Page 1

IFC090 FF 01/2006 7.10025.21.00

Supplementary

Installation and

Operating Instructions

IFC 090, IFC 090 i

With FOUNDATION

FIELDBUS Communication

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · e-mail: krohne@krohne.de

Page 2

Supplementary Documentation Page 2 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Contents:

1 Introduction 4

2 Installation and Operation 4

2.1 Technical Data IFC090 FF 4

2.2 Electrical Connection of Foundation Fieldbus Devices 4

2.3 Installation in the Hazardous Area, Bus Cable 5

2.4 Shielding and Grounding 6

2.5 IFC090 Menu Settings for Foundation Fieldbus 6

2.6 Foundation Fieldbus Functional Blocks 6

3 Foundation Fieldbus Principles 7

3.1 Resource Block 7

3.2 Transducer Block 8

3.3 Function Blocks 8

4 IFC090-FF Block Description 9

4.1 Resource Block 10

4.2 Transducer Block 14

4.3 Analog Input Block (Flow) 16

4.4 Integrator Blocks 1 and 2 (Flow(+)- and Flow(-)-Totalizer) 22

5 IFC090-FF Configuration 28

5.1 Resource Block Configuration 28

5.1.1 Resource Block Mode Handling 28

5.1.2 Write Protection 28

5.1.3 Resource State Re-Initialization 29

5.2 Transducer Block Configuration 29

5.2.1 Transducer Block Mode Handling 30

5.2.2 IFC090-FF Zero Point Calibration 30

5.3 Analog Input Block Configuration 30

5.3.1 Process Value Selection 31

5.3.2 Linearization and Scaling 31

5.3.3 Filtering 32

5.3.4 Input/Output Options 32

5.3.5 Output Status Options 32

5.3.6 Process Alarms 33

5.4 Integrator Blocks Configuration 34

5.4.1 Integrator Block Mode Handling 34

5.4.2 Integration Input – Rate or Accumulated Pulses 34

5.4.3 Adaptation of Integrator Inputs 34

5.4.4 Setting the Flow Direction 36

5.4.5 Type of Integration 36

5.4.6 Integrator Reset Strategies 37

5.4.7 Trip and Pre-trip Handling 39

5.4.8 Status Handling 39

5.4.9 Input Value Handling 39

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 3

Supplementary Documentation Page 3 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

6 Troubleshooting 42

6.1 BLOCK_ERROR 42

6.1.1 Resource Block 42

6.1.2 Transducer Block 42

6.1.3 Analog Input Block 43

6.1.4 Integrator Blocks 44

6.2 Transducer Block XD_ERROR 44

6.3 Measurement Value Status 44

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 4

Supplementary Documentation Page 4 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Introduction

1 Introduction

These instructions are supplementary to the “Installation and Operating Instructions IFC 090 K / F“. The details

depicted therein, in particular the Safety Information are valid and should be adhered to. The present

Supplementary Instructions provide additional information for the devices when being operated and connected

to a Foundation Fieldbus.

Note: Please set the controller to manual mode before changing parameters of the IFC 090.

The present Supplementary Instruction for the IFC 090 with Foundation Fieldbus- interface, plus a diskette with

the DD and CCF file are included in our scope of supply, in addition to those items delivered for the standard

device.

2 Installation and Operation

2.1 Technical Data IFC090 FF

Hardware

Physical to IEC 61158-2 and the FISCO model

Bus characteristics: 9... 30 V; 0.3 A max.; 4.2 W max.

Base current 10 mA

FDE bus with separate fault detection electronics

Fault current 6 mA; (fault current = max. continuous current – base current)

Starting current lower than the base current

“Ex“ approval EEx ia IIC T6 or EEx ib IIC/IIB T6 in conformity with the FISCO model

Connection independent of polarity

Software

DD, CFF File supplied on diskette, available also in the KROHNE Downlaod Center

Functional blocks flow [m3/s], integrator 1 [m3], integrator 2 [m3]; units are default units

Operator control local display and operator interface at device

2.2 Electrical Connection of Foundation Fieldbus Devices

Connect the bus cable as shown in the figure.

• Connect the cable cores to terminals D and DI.. Polarity reversal will not have any effect.

• The cable shield should be connected with minimum length to the FE functional ground.

• The equipotential bonding conductor must be connected to the device by connecting it to FE functional

ground.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 5

Supplementary Documentation Page 5 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

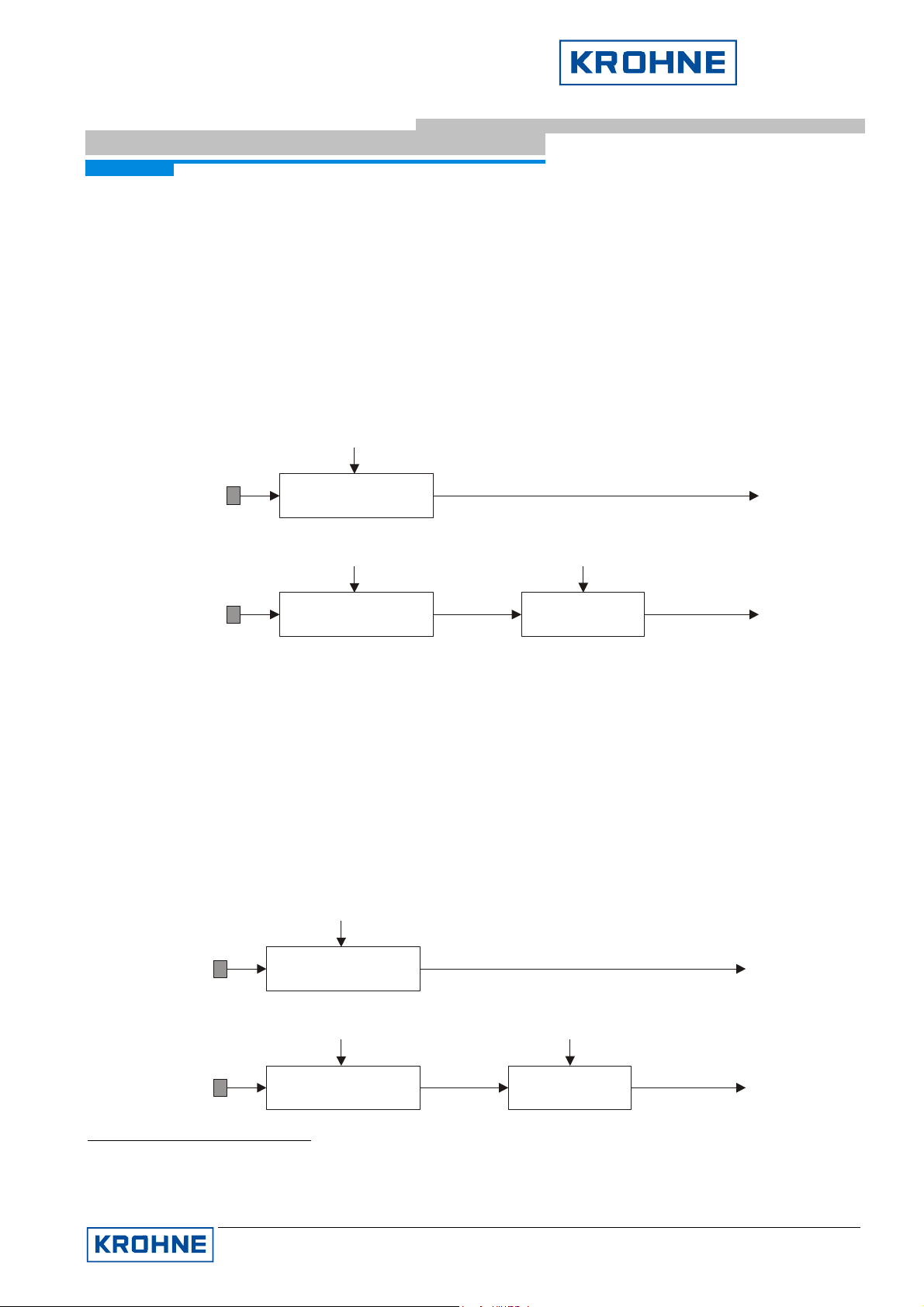

Foundation Fieldbus with Current Output (passive) Foundation Fieldbus with Binary Output (passive)

Installation and Operation

Non Ex Version

D

D

busconnection

FE

4-20mA

current

outputfieldbus

II

U min

= 8V

U max = 30V

Outputs intrinsically safe

4-20mA

current

output

fieldbus

IIDD

U min

= 8V

busconnection

powersupply

FE

power

supply

Non Ex Version

switching

fieldbus

DD

busconnection

FE

output

B

1

Outputs intrinsically safe

switching

output fieldbus

B

1

B

1

DD

busconnection

B

powersupply

1

FE

power

supply

U max = 30V

1

2.3 Installation in the Hazardous Area, Bus Cable

We recommend that a Foundation Fieldbus network in the hazardous area should be projected in accordance

with PTB’s FISCO model. The FISCO-Model is based on the following conditions:

• all electrical components which should be connected to the bus must be approved according to the FISCO

model (even the termination)

• the maximum cable length should not exceed 1000 m,

• the values of the cable are within the following ranges: R´=15...150Ω/km; L´=0,4...1mH/km;

C´=80...200nF/km, other limitations for the cable than the FISCO limitations are not existent. Nevertheless, a

twisted pair and shielded cable is strongly recommended. Example: a good quality cable could have the

following data: 44Ω/km, <90nF/km, <3dB attenuation at 39 kHz and 100 Ohm impedance at 31,25kHz.

• the approved input values of the field devices (Uo, Io, Po) comply to the output values of the power supply

(e.g. segment coupler) according to UI ≤ Uo, II ≤ Io und PI ≤ Po.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 6

Supplementary Documentation Page 6 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

2.4 Shielding and Grounding

For optimum electromagnetic compatibility of systems it is extremely important that the system components,

and particularly the bus cables connecting the components, are shielded and that such shields - if possible -

form an unbroken cover.

Installation and Operation

Hence, it follows that, for use in non-hazardous duty systems

possible.

In “Ex“ systems an adequate equipotential bonding in the hazardous and non-hazardous location along the

entire fieldbus installation is strongly recommended. Multiple grounding of the shield is of advantage.

Note: The use of twisted and shielded cables is strongly recommended, otherwise EMC protection of the IFC

090 cannot be assured.

, the cable shield should be grounded as often as

2.5 IFC090 Menu Settings for Foundation Fieldbus

(see also Section 4 in the Installation and Operating Instructions for the IFC090)

The following settings need to be made for operation of the IFC 090 on a Foundation Fieldbus network. Note

that the address can be set by the service “set slave address” as well.

Function (Fct.) Description

3.9 COM Select function for the communication port

♦ OFF ♦ HART ♦ PROFI PA *

• Note: * indicates Foundation Fieldbus Communication when selected

2.6 Foundation Fieldbus Functional Blocks

The IFC090 supports the H1 Foundation Fieldbus Communication Standard FF-003-2.2-1-1, Version 1.4.

Additionally, all relevant parameters in the device are offered via the FF interface. The IFC 090 defines the

following functional blocks:

• Three Function Blocks (FB): One Analog Input-FB for flow and two integrator-FBs for integration.

Reset function is possible.

• One Transducer Block for electromagnetic flow measurement.

• One standard Resource Block.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 7

Supplementary Documentation Page 7 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

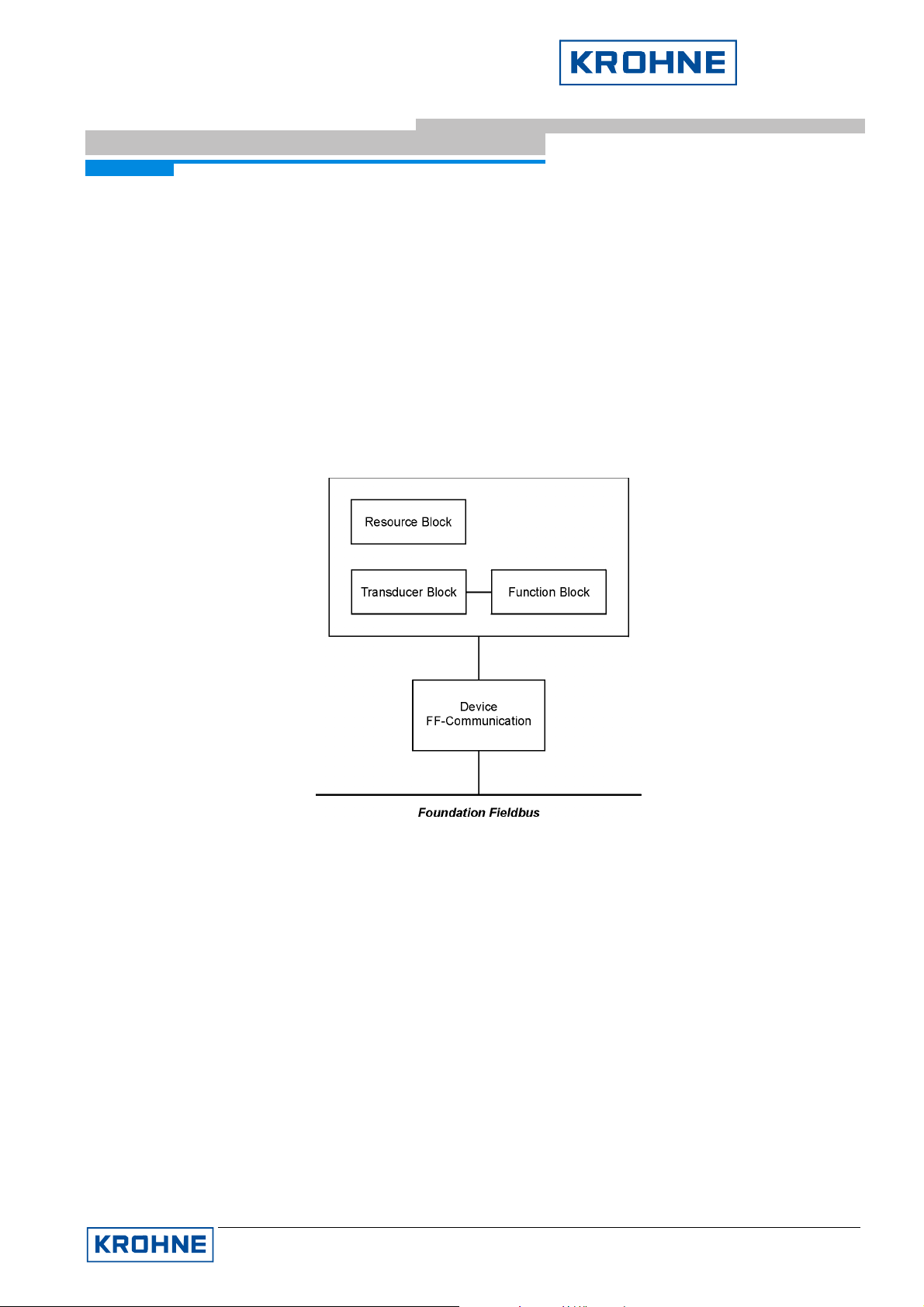

3 Foundation Fieldbus Principles

The Foundation Fieldbus is a Local Area Network (LAN) for connecting field devices like sensors and actuators.

One of the main benefits of Foundation Fieldbus is line saving in comparison to the traditional 4 ... 20 mA

technology.

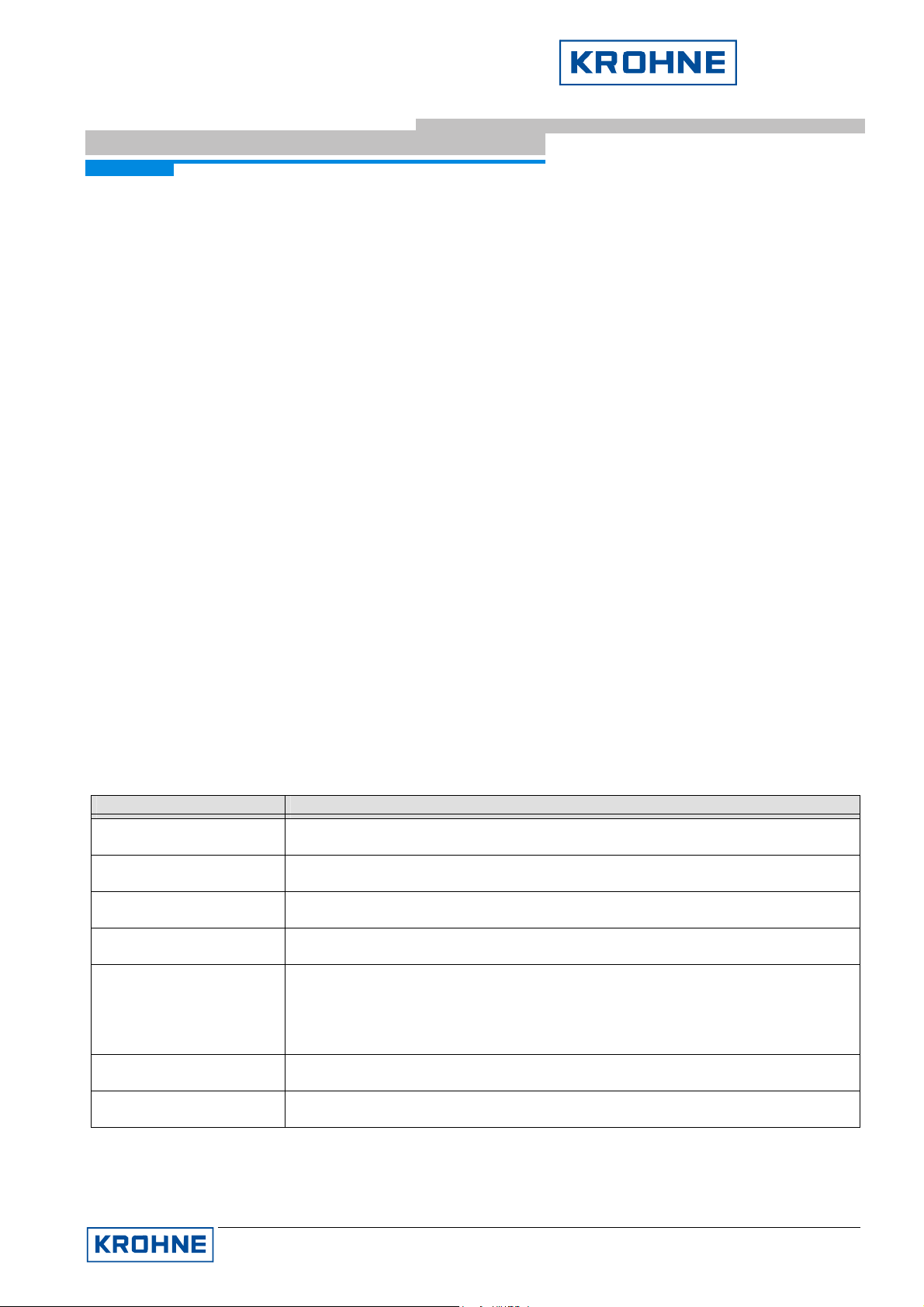

The different device functions are implemented in a block-based scheme within a User Application. In this block

scheme, a distinction is made between the following kinds of blocks (see Figure 1):

• Resource Block,

• Transducer Block(s) and

• Function Block(s).

Foundation Fieldbus Principles

Figure 1: Foundation Fieldbus block scheme

3.1 Resource Block

Each FF device possesses exactly one Resource Block describing the specific features of the fieldbus device.

The Resource Block is not related to any functional process of the device, but contains data that are specific for

the device (e.g. device name, serial number, supported features, etc).

In addition, the Resource Block provides dynamic diagnostic data giving information on the current state of the

hardware.

A basic set of Resource Block parameters is specified by Fieldbus Foundation (see FF-891, 3.1). This set can

be extended by additional manufacturer specific parameters (the IFC090-FF possesses the Foundation

specified parameters only).

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 8

Supplementary Documentation Page 8 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

3.2 Transducer Block

Foundation Fieldbus Principles

Transducer Blocks represent the interface between the device specific hardware (i.e. input/output functions) and

the FF specified Function Block model. Since there might be multiple functions in a device (measurement

values, positioning functions, etc), an FF device can have several Transducer Blocks1.

They provide device specific information in terms of sensor/actuator functions (e.g. type of sensor, range of

process value, etc) and they make available the process values to the function blocks or provide the actuator

input values obtained from function blocks to the hardware respectively.

3.3 Function Blocks

The main functional behavior of the FF device is implemented in one or several Function Blocks. Depending on

the device type there are Input Blocks (e.g. flow device → Analog Input Block, Discrete Input, etc), Output

Blocks (e.g. valve → Discrete Input, etc), or Control Blocks (PID, etc). These blocks have input and/or output

parameters to be linked to other devices and to control systems by the Fieldbus.

1

Note: This does not imply that an FF device has to have several Transducer Blocks if it provides several

functions.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 9

Supplementary Documentation Page 9 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

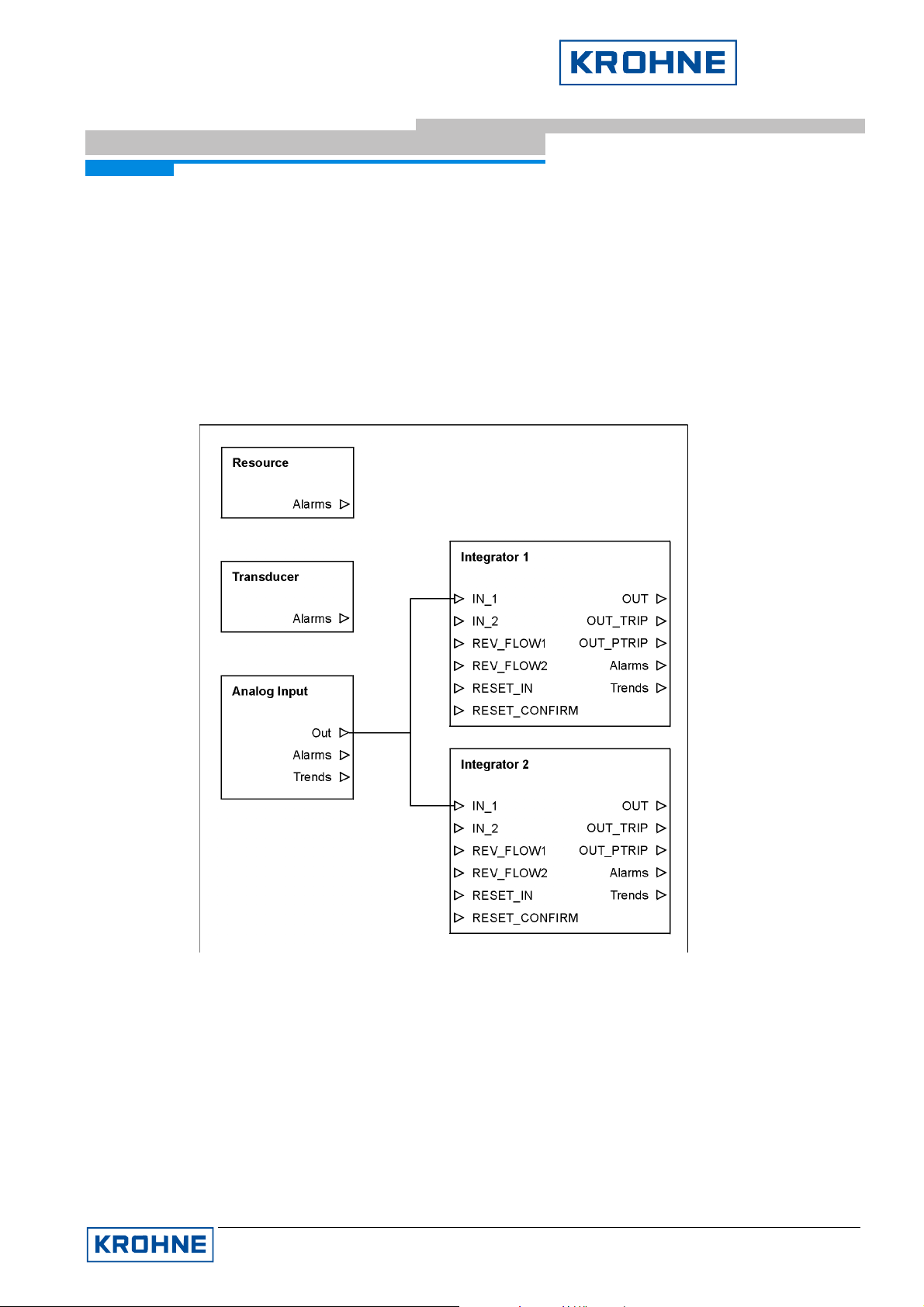

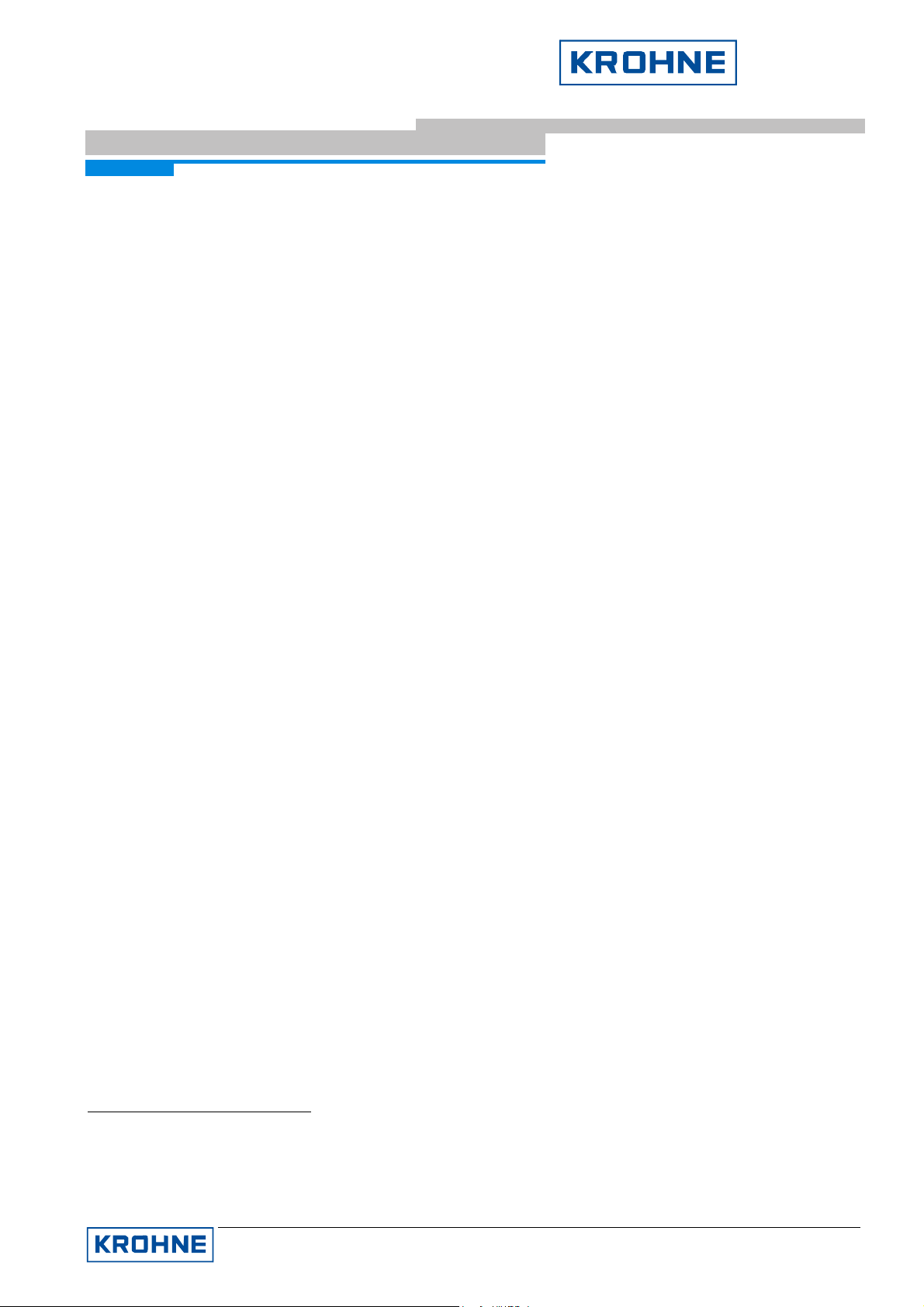

4 IFC090-FF Block Description

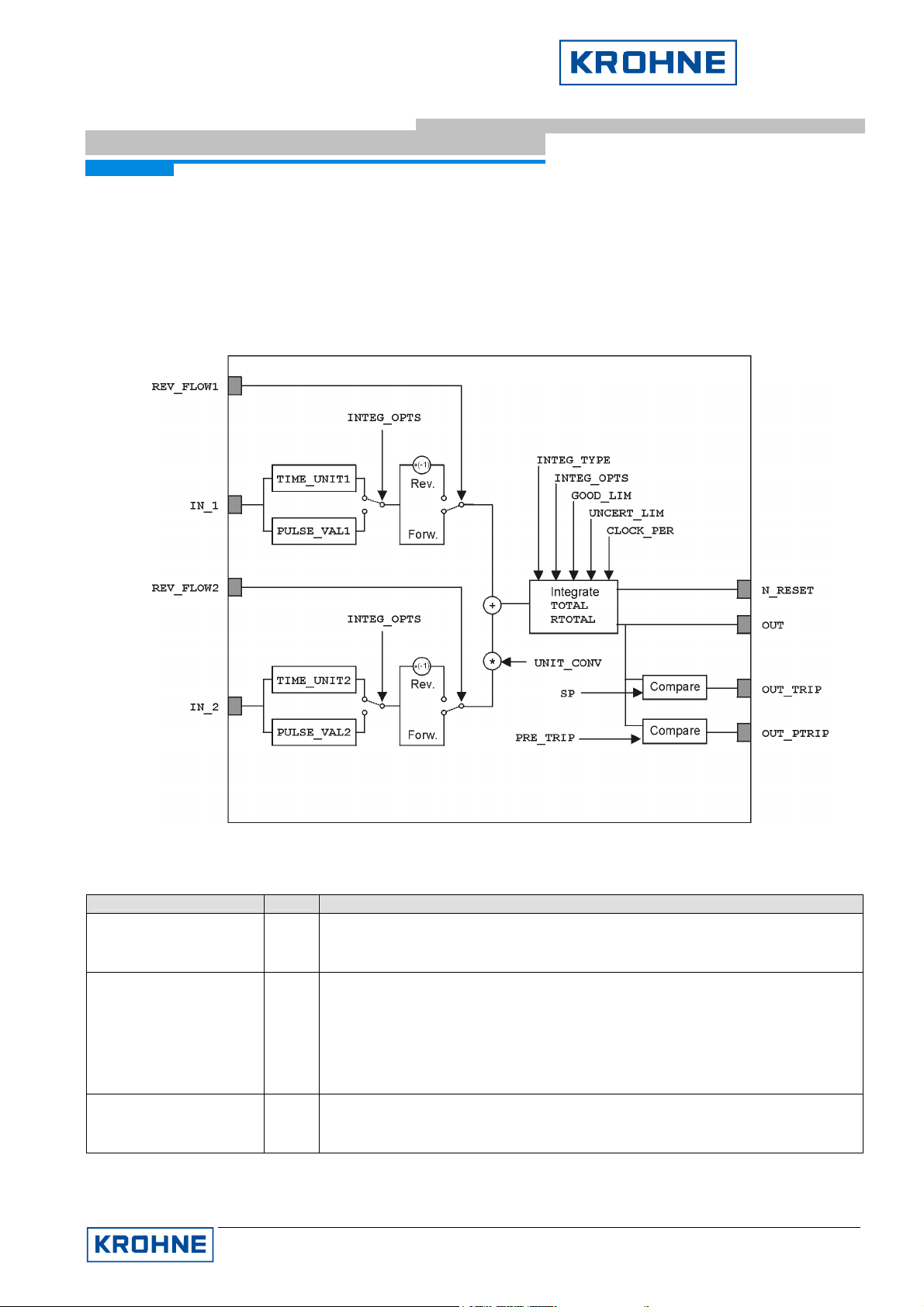

The IFC090-FF consists of the following blocks (see figure 2):

• 1 Resource Block,

• 1 Transducer Block (standard flow),

• 1 Analog Input Block (flow value) and

• 2 Integrator Blocks (1 for positive- and 1 for negative flow integration)

IFC090-FF Block Description

Figure 2: IFC090-FF block scheme

In the following, the different block parameters are described in detail.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 10

Supplementary Documentation Page 10 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

4.1 Resource Block

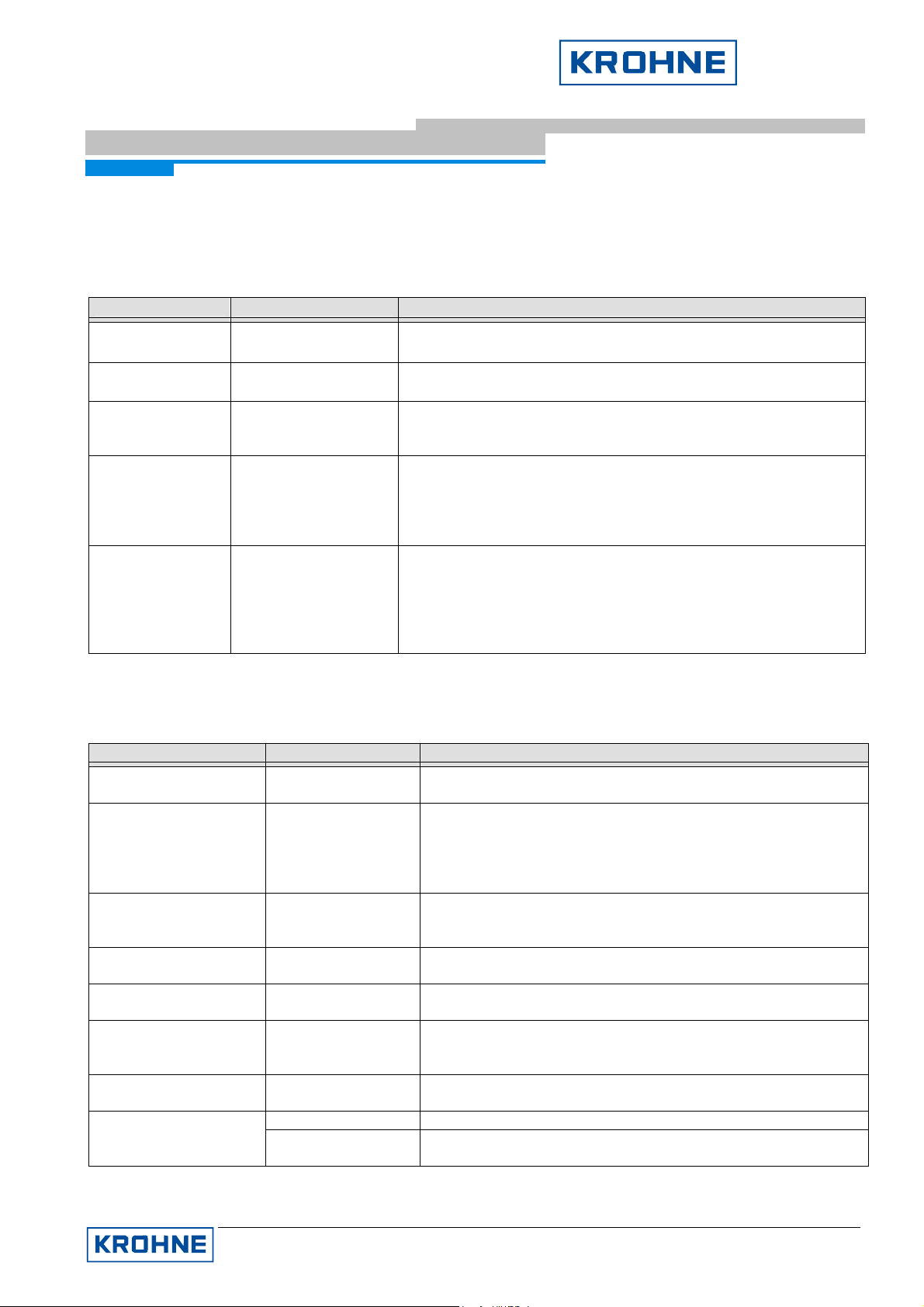

Table 1 lists the Resource Block parameters in alphabetical order (this list provides a description of the various

parameters only; for a more detailed description of how to configure these parameters: see chapter below.

IFC090-FF Block Description

Parameter Access

ACK_OPTION R/W

ALARM_SUM Mix

Description

Allows to enable automatic acknowledge of Resource Block alarms. The following

settings are valid for Resource Block:

Unack Alarm 1 (Discrete Alarm) clearing of soft write lock

Unack Alarm 8 (Block Alarm) block mode switches to Out of Service

If set, the respective alarm doesn’t have to be acknowledged when occurring.

see also: ALARM_SUM, WRITE_LOCK, WRITE_ALM

Display of process alarms. The current alarm is displayed in the current field and can

have the following values:

Discrete Alarm the soft write lock was cleared

Block Alarm block mode switches to Out of Service

The additional fields unacknowledged and unreported give respective information

about the current alarm state. The field disabled, which is the only writable field of this

parameter, can be used to disable these alarms.

see also: ACK_OPTION

ALERT_KEY R/W

ALERT_KEY parameter contains the identification number of the plant unit. It helps to

identify the location (plant unit) of an event. The handling of this parameter is up to the

control system or control person, respectively.

BLOCK_ALM R

Display of current block state. Field subcode gives information about the state current

errors. The following errors can occur:

Change in Simulation Jumper

Local Override

Device Fault State

Memory Failure

Lost Static Data

Lost NV Data

Power-up

Block was put Out of Service

The remaining fields give information about the state and the occurence of this alarm.

BLOCK_ERR R

Display of active block errors. The following errors are possible:

Power-up power supply of IFC090-FF was interrupted

Device needs Maintenance now fatal error of IFC090-FF hardware

Memory Failure memory of device has errors

Input Failure measurement value not o.k.

Other any other hardware problem

CLR_FSTATE R/W

Writing a Clear to this parameter will clear the device fault state if the field condition, if

any, has cleared.

NOTE:

This parameter is not supported!

Configuration Error

Out of Service block is in Out of Service mode

CONFIRM_TIME R/W

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

see also: FAULT_STATE

Time the resource waits for receipt confirmation of an earlier sent report, before trying

to send a new one. If zero (0), no retry will be performed.

Page 11

Supplementary Documentation Page 11 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

CYCLE_SEL R/W

CYCLE_TYPE R

DD_RESOURCE R

DD_REV R

DEV_REV R

DEV_TYPE R

FAULT_STATE R

IFC090-FF Block Description

Description

Used to select the block execution method for this resource. The following methods

are available:

Scheduled

Completion of block execution

see also: CYCLE_TYPE

Identifies the block execution methods available for this resource.

It is possible to deliver devices which have the DD for its resource within the device.

This parameter assigns the tag where to find the DD in the resource. Since the

IFC090-FF doesn't come with a 'build-in' DD, this value is blank.

Revision associated with the DD of the resource – used by interface devices to locate

the DD file for the resource.

KROHNE revision number associated with this resource – used by interface devices to

locate the DD file for the resource.

KROHNE model number of the IFC090-FF – used by interface devices to locate the

DD file for the resource.

Condition set by loss of communication to an output block.

NOTE:

Since the IFC090-FF doesn’t have an output block, this parameter isn’t supported.

FEATURES R

Used to show supported resource block options. The following features are supported

by the IFC090-FF:

Soft Write Lock

see also: FEATURE_SEL

FEATURE_SEL R/W

Used to select supported features. The following features are selectable:

Soft Write Lock enable soft write locking of parameters

see also: FEATURE_SEL

FREE_TIME R

Available time for configuration of further blocks.

NOTE:

Since the IFC090 blocks are preconfigured, this value is always zero (0).

FREE_SPACE R

Available memory for configuration of further blocks.

NOTE:

Since the IFC090 blocks are preconfigured, this value is always zero (0).

GRANT_DENY R/W

Options for controlling access of host computer and local control panels to operating,

tuning and alarm parameters of the block.

NOTE:

This parameter is not supported by IFC090-FF

HARD_TYPES R

The type available input signal that is delivered by the Transducer Block and used as

Analog Input Block input parameter. For the IFC090-FF this is ‘Scalar Input’ (1).

ITK_VER R

Major revision number of the interoperability test case used in certifying this device as

interoperable.

Reports

Reports enable sending of alert reports

LIM_NOTIFY R/W

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

NOTE:

Due to an error, this value is ‘0’, but has to be ‘4’ (since the IFC090-FF is interoperable

with interoperability test case version 4).

Maximum number of unconfirmed alert notifies messages allowed. This number

always has to be less than MAX_NOTIFY.

see also: MAX_NOTIFY

Page 12

Supplementary Documentation Page 12 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

MANUFAC_ID R

MAX_NOTIFY R

MEMORY_SIZE R

MIN_CYCLE_T R

MODE_BLK Mix

IFC090-FF Block Description

Description

Manufacturer identification number. For KROHNE devices this is always

00012C

= 30010 = KROHNE

16

Maximum number of unconfirmed notifies messages possible.

see also: LIM_NOTIFY

Available configuration memory in the empty resource.

NOTE:

This parameter is not supported by IFC090.

Time duration of the shortest cycle interval of which the IFC090 is capable. Within this

cycle all Function Blocks (1 Analog Input + 2 Integrators) have to be executed for one

time.

Display of the current (actual), desired (target), possible (permitted) and normal modes

of the Resource Block. By writing a permitted value to the target field, you can control

the execution modes of the block. The following block modes are allowed for the

IFC090-FF Resource Block:

Automatic Mode (AUTO)

In this mode, the complete resource is able to execute. All other blocks

(Transducer, Analog Input, Integrator) can switch to a mode different from Out of

Service)

Out of Service (OOS)

In this mode, the complete resource stops its execution. For the other blocks

it is not possible to switch to AUTO mode, unless the Resource Block does.

NOTE:

Under certain conditions (e.g. RS_STATE = ONLINE_LINKING) the Resource Block is

not capable of switching to AUTO mode.

see also: RS_STATE

NV_CYCLE_T R

Minimum time interval between two cycles of writing non-volatile parameters OUT, PV

and FIELD_VAL. Since these values are not saved, this value is always zero (0) which

means don’t save these parameters.

RESTART R/W

Allows a manual restart to be initiated. Several degrees of restart are possible:

RUN Setting for normal operation.

RESTART RESOURCE Warm start of the IFC090-FF.

RESTART WITH DEFAULTS Sets all FF parameters to their default values.

To be used with caution!

RESTART PROCESSOR Cold start of IFC090 measurement electronics

and warm start of FF process.

RS_STATE R

State of the function block application state machine. The following states are possible:

ONLINE Normal operation state: All defined links are established.

INITIALIZATION Initialization state: All alarms will be confirmed and

ONLINE-LINKING Link evaluation state: Wait until all links are established

STANDBY Out of Service state: Entered if mode of Resource Block is

SET_FSTATE R/W

Allows the Fault State conditions for output function blocks to be manually initiated by

setting to ‘Set’.

NOTE:

Since the IFC090-FF doesn’t have an output block, this parameter is not supported.

SHED_RCAS R/W

Time duration for the monitoring-cycle in which a function block in mode RCAS has to

answer on control system requests.

acknowledged.

OOS.

NOTE:

Since the IFC090-FF has no function block capable of switching to mode RCas, this

parameter is not supported.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 13

Supplementary Documentation Page 13 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

SHED_ROUT R/W

Description

Time duration for the monitoring-cycle in which a function block in mode Rout has to

answer on control system requests.

NOTE:

Since the IFC090-FF has no function block capable of switching to mode Rout, this

parameter is not supported.

STRATEGY R/W

Parameter used to group a set of blocks. This is done by assigning the same

STRATEGY numerical value to all blocks belonging to one group.

NOTE:

This parameter is neither checked nor used by the function block application! It can be

used by control system to group blocks!

ST_REV R

Static data revision counter. ST_REV will be incremented if a static Resource Block

parameter has changed. By checking this parameter, control systems are able to

realize if a static parameter has changed its value without checking all static

parameters all the time.

TAG_DESC R/W

User description of the intended application of the block. The user is free in setting this

value. The only limitation is the length of 32 characters at maximum. It is not checked

by the application, but has informational character only.

TEST_RW R/W

Read/write test parameter. It is only used during Fieldbus Foundation interoperability

testing and has no meaning for normal operation!

UPDATE_EVT R

Alert generated by a change to static data. The subfields of this parameter give

detailed information about the changed static parameter, time of change and state of

the update event.

WRITE_ALM R

Alarm generated, if the parameter write lock is cleared.

see also: ACK_OPTION, WRITE_LOCK, WRITE_PRI

WRITE_LOCK R/W

If this parameter is set to ‘Locked’ (2) all writable parameters in all blocks are write

protected, with the exception of WRITE_LOCK itself. Dynamic data will continue to be

updated.

To disable the write protection, set this parameter to ‘Not Locked’ (1).

IFC090-FF Block Description

WRITE_PRI R/W

see also: ACK_OPTION, WRITE_ALM, WRITE_PRI

Priority of the alarm generated by clearing the WRITE_LOCK:

0 alarm isn't be evaluated

1 no notification to the control system in case of an write protection alarm

2 reserved for block alarms

3-7 write protection is send as user/operator note to the control system,

according to the given priority (3 = low and 7 = high)

8-15 write protection alarm is sent with the appropriate priority

(15 = high and 8 = low).

Table 1: Resource Block parameters

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 14

Supplementary Documentation Page 14 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

4.2 Transducer Block

Table 2 lists the Transducer Block parameters in alphabetical order (this list gives a description of the various

parameters only; see chapter below. for a detailed description depicting how to configure these parameters):

IFC090-FF Block Description

Parameter Access

ALERT_KEY R/W

BLOCK_ALM R

BLOCK_ERR R

CAL_MIN_SPAN R

CAL_POINT_HI R/W

CAL_POINT_LO R/W

CAL_UNIT R/W

CAL_ZEROPOINT R/W

COLLECTION_DIRECTORY R

CYCLES_ZEROPOINT_CAL R/W

LIN_TYPE R/W

Description

Identification number of the plant unit. It helps to identify the location (plant

unit) of an event. The handling of this parameter is up to the control system

or control person, respectively.

Display of current block state. Field subcode gives information about the

state current errors. The following errors can occur:

Configuration Error

Block was put Out of Service

The remaining fields give information about the state and the occurrence of

this alarm.

Display of active block errors. The following errors are possible:

Out of Service block is in Out of Service mode

Device needs Maintenance now fatal error of IFC090-FF hardware

Minimum calibrated span value allowed.

Highest calibrated value. This value depends on the IFC090-FF pipe

diameter.

Lowers calibrated value. This is the absolute value of the lowest positive and

negative value, the device is capable of measuring, and it is constant to ‘0’.

Engineering units code index for the calibration values. This is always m3/s

(cubic meter per second).

Start zero point calibration by writing a value different from ‘0’.

NOTE:

Handle this parameter with caution, since a correct zero point calibration is

based some important conditions.

Directory that specifies the number, starting index, and DD2 item IDs of the

transducer block’s data collections. The first entry specifies the number of

data collections, and the remaining specifies the data collections.

Number of cycles to perform if a zero point calibration is started. Valid values

are in between 0 and 2000.

Linearization type used to describe the behavior of the sensor output. The

IFC090-FF has a linearization type of ‘linear with input’.

2

DD = Device Description

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 15

Supplementary Documentation Page 15 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

MODE_BLK Mix

Description

Display of the current (actual), desired (target), possible (permitted) and

normal modes of the Transducer Block. By writing a permitted value to the

target field, you can control the execution modes of the block. The following

block modes are allowed for the IFC090-FF Transducer Block:

Automatic Mode (AUTO)

In this mode, the transducer performs an automatic measurement update

and delivers it via its channels to connected input blocks (normally, the

integrated Analog Input Block)

Manual (MAN)

Different from the AUTO mode, the block doesn’t perform an automatic

delivery of valid measurement values, but freezes its primary value to the

last one obtained in Auto mode. The PRIMARY_VALUE status switches

to Uncertain:NonSpecific:Constant.

Out of Service (OOS)

In this mode, the transducer stops measurement update and sets the

status of the measured value (PRIMARY_VALUE) to

BadOutOfService:NotLimited.

NOTE:

If the Resource Block is in mode Out of Service, also the block will remain in

this mode.

IFC090-FF Block Description

PRIMARY_VALUE R

PRIMARY_VALUE_RANGE R

The measured value and status available to the Function Blocks.

The high and low range limit values, the engineering units code and the

number of digits to the right of the decimal point to be used to display the

PRIMARY_VALUE.

PRIMARY_VALUE_TYPE R/W

Type of sensor. The IFC090-FF is of type ‘volumetric flow’ (101).

NOTE:

Even though this parameter is writable, it does not accept a value different

from ‘volumetric flow’ (101).

SECONDARY_VALUE R

Normally, the secondary value, is related to the sensor. Since the IFC090-FF

has no secondary value, this is fixed to status Bad:NonSpecific:NotLimited

with value 0.0.

SECONDARY_VALUE_UNIT R/W

Normally the units to be used for the SECONDARY_VALUE. Since the

IFC090-FF has no secondary value, this is fixed to the unit of the primary

value.

SENSOR_CAL_DATE R/W

Date of last sensor calibration. If this is set ‘01/01/84 00:00:00’ it means that

the last calibration was that after production of device.

SENSOR_CAL_LOC R/W

SENSOR_CAL_METHOD R/W

Location of last sensor calibration.

Method of last sensor calibration. In the context of the ISO defined standard

method of calibrations, KROHNE performed a ‘factory trim standard

calibration’.

SENSOR_CAL_WHO R/W

SENSOR_RANGE R

Name of the person responsible for the last calibration.

The high and low range limit values, the engineering units code, and the

number of digits to the right of the decimal point for the sensor. These values

are equal to the one given for PRIMARY_VALUE_RANGE.

SENSOR_SN R

Sensor serial number. Must be the same as on the nameplate of the device’s

housing.

SENSOR_TYPE R/W

Type of sensor. For IFC090-FF this is fixed: ‘Electromagnetic’ (102)

NOTE:

Even though this parameter is writable, it does not accept a value different

from ‘Electromagnetic’ (102).

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 16

Supplementary Documentation Page 16 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

ST_REV R

Description

Static data revision counter. ST_REV will be incremented if a static

Transducer Block parameter has changed. By checking this parameter,

control systems are able to realize if a static parameter has changed its

value without checking all static parameters all the time.

IFC090-FF Block Description

STRATEGY R/W

Parameter used to group a set of blocks. This is done by assigning all blocks

belonging to one group the same STRATEGY numerical value.

NOTE:

This parameter is neither checked nor used by the function block application!

It can be used by control system to group blocks!

TAG_DESC R/W

User description of the intended application of the block. The user is free in

setting this value. The only limitation is the length of 32 characters at

maximum. It is not checked by the application, but has informational

character only.

TRANSDUCER_DIRECTORY R

Directory that specifies the number and starting indices of the transducers in

the transducer blocks.

Since the IFC090-FF possesses only one transducer, the directory consists

of one entry only (1 = number of transducers, 711 = starting index of the only

transducer).

UPDATE_EVENT R

Alert generated by a change to static data. The subfields of this parameter

give detailed information about the changed static parameter, time of change

and state of the update event.

XD_ERROR R

Error code that is specific to the sensor hardware. If a profoundly hardware

error is existent, this parameter shows the error ‘Electronics failure’ (20).

4.3 Analog Input Block (Flow)

Table 3 lists the Analog Input Block parameters in alphabetical order (this list gives a description of the various

parameters only; see chapter below for a detailed description of how to configure these parameters):

Parameter Access

ACK_OPTION R/W

ALARM_HYS R/W

Description

Allows to enable automatic acknowledge of Analog Input Block alarms. The

following settings are valid for Resource Block:

Unack Alarm 1 (Discrete Alarm) clearing of soft write lock

Unack Alarm 2 (High High Alarm) OUT value reaches the HI_HI_LIM

Unack Alarm 3 (High Alarm) OUT value reaches the HI_LIM

Unack Alarm 4 (Low Low Alarm) OUT value reaches the LOW_LOW_LIM

Unack Alarm 5 (Low Alarm) OUT value reaches the LO_LIM

Unack Alarm 8 (Block Alarm) block mode switches to Out of Service

If set, the respective alarm don’t has to be acknowledged on occurence

see also: ALARM_SUM

Amount the OUT value must return within the alarm limits before the alarm

condition (HI_HI_ALM; HI_ALM, LO_ALM, LOW_LOW_ALM) clears.

Alarm Hysteresis is expressed as percent of the OUT_SCALE span and is

set 0.5% by default.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 17

Supplementary Documentation Page 17 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

ßALARM_SUM R

Description

Display of process alarms. The current alarm is displayed in the current field

an can have the following values:

IFC090-FF Block Description

Discrete Alarm the soft write lock was cleared

HiHi Alarm the high limit alarm is active

Hi Alarm the high limit advance alarm is active

Lo Alarm the low limit advance alarm is active

LoLo Alarm the low limit alarm is active

Block Alarm block mode switches to Out of Service

The additional fields unacknowledged and unreported give respective

information about the current alarm state. The field disabled, which is the

only writable field of this parameter, can be used to disable these alarms.

see also: ACK_OPTION

ALERT_KEY R/W

ALERT_KEY parameter contains the identification number of the plant unit. It

helps to identify the location (plant unit) of an event. The handling of this

parameter is up to the control system or control person, respectively.

BLOCK_ALM R

Display of current block state. Field subcode gives information about the

state current errors. The following errors can occur:

Configuration Error

Block was put Out of Service

The remaining fields give information about the state and the occurrence of

this alarm.

BLOCK_ERR R

Display of active block errors. The following errors are possible:

Out of Service block is in Out of Service mode

Input Failure SIMULATE.status is Bad:NonSpecific

Simulate Active SIMULATE.enable = yes

Block Configuration Error channel unit != XD_SCALE.unit, or

CHANNEL != 1, or L_TYPE is uninitalized

CHANNEL R/W

Number of the transducer’s logical hardware channel that is connected to

this Analog Input block. The only valid value is ‘1’ (since the Transducer has

only one hardware channel). Every other value would cause an ‘Block

Configuration Error’ which is displayed in BLOCK_ERR.

The default value is ‘0’.

FIELD_VAL R

Raw value of the field device in percent of the PV range, with a status

reflecting the Transducer condition, before characterization (L_TYPE) or

filtering (PV_FTIME). See 5.3.3 for details.

GRANT_DENY R/W

Options for controlling access of host computer and local control panels to

operating, tuning and alarm parameters of the block.

NOTE:

This parameter is not supported by IFC090-FF.

HI_ALM R

With subject to the setting of HI_PRI, HI_ALM shows details about the high

alarm as acknowledge state and time stamp. See HI_PRI for details.

see also: HI_PRI, HI_LIM

HI_HI_ALM R

With subject to the setting of HI_HI_PRI, HI_HI_ALM shows details about the

high high alarm as acknowledge state and time stamp. See HI_HI_PRI for

details.

see also: HI_HI_PRI, HI_HI_LIM

HI_HI_LIM R/W

The limit value in engineering units as of the HI_HI_ALM is active (with

subject to HI_HI_PRI).

see also: HI_HI_PRI, HI_HI_LAM

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 18

Supplementary Documentation Page 18 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

HI_HI_PRI R/W

Description

Priority of the high high alarm that specifies the behavior if OUT reaches

HI_HI_LIM. The following values are valid:

0 exceeding of high high limit isn’t been evaluated

1 exceeding of high high limit is been evaluated, but

acknowledgement isn’t necessary

2-7 exceeding of high high limit is been evaluated and reported

according to the given priority (2 = low priority, 7 = high

priority).

Status of OUT changes to Good(NC):

UnackAdvisoryAlarmHighLimited.

8-15 exceeding of high high limit is been evaluated and reported

Status of OUT changes to Good(NC):

UnackCriticalAlarmHighLimited.

IFC090-FF Block Description

HI_LIM R/W

The limit value in engineering units as of the HI_ALM is active (with subject

to HI_PRI).

see also: HI_PRI, HI_LIM

HI_PRI R/W

Priority of the high alarm that specifies the behavior if OUT reaches HI_LIM.

The following values are valid:

0 exceeding of high limit isn’t been evaluated

1 exceeding of high limit is been evaluated, but

acknowledgement isn’t necessary

2-7 exceeding of high limit is been evaluated and reported

according to the given priority (2 = low priority, 7 = high

priority).

Status of OUT changes to

Good(NC):UnackAdvisoryAlarmHighLimited.

8-16 exceeding of high limit is been evaluated and reported

Status of OUT changes to

Good(NC):UnackCriticalAlarmHighLimited.

IO_OPTS R/W

Options which the user may select to alter input and output processing of the

Analog Input Block. The following option is supported by this block:

Low cutoff The Analog Input low cutoff algorithm is enabled, i.e. if PV is

less than LOW_CUT, PV is set to ‘0.0’

according to the given priority (2 = low priority, 7 = high

priority).

according to the given priority (2 = low priority, 7 = high

priority).

see also: LOW_CUT

L_TYPE R/W

Determines how the values, passed by the Transducer Block to the Analog

Input Block, may be used. The following settings are valid:

Direct values are used directly

Indirect values are in different units and must be converted

Indirect square root values are in different units and must be converted

with square root.

The conversion in case of ‘Indirect’ and ‘Indirect square root’ is

determined by parameters XD_SCALE and OUT_SCALE (see for

details).

see also: XD:SCALE, OUT_SCALE

LO_ALM R

With subject to the setting of LO_PRI, LO_ALM shows details about the high

alarm as acknowledge state and time stamp. See LO_PRI for details.

see also: LO_PRI, LO_LIM

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 19

Supplementary Documentation Page 19 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

LO_LIM R/W

Description

The limit value in engineering units as of the LO_ALM is active (with subject

to LO_PRI).

see also: LO_PRI, LO_LAM

IFC090-FF Block Description

LO_LO_ALM R

With subject to the setting of LO_LO_PRI, LO_LO_ALM shows details about

the high alarm as acknowledge state and time stamp. See LO_LO_PRI for

details.

see also: LO_LO_PRI, LO_LO_LIM

LO_LO_LIM R/W

The limit value in engineering units as of the LO_LO_ALM is active (with

subject to LO_LO_PRI).

see also: LO_LO_PRI, LO_LO_LAM

LO_LO_PRI R/W

Priority of the low alarm that specifies the behavior if OUT reaches

LO_LO_LIM. The following values are valid:

0 exceeding of low limit isn’t been evaluated

1 exceeding of low limit is been evaluated, but

acknowledgement isn’t necessary

2-7 exceeding of low limit is been evaluted and reported

according to the given priority (2 = low priority, 7 = high

priority).

Status of OUT changes to

Good(NC):UnackAdvisoryAlarm:LowLimited.

8-17 exceeding of low limit is been evaluated and reported

Status of OUT changes to Good(NC):

UnackCriticalAlarm:LowLimited.

LO_PRI R/W

Priority of the low low alarm that specifies the behavior if OUT reaches

LO_LIM. The following values are valid:

0 exceeding of low low limit isn’t been evaluated

1 exceeding of low low limit is been evaluated, but

acknowledgement isn’t necessary

2-7 exceeding of low low limit is been evaluted and reported

according to the given priority (2 = low priority, 7 = high

priority).

Status of OUT changes to

Good(NC):UnackAdvisoryAlarm:LowLimited.

8-18 exceeding of low low limit is been evaluated and reported

Status of OUT changes to

Good(NC):UnackCriticalAlarm:LowLimited.

LOW_CUT R/W

Limit used if option ‘Low cutoff’ is set (see IO_OPTS for details). A value of

zero percent of scale is used in block processing if the transducer value falls

below the LOW_CUT limit. This feature may be used to eliminate noise near

zero for a flow sensor.

according to the given priority (2 = low priority, 7 = high

priority).

according to the given priority (2 = low priority, 7 = high

priority).

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 20

Supplementary Documentation Page 20 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

MODE_BLK Mix

Description

Display of the current (actual), desired (target), possible (permitted) and

normal modes of the Analog Input Block. By writing a permitted value to the

target field, you can control the execution modes of the block. The following

block modes are allowed for the IFC090-FF Analog Input Block:

Automatic Mode (AUTO)

In this mode, the Analog Input Block performs its functional computations

in accordance with its configuration automatically. Measurement value

deliverance and alarm handling are active.

Manual (MAN)

In difference to AUTO mode, the block doesn’t perform an automatic

deliverance of valid measurement values, but freezes the measurement

to the last one obtained in Auto mode. The OUT status limit switches to

constant. In this mode it is possible to write to the OUT value an arbitrary

value to test blocks that use this OUT value as input. The alarm model

works in the same way as in Auto mode.

Out of Service (OOS)

In this mode, the Analog Input Block stops its execution. No valid

measurement value will be delivered, what can be seen at the status of

OUT (Bad:OutOfService:NotLimited).

IFC090-FF Block Description

OUT R/W

The primary analog value and status calculated as a result of executing the

block.

In Auto mode of this block, the value and its status is automatically

calculated on the base of the channel value obtained from the Transducer

Block and calculation methods of the Analog Input Block. In Man mode it is

possible to write to this value to specify a known, given value that can be

used to test the correct operation of other downstream function blocks.

OUT_SCALE R/W

Together with parameter XD_SCALE, OUT_SCALE is one of the two main

scaling parameters. It can’t be seen isolated. These two parameters specify

a mapping function from the channel value obtained from the. See 5.3.2 for

details.

PV R

Value and status of the process value with same unit as OUT_SCALE. PV is

the result after performing the linearization (see L_TYPE), the low cutoff (see

LOW_CUT, IO_OPTS) and the filtering (see PV_FTIME).

PV_FTIME R/W

SIMULATE R/W

Time constant of the single exponential filter for the PV in seconds.

Normally, SIMULATE is used to perform a channel value and status

simulation, i.e. instead of using the channel value obtained from the

Transducer Block, the user would be able to simulate a distinct (constant)

value and status as it comes from the Transducer. This is intensively used

while interoperability testing at the Fieldbus Foundation. Since it has no

practical use, this parameter isn’t supported by the IFC090-FF.

ST_REV R

Static data revision counter. ST_REV will be incremented if a static Analog

Input Block parameter has changed. By checking this parameter, control

systems are able to realize if a static parameter has changed its value

without checking all static parameters all the time.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 21

Supplementary Documentation Page 21 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

STATUS_OPTS R/W

Description

STATUS_OPTS specifies how the OUT value status has to be set. If no

status option is selected, the channel value status is used. Otherwise, the

OUT status is set subject to the following possible status options:

Uncertain if Limited Set the OUT status to Uncertain if if the

BAD if Limited Set the OUT status to BAD if the channel

Uncertain if Man mode Set the OUT status to Uncertain if the actual

IFC090-FF Block Description

STRATEGY R/W

Parameter used to group a set of blocks. This is done by assigning all blocks

belonging to one group the same STRATEGY numerical value.

NOTE:

This parameter is neither checked nor used by the function block application!

It can be used by control system to group blocks!

TAG_DESC R/W

User description of the intended application of the block. The user is free in

setting this value. The only limitation is the length of 32 characters at

maximum. It is not checked by the application, but has informational

character only.

UPDATE_EVT R

Alert generated by a change to static data. The subfields of this parameter

give detailed information about the changed static parameter, time of change

and state of the update event.

XD_SCALE R/W

Together with parameter OUT_SCALE, XD_SCALE is one of the two main

scaling parameters. It can’t be seen isolated. These two parameters specify

a mapping function from the channel value obtained from the. See 5.3.2 for

details.

NOTE:

Since the Transducer Block parameter PRIMARY_VALUE has a fixed, not

changeable unit, and the unit of XD_SCALE has to match meet the unit of

this parameter. It is possible to change the unit of XD_SCALE but this would

result in a BLOCK_ERR of ‘Block Configuration Error’ and associated OUT

value status.

Table 3: Analog Input Block parameters

channel value is limited.

value is limited.

mode of the Analog Input Block is Man.

Otherwise the channel status would be

used with constant limit.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 22

Supplementary Documentation Page 22 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

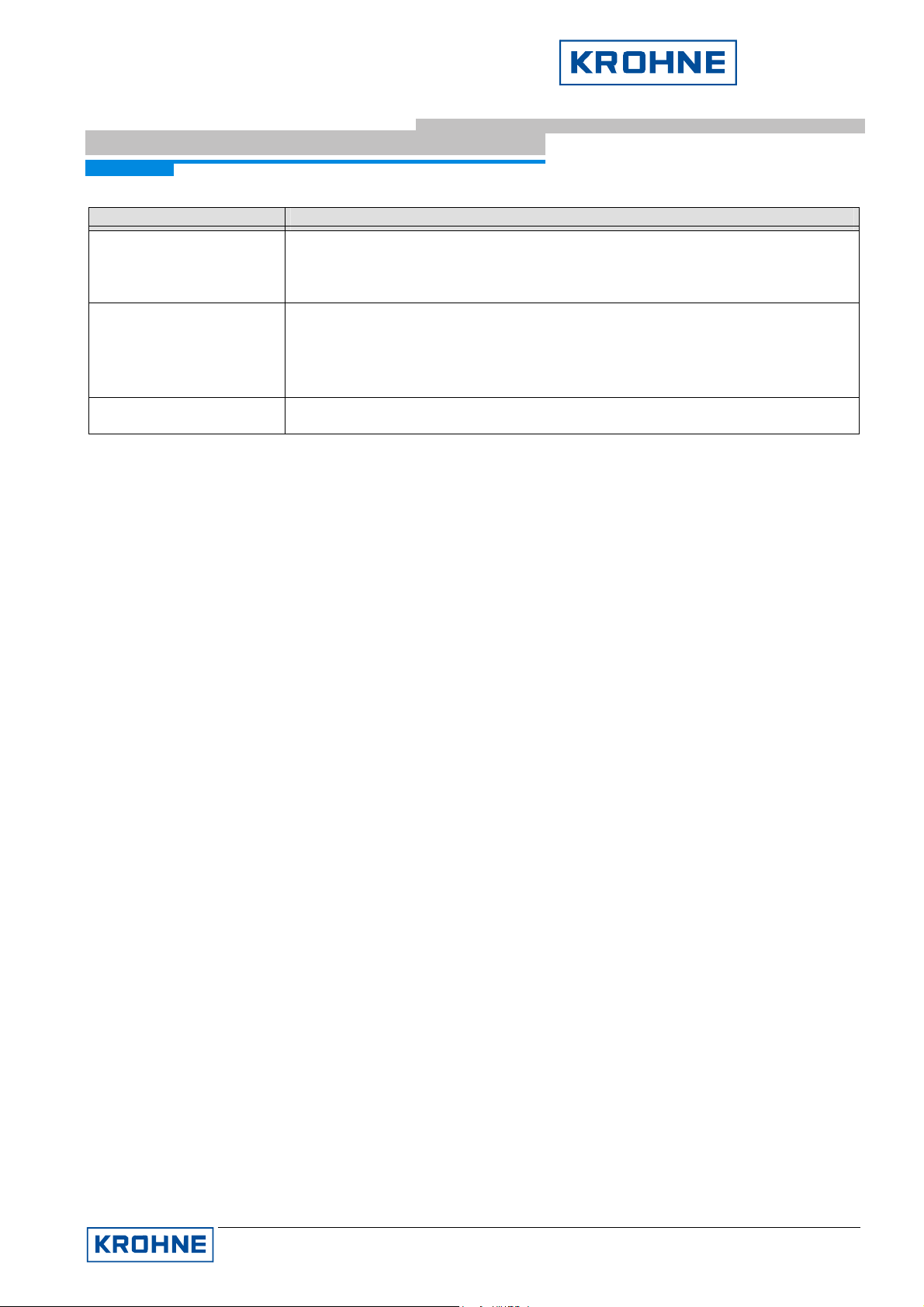

4.4 Integrator Blocks 1 and 2 (Flow(+)- and Flow(-)-Totalizer)

Table 4 lists the Integrator Blocks parameters in alphabetical order (this list gives a description of the various

parameters only; see chapter below for a detailed description of how to configure these parameters). The

descriptions are valid for both Integrators, ‘Flow(+) Totalizer’ and ‘Flow(-) Totalizer’ unless expressively pointed

out:

IFC090-FF Block Description

Figure 2: IFC090-FF Integrator Block

Parameter Access

ALERT_KEY R/W

Description

ALERT_KEY parameter contains the identification number of the plant unit. It

helps to identify the location (plant unit) of an event. The handling of this

parameter is up to the control system or control person, respectively.

BLOCK_ALM R

Display of current block state. Field subcode gives information about the state

current errors. The following errors can occur:

Configuration Error

Block was put Out of Service

The remaining fields give information about the state and the occurrence of

this alarm.

BLOCK_ERR R

Display of active block errors. The following errors are possible:

Out of Service block is in Out of Service mode

Memory Failure memory of device has errors

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 23

Supplementary Documentation Page 23 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

CLOCK_PER R/W

Description

CLOCK_PER specifies the time after which the Integrator OUT value should

be reset, if parameter INTEG_TYPE is set to ‘Periodic’.

see also: INTEG_TYPE

IFC090-FF Block Description

GOOD_LIM R/W

GOOD_LIM specifies the limit for Good status of parameter OUT. If the

percentage of Good input gets below this limit (and above UNCERT_LIM),

the status of OUT turns from Good to Uncertain (unless GOOD_LIM equals

UNCERT_LIM).

see also: UNCERT_LIM

GRANT_DENY R/W

Options for controlling access of host computer and local control panels to

operating, tuning and alarm parameters of the block.

NOTE:

This parameter is not supported by IFC090-FF

IN_1 R

Primary block input with status coming (normally) from another block’s output

parameter.

see also: IN_2

IN_2 R

Secondary block input with status, coming (normally) from another block’s

output parameter.

see_also: IN_1

INTEG_OPTS R/W

INTEG_OPTS is to be used to specify several integration options as type of

input used in each input, flow direction to be considered in the totalization,

status to be considered in the totalization and if the totalizatiion residue shall

be used in the next batch after a reset. The following INTEG_OPTS are

possible:

Input 1 accumulate IN_1 is used as pulse (otherwise as rate)

Input 2 accumulate IN_2 is used as pulse (otherwise as rate)

Flow forward only positive net flow will be taken into account

Flow reverse only negative net flow will be taken into account

Use Uncertain IN_1 and IN_2 input will be taken into account

Use BAD Input IN_1 or IN_2 with BAD status will be interpreted

Carry integration after a reset starts with the init value,

Add zero if Bad If one of the input (IN_1 or IN_2) statuses are

Confirm reset after a manual reset of totalization, the next

Generate reset event in case of reset (automatic or manual), an event

for totalization (NOTE: default settig for Integrator

1)

for totalization (NOTE: default settig for Integrator

2)

even if their states are Uncertain (otherwise the

value with the last Good status will be taken)

as Good (NOTE: only the status is interpreted as

Good, the value isn’t used for totalization, but the

good one, i.e. RTOTAL isn’t affected with this

setting.

but with the residual after the trip value.

BAD, not the last Good value is used for

totalization, but zero (0).

manual reset must be preceded by a reset

confirmation by the control system.

notification will be sent to the control system.

see also: INTEG_TYPE

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 24

Supplementary Documentation Page 24 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

INTEG_TYPE R/W

Description

INTEG_TYPE defines the type of counting (up or down) and the type of

resetting the totalization. The following types are available:

Up auto Totalization starts with 0.0 and counts up with

Up demand Totalization starts with 0.0 and counts up. A reset

Down auto Totalization starts with TOTAL_SP and counts

Down demand Totalization starts with TOTAL_SP and counts

Periodic Totalization starts with 0.0 and counts up. A

Demand Totalization starts with 0.0 and counts up. To

Periodic & Demand Same as ‘Periodic’ with the exception that

IFC090-FF Block Description

automatic reset if TOTAL_SP is reached.

isn’t performed except either a reset is initiated by

RESET_IN or OP_CMD_INT.

down with automatic reset if 0.0 is reached.

down. A reset isn’t performed except a reset is

initiated either by RESET_IN or OP_CMD_INT.

automatic reset is performed in accordance to the

time given in parameter CLOCK_PER (NOTE:

RESET_IN and OP_CMD_INT resets are disabled

and would produce a ‘Wrong Mode For Request’

error).

perform a reset, the operator has to write ‘reset’ to

parameter OP_CMD_INT.

RESET_IN and OP_CMD_INT resets are possible.

see also: RESET_IN, OP_CMD_INT, N_RESET

MODE_BLK Mix

Display of the current (actual), desired (target), possible (permitted) and

normal modes of the Integrator Block. By writing a permitted value to the

target field, you can control the execution modes of the block. The following

block modes are allowed for the IFC090-FF Integrator Block:

Automatic Mode (AUTO)

In this mode, the Integrator Block performs its functional computations in

accordance with its configuration automatically. Totalization is active.

Manual (MAN)

In difference to AUTO mode, the block doesn’t perform an automatic

totalization, but freezes the totalization value to the last one obtained in

Auto mode. The OUT status limits switches to constant. In this mode it is

possible to write to the OUT value an arbitrary value to test blocks that

use this OUT value as input.

Out of Service (OOS)

In this mode, the Integrator Block stops its execution. No totalization is

performed, what can be seen at the status of OUT

(Bad:OutOfService:NotLimited).

N_RESET R

Counts the number of totalization resets. The counter provides verification

that the totalization don’t has been reset since it was last checked.

OP_CMD_INT R/W

Setting this parameter to reset performs a totalization reset according to the

chosen integration type (see parameter INTEG_TYPE for details).

see also: INTEG_TYPE

OUT R/W

The totalization value and status calculated as a result of executing the block.

In Auto mode of this block, the value and its status is automatically calculated

on the base of the calculation methods of the Integrator Block. In Man mode it

is possible to write to this value to specify a known, given value that can be

used to test the correct operation of other downstream function blocks.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 25

Supplementary Documentation Page 25 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

OUT_PTRIP R/W

Description

Second discrete output. OUT_PTRIP can be used within a control system, to

get a discrete indication, that a specified value of totalization is reached (e.g.

as indication to start closing a valve). The specified value to reach can be set

in parameter PRE_TRIP.

NOTE:

If the totalization reaches PRE_TRIP, OUT_PTRIP is set to 255 (0xFF).

see also: PRE_TRIP, OUT_TRIP

IFC090-FF Block Description

OUT_RANGE R

Display scaling of the output OUT. It has no effect on the block and is used

by downstream blocks or control system to get the unit of the totalization.

OUT_TRIP R/W

Second discrete output. OUT_TRIP can be used within a control system, to

get a discrete indication, that the specified value of totalization for resetting

(automatic reset is selected) is reached. The specified value to reach can be

set in parameter TOTAL_SP.

see also: TOTAL_SP, OUT_PTRIP

OUTAGE_LIM R/W

PCT_INCL R

Maximum tolerable time for power failure. Not used by the IFC090-FF

Percentage of BAD and Uncertain net flow values used in conjunction with

GOOD_LIM and UNCERT_LIM to determine the status of the output value

OUT. It is calculated by the following equation:

PCT_INCL = 100 * (1 - (rtotal / atotal),

where rtotal is the portion of BAD and Uncertain net flows and atotal the

absolute value of all net flows.

see also: GOOD_LIM, UNCERT_LIM

PRE_TRIP R/W

When integration is counting up (see INTEG_TYPE) and the totalization

value equals or exceeds (TOTAL_SP - PRE_TRIP) then the discrete output

OUT_PTRIP is set to 0xFF.

If counting down and the value of OUT is equal to or less than PRE_TRIP,

the discrete output OUT_PTRIP is set to 0xFF.

see also: OUT_PTRIP

PULSE_VAL1 R/W

PULSE_VAL1 specifies the factor by witch IN_1 is to be multiplied if IN_1 is

used as input of accumulated pulses (i.e. ‘Input 1 accumulate’ is set in

INTEG_OPTS). In this respect, IN_1 will be converted according to the

following equation:

IN_1 = IN_1 * PULSE_VAL1

PULSE_VAL2 R/W

PULSE_VAL2 specifies the factor by witch IN_2 is to be multiplied if IN_2 is

used as input of accumulated pulses (i.e. ‘Input 1 accumulate’ is set in

INTEG_OPTS). In this respect, IN_2 will be converted according to the

following equation:

IN_2 = IN_2 * PULSE_VAL2

RESET_CONFIRM R/W

RESET_CONFIRM can be used by control systems to confirm a reset event

report if ‘Confirm reset’ is set in INTEG_OPTS.

RESET_IN R/W

RESET_IN can be used by control systems to reset the totalization by an

external signal. By setting 'value' to 'Reset' (0x01) and a status of

GoodNC:NS:NL, the integrator will be reset as if OP_CMD_INT was set to

'Reset'.

see also: OP_CMD_INT, INTEG_TYPE

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 26

Supplementary Documentation Page 26 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

REV_FLOW1 R/W

Description

REV_FLOW1 can be used to indicate a reverse IN_1 flow. If IN_1 flow is

positive (i.e. forward flow), setting this parameter to a value not equal to

‘Discrete state 0’ (0), will result in the same but negative value (i.e.

multiplication by (-1)).

NOTE:

If ‘Forward flow’ is selected in INTEG_OPTS (which is the default for

Integrator Block 1) the resulting net flow will always be 0.0 for negative net

flows! If ‘Reverse flow’ is selected in INTEG_OPTS (which is the default for

Integrator 2) the resulting net flow will always be 0.0 for positive flows!

IFC090-FF Block Description

REV_FLOW2 R/W

REV_FLOW2 can be used to indicate a reverse IN_2 flow . If IN_2 flow is

positive (i.e. forward flow), setting this parameter to a value not equal to

‘Discrete state 0’ (0), will result in the same but negative value (i.e.

multiplication by (-1)).

NOTE:

If ‘Forward flow’ is selected in INTEG_OPTS (which is the default for

Integrator Block 1) the resulting net flow will always be 0.0 for negative net

flows! If ‘Reverse flow’ is selected in INTEG_OPTS (which is the default for

Integrator 2) the resulting net flow will always be 0.0 for positive flows!

RTOTAL R

RTOTAL stands for ‘rejects total’ and integrates the net flow values with

status BAD (if ‘Use BAD’ is not set in INTEG_OPTS) and Uncertain (if ‘Use

Uncertain’ is not set on INTEG_OPTS) and is used to calculate the parameter

PCL_INCL (see PCL_INCL for details).

see also: PCL_INCL

SRTOTAL R

SRTOTAL stands for 'snapshot RTOTAL' and displays the value of RTOTAL

just before the last reset (if one has happened, inspect N_RESET to see if

one has happen). The initial value is set to zero (0).

SSP R

SSP stands for 'snapshot TOTAL_SP' and displays the value of TOTAL_SP

just before the last reset (if one has happened). The initial value is set to zero

(0).

ST_REV R

Static data revision counter. ST_REV will be incremented if a static Integrator

Block parameter has changed. By checking this parameter, control systems

are able to realize if a static parameter has changed its value without

checking all static parameters all the time.

STATUS_OPTS R/W

STATUS_OPTS specifies how the OUT, OUT_TRIP and OUT_PTRIP status

has to be set. If no status option is selected, the status is the result from the

block’s operation. Otherwise, the status is set subject to the following

possible status option:

Uncertain if Man mode Set the OUT, OUT_TRIP and OUT_PTRIP status to

STOTAL R

STOTAL stands for 'snapshot TOTAL' and displays the value of the

totalization (= OUT) just before a reset (if one has happened). The initial

value is set to zero (0).

STRATEGY R/W

Parameter used to group a set of blocks. This is done by assigning all blocks

belonging to one group the same STRATEGY numerical value.

NOTE:

This parameter is neither checked nor used by the function block application!

It can be used by control system to group blocks!

TAG_DESC R/W

User description of the intended application of the block. The user is free in

setting this value. The only limitation is the length of 32 characters at

maximum. It is not checked by the application, but has informational

character only.

Uncertain if the actual mode of the Integrator Block

is Man.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 27

Supplementary Documentation Page 27 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Parameter Access

TIME_UNIT1 R/W

Description

TIME_UNIT_1 specifies the time unit of IN_1, if IN_1 comes from a pulse

input block (i.e. ‘Input 1 accumulate‘ is set in INTEG_OPTS) and converts

the input IN_1 according to one of the following time unit:

s second

min minute

h hour

d day

IFC090-FF Block Description

TIME_UNIT2 R/W

TIME_UNIT_2 specifies the time unit of IN_2, if IN_2 comes from a pulse

input block (i.e. ‘Input 2 accumulate‘ is set in INTEG_OPTS) and converts

the input IN_2 according to one of the following time unit:

s second

min minute

h hour

d day

TOTAL_SP R/W

Setpoint for batch totalization. Meaning depends on the chosen type of

integration. (see INTEG_TYPE for details).

see also: INTEG_TYPE

UNCERT_LIM R/W

UNCERT_LIM specifies the limit for Uncertain status of parameter OUT. If

PCT_INCL gets below this limit, the status of parameter OUT turns from

Uncertain to BAD (unless GOOD_LIM equals UNCERT_LIM):

UNCERT_LIM ≤ PCT_INCL ⇒ OUT.status = Uncertain

PCT_INCL < UNCERT_LIM ⇒ OUT.status = BAD

see also: GOOD_LIM

UNIT_CONV R/W

UNIT_CONV is used as a factor to convert the engineering units of IN_2 into

the engineering units of IN_1, after IN_2 was converted according to it's time

unit.

This is only true, if IN_2 is connected to another output parameter!

NOTE:

This is necessary since in the integration process, the (converted) inputs

IN_1 and IN_2 are added which presupposes a common unit base.

UPDATE_EVT R

Alert generated by a change to static data. The subfields of this parameter

give detailed information about the changed static parameter, time of change

and state of the update event.

Table 4: Integrator Blocks parameters

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 28

Supplementary Documentation Page 28 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

5 IFC090-FF Configuration

5.1 Resource Block Configuration

This block contains the data associated with the underlying resource, i.e. data that are specific to the hardware.

It describes characteristics of the fieldbus device (e.g. device name, serial number, etc.) and is not included in

the functional tasks of the IFC090-FF. Thus, it consists of contained parameter3 only. As a rule, the configurable

items of the Resource Block are not used to modify a special detail, but the representation and behavior of the

complete device.

5.1.1 Resource Block Mode Handling

Since the Resource Block is characterizing the fieldbus device as a whole, its operation mode also affects the

complete IFC090-FF. To this end, the Resource Block supports the following operation modes

• Automatic (Auto), and

IFC090-FF Configuration

• Out of Service (OOS).

In Automatic mode, the complete Resource (i.e. Transducer and Function blocks) is able to operate and perform

their functional tasks. In the Out of Service mode, all other blocks are in Out of Service mode, too, and are not

capable of changing their mode unless the Resource block is set to to Automatic mode.

If a block is in Out of Service mode, this is also indicated by its BLOCK_ERR parameter.

5.1.2 Write Protection

Normally, all (writable) parameters of all blocks are not protected against accidental write accesses. To avoid

such accidental write accesses you can use the IFC090-FF building software write lock. This write lock can be

controlled by the parameter WRITE_LOCK, which can have the following settings:

• Not locked (numerical value: 1), or

• Locked (numerical value: 2).

If set to Locked, all writable parameters (with the exception of parameter WRITE_LOCK itself) are write

protected until the write lock is cleared (i.e. set to Not locked).

If the control system should be notified by an alarm, if the write lock is cleared, this can be controlled by the

parameter WRITE_PRI. This parameter expects a numerical value which specifies the behavior of the write lock

clearing alarm parameter WRITE_ALM. Subject to the following settings of WRITE_PRI, WRITE_ALM behaves

as follows:

3

A parameter is called “contained“ if it not use other blocks output parameters or can not be used by other

blocks input parameters, respectively.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 29

Supplementary Documentation Page 29 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

WRITE_PRI Behavior of WRITE_ALM

IFC090-FF Configuration

0

1

No alarm is been generated in WRITE_ALM

Alarm is been generated in WRITE_ALM, but the control system won’t be notified about

it.

2

3-7

reserved for block alarms

Clearing of write protection is sent as user/operator note to the control system, according

to the specified priority (3 = low and 7 = high).

8-15

Clearing of write protection is sent as alarm to the control system, according to the

specified priority (3 = low and 7 = high).

5.1.3 Resource State Re-Initialization

The resource consists of a state machine which reflects the current state of the FF specific part of the IFC090-

FF. This state is displayed in the Resource Block parameter RS_STATE and can have the following settings:

RS_STATE Description

ONLINE

This is the normal operation state. All FF links are established and the resource

works in automatic mode

INITIALIZATION

Resource’s initialization state. This state will be passed if the device is connected

with the fieldbus. All FF specific parts will be initialized with respect to saved

configuration

ONLINE LINKING

In this state, all parameters are initialized and the device is waiting for the links are

all established.

STANDBY

This state reflects, that all initializations are made, but the Resource Block is in Out

of Service mode.

In some situations it could be necessary to restart or re-initialize some portions of the device (due to a

completely wrong configuration, etc.). To perform this, some degrees of reset/re-initialization are supported by

the Resource Block parameter RESTART. Assigning a special value to this parameter, it is possible to enforce

re initializations as described in the following table:

RESTART Description

Run

Restart Resource

Restart with Defaults

Setting for normal operation.

Warm start of the IFC090-FF measurement electronics.

Sets all FF parameters to their factory default values.

NOTE: To be used with caution!

Restart Processor

Cold start of the IFC090-FF measurement electronics and warm start of the FF

specific application.

5.2 Transducer Block Configuration

The Transducer Block as interface between the device specific measurement hardware and the Fieldbus

Foundation specified Function Block model, decouples the sensor output functions required to read the

measurement value from the Function Blocks. Therefore, the Transducer Block is also based on contained

parameters only, but provides its measurement value in a channel based scheme to the Function Blocks.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 30

Supplementary Documentation Page 30 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Since most of the Transducer Block parameters are depending on device settings which are configurable over

the device’s display only, there are not many what the user has to configure.

5.2.1 Transducer Block Mode Handling

As in other blocks the mode handling in the Transducer Blocks can be controlled by the parameter MODE_BLK.

The Transducer Block supports the following modes:

• Automatic (AUTO),

• Manual (MAN), and

• Out of Service (OOS)

In Automatic mode, the Transducer operates in its standard way and delivers its measurement value and status

as parameter PRIMARY_VALUE via channel 1 to the Function Blocks4 (if any).

Different from the Automatic mode, in Manual mode the Transducer Block freezes its measurement value and

sets its status to Uncertain:NonSpecific Constant.

IFC090-FF Configuration

To stop the complete operation of the Transducer Block, set its mode to Out of Service. In this mode, the

Transducer Block freezes its measurement value to the last one obtained in Automatic mode and sets its status

to BAD:OutOfService:NonSpecific.

If the block is in Out of Service mode, this is also indicated by its BLOCK_ERR parameter.

5.2.2 IFC090-FF Zero Point Calibration

The Transducer Block allows a calibration of the devices zero point.

To do this, the number of calibration cycles has to be specified first by setting parameter

CYCLES_ZEROPOINT_CAL (default value is 250).

To start the zero point calibration, parameter CAL_ZEROPOINT has to be set to a value different to zero (0).

5.3 Analog Input Block Configuration

The Analog Input block is one of the 3 Function Blocks supported by the IFC090-FF. It can be used to process

the measurement value obtained from the Transducer Block in a user defined way and to deliver it to the control

system. To this end, there are some parameters in the Analog Input Block, that can be configured to get a

measurement value quality as desired by the user.

Analog Input Block Mode Handling

By selecting the operation mode in parameter MODE_BLK, the operator is able to control the activities of the

Analog Input block. The following lists the available modes and meanings:

4

Normally, this is the Analog Input block, but it has to be configured to process the channel value.

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg

Tel.: 0203-301 309 Fax: 0203-301389 · E-mail: krohne@krohne.de

Page 31

Supplementary Documentation Page 31 of 44

IFC090, IFC090 i with FF

IFC090 FF 01/2006

Analog Input block MODE_BLK Description

Automatic (AUTO) The Analog Input block performs its functional computations in

accordance to its configuration automatically. Measurement

deliverance and alarm handling are active

Manual (Man) The block doesn’t perform an automatic deliverance of valid

measurement values, but freezes the measurement processing to

the last value obtained in Automatic mode. The OUT status limit

switches to ‘Constant’. In this mode it is possible to write to the OUT

value an arbitrary value to test blocks that use this OUT value as

input.

The alarm model works in the same way as in Automatic mode.

Out of Service (OOS) The block stops its operation and freezes its measurement value to

the last one obtained in Automatic mode. The OUT status switches

to BAD:OutOfService:NonSpecific.

5.3.1 Process Value Selection

By selecting the channel of the Transducer Block, the operator determines which value should be used as

IFC090-FF Configuration

Analog Input block input value. The value received over this channel is the base of the measurement value

processing.

Since the Transducer Block of the IFC090-FF consists of one channel only, the Analog Input block parameter

CHANNEL must be set to ‘1’ to configure the Analog Input block for processing the IFC090-FF flow value.

If parameter CHANNEL is set to a different value than 1, the Analog Input parameter will display a

‘BlockConfigurationError’ in parameter BLOCK_ERR. The block isn’t able to set the actual mode to Automatic.

5.3.2 Linearization and Scaling

The Transducer Block delivers the IFC090-FF measurement value in units of m3/s statically. If this is the unit

that should be passed to the control system, no linearization is necessary and hence parameter L_TYPE has to

be set to ‘Direct’. Otherwise, the parameter has to be set with respect to the following kinds of scaling:

Direct

No linearization. The channel value obtained from the Transducer is used as it came in m3/s.

This presumes that XD_SCALE equals to OUT_SCALE, otherwise a ‘Block Configuration Error’ will be

displayed in BLOCK_ERR.

Indirect

Linear conversion. The channel value obtained from the Transducer will be mapped from the input scaling

(XD_SCALE) to the output scaling (OUT_SCALE).

Example:

Assumptions:

• Transducer Block delivers channel value in unit m3/s

• Analog Input Block should deliver values in unit liter/s

• 1 m3 = 1000 liter

KROHNE Messtechnik GmbH & Co. KG · Ludwig-Krohne-Str. 5 D-47058 Duisburg