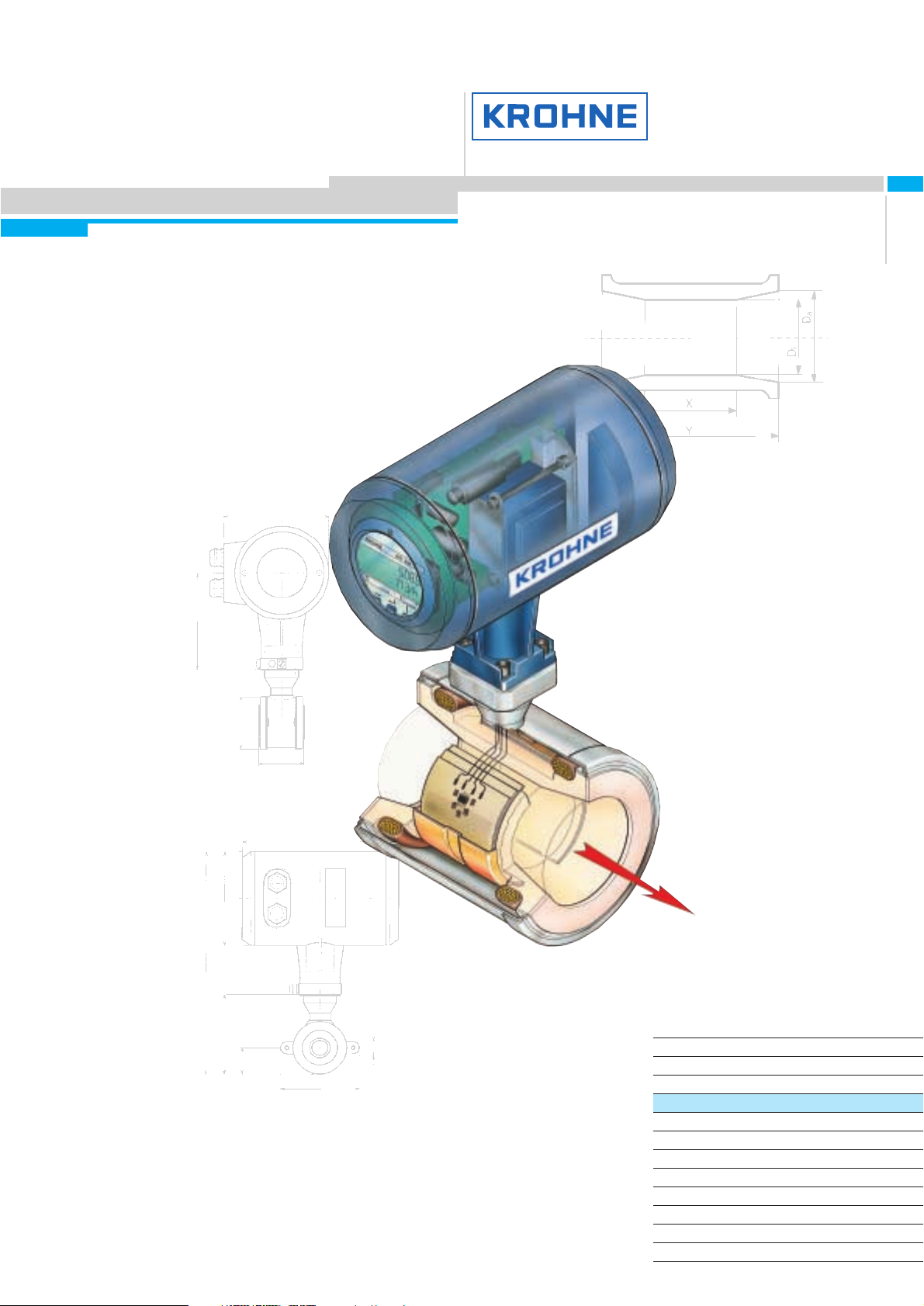

Capaflux IFM 5080 K-CAP

Electromagnetic Flowmeter

... non-contact process flow measurment

from 0.05 µS/cm electrical conductivity

● Ceramic measuring tube,

dimensionally stable,

vacuum resistant

● Optimum flow shaping

and unimpeded tube

cross-section

● Outstanding accuracy

● Non-wetted electrodes

GR

©

KROHNE 03/2002 7.02422.22.00

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Page 2

Capaflux IFM 5080 K-CAP

Electromagnetic Flowmeter

... non-contact process flow measurment

from 0.05 µS/cm electrical conductivity

non-contact flow measurement

no electrodes

easy to specify

unimpeded flow cross-sectional area

optimum flow shaping

resistant to abrasion

ceramic measuring tube

dimensionally stable vacuum-resistant

outstanding accuracy

Special advantages

● capacitive electrodes for non-contact measurement.

● the measuring section is resistant to abrasion from even high solids

contents.

● the ceramic measuring tube is dimensionally stable and vacuum-

resistant.

● the special shape of the measuring tube helps to optimize the flow

profile, even with minimum pressure drop, refer to diagram on

page 3.

● the measuring error is less than 0.5% of the measured value.

● the integral design ensures easy installation, safe and reliable

operation.

● the crevice-free measuring tube has no blind spots and conforms

to food requirements, the ceramic surface is ultrasmooth,

R

a

< 0,8 µm surface finish.

ATEX approval

Ex II 2 GD KEMA 01 ATEX 2232X

● CAPAFLUX IFM 5080 K/CAP-EEx:

EEx d IIC T6 … T4

EEx de IIC T6 … T4

● CAPAFLUX IFM 5080 K/CAP/i-EEx:

with outputs intrinsic safety

EEx d [ia] IIC T6 … T4

EEx de [ia] IIC T6 … T4

2

No restrictions ...

... through insulating products with a

film-forming tendency:

asphalt, latex suspensions

... through low electrical conductivity:

ultrahigh-purity water, alcohols,

glycerins, glycols

... through high solids contens:

fruit pieces, pulps, concrete

... for sterile processes:

chemical and food industries

... when used in hazardous areas:

ATEX approval

FM certification pending

... through electrode materials:

the capacitive electrodes are located

behind the ceramic tube, i.e. non-

contact measurement, no contact with

the process product.

Calibrated on EN 17 025

accredited calibration rigs,

accuracy of calibration better

than 99.97% of the measured value.

Page 3

CAPAFLUX 3

CAPAFLUX

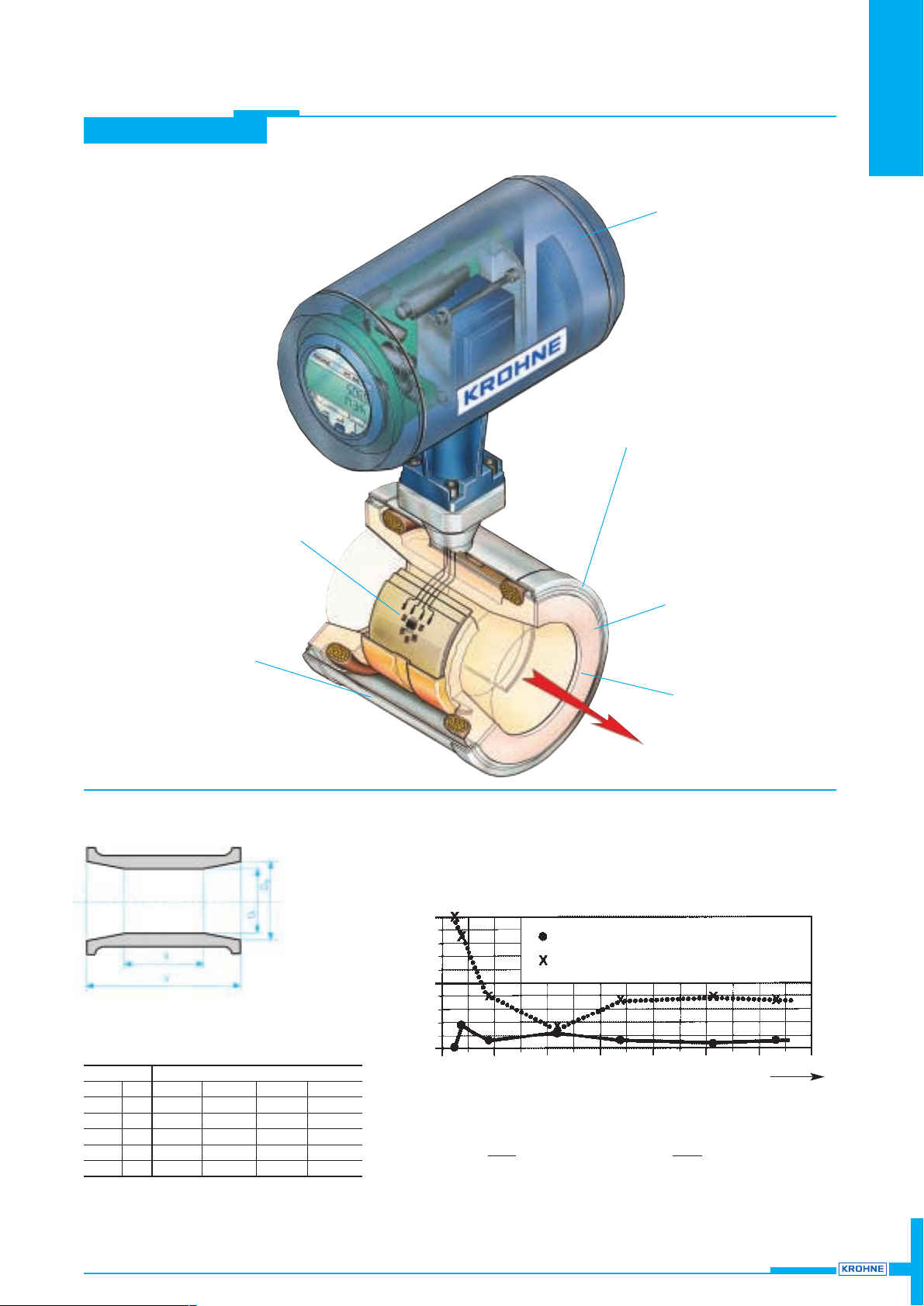

Highlights

Capacitive electrodes for

non-contact measurement

Hazardous-duty version,

flameproof enclosure

Self-supporting ceramics

measuring tube,

press-fitted into stainless

steel housing

Meter sizes DN 25-100 or 1”-4”

Measuring error ≤ 0.5% of the measured value,

‘sandwich’ design, easy installation,

reliable and safe operation

Electrical conductivity ≥ 0.05 µS/cm,

e.g. ultrahigh-purity water, alcohols,

glycerols, glycols, etc.

Dimensionally stable measuring tube,

very good thermal and long-time stability,

no flow, creep and no abrasion,

as is usually the case with plastic liners

No crevices, no blind spots in the

measuring tube, conforms to food

standards, extremely smooth,

surface roughness < 0.8 µm

Design

Flow profile influence

(± SE) as % of measured value

Example for DN80 (3’’) with quarter bend, straight inlet run

5 × DN (= 400 mm = 16’’) from quarter bend to electrode plane

Pressure drop:

∆P =

ρ× v

2

(in mbar)

800

ρ = product density in (kg/m

3

)

v = flow velocity in m/s

∆P =

ρ× v

2

(in psig)

550

ρ = specific gravity (e.g. water = 1)

v = flow velocity in ft/s

0 0.5 1.0 1.5 2.0 2.5 3.0[m/s] 3.5

v

0 1.5 3.0 4.5 6.0 7.5 9.0 [ft/s]10.5

CAPAFLUX IFM 5080 K-CAP

Conventional flangeless flowmeter

1.0

±SE

[%]

0.5

0

Meter size Dimensions in mm (inches)

DN mm inches D

a

D

i

XY

25 1 24 (0.95) 20 (0.79) 26 (1.02) 55 (2.17)

40 11/2 37 (1.46) 30 (1.18) 36 (1.42) 80 (3.15)

50 2 49 (1.92) 40 (1.57) 51 (2.01) 100 (3.94)

80 3 78 (3.06) 60 (2.36) 70 (2.76) 150 (5.91)

100 4 98 (3.84) 80 (3.15) 103 (4.06) 200 (7.87)

Page 4

Measuring ranges and error limits

Meter size 1)Electrical conductivity Error limits

2)

Full-scale range Q

100%

0.05-0.2 µS/cm > 0.2 µS/cm in m3/h in US gal/min

mm inches (water (water v >1 m/s v≤ 1 m/s v = 0.3 m/s v= 1 m/s v= 12 m/s v= 1 ft/s v= 40 ft/s

1-2.5 µS/cm) >2.5 µS/cm) > 3 ft/s ≤3 ft/s (minimum) (maximum) (minimum) (maximum)

DN 25 1 0.5302 1.767 21.20 2.334 93.34

DN 40 11/

2

1.358 4.524 54.28 5.979 239.0

DN 50 2 2.121 7.069 84.82 9.339 373.5

DN 80 3 5.429 18.10 217.1 23.900 955.6

DN100 4 8.483 28.27 339.2 37.350 1493.0

Calibrated on EN 17025 accredited calibration rigs Reference conditions similar to EN 29104

by direct comparison of volumes Product water at 10 – 30°C / 50 – 86°F

Electrical conductivity > 300µS/cm

Power supply (rated voltage) U

N

(± 2%)

Ambient temperature 20 – 22°C / 68 – 71.6°F

Warm-up time 60min

Inlet/outlet runs 10 x DN / 2 x DN (DN = meter size)

Primary head properly grounded and centered

Current output same error limits as above, additionally ±10 µA

Reproducibility or repeatability 0.1 % of MV, minimum 1 mm/s / 0.04 inches/s at constant flow, measuring time > 100 s

External influences typical values maximum values

Ambient temperature

Pulse output 0.003% of MV (3) 0.01% of MV (3)

Current output 0.01% of MV (3) 0.025% of MV (3)

}

at 1K /1.8°F variation

P

ower supply <0.02% of MV 0.05% of MV at 10 % variation

Load

<0.01% of MV 0.02% of MV at max. permissible load, see pages 5 and 6

(3) All KROHNE signal converters undergo burn-in tests, duration minimum 20 hours at varying ambient temperatures

– 20 to + 60 °C / – 4 to + 140 °F. The tests are controlled by computers.

CAPAFLUX

CAPAFLUX

4

1) Where low electrical conductivities are concerned,

the meter size should be such that flow velocity

v < 1 m/s (< 3 ft/s).

2) Error limits for display,

pulse output, digital values

<±0.5%

of measured

value

<±5mm/s

<±0.20

inches/s

depending on

product and

application

condition, please

consult your local

KROHNE office

for all

applications

Dimensions and weights

● all dimensions in mm and (inches)

● without grounding rings: Dimension a incl. gaskets between primary head and pipe flanges

● with groundings rings: Dimension a + 10 mm or a + 0.4’’, incl. 2 gaskets between measuring tube and grounding rings and

2 between grounding rings and pipe flanges

Meter size Dimensions in mm and (inches) approx. weight

DN mm inches a b c d e Ø f Ø di in kg (lb)

25 1 58 (2.28) 302 (11.89) 113 (4.45) 34 (1.34) 102 (4.02) 68 (2.68) 20 (0.79) 3.9 (8.6)

40 11/283 (3.27) 318 (12.52) 129 (5.08) 42 (1.65) 117 (4.61) 83 (3.27) 30 (1.18) 4.7 (10.4)

50 2 103 (4.06) 336 (13.23) 147 (5.79) 51 (2.01) 135 (5.31) 101 (3.98) 40 (1.57) 5.2 (11.5)

80 3 153 (6.02) 368 (14.49) 179 (7.05) 67 (2.64) 167 (6.57) 133 (5.24) 60 (2.36) 7.7 (17.0)

100 4 203 (7.99) 392 (15.43) 203 (7.99) 79 (3.11) 192 (7.56) 158 (6.22) 80 (3.15) 11.1 (24.5)

136 (5.35’’)

128 (5.04’’)

dia. f

d

c

b

dia. di

dia. 122 (4.80’’)

208 (8.19’’)

e

a

Page 5

CAPAFLUX 5

CAPAFLUX

CAPPAFLUX Primary head

Meter size DN 25, 40, 50, 80, 100 and 1”, 11/2”, 2”, 3”, 4”, flangeless version

Operating data

Temperatures Ambient temperature Product temperature

– 25 to + 60°C / – 13 to + 140°F – 25 to + 60°C / – 13 to + 140°F

– 25 to + 40°C / – 13 to + 104°F – 25 to + 100 °C / – 13 to + 212°F

● non Ex : + 140°C/+284°F

for max. 30 min

● Ex version : + 115°C/+239°F

Pressure DN 25 – 80: 40 bar / 580 psig

DN 100: 16 bar / 230 psig (option 25 bar)

1” – 4”: 16 bar / 230 psig for 150 lb

1” – 3”: 40 bar / 580 psig for 300 lb

}

pipe

4”: 25 bar / 360 psig for 300 lb

flanges

Vacuum 0 mbar abs. / 0 psia

Temperature change

Temperature rising in 10 minutes: ∆ T = 125 °C, or 257 °F

for sudden change: ∆ T = 120 °C, or 248 °F

Temperature falling in 10 minutes: ∆ T = 100 °C, or 212 °F

for sudden change: ∆ T = 180 °C, or 176 °F

Insulation class of field coils H

Electrode design capacitive signal pickup,

electrodes not in contact with the product

Protection category (IEC 529 / EN 60 529) IP 67 equivalent to NEMA 6

Items included with supply Standard Option

for pipe flanges DN 25 – 80 / PN 40

DN 100 / PN 16 DN 100 / PN 25

1” – 4” / 150 lb 1” – 4” / 300 lb

Centering material yes –

Stud bolts steel stainless steel

Grounding rings – yes

Gaskets 2 (without grounding rings) 4 (with grounding rings)

Ex versions: European standard - EEx d IIC T6-T4

FM approval – in preparation

Materials

Measuring section

DN 25, 1” zirconium oxide, ZrO

2

DN 40 – 100, 11/2” – 4” fused aluminium oxid, 99.7 % Al2O

3

Housing (with polyurethane finish) stainless steel 1.4301 / SS 304 – AISI

Gask

ets Gylon 3500 (beige) gaskets (application range similar to that of PTFE),

optionally Chemotherm (graphite) gaskets

Grounding rings (option) stainless steel 1.4571/ SS 316 Ti – AISI, others on request

Centerin

g material

DN 25, 1” EPDM rings

DN 40 – 100, 1

1

/2” – 4” rubber sleeves

Stud bolts

steel electrogalvanized, optionally stainlees steel 1.4301 / SS 304 – AISI

Technical data

The responsibility as to the suitability, intended use and corrosion-resistance of the materials used in their

construction rests solely with the purchaser.

Page 6

CAPAFLUX

6 CAPAFLUX

IFC 090 K-CAP Signal converter

Versions

IFC 090 K/B (Standard) Basic version, without local display and control elements

IFC 090 K/D (Option) Display version, with local display and control elements

IFC 090 K/D-EEx Ex version with “Increased Safety” outputs

Interfaces (option) – HART®

– RS 485/PROFIBUS/FIELDBUS (switch-selectable add-on module)

Add-on equipment (option) CONFIG-Software and adapter for operator control via MS-DOS PC,

connection to internal IMoCom interface (equipment bus)

Current output

Function – all operating data configurable

– galvanically isolated from current output and all input circuits

– for active or passive mode

Current: fixed ranges 0 – 20mA and 4 – 20 mA

variable ranges for Q = 0% I0%= 0 – 16mA

for Q = 100% I

100%

= 4 – 20mA }adjustable in 1 mA increments

for Q > 100% I

max

= 22mA

Active mode max. 500 Ω load

Passive mode external voltage: 15 ... 20V DC 20 ... 32V DC

load: min ... max. 0 ... 500Ω 250 ... 750Ω

Error identification 0/ 22 mA and variable

Forward/reverse flow measurement direction identified via status output

Pulse output

Function – all operating data configurable

– galvanically isolated from all input and output circuits

– digital pulse division, interpulse period non-uniform, therefore if frequency

and cycle meters connected allow for minimum counting interval:

gate time, totalizer ≥

1000

P100% [Hz]

Active mode connection: electronic totalizers

voltage: approx. 15 V DC, from current output

load: I

max

< 23mA, operation without current output

load: I

max

< 3mA, operation with current output

Passive mode connection: electronic or electromechanical totalizers

voltage: external, U

ext

≤ 30 V DC/≤ 24 V AC

load: I

max

≤ 150 mA

Pulse width automatic: pulse duty cycle 1:1, max 1000 pulses/s = 1 kHz

variable: 10 ms – 2 s P

100%

[pulses/s] = f

max

[Hz] =

1

2 x pulse width

Forward/reverse flow measurement flow direction identified via status output

Status output (passive)

Function configurable as measuring range identification for BA mode,

indicator for flow direction, errors or trip point

Connection voltage: external, U

ext

≤ 30 V DC/≤ 24 V AC

load current: I

max

≤ 150 mA

Control input (passive)

Function – configurable for range change, totalizer reset, error reset,

set outputs to min. values or hold actual output values

– initiate function by “low” or “high” control signals

Control signals U

max

: 24 V AC 32 V DC (any polarity)

low: ≤ 1.4 V ≤ 2 V

high: ≥ 3 V ≥ 4 V

Output/input combinations I = current output P = pulse output S = status output C = control input

The following combinations can be set:

1) I P S

2) I P C

3) I C S

4) I S1 S2

5) I C1 C2

Time constant 0.2 – 99.9 s, adjustable in increments of 0.1 second

Low-flow cutoff

Cutoff “on” value: 1 – 19%

Cutoff “off” value: 2 – 20%

}

of Q

100%

,

adjustable in 1% increments

Page 7

7

CAPAFLUX

CAPAFLUX

Local display 3-field LCD

Display function actual flowrate, forward, reverse and sum totalizers (7-digit),

or 25-character bar graph with percentage indication and status messages

Units: Actual flowrate m

3

/h, liters, US gallons/min or user-defined unit, e.g. hecto-liters/day

Totalizer m

3

, liters, US gallons or user-defined unit, e.g. hecto-liters or US million gallons

(adjustable count duration up to overflow)

Language of plain texts English, German, French, others on request

Display: Top field 8-character, 7-segment numeral and sign display,

and symbols for key acknowledgement

Middle field 10-character, 14-segment text display

Bottom field 4 markers to identify display in measuring mode

Power supply 1. AC Version 2. AC Version AC/DC-Version

Standard Option Option

1. Rated voltage 230 / 240 V 200 V 24 V AC 24 V DC

Tolerance band 200 – 260 V 170 – 220 V 20 – 27 V AC 18 – 32 V DC

2. Rated voltage 115 / 120 V 100 V – –

Tolerance band 100 – 130 V 85 – 110 V – –

Frequency 48 – 63 Hz 48 – 63 Hz –

Power consumption (incl. primary head) approx. 10 VA approx. 10 VA approx. 8 W

When connected to functional extra-low voltage, 24 V, safety separation (PELV) is essential

(to VDE 0100 / VDE 0106 and IEC 364 / IEC 536 or equivalent national standard.)

Housing

Material die-cast aluminium with polyurethane finish

Ambient temperature – 25 to + 60°C (– 13 to + 140°F)

Protection category (IEC 529 / EN 60 529) IP 67, equivalent to NEMA 6

Electrical connection

binary outputs

and inputs

for

internal

use only

current output

PE 100 – 240 V AC (PE protective conductor)

FE 24 V AC/DC (FE functional ground)

B1 pulse output (P),

status output (S)

or control input (C)

B2 status output (S)

or control input (C)

Electrical connection in conformity with

VDE 0100 “Regulations gover-ning heavycurrent installations with mains voltages up

to 1000 V” or equivalent national standard.

If to be connected to a functional extra-low

voltage source (24 V), protective separation

in conformity with VDE 0100, Part 410, or

equivalent national standard, must be

ensured.

Current output (I)

Operating data of receiver instruments, outputs and inputs, see pages 6 and 7.

passive active passive passive

Pulse output (P)

status output (S)

Control input (C)

(not with

Ex version)

P

electronic

or electro-

mechanical

totalizer

S

e.g.

signal

indicator

Loading...

Loading...