Page 1

Installation and

operating instructions

DW 181 – 184

Standard, high-temperature,

tropical and ATEX versions

Flow switches

©

KROHNE 01/2006 7.02125.23.00

CMD

Electromagnetic flowmeters

Variable area flowmeters

Mass flowmeters

Ultrasonic flowmeters

Vortex flowmeters

Flow controllers

Level measuring instruments

Pressure and temperature

Heat metering

Communications technology

Switches, counters, displays and recorders

Engineering systems & solutions

Page 2

Table of contents

General advice on safety………………………………………………………………………….. 4

Standards / Approvals…………………………………………………………………………….. 4

Ex safety instructions……………………………………………………………………………… 4

Handling……………………………………………………………………………………………… 4

Product liability and warranty……………………………………………………………………. 5

Items included with supply……………………………………………………………………….. 5

Documentation supplied………………………………………………………………………….. 5

Official approvals and certificates………………………………………………………………. 5

Principle components……………………………………………………………………………... 6

Equipment labels…………………………………………………………………………………… 7

Type code……………………………………………………………………………………………. 8

1 Mechanical Installation……………………………………………………………………… 9

1.1 Positioning the flow switch……………………………………………………………………. 9

1.2 Installation in hazardous areas (Ex applications)………………………………………….. 9

1.3 Connecting the DW 18 to the pipe…………………………………………………………… 9

1.4 Flow direction…………………………………………………………………………………... 9

2 Electrical Connections…………………………………………………………………….. 10

3 Commissioning……………………………………………………………………………… 11

3.1 General notes………………………………………………………………………………… 11

3.2 Adjusting the limit switches - standard and EEx ia flow switch versions………………. 11

3.2.1 Type G indicator……………………………………………………………………………. 11

3.2.2 Type A indicator…………………………………………………………………………..... 12

3.3 Adjusting the limit switches - EEx d flow switch version…………………………………. 12

3.3.1 MS 12/BRX switch…………………………………………………………………………. 12

4 Display………………………………………………………………………………………... 13

4.1 Local Flow indication………………………………………………………………………… 13

4.2 Limit Switches………………………………………………………………………………… 13

4.3 EEx d version…………………………………………………………………………………. 14

4.4 High-temperature version (KROHNE temperature class H3, non-EEx)………………... 15

4.5 Tropical version (non-EEx)………………………………………………………………….. 15

2 Installation and operating instructions DW 181 - 184

Page 3

5 Service………………………………………………………………………………………... 16

5.1 Maintenance………………………………………………………………………………….. 16

5.2 Exploded view of instruments………………………………………………………………. 16

5.3 Spare parts……………………………………………………………………………………. 18

5.4 Inspection procedure………………………………………………………………………… 21

5.4.1 Inspection procedure: measuring assembly…………………………………………….. 21

5.4.2 Inspection procedure: housing (DW181 & DW182 models)…………………………... 21

5.5 Basic servicing procedures………………………………………………………………….. 22

5.5.1 Changing the position of the dial on the type A indicator……………………………… 22

5.5.2 Removing the display assembly: operating faults in the housing DW18x Std /EExia flow

controllers equipped with type G or A indicators……………………………………….. 23

5.5.3 Cleaning the springs or changing the measuring system sub-assembly…………….. 24

5.5.4 Changing gaskets in DW 183 flow controllers…………………………………………. 24

6 Technical Data………………………………………………………………………………. 25

6.1 Flow range table by flow range code………………………………………………………. 28

6.2 Instrument version materials………………………………………………………………... 30

7 Dimensions and Weights………………………………………………………………….. 31

8 Measuring Principle………………………………………………………………………… 36

8.1 Measuring systems…………………………………………………………………………... 36

8.2 DW 183………………………………………………………………………………………... 36

Appendix A: Declaration of conformity: CE………………………………………………….. 37

Appendix B: If you need to return a device for testing or repair to KROHNE…………. 38

Installation and operating instructions DW 181 - 184 3

Page 4

General advice on safety

This manual gives a complete set of instructions for the installation, operation and

maintenance of the standard and ATEX versions of the DW 18 flow switches.

DW 18 flow switches must be used with liquids that do not have any gas pockets.

Special regulations are applicable to the use of equipment in hazardous locations,

and these are described in this booklet. Data is supplied on explosion protection.

Assembly, installation, commissioning and maintenance of equipment in

hazardous areas must only be carried out by qualified personnel with

relevant explosion protection training.

Standards / Approvals

DW 18 flow switches meet the protection requirements of Directive

89/336/EEC in conjunction with EN 50081-1 and EN 50082-2, and Directives

73/23/EEC and 93/68/EEC in conjunction with EN 61010-1, and also bear the

CE symbol.

These instruments, when ordered with the appropriate options, are certified for

use in hazardous locations by the INERIS certification agency under INERIS

03ATEX0045X. They respect the Health & Safety regulations in force by

conforming to EN 50014 (+ A1 & 2), EN 50018, EN 50020, EN50284, EN

50281-1-1 (+ A1) and EN 13463-1.

Ex safety instructions

The DW 18 flow switch series are suitable for monitoring flow of liquid in pipes in hazardous

areas. They may be approved for use in explosive atmospheres of all flammable substances in

Gas Group IIC in Zone 1 and applications requiring Category 2 equipment for EEx d applications

and Gas Group IIC in Zone 0 requiring Category 1 equipment with an intrinsically-safe power

supply for

EEx ia applications.

Ex Equipment Category Definitions

Category 1 G/D – instruments: for intrinsically-safe applications

The signal converter for the limit switch options and the measuring components are located in

hazardous areas requiring instruments qualified as being category 1. The G/D rating states that

the instrument is qualified for gas and dust environments. EEx ia-approved devices must be used

with a certified intrinsically-safe power supply.

Category 2 G/D – instruments: for applications using the EEx d-rated explosion-proof box

The signal converter for the limit switch options and the measuring components are located in

hazardous areas requiring instruments qualified as being category 2. The G/D rating states that

the instrument is qualified for gas and dust environments.

Handling

The device weighs between approx. 2 kg (4.5 lb) and 14 kg (30 lb). Carry using both hands to lift

the device carefully by the tube. If necessary, use lifting gear.

Avoid hard blows, jolts, impacts, etc. when handling the DW 18.

4 Installation and operating instructions DW 181 - 184

Page 5

Product liability and warranty

The DW 18 flow meter is designed solely for measuring the flow rate of liquids without any gas

pocket. Special codes and regulations apply to its use in hazardous areas.

Responsibility as to suitability and intended use of these level gauges rests solely with the user.

Improper installation and operation of our level gauges may lead to loss of warranty.

In addition, the "General conditions of sale", forming the basis of the purchasing contract, are applicable.

If you need to return the level gauge to the manufacturer or supplier, please refer to the information

given in Appendix B.

Items included with supply

The scope of supply encompasses, in the version ordered:

• Flow meter

Documentation supplied

• Installation and operating instructions (this manual) including description of special versions and

functions.

Official approvals and certificates

Application Approved by Instrument version Certification mark

ATEX certification

*This EC-type Examination Certificate is available in KROHNE’s download centre on

http://www.krohne.com/.

INERIS DW 18 TYPE 18. Certificate no.

INERIS 03ATEX0045X*

Installation and operating instructions DW 181 - 184 5

Page 6

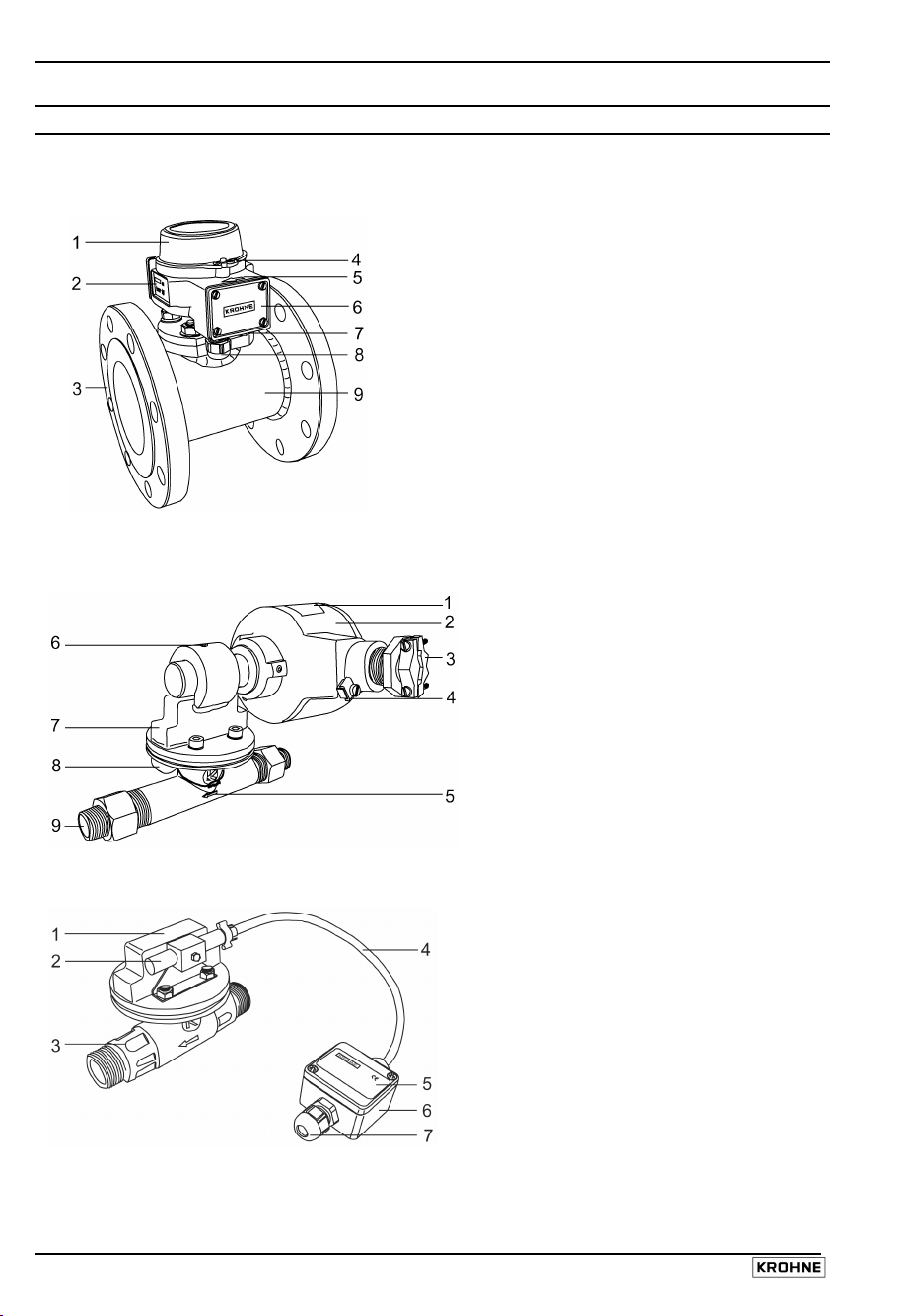

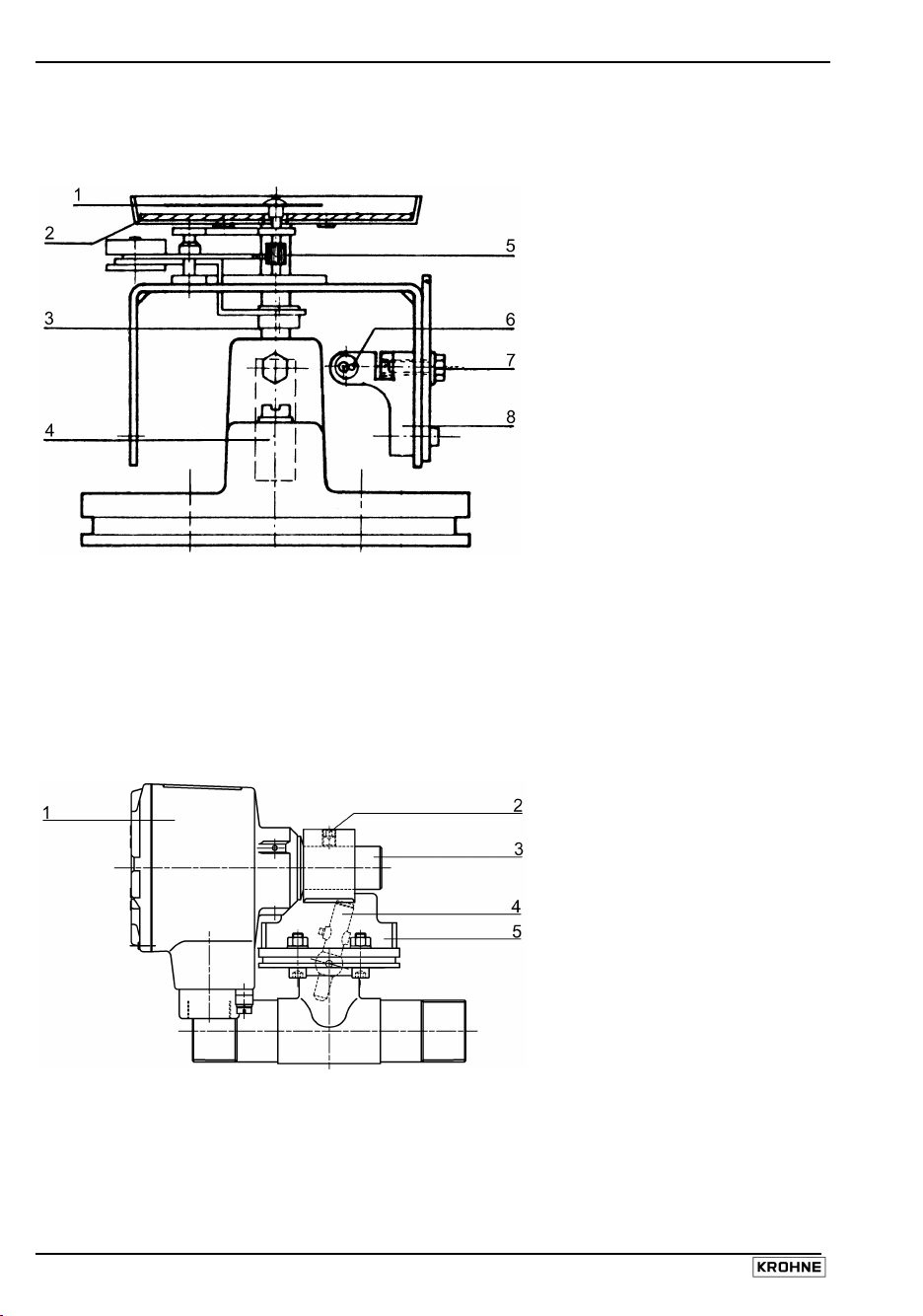

Principle components

DW 18 Standard or EEx ia version

1 Indicator type G (linear scale) or A

(dial)

2 Equipment label*

3 Flange (illustrated) or screwed

connection

4 Indicator cover locking pin

5 Flow direction arrow (DW183/4)

6 Wiring compartment cover

7 Gland (plugged)

8 Cable fitting (PG 13.5)

9 Measuring tube

DW 18 EEx d version

DW 18 HT (H3) version

1 Equipment labels*

2 MS 12/BRX switch housing

3 Cable fitting (to be supplied by the

customer)

4 PE terminal

5 Flow direction arrow (on measuring

tube for DW181/2)

6 Socket set screw for adjusting

switch position

7 Pressure housing

8 Equipment dog-tag (tag no., etc.)

9 Screw-on connection

1 Pressure housing

2 Switch sheathed in a PTFE

cartridge

3 Measuring tube

4 Electric cable in fibre glass

sheathing

5 MS 14 switch information label

6 Wiring box

7 Cable fitting (PG 9)

* Equipment labels shown on next page

6 Installation and operating instructions DW 181 - 184

Page 7

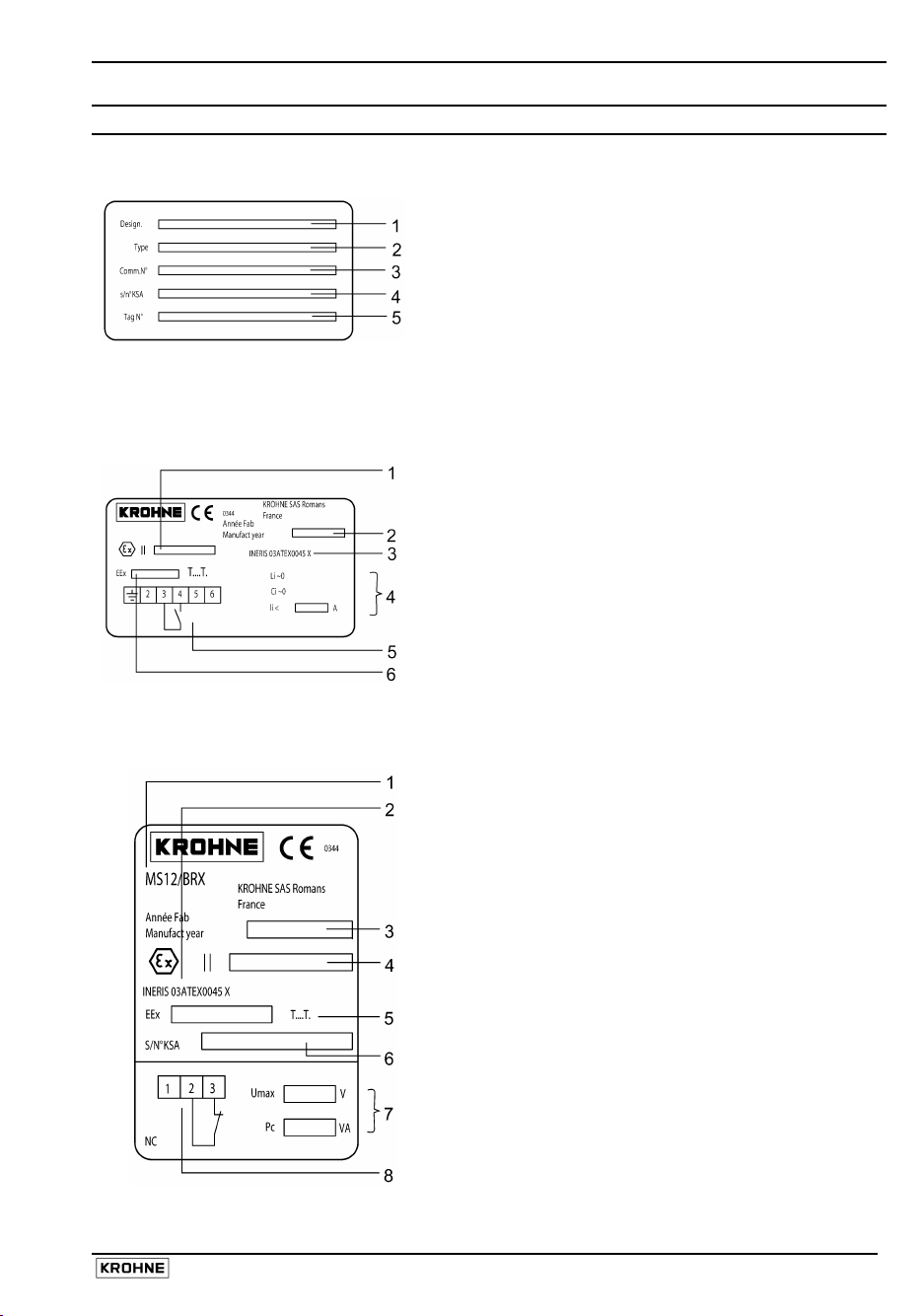

Equipment labels

Standard label (all devices)

EEx ia supplementary information label (e.g. version K1 NO)

EEx d supplementary information label (e.g. version NC)

1 Designation code acc. to order

2 Type code

3 Purchase order number

4 Factory serial number

5 Customer tag number

1 ATEX gas group and equipment

2 Year built

3 ATEX certification code

4 Electrical safety values

5 Wiring diagram

6 Protection concept & gas group +

1

2 ATEX certification code

3 Year built

4 ATEX gas group and equipment

5 Protection concept & gas group +

6 Factory serial number

7 Maximum switching capacity

8 Wiring diagram

options list (e.g.V7BD1...)*

(e.g. DW181/C/011/B/G/KA/N/G1)**

category (e.g. II 1 GD)

sub-div. and temperature class (e.g.

EEx ia IIC T3...T6)

Limit switch code

category (e.g. II 1/2 GD)

sub-div. and temperature class

(e.g. EEx d IIC T3...T6)

* See DW 181-184 Data sheet for a list of order options and designation codes

** See type code definitions on the next page

Installation and operating instructions DW 181 - 184 7

Page 8

Type code

Refer to the standard device label, item 2 on the previous page.

DW . . .

1 2 3 4 5 6 7 8

Type code element Code Code definition

1 Type series 181

2 Measuring system C

3 Code number 011 - 204 See section 7.1: Flow range table for the

4 Material of construction

- see also section 7.2

5 Indicator system G

6 Limit switches K1

7 Application field N

8 Connection G ¾…G2

* Refer to section 9.1

** Bistable.

NO is a “normally open” switch during operation (closed switch when flow is decreasing)

NC is a “normally closed” switch during operation (closed switch when flow is increasing).

/ . / . . . . / . . / . / . . . / . . / . .

182

183

184

E

P

B

RR

R

N

A

K2

KV1

KV2

Ex d

Ex ia

DN15…200

(½”…8”)

For horizontal or vertical pipes, screw

connection G¾…G2, measuring system C or

E*

For horizontal or vertical pipes, flange

connection DN15…65 and ½”…2”-150 lbs,

measuring system C or E*

For horizontal or vertical pipes, flange

connections DN65…200 and 3”…8”-150 lbs,

measuring system P*

For horizontal pipes (DN ≥250 or 10”, mounting

flange DN150 PN16 or 6”-150 lbs, measuring

system P*

Measuring disc in tapered tube

Nozzle with baffle

Baffle in constant diameter pipe

characteristics of each code number.

Bronze

Stainless steel (SS) 316 L

SS 316L measuring tube, steel connection

Steel

Linear scale marks

Dial with flow units

1 NC or 1 NO switch**

1 NC and 1 NO switch**

Amplifier relay: 1 change-over switch**

Amplifier relay: 2 change-over switches**

Normal locations

Hazardous locations

Intrinsically-safe applications

Pipe thread

Flange connection

8 Installation and operating instructions DW 181 - 184

Page 9

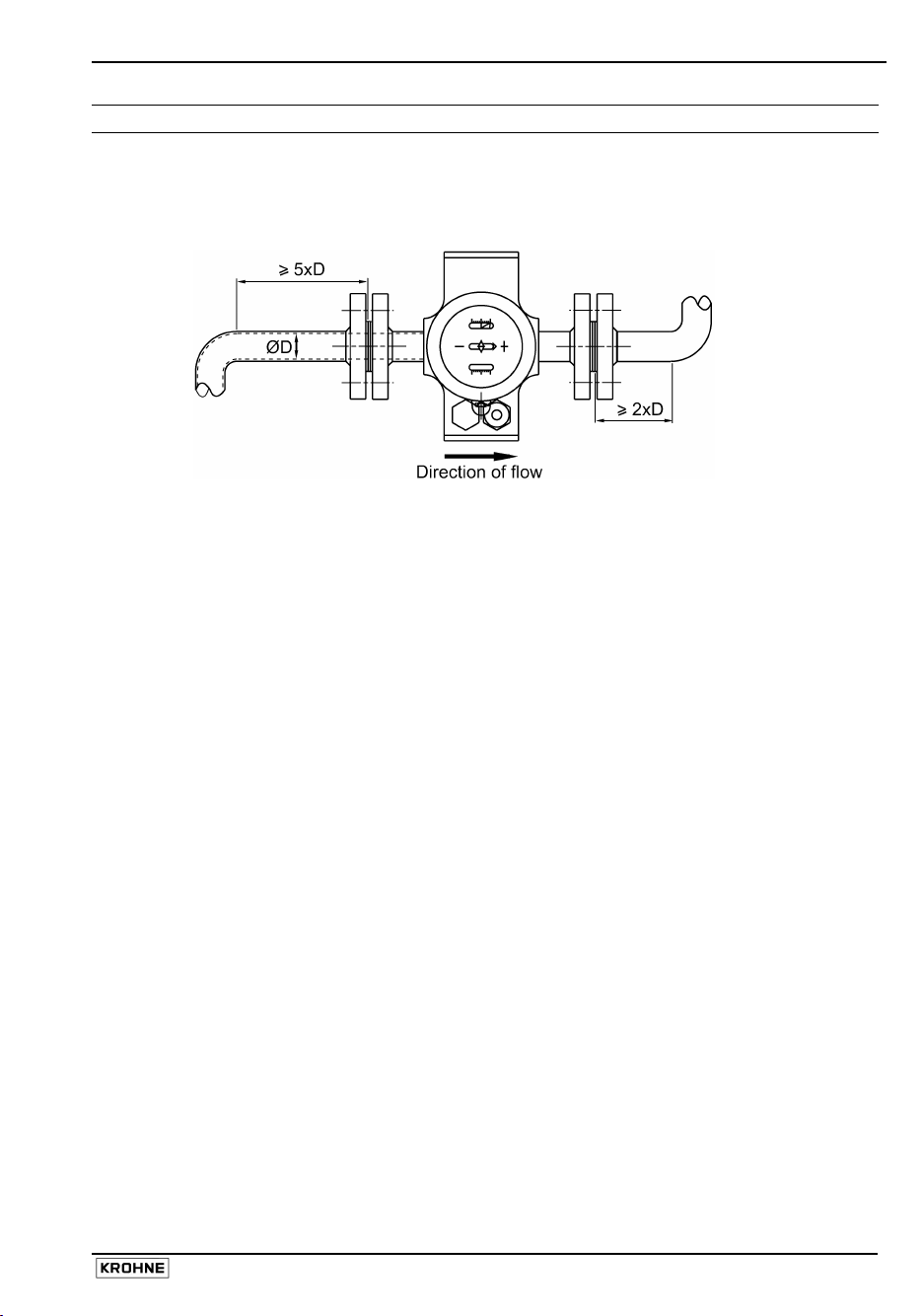

1 Mechanical Installation

1.1 Positioning the flow switch

No obstacles along the pipe within five diameters (D) upstream and two diameters downstream of

the instrument.

1.2 Installation in hazardous areas (Ex applications)

Read all instructions referring to flow switches in hazardous locations before installation.

Check that the flange, gasket and other materials in contact with the product are compatible. Refer

to the information given on the converter nameplate, the flange markings and specifications given

in the ATEX approval certificate.

1.3 Connecting the DW 18 to the pipe

• Before installation, clean the piping to remove any dust or weld debris.

• Fit the instrument on the pipe with the arrow on the housing pointing in the direction of flow.

• Flange connections: ensure that the gaskets are in place, flange facings are aligned and parallel

and that the bolts have been tightened with the amount of torque specified in European or local (if

outside the E.U.) standards.

1.4 Flow direction

The DW 183 and DW 184 can be installed in any position on the piping. However, the position of

installation and the flow direction must be indicated in the customer order (i.e. up, down, left to right

and right to left) as the weight of the baffle disc is taken into account when calibrating the

instrument. Flow direction must be indicated for DW 181 and DW 182 instruments equipped with

type A indicators.

The DW 184 is used for high-velocity or turbulent flows in pipes with diameters greater than

DN250. A special device, called a stilling well, is immersed in the liquid flow and channels the fluid

through a tube in which the disc moves, secured to the end of a rigid support. This reinforced pivot

enables the flow switch to be used in difficult conditions.

These instruments are only supplied with an index display (indicator type “G”) and switches. They

are not equipped with a graduated dial. The heights of the connection piece indicated for the

production of the mating flange must be respected.

Installation and operating instructions DW 181 - 184 9

Page 10

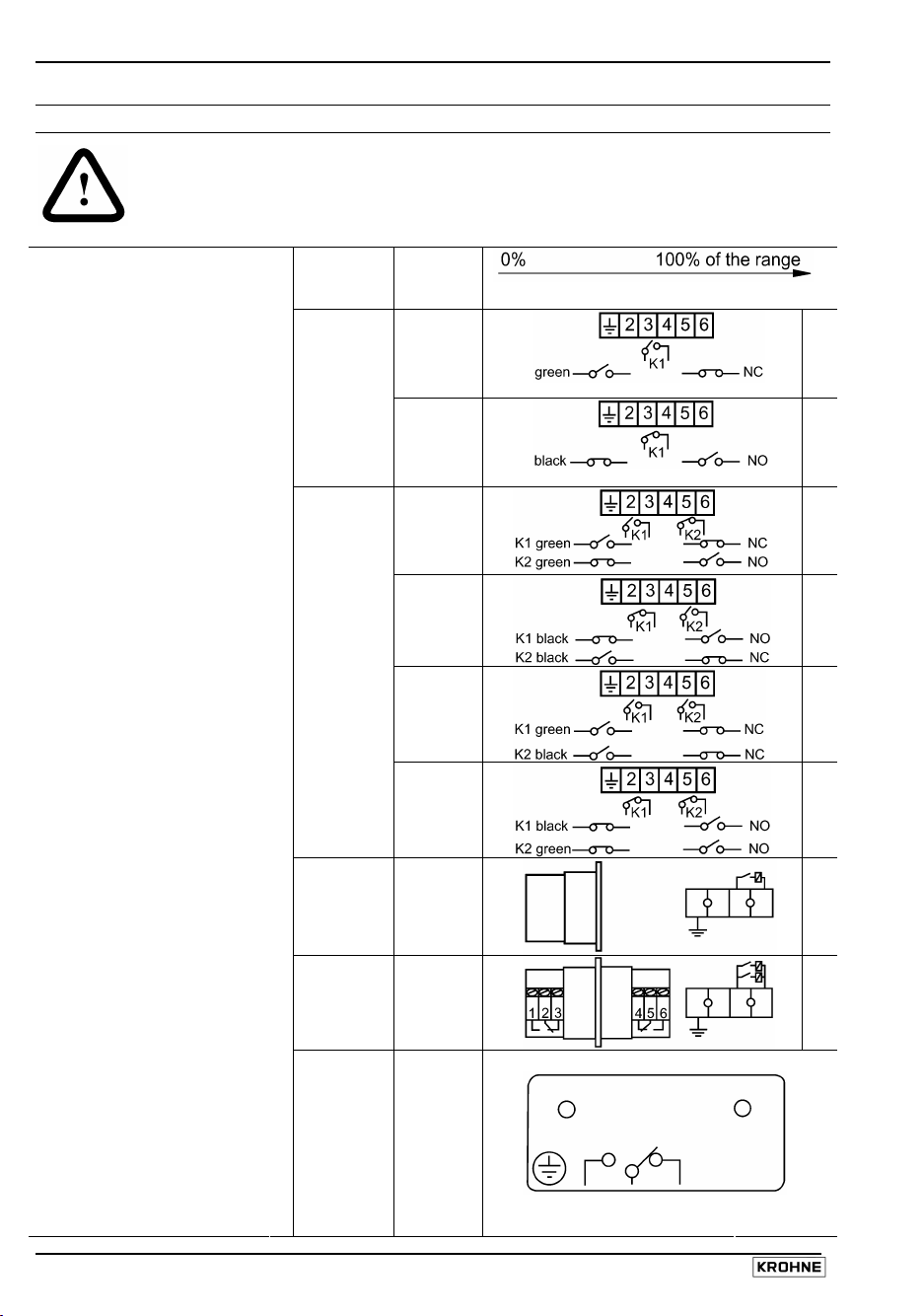

2 Electrical Connections

Disconnect the power supply before opening the housing

• The electrical connection

conforms to the standard

EN61010-1, protection

class 1 (for aluminium

housing) or class 2 (for

PVC housing), voltage

category III, and

interference degree 2.

• The DW range conforms

to EMC directives NF EN

50 081.1 (Emission) and

NF EN 50 082.2

(Immunity).

• It is obligatory to have a

switching or circuit

breaking device, following

present regulations. The

devices should completely

isolate the unit and be

easily accessible, close to

the unit.

• Both the live (L) and

neutral (N) wires should

be protected by a fuse

(4…6.3 A Time Lag).

During the wiring

procedure the ground wire

should always be

connected first (relevant

only for aluminium

housing).

• EEx ia versions must be

used with a certified

intrinsically-safe power

supply.

N.B. Use of the unit

outside the specifications

detailed in this manual can

compromise the safety

measures designed into the

unit. Always disconnect the

power supply before

accessing the terminals.

Number

of

switches

1

2

1

1

K1

+

K2

Switch

types

Type

K1

Type

K1

Type

K2

Type

K2

Type

K2

Type

K2

Type

KV1

Type

KV2

Change

over

(SPDT)

Limit switch adjustable over entire range

A

B

C

D

E

F

G

H

10 Installation and operating instructions DW 181 - 184

Page 11

3 Commissioning

3.1 General notes

The flow switch is delivered pre-calibrated and ready for use. Open the valves slowly when starting

operation.

3.2 Adjusting the limit switches - standard and EEx ia flow switch versions

The limit switches can be adjusted individually over the entire measuring range. To adjust, remove

the locking pin securing the cap and remove the cap.

3.2.1 Type G indicator

The limit switch adjustment is indicated by a green strip (normally closed switch) or a black strip

(normally open switch) in a graduated window. For flow switches manufactured before September 1,

1991, the strips are red (normally closed switch) or orange (normally open switch).

Each graduation corresponds to 1/10 of the total measuring range, i.e. 35 l/h for a flow range of

50…400 l/h. This system enables the limit switch to be adjusted without having to circulate fluid in

the pipe. It is only necessary to adjust the micrometer screw (item 2) in order to move the switch

support (item 3) which has the coloured strip on its upper section.

“G” linear index indicator assembly

1

Index

2 Micrometer screw

3 Switch support

4 Switch

5 Control magnet

6 Following magnet

Installation and operating instructions DW 181 - 184 11

Page 12

3.2.2 Type A indicator

The switch is adjusted by unlocking the adjustment screw (item 7) and repositioning the switch

support arm (item 8).

“A” graduated dial indicator assembly

1

Pointer

2 Dial

3 Following magnet

4 Control magnet

5 Mechanism

6 Switch

7 Adjustment screw

8 Switch support

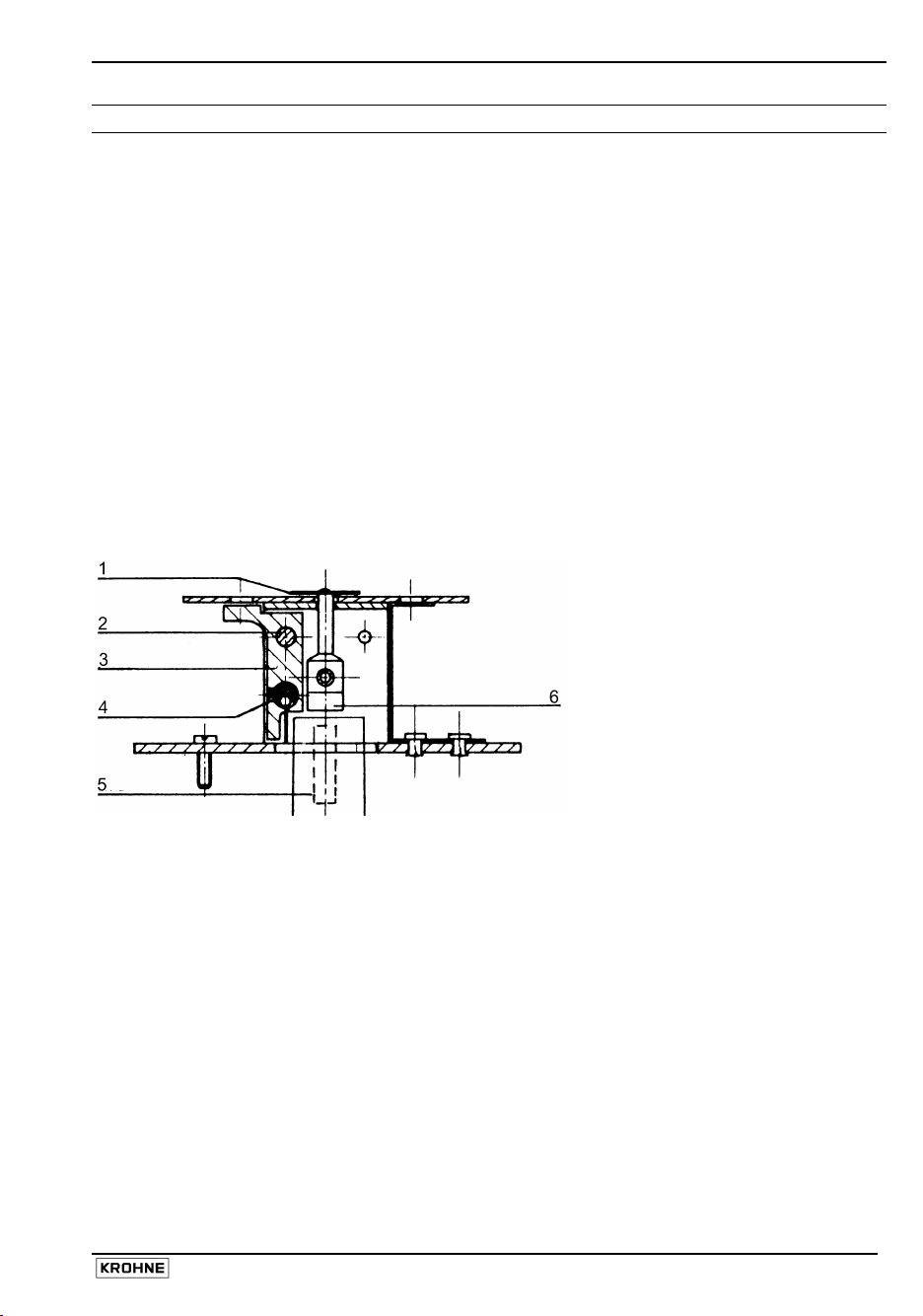

3.3 Adjusting the limit switches - EEx d flow switch version

3.3.1 MS 12/BRX switch

The switch is adjusted by unscrewing the limit switch adjustment screw M8x10 (2) on top of the

pressure housing with a 4mm hexagon key. The switch (in its metal sheath) may then be

repositioned as required before retightening the screw. The original position is etched onto the

sheath.

MS 12/BRX switch assembly

1

MS 12/BRX switch

2 Limit switch adjustment

screw

3 Switch sheath

4 Switch magnet

5 Pressure housing

12 Installation and operating instructions DW 181 - 184

Page 13

4 Display

4.1 Local Flow indication

Indicator “G” Indicator “A”

All flow switches can be equipped with

indicator G. Scale marks are from 1 to 10 to

allow visual control of the flow rate. The

switching point may be changed as and when

required.

High-temperature versions are supplied without a local indicator.

The DW 181, DW 182 and DW 183 flow

switches up to meter size DN100 (4”) can be

supplied with indicator A. The dial is marked in

flow units (e.g. l/h, m³/h) to provide more

accurate flow readings. The switching points are

factory marked on the dial. With this indicator it

is also possible to adjust the switching points at

non-flowing conditions.

4.2 Limit Switches

Every flow switch can be equipped with either one or two limit switches which can be adjusted over

the entire measurement range.

Limit switch specifications

Type and number of switches Switch rating

Standard

K1(K2) single (twin for K2) bi-stable limit switch 14VA max. (max. 350 V AC, max. 0.4 A)

reed type IA42 ATF 15-45

EExi safety values Ii < 500mA, Ci = 0 nF, Li = 0 µH

With change over

K1(K2) single (twin for K2) bi-stable limit switch 3 VA max. (max. 28 V DC, max. 0.25 A)

type reed CM21…

EExi safety values Ii< 500 mA, Ci= 0 nF, Li= 0 µH

With relay

KV1 (KV2) 2000 VA max. (max. 250 V AC, max. 8 A)

Power supply: 240/110/48/24 V AC (50/60 Hz)

110/48/24 V DC

Response time: 5…12ms

EEx d values See section 4.3: EEx d version

High-temperature version (non-EEx)

single bi-stable limit switch

The switch ratings are given for standard resistance loads. Make sure you use the correct

protection circuits when using other types of load (e.g. inductive).

relay type Finder

18 VA max. (max. 220 V, max. 0.8 A)

reed type IA13….

Installation and operating instructions DW 181 - 184 13

Page 14

4.3 EEx d version

The MS 12/BRX (EEx d) switch features a flameproof aluminium enclosure. The limit switches are

type K1 and K2 bi-stable reed switches without changeovers or KV1 relays and are supplied

without a local display.

Approval EEx d IIC T6…T1

INERIS certificate 03 ATEX 0045X

Technical data

MS 12/BRX switch

Switches NC*** and NO****

Switch rating

K1, K2

(reed switch)

KV1

(relay)

Max. switching

capacity dissipated

by Ex d housing

Ambient

temperature

Process

temperature

Protection category

to EN 60529/NEMA

250

Screw connection M20 x 1.5 without

* T80…T195°C depending on the ambient

temperature and process temperature (see

section 7: Technical data).

**Maximum surface temperature of device.

***Optional: M25x1.5 or NPT ¾ threads

14 VA (350 V AC;

0,25 mA

2000 VA (250 V AC;

8 A

20 VA; 1.5 A;

380 V AC

-40…+80°C or

-40…+175°F

max. 150°C or

max. 300°F*

IP 65 / NEMA 6 when

T195…80°C or

T380…175°F*,**

cable entry fitting***

14 Installation and operating instructions DW 181 - 184

Page 15

4.4 High-temperature version (KROHNE temperature class H3, non-EEx)

All DW 18 switches can be supplied for high-temperature service up to max. 300°C or 570°F but

without indicator.

The switches are located in a PTFE cartridge fastened directly to the measuring unit.

Sealing material:

DW 181 / DW 182 Klingerit (asbestos-free)

DW 183 / DW 184 Klingerit or fully welded (optional)

Cable connection (350 mm or 13 ¾ ”) to

aluminium terminal housing: fibre glass sheathing

Technical data

MS 14 (NC*** or NO****) switch

Max. switching

capacity

Ambient temperature -25…+60°C or

Protection category

to EN 60529/IEC 529

Cable fitting PG 9 (supplied)

*** NC: switch that is “normally closed” during operation (closed switch when flow is increasing)

**** NO: switch that is “normally open” during operation (closed switch when flow is decreasing)

20 VA; 0,5 A; 250 V DC

-15…+140°F

IP 44

4.5 Tropical version (non-EEx)

The flow switch junction boxes are equipped with an Amphenol socket outlet for use in tropical

climates. The matching plug is also supplied.

1-5 Terminals

6 Connecting plug

Switch used Terminals used Connection data

K1 1,2 4 For switch K1

For ground connection

K2 1,2

3,5

4

KV1 1,2

3,4,5

Installation and operating instructions DW 181 - 184 15

For switch K1

For switch K2

For ground connection

For power supply

For change over (SPDT)

Page 16

5 Service

5.1 Maintenance

In normal operation no maintenance is required. However, the flow switch must be cleaned if

particles in suspension in the liquid build up on the measuring mechanism.

Caution

Check that the cleaning product used will not chemically react with (i.e.

corrode) the component materials.

5.2 Exploded view of instruments

DW 183 Std / EEx ia DW 184 Std / EEx ia

52a Pressure resistant housing

52b PTFE ring

52c Washer

52d Tube

52e O-ring

53 Magnet lever with measuring disc

54 Measuring spring

55 Nut

56 Spring washer

57 Tubular body with collar and flanges

58 PTFE gasket

62a Pressure resistant housing

62b PTFE ring

62c Washer

62d Tube

62e O-ring

63a Measuring disc

63b Magnet lever

64 Measuring spring

65 Nut

66 Spring washer

67 Flange with stilling well

68 PTFE gasket

The parts listed above are not supplied separately. Please refer to section 5.3: Spare parts for

a list of available spare parts.

16 Installation and operating instructions DW 181 - 184

Page 17

DW 182 (181) Std / EEx ia with indication G DW 182 (181) Std / EEx ia with indication A

DW 182 H3/K1 High-temperature version (Std)

9 Pressure resistant housing

10 O-ring

11 Magnet lever

12 Measuring spring complete

13 PTFE-ring

14 Measuring disc

15 Tubular body

17 Snap ring

18 Screw

48 Reed switch H3/K1

49 Mount

50 Nut

51 Hexagon socket head screw

The parts listed above are not supplied

separately. Please refer to section 5.3: Spare

parts for a list of available spare parts.

Installation and operating instructions DW 181 - 184 17

Page 18

5.3 Spare parts

Measuring spring DW 181 / 182 "C"

Magnet lever (Tag 11)/ PTFE Ring (Tag 13)/ Measuring spring (Tag 12)/ Measuring disc (Tag 14)

DN N° Code DN N° Code

DN15

C011 XF71010100 C041 XF71010800

DN40

C012 XF71010200 C042 XF71010900

DN 25

C013 XF71010300

C014 XF71010400 C051 XF71011100

DN50

C021 XF71010500 C052 XF71011200

C043 XF71011000

C022 XF71010600 C053 XF71011300

C023 XF71010700

C054 XF71011400

Measuring spring DW 181 / 182 "E"

Magnet lever (Tag 11)/ PTFE Ring (Tag 13)/ Measuring spring (Tag 12)/ Measuring disc (Tag 14)

DN N° Code DN N° Code

DN15

E015 XF71011500 E045 XF71012300

E016 XF71011600

E017 XF71011700 E055 XF71012500

DN40

E046 XF71012400

DN50

E018 XF71011800 E056 XF71012600

DN 25

E019 XF71011900

E025 XF71012000

E026 XF71012100

E027 XF71012200

Measuring spring DW 183 (2 springs supplied – Tag 54)

Flow Direction Meter code n°

↔ ↑ ↓

P081 XF71012700 XF71012800 XF71012900

P082 XF71013000 XF71013100 XF71013200

P083 XF71013300 XF71013400 XF71013500

P084 XF71013600 XF71013700 XF71013800

P085 XF71013900 XF71014000 XF71014100

P086 XF71014200 XF71014300 XF71014400

P087 XF71014500 XF71014600 XF71014700

P088 XF71014800 XF71014900 XF71015000

P089 XF71015100 XF71015200 XF71015300

P101 XF71015400 XF71015500 XF71015600

P102 XF71015700 XF71015800 XF71015900

P103 XF71016000 XF71016100 XF71016200

P104 XF71016300 XF71016400 XF71016400

P105 XF71016500 XF71016600

P106 XF71016700 XF71016800 XF71016900

P107 XF71017000 XF71017100 XF71017200

P108 XF71017300 XF71017400 XF71017500

P109 XF71017600 XF71017700 XF71017800

P121 XF71017900 XF71018000

P122 XF71018100 XF71018200 XF71018300

P123 XF71018400 XF71018500

P124 XF71018600 XF71018700 XF71018800

P125 XF71018900

P126 XF71019000 XF71019100

P127 XF71019200 XF71019300

P128 XF71019400 XF71019500 XF71019600

P129 XF71019700 XF71019800

18 Installation and operating instructions DW 181 - 184

Page 19

Measuring spring DW 183 (2 springs supplied - Tag 54) continued from last page …

Meter code n°

↔ ↑ ↓

P151 XF71019900 XF71020000 XF71020100

P152 XF71020200 XF71020300 XF71020400

P153 XF71020500 XF71020600 XF71020700

P154 XF71020800 XF71020900 XF71021000

P155 XF71021100

P156 XF71021200 XF71021300 XF71021400

P157 XF71021500 XF71021600 XF71021700

P158 XF71021800 XF71021900 XF71022000

P159 XF71022100 XF71022200 XF71022300

P201 XF71022400 XF71022500 XF71022600

P202 XF71022700 XF71022800 XF71022900

P203 XF71023000 XF71023100

P204 XF71023200 XF71023300 XF71023400

P205 XF71023500 XF71023600 XF71023700

P206 XF71023800 XF71023900 XF71024000

Kit gasket DW 181 / 182

Tag Description Silicon code Viton code Perbunan code

2 O-ring D 88,49 X 3,53

8 O-ring 74 X 3 X 80 XF71030100 XF71030200 XF71030300

10 O-ring D 36,17 X 2,62

13 PTFE ring

Kit gasket DW 181…4 (ring for pressure resistant housing)

for special applications using DW 181…4 HT/H3 version

Description Code Description Code

PTFE XF71030400 Klingerit XF71030500

Pressure housing DW 181 / 182

Tag Description Standard code HT version code Ex version code

9 pressure housing

18 screw A2 70 CHC,

XF71040100 XF71040200 XF71040300

M6-20 DIN 912

16 nut A2 70 HM6

17 spring washer A4 W6

Reed switch "A" DW 181 / 182 / 183

Tag Description NO** code NC* code Changeover code

33 reed switch

32a nut A2 70H,M3

31 spring washer A2 M3 plate XF71050900 XF71051000 XF71051100

32 screw A2 70 H3-10 DIN933

30 clamp plate

Reed switch "G" DW 181 / 182 / 183

Tag Description NO** code NC* code Changeover code

34 reed switch G/K1

46 spring washer D5X9 XF71051200 XF710105300 XF71051400

47 snap ring AC E005 REF A

75 55

* NC: switch that is “normally closed” during operation (closed switch when flow is increasing)

** NO: switch that is “normally open” during operation (closed switch when flow is decreasing)

Installation and operating instructions DW 181 - 184 19

Page 20

Complete plastic housing for ...

Code Description Code Description

XF71060100 DW18/AK1 green XF71062900 DW18/GKV1 24VAC

XF71060200 DW18/AK1 black XF71063000 DW18/GKV1 48VAC

XF71060300 DW18/AK1 "INV" XF71063100 DW18/GKV1 110VAC

XF71063200 DW18/GKV1 220VAC

XF71060400 DW18/AK2 green/green

XF71060500 DW18/AK2 black/black XF71063300 DW18/GKV1 24VDC

XF71060600 DW18/AK2 green/black XF71063400 DW18/GKV1 48VDC

XF71060700 DW18/AK2 black/green XF71063500 DW18/GKV1 110VDC

XF71060800 DW18/AKV1 24VAC XF71063600 DW18/GKV2 NC 24VAC

XF71060900 DW18/AKV148VAC XF71063700 DW18/GKV2 NC 48VAC

XF71061000 DW18/AKV1 110VAC XF71063800 DW18/GKV2 NC 110VAC

XF71061100 DW18/AKV1 220VAC XF71063900 DW18/GKV2 NC 220VAC

XF71061200 DW18/AKV1 24VDC

XF71061300 DW18/AKV1 48VDC XF71064000 DW18/GKV2 NC 24VDC

XF71061400 DW18/AKV1 110VDC XF71064100 DW18/GKV2 NC 48VDC

XF71064200 DW18/GKV2 NC 110VDC

XF71061500 DW18/AKV2 24VAC

XF71061600 DW18/AKV2 48VAC XF71064300 DW18/KV1/BRX NC 220V AC

XF71061700 DW18/AKV2 110VAC XF71064400 DW18/KV1/BRX NC 110V AC

XF71061800 DW18/AKV2 220VAC XF71064500 DW18/KV1/BRX NC 110V DC

XF71061900 DW18/AKV2 24VDC XF71064600 DW18/KV1/BRX NC 48V AC

XF71062000 DW18/AKV2 48VDC XF71064700 DW18/KV1/BRX NC 48V DC

XF710612100 DW18/AKV2 110VDC XF71064800 DW18/KV1/BRX NC 24V AC

XF71064900 DW18/KV1/BRX NC 24V DC

XF71062200 DW18/GK1 green

XF71062300 DW18/GK1 black XF71065000 DW18/KV1/BRX NO 220V AC

XF71062400 DW18/GK1 INV.yellow XF71065100 DW18/KV1/BRX NO 100V AC

XF71065200 DW18/KV1/BRX NO 110V DC

XF71062500 DW18/GK2 green/green XF71065300 DW18/KV1/BRX NO 48V AC

XF71062600 DW18/GK2 black/black XF71065400 DW18/KV1/BRX NO 48V DC

XF71062700 DW18/GK2 green/black XF71065500 DW18/KV1/BRX NO 24V AC

XF71062800 DW18/GK2 black/green XF71065600 DW18/KV1/BRX NO 24V DC

NC: switch that is “normally closed” during operation (closed switch when flow is increasing)

NO: switch that is “normally open” during operation (closed switch when flow is decreasing)

Kit indicator type A Kit indicator type G

Tags Description Code Tags Description Code

22…29 Indicator sub-

assembly (A)

XF71065900 36…47 Indicator sub-

assembly (A)

XF71066000

Kit cap/cover DW 181/182/183

Tag Description Code

1 cap

2 O-ring Perb D 88,49 X 3,53 XF71070100

4 locking pin 316L for cover

5+6 gasket + cover + nut

20 Installation and operating instructions DW 181 - 184

Page 21

Kit measuring system Reed switch for EXD or HT versions

Tags Description Code Tag Description Code

52a…e,

53…56,57

/ RR

DW 183

XF71080100 48

XF71080400

/ RR / HT

- DW 183

XF71080300

MS 14/HT NC XF 71051500 DW 183

MS 14/HT NC XF 7101600

- MS 12/BRX (EXD) NC XF 71051700

- MS 12/BRX (EXD) NO XF 71051800

/ RR / EXD

5.4 Inspection procedure

5.4.1 Inspection procedure: measuring assembly

Check the condition of the measuring system, cone-disc or nozzle-disc. Check the condition of the

spring. In the event of leaks between the body and the cap, tighten the four bolts securing the cap.

Change the O-ring if necessary. Carefully follow the maintenance procedures in section 5.5.

5.4.2 Inspection procedure: housing (DW181 & DW182 models)

Check switch operation using an ohmmeter. Check the operation of the indicating mechanism. By

removing the lock ring (Tag no. 7, section 5.2) holding the housing onto the assembly, it is possible

to remove the housing from the measuring body without removing the flow switch from the pipe, or

stopping the flow. Carefully follow the maintenance procedures in section 5.5.

Installation and operating instructions DW 181 - 184 21

Page 22

5.5 Basic servicing procedures

DW 181…4 servicing by the customer is limited by warranty to:

• Changing the position of the dial on the type A indicator

• Removing the display assembly

• Removing the spring-loaded probe assembly

• Changing gaskets in DW 183 flow controllers

Other repairs must be done by KROHNE-authorized service staff.

Read all servicing instructions carefully.

5.5.1 Changing the position of the dial on the type A indicator

For the “A” indication version, it may be necessary to modify the position of the dial when flow

direction has been reversed, in order to read the flow rate correctly. Follow the steps 1 to 6.

Step 1

Remove the locking pin and remove the cap.

Warning :

Do not remove the 4 bolts holding the pressure housing onto the measuring

tube.

1

Dial

2 Screwdriver

Step 2

Extract the pointer using an extractor or the flats of two screwdrivers placed at either side of the

pointer.

Step 3

Unscrew the dial.

22 Installation and operating instructions DW 181 - 184

3

Pointer

4 Screwdriver

5 Dial

Page 23

Step 4

Reposition the dial as required; attachment holes are provided to reposition the dial in 90° steps. Fit

screws.

6

Dial

7 Screwdriver

Step 5

Hold the pivoting arm and fit the pointer aligned with zero.

Step 6

Reinstall the cap and locking pin.

8 Interference fit between pointer shaft and

hole in dial

9 Pointer

10 Dial

11 Pivoting arm

5.5.2 Removing the display assembly: operating faults in the housing DW18x Std /EExia

flow controllers equipped with type G or A indicators

Warning :

Do not remove the 4 bolts holding the pressure housing onto the measuring

tube.

If the fault lies inside the housing, return the display assembly to the factory for standard

replacement. The display may be removed under flow conditions.

• Remove the whole display assembly from the pressure housing by extracting the snap-ring

underneath the display. See section 5.2 for the exploded views of the DW18 Std/EExia devices to

locate this component (Tag no. 7).

Installation and operating instructions DW 181 - 184 23

Page 24

5.5.3 Cleaning the springs or changing the measuring system sub-assembly

Warning:

Remember to shut off the flow before

performing this operation

Step 1

UNSCREW the 4 nuts and washers dia. M12 (1).

Step 2

SEPARATE the two components (2) and (3) using a

screwdriver.

Step 3

REMOVE the pressure housing (2) in the direction of

the arrow F.

Either Step 4A…

CLEAN the springs (4)

… or Step 4B

CHANGE the measuring system sub-assembly

Step 5

REASSEMBLE by following instructions 1, 2, 3 and 4 in

reverse order. Take care to orient the measuring disc

(A) so that it is facing upstream.

5.5.4 Changing gaskets in DW 183 flow controllers

Warning:

Remember to shut off the flow before

performing this operation

Step 1

UNSCREW 4 nuts and washers dia. M12 (1).

Step 2

SEPARATE the two components (2) and (3) using a

screwdriver.

Step 3

REMOVE the pressure housing (2) in the direction of

the arrow F.

Step 4

REMOVE the gaskets from their recess (4).

Step 5

CHANGE the gaskets and reassemble by following

instructions 1, 2, 3 and 4 in reverse order. Take care to

orient the measuring disc (A) so that it is facing

upstream.

24 Installation and operating instructions DW 181 - 184

Page 25

6 Technical Data

DW 181 DW 182 DW 183 DW 184

Full-scale range (100% values)

Flow rate m3/h 0.16…30 0.16…30 24…250 –

(US GPM) (0.7…132) (0.7…132) (106…1100)

Flow velocity m/s

(ft/s)

Connection

Pipe thread G

Flanges to DIN 2501 –

(NFE 29203)

Flanges to ANSI B16.5 –

Class 150 lb/RF

Information on other standards and pressure ratings supplied on request

Measuring system

Measuring disc C C – –

with tapered tube

Nozzle with baffle E E – –

Baffle – – P P

Indicator

Scale division 1 to 10 G G G G

in flow units A A

Pipe run / flow direction

Vertical/upwards VU VU VU –

Vertical/downwards VO VO VO –

Horizontal/either way H H H H

Max. operating pressure*, ***

- ≤DN50 or 2”: ≤DN150 or 6”: -

40bar or

- ≥DN65 or 3”: ≥DN200 or 8”: -

16 bar or

DN150 PN16 DN150 PN16

<13 bar (for

DN80 PN40 DN80 PN40

<25 bar (for

* Information on higher pressure levels supplied on request, ** PN 16 optional,

*** Subject to process connection used and flange temperature

Installation and operating instructions DW 181 - 184 25

– – – 0.4…4

(0.66…1.31)

3

/4” … 2”

580psig

– – –

DN15- (DN65), DN150/

DN50/PN40 DN100, DN125, PN16…PN25

(DN65/PN16) DN150/PN16

DN80/PN40,

1

DN200/PN10

/2”…2” (21/2”) 3” (21/2”)…8” 6”

40 bar or

580 psig

230 psig

A (≤DN100 / 4”)

16 bar or

230 psig

10 bar or

145 psig**

–

25 bar or

365 psig

<13 bar (for

dangerous

fluids only –

group 1

Directive

dangerous fluids

only –group 1

Directive

67/548/CEE -)

67/548/CEE -)

<25 bar (for

dangerous

fluids only –

group 1

Directive

dangerous fluids

only –group 1

Directive

67/548/CEE -)

67/548/CEE -)

Page 26

Product temperature ***

Standard

Housing with ventilation

HT–version w/o

indicator

≤120°C or

≤250°F

≤150°C or

≤300°F

≤300°C or

≤570°F

≤120°C or

≤250°F

≤150°C or

≤300°F

≤300°C or

≤570°F

≤120°C or

≤250°F

≤150°C or

≤300°F

≤300°C or

≤570°F

*** Subject to process connection used and flange temperature

≤120°C or

≤250°F

≤150°C or

≤300°F

≤300°C or

≤570°F

26 Installation and operating instructions DW 181 - 184

Page 27

Special conditions for ATEX applications

Flow indicator DW18* EEx d

Authorized markings: II 1/2 GD EEx d IIC T…* IP65 T…°C**,***

Temperature Class Process temperature Ambient temperature range

T6 / T80°C or 175°F**

T5 / T95°C or 200°F**

T4 / T130°C or 265°F**

T3 / T195°C or 380°F**

T(fluid) ≤60°C or 140°F

T(fluid) ≤80°C or 175°F

T(fluid) ≤120°C or 250°F

T(fluid) ≤150°C or 300°F

-40…+50°C or -40…+120°F

-40…+50°C or -40…+120°F

-40…+60°C or -40…+140°F

-40…+80°C or -40…+175°F

Flow indicator DW18* EEx ia

Authorized markings:

II 1 GD EEx ia IIC T…* IP65 T…°C**,***

Temperature Class Process temperature Ambient temperature range

T6 / T80°C or 175°F**

T5 / T95°C or 200°F**

T4 / T130°C or 265°F**

T3 / T195°C or 380°F**

T(fluid) ≤60°C or 140°F

T(fluid) ≤80°C or 175°F

T(fluid) ≤120°C or 250°F

T(fluid) ≤150°C or 300°F

-40…+40°C or -40…+105°F

-40…+40°C or -40…+105°F

-40…+50°C or -40…+120°F

-40…+80°C or -40…+175°F

* Maximum surface temperature of device

** T3, T4, T5 or T6 according to process temperature and ambient temperature

*** T195…80°C according to process temperature and ambient temperature

Viscosity

Standard mPa.s

lb/ft.s

Special version mPa.s

lb/ft.s

Repeatability

≤30 or

≤20x10-3

>30 or

>20x10

-3

≤30 or

≤20x10-3

>30 or

>20x10-3

≤30 or

≤20x10-3

>30 or

>20x10-3

≤30 or

≤20x10-3

>30 or

>20x10-3

±3% ±3% ±3% ±3%

(switching point)

Measuring accuracy

(Indicator A)

Protection category

±15% ±15% ±15%

(≤DN100, 4”)

IP 55 (standard version)

–

to EN 60529 / IEC 529 IP 44 (high-temperature version)

IP 65 (ATEX version)

Electromagnetic

EN 50081-1 and 50082-2

compatibility (EMC)

Limit switches

Type Number and description

K1 1 N/C* or 1 N/O* switch (bistable) or 3-wire SPDT (change over)

K2 1 N/C* or 1 N/O* switch (bistable) or 3-wire SPDT (change over)

2 N/C* or 2 N/O* switches also possible in conjunction with high-

temperature version H3

KV1, KV2 1,2 changeover switches (bistable) with amplifier relay

Type Max. switching capacity rating

K1, K2 (standard) max. 14 VA (max. 350 V AC; max. 0.4 A)

K1, K2 with changeover max. 3 VA (max. 28 V DC; max. 0.25 A)

EEx d characteristics max. dissipation (Ex d housing): 20 VA; max. 380 V AC; max. 1.5 A

EEx ia safety values Ii < 500 mA, Ci = 0 nF, Li = 0 µH

Reed switch, HT 18 VA (max. 220 V; max. 0.8 A)

KV1, KV2 max. 2000 VA (max. 250 V AC, max. 8 A)

Amplifier relay characteristics

Power supply 240/110/48/24 V AC, 110/48/24 V DC

Response time 5…12 ms

* Refer to section 2: Electrical connections for definition.

Installation and operating instructions DW 181 - 184 27

Page 28

6.1 Flow range table by flow range code

Meter size

DW 181 DW 182 Code Flow range

– Indicator G and A

Flanges for q

Screw DIN ASME l/h US GPM mbar psig mbar psig

3

/4”

15 1/2”

C 011 20…160 0.09…0.70 16 0.23 80 1.16

C 012 50…400 0.22…1.76 67 0.97 176 2.55

C 013 150…1000 0.66…4.40 140 2.03 440 6.38

C 014 300…2500 1.32…11.01 150 2.18 490 7.11

E 015* 64…160 0.28…0.70 65 0.94 370 5.37

E 016* 100…250 0.44…1.10 150 2.18 870 12.62

E 017 160…400 0.70…1.76 18 0.26 110 1.60

E 018 250…630 1.10…2.77 40 0.58 270 3.92

E 019 400…1000 1.76…4.40 18 0.26 110 1.60

1” 25 1” C 021 200…1600 0.88…7.04 18 0.26 80 1.16

C 022 300…2500 1.32…11.01 26 0.38 180 2.61

C 023 500…4000 2.20…17.61 85 1.23 400 5.80

E 025 640…1600 2.82…7.04 15 0.22 110 1.60

E 026 1000…2500 4.40…11.01 45 0.65 240 3.48

E 027 1600…4000 7.04…16.61 25 0.36 140 2.03

11/2” 40 11/2” C 041 500…4000 2.20…17.61 14 0.20 68 0.99

C 042 800…6300 3.52…27.74 32 0.46 110 1.60

C 043 1200…10000 5.28…44.03 60 0.87 160 2.32

E 045 2500…6300 11.01…27.74 15 0.22 100 1.45

E 046 4000…10000 17.61…44.03 50 0.73 260 3.77

2” 50/65 2”/21/2” C 051 1200…10000 5.28…44.03 30 0.44 80 1.16

Pressure loss p

for q

min.

max.

max

C 052 2000…16000 8.81…70.45 65 0.94 260 3.77

C 053 2500…20000 11.01…88.06 72 1.04 350 5.08

C 054 7500…30000 33.02…132.09 47 0.68 360 5.22

E 055 6400…16000 28.18…70.45 20 0.29 110 1.60

E 056 8000…16000 35.00…70.45 30 0.44 140 2.03

* only with indicator G

28 Installation and operating instructions DW 181 - 184

Page 29

Meter size

DW 183

Indicator G –

Flow range

Code Indicator A –

Flow range

Code Pressure loss

p

max.

DIN ASME m3/h US GPM m3/h US GPM mbar psig

65/ 80 21/2”/3” 10…24 44…106 P 081 - - - 10 0.15

16…40 70…176 P 082 10…40 44…176 P 086 20 0.29

20…50 88…220 P 083 13…50 55…220 P 087 10 0.15

24…60 106…264 P 084 15…60 66…264 P 088 12 0.17

28…70 123…308 P 085 17…70 75…308 P 089 12 0.17

100 4” 16…40 70…176 P 101 - - - 10 0.15

24…60 106…264 P 102 15…60 66…264 P 106 23 0.33

32…80 141…352 P 103 20…80 88…352 P 107 14 0.20

40…100 176…440 P 104 25…100 110…440 P 108 23 0.33

28…120 211…528 P 105 30…120 132…528 P 109 33 0.48

125 5” 24…60 106…264 P 121 - - - 20 0.29

40…100 176…440 P 122 25…100 110…440 P 126 24 0.35

48…120 211…528 P 123 30…120 132…528 P 127 26 0.38

60…150 264…660 P 124 37…150 163…660 P 128 24 0.35

70…180 308…793 P 125 45…180 198…793 P 129 24 0.35

150 6” 40…100 176…440 P 151 - - - 30 0.44

60…150 264…660 P 152 37…150 163…660 P 156 32 0.46

70…180 308…793 P 153 45…150 198…793 P 157 37 0.54

90…120 528…969 P 154 55…220 242…969 P 158 34 0.49

100…250 440…1101 P 155 65…250 286…1101 P 159 30 0.44

200 8” 60…150 264…660 P 201 - - - 35 0.51

70…180 308…793 P 202 - - - 40 0.64

90…220 396…969 P 203 55…220 242…969 P 205 44 0.64

100…250 440…1101 P 204 65…250 286…1101 P 206 40 0.58

Installation and operating instructions DW 181 - 184 29

Page 30

Flow table

DW 184 for measuring tube

Flow velocity Scale ratio

m/s ft/s

…0.4 0.66…1.31 1 : 2

≥DN250 (10”)

0.2

(or 65) 0.2…1 1.31…3.28 1 : 2.5

1…4 3.28…13.12 1 : 4

4 13.12 1 : 4

6.2 Instrument version materials

Version Cap Gasket * Measuring

system

DW 181/B Stainless

Steel 316 L

DW 181/RR Stainless

Steel 316 L

DW 182/RR Stainless

Steel 316 L

DW 183/N Stainless

Steel 316 L

DW 183/R Stainless

Steel 316 L

DW 183/RR Stainless

Steel 316 L

DW 184/N Stainless

Steel 316 L

DW 184/R Stainless

Steel 316 L

DW 184/RR Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

Buna Stainless

Steel 316 L

*Viton, silicone, or Klingerit gaskets on request. DW 184/R: steel-clad flanges used in all cases.

* *Steel flanges for >DN100 or 4” instruments have stainless steel 316 L cladding.

Measuring

Connection Housing

tube

Bronze Bronze Polycarbonate

Stainless

Steel 316 L

Stainless

Steel 316 L

Stainless

Steel 316 L

Stainless

Steel 316 L

Polycarbonate

Polycarbonate

Steel Steel Polycarbonate

Stainless

Steel * * Polycarbonate

Steel 316 L

Stainless

Steel 316 L

Stainless

Steel 316 L

Polycarbonate

Steel Steel Polycarbonate

Stainless

Steel * * Polycarbonate

Steel 316 L

Stainless

Steel 316 L

Stainless

Steel 316 L

Polycarbonate

30 Installation and operating instructions DW 181 - 184

Page 31

7 Dimensions and Weights

Type Connection Dimension h Dimension L Weight

DIN ASME mm inches mm inches kg lb

DW 181 G3/4” 115 4.53 135 5.31 1.7 3.75

Std/EEx ia G1” 120 4.72 160 6.30 1.8 3.97

G11/2" 130 5.12 180 7.09 2.2 4.85

G2” 135 5.31 190 7.48 2.6 5.73

DW 182 15

Std/EEx ia 25 1" 120 4.72 200 7.87 4.0 8.82

40 11/2" 130 5.12 200 7.87 5.5 12.13

50 2" 135 5.31 200 7.87 7.2 15.87

65 21/2" 135 5.31 200 7.87 9.3 20.50

DW 183 65 21/2” 185 7.28 200 7.87 11.5 25.35

Std/EEx ia 80 3" 185 7.28 200 7.87 12.5 27.56

100 4" 195 7.68 200 7.87 14.0 30.86

125 5" 210 8.27 300 11.81 18.0 39.68

150 6" 220 8.66 300 11.81 23.0 50.71

200 8" 250 9.84 300 11.81 35.0 77.16

DW 184

150 6" 13.5 29.76

Std/EEx ia

DW 181 Std / EEx ia

1

/2” 115 4.53 200 7.87 3.0 6.61

DW 182 Std / EEx ia

Dimensions in mm (inches)

Installation and operating instructions DW 181 - 184 31

Page 32

DW 183 Std / EEx ia DW 184 Std / EEx ia

Dimensions in mm (inches)

Type Connection Dimension h Dimension L Weight

DIN ASME mm inches mm inches kg lb

DW 181 G3/4” 140 5.51 135 5.31 2.35 5.18

EEx d G1” 145 5.71 160 6.30 2.45 5.40

G11/2" 155 6.10 180 7.09 2.85 6.28

G2” 160 6.30 190 7.48 3.25 7.16

DW 182 15

1

/2” 140 5.51 300 11.81 3.65 8.05

EEx d 25 1" 145 5.71 300 11.81 4.65 10.25

40 11/2" 155 6.10 300 11.81 6.15 13.56

50 2" 160 6.30 300 11.81 7.85 17.31

65 21/2" 160 6.30 300 11.81 9.95 21.94

DW 183 65 21/2” 210 8.27 400 15.72 12.15 26.79

EEx d 80 3" 210 8.27 400 15.72 13.15 28.99

100 4" 220 8.66 400 15.72 14.65 32.30

125 5" 232 9.13 400 15.72 18.65 41.12

150 6" 245 9.65 400 15.72 23.65 52.14

200 8" 275 10.83 400 15.72 35.65 78.59

DW 184 150 6" n/a n/a n/a n/a 14.15 31.20

EEx d

32 Installation and operating instructions DW 181 - 184

Page 33

DW 181 EEx d* DW 182 EEx d*

DW 183 EEx d* DW 184 EEx d*

Dimensions in mm (inches)

* The MS 12 / BRX (EEx d) switch is supplied without cable fitting. Only EEx d-certified

components and fittings are to be used with the MS 12/BRX switch.

Installation and operating instructions DW 181 - 184 33

Page 34

Type Connection Dimension h Dimension L Weight

DIN ASME mm inches mm inches kg lb

DW 181 G3/4” 76 2.99 135 5.31 1.10 2.42

HT (H3) G1” 81 3.19 160 6.30 1.20 2.65

G11/2" 91 3.58 180 7.09 1.60 3.53

G2” 96 3.78 190 7.48 2.00 4.40

DW 182 15

1

/2” 76 2.99 300 11.81 2.40 5.29

HT (H3) 25 1" 81 3.19 300 11.81 3.40 7.50

40 11/2" 91 3.58 300 11.81 4.90 10.80

50 2" 96 3.78 300 11.81 6.60 14.55

65 21/2" 96 3.78 300 11.81 8.70 19.18

DW 183 65 21/2” 146 5.75 400 15.72 10.90 24.03

HT (H3) 80 3" 146 5.75 400 15.72 11.90 26.24

100 4" 156 6.14 400 15.72 13.40 29.54

125 5" 168 6.61 400 15.72 17.40 38.36

150 6" 181 7.13 400 15.72 22.40 49.38

200 8" 211 8.31 400 15.72 34.40 75.84

DW 184 150 6" n/a n/a n/a n/a 12.90 28.44

HT (H3)

DW 181 HT (H3) DW 182 HT (H3)

Dimensions in mm (inches)

34 Installation and operating instructions DW 181 - 184

Page 35

DW 183 HT (H3) DW 184 HT (H3)

Dimensions in mm (inches)

Installation and operating instructions DW 181 - 184 35

Page 36

8 Measuring Principle

8.1 Measuring systems

Measuring system C:

A hinged measuring disc moves freely in the axis of a tapered tube (DW 181, DW 182 only). At

flowing conditions, the system adjusts so that the force acting on the disc is in equilibrium with the

spring force. Each flow rate thus corresponds to a particular position of the indicator and

simultaneously actuates the limit switches.

Measuring system E:

Instead of being located in a tapered tube, this system incorporates a nozzle (DW 181, DW 182

only) to increase the flow velocity. This version is particularly suitable for liquids with solids

content.

Measuring system P

(DW 183 and 184 flow switches only)

This is used for large nominal pipe diameters (DW 183, DW 184). It is similar to system E but

does not require a nozzle.

Measuring system C Measuring system E (P)

8.2 DW 183

The model DW 183 is recommended for pipe diameters from DN65…200, which can be installed in

any position in the piping. The diameter of the measuring tube depends on the flow to be measured

and the connection is adapted to that of the piping.

The maximum flow rate is 4 m/sec. The DW 183 is available in the “N” (carbon steel) “R” (stainless

steel-coated carbon steel) or “RR” (stainless steel) versions. The indicator and the switches are the

same as those used in the standard model.

For instruments without flow indication, the scale ratio between min. and max. range values is

1:2.5. A scale ratio of 1:4 is possible if required by the two limit switches. For instruments with flow

indication, the scale ratio is 1:4.

For vertical installation, the position of the installation and the flow direction should have been

indicated in the order for calibration in order to take the weight of the disc into account.

36 Installation and operating instructions DW 181 - 184

Page 37

Appendix A: Declaration of conformity: CE

Installation and operating instructions DW 181 - 184 37

Page 38

Appendix B: If you need to return a device for testing or repair to KROHNE

If installed and operated in accordance with these operating instructions, your device will rarely

present any problems.

Should you nevertheless need to return a device for checkout or repair, please pay strict attention

to the following points:

Due to statutory regulations concerning protection of the environment and the health and safety of

our personnel, KROHNE may only handle, test and repair returned flow meters that have been in

contact with liquids if it is possible to do so without risk to personnel and environment. This means

that KROHNE can only service your unit if it is accompanied by a certificate in line with the

following model confirming that the flow meter is safe to handle.

If the unit has been operated with toxic, caustic, flammable or water-endangering liquids, you are

kindly requested

• to check and make sure, if necessary by rinsing or neutralizing, that all cavities are free from

such dangerous substances.

(Directions on how you can find out whether the unit has to be opened and then flushed out or

neutralized are obtainable from KROHNE on request.)

• to enclose a certificate with the level gauge confirming that it is safe to handle and stating the

liquid used.

KROHNE regrets that it cannot service your flow meter unless accompanied by such a certificate.

Specimen certificate

Company: Address:

Department: Name:

Tel. No.:

The enclosed flow meter,

Type:

KROHNE Order No. or Series

No.:

has been operated with the following liquid:

Because this liquid is

water-endangering

toxic

caustic

flammable

we have

checked that all cavities in the unit are free from such substances

flushed out and neutralized all cavities in the unit

We confirm that there is no risk to man or environment through any residual liquid contained in this

flow meter.

Date: Signature:

Company stamp:

38 Installation and operating instructions DW 181 - 184

Page 39

Note

Installation and operating instructions DW 181 - 184 39

Loading...

Loading...