Page 1

© EASTMAN KODAK COMPANY, 2005 HEALTH GROUP

Confidential

Restricted

Information

{TheoryGuide}{Production}{Health Group}{ExternalAndInternal}

THEORY GUIDE

for the

Kodak DirectView CR 825/850 SYSTEMS

Service Codes: 5634, 4825

Important

Qualified service personnel must repair this equipment.

Publication No. TG4825-1

10DEC05

Supersedes TG4825-1

09JAN04

H177_0500AC

Page 2

THEORY GUIDE

10DEC05

TG4825-1

Page

2 of 120

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

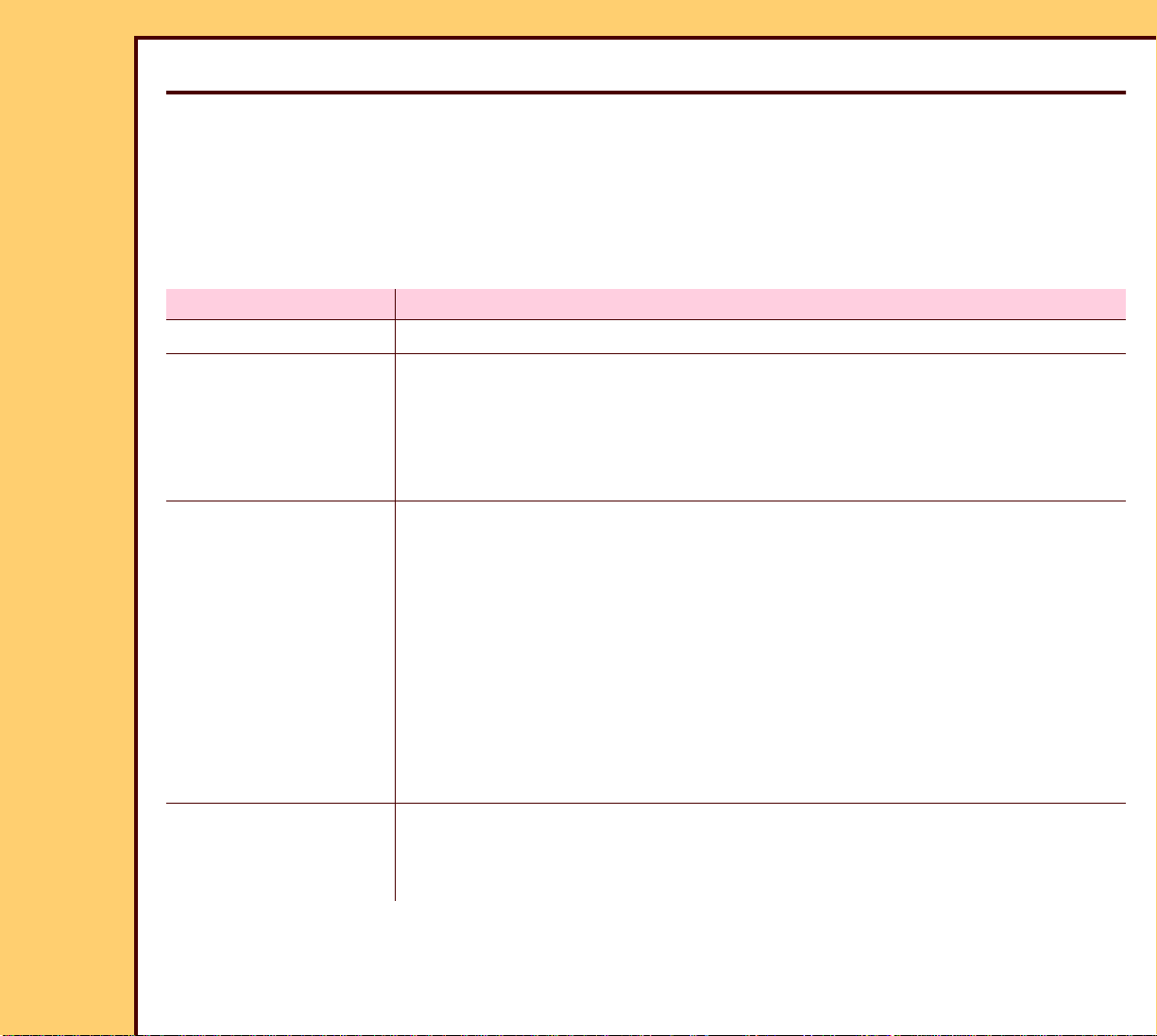

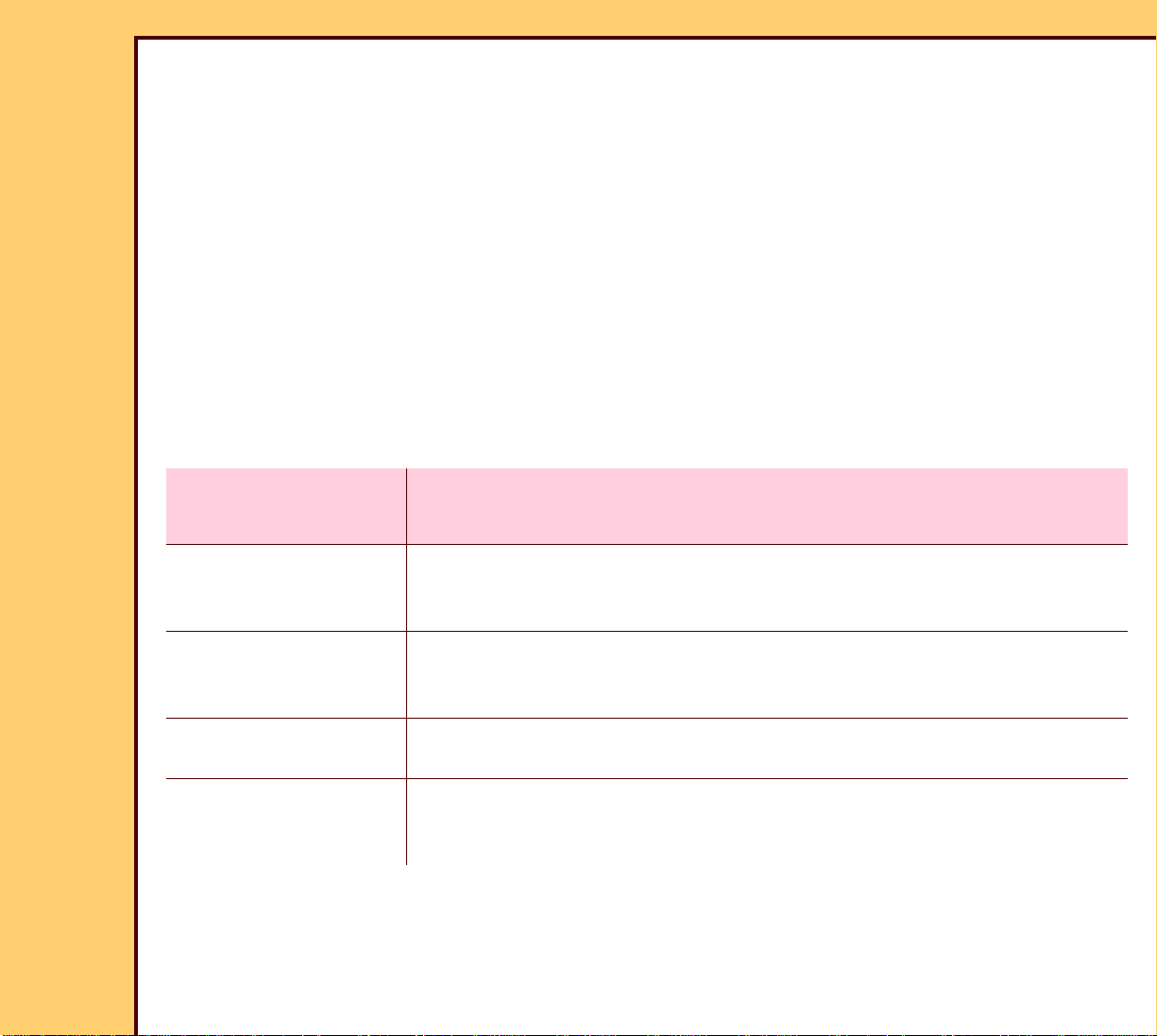

Table of Contents

Description Page

Equipment Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Main Subsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Radiography Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Comparison of Film/Screen and Computed Radiography (CR) . . . . . . . . . . . . 13

Overview of CR Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Exposing the STORAGE PHOSPHOR SCREEN. . . . . . . . . . . . . . . . . . . . . . 17

Stimulating the PHOSPHOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Changing Light Energy to an Analog Signal . . . . . . . . . . . . . . . . . . . . . . . . 20

Changing Analog Signals to Digital Signals . . . . . . . . . . . . . . . . . . . . . . . . 21

Processing the Digital Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview of Workflow Using the CR 825/850 SYSTEM . . . . . . . . . . . . . . . . . . . 23

Before Loading the CASSETTE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Loading the CASSETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fastening the PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preparing to Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Scanning the SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Erasing the SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Inserting the PLATE back into the CASSETTE SHELL . . . . . . . . . . . . . . . . . . . 30

Removing the CASSETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

STORAGE PHOSPHOR CASSETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Size and Resolution of SCREENS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Page 3

THEORY GUIDE

10DEC05

TG4825-1

Page

3 of 120

Fast Scan / Slow Scan Directions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Image Matrix Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Reading the BAR CODE LABEL of the CASSETTE . . . . . . . . . . . . . . . . . . . . . . 39

Cassette Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

DUPLEX CAM AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cassette Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cassette Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Plate Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Optical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

LASER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

GALVO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

COLLECTOR and PHOTOMULTIPLIER TUBE (PMT). . . . . . . . . . . . . . . . . . . . . . 62

Scan/Erase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

PLATE POSITIONING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

LEAD SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

EXTRACTION BAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

REFERENCE SENSOR S9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PLATE PRESENT SENSOR S5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

SLOW SCAN MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ENCODER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

ERASE AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

LAMP CURRENT SENSORS CS1 - CS5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Imaging Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Scanning the SCREEN - Slow Scan/Fast Scan. . . . . . . . . . . . . . . . . . . . . . . . . . 81

Obtaining the Image Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Processing the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Processing the Image. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Logic and Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Operator Input Compone nts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

BOARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Distribution of Images to the Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Page 4

THEORY GUIDE

10DEC05

TG4825-1

Page

4 of 120

Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

INTERLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

UNINTERRUPTIBLE POWER SUPPLY (UPS). . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Error and Activity Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Error Frequency Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Actuation Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Page 5

10DEC05

TG4825-1

Page

5 of 120

THEORY GUIDE Equipment Description

Section 1: Equipment Description

Features and Functions

The Kodak DirectView CR 825/850 SYSTEM is a LASER SCANNER that reads a latent

image made on a STORAGE PHOSPHOR SCREEN during an X-ray exam and provides a

digital image. Physicians and radiologists can then view, improve, store and make a print of

the image, and send the image across a computer network.

Size 63.5 x 73.6 cm (25 x 29 in.)

TOUCH SCREEN

MONITOR

• allows the operator to touch areas displayed on the screen to:

– enter exam and patient information

– view and improve images

• allows the FE to do service diagnostics

BAR CODE

READERS

• EXTERNAL BAR CODE READER:

– hand-held READER

– used to scan the BAR CODE LABEL on CASSETTES and

other BAR CODES used for entering data

• INTERNAL BAR CODE READER:

– automatically scans the BAR CODE LABEL on CASSETTES

when they are loaded

– provides information about the size, speed, and serial number

of the CASSETTE

INTERNAL PC • includes software for image processing and for providing

communication with external devices and the computer network

• access is through the front of the CR 825/850 SYSTEM

Page 6

10DEC05

TG4825-1

Page

6 of 120

THEORY GUIDE Equipment Description

Kodak DirectView

REMOTE

OPERATIONS

PANEL (ROP)

A device that is installed on the wall in an area separate from the CR

825/850 SYSTEM, used for viewing images and entering data. The

ROP includes:

• computer running an INTERNET BROWSER

• TOUCH SCREEN MONITOR - SVGA device with a 600 x 800

pixel resolution

• EXTERNAL BAR CODE READER - can read all formats identified

for the hand-held BAR CODE READER on the CR 825/850

SYSTEM

The ROP allows operators to:

• enter patient, exam, and CASSETTE (PEC) data into a CR 825/

850 SYSTEM

• check patient data

• view scanned X-ray images

• send images to other nodes on the network

PEC data entered through a ROP and sent across the network is

connected with the correct image.

Page 7

10DEC05

TG4825-1

Page

7 of 120

THEORY GUIDE Equipment Description

Configurations • Standalone - the CR 825/850 SYSTEM is not connected to other

CR 825/850 SYSTEMS:

– can include ROPs

– must have access to an output device for viewing the images

or to obtain a printout

• Cluster - 2 or more CR 850 SYSTEMS are in a network:

– can include up to 10 remote devices, for example Kodak

Directview CR 800/850/900/950 SYSTEMS, ROPs, and

Remote Patient Data Entry Stations (RPDES)

– allows all devices in the network to send infor mation to each

other

– must include one SERVER that stores all patient data

Note

• Devices in a cluster configuration can only send information to

other devices in the same cluster. Devices in one cluster cannot

send information to devices in other clusters.

Network

Communications

• The CR 825 SYSTEM will not operate in a cluster.

All CR 825/850 SYSTEMS and ROP devices:

• connect to the 10 Base-T or 100 Base-T Ethernet network of the

facility

• can send information to all connected DICOM digital imaging

equipment that is qualified with the Medical Image Manager (MIM)

and CR 825/850 SYSTEM

• use CATEGORY 5 CABLES to connect to the network

• use a gateway device qualified by Kodak to enable access to the

HIS/RIS system. The customer must provide this device.

Page 8

10DEC05

TG4825-1

Page

8 of 120

THEORY GUIDE Equipment Description

On-site Service • CASTERS allow the CR 825/850 SYSTEM to be moved for

service without leveling

• DATA PLATES and MODIFICATION LABELS are located for easy

access and viewing

• PLUGS and CONNECTORS are identified

• data in the Error and Activity logs can be sorted by field for

troubleshooting, for example by date and error code number

• FEs can view internal diagnostics, including error codes,

component tests, and tests of the SENSORS from the TOUCH

SCREEN MONITOR

Remote Service • remote access options:

– dedicated MODEM connected to the CR 825/850 SYSTEM

– MODEM SERVER provided by the customer

• one point of access to the service functions of all CR 825/850

SYSTEMS on the customer network from the remote service

access connection

• access to all service functions, except running the SCAN/ERASE

and Cassette Handling subsystems

• remote service:

– installing software

– setting up the configuration for the CR 825/850 SYSTEM

– retrieving and clearing Error and Activity Logs

– retrieving Image Processing Library (IPL) diagnostic images

Note

FEs providing remote service cannot view the information about the

patient on images.

Page 9

THEORY GUIDE Equipment Description

10DEC05

TG4825-1

Page

9 of 120

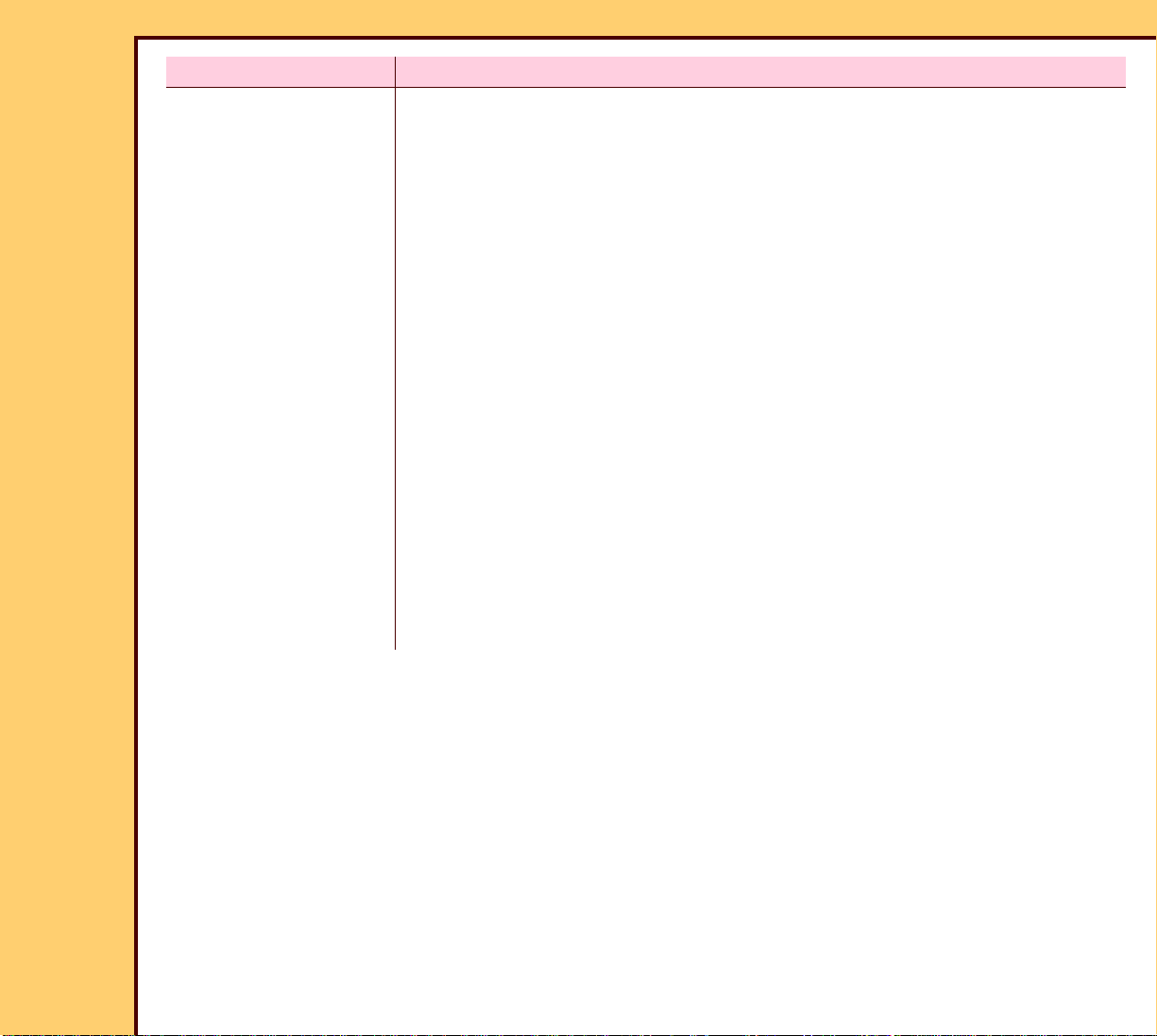

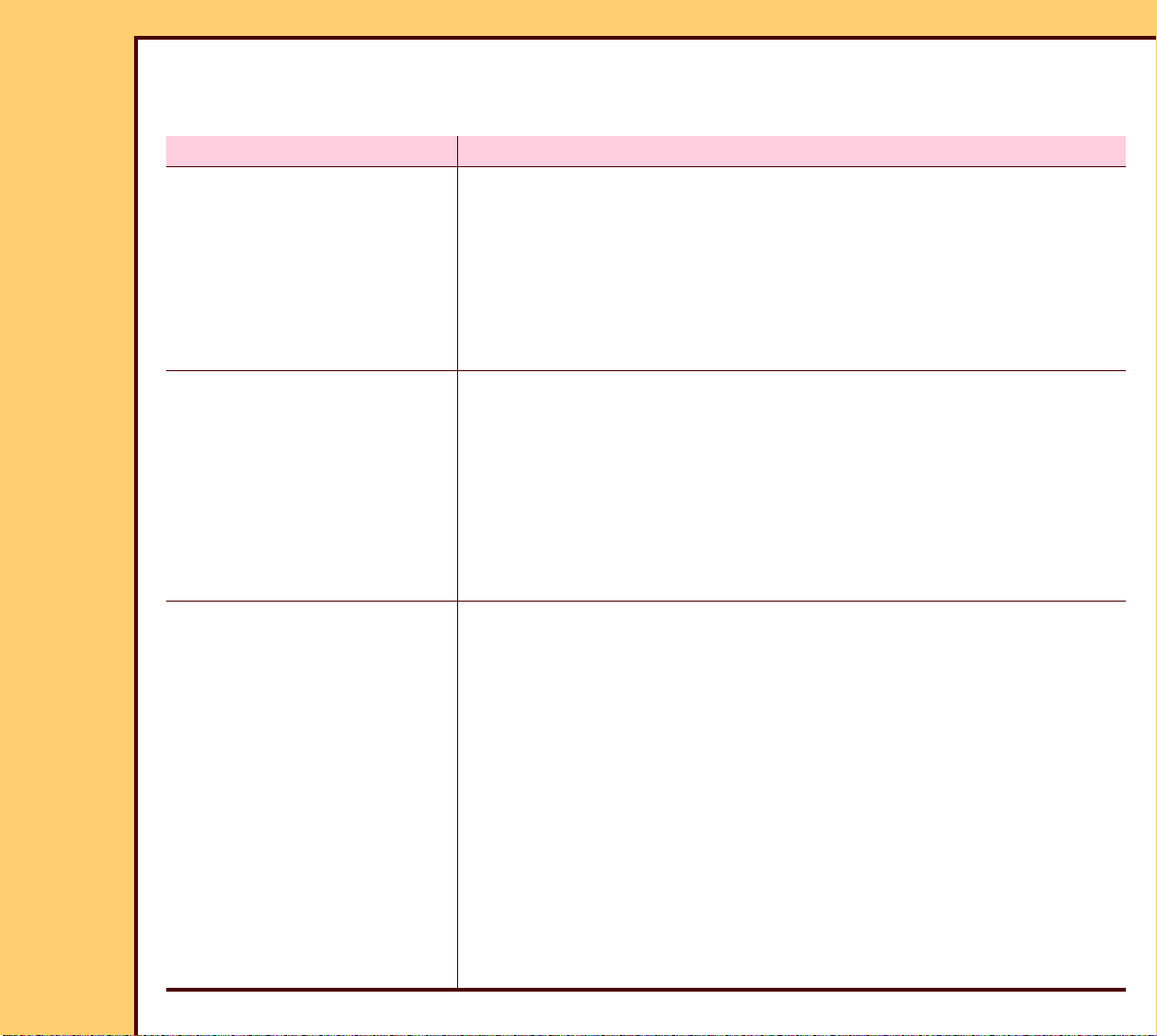

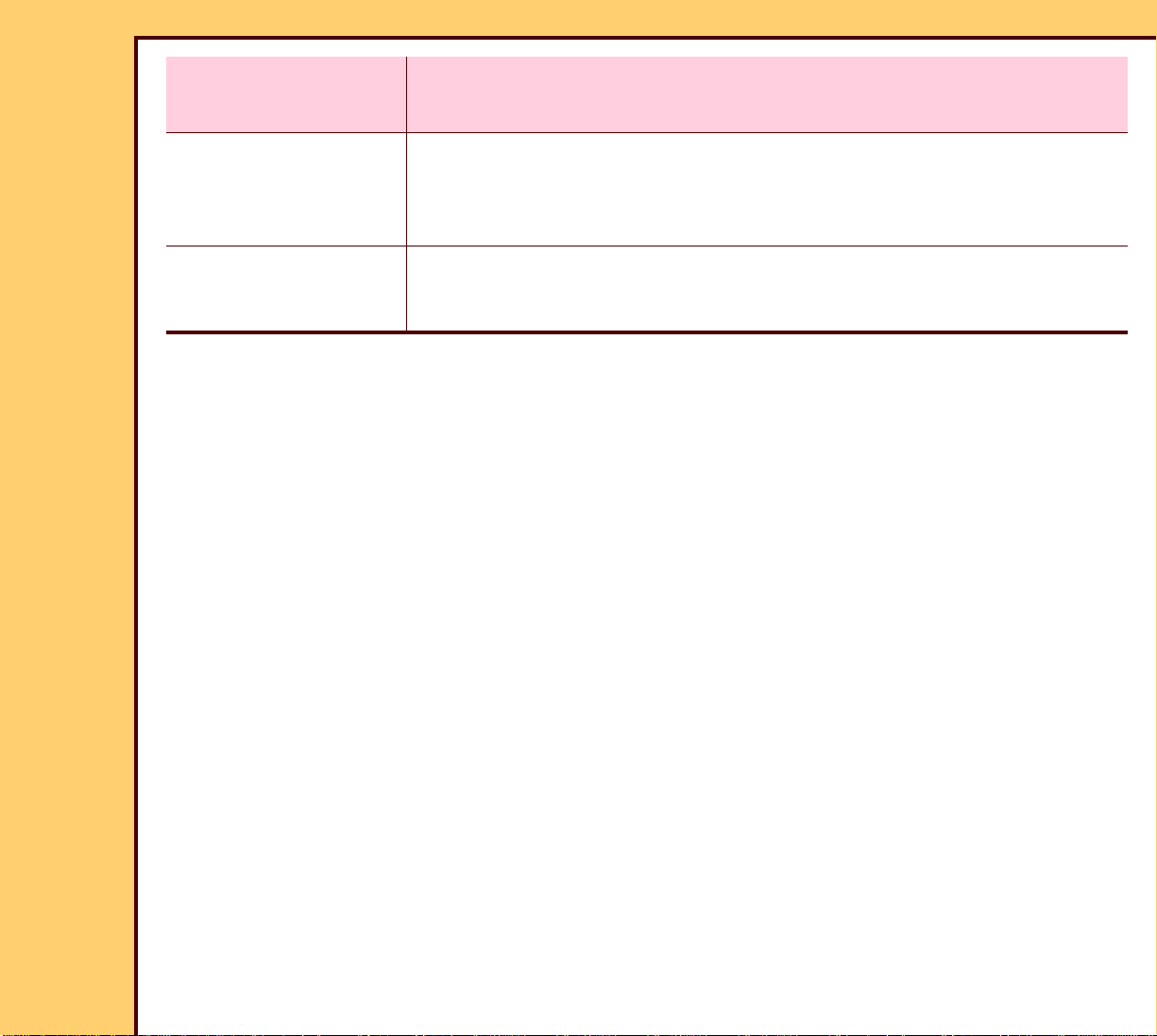

The following tabl e describes the specifications for the number of CASSETTES per hour:

Size CR 825 SYSTEM CR 850 SYSTEM

18 x 24 GP 72 90

24 x 30 GP 62 80

35 x 35 GP 70 90

35 x 43 GP 62 85

18 x 24 HR 70 90

24 x 30 HR 62 80

LONG-LENGTH

60 82

CASSETTE

To ler ance is ± 5

The CR 825 SYSTEM is identical to the CR 850 SYSTEM except the software decreases the

speed.

Page 10

10DEC05

TG4825-1

Page

10 of 120

THEORY GUIDE Equipment Description

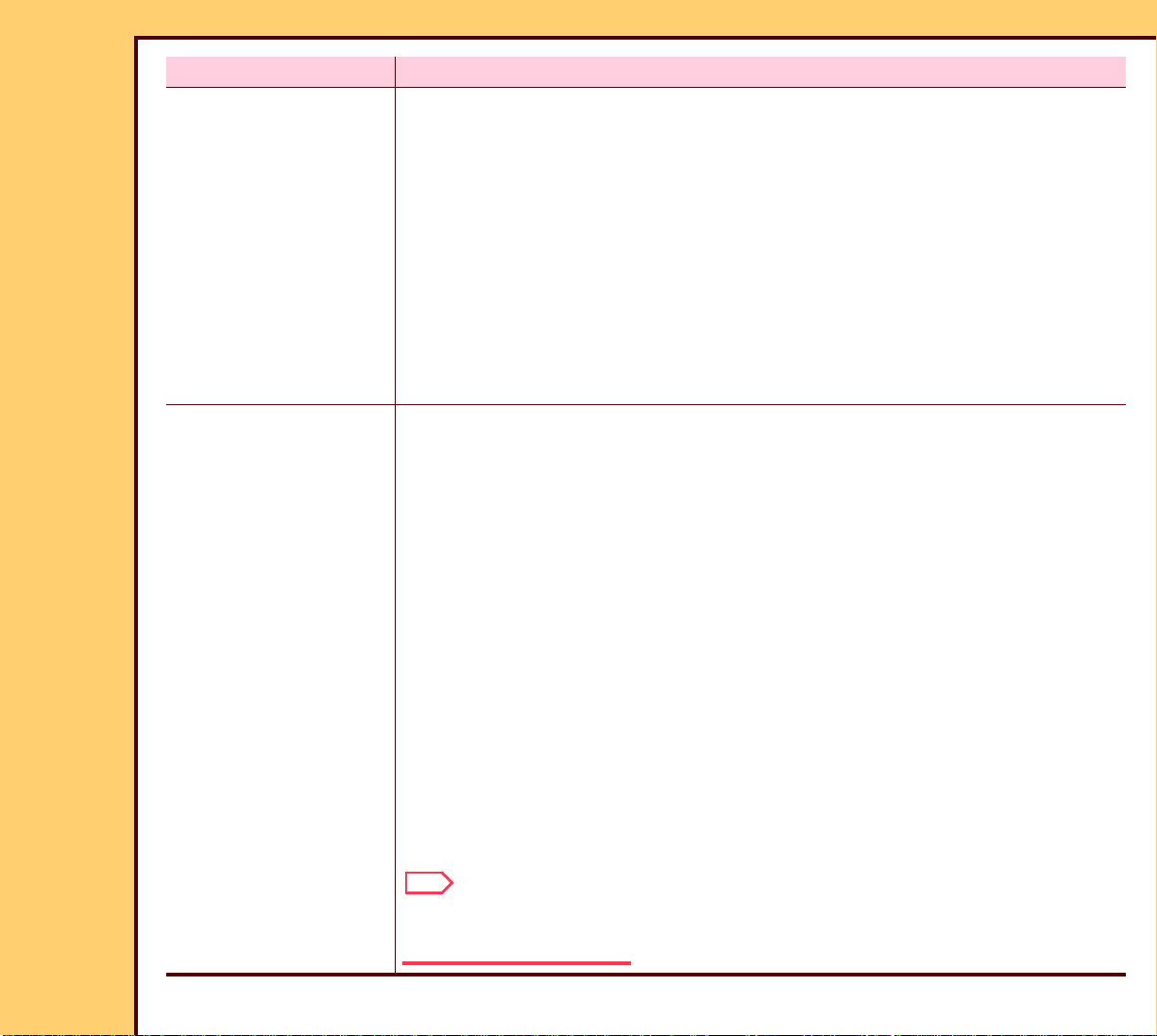

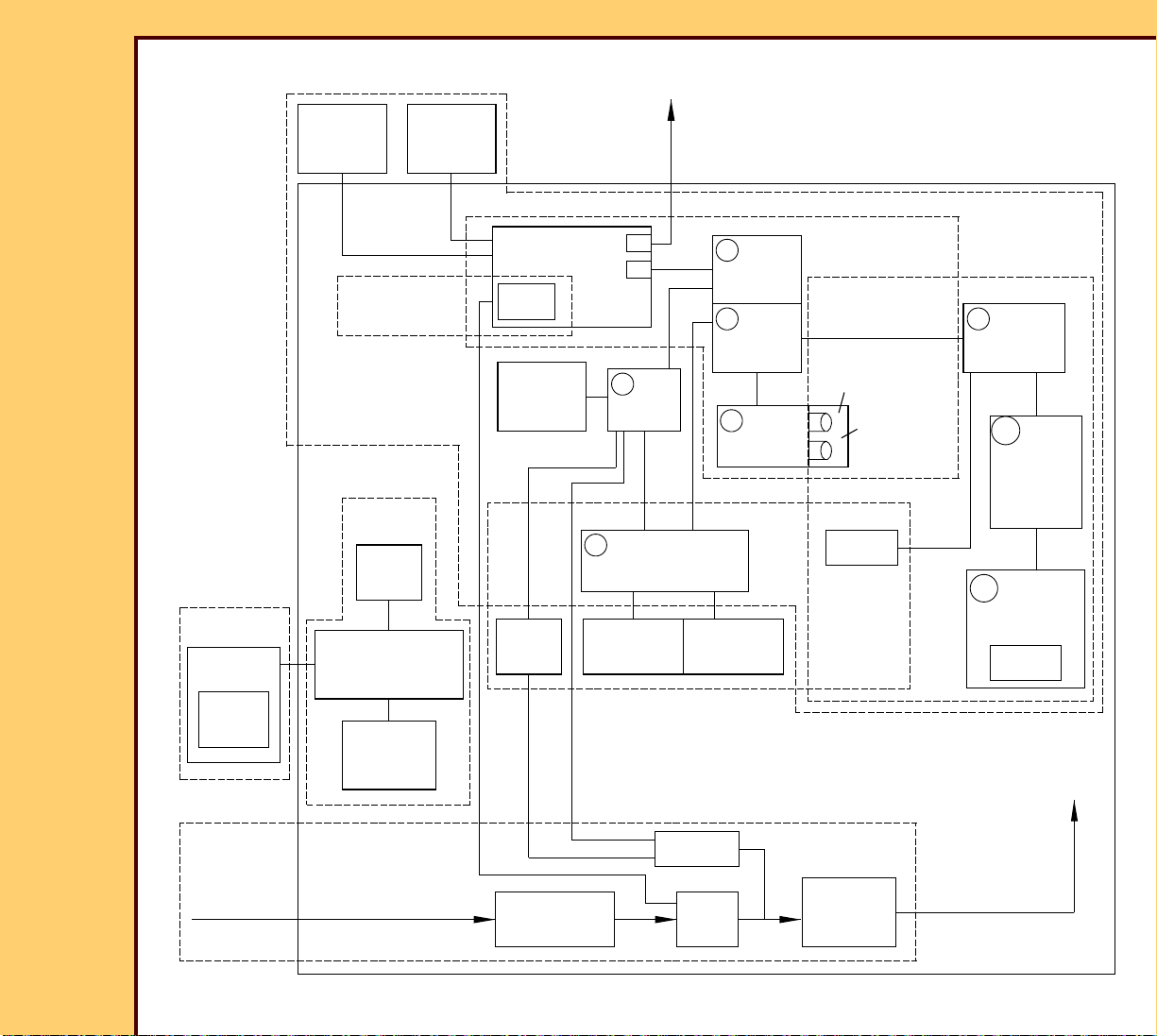

Main Subsystems

CASSETTE

SHELL

CASSETTE

PLATE

TOUCH

SCREEN

MONITOR

Error and Activity

Cassette Entry/

Cassette Transport

Logs

Cassette

Handling

DUPLEX

CAM AY

EXTERNAL

BAR CODE

READER

INTERNAL

PC

LOGS

INTERNAL

BAR CODE

READER

ERASE

LAMPS

to

network

Ethernet

CARDS

A1

MSC

BOARD

A6

SLOW SCAN

CONTROLLER BOARD

SLOW SCAN

ENCODER

SLOW SCAN

A2

MCPU

BOARD

A3

DIGITIZER

BOARD

A5

PMT/DAS

BOARD

Scan/Erase

MOTOR

CR 850 SYSTEM

PMTs

GALVO

Imaging

COLLECTOR

Logic and Control

Optical

A4

GALVO

BOARD

A18

LASER

DRIVER

PRE-

REGULATOR

BOARD

A17

LASER DIODE

DRIVER BOARD

LASER

SCREEN

AC power

90 - 264 V AC

H194_5044DC

Plate

Handling

T1

TRANSFORMER

K1 RELAY

UPS

Power Distribution

PS1

POWER

SUPPLY

DC power to

all BOARDS

and MOTORS

Page 11

10DEC05

TG4825-1

Page

11 of 120

THEORY GUIDE Equipment Description

Subsystem Description See:

CASSETTE • includes:

– STORAGE PHOSPHOR

SCREEN that captures and stores the X-

STORAGE

PHOSPHOR

CASSETTE

ray image for processing

– CASSETTE SHELL that holds the PLATE

• available in 5 sizes and 3 resolutions (GP,

HR, and EHR)

Cassette Handling • loads the CASSETTE into the CR 825/850

SYSTEM

• removes the PLATE from the CASSETTE

SHELL

• after scanning, installs the PLATE in the

CASSETTE SHELL

• allows the CASSETTE to be removed from

the CR 825/850 SYSTEM

Optical • controls and moves the laser beam to the

SCREEN

• captures the blue light emitted from the

SCREEN

Scan/Erase • moves the PLATE at a uniform speed:

– through the scanning area

– to the erase position

• removes the residual image on the SCREEN

by exposing it to intense light

Cassette Handling

Optical

Scan/Erase

• inserts the PLATE into the CASSETTE

SHELL again

Page 12

10DEC05

TG4825-1

Page

12 of 120

THEORY GUIDE Equipment Description

Subsystem Description See:

Imaging • assembles the data from the screen and

Imaging Sequence

changes it to digital format

• processes the image

Logic and Control • processes commands from the operator

• controls the operation of all subsystems

• sends processed images to the network for

distribution

Pow e r D i s t r ib u ti o n • provides power for all subsystems

• includes an UNINTERRUPTIBLE POWER

SUPPLY (UPS)

• has an INTERLOCK SWITCH that actuates

when the FRONT DOOR is opened

Error and Activity

Logs

• records logs of errors in the system

• records user actions

Logic and Control

Power Distribution

Logs

Page 13

10DEC05

TG4825-1

Page

13 of 120

THEORY GUIDE Radiography Theory

Section 2: Radiography Theory

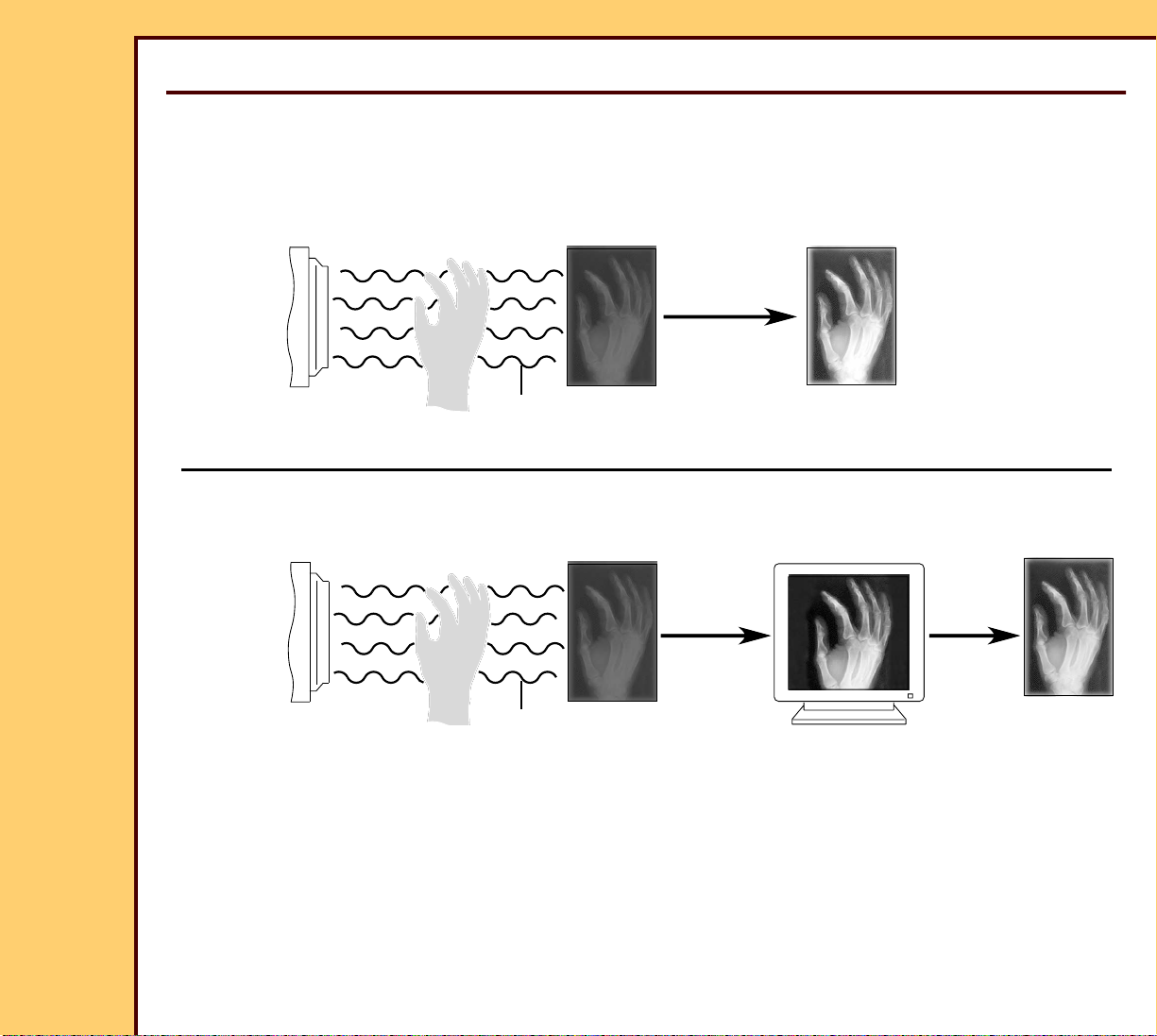

Comparison of Film/Screen and Computed Radiography (CR)

FILM/

X-RAY latent image

TUBE

(On Film)

FILM PROCESSING

visible image

(On Film)

SCREEN

AERIAL

IMAGE

FINAL VISIBLE

IMAGE

(Film or Viewer)

STORAGE

X-RAY

TUBE

(Storage Phosphor)

CONVERSIONS

visible imagelatent image

(CRT)

ENHANCED

PROCESSING

PHOSPHOR

SCREEN

X-rays are used in medical imaging to make an image of given body parts on a surface,

which can be read by a Radiologist or other medical personnel. The available systems for

capturing these images are:

• Screen/film - captures a projection image on an X-ray film

• Computed Radiography (CR) - captures a digital image

Page 14

THEORY GUIDE Radiography Theory

10DEC05

TG4825-1

Page

14 of 120

The following phases are necessary to capture and process projection radiographs for both

screen/film systems and CR systems:

Phase of Image Capture Description

Phase 1 Making the aerial image

In both screen/film and CR systems:

• an X-ray TUBE emits X-rays in the direction of an IMAGE

RECEPTOR

• when the X-rays reach the body of the patient, some are

absorbed by the patient and some are not. The result is an

“aerial” image with varying degrees of X-ray power (varying

numbers of X-ray photons)

Phase 2 Capturing the latent image

When the IMAGE RECEPTOR is exposed to the X-rays in the

aerial image, a latent image is captured on the RECEPTOR:

• screen/film systems - image is captured on sensitized

radiographic film

• CR systems - image is captured on a STORAGE

PHOSPHOR SCREEN. The X-ray photons that reach the

SCREEN charge the PHOSPHOR, making a latent image

on the screen.

Phase 3 Capturing, changing, and

storing the visible image

The latent image must be changed to a visible image, which

can be read by the Radiologist, moved from one place to

another, and stored for use at another time:

• screen/film systems - radiographic film is processed through

chemicals and the latent image is fixed onto the film

• CR systems - the latent image on the STORAGE

PHOSPHOR SCREEN is scanned by a laser beam, which

stimulates the charged PHOSPHOR on the SCREEN. Blue

light is emitted from the stimulated PHOSPHOR, assembled,

and changed into analog electrical signals. The analog

image is then changed into digital signals and processed.

The digital image is stored and displayed by a computer

system and can be routed to other computers and

PRINTERS through a network.

Page 15

THEORY GUIDE Radiography Theory

10DEC05

TG4825-1

Page

15 of 120

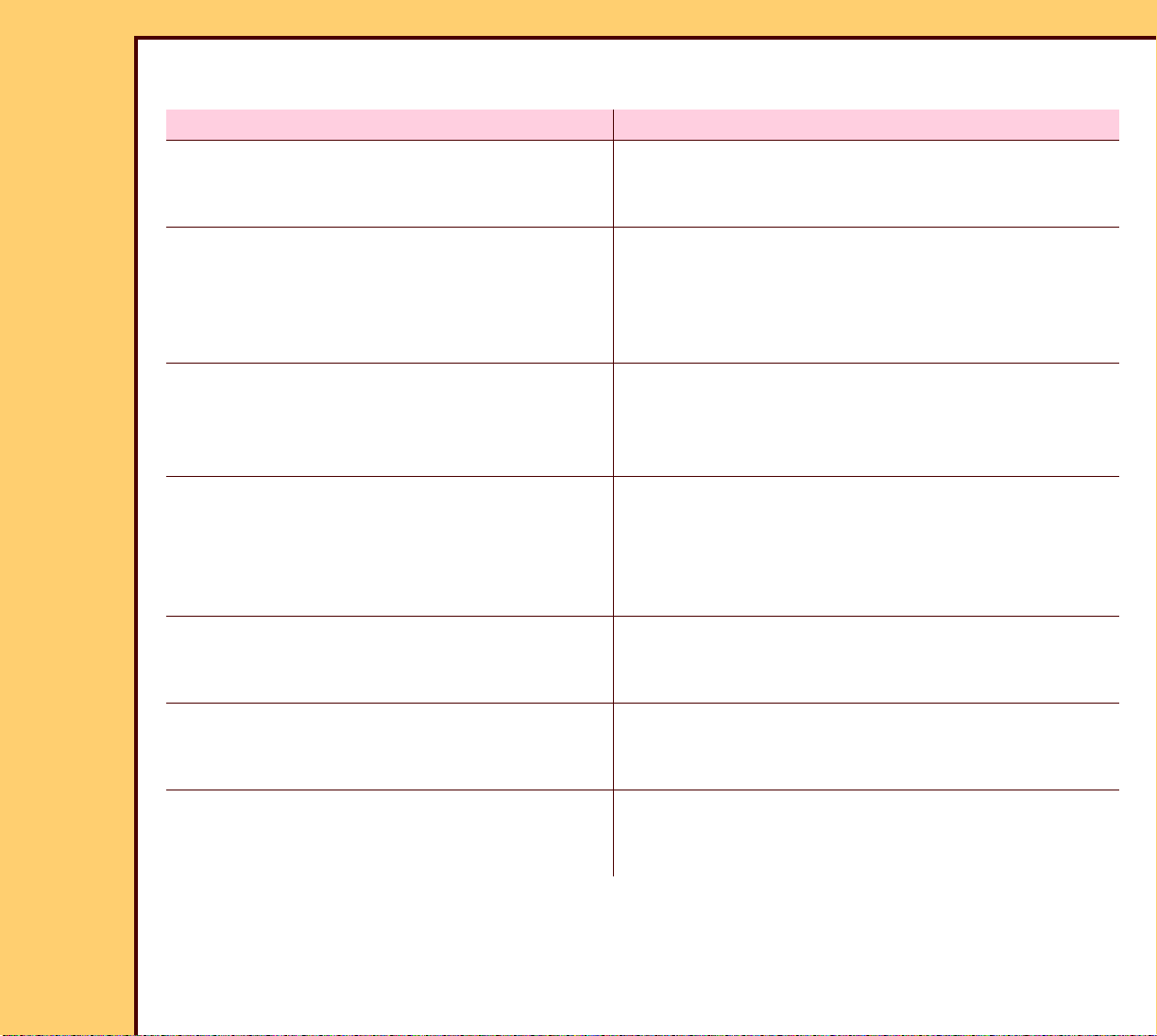

The following tabl e compares the analog and digital health image capture systems.

Analog Screen/Film Systems Digital CR Systems

Uses “Rare Earth” SCREENS GADOLINIUM OXYSULFIDE or

Uses a BARIUM FLOUROHALIDE STORAGE

PHOSPHOR SCREEN.

LANTHANUM OXYBROMIDE.

Speed range from 100 - 1000. Screen speed:

• General Purpose (GP), 200 - 250

• High Resolution (HP), 100 - 125

• Enhanced High Resolution (EHR), 100 - 125

Film processing parameters are important

No film processing is necessary.

in determining the quality of the image,

for example chemical temperature and

timing.

It is hard to obtain the same print quality

when copies are necessary because of

The user can print a copy of the digital image

at any time.

variations in GENERATORS,

PROCESSORS, positions, procedures,

and conditions for developing the film.

Overexposing or underexposing an image

normally makes it necessary to expose

the patient to ionizing radiation again.

Image quality is changed by conditions in

the environment, for example temperature

or humidity.

The image cannot be viewed in more

than one place at a time.

Exposure factors do not normally make it

necessary to expose the patient to ionizing

radiation again.

Image quality is not changed by conditions in

the environment.

CR images can be viewed at more than one

place at the same time, in the same building or

in remote nodes on the network.

Page 16

10DEC05

TG4825-1

Page

16 of 120

THEORY GUIDE Radiography Theory

Analog Screen/Film Systems Digital CR Systems

• Recording medium - film

• Output medium - film

• Storing medium - film

• Recording medium - STORAGE

PHOSPHOR SCREEN

• Output medium - film, paper, digital display

• Storing medium - digital

Image density and contrast are controlled

by kilovolts peak (kvP), milliampere

seconds (mA.s), and film type.

Viewing quality can only be improved by

increasing the brightness of the LAMP

that illuminates the film.

The quality of films that are not exposed

correctly cannot be improved.

Density and contrast are controlled by image

processing parameters. kvP, and mA.s continue

to be important image control factors for details

and noise in the digital image.

Digital images can be improved by processing

on a computer to change the density, contrast,

sharpness, and other factors.

Images that were not exposed correctly can be

improved. For example, software parameters

can improve image density and contrast.

Page 17

10DEC05

TG4825-1

Page

17 of 120

THEORY GUIDE Radiography Theory

Overview of CR Technology

Operations

The following operations are necessary to capture the latent image in the STORAGE

PHOSPHOR SCREEN and change it to a digital image that can be viewed on a computer

screen and sent to a PRINTER.

• Exposing the STORAGE PHOSPHOR SCREEN

• Stimulating the PHOSPHOR

• Changing Light Energy to an Analog Signal

• Changing Analog Signals to Digital Signals

• Processing the Digital Image

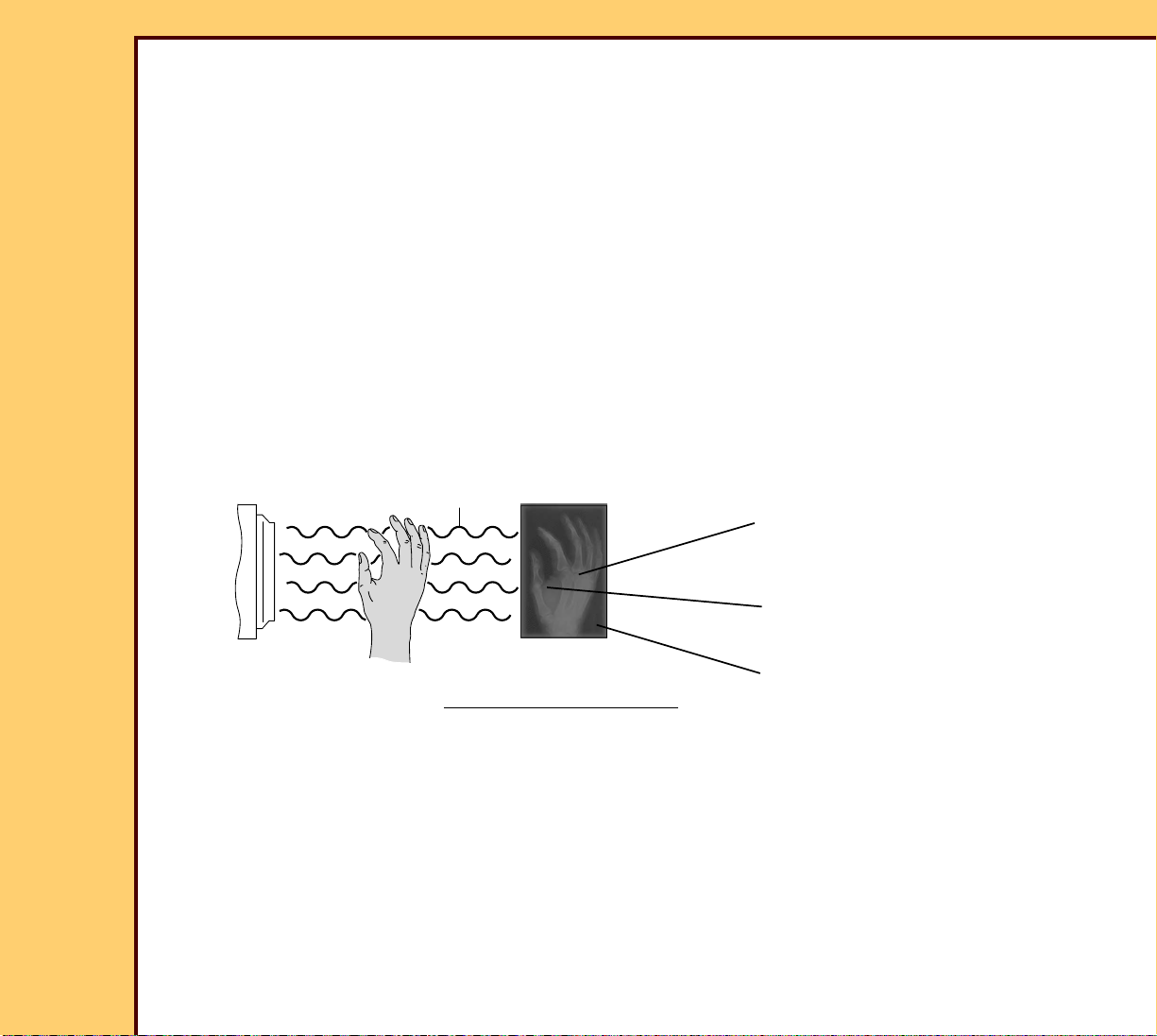

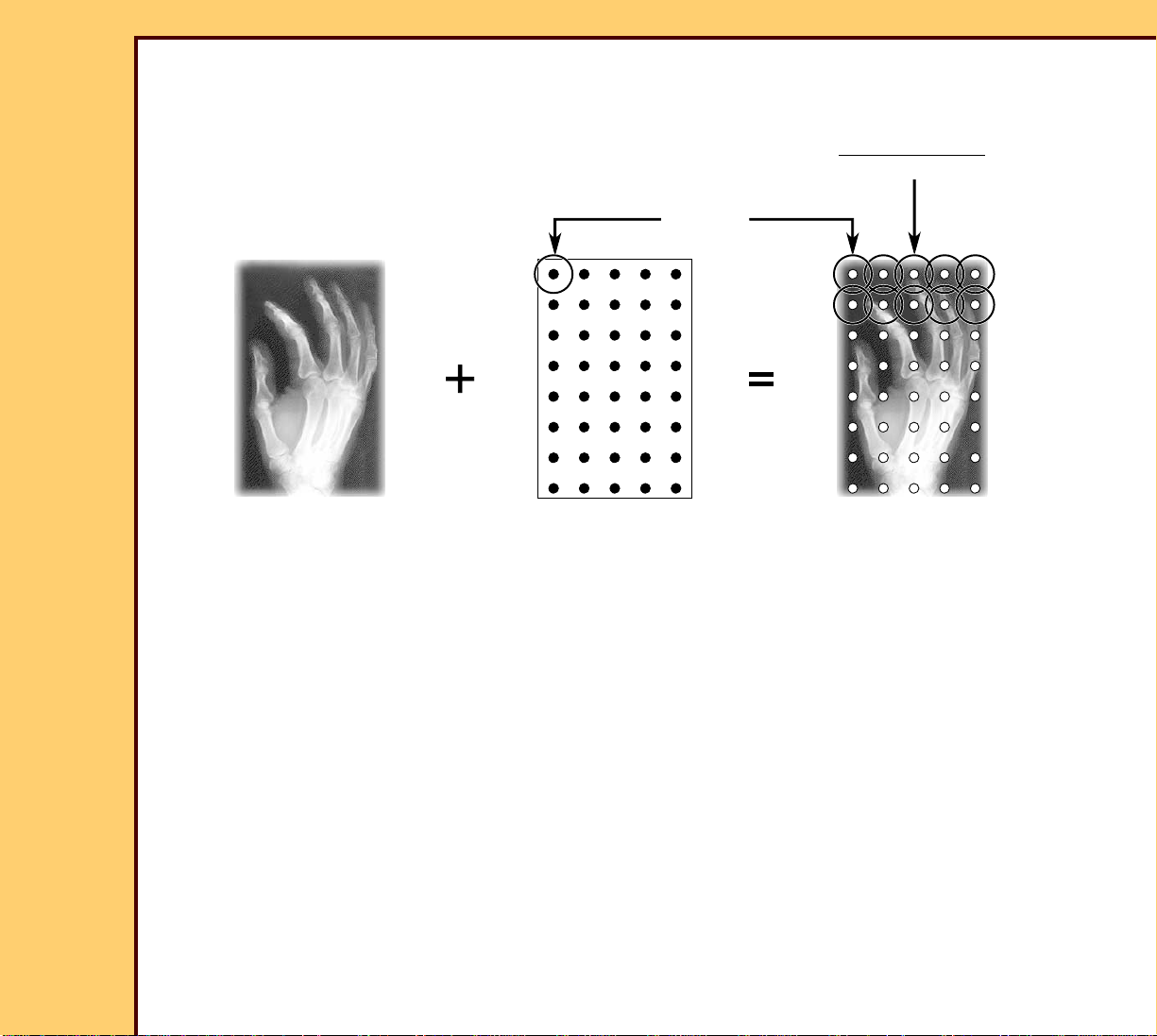

Exposing the STORAGE PHOSPHOR SCREEN

X-RAY

TUBE

H194_5033BC

aerial

image

STORAGE PHOSPHOR SCREEN

Charged storage phosphors

proportional to X-ray energy

absorbed by screen.

latent

image

Lighter values indicate that more

x-rays were absorbed by the

SCREEN - bone tissue

Mid-range values indicate that fewer

x-rays were absorbed by the

SCREEN - soft tissue

Darker values indicate that most

x-rays were absorbed by the

SCREEN - did not pass through the body

Page 18

THEORY GUIDE Radiography Theory

10DEC05

TG4825-1

Page

18 of 120

When a STORAG E PHOSPHOR SCREEN is exposed to X-rays:

• special PHOSPHOR on the SCREEN absorbs the radiation in degrees of intensity

determined the body par t and the type of SCREEN:

– soft body tissues absorb a small quantity of radiation - these areas are indicated in the

X-ray image by mid-range values

– bone tissues absorb most of the radiation - these areas are indicated in the X-ray

image by light values

– X-rays that do not hit any obstructions are indicated in the X-ray image by dark values

– High Resolution SCREENS absorb less energy than General Purpose SCREENS

• SCREEN has a latent image in the areas that were exposed to the radiation. The quantity

of stored energy or charge on the SCREEN is proportional to the quantity of

X-ray energy absorbed by the SCREEN.

Characteristics of the

STORAGE P HOSPHOR

SCREEN

Description

X-ray absorption About 50% of the X-ray energy is released in the form of

fluorescence when the SCREEN is exposed. The X-ray energy

remaining makes the latent image on the SCREEN.

Photostimulable

luminescence

When the charged PHOSPHOR on the SCREEN is stimulated by

light, the PHOSPHOR releases or discharges blue light proportional

to the energy the PHOSPHOR has stored.

Fading The latent image fades with time, but it is possible to read data from

the SCREEN for a number of days after scanning.

Residual image After a SCREEN is erased by exposing it to light, it keeps some

charge from the latent image. This charge does not make the

SCREEN less effective when it is used again.

Page 19

10DEC05

TG4825-1

Page

19 of 120

THEORY GUIDE Radiography Theory

Characteristics of the

STORAGE P HOSPHOR

SCREEN

Description

Signal accumulation Signals can accumulate on SCREENS that are not used for more

than 24 hours. Erasing these SCREENS decreases the residual

image to the optimum range for using the SCREEN again. Failure to

erase these signals can result in artifacts.

Long life The photostimulable luminescent quality of the SCREEN does not

decrease with time. The life of a SCREEN can be decreased by

damage to the material.

Stimulating the PHOSPHOR

It is necessary to stimulate the PHOSPHOR in the SCREEN to read the latent image. The

following components of the CR systems provide this function:

• light source:

– exposes the SCREEN with high-intensity light that stimulates the electrons and causes

the electrons to be luminescent

– laser beam moves from one side of the SCREEN to the other to ex pose the image

• DEFLECTOR:

– moves the laser beam across the SCREEN and then back to the starting position. At

the same time, the SCREEN moves perpendicular to the scanning direction of the

laser beam.

– is continually monitored and adjusted to check that the scanning operation is correct

and has a continual speed

• scanning optics:

– focuses and shapes the laser beam, keeping the speed and angle of the beam the

same when it moves across the SCREEN

– angle of a laser beam determines the size, shape, and speed of the beam. An

example is the beam of a flashlight moving across a flat surface from one edge to the

center and to the other edge.

Page 20

THEORY GUIDE Radiography Theory

10DEC05

TG4825-1

Page

20 of 120

Changing Light Energy to an Analog Signal

The following components of CR systems change the light energy in the exposed SCREEN to

an analog signal:

• LIGHT COLLECTOR:

– provides the collection of the blue light emitted when the SCREEN is stimulated by the

laser beam

– CR 825/850 SYSTEM uses an INTEGRATING CAVITY with MIRRORS to provide the

collection of the blue light

• BLUE FILTER:

– does not allow any red light reflected from the SCREEN to reach the LIGHT

DETECTORS

– allows only the blue light to reach the LIGHT DETECTORS

• LIGHT DETECTORS:

– are normally PHOTOMULTIPLIER TUBES (PMT)

– receive light that enters the COLLECTOR

– change the light photons into electrons when the photons enter through a

PHOTOCATHODE. When the electrons move through the LIGHT DETECTORS, the

electrons increase in number - “gain”.

– when more than one LIGHT DETECTOR is used in a system, the system adds and

changes the signals into one output. The output from the added PMTs can include

frequencies that are outside of the limits of the system - “noise”. An ANALOG FILTER

limits this noise.

Page 21

THEORY GUIDE Radiography Theory

10DEC05

TG4825-1

Page

21 of 120

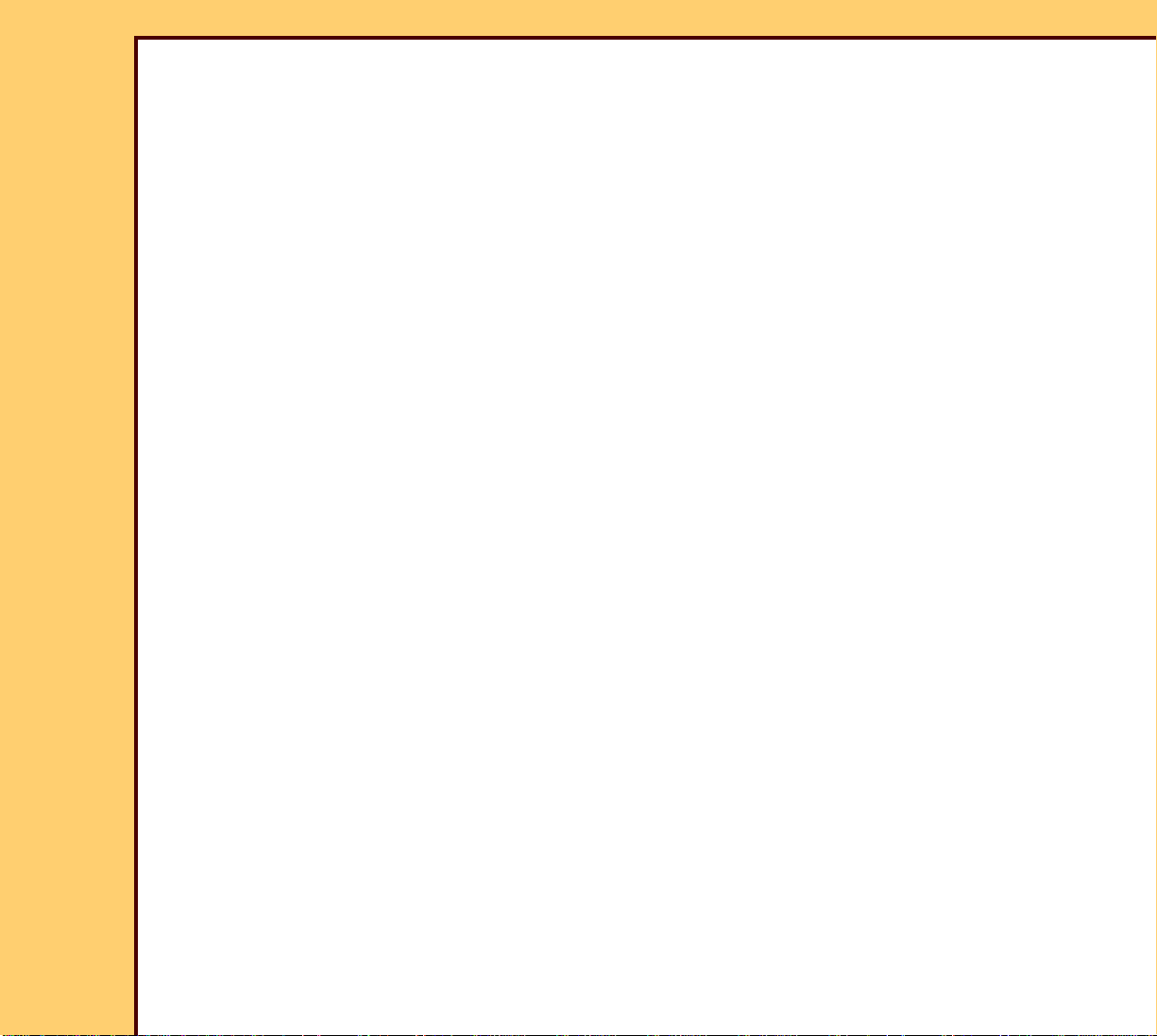

Changing Analog Signals to Digital Signals

SAMPLING

Y

image

sample

grid

X

analog image digital image

(continual values) (discrete values)

pixel code value

(0 - 4095)

image

matrix

H194_5014HC

Analog signals are changed to digital signals by sampling the blue light from the STORAGE

PHOSPHOR SCREEN and moving it through an ANALOG-TO-DIGITAL CONVERTER to

make a digital value for the br ightness of each sample.

Sampling is similar to making a photograph of the signal at a given time. The sample has

both a horizontal and a vertical value. The size of the sample is defined in the system

software for both the horizontal and ver tical directions.

• The horizontal value indicates a point in time in the motion of the laser beam across the

SCREEN.

• The vertical value indicates a line on the screen at a right angle to the scanning direction.

Page 22

THEORY GUIDE Radiography Theory

10DEC05

TG4825-1

Page

22 of 120

If you find both the horizontal and the vertical points of the sample on an imaginary matrix,

similar to the one in the graphic, the result indicates one pixel in the digital image.

Continual analog input values are changed to output values. In this process, the replacement

of small ranges of analog input values with one digital output value occurs. The digital output

value indicates one pixel of infor mation on the TOUCH SCREEN MONITOR.

The output is a linear digital signal. The CR 825/850 SYSTEM emits a 16-bit digital signal

with a total signal range of 65,536 levels. Because it is not possible for the human eye to see

this range of separate values, the CR 825/850 SYSTEM changes the 16-bit linear image data

to 12-bit log data. This 12-bit log provides data from 0 - 4095 values. These values are used

in the CR 825/850 SYSTEM.

Processing the Digital Image

Digital imaging allows users to improve diagnostic images by processing the images. After the

digital image is made, the digital data is processed using parameters set up in the software.

In the CR 825/850 SYSTEM, this processing occurs in the INTERNAL PC.

Examples of image processing used for digital images:

• segmentation

• tone scaling

• edge enhancement

• brightness - level

• contrast - window

Page 23

10DEC05

TG4825-1

Page

23 of 120

THEORY GUIDE Sequence of Operation

Section 3: Sequence of Operation

Overview of Workflow Using the CR 825/850 SYSTEM

1 The Radiology Department receives an exam request.

2 The Radiologist, the operator, assembles the patient information. Examples of patient

information are patient name, ID, and accession number.

Note

If the facility has a Hospital Information System/Radiographic Information System (HIS/RIS)

that is HL-7 compatible, the patient infor mation can be automatically downloaded to the

CR 825/850 SYSTEM through a HIS/RIS gateway. If no automatic connection is available, the

information can be manually entered at a ROP or a CR 825/850 SYSTEM.

3 The operator can select network nodes to send the image data to.

4 The operator uses a CR CASSETTE to do the exam, capturing the latent image on the

STORAGE PHOSPHOR SCREEN.

5 Using the CR 825/850 SYSTEM or the ROP, the operator enters the CASSETTE ID

Information by scanning the CASSETTE BAR CODE or entering it manually.

6 The operator inserts the exposed CASSETTE into the CR 825/850 SYSTEM. The system

scans the SCREEN, capturing the latent image on the SCREEN and changing it to a

digital image. After scanning, the SCREEN is automatically erased and inserted into the

CASSETTE SHELL.

7 The CR 825/850 SYSTEM processes the image. If the system is in:

• Pass-Through Mode - the image is automatically sent to all network nodes

• QA Mode - the operator can process the image and then send it to other network

nodes

8 If necessary, the image can be processed and sent to networ k nodes again.

Page 24

THEORY GUIDE Sequence of Operation

10DEC05

TG4825-1

Page

24 of 120

Before Loading the CASSETTE

1 After initializing, the CR 825/850 SYSTEM is ready to receive a CASSETTE for scanning.

2 The Radiology Technologist uses a Computed Radiology (CR) CASSETTE to capture the

latent image of the body part on the SCREEN.

Status Summary: Ready to Receive a CASSETTE

• DUPLEX CAM is at the home position 1

• DRIVE ROLLERS and IDLER ROLLERS are in contact with the

CASSETTE

• PIVOTING PLUSH is in the open position

• LIGHT SEAL BAR is in the open position

• CASSETTE DRIVE MOTOR is stopped

• EXTRACTION BAR is at the home position

Loading the CASSETTE

1 The operator loads the CASSETTE into the INPUT SLOT until the CASSETTE reaches

the CASSETTE ENTRY SENSOR S1.

2 The CASSETTE ENTRY SENSOR S1 detects the CASSETTE.

Note

The MSC BOARD continually monitors the CASSETTE LOAD SENSOR S2. At the S2

SENSOR, the system must detect a CASSETTE within 5 seconds or an error message

displays.

3 The INTERNAL BAR CODE READER reads the size, speed, and serial number of the

CASSETTE, then:

• emits a sound

• sends information to the MCPU BOARD A2:

– “CASSETTE Detected” message

– size of the CASSETTE

Page 25

THEORY GUIDE Sequence of Operation

10DEC05

TG4825-1

Page

25 of 120

4 The MCPU BOARD A2 sends:

• “CASSETTE Detected” message to the MSC BOARD A1

• “Scan Request” message to the INTERNAL PC

5 The INTERNAL PC:

• checks that it has the quantity of memory necessary to receive an image

• makes a raw image file to receive the image

• sends a “Scan Request Reply” message to the MCPU BOARD A2 with a value of

“OK”

6 The MCPU BOARD A2:

• sends a message to the MSC BOARD A1 to load the CASSETTE

• sends the information about the size and speed of the CASSETTE to the DIGITIZER

BOARD

Note

If the BAR CODE readout is not successful, the operator must enter the data manually. When

BAR CODE data is entered manually, the data is provided by the INTERNAL PC and not the

BAR CODE READER.

7 The CASSETTE DRIVE MOTOR M2 actuates. The MOTOR drives the TIMING BELTS,

which rotate the DRIVE ROLLERS.

8 The DRIVE ROLLERS drive the CASSETTE to the back until the CASSETTE REAR

SENSOR S3 detects the CASSETTE.

9 The CASSETTE REAR SENSOR S3 sends a signal to the MSC BOARD A1 to

deactuate the MOTOR.

10 After a delay of 20 ms, the MSC BOARD A1 deactuates the MOTOR.

Page 26

10DEC05

TG4825-1

Page

26 of 120

THEORY GUIDE Sequence of Operation

Status Summary: CASSETTE Loaded

• DUPLEX CAM is in the home position

• DRIVE/IDLER ROLLERS are engaged on the CASSETTE

• CASSETTE is at the CASSETTE REAR STOP and the CLAMP

BARS are open

• CASSETTE DRIVE MOTOR M2 is stopped

• PLATE remains inside the CASSETTE

• HOOKS on the EXTRACTION BAR are not extended

Fastening the PLATE

1 The DUPLEX CAM moves from position 1 directly to position 3. See “DUPLEX CAM

AY.”

2 When the CAM rotates, the SLED CAM and the HOOK CAM execute the following

actions. The first degrees of the CAM rotation move the HOOKS up. The remaining part

of the rotation releases the LATCHES of the CASSETTE and fastens the PLATE to the

EXTRACTION BAR.

• SLED CAM actions:

– SLED PLATE moves 1.5240 cm (0.600 in.) forward

– PIVOTING PLUSH rotates to make a light-tight environment around the

CASSETTE

• HOOK CAM actions:

– HOOK CAM moves against the HOOK YOKE FOLLOWER, which starts the

mechanical sequence to extend the HOOKS on the EXTRACTION BAR into the

LATCH AY. See “Plate Handling.”

– With the HOOKS in position inside the CASSETTE, the forward motion of the

SLED causes the SPRING-LOADED LATCH inside the PLATE to release and

fastens the PLATE to the EXTRACTION BAR.

3 The MSC BOARD A1 sends a signal to the MCPU BOARD that the CASSETTE is

loaded.

Page 27

10DEC05

TG4825-1

Page

27 of 120

THEORY GUIDE Sequence of Operation

Status Summary: PLATE Fastened

• DUPLEX CAM has reached position 3

• SLED is 1.524 cm (0.600 in.) forward from the home position

• CLAMP BARS are holding the CASSETTE

• PLATE is fastened to the EXTRACTION BAR

• EXTRACTION BAR is at home position with the fastened

PLATE

• PIVOTING PLUSH has made a light-tight environment

around the CASSETTE

• DUPLEX CAM MOTOR M1 is de-energized

Preparing to Scan

1 The SLOW SCAN MOTOR starts rotating the LEAD SCREW, pulling the PLAT E down

from the CASSETTE.

• When the EXTRACTION BAR moves down to the position immediately before

scanning starts, the LOWER ARM of the PLATE POSITIONING AY moves forward to

touch the back of the PLATE, which is partially out of the CASSETTE SHELL. The

LOWER ARM keeps the PLATE from touching the WALLS of the CASSETTE when it

moves out of the CASSETTE.

• After the LOWER ARM moves forward to touch the back of the PLATE, the UPPER

ARM of the PLATE POSITIONING AY also moves forward. It keeps the larger PLAT E

steady during scanning and when they leave and move back into the CASSETTE.

2 When the PLATE is moving into the start of scan position, the MCPU BOARD A2

energizes the PMTs and sets the SIGNAL CHANNEL for the PMTs to 0.

Page 28

THEORY GUIDE Sequence of Operation

10DEC05

TG4825-1

Page

28 of 120

3 The PLATE PRESENT SENSOR S5 detects that a PLATE is fastened and sends a

message of the status to the MSC BOARD A1.

Status Summary: Prepared for Scanning

• PMTs are energized

• SIGNAL CHANNEL is set to 0

Scanning the SCREEN

1 The MCPU BOARD A2:

• actuates the GALVO

• sends a signal to the MSC BOARD A1 to start the scan, which star ts the SLOW

SCAN MOTOR

• sends a signal to the INTERNAL PC that the scan is starting

2 The INTERNAL PC displays a TIMED PROGRESS BAR on the TO UCH SCREEN

MONITOR. This is a graphic display only and not a real-time indication of the status of

the scanning operation.

3 The SLOW SCAN MOTOR rotates, moving the SCREEN at a continual speed through

the field of scan in the slow scan direction.

4 The GALVO BOARD A4 controls the motion of the laser beam across the SCREEN in

the fast scan direction. The SCREEN is scanned one pixel at a time, one line at a time.

See “Scanning the SCREEN - Slow Scan/Fast Scan.”

Note

• The fast scan motion is an almost horizontal trace across the SCREEN, from the back of

the SCREEN toward the front. When it reaches the end of a line, it does a fast retrace to

start another line. During the scanning, the SCREEN is moving down at a controlled

speed to make each fast scan trace one pixel line higher up on the SCREEN than the line

before. The result is that the fast scan is in a slightly diagonal trace across the SCREEN.

• The slow scan runs for a determined number of lines in the vertical direction. A set

number of samplings occur for each line. The number is determined by the size of the

Page 29

THEORY GUIDE Sequence of Operation

10DEC05

TG4825-1

Page

29 of 120

SCREEN. Both the number of lines and the number of samplings are set up in the

calibration for that size of SCREEN.

5 When the end of the scan is reached, the MSC BOARD A1 sends a status message to

the MCPU BOARD A2.

6 The MCPU BOARD A2 de-energizes the PMTs, GALVO, and the LASER.

7 The MCPU BOARD A2 sends a “Scan End” message to the INTERNAL PC. The TIMED

PROGRESS BAR displays until the image is transferred to the INTERNAL PC.

Erasing the SCREEN

1 The MCPU BOARD A2 sends an “Erase Plate” command to the MSC BOARD, which

sends a signal to the SLOW SCAN to start the erasing operation.

2 The SLOW SCAN MOTOR actuates and moves the SCREEN into the erase position,

determined by the counts of the SLOW SCAN ENCODER.

3 The SLOW SCAN MOTOR stops and waits for a response from the MCPU BOARD A2.

4 The MCPU BOARD A2 sends the “Erase” command and time to the MSC BOARD A1,

which actuates the ERASE LAMPS.

5 The ERASE LAMPS illuminate for 2 - 16 seconds to remove the image from the

SCREEN.

Note

The length of time the ERASE LAMPS illuminate is determined by the highest pixel code

value of the image that was scanned. If one pair of LAMPS is not operating, the time

increases by a factor of 2. If more than one pair of LAMPS is not operating, a message

displays on the TOUCH SCREEN MONITOR.

6 When the SCREEN is erased, the MSC BOARD A1 sends the “Erase Done” status to

the MCPU BOARD A2.

Page 30

THEORY GUIDE Sequence of Operation

10DEC05

TG4825-1

Page

30 of 120

Inserting the PLATE back into the CASSETTE SHELL

1 The MCPU BOARD A2 issues a command to the MSC BOARD A1 to:

• return the EXTRACTION BAR to the home position

• insert the SCREEN into the CASSETTE

2 The MSC BOARD A1 reverses the SLOW SCAN MOTOR, which moves the PLATE up

into the open CASSETTE SHELL.

3 The PLATE POSITIONING AY guides the PLATE into the CASSETTE SHELL from the

back side.

4 When the EXTRACTION BAR reaches the home position, the SLOW SCAN MOTOR

stops. At the home position, the ENCODER counts are the saved value.

Status Summary: SCREEN Inserted Into the CASSETTE

• SLOW SCAN MOTOR is stopped

• SCREEN is inside the CASSETTE

• HOOKS are inside the SCREEN

Removing the CASSETTE

1 The MCPU BOARD A2 sends an “Eject Cassette” command to the MSC BOARD A1.

2 The CAM MOTOR M1 energizes.

3 The DUPLEX CAM moves toward position 4. See “DUPLEX CAM AY.”

4 When the DUPLEX CAM rotates, the SLED CAM and the HOOK CAM execute the

following actions:

• SLED CAM:

– SLED PLATE moves toward the back 0.896 cm (0.350 in.)

– PIVOTING PLUSH opens

Page 31

THEORY GUIDE Sequence of Operation

10DEC05

TG4825-1

Page

31 of 120

• HOOK CAM:

– HOOKS move up, releasing the pressure

– when the SLED moves toward position 4, the HOOKS move back into the

EXTRACTION BAR and the PLATE is latched inside the CASSETTE

5 The DUPLEX CAM moves to the home position 1. See “DUPLEX CAM AY.”

• SLED moves 0.640 cm (0.250 in.) toward the back

• DRIVE ROLLERS and IDLER ROLLER are in contact with the CASSETTE

• CLAMP BAR is disengaged

6 The CASSETTE DRIVE MOTOR M2 actuates, moving the CASSETTE toward the front

of the Cassette Handling subsystem.

7 When the CASSETTE LOAD SENSOR S2 is unblocked, it sends a message to the MSC

BOARD A2. This stops the CASSETTE DRIVE MOTOR M2.

8 The MSC BOARD A1 sends the “Cassette Ejected” status to the MCPU BOARD A2.

9 After the operator removes the CASSETTE from the Cassette Handling subsystem, the

MSC BOARD A1 sends a “Scan End” status to the MCPU BOARD A2.

Note

The CR 825/850 SYSTEM cannot process another PLATE until the “Scan End” status is

received.

Page 32

10DEC05

TG4825-1

Page

32 of 120

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

Section 4: STORAGE PHOSPHOR CASSETTE

Overview

CASSETTE

SHELL

PLATE

NOSEPIECE

STORAGE

PHOSPHOR

SCREEN

PLATE

PROTECTIVE COATING

PHOSPHOR/BINDER

BAR CODE LABEL

SIDE-1

ESTAR Base

LEAD (Pb) BACKSCATTER LAYER

BLACK CELLULOSE

ACETATE BACKING

EXTRUSION

ALUMINIUM (Ai)

H194_5024HCA

H194_5024HC

HONEYCOMB PANEL

STORAGE PHOSPHOR CASSETTES have a SCREEN with a layer of PHOSPHOR that is

charged by X-ray photons. STORAGE PHOSPHOR SCREENS can capture a wider range of

information within the aerial image than is possible with a screen/film system.

Page 33

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

10DEC05

TG4825-1

Page

33 of 120

STORAGE PHOSPHOR CASSETTES include:

Component Description

CASSETTE SHELL The SHELL has a CARBON FIBER FRONT and an aluminum BACK.

The SHELL is open on one side for removal of the PLAT E. A LATCH

on the inside of the PLATE holds it in place inside the SHELL.

PLATE Includes:

• STORAGE PHOSPHOR SCREEN - mad e of an ESTAR BASE

with a layer of PHOSPHOR PARTICLES suspended in a

POLYMER BINDING, a light-absorbing black BACKING, and a

LEAD BACKSCATTER LAYER. The PHOSPHOR LAYER has a

COATING that extends beyond the edge of the PHOSPHOR to

protect the PHOSPHOR from damage.

• BACKING - a rigid aluminum “honeycomb” PANEL that makes

inserting the SCREEN into the CASSETTE SHELL easier.

• 2 hard plastic STRIPS - fastened to the back side of the PLATE to

make the thickness of the PLATE the thickness of the PLATE

NOSEPIECE. This uniform thickness allows the PLATE GUIDE

ROLLERS to move smoothly on the back of the PLATE.

BAR CODE LABEL Each CASSETTE has a BAR CODE LABEL on the SIDE-1

EXTRUSION. The BAR CODE LABEL identifies the CASSETTE.

SIDE-1 EXTRUSION The edge of the PLATE with the LATCH. The EXTRACTION BAR

HOOKS insert into the LATCH to remove the PLATE from the

CASSETTE SHELL.

PLATE NOSEPIECE Plastic edge on the PLATE that guides the PLATE back into the

CASSETTE SHELL.

Page 34

10DEC05

TG4825-1

Page

34 of 120

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

Size and Resolution of SCREENS

Size of the SCREEN

GP-25 HR EHR

15 x 30 cm YES NO NO Kodak DirectView COMPUTED

35 x 43 cm YES NO NO CR 800/825/850/900/950 SYSTEMS

Resolution Compatible With:

RADIOGRAPHY SYSTEMS 800/

825/850/900/950 (CR 800/825/850/

900/950 SYSTEMS)

35 x 43 cm - Kodak DirectView

YES NO NO CR 800/825/850/900/950 SYSTEMS

CR LONG-LENGTH IMAGING

SYSTEM

35 x 35 cm YES NO NO Kodak DirectView CR 400/800/825/

850/900/950 SYSTEMS

24 x 30 cm YES YES YES CR 400/800/825/850/900/

950 SYSTEMS

24 x 18 cm YES YES YES CR 400/800/825/850/900/

950 SYSTEMS

Note

The 35 x 43 cm SCREEN and the Enhanced High Resolution (EHR) SCREEN are not

compatible with the CASSETTES of the same size used with the Kodak Digital Science

COMPUTED RADIOGRAPHY SYSTEM 400.

Page 35

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

10DEC05

TG4825-1

Page

35 of 120

The CR 825/850 SYSTEM uses SCREENS with the following resolutions.

Resolution of the

SCREEN

General Purpose

(GP-25)

• thicker PHOSPHOR COATING than the HR SCREEN, making the

image less sharp

Description

• no special exposure procedures are necessary

High Resolution

(HR)

• thinner PHOSPHOR COATING than the GP-25 SCREEN, making

the image sharper

• approximately 2 times the X-ray exposure is necessary

Enhanced High

Resolution (EHR)

• thinner PHOSPHOR COATING than the HR SCREEN, improving the

image quality

• approximately 4 times the X-ray exposure

The light intensity of the exposed GP-25 SCREEN is less than the HR and EHR SCREENS.

The CR 825/850 SYSTEM adjusts for the difference in light intensity by adjusting the pixel

code values in the image processing.

Page 36

10DEC05

TG4825-1

Page

36 of 120

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

Fast Scan / Slow Scan Directions

43 cm

low

can

35 cm

35 cm

35 cm

30 cm

24 cm

30 cm

15 cm

18 cm

24 cm

Fast Scan

H194_5022BC

The diagram indicates the direction of the 2 scanning actions for each size CASSETTE:

• slow scan - the SCREEN moves vertically from up to down during scanning

• fast scan - the laser beam moves hor izontally across the SCREEN at the same time it

moves down

The slow scan direction for CASSETTES is important, because problems in the slow scan

process can cause artifacts in the image. For example, banding artifacts can appear across

the SCREEN in the horizontal direction, but the cause of the artifact might be a problem with

the vertical slow scan motion of the SCREEN.

Page 37

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

10DEC05

TG4825-1

Page

37 of 120

Image Matrix Size

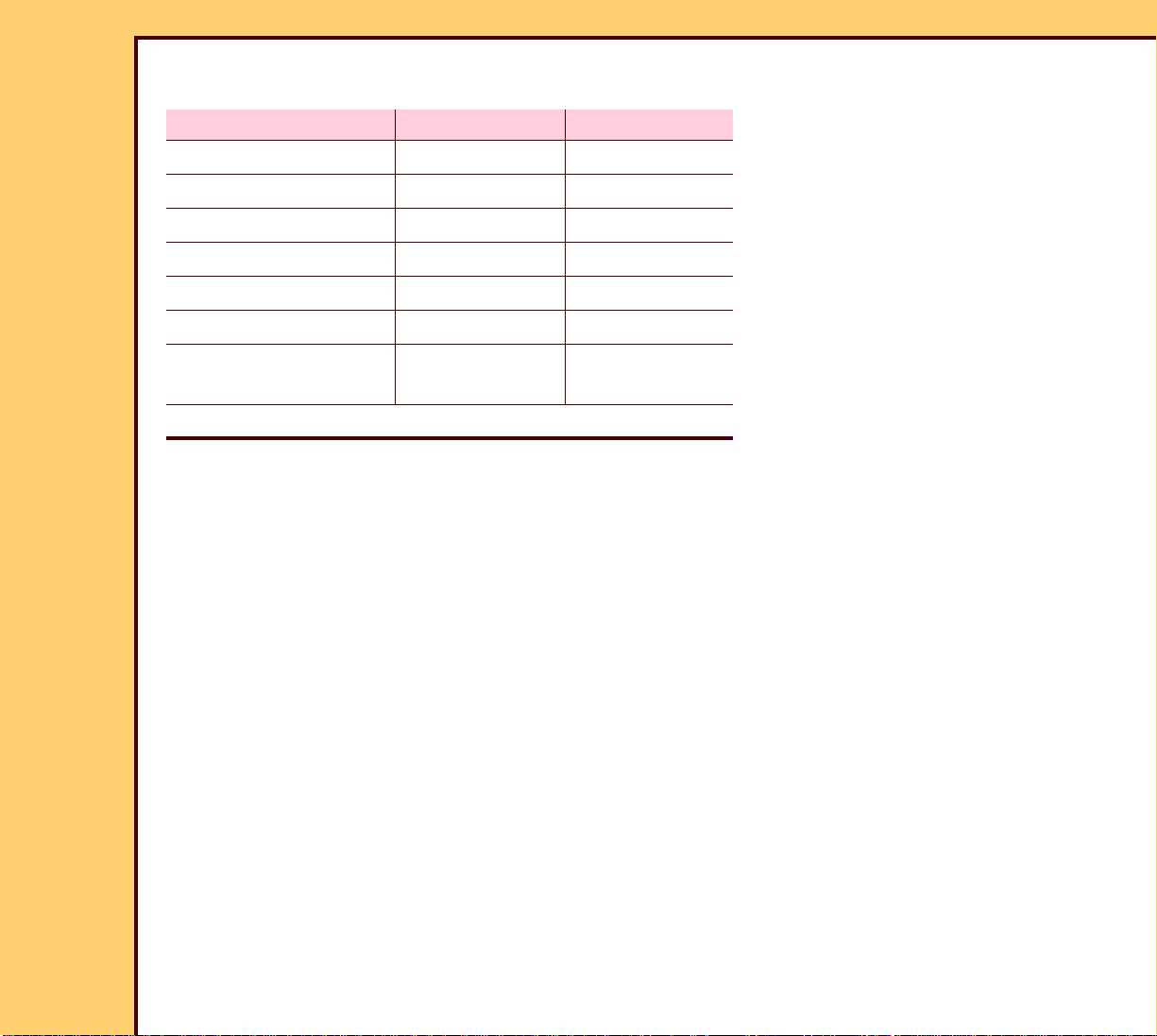

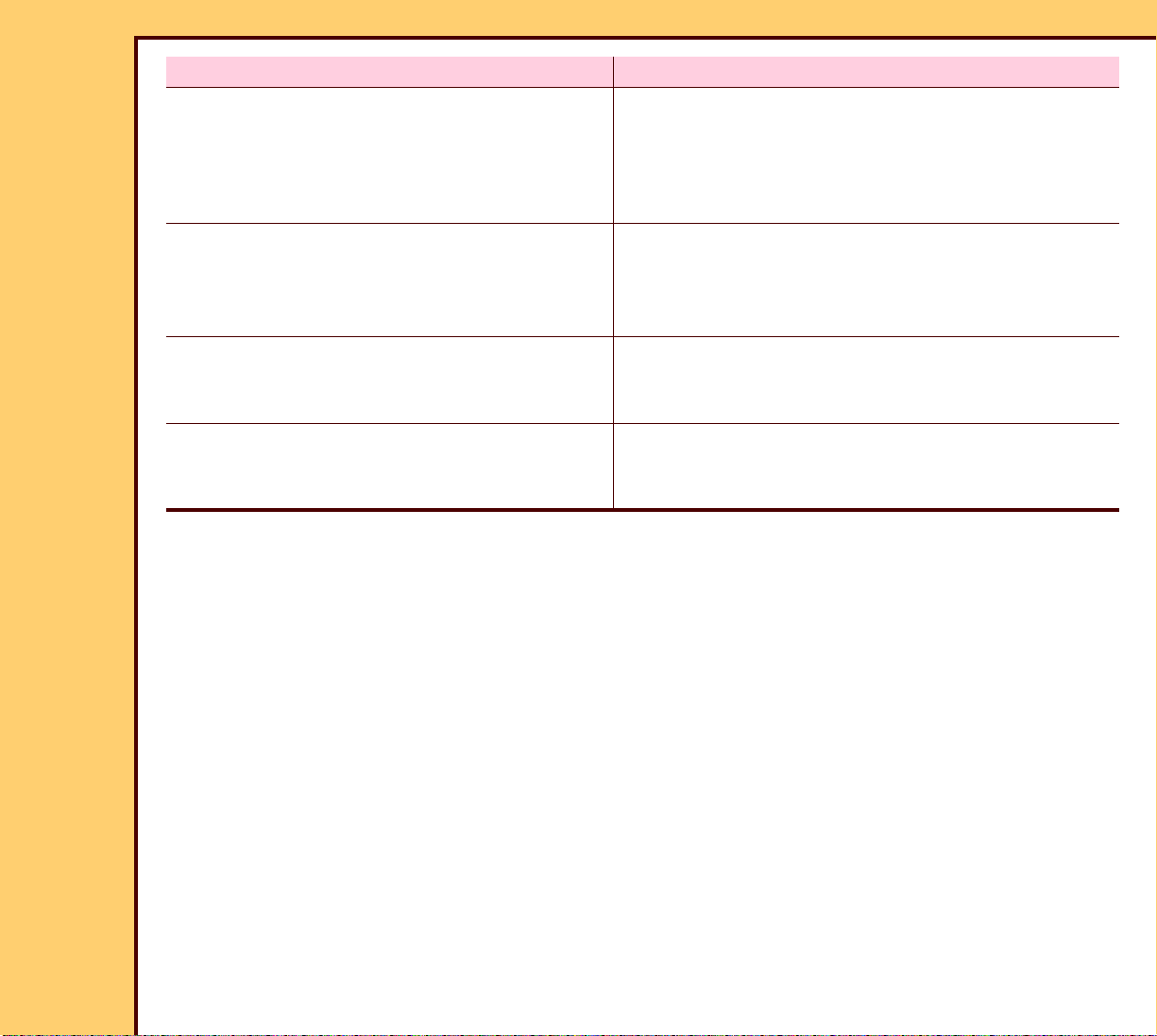

The CR 825/850 SYSTEM scans the STORAGE PHOSPHOR SCREENS at the resolutions in

the table below. The scan rate is the same for General Purpose (GP), High Resolution (HR)

SCREENS, and Enhanced High Resolution (EHR) of the same sizes.

Size of SCREEN

Image Size

Pixels x Lines

Sampling Rate

15 x 30 cm 1280 x 2560 8.33 pixels/mm 115 ± 2 4.0 LP/mm 6.5 MB

35 x 43 cm 2048 x 2500 5.8 pixels/mm 168 ± 2 2.8 LP/mm 10 MB

35 x 35 cm 2048 x 2048 5.8 pixels/mm 1 68 ± 2 2.8 LP/mm 8 MB

24 x 30 cm 2048 x 2500 8.33 pixels/mm 115 ± 2 4.0 LP/mm 10 MB

24 x 18 cm 2392 x 1792 9.95 pixels/mm 97 ± 2 4.8 LP/mm 8 MB

24 x 30 cm (EHR) 4800 x 6000 19.9 pixels/mm 49 ± 2 10.3 LP/mm 40 MB

24 x 18 cm (EHR) 4784 x 3584 19.9 pixels/mm 49 ± 2 10.3 LP/mm 30 MB

24 x 18 cm (HR) 2392 x 1792 9.95 pixels/mm 97 ± 2 5.15 LP/mm 10 MB

24 x 30 cm (HR) 2400 x 3000 9.95 pixels/mm 97 ± 2 5.15 LP/mm 8 MB

For smaller SCREENS, compared to larger SCREENS:

Pixel Size

in Microns

Spatial Resolution

LP = Line Pairs

File Size

• pixel size is smaller

• spot size of the laser beam and digitizing rate are the same

• scanning speed is slower. To make smaller pixels, the speed of the horizontal motion of

the laser beam during the fast scan and the transport speed of the SCREEN under the

COLLECTOR during the slow scan decrease. The decrease in pixel size increases the

spatial resolution of the image.

Page 38

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

10DEC05

TG4825-1

Page

38 of 120

The spatial resolution is determined by the following factors:

• scatter of the PHOSPHOR

• spot size and shape of the laser beam

• bandwidth of the electronics

Note

The image file size for the 24 x 30 cm SCREEN is larger than the image file size for the

35 x 35 cm SCREEN because of the higher sampling rate.

Page 39

10DEC05

TG4825-1

Page

39 of 120

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

Reading the BAR CODE LABEL of the CASSETTE

BAR CODE

H194_5025GCA

H194_5025GC

Page 40

THEORY GUIDE STORAGE PHOSPHOR CASSETTE

10DEC05

TG4825-1

Page

40 of 120

The BAR CODE LABEL identifies the CASSETTE and provides the size and resolution of the

SCREEN. The following tabl e describes the digits in the BAR CODE. Each digit indicates a

group of BARS on the BAR CODE.

Digit Value

1 Has the va lue “9”

2 Resolution:

1 = General Purpose (GP)

2 = High Resolution (HR)

3 = Enhanced High Resolution (EHR)

3 - 4 Size:

01 = 24 x 18 cm

02 = 24 x 30 cm

03 = 35 x 35 cm

04 = 35 x 43 cm

05 = 35 x 43 L

06 = 15 x 30 cm

07 = 24 x 30 cm (HR)

08 = 24 x 18 cm (EHR)

09 = 24 x 30 cm (EHR)

10 = 35 x 35 C

11 = 35 x 43 C

5 - 10 Serial number of the CASSETTE

Page 41

10DEC05

TG4825-1

Page

41 of 120

THEORY GUIDE Cassette Handling

Section 5: Cassette Handling

Overview

CASSETTE

SLED PLATE

DUPLEX CAM

INTERMEDIATE PLATE

EXTRACTION BAR

H194_5026HCA

H194_5026HC

The Cassette Handling subsystem moves the CASSETTE into position in the CR 825/850

SYSTEM to remove the PLATE from the CASSETTE for scanning the SCREEN. The

Cassette Handling subsystem includes the following components:

• DUPLEX CAM AY

• Cassette Entry

• Cassette Transpor t

• Plate Handling

Page 42

THEORY GUIDE Cassette Handling

10DEC05

TG4825-1

Page

42 of 120

Overview of operation:

1. The PLATE is released from the CASSETTE.

2. The EXTRACTION BAR fastens onto the PLATE and moves it down during scanning.

3. After scanning and erasing, the SCREEN moves up and is inserted into the CASSETTE

again.

4. The CASSETTE is moved to the CASSETTE LOADING STATION for removal by the

operator.

DUPLEX CAM AY

POSITION FLAG

HOME FLAG

T

A

I

O

T

O

R

N

HOOK CAM

CAM

MOTOR

DUPLEX

CAM

SLED

CAM

FOLLOWER

SLED

PLATE

S11 OUTER

CAM SENSOR

S10 INNER

CAM SENSOR

H177_1233ACC

H177_1233AC

Facing

CAM MOTOR

The DUPLEX CAM AY:

• executes the motions necessary to load and release the CASSETTE

• moves the EXTRACTION BAR HOOKS that pull the PLATE from the CASSETTE for

scanning the SCREEN

H194_5034ACA

H194_5034AC

Page 43

10DEC05

TG4825-1

Page

43 of 120

THEORY GUIDE Cassette Handling

Positions of the DUPLEX CAM

Home Position 1

Position 3

Position 2

Position 4

H194_5042DC

Page 44

10DEC05

TG4825-1

Page

44 of 120

THEORY GUIDE Cassette Handling

Component Description

SLED CAM The SLED CAM is the GROOVE in the side of the DUPLEX CAM. It

executes the motions necessary to load and release the CASSETTE.

SLED CAM

FOLLOWER

Moves the SLED PLATE backward and forward when the DUPLEX CAM

rotates.

SLED PLATE When the SLED PLATE moves backward and forward with the motion of

the DUPLEX CAM, the SLED PLATE engages components on the

INTERMEDIATE PLATE to actuate operations of the Cassette Handling

subsystem. Includes:

• CASSETTE ENTRY SENSOR S1

• CASSETTE LOAD SENSOR S2

• CASSETTE REAR SENSOR S3

• DRIVE MOTOR M2

INTERMEDIATE

PLATE

Components fastened to the INTERMEDIATE PLATE provide the

direction of motion for components on the SLED PLATE when it moves

backward and forward.

HOOK CAM The HOOK CAM is the outside edge of the DUPLEX CAM. The HOOK

CAM moves the EXTRACTION BAR HOOKS up and down when the

DUPLEX CAM rotates.

CAM MOTOR M1 Moves the DUPLEX CAM to each of 4 positions. The INNER CAM

SENSOR S10 and OUTER CAM SENSOR S11 send information to the

MSC BOARD A1, which sends a message to the CAM MOTOR M1 to

move the DUPLEX CAM to one of the 4 positions:

• position 1 = INNER CAM SENSOR S10 and OUTER CAM SENSOR

S11 are blocked

• position 2 = INNER CAM SENSOR S10 is blocked

• position 3 = no CAM SENSORS are blocked

• position 4 = OUTER CAM SENSOR S11 is blocked

Page 45

10DEC05

TG4825-1

Page

45 of 120

THEORY GUIDE Cassette Handling

Component Description

CAM SENSORS:

• INNER CAM

SENSOR S10

• OUTER CAM

SENSOR S11

When the DUPLEX CAM moves to each of 4 positions, the RING

FLAGS block or unblock the path of the beam of the INNER and

OUTER CAM SENSORS. The status of the SENSORS is sent to the

MSC BOARD A1, which starts the motion of the DUPLEX CAM to the

next position.

RING FLAGS:

• HOME FLAG

• POSITION

FLAG

Block and unblock the path to the INNER CAM SENSOR S10 and

OUTER CAM SENSOR S11 when the DUPLEX CAM rotates.

Page 46

10DEC05

TG4825-1

Page

46 of 120

THEORY GUIDE Cassette Handling

Cassette Entry

CASSETTE ENTRY

SENSOR S1

INPUT SLOT

A1

MSC

BOARD

A2

MCPU

BOARD

INTERNAL

BAR CODE

READER

H194_5051HCA

RS-232

H194_5051HC

The Cassette Entry components detect that a CASSETTE is loaded and send information

about the CASSETTE to the MSC BOARD A1 and the MCPU BOARD A2.

Page 47

10DEC05

TG4825-1

Page

47 of 120

THEORY GUIDE Cassette Handling

Component Description

CASSETTE ENTRY

SENSOR S1

The CASSETTE ENTRY SENSOR is continually monitored to detect

a CASSETTE. When a CASSETTE is inserted, the light beam of S1

is bl ocked.

INTERNAL BAR

CODE READER

Reads the BAR CODE information from BAR CODE LABEL on the

CASSETTE and sends it to the MCPU BOARD A2. The BAR CODE

READER also sends information to the MSC BOARD A1 using an

RS-232 connection.

1. The operator inserts a CASSETTE into the INPUT SLOT.

2. When the CASSETTE ENTRY SENSOR S1 is blocked by the end of the CASSETTE, a

“Cassette Detected” message is sent to the MSC BOARD A1.

3. The MSC BOARD A1 sends a signal to the INTERNAL BAR CODE READER, which then

reads the BAR CODE LABEL on the CASSETTE. The BAR CODE provides the following

information about the CASSETTE:

• size

• speed

• serial number

4. The INTERNAL BAR CODE READER sends the information about the CASSETTE to the

MSC BOARD A1.

5. The system emits a beep.

6. The MSC BOARD A1 sends:

• “Cassette Detected” message to the MCPU BOARD A2

• CASSETTE ID to the MCPU BOARD A2

7. The MCPU BOARD A2 sends:

• “Cassette Detected” message to the MSC BOARD A1

• “Scan Request” message to the INTERNAL PC

Page 48

THEORY GUIDE Cassette Handling

10DEC05

TG4825-1

Page

48 of 120

8. The INTERNAL PC:

• checks that it has the quantity of memory necessary to receive an image

• makes a raw image file to receive the image

• sends a “Scan Request Reply” message to the MCPU BOARD A2 with a value of “OK”

9. The MCPU BOARD (A2)

• sends a message to the MSC BOARD A1 to load the CASSETTE

• sends information about the size and speed of the CASSETTE to the DIGITIZER

BOARD

Page 49

10DEC05

TG4825-1

Page

49 of 120

THEORY GUIDE Cassette Handling

Cassette Transport

CASSETTE LOAD

DRIVE

ROLLERS

IDLER

ROLLERS

PIVOTING

PLUSH

SENSOR S2

CASSETTE REAR

SENSOR S3

END STOP

DRIVE

MOTOR

CASSETTE ENTRY

SENSOR S1

SLED PLATE

H194_5002HCA

H194_5002HC

The Cassette Transport components move the CASSETTE into the correct position for

scanning and provide a light-tight environment around the CASSETTE.

Page 50

10DEC05

TG4825-1

Page

50 of 120

THEORY GUIDE Cassette Handling

Component Description

DRIVE MOTOR Provides the motion of the DRIVE ROLLER that moves the

CASSETTE toward the END STOP.

DRIVE ROLLERS Move the CASSETTE from the Cassette Entry area to the END

STOP. At the END STOP, the CASSETTE is in the correct position

for scanning.

IDLER ROLLERS Hold the CASSETTE in the correct position when the DRIVE

ROLLERS move the CASSETTE toward the END STOP. The IDLER

ROLLER is on the opposite side of the CASSETTE from the DRIVE

ROLLER.

SLED CAM The part of the DUPLEX CAM that moves the SLED PLATE. See

DUPLEX CAM AY. Not visible in the graphic.

SLED PLATE Moves backward and forward when the CASSETTE moves toward

the END STOP and back to the Cassette Entry area. In combination

with the INTERMEDIATE PLATE, the SLED PLATE actuates the

motion of the PIVOTING PLUSH.

PIVOTING PLUSH When the CASSETTE is in scanning position, makes a light-tight

environment around all sides of the CASSETTE. The PIVOTING

PLUSH has FIBERS fastened to BARS on each side of the

CASSETTE. To prevent light from reaching the SCREEN when it is

removed from the CASSETTE, the PIVOTING PLUSH rotates

toward the CASSETTE.

CASSETTE ENTRY

SENSOR S1

CASSETTE LOAD

SENSOR S2

CASSETTE REAR

SENSOR S3

Detects that a CASSETTE was placed in the Cassette Transport

area.

Detects that a CASSETTE is loaded and has contact with the

DRIVE ROLLERS and IDLER ROLLERS.

Detects that a CASSETTE has reached the END STOP and

deactuates the DRIVE MOTOR.

Page 51

THEORY GUIDE Cassette Handling

10DEC05

TG4825-1

Page

51 of 120

1. The SLED CAM moves to position 2, which moves the SLED PLATE 0.640 cm (0.250 in.)

forward.

2. The DRIVE MOTOR M2 actuates. The DRIVE MOTOR M2 drives the TIMING BELTS,

which rotate the DRIVE ROLLERS. TIMING BELTS are not visible in the graphic.

3. The DRIVE ROLLERS drive the CASSETTE to the back until the CASSETTE REAR

SENSOR S3 detects the CASSETTE.

4. The CASSETTE REAR SENSOR S3 sends a signal to the MSC BOARD A1 to deactuate

the MOTOR.

5. After a delay of 20 ms, the MSC BOARD A1 deactuates the DRIVE MOTOR M2.

Page 52

10DEC05

TG4825-1

Page

52 of 120

THEORY GUIDE Cassette Handling

Plate Handling

Fastening the PLATE

to the EXTRACTION BAR

The Plate Handling components remove the

PLATE from the CASSETTE SHELL and

fasten it to the EXTRACTION BAR.

CASSETTE

EXTRACTION

BAR

HOOK YOKE LEVERS

Pulling the SCREEN

Down for Scanning

END STOP

HOOKS

The EXTRACTION BAR holds the

PLATE during the scanning operation, then

inserts it back into the CASSETTE SHELL.

CASSETTE

PLATE

SCREEN

EXTRACTION

BAR

H194_5028CCA

H194_5028CC

Page 53

10DEC05

TG4825-1

Page

53 of 120

THEORY GUIDE Cassette Handling

Component Description

HOOK CAM When the DUPLEX CAM moves through positions 1 - 4, the HOOK

CAM begins the actions to release the PLATE from the CASSETTE

and fasten it to the EXTRACTION BAR. For more information, see

DUPLEX CAM AY.

HOOK YOKE

FOLLOWER

Transfers the motion of the HOOK CAM to press down on the HOOK

YOKE AY. The HOOK YOKE FOLLOWER, HOOK CAM, and HOOK

YOKE AY are not visible in the graphic.

HOOK YOKE AY Moves the HOOK YOKE WHEELS and HOOK YOKE LEVERS to

start moving the HOOKS that fasten to the PLATE. HOOK YOKE

WHEELS are not visible in the graphic.

EXTRACTION BAR Removes the PLATE from the CASSETTE, moves the PLATE

vertically through the scanning and erasing operations, and returns it

to the CASSETTE. Includes:

• HOOK YOKE LEVERS - release the LATCH that fastens the

PLATE to the CASSETTE SHELL

• HOOKS - fasten the PLATE to the EXTRACTION BAR

1. When the DUPLEX CAM rotates from position 1 toward position 2, the HOOK CAM

presses down on the HOOK CAM FOLLOWER.

2. The HOOK YOKE FOLLOWER presses down on the HOOK YOKE AY, making the HOOK

YOKE WHEELS press down on the HOOK YOKE LEVERS of the EXTRACTION BAR.

3. The HOOKS move up into the 2 SLOTS in the PLATE.

4. When the DUPLEX CAM moves to position 2, the LATCH inside the PLATE releases the

SCREEN from the CASSETTE SHELL.

5. The spring-loaded HOOKS fasten to the PLATE.

6. The EXTRACTION BAR holds the PLATE when the PLATE is removed from the

CASSETTE SHELL, moved through the scan/erase operation, and inserted into the

CASSETTE SHELL again.

7. When the PLATE is inserted, the DUPLEX CAM rotates to positions 3 and 4, releases the

HOOKS and locks the PLATE inside the CASSETTE.

Page 54

10DEC05

TG4825-1

Page

54 of 120

THEORY GUIDE Optical

Section 6: Optical

Overview

INTERNAL

PC

motion

commands

A2

MCPU

BOARD

DIGITIZER

BOARD

A3

A5

PMT/DAS

BOARD

CONVERTER

digital

image

data

FOLD MIRROR

F-THETA LENS

A/D

PMTs

analog

image data

SCREEN

COLLECTOR

blue

light

red

laser

light

H194_5045DCA

H194_5045DC

A4

GALVO

BOARD

LASER DRIVER

A18

PRE-REGULATOR

BOARD

GALVO

A17

LASER DIODE

DRIVER BOARD

LASER

A1

MSC

BOARD

Page 55

THEORY GUIDE Optical

10DEC05

TG4825-1

Page

55 of 120

The Optical subsystem:

• makes the laser beam and provides the deflection of the beam onto the SCREEN

• moves the laser beam across the SCREEN at a controlled rate to release the stored

energy in the PHOSPHOR

• obtains the image by capturing the light that was released and changing it to a digital

format

The Optical subsystem includes the following main components:

• LASER

• GALVO

• COLLECTOR and PHOTOMULTIPLIER TUBE (PMT)

Page 56

10DEC05

TG4825-1

Page

56 of 120

THEORY GUIDE Optical

LASER

PLATE

F THETA LENS

H194_5029HCA

H194_5029HC

GALVO

FOLD MIRROR

SCREEN

FOLD MIRROR

F THETA LENS

GALVO

Page 57

10DEC05

TG4825-1

Page

57 of 120

THEORY GUIDE Optical

Component Description

LASER Type 30 mW LASER DIODE DRIVER BOARD that emits a red

beam of light of high intensity. The LASER DRIVER PREREGULATOR BOARD A18 controls the power of the LASER:

• Threshold” - supplies minimum power when the LASER is

moving to the start of the next line - retrace

• “Scan” - supplies full power to the LASER during scanning

• “Full-on” - used for diagnostics

COLLIMATING

OPTICS

MANUAL SAFETY

SHUTTER

Provides focus for the light beam to make the spot of light the

correct size on the SCREEN - not visible in the graphic.

Has a NEUTRAL DENSITY FILTER that decreases the power of the

light emitted by the LASER. When FEs check the operation of the

Optical subsystem, they can change the position of the SHUTTER to

make the light from the LASER move through the FILTER. The

FILTER decreases the power of the LASER, which prevents damage

to the eyes. The graphic on Page 54 indicates the position of the

MANUAL SAFETY SHUTTER when it is in the path of the LASER.

During normal operation of the CR 825/850 SYSTEM, the MANUAL

SAFETY SHUTTER does not block the path of the LASER.

GALVO Controls the motion of the light beam from the LASER across the

SCREEN in the fast scan direction - horizontal.

F-THETA LENS Changes the light beam from the LASER from a continual angular

position to a continual linear position.

FOLD MIRROR Changes the direction of the light beam from the LASER to align it

in the center of the COLLECTOR.

Page 58

10DEC05

TG4825-1

Page

58 of 120

THEORY GUIDE Optical

GALVO

A4

GALVO BOARD

A3

DIGITIZER

BOARD

Clock Signal

Plate Size

Offset and Amplitude

Line Start Signal

Actual

Position

Signal

Desired Position

Desired Position Signal

Closed Loop

Servo Circuit

Drive Signal

GALVO

GALVO

MIRROR

A18

LASER DRIVER

PRE-REGULATOR

BOARD

A17

LASER DRIVER

DIODE BOARD

H194_5041HC

The GALVO moves the laser beam to scan the SCREEN:

• rotates the GALVO MIRROR to cause the laser beam to scan across the SCREEN - fast

scan

• moves to the beginning of the next line on the SCREEN

• scans the next line until the SCREEN is fully scanned

The GALVO uses a feedback system in which the desired position of the GALVO MIRROR is

compared to the actual

position in the rotation, and corrections are made to keep the GALVO

in the correct position on the SCREEN at the correct time. When the GALVO is in the correct

position, the laser beam is also in the correct position.

Page 59

10DEC05

TG4825-1

Page

59 of 120

THEORY GUIDE Optical

Component Description

DIGITIZER BOARD

A3

Controls the operation of the GALVO BOARD, which moves the laser

beam.

GALVO Includes:

• MOTOR - rotates the SHAFT

• SHAFT - has a MIRROR at one end to send the laser beam

toward the F-THETA LENS

GALVO BOARD A4 Includes a feedback circuit that controls the position of the MIRROR.

The position of the MIRROR determines the position of the laser

beam. The GALVO BOARD uses the following information to define

the desired position of the MIRROR:

• clock signal from the DIGITIZER BOARD, which moves through

the desired position between the offset and amplitude.

• size of the PLATE from the DIGITIZER BOARD, which receives

the information from the BAR CODE LABEL on the CASSETTE

• values for the PLATE size, which were set up during calibration:

– offset - starting point

– amplitude - the distance to move across the SCREEN

Information from POSITION SENSORS determine the position of the

GALVO SHAFT in the scan - the actual position. The actual position

is compared to the desired position and corrections in position are

made to provide a smooth motion of the beam.

The GALVO BOARD also:

• emits “Line Start” signals to the DIGITIZER BOARD to provide the

information that a line is complete and it can start another line

• energizes the LASER DIODE DRIVER BOARD at times

determined by software

Page 60

THEORY GUIDE Optical

10DEC05

TG4825-1

Page

60 of 120

Traces in the Operation of the GALVO

POSITION

ACB

vs

TIME

DESIRED-POSITION

TRACE

ACTUAL-POSITION

TRACE

VELOCITY

D

SCAN

DWELL TIME

"0" Velocity

The following tabl e describes the positions within the 3 traces.

Page 61

10DEC05

TG4825-1

Page

61 of 120

THEORY GUIDE Optical

Traces of the GALVO Description

Desired position

trace

• position A - the DIGITIZER BOARD has sent a signal to the

GALVO to retrace

• between Positions A and B - the system is waiting for the GALVO

to complete the retrace

• between Positions B and C - the speed of the GALVO is

increasing to operating speed

• position C - the PIXEL CLOCK starts and the PMT/DAS BOARD

starts measuring the pixel data from the SCREEN. The laser

beam is at the edge of the SCREEN.

• between Positions C and D - the complete line of pixels is

scanned

• position D - the laser beam is at the other edge of the PLATE and

the PIXEL CLOCK stops

Actual position trace • matches the desired position trace during scanning of the

SCREEN

• does not match the desired position trace between Positions A

and B, indicating the time necessary for the GALVO to be stable

and start moving across the next line

Velocity trace • GALVO is moving in the scanning direction when the trace is

above the “0 Velocity” line in the diagram

• GALVO is moving in the retrace direction when the trace is below

the “0 Velocity” line

• GALVO is moving at a continual speed during scanning

• the speed of the GALVO increasing to operating speed between

Positions B and C

• the difference between the scanning and retrace speed is larger

than it appears in the diagram

Page 62

THEORY GUIDE Optical

10DEC05

TG4825-1

Page

62 of 120

COLLECTOR and PHOTOMULTIPLIER TUBE (PMT)

The COLLECTOR and the PMTs:

• provide the collection of the blue light emitted from the PHOSPHOR SCREEN

• measure the brightness of the blue light

• change the measurement of brightness to digital format

analog

signal

LIGHT COLLECTOR

PMT

(1 of 2)

red laser light

H194_5009GC

BLUE FILTER

blue light

PHOSPHOR SCREEN

Page 63

10DEC05

TG4825-1

Page

63 of 120

THEORY GUIDE Optical

Component Description

DIGITIZER BOARD

A3

Controls the operation of the GALVO BOARD A4 and the PMT/DAS

BOARD A5 to provide for the measurement and collection of image

data at the correct time:

• sends a signal to the GALVO to rotate the MIRROR to move the

laser beam in the fast scan direction across the SCREEN

• sends a signal to the PMT/DAS BOARD A5 to measure the

emitted light at controlled times. Each measurement makes a pixel

in the completed image.

LIGHT COLLECTOR Provides the collection of the blue light emitted from the SCREEN

and sends it toward the PMTs. The inside surface of the

COLLECTOR is reflective.

BLUE FILTER Removes any red laser light reflected from the SCREEN, allowing

only the blue light to reach the PMTs.

PHOTOMULTIPLIER

TUBES (PMT)

PMT/DAS BOARD

A5

2 LIGHT SENSORS, which emit a current signal corresponding to the

light reaching the FACE of the PMT. The PMTs use a high-voltage

POWER SOURCE to operate. The voltage of the POWER SOURCE

determines the sensitivity of the PMTs.

• Changes analog signals from the PMTs to digital format:

– amplifies the signals from the 2 PMTs

– adds the signals from the PMTs

– filters the summed signal

– changes the summed signal to a digital format

• Measures the strength of the laser beam and changes it to digital

format.

Page 64

THEORY GUIDE Optical

10DEC05

TG4825-1

Page

64 of 120

Collection of the Blue Light

ANODE

0 V DC

DYNODE 7

-100 V DC

DYNODE 8