Page 1

04/02

Addition to the

Magnetic-inductive

flowmeters

ALTOFLUX

IFM 4080 K-EEx

IFM 4080 K/i-EEx

Compact flowmeter

installation and

operating

instructions

7.30917.31.00

Page 2

WARNING !

No changes may be made to the devices. Unauthorized changes

might affect the explosion safety of the devices.

These additional instructions are an extension to the Installation and Operating

Instructions and only applies for the EEx version of the IFM 4080 K or IFM 4080 K / i EEx magnetic-inductive compact flowmeter. All technical information described in the

Installation and Operating Instructions are applicable, when not specifically excluded

or replaced by the instructions in these additional instructions.

CONTENTS

1 SYSTEM COMPONENTS...............................................................................................................2

1.1 General information...................................................................................................................2

1.2 Primary head...............................................................................................................................3

1.3 IFC 090/…-EEx signal converter.............................................................................................3

1.3.1 Electronics compartment ........................................................................................................3

1.3.2 Terminal compartment...........................................................................................................3

1.4 Electronics unit ........................................................................................................................... 4

1.4.1 Regular IFC090-EEx electronics unit .....................................................................................4

1.4.2 IFC 090i-EEx unit with MODIS modules ................................................................................4

2 ELECTRICAL CONNECTION........................................................................................................5

2.1 Equipotential bonding system ..................................................................................................5

2.2 Regular IFC 090-EEx electronics unit....................................................................................5

2.3 MODIS version IFC 090i-EEx electronics unit......................................................................6

2.3.1 Connection diagrams MODIS ................................................................................................8

3 OPERATION OF THE SIGNAL CONVERTER.........................................................................14

4 SERVICE..........................................................................................................................................14

4.1 Replacement of electronics unit or power fuse(s) ..............................................................15

4.1.1 Replacement of electronics unit............................................................................................16

4.1.2 Replacement of power fuse(s)...............................................................................................17

4.1.3 Changing power supply voltage............................................................................................20

5 CONNECTING CABLES...............................................................................................................21

6 MAINTENANCE..............................................................................................................................21

7 CONNECTION DIAGRAM .............................................................................................................22

8 ORDERING INFORMATION.........................................................................................................23

8.1 Regular IFC 090-EEx electronics unit..................................................................................23

8.2 MODIS version IFC 090i-EEx electronics unit....................................................................23

9 DATA PLATES................................................................................................................................24

10DECLARATION OF CONFORMITY............................................................................................25

11EC-TYPE EXAMINATION CERTIFICATE.................................................................................26

Be sure to follow these instructions !

IMPORTANT !

• The prescriptions and regulations as well as the electrical data described in the

EC-type examination certificate must be obeyed.

• Beside the instructions for electrical installations in non-hazardous locations according

to the applicable national standard (equivalent of IEC 364, e.g. VDE 0100), especially

the regulations in EN 60079-14 "Electrical installations in hazardous locations" or

equivalent national standard (e.g. DIN VDE 0165) must be followed.

• Installation, establishment, utilization and maintenance are only allowed to be

executed by personnel with an education in explosion safety !

1

Page 3

1 SYSTEM COMPONENTS

1.1 General information

The Altoflux IFM 4080 K/…-EEx magnetic-inductive compact flowmeter is in accordance with

the European Directive 94/9 EC (ATEX 100a) and approved for hazardous classified

locations of Zone 1 and 2 by the KEMA conform to the European Standards of the EN 500xx

series. The IFM 4080 K/…-EEx has the following approval number.

KEMA 01 ATEX 2200 X

The compact flowmeter is available in two types, namely:

• IFM 4080 K-EEx regular explosion protected version;

• IFM 4080 K/i-EEx, MODIS version. This type has intrinsically safe signal output circuits,

which are provided by two on the IFC 090i-EEx electronics unit installed MODIS modules.

The regular IFM 4080 K-EEx compact flowmeter is designed for ambient temperatures in the

range of -20°C (special -40°C) up to +60°C, the MODIS version type IFM 4080 K/i-EEx is

rated for ambient temperatures from -20°C up to +60°C.

The allowed process liquid temperature is a.o. limited by the combustible atmosphere that

(possibly) surrounds the apparatus, which again is determined by the temperature class of

the atmosphere (first column of the tables). See table 1 and 2 below for details.

For dusts the second column of the two below listed tables is applicable.

Max. surface

class

(for gases)

T6 T85°C 75°C 70°C 70°C

T5 T100°C 95°C 90°C 75°C

T4 T135°C 130°C 115°C 75°C

T3 T180°C 150°C 115°C 75°C

class

(for gases)

T6 T85°C 70°C 70°C 70°C

T5 T100°C 85°C 85°C 85°C

T4 T135°C 120°C 120°C 115°C

T3 T180°C 180°C 180°C 115°C

Use heat-resistant cables above - - 50°C

Table 2: Temperature classification DN25…150 with PFA liner.

The IFM 4080 K/…-EEx flowmeter consists of the IFC 090/…-EEx signal converter unit,

which is screwed on top of the primary head (i.e. measuring unit). The compact flowmeter is

marked with one of the codes below, depending on the meter size:

temperature

(for dusts)

Table 1: Temperature classification DN200 and larger.

Max. surface

temperature

(for dusts)

Maximum process liquid temperatureTemperature

Ta ≤ 40°C Ta ≤ 50°C Ta ≤ 60°C

Maximum process liquid temperatureTemperature

Ta ≤ 40°C Ta ≤ 50°C Ta ≤ 60°C

• DN25-150: II 2GD EEx d [ib] IIC T6…T3 (EEx d terminal compartment) or

II 2GD EEx de [ib] IIC T6 …T3 (EEx e terminal compartment).

• DN200 and up: II 2GD EEx de [ib] IIC T6…T3 (both EEx d and EEx e

terminal compartment).

2

Page 4

In case of the MODIS version IFM 4080 K/i-EEx , the electronics unit of type IFC 090i-EEx is

provided with protective modules, which provide intrinsically safe output signals of category

"ia". The flowmeter is then marked with one of the following codes:

• DN25-150: II 2GD EEx d [ia] [ib] IIC T6…T3 (EEx d terminal compartment) or

II 2GD EEx de [ia] [ib] IIC T6…T3 (EEx e terminal compartment).

• DN200 and up: II 2GD EEx de [ia] [ib] IIC T6…T3. (both EEx d and EEx e

terminal compartment)

For details see the EC-type examination certificate in Section 11 of these instructions.

1.2 Primary head

The primary head is the measuring unit of the IFM 4080 K/…-EEx compact flowmeter and

contains two field coils (see table 3 for type of protection) and two electrodes in type of

protection intrinsic safety category "ib" according to EN 50020.

Meter size Type of protection

DN25 up to DN150

DN200 and larger

Housing: Flameproof enclosure "d" according to EN 50018

Electrodes: Intrinsic safety "ib" according to EN 50020

Field coils: Increased safety "e" according to EN 50019

Electrodes: Intrinsic safety "ib" according to EN 50020

Table 3: Types of protection of primary head.

NOTE:

The intrinsically safe electrode circuits of the IFM 4080K/…-EEx compact flowmeter are

only internal circuits and not accessible for the customer.

1.3 IFC 090/…-EEx signal converter

The IFC 090/…-EEx signal converter consists of a cylindrical housing of die-casted

aluminum, which has two separate compartments, divided from each other by an integrated

wall with casted flameproof terminal feed-through. The neck at the bottom of the housing

contains a flameproof cable feed-through. The signal converter housing is on both ends

closed by a cylindrical threaded cover with O-ring sealing. The housing has an ingress

protection degree of at least IP67 conform to EN 60529.

1.3.1 Electronics compartment

The electronics compartment accommodates the pre-certified IFC 090…-EEx electronics unit

with approval number PTB 98 ATEX 2012 U. The compartment is designed with type of

protection flameproof enclosure "d" according to EN 50018. It is closed by a flameproof

display cover with glass window.

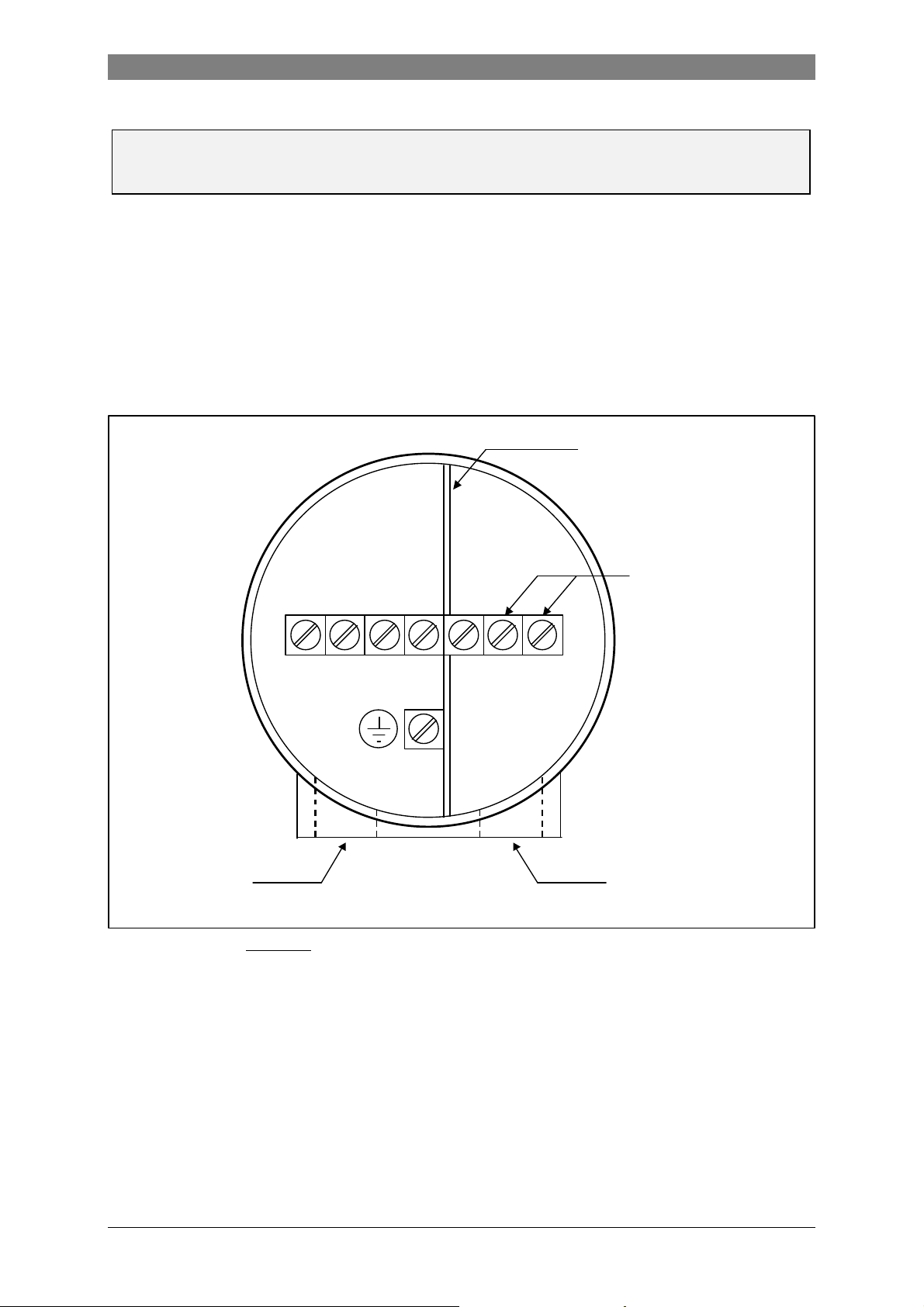

1.3.2 Terminal compartment

The terminal compartment has seven terminals for connection of the power supply and signal

output circuits. Chapter 2 and 7 show the terminal arrangement for the regular and MODIS

version of the IFC 090/…-EEx signal converter. The terminal arrangement of the MODIS

version (i.e. IFC 090i-EEx) is shown in figure 4 on page 6. Two of the terminals are used for

connection of the non-intrinsically safe power supply and four terminals (marked with "*")

for the intrinsically safe, category "ia" signal outputs of the MODIS modules. The nonintrinsically and intrinsically safe terminals are separated from each other by a metal dividing

plate, which is screwed to the remaining (not connected) M4 terminal. The two non-

intrinsically safe power supply terminals are covered by an insulating plate.

3

Page 5

The terminal compartment (with standard type of protection increased safety "e") is standard

equipped with two ATEX approved "EEx e" cable glands. The terminal compartment can also

be provided as a flameproof enclosure "d", in which case ATEX approved "EEx d" cable

glands of size Pg13.5, Pg16 or M20x1.5 are either factory installed or must be installed by

the customer. For flameproof conduit systems, the terminal compartment must have type of

protection flameproof enclosure "d" according to EN 50018. The conduits must be sealed by

"EEx d" approved (within the ATEX 100a directive) sealing devices (i.e. stopping box) directly

at the conduit entrances of the as flameproof enclosure performed terminal compartment.

1.4 Electronics unit

The IFM 4080 K/…-EEx magnetic-inductive compact flowmeter can be equipped with the

regular IFC 090-EEx or with the IFC 090i-EEx electronics unit with intrinsically safe signal

outputs (i.e. MODIS version). The next subsections give a detailed description of these units.

1.4.1 Regular IFC090-EEx electronics unit

The IFC 090-EEx is used in the regular IFM 4080 K-EEx and can be equipped with one of

the following power supplies (depends on the area of application).

Power

Terminal Function Electrical data

supply

L

AC-versions

AC/DC-version

The IFC 090-EEx electronics unit is equipped with the following in-/output circuits. Terminals

B1, B⊥ and B2 can be configured as status or pulse outputs or as control inputs via the

software. See the table below for the electrical data of these in-/output circuits.

Terminals Description Nominal voltage Maximum current

I+, I

B1, B⊥ , B2

Pulse, status, control in-/outputs 32 V 150 mA

N

PE

1L½

0L½

FE

Table 4: Electrical data of power supply.

Current output 15 V 22 mA

Table 5: Electrical data of in-/output circuits.

1.4.2 IFC 090i-EEx unit with MODIS modules

The IFC 090i-EEx electronics unit is equipped with a pair of MODIS-modules (see page 8). It

is equipped with one of the following power supplies.

Live

Neutral

Protective Earth

Live

Neutral

Functional Earth

Un = 100/115/200/230 Vac -15/+10%

Pn = approx. 10 VA, Um = 253 V

Un = 24 V ac/dc

AC: -15/+10%, Pn=10 VA

DC: -25/+30%, Pn=8 W

Um = 253 V

Power supply Terminals Function Electrical data

L

AC-version

AC/DC-version

NOTE: The mains fuses for both electronics units are listed in Section 8 of this manual.

N

PE

1L½

0L½

FE

Table 6: Electrical data of IFC 090i-EEx electronics unit.

Live

Neutral

Protective Earth

Live

Neutral

Functional Earth

4

Un = 100…230 Vac –15%/+10%

Pn = 15 VA, Um = 253 V

Un = 24 Vac/dc

AC:-15%/+10% or 20.4…26.4 Vac

DC:-25%/+30% or 18…32 Vdc

Pn = 10 W, Um = 253 V

Page 6

2 ELECTRICAL CONNECTION

⊥

Ri ≤ 500

Ω

I+ I

mA

½

B1 B

B2

I ≤ 150 mA

U

ext

≤ 32Vdc/24 Vac

000

I ≤ 150 mA

indicator

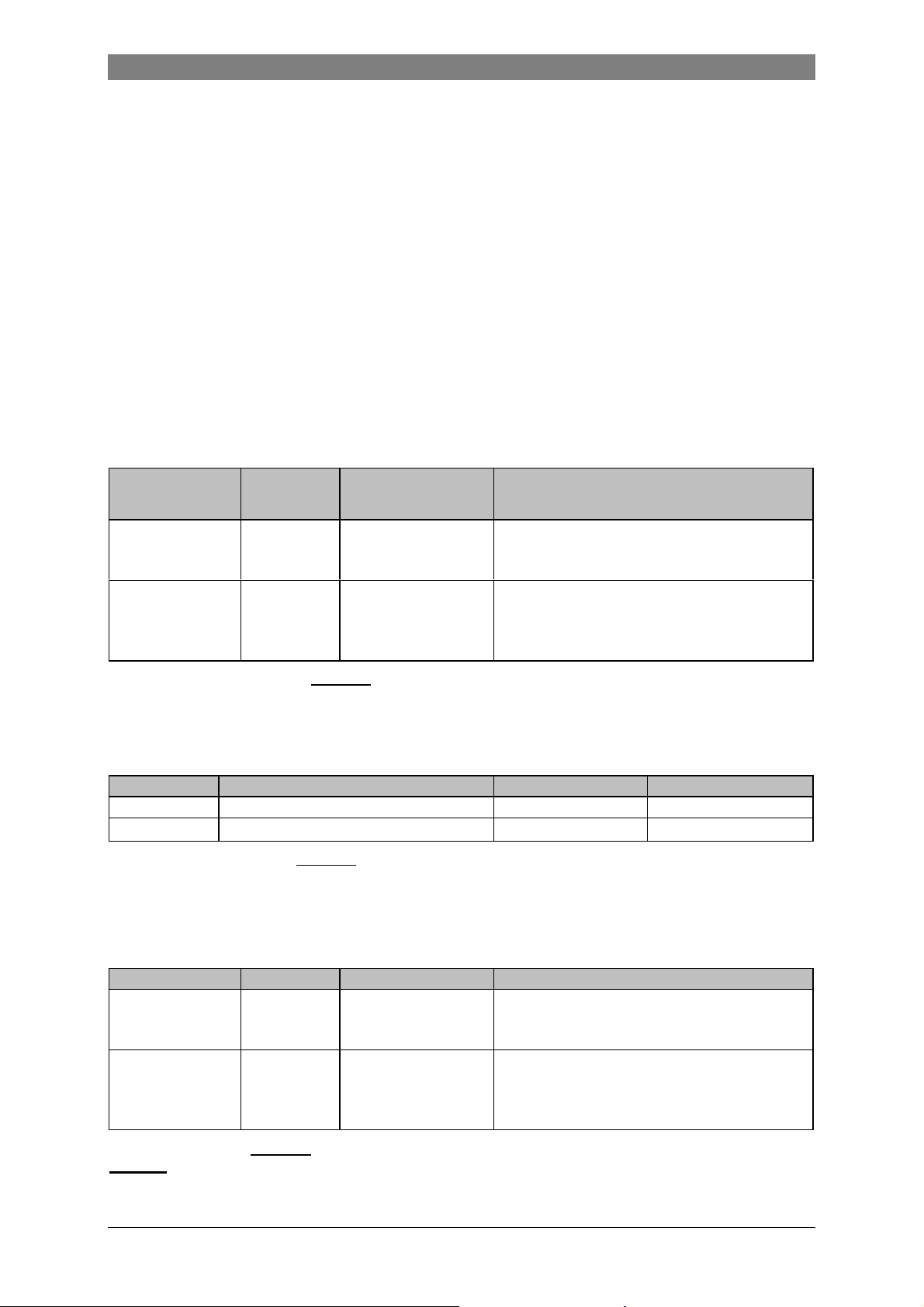

2.1 Equipotential bonding system

The IFM 4080 K-EEx and IFM 4080 K / i-EEx flowmeters must always be incorporated into

the equipotential bonding system of the hazardous area. This connection can be achieved

through the PE/FE conductor connected to the PE terminal in the terminal compartment

(see figure 1) or through a separate PE conductor, cross sectional area at least 4 mm2,

connected to the external PE clamp, placed below the converter housing.

2.2 Regular IFC 090-EEx electronics unit

The field cables that enter the terminal compartment of the IFC 090-EEx signal converter unit

(i.e. power supply, current and binary outputs) are non-intrinsically safe. To connect external

devices to the signal output terminals, the wiring requirements for the type of protection of

the compartment (standard: increased safety "e", optional: flameproof "d") must be conform

to the international or national standard involved (e.g. EN 60079-14).

The terminal arrangement is shown by figure 1 below.

PULSE, STATUS OUTPUTS

RESP. CONTROL INPUTS

B1 B

BINARY CURRENT

OUTPUTS OUTPUT

Figure 1: Terminal arrangement in terminal compartment.

B2 I+ I L N (100…240Vac / 48…63 Hz)

U

L

PE (Protective Earth) terminal

FE (Functional Earth) terminal

ext

e.g. signal

½

L

(24Vac/dc)

½

+

_

Figure 2 Passive pulse/status output Figure 3 Active current output

5

Page 7

Note:

terminals

½

L N 100…240 Vac

The binary outputs (terminals B1, B⊥ and B2) can only be configured as passive outputs,

the current output (terminals I+ and I) can only be configured as active output.

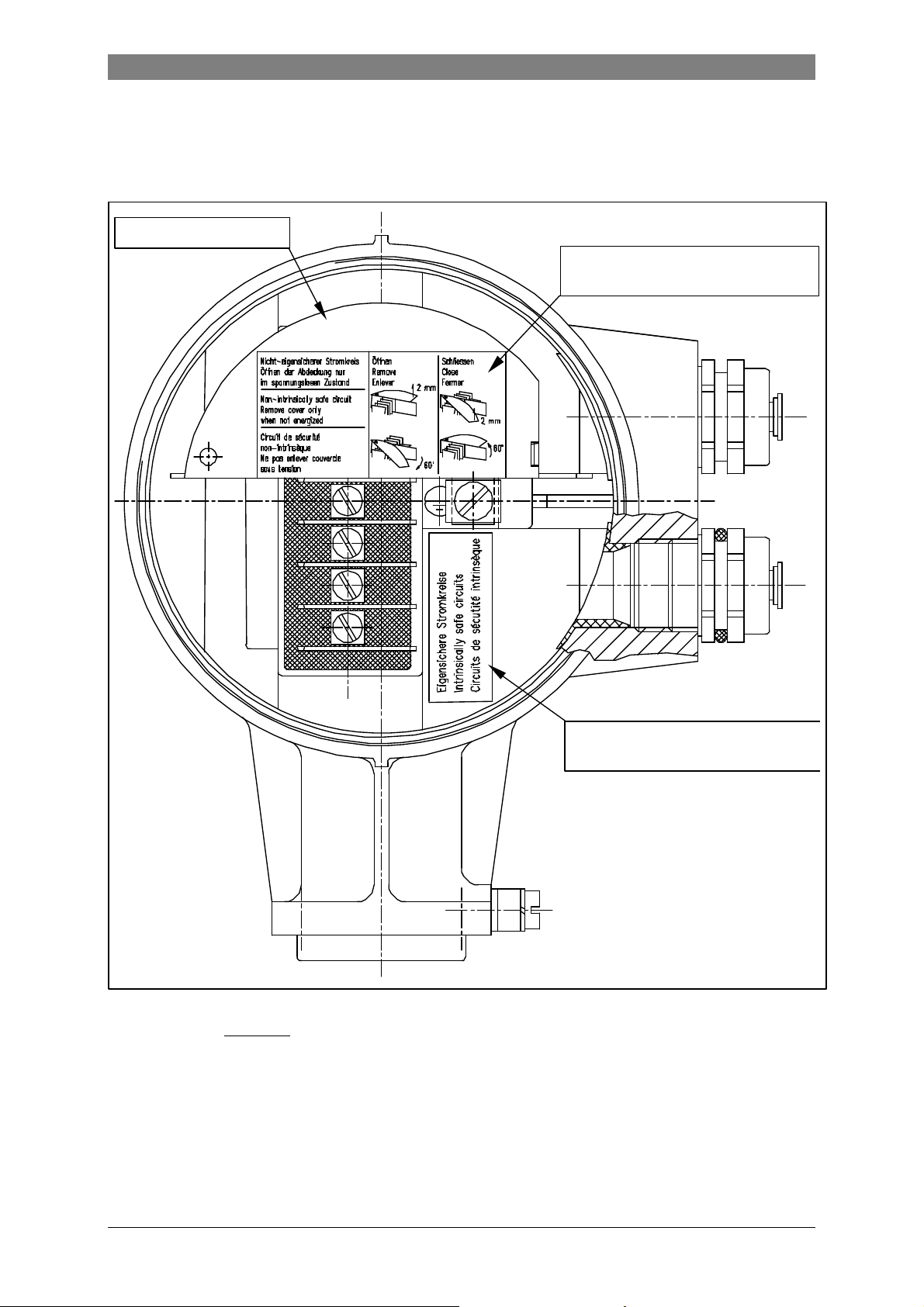

2.3 MODIS version IFC 090i-EEx electronics unit

The field cables of the non-intrinsically safe power supply and the intrinsically safe,

category "ia" signal outputs enter the terminal compartment of the IFC 090i-EEx signal

converter unit via two separate entrances. To connect external devices to the intrinsically

safe signal output terminals, the wiring requirements for their type of protection as well as of

the compartment (standard: increased safety "e", optional: flameproof enclosure "d") must be

conform to the international or national standard involved (e.g. EN 60079-14). Figure 4 below

shows the terminal arrangement inside the terminal compartment.

NC = not connected

Cable entrance for

intrinsically safe

signal cable

Connecting terminals

for intrinsically safe

signal in-/outputs

Metal dividing

plate IS / non-IS

Connecting

terminals for

non-intrinsically

safe power supply

NC 1L½0L

PE Protective Earth terminal

24 Vac/dc

Cable entrance for

non-intrinsically

safe power supply

cable

The non-intrinsically safe terminals for connection of the power supply (1L½ and 0L½) must

be connected according to the relevant standard code of practice for electrical apparatus

intended for use in potentially hazardous locations, type of protection Increased Safety "e" or

type of protection Flameproof Enclosure "d", depending on the type of protection of the

terminal compartment of the signal converter housing.

To gain access to the connection terminals of the power supply, the half-circular cover plate

of insulating material must be slightly lifted at one end and then rotated downwards, see the

instruction on the cover plate. After connection of the power supply cable, the half-circular

cover plate must be restored into its original position, so that the minimum clearances and

creepage distances towards the intrinsically safe signal in-/output terminals are maintained.

Figure 4: Terminal arrangement in terminal compartment.

6

Page 8

See for details figure 5 .

Insulating cover plate

Sticker with handling information

for insulating cover plate

Sticker indicating the intrinsically

safe signal in-/output circuits

Figure 5: Terminal compartment MODIS version IFC 090i-EEx.

7

Page 9

The PE (or FE) conductor must be connected to the press-fitted M5 clamp terminal marked

inside the terminal compartment. This conductor must be guided through the rectangular

opening in the metal dividing plate that separates the non-intrinsically safe power supply

terminals from the intrinsically safe signal in-/output terminals.

2.3.1 Connection diagrams MODIS

Section 7 shows the block diagram of the IFM 4080 K/ i…-EEx magnetic-inductive compact

flowmeter. The power supply (terminals 1L½, 0L½) is connected via cable B. The PE terminal

must be connected to the protective earth conductor of the mains supply.

The IFC 090i-EEx electronics unit is provided with intrinsically safe signal in-/output

circuits due to the installed pair of MODIS modules in accordance with the table below.

Module Terminal designation Function / Intrisically safe maximum data

Current output (0/4-20 mA), passive

P-SA

FA-ST

F-PA D, D ⊥

F-FF D, D ⊥

DC-I

(see note)

I ⊥ , I

B1, B1⊥ or B2, B2 ⊥

I+, B1+

Table 7: Overview of MODIS modules.

Ui = 30 V, Ii = 250 mA, Pi = 1.0 W

Ci = 5 nF, Li ≈ 0

Pulse (frequency) output or status in-/output, all passive

The function can be set by software

Ui = 30 V, Ii = 250 mA, Pi = 1.0 W

Ci = 5 nF, Li ≈ 0

Fieldbus module, type Profibus system, passive

Ui = 30 V, Ii = 300 mA, Pi = 4.2 W

Ci = 5 nF, Li ≈ 0

Fieldbus module, type Fieldbus Foundation, passive

Ui = 30 V, Ii = 300 mA, Pi = 4.2 W

Ci = 5 nF, Li ≈ 0

Intrinsically safe voltage source for the passive module

P-SA or FA-ST, so that active operation is possible.

Uo = 23.5 V, Io = 98 mA, Po = 0.6 W

Co = 132 nF 1, Lo = 4 mH

NOTES:

• Besides the shown intrinsically safe maximum values for voltages and current -which are

based on certain fault conditions as prescribed by the standard EN 50 020 - the nominal

values for current and voltage must also be respected otherwise a proper funtioning of

the modules is not guaranteed! See table 8 for the nominal values.

• The active module DC-I is needed in the 24 Vac/dc power supply version to form an

active current or pulse output in combination with one of the passive modules P-SA or

FA-ST. Due to limited space it is not available for 100...230 Vac supply versions.

Table 9 shows the possible combinations of the installed MODIS modules for the 24 Vac/dc

power supply version of the IFC 090i-EEx and table 10 for the 100-230 Vac version.

1

When modules P-SA (or FA-ST) and DC-I are connected in series, the internal capacitance Ci of 5 nF must be

subtracted from the Co of 132 nF. So the data plate will list a Co of 127 nF.

8

Page 10

MODIS modul Nominal values for voltage and current

P-SA

(passive current output )

FA-ST

(frequency/pulse/status output

or control input)

DC-I

(active voltage source)

Table 8: Nominal voltage and current values for the MODIS modules

IFC 090i-EEx version Part No. MODIS modules Terminal designation

Ex-i1 2.11582.01.00 P-SA FA-ST I ⊥ I B1 B1⊥

Ex-i2 2.11582.03.00 P-SA F-PA I ⊥ I D D ⊥

Ex-i3 2.11582.02.00 P-SA DC-I I+ I

Ex-i4 2.11582.05.00 FA-ST F-PA B1 B1⊥ D D ⊥

Ex-i5 2.11582.06.00 FA-ST DC-I B1+ B1

Ex-i6 2.11582.07.00 FA-ST FA-ST B2 B2⊥ B1 B1 ⊥

Ex-i7 2.11582.08.00 P-SA F-FF

Ex-i8 2.11582.09.00 FA-ST F-FF B1 B1⊥ D D ⊥

Current: 4 .. 20 mA

Working voltage: 8 .. 30V

Voltage drop : 8V at 4mA

Working voltage: 6 .. 30V

Working current: < 110 mA

Voltage drop: in ON-state: < 2V at 110 mA

Leakage current in OFF-state: < 900 µA at 30V

Control input:

Input voltage LOW level: < 3V

Input voltage HIGH level: > 7V

Frequency range : 0 .. 12 KHz

Voltage: 20V

Current 30 mA

Internal resistance: 260

I ⊥

I D

D ⊥

Table 9 : IFC 090i-EEx 24 Vac/dc versions.

IFC 090i-EEx version Part No. MODIS modules Terminal designation

Ex-i1 2.12253.01.00 P-SA FA-ST I ⊥ I B1 B1⊥

Ex-i2 2.12253.02.00 P-SA F-PA I ⊥ I D D ⊥

Ex-i4 2.12253.03.00 FA-ST F-PA B1 B1⊥ D D ⊥

Ex-i6 2.12253.04.00 FA-ST FA-ST B2 B2⊥ B1 B1 ⊥

Ex-i7 2.12253.05.00 P-SA F-FF I ⊥ I D D ⊥

Ex-i8 2.12253.06.00 FA-ST F-FF B1 B1⊥ D D ⊥

Table 10: IFC 090i-EEx 100-230 Vac versions.

Due to mechanical and electrical limitations, only the in table 9 and 10 listed pairs of MODIS

modules are possible. The two modules each use two terminals of the bottom four terminals

of the flameproof terminal feed-through in the dividing wall between the electronics and

terminal compartment of the signal converter housing, except for the combination with

module DC-I (only applicable for 24 Vac/dc versions), where only two of the four terminals

are used. Interconnection of the two modules, P-SA and DC-I resp. FA-ST and DC-I is made

internally.

9

Page 11

The flameproof terminal feed-through has seven terminals in total, the top two terminals are

used for connection of the power supply, the third one is only used for mounting of a metal

dividing plate with insulating cover plate. The remaining four are used for the intrinsically safe

signal in-/output circuits of the installed MODIS modules.

The metal dividing plate and the insulating cover plate warrant the required separation

distances (i.e. clearances, creepage distances and distances through insulation) between the

non-intrinsically safe power supply terminals and the intrinsically safe signal in-/output

circuits. The insulating cover plate is provided with a sticker that contains important

instructions how to remove and re-install the cover plate and the conditions under which it

should be established ( circuits not live !).

IMPORTANT !

Carefully follow the instructions on the sticker that is glued on top of the insulating

cover plate, that covers the non-intrinsically safe power supply terminals !

For the connection diagrams of the intrinsically safe signal in-/outputs of the installed MODIS

modules in the IFC 090i-EEx electronics unit (see figure 6, 7 and 8 on the following pages). It

has to be noted that the intrinsically safe signal in-/outputs may only be connected to the

following listed apparatus' (registering devices like amp-meters, pulse counters, etc.):

• EEx-approved intrinsically safe apparatus;

• EEx-approved associated apparatus;

• Passive apparatus as defined in your national standard for installation of electrical

apparatus in hazardous locations (equivalent of EN 60079-14, e.g. DIN VDE 0165).

Other types of apparatus may only be connected to the intrinsically safe signal in-/outputs

through EEx-approved safety barriers, isolating interface units and the like. These barriers or

units are not depicted in the connection diagrams of figure 6, 7 and 8 for reasons of

readability. It is assumed that they are an integrated part of the registering devices or as

separate devices connected in series with them. The registering devices may only be

installed in the hazardous location if they also have a type of protection for explosion safety

according to the European Standards of the EN 500xx series, or if they are constructed as

prescribed in your standard national code of practice.

When the intrinsically safe signal in-/outputs are connected to other intrinsically safe or

associated apparatus, the maximum safety values (i.e. entity parameters) of all intrinsically

safe circuits have to be considered.

IMPORTANT !

The 100…230 Vac power supply versions of the IFC 090i-EEx signal converter electronics

unit with MODIS modules can only be equipped with passive outputs. The connection

diagrams in the following figures 6 through 8 with the numbers 1, 3, 6 ,8 and 10 are

therefore not applicable for the 100…230 Vac power supply versions.

10

Page 12

Figure 6: Connection diagrams 1 through 4 of the intrinsically safe signal in-/outputs.

11

Page 13

Figure 7: Connection diagrams 5 through 8 of the intrinsically safe signal in-/outputs.

12

Page 14

Figure 8: Connection diagrams 9 through 12 of the intrinsically safe signal in-/outputs.

13

Page 15

3 OPERATION OF THE SIGNAL CONVERTER

The IFM 4080 K / i-EEx compact flowmeters are always equipped with magnet sensors. In

that way is possible to change the settings of the converter with aid of the magnet-bar

without the necessity to open the flameproof converter housing in the hazardous area.

For the program functions and settings of the converter the standard Installation and

operating instructions have to be consulted. It must be noted that - depending on the

IFC090 i-EEx version installed - not all output/input functions are available.

Following menus do not apply for the IFC090 i-EEx versions Ex-i2 and Ex-i3:

(see also section 4.4. "Table of settable Functions" in the of the standard "Installation and

operating instructions" of the IFC090 K/F signal converter)

• 1.01 à VALUE P

• 1.06 Output/input B1

• 1.07 Output/input B2

Fct. Text Description and settings

1.00 OPERATION Operations menu

1.01 FULL SCALE ...

à VALUE P

1.06 Output/Input B1

1.07 Output/Input B2

1.06 PULS B1

1.06

1.07

1.06

1.07

3.00 INSTALL. Installation menu

3.02 FLOWMETER ...

3.07 HARDWARE

As a consequence, the chapters included in the standard Installations and operating

instructions, giving detailed descriptions of these menus, must be skipped.

STATUS B1

STATUS B2

CONTROL B1

CONTROL B2

à VALUE P

• 1.06 PULS B1

• 1.06 STATUS B1

• 1.07 STATUS B2

• 1.06 CONTROL B1

• 1.07 CONTROL B2

• 3.02 à VALUE P

• 3.07 HARDWARE

4 SERVICE

See section 8 or contact your (local) Krohne sales representative for the ordering information

of spare parts or replacements of IFC 090…-EEx electronics units and/or power fuses.

14

Page 16

4.1 Replacement of electronics unit or power fuse(s)

B

IMPORTANT !

The following instructions must be followed carefully, if the IFC 090/…-EEx signal

converter housing has to be opened respectively closed again !

Before opening:

♦ Make absolutely sure that there is no explosion hazard !

♦ Gas-free certificate !

♦ Make sure that all connecting cables are safely isolated from the power supply !

♦ Allow the prescribed waiting time to elapse before opening the housing:

20 minutes for temperature class T6

11 minutes for temperature class T5

When the instructions above are strictly followed, the cover (with glass window) of the

electronics compartment may be removed. First unscrew the recessed head screw of the

interlocking device by a hollow-head screw wrench size 3, until the cover can rotate freely.

Unscrew the cover with the special plastic wrench (black) that is supplied with the apparatus.

After opening:

♦ The copper earth strip at the back of the electronics unit must be securely screwed to the

housing (back-end of electronics compartment) by screw SE (see figure 9 below). The

electronics unit is screwed into the electronics compartment by two screws D . Before

screws SE and D can be accessed, the display unit must be removed via screws A.

♦ Before the cover is screwed back into the housing, the screw-thread must be clean and

well-greased with an acid and resin-free grease, e.g. silicone grease.

♦ Screw the cover as tight as possible into the housing by hand, until it cannot be opened by

hand anymore. Screw the recessed head screw of the interlocking device tight.

SE

Note:

Safe earth

connection

SE

C

Flat cable of display unit

Figure 9: IFC 090-EEx electronics unit after removal of display unit.

A

Power fuse in fuse-holder

D

Mains transformer

Signal converter housing

D

Power supply PC-board

A

15

Page 17

4.1.1 Replacement of electronics unit

A

A

Refer to the standard Installation and Operating Instructions for detailed information about

resetting and reprogramming the new electronics unit after replacement. The customer

specific data (like the value of the internal totalizer) are stored in DATAPROM IC-18, which

must be transferred from the "old" to the "new" electronics unit. See Section 8.7 of the

standard Installation and Operating Instructions for detailed information.

Figure 10: Display unit of IFC 090…-EEx.

Before commencing work, note the instructions in Section 3.1 ("Before opening").

Then continue as follows:

1. Remove the display cover of the electronics compartment.

2. Unscrew the two screws A of the display unit (see figure 10) and turn it carefully aside.

3. Disconnect the 2-pole field circuit connector (item B in figure 9) and the 3-pole electrode

circuit connector (item C). Also see figure 11 on the next page.

4. Unscrew the two mounting screws D of the electronics unit and screw SE, which fixes the

copper earth strip to the back of the housing. A screwdriver with a long shaft (≥ 200 mm)

is most suitable for unscrewing screw SE (e.g. screwdriver type Philips No. 2).

5. Carefully remove the electronics unit of the converter housing (see the remark below).

6. Check if the voltage setting (only applicable for AC power supplies) and power fuse rating

are correct on the new electronics unit. If necessary, change the voltage setting or

replace the power fuse (see section 3.1.3 resp. 3.1.2 of this manual).

7. Carefully insert the electronics unit (keep cables aside, see remark below). Then mount

the unit completely into the housing and fix the screws. First the two screws D, then

screw SE and reconnect the 2-pole field circuit connector B and the 3-pole electrode

circuit connector C to the right counter-plugs on the electronics unit (see also figure 9).

8. Finally screw the display unit back on the frame of the electronics via the two screws A.

9. Screw the cover of the electronics compartment back into the housing.

Note the instructions of section 3.1 ("After opening") during reassembling.

IMPORTANT !

Carefully keep the connecting cables of the field coil and electrode circuits to the side of

the housing, while removing respectively inserting the electronics unit into the signal

converter housing. This is to prevent damaging of the connecting cables !

16

Page 18

Copper earth strip

SE

C: Electrode circuit

connector (3-pole)

Display unit

(back side)

B: Field circuit

connector (2-pole)

Flat cable of

display unit

Figure 11: IFC 090-EEx electronics unit (115/230 Vac version).

DD

4.1.2 Replacement of power fuse(s)

The power fuse(s) of the different IFC 090…-EEx electronics units (regular or MODIS) have

a different rating and are located on slightly different locations on the power supply printed

circuit board. Only the power fuse on the 100…230 Vac power supply version of the regular

IFC 090-EEx electronics unit can be reached without removing the complete unit out of the

housing (only the display unit has to be unscrewed).

Regular IFC 090-EEx with 24 Vac/dc power supply

Before commencing work, note the instructions in Section 3.1 ("Before opening").

Then continue as follows:

1. Remove the cover of the electronics compartment.

2. Unscrew the two screws marked with A of the display unit and turn it carefully aside.

3. Disconnect the 2-pole field circuit connector (item B) as well as the 3-pole electrode

circuit connector (item C). See figure 11 above.

4. Unscrew the two mounting screws D of the electronics unit and screw SE, which fixes the

copper earth strip to the integrated aluminum dividing wall at the back of the electronics

compartment. Use a screwdriver with a long shaft (≥ 200 mm) like type Philips No. 2 for

screw SE. Then take out the electronics unit, but be careful with the connecting cables,

so that they do not get damaged.

5. The defective power fuse(s) F1 and/or F2 (see figure 12 on the next page) can be

replaced now. The 24 Vac/dc power supply uses two sub-miniature fuses type TR 5 that

are rated T1.25A in accordance with IEC 127-3 publication (part No. 5.09080.00.00 ).

6. Reassemble in reverse order (points 3 through 1).

Note the instructions of section 3.1 ("After opening") during reassembling.

17

Page 19

Power fuses F1 and F2

F1F2

(see detail on the right)

Figure 12: IFC 090-EEx electronics unit with 24 Vac/dc power supply.

Regular IFC 090-EEx with 100…230 Vac power supply

Before commencing work, note the instructions in Section 3.1 ("Before opening").

Then continue as follows:

1. Remove the cover of the electronics compartment.

2. Unscrew the two screws A of the display unit and turn the display unit carefully aside.

3. The fuse-holder, in which the power fuse in accordance with IEC 127-2 size Ø5 x 20 mm

is mounted, is now accessible to replace the defect power fuse F1 by a new fuse with the

same rating. The rating depends on the voltage setting of the power supply unit. The

power supply of 100/115 Vac requires a fuse of T200mA (part No. 5.05678.00.00) and

the 200/230 Vac requires a fuse of T125mA (part No. 5.06627.00.00).

The fuse rating is also shown by the yellow sticker that is glued on the mains transformer,

which can only be seen after the regular IFC 090-EEx electronics unit is completely

removed from the flameproof signal converter housing. See figure 13 on the next page.

NOTE:

In case of any doubt about the fuse rating or the voltage setting of the unit, remove the

complete unit from the housing as described in section 3.1.1 on page 16 and check

the in figure 13 (on the next page) depicted items. Change when needed !

4. Reassemble the unit in reverse order (points 2 and 1).

Note the instructions of section 3.1 ("After opening") during reassembling.

18

Page 20

Mains transformer

115/230 Vac version

Indication of

Sticker with fuse rating

Power fuse F1 (in fuse-holder)

Voltage selector

voltage selector

(black dot = notch)

SIDE OF DISPLAY UNIT

Figure 13: Power supply version 115/230 Vac.

MODIS version IFC 090i-EEx

Before commencing work, note the instructions in Section 3.1 ("Before opening").

Then continue as follows:

1. Remove the cover of the electronics compartment.

2. Unscrew the two screws A of the display unit and turn it carefully aside.

3. Disconnect the 2-pole field circuit connector (item B) and the 3-pole electrode circuit

connector (item C). See figure 11 on page 15 for details.

4. Unscrew the two screws D and screw SE by a screwdriver with a long shaft (200 mm).

Take out the electronics unit, but do not damage the connecting cables. See the note

marked with IMPORTANT (gray-shaded box) below.

5. The defective power fuse (see figure 14 on the next page) can be replaced now. Use a

fuse rated at T1.25H250V (part No. 5.06232.00.00) for the 24 Vac/dc power supply and a

fuse of T1.6H250V (part No. 5.07823.00.00) for the 100…230 Vac power supply. Notice

that the locations are slightly different (the 24 Vac/dc supply version is shown).

6. Reassemble in reverse order (points 4 through 1).

Note the instructions of section 3.1 ("After opening") during reassembling.

IMPORTANT !

Carefully keep the connecting cables of the field coil and electrode circuits to the side of

the housing, while removing respectively inserting the electronics unit into the signal

converter housing. This is to prevent damaging of the connecting cables !

19

Page 21

NOTE:

Fuse_230V

The power fuse on the 100…230 Vac version is located on a slightly different

position than the fuse of the 24 Vac/dc version ! See location "

".

Fuse_230V

PTB 97 ATEX 2265 U

[EEx ia] IIC

PTB 97 ATEX 2265 U

Power fuse (24 Vac/dc power supply)

Figure 14: IFC 090i-EEx electronics unit (24 Vac/dc version is shown).

4.1.3 Changing power supply voltage

This only applies to the regular IFC 090-EEx electronics unit with 100-230 Vac power supply.

Before commencing work, note the instructions in Section 3.1 ("Before opening").

Then continue as follows:

1. Remove the cover of the electronics compartment.

2. Unscrew the two screws A of the display unit and turn the display unit carefully aside.

3. Unscrew the two mounting screws D of the electronics unit and screw SE, which fixes the

copper earth strip at the back of the housing. A screwdriver with a long shaft (200 mm)

can best be used to unscrew SE (e.g. screwdriver type Philips No. 2).

4. Disconnect the 2-pole and 3-pole connectors and carefully remove the electronics unit.

5. The voltage setting of the power supply can be changed by turning the dummy dual-in-

line block (i.e. voltage selector, see figure 13 on the previous page) over 180° in its

socket. The position of the notch on the dummy dual-in-line block indicates the voltage

setting. Also see the sticker that is glued on the mains transformer.

6. Reassemble in reverse order (points 4 through 1).

7. Screw the cover of the electronics compartment back into the housing.

Note the instructions of section 3.1 ("After opening") during reassembling.

IMPORTANT !

Carefully keep the connecting cables of the field coil and electrode circuits to the side of

the housing, while inserting the electronics unit into respectively removing it from the

signal converter housing. This is to prevent damaging of the connecting cables !

20

Page 22

5 CONNECTING CABLES

NOTE:

The below described cables are shown in the connection diagram on the following page.

Cable A:

Signal cable for current output and binary outputs (pulse and status output). The cable

parameters must be in accordance with the regulations in the EN 60079-14 "Electrical

installations in hazardous locations" or an equivalent national standard (e.g. DIN VDE 0165).

For the MODIS version with IFC 090i-EEx electronics unit (right detail in connection diagram)

the signal cable for the intrinsically safe signal in-/outputs must also conform the

requirements as specified in the relevant standard national code of practice for the

installation of electrical apparatus with type of protection Intrinsic Safety "i".

Cable B:

Power supply cable. The cable parameters must be in accordance with the regulations of the

EN 60079-14 "Electrical installations in hazardous locations" or an equivalent national

standard (e.g. DIN VDE 0165).

Rated voltage: ≥ 500 V

Examples: H07..-., H05..-.

Equipotential bonding conductor

Cross-sectional area: 4 mm2 (equivalent to AWG 10)

6 MAINTENANCE

The IFM 4080 K/…-EEx magnetic-inductive compact flowmeters are maintenance free with

regard to the flowmetering properties. Within the scope of the periodical inspections, which

are required for electrical apparatus that are installed and used in hazardous classified

locations, it is recommended to check the flameproof enclosure(s).

21

Page 23

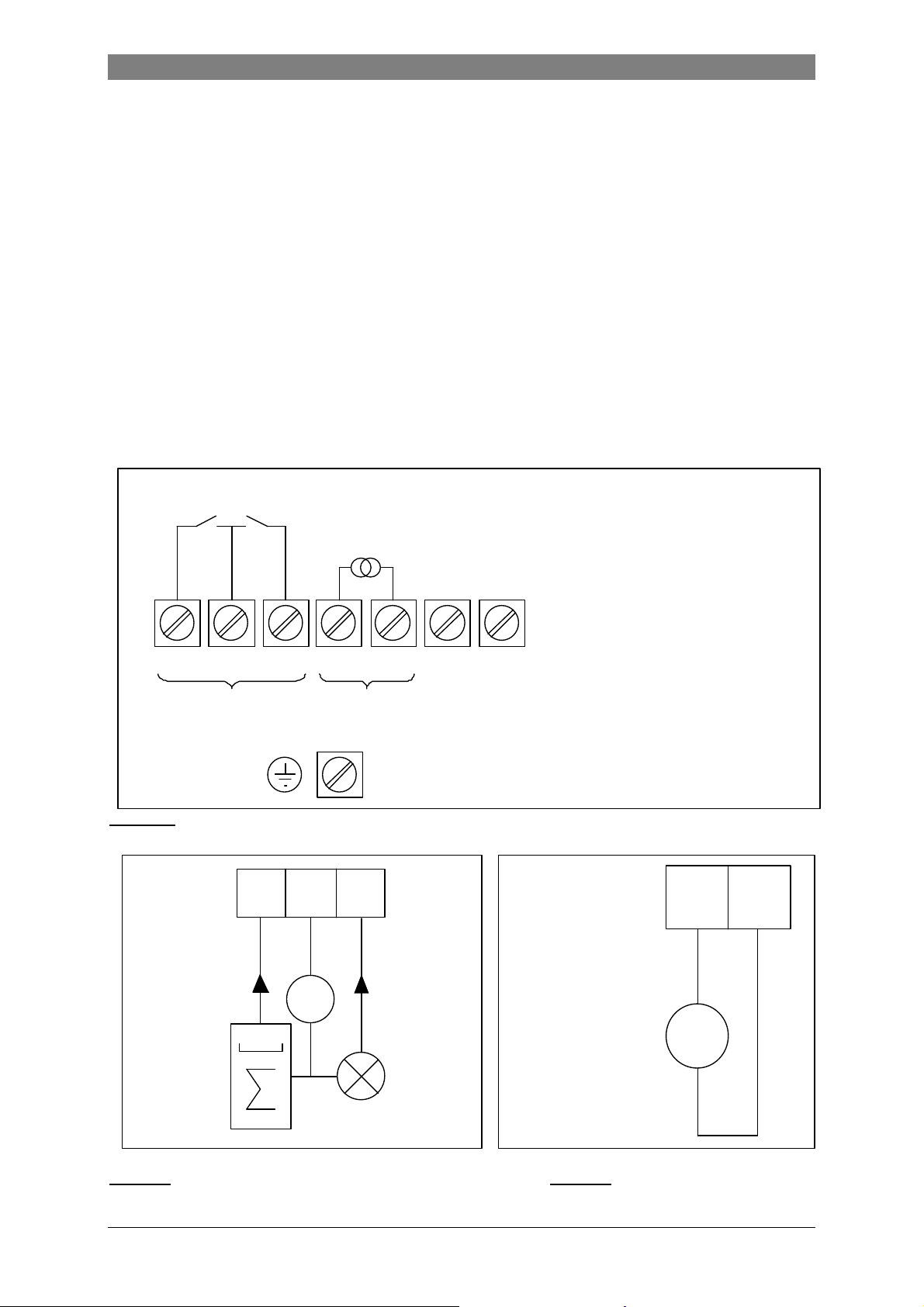

7 CONNECTION DIAGRAM

Flow tube

of Zone 1 and 2

E

Increased safe field coil circuit

Coil

B1 B⊥B2 I+ I L N

Standard "EEx e" (Optional "EEx d")

Signal Converter

FE

SIGNAL IN-/OUTPUTS L¾L¾FE 24 Vac/dc

2

B

A

E

Coil

Signal Converter

FE

OPTION: MODIS

B

A

L N PE 100-230 Vac

IFC 090-EEx

PE

INTRINSICALLY SAFE

SIGNAL IN-/OUTPUTS L N PE 100-230 Vac

(i.e. MODIS) L½L½FE 24 Vac/dc

PE

½

x x x x

1L½0L

ELECTRONICS COMPARTMENT (always "EEx d")

(OPTIONAL)

4 mm

≥

BINARY CURRENT MAINS

OUTPUTS OUTPUT SUPPLY

TERMINAL COMPARTMENT

Intrinsically safe ("ib") Increased safe ("e")

electrode circuits field coil circuits

(No. "2", "3", "1") (No. "7", "8")

Unused terminal

Separation plate

IFC 090i-EEx

Flameproof (EEx d)

terminal feed-through

Flameproof (EEx d) cable

feed-through LC-2/EEx

Hazardous locations

Field coil wires - green/blue

(PTFE insulated copper)

EQUIPOTENTIAL BONDING CONDUCTOR

Electrode cables - white/pink

(PTFE insulated shielded copper)

IFS 4000…-EEx

Primary Head

Intrinsically safe electrode circuits

22

Page 24

8 ORDERING INFORMATION

In case of questions about spare or replacing parts contact your local Krohne representative.

The part numbers of the several parts are listed in the sections below.

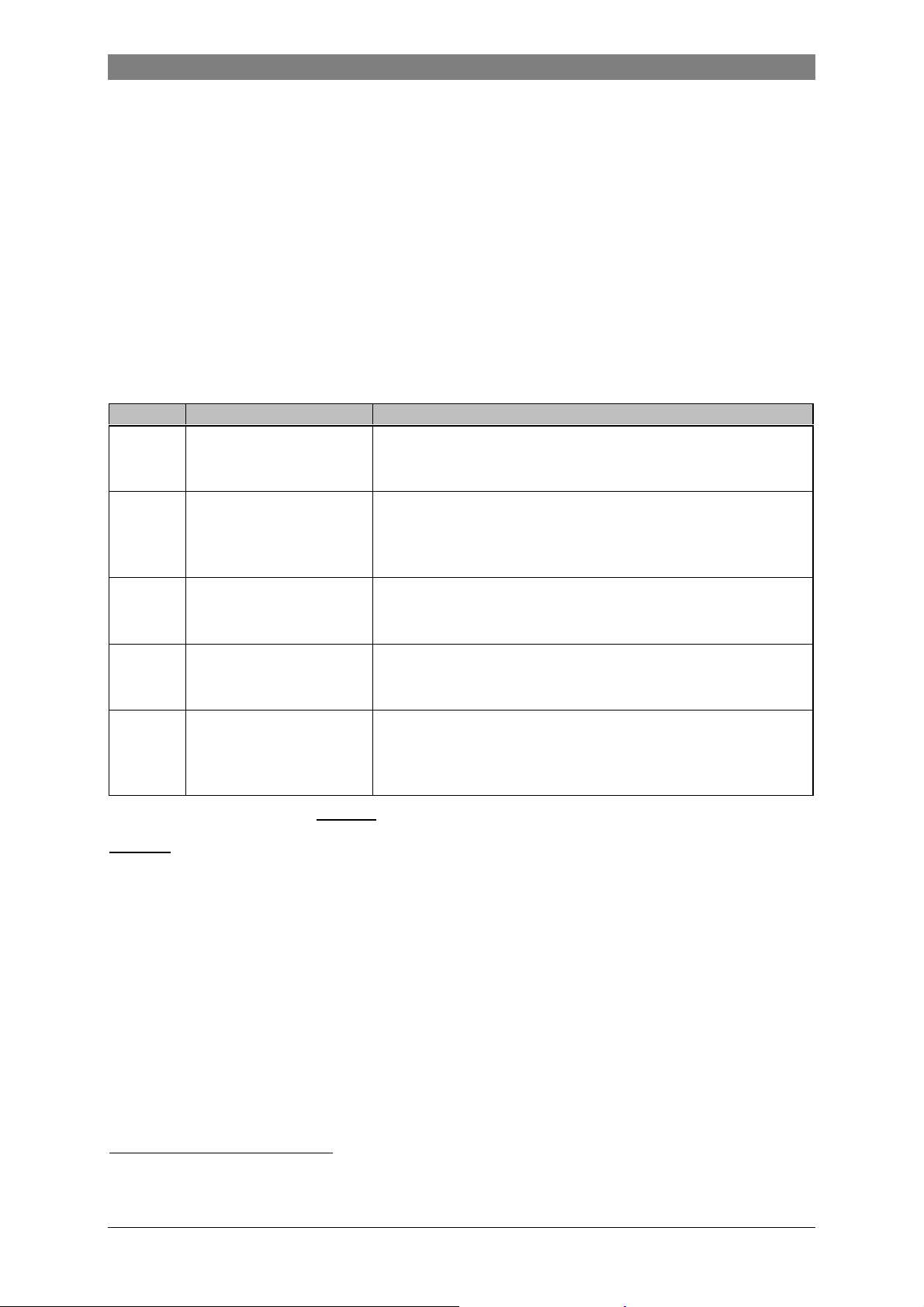

8.1 Regular IFC 090-EEx electronics unit

The below listed table shows the available regular (non-MODIS) IFC 090-EEx versions with

the possible power supply units and the accompanying power fuse(s).

IFC 090-EEx electronics unit Power fuse(s)

Power supply Part No. Symbol Type Rating Part No.

230/240 Vac F1 125 mA T 5.06627.00.00

115/120 Vac

200 Vac F1 125 mA T 5.06627.00.00

100 Vac

24 Vac/dc 2.10665.10.00 F1 + F2 TR5, 35A @ 250V 1.25 A T 5.09080.00.00

8.2 MODIS version IFC 090i-EEx electronics unit

Table 11 below summarizes the available IFC 090i-EEx electronics units (MODIS version)

and the matching part number. The accompanying power fuses are listed in table 12.

2.10664.10.00

2.10664.13.00

Table 10: IFC 090-EEx electronics units and power fuses.

F1 200 mA T 5.05678.00.00

F1

G-fuse Ø5x20

1500A @ 250V

200 mA T 5.05678.00.00

Version

Ex-i1 P-SA FA-ST 2.11582.01.00 2.12253.01.00

Ex-i2 P-SA F-PA 2.11582.03.00 2.12253.02.00

Ex-i3 P-SA DC-I 2.11582.02.00 not available

Ex-i4 FA-ST F-PA 2.11582.05.00 2.12253.03.00

Ex-i5 FA-ST DC-I 2.11582.06.00 not available

Ex-i6 FA-ST FA-ST 2.11582.07.00 2.12253.04.00

Ex-i7 P-SA F-FF 2.11582.08.00 2.12253.05.00

Ex-i8 FA-ST F-FF 2.11582.09.00 2.12253.06.00

The above listed IFC 090i-EEx electronics units are either provided with a 24 Vac/dc power

supply or a 100…230 Vac power supply. The table below lists the accompanying power fuse.

Power supply version

24 Vac/dc

100…230 Vac

MODIS modules Part number

Position A Position B 24 Vac/dc power supply 100…230 Vac power supply

Table 11: IFC 090i-EEx electronics units.

Power fuse

Type Rating Part number

G-fuse Ø5x20

1500A @ 250V

G-fuse Ø5x20

1500A @ 250V

Table 12: Power fuses of IFC 090i-EEx electronics units.

1.25 A T (T1.25H250V) 5.06232.00.00

1.6 A T (T1.6H250V) 5.07823.00.00

NOTES:

The in table 10 and 12 above listed G-fuses of size Ø5 x 20 mm and with 1500 A breaking

capacity at 250 V are in accordance with IEC publication 127-2.

Fuse type TR5 is of size sub-miniature and has a breaking capacity of 35 A at 250 V. It is in

accordance with IEC 127-3. The regular IFC 090-EEx electronics unit with 24 Vac/dc power

supply contains two of these fuses in the primary circuits, labeled as F1 and F2.

23

Page 25

9 DATA PLATES

Figure 15: Data plate of IFM 4080 K-EEx.

Figure 16: Data plate of IFM 4080 K/i-EEx.

24

Page 26

10 DECLARATION OF CONFORMITY

25

Page 27

11 EC-TYPE EXAMINATION CERTIFICATE

26

Page 28

27

Page 29

28

Page 30

730917.31.00

Subject to change without prior notice

Krohne Altometer

Kerkeplaat 12

3313 LC Dordrecht

The Netherlands

Tel.: ++ 31 (0)78 - 630 63 00

Fax.: ++ 31 (0)78 - 630 63 90

Loading...

Loading...