Page 1

10/98

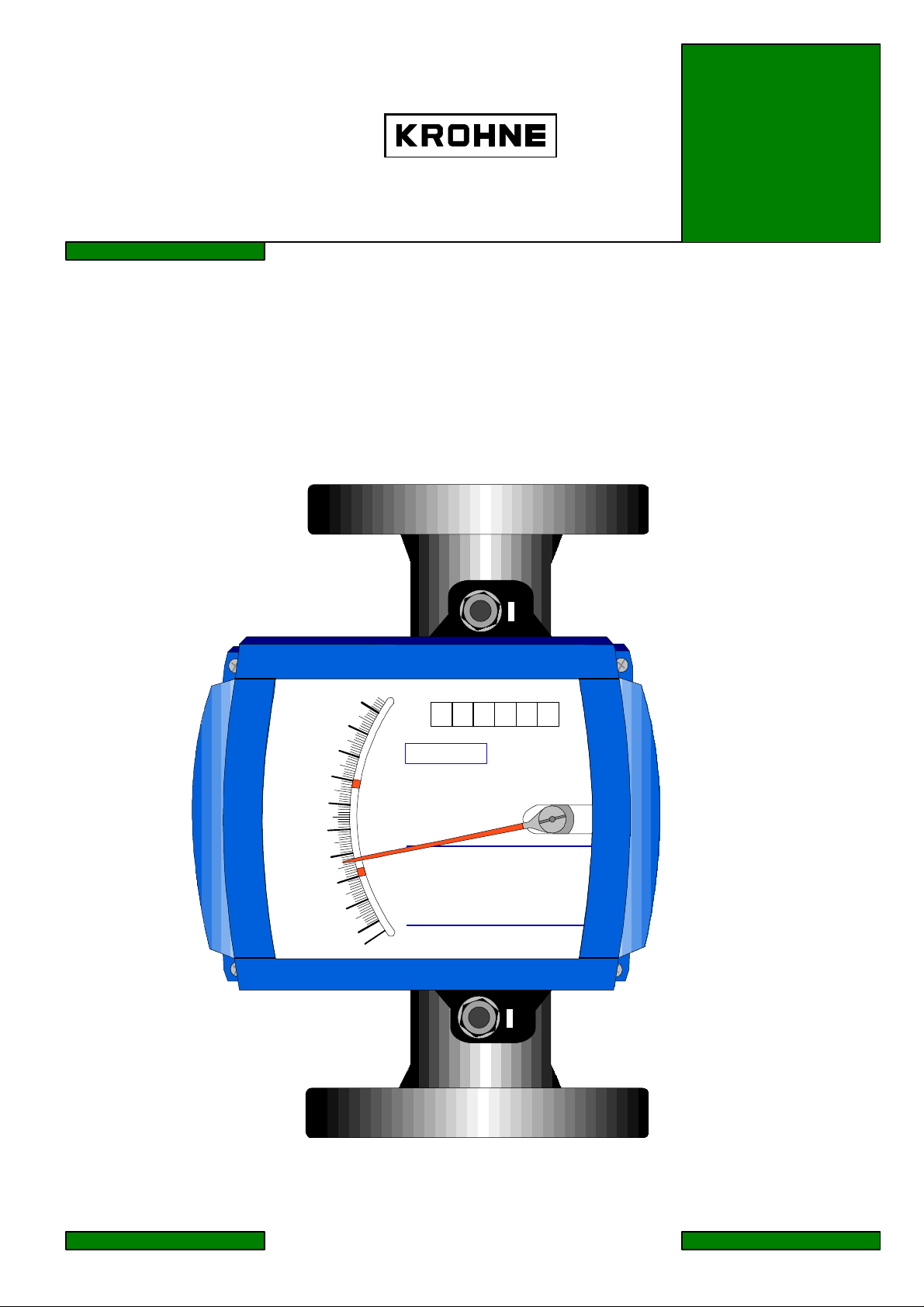

System Technology

kg/h

1000

900

800

700

600

500

kg

KROHNE

SN 586 677/01-03

MC H250/RR/M9/K2/ESK-Z

C K25.2 1.4571

F CIV 25 1.4571

MD 1997

2

H250

03687

Remote Operation

Instructions

HART Communicator 275

Asset Management

Solutions (AMS)

ESKII

400

300

200

100

RP

C2H50H

D 0.93 kg/l

V 2.5 mPa.s

T 23.5 C

P 0.4 MPa

FIA 1025

Page 2

ESKII Remote Operation - HC 275 / AMS

Dev.-Rev. 01, DD-Rev. 01

CONTENTS

1 GENERAL INFORMATION 3

2 HART COMMUNICATOR 275 (HC275) 3

2.1 Installation 3

2.2 Operating 3

3 ASSET MANAGEMENT SOLUTIONS (AMS) 5

3.1 Installation 5

3.2 Operating 5

© 1998 KROHNE Meßtechnik D-47058 Duisburg Page 2

Page 3

ESKII Remote Operation - HC 275 / AMS

Dev.-Rev. 01, DD-Rev. 01

1 General Information

The ESKII is a two-wire transmitter with 4..20mA current output and HART capability. It can be

mounted in H250 Variable Area Flowmeters with indicators M9 or M7. This document fills the gap

between the „Installation and operating instructions H250“ and the online help available under AMS.

General characteristics of the ESKII HART interface:

• Multidrop Mode is supported.

• Burst Mode is not supported.

• The ESKII transmitter implements a fixed optimized damping value on both the digital process

value transmitted via HART interface and the Analog Output.

2 HART Communicator 275 (HC275)

2.1 Installation

• Connection:

Refer to the wiring diagrams and descriptions in the

“Installation and Operating Instructions H250” (KROHNE) section 10.1.

• HC275 configuration:

The HC275 has to be programmed with the ESKII HART Device Description (DD).

Generally this must be done by the manufacturer or the distributor of the device.

(If the ESKII DD is not programmed in the HC275 the transmitter self test can’t be executed, the

Transmitter Specific Status Messages can’t be displayed and offline configuration is not

possible.)

2.2 Operating

See ESKII Menu Tree HC275 (Attachment A).

The ESKII operating concept bases on the HART DD for generic devices with the following

differences:

• Some parameters can only be read:

sensor units, range values (upper/lower range value), damping value, transfer function, write

protection, sensor units, final assembly number.

(For calibration of both the ESKII output information and the mechanical indicator of the

measuring instrument KROHNE offers a special program KroVaCal).

• Support of ESKII specific physical units

• Display format dependent on measuring range

• A ESKII Self Test can be performed and ESKII specific status messages can be displayed

© 1998 KROHNE Meßtechnik D-47058 Duisburg Page 3

Page 4

ESKII Remote Operation - HC 275 / AMS

Dev.-Rev. 01, DD-Rev. 01

• Meaning of General Status Messages:

Status Message Meaning

Field Device Malfunction Set if any „Critical Error“ has been reported.

Refer to Transmitter Specific Status messages.

Configuration Changed Set whenever any configuration parameter is changed.

Primary Variable Analog Output

Fixed

Analog Output Saturated During normal operation the maximum value for analog output

Primary Variable Out Of Limits Is set whenever the Process Value (PV) exceeds the Sensor

Set when:

• Device is set in Multidrop Mode

(Polling Address ≠ 0)

• Fixed Current Mode is entered

(during Loop Test and DAC Trim)

is 20.4mA because of the „Namur Failure Signal“ (I>20.8mA).

While Process Value (PV) will work up to the Sensor Limits

the analog output and its digital value is saturated at 20.4mA

and the flag is set.

Limits.

• Meaning of Transmitter Specific Status Messages:

Status Message Meaning

Critical Error Error: Summary of „Initialization Failed“ and „Internal Checksum

Error“. If set the measurement is invalid.

HART-Classes: Hardware, State, Uncorrectable, Summary.

Initialization Failed Error: If set the measurement is invalid.

HART-Classes: Hardware, State, Uncorrectable, Detail.

No Linearization Data Warning: If set the measured value is possibly incorrect.

HART-Classes: Software, State, Uncorrectable.

Internal Checksum Error Error: If set the measurement is invalid.

HART-Classes: Software, Event, Selfcorrecting/Uncorrectable,

Detail.

Internal Timeout Informational: Self correcting error.

HART-Classes: Software, Event, Selfcorrecting.

ADC zero scale not calibrated Warning: If set the measured value is possibly incorrect.

HART-Classes: Hardware, State, Uncorrectable.

ADC full scale not calibrated Warning: If set the measured value is possibly incorrect.

HART-Classes: Hardware, State, Uncorrectable.

No TC correction data Warning: If set the measured value is possibly incorrect.

HART-Classes: Software, State, Uncorrectable.

© 1998 KROHNE Meßtechnik D-47058 Duisburg Page 4

Page 5

ESKII Remote Operation - HC 275 / AMS

Dev.-Rev. 01, DD-Rev. 01

3 Asset Management Solutions (AMS)

3.1 Installation

• Connection:

Refer to the wiring diagrams and descriptions in the

“Installation and Operating Instructions H250” (KROHNE) section 10.1.

Also see the

“AMS Installation Guide” (Fisher Rosemount) section 5: “Installing Modems” and

appendix B: “Wiring Diagrams”.

• AMS Configuration:

If the ESKII Device Description is not already installed on the AMS System a

„ESKII Device Installation Kit“ (on floppy disk / CD-ROM from KROHNE) is needed.

For installing the DD with the Installation Kit refer to the

“AMS Installation Guide” (Fisher Rosemount) section 3:

“Installing Device Descriptions for Field Devices”, “Manually Installing Device Types”.

3.2 Operating

See ESKII Menu Tree AMS (Attachment B).

The operating concept bases on the AMS HART DD for generic devices. For differences in detail

see section 2.2 HART Communicator 275 (HC275) Operating.

© 1998 KROHNE Meßtechnik D-47058 Duisburg Page 5

Page 6

ESKII Remote Operation - HC 275 / AMS

Dev.-Rev. 01, DD-Rev. 01

Attachment A

ESKII Menu Tree HC275

1 Device Setup

2 Process Value

(PV)

3 Analog Output

4 Lower Range

Value

5 Upper Range

Value

1 Process

variables

2 Diagnostics

and Service

3 Basic Setup

4 Detailed Setup

5 Review

1 Process Value

2 Percent Range

3 Analog Output

1 Device specific

status

2 Self Test

3 Loop test

4 D/A Trim

1 Tag *

2 Sensor Unit

3 Range values

4 Device Info

5 Transfer function

6 Damping Value

1 Sensors

2 Signal

condition

3 Output

Condition

4 Device

Information

•No TC correction Data

•ADC fullscale not calibrated

•ADC zero not calibrated

•Internal timeout

•Internal checksum error

•No linearization data

•Initialization failed

•Critical error

1 Distributor

2 Model

3 Device Id

4 Tag *

5 Date *

6 Write Protect

7 Descriptor *

8 Message *

9 Final asmbly #

Revisions

1 Process value

2 Sensor Unit

3 Sensor Info

1 Damping Value

2 Lower Range

Value

3 Upper Range

Value

4 Transfer Function

5 Percent Range

1 Analog Output

2 HART Output

1 Distributor

2 Model

3 Device Id

4 Tag *

5 Date *

6 Write Protect

7 Descriptor *

8 Message *

9 Final asmbly #

Revisions

1 Universal Rev

2 Field Device Rev

3 Software Rev

1 Lower Sensor

2 Upper Sensor

1 Analog Output

2 Alarm type

3 Loop test

4 D/A trim

1 Poll Address *

2 Number of

1 Universal Rev

2 Field Device Rev

3 Software Rev

Limit

Limit

Response

Preambles *

* Parameter changeable (online help is available)

© 1998 KROHNE Meßtechnik D-47058 Duisburg Page 6

KROHNE ESKII 45f20101

Page 7

ESKII Remote Operation - HC 275 / AMS

Dev.-Rev. 01, DD-Rev. 01

Attachment B

ESKII Menu Tree AMS

•Process Value (PV)

•Percent Range

•Analog Output

Process Variables

Status

-----------------------------------

Diagnostics and Test

Calibrate

----------------------------------Assign / Replace

Delete

Rename

----------------------------------Audit Trail

Drawing Notes ...

Help ...

----------------------------------Clear Offline Configuration

Compare Configurations

Configuration Properties

Overview

• Primary variable out of

limits

• Primary variable analog

output saturated

• Primary variable analog

output fixed

• Configuration changed

• Field device malfunction

Self Test

Loop Test

Calibration Management

------------------------------D/A trim

Sensor

• Sensor Serial Number

• Upper Sensor Limit

• Lower Sensor Limit

Critical

• Critical error

• Initialization failed

• No linearization data

• Internal checksum error

• ADC zero not calibrated

• ADC fullscale not

calibrated

• No TC correction data

Process Input

• Sensor Unit

• Transfer Function

• Damping Value

Informational

• Internal Timeout

Analog Output

• Upper Range Value

• Lower Range Value

• Alarm Type

Device

• Model

• Distributor

• Hardware revision

•

Software revision

•

Write protect

•

Descriptor *

•

Message *

• Date *

• Final assembly number

* Parameter changeable (online help is available)

© 1998 KROHNE Meßtechnik D-47058 Duisburg Page 7

HART

• Tag *

• Polling Address *

• Universal revision

•

Field device revision

•

Number of Request

Preambles

•

Number of Response

Preambles *

• Physical Signaling Code

KROHNE ESKII 45f20101

Loading...

Loading...