Page 1

User’s Guide: Maintenance/Troubleshooting

Page 2

Table of contents

1 Cleaning This Machine

1.1 Before getting started .................................................................................................................... 1-2

1.2 Cleaning ........................................................................................................................................... 1-4

1.2.1 Cleaning the outside of this machine..................................................................................................1-4

1.2.2 Cleaning the Paper Feed Rollers ........................................................................................................1-5

1.2.3 Cleaning the laser lenses....................................................................................................................1-8

2 Checking and Replacing Consumables

Control Panel ......................................................................................................................................1-4

Exhaust Air Duct .................................................................................................................................1-4

Outer Covers.......................................................................................................................................1-4

Original Glass......................................................................................................................................1-5

Original Cover Pad..............................................................................................................................1-5

Cleaning the Paper Feed Rollers of the Manual Feed Tray ................................................................1-5

Cleaning the Paper Feed Unit of Tray 1/2/3 .......................................................................................1-6

Cleaning the Transport Roller of Tray 2/3 ...........................................................................................1-6

Cleaning the Paper Feed Roller of the ADF ........................................................................................1-7

2.1 Checking the status of consumables............................................................................................ 2-2

2.2 Replacing consumables................................................................................................................. 2-3

2.2.1 Replacing a Toner Cartridge...............................................................................................................2-3

2.2.2 Replacing an Imaging Unit..................................................................................................................2-6

2.2.3 Replacing a Waste Toner Bottle .......................................................................................................2-12

2.2.4 Replacing the Transfer Roller............................................................................................................2-14

2.2.5 Replacing the Transfer Belt Unit .......................................................................................................2-16

2.2.6 Replacing a Toner Filter....................................................................................................................2-22

2.2.7 Replacing a Fusing Unit....................................................................................................................2-23

2.2.8 Replacing a Staple Kit SK-602 .........................................................................................................2-27

2.2.9 Replacing a Staple Kit SK-501 .........................................................................................................2-30

Consumables replacement messages................................................................................................2-2

Checking the consumable level ..........................................................................................................2-2

Handling a Toner Cartridge.................................................................................................................2-3

Storing Toner Cartridges.....................................................................................................................2-3

Replacement procedure .....................................................................................................................2-4

3 Clearing Paper Jam and Staple Jam

3.1 To prevent a paper jam .................................................................................................................. 3-2

3.2 When a paper jam has occurred ................................................................................................... 3-3

3.2.1 Paper jam message screen.................................................................................................................3-3

3.2.2 Clearing a paper jam in the Manual Feed Tray or Transfer Roller ......................................................3-3

Clear procedure ..................................................................................................................................3-4

3.2.3 Clearing a paper jam in Tray 1 ............................................................................................................3-5

3.2.4 Clearing a paper jam in Tray 2/3 .........................................................................................................3-7

3.2.5 Clearing a paper jam in the ADF .........................................................................................................3-8

3.2.6 Clearing a paper jam in the Duplex Option.......................................................................................3-10

3.2.7 Clearing a paper jam in the Fusing Unit............................................................................................3-11

3.2.8 Clearing a paper jam in the Finisher (bizhub C3850FS only) ............................................................3-14

3.3 Troubleshooting for paper jam.................................................................................................... 3-15

3.4 Clearing a staple jam.................................................................................................................... 3-17

3.4.1 Clearing a staple jam in the Staple Kit SK-501.................................................................................3-17

Clear procedure ..................................................................................................................................3-5

Clear procedure ................................................................................................................................3-11

[Maintenance/Troubleshooting] Contents-1

Page 3

3.4.2 Clearing a staple jam in the Staple Kit SK-602.................................................................................3-19

4 Troubleshooting

4.1 The power is not turned on............................................................................................................ 4-2

4.2 The Touch Panel is not displayed.................................................................................................. 4-3

4.3 Cannot print..................................................................................................................................... 4-4

4.3.1 Cannot print ........................................................................................................................................4-4

4.3.2 Problems on print quality....................................................................................................................4-7

4.3.3 When the bit count does not match between the server and the client .............................................4-8

4.4 Cannot perform network scanning ............................................................................................. 4-10

4.5 Cannot perform fax/internet fax.................................................................................................. 4-11

4.5.1 Cannot perform Fax TX.....................................................................................................................4-11

4.5.2 Cannot perform Fax RX ....................................................................................................................4-12

4.6 Cannot perform copy.................................................................................................................... 4-13

4.7 Trouble in use of Finisher FS-P03 ............................................................................................... 4-15

4.8 Trouble in use of Finisher (bizhub C3850FS) .............................................................................. 4-16

4.9 Major messages and actions....................................................................................................... 4-17

Warning messages............................................................................................................................4-17

Error messages.................................................................................................................................4-18

Service call........................................................................................................................................4-21

5 Checking Counters

5.1 Checking the counter ..................................................................................................................... 5-2

6Index

[Maintenance/Troubleshooting] Contents-2

Page 4

1

Cleaning This Machine

Page 5

1.1 Before getting started

1 Cleaning This Machine

NOTICE

Thoroughly read all the precautions and warning labels, and be sure to follow their instructions. These labels

are provided inside the door of this machine or inside the machine.

1.1 Before getting started

Carefully handle this machine so that you can use it for an extended period of time. A failure caused by incorrect use or rough handling is not covered by the warranty

If dust or slips of paper are left inside or outside this machine, it may reduce printing quality. We recommend

that you periodically clean this machine. Follow the guideline shown below.

- When cleaning the inside of this machine or clearing a paper jam, exercise care not to touch around the

Fusing Unit because internal components such as the Fusing Unit may be hot.

- Do not place any objects on this machine.

- To clean this machine, use a soft cloth.

- Do not spray detergent directly on the surface of this machine. If detergent gets into this machine

through holes, slots, etc., it may damage internal circuits.

- Do not use abrading or corrosive agents, including solvents such as alcohol, benzene, or thinner, to

clean this machine.

- When using detergent such as neutral detergent, try it on an obscure part of this machine to check its

effectiveness.

- To clean this machine, do not use a sharp or textured object such as a wire, plastic cleaning pad, or

brush.

- When you close the door of this machine, do it carefully. Do not do anything that might make this ma-

chine oscillate.

- Do not cover this machine directly after using it. Turn the power off, then wait until this machine be-

comes cool.

- Do not leave the door of this machine open for a long period of time. Especially, in bright light, Imaging

Unit may be damaged.

- Do not open any door of this machine during printing.

- Do not align sheets of paper at the top of this machine.

- Do not grease or disassemble this machine.

- Do not set this machine on an incline.

- Do not touch the electric wiring, gears, or laser beam unit. Doing so may lead to a machine failure or

reduce printing quality.

- Do not load an excessive number of sheets of paper in the output tray. Doing so may cause a paper

jam or paper curling.

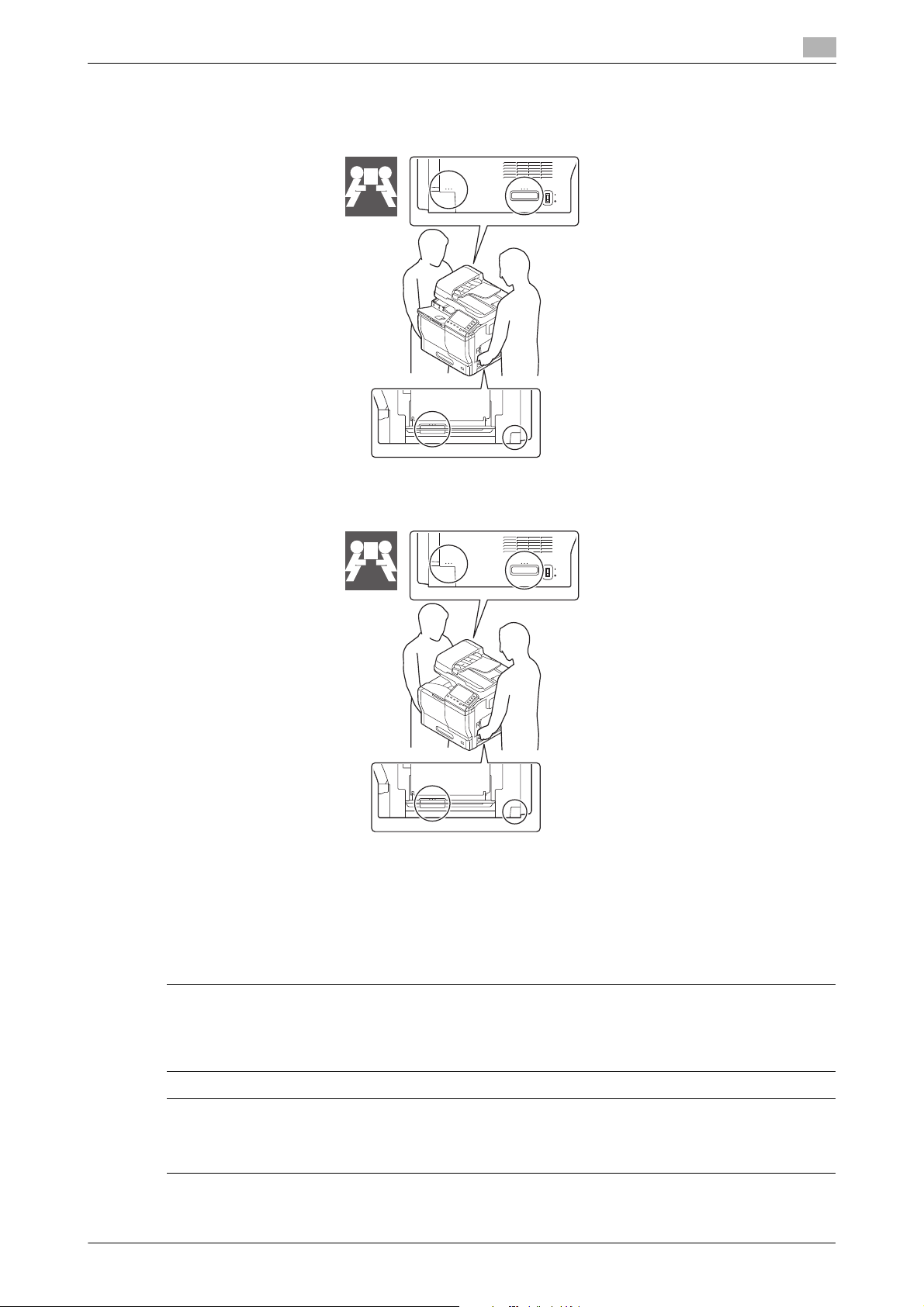

- When moving this machine, at least two people are required to do so. To prevent toner from spilling,

keep this machine horizontal when carrying it.

1

[Maintenance/Troubleshooting] 1-2

Page 6

1.1 Before getting started

bizhub C3850FS

bizhub C3850/bizhub C3350

- When carrying this machine, be sure to fold the Manual Feed Tray and hold the parts shown below.

53 kg

117 lbs

1

- When the optional Paper Feed Unit is installed, be sure to carry it separately from this machine. Also,

- Before connecting the power cable of this machine to the power outlet, check that internal components

- If your hand is stained by toner, wash it with cool water and neutral detergent.

7WARNING

- Before cleaning this machine, turn the power off, then disconnect the power cable and interface cable.

48 kg

105 lbs

do not hold handles (drawers) of the Paper Feed Unit or Right Door. Doing so may damage the Paper

Feed Unit.

removed at the time of cleaning have been installed to their original positions.

Exercise care not to spill water or detergent inside this machine. Doing so may cause a damage of this

machine or an electric shock.

7CAUTION

- If any toner enters your eyes, immediately wash them with cool water, then contact your doctor.

- The Fusing Unit is heated. The temperature of the Fusing Unit slowly reduces (wait for 1 hour).

[Maintenance/Troubleshooting] 1-3

Page 7

1.2 Cleaning

1.2 Cleaning

7WARNING

- Before cleaning this machine, turn the power off, then disconnect the power cable and interface cable.

Exercise care not to spill water or detergent inside this machine. Doing so may cause a damage of this

machine or an electric shock.

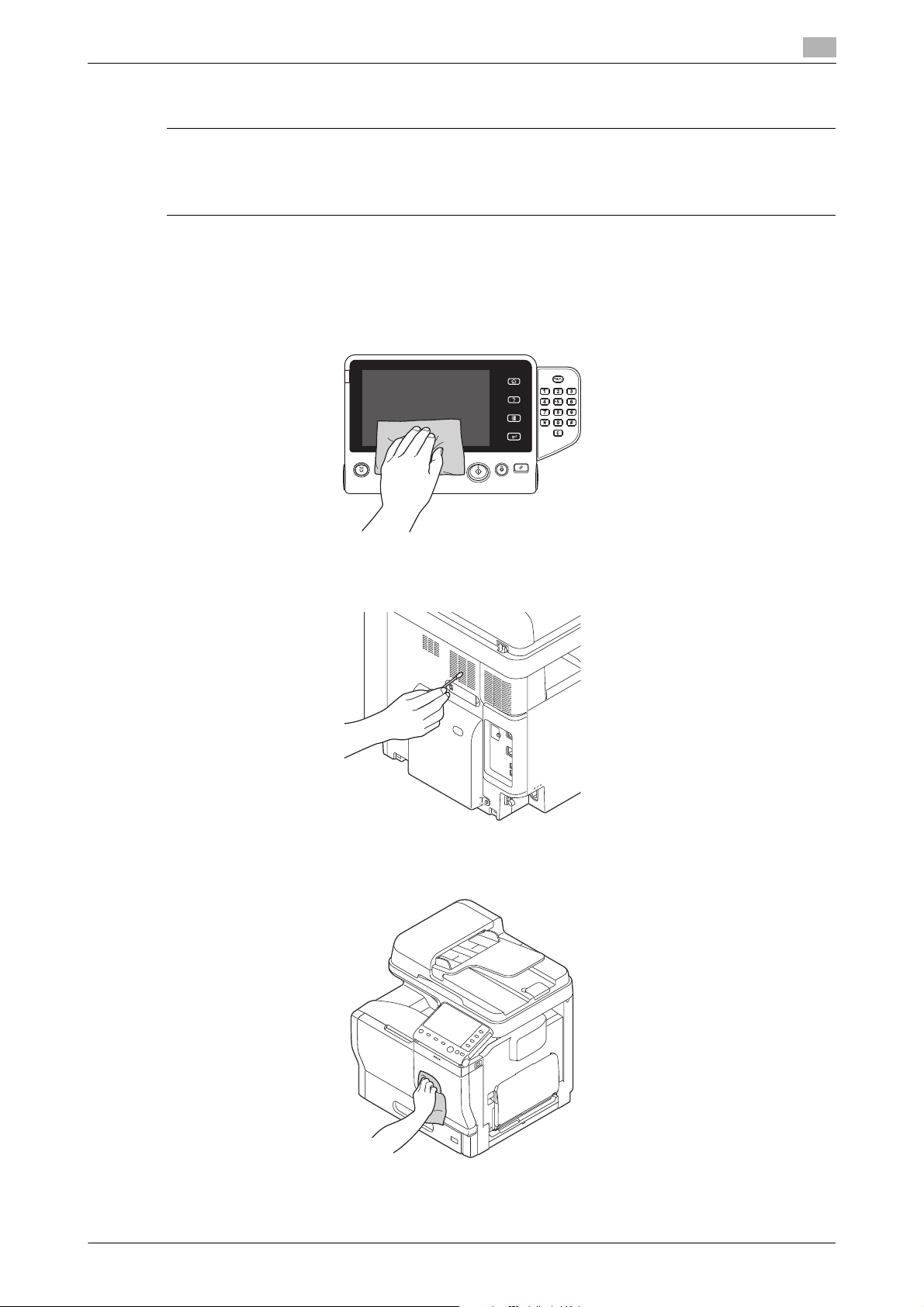

1.2.1 Cleaning the outside of this machine

Control Panel

1

Exhaust Air Duct

Outer Covers

[Maintenance/Troubleshooting] 1-4

Page 8

1.2 Cleaning

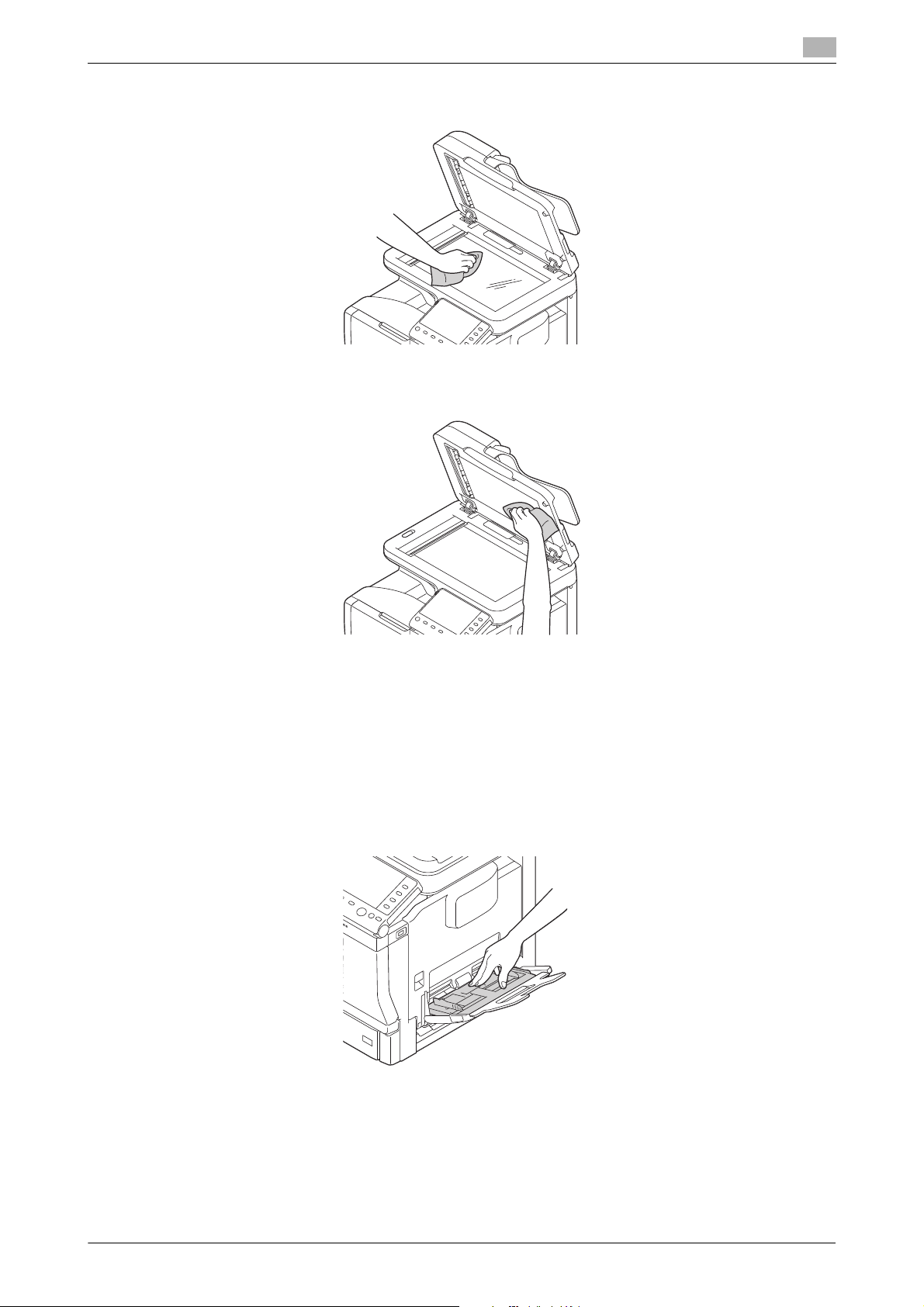

Original Glass

Original Cover Pad

1

1.2.2 Cleaning the Paper Feed Rollers

If the Paper Feed Rollers have been stained with paper powders or dust, a paper feeding failure may occur.

Cleaning the Paper Feed Rollers of the Manual Feed Tray

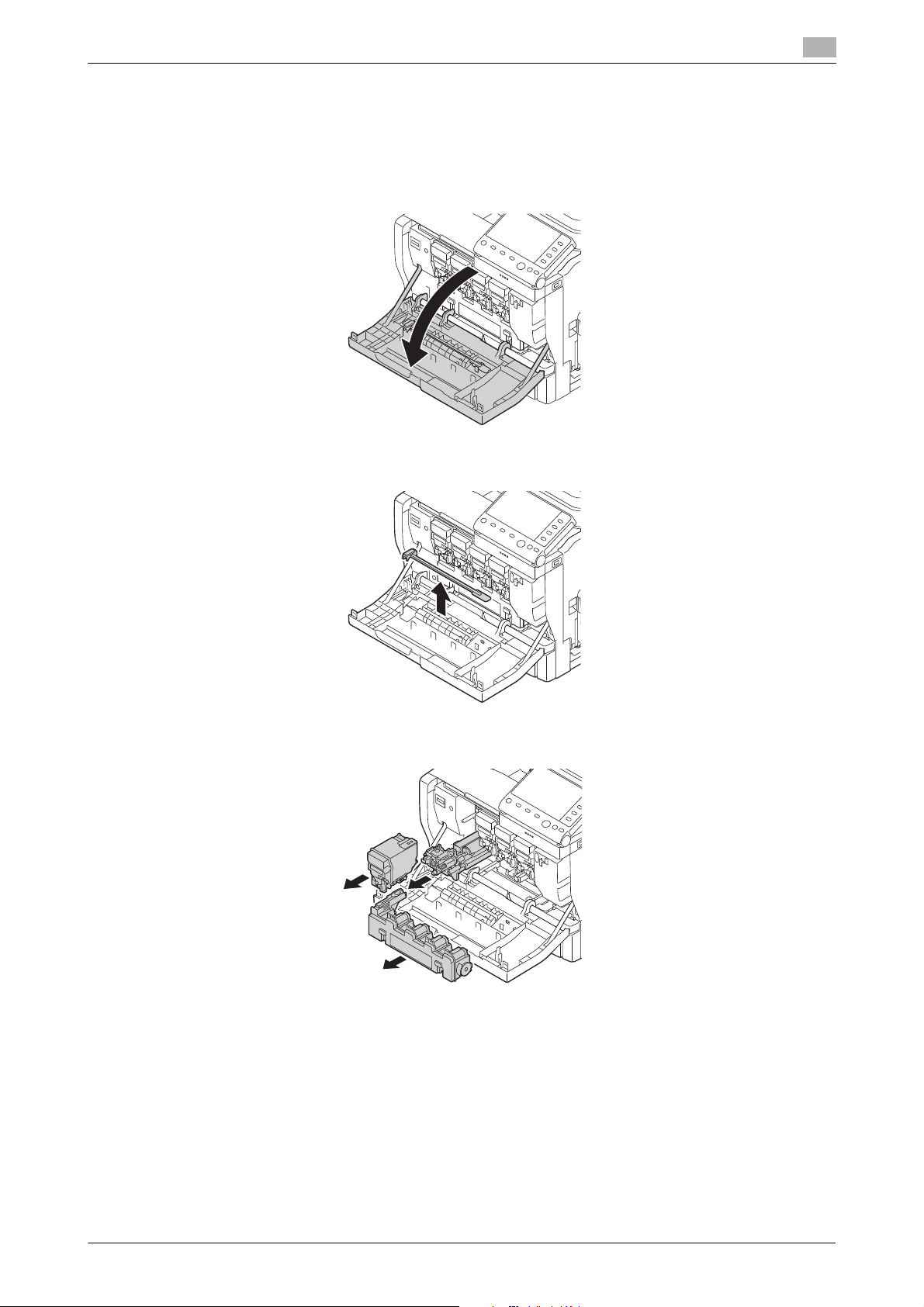

1 Open the Manual Feed Tray.

2 Press up the center of the flip-top plate until the lock latches (white) at the right and left are locked.

[Maintenance/Troubleshooting] 1-5

Page 9

1.2 Cleaning

3 Wipe off the Paper Feed Rollers with a soft and dry cloth.

4 Close the Manual Feed Tray.

Cleaning the Paper Feed Unit of Tray 1/2/3

0 Tray 2/3 is available when the optional Paper Feed Unit is installed.

1 Open the tray.

1

2 Wipe off the Paper Feed Rollers with a soft and dry cloth.

3 Close the Tray.

Cleaning the Transport Roller of Tray 2/3

0 Tray 2/3 is available when the optional Paper Feed Unit is installed.

1 Open the Right Door of Tray 2/3.

% When opening the Right Door of Tray 2/3, be sure to fold the Manual Feed Tray in advance.

[Maintenance/Troubleshooting] 1-6

Page 10

1.2 Cleaning

2 Wipe off the Transport Roller with a soft and dry cloth.

3 Close the Right Door of Tray 2/3.

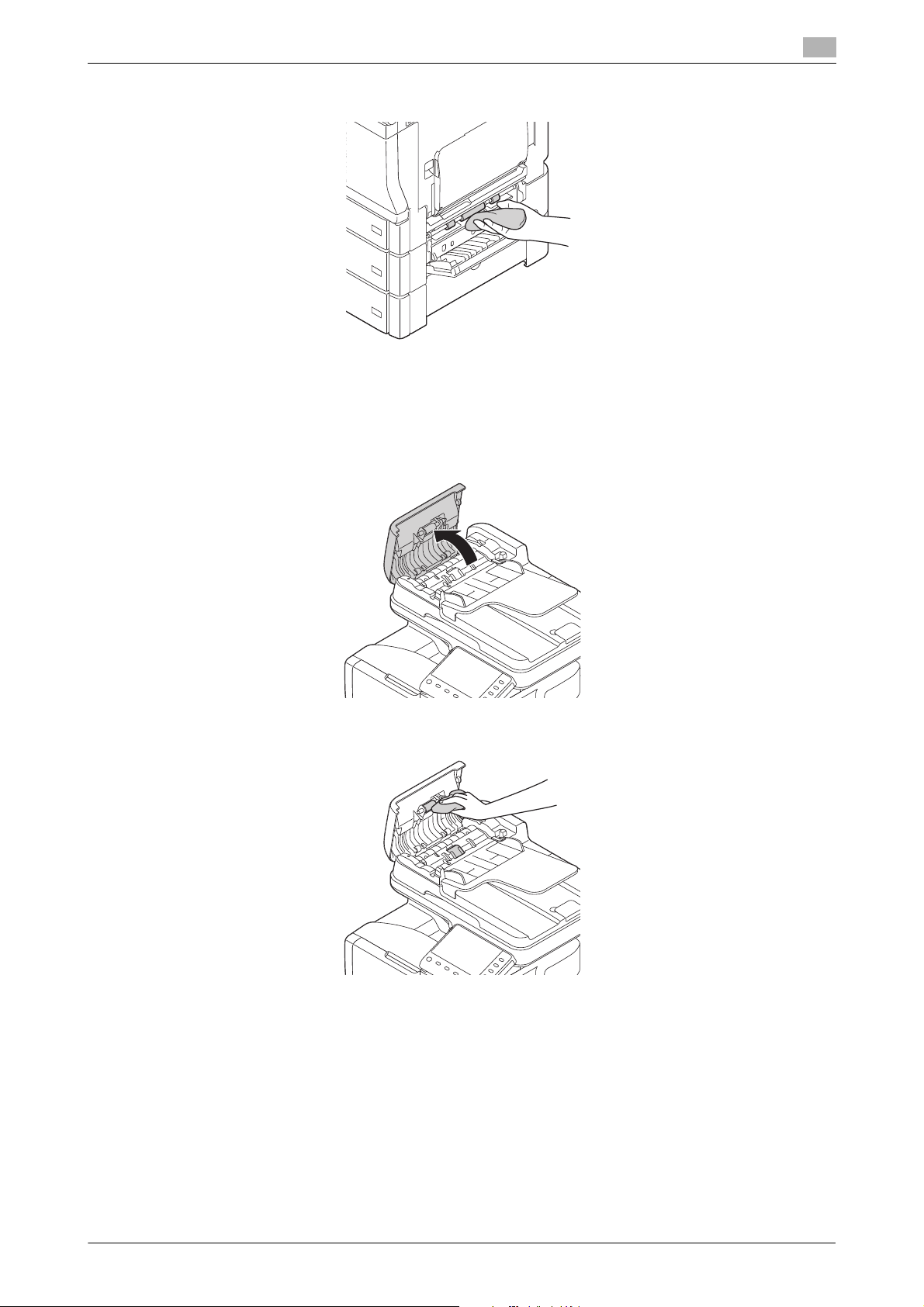

Cleaning the Paper Feed Roller of the ADF

1 Open the ADF Cover.

1

2 Wipe off the Paper Feed Roller at the rear side of the cover with a soft and dry cloth.

3 Close the ADF Cover.

[Maintenance/Troubleshooting] 1-7

Page 11

1.2 Cleaning

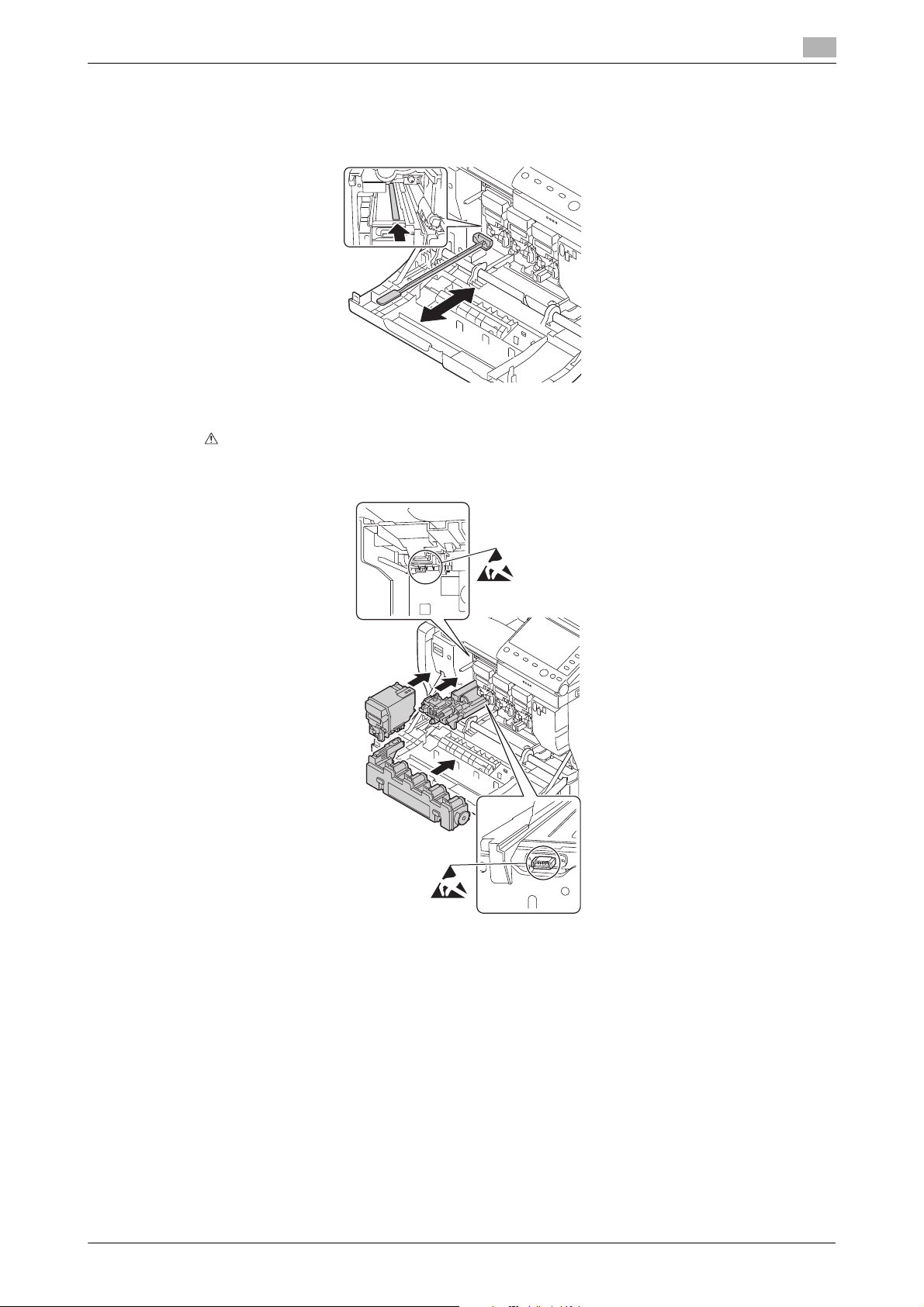

1.2.3 Cleaning the laser lenses

This machine has four laser lenses. Follow the steps shown below to clean all the laser lenses.

0 The Laser Lens Cleaning Tool is stored in the Front Cover.

1 Open the Front Cover.

2 Take out the Laser Lens Cleaning Tool.

1

3 Pull out the Waste Toner Bottle as well as the Toner Cartridge and Imaging Unit of the target color.

% For information on how to remove a Toner Cartridge, refer to page 2-3. Inclining the Toner Car-

tridge may cause toner to spill.

% For information on how to remove a Waste Toner Bottle, refer to page 2-12. Inclining the Waste

Toner Bottle may cause toner to spill.

% For information on how to remove an Imaging Unit, refer to page 2-6. Cover the removed Imaging

Unit with a cloth to keep from being affected by light.

[Maintenance/Troubleshooting] 1-8

Page 12

1.2 Cleaning

4 Align to the Print Head Glass, then insert the Laser Lens Cleaning Tool inside with the sponge side

5 Install all of Toner Cartridge, Waste Toner Bottle, and Imaging Unit.

1

facing downward, then move it back and forth several times.

% Repeat this operation for all the Print Head Glass.

CAUTION

Do not touch the copper terminals of the Toner Cartridge and Imaging Unit. Doing so may cause static electricity to damage the product.

% For information on how to install a Toner Cartridge, refer to page 2-3.

% For information on how to install a Waste Toner Bottle, refer to page 2-12.

% For information on how to install an Imaging Unit, refer to page 2-6.

6 Return the Laser Lens Cleaning Tool to the holder.

% The Laser Lens Cleaning Tool is an accessory of this machine. Return the Laser Lens Cleaner to

the laser lens cleaner holder so that you do not lose it.

[Maintenance/Troubleshooting] 1-9

Page 13

1.2 Cleaning

7 Close the Front Cover.

1

[Maintenance/Troubleshooting] 1-10

Page 14

2

Checking and Replacing

Consumables

Page 15

2.1 Checking the status of consumables

2 Checking and Replacing Consumables

2.1 Checking the status of consumables

Consumables replacement messages

Users will be informed of the time to replace consumables via a message displayed on the screen.

Message Description Reference

[Toner is low.] The toner is about to run out.

Prepare the specified Toner Cartridge.

[Replace toner] Toner is depleted. Replace the Toner Cartridge.page2-3

[Imaging Unit will require replacement soon.]

[Image Transfer Belt Unit will

require replacement soon.]

[Toner Filter will require replacement soon.]

[Fusing Unit will require replacement soon.]

[Waste Toner Box will require

replacement soon.]

[Waste Toner Box Full] The Waste Toner Bottle will become full soon.

[Transfer Roller Unit will require replacement soon.]

[Replace Staples] The staples in the Finisher have run out.

The operating life of the Imaging Unit has expired.

Replace the Imaging Unit.

The operating life of the Transfer Belt Unit has expired. Printing is possible, but the printing quality is not

assured.

Replace the Transfer Belt Unit.

The operating life of the Toner Filter has expired.

Replace the Toner Filter.

The operating life of the Fusing Unit has expired.

Printing is possible, but the printing quality is not assured.

Replace the Fusing Unit.

The Waste Toner Bottle will become full soon.

Prepare a new Waste Toner Bottle.

Replace the Waste Toner Bottle.

The operating life of the Transfer Roller has expired.

Printing is possible, but the printing quality is not assured.

Replace the Transfer Roller.

Replace the Staple Cartridge.

2

-

page 2-6

page 2-16

page 2-22

page 2-23

-

page 2-12

page 2-14

page 2-27

Checking the consumable level

Check the status of consumables (consumption level) using the Touch Panel. If necessary, each level can

be printed in list form.

1 Tap [Utility] - [Check Consumable Life].

2 Check the status of consumables.

% To print a consumption level list, tap [Print], select [Print], then tap [OK].

dReference

If a warning such as for toner replacement or a paper jam occurs on this machine, it can be sent to a registered

E-mail address. For information on the setting procedure, refer to Chapter 1 "Using Web Connection" in [User's Guide: Applied Functions].

[Maintenance/Troubleshooting] 2-2

Page 16

2.2 Replacing consumables

Tips

2.2 Replacing consumables

NOTICE

A failure, which was caused because you did not follow the procedures described in this user's guide, is not

included in the warranty.

2.2.1 Replacing a Toner Cartridge

Handling a Toner Cartridge

When handling a Toner Cartridge, be careful of the following.

- This machine supports four Toner Cartridges: black, yellow, magenta, and cyan. When handling a

Toner Cartridge, take care not to spill toner on this machine or your hand.

- Replace a Toner Cartridge with an unused product. If a toner cartridge is replaced with a used one,

the message window may not to be cleared or the toner level may not be displayed accurately.

- Do not forcibly open the Toner Cartridge. If toner has leaked, avoid toner inhaling or skin contact as

much as possible.

- If your clothes or hand has been stained with toner, wash it off with soap and water.

- If you have inhaled toner, move to a fresh air place, then gargle well with a large amount of water. If you

have had a symptom such as a cough, see your doctor.

- If any toner enters your eyes, immediately wash them with running water for 15 minutes or more. If pain

persists, see your doctor.

- If you have drunk toner, wash your mouth out well, then drink one or two glasses of water. See your

doctor, if necessary.

- Keep Toner Cartridge out of reach of babies and children.

- When handling a Toner Cartridge, do not touch the printed circuit board installed on the Toner Car-

tridge.

- When replacing a Toner Cartridge, do not touch the spring contact of the main unit.

- Do not touch the copper terminal of the Toner Cartridge. Doing so may cause static electricity

damaging the product.

2

Storing Toner Cartridges

Store Toner Cartridge as shown below.

- Do not open the protection bag before installing a Toner Cartridge.

- Store Toner Cartridges in a cold dark place, away from direct sunlight.

- Store Toner Cartridges in a place in which the temperature is 95 °F (35 °C) or less and the humidity is

85% or less with no dew condensation. If a Toner Cartridge is moved from a cold place to a warm

place with high humidity, a dew may form. which may affect printing quality. Before using a Toner Car-

tridge, leave it for approximately one hour to adjust to the ambient environment.

- Keep Toner Cartridges horizontal. Do not place a Toner Cartridge in the reverse direction from that

specified. Doing so may cause toner in a Toner Cartridge to become hard or uneven.

- Do not touch salty air or corrosive gases such as aerosol.

Guidance for recovering used Toner Cartridge

- Put the used Toner Cartridge in a bag, place the bag in the box in which the Toner Cartridge was in-

cluded at the time of purchase, then send the box to us. Securely seal the bag and box with tape, being

careful of the toner in the Toner Cartridge. The recovered Toner Cartridge and Imaging Unit are recycled.

[Maintenance/Troubleshooting] 2-3

Page 17

2.2 Replacing consumables

Y

M C K

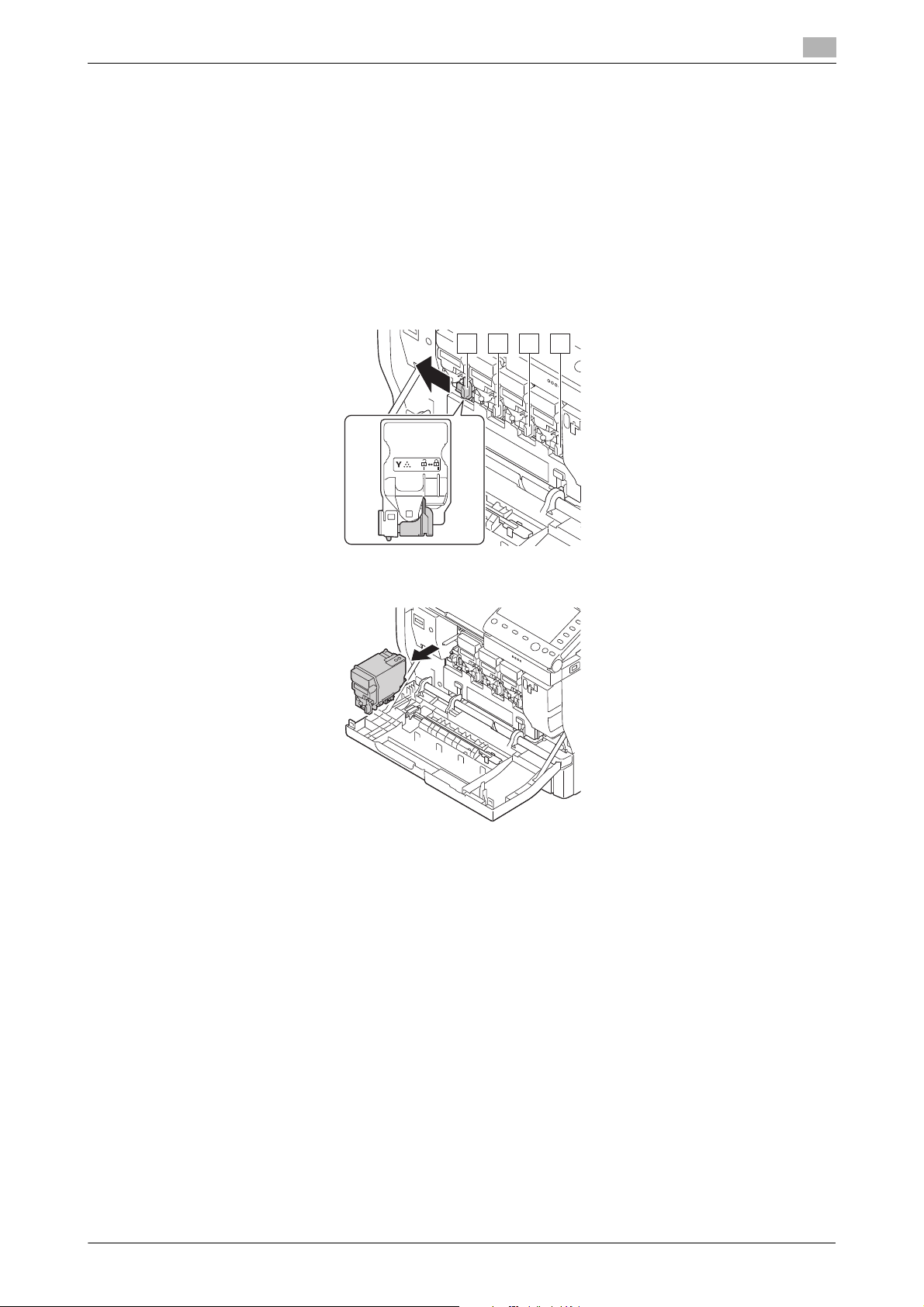

Replacement procedure

The following example shows how to replace a Yellow Toner Cartridge.

NOTICE

Do not use a recycle Toner Cartridge other than our genuine product. A failure or problem that affects printing

quality and that was caused due to use of a recycled Toner Cartridge is not covered by the warranty. Such a

failure or problem is not subject to technical support.

1 Check the color of the exhausted toner in the message window of the Control Panel.

2 Open the Front Cover.

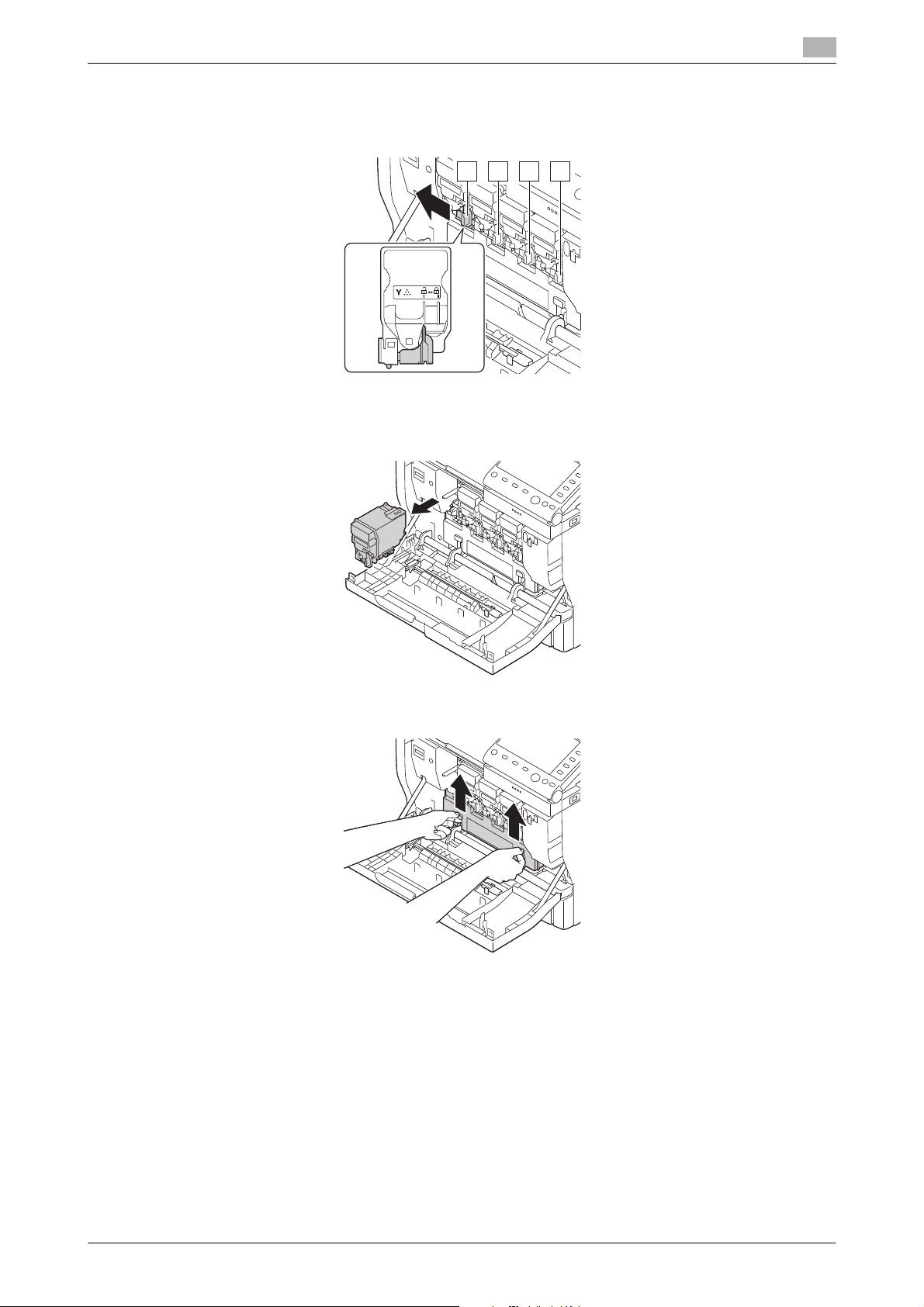

3 Pull the lever at the front left.

2

4 Hold the handle of the Toner Cartridge to be replaced, then pull out it.

NOTICE

When replacing the Toner Cartridge, be careful not to spill any toner. If toner has spilled, immediately

wipe it off using a soft and dry cloth.

5 Check the color of the new Toner Cartridge.

% To prevent toner from spilling, do not take the Toner Cartridge out of the bag until Step 4 is exe-

cuted.

[Maintenance/Troubleshooting] 2-4

Page 18

2.2 Replacing consumables

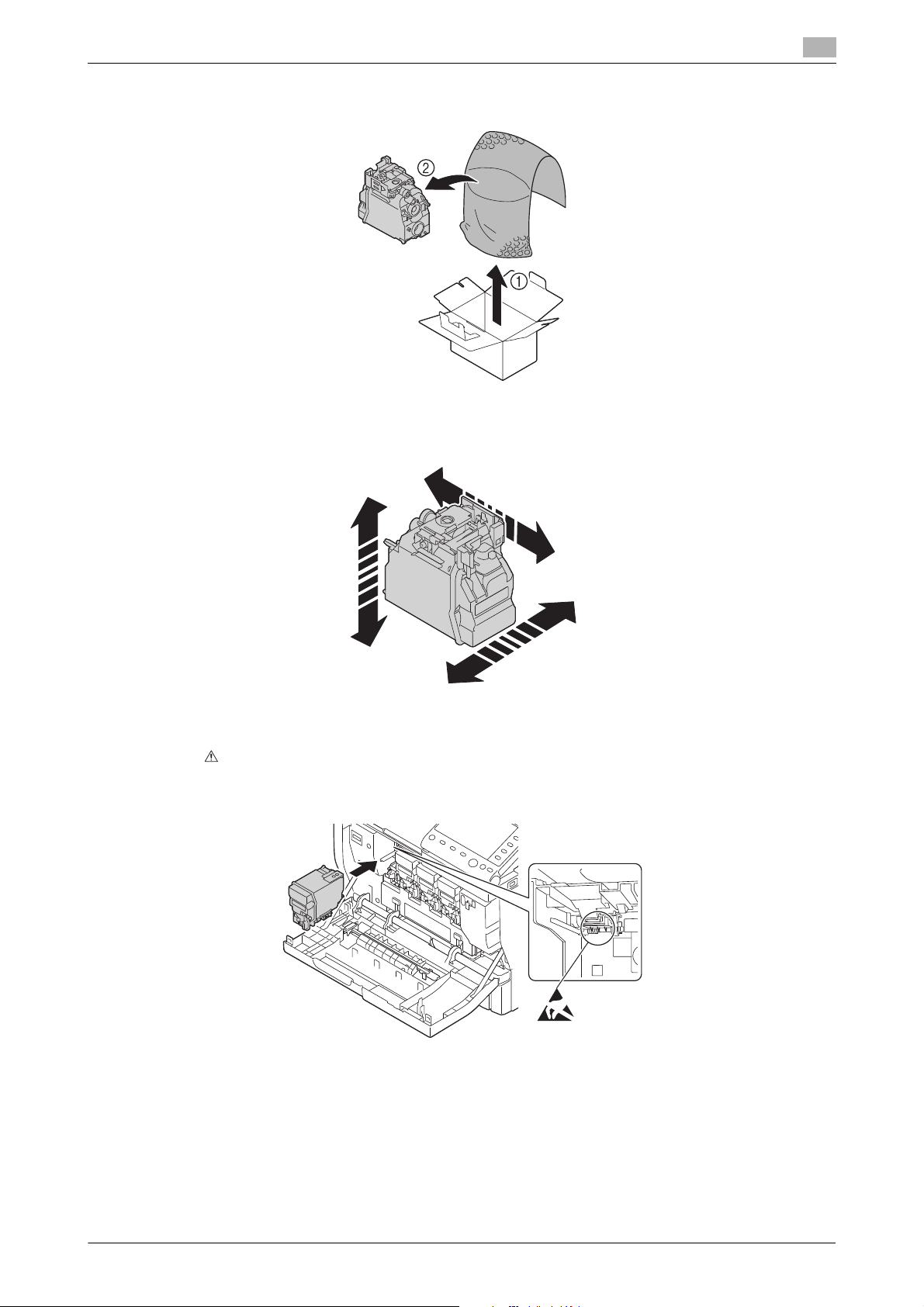

6 Take the Toner Cartridge out of the bag.

7 Hold a new Toner Cartridge upside down in your hands, then shake it several times in each of the ver-

tical, horizontal, and longitudinal directions.

2

8 Check that the color of the Toner Cartridge matches that of the insertion slot in the main unit, then

push the Toner Cartridge to the back.

CAUTION

Do not touch the copper terminal of the Toner Cartridge. Doing so may cause static electricity to damage the product.

[Maintenance/Troubleshooting] 2-5

Page 19

2.2 Replacing consumables

9 Pull the lever to the right to lock it.

% Carefully return the lever at the front to its original position. If the lever is not returned to its original

position, the Front Cover is not closed.

% If it is difficult to operate the lever, push the lever unit to the back.

10 Close the Front Cover.

2

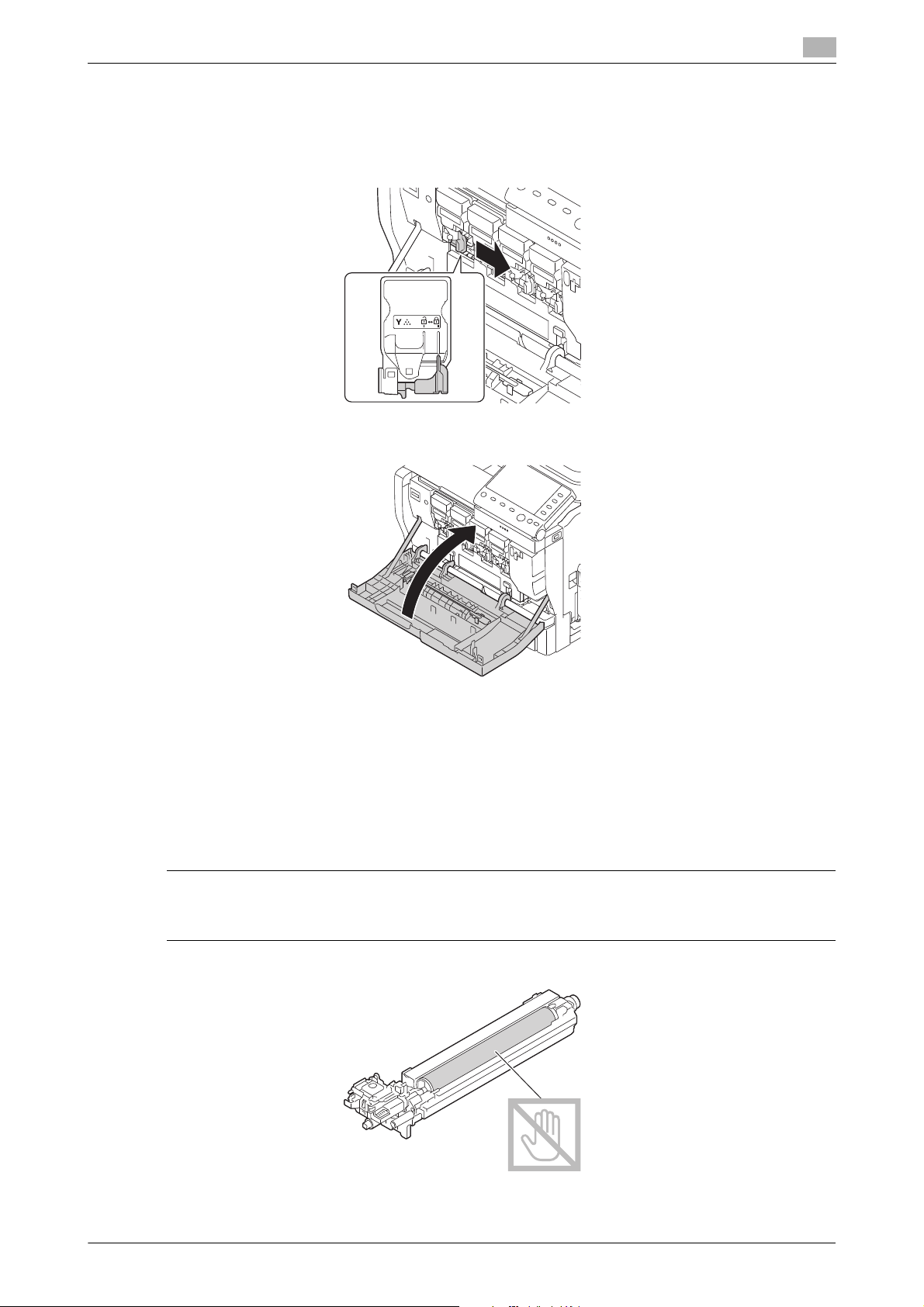

2.2.2 Replacing an Imaging Unit

The following example shows how to replace a yellow Imaging Unit.

Be sure to replace an Imaging Unit with an unused product. If an Imaging Unit is replaced with a used one,

the message window may not be cleared.

NOTICE

Do not touch the surface of the OPC drum. Doing so may reduce printing quality.

7CAUTION

- Do not touch the copper terminal of the Imaging Unit. Doing so may lead to static electricity damaging

the product.

1 Check the color of the Imaging Unit to be replaced in the message window of the Control Panel.

[Maintenance/Troubleshooting] 2-6

Page 20

2.2 Replacing consumables

Y

M C K

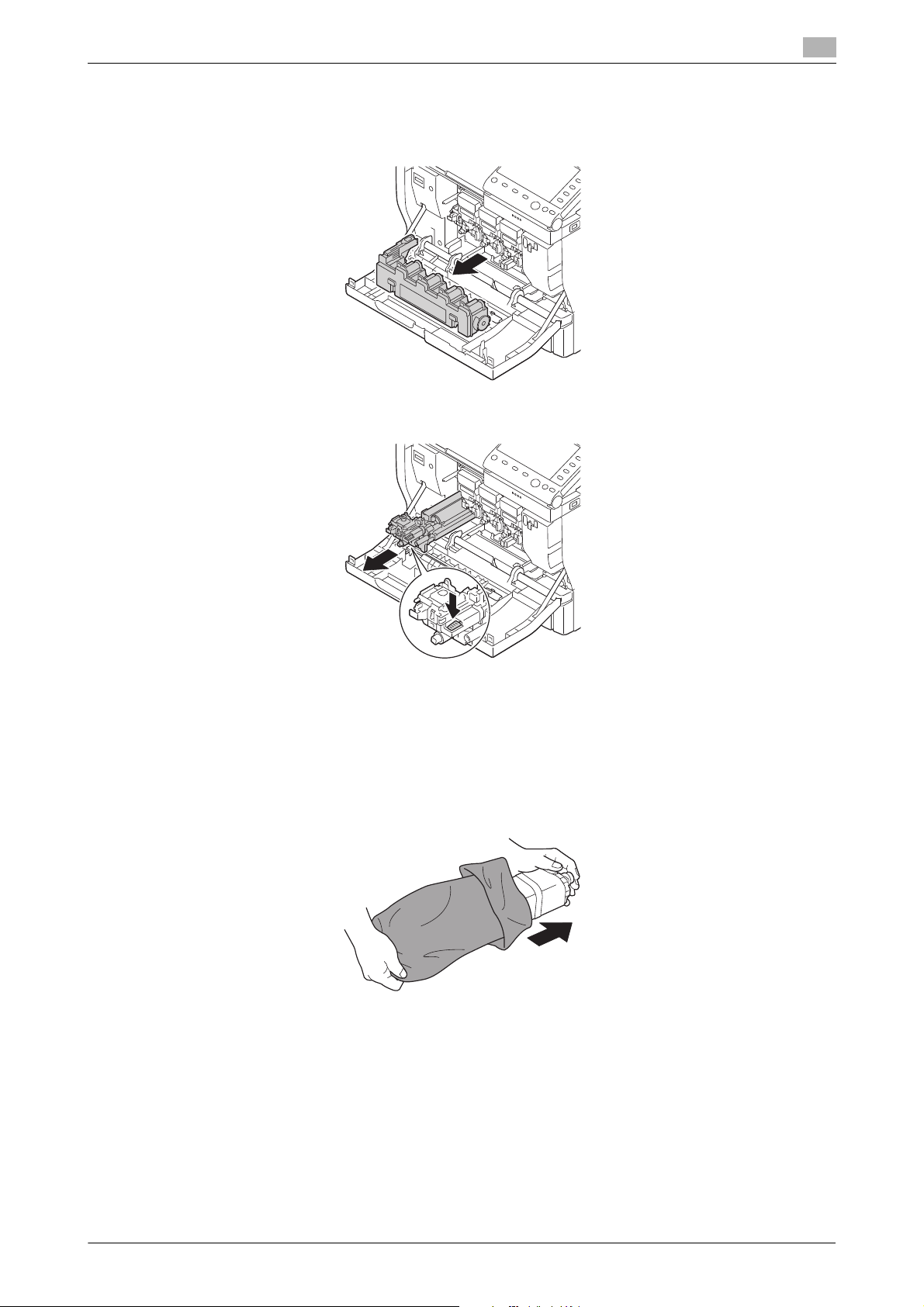

2 Open the Front Cover.

3 Pull the lever at the front of the Toner Cartridge to the left.

4 Hold the handle of the Toner Cartridge, then pull out it.

% Inclining the Toner Cartridge may cause toner to spill.

2

5 Press up the Waste Toner Bottle to unlock.

[Maintenance/Troubleshooting] 2-7

Page 21

2.2 Replacing consumables

6 Hold the handles at the right and left of the Waste Toner Bottle, then carefully pull out the Waste Toner

Bottle.

% Inclining the Waste Toner Bottle may cause toner to spill.

7 While holding down the tab of the Imaging Unit to be replaced, pull out the Imaging Unit.

2

% To dispose of the used Imaging Unit, use the recovery service or follow the regulations for your re-

gion.

8 Check the color of the new Imaging Unit.

9 Take the Imaging Unit out of the bag.

[Maintenance/Troubleshooting] 2-8

Page 22

2.2 Replacing consumables

10 Hold a new Imaging Unit with both your hands, then shake it several times as shown in the figure.

% Do not touch the bottom of the Imaging Unit. Doing so may damage it and subsequently reduce

printing quality.

11 Remove the protection tape from the Imaging Unit, then take off the protection paper (black).

2

12 Remove the protection tape from the Imaging Unit, then take off the protection paper.

[Maintenance/Troubleshooting] 2-9

Page 23

2.2 Replacing consumables

13 Remove the holding sheet and protection materials from the Imaging Unit.

14 Check that the color of the new Imaging Unit matches that of the insertion slot in the main unit, then

push the Imaging Unit to the back.

CAUTION

Do not touch the copper terminal of the Imaging Unit. Doing so may cause static electricity to damage

the product.

2

15 Push the Waste Toner Bottle to the back to lock it.

[Maintenance/Troubleshooting] 2-10

Page 24

2.2 Replacing consumables

16 Check that the color of the Toner Cartridge matches that of the insertion slot in the main unit, then

push the Toner Cartridge to the back.

% Push the Toner Cartridge to the back.

% CAUTION

Do not touch the copper terminal of the Toner Cartridge. Doing so may cause static electricity to

damage the product.

17 Pull the lever to the right to lock it.

% Carefully return the lever at the front to its original position. If the lever is not returned to its original

position, the Front Cover is not closed.

2

18 Close the Front Cover.

[Maintenance/Troubleshooting] 2-11

Page 25

2.2 Replacing consumables

2.2.3 Replacing a Waste Toner Bottle

If the Waste Toner Bottle becomes full, this machine stops printing, and restarts printing after the Waste

Toner Bottle is replaced.

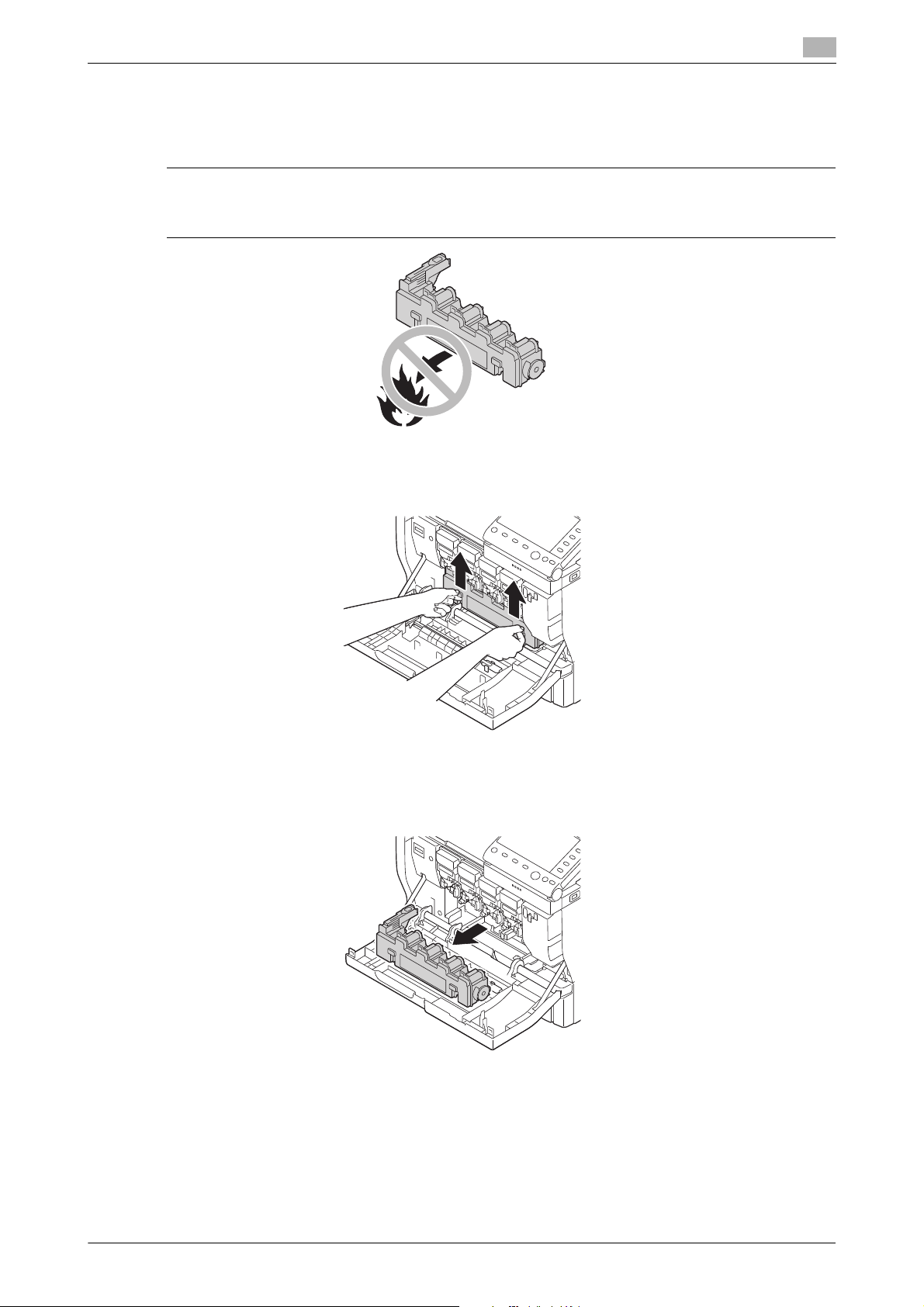

7WARNING

- Do not throw a toner container such as a toner bottle into a fire. Doing so may cause hot toner to spray

in all directions, which may cause burn injuries.

1 Open the Front Cover.

2 Press up the Waste Toner Bottle to unlock.

2

3 Hold the handles at the right and left of the Waste Toner Bottle, then carefully pull out the Waste Toner

Bottle.

% Inclining the Waste Toner Bottle may cause toner to spill.

4 Take a new Waste Toner Bottle out of the package box.

% Put the used Waste Toner Bottle in the plastic bag included in the package, then store it in the

package box.

% To dispose of the used Waste Toner Bottle, use the recovery service or follow the regulations in

your region.

[Maintenance/Troubleshooting] 2-12

Page 26

2.2 Replacing consumables

5 Push the Waste Toner Bottle to the back to lock it.

6 Close the Front Cover.

2

[Maintenance/Troubleshooting] 2-13

Page 27

2.2 Replacing consumables

2.2.4 Replacing the Transfer Roller

After the Transfer Roller replacement message has appeared, printing is possible, but the printing quality

reduces. Immediately replace the Transfer Roller.

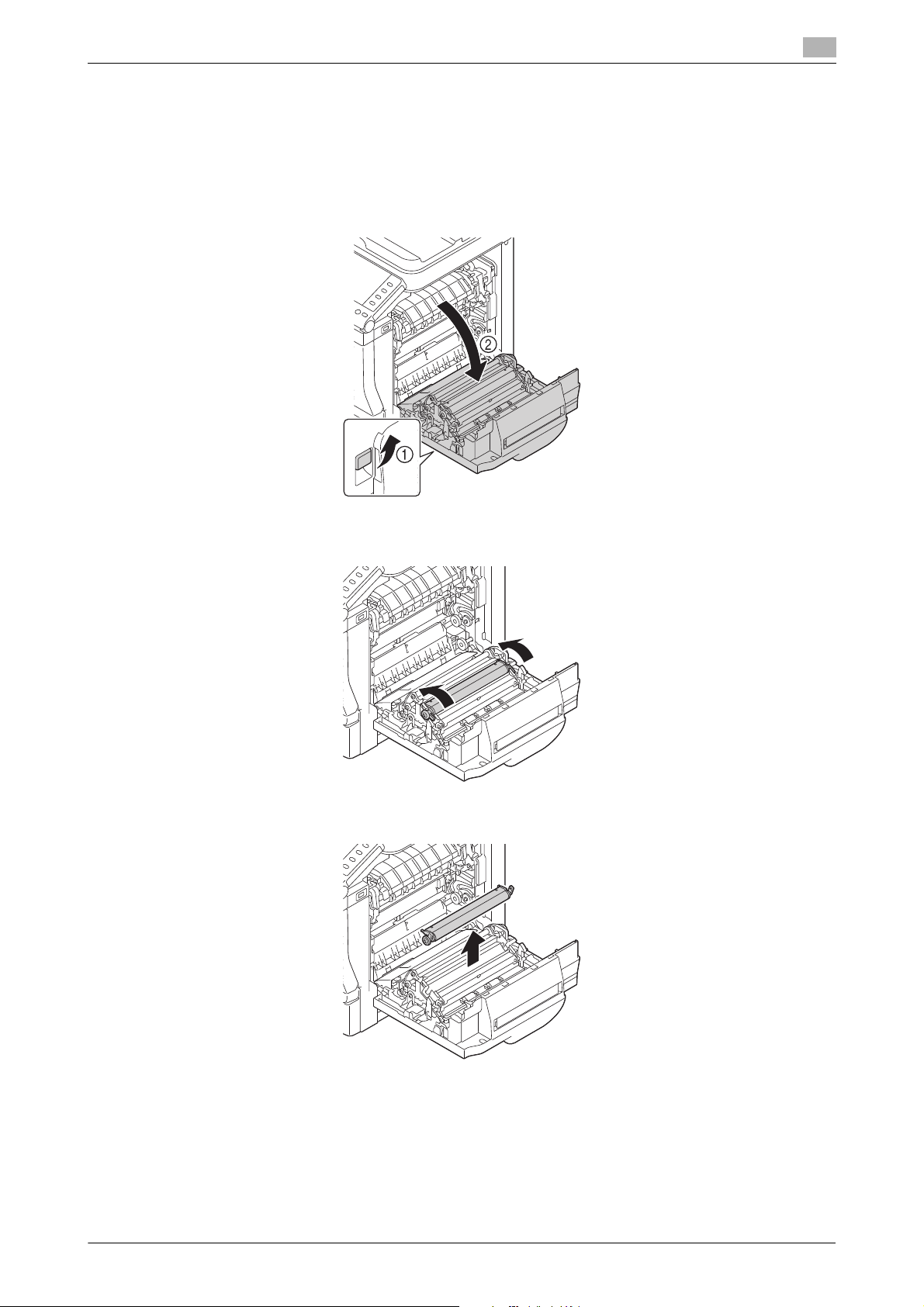

1 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

2

2 Press two tabs at the right and left of the Transfer Roller up to unlock.

3 Remove the Transfer Roller.

4 Take a new Transfer Roller out of the package box.

[Maintenance/Troubleshooting] 2-14

Page 28

2.2 Replacing consumables

5 Insert the shaft of the Transfer Roller into the bearing in the machine.

6 Press down two tabs at the right and left of the Transfer Roller to lock it.

2

7 While holding down the roller, press it inward until it clicks.

8 Close the Right Door.

9 Select [Utility] - [Administrator Settings] - [System Settings] - [Expert Adjustment] - [Life] - [New Release]

- [Transfer Roller Unit], then reset the counter.

[Maintenance/Troubleshooting] 2-15

Page 29

2.2 Replacing consumables

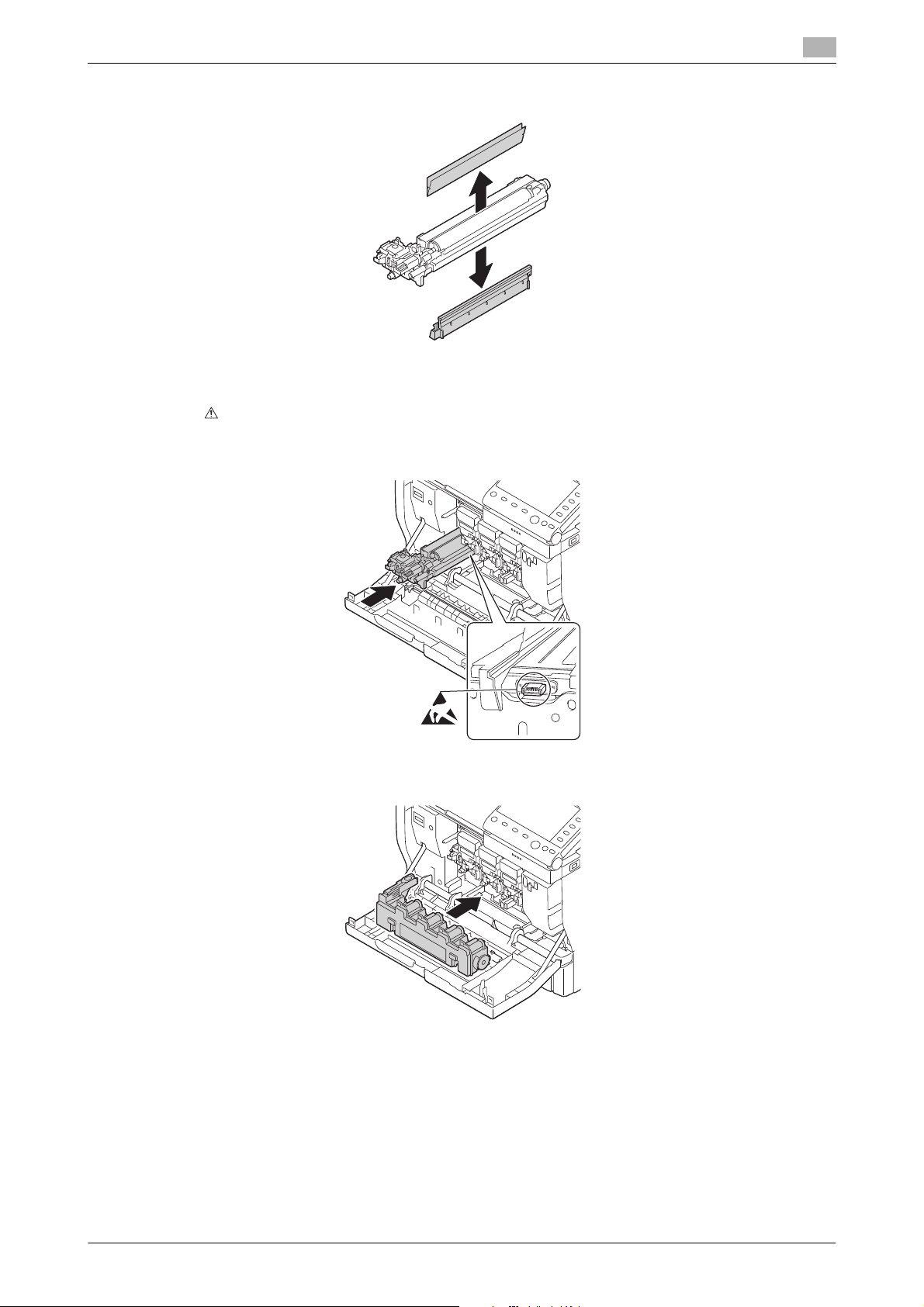

2.2.5 Replacing the Transfer Belt Unit

After the Transfer Belt Unit replacement message has appeared, printing is possible, but the printing quality

reduces. Immediately replace the Transfer Belt.

1 Turn the power of this machine off, then disconnect the power cable and interface cable.

2 Open the Front Cover.

3 Remove all of Toner Cartridge, Waste Toner Bottle, and Imaging Unit.

2

% For information on how to remove a Toner Cartridge, refer to page 2-3. Inclining the Toner Car-

tridge may cause toner to spill.

% For information on how to remove a Waste Toner Bottle, refer to page 2-12. Inclining the Waste

Toner Bottle may cause toner to spill.

% For information on how to remove an Imaging Unit, refer to page 2-6. Cover the removed Imaging

Unit with a cloth to keep from being affected by light.

4 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

[Maintenance/Troubleshooting] 2-16

Page 30

2.2 Replacing consumables

5 Insert the protection sheet under the Transfer Belt Unit.

% Insert the protection sheet until it stops.

6 Lower the Transfer Belt Unit guide.

2

[Maintenance/Troubleshooting] 2-17

Page 31

2.2 Replacing consumables

7 Hold the handles at the right and left, then carefully pull out the Transfer Belt Unit.

% Pull out the Transfer Belt Unit horizontally. Not doing so may damage the surface.

% After pulling out the Transfer Belt Unit halfway, draw out it while holding the handles on the right

and left sides.

2

8 Take a new Transfer Belt Unit out of the package box.

9 Remove protection paper.

% Do not touch the surface of the Transfer Belt Unit. Also, do not remove the blue lever.

[Maintenance/Troubleshooting] 2-18

Page 32

2.2 Replacing consumables

10 Remove the protection materials of the new Transfer Belt Unit.

11 Carefully insert the new Transfer Belt Unit along the guides at the right and left.

% Insert the Transfer Belt Unit horizontally. Not doing so may damage the surface.

% Insert the Transfer Belt to the back.

2

12 Lift the Transfer Belt Unit guide.

[Maintenance/Troubleshooting] 2-19

Page 33

2.2 Replacing consumables

13 Pull out the protection sheet.

14 Close the Right Door.

2

[Maintenance/Troubleshooting] 2-20

Page 34

2.2 Replacing consumables

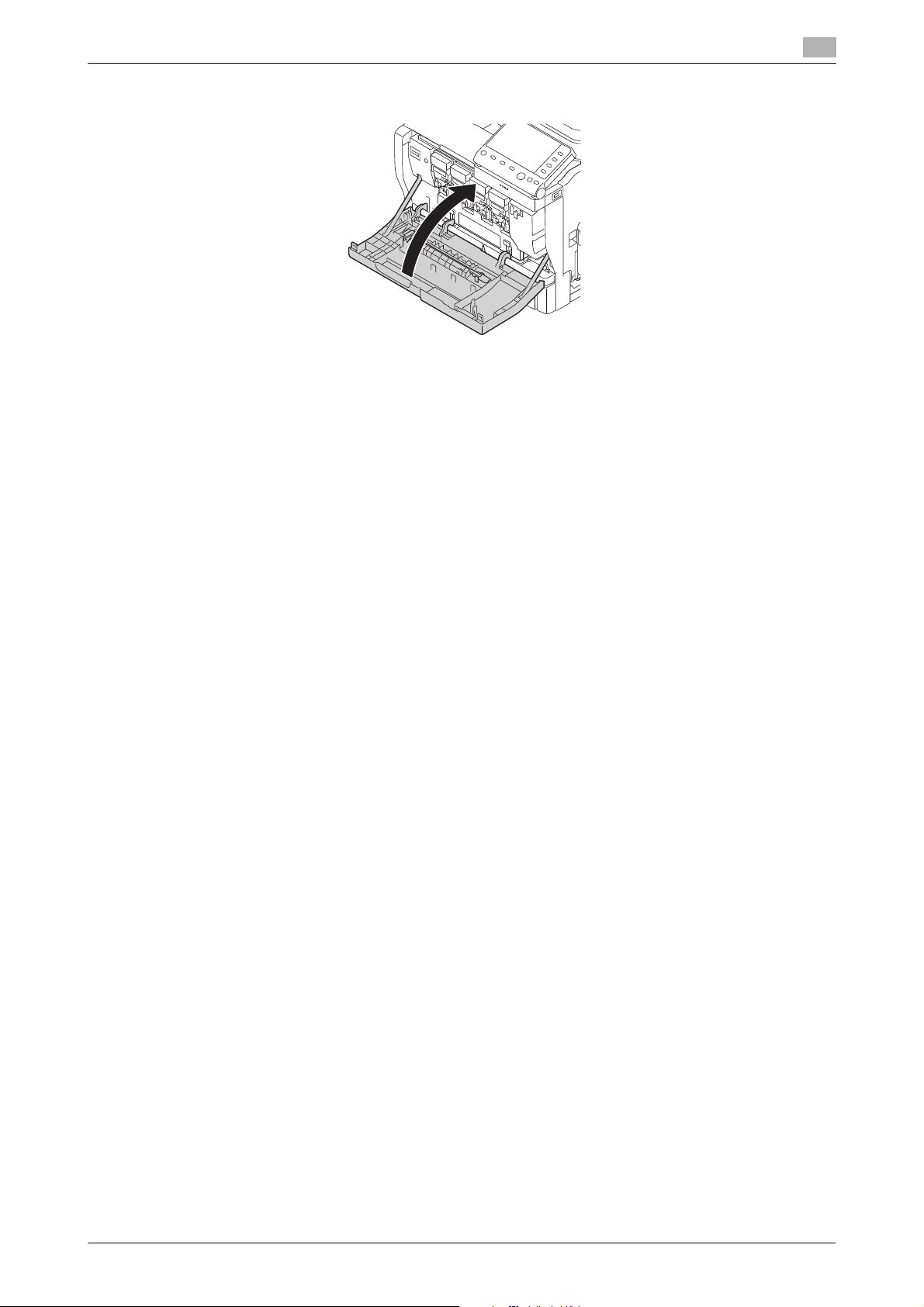

15 Install all of Toner Cartridge, Waste Toner Bottle, and Imaging Unit.

CAUTION

Do not touch the copper terminals of the Toner Cartridge and Imaging Unit. Doing so may cause static electricity to damage the product.

2

% For information on how to install a Toner Cartridge, refer to page 2-3.

% For information on how to install a Waste Toner Bottle, refer to page 2-12.

% For information on how to install an Imaging Unit, refer to page 2-6.

16 Close the Front Cover.

17 Connect the power cable, then turn the power of this machine on.

18 Select [Utility] - [Administrator Settings] - [System Settings] - [Expert Adjustment] - [Life] - [New Release]

- [Image Transfer Belt Unit], then reset the counter.

[Maintenance/Troubleshooting] 2-21

Page 35

2.2 Replacing consumables

2.2.6 Replacing a Toner Filter

0 The Toner Filter is in the Transfer Belt package.

1 Pull the filter case out from the main unit.

2 Push the Toner Filter from the bottom up, then take it out of the case.

2

3 Take a new Toner Filter out of the plastic bag.

% Put the used Toner Filter in the plastic bag that contained the new Toner Filter was contained.

4 Insert a new Toner Filter into the case.

[Maintenance/Troubleshooting] 2-22

Page 36

2.2 Replacing consumables

5 Install the filter case in the main unit.

6 Select [Utility] - [Administrator Settings] - [System Settings] - [Expert Adjustment] - [Life] - [New Release]

- [Toner Filter], then reset the counter.

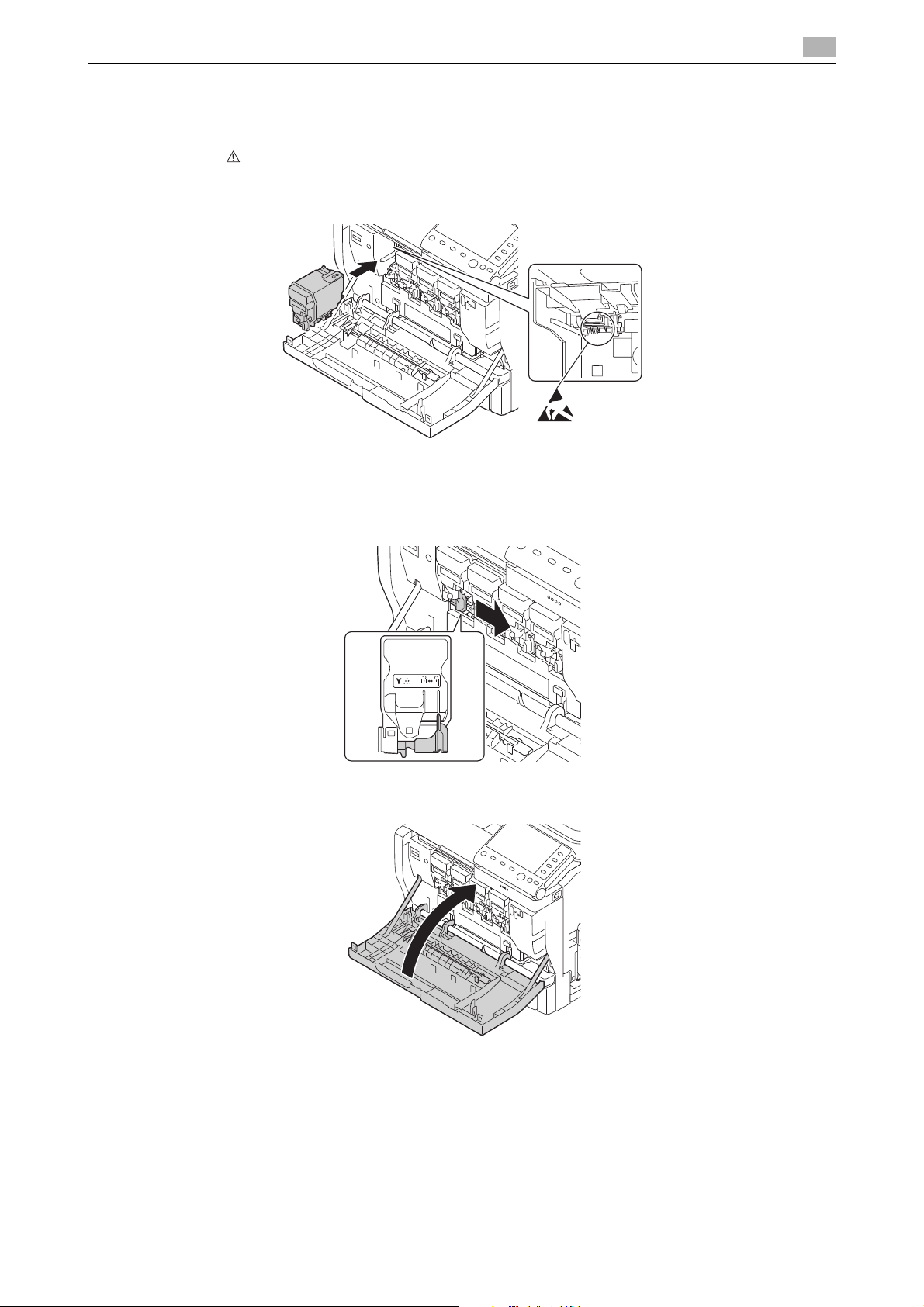

2.2.7 Replacing a Fusing Unit

After the Fusing Unit replacement message has appeared, printing is possible, but the printing quality re-

duces. Immediately replace the Fusing Unit.

2

7CAUTION

- The Fusing Unit is too hot. It may cause a burn injury; therefore, leave the Fusing Unit out for 20 minutes

or more until it reaches room temperature after turning the power off. Then, replace the Fusing Unit.

1 Turn off the power of this machine.

2 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

[Maintenance/Troubleshooting] 2-23

Page 37

2.2 Replacing consumables

3 Open the Fusing Cover.

4 Lower the levers at the right and left.

2

5 Remove the Fusing Unit.

[Maintenance/Troubleshooting] 2-24

Page 38

2.2 Replacing consumables

6 Take a new Fusing Unit out of the package box.

% Do not touch the surface of the Fusing Roller.

7 Lift the levers at the right and left.

2

8 Remove protection materials.

9 Lower the levers at the right and left.

[Maintenance/Troubleshooting] 2-25

Page 39

2.2 Replacing consumables

10 Lower the lever at the bottom.

11 Insert a new Fusing Unit to the back until it is fixed.

2

12 Lift the lever at the bottom.

[Maintenance/Troubleshooting] 2-26

Page 40

2.2 Replacing consumables

13 Close the Fusing Cover.

14 Close the Right Door.

% If the Right Door is not closed, check that the Fusing Unit is installed correctly.

2

15 Select [Utility] - [Administrator Settings] - [System Settings] - [Expert Adjustment] - [Life] - [New Release]

- [Fusing Unit], then reset the counter.

2.2.8 Replacing a Staple Kit SK-602

1 Open the Left Cover.

[Maintenance/Troubleshooting] 2-27

Page 41

2.2 Replacing consumables

2 Pull the tab.

3 Pull out the Staple Cartridge.

2

4 Lift an empty Staple Case while holding its both edges, then pull out it from the Staple Cartridge.

5 Mount a new Staple Case in the Staple Cartridge.

[Maintenance/Troubleshooting] 2-28

Page 42

2.2 Replacing consumables

6 Insert the Staple Cartridge until it clicks.

7 Return the tab to the original position.

2

8 Close the Left Cover.

[Maintenance/Troubleshooting] 2-29

Page 43

2.2 Replacing consumables

2.2.9 Replacing a Staple Kit SK-501

1 Rotate the Finisher FS-P03 90 degrees.

2 Open the cover of the Finisher FS-P03.

2

3 Take the Staple Cartridge out of the Finisher FS-P03.

4 Lift an empty Staple Case while holding its both edges, then pull out it from the Staple Cartridge.

[Maintenance/Troubleshooting] 2-30

Page 44

2.2 Replacing consumables

5 Mount a new Staple Case in the Staple Cartridge.

6 Insert the Staple Cartridge until it clicks.

2

7 Close the cover of the Finisher FS-P03.

8 Rotate the Finisher FS-P03 90 degrees to return it to its original position.

[Maintenance/Troubleshooting] 2-31

Page 45

3

Clearing Paper Jam and

Staple Jam

Page 46

3.1 To prevent a paper jam

3 Clearing Paper Jam and Staple Jam

3.1 To prevent a paper jam

To prevent a paper jam, check the following points.

- Do the paper match the specifications of this machine?

- Is the paper (in particular, the feeding side) even?

- Is this machine installed on a stable and horizontal location that has a hard and even surface?

- Is the paper kept away from humid conditions?

- Do you always align the paper guide to the paper size after loading paper into a tray? (If the paper guide

is not aligned to the paper size, it may reduce printing quality, cause a paper jam, or damage the machine.)

- Is the paper loaded into a tray with the required side facing upward? (The arrow indicating the print side

of paper may be shown on the packing label of paper.)

To prevent a paper jam, avoid the following actions.

- Do not load paper that is folded, creased, embossed, or bent into a tray.

- Do not load jammed paper into a tray more than once.

- Do not load a stack of paper into a tray. (When a stack of paper is fed, remove it from the tray once,

then flip through the paper to separate sheets.)

- Do not load paper of different types, sizes, or weights together into a tray.

- Do not load a quantity of paper that exceeds the maximum capacity of the paper tray in the tray.

- Do not leave a quantity of paper that exceeds the maximum capacity of the paper tray. (Up to 250

sheets can be output from the output tray. If 250 or more sheets are left in the tray, it will cause a paper

jam.)

3

[Maintenance/Troubleshooting] 3-2

Page 47

3.2 When a paper jam has occurred

Tips

3.2 When a paper jam has occurred

To prevent a failure, carefully remove jammed paper so that it does not tear. Even if only a large or small slip

of paper is left in this machine, it will cause a paper feed failure, resulting in a paper jam.

7CAUTION

- A print image is not fused before it is processed in the fusing unit. If you touch the print side, your hand

may become stained with toner. When removing jammed paper, be careful not to touch the print side.

Also, do not spill toner inside this machine.

- Toner that is not fused may stain your hand or clothes. If your clothes become stained with toner, try

to clean off as much as you can. If a stains remain on your clothes, wash with cool water, not hot water.

If your skin is stained with toner, wash with water or neutral detergent.

- If any toner enters your eyes, immediately wash them with cool water, then contact your doctor.

3.2.1 Paper jam message screen

If a paper jam occurs on this machine, a message notifying that a paper jam has occurred will be displayed

on the Touch Panel.

If a paper jam message remains displayed after a paper jam has been cleared, open and close the door of

this machine.

3

3.2.2 Clearing a paper jam in the Manual Feed Tray or Transfer Roller

7CAUTION

- The area around the fusing unit is hot. To avoid a burn injury, be careful not to touch any parts except

for the specified knob and dial. In case your hand or any other part of your body comes in contact with

the heated section, immediately run it under cold water and seek medical assistance.

[Maintenance/Troubleshooting] 3-3

Page 48

3.2 When a paper jam has occurred

Clear procedure

1 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

2 Carefully pull out the jammed paper.

3

NOTICE

If you touch the surface of the Transfer Belt Unit or Transfer Roller, it may reduce printing quality. Be

careful not to touch the surface of the Transfer Belt Unit or Transfer Roller.

[Maintenance/Troubleshooting] 3-4

Page 49

3.2 When a paper jam has occurred

3 Close the Right Door.

3.2.3 Clearing a paper jam in Tray 1

7CAUTION

- The area around the fusing unit is hot. To avoid a burn injury, be careful not to touch any parts except

for the specified knob and dial. In case your hand or any other part of your body comes in contact with

the heated section, immediately run it under cold water and seek medical assistance.

3

Clear procedure

1 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

[Maintenance/Troubleshooting] 3-5

Page 50

3.2 When a paper jam has occurred

2 Carefully pull out the jammed paper.

NOTICE

If you touch the surface of the Transfer Belt Unit or Transfer Roller, it may reduce printing quality. Be

careful not to touch the surface of the Transfer Belt Unit or Transfer Roller.

3

3 Close the Right Door.

4 Pull out Tray 1, then remove any paper left in the tray.

[Maintenance/Troubleshooting] 3-6

Page 51

3.2 When a paper jam has occurred

5 Flip through the removed paper, the align the edges.

6 Load paper into Tray 1, then close the tray.

3.2.4 Clearing a paper jam in Tray 2/3

0 Tray 2/3 is available when the optional Paper Feed Unit is installed.

1 Open the Right Door of Tray 2/3.

% When opening the Right Door of Tray 2/3, be sure to fold the Manual Feed Tray in advance.

3

2 Carefully pull out the jammed paper.

3 Close the Right Door of Tray 2/3.

4 Pull out Tray 2/3, then remove any paper left in the tray.

[Maintenance/Troubleshooting] 3-7

Page 52

3.2 When a paper jam has occurred

5 Flip through the removed paper, the align the edges.

6 Load paper into Tray 2/3, then close the tray.

3.2.5 Clearing a paper jam in the ADF

1 Open the ADF Cover.

3

2 Remove the remaining original from the Document Feed Tray.

[Maintenance/Troubleshooting] 3-8

Page 53

3.2 When a paper jam has occurred

3 Open the ADF.

4 Remove the jammed original.

3

5 Close the ADF.

6 Close the ADF Cover.

[Maintenance/Troubleshooting] 3-9

Page 54

3.2 When a paper jam has occurred

3.2.6 Clearing a paper jam in the Duplex Option

1 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

2 Carefully pull out the jammed paper.

3

3 Close the Right Door.

[Maintenance/Troubleshooting] 3-10

Page 55

3.2 When a paper jam has occurred

3.2.7 Clearing a paper jam in the Fusing Unit

7CAUTION

- The area around the fusing unit is hot. To avoid a burn injury, be careful not to touch any parts except

for the specified knob and dial. In case your hand or any other part of your body comes in contact with

the heated section, immediately run it under cold water and seek medical assistance.

3

Clear procedure

1 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

2 Press up the levers (2 places).

[Maintenance/Troubleshooting] 3-11

Page 56

3.2 When a paper jam has occurred

3 Open the Fusing Cover.

4 Carefully pull out the jammed paper.

3

% If you cannot remove the paper downward, remove it from the upper side of the Fusing Unit.

NOTICE

If you touch the surface of the Transfer Belt Unit or Transfer Roller, it may reduce printing quality. Be

careful not to touch the surface of the Transfer Belt Unit or Transfer Roller.

[Maintenance/Troubleshooting] 3-12

Page 57

3.2 When a paper jam has occurred

5 Close the Fusing Cover.

6 Press down the levers (2 places).

3

7 Close the Right Door.

[Maintenance/Troubleshooting] 3-13

Page 58

3.2 When a paper jam has occurred

3.2.8 Clearing a paper jam in the Finisher (bizhub C3850FS only)

1 Pull the lever (1), then open the Right Door (2).

% When opening the Right Door, be sure to fold the Manual Feed Tray in advance.

2 Check the Processing Tray of the Finisher, then carefully pull out the jammed paper from the outlet.

3

3 Close the Right Door.

[Maintenance/Troubleshooting] 3-14

Page 59

3.3 Troubleshooting for paper jam

3.3 Troubleshooting for paper jam

Symptom Cause Action

Multiple sheets are fed out as a

stack of paper.

A paper jam message persists. This machine must be reset. Open and close the Right Door

A paper jam has occurred during

2-sided printing.

A paper jam has occurred in the

ADF.

Sheet edges are not aligned. Remove sheets, align their edg-

Paper is damp. Remove the damp paper, then

A jammed paper or slip of paper

remains inside this machine.

Invalid paper (paper of an invalid

size, thickness, or type) is used.

A paper jam has not yet cleared. Recheck the paper path, then

An invalid original is used. Use an original that matches this

The number of original pages exceeds the maximum capacity.

The width of the lateral guide is

not adjusted to the size of the

original.

es, then load them into a tray

again.

replace it with new dry paper.

of this machine to reset.

Recheck the paper path, then

check that all paper jams are

cleared.

Use our recommended paper.

For information on the available

paper, refer to Chapter 6 "Loading Paper" in [User's Guide: Introduction].

2-sided printing is available for

plain paper (recycled paper) of

15-15/16 to 23-15/16 lb (60 to 90

2

), thick paper of 24-3/16 to

g/m

55-7/8 lb (91 to 210 g/m2), or

special paper of 15-15/16 to 2315/16 lb (60 to 90 g/m

the correct paper type using the

printer driver.

For information on the available

paper, refer to Chapter 6 "Loading Paper" in [User's Guide: Introduction].

Do not load sheets of different

types together.

Do not use an envelope, label

sheet, postcard, glossy paper, or

single side only paper for 2-sided

printing.

check that all paper jams are

cleared.

machine.

For information on the available

original size, refer to Chapter 5

"Loading the Original" in [User's

Guide: Introduction].

Remove excessive original pages on the ADF, then load them

again.

Adjust the lateral guide of the

ADF to the size of the original.

2

). Specify

3

[Maintenance/Troubleshooting] 3-15

Page 60

3.3 Troubleshooting for paper jam

Tips

Symptom Cause Action

A paper jam has occurred in the

paper tray.

A paper jam has occurred in the

Finisher.

Paper is not loaded in the correct

position in the paper tray.

The number of sheets in the paper tray exceeds the maximum

capacity.

The width of the paper guide has

not adjusted to the paper size.

Bent or creased paper has been

loaded into the paper tray.

Paper is damp. Remove damp paper, then load

Envelopes are loaded in Tray

2/3.

Thick paper, label sheets, postcards, glossy paper, or letterheads are loaded in Tray 2/3.

Label sheets are loaded in an incorrect orientation.

Envelopes are loaded in an incorrect orientation.

Invalid paper (paper of an invalid

size, thickness, or type) is used.

The Paper Feed Rollers are dirty. Clean the Paper Feed Rollers.

Invalid paper (paper of an invalid

size, thickness, or type) is used.

Remove the jammed paper, then

correctly load paper into the paper tray.

Remove excessive sheets in the

paper tray, then re-load paper

into the paper tray.

Adjust the paper guide in the paper tray to the paper size.

Remove the bent or creased paper, then load new paper into the

paper tray.

new dry paper into the paper

tray.

Load envelopes into Tray 1 or

the Manual Feed Tray.

Load thick paper, label sheets,

postcards, glossy paper, or letterheads into Tray 1 or the Man-

ual Feed Tray.

Correct the orientation of label

sheets.

Place an envelope with the flap

facing upward.

When the flap is in the long side

of an envelope, load it in the machine side.

Use our recommended paper.

For information on the available

paper, refer to Chapter 6 "Loading Paper" in [User's Guide: Introduction].

For details, refer to page 1-5.

Use the paper available with the

Finisher.

For information on the available

paper, refer to Chapter 10

"Specifications" in [User's

Guide: Introduction].

3

If a paper jam frequently occurs in a specific place, carry out checks, repairs, or cleaning focusing on the

location of the jam.

[Maintenance/Troubleshooting] 3-16

Page 61

3.4 Clearing a staple jam

3.4 Clearing a staple jam

3.4.1 Clearing a staple jam in the Staple Kit SK-501

1 Rotate the Finisher FS-P03 90 degrees.

2 Open the cover of the Finisher FS-P03.

3

3 Take the Staple Cartridge out of the Finisher FS-P03.

4 Lift the Face Plate, then remove jammed or spilled staples.

[Maintenance/Troubleshooting] 3-17

Page 62

3.4 Clearing a staple jam

Tips

5 Return the Face Plate until it clicks.

6 Insert the Staple Cartridge until it clicks.

3

7 Close the cover of the Finisher FS-P03.

8 Rotate the Finisher FS-P03 90 degrees to return it to its original position.

After clearing a staple jam, conduct idle stapling twice.

[Maintenance/Troubleshooting] 3-18

Page 63

3.4 Clearing a staple jam

3.4.2 Clearing a staple jam in the Staple Kit SK-602

1 Open the Left Cover.

2 Pull the tab.

3

3 Pull out the Staple Cartridge.

4 Lift the Face Plate, then remove one staple sheet.

[Maintenance/Troubleshooting] 3-19

Page 64

3.4 Clearing a staple jam

Tips

5 Return the Face Plate until it clicks.

6 Insert the Staple Cartridge until it clicks.

3

7 Return the tab to the original position.

8 Close the Left Cover.

After a staple jam is cleared, idle stapling is conducted one to nine times depending on the conditions.

[Maintenance/Troubleshooting] 3-20

Page 65

4

Troubleshooting

Page 66

4.1 The power is not turned on

4 Troubleshooting

4.1 The power is not turned on

Check the Power Switch for the status.

- Check whether the power plug of this machine is firmly plugged into the power outlet. Also check that

the breaker has not tripped.

- Check that the Power Switch is turned ON.

4

[Maintenance/Troubleshooting] 4-2

Page 67

4.2 The Touch Panel is not displayed

4.2 The Touch Panel is not displayed

If a certain length of time has elapsed without any operations being carried out on this machine, the Touch

Panel may turn off.

Check the following items:

- Select [Utility] - [Accessibility] - [Brightness Adjustment], then adjust the contrast (brightness) of the

Touch Panel.

- Touch the Touch Panel. In Power Save (Low Power/Sleep) mode, this machine returns from the Power

Save mode when the Touch Panel is touched or a key on the Control Panel is pressed, and the Touch

Panel appears normally.

- On the Control Panel, press the Power key. If the Weekly Timer setting has put the machine in Erp

Auto Power Off mode, press the Power key to display the Touch Panel. To use it outside the preset

operating hours, follow the on-screen instructions.

- Check that the Power Switch is turned ON.

4

[Maintenance/Troubleshooting] 4-3

Page 68

4.3 Cannot print

4.3 Cannot print

4.3.1 Cannot print

Description of problem Check points Remedy

A message saying

"Printer is not connected" or "Print Error" appears on the computer

screen.

A postscript error appears on the computer

screen.

Is the power turned on? Check the Power Switch of this machine.

Has the machine been

placed in ErP Auto Power Off mode?

Is another printer specified?

Is the network or USB

cable disconnected?

Has an error occurred on

the machine?

Is there sufficient computer memory available?

Is there sufficient computer memory available?

There may be an error in

the application software

settings.

Are the file printing settings correct?

If a hub is used, also check the hub power.

If the machine is placed in ErP Auto Power Off

mode, it cannot receive any jobs. Press the Pow-

er key to release the ErP Auto Power Off mode.

Check the specified printer name.

Make sure that the cables are correctly connected.

If a hub is used, also check the connection with

the hub.

Check the Control Panel of this machine.

Perform a test printing to check whether printing

is possible.

If test printing is successful, this indicates there

are no problems on this machine or with the

printer driver. In this case, remove the cause of

memory shortage.

If test printing fails, resolve any problems that

may be occurring in the machine or with the

printer driver.

Perform a test printing to check whether printing

is possible.

If test printing is successful, this indicates there

are no problems on this machine or with the

printer driver. In this case, remove the cause of

memory shortage.

If test printing fails, resolve any problems that

may be occurring in the machine or with the

printer driver.

Refer to the user's manual of the application software to check the settings.

Change the settings and try to print again.

4

[Maintenance/Troubleshooting] 4-4

Page 69

4.3 Cannot print

Description of problem Check points Remedy

Print processing on the

computer has finished,

but printing does not

start.

Cannot print in Secured

Job

A file saved on the HDD

has disappeared from a

computer.

Is another printer specified?

Is the network or USB

cable disconnected?

Is the machine in the Sub

Power Off mode?

Has an error occurred on

the machine?

Are unprocessed jobs

queued on the machine?

Did you specify [Store

Job] when executing the

print job?

Did you specify [Secured

Job] when executing the

print job?

If account track is enabled, are the account

name and password

correct?

If user authentication is

enabled, are the user

name and password

correct?

Is there sufficient computer memory available?

If network connection is

in place, is the printer

controller connected to

the network?

Is the machine in enhanced security mode?

Is [Password Rules] set

to [ON] on this machine?

Is the setting for deleting

files on the HDD configured on the machine?

4

Check the specified printer name.

Make sure that the cables are correctly connected.

If a hub is used, also check the connection with

the hub.

If the machine is in the Sub Power Off mode,

printing cannot be executed. Press Power key to

release the Sub Power Off mode.

Check the Control Panel of this machine.

Tap [Job List] to check the job sequence.

Check whether or not the target file is saved on

the HDD.

Check whether or not the target file is saved on

the HDD.

Enter the correct account name and password.

Enter the correct user name or password.

Perform a test printing to check whether printing

is possible.

If test printing is successful, this indicates there

are no problems on this machine or with the

printer driver. In this case, remove the cause of

memory shortage.

If test printing fails, resolve any problems that

may be occurring in the machine or with the

printer driver.

Check with the network administrator.

Configure authentication settings in enhanced

security mode.

For information on the authentication settings in

enhanced security mode, refer to [User's Guide:

Description of Utility Keys] - Chapter 5 "Administrator Settings" - [Enhanced Security Mode].

If [Password Rules] is set to [ON], set a password

that satisfies the password rules. For details, refer to [User's Guide: Description of Utility Keys] Chapter 5 "Administrator Settings" - [Security

Details]-[Password Rules].

Check the HDD settings for the machine. For information on the setting use to delete files on the

HDD, refer to [User's Guide: Description of Utility

Keys] - Chapter 5 "Administrator Settings" [Folder Settings].

[Maintenance/Troubleshooting] 4-5

Page 70

4.3 Cannot print

Description of problem Check points Remedy

Printing in user authentication or account track

mode is not available.

Printing is not available

when you have selected

[Public User] in user authentication.

Selection of items failed

in the printer driver.

A "conflict" message

saying "unable to configure" or "function will be

canceled" appears.

Cannot print according

to the settings you have

configured.

Images are not printed

correctly.

Paper is not fed from the

specified paper tray.

Are the user name or account name, and password correct?

Is the user authentication or account track enabled in the printer

driver?

Is the entered user name

or account name authorized?

Is printing by public users permitted on the machine?

Selection may not be enabled for certain combinations of functions.

Have you set up functions that cannot be

used in combination?

The settings may not be

configured correctly.

Even though a combination of functions may be

enabled in the printer

driver, that combination

may not be available on

this machine.

The paper size or paper

orientation specified in

the application may take

precedence over the

settings in the printer

driver when printing.

Is there sufficient computer memory available?

Does the specified paper

tray contain paper of the

correct size/orientation?

4

Enter the correct user name, account name and

password.

Enable user authentication or account track on

the printer driver.

Check that printing of the current user name/account name is permitted?

Check whether printing by public users is permitted. If not, grant printing permission to public users.

Grayed out items cannot be configured.

Check what functions are enabled and redo the

selection of functions.

Check the setting of each item of the printer driver.

Correct the settings in the application.

Simplify the images to reduce the data size.

Load paper of the appropriate size and orientation into the paper tray.

[Maintenance/Troubleshooting] 4-6

Page 71

4.3 Cannot print

4.3.2 Problems on print quality

Description of problem Cause Remedy

No data is printed. A Toner Cartridge is

Printed in jet black or all

over in color.

A print is faint. The laser lens is dirty. Clean the laser lens.

A print is dark. A Toner Cartridge is

damaged.

One or more Imaging

Unit are damaged.

Paper is damp. Adjust the humidity of the paper storage place.

The paper setting of the

printer driver does not

match the paper that is

actually loaded on this

machine.

The power supply does

not match the specification of this machine.

Multiple sheets are fed

out simultaneously.

Paper is not correctly

loaded into the paper

tray.

A Toner Cartridge is

damaged.

One or more Imaging

Unit are damaged.

Paper is damp. Remove the damp paper, then replace it with

Toner is running out in

the Toner Cartridge.

A Toner Cartridge is

damaged.

One or more Imaging

Unit are damaged.

The correct paper type is

not specified.

damaged.

One or more Imaging

Unit are damaged.

The original does not

stick fast to the Original

Glass.

The specified copy density is too high.

4

Remove the Toner Cartridge, then check it for

damage. If the Toner Cartridge is damaged, replace it.

Remove Imaging Unit, then check them for

damage. If necessary, replace Imaging Unit.

Remove the damp paper, then replace it with

new dry paper.

Load the correct paper in this machine.

Use the power supply that matches the specification.

Remove paper from the paper tray, then check it

for static electricity. Flip through the paper, then

return it into the paper tray.

Remove paper, align its edges, return it into the

paper tray, then adjust the paper guide.

Remove the Toner Cartridge, then check it for

damage. If the Toner Cartridge is damaged, replace it.

Remove Imaging Unit, then check them for

damage. If necessary, replace Imaging Unit.

new dry paper.

Replace the Toner Cartridge.

Remove the Toner Cartridge, then check it for

damage. If the Toner Cartridge is damaged, replace it.

Remove Imaging Unit, then check them for

damage. If necessary, replace Imaging Unit.

When printing on thick paper, envelope, label

sheet, postcard, glossy paper, single side only

paper, special paper, or letterhead, specify the

paper type using the printer driver.

Remove the Toner Cartridge, then check it for

damage. If the Toner Cartridge is damaged, replace it.

Remove Imaging Unit, then check them for

damage. If necessary, replace Imaging Unit.

Position the original so that it is pressed closely

against the Original Glass.

Set the copy density to a lower level.

[Maintenance/Troubleshooting] 4-7

Page 72

4.3 Cannot print

Tips

Description of problem Cause Remedy

Image colors run.

The background is dirty.

The degree of gloss is

uneven.

The density is uneven. A Toner Cartridge is

A Toner Cartridge is

damaged.

One or more Imaging

Unit are damaged.

The Original Cover Pad

is dirty.

The Original Glass is

dirty.

damaged.

Toner is running out in

one or more Toner Car-

tridge, or any Toner Cartridge is damaged.

This machine has not

been placed on a level

location.

4

Remove the Toner Cartridge, then check it for

damage. If the Toner Cartridge is damaged, replace it.

Remove Imaging Unit, then check them for

damage. If necessary, replace Imaging Unit.

Clean the Original Cover Pad.

Clean the Original Glass.

Remove the Toner Cartridge, then check it for

damage. If the Toner Cartridge is damaged, replace it.

Replace the Toner Cartridge.

Place this machine on a flat, hard, stable, and

horizontal surface (inclination within +/-1 degree).

4.3.3 When the bit count does not match between the server and the client

If the print server is Windows Server 2008/Server 2008 R2/Server 2012/Server 2012 R2 and its OS bit count

does not match that of the client computer, an additional driver may not be able to be installed normally on

the print server.

To solve this problem, specify the setup information file (ntprint.inf) of the operating system with a different

bit number when installing the additional driver on the print server.

The following describes how to install the additional driver by specifying a setup information file on a different

computer from that of the print server.

- Before starting this procedure, prepare to configure a different client computer from that of the print

server and install the operating system that has a bit number different from that of the print server.

- On the print server side, the system drive of the client computer is assigned as the network drive. Con-

figure the setting to share the drive to be assigned in advance.

This example shows the operation when installing Windows Server 2008 (32-bit version) on the print server

and Windows Vista (64-bit version) on the client computer.

1 Configure the setting to share the drive (ordinarily, drive C) where the client computer's operating sys-

tem is installed.

2 On the print server, assign the drive (example: "C") of the client computer, which is shared in Step 1,

as the network drive (example: "z").

3 Install the 32-bit operating system driver on the print server.

4 Open the Properties screen in the driver installed.

5 Select the [Sharing] tab, and select the [Share this printer] check box.

6 Click [Additional Drivers].

The Additional Drivers page appears.

7 Select the [x64] check box in the [Processor] column, and click [OK].

8 Specify the folder that contains the 64-bit operating system driver.

This displays a page to request a setup information file.

[Maintenance/Troubleshooting] 4-8

Page 73

4.3 Cannot print

9 Click [Browse], and specify the setup information file [ntprint.inf] on the client computer to which the

network drive is assigned.

% Specify the following file.

% The setup information file may be stored at a different location depending on your client computer.

10 Click [Open].

Installation starts.

11 When the installation is complete, click [Close].

Additional installation of the 64-bit operating system driver is then completed.

4

[z:\Windows\System32\DriverStore\FileRepository\ntprint.inf_xxx]

In the path above, "z" represents the assigned network drive. "_xxx" at the end of this path varies

depending on the driver version.

If folder [amd64] resides in the same hierarchy as that of [ntprint.inf], specify a setup information file

for 64-bit operating system under that folder. To additionally install a 32-bit operating system driver,

specify a setup information file under folder [i386] that is in the same hierarchy as that of [ntprint.inf].

[Maintenance/Troubleshooting] 4-9

Page 74

4.4 Cannot perform network scanning

4.4 Cannot perform network scanning

Description of problem Check points Remedy

Cannot send data. Is the volume per E-mail to

be sent exceeding the maximum receiving capacity of

the SMTP server?

Was the transmission procedure carried out correctly?

Are the network settings and

connection correct?

Is the correct E-mail address

set for this machine?

Are cables connected correctly?

Scanned data cannot be sent

(by SMB TX) to a specified

computer.

When sending scanned data

(by SMB TX) to a specified

computer, operations take

place slowly.

When sending scanned data

(by SMB TX) to a specified

computer, a "Server connection error" occurs.

When sending scanned data

(by SMB TX) to a specified

computer, a "login error" occurs.

Is the folder correctly specified?

Are you using the correct authentication method?

Have you specified a folder

name using more than 13

characters?

Is [LLMNR] enabled? Disable [LLMNR] using Web Connec-

Is the network cable connected?

Do packets from this machine reach the destination?

Is the [File Path] set correctly

for the destination?

Are you operating as a domain user?

4

If the volume of one E-mail message exceeds the maximum capacity of the

SMTP server for reception, an error occurs which will prevent transmission.

Check the transmission procedure, then

resend the fax.

Check the network settings and connection.

Check the E-mail address of the machine and configure it.

Make sure that the network cable is correctly connected.

If the path for the destination folder is

delimited by "/ (slash)", the folder cannot be specified. Use "\" to specify the

path for the destination folder.

When sending data to a destination PC

running operating software earlier than

Mac OS X 10.3.x, use the NTLMv1 authentication. To a destination PC running operating system later than Mac

OS X 10.4.x, send data using the

NTLMv2 authentication.

When sending data to a folder on a PC

running Mac OS X, specify a folder

name using up to 12 characters.

tion.

Make sure that the network cable is correctly connected.

Check that packets from this machine

reach the destination.

If not, take/check the action indicated

below:

• Replace the network cable with a

new one.

• Check if the wireless settings are

correct if wireless connection is

used. Or replace it with a wired connection.

• If no packets are sent out from this

machine, check the IP settings on

this machine.

• Check that the IP address of the

destination is correctly registered.

Check that the [File Path] of the destination is correctly registered.

If you are operating as a domain user,

create a domain user name that is different from the local user name. If your domain user name is the same as the local

user name, use the same password for

both.

[Maintenance/Troubleshooting] 4-10

Page 75

4.5 Cannot perform fax/internet fax

4.5 Cannot perform fax/internet fax

4.5.1 Cannot perform Fax TX

Description of problem Check points Remedy

Cannot send data. Was the transmission proce-

dure carried out correctly?

Is the fax number you entered for the destination correct?

Were the address book destination and program destination registered correctly?

Is the telephone line setting

correct?

Is the modular cable connected correctly?

Is there a problem with the

receiving machine?

If it is a password TX job,

have you sent the correct

password?

Was the sender's fax number

correctly registered with

"Check Dest. & Send"?

Is [PBX Connection Settings]

set correctly when you are

using this machine in the

PBX environment?

4

Check the transmission procedure, then

resend the fax.

If you are using a destination in the Address Book or Program, the registered

fax number may be incorrect.

Print the Speed Dial list to check whether the numbers are registered correctly.

Does the setting in [Dialing Method]

match the telephone line being used?

Check the setting and correct it if an error is found.

Is the modular cable connected?

Check the modular cable connection

and, if unplugged, plug it in securely.

Are TEL and LINE connected inversely?

Check the modular cable connection

and, if unplugged, plug it in securely.

Is the power of the receiving facsimile

turned off, is it out of paper or is there

another problem?

Call the recipient to determine whether

there is a problem.

Check the recipient's password then

resend the fax using a correct password.

Check that the fax number registered

with the recipient is correct.

Or set Check Dest. & Send to Disable,

then send a fax.

When setting [PBX Connection Settings]

to [ON] and dialing the recipient for

which [E] is registered at the head of a

fax number, check that the outside line

number is correctly registered in [PBX

Connection Settings].

When setting [PBX Connection Settings]

to [OFF], you can enter "P" (pause) and

the recipient fax number following the

outside line number to call the outside

line.

[Maintenance/Troubleshooting] 4-11

Page 76

4.5 Cannot perform fax/internet fax

4.5.2 Cannot perform Fax RX

Description of problem Check points Remedy

Cannot receive faxes. Is the power turned on? Check the Power Switch of this ma-

No printout produced. Is PC-Fax RX enabled? When PC-Fax RX is enabled, print the

chine.

If a hub is used, also check the hub

power.

Has the machine been

placed in ErP Auto Power Off

mode?

Is the Receive Mode set to

Manual RX?

Is the modular cable connected correctly?

Is [Closed Network RX] enabled?

Has a wrong SUB been sent

in F-code from the sender

side?

Is TSI Distribution enabled? Check forwarding destinations for TSI

Is Memory RX enabled? If Memory RX is enabled, print the fax

Is paper in the machine? Add paper.

Is paper jammed in the machine?

Is the machine out of toner? No fax can be received if the toner is ex-

If the machine is placed in ErP Auto

Power Off mode, it cannot receive any

jobs. Press the Power key to release the

ErP Auto Power Off mode.

Change the [RX Mode ]to [Auto RX].

When [RX Mode ]is set to [Manual RX],

receive faxes manually.

Is the modular cable connected?

Check the modular cable connection

and, if unplugged, plug it in securely.

If [Closed Network RX] is enabled, the

machine accepts faxes sent from specific recipients. For details, contact your

administrator.

If a wrong sub-address is received with

the Confidential User Box set, a communication error may occur, causing

failed reception. Check the sender side

to see if the sub-address is set.

fax from the Memory RX User Box.

Distribution.

from the Memory RX User Box.

Clear the jammed paper.

hausted. Replace the Toner Cartridge.

4

[Maintenance/Troubleshooting] 4-12

Page 77

4.6 Cannot perform copy

4.6 Cannot perform copy

Description of problem Check points Remedy

Copying does not start. Are the doors of the machine

securely closed?

Has paper of the correct size

for the original been loaded

into the paper tray?

The original does not feed. Is the ADF slightly open? Securely close the ADF.

Is the original one that does

not meet the specifications?

Has the original been positioned correctly?

The image is light. Is [Light] specified for the

The image is dark. Is [Dark] specified for the

The image is partially obscured or blurry.

The entire area of a copy gets

smudged.