Page 1

Installation and

operating instructions

ALTOFLUX 2W

IFM 4042 K

Electromagnetic flowmeters

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

Applicable to

Software Versions

● Display/Control unit

No. 3.19019.xx00

● ADC module

No. 3.19749.xx00

● I/O module

No. 3.18748.xx00

DIN A4: 7.10004.31.00

©

KROHNE 02/2001 US size: 7.10004.71.00

GR/OP

How to use these Instructions

The flowmeters are supplied ready for operation.

– Installation in the pipeline (Section 1) Pages 5-10

– Electrical connection (Section 2) Pages 11-13

– Start-up (Section 3) Page 17

Power the flowmeter. THAT’S ALL. The system is operative.

Page 2

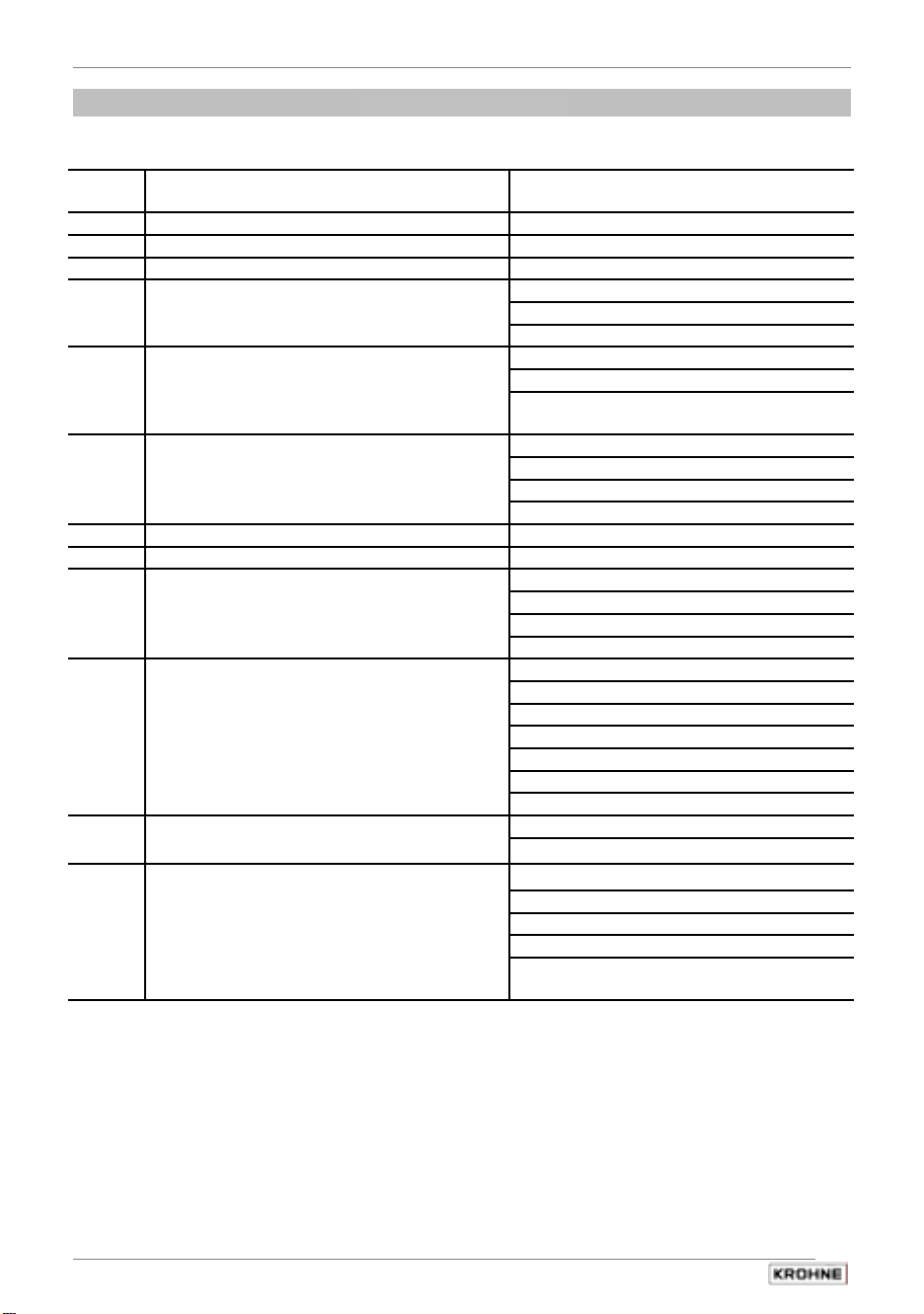

<RXURSHUDWLQJGDWD

Here you can note down the settings of the signal converter !

Fct. No. Function Settings

1.01 Full-scale range

1.02 Time constant

1.03 Low-flow cutoff - ON: - OFF:

1.04 Display

1.05 Current output

Flow

Counter

Messages

Function

Range

Error

1.06. Pulse output

Function

Pulse width

Pulses / Volume

1.07 Status output

3.01 Language

3.02 Primary head Meter size

GKL value

Flow direction

3.4 Application Empty pipe

Field current

Mode field current

Limit

Filter

3.5 Hardware Function of terminal B:

3.6 HART

off HART

Current 4 mA trim.:

Current 20 mA trim.:

Address

I-Multidrop:

2

ALTOFLUX 2W

02/2001

Page 3

&RQWHQWV

•

•

•

•

•

Your operatig data 2

System description 4

Product liability and warranty 4

CE / EMC / Standards / Approvals 4

Software history 4

7HLO$ ,QVWDOODWLRQDQG6WDUWXS

1 Installation 5 - 10

1.1 Items included with supply 5

1.2 Handling 5

1.3 Installation location 6

1.4 Suggestions for installation 7

1,5 Installation in the pipeline 8

1.6 Torques 9

1.7 Grounding 10

2 Electrical connection 11 – 16

2.1 Information on electrical connection and connection data 11

2.2 Output circuit diagrams 12 – 13

2.3 Characteristic of the outputs 14 – 16

3 Start-up 17

3.1 Power ON and measurement 17

3.2 Factory settings 17

7HLO% ,)&6LJQDOFRQYHUWHU ²

4 Operation of the signal converter 18 - 33

4.1 KROHNE operator control concept 18

4.2 Operating and check elements 19

4.3 Function of keys 20 – 21

4.4 Table of settable function 22 – 32

4.5 Error messages in measuring mode 33

4.6 Reset counter and cancel error messages 33

7HLO& 7HFKQLFDO'DWD%ORFNGLDJUDPXQG0HDVXULQJSULQFLSOH ²

5 Technical Data 34 - 40

5.1 Full-scale ranges 34

5.2 Error limits at reference conditions 35

5.3 IFC 040 Signal converter 36 – 37

5.4 IFS 4002 Primary head 38

5.5 Dimensions and weights 39

5.6 Limits 40

6 Block diagram of signal converter 41

7 Measuring principle 42

8 If you need to return flowmeters for testing or repair to KROHNE 43

02/2001

ALTOFLUX 2W

3

Page 4

6\VWHPGHVFULSWLRQ

ystem description

Electromagnetic 2-wire flowmeters with IFC 040 signal converter are precision instruments

designed for linear flow measurement of liquid products.

The process liquids need to be electrically conductive, ≥ 5 µS/cm

(for cold demineralized water ≥ 20 µS/cm).

Depending on the meter size, the full-scale range Q

100%

can be set between 85 Liter/h and 763 m3/h, equivalent to a flow velocity v = 0,3- 12 m/s,

see flow table in Section 5.1.

3URGXFWOLDELOLW\DQGZDUUDQW\

Electromagnetic 2-wire flowmeters with IFC 040 signal converter are designed solely for

measuring the volumetric flowrate of electrically conductive, liquid process products.

These flowmeters are also available for use in hazardous areas. Special codes and regulations

apply in this connection and these are referred to in the special ‘EEx’ notes.

Responsibility for suitability and intended use of these electromagnetic flowmeters rests solely

with the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the “General conditions of sale” forming the basis of the purchase contract are

applicable.

If flowmeters need to be returned to KROHNE, please note the information given on the last-but-

one page of these Instructions. KROHNE regret that they cannot repair or check your

flowmeter(s) unless accompanied by the completed form sheet.

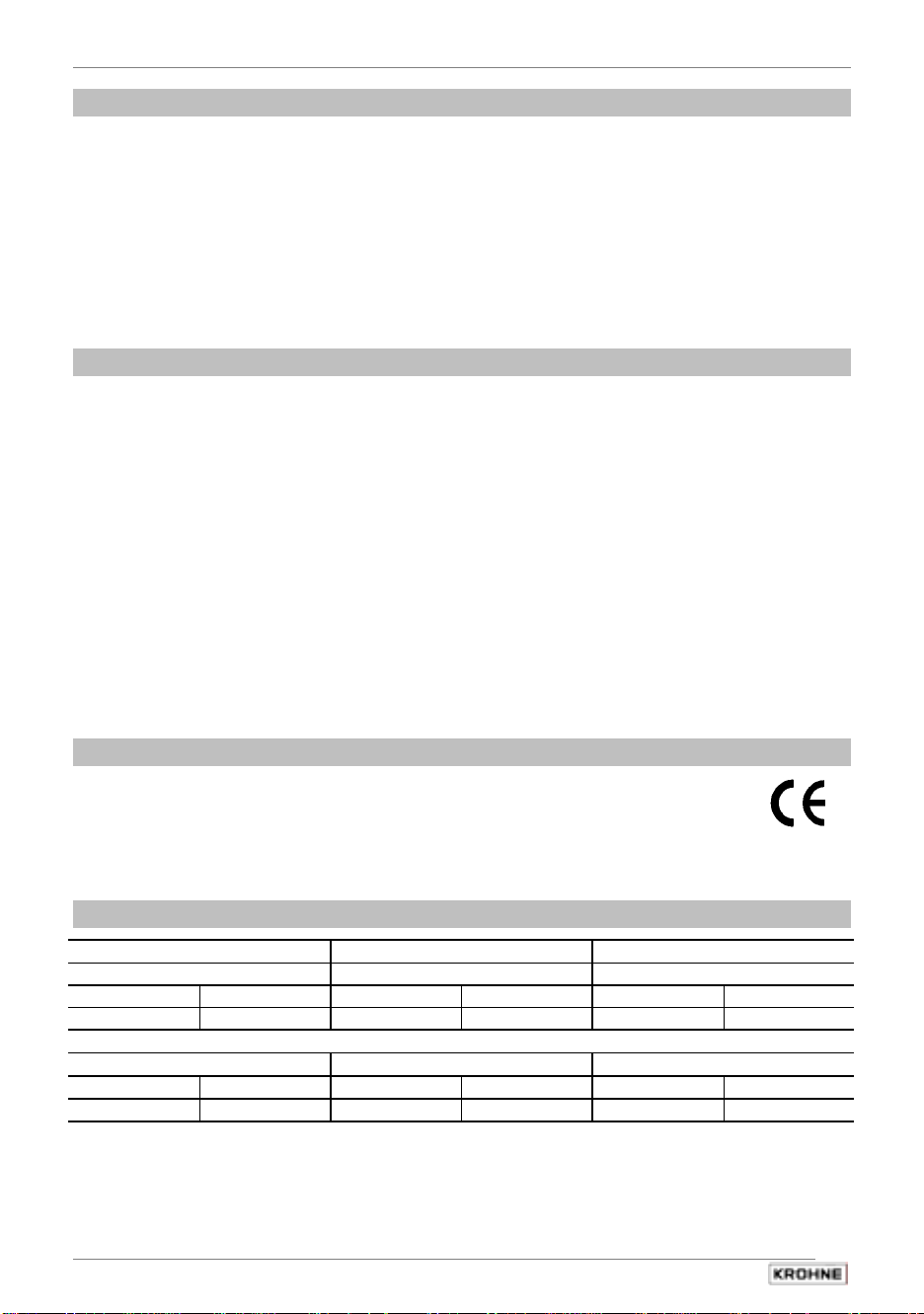

&((0&6WDQGDUGV$SSURYDOV

Electromagnetic flowmeters with IFC 040 signal converter

meet the protection requirements of Directive 89/336/EEC in conjunction with

EN 50081-1 (1992) and EN 50082-2 (1995), and Directives 73/23/EEC and

93/68/EEC in conjunction with EN 61010-1, and also bear the CE symbol..

6RIWZDUHKLVWRU\

Display and control unit PC user software Hart® module

IFC 040 IFC 040

Software Status Software Status Software Status

3.19019.xx00 current 3.19136.xx00 current 3.18748.xx00 current

ADC module I/O module

Software Status Software Status

3.19749.xx00 current 3.18748.xx00 current

4

ALTOFLUX 2W

02/2001

Page 5

Part A Installation and Start-up Section 1.1 + 1.2

,QVWDOODWLRQ

1.1 Items included with supply

Flowmeter in the size as ordered

•

Connecting wires for grounding, refer to Section 1.7 Grounding

•

Certificate of calibration data

•

Grounding rings (option), if ordered

•

Installation and operating instructions for the signal converter

•

Fitting accessories (stud bolts, screws, gaskets, etc.)

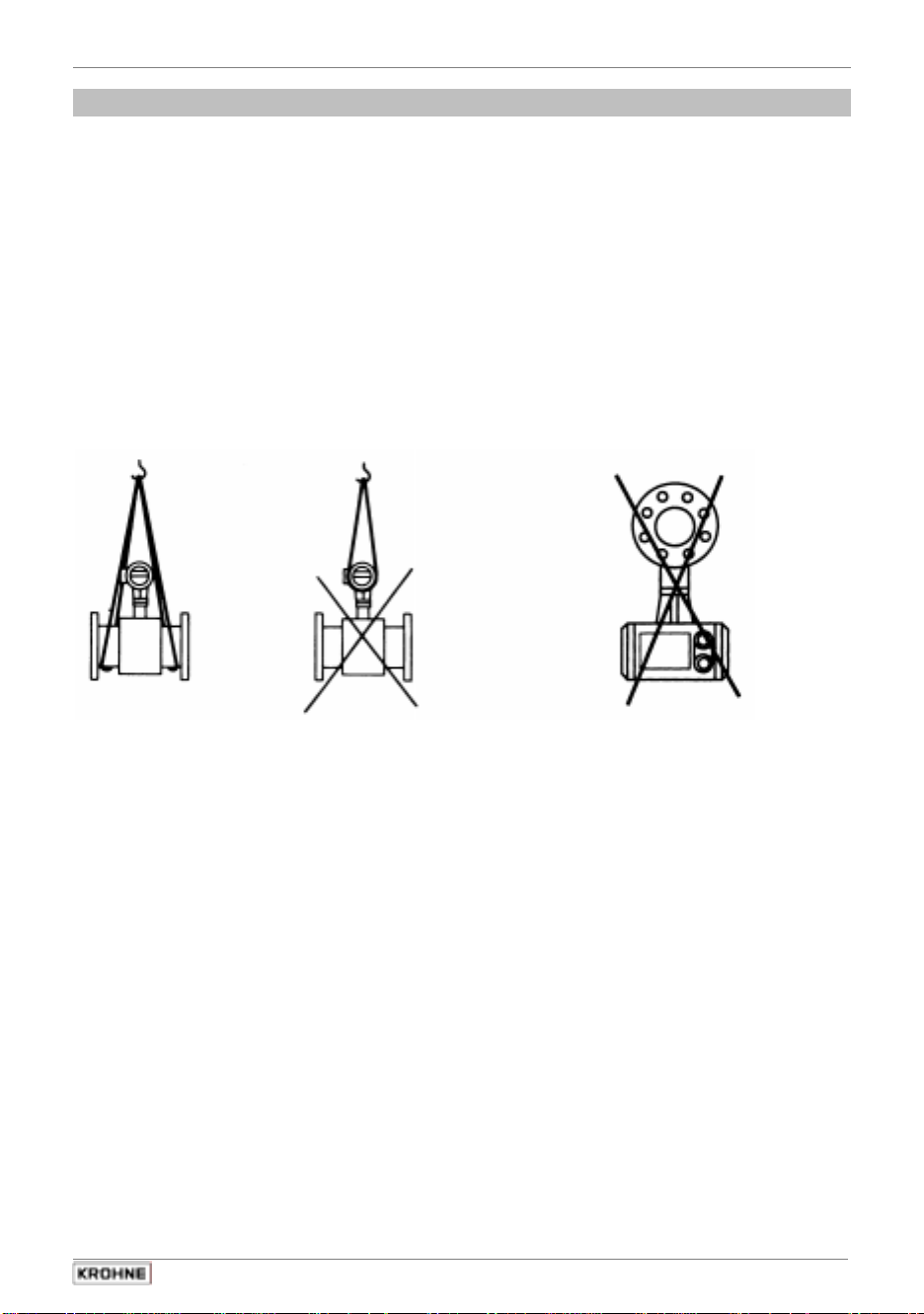

1.2 Handling

to be provided by customer!

are not supplied,

Do not lift flowmeter by the signal converter

housing or the terminal box.

Do not set flowmeter down on the signal

converter housing.

02/2001

ALTOFLUX 2W

5

Page 6

Section 1.3 Part A Installation and Start-up

1.3 Installation location

• Temperatures

Refer to Section 5.6 “Limits“ for operating pressure and vacuum load based on flange

standards and type of tube liner.

Standard -25 to +60 °C -13 to +140 °F

EEx -25 to +60 °C -13 to +140 °F

Storage and handling -25 to +60 °C -13 to +140 °F

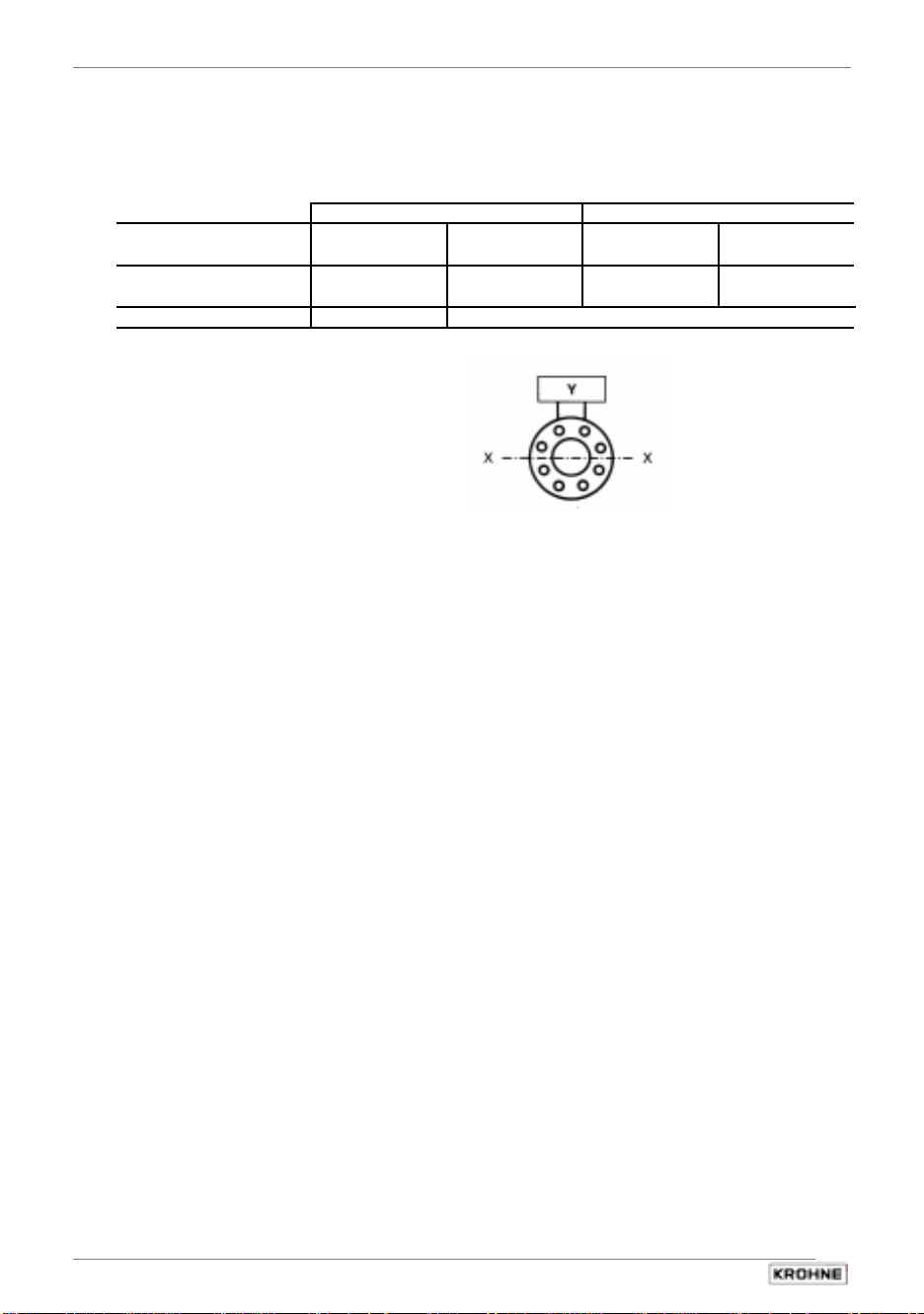

• Location and position as required,

but in a horizontal pipe run

electrode axis

Ambient temperature

-25 to +40 °C -13 to +104 °F

-25 to +40 °C -13 to +104 °F

Process temperature

-25 to ≤ + 60 °C -13 to ≤ +140 °F

-25 to ≤ +140 °C -25 to ≤ +284 °F

-25 to ≤ + 60 °C -13 to ≤ +140 °F

-25 to ≤ +140 °C -25 to ≤ +284 °F

X – • – • – • – X

should be approximately horizontal.

Y Signal converter housing

• Measuring tube must be completely filled at all times.

• Direction of flow is arbitrary: arrow on flowmeter can normally be ignored.

For exceptions, refer to Sect. 3.2 “Factory settings” in the Installation and Operating

Instructions for the signal converter.

• Stud bolts and nuts: to install, make sure there is sufficient room next to the pipe flanges.

• Vibration: support pipeline on both sides of flowmeter. Level of vibration in conformity with

IEC 068-2-34: below 2.2g for flowmeters in the 20-150 Hz frequency range.

• Do not expose to direct sunlight: fit a sunshade if necessary, not included with flowmeter,

to be provided by customer.

• Avoid strong electromagnetic fields in vicinity of flowmeter.

• Inlet run 5 × DN and outlet run 2 × DN, straight pipeline,

measured from electrode axis (DN = meter size)

• Vortex and corkscrew flow: increase length of inlet and outlet runs or

install flow conditioners.

• Mixing different process liquids: install flowmeter upstream of the mixing point or at an

adequate distance downstream (min. 30 × DN), otherwise display may be unsteady.

• Plastic pipelines and internally coated metal pipelines: grounding rings required,

refer to Sect. 1.7 “Grounding“.

• Insulated pipeline: do not insulate flowmeter.

• Zero setting: not necessary. To check, it should be possible to set “zero“ flow velocity

when the measuring tube is completely filled. Shutoff valves should therefore be provided,

either downstream of the flowmeter or upstream and downstream of the flowmeter.

• Electrical connection to VDE 0100 “Regulations governing heavy-current installations

with line voltages up to 1000 V” or equivalent national regulations.

• Hazardous areas: subject to special regulations,

refer to special ‘EEx’ information (texts with grey background).

6

ALTOFLUX 2W

02/2001

Page 7

Part A Installation and Start-up Section 1.4

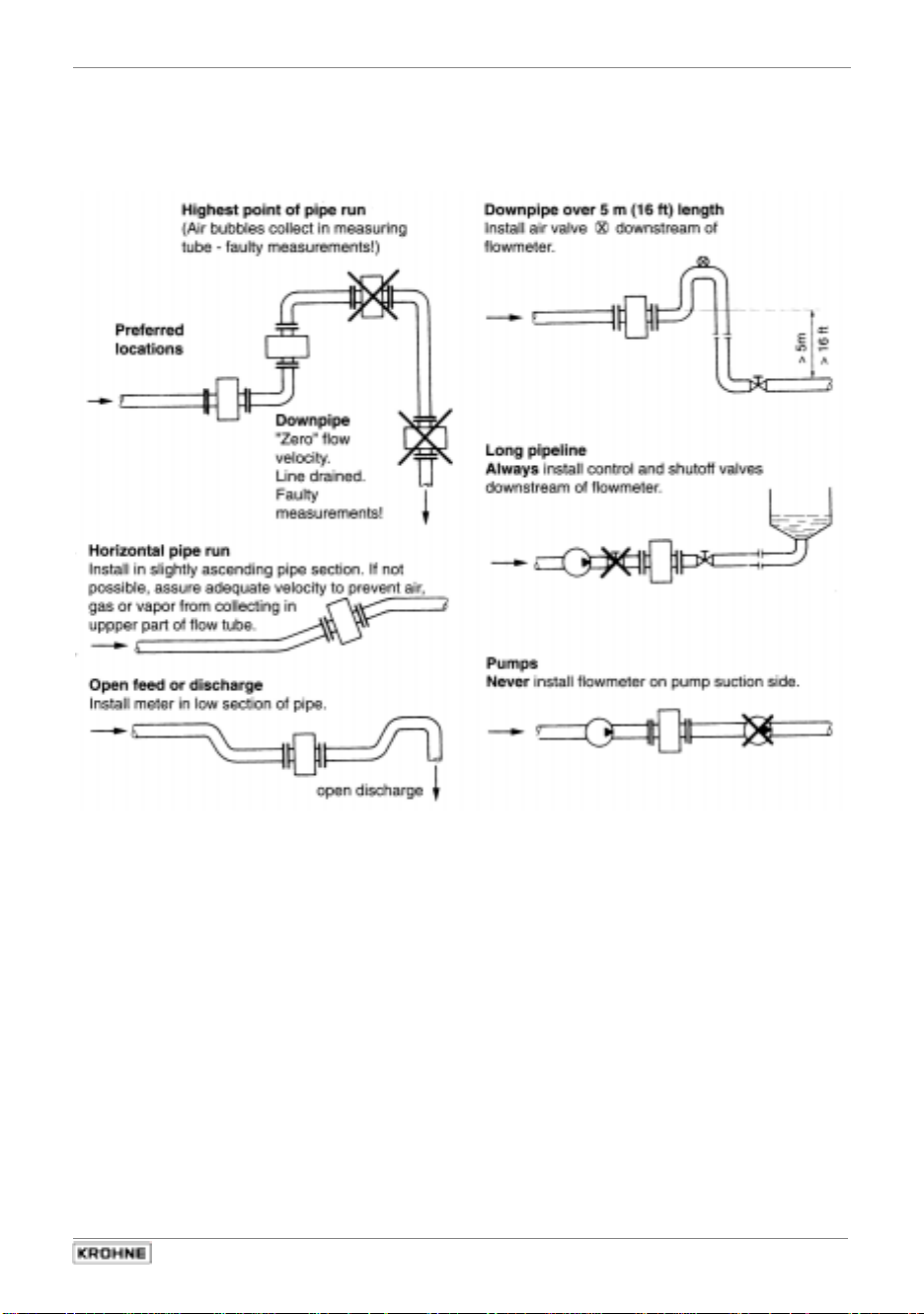

1.4 Suggestions for installation

To avoid measuring errors due to gas/air inclusion or to pipe running empty,

please observe the following:

02/2001

ALTOFLUX 2W

7

Page 8

Section 1.5 Part A Installation and Start-up

1.5 Installation in the pipeline

• Installation material not included, to be provided by customer

(stud bolts, nuts, gaskets, etc.).

• Pipe flanges and operating pressure: refer to “limits“ tables in Section 5.6

• Distance between pipe flanges:

see fitting dimension a in Section 5.5 “Dimensions and weights“

• High-temperature service

Where process temperatures exceed 100°C/212°F, provide facilities to compensate for

longitudinal expansion on heat-up of the pipeline.

For short pipelines, use resilient gaskets, and

for long pipelines install flexible pipe elements (e.g. elbows).

• Flange position: Install flowmeter in line with pipe axis.

Pipe flange faces must be parallel to each other.

• Gaskets

No additional gaskets required for primary heads fitted with tube liners of Teflon® - PFA or

Teflon® - PTFE. Refer to Sect. 1.6 for torques.

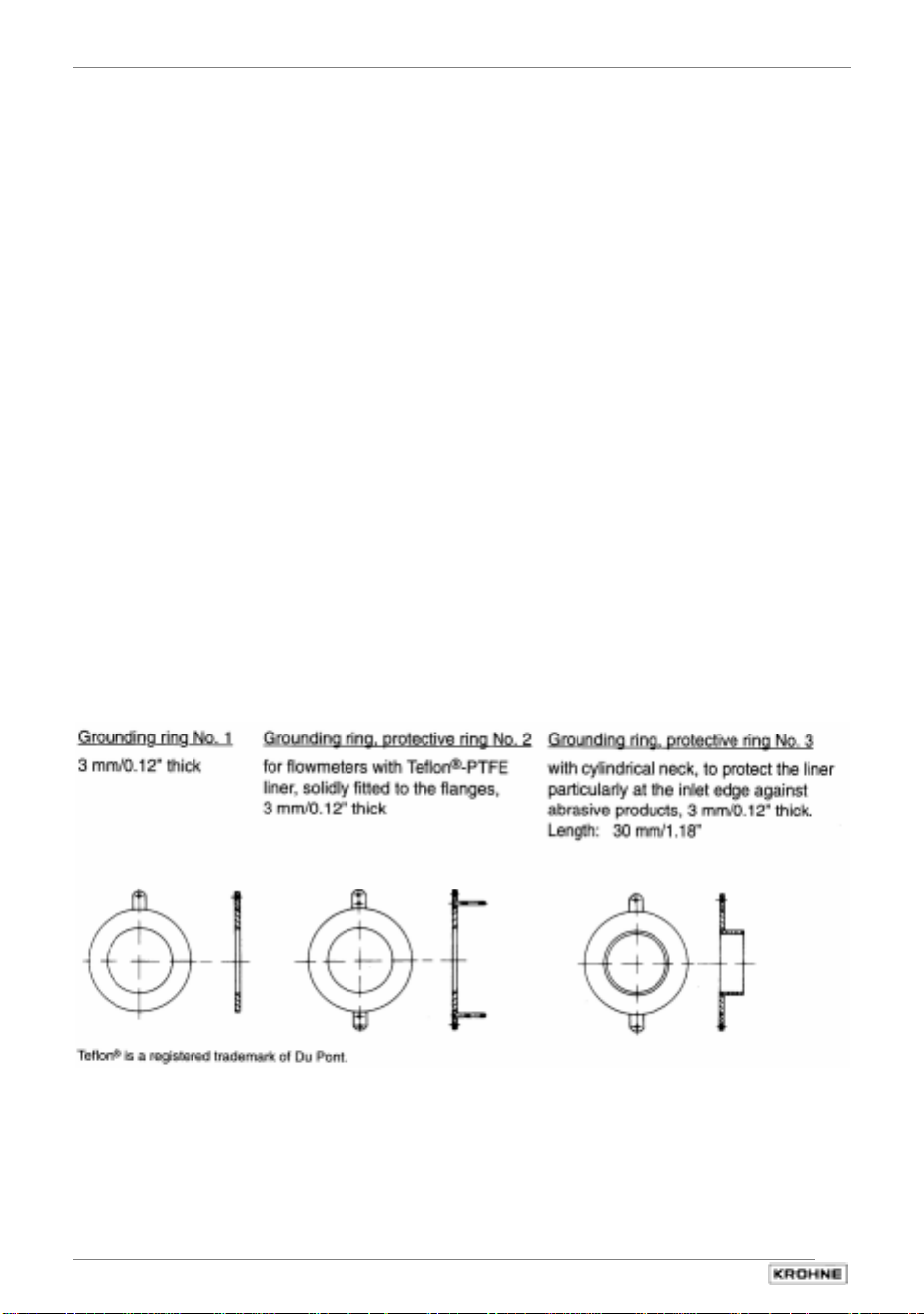

• Grounding rings / protection rings (option)

On plastic pipelines and internally coated metal pipelines, grounding rings are required to

form the conductive connection with the process liquid. Refer to Sect. 7 “Grounding“ for

electrical connection.

Please note: The cylindrical neck must be inside the measuring tube

(to protect the liner, particularly at the inlet edge).

8

ALTOFLUX 2W

02/2001

Page 9

Part A Installation and Start-up Section 1.6

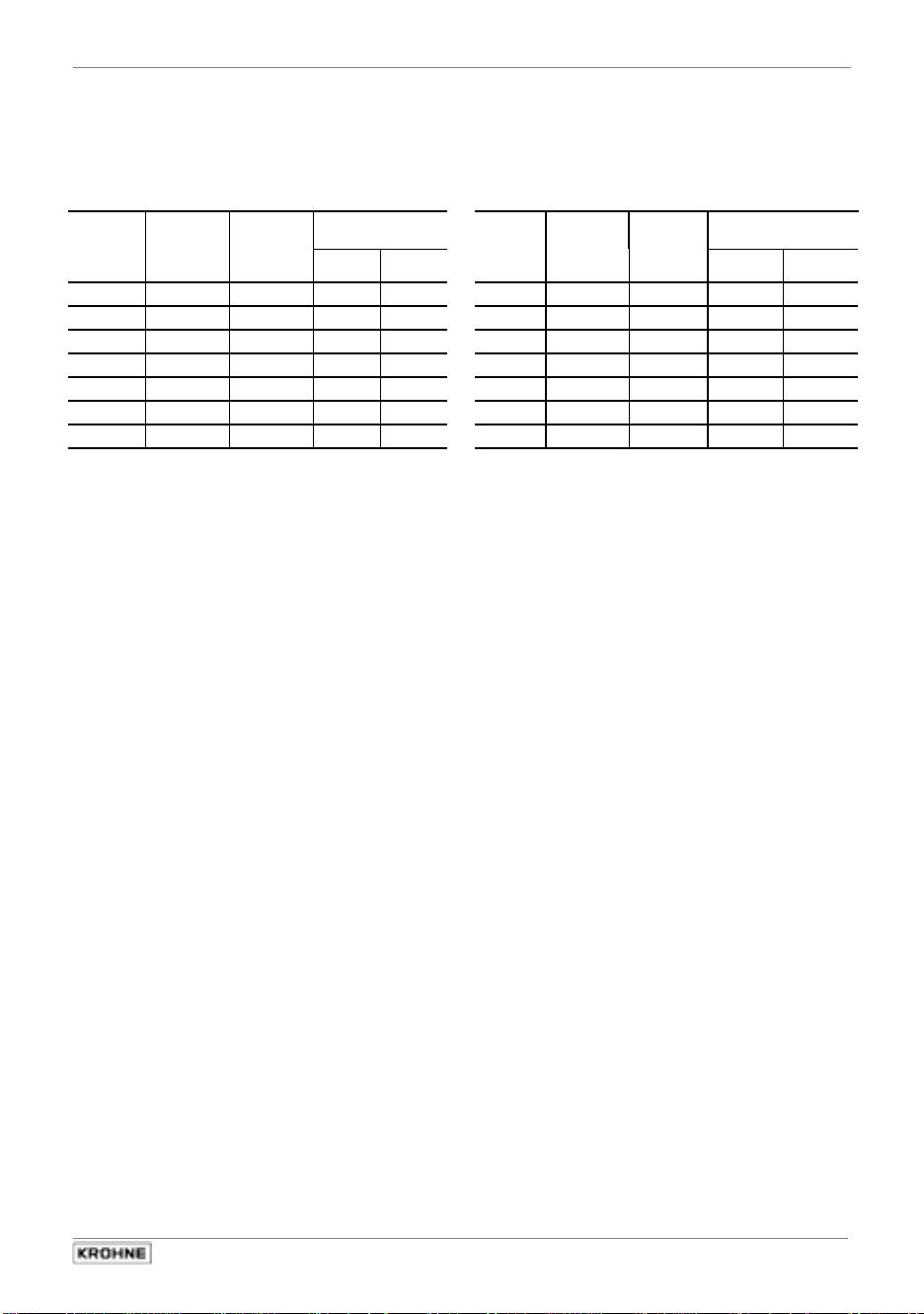

1.6 Torques

• Stud bolts:

See table for number and type.

• 10 Nm ~ 1.0 kpm ~ 7.23 ft × lbf

Meter

size

DN mm

10

15

25

50

80

100

150

tighten uniformly in diagonally opposite sequence.

Pressure

rating

PN

40

40

40

40

25

16

16

Bolts

Max.

torques

Nm

4 × M 12 7.6 5.5

4 × M 12 9.3 6.7

4 × M 12 22

4 × M 16 55

8 × M 16 47

8 × M 16 39

8 × M 20 68

ft × lbf

11

31

25

30

47

Meter

size

inches

3

/

1

/

1

2

3

4

6

Flange

class

Ib

150

8

2

150

150

150

150

150

150

Bolts

for

ANSI

class 150

flanges

4 × 1/2" 3.5

4 × 1/2" 3.5

4 × 1/2" 6.7

4 × 5/8” 24

4 × 5/8” 43

4 × 5/8” 34

8 × 3/4" 61

Nm

Max.

torques

ft × lbf

2.5

2.5

4.8

17.4

31.1

24.6

44.1

02/2001

ALTOFLUX 2W

9

Page 10

Section 1.7 Part A Installation and Start-up

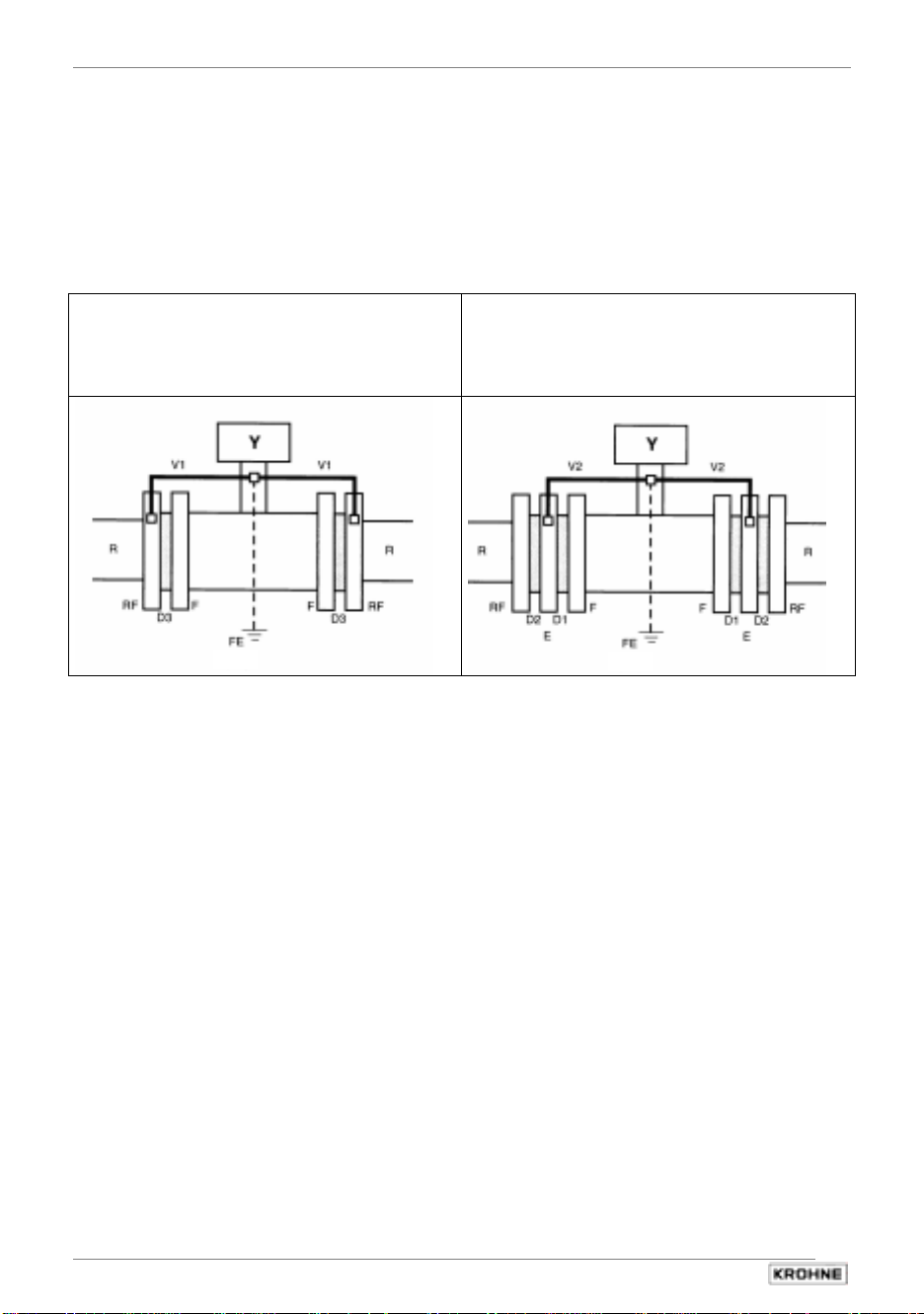

1.7 Grounding

• All flowmeters must be properly grounded to avoid personnel shock hazard.

• The ground conductor should not transmit any interference voltages, therefore do not

ground any other electrical devices together with this conductor.

Repeater power supply unit

• Protective separation (PELV) must be ensured

(VDE 0100 / VDE 0106 or IEC 364 / IEC 536, or equivalent national regulations).

• For measurement reasons, connect an FE functional ground conductor.

Metal pipelines, not internally coated

Metal pipelines,

with or without internal coating,

and plastic pipelines

grounding without grounding rings

grounding with grounding rings

D1, D2, D3 Gaskets, not included with supply, to be provided by customer.

E Grounding rings (option)

F Flowmeter flanges

FE Functional ground, wire ≥ 4 mm2 Cu (10 AWG), not included with supply,

to be provided by customer.

R Pipeline

RF Pipe flanges

V1, V2 Interconnecting wires, included with supply

Y Terminal box or signal converter

10

ALTOFLUX 2W

02/2001

Page 11

Part A Installation and Start-up Section 2.1

(OHFWULFDOFRQQHFWLRQ

2.1 Information on electrical connection and connection data

• Rated values: The flowmeter housings protect the electronic equipment from dust and

moisture and should always be kept properly closed. Creepage distances and clearances in air

have been dimensioned in conformity with VDE 0110 and IEC 664 for contamination category

2. Supply circuits and output circuits are designed to meet the standards of overvoltage classes

III and II, respectively.

• Safety isolation: The flowmeter must be provided with an isolating facility.

• Note information on instrument nameplate(s).

• PE conductor / FE functional ground must be connected to the separate U-clamp

terminal in the terminal compartment of the signal converter.

• For measurement reasons, the flowmeter must be properly grounded. The ground conductor

should not transmit any interference voltages. Therefore, do not ground any other electrical

devices together with this conductor.

• In hazardous areas, the ground conductor is used simultaneously for equipotential bonding.

CAUTION: Where a power booster (1L= / 0L=) is used, electrical isolation is required

between the power booster and the current output, otherwise the electronic equipment will

substain irreparable damage.

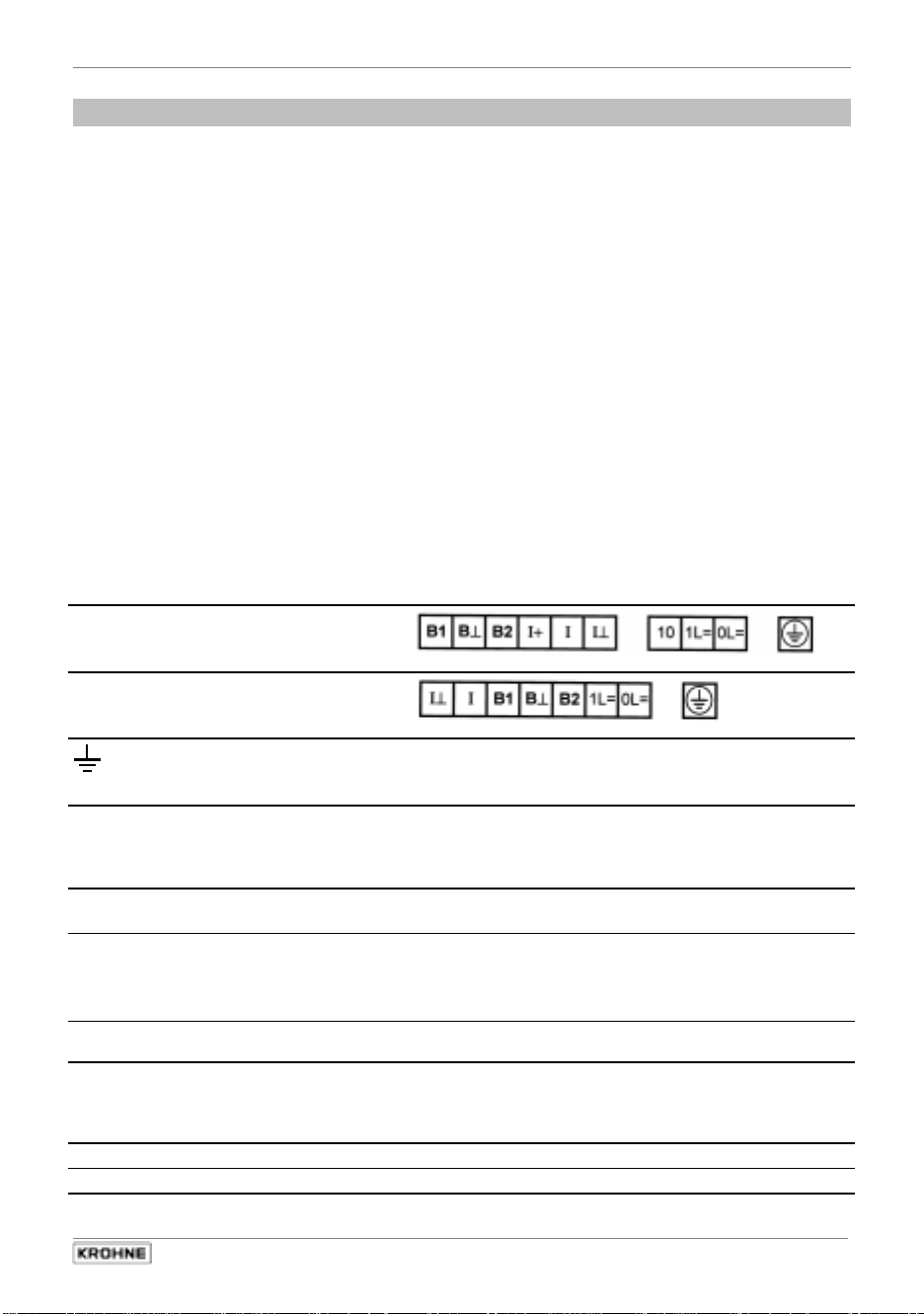

Standard power terminals

EEx power terminals

FE

PE

Current output

Ι

(not polarity sensitive)

Ι ⊥

B 2

Pulse or status output

NAMUR

B ⊥

B 1

Pulse or status output

high current

B ⊥

Functional ground

Safety conductor / equipotential bonding

V

= 36 V Ι

max

V

= 24 V Ι

nom

= 14 V Ι

V

min

NAMUR terminals (B2 + B ⊥)

= 0.4 mA Ι

Ι

open

High-current terminals (B1 + B ⊥)

closed: V

open: V

Common ground (negative) Take note of polarity!

B ⊥

1L=

Power booster

0L=

(not polarity sensitive)

Ι +

2nd power terminal

V

= 36 V V

max

V

= 24 V Ι

nom

not used, no internal connection

10 for internal use only

02/2001

ALTOFLUX 2W

= 22.4 mA (fault current)

max

= 4 - 20 mA

nom

= 3.6 mA (fault current)

min

closed

max

max

V

nom

min

nom

= 6 mA

= 2 V Ι

= 36 V Ι

= 24 V Ι

= 14 V

= 22 mA

max

max

nom

= 100 mA

= 2 mA

= 1,5 mA

11

Page 12

Section 2.2 Part A Installation and Start-up

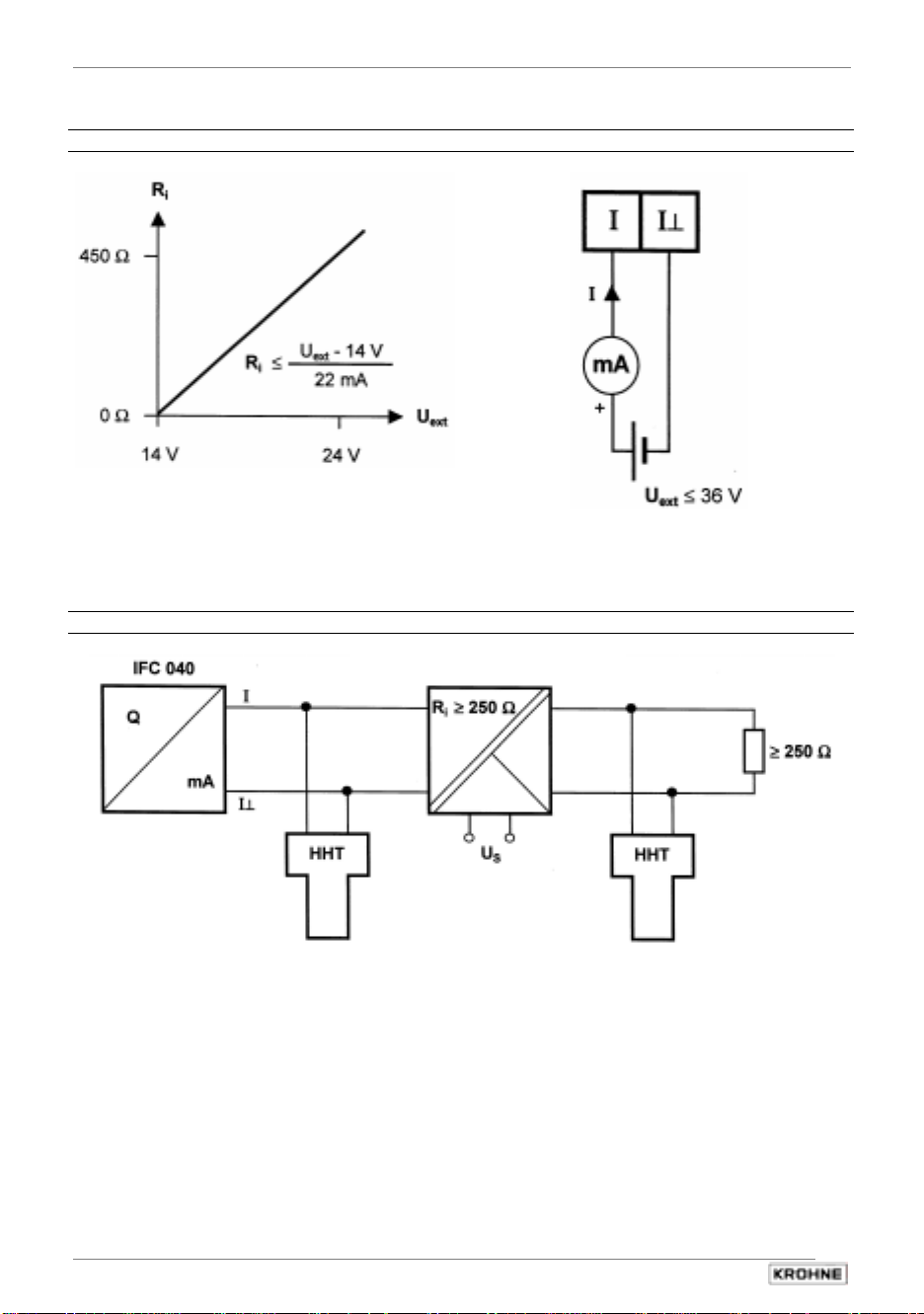

2.2 Output circuit diagrams

Supply power and current output - standard

Note data given in Sect. 2.1!

Supply power and current output - operation via repeater power supply unit

Repeater power supply unit

Repeater power supply unit, e.g.:

CEAG 6 / 420 or

Phoenix Contact PI/Ex-ME-RPSS-I/I Note data given in Sect. 2.1!

12

ALTOFLUX 2W

02/2001

Page 13

Part A Installation and Start-up Section 2.2

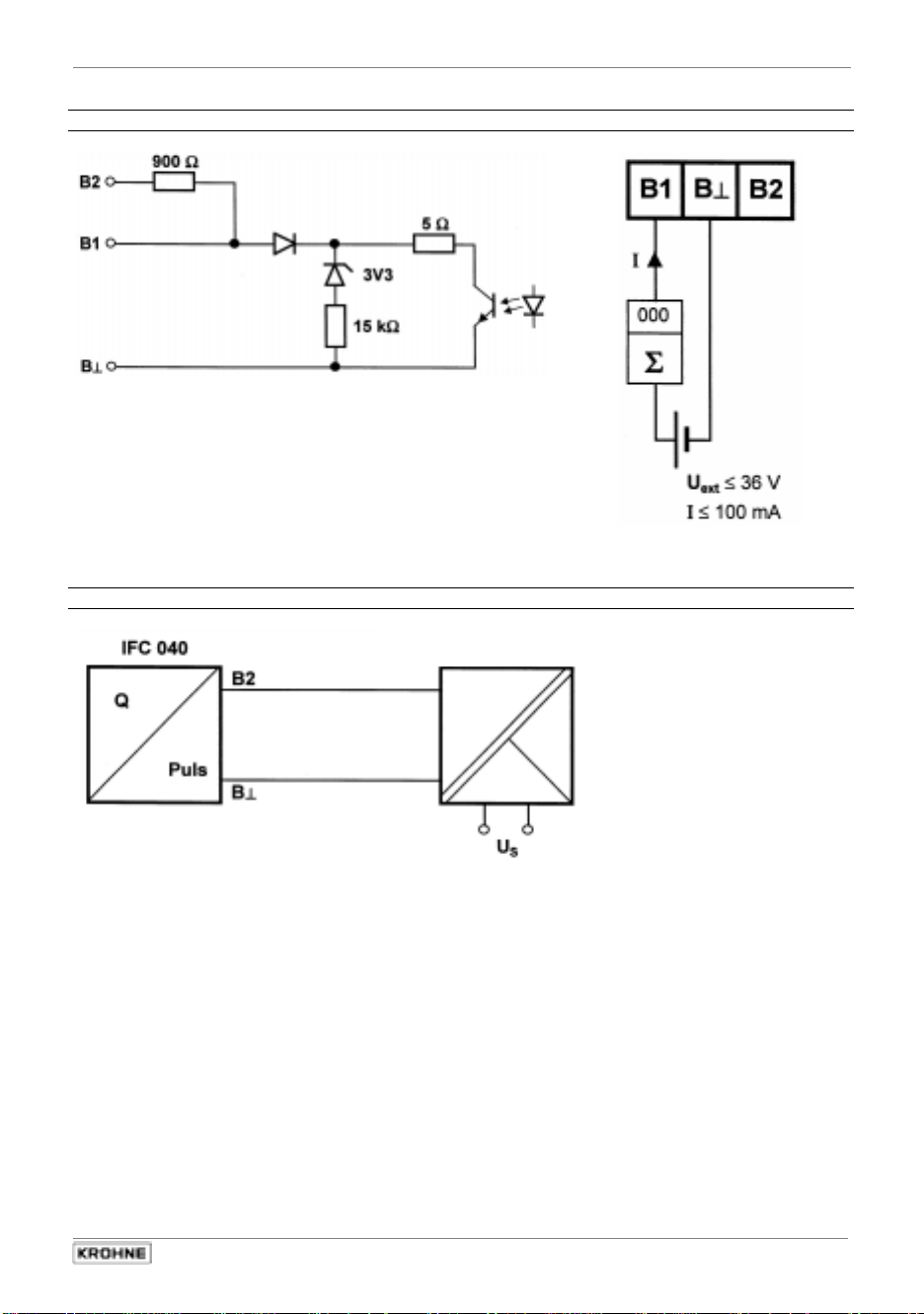

Pulse or status output

current limited

to 100 mA

Note data given in Sect. 2.1!

Pulse or status output - operation via repeater power supply unit

Repeater power supply unit

Repeater power supply unit e.g.:

Phoenix PI/Ex-ME-2NAM/COC Note data given in Sect. 2.1!

02/2001

ALTOFLUX 2W

13

Page 14

Section 2.3 Part A Installation and Start-up

2.3 Characteristic of the outputs

Fig. 1 Low-flow cutoff SMU (see Fct. 1.3 in Section 4.4)

I,P,S,..

-2.Number

-1.Number

L. F. Cutoff

Q

1.Number

2.Number

Fig. 2 Current output (see Fct. 1.5 in Section 4.4)

positive

direction

-Q

100%

negative

direction

I

100%

I,P

I,P

absolute

I

100%

I

0%

0

Q

Q

100%

-Q

100%

I,P

I

100%

I

0%

0

Q

negative-zero-positive

I

I

0%

100%

Q

0

Q

100%

I

I

0%

0

Q

Q

100%

14

ALTOFLUX 2W

02/2001

Page 15

Part A Installation and Start-up Section 2.3

Fig. 3 Pulse output

positive

direction

negative

direction

-Q

100%

(see Fct. 1.6 in Section 4.4)

I,P

I

100%

I

0%

0

I,P

I

100%

I

0%

0

Q

Q

100%

Q

-Q

100%

absolute

I

100%

I

I,P

0%

0

Q

Q

100%

Fig. 4 Status output: Automatic range change BA

I

I

100%

I

0%

-Q

100%

02/2001

-Limit

Limit

S

closed

ALTOFLUX 2W

Q

Q

100%

Qopen

(see Fct. 1.7 in Section 4.4)

15

Page 16

Section 2.3 Part A Installation and Start-up

Fig. 5 Status output: Limit switches

(see Fct. 1.7 in Section 4.4)

S

closed

open

-off limit

-on limit

off limit

on limit

Q

-on limit

Fig. 6 Noise / Change of flow (see Fct. 3.4 in Section 4.4)

Noise without Noise Filter

Flow Change

Noise Level

-off limit

S

closed

open

on limit

off limit

Q

Noise

-Noise Flow

0

Noise

Noise Flow

Fig. 7 Pulse duration (see Fct. 3.4 in Section 4.4)

Q

Pulse Width

16

ALTOFLUX 2W

Q

t

02/2001

Page 17

Part A Installation and Start-up Section 3.1+ 3.2

6WDUWXS

3.1 Power ON and measurement

• Before powering the system, please check that it has been correctly installed according to

Sections 1 and 2.

• The flowmeter is delivered ready for operational use. All operating data have been factory-

set in accordance with your specifications.

Please also refer to Section 3.2 “Factory settings”.

• Power the unit, and the flowmeter will immediately start process flow measurements.

• When powered, the display shows in succession: START UP and READY. This is followed by

indication of the current flow rate and/or the current counter count, on either a continuous or

alternating basis, depending on the setting under Fct. 1.04.

• For operator control, refer to Section 4.

3.2 Factory settings

All operating data are factory set according to your order specifications.

If you have not made any particular specifications at the time of ordering, the devices are

delivered with the standard parameters and functions listed in the table below.

To facilitate easy and rapid start-up, the current output is set to process flow measurement in

“absolute“, so that the current flow rate is displayed independent of the direction of flow. On the

display, measured values may possibly be shown with a “ - ” sign.

This factory setting for the current output may possibly cause measuring errors:

For example, when pumps are switched off and a “backflow“ occurs that is not within the range

of the low-flow cutoff SMU, or when separate displays and counts are required for both flow

directions.

To avoid faulty measurements, therefore, it may be necessary to change the factory setting of

some or all of the following functions. For operator control see Section 4.4:

• Low-flow cutoff SMU, Fct. 1.03

• Display, Fct. 1.04

• Current output, Fct. 1.05

• Pulse output, Fct. 1.06

Standard factory settings

Function Setting Function Setting

1.01 Full scale range Q

1.02 Time constant 3,0 s

1.03 Low-flow cutoff OFF: 0,4 % 3.01 Language English

1.04 Display Meter size see nameplate

Flow rate Percent Flow direction

Counter m3 (see arrow on primary head) Pos. flow

1.05 Current output 3.04 Application

Function Absolute Empty pipe yes

Range 4 - 20 mA Field current 100-50-25 mA

Error message 22 mA Mode field current two times

1.06 Pulse output Limit 150 %

Function off Filter off

Pulse per volume 1 Pulse / m3

Pulse width 50 ms 3.06 HART no

02/2001

100%

see nameplate 1.07 Status output off

ON: 0,5 % 3.02 Primary head

3.05 Hardware Pulse output

ALTOFLUX 2W

17

Page 18

Section 4.1 Part B IFC 040 Signal converter

2SHUDWLRQRIWKHVLJQDOFRQYHUWHU

4.1 KROHNE operator control concept

136.49 Measuring mode

m3/h

→

↵

Menu column Function column Data column

4.2 COUNTER RESET

4.0 RESET 4.1 ERROR RESET

3.6 HART

3.5 HA RDWARE

3.4 APPLICATION

3.3 ZERO SET

3.2 FLOW METER

Direction of

movement

3.0 INSTALLATION 3.1 LANGUAGE

2.2 HARDWARE INFO

2.0 TEST 2.1 TEST Q

1.7 STATUS OUTPUT

1.6 PULSE OUTPUT

CURRENT OUTPUT

1.5

1.4 DISPLAY

1.3 L.F.CUTOFF

1.2 TIME CONSTANT

1.0 OPERATION 1.1 FULL SCALE

↑

→

↑

↵ ↵

→

see

Section

4.4

18

ALTOFLUX 2W

02/2001

Page 19

Part B IFC 040 Signal converter Section 4.2

4.2 Operating and check elements

Control by way of ...

5

...

the 3 keys

, after twisting off the cover of

the electronics compartment using the

special wrench (supplied).

...

the 3 magnetic sensors

and the bar

magnet (supplied) without opening the

housing.

Flow

rate

IFC 090 D

IFC 040

16

2

3

+

Totalizer

m3/h

-

4

I

Overange

P

PLEASE NOTE !

Do not damage the screw thread and gasket of the cover, never allow dirt to accumulate, and

make sure they are well greased at all times.

Replace any damaged gasket immediately!

Display 1st line

Display 2nd line 4-character light writing

Display 3rd line Arrows to identify display

Flowrate

Counter

Overrange

+

-

Σ

Ι

P

Current flow rate

Positive counter

Negative counter

Sum counter (+ and -)

Overranging, current output

Overranging, pulse output

Keys for operator control of signal converter

Magnetic sensors to set the converter by means of a handheld bar magnet without

opening the housing.

Function of sensors same as keys

02/2001

ALTOFLUX 2W

19

Page 20

Section 4.3 Part B IFC 040 Signal converter

4.3 Function of keys

The cursor, flashing part of display or horizontal scrolling, has a grey background.

To start operator control

Measuring mode Operator control mode

13.57 1 FCt. 1. 0

m3 / h O P E R A T I O N

To select function

Increase number = select next function

FCt. 1.4 FCt. 1.5

D I S P L A Y C U R R E N T O U T P U T

To transfer to subfunction

→

↑

FCt. 1.5 info

C U R R E N T O U T P U T F U N C T I O N

To transfer to setting of subfunction

info Edit

F U N C T I O N P o S . d i r e c t i o n

To alter texts

When (e.g. flow) units are changed, the numerical value is converted automatically.

Edi t Edi t

P o S . d i r e c t i o n N e G . d i r e c t i o n

To transfer to next subfunction

Edi t i nfo

N e G . d i r e c t i o n 0 P e R . C u R R e n t

To transfer to setting of subfunction

→

↵

↑

↵

info 0 4. 0

0 P e R . C u R R e n t mA

20

↵

ALTOFLUX 2W

02/2001

Page 21

Part B IFC 040 Signal converter Section 4.3

To move cursor

To change a number

To terminate operator control

Press key

1.0 OPERATION, 2.0 TEST

is displayed.

(flashing position)

each keystroke moves 1 place to the right

0 4. 0 0 4. 0

0 4. 005. 0

repeatedly until one of the functions

↵

or

FCt. 3. 0End

I N S T A L L A T I O N Y E S

Store new parameters

→

mA mA

↑

mA mA

3.0 INSTALLATION

↵

Press key ↵ to confirm “

continued with the new parameters.

”, measuring mode

YES

Do not store new parameters

02/2001

Press key ↵ to confirm “NO”, return to Fct.

1.0 OPERATION

ALTOFLUX 2W

21

Page 22

Section 4.4 Part B IFC 040 Signal converter

4.4 Table of settable functions

Display texts

FCt. 1.1

FULL SCALE

XXX.XXX

↑ "user unit"

Range:

0.3-12 m/s = 1-40 ft/

FCt. 1.2

TIME CONSTANT

XX.X

Range 0.5 ... 99.9s

Standard 3.0s

FCt. 1.3

L.F. CUTOFF

XX XX

Range 1 ... 20%

st

(1

value < 2nd value)

Standard: 04 ... 05%.

m3/h

l/s

Ga./m

Perc.

Description and settings

Full-scale range

→

Set full-scale range, i.e. for the maximum occurring flow rate.

This affects all functions where values have to be set as % of

full-scale range:

Fct. 1.3 SMU Fct. 1.5 Current output

↵

s

Fct. 1.7 Status output Fct. 2.1 Test Q

Fkt. 3.4 Application

Time constant

→

Setting the time constant for a two-pole low pass for signal

S

flow rate in order to attain 67% of the new flow value.

damping. This time is needed after an abrupt change in the

↵

The time constant acts equally on the current output and the

display, and also on the status output when the ‘sign’ or ‘limit

value’ functions are selected.

The value can be transmitted via the HART interface with or

without use of the time constant.

If the time constant is changed, the noise level needs to be

reset if the noise filter is activated (see Fct. 3.4 Application

“Filter setting").

Low-flow cutoff (SMU)

For characteristic, see Fig. 1 in Section 2.3

→

At low flows, flow display and counting are suppressed. This

also applies to the negative flow direction.

↵

Cutoff ‘off’ value (1st figure) and cutoff ‘on’ value (2nd figure)

must be set as a percentage of the full-scale range (see Fct.

1.1 Full-Scale). The SMU acts on the current output, pulse or

status output, all counters and also values via the HART

interface and the display.

FCt. 1.4

inFo

diSPlaY Flow

Edit

↑ "user unit"

Standard: Percent

22

DISPLAY

Percent

no diSPlaY

m3/h

l/s

Ga./m

Display

Setting for display form of measured values and messages in

→

the local display. The following settings are possible:

Display of flow

↵

Select unit for display of current flow.

Nothing displayed when “no display" has been set.

↵

ALTOFLUX 2W

02/2001

Page 23

Part B IFC 040 Signal converter Section 4.4

Display texts

inFo

Edit

"user unit"

↑

Standard: m3

inFo

8.88888

88.8888

888.888

8888.88

88888.8

888888.

Auto.

Standard: 888888.

inFo

Edit

↑

Standard: No

inFo

Edit

↑

Standard: No

inFo

Edit

↑

Standard: No

inFo

diSP.meSSaGeS

Edit

↑

Standard: Yes

dim. counter

m3

Gal.

disPL,Format

"units see above"

PoS cnt.disP.

YES

NO

neG cnt.disP.

YES

NO

Sum cnt.disP.

YES

NO

YES

NO

Description and settings

Dimension of counters

↵

Select unit (dimension)

for positive, negative and sum counters.

l

↵

Display format

↵

Select format for positive, negative and sum counters. The

first six settings have fixed positions for the decimal point. If

an off-scale indication occurs here, the marker flashes

against the displayed value. Off-scale indication can be

prevented by selecting a different format.

The setting “Automatic" will change the display such that

always the highest counter value is displayed, if necessary in

↵

exponential format. An appropriate warning is shown when

an off-scale indication occurs, provided the display of

messages is activated in Function 1.4 “Display" setting

“Display of messages". A change of format will not alter the

value of the counter.

• Positive counter display

↵

• Negative counter display

• Sum counter display

↵

The positive, negative and sum counter display functions

allow the respective counter to be switched on (Yes) or off

(No).

When several displays are selected, display of numerical

↵

values is cyclic.

↵

↵

↵

Display of messages

↵

Setting as to whether, in addition, messages from self-test

functions are to be displayed (Yes) or not (No).

↵

02/2001

ALTOFLUX 2W

23

Page 24

Section 4.4 Part B IFC 040 Signal converter

Display texts

FCt. 1.5

CURRENT OUTPUT

For HART function “No" or

address “0"

inFo

Function

Edit

PoS.direction

neG.direction

abSolute

↑ neG-0-PoS

Standard: absolute

inFo

0 Perc.current

XX.X

Range 4.0 ... 14.0mA

Standard: 4.0 mA

inFo

100 Perc.current

XX.X

Range 10.0 ... 20.0 mA

I

< I

0%

100%

Standard: 20 mA

inFo

error current

XX.X

Range 3.6 ... 22.4 mA

I

< I0% or I

Error

100%

< I

Standard: 22 mA

mA

mA

mA

Error

off

Description and settings

Current output

For characteristic, see Fig. 2 in Section 2.3

→

Settings for the current output

Not possible when ”Address 1 –15” is set under Fct. 3.6

HART (equivalent to multidrop mode).

In that case, only a constant current needs to be set,

see Fct. 3.6 HART “I Multidrop".

Fct. 1.5 Current output then has “no function".

↵

Setting the characteristic of the current output

“off” = 0 per cent current output

Please note:

Fct. 1.7 Status output, “Automatic range change" setting.

↵

0 per cent current

↵

Setting of current at “zero” flow(I0%)

↵

100 per cent current

↵

Setting of current at 100 % flow (I

according to the full-scale range (Q

↵

under Fct. 1.1 Full Scale.

100%

100%

),

)

Fault current

↵

The fault current that is output in the event of a fault.

↵

Please note:

When the current output is overranged, the maximum current

is 21mA and has been preset by factory.

24

ALTOFLUX 2W

02/2001

Page 25

Part B IFC 040 Signal converter Section 4.4

Display texts

FCt. 1.6

PULSE OUTPUT

inFo

Edit

PoS.direction

neG.direction

abSolute

↑

Standard: absolute

Other selection

inFo

XXX0.

Range 30 ... 1000 ms

Standard: 50 ms

inFo

Pulse/Volume

XXX.XXX

↑

Range 0 ... 10 Hz

Standard:

1 pulse per m3

Function

off

PulSe width

mS

m3

Gal.

user unit"

“

Description and settings

Pulse output

Settings for the pulse output

→

Characteristic, see Fig. 3 in Section 2.3

Only possible when “Pulse output” is set under Fct. 3.5

Hardware.

When “Status output” selected, Fct. 1.6 has “no function".

Function

↵

Setting of the characteristic of the pulse output

“off” = switch at output open

↵

Pulse width

Minimum interpulse period = half pulse width

↵

Pulse width defines the time during which the switch at the

output is closed and high current flows between terminals B1

↵

or B2 and B⊥. The maximum pulse rate is selected at the

same time, as the interpulse period is at least equal to half

the pulse width:

rate Pulse

max

=

1

widthpulse1.5

×

Pulses / Volume

Number of pulses per unit volume

↵

Pulses/Volume is used to set the number of pulses that are

output for the given volume. If 10.0 is set at Unit m

l

pulses are output per cubic metre. If 0.01 is set at Unit l , one

pulse is output per 100 litres.

3

, 10

↵

A large pulse width together with a high pulse rate will

•

cause overranging. Therefore, pulse rate is limited so

that the minimum interpulse period does not drop below

half the pulse width. In that case, error message due to

overranging of the pulse output, i.e. marker flashes and,

if activated in Fct. 1.4 “Display", is output in the form of

horizontal scrolling.

02/2001

When the pulse output is overranged, the missing pulses

•

are output later, at times of lower flow.

ALTOFLUX 2W

25

Page 26

Section 4.4 Part B IFC 040 Signal converter

gang

Display texts

FCt. 1.7

STATUS OUTPUT

inFo

Edit

emPtY PiPe

(für Stromaus

↑ limit value

Standard: off

inFo

XXX

Range 5 ... 80%

Standard: 20%

Function

off

on

all error

SiGn

overflow

auto.ranGe

limit

Perc.

Description and settings

Status output

Settings for the status output

→

Only possible when “Status output” set under Fct. 3.5

Hardware.

When “Pulse output” selected, Fct. 1.7 has “no function".

↵

Setting the characteristic of the pulse output

Switch open Switch closed

permanently -

- permanently

error no error

positive flow negative flow

no overranging overranging

pipe/tube completely filled pipe/tube empty

↵

range above limit range below limit

)

normal function zoom-in function active

inactive active

When automatic range change selected

the limit value must be set as a percentage of the full-scale

↵

range (Q

↵

Below the set limit value, the current output has a zoom-in

), (see Fct. 1.1):

100%

function. The flow range from “0” to “Limit” is projected to the

I0% to I

100%

range.

inFo

XXX

Range 0.1 ... 110 %

Standard: 10 %

inFo

XXX

Range 0.1 ... 110 %

Standard: 20 %

26

1.limit.value

Perc.

2.limit.value

Perc.

For characteristic of automatic range change, see Fig. 4 in

Section 2.3

When limit value selected

the ‘on’ and ‘off’ values must be set as a percentage of the

↵

full-scale range (Q

↵

with adjustable hysteresis, as the ‘on’ value can be smaller or

) (see Fct. 1.1):

100%

larger than the ‘off’ value.

For characteristic of limit switch, see Fig. 5 in Section 2.3

↵

↵

ALTOFLUX 2W

02/2001

Page 27

Part B IFC 040 Signal converter Section 4.4

Display texts

FCt. 2.1

Edit

YeS Sure

↑

↑

FCt. 2.2

HARDWARE INFO

inFo.no

modul ADC

StAtUS

modul ADC

inFo.no

StAtUS

inFo.no

modul diSPlaY

StAtUS

modul diSPlaY

inFo.no

modul HART

StAtUS

modul HART

TEST Q

not Sure

-110.0

-100.0

-50.0

-10.0

0.0

10.0

50.0

100.0

110.0

Perc.

x.xxxxx.

xxxx

xxxxxx

xxxx

modul IO

x.xxxxx.

xxxx

modul IO

xxxxxx

xxxx

x.xxxxx.

xxxx

xxxxxx

xxxx

x.xxxxx.

xxxx

xxxxxx

xxxx

Description and settings

Test measuring range Q

→

Operator inquiry as to whether test to be carried out?

↵

If “YeS Sure”, fixed values for the outputs can be set relative

to the full-scale range.

No setting for the outputs. When the function is terminated,

the outputs operate as before.

↵

Hardware information and error status

→

In the event of an error, scan and note down all information

↵

(software number = Info Number, and status).

Important if factory needs to be consulted.

↵

Settings are not possible here.

↵

↵

↵

↵

↵

↵

↵

↵

↵

↵

↵

↵

↵

↵

02/2001

ALTOFLUX 2W

27

Page 28

Section 4.4 Part B IFC 040 Signal converter

Display texts

FCt. 3.1

LANGUAGE

Edit

EnGliSh

French

↑ German

Standard: English

FCt. 3.2

FLOW METER

inFo

diameter

XXX.X

mm

Range

10 - 250 mm = 3/8“ - 6“

Standard: see nameplate

inFo

Full Scale

XXX.XXX

m3/h

Ga./m

↑ "user unit"

Range:

0.3-12 m/s = 1-40 ft/

inFo

PrimarY conStant

XX.XXXX

GKL

Range 1.0 ... 19.9999

Standard: see nameplate

X.XXXX

K50

Range 0.5 ... 1,5

Standard: see nameplate

X.XXXX

K25

Range 0.5 ... 1.5

Standard: see nameplate

inFo

Flow direction

Edit

PoS. Flow

↑ neG. Flow

Standard: pos. flow

l/s

Description and settings

Select language for display texts

→

↵

Primary head – to set data

Data have been factory-set. Changes here only necessary

→

when the electronic unit has been replaced.

Meter size (nominal diameter)

↵

Set nominal diameter / meter size of the primary head

(flowmeter). DN 150 / 6” is currently the largest size

↵

available.

Full-scale range

↵

Set full-scale range, i.e. the maximum occurring flow. This

affects all functions in which values have to be set as % of

the full-scale range:

Fct. 1.3 Low-flow cutoff Fct. 1.5 Current output

↵

s

Fct. 1.7 Status output Fct. 2.1 Test Q

Fct. 3.4 Application

Primary constant

↵

The primary constant is used for setting three calibration

values for the primary head.

↵

GKL describes the calibration value at 100mApp field current

(see nameplate).

K50 describes the variation at 50mApp field current compared

to 100mApp (see nameplate).

↵

K25 describes the variation at 25mA

to 100mApp (see nameplate).

↵

field current compared

pp

Define direction of flow

according to direction shown by arrow on the primary head

↵

Set the main direction of flow or

the forward flow in the case of F/R mode:

in direction of arrow = PoS. DFl. (positive flow)

↵

opposite dir. of arrow = neG. DFl. (negative flow)

28

ALTOFLUX 2W

02/2001

Page 29

Part B IFC 040 Signal converter Section 4.4

Display texts

FCt. 3.3

ZERO POINT

Edit

YeS Sure

↑

8 XXX.X

Edit

not Save

Yes Save

not Sure

Perc.

Description and settings

Calibrate the zero

→

Carry out only after a replacement of the electronic unit or if,

at low flow, an offset is presumed.

↵

Please note!

Measuring tube must be completely filled with the

•

process liquid!

Flow must truly be “zero”!

•

Display of current flow rate as a percentage of the full-scale

range. (The segments of the “8” are reduced in keeping with

↵

the progress of measurement.)

Save new zero value?

↵

02/2001

ALTOFLUX 2W

29

Page 30

Section 4.4 Part B IFC 040 Signal converter

Display texts

FCt. 3.4

APPLICATION

inFo

emPtY PiPe

Edit

YES

↑ NO

Standard: Yes

inFo

Field current

Edit

100-50-25mA

50-25mA

↑ 25mA

Standard: 100-50-25mA

inFo

ModuS F.current

Edit

two timeS

↑ three timeS

Standard:

two times

inFo

limit

Edit

150 Perc.

300 Perc.

↑ 1000 Perc.

Standard: 150 %

inFo

Filter

Edit

Filter off

PulSe Filter

↑ noiSe Filter

Standard: filter off

Description and settings

Application = set characteristic of measuring point

→

Pipe/tube has run dry

↵

The empty pipe identifier can be switched on (YES) and off

(NO). A load-independent current of approx. 25nA flows

continuously from the electrodes to ground (pipeline /

↵

grounding rings). If this current can no longer flow, and the

empty pipe identifier is activated, the measured value is set to

zero and an error message is enabled (see Fct. 1.4, setting of

“Display messages"). If not required, deactivate the empty

pipe identifier (=NO).

Field current

Default value for maximum allowable field current.

↵

If the available energy is not sufficient for the set maximum

field current, automatic reduction to the next lower value.

Where flow is pulsating, it is advised to reduce the field

current from 100mA

↵

(setting: 50-25mA). Above approx. 10-20% flow, continuous

(setting: 100-50-25mA) to 50mA

pp

measurement is then present.

F current mode

↵

• The double setting is standard

(follows flow at a faster rate),

• The triple setting reduces strong interference

↵

(e.g. from solids contents).

Limitation

↵

1 150% setting is standard,

2 300% and 1000% settings (advisable with pulsating flow

or low conductivity),

all as percentage of full-scale value, see Fct. 1.1.

↵

Please note:

3 if noise filter used (see following function), set limitation

to 1000%.

4 Do not increase limitation if process liquids contain

solids.

Filter

↵

• Filter ‘off’ setting is standard,

• Noise filter if conductivity is low

• Activate pulse filter if solids contents or other pulsed

↵

(for characteristic, see Fig. 6 in Section 2.3)

interference involved

(for characteristic see Fig. 7 in Section 2.3).

Please note:

Further settings are required when pulse filter or noise filter is

activated, see below:

pp

30

ALTOFLUX 2W

02/2001

Page 31

Part B IFC 040 Signal converter Section 4.4

Display texts

selection

“Pulse Filter"

inFo

PulSe duration

XX.X

Range 0.1 ... 25.0 s

Standard: 1.0 s

inFo

XXX

Range 1 ... 100 %

Standard: 5 %

selection

“noiSe Filter"

inFo

noiSe SuPPreS

Edit

↑

Standard:

inFo

XXX

Range 5 ... 100 %

Standard: 20 %

inFo

XX.X

Range 0.1 ... 25.0 %

Standard: 5 %

PulSe limit

two timeS

three timeS

four timeS

two times

noiSe Flow

noiSe level

Perc

Perc.

Perc.

Description and settings

... pulsed interference is suppressed. In addition to the setting

“Limitation” over the total measuring range, see above,

“Pulse duration” and “Pulse limitation” dynamically limit

abrupt changes in the measured value.

Pulse duration

↵

Setting the pulse duration limitation

S

↵

Time must be longer than the duration of the pulsed

interference (see Fig. 7 in Section 2.3).

Pulse limitation

↵

The pulse limitation allows setting of the size of change from

one measured value to the next (as percentage of the full-

↵

scale range, see Fct. 1.1).

... suppresses unsteady measured values caused e.g. by low

electrical conductivity of the process liquid or high solids

contents. When noise filter is activated, the “Limitation”, see

above, should be set to 1000%, otherwise measured values

are too low in the upper flow range.

Noise rejection

.

↵

The level of noise rejection can be selected as a factor of the

interference level.

↵

Noise flow

Adjustment when noise is dependent on flow.

↵

approx. 20% in normal 2-wire operation

•

approx. 80% when operated with power booster

•

↵

in both cases as percentage of full-scale range (see Fct. 1.1)

(see Fig. 6 in Section 2.3)

Noise level

Setting of the noise level (unsteadiness) that can be

↵

observed without use of the filter.

Setting the noise level “peak-to-peak”

(e.g. width on a recorder or difference between minimum and

↵

maximum value in display) as percentage of full-scale range

(see Function 1.1).

Measurement at high flow rate (maximum flow rate) when

filter deactivated. If time constant has been changed (see Fct.

1.2) this setting must be carried out again. The filter will not

take effect if the noise level is set too low. It is better to set

the noise level too high rather than too low (see Fig. 6 in

Section 2.3).

02/2001

ALTOFLUX 2W

31

Page 32

Section 4.4 Part B IFC 040 Signal converter

Display texts

FCt. 3.5

HARDWARE

inFo

Function term.B

Edit

PulSe outPut

↑ StatuSoutPut

Standard: pulse output

FCt. 3.6

HART

inFo

Function

Edit

YES

↑ NO

Standard: No

inFo

I 4mA trim.

X.XXX

mA

Range 3.700 ... 5.000 mA

Standard: 4.000 mA

inFo

I 20mA trim.

XX.XXX

mA

Range 18.000 ... 21.000 mA

Standard: 20.000 mA

inFo

AdreSS

XX

Adr

Range 0 ... 15

Standard: 0

selection “1 ... 15"

inFo

i multi droP

XX.X

mA

Range 4.0 ... 20.0 mA

Standard: 5.0 mA

Description and settings

Hardware

Setting the function of terminals B1 and B2

→

↵

This is active when “Pulse output” selected (see Fct. 1.5) and

the status output (see Fct. 1.6) has “no function“.

↵

This is active when “Status output” selected (see Fct. 1.6)

and the pulse output (see Fct. 1.5) has “no function".

®

HART

Settings for HART® communication

→

(FSK modulation with 1200 bauds on the current output)

Function

activate (=YES) or deactivate (=NO) the interface

↵

When HART

®

interface is activated, the decimal point on the

left in the display flashes when communication is taking place

(in the multidrop mode only when the appropriate device

↵

responds).

The ‘I 4mA trim.’ and ‘I 20mA trim.’ values correspond to the

↵

values to be set via the HART

↵

These values have no function when HART® is deactivated.

®

interface (Cmd #45 and #46).

↵

↵

Address

↵

Set address for a device in the case of HART

communication.

↵

®

If the address is greater than “0”, the current output is

operated with constant current (multidrop).

Multidrop mode

↵

In the multidrop mode a constant current is present at the

current output. This is 4 mA in accordance with the HART

↵

agreements. However, if there are sufficient reserves in the

network, better measuring results are obtained with 5 mA to 6

mA (signal-to-noise ratio). Set 4mA when operating with the

power booster (no benefit from higher values).

®

32

ALTOFLUX 2W

02/2001

Page 33

Part B IFC 040 Signal converter Section 4.5 + 4.6

4.5 Error messages in measuring mode

Warnings Description of error Eliminate error

Pipe empty (1)

Field coil defective

Linearity

Low energy

Overranging (2)

Overflow current

Overflow pulse (3)

Overflow counter

Line interrupt (4)

Fatal error

Is checked only when “Application“ is activated in Fct. 3.4

(1)

Value for checking overranging is set in Fct. 3.4 "Application" relative to full-scale range

(2)

Missing pulses are recovered at times when pulse rate is low

(3)

Is checked only when a counter is activated in Fct. 1.4 "Display"

(4)

Pipe (partially) empty Fill pipe

Poor grounding, or none at all Check grounding system

Electrical conductivity too low Check process liquid

Electrodes contaminated Clean electrodes

Electrode wire break Repair wires

Short-circuit, break, or excess

temperature

Analog/digital converter (ADC)

defective

Primary head defective Replace primary head

K 50 constant incorrect Correct, see nameplate

ADC zero incorrect Replace electronic unit

Energy too low for correct

measurements

ADC overranged Change Fct. 3.4 Limitation

Measured value higher than fullscale range

Pulse rate too high,

max. 1 / (1.5×pulse width)

Overflow of a counter Reset counter

Power failure Delete error message and, if

Severe error, measurement

interrupted

Check and eliminate fault

Replace electronic unit

Voltage is less than 14 V,

increase energy

Check device parameters and

correct if necessary

Check device parameters and

correct if necessary

necessary, reset counter

Replace electronic unit

4.6 Reset counters and cancel error messages

Display texts

... measuring mode ...

Description and settings

Entry into RESET menu

↵

FCt. 4.0

RESET MENUE

FCt. 4.1

ERROR RESET

→

Resetting the messages

power failure and counter overflow

↑

rESEt

NO

↵

→

Reset

all counters

FCt. 4.2

YES

↑

COUNTER RESET

rESEt

NO

YES

↑

02/2001

↵

ALTOFLUX 2W

33

Page 34

Section 5.1 Part C Technical data, Block diagram and Measuring principle

7HFKQLFDOGDWD

5.1 Full-scale ranges

Full-scale range Q

100%

Flow Q = 100% 85 Liter/h - 763 m3/h (0.37 – 3361 US Gal/min), adjustable as required,

equivalent flow velocity 0,3 – 12 m/s (1 – 40 ft/s)

Units m3/h, Liter/s, US Gal/min user-defined unit, e.g. US MGal/min

Flow tables

v = flow velocity in m/s v = flow velocity in ft/s

Meter size Full-scale range Q

100%

in m3/h

v=0.3m/s v=1m/s v=12 m/s v=1 ft/s v=3.3 ft/s v=40 ft/sDNmminch

(minimum) (maximum)

103/

151/

0.0849 0.2827 3.392 103/

8

0.1909 0.6362 7.634 151/

2

25 1 0.5302 1.767 21.20 25 1 0.5302 1.767 21.20

50 2 2.121 7.069 84.82 50 2 2.121 7.069 84.82

80 3 5.429 18.10 217.1 80 3 5.429 18.10 217.1

100 4 8.483 28.27 339.2 100 4 8.483 28.27 339.2

150 6 19.09 63.62 763.4 150 6 19.09 63.62 763.4

Meter size Full-scale range Q

In US Gal/min

DNmminch

(minimum) (maximum)

0.0849 0.2827 3.392

8

0.1909 0.6362 7.634

2

100%

34

ALTOFLUX 2W

02/2001

Page 35

Part C Technical data, Block diagram and Measuring principle Section 5.2

5.2 Error limits at reference conditions

Display, digital values, pulse output

• calibated in accredited test rigs to EN 17 025 by direct comparison of volume

maximum error in % of measured values (not typical values)

F

Flow velocity in m/s and ft/s

v

Reference conditions similar to EN 29104

Product water at 10 – 30 °C / 50 – 86 °F

Electrical conductivity

Power supply (rated voltage)

Ambient temperature 20 - 22 °C / 68 – 71.6 °F

Warm-up time 60 min

Inlet / outlet runs 10 × DN / 2 × DN (DN = meter size)

Primary head properly grounded and centered

Measuring time 100 s

>300 µS/cm

(±2%)

U

N

Meter size Maximum error

DN mm inch

DN 10 - 1503/8” – 6“

Current output

Reproducibility

at

constant flow

v ≥ 1 m/s / ≥ 3 ft/s:

0,5% MV

≤ ±

Same error limits as above, additionally ± 10 µA

v ≥ 1 m/s / ≥ 3 ft/s:

0,1% MV

≤ ±

in % of measured value (MV)

v < 1 m/s / < 3 ft/s:

5 mm/s /

≤ ±

v < 1 m/s / < 3 ft/s:

1 mm/s /

≤ ±

at ...

≤ ±

≤ ±

0.2 inch/s

0.04 inch/s

External influences typical values maximum values

Ambient temperature

Pulse output 0,003 % MV 1)0,01 % MV

Current output 0,01 % MV 1)0,025 % MV

Power supply

All KROHNE signal converters undergo burn-in tests, duration minimum 20 hours at varying ambient temperature

1)

–20 to + 60 °C / -4 to +140 °F. The tests are controlled by computers.

02/2001

< 0,02 % MV 0,05 % MV at 10 % variation

ALTOFLUX 2W

1)

1)

at 1 K / 1.8 °F variation

}

35

Page 36

Section 5.3 Part C Technical data, Block diagram and Measuring principle

5.3 IFC 040 Signal converter

Current output

Function • all operating data configurable

• for passive mode

• standard HART® communication

Current: fixed ranges

variable ranges

Current: fixed ranges

4-20 mA

for Q = 0% I

for Q > 100% I

for Q = 100% I

4-20 mA

= 4– 14 mA

0%

= 10– 20 mA

100%

= 21 mA

max

adjustable in

0.1 mA increments

variable ranges

for Q = 0%

Binary output

Function • used as pulse or status output

• all operating data configurable

• galvanically isolated from current output and all

input circuits

Passive mode Selectable according to NAMUR (DIN 19 234)

or as contact:

• open • open

• closed • closed

Pulse output digital pulse division, interpulse period non-uniform,

therefore if frequency and cycle meters connected

allow for minimum counting interval:

gate time, counter ≥

10

100%

HzP

[]

pulse width 30 – 1000 ms

(adjustable in 10 ms increments)

Status output configurable as measuring range identification for

automatic range change, indicator for flow direction,

overflow, errors, trip point or empty pipe indication

Time constant 0.5 – 99.9 s, adjustable in 0.1 s increments

Low-flow cutoff cutoff “on“ value: 1 – 19%

cutoff “off“ value: 2 – 20%

36

ALTOFLUX 2W

cutoff “on“ value: 1 –

19%

cutoff “off“ value: 2 –

20%

02/2001

Page 37

Part C Technical data, Block diagram and Measuring principle Section 5.3

Local display

3-field LCD

Display function actual flowrate, forward, reverse and sum counters

(6-digit), and status messages

units: actual flowrate

m3/h, liter/s., US gallon/min or in user defined unit,

e.g. US Mgallon/day

counter

m3, liter, US gallon or in user defined unit,

e.g. US Mgallon/day

Language of plain text English, German, French, others on request

Display: top field

6-character, 7-segment, numeral and sign display,

and symbols for key acknowledgement

middle field

bottom field

4-character, 14-segment text display

6 markers to identify display in measuring mode and

messages of outputs

Hazardous duty versions

Connections in following protection classes can be

selected by customer during installation:

intrinsic safety “i“

•

increased safety “e“

•

flameproof enclosure “d“

•

or

Power supply

Current output (2-wire connection) 4-20 mA via proprierity power supply 14-36 V

A)

Power Booster

B)

Additionally to A) = 2×2 –wire

connection

For demanding applications without changing or

removing the meter. Connect power terminals to...

proprierity power supply

•

22 mA, 14-36 V DC

24 V DC, max. 1 W

•

or

(same protection as A = galvanically isolated)

Housing

Material die-cast aluminium with polyurethane finish

Ambient temperature - 25 to + 60°C / -13 to +140 °F

Protection category (IEC 529/ EN 60529) IP 67, equivalent to NEMA 6

02/2001

ALTOFLUX 2W

37

Page 38

Section 5.4 Part C Technical data, Block diagram and Measuring principle

5.4 IFS 4002 Primary head

Meter sizes DN 10, 15, 25, 50, 80, 100, 150 and

3

/8“, 1/2", 1“, 2“, 3“, 4“, 6“

Pipe flanges

to DIN 2501 (= BS 4504)

to ANSI B 16.5

Electrical conductivity

DN 10, DN 15, DN 25, DN 50, DN 80 / PN 40

DN 100, DN 150 / PN 16,

3

/8“, 1/2", 1“, 2“, 3“, 4“, 6“, class 150 lb / RF

≥ 5 µS/cm

≥ 20 µS/cm for demineralized cold water

Temperatures Ambient temperature

-25 to + 60 °C

-13 to +140 °F

-25 to + 40 °C

-13 to +104 °F

Insulation class of field coils

H / ≤ 140 °C / ≤ 284 °F process temperature

Process temperature

-25 to ≤ + 60 °C

-13 to ≤ +140 °F

-25 to ≤ +140 °C

-13 to ≤ +284 °F

Power supply for field coils from signal converter

Electrode design Flat elliptical electrodes, fixed mounted,

surface polished

Protection category (EN 60 529 / IEC 529) IP67, equivalent to NEMA 6

Grounding rings Available as option

Materials

Measuring tube austenitic stainless steel

Liner

DN 10 – 15 / 3/8“- 1/2" Teflon® - PTFE

DN 25 – 150 / 1“- 6“ Teflon® - PFA

(reinforced with stainless steel mesh)

Electrodes

Standard Hastelloy C

Option Stainless steel 1.4571 or SS 316 Ti,

Hastelloy B, titanium, tantalum, platinum-

Iridium, others on request

Connecting flanges *

DIN: DN 10 - 80 (3/8“ - 3“) steel 1.0460 (C 22.8) or ANSI C 1020

≥ DN 100 ( ≥ 4)

steel1.0038 (RST 37.2) or ANSI C 1035

ANSI steel ASTM A 105 N

Housing *

DN 10-15 / 3/8“- 1/2" GTW-S 30

≥ DN 25 / ≥ 1“

Grounding rings

Sheet steel

Stainless steel 1.4571 or SS 316 Ti,

Hastelloy C, Hastelloy B, titanium, tantalum

*

with polyurethane coating

38

ALTOFLUX 2W

02/2001

Page 39

Part C Technical data, Block diagram and Measuring principle Section 5.5

g

g

g

5.5 Dimensions and weights

Flange connections to ... Dimensions

DIN 2501

Ansi B 16.5

Dimension “a“ without flange gaskets (not necessary with Teflon® PTFE liner or PFA liner

•

For meter size

•

Meter size Dimensions

DIN ANSI

DN PN inch DIN ISO 13359 ANSI

10 40

15 40

25 40 1 150 (5.91) 200 (7.87) 150 (5.91) 301 (11.85) 121 (4.76) 115 (4.53) 108 (4.25) 9.5 (21) 11 (25)

50 40 2 200 (7.87) 200 (7.87) 200 (7.87) 383 (15.08) 160 (6.30) 165 (6.50) 152 (6.00) 11 (25) 11 (25)

80 40 3 200 (7.87) 200 (7.87) 200 (7.87) 400 (15.75) 173 (6.81) 200 (7.87) 191 (7.50) 15 (33) 16 (36)

100 16 4 250 (9.84) 250 (9.84) 250 (9.84) 451 (17.76) 233 (9.17) 220 (8.66) 228 (8.98) 18 (40) 21 (46)*

150 16 6 300 (11.81) 300 (11.81) 300 (11.81) 492 (19.37) 257 (10.12) 285 (11.22) 279 (10.98) 25 (55) 21 (46)*

DN 10- 150 PN 40, 16 see table

3

/8“- 6“ 150 lb/ RF

300 lb/ RF

≥

3

/8“ a flange connection 1/2" is necessary.

in mm and (inch)

a

(fitting length)

3

150 (5.91) - 150 (5.91) 330 (12.99) 121 (4.76) 90 (3.54) 88.9 (3.50) 7.5 (17) 8.5 (19)

/

8

1

150 (5.91) 200 (7.87) 150 (5.91) 330 (12.99) 121 (4.76) 95 (3.74) 88.9 (3.50) 7.5 (17) 8.5 (19)

/

2

see table

dimensions supplied on request

bc

max. process pressure ratin

•

DN 10 – 40 / 3/8“ - 11/2"

in mm and (inch)

ø D

DIN, ISO ANSI

acc. DIN flanges, see column “PN“

PN 40 = 580 psi

Tolerance details

approx. Weight in

with DIN

flanges

and PN 16 = 232 psi

for fitting length

kg (lb)

with ANSI

flanges

dimensions “a“

Standard min ± 1mm / ± 0.04“

ISO DIN 13 359 +0 / -3 mm / +0 / -0.12“

DN 50 – 150 / 2“ – 6“

02/2001

ALTOFLUX 2W

39

Page 40

Section 5.6 Part C Technical data, Block diagram and Measuring principle

(

(

5.6 Limits

PLEASE NOTE !

• The limits specified in the table for process

• Abbreviation used:

temperature and operating pressure make

allowance for the tube liner and the flange

standard.

DIN = DIN 2501 (= BS 4504)

ANSI = ANSI B 16.5

• Refer to certificates of conformity for max.

allowable operating data for hazardous-duty

versions, provided only with hazardous-duty

equipment.

®

Limits for Teflon

Liner Flanges Max. operating pressure in bar (psig)

Standard

PFA

DIN DN 25, 50, 80 PN 40 40

ANSI 1“, 2“, 3“, 4“, 6“ 150 lb 19.6(284)19.0(275)18.7(271)18.1(262)17.7(256)17.0(246)16.2 (235)

PTFE

DIN DN 10, DN 15 PN 40 40

ANSI3/8“, 1/2" 150 lb 19.6(284)19.0(275)18.7(271)18.1(262)17.7(256)17.0(246)16.2 (235)

PFA liner und Teflon® PTFE liner

at a process temperature of ...

Nominal

diameter

DN 100, DN 150 PN 16 16(232)16(232)16(232)16(232)16(232)16(232)16 (232)

Pressure

rating /

Class

300 lb on request

300 lb on request

≤

(≤

105 °F)

≤

40 °C

(≤

580)40(580)40(580)40(580)40(580)40(580)40 (580)

580)40(580)40(580)40(580)40(580)40(580)40 (580)

60°C

140 °F)

≤

(≤ 158 °F)

≤

70 °C

1)

90 °C

(≤

195 °F)

ambient temperature with max. +40 °C / +104 °F

≤

100 °C

(≤

210 °F)

≤

120 °C

(≤

250 °F)

≤

140 °C

(≤

284 °F)

1)

Vacuum load

Liner Nominal diameter Max. operating pressure in mbar (psia)

DIN ANSI

PFA

DN 25 - 150 1“- 6“ 0 (0) 0 (0) 0 (0) 0 (0) 0 (0) 0 (0) 0 (0)

PTFE

DN 10, DN 15

3

/8“, 1/2“ 0 (0) 0 (0) 0 (0) 0 (0) 0 (0) 500 (7.3) 750 (9.7)

40

≤

(≤

105 °F)

40 °C

≤

60 °C

(≤

140 °F)

ALTOFLUX 2W

≤

(≤ 158 °F)

at a process temperature of ...

70 °C

≤

90 °C

(≤

195 °F)

Teflon® is a registered trademark of Du Pont.

≤

100 °C

(≤

210 °F)

≤

120 °C

(≤

250 °F)

02/2001

≤

140 °C

(≤

284 °F)

Page 41

Part C Technical data, Block diagram and Measuring principle Section 6

%ORFNGLDJUDPRIVLJQDOFRQYHUWHU

1 AD converter

overdrive-proof signal processing,

•

processes flow peaks

up to 20 m/s (65ft/s) more rapidly and

accurately

than competition modules

digital signal processing and sequence

•

control

high-resolution Delta-Sigma A/D

•

converter,

digitally controlled and monitored

high signal-to-noise ratio, signal

•

processing: patent pending

2 Field power supply

The low-loss field power supply generates

•

the pulsed, electronically controlled DC

current for the magnetic coils of the

primary head

The field current ensures matched to the

•

power, an optimum signal amplitude and

signal-to-noise separation

3 Current output, HART® modem

galvanically isolated from all other

•

terminals, but not from power booster

converts the digital output signal from the

•

µP 2 microprocessor into a proportional

current

communication via HART®

•

4 Binary output

galvanically isolated from other groups

•

can be used as pulse or status output

•

output (B1), terminal for up to 100 mA

•

output (B2), terminal according NAMUR

•

(DIN 19 234)

5 Display/operator control unit

large LCD display, 3-line

•

3 keys for operator control of the signal

•

converter

connection to the internal IMoCom bus

•

6 IMoCom bus plug connector

for connection of external control and test

•

devices

Power booster input

7

02/2001

ALTOFLUX 2W

41

Page 42

Section 7 Part C Technical data, Block diagram and Measuring principle

0HDVXULQJSULQFLSOH

The flowmeter is designed for electrically conductive fluids.

Measurement is based on Faraday’s law of induction, according to which a voltage is induced in

an electrically conductive body which passes through a magnetic field. The following expression

is applicable to the voltage:

U = K × B × v × D

U = induced voltage

K = an instrument constant

v = mean velocity

B = magnetic field strength

D = tube diameter

Thus the induced voltage is proportional to the mean flow

velocity, when the field strength is constant.

Inside the electromagnetic flowmeter, the fluid passes

through a magnetic field applied perpendicular to the

direction of flow. An electric voltage is induced by the

movement of the fluid (which must have a minimum

electrical conductivity). This is proportional to the mean

flow velocity and thus to the volume of flow:

The induced voltage signal is picked up by two electrodes which are in conductive contact with the

fluid and is transmitted to a signal converter for a standardized output signal.

This method of measurement offers the following advantages:

1. No pressure loss through pipe constriction or protruding parts.

2. Since the magnetic field passes through the entire flow area, the signal represents a mean

value over the pipe cross-section; therefore, only relatively short straight inlet pipes

DN from the electrode axis are required upstream of the primary head.

5

x

3. Only the tube liner and the electrodes are in contact with the fluid.

4. Already the original signal produced is an electrical voltage which is an exact linear function

of the mean flow velocity.

5. Measurement is independent of the flow profile and other properties of the fluid.

The magnetic field of the primary head is generated by a square wave current fed from signal

converter to the field coils.

This field current alternates between positive and negative values. Alternate positive and negative

flowrate-proportional signal voltages are generated at the same frequency by the effect of the

magnetic field, which is proportional to the current. The positive and negative voltages at the

primary head electrodes are subtracted from one another in the signal converter. Subtraction

always takes place when the field current has reached its stationary value, so that constant

interference voltages or external or fault voltages changing slowly in relation to the measuring

cycle are suppressed. Power line interference voltages coupled in the primary head or in the

connecting cables are similarly suppressed.

42

ALTOFLUX 2W

02/2001

Page 43

Part C Technical data, Block diagram and Measuring principle Section 8

g

,I\RXQHHGWRUHWXUQIORZPHWHUVIRUWHVWLQJRUUHSDLUWR.52+1(

Your electromagnetic flowmeter

• has been carefully manufactured and tested by a

company with ISO 9001 certification

• and volumetrically calibrated in one of the world’s

most accurate test rigs.

If installed and operated in accordance with these

operating instructions, your flowmeter will rarely

present any problems. Should you nevertheless

need to return a flowmeter for checkout or repair,

please pay strict attention to the following points:

Due to statutory regulations concerning protection of

the envi-ronment and the health and safety of our

personnel, Krohne may only handle, test and repair

returned flowmeters that have been in contact with

liquids if it is possible to do so with-out risk to

personnel and environment. This means that

Krohne can only service your flowmeter if it is

accompanied by a certificate in line with the followin

model confirming that the flowmeter is safe to

handle.

Specimem certificate

can only service your flowmeter if it is accompanied

by a certificate in line with the following model

confirming that the flowmeter is safe to handle.

If the flowmeter has been operated with toxic,

caustic, flammable or water-endangering liquids, you

are kindly requested

• to check and ensure, if necessary by rinsing or

neutraliz-ing, that all cavities in the flowmeter are

free from such dangerous substances.

(Directions on how you can find out whether the

primary head has to be opened and then flushed

out or neutralized are obtainable from Krohne on

request.)

• to enclose a certificate with the flowmeter

confirming that the flowmeter is safe to handle

and stating the liquid used. Krohne regret that

they cannot service your flowmeter unless

accompanied by such a certificate.

02/2001

ALTOFLUX 2W

43

Loading...

Loading...