Page 1

OPTIWAVE 1010

Handbook

2-wire / 6 GHz Radar (FMCW) Level Meter

for continuous measuring of clean liquids in the BM 26 Advanced (Magnetic Level

Indicator)

© KROHNE 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2014 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 3

OPTIWAVE 1010

CONTENTS

1 Safety instructions 6

1.1 Software history ............................................................................................................... 6

1.2 Intended use ..................................................................................................................... 6

1.3 Certification ...................................................................................................................... 7

1.4 Radio approvals ................................................................................................................ 7

1.4.1 European Union (EU)............................................................................................................... 7

1.4.2 U.S.A. and Canada................................................................................................................... 8

1.5 Safety instructions from the manufacturer ..................................................................... 9

1.5.1 Copyright and data protection ................................................................................................ 9

1.5.2 Disclaimer ............................................................................................................................... 9

1.5.3 Product liability and warranty .............................................................................................. 10

1.5.4 Information concerning the documentation......................................................................... 10

1.5.5 Warnings and symbols used................................................................................................. 11

1.6 Safety instructions for the operator............................................................................... 11

2 Device description 12

2.1 Scope of delivery............................................................................................................. 12

2.2 Device description .......................................................................................................... 13

2.3 Visual Check ................................................................................................................... 14

2.4 Nameplates .................................................................................................................... 15

2.4.1 Nameplate (example)............................................................................................................ 15

3 Installation 16

3.1 General notes on installation ......................................................................................... 16

3.2 Storage ........................................................................................................................... 16

3.3 Transport ........................................................................................................................ 17

3.4 Pre-installation requirements ....................................................................................... 17

3.5 Pressure and temperature ranges ................................................................................ 17

3.6 Recommended mounting position ................................................................................. 20

3.7 Mounting restrictions ..................................................................................................... 20

3.8 Stilling wells ................................................................................................................... 21

3.9 How to attach the weather protection to the device...................................................... 22

4 Electrical connections 23

4.1 Safety instructions.......................................................................................................... 23

4.2 Electrical installation: 2-wire, loop-powered ................................................................ 23

4.3 Electrical connection for current output ....................................................................... 24

4.3.1 Non-Ex devices ..................................................................................................................... 24

4.3.2 Devices for hazardous locations........................................................................................... 24

4.4 Protection category ........................................................................................................24

4.5 Networks ........................................................................................................................ 25

4.5.1 General information.............................................................................................................. 25

4.5.2 Point-to-point connection..................................................................................................... 25

4.5.3 Multi-drop networks ............................................................................................................. 26

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

3

Page 4

CONTENTS

OPTIWAVE 1010

5 Start-up 27

5.1 How to start the device................................................................................................... 27

5.1.1 Start-up checklist ................................................................................................................. 27

5.1.2 How to start the device ......................................................................................................... 27

5.2 Operating concept ..........................................................................................................27

5.3 Remote communication with PACTware™ .................................................................... 28

5.3.1 General notes........................................................................................................................ 28

5.3.2 Software installation............................................................................................................. 28

5.4 Remote communication with the AMS™ Device Manager............................................. 29

6 Operation 30

6.1 Software configuration ................................................................................................... 30

6.1.1 General notes........................................................................................................................ 30

6.1.2 Procedure.............................................................................................................................. 30

6.2 How to load settings from the device to PACTware™ ................................................... 31

6.3 Menu overview................................................................................................................ 32

6.4 Device settings ............................................................................................................... 33

6.4.1 Supervisor access rights ...................................................................................................... 33

6.4.2 How to change device settings ............................................................................................. 33

6.4.3 Data about menu items and parameters (online Help)........................................................ 34

6.4.4 Basic parameters.................................................................................................................. 35

6.4.5 Signal output ......................................................................................................................... 36

6.4.6 Import / export ...................................................................................................................... 36

6.4.7 Application............................................................................................................................. 37

6.4.8 HART...................................................................................................................................... 38

6.5 Status and error messages............................................................................................ 39

6.5.1 Device status......................................................................................................................... 39

6.5.2 Error handling....................................................................................................................... 40

7 Service 44

7.1 Periodic maintenance..................................................................................................... 44

7.2 Service warranty............................................................................................................. 44

7.3 Spare parts availability...................................................................................................44

7.4 Availability of services .................................................................................................... 44

7.5 Returning the device to the manufacturer..................................................................... 45

7.5.1 General information.............................................................................................................. 45

7.5.2 Form (for copying) to accompany a returned device............................................................ 46

7.6 Disposal .......................................................................................................................... 46

8 Technical data 47

8.1 Measuring principle........................................................................................................47

8.2 Technical data................................................................................................................. 48

8.3 Minimum power supply voltage ..................................................................................... 53

8.4 Pressure ratings............................................................................................................. 54

8.5 Dimensions and weights ................................................................................................ 55

4

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 5

OPTIWAVE 1010

CONTENTS

9 Description of HART interface 58

9.1 General description ........................................................................................................58

9.2 Software description ...................................................................................................... 58

9.3 Connection variants........................................................................................................58

9.3.1 Point-to-Point connection - analogue / digital mode........................................................... 59

9.3.2 Multi-Drop connection (2-wire connection) ......................................................................... 59

9.4 HART® device variables ................................................................................................. 59

9.5 Field Communicator 375/475 (FC 375/475) ................................................................... 59

9.5.1 Installation ............................................................................................................................ 59

9.5.2 Operation............................................................................................................................... 60

9.6 Asset Management Solutions (AMS) .............................................................................. 60

9.6.1 Installation ............................................................................................................................ 60

9.6.2 Operation............................................................................................................................... 60

9.6.3 Parameter for the basic configuration ................................................................................. 60

9.7 Field Device Tool / Device Type Manager (FDT / DTM).................................................. 61

9.7.1 Installation ............................................................................................................................ 61

9.7.2 Operation............................................................................................................................... 61

9.8 Process Device Manager (PDM)..................................................................................... 61

9.8.1 Installation ............................................................................................................................ 61

9.8.2 Operation............................................................................................................................... 61

9.9 HART® menu tree for Basic-DD .................................................................................... 62

9.9.1 Overview Basic-DD menu tree (positions in menu tree)...................................................... 62

9.9.2 Basic-DD menu tree (details for settings)............................................................................ 62

9.10 HART® menu tree for AMS........................................................................................... 62

9.10.1 Overview AMS menu tree (positions in menu tree) ............................................................ 62

9.10.2 AMS menu tree (details for settings).................................................................................. 63

9.11 HART® menu tree for PDM .......................................................................................... 64

9.11.1 Overview PDM menu tree (positions in menu tree)............................................................ 64

9.11.2 PDM menu tree (details for settings) ................................................................................. 65

10 Appendix 67

10.1 Order code .................................................................................................................... 67

10.2 Spare parts ................................................................................................................... 70

10.3 Accessories................................................................................................................... 71

10.4 Glossary ........................................................................................................................ 72

11 Notes 75

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

5

Page 6

1 SAFETY INSTRUCTIONS

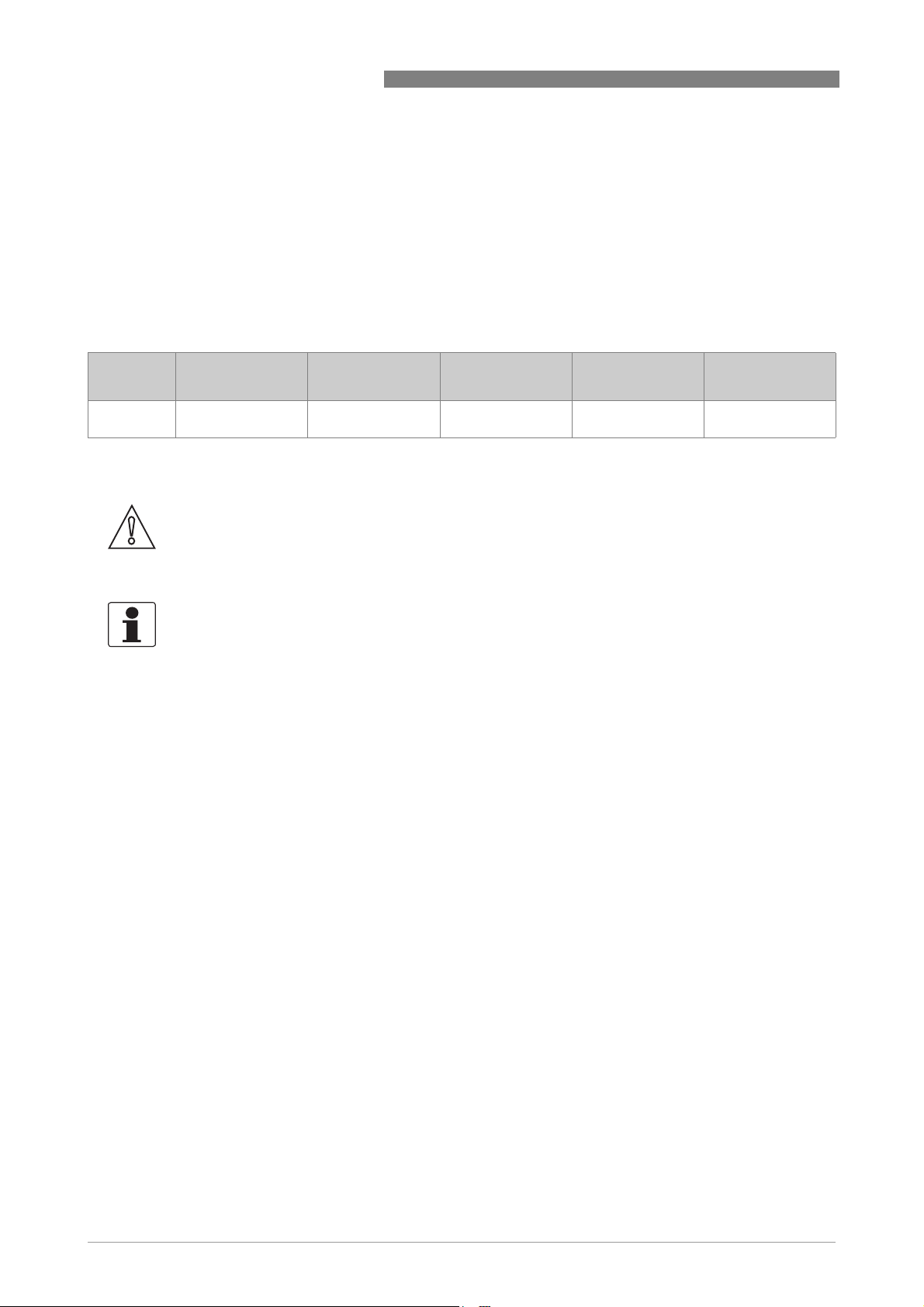

1.1 Software history

"Firmware revision" agrees with NAMUR NE 53. It is a series of numbers used to record the

revision status of embedded software (firmware) in electronic equipment assemblies. It gives

data on the type of changes made and the effect that changes have on compatibility.

Data about software revisions is shown in the DTM for PACTware™. For more data,. If it is not

possible to refer to data in the software, record the serial number of the device (given on the

device nameplate) and speak to the supplier.

OPTIWAVE 1010

Release

date

YYYY-MM-DDConverter and

Printed circuit

assembly

sensor board

1.2 Intended use

CAUTION!

Responsibility for the use of the measuring devices with regard to suitability, intended use and

corrosion resistance of the used materials against the measured fluid lies solely with the

operator.

INFORMATION!

The manufacturer is not liable for any damage resulting from improper use or use for other than

the intended purpose.

This radar level transmitter measures distance and level of liquids. It does not touch the

measured product.

This radar level transmitter can only be used if it is correctly installed and aligned on a bypass

chamber or a stilling well. The bypass chamber or stilling well must be metallic and electrically

conductive. The stilling well must installed in a metal or reinforced concrete tank to prevent

radio frequency interference.

Firmware

revision

1.00.xx 400xxxxx01 - HB OPTIWAVE

Hardware

revision

Changes and

compatibility

Documentation

1010 R01

6

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 7

OPTIWAVE 1010

1.3 Certification

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

In accordance with the commitment to customer service and safety, the device

described in this document meets the following safety requirements:

• Electromagnetic Compatibility (EMC) Directive 2004/108/EC in conjunction with EN 61326-1

(2013).

• Radio Equipment and Telecommunications Terminal Equipment (R & TTE) Directive

1999/05/EC in conjunction with ETSI EN 302 372 (2006). For more data, refer to

Union (EU)

• Low-Voltage Directive 2006/95/EC in conjunction with EN 61010-1 (2001).

SAFETY INSTRUCTIONS 1

European

on page 7.

All devices are based on the CE marking and meet the requirements of NAMUR Guideline NE 21,

NE 43 and NE 53.

1.4 Radio approvals

1.4.1 European Union (EU)

LEGAL NOTICE!

This level transmitter is intended for installation in closed tanks. It meets the requirements of

the R & TTE (Radio Equipment and Telecommunications Terminal Equipment) Directive

1999/05/EC for use in the member countries of the EU.

An industry agreement includes approval for use of the frequency band (5.7...6.7 GHz) in

industrial environments.

According to article 6.4 of the R&TTE Directive, the product is marked by the CE sign + notified

body number (0682) + Class II identifier (= alert sign).

Refer to EN 302372 for installation conditions.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

7

Page 8

1 SAFETY INSTRUCTIONS

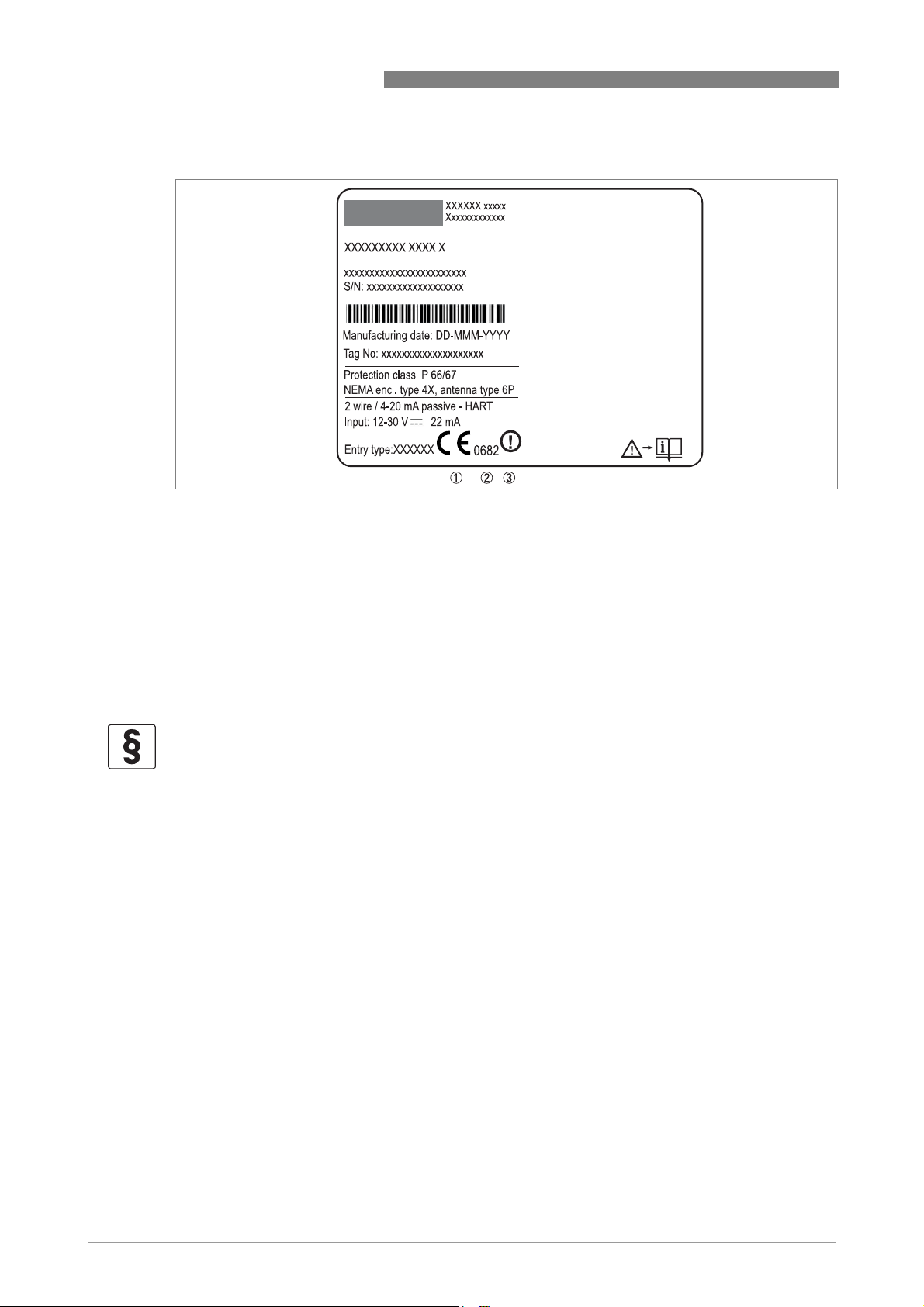

Figure 1-1: Radio approval information on the nameplate

1 CE sign

2 Notified body number (0682 = CETECOM ICT Services GmbH)

3 Class II identifier

OPTIWAVE 1010

According to ETSI EN 302 372 (2006-04), the radiated power outside a metallic tank is less than

-30 dBm.

The radio approval report is given on the DVD-ROM supplied with the device.

1.4.2 U.S.A. and Canada

LEGAL NOTICE!

English: This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry

Canada. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference which may cause un-

desired operation.

Français: Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes:

1. l'appareil ne doit pas produire de brouillage, et

2. l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouil-

lage est susceptible d'en compromettre le fonctionnment.

Changes or modifications made to this equipment not expressly approved by the manufacturer

may void the FCC and IC authorizations to operate this equipment.

This legal information is shown on a label on the side of the device.

The radio approval report is given on the DVD-ROM supplied with the device.

8

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 9

OPTIWAVE 1010

1.5 Safety instructions from the manufacturer

1.5.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

SAFETY INSTRUCTIONS 1

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.5.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

9

Page 10

1 SAFETY INSTRUCTIONS

1.5.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation or operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.5.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of icons as shown below.

OPTIWAVE 1010

10

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 11

OPTIWAVE 1010

1.5.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

SAFETY INSTRUCTIONS 1

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

This symbol refers to all important consequences of the previous actions.

1.6 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

11

Page 12

2 DEVICE DESCRIPTION

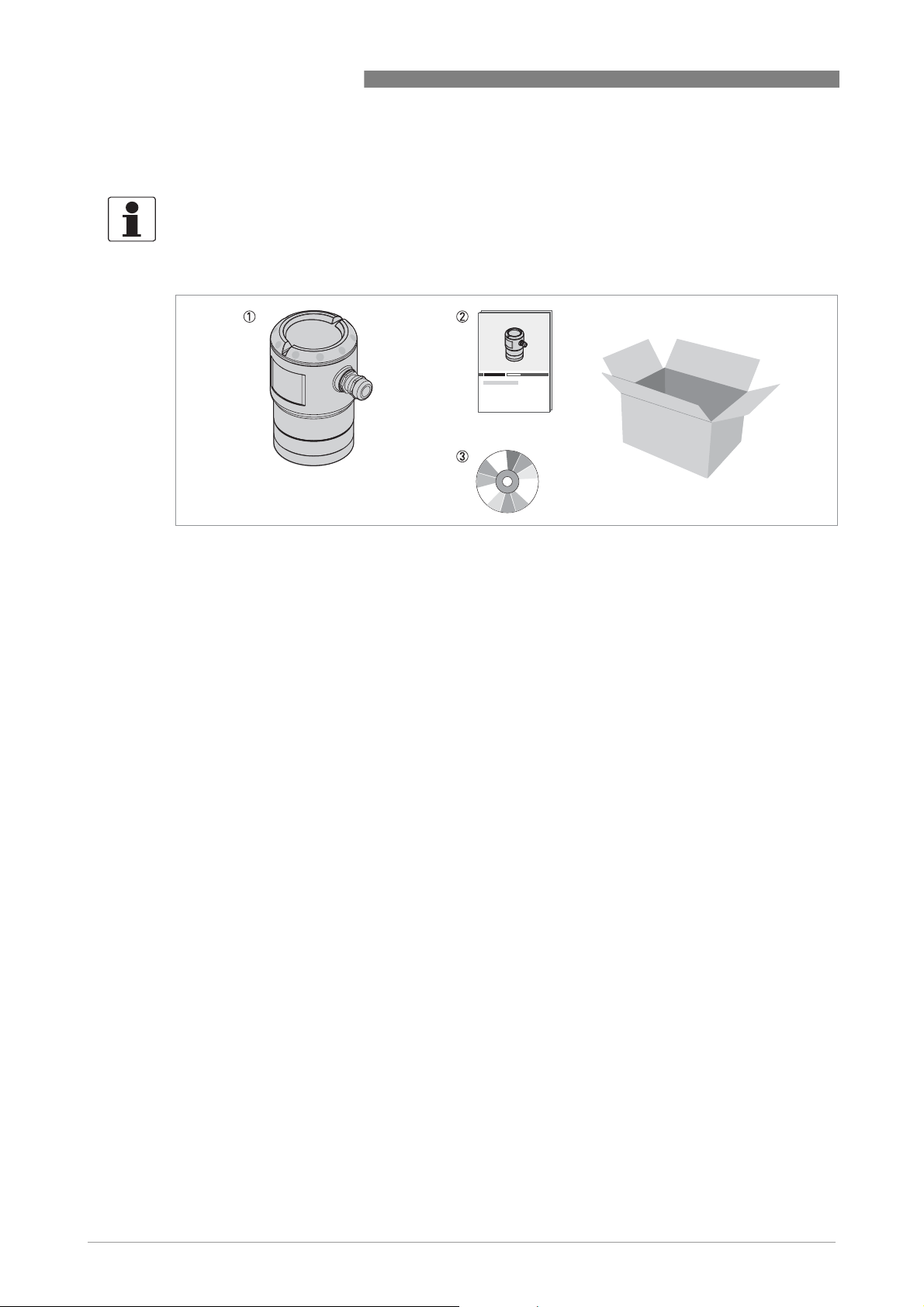

2.1 Scope of delivery

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

OPTIWAVE 1010

Figure 2-1: Scope of delivery

1 Device and measuring chamber

2 Quick Start

3 DVD-ROM (including Handbook, Quick Start, Technical Datasheet and related software)

12

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 13

OPTIWAVE 1010

2.2 Device description

OPTIWAVE 1010 is an FMCW radar designed for use with the BM 26 Advanced (a magnetic level

indicator or MLI), bypass chamber or stilling well. If the device is used with an MLI, it measures

the distance to the float. If the device is used with a bypass chamber or stilling well, it measures

the distance to the surface of the liquid. Radar is a non-contact technology. For more data about

the measuring principle, refer to

Measuring principle

DEVICE DESCRIPTION 2

on page 47.

Figure 2-2: Radar level transmitter mounted on a magnetic (bypass) level indicator

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

13

Page 14

2 DEVICE DESCRIPTION

2.3 Visual Check

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

OPTIWAVE 1010

Figure 2-3: Visual check

1 Device nameplate (for more data)

2 Process connection data (size and pressure rating, material reference and heat number)

3 Gasket material data - refer to the illustration that follows

Figure 2-4: Symbols for the supplied gasket material (on the side of the process connection)

1 EPDM

2 Kalrez

®

6375

If the device is supplied with an FKM/FPM gasket, there is no symbol on the side of the process

connection.

14

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 15

OPTIWAVE 1010

2.4 Nameplates

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

2.4.1 Nameplate (example)

DEVICE DESCRIPTION 2

Figure 2-5: Non-Ex nameplate attached to the housing

1 Cable entry size

2 Input / output option

3 Degree of ingress protection (according to EN 60529 / IEC 60529)

4 Customer tag number

5 Date of manufacture

6 Order number

7 Type code (defined in order)

8 Model name and number

9 Company name and address

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

15

Page 16

3 INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

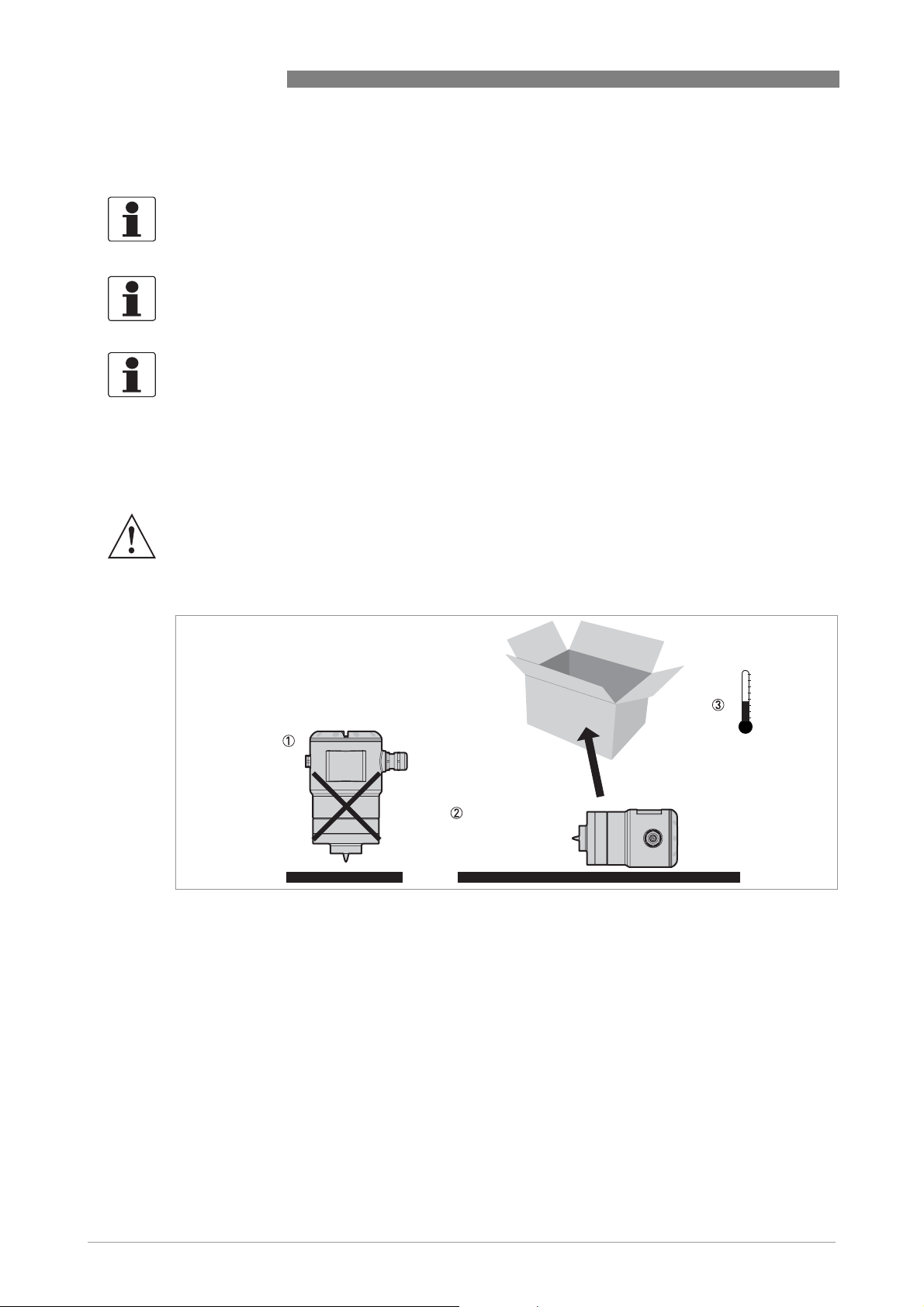

WARNING!

Do not keep the device in a vertical position. This will damage the wave guide connection and the

device will not measure correctly.

OPTIWAVE 1010

16

Figure 3-1: Storage conditions

1 When you put the device into storage, do not keep it in a vertical position

2 Put the device on its side. We recommend that you use the packaging in which it was delivered.

3 Storage temperature range: -40...+85°C / -40...+185°F

• Store the device in a dry and dust-free location.

• Store the device in its original packing.

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 17

OPTIWAVE 1010

3.3 Transport

WARNING!

•

Depending on the version, the device will weight approx. x...xx kg / xx...xx lb. To carry, use

both hands to lift the device carefully by the converter housing. If necessary, lift the device

with a hoist.

•

When handling the device, avoid hard blows, jolts, impact, etc. to prevent damage.

3.4 Pre-installation requirements

INFORMATION!

Obey the precautions that follow to make sure that the device is correctly installed.

• Make sure that there is sufficient space on all sides.

• Protect the signal converter from direct sunlight.

• Do not subject the signal converter to heavy vibrations.

INSTALLATION 3

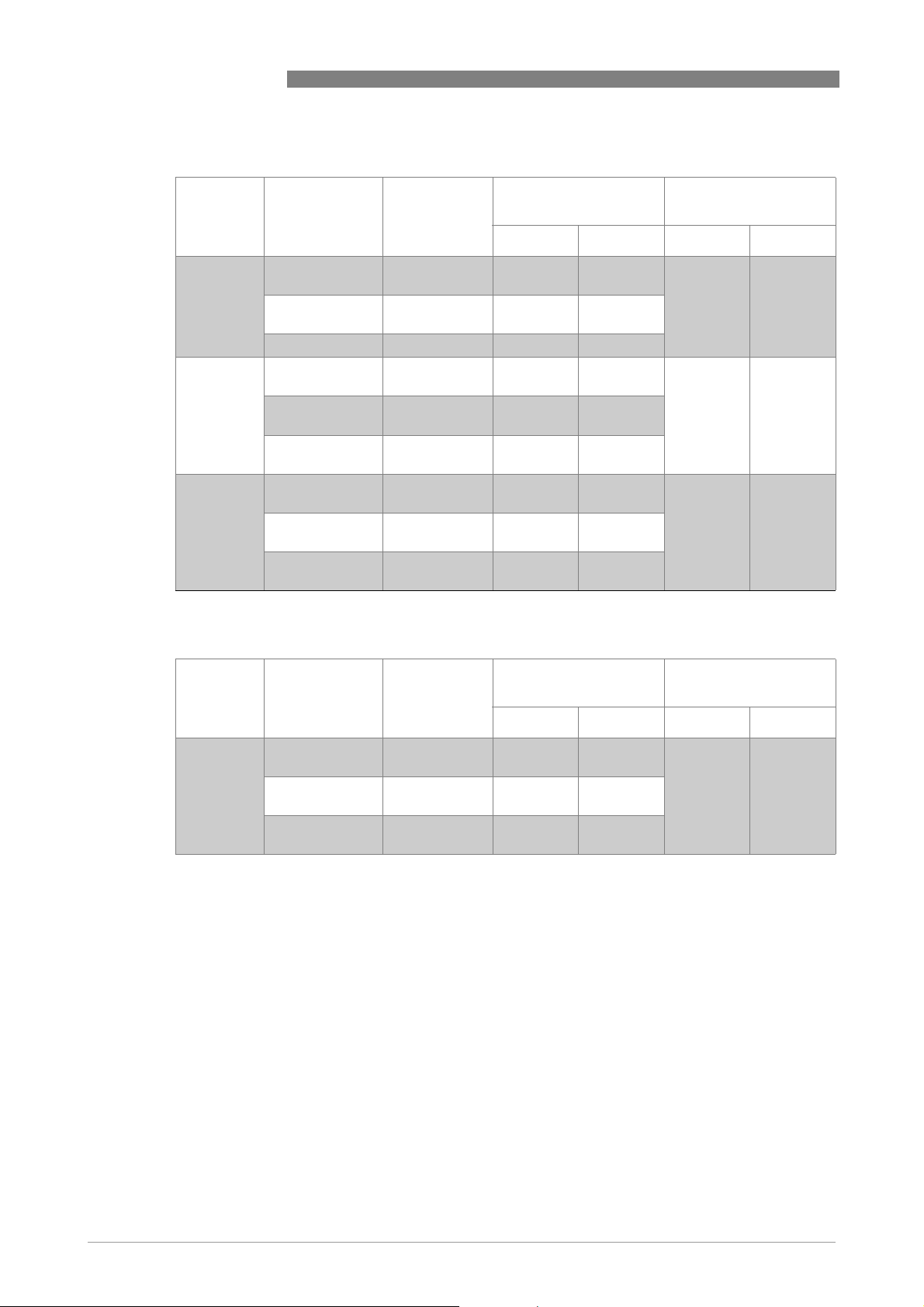

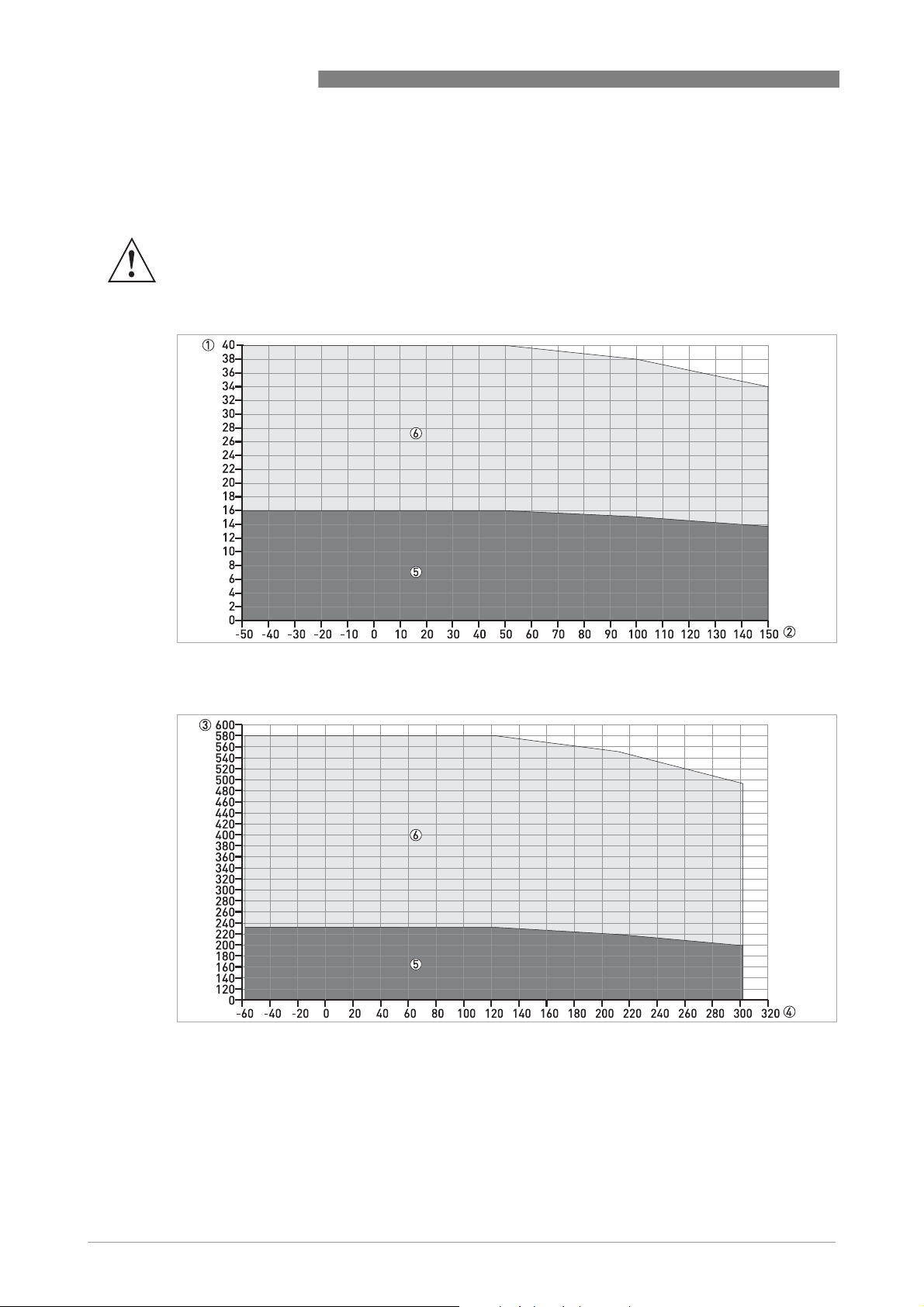

3.5 Pressure and temperature ranges

DANGER!

If the ambient temperature is more than +70

device. Use a protective cover or metallic grid to prevent injury.

Figure 3-2: Pressure and temperature ranges

1 Flange temperature

Non-Ex devices: Depends on the device versions (standard, HP and HT/HP versions) and the seal material. Refer to

the table that follows.

Ex devices: see supplementary operating instructions

2 Ambient temperature

Non-Ex devices: -40...+80°C / -40...+176°F

Ex devices: see supplementary operating instructions

3 Process pressure

Depends on the type of antenna and process connection. Refer to the table that follows.

°

C / +158°F, there is a risk of injury if you touch the

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

17

Page 18

3 INSTALLATION

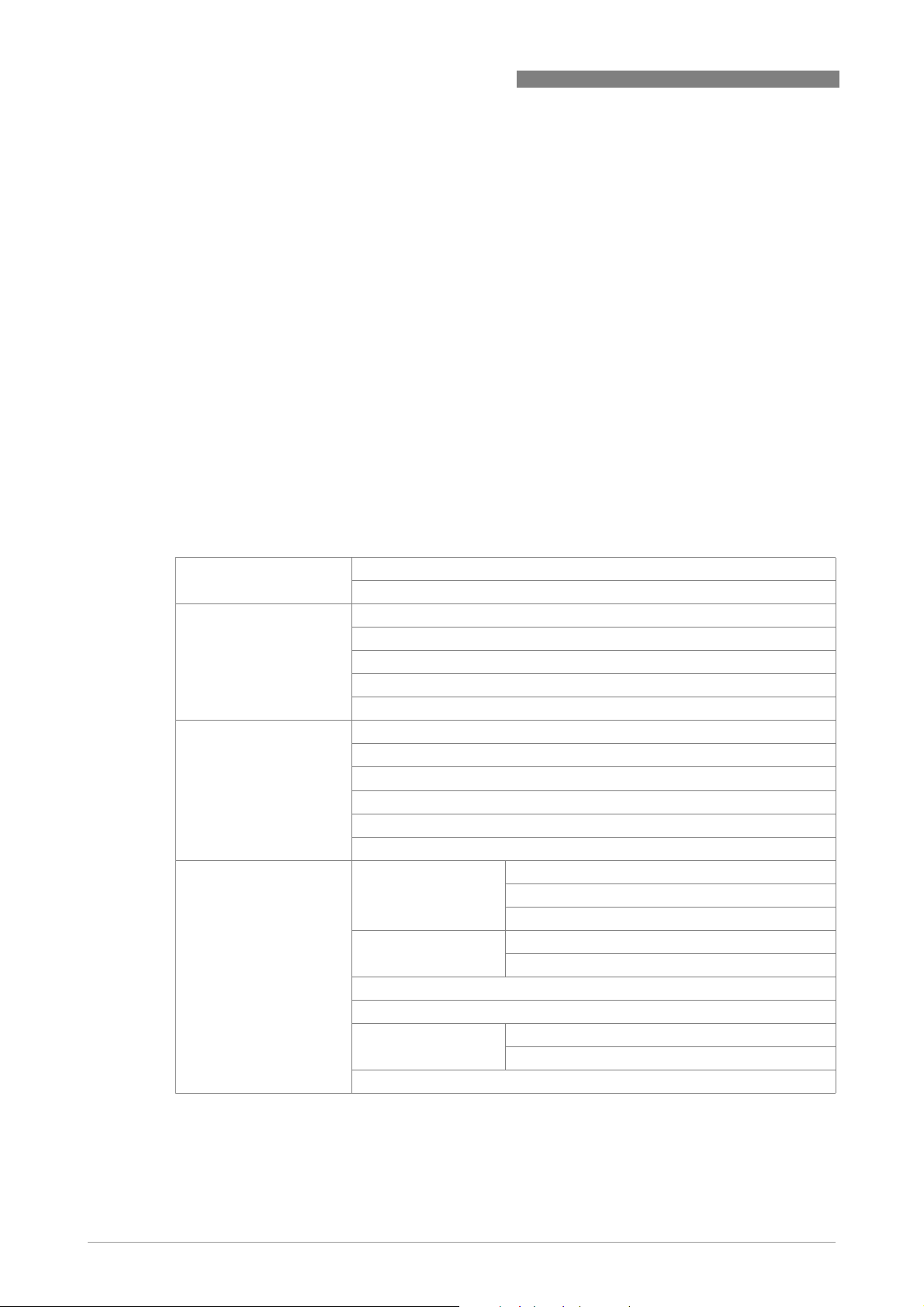

Aluminium housing for non-Ex and Ex i-approved devices

OPTIWAVE 1010

Version Seal Temperature

extension

Process connection

temperature

Process pressure

[°C] [°F] [barg] [psig]

Standard FKM/FPM with

PEEK

Kalrez® 6375

with PEEK

EPDM with PEEK without -40...+100 -40...+212

HP 1 FKM/FPM with

Metaglas®

Kalrez® 6375

with Metaglas®

EPDM with

Metaglas®

HT or

HT/HP

1 HP = high-pressure version. HT = high-temperature version. HT/HP = high-pressure / high-temperature version.

1

FKM/FPM with

Metaglas®

Kalrez® 6375

with Metaglas®

EPDM with

Metaglas®

without -30...+100 -22...+212 -1...16 -14.5...232

without -20...+100 -4...+212

without -30...+100 -22...+212 -1...40 -14.5...580

without -20...+100 -4...+212

without -40...+100 -40...+212

with -30...+150 -22...+302 -1...40 -14.5...580

with -20...+150 -4...+302

With -40...+120 -40...+248

Stainless steel housing for non-Ex and Ex d-approved devices

Version Seal Temperature

extension

Standard FKM/FPM with

Metaglas®

Kalrez® 6375

with Metaglas®

EPDM with

Metaglas®

without -30...+150 -22...+302 -1...40 -14.5...580

without -20...+150 -4...+302

without -40...+120 -40...+248

For more data on pressure ratings, refer to

Process connection

temperature

[°C] [°F] [barg] [psig]

Pressure ratings

Process pressure

on page 54

18

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 19

OPTIWAVE 1010

Ambient temperature / flange temperature, flange and threaded connection, in °C

Figure 3-3: Ambient temperature / flange temperature, flange and threaded connection, in °C

INSTALLATION 3

Ambient temperature / flange temperature, flange and threaded connection, in °F

Figure 3-4: Ambient temperature / flange temperature, flange and threaded connection, in °F

1 Maximum ambient temperature, °C

2 Maximum flange temperature, °C

3 Maximum ambient temperature, °F

4 Maximum flange temperature, °F

5 Metallic Horn antennas

There is no change (de-rating) in ambient temperature below 0°C/ 0°F. The process connection

temperature must agree with the temperature limits of the gasket material. For pressure rating

data,.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

19

Page 20

3 INSTALLATION

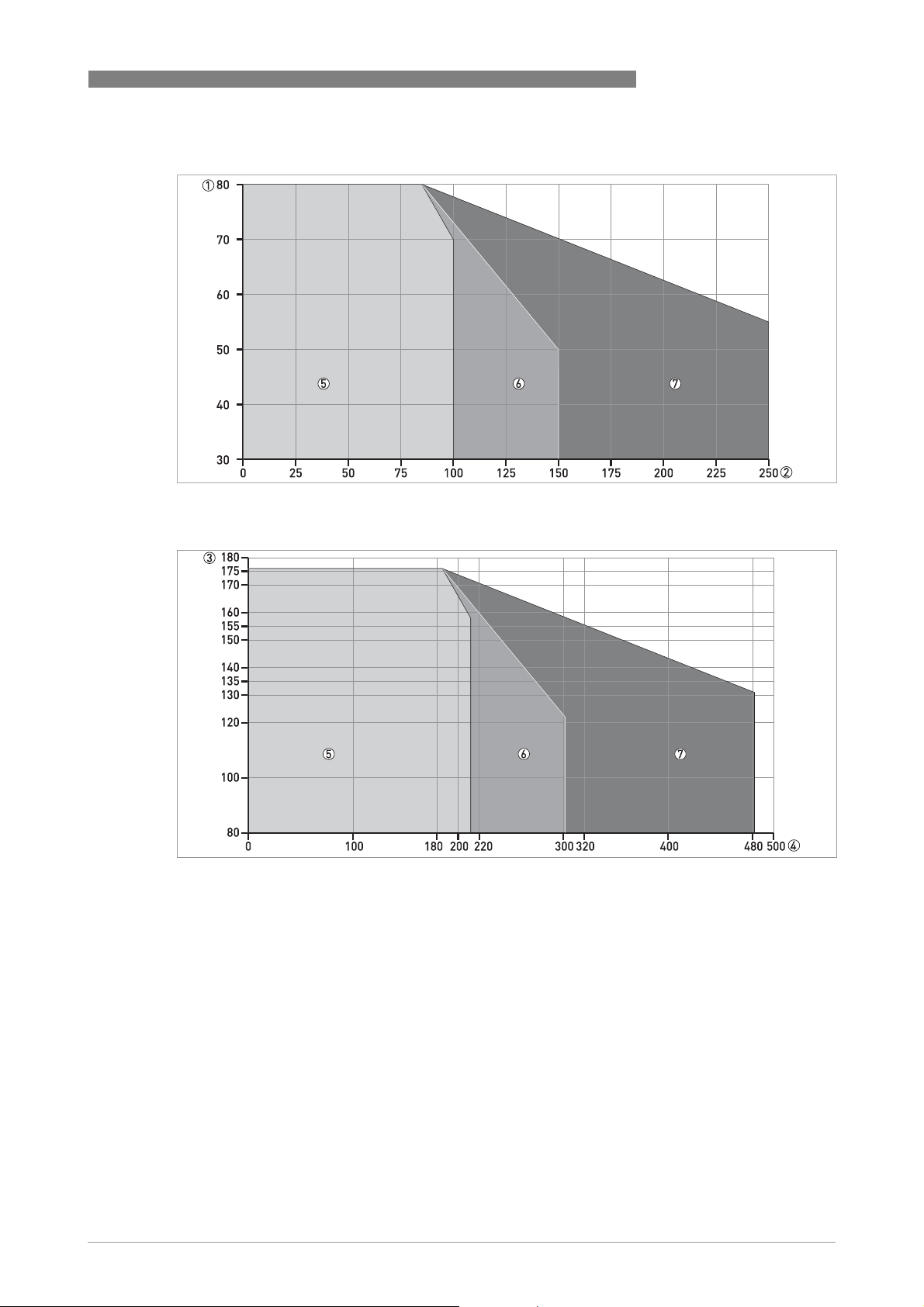

3.6 Recommended mounting position

CAUTION!

Follow these recommendations to make sure that the device measures correctly. They have an

effect on the performance of the device.

CAUTION!

Make sure that the cable glands are aligned with the process connections of the bypass

chamber.

OPTIWAVE 1010

Figure 3-5: Recommended mounting position

1 Internal tube diameter. Min. / Max.: 32...67 mm / 1.26...2.64¨

2 Float offset. Min. / Max.: 0...150 mm / 0...5.91¨

3 Distance to top process connection (bypass chamber). Min. / Max.: 0...800 mm / 0...2.64¨

4 Distance to bottom process connection (bypass chamber). Min. / Max.: 32...67 mm / 1.26...2.64¨

3.7 Mounting restrictions

CAUTION!

Follow these recommendations to make sure that the device measures correctly. They have an

effect on the performance of the device.

We recommend that you prepare the installation when the tank is empty.

CAUTION!

If there are parasitic signals, the device will not measure correctly. Parasitic signals are caused

by sudden changes in bypass chamber diameter in the path of the radar beam.

20

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 21

OPTIWAVE 1010

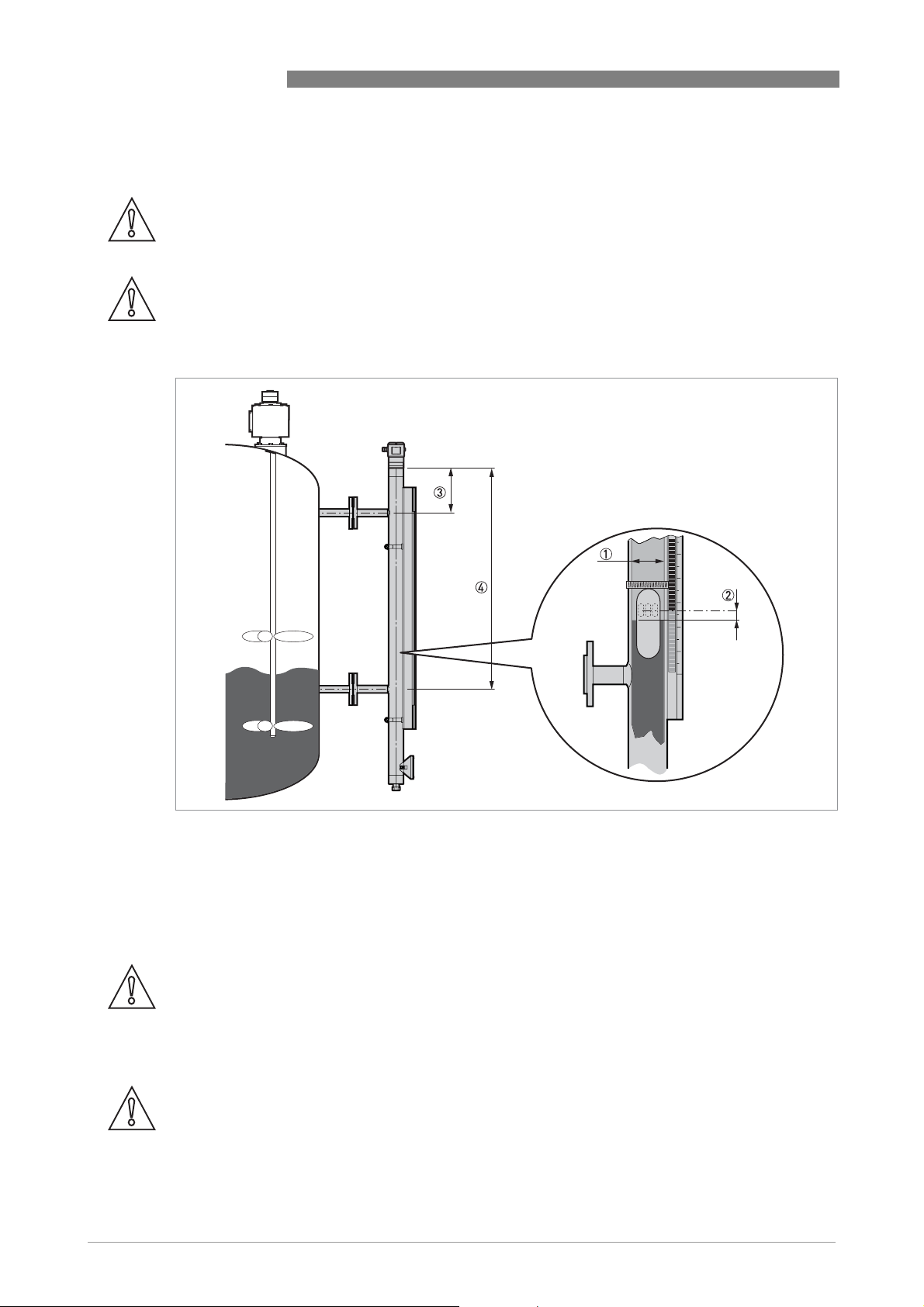

3.8 Stilling wells

Install the device in a metal stilling well if the radar level transmitter is attached to the top of the

tank and not on the top of a magnetic (bypass) level indicator or a bypass chamber.

CAUTION!

If the stilling well has liquid circulation holes, then the tank must be made of metal or reinforced

concrete to prevent radio frequency interference.

INSTALLATION 3

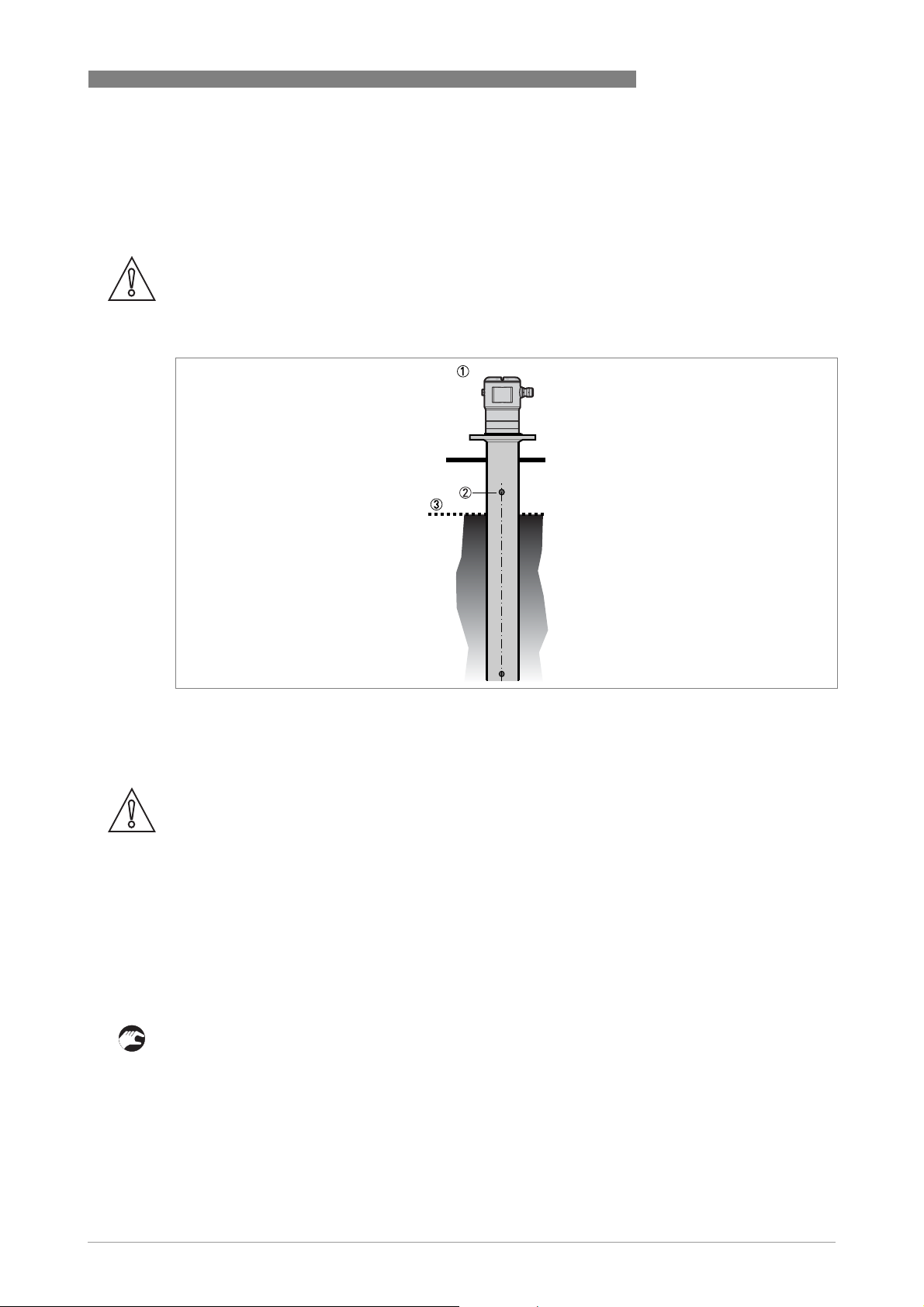

Figure 3-6: Installation recommendations for stilling wells

1 A stilling well solution

2 Air circulation hole

3 Level of the liquid

CAUTION!

Installation requirements

•

The standpipe must be electrically conductive.

•

The standpipe must be straight. There must be no sudden changes in internal diameter

greater than 1 mm / 0.04

•

The standpipe must be vertical.

•

Recommended surface roughness: <±0.1 mm / 0.004¨.

•

Make sure that there are no deposits at the bottom of the standpipe.

•

Make sure that there is liquid in the standpipe.

¨

.

General notes

Installation in tanks containing one liquid and foam

• Drill an air circulation hole (max. Ø10 mm / 0.4¨) in the stilling well above the maximum level.

• Remove the burr from the hole.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

21

Page 22

3 INSTALLATION

Installation in tanks containing one liquid or more without foam

• Drill an air circulation hole (max. Ø10 mm / 0.4¨) in the stilling well above the maximum level.

• Drill 1 or more liquid circulation holes in the stilling well (if there is more than 1 liquid in the

tank).

i These holes help the liquid to move freely between the stilling well and the tank.

• Remove the burr from the hole.

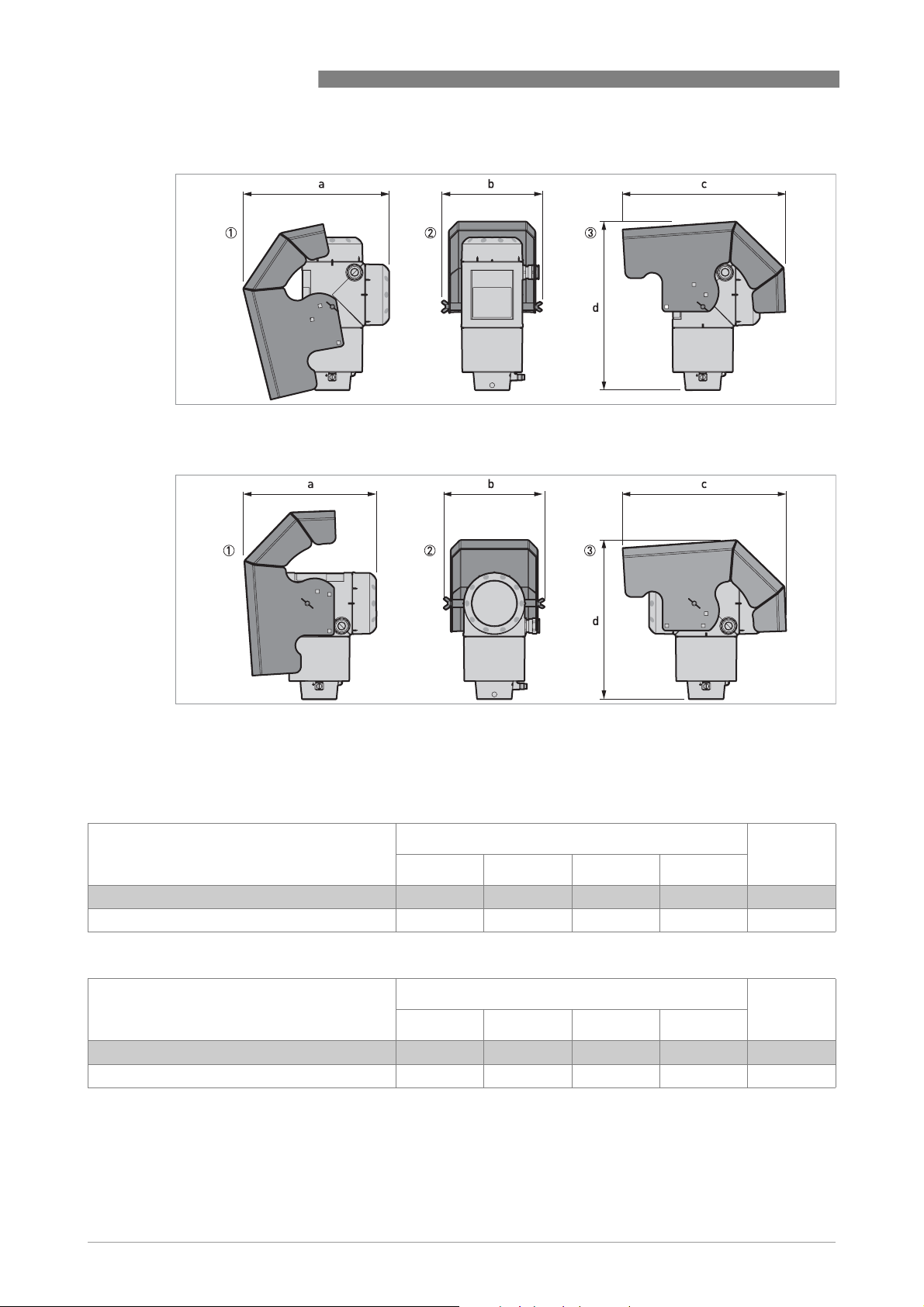

3.9 How to attach the weather protection to the device

The device and the weather protection option are supplied disassambled in the same box. You

must attach the weather protection when you install the device.

OPTIWAVE 1010

Figure 3-7: Equipment needed

1 Device

2 Weather protection (option).

3 2 butterfly screws and spring washers. The manufacturer attaches these parts to the device before delivery.

The overall dimensions of the weather protection are.

22

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 23

OPTIWAVE 1010

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

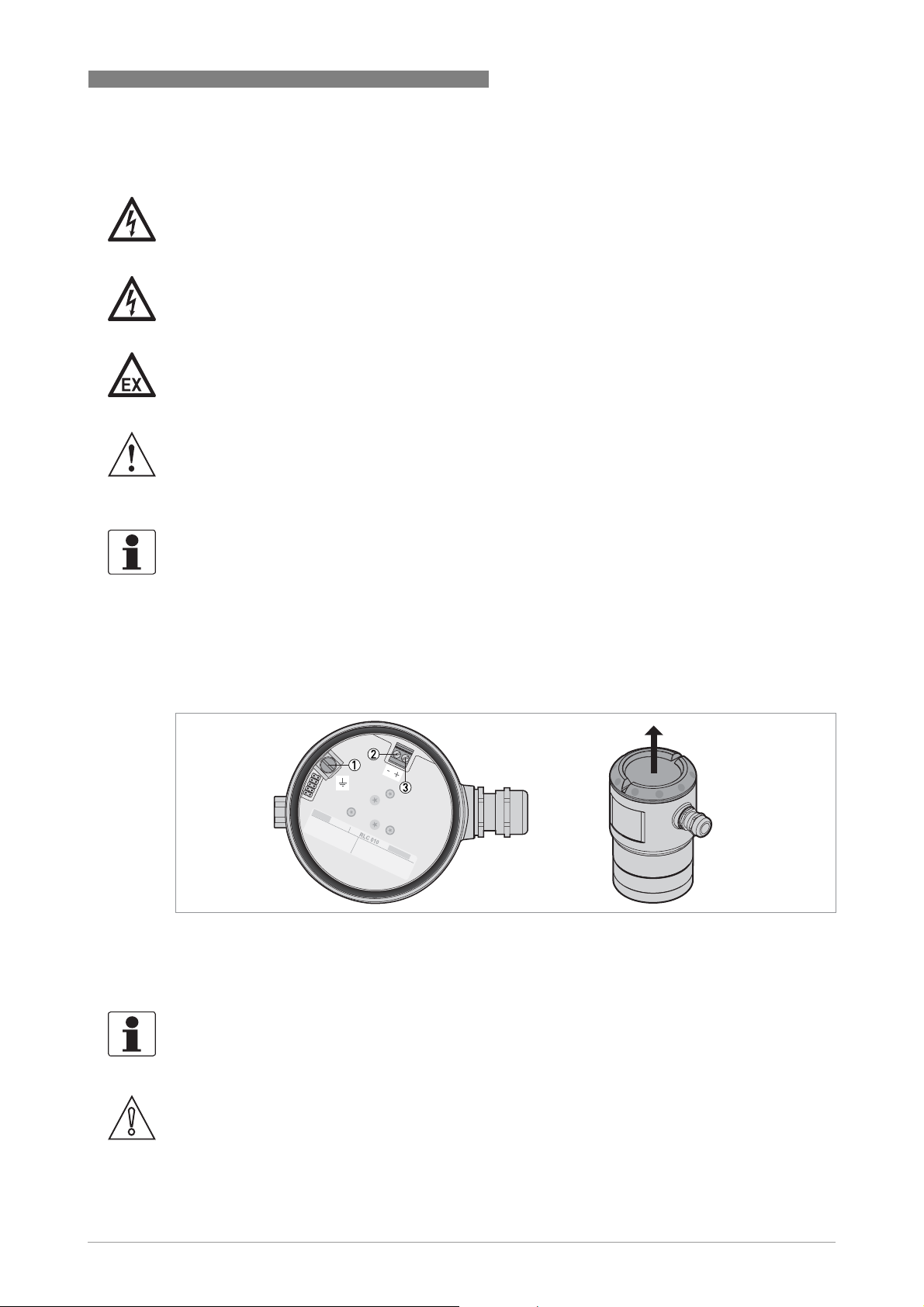

4.2 Electrical installation: 2-wire, loop-powered

Figure 4-1: Terminals for electrical installation

1 Grounding terminal in the housing (if the electrical cable is shielded)

2 Current output -

3 Current output +

INFORMATION!

Electrical power to the output terminal energizes the device. The output terminal is also used for

®

HART

communication.

CAUTION!

Use the applicable electrical cables with the cable glands.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

23

Page 24

4 ELECTRICAL CONNECTIONS

4.3 Electrical connection for current output

4.3.1 Non-Ex devices

Figure 4-2: Electrical connections for non-Ex devices

1 Power supply

2 Resistor for HART

3 Optional connection to the grounding terminal

4 Output: 14.5...30 VDC for an output of 22 mA at the terminal

5 Device

®

communication

OPTIWAVE 1010

4.3.2 Devices for hazardous locations

DANGER!

For electrical data for device operation in hazardous locations, refer to the related certificates of

compliance and supplementary instructions (ATEX, IECEx, FM, CSA, ...). You can find this

documentation on the DVD-ROM delivered with the device or it can be downloaded free of charge

from the website (Download Center).

4.4 Protection category

INFORMATION!

The device fulfils all requirements per protection category IP 66/67. It also fulfils all

requirements per NEMA type 4X (housing) and type 6P .

DANGER!

Make sure that the cable gland is watertight.

24

Figure 4-3: How to make the installation agree with protection category IP 67

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 25

OPTIWAVE 1010

• Make sure that the gaskets are not damaged.

• Make sure that the electrical cables are not damaged.

• Make sure that the electrical cables agree with the national electrical code.

• The cables are in a loop in front of the device 1 so water does not go into the housing.

• Tighten the cable feedthroughs 2.

• Close unused cable feedthroughs with dummy plugs 3.

4.5 Networks

4.5.1 General information

The device uses the HART® communication protocol. This protocol agrees with the HART®

Communication Foundation standard. The device can be connected point-to-point. It can also

operate in a multi-drop network of up to 15 devices.

The device output is factory-set to communicate point-to-point. To change the communication

mode from point-to-point to multi-drop.

4.5.2 Point-to-point connection

ELECTRICAL CONNECTIONS 4

Figure 4-4: Point-to-point connection (non-Ex)

1 Address of the device (0 for point-to-point connection)

2 4...20 mA + HART

3 Resistor for HART® communication

4 Power supply

5 HART

6 HART

®

converter

®

communication software

®

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

25

Page 26

4 ELECTRICAL CONNECTIONS

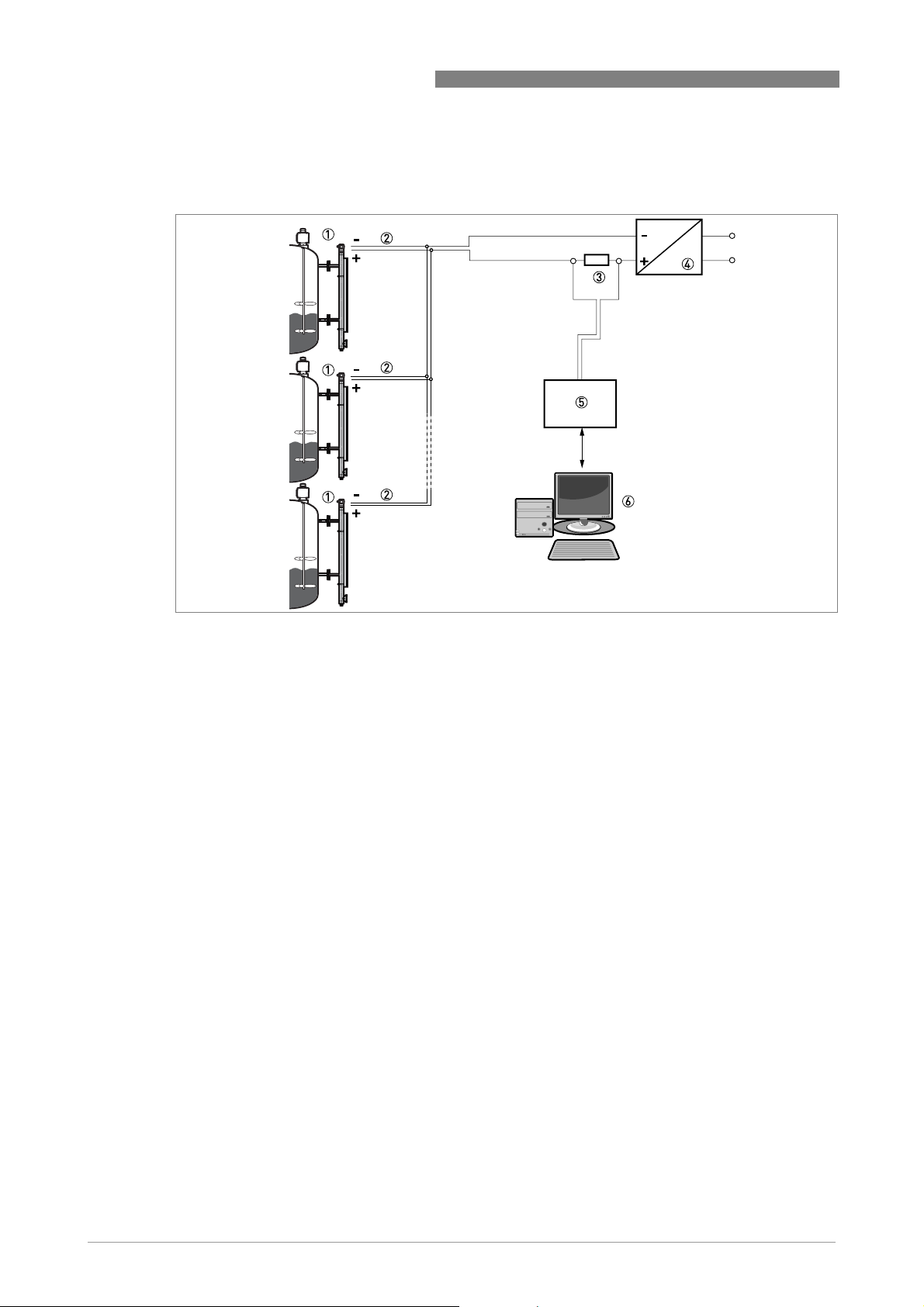

4.5.3 Multi-drop networks

OPTIWAVE 1010

Figure 4-5: Multi-drop network (non-Ex)

1 Address of the device (each device must have a different address in multidrop networks)

2 4mA + HART

3 Resistor for HART® communication

4 Power supply

5 HART

6 HART

®

®

converter

®

communication software

26

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 27

OPTIWAVE 1010

5.1 How to start the device

5.1.1 Start-up checklist

Check these points before you energize the device:

• Are all the wetted components (PEEK element, flange and gaskets) resistant to the product in

the tank?

• Does the information on the device nameplate agree with the operating data?

• If the device is supplied with a magnetic (bypass) level indicator: Did you correctly install the

magnetic level indicator adjacent to the tank?

• If the device is supplied without a magnetic (bypass) level indicator: Did you correctly install

the device on top of the bypass chamber or stilling well?

• Do the electrical connections agree with the national electrical codes? Use the applicable

electrical cables with the cable glands.

DANGER!

Before you energize the device, make sure that the supply voltage is correct.

START-UP 5

DANGER!

Make sure that the device and the installation agrees with the requirements of the Ex certificate

of compliance.

5.1.2 How to start the device

• Connect the converter to the power supply.

• Energize the converter.

INFORMATION!

The OPTIWAVE 1010 is set up for your application when it is attached to the top of the BM 26

Advanced Magnetic (Bypass) Level Indicator at the factory. The 0% level (empty) is aligned with

the center of the bottom process connection and the 100% level (full) is aligned with the center of

the top process connection. You can use the HART communication protocol to change these

parameters.

5.2 Operating concept

You can read measurements and configure the device with:

• A connection to a system or PC with PACTware™. You can download the Device Type

Manager (DTM) file from the website. It is also supplied on the DVD-ROM delivered with the

device.

• A connection to a system or PC with AMS™. You can download the Device Description (DD)

file from the website. It is also supplied on the DVD-ROM delivered with the device.

• A connection to a HART

file from the website. It is also supplied on the DVD-ROM delivered with the device.

®

Field Communicator. You can download the Device Description (DD)

For more data about how to use the DTM in PACTware,. For more data about the menu tree for

the Basic-DD, AMS and PDM,.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

27

Page 28

5 START-UP

5.3 Remote communication with PACTware™

5.3.1 General notes

PACTware™ displays measurement information clearly on a computer (PC) and lets you

configure the device from a remote location. It is an Open Source, open configuration software

for all field devices. It uses Field Device Tool (FDT) technology. FDT is a communication standard

for sending information between the system and the field device. This standard agrees with

IEC 62453. Field devices are easily integrated. Installation is supported by a user-friendly

Wizard.

OPTIWAVE 1010

Figure 5-1: Start page for PACTware™

5.3.2 Software installation

Equipment needed

• A computer

• One of these two solutions: 1 the DVD-ROM delivered with the device or 2 a high-speed

Internet connection

• A web browser, if it is necessary to download files from the Internet

Software needed

• Microsoft® .NET Framework 1.1 or a later version

• PACTware™ 4.0 or a later version

• Device Type Manager (DTM) for the OPTIWAVE 1010 radar level transmitter

This software is supplied on the DVD-ROM delivered with the device. It can also be downloaded

from the “Download center: Software” web page on the manufacturer’s website.

28

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 29

OPTIWAVE 1010

Installation procedure

1 Install Microsoft® .NET Framework 1.1.

2 Install PACTware™ 4.0 or later version.

3 Install the OPTIWAVE 1010 DTM on your workstation or your portable computer. Follow the

instructions in the Installation wizard.

4 Plug the HART modem into your computer (Serial or USB HART® modem). If you are using a

USB® HART modem, you must install the Driver for the USB HART® modem first. Make sure

that the location of the port for the HART® modem is clearly identified.

5 Start the PACTware™ program.

i End of the procedure.

5.4 Remote communication with the AMS™ Device Manager

The AMS™ Device Manager is an industrial Plant Asset Management (PAM) software tool. Its

role is to:

• Store configuration information for each device.

• Support HART® devices.

• Store and read process data.

• Store and read diagnostic status information.

• Help plan preventive maintenance to reduce a plant's downtime to a minimum.

START-UP 5

The DD file is given on the DVD-ROM supplied with the device. You can also download it from our

website.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

29

Page 30

6 OPERATION

6.1 Software configuration

6.1.1 General notes

How to configure the software for device communication.

Before the program can send data to and receive data from the device, it is necessary to add

elements to a project structure. The project structure is built in the PACTware™ Project pane.

The Project pane is on the left side of the window.

This procedure will open the communication port, but does not start the communication with the

device.

6.1.2 Procedure

INFORMATION!

This procedure will open the communication port, but DOES NOT start the communication with

the device.

OPTIWAVE 1010

• HOST PC is shown in the Project pane. Go to the main toolbar and click on the View menu

button. Click on "Device catalog F3" to open the Device Catalog pane.

• Double click on “HART Communication” in the Device Catalog pane. The "COM4" element is

added below "HOST PC” in the project structure.

• Click on "OK" to save changes or "Cancel" to cancel the new configuration.

• Double click on the "OPTIWAVE 1010" item in the Device Catalog pane. This step will add the

device DTM to the project structure in the Project pane.

i The software is correctly configured for device communication, but the port is not open and

the device cannot communicate with the software at this time.

• (a) Double click on the "OPTIWAVE 1010" element in the project structure (Project pane), or (b)

Right click on "OPTIWAVE 1010" element in the project structure (Project pane) and select

"Parameter" in the drop-down list box.

i This step will open the OPTIWAVE 1010 Parameter (configuration) window.

• Right click on the "OPTIWAVE 1010" element in the Project pane and select "Connect" in the

drop-down list box.

i The software is correctly configured for device communication and the port is open, but the

device cannot communicate with the software at this time. End of the procedure.

30

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 31

OPTIWAVE 1010

6.2 How to load settings from the device to PACTware™

There are 3 alternative procedures.

Procedure 1: Click on "Load from Device" in the Device menu

OPERATION 6

Figure 6-1: Click on "Load from Device" in the Device menu

• Click on the Device button in the main toolbar.

• Select "Load from device" from the list.

i End of the procedure.

Procedure 2: Click on the "Load from Device" icon in the main toolbar

Figure 6-2: Click on the "Load from Device" icon in the main toolbar

• Click on this icon (you can find this icon below the main toolbar).

i End of the procedure.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

31

Page 32

6 OPERATION

Procedure 3: Right click on the "OPTIWAVE 1010" element in the Project pane

OPTIWAVE 1010

Figure 6-3: Right click on the "OPTIWAVE 1010" element in the Project pane

• Right click on the "OPTIWAVE 1010" element in the Project pane.

• Select "Load from device" from the list.

i End of the procedure.

6.3 Menu overview

• Login/Logout

• Import/Export

• Basic parameters

• Signal output

• Application

• HART

• Service

• DTM settings

The service menu is password locked. This menu is for qualified service personnel only.

32

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 33

OPTIWAVE 1010

6.4 Device settings

6.4.1 Supervisor access rights

It is necessary to have "Supervisor" access rights to change device settings.

The device configuration is locked (write protected). To unlock the configuration and change

device settings, you need to log in as a "Supervisor". If you do not log in as a Supervisor, you can

only read the device configuration.

Procedure

• (a) Double click on the "OPTIWAVE 1010" element in the project structure (Project pane) or (b)

Right click on "OPTIWAVE 1010" element in the project structure (Project pane) and select

"Parameter" in the drop-down list box.

• Click on the Log In / Log Out menu and select "Supervisor".

• Enter the password (the default password is 123412).

• The device configuration is unlocked. Change the device settings. Refer to the handbook for

more data on menu items and their parameters.

i End of the procedure.

OPERATION 6

6.4.2 How to change device settings

CAUTION!

If you change the device settings, the DTM saves the device configuration in the computer

database. It does not send the changes to the device. For morea data about how to store the new

settings to the device,.

At the bottom right of the window there are 3 buttons. These buttons are used only to update the

computer database. If you click on "OK" or "Apply", no data is sent to the device. This function

obeys FDT guidelines for certification of the DTM.

Figure 6-4: Use "OK" or "Apply" to update the computer database

When you change the value of a menu item, a pencil symbol is shown adjacent to the changed

value:

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

33

Page 34

6 OPERATION

Figure 6-5: Pencil symbol: changed value

If the value is too large or too small, a red exclamation mark is shown adjacent to the incorrect

value:

OPTIWAVE 1010

Figure 6-6: Exclamation mark (!): the value is too large or too small

6.4.3 Data about menu items and parameters (online Help)

More data is available for menu items in the Basic Parameters, Signal output, Application and

HART menus.

Put the mouse pointer on a box in the menu. A tooltip gives a description of the menu item.

34

Figure 6-7: Data about parameters – part1: tooltip

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 35

OPTIWAVE 1010

Right click on the text for data about parameters. A tooltip shows the default value, data set

value (new value), minimum value and maximum value of the menu item.

Figure 6-8: Data about parameters – part 2: values

6.4.4 Basic parameters

OPERATION 6

Use the "basic parameters" menu to specifiy the basic configuration of the device. The

supervisor can specify the minimum distance (NO), maximum distance (ND), float offset (FO) and

tube internal diameter (PD).

For more data about float offset,.

Figure 6-9: Basic parameters menu

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

35

Page 36

6 OPERATION

6.4.5 Signal output

Use the "signal output" pane to specifiy the type of data that the current output must supply. The

supervisor can set the measurement function (e.g. level, distance etc.), the output range, the

error delay, minimum distance (NO) and maximum distance (ND).

INFORMATION!

Minimum distance (NO) and maximum distance (ND) is also given in the "basic parameter"

menu.

OPTIWAVE 1010

Figure 6-10: Signal output menu

6.4.6 Import / export

You can use the import /export function to do 2 procedures:

• Import device configuration data in a CFG file. You can then transmit the data to the device

(Store to device).

• Export device configuration data (parameters etc.) in a CFG file. You can use this data for the

configuration of other devices.

INFORMATION!

You can save measurement data in a DAT file when you use the "Record" function in the Analysis

Values menu. For more data, refer to the "Analysis values" section.

36

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 37

OPTIWAVE 1010

Figure 6-11: Import / export function

OPERATION 6

Export device configuration data

• Click on "Import / Export" in the menu list.

• Click on the Export button.

• Click on the >> button.

• Enter a file name and click on the Save button.

• Enter comments and supplementary data in the "File Comment" and "...comment for export

file" boxes.

• Click on the "tick" button to complete the procedure.

Import device configuration data

• Click on "Import / Export" in the menu list.

• Click on the Import button.

• Click on the >> button.

• Find the file and click on the Open button.

• Enter comments and supplementary data in the "File Comment" and "...comment for export

file" boxes.

• Click on the "tick" button to complete the procedure.

6.4.7 Application

Use the "application" menu to specifiy how the device monitors level. The supervisor can give the

time constant, maximum tracing speed, multiple reflections and minimum peak to identify the

correct signal and follow it as level changes.

Figure 6-12: Application menu

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

37

Page 38

6 OPERATION

6.4.8 HART

This menu lists all the data necessary for use in a HART® network. The supervisor can specify

the tag name, device address, descriptor, date, message, W-Preamble, length unit and use a

write lock to prevent changes to the data.

Figure 6-13: HART menu

OPTIWAVE 1010

38

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 39

OPTIWAVE 1010

6.5 Status and error messages

6.5.1 Device status

Error data is given if you use PACTware™ software with the appropriate DTM on a PC. The

sofware will show a symbol on the bottom left of the window if one or more error conditions are

found. This data agrees with NAMUR Recommendation NE 107 (Self-Monitoring and Diagnosis of

Field Devices) and VDI/VDE 2650.

Types of error message

OPERATION 6

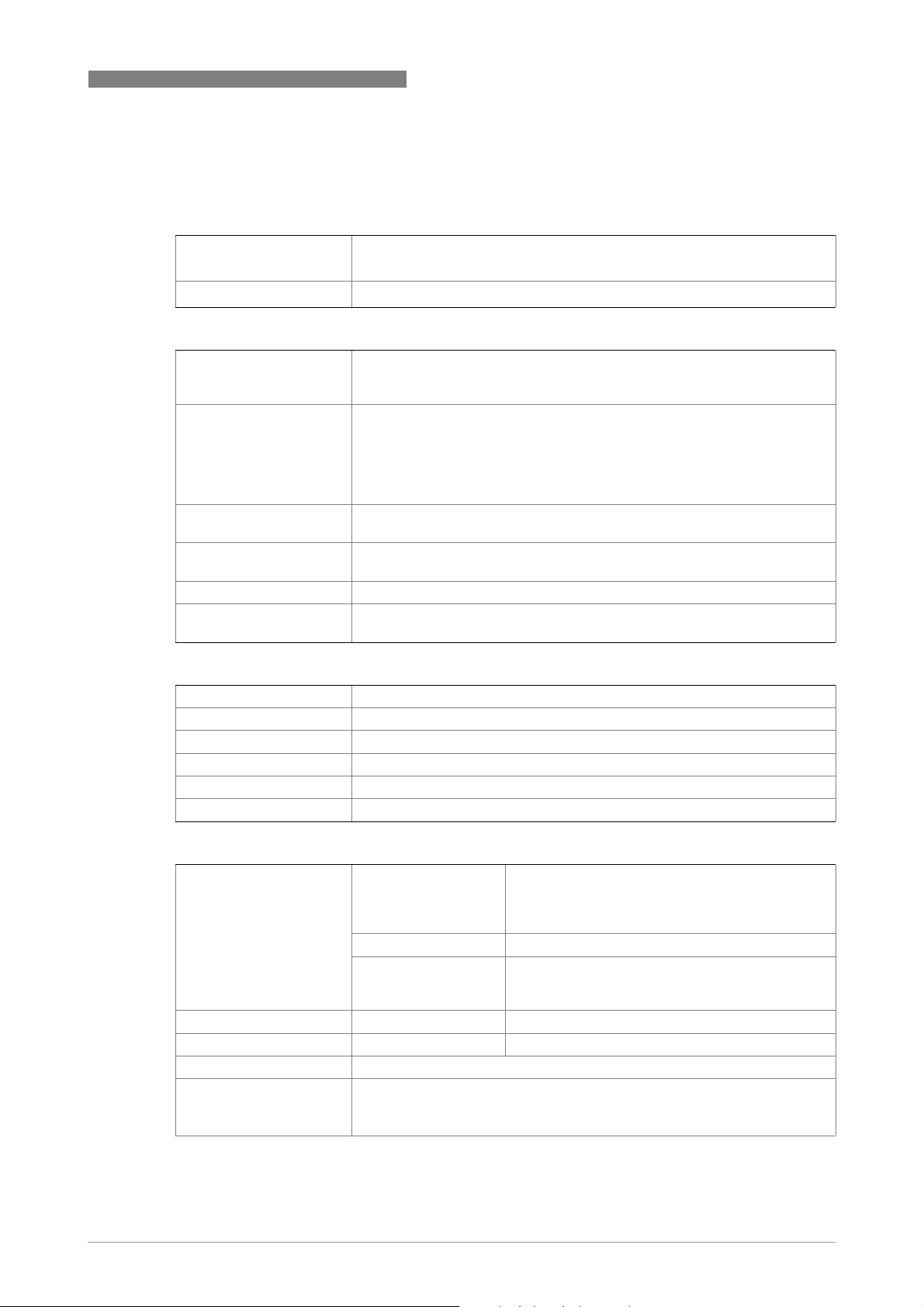

NE 107 status Type of

Description

error

Failure Error If an error message is shown on the diagnostics screen in the DTM, the current

Out of specification Warning If a warning message is shown, there is no effect on the current output value.

Maintenance

NE 107

symbol

NE 107

Status

output goes to the error signal value set in "Signal output", menu item "range

current output".

Description Error type Possible errors

shown

Failure The device does not operate

Function

check

Out of

specification

Maintenance The device does not operate

Information This status message is shown at

correctly. The fault message

stays on.

The device operates correctly,

but the measured value is

incorrect. This fault message is

only temporary. This symbol is

shown when the user configures

the device with the DTM or a

HART® Communicator.

It is possible that the measured

value is unstable if the operating

conditions do not agree with the

device specification.

correctly because of bad

environmental conditions (e.g.

build-up on the antenna). The

measured value is correct, but

maintenance is neccessary a

short time after this symbol is

shown.

the same time as the error "no

measuring value".

Hardware error Microwave error

Hardware error EEPROM error (Config.)

Hardware error EEPROM error (HART)

Hardware error Output current calibration not valid

Error No signal

Error No measuring value

Error Hardware error

Error Current output set to error

– –

Warning Signal weak

Warning Signal strong

Warning Spectrum quality bad

Warning Measurement old

Warning Sweep timing error

Warning CPLD revision mismatch

Warning Capacitor voltage low

Information Peak lost in tank bottom

Information Peak lost in blocking distance

For data on errors, refer to

Error handling

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

on page 40.

39

Page 40

6 OPERATION

6.5.2 Error handling

Figure 6-14: Error record screen in the DTM for PACTware™

Description of errors and corrective actions

Error Message Cause Corrective action

OPTIWAVE 1010

Failure (NE 107 status signal)

Microwave error The device's hardware is defective. Replace the signal converter.For more data, refer to

EEPROM error

(Config.)

EEPROM error

(HART)

Output current

calibration not

valid

No signal

No measuring

value

Hardware error

Current output set

to error

Service warranty

on page 44.

Out of specification (NE 107 status signal)

Signal weak The signal amplitude is less than the

Signal strong This error can occur if there is a large

Spectrum quality

bad

average value. This can occur if the

liquid is agitated or if there is foam in the

tank. If this error occurs frequently, the

device will possibly show the "No

measuring value" error message. 1

change in signal amplitude. 1

The quality of the spectrum is poor. If

this message is temporarily shown, this

will not affect the performance of the

device. If this message is continuously

shown, the measured values can be

incorrect. The error message

"Measurement old" will then be shown.

Possible causes are foam, vortices,

turbulent product surface and internal

tank elements.

If this error occurs frequently, it is possible that you

must install a float with a radar target (if there is no

float supplied with the device).

No corrective action is necessary.

Do a check of the device, tank and the process. Change

the device settings. If necessary, contact the supplier.

40

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 41

OPTIWAVE 1010

OPERATION 6

Error Message Cause Corrective action

Measurement old This is a temporary error message. If the

device cannot get a measurement in this

time limit, the displayed measurement

is no longer correct. The voltage is

possibly too low. If the device continues

to show the message "Spectrum quality

bad", then this message is also shown.

Do a check of the voltage at the device terminals. Refer

also to the error message "Spectrum quality bad".

Maintenance (NE 107 status signal)

Sweep timing error

CPLD revision

mismatch

Capacitor voltage

low

Information

Peak lost in tank

bottom

Peak lost in

blocking distance

Device reset The device detected an internal error

Current Output

Drift

Temperature out

of range

Converter memory

failure

Converter Voltage

failure

Internal

Communication

Overfill The level is in the blocking distance.

Peak Lost (Level

Lost)

Sensor no Signal The device's hardware is defective. Replace the signal converter.

The level is in the blocking distance.

There is a risk that the product will

overflow and/or cover the device.

(watchdog timer issue).

The current output is not calibrated. Speak to the supplier to get the calibration procedure.

Hardware error. Replace the device.

The ambient temperature is outside the

given range. This can cause loss or

corruption of data.

The device's hardware is defective. Replace the signal converter.

The device's hardware is defective. Replace the signal converter.

The device's hardware or software is

defective. The converter cannot transmit

signals to or receive signals from the

antenna electronics.

There is a risk that the product will

overflow and/or cover the antenna.

Remove some of the product until the level is below the

blocking distance.

Record the data that is in menu item 2.2.2 DIAGNOSTIC

(Configuration mode / Supervisor menu). Speak to the

supplier.

Measure the ambient temperature. De-energize the

device until the ambient temperature is back in the

given range. If the temperature does not stay in the

correct range, make sure that there is insulation

around the signal converter. If this error occurs 2

times, replace the device.

De-energize the device. Make sure that the signal

cable engages in the terminal and the screw

connection is tight. Energize the device. If the problem

continues, replace the signal converter.

Use a different procedure to measure the level in the

tank. Remove some of the product until the level is

below the blocking distance.

If a viscous product touched the antenna:

• remove the device and clean the antenna, or

• If the device has a purging option, use the purging

system to clean the antenna.

The signal peak is not found within the

measuring window that filters the

signals received by the antenna. The

measurement is not correct. The device

will automatically increase this window

to find the correct signal.

Do a check of the device, tank and the process.

Reconfigure the device and record a new empty

spectrum. Follow the instructions on page . If

necessary, speak to the supplier.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

41

Page 42

6 OPERATION

Error Message Cause Corrective action

OPTIWAVE 1010

Sensor Microwave

failure

Sensor Memory

failure

Sensor Voltage

failure

Sensor Not

compatible

The device's hardware is defective. Replace the signal converter.

The device's hardware is defective. Replace the signal converter.

The device's hardware is defective. Do a check of the power supply at the device terminals.

The software version of the sensor is not

compatible with the software version of

the signal converter.

Defective wiring.

Out of specification (NE 107 status signal)

Temperature Out

of Range

Overfill The level is in the blocking distance.

Peak Lost The signal peak is not found within the

The ambient temperature is outside the

given range. This can cause loss or

corruption of data.

There is a risk that the product will

overflow and/or cover the device.

measuring window that filters the

signals received by the antenna. The

measurement is not correct. The device

will automatically increase this window

to find the correct signal.

Make sure that voltage values are in the specified

limits in menu item 2.2.2 DIAGNOSTIC (Configuration

mode / Supervisor menu). If the voltage is correct,

replace the signal converter.

Go to menu 1.1.0 IDENT. in Configuration mode.

Record the version numbers of the device software

given in menu items 1.1.2, 1.1.3 and 1.1.4. Give this

data to the supplier.

Measure the ambient temperature. De-energize the

device until the ambient temperature is back in the

given range. If the temperature does not stay in the

correct range, make sure that there is insulation

around the signal converter. If this error occurs 2

times, replace the device.

Remove some of the product until the level is below the

blocking distance.

Do a check of the device, tank and the process and

make sure that the data agrees with the device

configuration. If necessary, record a new empty

spectrum. Follow the instructions on page . If

necessary, speak to the supplier.

Maintenance (NE 107 status signal)

Empty Spectrum

Invalid

Signal Weak The signal amplitude is less than the

Signal Strong This error can occur if there is a large

Bad Measurement

Quality

Temperature

<-35°C/ -31°F

The empty spectrum stored in the device

does not agree with the installation. If

you change the device configuration

(tank height etc.), this message will be

shown. The recorded empty spectrum

will not be used by the device while this

error message is shown.

average value. This can occur if the

liquid is agitated or if there is foam in the

tank. If this error occurs frequently, the

device will possibly show the "Peak Lost

(Level Lost)" error message. 1

change in signal amplitude. 1

The measurement is incorrect and

continues to be incorrect after more

than 10 s. This error can occur if the

tank contents are immediately below the

antenna. 1

The process connection or the ambient

temperaure is less than -35°C/ -31°F.

This temperature is near to the

minimum limit for device operation.

1

Record a new empty spectrum. Follow the instructions

on page .

If this error occurs frequently, it is possible that you

must install the device in a stilling well or use a

different antenna type.

No corrective action is necessary.

Record the process with the PACTware™ software tool

to find the cause of the problem. If necessary, speak to

the supplier.

Measure the ambient temperature. De-energize the

device until the ambient temperature is back in the

given range. If the temperature does not stay in the

correct range, make sure that there is insulation

1

around the signal converter.

42

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 43

OPTIWAVE 1010

OPERATION 6

Error Message Cause Corrective action

Temperature

>+75°C / +167°F

1 This error message does not have an effect on the current output signal

The ambient temperaure is more than

+75°C / +167°F. This temperature is near

to the maximum limit for device

operation. 1

Measure the ambient temperature. De-energize the

device until the ambient temperature is back in the

given range. If the temperature does not stay in the

correct range, make sure that there is insulation

around the signal converter.

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

43

Page 44

7 SERVICE

7.1 Periodic maintenance

No maintenance is necessary.

7.2 Service warranty

WARNING!

Only approved personnel can do an inspection of the device and repairs. If you find a problem,

send the device back to the supplier for inspection and/or repairs.

INFORMATION!

The converter housing (compact or remote version) can be detached from the process

connection assembly under process conditions.

Servicing by the customer is limited by warranty to:

• Device with a flanged process connection: The removal and installation of the device. For

more data.

• Device with a welded process connection: The removal and installation of the circuit boards.

For more data.

OPTIWAVE 1010

For more data on how to prepare the device before you send it back to the supplier, refer to

Returning the device to the manufacturer

7.3 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

7.4 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

on page 45.

44

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 45

OPTIWAVE 1010

7.5 Returning the device to the manufacturer

7.5.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

SERVICE 7

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

45

Page 46

7 SERVICE

7.5.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

OPTIWAVE 1010

This medium is: radioactive

water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

7.6 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

46

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 47

OPTIWAVE 1010

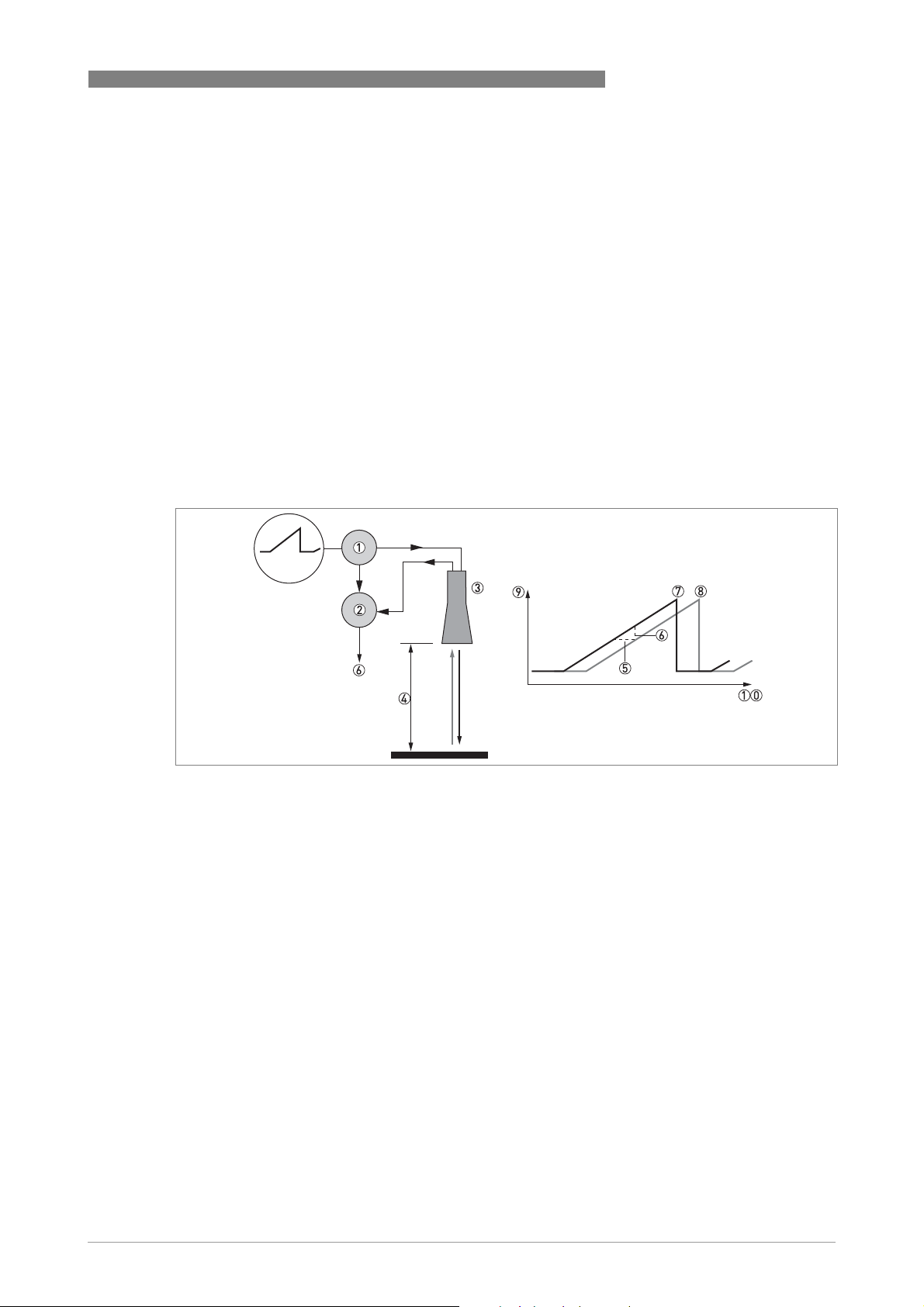

8.1 Measuring principle

A radar signal is emitted via an antenna, reflected from the product surface and received after a

time t. The radar principle used is FMCW (Frequency Modulated Continuous Wave).

The FMCW-radar transmits a high frequency signal whose frequency increases linearly during

the measurement phase (called the frequency sweep). The signal is emitted, reflected on the

measuring surface and received with a time delay, t. Delay time, t=2d/c, where d is the distance

to the product surface and c is the speed of light in the gas above the product.

For further signal processing the difference Δf is calculated from the actual transmitted

frequency and the received frequency. The difference is directly proportional to the distance. A

large frequency difference corresponds to a large distance and vice versa. The frequency

difference Δf is transformed via a Fourier transformation (FFT) into a frequency spectrum and

then the distance is calculated from the spectrum. The level results from the difference between

tank height and measuring distance.

TECHNICAL DATA 8

Figure 8-1: Measuring principle of FMCW radar

1 Transmitter

2 Mixer

3 Antenna

4 Distance to product surface, where change in frequency is proportional to distance

5 Differential time delay, Δt

6 Differential frequency, Δf

7 Frequency transmitted

8 Frequency received

9 Frequency

10 Time

www.krohne.com09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

47

Page 48

8 TECHNICAL DATA

OPTIWAVE 1010

8.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle 2-wire loop-powered level transmitter; C-band (6 GHz) FMCW radar

Application range Level measurement of clean liquids

Primary measured value Distance and reflection

Secondary measured value Level and volume

Design

Construction The measurement system consists of a wave guide connection and a signal

Options Weather protection

Measuring range 0...5.3 m / 0...17.4 ft (max. 8 m / 26.2 ft on request)

Top dead zone Minimum value: 300 mm / 11.8¨ from the process connection

User interface

User interface PACTware™

converter

Measuring accuracy

Repeatability ±1mm/ ±0.04¨

Accuracy ±10 mm / ±0.4¨

Reference conditions acc. to EN 61298-1

Temperature +15...+25°C / +59...+77°F

Pressure 1013 mbara ±50 mbar / 14.69 psia ±0.73 psi

Relative air humidity 60% ±15%

Target Metal plate in an anechoic chamber

48

www.krohne.com 09/2014 - 4003537401 - MA OPTIWAVE 1010 R01 en

Page 49

OPTIWAVE 1010

TECHNICAL DATA 8

Operating conditions

Temperature

Ambient temperature -40…+80°C/ -40…+176°F

Storage temperature -40…+85°C/ -40…+185°F