Page 1

Supplementary instructions

Supplementary instructions

IFC 300

IFC 300

IFC 300IFC 300

Supplementary instructions Supplementary instructions

Signal converter for electromagnetic flowmeters

Description of PROFIBUS interface

Description of PROFIBUS interface

Description of PROFIBUS interfaceDescription of PROFIBUS interface

PROFIBUS PA:

PROFIBUS PA:

PROFIBUS PA:PROFIBUS PA:

PROFIBUS device with MBP Physical Interface and PA Profile 3.0 (V3.0.2 / 100811)

PROFIBUS DP:

PROFIBUS DP:

PROFIBUS DP:PROFIBUS DP:

PROFIBUS device with RS485 Physical Interface and PA Profile 3.0 (V3.0.2 / 100811)

© KROHNE 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 2

CONTENTS

IFC 300

1 Safety instructions 4

1.1 Scope of the document..................................................................................................... 4

1.2 Scope of delivery............................................................................................................... 4

1.3 Special notes .................................................................................................................... 4

2 PROFIBUS DP 5

2.1 Software history ............................................................................................................... 5

2.2 System configuration of PROFIBUS DP network............................................................. 6

2.3 Electrical connection for DP signal converter................................................................. 7

2.4 Technical data................................................................................................................... 9

2.5 GSD files for the data transfer ....................................................................................... 10

2.5.1 Cyclic data exchange............................................................................................................. 10

2.5.2 Baud rate............................................................................................................................... 10

2.5.3 Ident.-No. supported............................................................................................................. 10

2.5.4 Manufacturer specific GSD files: KR024500.GSD and KR014500.GSD ................................ 11

2.5.5 Differencies of the manufacturer specific GSD files: KR024500.GSD and KR014500.GSD. 13

2.5.6 Profile specific GSD file: PA039740.GSD .............................................................................. 13

2.5.7 Using the display menu to distinguish between Rev 1 and Rev 2 ........................................13

3 PROFIBUS PA 14

3.1 Software history ............................................................................................................. 14

3.2 System configuration of PROFIBUS PA network ........................................................... 16

3.3 Electrical connection for PA signal converter ............................................................... 17

3.4 Technical data................................................................................................................. 18

3.5 GSD files for the data transfer ....................................................................................... 19

3.5.1 Cyclic data exchange............................................................................................................. 19

3.5.2 Ident.-No. supported............................................................................................................. 19

3.5.3 Manufacturer specific GSD files: KR024501.GSD and YP024501.GSD................................. 20

3.5.4 Profile specific GSD file: PA139740.GSD .............................................................................. 22

3.5.5 Using the display menu to distinguish the current revision of the device (PA) ................... 23

3.6 Signal converter IFC 300 PROFIBUS PA with MBP interface as replacement for older

signal converter IFC 090 PA.................................................................................................. 23

3.6.1 Ident.-No. supported............................................................................................................. 23

3.6.2 Manufacturer specific GSD files (PA): KROHF401.GSD and YP01F401.GSD for the older sig-

nal converter IFC090 with PROFIBUS MBP interface.................................................................... 23

4 Application profile 25

4.1 Function blocks .............................................................................................................. 25

4.2 Data structure of function block output values ............................................................. 25

4.2.1 Float value............................................................................................................................. 25

4.2.2 Status value........................................................................................................................... 26

4.3 Diagnosis parameter ...................................................................................................... 28

4.3.1 Diagnosis............................................................................................................................... 28

4.3.2 DIAGNOSIS (if "Classic Status" and "Diagnosis" selected).................................................. 28

4.3.3 DIAGNOSIS_EXTENSION (if "Classic Status" and "Diagnosis" selected) ............................ 30

4.3.4 Mapping of DIAGNOSIS_EXTENSION bits into DIAGNOSIS bits........................................... 31

2

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 3

IFC 300

CONTENTS

5 Profibus settings 34

5.1 Menu A, quick setup ....................................................................................................... 34

5.2 Menu B, test.................................................................................................................... 34

5.3 Menu C, setup................................................................................................................. 35

5.4 Menu D, service .............................................................................................................. 38

6 Notes 39

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

3

Page 4

1 SAFETY INSTRUCTIONS

1.1 Scope of the document

These instructions are supplementary to the signal converter Handbook. For all other data, use

the relevant chapters of the Handbook. If you do not have this document, please contact the

nearest office or download them from the manufacturer's internet site.

INFORMATION!

The information in this chapter only contains the data applicable to PROFIBUS communication.

The technical data in the Handbook shall be valid in its current version, provided that it is not

rendered invalid or replaced by this supplement.

1.2 Scope of delivery

The information in this chapter only contains the data applicable to PROFIBUS communication.

The technical data in the Handbook shall be valid in its current version, provided that it is not

rendered invalid or replaced by this supplement.

A device for PROFIBUS communication is supplied with:

IFC 300

• Supplementary instructions for PROFIBUS communication

• PROFIBUS device data files (GSD) on a CD-ROM supplied with the device

1.3 Special notes

Don't switch off (power off) the signal converter immediately after manual change of parameter

values:

• Please wait approx. 10 seconds before you switch off the signal converter after you have done

both a parameter download via PROFIBUS or a manual change of a parameter value via the

local display.

• Please wait approx. 15 seconds before you switch off the signal converter after you have

carried out a "Factory Reset" (PROFIBUS "Coldstart") via PROFIBUS or local display.

"Deactivation of the Service Parameter Lock" of the signal converter via PROFIBUS:

• After writing down the service password (via PROFIBUS) the "Deactivation of the Service

Parameter Lock" will last at least 10 minutes if the internal password timer of the signal

converter won't be retriggered by writing this password again. The "Deactivation of the

Service Parameter Lock" will be terminated at once by a PROFIBUS Coldstart / Warmstart or

if the internal password timer of the signal converter elapsed.

4

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 5

IFC 300

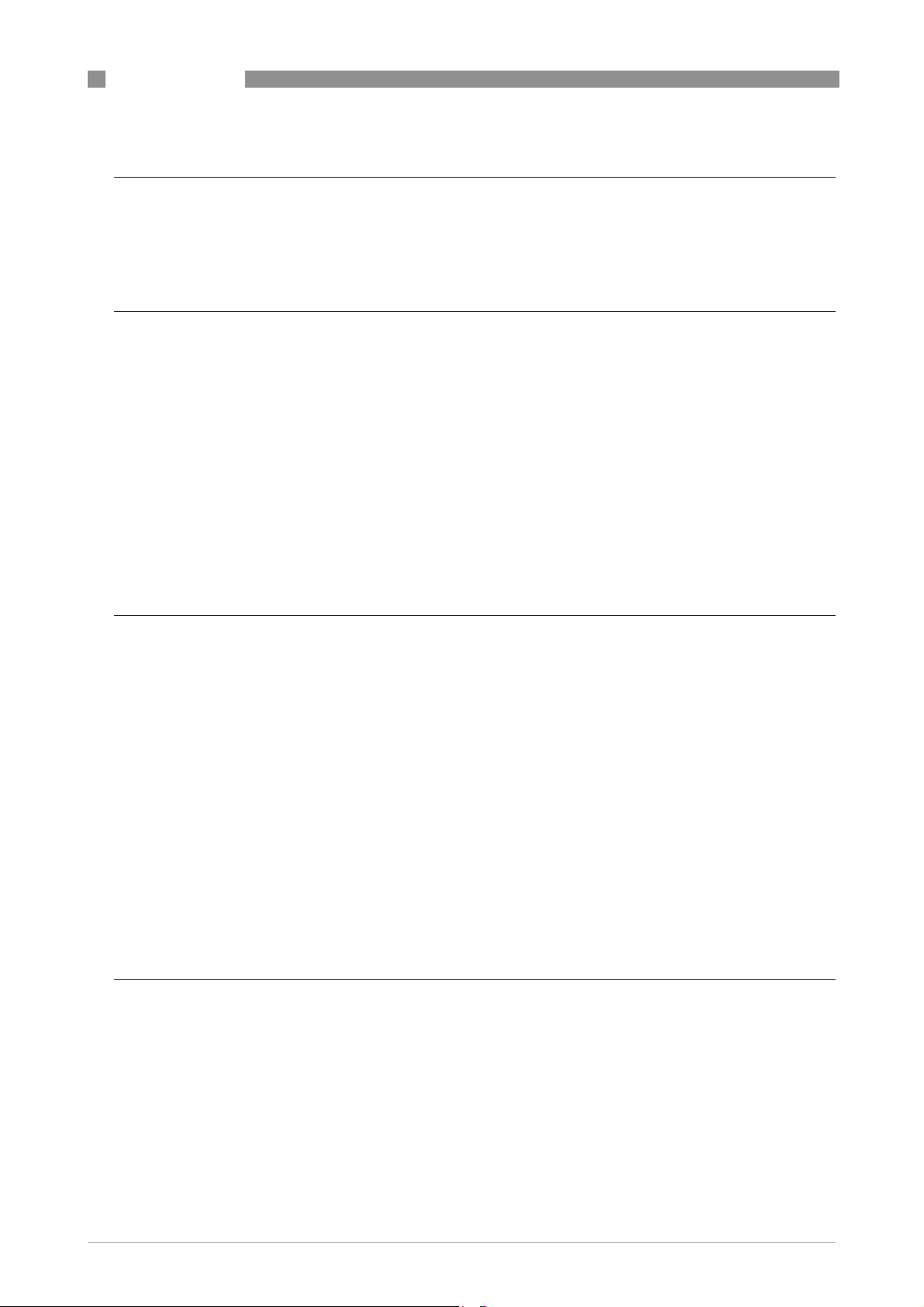

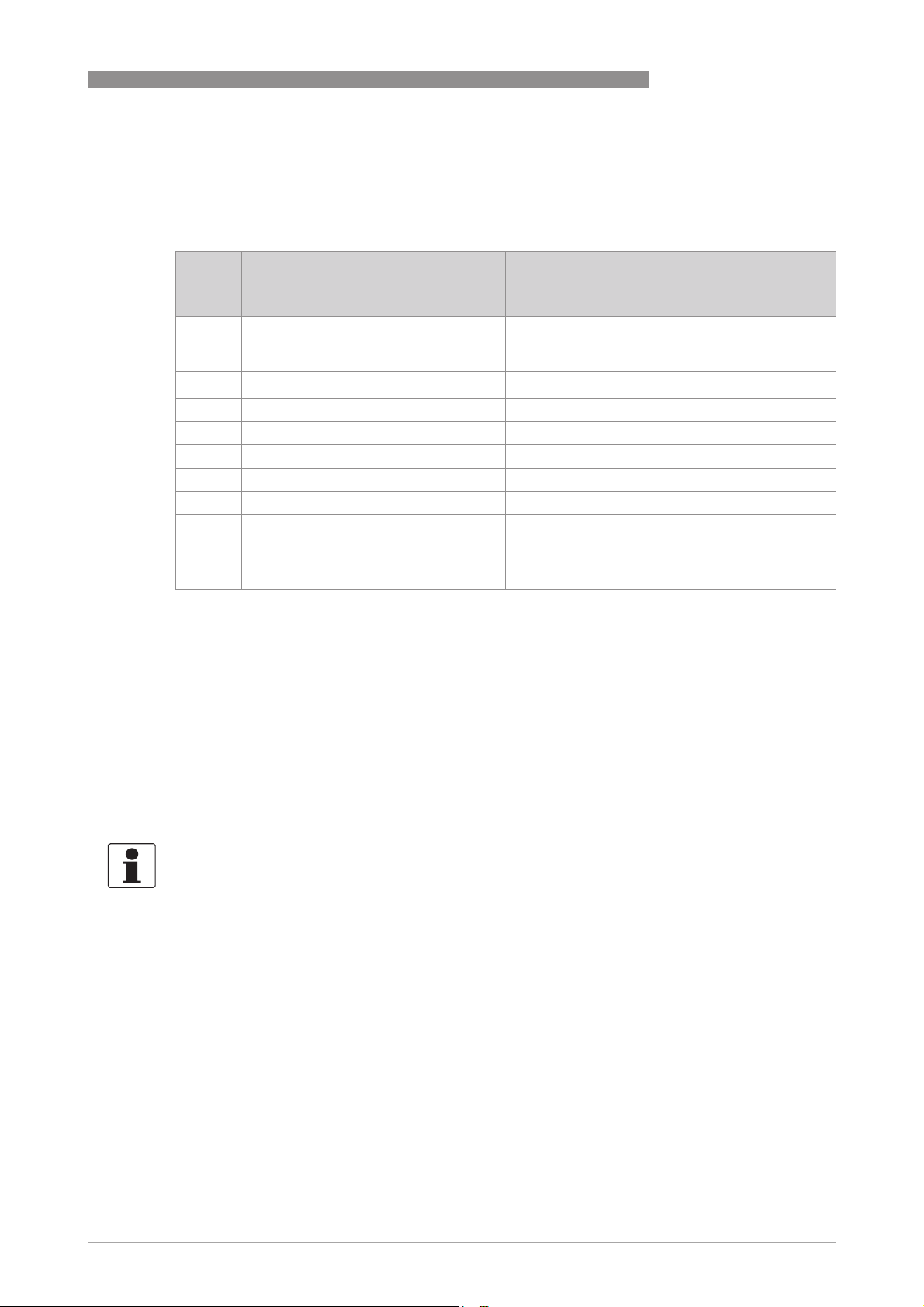

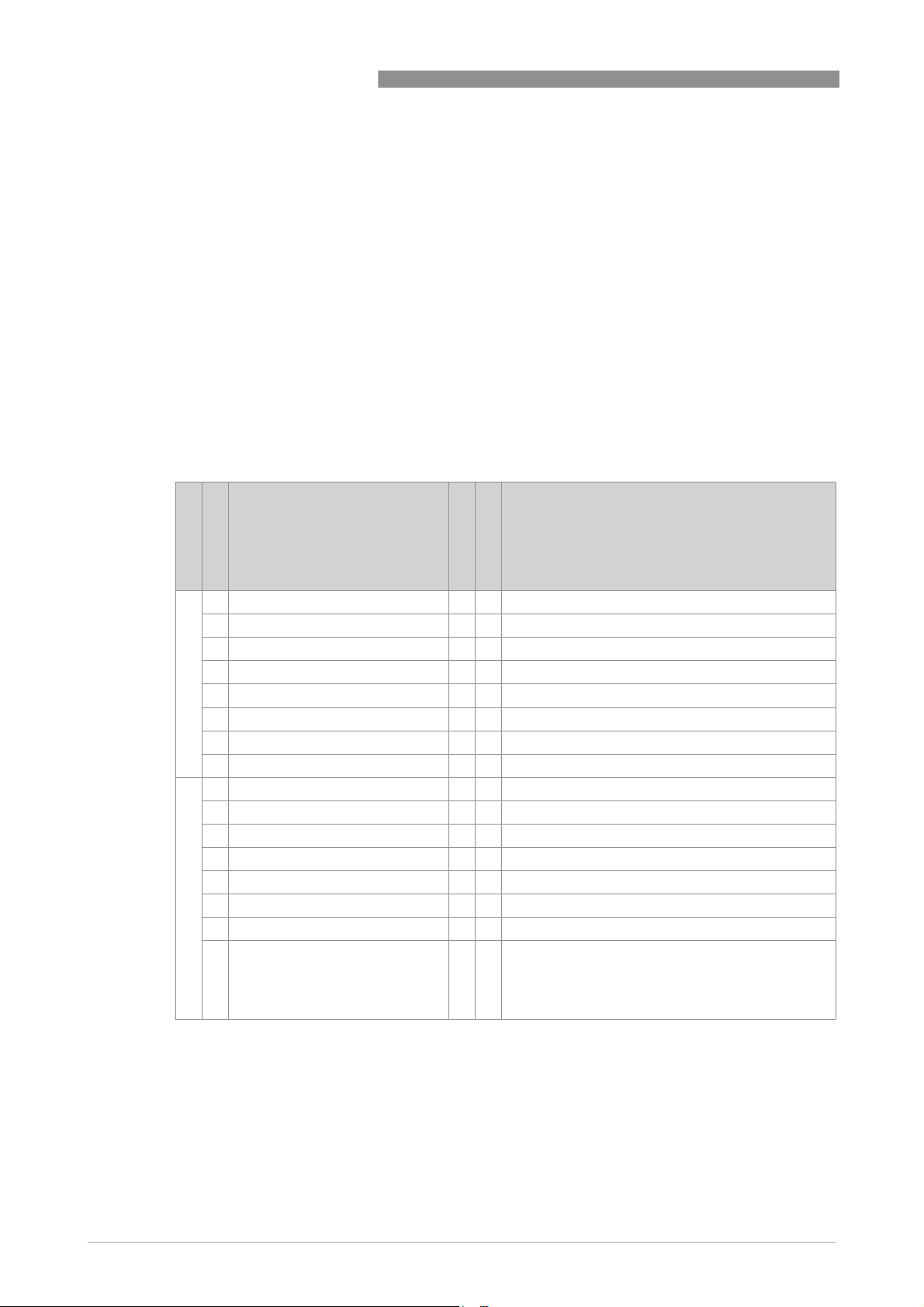

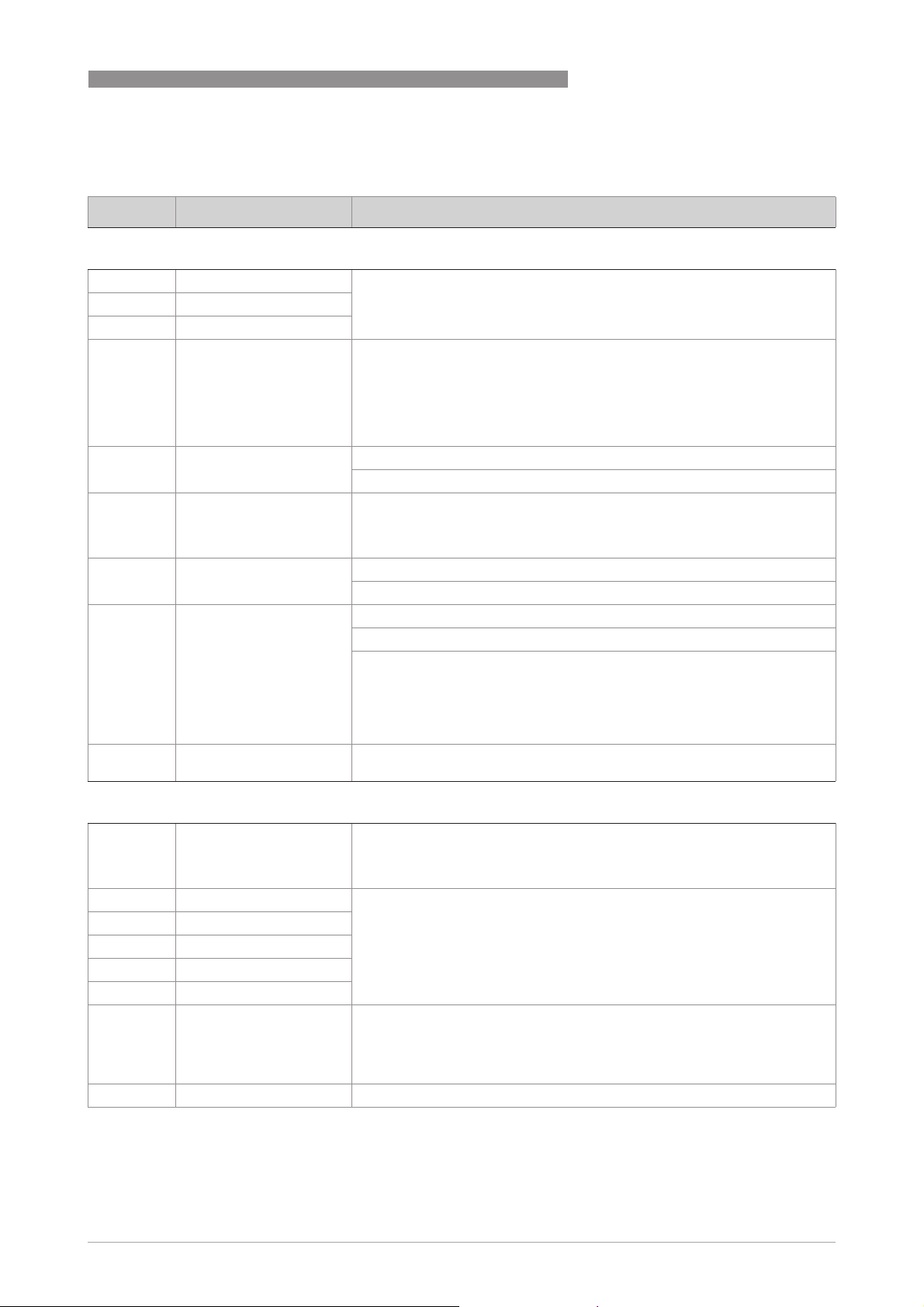

2.1 Software history

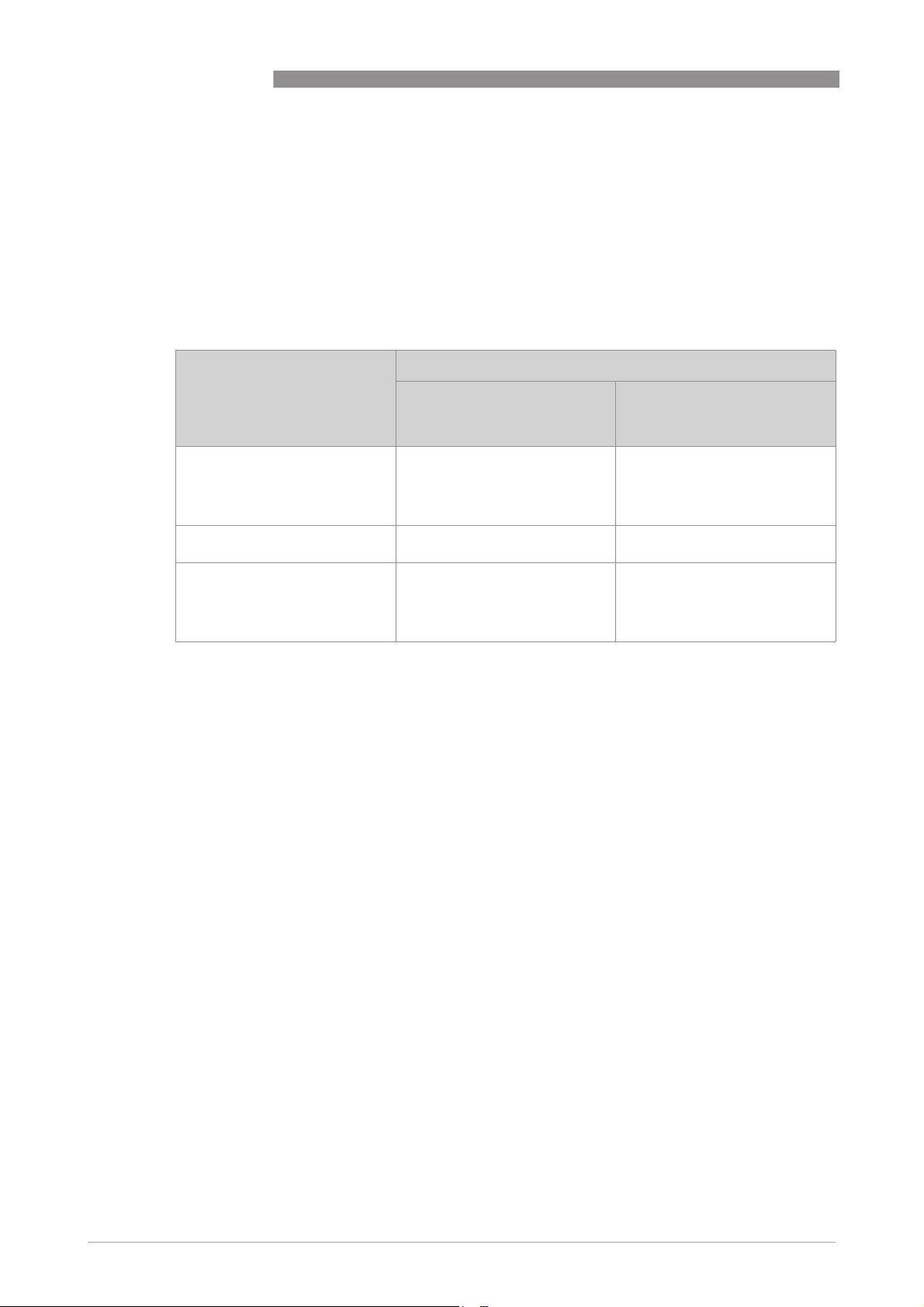

Issued Signal converter Application program System integration

PROFIBUS DP 2

Mth./

Hardware Firmware Hardware Software Driver Version Model name

year

04/05

09/05

01/06 Signal

04/08 Signal

Signal

converter

with

RS485

interface +

PA Profile

3.0

(special)

converter

with

RS485

interface +

PA Profile

3.0

(special)

converter

with

RS485

interface +

PA Profile

3.0

V1.1.3 / 050413

V1.2.0 / 060215

V2.0.0 / 060112

V2.0.0 / 060126

V3.0.2 / 080422 Simatic

Simatic

PCS7

other SPS

of other

manufact.

Laptop - DD

Simatic

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

HW Config

other

Software of

other SPS

manufact.

- DTM ≥ - -

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP3)DD(Ident.-No.)

Pactware DTM ≥ GFP*DTM1.3.1

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP3)DD(Ident.-No.)

Pactware DTM ≥ GFP*DTM1.3.1

GSD

manuf.

specific

GSD

profile

specific

(Ident.-No.)

GSD

manuf.

specific

GSD

profile

specific

GSD

manuf.

specific

GSD

profile

specific

KR014500.GSD IFC300(RS485)

PA039740.GSD Flow with 1AI,

- -

KR014500.GSD*

KR024500.GSD

PA039740.GSD Flow with 1AI,

I3P*DD0300.03** -

FDT1.2

KR014500.GSD*

KR024500.GSD

PA039740.GSD Flow with 1AI,

I3P*DD0300.03** -

FDT1.2

Rev.1

1TOT (PhyL 0)

IFC300(RS485)

Rev.1

IFC300(RS485)

Rev.2

1TOT (PhyL 0)

-

IFC300(RS485)

Rev.1

IFC300(RS485)

Rev.2

1TOT (PhyL 0)

-

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

5

Page 6

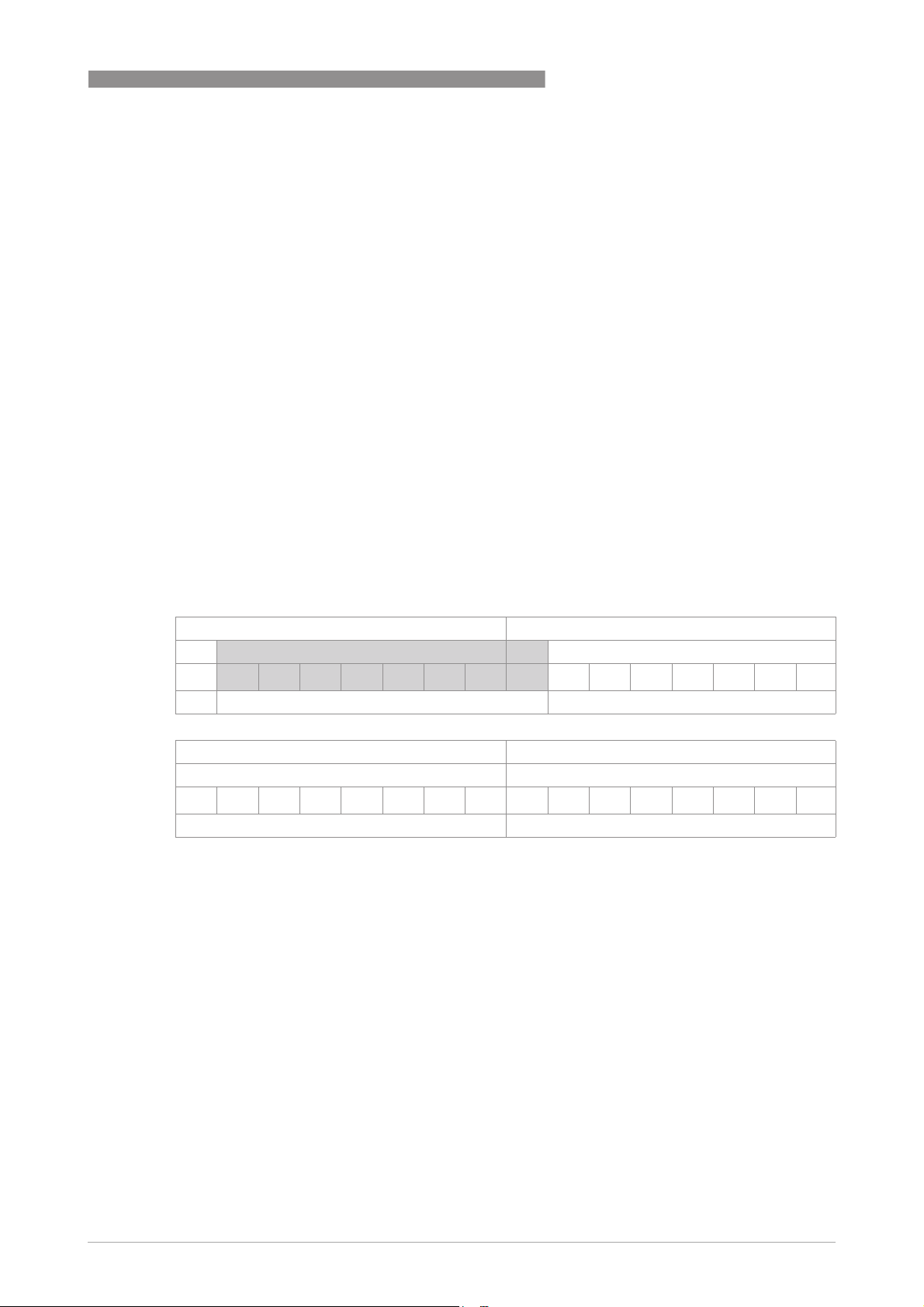

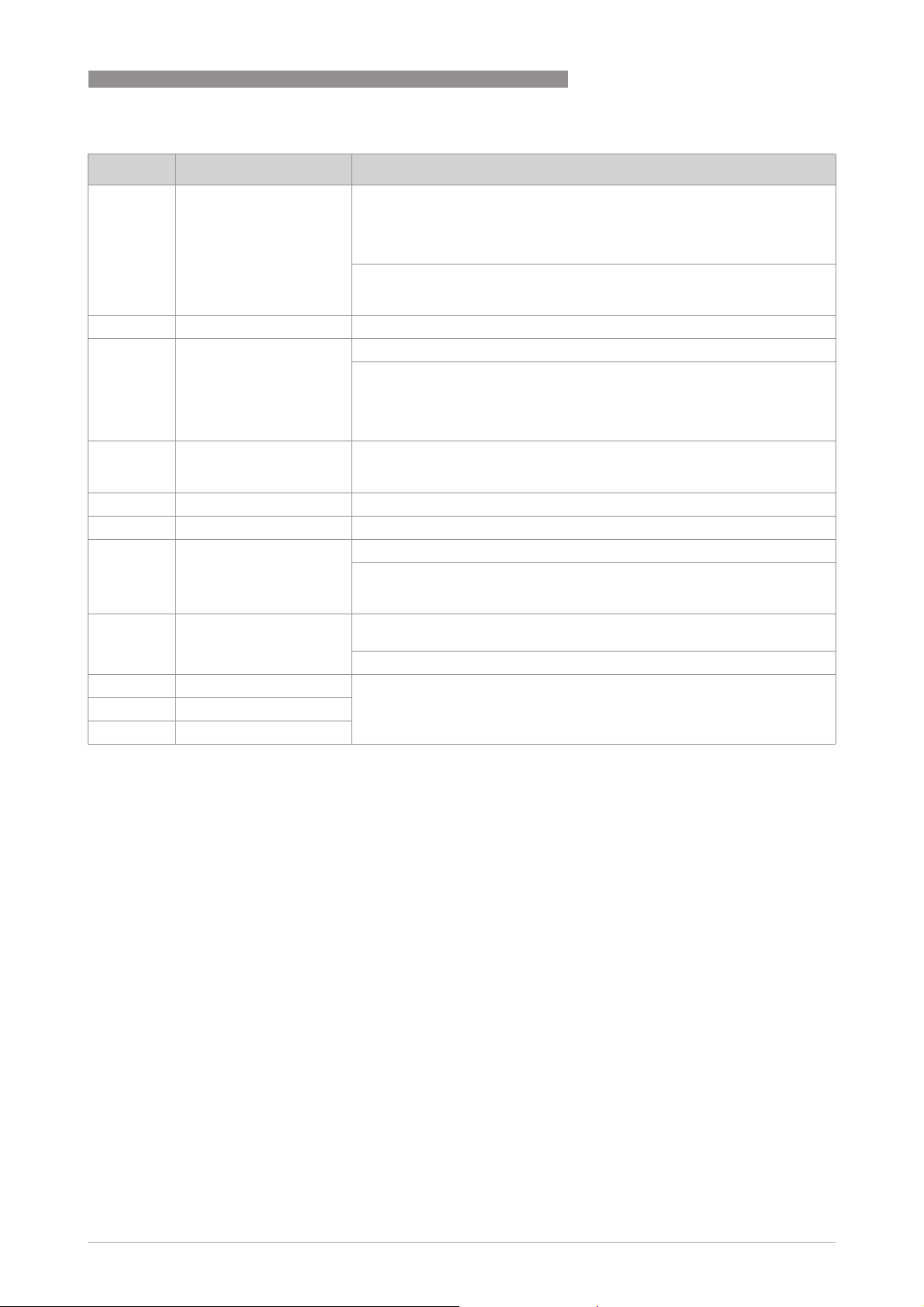

2 PROFIBUS DP

Issued Signal converter Application program System integration

IFC 300

Mth./

Hardware Firmware Hardware Software Driver Version Model name

year

01/11 Signal

converter

with

RS485

interface +

PA Profile

3.0

*: If the GSD file "KR014500.GSD" is used, there will be supported only a limited amount of

functions by the software version (V1.2.0 / 060215 or V2.0.0 / 060112): I&M functions and fail safe

mode are not accessible. For full support of all profile specific or manufacturer specific

functions/parameters use the GSD file "KR024500.GSD".

GFP*: Generic Flow PROFIBUS

I3P*: IFC300 PROFIBUS

**: PDM 5.2 PDM 6.0

V3.0.2 / 100811 Simatic

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP3)DD(Ident.-No.)

Pactware DTM ≥ GFP*DTM1.3.1

GSD

manuf.

specific

GSD

profile

specific

KR014500.GSD*

KR024500.GSD

PA039740.GSD Flow with 1AI,

I3P*DD0300.03** -

FDT1.2

I3P*DTM1.0.7

FDT1.2

IFC300(RS485)

Rev.1

IFC300(RS485)

Rev.2

1TOT (PhyL 0)

-

-

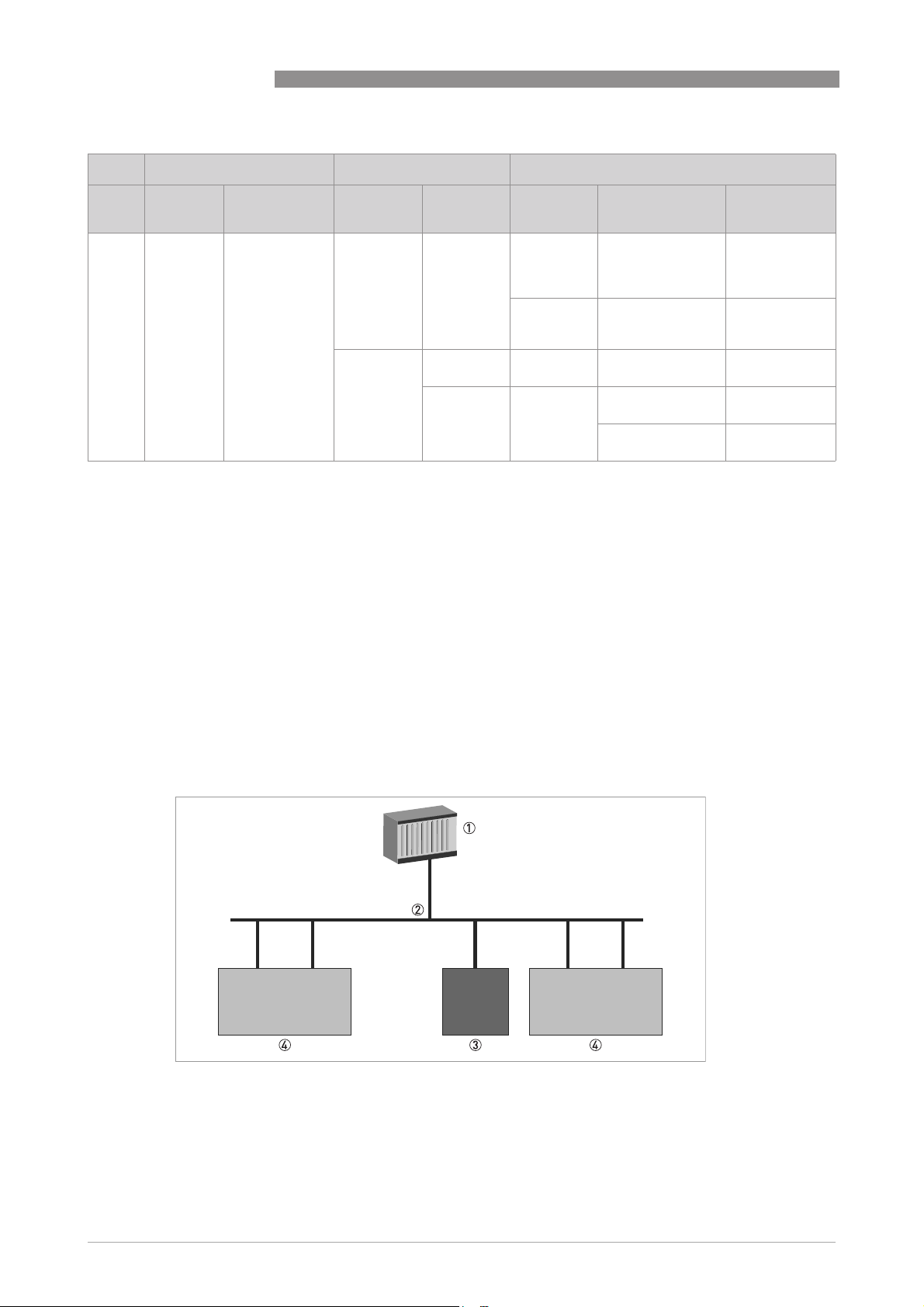

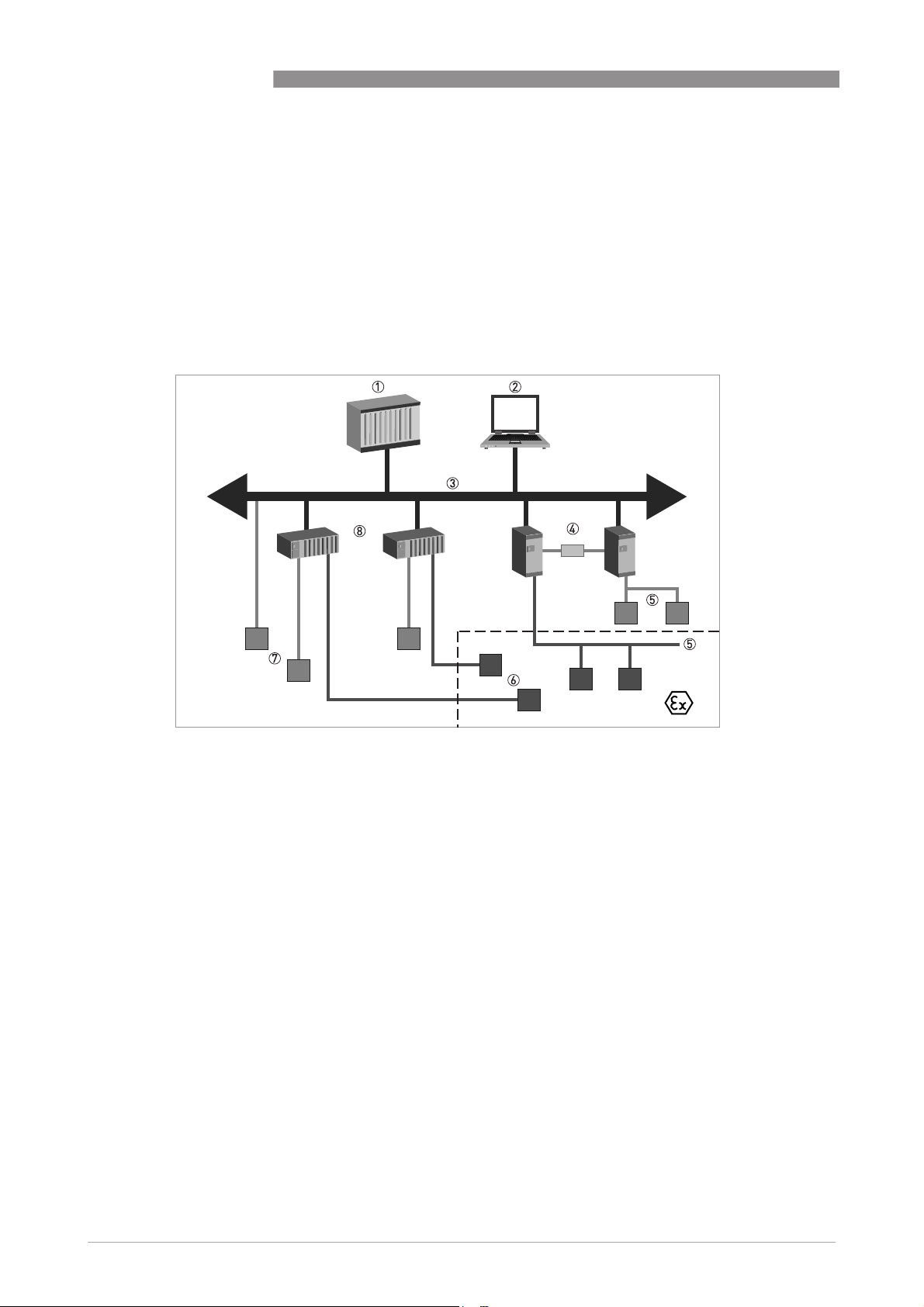

2.2 System configuration of PROFIBUS DP network

The following diagram shows a typical network configuration with PROFIBUS devices with RS485

interface in a non-hazardous environment. The PROFIBUS devices with RS485 interface do not

need any segment coupler. They are connected directly to the PROFIBUS DP network.

Figure 2-1: PROFIBUS DP network

1 SPS

2 PROFIBUS DP with max. 12 Mbit/s

3 Signal converter

4 Other devices with PROFIBUS RS485 interface

6

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 7

IFC 300

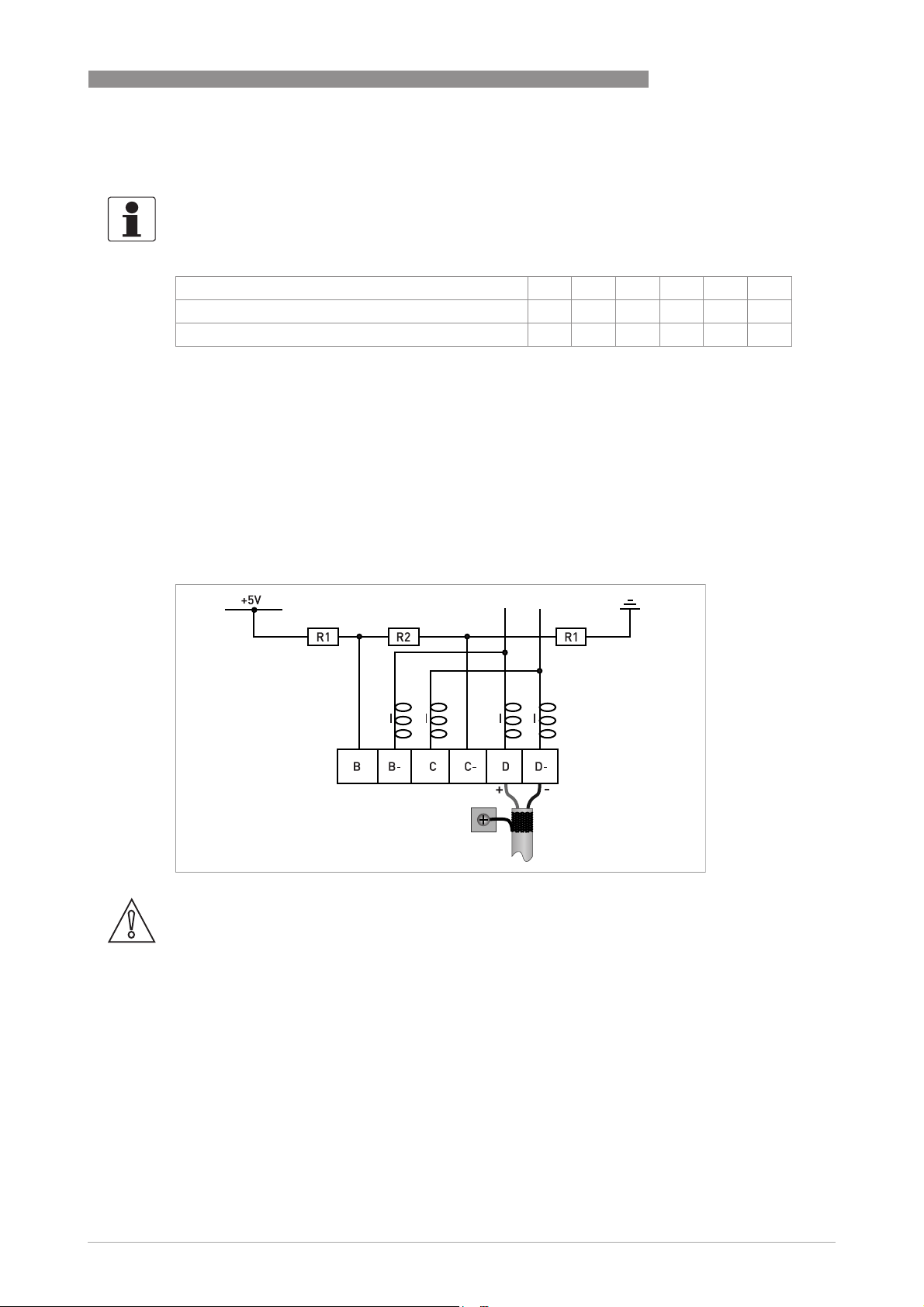

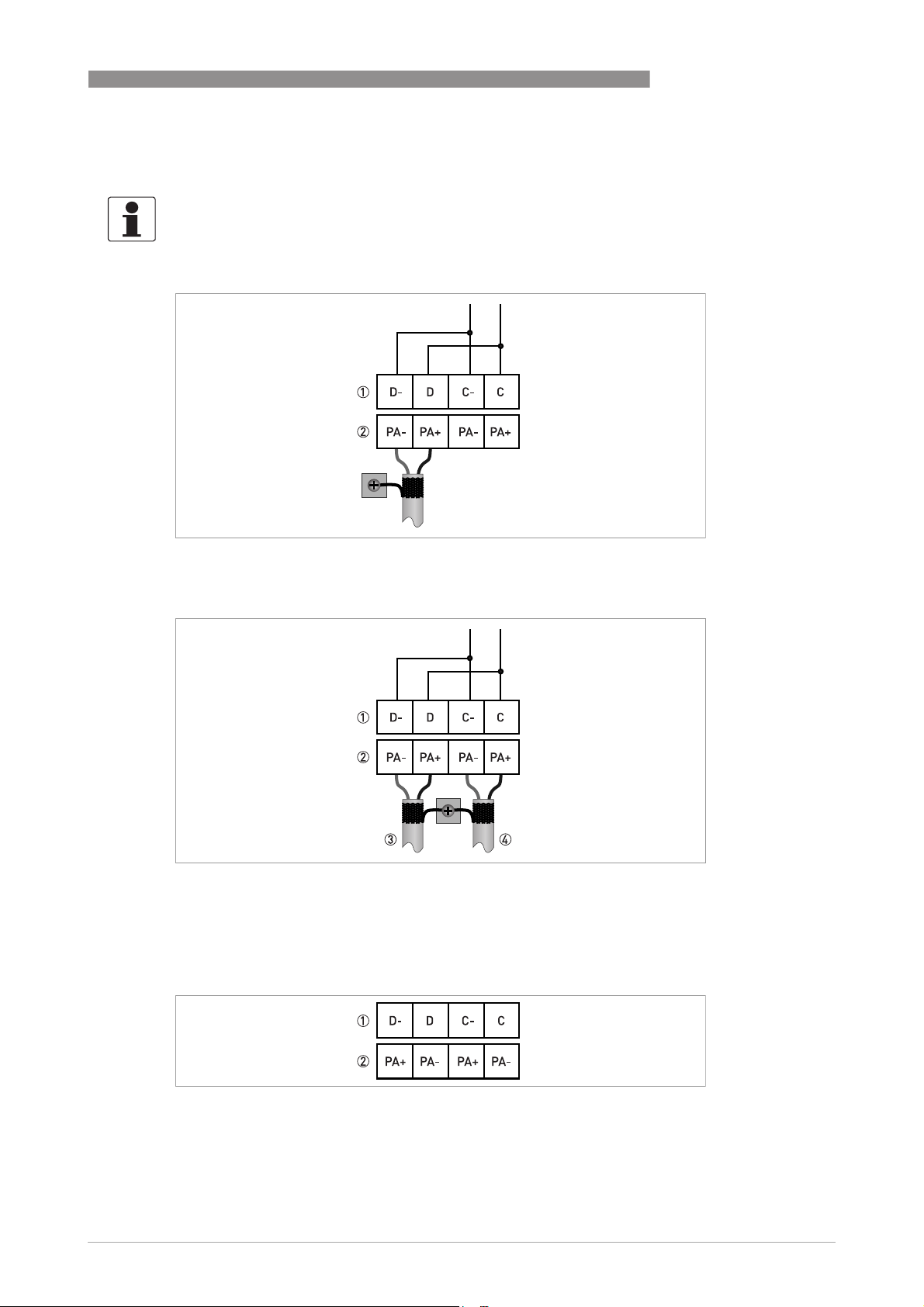

2.3 Electrical connection for DP signal converter

INFORMATION!

For a detailed description of the electrical connections please refer to the standard signal

converter handbook.

Signal converter terminals B B- C C- D D-

PROFIBUS designation T +B -A -T +B -A

1 2 3 4 5 6

1 Termination positive

2 TxD+/RxD+ second connection

3 TxD-/RxD- second connection

4 Termination negative

5 TxD+/RxD+ first connection

6 TxD-/RxD- first connection

PROFIBUS DP 2

External connection with spur

CAUTION!

Spurs are not allowed at high data rates!

I = 110 nH

R1 = 390 Ω

R2 = 220 Ω

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

7

Page 8

2 PROFIBUS DP

External connection at last device with active internal bus termination

I = 110 nH

R1 = 390 Ω

R2 = 220 Ω

IFC 300

External connection to a trunk

1 e.g. incoming data lines

2 e.g. outgoing data lines

I = 110 nH

R1 = 390 Ω

R2 = 220 Ω

8

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 9

IFC 300

2.4 Technical data

Hardware

Type PROFIBUS RS485 interface according to IEC 61158-2

Connection Dependent of polarity; please note at electrical connection!

Software

GSD GSD file on CD-ROM or from internet site

Device profile PA Profile compact class B, V 3.0

Address range 0…126 (default 126)

Local control Local display and operator interface at device

SAPs 2 x MS1 SAPs – acyclic interface to PLC

Function blocks 1 x TB = Transducer Block: contains the parameters and functions

PROFIBUS DP 2

0…125 via PROFIBUS service set_slave_add

0…126 via local display

126 via factory_reset = 2712

3 x MS2 SAPs – the number of MS2 Service Access Points is typically

equal to the maximum number of master class 2 tools

defined in PA Profile 3.0

1 x PB = Physical Block: contains the parameters defined in PA

Profile 3.0

5 x AI = Analog Input Blocks: contains the parameters defined in PA

Profile 3.0

3 x TOT = Totalizer Function Blocks: contains the parameters defined

in PA Profile 3.0

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

9

Page 10

2 PROFIBUS DP

2.5 GSD files for the data transfer

A PROFIBUS GSD ZIP file (e.g. GSD-31777813.zip; including both all GSD files and additional data

files) you can get on a CD ROM or can be downloaded from the internet. The GSD file contains

information that will be needed for project planning of the PROFIBUS communication network.

The relevant data files (e.g. _ _ _ _ .bmp / _ _ _ _ .dib) must be loaded into the bus configuration

system/master system before start-up of the bus system.

2.5.1 Cyclic data exchange

During network configuration the user has to define which function block outputs of the signal

converter should be transferred cyclically to the master. Network configuration will be done

using one of the GSD files described before. The order of transmission of a function block always

remains the same even if a function block is defined as an "Empty" block (if so, no function block

output data will be sent to the master and all function block outputs following the empty block

output data will be sent to the master and all function block outputs following the empty block

output data will be sent to the master and all function block outputs following the empty block output data will be sent to the master and all function block outputs following the empty block

will move up one position)

will move up one position).

will move up one position)will move up one position)

2.5.2 Baud rate

IFC 300

(if so, no function block

(if so, no function block (if so, no function block

Supported baud rates are listed in the GSD file (see below). After power-on or PROFIBUS

timeout a baud rate search is active to detect the current transfer speed on the bus. It is not

necessary to set the baud rate manually.

If the data transmission rate is changed during operation the baud rate search will not be started

by the device. A new power-up or a manual interruption of the PROFIBUS communication is

required to activate the baud rate search in this case.

2.5.3 Ident.-No. supported

The signal converter with PROFIBUS RS485 interface is based on PROFIBUS PA Profile V 3.0. The

device supports two Ident-No.:

• Ident-No. "4500hex" belongs to the GSD file KR014500.GSD and KR024500.GSD and includes

the complete functionality of the electromagnetic flowmeter.

• The application of the manufacturer independent Ident-No. "9740hex" (GSD file

"PA039740.GSD") provides interchangeability of devices, i.e. an exchange of electromagnetic

flowmeters of different vendors.

Please follow the instructions in the manual of the host supplier when installing the GSD File you

need and the additional files (_ _ _ _ .bmp and _ _ _ _ .dib) into the PLC.

INFORMATION!

If separated by the bus configuration system the device entry of the PROFIBUS RS485 interface

with PA Profile 3.0 will be located within the slave family PROFIBUS PA.

10

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 11

IFC 300

PROFIBUS DP 2

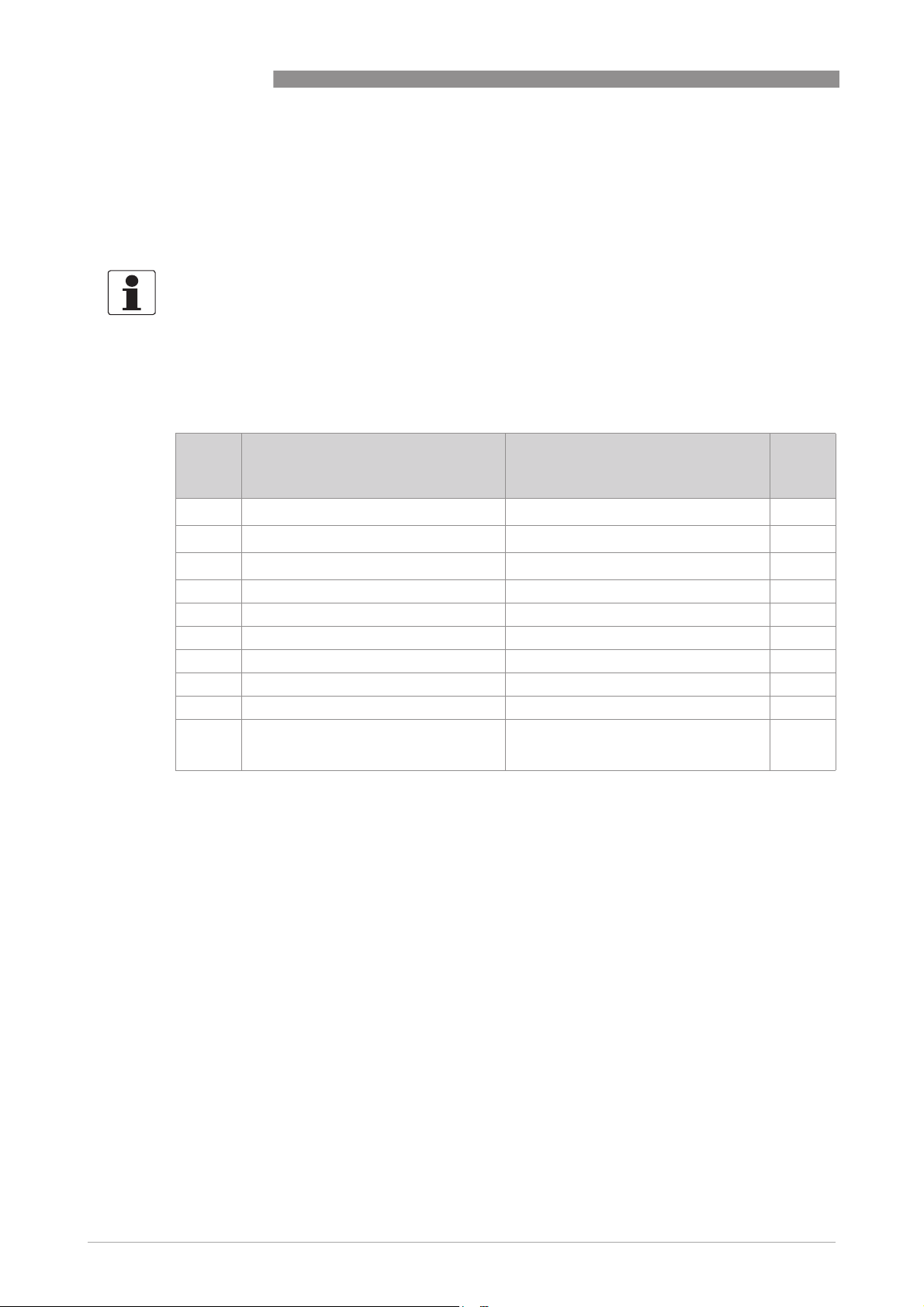

2.5.4 Manufacturer specific GSD files: KR024500.GSD and KR014500.GSD

The manufacturer delivers the GSD files with the entire device functionality, which is listed as

follows:

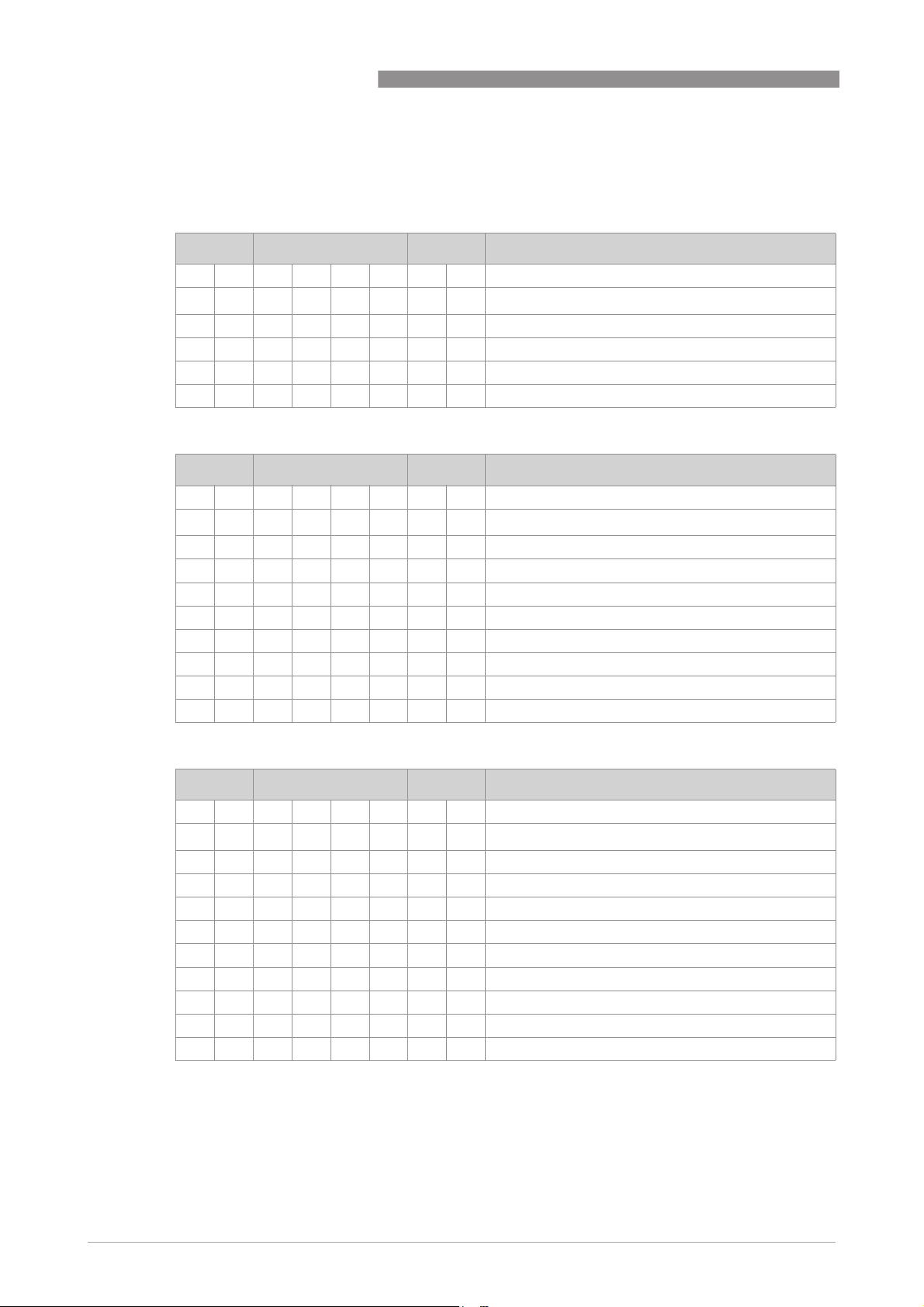

Block

number

1 Volume Flow AI-FB

2 Volume Totalizer Totalizer-FB

3 Volume Totalizer Totalizer-FB

4 Mass Totalizer Totalizer-FB kg

5 Mass Flow AI-FB kg/s

6 Speed Flow AI-FB m/s

7 Coil Temperature AI-FB K

8 Conductivity AI-FB S/m

X Electronic Temperature AI-FB °C

X Supply

Default configuration

Function block output: value and

status

(internal supply voltage for the

PROFIBUS interface)

KR024500.GSD

KR014500.GSD

Ident-No. 4500

AI-FB V

Default

unit

m3/h

3

m

3

m

• AI: Analog Input Function Block

• FB: Function Block

• X: Block number 1, 5, 6, 7 or 8

There will be two additional output values available by changing the function block channel

parameters of the above mentioned "Analog Input Function Blocks".

There are separate settings to select the units for local display and PROFIBUS. Modifications of

the units of the display will have no effect on the data transferred via PROFIBUS.

A master class 2 tool is required to modify the units for PROFIBUS transfer.

INFORMATION!

During network configuration the user has to define which function block outputs of the signal

converter should be transferred cyclically to the master. This is performed by a bus

configuration tool (e.g. "HW- Config" for PC-S7 from Siemens). This tool offers specific functions

as follows:

1. It is possible to configure an "Empty" block (the code of an "Empty" block is defined as 0x00) on

each block number. This implies: no data are transmitted in the cyclic data telegram for this

block.

2. There is NO "Totalizer (TOT)" function block allowed on block position 1, 5, 6, 7 and 8! On these

positions, only an "Analog Input (AI)" function block or an "Empty" block is allowed!

–

(Note: All codes supported by "Analog Input (AI)" - and "Totalizer (TOT)"

function blocks will

be found in the corresponding GSD files.)

3. There is NO "Analog Input (AI)" function block allowed on block position 2, 3 and 4! On these

positions, only a "Totalizer (TOT)" function block or an "Empty" block is allowed!

4. There is a choice of 7 different totalizer functions, which can be allocated to the blocks 2, 3

and/or 4.

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

11

Page 12

2 PROFIBUS DP

Definition of totalizer functions

Total cyclic transfer of the totalizer value with status to the master

SetTot + Total cyclic transfer of the totalizer value with status to the master + cyclic

ModeTot + Total cyclic transfer of the totalizer value with status to the master + cyclic

SetTot + ModeTot + Total cyclic transfer of the totalizer value with status to the master + cyclic

SetTot cyclic control data from master to the device via the parameter

ModeTot cyclic control data from master to the device via the parameter

SetTot + ModeTot cyclic control data from master to the device via the parameters

Both, the Byte SetTot and ModeTot are cyclically sent from the master to the device if these bytes

are inserted as output data via the PLC configurator. The meaning of these control bytes are as

follows:

IFC 300

control data from master to the device via the parameter SetTot

control data from master to the device via the parameter ModeTot

control data from master to the device via the parameters SetTot and

ModeTot (in the given order)

SetTot

ModeTot

SetTot and ModeTot (in the given order)

Function of control bytes

SetTot

SetTot

SetTotSetTot

SetTot = 0 Totalizer is totalizing.

SetTot = 1 Totalizer will be reset to 0 and stays at 0 until SetTot is switched back

SetTot = 2 Totalizer is set to the value defined by PresetTot. PresetTot can be

SetTot > 2 Not allowed. Value is ignored; totalizer remains in its last valid

ModeTot

ModeTot

ModeTotModeTot

ModeTot = 0 Totalizer totalizes positive and negative values.

ModeTot = 1 Totalizes only positive values.

ModeTot = 2 Totalizes only negative values.

ModeTot = 3 Totalizer is stopped, no totalization will be done.

ModeTot = 248 Totalizes all values as positive, negative values will be multiplied with

ModeTot = 249 Totalizes all values as negative, positive values will be multiplied with

again to 0. If the value of SetTot changes from "1" to "0" the totalizer

starts counting from 0.

written via an acyclic master (totalizer in block 2 = Slot 2 Index 32;

totalizer in block 3 = Slot 3 Index 32; totalizer in block 4 = Slot 4 Index

32). If the value of SetTot changes from "2" to "0" the totalizer starts

counting from the current value defined by PresetTot.

setting.

-1.0.

-1.0.

12

All other values of ModeTot not allowed. Value is ignored; totalizer remains in its last valid

setting.

The standard block configuration may be changed by the customer but using the default settings

is highly recommended. If the standard block configuration should be changed by the customer

an acyclic master tool or the device display menu must be used to change the "channel

parameter" value of the block which should be connected to another transducer output value.

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 13

IFC 300

PROFIBUS DP 2

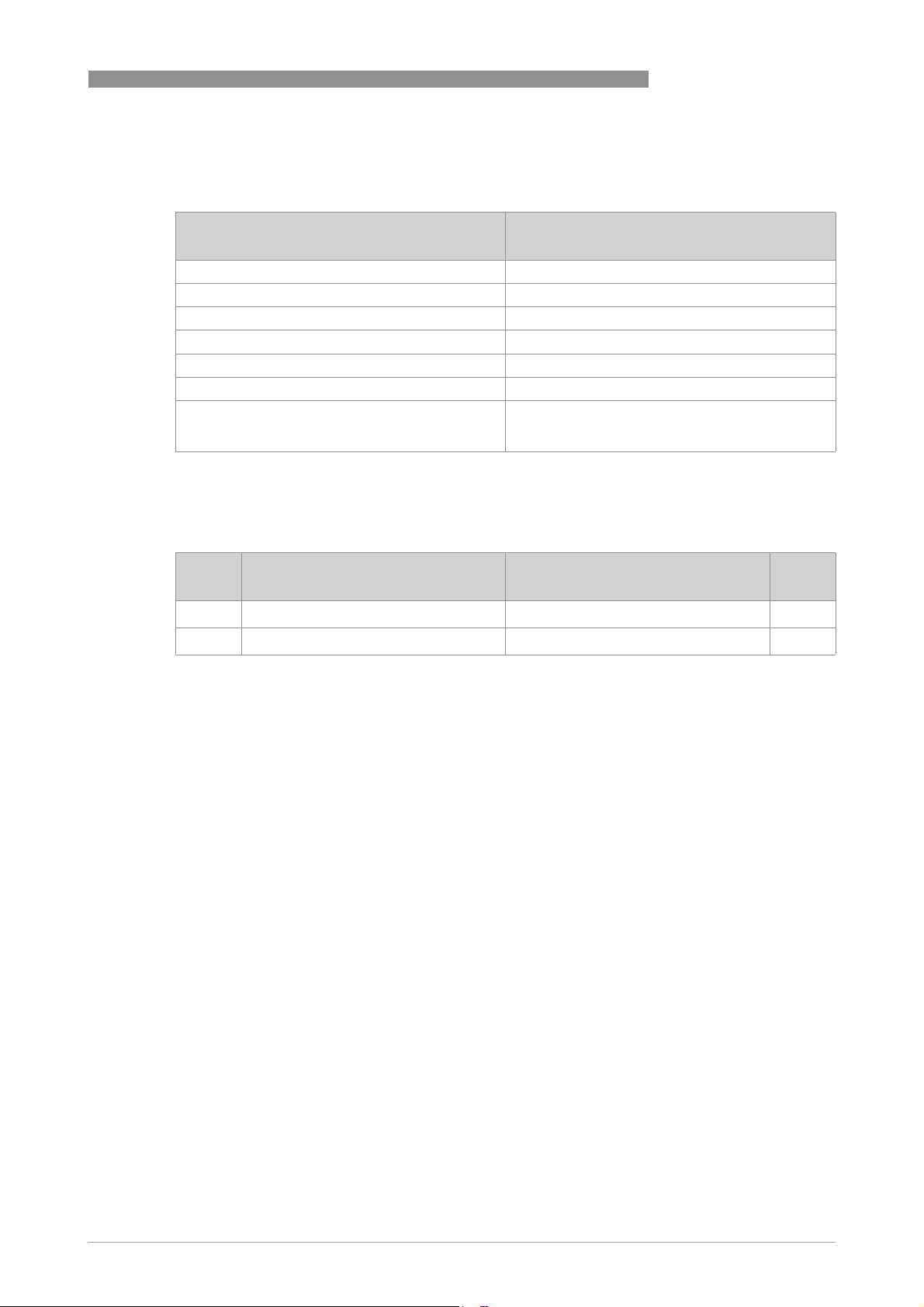

2.5.5 Differencies of the manufacturer specific GSD files: KR024500.GSD and

KR014500.GSD

KR024500.GSD

(includes the complete functionality)

GSD Revision 5.02 GSD Revision 3

PROFIBUS-PA Profile 3.0x and I&M PROFIBUS PA Profile 3.0x

Ident_Maintenance_supp = 1 (== supported) -

Fail_Safe (Extended DP-Features) -

C2_Max_Data_Len = 132 C2_Max_Data_Len = 128

Max_Initiate_PDU_Length = 132 Max_Initiate_PDU_Length = 128

Unit_Diag_Bit(82) = "DP - measurement not

available"

Unit_Diag_Bit(83) = "DP - power fail"

2.5.6 Profile specific GSD file: PA039740.GSD

The functionality of the profile specific GSD file is limited. This GSD file includes only two blocks:

Block

number

1 Volume Flow AI-FB

2 Volume Totalizer Totalizer-FB

Standard configuration

Function block output value

KR014500.GSD

(functions are only partially supported)

Unit_Diag_Bit(82) = "reserved (82)"

Unit_Diag_Bit(83) = "reserved (83)"

PA039740.GSD

Ident-No. 9740

Default

unit

m3/h

3

m

The device has to be switched from full functionality (manufacturer specific) to interchangeable

basic configuration (profile specific) by using both a master class 2 tool or the device display

menu (IDENT_NUMBER_SELECTOR: Slot 0, Index 40; change byte value to 0). In the next step,

the device has to be configured using the PA039740.GSD file.

2.5.7 Using the display menu to distinguish between Rev 1 and Rev 2

Rev 1 [= = DP signal converter (RS485) Rev 1] and Rev 2 [= = DP signal converter (RS485) Rev 2]

Use the display to open the Fct. 3.5 of the signal converter (if not available, see below Rev 1). You

will get the following information:

• KROHNE Ident.-No. (of the assembled PROFIBUS PCB)

• Software revision (of the PROFIBUS software)

• Date of production (of the PROFIBUS device)

Your device is Rev 1, if

• the Fct. No. mentioned above is not available

• the indicated software revision number is = 1.0.x

Your device is Rev 2, if

• the indicated software revision number is = 1.1.x

• the indicated software revision number is ≥ 2.0

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

13

Page 14

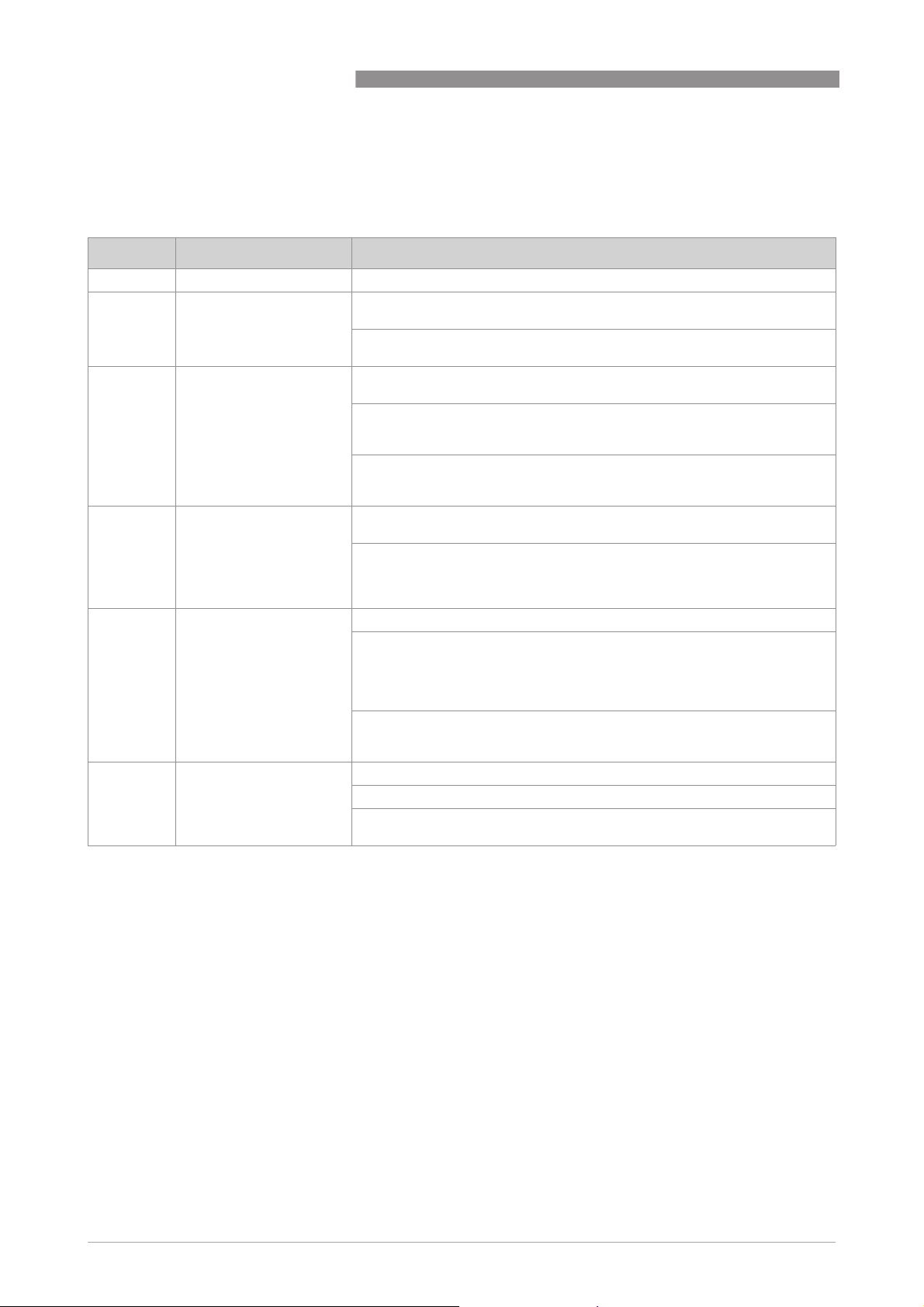

3 PROFIBUS PA

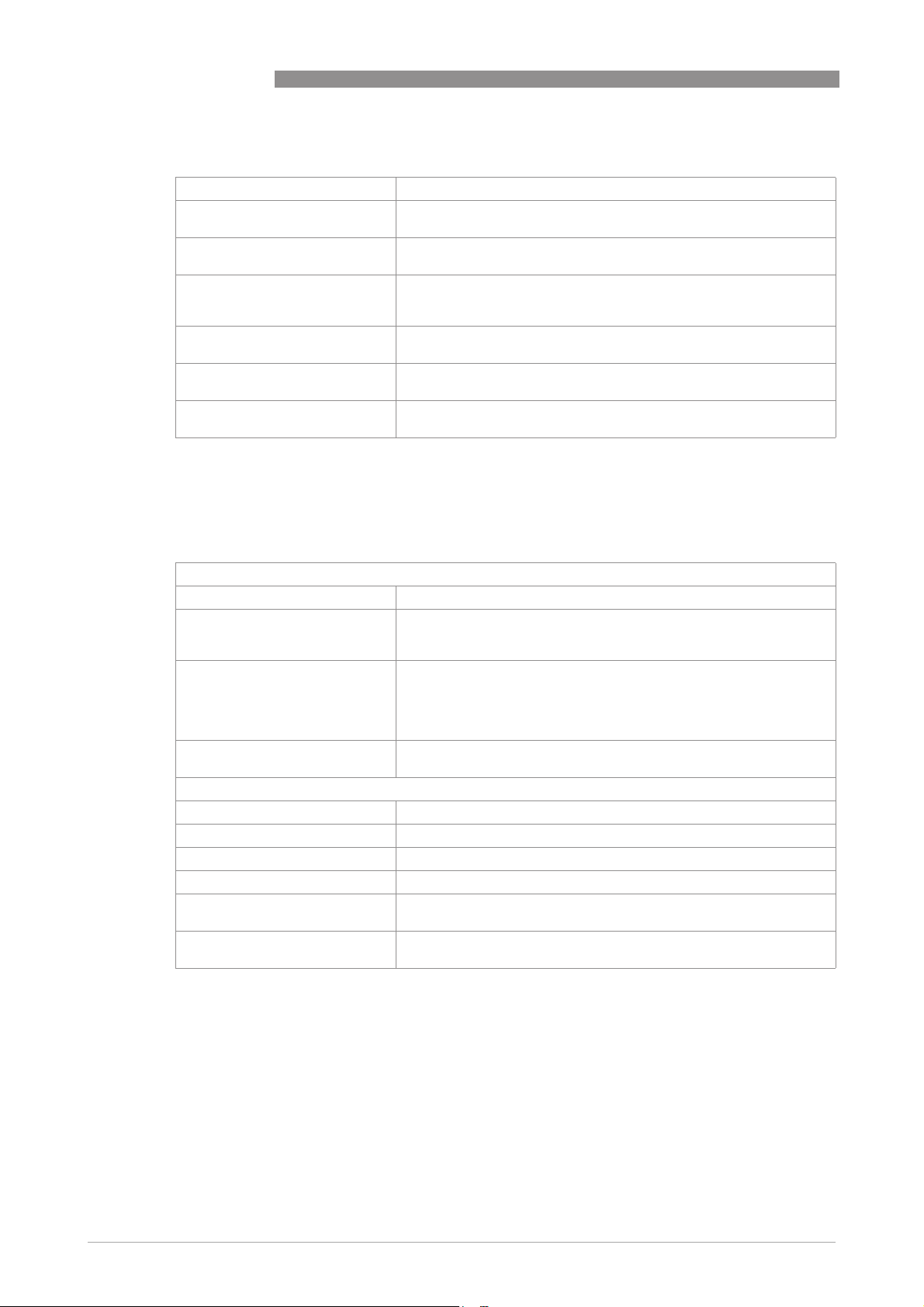

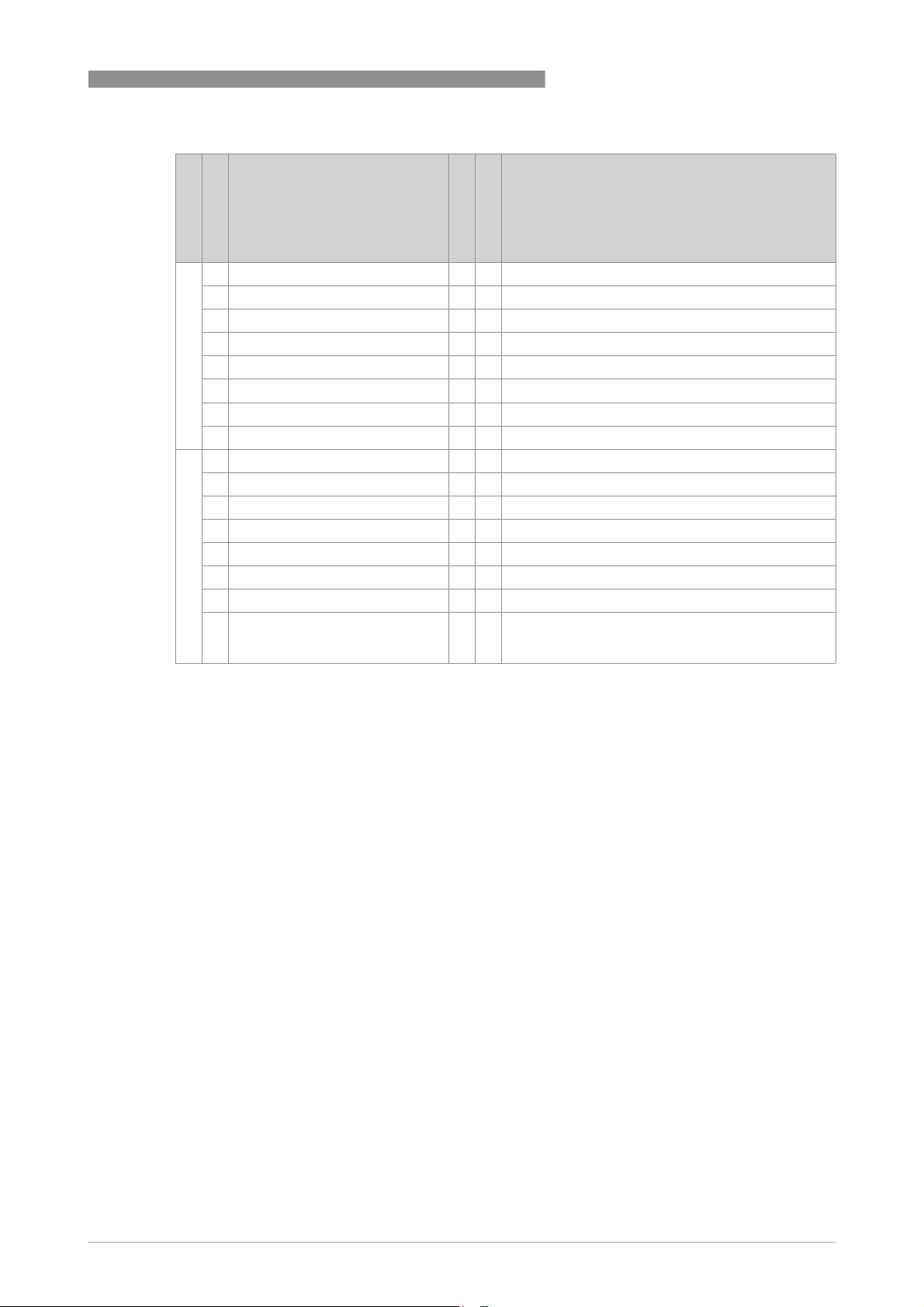

3.1 Software history

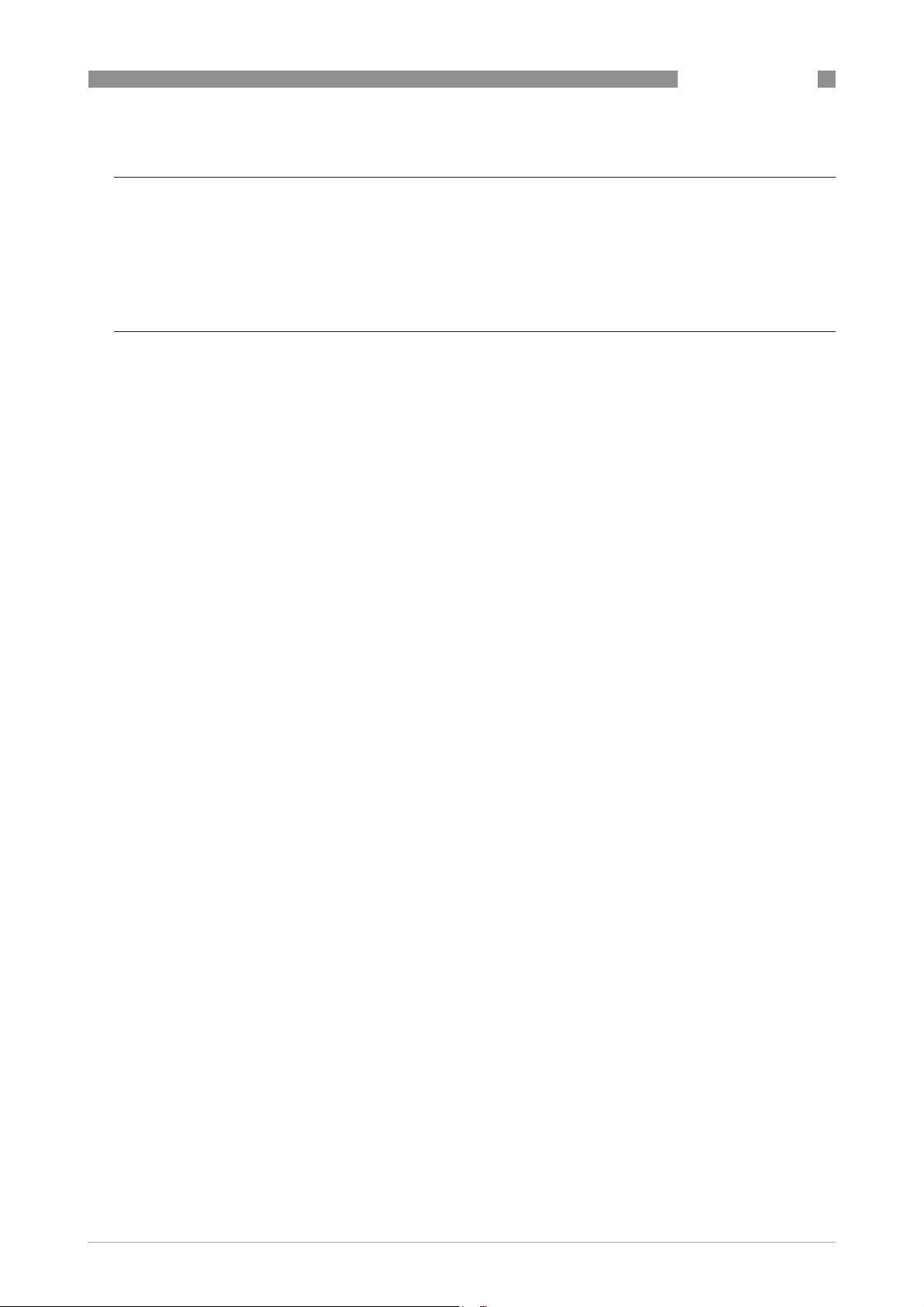

Issued Signal converter Application program System integration

IFC 300

Mth./

Hardware Firmware Hardware Software Driver Version Model name

year

01/06 Signal

04/08 Signal

converter

with MBP

interface +

PA Profile

3.0

converter

with MBP

interface +

PA Profile

3.0

V2.0.0 / 060112

V2.0.0 / 060126

V3.0.2 / 080422 Simatic

Simatic

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP3)DD(Ident.-No.)

Pactware DTM ≥ GFP*DTM1.3.1

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP3)DD(Ident.-No.)

Pactware DTM ≥ GFP*DTM1.3.1

GSD

manuf.

specific for

stand.

DP/PA

segment

coupler

GSD

manuf.

specific for

SK2/SK3

segment

coupler of

P&F

GSD

profile

specific

GSD

manuf.

specific for

stand.

DP/PA

segment

coupler

GSD

manuf.

specific for

SK2/SK3

segment

coupler of

P&F

GSD

profile

specific

KR024501.GSD IFC300 (MBP)

YP024501.GSD YP0 IFC300

PA139740.GSD Flow with 1AI,

I3P*DD0300.03** -

FDT1.2

KR024501.GSD IFC300 (MBP)

YP024501.GSD YP0 IFC300

PA139740.GSD Flow with 1AI,

I3P*DD0300.03** -

FDT1.2

Rev.2

(MBP) Rev.2

1TOT (PhyL 1)

-

Rev.2

(MBP) Rev.2

1TOT (PhyL 1)

-

14

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 15

IFC 300

Issued Signal converter Application program System integration

PROFIBUS PA 3

Mth./

Hardware Firmware Hardware Software Driver Version Model name

year

01/11 Signal

converter

with MBP

interface +

PA Profile

3.0

GFP*: Generic Flow PROFIBUS

I3P*: IFC300 PROFIBUS

**: PDM 5.2 PDM 6.0

V3.0.2 / 100811 Simatic

PCS7

other SPS

of other

manufact.

Laptop / PC PDM

HW Config

other

Software of

other SPS

manufact.

(≥ 6.0 SP3)DD(Ident.-No.)

Pactware DTM ≥ GFP*DTM1.3.1

GSD

manuf.

specific for

stand.

DP/PA

segment

coupler

GSD

manuf.

specific for

SK2/SK3

segment

coupler of

P&F

GSD

profile

specific

KR024501.GSD IFC300 (MBP)

YP024501.GSD YP0 IFC300

PA139740.GSD Flow with 1AI,

I3P*DD0300.03** -

FDT1.2

I3P*DTM1.0.7

FDT1.2

Rev.2

(MBP) Rev.2

1TOT (PhyL 1)

-

-

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

15

Page 16

3 PROFIBUS PA

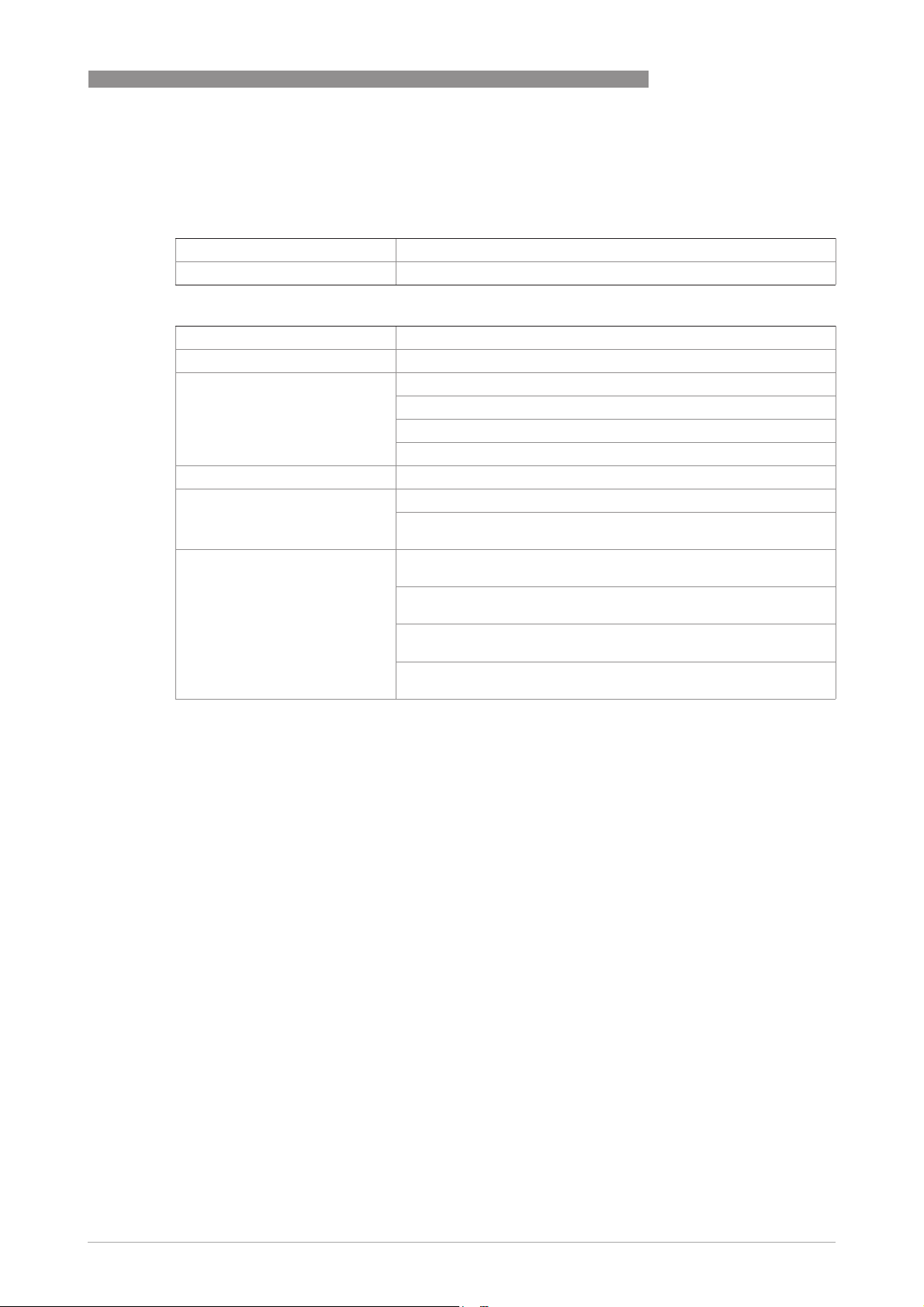

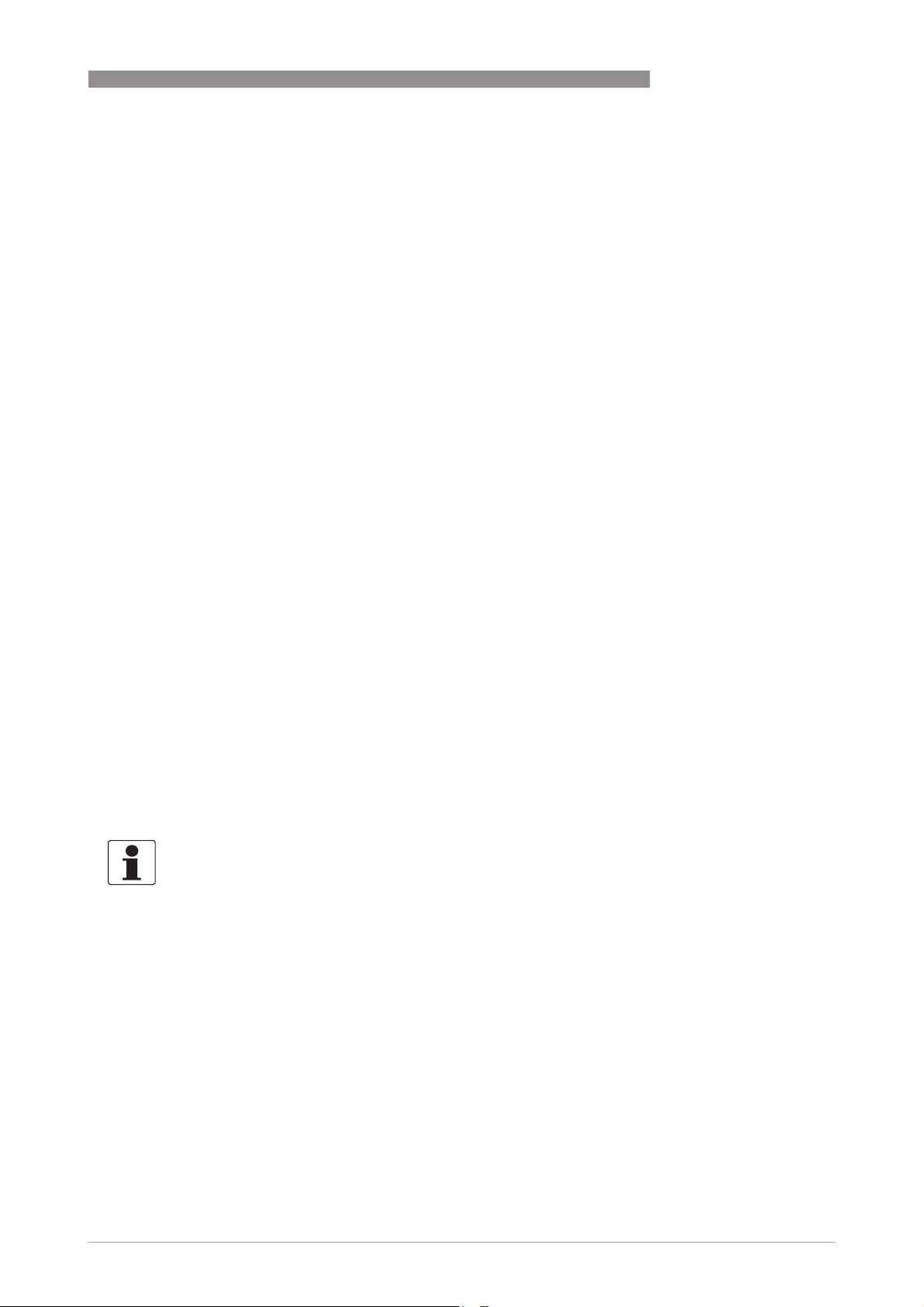

3.2 System configuration of PROFIBUS PA network

The following diagram shows a typical instrumentation with PROFIBUS PA devices with MBP

interface in hazardous and non-hazardous locations, including connections of conventional

devices (e.g. with 4...20 mA signals) in a PROFIBUS network.

As a rule, the PROFIBUS PA segment is connected to a segment coupler which, among other

things, carries out the conversion to the PROFIBUS DP bus line. It should be mentioned that the

segment coupler is normally set to a fixed baud rate on the DP side.

IFC 300

Figure 3-1: PROFIBUS PA network

1 Control system (PLC); class 1 master

2 Engineering or operation control tool; class 2 master

3 PROFIBUS DP network with max. 12 Mbit/s

4 PROFIBUS PA segment coupler DP / PA

5 Device with PROFIBUS PA interface, 31.25 kbit/s

6 HART

7 More devices with 4…20 mA

8 Analogue I/O module

®

device

16

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 17

IFC 300

3.3 Electrical connection for PA signal converter

INFORMATION!

For a detailed description of the electrical connections please refer to the standard signal

converter handbook.

External connection with spur

PROFIBUS PA 3

1 Device internal terminal names

2 External bus connections

External connection to a trunk

1 Device internal terminal names

2 External bus connections

3 e.g. incoming data lines

4 e.g. outgoing data lines

Alternative wiring because the current linkage between the device and the PROFIBUS

PA cable is independent of polarity

1 Device internal terminal names

2 External bus connection

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

17

Page 18

3 PROFIBUS PA

INFORMATION!

Although the PROFIBUS MBP technology supports power supply via the PROFIBUS line the

"signal converter PROFIBUS MBP interface" will operate only if the additional power supply for

the device is connected / available.

For a detailed description please check the signal converter handbook. Refer also to the

PROFIBUS PA user and installation guideline (Version 2.2, February 2003 PNO order no. 2.092).

3.4 Technical data

Hardware

Type PROFIBUS RS485 interface according to IEC 61158-2 with

Connection Independent of polarity at electrical connection

Base current 10.5 mA

FDE Yes, separate fault disconnection electronics provided (FDE = Fault

Fault current 6 mA (fault current = max. continuous current – base current)

Starting current <12 mA

Ex approval Ex ia IIC or Ex ib IIC/IIB, FISCO Device

IFC 300

31.25 kbits/s; voltage mode

Disconnection Electronics)

For detailed information refer to standard product documentation.

Software

GSD GSD file on CD-ROM or from internet site

Device profile PA Profile compact class B, V 3.0

Address range 0…126 (default 126)

0…125 via PROFIBUS service set_slave_add

0…126 via local display

126 via factory_reset = 2712

Local control Local display and operator interface at device

SAPs 2 x MS1 SAPs – acyclic interface to PLC

3 x MS2 SAPs – the number of MS2 Service Access Points is typically

equal to the maximum number of master class 2 tools

Function blocks 1 x TB = Transducer Block: contains the parameters and functions

defined in PA Profile 3.0

1 x PB = Physical Block: contains the parameters defined in PA

Profile 3.0

5 x AI = Analog Input Blocks: contains the parameters defined in PA

Profile 3.0

3 x TOT = Totalizer Function Blocks: contains the parameters defined

in PA Profile 3.0

18

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 19

IFC 300

3.5 GSD files for the data transfer

A PROFIBUS GSD ZIP file (e.g. GSD-31777813.zip; including both all GSD files and additional data

files) you can get on a CD ROM or can be downloaded from the internet. The GSD file contains

information that will be needed for project planning of the PROFIBUS communication network.

The relevant data files (e.g. _ _ _ _ .bmp / _ _ _ _ .dib) must be loaded into the bus configuration

system/master system before start-up of the bus system.

3.5.1 Cyclic data exchange

During network configuration the user has to define which function block outputs of the signal

converter should be transferred cyclically to the master. Network configuration will be done

using one of the GSD files described before. The order of transmission of a function block always

remains the same even if a function block is defined as an "Empty" block (if so, no function block

output data will be sent to the master and all function block outputs following the empty block

output data will be sent to the master and all function block outputs following the empty block

output data will be sent to the master and all function block outputs following the empty block output data will be sent to the master and all function block outputs following the empty block

will move up one position)

will move up one position).

will move up one position)will move up one position)

3.5.2 Ident.-No. supported

PROFIBUS PA 3

(if so, no function block

(if so, no function block (if so, no function block

The signal converter with PROFIBUS MBP interface is based on PROFIBUS PA Profile V 3.0. The

device supports three Ident-No.:

• Ident-No. "4501hex" belongs to the GSD file KR024501.GSD and YP024501.GSD and includes

the complete functionality of the electromagnetic flowmeter.

• The application of the manufacturer independent Ident-No. "9740hex" (GSD file

"PA039740.GSD") provides interchangeability of devices, i.e. an exchange of electromagnetic

flowmeters of different vendors.

• Ident-No. "F401hex"

For detailed information refer to

as replacement for older signal converter IFC 090 PA

Please follow the instructions in the manual of the host supplier when installing the GSD File you

need and the additional files (_ _ _ _ .bmp and _ _ _ _ .dib) into the PLC.

Signal converter IFC 300 PROFIBUS PA with MBP interface

on page 23.

INFORMATION!

If separated by the bus configuration system the device entry of the PROFIBUS MBP interface

with PA Profile 3.0 will be located within the slave family PROFIBUS PA.

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

19

Page 20

3 PROFIBUS PA

3.5.3 Manufacturer specific GSD files: KR024501.GSD and YP024501.GSD

The KR024501.GSD file is for use with the standard DP/PA coupler and the YP024501.GSD file is

for use with the transparent DP/PA coupler SK2/SK3 of Pepperl & Fuchs (up to 12 MBaud on the

DP segment).

INFORMATION!

For devices with MBP interface there are always two types of GSD files in our GSD compilation:

•

One standard GSD file for a standard DP/PA segment coupler with file name: "KR0….GSD"

•

One special GSD file specific for the segment coupler SK2/SK3 of Pepperl & Fuchs with file

…

name: "YP0

It should be noted that both GSD files support device functionality as described below:

.GSD"

IFC 300

Block

number

1 Volume Flow AI-FB

2 Volume Totalizer Totalizer-FB

3 Volume Totalizer Totalizer-FB

4 Mass Totalizer Totalizer-FB kg

5 Mass Flow AI-FB kg/s

6 Speed Flow AI-FB m/s

7 Coil Temperature AI-FB K

8 Conductivity AI-FB S/m

X Electronic Temperature AI-FB °C

X Supply

Default configuration

Function block output: value and

status

(internal supply voltage for the

PROFIBUS interface)

KR024501.GSD

YP024501.GSD

Ident-No. 4501

AI-FB V

Default

unit

m3/h

3

m

3

m

• AI: Analog Input Function Block

• FB: Function Block

• X: Block number 1, 5, 6, 7 or 8

There will be two additional output values available by changing the function block channel

parameters of the above mentioned "Analog Input Function Blocks".

20

There are separate settings to select the units for local display and PROFIBUS. Modifications of

the units of the display will have no effect on the data transferred via PROFIBUS. A master class

2 tool is required to modify the units for PROFIBUS transfer.

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 21

IFC 300

PROFIBUS PA 3

INFORMATION!

During network configuration the user has to define which function block outputs of the signal

converter should be transferred cyclically to the master. This is performed by a bus

configuration tool (e.g. "HW- Config" for PC-S7 from Siemens). This tool offers specific functions

as follows:

1. It is possible to configure an "Empty" block (the code of an "Empty" block is defined as 0x00) on

each block number. This implies: no data are transmitted in the cyclic data telegram for this

block.

2. There is NO "Totalizer (TOT)" function block allowed on block position 1, 5, 6, 7 and 8! On these

positions, only an "Analog Input (AI)" function block or an "Empty" block is allowed!

–

(Note: All codes supported by "Analog Input (AI)" - and "Totalizer (TOT)"

be found in the corresponding GSD files.)

3. There is NO "Analog Input (AI)" function block allowed on block position 2, 3 and 4! On these

positions, only a "Totalizer (TOT)" function block or an "Empty" block is allowed!

4. There is a choice of 7 different totalizer functions, which can be allocated to the blocks 2, 3

and/or 4.

Definition of totalizer functions

Total cyclic transfer of the totalizer value with status to the master

SetTot + Total cyclic transfer of the totalizer value with status to the master + cyclic

control data from master to the device via the parameter SetTot

ModeTot + Total cyclic transfer of the totalizer value with status to the master + cyclic

control data from master to the device via the parameter ModeTot

SetTot + ModeTot + Total cyclic transfer of the totalizer value with status to the master + cyclic

control data from master to the device via the parameters SetTot and

ModeTot (in the given order)

SetTot cyclic control data from master to the device via the parameter

SetTot

ModeTot cyclic control data from master to the device via the parameter

ModeTot

SetTot + ModeTot cyclic control data from master to the device via the parameters

SetTot and ModeTot (in the given order)

function blocks will

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

21

Page 22

3 PROFIBUS PA

Both, the Byte SetTot and ModeTot are cyclically sent from the Master to the device if these bytes

are inserted as output data via the PLC configurator. The meaning of these control bytes are as

follows:

Function of control bytes

SetTot

SetTot

SetTotSetTot

SetTot = 0 Totalizer is totalizing.

SetTot = 1 Totalizer will be reset to 0 and stays at 0 until SetTot is switched back

SetTot = 2 Totalizer is set to the value defined by PresetTot. PresetTot can be

SetTot > 2 Not allowed. Value is ignored; totalizer remains in its last valid

ModeTot

ModeTot

ModeTotModeTot

ModeTot = 0 Totalizer totalizes positive and negative values.

ModeTot = 1 Totalizes only positive values.

ModeTot = 2 Totalizes only negative values.

ModeTot = 3 Totalizer is stopped, no totalization will be done.

ModeTot = 248 Totalizes all values as positive, negative values will be multiplied with

ModeTot = 249 Totalizes all values as negative, positive values will be multiplied with

IFC 300

again to 0. If the value of SetTot changes from "1" to "0" the totalizer

starts counting from 0.

written via an acyclic master (totalizer in block 2 = Slot 2 Index 32;

totalizer in block 3 = Slot 3 Index 32; totalizer in block 4 = Slot 4 Index

32). If the value of SetTot changes from "2" to "0" the totalizer starts

counting from the current value defined by PresetTot.

setting.

-1.0.

-1.0.

All other values of ModeTot not allowed. Value is ignored; totalizer remains in its last valid

setting.

The standard block configuration may be changed by the customer but using the default settings

is highly recommended. If the standard block configuration should be changed by the customer

an acyclic master tool or the device display menu must be used to change the "channel

parameter" value of the block which should be connected to another transducer output value.

3.5.4 Profile specific GSD file: PA139740.GSD

The functionality of the profile specific GSD file is limited. This GSD file includes only two blocks:

Block

number

1 Volume Flow AI-FB

2 Volume Totalizer Totalizer-FB

The device has to be switched from full functionality to interchangeable basic configuration by

using one of both a master class 2 tool (IDENT_NUMBER_SELECTOR: Slot 0, Index 40; change

byte value to 0) or the device display menu. In the next step, the device has to be configured using

the PA039740.GSD file.

Standard configuration

Function block output value

PA139740.GSD

Ident-No. 9740

Default

unit

m3/h

3

m

22

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 23

IFC 300

PROFIBUS PA 3

3.5.5 Using the display menu to distinguish the current revision of the device (PA)

Use the display to open the Fct. B3.5 or C5.8.2 of the signal converter. You will get the following

information:

• KROHNE Ident.-No. (of the assembled PROFIBUS PCB)

• Software revision (of the PROFIBUS software)

• Date of production (of the PROFIBUS device)

3.6 Signal converter IFC 300 PROFIBUS PA with MBP interface as

replacement for older signal converter IFC 090 PA

3.6.1 Ident.-No. supported

Ident.-No. "F401hex":

Ident.-No. "F401hex": This Ident.-No. supports a compatibility mode concerning the cyclic data

Ident.-No. "F401hex":Ident.-No. "F401hex":

transfer (cyclic measurement values and diagnosis) if the IFC300 with PROFIBUS MBP interface

will be used for replacement of an "IFC090PA". It is not

configuration. Communication functions are restricted to those functions supported by IFC090

converters. Take care to set the "IFC300 PROFIBUS MBP interface" parameters in a way to get

the same behaviour as of "IFC090PA" concerning calculation of measuring values and totalizers

(this has to be done manually).

not necessary to adapt the PLC

notnot

3.6.2 Manufacturer specific GSD files (PA): KROHF401.GSD and YP01F401.GSD for the

older signal converter IFC090 with PROFIBUS MBP interface

The PROFIBUS signal converter with MBP Interface operating in the IFC090 compatibility mode

ensures operation with a PLC system with software parameters based on the IFC090PA. This

option is important for those customers who do not want to change the parameters in the PLC

software after having replaced the IFC090PA by an IFC300 with PROFIBUS MBP interface. The

existing GSD files of the IFC090PA ("KROHF401.GSD" or "YP01F401.GSD") can still be used.

In this application, the compatibility mode of the IFC300 with PROFIBUS MBP interface has to be

selected (display menu D2.9 - Identification No. -> choose IFC090); some other entries have to be

performed in a next step.

The overall situation is described using the following example: Consider an "IFC090PA" standard

configuration based on IFS…FLUX* flow sensor and "IFC090PA" flow signal converter. Consider

the following two options for replacements (IFS ….FLUX = IFS flow sensor compliant with

IFC090PA):

1. The IFC090PA flow signal converter will be replaced by an IFC300 PROFIBUS MBP interface

flow signal converter. The IFS …FLUX flow sensor is kept.

2. In addition to 1., also the IFS …FLUX flow sensor will be replaced by an OPTIFLUX flow sensor.

Options for flow

sensor installation:

Option 1.: IFS...FLUX

Option 2.: OPTIFLUX

IFC 300 PROFIBUS signal

converter with MBP

→

interface →

device

software

PROFIBUS

PA software

Integration into the

PLC via

a) IFC090PA.GSD

b) IFC300(MBP).GSD

PLC

PROFIBUS PA parameter set

→

in the Ctrl software of the

PLC

a) no change

b) change

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

23

Page 24

3 PROFIBUS PA

For both replacements 1. and 2., there are 2 options how to deal with the GSDs. In order to

provide communication between "IFC300 with PROFIBUS MBP interface" and the PLC, you may -

in principle – use the GSD of the "IFC090PA" ("KROHF401.GSD" or "YP01F401.GSD") and

–alternatively - the GSD of the "IFC300 with PROFIBUS MBP interface" ("KR024501.GSD" or

"YP024501.GSD").

IFC 300

However, both sets of GSDs, when applied, do not

do not provide the same level of functionality in the

do notdo not

PLC. The available PROFIBUS functionality of the "IFC300 with PROFIBUS MBP interface" in the

PLC as function of installed flow sensor and GSD used for integration into the PLC is as follows:

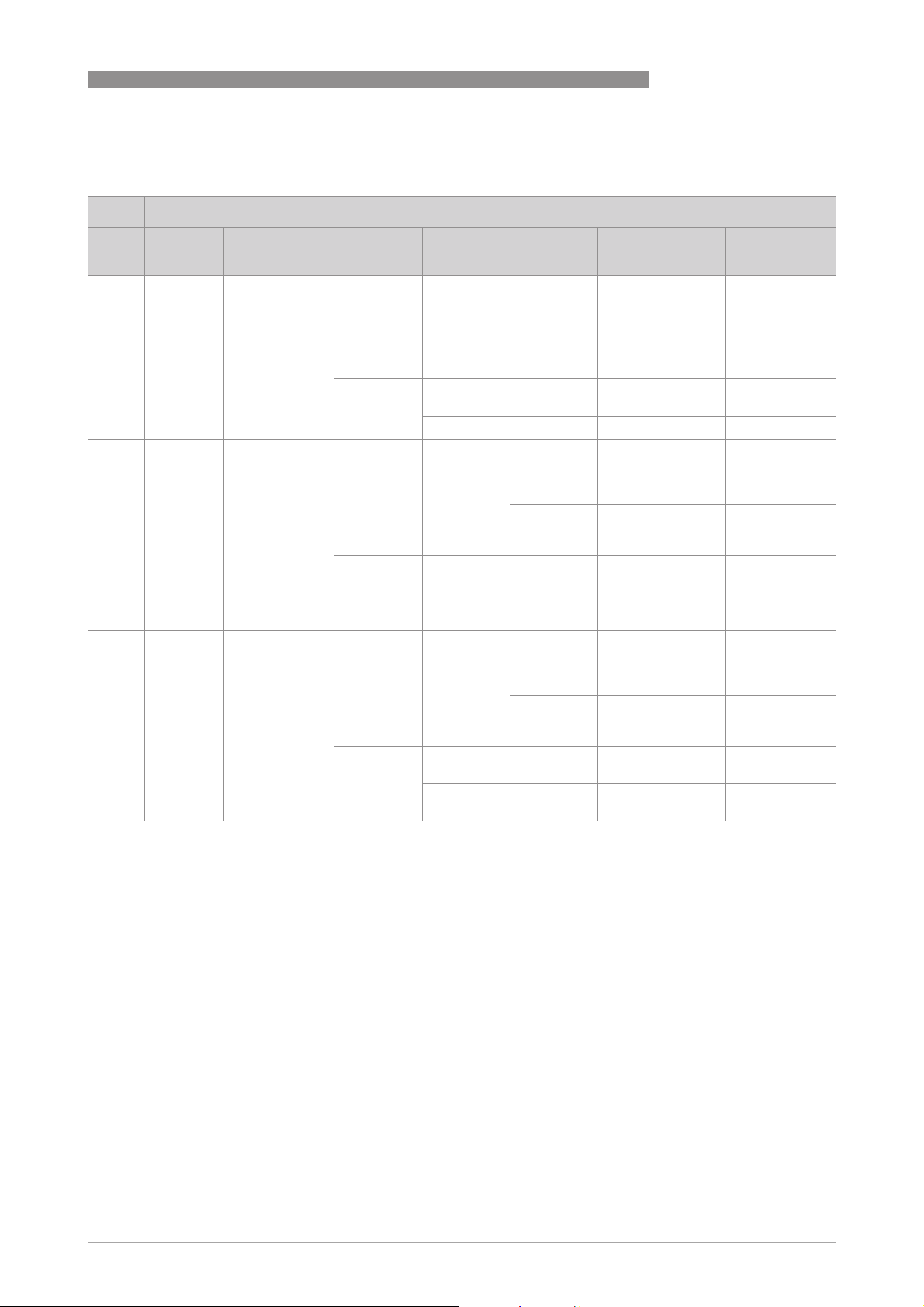

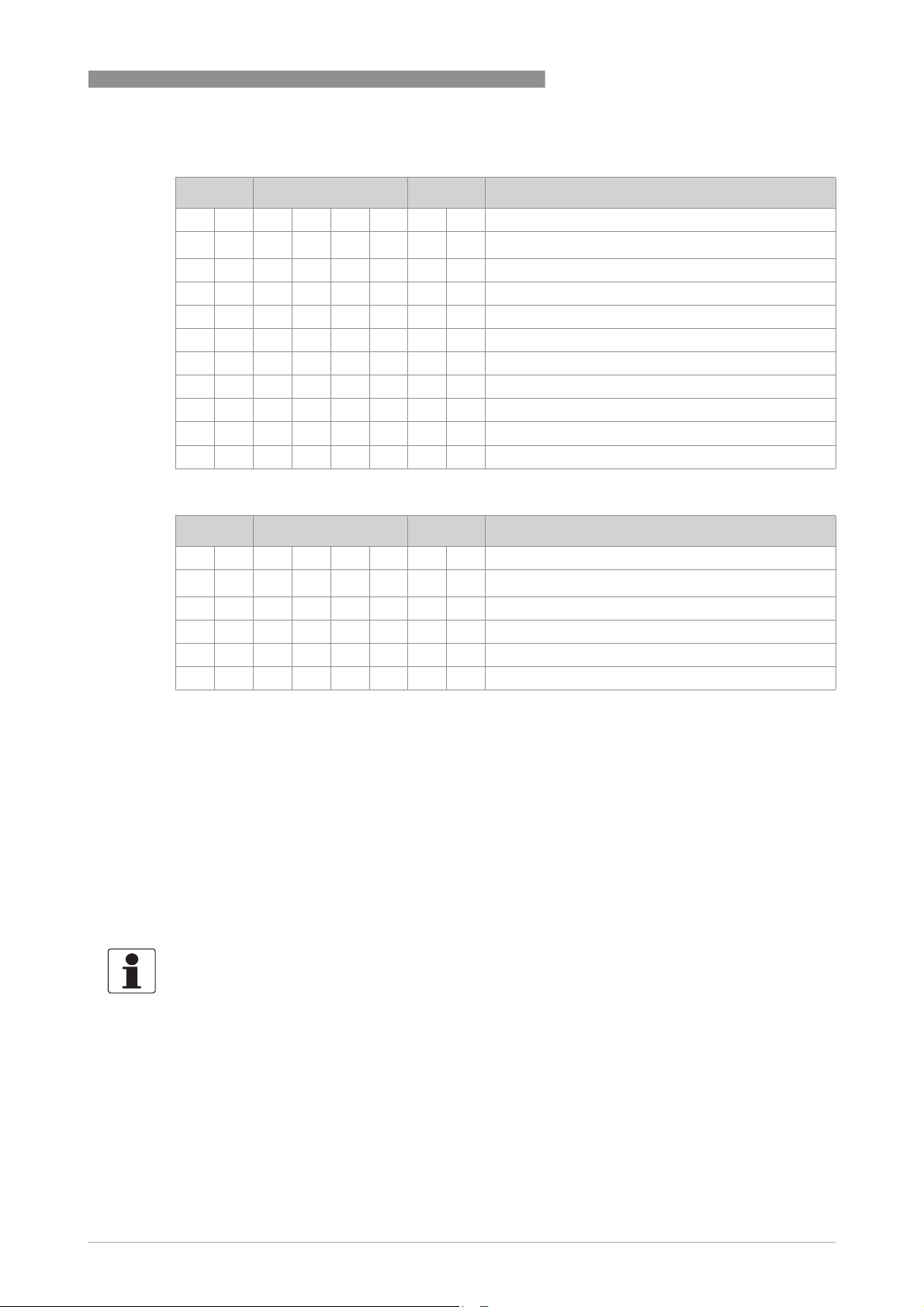

Installed flow sensor Integration into the PLC via

IFC090PA.GSD

KROHF401.GSD

IFC300 with PROFIBUS MBP

interface GSD

KR024501.GSD

IFS…FLUX flow sensor

(Option 1.)

OPTIFLUX flow sensor (Option 2.) "IFC090PA" profile 2 functionality "IFC300 with PROFIBUS MBP

How to deal with the PA

parameter set in the PLC Ctrl

software

"IFC090PA" profile 2 functionality "IFC300 with PROFIBUS MBP

The "IFC090PA" parameter set

for the PLC Ctrl software can be

used as existing in the PLC

interface" functionality (some

"IFC300 with PROFIBUS MBP

interface" self-test functions not

available)

interface" functionality

The "IFC090PA" parameter set

for the Ctrl software has to be

adapted with reference to the

interface of "IFC300 with

PROFIBUS MBP interface"

If the GSDs of the "IFC090PA" ("KROHF401.GSD" or "YP01F401.GSD") are used…

• The IFC090PA parameter set for the PLC control software will be maintained, i.e. there is no

adaptation needed with reference to the replaced interface of the IFC300 with PROFIBUS

MBP interface.

• In this usage of the GSD the PA Profile 2.0

replacements, i.e. it is not possible to reset the PA totalizer via the PLC.

PA Profile 2.0 functionality is provided in the PLC for both

PA Profile 2.0PA Profile 2.0

24

If the GSD of "IFC300 with PROFIBUS MBP interface” (KR024501.GSD or

YP024501.GSD) is used…

• The IFC090PA parameter set for the PLC control software has to be adapted with reference to

the IFC300 PROFIBUS MPB interface.

• In this usage of the GSD the PA Profile 3.0

of the "IFC300 with PROFIBUS MBP interface" are being made available.

PA Profile 3.0 functionality is provided and all diagnostic features

PA Profile 3.0PA Profile 3.0

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 25

IFC 300

APPLICATION PROFILE 4

4.1 Function blocks

The PROFIBUS MBP interface is based on the PROFIBUS PA Profile Version 3.0 and supports the

following blocks:

• 1 physical block.

This block contains the parameters defined in PA Profile 3.0.

• 1 transducer block for electromagnetic flow devices.

This block provides the parameters and functions defined in PA Profile 3.0.

• 5 Analog Input (AI) function blocks.

As default: Volume Flow / Mass Flow / Speed Flow / Coil Temperature / Conductivity.

• 3 totalizer (TOT) function blocks.

As default the first two totalizers will totalize volume and the third one will totalize mass.

4.2 Data structure of function block output values

The data structure of function block outputs consists of 5 bytes: a 4 byte float value (Float Format

according IEEE Standard 754 Short Real Number) followed by a 1 byte status value. If all 8

function block outputs have been configured (see above), 40 bytes will be transmitted.

4.2.1 Float value

Example of float format

Byte n Byte n+1

Bit7 Bit6 Bit7 Bit6

VZ

Byte n+2 Byte n+3

Bit7 Bit7

-82-9

2

Mantissa Mantissa

Example (binary): 40 F0 00 00 (hex) = 0100 0000 1111 0000 0000 0000 0000 0000

Formula:

Formula:

Formula:Formula:

value = (-1)

value = (-1)

value = 1 * 4 * (1 + 0.5 + 0.25 + 0.125)

value = 7.5

7

6

5

4

3

2

1

0

2

2

2

2

2

2

2

2

Exponent Mantissa

-102-112-122-132-142-152-162-172-182-192-202-212-222-23

2

VZ

(Exponent – 127)

0

* 2

* 2

(129 – 127)

* (1 + Mantissa)

* (1 + 2-1 + 2-2 + 2-3)

-12-22-32-4

2

-52-62-7

2

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

25

Page 26

4 APPLICATION PROFILE

4.2.2 Status value

The meanings of the status byte (unsigned integer) are described in the following tables.

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

2

2

2

0 0 = bad

0 1 = uncertain

1 0 = good (Non Cascade)

1 1 = good (Cascade) - not supported

Status = bad

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

2

0 0 0 0 0 0 = non-specific

0 0 0 0 0 1 = configuration error

0 0 0 0 1 0 = not connected

0 0 0 0 1 1 = device failure

0 0 0 1 0 0 = sensor failure

0 0 0 1 0 1 = no communication (last usable value)

0 0 0 1 1 0 = no communication (no usable value)

0 0 0 1 1 1 = out of service

5

2

2

3

2

2

4

3

2

2

IFC 300

2

1

2

2

2

0

2

2

1

0

2

2

Status = uncertain

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

0 1 0 0 0 0 = non-specific

0 1 0 0 0 1 = last usable value

0 1 0 0 1 0 = substitute-set

0 1 0 0 1 1 = initial value

0 1 0 1 0 0 = sensor conversion not accurate

0 1 0 1 0 1 = engineering unit violation (unit not in the valid set)

0 1 0 1 1 0 = sub-normal

0 1 0 1 1 1 = configuration error

0 1 1 0 0 0 = simulated value

0

2

2

26

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 27

IFC 300

APPLICATION PROFILE 4

Status = good (Non Cascade)

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

1 0 0 0 0 0 = ok

1 0 0 0 0 1 = update event

1 0 0 0 1 0 = active advisory alarm (priority < 8)

1 0 0 0 1 1 = active advisory alarm (priority > 8)

1 0 0 1 0 0 = unacknowledged update event

1 0 0 1 0 1 = unacknowledged advisory alarm

1 0 0 1 1 0 = unacknowledged critical alarm

1 0 1 0 0 0 = initiate fail safe

1 0 1 0 0 1 = maintenance required

Status = Limits

0

2

2

Quality Quality substatus Limits

Gr Gr QS QS QS QS Qu Qu

7

6

5

4

3

2

1

2

2

2

2

2

2

0

2

2

0 0 = ok

0 1 = low limited

1 0 = high limited

1 1 = constant

Check the first two quality bits in order to get the quality information of the measurement value:

• Good (Non Cascade):

Good (Non Cascade): function block output value is ok and can be used without restrictions

Good (Non Cascade):Good (Non Cascade):

• Good (Cascade):

Good (Cascade): will not be supported, because it is not applicable for the device

Good (Cascade):Good (Cascade):

• Uncertain:

Uncertain: function block output value can be used but the accuracy can not be guaranteed

Uncertain:Uncertain:

(e.g. function block outputs value has been frozen or A/D converter is saturated or out of

range)

• Bad:

Bad: function block output value is bad - don’t use it for process control!

Bad:Bad:

The "Quality-Substatus" and "Limit" bits will be used for further diagnostics or limit checking.

INFORMATION!

The status should be monitored because a number will be transmitted even if the status of the

measurement value is bad or uncertain. This is the only way to check the quality of the

transmitted measurement values.

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

27

Page 28

4 APPLICATION PROFILE

4.3 Diagnosis parameter

4.3.1 Diagnosis

Parameter DIAGNOSIS will contain detailed information of the device, bitwise coded. More than

one message possible at once (as below-mentioned). If MSB of byte 4 is set to 1 than more

diagnose information is available in the DIAGNOSIS_EXTENSION parameter.

The manufacturer specific parameter "DIAGNOSIS_EXTENSION" will contain bitwise coded

more detailed information of the internal status conditions and error conditions of the

PROFIBUS device.

The corresponding GSD file will contain all messages supported by this device - have a look at

the UNIT_DIAG_BIT(i) definitions.

4.3.2 DIAGNOSIS (if "Classic Status" and "Diagnosis" selected)

IFC 300

Octet number

Bit number

Subparameter

1 0 DIA_HW_ELECTR 0 Hardware failure electronics

1 DIA_HW_MECH 0 Hardware failure mechanics

2 DIA_TEMP_MOTOR 0 Motor temperature too high

3 DIA_TEMP_ELECTR 0 Electronic temperature too high

4 DIA_MEM_CHKSUM 0 Memory error

5 DIA_MEASUREMENT 0 Measurement failure

6 DIA_NOT_INIT 0 Device not initialized

7 DIA_INIT_ERR 0 Device initialization failed

2 0 DIA_ZERO_ERR 0 Zero point error

1 DIA_SUPPLY 0 Power supply failed

2 DIA_CONF_INVAL 0 Configuration invalid

3 DIA_WARMSTART A 0 Restart (warmstart)

4 DIA_COLDSTART A 0 Coldstart (with default data)

5 DIA_MAINTENANCE R 0 Maintenance required

6 DIA_CHARACT R 0 Characteristics invalid

7 IDENT_NUMBER_VIOLATION R 0 Ident. No. violation:

Indication type

Default value

Description

Set to 1 if the Ident_Number of the running cyclic

data transfer and the value of physical block

IDENT_NUMBER_SELECTOR parameter are

different

28

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 29

IFC 300

APPLICATION PROFILE 4

Octet number

Bit number

Subparameter

3 0 Reserved 0 Reserved for use by PNO

1 Reserved 0 Reserved for use by PNO

2 Reserved 0 Reserved for use by PNO

3 Reserved 0 Reserved for use by PNO

4 Reserved 0 Reserved for use by PNO

5 Reserved 0 Reserved for use by PNO

6 Reserved 0 Reserved for use by PNO

7 Reserved 0 Reserved for use by PNO

4 0 Reserved 0 Reserved for use by PNO

1 Reserved 0 Reserved for use by PNO

2 Reserved 0 Reserved for use by PNO

3 Reserved 0 Reserved for use by PNO

4 Reserved 0 Reserved for use by PNO

5 Reserved 0 Reserved for use by PNO

6 Reserved 0 Reserved for use by PNO

7 EXTENSION_AVAILABLE 0 Extension available:

Indication type

Default value

Description

More diagnose information available in the

Diagnosis_Extension parameter (if available)

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

29

Page 30

4 APPLICATION PROFILE

4.3.3 DIAGNOSIS_EXTENSION (if "Classic Status" and "Diagnosis" selected)

Octet number

Bit number

Subparameter

1 0 ADC_ELEC_TEMPERATURE (S) electronic temperature

1 ADC_GAIN_ERROR (S) gain error

2 ADC_F_FREQ_TOO_HIGH (S) field frequency too high

3 Reserved

4 ADC_COIL_TEMPERATURE (S) coil temperature

5 ADC_F_CURR_DEVIATION (S) field current deviation

6 ADC_F_COIL_BRIDGED (S) field coil bridged

7 ADC_F_COIL_BROKEN (S) field coil broken

2 0 ADC_ELECTRODE_NOISE (S) electrode noise

1 ADC_FLOW_PROFILE (S) flow profile

2 ADC_LINEARITY (S) linearity

3 ADC_ELECTRODE_SYM (S) electrode symmetry

4 Reserved

5 Reserved

6 ADC_PIPE_NOT_FULL (S) pipe not full

7 ADC_EMPTY_PIPE_0 (S) empty pipe (Uncertain)

3 0 Reserved

1 ADC_FIELD_FREQ_HIGH (F) field frequency too high

2 ADC_EMPTY_PIPE_1 (F) empty pipe (Application Error)

3 ADC_DC_OFFSET (F) DC Offset

4 Reserved

5 ADC_FIELD_CURR_LOCAL (F) field current local

6 ADC_SENSOR_LOCAL (F) sensor local

7 ADC_SENSOR_GLOBAL (F) sensor global

4 0 ADC_FLOW_EXCEED_LIM0 (F) flow exceeding limit

1 ADC_FLOW_EXCEED_LIM1 (F) flow exceeding limit

2 MEAS_AVAILABLE_NO (I) measurement value not available

3 POWER ON ERROR (I) power fail

4 ADC_TEST_SENSOR (C) test sensor

5 ADC_WARNING_W1 (S) uncertain measurement

6 ADC_WARNING_W2 (F) application error

7 ADC_SENSOR_ELECTRONIC (F) sensor electronic

Comment*

(F) field current local

(F) field current local(F) field current local

(F) sensor local

(F) sensor local(F) sensor local

(F) sensor global

(F) sensor global(F) sensor global

(F) sensor electronic

(F) sensor electronic(F) sensor electronic

IFC 300

30

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 31

IFC 300

APPLICATION PROFILE 4

Octet number

Bit number

Subparameter

5 0 BM_TEST_ACTIV (C) checks in progress (global)

1 BM_MEAS_UNC (S) uncertain measurement (global)

2 BM_APP_ERROR (F) application error (global)

3 BM_DEV_ERROR (F) error in device (global)

4 NO_BASIC_DEVICE_COM (F) int. communication timeout

5 PARA UPDATE ERROR (F) parameter update error

6 PARA UPDATE IN PROGRESS update in progress

7 ERROR_CPU_CM (F) CPU failure

6 0 ERROR_EEPROM (F) EEPROM failure

1 CYCLE_EEPROM (S) EEPROM cycle overflow

2 ERROR_CPU_MEM (F) CPU Memory failure

3 ERROR_RAM_EXT (F) ext. RAM failure

4 ERROR_FRAM (F) FRAM failure

5 CYCLE_FRAM (S) FRAM cycle overflow

6 ERROR_FLASH_EXT (F) external Flash failure

7 ERROR_SPC4 (F) SPC4 failure

Comment*

(F) error in device (global)

(F) error in device (global)(F) error in device (global)

(F) int. communication timeout

(F) int. communication timeout(F) int. communication timeout

(F) parameter update error

(F) parameter update error(F) parameter update error

(F) CPU failure

(F) CPU failure(F) CPU failure

(F) EEPROM failure

(F) EEPROM failure(F) EEPROM failure

(F) CPU Memory failure

(F) CPU Memory failure(F) CPU Memory failure

(F) ext. RAM failure

(F) ext. RAM failure(F) ext. RAM failure

(F) FRAM failure

(F) FRAM failure(F) FRAM failure

(F) external Flash failure

(F) external Flash failure(F) external Flash failure

(F) SPC4 failure

(F) SPC4 failure(F) SPC4 failure

*: for a more detailed description of the above-mentioned subparameters please check the

signal converter handbook (section: Status messages and diagnostic information)

(F): Device Error

(F): Device Error

(F): Device Error(F): Device Error

(F): Application Error

(S): Uncertain measurement / measurement out of specification

(C): Simulation of the measured value

(I): Information

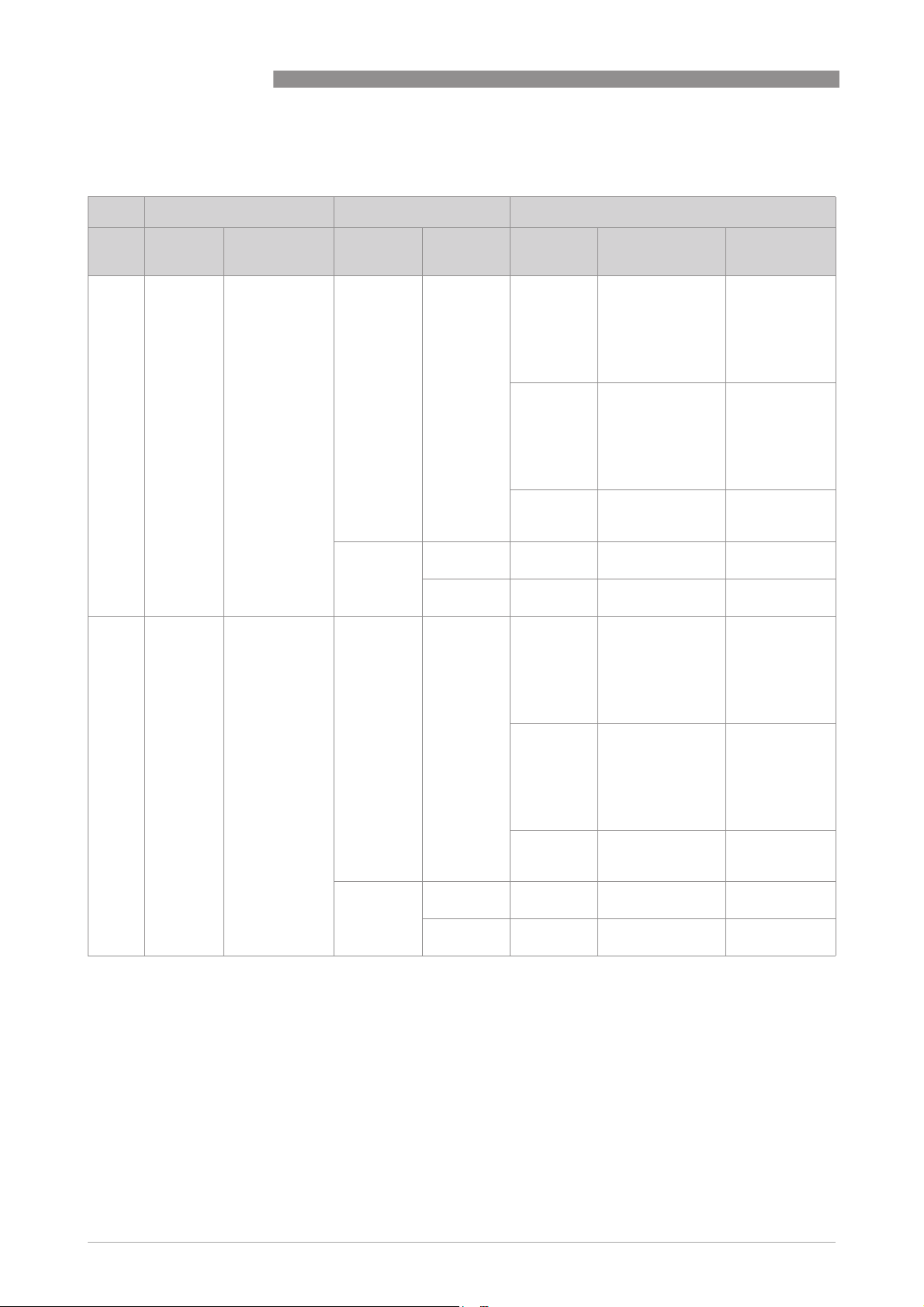

4.3.4 Mapping of DIAGNOSIS_EXTENSION bits into DIAGNOSIS bits

How to read this table:

If e.g. an ADC_EMPTY_PIPE_0 error has been detected by the device itself the below-mentioned

DIAGNOSIS_EXTENSION bits will be set:

• DIAGNOSIS_EXTENSION (Octet 2 / Bit 7): ADC_EMPTY_PIPE_0

• DIAGNOSIS_EXTENSION (Octet 4 / Bit 5): ADC_WARNING_W1

• DIAGNOSIS_EXTENSION (Octet 5 / Bit 1): BM_MEAS_UNC

These bits will be mapped to the below-mentioned DIAGNOSIS bits (which will be set

additionally):

• DIAGNOSIS (Octet 1 / Bit 5): DIA_MEASUREMENT

• DIAGNOSIS (Octet 4 / Bit 7): EXTENSION_AVAILABLE

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

31

Page 32

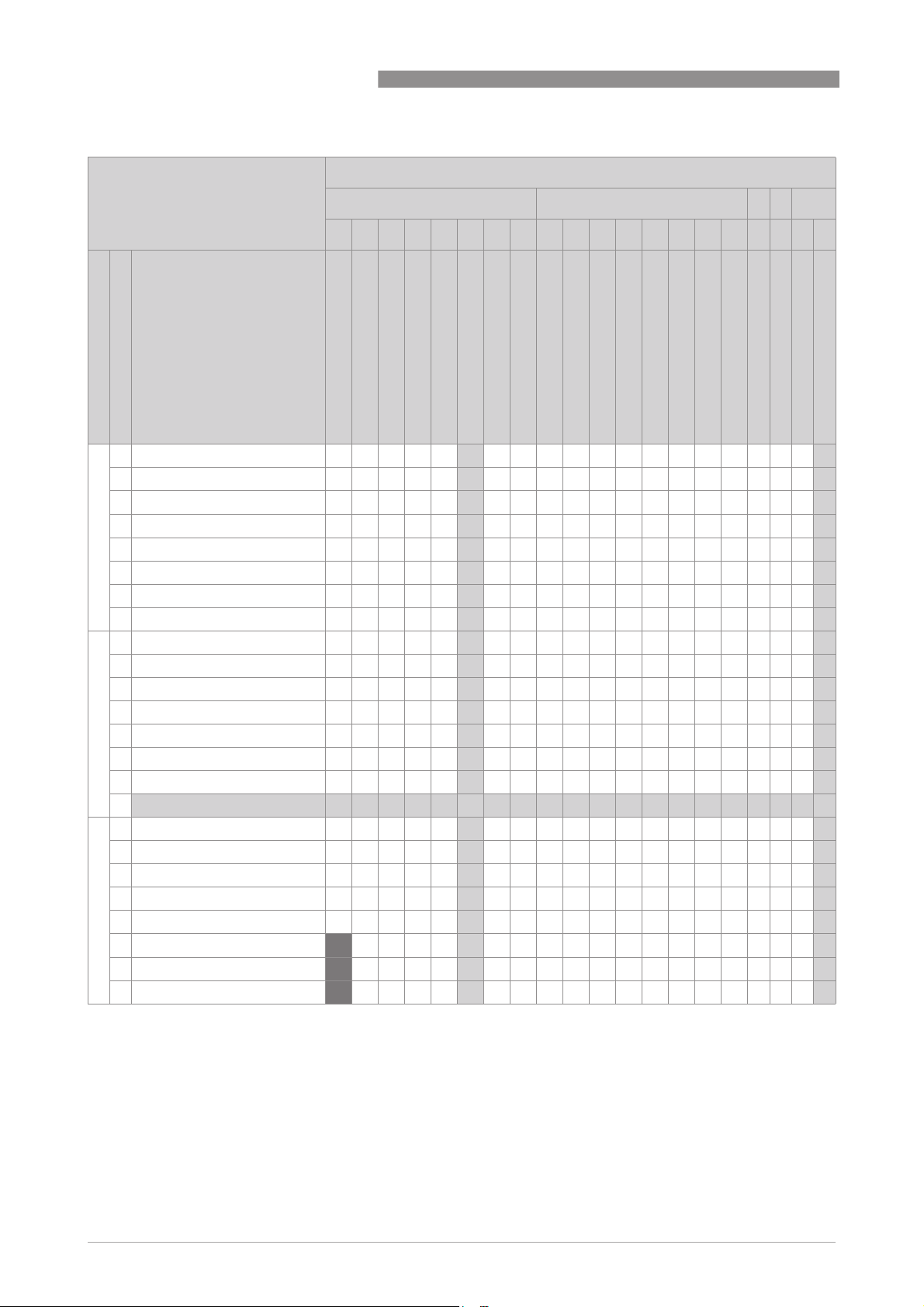

4 APPLICATION PROFILE

IFC 300

DIAGNOSIS_EXTENSION DIAGNOSIS

1 2 3 ... 4

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 ... 6 7

Octet number

Bit number

Subparameter

1 0 ADC_ELEC_TEMPERATURE X X

1 ADC_GAIN_ERROR X X

2 ADC_F_FREQ_TOO_HIGH X X

3 Reserved

4 ADC_COIL_TEMPERATURE X X

5 ADC_F_CURR_DEVIATION X X

6 ADC_F_COIL_BRIDGED X X

7 ADC_F_COIL_BROKEN X X

2 0 ADC_ELECTRODE_NOISE X X

1 ADC_FLOW_PROFILE X X

2 ADC_LINEARITY X X

3 ADC_ELECTRODE_SYM X X

4 Reserved

5 Reserved

6 ADC_PIPE_NOT_FULL X X

7 ADC_EMPTY_PIPE_0 X X

3 0 Reserved

1 ADC_FIELD_FREQ_HIGH X X

2 ADC_EMPTY_PIPE_1 X X

3 ADC_DC_OFFSET X X

4 Reserved

5 ADC_FIELD_CURR_LOCAL XXXX X

6 ADC_SENSOR_LOCAL XXXX X

7 ADC_SENSOR_GLOBAL XXXX X

DIA_HW_ELECTR

DIA_HW_MECH

DIA_TEMP_MOTOR

DIA_TEMP_ELECTR

DIA_MEM_CHKSUM

DIA_MEASUREMENT

DIA_NOT_INIT

DIA_INIT_ERR

DIA_ZERO_ERR

DIA_SUPPLY

DIA_CONF_INVAL

DIA_WARMSTART

DIA_COLDSTART

DIA_MAINTENANCE

DIA_CHARACT

IDENT_NUMBER_Violation

Reserved

...

Reserved

EXTENSION_AVAILABLE

32

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 33

IFC 300

APPLICATION PROFILE 4

DIAGNOSIS_EXTENSION DIAGNOSIS

1 2 3 ... 4

0 1 2 3 4 5 6 7 0 1 2 3 4 5 6 7 0 ... 6 7

Octet number

Bit number

Subparameter

4 0 ADC_FLOW_EXCEED_LIM0 X X

1 ADC_FLOW_EXCEED_LIM1 X X

2 MEAS_AVAILABLE_NO X

3 POWER ON ERROR X

4 ADC_TEST_SENSOR X

5 ADC_WARNING_W1 X X

6 ADC_WARNING_W2 X X

7 ADC_SENSOR_ELECTRONIC XXXX X

5 0 BM_TEST_ACTIV X

1 BM_MEAS_UNC X X

2 BM_APP_ERROR X X

3 BM_DEV_ERROR X X

4 NO_BASIC_DEVICE_COM X X

5 PARA UPDATE ERROR X X

6 PARA UPDATE IN

PROGRESS

7 ERROR_CPU_CM XXXX X

6 0 ERROR_EEPROM XXXX X

1 CYCLE_EEPROM X X

2 ERROR_CPU_MEM XXXX X

3 ERROR_RAM_EXT XXXX X

4 ERROR_FRAM XXXX X

5 CYCLE_FRAM X X

6 ERROR_FLASH_EXT XXXX X

7 ERROR_SPC4 XXXX X

DIA_HW_ELECTR

DIA_HW_MECH

DIA_TEMP_MOTOR

DIA_TEMP_ELECTR

DIA_MEM_CHKSUM

DIA_MEASUREMENT

DIA_NOT_INIT

DIA_INIT_ERR

DIA_ZERO_ERR

DIA_SUPPLY

DIA_CONF_INVAL

DIA_WARMSTART

DIA_COLDSTART

DIA_MAINTENANCE

DIA_CHARACT

IDENT_NUMBER_Violation

Reserved

...

Reserved

X X

EXTENSION_AVAILABLE

X :Ext_Diag (Bit 3 of Station_Status_1) will be set too!

X :Corresponding DIAGNOSIS bits is set to 1 if status occured

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

33

Page 34

5 PROFIBUS SETTINGS

IFC 300

For a detailed description of the menus and functions refer to the standard product

documentation of the signal converter. Some special settings concerning the PROFIBUS

features are easily operated via the local display menu (refer to the following sections).

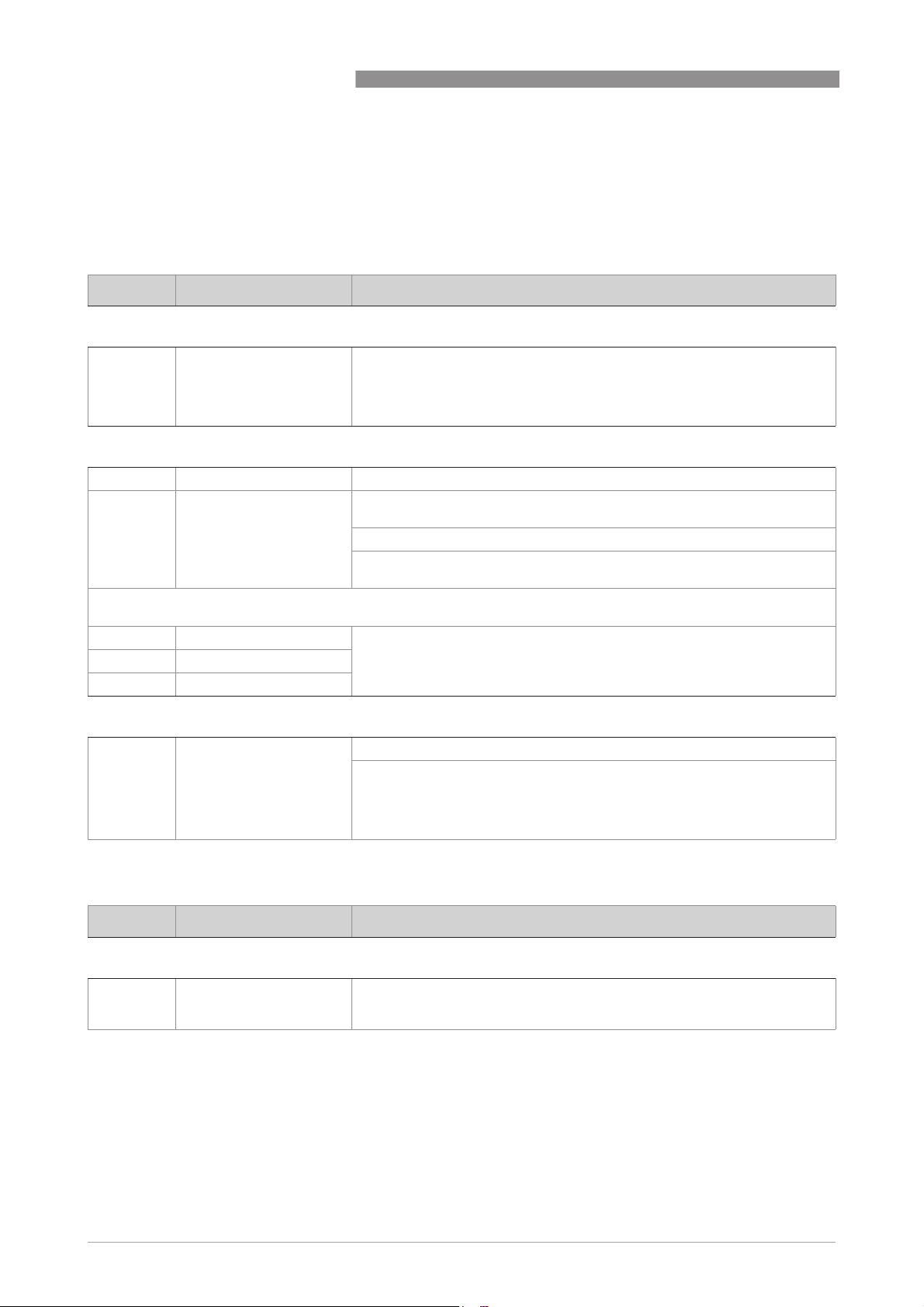

5.1 Menu A, quick setup

No. Function Settings / descriptions

A2 Tag

A2 Tag Tag descriptor of the physical block of the PROFIBUS module will be

A3 reset

A3 reset -

A3.1 reset errors This menu function can be used to reset all errors that are not removed

The following reset menus for the totalizer are only available, if the quick access has been activated in the menu "setup

> device > quick setup". Each totalizer can be activated for quick access independently.

A3.2 FB2 totalizer 1 For PROFIBUS devices: The totalizer can be reset to zero in this menu.

A3.3 FB3 totalizer 2

A3.4 FB4 totalizer 3

displayed. The Tag descriptor provides an application specific reference to

the blocks. It will be assigned by the user of the device. The Tag descriptor is

an octet string (a visible string will be preferred) consisting of 32 byte. The

first 21 characters will be displayed only!

automatically (power fail, totalizer overflow)

reset? Select: no / yes

no: Exit the function.

yes: Resets the errors and exits the function.

A4 station address

A4 station address Selects the address of the device at the PROFIBUS interface.

The PROFIBUS address can also be changed using the PROFIBUS service

"set_slave_add". The input range is 0...125 according to the PROFIBUS

specification. Address 126 is the default address and cannot be set via the

PROFIBUS service "set_slave_add" - use menu instead to reset to default

address.

5.2 Menu B, test

No. Function Settings / descriptions

B3 information

B3.5 PROFIBUS Available if there is a PROFIBUS interface in existence; displays the

following mentioned information about the PROFIBUS interface:

Ident No. / software revision no. of the PROFIBUS software / production date

34

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 35

IFC 300

PROFIBUS SETTINGS 5

5.3 Menu C, setup

No. Function Settings / descriptions

C3 I/O totalizer

C3.1 FB2 totalizer 1 Set function of totalizer

C3.2 FB3 totalizer 2

C3.3 FB4 totalizer 3

C3..1 funct. of totalizer Select:

C3..2 measurement Selection of the measurement for totalizer

C3..3 preset value Predefines a threshold (using high low limit value of the totalizer affected;

C3..4 reset totalizer The current value of the totalizer can be set to zero.

C3..5 error behaviour Defines the behaviour of this function block in case of errors.

C3..6 information Serial no. of the I/O board, software version no. and production date of the

stands for 1, 2, 3 (= totalizer 1, 2, 3)

sum totalizer (counts positive and negative values) /

+totalizer (counts only the positive values) /

-totalizer (counts only the negative values) /

hold totalizer (totalizer is stopped, no counting) /

all as positive (neg. input will be multiplied with -1.0) /

all as negative (pos. values will be multiplied with 1.0)

Select: volume flow / mass flow (not

the THRESHOLD bit will be set in the long status information bytes of the

interface if the actual value of the totalizer is outside these limits. This can

be also used for a status output.

Select: no / yes (reset totalizer 1…3)

Select: hold meas. value / ignore error / stop totalizer

hold meas. value:

hold meas. value: Totalization is continued based on the last incoming value

hold meas. value:hold meas. value:

with good status before the first occurrence of bad status.

ignore error:

ignore error: Totalization is continued using the input values despite the bad

ignore error:ignore error:

status. The status is ignored.

stop totalizer:

stop totalizer: Totalization is stopped during occurrence of bad status of

stop totalizer:stop totalizer:

incoming values.

circuit board will be displayed

not valid for PF (partly filled))

notnot

C4 I/O PROFIBUS

C4 I/O PROFIBUS Using the menu functions mentioned below you will be able to control

C4.1 FB1 analog inp. There are 5 analog input blocks.

C4.2 FB5 analog inp.

C4.3 FB6 analog inp.

C4.4 FB7 analog inp.

C4.5 FB8 analog inp.

C4..1 measurement Select measurement for the analog input blocks:

C4..2 time constant Set time constant for this function block ().

basically the five analog input blocks of this PROFIBUS device. These five

menus are identical so they are grouped together and their functions are

described in one go.

stands for the 5 analog input blocks: FB1 ( = 1), FB5 ( = 2), FB6 ( = 3),

FB7 ( = 4) and FB8 ( = 5)

flow speed / volume flow / mass flow (not

temperature / conductivity (not

(capacitive)) / temperature (electronic temperature) / supply (internal supply

voltage for PROFIBUS interface)

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

not valid for PF (partly filled) and CAP

notnot

not valid for PF (partly filled)) / coil

notnot

35

Page 36

5 PROFIBUS SETTINGS

No. Function Settings / descriptions

C4..3 error behaviour Defines the behaviour of this function block in case of errors.

Select: hold value / ignore error / replace value

hold value:

hold value: Last valid OUT value stored will be used as OUT value.

hold value:hold value:

ignore error:

ignore error: OUT has the wrong calculated value and status "Bad" as

ignore error:ignore error:

calculated.

replace value:

replace value: The "replacement value" will be used as OUT value.

replace value:replace value:

C4..4 replacement value Available, if the error behaviour "replace value" is selected. Defines the

C5 device

C5.1.1 Tag Tag descriptor of the physical block of the PROFIBUS module will be

C5.3 1. meas. page Setting of the measurement for the 1st measuring page.

C5.3.2 measurement 1.line Specify measurement for 1st line.

C5.3.8 measurement 2.line Specify measurement of 2nd line (only available if this 2.line is activated)

C5.3.10 measurement 3.line Specify measurement of 3rd line (only available if this 3.line is activated)

C5.4 2. meas. page Setting of the measurement for the second measuring page.

C5.4.1

C5.4.3

C5.4.5

C5.4.2

C5.4.4

C5.4.6

C5.6 special functions -

C5.6.1 reset errors This menu function can be used to reset all errors that are not removed

C5.6.2 save settings Save current settings.

measurement 1.line

measurement 2.line

measurement 3.line

format 1.line

format 2.line

format 3.line

value that replaces the measured value at this function block in case of an

error.

displayed. The Tag descriptor provides an application specific reference to

the blocks. It will be assigned by the user of the device. The Tag descriptor is

an octet string (a visible string will be preferred) consisting of 32 byte. The

first 21 characters will be displayed only!

Select: volume flow / mass flow (not

value / flow speed / coil temperature / conductivity (not

filled)) and CAP (capacitive)) / level (only

Select: bar graph (for the measurement selected in the first line) / volume

flow / mass flow (not

speed / FB2 totalizer 1 / FB3 totalizer 2 / FB4 totalizer 3 / conductivity (not

valid for PF (partly filled) and CAP (capacitive)) / coil temperature / operating

hours / level (only

Select: volume flow / mass flow (not

value / flow speed / coil temperature / conductivity (not

filled) and CAP (capacitive)) / FB2 totalizer 1 / FB3 totalizer 2 /

FB4 totalizer 3 / operating hours / level (only

current input A / current input B

For PROFIBUS devices this page shows only the PROFIBUS values

FB1…FB8.

Select the measurement of the 1st, 2nd and 3rd line:

FB1 analog inp. / FB2 totalizer 1 / FB3 totalizer 2 / FB4 totalizer 3 / FB6

analog inp. / FB7 analog inp. / FB8 analog inp.

Fixed number of digits after the decimal point or automatic, where the

number of digits is automatically adjusted to the available space.

automatically (power fail, totalizer overflow)

reset? Select: no / yes

Select: break (exit function without saving) / backup 1 (save in storage

location 1) / backup 2 (save in storage location 2)

Query: continue copy? (cannot be undone)

Select: no (exit function without saving) / yes (copy current settings to

storage backup 1 or backup 2)

not valid for PF (partly filled)) / diagnosis value / flow

not not

only valid for PF (partly filled))

onlyonly

not valid for PF (partly filled)) / diagnosis

notnot

only valid for PF (partly filled))

onlyonly

not valid for PF (partly filled)) / diagnosis

notnot

only valid for PF (partly filled)) /

onlyonly

not valid for PF (partly

notnot

not valid for PF (partly

notnot

IFC 300

not

not not

36

www.krohne.com 02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

Page 37

IFC 300

No. Function Settings / descriptions

PROFIBUS SETTINGS 5

C5.6.3 load settings Load saved settings.

C5.8 physical block This menu is only available, if a PROFIBUS interface is present.

C5.8.1 station address Selects the PROFIBUS station address of the device.

C5.8.2 information Available if there is a PROFIBUS interface in existence; displays the

C5.8.3 diag. extension Content of the PROFIBUS diagnosis extension is displayed.

C5.8.4 diag. extension 2 Content of the additional, internal diagnosis stored is displayed.

C5.8.6 diag. extension h h = history

C5.9 quick setup Activate quick access in quick setup menu; default setting: quick setup is

C5.9.1 reset totalizer 1 The reset can be activated in the "quick setup" to get a quick access of the

C5.9.2 reset totalizer 2

C5.9.3 reset totalizer 3

Select: break (exit function without loading) / factory settings (load in state

as delivered) / backup 1 (load data from storage location 1) / backup 2 (load

data from storage location 2) / load sensor data (factory settings of

calibration data)

Query: continue copy? (cannot be undone)

Select: no (exit the function without saving) / yes (load data from the selected

storage location)

The PROFIBUS address can also be changed using the PROFIBUS service

"set_slave_add". The input range is 0...125 according to the PROFIBUS

specification. Address 126 is the default address and cannot be set via the

PROFIBUS service "set_slave_add" - use menu instead to reset to default

address.

following mentioned information about the PROFIBUS interface:

Ident No. / software revision no. of the PROFIBUS software / production date

Content of the PROFIBUS diagnosis extension is displayed.

Shows diagnosis information of all diagnosis bits, which are set again since

the last delete.

active (yes)

Select: yes (switched on) / no (switched off)

function.

Select: yes (activated) / no (switched off)

www.krohne.com02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

37

Page 38

5 PROFIBUS SETTINGS

IFC 300

5.4 Menu D, service

This menu is protected. You will need to use the service password to gain access.

No. Function Settings / descriptions