Kia Sportage 2004 User Manual

Body shop Manual

CONTENTS

FOREWORD

This Body Shop Manual illustrates body structures and

service procedures for the SPORTAGE.

This manual illustrates the replacement of major body

panels, plastic parts, body dimensions, sealing

treatment etc., in a systematic manner which is

necessary for effective and lasting body repairs.

You are encouraged to become familiar with this

manual and understand each section in order to

perform proper repair procedures. Keep this manual in

a convenient location so that it is readily available.

All information in this manual including specifications,

data and illustrations is made based on the vehicles

built at the time the manual was printed.

Information regarding the removal/replacement of

components not specifically covered in this manual can

be found in the SPORTAGE Service Manual. Information

regarding electrical harness routing/ connections, etc.

can be found in the SPORTAGE Electrical Troubleshooting

Manual.

The descriptions and specifications contained in this

manual were in effect at the time this manual was

approved for printing. Kia Motors Corporation reserves

the right to discontinue models at any time, or change

specifications or design without notice and without

incurring obligation.

Title

GENERAL INFORMATION

BODY STRUCTURE

REPLACING BODY PANELS

BODY DIMENSIONS

WATERPROOFING AND

RUSTPROOFING

BODY MODIFICATION TOOLS

PLASTIC PARTS

Group

00

11

21

31

41

51

61

Kia Motors Corporation

SEOUL, KOREA

CAUTION :

Severe engine and transaxle damage may

result from the use of poor quality fuels and

lubricants that do not meet Kia specifications.

You must always use high quality fuels and

lubricants that meet the specifications

described on the specification section in the

relevant group of the Workshop Manual.

Copyright 2004, Kia Motors Corporation

Printed in Korea, August 2004

Pub. No. : A1FB-EG48A (English)

All rights reserved. No part of this publication may be reproduced, stored in any retrieval system or

transmitted in any form or by any means without the prior written permission of Kia Motors Corporation.

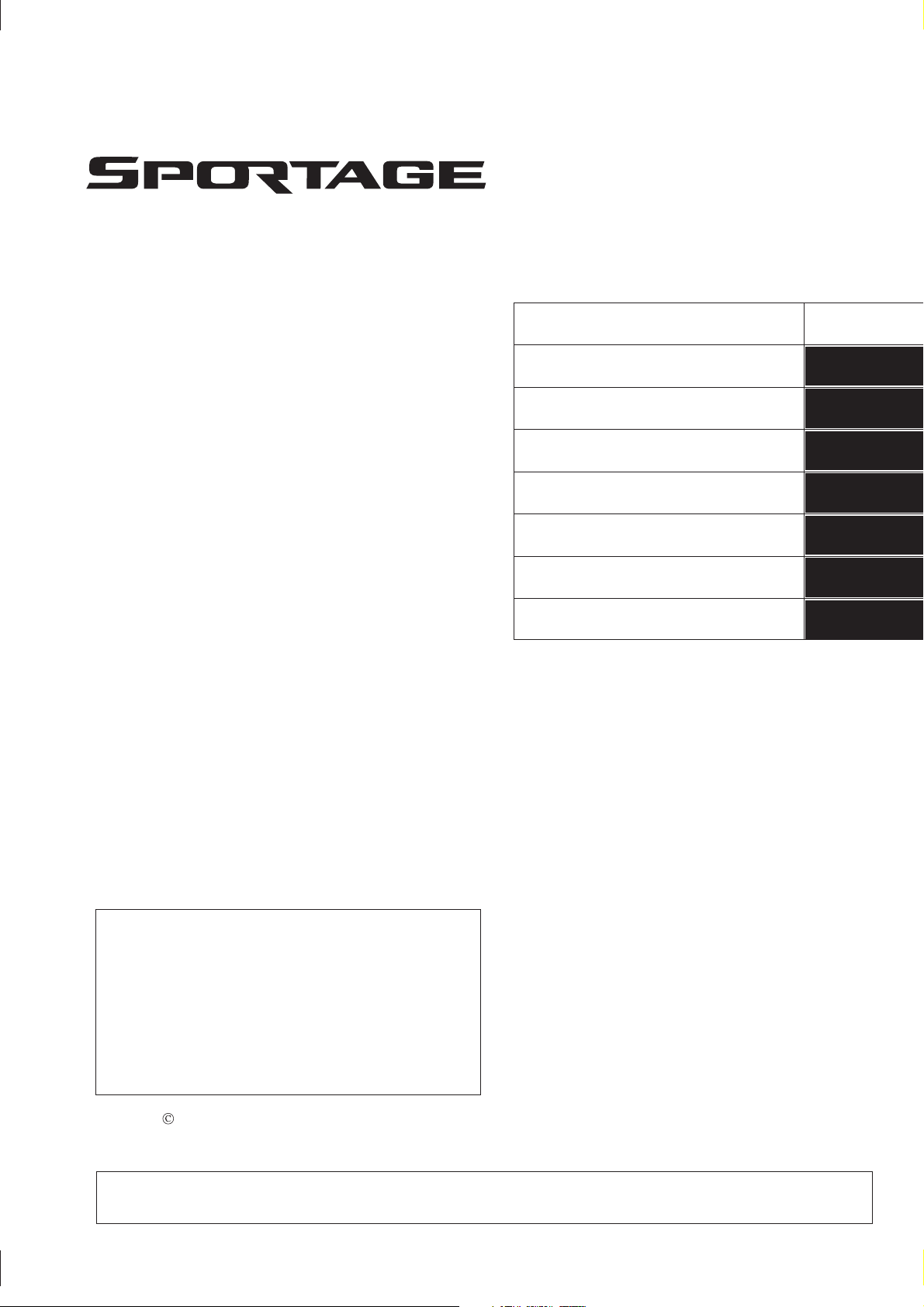

21-18 Replacing body panels

A

B

D

C

E

E

D

B

C

A

6 Points

5 Points

BMKM

030

IMPORTANT SAFETY NOTICE

Proper service methods and repair procedures are essential for safe, reliable operation of all

motor vehicles as well as personal safety of the operator. The service procedures and

descriptions in this body shop manual provide general directions for a service and repair.

Procedure, techniques, tools, and parts for service including the skill of the technician vary.

It is impossible to provide advice or caution as to each case in this manual.

Accordingly, anyone who intends to use a replacement part, service procedure, or tool, which is

not recommended by the vehicle manufacturer, must first assure thoroughly that neither their

personal safety nor the safe operation of the vehicle will be first jeopardized by the replacement

part, service procedure, or tool they select.

IN THIS MANUAL

WARNING :

CAUTION :

NOTE :

The following list contains some general WARNINGS that you should follow while working on a

vehicle.

Always wear safety glasses for eye protection.

Use safety stands whenever a procedure requires you to be under the vehicle.

Make sure that the ignition switch is always in the OFF position, unless otherwise required by

the procedure.

Set the parking brake when working on the vehicle. If you have an automatic transaxle, set in

park unless instructed otherwise for a specific operation

Place supporters against the front and rear surfaces of the tires to help prevent the vehicle

from moving

Operate the engine only in a well-ventilated area to avoid the danger of carbon monoxide

poisoning.

Keep yourself and your clothing away from moving parts when the engine is running,

especially the drive belts.

To prevent serious burns, avoid contact with hot metal parts such as the radiator, exhaust

manifold, tail pipe, catalytic converter and muffler.

Do not smoke while working on a vehicle.

To avoid injury, always remove rings, watches, loose hanging jewelry, and loose clothing

before beginning to work on a vehicle.

When it is necessary to work under the hood, keep hands and other objects clear of the

radiator fan blades! Your vehicle may be equipped with a cooling fan that may turn on, even

though the ignition switch is in the OFF position. For this reason care should be taken to

ensure that the radiator fan electric motor is completely disconnected when working under the

hood and the engine is not running.

Remind you to be especially careful in those areas where carelessness can

cause personal injury.

To prevent you from making errors that could damage the vehicle as well as

personal injury.

Gives you added information that will help you complete a particular procedure.

General information

Fundamental procedures

Vehicle protection ........................................................................................ 00- 1

A word about safety ..................................................................................... 00- 1

Welding procedures .................................................................................... 00- 1

Body frame straightener ............................................................................. 00- 2

Electrical procedures .................................................................................. 00- 2

For best results

Disassembly .................................................................................................. 00- 3

Preparation of assembly ............................................................................ 00- 5

Assembly ........................................................................................................ 00- 6

Rustproof treatment after assembly

General information

0 0

00- 7

Vehicle lift (2-Support type) & safety stand positions

Jack and safety stand positions

.............................................................

..................

00- 8

00- 8

Towing..................................................................................................................00- 9

Body colors and major specifications

Kia color codes ............................................................................................ 00- 10

Paint manufacture codes ............................................................................00- 10

General information 00-1

Fundamental procedures

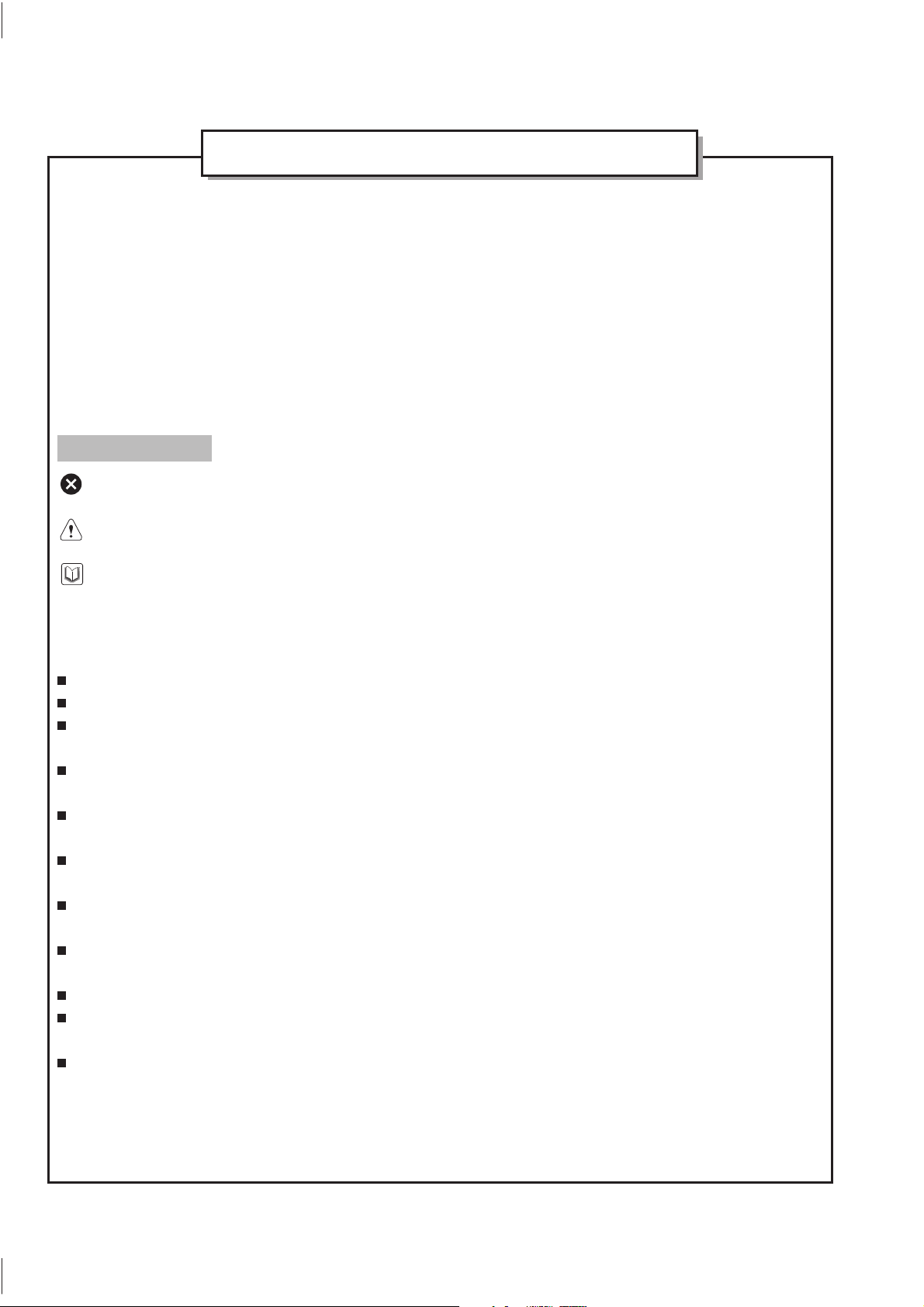

Vehicle protection

1. Cover the seats before performing any procedure to

keep them from getting dirty.

2. Cover all glasses, seats and mats with a heat

resistant cover when welding.

AFJ3B3001

3. Protect moldings, garnishes and ornaments.

A word about safety

1. Wear the appropriate safety equipment that is

necessary for the procedure being performed.

2. When welding or performing other procedures that

require the use of an open flame near the fuel tank,

disconnect and remove the tank and fuel pipe, and

cap the pipe to prevent fuel leakage.

ASD1BM003

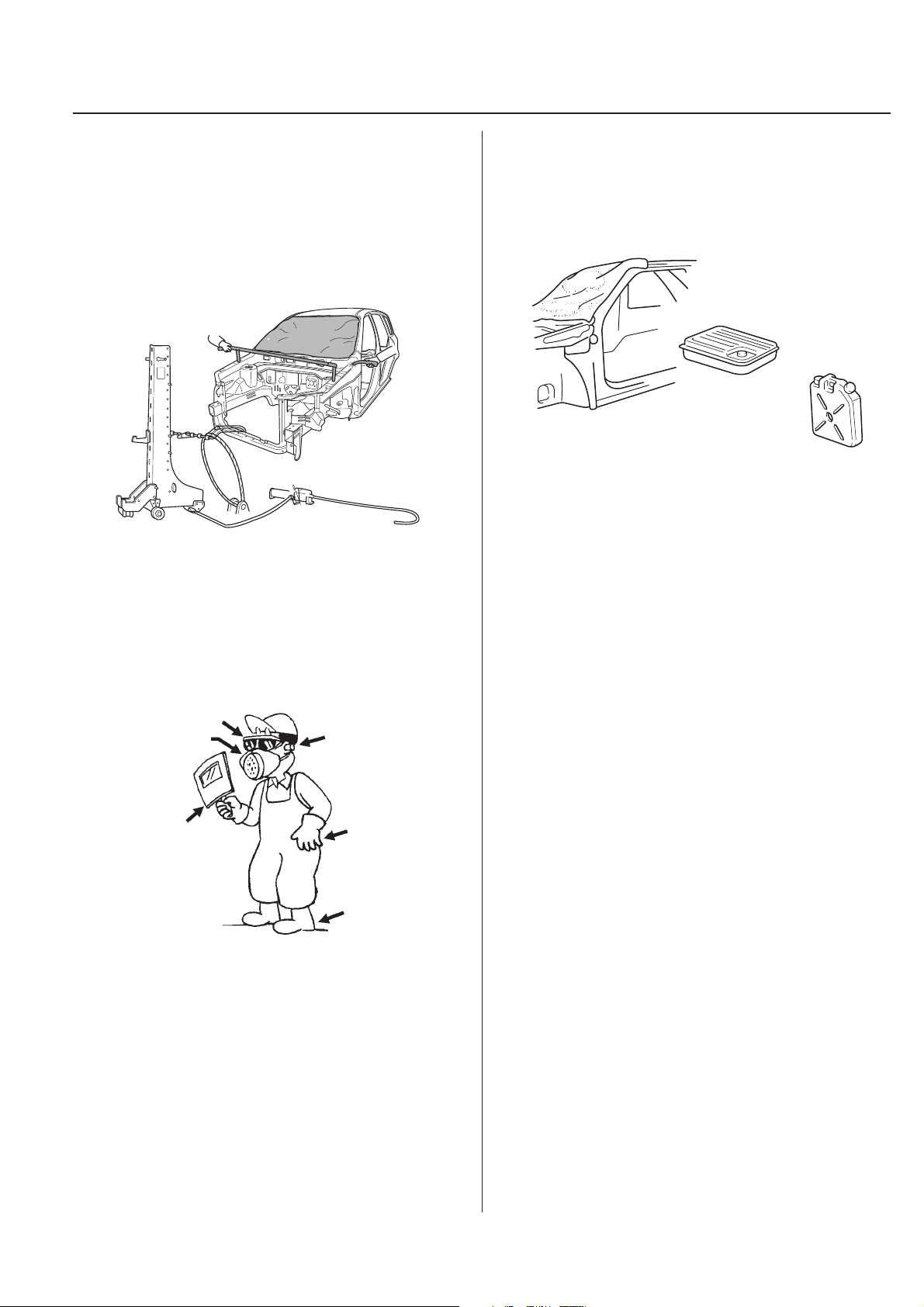

Welding procedures

Observe the following tips when welding.

1. Wear appropriate eye protection.

2. Carefully follow the manufacturers operating

instructions for the welding machine you are using.

3. Do not weld, smoke or allow open flames around

volatile chemicals, cleaners or solvents or in any

area where they have just been used.

Safety

glasses

Mask

Face shield

Ear

protectors

Gloves

Safety

shoes

00003

00-2 General information

Body frame straightener

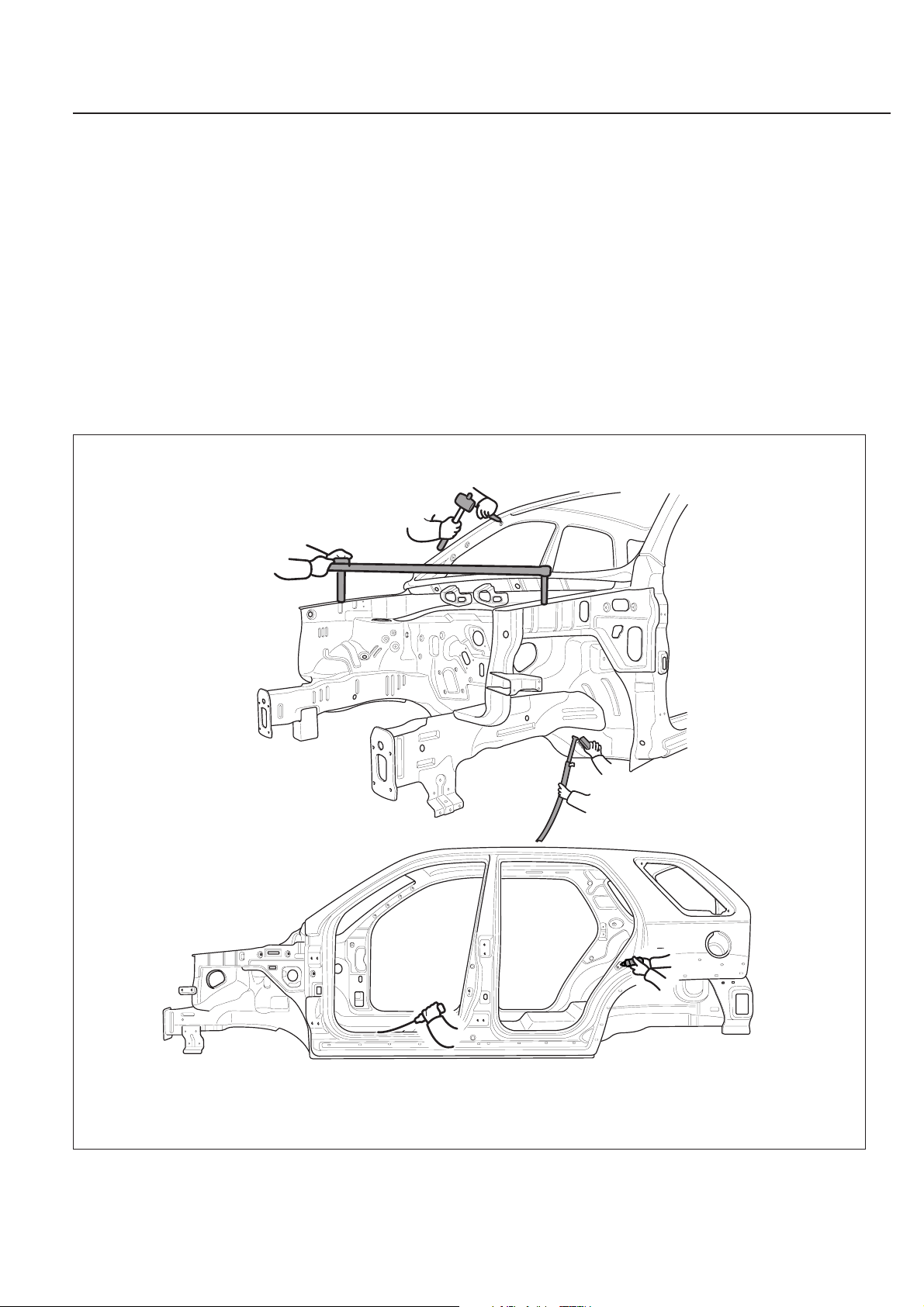

When using a frame straightener, do not enter the area

where the body is being straightened by the chain.

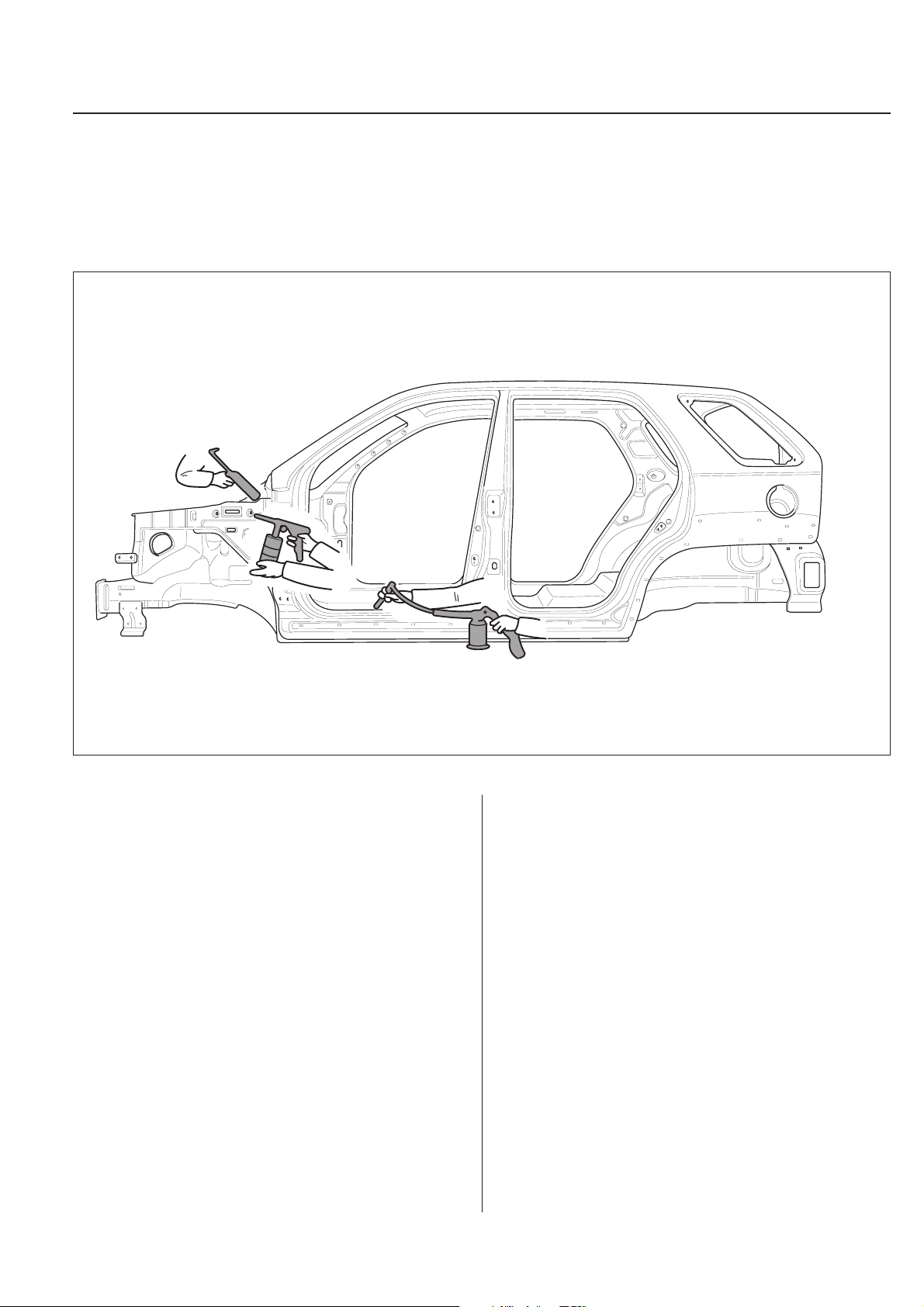

Electrical procedures

1. Disconnect the negative battery terminal.

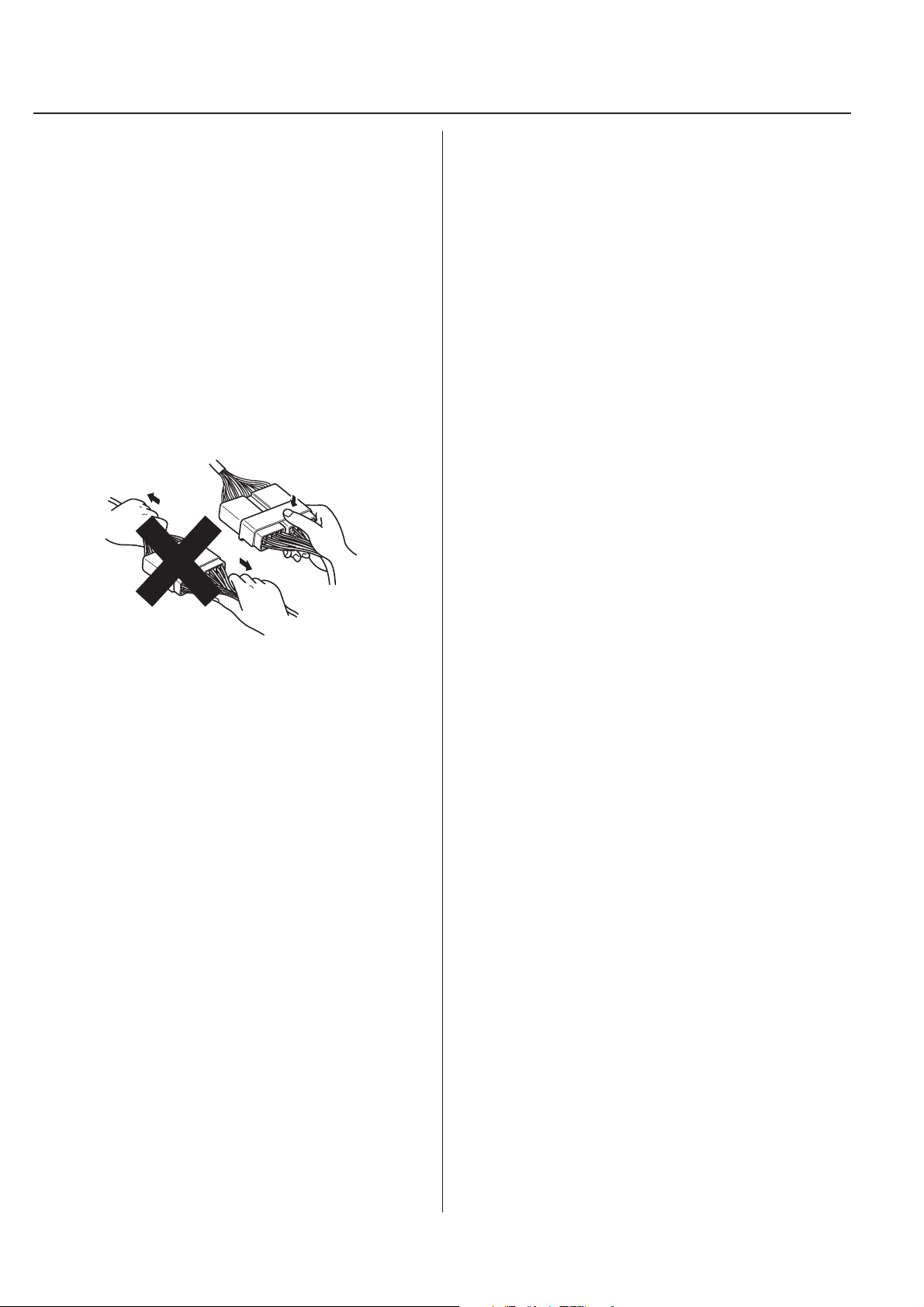

2. Do not pull on wires when disconnecting electrical

connectors. Be careful to hold the connector itself

when disconnecting it.

Insert the connector until it “clicks” when connecting

3.

the connector.

4. Handle all electrical components with care.

ba2c015f

General information 00-3

For best results

Disassembly

Measuring dimensions before beginning

Measure the dimensions of the damaged area according to the body dimension drawings before disassembling

and repairing. Adjust dimensions with body frame adjuster if deformed.

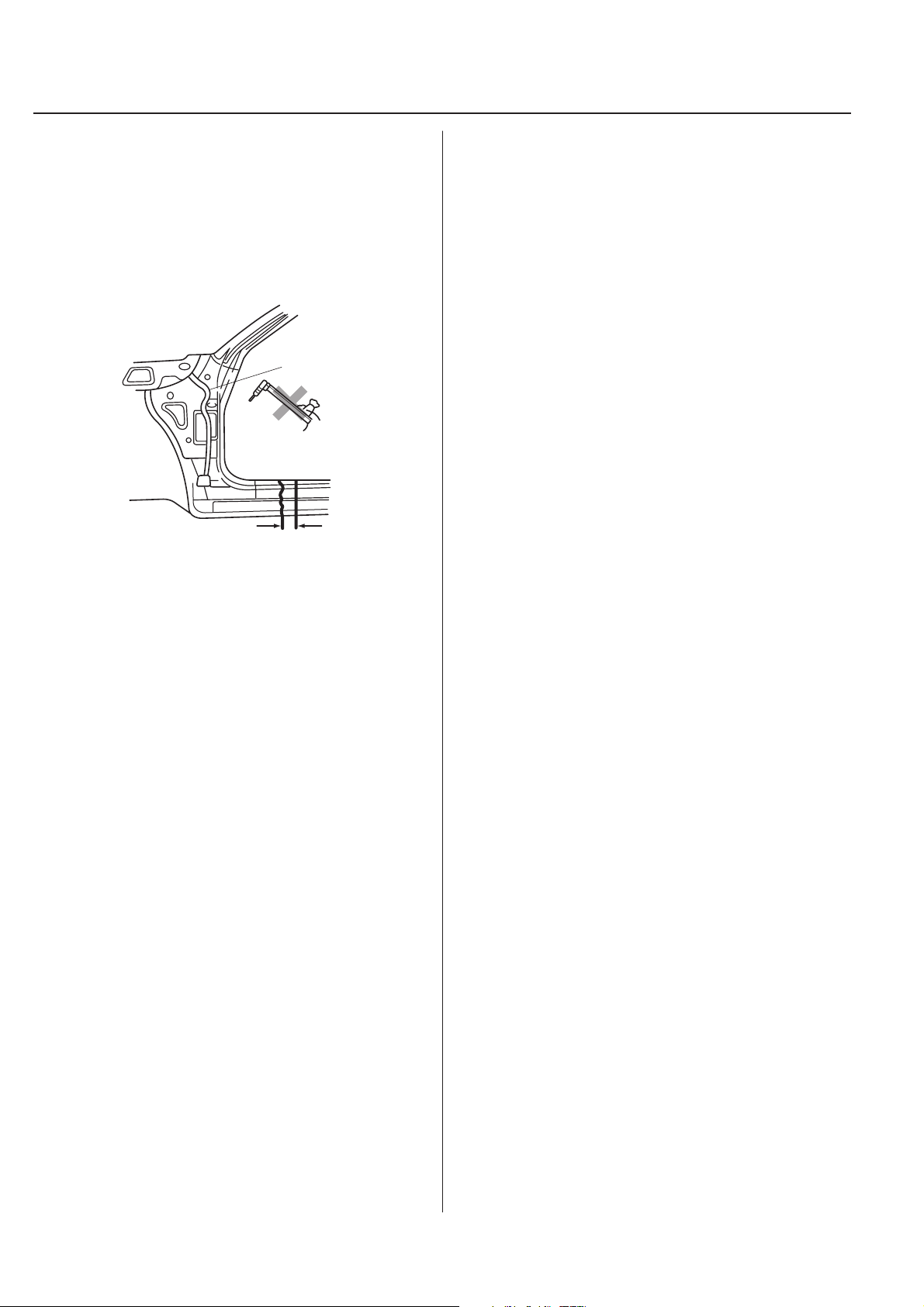

Selecting cutting area

Select a cutting area that is easily accessible and that is prone to the least amount of distortion when welding.

Select an area that would allow the new part to overlap repair area by 1.2~2.0 in (30~50 mm).

Protecting body from damage

Secure the body with clamps and jacks to prevent damage to the body when working on it.

BMKM100

00-4 General information

Disassembling related parts

Use caution when removing body molding and trim from

the area to be worked. Apply masking tape where

needed to prevent damage to the part being removed

or to the vehicle body. Before starting repairs, check if

pipes, hoses or electrical components are present near

damaged area.

Wire harness

Repair work area

Cutting area

1SD1BM005

General information

Preparation of assembly

Applying spot sealer

Remove paint from the surface of new parts and body to be spot welded, and apply spot sealer for rustproofing.

Selecting a welding method

If the thickness of the area to be welded with the panels overlapped is greater than 0.1 in (3 mm), do plug welding

using a carbon arc welding machine.

Thicker than

0.1 in (3mm)

00-5

Machining holes for plug welding

Drill a hole of approximately 0.2~0.24 in (5~6 mm) in

diameter in those areas which are not suitable for spot

welding.

ASD1BM007

BMKM101

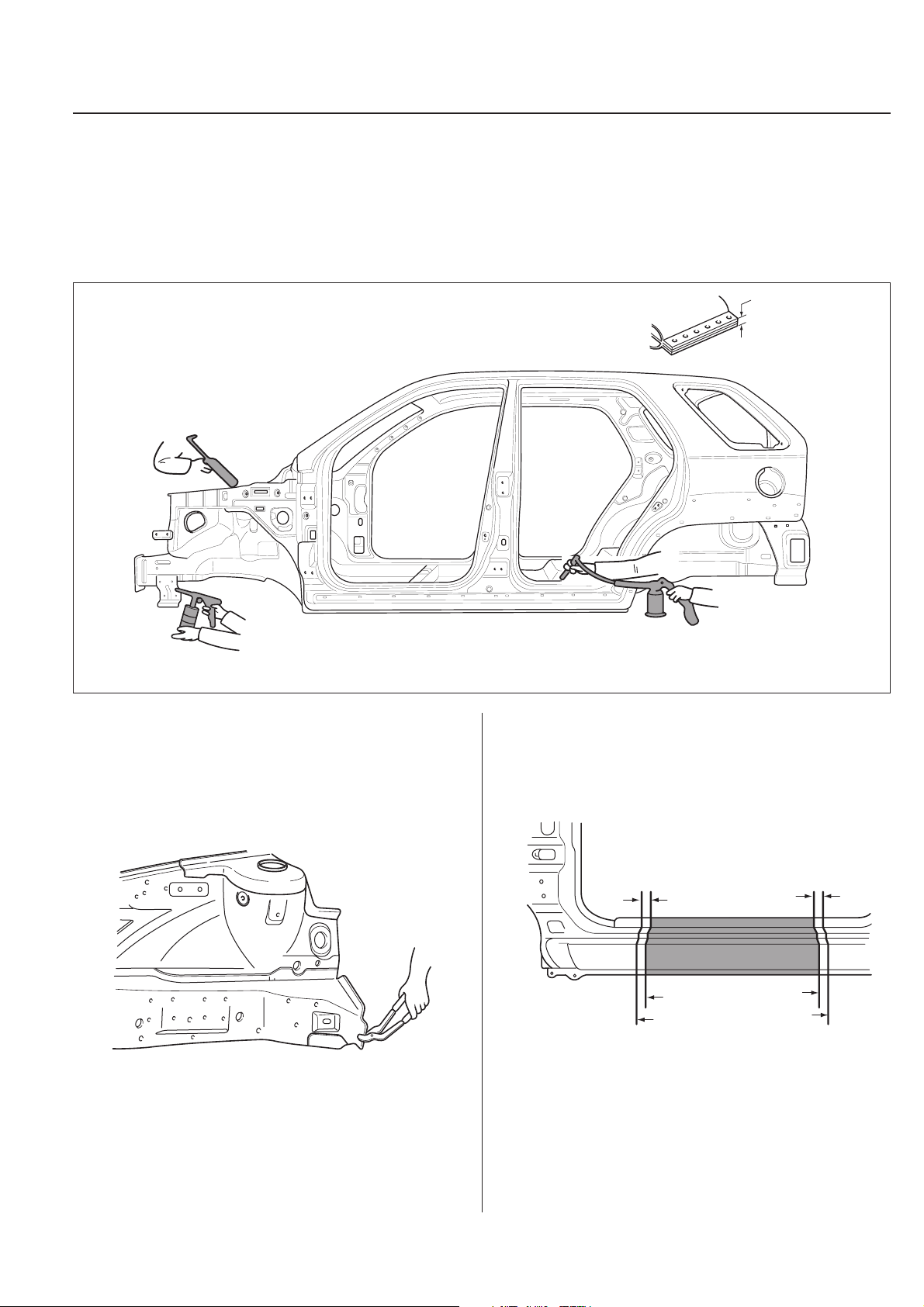

Adjusting a new part

The new part should be cut larger than the repair area,

overlapping the repair area by 1.2~2.0 in (30~50 mm).

1.2~2.0 in

(30~50 mm)

Overlap

body side to modify

new part to modify

1.2~2.0 in

(30~50 mm)

Overlap

00012

00-6 General information

Assembly

Measuring dimensions before welding

When assembling a new part, assemble it according to the body dimensions given in Section 31, and start welding

after checking the gaps with nearby parts.

Caution when welding

The number of welding points should be determined based on the criteria below:

Old part

Pitch: 2.0 in (50 mm)

Spot welding

Plug welding

A

9

Pitch:

1.4 in (35 mm)

Repair part

Repair part

more than

0.1 in (3 mm)

Increase the

number of spot

welds by 30%.

Pitch:

Same number of

welds as original

part.

BMKM102

Caution when spot welding

The tip of the spot welding machine should be maintained to a minimum of 0.1 in (3 mm) because it greatly

affects welding strength. When possible, spot welding should be done between the existing spot welded points.

Before and after spot welding, weld a test piece(test pin) of the same material as the body panel, and check the

welding strength.

Using a test piece(test pin)

Using a hammer and a chisel

Good

0.1 in

(3 mm)

No good

Existing welded spots

New welded spots

Center

diameter

0.1 in

(3 mm)

Nugget diameter

to be 4/5 of chip

diameter

ASD1BM010

Rustproof treatment after assembly

Body sealing

Apply body sealer where necessary.

Applying rustproof material

Apply rustproofing material(wax, oil, etc.) behind welded area.

General information

00-7

Applying undercoat

Apply undercoat on the body where necessary.

BMKM103

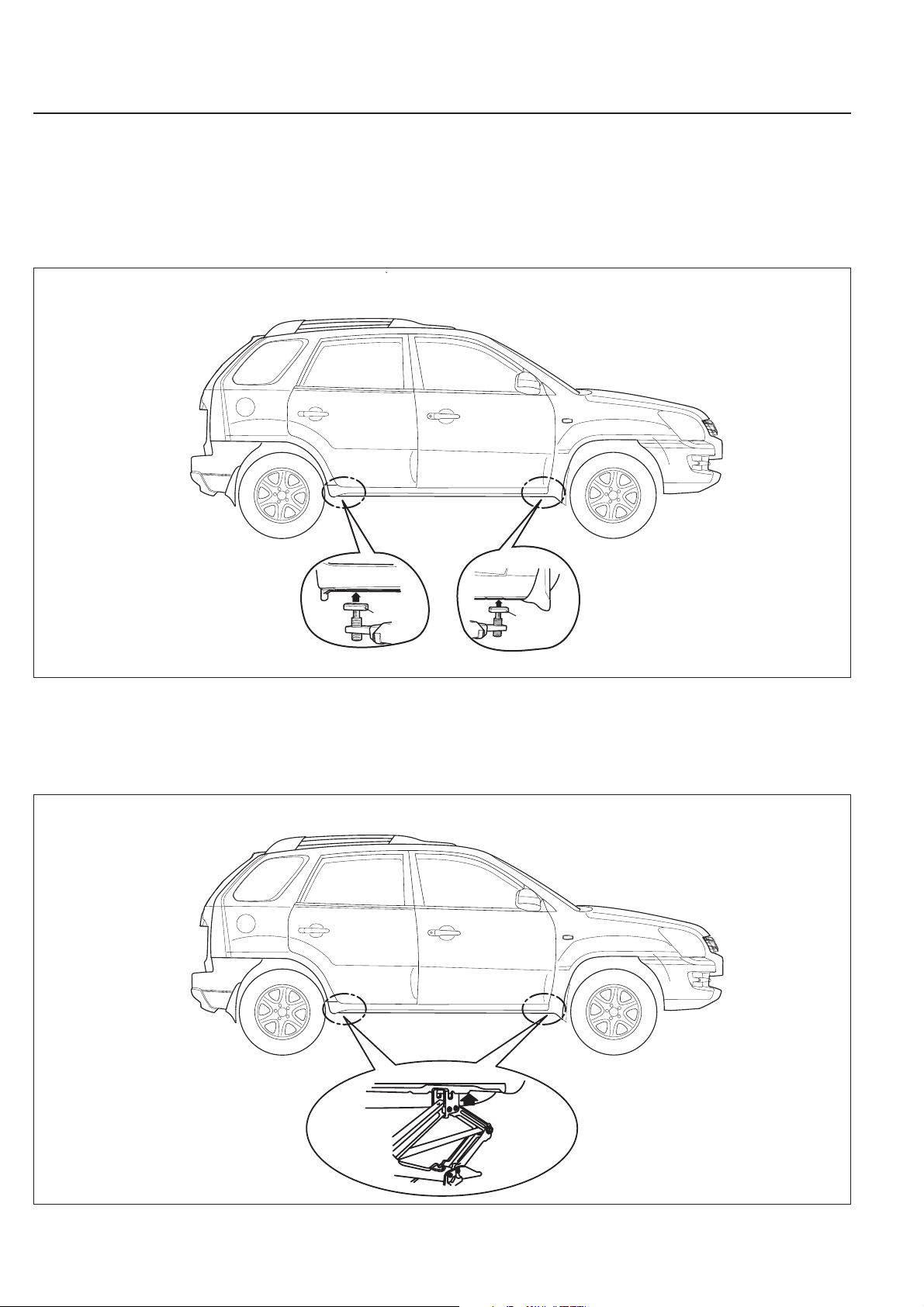

00-8 General information

Vehicle Lift (2-Support Type) And Safety Stand Positions

1. Place the lift blocks under the support points as shown in the illustration

2. Raise the hoist a few inches and rock the vehicle to be sure it is firmly supported.

3. Raise the hoist to full height to inspect the lift points for secure support.

Jack Support Positions

[Rear]

Lift Block

Lift Block

[Front]

AAIE010A

AAIE010B

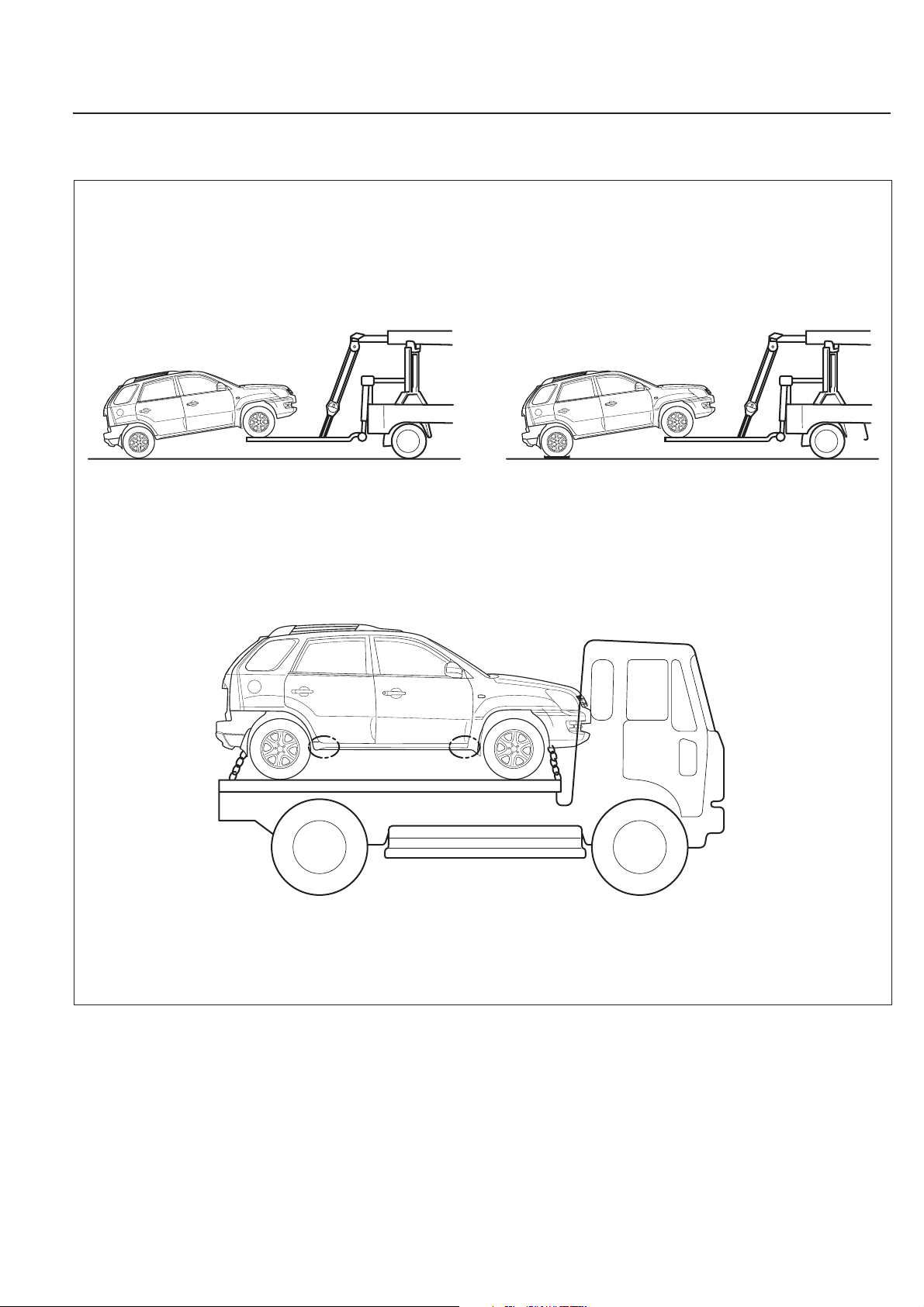

Towing

[2WD] [4WD]

[Wheel lift]

General information 00-9

[Flat - bed]

AAIE010C

If emergency towing is necessary, we recommend having it done by an authorized KIA dealer or a commercial towtruck service.

Profer lifting and towing procedures are necessary to prevent damage to the vehicle.

The use of wheel dollies or flatbed is recommended.

On 2WD vehicles, it is accptable to tow truck and wheel dollies are nou used, the front of the vehicle should always

be lifted, not the rear.

On 4WD vehicles, your vehicle must be towed with a wheel lift and dollies or flatbed equipment with all the wheels off

the ground.

When being towed by a commercial tow truck and wheel dollies are not used, the front of the vehicle should always

be lifted, not the rear.

00-10 General information

Body colors and major specifications

Kia color codes

Kia code Paint color

6D

9P

3P

K6

1L Vert Jade Pearl

9L

Y3 Greenish Gold

S6 Satin Silver

S4

UD

Paint manufacture codes

Kia code

Color name

Dupont Standox

Spies

Hecker

Smoky Brown

Black Cherry

Volcanic Red

Smart Blue

Natural Olive

Grayish Silver

Clear White

BASF

Akzo

Nobel

PPG

6D

9P

3P

K6

1L

9L

Y3

S6

S4

UD

Smoky Brown

Black Cherry

Volcanic Red

Smart Blue

Vert Jade Pearl

Natural Olive

Greenish Gold

Satin Silver

Grayish Silver

Clear White

X1950 755710 KIA9816

X1951 755711 KIA9410

X1952 755712 KIA9320

X1953 755713 KIA9540

X1954 755714 KIA9525

X1955 755715

X1956

X1957

X1958

F2756 755719

755716

755717

755718

6D

9P

3P

K6

1L

9L

Y3

S6

S4

UD

6D

9P

3P

K6

1L

9L

Y3

S6

S4

UD

KIA9626

KIA9815

KIA9739

KIA9738

KIA4004

6D

9P

3P

K6

1L

9L

Y3

S6

S4

UD

Body structure

Body composition

Body shell ..................................................................................................... 11- 1

Body service holes ..................................................................................... 11- 1

High tension steel sheet used area

Radiator support panel ................................................................................ 11- 2

Fender apron panel....................................................................................... 11- 3

Cowl & Dash panel ....................................................................................... 11- 4

Side body panel............................................................................................. 11- 5

Center floor panel .......................................................................................... 11- 6

Rear floor panel ............................................................................................. 11- 7

Roof panel(Without sunroof) ............................................................................................ 11- 8

Roof panel (With sunroof) ........................................................................... 11- 9

Fender panel & Hood panel & Tail gate panel ........................................ 11-10

Door panel ....................................................................................................... 11-11

Body structure

1 1

Zine-galvanized steel sheet used area

Radiator support panel ................................................................................ 11-12

Fender apron panel....................................................................................... 11-13

Cowl & Dash panel ....................................................................................... 11-14

Side body panel............................................................................................. 11-15

Center floor panel .......................................................................................... 11-16

Rear floor panel ............................................................................................. 11-17

Roof panel(Without sunroof) .................................................................... 11-18

Roof panel (With sunroof) ........................................................................... 11-19

Fender panel & Hood panel & Tail gate panel ........................................ 11-20

Door panel ....................................................................................................... 11-21

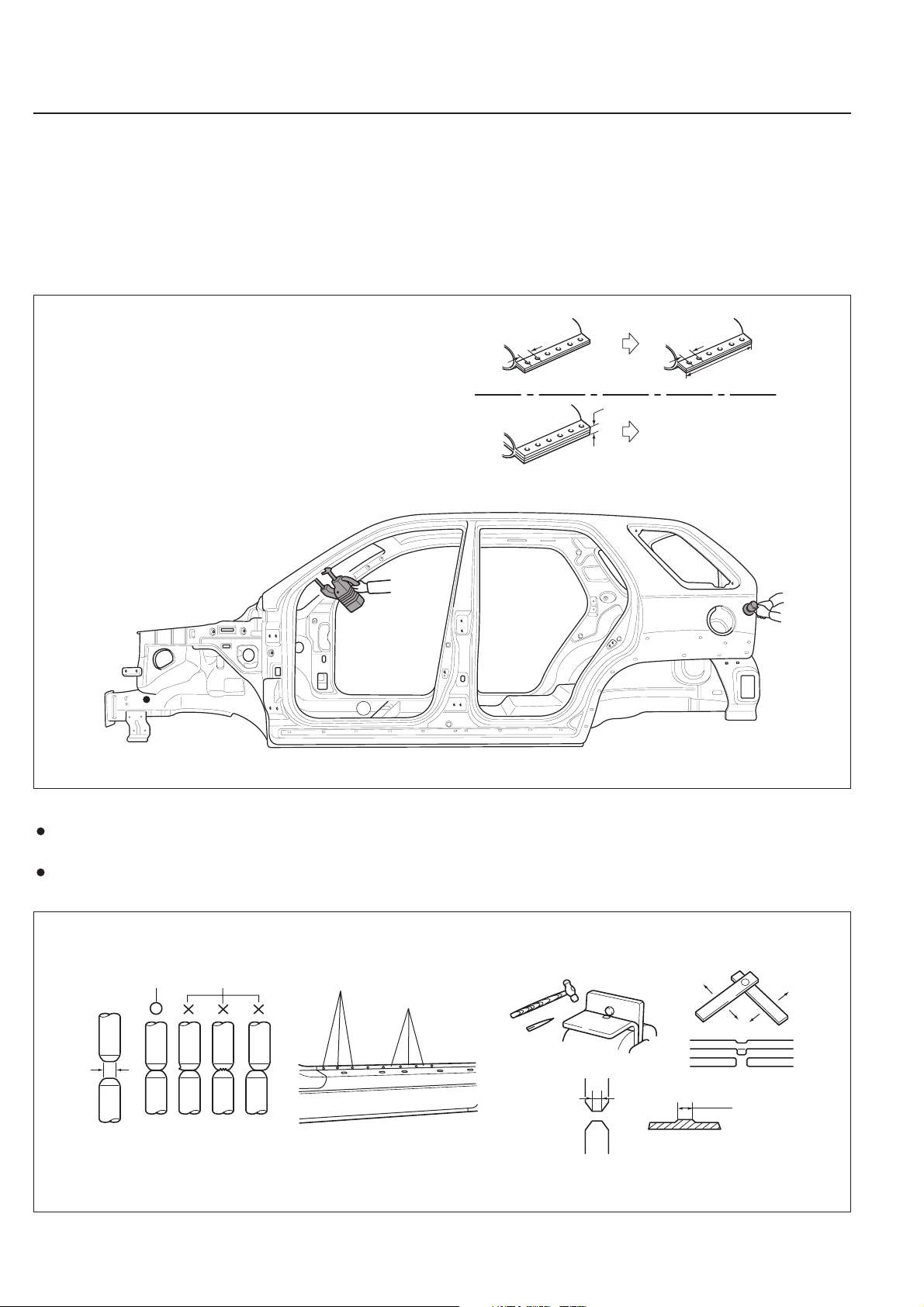

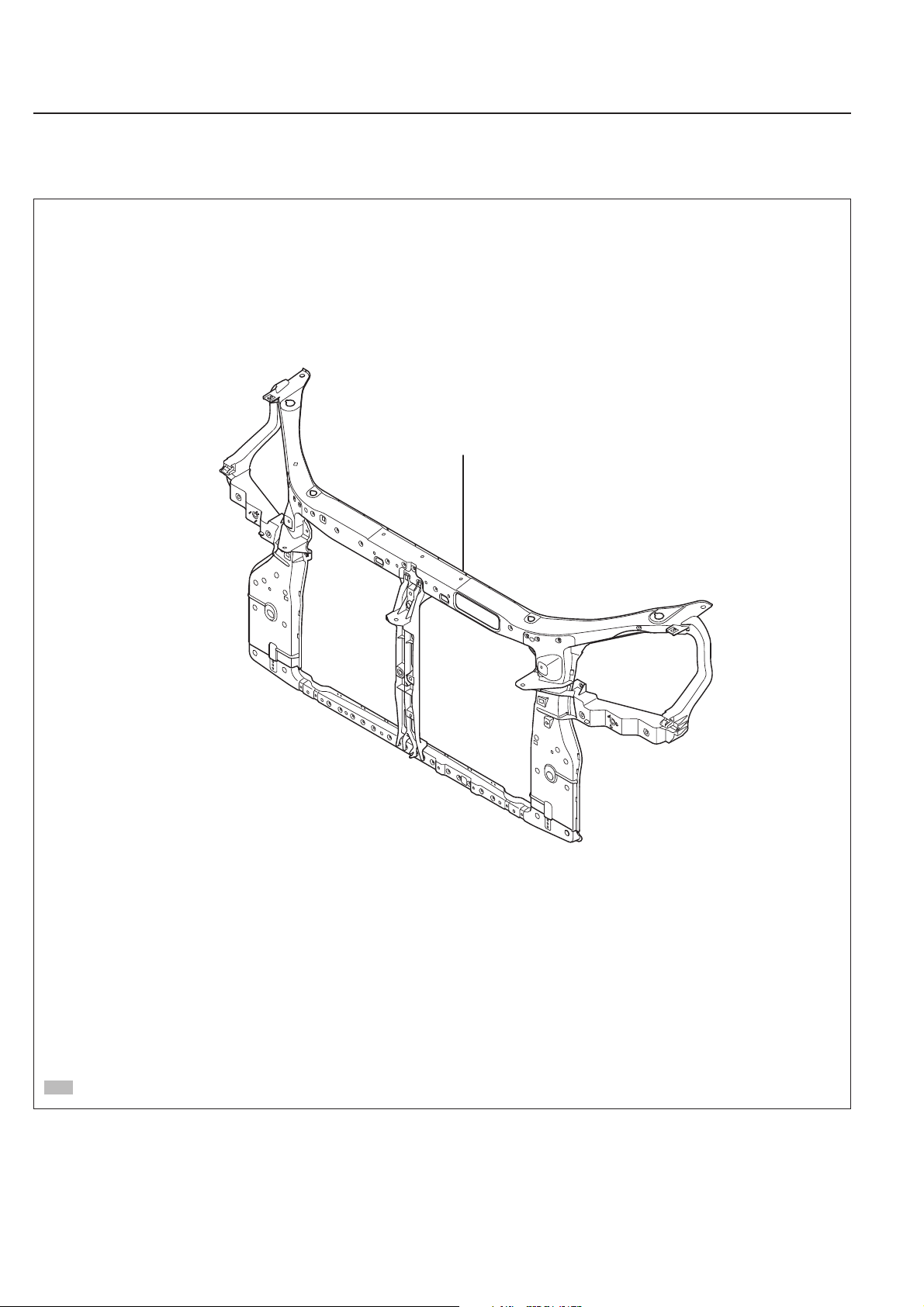

Body structure 11-1

Body composition

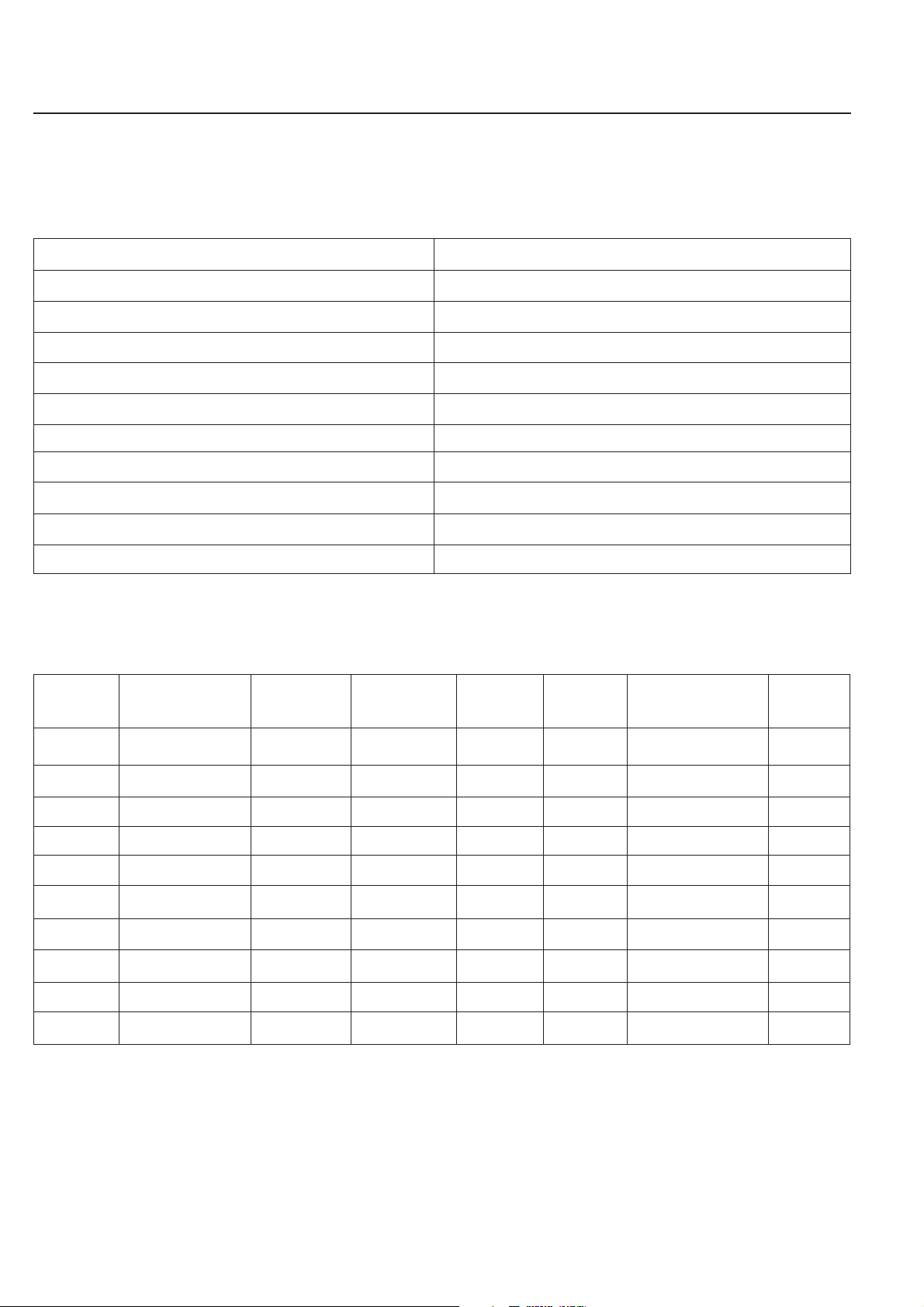

Body shell

The body consists of the body shell, frame and cross members, etc, welded together. This provides safety, durability,

noise protection, rustproofing and vibration proofing of the vehicle.

Body service holes

Body service holes are provided in the inner panel to improve serviceability of the body.

BMKM001

BMKM002

11-2 Body structure

High tension steel sheet used area

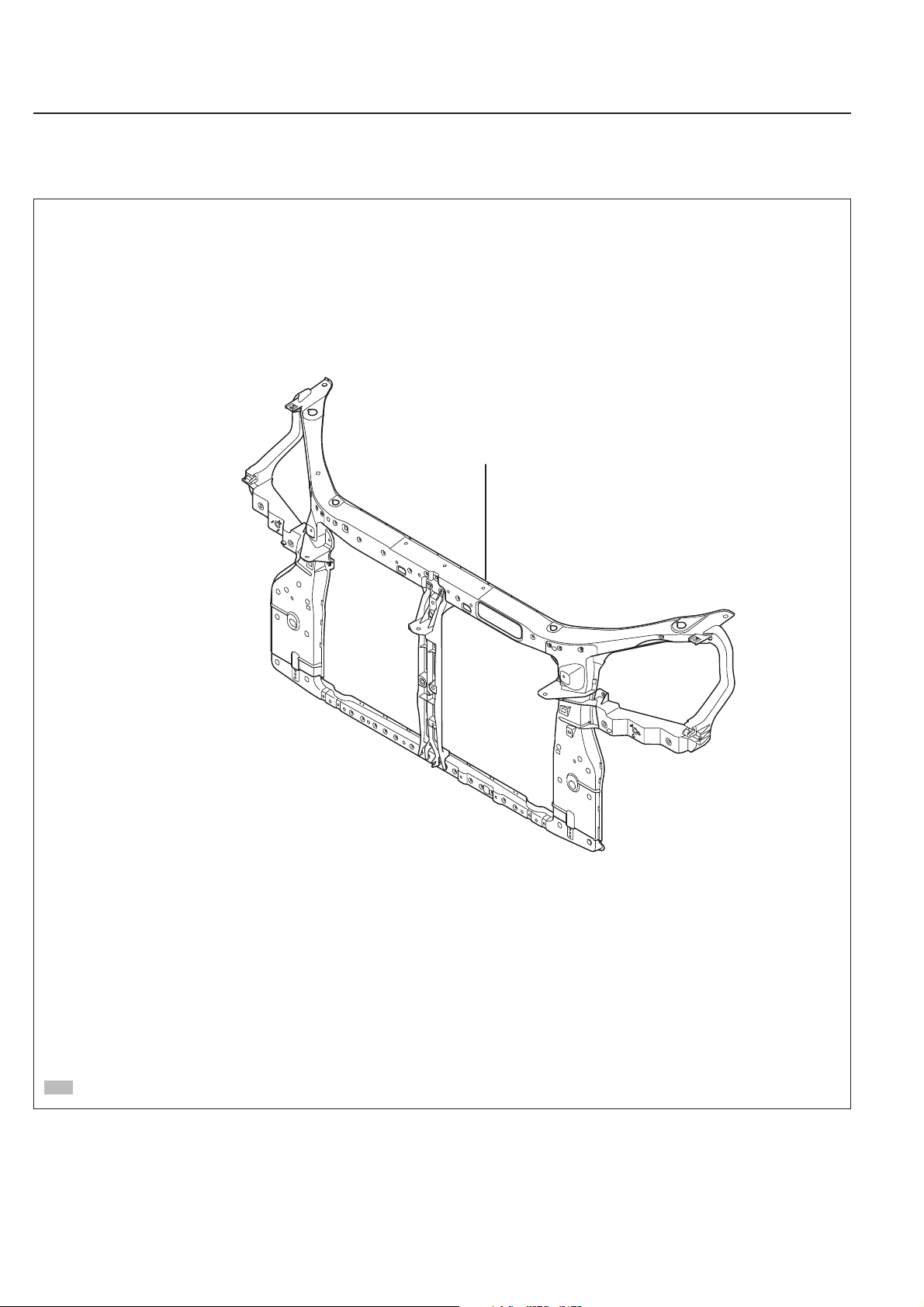

Radiator support panel

1

HIGH TENSION STEEL SHEET USED AREA

(1) Radiator support panel complete

BMKM003

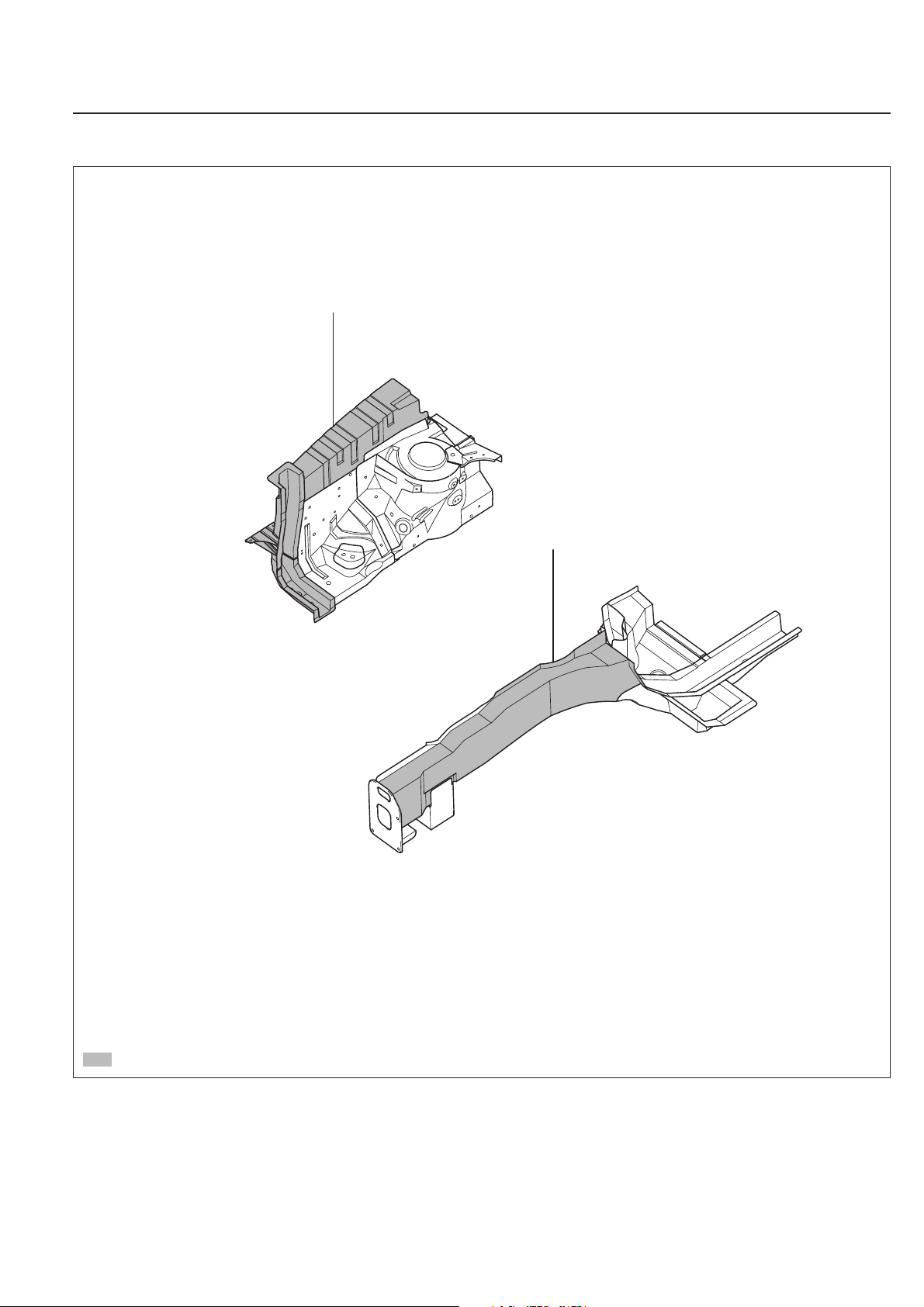

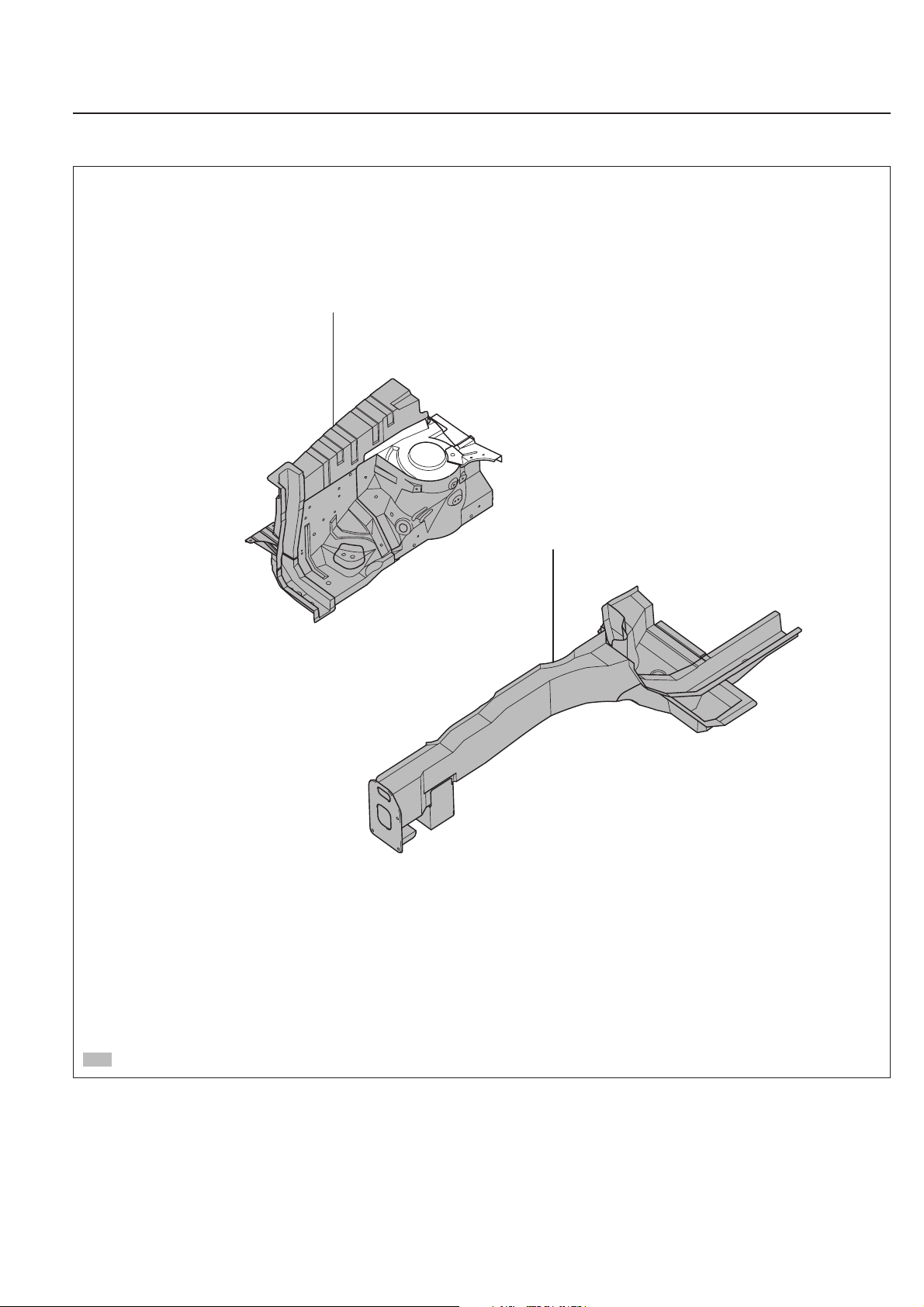

Fender apron panel

Body structure 11-3

1

2

HIGH TENSION STEEL SHEET USED AREA

(1) Fender apron panel assembly

BMKM004

(2) Front side outer member assembly

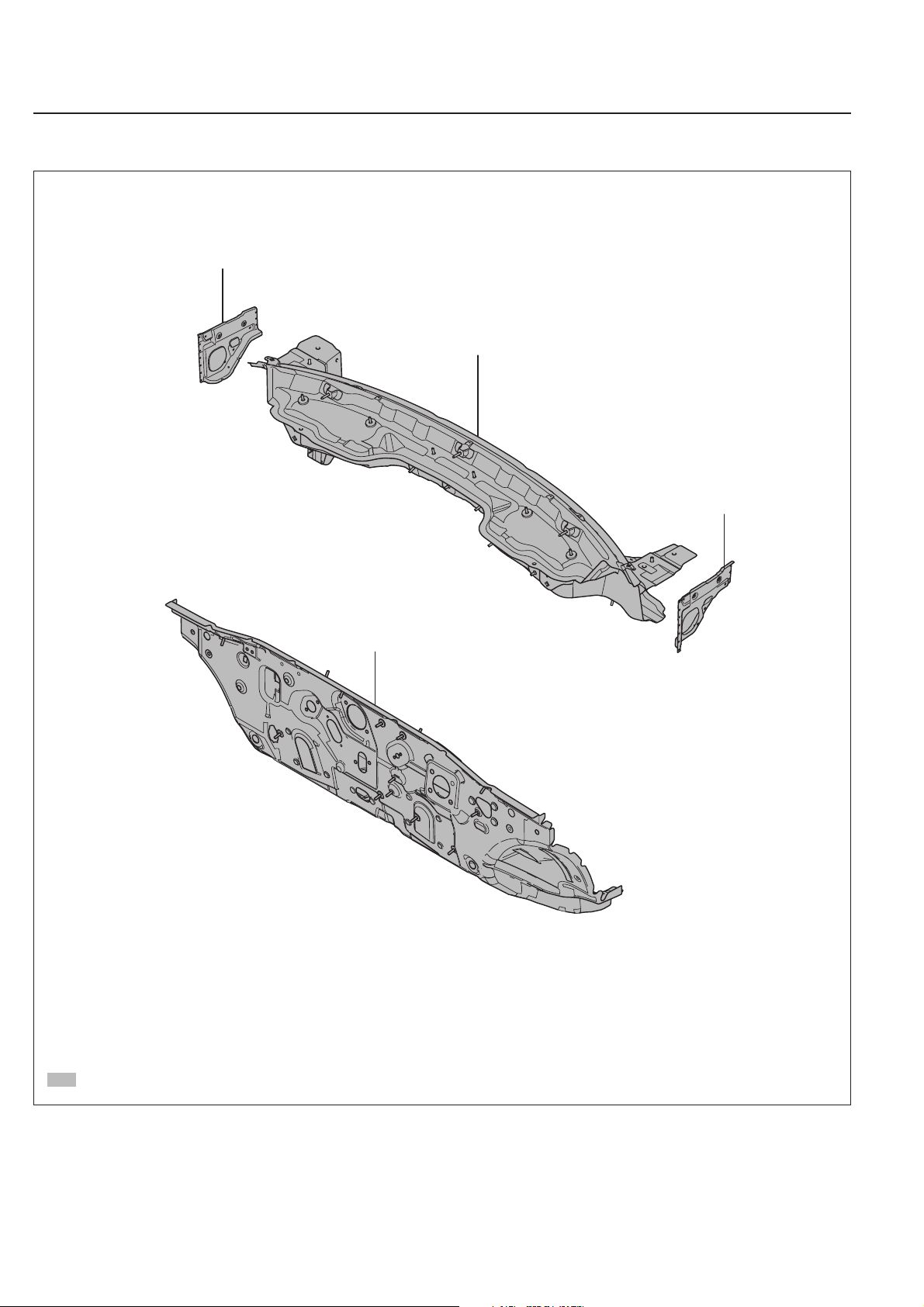

11-4 Body structure

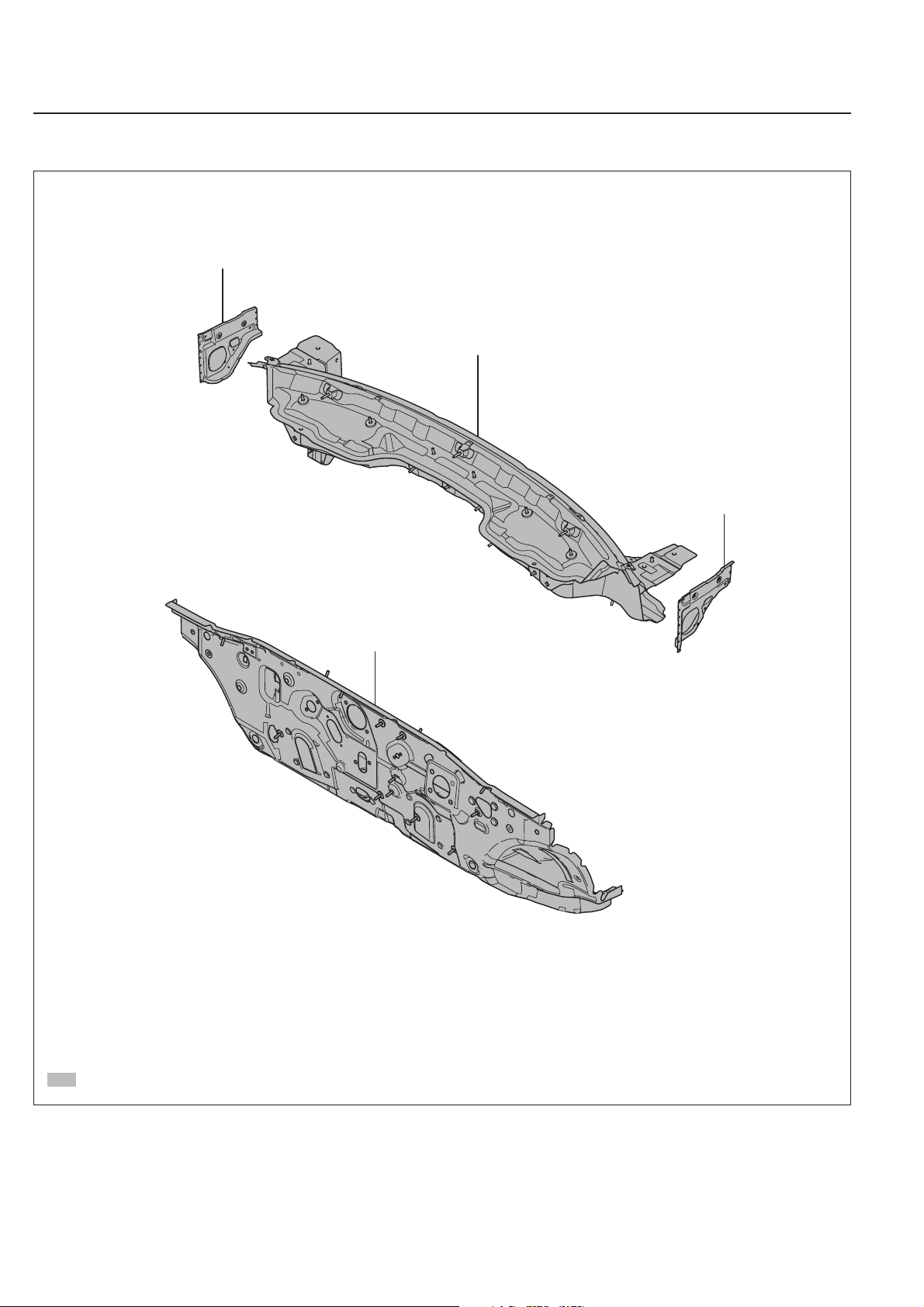

Cowl panel & Dash panel

2

1

2

HIGH TENSION STEEL SHEET USED AREA

3

BMKM005

(1) Cowl panel complete

(2) Cowl side outer panel

Dash panel complete

(3)

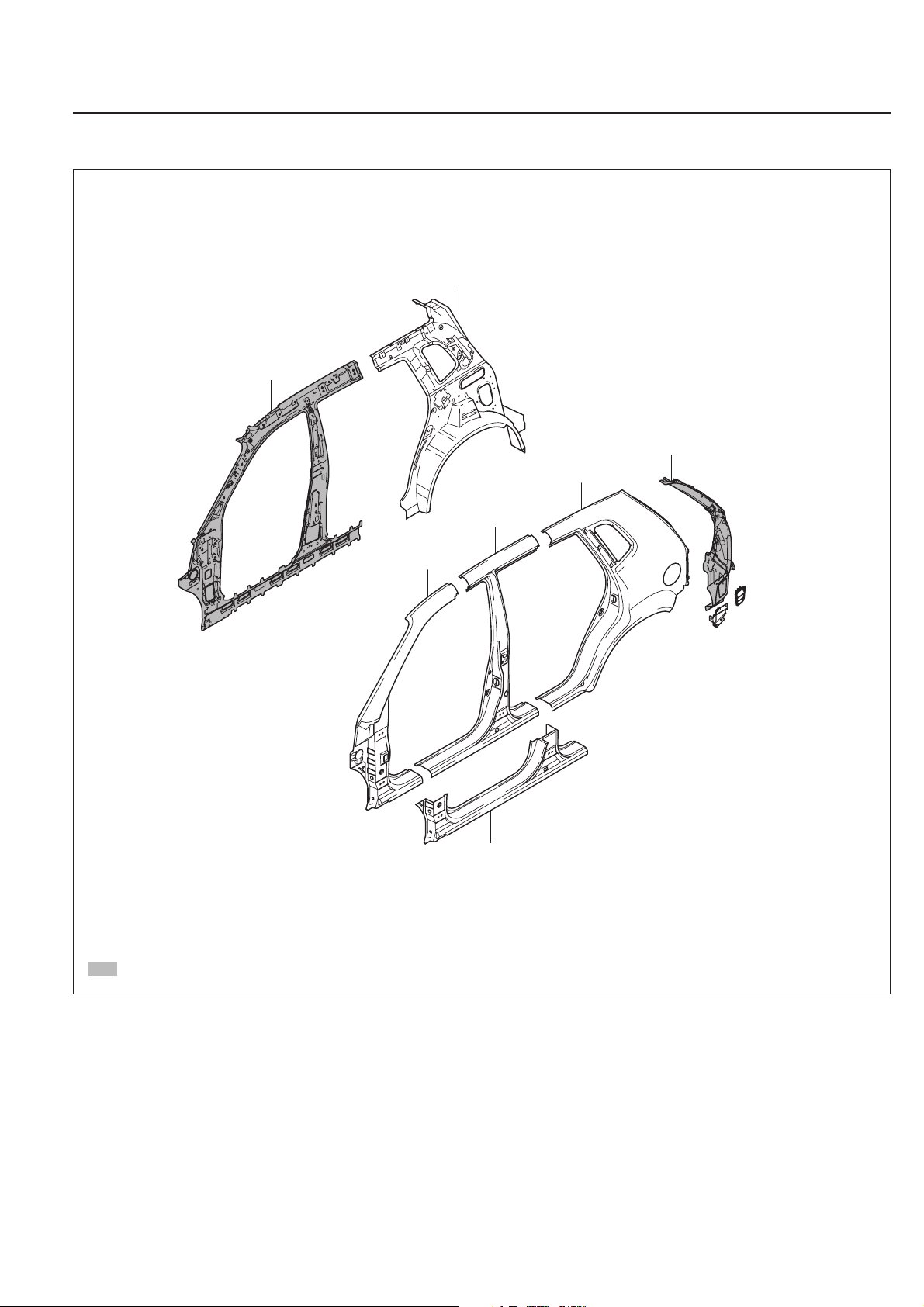

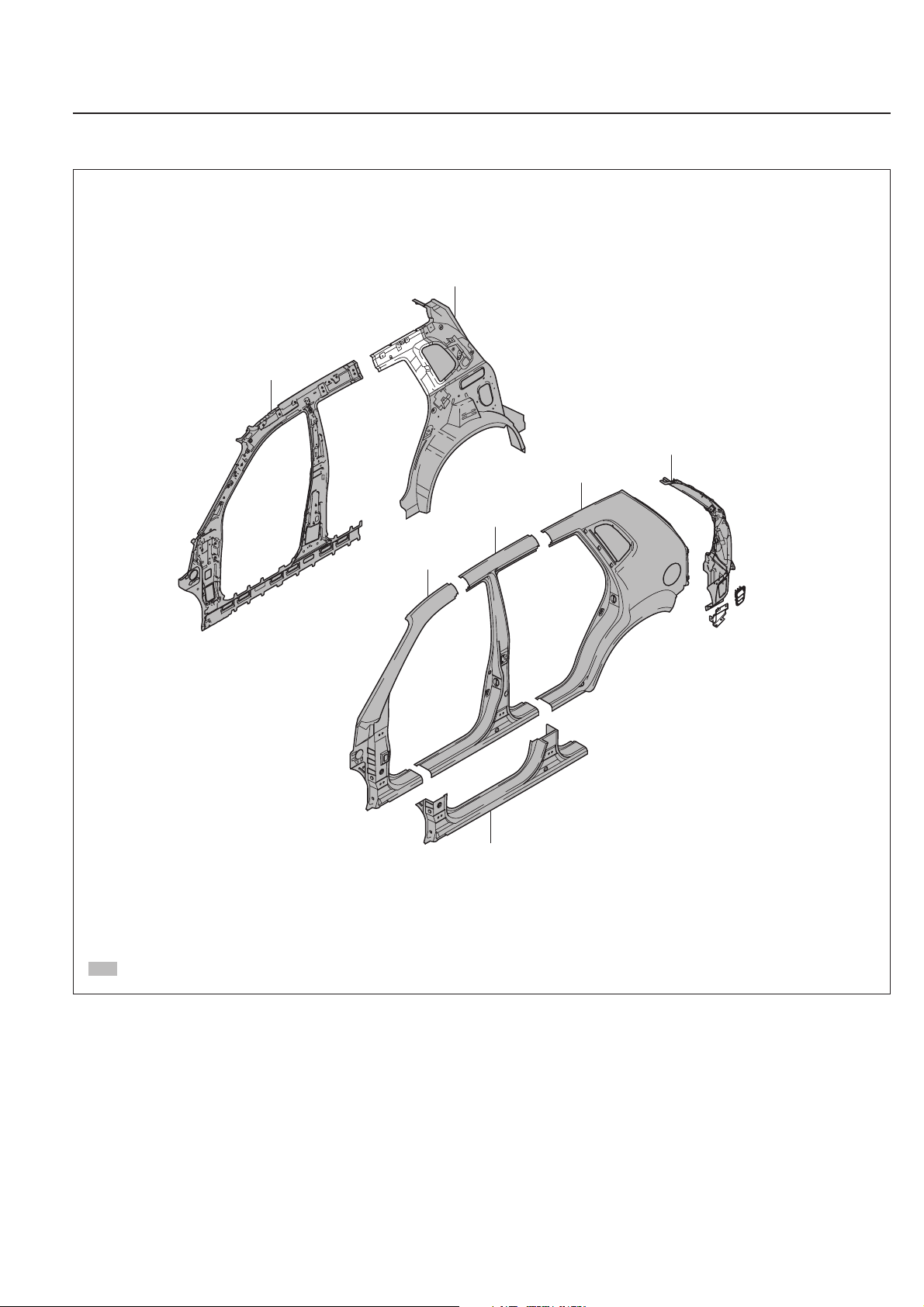

Side body panel

Body structure 11-5

2

1

3

4

5

HIGH TENSION STEEL SHEET USED AREA

6

7

BMKM 006

(1) Front inner pillar assembly

(2) Quarter inner panel assembly

(3) Side outer rear extension assembly

(4) Quarter outer panel assembly

(5) Center outer pillar assembly

(6) Pillar outer panel assembly

(7) Side assembly outer panel

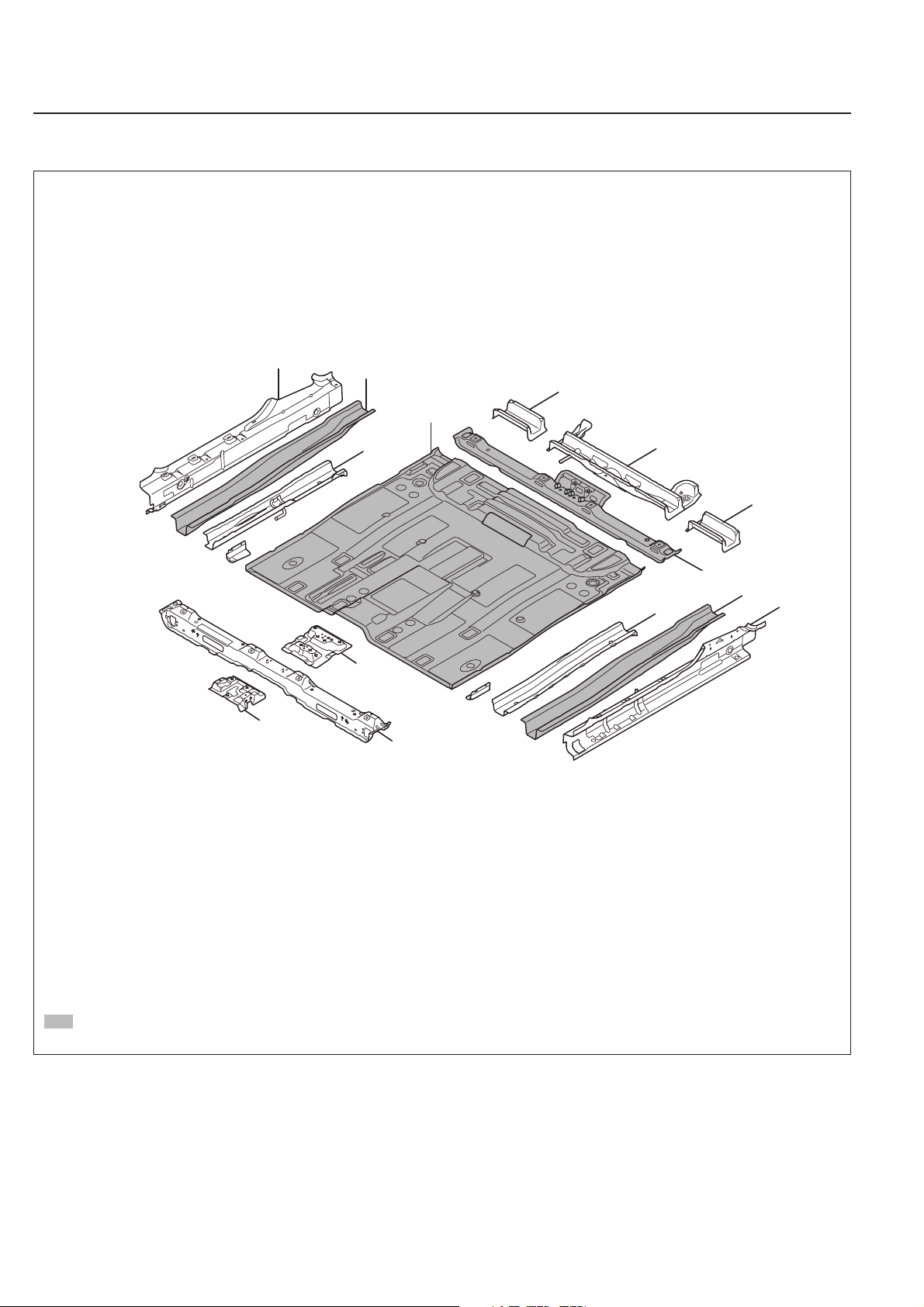

11-6 Body Structure

Center floor panel

10

3

1

4

7

2

5

8

9

6

7

1

4

5

3

HIGH TENSION STEEL SHEET USED AREA

(1)

Front seat cross rear member assembly

(2) Center floor panel

(3) Side sill inner panel assembly

(4) Center floor side outer member assembly

(5) Center floor side inner member assembly

BMKM 007

(6) Propeller shaft mounting bracket

(7) Skid plate mounting gusset

(8) Parking brake lever reinforcement assembly

(9) Front seat cross front member assembly

(10) Center support bracket

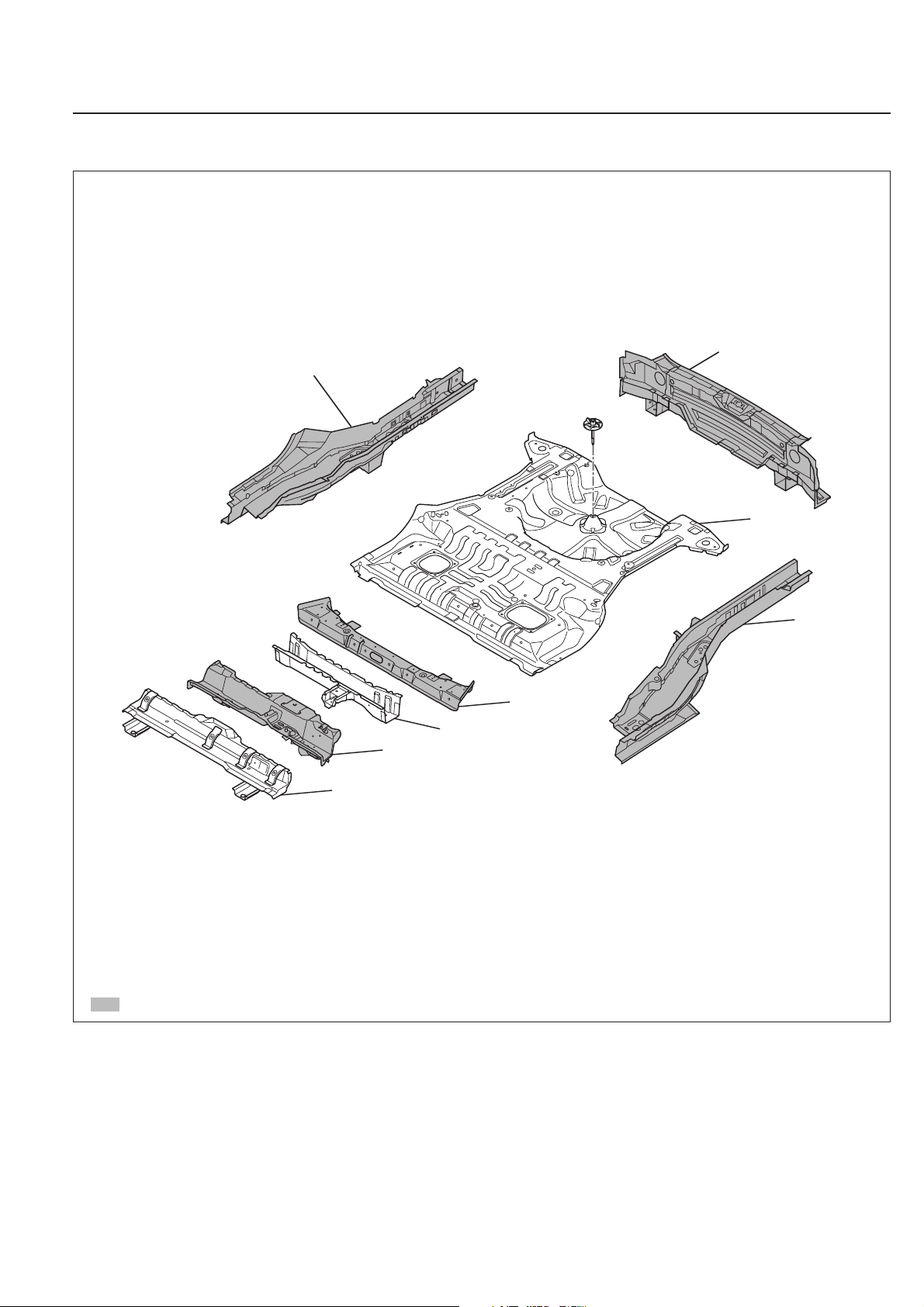

Rear floor panel

Body structure 11-7

7

2

1

5

6

HIGH TENSION STEEL SHEET USED AREA

(1) Rear floor panel

(2)

Rear floor side member assembly

(3) Rear floor upper cross member assembly

(4) Rear floor lower No.3 cross member assembly

2

3

4

BMKM008

(5)

Rear floor lower No.2 cross member assembly

(6) Rear floor lower No.1 cross member assembly

(7) Rear end cross member assembly

11-8 Body Structure

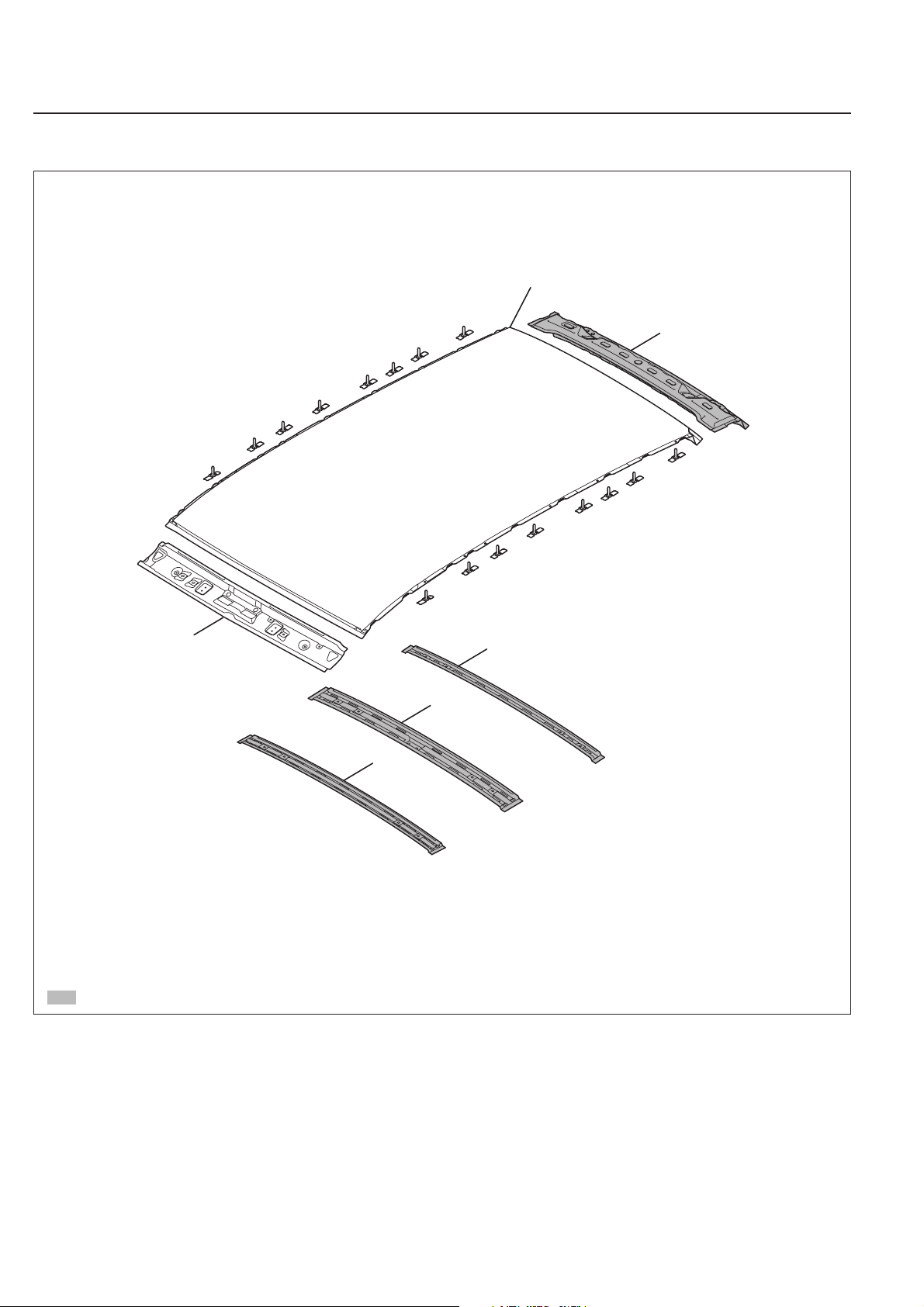

Roof panel (Without sunroof)

3

2

1

HIGH TENSION STEEL SHEET USED AREA

(1) Roof front rail assembly

(2) Roof rear rail assembly

(3) Roof panel

6

5

4

BMKM009

(4) Roof center No.1 rail

(5) Roof center No.2 rail

(6) Roof center No.3 rail

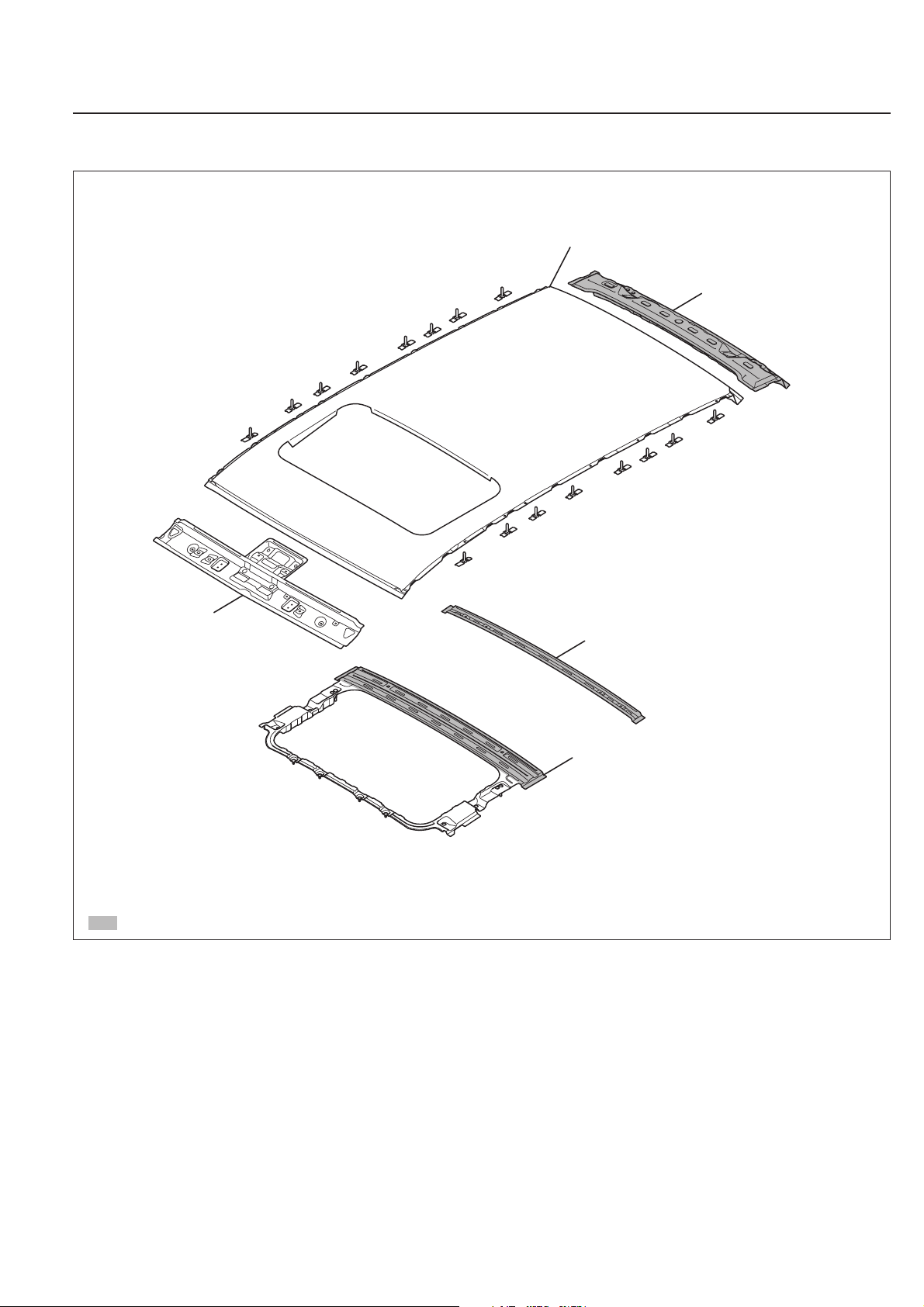

Roof panel (With sunroof)

Body structure 11-9

3

2

1

HIGH TENSION STEEL SHEET USED AREA

(1) Roof front rail assembly

(2) Roof rear rail assembly

(3) Roof panel

5

4

BMKM010

(4) Sunroof reinforcement

(5) Roof center No.3 rail

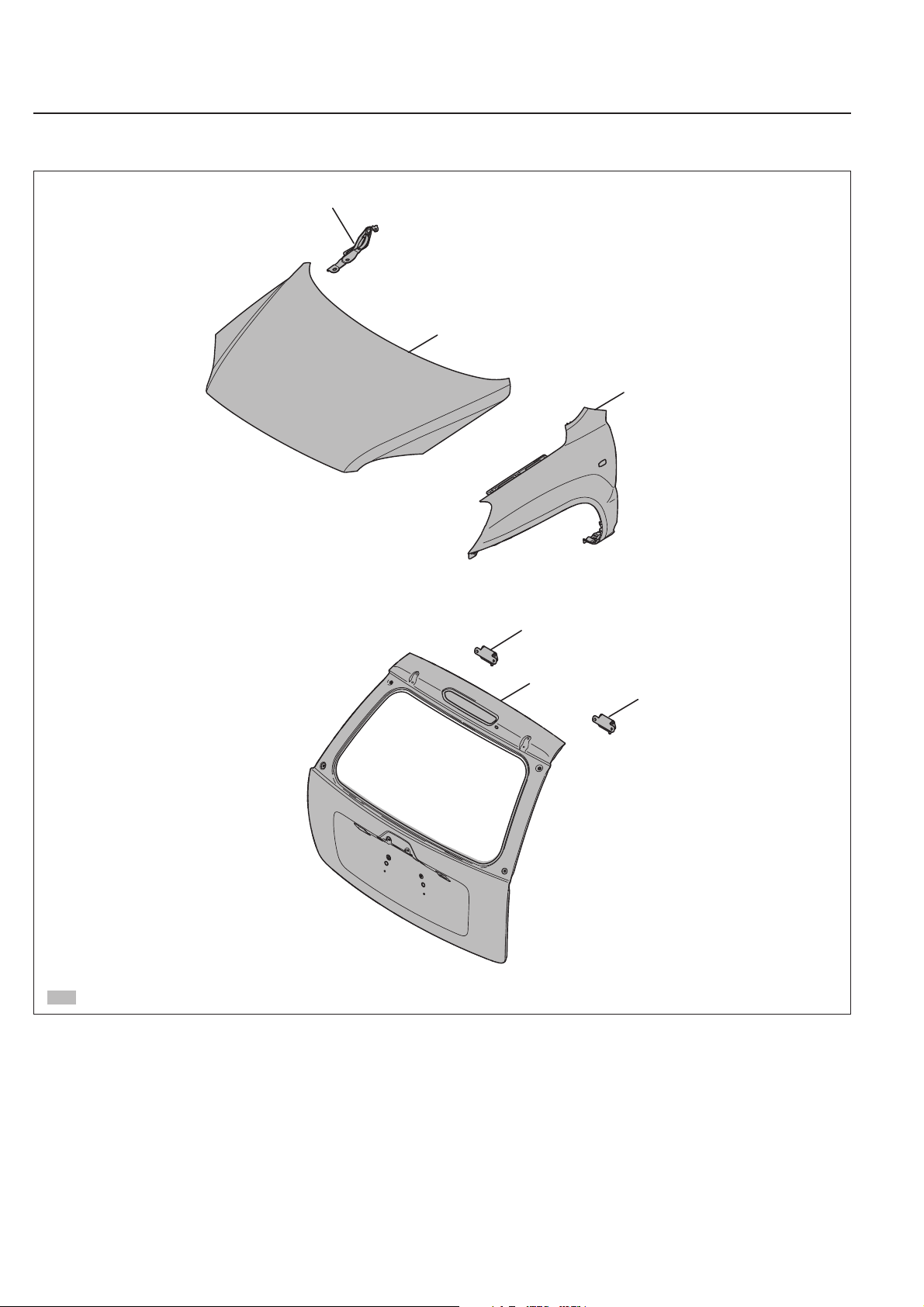

11-10 Body Structure

Fender panel & Hood panel & Tail gate panel

2

1

3

HIGH TENSION STEEL SHEET USED AREA

(1) Hood panel assembly

(2) Hood hinge assembly

(3) Fender panel

5

4

5

BMKM011

(4) Tail gate panel assembly

(5) Tail gate hinge assembly

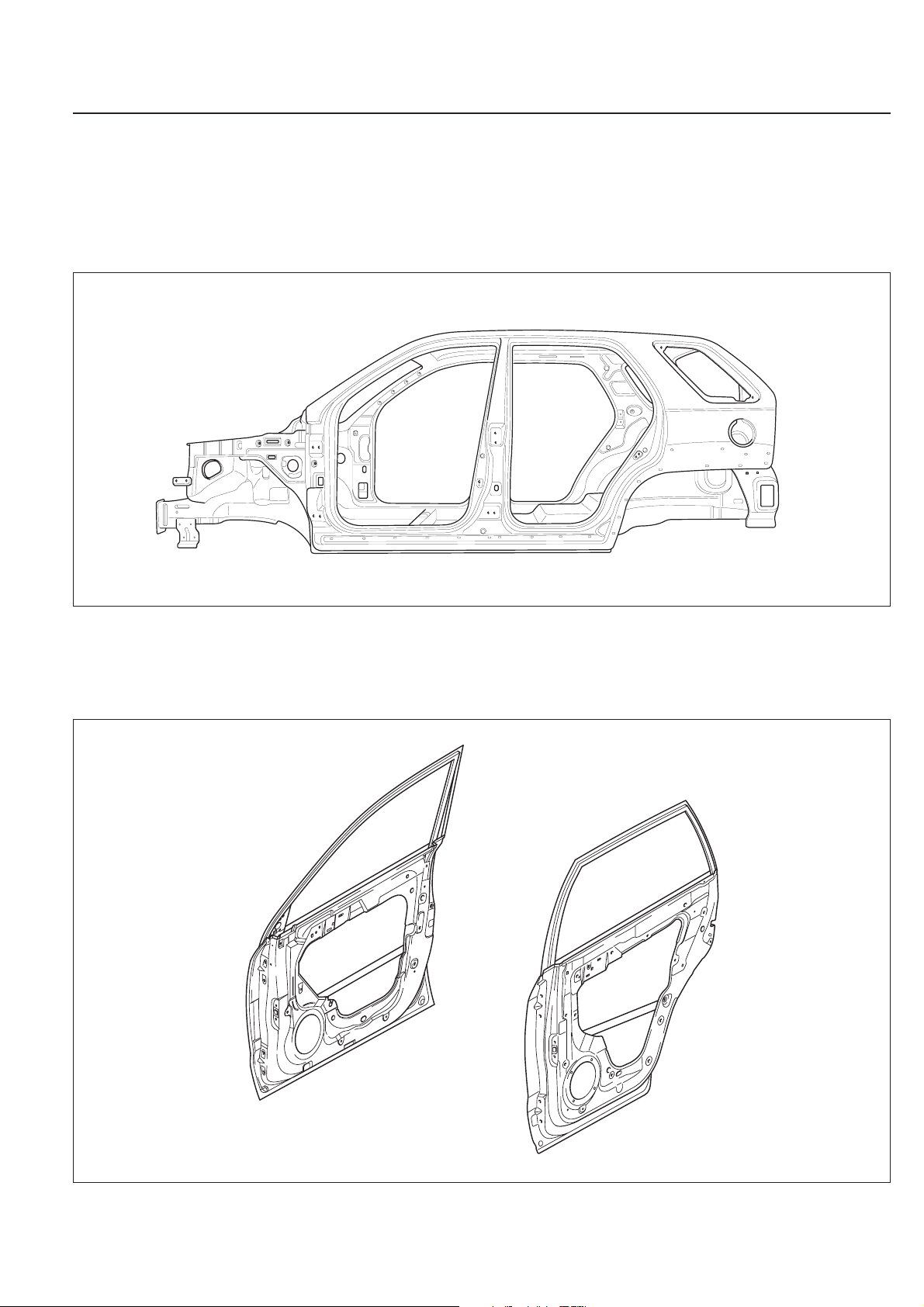

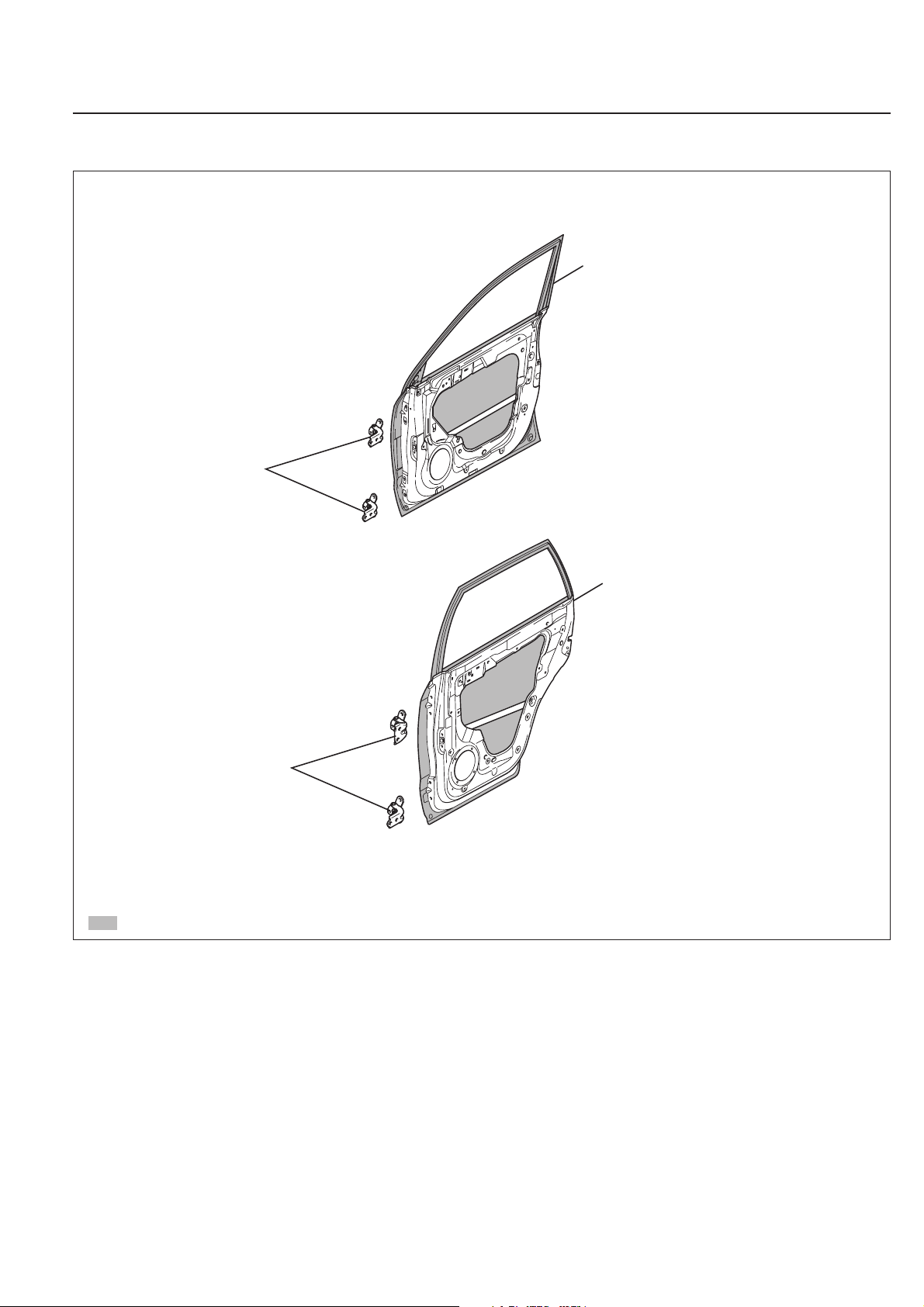

Door panel

Body structure 11-11

1

3

4

HIGH TENSION STEEL SHEET USED AREA

(1) Front door panel assembly

(2) Rear door panel assembly

2

7

BMKM012

(3) Front door hinge assembly

(4) Rear door hinge assembly

11-12 Body structure

Zinc-galvanized steel sheet used area

Radiator support panel

1

ZINC-GALVANIZED STEEL SHEET USED AREA

(1) Radiator support panel complete

BMKM013

Fender apron panel

Body structure 11-13

1

2

ZINC-GALVANIZED STEEL SHEET USED AREA

(1) Fender apron panel assembly

BMKM014

(2) Front side outer member assembly

11-14 Body structure

Cowl panel & Dash panel

2

1

2

ZINC-GALVANIZED STEEL SHEET USED AREA

3

BMKM015

(1) Cowl panel complete

(2) Cowl side outer panel

Dash panel complete

(3)

Side body panel

Body structure 11-15

2

1

3

4

5

ZINC-GALVANIZED STEEL SHEET USED AREA

6

7

BMKM016

(1) Front inner pillar assembly

(2) Quarter inner panel assembly

(3) Side outer rear extension assembly

(4) Quarter outer panel assembly

(5) Center outer pillar assembly

(6) Pillar outer panel assembly

(7) Side assembly outer panel

Loading...

Loading...