Page 1

www.krohne.com

7022812100

C

KROHNE 03/2005

GM

Operating Instructions

Installation and

H54 / M4

Variable Area Flowmeter

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

For explosion protected devices please refer to Supplementary

Communications technology

Installation an Operating Instructions:

Engineering systems & solutions

GA24/... Cat. II2GD

Switches, counters, displays and recorders

Cat. II3GD without electr. built-in parts Id. No. 702271##00

Heat metering

Pressure and temperature

Variable area flowmeters

Page 2

Product liability and warranty

The variable area flowmeter is suitable for measuring the volume flow of liquids, gases and vapor.

Special regulations apply for use in explosion-hazardous areas. Responsibility for the suitability and

usage to the intended purpose of these flowmeters rests solely with the operator.

Improper installation or improper operation of the flowmeters may lead to the loss of warranty. In addition,

the "General conditions of sale" which forms the basis of the purchase contract are applicable.

The calculation of the pressurized parts is effected with allowance for corrosion, erosion through abrasion

or cavitation.

If the flowmeter needs to be returned to KROHNE Messtechnik, please note the information at the end of

these installation and operating instructions.

Scope of delivery

The scope of delivery of the variable area flowmeter in the version respectively ordered includes:

- Installation and operating instructions Ident. No. 702281##00

For explosion protected devices please refer to Supplem. Installation an Operating Instructions:

H54/... Cat. II2GD Cat. II3GD without electr. built-in parts Id. No. 702271##00

- Supply without installation accessories (screw bolts, flange seal and cabling)

Special certificates (supplied to order only)

- Record on setting in works

- Test certificate to EN 10204:

- Pressure test, paint penetration test, irradiation test, leak test,

ultrasonic test, helium leakage test,

- Cleaning to works regulations.

2 H54 Installation and operating instructions

Page 3

Table of Contents

Product liability and warranty ................................................................................................................... 2

1 General................................................................................................................................................ 4

1.1 Type code ........................................................................................................................................ 4

1.2 Marking ............................................................................................................................................ 4

1.3 Key for Pressure Equipment Directive ............................................................................................5

1.4 Functional principle.......................................................................................................................... 5

2 Installation and Start-up.................................................................................................................... 6

2.1 Protection during shipment.............................................................................................................. 6

2.2 Prerequisite for the installation ........................................................................................................ 6

2.3 Preparation of the pipeline............................................................................................................... 6

2.4 Installation in the pipeline ................................................................................................................ 6

2.5 Fastening torque.............................................................................................................................. 6

2.6 Magnetic filters ................................................................................................................................ 7

2.7 Observance of the IP degree (NEMA Type) of protection............................................................... 7

2.8 Start-up............................................................................................................................................ 7

2.9 Measurement of liquids ................................................................................................................... 7

2.10 Measurement of gases.................................................................................................................... 7

3 Flow tables ......................................................................................................................................... 8

4 Materials ............................................................................................................................................. 9

5 Technical Data.................................................................................................................................. 10

6 Medium Temperatures..................................................................................................................... 10

7 Dimensions and weights................................................................................................................. 11

8 Limit switches .................................................................................................................................. 12

8.1 Electrical connection...................................................................................................................... 12

8.2 Setting............................................................................................................................................ 12

8.3 Technical data of limit switches ..................................................................................................... 12

9 Electrical signal output ESK II........................................................................................................ 13

10 Electrical signal output ESK3-PA................................................................................................... 14

11 Maintenance ..................................................................................................................................... 15

Information on returning instruments.................................................................................................... 15

Form for returning the instrument.......................................................................................................... 16

3 H54 Installation and operating instructions

Page 4

1 General

1.1 Type code

The type code consists of the following elements: 1)

H 5 4 / / / /

1 2 3 4 5 6

1 Series measuring unit H54

2 Materials

RR : stainless Steel

C : stainless steel with PTFE liner

3 Heating jacket design

B : with heating jacket

4 Display part series

M4 : mechanical indicator

M10 : electronic transmitter with LC display M10

5 Signal output (M4 display)

ESK : electronic transmitter

6 Limit switch

K1 : one limit switch

K2 : two limit switches

1) Positions which are not used in the type code are not required.

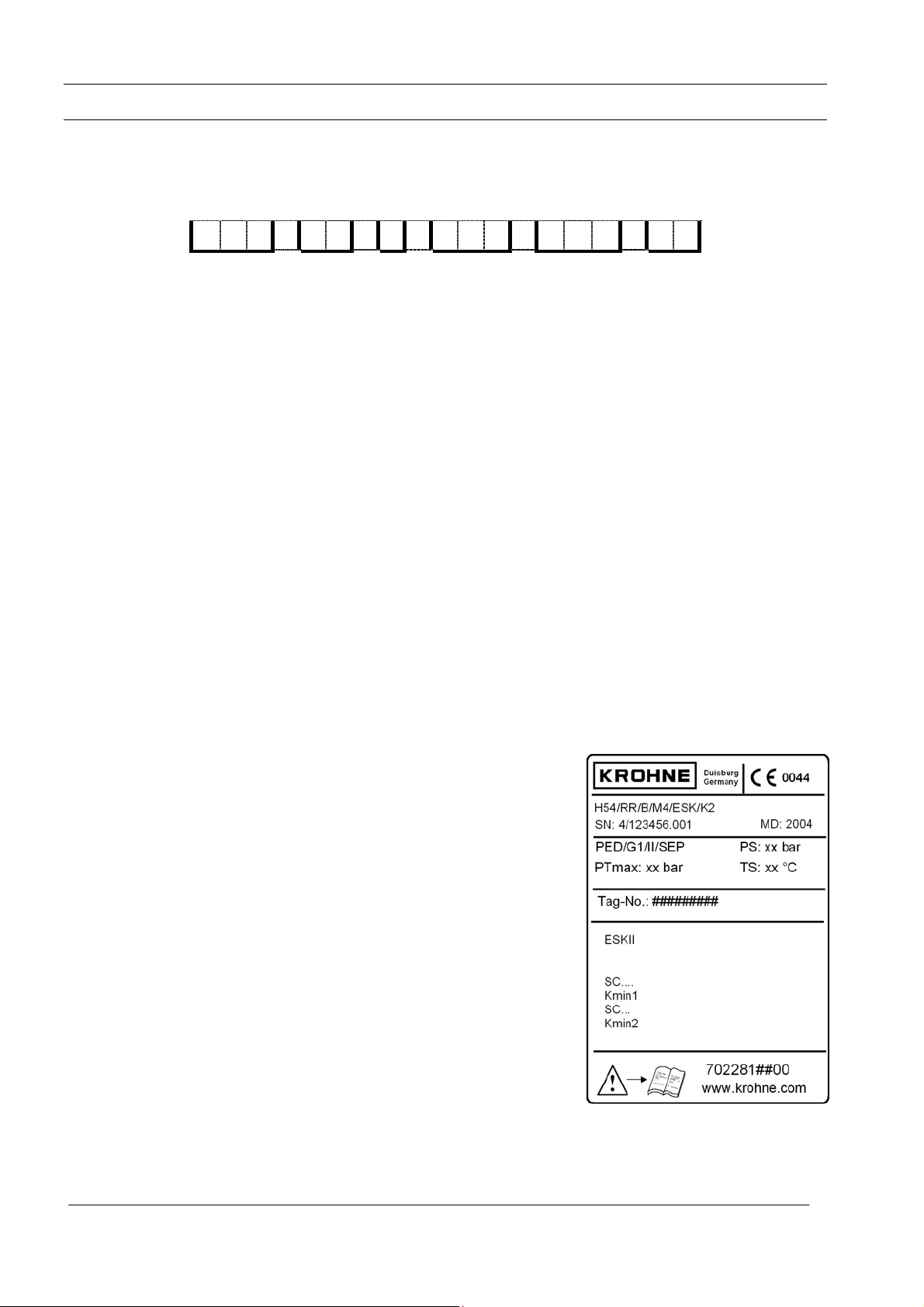

1.2 Marking

The type marking of the complete instrument is carried out at the display part by means of the rating plates

shown here (also refer to the type code).

Example:

MD: Manufacturing date

PS: Max. permissible operating

pressure at max. permissible operating temperature TS

PT max: Maximum pressure tested

TS: Max. operating temperature

PED: Directive for Pressure Equipment

Tag No : Measuring point tag

0044: Identification number of the supervising office for

EC Directive for Pressure Equipment 97/23/EC

SN: Serial number

SO: Sales order / item

KO: KROHNE order

V251…: Product configurator code

AC: Article code

4 H54 Installation and operating instructions

Page 5

1.3 Key for Pressure Equipment Directive

PED / / /

1 2 3 4 5

1 Pressure Equipment Directive

2 Fluid

G Gases, liquefied gases, gases dissolved under pressure, vapors and those liquids

whose vapor pressure lies more than 0.5 bars over the normal atmospheric pressure

(1013 mbars) at the maximum permissible temperature

L Liquids whose vapor pressure lies a maximum of 0.5 bars above the atmospheric

pressure at the maximum permissible temperature

3 Fluid group

1 Group 1: Explosion-hazardous, highly flammable, readily flammable, flammable

(when the maximum permissible temperature lies above the flash point),

highly toxic, toxic, fire stimulating

2 Group 2: All the fluids not specified in Group 1

4 Category

3.3 In accordance with Article 3.3 of Directive 97/23/EC

I Category I to 97/23/EC

II Category II to 97/23/EC

III Category III to 97/23/EC

5 Conformity evaluation process

SEP Solid engineering practice

A Module A internal process inspection

A1 Module A1 internal process inspection with supervision of the acceptance

H Module H Comprehensive quality assurance

The PED key marking is contained on the rating plate of the instrument.

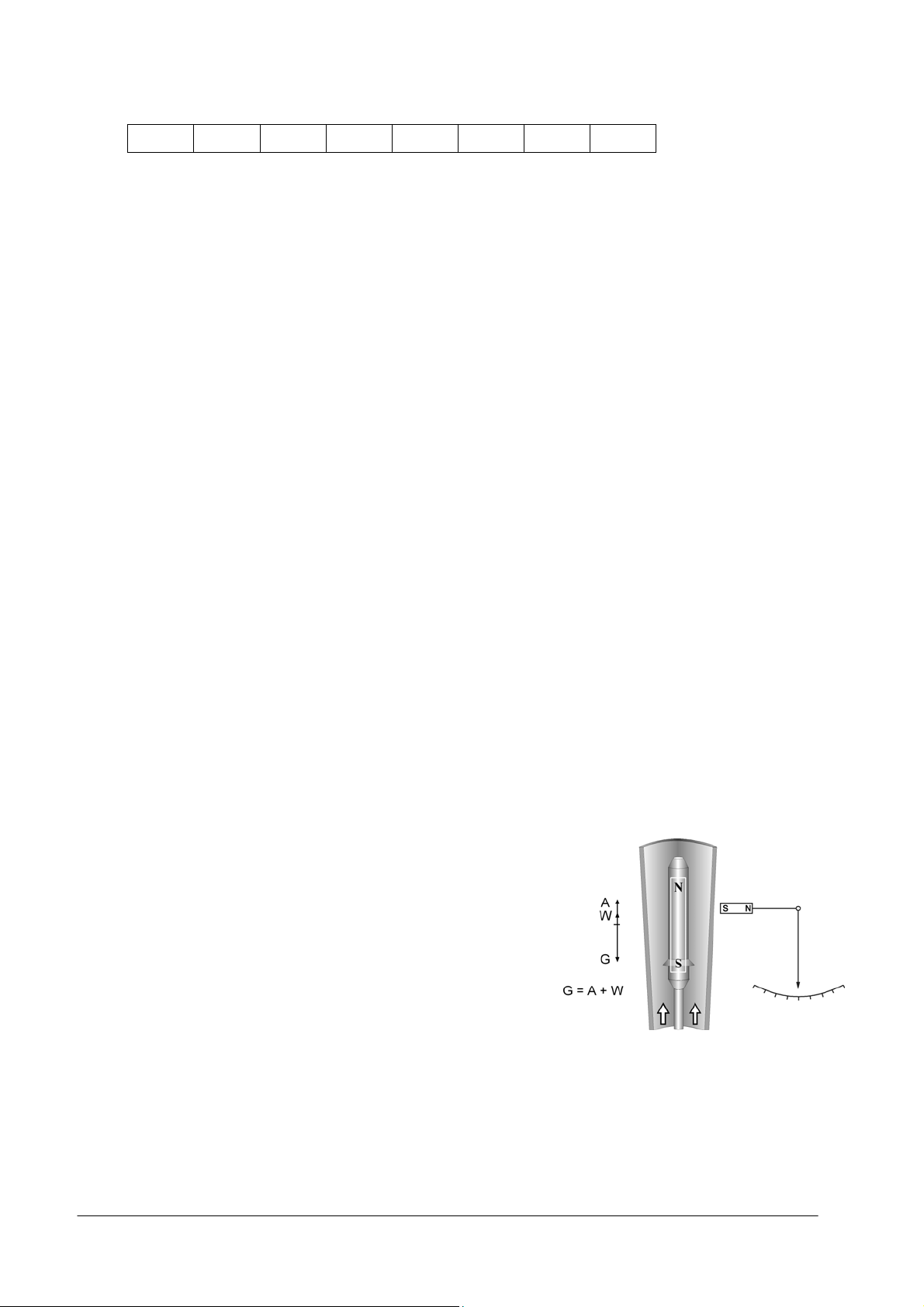

1.4 Functional principle

The flowmeter operates in accordance with the float measuring

principle.

A metal cone is installed in the measuring unit H54, in which

a suitably formed float can move freely up and down.

The flowmeter is inserted into a vertical pipeline and the

medium flows through it from bottom to top.

The guided float adjusts itself so that the buoyancy force

A acting on it, the wave resistance W and its weight G are

in equilibrium (G = A + W).

An annular gap which depends on the flow rate results.

The height of the float in the measuring unit, which depends

on the flow, is transmitted by a magnetic coupling and

displayed on a scale. Strong magnetic fields can lead to

deviations in the measured value.

The installation of several instruments in immediate vicinity to

each other does not cause notable influences.

5 H54 Installation and operating instructions

Page 6

2 Installation and Start-up

2.1 Protection during shipment

The sensing arm and cam plate are secured by a rubber band.

2.2 Prerequisite for the installation

The operating pressure of the plant may not exceed the value indicated on the rating plate.

Ensure that the parts coming into contact with the medium are compatible with the material. (For the list

of the materials please refer to the chapter on the materials of the instrument designs.)

The ambient and medium temperatures may not exceed certain maximum values.

The variable area flowmeter has to be installed vertically (float measuring principle - flow direction from

bottom to top).

In order to prevent distortions the connecting flanges have to face each other axially and in parallel.

2.3 Preparation of the pipeline

The pipeline is to be supported by suitable installation measures, so that vibrations at the pipeline are

prevented and axial stresses on the instrument are minimized.

A straight unimpeded inflow section of ≥ 5 x DN before the instrument and a straight

outflow section of ≥ 3 x DN behind the instrument are recommended.

Shutoff and control devices are to be positioned in the flow direction behind the measuring unit.

For installation recommendations please also refer to the Directive VDE/VDI 3513, Sheet 3.

2.4 Installation in the pipeline

The instrument may not be subjected to tensile or compressive stresses through the pipelines.

Immediately before carrying out the installation check whether the instrument is free of foreign particles.

Screws, bolts and seals (provided by customer) are to be selected in accordance with the pressure stage

of the connecting flange or the operating pressure.

The inside diameter of the flange deviates from the standard dimensions.

Flange seal standard DIN 2690 (ASME B16.21) can be applied without any limitation.

Align the seals. Tighten the nuts with the tightening torques of the corresponding pressure stage.

2.5 Fastening torque

The flange bolts are to be tightened with the following maximum torques in case of measuring units with

PTFE liner or of measuring units with ceramic lining and PTFE sealing surface:

Nominal size to

DIN 2501 ASME B 16.5 DIN ASME DIN ASME 150 lbs

DN PN Inch lbs 150 lbs 300 lbs Nm ft·lbf Nm ft·lbf

15 40 ½” 150/300 4 x M 12 4 x ½” 4 x ½” 9.8 7.1 5.2 3.8

25 40 1” 150/300 4 x M 12 4 x ½” 4 x 5/8” 21 15 10 7.2

50 40 2” 150/300 4 x M 16 4 x 5/8” 8 x 5/8” 57 41 41 30

80 16 3” 150/300 8 x M 16 4 x 5/8” 8 x ¾” 47 34 70 51

100 16 4” 150/300 8 x M 16 8 x 5/8” 8 x ¾” 67 36 50 36

Bolts Max. tightening torque

125 16 5" 150/300 8 x M 16 8 x 5/8“ 8 x ¾“ 67 48 75 54

150 16 6" 150/300 8 x M 20 8 x ¾“ 8 x ¾“ 88 64 94 68

6 H54 Installation and operating instructions

Page 7

2.6 Magnetic filters

Magnetic filters are used when the medium contains particles which can be influenced magnetically. The

magnetic filter is to be installed in the flow direction before the flowmeter. Magnetic bars are positioned

helically in the filter so that an optimal efficiency at a low pressure loss is achieved. All the magnets are

coated individually with PTFE to protect against corrosion. Two models are available:

Type F Type FS

Fitting part with flange Fitting part without flange

Overall length 100 mm Overall length 50 mm

Materials 1.4571 (316 Ti)

2.7 Observance of the IP degree (NEMA Type) of protection

The following instructions are to be observed in order to observe the IP degree (Nema Type) of electrical

built-in parts.

- After the connecting cable has been introduced, tighten the outlet nut.

- All the cable glands which are not used remain closed with blanking plugs.

- Do not kink lines directly at the cable gland.

- Provide a drain bend

- The feed lines may not be subjected to mechanical strains. Refer to the description

of the electrical supplementary components for this device.

Cable glands / screwed glands: PG11 - line diameter 8 to 10mm

2.8 Start-up

A minimum operating pressure (pre-pressure) is required to operate the instrument.

Medium Pressure loss : Operating pressure

Liquids 1 : 2

Gases (without damping) 1 : 5

Gases (with damping) 1 : 2

For the pressure losses please refer to the flow tables

2.9 Measurement of liquids

Vent the pipeline during starting-up in order to avoid liquid beats.

Open valves slowly!

2.10 Measurement of gases

Pulsations of the medium are to be kept away from the instrument.

In case of gases increase the operating pressure slowly.

The flow is to be varied by means of adjusting valves, so that the float is not subjected to blows

(e.g. through solenoid valves) thus ensuring that damage to the measuring unit cannot occur.

Instruments for measuring the flow rate of gases can be equipped with a gas damping, in order to avoid

possible compression vibrations of the float.

If vibrations nevertheless occur at the float, these can be eliminated by installing a throttle valve or a

suitable aperture hole (on request) behind the instrument.

A float damping is recommended for gas measurement.

7 H54 Installation and operating instructions

Page 8

3 Flow tables

General

Reference conditions: Water at 20°C

Air at 20°C, 1.013 bar abs.

The conversion to other media or operating data (pressure, temperature, density, viscosity) is carried out

by means of the KROHNE calculation procedure KroVaCal on the basis of the VDE /VDI Guideline 3513.

The specified flow values amount to 100% values of the measuring range.

The turn-down range amounts to 10 : 1

The specified pressure losses apply for water and air at the maximum flow rate.

3.1 Flow table H 54 / DN15

Float material CrNi steel

Float form Water: N

Air: NA

Nominal size Water Air Max. pressure loss

DN ASME

mm inches No. No. l/h US GPM m3/h SCFM mbar psig

15 1½“

Cone Float

N NA N / NA

R10.03 10 16 0.07 0.4 0.28 60 0.87

R10.04 11 25 0.11 0.9 0.56 60 0.87

R10.06 11 40 0.18 1.2 0.74 60 0.87

R10.08 11 63 0.28 1.8 1.11 60 0.87

R11.07 31 100 0.44 2.8 1.74 65 0.94

R11.10 32 160 0.70 5 3.10 65 0.94

R11.17 33 250 1.10 8.5 5.27 70 1.02

R11.27 34 400 1.76 11.5 7.13 80 1.16

R12.21 42 630 2.77 20 12.4 100 1.45

R12.32 43 1000 4.40 26 16.1 140 2.03

8 H54 Installation and operating instructions

Page 9

3.2 Flow table H54 DN25 … DN150

Float material CrNi steel

Float form Water: CIVB, CIVTF

Air: CIVT, DIVBLD

Nominal

Cone

Float

size

DN ASME

mm inches No. No.

25 1" K20.12 21

K20.16

K20.23

K20.33

K20.49

K20.55

40 1 1/2" K40.37 41

K40.50

K40.54

50 2" K50.34 51

K50.57

K50.60

80 3" K80.23 81

K80.37

K80.40

K80.50

100 4" K102.35

K102.41

125 5" K122.39

K122.42

150 6" K152.45

CIV 102 50.000 220 120 1.74

CIV 102 63.000 277

TR 122 80.000 352 130 1.89

TR 122 90.000 396

TR 152 150.000 660 150 2.18

Water Air Max. pressure loss

C IV B C IV TF C IV T D IV BLD C IV B C IV TF C IV T C IV BLD

l/h US

800 3.52 500 2.20 12 7.44 20 12.4 46 0.67 19 0.28 13 0.19 21 0.30

1.000 4.40 600 2.64 15 9.31 25 15.5 48 0.70 19 0.28 14 0.20 24 0.35

1.600 7.04 1000 4.40 24 14.9 40 24.8 50 0.73 21 0.30 16 0.23 30 0.44

2.500 11.0 1600 7.04 35 21.7 60 37.2 60 0.87 26 0.38 19 0.28 38 0.55

4.000 17.6 2500 11.0 55 34.1 100 62.0 90 1.31 36 0.52 25 0.36 60 0.87

5.000 22.0 3000 13.2 70 43.4 130 80.6 110 1.60 48 0.70 32 0.46 80 1.16

6.300 27.7 4000 17.6 85 52.7 200 124 60 0.87 31 0.45 19 0.28 75 1.09

10.000 44.0 6000 26.4 125 77.5 280 174 90 1.31 41 0.59 25 0.36 100 1.45

12.500 55.0 7500 33.0 150 93.1 350 217 110 1.60 51 0.74 30 0.44 110 1.60

12.500 55.0 7000 30.8 160 99.3 450 279 65 0.94 30 0.44 11 0.16 90 1.31

16.000 70.5 9000 39.6 180 111 650 403 75 1.09 32 0.46 11 0.16 120 1.74

20.000 88.1 12000 52.8 200 124 750 465 100 1.45 44 0.64 12 0.17 140 2.03

20.000 88.1 12000 52.8 250 155 520 323 60 0.87 25 0.36 14 0.20 50 0.73

25.000 110 14000 61.6 300 186 620 385 70 1.02 26 0.38 14 0.20 52 0.75

30.000 132 16000 70.5 350 217 700 434 80 1.16 27 0.39 14 0.20 54 0.78

40.000 176 20000 88.1 400 248 900 558 90 1.31 29 0.42 15 0.22 56 0.81

l/h US

GPM

m3/h SCFM m3/h SCFM mbarpsig mbarpsig mbarpsig mbarpsig

GPM

135 1.96

140 2.03

4 Materials

Materials

Design

H 54

H 54 / RR CrNi-steel

H 54 / R PTFE * CrNi-steel

H 54 / Hastelloy Hastelloy B3 or C4 CrNi-Stahl HC

* With this liner, flanges are those of the next meter size up,

e.g. cone 20.12 with flange DN40 instead of DN 25

** Alternatively: cone of glass, gasket of PTFE (Only for cone DN 15)

9 H54 Installation and operating instructions

Measuring tube

1.4571

(316Ti)

1.4571

(316Ti)

with PTFE liner

Flange Cone Internals, seal

CrNi-steel

1.4571

(316Ti)

CrNi-steel

CrNi-steel

1.4571 (316Ti)

PTFE ** PTFE PTFE

1.4571 (316Ti)

Hastelloy B3 or

cladded

1.4571

(316Ti)

C4

strip

CrNi-steel

1.4571 (316Ti)

Hastelloy B3

or C4

Float

CrNi-steel

1.4571 (316Ti)

Hastelloy B3

or C4

Page 10

5 Technical Data

Accuracy class

to VDI/VDE Directive 3513, Sheet 2

Connections H 54

Flange dimensions to DIN EN 1092-1

Flange dimensions to ASME B 16.5

Pipe connection for Ermeto

Pipe connection for air cooling

Overall height

With flange connection (without seals)

Operating pressure PS

Directive 97/23/ EC of the Council of April 29, 1999 on mobile pressurized equipment (Directive for

Pressure Equipment) is applied. The maximum permissible operating pressure PS is calculated for the

maximum operating temperature TS. Both limits (PS and TS) are listed on the rating plate. As a rule PS

corresponds to the nominal pressure of the connection.

Pressure Tested PT

The pressure tested is calculated in accordance with the Directive for Pressure Equipment (97/23/EC) or AD

2000-HP30 under consideration of the maximum permissible operating pressure as well as the maximum

operating temperature.

Degree of protection

in accordance with EN 60529 / IEC 60529

1.0

DN 15 … DN 80 / PN 40

DN 80 … DN 150 / PN 16

½" … 6" class 150 lbs / RF or 300 lbs / RF

Ermeto 12

Ermeto 6, 8, 10 or 12

other on request

500 mm

IP 67, NEMA Type 4X / 6

6 Medium Temperatures

Max. Medium Temperatures TS without electrical built-in components -80 °C to +400 °C

Max. Medium Temperatures with ESK, K, KD

H 54 / M4 / ESK

H 54 / M4 / K ( KD )

Ambient temperature T

Ambient temperature T

amb.

with ESK, K, KD

amb.

Other temperatures on request

160 °C (DN 15 : 80 °C)

180 °C (DN 15 : 100 °C)

-40°C to + 90°C

-25 °C to +60 °C

10 H54 Installation and operating instructions

Page 11

7 Dimensions and weights

226

c 45 do

a

321

500 (DN 150 : 600)

b du

Nominal size Dimensions [mm]

DIN ASME

a b c du do

approx.

weight *

DN PN inches mm kg

15 40

25 40

40 40

50 40

80 40

½“

1“

1½“

2

3

23 410 97 125 23 23 5

34.5 380 109 165 34.5 34.5 7

50 380 120 175 45 50 9

67 380 128 185 57 67 12

89 380 147 190 89 89 25

80 16 3 89 380 147 190 89 89 27

100 16 4 106 380 164 205 93 106 29

125 16 5 148 380 175 225 115 148 35

150 16 6 175 380 190 240 127 175 42

* Weights with DIN-Flanges

11 H54 Installation and operating instructions

Page 12

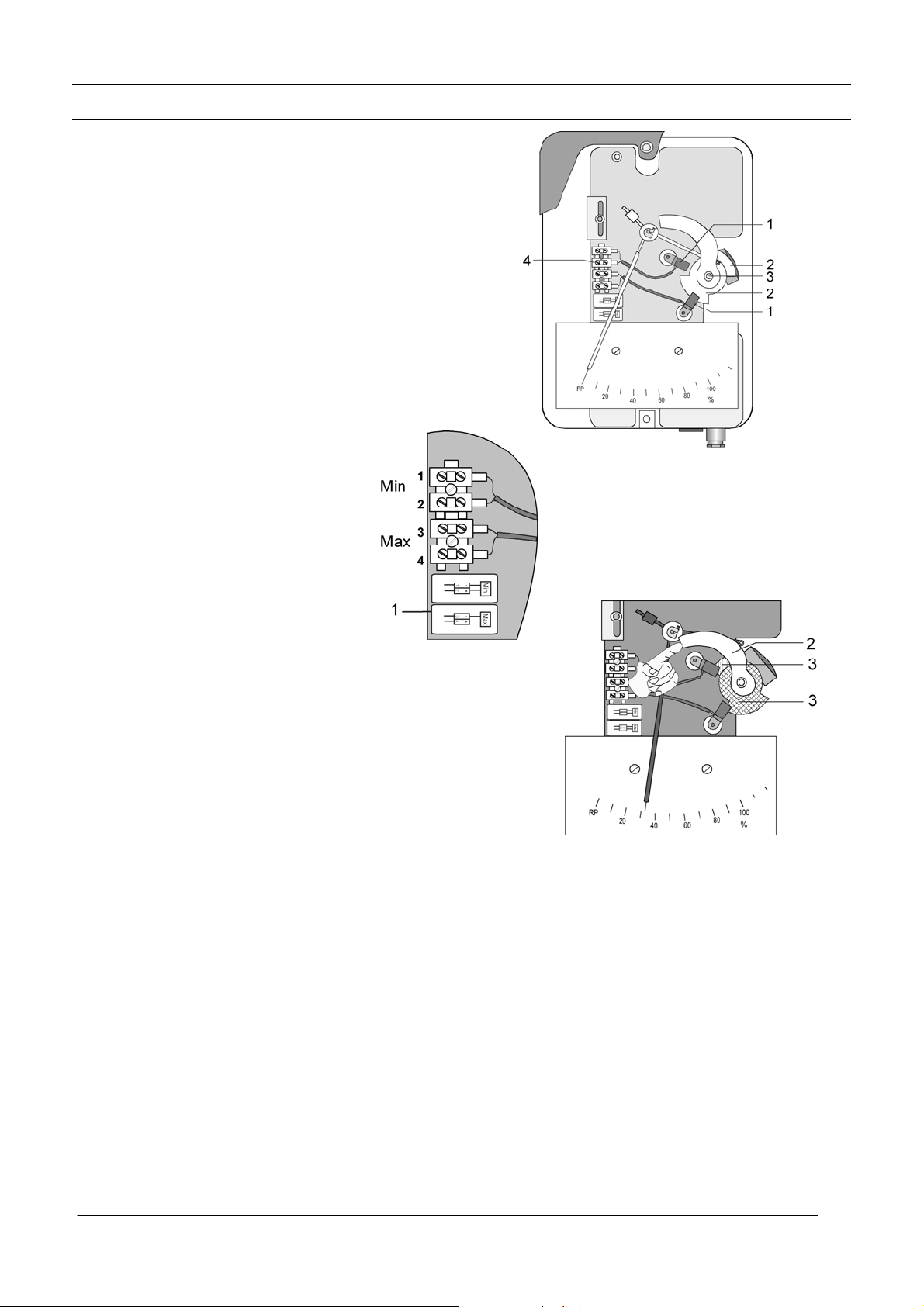

8 Limit switches

Description

The variable area flowmeter H54 can be equipped with

a maximum of two electronic limit switches.

The limit switch functions with a slot-type initiator (1) which is

operated inductively through a metal vane (2).

Contact types:

SC3,5-N0-Y 2-wire technology (NAMUR)

SJ3,5-SN 2-wire technology safety-oriented

SJ3,5-S1N 2-wire technology safety-oriented (inverted)

8.1 Electrical connection

SC3,5-N0-Y, SJ3,5-SN, SJ3,5-S1N:

Limit switch Min Terminal 1 Limit switch Min Terminal 2 +

Limit switch Max Terminal 3 Limit switch Max Terminal 4 +

The label (1) shows the type of contact (1).

8.2 Setting

The limit switches K1 and K2 are set individually from each other

as normally open or normally close!

Lift the cam disk (2) and set the pointer at the switch point.

The metal vanes (3) are set via slipping clutch.

8.3 Technical data of limit switches

Technical data 2-wire 2-wire 2-wire

SC3,5-N0-Y SJ3,5-SN SJ3,5-S1N

NAMUR NAMUR NAMUR

Switching element function NC contact NC contact NO contact

Nominal voltage U0 8 V 8V 8V

Power consumption:

Pointer vane not detected ≥ 3 mA ≥ 3 mA ≤ 1 mA

Pointer vane detected ≤ 1 mA ≤ 1 mA ≥ 3 mA

An isolating switching amplifier, e.g. Pepperl + Fuchs Series KF .. -SR2 ..., is required in order to operate the

SC3,5-N0-Y limit switch (refer to the chapter on the spare part list).

SJ3,5-SN and SJ3,5-S1N limit switches in 2-wire technology safety-oriented are connected to a safety-oriented

isolating switching amplifier, e.g. Pepperl & Fuchs K… –SH- ... (large S on the front)

12 H54 Installation and operating instructions

Page 13

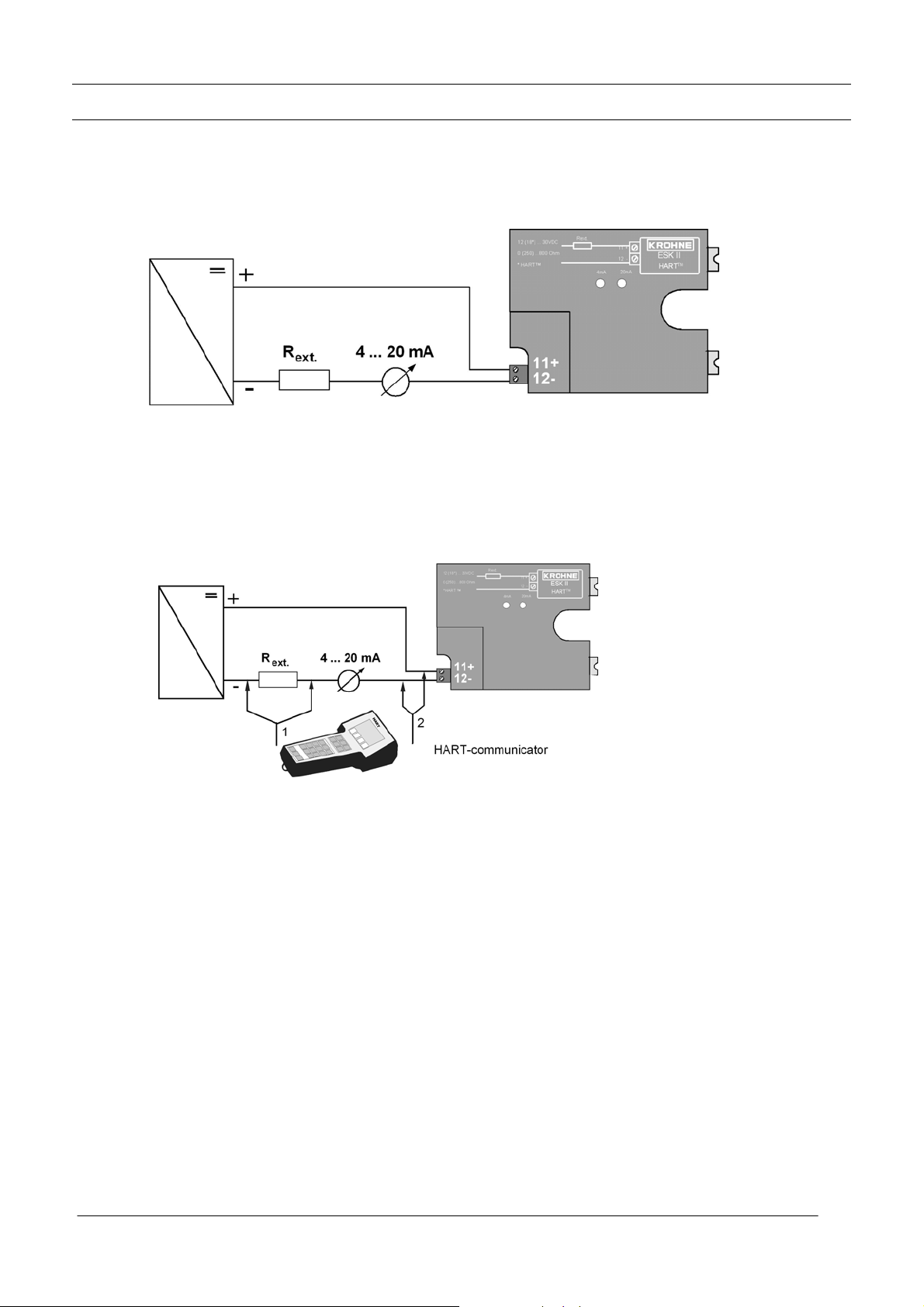

9 Electrical signal output ESK II

9.1 Electrical connection

The connecting terminals of the M9 display have a pluggable design and can be removed in order to

connect the lines.

9.2 HART

HART

When HART

measured value transfer (4...20mA).

Exception at Multidrop operation. In Multidrop operation a maximum of 15 instruments with HART

function can be operated in parallel, whereby their current outputs are switched inactive (approx. 4 mA).

If a HART

used, the resistor which is connected in series (R

In this type of operation the auxiliary power must amount to at least 18 V. The communicator or the PC

is connected as shown in the drawing above.

It can be operated optionally via the connecting terminals of the ESK II (2) or via an external resistance

(1) connected in series. The counter cannot be read out or operated by means of HART

communication!

TM

communication with the ESK II

TM

communication is not compellingly required in order to operate the ESK II.

TM

communication is carried out with the ESK II, this does not by any means impair analog

TM

communicator (type Fisher Rosemount, Model 275) or a PC with HART

) has to exceed 250 Ohms.

ext.

TM

modem is

TM

TM

9.3 Technical data of ESK II

Auxiliary power 12 (18 * ) to 30 V DC

Measurement signal 4.00 to 20.00 mA for 0 to 100 % flow value

> 20.8 mA for alarm status

Auxiliary power influence < 0.1%

Dependency on external resistance < 0.1%

Temperature influence < 5 µA / K

Max. external resistance / load 0 (250 * ) to 800 Ohms

* These values are to be observed as minimum values during HART

TM

communication.

13 H54 Installation and operating instructions

Page 14

10 Electrical signal output ESK3-PA

10.1 Bus cable

The statements of the FISCO model only apply if the bus cable used fullfills the following specifications:

R´ = 15...150 Ohm/km

L´ = 0.4...1 mH/km

C´ = 80...200 nF/km.

10.2 Shielding and grounding

In order to ensure optimum electromagnetic compatibility of systems it is very important that the system

components, and in particular the bus cables which connect the components, are shielded and that

these shields form an electrically unbroken envelope as far as possible.

10.3 PROFIBUS-PA connection

For the connection of the bus cable refer to the adjacent figure.

Connect the cable conductors to D and D- (polarity reversal

does not have any influence). The cable shield should be connected

with minimum length to the functional grounding FE.

10.4 Technical data of the ESK3-PA

Hardware to IEC 1158-2 and the FISCO model

Supply voltage via 2-wire bus connection: .........9 to 32 V DC

Basic current .......................................................12 mA

Starting current ...................................................< Basic current

FDE (fault drop electronics) ................................< 18 mA

Accuracy to VDI/ VDE 3513................................1.6

Measured value resolution..................................< 0.1% of upper range value

Temperature influence........................................< 0.05% / K of upper range value

Software

GSD ..................................(device master file) is supplied on a diskette

or via Internet www.krohne.com

Device profile ....................Complete implementation of Profile B, V3.0

Function blocks

Flow rate (AI0) ..................Optionally for volume or mass rate of flow

Default units: Qv [m3/h]; Qm [kg/h]

D

D

FE

Counter (TOT0).................Volume counter Default unit: [m3]

Counter (TOT1).................Mass counter Default unit: [kg]

Address range...................0-126, default 126 ("Set slave address" is supported)

SAPs .................................Service_Access_Points 1

DD ..................................... Device Description DD for PDM

Operation ..........................Via PROFIBUS PA (no local operation at the instrument)

14 H54 Installation and operating instructions

Page 15

11 Maintenance

The flowmeter is also to be inspected for soiling, corrosive erosion and mechanical wear or damage to the

measuring tube and the display in the context of the routine operational maintenance of the installation and the

pipelines. We recommend at least annual inspections. In order to clean the instrument remove it from the

pipeline.

Note

Pressurized lines have to be relieved before the measuring unit is removed.

Corresponding safety precautions with regard to residual liquids in the measuring unit in case of instruments

which are used to measure aggressive media.

New seals must always be used when remounting the measuring unit in the pipeline.

Electrostatic charges are to be avoided when the surfaces (e.g. viewing window) are cleaned!

Information on returning instruments

Your instrument has been manufactured carefully

and tested several times. If installed and operated in

accordance with these instructions your instrument

will rarely present any problems. Should you

nevertheless need to return an instrument for

checking or repair, please pay strict attention to the

following points:

Due to statutory regulations concerning protection

of the environment and safeguarding the health and

safety of our personnel, KROHNE may only handle,

test and repair returned instruments that have been

in contact with liquids if it is possible to do so

without risk to personnel and environment.

This means that KROHNE can only service your

device if it is accompanied by a certificate in line

with the following model confirming that the device

is safe to handle.

If the instrument has been operated with toxic,

caustic, flammable or water-endangering liquids,

you are kindly requested:

- To check and ensure, if necessary by rinsing

or neutralizing, that all the cavities in

the instrument are free from such dangerous

substances. (Directions on how you can find out

whether the primary head has to

be opened and flushed out and neutralized

are obtainable from KROHNE on request.)

- To enclose a certificate with the device confirming

that the device is safe to handle and

stating the liquid used.

KROHNE regret that we cannot service your device

unless it is accompanied by such a certificate and

thank you for your understanding.

15 H54 Installation and operating instructions

Page 16

Form for returning the instrument

Company: ...................................................... Address: .......................................................................

Department: .................................................. Name: ..........................................................................

Tel. No.: ........................................................ Fax. No.: ......................................................................

The enclosed instrument

Type: ...............................................................................................................................................................

KROHNE Order No. or Series No.:.................................................................................................................

has been operated with the following process liquid: .....................................................................................

Because this process liquid is water-endangering * / toxic * / caustic * / flammable *

we have

- Checked that all cavities in the instrument are free from such substances *

- Flushed out and neutralized all cavities in the instrument *

(* delete where not applicable)

We confirm that there is no risk to man or environment through any residual liquid contained in the instrument.

Date: ............................................................. Signature .......................................................................

Company stamp:

H54 Installation and Operating Instructions

16

Loading...

Loading...