Page 1

DK46I - DK47I

DK46I - DK47I

DK46I - DK47IDK46I - DK47I

Variable area flowmeter

Handbook

Handbook

HandbookHandbook

Page 2

CONTENTS

1 Safety instructions......................................................................... 4

1.1 Intended use......................................................................................................... 4

1.2 Certifications........................................................................................................ 4

1.3 Safety instructions from the manufacturer......................................................... 5

1.3.1 Copyright and data protection................................................................................... 5

1.3.2 Disclaimer.................................................................................................................. 5

1.3.3 Product liability and warranty ................................................................................... 6

1.3.4 Information concerning the documentation .............................................................6

1.3.5 Display conventions................................................................................................... 7

1.4 Safety instructions for the operator .................................................................... 7

2 Instrument description.................................................................. 8

2.1 Scope of supply .................................................................................................... 8

2.2 Device versions .................................................................................................... 9

2.2.1 Versions .....................................................................................................................9

2.2.2 Versions with regulator .............................................................................................9

2.3 Nameplate.......................................................................................................... 10

2.4 Description code ................................................................................................ 11

DK46I - DK47I

3 Installation................................................................................... 12

3.1 Notes on installation.......................................................................................... 12

3.2 Storage............................................................................................................... 12

3.3 Installation requirements .................................................................................. 13

3.3.1 Installing in the pipeline ......................................................................................... 13

3.4 Start-up .............................................................................................................. 13

4 Electrical connections ................................................................. 14

4.1 Safety instructions ............................................................................................. 14

4.2 Limit switches .................................................................................................... 14

4.3 Setting the limit switch ...................................................................................... 16

4.4 Minimum clearance between two limit switches.............................................. 17

4.5 Switching performance...................................................................................... 17

4.6 Conversion of the function................................................................................. 18

5 Service......................................................................................... 19

5.1 Maintenance....................................................................................................... 19

5.2 Spare parts availability ...................................................................................... 21

5.3 Availability of services........................................................................................ 21

5.4 Returning the device to the manufacturer ........................................................ 22

5.4.1 General information ................................................................................................ 22

5.4.2 Form (for copying) to accompany a returned instrument ......................................23

5.5 Disposal.............................................................................................................. 23

6 Technical data ............................................................................. 24

6.1 Functional principle ........................................................................................... 24

2

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 3

DK46I - DK47I

7 KROHNE measuring technology - Product overview................... 36

CONTENTS

6.2 Technical data.................................................................................................... 25

6.3 Dimensions and weights.................................................................................... 27

6.4 Measuring ranges .............................................................................................. 28

6.5 Differential pressure regulators ....................................................................... 30

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

3

Page 4

1 SAFETY INSTRUCTIONS

1.1 Intended use

The variable area flowmeters are suitable for measuring gases, vapors and liquids.

These flowmeters are particularly suitable for measuring:

• Liquids

• Hydrocarbons

• Water

• Chemicals with low corrosiveness

• Industrial gases

WARNING!

The operator shall bear sole responsibility for the use of the flowmeters with regard to

suitability, intended use and corrosion resistance of the materials used to the process product.

The manufacturer shall not be liable for any damage resulting from improper use or use for

other than the intended purpose.

Do not use any abrasive or highly viscous process products.

DK46I - DK47I

1.2 Certifications

The flowmeter meets the statutory requirements of the following EC directives:

• Pressure Equipment Directive 97/23/EC

• EMC Directive 89/336/EC for instruments with electrical options

KROHNE Messtechnik GmbH & Co. KG certifies successful testing of the product by providing

the CE Declaration of Conformity.

4

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 5

DK46I - DK47I

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to German copyright. Contributions from

third parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

SAFETY INSTRUCTIONS 1

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect, incidental, punitive and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

5

Page 6

1 SAFETY INSTRUCTIONS

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

DK46I - DK47I

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

6

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 7

DK46I - DK47I

1.3.5 Display conventions

The following symbols are used to help you navigate this documentation more easily:

WARNING!

These warning signs must be observed without fail. Even only partial disregarding such

warnings can result in serious health damage, damage to the device itself or to parts of the

operator

DANGER!

This symbol designates safety advice on handling electricity.

CAUTION!

These warnings must be observed without fail. Even only partial disregarding such warnings can

lead to improper functioning of the device.

’

s plant.

SAFETY INSTRUCTIONS 1

LEGAL NOTICE!

This symbol designates information on statutory directives and standards.

NOTE!

This symbol designates important information for the handling of the device.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i CONSEQUENCE

CONSEQUENCE

CONSEQUENCECONSEQUENCE

This symbol designates all important consequences of the previous actions.

1.4 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

7

Page 8

2 INSTRUMENT DESCRIPTION

2.1 Scope of supply

NOTE!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to your local office.

NOTE!

Check the packing list to make sure that you have received your complete order.

NOTE!

Please check on the device nameplates, that the device is supplied according to your order.

Check for the correct mains voltage printed on the nameplate. If not, contact your local

representative for advice.

DK46I - DK47I

Figure 2-1: Scope of supply

1 Flowmeter in the version ordered

2 Manual

3 Certificates, calibration certificate (supplied to order only)

8

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 9

DK46I - DK47I

2.2 Device versions

2.2.1 Versions

INSTRUMENT DESCRIPTION 2

Figure 2-2: Device versions

1 DK46I with valve and an overall length of 135 mm (5.32 inch)

2 DK47I with valve and an overall length of 245 mm (9.65 inch)

2.2.2 Versions with regulator

Figure 2-3: DK47I with differential pressure regulators

1 DK47I with inlet pressure regulator

2 DK47I with outlet pressure regulator

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

9

Page 10

2 INSTRUMENT DESCRIPTION

2.3 Nameplate

INFORMATION!

Before installing the flowmeter, make sure that the information given on the nameplate

corresponds to the ordering data.

DK46I - DK47I

Figure 2-4: Nameplates (Examples)

1 Type of meter

2 Manufacturer

3 KROHNE website

4 Design data: temperature & pressure rating

5 DGRL data

Additional markings on the flowmeter

• SN - serial number

• SO - sales order / item

• Tag-No - measuring point (customer spec.)

• MD - year of manufacture

• KO - KROHNE order

• Vx - product configurator code

• AC - article code

10

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 11

DK46I - DK47I

2.4 Description code

The description code consists of the following elements*:

1 R - With integral inlet pressure regulator (only DKR46)

2 Instrument type:

46I - Measuring cone overall length 65 mm

47I - Measuring cone overall length 150 mm

3 Material for top and bottom fittings:

R - Stainless steel

4 Differential pressure regulator:

RE - Inlet pressure regulator

RA - Outlet pressure regulator

INSTRUMENT DESCRIPTION 2

5 K1 - one limit switch

K2 - two limit switches

* positions which are not needed are omitted (no blank positions)

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

11

Page 12

3 INSTALLATION

3.1 Notes on installation

NOTE!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to your local office.

NOTE!

Check the packing list to make sure that you have received your complete order.

NOTE!

Please check on the device nameplates, that the device is supplied according to your order.

Check for the correct mains voltage printed on the nameplate. If not, contact your local

representative for advice.

DK46I - DK47I

3.2 Storage

• Store the flowmeter in a dry and dust-free location.

• Avoid lasting direct exposure to the sun.

• Store the flowmeter in its original packaging.

• The permissible storage temperature is from -40 to +80°C for standard meters.

12

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 13

DK46I - DK47I

3.3 Installation requirements

3.3.1 Installing in the pipeline

CAUTION!

When installing the flowmeter in the pipeline please observe the following points:

•

The variable area flowmeter has to be installed vertically (float measuring principle), flow

direction from bottom to top.

For installation recommendations please also refer to the Directive VDI/VDE 3513, Sheet 3.

•

Before installing the flowmeter, blow or flush out the pipeline leading to the flowmeter.

•

Pipelines for gas flow are to be dried before the flowmeter is installed.

•

Use connectors appropriate to the flowmeter version for the connection.

•

Align the pipes axially with the bolt holes on the flowmeter without incurring stresses.

•

If necessary, support the pipeline on both sides of the flowmeter in order to prevent vibration

from being transferred to the flowmeter.

•

Do not lay signal cables directly next to cables for the power supply.

INSTALLATION 3

3.4 Start-up

CAUTION!

When starting up the flowmeter, the following points must be observed:

•

•

•

•

•

•

•

•

•

Compare the actual operating pressure and the process temperature of the system with the

specifications on the nameplate (PS and TS); these limits must not be exceeded.

Make sure materials are compatible.

Close the needle valve at the flowmeters.

Slowly open the shut-off valve upstream and downstream of the flowmeter.

When measuring liquids, vent the pipes carefully.

When measuring gases, increase pressure slowly.

void float impact (e.g. caused by solenoid valves), as this is likely to damage the measuring

section or float.

Open needle valve at the flowmeters and set the required flow rate.

The top edge of the float marks the reading line for flow values:

Figure 3-1: Reading edge

1 Reading edge

2 Dk46I, DK47I - floatform ball

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

13

Page 14

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe national installation regulations!

WARNING!

Observe the regional occupational health and safety regulations without fail. Only work on the

device electrics if you are appropriately trained.

NOTE!

Please check on the device nameplates, that the device is supplied according to your order.

Check for the correct mains voltage printed on the nameplate. If not, contact your local

representative for advice.

DK46I - DK47I

4.2 Limit switches

The flowmeter can be equipped with a maximum of two limit switches

Type RC...-N3 and RB...-E2 with bistable function

Type RC...-N0 with monostable function

Function monostable: Switching pulse by transit of the float in the operating point, independently

of the moving direction.

Function bistable: Stable changeover by transit of the float through the operating point.

Example: Float above limit: output "High"

Float below limit: output "Low"

14

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 15

DK46I - DK47I

Electrical connection limit switches - 2-wire terminal box

1 lower limit switch - to terminal 1

2 upper limit switch - to terminal 2

The junction box includes an EMC filter unit.

ELECTRICAL CONNECTIONS 4

Electrical connection limit switches - 2-wire without terminal box

1 Limit switch (without terminal box)

2 Colour coding blue -

3 Colour coding brown +

4 external EMC filter

5 Receiver device

EMC filter unit and back rail of the flowmeter must be galvanically connected and grounded.

Electrical connection limit switch - 3-wire (RB...-E2)

• bn - brown: supply voltage +

• bk - black - switch

• bu - blue: supply voltage -

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

15

Page 16

4 ELECTRICAL CONNECTIONS

4.3 Setting the limit switch

Following procedure is to perform (DK../../K):

• Detach clamping screws 1

• Slide the limit switches over the measuring glass.

• Use the two clamping screws 1 to fasten the limit switch 3 to the back rail 1 of the

measuring device.

• Reinstall the protection cover after installation.

DK46I - DK47I

To install, first remove the measuring glass as described under chapter Maintenance.

CAUTION!

When setting the ring sensor, make sure the cable is laid such that it cannot be damaged!

Avoid CANT - glass breakage!

The connecting lead for the limit switch is routed the hole in the device bottom fitting and sealed.

For bistable limit switches with external EMC filter in separate DIN-rail housing, observe the

following:

EMC filter unit and back rail of the flowmeter must be galvanically connected and grounded.

An isolation switching amplifier with intrinsically safe control circuits NAMUR is necessary for

operation of the NAMUR limit switches.

16

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 17

DK46I - DK47I

ELECTRICAL CONNECTIONS 4

4.4 Minimum clearance between two limit switches

Where two sensors are in one device, and also where DK glass devices with limit switches are

arranged close together, minimum clearances must be maintained in order to avoid mutual

influence of the switches.

Min. clearance RC… 2-wire RB… 3-wire

1 16 mm (0.63") 45 mm (1.773")

2 6 mm (0.236") 30 mm (1.182")

4.5 Switching performance

Limit switch RC...-N0

Ball outside sensor: Signal ≥3 mA

Ball inside sensor: Signal ≤1 mA

Limit switch RC...-N3

Independent of ball position see image 1 : Signal ≥3 mA

Pre condition: The ball is located outside the sensor.

NOTE!

To get a correct mode of operation after power on the limit switches RC...-N3

through for one time 1 and 2.

Limit switch RB...-E2

Independent of ball position like transit 2: Signal ≤1 V

Pre condition: The ball is located outside the sensor.

RC...-N0

RC...-N0RC...-N0

RC...-N3

RC...-N3RC...-N3

RB...-E2

RB...-E2RB...-E2

RC...-N3 have to pass

RC...-N3RC...-N3

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

17

Page 18

4 ELECTRICAL CONNECTIONS

4.6 Conversion of the function

The bistable limit switch RC 10...N3 can be changed from NO to NC function.

The precut cable with connectors must be sufficiently long for this!

When setting the limit switch, make sure the cable is laid such that it cannot be damaged!

• Detach clamping screws 1

• Detach tensioning screw 2. Turn anti-clockwise.

• Carefully pull out the measuring glass together with the limit switch.

• Turn the limit switch 180°.

• Assemble in reverse order.

• Turn tensioning screw 2 hand-screwed

• Use a 3mm pin to tighten the lock nut with 4x ... max. 5x

DK46I - DK47I

4x ... max. 5x, 120° turns 3 clockwise.

4x ... max. 5x4x ... max. 5x

18

CAUTION!

To avoid glass breakage, the measuring glass must be

inserted concentrically between the gaskets.

Before restarting the flowmeter, check leak-tightness by suitable means.

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 19

DK46I - DK47I

5.1 Maintenance

Within the scope of routine maintenance of the system and pipelines, the flowmeter should also

be inspected for signs of fouling, corrosion, mechanical wear and leaks, as well as damage to

the measuring tube and indicator.

We advise that inspections be carried out at least once a year.

The device must be removed from the piping before cleaning.

CAUTION!

Pressurized pipes must be depressurized before removing the device.

In the case of flowmeters used for measuring aggressive or hazardous products, appropriate

safety precautions must be taken with regard to residual liquids in the measuring section.

Always use new gaskets when reinstalling the flowmeter in the pipeline.

SERVICE 5

CAUTION!

Under certain circumstances the valve packing gland may have to be adjusted during its service

life. This means that the union nut has to be retightened. If necessary, press the retaining pin

against its internal spring.

Apply a tightening torque of not more than 5 Nm.

CAUTION!

Valves that have not been actuated for a longer period of time may exhibit a higher initial

actuation torque.

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

19

Page 20

5 SERVICE

Changing the measuring cone

• Close valve upstream and downstream of the device.

• Close needle valve.

• Push protective cover upwards and remove to front.

• Turn the lock nut in the device base 1 anti-clockwise.

Devices with a top and bottom fitting made of PVDF (DK.../PV) have a tensioning screw in the

device head(Allen key 6mm).

This can be unlocked with approx. 1 full turn.

The measuring glass can be removed to the front.

DK46I - DK47I

Figure 5-1: Mainenance

CAUTION!

Residual liquid or gas may leak out!

• Install in the reverse order:

• Fix the measuring glass in position by tightening the lock

nut finger-tight in the device base 1 first of all.

• Use a 3mm pin to tighten the lock nut with 4x ... max. 5x

4x ... max. 5x 120° turns clockwise. 2

4x ... max. 5x4x ... max. 5x

CAUTION!

To avoid glass breakage, the measuring glass must be

inserted concentrically between the gaskets.

Before restarting the flowmeter, check leak-tightness by

suitable means.

20

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 21

DK46I - DK47I

5.2 Spare parts availability

The manufacturer adheres to the basic principle that operational spare parts for each device or

each important accessory part will be kept available for a period of 10 (ten) years after delivery of

the last production run for that device.

Operational spare parts are defined as parts that are subject to faults in normal operation.

5.3 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, technical support and training.

NOTE!

For more precise information, please contact your local representative.

SERVICE 5

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

21

Page 22

5 SERVICE

5.4 Returning the device to the manufacturer

5.4.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

DK46I - DK47I

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralizing, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

22

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 23

DK46I - DK47I

5.4.2 Form (for copying) to accompany a returned instrument

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 5

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

5.5 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

23

Page 24

6 TECHNICAL DATA

6.1 Functional principle

The flowmeter operates on the float measuring principle.

The measuring section consists of a glass cone in which a float can move freely up and down.

The medium flows through the flowmeter from bottom to top.

The float adjusts itself so that the buoyancy force A acting on it, the form drag W and its weight G

are in equilibrium.

DK46I - DK47I

G = A + W

Figure 6-1: Operating principle

The flow-dependent height of the float can take reading on a scale of the measuring glass.

The top edge of the float marks the reading line for flow values.

24

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 25

DK46I - DK47I

6.2 Technical data

Application range Flow measurement of liquids and gases

Measuring accuracy Directive VDI / VDE 3513, sheet 2

DK46 I Class 4

DK47 I Class 2.5

Operating pressure PS Pressure equipment directive 97/23/EC

Test pressure PT Pressure equipment directive 97/23/EC

Max. perm. operating gauge press. PS at TS =

212°F (100°C)

DK…/R (head piece and foot piece made from

stainless steel)

DK…/N (head piece and foot piece made from

brass)

1 higher pressures upon request

TECHNICAL DATA 6

145 psig (10 bar) 1

145 psig (10 bar) 1

Materials

Head piece, foot piece CrNi steel 1.4404 / 316 L, nickle-plated brass

Head piece, foot piece optional Hastelloy

Measuring tube Borosilicate glass

Float (sphere) CrNi steel 1.4401 / 316

Float options Glass, POM, titanium, Hastelloy C4

DK48 float (All) CrNi steel 1.4571 / 316 titanium, aluminum, PEEK, glass

Metering unit CrNi steel 1.4571 / 316 Ti

Valve spindle CrNi steel 1.4404 / 316 L

Standard seals PTFE / FPM

Seals options PTFE / FFKM, PTFE / EPDM

Seals options EPDM, FFKM

Protective cover Polycarbonate

Temperatures

Temperatures

TemperaturesTemperatures

Max. temperature of medium Tm +212°F (+100°C)

Max. Tm with limit switches +149°F (+65°C)

Min. temperature of medium Tm +23°F (-5°C) 1

Max. ambient temperature Tamb. +212°F (+100°C)

Max. Tamb. with limit switches +149°F (+65°C)

Min. ambient temperature Tamb. -4°F (-20°C) 1

1 other temperatures upon request

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

25

Page 26

6 TECHNICAL DATA

Technical data limit switches

Technical data limit switches

Technical data limit switchesTechnical data limit switches

Clamp-type terminal Connection box M16 x 1.5 - Cable diameter 5...10 mm

Limit switches RC10-14-N3 RC15-14-N3 RC10-14-N0 RC15-14-N0 RB15-14-E2

Switching function Bistable Bistable Monostable Monostable Bistable, 3-

Connection technology NAMUR, two-

Rated voltage U0 8 VDC 8 VDC 8 VDC 8 VDC

Current consumption 1 mA passage ↓ 3 mA - sphere beyond

Current consumption 3 mA passage ↓ 1 mA - sphere is in limit

Operating voltage Ub 10…30 VDC

Operating current Ib 0…100mA

No-load current 20mA

Output Ua - passage ↓ ≤ 1 VDC

Output Ua - passage ↑ ≥ Ub – 3 VDC

wire

NAMUR, twowire

NAMUR, twowire

monitor

NAMUR, twowire

DK46I - DK47I

wire

Three-wire

Application range of limit switches

Application range of limit switches

Application range of limit switchesApplication range of limit switches

DK46 I, DK47 I

Sphere Limit switches

Ø 4mm RC10

Ø 6 mm RC15 / RB15

Ø 8 mm -

The limit switches RC15 and RB15 (as max. contact) can only be used for up to 60 l/h (16 gal/h)

water (external diameter of the measuring glass).

26

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 27

DK46I - DK47I

6.3 Dimensions and weights

Dimensions

Dimensions

DimensionsDimensions

TECHNICAL DATA 6

[inch]

[mm]

DK46 I 5.32

DK47 I 9.65

Weights

Weights

WeightsWeights

Device DK46 I DK47 I

Weight [kg] 0.5 0.7

Weight with regulator 2.1 2.3

Process connection

Process connection

Process connectionProcess connection

a

135

245

b

± 0.01

± 0.25

4.49

8.82

114

224

c d e f

0.17

4.3

0.17

4.3

1.77

45

5.12

130

1.30

33

1.30

33

approx.

3.23

3.23

82

82

g

1.1

28

1.1

28

Standard 1/4" NPT internal thread

Options G 1/4, Ermeto 6 or 8, tube connection 6 mm or 8

mm, Dilo, Gyrolok, Swagelok

1 other connections upon request

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

1

27

Page 28

6 TECHNICAL DATA

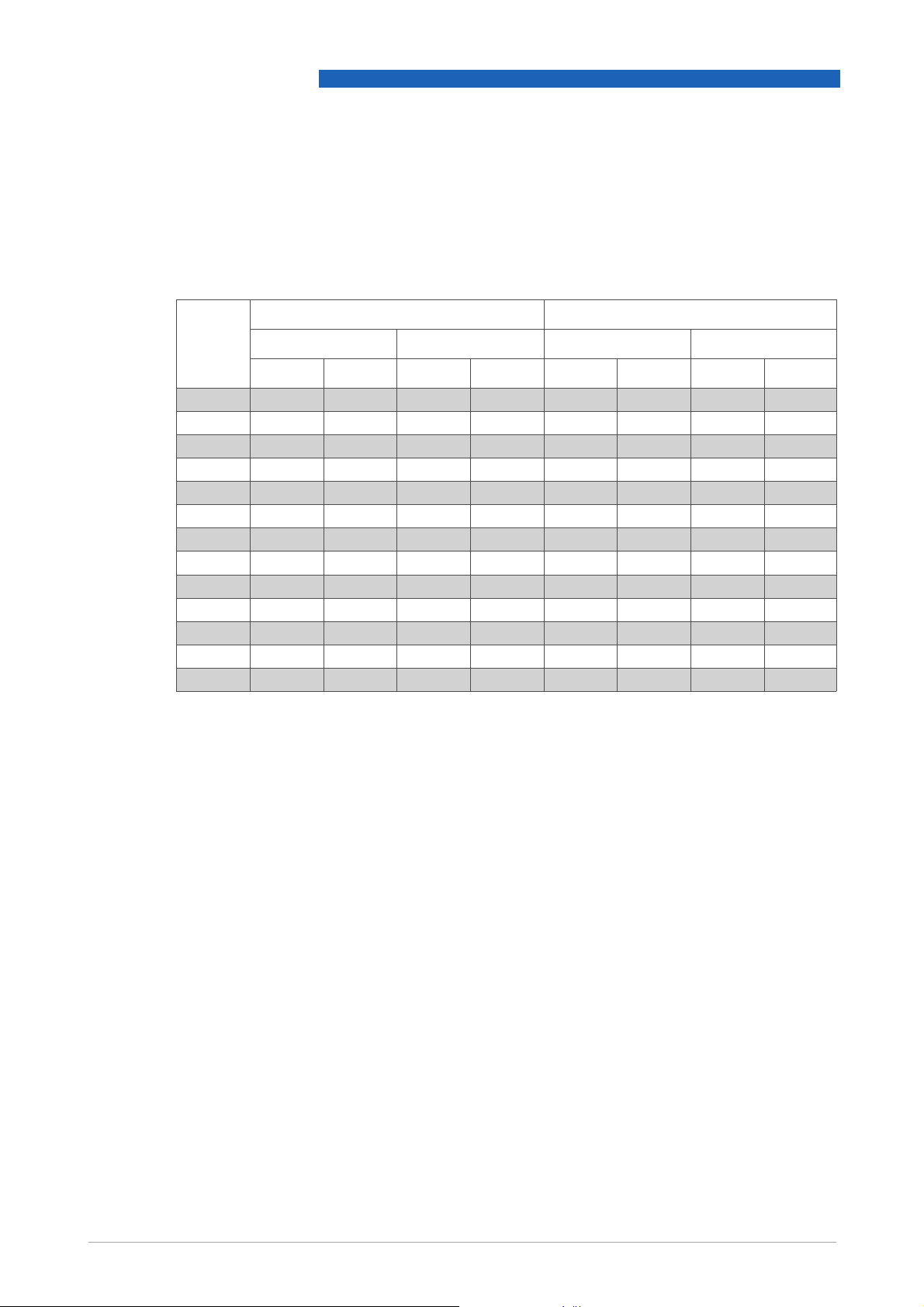

6.4 Measuring ranges

Measuring span 10 : 1

Flow values 100%

DK46I - DK47I

Water Air

Sphere Ø

mm

4 0.65 2.5 - - 0.22 5 - 4 - - - - 0.3 8 - 4 - - - - 0.6 16 0.6 16

4 - - - - 1.5 40 1.5 40

4 - - - - 2.5 60 3.8 100

6 1.3 5 1.3 5 3.8 100 - 6 3 12 3 12 9 250 9 250

6 6.5 25 6.5 25 18 500 18 500

6 11 40 11 40 30 800 30 800

6 16 60 16 60 45 1200 - 6 25 100 25 100 - - - 8 30 120 - - - - - 8 42 160 - - - - - -

DK46 I DK47 I DK46 I DK47 I

[GPH] [l/h] [GPH] [l/h] [SCFH] [l/h] [SCFH] [l/h]

Reference condition:

water 68°F (20°C)

air 68°F (20°C), 17.4 psi (1.2 bar abs.) in a standard state

28

Other flow rate measuring ranges can be provided upon request.

The conversion of other materials or operating data (pressure, temperature, density, viscosity) is

done with the help of the calculation procedure as detailed in Directive VDI /VDE 3513

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 29

DK46I - DK47I

Valves

Valve characteristics

TECHNICAL DATA 6

Max flowrate

Water [l/h] Air [l/h]

Spindle Ø

[mm]

1 1.32 5 3.5 100 0.021 0.018

2.5 13.2 50 35 1000 0.17 0.15

4.5 42.3 160 177 5000 0.56 0.48

[GPH] [l/h] [SCFH] [l/h] [gal/min] [m3/h]

spindle Ø 1.0mm spindle Ø 2.5mm

CV/Kv valve characteristic

value

spindle Ø 4.5mm

1 Flow, air

2 Flow, water

3 Spindle rotation n

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

29

Page 30

6 TECHNICAL DATA

6.5 Differential pressure regulators

Differential pressure regulators are used to provide constant flow rates in the case of variable

inlet or outlet pressures. Minimum pressure levels are necessary to operate the regulators (see

regulator characteristics).

Differential pressure regulators are not pressure reducing valves.

Differential pressure regulators are not pressure reducing valves.

Differential pressure regulators are not pressure reducing valves.Differential pressure regulators are not pressure reducing valves.

1 Inlet pressure regulators, type RE, NRE

Inlet pressure regulators, type RE, NRE

Inlet pressure regulators, type RE, NRE Inlet pressure regulators, type RE, NRE

The regulators keep the flow rate constant in the case of a variable inlet pressure and a constant

outlet pressure.

DK46I - DK47I

Example - inlet pressure

regulator RE1000:

Current flow rate:

Outlet pressure p2 constant: 14.7 psi (1.013 bar abs.)

3

/h (1000 l/h) air

35 ft

The flow rate is constant in the device in the case of a fluctuating inlet pressure greater than 7.3

psig (0.5 bar).

2 Outlet pressure regulator, type RA, NRA

Outlet pressure regulator, type RA, NRA

Outlet pressure regulator, type RA, NRA Outlet pressure regulator, type RA, NRA

The regulators keep the flow rate constant in the case of a constant inlet pressure and a variable

outlet pressure. There must be a pressure differential between the inlet and the outlet pressure

for the outlet pressure regulator to function. The inlet pressure p1 must always be greater than

the outlet pressure p2.

Example - outlet pressure

regulator NRA 800

Current flow rate:

Inlet pressure constant: 87 psig (6 bar)

28.3 ft

3

/h (800 l/h) air

The flow rate is constant in the device in the case of a fluctuating outlet pressure of 0 ... 80 psig

(5.5 bar).

Regulator characteristics

Regulator characteristics

Regulator characteristicsRegulator characteristics

30

1 Inlet pressure regulators, type RE and

NRE

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

2 Outlet pressure regulators, type RA and

NRA

Page 31

DK46I - DK47I

Control ranges

Control ranges

Control rangesControl ranges

TECHNICAL DATA 6

Inlet pressure regulator

Max flow rate

Water Air Min. inlet pressure Up1

[gal/h] [l/h] [ft3/h] [l/h] [psig] [bar]

RE-1000 ...10 ...40 ...35 ...1000 7.3 0.5

RE-4000 ...21 ...80 ...70 ...2000 14.5 1

...26 ...100 ...106 …3000 21.8 1.5

...42 ...160 ...141 ...4000 29 2

NRE-100 ...0.66 ...2.5 ...3.5 ...100 1.5 0.1

NRE-800 ...8.8 ...250 1.5 0.1

...28 ...800 2.9 0.2

...6.6 ...25 5.8 0.4

Outlet pressure regulator

Max flow rate

Water Air Min. pressure diff.

[gal/h] [l/h] [ft3/h] [l/h] [psig] [bar]

RA-1000 ...10 ...40 ...35 ...1000 7.3 0.5

RA-4000 ...26 ...100 ...70 …2000 14.5 1

...106 ...3000 21.8 1.5

...42 ...160 ...141 ...4000 29 2

NRA-800 ...0.26 ...1 ...8.8 ...250 1.5 0.1

...18 ...500 2.9 0.2

...6.6 ...25 ...28 ...800 5.8 0.4

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

31

Page 32

6 TECHNICAL DATA

Technical data, differential pressure regulator

Technical data, differential pressure regulator

Technical data, differential pressure regulatorTechnical data, differential pressure regulator

Standard connection 1/4" NPT

Option Serto, Ermeto 6 or 8, tube nozzle 6 mm or 8 mm,

Max. operating gauge pressure PS 145 psig (10 bar) 2

Material CrNi-Steel 1.4404

Temperature TS = 212°F (100 °C)

1 other connections upon request

2 higher pressures upon request

3 higher temperatures upon request

Dimensions with the differential pressure regulator

Dimensions with the differential pressure regulator

Dimensions with the differential pressure regulatorDimensions with the differential pressure regulator

DK46I - DK47I

Dilo, Gyrolok, Swagelok, G 1/4 1

3

Dimensions

[inch]

[mm]

DK46 I 8.27

DK47 I 8.27

a

approx.

210

210

b c

approx.

7.37

187

11.11

282

0.51

13

0.51

13

d e f

approx.

2.76

70

2.76

70

0.75

19

0.75

19

1.54

39

1.54

39

DK with inlet pressure regulator DK with outlet pressure regulator

g

3.55

90

3.55

90

32

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 33

DK46I - DK47I

.

TECHNICAL DATA 6

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

33

Page 34

6 TECHNICAL DATA

.

DK46I - DK47I

34

www.krohne.com 08/2008 • 4000360001 MA DK46I-47I-R01-en

Page 35

DK46I - DK47I

.

TECHNICAL DATA 6

www.krohne.com08/2008 • 4000360001 MA DK46I-47I-R01-en

35

Page 36

DK46I - DK47I nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

nn

KROHNE measuring technology - Product overview

• Electromagnetic flowmeters • Level measuring instruments

• Variable area flowmeters • Temperature measuring instruments

• Mass flowmeters • Pressure measuring instruments

• Ultrasonic flowmeters • Analysis

• Vortex flowmeters • Oil and gas industry

• Flow controllers

Addresses:

Great Britain

Germany

Northern sales office

KROHNE Messtechnik GmbH & Co. KG

Bremer Str. 133

D-21073 Hamburg

Phone:+49 (0)40 767 3340

Fax:+49 (0)40 767 33412

nord@krohne.com

ZIP code: 10000 - 29999, 49000 - 49999

Western and middle sales office

KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Straße

D-47058 Duisburg

Phone:+49 (0)203 301 4416

Fax:+49 (0)203 301 10416

west@krohne.com

ZIP code: 30000 - 34999, 37000 48000, 50000 - 53999, 57000 - 59999,

98000 - 99999

Southern sales office

KROHNE Messtechnik GmbH & Co. KG

Landsberger Str. 392

D-81241 Munich

Phone:+49 (0)89 121 5620

Fax:+49 (0)89 129 6190

sued@krohne.com

ZIP code: 0 - 9999, 80000 - 89999,

90000 - 97999

Southwestern sales office

KROHNE Messtechnik GmbH & Co. KG

Rüdesheimer Str. 40

D-65239 Hochheim/Main

Phone: +49(0)6146) 827 30

Fax:+49 (0)6146 827 312

rhein-main@krohne.com

ZIP code: 35000 - 36999, 54000 56999, 60000 - 79999

Instrumentation and control

equipment catalog

TABLAR Messtechnik GmbH

Ludwig-Krohne-Str. 5

D-47058 Duisburg

Phone:+49 (0)2 03 305 88 0

Fax:+49 (0)2 03 305 8888

kontakt@tablar.de; www.tab lar.de

KROHNE sales

companies

International

Australia

Australia

AustraliaAustralia

KROHNE Australia Pty Ltd

Quantum Business Park 10/287

Victoria Rd Rydalmere NSW 2116

Phone: +61 2 8846 1700

Fax: +61 2 8846 1755

krohne@krohne.com.au

Austria

Austria

AustriaAustria

KROHNE Gesellschaft m.b.H.

Modecenterstraße 14

A-1030 Vienna

Phone:+43 (0)1/203 45 32

Fax:+43 (0)1/203 45 32 99

info@krohne.at

Belgium

Belgium

Belgium Belgium

KROHNE Belgium N.V.

Brusselstraat 320

B-1702 Groot Bijgaarden

Phone:+32 (0)2 4 66 00 10

Fax:+32 (0)2 4 66 08 00

krohne@krohne.be

Brazil

Brazil

Brazil Brazil

KROHNE Conaut Controles

Automaticos Ltda.

Estrada Das Águas Espraiadas, 230

C.P. 56 06835 - 080 EMBU - SP

Phone:+55 (0)11-4785-2700

Fax:+55 (0)11 4785-2768

conaut@conaut.com.br

China

China

ChinaChina

KROHNE Measurement Instruments

(Shanghai) Co. Ltd., (KMIC)

9th Floor, Puyuan Science Park,

Building A

396 Guilin Road

Shanghai 200233

Tel.: +86 (021) 6470 5656

Fax: +86 (021) 6451 6408

info@krohne-asia.com

Czech Republic

Czech Republic

Czech RepublicCzech Republic

Krohne CZ, spol. s r.o.

Sobìsická 156

63800 Brno

Phone: +420 (0)545.242 627

Fax: +420 (0)545 220 093

brno@krohne.cz

France

France

FranceFrance

KROHNE S.A.S.

Les Ors BP 98

F-26103 ROMANS Cedex

Phone:+33 (0)4 75 05 44 00

Fax:+33 (0)4 75 05 00 48

info@krohne.fr

Great Britain

Great BritainGreat Britain

KROHNE Ltd.

Rutherford Drive

Park Farm Industrial Estate

Wellingborough

Northants NN8 6AE

Phone:+44 (0)19 33 408 500

Fax:+44 (0)19 33 408 501

info@krohne.co.uk

CIS

CIS

CISCIS

Kanex KROHNE Engineering AG

Business Centre "POLLARS", office

164

Derbenevskaya nab., 11-B

113114 Moscow/Russia

Tel. / Fax: +7 (0)495 913-68-41

Tel. / Fax: +7 (0)495 913-68-42

Tel. / Fax: +7 (0)495 913-68-43

Tel. / Fax: +7 (0)495 913-68-44

krohne@krohne.ru

India

India

IndiaIndia

Krohne Marshall Ltd.

A-34/35, M.I.D.C. Industrial Area,

H-Block

Pimpri Poona 411018

Phone:+91 (0)202 744 2020

Fax:+91 (0)202 744 2020

pcu@vsnl.net

Iran

Iran

IranIran

KROHNE Liaison Office

North Sohrevardi Ave. 26,

Sarmad St., Apt. #9

Tehran 15539

Phone: +9821 8874 5973

Fax: +9821 8850 1268

krohne@krohneiran.com

Italy

Italy

ItalyItaly

KROHNE Italia Srl.

Via V. Monti 75

I-20145 Milan

Phone:+39 02 4300 661

Fax:+39 02 4300 6666

info@krohne.it

Korea

Korea

KoreaKorea

KROHNE Korea

Room 508 Miwon Bldg 43

Yoido-Dong Youngd eungpo-Ku

Seoul, Korea

Phone: 00-82-2-782-1900

Fax: 00-82-2-780-1749

mail@krohne.co.kr

Netherlands

Netherlands

NetherlandsNetherlands

KROHNE Nederland B.V.

Kerkeplaat 14

NL-3313 LC Dordrecht

Phone:+31 (0)78 630 6200

Fax:+31 (0)78 630 6405

Service Direct: +31 (0)78 630 6222

info@krohne.nl

Norway

Norway

NorwayNorway

KROHNE Norway A.S.

Ekholtveien 114

NO-1521 Moss

Phone:+47 (0)69 264 860

Fax:+47 (0)69 267 333

postmaster@krohne.no

Poland

Poland

PolandPoland

KROHNE Polska Sp.z.o.o.

ul. Stary Rynek Oliwski 8a

80-324 Gdansk

Phone: +48 (0)58 520 9211

Fax.:+48 (0)58 520 9212

info@krohne.pl

Switzerland

Switzerland

SwitzerlandSwitzerland

KROHNE AG

Uferstr. 90

CH-4019 Basel

Phone:+41 (0)61 638 30 30

Fax:+41 (0)61 638 30 40

info@krohne.ch

Singapore

Singapore

SingaporeSingapore

Tokyo Keiso - KROHNE (Singapore)

Pte. Ltd.

14, International Bus iness Park,

Jurong East

Chiyoda Building, #01-01/02

Singapore 609922

Phone: (65) 6567 4548

Fax : (65) 6567 9874

tks@tokyokeiso-krohne.com.sg

Republic of South Africa

Republic of South Africa

Republic of South AfricaRepublic of South Africa

KROHNE Pty. Ltd.

Bushbock Close

Corporate Park South

Midrand, Gauteng

P.O. Box 2069

Midrand, 1685

Tel.: +27 (0)11 314 1391

Fax: +27 (0)11 314 1681

midrand@krohne.co.za

Spain

Spain

SpainSpain

I.I. KROHNE IBERIA, S.r.l.

Poligono Indust rial Nilo

Calle Brasil, nº. 5

28806 Alcalá de Henares Madrid

Phone: +34 (0)91 883 2152

Fax: +34 (0)91 883 4854

krohne@krohne.es

USA

USA

USAUSA

KROHNE, Inc.

7 Dearborn Road

Peabody, MA 01960

Phone: +1 (800) FLOWING

Phone: +1 (978) 535 6060 (in MA)

info@krohne.com

Representatives

Algeria

Argentina

Cameroon

Canada

Chile

Columbia

Croatia

Denmark

Ecuador

Egypt

Finland

Gabon

Ghana

Greece

Hong Kong

Hungary

Indonesia

Iran

Ireland

Israel

Ivory Coast

Japan

Jordan

Kuwait

Libya

Lithuania

Malaysia

Mauritius

Mexico

Morocco

New Zealand

Peru

Portugal

Romania

Saudi Arabia

Senegal

Slovakia

Slovenia

Sweden

Taiwan

Thailand

Tunisia

Turkey

Venezuela

Yugoslavia

Other countries

KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Str. 5

D-47058 Duisburg

Phone:+49 (0)203 301 0

Fax:+49 (0)203 301 389

export@krohne.com

© KROHNE 08/2008 4000360001 MA DK46I-47I-R01-en Subject to change without notice

www.krohne.com

Loading...

Loading...