Page 1

© EASTMAN KODAK COMPANY, 2006 HEALTH GROUP

Confidential

Restricted

Information

{InstallationInstructs}{Production}{Health Group}{ExternalAndInternal}

INSTALLATION INSTRUCTIONS

for the

Kodak DirectView CR 825/850 SYSTEMS

Service Codes: 5634, 4825

Important

Qualified service personnel must install this equipment.

Publication No. II4825-1

10MAR06

Supersedes II4825-1

10DEC05

H177_0500AC

Page 2

INSTALLATION INSTRUCTIONS

10MAR06

II4825-1

Page

2 of 72

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Necessary Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Energizing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Obtaining a “Session ID” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Doing the Calibration for the TOUCH SCREEN . . . . . . . . . . . . . . . . . . . . . 29

Setting the Site Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting the “User Name” and “Password” . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installing and Setting Up Optional Features . . . . . . . . . . . . . . . . . . . . . . . . 33

Setting the “Global” Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Setting the HIS/RIS Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Adding a PRINTING DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adding a STORAGE DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Setting the Profile Destination Configuration . . . . . . . . . . . . . . . . . . . . . . . 54

Enabling the BAR CODE READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Setting the Requirements Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Configuring the MONITOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Doing the Configuration for the Kodak DirectView CR LONG-LENGTH

IMAGING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Storing the Setup Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Installing the Kodak REMOTE PATIENT DATA ENTRY STATION (RPDES) 62

Setting the Configuration for the RPDES . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Page 3

INSTALLATION INSTRUCTIONS

10MAR06

II4825-1

Page

3 of 72

Operating the RPDES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Making a SHORTCUT for the RPDES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Setting the Host File for the Kodak DirectView CAPTURE LINK SYSTEM. 65

Installing the Kodak DirectView REMOTE OPERATIONS PANEL (ROP) . 66

Checking the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Page 4

10MAR06

II4825-1

Page

4 of 72

INSTALLATION INSTRUCTIONS Safety

Section 1: Safety

This information defines the safety and information icons used in this publication.

Radiation

This icon is used for conditions that could cause personal injury from radiation.

Laser Warning

This icon is used for conditions when a laser beam could cause injury to a person.

Caution

This icon is used for conditions that could cause injury to a person, or damage to the

equipment or software data.

ESD

Possible damage from electrostatic discharge.

This icon is used for conditions that could cause damage to the equipment.

Electrostatic discharge (ESD) is a primary source of:

• equipment failure

• equipment repairs

A person cannot detect an electrical charge of less than 3,500 V, but 30 V can cause

damage to components in the equipment.

Page 5

INSTALLATION INSTRUCTIONS Safety

10MAR06

II4825-1

Page

5 of 72

Preventive Measures

• Check for an ESD WARNING LABEL before doing any procedure with ESD-sensitive

components. All sensitive components have graphic LABELS that frequently include

instructions. Use all label instructions.

• Wear a GROUNDING STRAP when you touch ESD-sensitive components. Check that the

CLIP remains fastened to a ground that has a clean surface with no paint.

• Repair components in an ESD-protection area or use a PORTABLE GROUNDING MAT.

• When moving ESD-sensitive components from area to area, insert and transport the

components in the special material made for the transport of these components.

Important

This icon is used for important information.

Note

This icon is used for additional information.

Page 6

10MAR06

II4825-1

Page

6 of 72

INSTALLATION INSTRUCTIONS Necessary Materials

Section 2: Necessary Materials

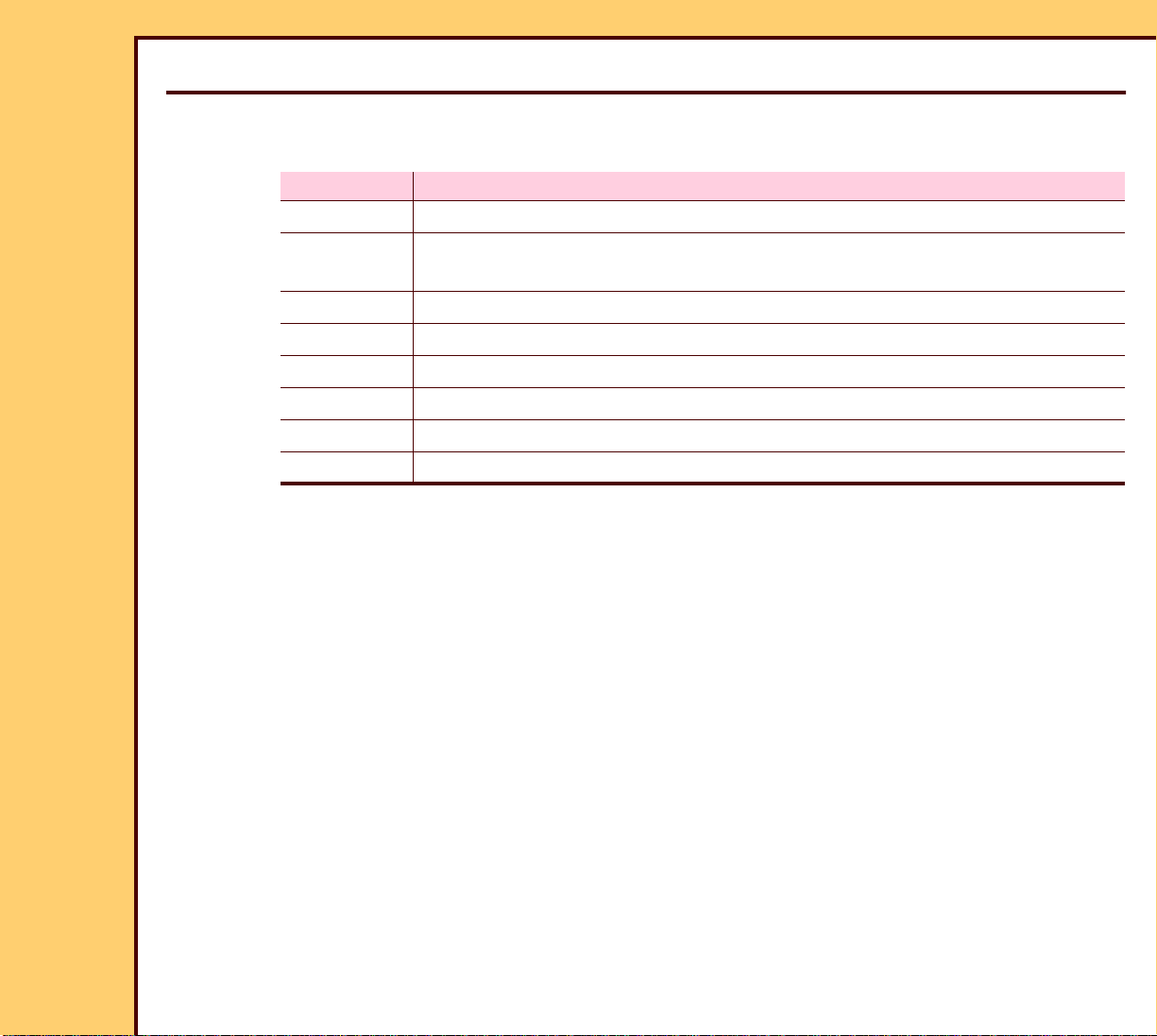

Tools

Par t No . Description

- - - COMPUTED RADIOGRAPHY CASSETTES

1064930 Kodak INTENSIFYING SCREEN CLEANER AND ANTISTATIC

SOLUTION

TL-5259 COPPER and ALUMINUM FILTERS

- - - tape

3E0899 LINT-FREE CLOTH

TL-4818 DOSIMETER

5E6777 OIL

- - - LEAD APRON or LEAD SHEET

Page 7

10MAR06

II4825-1

Page

7 of 72

INSTALLATION INSTRUCTIONS Installation

Section 3: Installation

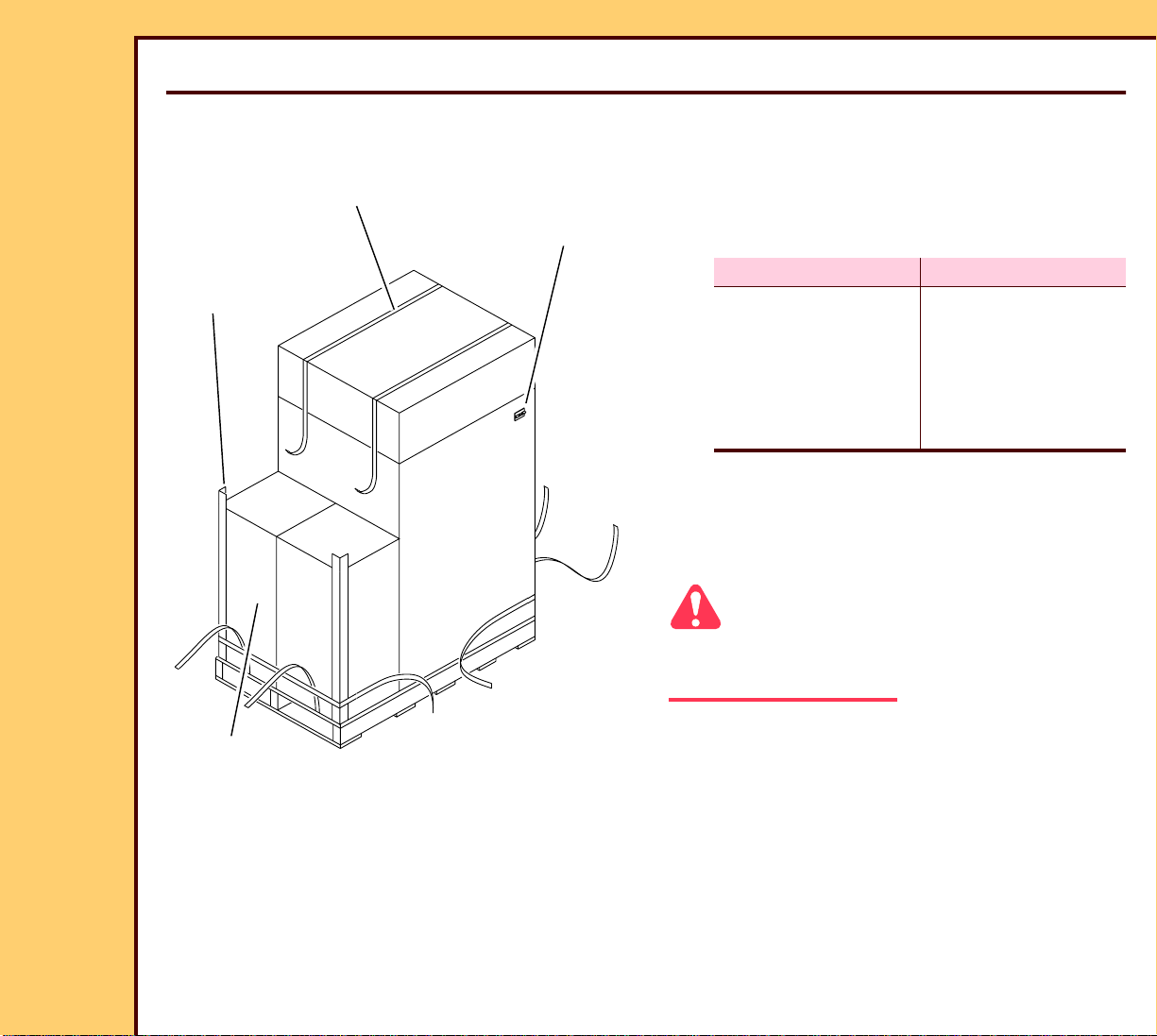

Unpacking the Equipment

1 Check the SHOCK WATCH on the side

3 STRAPS

SHOCK

WATCH

of the carton.

2 Is the SHOCK WATCH red?

2 CORNER

PROTECTORS

2 cartons

H194_0116GCA

H194_0116GC

Yes No

Stop the

installation

Continue with

Step 3.

procedure and call

the Technical

Support Center

(TSC).

3 Record any problems that occur during

this installation. Include this information

in the “OUT OF BOX SURVEY” you

provide to the customer.

Caution

Be careful when you cut the STRAPS. The

STRAPS are tight.

4 Cut the 3 STRAPS.

5 Remove:

• 2 CORNER PROTECTORS

• 2 cartons

– ASSEMBLY KIT 1

– ASSEMBLY KIT 2

6 Unpack the 2 cartons.

Page 8

10MAR06

II4825-1

Page

8 of 72

INSTALLATION INSTRUCTIONS Installation

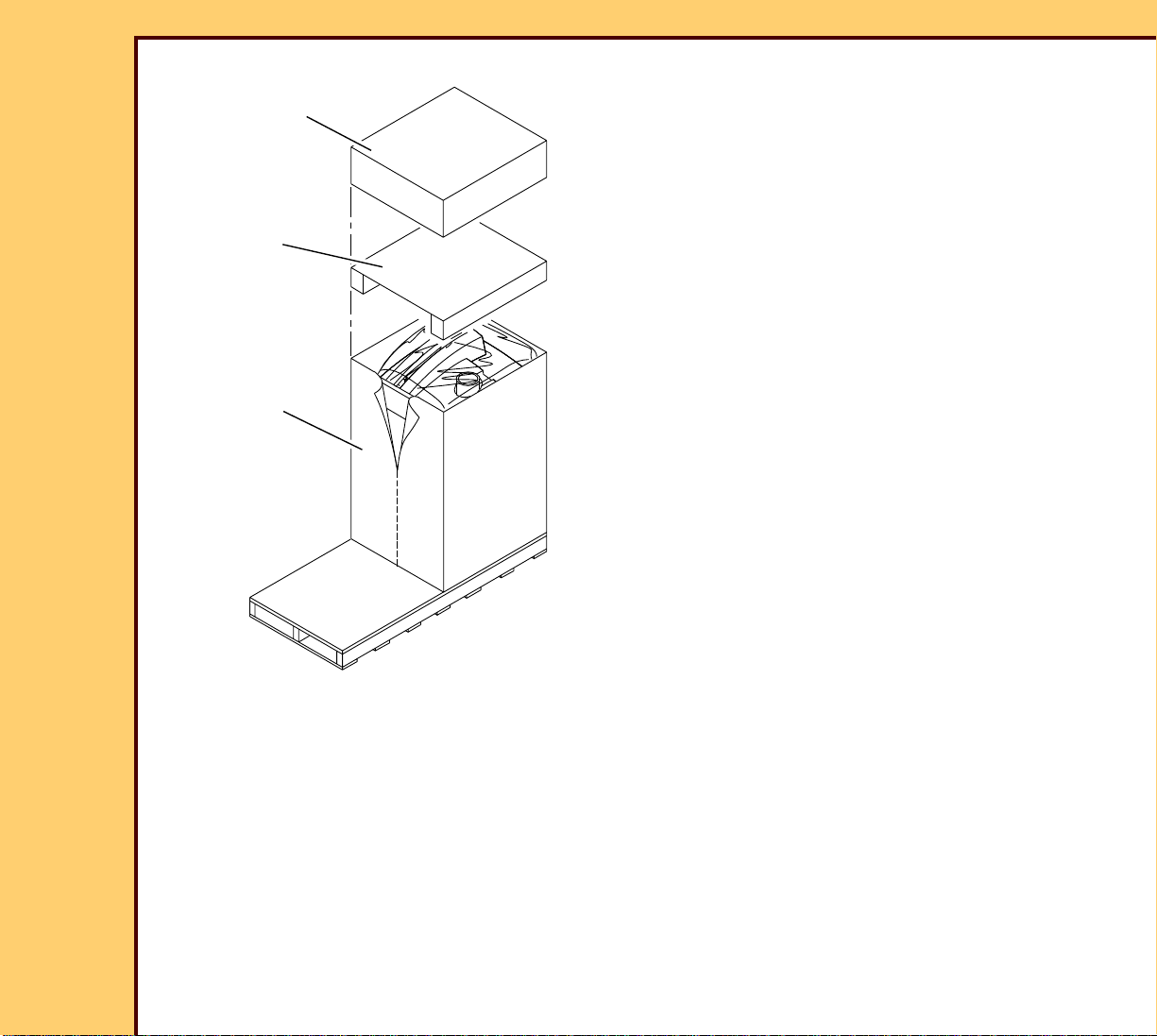

7 Remove:

SHORT CAP

• SHORT CAP

• CORRUGATED SUPPORT

8 Cut the carton.

CORRUGATED

SUPPORT

carton

H194_0117GCA

H194_0117GC

9 Remove the carton.

Page 9

10MAR06

II4825-1

Page

9 of 72

INSTALLATION INSTRUCTIONS Installation

10 Cut the tape.

RAMP

PLASTIC

BAG

11 Remove the RAMP SUPPORT from

behind the RAMP.

12 Align the mark on the RAMP SUPPORT

with the mark on the RAMP.

13 Place the RAMP SUPPORT on the

RAMP.

mark

RAMP

SUPPORT

tape

H194_0118GCA

H194_0118GC

14 Remove:

• RAMP

• PLASTIC BAG

Page 10

10MAR06

II4825-1

Page

10 of 72

INSTALLATION INSTRUCTIONS Installation

Important

Keep the REAR SHIPPING BRACKET.

15 Remove and keep:

• 10 BOLTS

• 4 SIDE SHIPPING BRACKETS

• REAR SHIPPING BRACKET

10 BOLTS

REAR SHIPPING

BRACKET

H194_0119ACA

H194_0119AC

4 SIDE SHIPPING

BRACKETS

16 Fasten the RAMP to the PALLET.

RAMP

PALLET

H194_0120ACA

H194_0120AC

Caution

The weight is 308 kg (680 lb). Use more

than one person to move down the RAMP.

17 Carefully move the system down the

RAMP.

Page 11

10MAR06

II4825-1

Page

11 of 72

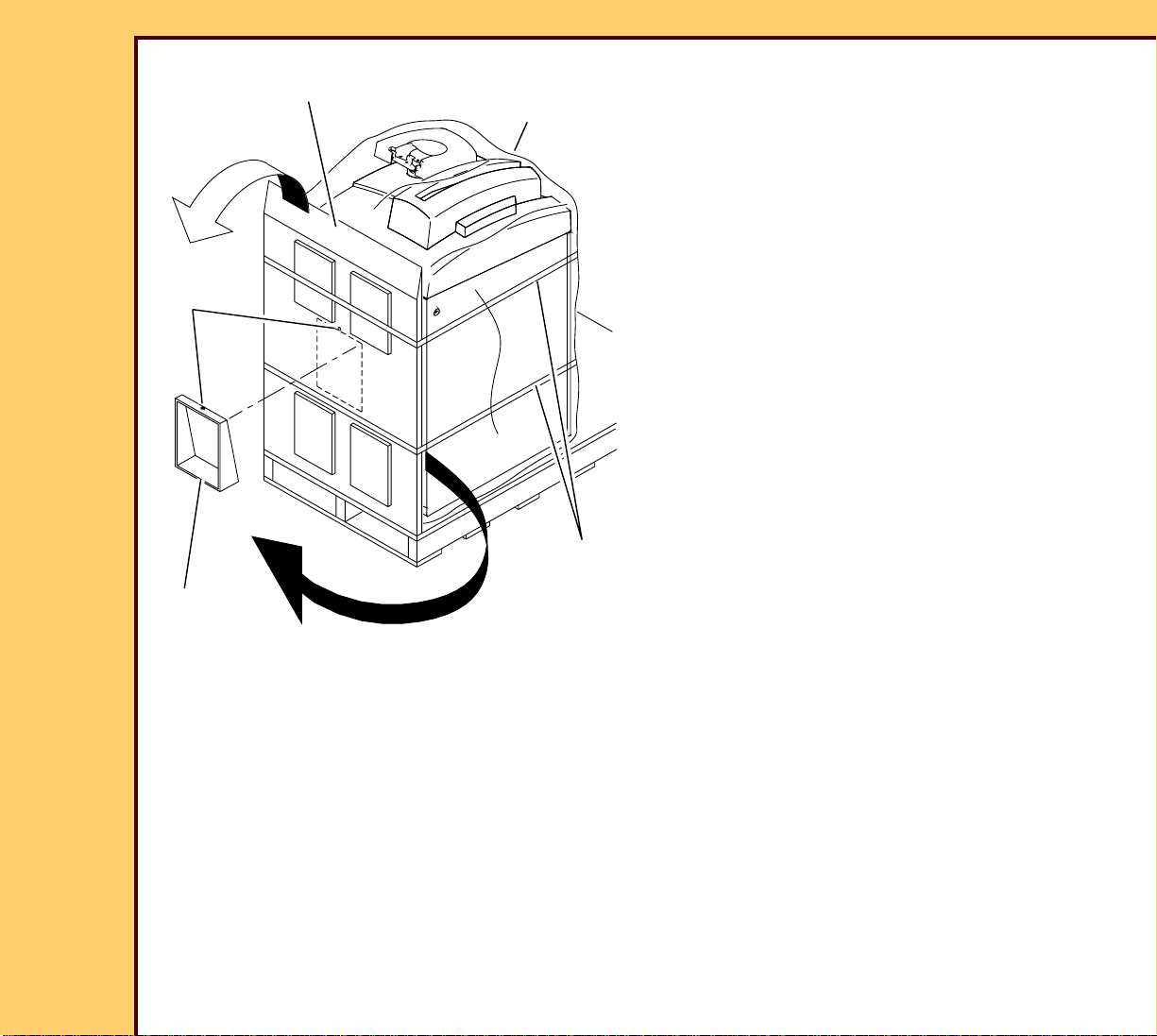

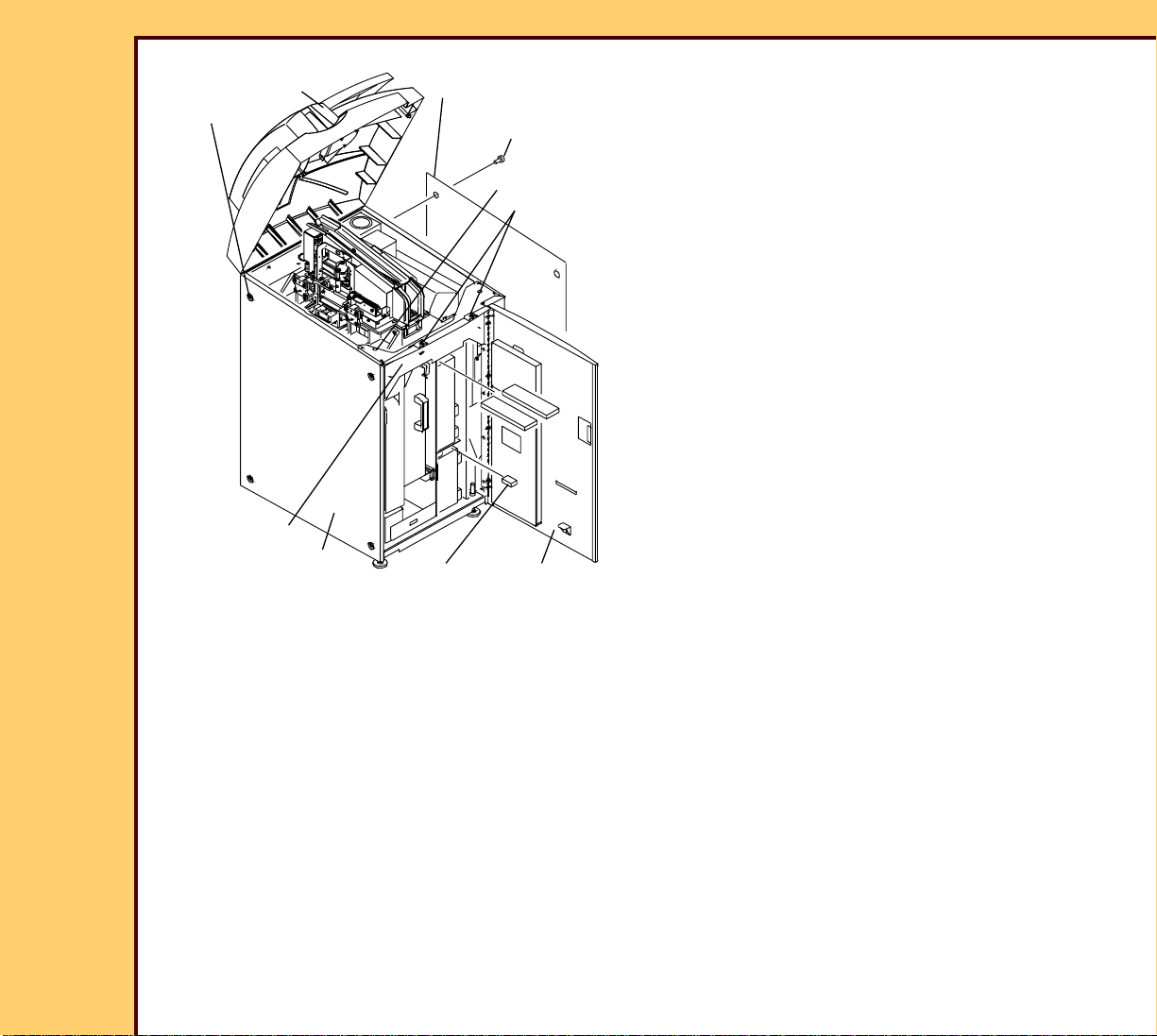

INSTALLATION INSTRUCTIONS Installation

18 Open the FRONT DOOR.

TOP COVER

2 SCREWS

LEFT PANEL

2 SCREWS

19 Loosen the 2 SCREWS.

20 Open the TOP COVER.

21 Remove:

7 SCREWS

2 SCREWS

• FOAM PACKING MATERIAL

• 7 SCREWS

• CROSSBRACE

• 2 SCREWS

• LEFT PANEL

• 2 SCREWS

• RIGHT PANEL

CROSSBRACE

H194_0101GCA

H194_0101GC

RIGHT

PANEL

FOAM PACKING

MATERIAL

FRONT

DOOR

Page 12

10MAR06

II4825-1

Page

12 of 72

INSTALLATION INSTRUCTIONS Installation

22 Check the SHOCK WATCH on the side

of the frame.

23 Is the SHOCK WATCH red?

SHOCK WATCH

H194_1400ACA

H194_1400AC

OPTICS

SHIPPING

BRACKET

Yes No

Stop the installation

procedure and call the

TSC.

24 Remove and discard:

• 2 BOLTS

• OPTICS SHIPPING BRACKET

Continue with

Step 24.

H194_0113ACA

H194_0113AC

2 BOLTS

Page 13

10MAR06

II4825-1

Page

13 of 72

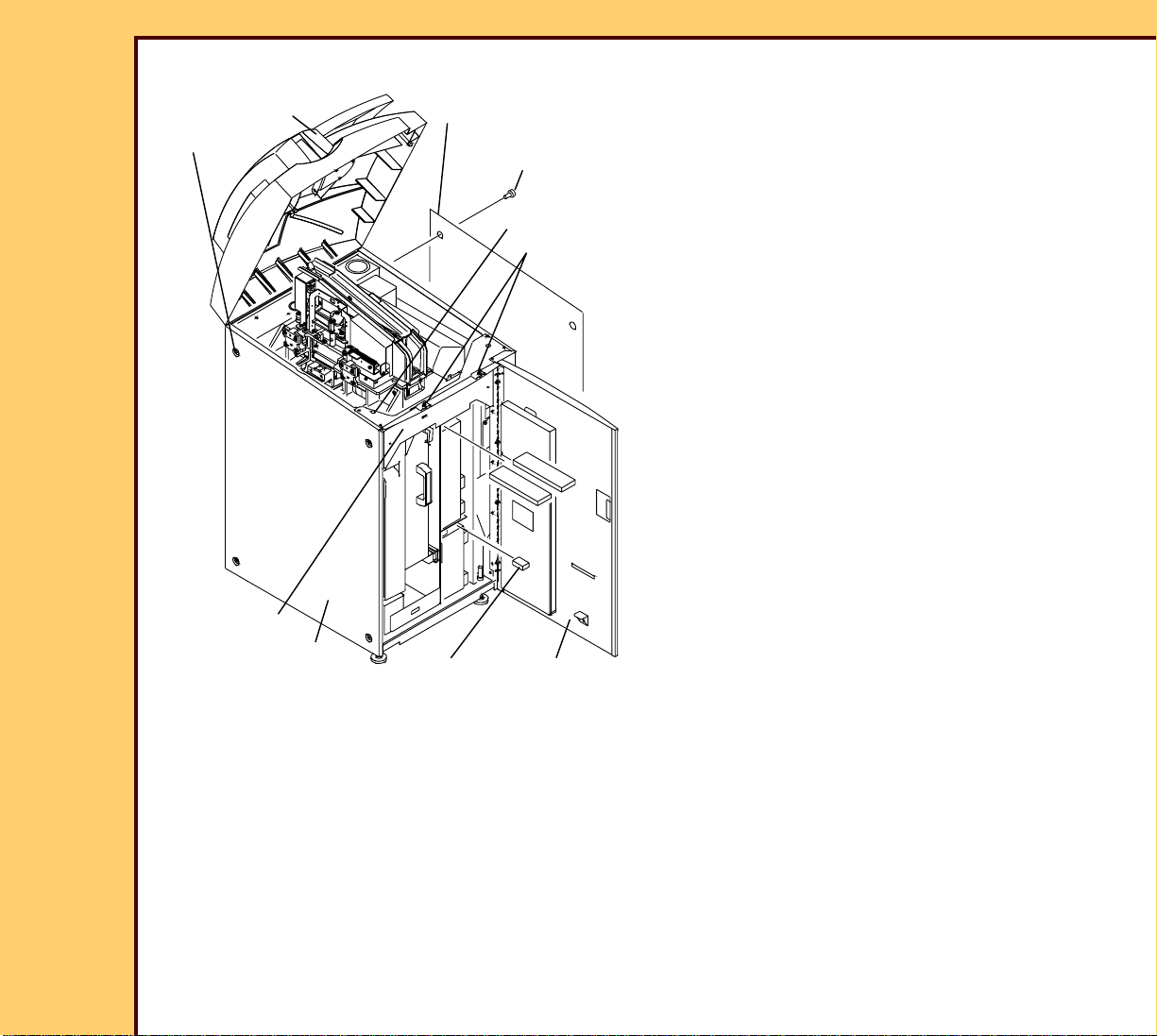

INSTALLATION INSTRUCTIONS Installation

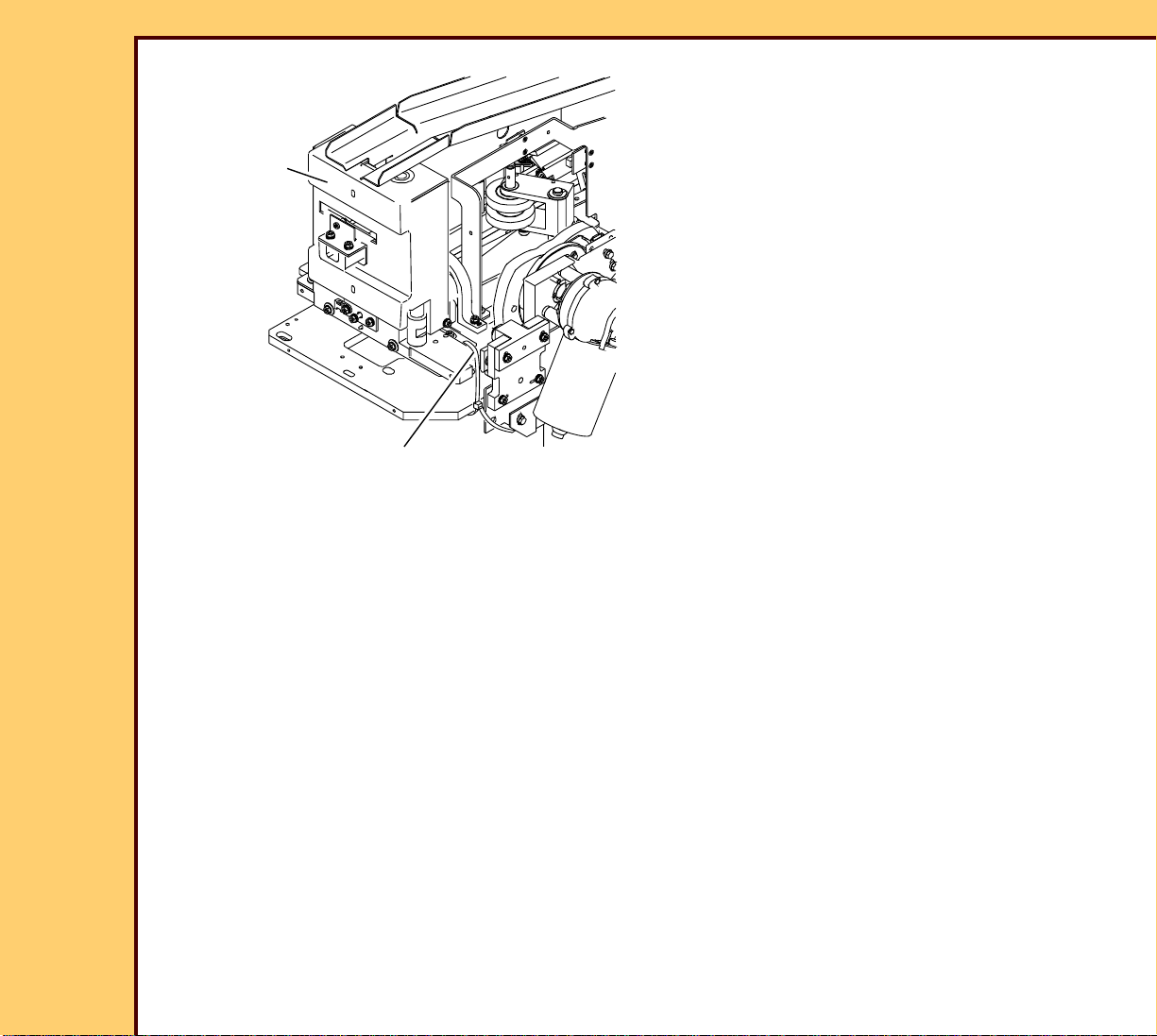

25 Remove the 8 SCREWS from the

REAR PANEL.

26 Remove and discard 2 SHIPPING

PLATES.

27 Install the 8 SCREWS in the REAR

PANEL.

28 Remove:

• 8 SCREWS

• REAR ACCESS PANEL

REAR PANEL

2 SHIPPING PLATES

REAR

ACCESS

PANEL

8 SCREWS

8 SCREWS

H194_0121GCA

H194_0121GC

Page 14

10MAR06

II4825-1

Page

14 of 72

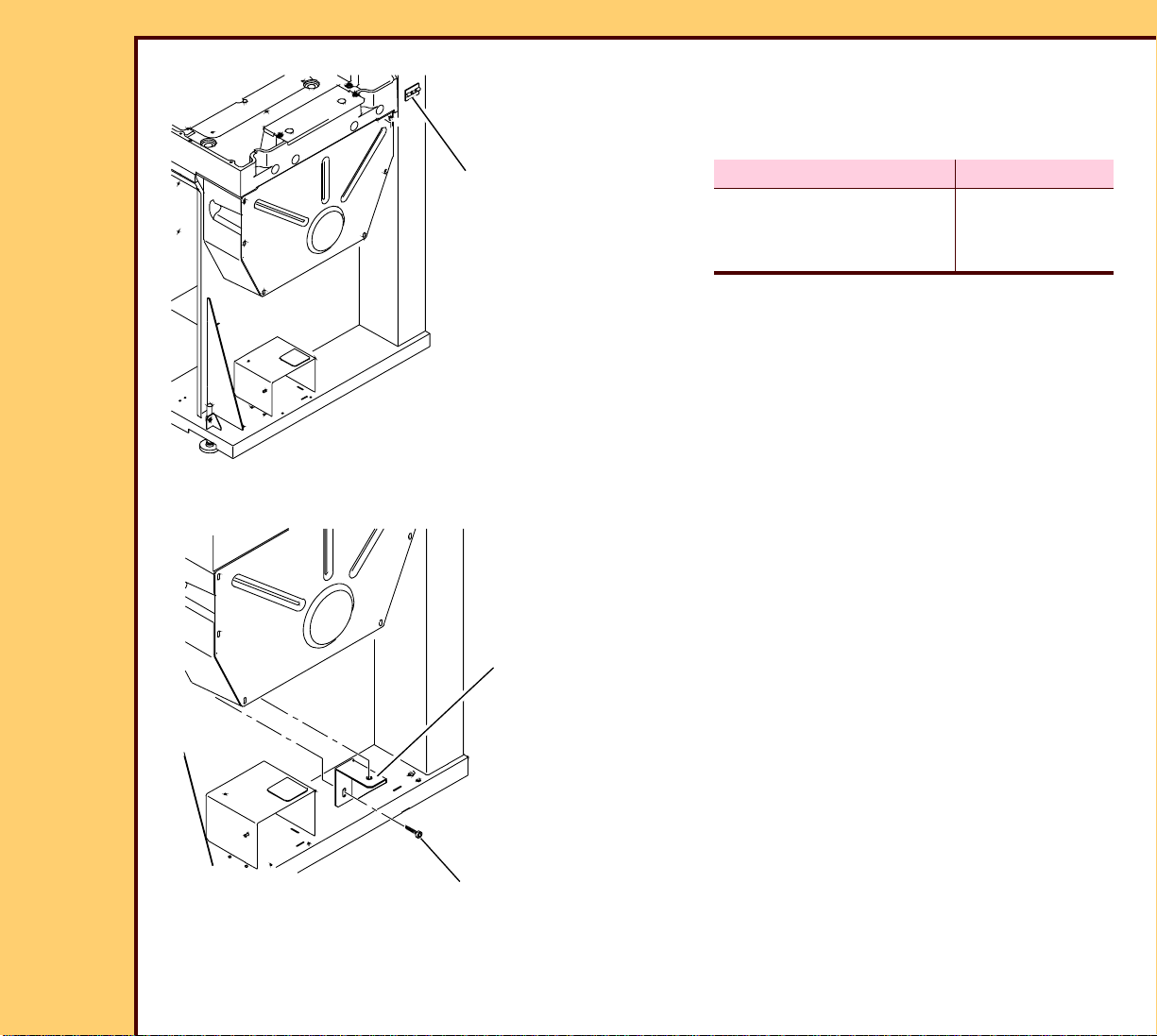

INSTALLATION INSTRUCTIONS Installation

Important

Do not remove the SHIPPING BRACKET.

29 Remove and discard the 4 BOLTS.

30 Remove the SCREW from the ACCESS

PLATE.

4 BOLTS

H194_0123ACA

H194_0123AC

Page 15

10MAR06

II4825-1

Page

15 of 72

INSTALLATION INSTRUCTIONS Installation

31 Rotate the 2 JACK BOLTS clockwise

FRAME

until the SHIPPING BRACKET is loose.

32 Remove and discard the SHIPPING

BRACKET.

33 Install the SCREW into the ACCESS

PLATE.

34 Rotate the 2 JACK BOLTS

JACK BOLT

SCREW

SHIPPING

BRACKET

ACCESS

PLATE

counterclockwise until the 2 JACK

BOLTS do not touch the FRAME.

H194_0124GCA

H194_0124GC

JACK BOLT

FRAME

Page 16

10MAR06

II4825-1

Page

16 of 72

INSTALLATION INSTRUCTIONS Installation

35 Cut and discard the TIE WRAP from

the CASSETTE HANDLING

CASSETTE

HANDLING

ASSEMBLY

H194_0109ACA

H194_0109AC

TIE WRAP

ASSEMBLY.

Page 17

10MAR06

II4825-1

Page

17 of 72

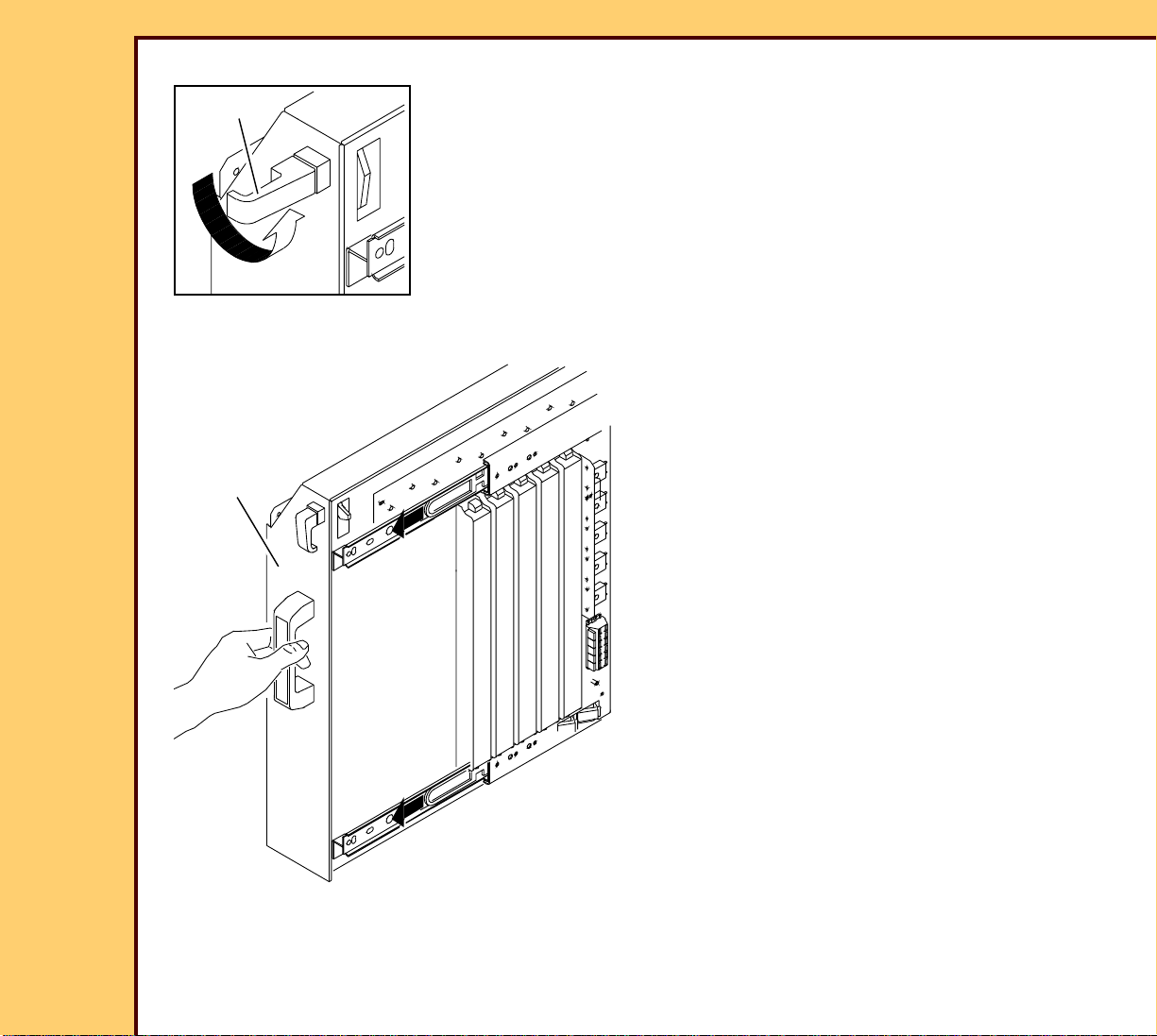

INSTALLATION INSTRUCTIONS Installation

36 Disengage the LATCH on the ERASE

LATCH

LAMP AY.

37 Pull the ERASE LAMP AY from the

system.

ERASE

LAMP AY

H196_0151CCA

H196_0151CC

Page 18

10MAR06

II4825-1

Page

18 of 72

INSTALLATION INSTRUCTIONS Installation

38 Remove and discard the SHIPPING

PLATE.

SHIPPING PLATE

H177_0128GCA

H177_0128GC

Page 19

10MAR06

II4825-1

Page

19 of 72

INSTALLATION INSTRUCTIONS Installation

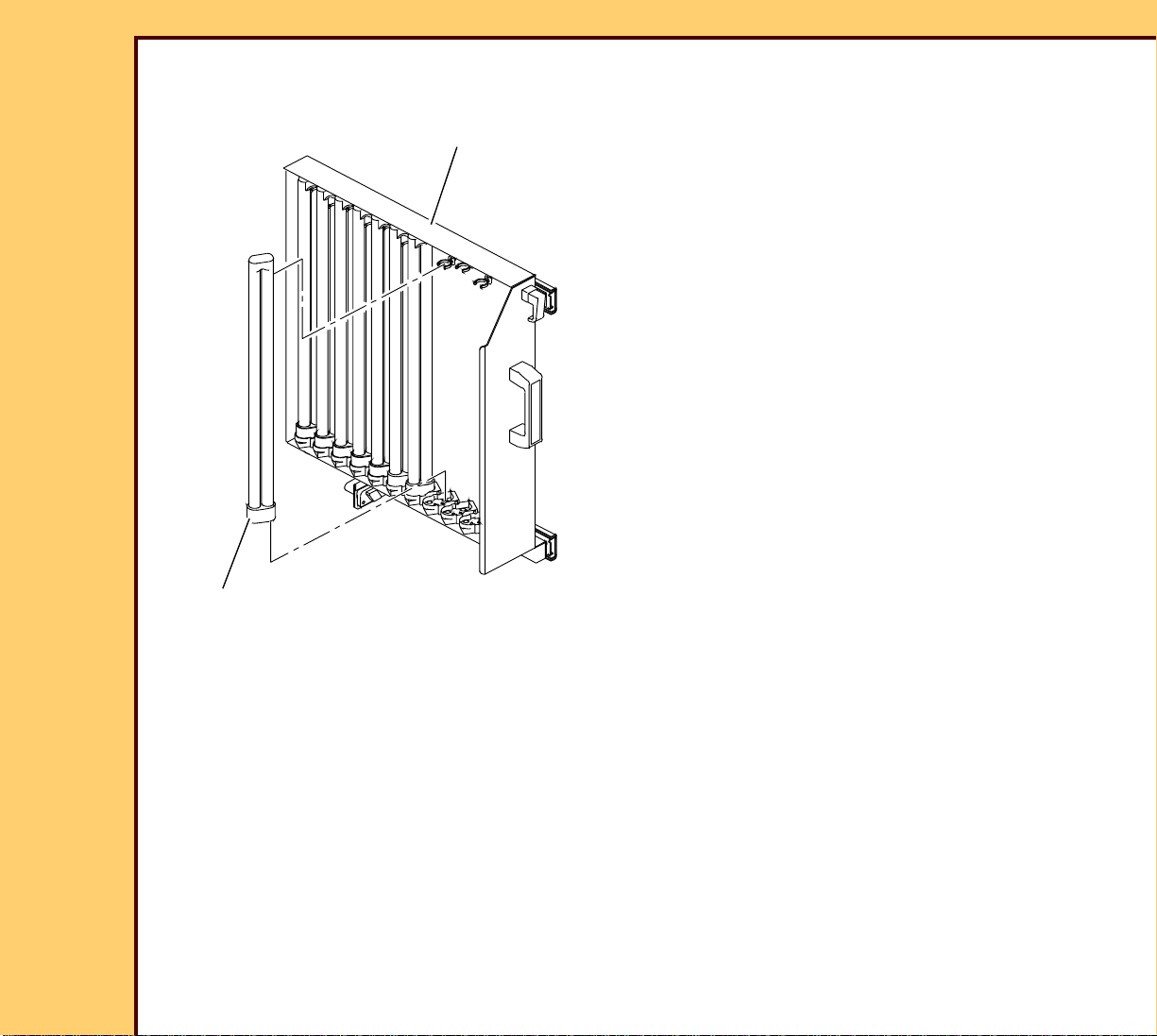

39 Install the 10 ERASE LAMPS into the

ERASE LAMP AY.

ERASE LAMP AY

40 Push the ERASE LAMP AY into the

system.

321

451 2 435

10 ERASE LAMPS

H194_0031GCA

H194_0031GC

Page 20

10MAR06

II4825-1

Page

20 of 72

INSTALLATION INSTRUCTIONS Installation

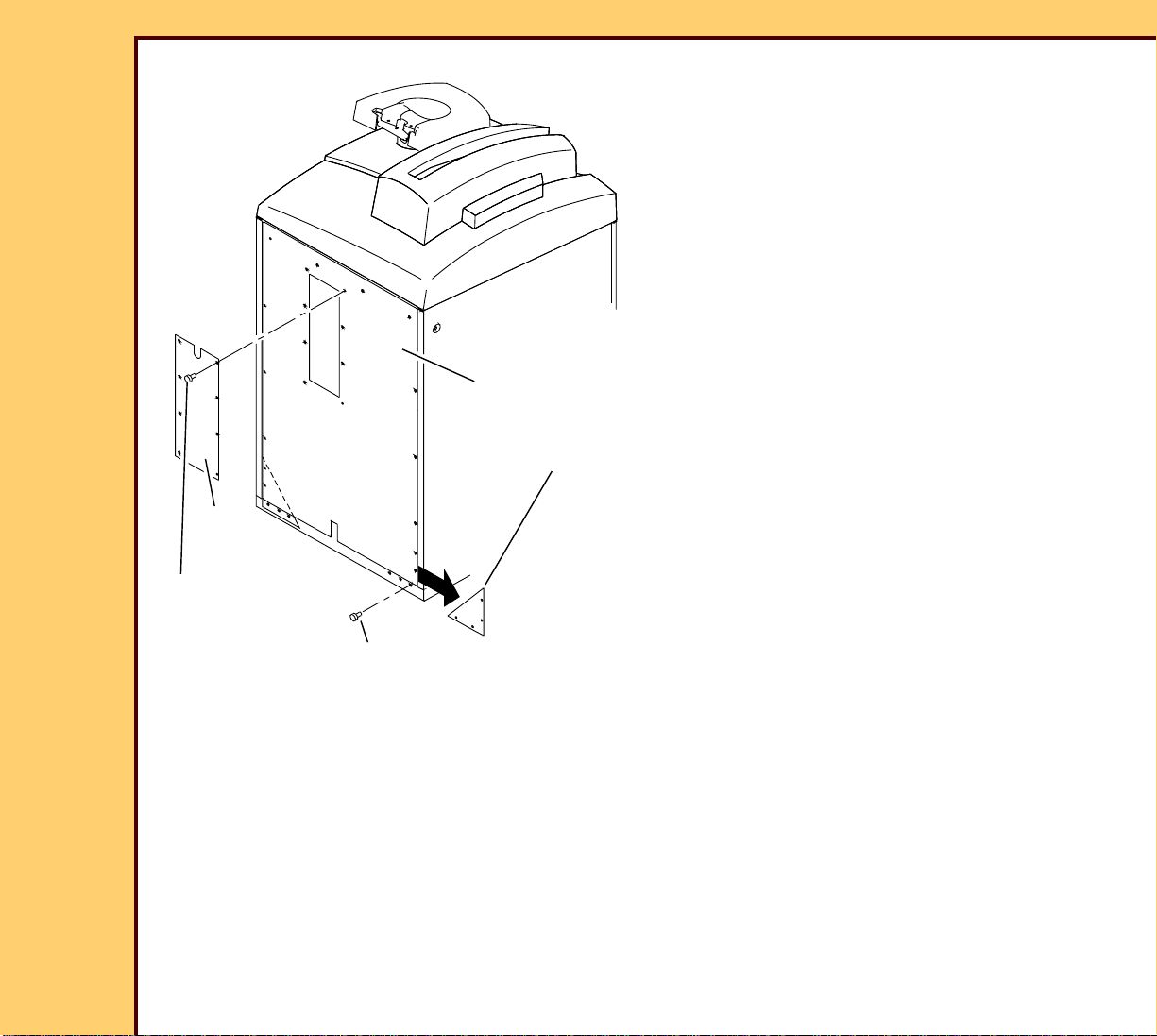

TOP COVER

2 SCREWS

LEFT PANEL

2 SCREWS

41 Install:

• RIGHT PANEL

• 2 SCREWS

7 SCREWS

2 SCREWS

• LEFT PANEL

• 2 SCREWS

• CROSSBRACE

• 7 SCREWS

42 Close the TOP COVER.

CROSSBRACE

H194_0101GCA

H194_0101GC

RIGHT

PANEL

FOAM PACKING

MATERIAL

FRONT

DOOR

Page 21

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

21 of 72

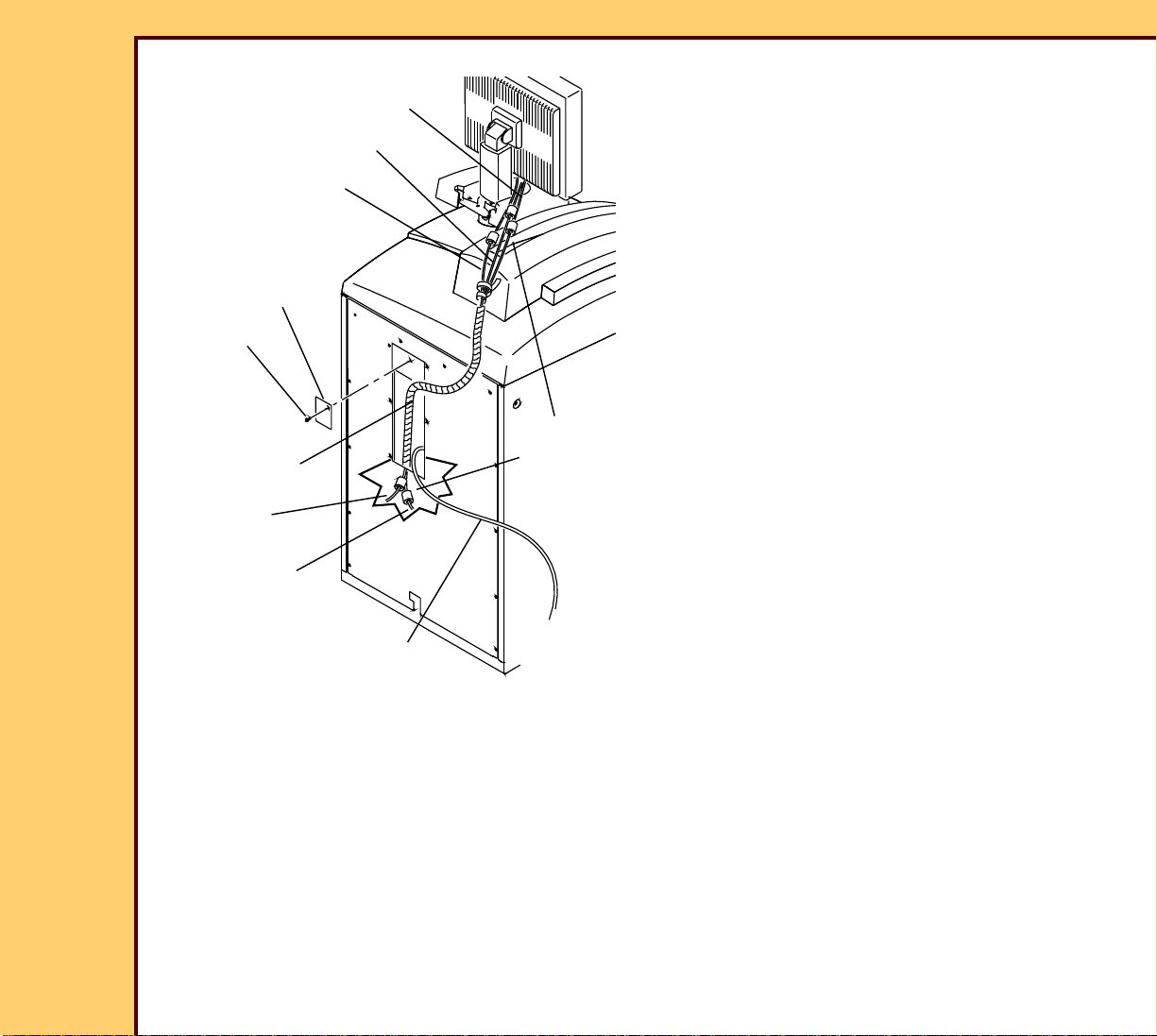

Installing the Equipment

MONITOR

MOUNT

MONITOR

SHOULDER

SCREW

COVER

4 SCREWS

2 SCREWS

SCREW

WIRE

WRAP

BRACKET

MONITOR

POST AY

SPACER

DISK

1 Remove:

• SCREW

• WIRE WRAP

• BRACKET

• COVER

2 Install:

• SPACER DISK

• 2 SCREWS

• MONITOR POST AY

• SHOULDER SCREW

• MONITOR

• MONITOR MOUNT

• 4 SCREWS

H177_0161GCA

H177_0161GC

2 TABS

• MONITOR onto the MONITOR

POST AY

• 2 SCREWS

Important

The COVER must engage the 2 TABS on

the MONITOR MOUNT.

3 Install:

• COVER

• BRACKET

• WIRE WRAP

• SCREW

Page 22

10MAR06

II4825-1

Page

22 of 72

INSTALLATION INSTRUCTIONS Installation

4 Install:

SERIAL CABLE

• 5 FERRITE BEADS to:

POWER CABLE

VIDEO CABLE

PLATE

SCREW

WIRE WRAP

VIDEO

CABLE

POWER

CABLE

H194_0128GCA

H194_0128GC

– NETWORK CABLE to PC

– SERIAL CABLE (COM1)

– both ends of the POWER CABLE

– both ends of the VIDEO CABLE

• PLATE

• SCREW

• WIRE WRAP

5 FERRITE

BEADS

NETWORK

CABLE

Page 23

10MAR06

II4825-1

Page

23 of 72

INSTALLATION INSTRUCTIONS Installation

MONITOR

KEYBOARD

COMPUTER

J

MODEM

3.0 GHz

K

B

C

A

L

I

D

F

optional

BAR CODE

READER

MOUSE

MODEM

2.4 GHz

H

E CABLE

H194_0126HC

G

Page 24

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

24 of 72

5 Connect:

CABLE Description From: To:

A SERIAL IN MONITOR COMPUTER COM 1 CONNECTOR

B VGA IN MONITOR COMPUTER MONITOR CONNECTOR

C MONITOR POWER MONITOR MONITOR POWER/SOUND CABLE

D Y CABLE BAR CODE

KEYBOARD EXTENSION CABLE

READER

E BAR CODE READER Y CABLE KEYBOARD CABLE

F KEYBOARD

Y CABLE COMPUTER KEYBOARD CONNECTOR

EXTENSION CABLE

G MOUSE MOUSE MOUSE EXTENSION CABLE

H MOUSE EXTENSION MOUSE CABLE COMPUTER MOUSE CONNECTOR

I RS-232 optional MODEM COMPUTER COM 2 CONNECTOR 2.4

GHZ COM 4 on 3.0 GHZ

J NETWORK CUSTOMER

NETWORK

COMPUTER NETWORK CARD

CONNECTOR

K NETWORK MCPU BOARD

(A2)

COMPUTER ONBOARD NETWORK

CONNECTOR

L KEYBOARD KEYBOARD KEYBOARD CONNECTION CABLE

Page 25

10MAR06

II4825-1

Page

25 of 72

INSTALLATION INSTRUCTIONS Installation

6 Remove the optional MODEM from the

POWER ADAPTER

carton.

7 Check that the MODEM DIP

telephone line

SWITCHES on the back of the MODEM

are set correctly. If necessar y, change

RS-232

CABLE

the settings.

8 Connect to the MODEM:

• POWER ADAPTER

optional MODEM

• telephone line

H194_0127ACA

H194_0127AC

8 SCREWS

REAR

ACCESS

PANEL

MODEM DIP SWITCHES

OFF

ON

12345678910

H194_0132ACA

H194_0132AC

• RS-232 CABLE

9 Connect the RS-232 CABLE to the

COM 2 connection on the computer.

Caution

Dangerous Voltage

10 Connect:

• POWER ADAPTER to the power

source

• telephone line

11 Energize the MODEM.

12 Have the TSC make a call to the

telephone number on the MODEM to

check the connection.

13 Install:

• 8 SCREWS

• REAR ACCESS PANEL

Page 26

10MAR06

II4825-1

Page

26 of 72

INSTALLATION INSTRUCTIONS Installation

14 Check the voltage at the site.

15 Select the correct POWER CORD for

the site.

Caution

Dangerous Voltage

16 Connect the POWER CORD to:

• CR 825/850 SYSTEM

• power source

CR 850 SYSTEM

H194_0129GCA

H194_0129GC

POWER CORD

power source

Page 27

10MAR06

II4825-1

Page

27 of 72

INSTALLATION INSTRUCTIONS Installation

17 Place the system in the correct position

at the site.

18 Open the FRONT DOOR.

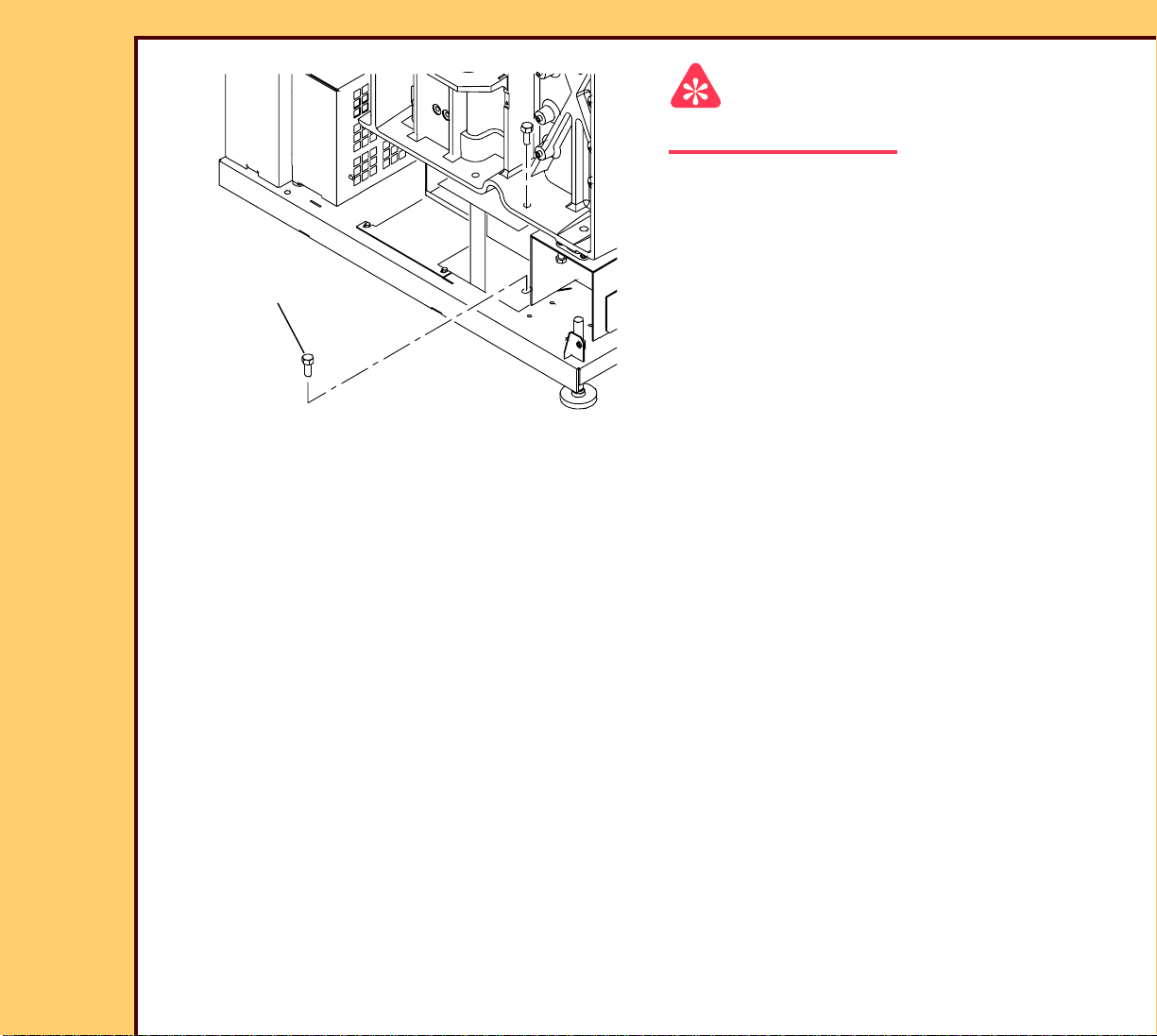

19 Loosen the 2 LOCKING NUTS.

20 Rotate the 2 HOLD DOWN FEET until

the HOLD DOWN FEET make contact

with the floor.

2 LOCKING

NUTS

H177_0132GCA

H177_0132GC

FRONT DOOR

2 HOLD DOWN FEET

21 Tighten the 2 LOCKING NUTS.

Page 28

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

28 of 72

Energizing the System

T

ES

/T

PC

UPS

DC

BA

FRONT

DOOR

POWER

LED

Laser Warning

• This equipment uses a visible red

LASER. Prevent direct exposure to the

beam from the LASER when the system

is energized.

• Dangerous Voltage

1 Energize the system.

a Open the FRONT DOOR.

b On the UPS, press and hold the “I/

Test” until a beep sounds.

c Wait 5 seconds.

d Check that the LED on the PC

illuminates and remains illuminated.

e Close the FRONT DOOR.

I/Test

H177_0133GCB

H177_0133GC

/TEST

Line

On Battery

Bypass

On Line

f Wait for the system to initialize.

2 Energize the MONITOR.

Page 29

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

29 of 72

Obtaining a “Session ID”

Important

You must have a “Session ID” for access to “Service Functions” and “Diagnostics”.

1 Obtain a “Session ID”, see SERVICE BULLETIN 843.

Doing the Calibration for the TOUCH SCREEN

1 From the main menu, click:

• [Key Operator Functions]

• [System Configuration]

• [Next]

• [Next]

• [Next]

• [Calibrate the Touch Screen]

2 Touch the TARGET when it moves to the 3 areas on the screen.

3 Does the cursor position change when you touch the TARGET?

Yes No

a. Touch [YES].

b. Continue with Step 4.

a. Touch [NO].

b. Do Step 1 - Step 3 again.

c. If necessary, install a new

MONITOR.

4 Touch [Main Menu].

Page 30

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

30 of 72

Setting the Site Parameters

1 From the main menu, touch:

• [Service Functions]

• [Network Configuration]

2 Type:

• “Local IP Address”

• “Computer/Station Name”

• “Subnet Mask”

• “Default Gateway”

• “RAS IP Address Range”

• “Network Speed/Duplex”

3 At the “Microsoft Internet Explorer” message, click [OK].

Note

The system boots.

4 If necessary, at the “AddOnInit-SUCCESS” screen, click [OK].

5 If the “Desktop” screen displays for

more than one minute, click [Restart].

Page 31

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

31 of 72

Setting the “User Name” and “Password”

Important

You must set up the “User Name” and “Password” for all users on site.

1 At the “Login” screen, for the “User Name” and “Password”, type: SA

2 Click [Enter].

3 Obtain the password from the “System Administrator” (SA).

4 If the SA is not on site, for the SA password, type: SECURITY

5 At the “Change Password” screen, type:

• in the “Current Password” field: SA

• in the “New Password” field the password obtained from Step 3

6 Click:

• [Save Changes]

• [User Configuration]

• [Create New User]

7 At the “Add New User” screen, type:

• in the “User Name” field: AC

• in the “Password” field: 333333

• in the “Full Name” field: Kodak Applications Consultant

• in the “Employee Number” field: 123456

8 Select “Applications Consultant” for “Role”.

9 Click:

• [Save Changes]

• [OK]

10 Do Steps 6 - 9 for all other users on site.

Page 32

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

32 of 72

11 Click:

• [Back]

• [Back]

• [Logout]

12 At the “Login” screen, type:

• in the “User Name” field: AC

• in the “Password” field: 333333

13 Click [Login].

Important

• The default password length configuration is 6 digits.

• For the Application Consultant (AC) password only, if the password length configuration is:

– more than 6 digits, you must type the number 5 at the end for the additional digits

– less that 6 digits, you must type the corresponding digits up to the password length

Example:

• for a 10-digit password length configuration, type: 3305455555

• for a password length configuration of less than 6 digits, type: 3305

14 At the “Change Password” screen, type:

• in the “Current Password” field: 333333

• in the “New Password” field: 330545

• in the “Confirm New Password” field: 330545

15 Click [Save Changes].

Page 33

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

33 of 72

Installing and Setting Up Optional Features

Important

It might be necessary to enable upgrade options for each system.

1 From the main menu, touch:

• [Key Operator Functions]

• [System Configuration]

• [Option Registration]

2 Insert the OPTIONS DISKETTE included with the system.

3 Click [ADD UPGRADE OPTIONS].

4 Do Steps 1 - 3 again for all OPTIONS DISKETTE included with the system.

Page 34

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

34 of 72

Setting the “Global” Parameters

1 From the main menu, touch:

• [Key Operator Functions]

• [System Configuration]

• [Next]

• [Next]

• [Regional Settings]

Important

If you change the “Time Zone”, you must also change the time.

2 Type:

• “Current Date and Time”

• “Time Zone”

• “Language”

Page 35

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

35 of 72

3 Touch:

• [SAVE CHANGES]

• [BACK]

• [Previous]

• [Delivery Preferences]

• [Default Value]

4 Type:

• “Default Hospital Name”

• “Default Hospital Address”

Page 36

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

36 of 72

5 Touch:

• [SAVE CHANGES]

• [BACK]

• [Delivery Options]

6 Select “Run in QA Mode”.

Note

“Run in QA Mode” allows the customer or user to review all images before the images are

sent to a “Destination”.

Page 37

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

37 of 72

7 Touch:

• [SAVE CHANGES]

• [Back]

• [NEXT]

• [Miscellaneous]

8 Check:

• “Default Body Part” is “Chest”

• “Default Projection” is “AP”

• “Default Study Modality” is “CR”

Page 38

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

38 of 72

9 Touch:

• [NEXT]

• [System Maintenance Defaults]

10 Check that the values are:

• “80%”

• “70%”

• “5”

11 Touch:

• [SAVE CHANGES]

• [Back]

• [Previous]

• [Previous]

Page 39

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

39 of 72

12 Is the Hospital Information System (HIS) and the Remote Information System (RIS) or

the Kodak DirectView REMOTE OPERATIONS PANEL (ROP) connected?

Yes No

Continue with

Setting the HIS/RIS Parameters.

Adding a PRINTING DEVICE.

Advance to

Setting the HIS/RIS Parameters

“Polling”

1 From the “System Configuration” screen, touch:

• [HIS/RIS - Broker Configuration]

• [PACS Common Configuration]

2 Obtain from the customer:

• “PACS Broker Port” number

• “PACS Broker / AE Title”

• “PACS Broker IP address”

• “Station Name / AE Title”

Page 40

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

40 of 72

3 Type the correct information in the following fields:

• “PACS Broker Port”

• “PACS Broker / AE Title”

• “PACS Broker IP address”

4 Touch:

• [Back]

• [Polling Configuration]

Important

“Polling” is an option purchased by the customer. The values selected in this screen

determines the “Polling” of all patient information for this “Station” from the “Broker”.

5 If necessary, type the “Station Name / AE Title”.

Page 41

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

41 of 72

6 If necessary, select:

• “Filter By Station Name”

• “Filter By AE Title”

7 Select or clear the check box:

“Polling” Only “Polling” and “Remote Query” “Remote Query” Only

a. Select the “Remote

Query Active” check box.

b. Clear the “Poll Model

Active” check box.

a. Select:

• “Poll Model Active”

check box

• “Remote Query

a. Select the “Remote

Query Active” check box.

b. Clear the “Poll Model

Active” check box.

Active” check box

Important

• If “Push” is selected, the “Minutes Between Search Updates” could be changed to 720

minutes because the “Broker” will automatically send any new patient information.

• The default times for:

– “Hours Before Current Time” = “3”

– “Hours After Current Time” = “3”

– “Minutes Between Search Updates” = “10”

8 Change the times to:

• “Hours Before Current Time” = “24”

• “Hours After Current Time” = “24”

• “Minutes Between Search Updates” = “3”

9 Touch:

• [SAVE CHANGES]

• [BACK]

• [Push Configuration]

Page 42

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

42 of 72

Setting the “Push” Option

Important

The “Push” function is determined by the features of the “Broker”.

10 Check the “Verify and Validate” database at the TSC to identify if the “Broker” has the

“Push” function.

11 If the customer wants the “Push” option, select the “Push Connection Active” check box

at each system.

12 Type a value between 10225 - 65535 into the “PACS Push Port Number” field.

Note

• The default number is 5401.

• The same port number can be used for all systems.

13 Type any name into the “PACS Push AE Title” field except the computer name.

14 Record all the data from the “Push” screen.

Page 43

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

43 of 72

15 The following “Events” from the “DICOM Event Notification” must be “Filtered” for the

PACS port modality of the system:

• Study Started

• Study Updated

• Study Completed

Note

If the information is not “Filtered”, the identified system will receive data for all patients.

16 Provide the information from the “Push” screen to the customer for the “Broker”

equipment.

Adding a PRINTING DEVICE

1 From the Key Operator Menu, touch:

• [Service Functions]

• [Service Utilities]

• [Stop User Interface]

Important

You must have the KEYBOARD and MOUSE connected. See “Installing the Equipment.”

2 Double-click the “MIMDUI” icon.

3 Select Connect>Connect to MiM.

Page 44

10MAR06

II4825-1

Page

44 of 72

INSTALLATION INSTRUCTIONS Installation

Important

• “HARD DISK” is the displayed “Destination”. The parameters must not be changed.

“HARD DISK” must not be deleted.

• For existing parameter settings, see the CR SETUP CD 7F3016.

4 At the “MIM Service Application” screen, touch:

• [Configure]

• [Destination]

5 At the “Installed Destinations” screen, touch:

• [Add]

• [Print]

• [Network]

• [Qualified]

Page 45

10MAR06

II4825-1

Page

45 of 72

INSTALLATION INSTRUCTIONS Installation

Important

For PRINTERS that are not in the “Qualified

Printer List” you must see the “V and V

Database” for a “Qualified” configuration

6 At the “Choose a New Network Print

Destination” screen, select the correct

PRINTER from the list.

7 Click [OK].

8 At the “General” screen, type the

information provided by the Project

Manager.

9 Click [Next].

10 At the “General” screen, type the

correct parameters.

11 Click [Next].

12 In the “Media” screen, select the

correct:

• “Media Size”

• “Media Type”

13 Touch [Next].

Page 46

10MAR06

II4825-1

Page

46 of 72

INSTALLATION INSTRUCTIONS Installation

Important

• For the configuration of a PRINTER that

has 2 or more film sizes, each film size

must be configured with a separate

“Destination”.

• The numbers that the “Media” screen

display might not match the numbers

displayed in the screen.

14 In the “Media” screen, select all the

types that the customer uses.

15 Touch [Finish].

Note

• Only change the default numbers for

qualified “Destinations” when instructed

by the TSC.

• If an item is not checked in the “Media”

or “Supported Items” screens, the

customer will not have access to that

item.

Page 47

10MAR06

II4825-1

Page

47 of 72

INSTALLATION INSTRUCTIONS Installation

16 In the “DICOM” screen, type the correct

parameters.

17 Touch [Next].

18 At the “Supported Items” screen, check

that the correct items are selected.

19 Touch [Next].

Page 48

10MAR06

II4825-1

Page

48 of 72

INSTALLATION INSTRUCTIONS Installation

20 At the “Interpolation” screen, check that

the correct items are selected. See the

“V and V Database” or the CR SETUP

CD 7F3016

21 Touch [Next].

22 At the “Format Types” screen, check

that the correct items are selected.

23 Touch [Next].

Page 49

10MAR06

II4825-1

Page

49 of 72

INSTALLATION INSTRUCTIONS Installation

24 At the “Formatting” screen, check that

the correct items are selected.

25 Touch [Next].

26 At the “Image Processing” screen,

check that the correct items are

selected.

27 Touch [Next].

Page 50

10MAR06

II4825-1

Page

50 of 72

INSTALLATION INSTRUCTIONS Installation

28 At the “AUTORAD” screen, click the

“SCU” tab

29 At the “SCU” screen, check that the

correct items are selected.

30 Touch [Next].

31 At the “M952 Usage” screen, check that

the correct items are selected.

32 Touch [Finish].

33 To add more “Print Destinations”, do

Steps 6 - 32 again.

Page 51

10MAR06

II4825-1

Page

51 of 72

INSTALLATION INSTRUCTIONS Installation

Adding a STORAGE DEVICE

Important

Some systems do not support “DICOM ECHO” if the “Ping” function is disabled.

1 Check that the configuration of the “Destination” is correct.

a At the “Service Application” screen, click “Diagnostics/Network”.

b Select:

• “Ping”

• “DICOM ECHO”

• “Run”

c Type the information for the new “Destination”:

• “IP address”

• “Port Number”

• “AE Title”

d Click [OK].

e If “Passed” displays, click [Cancel] from the “Network Diagnostics” screen and

continue with Step 2.

f If “Passed” does not display, check:

• “Destinations” are correct

• customer network is operating correctly

• PRINTER is energized and set to receive information from the system

g Click [Cancel] from the “Network Diagnostics” screen.

Page 52

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

52 of 72

2 At the “Installed Destinations” window, touch:

• [Add]

• [Store]

• [Network]

• [Qualified]

3 Touch [OK].

4 At the “General” window, type:

• “Logical Name”

• “IP Address”

5 Touch [Finish].

6 In the “DICOM Information” window,

type the correct information:

• “Port Number”

• “AE Title”

• “Response Message”

7 Touch:

• [OK]

• [Set]

8 At the “Installed Destinations” window,

click [Close].

Page 53

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

53 of 72

9 Check that the configuration of the “Destination” is correct.

a At the “Service Application” window, select “Diagnostics/Network”.

b Select:

• “Ping”

• “Dicom Echo”

• “Run”

c Type the information for the new “Destination”:

• “IP address”

• “AE Title”

• “Port Number”

d Touch [OK].

e If “Passed” displays, advance to Step g.

f If “Passed does not display, check:

• “Destinations” are correct

• customer network is operating

• STORAGE DEVICE is energized and is set to receive information

g Select “Cancel” from the “Network Diagnostics” window.

10 If all “Destinations” were set, from the “Service Applications” window touch:

• [Connect]

• [Save Configuration]

11 At the prompt, store the data to the MIM DISK.

12 Close the “Service Applications” window.

13 Double-click the “CR Shutdown” icon.

14 Energize the CR 975 SYSTEM.

15 From the main menu touch [Key Operator Functions].

Page 54

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

54 of 72

16 Check that the new “Destinations” are correct.

17 Do you want to modify the “Existing Profile”?

Yes No

Touch:

• [Make Appropriate]

• [Save Changes]

• [Configuration]

• [Save Configuration]

• [Connect]

• [Exit]

• “CR Shutdown” icon

Touch:

• [Default]

• [Save Changes]

• [Configuration]

• [Save Configuration]

• [Connect]

• [Exit]

• “CR Shutdown” icon

Setting the Profile Destination Configuration

1 From the main menu, touch:

• [Key Operator Functions]

• [System Configuration]

• [Profile Destination]

• [Modify Existing]

2 Obtain the default “Destinations” from your customer.

3 Touch:

• [Save Profile]

• [Back]

Page 55

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

55 of 72

Enabling the BAR CODE READER

“Country Code”

1 From the main menu, touch:

• [Key Operator Functions]

• [System Configuration]

2 Touch:

• [Next]

• [Bar Code Configuration]

• [Set Country Code]

3 Select the correct option from the list.

4 Touch:

• [BACK]

• [Program Bar Code Scanner]

• [CONFIGURE COUNTRY CODE]

5 Use the BAR CODE READER to read

the bar codes in sequence from the top

of the screen to the bottom of the

screen.

6 Touch [BACK].

Page 56

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

56 of 72

“Code 39 Full ASCII”

7 Obtain the mode information from the customer.

8 Touch [Code 39 Full ASCII Mode].

9 Use the BAR CODE READER to read

the correct bar code:

• “Code 39 Full ASCII ON”

• “Code 39 Full ASCII OFF”

10 Touch [BACK].

“Automatic Trigger” and “Manual Trigger”

Important

• “Automatic Trigger” indicates that the BAR CODE READER is continually “On”.

• “Manual Trigger” indicates that the BAR CODE READER operates when the TRIGGER is

actuated.

11 Touch [CONFIGURE AUTOMATIC TRIGGER].

Page 57

10MAR06

II4825-1

Page

57 of 72

INSTALLATION INSTRUCTIONS Installation

12 Use the BAR CODE READER to read

“Automatic Trigger” or “Manual Trigger”.

13 Touch [BACK].

“Prefix and Suffix”

14 Touch [CONFIGURE PREFIX SUFFIX].

15 Use the BAR CODE READER to read

the bar codes in the sequence, 1 - 7.

16 Touch [Next].

Page 58

10MAR06

II4825-1

Page

58 of 72

INSTALLATION INSTRUCTIONS Installation

17 Use the BAR CODE READER to read

the bar codes in the sequence, 1 - 7.

18 Touch [Next].

19 Use the BAR CODE READER to read

the test bar code.

20 Does the screen display:

“Valid Scan” “Invalid Scan”

Continue with

Step 21.

Do Step 14 -

Step 20 again.

21 Touch [BACK].

Page 59

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

59 of 72

Setting the Requirements Fields

1 Obtain from your customer, the required fields to be complete for a patients study.

2 From the main menu, touch:

• [Key Operator Functions]

• [Required Fields]

3 Select the fields obtained in Step 1.

4 Touch:

• [Save]

• [Back]

• [Next]

Configuring the MONITOR

1 Obtain the model information from the back of the MONITOR.

2 From the main menu, touch:

• [Key Operator Functions]

• [System Configuration]

• [Next]

• [Next]

• [Configure Monitor]

Page 60

10MAR06

II4825-1

Page

60 of 72

INSTALLATION INSTRUCTIONS Installation

3 At the “Configure Monitor” screen, select the correct MONITOR from the list.

4 Touch:

• [SUBMIT]

• [MAIN MENU]

Doing the Configuration for the Kodak DirectView CR LONG-LENGTH IMAGING SYSTEM

1 Is the CR LONG-LENGTH IMAGING SYSTEM installed with your system?

Yes No

a. Configure your system for the CR LONG-

LENGTH IMAGING SYSTEM. See the

SERVICE MANUAL for the Kodak DirectView

CR LONG-LENGTH IMAGING SYSTEM

SM1971-1.

b. Continue with Storing the Setup Data.

Continue with Storing the Setup

Data.

Page 61

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

61 of 72

Storing the Setup Data

1 From the main menu, touch:

• [Key Operator Functions]

• [System Configuration]

• [Save All Configurations]

2 Obtain an empty user reference DISKETTE from the customer.

3 Insert the DISKETTE into the computer.

4 Touch:

• [Floppy]

• [OK]

5 Remove and store the user reference DISKETTE at the installation site.

Page 62

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

62 of 72

Installing the Kodak REMOTE PATIENT DATA ENTRY STATION (RPDES)

Important

• The site must not use the Dynamic Host Control Protocol (DHCP). DHCP changes the IP

address of the RPDES or the Kodak DirectView REMOTE OPERATIONS PANEL (ROP)

for the following conditions:

– “Site System Shutdown”

– “Site Boot”

– “Site License Expiration”

• The site must provide an IP address that does not change the application computer for

the RPDES.

• The RPDES is an option purchased by the customer.

1 Check:

• system is connected to the site network

• computer must have:

– Microsoft INTERNET EXPLORER 5.0 or higher installed

– Windows 98 or Windows NT 4.0 OPERATING SYSTEM

• options for the RPDES must be actuated from the OPTIONS DISKETTE

• KEYBOARD and MOUSE

2 Insert the OPTIONS DISKETT E.

3 Install the option for the RPDES through the “Upgradeable Options” screen.

Page 63

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

63 of 72

Setting the Configuration for the RPDES

1 Log on with the key operator information.

2 From the main menu, touch:

• [Key Operator Functions]

• [System Configuration]

• [NEXT]

• [External Devices]

• [Kodak Remote Operation Panel Setup]

Note

The IP address for each connected ROP and RPDES displays.

3 Type the IP address for the computer.

4 Touch [SAVE CHANGES].

Page 64

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

64 of 72

Operating the RPDES

1 Double-click the “Internet Explorer” icon.

2 At “http://”, type the IP address for the system.

3 Click [Enter].

4 Add the address to the “Favorites” menu.

Caution

If you press [Submit] without typing information, blank records are sent to the system.

5 Type the patient information.

6 Click [Submit].

Page 65

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

65 of 72

Making a SHORTCUT for the RPDES

1 Select New>SHORTCUT.

2 Click [Browse].

3 Locate the “IEXPLORE.exe” file.

Important

The “-k” option allows Microsoft INTERNET EXPLORER to operate in full screen mode.

4 Add the IP address for the system to the end of the line.

Note

The IP address for the system in this example is 129.126.6.62.

Example: “C:\Program Files\Plus!\MicrosoftInternet\IEXPLORE.EXE -k http://129.126.6.62/

RPDES”

5 Click [Next].

6 Select a name for the new SHORTCUT.

7 Click [Finish].

8 Double-click the “SHORTCUT” icon to check that it operates correctly.

9 Press [Ctrl] + [W] to exit.

Setting the Host File for the Kodak DirectView CAPTURE LINK SYSTEM.

1 Is your system part of the Kodak DirectView CAPTURE LINK SYSTEM?

Yes No

Continue with Step 2. Advance to Step 7.

2 Select C:>winnt>system32>drivers>etc\hosts.

Page 66

10MAR06

II4825-1

Page

66 of 72

INSTALLATION INSTRUCTIONS Installation

3 Use the “Notepad” to open the “Hosts File”.

4 Type the name and IP address of:

• Kodak DirectView CAPTURE LINK SERVER

• all devices in the CAPTURE LINK SYSTEM

5 Select File>Save.

6 Close the window.

7 Click the “Restart” icon.

Installing the Kodak DirectView REMOTE OPERATIONS PANEL (ROP)

1 Install the ROP. See the INSTALLATIONS INSTRUCTIONS for the Kodak DirectView

REMOTE OPERATIONS PANEL 5E2249.

Page 67

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

67 of 72

Checking the Operation

1 From the main menu, touch:

• [Key Operator]

• [SMPTE Test Pattern]

Page 68

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

68 of 72

2 Touch [CREATE 35 x 43 cm SMPTE].

3 Send the SMPTE test pattern to a each PRINTER.

4 Locate a DENSITOMETER at the customer site.

5 From the PRINTER, use the DENSITOMETER to measure the density of the gray

patches of the SMPTE test pattern from 0% - 100%, .

SMPTE

Gray Patch

AIM

Density

0% 3.00 +/-0.10

Tolerance

6 Record each gray patch measurement.

7 Compare the measurement to the AIM

density and the tolerance.

10% 2.75 +/-0.10

20% 2.44 +/-0.10

30% 2.16 +/-0.10

40% 1.88 +/-0.10

50% 1.61 +/-0.10

60% 1.33 +/-0.10

70% 1.05 +/-0.10

80% 0.77 +/-0.10

90% 0.49 +/-0.10

100% 0.21 +/-0.10

8 Do all measured densities match the AIM density +/-0.10?

Yes No

Continue with Step 9. a. Check that the MIM “Destinations” are set correctly.

b. Ask the customer to make a call to the equipment

service representative for the PRINTER.

c. Continue with Step 9.

9 From the system, touch [Back].

Page 69

10MAR06

II4825-1

Page

69 of 72

INSTALLATION INSTRUCTIONS Installation

Important

• You must have approval before sending the SMPTE test pattern.

• Sending a SMPTE test pattern directly to the “Hospital Archive” can cause the

WORKSTATION to lock.

• The tolerance of the “AIM density” can increase or decrease to match the customer

specifications and the WORKSTATION.

• Each gray patch displayed must be the size of the PROBE CUP.

10 Send the SMPTE test pattern to each WORKSTATION “destination”.

11 Use the PHOTOMETER to measure the luminance of the gray patches of the SMPTE

test pattern from 0% - 100% on the WORKSTATION MONITOR.

a. Place the PHOTOMETER PROBE on a flat surface to prevent light from being

detected.

b. Energize the PHOTOMETER.

c. Press “UNITS” until the PHOTOMETER displays “fL”.

d. Press “ZERO” until the PHOTOMETER displays “0.00 fL”.

Page 70

10MAR06

II4825-1

Page

70 of 72

INSTALLATION INSTRUCTIONS Installation

SMPTE

Gray Patch

AIM

Luminance

0% 0.12 +/-0.05

Tolerance

12 Record each gray patch measurement.

13 Compare the measurement to the AIM

luminance and the tolerance.

10% 0.35 +/-0.05

20% 0.76 +/-0.05

30% 1.46 +/-0.05

40% 2.71 +/-0.05

50% 4.86 +/-0.05

60% 8.59 +/-0.05

70% 15.26 +/-0.05

80% 26.36 +/-0.05

90% 46.36 +/-0.05

100% 80.00 +/-0.05

14 Do all measured luminance match the AIM luminance +/-0.05?

Yes No

Continue with Step 15. • Ask the customer to make a call to the equipment

service representive for the WORKSTATION to do a

calibration of the WORKSTATION.

• Continue with Step 15.

15 From the “Diagnostic Menu”, run the [Autolooper Test] 10 times for each size

CASSETTE.

16 Use the Kodak DirectView TOTAL QUALITY TOOL to test and adjust the output image

quality.

17 Check that the software version is 3.0 or higher for the ROP. For more information, see

the INSTALLATION INSTRUCTIONS for the Kodak DirectView REMOTE OPERATIONS

PANEL (ROP) 5E2249.

18 Do the Field Service Installation Checklist for the CR SYSTEM 6F5825.

Page 71

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

71 of 72

19 Record the following for feedback to the Kodak Scan Plus CUSTOMER SERV ICE

SYSTEM:

• total scan counts

• “XN” for the “Activity Code”

• any problems occurred with the installation

• RAM “Activity Code”

• necessary “MGC” or “VC”

• “ST” or any other code

Page 72

INSTALLATION INSTRUCTIONS Installation

10MAR06

II4825-1

Page

72 of 72

Publication History

Publication

Date

Publication

No.

ECO No.

Changed

Pages

File Name Notes

10APR03 II4825-1 ---- All ii4825_1.fm New Publication

16DEC03 II4825-1 ---- 2, 7, 8, 50,

ii4825_1.fm Revised

51, and 73

20JUL04 II4825-1 ---- 28, 31, 32,

ii4825_1.fm Revised

and 70

10DEC05 II4825-1 ---- 1, 5, 10, 19,

ii4825_1.fm Revised

21, 23, 27,

and 28-72

10Mar06 II4825-1 ---- Page 21 ii4825_1.fm Updated

MONITOR

installation

procedure

Kodak, DirectView and Scan Plus are trademarks of Eastman Kodak Company.

Printed in U.S.A. • ii4825_1.fm

EASTMAN KODAK COMPANY

Rochester, NY 14650

HEALTH GROUP

Loading...

Loading...