Page 1

DK46 - DK800

DK46 - DK800

DK46 - DK800DK46 - DK800

Variable area flowmeter

Handbook

Handbook

HandbookHandbook

© KROHNE 05/2011 - 4000302403 MA DK46-800-R03-en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2011 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 3

DK46 - DK800

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Certifications .................................................................................................................... 5

1.3 Safety instructions from the manufacturer ..................................................................... 6

1.3.1 Copyright and data protection ................................................................................................ 6

1.3.2 Disclaimer ............................................................................................................................... 6

1.3.3 Product liability and warranty ................................................................................................ 7

1.3.4 Information concerning the documentation........................................................................... 7

1.3.5 Warnings and symbols used................................................................................................... 8

1.4 Safety instructions for the operator................................................................................. 8

2 Device description 9

2.1 Scope of supply................................................................................................................. 9

2.2 Device versions............................................................................................................... 10

2.3 Nameplate ...................................................................................................................... 11

2.4 Description code............................................................................................................. 12

3 Installation 13

3.1 Notes on installation ......................................................................................................13

3.2 Storage ........................................................................................................................... 13

3.3 Installation conditions ....................................................................................................14

3.3.1 Installation in the piping ....................................................................................................... 14

3.3.2 Panel mounting..................................................................................................................... 14

4 Electrical connections 15

4.1 Safety instructions.......................................................................................................... 15

4.2 Limit switch .................................................................................................................... 16

4.3 Limit switch settings ......................................................................................................17

4.4 Minimum clearance between two limit switches .......................................................... 18

4.5 Switching performance .................................................................................................. 18

4.6 Limit switch function reversal........................................................................................ 19

4.7 Grounding connection .................................................................................................... 20

4.8 Protection category ........................................................................................................20

5 Start-up 21

5.1 Start-up........................................................................................................................... 21

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

3

Page 4

CONTENTS

DK46 - DK800

6 Service 22

6.1 Maintenance ................................................................................................................... 22

6.2 Changing the measuring cone ....................................................................................... 23

6.3 Spare parts availability...................................................................................................24

6.4 Availability of services .................................................................................................... 24

6.5 Returning the device to the manufacturer..................................................................... 24

6.5.1 General information.............................................................................................................. 24

6.5.2 Form (for copying) to accompany a returned device............................................................ 25

6.6 Disposal .......................................................................................................................... 25

7 Technical data 26

7.1 Operating principle......................................................................................................... 26

7.2 Technical data................................................................................................................. 27

7.3 Dimensions and weights ................................................................................................ 30

7.4 Measuring ranges...........................................................................................................32

7.5 Differential pressure regulators .................................................................................... 35

8 Notes 39

4

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 5

DK46 - DK800

1.1 Intended use

The variable area flowmeters are suitable for measuring gases, vapors and liquids.

These flowmeters are particularly suitable for measuring:

• Liquids

• Hydrocarbons

• Water

• Chemicals with low corrosiveness

• Industrial gases

DANGER!

In case of instruments which are used in explosive endangered areas please consider the

supplementary installation and operating instructions mentioned in the Ex-manual.

WARNING!

The operator shall bear sole responsibility for the use of the flowmeters with regard to

suitability, intended use and corrosion resistance of the materials used to the process product.

The manufacturer shall not be liable for any damage resulting from improper use or use for

other than the intended purpose.

Do not use any abrasive or highly viscous process products.

SAFETY INSTRUCTIONS 1

1.2 Certifications

CE marking

The flowmeter meets the statutory requirements of the following EC directives:

• Pressure Equipment Directive 97/23/EC - article 3.3

• EMC Directive 2004/108/EC for instruments with electrical options

• ATEX Directive 94/9/EC for instruments in Ex-areas

The manufacturer certifies successful testing of the product by providing the CE Declaration of

Conformity.

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

5

Page 6

1 SAFETY INSTRUCTIONS

1.3 Safety instructions from the manufacturer

1.3.1 Copyright and data protection

The contents of this document have been created with great care. Nevertheless, we provide no

guarantee that the contents are correct, complete or up-to-date.

The contents and works in this document are subject to copyright. Contributions from third

parties are identified as such. Reproduction, processing, dissemination and any type of use

beyond what is permitted under copyright requires written authorisation from the respective

author and/or the manufacturer.

The manufacturer tries always to observe the copyrights of others, and to draw on works created

in-house or works in the public domain.

The collection of personal data (such as names, street addresses or e-mail addresses) in the

manufacturer's documents is always on a voluntary basis whenever possible. Whenever

feasible, it is always possible to make use of the offerings and services without providing any

personal data.

DK46 - DK800

We draw your attention to the fact that data transmission over the Internet (e.g. when

communicating by e-mail) may involve gaps in security. It is not possible to protect such data

completely against access by third parties.

We hereby expressly prohibit the use of the contact data published as part of our duty to publish

an imprint for the purpose of sending us any advertising or informational materials that we have

not expressly requested.

1.3.2 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

6

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 7

DK46 - DK800

1.3.3 Product liability and warranty

The operator shall bear responsibility for the suitability of the device for the specific purpose.

The manufacturer accepts no liability for the consequences of misuse by the operator. Improper

installation and operation of the devices (systems) will cause the warranty to be void. The

respective "Standard Terms and Conditions" which form the basis for the sales contract shall

also apply.

1.3.4 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

SAFETY INSTRUCTIONS 1

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

7

Page 8

1 SAFETY INSTRUCTIONS

1.3.5 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This information refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

DK46 - DK800

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.4 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

8

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 9

DK46 - DK800

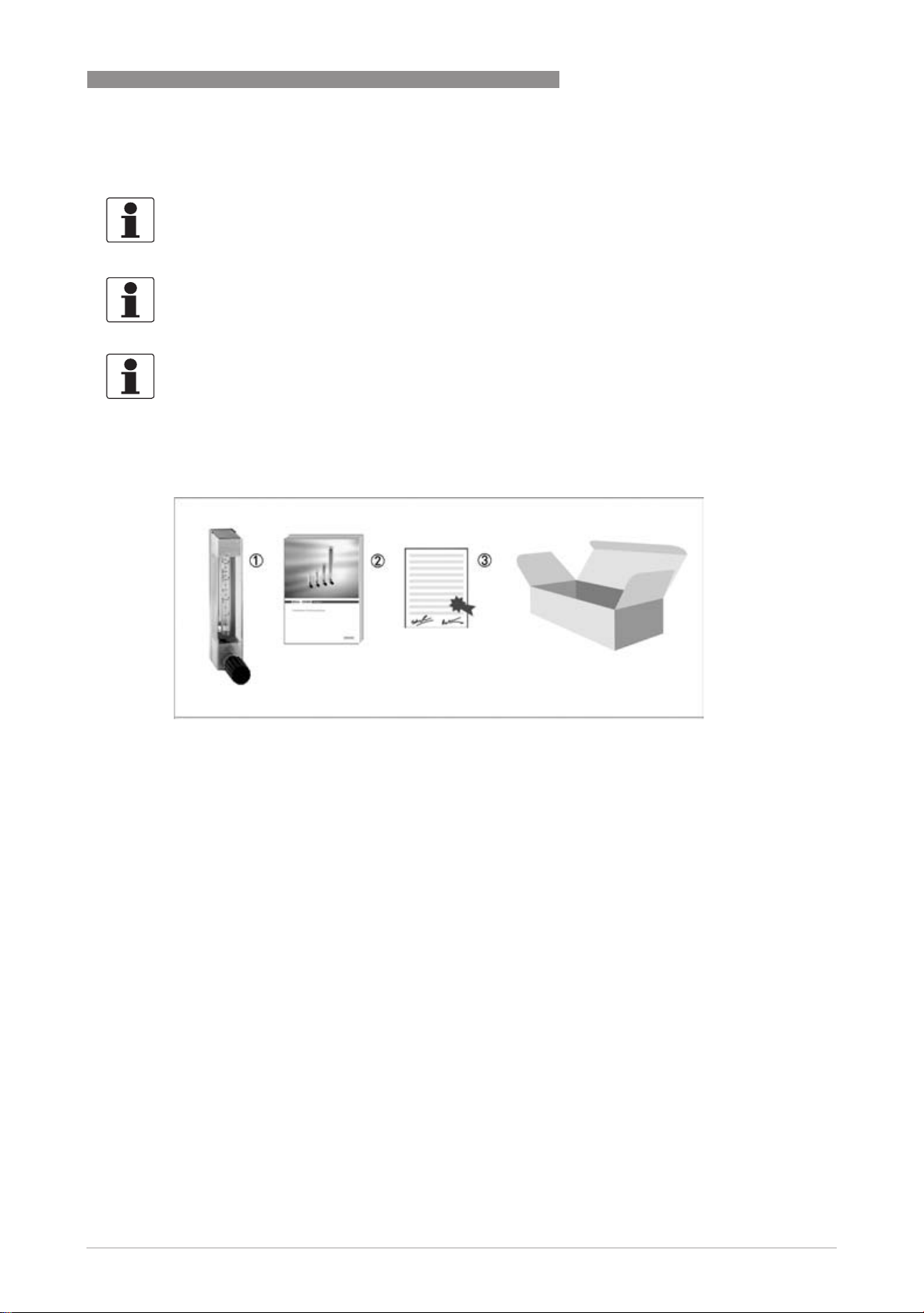

2.1 Scope of supply

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-1: Scope of delivery

1 Flowmeter in the ordered version

2 Manual

3 Certificates, calibration certificate (supplied to order only)

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

9

Page 10

2 DEVICE DESCRIPTION

2.2 Device versions

DK46 - DK800

Figure 2-2: Device versions

1 DK46 with valve and an overall length of 111 mm

2 DK47 with valve and an overall length of 196 mm

3 DK48 with valve and an overall length of 346 mm

4 DK800 with valve and an overall length of 146 mm

Figure 2-3: DK47 with differential pressure regulators

1 DK47 with inlet pressure regulator

2 DK47 with outlet pressure regulator

10

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 11

DK46 - DK800

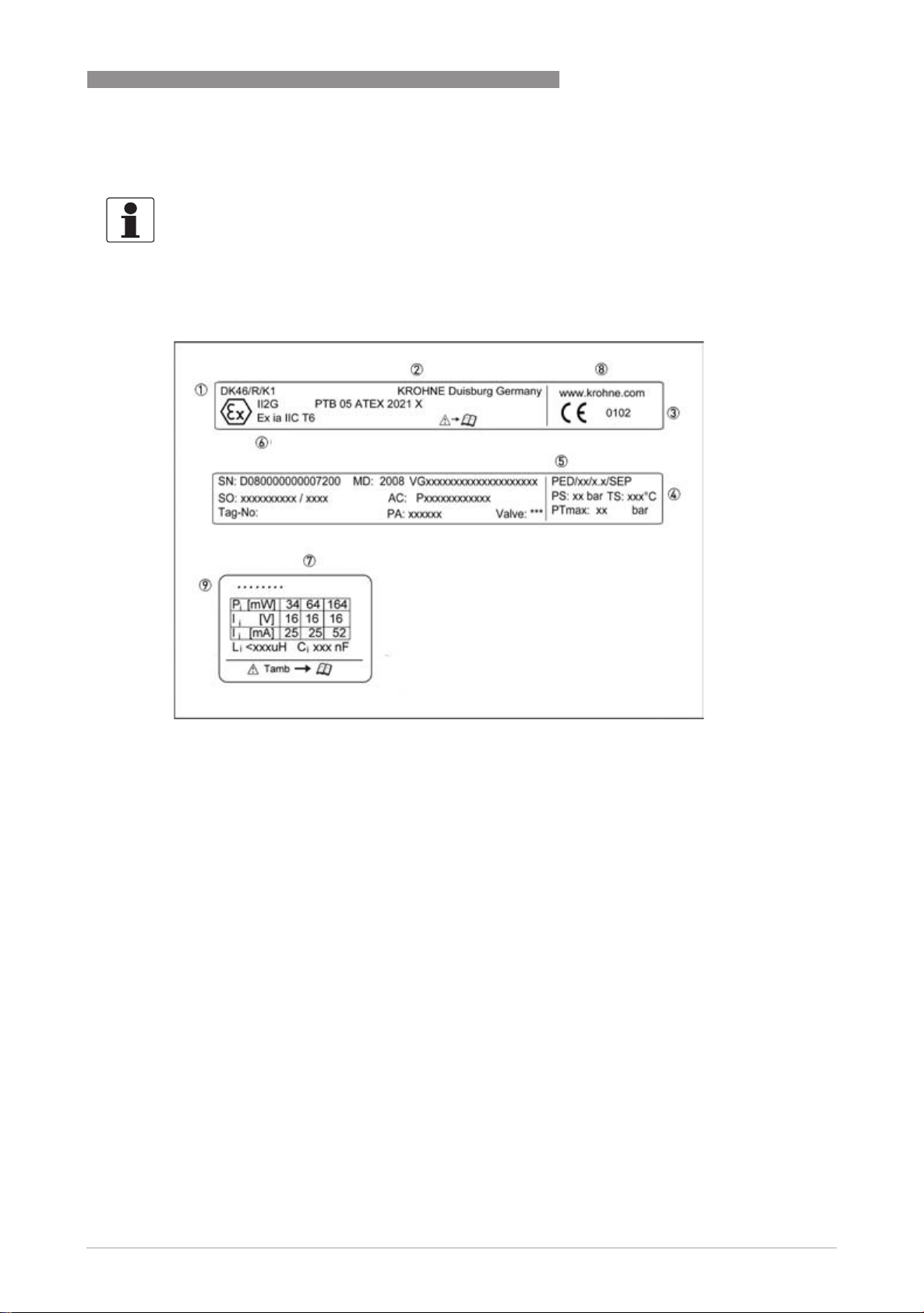

2.3 Nameplate

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-4: Nameplates (Examples)

1 Type of meter

2 Manufacturer

3 Appointed ATEX body

4 Design data: temperature & pressure rating

5 DGRL data

6 Ex data

7 Electrical connection data

8 KROHNE website

Additional markings on the measuring device

• SN - serial number

• SO - sales order / item

• Tag-No - Measuring point identifier

• MD - manufacturing date

• PA - KROHNE order

• Vx - product configurator code

• AC - article code

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

11

Page 12

2 DEVICE DESCRIPTION

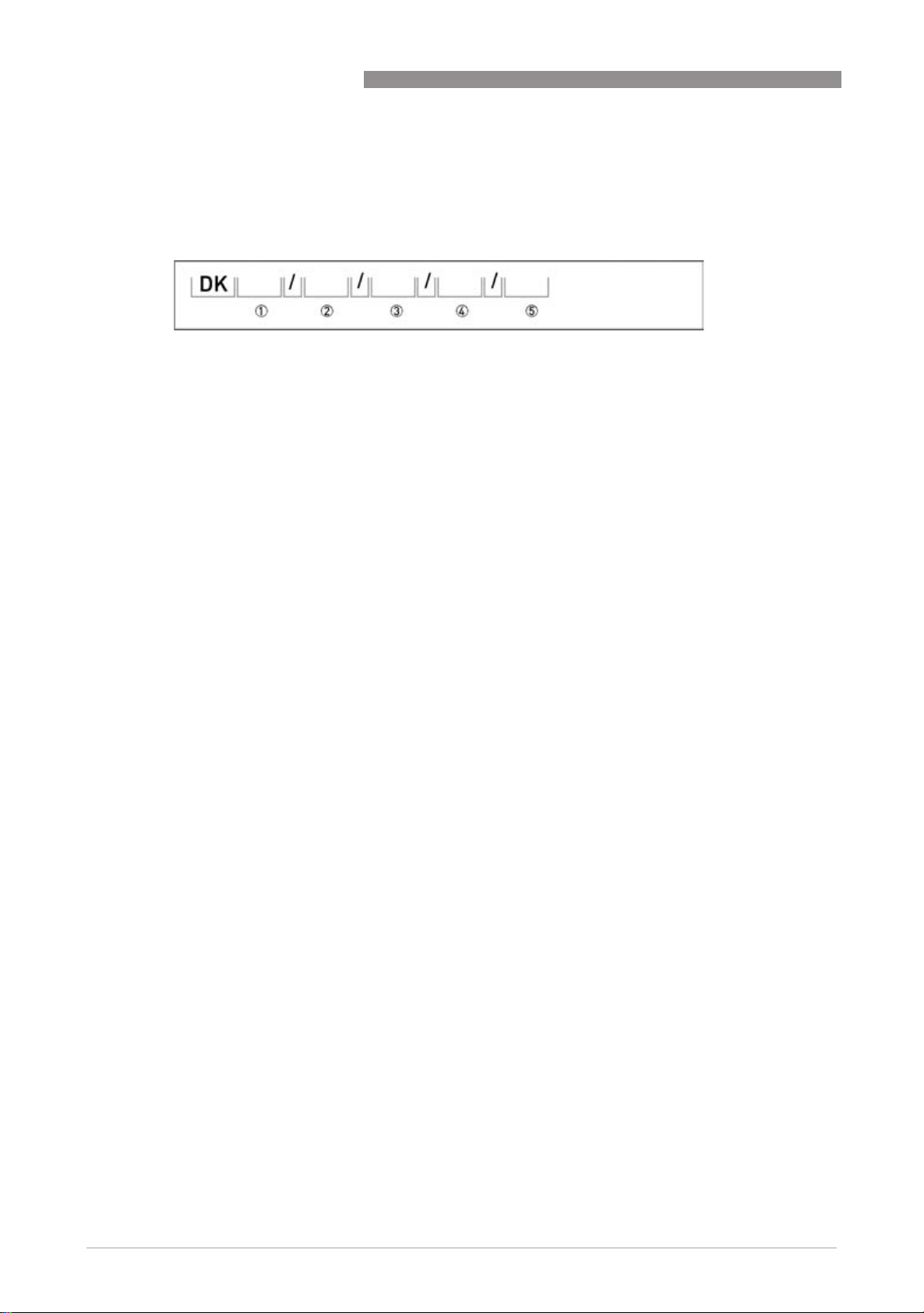

2.4 Description code

The description code* consists of the following elements:

1 R - with integrated inlet pressure regulator (DKR46 only)

2 Device type:

46 - Overall length of measuring cone 65 mm

47 - Overall length of measuring cone 150 mm

48 - Overall length of measuring cone 300 mm

800 - Overall length of measuring cone 100 mm

3 Material for top and bottom fittings

N - brass

R - stainless steel

PV - PVDF

DK46 - DK800

4 Differential pressure regulators

RE - inlet pressure regulator

RA - outlet pressure regulator

5 K1 - one limit switch / K2 - two limit switches

* positions which are not needed are omitted (no blank positions)

12

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 13

DK46 - DK800

3.1 Notes on installation

INFORMATION!

Inspect the cartons carefully for damage or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Check the packing list to check if you received completely all that you ordered.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry and dust-free location.

• Avoid lasting direct exposure to the sun.

• Store the device in its original packing.

• The permissible storage temperature for standard devices is -40...+80°C / -40...+176°F.

INSTALLATION 3

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

13

Page 14

3 INSTALLATION

3.3 Installation conditions

3.3.1 Installation in the piping

CAUTION!

When installing the device in the piping, the following points must be observed:

•

The variable area flowmeter must be installed vertically (measuring principle). Flow direction

from bottom to top. For installation recommendations please refer also to VDI/VDE 3513

Sheet 3.

•

Before connecting, blow or flush out the pipes leading to the device.

•

Pipes for gas flow need to be dried before the device is installed.

•

Use connectors suitable for the particular device version.

•

Align the pipes axially with the connections on the measuring device so they are free of

stresses.

•

If necessary, support the piping to reduce vibrations being transmitted to the measuring

device.

•

Do not lay signal cables directly next to cables for the power supply.

DK46 - DK800

3.3.2 Panel mounting

Prepare the panel cutout as shown in the drawing (see chapter - Technical Data - Dimensions).

To mount in the panel, slightly loosen the two screws 1 on the front panel of the measuring

device. Insert the device into the panel cutout from the front, align and fasten with the two

screws 1.

14

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 15

DK46 - DK800

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

DANGER!

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

ELECTRICAL CONNECTIONS 4

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

15

Page 16

4 ELECTRICAL CONNECTIONS

4.2 Limit switch

The flowmeters can be equipped with a maximum of two limit switches. The switching function of

the limit switch can be designed as monostable or bistable.

Monostable function: Switching pulse as float passes through switching point,

independent of direction of movement.

Bistable function: Stable changeover as float passes through switching point.

Example (bistable): Float above limit: Output "High"

Float below limit: Output "Low"

For switching patterns and electrical connection values of different limit switches, see -

Technical Data - Limit Switches

Connection of limit switch - 2 wire NAMUR

DK46 - DK800

1 Lower limit switch to terminal 1

2 Upper limit switch to terminal 2

The connection box includes an EMC filter unit.

Electrical connection limit switches - 2-wire NAMUR no terminal box

1 Limit switch (no terminal box)

2 Blue cable -

3 Brown cable +

4 External EMC filter

5 Receiver device

When connecting to an EMC filter, the ground terminal must be connected to the back rail of the

flowmeter.

Electrical connection limit switch - 3-wire (transistor)

16

bn - brown: supply voltage +

bk - black - switch

bu - blue: supply voltage -

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 17

DK46 - DK800

4.3 Limit switch settings

The following procedures are to be performed (DK../../K):

• Remove both clamping screws 1

• Slide the limit switch over the measuring glass

• Use the two clamping screws 1 to fasten the limit switch 3 to the back rail 2 of the

measuring device.

• Reinstall the protective cover following installation.

ELECTRICAL CONNECTIONS 4

For installation after the fact, the measuring glass must be removed. (refer to chapter entitled

"Service")

CAUTION!

When setting the limit switch, be careful to lay the cable so that it does not get damaged.

Avoid canting of the limit switch during installation: glass breakage

The connecting lead of the limit switch is guided through a hole in the base of the device and

sealed.

Observe the following for bistable limit switches with external EMC filters in separate DIN rail

housing:

The EMC filter unit and the back rail of the meter must be galvanically connected and grounded.

An isolation switching amplifier with intrinsically safe circuit controls is necessary to operate the

NAMUR limit switches.

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

17

Page 18

4 ELECTRICAL CONNECTIONS

4.4 Minimum clearance between two limit switches

Where two limit switches are used in one device and also where meters with limit switches are in

close proximity of each other, minimum clearances must be maintained in order to avoid mutual

influence of the switches.

DK46 - DK800

Minimum

clearance

1 16mm 0,63" 45mm 1,77"

2 6mm 0,236" 30mm 1,18"

NAMUR 2-wire transistor 3-wire

4.5 Switching performance

Limit switch NAMUR monostable:

Float outside limit switch: signal ≥3 mA

Float inside limit switch (centre): signal ≤1 mA

Limit switch NAMUR bistable:

Regardless of the position of the float: after passage 1 signal ≥3 mA

Prerequisite: the float is outside the limit switch.

INFORMATION!

For proper initialisation following power up, the NAMUR bistable limit switches should pass

through each of 1 and 2 once.

18

Limit switch 3-wire limit switch (transistor)

Independent of the position of the float: after passage 2 signal ≤1 V

Prerequisite: the float is outside the limit switch.

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 19

DK46 - DK800

4.6 Limit switch function reversal

The bistable limit switches can be changed from closers to openers.

The prefabricated connection cable must be long enough to do this.

When installing and setting, make sure the cable is not damaged when laid.

• Loosen terminal screw 1

• Turn tensioning screw 2 counter-clockwise to loosen

• Pull out the measuring glass along with the limit switch

• Turn limit switch 180°

• Install the measuring glass

• Tighten tensioning screw 2 by hand

• Use a 3mm pin to tighten tensioning screw by turning 4 or max. 5 times in 120° increments 3

in a clockwise direction.

ELECTRICAL CONNECTIONS 4

CAUTION!

To avoid breakage, the measuring glass must be positioned centrically between the gaskets.

Test the leak tightness by suitable means prior to start up.

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

19

Page 20

4 ELECTRICAL CONNECTIONS

4.7 Grounding connection

The measuring section is grounded on the back rail 1 (M4 thread). The connection guarantees

only an electrostatic connection of the device and does not comply with the requirements of

potential equalisation connection.

DANGER!

The grounding wire may not transfer any interference voltage.

Do not use this grounding wire to ground any other items of electrical equipment.

DK46 - DK800

4.8 Protection category

The limit switch with connection housing meets all requirements as per protection category IP

65.

Therefore it is essential to observe the following points:

• Use only original gaskets. They must be clean and free of any damage. Defective gaskets have

to be replaced.

• The electrical cables used must be undamaged and must comply with regulations.

• The cables must be laid with a loop 3 upstream of the measuring device to prevent water

from getting into the housing.

• The cable glands 2 must be tightened.

• Close the unused cable glands using blanking plugs 1.

20

DANGER!

After all servicing and maintenance work on the device, the specified protection category has to

be ensured again.

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 21

DK46 - DK800

5.1 Start-up

CAUTION!

When starting up the flowmeter, the following points must be observed:

•

•

•

•

•

•

•

•

•

START-UP 5

Compare the actual operating pressure and the process temperature of the system with the

specifications on the nameplate (PS and TS); these limits must not be exceeded.

Make sure materials are compatible.

Close the needle valve at the flowmeters.

Slowly open the shut-off valve upstream and downstream of the flowmeter.

When measuring liquids, vent the pipes carefully.

When measuring gases, increase pressure slowly.

void float impact (e.g. caused by solenoid valves), as this is likely to damage the measuring

section or float.

Open needle valve at the flowmeters and set the required flow rate.

The top edge of the float marks the reading line for flow values:

Figure 5-1: Reading edge

1 Reading edge

2 Floatform AIII

3 Floatform ball

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

21

Page 22

6 SERVICE

6.1 Maintenance

Within the scope of routine maintenance of the system and pipings, the flowmeter should also be

inspected for signs of dirt, corrosion, mechanical wear and leaks, as well as damage to the

measuring device.

We advise that inspections be carried out at least once per year.

The device must be removed from the piping before cleaning.

CAUTION!

Pressurized pipes must be depressurized before removing the device.

In the case of devices used for measuring aggressive or hazardous media, appropriate safety

precautions must be taken with regard to residual liquids in the measuring unit.

Always use new gaskets when reinstalling the device in the pipings.

CAUTION!

The packing seal for the valve may have to be adjusted during the service life. The lock nut must

be tightened for this.

Apply a tightening torque of not more than 5 Nm.

DK46 - DK800

CAUTION!

Valves that have not been used for a longer period of time may exhibit a higher actuating torque.

22

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 23

DK46 - DK800

6.2 Changing the measuring cone

• Close the valves located upstream and downstream of the device.

• Close needle valve

• Push protective cover upwards and remove towards the front

• Turn tensioning screw 1 counter-clockwise to loosen

Devices with a top and bottom fitting made of PVDF (DK.../PV) have a tensioning screw in the

device head (6mm Allen key). This can be loosened with approx. 1 full turn.

The measuring glass can be removed to the front.

SERVICE 6

Figure 6-1: Maintenance

CAUTION!

Residual liquid or gas may leak out!

• Install in the reverse order

• Tighten tensioning screw 1 by hand

• Use a 3mm pin to tighten tensioning screw 4 or max. 5 times in 120° increments 2 in a

clockwise direction.

CAUTION!

To avoid breakage, the measuring glass must be positioned centrically between the gaskets.

Test the leak tightness by suitable means prior to start up.

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

23

Page 24

6 SERVICE

6.3 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

6.4 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local representative.

6.5 Returning the device to the manufacturer

DK46 - DK800

6.5.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralizing, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

24

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 25

DK46 - DK800

6.5.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

SERVICE 6

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

6.6 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

25

Page 26

7 TECHNICAL DATA

7.1 Operating principle

The flowmeter operates on the float measuring principle

The measuring unit consists of a glass cone in which a float can move freely up and down. The

medium flows through the flowmeter from bottom to top.

The float adjusts itself so that the buoyancy force A, acting on it, the form drag W and its weight G

are in equilibrium: G = A + W.

DK46 - DK800

Figure 7-1: Operating principle

The height of the float is read on the scale of the measuring glass and indicates the flow rate.

The top edge of the float marks the reading line for flow values.

26

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 27

DK46 - DK800

7.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Application range Flow measurement of liquids and gases

Operating method / measuring principle Variable area measuring principle

Measurement

Primary measured value Float position

Secondary measured value Operating and standard volumetric flow

Measuring accuracy

Directive VDI / VDE 3513, sheet 2 (qG = 50%)

DK46 4.0%

DK47 2.5%

DK48 1.0%

DK800 2.5%

TECHNICAL DATA 7

Operating conditions

Temperature

Temperature

TemperatureTemperature

Max. operating temperature TS -5...+100°C / +23...+212°F

Pressure

Pressure

PressurePressure

Operating pressure PS Pressure Equipment Directive 97/23/EC

Test pressure PT Pressure Equipment Directive 97/23/EC

Max. permitted operating gauge pressure PS at TS = 100°C / 212°F:

DK…/R (stainless steel top and bottom fittings ) 10bar / 145psig 1

DK…/N (brass top and bottom fittings ) 10bar / 145psig 1

DK…/PV (PVDF top and bottom fittings ) 4bar / 58psig

Installation conditions

Inlet and outlet None

1 higher pressures upon request

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

27

Page 28

7 TECHNICAL DATA

Materials

Top fitting, bottom fitting CrNi steel 1.4404 / 316 L, nickel-plated brass, PVDF 1

Top fitting, bottom fitting (optional)

Measuring tube Borosilicate glass

Float (ball) CrNi steel 1.4401 / 316

Float options

Float AIII CrNi steel 1.4404 / 316 L, Aluminium, Polypropylene (PP)

Metering unit CrNi steel 1.4571 / 316 Ti

Valve spindle CrNi steel 1.4404 / 316 L

Gaskets (standard) PTFE / FPM

Gaskets (optional) PTFE / FFKM, PTFE / EPDM

Gaskets (optional) EPDM, FFKM

Protective cover Polycarbonate

1 top and bottom fittings made of PVDF not on DK48

Hastelloy

®

Glass, POM, titanium, Hastelloy® C4

DK46 - DK800

Temperatures

Max. temperature of medium T

Max. T

Max. ambient temperature T

Max. T

Other temperatures on request.

with limit switches -5...+65°C +23...+149°F

m

with limit switches -20...+65°C -4...+149°F

amb.

amb.

m

-5...+100°C +23...+212°F

-20...+100°C -4...+212°F

28

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 29

DK46 - DK800

Technical Data Limit Switches

1 For devices with the valve at the top (at the outlet) and devices with outlet pressure regulators, the function is inverted!

TECHNICAL DATA 7

Terminal connection Connection box M16 x 1.5

Clamping range 3...7mm - 0.12...0.28"

Limit switch I7R2010-NL I7R2015-NL I7R2010-N I7R2015-N RB15-14-E2

RC10-14-N3 RC15-14-N3 RC10-14-N0 RC15-14-N0

Ring diameter 10mm 15mm 10mm 15mm 15mm

Switching function bistable bistable monostable monostable bistable

NAMUR yes yes yes yes no

Connection technology 2-wire 2-wire 2-wire 2-wire 3-wire

Nominal voltage U

Current consumption 1mA passage ↓ 1 3mA - float outside

Current consumption 3mA passage ↑ 1 1mA - float in the limit

Operating voltage U

Operating current I 0…100mA

No load current I 20mA

Output Ua - passage ↓ ≤1VDC 1

Output Ua - passage ↑ ≥U

0

ext.

8VDC 8VDC 8VDC 8VDC

switch

10…30VDC

–3VDC 1

b

Field of application for limit switches

DK46, DK47, DK800 DK48

Float Ring diameter Cone no. Ring diameter

Ø 4mm / 0.158" 10mm / 0.394” G13.11 -

Ø 6mm / 0.236" 15mm / 0.591” G14.06 -

Ø 8mm / 0.315" - G14.08 -

G15.07 10mm / 0.394”

G15.09 10mm / 0.394”

G15.12 10mm / 0.394”

G16.08 10mm / 0.394”

G16.12 10mm / 0.394”

G17.08 15mm / 0.591”

G17.12 15mm / 0.591”

G18.06 -

G18.08 -

G18.12 -

The limit switches with ring diameters of 15mm as max. contact can only be used up to 60l/h -

15.8GPH water or 2400l/h - 89,3SCFH air (outer diameter of the measuring glass).

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

29

Page 30

7 TECHNICAL DATA

7.3 Dimensions and weights

Dimensions

DK46 - DK800

Device a b

d f approx.

± 0.25

[mm] ["] [mm] ["] [mm] ["] [mm] ["]

DK46 111 4.37 90 3.55 45 1.77 82 3,2

DKR46 136 5,36 90 3,55 - - 125 4,92

DK800 146 5.75 125 4.92 80 3.15 82 3,2

DK47 196 7.72 175 6.89 130 5.12 82 3,2

DK48 346 13.6 325 12.8 280 11.0 82 3,2

c = 4,3mm / 0,169"

e = 33mm / 1,3"

f ca. 82mm / 3,2"

g = 28mm / 1,1"

Dimensions of panel cutout and faceplate

Device a c

[mm] ["] [mm] ["]

DK46 128 5.04 145 5.71

DK800 163 6.42 180 7.09

DK47 213 8.39 230 9.06

DK48 363 14.3 380 15.0

b = 32mm / 1.26" d = 40mm / 1.58"

e = 27.5mm / 1.08"

30

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 31

DK46 - DK800

Weights

Process connection

1 other connection upon request

TECHNICAL DATA 7

DK46 DK800 DK47 DK48

[kg] [lb] [kg] [lb] [kg] [lb] [kg] [lb]

Weight 0.4 0.88 0.5 1.1 0.6 1.3 0.7 1.5

Weights with regulator 2.1 4.6 2.2 4.9 2.3 5.1 2.4 5.3

Standard ¼" NPT internal thread

Options G¼, Ermeto 6 or 8, tube connection 6mm or 8mm, Dilo, Gyrolok, Swagelok 1

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

31

Page 32

7 TECHNICAL DATA

DK46 - DK800

7.4 Measuring ranges

Measuring ranges DK(R)46 - DK47 - DK800

Measuring span: 10 : 1 Float forms:

Declaration of flow: Values = 100%

Water: 20°C [68°F]

Air: 20°C [68°F], 1,2 bar abs. [17.4 psia]

Float material: CrNi steel Ball AIII 4-H

Water Air

Float Ø DK46 DK47 DK800 DK(R)46 DK47 DK800

[mm] ["] [l/h] [GPH] [l/h] [GPH] [l/h] [GPH] [Nl/h] SCFH [Nl/h] SCFH [Nl/h] SCFH

40.1582.5 0.65 - - 2.5 0.65 5 1 0,22 1 - - 5 1 0,18 1

- - - - - - 8 1 0,3 1 - - 8 1 0,3 1

- - - - - - 16 0,6 16 1 0,6 16 0,6

- - - - - - 40 1,5 40 1,5 40 1,5

- - - - - - 60 2,2 100 3,8 60 2,2

6 0.236 5 1.3 5 1.3 5 1.3 100 3,8 250 9,5 100 3,8

12 3.0 12 3.0 12 3.0 250 9,5 500 19 250 9,5

25 6.5 25 6.5 25 6.5 500 19 800 30 500 19

40 11 40 11 40 11 800 30 - - 800 30

60 2 16 2 60 16 60 16 1200 2 45 2 - - 1000 38

100 2 25 2 100 25 100 25 - - - - 1800 65

- - - - 120 30 - - - - 2400 90

- - - - 160 42 - - - - 3000 110

- - - - - - - - - - 4000 140

- - - - - - - - - - 5000 180

8 0.315 120 2 30 2 - - - - - - - - - -

160 2 42 2 - - - - - - - - - -

1 with float AIII 4-H

2 not for DKR46

32

INFORMATION!

The operating pressure should be at least twice the pressure loss for liquids, and at least 5 times the

pressure loss for gases! The specified pressure drops are valid for water and air at maximum flow rate.

Other flow ranges on request. Conversion of other media or operating data (pressure, temperature, density,

viscosity) is performed using the calculation method in accordance with VDI /VDE Directive 3513

Reference condition for gas measurements:

Reference condition for gas measurements:

Reference condition for gas measurements:Reference condition for gas measurements:

The flow measurement of gases are refered to

3

Nl/h or Nm

/h: Volume flow in Normal state 0°C, 1.013 bar abs. (DIN 1343)

SCFM or SCFH: Volume flow in Standard state 15°C, 1.013 bar abs. (ISO 13443)

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 33

DK46 - DK800

TECHNICAL DATA 7

Measuring ranges DK48

Measuring span: 10 : 1 Float form:

Declaration of flow: Values = 100%

Water: 20°C [68°F]

Air: 20°C [68°F], 1,013 bar abs. [14.7 psia]

AIII

Water Air

Material Stainless Steel Polypropylene (PP) Aluminium Stainless Steel

Cone no. [l/h] [GPH] [Nl/h] [SCFH] [Nl/h] [SCFH] [Nl/h] [SCFH]

G 13.11 1 0.4 0.1 - - 7 0.25 16 0.6

G 14.06 0.6 0.16 - - 12 0.45 25 0.95

G 14.08 1 0.25 - - 20 0.75 40 1.5

G 15.07 1.6 0.4 - - 30 1.1 60 2.2

G 15.09 2.5 0.65 - - 40 1.5 90 3.5

G 15.12 4 1.0 - - 60 2.2 140 5.0

G 16.08 6 1.6 - - 100 3.7 200 7.5

G 16.12 10 2.5 - - 160 6.0 300 11

G 17.08 16 4.0 - - 250 9.0 500 19

G 17.12 25 6.5 - - 400 15 800 30

G 18.06 40 10 400 15 600 22 1200 45

G 18.08 63 16 600 22 1000 37 2000 75

G 18.12 100 25 1000 37 1600 60 3000 110

1 reduced accuracy : 2.5%

INFORMATION!

The operating pressure should be at least twice the pressure loss for liquids, and at least 5

times the pressure loss for gases! The specified pressure drops are valid for water and air at

maximum flow rate. Other flow ranges on request. Conversion of other media or operating data

(pressure, temperature, density, viscosity) is performed using the calculation method in

accordance with VDI /VDE Directive 3513

Reference condition for gas measurements:

Reference condition for gas measurements:

Reference condition for gas measurements:Reference condition for gas measurements:

The flow measurement of gases are refered to

3

Nl/h or Nm

/h: Volume flow in Normal state 0°C, 1.013 bar abs. (DIN 1343)

SCFM or SCFH: Volume flow in Standard state 15°C, 1.013 bar abs. (ISO 13443)

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

33

Page 34

7 TECHNICAL DATA

Valves

Declaration of flow: Values = 100%

Water: 20°C [68°F]

Air: 20°C [68°F], 1,013 bar abs. [14.7 psia]

Valve spindle Water Air Kv Cv

DK46 - DK800

Max. flowrate Valve characteristic value

Ø [mm] Ø [inches] [Nl/h] [GPH] [Nl/h] [SCFH]

1 0.039 5 1.3 100 3,7 0.018 0,02

2.5 0.98 50 13 1000 37 0.15 0,17

4.5 0.177 160 42 4300 160 0.48 0,55

[m3/h]

[GPM]

Valve characteristics

Spindle Ø 1.0mm - 0,039" Spindle Ø 2.5mm - 0,098"

Spindle Ø 4.5mm - 0,177"

34

1 Flow, air

2 Flow, water

3 Spindle revolution n

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 35

DK46 - DK800

7.5 Differential pressure regulators

Differential pressure regulators are used to guarantee constant flow during fluctuating inlet and

outlet pressure. Minimum pressures are required to operate the regulators (see regulator

characteristics).

Differential pressure regulators are not equivalent to pressure reducing valves!

1 Inlet pressure regulators, type RE, NRE

The regulators keep the flow rate constant in the case of a variable inlet pressure and a constant

outlet pressure.

TECHNICAL DATA 7

Example - inlet pressure

regulator RE1000:

The flow rate in the meter remains constant with a fluctuating inlet pressure greater than 0.5 bar.

Current flow rate: 1000l/h air

Outlet pressure p2 constant: 1.013 bar abs.

2 Outlet pressure regulator, type RA, NRA

The regulators keep the flow rate constant in the case of a constant inlet pressure and a variable

outlet pressure. There must be a pressure differential between the inlet and the outlet pressure

for the outlet pressure regulator to function. The inlet pressure p1 must always be greater than

the outlet pressure p2.

Example - outlet pressure

regulator NRA 800

Current flow rate: 800l/h air

Inlet pressure constant: 6 bar

The flow rate in the meter remains constant with a fluctuating outlet pressure of 0...5.5 bar.

Regulator characteristics

1 Inlet pressure regulators, type RE and NRE 2 Outlet pressure regulators, type RA and

NRA

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

35

Page 36

7 TECHNICAL DATA

Control range

Declaration of flow: Values = 100%

Water: 20°C [68°F]

Air: 20°C [68°F], 1,013 bar abs. [14.7 psia]

Inlet pressure regulator 1

[l/h] [GPH] [Nl/h] [SCFH] p1 [bar] p1 [psig]

RE-1000 ...40 ...11 ...1000 ...37 0.5 7,25

RE-4000 ...80 ...20 ...2000 ...75 1 14,5

...100 ...25 …3000 ...110 1.5 21,8

...160 ...42 ...4000 ...150 2 29

NRE-100 ...2.5 ...0.6 ...100 ...3,7 0.1 1,45

NRE-800 - - …250 ...9,0 0.1 1,45

- - …800 ...30 0.2 2,9

...25 ...6.60 - - 0.4 5,8

DK46 - DK800

Max. flowrate

Water Air Min. inlet pressure

Outlet pressure regulator 2

Max. flowrate

Water Air Min. pressure diff. *

[l/h] [GPH] [Nl/h] [SCFH] Δp [bar] Δp [psig]

RA-1000 ...40 ...11 ...1000 ...37 0,4 5,8

RA-4000 ...100 ...25 …2000 ...75 1,2 17,4

- - ...3000 ...110 1,2 17,4

...160 ...42 ...4000 ...150 1,5 21,8

NRA-800 ...1 ...0.25 ...250 ...9,0 0,05 0,73

- - ...500 ...19 0,1 1,45

- - …800 ...30 0,2 2,9

...25 ...6.6 - - 0,4 5,8

Table 7-1: * Pressure difference between inlet and outlet pressure

Reference condition for gas measurements:

Reference condition for gas measurements:

Reference condition for gas measurements:Reference condition for gas measurements:

The flow measurement of gases are refered to

3

Nl/h or Nm

SCFM or SCFH: Volume flow in Standard state 15°C, 1.013 bar abs. (ISO 13443)

/h: Volume flow in Normal state 0°C, 1.013 bar abs. (DIN 1343)

36

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 37

DK46 - DK800

Technical data, differential pressure regulator

1 other connections on request

2 higher pressures on request

3 higher temperatures on request

4 other materials on request

TECHNICAL DATA 7

Standard connection ¼" NPT

Optional Serto, Ermeto 6 or 8, tube nozzle 6mm or 8mm,Dilo, Gyrolok, Swagelok,

Max. operating gauge

pressure PS

Product temperature TS = 100°C / 212°F 3

Material CrNi steel 1.4404

Gasket PTFE 4

Membrane PTFE filled with carbon / graphite

O-ring FPM 4

G¼ 1

10 bar / 145psig

4 bar / 58psig for DK.../PV 2

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

37

Page 38

7 TECHNICAL DATA

Dimensions with the differential pressure regulator

DK46 - DK800

a

b c d e f

approx.

[mm] ["] [mm] ["] [mm] ["] [mm] ["] [mm] ["] [mm] ["]

DK46 210 8.27 163 6.42 70 2.76 19 0.75 39 1.54 90 3.55

DK47 210 8.27 233 9.18 70 2.76 19 0.75 39 1.54 90 3.55

DK48 210 8.27 383 15.1 70 2.76 19 0.75 39 1.54 90 3.55

DK800 210 8.27 183 7.21 70 2.76 19 0.75 39 1.54 90 3.55

1 DK with inlet pressure regulator 2 DK with outlet pressure regulator

approx.

38

www.krohne.com 05/2011 - 4000302403 MA DK46-800-R03-en

Page 39

DK46 - DK800

NOTES 8

www.krohne.com05/2011 - 4000302403 MA DK46-800-R03-en

39

Page 40

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Measuring systems for the oil and gas industry

• Measuring systems for sea-going tankers

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

D-47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

© KROHNE 05/2011 - 4000302403 MA DK46-800-R03-en - Subject to change without notice.

www.krohne.com

Loading...

Loading...