Page 1

© EASTMAN KODAK COMPANY, 2005 HEALTH GROUP

{PreventiveMaint}{Production}{Health Group}{None}

PREVENTIVE MAINTENANCE

for the

Kodak DirectView CR 825/850 SYSTEMS

Service Codes: 5634, 4825

Important

Qualified service personnel must do these procedures.

Publication No. PM4825-1

10DEC05

Supersedes PM4825-1

09JAN04

H177_0500AC

Page 2

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

2 of 30

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Necessary Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintenance Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Checking the Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Checking the Scan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning the FILTER - 2.4 GHz PC only . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cleaning the PMT/DAS BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning the PMTs and COLLECTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning and Applying Lubricant to the CASSETTE HANDLING AY. . . . 9

Cleaning the BAR CODE READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cleaning the EXTRACTION BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning and Applying Lubricant to the SLOW SCAN SLIDES . . . . . . . . 13

Cleaning the ERASE LAMP AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing the New LIGHT SEALS on the TOP COVER . . . . . . . . . . . . . . . 16

Installing the New CLAMP BAR PLUSH. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing the New RIGHT and LEFT LIGHT BAFFLES. . . . . . . . . . . . . . . . 19

Installing the New REAR CLIP AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the New LIGHT SEAL PLUSH . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installing the New LEAF SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the New FIXED LIGHT SEAL PADDLE . . . . . . . . . . . . . . . . . . . . . 24

Installing the New LIGHT SEAL PADDLE. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing the New CASSETTE DRIVE ROLLERS . . . . . . . . . . . . . . . . . . . . 26

Checking the CAM and MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Checking the Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Checking the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Page 3

10DEC05

PM4825-1

Page

3 of 30

PREVENTIVE MAINTENANCE

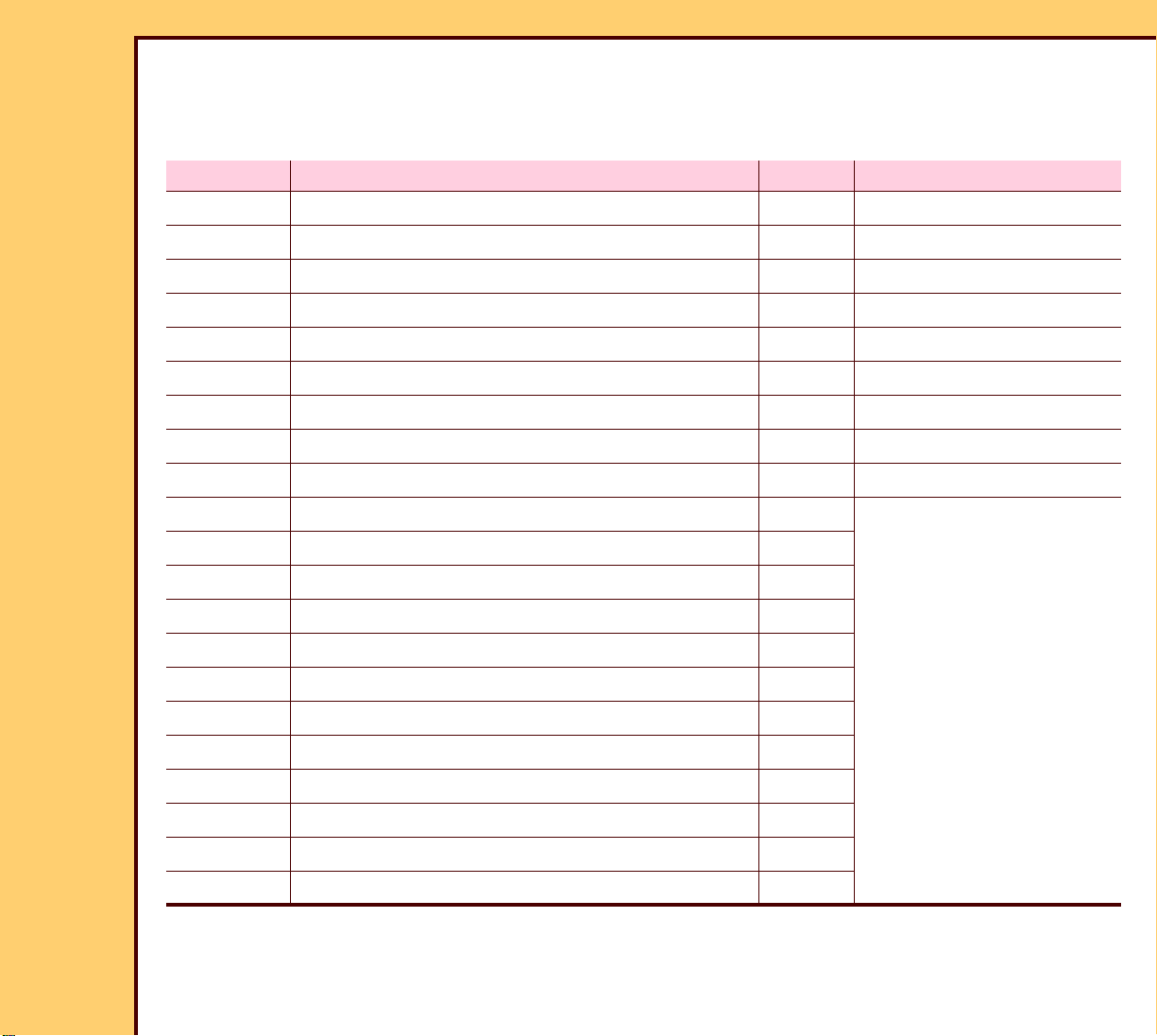

Necessary Materials

Part No . Description Quantity Notes

--- soap - solution --- Purchase locally

3E0899 soft LINT-FREE CLOTH --- Package of 300

1C8026 LUBRICANT ---

TL-4071 VACUUM CLEANER ---

1C8000 LENS CLEANER --952807 LENS PAPER --- Package of 50

5E6777 SPINDLE OIL --- 4-oz BOTTLE

1C8067 CANNED AIR --- Package of 2

7E7978 PM KIT 1

6E5266 LIGHT SEAL - left 1 Included in PM KIT.

6E5267 LIGHT SEAL - right 1

1F2215 PLUSH - clamp bar 2

1F5142 LIGHT BAFFLE - right 1

1F6140 LIGHT BAFFLE - left 1

1F7859 LIGHT SEAL AY - front 1

1F2941 CLIP AY 1

1F5817 PLUSH - light seal 2

1F6723 SPRING - leaf 3

9F6823 PADDLE - light seal, fixed 1

1F5967 PADDLE - light seal, plush 3

1F5661 ROLLER - cassette drive 2

Page 4

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

4 of 30

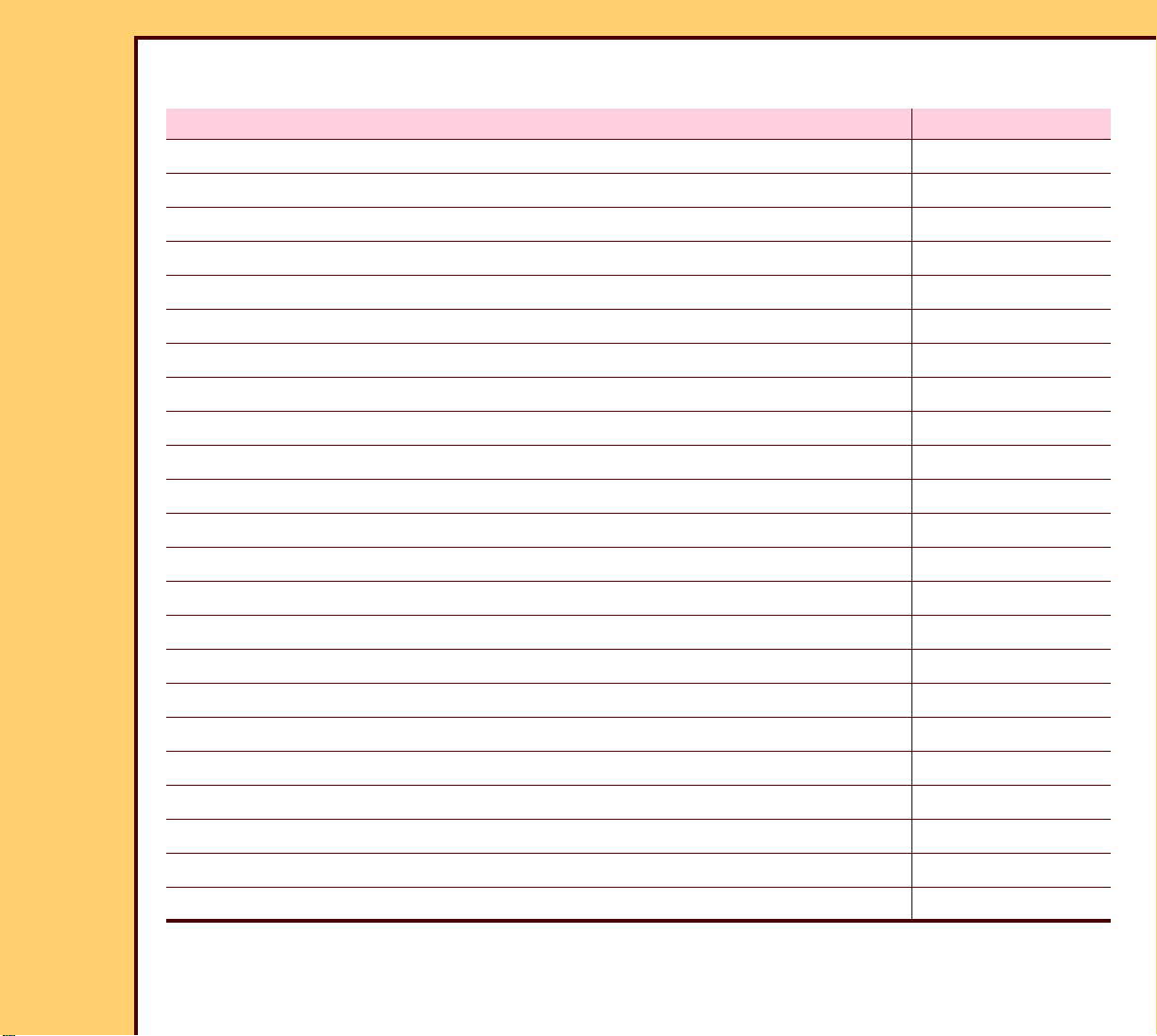

Maintenance Plan

Procedure Do:

Checking the Error Logs Every service call

Checking the Scan Operation Every service call

Cleaning the FILTER - 2.4 GHz PC only Every 6 months

Cleaning the PMT/DAS BOARD Every 6 months

Cleaning the PMTs and COLLECTOR AY Ever y 6 months

Cleaning and Applying Lubricant to the CASSETTE HANDLING AY Every 6 months

Cleaning the BAR CODE READER Every 6 months

Cleaning the EXTRACTION BAR Every 6 months

Cleaning and Applying Lubricant to the SLOW SCAN SLIDES Every 6 months

Cleaning the ERASE LAMP AY Every 6 months

Cleaning the System Every 6 months

Installing the New LIGHT SEALS on the TOP COVER Every 6 months

Installing the New CLAMP BAR PLUSH Every 6 months

Installing the New RIGHT and LEFT LIGHT BAFFLES Every 6 months

Installing the New REAR CLIP AY Every 6 months

Installing the New LIGHT SEAL PLUSH Every 6 months

Installing the New LEAF SPRINGS Every 6 months

Installing the New FIXED LIGHT SEAL PADDLE Every 6 months

Installing the New LIGHT SEAL PADDLE Every 6 months

Installing the New CASSETTE DRIVE ROLLERS Every 6 months

Checking the CAM and MOTOR Every 6 months

Checking the Adjustments Every 6 months

Checking the Operation Every service call

Page 5

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

5 of 30

Checking the Error Logs

1 Check the Error Logs. See Checking the Error Logs.

Important

If you see more than one error code of the same component or assembly, you might have to

install new parts or do adjustments during this procedure.

2 Do an evaluation of the error logs.

3 Continue with Checking the Scan Operation.

Checking the Scan Operation

Important

You must check the scan operation before de-energizing the system.

1 Observe the scan operation or all CASSETTE sizes and make repairs before doing

preventive maintenance procedures.

2 Is this service call a 6 - month call?

Yes No

Continue with Cleaning the FILTER

- 2.4 GHz PC only.

Advance to Checking the Operation.

Page 6

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

6 of 30

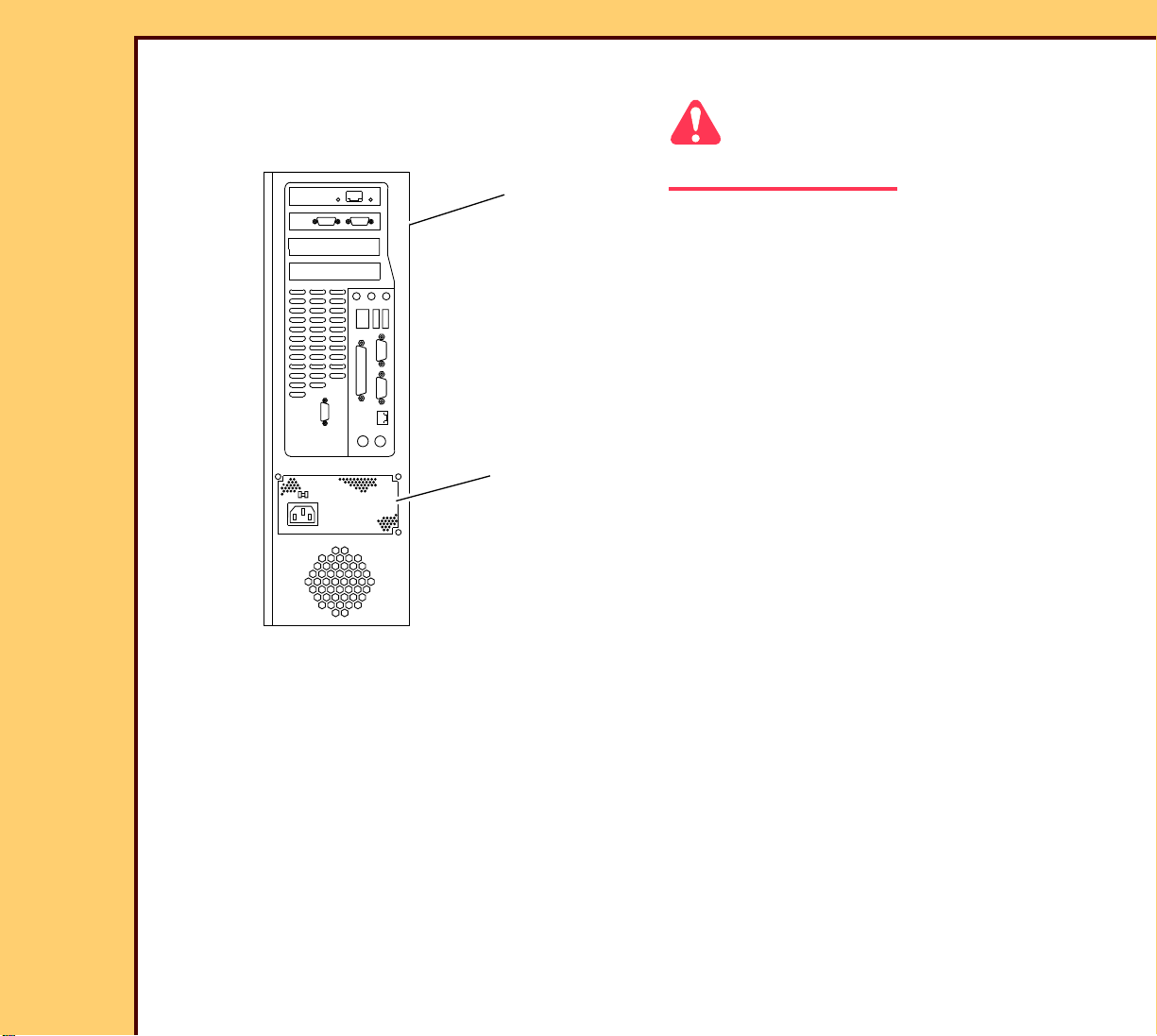

Cleaning the FILTER - 2.4 GHz PC only

2.4 GHz

computer

FILTER

Caution

Dangerous Voltage

1 De-energize the system. See

Energizing the System.

2 Remove the REAR PANEL.

3 Use the VACUUM CLEANER to remove

dust from the FILTER in the computer.

4 Install the REAR PANEL.

5 Continue with Cleaning the PMT/DAS

BOARD.

H194_0029GCA

H194_0029GC

Page 7

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

7 of 30

Cleaning the PMT/DAS BOARD

PMT/DAS BOARD

1 Remove the PMT/DAS BOARD.

Caution

• Use the VACUUM CLEANER to remove

dust before using the CANNED AIR.

• Use the CANNED AIR to move debris

away from the OPTICAL CAVITY.

2 Use the VACUUM CLEANER to remove

dust from the PMT/DAS BOARD.

3 If necessary, use the CANNED AIR

1C8067 to remove dust from the PMT/

DAS BOARD.

4 Continue with Cleaning the PMTs and

COLLECTOR AY.

H194_1076GCA

H194_1076GC

Page 8

10DEC05

PM4825-1

Page

8 of 30

PREVENTIVE MAINTENANCE

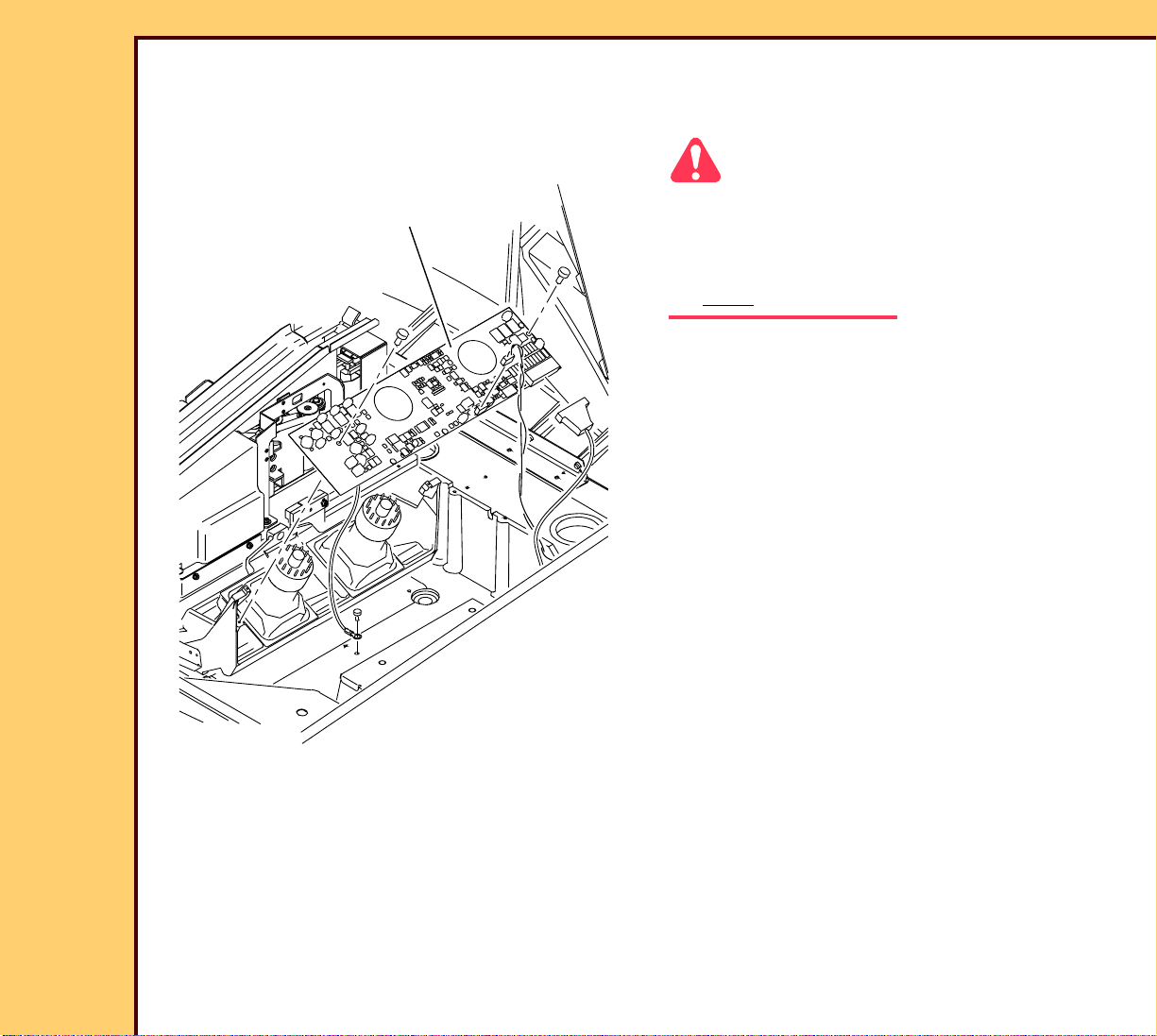

Cleaning the PMTs and COLLECTOR AY

1 If necessary remove the PMT/DAS BOARD.

2 Remove the PMTs and COLLECTOR AY.

COLLECTOR AY

H194_1077GCA

H194_1077GC

2 PMTs

OPTICAL

CAVITY

Caution

• Use the VACUUM CLEANER to remove

dust before using the CANNED AIR.

• Use the CANNED AIR to move debris

away from the OPTICAL CAVITY.

3 Use the VACUUM CLEANER to remove

dust from:

• 2 PMTs

• COLLECTOR AY

• OPTICAL CAVITY

4 If necessary, use the CANNED AIR to

remove dust from:

• 2 PMTs

• COLLECTOR AY

• OPTICAL CAVITY

5 Install:

• PMTs and COLLECTOR AY

• PMT/DAS BOARD

6 Continue with Cleaning and Applying

Lubricant to the CASSETTE

HANDLING AY.

Page 9

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

9 of 30

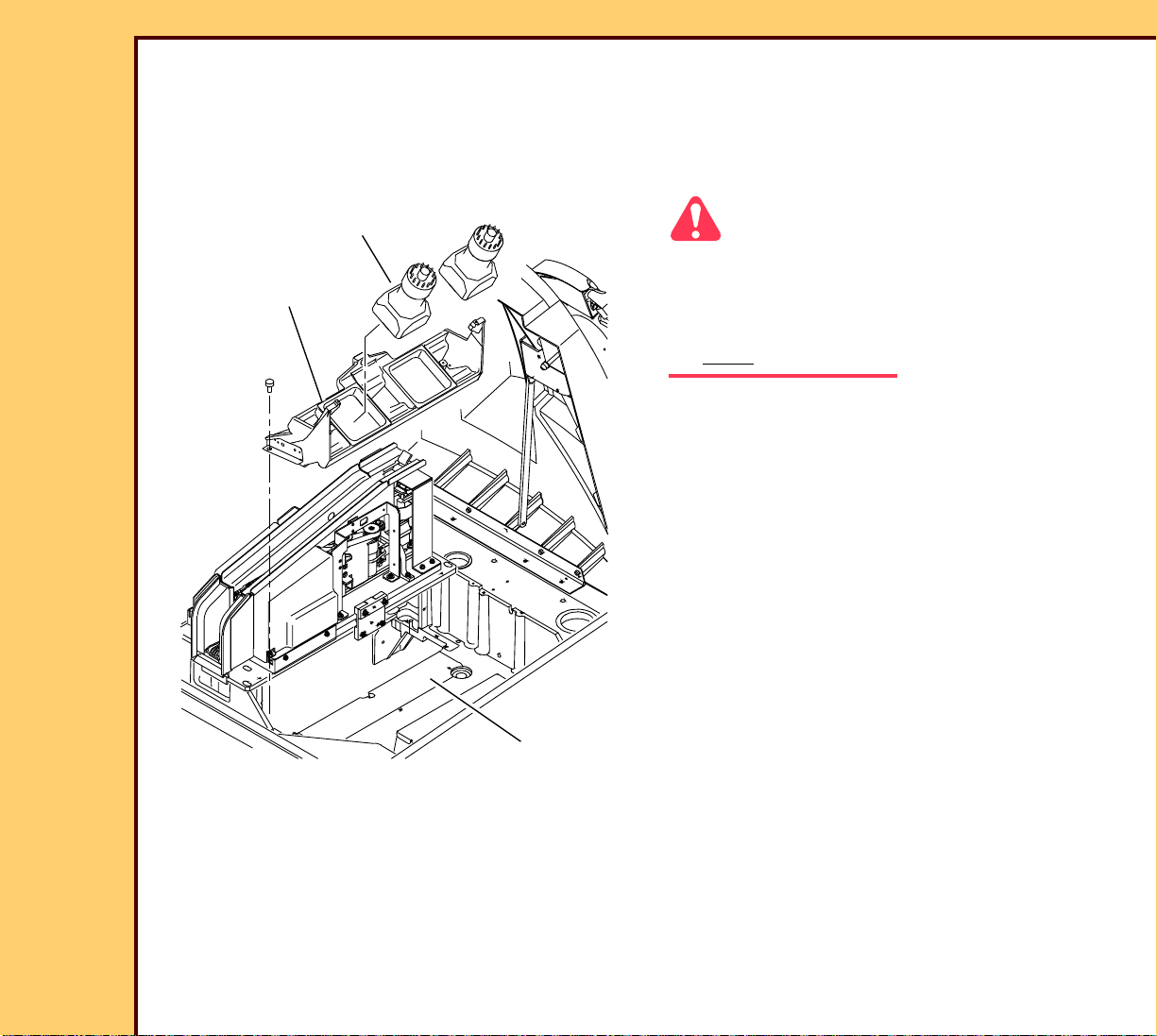

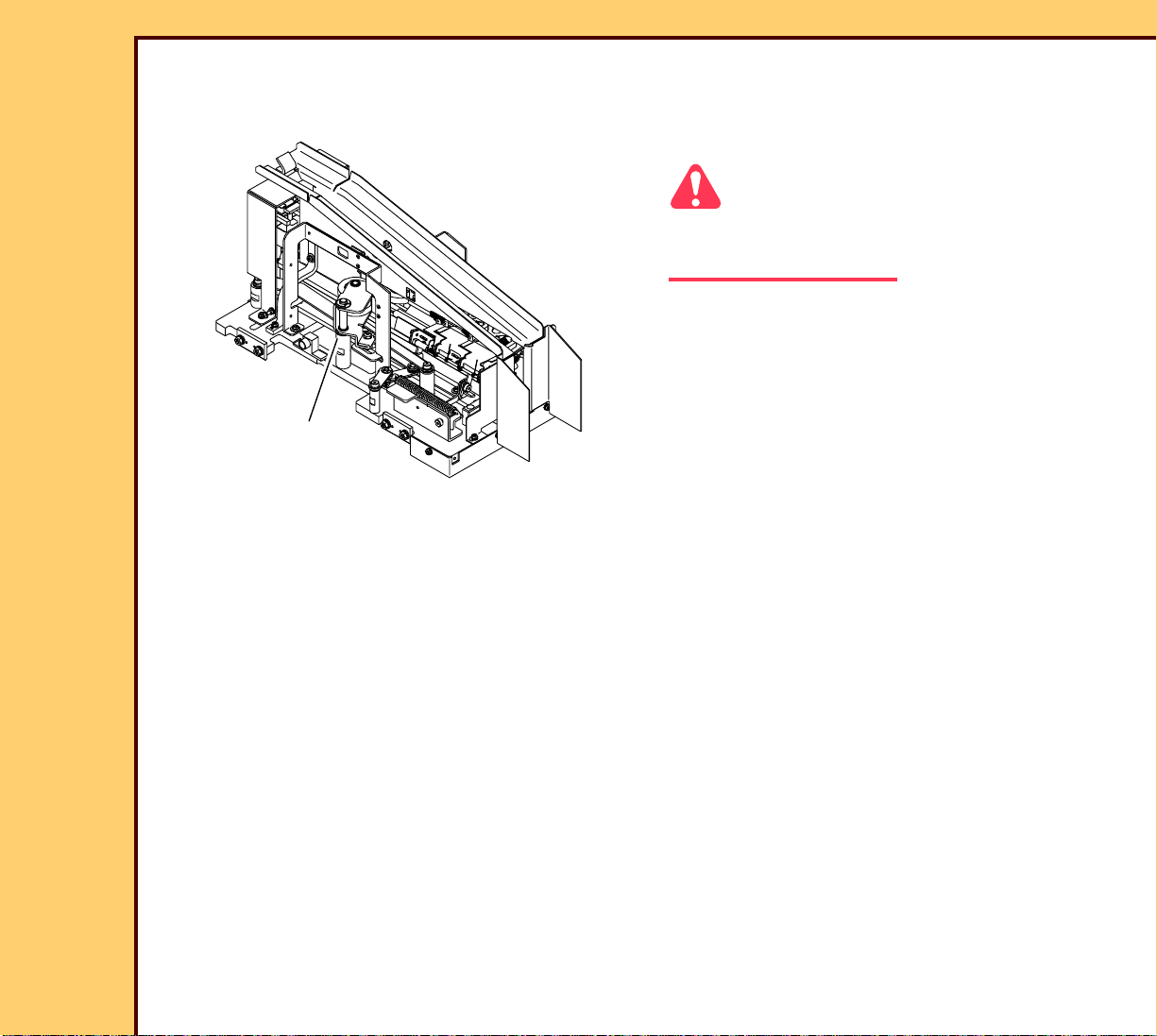

Cleaning and Applying Lubricant to the CASSETTE HANDLING AY

1 Remove the CASSETTE HANDLING

AY.

Caution

Use the VACUUM CLEANER to remove

dust before using the CANNED AIR.

2 Use the VACUUM CLEANER to remove

dust from the CASSETTE HANDLING

AY.

3 If necessary, use the CANNED AIR to

CASSETTE

HANDLING AY

H194_1078ACA

H194_1078AC

remove dust from the CASSETTE

HANDLING AY.

Page 10

10DEC05

PM4825-1

Page

10 of 30

PREVENTIVE MAINTENANCE

DRIVE

ROLLER AY

CAM BLOCK

STOP PIN

LEFT LIGHT

SEAL AY

STOP PIN

4 Apply lubricant to:

• STOP PIN for the RIGHT LIGHT SEAL AY

• STOP PIN for the LEFT LIGHT SEAL AY

• CAM BLOCK for the FRONT LIGHT SEAL

• CAM BLOCK for the DRIVE ROLLER AY

5 Continue with Cleaning the BAR CODE READER.

CAM BLOCK

FRONT LIGHT SEAL

RIGHT LIGHT

SEAL AY

H194_1079HCA

H194_1079HC

Page 11

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

11 of 30

Cleaning the BAR CODE READER

1 If necessary, remove the CASSETTE

HANDLING AY.

Caution

Use the VACUUM CLEANER to remove

dust before using the CANNED AIR.

2 Use the VACUUM CLEANER to remove

dust from the BAR CODE READER.

3 If necessary, use the CANNED AIR to

remove the dust from the BAR CODE

BAR CODE

READER

H194_1080ACA

H194_1080AC

4 If the CANNED AIR does not remove the contamination from the BAR CODE READER,

clean the BAR CODE READER with:

READER.

• LENS CLEANER SOLUTION 1C8000

• LENS PAPER 952807

5 Continue with Cleaning the EXTRACTION BAR .

Page 12

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

12 of 30

Cleaning the EXTRACTION BAR

EXTRACTION BAR

H194_1081ACA

H194_1081AC

1 If necessary, remove the CASSETTE

HANDLING AY.

Caution

Use the VACUUM CLEANER to remove

dust before using the CANNED AIR.

2 Clean the EXTRACTION BAR with a

LINT-FREE CLOTH.

3 Install the CASSETTE HANDLING AY.

4 Continue with Cleaning and Applying

Lubricant to the SLOW SCAN

SLIDES.

Page 13

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

13 of 30

Cleaning and Applying Lubricant to the SLOW SCAN SLIDES

EXTRACTION BAR

SLOW SCAN

SLIDES

SLOW SCAN AY

H194_1082BCA

H194_1082BC

1 Use a LINT-FREE CLOTH to clean:

• SLOW SCAN SLIDES

• top of the EXTRACTION BAR

LEAD

SCREW

holes

CARRIAGE

Caution

Do not apply SPINDLE OIL on the LEAD SCREW.

2 Apply 2 drops of SPINDLE OIL on each of the 2 SLOW SCAN SLIDES.

3 Rotate the LEAD SCREW up and down to apply the lubricant.

4 Apply 2 drops of SPINDLE OIL in the holes on the CARRIAGE.

5 Continue with Cleaning the ERASE LAMP AY.

Page 14

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

14 of 30

Cleaning the ERASE LAMP AY

LATCH

4512 435

ERASE

LAMPS

1 Disengage the LATCH.

2 Pull the ERASE LAMP AY.

3 Use a LINT-FREE CLOTH to clean

ERASE LAMPS.

4 Use the VACUUM CLEANER to remove

dust from the ERASE LAMP AY.

5 If necessary, use the CANNED AIR to

remove the dust from the ERASE LAMP

AY.

6 Continue with Cleaning the System.

H177_2104GCB

H177_2104GC

ERASE

LAMP AY

Page 15

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

15 of 30

Cleaning the System

Caution

Dangerous Voltage

1 De-energize the system. See Energizing the System.

2 Use the VACUUM CLEANER to remove dust from the inside of the system.

3 Continue with Installing the New LIGHT SEALS on the TOP COVER.

Page 16

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

16 of 30

Installing the New LIGHT SEALS on the TOP COVER

TOP COVER

1 Open the TOP COVER.

Important

• The narrow end of the LIGHT SEAL must be toward the front edge of the SLOT.

narrow ends of

LIGHT SEALS

LEFT

LIGHT

SEAL

RIGHT

LIGHT

SEAL

Top View

front edge of SLOT

back edge of SLOT

H194_1083BCA

H194_1083BC

• The LIGHT SEAL must make a seal against the back edge of the SLOT.

2 Remove:

• LEFT LIGHT SEAL - discard

• RIGHT LIGHT SEAL - discard

3 Install the new:

• LEFT LIGHT SEAL

• RIGHT LIGHT SEAL

4 Continue with Installing the New CLAMP BAR PLUSH.

Page 17

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

17 of 30

Installing the New CLAMP BAR PLUSH

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

4 SCREWS

2 COVERS

2 SCREWS

1 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

• RIGHT CASSETTE GUIDE

• 2 SCREWS

• CASSETTE LOAD CRADLE

H194_1062GCA

H194_1062GC

CASSETTE

LOAD CRADLE

Page 18

10DEC05

PM4825-1

Page

18 of 30

PREVENTIVE MAINTENANCE

CLAMP BAR PLUSH

CLAMP BAR

2 SCREWS

2 Remove:

• 2 SCREWS

• CLAMP BAR PLUSH

3 Install:

• new CLAMP BAR PLUSH

• 2 SCREWS

4 Reverse Step 1.

5 Continue with Installing the New

RIGHT and LEFT LIGHT BAFFLES.

H194_1084GCA

H194_1084GC

Page 19

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

19 of 30

Installing the New RIGHT and LEFT LIGHT BAFFLES

1 Remove:

• 2 SCREWS

CASSETTE

LOAD CRADLE

2 SCREWS

LEFT LIGHT

BAFFLE

2 SCREWS

H194_1074ACA

H194_1074AC

2 SCREWS

• CASSETTE LOAD CRADLE

2 Remove:

• 2 SCREWS

• LEFT LIGHT BAFFLE - discard

H194_1085ACA

H194_1085AC

RIGHT LIGHT

BAFFLE

CASSETTE

LOAD CRADLE

• 2 SCREWS

• RIGHT LIGHT BAFFLE - discard

3 Install:

• new LEFT LIGHT BAFFLE

• 2 SCREWS

• new RIGHT LIGHT BAFFLE

• 2 SCREWS

4 Reverse Step 1.

5 Continue with Installing the New

REAR CLIP AY.

Page 20

10DEC05

PM4825-1

Page

20 of 30

PREVENTIVE MAINTENANCE

Installing the New REAR CLIP AY

1 Open the TOP COVER.

2 Remove:

REAR BRACKET AY

4 SCREWS

REAR CLIP AY

H194_1086GCA

H194_1086GC

• 4 SCREWS

• REAR BRACKET AY

3 Remove:

• 2 SCREWS

• REAR CLIP AY - discard

2 SCREWS

H194_1087ACA

H194_1087AC

4 Install:

• new REAR CLIP AY

• 2 SCREWS

5 Reverse Step 2.

6 Continue with Installing the New

LIGHT SEAL PLUSH.

Page 21

10DEC05

PM4825-1

Page

21 of 30

PREVENTIVE MAINTENANCE

Installing the New LIGHT SEAL PLUSH

LEFT CASSETTE GUIDE

RIGHT CASSETTE GUIDE

4 SCREWS

2 COVERS

2 SCREWS

1 Remove:

• 2 COVERS

• 4 SCREWS

• LEFT CASSETTE GUIDE

• RIGHT CASSETTE GUIDE

• 2 SCREWS

• CASSETTE LOAD CRADLE

H194_1062GCA

H194_1062GC

CASSETTE

LOAD CRADLE

Page 22

10DEC05

PM4825-1

Page

22 of 30

PREVENTIVE MAINTENANCE

2 Remove:

• 2 SCREWS

• RIGHT PLUSH PADDLE AY

• 2 SCREWS

• LIGHT SEAL PLUSH

3 Install:

• new LIGHT SEAL PLUSH

• 2 SCREWS

• RIGHT PLUSH PADDLE AY

2 SCREWS

H194_1088GCA

H194_1088GC

LIGHT SEAL

PLUSH

RIGHT PLUSH

PADDLE AY

2 SCREWS

• 2 SCREWS

4 Reverse Step 1.

5 Continue with Installing the New LEAF

SPRINGS.

Page 23

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

23 of 30

Installing the New LEAF SPRINGS

1 Remove:

• 3 SCREWS

• 3 LEAF SPRINGS - discard

2 Install:

• 3 new LEAF SPRINGS

• 3 SCREWS

3 Continue with Installing the New

FIXED LIGHT SEAL PADDLE.

3 SCREWS

3 LEAF

SPRINGS

H194_1090GCA

H194_1090GC

Page 24

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

24 of 30

Installing the New FIXED LIGHT SEAL PADDLE

1 Remove:

• 2 SCREWS

• FIXED LIGHT SEAL PADDLE -

discard

2 Install:

• new FIXED LIGHT SEAL PADDLE

• 2 SCREWS

3 Continue with Installing the New

LIGHT SEAL PADDLE.

2 SCREWS

FIXED LIGHT

SEAL PADDLE

H194_1091GCA

H194_1091GC

Page 25

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

25 of 30

Installing the New LIGHT SEAL PADDLE

RIGHT PLUSH

3 SCREWS

3 LIGHT SEAL

PADDLES

PADDLE AY

1 Remove:

• 3 SCREWS

• 3 LIGHT SEAL PADDLES - discard

2 Install:

• 3 new LIGHT SEAL PADDLES

PLUSH

• 3 SCREWS

• RIGHT PLUSH PADDLE AY

• 2 SCREWS

3 Continue with Installing the New

CASSETTE DRIVE ROLLERS.

H194_1092GCA

H194_1092GC

2 SCREWS

Page 26

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

26 of 30

Installing the New CASSETTE DRIVE ROLLERS

1 Remove the CASSETTE DRIVE AY.

E-RING

WASHER

PULLEY

BUSHING

SHAFT

PIN

2 PINS

BELT

2 E-RINGS

PULLEY

2 SETSCREWS

CASSETTE

CASSETTE

DRIVE AY

DRIVE AY

MOTOR

BUSHING

2 Remove and discard the 2 CASSETTE

DRIVE ROLLERS.

3 Install:

• 2 new CASSETTE DRIVE

ROLLERS

• CASSETTE DRIVE AY

4 Continue with Checking the CAM and

MOTOR.

2 CASSETTE

2 CASSETTE

DRIVE ROLLERS

DRIVE ROLLERS

H194_1007GCA

H194_1007GCB

H194_1007GC

H194_1007GC

Page 27

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

27 of 30

Checking the CAM and MOTOR

MOTOR

SHAFT

CAM

H177_3031ACA

H177_3031AC

1 Remove the CAM MOTOR AY.

2 Pull the CAM toward the MOTOR.Check

that the CAM does not move on the

SHAFT of the MOTOR by pulling to

CAM toward the MOTOR.

3 Does the CAM move on the SHAFT?

Yes No

Install new CAM

MOTOR AY.

Continue with Step

4.

4 Install the CAM MOTOR AY.

5 Continue with Checking the

Adjustments.

Page 28

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

28 of 30

Checking the Adjustments

1 Do:

• GALVO BOARD

• GALVO ROTATION

• FOLD MIRROR

• COLLECTOR AY

• INTERMEDIATE PLATE

• CAM SENSOR BOARD A8

• CAM MOTOR AY

• SLED CAM FOLLOWER

• CLAMP BAR

• CASSETTE END STOP

• REAR CASSETTE SENSOR

• EXTRACTION BAR HOME POSITION

• PLATE POSITIONING AY

• RIGHT and LEFT PLUSH AY - Alignment

• LEFT PLUSH AY - Vertical Position

• INTERNAL BAR CODE READER

• CASSETTE LOAD CRADLE

2 Continue with Checking the Operation.

Page 29

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

29 of 30

Checking the Operation

1 Do:

• Setting the Laser Calibration Voltage

• Calibration for the CR 825/850 SYSTEM

• Checking the Operation

Page 30

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1

Page

30 of 30

Publication History

Publication

Date

Publication

No.

ECO No.

Changed

Pages

File Name Notes

09JAN04 pm4825-1 ---- - - - pm4825_1.fm New Publication

10DEC05 pm4825-1 ---- 3,6 pm4825_1.fm Revised

Kodak and DirectView are trademarks of Eastman Kodak Company.

Printed in U.S.A. • pm4825_1.fm

EASTMAN KODAK COMPANY

Rochester, NY 14650

HEALTH GROUP

Loading...

Loading...