Page 1

Supplementary instructions

Supplementary instructions

GFC 300

GFC 300

GFC 300GFC 300

Supplementary instructions Supplementary instructions

Signal converter for gas ultrasonic flowmeters

Description of Foundation Fieldbus interface

Description of Foundation Fieldbus interface

Description of Foundation Fieldbus interfaceDescription of Foundation Fieldbus interface

Electronic Revision: ER 1.1.xx

The documentation is only complete when used in combination with the relevant

documentation for the measuring sensor.

© KROHNE 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 2

CONTENTS

GFC 300

1 Safety instructions 3

1.1 Scope of the document..................................................................................................... 3

1.2 Device description ............................................................................................................ 3

2 Technical data 4

2.1 Foundation Fieldbus data................................................................................................. 4

3 Electrical connections 5

3.1 Cable types ....................................................................................................................... 5

3.2 Shielding and grounding .................................................................................................. 5

3.3 Electrical connection of FOUNDATION Fieldbus ............................................................. 6

3.4 Topology of FF networks .................................................................................................. 7

4 Operation 8

4.1 Settable functions............................................................................................................. 8

4.2 Description of the FF block system.................................................................................. 9

4.3 Used abbreviations ........................................................................................................... 9

4.4 Resource Block (RB) ...................................................................................................... 10

4.4.1 Foundation Fieldbus parameters for Resource Block......................................................... 10

4.4.2 Manufacturer specific parameters of the signal converter for Resource Block................. 16

4.5 Analog Input Block (AI 1...6) ........................................................................................... 21

4.6 Transducer Block (TB).................................................................................................... 29

4.6.1 Transducer Main Block......................................................................................................... 29

4.6.2 Transducer Auxiliary Block................................................................................................... 39

4.6.3 Transducer Specification Block............................................................................................ 46

4.7 Arithmetic Block (AR) ..................................................................................................... 55

4.8 Integrator Block (IT) ....................................................................................................... 61

4.9 Proportional Integral Derivative Block (PID) ................................................................. 68

5 Notes 82

2

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 3

GFC 300

1.1 Scope of the document

These instructions are supplementary to the standard product documentation of the signal

converter. The details depicted therein, in particular the safety information are valid and should

be adhered to. The present supplementary instructions provide additional information for the

devices when being operated and connected to a Foundation Fieldbus.

INFORMATION!

The present supplementary instruction for the signal converter with Foundation Fieldbus

interface, plus the software with the DD and CCF files are included in our scope of supply, in

addition to those items delivered for the standard device.

1.2 Device description

The ultrasonic flowmeters are designed exclusively for the continuous measurement of actual

volume flow, mass flow, molar mass, flow speed, velocity of sound, gain, SNR and diagnosis

value.

Your measuring device is supplied ready for operation. The factory settings for the operating

data have been made in accordance with your order specifications.

SAFETY INSTRUCTIONS 1

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

3

Page 4

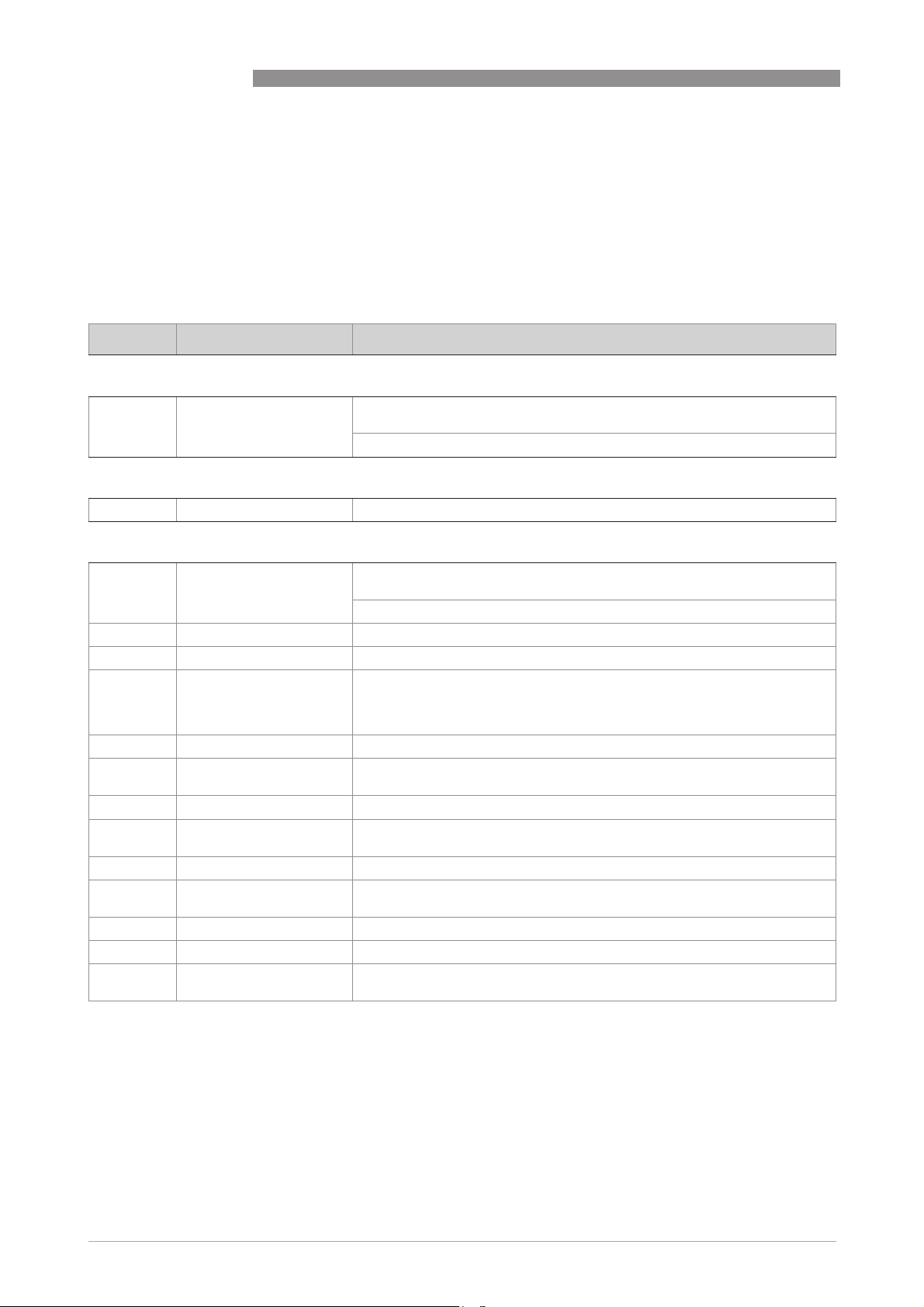

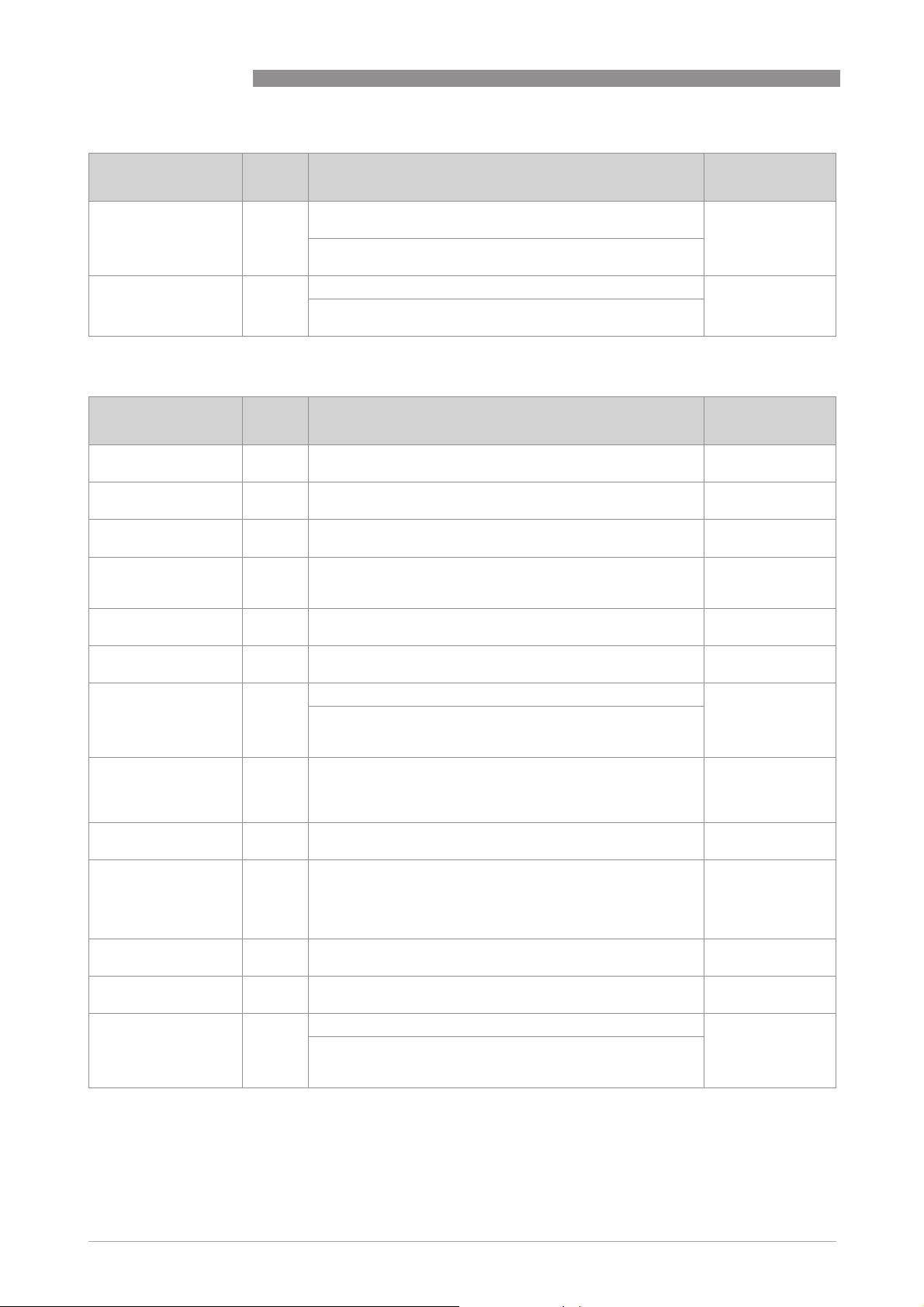

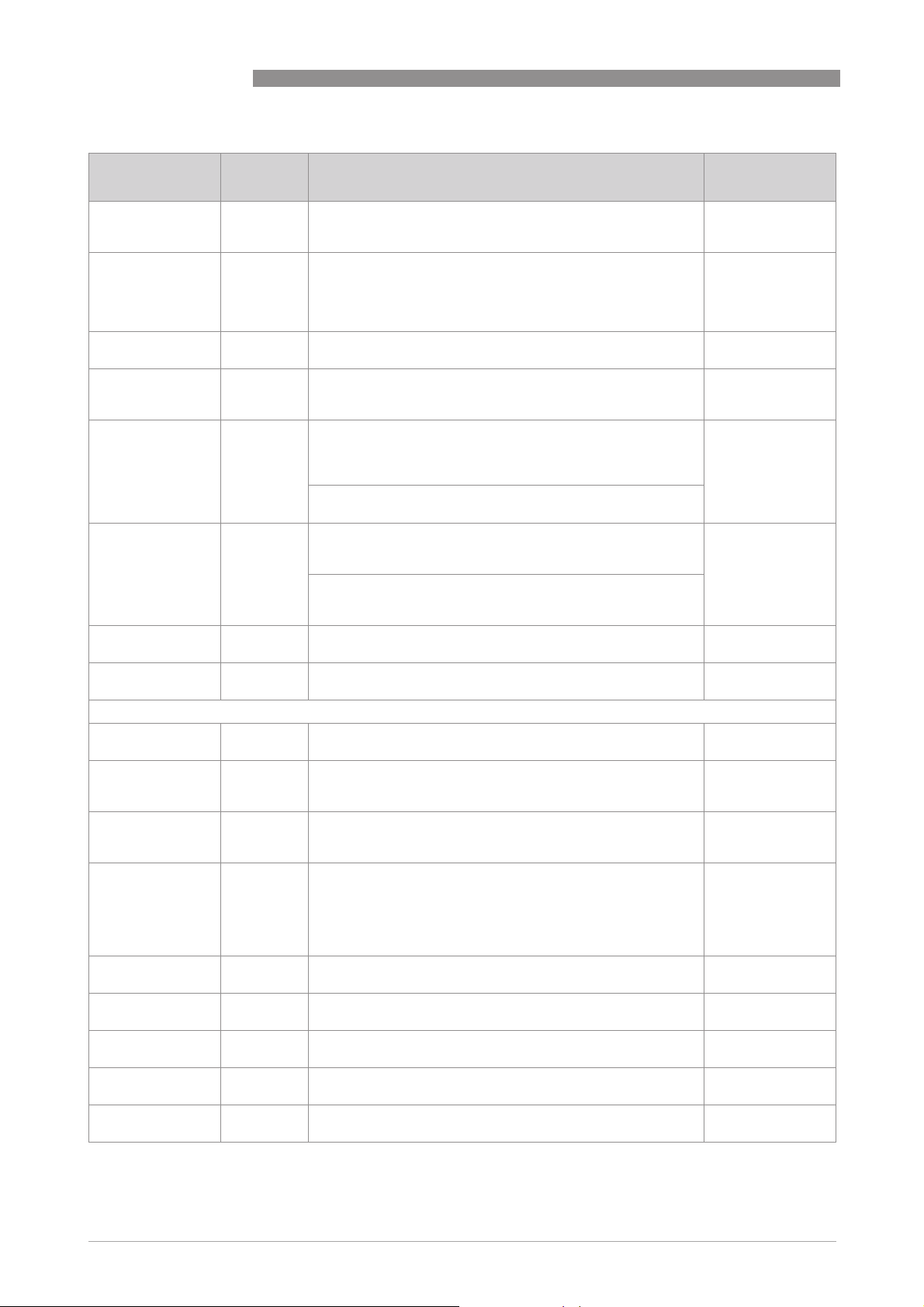

2 TECHNICAL DATA

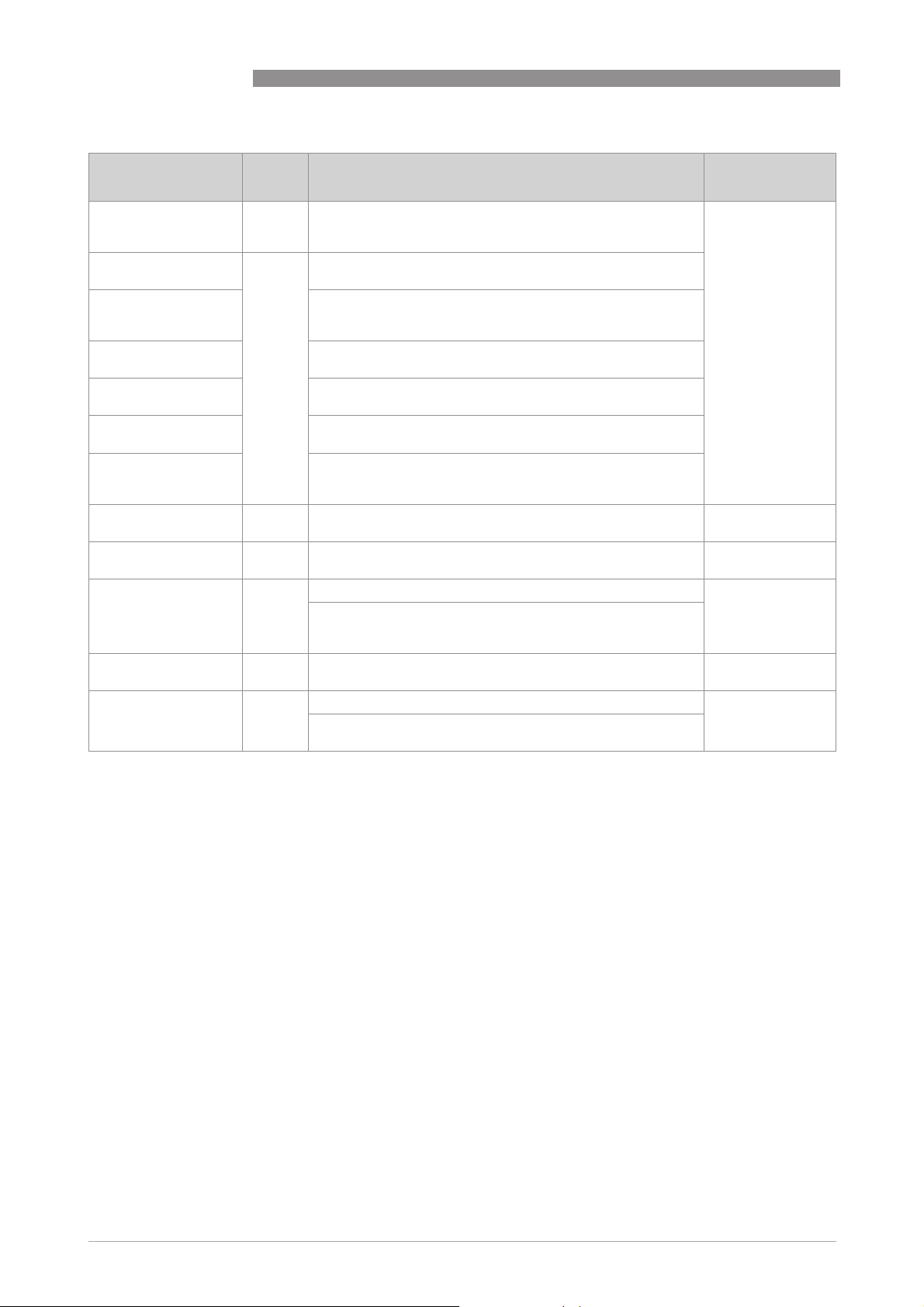

2.1 Foundation Fieldbus data

Description

Type Ultrasonic flowmeter

Physical layer Foundation Fieldbus protocol that agrees with IEC 61158-2 and FISCO model;

galvanically isolated

Communication standard H1

ITK version 5.2

Data blocks

Function blocks 1 x Enhanced Resource Block (RB)

1 x Customer Transducer Block Main (TB)

1 x Customer Transducer Block Auxiliary (TB)

1 x Customer Transducer Block Special (TB)

6 x Analog Input Block (AI)

2 x Integrator Block (IT)

1 x Proportional Integral Derivate Block (PID)

1x Arithmetic Block (AR)

Execution time Analog Input Block: 10 ms

Integrator Block: 15 ms

Proportional Integral Derivate Block: 25 ms

Arithmetic Block: 20 ms

GFC 300

Electrical connections

Device power supply Not intrinsically safe: 9...32 VDC

Intrinsically safe: 9...24 VDC

Basic current 10.5 mA

Maximum error current 16.5 mA (= basic current + error current = 10.5 mA + 6 mA)

Start current after 10 ms 14 mA

Polarity sensitivity No

Minimum cycle time 250 ms

4

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 5

GFC 300

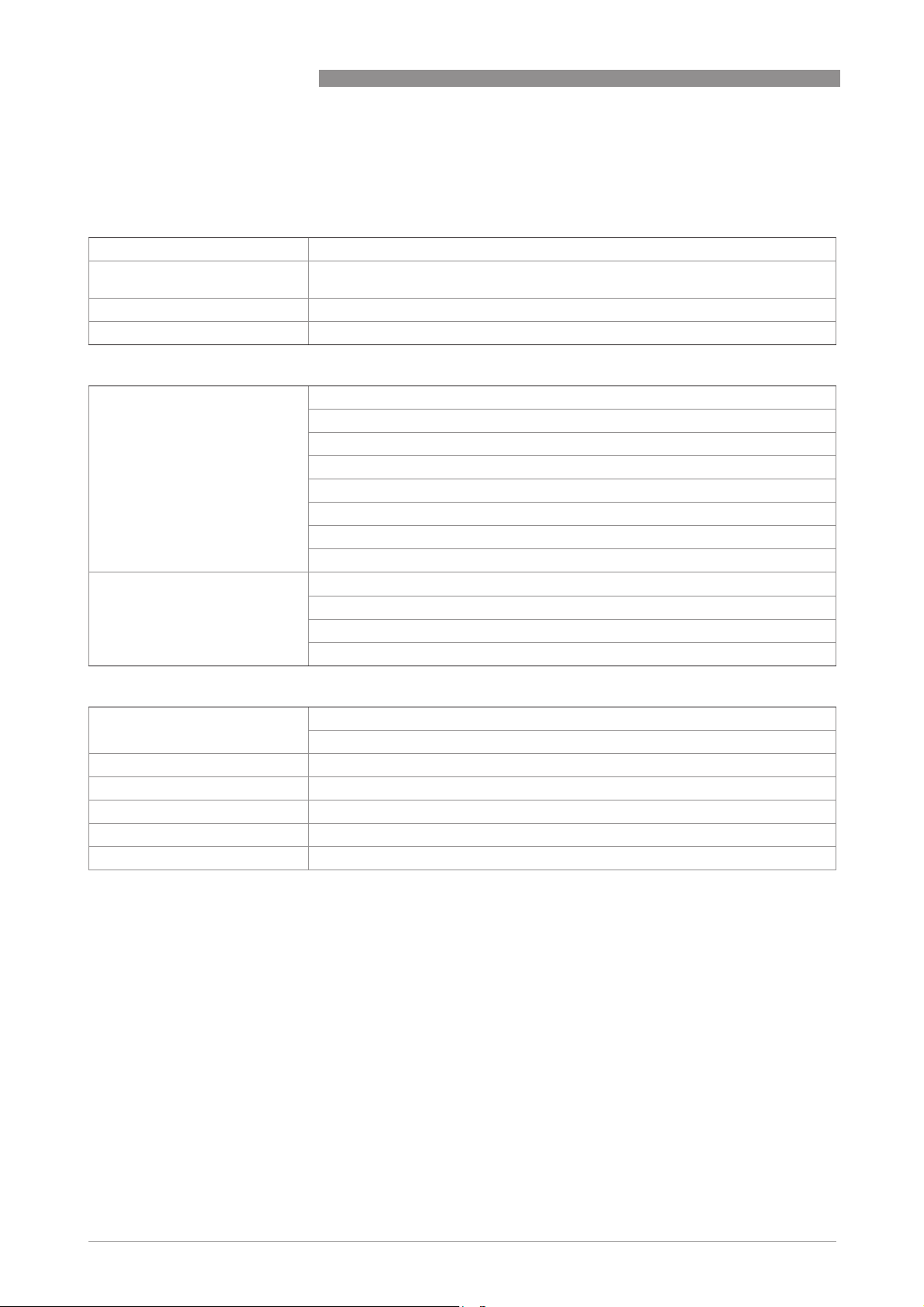

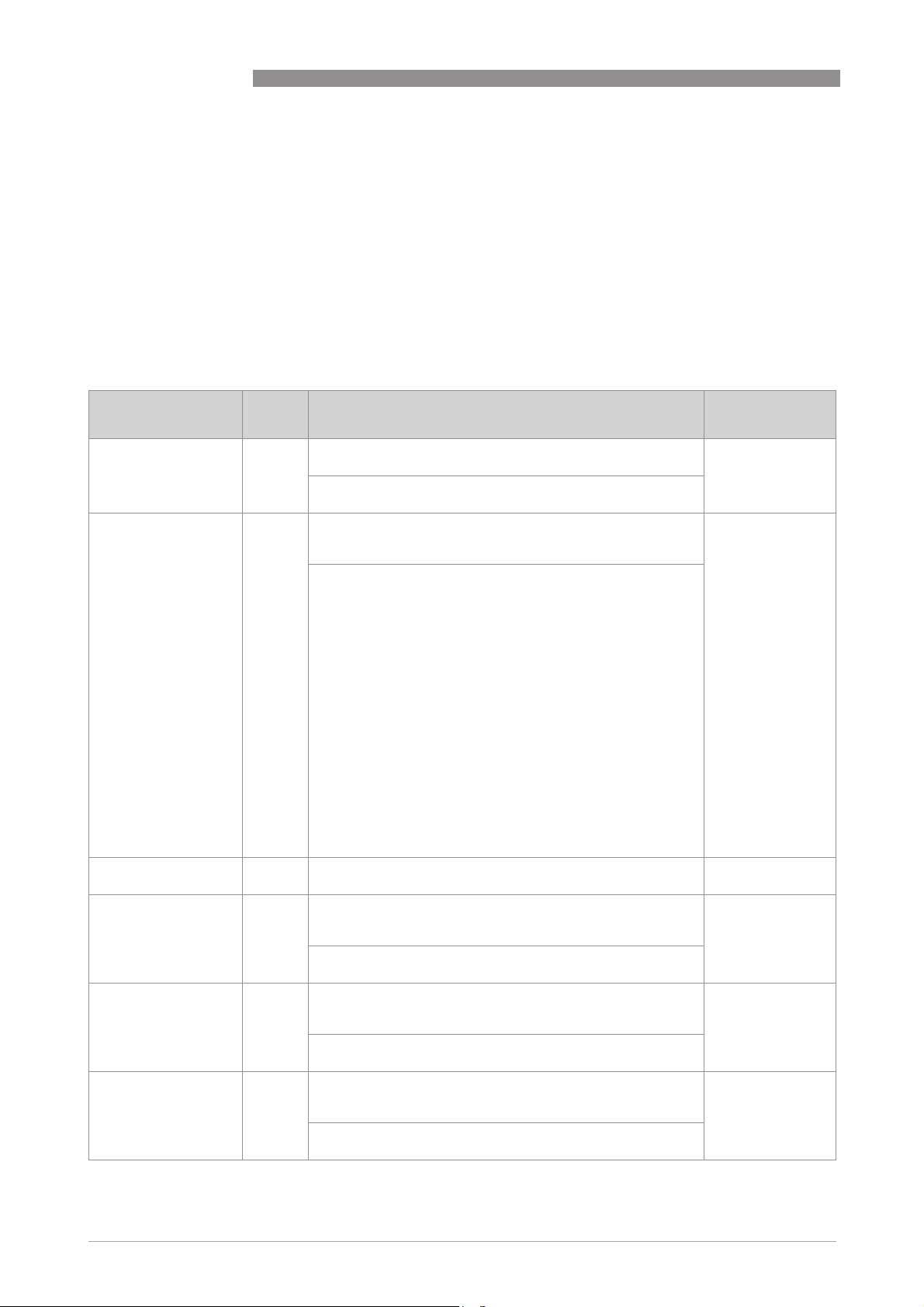

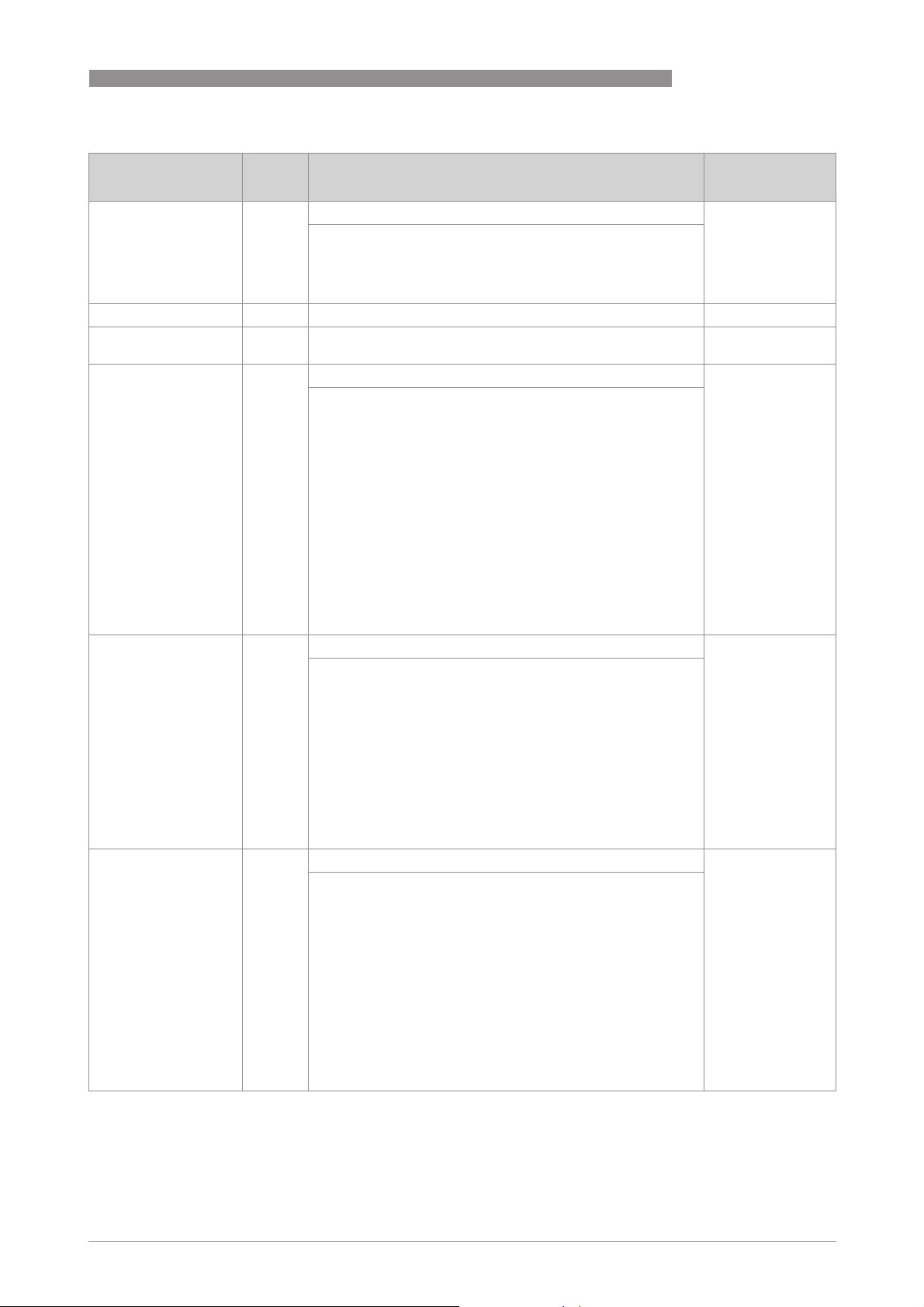

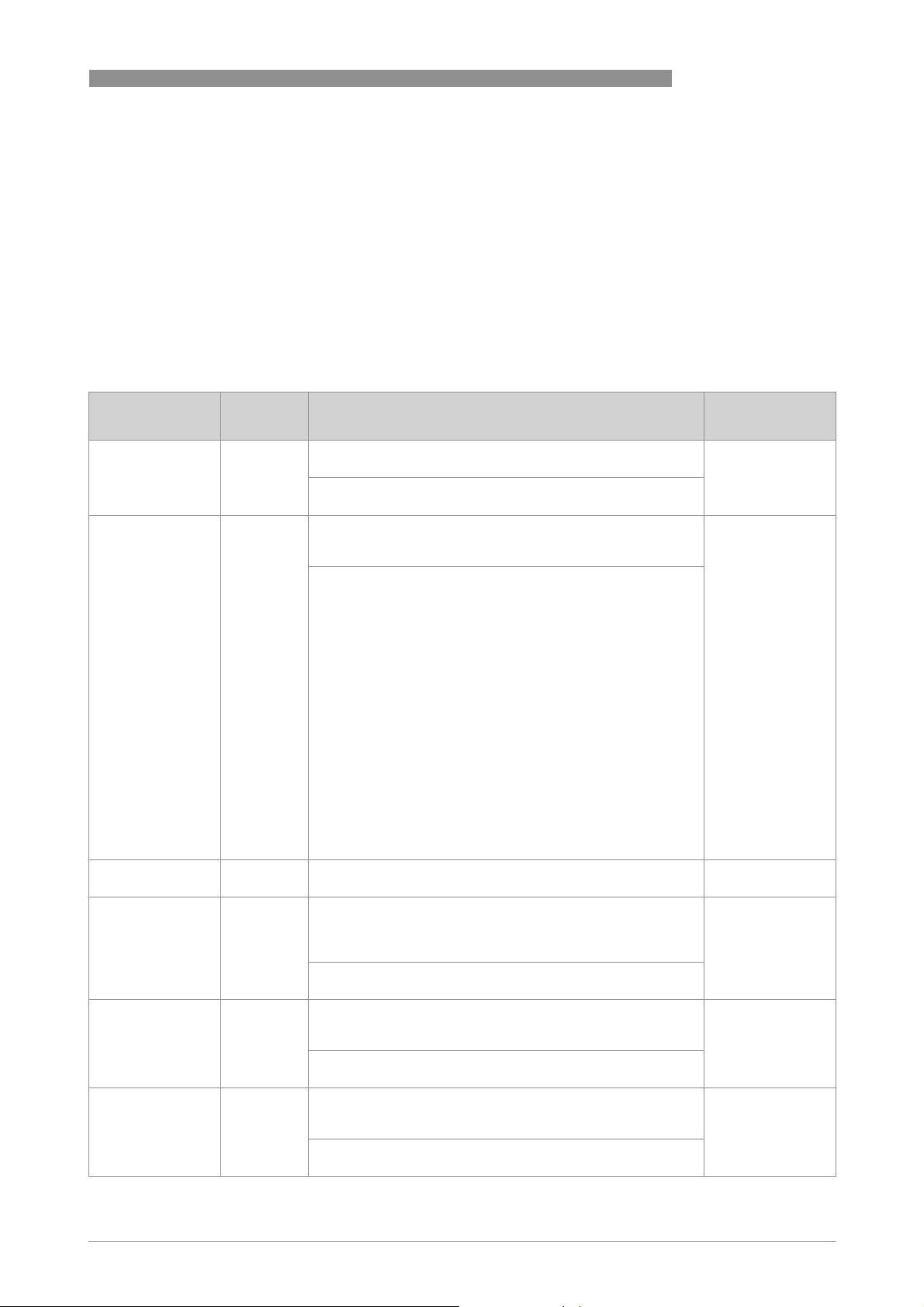

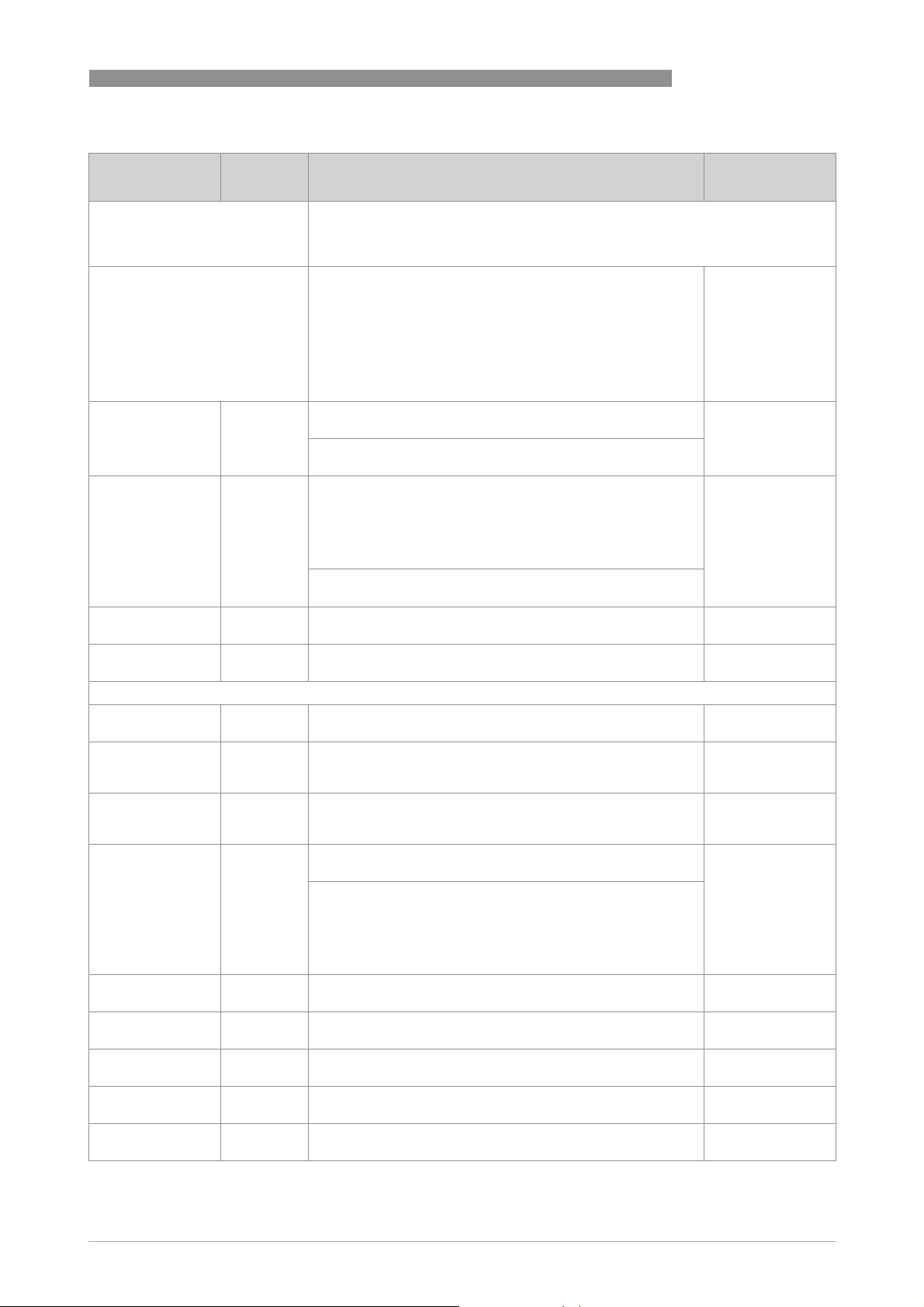

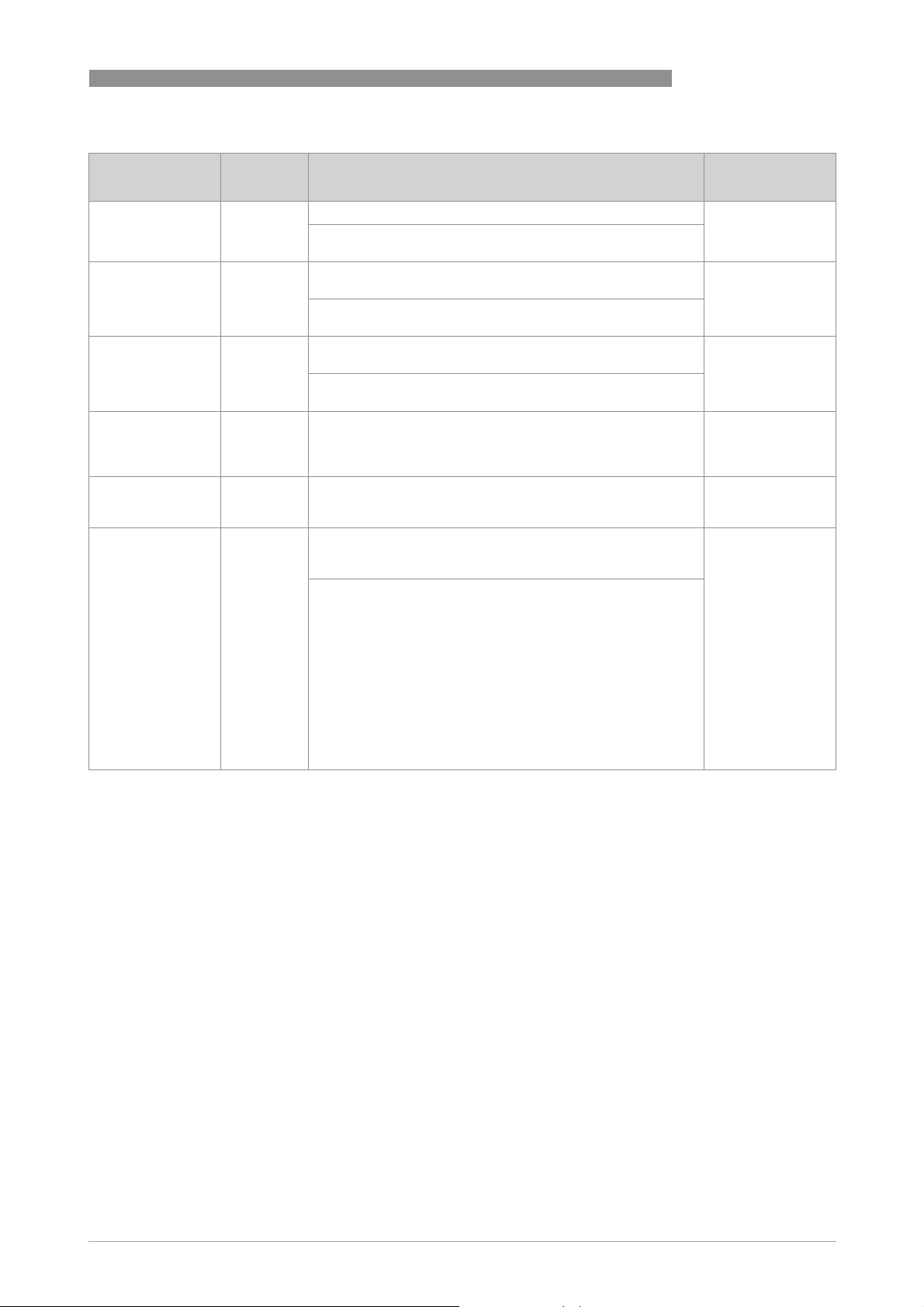

3.1 Cable types

The cable types are specified according to IEC 61158-2. Shielded cables offer the advantage of

malfunction-free operation with adequate protection against electromagnetic influences, and

make it possible to employ the full performance of the Foundation Fieldbus system.

ELECTRICAL CONNECTIONS 3

Core cross-section

Cable type AAAA BBBB CCCC DDDD

Max. length

incl. branch line

0.8 mm2 or

AWG 18

twisted pair,

individually

shielded

1900 m / 6200 ft 1200 m / 3900 ft 400 m / 1300 ft 200 m / 650 ft

0.32 mm2 or

AWG 22

individual or

multiple twisted

pairs with overall

shield

0.13 mm2 or

AWG 26

multiple twisted

pairs, without

shielding

1.25 mm2 or

AWG 16

multiple nontwisted cables,

without shielding

In non-hazardous areas the maximum number of field devices is limited to 32. For detailed

information refer to the following table.

In non-hazardous areas the ignition protection class of the devices and the limited electric power

available limit the number of field devices to 4.

Number of devices Cable lengths for number of devices per branch line

1 device 2 devices 3 devices 4 devices

25...32 1m/ 3.3ft 1m/ 3.3ft 1m/ 3.3ft 1m/ 3.3ft

19...24 30 m / 100 ft 1m/ 3.3ft 1m/ 3.3ft 1m/ 3.3ft

15...18 60 m / 200 ft 30 m / 100 ft 1m/ 3.3ft 1m/ 3.3ft

13...14 90 m / 300 ft 60 m / 200 ft 30 m / 100 ft 1m/ 3.3ft

1..12 120 m / 400 ft 90 m / 300 ft 60 m / 200 ft 30 m / 100 ft

All bus segments must be fitted with a terminator at both ends.

3.2 Shielding and grounding

• For optimum electromagnetic compatibility of systems it is extremely important that the

system components, and particularly the bus cables connecting the components, are

shielded and that such shields - if possible - form an unbroken cover.

• Hence, it follows that, for use in non-hazardous duty systems, the cable shield should be

grounded as often as possible.

• In Ex systems an adequate equipotential bonding in the hazardous and non-hazardous

location along the entire Fieldbus installation is strongly recommended. Multiple grounding

of the shield is of advantage.

INFORMATION!

The use of twisted and shielded cables is strongly recommended, otherwise EMC protection of

the signal converter cannot be assured.

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

5

Page 6

3 ELECTRICAL CONNECTIONS

3.3 Electrical connection of FOUNDATION Fieldbus

INFORMATION!

The wiring between the device and the FOUNDATION Fieldbus cable is independant of polarity.

The signal converter FOUNDATION Fieldbus interface will operate only if the additional power

supply for the device is connected/available.

For a detailed description of the electrical connections please refer to the standard signal

converter handbook.

Connection to a spur

or

GFC 300

Connection to a trunk

1 e.g. incoming data lines

2 e.g. outgoing data lines

or

6

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 7

GFC 300

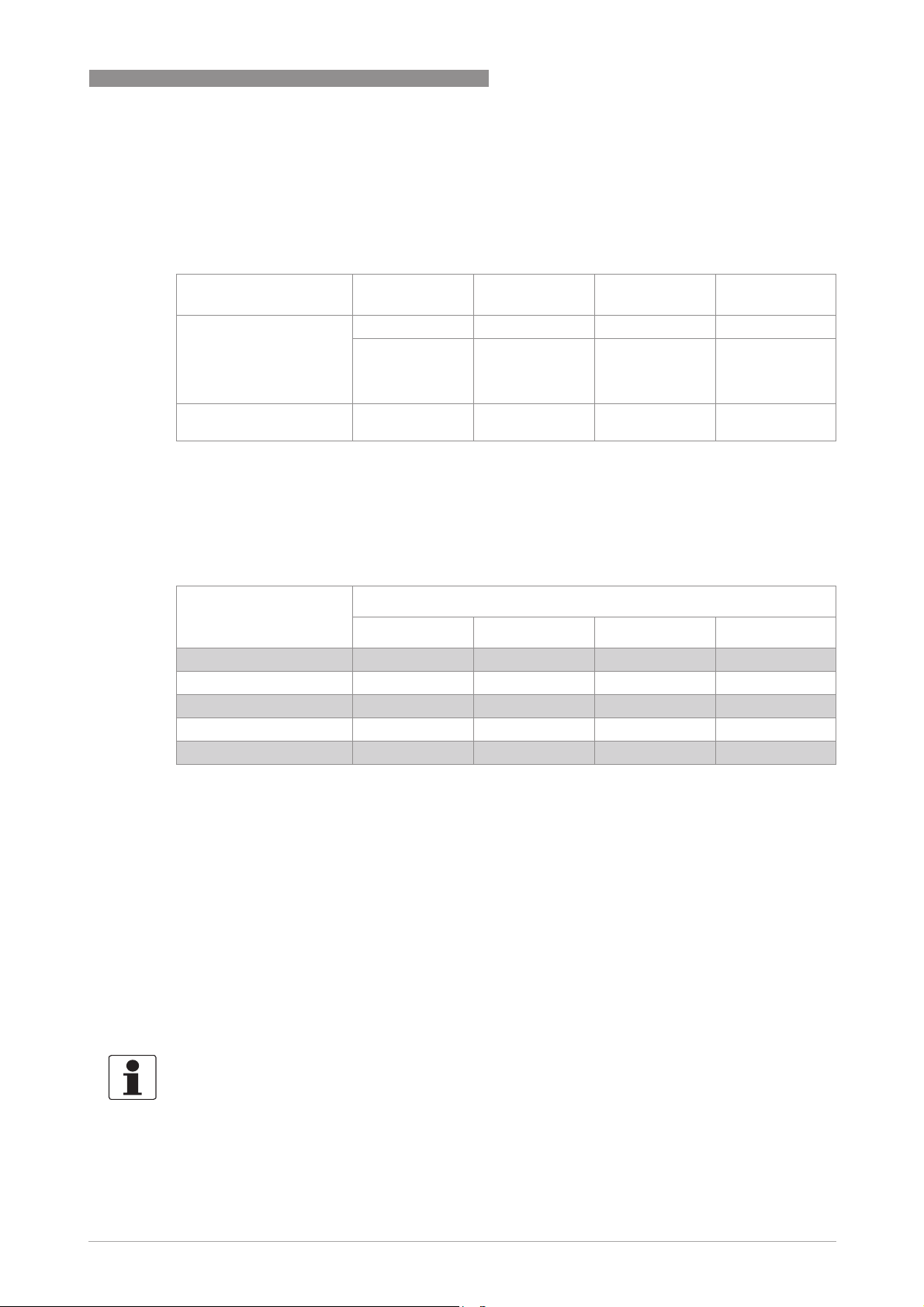

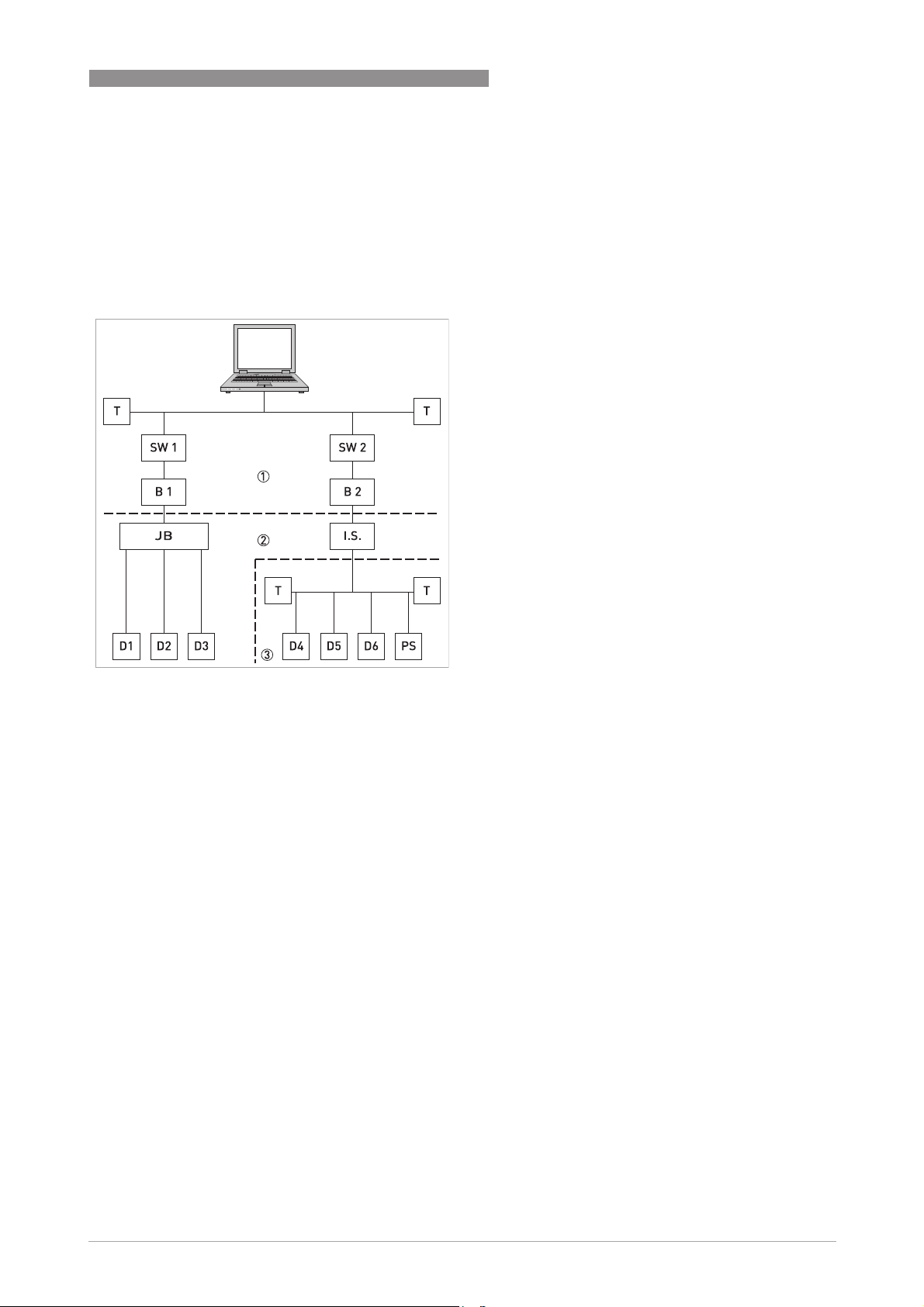

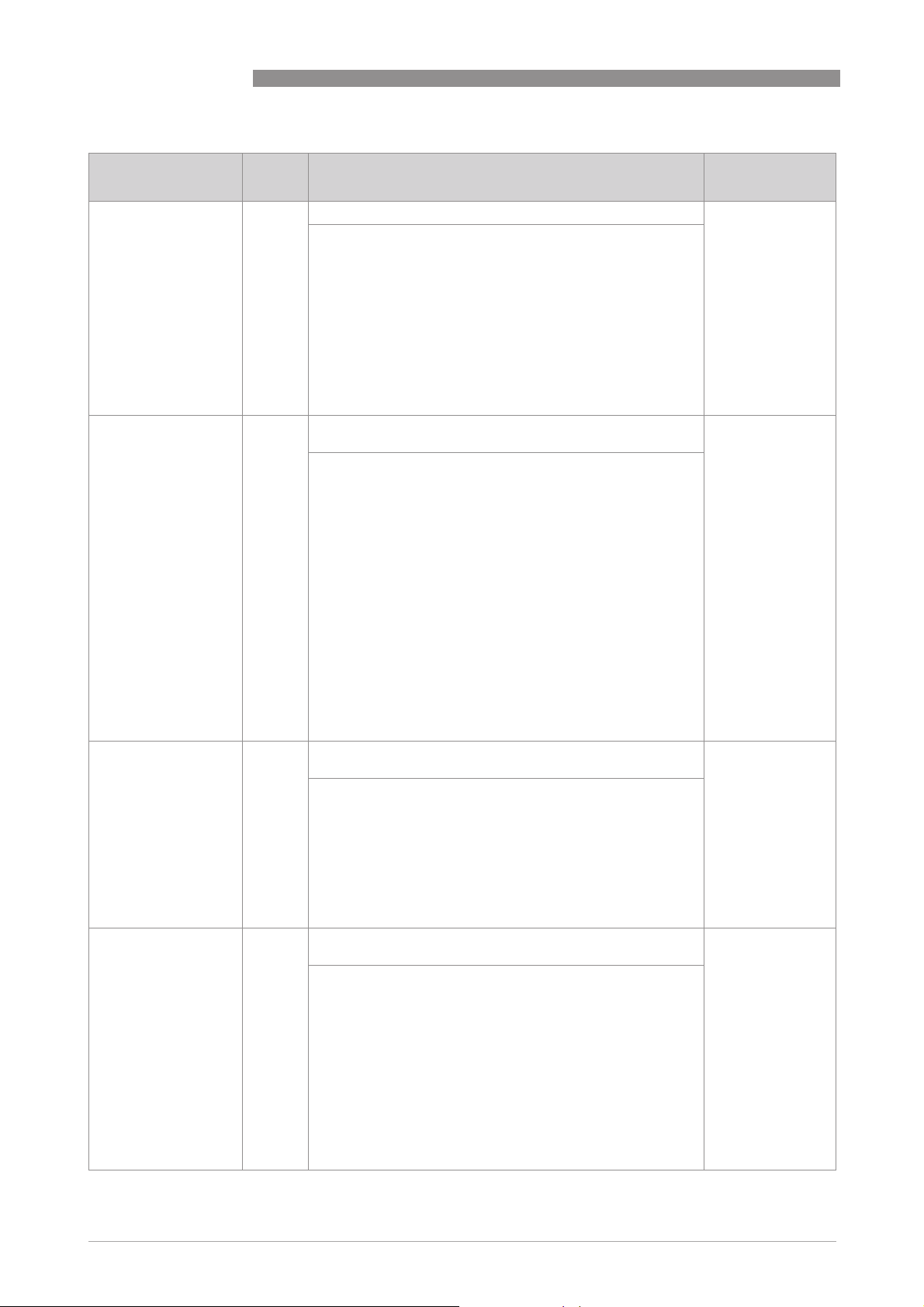

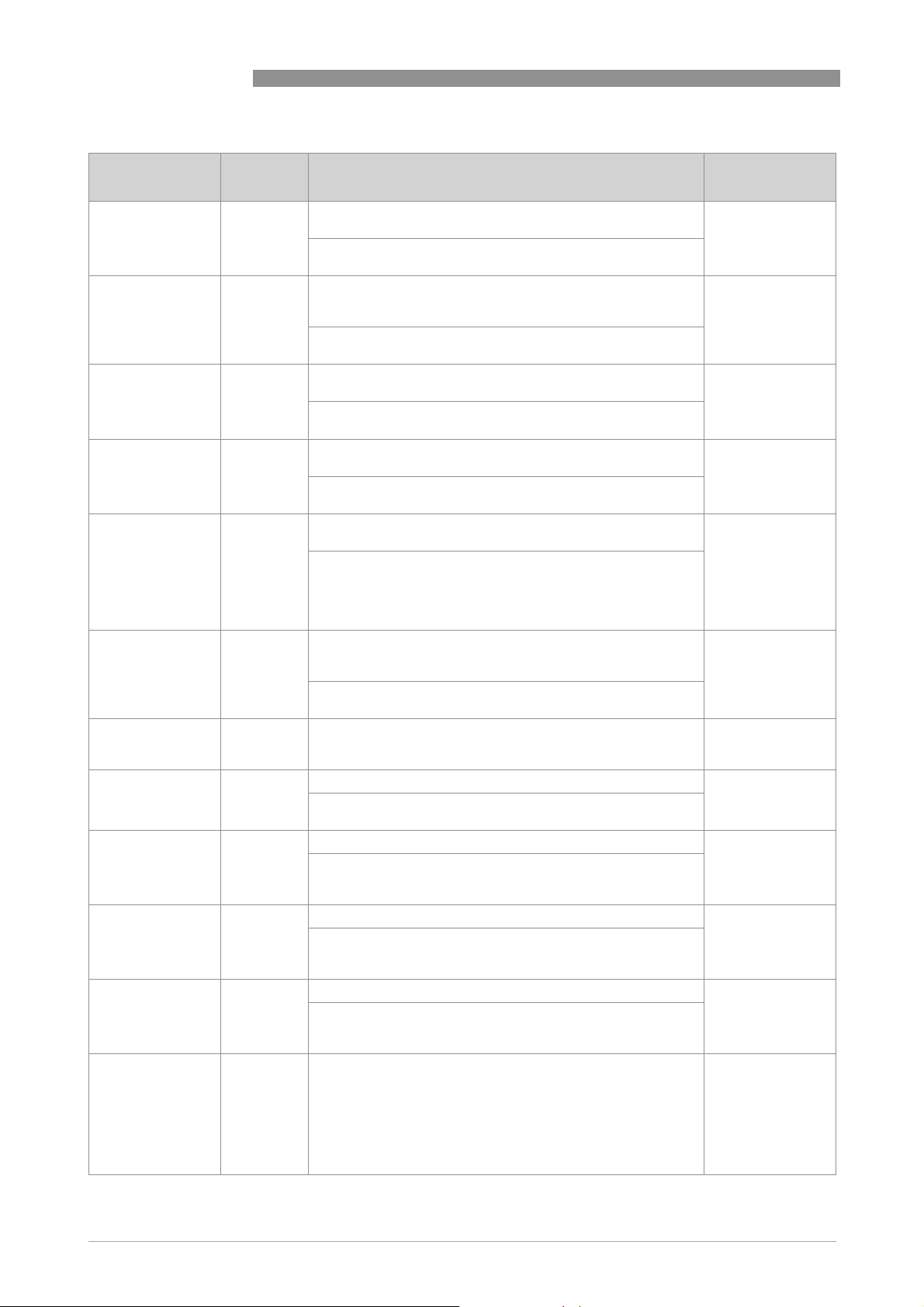

3.4 Topology of FF networks

An example of mixed topology of FF networks is shown in the following example.

Connection is best made via short branch cables and T connectors. This connection type makes it

possible to connect and disconnect the devices without interrupting the bus or the

communication.

ELECTRICAL CONNECTIONS 3

1 HSE network

2 H1 bus

3 Intrisically safe, explosive area

B1+B2 Bridge = coupling element for H1 bus

and HSE network

D1-D3 Device = field devices, own power

supply, for non potentially explosive

areas

D4-D6 Intrinsically safe devices, external

power supply, for potentially explosive

areas

I.S. Intrinsically safe barrier

JB Junction box for field devices

PS Power supply

Switch = connection of multiple HSE

sub networks

TTerminator

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

7

Page 8

4 OPERATION

GFC 300

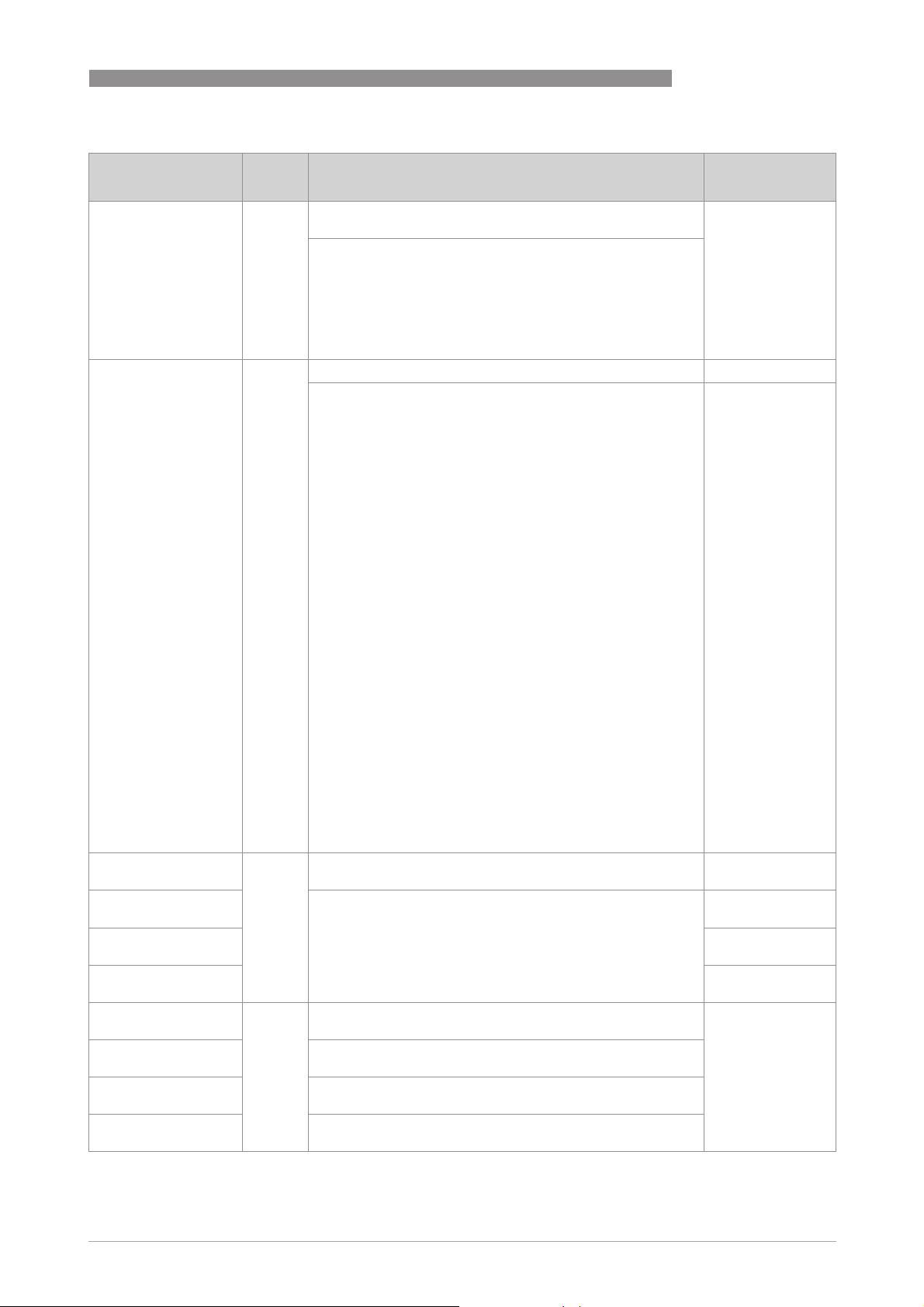

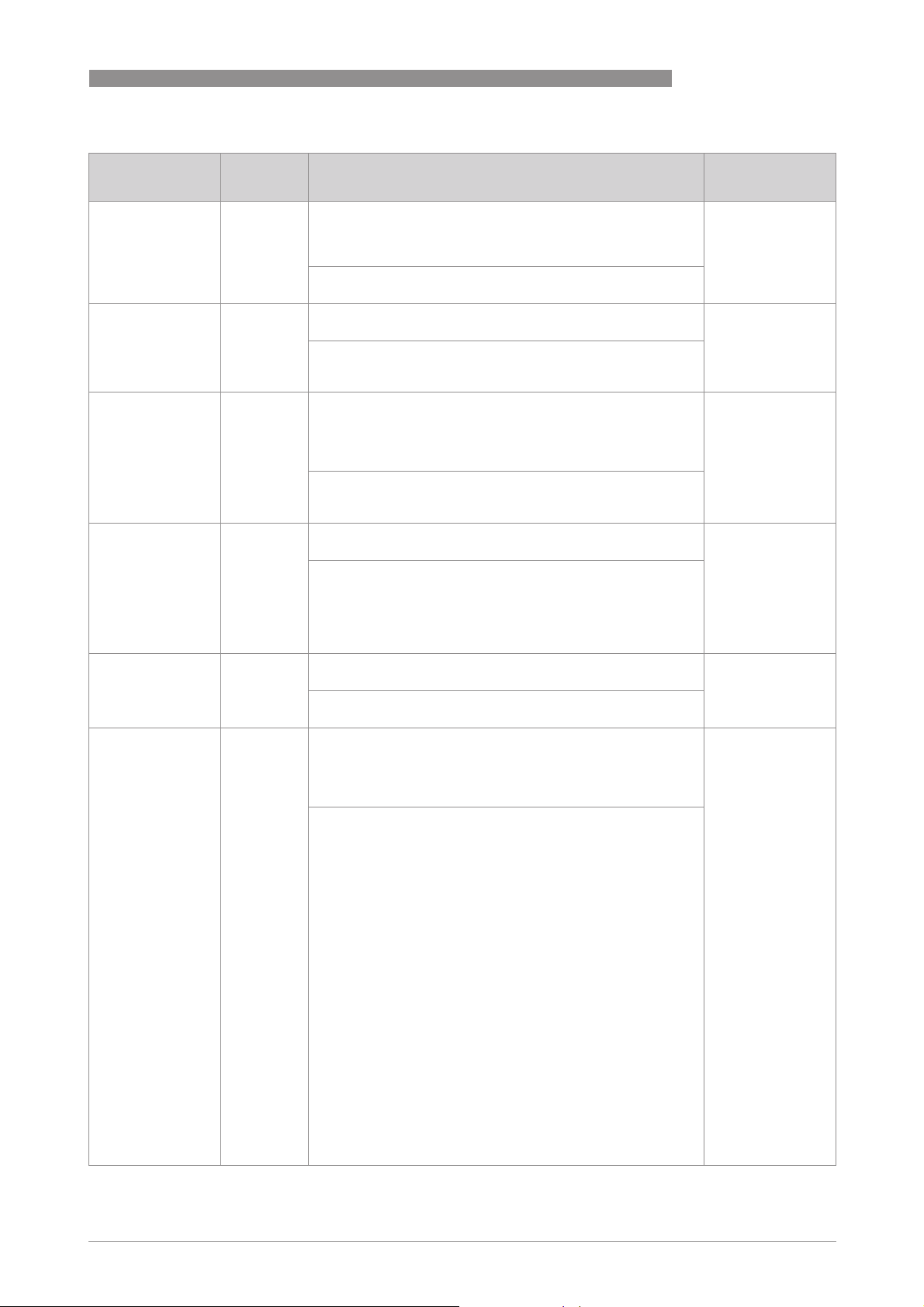

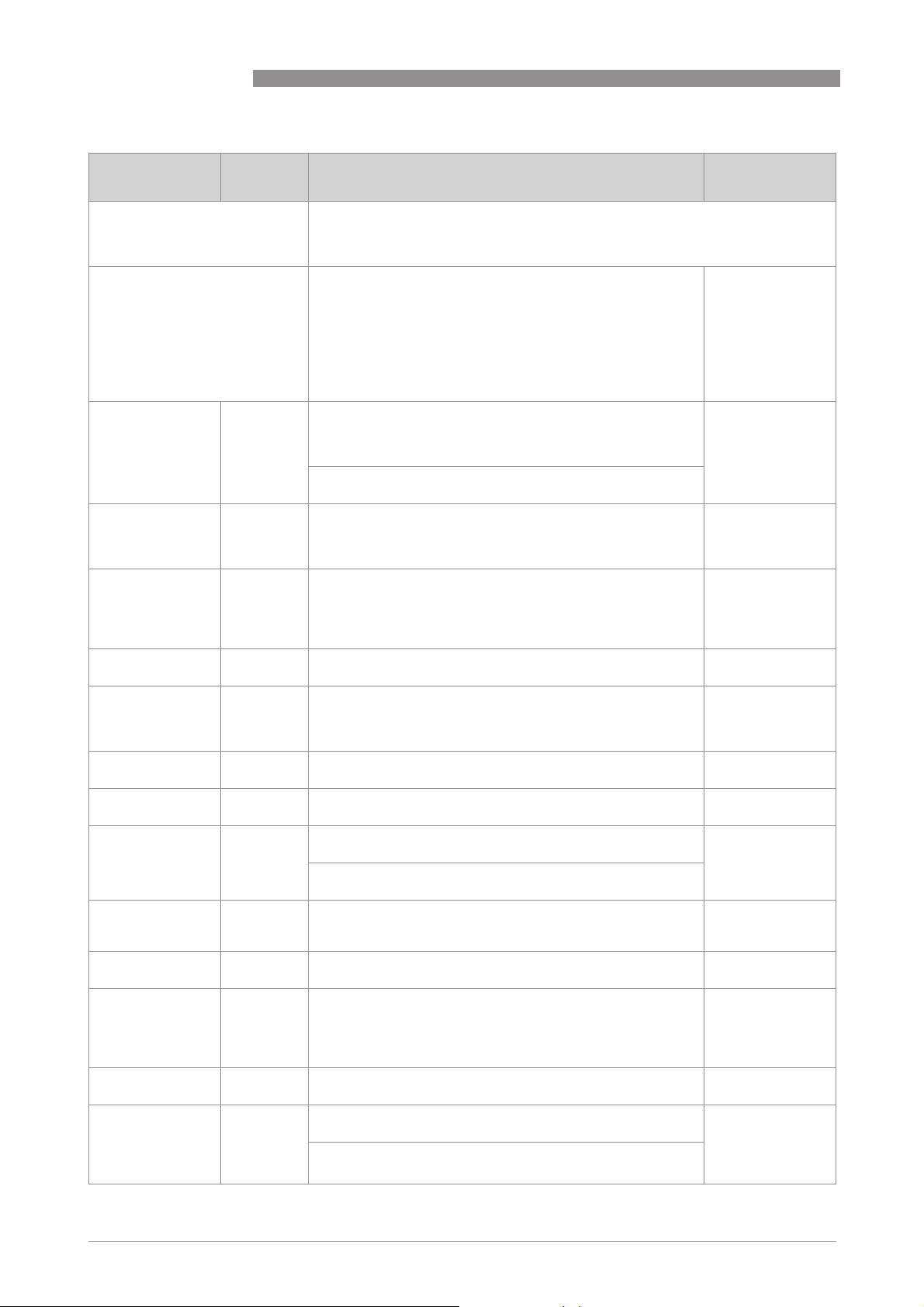

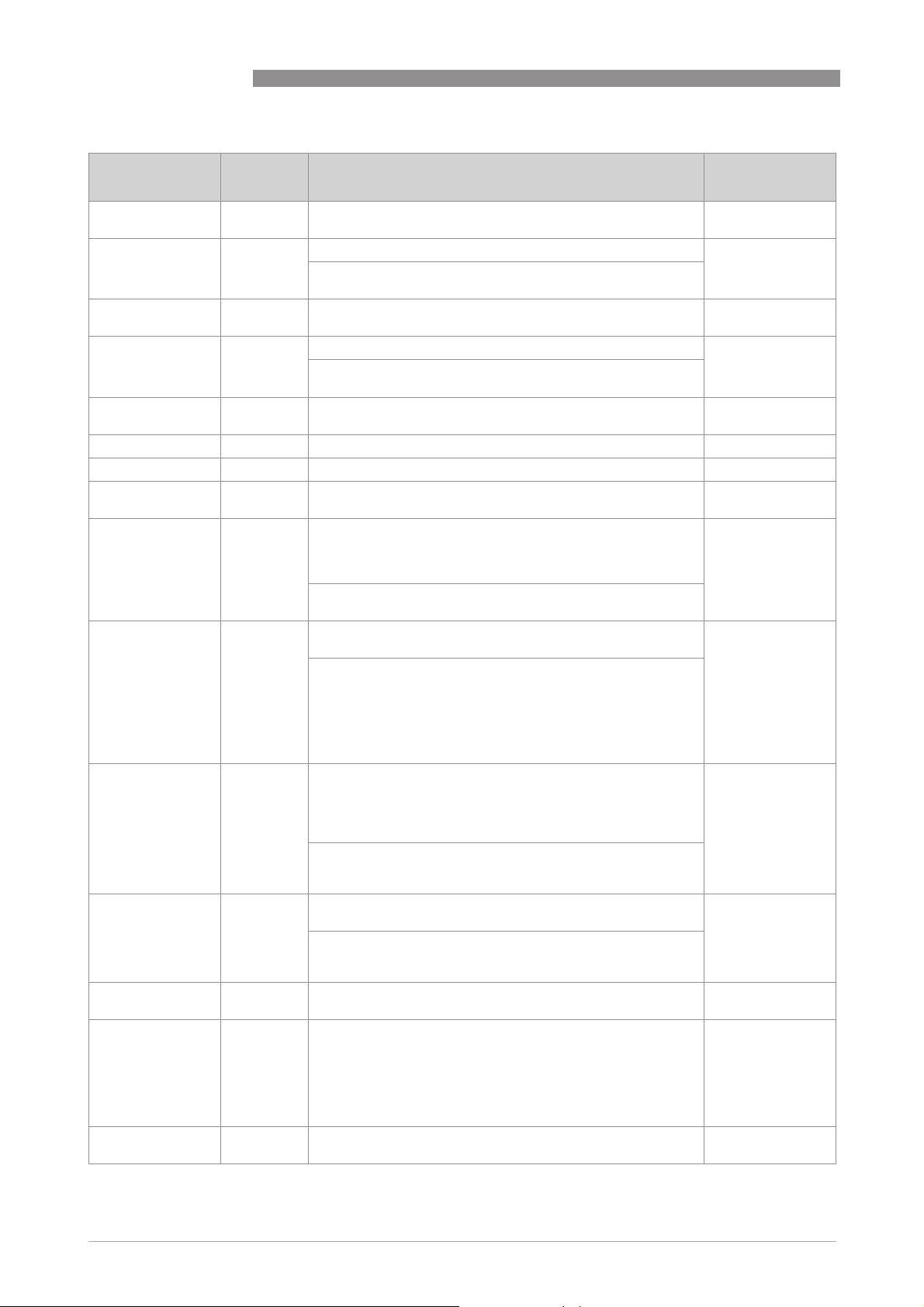

4.1 Settable functions

• For Foundation Fieldbus the totalizers of the signal converter are not available!

• The following tables describe only the menus, functions and parameters that are different

between the standard signal converter and the Foundation Fieldbus signal converter.

• For the electrical connections of the outputs, inputs and all settings of functions that are not

listed in the following tables refer to the standard product documentation.

No. Displayed text Description and settings

A quick setup

A2 Tag Identifier for the measurement in a plant, appears in the display header

B test

B3.5 Foundation fieldbus Display information about Foundation fieldbus interface.

(maximum 8 digits).

Note: Only read, not changeable!

C setup

C5.1.1 Tag Identifier for the measurement in a plant, appears in the display header

C3 Totalizer Not available for Foundation Fieldbus devices!

C4 I/O HART Not available for Foundation Fieldbus devices!

C5.4 2. meas. page In case of Foundation Fieldbus device, the second measurement page is

C5.4.1 measurement 1.line Select: AI1...6 analog inp. / PID / INT1..2 integrator / AR

C5.4.2 format 1.line Fixed number of digits after the decimal point or automatic, where the

C5.4.3 measurement 2.line Select: AI1...6 analog inp. / PID / INT1..2 integrator / AR

C5.4.4 format 2.line Fixed number of digits after the decimal point or automatic, where the

C5.4.5 measurement 3.line Select: AI1...6 analog inp. / PID / INT1..2 integrator / AR

C5.4.6 format 3.line Fixed number of digits after the decimal point or automatic, where the

C5.8 Foundation Field -

C5.8.1 Simulate Select: disabled / enabled

C5.8.2 Information Display information about hardware and software versions, the calibration

(maximum 8 digits).

Note: Only read, not changeable!

meant to check the output values of the different function blocks. Only

Foundation Fieldbus values can be selected here. The analogue inputs are

shown with exactly the value, seen on the bus system.

number of digits is automatically adjusted to the available space.

number of digits is automatically adjusted to the available space.

number of digits is automatically adjusted to the available space.

and test date of this interface.

8

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 9

GFC 300

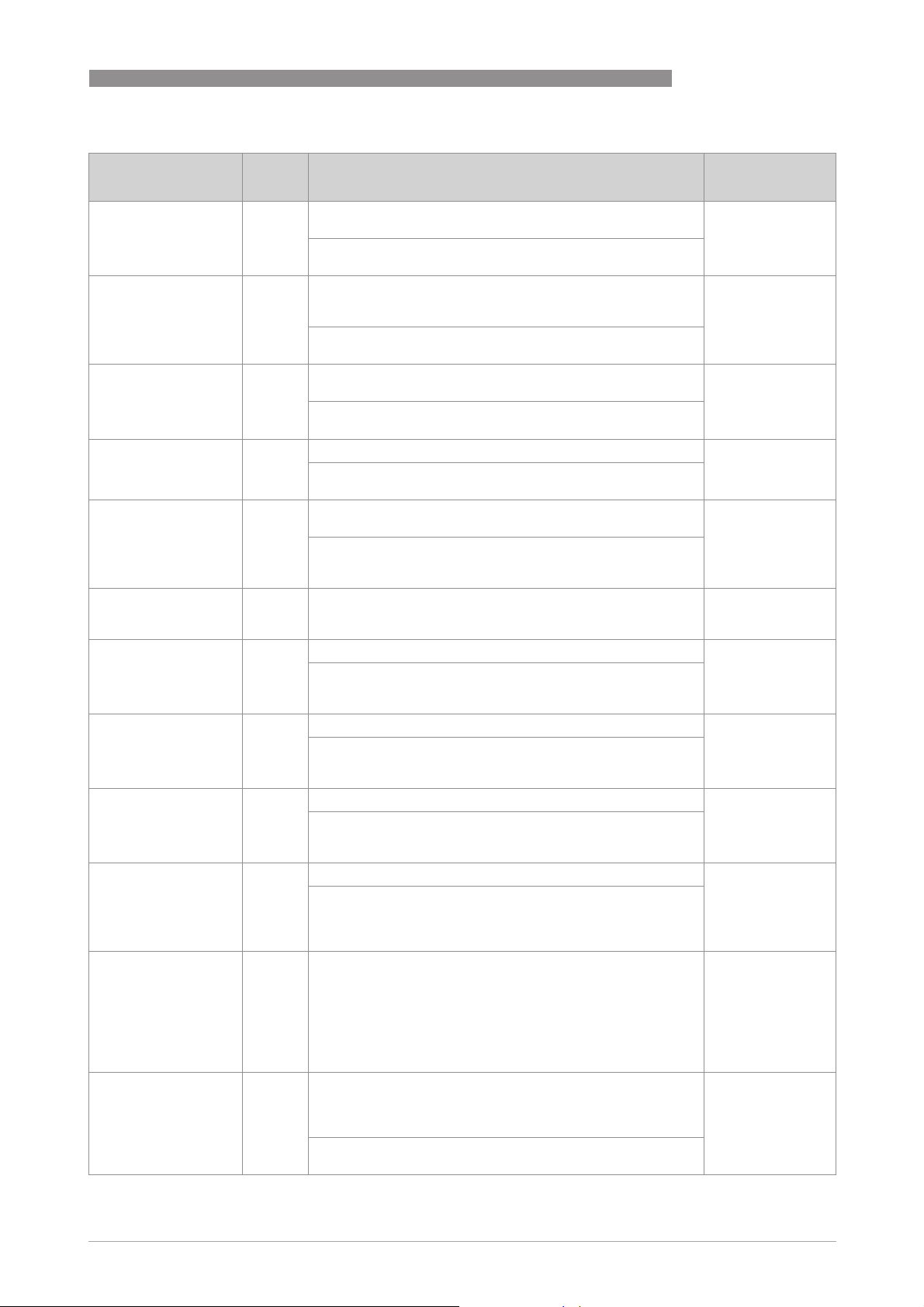

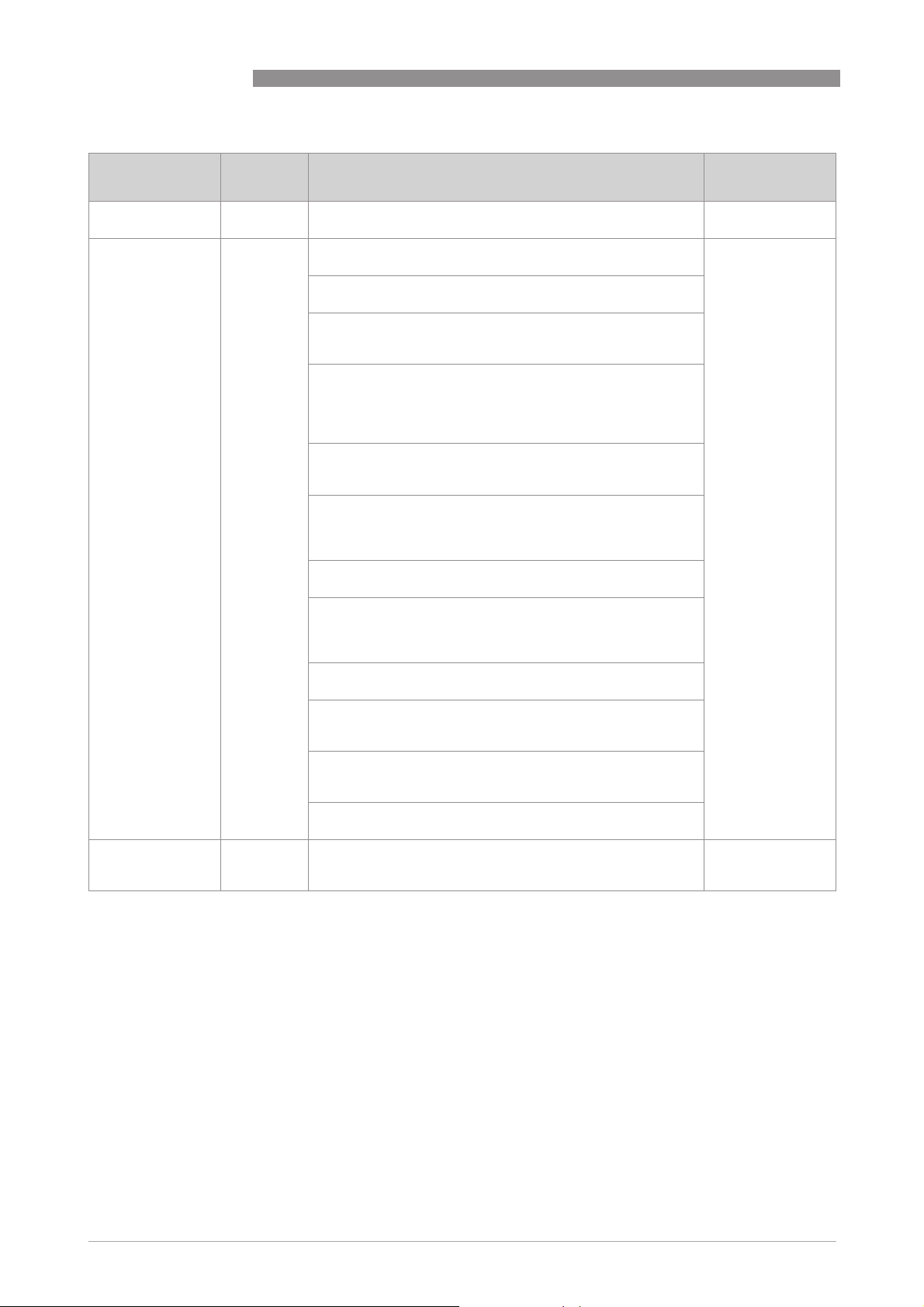

4.2 Description of the FF block system

The Foundation Fieldbus is a Local Area Network (LAN) for connecting field devices like sensors

and actuators. One of the main benefits of Foundation Fieldbus is line saving in comparison to

the traditional 4...20 mA technology.

The different device functions are implemented in a block-based scheme within a user

application. In this block scheme, a distinction is made between the Resource Block, Transducer

Block and Function Block.

OPERATION 4

1 Resource Block (RB)

2 Transducer Block (TB)

3 Function Block (FB)

4 Device FF communication

5 Foundation Fieldbus

4.3 Used abbreviations

AI Analogue Input Block BLK Block mode

AR Arithmetic Block MAN Manual mode

IT Integrator Block Mix Mix mode (R, W and R/W)

PID Proportional Integral Derivate Block Auto Automatic mode

RB Resource Block OOS Out Of Service mode

TB Transducer Block OD Object Directory

R Read SP Set Point

W Write IV Initial Value

R/W Read and Write PV Process Value (factory settings)

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

9

Page 10

4 OPERATION

4.4 Resource Block (RB)

The following tables list the Resource Block parameters in alphabetical order.

It describes characteristics of the Fieldbus device (e.g. device name, serial number, etc.) and is

not included in the functional tasks of the signal converter for FF.

The following tables contain short parameter description, factory settings (Initial Value (IV)) and

possible settings.

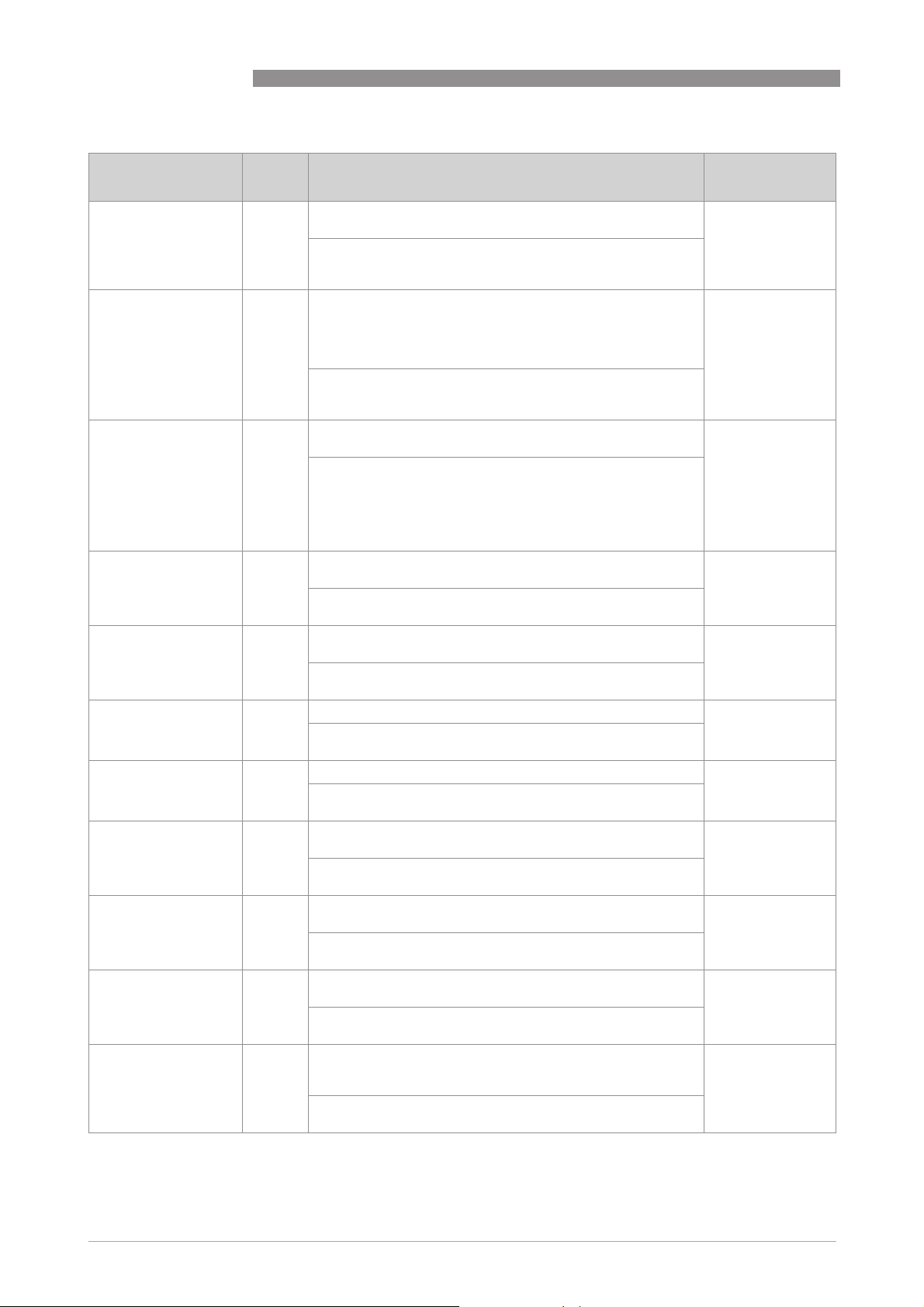

4.4.1 Foundation Fieldbus parameters for Resource Block

Parameter

Parameter

ParameterParameter

DD name

ALERT_KEY

ALERT_KEY

ALERT_KEYALERT_KEY

Alert Key

Alert Key

Alert KeyAlert Key

BLOCK_ERR

BLOCK_ERR

BLOCK_ERRBLOCK_ERR

Block Error

Block Error

Block ErrorBlock Error

MODE_BLK

MODE_BLK

MODE_BLKMODE_BLK

Block Mode

Block Mode

Block ModeBlock Mode

TARGET

Target

ACTUAL

Actual

PERMITTED

Permitted

Access Description and settings Initial Value

R/W The identification number of the plant unit. This information

may be used in the host for sorting alarms, etc.

Setting:

1...255

R This parameter reflects the error status associated with the

hardware or software components associated with a block. It

is a bit string, so that multiple errors may be shown.

Setting:

• Other: Non-specific error active

• Block Configuration: Error detected in block configuration

• Link Configuration: Error detected in link configuration

• Simulation Active: Simulation enabled in this block

• Local Override: Output tracking of faultstate active

• Device Fault State: Device faultstate set

• Device Maintenance: Device needs maintenance soon

• Input Failure: Process variable has bad status

• Output Failure: Failure detected in output hardware

• Memory Failure: Memory error detected

• Lost Static Data: Static parameters cannot be recovered

• Lost NV Data: Non-volatile parameters cannot be recovered

• Readback Check: Failure detected in READBACK

• Maintenance Needed: Device NEEDS maintenance NOW

• Power Up: Recovery from power failure

• Out Of Service: Block actual mode is out of service

Mix The actual, target, permitted and normal modes of the block. -

R/W This is the mode requested by the operator. Only one mode

from those allowed by the permitted mode parameter may be

requested.

Setting:

Auto / OOS

R This is the current mode of the block, which may differ from

the target based on operating conditions. Its value is

calculated as part of block execution.

Setting:

Auto / OOS

R/W Defines the modes which are allowed for an instance of the

block. The permitted mode is configured based on application

requirement.

Setting:

Auto / OOS

GFC 300

0

OOS (Out of

Service)

OOS

OOS

Auto

OOS

10

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 11

GFC 300

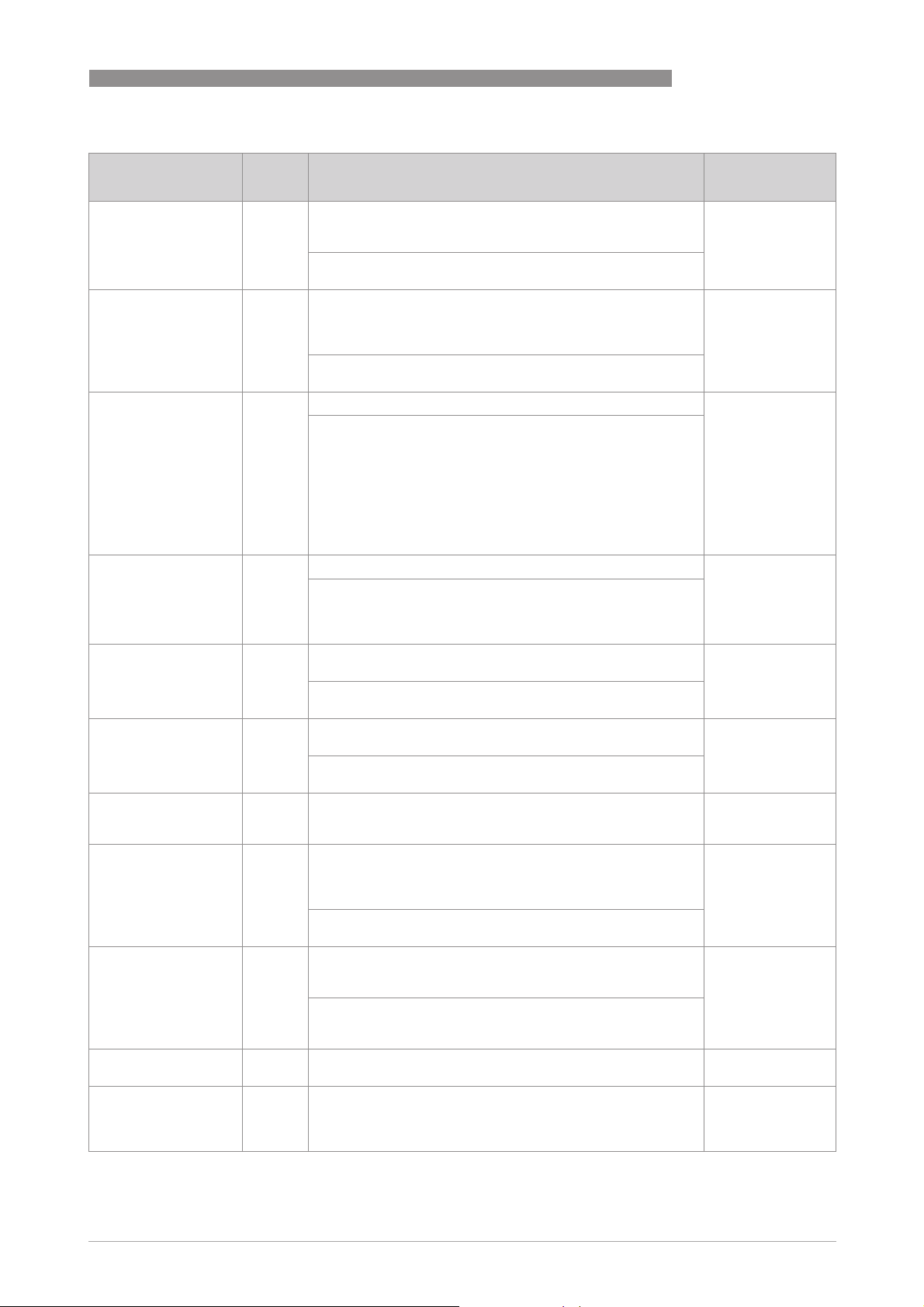

Parameter

Parameter

ParameterParameter

DD name

OPERATION 4

Access Description and settings Initial Value

NORMAL

Normal

ST_REV

ST_REV

ST_REVST_REV

Static Revision

Static Revision

Static RevisionStatic Revision

STRATEGY

STRATEGY

STRATEGYSTRATEGY

Strategy

Strategy

StrategyStrategy

TAG_DESC

TAG_DESC

TAG_DESCTAG_DESC

Tag Description

Tag Description

Tag DescriptionTag Description

ACK_OPTION

ACK_OPTION

ACK_OPTIONACK_OPTION

Acknowledge Option

Acknowledge Option

Acknowledge OptionAcknowledge Option

ALARM_SUM

ALARM_SUM

ALARM_SUMALARM_SUM

Alarm Summary

Alarm Summary

Alarm SummaryAlarm Summary

Current R The active status of each alarm. Uninitialized

Unacknowledged R The unacknowledged state of each alarm. Uninitialized

Unreported R The unreported status of each alarm. Uninitialized

Disabled R/W The disabled state of each alarm. Uninitialized

BLOCK_ALM

BLOCK_ALM

BLOCK_ALMBLOCK_ALM

Block Alarm

Block Alarm

Block AlarmBlock Alarm

Unacknowledged R/W A discrete enumeration which is set to "Unacknowledged"

R/W This is the mode which the block should be set to during

normal operating conditions.

Setting:

Auto / OOS

R The revision level of the static data associated with the

function block. The revision value will be incremented each

time a static parameter value in the block is changed.

Setting:

0...65535

R/W The strategy field can be used to identify grouping of blocks.

This data is not checked or processed by the block.

Setting:

0...65535

R/W The user description of the intended application of the block. blanks

Setting:

≤32 digits

R/W Selection of whether alarms associated with the function

block will be automatically acknowledged.

Setting:

Disc Alm Auto Ack / Blk Alm Auto Ack / Fail Alm Auto Ack / Off

Spec Alm Auto Ack / Maint Alm Auto Ack / Check Alm Auto Ack

R The current alert status, unacknowledged states, unreported

states and disabled states of the alarms associated with the

function block.

Setting:

Discrete Alarm / Block Alarm / Fail Alarm / Off Spec Alarm /

Maintenance Alarm / Check Alarm

Setting:

Disc Alm Unack / Block Alm Unack / Fail Alm Unack / Off Spec

Alm Unack / Maint Alm Unack / Check Alm Unack

Setting:

Disc Alm Unrep / Block Alm Unrep / Fail Alm Unrep / Off Spec

Alm Unrep / Maint Alm Unrep / Check Alm Unrep

Setting:

Disc Alm Disabled / Block Alm Disabled / Fail Alm Disabled /

Off Spec Alm Disabled / Maint Alm Disabled / Check Alm

Disabled

The block alarm is used for all configuration, hardware,

connection failure or system problems in the block. The cause

of the alert is entered in the subcode field. The first alert to

become active will set the "Active" status in the "Status"

attribute. As soon as the "Unreported" status is cleared by the

alert reporting task, another block alert may be reported

without clearing the "Active" status, if the subcode has

changed.

when an alarm occurs, and set to "Acknowledged" by a write

from a human interface device or other entity which can

acknowledge that the alarm/event has been noticed.

Setting:

Uninitialized / Acknowledged / Unacknowledged

Auto

0 (=uninitialized)

0

Uninitialized

-

-

Uninitialized

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

11

Page 12

4 OPERATION

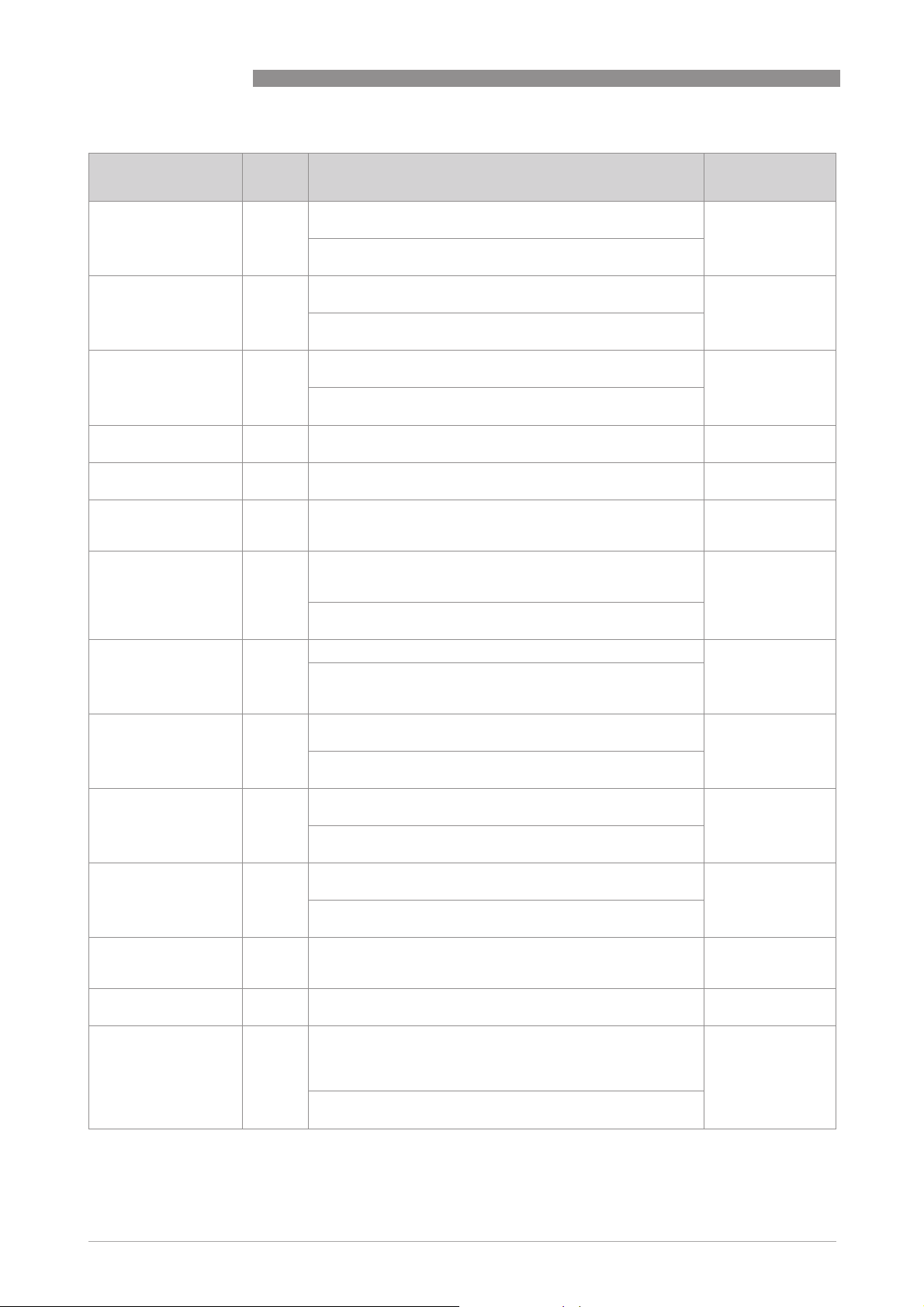

Parameter

Parameter

ParameterParameter

DD name

GFC 300

Access Description and settings Initial Value

Alarm State R A discrete enumeration which gives an indication of whether

Time Stamp R The time when evaluation of the block was started and a

Subcode R An enumeration specifying the cause of the alert to be

Value R The value of the associated parameter at the time the alert

CLR_FSTATE

CLR_FSTATE

CLR_FSTATECLR_FSTATE

Clear Fault State

Clear Fault State

Clear Fault StateClear Fault State

CONFIRM_TIME

CONFIRM_TIME

CONFIRM_TIMECONFIRM_TIME

Confirm Time

Confirm Time

Confirm TimeConfirm Time

CYCLE_SEL

CYCLE_SEL

CYCLE_SELCYCLE_SEL

Cycle Selection

Cycle Selection

Cycle SelectionCycle Selection

CYCLE_TYPE

CYCLE_TYPE

CYCLE_TYPECYCLE_TYPE

Cycle Type

Cycle Type

Cycle TypeCycle Type

DD_RESOURCE

DD_RESOURCE

DD_RESOURCEDD_RESOURCE

DD Resource

DD Resource

DD ResourceDD Resource

DD_REV

DD_REV

DD_REVDD_REV

DD Revision

DD Revision

DD RevisionDD Revision

DEV_REV

DEV_REV

DEV_REVDEV_REV

Device Revision

Device Revision

Device RevisionDevice Revision

R/W Writing a "Clear" to this parameter will clear the device fault

R/W The minimum time between retries of alert reports. 640000

R/W Used to select the block execution method for this resource. Uninitialized

R Identifies the block execution methods available for this

R String identifying the tag of the resource which contains the

R Revision of the DD associated with the resource - used by an

R Manufacturer revision number associated with the resource -

the alert is active and whether it has been reported.

Setting:

Uninitialized / Clear - reported / Clear - not reported / Active reported / Active - not reported

change in alarm/event state was detected that is unreported.

The time stamp value will be maintained constant until alert

confirmation has been received - even if another change of

state occurs.

Setting:

MM / DD / YY (Month / Day / Year)

HH:MM:SS (Hour:Minute:Second)

reported.

Setting:

Other / Block Configuration / Link Configuration / Simulation

Active / Local Override / Device Fault State / Device

Maintenance / Input Failure / Output Failure / Memory

Failure / Lost Static Data / Lost NV Data / Readback Check /

Maintenance Needed / Power Up / Out Of Service

was detected.

Setting:

0...255

state if the field condition, if any, has cleared.

Setting:

Uninitialized / Off / Clear

Setting:

0...4294967295 in [1/32 ms]

Setting:

Scheduled / Block execution

resource.

Setting:

Scheduled / Block execution

Device Description for this resource.

Setting:

≤ 32 digits

interface device to locate the DD file for the resource.

Setting:

Dependent on device version.

used by an interface device to locate the DD file for the

resource.

Setting:

Dependent on device version.

Uninitialized

Uninitialized

Other

0

Off

Scheduled

Block execution

blanks

Dependent on

device version.

Dependent on

device version.

12

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 13

GFC 300

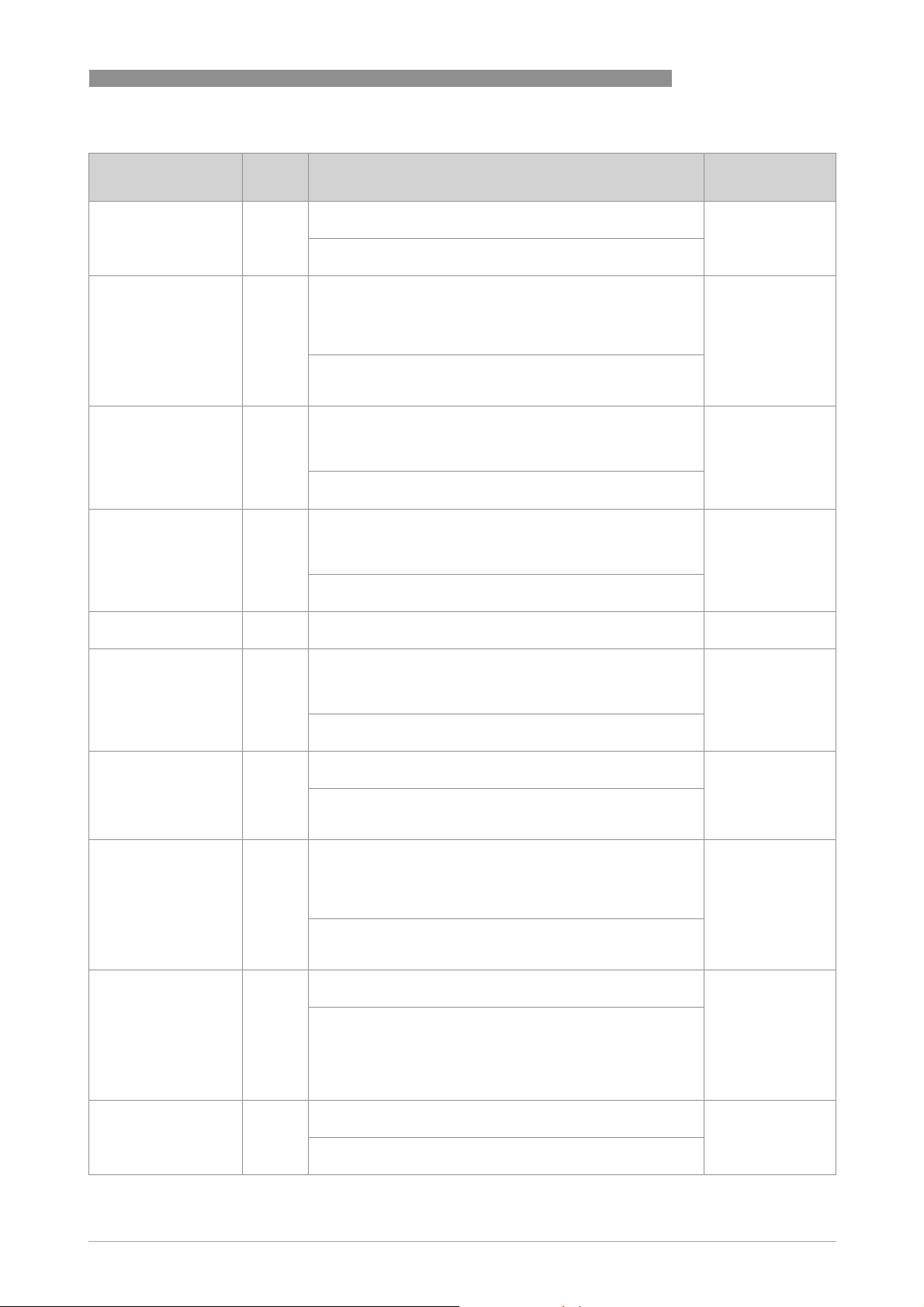

Parameter

Parameter

ParameterParameter

DD name

DEV_TYPE

DEV_TYPE

DEV_TYPEDEV_TYPE

Device Type

Device Type

Device TypeDevice Type

FAULT_STATE

FAULT_STATE

FAULT_STATEFAULT_STATE

Fault State

Fault State

Fault StateFault State

FEATURES

FEATURES

FEATURESFEATURES

Features

Features

FeaturesFeatures

FEATURES_SEL

FEATURES_SEL

FEATURES_SELFEATURES_SEL

Features Selection

Features Selection

Features SelectionFeatures Selection

FREE_SPACE

FREE_SPACE

FREE_SPACEFREE_SPACE

Free Space

Free Space

Free SpaceFree Space

FREE_TIME

FREE_TIME

FREE_TIMEFREE_TIME

Free Time

Free Time

Free TimeFree Time

GRANT_DENY

GRANT_DENY

GRANT_DENYGRANT_DENY

Grant Deny

Grant Deny

Grant DenyGrant Deny

GRANT

Grant

DENY

Deny

HARD_TYPES

HARD_TYPES

HARD_TYPESHARD_TYPES

Hardware Types

Hardware Types

Hardware TypesHardware Types

ITK_VER

ITK_VER

ITK_VERITK_VER

ITK Version

ITK Version

ITK VersionITK Version

(Interoperatibility Test

Kit)

OPERATION 4

Access Description and settings Initial Value

R Manufacturer's model number associated with the resource -

used by interface devices to locate the DD file for the

resource.

Setting:

GFC300

R Condition set by loss of communication to an output block,

failure promoted to an output block or a physical contact.

When fault state condition is set, then output function blocks

will perform their "FSTATE" actions.

Setting:

Uninitialized / Off / Clear

R Used to shows supported resource block options. Reports

Setting:

Reports / Soft W Lock / MVC Report Distribution supported /

MVC Publishing/Subcribing supported / Multi-bit Alarm (BitAlarm) Support

R/W Used to select resource block options. Reports

Setting:

Reports / Soft W Lock / MVC Report Distribution supported /

MVC Publishing/Subscribing supported / Multi-bit Alarm (BitAlarm) Support

R Percent of the memory available for further configuration.

Zero in a preconfigured resource.

Setting:

0.0…100.0

R Percent of the block processing time that is free to process

additional blocks.

Setting:

0.0…100.0

R/W Options for controlling access of host computers and local

control panels to operating, tuning and alarm parameters of

the block.

R/W Depending on the philosophy of the plant, the operator or a

higher level device (HLD) or a local operator's panel (LOP) in

the case of "Local", may turn on an item of the "Grant"

attribute - "Program, Tune, Alarm or Local".

Setting:

Program / Tune / Alarm / Local / Operate

R/W The Denied attribute is limited for use by a monitoring

application in an interface device and may not be changed by

an operator.

Setting:

Program denied / Tune denied / Alarm denied / Local denied /

Operate denied

R The types of hardware available as channel numbers. Scalar input

R Major revision number of the interoperability test case used to

register this device.

GFC300

Clear

Soft W Lock

MVC Report

Distribution

supported

MVC

Publishing/Subcrib

ing supported

Multi-bit Alarm

(Bit-Alarm)

Support

Soft W Lock

0.0

0.0

-

Uninitialized

Uninitialized

5

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

13

Page 14

4 OPERATION

Parameter

Parameter

ParameterParameter

DD name

LIM_NOTIFY

LIM_NOTIFY

LIM_NOTIFYLIM_NOTIFY

Limit Notify

Limit Notify

Limit NotifyLimit Notify

MANUFAC_ID

MANUFAC_ID

MANUFAC_IDMANUFAC_ID

Manufacturer ID

Manufacturer ID

Manufacturer IDManufacturer ID

MAX_NOTIFY

MAX_NOTIFY

MAX_NOTIFYMAX_NOTIFY

Maximum Notify

Maximum Notify

Maximum NotifyMaximum Notify

MEMORY_SIZE

MEMORY_SIZE

MEMORY_SIZEMEMORY_SIZE

Memory Size

Memory Size

Memory SizeMemory Size

MIN_CYCLE_T

MIN_CYCLE_T

MIN_CYCLE_TMIN_CYCLE_T

Minimium Cycle Time

Minimium Cycle Time

Minimium Cycle TimeMinimium Cycle Time

NV_CYCLE_T

NV_CYCLE_T

NV_CYCLE_TNV_CYCLE_T

Nonvolatile Cycle

Nonvolatile Cycle

Nonvolatile Cycle Nonvolatile Cycle

Time

Time

TimeTime

RESTART

RESTART

RESTARTRESTART

Restart

Restart

RestartRestart

RS_STATE

RS_STATE

RS_STATERS_STATE

Resource State

Resource State

Resource StateResource State

SET_FSTATE

SET_FSTATE

SET_FSTATESET_FSTATE

Set Fault State

Set Fault State

Set Fault StateSet Fault State

SHED_RCAS

SHED_RCAS

SHED_RCASSHED_RCAS

Shed Remote Cascade

Shed Remote Cascade

Shed Remote CascadeShed Remote Cascade

SHED_ROUT

SHED_ROUT

SHED_ROUTSHED_ROUT

Shed Remote Out

Shed Remote Out

Shed Remote OutShed Remote Out

TEST_RW

TEST_RW

TEST_RWTEST_RW

Test R Write

Test R Write

Test R WriteTest R Write

UPDATE_EVT

UPDATE_EVT

UPDATE_EVTUPDATE_EVT

Update Event

Update Event

Update EventUpdate Event

Unacknowledged R/W A discrete enumeration which is set to "Unacknowledged"

Access Description and settings Initial Value

R/W Maximum number of unconfirmed alert notify messages

allowed.

Setting:

0...255

R Manufacturer identification number - used by an interface

device to locate the DD file for the resource.

Setting:

KROHNE

R Maximum number of unconfirmed alert notify messages

possible.

Setting:

0...255

R Available configuration memory in the empty resource. To be

checked before attempting a download.

R Time duration of the shortest cycle interval of which the

resource is capable (in [1/32 ms]).

R Interval between writing copies of NV parameters to non-

volatile memory. Zero means never (in [1/32 ms]).

R/W Allows a manual restart to be initiated. Several degrees of

restart are possible. They are 1: Run, 2: Restart resource, 3:

Restart with defaults and 4: Restart processor.

Setting:

Uninitialized / Run / Resource / Defaults / Processor

R State of the function block application state machine. Standby

Setting:

Uninitialized / Start_Restart / Initialization / Online Linking /

Online / Standby / Failure

R/W Allows the fault state condition to be manually initiated by

selecting "Set".

Setting:

Off

R/W Time duration at which to give up on computer writes to

function block RCAS locations.

Setting:

0...4294967295 in [1/32 ms]

R/W Time duration at which to give up on computer writes to

function block ROUT locations.

Setting:

0...4294967295 in [1/32 ms]

Read/write test parameter - used only for conformance

testing.

Note: Subelements "1..15" have no function!

This alert is generated by any change to the static data. -

when an update occurs, and set to "Acknowledged" by a write

from a human interface device or other entity which can

acknowledge that the alarm/event has been noticed.

Setting:

Uninitialized / Acknowledged / Unacknowledged

GFC 300

20

KROHNE

20

0

6400

256000

Run

Off

640000

640000

-

Uninitialized

14

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 15

GFC 300

Parameter

Parameter

ParameterParameter

DD name

OPERATION 4

Access Description and settings Initial Value

Update State R A discrete enumeration which gives an indication of whether

Time Stamp R The time when evaluation of the block was started and a

Static Revision R The static revision of the block whose static parameter was

Relative Index R The OD index of the static parameter whose change caused

WRITE_ALM

WRITE_ALM

WRITE_ALMWRITE_ALM

Write Alarm

Write Alarm

Write AlarmWrite Alarm

Unacknowledged R/W A discrete enumeration which is set to "Unacknowledged"

Alarm State R A discrete enumeration which gives an indication of whether

Time Stamp R The time when evaluation of the block was started and a

Subcode R An enumeration specifying the cause of the alert to be

Discrete Value R The value of the associated parameter at the time the alert

Mix This alert is generated if the write lock parameter is cleared. -

the alert has been reported.

Setting:

Uninitialized / Reported / Not reported

change in alarm/event state was detected that is unreported.

The time stamp value will be maintained constant until alert

confirmation has been received - even if another change of

state occurs.

Setting:

MM / DD / YY (Month / Day / Year)

HH:MM:SS (Hour:Minute:Second)

changed and is being reported. It is possible for the present

value of static revision to be greater than this because static

can be changed at any time.

Setting:

0…65535

this alert, minus the FB starting index. If the update event was

caused by a write to multiple parameters at the same time,

then this attribute will be zero.

Setting:

0…65535

when an alarm occurs, and set to "Acknowledged" by a write

from a human interface device or other entity which can

acknowledge that the alarm/event has been noticed.

Setting:

Uninitialized / Acknowledged / Unacknowledged

the alert is active and whether it has been reported.

Setting:

Uninitialized / Clear - reported / Clear - not reported / Active reported / Active - not reported

change in alarm/event state was detected that is unreported.

The time stamp value will be maintained constant until alert

confirmation has been received - even if another change of

state occurs.

Setting:

MM / DD / YY (Month / Day / Year)

HH:MM:SS (Hour:Minute:Second)

reported.

Setting:

Other / Block Configuration / Link Configuration / Simulation

Active / Local Override / Device Fault State / Device

Maintenance / Input Failure / Output Failure / Memory

Failure / Lost Static Data / Lost NV Data / Readback Check /

Maintenance Needed / Power Up / Out Of Service

was detected.

Setting:

Discrete State 0...16

Uninitialized

Uninitialized

0

0

Uninitialized

Uninitialized

Uninitialized

Other

State 0

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

15

Page 16

4 OPERATION

Parameter

Parameter

ParameterParameter

DD name

WRITE_LOCK

WRITE_LOCK

WRITE_LOCKWRITE_LOCK

Write Lock

Write Lock

Write LockWrite Lock

WRITE_PRI

WRITE_PRI

WRITE_PRIWRITE_PRI

Write Priority

Write Priority

Write PriorityWrite Priority

4.4.2 Manufacturer specific parameters of the signal converter for Resource Block

Parameter

Parameter

ParameterParameter

DD name

DEV_DESCRIPTION

DEV_DESCRIPTION

DEV_DESCRIPTIONDEV_DESCRIPTION

Device Description

Device Description

Device DescriptionDevice Description

DB_DEVICE

Data Base GDC

C_NUMBER_DEVICE

C-Number Device

C_NUMBER_

PRODUCT

C-Number Production

CONVERTER_MODEL

Converter Model

LOGICAL_PLACE

Logical Place

SUPPLY_OPTION

Supply Option

DISPLAY_OPTION

Display Option

IO_SELECTION

IO1 Modular IO

IO_MODULE_A

IO2 Module Term. A

IO_MODULE_B

IO Module Term. B

DIAGNOSIS

DIAGNOSIS

DIAGNOSISDIAGNOSIS

Diagnosis

Diagnosis

DiagnosisDiagnosis

MEMORY_SUMMARY

Memory Summary

Access Description and settings Initial Value

R/W If set, no writes from anywhere are allowed, except to clear

WRITE_LOCK. Block inputs will continue to be updated.

Setting:

Uninitialized / Not locked / Locked

R Priority of the alarm generated by clearing the write lock. 0

Setting:

0...15

Not locked

Access Description and settings Initial Value

R Describes some characteristics of the device. -

R Data base version of the GDC device. Current data base

R Current C-Number of this device. Current C-Number

R C-Number of production; this number identifies the type of

electronics, can be found on the signal converter assembly

sticker as well.

R The model of signal converter. GFC300

R Setting:

Error / Standard / Extended standard / Special

R Supply of sensor and electronics option. As ordered

Setting:

Configuration error / Unknown / 100…230 VAC / 12...24 VDC /

24 VAC/DC

R Setting:

Configuration error or missing / Standard / Eastern Europe /

Northern Europe / Southern Europe / Far East / Japanese /

Chinese / Russian

R Setting:

Configuration error or missing / Foundation Fieldbus

R Setting:

Configuration error or missing / Without carrier / Exi

Opt.:Current Out act + PO/CI pas / Exi Opt. : CurrOut pas +

PO/CI pas / Exi Opt.2 : CurrIn act + PO/CI pas / Exi Opt.2 :

CurrIn pas + PO/CI pas / Exi Opt.3 : 2x CurrIn act

R Not used. -

R Detailed diagnosis of the device. -

R Summary of self diagnosis. ok

Setting:

ok / bit 8…15 not used / EEPROM / FRAM / FLASH / ROM

application / ROM boot area / RAM ext / RAM int / Task Control

version

of device

Current C-Number

of production

Standard

As ordered

Foundation

Fieldbus

-

GFC 300

16

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 17

GFC 300

Parameter

Parameter

ParameterParameter

DD name

OPERATION 4

Access Description and settings Initial Value

FRAM_DIAG

FRAM Diagnosis

workLOAD R Work load of the processor. Current work load

DIAGNOSIS_BLK

DIAGNOSIS_BLK

DIAGNOSIS_BLKDIAGNOSIS_BLK

Diagnosis Block

Diagnosis Block

Diagnosis BlockDiagnosis Block

RB_DIAG

RB Diagnosis

TB1_DIAG

TB1 Diagnosis

TB2_DIAG

TB 2

R Result of FRAM self diagnosis. ok

Setting:

ok / not supported action / unknown / busy / wait / first init /

changed / bit09 / parameter error/ page error/ chip error/

write error / warning: inconsistent / warning: uncertain /

warning: write cycles / warning: one header / ok, page high

R Detailed diagnosis of the blocks. -

R Reason for bits set at BLK_ERR and other diagnosis. Current diagnosis

Setting:

Startup Device / RB: MODE_BLK.ACTUAL is OOS / Memory

failure / Operating System / new: ID, DEV_TYPE, SNR / no GDC

Communication / Startup GDC, data invalid / Startup Sensor,

data valid / C-Number doesn't match to FF Software /

Hardware changed, C raw != C detected / Data Base doesn't

match to FF Software / MODE_BLK.PERMITTED doesn't

include Auto / MODE_BLK.TARGET is set OOS / GDC bold F

message / GDC F message / write from GDC to RB/TB doesn't

work / GDC Mfr unknown / GDC serial number / Boardinfo

incomplete or corrupt / action: write from GDC to RB/TB /

GDC W: no, M: no / GDC W: no, M: some /

GDC W: some, M: no / GDC W: no, M: all /

GDC W: all, M: no / GDC W: some, M: some /

GDC W: some, M: all / GDC W: all, M: some /

GDC Communication few loss / RS_STATE is not On-Line /

simulation active / unknown reason / Ok

R Reason for bits set at BLK_ERR and other diagnosis. Current diagnosis

Startup Device / RB: MODE_BLK.ACTUAL is OOS / Memory

failure / no GDC Communication / Startup GDC, data invalid /

Startup Sensor, data valid / Data Base doesn't match to FF

Software / MODE_BLK.PERMITTED doesn't include Auto /

MODE_BLK.TARGET is set OOS / GDC bold F message / GDC F

message / write from GDC to RB/TB doesn't work / Sensor

serial number / Sensor calibration date / GDC unit not

convertible to TB.prim_val / prim_val is outside range /

action: write from GDC to RB/TB / GDC Communication few

loss / no unit of GDC / GDC unit can't be converted to

TB.prim_range / a GDC value was not received / a GDC short

status is fatal or warn2 / PRIMARY_VALUE_1.status is

Uncertain / unknown reason / Ok

R Reason for bits set at BLK_ERR and other diagnosis. Current diagnosis

Setting:

Startup Device / RB: MODE_BLK.ACTUAL is OOS / Memory

failure / no GDC Communication / Startup GDC, data invalid /

Startup Sensor, data valid / Data Base doesn't match to FF

Software / MODE_BLK.PERMITTED doesn't include Auto /

MODE_BLK.TARGET is set OOS / GDC bold F message / GDC F

message / write from GDC to RB/TB doesn't work / Sensor

serial number / Sensor calibration date / GDC unit not

convertible to TB.prim_val / prim_val is outside range /

action: write from GDC to RB/TB / GDC Communication few

loss / no unit of GDC / GDC unit can't be converted to

TB.prim_range / a GDC value was not received / a GDC short

status is fatal or warn2 / PRIMARY_VALUE_1.status is

Uncertain / temperatur input / pressure input / p & T input /

unknown reason / Ok

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

17

Page 18

4 OPERATION

Parameter

Parameter

ParameterParameter

DD name

GFC 300

Access Description and settings Initial Value

TB3_DIAG

TB 3

AI1/2/3/4/5/6_DIAG

AI1/2/3/4/5/6

Diagnosis

PID_DIAG

PID Diagnosis

IT1/2_DIAG

IT1/2 Diagnosis

R Reason for bits set at BLK_ERR and other diagnosis. Current diagnosis

Startup Device / RB: MODE_BLK.ACTUAL is OOS / Memory

failure / no GDC Communication / Startup GDC, data invalid /

Startup Sensor, data valid / Data Base doesn't match to FF

Software / MODE_BLK.PERMITTED doesn't include Auto /

MODE_BLK.TARGET is set OOS / GDC bold F message / GDC F

message / write from GDC to RB/TB doesn't work / Sensor

serial number / Sensor calibration date / GDC unit not

convertible to TB.prim_val / prim_val is outside range /

action: write from GDC to RB/TB / GDC Communication few

loss / no unit of GDC / GDC unit can't be converted to

TB.prim_range / a GDC value was not received / a GDC short

status is fatal or warn2 / PRIMARY_VALUE_1.status is

Uncertain / unknown reason / Ok

R Reason for OUT.status not Good, bits at BLK_ERR and other

diagnosis.

Setting:

Startup Device / RB : MODE_BLK.ACTUAL is OOS / Memory

failure / no schedule / period of execution / period of

execution to large / MODE_BLK.PERMITTED doesn't include

Auto / MODE_BLK.TARGET is set OOS / MODE_BLK.TARGET is

set MAN / MODE_BLK.ACTUAL is MAN , Startup to Auto /

CHANNEL is uninitialized / UNIT of CHANNEL selected

TB.prim_val not convertible to XD UNIT / XD_SCALE :

difference between EU_100 and EU_0 is to less / OUT_SCALE :

difference between EU_100 and EU_0 is to less / L_TYPE is

uninitialized / L_TYPE is direct , XD_SCALE is not equal

OUT_SCALE / IO_OPTS no unit conversion , XD UNIT doesn’t

match to UNIT of TB.prim_val / SIMULATE_STATUS is not

Good , Simulation is active / SIMULATE_STATUS limitted ,

STATUS_OPTS is set , Simulation active / Simulation is active /

Transducer Block MODE_BLK.ACTUAL is OOS / CHANNEL

selected TB.prim_val.status is Bad / TB.prim_val.status is

limitted , STATUS_OPTS is set / CHANNEL selected

TB.prim_val.status is Uncertain / OUT.value exceeds

OUT_SCALE / unknown reason / Ok

R Reason for OUT.status not Good, bits at BLK_ERR and other

diagnosis.

Setting:

Startup Device / RB: MODE_BLK.ACTUAL is OOS / Memory

failure / no schedule / period of execution / period of

execution to large / MODE_BLK.PERMITTED doesn't include

Auto / MODE_BLK.TARGET is set OOS / MODE_BLK.TARGET is

set MAN / MODE_BLK.ACTUAL is MAN, Startup to Auto /

BYPASS is uninitialized / SHED_OPT is uninitialized /

PV_SCALE : EU_100 <= EU_0 / OUT_SCALE: EU_100 <= EU_0 /

TRK_SCALE: EU_100 <= EU_0 / FF_SCALE: EU_100 <= EU_0 /

unknown reason / Ok

R Reason for OUT.status not Good, bits at BLK_ERR and other

diagnosis.

Setting:

Startup Device / RB: MODE_BLK.ACTUAL is OOS / Memory

failure / no schedule / period of execution / period of

execution to large / MODE_BLK.PERMITTED doesn't include

Auto / MODE_BLK.TARGET is set OOS / MODE_BLK.TARGET is

set MAN / MODE_BLK.ACTUAL is MAN, Startup to Auto /

INTEG_TYPE is uninitialized / IN_1 and IN_2 are not

connected / TIME_UNIT1 and TIME_UNIT2 are uninitialized /

CLOCK_PER <= period of execution / TIME_UNIT and

TIME_UNIT2 is uninitialized / IN_1.status is Bad / IN_2.status

is Bad / IN_1.value is NaN or INF / IN_2.value is NaN or INF /

PCT_INCL < UNCERT_LIM / PCT_INCL < GOOD_LIM /

PULSE_VAL1 and PULSE_VAL2 are 0 / TOTAL_SP is 0: cyclic

reset / unknown reason / Ok

Current diagnosis

Current diagnosis

Current diagnosis

18

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 19

GFC 300

Parameter

Parameter

ParameterParameter

DD name

OPERATION 4

Access Description and settings Initial Value

AR_DIAG

AR Diagnosis

DIAGNOSIS_DEV

DIAGNOSIS_DEV

DIAGNOSIS_DEVDIAGNOSIS_DEV

Diagnosis Device

Diagnosis Device

Diagnosis DeviceDiagnosis Device

R Reason for OUT.status not Good, bits at BLK_ERR and other

R Display of maximum 8 (error) messages. Current diagnosis

diagnosis.

Startup Device / RB: MODE_BLK.ACTUAL is OOS / Memory

failure / no schedule / period of execution / period of

execution to large / MODE_BLK.PERMITTED doesn't include

Auto / MODE_BLK.TARGET is set OOS / MODE_BLK.TARGET is

set MAN / MODE_BLK.ACTUAL is MAN, Startup to Auto /

ARITH_TYPE is uninitialized / RANGE_HI < RANGE_LO /

COMP_LIM_HI < COMP_LIM_LO / OUT_LIM_HI < OUT_LIM_LO

/ IN_x.status is Bad / unknown reason / Ok

Setting:

No message

F:

F: error in device / IO 1 / parameter / IO 2 / configuration /

F: F:

display / current in-/output A / current in-/output B / current

in-/output C / software user interface / hardware settings /

hardware detection / RAM/ROM error IO1 / RAM/ROM error

IO2 / Fieldbus / communication dsp-up / sensor driver /

uProc. / dsp / parameter frontend / application error / open

circuit A / open circuit B / open circuit C / over range A

(current) / over range B (current) / over range C (current) /

over range A (pulse) / over range B (pulse) / over range D

(pulse) / active settings / factory settings / backup 1 settings /

backup 2 settings / wiring A (output) / wiring B (output) /

wiring A (input) / wiring B (input) / flow exceeding limit / signal

lost path 1 / signal lost path 2 / signal lost path 3 / transducer

delay / temperature input / pressure input / p & T input / VoS

monitor

S:

S: out of specification / overflow counter 1 (C) / overflow

S: S:

counter 1 (B) / overflow counter 2 / overflow counter 3 /

backplane invalid / error current A / error current B /

unreliable 1 / unreliable 2 / unreliable 3 / front end calibration

/ dsp timing error

Current diagnosis

Current diagnosis

DISPLAY_CNFG

DISPLAY_CNFG

DISPLAY_CNFGDISPLAY_CNFG

Display Configuration

Display Configuration

Display ConfigurationDisplay Configuration

DISP_LINE1

Display Line 1

DISP_LINE2

Display Line 2

DISP_LINE3

Display Line 3

ELECTRONIC_INFO

ELECTRONIC_INFO

ELECTRONIC_INFOELECTRONIC_INFO

Electronic Information

Electronic Information

Electronic InformationElectronic Information

IDENT_NUMBER

Ident Number

ELECTRONIC_REV

Electronic Revision

PRODUCTION_DATE

Production Date

C:

C:checks in progress / simulation flow / simulation VoS /

C:C:

simulation fieldbus

I:

I: counter 1 stopped (C) / counter 1 stopped (B) / counter 2

I: I:

stopped / counter 3 stopped / power fail / control input A

active / control input B active / over range display 1 / over

range display 2 / backplane sensor / backplane settings /

backplane difference / optical interface / write cycles overfl. /

baudrate search / no data exchange / start up

R/W Select the function block output value to display at which line.

R Information about ident number, electronic revision and

For details see subelements.

Setting:

AI1 / AI2 / AI3 / AI4 / AI5 / AI6 / PID / INT1 / INT2 / AR

production date. For details see subelements.

Actual ident number

Actual electronic revision

Date of production

-

AI1

AI2

AI3

-

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

19

Page 20

4 OPERATION

Parameter

Parameter

ParameterParameter

DD name

FF_BOARD_INFO

FF_BOARD_INFO

FF_BOARD_INFOFF_BOARD_INFO

FF Circuit

FF Circuit

FF CircuitFF Circuit

Board Information

Board Information

Board InformationBoard Information

IDENT_NUMBER

Ident Number

HARDWARE_ID

Hardware Ident

Number

SOFTWARE_VER

FF Software Version

PRODUCTION_DATE

Production Date

CALIBRATION_DATE

Calibration Date

FF_SERIAL_NO

FF Board

Serial Number

OPERATION_HOUR

OPERATION_HOUR

OPERATION_HOUROPERATION_HOUR

Operation Hours

Operation Hours

Operation HoursOperation Hours

PASSWRD

PASSWRD

PASSWRDPASSWRD

Password

Password

PasswordPassword

PROTECT_INFO

PROTECT_INFO

PROTECT_INFOPROTECT_INFO

Protection Information

Protection Information

Protection InformationProtection Information

SERIAL_NO

SERIAL_NO

SERIAL_NOSERIAL_NO

Serial Number

Serial Number

Serial NumberSerial Number

SW_SIMULATE

SW_SIMULATE

SW_SIMULATESW_SIMULATE

Software Simulate

Software Simulate

Software SimulateSoftware Simulate

GFC 300

Access Description and settings Initial Value

R For details see subelements. "Actual values"

R Actual ident number

Actual hardware number

Actual software version

Date of production

Date of calibration

Actual serial number

R Operation hours since first power-up. Curent operation

hours

R/W Password to activate access rights to restricted parameters. 0

R Current protection level to restricted parameters. Production

Setting:

Concentration / bit 5…7 (not used) / User / User / Service

Level / Production / Custody Transfer / Write Lock

R Device serial number and serial number of the system. Current serial

number

R/W Enable/disable simulation like simulate "Hardware jumper". Disable

Setting:

Disable / Active

20

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 21

GFC 300

4.5 Analog Input Block (AI 1...6)

The following tables list the Analog Input Block parameters in alphabetical order.

It describes characteristics of the measurement values obtained from the Transducer Block in a

user defined way and to deliver it to the control system. There are also some parameters in the

Analog Input Block, that can be configured to get a measurement value quality as desired by the

user.

The following tables contain short parameter description, factory settings (Initial Value (IV)) and

possible settings.

Parameter

Parameter

ParameterParameter

DD name

Alert Key

Alert Key R/W The identification number of the plant unit. This information

Alert KeyAlert Key

BLOCK_ERR

BLOCK_ERR

BLOCK_ERRBLOCK_ERR

Block Error

Block Error

Block ErrorBlock Error

MODE_BLK

MODE_BLK

MODE_BLKMODE_BLK

Block Mode

Block Mode

Block ModeBlock Mode

TARGET

Target

ACTUAL

Actual

PERMITTED

Permitted

Access Description and settings Initial Value

may be used in the host for sorting alarms, etc.

Setting:

1...255

R This parameter reflects the error status associated with the

hardware or software components associated with a block. It

is a bit string, so that multiple errors may be shown.

Setting:

• Other: Non-specific error active

• Block Configuration: Error detected in block configuration

• Link Configuration: Error detected in link configuration

• Simulation Active: Simulation enabled in this block

• Local Override: Output tracking of faultstate active

• Device Fault State: Device faultstate set

• Device Maintenance: Device needs maintenance soon

• Input Failure: Process variable has bad status

• Output Failure: Failure detected in output hardware

• Memory Failure: Memory error detected

• Lost Static Data: Static parameters cannot be recovered

• Lost NV Data: Non-volatile parameters cannot be recovered

• Readback Check: Failure detected in READBACK

• Maintenance Needed: Device NEEDS maintenance NOW

• Power Up: Recovery from power failure

• Out Of Service: Block actual mode is out of service

Mix The actual, target, permitted and normal modes of the block. -

R/W By setting this parameter to an allowed value (one of the value

from permitted modes) user can change the block execution

mode. Changing of modes is required to change the access

permissions available to various parameters.

Setting:

Auto / OOS

R This is the current mode of the block, which may differ from

the target based on operating conditions. Its value is

calculated as part of block execution.

Setting:

Auto / OOS

R/W Defines the modes which are allowed for an instance in the

block. The permitted mode is configured based on application

requirements.

Setting:

Auto / OOS

OPERATION 4

0

Other

OOS

OOS

Auto

OOS

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

21

Page 22

4 OPERATION

Parameter

Parameter

ParameterParameter

DD name

Access Description and settings Initial Value

GFC 300

NORMAL

Normal

ST_REV

ST_REV

ST_REVST_REV

Static Revision

Static Revision

Static RevisionStatic Revision

STRATEGY

STRATEGY

STRATEGYSTRATEGY

Strategy

Strategy

StrategyStrategy

TAG_DESC

TAG_DESC

TAG_DESCTAG_DESC

Tag Description

Tag Description

Tag DescriptionTag Description

ACK_OPTION

ACK_OPTION

ACK_OPTIONACK_OPTION

Acknowledge

Acknowledge

Acknowledge Acknowledge

Option

Option

OptionOption

ALARM_HYS

ALARM_HYS

ALARM_HYSALARM_HYS

Alarm Hysteresis

Alarm Hysteresis

Alarm HysteresisAlarm Hysteresis

ALARM_SUM

ALARM_SUM

ALARM_SUMALARM_SUM

Alarm Summary

Alarm Summary

Alarm SummaryAlarm Summary

Current R The active status of each alarm. Uninitialized

Unacknowledged R The unacknowledged state of each alarm. Uninitialized

Unreported R The unreported states of each alarm. Uninitialized

Disabled R The disabled state of each alarm Uninitialized

BLOCK_ALM

BLOCK_ALM

BLOCK_ALMBLOCK_ALM

Block Alarm

Block Alarm

Block AlarmBlock Alarm

R/W This is the mode which the block should be set to during

normal operating conditions.

Setting:

Auto / OOS

R The revision level of the static data associated with the

function block. The revision value will be incremented each

time a static parameter value in the block is changed.

Setting:

0...65535

R/W The strategy field can be used to identify grouping of blocks.

This data is not checked or processed by the block.

Setting:

0...65535

R/W This is the user description of the intended application of the

block.

Setting:

≤32 digits

R/W Selection of whether alarms associated with the function

block will be automatically acknowledged.

Setting:

HiHi Alm Auto Ack / Hi Alm Auto Ack / LoLo Alm Auto Ack / Lo

Alm Auto Ack / Blk Alm Auto Ack / Fail Alm Auto Ack / Off

Spec Alm Auto Ack / Maint Alm Auto Ack / Check Alm Auto

Ack

R/W Amount the PV must return within the alarm limits before the

alarm condition clears. Alarm hysteresis is expressed as a

percent of the PV span.

Setting:

0...50%

Mix The current alert status, unacknowledged states, unreported

states and disabled states of the alarms associated with the

function block.

Setting:

HiHi Alarm / Hi Alarm / LoLo Alarm / Lo Alarm / Block Alarm

Setting:

HiHi Alarm Unack / Hi Alarm Unack / LoLo Alarm Unack / Lo

Alarm Unack / Block Alarm Unack

Setting:

HiHi Alarm Unrep / Hi Alarm Unrep / LoLo Alarm Unrep / Lo

Alarm Unrep / Block Alarm Unrep

Setting:

HiHi Alarm Disabled / Hi Alarm Disabled / LoLo Alarm

Disabled / Lo Alarm Disabled / Block Alarm Disabled

Mix The block alarm is used for all configuration, hardware,

connection failure or system problems in the block. The cause

of the alert is entered in the subcode field. The first alert to

become active will set the "Active" status in the "Status"

attribute. As soon as the "Unreported" status is cleared by the

alert reporting task, another block alert may be reported

without clearing the "Active" status, if the subcode has

changed.

Auto

0

0

blanks

Uninitialized

0.5

-

-

22

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 23

GFC 300

Parameter

Parameter

ParameterParameter

DD name

OPERATION 4

Access Description and settings Initial Value

Unacknowledged R/W A discrete enumeration which is set to "Unacknowledged"

Alarm State R A discrete enumeration which gives an indication of whether

Time Stamp R The time when evaluation of the block was started and a

Subcode R An enumeration specifying the cause of the alert to be

Value R The value of the associated parameter at the time the alert

CHANNEL

CHANNEL

CHANNELCHANNEL

Channel

Channel

ChannelChannel

R/W The number of the logical hardware channel that is connected

when an alarm occurs, and set to "Acknowledged" by a write

from a human interface device or other entity which can

acknowledge that the alarm/event has been noticed.

Setting:

Uninitialized / Acknowledged / Unacknowledged

the alert is active and whether it has been reported.

Setting:

Uninitialized / Clear - reported / Clear - not reported / Active reported / Active - not reported

change in alarm/event state was detected that is unreported.

The time stamp value will be maintained constant until alert

confirmation has been received - even if another change of

state occurs.

Setting:

MM / DD / YY (Month / Day / Year)

HH:MM:SS (Hour:Minute:Second)

reported.

Setting:

Other / Block Configuration / Link Configuration / Simulation

Active / Local Override / Device Fault State / Device

Maintenance / Input Failure / Output Failure / Memory

Failure / Lost Static Data / Lost NV Data / Readback Check /

Maintenance Needed / Power Up / Out Of Service

was detected.

Setting:

0...255

to this I/O block. This information defines the transducer to be

used going to or from the physical world.

Note:

Note:

Note:Note:

W = Writeable only by setting "OOS" in MODE_BLK

Setting:

0 Uninitialized

1 volume flow

2 corr. volume flow

3 mass flow

4 molar mass

5 enthalpy flow

6 spec. enthalpy

7 density

8 flow speed

9 process temperature

10 process pressure

11 electronic temperature

12 velocity of sound

13 gain

14 SNR

15 velocity of sound 1

16 gain 1

17 SNR 1

18 velocity of sound 2

19 gain 2

20 SNR 2

21 velocity of sound 3

22 gain 3

23 SNR 3

Uninitialized

Uninitialized

Uninitialized

Other

0

Uninitialized

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

23

Page 24

4 OPERATION

Parameter

Parameter

ParameterParameter

DD name

FIELD_VAL

FIELD_VAL

FIELD_VALFIELD_VAL

Field Value

Field Value

Field ValueField Value

Status R Digital transducers, unlike their analogue versions, can detect

Value R A numerical quantity entered by a user or calculated by the

GRANT_DENY

GRANT_DENY

GRANT_DENYGRANT_DENY

Grant Deny

Grant Deny

Grant DenyGrant Deny

GRANT

Grant

DENY

Deny

HI_ALM

HI_ALM

HI_ALMHI_ALM

High Alarm

High Alarm

High AlarmHigh Alarm

HI_HI_ALM

HI_HI_ALM

HI_HI_ALMHI_HI_ALM

High High Alarm

High High Alarm

High High AlarmHigh High Alarm

Settings of 5 subelements for previous 2 parameters High Alarm and High High Alarm:

Unacknowledged R/W Setting:

Alarm State R Setting:

Time Stamp R Setting:

Subcode R Setting:

Value R A numerical quantity entered by a user or calculated by the

HI_HI_LIM

HI_HI_LIM

HI_HI_LIMHI_HI_LIM

High High Limit

High High Limit

High High LimitHigh High Limit

HI_HI_PRI

HI_HI_PRI

HI_HI_PRIHI_HI_PRI

High High Priority

High High Priority

High High PriorityHigh High Priority

HI_LIM

HI_LIM

HI_LIMHI_LIM

High Limit

High Limit

High LimitHigh Limit

HI_PRI

HI_PRI

HI_PRIHI_PRI

High Priority

High Priority

High PriorityHigh Priority

Access Description and settings Initial Value

R Raw value of the field device in percent of the PV range, with a

status reflecting the transducer condition, before signal

characterization (L_TYPE) or filtering (PV_FTIME).

faults that make the measurement bad or prevent the

actuator from responding. This additional, valuable

information will be passed along with each transmission of a

data value in the form of a status attribute.

algorithm.

Options for controlling access of host computers and local

control panels to operating, tuning and alarm parameters of

the block.

R/W Depending on the philosophy of the plant, the operator or a

higher level device (HLD) or a local operator's panel (LOP) in

the case of "Local", may turn on an item of the "Grant"

attribute - "Program, Tune, Alarm or Local".

Setting:

Program / Tune / Alarm / Local / Operate

R/W The deny attribute is provided for use by a monitoring

application in an interface device and may not be changed by

an operator.

Setting:

Program denied / Tune denied / Alarm denied / Local denied /

Operate denied

The status for High Alarm and its associated time stamp.

Settings of 5 subelements see in the following part.

Mix The status for High High Alarm and its associated time stamp.

Settings of 5 subelements see in the following part.

Uninitialized / Acknowledged / Unacknowledged

Uninitialized / Clear - reported / Clear - not reported / Active reported / Active - not reported

MM / DD / YY (Month / Day / Year)

HH:MM:SS (Hour:Minute:Second)

Other / Block Configuration / Link Configuration / Simulation

Active / Local Override / Device Fault State / Device

Maintenance / Input Failure / Output Failure / Memory

Failure / Lost Static Data / Lost NV Data / Readback Check /

Maintenance Needed / Power Up / Out Of Service

algorithm.

R/W The setting for High High Alarm in engineering units.

Setting range see in the following part.

R/W Priority of the High High Alarm.

Setting see in the following part.

R/W The setting for High Alarm in engineering units.

Setting range see in the following part.

R/W Priority of the High Alarm.

Setting see in the following part.

GFC 300

-

Bad

Non Specific

Not Limited

0.0

-

Uninitialized

Uninitialized

-

-

Uninitialized

Uninitialized

Uninitialized

Other

0.0

NaN

0

NaN

0

24

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 25

GFC 300

Parameter

Parameter

ParameterParameter

DD name

OPERATION 4

Access Description and settings Initial Value

Setting range for previous 2

parameters:

x_y_LIM

x_y_Limit

Setting for previous 2

parameters:

x_y_PRI

x_y_Priority

IO_OPTS

IO_OPTS

IO_OPTSIO_OPTS

IO Options

IO Options

IO OptionsIO Options

(IO = Input/Output)

(IO = Input/Output)

(IO = Input/Output)(IO = Input/Output)

L_TYPE

L_TYPE

L_TYPEL_TYPE

Linearization Type

Linearization Type

Linearization TypeLinearization Type

LO_ALM

LO_ALM

LO_ALMLO_ALM

Low Alarm

Low Alarm

Low AlarmLow Alarm

LO_LO_ALM

LO_LO_ALM

LO_LO_ALMLO_LO_ALM

Low Low Alarm

Low Low Alarm

Low Low AlarmLow Low Alarm

Settings of 5 subelements for previous 2 parameters Low Alarm and Low Low Alarm:

Unacknowledged R/W Setting:

Alarm State R Setting:

Time Stamp R Setting:

Subcode R An enumeration specifying the cause of the alert to be

Value R A numerical quantity entered by a user or calculated by the

LO_LIM

LO_LIM

LO_LIMLO_LIM

Low Limit

Low Limit

Low LimitLow Limit

LO_LO_LIM

LO_LO_LIM

LO_LO_LIMLO_LO_LIM

Low Low Limit

Low Low Limit

Low Low LimitLow Low Limit

LO_PRI

LO_PRI

LO_PRILO_PRI

Low Priority

Low Priority

Low PriorityLow Priority

LO_LO_PRI

LO_LO_PRI

LO_LO_PRILO_LO_PRI

Low Low Priority

Low Low Priority

Low Low PriorityLow Low Priority

R/W Options which the user may select to alter input and output

R/W Determines if the values passed by the TB to the AI block may

R/W The setting for Low Alarm in engineering units.

R/W The setting for Low Low Alarm in engineering units.

R/W Priority of the Low Alarm.

R/W Priority of the Low Low Alarm.

-3.39 E38…+3.39 E38 / - INF (- infinite) / + INF (+ infinite)

0: The associated alert may clear when the priority is changed

to 0, but it will never occur.

1: The associated alert is not send as a notification. If the

priority is above 1, then the alert must be reported.

2: Reserved for alerts that do not require the attention of a

plant operator, e.g. diagnostic and system alerts. Block alarm,

error alarm and update event have a fixed priority of 2.

3...7: Increasing higher priorities - advisory alarms.

8...15: Increasing higher priorities - critical alarms.

block processing.

Setting:

Low Cutoff / Units Conversion

be used directly (Direct) or if the value is in different units and

must be converted linearly (Indirect) or with square root (Ind

Sqr Root), using the input range defined by the transducer and

the associated output range.

W = Writeable only by setting "OOS" in MODE_BLK

Setting:

Uninitialized / Direct / Indirect / Ind Sqr Root

The status for Low Alarm and its associated time stamp.

Settings of 5 subelements see in the following part.

The status for Low Low Alarm and its associated time stamp.

Settings of 5 subelements see in the following part.

Uninitialized / Acknowledged / Unacknowledged

Uninitialized / Clear - reported / Clear - not reported / Active reported / Active - not reported

MM / DD / YY (Month / Day / Year)

HH:MM:SS (Hour:Minute:Second)

reported.

Setting:

Other / Block Configuration / Link Configuration / Simulation

Active / Local Override / Device Fault State / Device

Maintenance / Input Failure / Output Failure / Memory

Failure / Lost Static Data / Lost NV Data / Readback Check /

Maintenance Needed / Power Up / Out Of Service

algorithm.

Setting range see in the following part.

Setting range see in the following part.

Setting see in the following part.

Setting see in the following part.

0

Uninitialized

Uninitialized

-

-

Uninitialized

Uninitialized

Uninitialized

Other

0.0

(-NaN)

(-NaN)

0

0

www.krohne.com07/2012 - 4001866001 - AD GFC 300 FF R01 en

25

Page 26

4 OPERATION

Parameter

Parameter

ParameterParameter

DD name

Access Description and settings Initial Value

GFC 300

Setting range for previous 2

parameters:

x_y_LIM

x_y_Limit

Setting for previous 2

parameters:

x_y_PRI

x_y_Priority

LOW_CUT

LOW_CUT

LOW_CUTLOW_CUT

Low Cutoff

Low Cutoff

Low CutoffLow Cutoff

OUT

OUT

OUTOUT

Output

Output

OutputOutput

Status R Digital transducers, unlike their analogue versions, can detect

Value R/W A numerical quantity entered by a user or calculated by the

OUT_SCALE

OUT_SCALE

OUT_SCALEOUT_SCALE

Output Scale

Output Scale

Output ScaleOutput Scale

EU_100

EU at 100%

EU_0

EU at 0%

Units Index R/W Device Description units code index for the engineering unit

Decimal Point R/W The number of digits to the right of the decimal point which

PV

PV

PVPV

Process Value

Process Value

Process ValueProcess Value

Status R Digital transducers, unlike their analogue versions, can detect

Value R A numerical quantity entered by a user or calculated by the

PV_FTIME

PV_FTIME

PV_FTIMEPV_FTIME

PV F Time

PV F Time

PV F TimePV F Time

(Process Value

(Process Value

(Process Value (Process Value

Filter Time

Filter Time

Filter Time Filter Time

Constant)

Constant)

Constant)Constant)

R/W Limit used in square root processing. A value of zero percent

R/W The primary analogue discrete value calculated as a result of

R/W The high and low scale values, engineering units code and

R/W The engineering unit value which represents the upper end of

R/W The engineering unit value which represents the lower end of

R/W Time constant of a single exponential filter for the PV, in

-3.39 E38…+3.39 E38 / - INF (- infinite) / + INF (+ infinite)

0: The associated alert may clear when the priority is changed

to 0, but it will never occur.

1: The associated alert is not send as a notification. If the

priority is above 1, then the alert must be reported.

2: Reserved for alerts that do not require the attention of a

plant operator, e.g. diagnostic and system alerts. Block alarm,

error alarm and update event have a fixed priority of 2.

3...7: Increasing higher priorities - advisory alarms.

8...15: Increasing higher priorities - critical alarms.

of scale is used in block processing if the transducer value

falls below this limit, in %of scale. This feature may be used to

eliminate noise near zero for a flow sensor.

Setting:

≥0.0

executing the function.

Note:

Note:

Note:Note:

W = Writeable only by setting "OOS" in MODE_BLK

faults that make the measurement bad or prevent the

actuator from responding. This additional, valuable

information will be passed along with each transmission of a

data value in the form of a status attribute.

algorithm.

number of digits to the right of the decimal point to be used in

displaying the OUT parameter and parameters which have the

same scaling as OUT.

range of the associated block parameter.

range of the associated block parameter.

descriptor for the associated block value.

Setting:

All units are possible.

should be used by an interface device in displaying the

specified parameter.

Either the primary analogue value for use in executing the

function or a process value associated with it.

faults that make the measurement bad or prevent the

actuator from responding. This additional, valuable

information will be passed along with each transmission of a

data value in the form of a status attribute.

algorithm.

seconds.

Setting:

0.0…60.0

0

0

-

-

-

-

100.0

0.0

Uninitialized

0

-

0

0.0

0

26

www.krohne.com 07/2012 - 4001866001 - AD GFC 300 FF R01 en

Page 27

GFC 300

Parameter

Parameter

ParameterParameter

Access Description and settings Initial Value

OPERATION 4

DD name

SIMULATE

SIMULATE

SIMULATESIMULATE

Simulate

Simulate

SimulateSimulate

Simulate Status R/W Used for the transducer status when simulation is enabled. 0

Simulate Value R/W Used for the transducer value when simulation is enabled. 0.0

Transducer Status R Status of value supplied by transducer. 0

Transducer Value R Current value supplied by transducer. 0.0

Simulate

En/Disable

STATUS_OPTS

STATUS_OPTS

STATUS_OPTSSTATUS_OPTS

Status Option

Status Option

Status OptionStatus Option

UPDATE_EVT

UPDATE_EVT

UPDATE_EVTUPDATE_EVT

Update Event

Update Event

Update EventUpdate Event

Unacknowledged RW A discrete enumeration which is set to "Unacknowledged"

Update State R A discrete enumeration which gives an indication of whether

Time Stamp R The time when evaluation of the block was started and a

Static Revision R The static revision of the block whose static parameter was

Relative Index R The OD index of the static parameter whose change caused

XD_SCALE

XD_SCALE

XD_SCALEXD_SCALE

Transducer Scale

Transducer Scale

Transducer ScaleTransducer Scale

EU_100

EU at 100%

Mix Allows the transducer analogue input or output to the block to

R/W The parameter "SW_Simulated" in RB Block must be enabled. Disabled

R/W Options which the user may select in the block processing of

R/W The high and low scale values, engineering units code and

R/W The engineering unit value which represents the upper end of

be manually supplied when "Simulate" is enabled. When

simulation is disabled, the simulate value and status track the

actual value and status.

Setting:

-3.39 E38 … +3.39 E38, - INF, + INF

Setting:

Uninitialized / Disabled / Active

status.

Setting:

Propagate Fault Forward / Uncertain if limited / BAD if

limited / Uncertain if Man.

This alert is generated by any change to the static data. -

when an alarm occurs, and set to "Acknowledged" by a write

from a human interface device or other entity which can

acknowledge that the alarm/event has been noticed.