Page 1

Handbook

Handbook

H250 M40

H250 M40

H250 M40H250 M40

Variable area flowmeter

HandbookHandbook

© KROHNE 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 2

:

IMPRINT

:::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2018 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 3

H250 M40

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Certifications .................................................................................................................... 6

1.3 Pressure equipment directive.......................................................................................... 6

1.4 Safety instructions from the manufacturer ..................................................................... 8

1.4.1 Copyright and data protection ................................................................................................ 8

1.4.2 Disclaimer ............................................................................................................................... 8

1.4.3 Product liability and warranty ................................................................................................ 9

1.4.4 Information concerning the documentation........................................................................... 9

1.4.5 Warnings and symbols used................................................................................................. 10

1.5 Safety instructions for the operator............................................................................... 10

2 Device description 11

2.1 Scope of delivery............................................................................................................. 11

2.2 Device version................................................................................................................. 12

2.2.1 Indicator versions ................................................................................................................. 13

2.2.2 Float damping ....................................................................................................................... 15

2.2.3 Pointer damping.................................................................................................................... 15

2.3 Nameplate ...................................................................................................................... 16

2.4 Description code............................................................................................................. 17

2.5 Electronic revision.......................................................................................................... 18

3 Installation 19

3.1 General installation notes .............................................................................................. 19

3.2 Storage ........................................................................................................................... 19

3.3 Installation conditions ....................................................................................................20

3.3.1 Tightening torques................................................................................................................ 22

3.3.2 Magnetic filters ..................................................................................................................... 22

3.3.3 Heat insulation ...................................................................................................................... 23

4 Electrical connections 24

4.1 Safety instructions.......................................................................................................... 24

4.2 Electrical connection for indicator M40 ......................................................................... 25

4.2.1 Connection of the limit switches K1/K2................................................................................ 25

4.2.2 Current output ESK4 / ESK4A............................................................................................... 28

4.2.3 ESK4-T limit outputs............................................................................................................. 31

4.2.4 ESK4-T pulse output ............................................................................................................. 33

4.2.5 ESK4-T binary input .............................................................................................................. 34

4.2.6 ESK4-FF / ESK4-PA fieldbus communication...................................................................... 35

4.2.7 Harting HAN 7D connection.................................................................................................. 36

4.3 Grounding connections................................................................................................... 37

4.4 Ingress protection .......................................................................................................... 37

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

3

Page 4

CONTENTS

H250 M40

5 Start-up 38

5.1 Standard device .............................................................................................................. 38

5.2 Indicator ESK4-T ............................................................................................................ 38

6 Operation 39

6.1 ESK4 / ESK4A - Loop Check Mode................................................................................. 39

6.2 Operating elements ESK4-T........................................................................................... 40

6.3 Basic principles of operation ESK4-T ............................................................................ 41

6.3.1 Description of the operating keys......................................................................................... 41

6.3.2 Navigation within the menu structure.................................................................................. 41

6.3.3 Change the settings in the menu..........................................................................................42

6.4 Overview of the units ESK4-T......................................................................................... 43

6.5 Error messages ESK4-T................................................................................................. 44

6.6 ESK4-T menu.................................................................................................................. 46

6.6.1 Factory settings .................................................................................................................... 46

6.6.2 Menu structure ..................................................................................................................... 47

6.6.3 Menu description .................................................................................................................. 49

7 Service 56

7.1 Maintenance ................................................................................................................... 56

7.2 Replacement and retrofitting......................................................................................... 56

7.2.1 Replacing floats .................................................................................................................... 56

7.2.2 Retrofitting of the float damping .......................................................................................... 57

7.2.3 Retrofitting of the limit switch .............................................................................................. 58

7.2.4 Replacement - Retrofitting ESK4 / ESK4A ........................................................................... 59

7.2.5 Replacement - Retrofitting add-on module ESK4-T / PA / FF............................................. 60

7.3 Spare parts availability...................................................................................................60

7.3.1 List of spare parts................................................................................................................. 60

7.4 Availability of services .................................................................................................... 64

7.5 Returning the device to the manufacturer..................................................................... 64

7.5.1 General information.............................................................................................................. 64

7.5.2 Form (for copying) to accompany a returned device............................................................ 65

7.6 Disposal .......................................................................................................................... 65

7.7 Disassembly and recycling............................................................................................. 66

7.7.1 Description of the device components ................................................................................. 66

7.7.2 Indicator versions ................................................................................................................. 67

8 Technical data 70

8.1 Functional principle........................................................................................................ 70

8.2 Technical data................................................................................................................. 71

8.3 Dimensions and weight .................................................................................................. 79

8.4 Measuring ranges...........................................................................................................82

9 Notes 90

4

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 5

H250 M40

1.1 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in

industrial environment. There may be potential difficulties in ensuring electromagnetic

compatibility in other environments, due to conducted as well as radiated disturbances.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

The variable area flowmeters are suitable for measuring clean gases, vapours and liquids.

Intended use:

• The product may not contain any ferromagnetic particles or solids. It may be necessary to

install magnetic filters or mechanical filters.

• The product must be sufficiently liquid and free of deposits.

• Avoid pressure surges and pulsing flows.

• Open valves slowly. Do not use solenoid valves.

SAFETY INSTRUCTIONS

1

Use suitable measures to eliminate compression vibrations during gas

measurements:

• Short pipeline lengths to next restriction

• Nominal pipe size not greater than nominal device size

• Use of floats with damping

• Increase in operating pressure (while taking into account the resulting change in density and

thus change in scale)

Observe installation conditions according to VDI/VDE 3513-3.

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

CAUTION!

Do not use any abrasive media containing solid particles or highly viscous media.

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

5

Page 6

1

SAFETY INSTRUCTIONS

1.2 Certifications

CE marking

The device fulfils all applicable statutory requirements of the EU directives:

• Pressure equipment directive

• For devices with electrical installations: EMC directive

• Devices for use in hazardous areas: ATEX directive

as well as

• NAMUR recommendations NE 21, NE 43 and NE 107

The manufacturer certifies successful testing of the product by applying the CE marking.

An EU declaration of conformity regarding the directives in question and the associated

harmonised standards can be downloaded from our internet site.

H250 M40

1.3 Pressure equipment directive

A conformity assessment in accordance with pressure equipment directive has been carried out

for the devices described. Conformity is certified by applying the CE mark. The number of the

notified body is also stated.

The PED key describes the rating of the devices:

Example: PED/G1/III/H

G Gases and vapours

1Fluid group 1

III Category III

H Conformity assessment method according to Module H

The PED key identification can be found on the nameplate of the device (for details refer to

Nameplate

INFORMATION!

The stated pressures (PS) and temperatures (TS) only apply as refers to the pressure resistance

of the sensor body. As regards the functionality of the entire device, further restrictions of the

maximum temperature may need to be observed (e.g. ATEX approval). Devices rated below

category I due to their size, do not receive the CE mark in the scope of the PED. These devices

are subject to applicable sound engineering practice (SEP).

on page 16).

6

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 7

H250 M40

SAFETY INSTRUCTIONS

1

Residual risk

A risk analysis in accordance with the pressure equipment directive has been carried out for the

devices . The residual risk is described as follows:

• The devices are designed according to the valid and applicable rules and standards for static

operation and their pressure resistance is calculated for the declared maximum pressure

and temperature (no calculation for cyclical change).

• Responsibility for the use of the measuring devices with regard to corrosion resistance of the

used materials against the measured fluid lies solely with the operator.

• Avoid abrasion.

• Avoid pulsation and cavitation.

• Protect devices from vibration and high-frequency oscillation.

• Draining (backflow) may be delayed due to the float in the measuring tube.

• Implement appropriate measures to counteract external fire hazards

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

7

Page 8

1

SAFETY INSTRUCTIONS

1.4 Safety instructions from the manufacturer

1.4.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

H250 M40

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.4.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

8

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 9

H250 M40

1.4.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.4.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

SAFETY INSTRUCTIONS

1

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

9

Page 10

1

SAFETY INSTRUCTIONS

1.4.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

H250 M40

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.5 Safety instructions for the operator

10

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 11

H250 M40

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION

2

Figure 2-1: Scope of delivery

1 Measuring device in ordered version

2 For the ESK4-T version - bar magnet

3 Documentation

4 Certificates, calibration report (supplied to order only)

5 Wrench

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

11

Page 12

2

DEVICE DESCRIPTION

2.2 Device version

• H250 with indicator M40

• H250 with M40 indicator with display cut-out for ESK4-T

Figure 2-2: Device version - H250 with M40 indicator

Description of the device version

1. H250/RR/M40

• Local indicator without auxiliary power

• Max. 2 limit switches, type NAMUR, NAMUR safety-oriented or transistor (3-wire)

• Electrical signal output 4...20 mA, HART

• Intrinsically safe (Ex i) or in explosion-proof enclosure (Ex d)

®

or Fieldbus communication

H250 M40

2. H250/RR/M40

• Additional LCD, measured value and/or flow counter

• 2 configurable binary outputs, limit value or pulse output

• 1 binary input, Start / Stop / Reset flow counter

®

• 2-wire current output 4…20 mA, HART

communication

• Intrinsically safe (Ex i) or in explosion-proof enclosure (Ex d)

Optional versions:

•

H250 with indicator M40 as high temperature version HT

•

H250 with indicator M40 with increased corrosion protection (special paint finish)

•

H250H for use in horizontal pipelines

•

H250U for use in vertical fall pipes

•

H250F with hygienic measuring tube design for Food & Pharma

•

H250C with PTFE / TFM liner for aggressive media

Indicator options

• M40 - Aluminium, two-layer powder coating (epoxy / polyester)

• M40R - Stainless steel without coating

12

Offshore wet coating for aluminium or stainless steel on request

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 13

H250 M40

2.2.1 Indicator versions

The M40 indicator can be fitted with various modules.

DEVICE DESCRIPTION

2

Figure 2-3: Basic version

1 Pointer module

2 Bolts for ESK4 / ESK4A attachment

3 Base plate

4 Module profile

5 Pressure piece for ESK4 / ESK4A attachment

6 Housing cover locking device

7 Ground terminal external

Figure 2-4: Versions K1 / K2 and ESK4 / ESK4A

1 Indicator with K2 contact module

2 Indicator with ESK4 / ESK4A current output 4...20 mA

Both versions can be combined with one another.

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

13

Page 14

2

DEVICE DESCRIPTION

Figure 2-5: Version ESK4-T

1 ESK4 / ESK4A connection

2 Module cover

3 Display

4 Display module ESK4-IO

5 Operating keys ^ ↑

6 Connection binary outputs and reset input

7 Module connection cable

H250 M40

14

Figure 2-6: Version Fieldbus ESK4-FF / ESK4-PA

1 Basic module with electronic magnet sensors ESK4 / ESK4A

2 Connection bus module

3 DIP switch for bus settings

For more details refer to the supplementary instructions "H250 M40 Foundation Fieldbus" or

"H250 M40 Profibus PA".

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 15

H250 M40

2.2.2 Float damping

Float damping is characterised by high standstill times and self-centering. The damping sleeve

is made of high performance ceramic or PEEK, depending on the medium and the application.

Float damping can also be retrofitted for the user (refer to "Service").

Use of damping

• Generally when CIV and DIV floats are used for gas measurement.

• For TIV floats (H250/RR and H250/HC only) with an operating primary pressure:

EN 1092-1 ASME B16.5 [bar] [psig]

DN50 1/2" ≤0.3 ≤4.4

DN25 1" ≤0.3 ≤4.4

DN50 2" ≤0.2 ≤2.9

DN80 3" ≤0.2 ≤2.9

DN100 4" ≤0.2 ≤2.9

DEVICE DESCRIPTION

Nominal size according to Operating primary pressure

2

2.2.3 Pointer damping

In principle, the indicating element with its magnetic system contains indicator damping. An

additional eddy current brake is advantageous in the event of fluctuating or pulsing flows. The

magnets on the eddy current brake surround the pointer vane without touching it, damping its

movement. The result is a much steadier pointer position, without distorting the measured

value. The eddy current brake can be retrofitted during operation without recalibration. Note the

maximum tightening torque (0.12 Nm) for the turnbuckle!

Figure 2-7: Pointer damping

1 Eddy current brake

2 Pointer vane

3 Support

4 Pointer cylinder

5 Turnbuckle, max. tightening torque is 0.12 Nm

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

15

Page 16

2

DEVICE DESCRIPTION

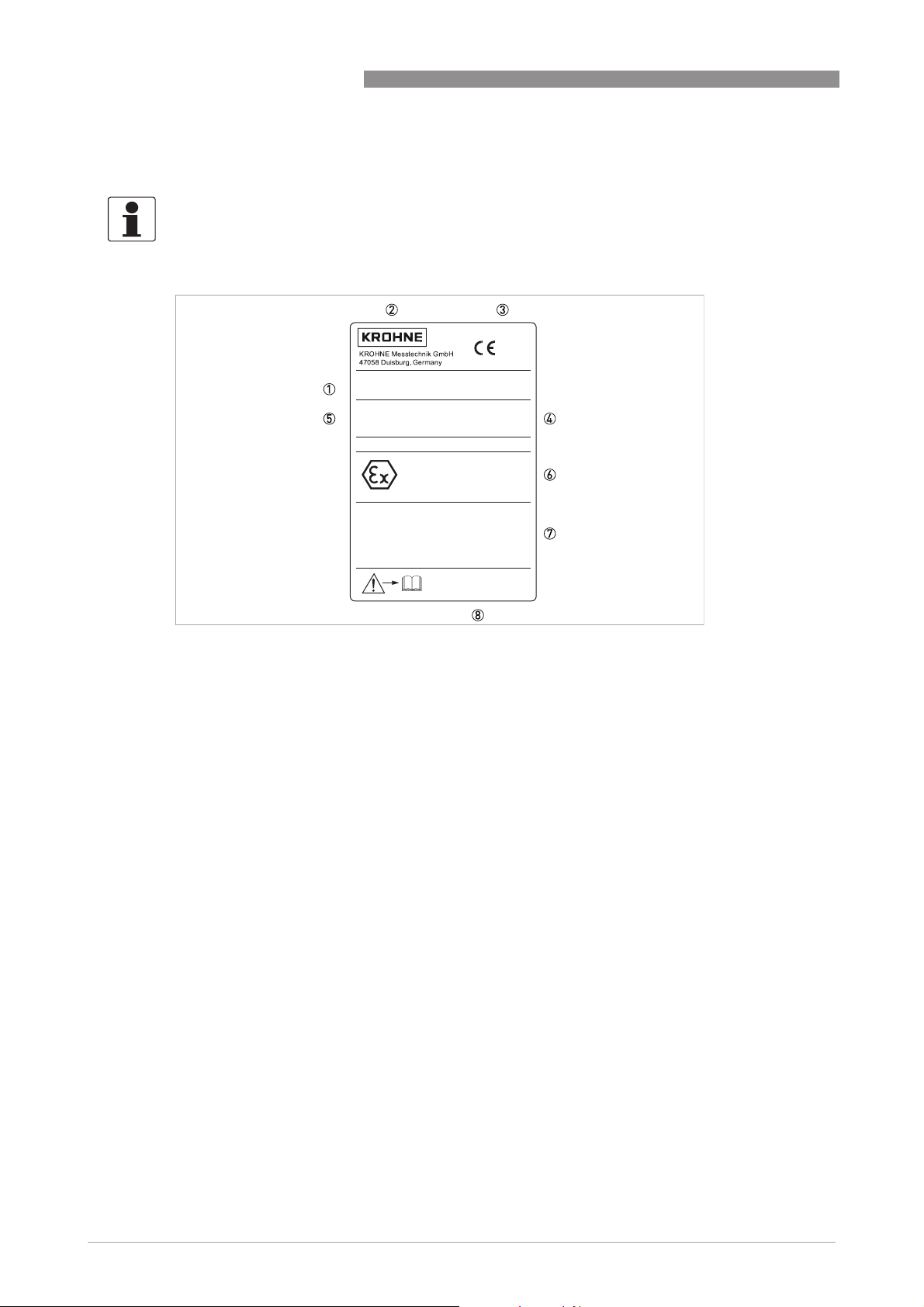

2.3 Nameplate

INFORMATION!

Check on the device nameplates, that the device is supplied according to your order.

H250/.././M40/..-Ex

P/A: 011123456.001

PED/G1/II/H

PTmax: xxx bar

Tag-No.:

PTB 11 ATEX 2012 X

II2G Ex ia IIC T6

IECEx PTB 11.0069 X

amb

: -20°C... +60°C (T6: +40°C)

T

Ui = xxV Ii = xxmA Pi = xW

ESK...

Ci = xxnF Li = xuH

Ui = xxV Ii = xxmA Pi = xW

Kmin1

Ci = xxnF Li = xuH

Ui = xxV Ii = xxmA Pi = xW

Kmin2

Ci = xxnF Li = xuH

MD:201x

PS: xxx bar

TS: xx °C

0035

0102

H250 M40

www.krohne.com

Figure 2-8: Example of a nameplate

1 Device type

2 Manufacturer

3 Notified body

4 Rating data: temperature & pressure rating

5 PED data

6 Ex data

7 Electrical connection data

8 Internet site

Additional markings on the indicator

• SN - serial number

• SO - sales order / item

• PA - production order

• Vx - product configurator code

• AC - article code

16

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 17

H250 M40

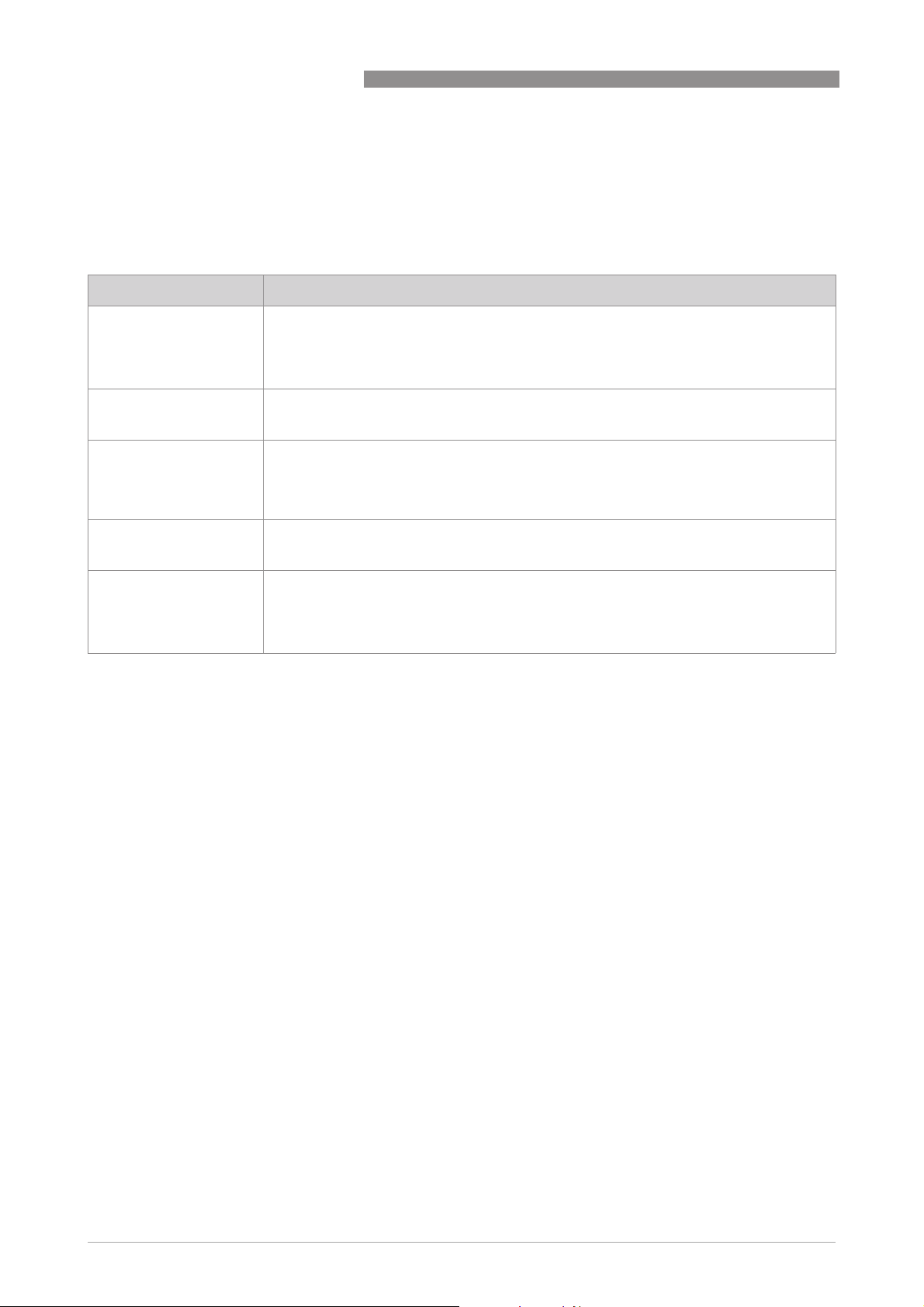

2.4 Description code

The description code consists of the following elements *:

Figure 2-9: Description code

1 Device type

Device type

Device typeDevice type

H250 - standard version

H250H - horizontal flow direction

H250U - flow direction from top to bottom

2 Materials / versions

Materials / versions

Materials / versionsMaterials / versions

RR - stainless steel

C - PTFE or PTFE/ceramics

HC - Hastelloy

Ti - Titanium

Mo - Monel

In - Inconel

F - aseptic version (food)

3 Heating jacket version

Heating jacket version

Heating jacket versionHeating jacket version

B - with heating jacket

4 Type series of indicators

Type series of indicators

Type series of indicatorsType series of indicators

M40 - Indicator M40

M40R - indicator in stainless steel housing

5 High-temperature version

High-temperature version

High-temperature versionHigh-temperature version

HT - version with HT extension

6 Electrical signal output

Electrical signal output

Electrical signal outputElectrical signal output

ESK - electrical signal output 4...20 mA (ESK4 / ESK4A)

- optionally available with counter, I/O module and display (ESK4-T)

- Foundation Fieldbus (ESK4-FF)

- Profibus PA (ESK4-PA)

7 Limit switches

Limit switches

Limit switchesLimit switches

K1 - one limit switch

K2 - two limit switches

8 Explosion protection

Explosion protection

Explosion protectionExplosion protection

Ex - Explosion-protected equipment

9 SIL version

SIL version

SIL versionSIL version

SE - SIL compliant electronic signal output

SK - SIL compliant limit switch

®

DEVICE DESCRIPTION

2

* positions which are not needed are omitted (no blank positions)

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

17

Page 18

2

DEVICE DESCRIPTION

2.5 Electronic revision

The electronic revision (sticker on the base module ESK4 / ESK4A) indicates the respective

hardware/software status of the electronics. All add-on modules (ESK4-T, ESK4-FF and ESK4PA) have an additional sticker indicating their respective firmware version.

Electronic revision Explanations

H250 M40

ER 1.1.x Basic version (cannot be combined with other indicator versions):

ESK4 / current output 4…20 mA with HART

(ESK4 HART DD 01.01. AMS10x AMS11x

ESK4 HART DD 01.01. PDM6.0

ESK4 HART DTM 1.0.3 FDT1.2)

ER 2.0.x Functional add-on to ER 1.1.x:

ER 2.1.x Functional add-on to ER 2.0.x:

ER 2.2.x Functional add-on to ER 2.1.x:

ER 3.0.x Functional add-on:

Table 2-1: Electronic revision

can be combined with indicator version ESK4 FF / Foundation Fieldbus;

(Firmware version FF module from 1.0.2)

can be combined with indicator version ESK4-PA / Profibus PA

(Firmware version PA module from 1.0.0)

can be combined with indicator version ESK4-T / LCD, binary inputs/outputs

(Firmware version T module from 1.1.0)

Support of failure signal (low) according to NE 43

for the ESK4 current output module

®

Update for HART

can be combined with ESK4-FF (Firmware version FF module from 1.0.2)

Firmware Version ESK4-PA (... PA module from 1.0.0)

Firmware Version ESK4-T (... T module from 1.2.0)

communication from 5.9 to 7.4 including new DD/DTM

®

communication

18

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 19

H250 M40

3.1 General installation notes

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry, dust-free location.

• Avoid direct exposure to the sun.

• Store the measuring device in the original packaging.

• The permissible storage temperatures for standard devices are: -40...+80°C / -40...+176°F

INSTALLATION

3

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

19

Page 20

3

INSTALLATION

3.3 Installation conditions

CAUTION!

When installing the device in the piping, the following points must be observed:

•

The variable area flowmeter must be installed vertically (measuring principle). Flow direction

from bottom to top. For installation recommendations please refer also to directive

VDI/VDE 3513, sheet 3.

H250Hs are installed horizontally and H250U devices are installed vertically with the flow

direction from top to bottom.

•

A straight unimpeded inlet run of ≥ 5 DN upstream of the device and a straight outlet run of

≥ 3 DN downstream of the device are recommended.

•

Screws, bolts and gaskets are to be provided by the customer and must be selected in

accordance with the pressure rating of the connection or the operating pressure.

•

The inner diameter of the flange deviates from the standard dimensions. Flange seal

standard DIN 2690 or ASME B16.21 can be applied.

•

Align the gaskets. Tighten the nuts with the tightening torques of the appropriate pressure

rating.

For devices with PTFE liner or ceramic liner and PTFE raised faces, refer to chapter

"Tightening torques".

•

Control devices are to be positioned downstream of the measuring device.

•

Shutoff devices are preferably to be positioned upstream of the measuring device.

•

Before connecting, blow or flush out the pipes leading to the device.

•

Piping for gas flow need to be dried before the device is installed.

•

Use connectors suitable for the particular device version.

•

Align the piping centrically with the connection bores on the measuring device so they are

free of stresses.

•

If necessary, the piping has to be supported to reduce the vibrations transmitted to the

measuring device.

•

Do not lay signal cables directly next to cables for the power supply.

H250 M40

20

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 21

H250 M40

INSTALLATION

3

Minimum distance between devices

When several devices are installed next to each other, a minimum distance of > 300 mm / 11.8"

between the devices is necessary.

Figure 3-1: Minimum distance between devices

Take special note of the installation position for the H250H with horizontal flow

direction:

Figure 3-2: Installation position for H250H

In order to comply with thermal parameters and measuring accuracy, H250H flowmeters for

horizontal installation are to be installed in the pipeline so that the display is located on the side

of the measuring tube. The maximum product and ambient temperatures indicated as well as

the measuring accuracy are based on lateral installation of the indicator.

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

21

Page 22

3

INSTALLATION

3.3.1 Tightening torques

For devices with PTFE liner or ceramic liner and PTFE raised face, tighten the flange threads

with the following torques:

Nominal size according to Stud bolts Max. torque

EN 1092-1 ASME B16.5 EN ASME EN 1092-1 ASME 150 lb

DN PN Inch lb 150 lb 300 lb Nm ft*lbf Nm ft*lbf

15 40 1/2" 150/300 4x M12 4x 1/2" 4x 1/2" 9.8 7.1 5.2 3.8

25 40 1" 150/300 4x M12 4x 1/2" 4x 5/8" 21 15 10 7.2

50 40 2" 150/300 4x M16 4x 5/8" 8x 5/8" 57 41 41 30

80 16 3" 150/300 8x M16 4x 5/8" 8x 3/4" 47 34 70 51

100 16 4" 150/300 8x M16 8x 5/8" 8x 3/4" 67 48 50 36

Table 3-1: Tightening torques

3.3.2 Magnetic filters

H250 M40

The use of magnetic filters is recommended when the medium contains particles which can be

influenced magnetically. The magnetic filter is to be installed in the flow direction upstream of

the flowmeter. Bar magnets are positioned helically in the filter to provide optimal efficiency at

low pressure loss. All of the magnets are coated individually with PTFE to protect against

corrosion. Material: 1.4404 / 316L

Figure 3-3: Types of magnetic filters

1 Type F - fitting part with flange - overall length 100 mm / 4"

2 Type FS - fitting part without flange - overall length 50 mm / 2"

22

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 23

H250 M40

3.3.3 Heat insulation

CAUTION!

The indicator housing may not be heat-insulated.

The heat insulation 3 may only reach as far as the housing fastening 4.

Figure 3-4: Heat insulation

1 Standard indicator M40

2 Indicator with HT extension

INSTALLATION

3

CAUTION!

The heat insulation 1 may only reach to the rear of the housing 2. The area around the cable

entries 3 must be freely accessible.

Figure 3-5: Heat insulation - cross-section

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

23

Page 24

4

ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

H250 M40

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

24

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 25

H250 M40

ELECTRICAL CONNECTIONS

4.2 Electrical connection for indicator M40

4.2.1 Connection of the limit switches K1/K2

The M40 indicator can be fitted with a maximum of two limit switches.

The limit switch operates as a proximity switch which is activated inductively by the semicircular

metal vane of the pointer. The switching points are set using the contact pointers.

The position of the contact pointers is indicated on the scale.

4

Figure 4-1: Design of limit switch module

1 MIN contact

2 MAX contact

3 Locking screw

4 Peak value

5 Connection terminal

The connection terminals have a pluggable design and can be removed to connect the cables.

The built-in limit switch types are shown on the nameplate of the indicator.

Contact MIN MAX

Terminal number 1 2 3 4 5 6

Connection 2-wire NAMUR - + - +

Connection 3-wire + - + -

Connection Reed SPST + - + -

Table 4-1: Electrical connection of the limit switches

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

25

Page 26

4

ELECTRICAL CONNECTIONS

Connection diagram for the limit switches

Figure 4-2: Connection terminals for limit switches

1 Limit switch 2-wire NAMUR

2 Limit switch 3-wire

3 Limit switch Reed SPST

4 Terminal connection of Min. contact

5 Terminal connection of Max. contact

6 3-wire load

7 NAMUR isolated switching amplifier

8 3-wire power supply

H250 M40

Limit setting

Figure 4-3: Limit setting

1 Contact pointer MAX

2 Contact pointer MIN

3 Locking screw (max. tightening torque is 0.2 Nm)

4 Scale support

Setting is carried out directly via contact pointers 1 and 2:

• Pull the upper scale support 2 mm / 0.08" flexibly upwards and pull out the scale from its

locking point to the side.

• Loosen the locking screw 3 slightly.

• Slide in the scale up to the locking point.

• Set contact pointers 1 and 2 to the desired switching point.

26

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 27

H250 M40

ELECTRICAL CONNECTIONS

4

After the setting:

• Pull the upper scale support 2 mm / 0.08" flexibly upwards and pull out the scale again from

its locking point to the side.

• Tighten the locking screw 3 with max. 0.2 Nm.

• Slide in the scale up to the locking point.

CAUTION!

If the maximum torque (0.2 Nm) is exceeded, the locking screw can be torn off during tightening!

Definition of switch contact

Figure 4-4: Definition of switch contact

1 MIN contact

2 MAX contact

3 Pointer vane with switching vane

If the pointer vane goes into the slot, an alarm is triggered.

If the pointer vane is outside of the proximity switch, a wire break in a NAMUR contact also

triggers the alarm.

The 3-wire limit switch does not have any wire break detection.

Figure 4-5: Definition MIN-MIN - MAX-MAX

1 MIN 2 contact or MAX 1 contact

2 MIN 1 contact or MAX 2 contact

Contact Type Current consumption

MIN 1 NAMUR ≤ 1mA

MIN 2 NAMUR ≤ 1mA

MAX 1 NAMUR ≥ 3mA

MAX 2 NAMUR ≥ 3mA

Table 4-2: Current consumption in the position shown:

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

27

Page 28

4

ELECTRICAL CONNECTIONS

4.2.2 Current output ESK4 / ESK4A

The connecting terminals of the ESK4 / ESK4A have a pluggable design and can be removed in

order to connect the cables.

Figure 4-6: ESK4 / ESK4A connection

1 Current output of ESK4 / ESK4A

2 Power supply 14...30 VDC

3 Measuring signal 4...20 mA

4 External load, HART

®

communication

H250 M40

Power supply M40 with galvanic isolation

Wiring must be planned with great care when it comes to connecting other devices such as

evaluation units or process control. Internal connections in these devices (e.g. GND with PE,

mass loops) may lead to non-permitted voltage potentials which could negatively affect the

function of the converter itself or that of a device connected to it. In such cases a protected extralow voltage (PELV) is recommended.

Figure 4-7: Power supply M40 with galvanic isolation

1 Terminal connection

2 Converter supply isolator with galvanic isolation

3 Power supply (refer to isolator information)

4 Measuring signal 4...20 mA

5 External load, HART

®

communication

28

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 29

H250 M40

ELECTRICAL CONNECTIONS

4

Power supply

INFORMATION!

The supply voltage has to be between 14 VDC and 30 VDC. This is based on the total resistance of

the measuring loop. To calculate this, the resistance of each component in the measuring loop

(not including the device) must be added up.

The required supply voltage can be calculated using the following formula:

= RL * 24 mA + 14 V

U

ext.

with

U

= minimum supply voltage

ext.

R

= total measuring loop resistance

L

INFORMATION!

The power supply has to be able to supply a minimum of 30 mA.

HART

HART® communication

HARTHART

When HART® communication is carried out with the ESK4, the analogue measured data

transmission (4...20 mA) is not impaired in any way.

Exception for multidrop operation. In multidrop operation a maximum of 15 devices with HART

function can be operated in parallel, whereby their current outputs are switched to inactive (I

approx. 4 mA per device).

®

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

29

Page 30

4

ELECTRICAL CONNECTIONS

Load for HART® communication

INFORMATION!

®

For HART

The maximum load resistance is calculated as follows:

communication a load of at least 230 Ω is required.

DANGER!

Use a twisted two-core cable to prevent electrical interference from impeding the DC output

signal.

In some cases a shielded cable may be necessary, e.g if noise levels higher than the NE 21

specification are anticipated.

H250 M40

Configuration

The ESK can be configured via HART® communication. DD (Device Description) for AMS and PDM

TM

as well as a DTM (Device Type Manager) for PACTware

They can be downloaded free of charge from the website of the manufacturer.

The current flow rate can be transmitted using the integrated HART

counter can be configured. Two limit values can be monitored. The limit values are assigned

either to flow values or to the counter overflow.

are available for the configuration.

®

communication. A flow

Self monitoring - Diagnostics

During both start-up and operation, a wide variety of diagnostic functions are performed

cyclically in the ESK4 / ESK4A in order to guarantee function reliability. When an error is

detected, a failure signal (high) is activated (current > 21 mA, typically 22 mA) via the analogue

®

output. In addition more detailed information can be requested via HART

signal is not activated for information and warnings.

(CMD#48). The failure

Diagnostic functions (Monitoring):

• Plausibility of FRAM data

• Plausibility of ROM data

• Working range of internal reference voltages

• Signal detection of the measuring range of the internal sensors

• Temperature compensation of the internal sensors

• Calibration based on the application

• Plausibility of counting value

• Plausibility of physical unit, system and selected unit

30

For ESK4A (HART

®

7) the diagnosis is reported in compliance with NE 107.

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 31

H250 M40

4.2.3 ESK4-T limit outputs

Once the housing cover has been unscrewed, the scale can be removed. The connection

terminals have a pluggable design and can be removed to connect the cables.

ELECTRICAL CONNECTIONS

4

Figure 4-8: Position of the connection terminals

1 Binary output 1

2 ESK4 / ESK4A power supply / current output

3 Binary output 2

4 Binary input

The binary inputs/outputs are electrically isolated from each other and from the ESK4 / ESK4A

current output.

INFORMATION!

The binary inputs/outputs can only be operated if the power supply is applied to ESK4 / ESK4A

terminal 11+ and 12-. The binary inputs/outputs are inactive by default and must thus be

activated prior to first use (for details refer to ESK4-T menu on page 46

Connection binary outputs

Connection binary outputs

Connection binary outputsConnection binary outputs

).

In accordance with the desired signal transmission, select one of the following connection types

for binary outputs B1 and B2:

• NAMUR (DC interface acc. to EN 60947-5-6)

• Transistor output (passive, Open Collector)

Binary output B1 B2

Terminal no. 1 2 3 4 5 6

Connection NAMUR + - + -

Connection transistor output + B

Table 4-3: Terminal assignment of the binary output

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

OC

+ B

OC

31

Page 32

4

ELECTRICAL CONNECTIONS

Figure 4-9: Connection switching output

1 NAMUR terminal connection

2 Isolated switching amplifier

3 OC switch output terminal connection

4 Power supply U

5 Load R

L

ext.

H250 M40

NC contact NO contact

Switching value reached < 1 mA > 3 mA

Switching value not reached > 3 mA < 1 mA

Table 4-4: Value range for NAMUR

Value range applies only when connected to a switching amplifier with the following

reference values:

• Open-circuit voltage U0 = 8.2 VDC

• Internal resistance R

Signal voltages UL [V] UH [V]

via load R

Table 4-5: Value range for transistor output

Signal currents IL [mA] IH [mA]

Category 2 0 2 20 110

Table 4-6: Value range for transistor output

L

= 1 kΩ

i

lower limit upper limit lower limit upper limit

0 2 16 30

lower limit upper limit lower limit upper limit

32

To ensure the value ranges, a load RL between 250 Ω and 1 kΩ is recommended for the passive transistor

output with a nominal voltage of 24 VDC.

If other loads are used, caution is advised as the range of values of the signal voltages then no longer

corresponds to the range of values for the inputs of process control systems and controls (DIN IEC 946).

CAUTION!

The upper limit of the signal current must not be exceeded as this may damage the transistor

output.

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 33

H250 M40

4.2.4 ESK4-T pulse output

INFORMATION!

The binary outputs can also be operated as pulse outputs. When using the binary outputs as a

pulse output, two separate signal circuits are required. Each signal circuit requires its own

power supply.

The total resistance 4 must be adapted so that the total current I

Figure 4-10: Electrical connection of pulse output

1 Terminal for power supply - current output

2 Terminal B2

3 Flow measurement 4...20 mA

4 Pulse output load e.g. counter

5 Power supply for ESK4

6 Power supply for pulse output

ELECTRICAL CONNECTIONS

does not exceed 100 mA.

tot

4

The pulse output B2 is a passive "open collector" output which is electrically isolated from the

current output and output B1. It can be operated as a low-resistance output or as a NAMUR

output.

Figure 4-11: Data for pulse output

= 10 Hz

1 f

max

2 t

on

3 t

off

The pulse width t

can be configured from 50...500 ms in the indicator menu.

on

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

33

Page 34

4

ELECTRICAL CONNECTIONS

4.2.5 ESK4-T binary input

The binary input can be used to control the internal flow counter (start/stop/reset).

Binary input B3

Terminal no. 7 8

Connection + -

Table 4-7: Value range for NAMUR

H250 M40

Figure 4-12: Binary input

1 Function active HI

2 Function active LO

This binary input can be activated in the menu of the indicator and can be configured to ACTIVE

HI or ACTIVE LO.

If the input is set as ACTIVE LO, an interruption causes the counter to be reset.

For further information on configuration of each function refer to

Input voltage UL [V] UH [V]

lower limit upper limit lower limit upper limit

Terminal (7) (8) 0 2 16 30

Table 4-8: Value range

The binary input has an internal resistance R

of 20 kΩ.

i

ESK4-T menu

on page 46.

34

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 35

H250 M40

ELECTRICAL CONNECTIONS

4.2.6 ESK4-FF / ESK4-PA fieldbus communication

4

Figure 4-13: ESK4-FF / ESK4-PA fieldbus communication

1 FF HSE Bus / Profibus DP

2 Linking device / bus coupler

3 FF H1 Bus / Profibus PA, 2-wire with shielding

4 H250/M40/ESK4-FF / H250/M40/ESK4-PA

ESK4-FF / ESK4-PA

• 2-wire, bus-supplied

• Polarity protected

• Bus voltage 9...32 VDC

• Nominal current 16 mA

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

35

Page 36

4

ELECTRICAL CONNECTIONS

4.2.7 Harting HAN 7D connection

Figure 4-14: Terminal assignment

1 Terminal assignment of HAN® 7D - View of plug connection

H250 M40

1 Pin number HAN® 7D

K1/K2 NAMUR

contacts

R1/R2 Reed

contacts

ESK4/ESK4A Terminal number

NAMUR Reed

1 2 NAMUR MIN (-) 2 Reed MIN - 1 1

2 2 NAMUR MIN (+) 2 Reed MIN - 2 3

3 3 NAMUR MAX (-) 3 Reed MAX - 4 4

4 3 NAMUR MAX (+) 3 Reed MAX - 5 6

5 - - 4 4...20mA (+) 11

6 - - 4 4...20mA (-) 12

7 - - -

8 - - -

Table 4-9: Terminal assignment - Harting plug to terminal number

Combinations of K1 / K2 and ESK4 / ESK4A are possible.

1 Pin number HAN® 7D

1 5 Binary output B1 open coll. (+) 1

2 5 Binary output B1 open coll. (-) 3

3 7 Binary output B2 open coll. (+) 4

4 7 Binary output B2 open coll. (-) 6

5 6 4...20mA (+) 11

6 6 4...20mA (-) 12

7 -

8 -

Table 4-10: Terminal assignment - Harting plug to terminal number for ESK4-T

ESK4-T Terminal number

36

INFORMATION!

No Harting connection for module ESK4-FF/PA is provided and is only available on request.

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 37

H250 M40

4.3 Grounding connections

Figure 4-15: Grounding connections

1 Grounding connection on the indicator

2 Outer grounding connection

DANGER!

The grounding wire may not transfer any interference voltage.

Do not use this grounding cable to ground any other electrical devices.

ELECTRICAL CONNECTIONS

4

4.4 Ingress protection

The measuring device meets all requirements of ingress protection IP66/68.

DANGER!

After all servicing and maintenance work on the measuring device, the specified protection class

must be ensured again.

Therefore it is essential to observe the following points.

• Use only original gaskets. They must be clean and free of any damage. Defective gaskets must

be replaced.

• The electrical cables must be undamaged and must comply with regulations.

• The cables must be laid with a loop 3 upstream of the measuring device to prevent water

from getting into the housing.

• The cable feedthroughs 2 must be tightened.

• Close the unused cable feedthroughs using blanking plugs 1.

Figure 4-16: Laying the cable

1 Use blanking plugs if no cable is routed through

2 Tighten cable feedthrough firmly

3 Lay the cable in a loop

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

37

Page 38

5

START-UP

5.1 Standard device

CAUTION!

When starting up the device, the following points must be observed:

•

Compare the actual operating pressure and the product temperature of the system with the

specifications on the nameplate (PS and TS). These specifications may not be exceeded.

•

Make sure materials are compatible.

•

Slowly open the shut-off valve.

•

When measuring liquids ensure that the pipelines are carefully evacuated.

•

When measuring gases, increase pressure slowly.

•

Avoid float impact (e.g. caused by solenoid valves), as this is likely to damage the measuring

unit or float.

A minimum operating pressure (primary pressure) is necessary to operate the device:

Medium Pressure loss : operating pressure

H250 M40

Liquids 1 : 2

Gases without float damping 1 : 5

Gases with float damping 1 : 2

5.2 Indicator ESK4-T

INFORMATION!

The device is always preset for the user and his application.

Start

After the device is switched on, the display shows

• "INITIALISING"

• Firmwareversion IO-Modul

The device first performs a self-test. Here, all of the parameters preset for the customer are

analysed and checked for plausibility. The device then switches to measuring mode and indicates

the current measured value.

Operation

INFORMATION!

The device is low-maintenance

Comply with the application limits with regard to temperature of the medium and ambient

temperature.

38

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 39

H250 M40

6.1 ESK4 / ESK4A - Loop Check Mode

The ESK4 / ESK4A is equipped with a loop check function, enabling a simple test of the entire

4…20 mA current loop.

It is activated and operated using a microswitch 1.

OPERATION

6

Figure 6-1: Position of the microswitch

CAUTION!

When activating the loop check mode, ensure that no alarms are unintentionally triggered in the

downstream system components.

Figure 6-2: Loop Check Mode

• Press and hold the microswitch 1 for more than 6 seconds to activate the loop check mode 3.

The current output jumps to constant 4 mA.

• Change the current output from constant 4 mA to constant 20 mA as often as you like by briefly

pressing it (less than 6 seconds) to check the function of the measuring circuit.

• Exit loop check mode by holding down the microswitch (longer than 6 seconds). The current

output jumps back to measuring mode 2.

INFORMATION!

If the microswitch has not been pressed for longer than 60 seconds, the ESK4 / ESK4A

automatically returns to measuring mode 2.

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

39

Page 40

6

OPERATION

6.2 Operating elements ESK4-T

H250 M40

The device is operated with the cover on the front open, using the mechanical keys

cover closed using a bar magnet

bar magnet.

bar magnetbar magnet

keys, or with the

keyskeys

CAUTION!

The switching point of the magnetic sensors is directly at the height of the corresponding circle

(see figure). Only touch the circle vertically and from the front using the bar magnet. Touching it

from the side may cause an error in the measurement as the float position is recorded by the

magnetic field sensors.

Figure 6-3: Display and operating elements

1 Enter button (circuit for bar magnet)

2 Up button (circuit for bar magnet)

3 Right button (circuit for bar magnet)

The mechanical keys and keys for the bar magnet have the same functionality. In this

documentation the keys are represented as symbols to describe the operating functions:

Key Symbol

1 Enter ^^^^

2 up ↑

3 right →

Table 6-1: ESK4-T operation keys

40

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 41

H250 M40

6.3 Basic principles of operation ESK4-T

6.3.1 Description of the operating keys

OPERATION

6

→

↑

^^^^

Table 6-2: Description of the operating keys

Switch from measuring mode to menu mode

Switch to one menu level lower

Open menu item and activate change mode

Confirm query whether data should be accepted

In change mode:

In change mode: Move the input cursor one position to the right. After the last digit the

In change mode:In change mode:

input cursor jumps back to the beginning.

Change between the menu items within a menu level

In measuring mode:

In measuring mode: Switch between measured values and error messages

In measuring mode:In measuring mode:

In change mode:

In change mode: Changing parameters or settings. Run through the available characters

In change mode:In change mode:

(including decimal point.

In measuring mode:

In measuring mode: Switch between measured value display and error messages /

In measuring mode:In measuring mode:

warnings

Switch to one menu level higher

Return to measuring mode with a query whether the data should be accepted

Cancel the query, whether data should be accepted

6.3.2 Navigation within the menu structure

Navigate through the menu using the →, ↑ and ^^^^ keys. Pressing the → key takes you one menu

lower. Using the ↑ key takes you one menu item higher (e.g. from 1 to 2). Pressing the ^^^^ key

takes you one menu higher.

If you are already at the lowest level (function level), the key takes you to the change mode,

where you can set data and values.

If you are at the first level (main menu), you can use the ^^^^ key to exit the menu mode and return

to the measuring mode.

If settings were changed, the query whether they should be saved will appear. Confirm this query

with the → key or cancel it with the ^^^^ key.

Measuring

mode

Table 6-3: Navigation within the menu structure

→ Main menu↑→ Submenu↑→ Function↑→ Edit

^^^^ ^^^^ ^^^^ ^^^^

→ ↑ ^^^^

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

41

Page 42

6

OPERATION

6.3.3 Change the settings in the menu

Starting operation

Operation is started using the → key.

If an operation lock is set, the code (→ → → ^ ^ ^ ↑ ↑ ↑) must be entered. The code can be set

in menu 3.13. The code shown here is set at the factory but not activated. If no key is activated

within 5 seconds or an incorrect code is entered, a warning message is displayed and the

indication returns to measuring mode.

Exit operation

Operation is exited by pressing the ^^^^ key several times.

If data have been changed:

H250 M40

Save Yes → Changes are accepted. An update is carried out and the display returns to

Save No ^^^^ Changes are discarded and the display returns to measuring mode.

measuring mode.

CAUTION!

Each time parameters or settings are changed, the measuring device carries out an internal

plausibility check.

If inplausible entries were made, a warning message is shown. If this warning is confirmed with

the ^^^^ key, the display returns to the respective menu item without saving the relevant change. A

new entry can now be made.

Example: Changing the flow unit from m3/h to l/h

Display Display

Example: 7.2

m

1x → Fct. 1111

OPERATION

2x ↑ Fct. 3333

INSTALLATION

1x → Fct 3.1111

LANGUAGE

10x ↑ Fct 3.11

F.S.& UNIT

3

/h

11

1111

1x → Fct. 3.11.1111

1x → 10.0000

4x ↑ 10000

3x ^^^^ 7200

MEAS’D VALUE

3

/h

m

l/h

Confirm with →

deny ^

l/h

42

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 43

H250 M40

6.4 Overview of the units ESK4-T

Volume units can either represent real operating volumes (no prefix before the unit) or standard

volumes virtually converted to reference statuses.

Prefix Volume definition

None

N

S

Measured variables Units

Operating volume flow e.g. m3/h or ft3/h

Volume flow at standard (norm.) conditions (0°C - 1.013 bara) acc. to DIN 1343 e.g. Nm

Volume flow at standard (std.) conditions (15°C - 1.013 bara) acc. to ISO 13443 e.g. Sft

OPERATION

3

/h

3

/h

6

Operating

volume flow

Standard (norm.)

volume flow

Standard (std.)

volume flow

Mass flow g/s g/min g/h -

Operating

volume totalizer

Standard (norm.)

volume totalizer

Standard (std.)

volume totalizer

Mass totalizer kg g t lb

Temperature °C °F K

Table 6-4: Overview of the units ESK4-T

m3/s m3/min m3/h m3/d

L/s L/min L/h -

ft3/s ft3/min ft3/h ft3/d

gal/s gal/min gal/h gal/d

bbl/s bbl/min bbl/h bbl/d

ImpGal/s ImpGal/min ImpGal/h ImpGal/d

Nm3/s Nm3/min Nm3/h Nm3/d

NL/s NL/min NL/h -

Sm3/s Sm3/min Sm3/h Sm3/d

SL/s SL/min SL/h -

Sft3/s Sft3/min Sft3/h Sft3/d

kg/s kg/min kg/h kg/d

- t/min t/h t/d

lb/s lb/min lb/h lb/d

- STon/min STon/h STon/d

- - LTon/h LTon/d

3

m

ImpGal gallon bbl bbl (liq)

3

Nm

3

Sft

STon LTon

l hl

NL

SL

Sm

3

3

ft

In addition to the predefined units shown here, a user-defined unit can be activated in Menu 3.12

by entering a conversion factor and a unit designation as free text.

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

43

Page 44

6

OPERATION

6.5 Error messages ESK4-T

Error messages and warnings are indicated by one of the following symbols in the bottom left

corner of the display. The ^^^^ key switches from the measured value display to the display of

current errors / warnings. The table below contains a description of possible error messages.

H250 M40

Symbol NE107

Description Consequence

Category

FFFF Failure No measured value available

S Out of specification Measurement available but increasing measurement

M Maintenance required Measurement still sufficiently accurate but

C Check request Device is in test or linearization mode. The output

I Information No influence on the measurement, information only.

Table 6-5: Description of the symbols

Output signal invalid.

Error current signal is output.

uncertainty. Device must be checked.

maintenance required.

signal temporarily does not correspond to the

measurement.

Error message Description Category Remedy

NOT LINEARIZED Linearization faulty or not

NEW LINEARI. TABLE

BAD

LINEARIZATIO UNDER

CONFIG

UNIT SYSTEM

CONFLICT

TOO FEW ENTRIES The linearization table has

NOT MONOTONOUS The sequence of the

FIRST NOT 0 % The first flow value if the

LAST NOT 100 % The last flow value if the

activated = measuring

error

Faulty or missing data in

the linearization table =

measuring error

The device is in

linearization mode =

measuring error

The unit for the

linearization flow is

incompatible with the

selected flow type

(mass/volume)

too few data points

linearization values is not

strictly monotonic

increasing

linearization table is not

0%

linearization table is not

100%

S

S 1

S

S Correct error, carry out linearization again if

S

S Check linearization and/or carry it out again

Activate linearization or carry it out again (HART®

communication and linearization software are

required; the original calibration values must be

known), or send the device back to the

manufacturer for linearization.

Complete the linearization and activate it (HART®

communication and linearization software are

required), or send the device back to the

manufacturer for linearization.

necessary (HART

linearization software are required), or send the

device back to the manufacturer for linearization.

Carry out linearization at at least 5 points (HART®

communication and linearization software are

required), or send the device back to the

manufacturer for linearization.

(HART

software are required), or send the device back to

the manufacturer for linearization.

®

communication and

®

communication and linearization

44

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 45

H250 M40

Error message Description Category Remedy

OPERATION

6

NO ZERO CAL

OF AO

NO F.SC. CAL

OF AO

NO TEMP.

COMPENSATION

WRONG ELEC.REV. The ER revision of the

OUTPUT NOT

LINEARIZED

COUNTER LOST Totalizer value was reset

FRAM WRITE FAULT Internal communication

ROM/FLASH ERROR Memory error detected

RESTART OF DEVICE A device restart has taken

MULTIDROP MODE

CRYSTAL OSC FAULT Internal error in device F The device must be sent back to the manufacturer

REF VOLTAGE FAULT Internal error in device

SENSOR A FAULT Internal error in device F 1

SENSOR B FAULT Internal error in device

MEMORY

CORRUPTION

AO FIXED The current output is set

AO SATURATED Current output saturated I The current output is saturated at >20.4 mA and is

The current output zero

point 4.00mA is not

calibrated. = possible

measuring error in

process control.

The current output 100% =

20.00mA is not calibrated.

= possible measuring

error in process control.

The sensor temperature

compensation of the

device is faulty or was not

carried out = possible

measuring error

ESK4 / ESK4A is not

compatible with the addon module, or the ribbon

cable connection is not

connected properly.

Linearization is not

activated = measuring

error

by error/overflow

error

during self-test.

place

The HART® multidrop

mode is activated. The

current output is set to a

fixed value of 4.5 mA.

Internal memory error,

caused by a hardware or

software problem

to a fixed value.

S Perform calibration using ammeter and menu

3.10 or using standard HART

control system and poss. external ammeter.

Caution: during calibration, switch the measuring

point to manual control.

S Perform calibration using ammeter and menu

item 3.11 or using standard HART

external ammeter if necessary. Caution: during

calibration, switch the measuring point to manual

control.

S The device, together with an indication of the

S Check that the ribbon cable fits properly. Check

S

S 1 Because the reset time is not known: Controlled

F Check whether the display is plugged in correctly

F Restart device. If the error occurs again: send the

I The device has been restarted using menu item

I

F Restart the device; if the error occurs again the

I The current output is fixed and does not reflect

error, must be sent back to the manufacturer for

checking.

module compatibility (for details refer to

Electronic revision

Activate linearization or carry it out again (HART®

communication and linearization software are

required; the original calibration values must be

known), or send the device back to the

manufacturer for linearization.

reset of the counter using menu item 1.6.1 or

using HART

and restart the device. If the error occurs again:

send the device back to the manufacturer with an

indication of the error.

device back to the manufacturer with an

indication of the error.

1.6.2 since the last time the error messages were

reset.

The HART® multidrop mode is activated with

selection of a polling address not equal to 0 using

menu item 3.7. Polling address 0 reactivates the

current output.

with an indication of the error.

device must be sent back to the manufacturer

with an indication of the error.

the measured value. This is the case in multidrop

mode, with current output test/calibration using

the menu or HART

no longer linked to the measurement.

on page 18).

®

tools/process control system.

®

.

®

tools/process

®

tools and

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

45

Page 46

6

OPERATION

Error message Description Category Remedy

H250 M40

ERROR TIMEOUT Data not transferred, or

WARNING TIMEOUT I

Table 6-6: Error messages ESK4-T

1 Category can be changed by user.

transferred incorrectly

from the ESK to the

counter module

6.6 ESK4-T menu

6.6.1 Factory settings

Function Setting

1.1.1 OUTPUT B1 INACTIVE

1.2.1 OUTPUT B2 INACTIVE

1.3.1 PULSE WIDTH 50ms

1.3.2 PULSE/UNIT 1 Pulse/Unit

1.4 DISPLAY MEAS’D VALUE

1.4.2 ROTATION 0°

1.5 TIME CONST 1.0s

1.6.1 COUNTER NO

1.6.2 ERROR NO

1.6.3 RE-INIT IO NO

3.1 LANGUAGE ENGLISH

3.2 FUNCTION B1 INACTIVE

3.3 CONTACT B1 NORM.OPEN

3.4 FUNCTION B2 INACTIVE

3.5 CONTACT B2 NORM.OPEN

3.6 FUNCTION B3 INACTIVE

3.7 MULTIDROP POLLING ADD: 00

3.8 4mA CALIBR. 4.000mA

3.9 20mA CALIBR. 20.000mA

3.10 ALARM CURR. ALARM HIGH

3.11 F.S.& UNIT Application specific

3.11.2 COUNTER Application specific

3.12 USER DEFINED User defined unit / factor

3.13 L.FL.CUTOFF 4% ON; 6% OFF

3.14 DESCRIPTOR Free text

3.15 ENTRY CODE OFF

3.16 DEFAULT VAL. NO

Table 6-7: Factory settings

F Confirm menu item "1.6.3 WRITE INFO I/O".

46

INFORMATION!

The measuring device has been preset at the factory in accordance with the customer order.

Therefore subsequent configuration via the menu is only necessary if the intended use of the

device is changed.

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 47

H250 M40

OPERATION

6.6.2 Menu structure

Main menu Submenu 1 Submenu 2

1 OPERATION 1.1 OUTPUT B1 1.1.1 INACTIVE, MEAS.VAL. B1, CNT. VAL. B1, PULSE WIDTH

1.1.2 HYST. B1, PULSE/UNIT

1.2 OUTPUT B2 1.2.1 INACTIVE, MEAS.VAL. B2, CNT. VAL. B2, PULSE WIDTH

1.2.2 HYST. B2, PULSE/UNIT

1.3 PULSE OUTP. 1.3.1 PULSE WIDTH

1.3.2 PULSE/UNIT

1.4 DISPLAY 1.4.1 MEAS'D VALUE, COUNTER, MV/COUNTER, MV&COUNTER,

1.5 TIME CONST -

1.6 RESET 1.6.1 COUNTER

2 TEST & INFO 2.1 4-20mA OUTP 2.1.1 NORMAL OP

2.2 ALARM CURR. ALARM HIGH, ALARM LOW

2.3 OUTPUT B1 2.3.1 NORMAL OP

2.4 OUTPUT B2 2.4.1 NORMAL OP

2.5 INPUT B3 ACTIVE HI, ACTIVE LO, ON, OFF

2.6 DEV. IDENT. 2.6.1 ELEC. REV.

PERCENT

1.4.2 ROTATION

1.6.2 ERROR

1.6.3 WRITE INFO IO

2.1.2 4.0mA

2.1.3 5.6mA

2.1.4 7.2mA

2.1.5 8.8mA

2.1.6 10.4mA

2.1.7 12.0mA

2.1.8 13.6mA

2.1.9 15.2mA

2.1.10 16.8mA

2.1.11 18.4mA

2.1.12 20.0mA

2.1.13 21.6mA

2.3.2 OPEN

2.3.3 CLOSED

2.4.2 OPEN

2.4.3 CLOSED

2.6.2 SN ESK4

2.6.3 PROD. ORDER

2.6.4 DEV. SN.

6

www.krohne.com10/2018 - 4000640705 - MA H250-M40 R05 en

47

Page 48

6

OPERATION

Main menu Submenu 1 Submenu 2

2 TEST & INFO 2.7 SOFT.VERSION 2.7.1 FW. ESK4

2.7.2 FW. ESK4 I/O

2.8 TAG NB. 8 characters

2.9 LONG TAG 32 characters

3 INSTALLATION 3.1 LANGUAGE 3.1.1 ENGLISH

3.1.2 DEUTSCH

3.1.3 FRANCAIS

3.1.4 ITALIANO

3.1.5 ESPANOL

3.1.6 CESKY

3.1.7 POLSKI

3.1.8 NEDERLANDS

3.1.9 DANSK

3.2 FUNCTION B1 INACTIVE, SWITCH POINT, COUNT. LIMIT, PULSE OUTP.

3.3 CONTACT B1 NORM.OPEN, NORM.CLOSED

3.4 FUNCTION B2 INACTIVE, SWITCH POINT, COUNT. LIMIT, PULSE OUTP.

3.5 CONTACT B2 NORM.OPEN, NORM.CLOSED

3.6 FUNCTION B3 INACTIVE, ACTIVE HI, ACTIVE LO, STARTH STOPL, STARTL STOPH

3.7 MULTIDROP POLLING ADD.

3.8 4mA CALIBR. 4.000mA

3.9 20mA CALIBR. 20.000mA

3.10 ALARM CURR. OFF, ALARM HIGH, ALARM LOW

3.11 F.S.& UNIT 3.11.1 MEAS'D VALUE

3.11.2 COUNTER

3.12 USER DEFINED 3.12.1 MEAS'D VALUE

3.12.2 COUNTER

3.13 L.FL.CUTOFF 3.13.1 CONTROL ON, CONTROL OFF

3.13.2 ON VALUE

3.13.3 OFF VALUE

3.14 DESCRIPTOR Free text

3.15 ENTRY CODE OFF, ON

3.16 DEFAULT VAL. SET ALL

Table 6-8: Menu structure

H250 M40

48

www.krohne.com 10/2018 - 4000640705 - MA H250-M40 R05 en

Page 49

H250 M40

OPERATION

6.6.3 Menu description

1 OPERATION

Selection / Input Explanation

1.1 OUTPUT B1

1.1 OUTPUT B1 Output B1 is a binary switching output. In Fct. 3.2, one of the following functions can be

1.1 OUTPUT B11.1 OUTPUT B1

1.1.1

INACTIVE -

MEAS.VAL. B1 Switching point of flow value

selected for this output:

INACTIVE, SWITCH POINT, COUNT. LIMIT, PULSE OUTP.

One of the following functions can be selected as contact type in Fct. 3.3:

NORM.OPEN 1 / NORM.CLOSED 2

Value range: 0.0…full scale range

The switching point is entered in flow units.

If the current flow value exceeds this pre-determined switching point, output B1 changes

its binary state 3.

6

In Fct. 1.1.2 a hysteresis can be specified additionally.

CNT. VAL. B1 Switching point of totaliser value

PULSE WIDTH Pulse weight (pulse/unit)

1.1.2 HYST. B1 Hysteresis for the switching point of the flow value

Value range: 0.0…counter limit

The switching point is entered in volume or mass units.

If the the current counter value exceeds this pre-determined switching point, output B1

changes its binary state 3.

There is no hysteresis setting for the switching point of the counter value.

The weight is only displayed here.

A configuration takes place in Fct. 1.3.1 PULSE WIDTH, 1.3.2 PULSE/UNIT and 3.11.2

COUNTER.

Value range: 0.0…switching point

If the current flow value exceeds the pre-determined switching point from Fct. 1.1.1,