Page 1

96M1825

Multipurpose Digital Contact Sensor

GT- 7 0 A

Safety Precautions

■

General cautions

• At startup and during operation, be sure to monitor the function

performance of the GT-70A Series.

• Do not modify the GT-70A Series or use it in any way other than

described in the specifications. The function performance of

products used or modified in this way cannot be guaranteed.

• When the GT-70A Series is used in combination with other

instruments, function performance may be degraded, depending on

operating conditions and the surrounding environment. Use the GT70A Series after fully studying the effect of combined use with other

instruments.

• Do not use the GT-70A Series for the purpose of protecting the

human body.

• Do not expose the GT-70A Series and peripheral devices to sudden

temperature change. This may cause condensation, damaging the

equipment.

WARNING

WARNING

CAUTION

Series Instruction Manual

If the following conditions are encountered,

immediately turn OFF the power. Continuing to use

the GT-70A Series under these abnormal conditions

may cause equipment failure.

• When water or foreign matter enters the controller

• When the GT-70A Series is dropped or the housing

is damaged

• When the GT-70A Series produces smoke or an

abnormal smell

• Do not use the GT-70A Series with a voltage other

than specified voltage, as this may cause fire,

electric shock or equipment failure.

• Do not disassemble or modify the GT-70A Series.

This may cause fire or electric shock.

•

Be sure to turn OFF the power of the GT-70A Series and

any connected devices before connecting or

disconnecting the cables. Otherwise, there may be a risk

of damage.

•

Do not turn OFF the power while setting parameters.

Otherwise, the settings may be partially or completely lost.

●

Environmental conditions

To use the GT-70A Series properly and safely, do not install the GT-70A

Series in the following locations. Use of this equipment in an improper

environment may cause equipment failure.

•

Locations with high humidity, a large amount of dust, or poor ventilation

•

Locations where the temperature rises excessively due to direct

sunlight, etc.

•

Locations near corrosive or flammable gas

•

Locations where the GT-70A Series is directly subjected to

vibration or impact

•

Locations where water, oil or chemicals may come into contact with

the GT-70A Series

•

Locations where static electricity may easily occur

●

Noise countermeasures

Installation near the noise source such as a power source and a

power cable may cause malfunction or failure of the equipment.

Adopt appropriate countermeasures against noise by using a noise

filter or wiring cables in separate ducts, attaching insulation to the

amplifier or the sensor head, etc.

●

Effects of ambient temperature

Change in ambient temperature may cause detection errors. Keep

ambient temperature at a constant level.

It will take about 40 minutes for the internal temperature distribution

of the equipment to completely adjust when the ambient

temperature has changed by 10°C.

●

Warming up

Wait about 30 minutes after the power is turned ON before beginning

operation. Immediately after the power is turned ON, the circuit

becomes unstable, possibly causing the indicated value to slightly

fluctuate.

●

Handling of the sensor head

•

The GT-70A Series and peripheral devices are precision machines.

Do not drop, or cause any other impact to these devices.

•

Do not apply weight greater than what is listed below to the spindle part.

Do not apply torque in the rotation direction. Otherwise the spindle may

break.

•

Although the sensor head has a waterproof structure, avoid using in

water or in the place where liquid such as water and oil may come into

contact with the sensor head.

30 N 100 N

●

Extending cable between amplifier and sensor head

Do not cut or extend the cable between the amplifier and the sensor

head. This may change the characteristics, causing the

specifications not to be satisfied.

●

Power su pply

•

Noise superimposed on the power supply may cause malfunction.

Be sure to use the DC stabilized power supply provided with an

insulation transformer.

•

In the case of a commercially available switching regulator, be

sure to ground the frame ground terminal or the ground terminal.

●

Effects of vibration

Vibrating the detection target may cause fluctuation in the indicated

value. In this case, extend the response time. This ensures more

accurate detection values.

●

Effects of magnetic fields

Contact by an external magnetic field to the sensor head will

influence the output. Avoid installing the GT-70A Series near motors

or other equipment and devices that generate strong magnetic

fields.

●

About dust protective boot

An optional dust protective boot is available (GT-H10: OP-78041, GTH22: OP-78042) for when the included dust protective boot has been

cracked or damaged. Please note that we cannot guarantee the

protection rating IP67 when the optional part is used. If you need a

guarantee for the protection rating IP67, replace the sensor head

itself.

1 N

1

GT-M-E

Page 2

CE Mark

Note

The GT-70A Series conforms to CE regulations in Europe.

The applicable regulations (EMC directive) are as follows.

EMI:EN61326,classA

EMS:EN61326

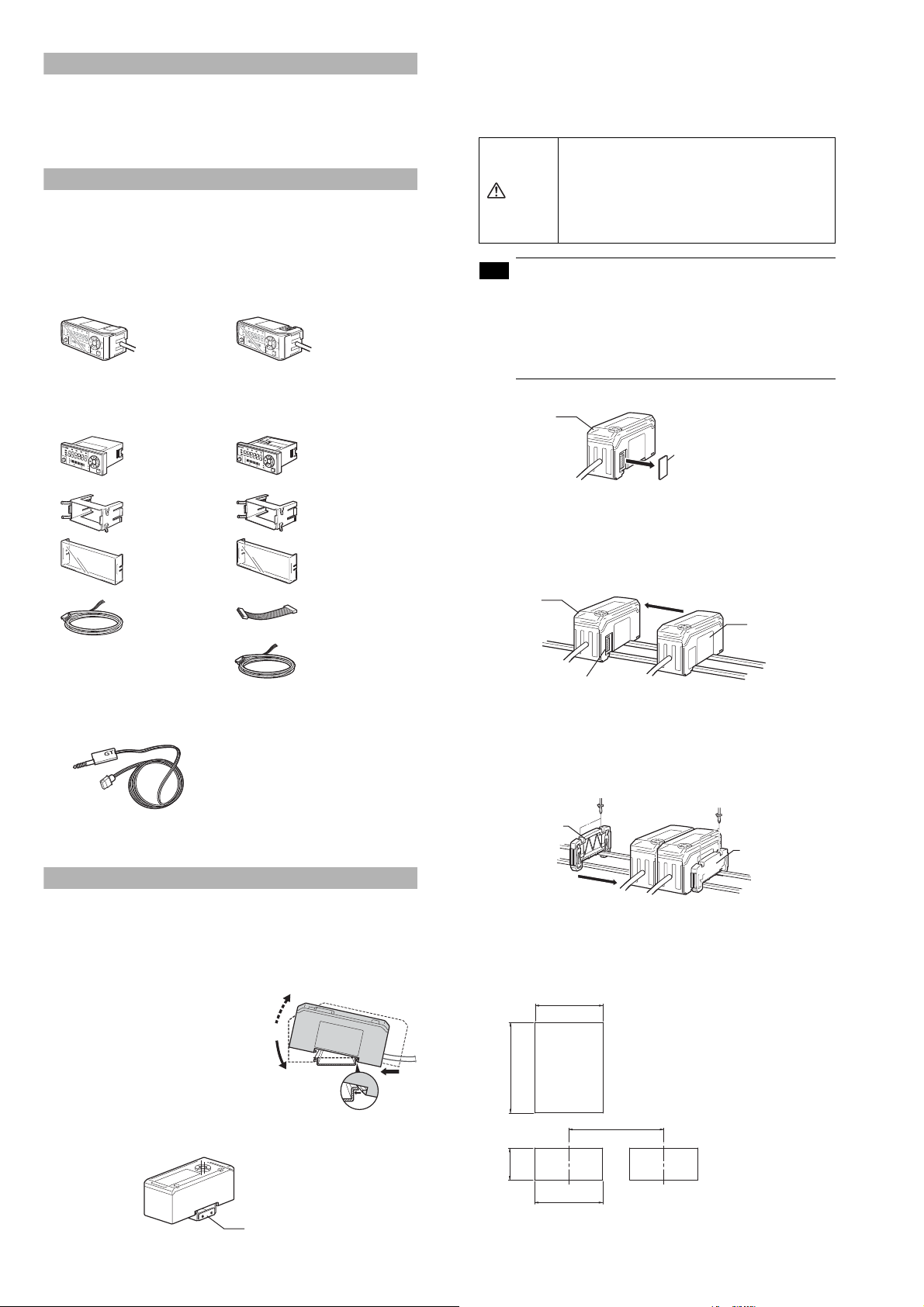

Package Contents

The product package of each model should include the following items.

Check that all items are included before use.

■

Amplifier parts

●

DIN rail mounting type

GT-71A/GT-71AP (Main unit)

P

H

H

I

B

H

P

P

G

O

C

A

L

C

LO

S

E

T

1

2

3

T

IM

SET

H

I

P

V

L

O

P

R

E

SE

T

M

O

D

E

S

E

R

IE

S

Amplifier x 1 Amplifier x 1Instruction manual x 1

●

Panel mounting type

GT-75A/GT-75AP (Main unit)

P‑H

HI

B‑H

P‑P

G

O

CA

LC

LO

1

2

3

T

I

M

H

I

Amplifier x 1

R

V

L

P

O

R

E

S

E

T

Panel mounting bracket x 1

Front protective cover x 1

Power cable (2 m) x 1

(Number of conductors: 8)

GT-72A/GT-72AP (Expansion unit)

P

H

H

I

B

H

P

-P

G

O

C

A

L

C

LO

S

E

T

1

2

3

T

I

M

SET

H

I

P

V

L

O

P

R

ES

E

T

M

O

D

E

S

E

R

I

E

S

GT-76A/GT-76AP (Expansion unit)

P‑

H

HI

B‑H

P‑

P

GO

C

A

L

C

L

O

1

2

3

TIM

HI

Amplifier x 1

RV

LO

P

R

E

S

E

T

Panel mounting bracket x 1

Front protective cover x 1

Expansion cable (50 mm) x 1

●

DIN rail mounting type (Expansion unit)

This section describes how to mount the DIN rail mounting type: GT72A/72AP (Expansion unit).

The expansion unit can only be used in addition to the main unit.

Up to nine expansion units can be added to one main unit.

• When adding an amplifier (expansion unit), be

sure the power of both main and expansion

units is OFF before operation. Mounting when

CAUTION

the power is ON may damage the equipment.

• Be sure to completely contact an expansion unit

to a main unit. Oblique or improper connections

may damage the equipment.

• When adding an expansion unit(s), be sure to use a

24 VDC power supply.

• An expansion unit of different output type cannot be

added (for example, an expansion unit of NPN output

cannot be added to a main unit of PNP output).

• An expansion unit of the DIN rail mounting type cannot

be added to a main unit of the panel mounting type.

1

Detach the expansion cover of the main unit.

Main unit

Expansion cover

2

Mount the expansion unit to be added to the DIN rail.

Refer to page 2, "DIN rail mounting type (Main unit)", for details

about how to mount.

3

Push and fix the expansion unit to the connector of the main

unit until it clicks.

Main unit

Expansion unit

Instruction manual x 1

■

Sensor head parts

Power cable (2 m) x 1

(Number of conductors: 6)

GT-H10/GT-H22 GT-H10L/GT-H22L

Sensor head x 1

Handling instruction x 1

We have taken all possible precautions in packaging; however, if any parts

are found to be defective or broken, please contact your nearest KEYENCE

sales office.

Mounting the Amplifier and Wiring

■

Mounting the amplifier

●

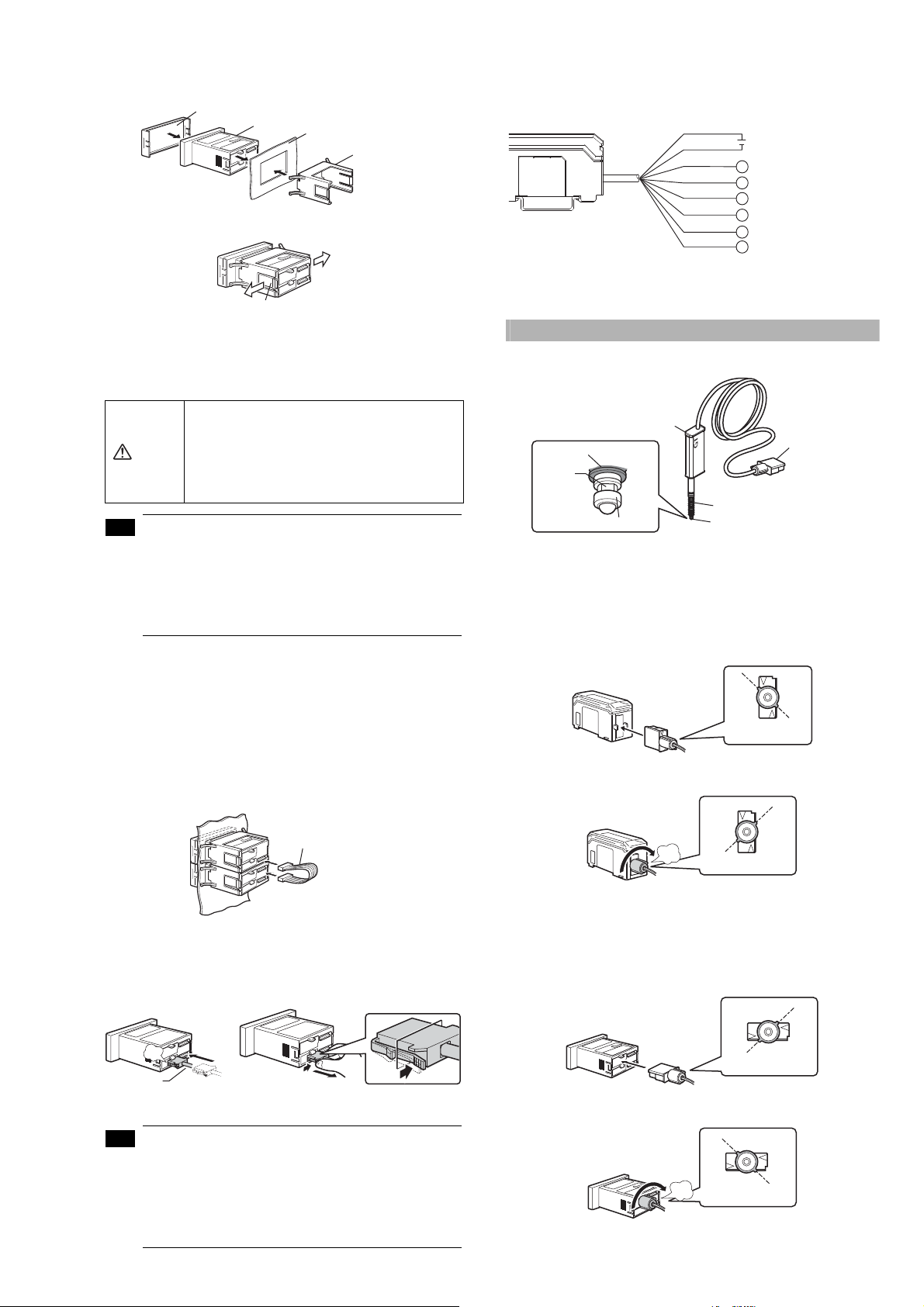

DIN rail mounting type (Main unit)

This section describes how to mount the DIN rail mounting type: GT71A/71AP (Main unit).

1

Fit the tab of the lower part of the

main unit to the DIN rail. While

inserting the main unit in the

direction of Arrow (1), push the body

down in the direction of Arrow (2).

2

To detach the amplifier, while

pushing the main unit in the

direction of Arrow (1), pull the body

up in the direction of Arrow (3).

When using a fixture (OP-76877), mount as shown below.

(3)

(2)

Connector

4

Mount the end units (OP-26751: a set of two pieces) on both

sides of the amplifiers (the main unit and the expansion unit),

then fix the end units with screws on the upper part of each

end unit (2 points x 2 units).

The mounting method of the end unit is the same as that of the

amplifier.

End unit

End unit

●

Panel mounting type (Main unit)

This section describes how to mount the panel mounting type: GT75A/GT-75AP (Main unit).

1

Create a panel opening for mounting referring to the

dimensions below.

(1)

X

+0.4

-0

21

45

(unit: mm)

X=24 x (Number of amplifier unit -1)+21

63 min.

GT-M-E

Fixture: OP-76877

45

2

Insert the main unit, back end first, into the opening of the

panel.

2

Panel cut dimension

Page 3

3

Note

Note

Insert the panel mounting bracket in the direction shown below

into the main unit from the back, then fit the front protective

cover to the main unit face.

Front protective cover

Amplifier

Panel

Panel mounting bracket

To detach the panel mounting bracket, pull it while pushing apart the

tabs provided on its both ends.

Ta b

●

Panel mounting type (Expansion unit)

This section describes how to mount the panel mounting type: GT76A/76AP (Expansion unit).

The expansion unit can only be used in addition to the main unit.

Up to nine expansion units can be added to one main unit.

•

Turn OFF the power before connecting the

expansion cable. Inserting or pulling the cable

when the power is turned ON may damage the

CAUTION

equipment.

• Be sure to completely connect the expansion

cable. Oblique or improper connections may

damage the equipment.

• When adding an expansion unit(s), be sure to use a

24 VDC power supply.

• An expansion unit of different output type cannot be

added (for example, an expansion unit of NPN output

cannot be added to a main unit of PNP output).

• An expansion unit of the panel mounting type cannot

be added to a main unit of the DIN rail mounting type.

1

Create panel openings for mounting according to the number of

expansion units to be mounted (the expansion unit to be added).

Refer to page 2, "Panel mounting type (Main unit)", for details about

panel cut dimensions.

2

Mount the amplifier (the expansion unit to be added) to the panel.

Refer to page 2, "Panel mounting type (Main unit)", for details about

how to mount.

3

Connect the amplifiers (the main unit and the expansion unit)

with an expansion cable.

●

I/O cable

The following illustrates the I/O power cable (also applicable to the

panel mounting type).

Refer to page 10 of this manual for details about I/O circuits.

*1

Brown

*1

Blue

Black

White

Gray

Pink

Violet

Pink/Violet

*1 Expansion units (GT-72A/72AP/76A/76AP) do not include brown and blue cables.

Power supply is 24 VDC when an expansion unit(s) is added.

*2 Default: BANK A input

*3 Default: TIMING input

12-24 VDC

HIGH output

LOW output

GO output

PRESET input

BANK A, or RESET input

BANK B, or TIMING input

Connecting and Mounting the Sensor Head

■

Names of parts of the sensor head

Indicator

Unlocked

Connection

plug

Dust protective boot

Spindle

Dust protective boot*

Contact point

* Not included in the GT-H10L and GT-H22L.

■

Connecting the sensor head

●

DIN rail mounting type

1

Switch the connection plug of the sensor head to "unlocked",

Contact point

then insert it into the connector on the side face of the

amplifier.

2

Turn the round end of the connection plug clockwise until it

clicks to switch to "locked".

*2

*3

Expansion cable

■

Wiring of amplifier

●

How to connect the power cable to the panel mounting type

The accessory power cable (I/O cable) must be connected to the

amplifier of the panel mounting type.

click

Power cable

(When connecting the power cable)

(When disconnecting the power cable)

• The number of power cable conductors is different

between the main unit and the expansion unit (Main

unit: 8 conductors, Expansion unit: 6 conductors).

• The power of the expansion unit is supplied through

the expansion cable being connected to the main

unit. If the I/O line of the expansion unit is not used,

cut the cable at the edge of the connector.

click

•

To detach the connection plug of the sensor head, follow the

Locked

above procedures in the opposite order.

●

Panel mounting type

1

Switch the connection plug of the sensor head to "unlocked",

then insert it into the connector on the back face of the

amplifier.

Unlocked

2

Turn the round end of the connection plug clockwise until it

clicks to switch to "locked".

click

•

To detach the connection plug of the sensor head, follow the

Locked

above procedures in the opposite order.

3

GT-M-E

Page 4

■

y

Note

Note

Note

Note

Note

Note

Note

Mounting the sensor head

●

Mounting directly to the jig

Before mounting the sensor head directory to the jig, create a hole

on the jig. Attach the sensor head using the optional Head mounting

bracket A (OP-76874).

Mounting illustration

Optional Head mounting

bracket A (OP-76874)

●

Mounting on the side of a surface

To mount the sensor head on the side face of a table, use the

optional Head mounting bracket B (OP-76875).

Mounting illustration

Optional Head mounting

bracket B (OP-76875)

Tightening sleeve Nut Mounting bracket

Tightening sleeve

Ke

1

Cut the jig to create a sensor head mounting hole referring to

Nut

wrench

the illustration below.

Tightening sleeve insertion side

C0.5 to C1.0

+0.027

φ10 G8( )

+0.005

2

Insert the tightening sleeve into the hole (from the recessed

5.5 to 11.3

Nut mounting side

side), and loosely tighten with the nut.

Tightening sleeve

Nut

Recessed side

Strongly tightening the nut without the sensor head

inserted may deform the tightening nut.

1

Insert the tightening sleeve into the mounting bracket from the

side with a depression, and loosely tighten with the nut.

Tightening sleeve

Mounting bracket

Nut

Notice the correct angle of the tightening sleeve.

• If the sleeve is inserted from the wrong side, the

sensor head cannot be secured.

• Strongly tightening the nut without the sensor head

inserted may deform the tightening nut.

2

Insert the sensor head into the tightening sleeve, and tighten

the nut with a wrench.

Wrench

Dust protective boot

Nut

3

Insert the sensor head in the tightening sleeve. While securing

the tightening sleeve with the included key wrench, tighten the

nut with a separate wrench.

Wrench

Key wrench

Dust protective boot

• Never apply tightening torque over 10 N•m

(The recommended tightening torque is 5 to 7 N•m).

• Care must be taken not to damage the dust protective

boot when tightening.

4

Rotate the dust protective boot so that the side line is straight.

Check with the spindle pushed in.

Never apply tightening torque over 10 N•m

(The recommended tightening torque is 5 to 7 N•m).

Use the wrench that fits the width of the nut.

3

Secure the sensor head with M4 screws.

M4 screws

• Never apply tightening torque over 1.4 N•m.

• Care must be taken not to damage the dust protective

boot when tightening.

4

Rotate the dust protective boot so that the side line is straight.

Check with the spindle pushed in.

GT-M-E

• If the dust protective boot is not straight, it becomes

easier to damage when the spindle is moved.

• If the end of the sensor head cable is bent repeatedly,

the cable may break.

• If the dust protective boot is not straight, it becomes

easier to damage when the spindle is moved.

• If the end of the sensor head cable is bent repeatedly,

the cable may break.

4

Page 5

How to detach the contact point

Note

Note

While securing the spindle with the accessory key wrench, detach the contact

point with pliers. Then attach a new contact point.

Spindle

Pliers

Contact point

4. HIGH setting value display

Displays/Sets an upper limit value of the range of the detection target.

5. LOW setting value display

Displays/Sets a lower limit value of the

6. Preset value setup display

Displays/Sets an arbitrary value to be added to or subtracted from

the display value.

range

of the detection target.

Zero-Point Correction

When you use this equipment for the first time or after the sensor head

is changed, be sure to correct the reference zero point.

Key wrench

• Detach the sensor head before replacing the contact point.

• When applying pliers to the contact point, be sure not to

rotate the main part and cover the contact point with a

cloth.

• Never apply tightening torque over 0.2 Nym when attaching a

contact point. Note that tightening torque 0.002 N

should be applied only when attaching a fluorine contained

resin contact (OP-80228). Do not use pliers, but place it with

your fingers. (Applying an adhesive, a thread locking agent, is

recommended to prevent the nut from getting loose.)

• Fix the roller contact point or the offset contact point

with the fixing nut in the same direction as in actual use.

Applying

recommended to prevent the nut from getting loose.

• Position the roller contact point carefully in the proper

direction. Care must be taken not to apply misdirected

force to the shaft.

an adhesive

, a thread locking agent, is

Cover the contact

point with a cloth

y

m or less

Amplifier display

■

Names of parts of the amplifier

Digital LED display

Detection level

indicator

[SET] button

Timing input indicator

■

Digital LED display

The main display during detection can be switched to the displays as

shown below by pressing the left/right Arrow buttons.

6. Preset value setup display

5. LOW setting value display

4. HIGH setting value display

* The display of 2. Calculated value display will appear only when an

expansion unit(s) is added.

1. P.V. value display ([P.V. = Present Value] Criterion value display)

Displays a value to be used for output judgment.

2. Calculated value display

Displays a calculated value such as a maximum or minimum value

of plural detection points created when adding an expansion unit(s)

(Displayed only when an expansion unit(s) is added).

3. R.V. value display ([R.V. = Raw Value] Raw value display)

Displays an actual detection value of the detection target.

Status indicator Arrow buttons

Preset indicator

HIGH position indicator/

LOW position indicator

1. P.V. value display

PV indicator

2. Calculated value display*

3. R.V. value display

[MODE] buttonBar LEDsBank indicator

• Zero-point correction is disabled when "------", "- FFFF"

or "FFFF" is displayed.

• Perform zero-point correction approx. every 1 million times

of use.

■

Setup using buttons

1

Set any main display and perform

the detection of the detection

target (master workpiece) to

serve as a reference for zeropoint correction.

Master workpiece

2

While the state of the master workpiece is being detected, press

the top/bottom Arrow buttons simultaneously.

After "PrESEt" has blinked several times on the digital LED display of

the amplifier, "0.000"* will appear.

The zero-correction is completed.

* When the preset function is set, the preset value will appear.

■

Setup using external input (Pink line)

1

Perform detection of the detection target (master workpiece) to

serve as a reference for zero-point correction.

2

Cause the pink line of I/O cable to short out.

Refer to page 10 of this manual for details about external input circuit

diagrams.

Setup of Range Limit Values

The range criteria values are an upper limit value (HIGH setting value)

and a lower limit value (LOW setting value). Setting these values enables

three types of judgment (display/output): above the upper limit (HIGH),

below the lower limit (LOW), and within the range (GO).

■

Manual setup of range limit values

The following shows how to set manually an upper limit value (HIGH

setting value) and a lower limit value (LOW setting value).

1

When in the main display, press the

left/right Arrow buttons until the HIGH

setting value display appears.

2

Enter an upper limit value (HIGH

setting value) with the top/bottom Arrow buttons.

3

Press the right Arrow button once to

cause the LOW setting value display

to appear.

4

Enter a lower limit value (LOW setting value) with the top/

bottom Arrow buttons.

The setup of range criteria values is completed.

To return to the P.V. value display, press the left/right Arrow buttons.

HIGH setting value display

LOW setting value display

5

GT-M-E

Page 6

Tips for Convenient Functions

This is a method for setting a range based on

the detection value of a master workpiece

when the master workpiece is available.

Note

Note

Note

Note

Note

■

Automatic setup of range criteria values

This function automatically sets an upper limit value (HIGH setting

value) and a lower limit value (LOW setting value).

For master workpieces, set by "tolerance tuning"; and for actual

works (good or defective), set by "two-point tuning".

Tolerance tuning

HIGH setting value

Tolerance tuning setting range

LOW setting value

Tolerance tuning is disabled when "------", "- FFFF" or

"FFFF" is displayed.

1

When in the main display, press the

left/right Arrow buttons until the P.V.

value display appears, then perform

detection of the master workpiece.

Tolerance tuning is enabled only when in the P.V. value

display.

2

Press the [SET] button while the master workpiece is being

detected to capture the detected value.

3

Press the upper/bottom Arrow buttons to enter a tolerance

tuning setting range.

4

Press the [SET] button to fix the tolerance tuning setting range.

After [SEt] blinks several times on the digital LED display of the

amplifier, the P.V. value display automatically appears.

Tolerance tuning is completed.

Two-point tuning

This is the method of setting the median values of the detected

good and/or defective workpieces as a range when the good

workpiece and HIGH/LOW defective workpieces are available.

Two-point tuning is disabled when "------" is displayed

as a P.V. value. When "- FFFF" or "FFFF" is displayed,

setting cannot be done accurately.

6

Detect the LOW defective workpiece and press the [SET]

button to capture the detected value.

The median value of this detected value

and the one captured in step 5 blinks.

LOW setting value is fixed.

Two-point tuning is completed.

Press the left/right Arrow buttons

to return to the P.V. value display.

■

Preset

This function displays the value obtained by adding or subtracting a

preset value to or from the detected value.

By using this function and the zero point correction function together,

you can set an arbitrary value as a reference point of the work.

■

Bank switching

By using the bank switching, you can register up to four patterns of

the HIGH setting value, LOW setting value and preset value,

respectively.

The bank switching is useful when there are multiple detection

targets since the pre-registered settings (four patterns) can be

easily switched.

■

Calculation with expansion unit

The GT-70A Series can calculate various values using the detected values

of multiple detection points such as the maximum value or the minimum

value when an expansion unit(s) is added (up to nine units).

Refer to pages 2 to 3 of this manual for details about how to add an

expansion unit.

The outline of the calculation function is shown below.

Calculation

No.

function

C1 Max. value

C2 Min. value

C3 Evenness

C4 Average

Reference

C5

difference

C6 Twist

C7 Curve

C8 Thickness

Displays the maximum value of the values

of the main unit and expansion unit(s)

Displays the minimum value of the values

of the main unit and expansion unit(s)

Displays a difference between the maximum

value and the minimum value of the values of

the main unit and expansion unit(s)

Displays the average obtained by dividing the

sum of the values of the main unit and expansion

unit(s) by the number of units connected

Displays a difference obtained by

subtracting the display value of the main

unit from that of each expansion unit

Displays a degree of twist obtained from

the values of four detection points

Displays a degree of curve obtained from

the values of three detection points

Displays a thickness obtained by

sandwiching the detection target between

the main unit and the expansion unit

The calculation function is selectable only on a main

unit with one or more expansion units added.

HIGH defective

Description

workpiece

Good

workpiece

HIGH

setting value

LOW

setting value

LOW defective

workpiece

Number of units

connected

2 to 10 units

2 to 10 units

2 to 10 units

2 to 10 units

2 to 10 units

4 units only

3 units only

2 units only

1

When in the main display, press the left/

right Arrow buttons until the HIGH

setting value display appears.

2

Detect the good workpiece and press the [SET] button to

capture the detected value.

"SEt" and the detected value blink alternately, and the value of the

good workpiece is fixed.

3

Detect the HIGH defective workpiece and press the [SET]

button to capture the detected value.

The median value of this detected value and the one captured in

step 2 blinks.

HIGH setting value is fixed.

4

Press the right Arrow button until the

LOW setting value display of the main

display appears.

5

Detect the good workpiece again and press the [SET] button to

capture the detected value.

GT-M-E

HIGH setting value display

LOW setting value display

■

Keylock

The keylock allows you to avoid erroneous button operation during

detection.

When the keylock is active, setup operations other than changing

the display are disabled.

The keylock setup can be set on the main display only.

●

Set the keylock

When in the main display, while pressing

the [MODE] button, press the upper

Arrow button for at least two seconds.

The keylock display will appear for several

seconds and then change to the main display.

●

Cancel the keylock

When in the main display, while pressing

the [MODE] button, press the upper

Arrow button for at least two seconds.

The keylock cancel display will appear for several

seconds and then change to the main display.

Keylock cancel display

6

Keylock display

Page 7

■

Note

Initial reset (Reset to the default state)

This function cancels all the functions you set and allows the

equipment to be reset to the default state.

• The initial reset can be set on the main display only.

• The initial reset cannot cancel "span adjustment results".

1

When in the main display, while

pressing the [MODE] button, press

the [SET] button five times.

"rSt.no" will appear.

2

Press the top/bottom Arrow buttons

to select "rSt.YES".

Detection mode (press and hold the [MODE] button in the main screen)

MODE

Standard

NG hold

Peak hold

Bottom hold

Peak to peak

Response time

3

Press the [MODE] button.

"rSt.End" will appear.

The initial reset is completed.

■

Switching the display unit

The display unit can be switched from the initial reset screen.

This section explains how to switch from "mm" display to "inch" display.

1

Display "rSt.YES" from the initial reset screen.

Refer to "Initial reset" for more details on how to display "rSt.YES".

2

Pressing the [MODE] button, press the [SET] button for 2

seconds or more.

3

Use the up and down Arrow button to

select "inch".

4

Press the [MODE] button.

"rSt.End" will appear.

Switching the display unit is completed.

Setting Mode Display

■

Function setting mode

You can set the following functions in the function setting mode.

No.

Item Description

Detection mode

Response

time

Timing type

Self timing

level

Select the detection mode.

Longer response time makes the average

data time longer, which stabilizes the value.

For the timing input, select "External timing"

or "Self timing (internal timing)".

When the self timing is selected in , set

the self timing level.

When the value rises above (or falls below) the

Self timing

delay type

User specified

delay time

Static hold

delay stability

criterion

Static hold

delay stability

width

Calculation

mode

self timing level with "Std" selected in ,

select "Fix the criterion value when the setting

time is elapsed" or "Fix the criterion value after

the display value is stabilized (static hold)".

Set the delay time when "Fix the criterion value

when the setting time is elapsed" is selected in .

Set the reference of stability criterion when "Fix

the criterion value after the display value is

stabilized (static hold)" is selected in .

Enter the optional numerals when USEr (user

specification) is selected in .

Set the calculation method when an

expansion unit(s) is added. *The calculation

mode will appear only when an expansion

unit(s) is added.

MODE

Display for entering the setting value

Timing type

Available to set only when any of Std, P-H and b-H is selected in [ Detection mode].

MODE

External timing input

Rising self

Falling self

Self timing level

Available to set only when item other than t-in is selected in [ Timing type].

MODE

Display for entering the setting value

Self timing delay type

Available to set when the following conditions are provided.

•

Std is selected in [ Detection mode].

•

Item other than t-in is selected in [ Timing type].

MODE

Static hold

Delay timer

User specified delay time

Available to set only when t.d is selected in [ Self timing delay type].

MODE

Display for entering the setting value

Static hold delay stability criterion

Available to set only when Stb.d is selected in [ Self timing delay type].

MODE

Default

User

Static hold delay stability width

Available to set only when USEr is selected in [ Static hold delay stability criterion].

Display for entering the setting value

7

MODE

GT-M-E

Page 8

OFF

Calculation mode

*The calculation mode will appear only when an expansion unit(s) is added.

Max. value

Min. value

Evenness

Average

Reference difference

Tw is t

Curve

Thickness

MODE

MODE

Normal

Measurement direction change

(press and hold the [MODE] + [SET] buttons in the main screen)

Reverse

Display for entering the setting value

Lever ratio

MODE

N.O.

Output format

N.C.

MODE

Display for entering the setting value

Number of display digits

MODE

Hysteresis

Display for entering the setting value

Input line function 1

Input line function 2

MODE

MODE

Bank A

Reset input

■

Basic setting mode

You can set the following functions in the basic setting mode.

No.

Item Description

Measurement

direction

change

Set the "Normal" or "Reverse" when the

spindle of the sensor head is inserted.

Lever ratio Set the ratio of the detected value.

Output format

Number of

display digits

Set "ON (N.O.)" or "OFF (N.C.)" for output

judgment.

Set the number of display digits.

Hysteresis Set the hysteresis value.

Input line

function 1

Input line

function 2

Set the input line function 1 (Violet).

Set the input line function 2 (Pink/Violet).

MODE

Timing input

Bank B

■

Additional function setting mode

You can set the following functions in the additional function setting mode.

No.

Item Description

Preset

memory

Power-saving

function (ECO)

Jam detection

function

Check point

setting

Display filter

function

Set the memory status for "zero-point

correction".

To decrease the power consumption or not to

display the numerical value, set this function.

When the spindle does not return due to an

undetected event in external timing input, set

to detect such an event as an error.

Set the point to detect as an error for .

Set the filter to stabilize the display.

Preset memory (press and hold the [MODE] + left buttons in the main screen)

MODE

YES

NO

GT-M-E

Power-saving function

MODE

OFF

ECO Half

ECO All

Jam detection function

Available to set only when t-in is selected in [ Timing type].

MODE

OFF

ON

User

8

Page 9

Jam detection teaching

Available to set when USEr is selected in [ Jam detection function].

Reference position

fixed

Check point setting

Available to set when USEr is selected in [ Jam detection function].

MODE

Display for entering the setting value

Display filter function

MODE

ON

OFF

■

Calibration setting mode

You can set the following functions in the calibration setting mode.

No.

Item Description

Calibration Set the calibration function.

2nd point

target value

Set the target value of the span adjustment

(2nd point).

Calibration function setting

(press and hold the [MODE] + right buttons in the main screen)

MODE

Default

Adjustment

Error message

Error display Cause Corrective action

*1 If not recovered by this action, there may be a possibility of failure or

permanent damage. In this case, change the amplifier unit.

The sensor head

cable is disconnected.

• The sensor head

cable is broken.

• The sensor head is

damaged.

An overcurrent flows

in the output line.

Failed to write/read

data.

Spindle movement is

not detected

The value fell below (rose

above) the timing level

during the delay time.

When setting the

internal timing, detection

was completed when the

value fell below (rose

above) the timing level

before the criterion value

(P.V. value) is fixed.

Contact between the

amplifiers is lost.

In the case of using the

calculation function,

the number of the

expansion unit when

the power is turned ON

differs from the number

of the expansion unit in

the memory of the

main unit when the

calculation is set.

• When using the

reference difference

(rEF) calculation

function, an error

occurred in the main

unit.

• When using other

than the reference

difference (rEF)

calculation function,

an error occurred in

an expansion unit.

Connect the sensor head to

the amplifier.

Change the sensor head.

• Check that the load is within

the rating.

• Check that the output line is

not contacting other lines and

frames.

Reboot the equipment and

perform initial reset.

• If something is caught in the

spindle, causing the spindle not to

move, change the sensor head.

• Check the external timing input.

(Press the SET button to reset.)

Change the delay timer time

setting. (Press the SET button

to reset.)

The value should not fall below

(rise above) the timing level

before the criterion value is

fixed. Alternatively, lengthen

the static hold delay stabilizing

amplitude so that the criterion

value can be easily fixed.

After turning OFF the power,

check the connection between

the amplifiers.

• Reset the calculation mode

or perform the initial reset of

the main unit.

• After turning OFF the power,

check the connections

between the amplifiers.

Check each main/expansion

unit for the cause of the error.

*1

1st point detection/capture

Available to set only when AdJ is selected in [ Calibration function setting].

Blink alternately

Detect 1st point

Capture the detection value

*Target value for the first point is the PrESEt value.

2nd point target value setting

MODE

Display for entering the setting value

2nd point detection/capture

Blink alternately

Detect 2nd point

Capture the detection value

Specifications

■

Sensor head

Model GT-H10 GT-H22 GT-H10L GT-H22L

Detecting range 10mm 22mm 10mm 22mm

Mechanical response

(at an ambient temperature of 23°C)

Repeat accuracy

*1

When installed

facing down

Measuring

Force

When installed

*2

sideways

When installed

facing up

Ambient

Environmental

resistance

temperature

Relative

humidity

Protective construction IP67

Main unit cover

Indicator Polyalylate

Material

Dust protective boot

Contact point SUS440C

Cable PVC

*3

Weight

*1

The read value at the detection center under an ambient temperature

of 23°C and a response time of 100 ms (default state).

*2 At the center of the movable range of the sensor head installed.

Varies according to the mounted condition of the dust protective boot.

*3 The connector cable (2 m) is included.

10 Hz max.

8 Hz max. 7 Hz max. 5 Hz max.

3 µm 8 µm 3 µm 8 µm

1.0 N 1.5 N 0.3 N 0.35 N

0.9 N 1.4 N 0.25 N 0.3 N

0.8 N 1.3 N 0.2 N 0.25 N

-10°C to +55°C

35 to 85%RH

SUS430

NBR

Approx.

115 g

Approx.

135 g

Approx.

115 g

Approx.

135 g

9

GT-M-E

Page 10

■

Brown

*1

Blue

*1

Pink, Violet, Pink/Violet

*3

Black (HI output)

White (LO output)

Gray (GO output)

12-24 VDC

*2

5-40 VDC

5-40 VDC

5-40 VDC

0 V

External input

Load

Load

Load

Input circuit

Overcurrent

protection circuit

Main circuit

*1 Brown and blue are available for main units (GT-71A/71AP/75A/75AP) only.

Not available for expansion units (GT-72A/72AP/76A/76AP).

*2 When expanded, 24 VDC.

*3 Refer to external input circuit diagram for details about external input.

Brown

*1

Blue

*1

Pink, Violet, Pink/Violet

*3

Black (HI output)

White (LO output)

Gray (GO output)

12-24 VDC

*2

0 V

External input

Load

Load

Load

*1 Brown and blue are available for main units (GT-71A/71AP/75A/75AP) only.

Not available for expansion units (GT-72A/72AP/76A/76AP).

*2 When expanded, 24 VDC.

*3 Refer to external input circuit diagram for details about external input.

Input circuit

Overcurrent

protection circuit

Main circuit

Amplifier

*1

Ty pe

Main unit/

Expansion unit

Mounting type

Model

NPN output GT-71A GT-72A GT-75A GT-76A

PNP output GT-71AP GT-72AP GT-75AP GT-76AP

Supply voltage

*3

DIN rail mounting Panel mounting

Main unit

*2

Expansion

unit

Main unit

12 to 24 VDC, Ripple (P-P): 10% max.

Class 2

Expansion

unit

Display range -99.999 to 999.999

Display resolution 1 µm

Sampling rate 2000 times/sec

Normal mode 24 V: 1200 mW (50 mA) max.

Current consumption

12 V: 1140 mW (95 mA) max.

Eco mode 24 V: 840 mW (35 mA) max.

12V: 600mW (50mA) max.

Response time

Control

output

(HIGH/

GO/LOW)

NPN

PNP

HSP(1.5 ms), 5 ms, 10 ms, 100 ms,

500ms, 1s, 5s

NPN open collector 40 V 50 mA max.

Residual voltage: 1 V max.

PNP open collector 30 V 50 mA max.

Residual voltage: 1 V max.

Non-voltage input (contact/non-contact

Control

input

Environmental

resistance

Timing input

Preset input

Bank input

Reset input

Ambient

temperature

Relative

humidity

Vibration

inputs)

Input time: 2 ms min.

Non-voltage input (contact/non-contact

inputs)

Input time: 20 ms min.

-10 to +55°C (No freezing)

35 to 85%RH (No condensation)

10 to 55 Hz, Horizontal amplitude: 1.5 mm,

2 hours each in X, Y, and Z axis

Main unit cover: Polycarbonate

Material

Keytop : Polyacetal

Front sheet: Polycarbonate

Cable : PVC

GT-71A(AP), 72A(AP): Approx. 110 g

(Including a power cable)

Weight

GT-75A(AP), 76A(AP): Approx. 110 g

(Including a panel mounting bracket, front

protective cover, power cable)

*1 When adding an expansion unit(s), be sure to use the end units

(OP-26751).

*2 Maximum number of units connectable is 10 units including 1 main

unit and 9 expansion units. When expanded, the output current of

each unit should be 20 mA max.

*3 When expanded, the power supply should be 24 VDC.

Circuit diagram

■

I/O circuit diagram

GT-71A/GT-72A/GT-75A/GT-76A

■

External input circuit diagram

GT-71A/GT-72A/GT-75A/GT-76A

DC5V

Main

circuit

(Short circuit current: 1 mA max.)

*1 Blue is available for main units (GT-71A/71AP/75A/75AP) only.

Not available for expansion units (GT-72A/72AP/76A/76AP).

Pink: Preset input

Violet: Bank A input/ Reset input change

Pink/Violet: Bank B input/ Timing input change

*1

Blue

GT-71AP/GT-72AP/GT-75AP/GT-76AP

12 V~24 VDC

*1

Brown

Main circuit

(Short circuit current: 2 mA max.)

*1 Brown is available for main units (GT-71A/71AP/75A/75AP) only.

Not available for expansion units (GT-72A/72AP/76A/76AP).

Pink: Preset input

Violet: Bank A input/ Reset input change

Pink/Violet: Bank B input/ Timing input change

Warranty

KEYENCE warrants its Products to be free from defects of material and

workmanship and will, without charge, replace or repair (at KEYENCE's

sole option) any Products found defective upon inspection at its factory,

or other designated point provided the equipment has been returned,

transportation prepaid, within one year from the date of shipment.

Warranty is specifically at the factory. Any on-site service will be

provided at the sole expense of the Purchaser at standard field service

rates. All associated equipment must be protected by properly rated

electronic/electrical protection devices.

KEYENCE shall not be liable for any damage due to improper

engineering, installation, interfacing, use, modification or any action not

in accordance with this instruction manual. Proper installation,

operation and maintenance of the product in accordance with this

instruction manual become the responsibility of the user upon receipt of

the Product. The user shall indemnify KEYENCE and hold KEYENCE

harmless from any liability or damage whatsoever arising out of any

action not in accordance with this instruction manual. Components

which wear are not warranted.

OTHER THAN AS STATED HEREIN, THE PRODUCTS ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER.

ALL EXPRESS, IMPLIED, AND STATUTORY WARRANTIES,

INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

AND NON-INFRINGEMENT OF PROPRIETARY RIGHTS, ARE

EXPRESSLY DISCLAIMED. IN NO EVENT SHALL KEYENCE AND

ITS AFFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY

FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL

OR CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT

LIMITATION, ANY DAMAGES RESULTING FROM LOSS OF USE,

BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR

INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS,

THE COST OF PROCUREMENT OF SUBSTITUTED GOODS,

SERVICES OR TECHNOLOGIES, OR FOR ANY MATTER ARISING

OUT OF OR IN CONNECTION WITH THE USE OR INABILITY TO

USE THE PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS

AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD

PARTY'S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

THE PURCHASER. No representation or warranty, express or implied,

made by any sales representative, distributor, or other agent or

representative of KEYENCE which is not specifically set forth herein

shall be binding upon KEYENCE. In some jurisdictions, some of the

foregoing warranty disclaimers or damage limitations may not apply.

GT-71AP/GT-72AP/GT-75AP/GT-76AP

GT-M-E

Copyright (c) 2007 KEYENCE CORPORATION. All rights reserved.

1825E 0099-2 96M1825 Printed in Japan

10

Loading...

Loading...