Page 1

Condensed

Instructions

IFC 210 E

IFC 210 E-EEx

Signal converters for

electromagnetic flowmeters

©

KROHNE 05/2002 7.10006.11.00

Applicable to

Software Versions

● Operating and check elements

No. 3.18393.01

● Amplifier (ADC)

No. 3.17116.01

● Outputs/inputs (I/O)

No. 3.19005.01

Contents

1 Electrical connection: Power Pages 2-11

2 Electrical connection: Outputs Pages 12-18

3 Start-up Pages 19

4 Operator control of signal converter Pages 20-27

PLEASE NOTE

These concise instructions do not include the following:

device description, technical data, standards, approvals, etc.,

nor conditions pertaining to product liability and warranty.

The operator is, however, obligated to take note of these

sections in the detailed Installation and Operating Instructions.

References to chapters

All references to chapters in these Condensed Instructions

refer to those of the detailed “Installation and Operating

Instructions”. It is important that the detailed Instructions

be referred to for all chapters omitted from these

Condensed Instructions. This particularly concerns

installation and operation in hazardous areas!

Page 2

Sect. 1.1 Part A System installation and start-up

1 (OHFWULFDOFRQQHFWLRQSRZHUVXSSO\

1.1 Location and important installation notes

Electrical connection in accordance with VDE 0100

•

installations with line voltages up to 1000 V” or

•

Do not cross or loop

•

•

•

•

•

•

•

•

separate cable

Use

outputs and inputs.

Protect flowmeters or switchgear cabinets with built-in devices from direct

sunshade if necessary.

installed in switchgear cabinets

When

use fans or heat exchangers. (dust-free air and no aggressive gases)

Do not expose signal converters to intense

distance between primary head and signal converter

Keep

Sect. 1.3.4 for maximum permissible length of signal and field current cables.

Use the supplied KROHNE

optional

Always

ensure

head.

If the GK is not identical, set the signal converter to the GK of the primary head.

Refer also to Section 4.

Dimensions of signal converter,

signal cable B

calibrate

primary constant GK is identical

IMPORTANT!

For EEx versions, also pay regard to all special directions included in Sect. 6.1

and 13.

Only the EEx primary head may be installed in the hazardous area.

The signal converter must be installed outside the hazardous area!

cables

.

entries (see below) for power supply, field current cables, signal lines,

signal cable A

(Type BTS).

primary head and signal converter

refer to Section 10.4.

equivalent others national regulations

, signal converters must be adequately cooled, e.g.

vibration

(Type DS), standard length 10 m (33 ft), or

; refer to instrument nameplate for the primary

”Regulations governing heavy-current

.

together

sunlight

as short as possible. Refer to

. Therefore, when installing,

. Fit a

.

2 IFC 210 E

05/2002

Page 3

Part A System installation and start-up Sect. 1.2

1.2 Power supply - Electrical connection

PLEASE NOTE !

•

Rated values: The flowmeter housings meets the requirements of IP 20 in conformity

with EN 60529.

No protection against water and moisture. If necessary, take appropriate protective

measures.

The selected creepage distances and clearances have been dimensioned in conformity with

VDE 0110 and IEC 664 for contamination category 2. Supply circuits and output circuits are

designed to meet the standards of overvoltage class II.

•

Fuse protection, disconnecting device: fuse protection for the feeding power circuit, and also

a disconnecting device (switch, circuit breaker) for isolating the signal converters must be

provided (see also Sect. 1.3.5).

Power supply 100-230 V AC (Tolerance zone: 85-255 V AC)

•

Note information on instrument nameplate: supply voltage and frequency

•

Connection diagrams for electrical connection between primary head and signal converter:

refer to Section 1.3.5.

Power supply 24 Volt AC / DC (Tolerance zone: AC 20.4 - 26.4 V / DC 18 - 31.2 V)

•

Note information on instrument nameplate: supply voltage and frequency

•

For measurement reasons, connect an FE functional ground conductor.

•

If connected to a functional extra-low voltage source (24 V AC / DC, 48 V AC), provide for

protective separation (PELV) in conformity with e.g. VDE 0100 / VDE 0106 or

IEC 364 / IEC 536, or equivalent national regulations.

•

Connection diagrams for power supply and electrical connection between primary head and

signal converter: refer to Section 1.3.5.

IMPORTANT!

For EEx versions, also pay regard to all special directions included in Sect. 6.1

and 13.

Only the EEx primary head may be installed in the hazardous area.

The signal converter must be installed outside the hazardous area!

IFC 210 E 3

05/2002

Page 4

Sect. 1.3.1 Part A System installation and start-up

1.3 Electrical connection of separate primary heads

1.3.1 General remarks on signal lines A and B and field current line C

Proper operation of the equipment is ensured when KROHNE signal lines A and B are used with

foil screen and magnetic shield.

•

Signal lines must be firmly installed.

•

Shields are connected via stranded drain wires.

•

Underwater or underground routing is possible.

•

Insulating material flame-retardant to IEC 332.1 / VDE 0742.

•

Low-halogen, unplasticized signal lines which remain flexible at low temperatures.

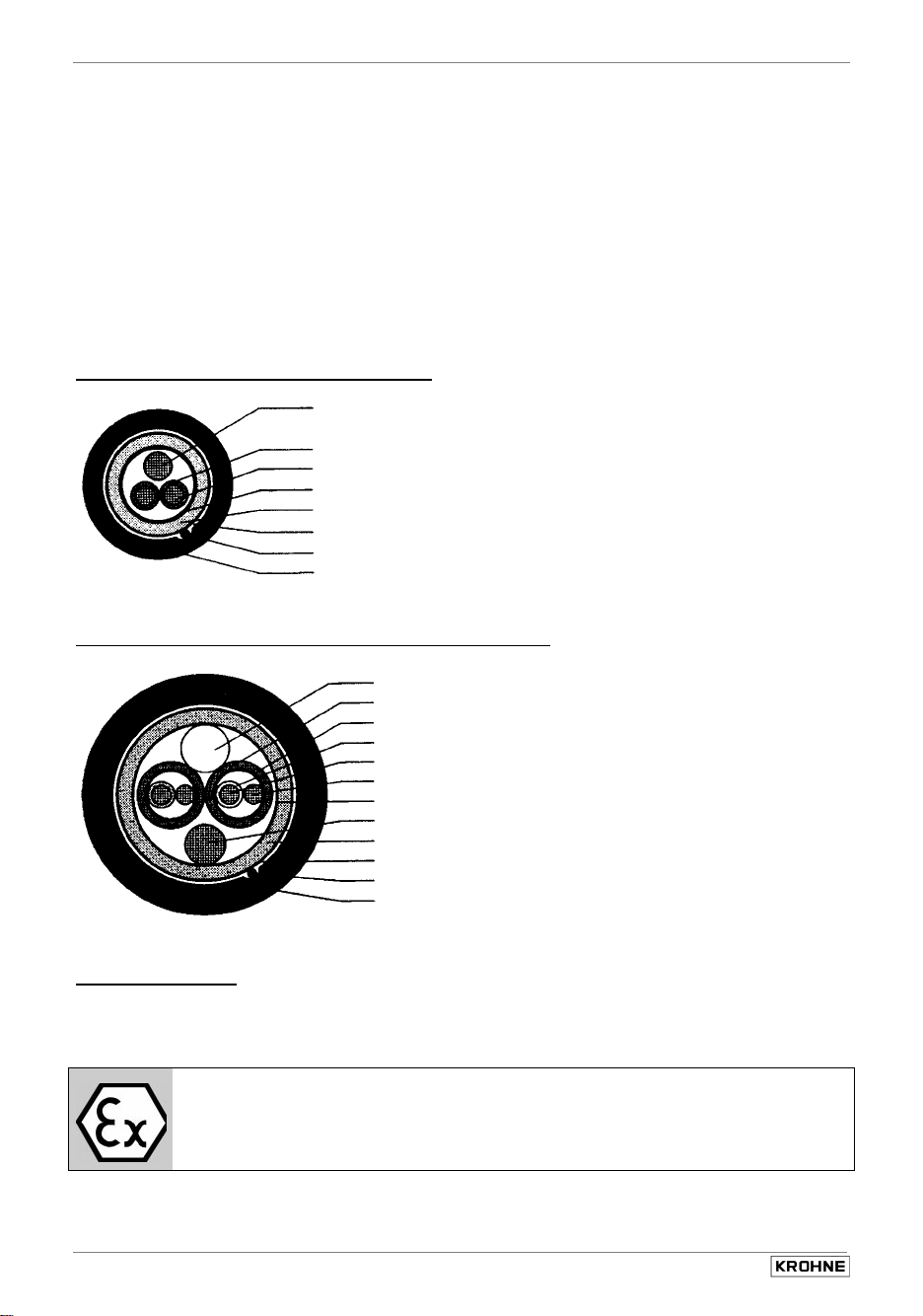

Signal line A (type DS) with double shielding

1 Stranded drain wire, 1st shield, 1.5 mm

2 Insulation

3 Stranded wire 0.5 mm2 (3.1 red/3.2 white)

4 Special foil, 1st shield

5 Insulation

6 Mu-metal foil, 2nd shield

7 Stranded drain wire, 2nd shield, 0.5 mm2

8 Outer sheath

Signal line B (type BTS) with triple shielding (bootstrap line)

1 Dummy glider wire

2 Insulation (2.1 red/2.2 white)

3 Special foil, 1st shield (3.1/3.2)

4 Insulation (4.1/4.2)

5 Stranded wire 0.5 mm

6 Stranded drain wire, 1st shield, 0.5 mm2 (6.1 / 6.2)

7 Special foil, 2nd shield

8 Stranded drain wire, 2nd shield, 1,5 mm2

9 Insulation

10 Mu-metal foil, 3rd shield

11 Stranded drain wire, 3rd shield,, 0,5 mm2

12 Outer sheath

Field current line C

Line 2 × 0,75 mm2, 2 × 1,5 mm2 or 4 × 1,5 mm2Cu, single shielding

(Cu = copper cross section)

The cross section depends on the required cable length, see table in Section 1.3.4.

IMPORTANT!

For EEx versions, also pay regard to all special directions included in Sect. 6.1

and 13.

Only the EEx primary head may be installed in the hazardous area.

The signal converter must be installed outside the hazardous area!

2

2

(5.1 red/5.2 white)

4 IFC 210 E

05/2002

Page 5

Part A System installation and start-up Sect. 1.3.2

1.3.2 Stripping (preparation) of signal cables

Please note: The numbers in the drawings designate the stranded drain wires of signalling cables

A and B, see sectional drawings in Sect. 1.3.1.

primary head Converter

Length primary head Length Converter

mm inch mm inch

a 90 3.60 a 40 2.80

b 8 0.30 b 10 0.30

c 25 1.00

d 8 0.30 d 5 0.30

e 70 2.80 e 20 2.00

Signal cable A (type DS),

double shielding

for primary head

Signal cable A (type DS),

double shielding

for IFC 210 E Converter

Signal cable A

bending radius

bending radius

≥

50 mm (≥ 2”)

≥

50 mm (≥ 2”)

Signal line B (type BTS),

with triple shielding (bootstrap)

for primary head

Signal cable B

bending radius

bending radius

≥

50 mm (≥ 2”)

≥

50 mm (≥ 2”)

Customer-supplied materials

V Tin-coat all stranded drain wire ends!

W Insulation tubing (PVC), Ø 2.0-2.5 mm (Ø 1”)

X Heat-shrinkable tubing or cable sleeve

Y Wire end sleeve to DIN 41 228: E 1.5-8

Z Wire end sleeve to DIN 41 228: E 0.5-8

Signal line B (type BTS),

with triple shielding (bootstrap)

for IFC 210 E Converter

IFC 210 E 5

05/2002

Page 6

Sect. 1.3.3 Part A System installation and start-up

1.3.3 Grounding of primary head

•

All flowmeters must be grounded.

•

The grounding conductor should not transmit any interference voltages.

•

Do not ground any other electrical device together with this conductor.

•

The primary head is connected to ground by means of an FE functional ground conductor.

•

Special information on grounding various primary heads is contained in the separate

installation instructions for primary heads.

•

These instructions also contain detailed descriptions on how to use grounding rings and how

to install primary heads in metal or plastic pipes or internally coated pipelines.

IMPORTANT!

For EEx versions, also pay regard to all special directions included in Sect. 6.1

and 13.

Only the EEx primary head may be installed in the hazardous area.

The signal converter must be installed outside the hazardous area!

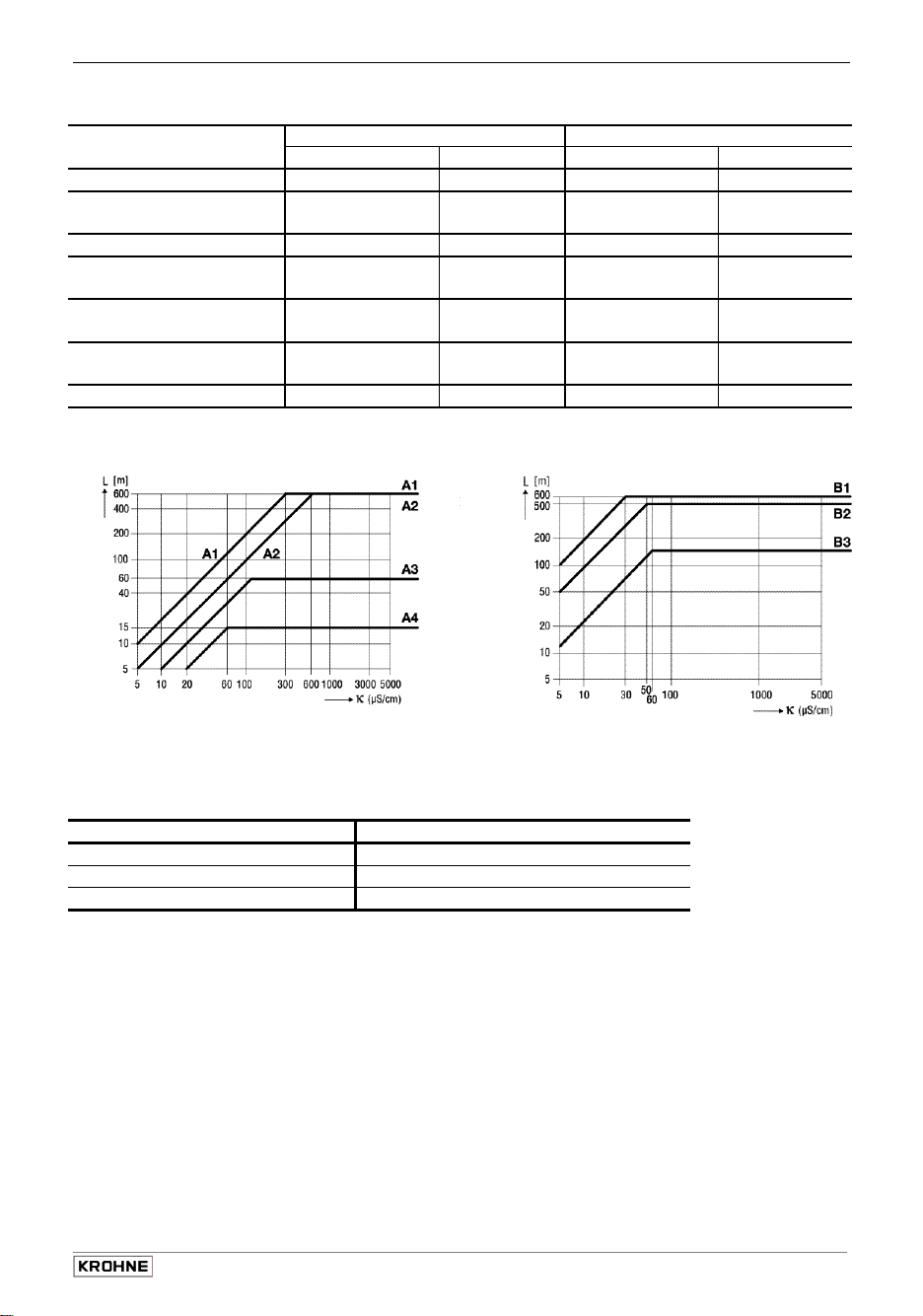

1.3.4 Cable lengths (max. distance between signal converter and primary head)

Abbreviations and explanatory notes

used in the following tables, diagrams and connection diagrams

A Signal cable A (type DS), with double shielding, see diagram A for max. length

B Signal line B (type BTS) with triple shielding, max. length see diagram B

C Field current cable min. cross-section (AF) and max. length, see Table

D High-temperature silicone cable, 3 × 1.5 mm

2

(14 AWG) Cu, (with single shielding,

max. length 5 m (16 ft)

E High-temperature silicone cable, 2 × 1.5 mm

2

(14 AWG) Cu, max. length 5 m (16 ft)

Cross section of field current line C in Cu, see table

A

F

L Cable length

Electrical conductivity of the process liquid

κ

ZD Intermediate connection box required in connection with cables D and E for primary heads

ALTOFLUX IFS 4000 F, PROFIFLUX IFS 5000 F and VARIFLUX IFS 6000 F in cases

where process temperatures exceed 150 °C (302 °F)

6 IFC 210 E

05/2002

Page 7

Part A System installation and start-up Sect. 1.3.4

Recommended length of signal cable A (Type DS) and B (Type BTS)

Primary head Meter size Signal cable

DN mm inch A B

AQUAFLUX F 10 - 1600

ECOFLUX IFS 1000 F 10

- - 15

25

ALTOFLUX IFS 2000 F 150 - 250 6 - 10 A1 B1

ALTOFLUX IFS 4000 F 10

200 - PROFIFLUX IFS 5000 F 2.5

- - 15

25

VARIFLUX IFS 6000 F 2.5 - 15

25 - 80 1 - 3 A2 B2

ALTOFLUX M 900 10 - 300

150

150

1600

100

3

/8 - 64 A1 B1

3

/

- - ½

8

1

3

/

8

8

1

/

10

1

1

/10 - ½ A4 B3

3

/8 - 12 A1 B1

6

- - 6

64

- - ½

4

A4

A3

A2

A1

A4

A2

B3

B2

B2

B1

B3

B2

Diagram A Diagram B

Field current cable C

Length L Cross section AF (Cu), minimum

0 – 150 m 5 – 500 ft 2 x 0.75 mm2 / 2 × 18 AWG

150 – 300 m 500 – 1000 ft 2 x 1.50 mm2 / 2 × 14 AWG

300 – 600 m 1000 – 1900 ft 4 x 1.50 mm2 / 2 × 12 AWG

IFC 210 E 7

05/2002

Page 8

Sect. 1.3.5 Part A System installation and start-up

1.3.5 Connection diagrams for power supply and primary head

PLEASE NOTE: Undocumented contacts/terminals to remain unwired.

The figures in brackets indicate the stranded drain wires for the shields

(see cross-sectional drawing of signal cable in Section 1.3.1).

•

Electrical connection to VDE 0100 "Regulations governing heavy-current installations with

line voltages up to 1000 V" or equivalent national regulations.

•

24 V AC / DC power supply:

Functional extra-low voltage with protective separation in

conformity with VDE 0100, Part 410 or equivalent national

regulations (IFC 020 E: 24 V DC in preparation).

•

Fuse protection of the feed line circuit with I

≤ 16 A is required. Also, a disconnecting

RAT

device (switch/circuit breaker) must be provided in the vicinity of the solidly connected signal

converters or device groups, refer to EN 61 010. This disconnecting device must be easy to

reach and also identifiable as such.

Contacts 2d, 2z, 4d, 4z of

*

XA must be electrically

connected.

Connection to 8d and/or

**

8z of XA.

Contacts d2 to d32 of XB

***

are of leading type, for

connection of PE (safety

conductor) or FE

(functional ground).

At least 4 contacts with

adequate cross-section to

be electrically connected.

Important:

Electrical connection of EEx primary heads and EEx signal converters

To be carried out as described in Sect. 1.3.6.

8 IFC 210 E

05/2002

Page 9

Part A System installation and start-up Sect. 1.3.5

I Signal cable A (type DS) II Signal cable B (type BTS)

IFC 210 E IFC 210 E

Process temperature < 150°C (302°F)

Primary head Primary head

III Signal cable A (type DS) IV Signal cable B (type BTS)

IFC 210 E IFC 210 E

Process temperature > 150°C (302°F)

Primary head Primary head

IFC 210 E 9

05/2002

Page 10

Sect. 1.3.6 Part A System installation and start-up

1.3.6 EEx-Connection diagrams for power supply and primary head

Connection diagrams

PLEASE NOTE: Undocumented contacts/terminals to remain unwired.

The figures in brackets indicate the stranded drain wires for the shields

(see cross-sectional drawing of signal cable in Section 1.3.1).

•

Electrical connection to VDE 0100 "Regulations governing heavy-current installations with

line voltages up to 1000 V" or equivalent national regulations.

•

24 V AC / DC power supply:

Functional extra-low voltage with protective separation in

conformity with VDE 0100, Part 410 or equivalent national

regulations (IFC 020 E: 24 V DC in preparation).

•

Fuse protection of the feed line circuit with I

≤ 16 A is required. Also, a disconnecting

RAT

device (switch/circuit breaker) must be provided in the vicinity of the solidly connected signal

converters or device groups, refer to EN 61 010. This disconnecting device must be easy to

reach and also identifiable as such.

Contacts 2d, 2z, 4d, 4z of

*

XA must be electrically

connected.

Connection to 8d and/or

**

8z of XA.

Contacts d2 to d32 of XB

***

are of leading type, for

connection of PE (safety

conductor) or FE

(functional ground).

At least 4 contacts with

adequate cross-section to

be electrically connected.

Important:

In respect of EEx versions, pay regard to all directions marked with the symbol,

and also the information given in Sect. 6.1 and 13.

Only the EEx primary head may be installed in the hazardous area.

The signal converter must be installed outside the hazardous area!

10 IFC 210 E

05/2002

Page 11

Part A System installation and start-up Sect. 1.3.6

I Signal cable A (type DS) II Signal cable B (type BTS)

IFC 210 E-EEx IFC 210 E-EEx

Process temperature < 150°C (302°F)

PE/PA

PE/PA

Hazardous area

PA

Primary head Primary head

Hazardous area

PA

III Signal cable A (type DS) IV Signal cable B (type BTS)

Process temperature > 150°C (302°F)

IFC 210 E-EEx IFC 210 E-EEx

PE/PA

Hazardous area

PE/PA

Hazardous area

PA

PA

Primary head Primary head

IFC 210 E 11

05/2002

PA

PA

Page 12

Sect. 2.1 Part A System installation and start-up

(OHFWULFDOFRQQHFWLRQRIRXWSXWVDQGLQSXWV

2

Important:

In respect of EEx versions, pay regard to all directions marked with the symbol,

and also the information given in Sect. 6.1 and 13.

Only the EEx primary head may be installed in the hazardous area.

The signal converter must be installed outside the hazardous area!

2.1 Current output I

The current output is galvanically isolated from all input and output circuits.

•

Setting data and functions can note down in Section 3.3.

•

Please also refer to Sect. 3.2 Factory settings.

Typical current

•

output

All operating data and functions can be set, see Sect. 4 and 5.6, Fct. 1.05 for operator control

•

The current output can also be used as an internal voltage source for the binary outputs and

•

inputs.

U

•

= 22-25 V DC

int

I = 23 mA when operated

output

I = 3 mA when operated

•

Connection diagrams

, see Sect. 2.5: diagrams

approx. 22-25 V DC positive

voltage of current output

current sink

chassis ground, current output

without

with

receiver instruments at the current

receiver instruments at the current output

c d e g i k l

12 IFC 210 E

05/2002

Page 13

Part A System installation and start-up Sect. 2.2

2.2 Pulse output P

•

The pulse output is galvanically isolated from the current output and all input circuits.

•

Setting data and functions can note down in Section 3.3.

Please also refer to Sect. 3.2 Factory settings.

•

Typical pulse output P

•

All operating data and functions can be set, see Sect. 4 and 5.7, Fct. 1.06 for operator control

•

The pulse output can be operated in the active or passive mode.

•

Active mode:

•

Passive mode:

Please note:

A fixed pulse width (0.01 – 1s) must be set for operation with EMC

•

Digital pulse division, interpulse period is non-uniform. Therefore, if frequency meters or

•

cycle counters are connected, allow for minimum counting interval:

•

gate time, counter ≤

•

Connection diagrams, see Sect. 2.5: diagrams

The current output is the internal voltage source,

connection of electronic totalizers (EC)

External DC or AC voltage source required,

connection of electronic (EC) or electromechanical (EMC) totalizers

totalizer. Only then is an optocoupler active for higher output currents.

1000

[Hz]

P

100%

e

f k l

P pulse output

P pulse output

IFC 210 E 13

05/2002

Page 14

Sect. 2.3 Part A System installation and start-up

2.3 Status outputs B1 and B2

•

The status outputs are galvanically isolated from the current output and all input circuits.

•

Setting data and functions can note down in Section 3.3.

Please also refer to Sect. 3.2 Factory settings.

•

Typical status outputs B1 and/or B2

B1/B2 status outputs B1/B2

B⊥ chassis ground,

binary outputs and inputs

•

All operating data and functions can be set,

see Sect. 4 and 5.9, Fct 1.07 and/or 1.08 for operator control

The status outputs can be operated in the active or passive mode.

Active mode: The current output is the internal voltage source.

Passive mode: External DC or AC voltage source required.

Characteristics of the status outputs Switch open Switch closed

OFF (switched off) no function

ON (e.g. operation indicator) power OFF Hilfsenergie EIN

SIGN I (F/R mode) Forward flow Reverse flow

SIGN P (F/R mode) Forward flow Reverse flow

TRIP POINT (limit switch) inactive active

AUTO RANGE (automatic range

change)

OVERFLOW I (I overranged) current output OK current output overranged

OVERFLOW. P (P overranged) pulse output OK pulse output overranged

SMU I (low-flow cutoff active) Inactive active

SMU P (low-flow cutoff active) Inactive active

Inverse B1 (switches B2 inversely to B1) B2 open, B1 closed B2 closed, B1 open

ALL. ERROR (all errors) errors no error

FATAL.ERROR (fatal errors only) errors no error

EMPTY PIPE (option) when measuring tube is empty when measuring tube is full

high range low range

•

Connection diagrams, see Sect. 2.5: diagrams

g

h k l

14 IFC 210 E

05/2002

Page 15

Part A System installation and start-up Sect. 2.4

2.4 Control inputs B1 and B2

•

The control inputs are galvanically isolated from the current output and all input circuits.

•

Setting data and functions can note down in Section 3.3.

Please also refer to Sect. 3.2 Factory settings.

•

Typical current inputs B1 and B2

B1/B2

B⊥

•

All operating data and functions can be set,

see Sect. 4 and 5.10, Fct 1.07 and/or 1.08 for operator control

•

The control inputs must be operated in the passive mode.

Function of the control inputs inactive active

no voltage voltage present

Off No functions

External range High range Low range

Hold measured values Measured values follow the Hold measured values

measurement

Measured values at zero Measured values follow the

measurement

Measured values set to

“zero“

Reset totalizer inactive Reset totalizer

Delete errors inactive Delete error messages

Connection diagram, see Sect. 2.5: diagram

i

j

IFC 210 E 15

05/2002

Page 16

Sect. 2.5 Part A System installation and start-up

2.5 Connection diagrams for outputs and inputs

I

P

B1, B2

Current output I

c

= 0/4-20 mA

U

< 800 Ω

R

L

Important:

In respect of EEx versions, pay regard to all directions marked with the symbol,

and also the information given in Sect. 6.1 and 13.

Only the EEx primary head may be installed in the hazardous area.

The signal converter must be installed outside the hazardous area!

Current output (included HART

Pulse output

Status output (S) and / or

Control input (C)

Totalizer

- electromechanical (EMC)

- electronic (EC)

milliammeter

0-20 mA or 4-20 mA and other

Key, N/O contact

External voltage source (U

DC or AC voltage,

connection polarity arbitrary

DC voltage,

external power source (U

®

Please note ! Unwired contacts may not have

)

any conductive connection with other electrically

conducting parts.

Electrical connection to socket connector XC

Wiring diagrams c to l of outputs and inputs.

Interface operation with HART® or

RS 485 (Option) see Sect. 6.2.1 and 6.2.2.

Power for operation (activation) of outputs and

inputs supplied by the current output.

),

ext

Active mode

External power source required for operation

(activation) of outputs and inputs.

),

ext

Passive mode

note connection polarity

aktiv

Current output I

d

15-22 V DC 22-32 V DC

U

ext

R

0-500 Ω 0-800

L

= 0/4-20 mA

I

passiv

Ω

16 IFC 210 E

05/2002

Page 17

Part A System installation and start-up Sect. 2.5

Pulsoutput P

e

for electronic totalizer (EC)

= 22-25 V DC from current output

U

int

≤ 3 mA operation with current output I

I

max

≤ 23 mA operation

I

max

activ

without

current output I

R = 10 kΩ, prevents incorrect counts

when pulse output in open circuit

Where frequencies are > 100 Hz, use shielded

cables (RFD)

Statusoutput S

g

(connection to B2 and/or B1)

= 22-25 V DC from current output

U

int

≤ 3 mA operation with current output I

I

max

≤ 23 mA operation without current output I

I

max

activ

Pulsoutput P

f

for electronic totalizer (EC) or

passiv

electromechanical totalizer (EMC)

EMC:

EC:

Pulses

R (load)

U

I

max

U

≤ 32 V DC /

ext

≤ 150 mA

≤ 32 V DC

ext

≤ 1 kHz

1-10 kΩ 1-3 kΩ

≤ 24 V AC

f ≤ 50 Hz

≤ 20 mA

I

max

< 10 kHz

R = load impedance with EC totalizer operation; for

value refer to table above

Where frequencies are > 100 Hz, use shielded cables

(RFD)

Statusoutput S

h

(connection to B2 and/or B1)

U

≤ 32 V DC / ≤ 24 V DC

ext

I

max

≤ 150 mA

passiv

IFC 210 E 17

05/2002

Page 18

Sect. 2.5 Part A System installation and start-up

Control input C

i

(connection to B2 and/or B1)

= 22-25 V DC from current output

U

int

≤ 4 mA (max. contact rating)

I

con

active

Control input C

j

(connection to B2 and/or B1)

U

≤ 32 V DC / ≤ 24 V AC

ext

I

con

≤ 6 mA (max. contact rating)

passive

F/R measurement (F=forward) (R=reverse)

k

Current output I

pulse output P

without external changeover relay

= 22-25 V DC from current output

U

int

≤ 3 mA operation

I

max

≤ 23 mA operation

I

max

and/or

active

(for EC)

aktive

current output I

with

without

current output I

F/R measurement (F=forward) (R=reverse)

l

Current output I

pulse output P

without external changeover relay

EMC:

EC:

Pulses

R (load)

≤ 32 V DC /

U

ext

≤ 150 mA

I

max

≤ 32 V DC

U

ext

and/or

passive

(for EC or EMC)

passive

≤ 24 V AC

f ≤ 50 Hz

≤ 20 mA

I

max

≤ 1 kHz

< 10 kHz

1-10 kΩ 1-3 kΩ

= 10 kΩ, prevents incorrect counts

R

when pulse output in open circuit

Where frequencies are > 100 Hz, use shielded

*

cables (RFD)

R = load impedance with EC totalizer operation; for

value refer to table above

Where frequencies are > 100 Hz, use shielded

*

cables (RFD)

18 IFC 210 E

05/2002

Page 19

Part A System installation and start-up Sect. 3.1

6WDUWXS

3

3.1 Power-on and measurement

•

Before powering the system, please check that it has been correctly installed according to

Sect. 1 and 2.

•

The flowmeter is delivered ready for operational use. All operating data have been factory set

in accordance with your specifications.

Please refer to Sect. 3.2 “factory settings”.

•

Power the unit, and the flowmeter will immediately start process flow measurement.

•

Refer to Sect. 4 and 5 for operator control.

3.2 Factory setting

All operating data are factory set according to your order specifications.

If you have not made any particular specifications at the time of ordering, the instruments will be

delivered with the standard parameters and functions listed in the Table below.

To facilitate easy and rapid initial start-up, current output and pulse output are set to process flow

measurement in “2 flow directions”, so that the current flowrate is displayed and the volumetric

flow counted independent of the flow direction. The measured values may possibly be shown with

a “ – ” sign.

This factory setting for the current and pulse outputs may possibly lead to measuring errors,

particularly in the case of volume flow counting:

For example, if pumps are switched off and a “backflow” occurs which is not within the range of

the low-flow cutoff (SMU), or if separate displays and counts are required for both flow directions.

To avoid faulty measurements, therefore, it may be necessary to change the factory setting of

some or all of the following functions:

– low-flow cutoff SMU, Fct. 1.03, Sect. 5.3

– display, Fct. 1.04, Sect. 5.4

– current output I, Fct. 1.05, Sect. 5.6

– pulse output P, Fct. 1.06, Sect. 5.7

Operation see

Standard factory settings

Function Setting Function Setting

1.01 Full-scale range Q

1.02 Time constant 3 s, for I, B1, B2 directions

and display 1.08 Control input B2 off

1.03 Low-flow ON: 1% 3.01 Language for display only English

cutoff SMU OFF: 2% 3.02 Flowmeter

1.04 Display diameter see nameplate

flow rate m3/hr or US Gal /mi n flow direction (see arrow

totalizer(s) m3 or US Gal on primary head) } + direction

Messages no 3.04 Entry code no

Trend Mittelwert 3.05 User unit Liter/hr or USMGal/day

Updating 1 sec. 3.06 Application: Flow steady

Scaling auto 3.07 Hardware: Terminal B1 Statusoutput

1.05 Current output I Terminal B2 Control input

function 2 directions 3.08 Location ALTOMETER

Range I 4-20 mA 3.09 Communication off

I Max 22 mA

I Error 22 mA

1.06 Pulse output P

function 2 directions

pulse width 50 ms

pulse value 1 pulse/s

Section 4 and 5

1.07 Status output B1 flow

100%

.

IFC 210 E 19

05/2002

Page 20

Sect. 2.5 Part A System installation and start-up

2SHUDWLRQRIWKHVLJQDOFRQYHUWHU

4

4.1 KROHNE operator control concept

1 3 6. 4 9

m 3 /hr

→

Measuring mode

Code 1

Menu column

3.00 Installation

2.00 Test

When this display appears, press following keys:

→ → → ↵ ↵ ↵ ↑ ↑ ↑

Function column

3.09 Communication

3.08 Location

3.07 Hardware

3.06 Application

3.05 User Units

3.04 Entrycode

3.03 Zero Point

3.02 Flow Meter

3.01

Language

2.03 Test Display

2.02 Hardwareinfo

2.01 Test Q

1.08 Out-/Input B2

Data column

1.07 Out-/Input B1

1.06 Pulsoutput P

1.05 Currentoutput I

1.04 Display

1.03 Low Flow Cutoff

1.02Timeconstant

1.01 Full Scale

→

↑

Direction of movement

1.00 Operation

↑

↓

↵

20 IFC 210 E

↓

Sect.

4.4

↵

05/2002

see

→

Page 21

Part B IFC 210 Signal converter Sect. 4.2

4.2 Table of settable functions

Fct. Display- Texts Description and settings

1.00 OPERATION Operations menu

1.01 FULL SCALE Full-scale range for flowrate Q

Select unit

3

• m

/hr • Liter/Sec • US.Gal/min

• user unit, factory set is Liter/hr or US MGal/day (see Fct. 3.05)

Press

key to transfer to number setting.

→

Setting ranges:

The ranges are dependent on the meter size (DN) and the

flow velocity (v):

Nom. dia. /meter size v

• DN 2.5–1600 /

1

/10 – 64:

0.0237 – 401 080 US Gal/min

Press

key to return to Fct. 1.01 FULL SCALE.

↵

VALUE P Pulse value has been changed.

With the old pulse values the output frequency (F)

would have been exceeded or not reached.

P

min

= F

min

/ Q

100%

P

max

= F

1.02 TIMECONST. Time constant

Select:: • ALL (applies to display and all outputs)

• ONLY Current output (only display, current and status outputs)

Press ↵ key to transfer to number setting.

Range: • 0.2 – 99.9 Sec

Press ↵ key to return to Fct. 1.02 TIMECONST.

1.03 L.F.CUTOFF Low-flow cutoff (SMU)

• OFF (fixed values: ON = 0.1% / OFF = 0.2%)

PERCENT (variable values) ON OFF

1 – 19% 2 – 20%

Press → key to transfer to number setting.

Note: Cutoff off value must be greater than cutoff on value.

Press ↵ key to return to Fct. 1.03 L.F. CUTOFF.

1.04 DISPLAY Display functions

Contrast Set display contrast

• range from + 15 (high contrast) to - 15 (low contrast)

Press ↵ key to transfer to subfunction “Flow”.

Flow Set format for flow rate display

• #### • ### . # • ## . ## • # . #### • Auto

Press key

→ to move to unit selection.

Selection unit: • m3/hr • Liter/Sec • US Gal/min

user unit, factory set is Liter/hr or US MGal/day (see Fct. 3.05)

Press ↵ key to transfer to subfunction “Totalizer”.

Totalizer Set format for display of volume

Select decimal positions:

• ####### • ###### . # • ##### . ## • #### . ###

• ### . #### • ## . ##### • # . ###### • Auto

Press

→ key to move to unit selection.

• m3 • Liter • US Gal

user unit, factory set is Liter or US MGal (see Fct. 3.05)

Press ↵ key to transfer to subfunction “Messages”.

100%

π

Q

= DN2 × v

min

4

= 0,3 m/s (1 ft/s) v

min

Q

min

π

= DN2 × v

max

4

= 12 m/s (40 ft/s)

max

0.0053 – 86 859 m

/ Q

max

Check new values!

100%

3

/hr

max

IFC 210 E 21

05/2002

Page 22

Sect. 4.2 Part B IFC 210 Signal converter

Fct. Display- Texts Description and settings

Messages Additional displays wanted in measuring mode?

• no • yes (overlay additional messages)

Press ↵ key to transfer to subfunction “Trend”.

Trend Set graphic display

Selection: • Average (show average values over time base)

• Min. & Max. (min./max. values over time base)

• Every Value (all values numbered consecutively)

Press ↵ key to transfer to subfunction “Updating”.

When

“every value“

selected, transfer to subfunction

“Scaling“.

Updating Update measured values in graphic display

(this not shown when “every value“, see above, selected)

Selection: • 0.1 Sec. • 0.2 Sec. • 0.5 Sec. • 1 Sec.

• 2 Sec. • 5 Sek. • 1 Min. • 2 Min. • 5 Min.

Press ↵ key to transfer to subfunction “Scaling”.

Scaling Set scaling of graphic display

Selection: • 0% ... 100% • - 25% ... 100%

• 0% ... 50% • 50% ... 100%

• -100% ... 0% • 25% ... -100%

• - 50% ... 0% • -100% ... - 50%

• Auto

Press

key to return to Fct. 1.04 DISPLAY.

↵

1.05 Current output I Set Current output I

Function Set Function

• Off (switched off)

• 1 Direction (1 flow direction)

• 2 Directions (forward/reverse flow, F/R flow measurement)

Range I Set measuring range (I0% ... I

Press ↵ key to transfer to subfunction “Range I”.

)

100%

• 0 - 20 mA • 4 - 20 mA (fixed ranges))

• mA (user-defined range)

• Range: I0% - I

(Value I0% < I

Press → key to transfer to number setting.

Press ↵ key to transfer to subfunction “I Max”.

!) 0 - 16 mA 4 - 20 mA

100%

100%

I Max Set I Max

Selection: • 20,5 mA • 22 mA

I Error Set current for error identification (I

Press ↵ key to transfer to subfunction “I Error”.

)

Error

• 22 mA • 0.0 mA (... < I0%, variable only, see above ifI0% > 1 mA)

Press → key to transfer to number setting.

Press ↵ key to transfer to subfunction “Range I”.

Reverse Range Set full-scale range for reverse flow

(appears only when 2 Directions selected, see above)

setting range: 005 - 150% of Q

100%

(different value for reverse flow)

Press → key to transfer to number setting.

Press

key to return to Fct. 1.05 “Current output I”.

↵

22 IFC 210 E

05/2002

Page 23

Part B IFC 210 Signal converter Sect. 4.2

Fct. Display- Texts Description and settings

1.06 Pulsoutput P Set Pulsoutput P

Function Set Function

Selection: • Off (switched off)

• 1 Direction (1 flow direction)

• 2 Directions (forward/reverse flow, F/R flow measurement)

Pulswidth Set pulse width

Selection: • 0.01 - 1.00 Sec (only for F

• automatic (= 50% of the period duration)

of the 100% output frequency))

• symmetrical (= pulse duty ratio 1:1 over total range)

Pulsvalue Set pulse value

pulse value per unit

• PulS/ user-defined unit, factory-set is Liter or US

pulse value per unit

• PulSe/user-defined unit, factory-set is hr

1.07 Output/Input B1 Assignment of terminal B1 see Fct. 3.07 Hardware:

Either STATUS OUTPUT or CONTROL INPUT

For settings, refer to one of the following descriptions.

1.08 Output/Input B2 Assignment of terminal B2 see Fct. 3.07 Hardware:

Either STATUS OUTPUT or CONTROL INPUT

For settings, refer to one of the following descriptions.

1.0_ Status output Setting as status output

B1 and/or B2 • Off (status output switched off)

• On (status output switched on, e.g. as operation indicator)

EMPTY PIPE (signals that pipe is empty , only if option installed)

• SIGN.I or P (F/R flow measurement)

• Overflow I or P (overranging of outputs)

• SMU I or P (signals when low-flow cutoff is active)

• Inverse B1

Selection: • + direction • - direction • 2 directions

Setting range 005 - 150%

Setting range 05 - 80% (= ratio of lower to upper range)

• All Errors

• Fatal error only

1.0_ Controlinput Set as Control input

B1 and/or B2 • Off (switched off)

• Ext.Range (external range change)

Setting range: 05 - 80% (= ratio of lower to upper range from

1:20 to 1:1.25. Value must be greater than that of Fct. 1.03 L.F. CUTOFF).

• Outp.Hold (hold value of outputs)

• Outp.Zero (set outputs to min.values)

• Total. Reset (reset totalizers)

• Error. Reset (delete error messages)

Press ↵ key to transfer to subfunction “Pulswidth”.

Press ↵ key to transfer to subfunction “Pulsvalue”.

3

• 1/Liter • 1/US Gal

volume

time

Press

• Trip Point: (press key ↵ to transfer to Characteristics)

(press ↵ key to transfer to number setting)

• automatic range change (press ↵ key to transfer to number setting)

Press

Press ↵ key to transfer to number setting.

Press

key to return to Fct. 1.06 “Pulsoutput P”.

↵

key to return to Fct. 1.07 a

↵

key to return to Fct. 1.07 a

↵

• 1/m

M.Gal (see Fct. 3.05)

• PulSe/Sec (=Hz ) • PulSe/min • PulSe/hr

(see Fct. 3.05)

nd/or 1.08 “

nd/or 1.08 “

< 50 pulse/s)

max

Statusoutput”

Statusoutput”

}

I = I only

P = ALL

IFC 210 E 23

05/2002

Page 24

Sect. 4.2 Part B IFC 210 Signal converter

Fct. Display-Texts Description and settings

2.00 Test Test menu

2.01 Test Q Test measuring range Q

Precautionary query

• SURE NO

• SURE YES

Press ↵ key to return to Fct. 2.01 TEST Q .

Press → key to transfer to number setting.

select value: -110 / -100 / -50 / -10 / 0 / +10 / +50 / +100 / +110 PCT..

of set full-scale range Q

100%

.

Displayed value present at outputs I and P.

Press ↵ key to return to Fct. 2.01 “TEST Q” .

2.02 Hardwareinfo Hardware information and error status

Before consulting factory, please note down all codes.

Modul ADC X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Modul IO X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Press

key to transfer to next info.

↵

Modul DISP.. X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Modul RS X . X X X X X . X X (only provided if “computer interface”

Y Y Y Y Y Y Y Y Y Y Option installed)

2.03 Test Display

Press ↵ key to return to Fct. 2.02 “Hardwareinfo”.

Press → key to start test of display, duration approx. 5 sec.

Fct. Display-Texts Description and settings

3.00 Installation Installation menu

3.01 Language Select language for display texts

• GB / USA (English) • F (French)

• D (German) • others on request

Press ↵ key to return to Fct. 3.01 “Language”.

3.02 Flowmeter Set data for primary head

Diameter Select size from meter size table

• DN 2.5 - 3000 mm equivalent to 1/10 – 120 inch

Full Scale Full-scale range for flow Q

Select with ↑ key.

Press ↵ key to transfer to subfunction “Full Scale”.

100%

Selection unit: • m3/hr • Liter/Sec • US Gal/min

user unit, factory set is Liter/hr or US MGal/day (see Fct. 3.05)

Press → key to transfer to number setting.

Setting ranges:

The ranges are dependent on the meter size (DN) and the

flow velocity (v): Q

Nom. dia. /meter size V

= DN2 x v

min

= 0,3 m/s (1 ft/s) V

min

min

Q

= DN2 x v

max

= 12 m/s (40 ft/s)

max

max

• DN 2.5–1600 / 1/10 – 64: 0.0053 – 86 859 m3/hr

0.0237 – 401 080 US Gal/min

Press ↵ key to transfer to subfunction “Gk Value”.

Value P Pulse value has been changed.

With the old pulse values the output frequency (F)

would have been exceeded or not reached.

P

min

= F

min

/ Q

100%

P

max

= F

max

/ Q

Check new values!

100%

Gk Value Set primary constant GK

see primary head nameplate.

Range: • 1.0000 - 9.9999

Press ↵ key to transfer to subfunction “Field Frequenz”.

24 IFC 210 E

05/2002

Page 25

Part B IFC 210 Signal converter Sect. 4.2

Fct. Display-Texts Description and settings

Field Frequenz Set Magnetic field frequency (f

1

•

/2 × f

•

Netz

Select with ↑ key.

1

/6 × f

Netz

Press ↵ key to transfer to subfunction “Flow Direction”.

= power frequency)

Netz

•

1

/18 × f

Netz

•

1

/36 × f

Netz

for DC devices to subfunction „Line Frequenz“

Line Frequenz Normal line frequency in your country

This function is only provided for units with DC power supply

• 50 Hz • 60 Hz

Press ↵ key to transfer to subfunction “Flow Direction”.

Select with ↑ key.

Flow Direction Define flow direction (in F/R mode: forward flow).

• + Direction • - Direction

Press ↵ key to return to Fct. 3.02 “Flowmeter”.

Select with ↑ key.

3.03 Zero Point Zero calibration

• return (quit function without making change)

• calculate (calculate new zero value)

Press ↵ key to start, duration approx. 15-90 seconds.

Save new value, select with ↑ key:

• save no (do not save zero value)

• save yes (save new zero value)

• change (change zero value manually)

Press → key to transfer to unit selection:

• m3/h • Liter/s • US Gal/min

• any unit, see Fct. 3.05 (factory setting: Liter/h)

Value may be max. 10% of Q

Press ↵ key to return to Fct. 3.03 “Zero Point”.

Press → key to transfer to number setting.

100%

3.04 Entrycode Entry code required to enter setting mode?

• NO (= entry with → only)

• YES(= entry with → and Code 1:→ → → ↵ ↵ ↵ ↑ ↑ ↑ )

Press ↵ key to return to Fct. 3.04 “Entrycode”.

3.05 User Units Set any required unit for flowrate and counting

Text Volumen Set text for required flowrate unit (max. 5 characters)

Factory-set: Liter or MGal .

Characters assignable to each place: • A-Z, a-z, 0-9, or — (= blank character)

Press ↵ key to transfer to subfunction “Factor Volumen”.

Factor Volumen Set conversion factor (FM) for volume

Factory set 1.00000 for Liter or 2.64172E-4 for US MGal

(exponent notation, here: 1x 103 or 2.64172x10-4).

Factor FM = volume per 1m3.

Setting range • 1.00000 E-9 to 9.99999 E+9 (= 10-9 to 10+9)

Press ↵ key to transfer to subfunction “Text Time”.

Text Time Set text for required time unit (max. 5 characters)

Factory-set: hr.

Characters assignable to each place: • A-Z, a-z, 0-9, or — (= blank character)

Press ↵ key to transfer to subfunction “Factor Time”.

Factor Time Set conversion factor (FT) for time

Factory-set: 3.60000 E+3 for hour or 8.64000 E+4 for day

(exponent notation, here: 3.6 x103 or 8.64 x10-4).

Set factor FT in seconds.

Setting range • 1.00000 E-9 to 9.99999 E+9 (= 10-9 to 10+9)

Press ↵ key to return to Fct. 3.05 “User Units”.

3.06 Application Set application conditions

Flow Set characterization for flow

• Steady (steady flow, max. 150% of Q

• Pulsating (pulsating flow, up to 1000% of Q

100%

)

100%

e.g. caused by reciprocating pumps, refer to Sect. 6.4)

Press ↵ key to transfer to subfunction “Empty Pipe”.

Empty Pipe Signal when measuring tube is empty (refer to Sect. 6.3 )

• no • yes (possible only with built-in option)

Press ↵ key to return to Fct. 3.06 “Application”.

IFC 210 E 25

05/2002

Page 26

Sect. 4.3 Part B IFC 210 Signal converter

Fct. Display-Texts Description and settings

3.07 Hardware Assign outputs and inputs to terminals B1 and B2

Terminal B1 Define function of terminal B1 (valid for Fct. 1.07)

Terminal B2 Define function of terminal B2 (valid for Fct. 1.08)

Fieldcurrent Define field current supply

• Intern

• Extern (> DN 1600 / > 64“ with power driver)

3.08 Location Set measuring point tag

Factory setting: ALTOMETER

Characters assignable to each place:

• A-Z, a-z, 0-9 or „-“ (=blank character).)

3.09 Communication Set comminucation interface

• Off (switched off))

• HART (HART®-interface switched on))

• KROHNE (KROHNE RS 485-interface switched on),

(only provided if daughter board installed (option).)

• Address: „HART“ 00-15 / „KROHNE“ 000-239

• Baud rate: 1200, 2400, 4800, 9600 or 19200

(appears with selection “KROHNE” only)“)

• Statusoutput • Controlinput (

Press ↵ key to transfer to subfunction “Terminal B2”.

• Statusoutput • Controlinput (

Press ↵ key to transfer to subfunction “Fieldcurrent”.

Press ↵ key to return to Fct. 3.07 “Hardware”.

Press ↵ key to return to Fct. 3.08 “Location”.

Press ↵ key to return to Fct. 3.09 “Communication”.

Select with ↑ key.

Select with ↑ key.

)

)

4.3 Error messages in measuring mode

The following list gives all errors that can occur during process flow measurement. Errors shown

in display when “Yes” set in Fct. 1.04 Display, subfunction “Messages.”.

Error messages Description of error Error clearance

Line Int. Power failure Note:

no counting during power failure

Overflow I Current output overranged

(Flow > I Max)

Overflow P Pulse output overranged.

(Flow > I Max)

Totalizer Totalizer has been reset. Cancel error message in

ADC Analog / digital

converter overranged

Fatal Error Fatal error, all outputs set

to “min. values“

Empty Pipe Pipe has run dry.

This message appears only when

the “empty pipe identifier”

option is installed and the function

is switched on under Fct. 3.06

Application, submenue ”Empty Pipe”.

Cancel error in Reset-Quit menu, see

Sect. 4.6.

Reset totalizer if necessary.

Check and if necessary correct

instrument parameters. After

elimination of cause, error message

deleted automatically.

Check and if necessary correct

instrument parameters. After

elimination of cause, error message

deleted automatically.

Reset/Quit. menu, see Sect. 4.6.

Error message deleted automatically

after elimination of cause.

Please consult factory.

Fill pipe.

26 IFC 210 E

05/2002

Page 27

Part B IFC 210 Signal converter Sect. 4.4

4.4 Reset totalizer and cancel error messages

Cancel error messages in RESET / QUIT menu

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

↵

↑ →

... No Do not delete error messages,

↑

↵

↵

Reset totalizer(s) in RESET / QUIT menu

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

↵

↑ →

↵

→

↑

↵

Code 2 - -

Error Quit .... Menu for error acknowledgement

... Yes Delete error messages

Reset totalizer …

- - - - - - - - - - - - / - - - Return to measuring mode

Code 2 - -

Error Quit .... Menu for error acknowledgement

Reset totalizer … Menu for resetting totalizer

... No Do not delete error messages,

... Yes Reset totalizer

- - - - - - - - - - - - / - - - Return to measuring mode

Key in entry code 2 for Reset / Quit

menu: ↑ →

press ↵ twice = return to measuring mode.

Key in entry code 2 for Reset / Quit

menu: ↑ →

press ↵ twice = return to measuring mode.

4.5 Examples of setting the signal converter

As an example the cursor, flashing part of display, is shown below in bold type.

•

Change measuring range of current output and value for error messages (Fct. 1.05):

•

Change measuring range from 04-20 mA to 00-20 mA

•

Change value for error messages from 0 mA to 22 mA

Key Display Description

→

Fct. 1.00 Operation

→

4 × ↑

→

→ ↵

→

2 × ↑

2 × ↵

→

↑

↵

↵

↵

↵

If “Yes” set under Fct. 3.04 Entry Code, key in the

9-keystroke Code 1 now: → → → ↑ ↑ ↑ ↵ ↵ ↵

Fct. 1.01 Full Scale

Fct. 1.05 Currentoutput I

Function

Range I

04-20 mA Old current range

00-20 mA New current range

I Error

0 mA Old value for error messages

22 mA New value for error messages

Fct. 1.05 Currentoutput I

Fct. 1.00 Operation

Store Yes

- - - - - - - - - - - - / - - - Measuring range with new data for the current output

IFC 210 E 27

05/2002

Loading...

Loading...